Patents

Literature

150results about How to "Retain mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

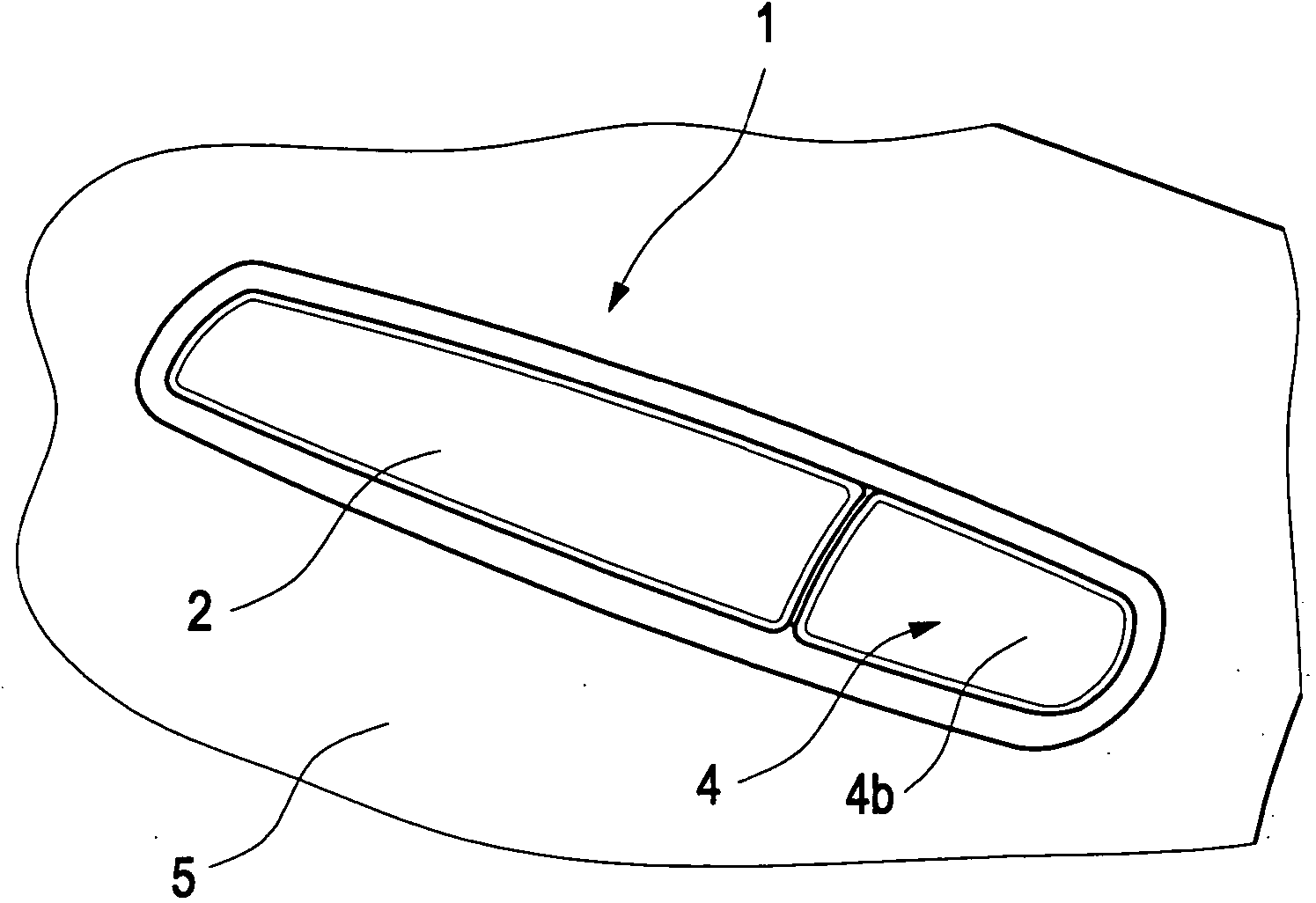

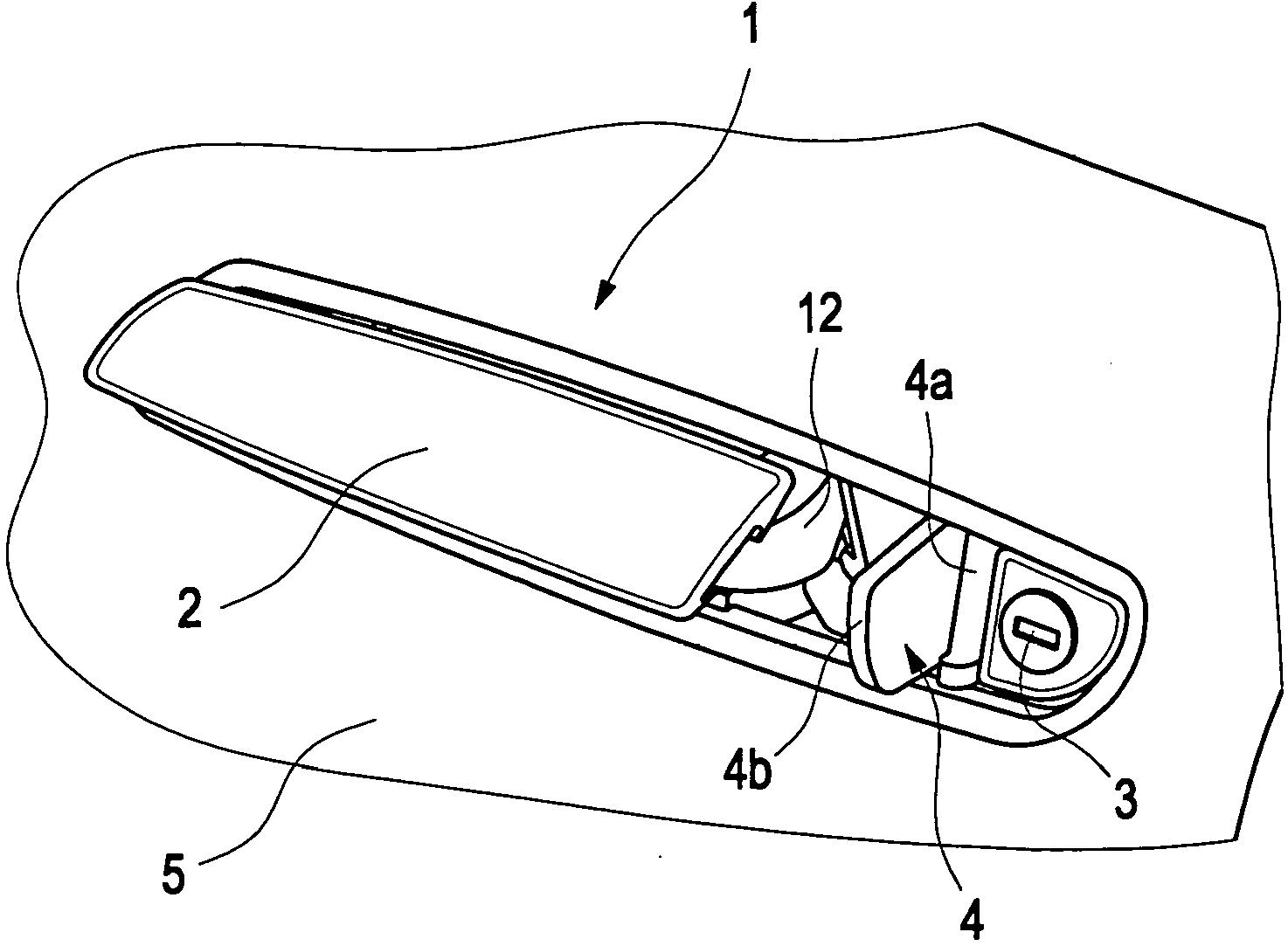

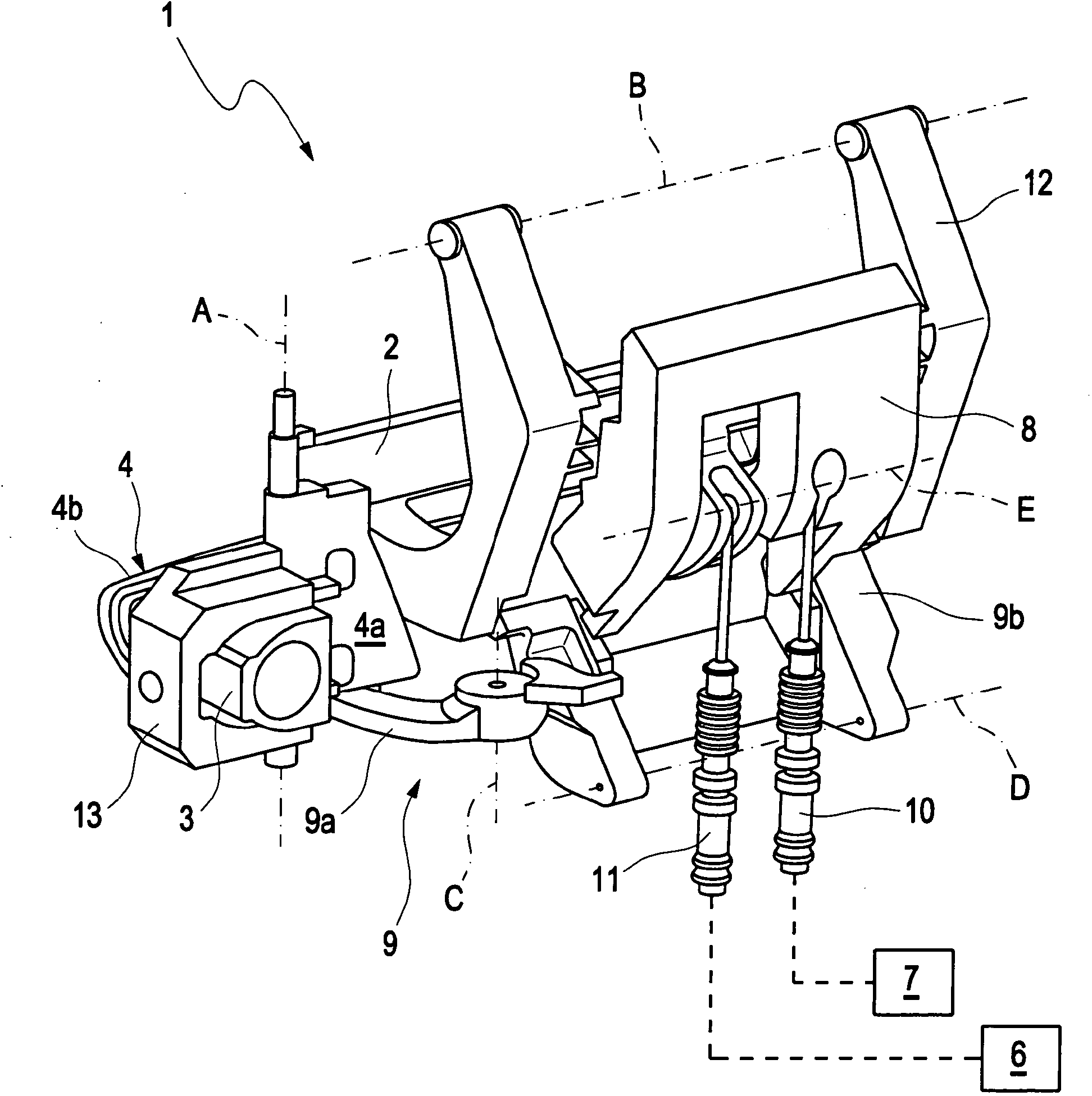

Door handle assembly for a vehicle

ActiveCN103339334AEasy to installPreserve aestheticsElectrical locking circuitsFastening meansRest positionCar door

Door handle assembly (1) for a vehicle, comprising a door handle (2) for actuating a door lock (6), which door handle can be brought, actuated by an externally applied force, from a rest position in which it is flush with the outer contour of the door into an exposed working position, and a closing cylinder (3), coordinate with the door handle (2), for locking or unlocking the door lock (6). The closing cylinder (3) can be covered by a cover flap (4) the manual actuation of which releases the closing cylinder (4) and allows the door handle (2) to be brought from the rest position into the working position.

Owner:AUDI AG

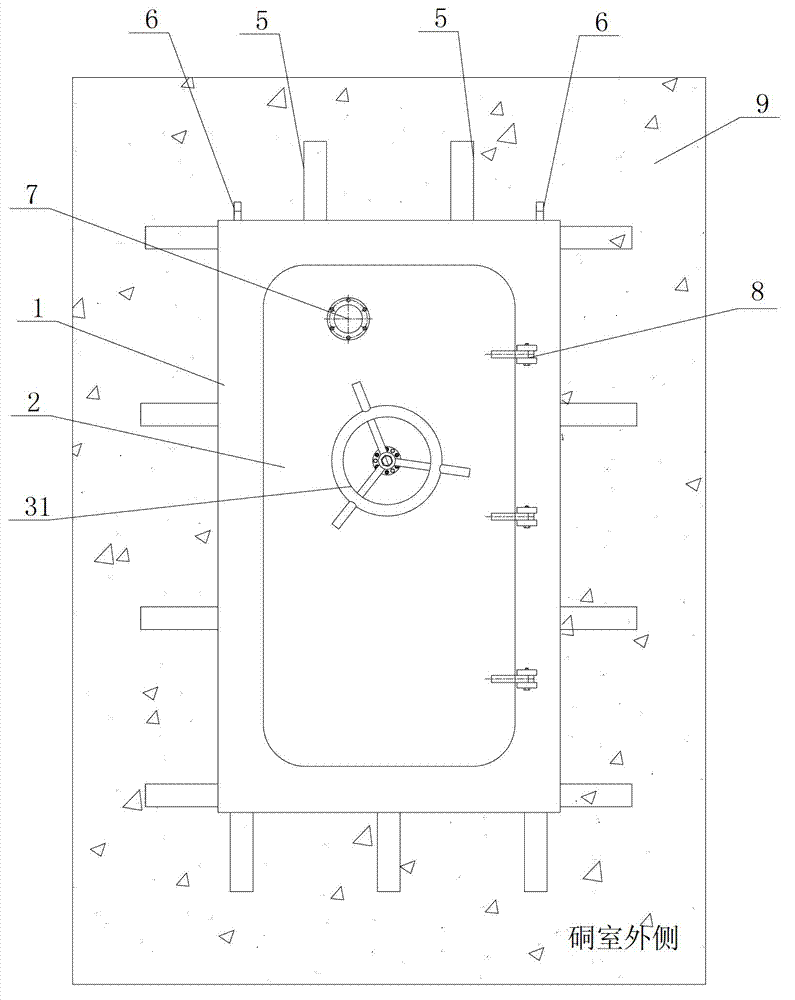

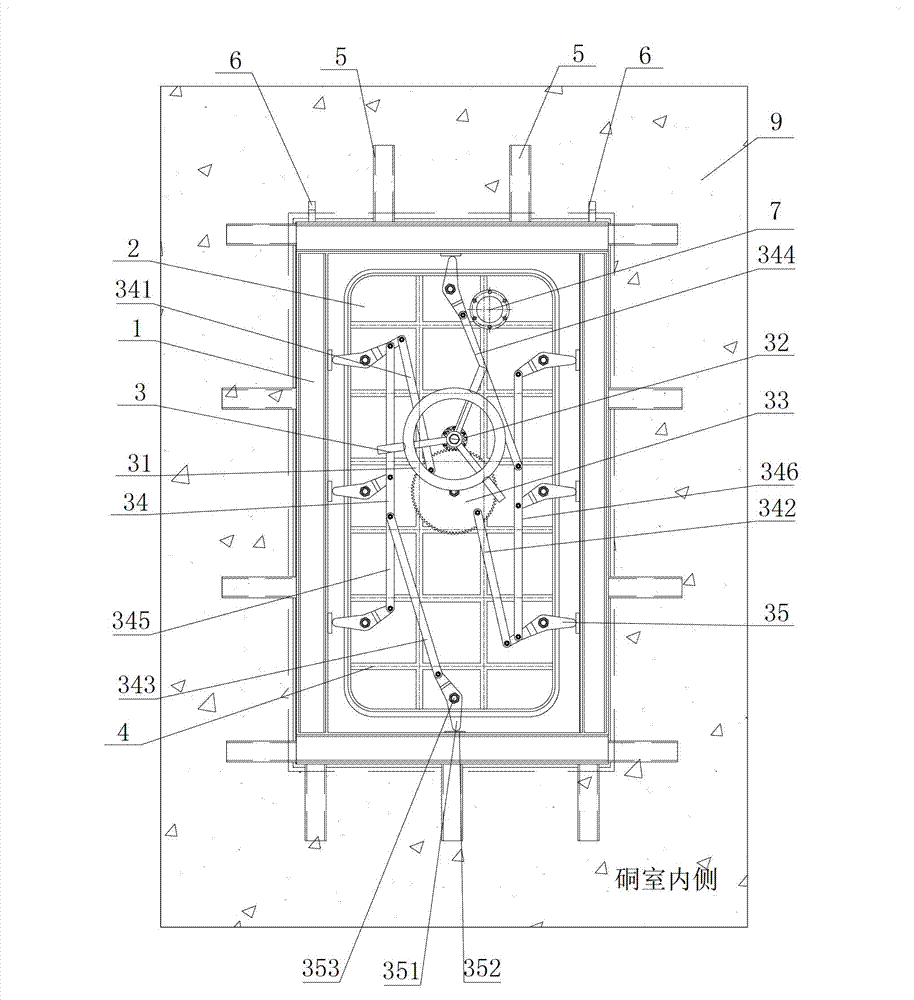

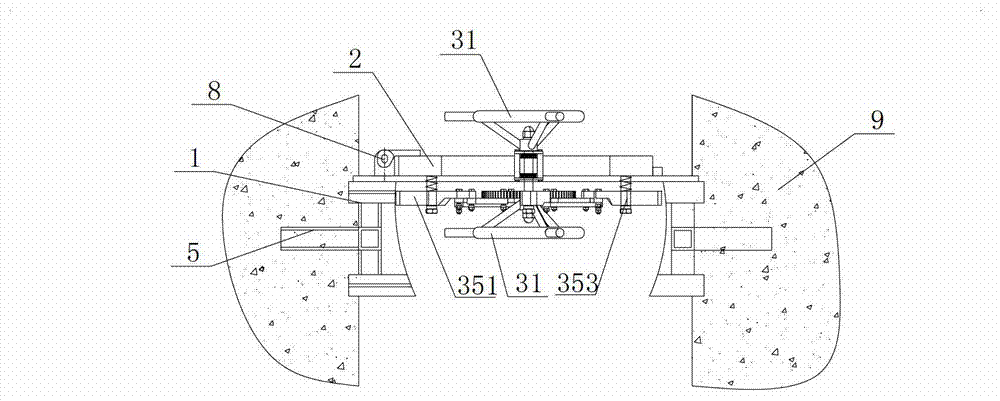

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

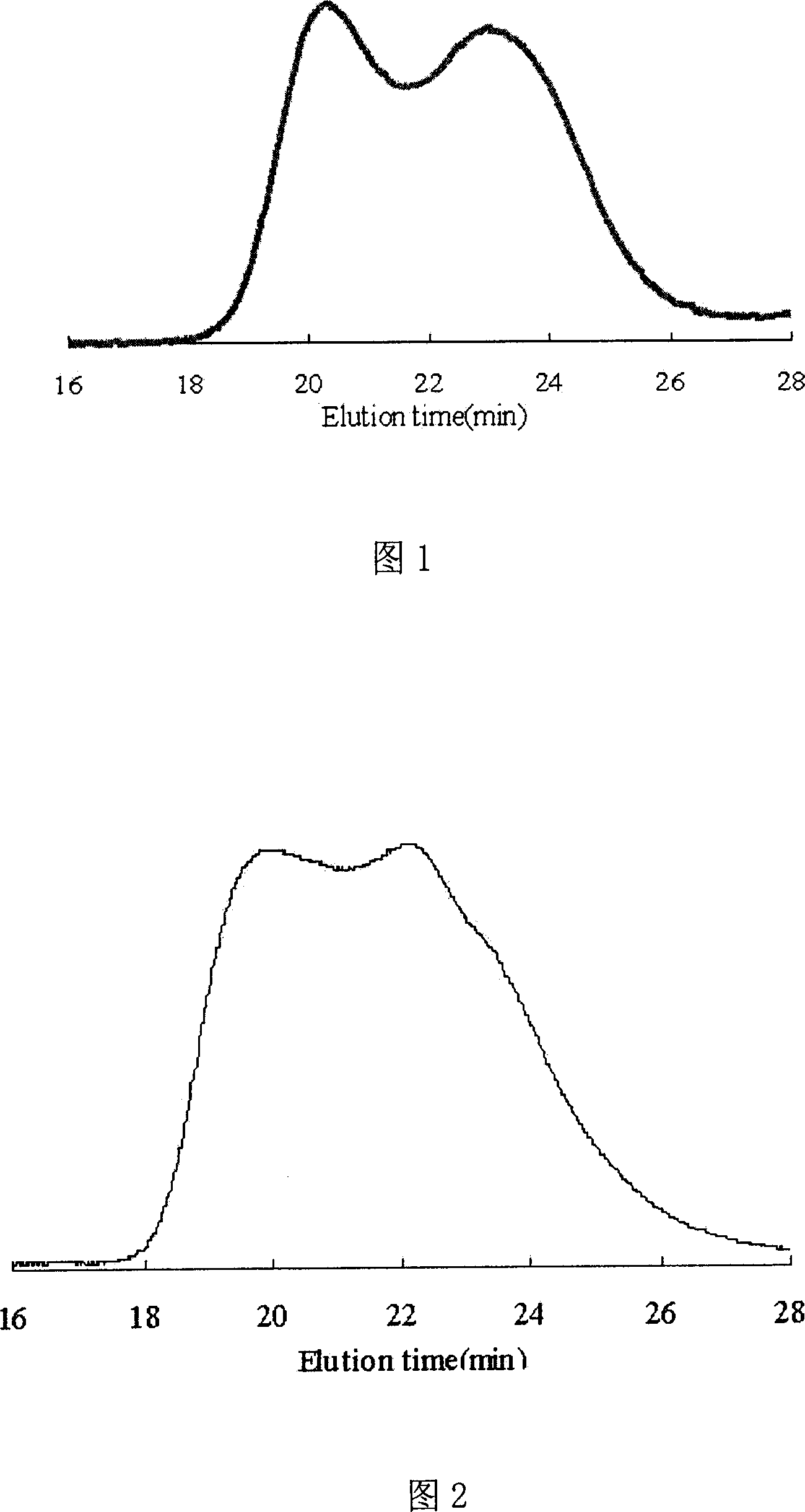

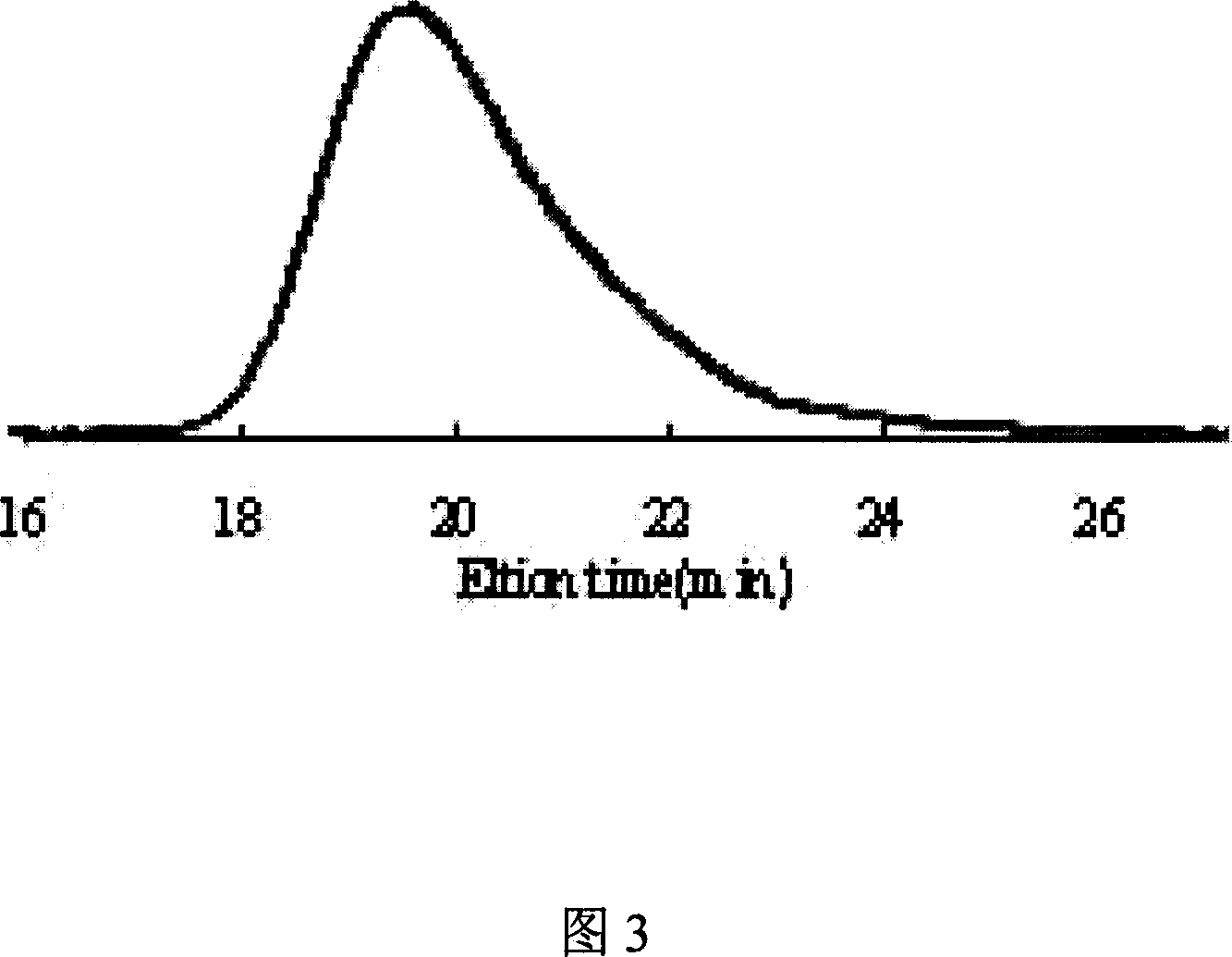

Splitblip molecular weight distribution high-cis-polydiene and preparation method thereof

InactiveCN101085818AHigh catalytic activityImprove catalytic performancePolymer scienceHigh molecular mass

The invention relates to a kind of sym-form polydiene rubber with bimodal molecular weight distribution and the preparation method. The conjugated polydiene with bimodal / acromion molecular weight distribution can be produced in one single reactor directly. The invention is characterized by high catalytic activity, stable catalytic property, easy controllable polymerization and conjugated polydiene with structure unit larger than 96%. The polymer produced in this invention can not only retain mechanical performance of high molecular part, but aslo retains the processing performance of low molecular weight part.

Owner:BEIJING UNIV OF CHEM TECH

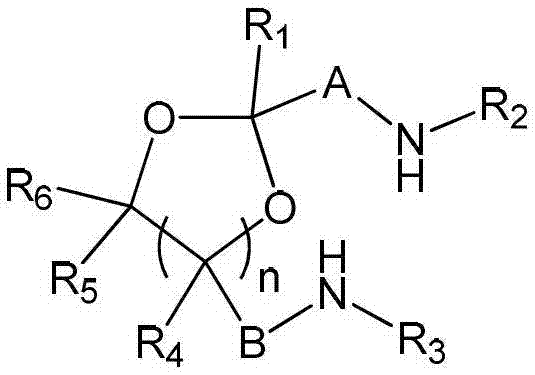

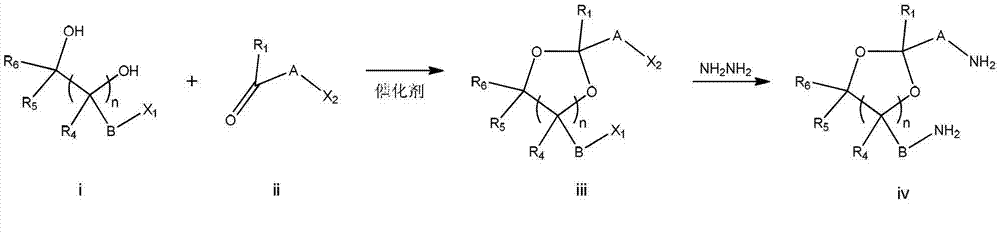

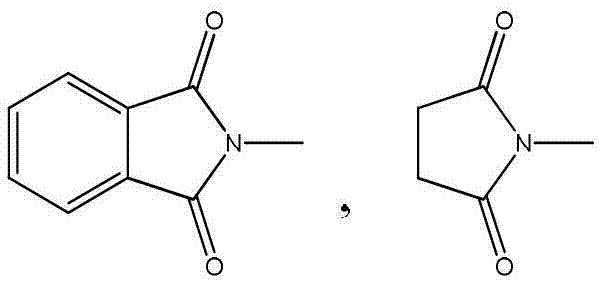

Degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent and application thereof

ActiveCN103242509ARetain mechanical propertiesImprove recycling efficiencyOrganic chemistryFibre chemical featuresPolymer scienceFirming agent

The invention provides a degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent. The curing agent can be polymerized with an epoxy resin so as to generate a degradable cross-linking polymer, wherein the degradable cross-linking polymer can be degraded in a mixing system of acid and solvents under the heating and stirring condition. The invention further provides an enhanced composite material which is prepared from the curing agent, the epoxy resin, auxiliary materials and enhancing materials; and the enhanced composite material can be degraded in the mixing system of acid and solvents under the heating and stirring condition, and can be recycled and reused after being neutralized. The enhanced composite material has excellent mechanical properties, is applicable to application fields of different composite materials, and the degrading and recycling method is simple, economic, mild in condition and easy to control.

Owner:ADESSO ADVANCED MATERIALS WUHU CO LTD

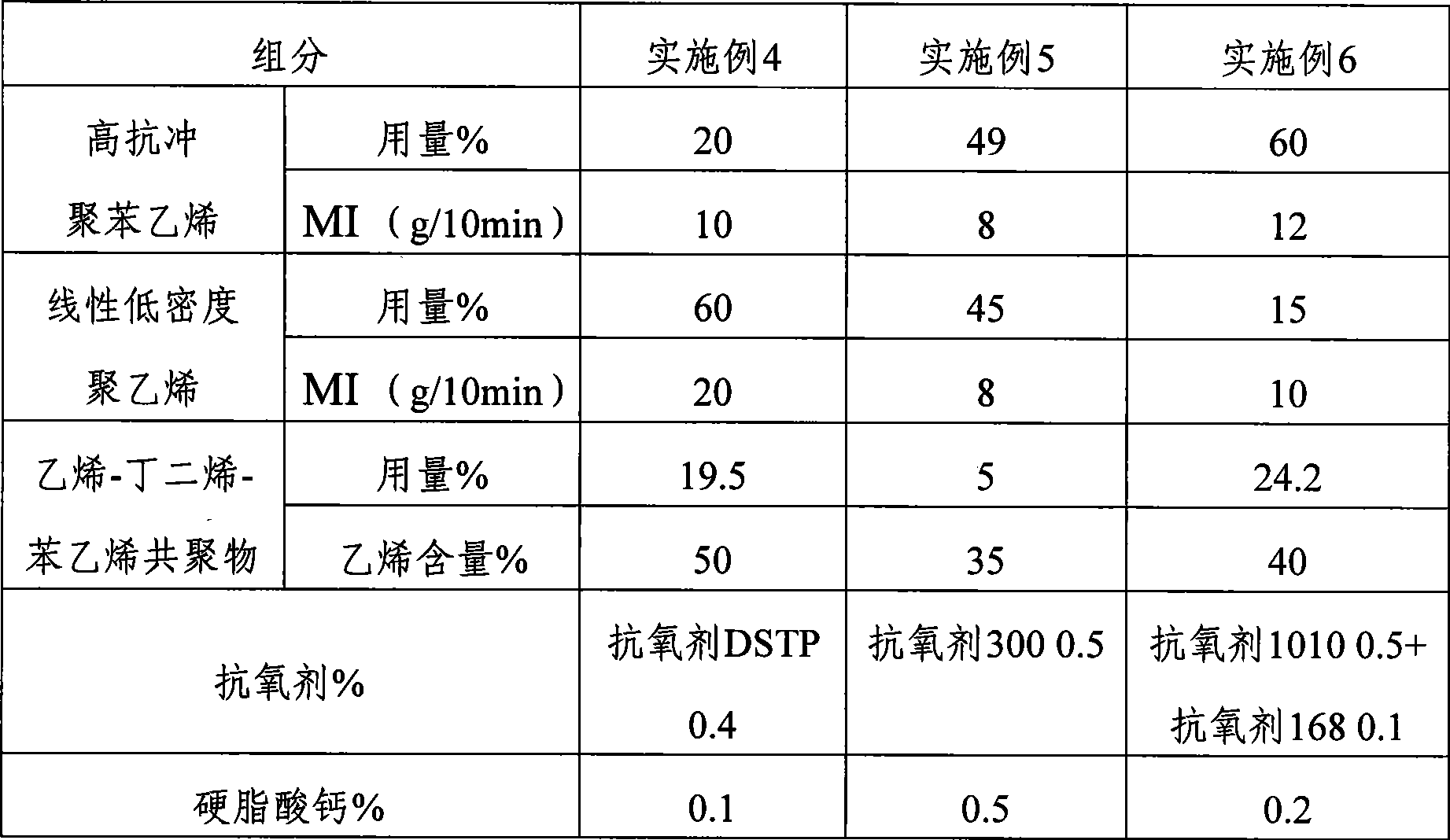

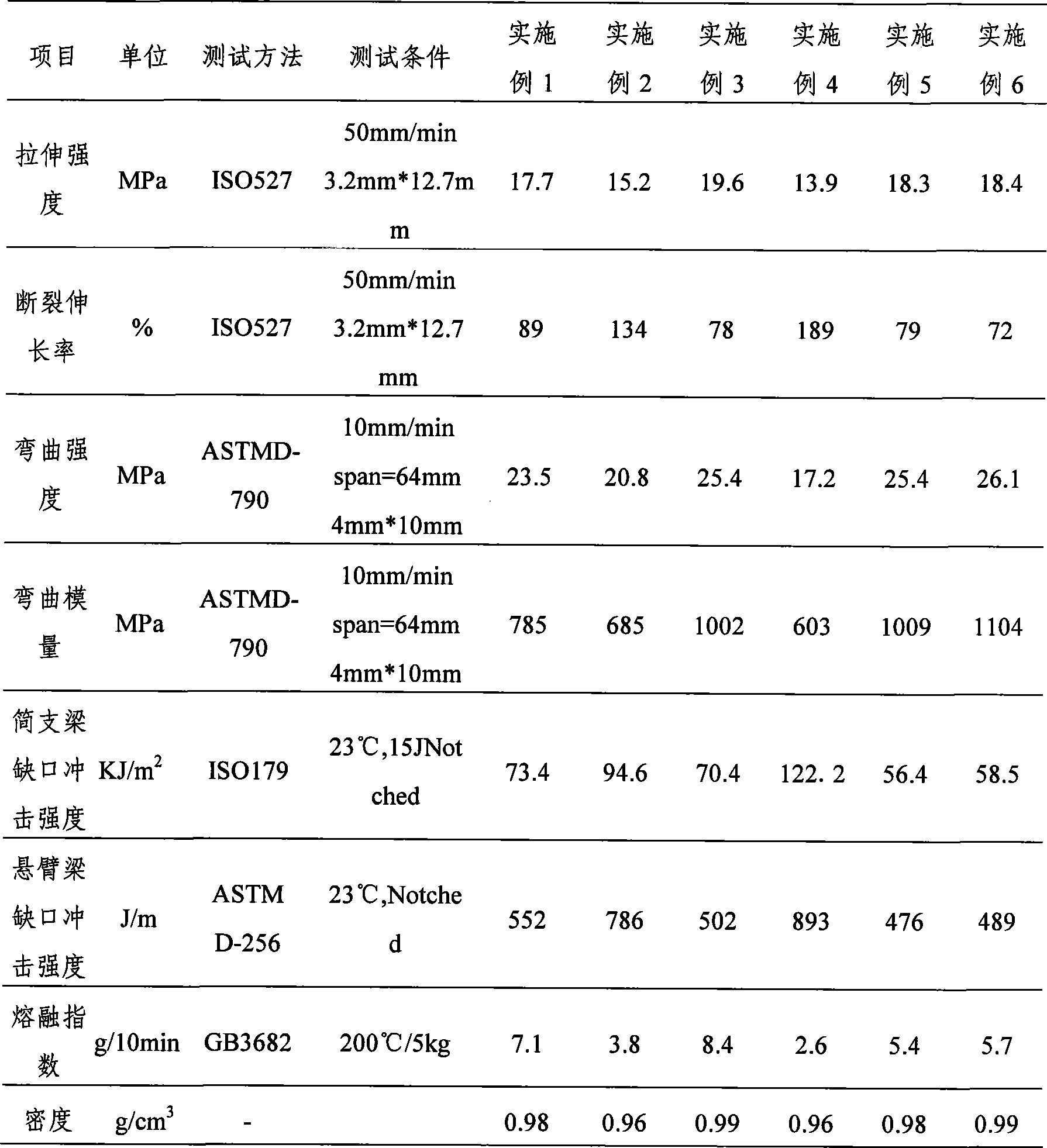

Solvent-resistance polystyrene ternary alloy material for refrigerator inner liner plates and preparation method and application thereof

ActiveCN101544806AGood solvent resistanceImprove mechanical propertiesDomestic cooling apparatusLighting and heating apparatusLinear low-density polyethylenePolymer alloy

The invention provides a solvent-resistance polystyrene ternary alloy material used for refrigerator inner liner plates. The solvent-resistance polystyrene ternary alloy material comprises 20 to 65 percent of high-impact polystyrene, 15 to 60 percent of linear low-density polyethylene, 5 to 25 percent of ethane-butadiene-styrol copolymer compatilizer, 0.1 to 0.6 percent of antioxidant and 0.1 to 0.6 percent of calcium stearate. The invention also provides a preparation method and an application of the alloy material. The polyethylene has excellent solvent-resistance, the polystyrene has good mechanical strength, and the invention enables the polyethylene and the polythene to be mixed into an interpenetrating network structure through a special solvent polymer to form stable polymer alloy, therefore, the invention not only retains the mechanical property of the polystyrene but also has the excellent solvent-resistance of the polyethylene simultaneously, the solvent-resistance polystyrene product widely applied to the refrigerator inner liner plates is obtained, the material cost of the refrigerator inner liner plates is reduced, and the refrigerator inner liner plate material with stable supply of goods and quick delivery is provided.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

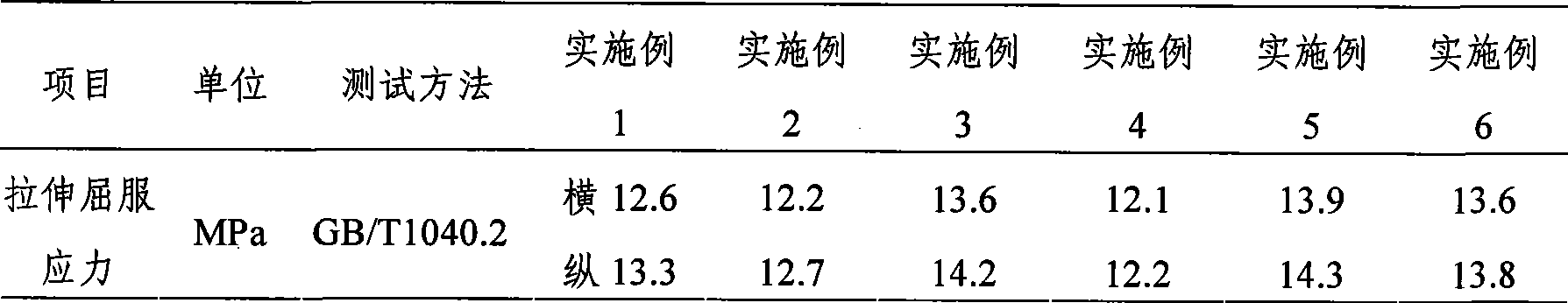

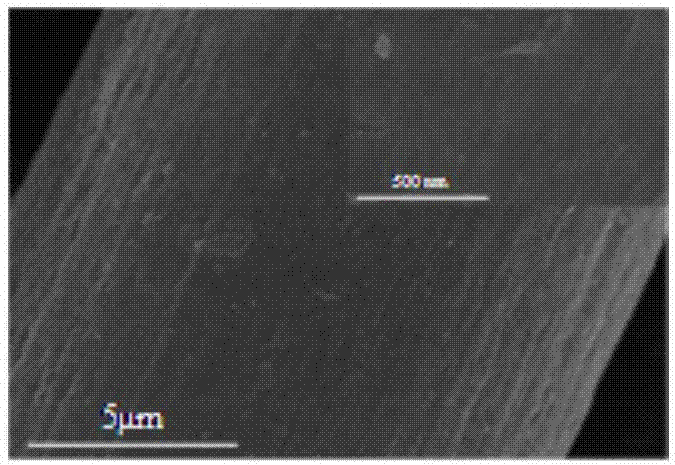

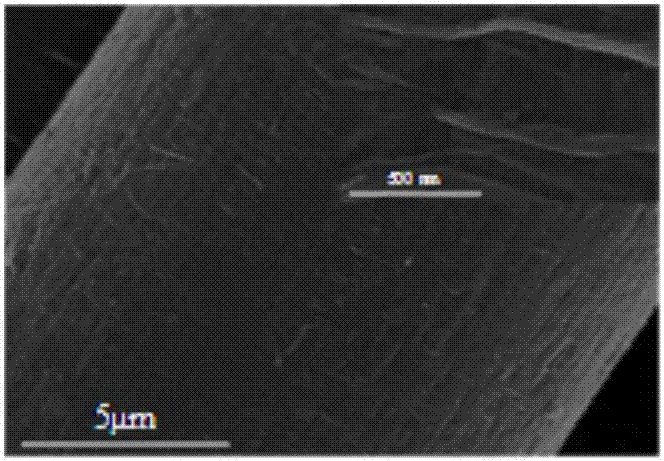

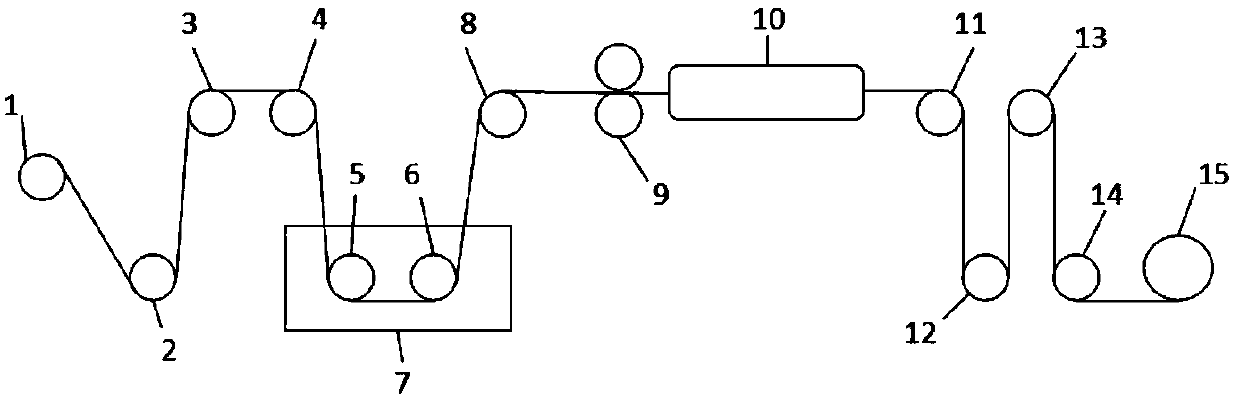

Method for compounding functional nanoparticles on surfaces of polymer filaments

ActiveCN103556451ADoes not affect mechanical propertiesRetain mechanical propertiesVegetal fibresFiberPolymer science

The invention relates to a method for compounding functional nanoparticles on surfaces of polymer filaments, belonging to the technical field of new fiber materials. The method comprises the steps of protein-based modification on surfaces of functional nanoparticles, preparation of a blended solution, formation of polymer filaments with surfaces compounded with the blended solution and control of thickness, phase inversion primary formation of the polymer filaments with surfaces compounded with the blended solution and thermosetting formation of the polymer filaments with surfaces compounded with the blended solution, thus obtaining the polymer filaments with surfaces compounded with the functional nanoparticles. In the preparation method, carbon nano tubes, graphene, carbon black, titanium dioxide, zinc dioxide, iron particles, iron oxide, aluminium oxide, silver particles and other nanoparticles can be compounded on the surfaces of the polymer filaments. The polymer filaments after compounding have good mechanical properties and functionality. The preparation method is simple to operate, dispenses with special equipment and achieves industrial production easily.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

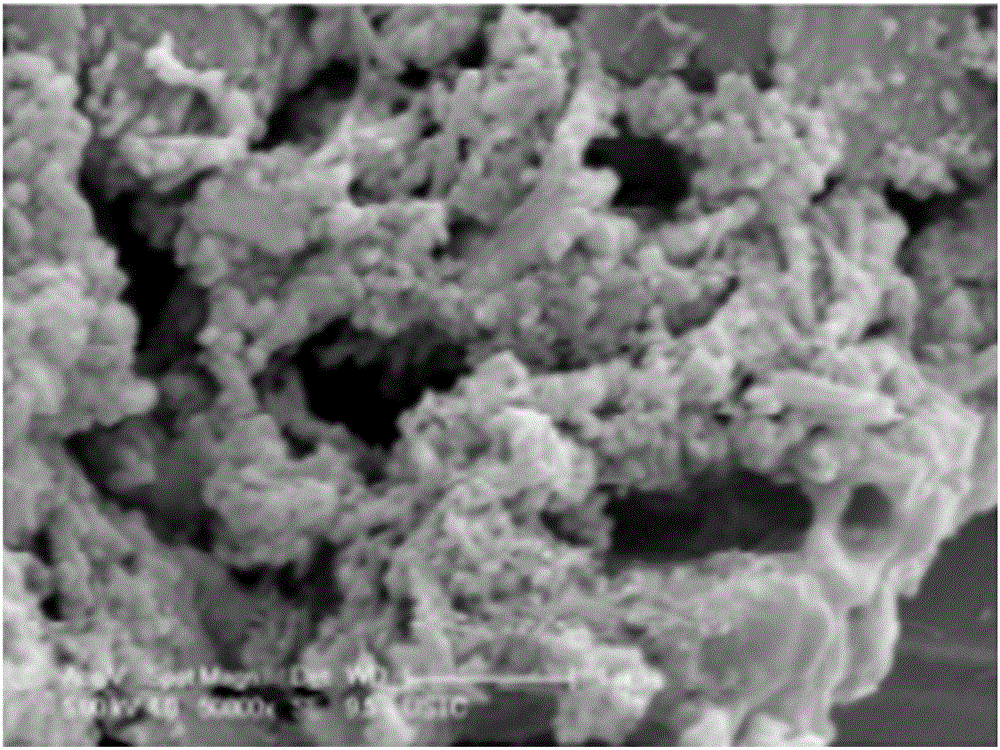

Graphene-like modified thermal conductive plastic and preparation method thereof

The invention belongs to the technical field of modified thermal conductive plastics and in particular relates to a graphene-like modified thermal conductive plastic and a preparation method thereof. The graphene-like modified thermal conductive plastic comprises the components of a plastic base material and graphene-like, wherein the plastic base material accounts for 80-90 weight percentage of total mass; the graphene-like accounts for 10-20 weight percentage of total mass; and the carbon content of the graphene-like is more than or equal to 97 percent; the bulk density of the graphene-like is 0.15-0.3g / ml. Because the graphene-like modified thermal conductive plastic is prepared by mixing high-density graphene-like powder and the plastic base material, and the bulk density of the graphene-like powder reaches 0.15-0.3g / ml, so that the graphene-like powder can be fully mixed with the plastic base material, and the graphene-like powder in a layered structure can be uniformly distributed in the plastic base material and forms a meshed structure with a plastic high polymer. Therefore, various mechanical properties of the plastics are remained to the greatest degree, and the plastic has excellent thermal conductive performance.

Owner:宁波信远炭材料有限公司

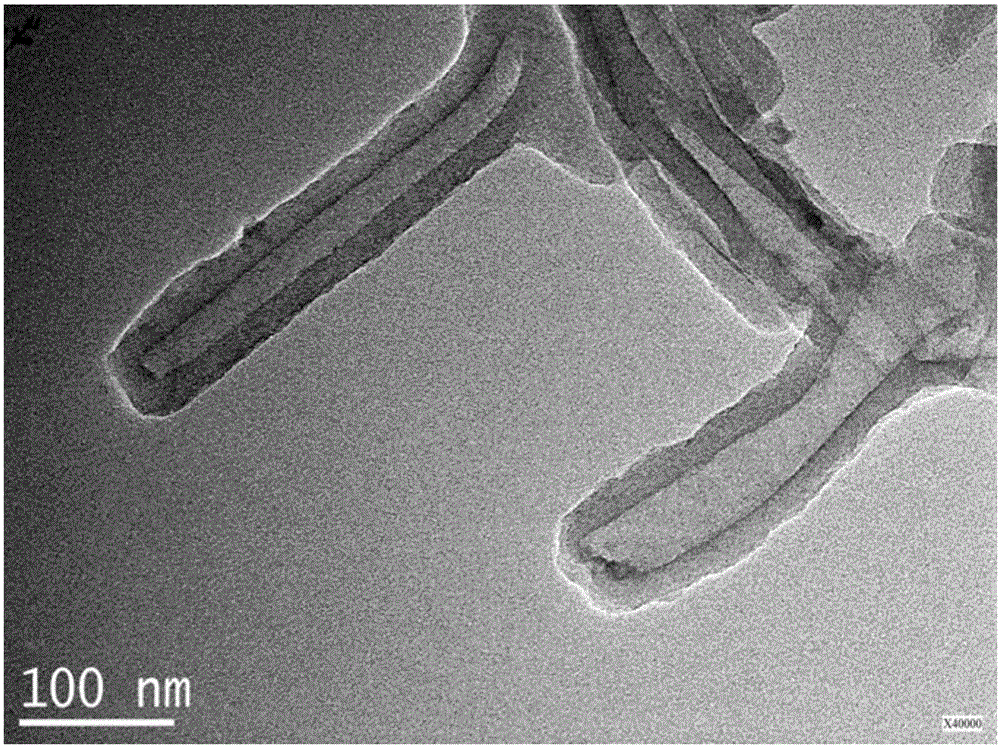

Method for enhancing properties of epoxy-resin-base fiber composite material

The invention discloses a method for enhancing properties of an epoxy-resin-base fiber composite material. The method is characterized in that an epoxy resin is used as the epoxy-resin-base fiber composite material, and a continuous fiber male fabric is used as reinforcing fibers; and a halloysite / carbon nano composite material is uniformly dispersed in the epoxy resin base of the epoxy-resin-base fiber composite material to prepare the halloysite / carbon-modified epoxy-resin-base fiber composite material, thereby improving the interface combination between the epoxy resins and fibers, and enhancing the properties of the epoxy-resin-base fiber composite material. By using the halloysite / carbon nano composite material as the additive, the halloysite and carbon layer can better implement the synergistic effect, thereby performing the better functions of transferring stress between the bases and between the base and fiber reinforcer and establishing a heat-conducting network; and under the interface combination action between the reinforcing fibers and resin, the epoxy-resin-base fiber composite material has favorable bending property and heat-conducting property.

Owner:HEFEI UNIV OF TECH

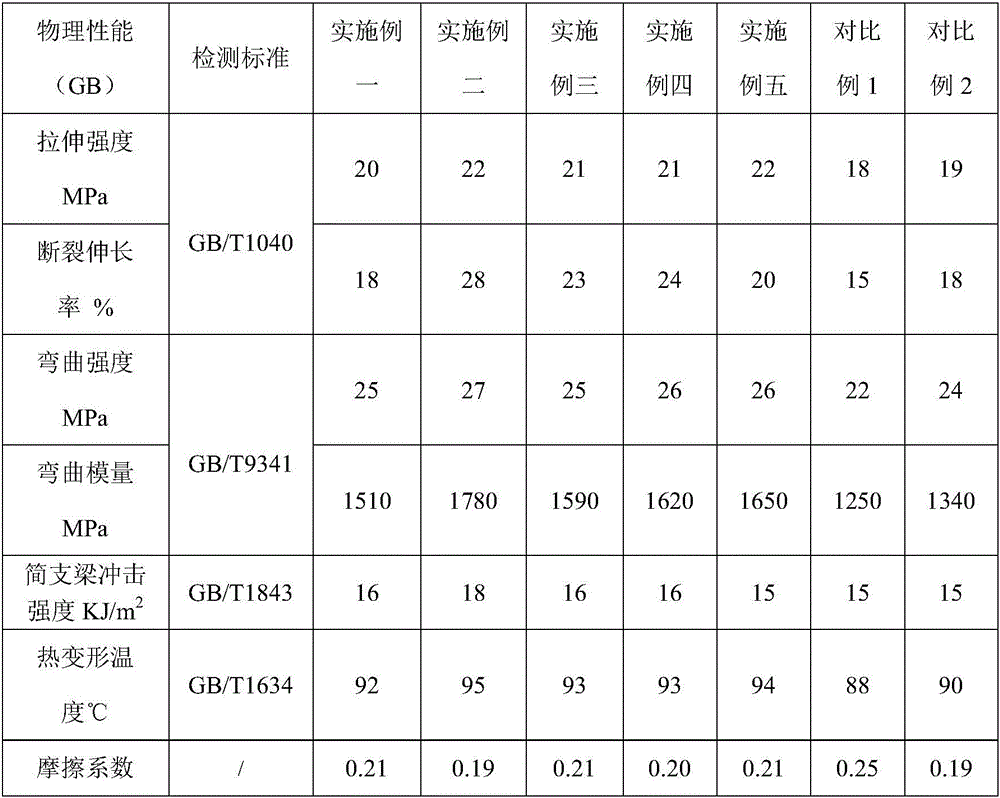

Low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material and preparation method thereof

InactiveCN106366456AEvenly dispersedImprove interface compatibilityPolypropylene compositesPolymer science

The invention discloses a low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material and a preparation method thereof. The low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material comprises the following components in parts by weight: 80-90 parts of polypropylene, 5-8 parts of modifying montmorillonite, 4-10 parts of a compatilizer, 0.2-0.5 part of an antioxidant, 0.3-0.6 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material prepared by the preparation method provided by the invention, by a melting intercalation method, a polymer is inserted into spaces between montmorillonite layers and thus the montmorillonite is dispersed into the polymer in a layered structure, so that a similar fiber enhancement role can be played; in addition, a grafting reaction can also be performed on double bonds in a modifier and main chains of the polypropylene, the montmorillonite layers are splayed out by heat released during the grafting reaction, and through chemical bonding of grafts and polymer molecule, the montmorillonite layers are forcibly dispersed uniformly in the polymer matrix so as to form an intercalated nanocomposite material, so that the low-filling high-performance nanomontmorillonite-reinforced polypropylene composite material has excellent mechanical properties, and thus the application range is widened.

Owner:ORINKO NEW MATERIAL CO LTD

Polyamide- and polyolefin-based fire-retarded compositions

The present invention relates to fire-retarded compositions comprising, by weight, the total being 100 parts:50 to 75 parts of a blend of a polyamide (A) and a polyolefin (B),25 to 50 parts of a blend comprising:0.1 to 48.8 parts of a fire retardant,0.1 to 30 parts of a phosphorus-containing plasticizer,0.1 to 10 parts of a zeolite,the total of these three products being between 25 and 50.These compositions have a V0 or V1 classification according to the UL94-VB test when a fire test is carried out on test specimens 1.6 mm in thickness. They have many advantages, in particular the elongation at break measured according to ISO R 527-1B exceeds 100%. As regards the impact strength, they have a non-brittle behaviour in multiaxial impact at room temperature according to ISO 6603-2 (at a rate of 7.7 m / s). They retain at least 50% of their mechanical properties after ageing for seven days at 120° C. in hot air.These compositions are useful for insulating and protecting electrical cables and optical fibres and for moulding electrical cases and connectors.

Owner:ATOFINA

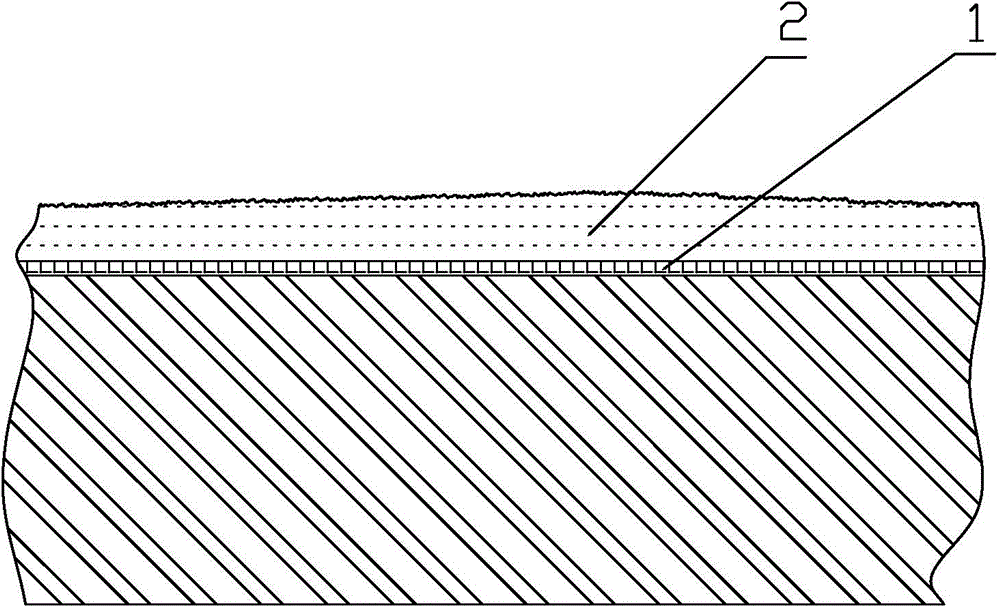

Wear-resistant hydrophobic nano composite film and preparation method thereof

InactiveCN104694877AImprove mechanical propertiesImprove hydrophobicityVacuum evaporation coatingSputtering coatingComposite filmWear resistant

The invention relates to a wear-resistant hydrophobic nano composite film and a preparation method thereof, belonging to the technical field of metal surface treatment and modification. The composite film is based on high-speed steel, or titanium alloy, or hard alloy, or pure metal, and a pure metal film and a microstructure nano composite film are sequentially prepared on the base surface. The preparation method comprises the following steps: depositing a nano composite hard film with excellent mechanical properties on the base material surface by arc ion plating, and generating a micro / nano dual structure on the film surface by an ultra-fast laser processing technique to obtain the surface film with favorable mechanical properties and certain hydrophobicity. The film maintains excellent mechanical properties of the nano composite hard film: high surface hardness, high toughness, high wearability and high scratch resistance; and the microstructure on the film surface is constructed, so that the film has certain hydrophobicity. The preparation method has the advantages of simpler equipment, low cost, low energy consumption and no pollution, and can implement efficient green manufacturing.

Owner:常州翊迈新材料科技有限公司

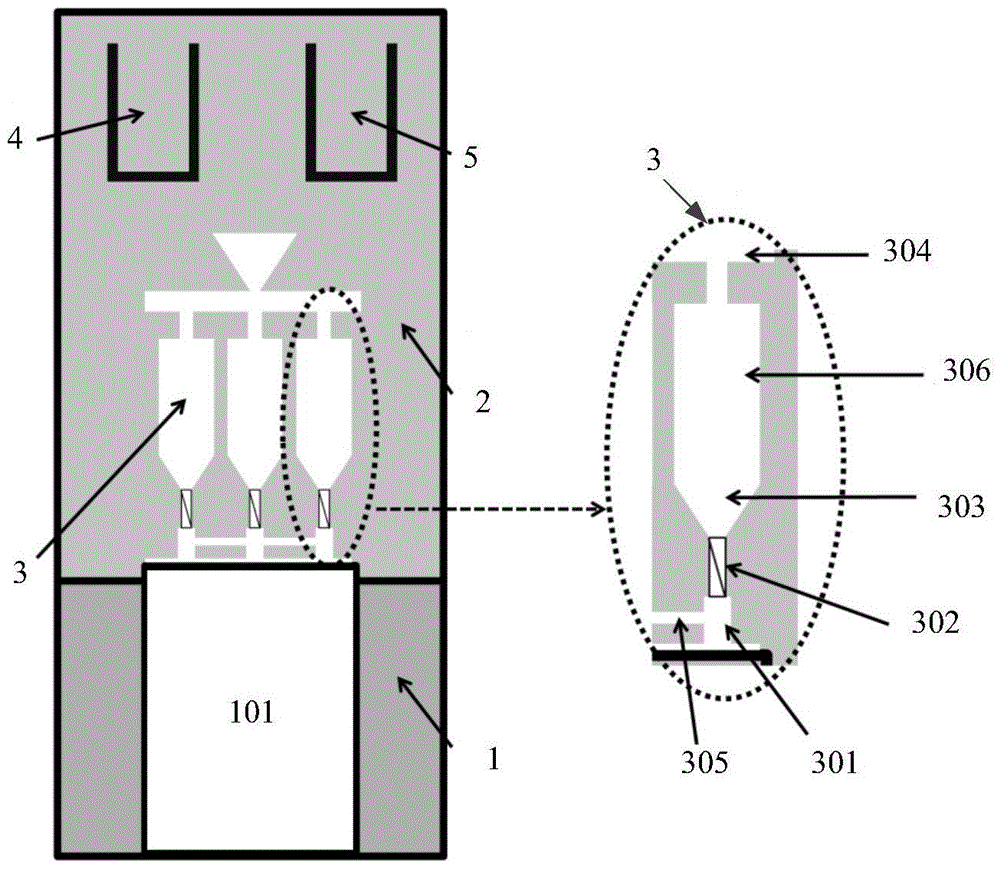

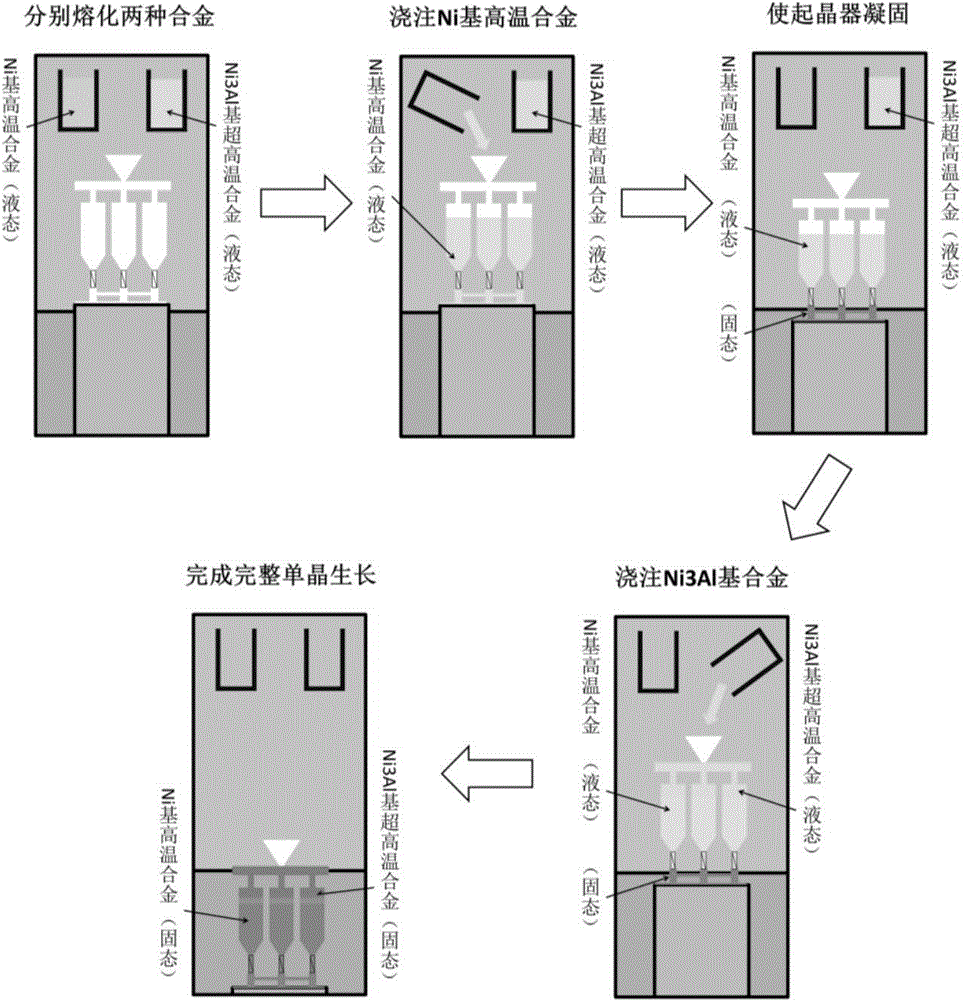

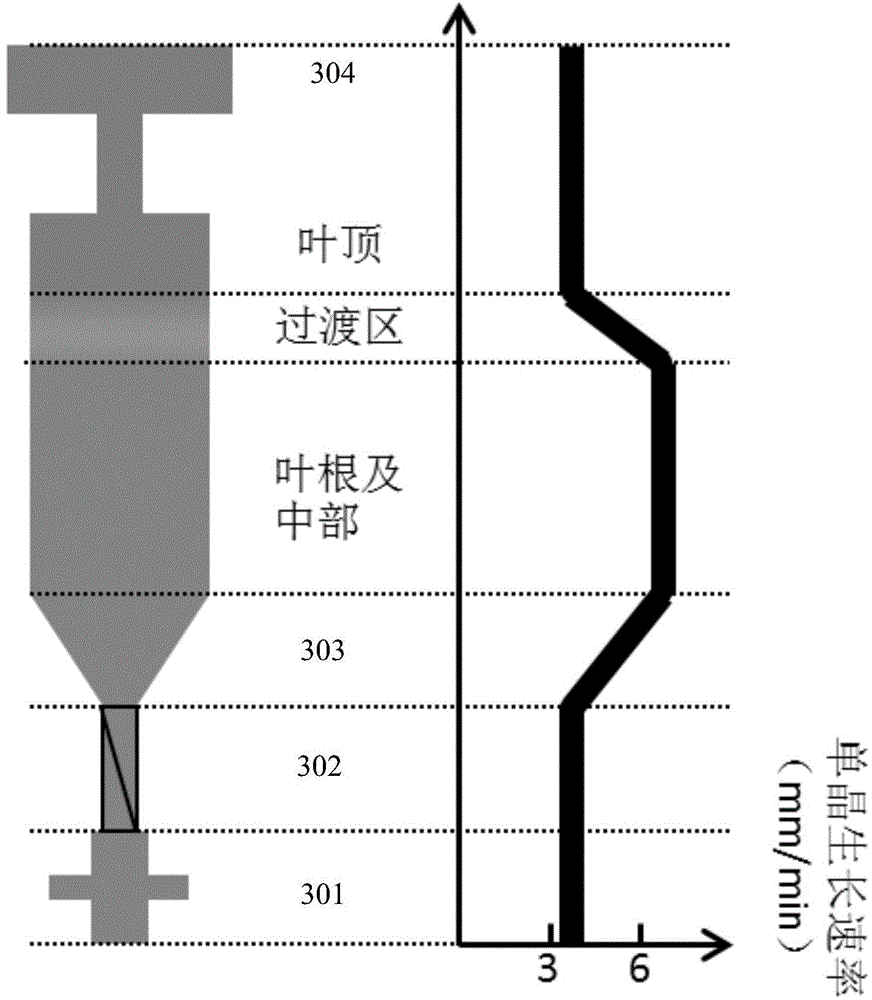

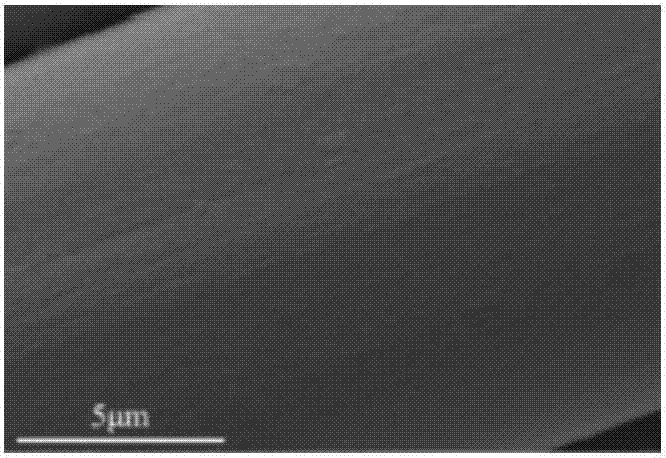

Two-alloy compounded functionally gradient monocrystal blade material and preparation method thereof

InactiveCN104858399ARealize design requirementsSpread evenlyPolycrystalline material growthBlade accessoriesGrowth controlSingle crystal

The invention discloses a two-alloy compounded functionally gradient monocrystal blade material and a preparation method thereof and belongs to the technical field of high-temperature alloy and preparation thereof. The blade root and middle part of a monocrystal blade are made of Ni-based high-temperature alloy, and the blade top of the monocrystal blade is made of monocrystal blade material of Ni3Al-based hyperthermia alloy; the blade root and middle part of the material are predicted to have a better medium and low temperature service performance, and the blade top of the material is predicted to have better hyperthermia service performance. The preparation method comprises the steps of design of form, pouring technology, monocrystal growth control and thermal treatment system. According to the invention, through the design of a narrow passage of a graining device, the longitudinal distribution of two alloys in the blade can be accurately controlled, so that the process stability and material designability are greatly improved; the obtained monocrystal blade material realizes functionally gradient service and meets the design demands of new-generation aero-engines.

Owner:BEIHANG UNIV

Reduced graphene oxide/polyacrylonitrile composite fiber and preparation method thereof

ActiveCN107956110AImprove conductivityEffective compoundFibre typesChemical LinkageReduction treatment

The invention relates to a reduced graphene oxide / polyacrylonitrile composite fiber and a preparation method thereof. The method is that after graphene oxide is assembled onto the surfaces of amino group-containing polyacrylonitrile fibers by magnetic attraction and chemical bonding, reduction treatment is carried out, so that the reduced graphene oxide / polyacrylonitrile composite fiber is obtained. The average volume resistivity of the reduced graphene oxide / polyacrylonitrile composite fiber prepared by the method is less than or equal to 30 Omega.cm, reduced by 12 orders of magnitude in comparison with the average volume resistivity of the raw filament; moreover, the decrease rate of the breaking strength is less than or equal to 5 percent relative to the decrease rate of the breaking strength of the raw filament, the increase rate of the elongation at break is greater than or equal to 58 percent relative to the increase rate of the elongation at break of the raw filament, and afterdeionized water is utilized to wash the composite fiber for 10 to 20 times, the average volume resistivity of the fiber is less than or equal to 33 Omega.cm. The method disclosed by the invention hasthe advantages of reducing agent selection diversity, good reduction effect, low production cost and the like, the produced fiber has good conductivity and durability, and furthermore, the inherent excellent mechanical property of the fiber is kept.

Owner:DONGHUA UNIV

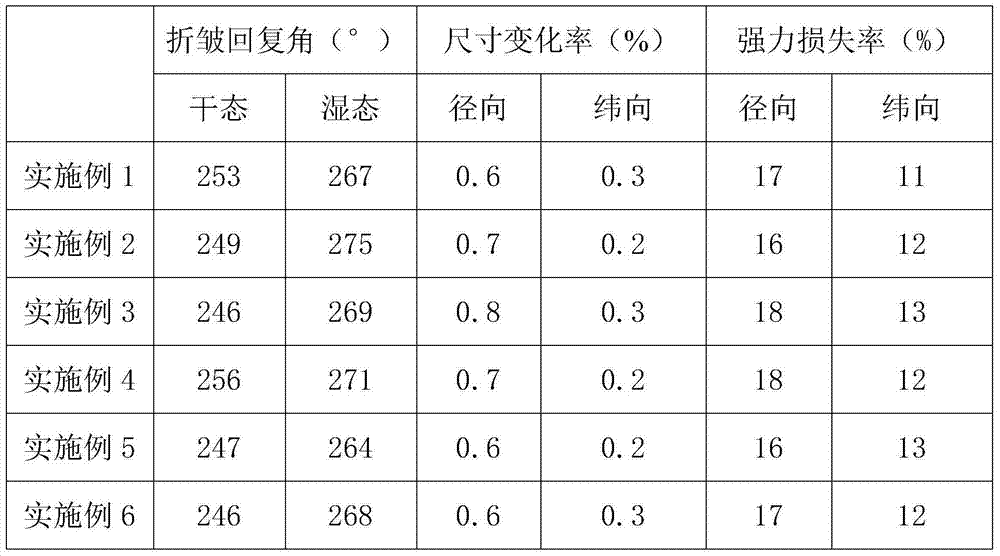

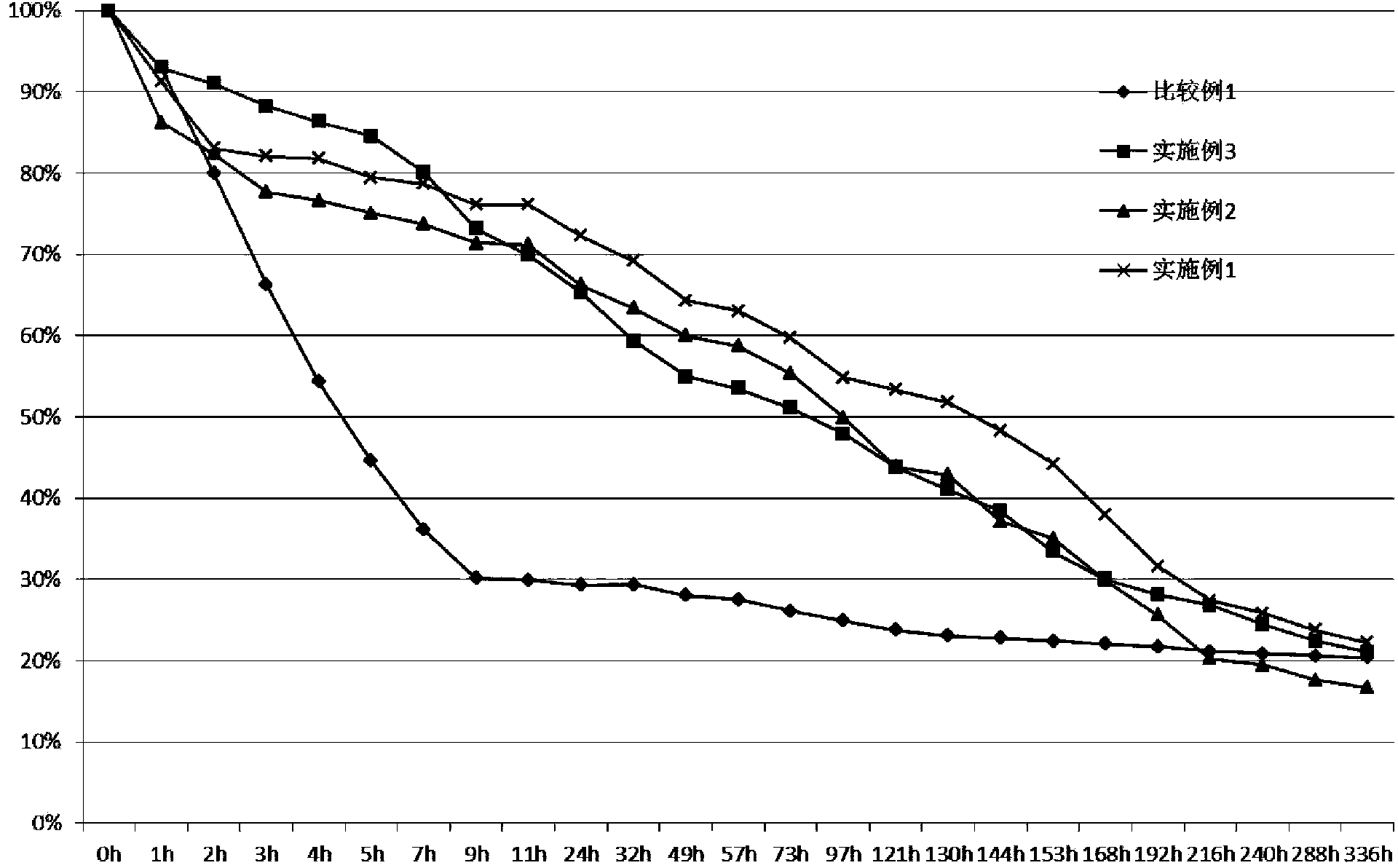

Noniron finishing method of silk fabric

InactiveCN104762821AGood shrink resistanceGuaranteed feelBiochemical fibre treatmentAnimal fibresWarm waterEngineering

The invention discloses a noniron finishing method of a silk fabric. The noniron finishing method particularly comprises the following steps: moistening and rinsing the silk fabric with warm water twice, refining and expanding the silk fabric by using a biological enzyme, after rinsing with warm water, padding the expanded silk fabric in a wash and wear finisher containing silk fibroin, citric acid and chitosan quaternary ammonium salt, then predrying the silk fabric, tentering at constant temperature, baking at high temperature, washing with water and drying, and pressing-packaging to obtain the noniron finished silk fabric. According to the noniron finishing method, a biological enzyme technology is combined with a padding technology, the silk fabric is subjected to noniron finishing by using the silk fibroin, the citric acid and the chitosan quaternary ammonium salt, so that the noniron finishing method has the advantages of simple and effective, environmental-friendly and biological effects. The silk fabric prepared by adopting the noniron finishing method reaches a noniron degree, and has a good crease-resisting and deformation-resisting capabilities; the dyeing performance of the fabric is improved; the handfeel, the style and the mechanical property of the fabric are reserved, and thus the noniron finishing method is an ideal noniron finishing method of the silk fabric.

Owner:SUZHOU WILDER IND & TRADE

Weather-proof migration-proof long-acting type microcapsule essence and preparation method thereof

ActiveCN103849466AImprove heat resistanceImprove mechanical stabilityEssential-oils/perfumesMicroballoon preparationWeather resistancePolyvinyl alcohol

The invention discloses a weather-proof migration-proof long-acting type microcapsule essence and a preparation method thereof. An oil soluble essence oil is used as a capsule core, and a first wall material layer, a second wall material layer and a third wall material layer are sequentially coated outside the capsule core from inside to outside, the first wall material layer is a terpolymer of gelatin, Arabic gum and carboxymethylcellulose, with a thickness of 0.5-1.5 mu m; the second layer material layer is an amino resin polymer, with a thickness of 1-3 mu m; and the third wall material layer is a polyvinyl alcohol compound with a thickness of 0.5-1.5 mu m. The microcapsule essence disclosed by the invention is a powdery product with good liquidity, and particle size distribution of 1-15 mu m, and is uniformly dispersed in a high polymer material and good in weather resistance and migration resistance. The decompsotion temperature and the softening temperature of the microcapsule essence disclosed by the invention can be about 240 DEG C; and the microcapsule essence is firm in capsule material, and can not be greatly broken in an extrusion molding process.

Owner:HEFEI UNIV OF TECH

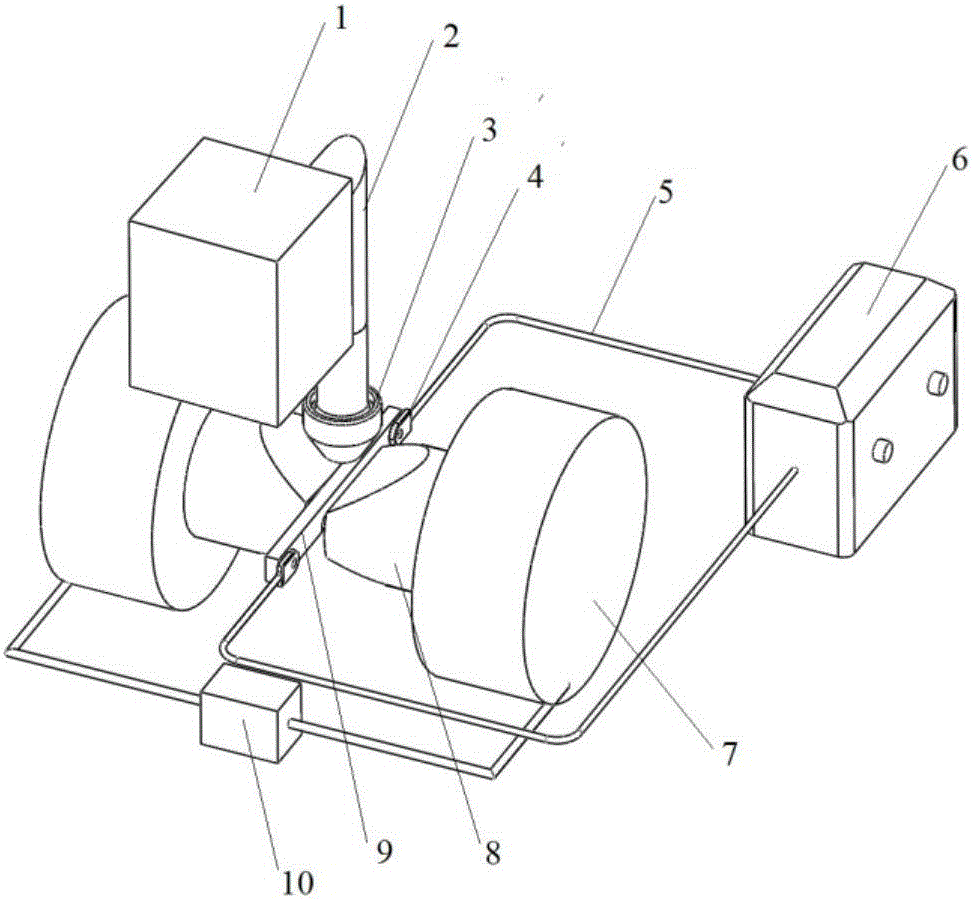

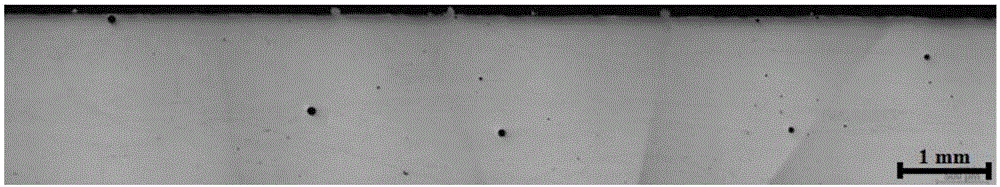

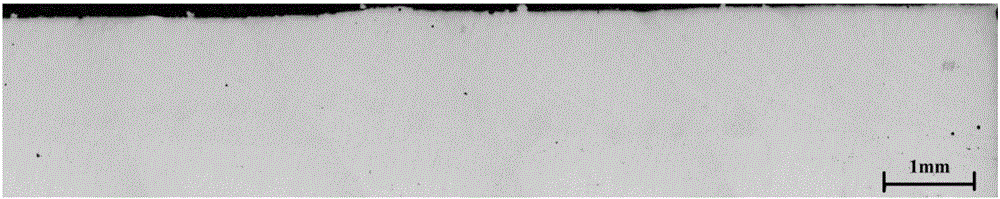

Laser weld-bonding method

InactiveCN102126086AHigh degree of automationReduce decompositionLaser beam welding apparatusDecompositionAdhesive

The invention provides a laser weld-bonding method, relating to a welding method. The invention solves the problem that the welding quality is affected by gases generated from mass decomposition of adhesive layers in a laser weld-bonding process. The laser weld-bonding method comprises the following steps that: two metal sheets subjected to oxidation film and rust removal are heated, applied with adhesive and overlapped, and then are irradiated respectively under two laser beams, and after an adhesive layer between welded metal sheets is cured, the laser weld-bonding is finished. The laser weld-bonding method has obvious efflux of the adhesive layer in a welding process, and the efflux adhesive layer contains air bubbles, therefore, it is proved that the laser weld-bonding method can exhaust gases generated by heat decomposition of the adhesive layer, and reduce the affects of the gases on performance of joints.

Owner:HARBIN INST OF TECH

Preparation method of porosity controllable nickel base coating layer

ActiveCN106191854ARetain mechanical propertiesRetain propertiesMetallic material coating processesPorosityPower flow

The invention relates to a preparation method of a porosity controllable nickel base coating layer. The preparation method comprises the steps of: (A) polishing, cleaning and dirt removal; (B) laser cladding: a coaxial powder feeder is used for feeding nickel base powder to the surface of a basal body to form a laser cladding molten pool; and laser scanning is used for laser cladding layer by layer to enable the cladding molten pool to form bubbles; and (C) Lorentz force and volume force coupling: on the basis of bubble formation in the cladding molten pool in the step (B), gradient-adjustable Lorentz force is introduced to adjust distribution of the bubbles formed in the process in the step (B), so that formed air holes are gradually or uniformly distributed in the cladding layer in the depth direction from surface to inside. The method influences the reducing gradient of the Lorentz force through adjusting the magnitude of direct current applied to the surface of a substrate and the strength gradient of the magnetic field on the surface of the molten pool. The method is suitable for laser cladding of the nickel base coating layer, can be synchronously suitable for such processing modes as welding and laser cladding for molten pool production, and is wide in application range.

Owner:ZHEJIANG UNIV OF TECH

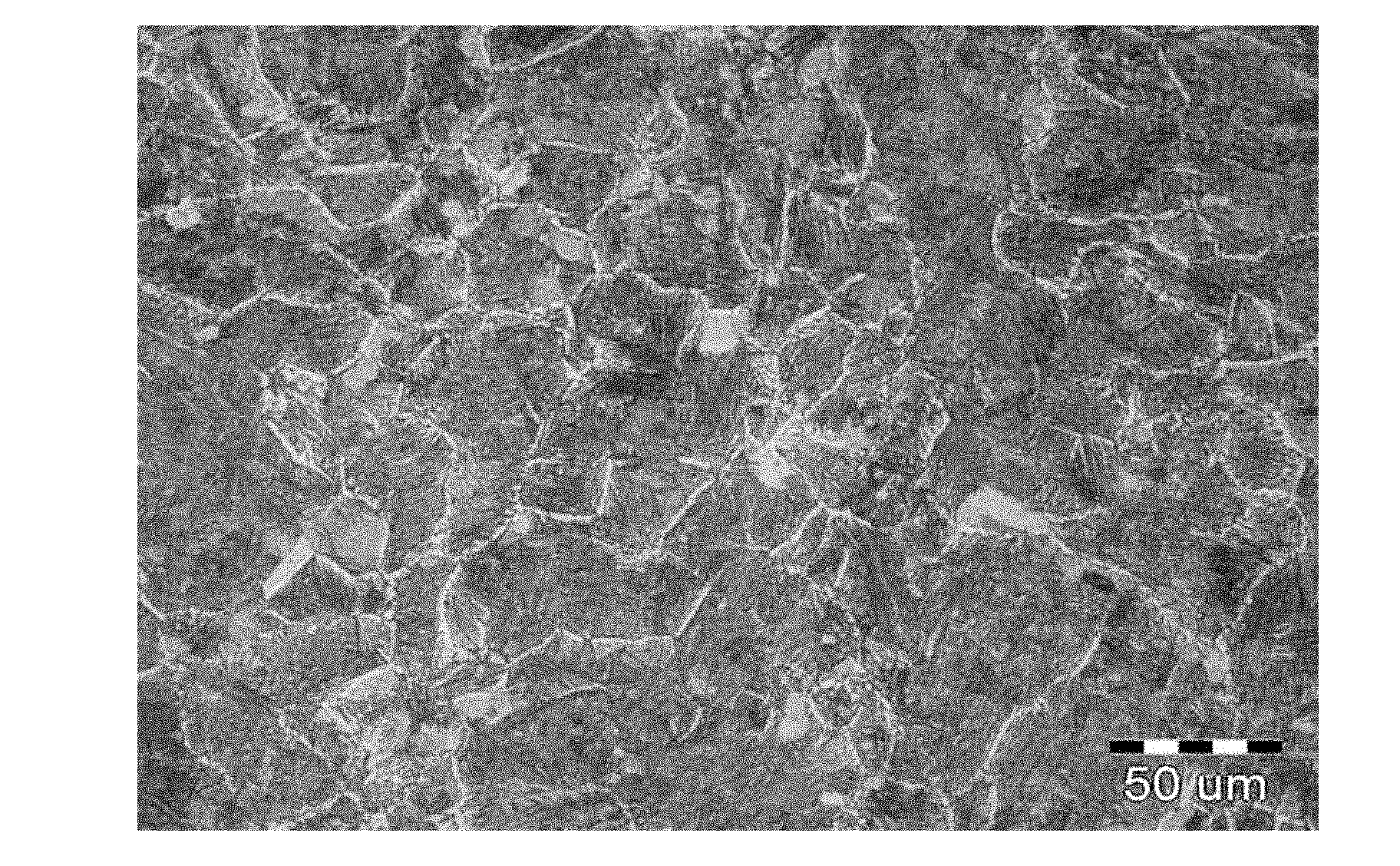

Carbon fiber surface treating agent based on graphene oxide and treatment method thereof

The invention discloses a carbon fiber surface treating agent based on graphene oxide and a treatment method thereof and relates to surface treatment of carbon fibers. The carbon fiber surface treating agent based on graphene oxide comprises, by mass, 100 parts of epoxy resin, 50-200 parts of acetone and 0.05-5 parts of graphene oxide. The carbon fibers are used as raw materials, and a solution-type carbon fiber surface treating agent containing graphene oxide with specific oxygen functional group content and dispersing layer number is subjected to secondary starching. On the basis of originalstarching treatment for the carbon fibers, the surfaces of the carbon fibers are subjected to surface treatment similar to secondary starching, a graphene oxide / epoxy resin treating agent layer is formed on the surfaces of the carbon fibers, the aim of improving the interface adhesive performance between the carbon fibers and resin matrixes is achieved, and accordingly the carbon fiber surface treatment method, the carbon fibers and products thereof are convenient to operate, simple in equipment and suitable for industrial production.

Owner:XIAMEN UNIV

Environment-friendly lead-free novel alloy material pipe and preparation method thereof

The invention provides an environment-friendly lead-free novel alloy material pipe and a preparation method thereof. The alloy material pipe is composed of the following components: zinc accounting for 1-3% of the total weight of the alloy material, tin accounting for 1-3% of the total weight of the alloy material, aluminum accounting for 0.5-2.5% of the total weight of the alloy material, antimony accounting for 0.05-0.5% of the total weight of the alloy material, silicon accounting for 0.5-1% of the total weight of the alloy material, and the balance of copper. According to the environment-friendly lead-free novel alloy material pipe, the traditional lead element is replaced by the silicon element; zinc, tin, aluminum, antimony, silicon and copper are blended in a certain ratio and continuously cast at an appropriate temperature to form a rough pipe casting; next, the rough pipe casting is extruded by an extruder to produce a tin bronze pipe completely containing no lead element; as a result, the mechanical properties, such as cutability, of the existing tin bronze are maintained without increasing cost, and the requirement on the environmental protection property of the alloy is also met.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

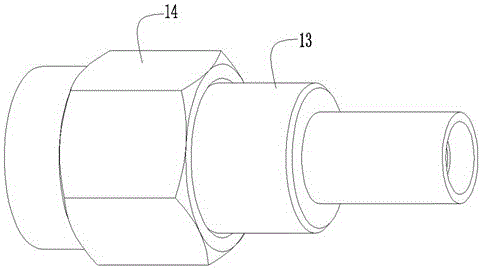

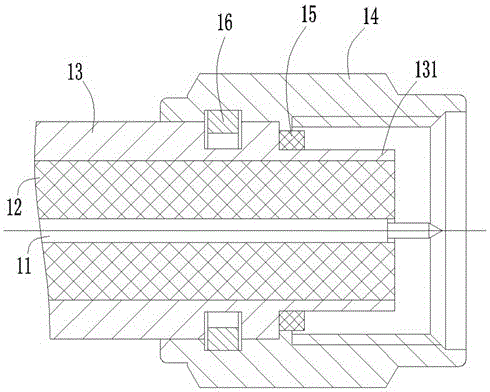

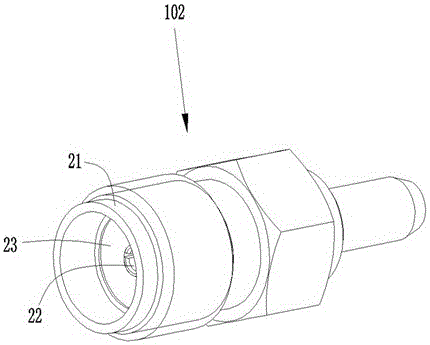

Coaxial connector and plug and socket thereof

ActiveCN105846258AIncreased form factorRetain mechanical propertiesCouplings bases/casesTwo-part coupling devicesEnvironmental resistanceElectrical conductor

The invention relates to the field of electrical connectors, in particular to a coaxial connector and a plug and a socket thereof. The coaxial connector comprises the plug and the socket, wherein the plug comprises an outer plug conductor and a connection nut; the connection nut is rotationally assembled on the outer plug conductor; the socket comprises an outer socket conductor; the outer plug conductor is provided with an insertion part which is used for inserting of the outer socket conductor; a set distance is formed between the outer wall surface of the insertion part and the inner wall surface of the connection nut; a thickening part is arranged on an outer layer of the insertion part; expansion parts matched with the thickening part are arranged in holes of the outer socket conductor and the connection nut; the set distance is the distance between the outer side surface of the thickening part and the inner wall surface of the expansion part in the hole of the connection nut; and an outer thread matched with the connection nut is formed in the outer socket conductor. By the coaxial connector, the strength, the reliability and the characteristic impedance can be improved under the condition of not increasing the boundary dimension of the SMA radio-frequency coaxial connector and reserving the mechanical property and the environmental resistance of the SMA connector.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

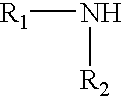

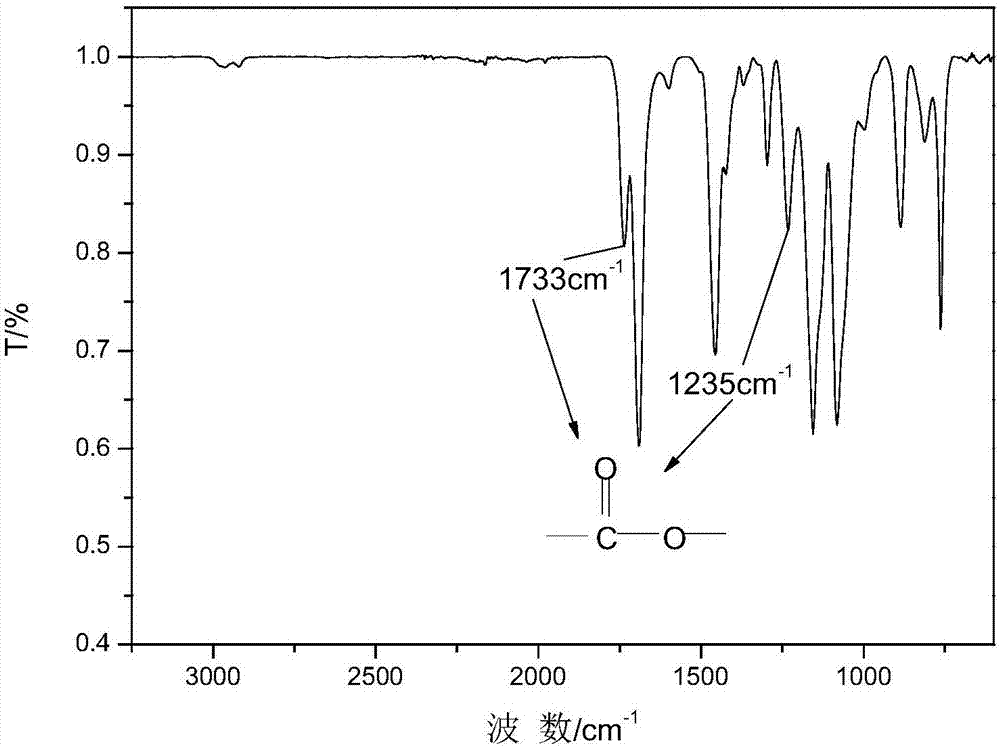

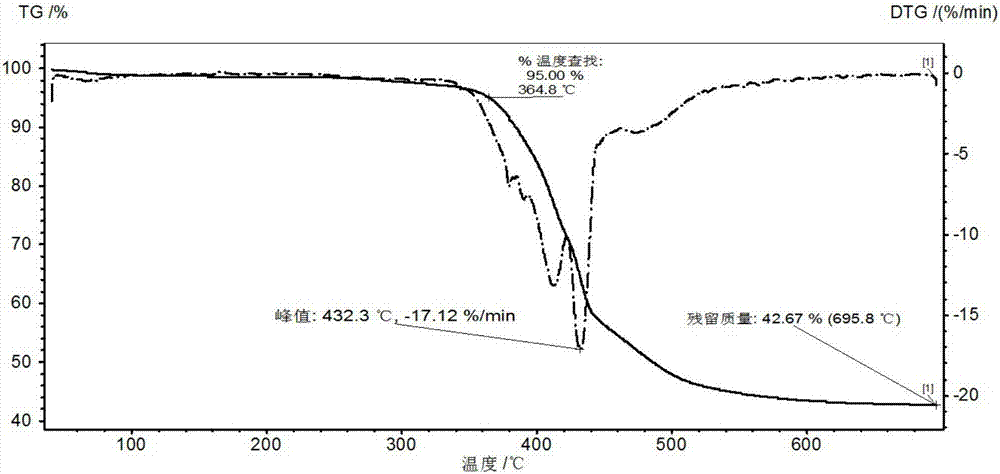

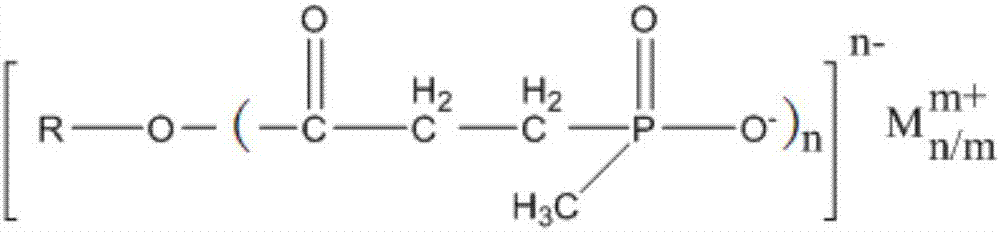

Single molecular expansion type alkyl phosphinate flame retardant and preparation method thereof

ActiveCN106967116AImprove flame retardant performanceHigh carbon residue rateGroup 5/15 element organic compoundsAmidogenMechanical property

The invention discloses a single molecular expansion type alkyl phosphinate flame retardant. A structural general formula is shown in the description, a molecular structure is starlike, R-O- is a hydroxyl dehydrogenized structure after a nitrogen-containing polyhydroxy compound is subjected to esterification reaction, the formula (shown in the description) is a hydroxyl removed structure provided with molecular hydroxyl and obtained after organic phosphonic acid esterification reaction, n corresponds to the number of hydroxy and amidogen of the nitrogen-containing polyhydroxy compound, and M is a metal or semi-metal having the valence m. The invention further discloses a preparation method the flame retardant. The three-source proportion of the flame retardant can be regulated and controlled by selecting different nitrogen-containing polyhydroxy compounds. The molecular structure contains P-C keys and has excellent heat stability and good chemical properties. A specific carboxylic ester structure has good mixing compatibility with a polymer, and the original mechanical properties of the polymer can be retained to the greater degree. Metal ions in molecules can prevent the flame retardant from migrating from the polymer and meanwhile have a catalytic charing effect.

Owner:HONGHU YITAI TECH CO LTD

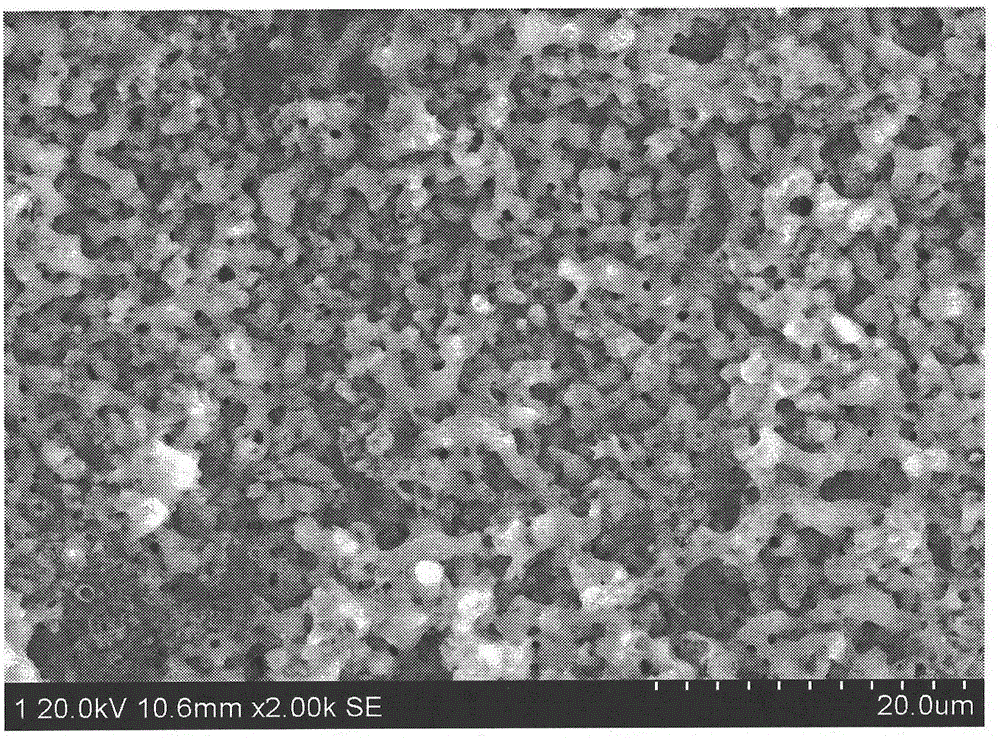

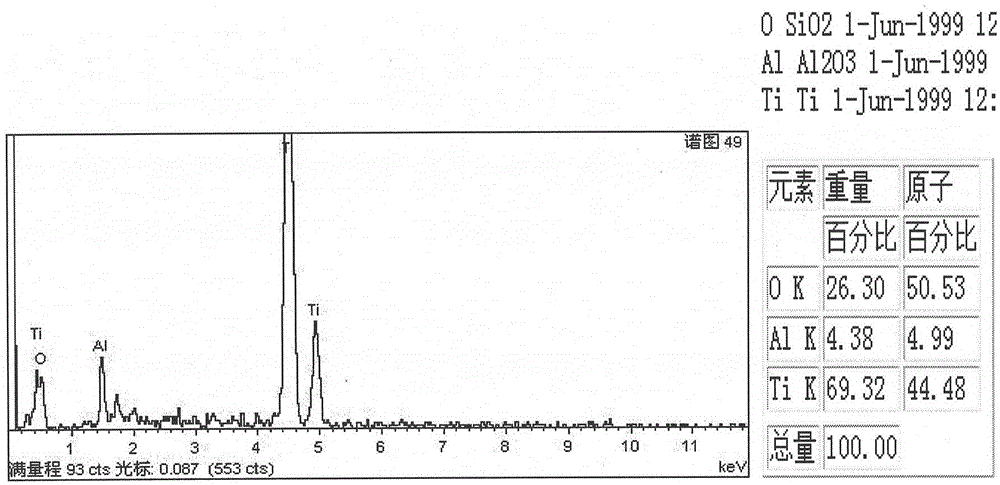

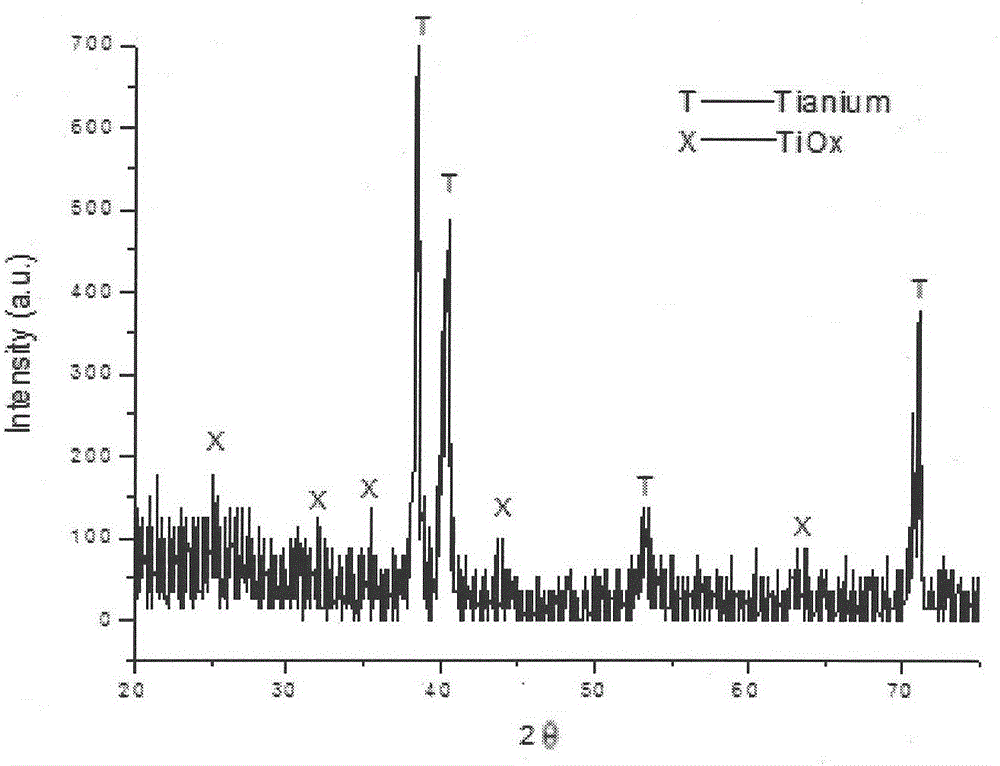

Preparing method for high-strength and large-specific-surface-area titanium black coating

ActiveCN105734642AImprove conductivityImprove photocatalytic performanceSurface reaction electrolytic coatingSolid state diffusion coatingHigh intensityPre treatment

The invention relates to a preparing method for a high-strength and large-specific-surface-area titanium black coating. The preparing method comprises the following steps that firstly, a titanium or titanium alloy base body is pretreated; secondly, a porous titanium dioxide coating is prepared; thirdly, sample plasma cleaning is conducted; fourthly, TiOx modification treatment is conducted; and fifthly, TiNxOy doping treatment is conducted. According to the preparing method, the large-specific-surface-area titanium black coating which is endowed with optical and electrical conduction functional characteristics and is capable of meeting the requirements for friction, strength and binding force can be obtained.

Owner:广东博友制钛科技有限公司

Improving method of water resistance of polyurethane material

InactiveCN103709359ARetain mechanical propertiesImprove hydrolysis resistanceApplication areasPolytetrafluoroethylene

The invention discloses an improving method of water resistance of a polyurethane material, belonging to the technical field of material modifying methods. The method is to add 5-40 parts by weight of polytetrafluoroethylene micro powder into every 100 parts by weight of the polyurethane materials. According to the improving method disclosed by the invention, the polytetrafluoroethylene micro powder is added into a polyurethane material system, so that not only can mechanical performance of the polyurethane be kept, but also hydrolysis resistance of the polyurethane can be improved, and therefore, the application field of the polyurethane material is expanded.

Owner:HANGZHOU SHUNLONG RUBBER ROLL

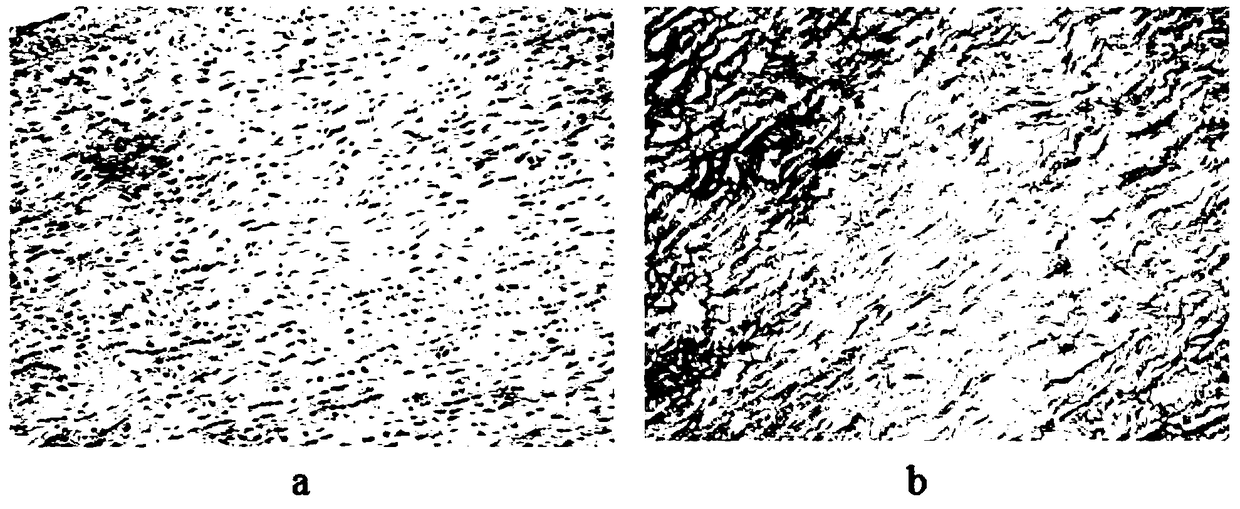

Preparation method and use of decellularized tendon material

The invention discloses a preparation method of a decellularized tendon material. The preparation method comprises the following steps of 1, taking fresh tendon and carrying out cleaning, 2, compressing the tendon along the thickness direction at a compression ratio of 60-90%, 3, carrying out repeated freezing-thawing on the compressed tendon, and 4, treating the tendon subjected to the step 3 by nuclease and carrying out cleaning. The invention also discloses the decellularized tendon material obtained by the preparation method and a use thereof. The decellularized tendon material realizes thorough decellularization and has low immunogenicity, good biomechanical properties and good biocompatibility. The preparation method has simple processes, a low cost and a good application prospect.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

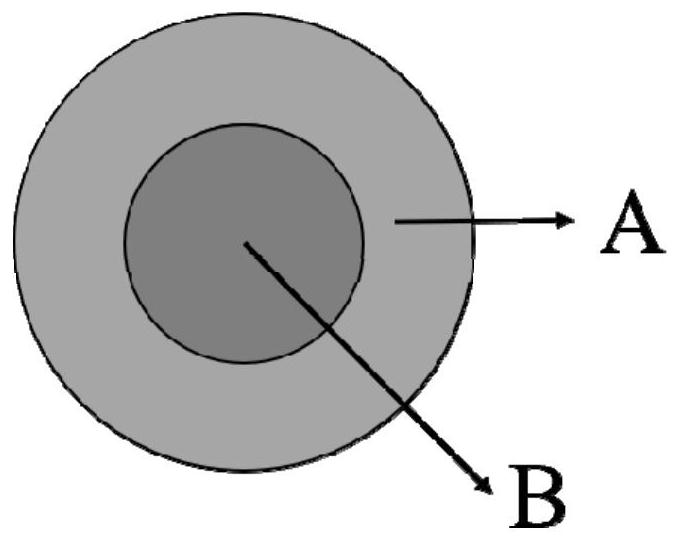

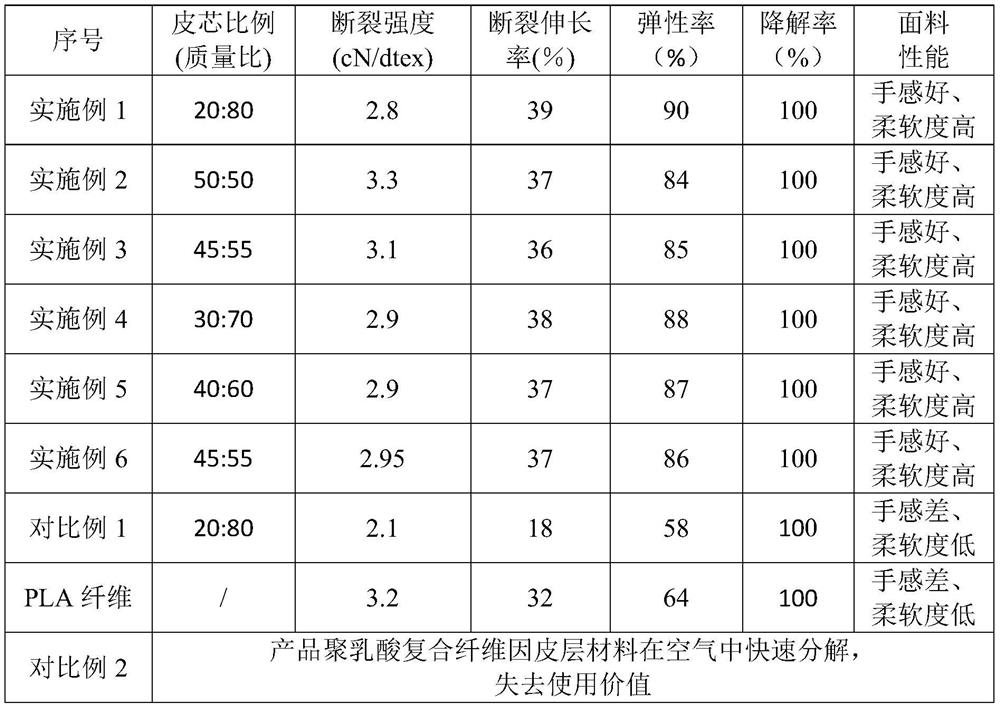

Degradable polyester/polyether block copolymer, polylactic acid degradable composite fiber and preparation method thereof

PendingCN113603875ALow costImprove mechanical propertiesConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention discloses a degradable polyester / polyether block copolymer, a polylactic acid degradable composite fiber and a preparation method of the polylactic acid degradable composite fiber, and belongs to the technical field of textile fibers.The polylactic acid degradable composite fiber is of a skin-core structure, and the skin layer material of the skin-core structure is polylactic acid; the core layer material of the skin-core structure is the degradable polyester / polyether block copolymer; the performance of the PLA fiber is improved, and the cost can be reduced; compared with a pure PLA fiber, the polylactic acid degradable composite fiber with the skin-core structure has better mechanical properties, and the problems of poor hand feeling, elasticity, toughness and the like of the PLA fiber are effectively solved.

Owner:SICHUAN UNIV

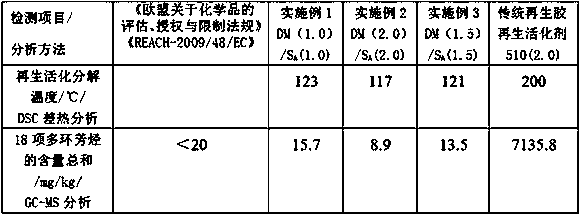

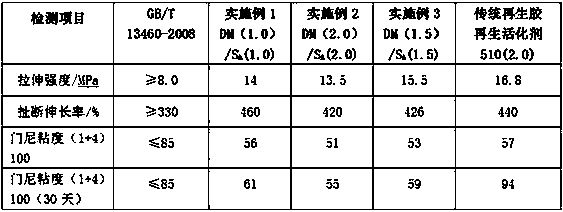

Method of producing environment-friendly regenerated rubber via low-temperature desulfurization

ActiveCN108219192AFast link breakImprove mechanical propertiesPlastic recyclingSocial benefitsPlasticizer

The invention discloses a method of producing environment-friendly regenerated rubber via low-temperature desulfurization. The method includes the steps of: 1) low-temperature desulfurization througha desulfurization tank or an internal mixer: feeding rubber powder, a composite regenerating activator, and a Mooney stabilizer into the desulfurization tank or internal mixer, performing pressurizedmixing for a certain time, adding an environment-friendly softener such as rosin, performing pressurized mixing for a certain time, heating the material to 120 + / - 5 DEG C for desulfurization regeneration; 2) after regeneration for a certain time, cooling the material to lower than 70 DEG C, discharging the material into a cooling stirrer; 3) at 120 + / - 5 DEG C, delivering the material to a doublescrew plasticizer, cooling the material and discharging the material to a storage plate, and delivering the material to a refiner; 4) circulating the rubber at 40 DEG C in a thin-passing manner for 5min, and automatically cutting and weighing the rubber. The technology has outstanding economic and social benefits.

Owner:XUZHOU COLLEGE OF INDAL TECH

Composite stent as well as preparation method and application thereof

ActiveCN112587731AImprove mechanical propertiesGood osteoinductivityCoatingsMicrocapsulesCalcium silicatePolyester

The invention discloses a composite stent as well as a preparation method and application thereof. The composite stent comprises a stent matrix, drug-loaded microspheres and an alginate layer; the stent matrix is of a three-dimensional porous structure; the drug-loaded microspheres are fixed to the surface and pore channels of the stent matrix; the alginate layer covers the surfaces of the drug-loaded microspheres and the stent matrix; drug-loaded microspheres comprise carrier microspheres and drugs loaded on the carrier microspheres; the drugs consist of a bone repair medicine, and / or a growth factor; and the raw materials of the carrier microspheres are composed of degradable polyester and mesoporous calcium silicate. The composite stent is stable in structure, and has good drug slow releasing effect as well as osteogenic differentiation capacity; and moreover, the composite stent is capable of effectively promoting repair and reconstruction of bone tissue.

Owner:GUANGDONG PROV MEDICAL INSTR INST

PEEK (Polyetheretherketone) balloon dilatation catheter

InactiveCN101822867AEliminate induced toxic effectsAvoid damageStentsBalloon catheterBalloon dilatation catheterCell damage

The invention relates to a PEEK balloon dilatation catheter for an intravascular interventional treatment operation, which comprises a balloon, a distal tube and a proximal tube, wherein PEEK (Polyetheretherketone) resin is adopted as the main raw material of the proximal tube, so that the PEEK balloon dilatation catheter not only has good high-temperature resistance, mechanical property, lubricating property and dimensional stability, but also prevents harmful metal ions from entering a human body to induce a toxic effect and generate cell damage and inflammation reactions from a source.

Owner:DONGGUAN DIKAI MEDICAL

Method for preparing environment-friendly high-strength tire reclaimed rubber through microwaves

ActiveCN105254919AKeep the craftRetain mechanical propertiesPlastic recyclingSocial benefitsBiochemical engineering

The invention discloses a method for preparing environment-friendly high-strength tire reclaimed rubber through microwaves. The preparation method includes the following steps that rubber powder obtained after waste products are crushed, softener, compound regenerant and a coupling agent are mixed to prepare initially-modified rubber powder, wherein the tensile strength of the rubber powder is larger than or equal to 25 MPa, and the elongation at break is larger than or equal to 500%; microwave reclaimed rubber is prepared under the conditions that the radiation frequency is 2,450 MHz, the microwave radiation power ranges from 800 W to 1,200 W and the microwave radiation time is controlled to range from 1 min 40 s to 2 min 30 s, the microwave reclaimed rubber immediately enters a cooling device to be cooled and refined, and then the reclaimed rubber is obtained. Compared with a traditional waste rubber high-temperature regeneration method, by means of the method for preparing the environment-friendly high-strength tire reclaimed rubber, a molecular backbone is protected against damage, cross bonds can be broken, regeneration time is short, regeneration temperature is low, production efficiency is 5 times that of the traditional method, the performance of recycled rubber is reserved, and remarkable economic benefits and social benefits are achieved.

Owner:XUZHOU COLLEGE OF INDAL TECH

Micro-pore acellular porcine aorta matrix

InactiveCN109078226AUse low concentrationPreserve three-dimensional structure and biomechanical propertiesTissue regenerationProsthesisInfiltrative GrowthChemistry

The invention provides a micro-pore acellular porcine aorta matrix which is characterized in that the micro-pore acellular porcine aorta matrix has a micro-pore structure, a micro-pore of the micro-pore structure is circular or elliptic, and a pig aorta is placed into low-concentration decontaminant buffer solution under a vacuum condition to be repeatedly frozen and thawed and then sequentially oscillated and cleaned in low-concentration decontaminant buffer solution, sterile deionized water and phosphate solution to obtain the micro-pore acellular porcine aorta matrix. The micro-pore acellular porcine aorta matrix effectively retains a three-dimensional structure and biomechanical property of a porcine aorta tissue, toxicity of a decontaminant does not remain, infiltrative growth of fibroblasts and vascular endothelial cells can be promoted, so that regeneration of blood vessels and collagen is promoted, and the matrix has excellent in-vivo remodeling performance.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com