Magnesium alloy bused composite material and preparing method thereof

A composite material and magnesium alloy technology, which is applied in the field of magnesium alloy-based composite materials and its preparation in the form of particle reinforcement, can solve the problems of TiC hardness decrease and composite material performance degradation, and achieve uniform distribution, not easy to segregate, and good interface bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of 10% TiB 2 / AZ91 composite material

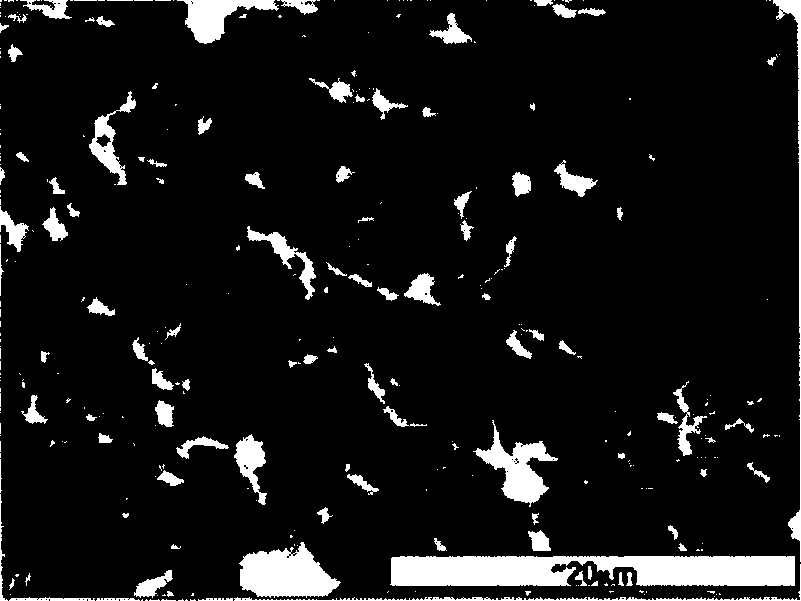

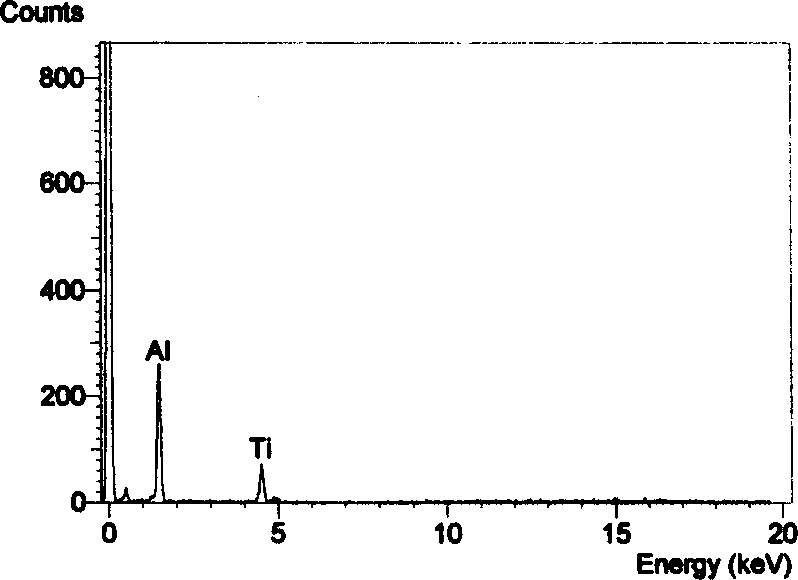

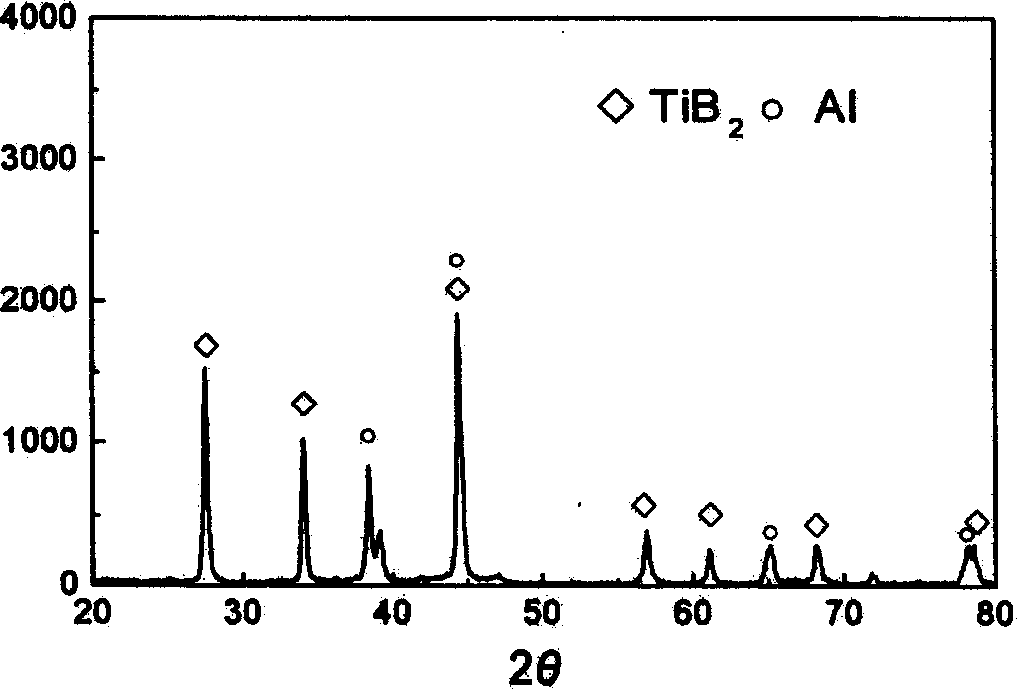

[0033] The Al powder of ~29 microns, the Ti powder of ~15 microns, and the B powder of ~3 microns are taken, and the matrix magnesium alloy adopts AZ91 die-casting magnesium alloy, pure magnesium ingot and pure zinc ingredients. The above three powders are mixed in a small roller mill for 8 hours according to the ratio of atomic ratio Ti: B=0.5 and Al content of 50% by weight, and then pressed into a cylindrical reaction prefabricated block of φ55×30 on a 20-ton press , The compaction rate of the green compact is 75% of the theoretical density of the mixed powder. Place the reaction prefabricated block in a vacuum heating device, and raise the temperature to 660°C at a heating rate of 20°C / min to initiate a chemical synthesis reaction, and the product is TiB 2 / Al mesophase carrier, its microscopic scanning structure, energy spectrum analysis and X-ray diffraction analysis such as figure 1 , figure 2 and image 3...

Embodiment 2

[0035] Preparation of 13% TiB 2 / ZM5 composite material

[0036] Al powder of ~74 microns, Ti powder of ~74 microns and B powder of ~3 microns are taken, and ZM5, pure magnesium ingot and pure zinc are used as ingredients for the matrix magnesium alloy. The above three kinds of powders are mixed according to the atomic ratio Ti: B=0.55, and the Al content is 35% by weight, mixed in a small roller mill for 12h, and then pressed into a cylindrical reaction prefabricated block of φ55×25 on a 20-ton press, pressed The billet compaction rate is 70% of the theoretical density of the mixed powder. Place the reaction prefabricated block in a heating device under the protection of high-purity argon, and raise the temperature to 760°C at a heating rate of 30°C / min to initiate a chemical synthesis reaction to prepare TiB 2 / Al mesophase support, which subsequently contains the corresponding TiB 2 The mesophase carrier of the ceramic particles was added to the magnesium alloy solution ...

Embodiment 3

[0038]Preparation of 3% TiB 2 / AZ91 composite material

[0039] The Al powder of ~29 microns, the Ti powder of ~15 microns, and the B powder of ~3 microns are taken, and the matrix magnesium alloy is AZ91. The above three powders are mixed in a small roller mill for 8 hours according to the atomic ratio Ti: B=0.5, and the Al content is 40% by weight, and then pressed into a cylindrical reaction prefabricated block of φ55×30 on a 20-ton press , The compaction rate of the green compact is 80% of the theoretical density. Place the reaction prefabricated block in a vacuum heating device, and raise the temperature to 660°C at a heating rate of 10°C / min to initiate a chemical synthesis reaction, and the product is TiB 2 / Al mesophase carrier. This subsequently contains the corresponding TiB 2 The mesophase carrier of the ceramic particles was added into the molten magnesium at 700°C protected by a flux, and stirred after the mesophase carrier was melted, the stirring temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com