A high-performance low-density dual-phase high-entropy alloy and its preparation method

A high-entropy alloy, low-density technology, applied in the field of metal materials, can solve the problems of reduced alloy density, insufficient forming ability, and high density, and achieve the effects of good fluidity and casting forming ability, solving preparation problems, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment discloses a high-performance low-density duplex high-entropy alloy, the chemical formula of the alloy is AlCrFeNiTi, abbreviated as alloy 1, wherein the proportion of each element is a molar atomic ratio.

[0032] The present embodiment of high performance low density Al a Crb Fe c Ni d Ti e The preparation method of the alloy, including the following steps:

[0033] (1) Cleaning: The Alloying Elements of Al, Cr, Fe, Ni and Ti are removed by mechanical grinding, and then placed in different beakers and added to alcohol, and the alloying elements after cleaning are removed and blown dry;

[0034] (2) Ingredients: take materials from the cleaned alloy raw materials, weigh the Corresponding Mass Al, Cr, Fe, Ni and Ti elements according to the molar atom ratio of the alloy and mix them;

[0035] (3) Drying: the mixed alloying elements are dried in the drying box;

[0036] (4) Alloy smelting: the mixed material is placed in the arc melting furnace, the fur...

Embodiment 2

[0039] The present embodiment discloses a high-performance low-density duplex high-entropy alloy, the chemical formula of the alloy is Al a Cr b Fe c Ni d Ti e , abbreviated as alloy 2, where the atomic ratio of each element is a:b:c:d:e.

[0040] The preparation method of the high entropy alloy is the same as the preparation method of Example 1, the difference is that the corresponding mass of Al, Cr, Fe, Ni and Ti elements are weighed according to the atomic ratio of the alloy during the batching process and mixed.

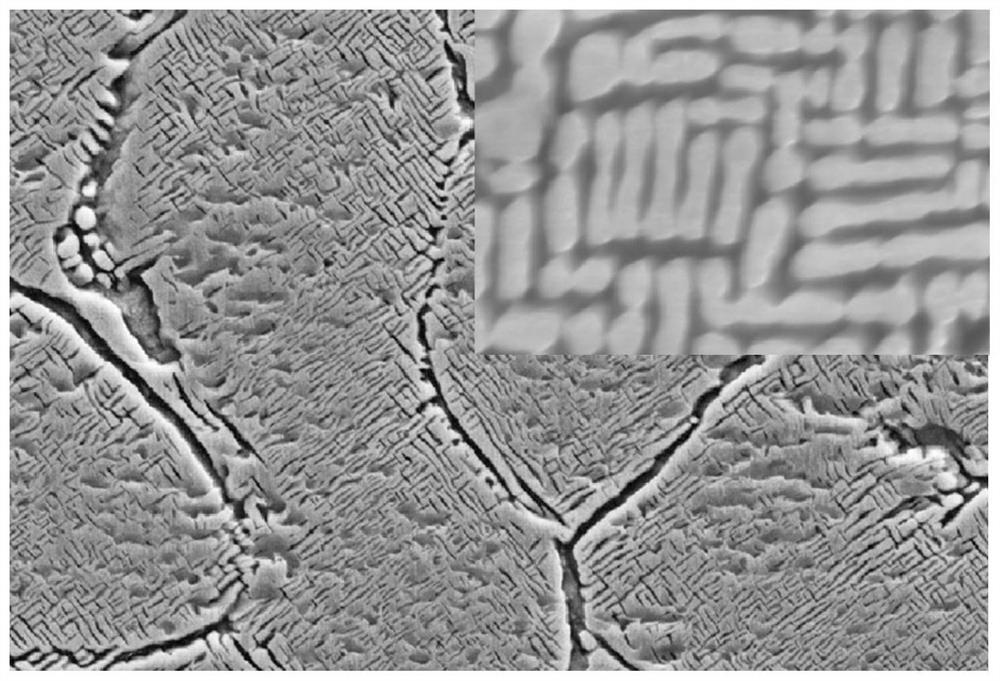

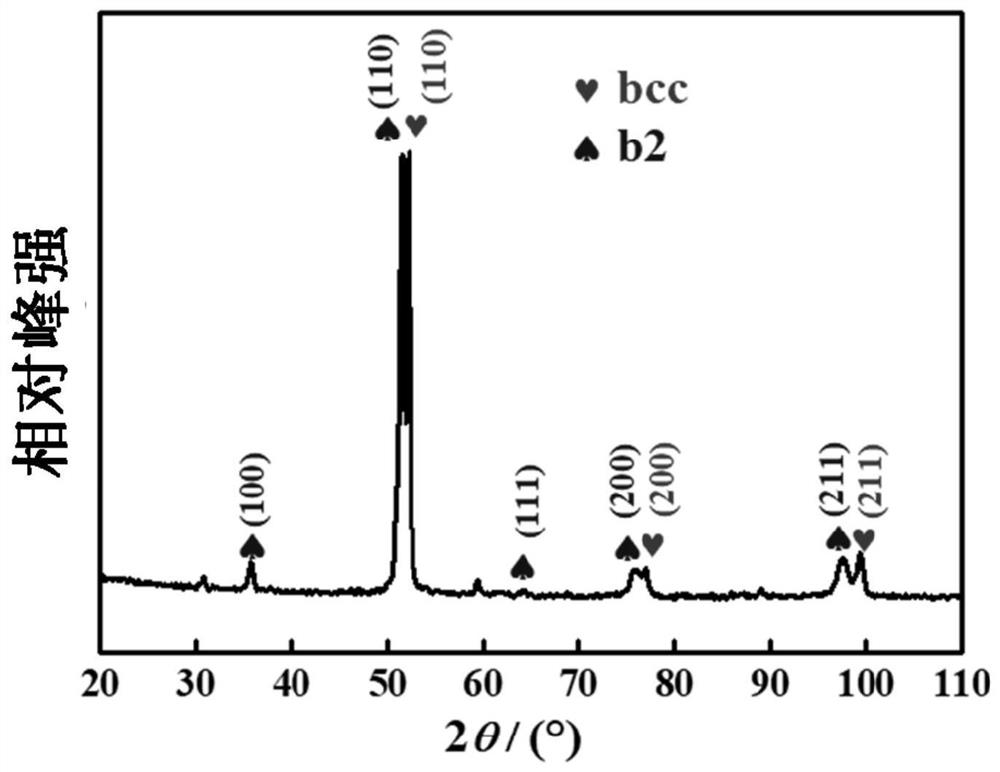

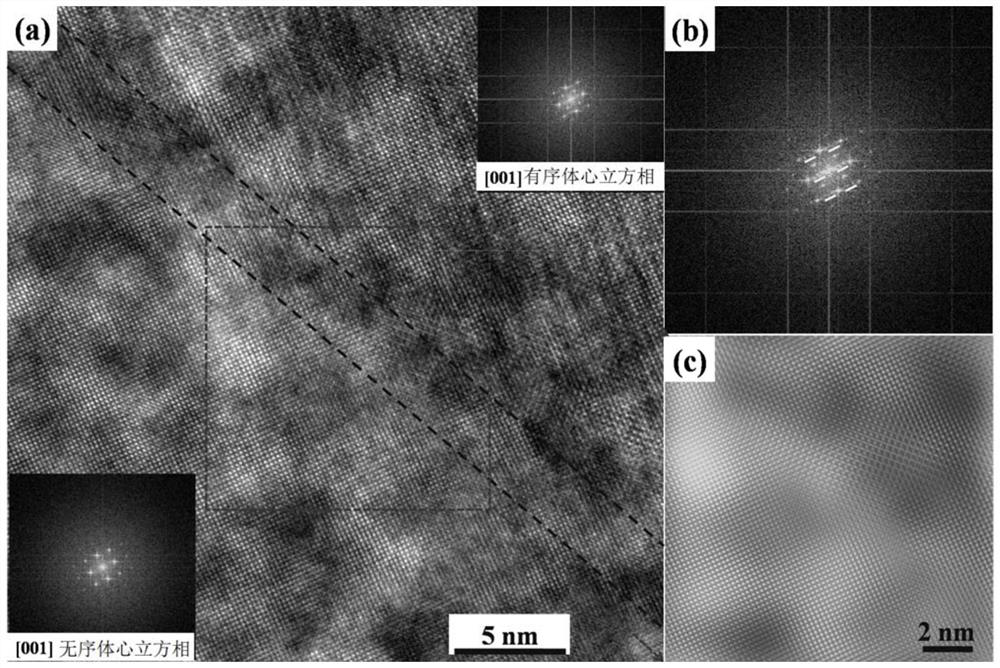

[0041]Microscopic tissue observation of Examples 1 and 2 by scanning electron microscopy, analysis of the crystal structure of Example 2 by X-ray diffraction pattern, Figure 1 For examples 1 and 2 of the microstructure picture, Figure 2 For the XRD spectrum of Example 2, according to the detection results, the alloy is composed of a two-phase structure of a layer of sheets, the two phases are the ordered body centripetal cubic phase and the disordered centripetal cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com