Patents

Literature

139results about How to "High ion selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

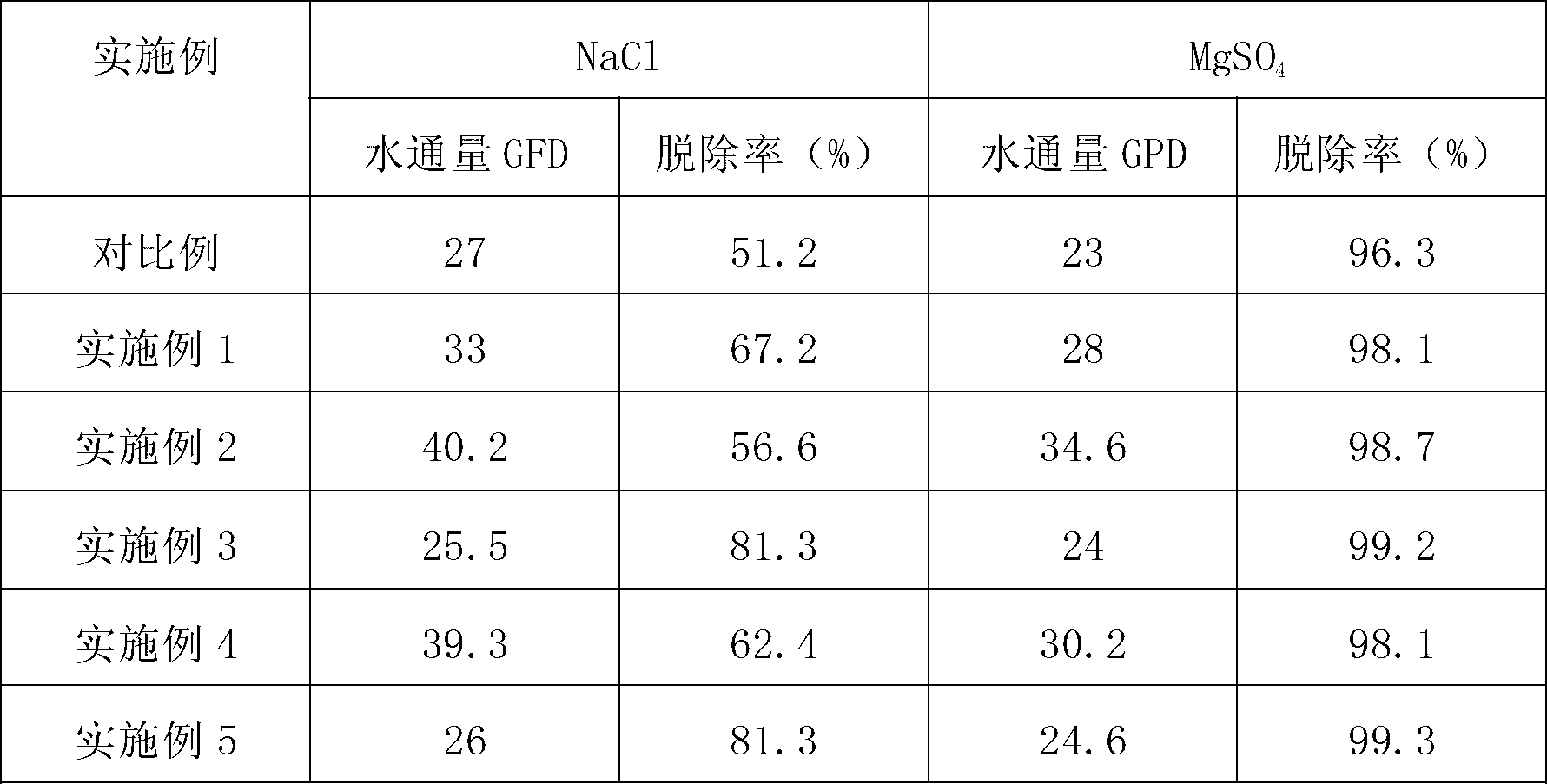

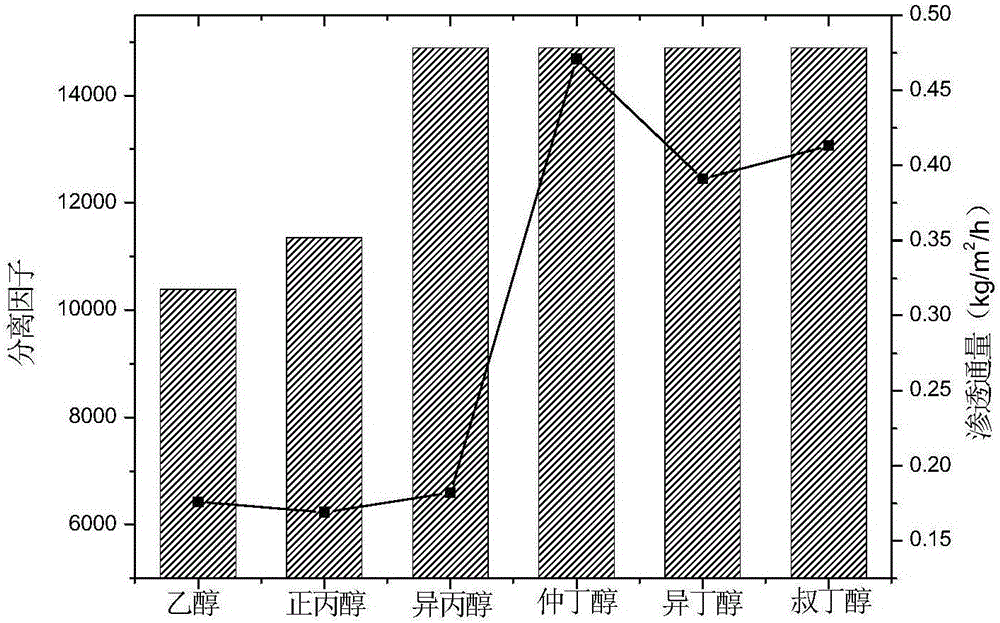

Nanofiltration membrane with nanometer hybridized desalination layer

The invention discloses a nanofiltration membrane with a nanometer hybridized desalination layer. The desalination layer formed through interphase hybridization of an inorganic nanoparticle with a particle size of 1 to 1000 nm and polyamide or polyimide is arranged on a porous supporting layer of the membrane. A preparation method for the nanofiltration membrane mainly comprises the following steps: pre-dispersion of the nanoparticle, preparation of a solution A, preparation of a solution B, interfacial polymerization, surface polishing and roller squeezing, rinsing with deionized water, moisture retention with glycerin and drying, wherein air drying and sulfonation can be carried out after surface polishing and roller squeezing. According to the invention, nanometer hybridization effects of a high polymer nano-material in the nanofiltration membrane are made full use of, so hydrophilic performance, antioxidation performance and anti-pollution performance of the nanofiltration membrane are improved, and the nanofiltration membrane has the advantages of low pollution, great flux and a high removal rate. The preparation method is scientific and reasonable, enables the nanometer composite nanofiltration membrane with a specific nanoparticle and polyamide hybridized desalination layer to be prepared and has higher ion selectivity, low pollution capability and temperature stability.

Owner:VONTRON TECH CO LTD

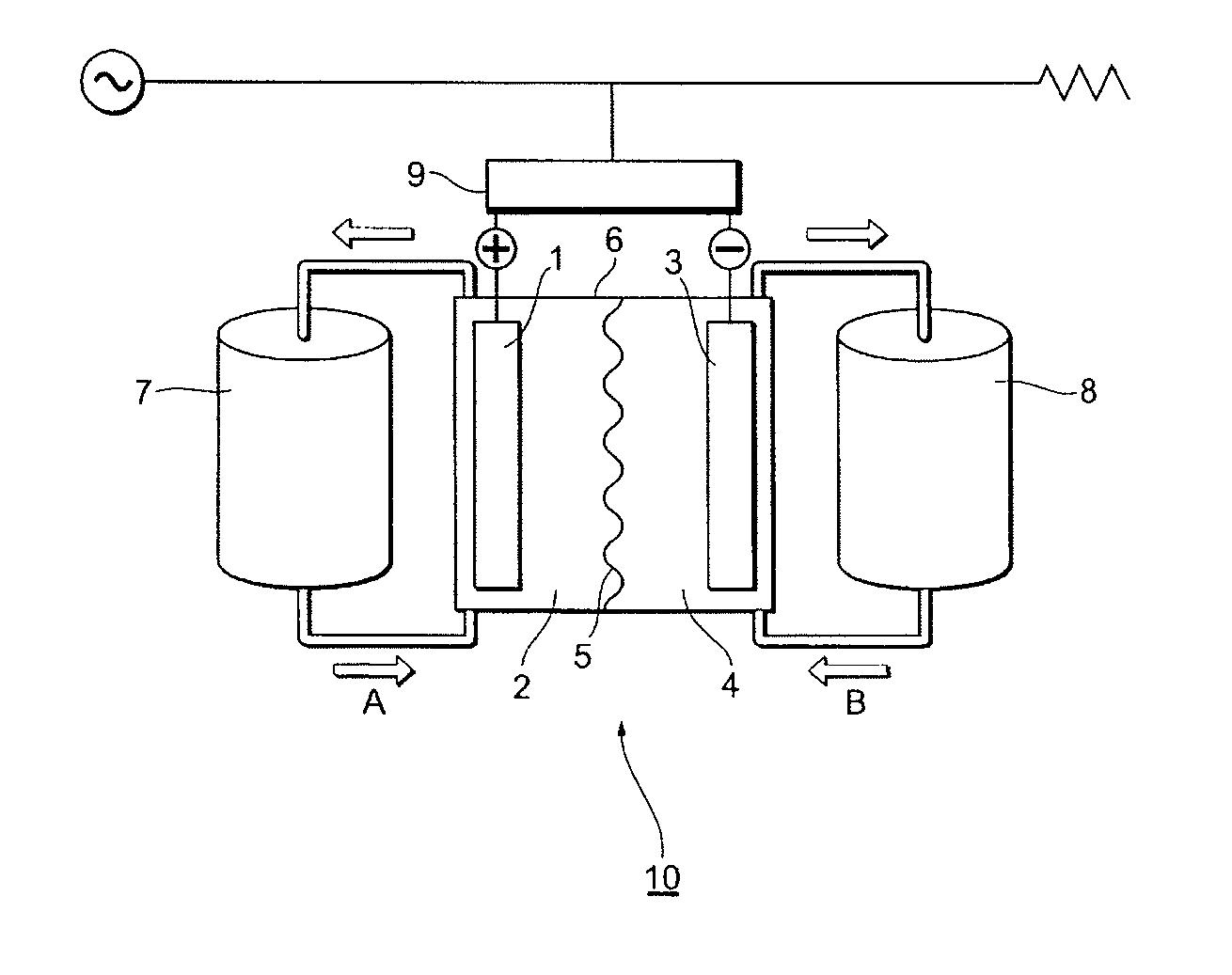

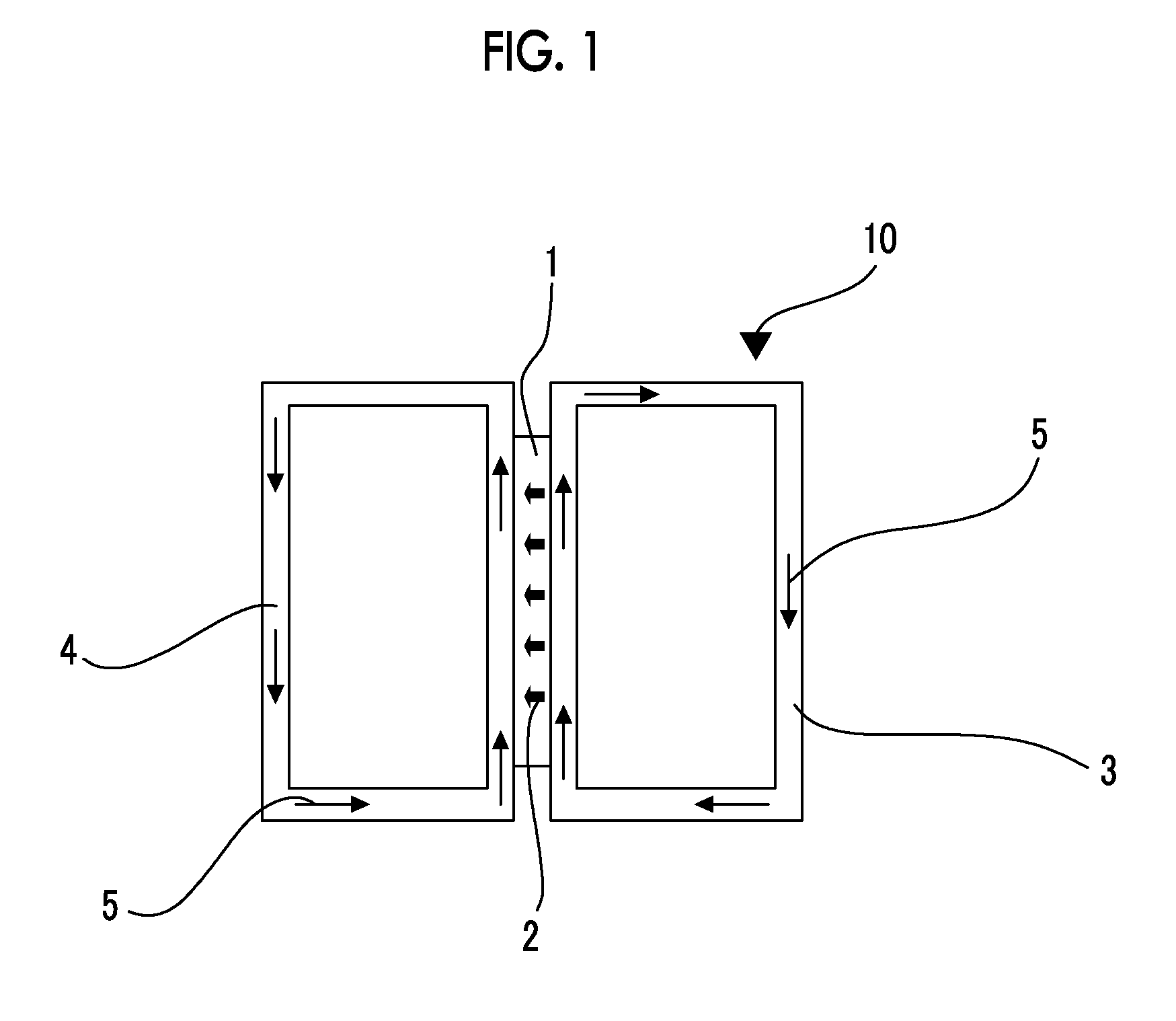

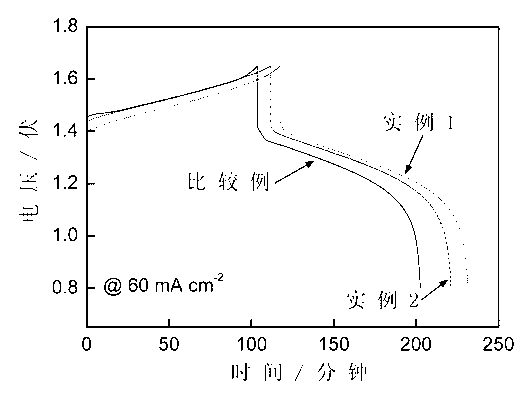

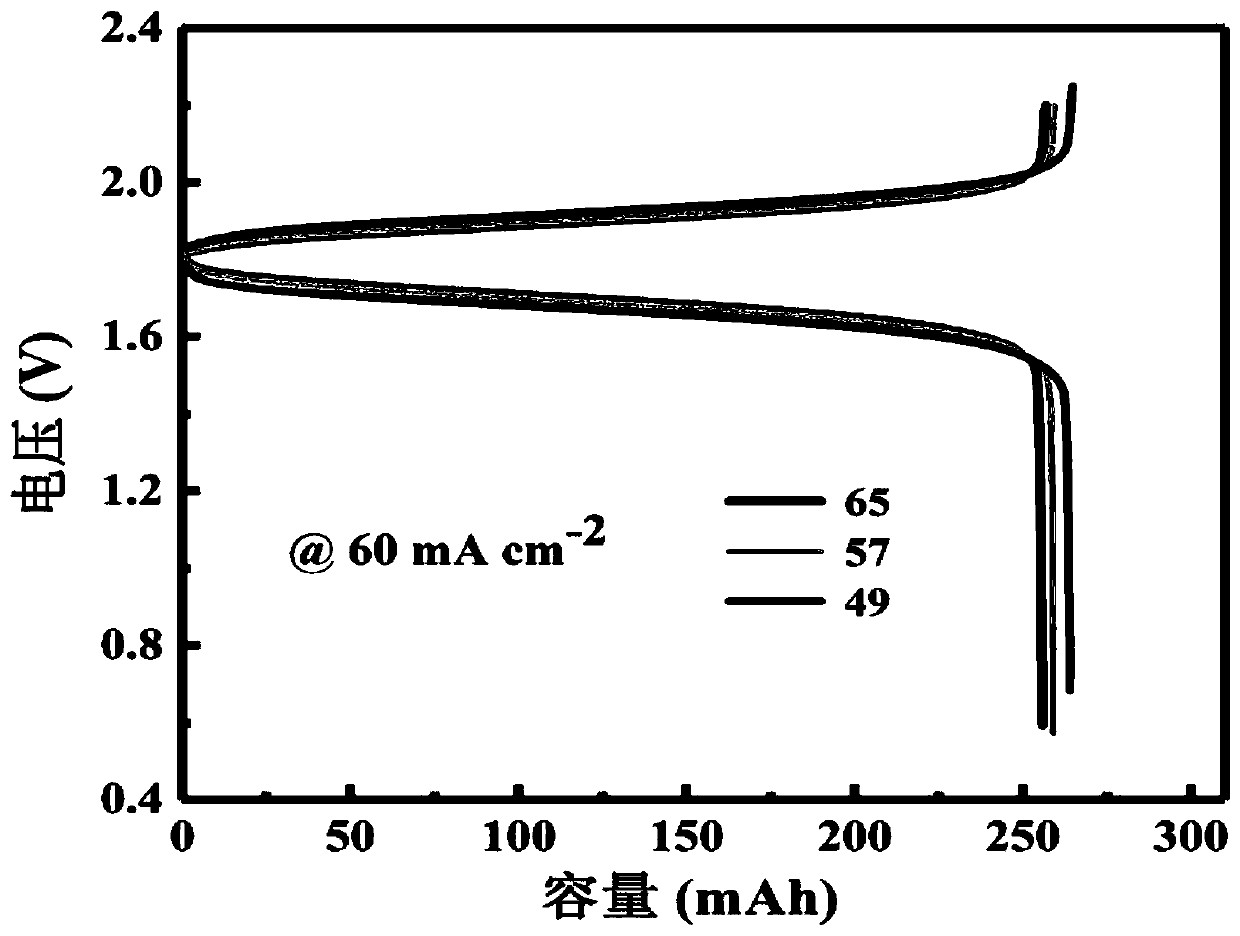

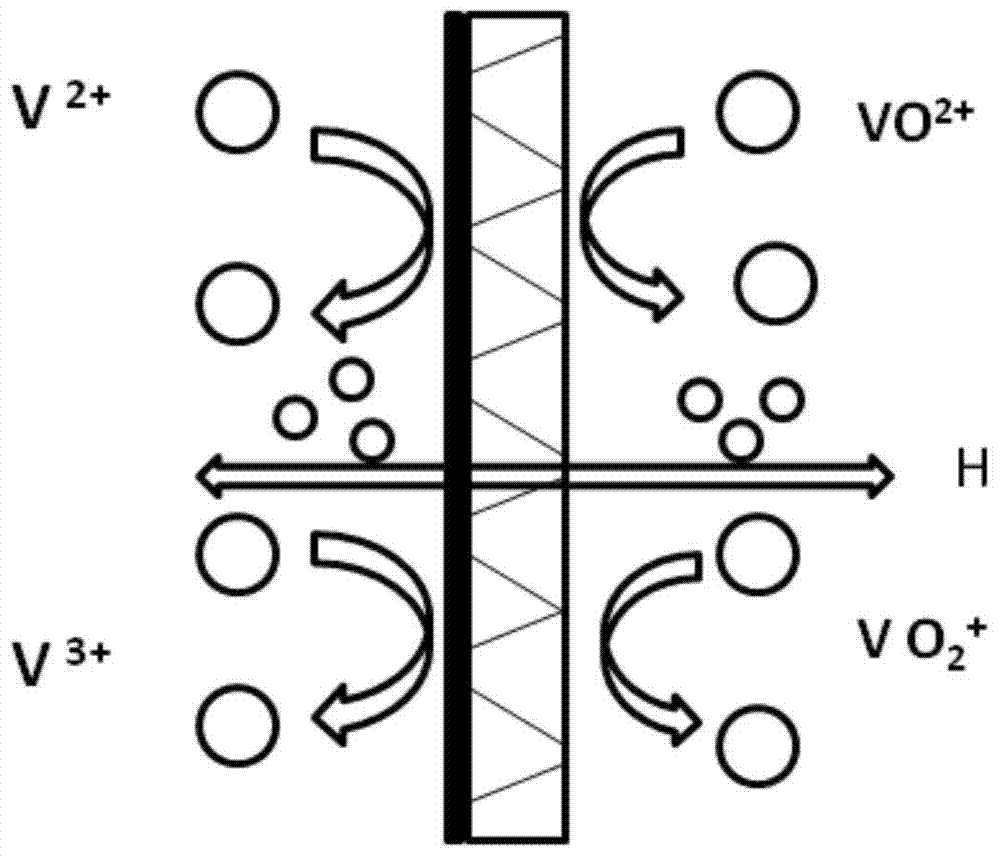

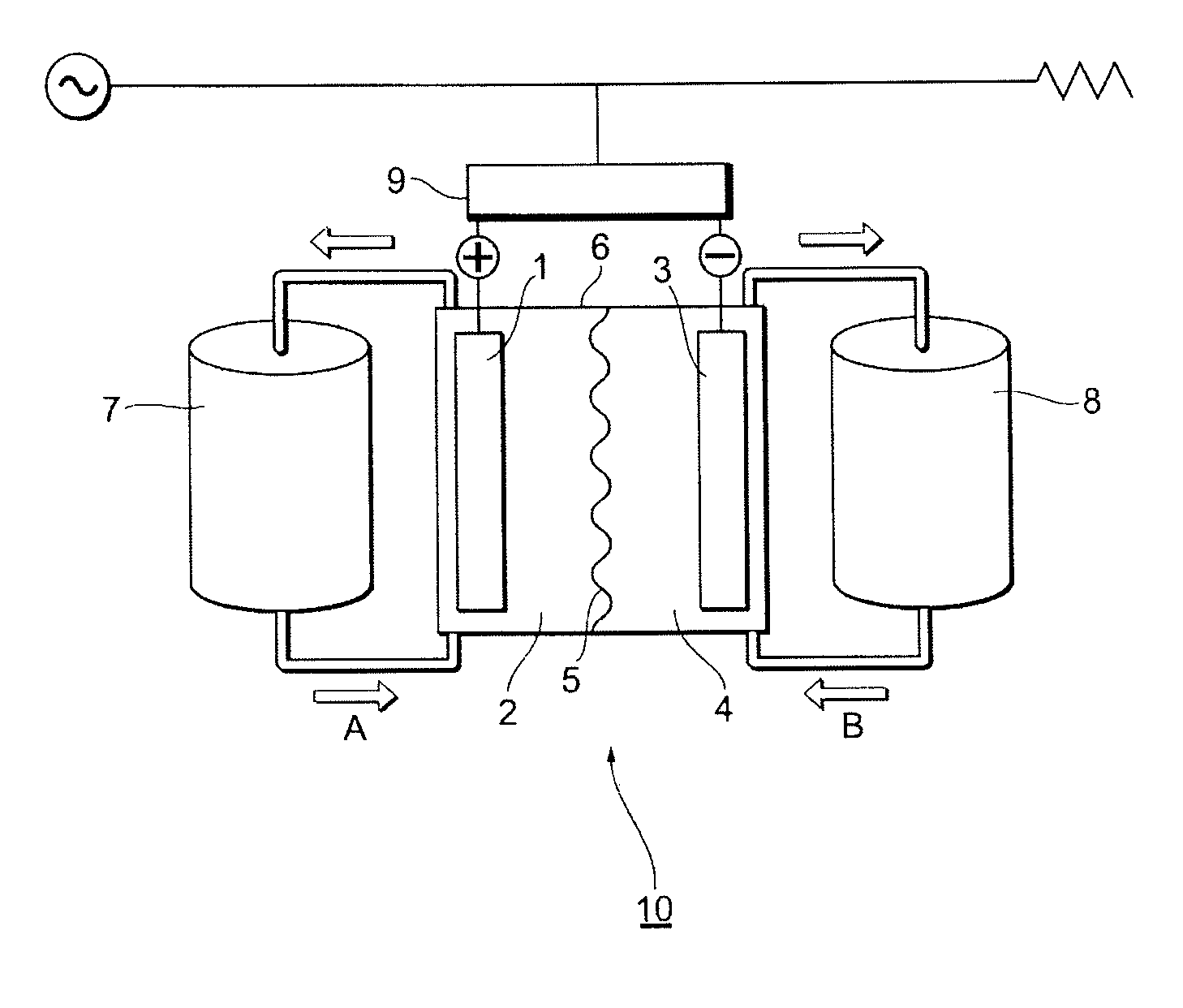

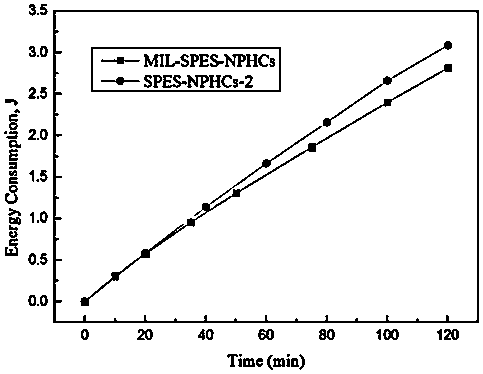

Redox flow secondary battery and electrolyte membrane for redox flow secondary battery

ActiveUS20140370404A1High ion selectivityPrevent penetrationElectrolyte holding meansNon-metal conductorsPorous membraneBarrier membrane

This redox flow secondary battery has an electrolyte tank (6) containing: a positive electrode cell chamber (2) containing a positive electrode (1) comprising a carbon electrode; a negative electrode cell chamber (4) containing a negative electrode (3) comprising a carbon electrode; and an electrolyte membrane (5) as a barrier membrane that separates / isolates the positive electrode cell chamber (2) and the negative electrode cell chamber (4). The positive electrode cell chamber (2) contains a positive electrode electrolyte containing an active substance, the negative electrode cell chamber (4) contains a negative electrode electrolyte containing an active substance, and the redox flow secondary battery charges and discharges on the basis of the change in valency of the active substances in the electrolytes. The electrolyte membrane (5) contains an ion exchange resin composition that is primarily a polyelectrolyte polymer, and the electrolyte membrane (5) has a reinforcing material comprising a fluorine-based porous membrane.

Owner:ASAHI KASEI KK

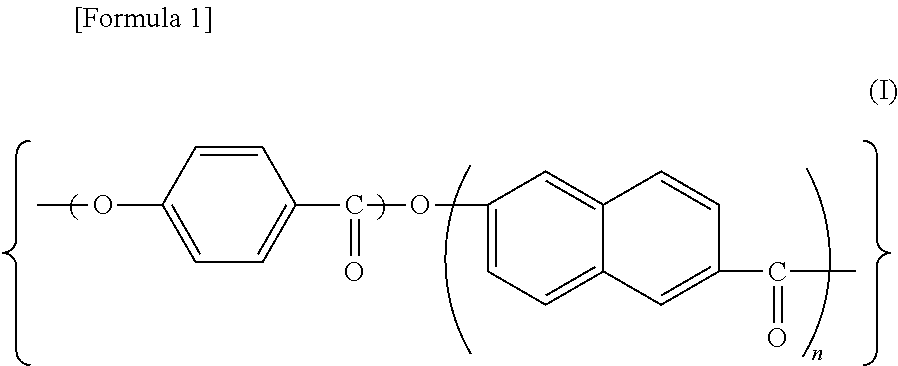

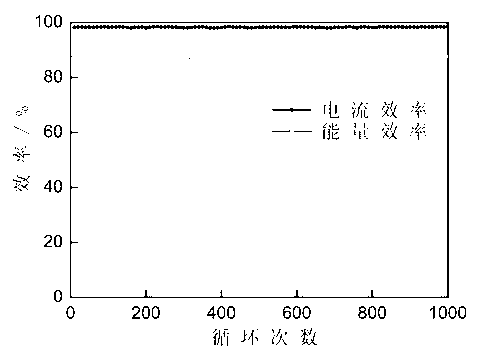

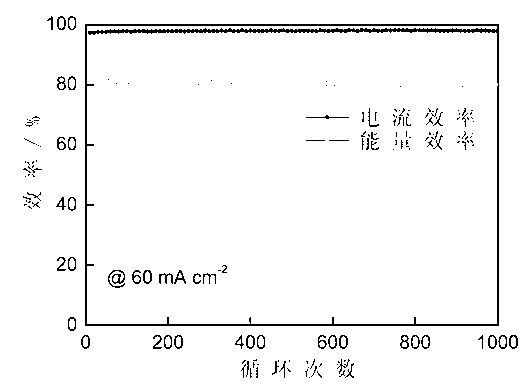

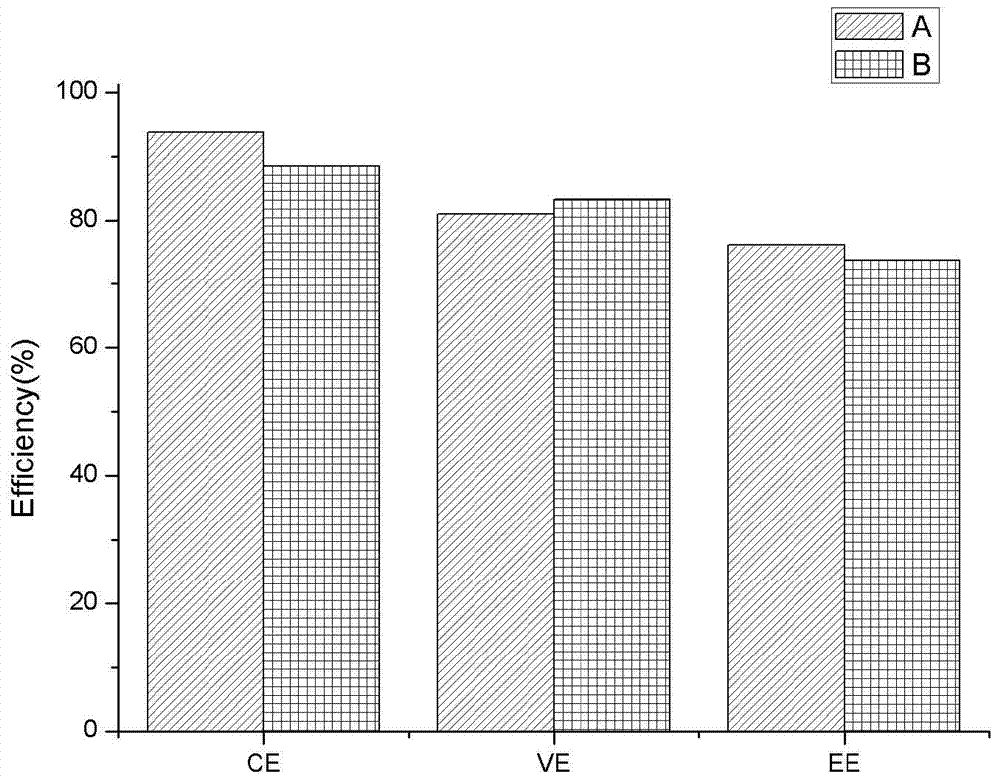

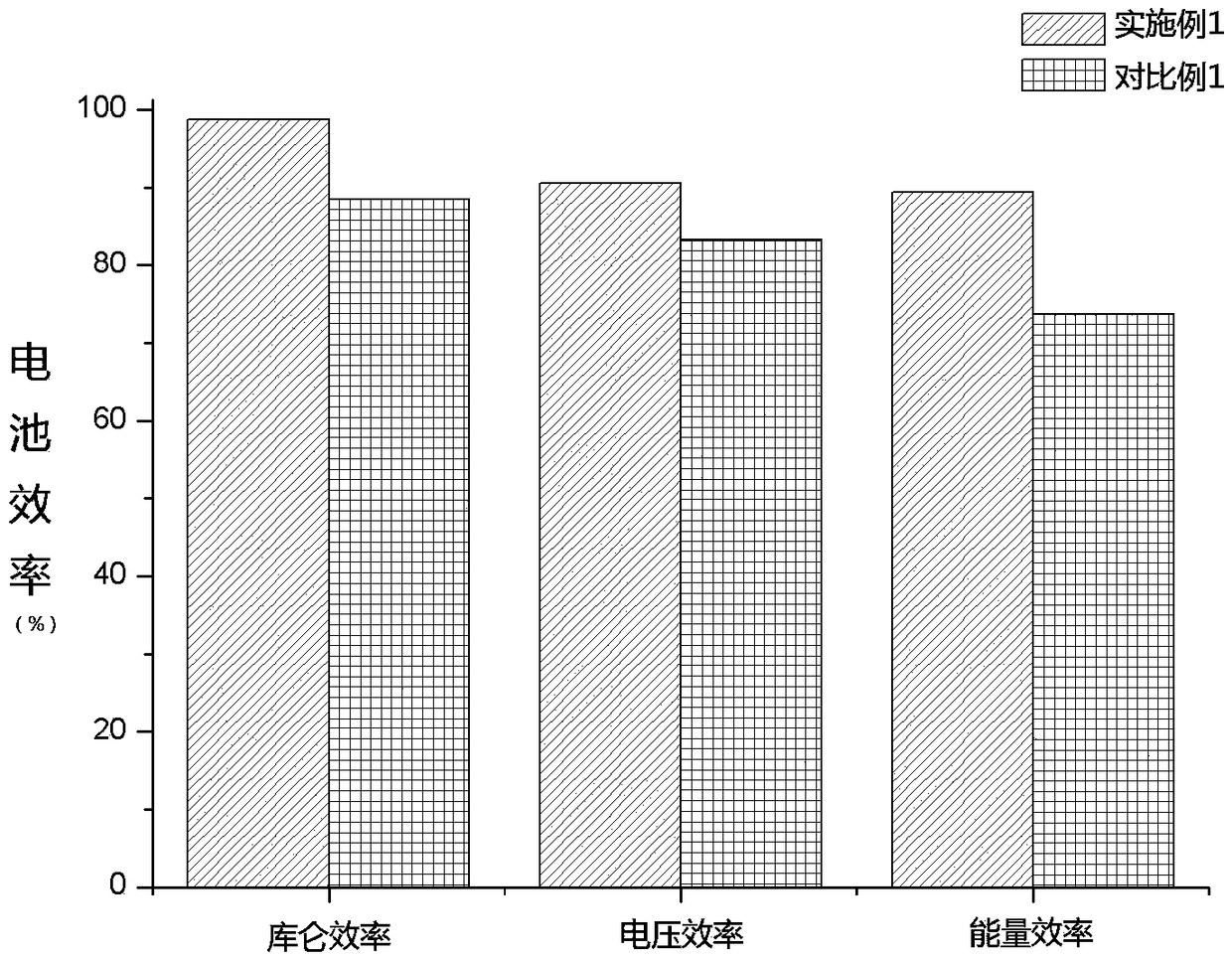

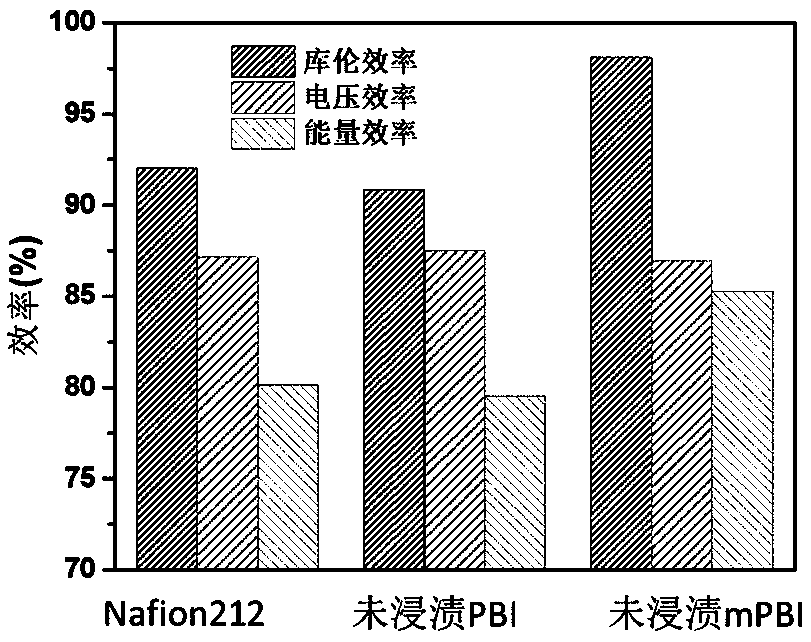

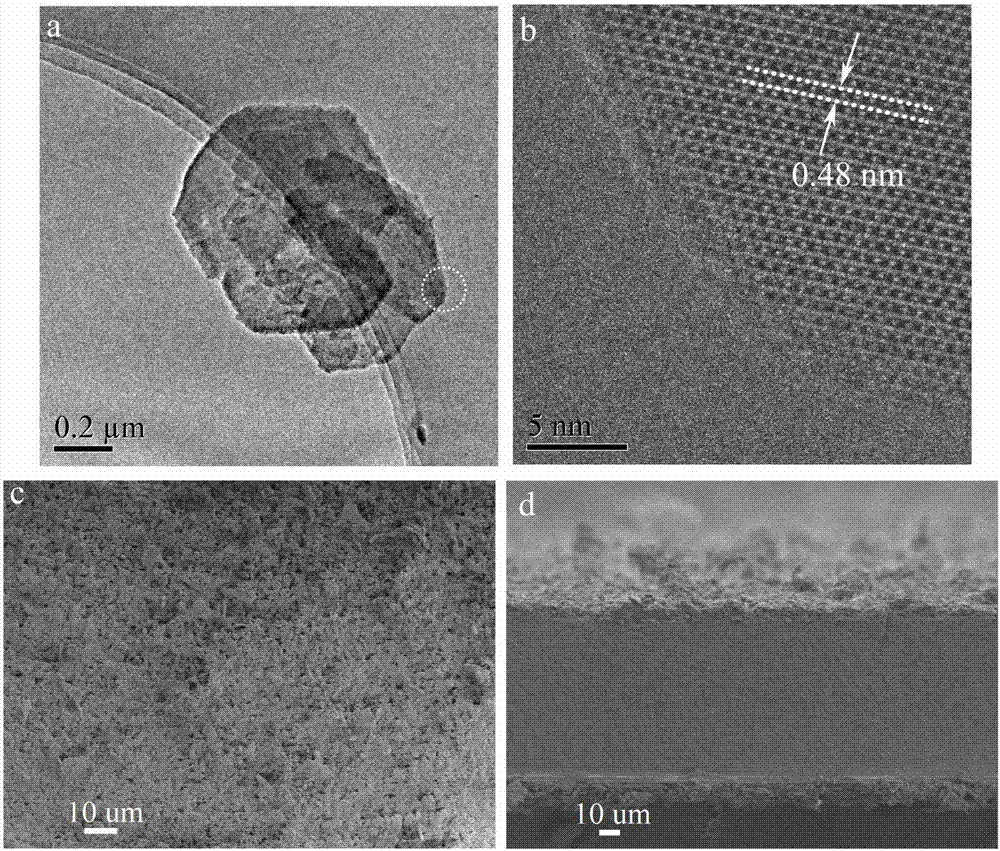

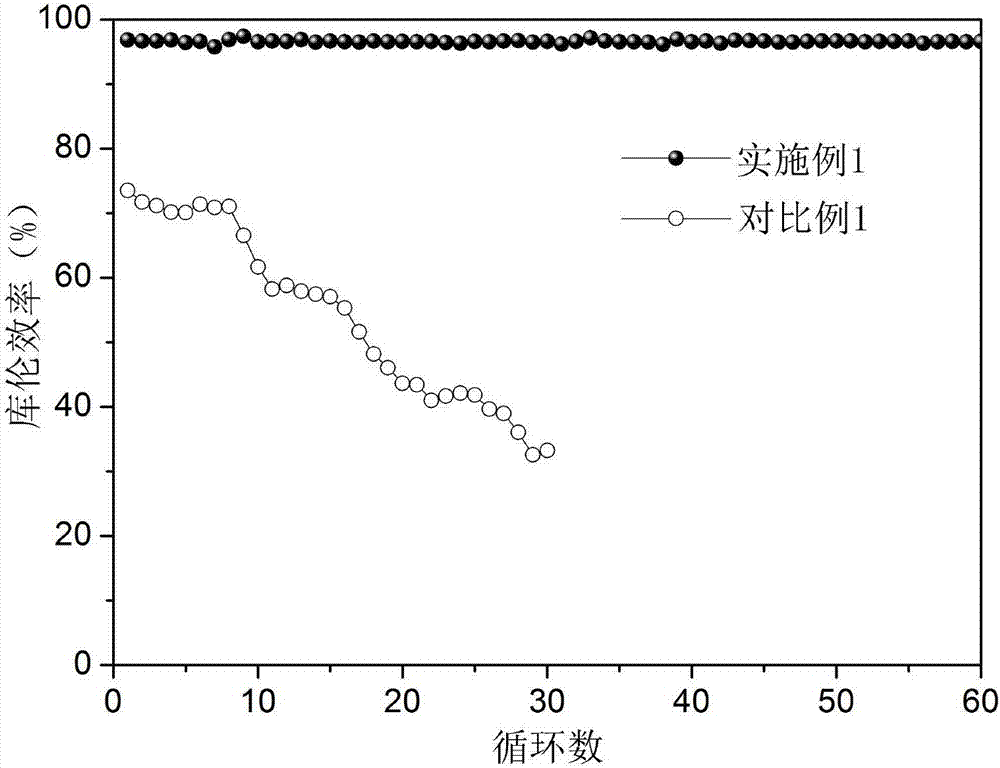

A composite ion-exchange membrane and a preparation method thereof, and a redox flow battery

ActiveCN103236553AHigh ion selectivityLow costCell electrodesRegenerative fuel cellsPolymer scienceSulfonated polymer

The present invention discloses a composite ion-exchange membrane and a preparation method thereof, and a redox flow battery. The composite ion-exchange membrane is prepared by using a sulfonated polymer as a matrix, incorporating inorganic materials into the matrix, and mixing the sulfonated polymer and the inorganic materials uniformly. The ion-exchange capacity of the sulfonated polymer is 0.1-5mmol / g, the mass percentage of the sulfonated polymer is 80-99.99wt%, the mass percentage of the inorganic materials is 0.01-20wt%, and the mass percentagesof the sulphonated polymer and the inorganic materials sum to 100wt%. According to the present invention, by introducing a certain amount of inorganic materials into a certain amount of the sulfonated polymer matrix for modification, the composite ion-exchange membrane is allowed to both have a high ionic selectivity and a high stability. By applying the prepared composite ion-exchange membrane in the redox flow cell, higher battery efficiency and more stable battery performance can be achieved. The preparation method of the composite ion-exchange membrane is simple and is conducive to promoting the industrial development of redox flow batteries.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

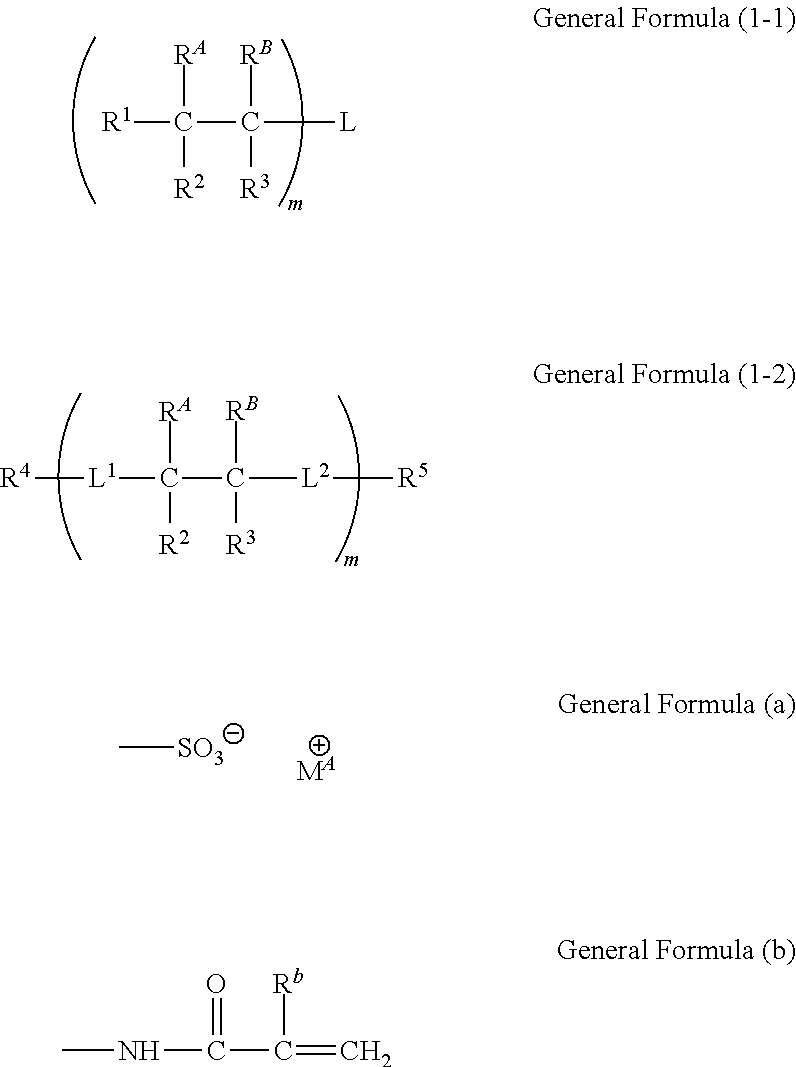

Curable composition, polymer functional cured product, water-soluble acrylamide compound, and method for manufacturing same

InactiveUS20160369017A1Reduce water permeabilityLower resistanceMembranesCation exchanger materialsPolymer scienceAqueous solubility

There is provided a curable composition including a water-soluble acrylamide monomer represented by the following General Formula (1-1) or (1-2), a polymer functional cured product, a water-soluble acrylamide compound, and a method for manufacturing the same.In General Formulas (1-1) and (1-2), m represents an integer of 2 or greater, and L represents an m-valent group or a single bond. Here, in a case where L is a single bond, m is 2. L1 and L2 each represent a single bond or a divalent linking group. R1 to R5 each represent a hydrogen atom or a substituent, and may be bonded to each other to form a ring, and may be bonded to L, L1, or L2 to form a ring. Either one of RA and RB represents a group represented by General Formula (a), and the other represents a group represented by General Formula (b).

Owner:FUJIFILM CORP

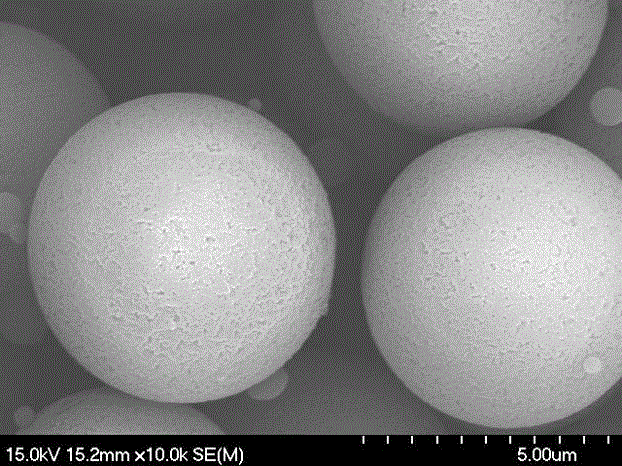

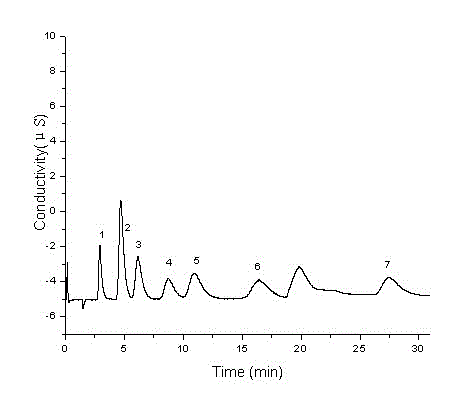

Preparation method of surface-grafting anion chromatography stationary phase

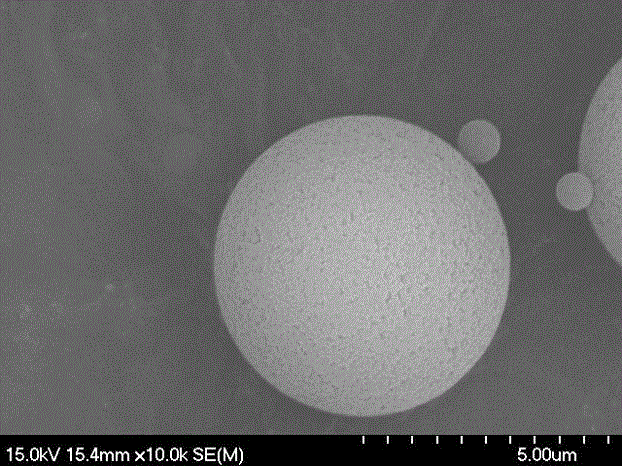

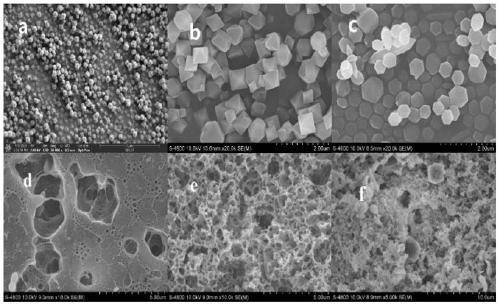

InactiveCN102941074ALow costNarrow particle size distributionOther chemical processesGlycidyl methacrylateMicrosphere

The invention relates to an anion chromatographic column a preparation method thereof, particularly relates to a preparation method of a surface-grafting anion chromatography stationary phase. The method disclosed herein is characterized by: preparing monodispersed linear polystyrene microspheres seeds by dispersion polymerization, activating the seeds, then synthesizing polystyrene-divinyl benzene-glycidyl methacrylate microballoons by one-step seed swelling method, and extracting to remove the pore forming agent; adopting multi-step grafting synthetic method, taking methylamine and 1,4-butanediol diglycidyl ether as raw materials, and introducing a large amount of positively charged quaternary ammonium groups as the anion exchange functional group to the surface of the prepared polystyrene-divinyl benzene-glycidyl methacrylate microballoons; and packing by homogenate method. According to the invention, the method disclosed herein has the advantages of low cost and simple process, the prepared filling material has uniform granularity and has no need to be screened, and the particle size distribution is narrow.

Owner:ZHEJIANG UNIV

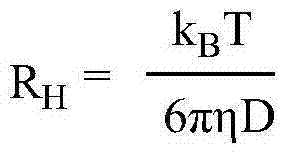

Two-dimensional/one-dimensional heterogeneous nanochannel film and preparation method and application thereof

ActiveCN110170253AImprove energy conversion effectImprove throughputSemi-permeable membranesComposite filmRoom temperature

The invention provides a preparation method of a two-dimensional / one-dimensional heterogeneous nanochannel film. The method is characterized by comprising the following steps that step 1, graphene oxide is dissolved in an aqueous piperazine solution, and ultrasonic treatment is performed at the room temperature to obtain a uniformly dispersed first solution; step 2, the first solution is added dropwise to the upper layer of a porous aluminum oxide film, and after the solvent is evaporated at the room temperature, a first composite film with a graphene oxide film layer and a porous aluminum oxide film layer is obtained; step 3, a benzenetricarbonyl trichloride solution is added dropwise to the upper surface of the graphene oxide film layer of the first composite film, and drying is carriedout to obtain the two-dimensional / one-dimensional heterogeneous nanochannel film. The invention provides the two-dimensional / one-dimensional heterogeneous nanochannel film prepared by using the methodand application of the two-dimensional / one-dimensional heterogeneous nanochannel film in salt difference energy conversion.

Owner:FUDAN UNIV

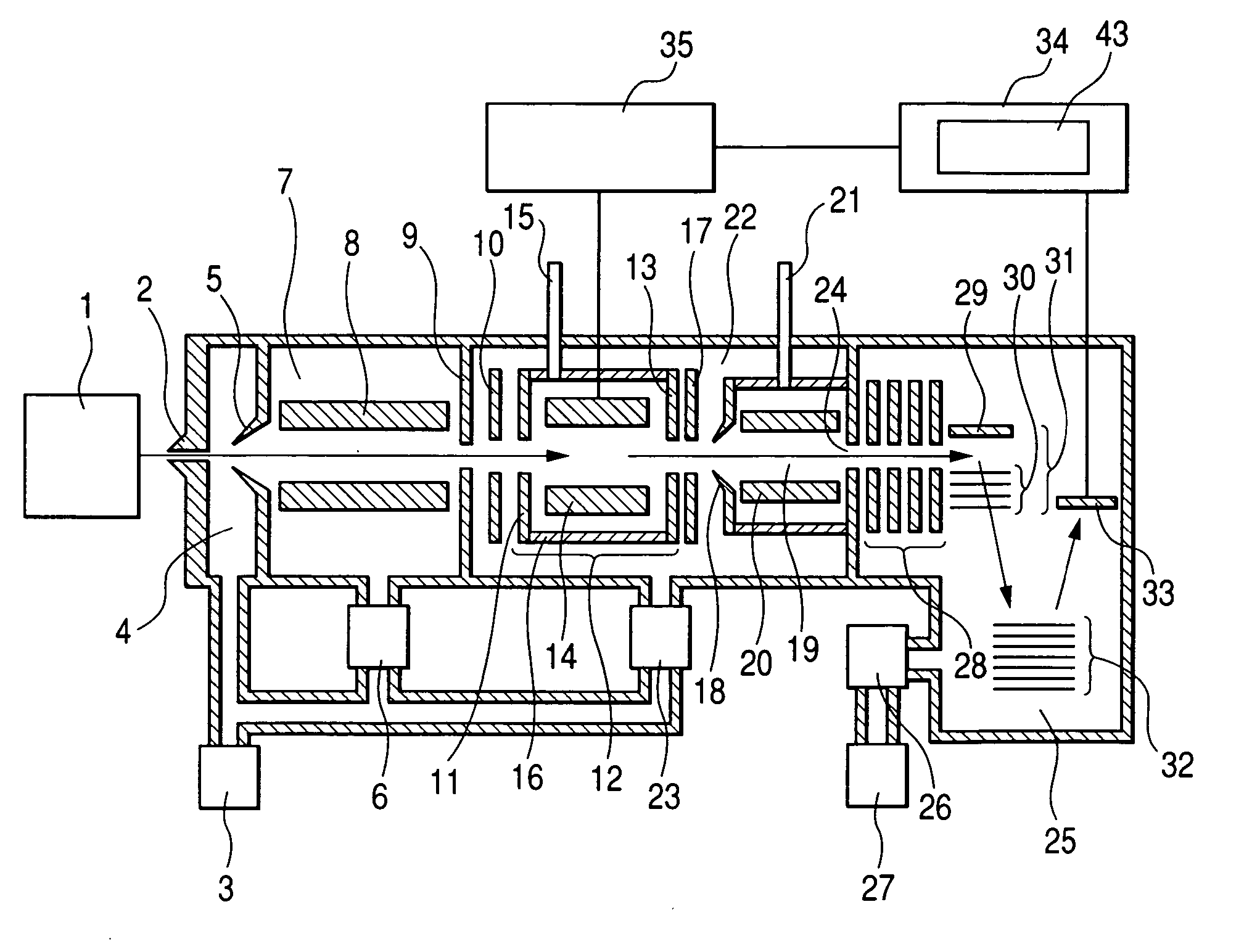

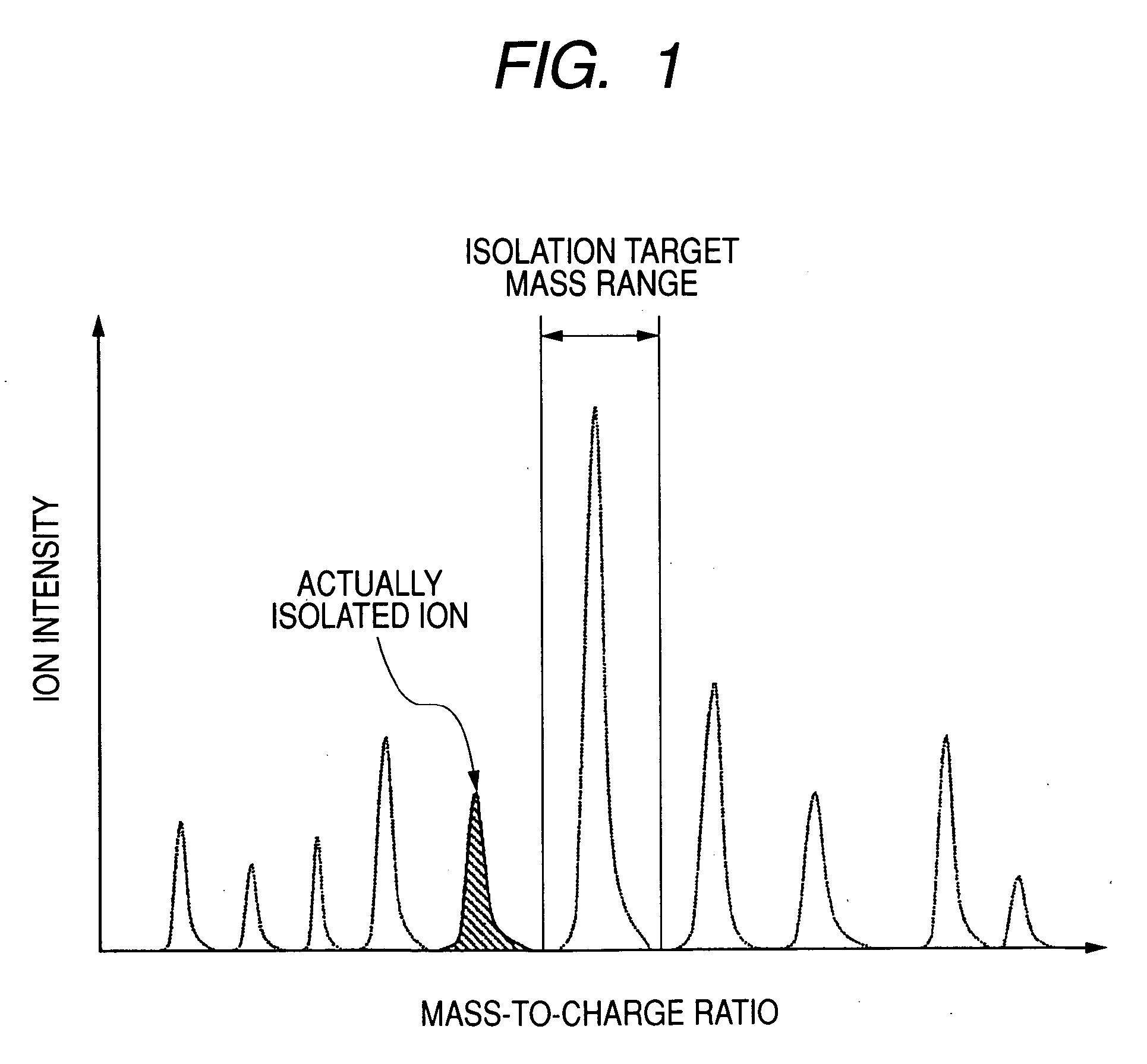

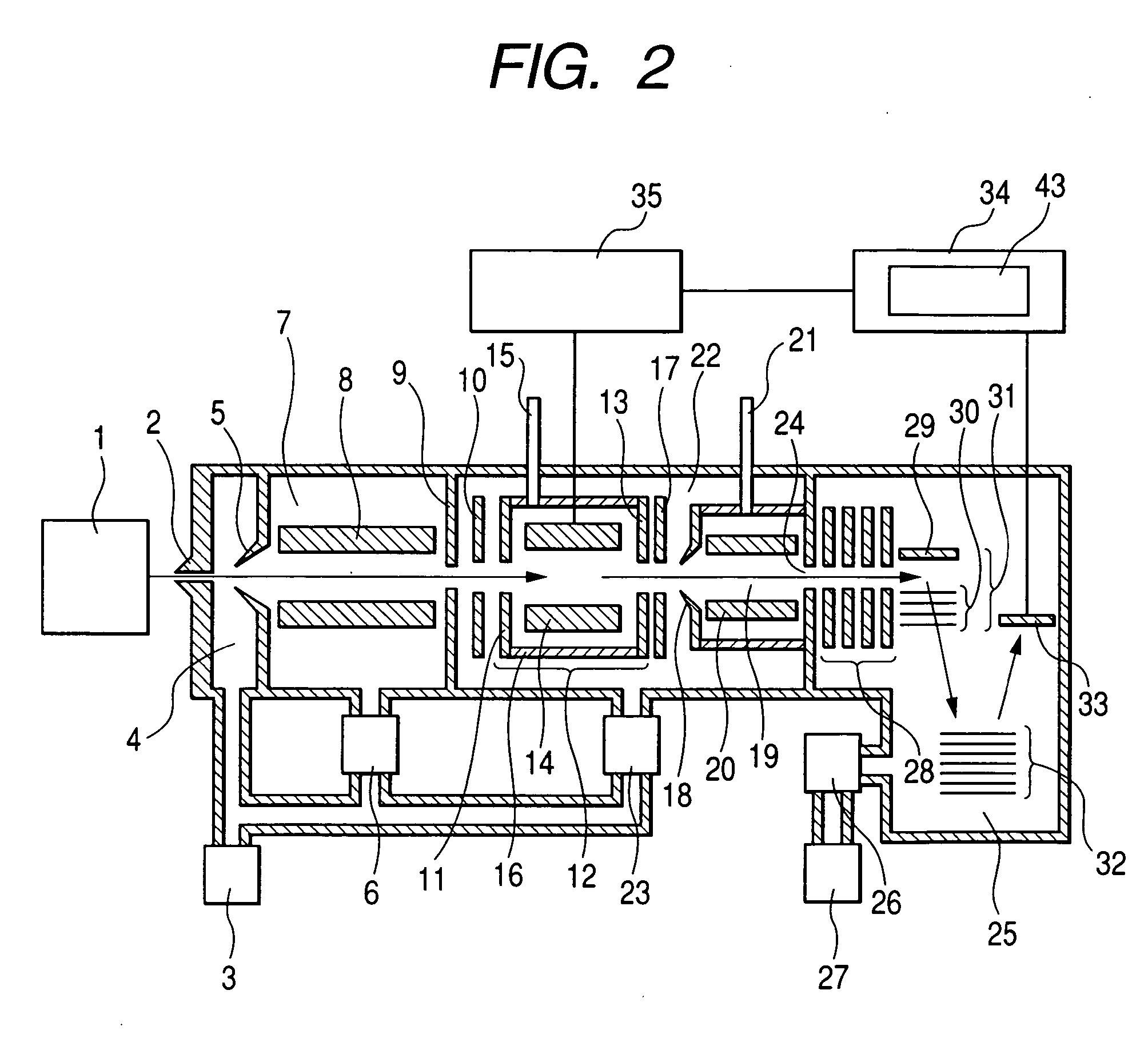

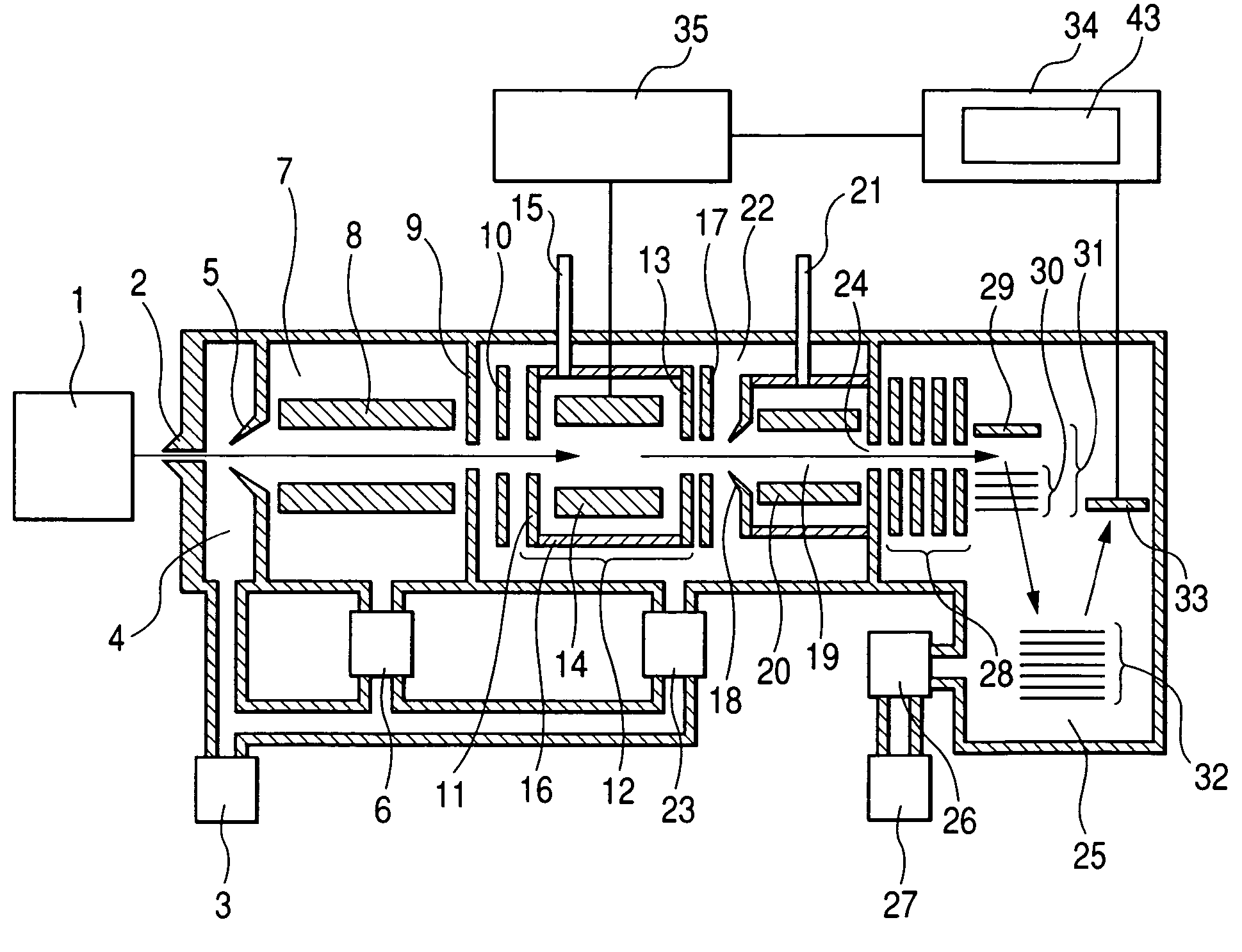

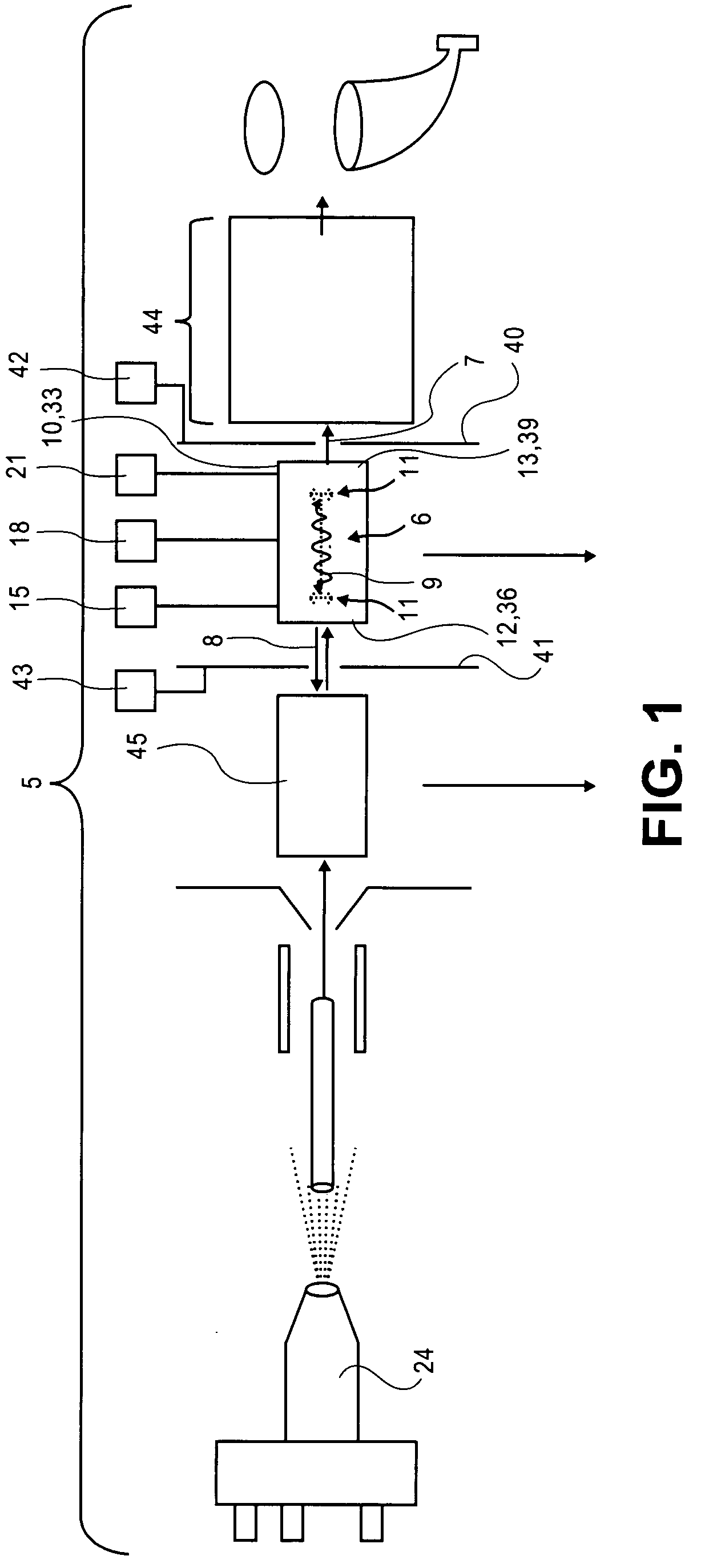

Mass spectrometer

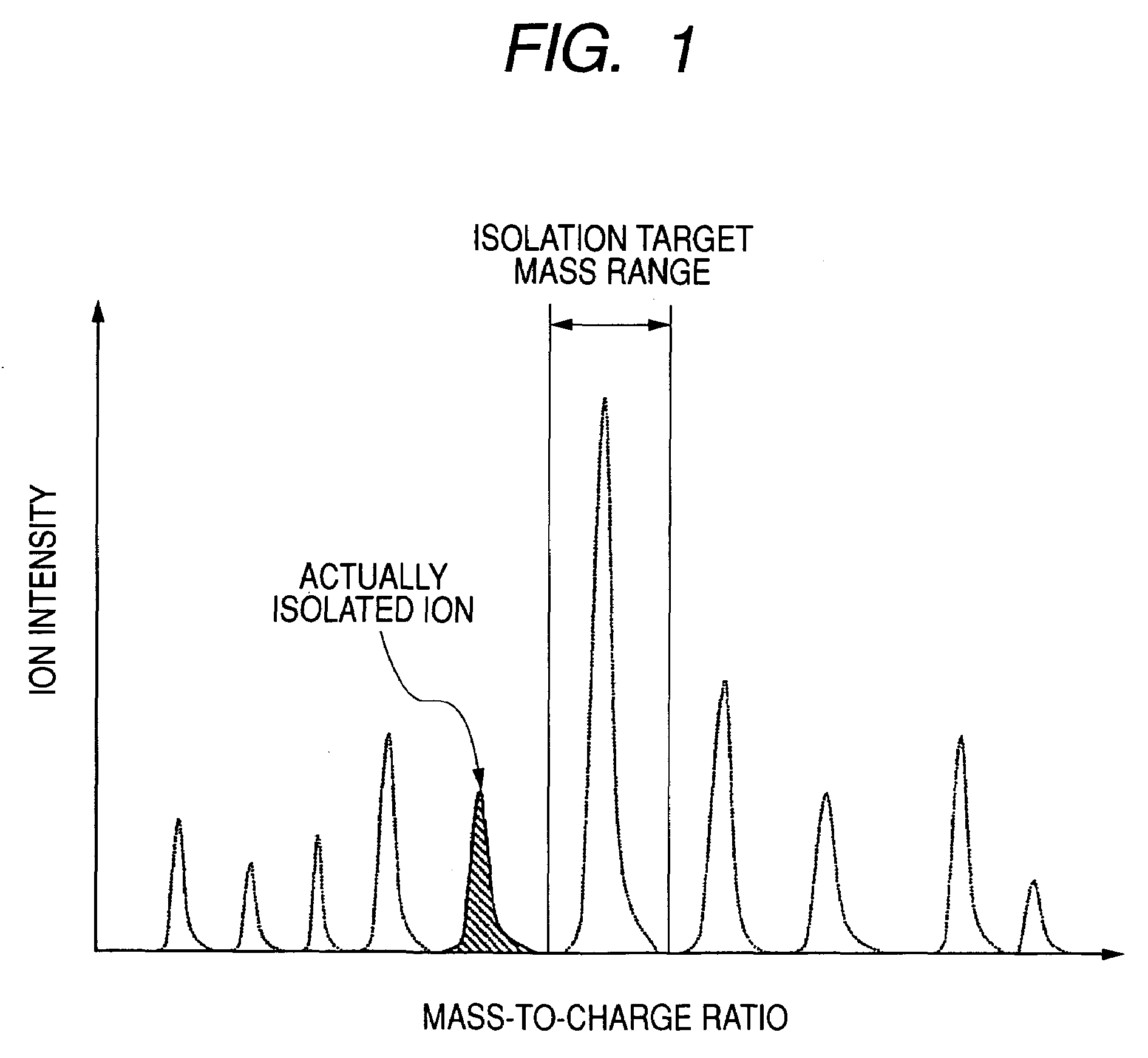

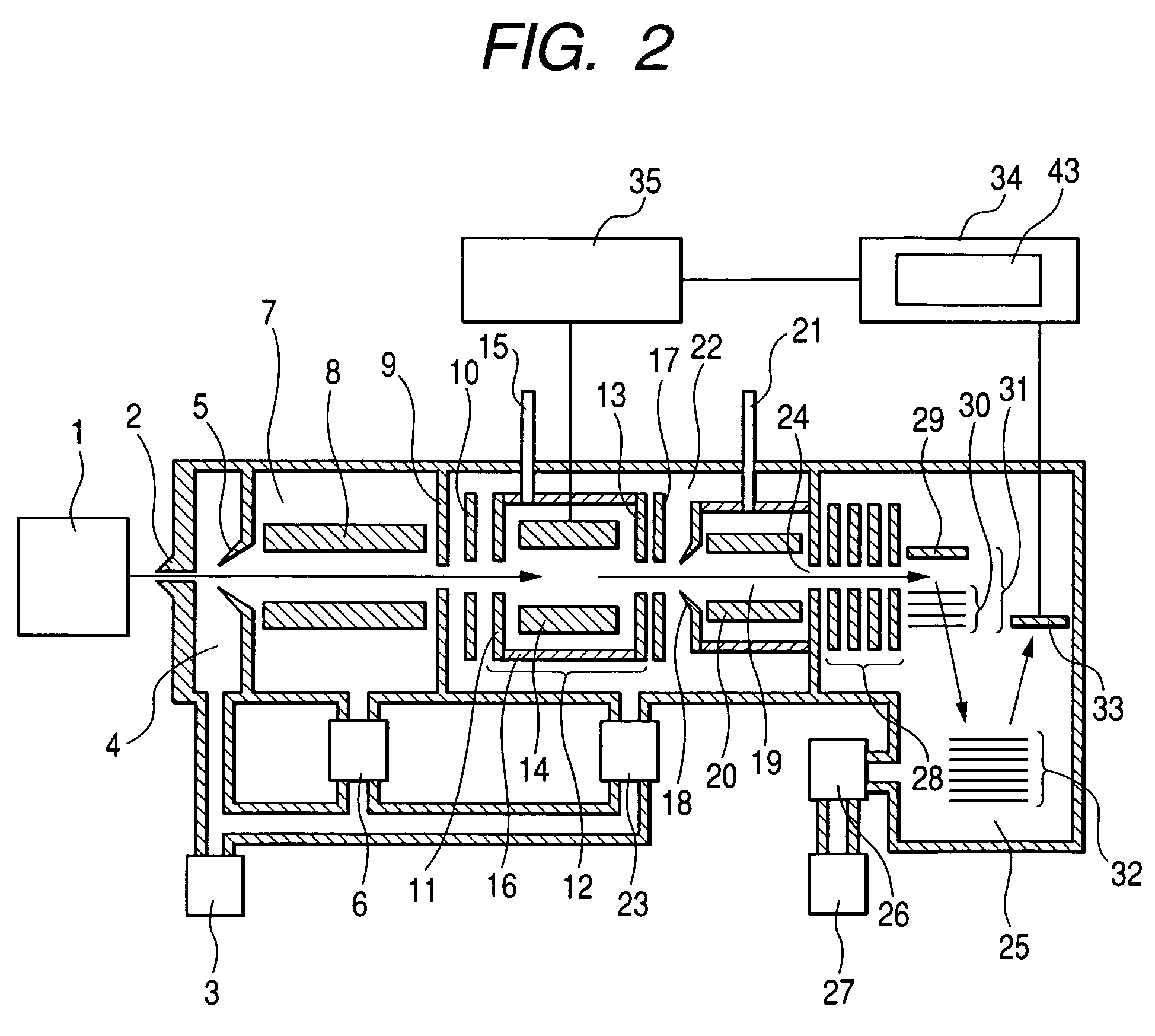

ActiveUS20060289743A1High-sensitivity analysisHigh ion selectivityParticle separator tubesIsotope separationIon trap mass spectrometryMass Spectrometry-Mass Spectrometry

A mass spectrometer capable of realizing a high-sensitivity ion analysis and a high ion selectivity performance. The mass spectrometer includes the ion source where ions are produced, the ion trap where ions are accumulated, isolated, dissociated, and ejected, the detector to detect ions to be detected, and the controller to control operations of the ion trap. It has the features that the total ion accumulation in or just before each period is calculated based on the result obtained from the mass spectrometry in the preceding period, and that in at least one out of all periods, the condition of voltage applied to the ion trap is corrected depending on the total ion accumulation. Compared to the related art, the mass spectrometer of the present invention provides much improved performance in analysis sensitivity and ion selectivity.

Owner:HITACHI HIGH-TECH CORP

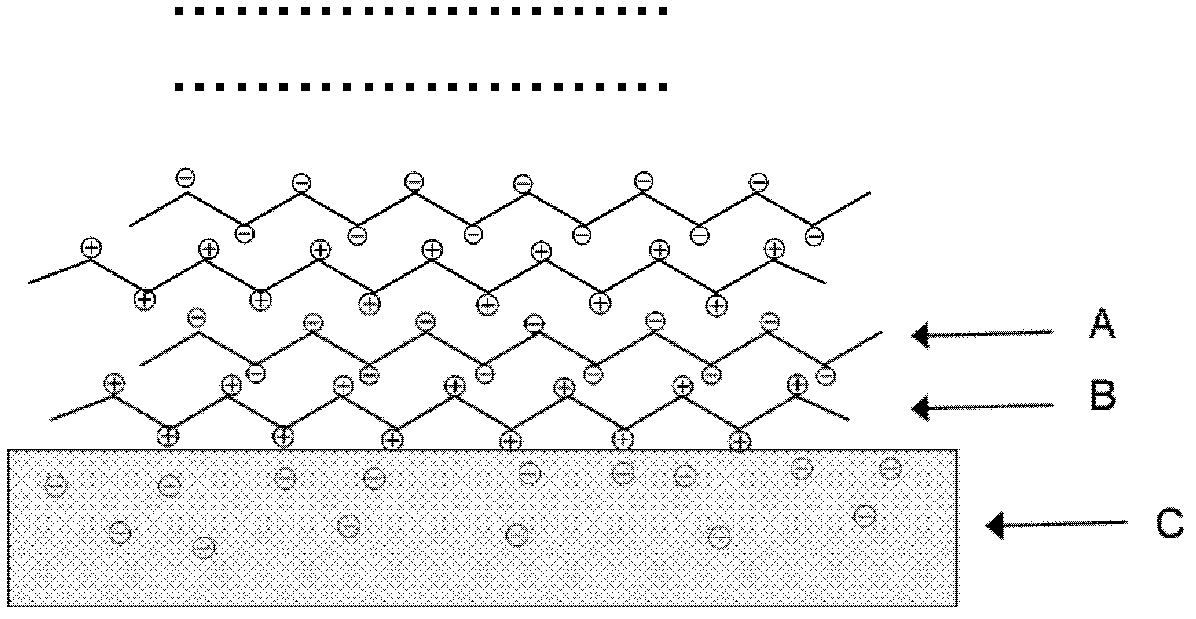

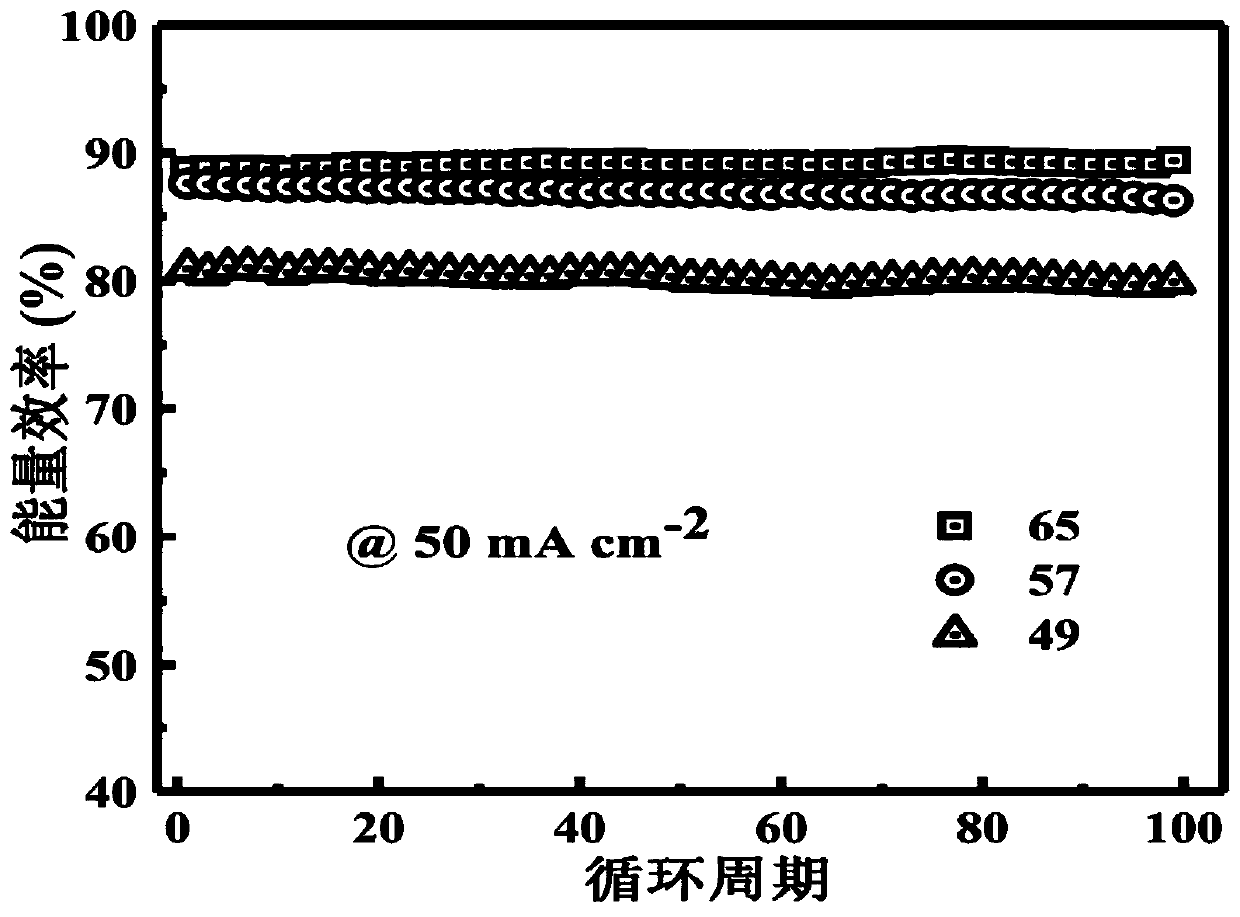

Composite film for flow energy storage battery and application thereof

InactiveCN102867928AHigh ion selectivityImprove hydrophilicitySynthetic resin layered productsCell component detailsComposite filmOrganic polymer

The invention discloses a composite film for a flow energy storage battery and an application of the composite film in the flow energy storage battery. The composite film disclosed herein is characterized by using one or more than two of organic polymer resin or sulfonated polymer resin as raw material to prepare a porous film as a matrix, and successively alternately self-assembling cationic polymer resin and anion polymer resin layer by layer on the surface of the matrix by static electricity to form the composite film. The composite film disclosed herein has the advantages of simple preparation method, environmentally friendly process, controllable number of assembling layers, and adjustable ionic selectivity. Compared with original porous films, the composite film disclosed herein has good hydrophilicity and vanadium ion blocking ability, and an all vanadium flow energy storage battery assembled by using the composite film has higher efficiency and longer self-discharge time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

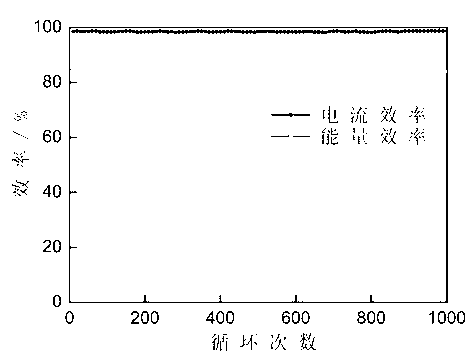

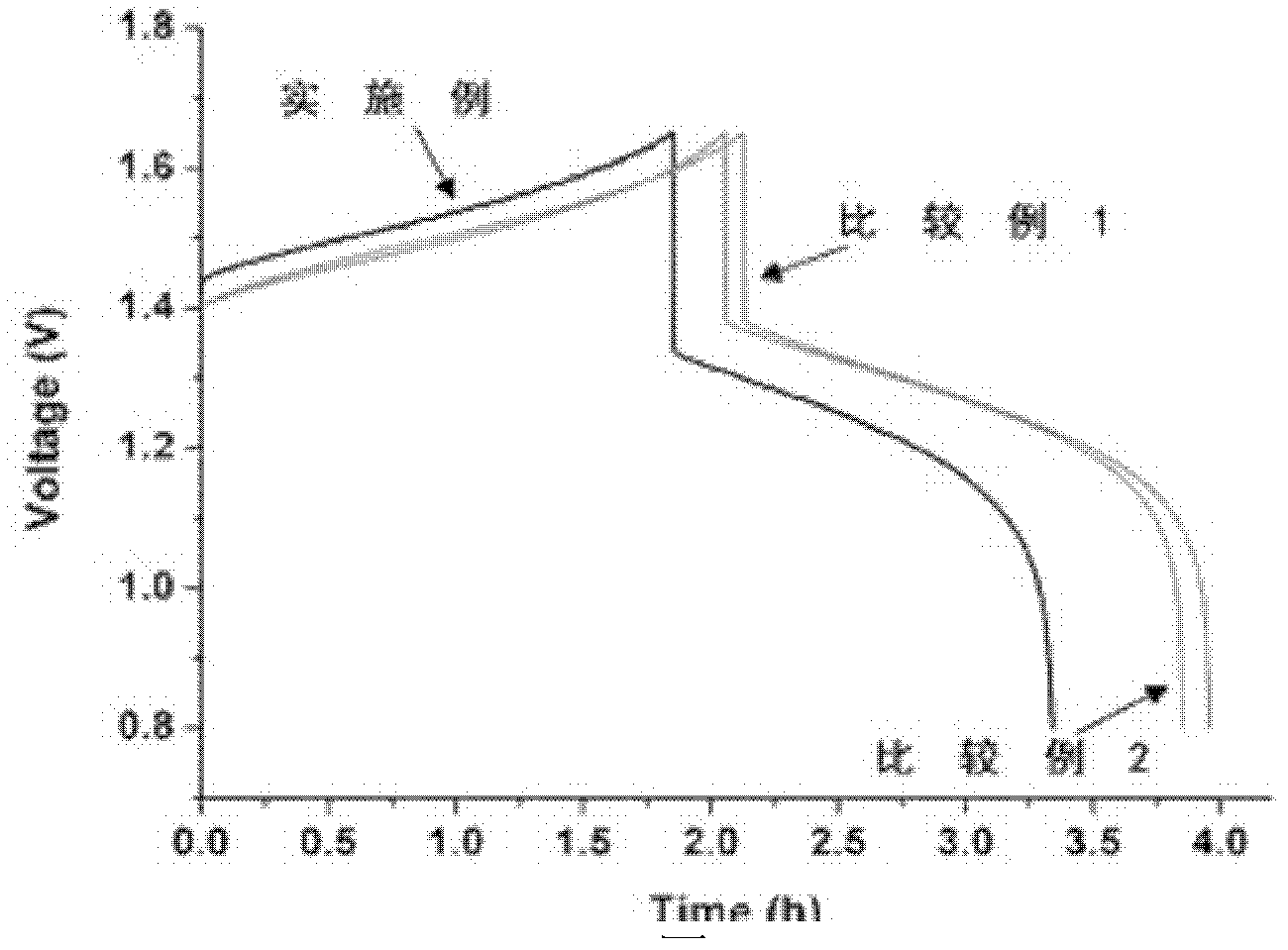

Sulfonated polyether ether ketone-based blend ion exchange membrane for flow battery, and preparation method thereof

ActiveCN103219532AImprove proton conductivityLow swelling rateFinal product manufactureRegenerative fuel cellsPhysical chemistryIon-exchange membranes

The invention discloses a sulfonated polyether ether ketone-based blend ion exchange membrane for a flow battery, and a preparation method of the sulfonated polyether ether ketone-based blend ion exchange membrane; the ion exchange membrane takes sulfonated polyether ether ketone as a substrate, and is prepared by adding at least one partly-fluorinated high polymer material into the substrate and evenly blending. The invention also discloses the flow battery using the sulfonated polyether ether ketone-based blend ion exchange membrane, and a preparation method of the flow battery. The ion exchange membrane has low active substance permeability and high heat stability and high chemical stability, and effectively improves the performances of the applied flow battery.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

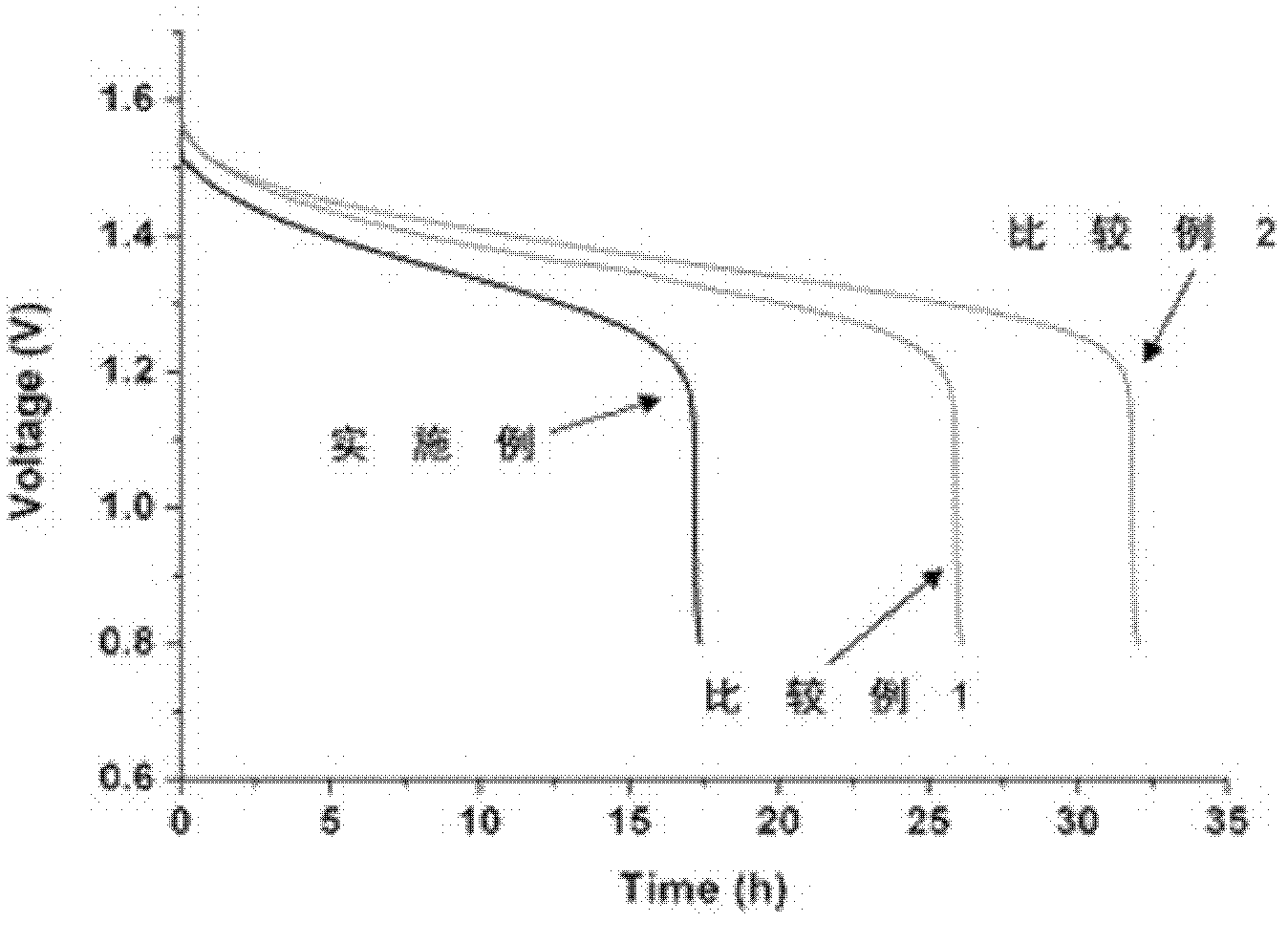

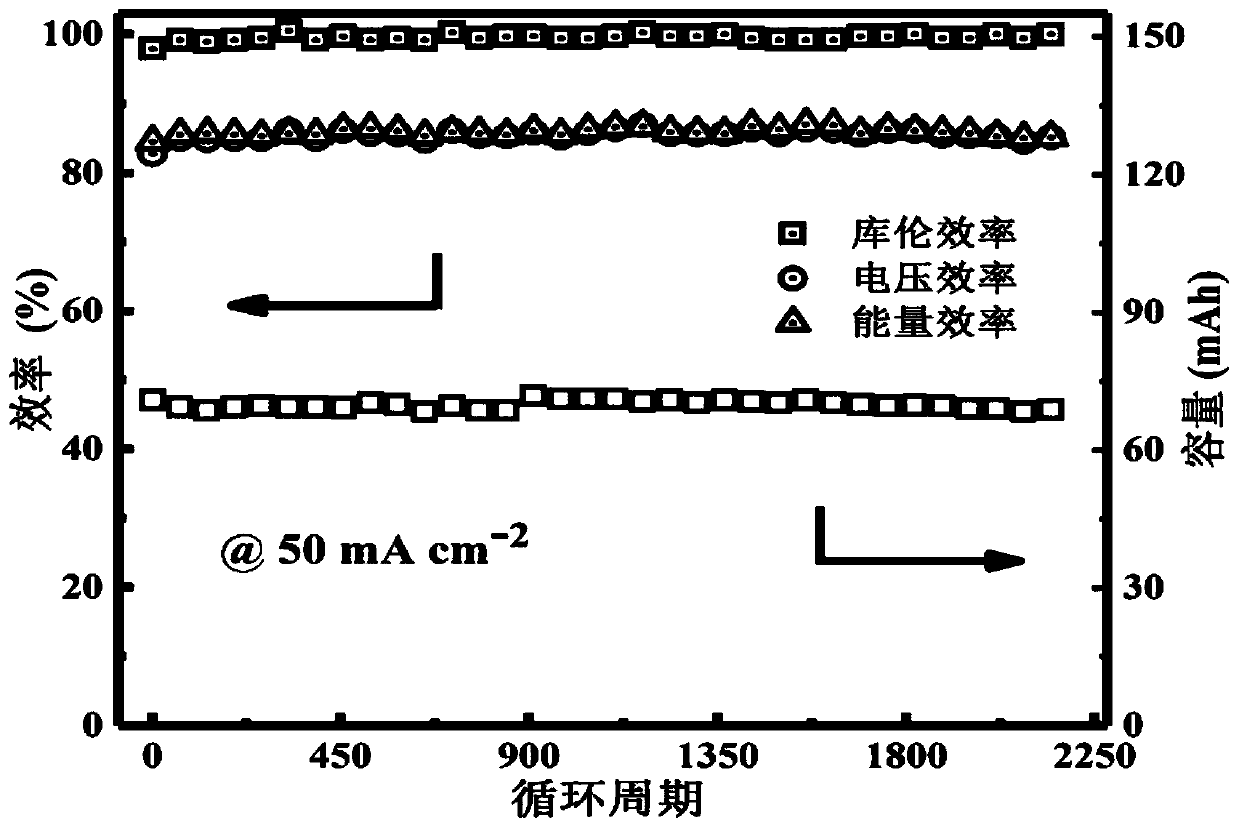

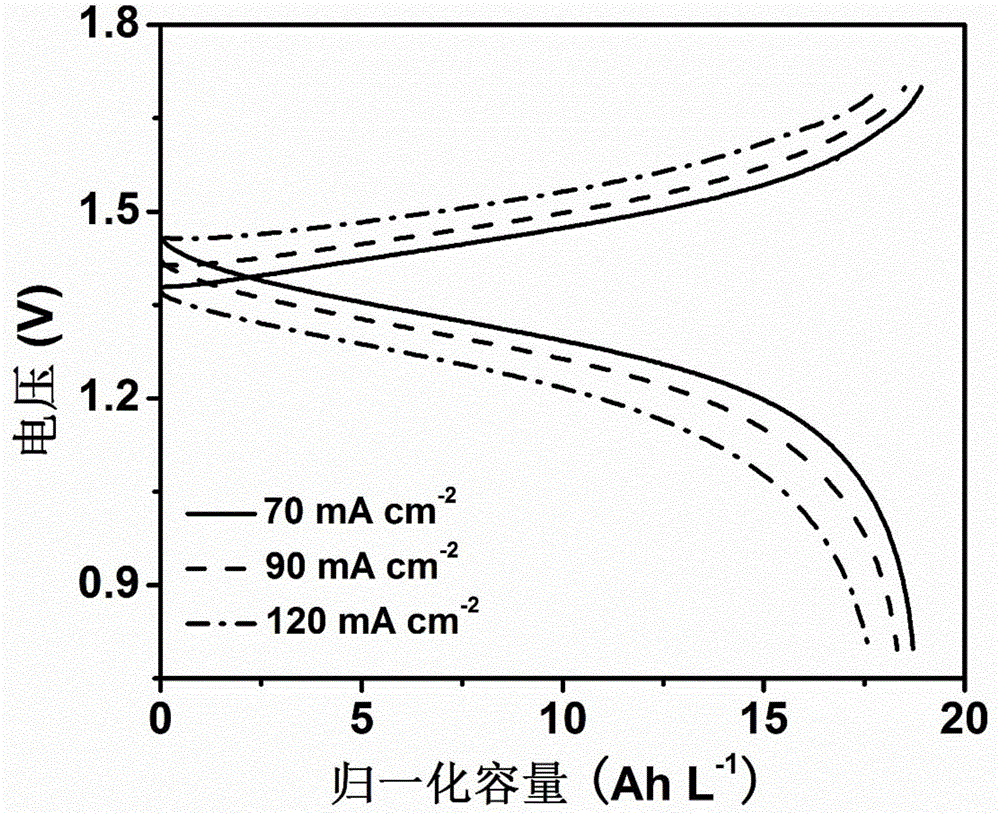

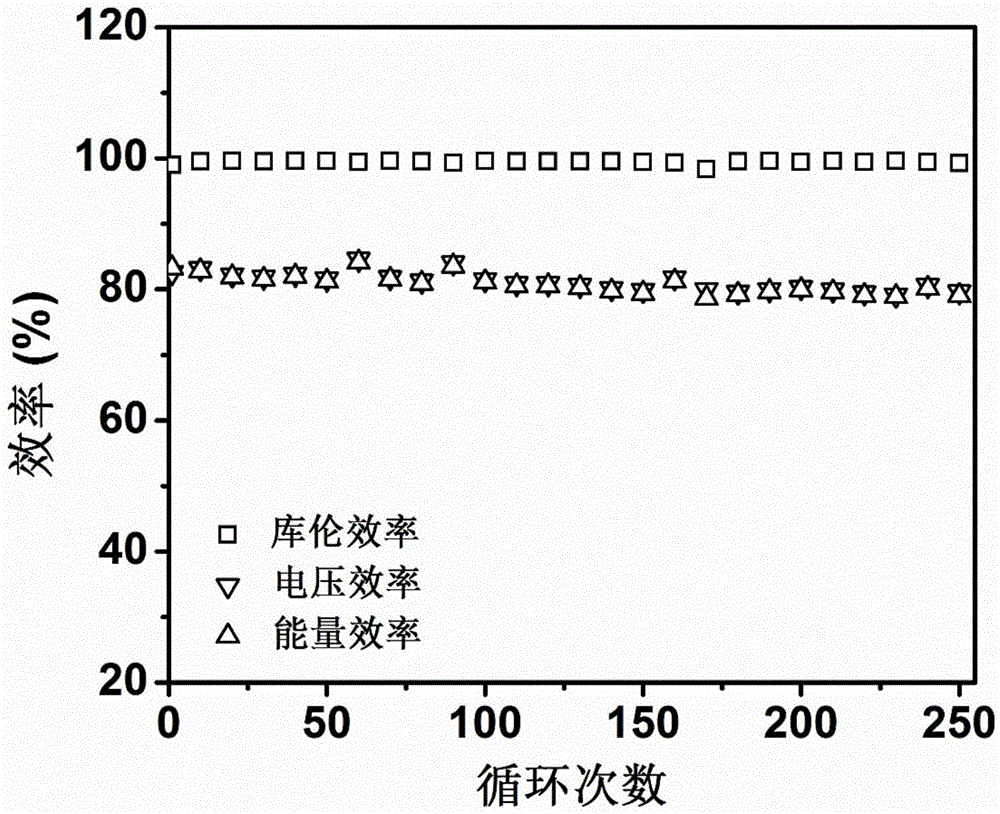

Preparation method of ion exchange membrane for alkaline redox flow battery

InactiveCN110534682AHigh ion selectivityHigh proton conductivityCell electrodesRegenerative fuel cellsKetoneCarbon felt

The invention relates to the field of alkaline redox flow battery energy storage, in particular to a preparation method of an ion exchange membrane for an alkaline redox flow battery, which is mainlyused for solving the problem of the high price of a Nafion diaphragm in the alkaline redox flow battery at the present stage, so that the cost of the redox flow battery is greatly reduced. An alkalineaqueous solution of ferricyanide (such as Na3[Fe(CN)6], K3[Fe(CN)6], (NH4)3[Fe(CN)6] and the like) is used as a positive electrolyte, and a strong alkaline solution (such as KOH, NaOH and the like) is used as a negative electrolyte; graphite felt and carbon felt are selected as positive electrode materials, and a zinc plate is selected as a negative electrode material; and the ionized sulfonatedpolyether ether ketone (SPEEK) diaphragm is used as an ion exchange membrane to assemble the battery. Therefore, the alkaline redox flow battery system with low cost and high performance is obtained.The flow battery system provided by the invention has the advantages of the high open-circuit voltage, the low cost, the high efficiency, the good cycling stability, safety, reliability and the like,and has a wide application prospect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Compound arsenic-removing adsorbent and preparation method thereof

ActiveCN102114403AHigh ion selectivityGood choiceOther chemical processesGranulation by material expressionSorbentWater flow

The invention provides an arsenic-removing adsorbent for drinking water and a preparation method thereof. The adsorbent contains composite metal oxide and a polymer material binder. The arsenic-removing adsorbent has high adsorption property, high adsorption selectivity on arsenic in the drinking water, and high adsorption capacity; adsorbent particles have high strength in a dry state or in a moist state, and the adsorbent has low breakage rate of the particles and cannot be dissolved out during use; and the adsorbent is used under the conditions of long time and larger change of waterflow pressure.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Arsenic removal adsorbent and preparation method thereof

The invention provides an arsenic removal adsorbent and a preparation method thereof. The adsorbent contains sulfate akaganeite and high-molecular material agglomerant. In the invention, the particles of the arsenic removal adsorbent have high adsorption property to have high adsorption selectivity to arsenic in drinking water, the adsorption capacity is high, the adsorbed particles have large strength under a drying state or a moisture state, the particle crushing rate is low during use, no adsorbent is dissolved out, and the arsenic removal adsorbent is suitable for being used for a long time and under the condition of larger water flow pressure change.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Liquid flow cell composite membrane and application thereof

InactiveCN104716355AImprove hydrophilicityImprove performanceRegenerative fuel cellsCoatingsMembrane configurationOrganic polymer

The invention relates to a liquid flow cell composite membrane and application thereof in liquid flow cells, a pore membrane prepared from raw materials of one or two or more kinds of organic polymer resin is used as a matrix, one side surface of the matrix is composited with a dense membrane prepared from cation exchange resin, and the composite membrane is simple in preparation method and environmental friendly in process. Compared with the original pore membrane, the composite membrane has higher hydrophily and ionic selectivity, and can effectively inhibit the electrolyte solution migration problem, and the type and use scope of the liquid flow cell pore membrane material can be expanded.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

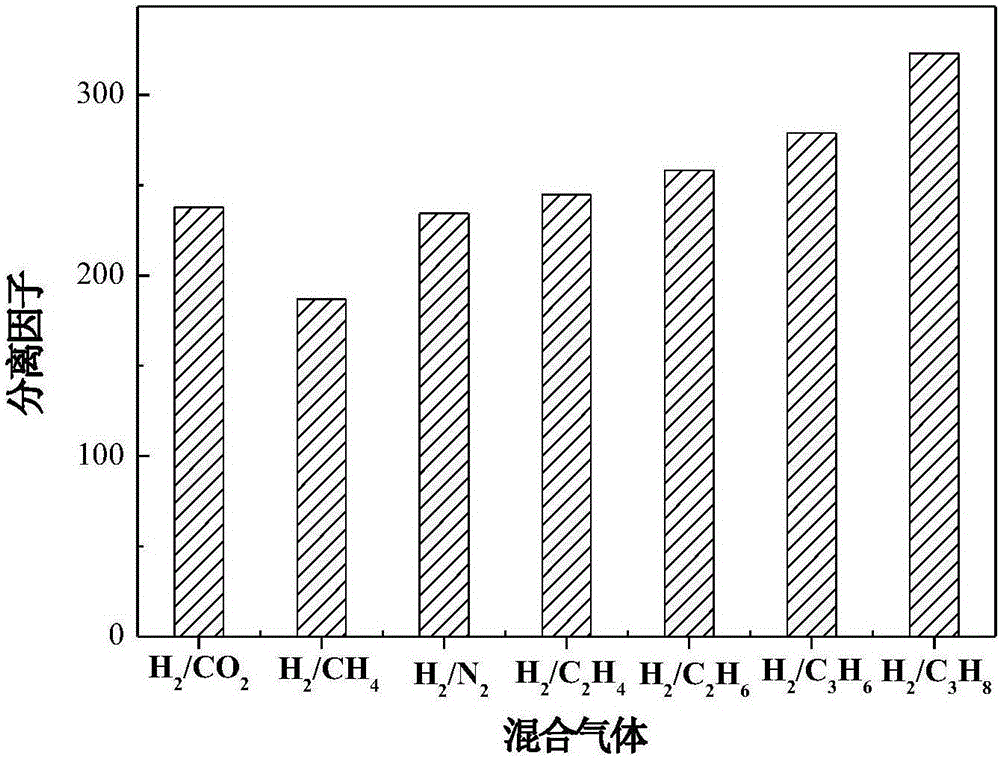

Preparation method and application of graphene oxide skeleton material self-assembly membrane

The invention provides a preparation method and application of a graphene oxide skeleton material self-assembly membrane. The preparation method comprises the steps of firstly, providing a carrier, and carrying out charge modification on the surface of the carrier by using an amino-containing group; then, enabling a group containing double active terminals to have a thermal reaction with a graphene oxide solvent so as to prepare a graphene oxide skeleton structure solution with controllable interlayer spacing; finally, adopting a chemical deposition self-assembly method to enable the graphene oxide skeleton structure solution to form a dense self-assembly membrane on the surface of the carrier. The method improves the combining capacity of graphene oxide and the carrier by carrying out charge modification on the carrier. The graphene oxide skeleton material self-assembly membrane prepared by the method has excellent gas, liquid and ion selectivity, has higher compactness and mechanical strength, and has adjustable screening pore path and membrane thickness.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Mass spectrometer

ActiveUS7566870B2High-sensitivity analysisHigh ion selectivityStability-of-path spectrometersIsotope separationState of artIon trap mass spectrometry

A mass spectrometer capable of realizing a high-sensitivity ion analysis and a high ion selectivity performance. The mass spectrometer includes the ion source where ions are produced, the ion trap where ions are accumulated, isolated, dissociated, and ejected, the detector to detect ions to be detected, and the controller to control operations of the ion trap. It has the features that the total ion accumulation in or just before each period is calculated based on the result obtained from the mass spectrometry in the preceding period, and that in at least one out of all periods, the condition of voltage applied to the ion trap is corrected depending on the total ion accumulation. Compared to the related art, the mass spectrometer of the present invention provides much improved performance in analysis sensitivity and ion selectivity.

Owner:HITACHI HIGH-TECH CORP

Preparation method of fluoride removal electro adsorption electrode for drinking water and fluoride removal electro adsorption electrode

InactiveCN102234145AHigh ion selectivityGood choiceWater contaminantsWater/sewage treatment by ion-exchangeElectricitySorbent

The invention provides a preparation method of a fluoride removal electro adsorption electrode for drinking water and a fluoride removal electro adsorption electrode. The method comprises the following steps: (1) mixing a conductive material and an adsorbent to obtain a conductive mixture, wherein a weight ratio of the conductive material and the adsorbent is 3-55: 45-97; (2) adding hot melt adhesive into the mixture obtained in the above step to stir uniformly and obtaining an electro adsorption mixture, wherein a weight ratio of the hot melt adhesive and the conductive mixture is 5-50: 50-95; (3) adding the electro adsorption mixture into a mould, and followed by hot pressing moulding to obtain the fluoride removal electro adsorption electrode. Combined electrode prepared with the method in the invention has the advantages of strong fluoride removal and adsorption capability, high strength, no fragmentation in long-term use, small mass loss, no digestion, free of secondary pollution, safety and reliability, and is suitable for long-term usage under a condition of big change of water flow pressure.

Owner:BEIJING FORESTRY UNIVERSITY

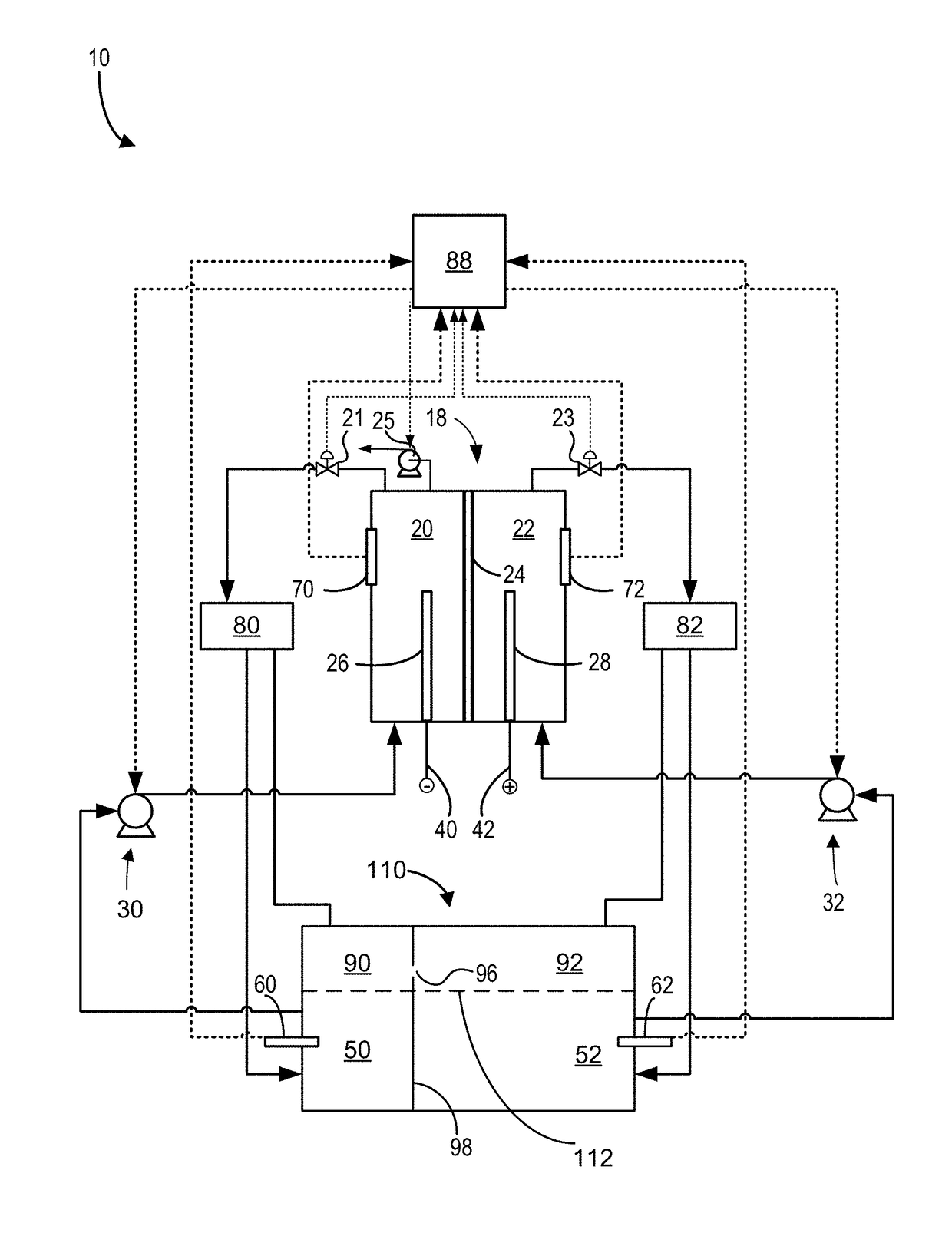

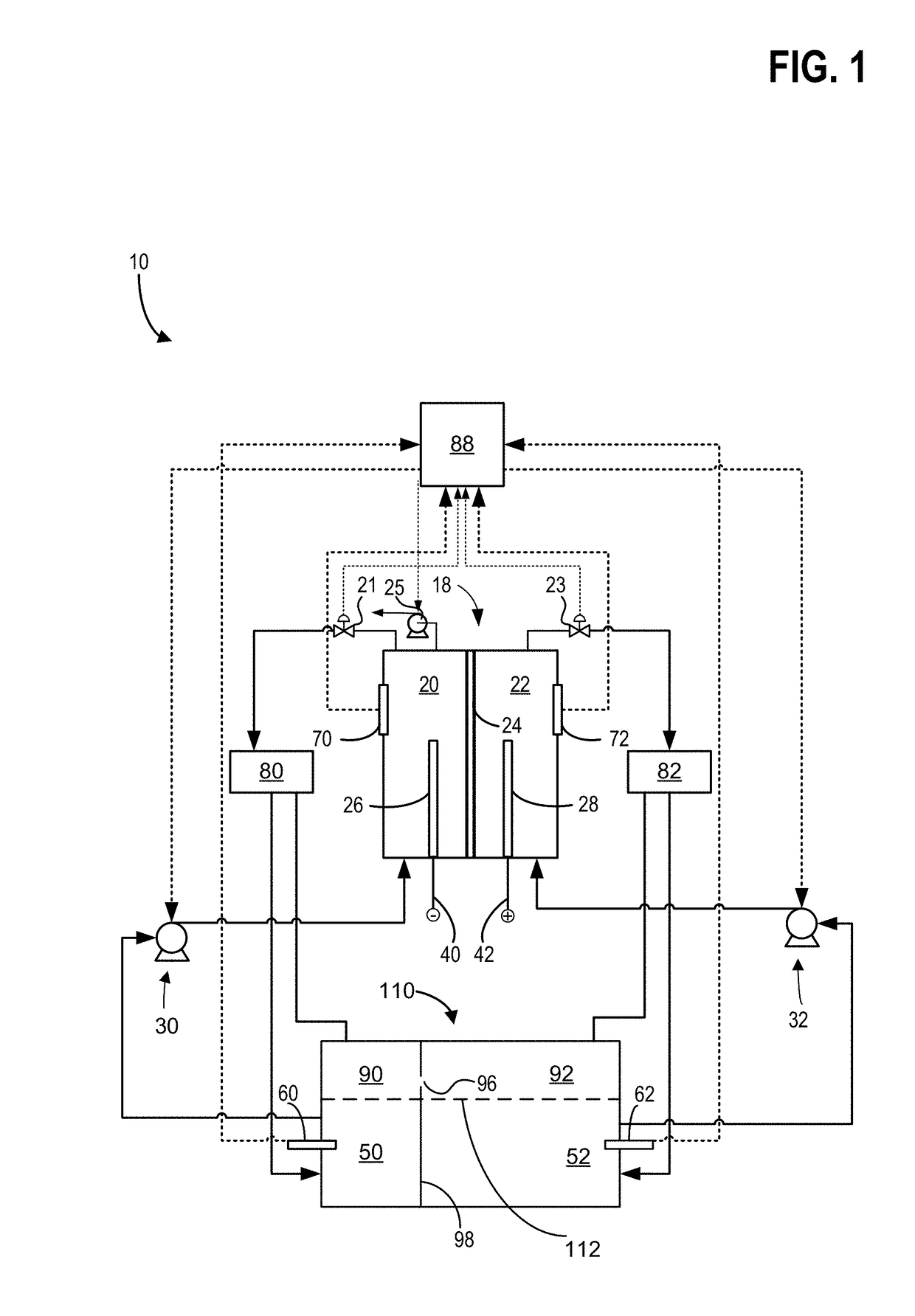

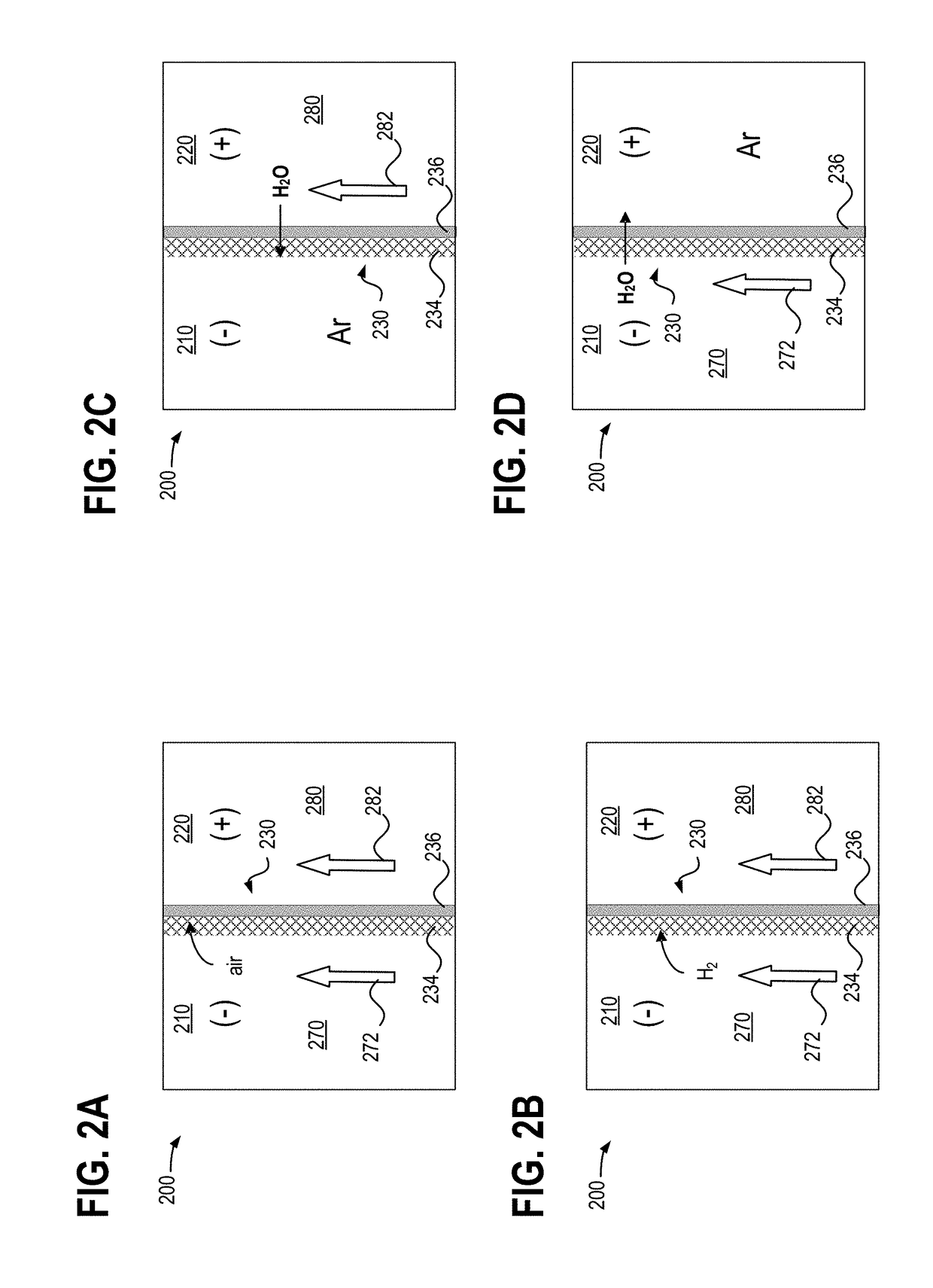

Methods and systems for operating a redox flow battery system

ActiveUS20180316032A1Degraded performance and loss of performanceHigh ion selectivityReactant parameters controlRegenerative fuel cellsCompartment pressureRedox

A method of operating a redox flow battery, may include maintaining a positive electrode compartment pressure greater than a negative electrode compartment pressure, and maintaining a cross-over pressure less than a membrane break-through pressure, wherein the cross-over pressure equals the negative electrode compartment pressure subtracted from the positive electrode compartment pressure. In this way, ionic resistance across the separator can be maintained at a lower level by reducing gas bubbles trapped therein while reducing separator break-through, thereby increasing performance of the redox flow battery system.

Owner:ESS TECHNOLOGY

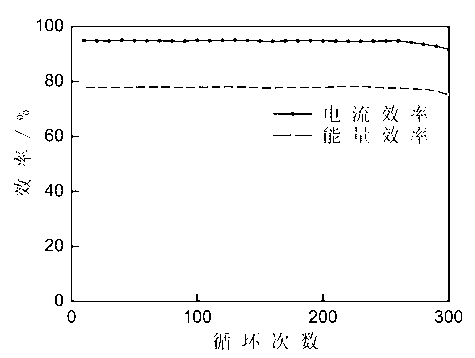

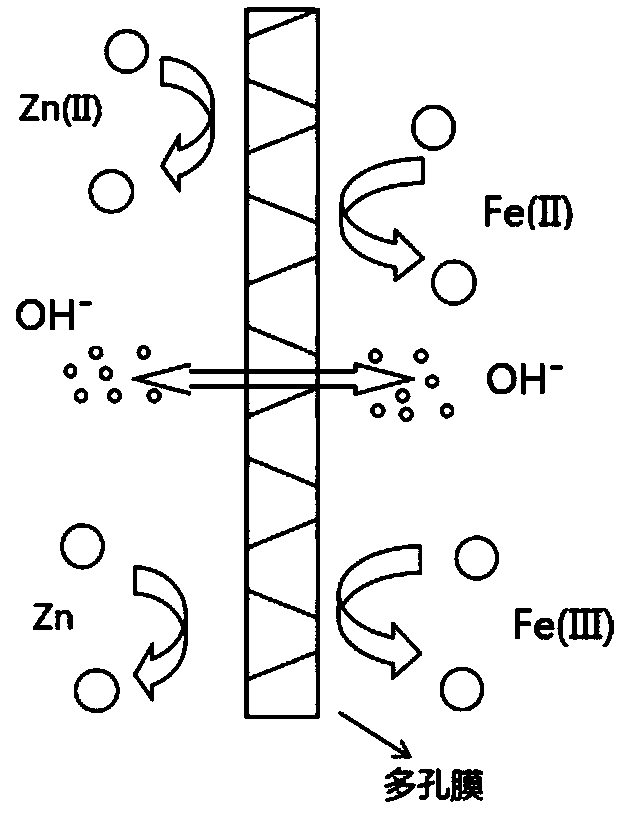

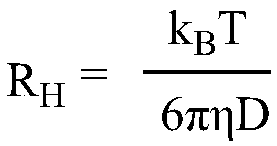

Application of porous membrane in alkaline zinc-iron flow battery

InactiveCN108134107AOvercoming the problem of poor stabilityAperture adjustableRegenerative fuel cellsPhase conversionPhysical chemistry

The invention discloses an application of a porous membrane in an alkaline zinc-iron flow battery. The porous membrane is a porous conductive membrane prepared from one, two or more organic polymer resin as a raw material with a phase conversion method. The porous conductive membrane has the membrane pore size of 1-10 nm and porosity of 40%-70%. The porous conductive membrane has higher ion selectivity and can effectively solve the migration problem of electrolyte solutions, prolong the cycle life of the battery and improve the performance of the battery, and meanwhile, the production cost ofmembrane materials of flow energy storage batteries is substantially reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Redox flow secondary battery and electrolyte membrane for redox flow secondary battery

ActiveUS20140349160A1Improve current efficiencySuppress eliminationNon-metal conductorsCell electrodesPolymer electrolytesChemical physics

The purpose of the present invention is to provide a redox flow secondary battery which has low electrical resistance and excellent current efficiency in addition to durability. The present invention relates to: an electrolyte membrane for redox flow secondary batteries, which contains an ion exchange resin composition containing a fluorine-based polymer electrolyte; and a redox flow secondary battery which uses the electrolyte membrane for redox flow secondary batteries.

Owner:ASAHI KASEI KK

Preparation method of fluoride removal electric adsorption lanthanum-loaded electrode for drinking water and fluoride removal electrode

InactiveCN103641201AHigh ion selectivityGood choiceWater contaminantsWater/sewage treatment by ion-exchangeComposite electrodeWater flow

The invention provides a preparation method of a fluoride removal electric adsorption lanthanum-loaded electrode for drinking water and a fluoride removal electric adsorption electrode prepared by the method. The method comprises the steps of (1) loading lanthanum into a carbon aerogel material to prepare a conductive adsorbent, wherein the weight part ratio of lanthanum to the carbon aerogel material is (5-60):(40-95); (2) adding a hot melt adhesive into the lanthanum-loaded carbon aerogel material prepared in the step (1), and mixing uniformly to prepare an electric adsorption mixture, wherein the weight part ratio of the hot melt adhesive to the lanthanum-loaded carbon aerogel material is (10-40):(60-90); (3) putting the electric adsorption mixture into a mold, and performing hot press molding. The composite electrode prepared by the method provided by the invention is strong in fluoride removal adsorptivity and high in strength, can not be broken after long-term use, is small in mass loss without dissolution and the problem of secondary pollution, is safe and reliable, and is suitable for long-term use under the condition with large water flow pressure changes.

Owner:BEIJING FORESTRY UNIVERSITY

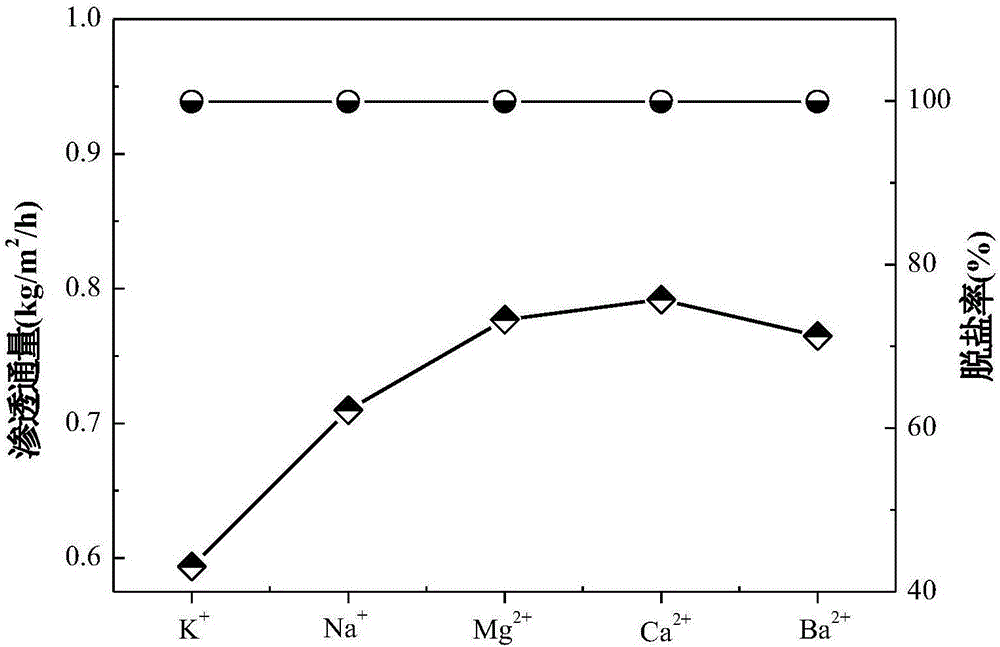

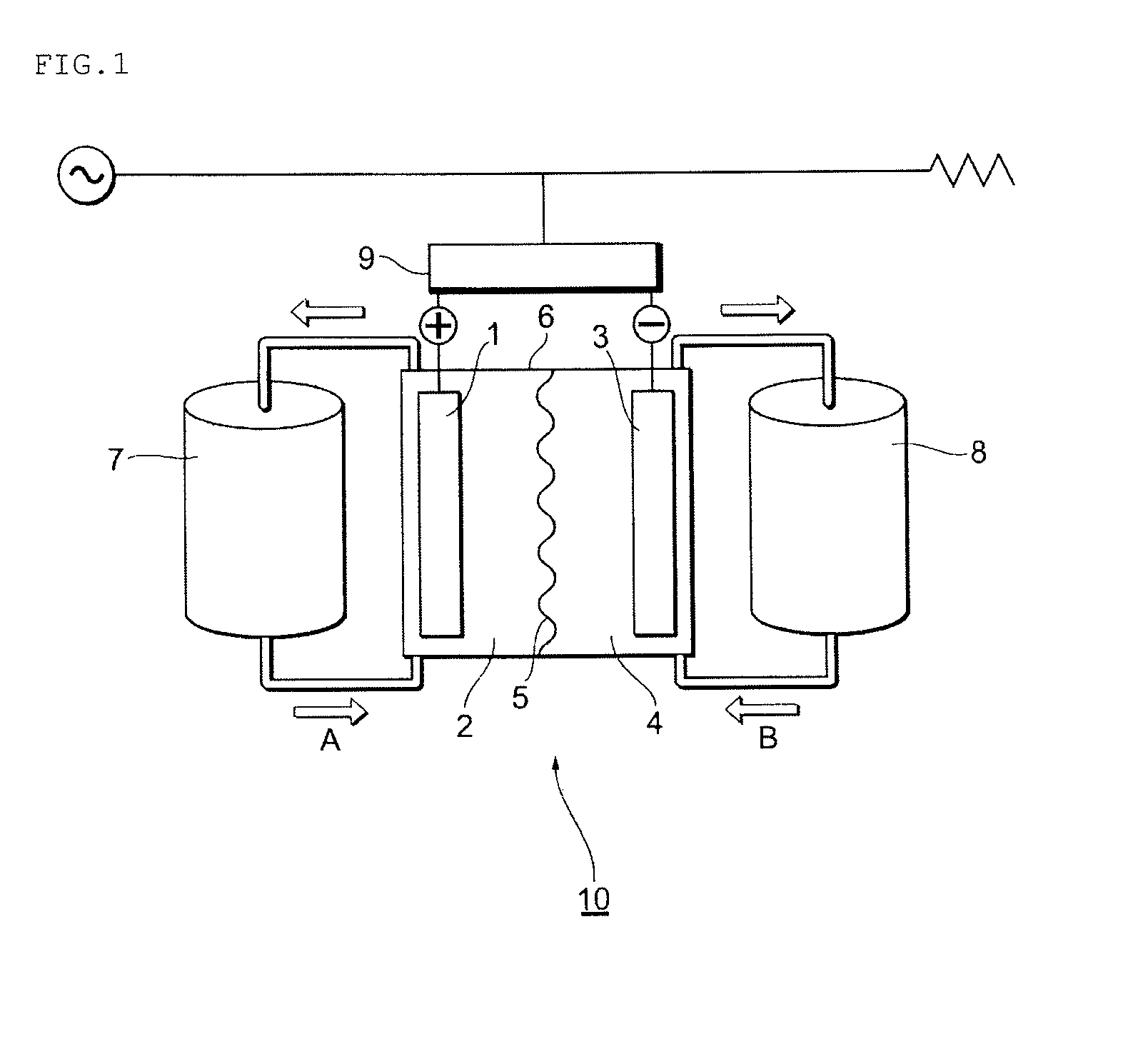

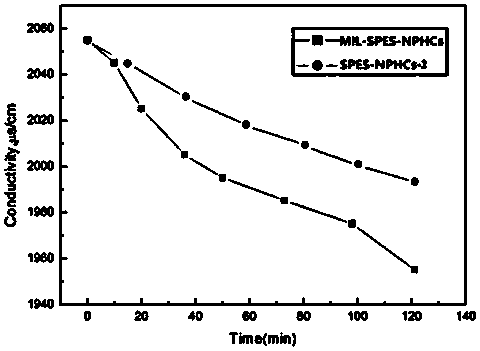

Mixed matrix cation exchange membrane based on metal organic framework compound and preparation method thereof

ActiveCN111249928AImprove hydrophilicityGood antimicrobial performanceSemi-permeable membranesMembranesMetal-organic frameworkIon exchange

The invention discloses a mixed matrix cation exchange membrane based on a metal organic framework compound and a preparation method of the mixed matrix cation exchange membrane, and belongs to the technical field of membrane separation. According to the mixed matrix cation exchange membrane, sulfonated polyethersulfone is used as a membrane matrix material, hydrophilic MIL-101, UIO-66, ZIF-8, modified chitosan, sodium alginate and chitin are used as additive substances, and finally the mixed matrix cation exchange membrane is obtained through a blending method. The invention provides a simplefilm membrane method. The obtained mixed matrix cation exchange membrane has improved porosity and good hydrophilicity, the addition of the organic metal framework compound improves the ion exchangeperformance of the membrane, reduces the membrane resistance and improves the anti-pollution performance of the membrane, and the sulfonated polyethersulfone is used as the matrix to enhance the mechanical strength, ion exchange performance and thermal stability of the membrane.

Owner:SHANDONG UNIV OF SCI & TECH

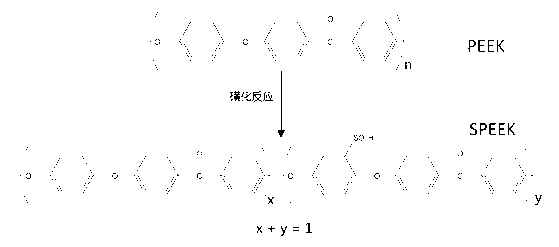

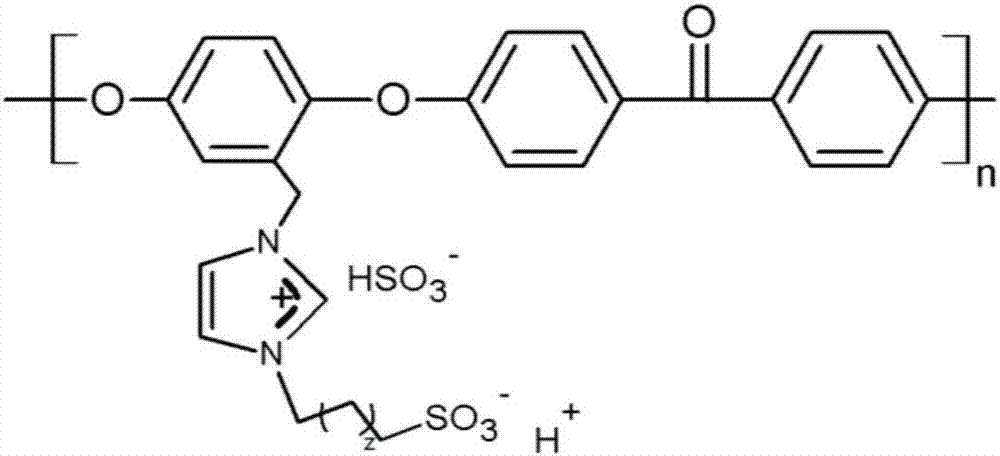

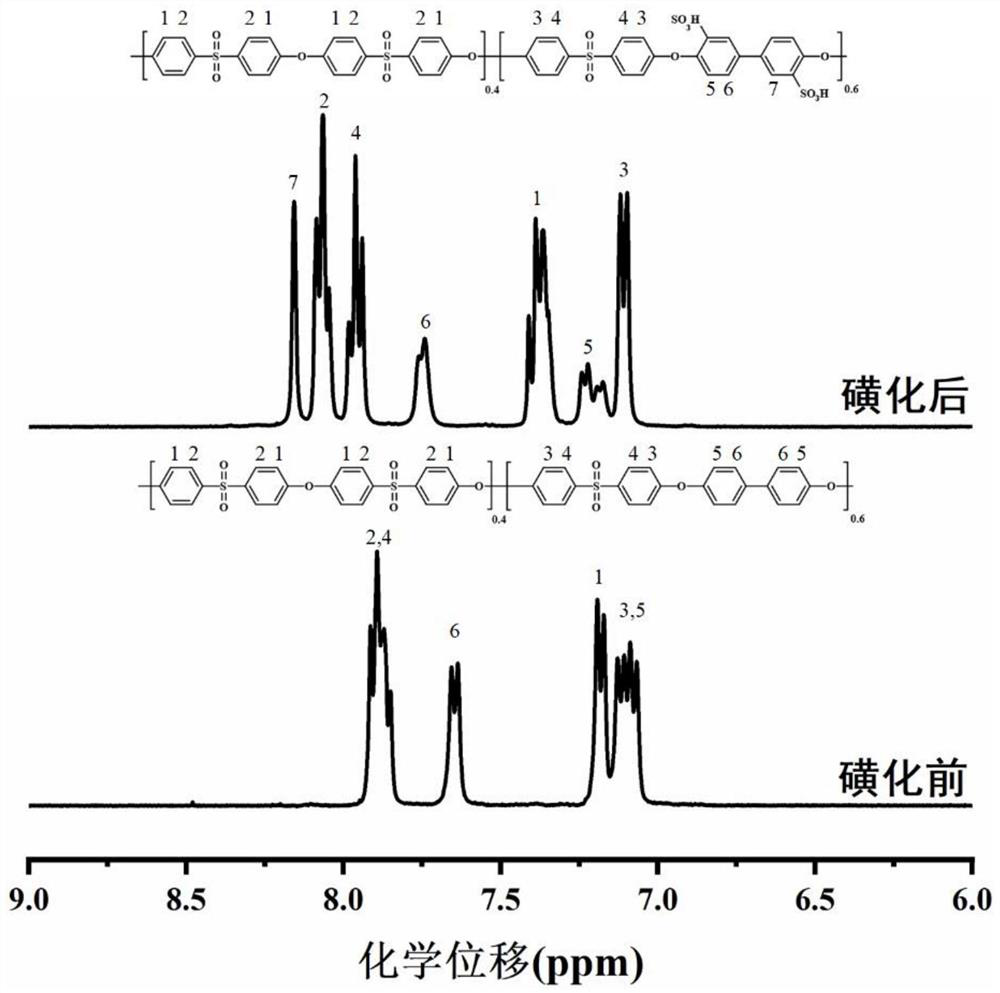

Preparation method of amphoteric functional PEEK (polyetheretherketone) ion exchange membrane

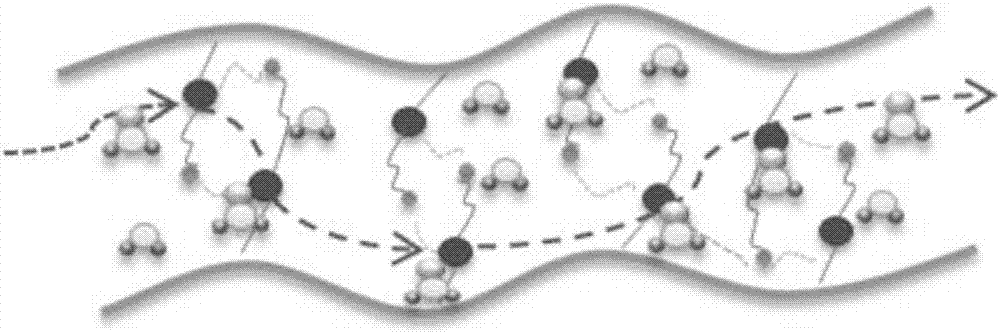

ActiveCN106910922AHigh ion conductivityHigh ion selectivityRegenerative fuel cellsSulfonateSide chain

The invention discloses a preparation method of an amphoteric functional PEEK (polyetheretherketone) ion exchange membrane, and particularly relates to a preparation method of an ion exchange membrane having high ion selectivity and used for a VFB (vanadium flow battery). Side chains of a membrane material contain amphoteric functional groups. The preparation method comprises steps as follows: 1) preparation of sodium imidazolate; 2) halomethylation of PEEK; 3) imidazole modification of PEEK; 4) bifunctionalization of PEEK. The amphoteric functional groups are introduced into the ion exchange membrane, the vanadium resisting capability of the membrane is improved by use of the Donnan effect of electropositive groups, proton conduction can be guaranteed through contained sulfonate radical, and the ion exchange membrane having high ion selectivity is obtained. The preparation process is simple and low in cost, and the prepared amphoteric ion exchange membrane has high ion selectivity and is suitable for being applied to the VFB.

Owner:DALIAN UNIV OF TECH

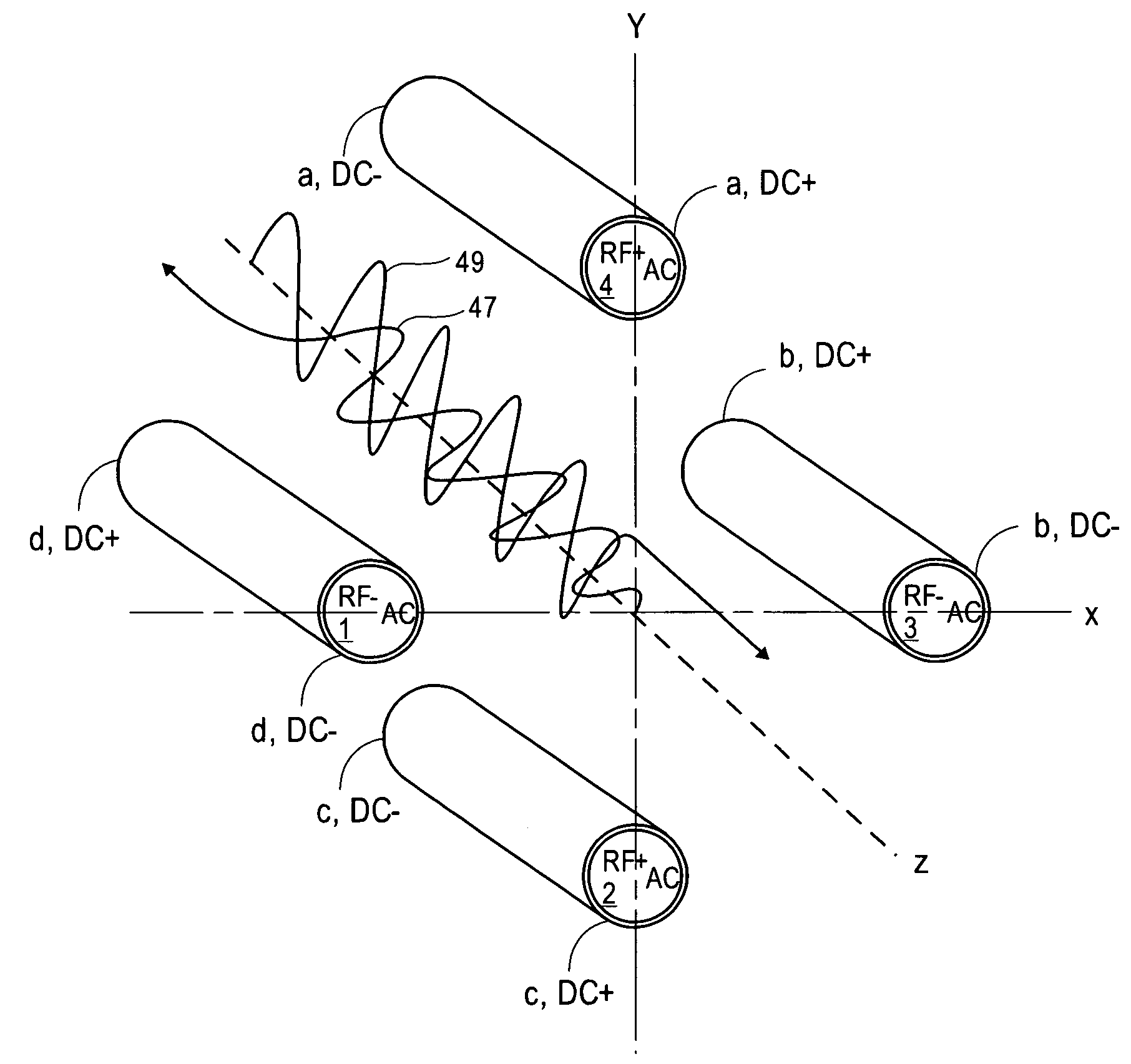

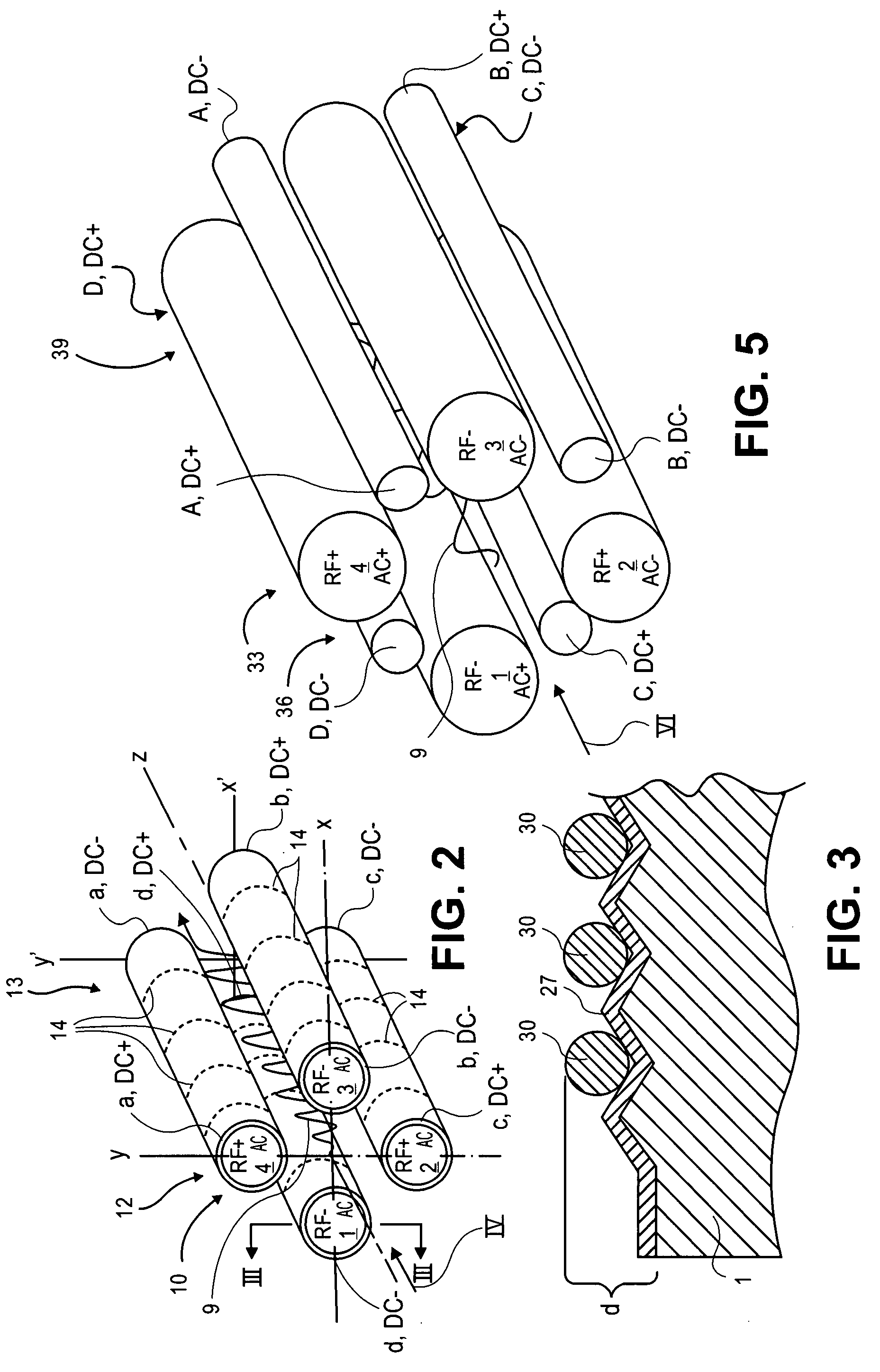

Separation and axial ejection of ions based on m/z ratio

ActiveUS7633060B2Increase abundanceHigh ion selectivityParticle separator tubesIsotope separationSpectrometerAtomic physics

A mass spectrometer includes a multipole having a main RF field for radially containing ions generally on a central axis. The multipole has first and second axial DC fields in opposite first and second direction along a length of the multipole. The first and second axial DC fields approach or add substantially to zero on the central axis. The multipole has an excitation voltage applied thereto for selectively exciting the ions of desired m / z ratios off the central axis. The excitation voltage thus causes excursion of the ions into a region where either the first or second axial DC field is strong. Thus, excitation of the ions and the DC fields cause ion drift toward a front end or a back end of the multipole. Further excitation moves the ions into regions of the DC fields that overcome barriers and causes axial ejection of the ions from the multipole.

Owner:THERMO FINNIGAN

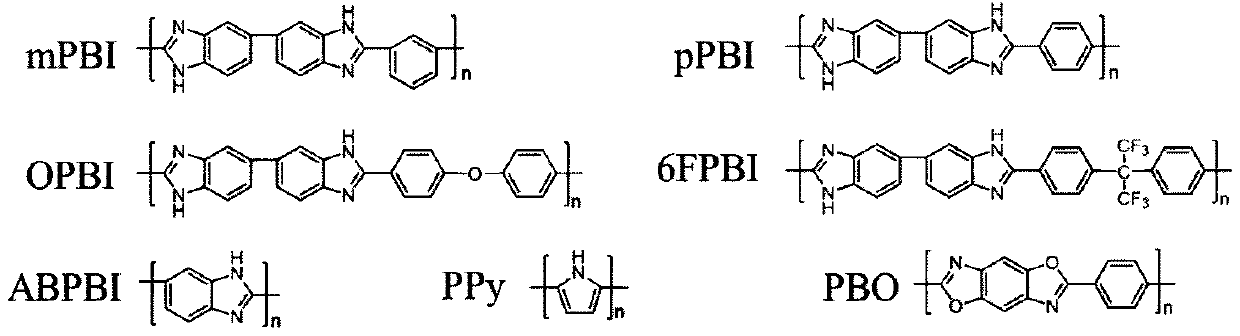

Preparation method of ion exchange membrane and application thereof

ActiveCN110783591APermeation barrierReduce thicknessFinal product manufactureRegenerative fuel cellsPolymer resinPhysical chemistry

The invention relates to a preparation method of an ion exchange membrane and an application thereof, belongs to the technical field of ion exchange membrane preparation process, and mainly solves thetechnical problems of low ion conductivity, poor mechanical stability and the like existing in the present ion exchange membrane. The technical scheme of the invention is as follows: the preparationmethod of the ion exchange membrane comprises the following steps: 1) dissolving a perfluorosulfonic acid resin in a high boiling point polar solvent to prepare a perfluorosulfonic acid resin solution; 2) coating the perfluorosulfonic acid resin solution on a clean polytetrafluoroethylene porous mesh cloth through casting, dipping or scraper to prepare a mesh cloth supported perfluorosulfonic acidmembrane; and 3) soaking the mesh cloth supported perfluorosulfonic acid membrane in the nitrogen-containing heterocyclic polymer resin solution, then thoroughly drying the membrane, rinsing with water for many times and drying the membrane so as to obtain the ion exchange membrane. The preparation method has the advantages of high ion selectivity, high mechanical and chemical stability and the like.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

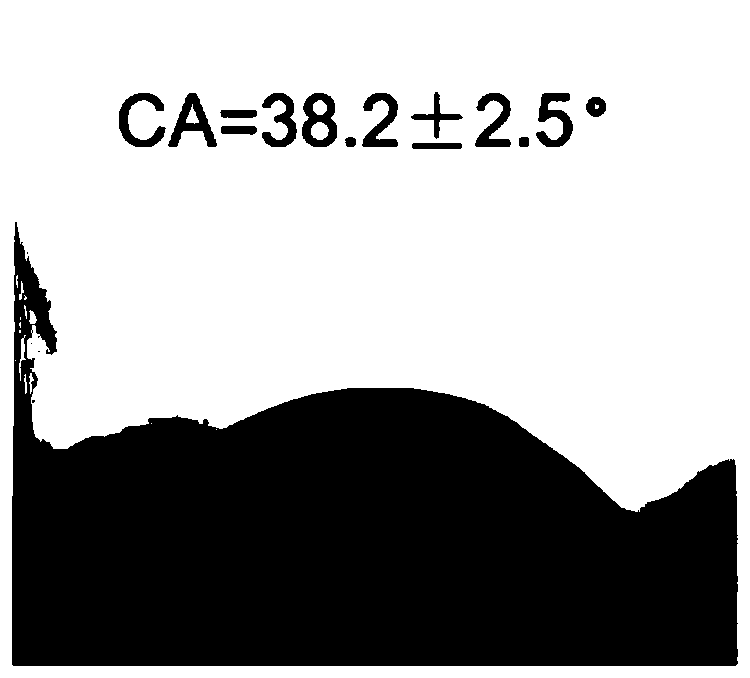

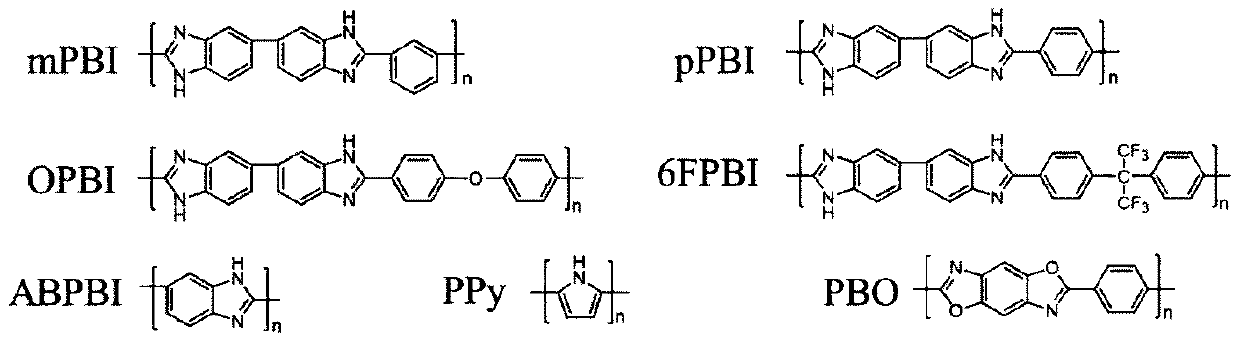

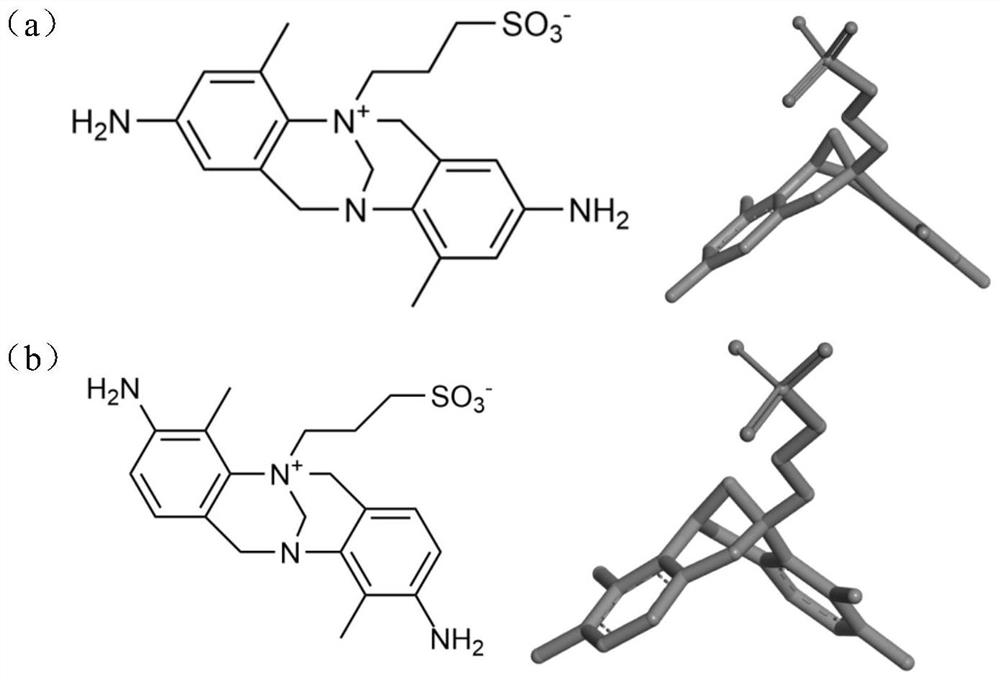

High-selectivity self-microporous polyamide nanofiltration composite membrane and preparation method thereof

ActiveCN113385049AWide pore size distributionMany free poresSemi-permeable membranesGeneral water supply conservationPolyamideNanofiltration

The invention discloses a high-selectivity self-microporous polyamide nanofiltration composite membrane and a preparation method thereof. The composite membrane is formed by compounding an ultrafiltration base membrane and a polyamide separation layer, wherein the polyamide separation layer is formed by polymerizing a water-phase mixed amine solution and an organic acyl chloride solution on the surface of the ultrafiltration base membrane, the water-phase mixed amine solution is a mixed solution of organic amine and an amine monomer which contains a sulfonic acid quaternary ammonium salt group and has a rigid twisted structure; the ultrafiltration base membrane can also adopt a surface hydrophilic modified ultrafiltration base membrane, and the polyamide separation layer is polymerized on the surface of the hydrophilic modified ultrafiltration base membrane in an in-situ support-free interface polymerization mode, so that the ultrathin high-selectivity self-microporous polyamide nanofiltration composite membrane can be obtained. The high-selectivity self-microporous nanofiltration membrane is prepared by introducing a novel amine monomer which contains a sulfonic acid quaternary ammonium salt group and has a rigid twisted structure, and the problems that an existing self-microporous nanofiltration membrane is relatively hydrophobic, so that the flux is low, the selectivity is insufficient, the pollution resistance is poor due to large membrane surface roughness and the like can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

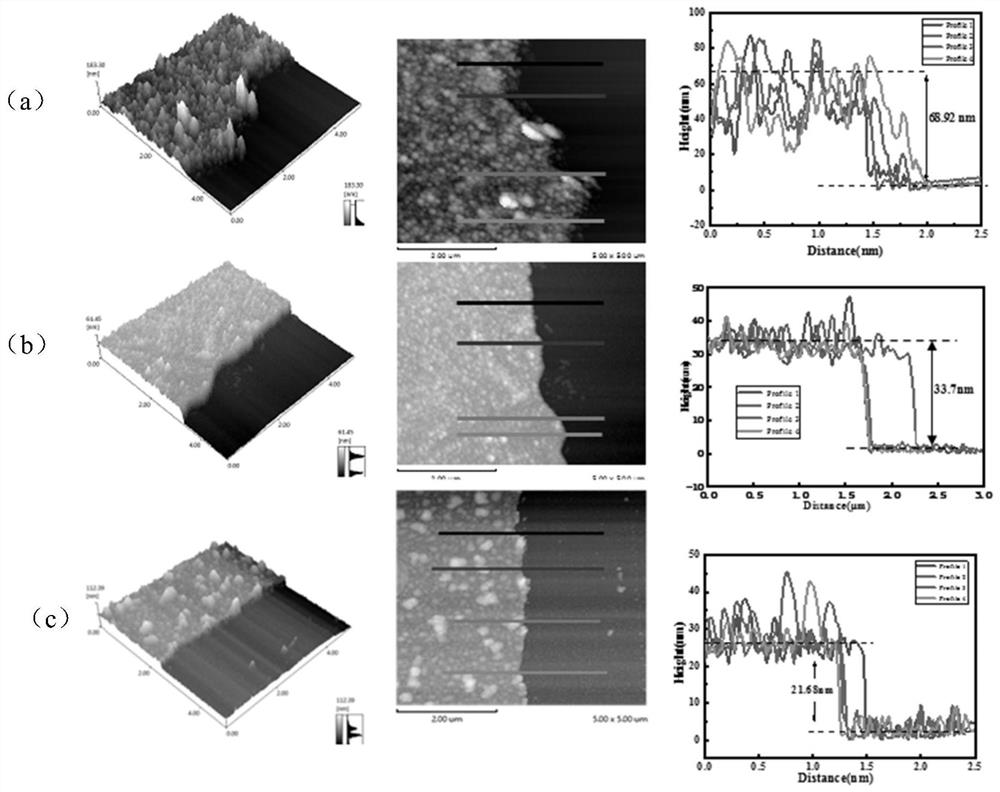

Sulfonated polyarylether compound and preparation method thereof, ion-selective composite porous membrane and preparation method and application thereof

ActiveCN113278152AHigh ion selectivityImprove thermal stabilitySemi-permeable membranesElectro-spinningSpinningIon current

The invention provides a sulfonated polyarylether compound and a preparation method thereof, an ion-selective composite porous membrane and a preparation method and application thereof, and belongs to the technical field of functional materials. A main chain of the sulfonated polyarylether compound provided by the invention is charged, the sulfonated polyarylether compound has good ion selectivity, the sulfonated polyarylether compound is compounded with a two-dimensional material, the ion selective composite porous membrane with an asymmetric structure is prepared through suction filtration and electrostatic spinning, and the ion-selective composite porous membrane is relatively large in membrane pore and relatively high in water and ion flux, has a typical ion current rectification effect, and can realize high output power, high energy utilization rate and stable salinity gradient power generation. Meanwhile, the ion-selective composite porous membrane contains a high polymer material sulfonated polyarylether compound, is relatively good in flexibility, and has good thermal stability, chemical stability and membrane-forming property of a polyarylether material.

Owner:JILIN UNIV

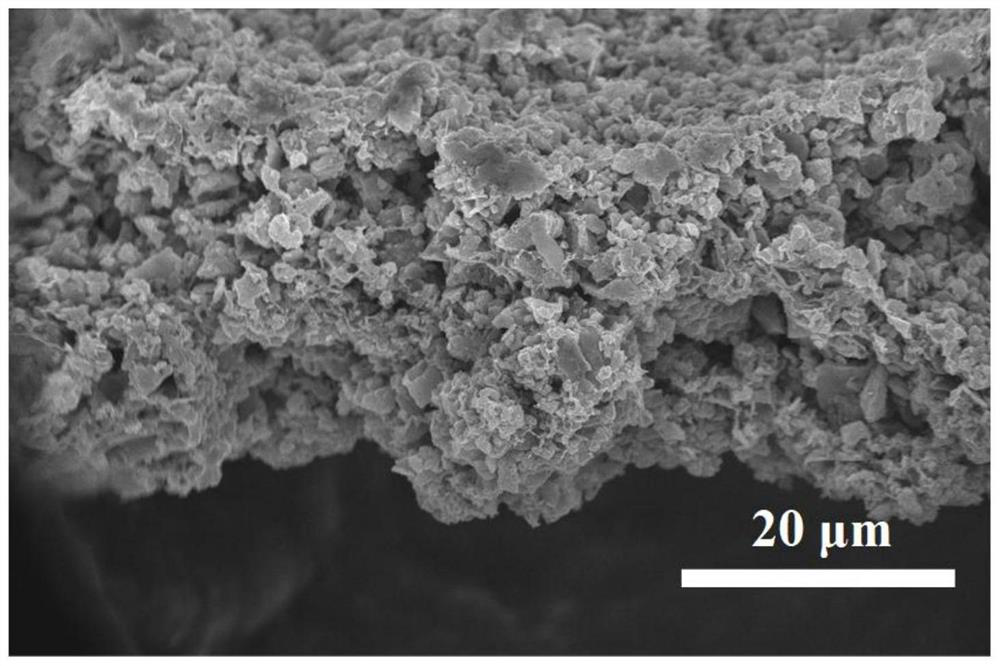

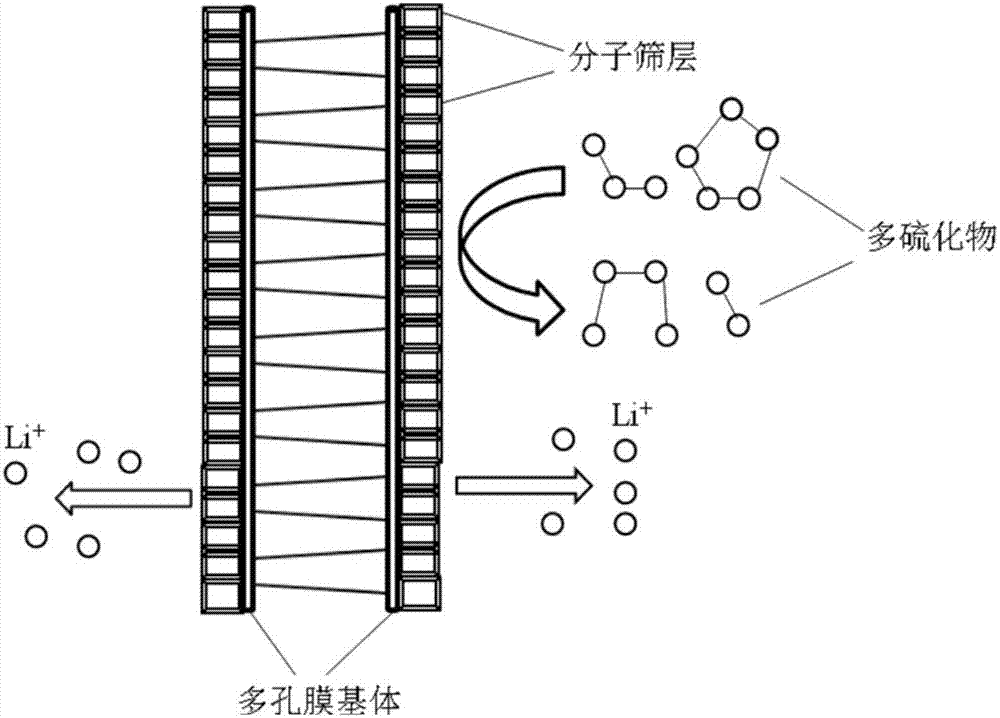

An application of a molecular sieve composite porous membrane in a lithium-sulfur battery

InactiveCN107546356AHelp with transmissionBlock "Flying Shuttle" EffectCell component detailsOrganic polymerCrystal

An application of a molecular sieve composite porous membrane in a lithium-sulfur battery is disclosed. The molecular sieve composite porous membrane is a composite porous membrane formed by adoptinga porous membrane prepared from one or more than two types of organic polymer resin as a matrix, and by compositing inorganic molecular sieve layers on the two side surfaces of the matrix. The molecular sieve composite porous membrane has high electrolyte absorbing capability and storage capability in the lithium-sulfur battery, and facilitates lithium ion transfer. The pore diameter of molecularsieve layers of the composite membrane can be controlled to be a size between a polysulfide size and a lithium ion size, and therefore the shuttle effect of polysulfide is effectively inhibited underthe premise of not influencing lithium ion conductivity, loss of active compounds is reduced, and the battery efficiency and stability are improved. In addition, the molecular sieve layers of the composite membrane have good thermal conductance, can inhibit generation of negative electrode lithium sheet dendritic crystals, and prevent battery short circuits because a separating membrane is piercedby the dendritic crystals in a battery using process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

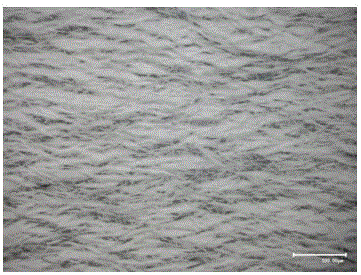

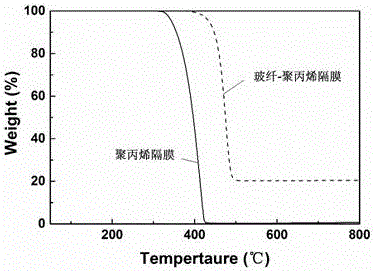

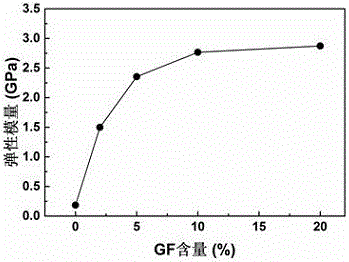

Preparation method of high content glass fiber filled polypropylene battery diaphragm

ActiveCN106571438AUniform pore size distributionImprove heat resistanceCell seperators/membranes/diaphragms/spacersElectrical batteryLithium sulfur

Belonging to the technical field of battery diaphragm preparation, the invention specifically discloses a preparation method of a high content glass fiber filled polypropylene battery diaphragm. The method includes the steps of: S1. adding glass fiber into an ethanol aqueous solution containing a silane coupling agent to conduct soaking, then performing filtering and drying to obtain modified glass fiber; S2. blending the modified glass fiber obtained by S1 with polypropylene to prepare a blended material, and subjecting the blended material to melt extrusion so as to obtain master batch; S3. conducting extrusion molding on the master batch obtained in S2, and carrying out drafting to obtain a modified glass fiber polypropylene composite material; and S4. stretching the composite material obtained in S3 to prepare a porous film, soaking the porous film in a polar polymer solution, and performing drying, thus obtaining the polypropylene battery diaphragm. The glass fiber filled polypropylene battery diaphragm prepared by the method provided by the invention has the advantages of uniform pore size distribution, good heat resistance, high mechanical strength and superior safety performance, also has high ion selectivity, and is expected to be applied in power batteries, high temperature lithium ion batteries, lithium sulfur batteries, lithium air batteries and other fields.

Owner:SUN YAT SEN UNIV

Multilayer composite proton exchange film containing perfluorosulfonic acid resin and preparation method thereof

The invention relates to the ion exchange film field and particularly relates to a multilayer composite proton exchange film containing perfluorosulfonic acid resin and a preparation method thereof. The perfluorosulfonic acid resin is dissolved in corresponding solvent to form preparation liquid having a certain concentration, a film is formed through scraping under the certain temperature and atmosphere, the solvent is volatilized into a film, the perfluorosulfonic acid resin film is taken as a perfluorosulfonic acid resin base film, an inorganic functional layer is prepared on the surface thereof through the hydrothermal method, and the composite proton exchange film is finally obtained. The method is advantaged in that a problem of low ion selectivity of a conventional perfluorosulfonicacid film is solved through the composite inorganic functional layer, moreover, mechanical properties of the composite film are significantly improved, produced products have better performance thancommercially available products, the cost is lower than similar products, and the method is of great significance for wider application of ion exchange films.

Owner:辽宁科京新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com