Starch-based nitrogen doped mesoporous molding carbon as well as preparation method and application thereof

A technology of nitrogen doping and pore forming, which is applied in hydrogen halide addition preparation, chemical instruments and methods, catalyst activation/preparation, etc. It can solve the problems of unsuitability for large-scale production, high requirements for reaction conditions, and high cost of templates. Achieve excellent catalytic performance, simple and easy-to-control preparation process, and stable batch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

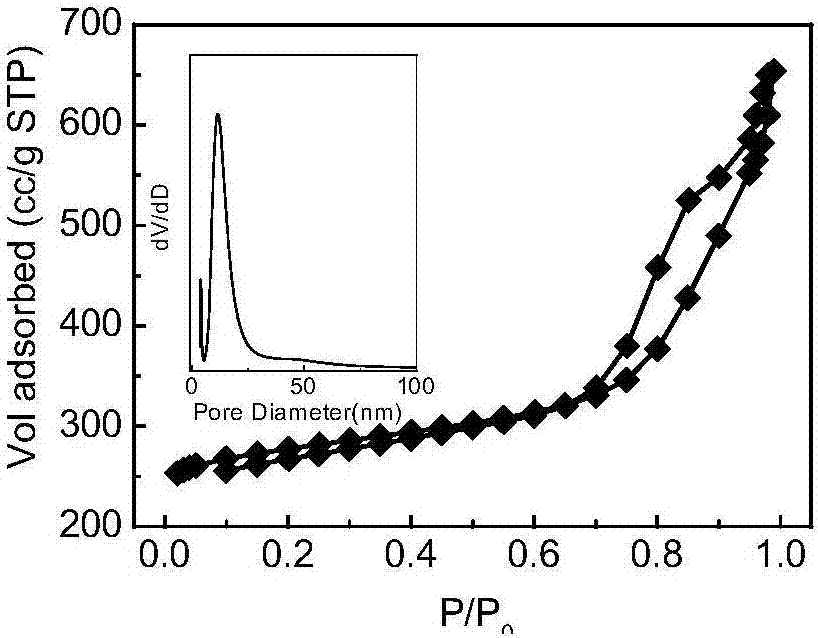

Embodiment 1

[0044] Grind 50g of wheat starch and 5g of silica balls with a particle size of 15nm fully, add 25mL of water, stir evenly and extrude into strips with a particle size of 3.5mm and a length of 5cm. Place it at room temperature for 4 hours, and then put it in an oven at 110°C Drying for 12 hours yielded a carbon precursor. The dried samples were placed in a tube furnace, and treated at 850 °C for 3 h under a nitrogen atmosphere, with a heating rate of 3 °C / min. The heat-treated sample was put into a plastic beaker, and the template was removed with 10% HF solution, then washed with deionized water, and dried at 110°C to obtain starch-based nitrogen-doped mesoporous carbon. The particle size of the obtained carbon material is Ф3.5×5cm, and the content of N is 1.5%. The specific surface area is 800cc / g, the pore size is 10.2nm, and the pore volume is 0.86cc / g.

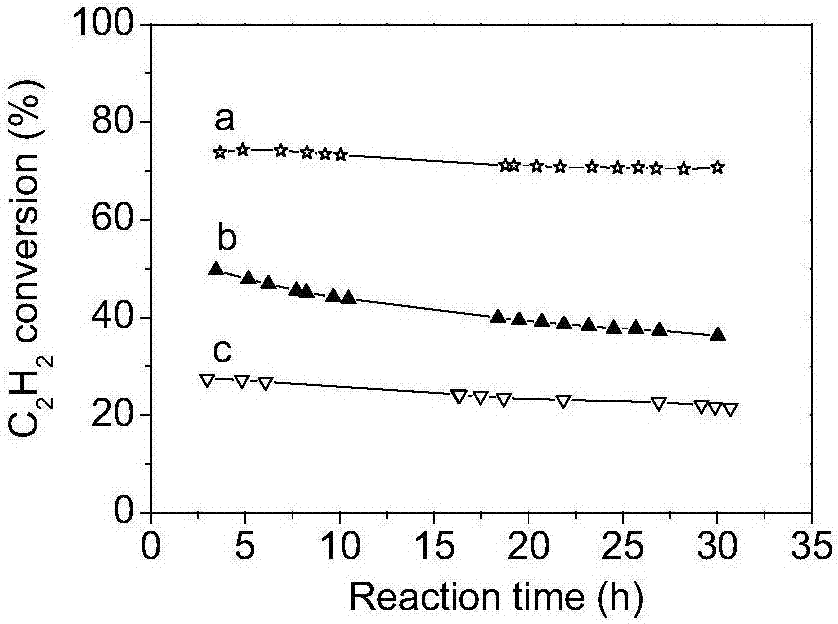

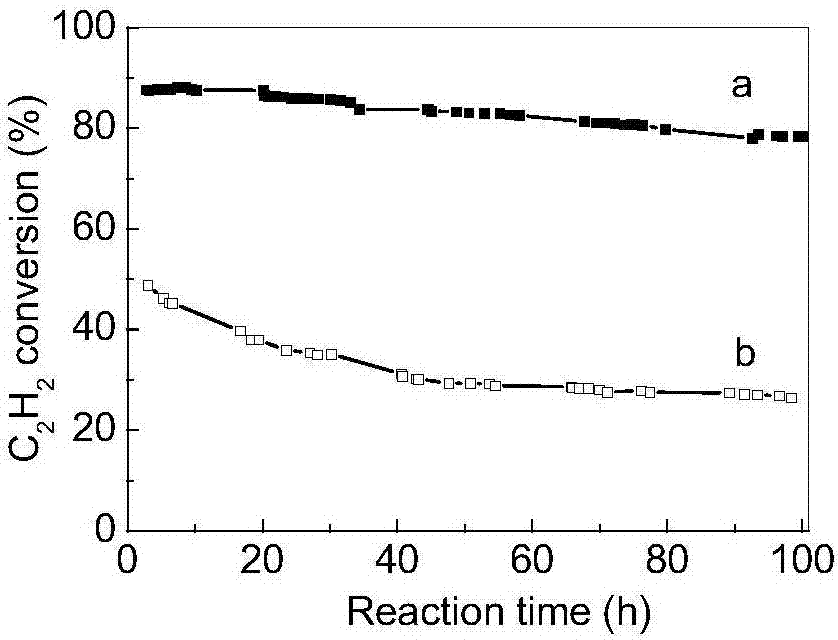

[0045] Take 2mL of catalyst for acetylene hydrochlorination. The pressure of acetylene and hydrogen chloride is: 0.1...

Embodiment 2

[0049] 40g of wheat starch and 10g of corn starch and 12.5g of silicon dioxide balls with a particle size of 30nm are fully ground, add 25mL of water, stir evenly and form a tablet to obtain a sheet-shaped carbon precursor with a diameter of 2cm and a thickness of 1cm, and then Place at room temperature for 4h. Then put it into an oven and dry it at 110 degrees for 8 hours to obtain a catalyst precursor. The dried samples were placed in a tube furnace, and treated at 700 °C for 3 h under a nitrogen atmosphere, with a heating rate of 2 °C / min. The heat-treated sample was put into a plastic beaker, the template was removed with 10% HF solution, then washed with deionized water, and dried at 110oC to obtain starch-based nitrogen-doped mesoporous carbon. The particle size of the obtained shaped mesoporous carbon material is Ф2×1 cm, and the content of N is 1.8%. The specific surface area is 670m 2 / g, the pore size is 18.2nm, and the pore volume is 0.76cc / g.

[0050] Take 2mL ...

Embodiment 3

[0053] 50g of wheat starch and 10g of nano-magnesium oxide with a particle size of 20nm were fully ground, added 25mL of water, stirred evenly and pressed into tablets to obtain a sheet-shaped carbon precursor with a diameter of 2cm and a thickness of 1cm, and then placed at room temperature for 4h. Then put it into an oven and dry it at 110 degrees for 8 hours to obtain a catalyst precursor. The dried samples were placed in a tube furnace, and treated at 700 °C for 3 h under a nitrogen atmosphere, with a heating rate of 2 °C / min. The heat-treated sample was put into a plastic beaker, and the template was removed with 5% HCl solution, then washed with deionized water, and dried at 110°C to obtain starch-based nitrogen-doped mesoporous carbon. The particle size of the obtained shaped mesoporous carbon material is Ф3.5×5 cm, and the content of N is 1.2%. The specific surface area is 960m 2 / g, the pore size is 17.1nm, and the pore volume is 0.86cc / g.

[0054] Take 2mL of cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com