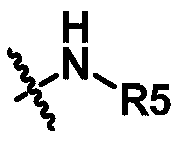

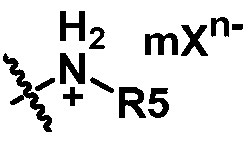

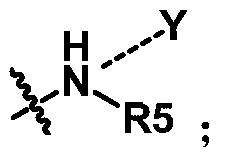

Degradable organic amines and organic aromatic ammonium salts latent epoxy resin curing agent and application

A technology of epoxy resin curing and aromatic amines, applied in the field of epoxy resin curing agent, can solve the problems of difficult recycling of composite materials, environmental pollution, and lack of degradation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Embodiment 1: the preparation of curing agent i

[0103]

[0104] method 1:

[0105] In a 1-liter three-necked round-bottom flask, dissolve 100 grams of potassium 4-nitrophenoxide and 98.3 grams of dibromomethane in 400 milliliters of N,N-dimethylformamide (DMF), and heat the resulting solution at 120°C for 18 hours After that, the DMF was recovered by vacuum concentration. After the residue was cooled, water was added until a yellow solid was precipitated, filtered, and the solid was dried in vacuum to obtain 70 g of 4,4'-dinitrodiphenoxymethane.

[0106] In a 2-liter three-necked round-bottomed flask, the intermediate 4,4'-dinitrodiphenol-methane was dissolved in 1.5 liters of tetrahydrofuran, 7 grams of 10% Pd / C and 140 grams of 80% hydrazine hydrate were added, and heated to reflux for 10 hours, cooling and suction filtration to recover 10% Pd / C, and after the mother liquor was rotary evaporated to dryness, the residue was recrystallized with petroleum ether / et...

Embodiment 2

[0112] Embodiment 2: the preparation of curing agent ii

[0113]

[0114] In a 5-liter three-necked round-bottomed flask, 100 grams of 3-methyl-4-nitrophenol and 40 grams of potassium hydroxide were dissolved in 2.5 liters of ethanol, and reacted at room temperature for 5 hours. After the solvent was evaporated to dryness, 120 grams of Potassium 3-methyl-4-nitrophenoxide.

[0115] Dissolve this solid and 56 g of dibromomethane in 500 ml of DMF, react at 120°C for 18 hours, concentrate under reduced pressure to recover DMF, add water to the residue after cooling until a yellow solid precipitates, collect the precipitated solid by filtration, and dry in vacuo to obtain 80 g of bis (3-Methyl-4-nitrophenol)methane.

[0116] In a 2-liter three-necked round-bottomed flask, add 80 grams of bis(3-methyl-4-nitrophenol)methane, 1.5 liters of dioxane and 4 grams of Raney-Ni, and add 140 grams of 80% Hydrazine hydrate, and heated to reflux for 10 hours, suction filtered, reclaimed Ra...

Embodiment 3

[0119] Embodiment 3: the preparation of curing agent iii

[0120]

[0121] In a 1-liter three-necked round-bottom flask, 100 grams of potassium 3-nitrophenoxide and 98.3 grams of dibromomethane were dissolved in 400 milliliters of N,N-dimethylformamide (DMF), and the resulting solution was heated at 125°C for reaction After 10 hours, the DMF was recovered by concentration in vacuo. After the residue was cooled, water was added until no more yellow solid was precipitated. The precipitated solid was collected by filtration and dried in vacuo to obtain 70 g of bis(3-nitrophenol)methane.

[0122] In a 2-liter three-necked round-bottomed flask, dissolve the intermediate in 1.5 liters of dioxane, add 7 grams of Raney-Ni, and add 140 grams of 80% hydrazine hydrate dropwise under heating and reflux. After the addition is completed, TLC monitors Reaction progress, until the end of the reaction, filter with suction, recover Raney-Ni, concentrate the mother liquor in vacuo, and recrys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com