Three-dimensional graphene and preparation method of graphene composite material

A graphene, three-dimensional technology, applied in the field of graphene, can solve the problems of large electron and ion transmission distance, low electrode volume energy density, unfavorable large rate performance, etc., to achieve high volume density, good mechanical properties, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

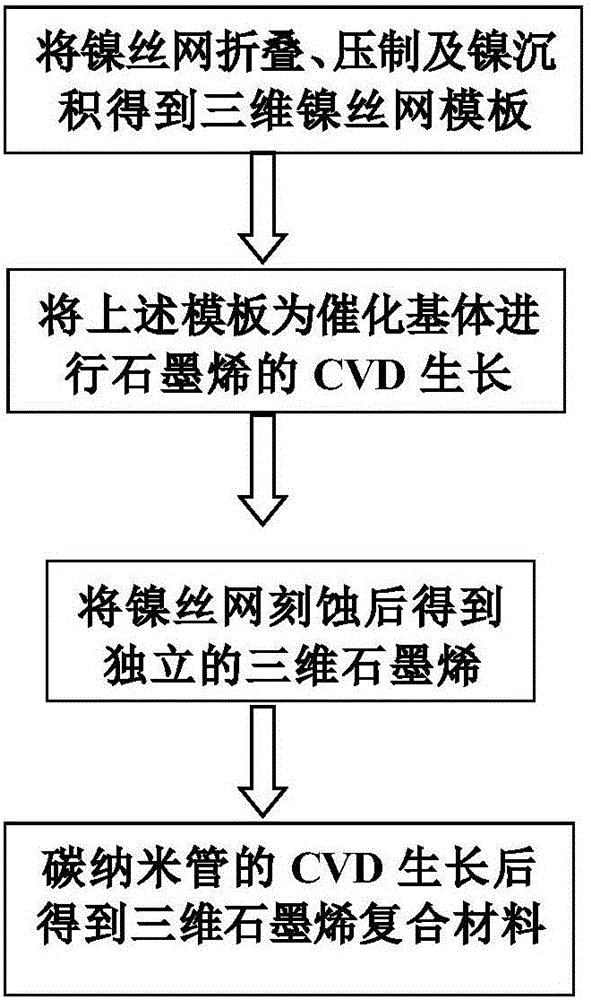

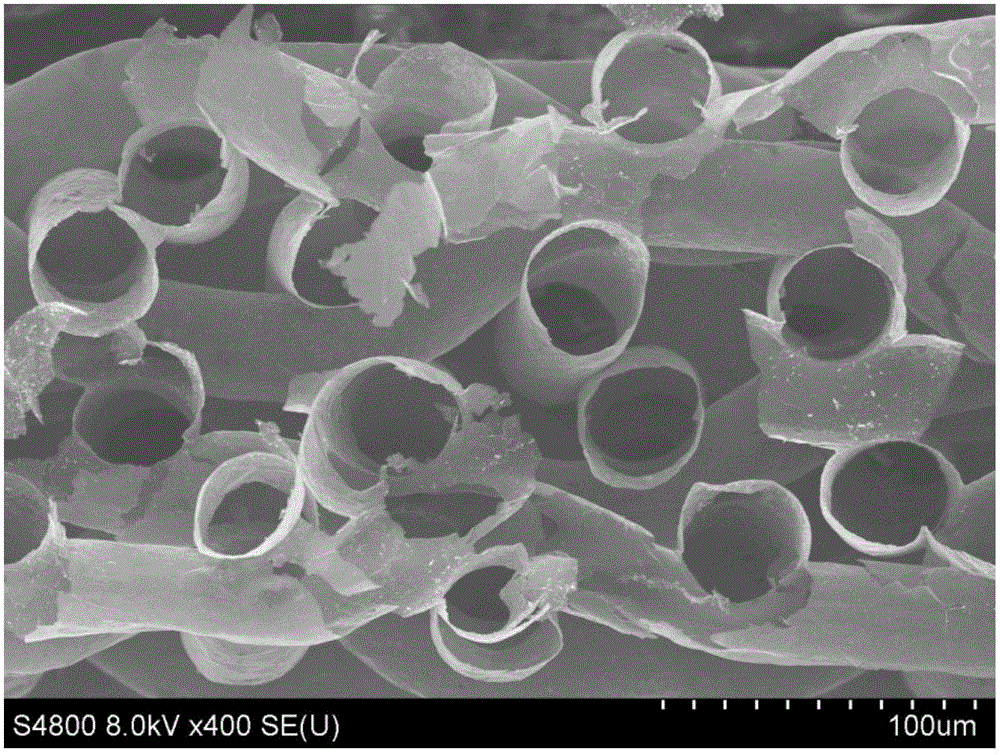

[0036] The invention provides a method for preparing three-dimensional graphene, comprising the following steps: S1) depositing a metal substrate on the surface of a wire mesh to obtain a wire mesh template; S2) growing graphene on the surface of the wire mesh template by chemical vapor deposition , to obtain a graphene-grown screen template; S3) etching the graphene-grown screen template with an acid solution to obtain three-dimensional graphene.

[0037] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0038] The wire mesh is preferably stainless steel wire mesh, copper wire mesh or nickel wire mesh; but because stainless steel mesh is usually used as a filter mesh, its corrosion resistance and acid and alkali resistance are very strong, which makes it difficult to remove in the etching stage , it is difficult for the copper mesh to achieve a higher mesh number, and the mesh number of the ...

Embodiment 1

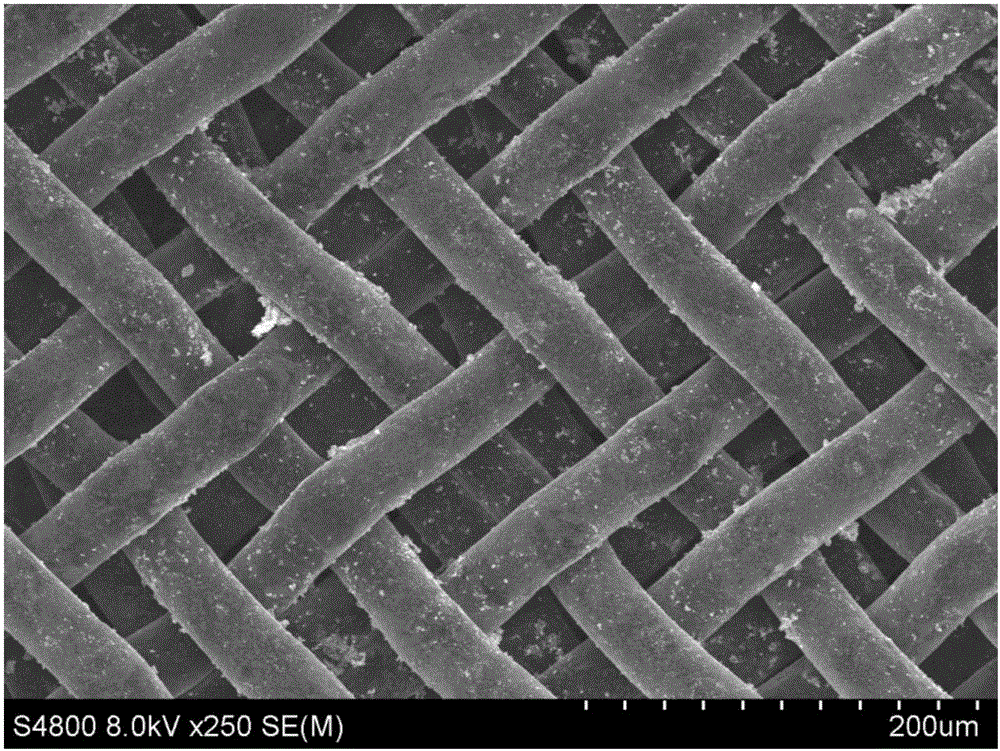

[0059] 1.1 First cut a long piece of nickel wire mesh, and fold it into the desired number of layers, for example, the folded size is 5cm (length) × 3cm (width). Then put it in a tablet press and pressurize it at 25MPa to preliminarily press it into a three-dimensional template with a certain chimeric force; then use it as the working electrode, the Ag / AgCl electrode as the reference electrode, and the pure nickel sheet as the counter electrode to form a three-electrode system For the electrochemical deposition of nickel, the electrolyte is 270g / L NiSO 4 ·6H 2 O, 40g / L NiCl 2 ·6H 2 O and 40g / L of H 3 BO 3 mixed solution. The electroplating parameters are: the electroplating voltage is -1V, and the electroplating time is 8000s. After the electroplating, ultrasonic cleaning with 1mol / L hydrochloric acid, deionized water and absolute ethanol obtained a three-dimensional nickel mesh catalytic template with good connectivity, that is, a mesh template.

[0060] 1.2 Put the th...

Embodiment 2

[0069] 2.1 First cut a long piece of nickel wire mesh, and fold it into the required number of layers, for example, the folded size is 5cm (length) × 3cm (width). Then put it in a tablet press and pressurize it at 25MPa to preliminarily press it into a three-dimensional template with a certain chimeric force; then use it as the working electrode, the Ag / AgCl electrode as the reference electrode, and the pure nickel sheet as the counter electrode to form a three-electrode system For the electrochemical deposition of nickel, the electrolyte is 270g / L NiSO 4 ·6H 2 O, 40g / L NiCl 2 ·6H 2 O and 40g / L of H 3 BO 3 mixed solution. The electroplating parameters are: the electroplating voltage is -1V, and the electroplating time is 8000s. After the electroplating, ultrasonic cleaning with 1mol / L hydrochloric acid, deionized water and absolute ethanol obtained a three-dimensional nickel mesh catalytic template with good connectivity, that is, a mesh template.

[0070] 2.2 Put the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com