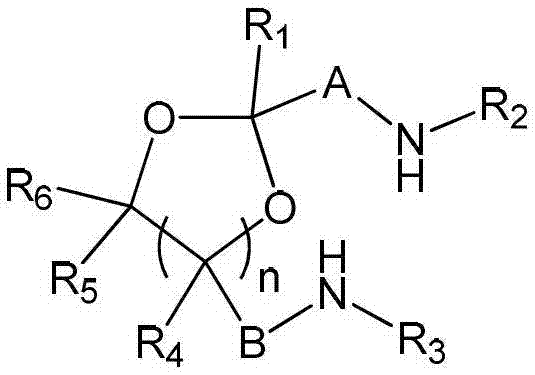

Degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent and application thereof

An epoxy resin curing and cyclic acetal technology, which is applied in the fields of organic chemistry, fiber chemistry, textiles and papermaking, etc., can solve the problems of difficult recycling of composite materials, environmental pollution, and lack of degradation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

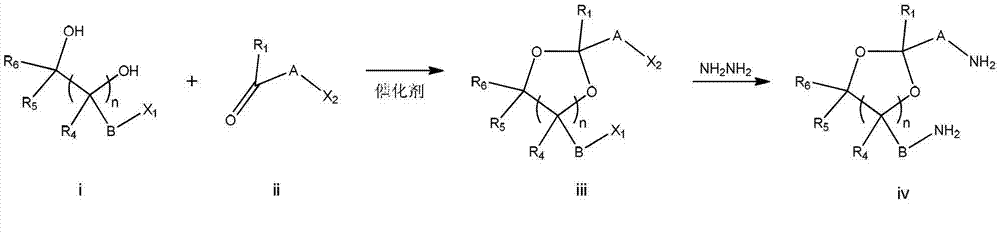

Method used

Image

Examples

Embodiment 1

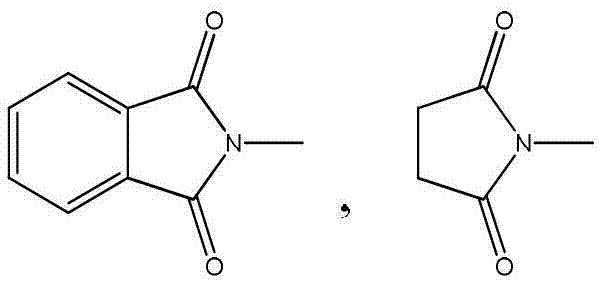

[0142] Embodiment 1: the preparation of curing agent I

[0143]

[0144] Curing agent Ⅰ

[0145] Method 1: 189 grams of N-(2-acetaldehyde)phthalimide, 221 grams of N-(2,3-propanediol)phthalimide, 5 grams of anhydrous p-toluenesulfonic acid, 1 liter of toluene was mixed at room temperature, DEAN-STARK refluxed to separate water, reacted for 20 hours, the reaction was completed, lowered to room temperature, added 2 liters of petroleum ether with a boiling range of 60-90, filtered, and used 1 liter of petroleum ether with a boiling range of 60-90°C Wash the solid with ether, dry the solid to obtain 950 g of crude product, add 3.4 liters of 20% NaOH solution, heat and reflux for 10 hours, cool, add chloroform / isopropanol for extraction, separate layers, dry the organic phase with anhydrous sodium sulfate, and distill under reduced pressure , Obtain 80 grams of curing agent I.

[0146] Method 2: Put 800 grams of toluene and 440 grams of 3-chloroglycerin into the reaction flask...

Embodiment 2

[0150] Embodiment 2: the preparation of curing agent II

[0151]

[0152] Curing agent Ⅱ

[0153] (1) In a 5-liter stirred tank, dissolve 221 grams of sodium hydroxide in 1.5L of ethanol, control the temperature below 40°C, add 700 grams of ethanol (3L) solution of p-nitrophenol dropwise at this temperature, drop During the addition process, a solid was produced. After the dropping, reacted at 40°C for 2 hours, and spin-dried to obtain a solid that was p-nitrophenol sodium salt.

[0154] (2) Put 800 grams of toluene and 480 grams of 3-chloroglycerin into the reaction flask, add 660 grams of m-nitroacetophenone and 1.5 grams of p-toluenesulfonic acid under stirring, the system is heated up slowly, and the Dean-Stark refluxes to separate water. TLC detects the end point of the reaction. After the reaction is over, cool down to below 40°C, add an appropriate amount of sodium carbonate to the reaction bottle to adjust the pH value of the reaction solution system to near neutra...

Embodiment 3

[0159] Embodiment 3: the preparation of curing agent III

[0160]

[0161] Curing agent Ⅲ

[0162] (1) Put 800 grams of toluene and 440 grams of 3-chloroglycerin into the reaction bottle, add 600 grams of p-nitrobenzaldehyde and 3 grams of p-toluenesulfonic acid under stirring, the system is heated up slowly, Dean-Stark reflux water separation, TLC detection At the end of the reaction, after the reaction is over, lower the temperature to below 40°C, add an appropriate amount of sodium carbonate to the reaction bottle, adjust the pH value of the reaction solution system to be close to neutral, then concentrate the reaction solution under reduced pressure, recover most of the toluene, and heat the residue with water. The precipitated solid was filtered and dried to obtain about 1000 g of solid, which was directly carried out to the next step without purification.

[0163] (2) In a 1-liter three-necked round-bottom flask, put 400 milliliters of N,N-dimethylformamide (DMF) int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com