Preparation method of polyvinylidene fluoride (PVDF) composite mesoporous membrane

A polyvinylidene fluoride and composite membrane technology, which is applied in chemical instruments and methods, membrane technology, and semipermeable membrane separation, can solve the problems of high requirements for inorganic particles, uneven pore size of kaolin, and low modification efficiency. Achieve the effect of low cost, uniform distribution and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

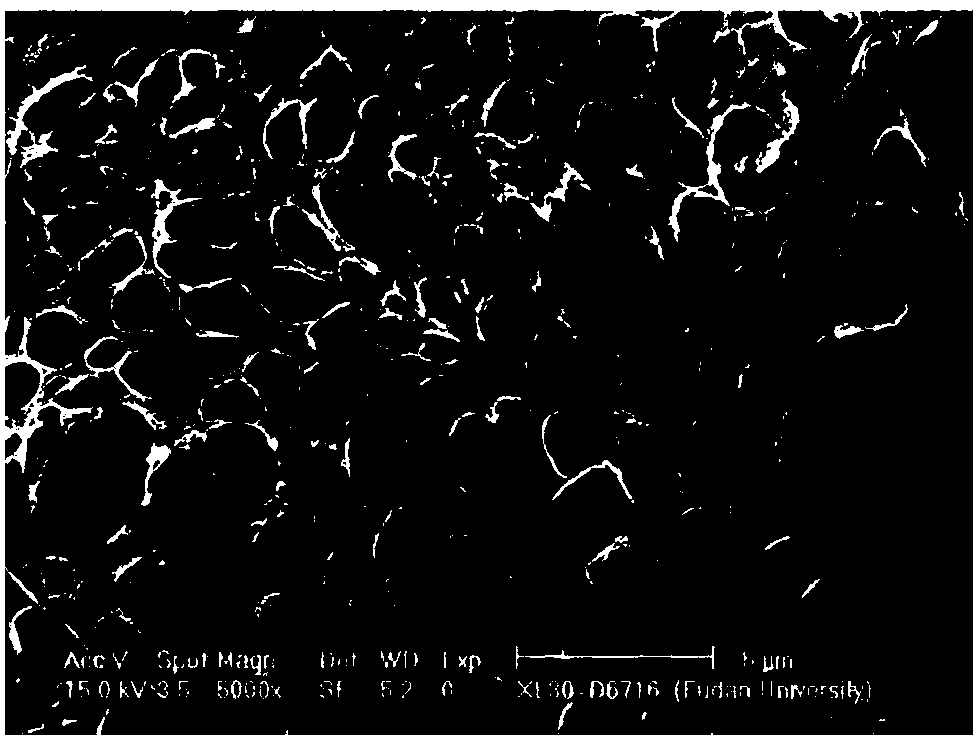

[0037] Preparation of Polytetrafluoroethylene Composite Mesoporous Membrane Without Diluent

[0038] (1) First, weigh the polyvinylidene fluoride (PVDF) that has been baked in an oven at 105°C for 4 hours, and its mass fraction is 10% (PVDF), 1% porogen polyvinylpyrrolidone (PVP), and dissolve them in In N,N-methylacetamide (DMAc) solvent, place in a 60°C water bath, stir magnetically (the stirring speed is constantly adjusted from 800rpm to 150rpm) for 8h, and make a polyvinylidene fluoride (PVDF) casting solution;

[0039] (2) Next, add mesoporous silica (SBA-15) with a mass fraction of 1% to the above casting solution, place in a 60°C water bath, and stir mechanically for 15 hours to make a PVDF-SBA-15 casting film liquid, seal it with a parafilm, and let stand at room temperature (25°C) for 2 days for defoaming;

[0040] (3) Then, use the automatic film coating machine to apply the prepared PVDF-SBA-15 film casting solution on a clean glass substrate, and immerse it in 50...

Embodiment 2

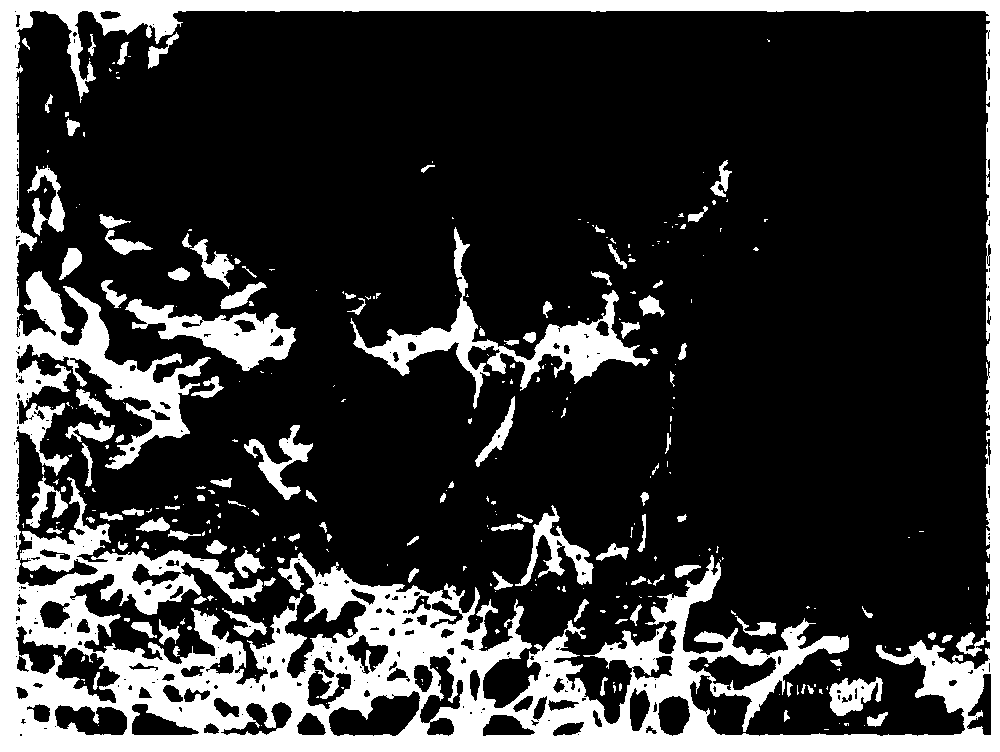

[0043] Preparation of Polyvinylidene Fluoride Composite Mesoporous Membrane Added Diluent Acetone

[0044] (1) First, weigh 15% polyvinylidene fluoride (PVDF) and 4% porogen polyvinylpyrrolidone (PVP) which were baked in an oven at 105°C for 4 hours, and dissolve them in N,N-methyl ethyl ether In amide (DMAc) solvent, placed in a 65°C water bath, magnetically stirred (stirring speed is constantly adjusted from 800rpm to 150rpm) for 8h, to make polyvinylidene fluoride (PVDF) casting solution;

[0045] (2) Next, add mesoporous silica (SBA-15) with a mass fraction of 3% and 0.1mL / g acetone to the above casting solution, place in a 65°C water bath, and stir mechanically for 15 hours to make PVDF -SBA-15 casting solution, seal it with a parafilm, and let it stand at room temperature (25°C) for 2 days for defoaming;

[0046] (3) Then, use the automatic film coating machine to apply the prepared PVDF-SBA-15 film casting solution on a clean glass substrate, and immerse it in 50% etha...

Embodiment 3

[0049] Preparation of Polyvinylidene Fluoride Composite Mesoporous Membrane Added Diluent Acetone

[0050] (1) First, weigh 18% polyvinylidene fluoride (PVDF) and 7% porogen polyvinylpyrrolidone (PVP) which have been baked in an oven at 105°C for 4 hours, and dissolve them in N,N-dimethyl In acetamide (DMAc) solvent, placed in 65°C water bath, magnetically stirred (stirring speed is constantly adjusted from 800rpm to 150rpm) for 8h, to make polyvinylidene fluoride (PVDF) casting solution;

[0051] (2) Next, add mesoporous silica (SBA-15) with a mass fraction of 4% and 0.2mL / g acetone to the above casting solution, place in a 65°C water bath, and stir mechanically for 15 hours to make PVDF -SBA-15 casting solution, seal it with a parafilm, and let it stand at room temperature (25°C) for 2 days for defoaming;

[0052] (3) Then, use the automatic film coating machine to apply the prepared PVDF-SBA-15 film casting solution on a clean glass substrate, and immerse it in 50% ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com