Patents

Literature

492results about How to "Clean surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

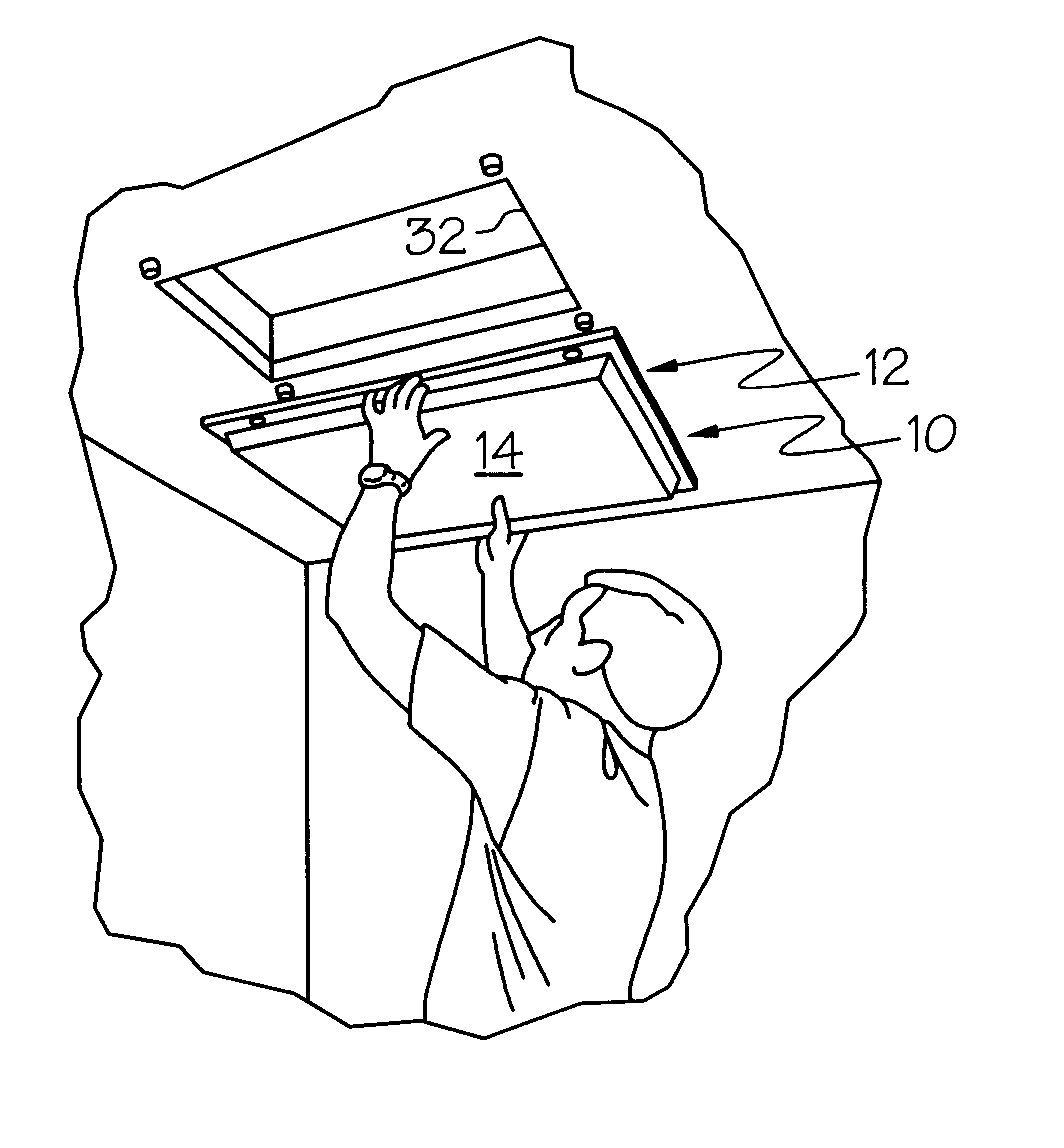

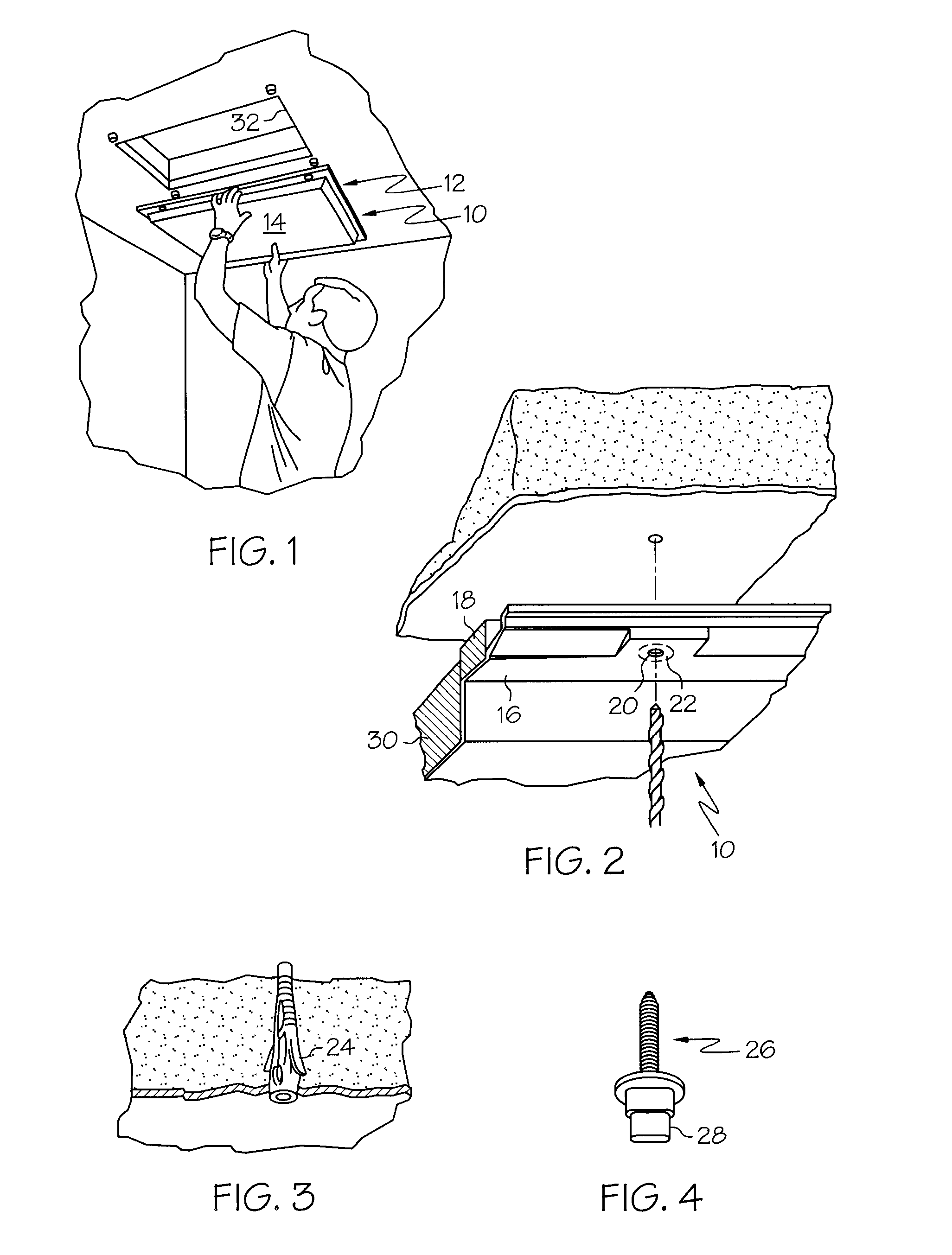

Insulated attic access cover

An insulated attic access cover which is easily installed from below the attic access opening and includes a flat panel with a central insulation portion, flanges which carry a seal and attachment points to secure the cover to the ceiling.

Owner:ADO PROD

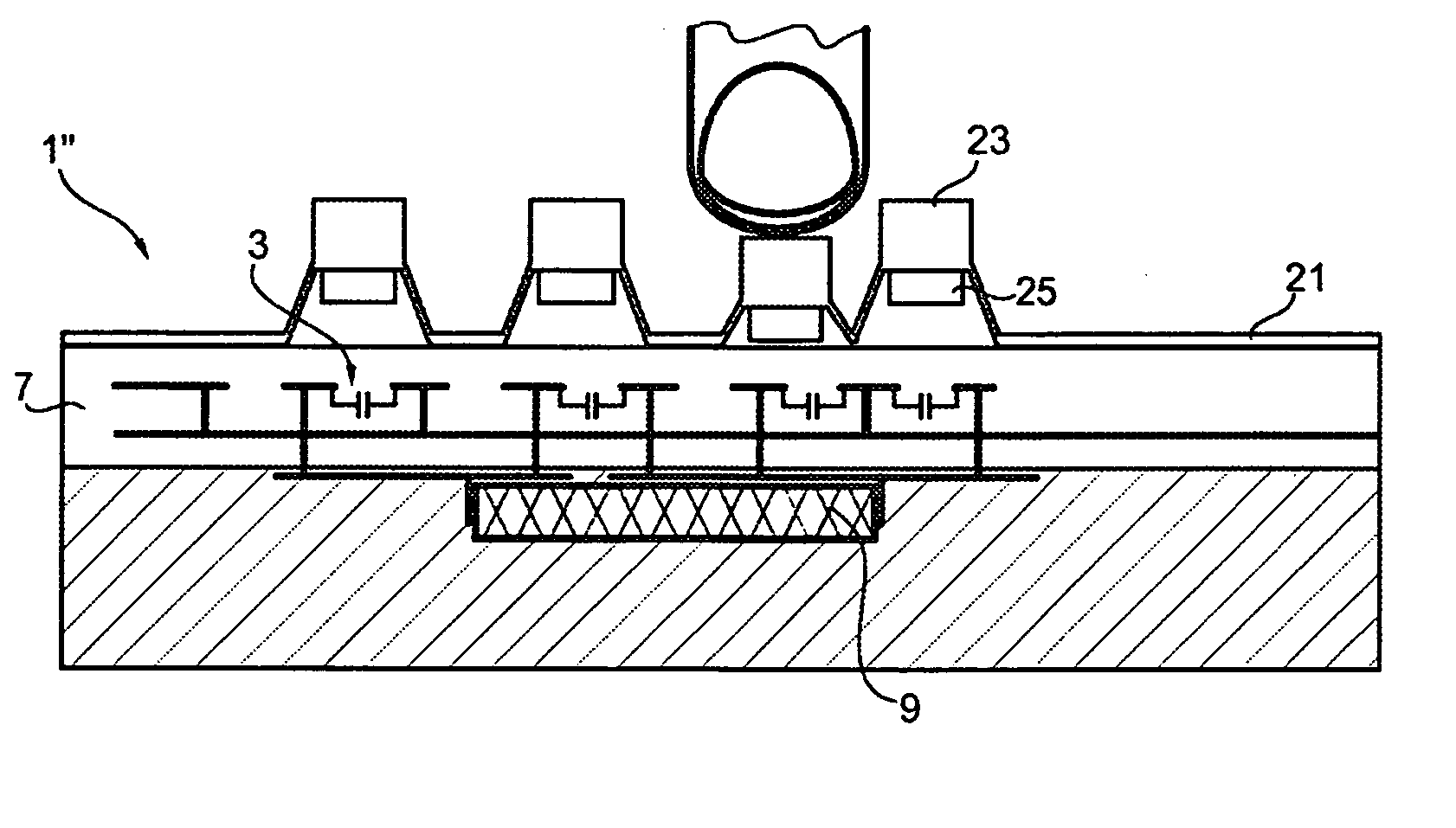

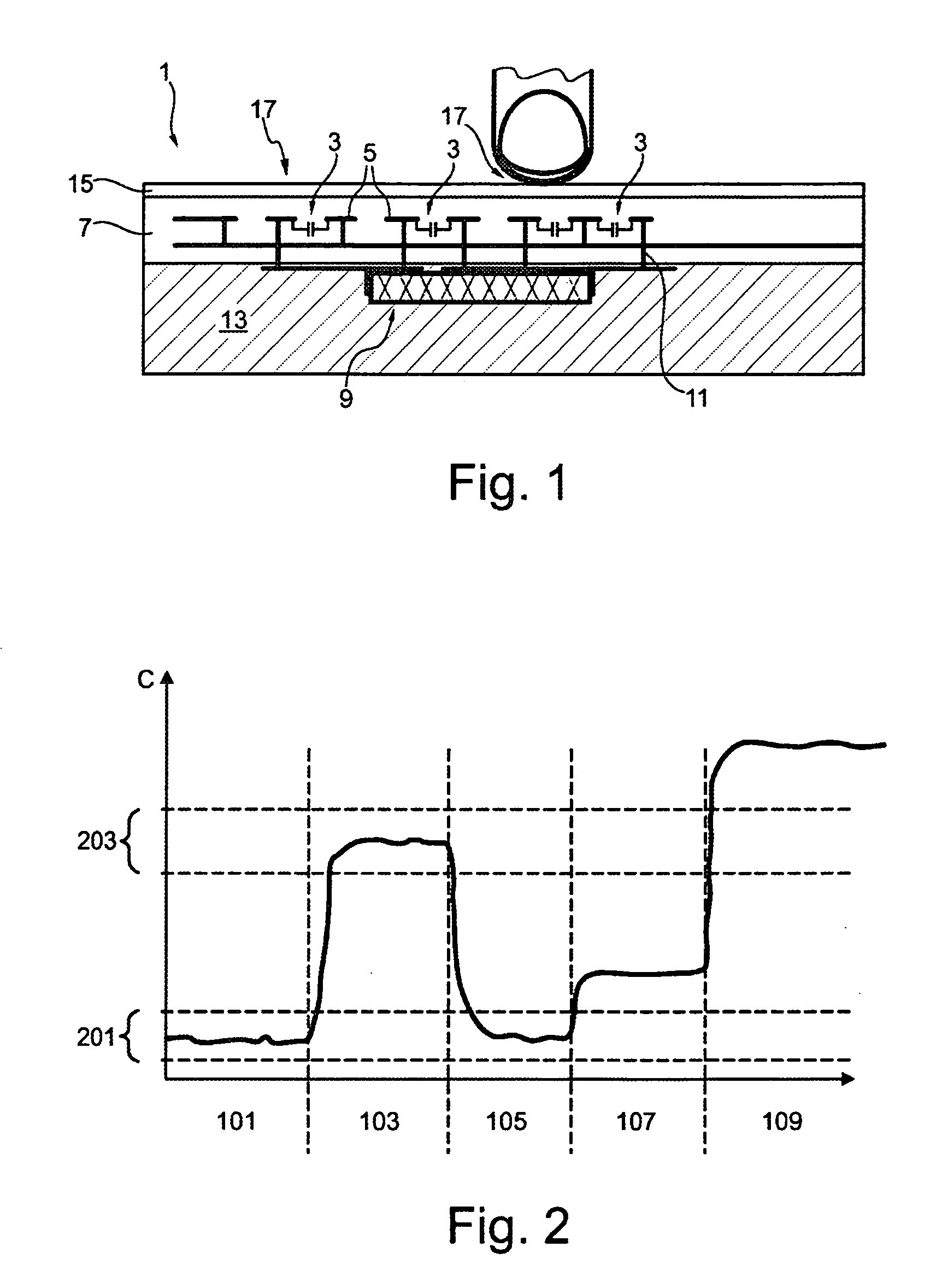

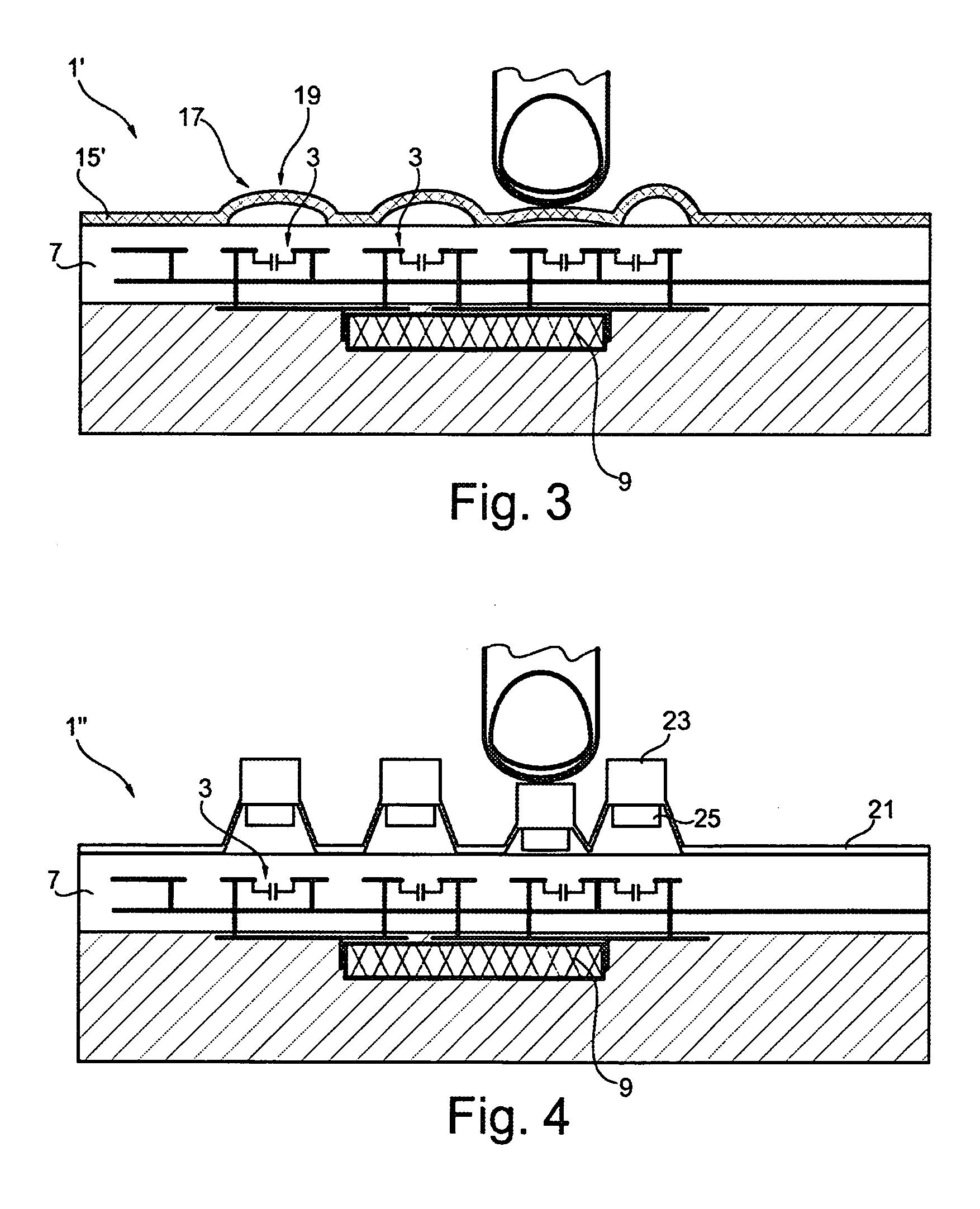

Keyboard having capacitance-sensitive key fields

InactiveUS20110095919A1Clean surfaceShort timeAcutation objectsElectronic switchingCapacitanceElectronics

A keyboard having a plurality of key fields and a plurality of capacitive elements, which are associated with the key fields, and measuring electronics is proposed. The measuring electronics are implemented for the purpose of detecting a change of the capacitance value of one of the capacitive elements between a non-actuation level, which is in a first capacitance value range, and an actuation level, which is in a second capacitance value range, and then outputting an actuation signal. The measuring electronics are also implemented to detect a change of the capacitance value of the non-actuation level and a manipulation level above the second capacitance value range and to then output an alarm signal. The attempt to manipulate the keyboard can thus be detected on the basis of the capacitance value increase associated therewith.

Owner:VERIFONE GMBH

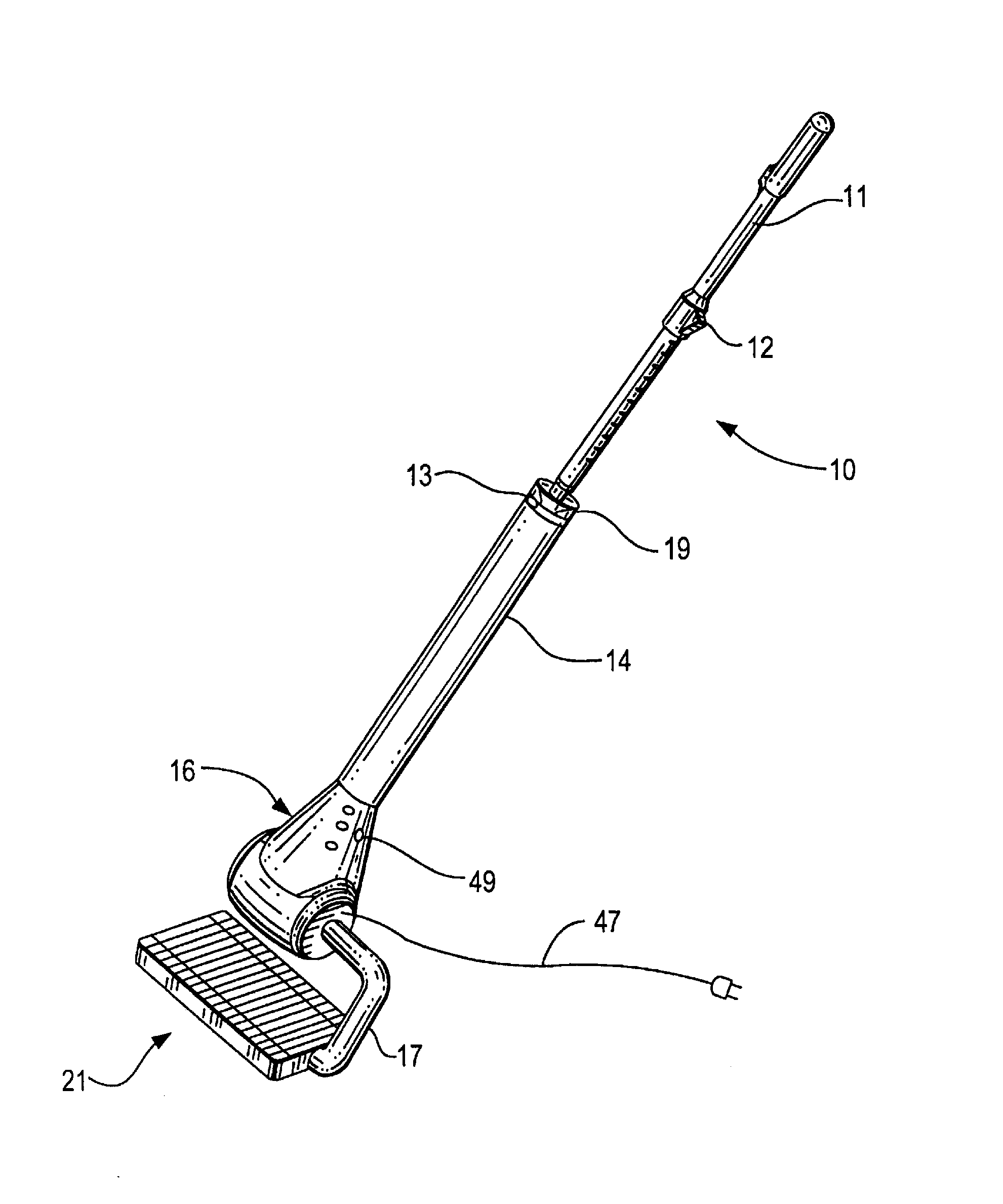

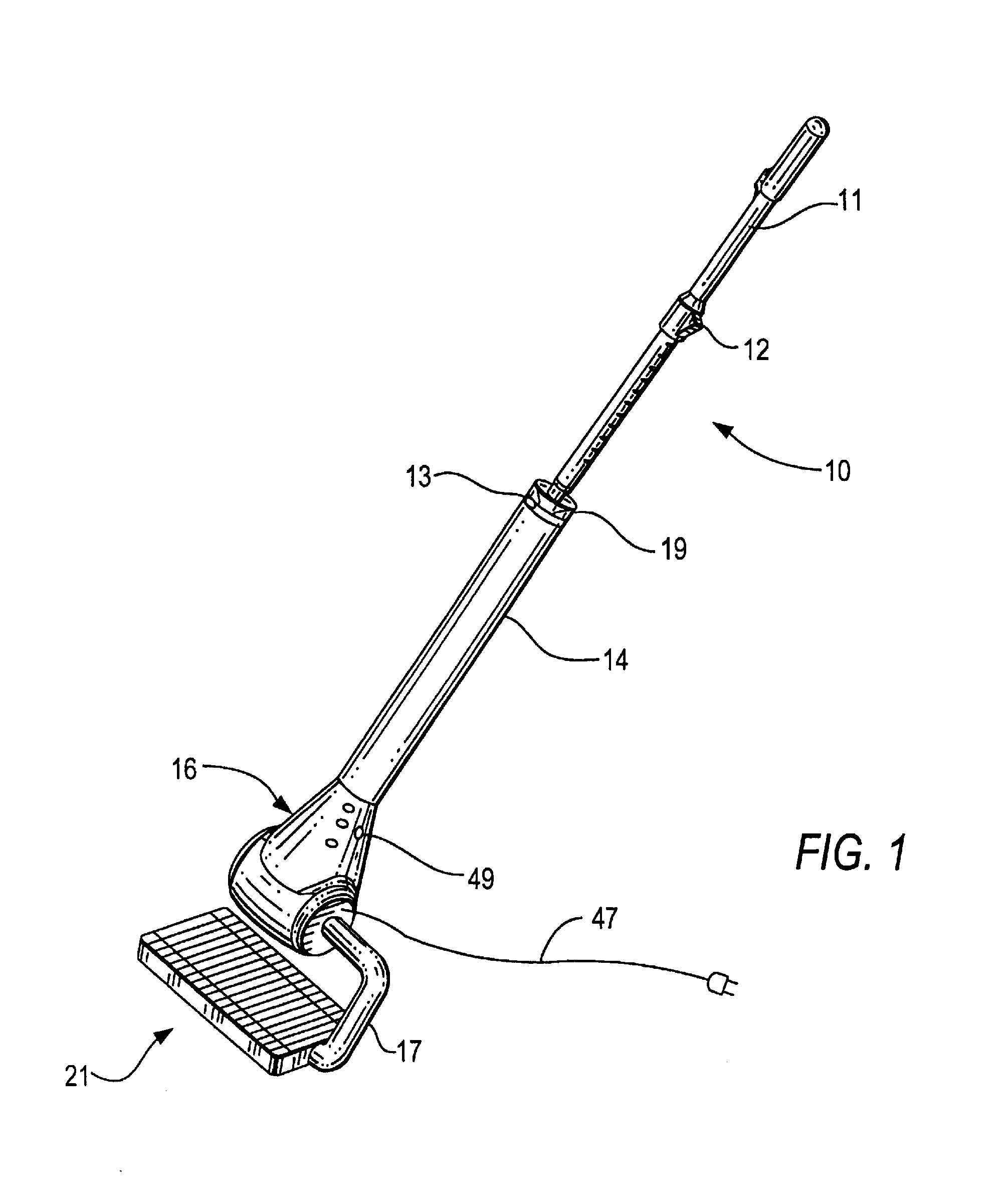

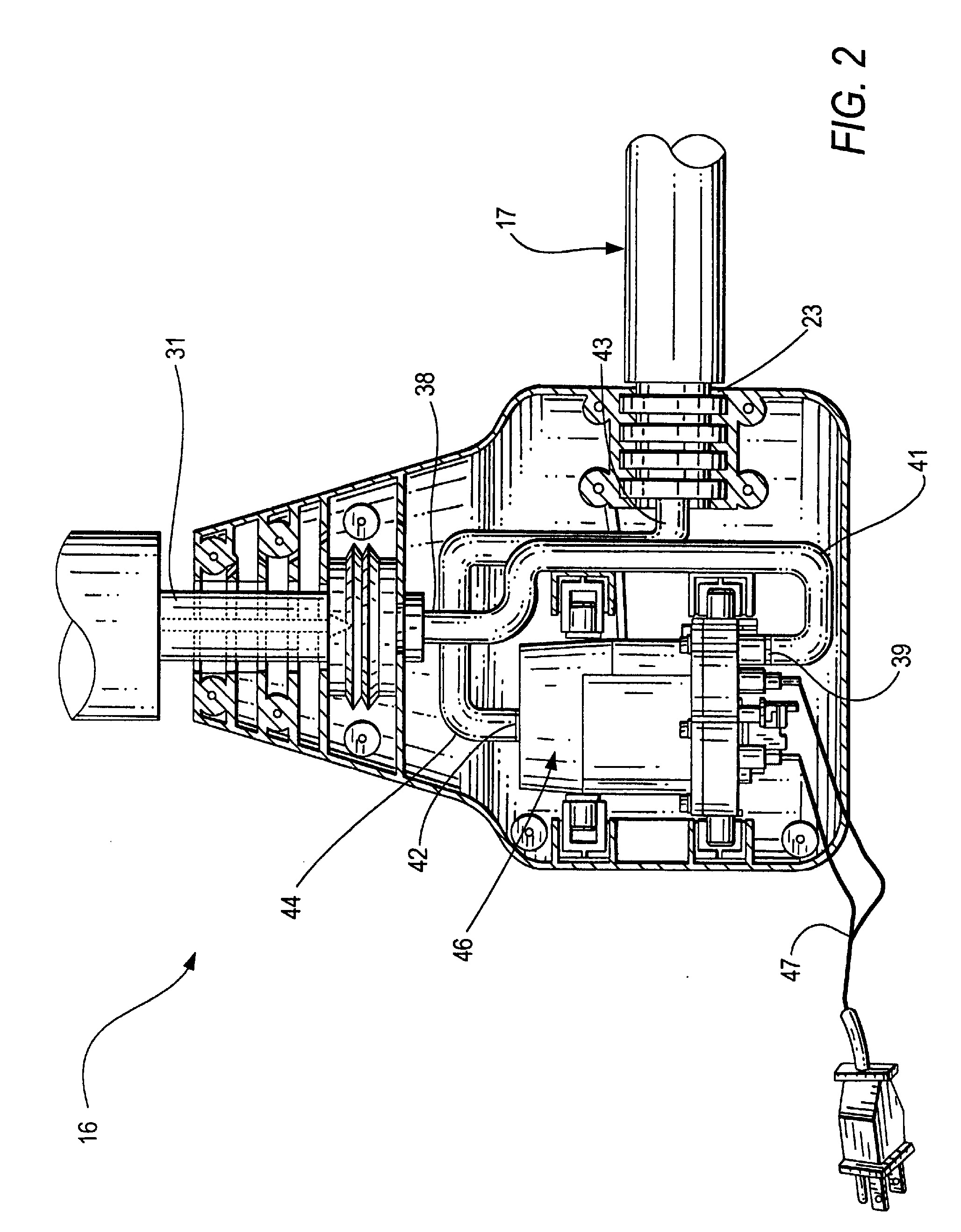

Steam mop

InactiveUS20080236635A1Clean surfaceEasy to useSteam generation heating methodsCarpet cleanersSteam mopEngineering

A steam mop having a main body with a boiler, a water container, a mechanical water pump between the boiler and container and at least one side arm connecting the boiler steam outlet to a fabric steam pocket frame. The water pump is actuated by movement of the mop when cleaning to send water to the boiler. The steam pocket frame is substantially rectangular with a plurality of baffles to distribute steam disposed substantially perpendicular to a steam channel having openings to distribute steam between the baffles. A replaceable fabric pocket fits snugly over the frame to distribute cleaning steam to the surface to be cleaned.

Owner:EURO PRO OPERATING

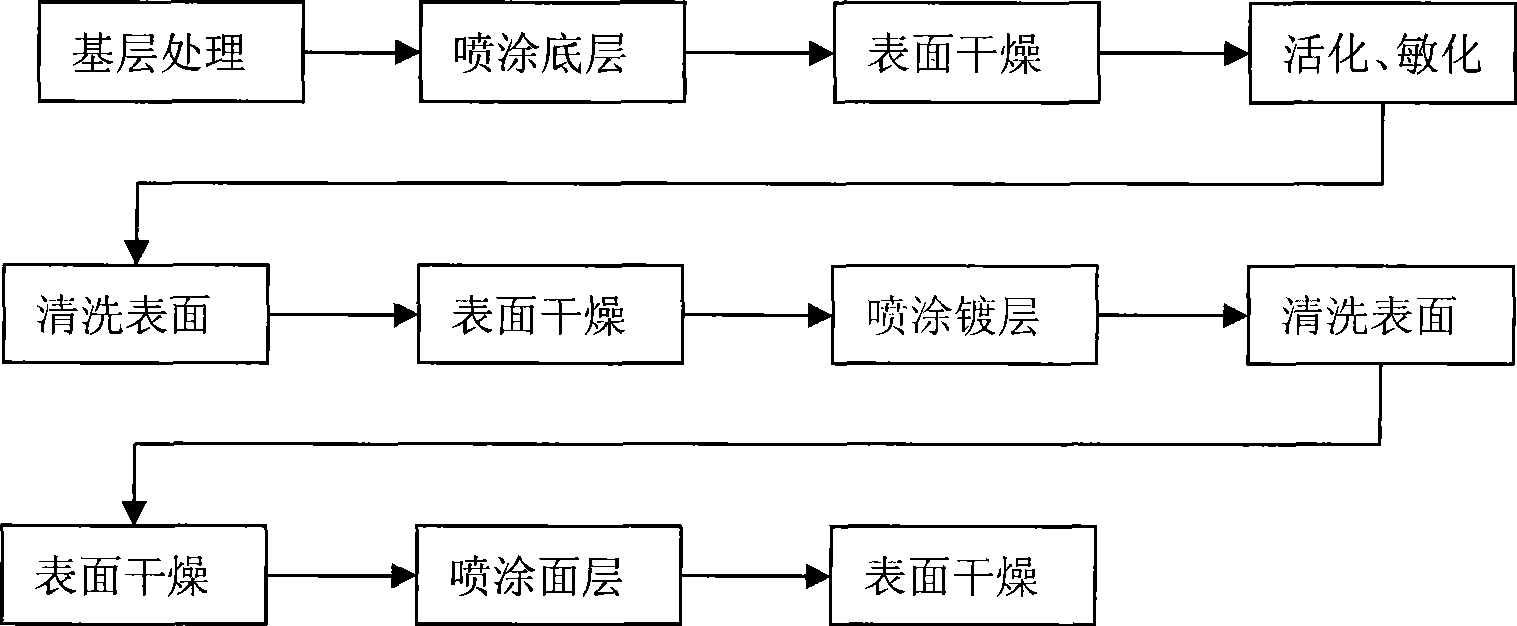

Nano spray plating technique for silver mirror

InactiveCN101469427AAvoid processing powerAvoid environmental problemsLiquid/solution decomposition chemical coatingSuperimposed coating processSurface layerWeather resistance

The invention provides nanometer spray plating for a silver mirror, namely obtain a high glaze metal mirror face by adopting coating technique, which is similar to the brand new decorative effect of plating. The whole technique consists of a paint bottom layer, a metal reflecting layer (spray plating layer) and a paint surface layer. The coating has excellent adhesive attraction, shock resistance, corrosion resistance, weather resistance and marresistance, has rich colors and is bright like a mirror. The nanometer spray plating can be used to various materials such as metal, resin, ABS, PC, PP+PS carbon element resin, plastic, glass, pottery and porcelain, acrylic, wood, plastic wood and calcium plastic.

Owner:汪正红

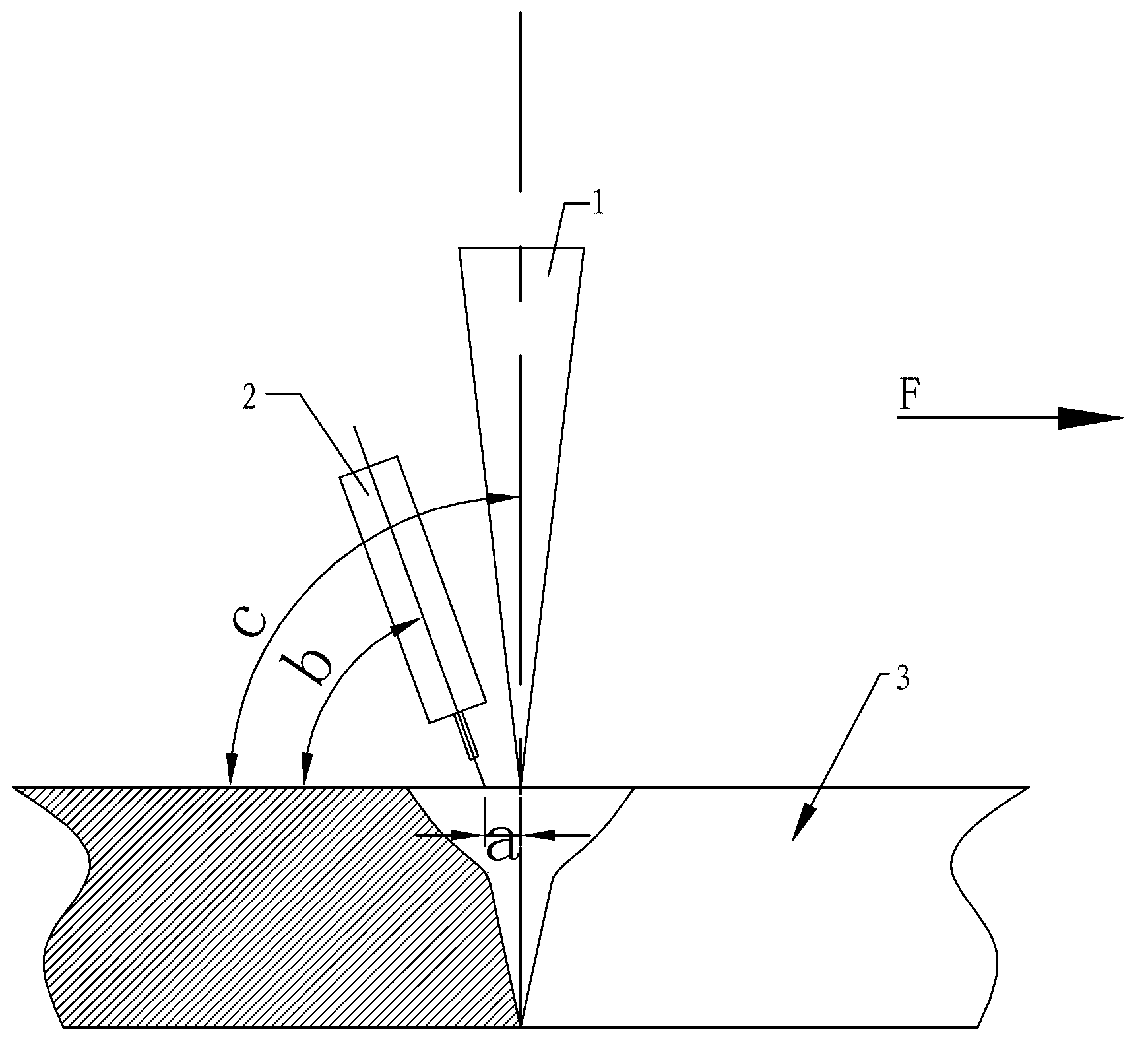

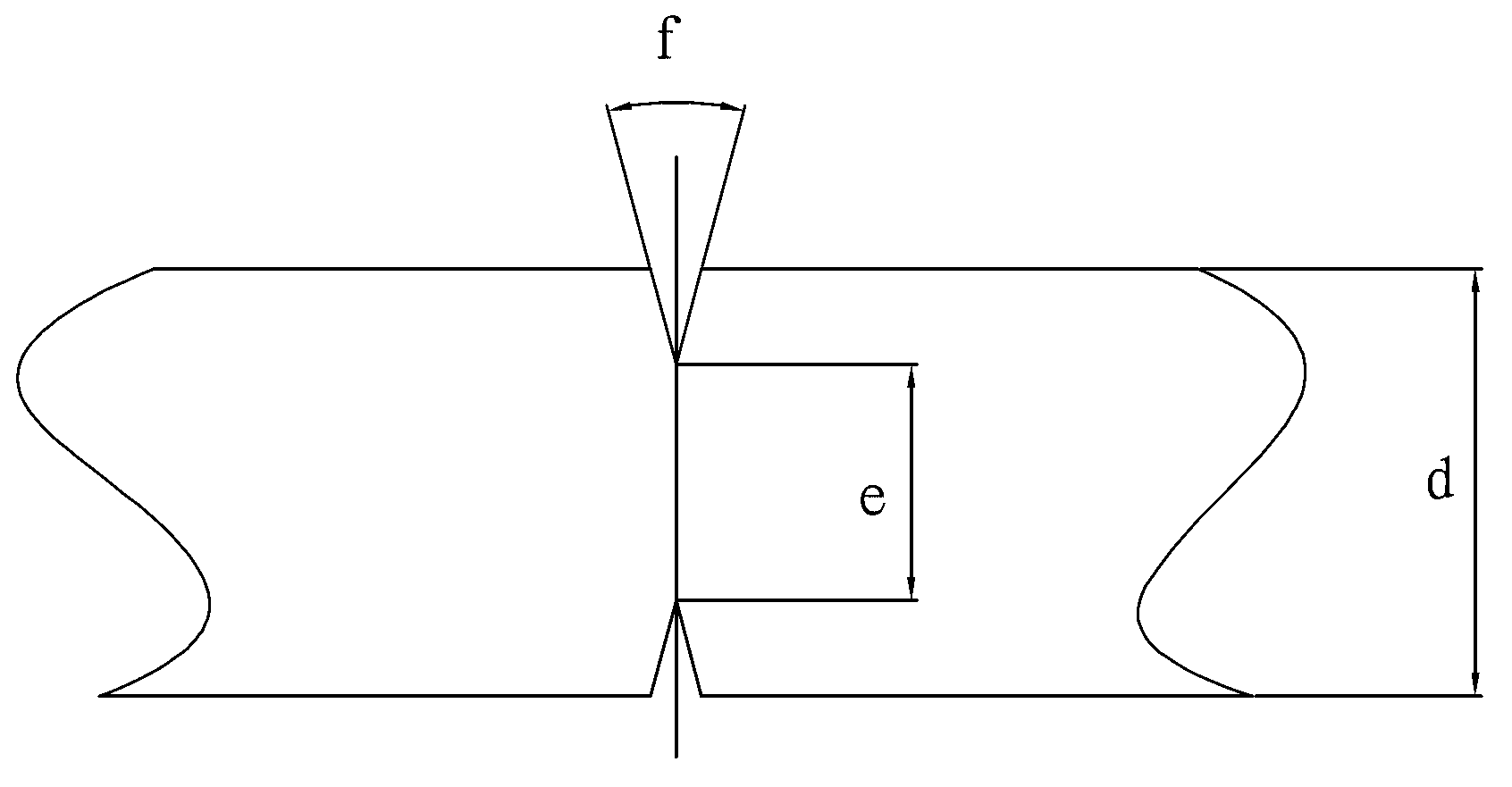

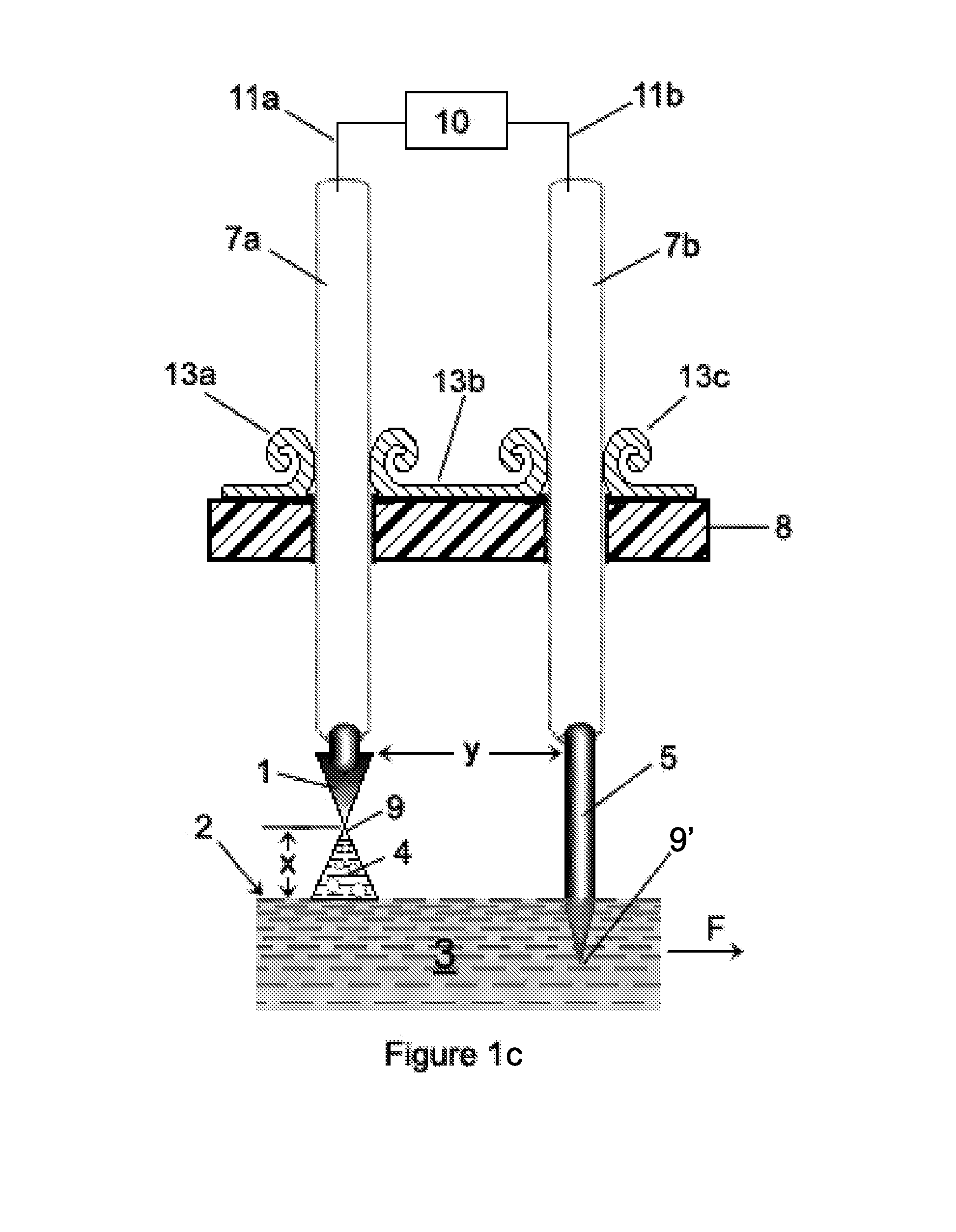

Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

The invention discloses a laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel. The laser and MIG arc composited welding method is characterized by comprising the following steps of: design of a welding joint; design of a welding mode; setting of a composite way and heat source spaces; selection of protective gas for the composite welding; setting of welding technology parameters according to the composite way; and synchronous implementation of the composite welding. Compared with the prior art, the laser and MIG arc composited welding method has the advantages of being capable of implementing the welding of the high-nitrogen steel with middle thickness and achieving weld joints which have clean and smooth surfaces and are good in forming and free from sunken parts; and meanwhile, the welding method has the characteristics of low loss and uniform distribution of nitrogen elements at connectors, high welding penetration, high welding speed, small deformation of workpieces, low assembly requirements and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

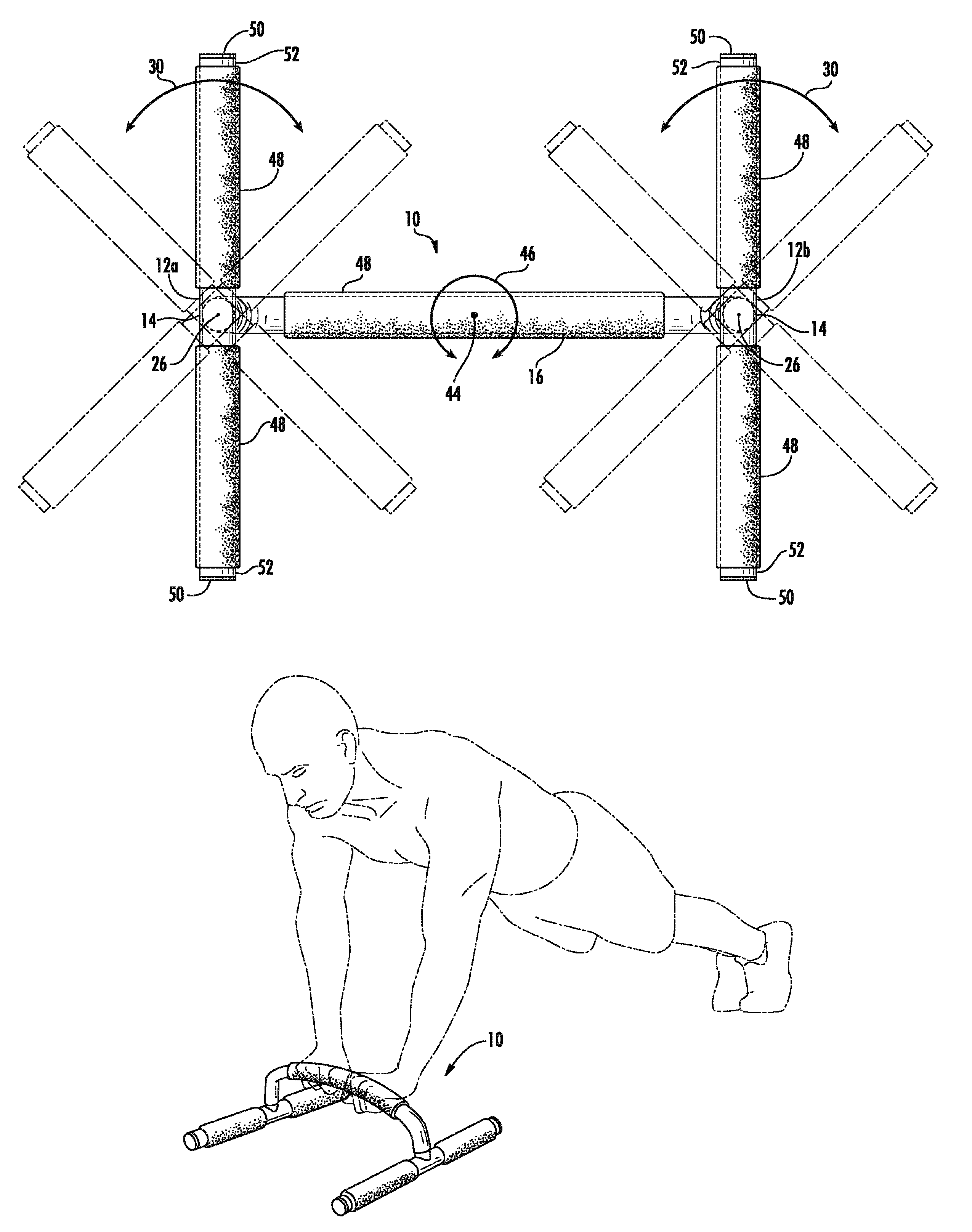

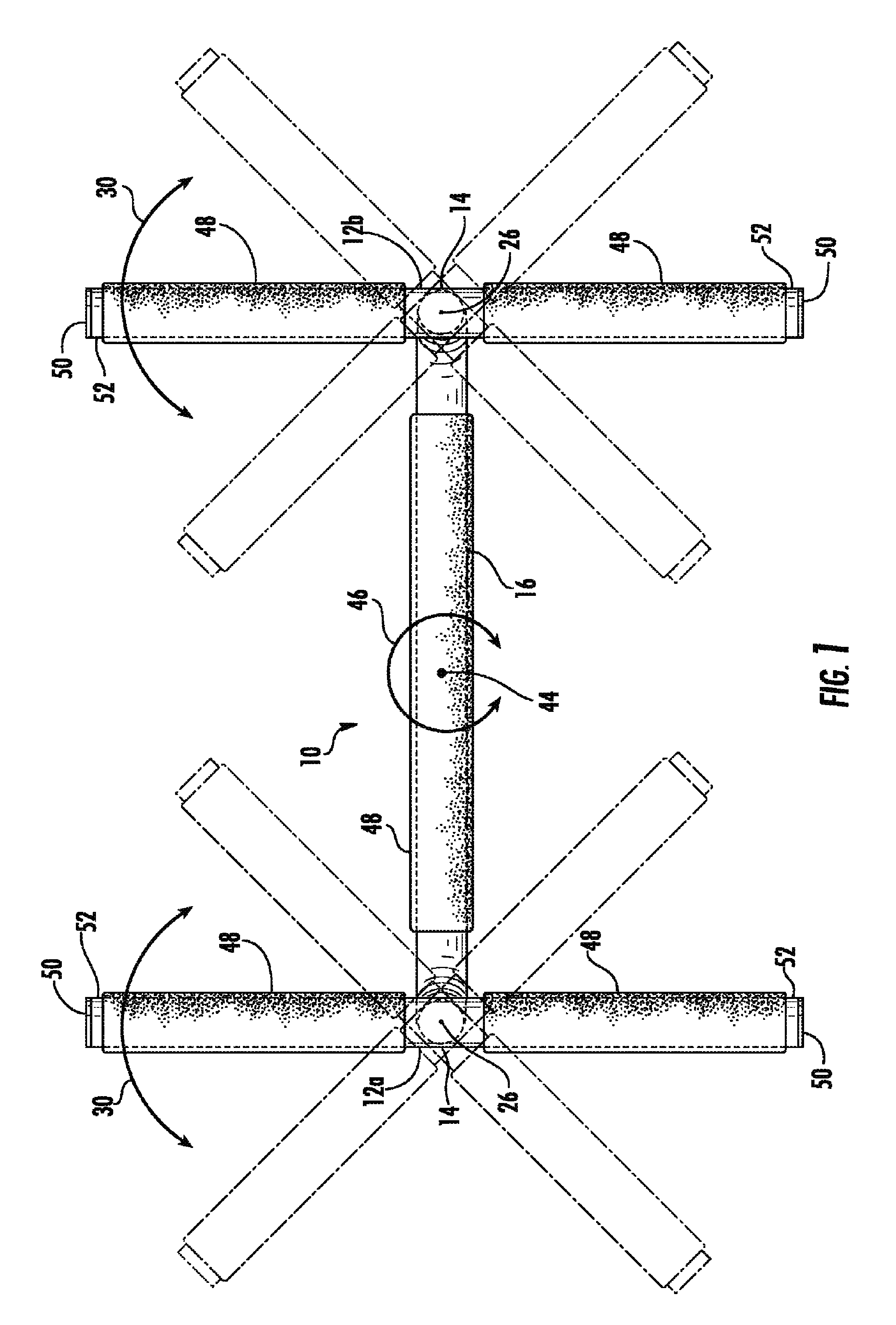

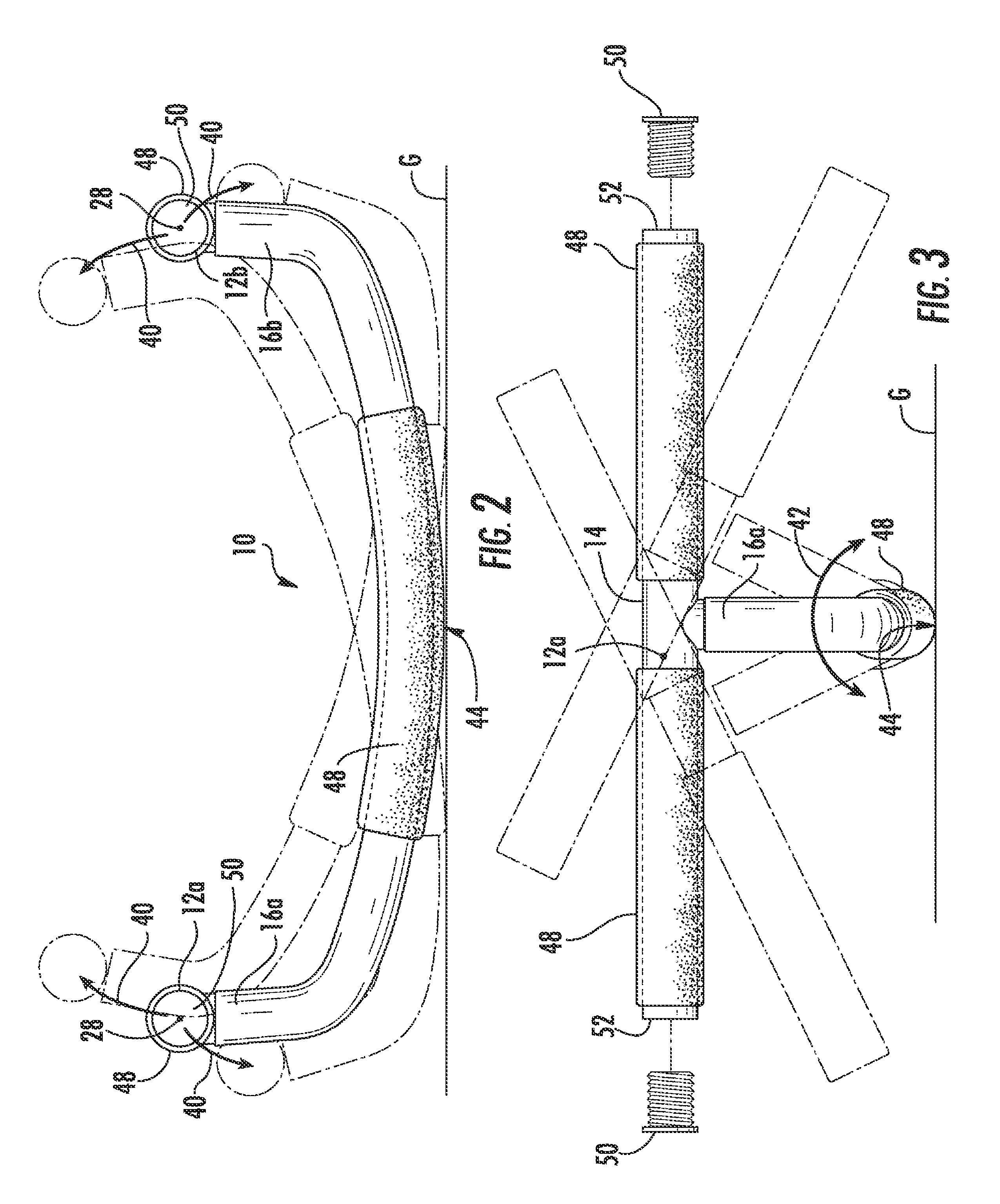

Core-strengthening exercise apparatus

A core-strengthening exercise apparatus is comprised generally of three primary components, namely a pair of identically shaped and configured swing arms each of which is pivotally mounted at or proximate to its midpoint to a substantially C-shaped transverse bar member. The apparatus has two general modes of use. In a first mode of use, referred to as the “static mode”, the subject apparatus may be oriented such that its swing arms rest on the floor with the bar member extending therebetween a distance above the floor to provide a stable gripping surface over which a plurality of exercises may be performed. In a second mode of use, referred to as the “dynamic mode”, the apparatus is flipped over such that only the bar member is in contact with the floor supporting the swing arms there above. In this mode, the user supports his or her upper body in the plank position over the apparatus by grasping either end of each swing arm and resting his or her forearms along the longitudinal axis thereof. The unique curvature and configuration of the bar member creates an inherently unstable interface between the user and the floor permitting side-to-side or back-to-front rocking motions, pivoting motions about a vertical axis, or combinations thereof, all requiring control over core muscles to prevent loss of balance.

Owner:SPRAGUE EDWIN J

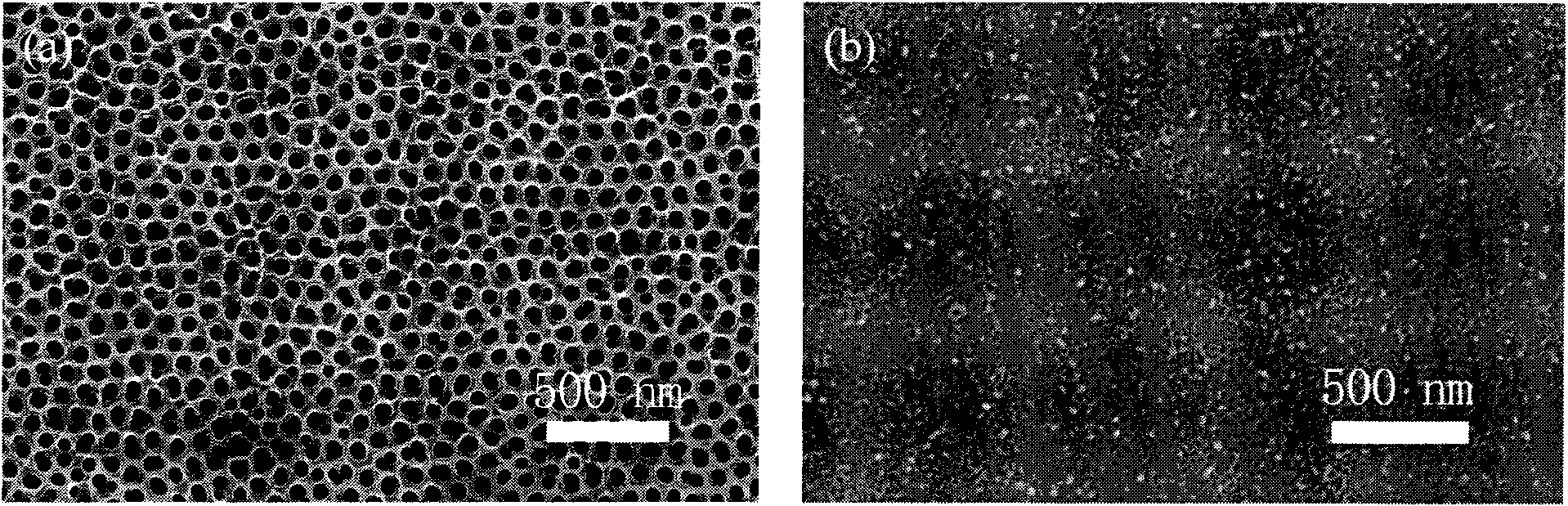

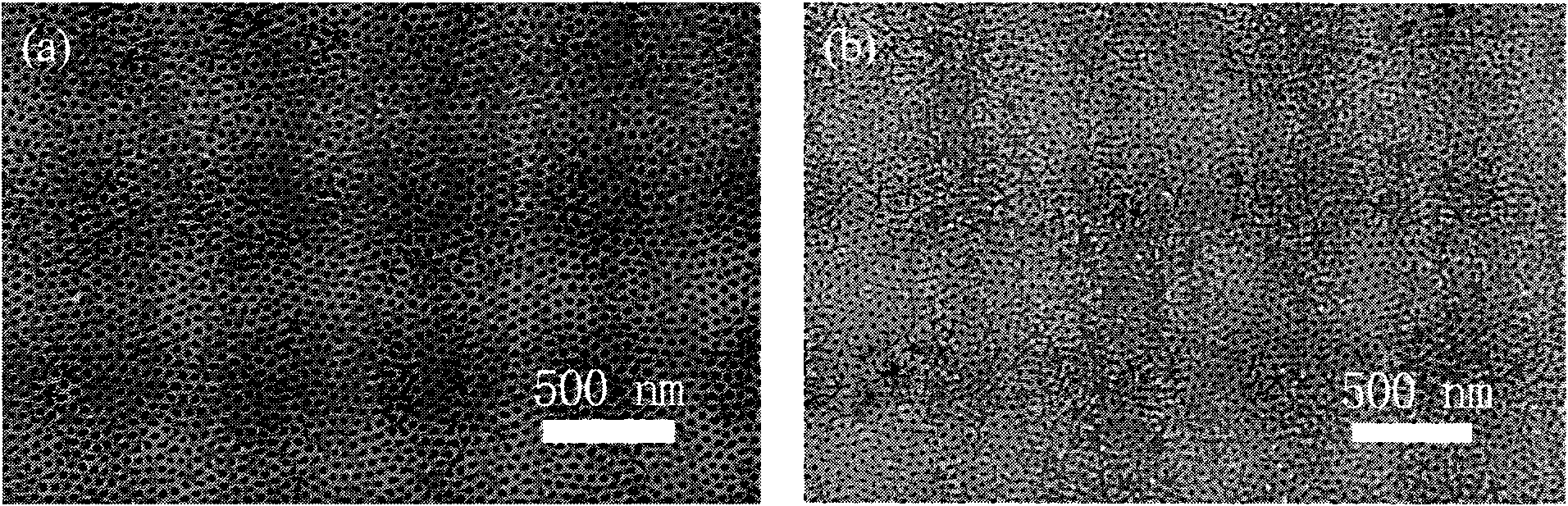

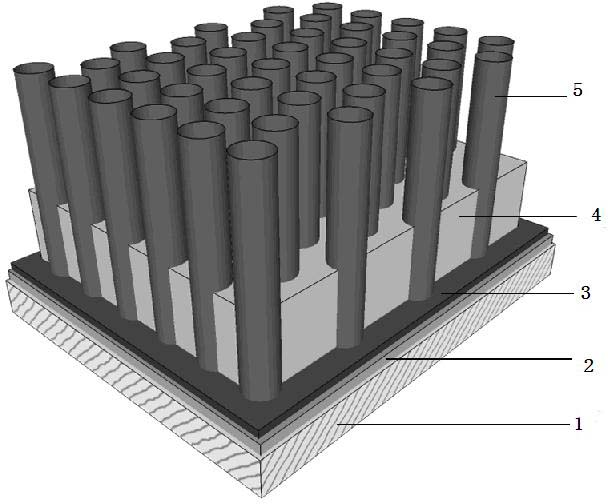

Method for preparing pore diameter controllable through hole anodized aluminum oxide film

The invention relates to technology for preparing an anodized aluminum oxide film, in particular to a method for preparing a pore diameter controllable through hole anodized aluminum oxide film. The method comprises the following steps of: performing anode electrolysis treatment on an anodized aluminum oxide film with an aluminum substrate in mixed solution of perchloric acid and acetone to obtain a pore diameter controllable anodized aluminum oxide film with two open ends in short time (2-300 seconds), wherein the pore diameters at the top end and the bottom end fo the anodized aluminum oxide film are accurately controllable in ranges of between 10 and 100nm and between 5 and 25nm; and putting the aluminum oxide film with the aluminum substrate subjected to stage depressurization-method oxidation into acetone solution of perchloric acid, and applying voltage 5-15V higher than film forming voltage for anode electrolysis treatment to obtain the pore diameter controllable through hole anodized aluminum oxide film. In the method, the pore diameters at the top end and the bottom end of the anodized aluminum oxide film can be respectively controlled, holing and removal of the aluminum substrate are completed by one step, and a plurality of problems of complicated process, time consumption, difficult control of pore diameters and the like in the conventional process for preparing the through hole anodized aluminum oxide film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

Copper base material cleaning agent and preparation method thereof

The invention provides a copper base material cleaning agent. The copper base material cleaning agent is composed of, by weight, 0.05%-2% of organic acid activators, 0.05%-1% of a nonionic surface activator, 0.01%-0.6% of an anion surface activator, 0.005%-0.2% of an antioxidant, 0.005%-0.2% of a chelating agent, and the balance deionized water. In addition, the invention discloses a preparation method of the copper base material cleaning agent. The copper base material cleaning agent is free of attenuation and controlling over the attenuation, can be directly used, does not contain heavy metal, is free of residues and can meet the processing requirements for copper before hot dipping; the surface of a copper base material processed by the cleaning agent is pure and is free of dark spots, oil contaminations, fingerprints and the like; accessories obtained after tinplating are free of exposed copper, dark spots and other defects, and the surfaces of the accessories are smooth.

Owner:THE NORTHWEST MACHINE

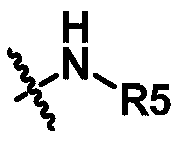

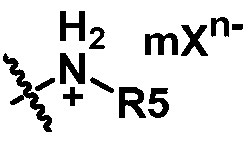

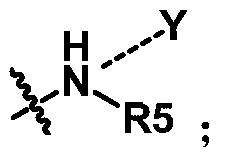

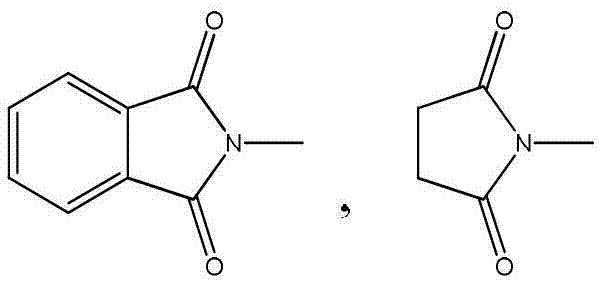

Degradable organic amines and organic aromatic ammonium salts latent epoxy resin curing agent and application

ActiveCN103254406AHigh quality recoveryClean surfaceOrganic compound preparationPlastic recyclingSolventChemistry

The invention provides a degradable organic amines and organic aromatic ammonium salts latent epoxy resin curing agent. The curing agent can be polymerized with epoxy resin to generate a degradable cross-linked polymer, and the degradable cross-linked polymer can be degraded in a mixed system of acid and solvent under the condition of heating and stirring. The invention also provides a prepreg which is composed of the curing agent, the epoxy resin, an auxiliary material and a reinforcing material. The invention also provides a reinforced composite material which is prepared by the curing agent, the epoxy resin, the auxiliary material and the reinforcing material. The reinforced composite material can be prepared by virtue of a prepreg forming method. The reinforced composite material can be degraded in the mixed system of the acid and the solvent under the condition of heating and stirring and recycled after neutralization. The reinforced composite material has excellent mechanical property and is suitable for different composite material application field. The degraded recycling method of the reinforced composite material is simple, economical, temperate in condition and easy to control.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

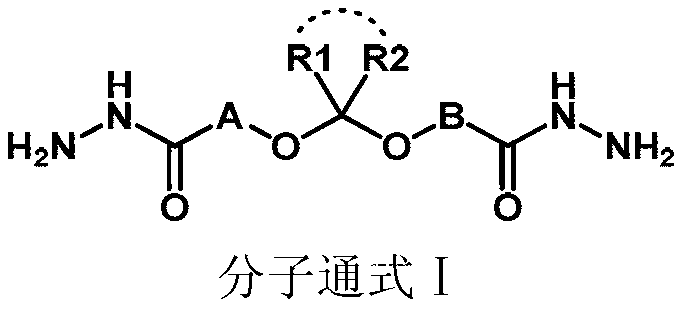

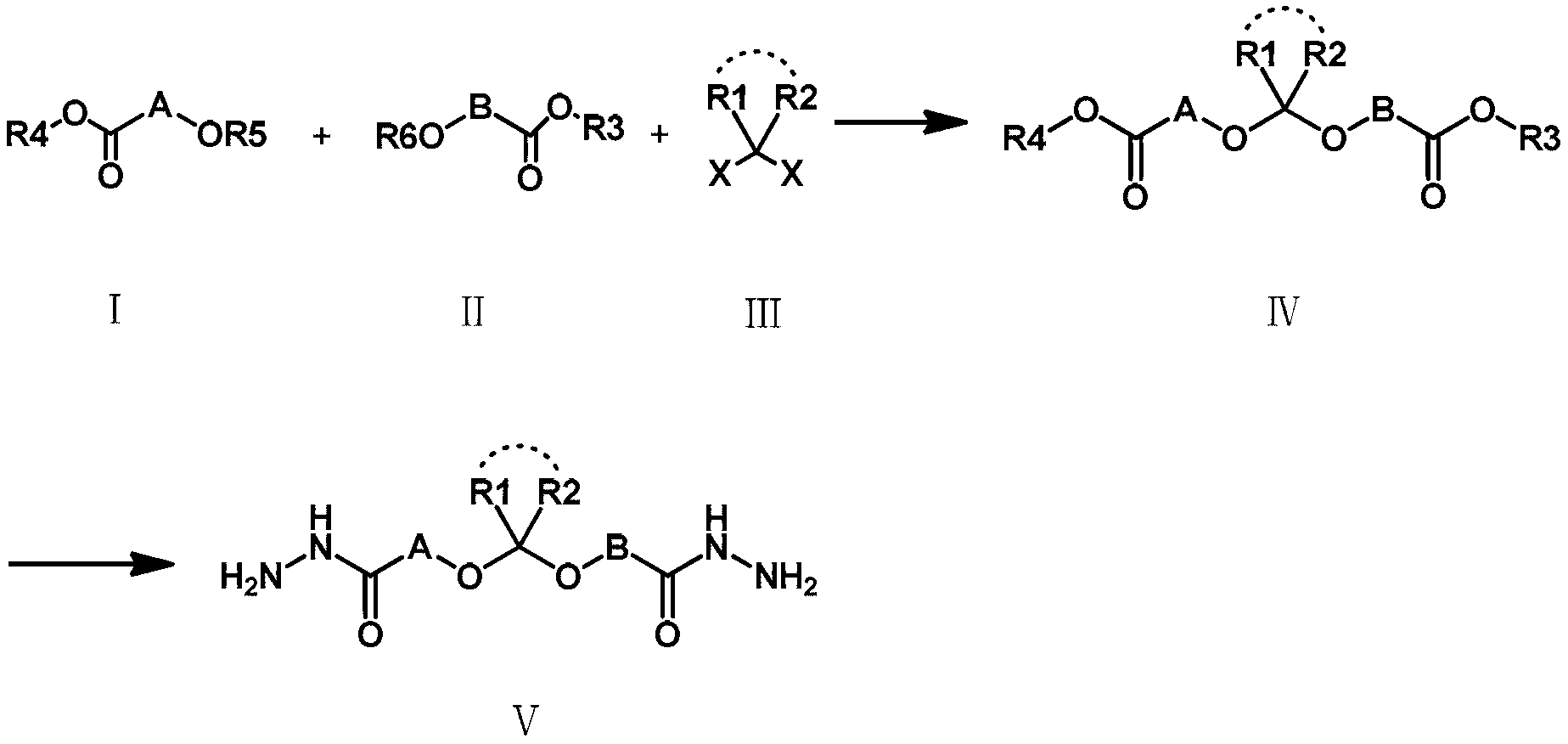

Degradable hydrazide latent epoxy resin curing agent and application thereof

ActiveCN103193959AOptimize operating timeModerate viscosityHydrazide preparationPlastic recyclingEpoxyCrosslinked polymers

The invention provides a degradable hydrazide latent epoxy resin curing agent. The curing agent can be polymerized with epoxy resin to generate a degradable crosslinked polymer; and the degradable crosslinked polymer can be degraded in a mixed system of an acid and a solvent under the conditions of heating and stirring. The invention also provides a prepreg, consisting of the curing agent, the epoxy resin, an auxiliary material and a reinforcing material. The invention also provides a reinforcing composite material which is prepared from the curing agent, the epoxy resin, the auxiliary material and the reinforcing material. The reinforcing composite material can be prepared by a prepreg forming method. The reinforcing composite material can be degraded in the mixed system of the acid and the solvent under the conditions of heating and stirring, and can be recycled and reused after being neutralized. The reinforcing composite material has excellent mechanical property and is suitable for the field of application of different composite materials; and the degrading and recycling method of the reinforcing composite material is simple, economic, mild in condition and easy to control.

Owner:芜湖天道绿色新材料有限公司

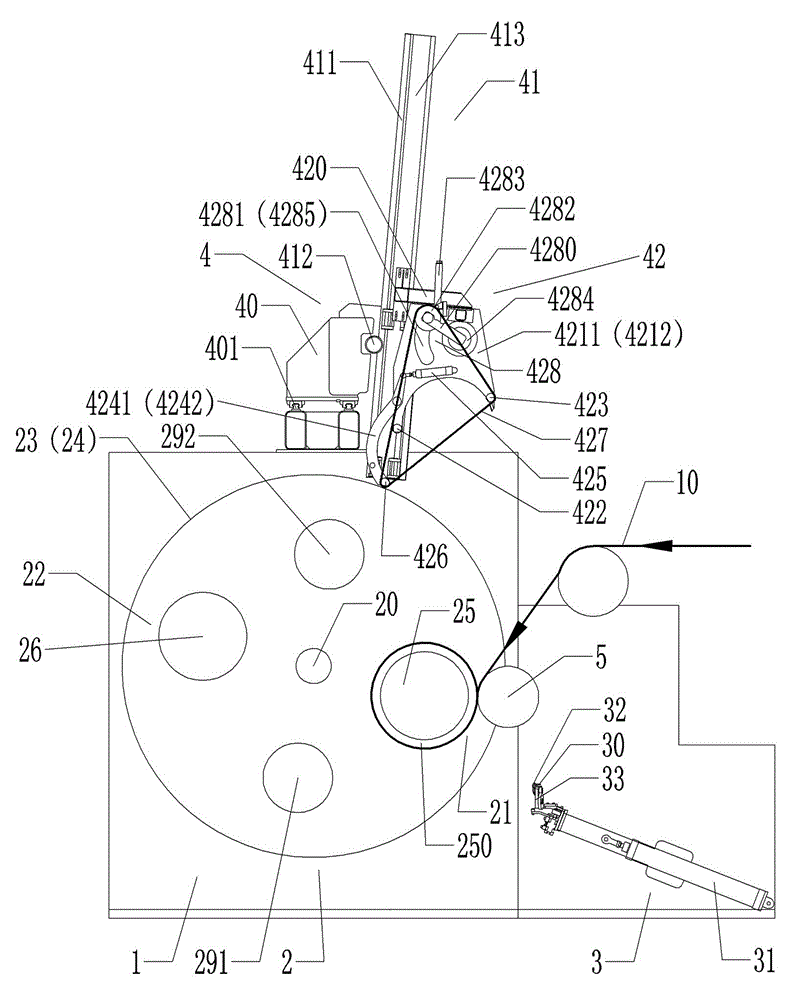

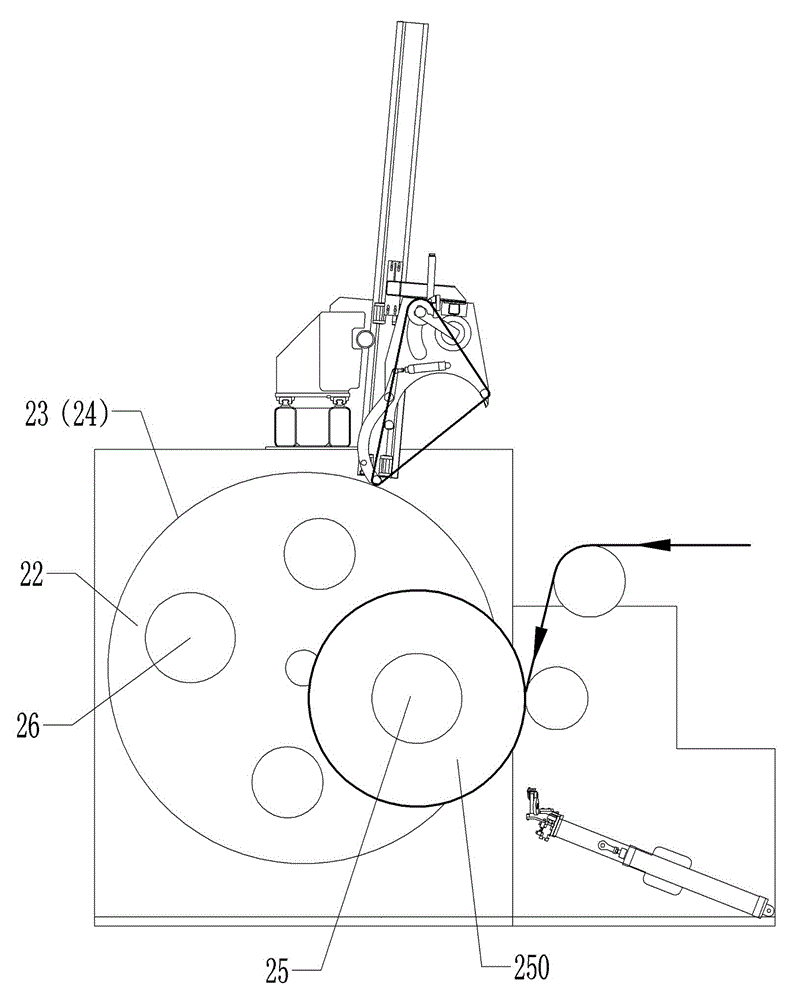

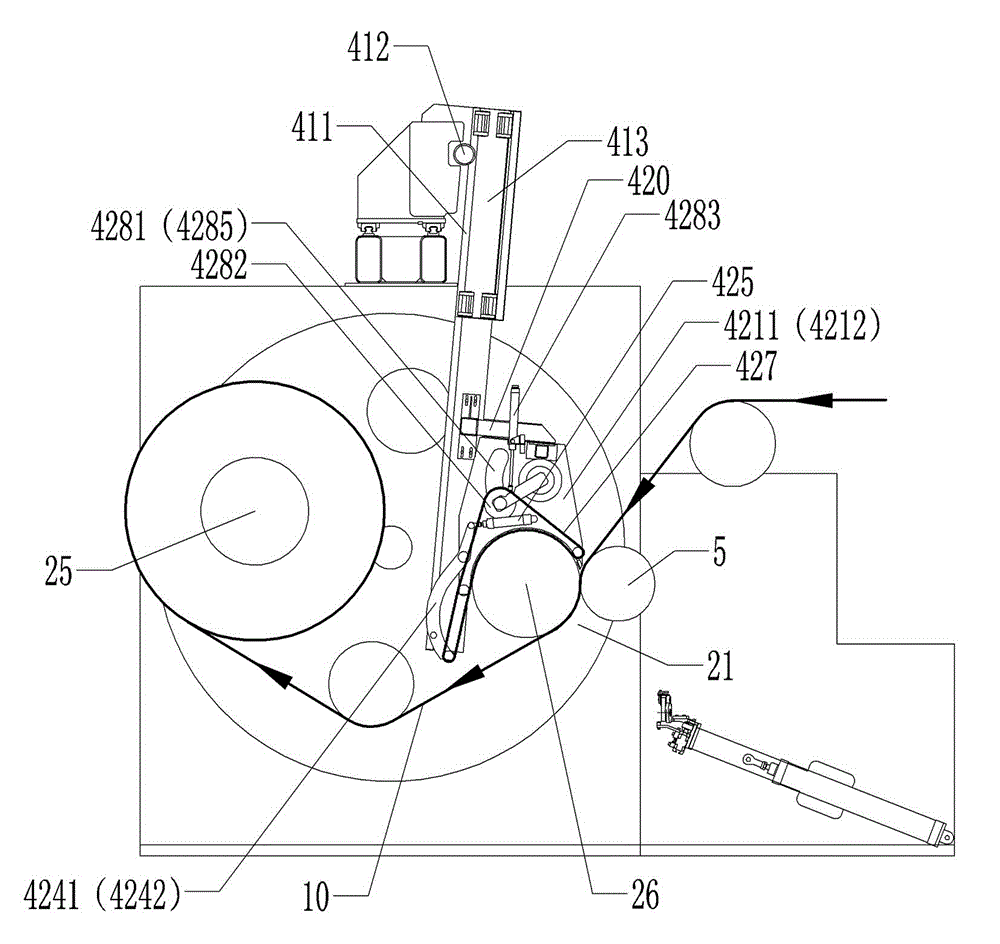

Automatic taking-up and roll changing device

An automatic taking-up reel alternation device comprises a machine frame, a double-station taking-up mechanism and an automatic roll changing mechanism, wherein the automatic roll changing mechanism comprises a cutter mechanism and an automatic roll feeding mechanism, and the automatic roll feeding mechanism comprises an arc-shaped roll feeding mechanism and a press roller. The cutter mechanism and the press roller are arranged on the machine frame. The press roller abuts against and is pressed on a taking-up shaft of a taking-up station through an elastic part. The automatic roll feeding mechanism is arranged on the machine frame at at-leaset one end of the double-station taking-up mechanism, the cutter mechanism and the arc-shaped roll feeding mechanism are located outside the double-station taking-up mechanism and are respectively located on two sides of a sheet on the double-station taking-up mechanism. The arc-shaped roll feeding mechanism and the taking-up shaft of the taking-up station are matched in a fitting or separated mode. When the arc-shaped roll feeding mechanism is fit with the taking-up shaft of the taking-up station, the opening of the arc-shaped roll feeding mechanism corresponds to the press roller, the leading-in end of the arc-shaped roll feeding mechanism is in contact with the sheet passing through the leading-in end, and a shear space is formed between the leading-in end of the arc-shaped roll feeding mechanism and the taking-up shaft of the taking-up station. The cutter mechanism extends into and retreats out of the shear space.

Owner:GUANGDONG JINMING MACHINERY

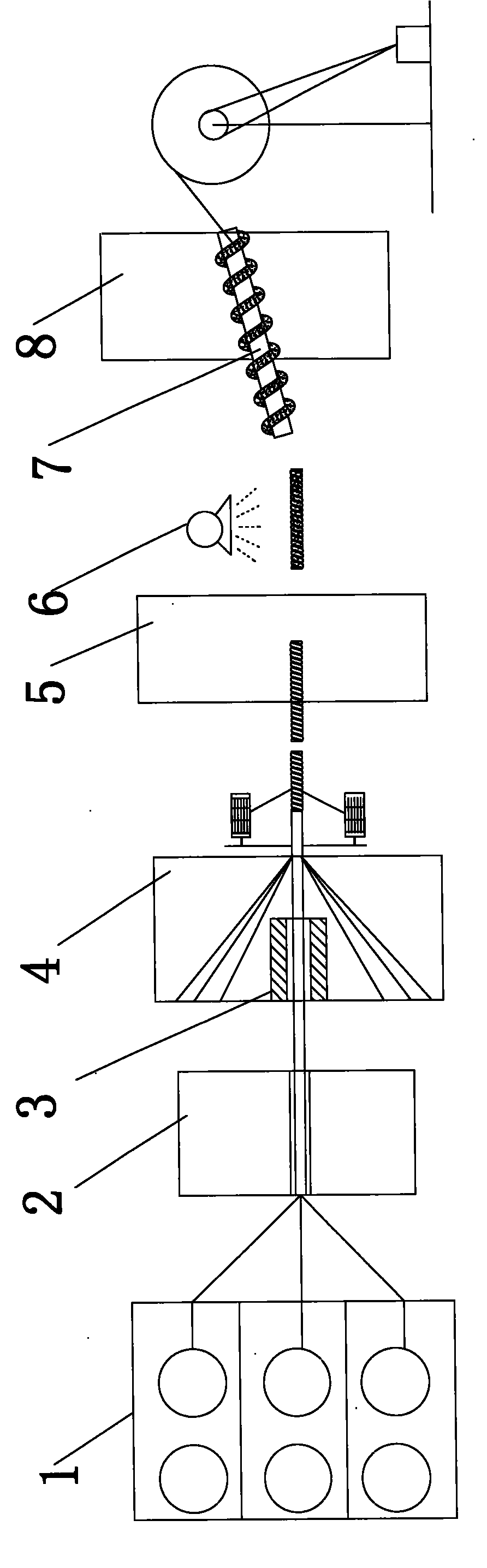

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

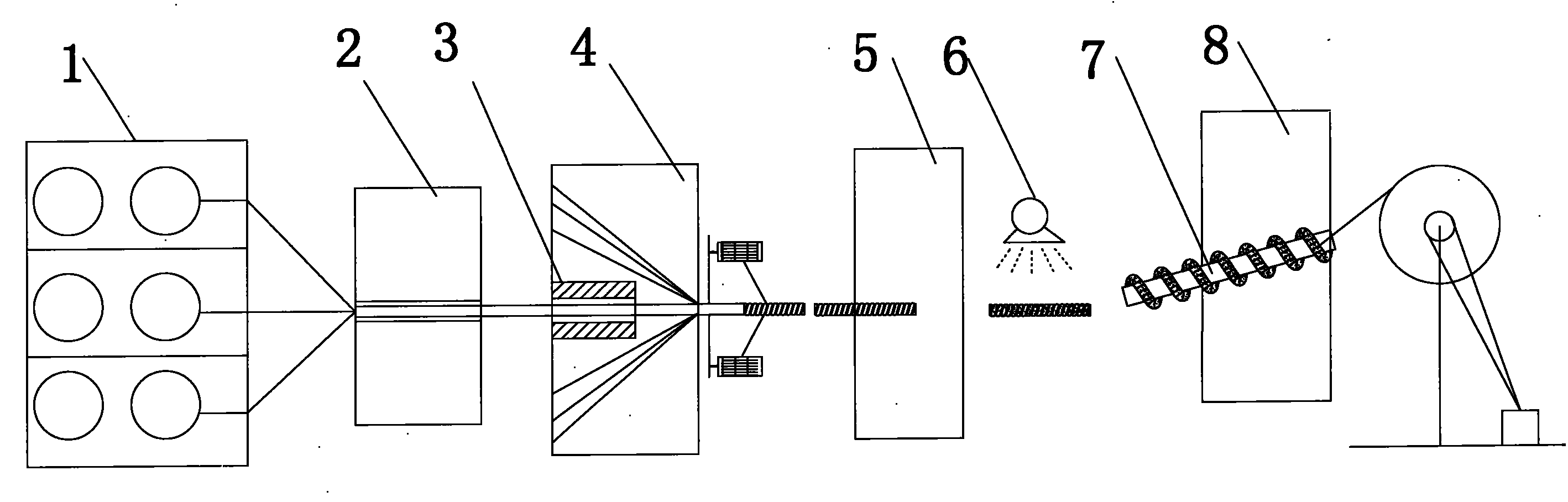

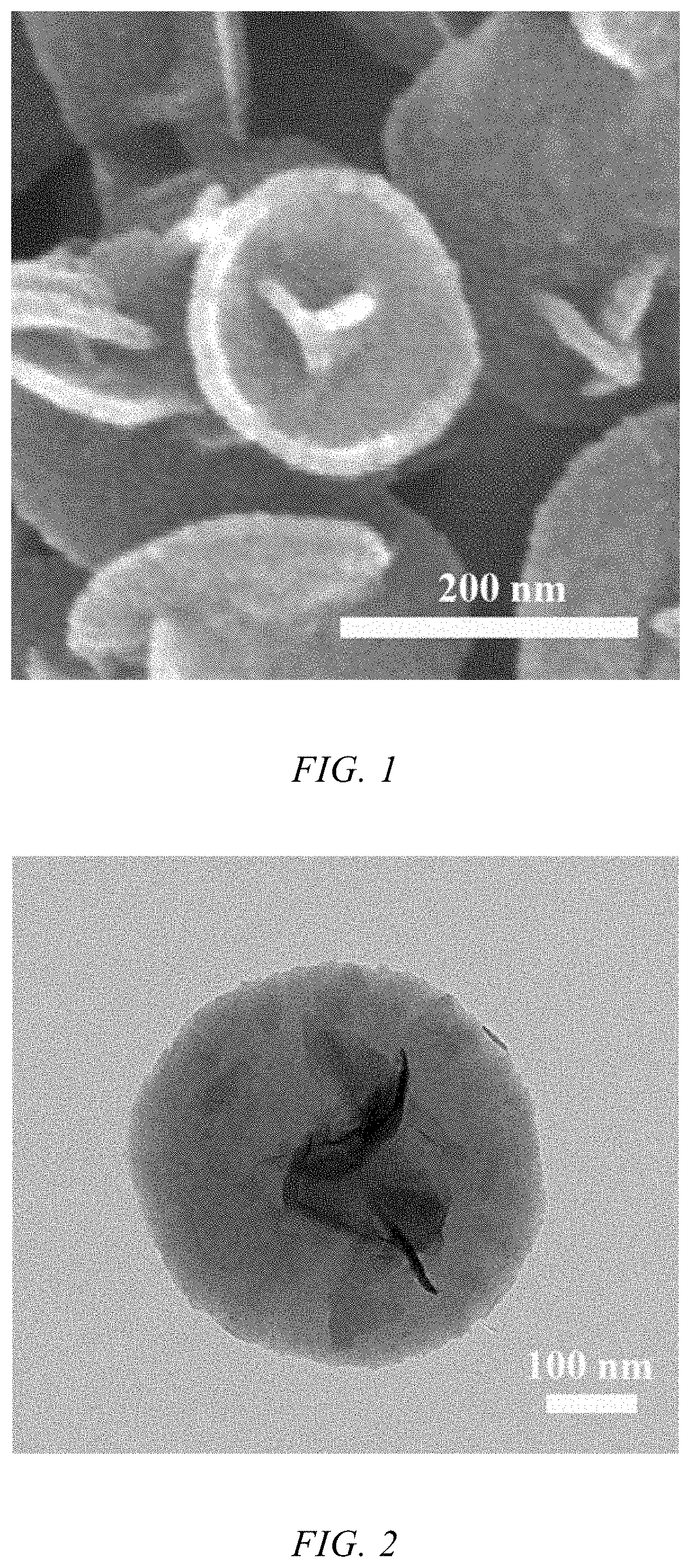

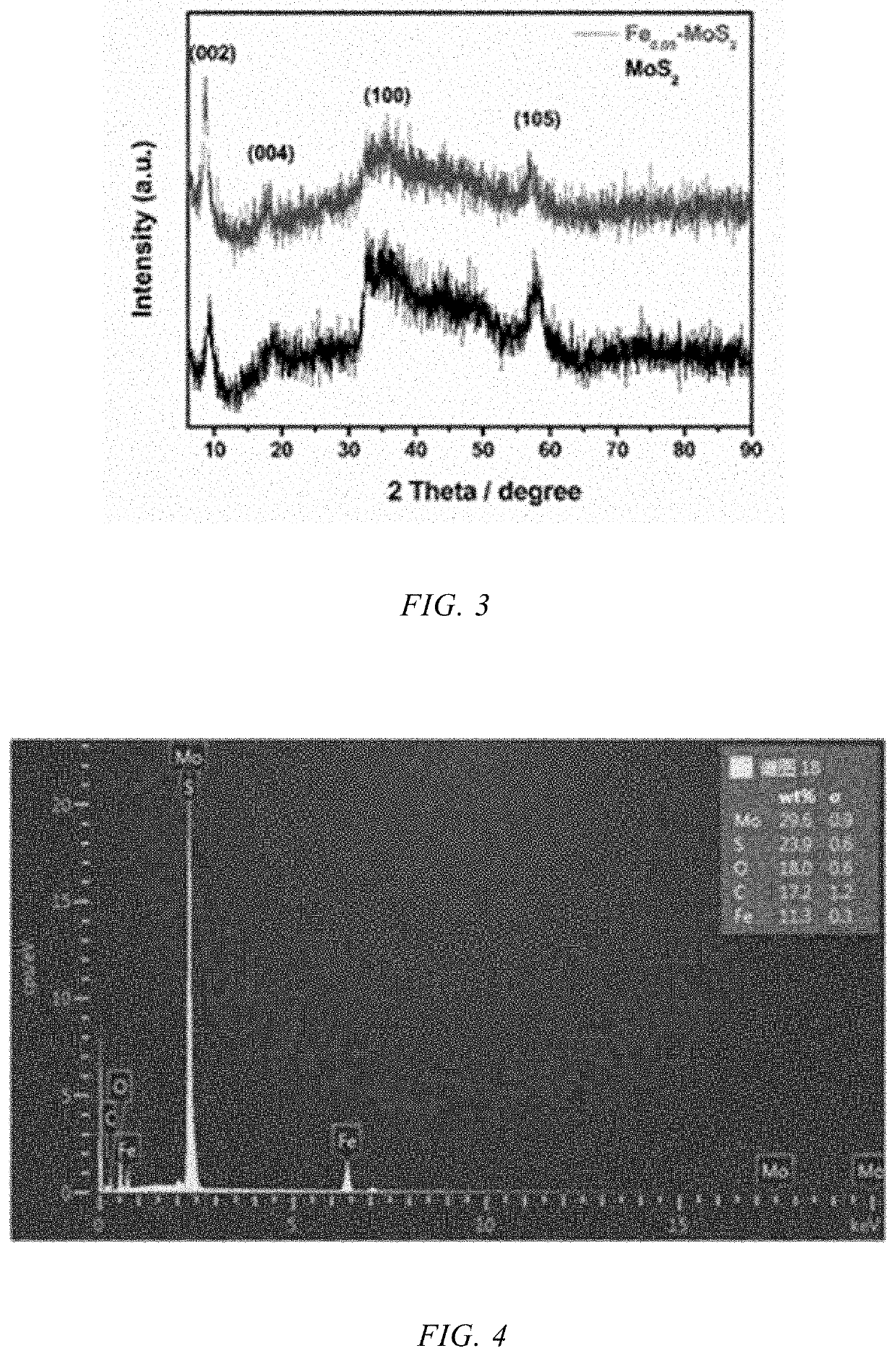

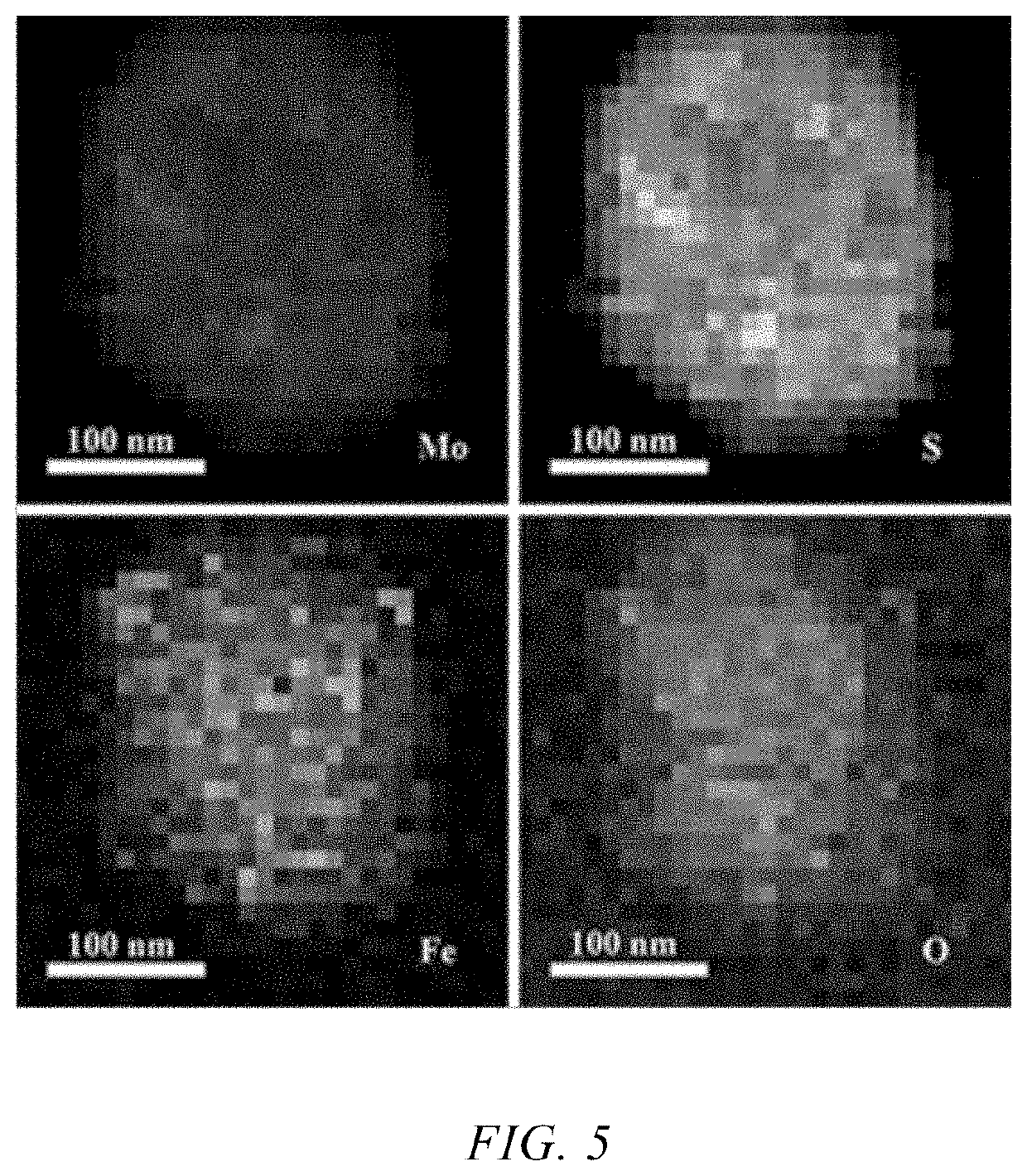

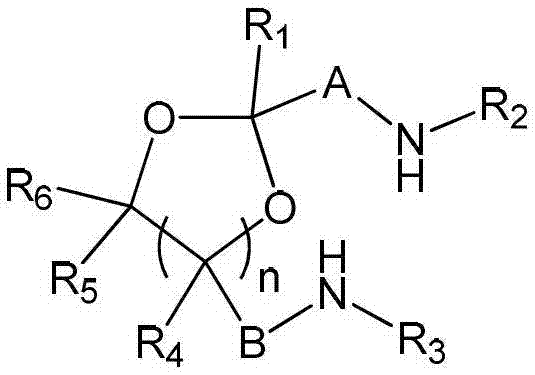

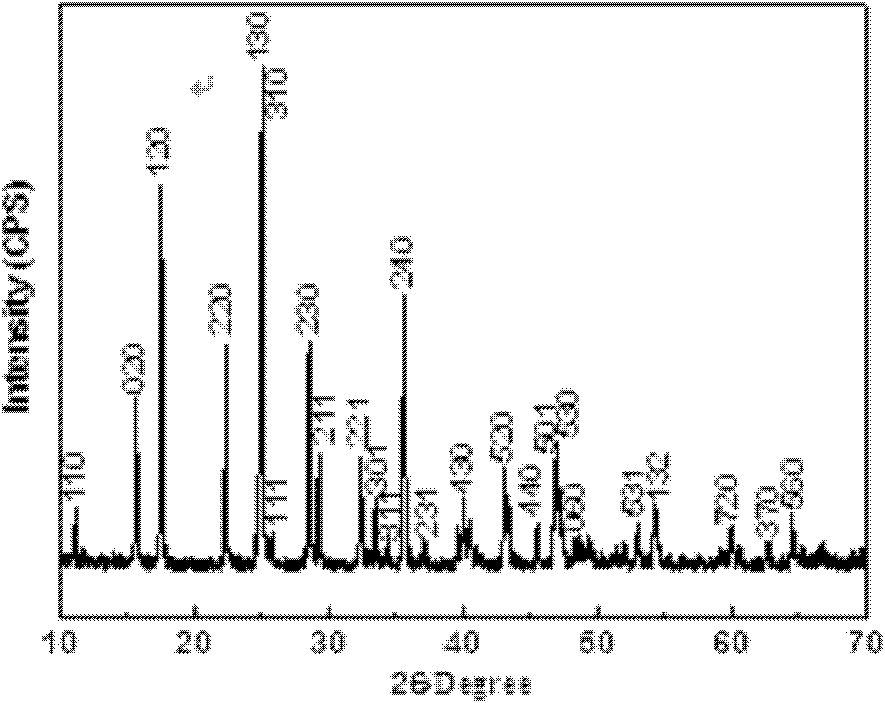

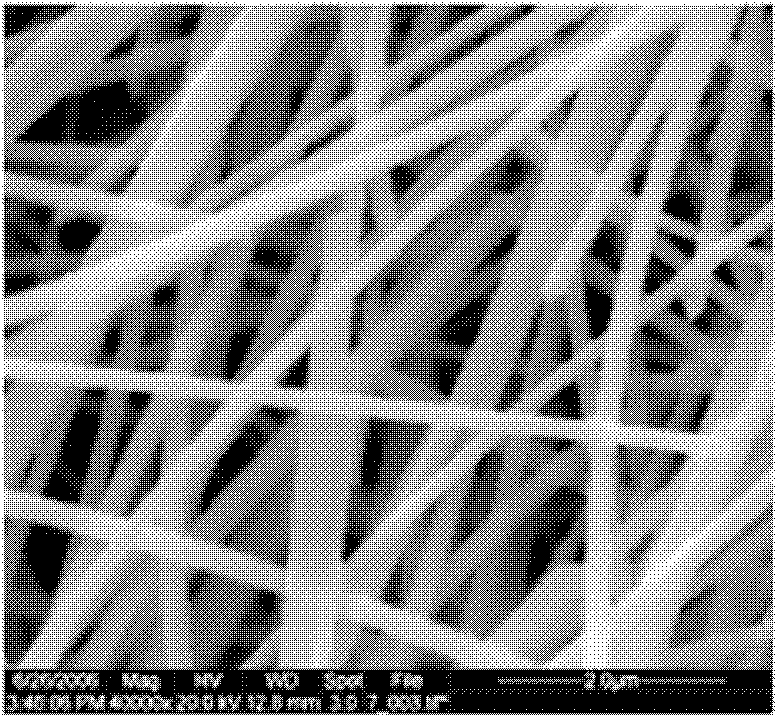

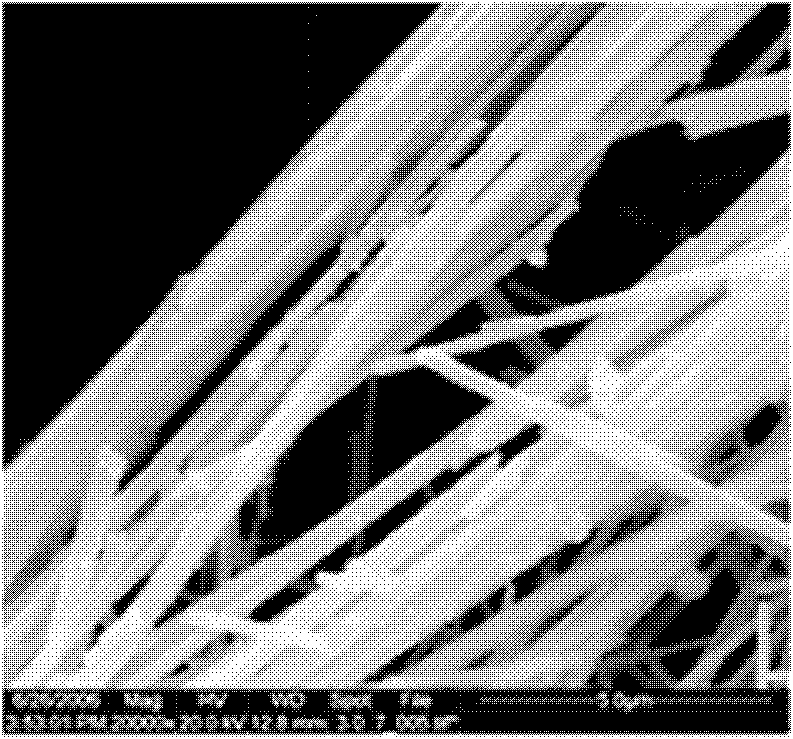

Fe-doped mos2 nano-material, preparation method therefor and use thereof

ActiveUS20210062350A1Surface cleaningEasy to cleanPhysical/chemical process catalystsMultiple component coatingsActive agentEngineering

The invention discloses a method for preparing a Fe-doped MoS2 nano-material, which comprises the following steps: dissolving a ferric salt and ammonium tetrathiomolybdate in DMF and reacting at 180-200° C. for 6-24 hrs to obtain a Fe-doped MoS2 nano-material. The present invention also provides a Fe-doped MoS2 nano-material supported by nickel foam, which includes a nickel foam substrate and the Fe-doped MoS2 nano-material loaded on the nickel foam substrate. Furthermore, the present invention also provides a preparation method and use of the above materials. In the invention, the desired product can be obtained by a one-pot solvothermal reaction, and thus the operation is simple. There is no need to introduce a surfactant for morphological control during the preparation process, and the resulting product has a clean surface and is easy to wash.

Owner:SUZHOU UNIV

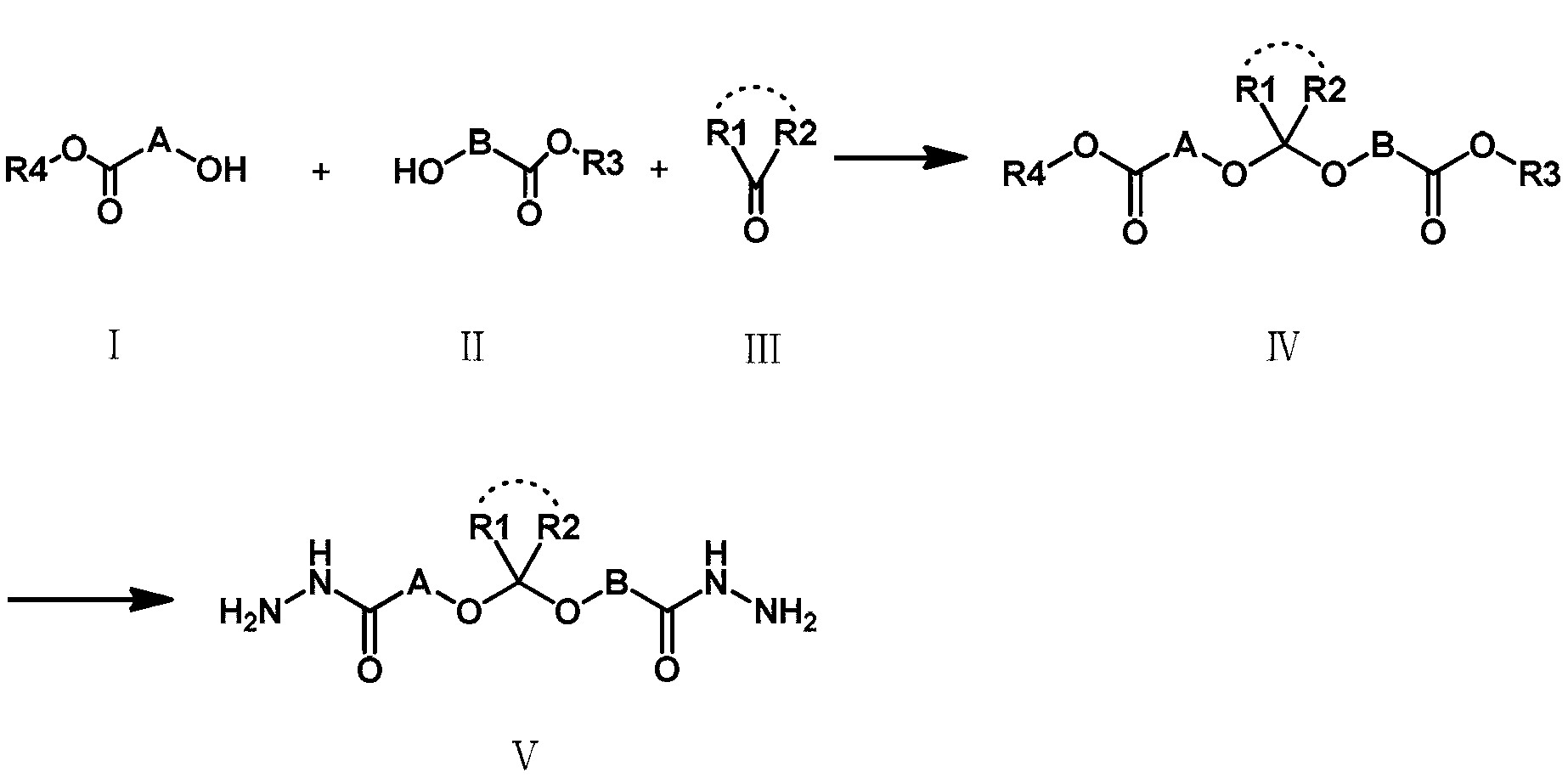

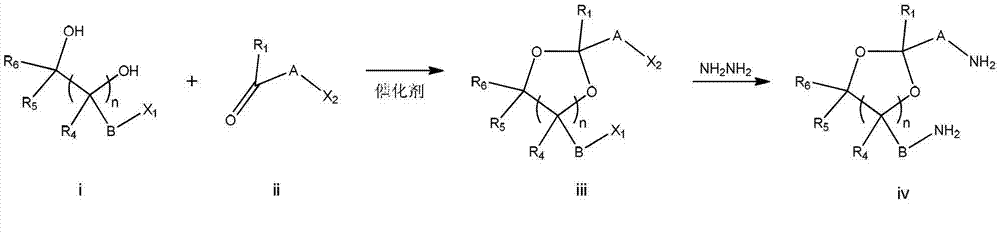

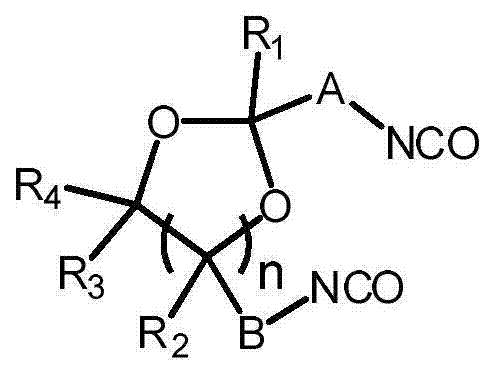

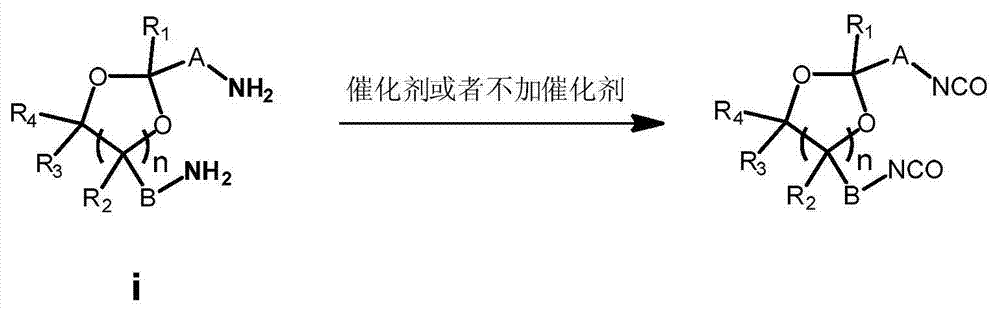

Degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent and application thereof

ActiveCN103242509ARetain mechanical propertiesImprove recycling efficiencyOrganic chemistryFibre chemical featuresPolymer scienceFirming agent

The invention provides a degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent. The curing agent can be polymerized with an epoxy resin so as to generate a degradable cross-linking polymer, wherein the degradable cross-linking polymer can be degraded in a mixing system of acid and solvents under the heating and stirring condition. The invention further provides an enhanced composite material which is prepared from the curing agent, the epoxy resin, auxiliary materials and enhancing materials; and the enhanced composite material can be degraded in the mixing system of acid and solvents under the heating and stirring condition, and can be recycled and reused after being neutralized. The enhanced composite material has excellent mechanical properties, is applicable to application fields of different composite materials, and the degrading and recycling method is simple, economic, mild in condition and easy to control.

Owner:ADESSO ADVANCED MATERIALS WUHU CO LTD

Galvanized steel sheet coating material and its production method

InactiveCN1807667AExtended service lifeImprove fatigue resistanceMetallic material coating processesSheet steelRare earth

The invention discloses a coating material and producing method of galvanized steel sheet, which comprises the following elements: Al 50%-60%, Zn 38%-47%, SiO 5%-3%, RE 0. 05%-0. 3%, wherein the producing method comprises the following steps: adding 50%-60%Al in founding furnace; heating-up to 795-805deg. c; adding in 0. 5-3 percent Si; mixing equably; heating-up to 845-855deg. c and joining 0. 05-0. 3% RE; stirring equably; heating-up to 860-880deg. c and adding in 38-47 percent Zn; mixing evenly and placing for 35min. The invention improves corrosion resistance and fire resistant property of coated rolled steel.

Owner:JIANGSU LINLONG NEW MATERIALS

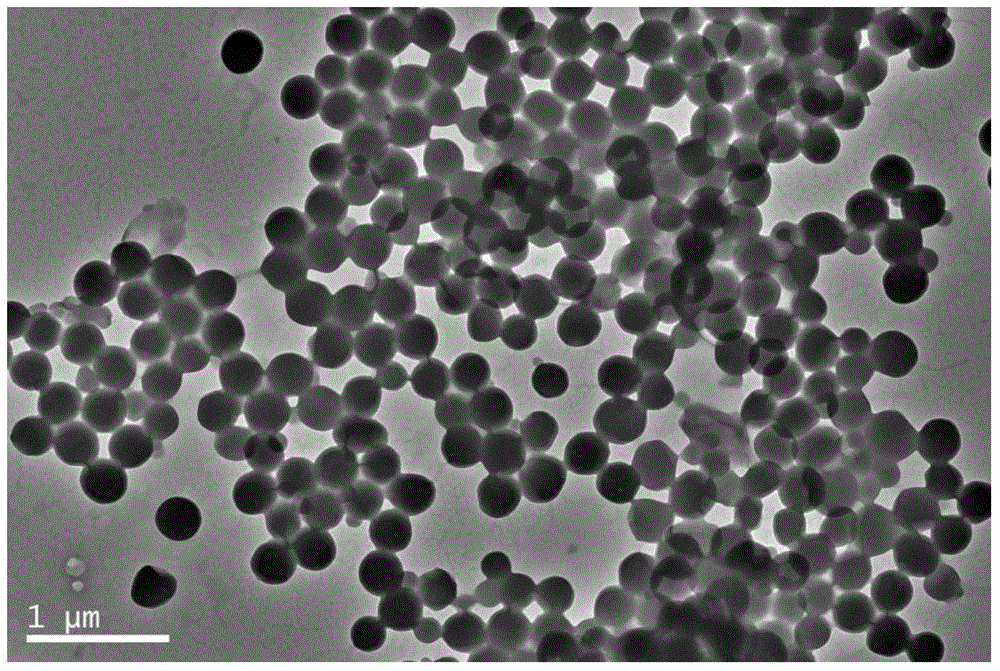

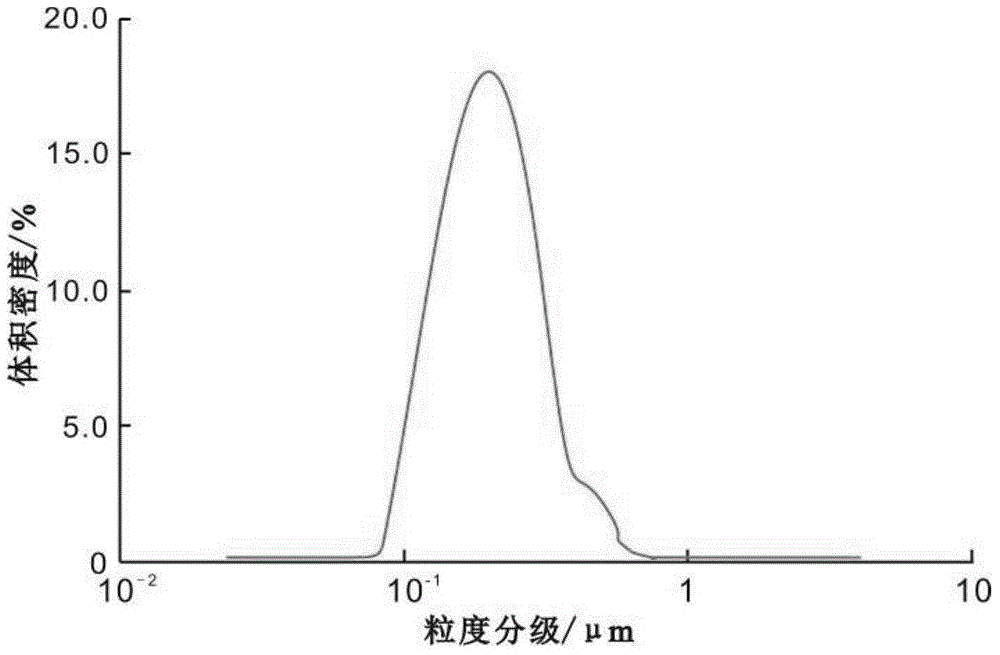

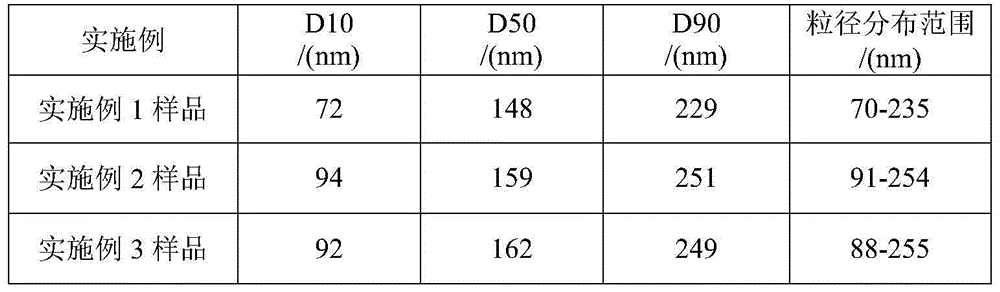

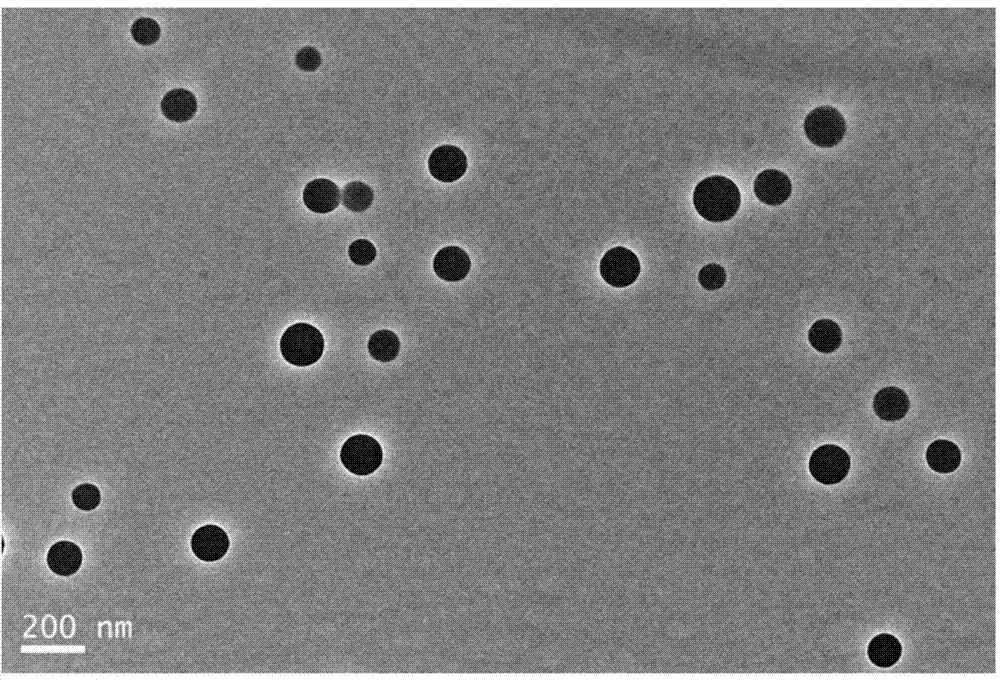

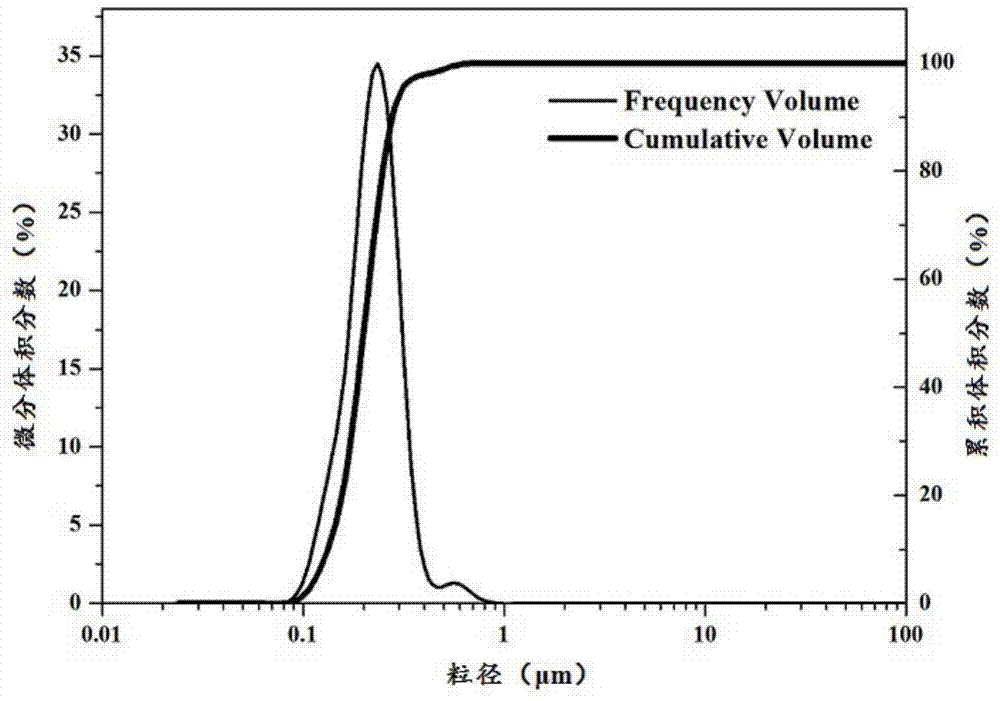

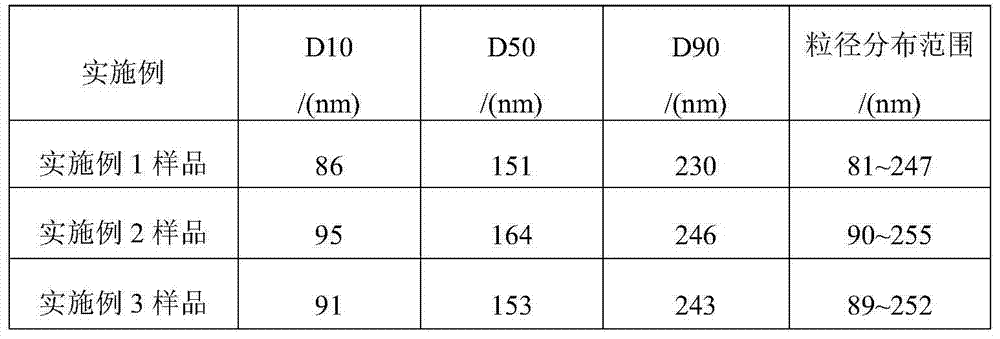

Temperature-sensitive-type intelligent nano particles used in drilling fluid and preparation method thereof

InactiveCN105038728AGood dispersionImprove water resistanceDrilling compositionHydrophilic monomerPressure transmission

The invention relates to a temperature-sensitive-type intelligent nano particles used in a drilling fluid and a preparation method thereof. In the invention, a silane coupling agent is used for performing ultrasound surface modification to nano SiO2 and a vinyl functional group is introduced. With the surface-modified nano SiO2, a temperature-sensitive-type monomer and a hydrophilic monomer are subjected to a polymerization reaction in a water medium with a co-solvent with addition of an initiator, wherein granularity distribution of the temperature-sensitive-type intelligent nano particles is D10 <= 100 nm, D 50 <= 165 nm and D90 <= 260 nm. When the temperature is higher than a sensitive value, the nano particles achieve double functions of both physical blocking and chemical inhibition, so that a continuous compact hydrophobic blocking layer is formed inside shale, thereby achieving effects of preventing and delaying pressure transmission and filtration invasion, and further enhancing stability of a shale well wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of shale micro/nano particle plugging agent for water-base drilling fluids

ActiveCN104762071AGood monodispersity and water resistanceClean surfaceDrilling compositionSolventNanometre

The invention relates to a preparation method of a shale micro / nano particle plugging agent for water-base drilling fluids. The method comprises the following step: adding an initiator to initiate polymerization reaction on acrylate or methacrylate monomer and vinyl monomer in a water medium in the presence of a cosolvent. The particle size distribution of the micro / nano particle plugging agent is D10<=100nm, D50<=165nm and D90<=260nm. The water-base shale micro / nano particle plugging agent provided by the invention is micro / nano deformable polymer latex particles, can form a continuous compact plugging layer inside the shale under the actions of adsorption, bridging and deformable filling, performs the function of preventing and relieving pressure transfer and filtrate invasion, and enhances the stability of the shale well wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

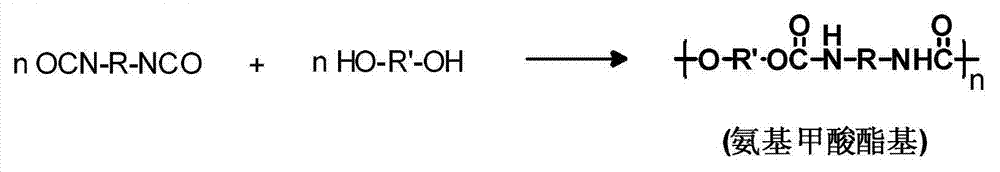

Degradable isocyanate and application thereof

InactiveCN103694140AEasy to controlEfficient recyclingIsocyanic acid derivatives preparationOrganic compound preparationPolymer scienceFirming agent

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

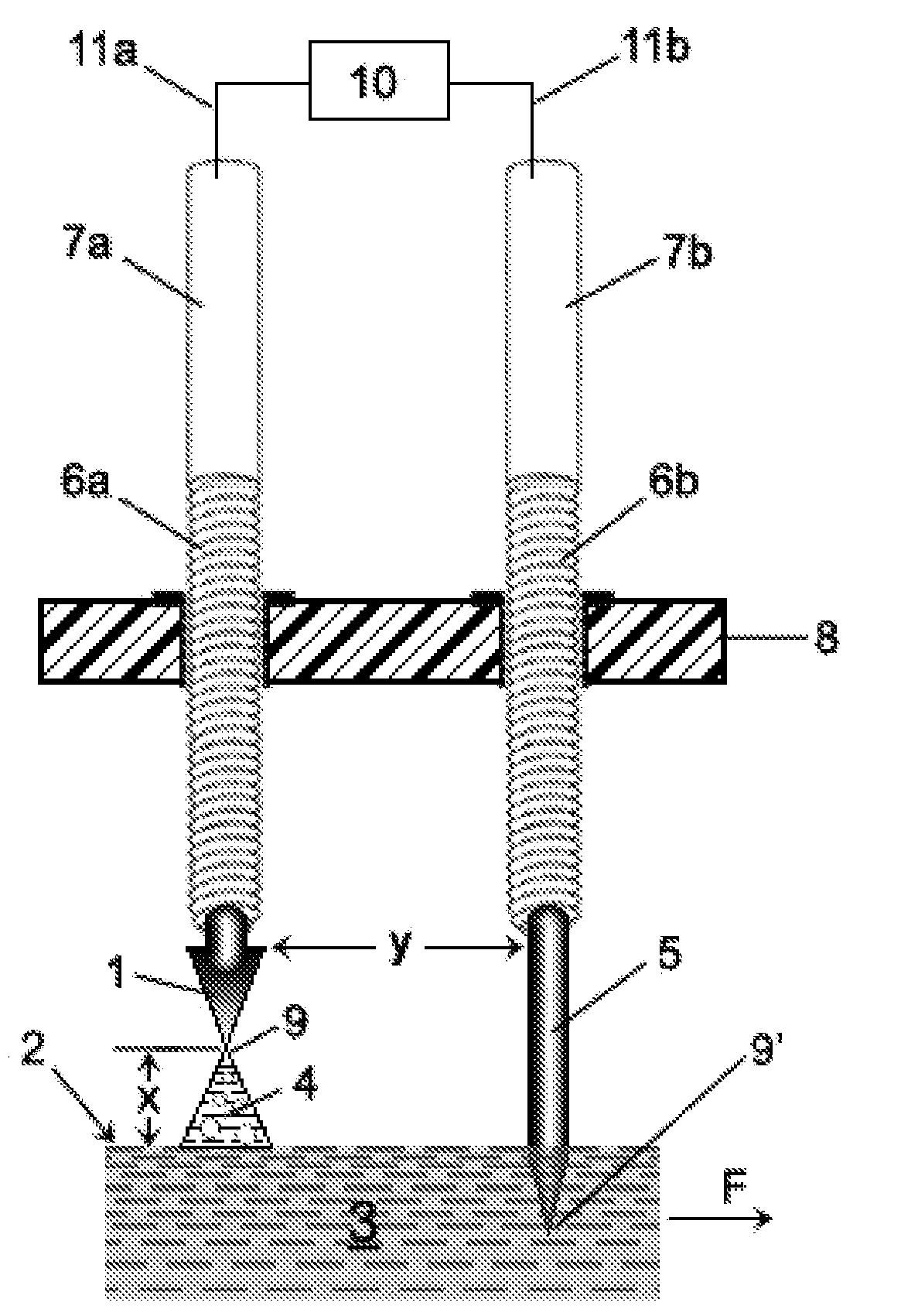

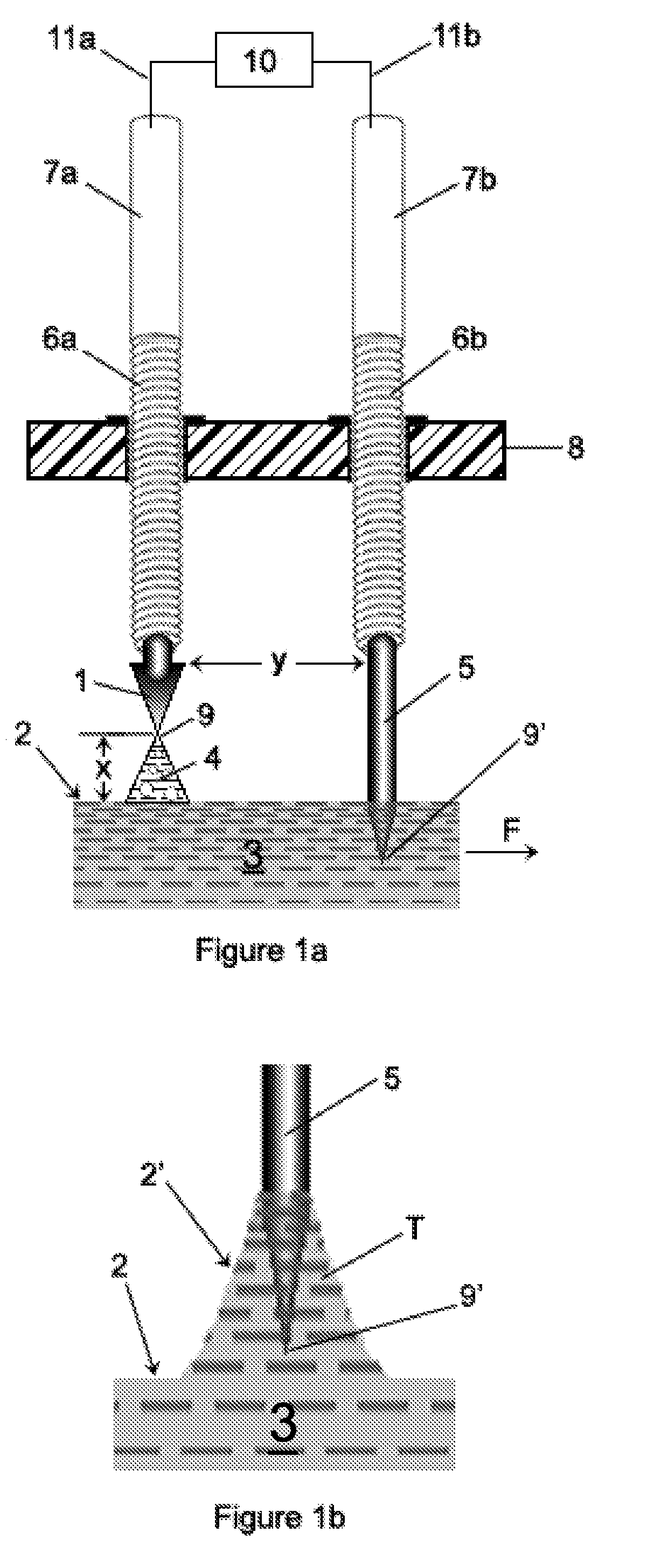

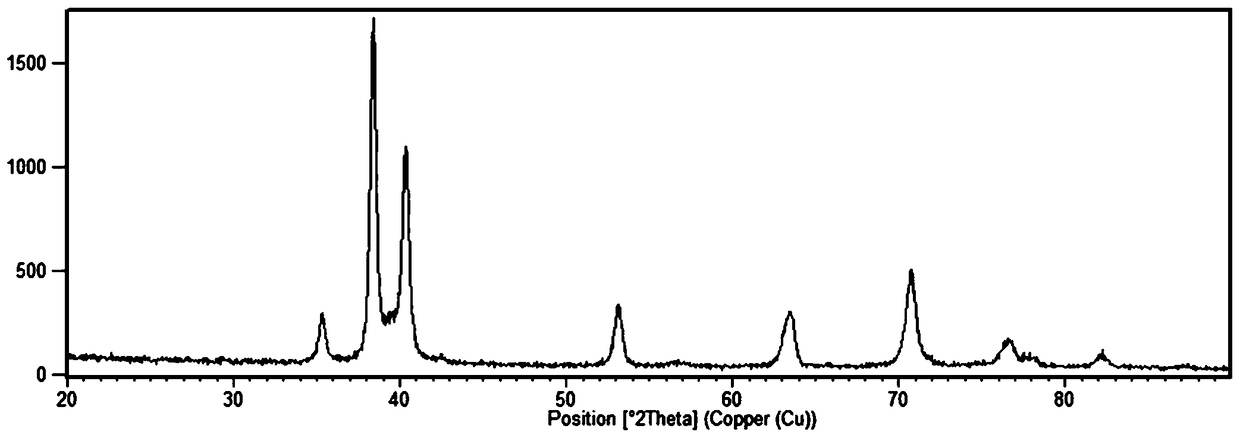

Novel Gold-Based Nanocrystals for Medical Treatments and Electrochemical Manufacturing Processes Therefor

ActiveUS20130259903A1Clean surfaceLess toxicAntibacterial agentsPowder deliveryMacrophage migration inhibitory factorChronic inflammatory disease

The present invention relates to novel gold nanocrystals and nanocrystal shape distributions that have surfaces that are substantially free from organic impurities or films. Specifically, the surfaces are “clean” relative to the surfaces of gold nanoparticles made using chemical reduction processes that require organic reductants and / or surfactants to grow gold nanoparticles from gold ions in solution. The invention includes novel electrochemical manufacturing apparatuses and techniques for making the gold-based nanocrystals. The invention further includes pharmaceutical compositions thereof and the use of the gold nanocrystals or suspensions or colloids thereof for the treatment or prevention of diseases or conditions for which gold therapy is already known and more generally for conditions resulting from pathological cellular activation, such as inflammatory (including chronic inflammatory) conditions, autoimmune conditions, hypersensitivity reactions and / or cancerous diseases or conditions In one embodiment, the condition is mediated by MIF (macrophage migration inhibiting factor).

Owner:CLENE NANOMEDICINE INC A NEVADA CORP

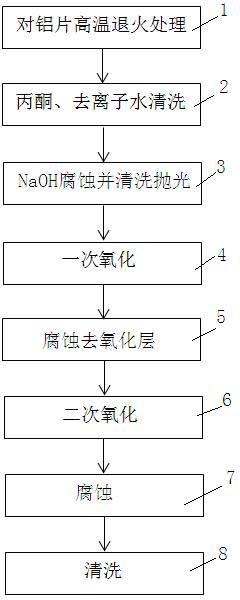

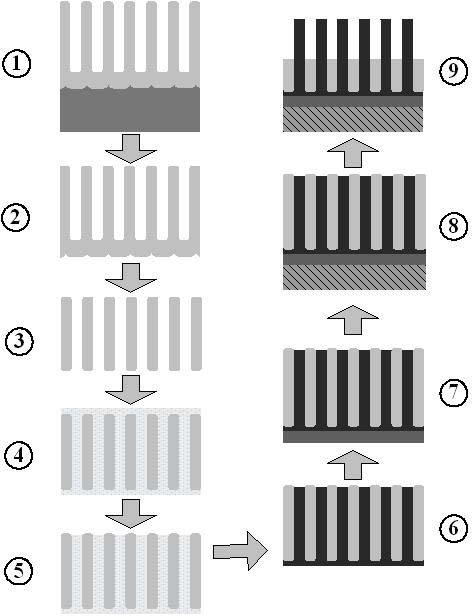

Method for making anodized aluminum template and method for making field emission cathode array material using the template

ActiveCN102262989AArrangement rulesImprove uniformityAnodisationCold cathode manufactureNanoholeCarbonization

The invention relates to a method for manufacturing an anodic aluminum oxide template and a method for manufacturing a field emission cathode array material by using the aluminum oxide template. The anodic aluminum oxide template with a regular appearance and a clean surface is manufactured by adopting a series of surface protection measures; and a field emission vertical nanowire or nanotube array cathode material is manufactured by pouring organic substances, metal organic solution or sol into a nano hole of the aluminum oxide template by a water method, a heat method and the like through processes such as gelation, high temperature carbonization, aluminum oxide template removal and the like. The field emission cathode material manufactured by the method has regular appearance and low starting voltage during field emission performance test; furthermore, the method process is simpler; and manufacturing of large-area field emission materials can be realized easily.

Owner:FUZHOU UNIV

Method for preparing silicon carbide particle reinforced aluminum matrix composite material

The invention belongs to the field of metal materials, and relates to a method for preparing a silicon carbide particle reinforced aluminum matrix composite material. The method comprises the following steps of: carrying out ball milling on Al-Si alloy powder for 4-16 hours, mixing the Al-Si alloy powder with modified graphite powder or copper-coated graphite powder through adopting a physical mechanical method for 4-20 hours, putting the mixture into a mould to be subjected to cold press molding, and putting a cold press molding block body into a vacuum furnace or a sintering furnace under the inert atmosphere protection, wherein the heating temperature is 670-1200 DEG C, and the insulating time is 15-120 minutes; and then carrying out hot extrusion molding on the block, and cooling the furnace so as to obtain the in-situ formation silicon carbide particle reinforced aluminum matrix composite material. By utilizing the method, the silicon carbide particle reinforced aluminum matrix composite material with excellent comprehensive mechanical properties such as high strength and high abrasion resistance can be prepared, and the preparation method is simple, low in cost and suitable for large-scale industrial production.

Owner:SHANDONG UNIV

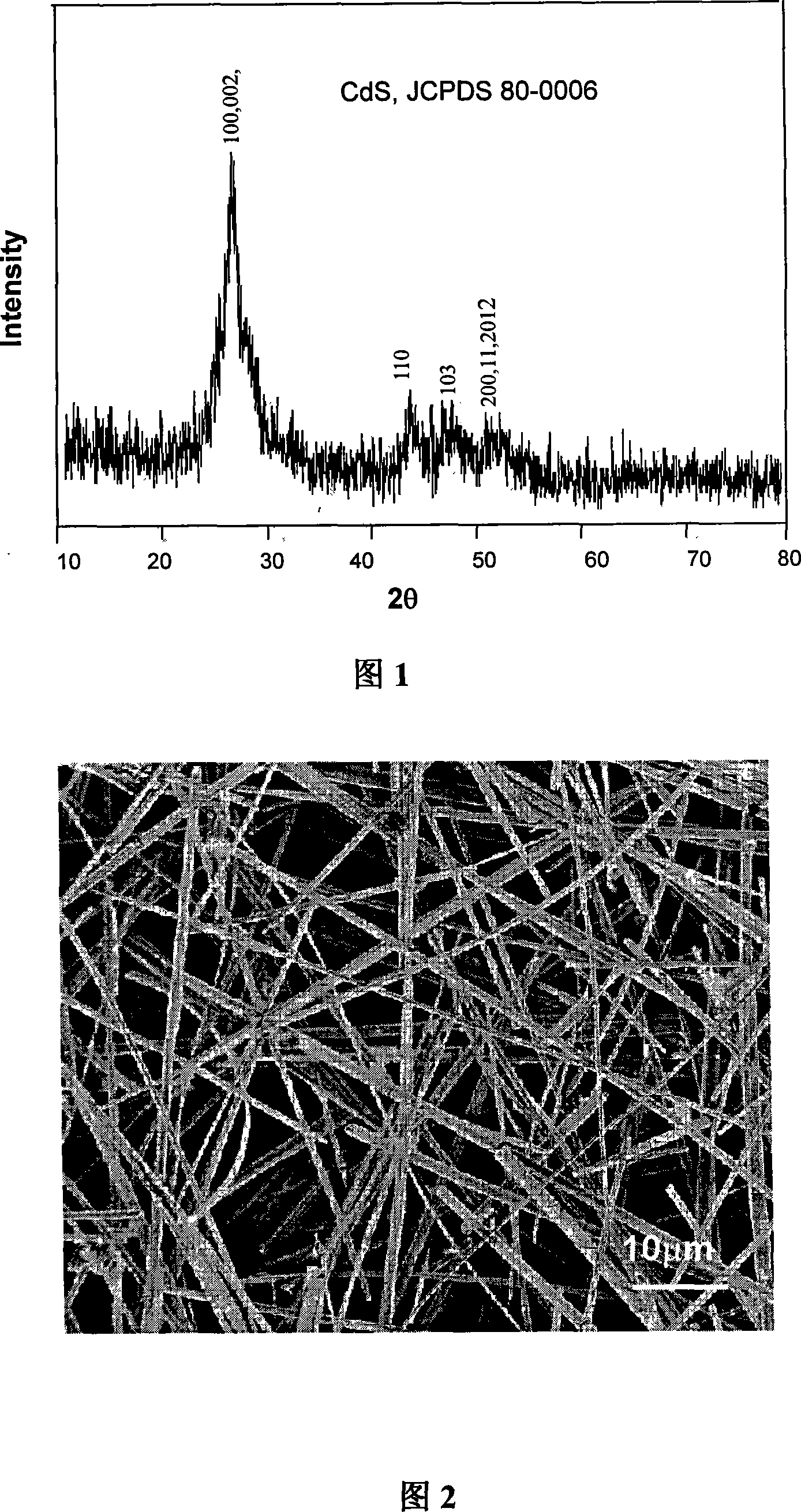

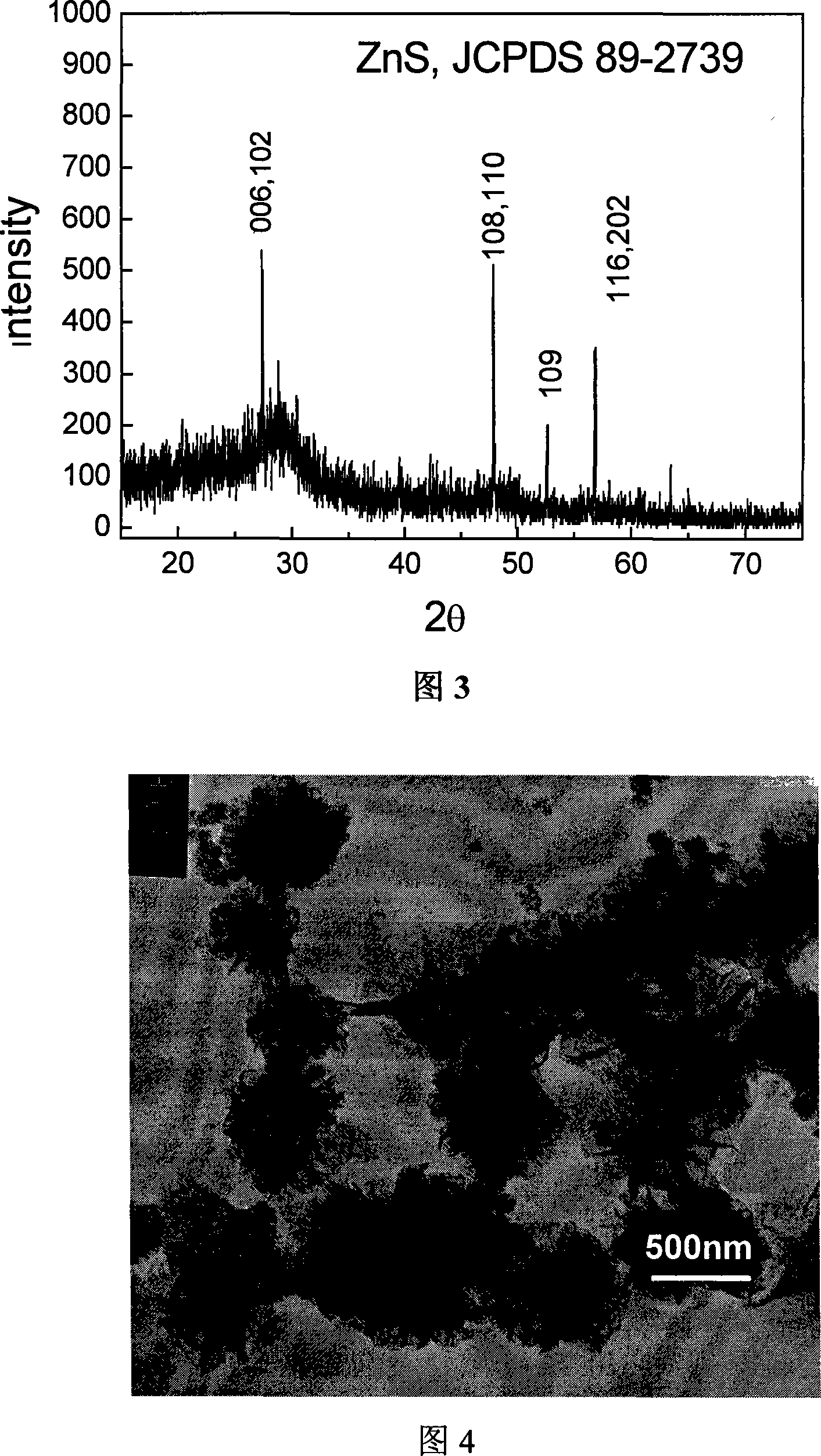

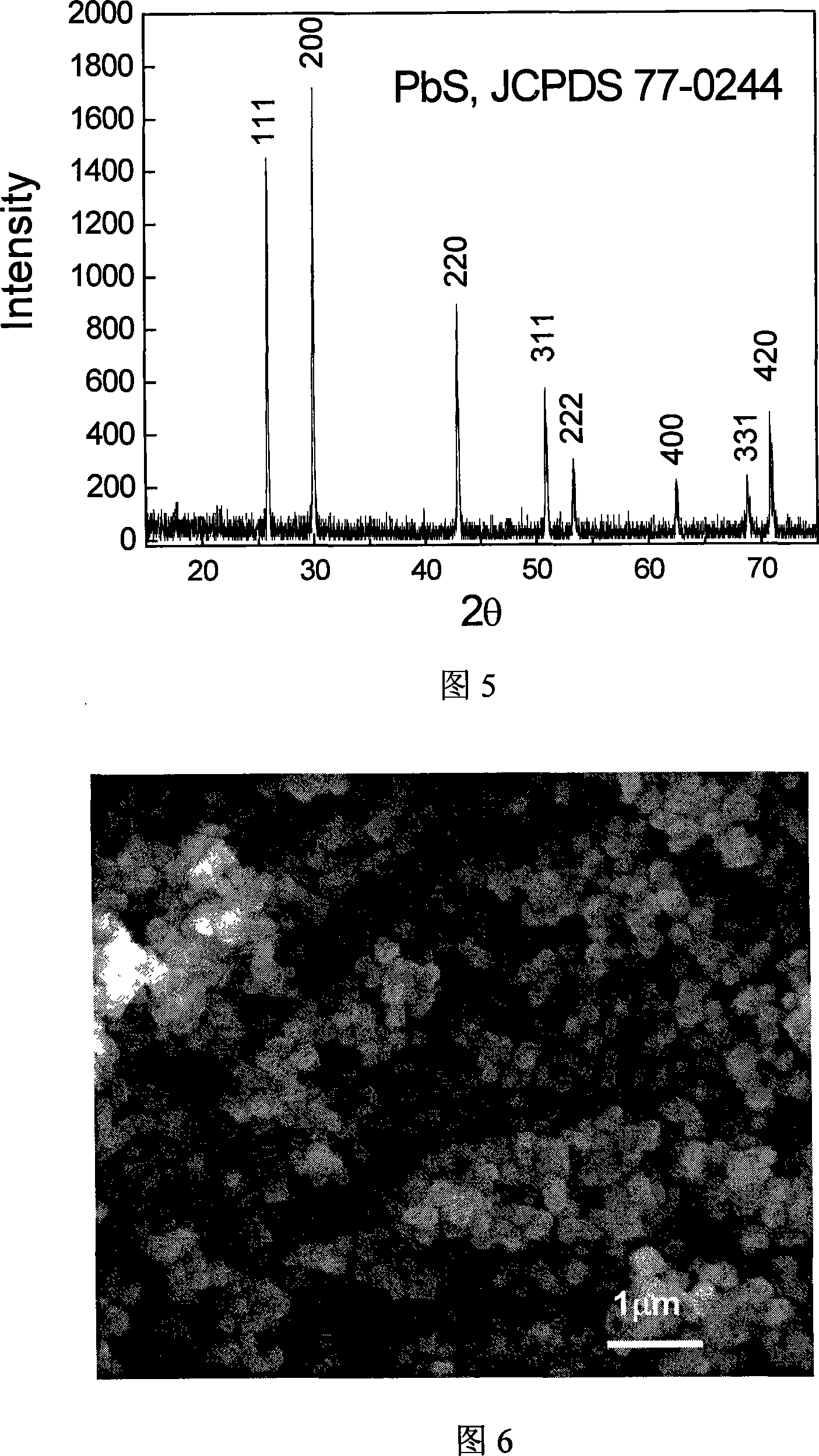

Compound alkali metal hydrate dissolvent synthesis method for metallic sulfide nano crystal material

InactiveCN101112974AFew controllable parametersLower synthesis costAlkali metal sulfides/polysulfidesSolventChemistry

The invention discloses a preparation method for a metal sulfide and a composite metal sulfide nano crystal material, which is suitable for the preparation of the nano crystal materials of cadmium sulfide, cuprous sulfide, zinc sulfide, lead sulfide, bismuth sulfide, and zinc-cadmium sulfide. The method is characterized in that water or organic solvent used in the existing hydrothermal or solvent thermal synthetic methods is replaced with melt composite alkali metal hydroxide which is synthesized through a chemical reaction under the normal atmosphere and a temperature between 100 and 300 DEG C. The raw materials used are soluble inorganic metal salts and sulfide or sulfide compounds, thereby having less controllable parameters and simple art, and being able to amplify manufacturing during the process of synthesis. Metal sulfide crystal produced has the advantages of good crystal, clean surface and even size, and is suitable for the research on the intrinsic properties and the maximum play of the functions of the nano crystal materials. The metal sulfide and the composite metal nano crystal materials have properties of a semiconductor, LED and optoelectronic, thereby being suitable for biomarker and preparation of a nano electronic apparatus, an LED apparatus and an optoelectronic apparatus.

Owner:CHONGQING UNIV

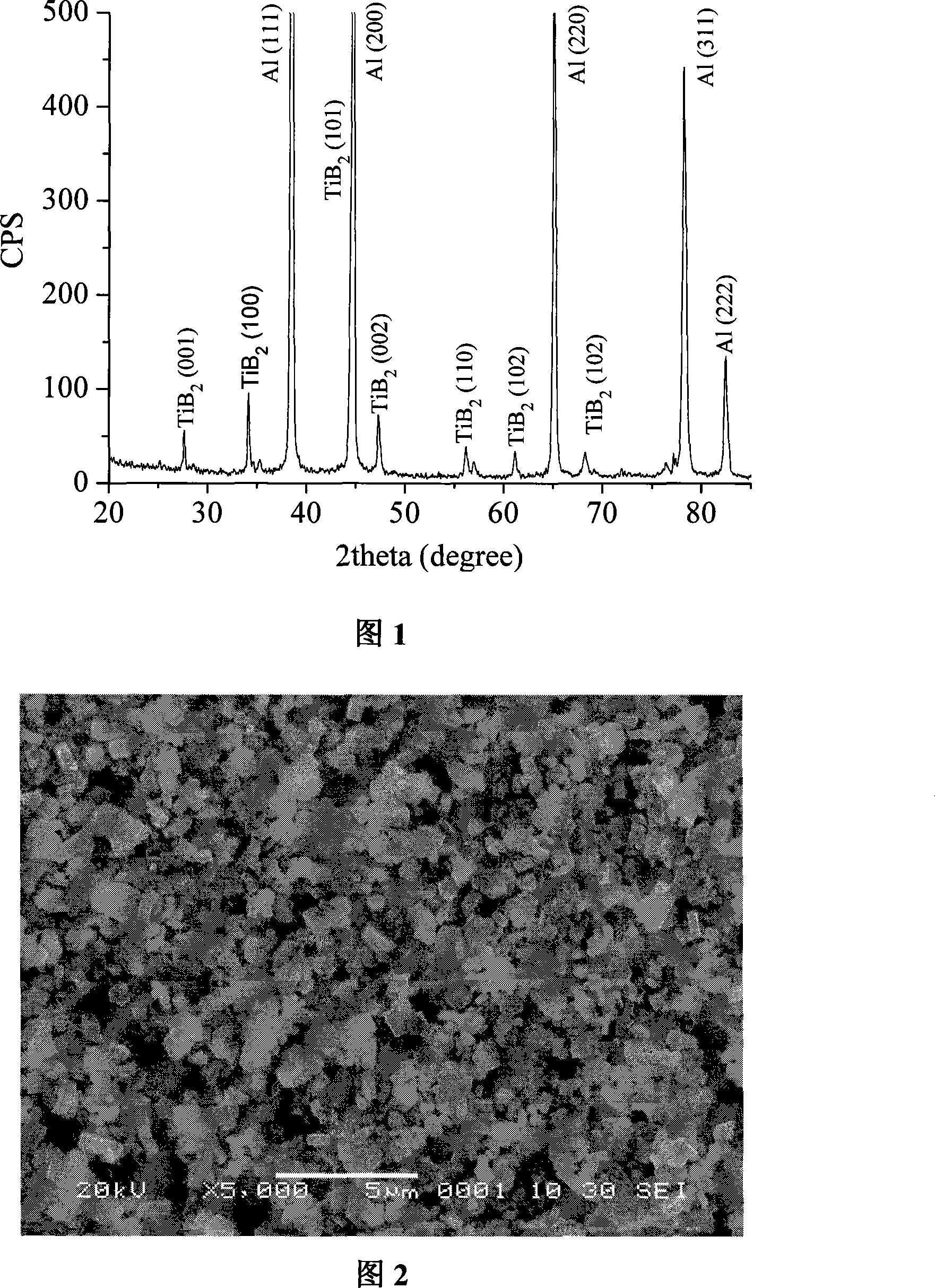

Endogenesis sub-micron TiB2 particle enhanced aluminum-base composite material and preparing technique thereof

The invention provides an endogenous submicron TiB2 particle-reinforced aluminum-based composite material and a preparation process, the composition: Zn 4.5-10wt%, Mg 1.0-3.0wt%, Cu 1.0-5.0wt%, Zr 0.05-0.25wt%, TiB2 Particles 5-20wt%. Process: After the industrial pure aluminum ingot is completely melted, cover the aluminum melt with a covering agent and raise the temperature; after the aluminum melt is kept warm, add the dried Al-Ti master alloy, KBF4 or NaBF4 reaction salt, and stir; after the reaction, Remove reaction salt slag, add industrial pure Zn, Mg, Al-Cu, Al-Zr master alloy, refining and degassing treatment, remove scum, pour into mold after standing; billet homogenization treatment, wagon, and then hot extrusion Pressing or rolling processing; the composite material after extrusion or rolling is subjected to solution aging treatment, and quenched in water at room temperature to obtain an ultra-high-strength aluminum-based composite material. The endogenous submicron TiB2 particles are fine, the surface is clean, and the utilization rate of the reinforcement phase is high; the process is simple and suitable for large-scale production.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

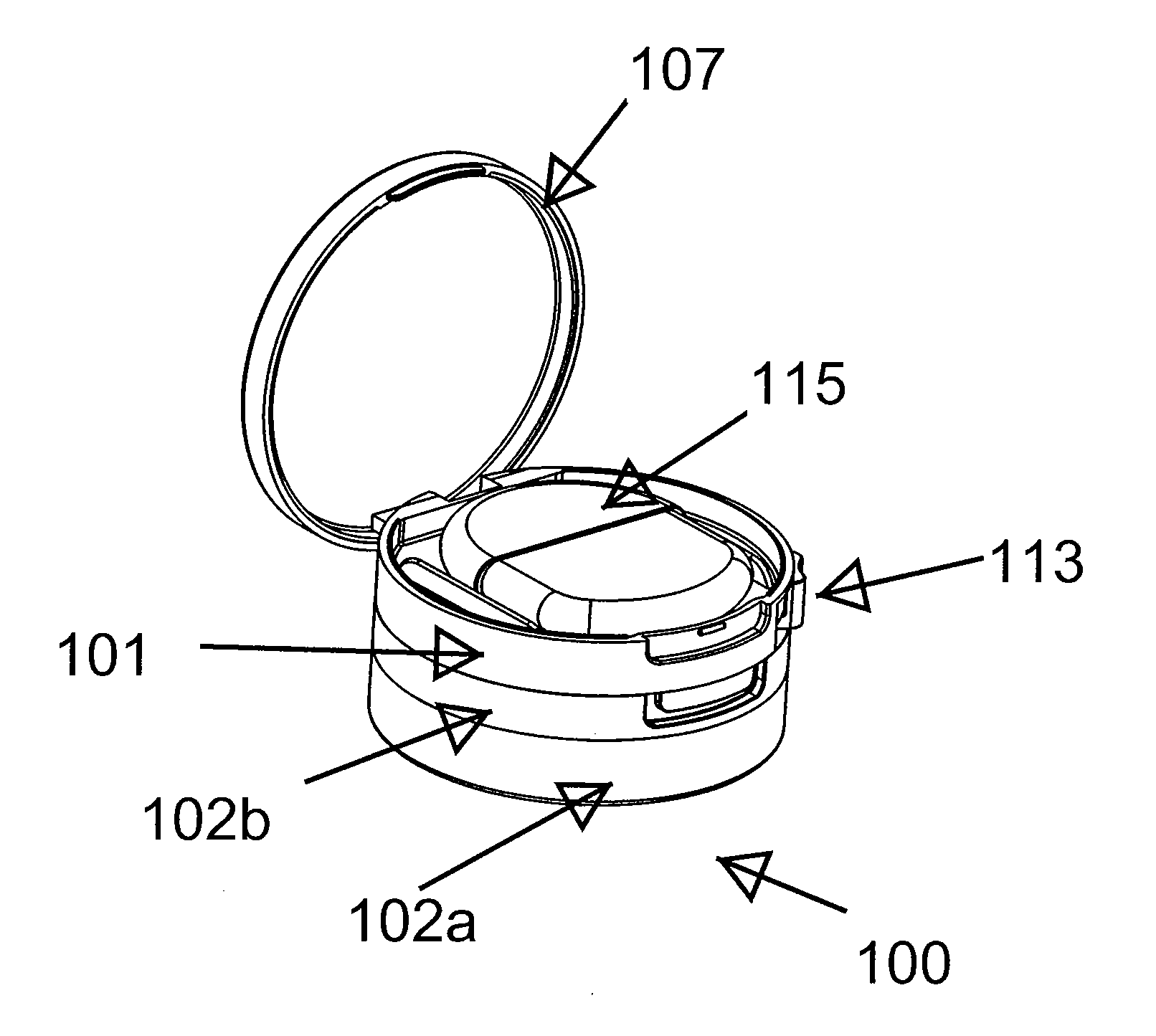

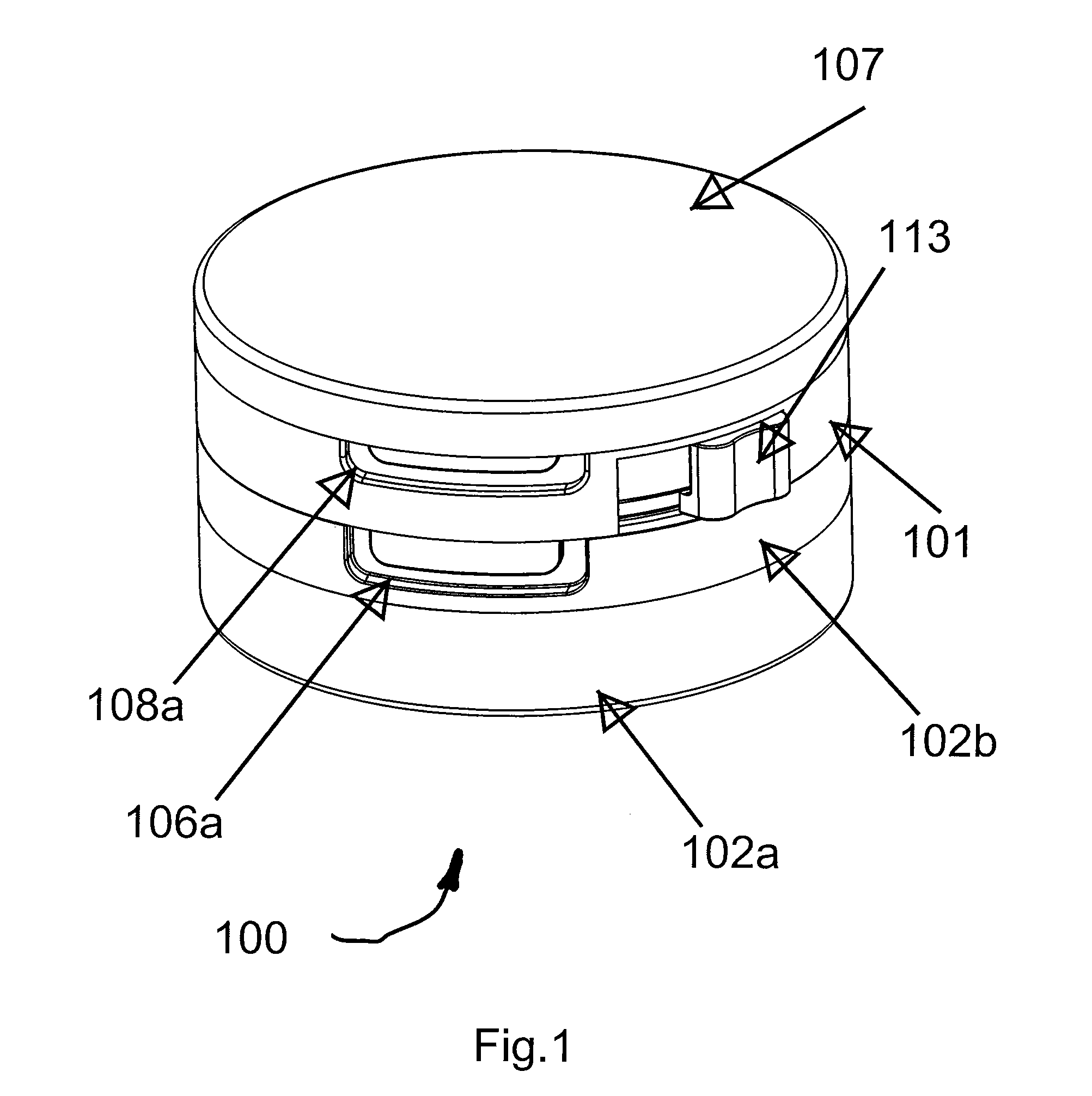

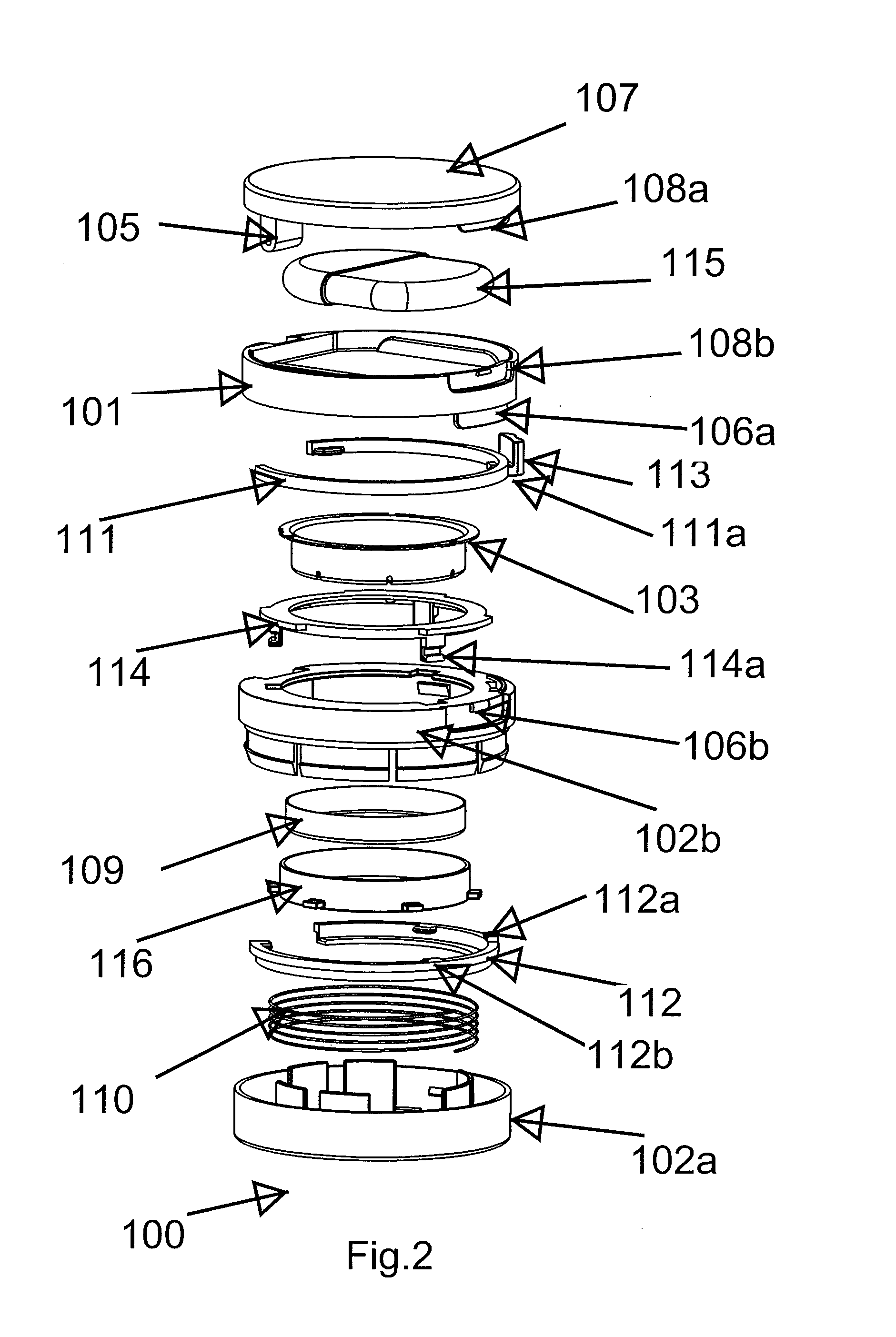

Container for powder products and scraper therefor

ActiveUS20110048443A1Less susceptible to outer environmentClean surfaceCurling devicesPackaging toiletriesMaterials scienceMechanical engineering

The present invention generally relates to containers for powder products. The present invention described herein relates to a container capable of generating powder in loose form. The invention further relates to cosmetic containers for powder products that present pressed and loose powder products for usage as per the convenience of user. Further the invention also relates to a scraper for such a container.

Owner:ZEN DESIGN SOLUTIONS

Preparation method of TiB nano-reinforced titanium-based composite material

The invention relates to a preparation method of a TiB nano-reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. According to the method, the composite material is prepared through ball milling, spark plasma sintering and hot rolling. The original powder is prepared through ball milling, the advantages that the sintering efficiency of the discharge plasma is high, and the external pressure and the sintering atmosphere can be controlled are utilized, so that under the low sintering temperature and the high pressure, and on the premise that the TiB2 particles and the surrounding titanium or titanium alloy matrix do not generate in-situ reaction, a sintering block body with high compactness is prepared; and finally, the TiB2 particles in the sintered block body are subjected to in-situ reaction with the surrounding titanium or titanium alloy matrix through hot rolling to form whiskers, and meanwhile, the crystal grains of the matrix are deformed, the porosity in the structure is reduced, and the strength and the plasticity of the composite material are improved. The TiB nano crystal whisker generated in situ in the method is cleanin surface and is uniformly distributed in a matrix and free of agglomeration, has good interface bonding and lattice relationship with the titanium matrix, and can effectively refine matrix crystal grains.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

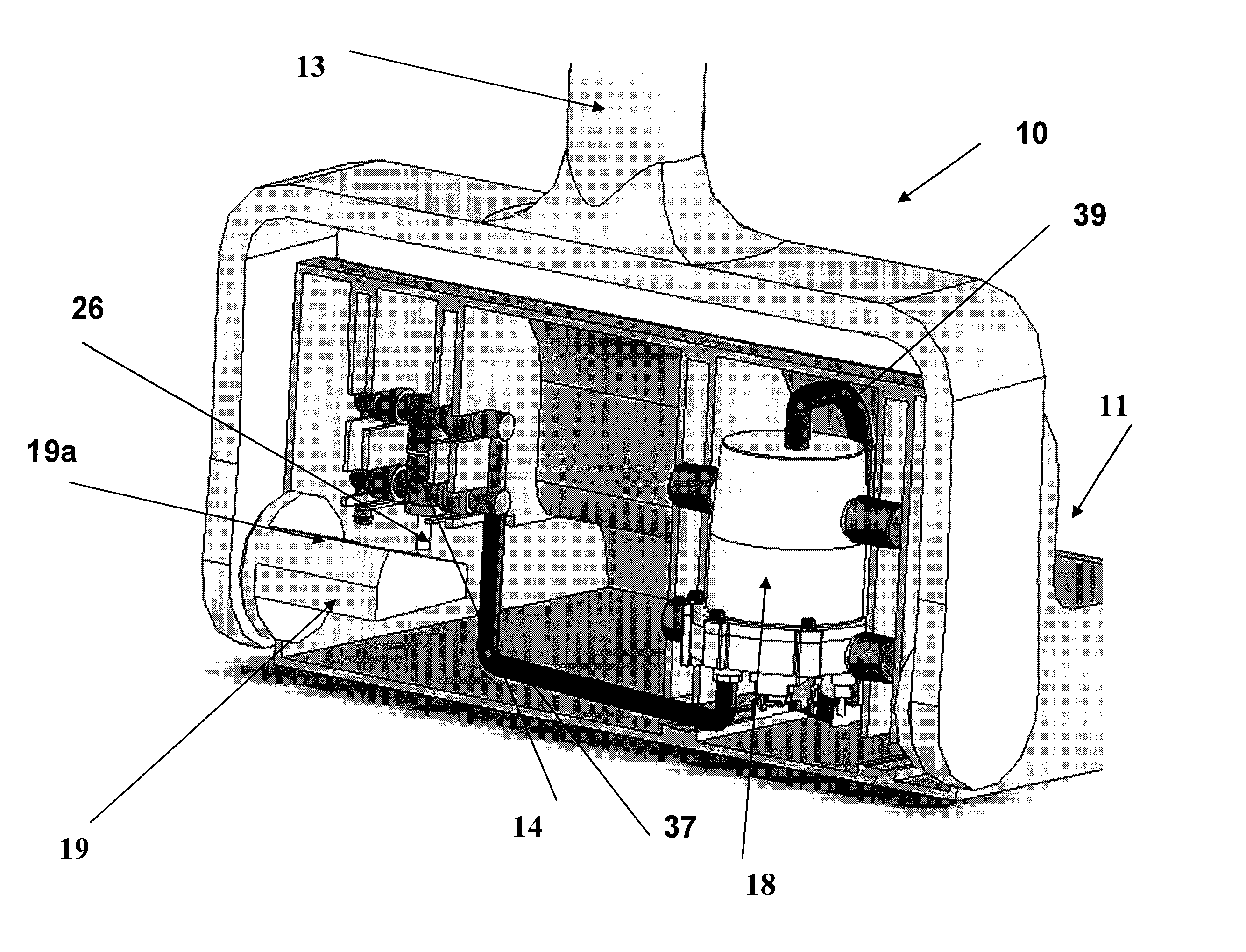

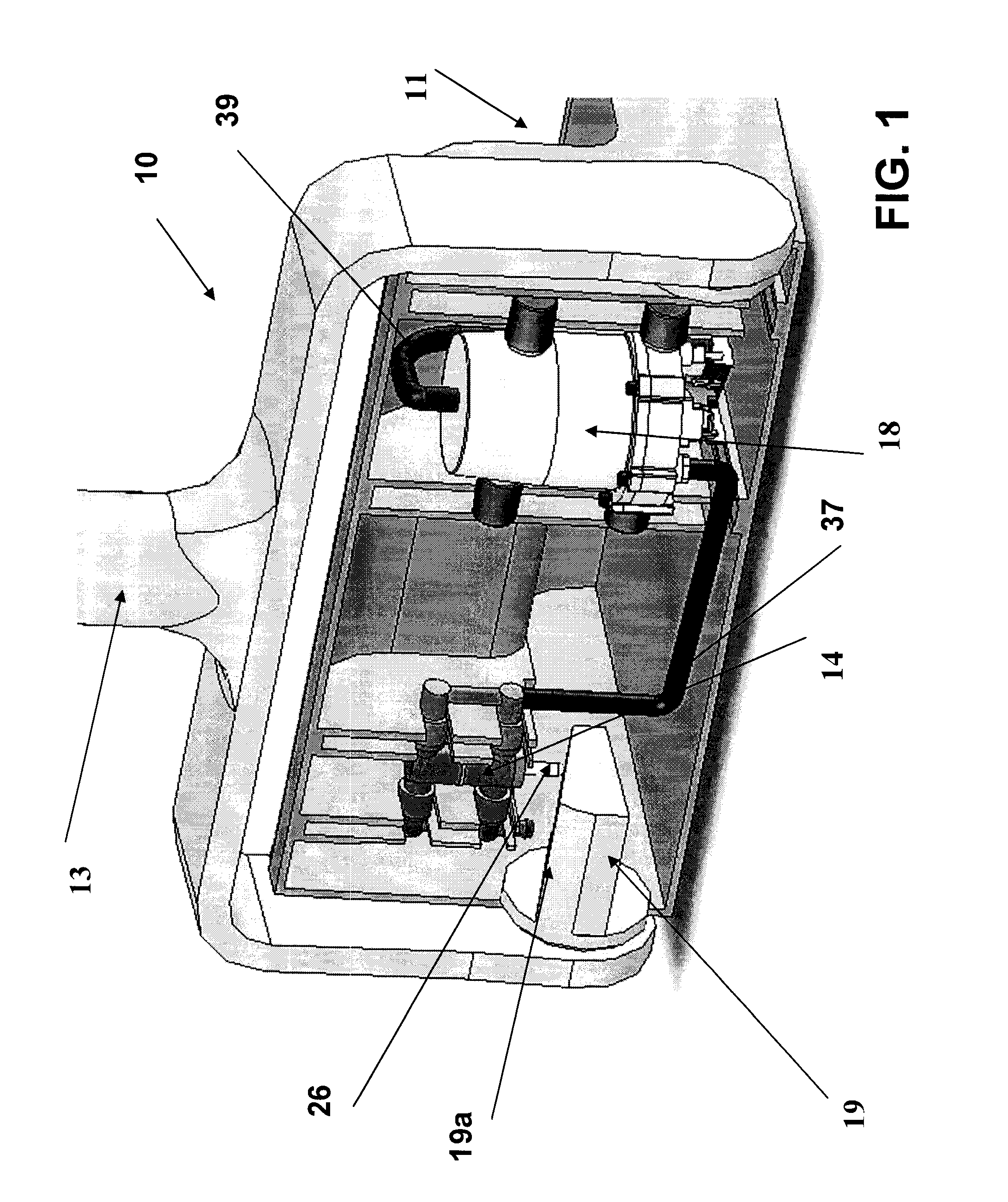

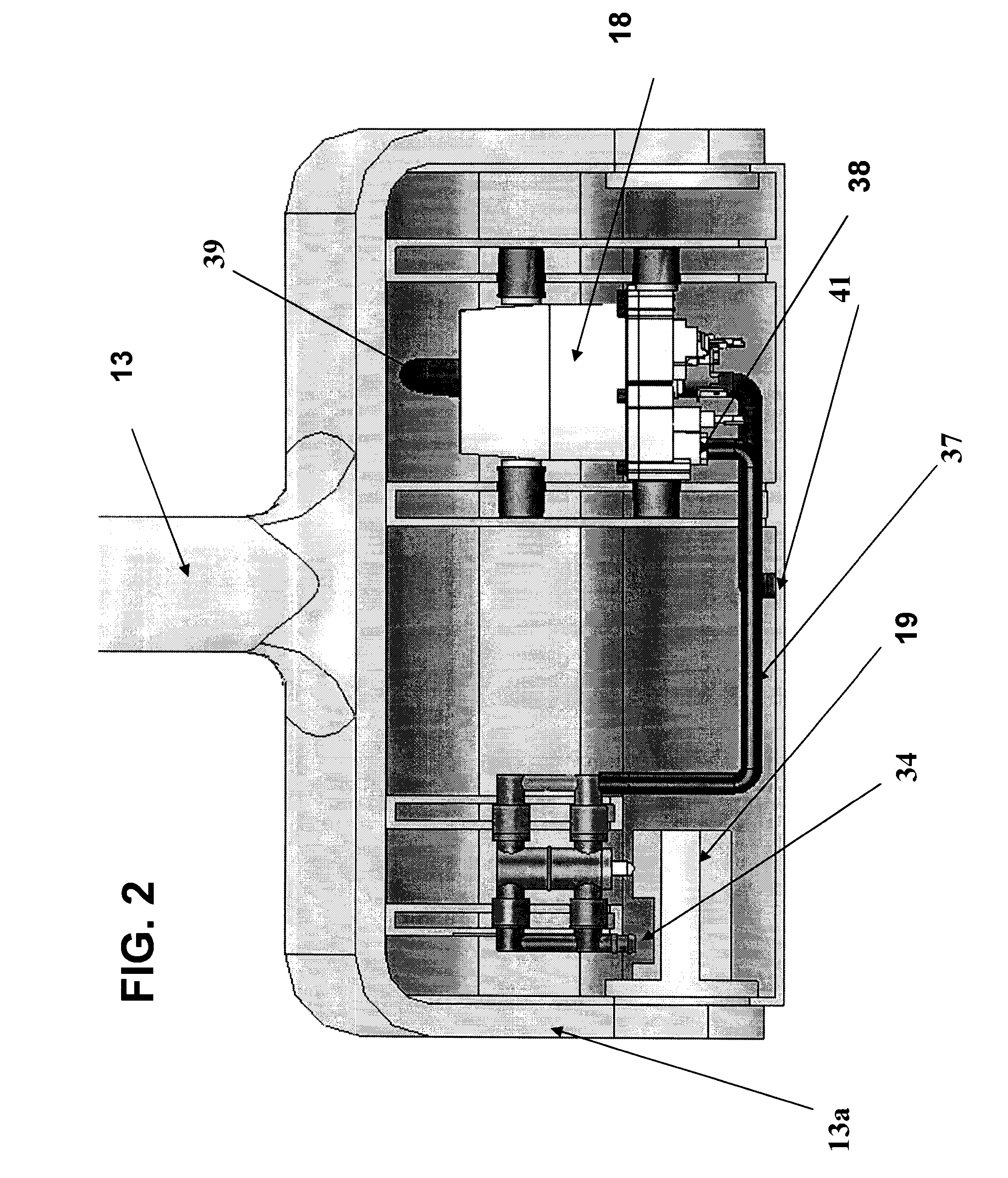

Actuator for steam mop

ActiveUS20080034514A1Clean surfaceEasy to controlBrush bodiesVehicle cleaning apparatusSteam mopEngineering

A steam mop having a main body including a water pump and a boiler. Generation of steam is provided when the water pump is actuated by angular movement of the mop handle which changes the angle between the handle and mop head for operating a two way piston pump to pump water to the boiler. Steam is fed to a steam pad that may have a replaceable fabric pad fit snugly on the frame to distribute cleaning steam to the surface to be cleaned.

Owner:SHARKNINJA OPERATING LLC

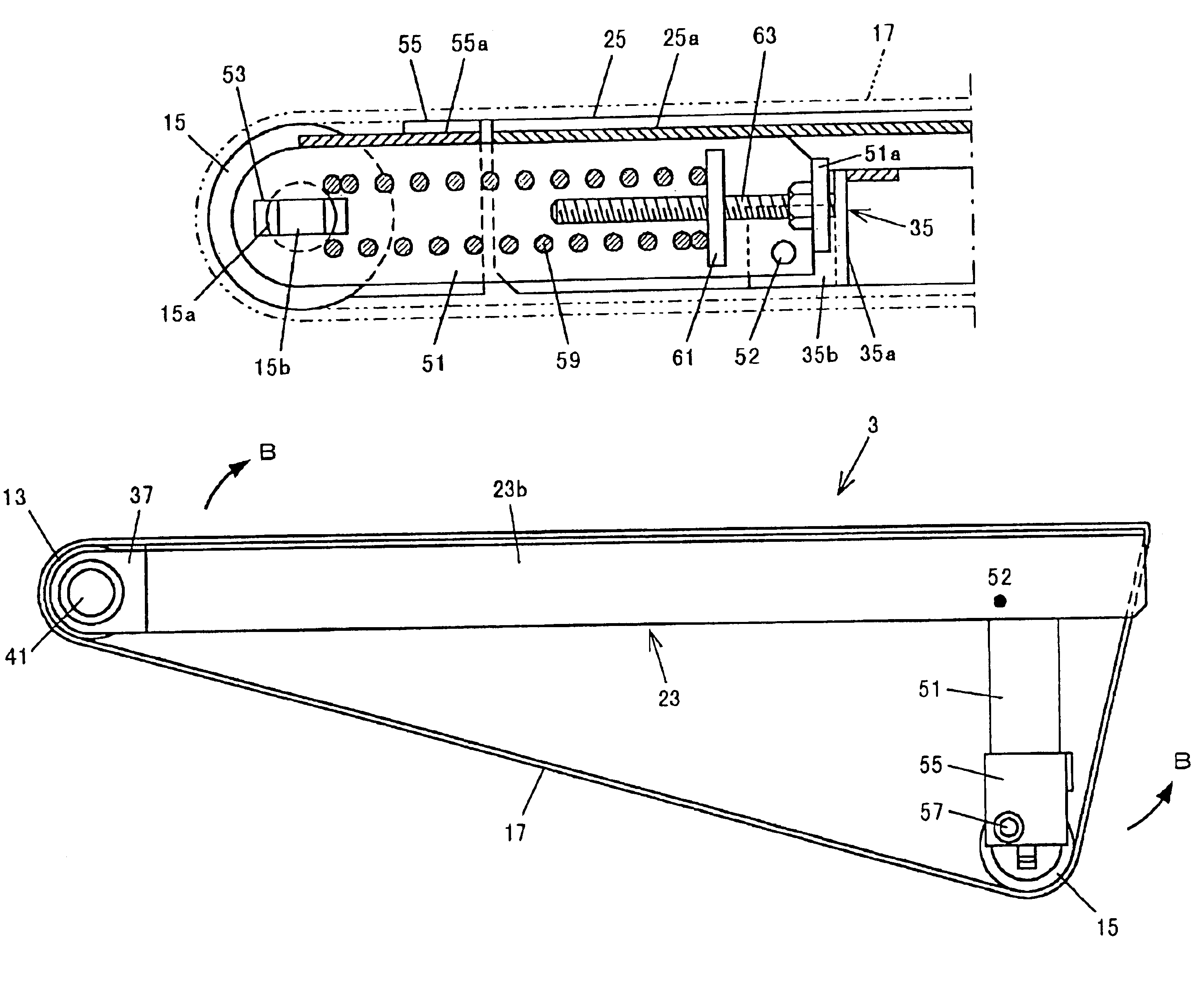

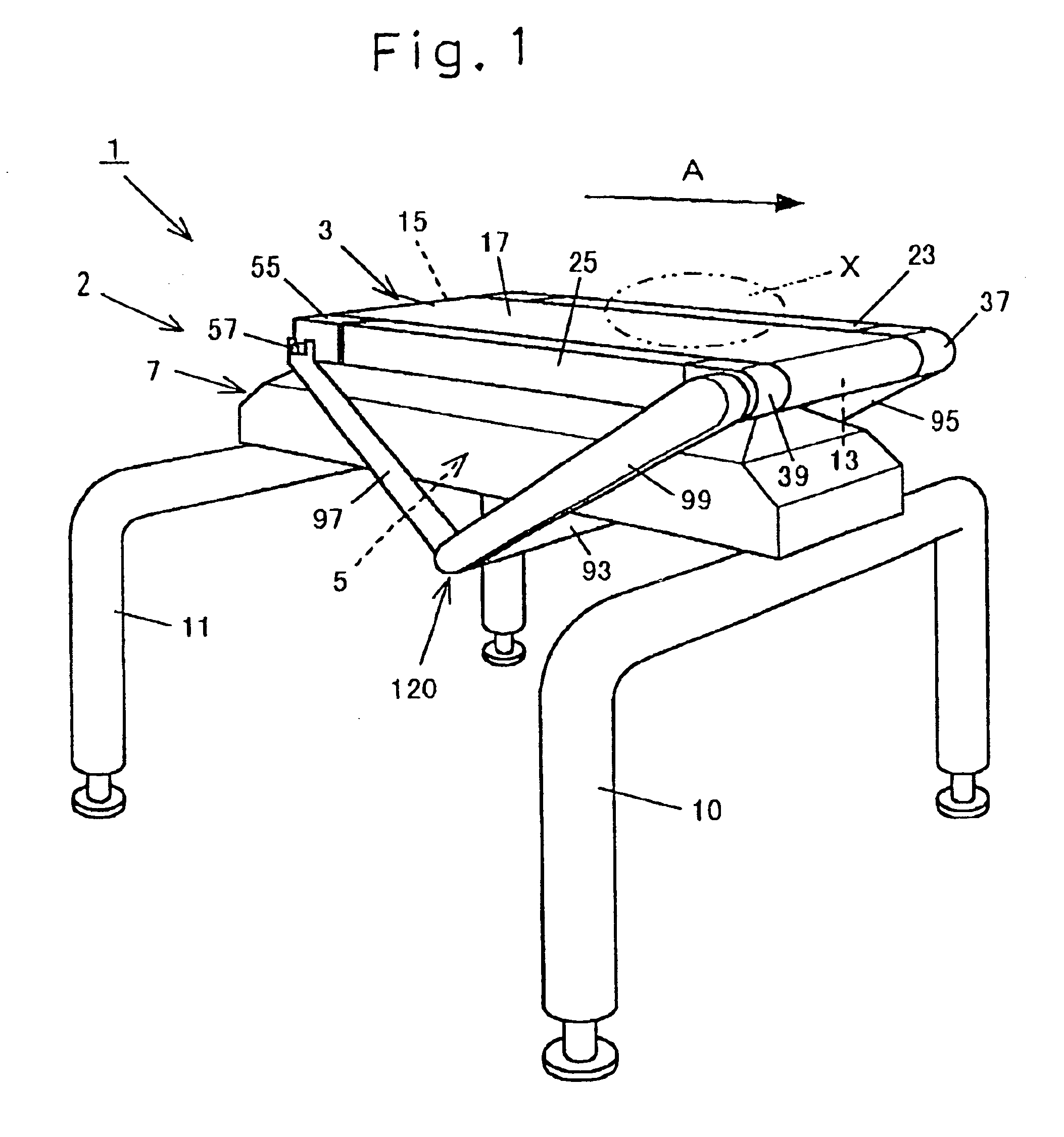

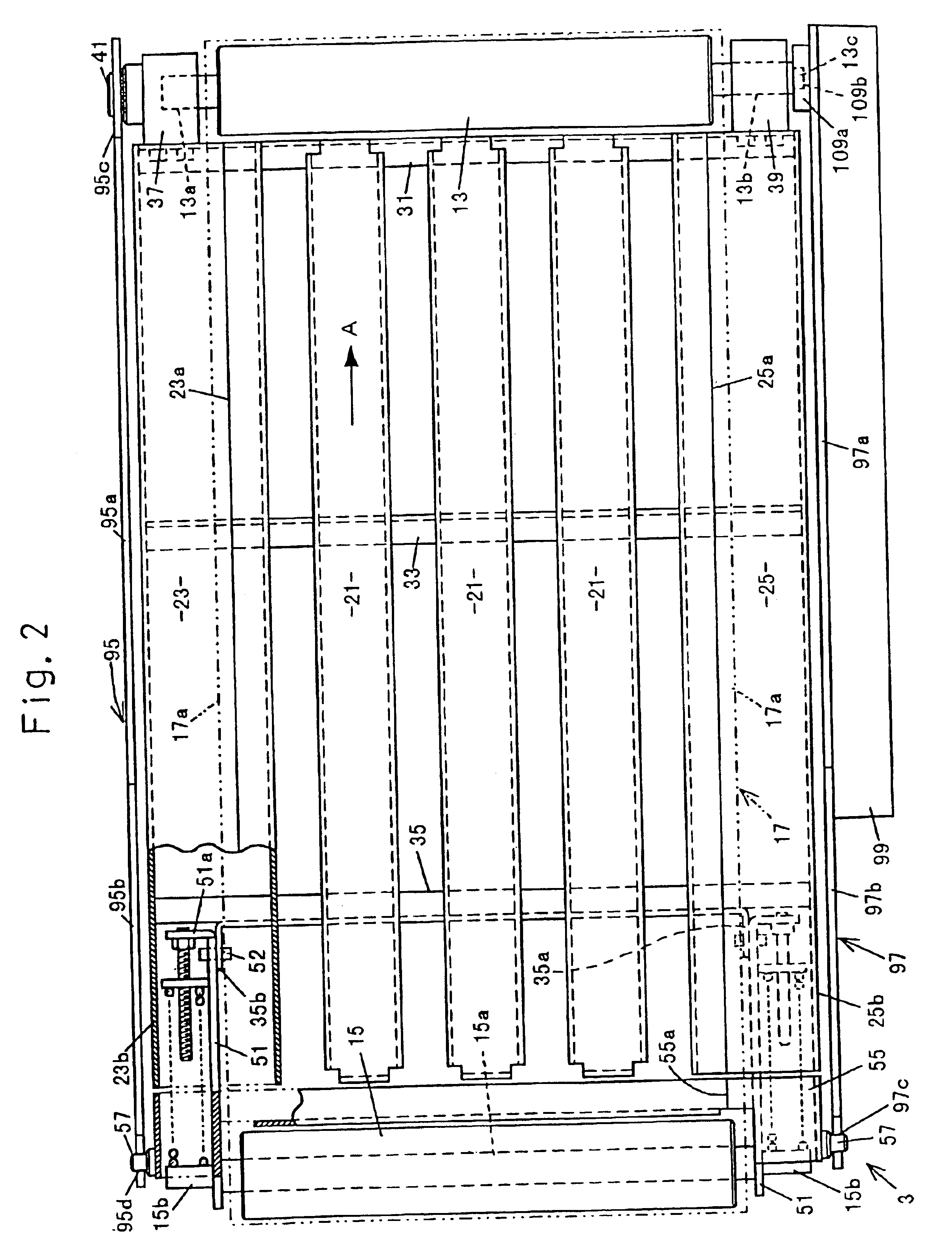

Conveyor apparatus and commodity inspecting equipment utilizing the same

InactiveUS6958452B2Balance weightEasy to implementConveyorsWeighing apparatus detailsElectrical and Electronics engineeringEngineering

A weighing conveyor having an increased weighing accuracy. This conveyor includes a conveyor apparatus 3 for transporting an article X to be weighed, a load detector 5 for detecting the weight of the article X to be weighed, and a housing 7 for accommodating the load detector 5, in which a fixed end 5b of the load detector is connected with the housing 7 and a free end 5c thereof is connected with a support member 120 for supporting the conveyor apparatus 3, and the support member 120 protrudes outwardly of the housing 7 from a bottom surface thereof.

Owner:ISHIDA CO LTD

Wood protecting agent and method of producing the same

The invention discloses a wood additive and making method to solve the problem of low solubility and bad penetrability of boron system compound as wood protective in the water, which is made of 100wt% borate and 0. 1-5wt% composite surface activator. The making method comprises the following steps: 1. blending boric acid and borax evenly to place in the 25-75 deg. c environment to do solid-phased reaction; drying; obtaining the borate; 2. blending the composite surface activator and borate evenly to obtain the wood protective. The invention has the function of preservation, insect protection, termite-resistant, flame-proof and smoke inhibition, which doesn't harm human and animals without influencing the appearance, dynamics and manufacturing property of the wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of Sb2S3 nanowire

The invention provides a preparation method of an Sb2S3 nanowire. 10 mmol of Sb2Cl3 is dissolved into 2 ml of glycol; after the Sb2Cl3 is totally dissolved, 10 ml of deionized water is added while stirring to form white emulsion A; 15 mmol of Na2S.9H2O is dissolved into 10 ml of deionized water to form solution B; the solution B is added into the solution A at the rate of 2 drips / second to form a precursor; mineralizer is added into the precursor to prepare 30 ml of solution C, and the solution C is put in an agitated reactor; the agitated reactor is put into an incubator; when temperature rises to 240 DEG C, temperature is kept for 8-16 hours; and after reaction ends, the product is washed by deionized water to be neutral and is dried for 4h in vacuum in the incubator of 80 DEG C. The invention has simple preparation method, short reaction period and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com