Preparation method of amphoteric functional PEEK (polyetheretherketone) ion exchange membrane

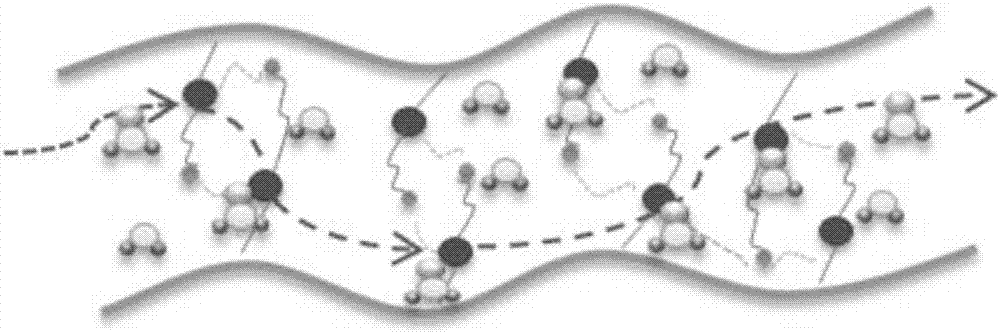

An ion exchange membrane, polyether ether ketone technology, which is applied in the field of preparation of high ion selectivity amphoteric functional ion exchange membrane of all-vanadium redox flow battery, can solve the problems of high price, poor ion selectivity, and limited membrane commercial application. , to achieve the effect of preventing permeation, high ion selectivity, high Coulombic efficiency and energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of imidazole sodium salt: under nitrogen atmosphere, disperse sodium hydride in tetrahydrofuran, add dropwise imidazole / tetrahydrofuran solution, stir magnetically for 2 hours, remove solvent to obtain white solid which is imidazole sodium salt, (sodium hydride:imidazole:tetrahydrofuran=0.48 g:1.36g:40ml);

[0029] Polyetheretherketone halomethylation: prepare 1g of polyetheretherketone into a w / v concentration of 1% polyetheretherketone / concentrated sulfuric acid solution; add 18mL of chloromethyl octyl ether, stir and react at -13°C for 15min; Precipitate in water, wash repeatedly until neutral, and dry at room temperature to obtain chloromethylated polyether ether ketone;

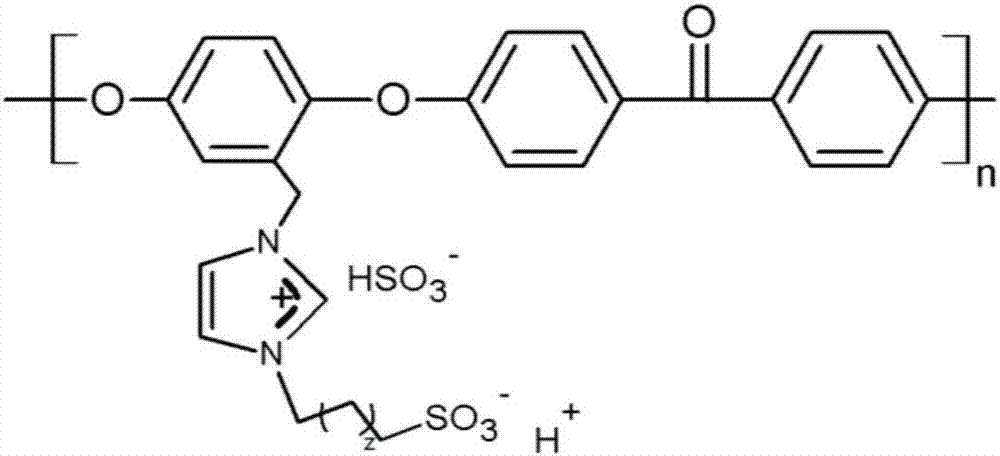

[0030] Polyetheretherketone imidazole modification: Take 1g of chloromethylated polyetheretherketone (DC=0.76) and dissolve it in 20ml of N-methylpyrrolidone. After it is completely dissolved, add imidazole sodium 1.25 times the amount of chloromethyl substance , stirred at room tempe...

Embodiment 2

[0034] Preparation of imidazole sodium salt: under nitrogen atmosphere, sodium hydride was dispersed in acetonitrile, imidazole / acetonitrile solution was added dropwise, magnetically stirred for 2 hours, the solvent was removed to obtain a white solid which was imidazole sodium salt, (sodium hydride: imidazole: tetrahydrofuran = 0.48 g:1.36g:40ml);

[0035] Halomethylation of polymers: Prepare 1g of polyetheretherketone into a w / v concentration of 1.25% polyetheretherketone methanesulfonic acid solution; add 18mL of chloromethyl octyl ether and 0.6mL of tin tetrachloride, Stir and react for 45 minutes; pour into water to precipitate, wash repeatedly until neutral, and dry at room temperature to obtain chloromethylated polyether ether ketone;

[0036] Polymer imidazole modification: take 1g of chloromethylated polyetheretherketone (DC=0.76) and dissolve it in 20ml of N-methylpyrrolidone. ℃ for 8 hours, precipitated in deionized water, washed several times, and dried to obtain ...

Embodiment 3

[0040] Preparation of imidazole sodium salt: under nitrogen atmosphere, sodium hydride was dispersed in acetonitrile, imidazole / acetonitrile solution was added dropwise, magnetically stirred for 2 hours, the solvent was removed to obtain a white solid which was imidazole sodium salt, (sodium hydride: imidazole: tetrahydrofuran = 0.48 g:1.36g:40ml);

[0041] Halomethylation of polymers: Prepare 1g of polyetheretherketone into a w / v concentration of 1.25% polyetheretherketone methanesulfonic acid solution; add 18mL of chloromethyl octyl ether and 0.6mL of tin tetrachloride, Stir and react for 150 minutes; pour into water to precipitate, wash repeatedly until neutral, and dry at room temperature to obtain chloromethylated polyether ether ketone;

[0042] Polymer imidazole modification: Take 1g of chloromethylated polyetheretherketone (DC=1.04) and dissolve it in 20ml of N-methylpyrrolidone. After stirring for 24 hours, it was precipitated in deionized water, washed several times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com