Patents

Literature

252results about How to "Retain performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

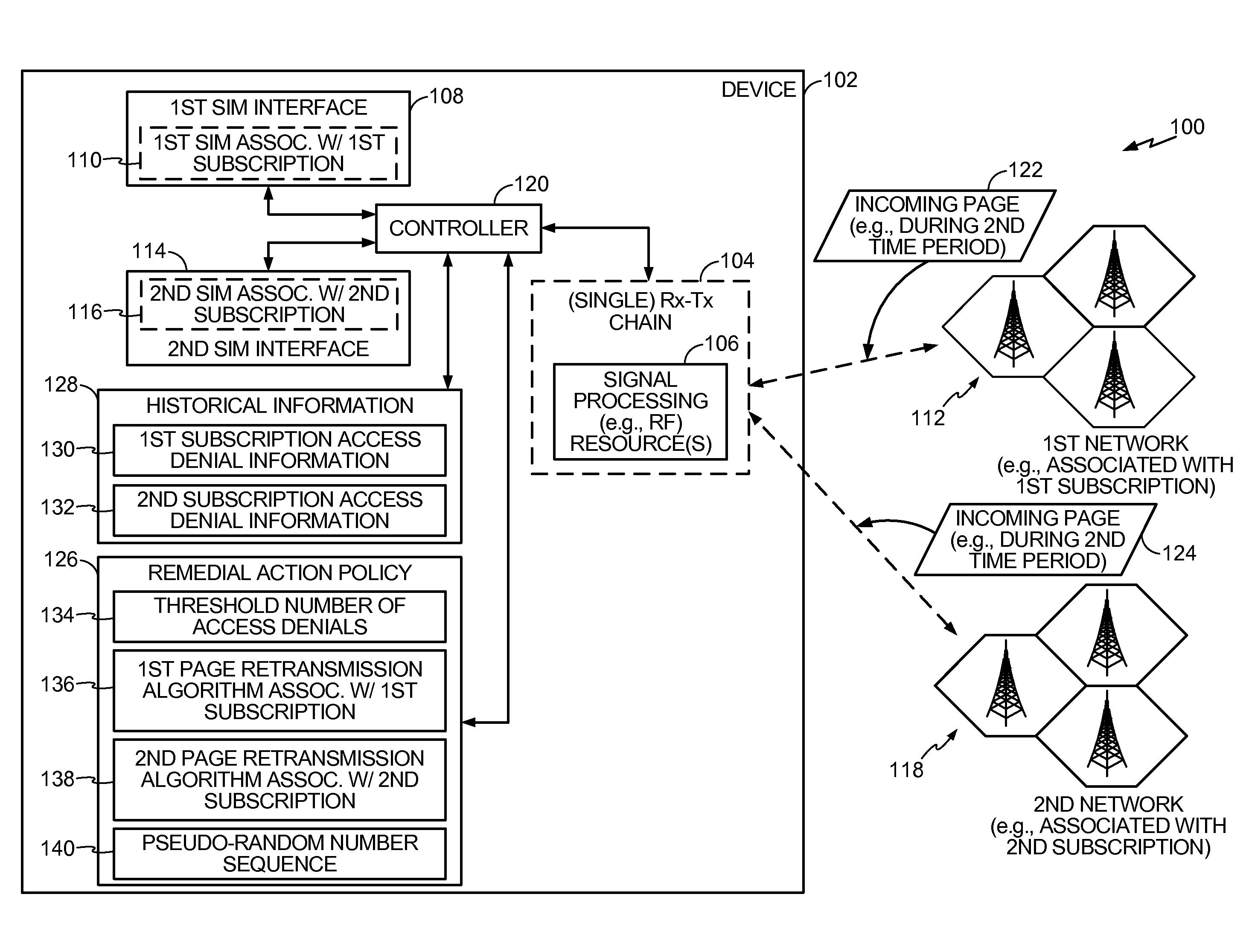

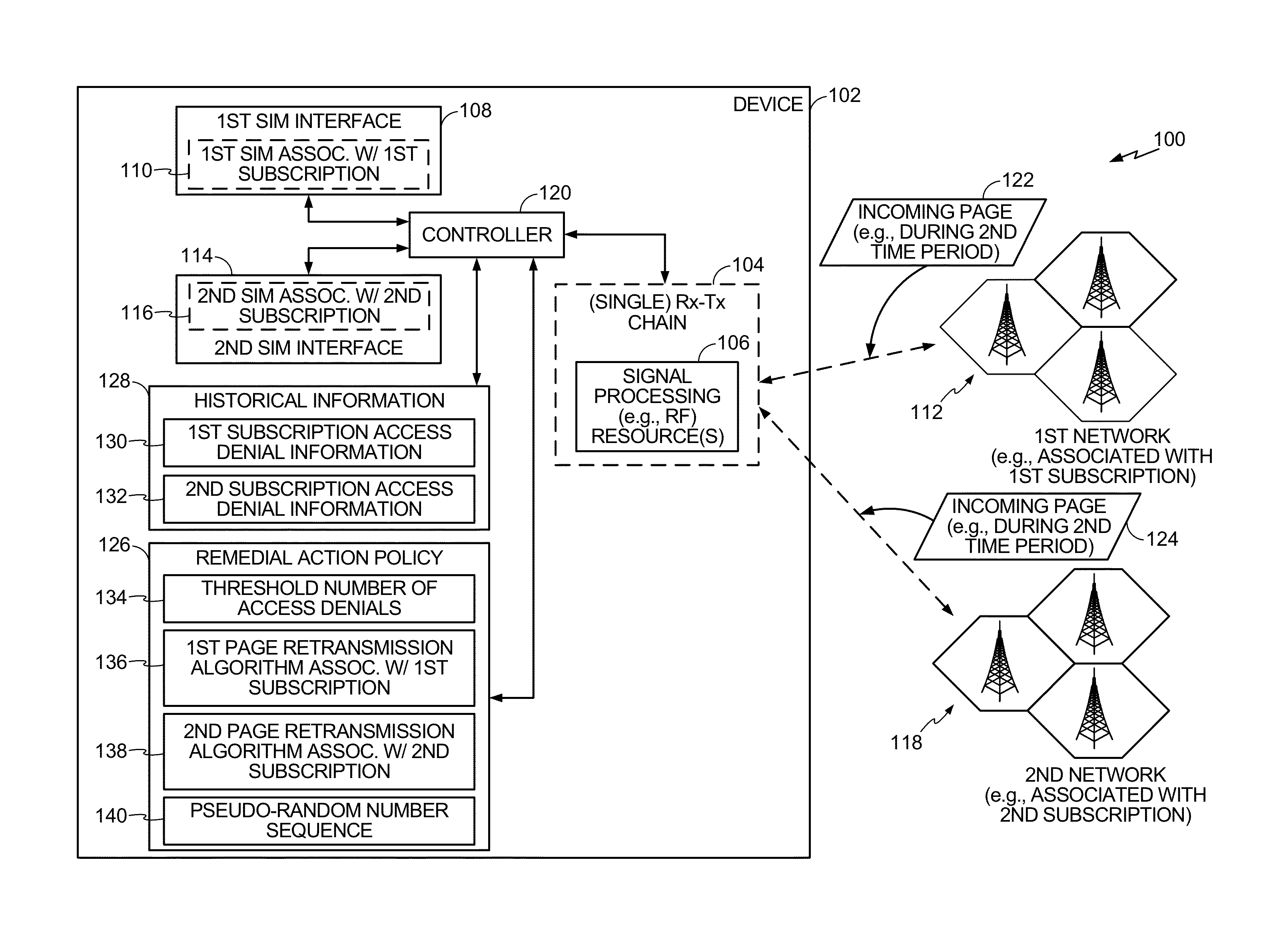

Multiple subscription resource access control

InactiveUS20120231802A1Preserve paging performancePerformanceWireless communicationTime segmentRemedial action

A particular method includes receiving multiple requests to access a signal processing resource of a device that supports multiple subscriptions during a first time period. During the first time period, a first subscription is granted access to the signal processing resource, and a second subscription is denied access to the signal processing resource. A remedial action policy and historical information related to subscription access to the signal processing resource may be used to determine whether to grant access to the signal processing resource to the second subscription during a second time period. When access to the signal processing resource is granted to the second subscription during the second time period, hysteresis may be used to determine whether to grant access to the first subscription during a third time period after the second time period in order to preserve paging performance of the first subscription.

Owner:QUALCOMM INC

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

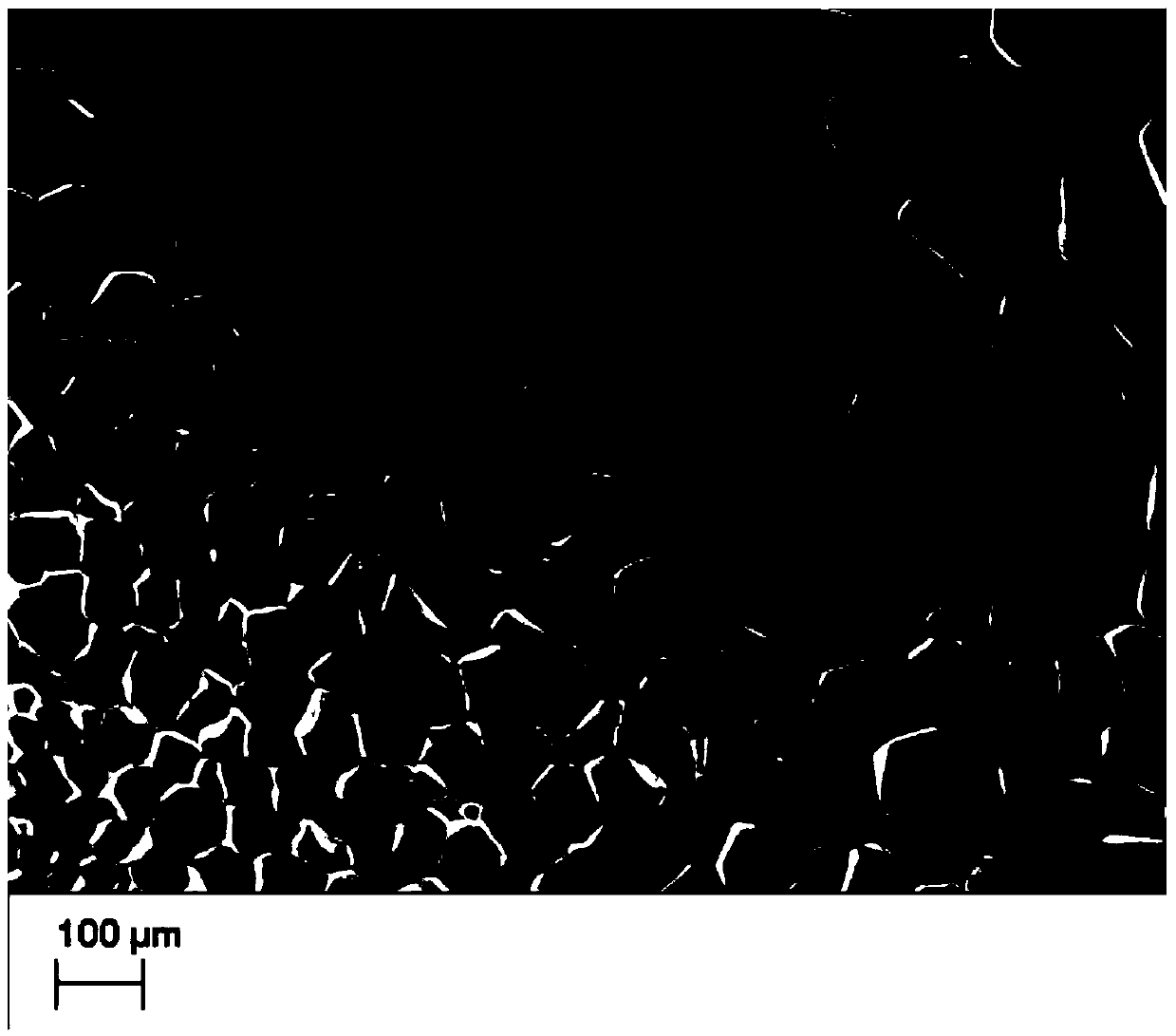

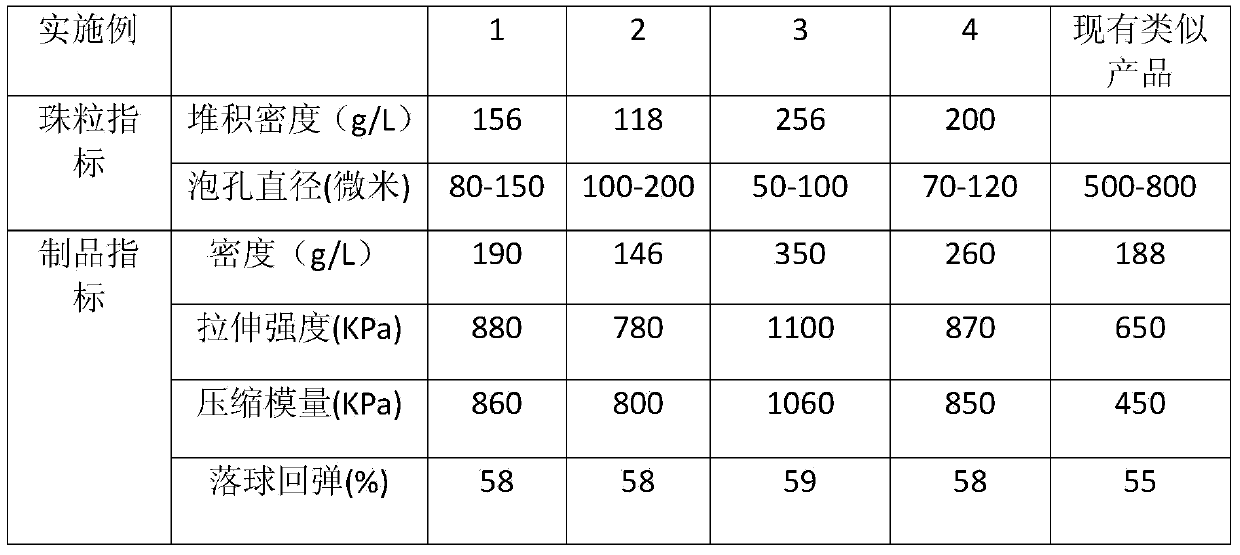

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

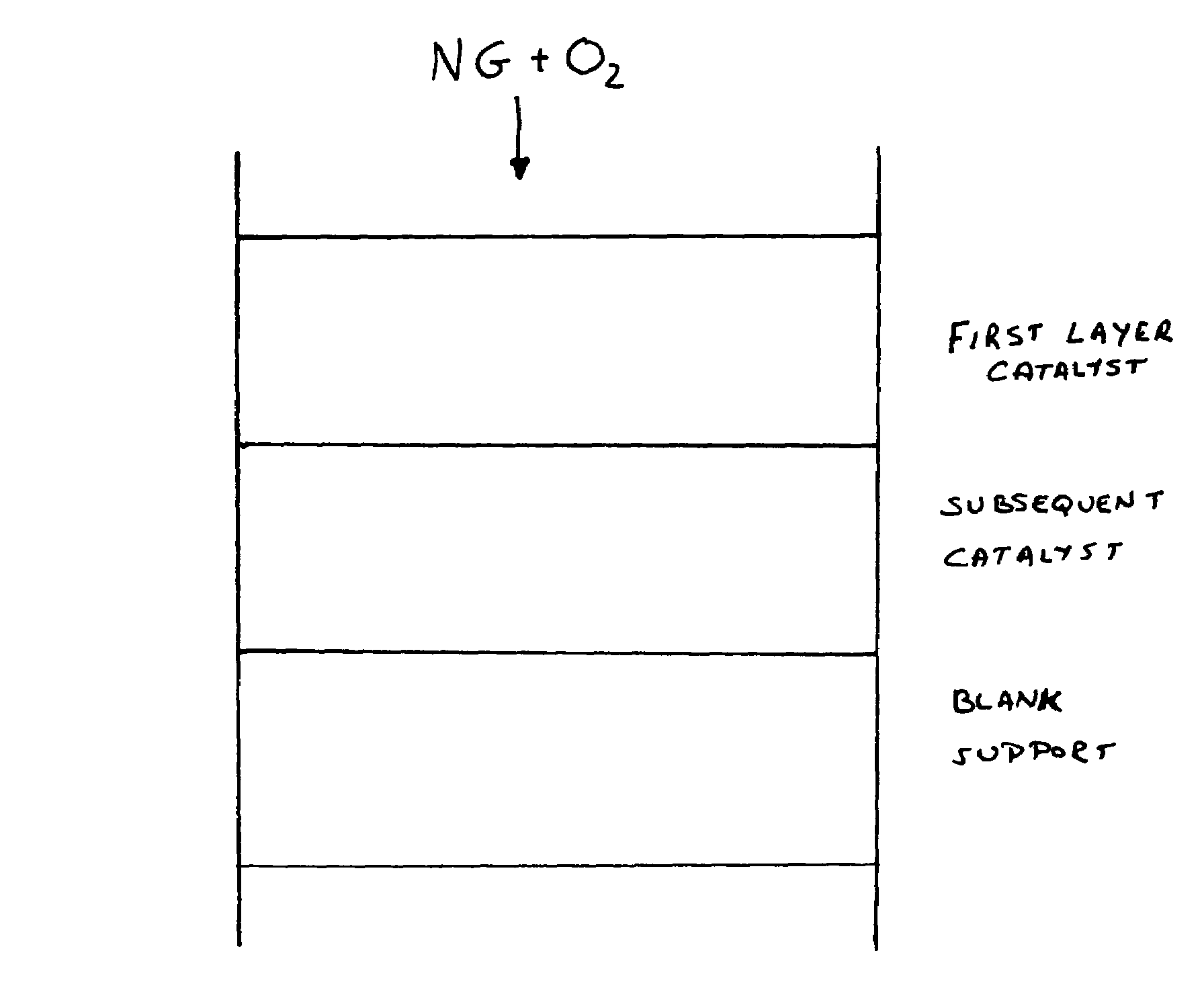

Catalyst configuration and methods for syngas production

InactiveUS7214331B2Retains integrityRetain performanceMethane captureExhaust apparatusSyngasPartial oxidation

An improved process for the catalytic partial oxidation of hydrocarbons to produce hydrogen and carbon monoxide is disclosed. The process also utilizes a novel catalyst configuration containing at least two serially aligned layers containing a noble metal or transition metal catalyst supported on a support. Alternatively the process employs only the first layer of a catalytically active metal dispersed on an inert carrier support to partially oxidize hydrocarbons.

Owner:BOC GRP INC

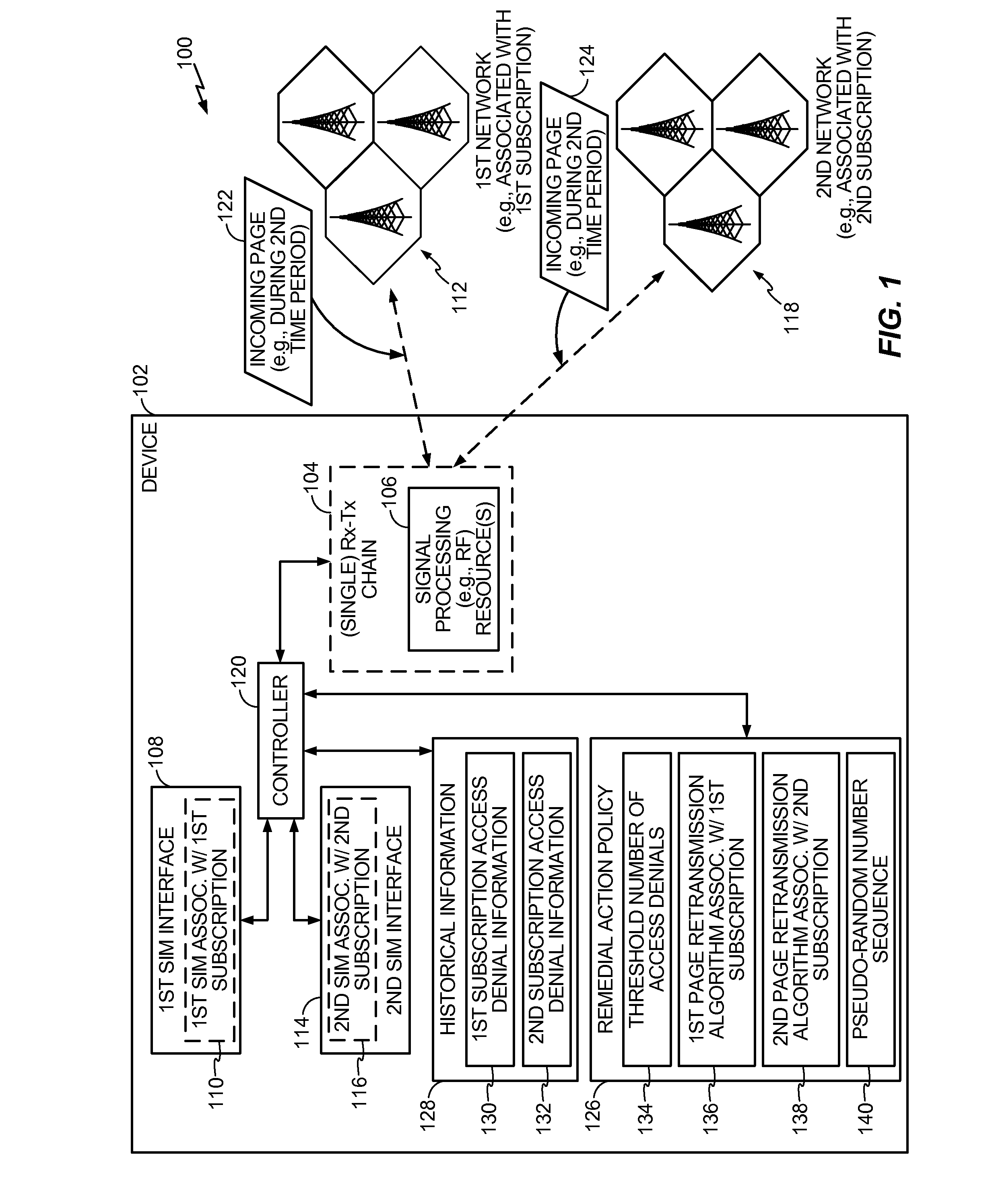

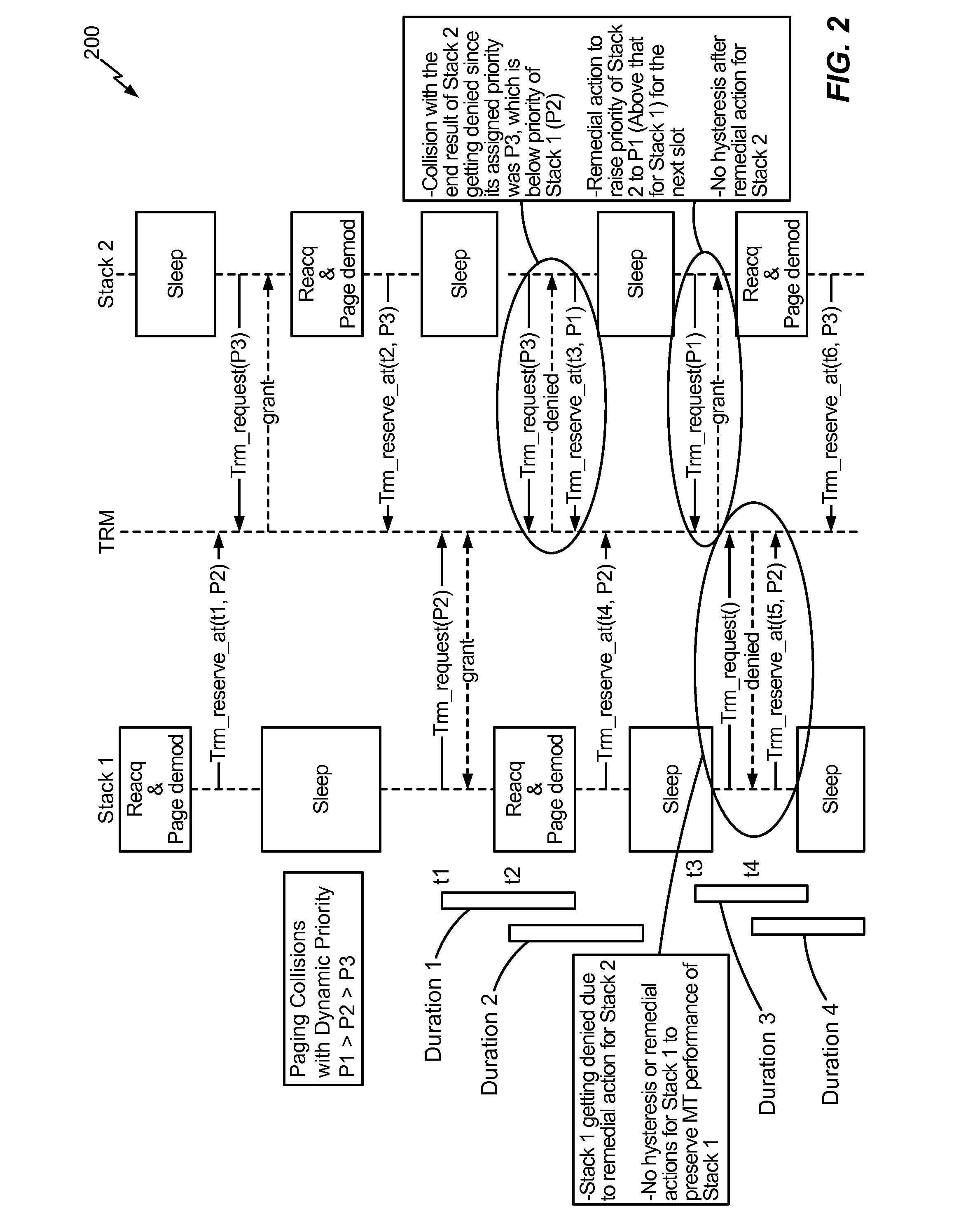

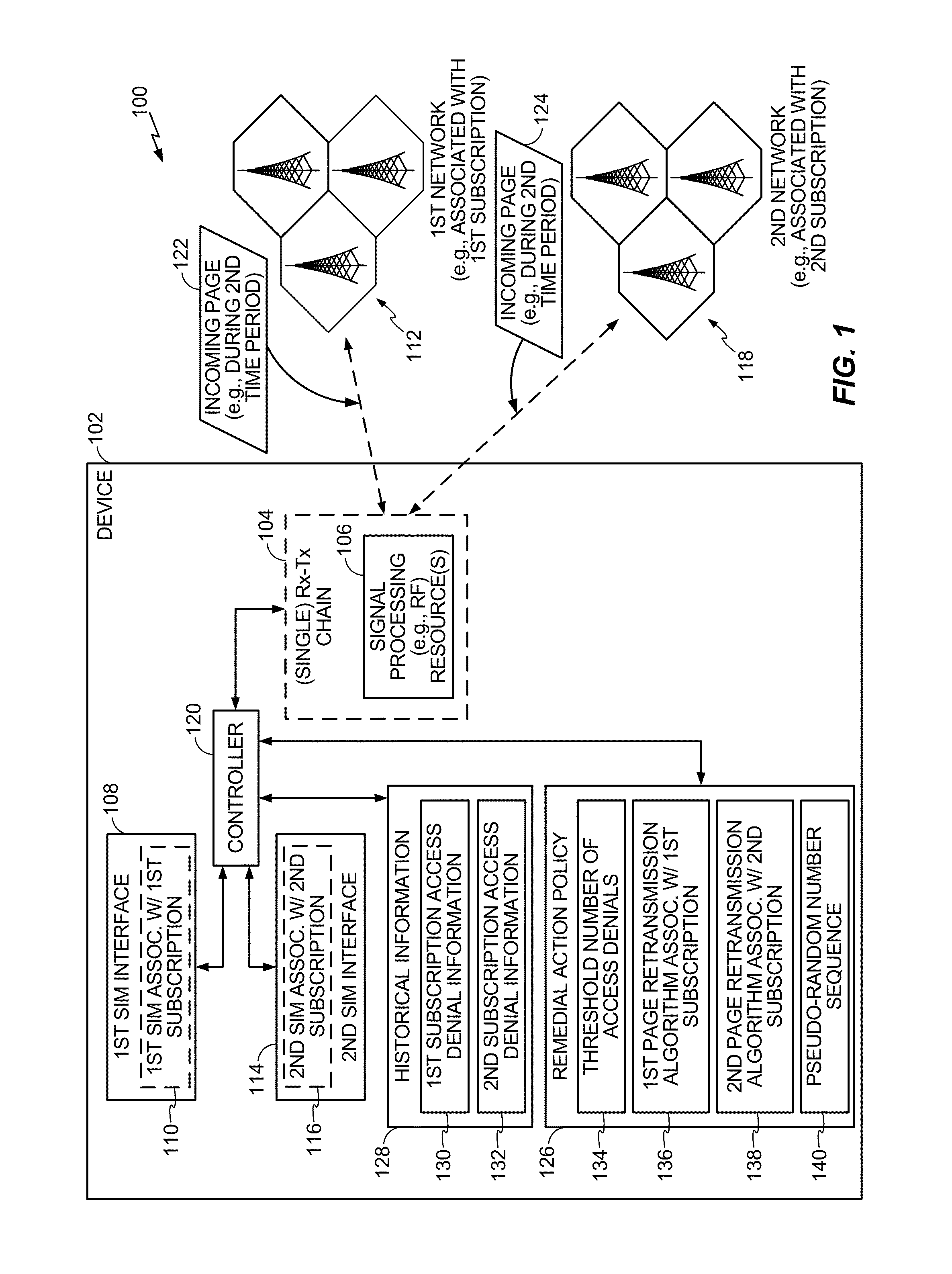

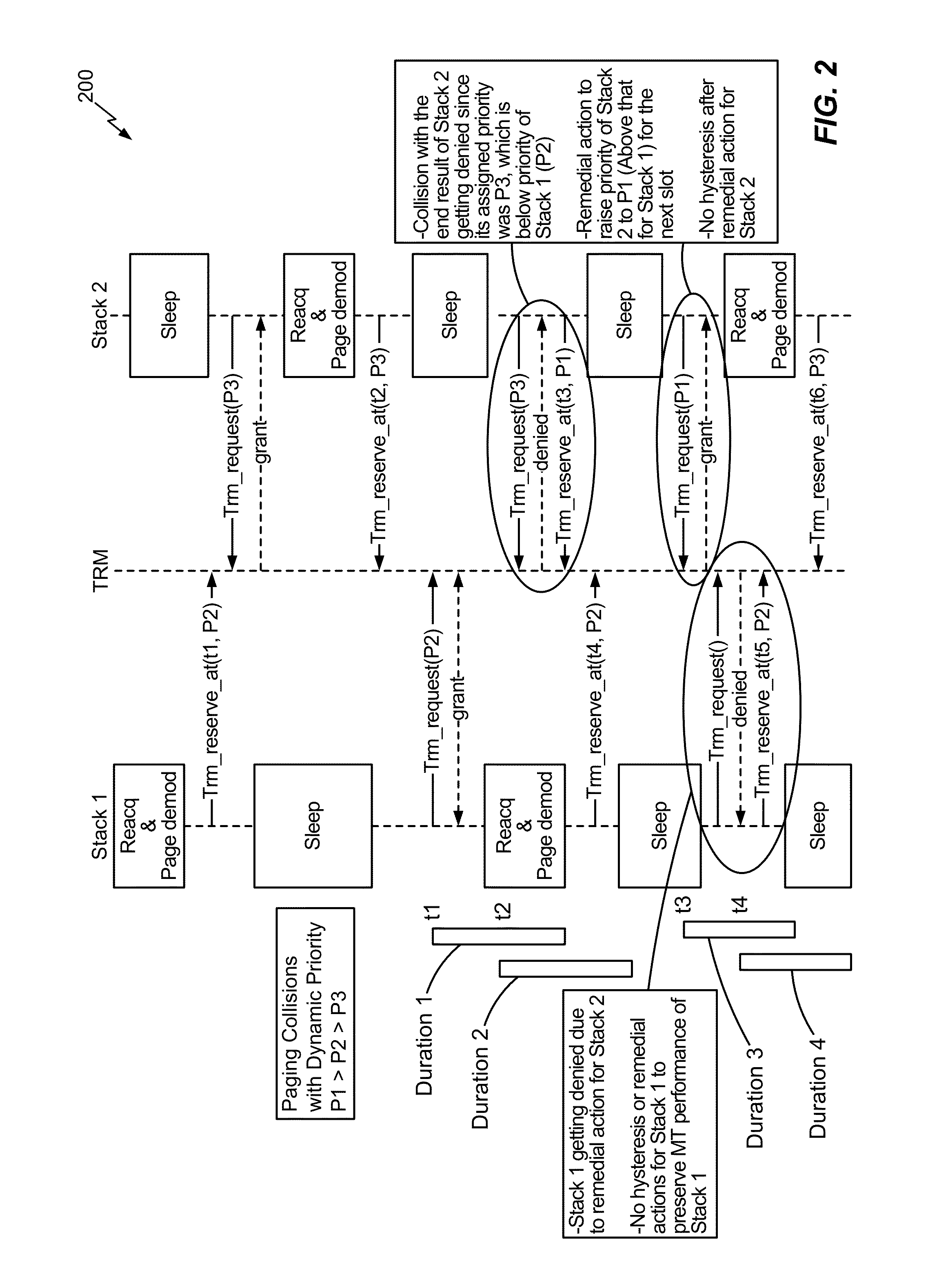

Multiple Subscription Resource Access Control

ActiveUS20130316718A1Preserve paging performancePerformanceNetwork data managementRemedial actionTelephone network

The various embodiments include methods for managing how a MSMS communication device that is accessing an arbitrary combination of multiple telephony networks processes paging collisions. The embodiment methods promote improving a subscription's page blocking rate by causing a MSMS communication device to implement a retransmission remedial action for a blocked subscription. In the various embodiments, the MSMS communication device may implement the retransmission remedial action by increasing a blocked subscription's priority during a subsequent retransmission interval to increase the likelihood that the blocked subscription will receive a repeated page message from its mobile network during this retransmission interval. In some embodiments, the blocked subscription's current priority may be based on the number of retransmission intervals that are presently occurring.

Owner:QUALCOMM INC

High-performance magnesium-aluminum-chromium composite spinel brick and manufacturing method thereof

The invention relates to a high-performance magnesium-aluminum-chromium composite spinel brick for RH refining furnace dip pipes and non-ferrous smelting furnaces. The high-performance magnesium-aluminum-chromium composite spinel brick is characterized by comprising the following raw materials: 14.0-20.0 parts of low-chromium fused magnesium chromium sand (6-8% of Cr2O3, at least 78% of MgO), 71.6-82.0 parts of high-purity fused magnesite, 2.0-4.4 parts of nano Cr2O3 powder, 2.0-4.0 parts of uf-Al2O3 micropowder and 2-4 parts of binder. The manufacturing method comprises the following steps: mixing, molding, drying, firing and the like. The magnesium-aluminum-chromium composite spinel brick provided by the invention has the advantages of high sintering tendency, high crystal compactness, low porosity (at most 10%), high compressive strength (at least 100 MPa), high thermal shock stability (at least 18 times by 1100 DEG C water cooling) and the like. The Cr2O3 content of the product isat most 6%, thereby reducing the Cr2O3 content in the brick, lowering the production cost and finally effectively reducing the environmental pollution of waste magnesium-chromium bricks after use.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

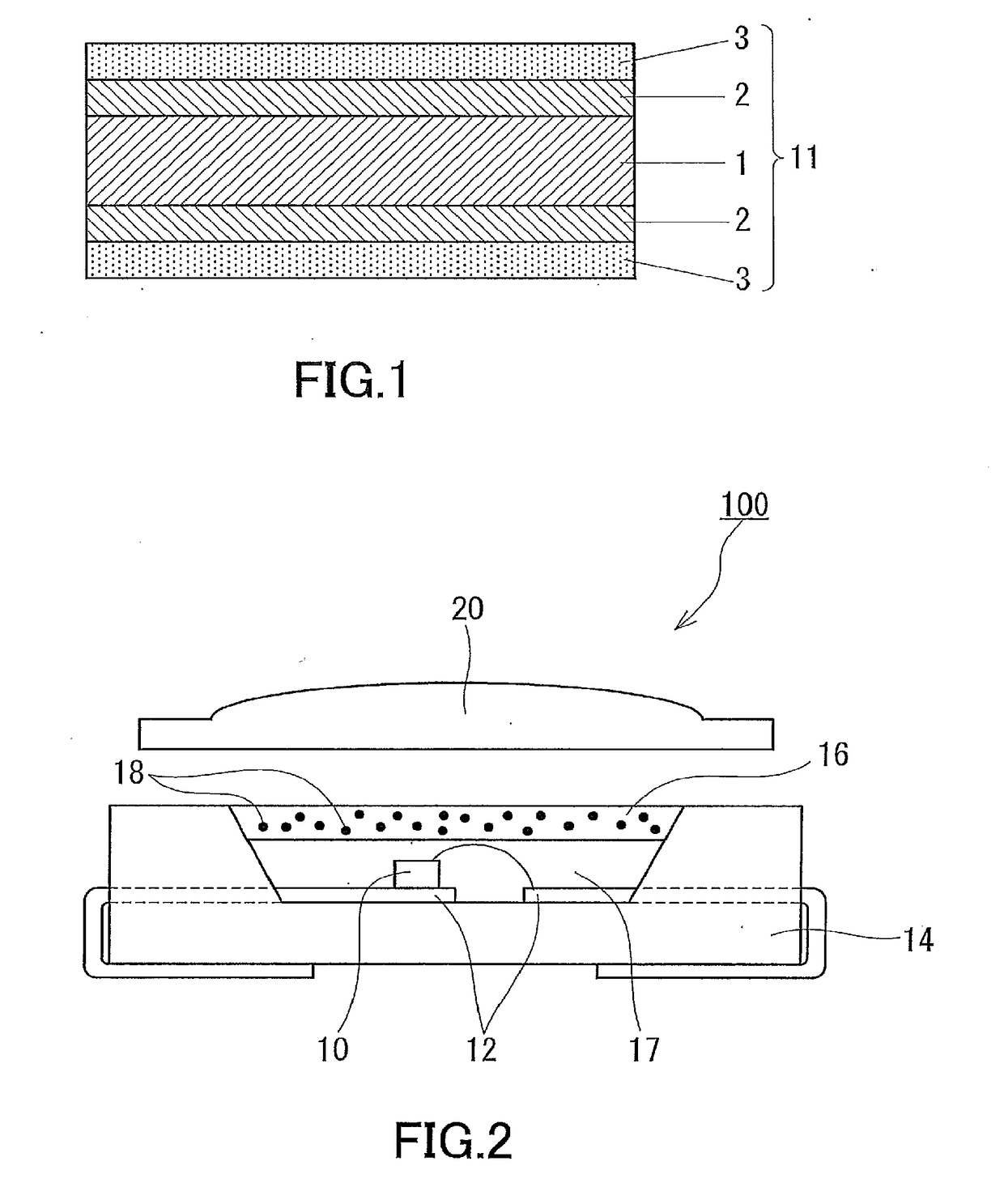

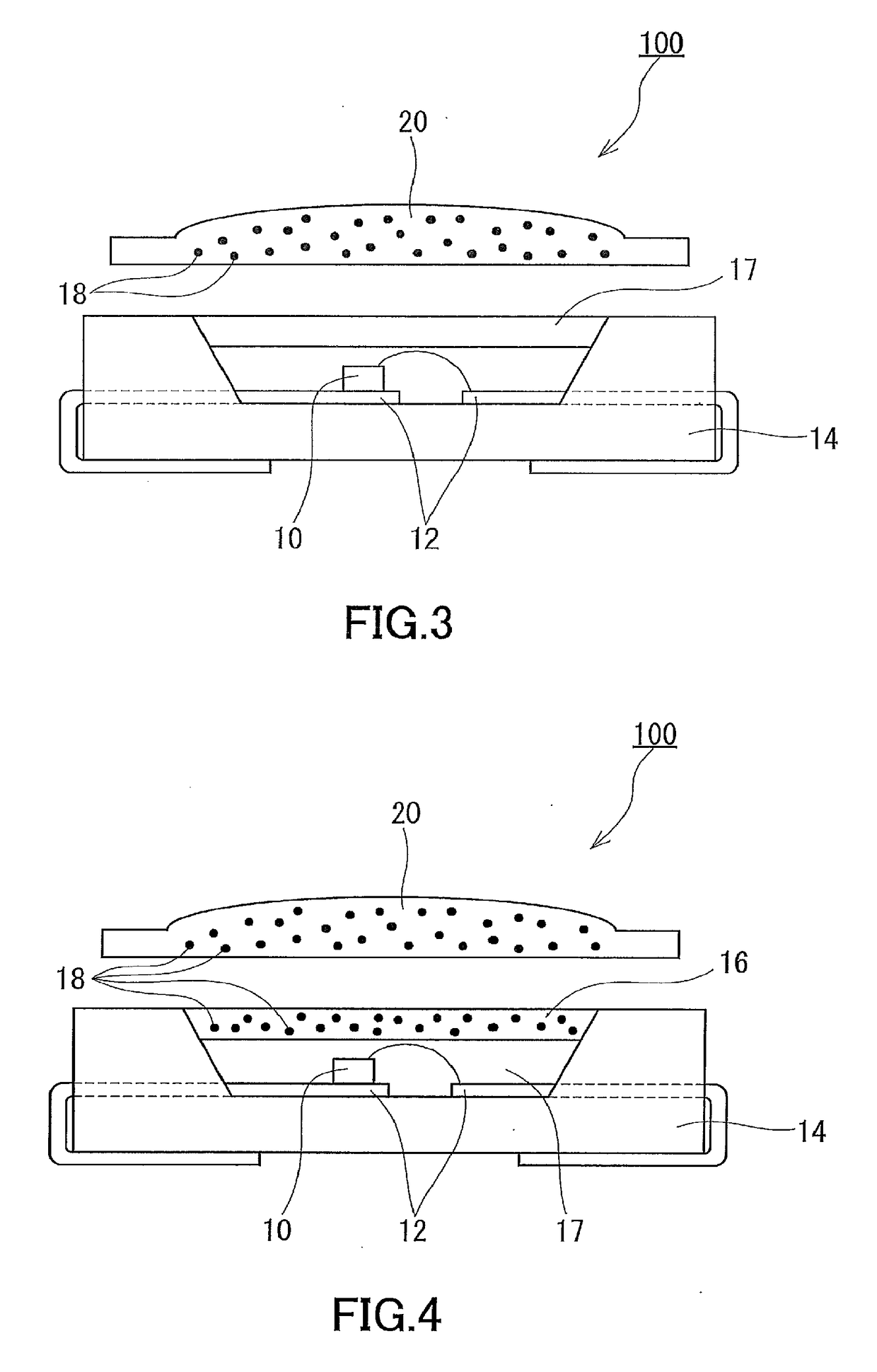

Electronic device

InactiveUS20170096538A1Highly resistant to physical stressExcellent gas barrier propertiesElectroluminescent light sourcesSynthetic resin layered productsMetalPhosphorus atom

The present invention relates to an electronic device having an electronic device body 1 the surface of which is covered by a protective sheet. The protective sheet includes a multilayer structure including a base (X) and a layer (Y) stacked on the base (X). The layer (Y) includes a metal oxide (A), a phosphorus compound (B), and cations (Z) with an ionic charge (FZ) of 1 or more and 3 or less. The phosphorus compound (B) includes a compound containing a moiety capable of reacting with the metal oxide (A). In the layer (Y), the number of moles (NM) of metal atoms (M) constituting the metal oxide (A) and the number of moles (NP) of phosphorus atoms derived from the phosphorus compound (B) satisfy a relationship of 0.8≦NM / NP≦4.5, and NM, the number of moles (NZ) of the cations (Z), and FZ satisfy a relationship of 0.001≦FZ×NZ / NM≦0.60.

Owner:KURARAY CO LTD

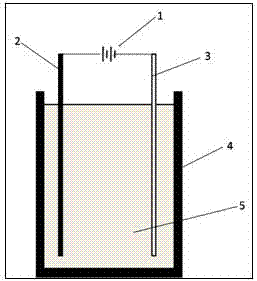

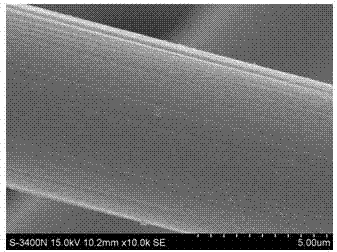

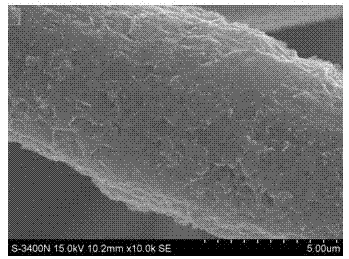

Preparation method of graphene/carbon fiber composite

ActiveCN103614902A2D structure retentionKeep excellent performanceCarbon fibresElectrophoretic coatingsElectrophoresesOrganosolv

The invention discloses a preparation method of a graphene / carbon fiber composite. The preparation method comprises the steps: firstly, with graphite powder or natural flake graphite as the raw material, directly and ultrasonically stripping the graphite powder or natural flake graphite in an organic solvent to prepare a graphene dispersing solution; then, adding an organic amine salt with aromatic groups into the obtained graphene dispersing solution to enable the graphene to have positive charges because of adsorbing organic amine ions; next, depositing the graphene with the positive charges on carbon fiber or a carbon fiber product under the action of an external electric field to form the graphene / carbon fiber composite with the organic amine salt; and finally, removing the organic amine salt through thermal treatment to obtain the graphene / carbon fiber composite, wherein the organic amine salt is deposited in an electrophoresis deposition process. The method has the advantages of simplicity in operation, low cost, good uniformity of the graphene / carbon fiber composite, easiness for control and the like.

Owner:SHANGHAI INST OF TECH

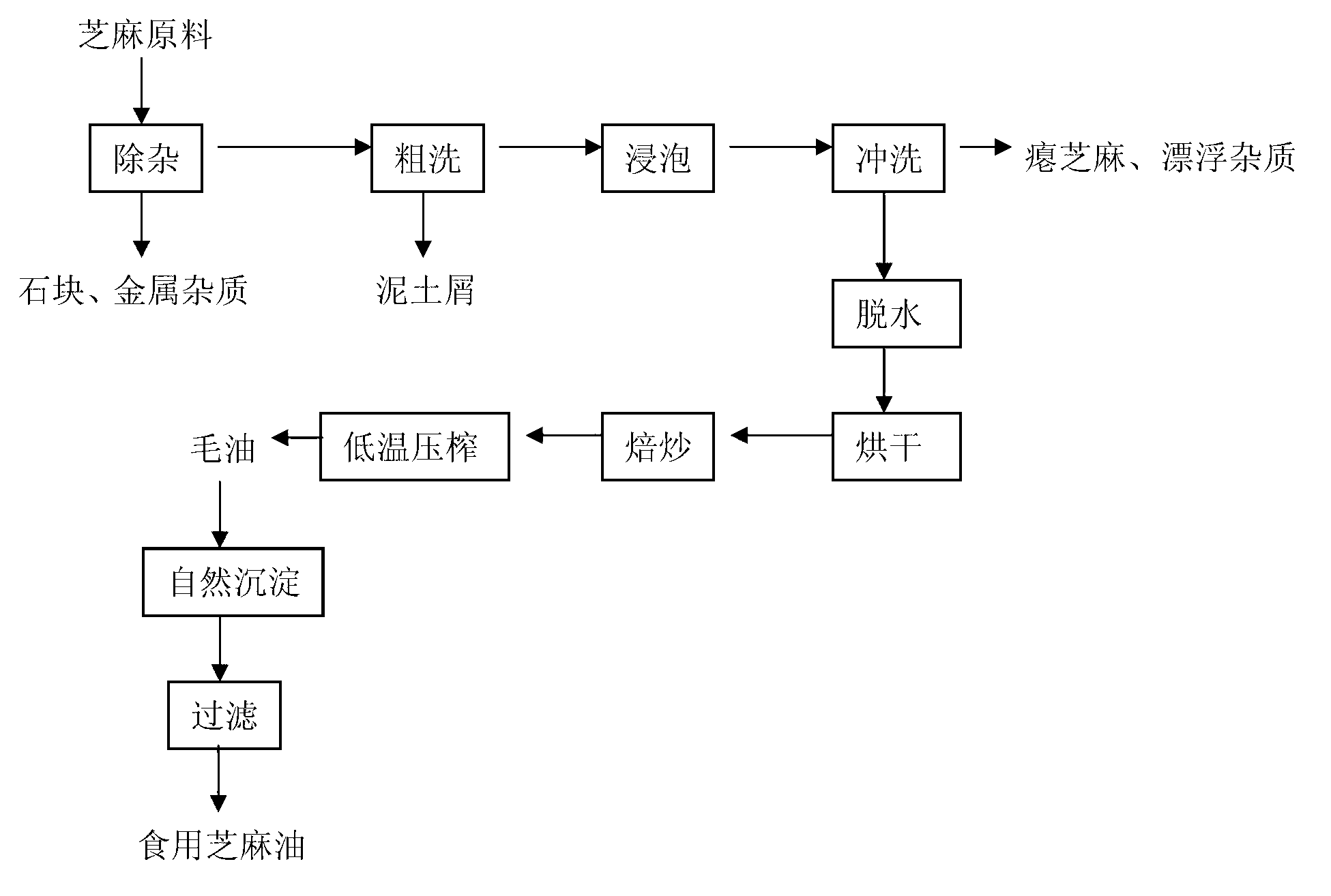

Process for preparing sesame oil

The invention relates to a process for preparing sesame oil. The process comprises the following steps of: removing impurities from sesame serving as a raw material, roughly washing the sesame, immersing and flushing the sesame, dehydrating and drying the sesame until the water content is reduced to 4.5 to 7wt%, then baking until the water content is reduced to below 2.5wt%, squeezing by a vertical type hydraulic squeezing machine at low temperature to obtain oil, and performing natural sedimentation and filtration on the squeezed rough oil to obtain the edible sesame oil. The technical steps are reasonable; the process is easy to operate; the prepared sesame oil has no rich sesame oil flavor; the flavor is natural and pure; the gloss is clear and crystal; the taste is mellow; and the original essence in the sesame can be retained to the maximum extent.

Owner:SHANGHAI LIANGYOU GRP +2

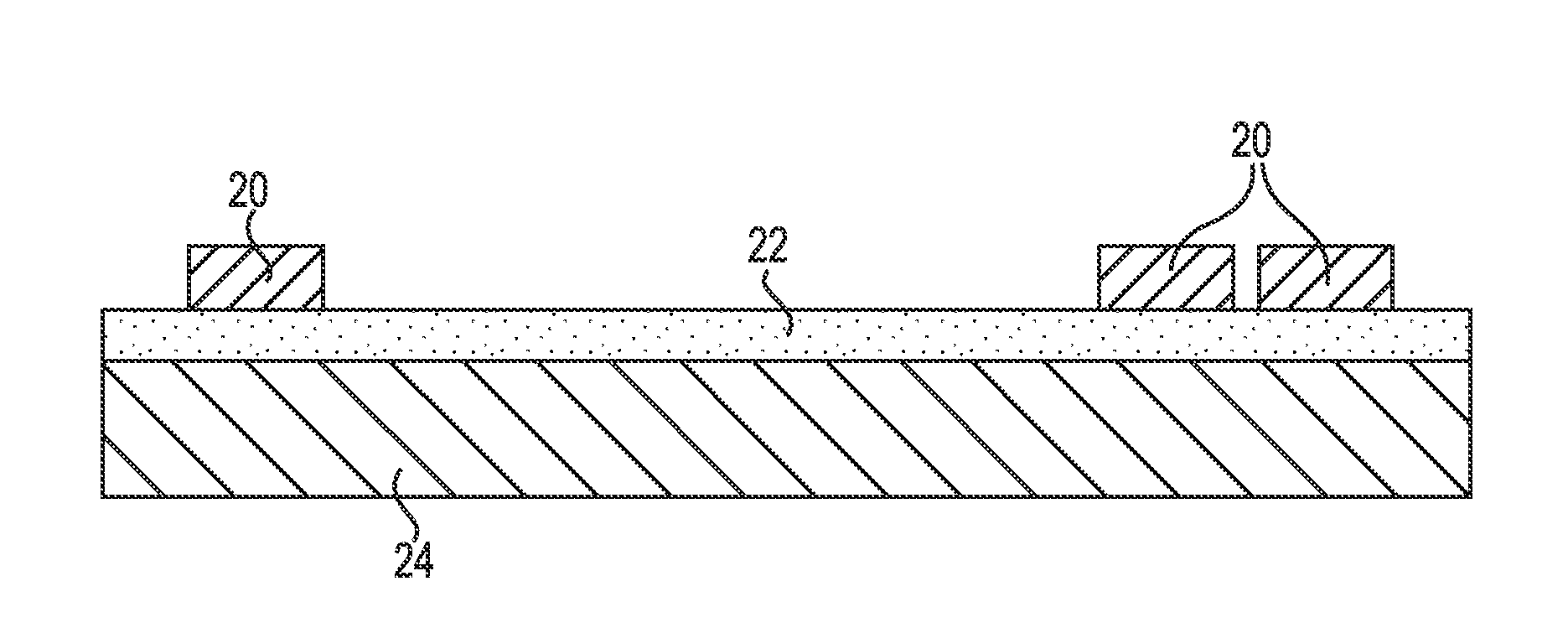

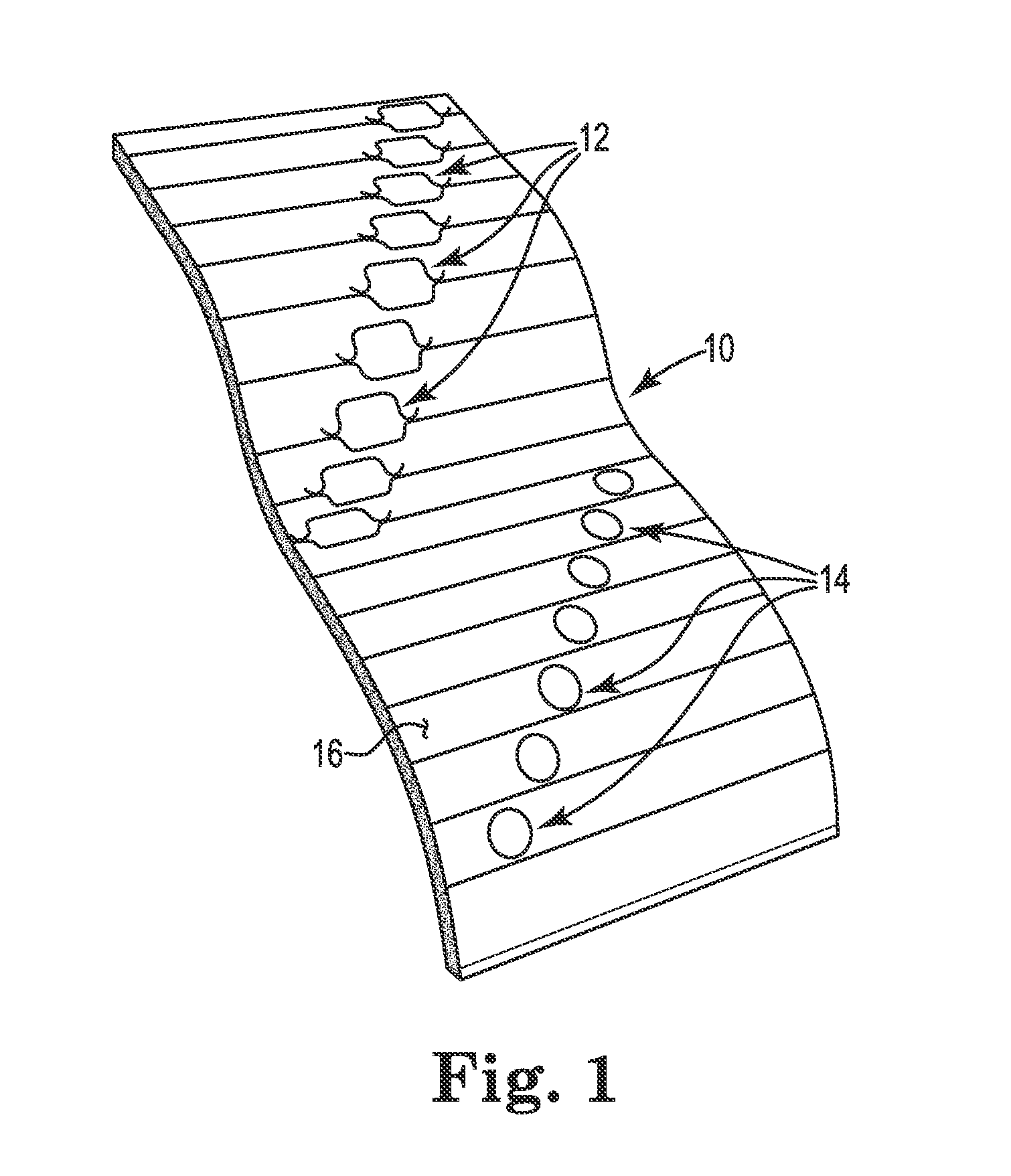

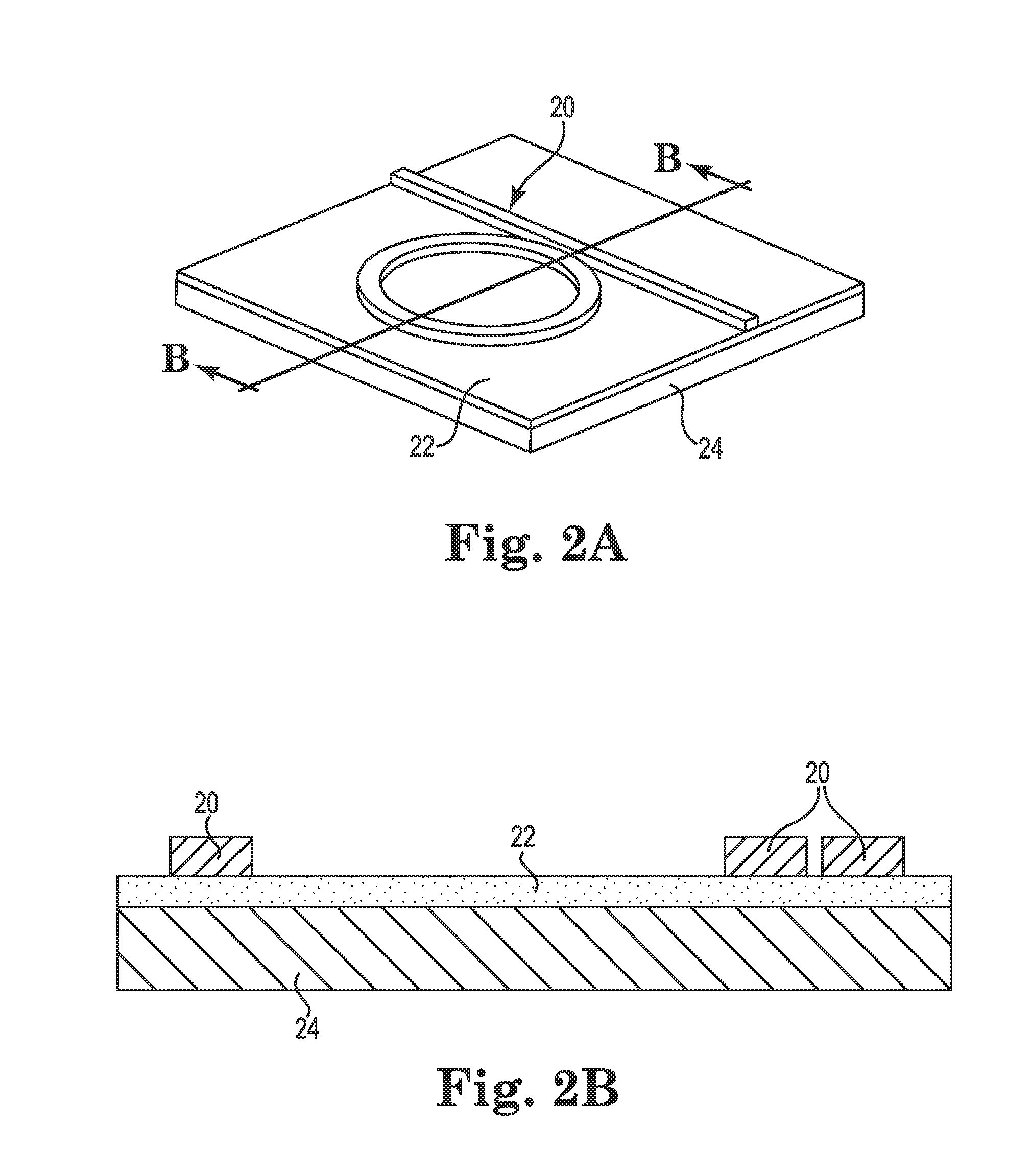

Method of forming flexible and tunable semiconductor photonic circuits

InactiveUS20140234995A1Preserved optical functionalityRetain performanceSemiconductor/solid-state device manufacturingOptical light guidesPhotonicsCrystalline semiconductor

Methods to physically transfer highly integrated silicon photonic devices from high-quality, crystalline semiconductors on to flexible plastic substrates by a transfer-and-bond fabrication method. With this method, photonic circuits including interferometers and resonators can be transferred onto flexible plastic substrates with preserved optical functionalities and performance.

Owner:RGT UNIV OF MINNESOTA

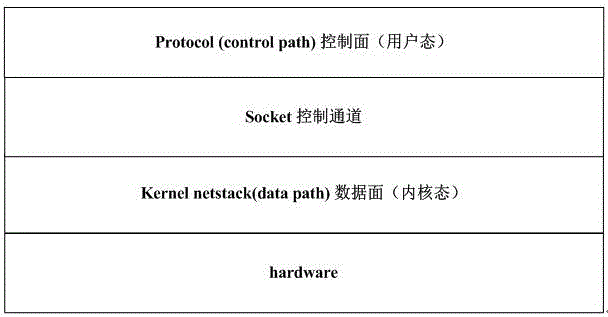

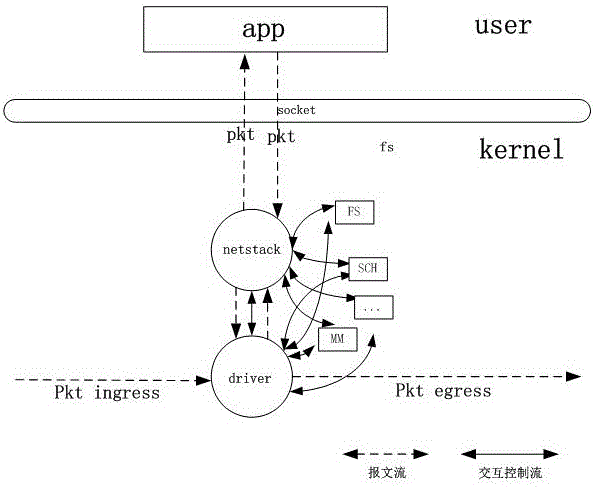

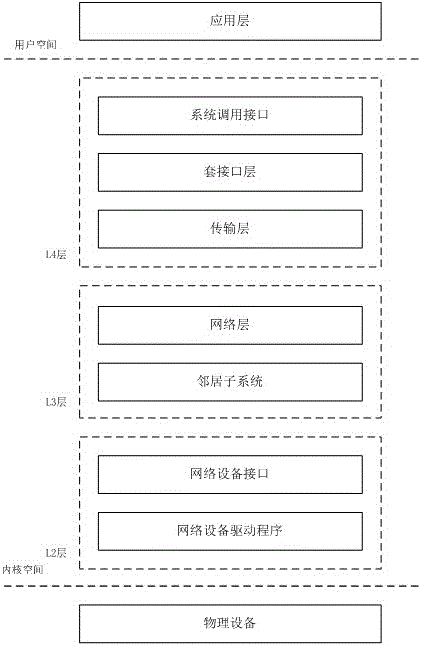

Three-layer switch equipment based user mode protocol stack implementation method and system

ActiveCN106302199AImprove performanceRetain performanceData switching networksInteraction layerNetworking protocol

The invention relates to protocol stack technologies and discloses a three-layer switch equipment based user mode protocol stack implementation method. The method includes steps: step one, constructing a user mode protocol stack in a user mode, transplanting a layer L2 and a layer L3 to the user mode protocol stack, and keeping a layer L4 and a kernel driver in a kernel mode, wherein the layer L2 is mainly used for management of network equipment interfaces and interaction with network equipment drivers, and the L3 layer is a kernel of the protocol stack and mainly used for realizing various network protocols; step two, establishing communication between the layer L2 and the kernel driver kept in the kernel mode by means of memory mapping, and realizing communication between the layer L3 and the layer L4 through a socket I / O provided by the kernel. By adoption of the method for implementation of the user mode protocol stack, subsequent large-scale development is carried out under the user mode, and accordingly development difficulty is lowered, and performances of a data forwarding plane are improved.

Owner:成都瑞视恒基通信技术有限公司

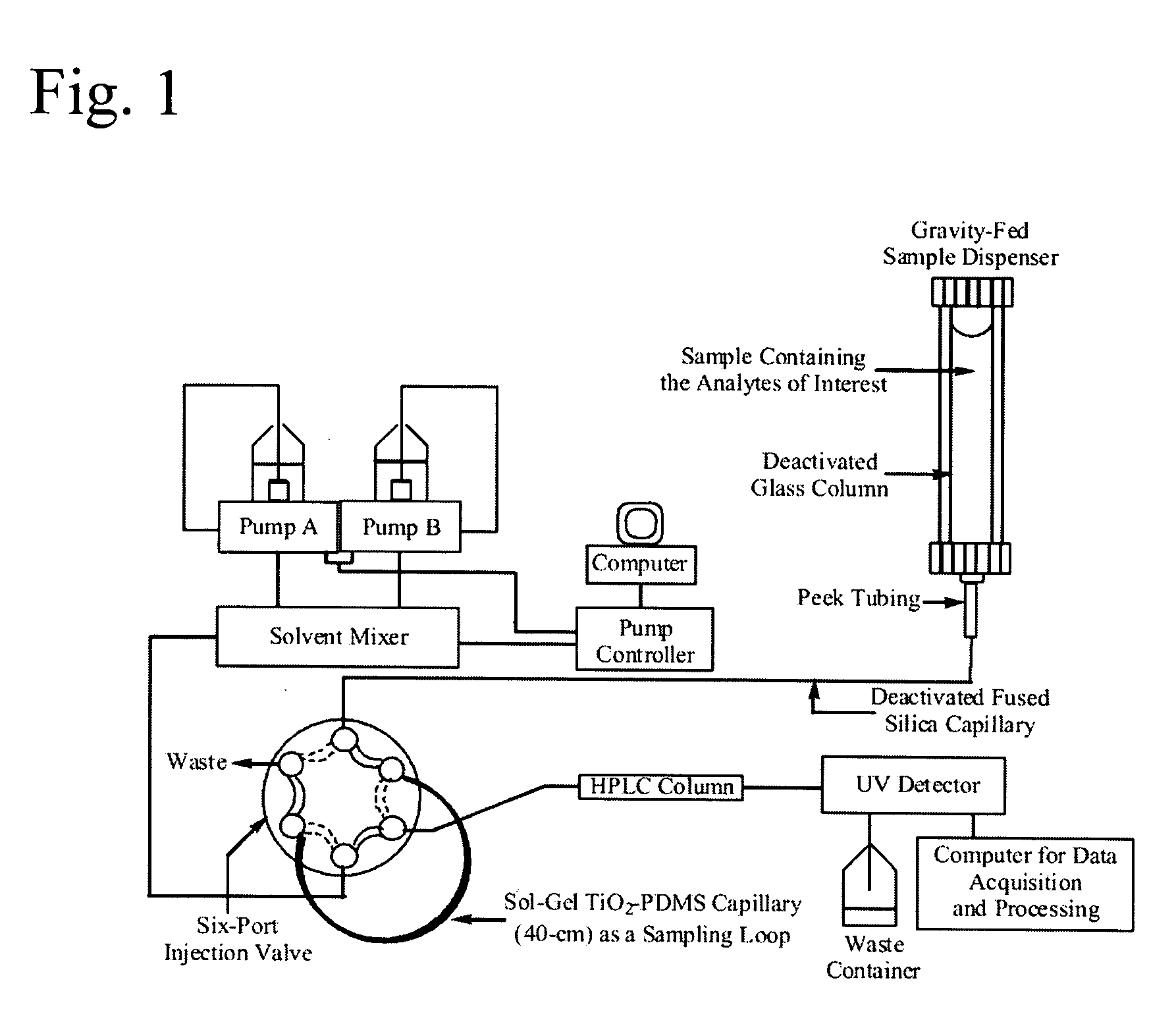

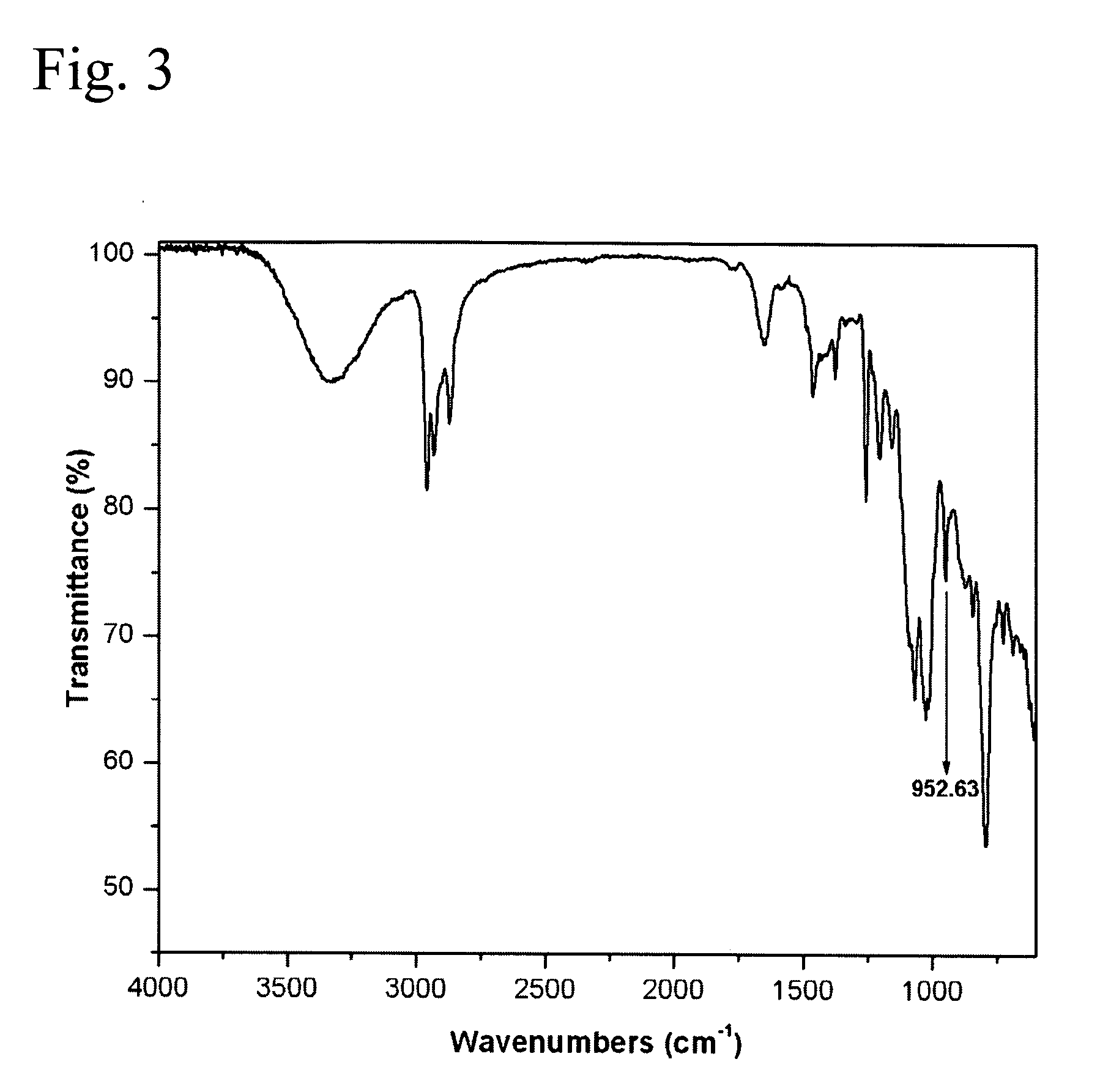

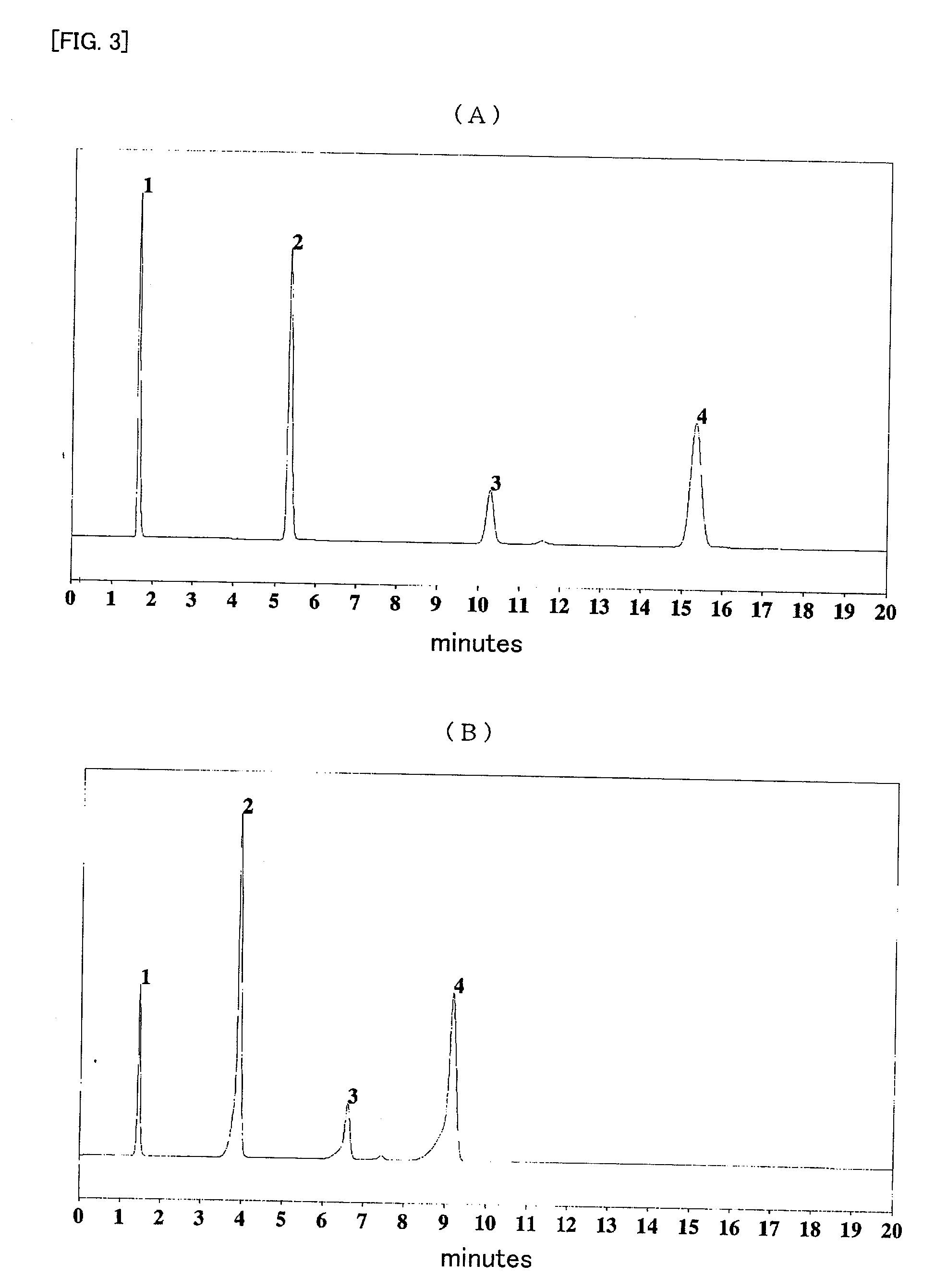

Titania-Based Coating for Capillary Microextraction

InactiveUS20060013982A1Avoid breakingRetains extraction performanceComponent separationMixing methodsSilicon dioxideDimethyl siloxane

A method is presented describing in situ preparation of the titania-based sol-gel PDMS coating and its immobilization on the inner surface of a fused silica microextraction capillary. Sol-gel titania-poly (dimethylsiloxane) (TiO2-PDMS) coating was developed for capillary microextraction (CME) to perform on-line preconcentration and HPLC analysis of trace impurities in aqueous samples. The sol-gel titania-based coatings demonstrated strong pH stability and enhanced extraction capability over other commercially availble GC coatings. Extraction characteristics of a sol-gel titania-PDMS capillary remained practically unchanged after continuous rinsing with a 0.1 M NaOH solution (pH=13) for 12 hours.

Owner:UNIV OF SOUTH FLORIDA

Production of aromatic copolymide fiber dissolving pulp

InactiveCN1456719AAchieve reuseNo protection issuesArtificial filament recoveryPlastic recyclingDissolving pulpAramid

Owner:上海依极科技有限公司

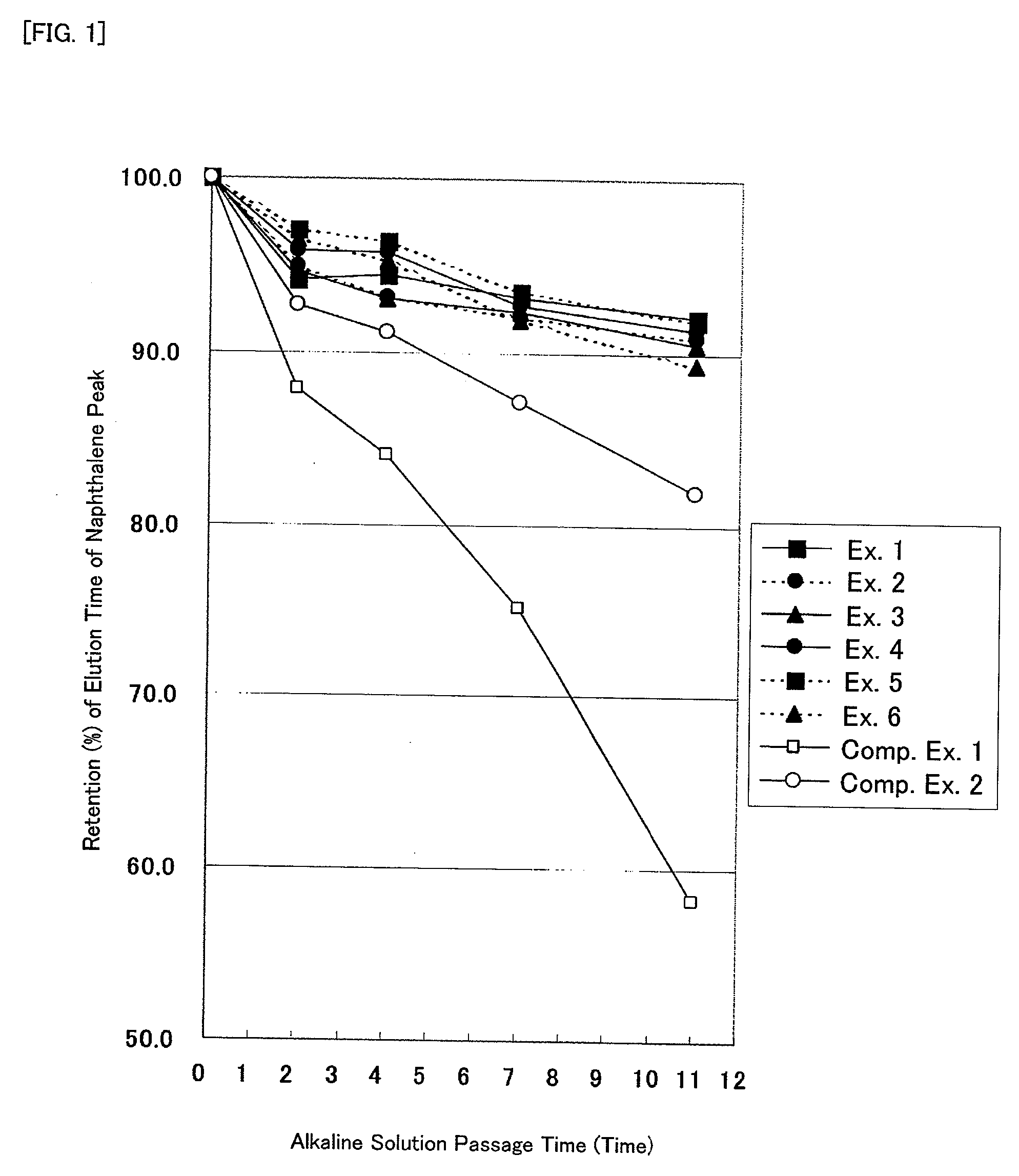

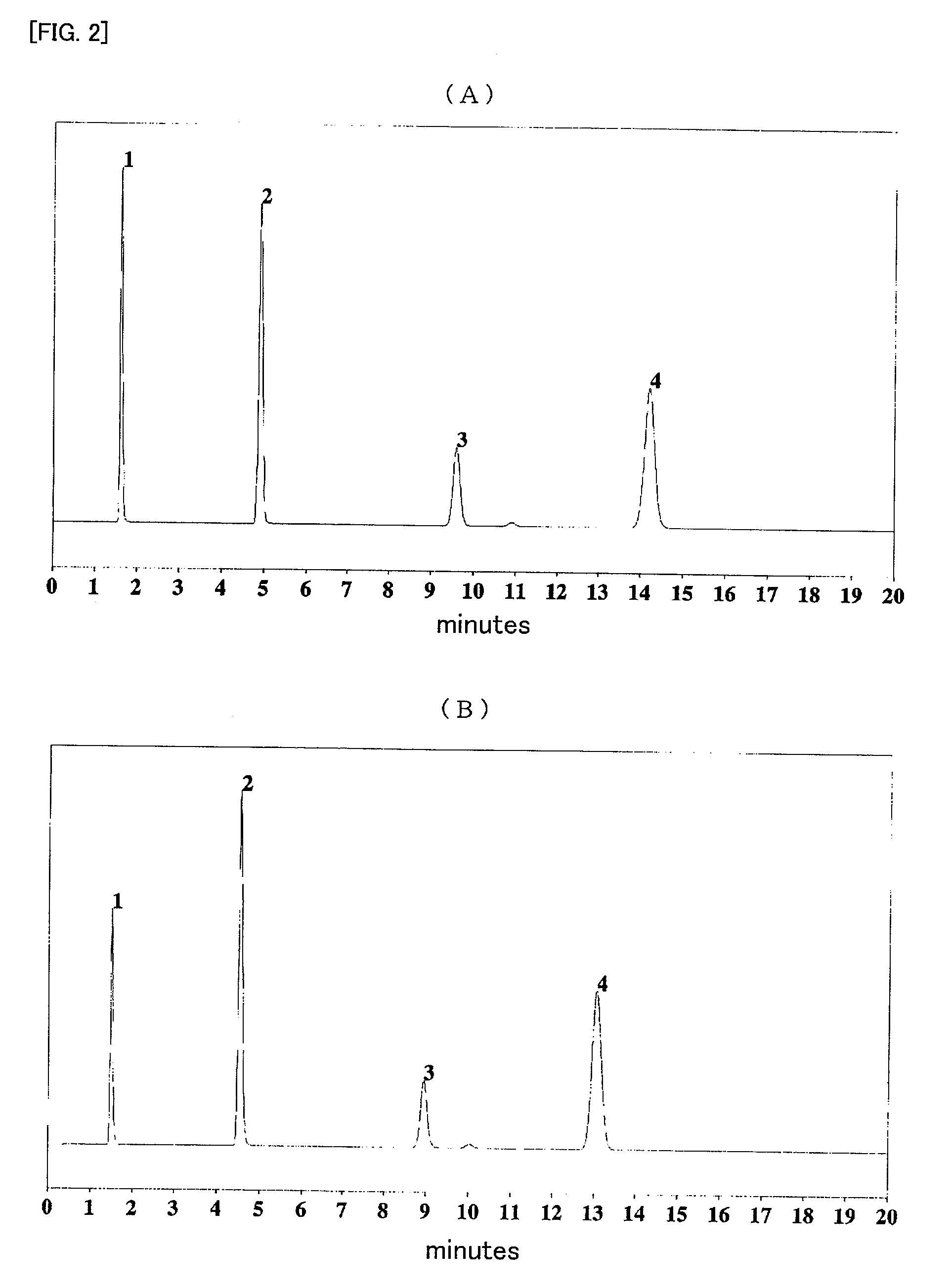

Modified silica gel and use thereof

InactiveUS20090206034A1Improve the immunityRetain their separation performanceIon-exchange process apparatusIon-exchanger regenerationSilane compoundsPolymer science

A modified silica gel, in which a surface of a silica gel is partially or entirely coated with a polymer or a copolymer of at least one alkyldisilane compound selected from the group consisting of:compounds represented by General Formula [I]:wherein each X1 is the same or different, and is a hydrogen atom, a halogen atom, or a C1-C4 alkoxy group; and n is an integer from 1 to 10; andcompounds represented by General Formula [II]:wherein each X2 is the same or different, and is a hydrogen atom, a halogen atom, or a C1-C4 alkoxy group; each R1 is the same or different and is a C1-C30alkyl group; and m is an integer from 1 to 10.

Owner:DAISO CO LTD

Method for enhancing washing resistance of nano-silver antibacterial cotton fabric by surface modification of cotton fabric

The invention discloses a method for enhancing washing resistance of nano-silver antibacterial cotton fabric by surface modification of cotton fabric. The method comprises the following steps: Step 1, impregnating cotton fabric into a cysteine hydrochloride solution, heating to carry out an esterification reaction between carboxyl group of cysteine hydrochloride and hydroxyl group of cellulose, cleaning, and drying; and Step 2, impregnating the above modified cotton fabric into nano-silver sol, fixing nano-silver by complexation of mercapto group, drying, and cleaning to finally obtain the antibacterial cotton fabric. Particle size of nano-silver particles obtained is 20-60 nm. Sterilizing rates of escherichia coli and staphylococcus aureus both reach 100%. After 20 times of standard washing, sterilizing rate of escherichia coli and staphylococcus aureus is still maintained at 100%. The method of the invention has high safety to human body and is pollution-free to the environment. By the method, excellent performance of the cotton fabric is maintained. The method has practical application potential in antibacterial modification of cotton fabric.

Owner:ZHEJIANG SCI-TECH UNIV

Production method of cement-based grouting material

The invention provides a production method of a cement-based grouting material. The method comprises the steps that aggregate and / or a binding material are mixed with a liquid additive, weight ratio of the aggregate and / or the binding material with the liquid additive in the mixture is (90-110) : (0.1-30); the obtained mixture is subjected to a drying process and can be mixed with polymer rubber powder which can re-disperse to obtain the cement-based grouting material. According to the production method, a liquid additive which is not easy to dehydrate and dry, which relates to polycarboxylate superplasticizer particularly, can be dried easily, the performance of the additive can be retained to the greatest extent, the aggregate or the binding material which is subjected to preprocessing of the liquid additive is mixed into other materials according to a specified proportion of the cement-based grouting material, and a cement-based grouting material product with good performance can be produced.

Owner:SHANGHAI TAIJIE CHEM

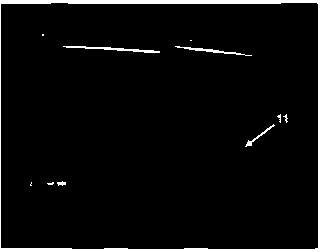

Efficient preparation method for planar miniature supercapacitor electrode with interdigital structure

InactiveCN108428566ARapid assessmentLow costHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorCapacitor

The invention relates to an efficient preparation method for a planar miniature supercapacitor electrode with an interdigital structure, which comprises the steps of (1) obtaining a film based on a two-dimensional nanomaterial on a substrate; (2) directly scraping a part required to be removed on the film according to a pre-designed pattern by using a scraping tool with a pointed end to obtain a planar miniature supercapacitor electrode with an interdigital structure, wherein the size of the pointed end of the scraping tool is not greater than the size of a narrowest part of the part requiredto be removed. The preparation method has the advantages of simplicity, high efficiency, high universality, low cost and environmental friendliness.

Owner:ZHEJIANG UNIV OF TECH

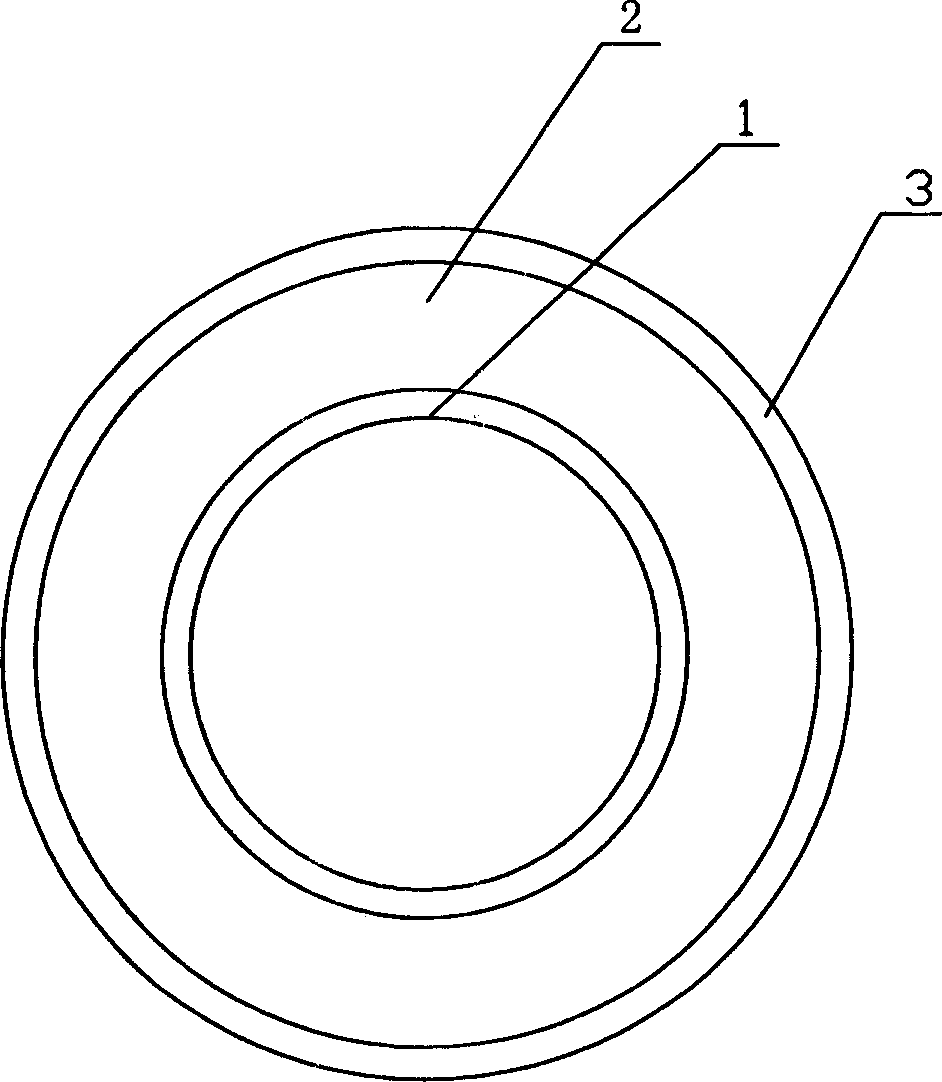

Sealing gasket and manufacturing method

The present invention relates to a method for preparing gasket seal. Said preparation method includes according to size requirement cutting metal ring; according to compression ratio of graphite plate and density of gasket cutting out width of graphite tape, according to the specification size required for gasket selecting proper mould; placing the graphite tape into the mould by turns and prepressing graphite ring; moulding the metal ring and graphite ring by means of mould and nesting metal ring with graphite ring together; demoulding; and edging and shaping so as to obtain the gasket seal.

Owner:NINGBO TIANSHENG SEALING PACKING

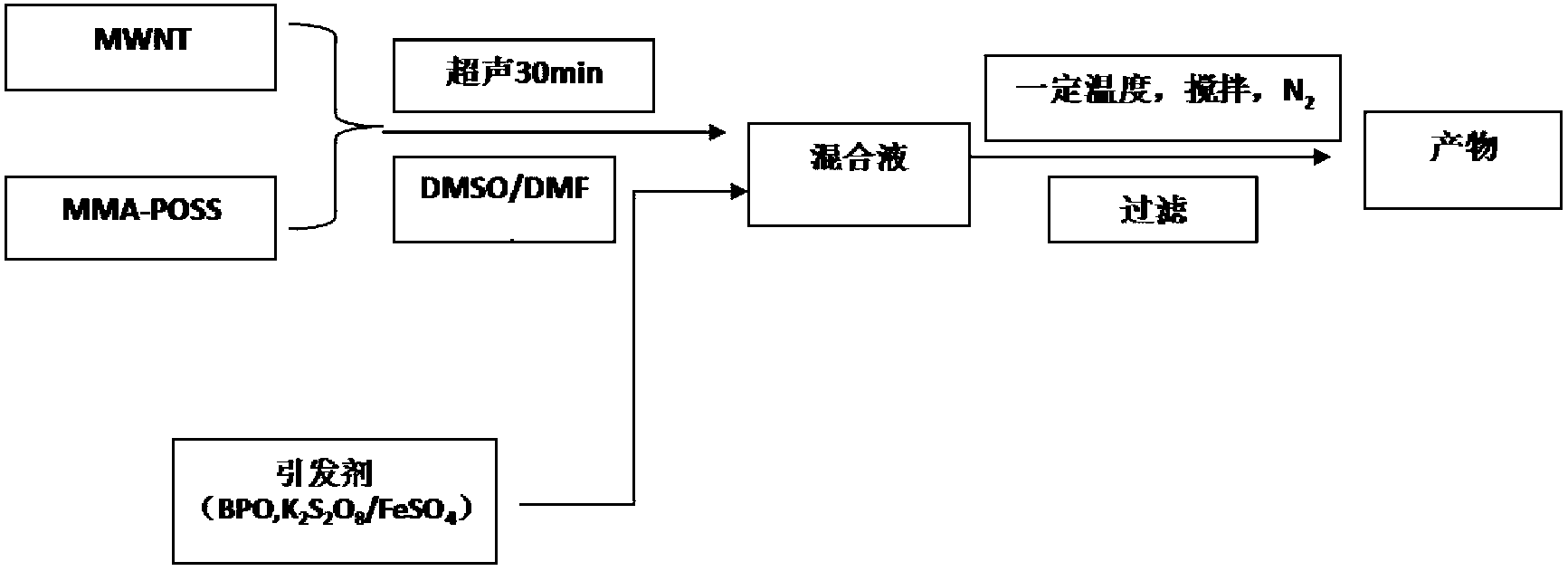

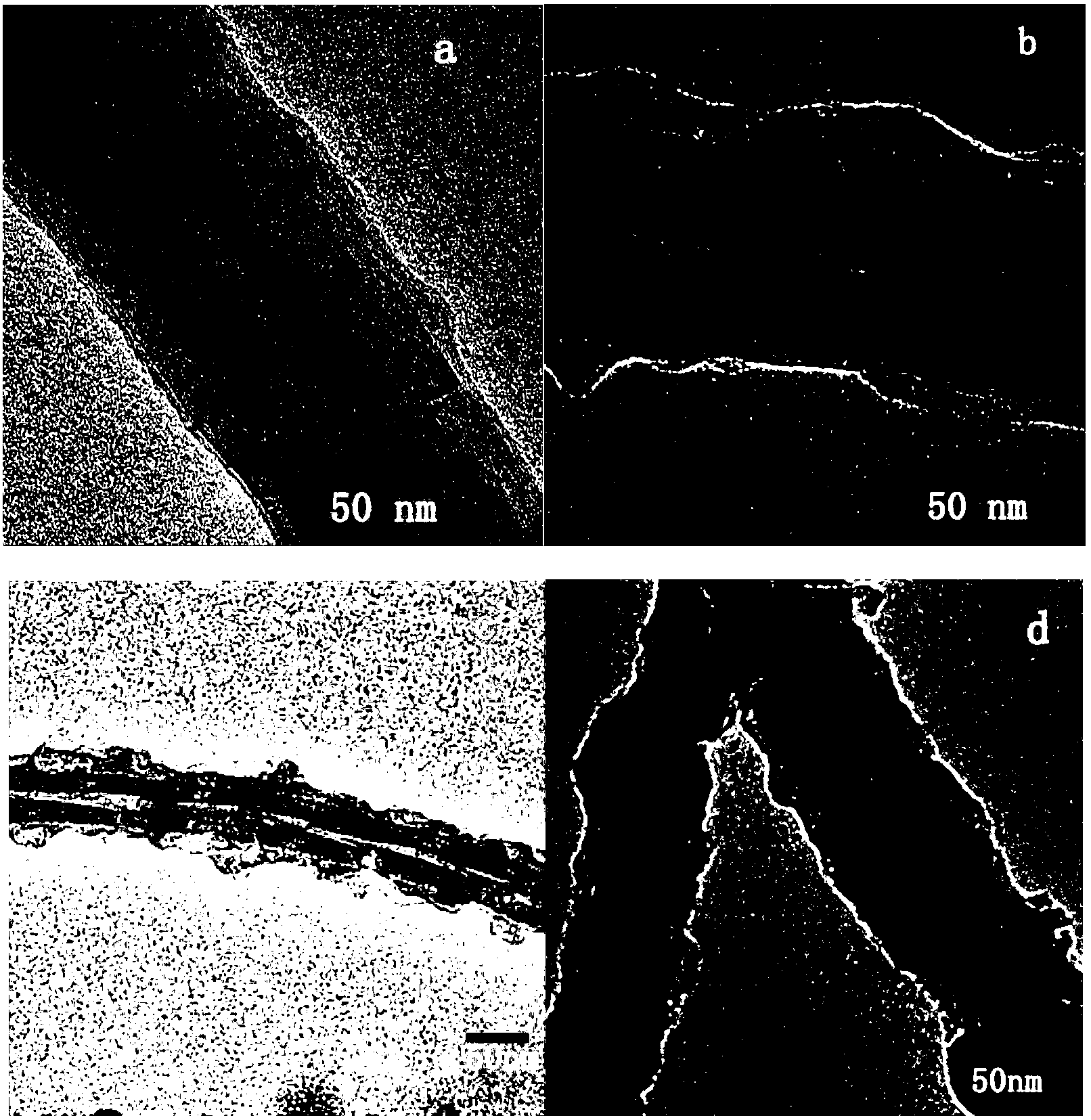

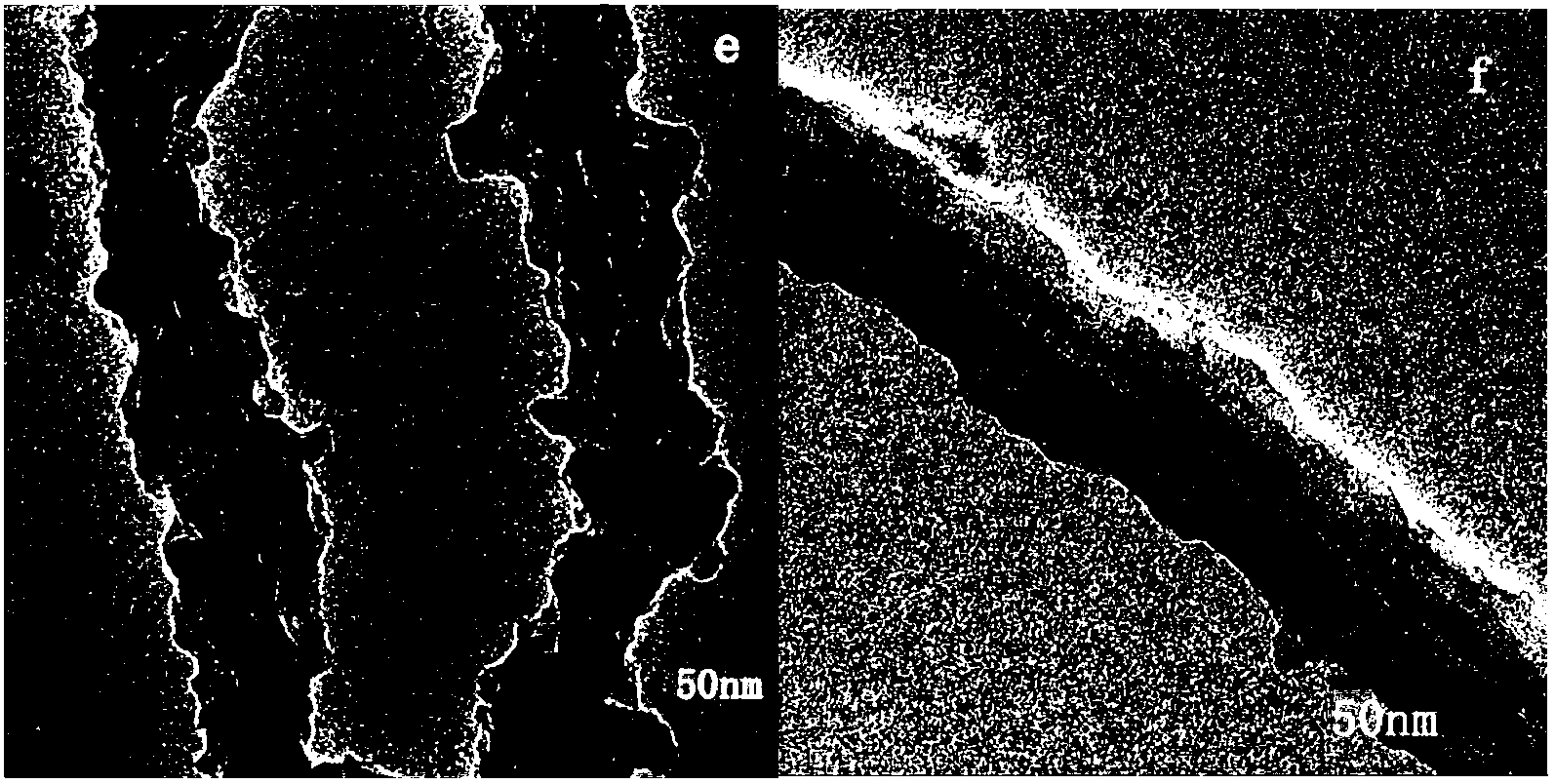

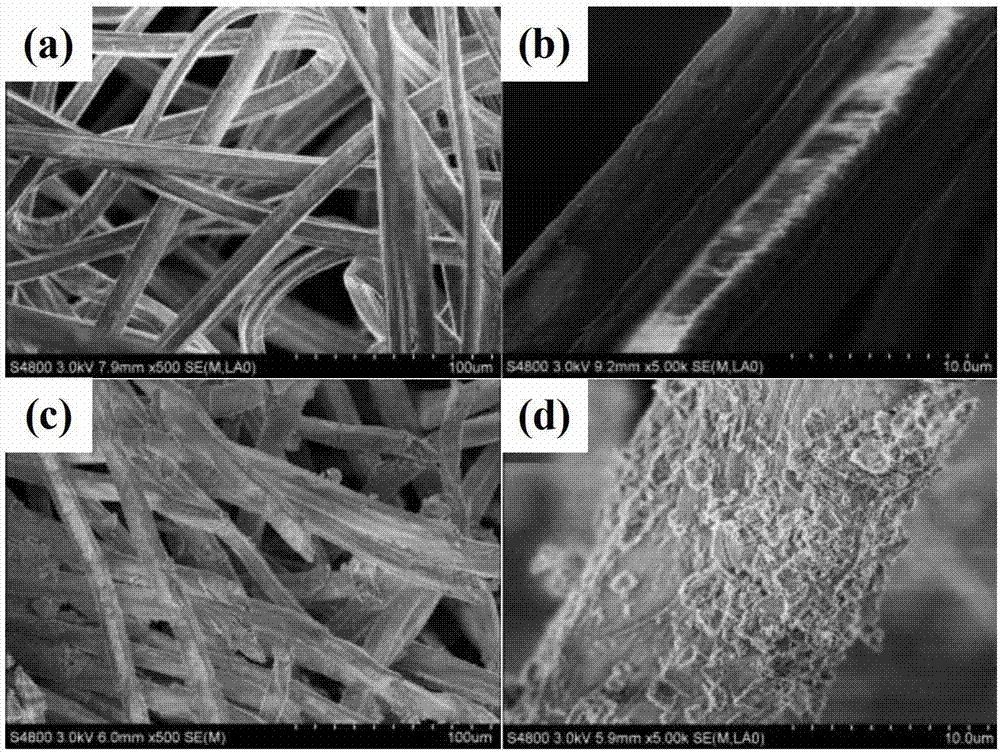

Method for making core-shell polyhedral oligomeric silsesquioxane (POSS) coated multi-walled carbon nanotube (MWNT)

ActiveCN103173041ARetain performanceNo damagePigment treatment with organosilicon compoundsMethacrylateBenzoyl peroxide

A method for making a core-shell POSS coated MWNT belongs to the technical field of composite material preparation. The MWNT having different POSS coating thicknesses is made through a solution process by the initiation of octamethyl acrylate based POSS monomers under a free radical initiator (benzoyl peroxide / ferrous sulfate / potassium persulphate), wherein the coating thicknesses are 5-10nm, 15-25nm and 30-50nm respectively. The method does not need any pretreatment processes comprising acidification or oxidation of carbon nanotubes, has no destroy to the structure of the carbon nanotubes, has small influences of the influences of the carbon nanotubes, simultaneously selects the industrially commonly used free radical initiator and its initiation system, and is an effective way for preparing the core-shell MWNT; and the method has the advantages of simple technology, low production cost, wide industrial prospect and the like.

Owner:BEIJING UNIV OF CHEM TECH

Three-dimensional ordered porous bracket material of chitosan fiber/bioactive glass and preparation method of three-dimensional ordered porous bracket material

InactiveCN103191463ARetain performanceGood dimensional stabilityProsthesisFiberBiocompatibility Testing

The invention relates to a preparation technology of an artificial bone repairing material in the fields of an inorganic nonmetallic material and a biomedical material, and particularly relates to a three-dimensional ordered porous bracket material of chitosan fiber / bioactive glass and a preparation method of the three-dimensional ordered porous bracket material. The porous bracket material is composite bioactive glass at the surface of a chitosan fiber; the aperture is 80-500mu m; adhesive proliferation of a human bone cell is facilitated; and rapid forming of a new bone is facilitated. The preparation method comprises the steps of: coating mixed pulp of the bioactive glass on chitosan fiber cloth which is reinforced by puncture by a sol-gel dip-coating method, drying and repeating for 0-3 times. The three-dimensional ordered porous bracket material has the advantages of good biological activity, biocompatibility, biological degradability and the like, has obvious mechanical strength and good mechanical property, and can meet the demands of providing stress support to a bone repair part.

Owner:SHANGHAI NORMAL UNIVERSITY

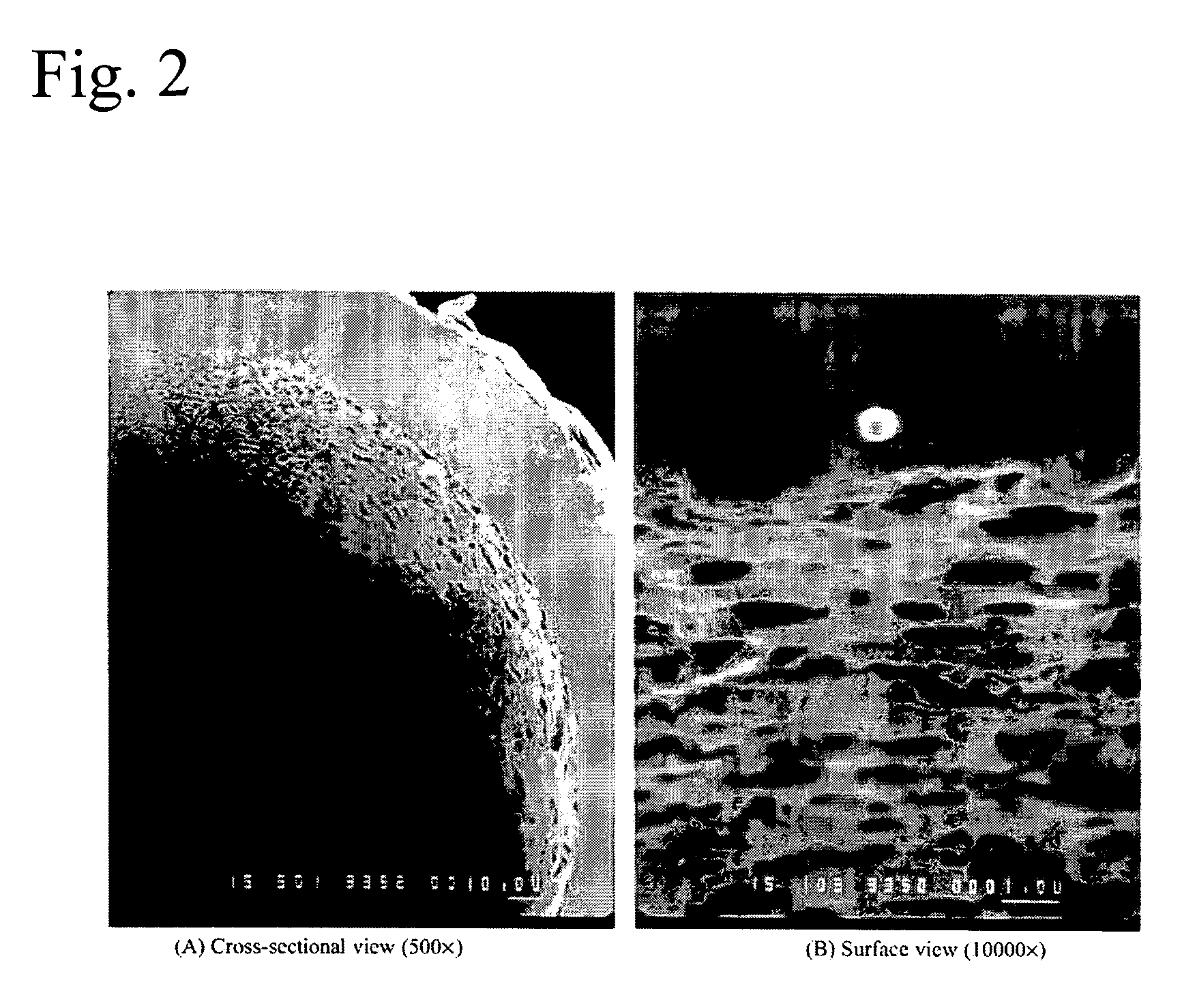

Preparation method of polyvinylidene fluoride (PVDF) composite mesoporous membrane

InactiveCN103861476AAperture adjustableHigh hydrothermal stabilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisOrganic solventPolyvinylidene difluoride

The invention belongs to the technical field of preparation of composite membranes, and relates to a preparation method of a polyvinylidene fluoride (PVDF) mesoporous membrane, and the method includes the following steps: dissolving polyvinylidene fluoride powder in an organic solvent, adding a pore forming agent, stirring evenly to prepare a polyvinylidene fluoride membrane casting solution; adding SBA-15 to obtain a mixed solution, heating and stirring the mixed solution to prepare a polyvinylidene fluoride-silica membrane casting solution; sealing, standing for defoaming; using an automatic coating machine to coat a glass substrate with the PVDF-SBA-15 membrane casting solution, and immersing the glass substrate in a solidification liquid to obtain a polyvinylidene fluoride-silica composite membrane. The preparation method is simple in operation, the membrane is prepared at low temperature, the polymer degradation can be reduced, the strength of the membrane is ensured, the prepared PVDF-SBA-15 can effectively improve the hydrophilic ability and water flux of the membrane, and the membrane has good application prospects in the field of water pollutant removal.

Owner:TONGJI UNIV

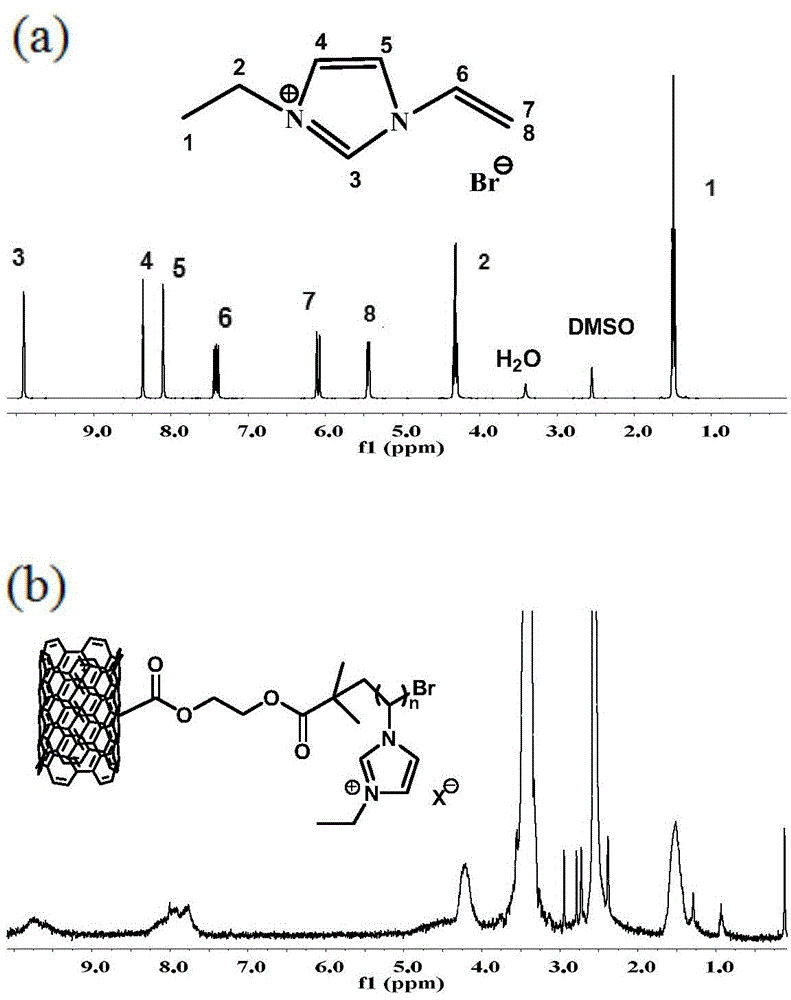

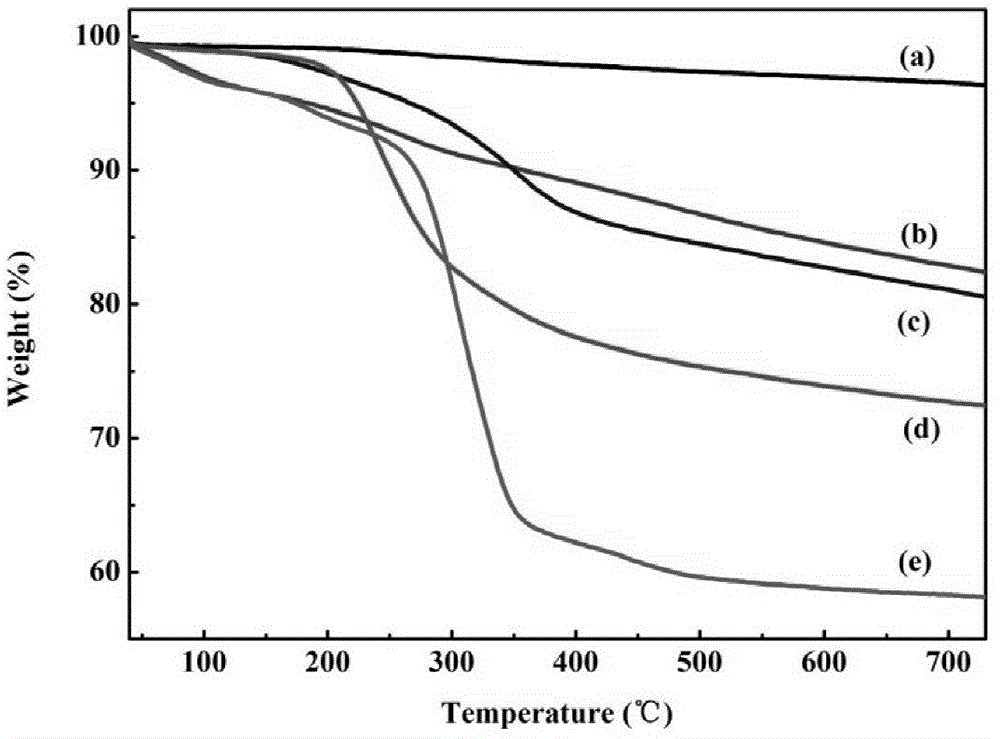

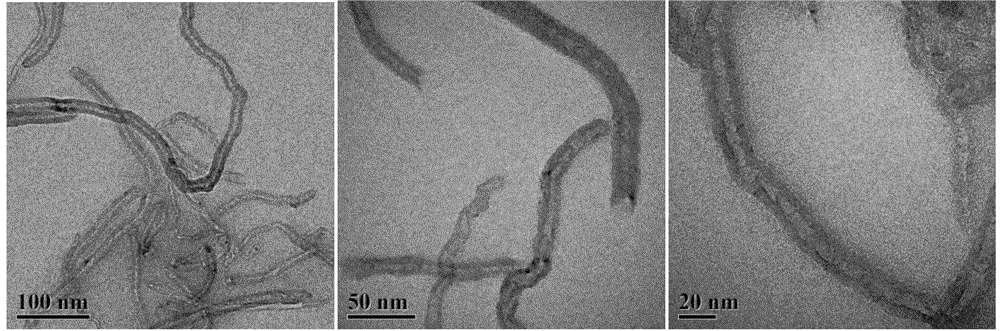

Ionic liquid polymer grafted magnetic carbon nanotube and preparation method thereof

The invention discloses a preparation method of an ionic liquid polymer grafted magnetic carbon nanotube. The method comprises the following steps: reacting halogenated hydrocarbon with 1-vinyl imidazole to synthesize an ionic liquid for later use, carrying out acidifying oxidation treatment on an original carbon nanotube by using concentrated sulfuric acid and concentrated nitric acid, and reacting the obtained carbon nanotube with thionyl chloride and ethylene glycol to obtain a hydroxylated carbon nanotube; loading an initiator bromoisobutyryl bromide to the surface of the hydroxylated carbon nanotube, and initiating polymerization of the ionic liquid on the surface of the carbon nanotube; and carrying out one-step simple ion exchange to introduce magnetic anions in order to synthesize the novel magnetic carbon nanotube. The magnetic carbon nanotube prepared in the invention has nanometer dimension and strong magnetism, and can be rapidly separated and enriched through simple magnetic field action.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

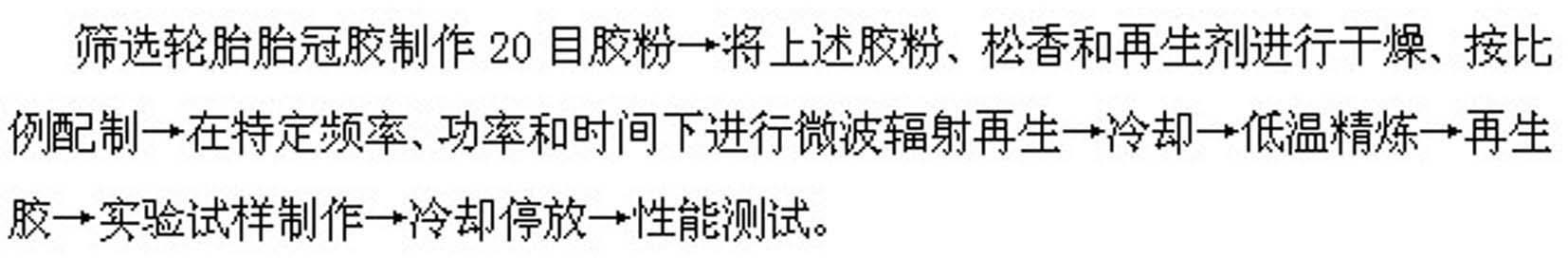

Microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber

InactiveCN102634056AProtection from destructionSure breakPlastic recyclingRubber materialWaste rubber

The invention discloses a microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber, and belongs to the technical field of waste rubber reclaiming. The method comprises the following steps of: mixing waste rubber outer tire crown powder with the particle size of 20 meshes, rosin and dipentene according to a certain proportion; uniformly feeding the materials with a certain thickness on a roller way conveying device; determining the length of a roller way according to microwave radiation time; arranging a high-frequency microwave radiation device on the roller way; conveying the materials on the roller way for reclaiming the materials by microwave radiation during conveying; continuously putting the reclaimed rubber materials into a cooling device through the roller way; directly discharging the cooled materials to an open mill for performing refining, wherein the refining temperature is controlled to be 35-50 DEG C; and refining at low temperature on the open mill for 20 minutes to obtain a refined rubber sheet with smooth surface and uniform texture. A test result shows that the tensile strength of the reclaimed rubber is more than 18MPa, the breaking elongation is over 400%, and the Weigert plasticity is 0.35-0.45. The microwave radiation reclaiming method has the advantages of environment friendliness, short reclaiming time, low reclaiming temperature, energy conservation and high production efficiency.

Owner:XUZHOU COLLEGE OF INDAL TECH

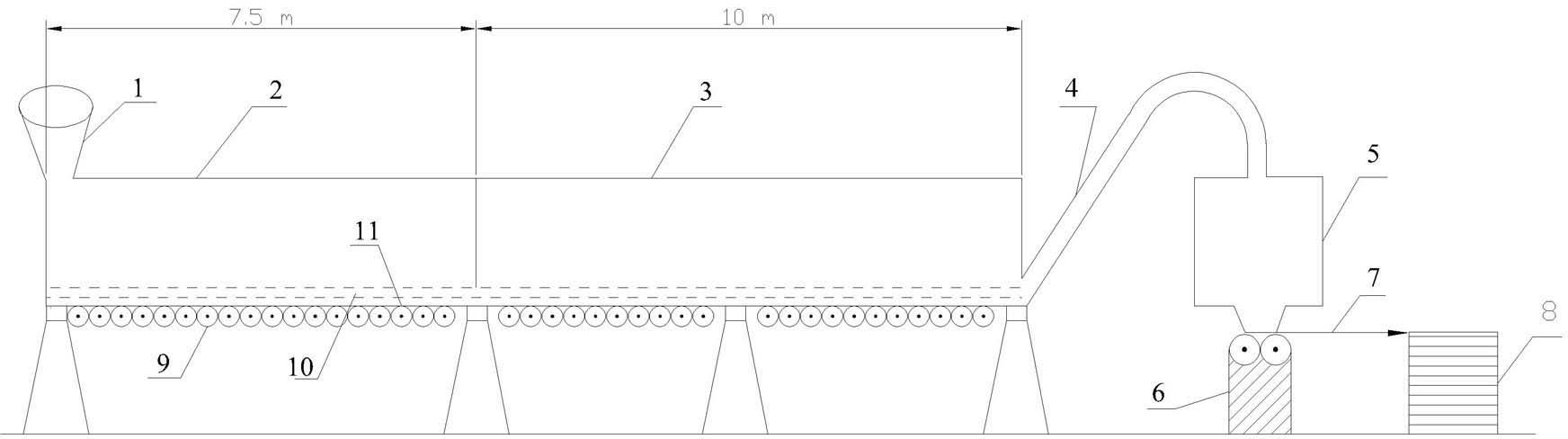

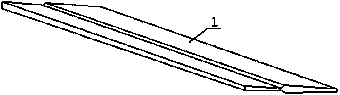

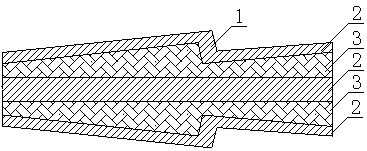

Method for manufacturing composite material component

The invention discloses a method for manufacturing a composite material component. The method comprises the following steps of S1: coating the side wall of a cavity of a die with a demolding agent; S2: paving a prefabricated body in the cavity: S21: paving continuous fibers on two layers on the outmost surface of the prefabricated body, and arranging a combined paved layer structure of the continuous fibers and chopped fibers between the two layers of the continuous fibers, and S22: positioning the prefabricated body in cavities formed in an upper die board and a lower die board, and performing high-temperature compaction; S3, sealing the upper die board and the lower die board for die assembling, locking the upper and lower die boards by a locking bolt; S41: heating the die to required glue injection temperature; S42: vacuuming through a glue outlet until the vacuum environment is stable; S5: injecting resin into the cavity, closing the glue outlet and a glue injection opening after the glue is completely discharged from the glue outlet, and stopping glue injection; and S6: heating and solidifying the die, and demolding to obtain a required product. The method has the beneficial effects that the composite material component meeting the requirement on the appearance is manufactured, so that the product is unlikely to deform, and the processing cost can be effectively lowered.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

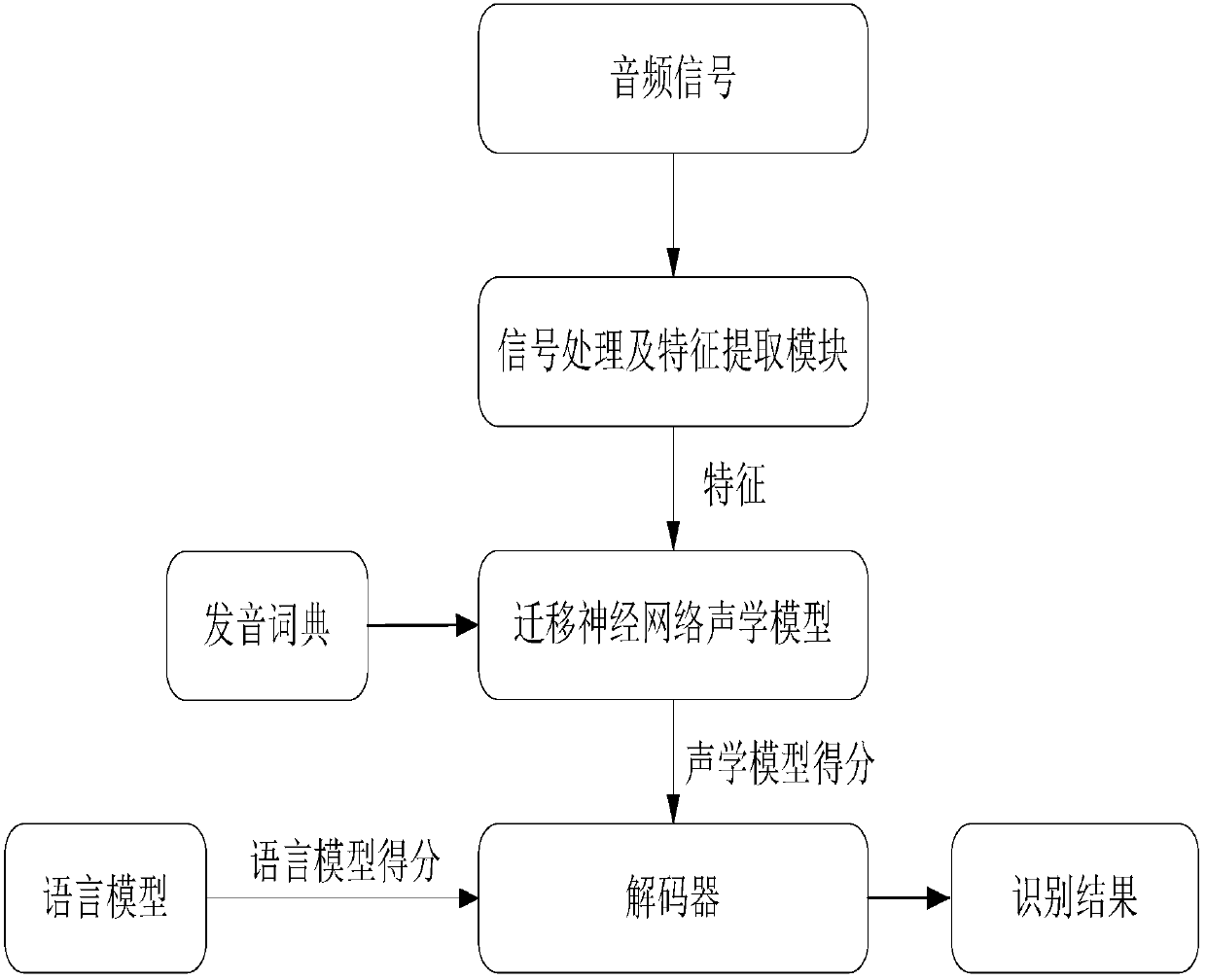

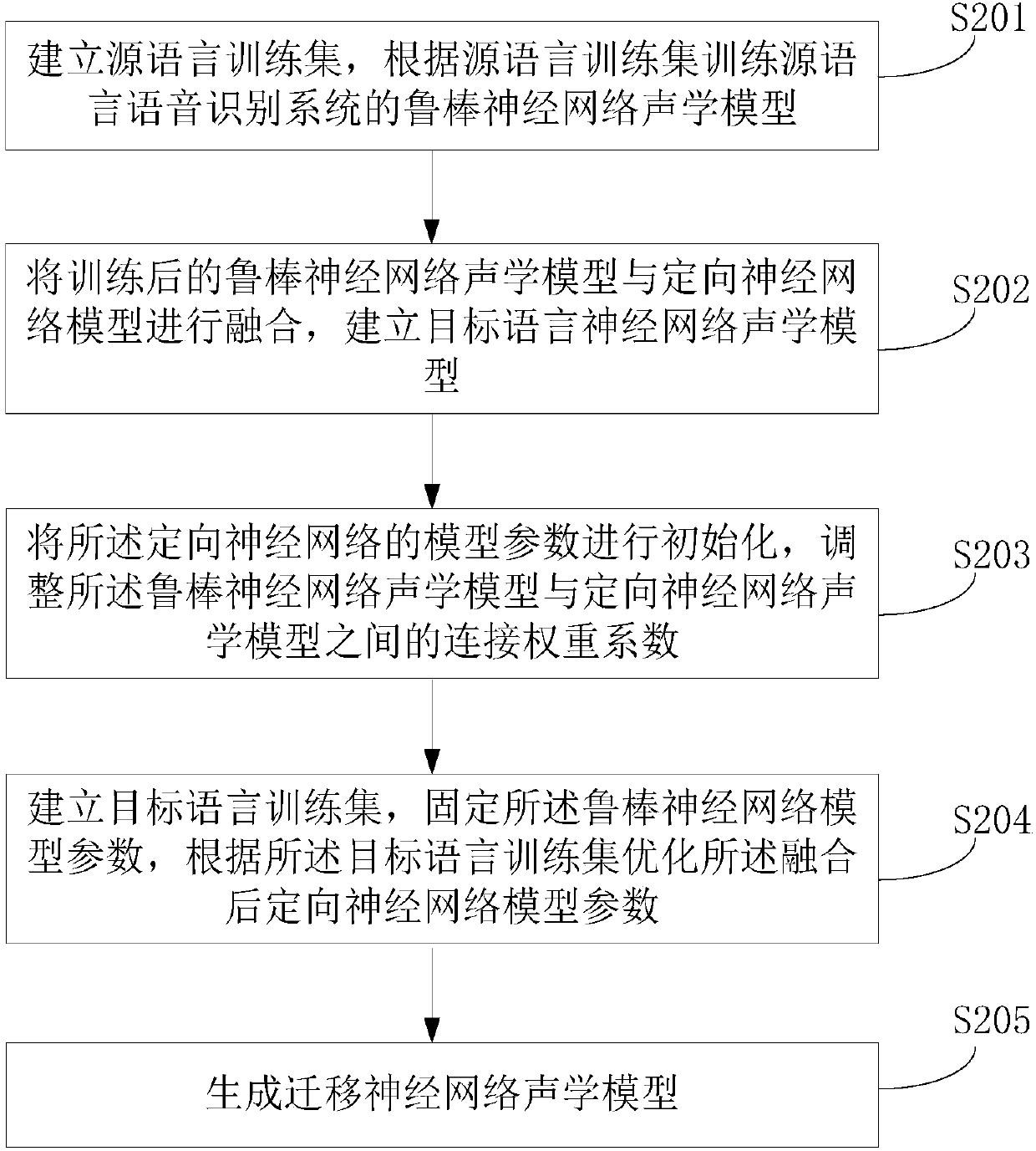

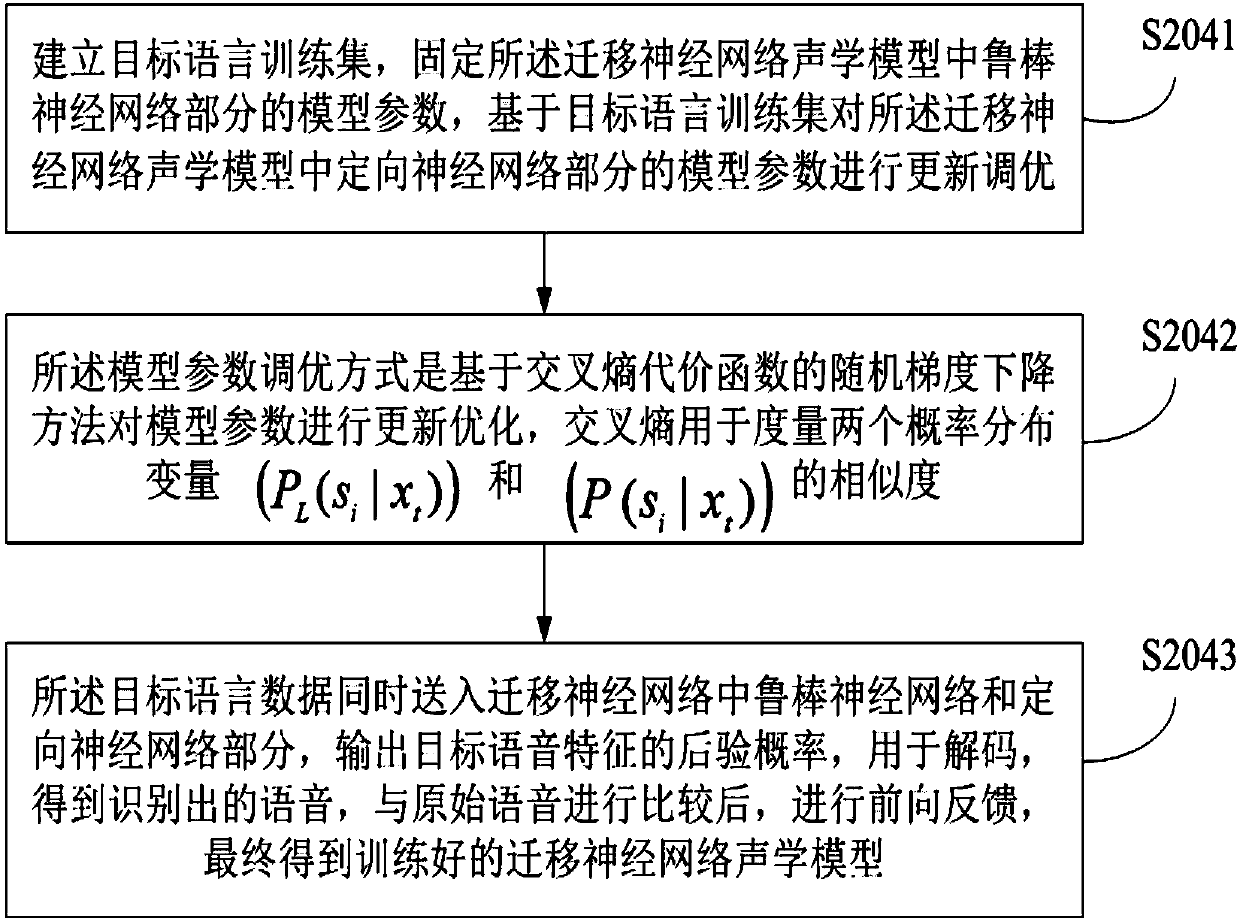

Speech recognition system and method based on transfer neural network acoustic model

ActiveCN110070855ARetain performanceImprove performanceSpeech recognitionLanguage modelSpeech identification

The invention relates to a speech recognition system and method based on a transfer neural network acoustic model. The system includes a signal processing and feature extraction module, a language model, a decoder and a migrating neural network acoustic model, wherein the migrating neural network acoustic model includes a robust neural network and a directional neural network. According to the system, the model parameters of a robust neural network model is fixed, meanwhile through layer-to-layer transverse connection of the neural networks, information of a robust acoustic model is transferred into a target acoustic model, the performance of an original robust acoustic model is retained, and meanwhile target language is specifically optimized. The problem of fast construction of the robust acoustic model of less-resource languages is solved, and through a mode in which the acoustic model of a language with sufficient data is used for model parameter migration, the performance of the acoustic model of a target less-resource language is improved and the convergence speed of training is increased.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +1

Synthetic-leather-used UV solidifying and flame-retarding polyurethane and preparation method thereof

ActiveCN105131227AHigh flame retardant efficiencyEasy to control performanceEnvironmental resistanceSide chain

The invention discloses synthetic-leather-used UV solidifying and flame-retarding polyurethane and a preparation method thereof. The method is characterized by comprising the steps that low-viscosity liquid dihydric alcohol and diisocyanate serve as raw materials, side-group phosphorus / nitrogen-containing dihidroxy acrylate is introduced into the polyurethane structure in the form of chain extender, and then side-group phosphorus-containing monohydroxy acrylate is used for sealing the end. Both a main chain and a side chain of the obtained UV solidifying polyurethane contain photosensitive perssad, through the UV solidification, the crosslinking degree and relative molecular mass of resin can be improved, the contradiction between the fact that photosensitive perssad in traditional UV solidifying polyurethane is low in content and the fact that the molecular weight of coating polymer is high in requirement is reconciled, and meanwhile the comprehensive performance of the polyurethane such as wear resistance, scratch resistance, waterproofness, heat resistance and solvent resistance is improved; phosphorus / nitrogen flame-retarding ingredients are 'suspended'on the macromolecular side chain of the polyurethane, the flame-retarding effect is good, and fire retardant is not migrated or separated out and is resistant to hydrolysis in the storage and using processes; in addition, no organic solvent is used in the preparation process of the polyurethane, and the synthetic-leather-used UV solidifying and flame-retarding polyurethane has the advantages of being prominent in greenness, environment-friendliness, health, safety and the like and can be used in synthetic leather manufacturing and coating materials such as leather and textiles.

Owner:SICHUAN UNIV

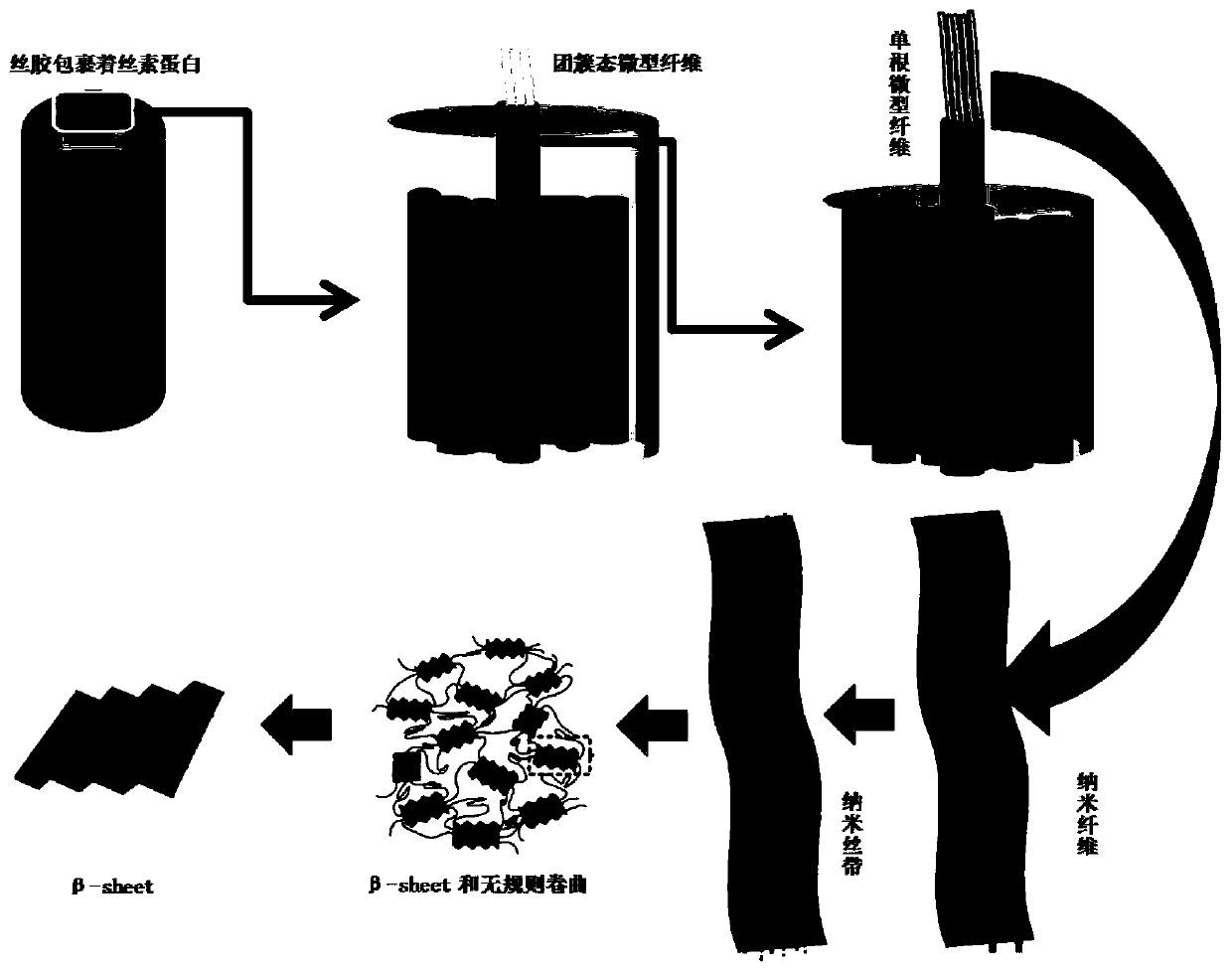

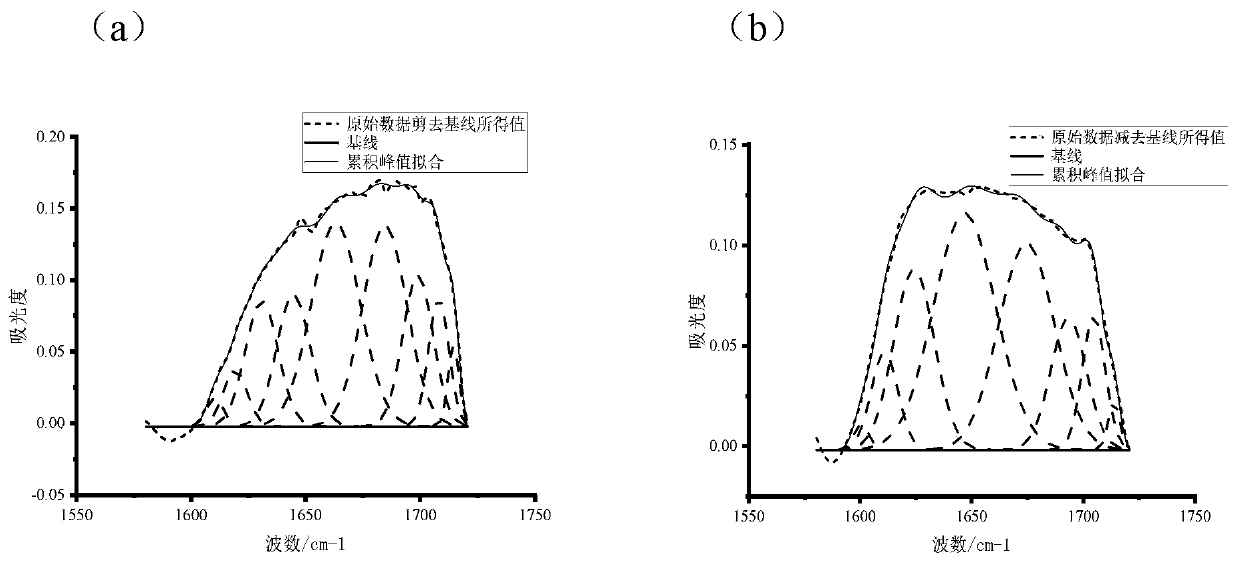

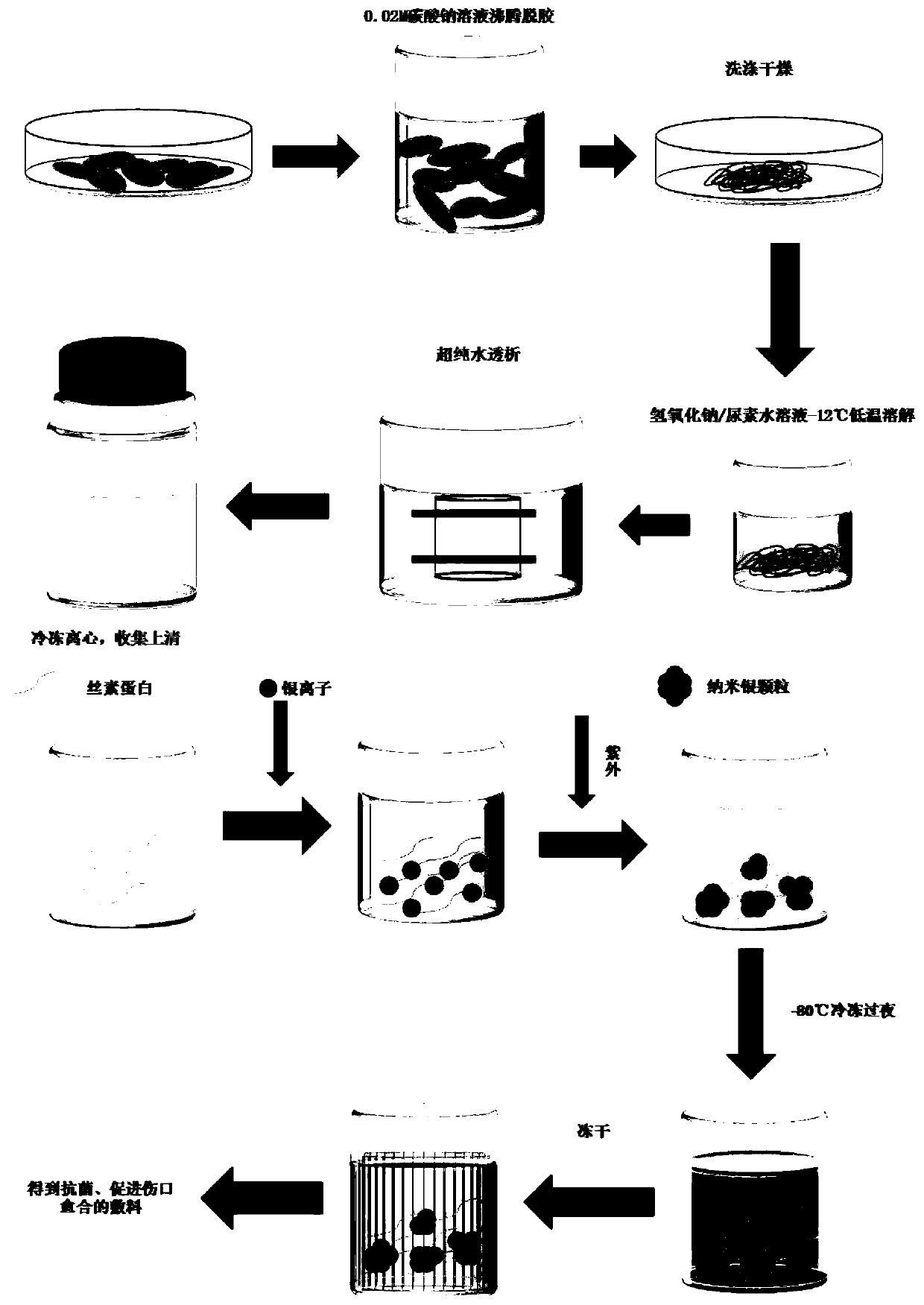

Preparation method of silk fibroin nanofibers and preparation method of silver-loaded antibacterial dressing based on silk fibroin nanofibers

InactiveCN110639050ARetain structureRetain performancePharmaceutical delivery mechanismAbsorbent padsSodium bicarbonateFreeze-drying

The invention discloses a preparation method of silk fibroin nanofibers and a preparation method of a silver-loaded antibacterial dressing based on the silk fibroin nanofibers. The preparation methodof the silk fibroin nanofibers comprises the following steps: 1) putting silkworm cocoons into a sodium carbonate solution, and performing degumming to obtain silk fibroin; 2) dissolving the silk fibroin in a sodium hydroxide / urea aqueous solution to obtain a dissolved solution; 3) putting a dialysis bag into a sodium bicarbonate / EDTA solution, performing boiling treatment, taking out the dialysisbag, putting the dialysis bag into an EDTA solution, and performing boiling treatment; and 4) pouring the solution obtained in the step 2) into the treated dialysis bag, performing dialysis, performing ultrasonic treatment, and performing freeze centrifugation to obtain the silk fibroin nanofiber aqueous solution. The invention also discloses the preparation method of the silver-loaded antibacterial dressing, and the method comprises the following steps: 1) preparing the silk fibroin nanofiber aqueous solution by using the above method; 2) dissolving silver nitrate in the obtained silk fibroin nanofiber aqueous solution, wherein the mass-to-volume ratio of the silver nitrate to the silk fibroin nanofiber aqueous solution is 0.02%-0.08%, and performing irradiation from the cup bottom underultraviolet conditions; and 3) after the ultraviolet irradiation is completed, performing pre-cooling, performing freezing, and finally performing vacuum freeze drying to obtain the silver-loaded antibacterial dressing.

Owner:CHONGQING MEDICAL UNIVERSITY

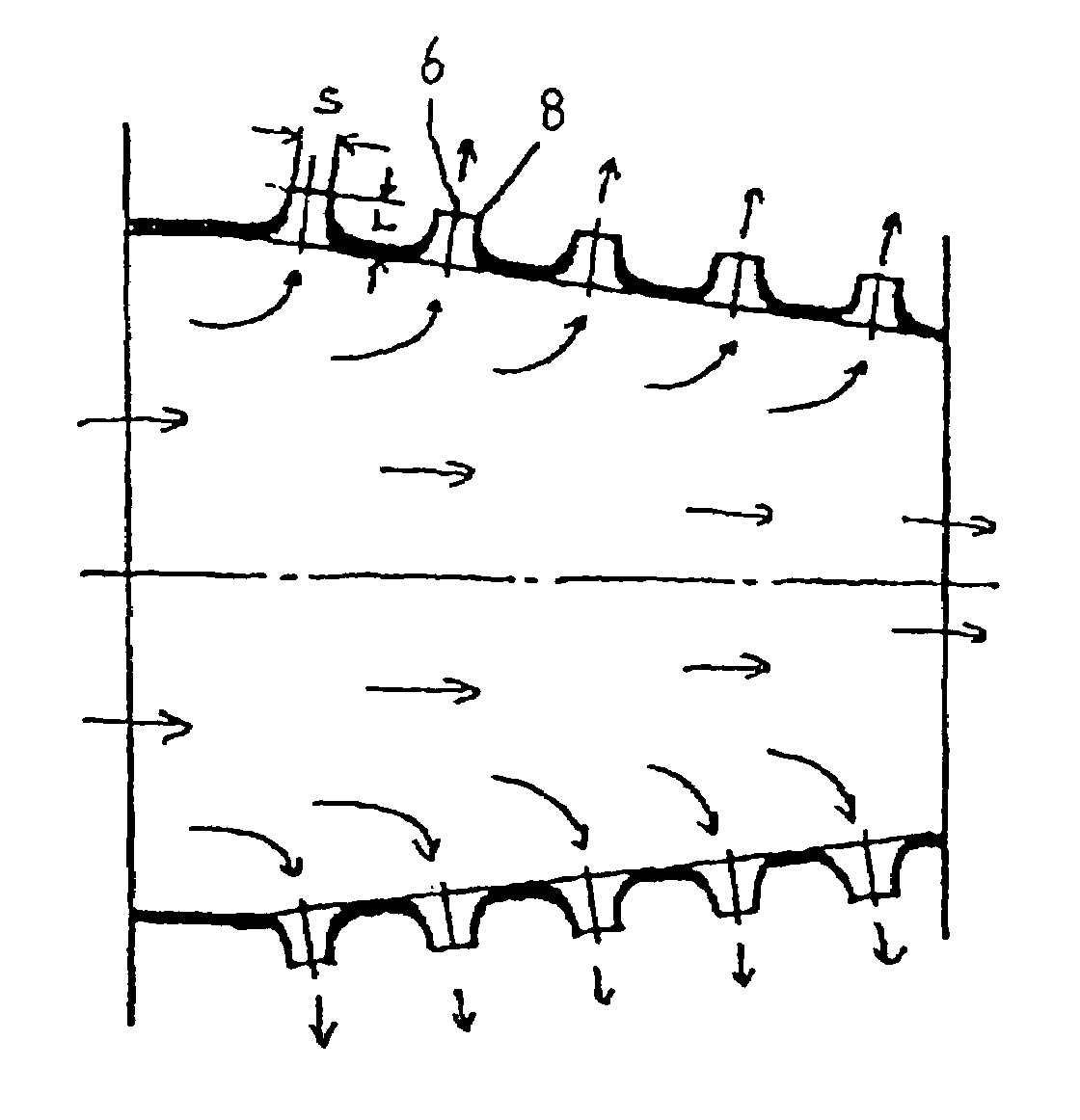

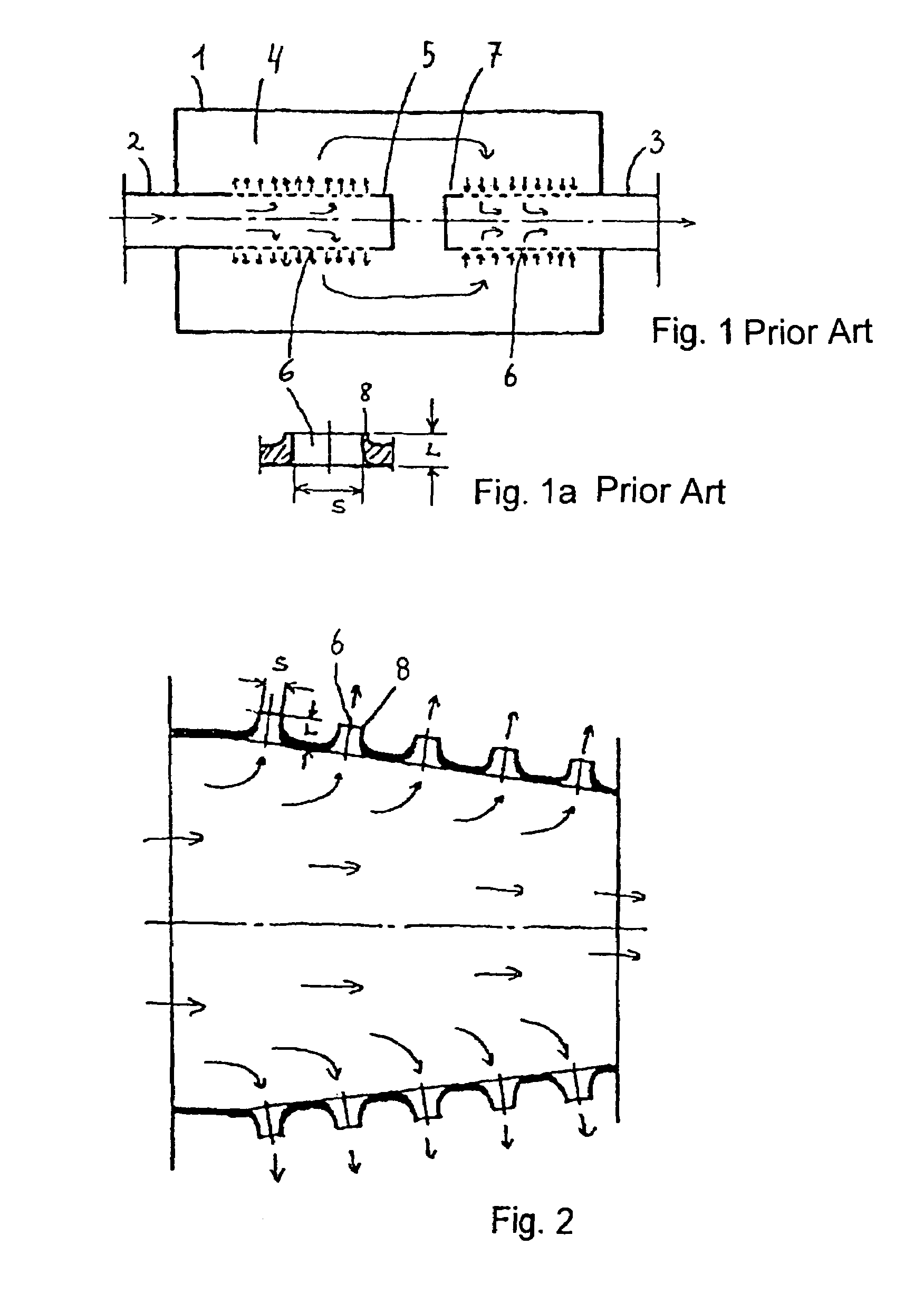

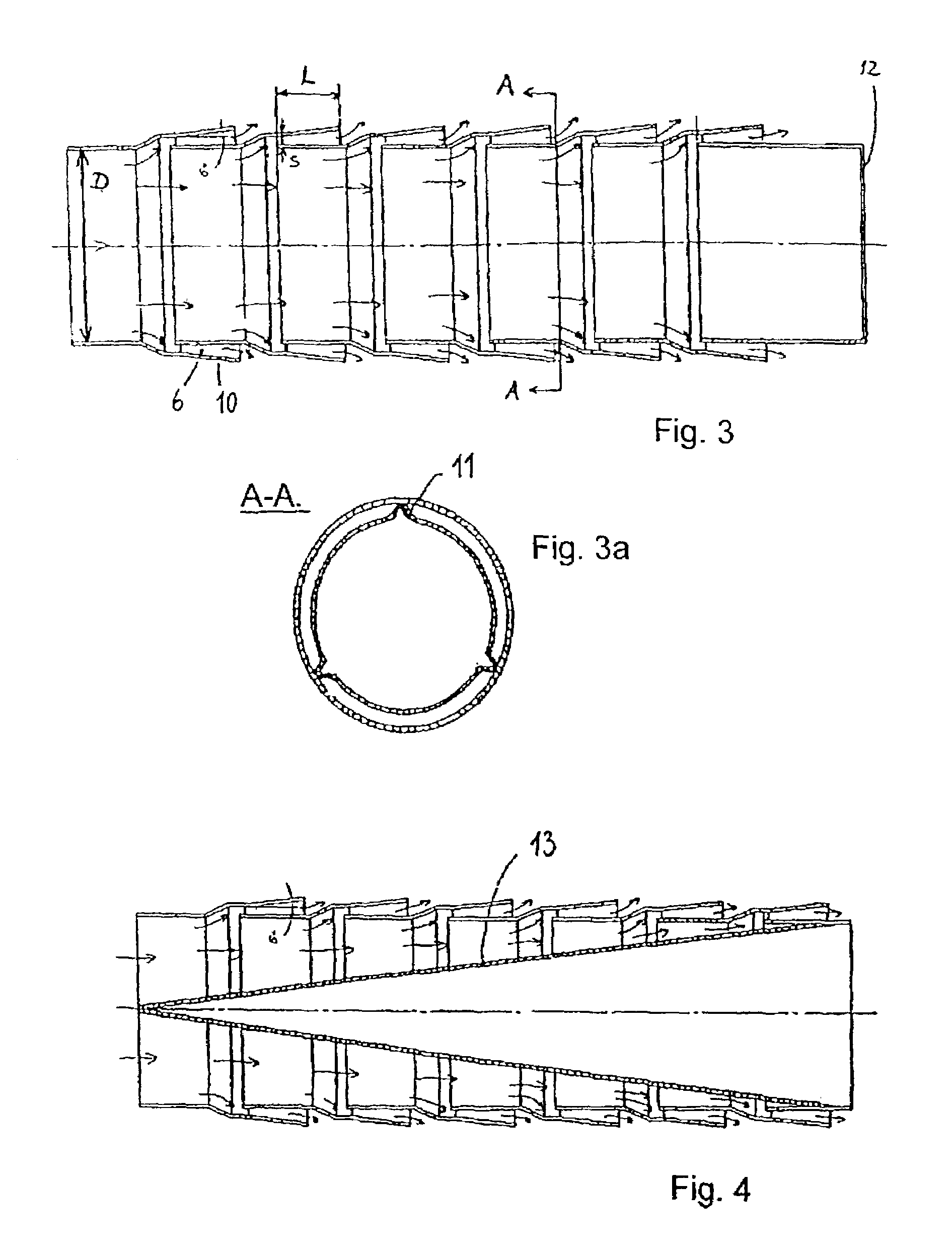

Silencer

InactiveUS7159692B1Reduce pressure dropRetain performanceSilencing apparatusMachines/enginesTraffic volumeAirflow

A silencer that comprises a casing, one or more pipes or passages leading a flow of gas to the casing and a device for leading gas from the casing. The silencer further has at least one internal chamber, one or more flow inlets to the chamber and one or more flow outlets from the chamber, and one or more flow distributing devices connected to the flow inlet(s) and / or to the flow outlet(s). The flow distributing device comprises one or more walls or profiles extending on a geometrical surface that defines a boundary between an inner volume of the flow distributing device and the chamber. The silencer further has one or more apertures for a flow of gas through the apertures and for leading gas either out of the inner volume into the chamber, or into the inner volume from the chamber. The apertures have a smallest cross-sectional transverse dimension s and a length L, the dimension s being at the maximum 0.2 times the smallest cross-sectional dimension D of the inlet or outlet. The length L is at least the same as the dimension s.

Owner:SILENTOR HLDG AS

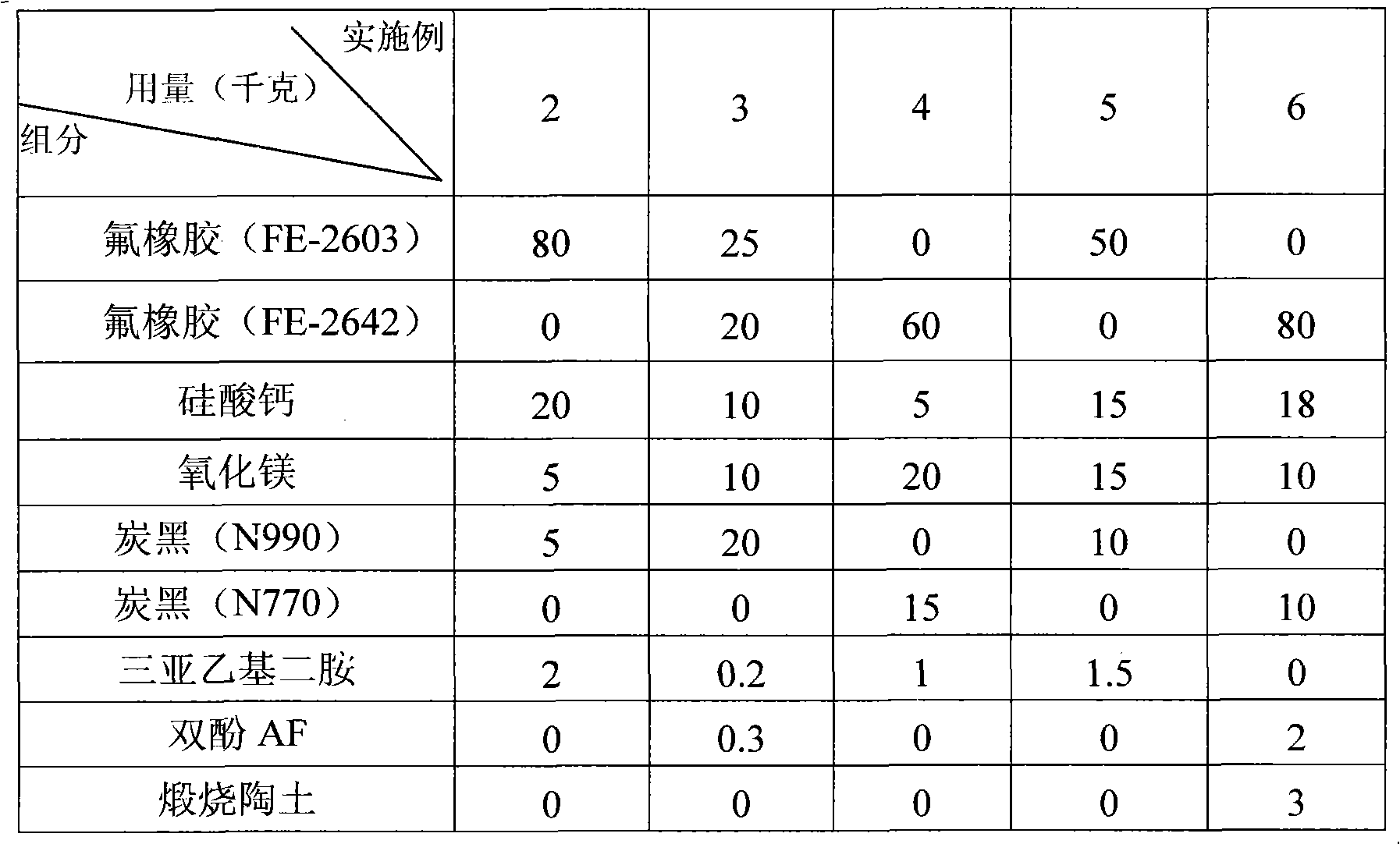

Fluoride rubber and plastic sealing material and preparation method thereof

ActiveCN101838430AHigh temperature resistantOil resistantOther chemical processesCalcium silicateCross-link

The invention discloses a fluoride rubber and plastic sealing material with good performance and low cost, and a preparation method of the rubber. The sealing material comprises the following raw materials in part by weight: 40-80 parts of fluorous rubber, 5-20 parts of calcium silicate, 5-20 parts of carbon black, 5-20 parts of magnesium oxide and 0.5-2 parts of cross-linking agent. The method comprises the steps of arranging the fluorous rubber in an internal mixer at the temperature of 150-160 DEG C with the plasticating time of 4min-10min, adding the carbon black, 1 / 3 of the magnesium oxide and 1 / 3 of the calcium silicate with the plasticating time of 6min-8min, then adding the rest magnesium oxide and calcium silicate, plasticating, stopping, overturning the warehouse to output the materials for spare use, arranging the materials in an open mill, adding the cross-linking agent at the temperature less than or equal to 65 DEG C, thinly introducing four times after material feed, packing with a triangular bag five times, and feeding plates.

Owner:河北鑫科新材料科技有限公司

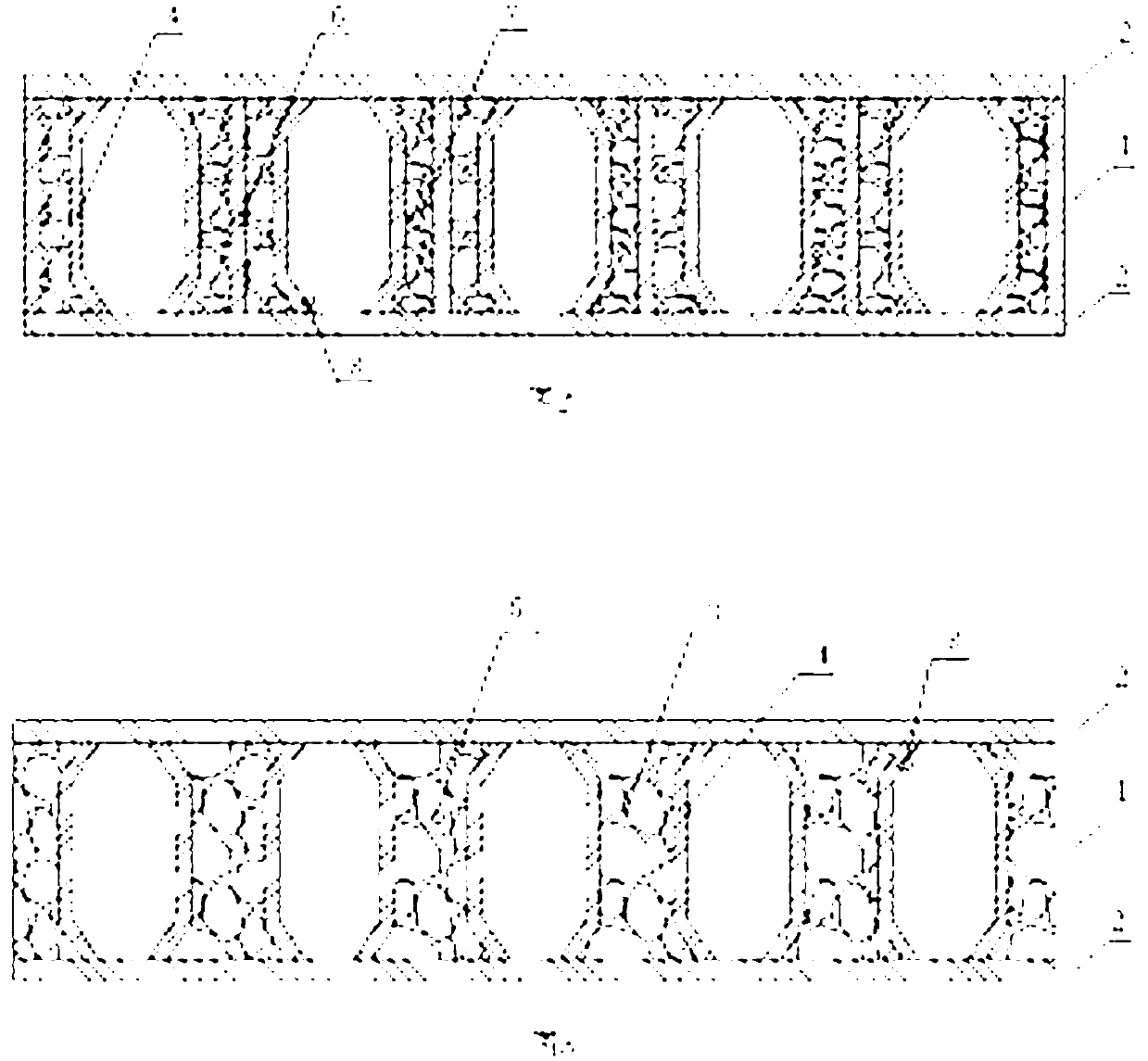

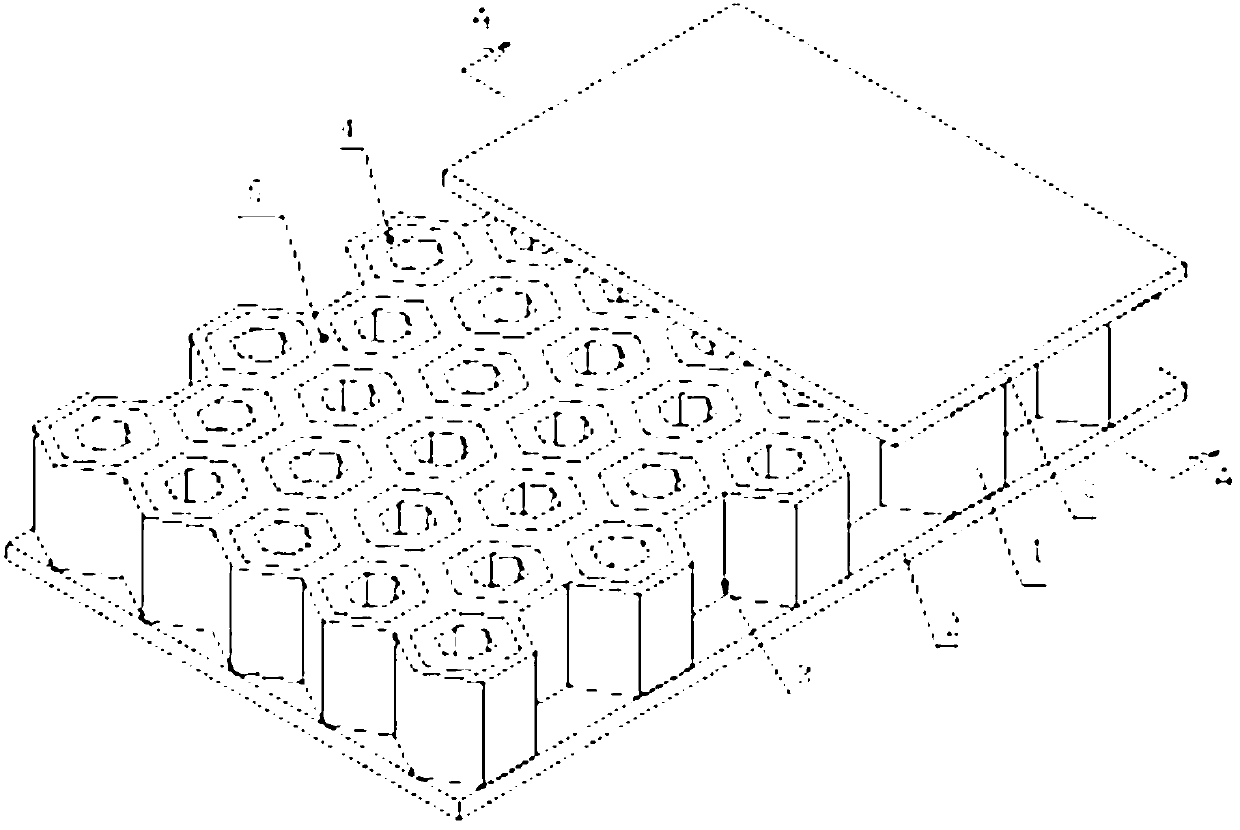

Aluminum plastic composite plate having honeycomb structure

The invention discloses an aluminum plastic composite plate having a honeycomb structure. The aluminum plastic composite plate which is formed by a core (1) and aluminum panels (2) clamping two sides of the core (1) is characterized in that the core (1) adopts a single-layer honeycomb structure and is composed of a one-piece honeycomb frame (3) and fixing cylinders (4); orthohexagonal honeycomb holes are uniformly distributed on the honeycomb frame (3) in an equal interval arrangement manner; the fixing cylinders (4) are embedded into all the honeycomb holes; thick plastic walls (5) are formed on the honeycomb frame (3); and the fixing cylinders (4) and the aluminum panels (2) form one body through compounding with the thick walls (5). The self core performances of the aluminum plastic composite plate having the structure are improved, the combination structure of the core and aluminum panels of the aluminum plastic composite plate having the structure is improved, and the comprehensive performances of the aluminum plastic composite plate having the structure are better than that of present aluminum honeycomb plates.

Owner:DUJIANGYAN JINXIANG DECORATION ENG

Heat preservation device with ceramic inner container

The invention provides a heat preservation device with a ceramic inner container, for further improving the heat preservation effect of existing vacuum cups, kettles and drinking cups, and overcoming the defects that stainless steel cups easily precipitate harmful substances and glass inner containers or ceramic inner containers are easily broken. The heat preservation device with the ceramic inner container is better in heat preservation effect, more attractive, unlikely to damage, better in corrosion resistance, easy to clean and good in mouthfeel when being used for accommodating water. The heat preservation device comprises a stainless steel outer container, a stainless steel vacuum inner container and a ceramic coating, wherein the ceramic coating is positioned on the inner wall of the stainless steel vacuum inner container; the ceramic coating is prepared from the following raw materials: 30-40 parts of silica sol, 25-50 parts of silane coupling agent, 2-8 parts of iron ions, 2-8 parts of manganese ions, mixed acid and 50-80 parts of white steel; and the mixed acid comprises acetic acid and acrylic acid. The heat preservation device, which has good attrition, acid, alkali, cold, heat and corrosion resistance, is suitable for popularization and application.

Owner:陈守伟 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com