Method of producing environment-friendly regenerated rubber via low-temperature desulfurization

A reclaimed rubber, environmental protection technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems that affect the health of enterprise operators, affect the health of workers, pollute the environment, etc., achieve fast chemical bond chain breaking, remove easy agglomeration, The effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

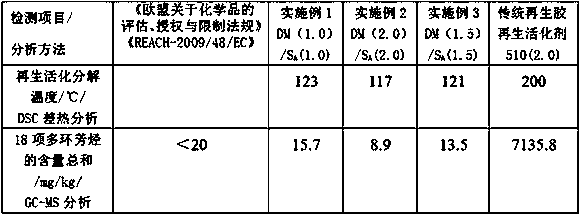

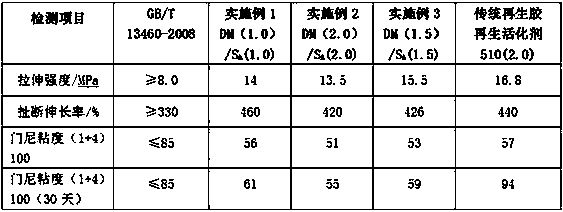

Embodiment 1

[0034] Each raw material and its mass parts are:

[0035] Whole tire rubber powder (60 mesh) 100 parts

[0036] Activator DM 1.0 parts

[0037] Stearic acid S A 1.0 copies

[0038] Mooney stabilizer 264 (winter) 1.3 parts

[0039] Rosin 1.0 parts

[0040] Pine tar 24.0 parts

[0041] The compound high-efficiency regenerative activator is composed of regenerative activator DM and stearic acid S A Prepared according to the mass ratio of 1:1, respectively 1.0 parts by mass.

[0042] The preparation is carried out according to the following steps: the particle size of the steel wire tire rubber powder used for regeneration is selected to be 60 mesh. First, perform a stage of regeneration: in winter, place 100.0 parts by mass of 60-mesh whole tire rubber powder, 2.0 parts by mass of compound high-efficiency regeneration activator (DM / stearic acid by mass 1.0 / 1.0) and 1.3 parts by mass of 264 Mooney stabilizer. Mix in an internal mixer (glue capacity 5L) for 1 min; then add...

Embodiment 2

[0044] Each raw material and its mass parts are:

[0045] Whole tire rubber powder (80 mesh) 100 parts

[0046] Activator DM 2.0 parts

[0047] Stearic acid S A 2.0 copies

[0048] Mooney stabilizer 264 (spring, autumn) 1.5 parts

[0049] Rosin 1.0 parts

[0050] 16.0 parts of tall oil

[0051] The compound high-efficiency regenerative activator is composed of regenerative activator DM and stearic acid S A It is formulated according to the mass ratio of 1:1.

[0052] The preparation is carried out according to the following steps: the particle size of the steel wire tire rubber powder used for regeneration is selected to be 80 mesh. First perform a stage of regeneration: 100.0 parts by mass of 80-mesh whole tire rubber powder, 4.0 parts by mass of compound high-efficiency regeneration activator (DM / stearic acid 2.0 / 2.0), and 1.5 parts by mass of Mooney stabilizer 264 (spring and autumn) Place them together in a desulfurization tank and knead for 2 minutes; then add envi...

Embodiment 3

[0054] Each raw material and its mass parts are:

[0055] Whole tire rubber powder (60 mesh) 100 parts

[0056] Activator DM 1.5 parts

[0057] Stearic acid S A 1.5 servings

[0058] Mooney stabilizer 264 (summer) 1.6 parts

[0059] Rosin 1.0 parts

[0060] Pine tar 24.0 parts

[0061] The composite high-efficiency regenerative activator DM / stearic acid is composed of regenerative activator DM and stearic acid in a mass ratio of 1:1.

[0062] The preparation is carried out according to the following steps: the particle size of the steel wire tire rubber powder used for regeneration is selected to be 60 mesh. First perform a stage of regeneration: put 100.0 parts by mass of 60-mesh whole tire rubber powder, 3.0 parts by mass of compound high-efficiency regeneration activator DM / stearic acid (1.5 / 1.5) and 1.6 parts of Mooney stabilizer 264 (summer) in the open Mix on the mill for 2 minutes; then add the environmentally friendly softener pine tar to the mixed rubber powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com