Door handle assembly for a vehicle

A technology of door handles and components, applied in the direction of vehicle locks, lock applications, connecting components, etc., can solve problems such as the lock cylinder can no longer be reached

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

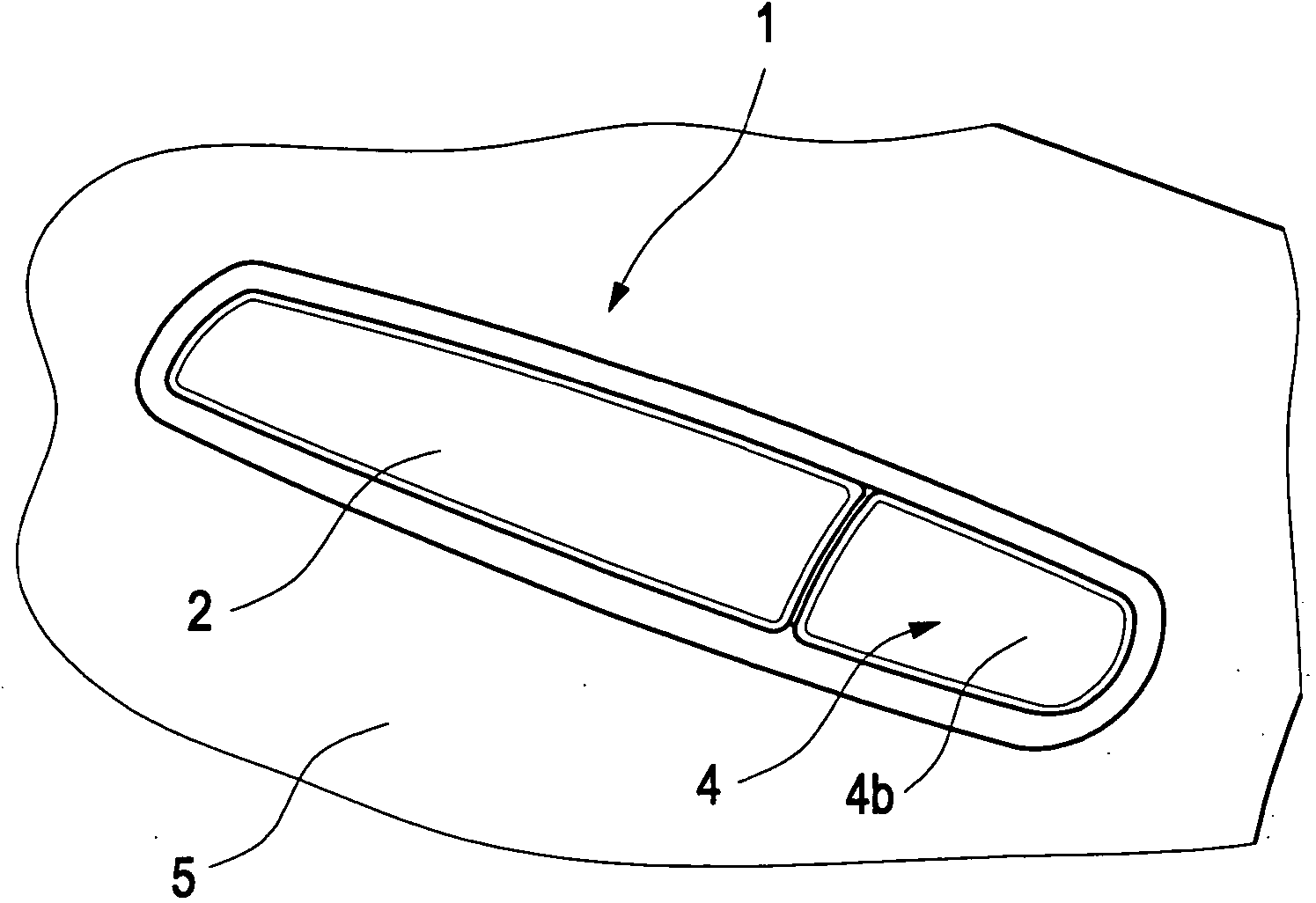

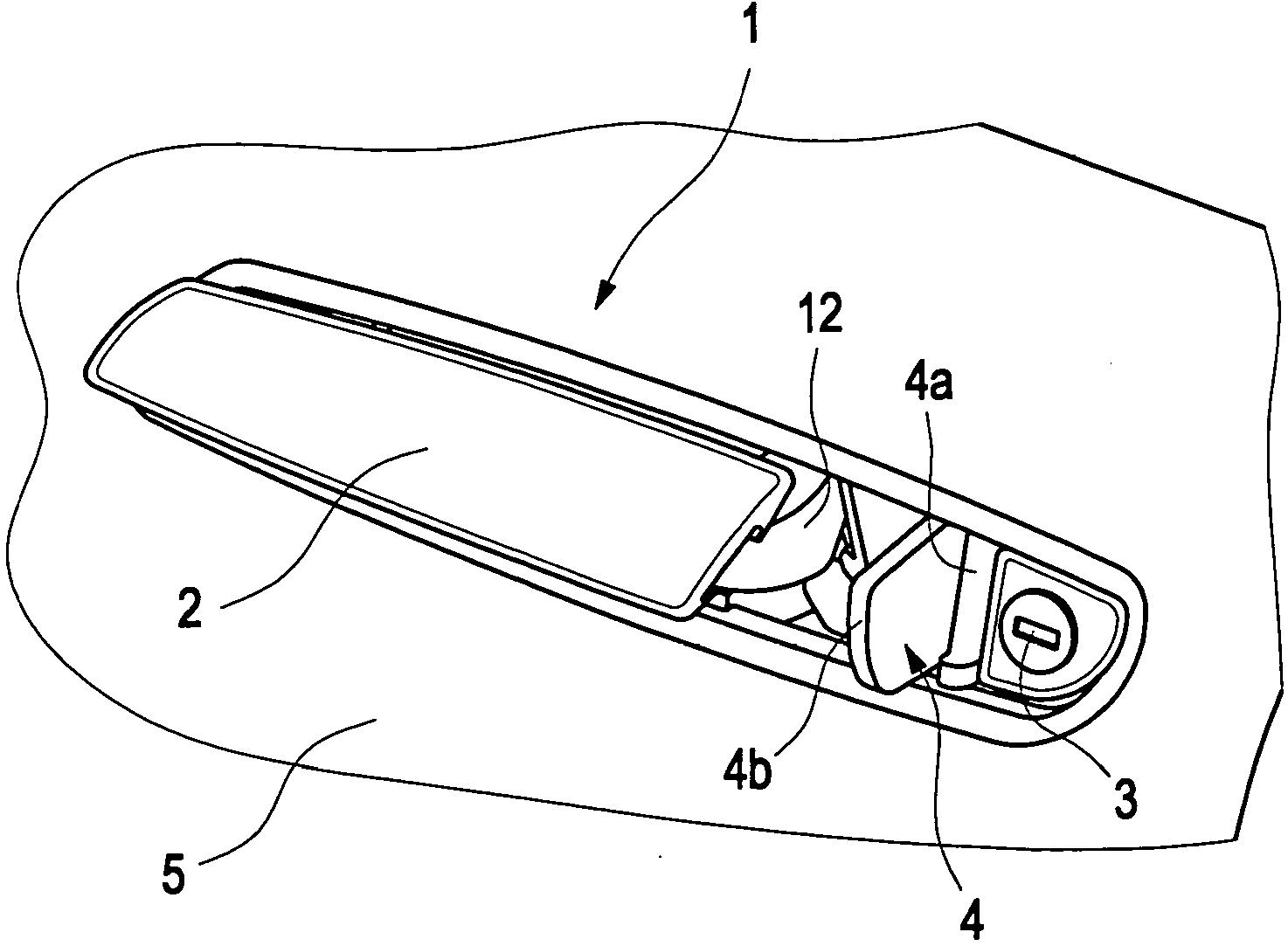

[0022] according to figure 1 and figure 2 , viewed from the outside of the vehicle, the door handle assembly 1 shows a door handle 2 that is flush with the body line and a side-by-side movable cover 4 that is flush with the body line, the movable cover includes a valve 4a and a Shutter 4b on the valve. The surface of the door handle 2 and the surface of the shutter 4b are in the same plane as the door 5 surrounding them. The shutter 4b covers the lock cylinder 3 below it in normal use, such as figure 1 shown. In special cases, especially when the action of bringing the door handle 2 from the rest position to the working position by external force fails, the movable cover plate 4 can be manually swung to expose the lock cylinder 3, so as to insert the mechanical key, and At the same time bring the door handle 2 into the working position, e.g. figure 2 shown.

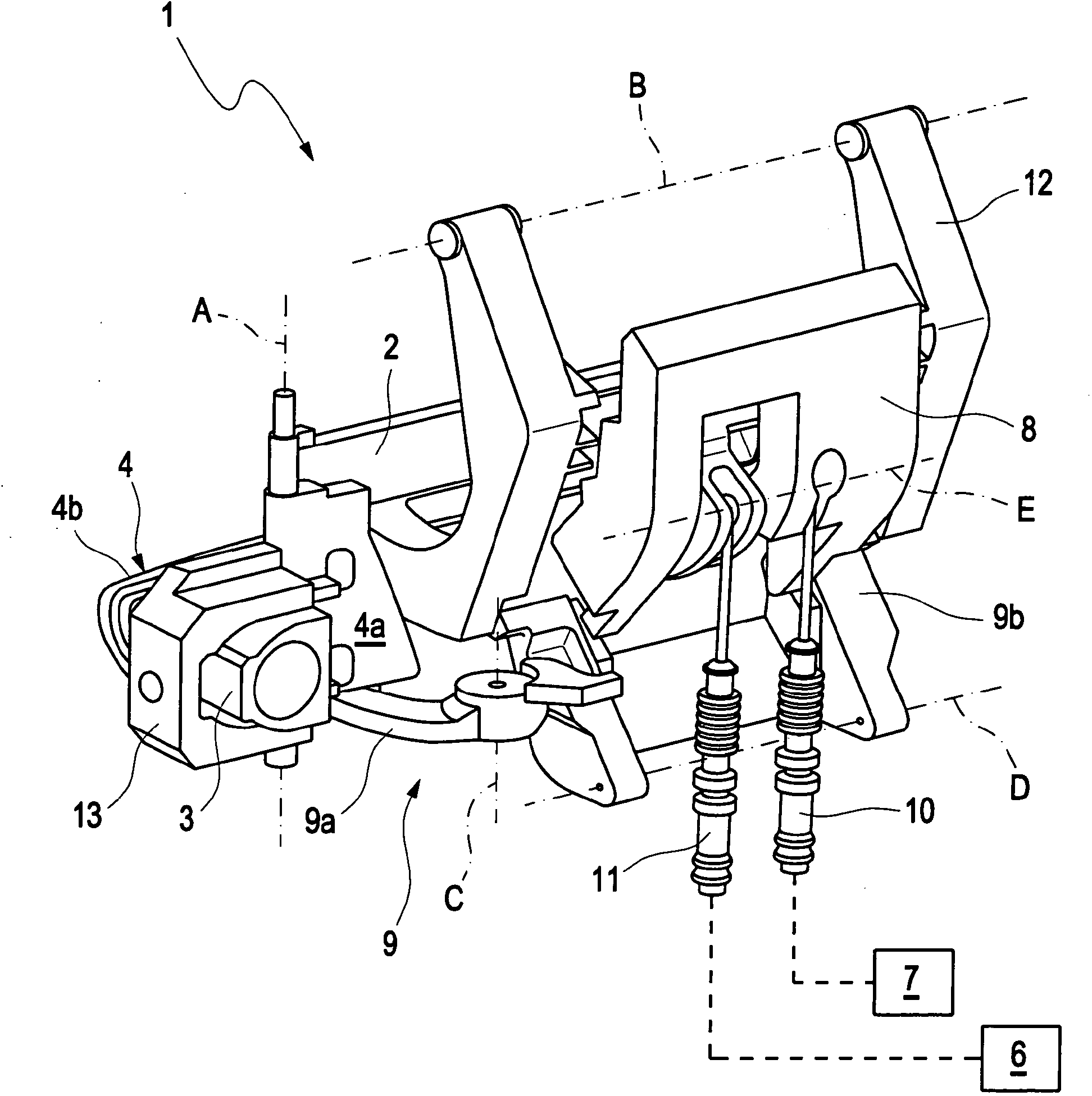

[0023] according to image 3 and Figure 4 , the door handle assembly 1 viewed from its rear side shows the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com