Patents

Literature

1290 results about "Sodium hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium hydride is the chemical compound with the empirical formula NaH. This alkali metal hydride is primarily used as a strong yet combustible base in organic synthesis. NaH is representative of the saline hydrides, meaning it is a salt-like hydride, composed of Na⁺ and H⁻ ions, in contrast to the more molecular hydrides such as borane, methane, ammonia and water. It is an ionic material that is insoluble in organic solvents (although soluble in molten Na), consistent with the fact that H⁻ remains an unknown anion in solution. Because of the insolubility of NaH, all reactions involving NaH occur at the surface of the solid.

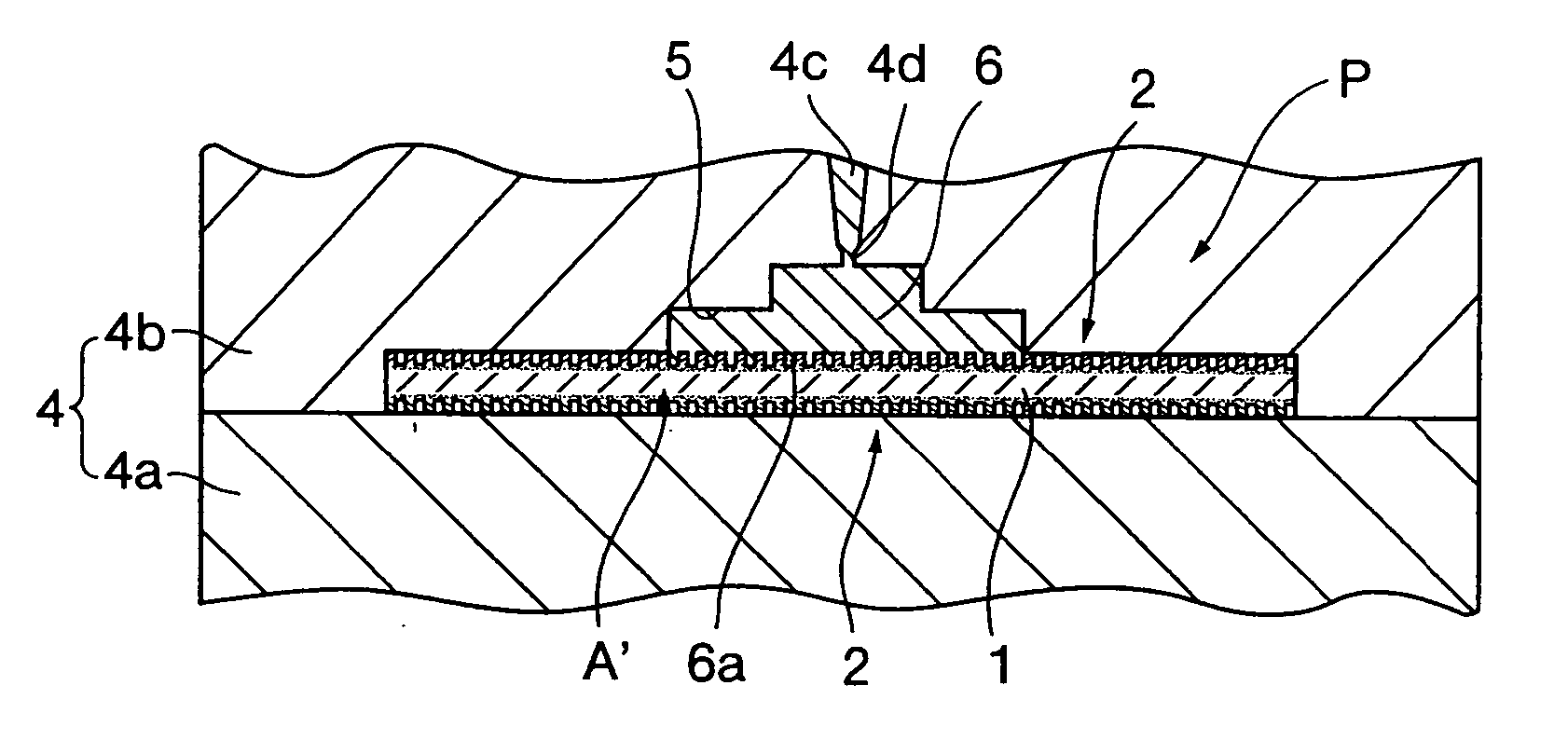

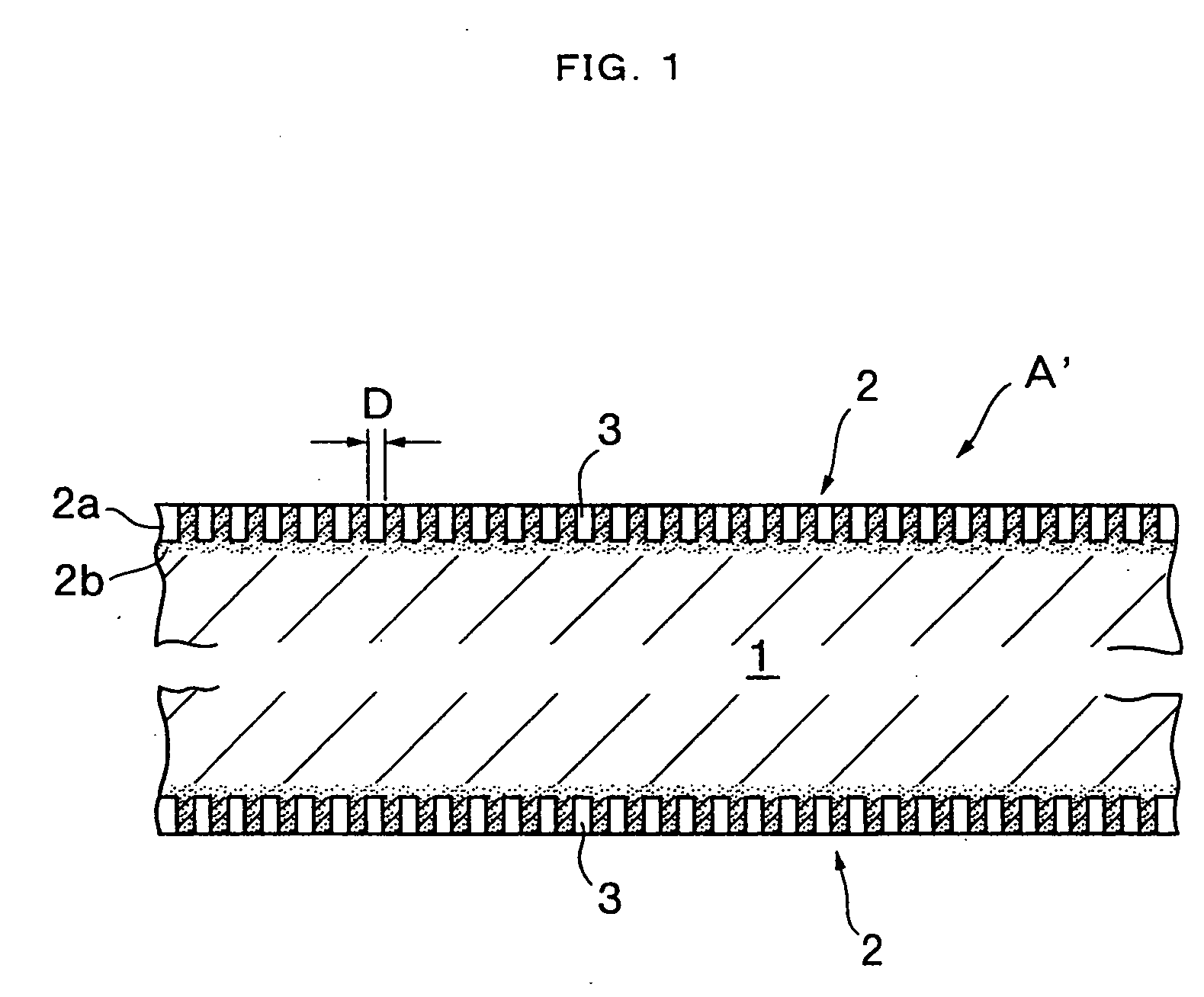

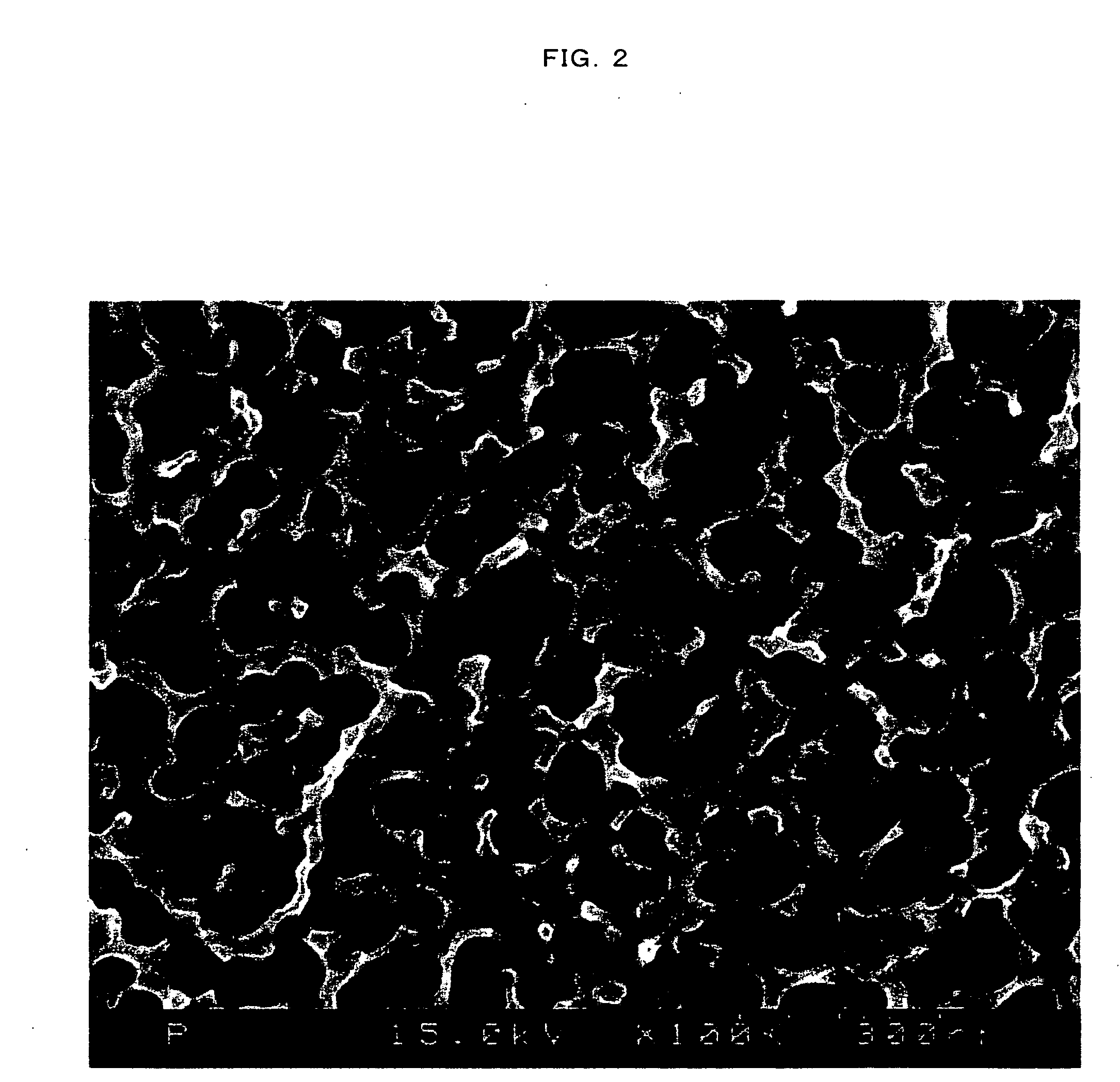

Composite of aluminium material and synthetic resin molding and process for producing the same

ActiveUS20060055084A1Stable and fast compositeHigh tensile strengthAnodisationNatural mineral layered productsO-Phosphoric AcidSynthetic resin

The present invention is to provide a process for producing a composite of an aluminum material and a synthetic resin molding that can be produced at a high efficiency and to provide a stable and fast composite that is large in a peel strength and a mechanical strength. The process for producing a composite according to the present invention is characterized in that an aluminum raw material is oxidized in an electrolytic bath of phosphoric acid or sodium hydride, thereby an anodic oxidation coating provided with innumerable pores 3 having a diameter of 25 nm or more made open in the surface thereof is formed thereon, and a synthetic resin mold 6 is coupled with the anodic oxidation coating 2 in such a condition that the part 6a thereof is intruded in the innumerable pores.

Owner:CHERRY CHIEF MAF CORP

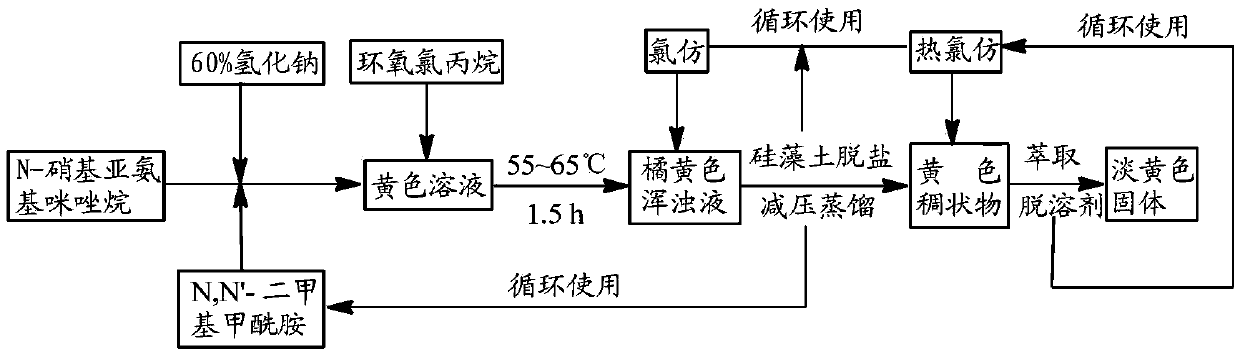

Method for preparing cycloxylidin

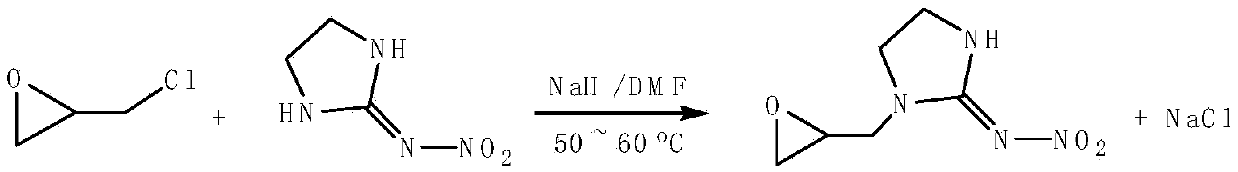

The invention discloses a method for preparing cycloxylidin, which belongs to the technical field of pesticides preparation. The method comprises the following steps: under nitrogen protection, N-nitroiminoimidazolidine and an organic solvent are added in a reactor, then sodium hydride is added in batches, and the material is heated to the temperature of 50-60 DEG C, chloropropylene oxide is added drop by drop in the reactor, after the reaction product is cooled, chloroform is added, and the product is filtered by diatomite, then evaporative crystallization is carried out, and the crystals can be precipitated, vacuum distillation is carried out on a processed filtrate to obtain a light yellow dense solid, then heat chloroform is used for extraction, and finally heat ethanol or acetone is used for recrystallization to obtain cycloxylidin: 1-(2,3-glycidyl)-N-nitroimidazoline-2-ylamine, wherein the yield is about 83%. The method has the advantages of short reaction time, high yield and green environmental protection, and is more suitable for large-scale industrial production.

Owner:山东聚强绿洲生物科技有限公司

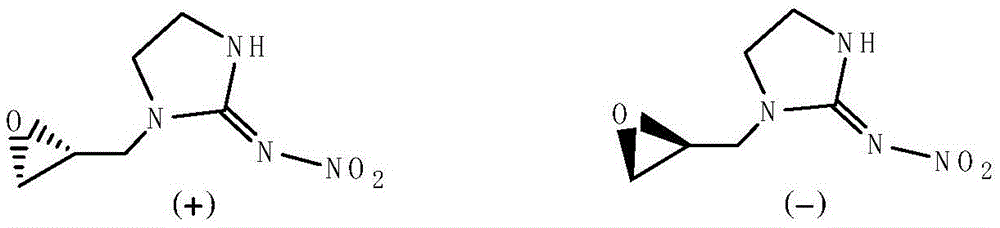

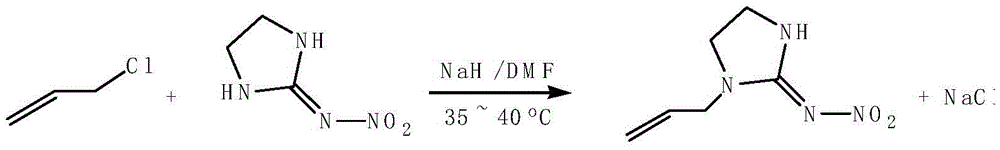

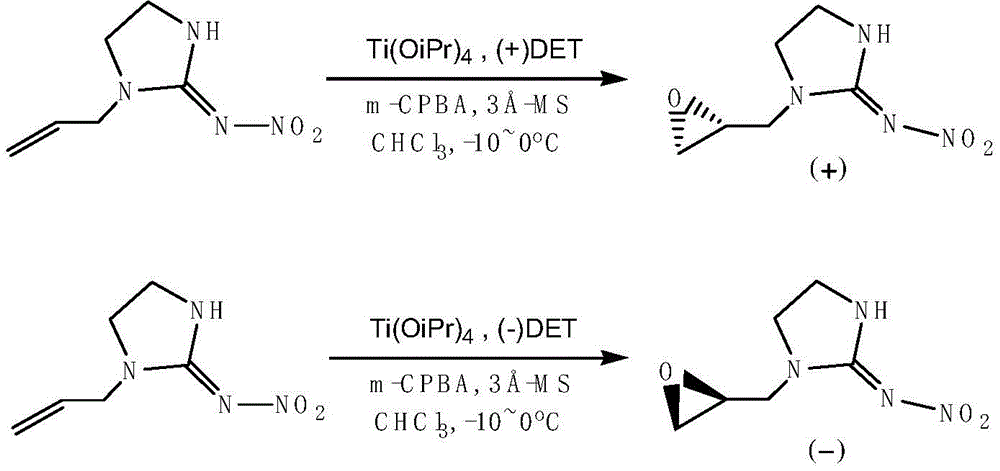

Preparation method for cycloxylidin enantiomer with photoactivity

InactiveCN105481839APrevent self-aggregationMild thermal conditionsOrganic chemistry methodsHydrogenResonance

The invention discloses a preparation method for a cycloxylidin enantiomer with photoactivity, which belongs to the technical field of asymmetric catalytic synthesis of medicines with optical activity. The method comprises a first step of synthesizing 1-allyl-N-2-nitroiminoimidazolidine and a second step of synthesizing the 1-(1,2-glycidyl)-N-2-nitroiminoimidazolidine enantiomer. The method employs sodium hydride to effectively completely remove hydrogen with weak acidity in a resonance structure of N-nitroiminoimidazolidine and convert the hydrogen into a sodium salt, wherein organic by-products are not produced; through asymmetric epoxidation, levorgyrate or dextrorotary enantiomer products with high yield can be obtained; and the method prepares high-purity enantiomer products, substantially improves insecticidal activity of the products and reduces environmental pollution.

Owner:安徽千和新材料科技发展有限公司

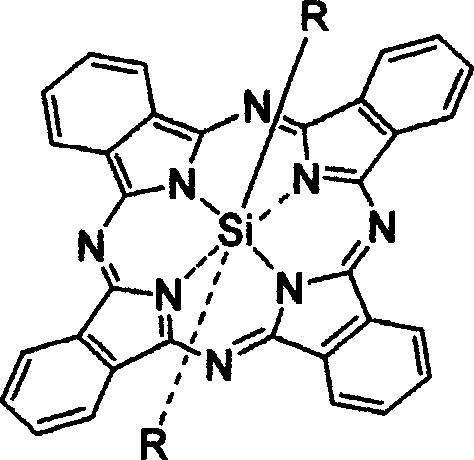

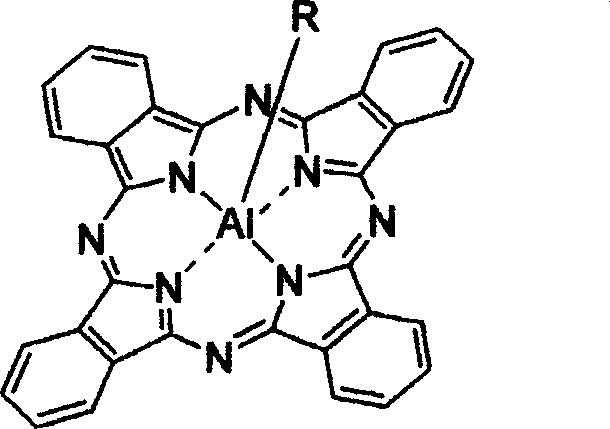

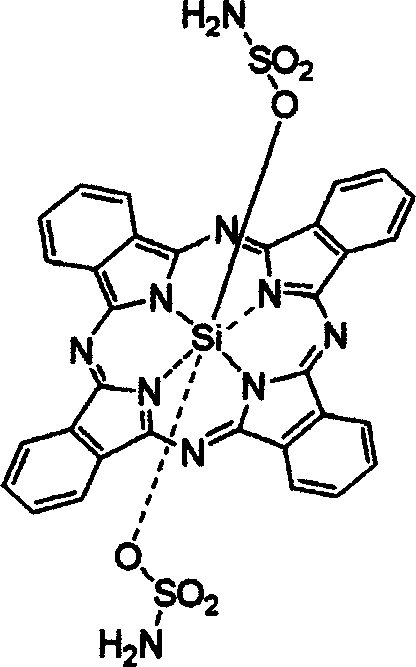

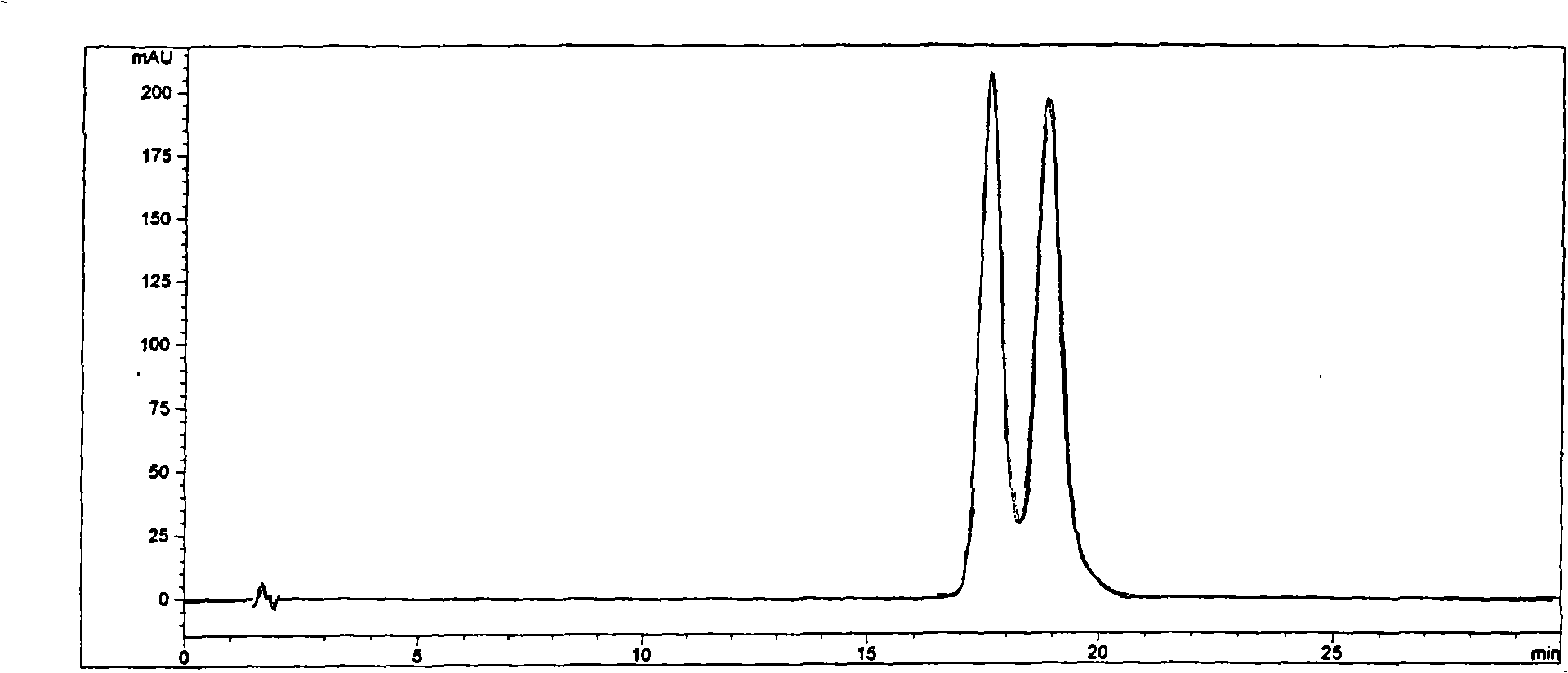

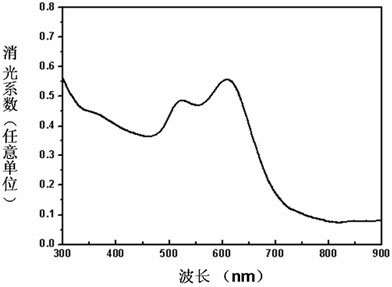

Axial substituted phthalocyanine compound, its preparation and application in optical kinetic treatment

InactiveCN1583762AEasy to makeFast productionSilicon organic compoundsEnergy modified materialsHydrogenPhthalocyanine

An axial substituted phthalocyanine complex, its manufacture and applications in optical dynamics therapy are disclosed. It is prepared by: refluxing silicon dichloride phthalocyanine and monoaluminium phthalocyanine with substitutes contained appropriate compounds and sodium hydrogen or potassium carbonate in appropriate solvent for a certain time, washing with solvent, separating through liquid chromatography, and purifying to obtain products. The complex is prepared simply and quickly, uneasy to be agglomerated, strong optical sensitive, valuble as a drug in optical dynamic treatment. Its structure is clear without isomer.

Owner:FUZHOU UNIV

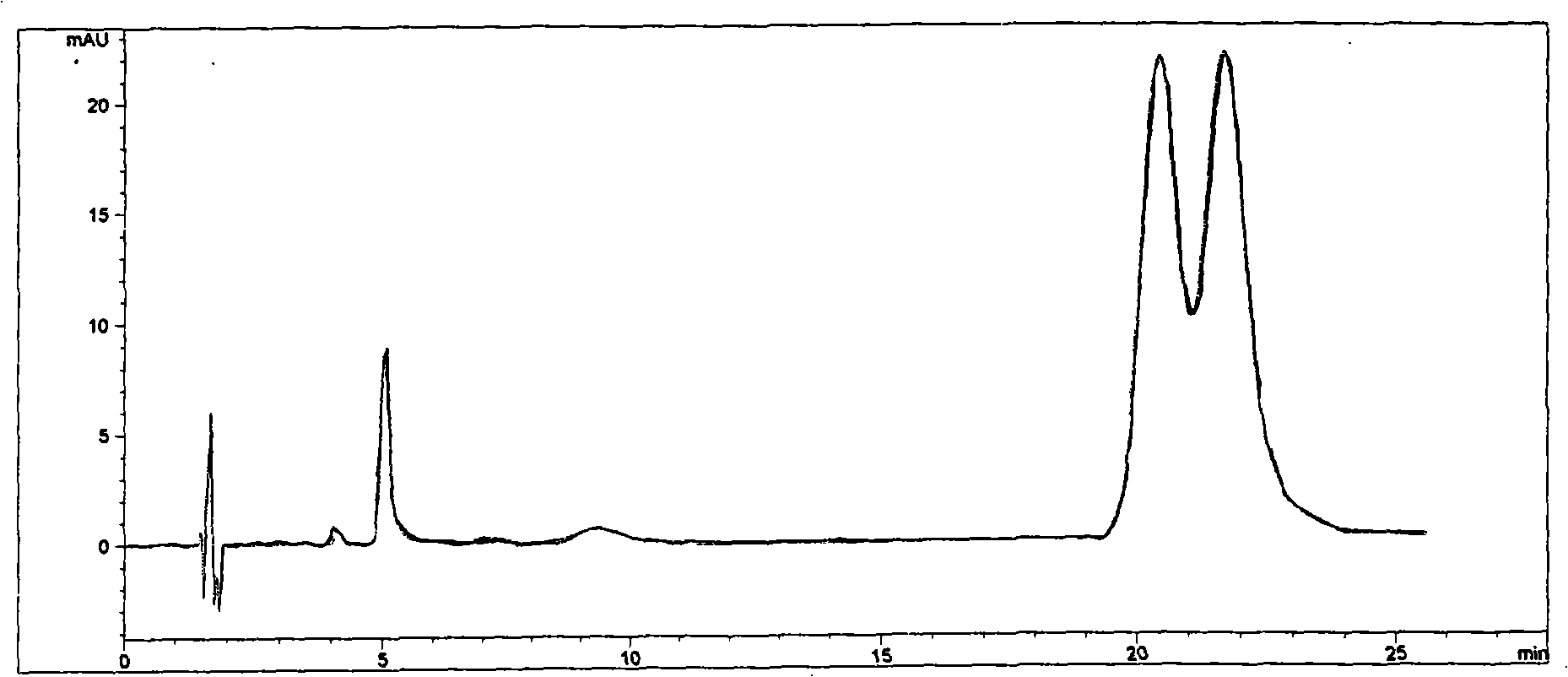

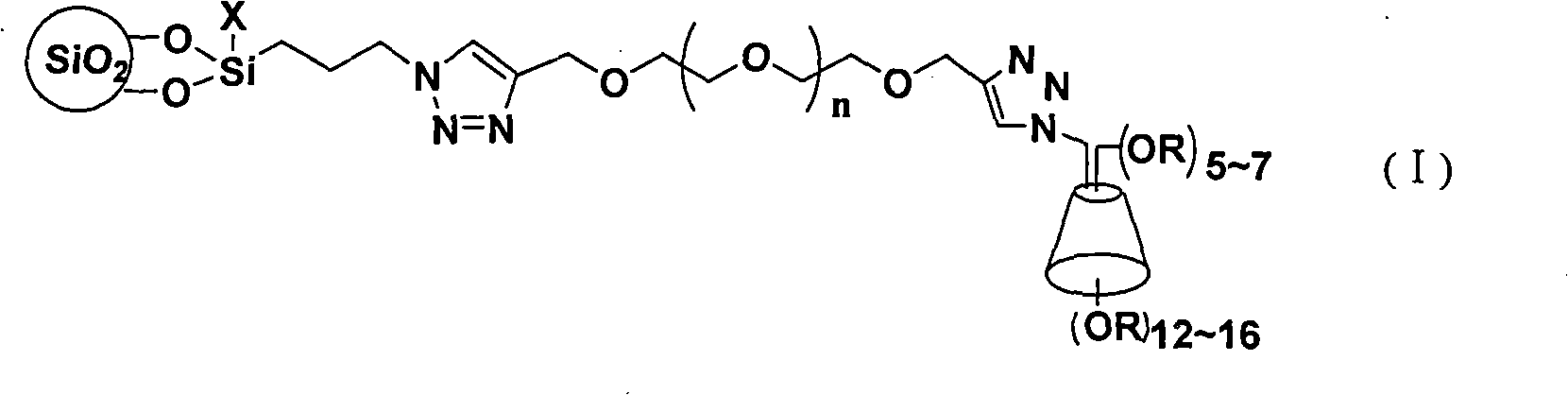

Cyclodextrin chiral chromatogram fixed phase and preparation method thereof

InactiveCN101306354AHigh column efficiencyHigh selectivityOther chemical processesAzirineChemical reaction

The invention discloses a cyclodextrin chiral stationary phase, the structure of which is shown in the general formula (I), wherein X is -OCH3 or -OCH2CH3, n is equal to 1-7, and R is -H, -CH3, -COCH3, -COC6H5 and -CONHC6H5. The preparation method of the stationary phase comprises the following steps: a silane coupling agent, sodium azide and a catalyst are added into an organic solvent, then spheroidal silicon is added for preparing azide silica gel derivant; oligomeric ethylene glycol, sodium hydride and propargyl bromide are added into tetrahydrofuran for preparing bialkynyl oligomeric ethylene glycol; monosubstituted nascent and derivative cyclodextrin containing azid groups is prepared; finally, the click chemistry reaction method is used for bonding the cyclodextrin. The cyclodextrin chiral stationary phase has the advantages that the selectivity of the bonding reaction is high, and the surface bonded amount is large; the chiral separation ability is strong, thereby being especially suitable for the chiral separation of a high efficiency liquid chromatography in the reversed-phase mode; the preparation method is simple and has less steps, the bonding reaction is the click chemistry reaction, the reaction condition is mild, and the reaction is carried out in the water solution.

Owner:EAST CHINA UNIV OF SCI & TECH

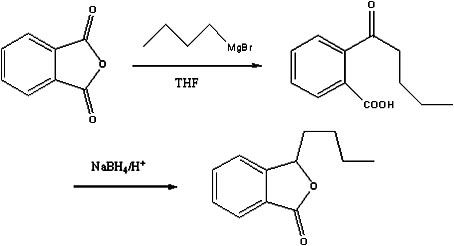

Preparation method of butylphthalide

InactiveCN101962374AReaction raw materials are readily availableFew reaction stepsOrganic chemistryBenzoic acidGrignard reagent

The invention discloses a preparation method of butylphthalide, which comprises the following steps: taking phthalic anhydride as a raw material; enabling the phthalic anhydride to carry out addition reaction with the Grignard reagent of butyl halide to obtain an intermediate of o-valeryl benzoic acid; and then, reducing by sodium borohydride, and carrying out acidic cyclization to obtain the butylphthalide. The phthalic anhydride and the butyl halide which are used as raw materials in the preparation method of the butylphthalide of the invention are commercial products, and the reaction raw materials can be obtained easily. Because the Grignard reaction, the sodium borohydride reduction and the acidic cyclization are classical reactions, the operation is simple, the industrialized production can be realized easily, the yield of the butylphthalide reaches 50-60%, and the purity of the butylphthalide reaches 97-98%.

Owner:SHANGHAI INST OF TECH

Foam drainage gas recovery method for natural gas horizontal well

InactiveCN102587865AThe effect of drainage and gas recovery is obviousSimple and safe operationFluid removalDrilling compositionRecovery methodPolyethylene glycol

The invention relates to a foam drainage gas recovery method used for a natural gas horizontal well. The method is capable of injecting a foam scrubbing agent into the bottommost end of a gas well shaft, so that the whole shaft is filled with foam fluid and optimal drainage gas recovery effect is achieved. The technical scheme of the method comprises the following steps: firstly, manufacturing a dynamical underground foam scrubbing bar which consists of a gas nozzle, a tail wing, a boosting agent, a shell and a protection head sleeve, wherein the material for manufacturing the tail wing, the shell and the protection head sleeve is the solid foam scrubbing agent which consists of polyoxyethylene alkyl ethers, polyethylene glycol, urea, imidazoline, sodium dodecyl benzene sulfonate and saturated alcohol sulfate; and the boosting agent is one of dry ice, sodium hydride or potassium oxide; and secondly, throwing the dynamical underground foam scrubbing bar to the bottom of the well, wherein the boosting agent is in contact with water to generate a large amount of gas, so that the foam scrubbing bar is pushed to the bottommost end; and as the foam scrubbing agent is dissolved, a large amount of foam is formed to achieve the optimal effect of drainage gas recovery. The method disclosed by the invention has a wide application range without any wellhead equipment and energy, is simpleand safe in operation, low in cost and has no pollution to the environment.

Owner:SOUTHWEST PETROLEUM UNIV

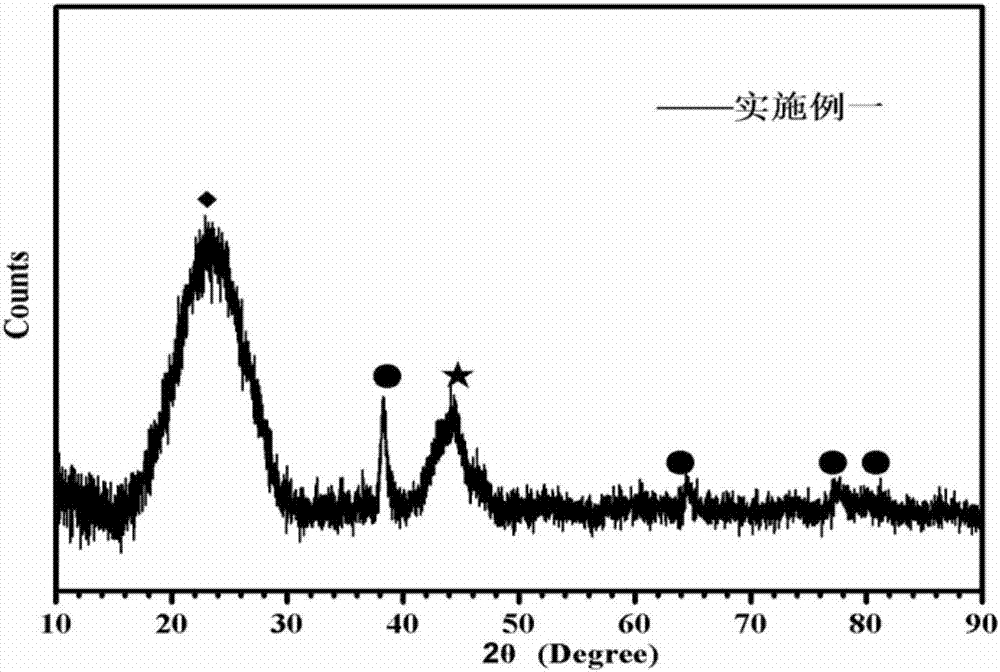

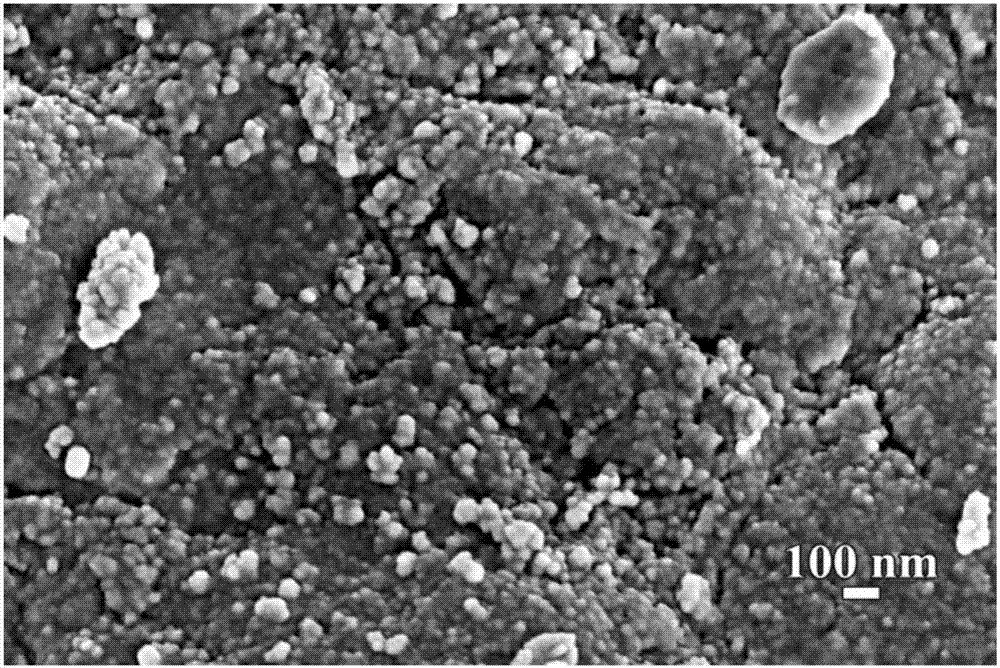

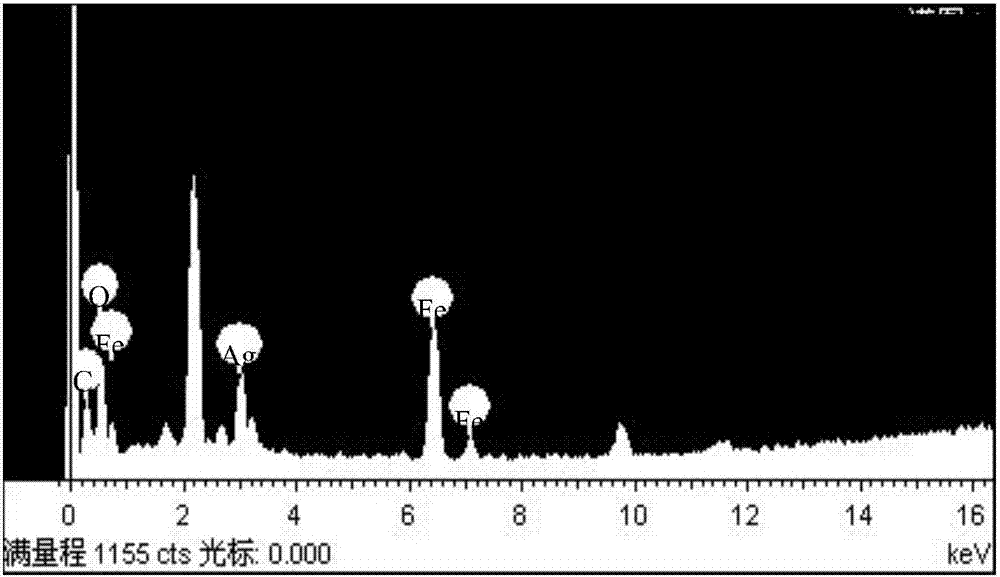

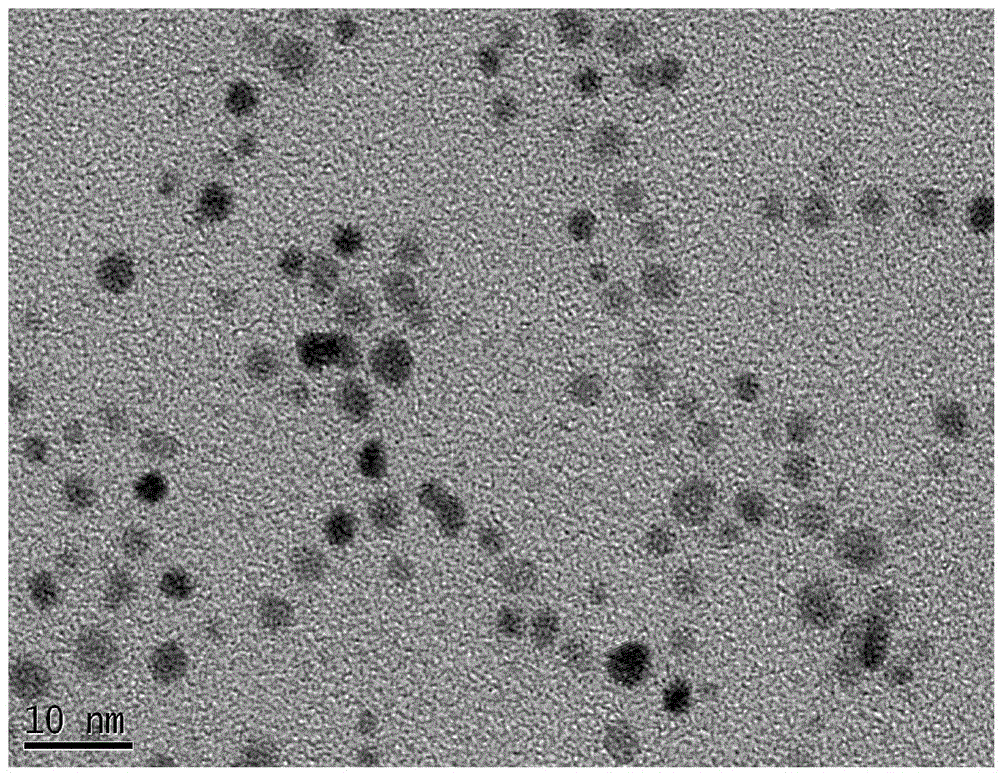

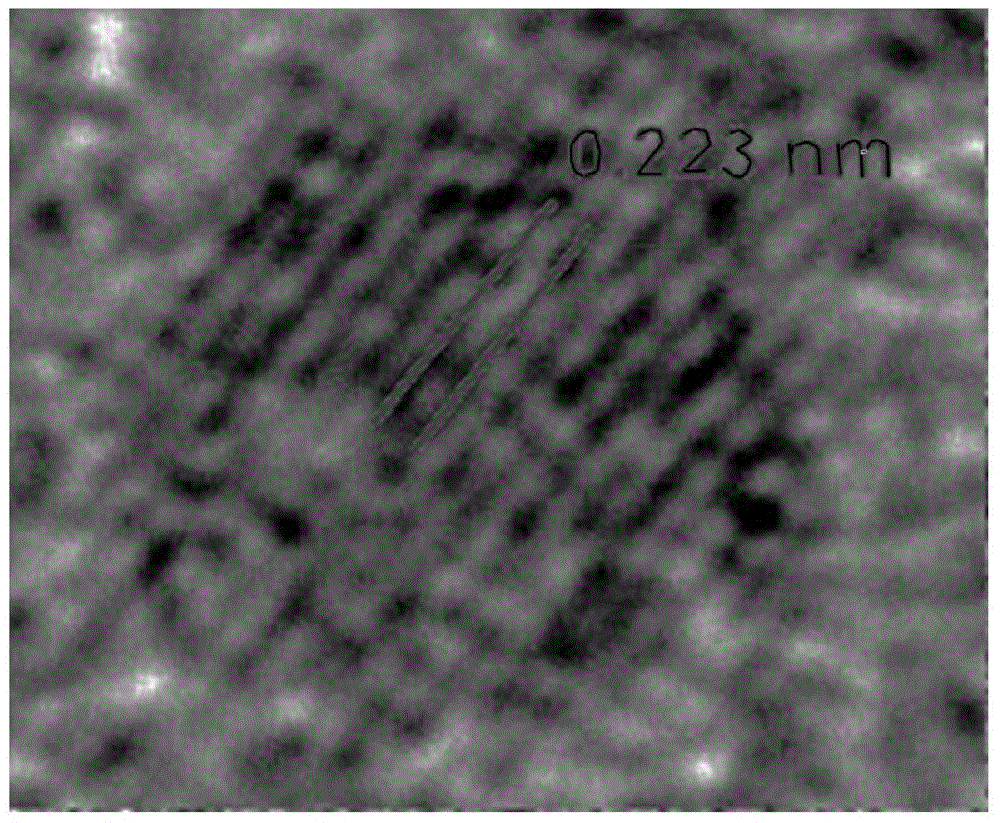

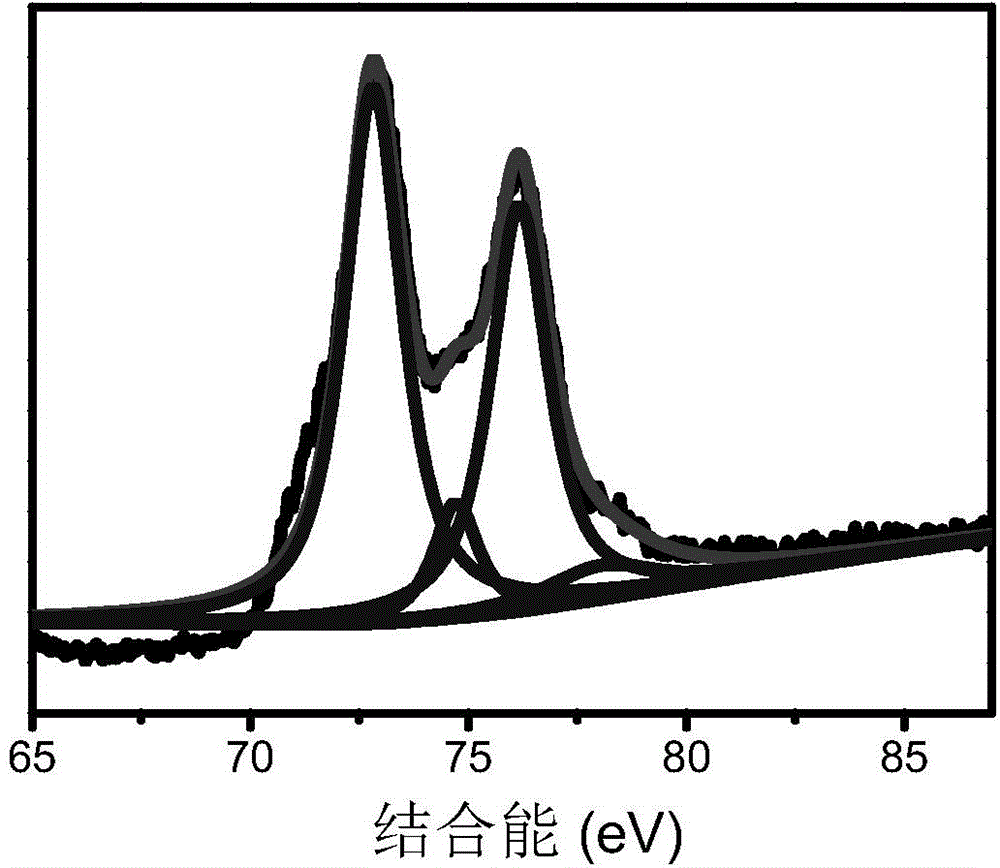

Composite material of nano zero-valent iron and silver metal cluster loaded on activated carbon and preparation method of composite material

InactiveCN106955667AHigh social and economic valueHuge specific surface areaOther chemical processesSpecific water treatment objectivesSolventActivated carbon

The invention relates to a composite material of nano zero-valent iron and a silver metal cluster loaded on activated carbon and a preparation method of the composite material. The method comprises the steps of firstly carrying out acidifying treatment on the activated carbon, cleaning and drying; secondly, adding polyethylene glycol to a mixed ferrous sulfate solution employing ethanol and water as mixed solvents, dissolving, adding NaOH to adjust the pH value; adding acidified activated carbon to the mixed solution, fully stirring and then adding a sodium borohydride solution to obtain nano zero-valent iron-loaded activated carbon; and finally washing the nano zero-valent iron-loaded activated carbon, and adding the nano zero-valent iron-loaded activated carbon to a silver salt solution as quickly as possible and reacting to obtain the material. The preparation method is simple in process, and simple in operation; and in a practical water purification application, various pollutants in drinking water are efficiently converted and degraded by combining the strong adsorption ability of the activated carbon and a micro-galvanic cell formed between iron and silver nanoparticles.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

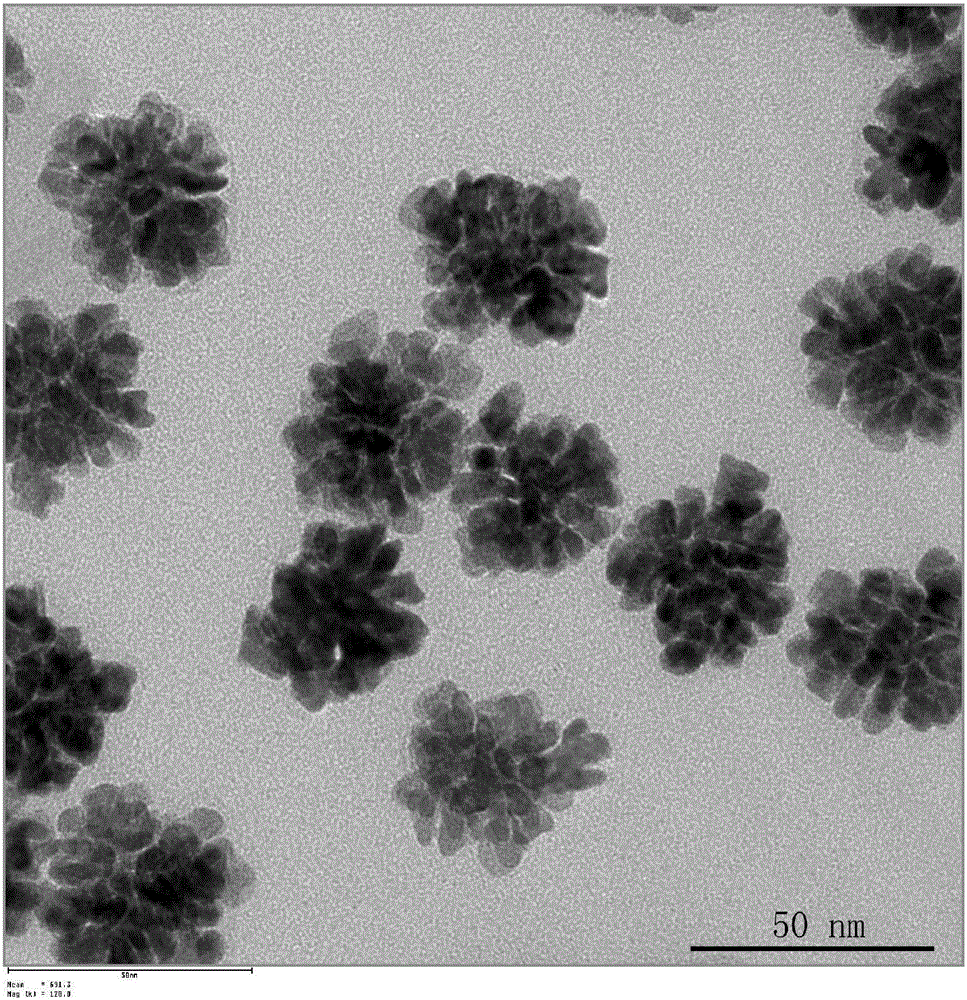

Platinum nano-material with activity of four mimic enzymes and preparation method thereof

InactiveCN104308139AEasy to manufactureSmall particle sizeMaterial nanotechnologyDismutasePeroxidase

The invention discloses a platinum nano-material with the activity of four mimic enzymes and a preparation method thereof. The preparation method comprises the following steps: using citrate ions as a modifier, reducing chloroplatinic acid by utilizing sodium borohydride, and preparing the platinum nano-material modified by citric acid. The platinum nano-material is simply and quickly prepared, the particle size is small, and the dispersibility and stability of a water solution are high. The obtained platinum nano-material has the activity of four mimic enzymes at the same time, and comprises peroxidase, oxidase, catalase and superoxide dismutase. The activity of the four mimic enzymes of the platinum nano-material can be adjusted and controlled through the concentration of the citrate ions used in the preparation process.

Owner:FUJIAN MEDICAL UNIV

Process, method, and system for removing heavy metals from fluids

InactiveUS20130306521A1Enhanced surface contactIncrease surface areaRefining with non-metalsRefining with metal saltsThioureaHydrazine compound

Trace amount levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with a sufficient amount of a reducing agent to convert at least a portion of the non-volatile mercury into a volatile form of mercury, which can be subsequently removed by any of stripping, scrubbing, adsorption, and combinations thereof. In one embodiment, at least 50% of the mercury is removed. In another embodiment, the removal rate is at least 99%. In one embodiment, the reducing agent is selected from sulfur compounds containing at least one sulfur atom having an oxidation state less than +6; ferrous compounds; stannous compounds; oxalates; cuprous compounds; organic acids which decompose to form CO2 and / or H2 upon heating; hydroxylamine compounds; hydrazine compounds; sodium borohydride; diisobutylaluminium hydride; thiourea; transition metal halides; and mixtures thereof.

Owner:CHEVROU USA INC

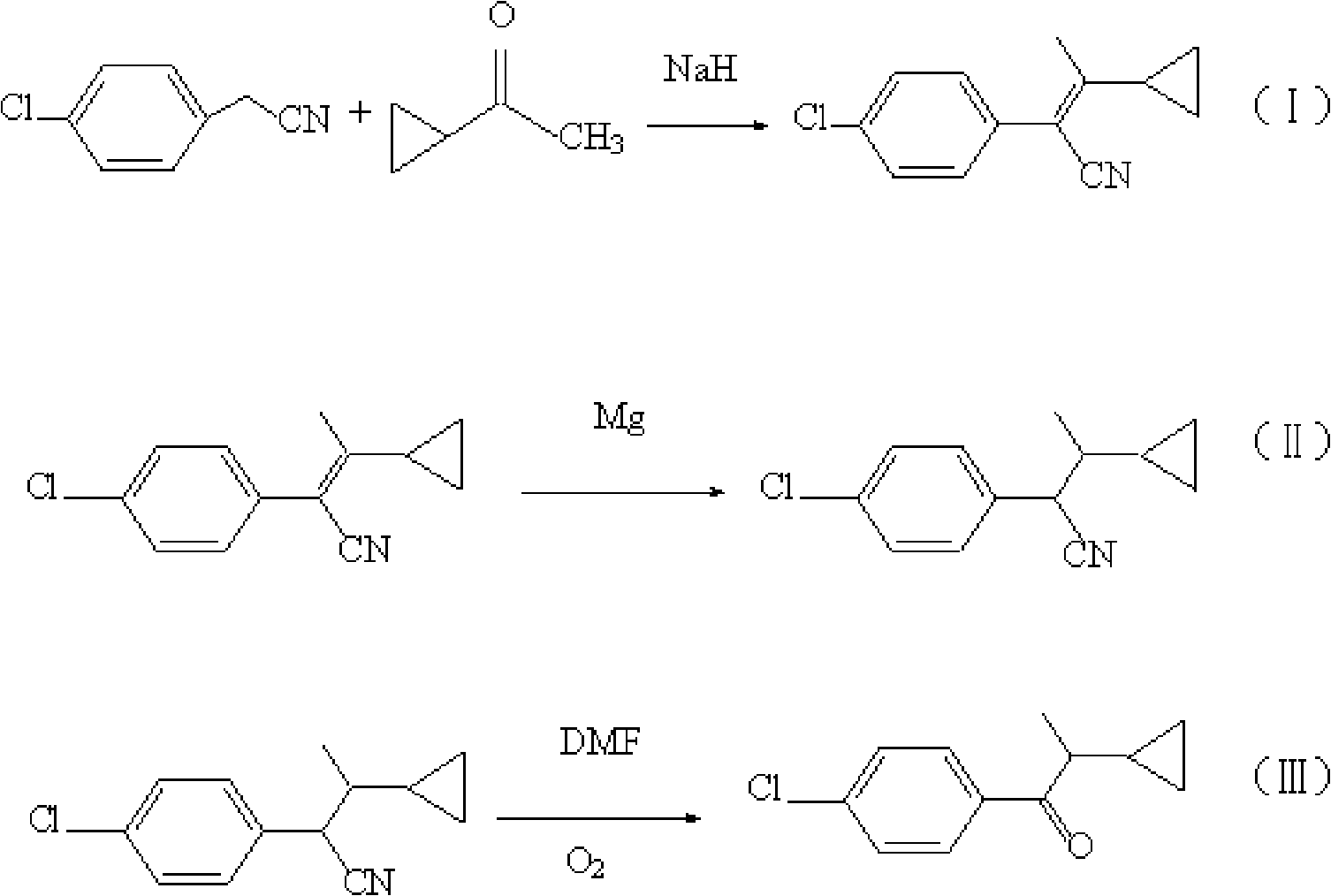

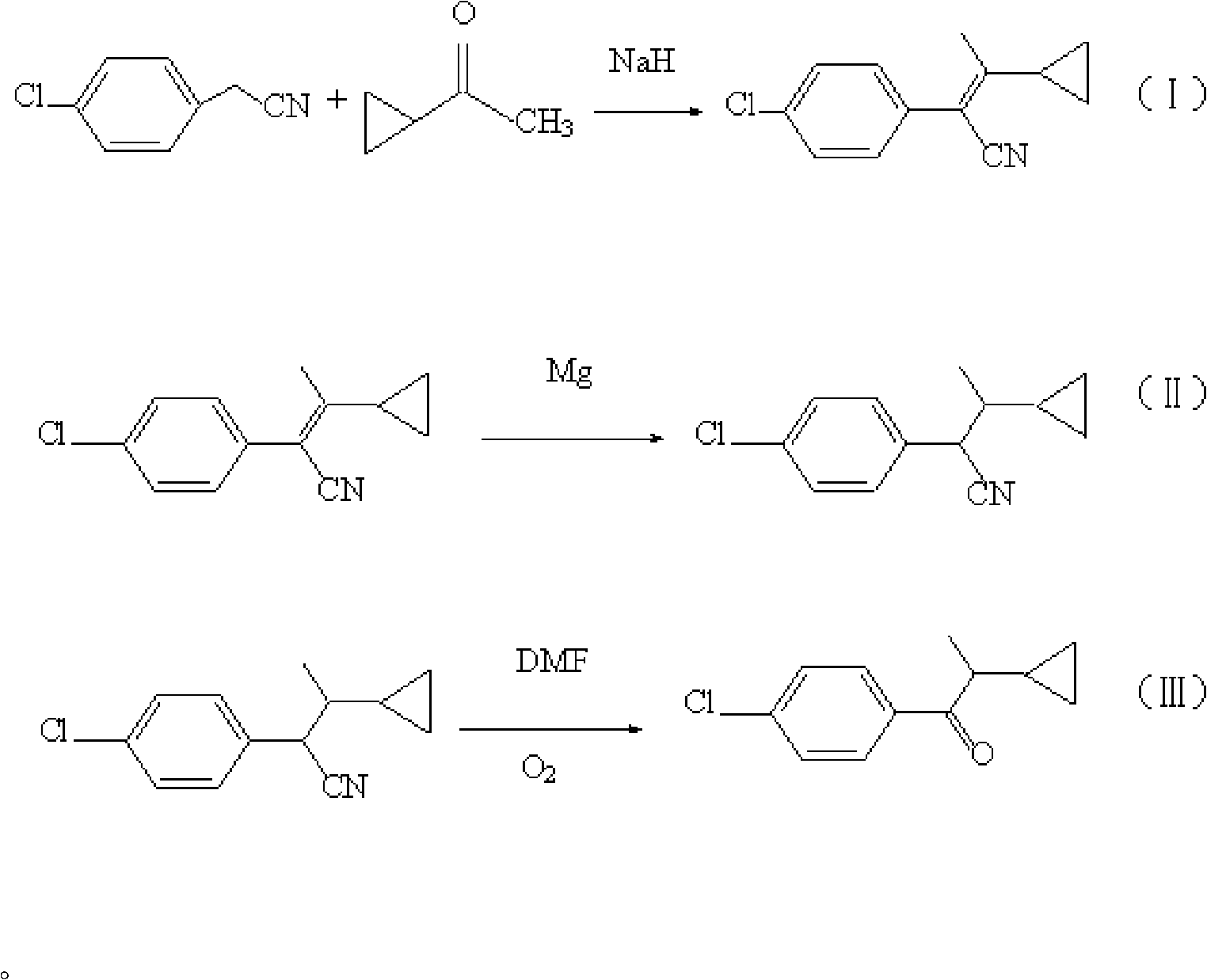

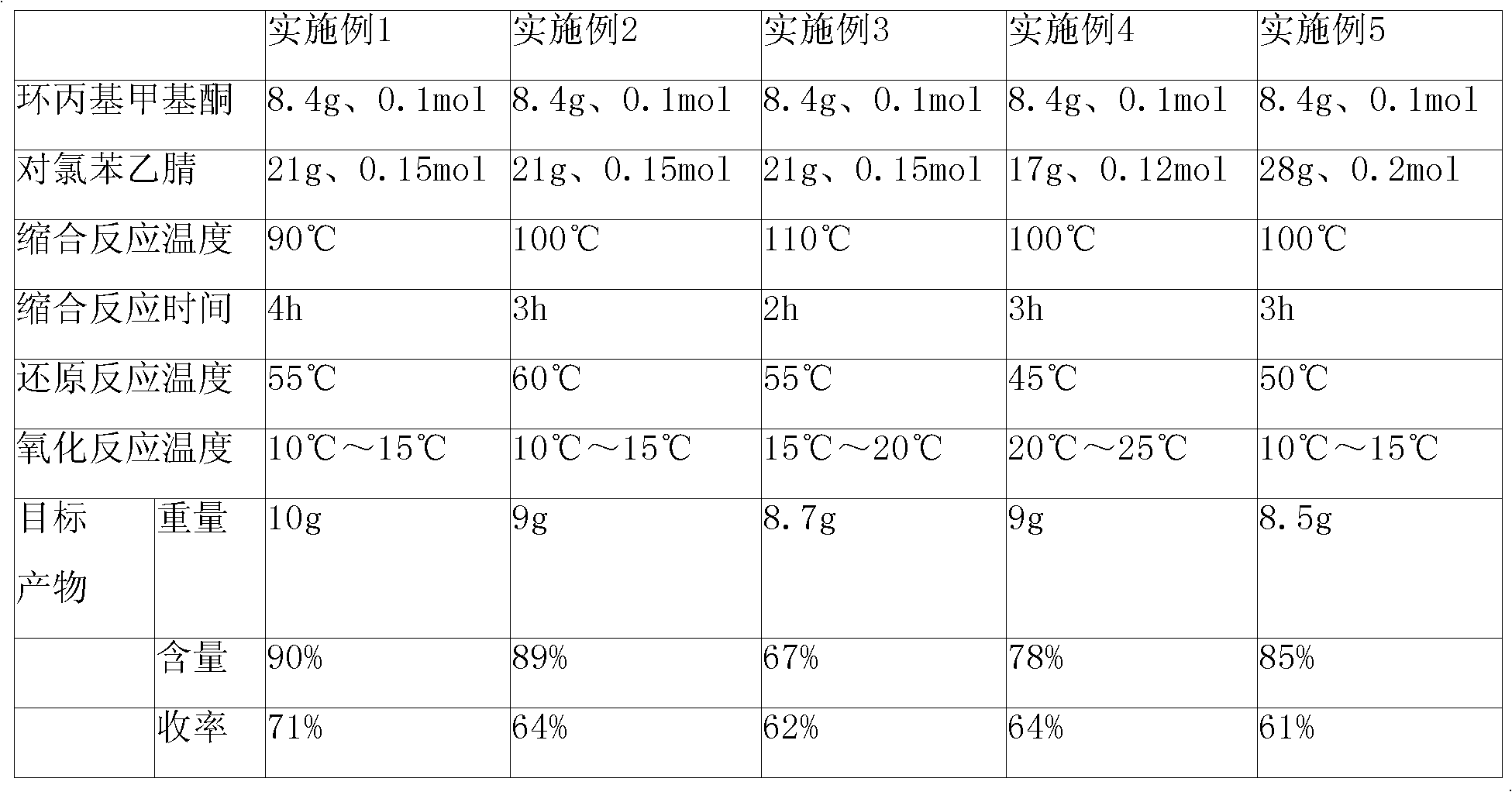

Method for preparing 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone

ActiveCN101786948ACheap and easy to getSimple stepsOrganic compound preparationCarbonyl compound preparationOxygenPhenyl group

The invention discloses a method for preparing 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone. The method comprises the following steps of: firstly, carrying out reaction on cyclopropyl methyl ketone and p-chlorobenzyl for 2-4 hours at the temperature ranging from 90 DEG C to 110 DEG C, and obtaining a compound I after post treatment, wherein the cyclopropyl methyl ketone and the p-chlorobenzyl are used as reactants, sodium hydride is used as a catalyst and toluol is used as solvent; secondly, leading the compound I to react with magnesium in a isopropanol dissolvent at the temperature ranging from 45 DEG C to 60 DEG C, and obtaining a compound II after post treatment; and thirdly, adding the compound II to DMF (Dimethyl Formamide), then adding sodium hydroxide, importing oxygen for 8 hours to15 hours under stirring for reaction, controlling the temperature to range from 10 DEG C to 25 DEG C, and finally obtaining the 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone after post treatment. The preparation method has the advantages of simple steps, cheap and easily obtained raw materials, no deadly poison, low cost; less three-waste (waste gas, waste water and industrial residue) pollution, suitability for industrial production and higher yield and content of end products.

Owner:江苏省农用激素工程技术研究中心有限公司

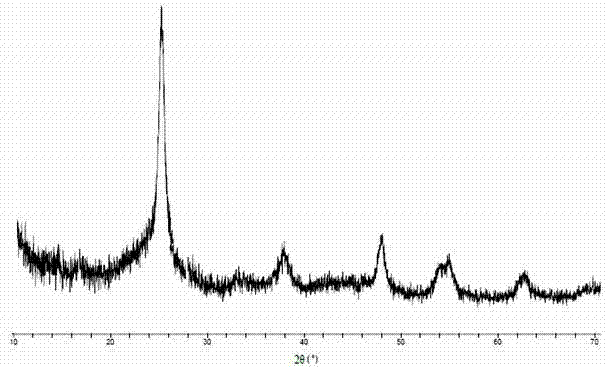

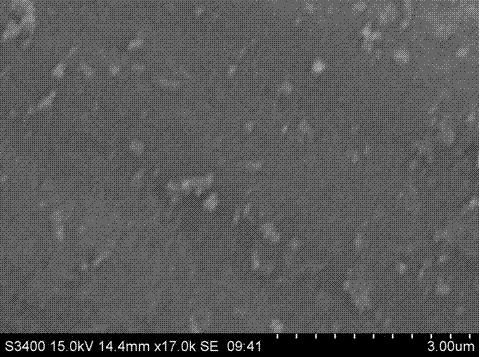

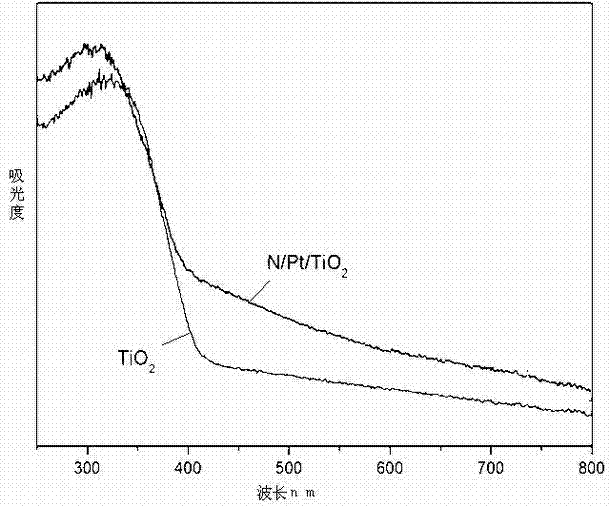

Method for preparing platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst

InactiveCN102211033APromote degradationHigh photocatalytic degradation ratePhysical/chemical process catalystsWater/sewage treatment by irradiationPolyethylene glycolHydrolysis

The invention discloses a method for preparing a platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst, which comprises the following steps of: adding tetrabutyl titanate into absolute ethanol, stirring for a period of time, slowing dripping into distilled water, adding acetylacetone and polyethylene glycol, regulating a pH value, and strongly stirring for complete hydrolysis to obtain a clear and transparent sol; adding urea with stirring, reacting, adding treated active carbon, continuously stirring, and performing ultrasonic dispersion, standing, filtration, washing, drying and roasting to obtain a nitrogen-doped active carbon supported TiO2 photocatalyst; immersing the nitrogen-doped active carbon supported TiO2 photocatalyst in a chloroplatinic acid solution, adding sodium borohydride for reduction, and drying to obtain a platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst. The invention solves the problem that a titanium dioxide catalyst in a suspension system is difficult to recover, the photocatalytic efficiency of the platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst on a liquid phase dye is further improved, and the platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst has stronger response under the condition of visible light.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

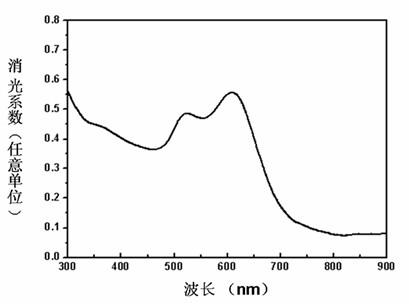

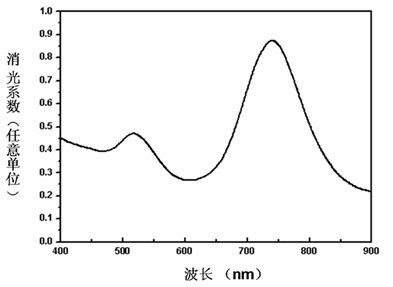

A preparation method of gold nanorods whose aspect ratio can be adjusted in a wide range

The present invention is a preparation method of gold nanorods whose length-to-diameter ratio can be adjusted in a large range. The strong reducing agent sodium borohydride reduces tetrachloroauric acid to obtain gold seed solution; the preparation of growth solution: prepare the mixed solution of hexadecyltrimethylammonium bromide, tetrachloroauric acid and silver nitrate, and the mol ratio of the three is 20:1:0.1~20:1:5, add crotonic acid solution to obtain a growth solution; growth of gold nanorods: inject gold seed solution into the growth solution, react for 6-12 hours, and obtain gold nanorods. The invention adopts crotonic acid as growth solution modifier, and solves the biological toxicity and biological modification problems caused by CTAB. The yield of the short-length-diameter ratio gold nanorods prepared can be as high as about 90%, the size distribution is narrow, and the length-diameter ratio is about 1.92. The aspect ratio of the prepared gold nanorods can be adjusted in a wide range from 1.9 to 7.5.

Owner:SOUTHEAST UNIV

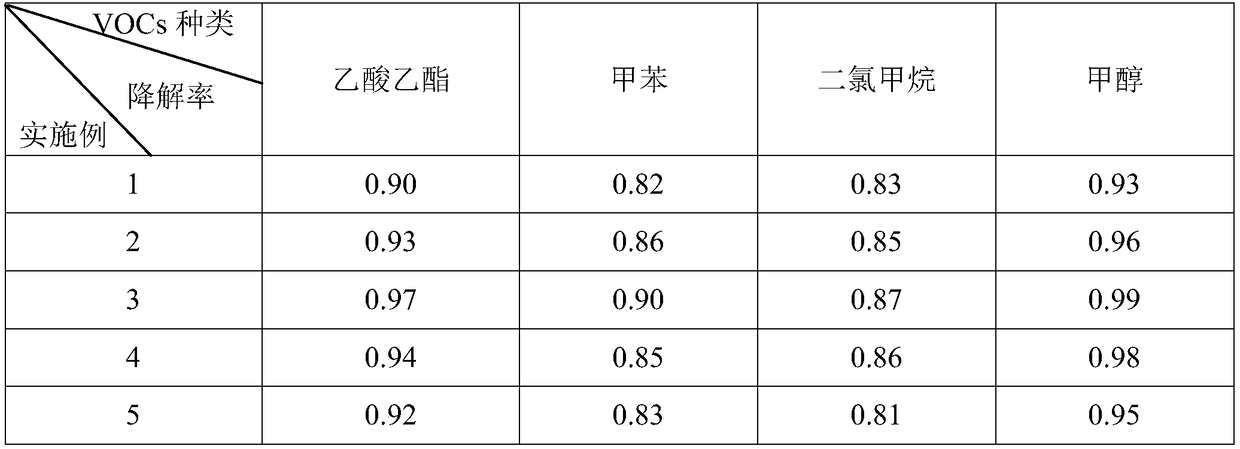

Preparation method of noble metal-loaded activated carbon fiber monoatomic catalyst for catalytic degradation of VOCs at room temperature

ActiveCN109012659ASimple preparation processSuitable for mass productionGas treatmentDispersed particle separationFiberActivated carbon

The invention discloses a preparation method of a noble metal-loaded activated carbon fiber monoatomic catalyst for catalytic degradation of VOCs at room temperature. The method includes the steps of:(a) pretreatment of a carrier: immersing activated carbon fiber in a sulfuric acid solution, performing ultrasonic treatment, then subjecting the ultrasound treated solution to heating reaction in awater bath pot, then performing cleaning with distilled water to neutral, and conducting natural airing to obtain modified activated carbon fiber; (b) noble metal loading: impregnating the modified activated carbon fiber in a noble metal solution, and performing ultrasonic treatment and standing, then adding a sodium hydride solution to reduce noble metal, finally taking out the activated carbon fiber, and conducting washing and drying to obtain a noble metal-loaded activated carbon fiber semi-finished product; and (c) calcination: putting the noble metal-loaded activated carbon fiber semi-finished product in a muffle furnace for calcination, thus obtaining the noble metal-loaded activated carbon fiber monoatomic catalyst finally. The method provided by the invention greatly improves the catalytic degradation efficiency of the monoatomic catalyst.

Owner:TIANJIN UNIV

Method of synthesizing near-infrared CdHgTe and CdHgTe/CdS fluorescence quantum points

InactiveCN101016461AThe method steps are simpleMild conditionsLuminescent compositionsQuantum yieldSolvent

The invention discloses a synthetic method of near-infrared CdHgTe and CdHgTe / CdS fluorescence quantum point, which comprises the following steps: choosing water as dissolvent; choosing cadmium salt, mercuric salt and sodium hydride telluride as reacting forerunner body; choosing sulfhydryl group compound as stabilizer; synthesizing CdHgTe quantum point through heating directly with luminous position at 600-900 nanometer, quantum yield at 10-30% and half-peak width of sending peak at 40-70 nanometer; injecting into cadmium salt, sulfide and sulfhydryl group compound; heating; getting CdHgTe / CdS core-shell quantum point with fluorescence spectrum red shift at 10-20 nanometer. This invention possesses simple steps, warm condition and high quantum yield, which can be used to cell image formation and tissue image formation widely.

Owner:SHANGHAI JIAO TONG UNIV

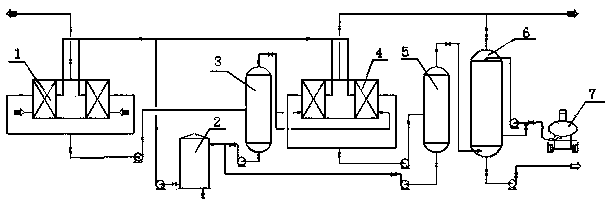

Auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process

The invention discloses auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methyl-2-pyrrolidinone is 0.93-1.15 to 1.00-1.28 to 1.98-2.98 to 1.18 to 1.48. The industrial synthetic process mainly comprises the following steps: firstly, in a sodium hydrosulfide dehydration treatment stage, a pipeline filter is adopted to filtrate a sodium hydrosulfide solution to treat mechanical impurities in the solution, then a sodium hydroxide solution with the concentration 84 mol percent is added in the formula for chemical treatment on the sodium hydrosulfide; secondly, in the condensation polymerization stage, anaerobic deionized water is added to further appropriately adjust the molecular weight and molecular weight distribution coefficient of synthesized polyphenylene sulfide resin; thirdly, deionized water is adopted for repeatedly scrubbing for 3 to 6 times, and finally, the target product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process provided by the invention is obtained. The resin in the obtained product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is low in polydispersity index and high in oxygen index, and has an excellent electrical insulation property.

Owner:周洪

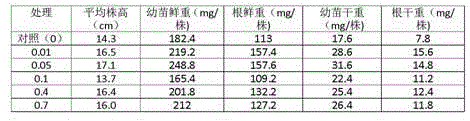

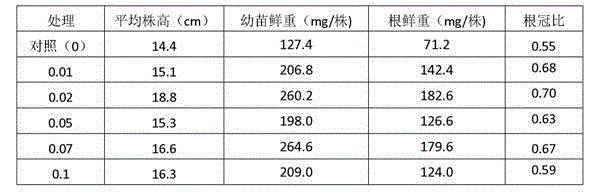

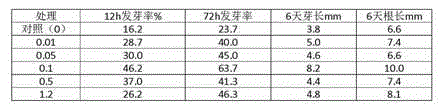

Method for improving wheat drought resistance and salt stress resistance by taking sodium hydrosulfide as hydrogen sulfide donor

The invention discloses a method for improving wheat drought resistance and salt stress resistance by taking sodium hydrosulfide as a hydrogen sulfide donor. The method concretely comprises the steps of before sowing, soaking wheat seeds into a sodium hydrosulfide water solution with the concentration of 0.03-1.2mmol / L for 12-24 hours under the condition of room temperature, or carrying out root soaking, root-irrigation or foliage spray treatment on wheat seedlings at the seedling stage by using a sodium hydrosulfide mixed water solution with the concentration of 0.01-0.6mmol / L under the condition of room temperature; and at the later period of wheat growth, spraying a sodium hydrosulfide mixed solution with the concentration of 0.05-0.8mmol / L onto the leaf surfaces of the wheat plants. According to the method, different sodium hydrosulfide application ways and concentrations are adopted according to the different growth stages of the wheat plants, so that the substances related with stress resistance in the plants can be increased, and the stress resistance of the plants can be improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

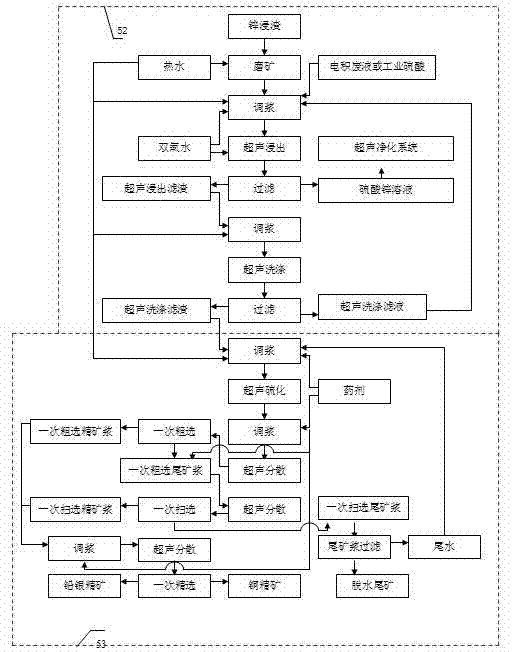

Reagent formula used for zinc leaching residue floatation process and application method of reagent formula

The invention relates to a reagent formula used for a zinc leaching residue floatation process and an application method of the reagent formula. The reagent is a floatation reagent which is added into floatation processes such as sulfurizing, rough floatation, scavenging and concentration. The reagent formula is characterized in that 1) one or two of sodium sulphide and sodium hydrosulfide are added into a sulfurizing process as a sulfurizing reagent; 2) in the rough floatation process, N,N-sodium diethyldithiocarbamate, butyl ammonium black powder and 25# black powder are added as lead mineral collecting agents, Y89 and (or) pentyl xanthate are added as silver mineral collecting agent(s); 3) in a scavenging process, one or two of sodium sulphide and sodium hydrosulfide are added as the sulfutizing agent(s), N,N-sodium diethyldithiocarbamate, butyl ammonium black powder and 25# black powder are added as the lead mineral collecting agents, and the Y89 and (or) pentyl xanthate are added as the silver mineral collecting agent(s); and 4) carboxymethylcellulose is added as a gangue inhibiting agent in a concentration process. After applying the reagent formula disclosed by the invention, by adopting one-time rougher floatation, one-time scavenging and one-time concentration, lead yield can reach up to more than 95% and lead tail run can reach 0.1-0.2%.

Owner:XINGMIN TECH ZHUZHOU

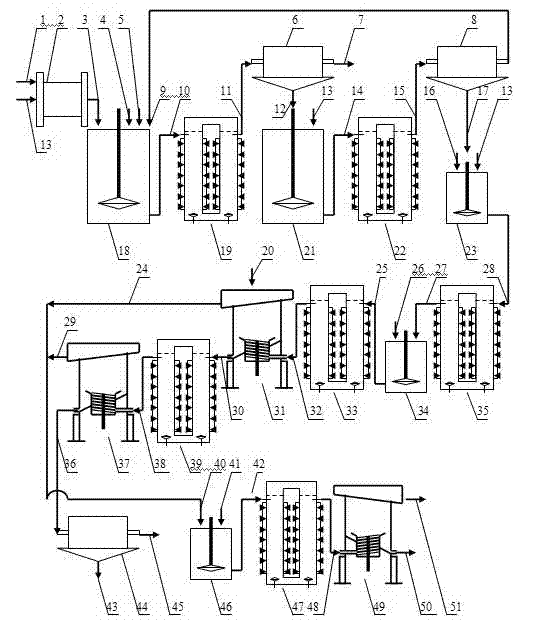

Device and method for producing sodium bisulfide by utilizing refinery dry gas

ActiveCN103754833ARaise the possibilityRealize resource utilizationSulfur compoundsResource utilizationGas composition

The invention relates to a device and method for producing sodium bisulfide by utilizing refinery dry gas. Aiming at the gas composition characteristics of the refinery dry gas, the dry gas refining desulphurization process is processed by utilizing an ultra-high gravity technology, and H2S in acid tail gas after dry gas refining desulphurization is selectively removed, so that the content of the purified H2S is over 99 percent, the purified and refined H2S is absorbed for preparing high-purity NaHS by adopting a continuous alkali liquor cycle, the concentration purity is over 42 percent, the process technology is greatly innovated, the investment is saved, secondary pollution is avoided, a process of a traditional out-dated NaHS product can be replaced, the device has a certain economic benefits and high-efficiency resource utilization rate, the H2S in the acid gas is almost recycled completely, the requirements of environment friendliness and emission are met, high social benefits are achieved, and recycling comprehensive utilization of refinery acid tail gas is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

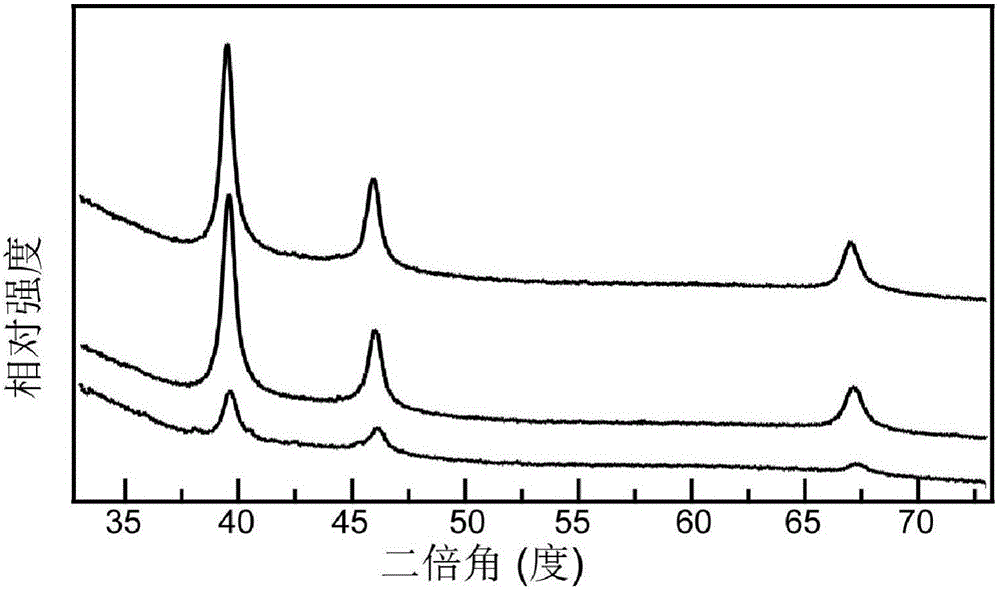

Platinum/silver alloy nano-particle catalyst, method for preparing same and application of platinum/silver alloy nano-particle catalyst

InactiveCN105771979ALarge specific surface areaEasy to prepareElectrolytic organic productionMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationAlloy

The invention discloses a platinum / silver alloy nano-particle catalyst, a method for preparing the same and application of the platinum / silver alloy nano-particle catalyst. The method includes mixing cetyl trimethyl ammonium bromide aqueous solution, chloroplatinic acid aqueous solution and sodium borohydride ice aqueous solution with one another to obtain seed solution; mixing cetyl trimethyl ammonium bromide aqueous solution, chloroplatinic acid aqueous solution, silver nitrate aqueous solution, hydrochloric acid solution, ascorbic acid aqueous solution and the seed solution with one another to obtain the platinum / silver alloy nano-particle catalyst. The platinum / silver alloy nano-particle catalyst, the method and the application have the advantages that the method is simple, and reaction conditions are mild; the platinum / silver alloy nano-particle catalyst can be in different morphologies along with difference in the proportions of the added chloroplatinic acid aqueous solution to the added silver nitrate aqueous solution and have large specific surface areas; working electrodes further can be made from the platinum / silver alloy nano-particle catalyst, alcohol solution can be catalytically oxidized by the aid of electrochemical processes, and the alcohol catalytic oxidation activity of the platinum / silver alloy nano-particle catalyst is superior to the alcohol catalytic oxidation activity of commercial Pt / C catalysts.

Owner:上海耀华铂制品有限公司

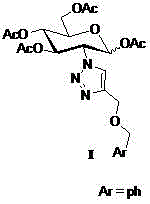

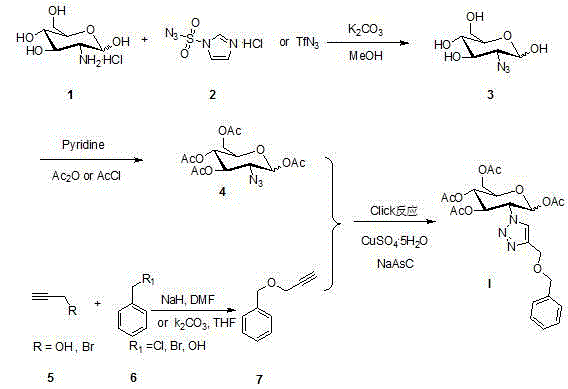

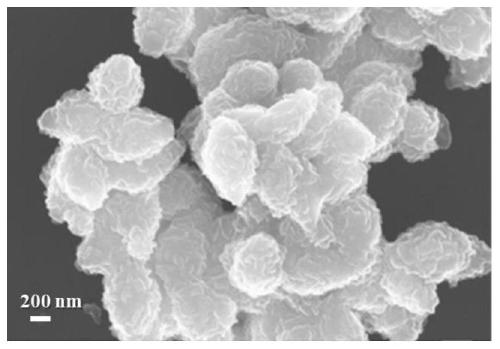

2-(1',2',3'-triazole-4'-benzyloxy)-1,3,4,6-O-acetyl-D-glucose and preparation method and application thereof

ActiveCN104817605AGood anti-rectal cancer activitySugar derivativesSugar derivatives preparationTriazole derivativesPharmaceutical Substances

The core structure of 2-(1',2',3'-triazole-4'-benzyloxy)-1,3,4,6-O-acetyl-D-glucose with an anti-colorectal carcinoma activity is that a 1,2,4-triazole derivative substitutes 2-site of 1,3,4,6-O- acetyl-D-glucose. The above compound has a good activity of inhibiting colorectal carcinoma cells, and can be used as an anti-colorectal carcinoma medicine. A synthesis method of the above compound comprises the following steps: 2-amino-D-glucose hydrochloride and an azidation reagent are used as raw materials to generate a 2-azido-1,3,4,6-O-acetyl-D-glucose intermediate under an alkaline condition; 3-propargyl bromide and phenylcarbinol react under the action of sodium hydride to generate phenyl propargyl ether; and the 2-azido-1,3,4,6-O-acetyl-D-glucose intermediate and phenyl propargyl ether undergo a click reaction in a solvent under the catalysis of monovalent copper to generate 2-(1',2',3'-triazole-4'-benzyloxy)-1,3,4,6-O-acetyl-D-glucose.

Owner:HUBEI ENG UNIV

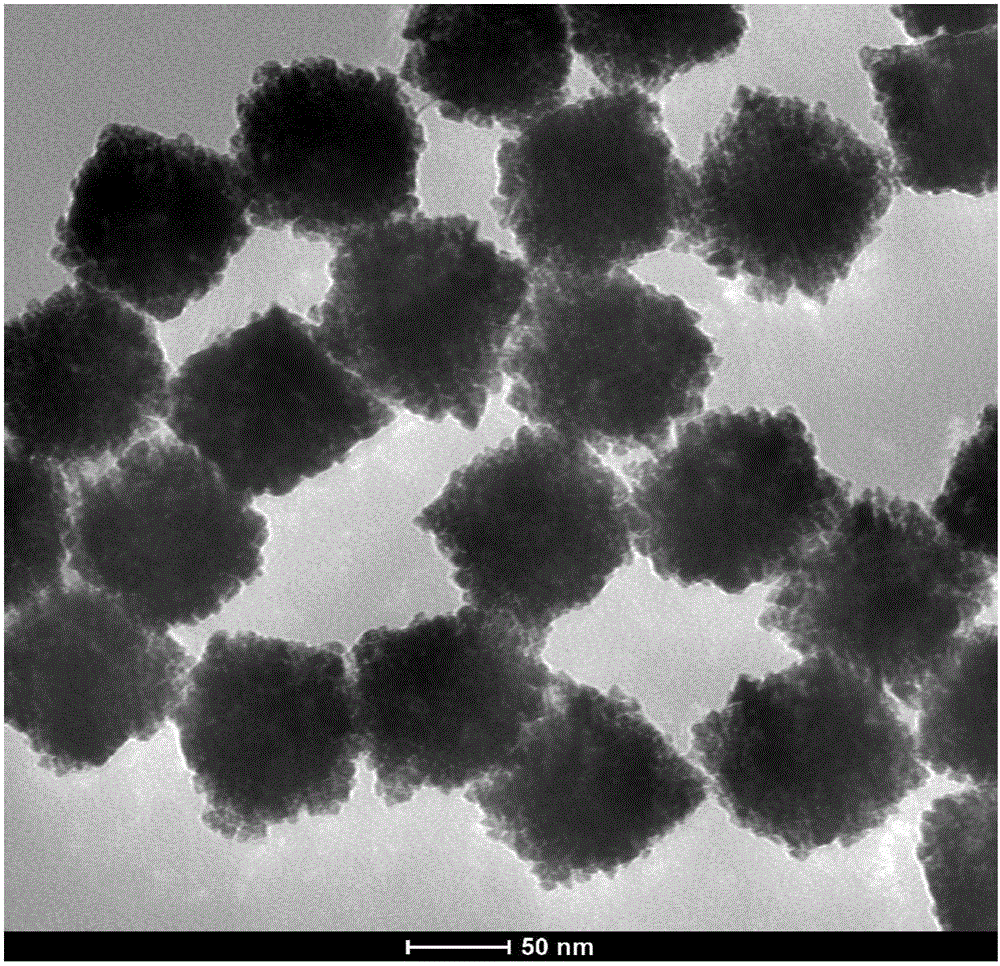

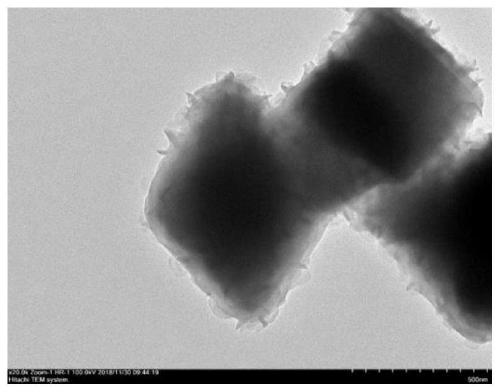

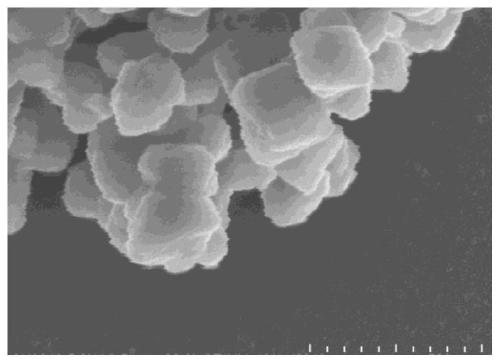

Preparation method of MOF-metal nanoparticle-COF-based composite material

The invention discloses a preparation method of the MOF-metal nanoparticle-COF composite material. The method comprises the following steps: dispersing MOF into a solution containing a metal ion precursor, adding a sodium borohydride solution or performing illumination reduction, or performing hydrogen reduction after centrifugation to obtain the MOF-metal nanoparticle composite material. Activating at a high temperature of 120-150 DEG C and then dispersing in 1, 3-butanediol; the method comprises the following steps: adding 1, 4-dioxane and mesitylene into a mixed solvent of 1, 4-dioxane andmesitylene; then adding a small amount of aldehyde group organic ligand and ultrasonically and uniformly mixing; subsequent addition of acetic acid, adding a corresponding amount of amino organic ligand, and continuously stirring for a period of time to obtain an MOF-metal nanoparticle-COF seed crystal compound; and adding an aldehyde group organic ligand and an amino group organic ligand, uniformly stirring and mixing, adding a corresponding amount of acetic acid, and continuously stirring, heating and preserving heat to obtain the MOF-metal nanoparticle-COF compound. Covalent binding of thetwo materials is achieved through a Schiff base reaction between aldehyde groups on the surfaces of the seed crystals and amino groups on the surfaces of the MOF materials, the binding force is stableand firm, the preparation method is simple, the method can be used for mass production, and traditional high-temperature and high-pressure reaction conditions are not needed in the compounding process.

Owner:UNIV OF SCI & TECH BEIJING

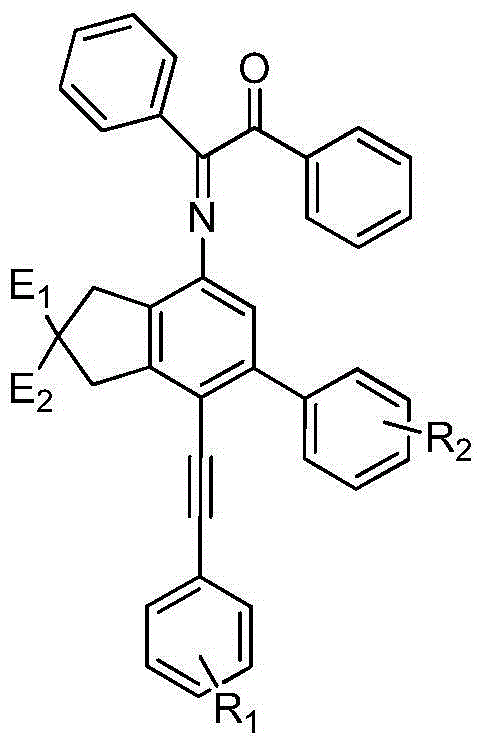

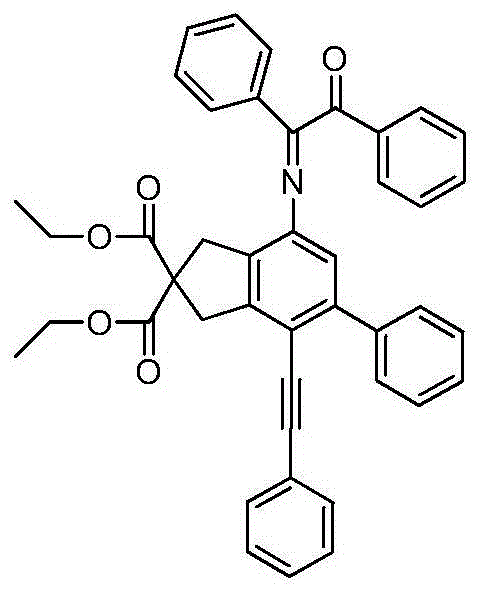

Benzoin oxime derivative and preparation method thereof

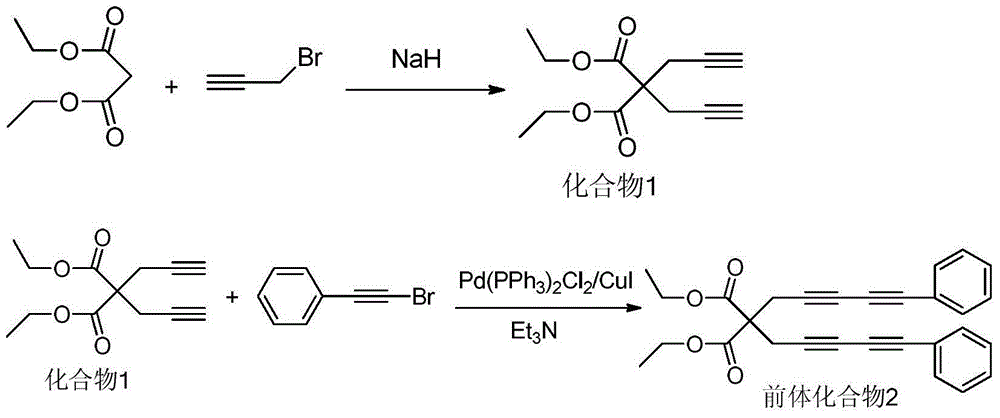

ActiveCN104447396AComplex structureBroad use prospectsImino compound preparationChemical industryMalonate

The invention relates to a benzoin oxime derivative and a preparation method thereof. A structural formula of the benzoin oxime derivative is shown in the specification. The preparation method comprises the following steps: reacting malonate with propargyl bromide in anhydrous acetonitrile under the catalysis of sodium hydride to obtain a white solid product; by taking triethylamine as alkali, reacting the white solid product with phenylethynyl bromine or substituted phenylethynyl bromine in anhydrous acetonitrile under the catalysis of Pd(PPh3)2Cl2 / CuI to obtain a light brown solid product; reacting the light brown solid product with benzoin oxime in toluene at 95-105 DEG C to obtain the benzoin oxime derivative. A brand new synthetic method of polysubstituted benzoin oxime is provided, and a series of new benzoin oxime derivatives are generated. Compared with normal benzoin oxime derivatives, the benzoin oxime derivative prepared by virtue of the preparation method has relatively complex and diverse structures by virtue of multiple cycles, and presents relatively wide application prospects in chemical industry production and clinic medicines.

Owner:ANHUI NORMAL UNIV

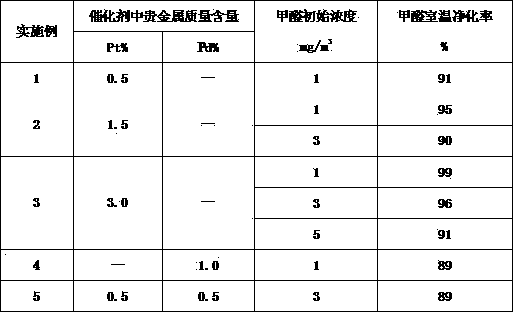

Preparation method and application of noble metal monolithic catalyst for purifying formaldehyde

ActiveCN104368335ASolve the problem of inability to purify low-concentration formaldehyde at room temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsLiving roomCatalytic oxidation

The invention discloses a preparation method and an application of a noble metal monolithic catalyst for purifying formaldehyde. With adopting of a homogeneous deposition composite in-situ reduction method, firstly a platinum and palladium precursor is uniformly deposited on a flaky and regular activated carbon fibrofelt through an equivalent saturated impregnation method, then sodium borohydride is used as a reducing agent and is directly subjected to an oxidation-reduction reaction with the noble metal precursor on the surface of the activated carbon fibrofelt, and noble metal metallic-state microcrystals are formed in-situ; the noble metal content in the monolithic catalyst prepared by the preparation method is 0.5-3.0 wt%; when the monolithic catalyst is applied in formaldehyde catalytic oxidation purification treatment, under conditions of the initial formaldehyde concentration of 1-5 mg / m<3> and the air speed of 180000 mL / gcat.h, the formaldehyde room-temperature purification rate is 89% or more, so the monolithic catalyst is an excellent monolithic type catalyst for room temperature purification treatment of low-concentration formaldehyde, and is suitable for deep purification treatment of formaldehyde harmful gas in industries and living rooms.

Owner:SHENZHEN AIDI YICHUANG TECH CO LTD

Quantum dot fluorescent aspirin imprinted sensor and its preparation method and use

InactiveCN104165874AGood optical stabilityAvoid slow recognitionFluorescence/phosphorescenceFunctional monomerDrug content

The invention provides a quantum dot fluorescent aspirin imprinted sensor and its preparation method and use and belongs to the technical field of material preparation and drug content detection. The preparation method comprises the following steps of preparing a precursor NaHTe solution from sodium borohydride, tellurium powder and water in an ultrasonic environment, injecting the precursor NaHTe solution into a CdCl2.2.5H2O solution fed with nitrogen for oxygen removal, having a pH value of 10.5-11.5 and containing thioglycollic acid (TGA), carrying out backflow reaction processes in a nitrogen protective atmosphere at a temperature of 100-110 DEG C to obtain quantum dots having different sizes according to different backflow time periods, and synthesizing a fluorescent molecule imprinted polymer from the CdTe quantum dots as fluorescent carriers, aspirin as a template molecule, (3-aminopropyl)triethoxysilane (APTES) as a functional monomer and tetraethyl orthosilicate (TEOS) as a cross-linking agent by a sol-gel method, wherein the fluorescent molecule imprinted polymer can be used for optical detection of aspirin. The fluorescent molecule imprinted polymer has good optical and pH stability and has an aspirin selective-identification function.

Owner:JIANGSU UNIV

P-aramid nanofiber solution and preparation method thereof

The invention relates to a novel method for preparing a p-aramid nanofiber solution, belongs to the field of macromolecules and also belongs to the field of nano-materials. According to the solution, p-aramid nanofibers have the diameter of 20-50nm and the length of about 10 microns. The method comprises the steps: purging a dry three-mouthed bottle with nitrogen gas for 10 minutes under the protection of nitrogen gas, adding a deprotonation reagent (sodium hydride or potassium hydride or lithium hydride) and anhydrous dimethyl sulfoxide under the protection of nitrogen gas, mechanically stirring, heating to the temperature of 70 DEG C within 20 minutes, continuously reacting for 40 minutes, and then, cooling to the temperature of 30 DEG C; and then, slowly adding poly-p-phenylene terephthalamide staple fibers, and reacting for 6-72 hours at the temperature of 30 DEG C, thereby obtaining an orange-red solution containing the p-aramid nanofibers, wherein the weight percent of the p-aramid nanofibers is 0.05-3.6%. The method disclosed by the invention is simple and is strong in operability, and a feasible method is provided for the low-cost and large-scale preparation of p-aramid nanofiber materials.

Owner:LUDONG UNIVERSITY

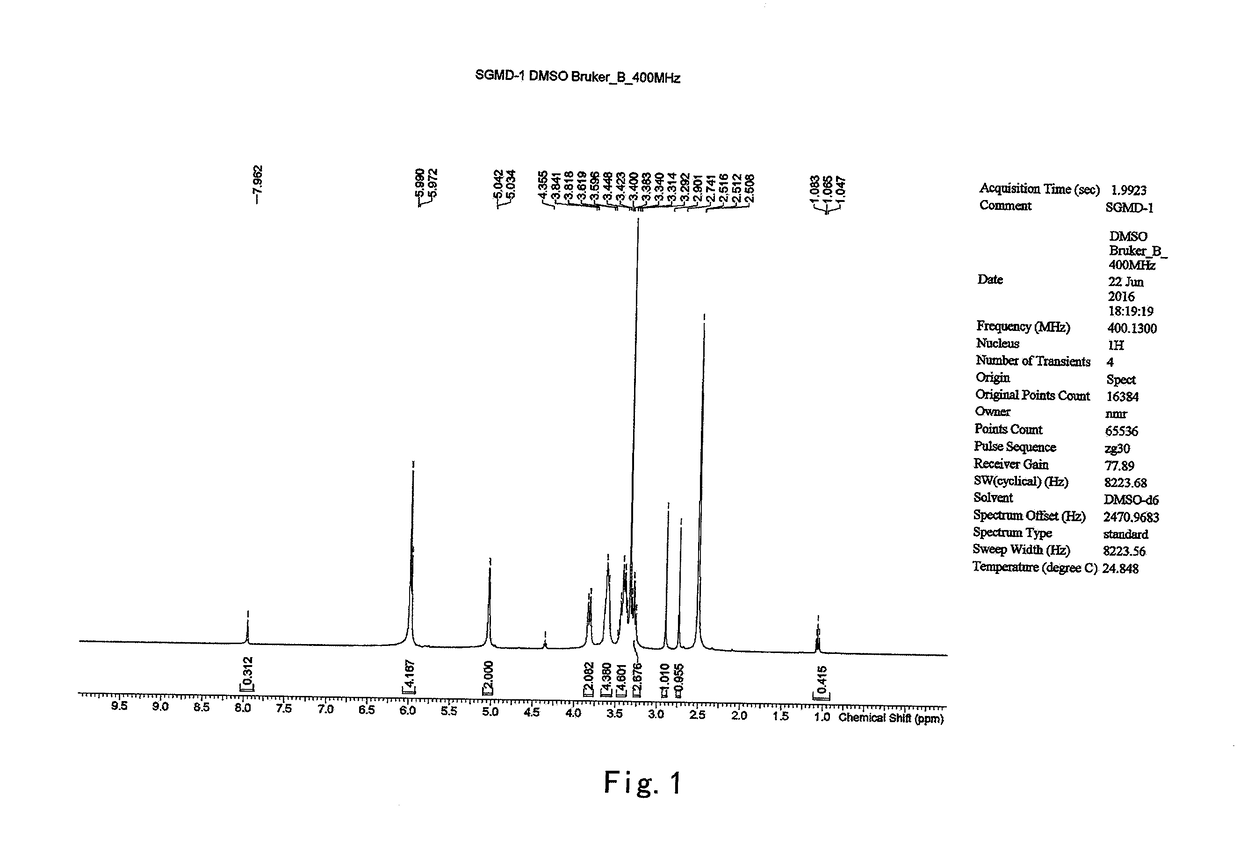

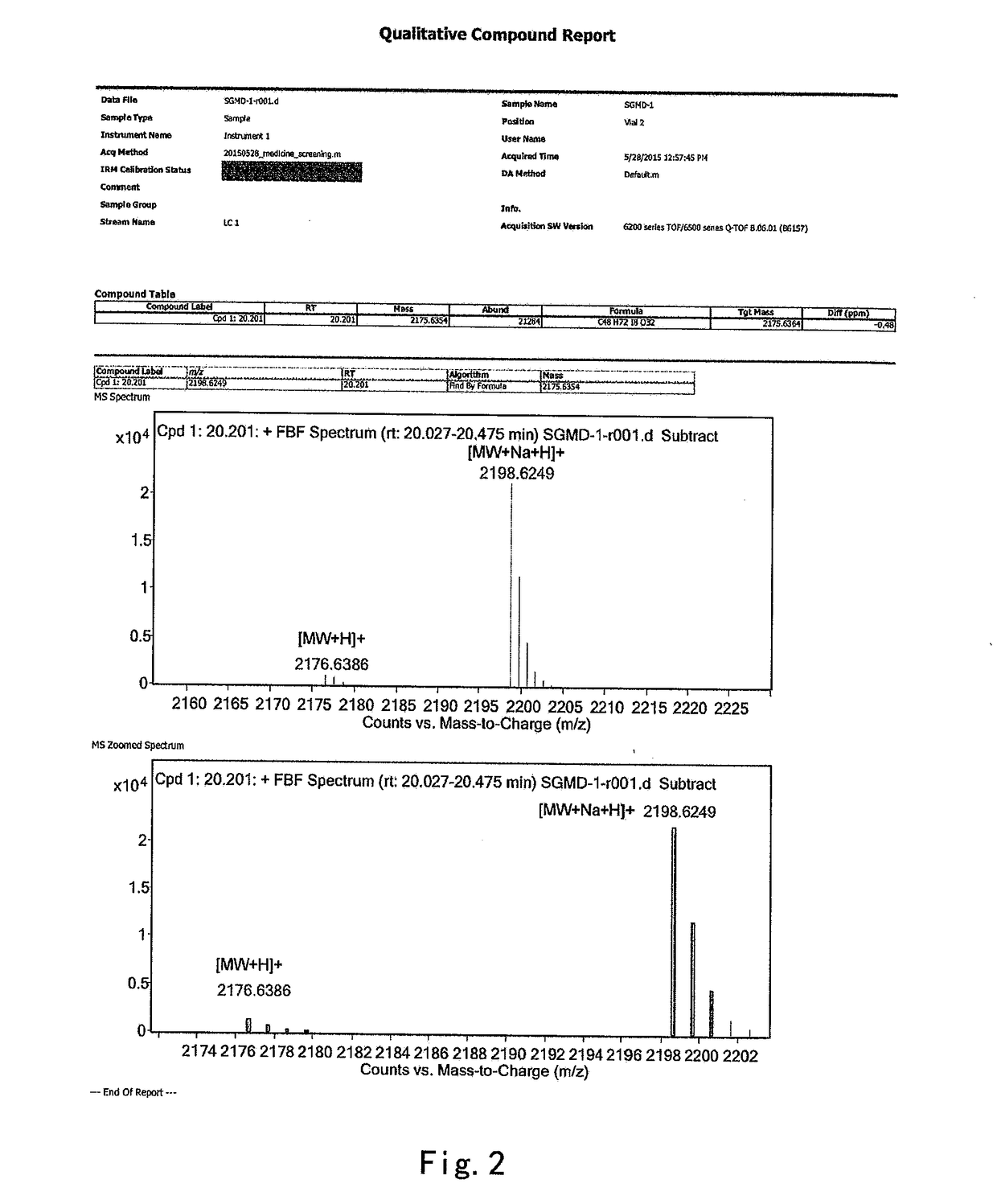

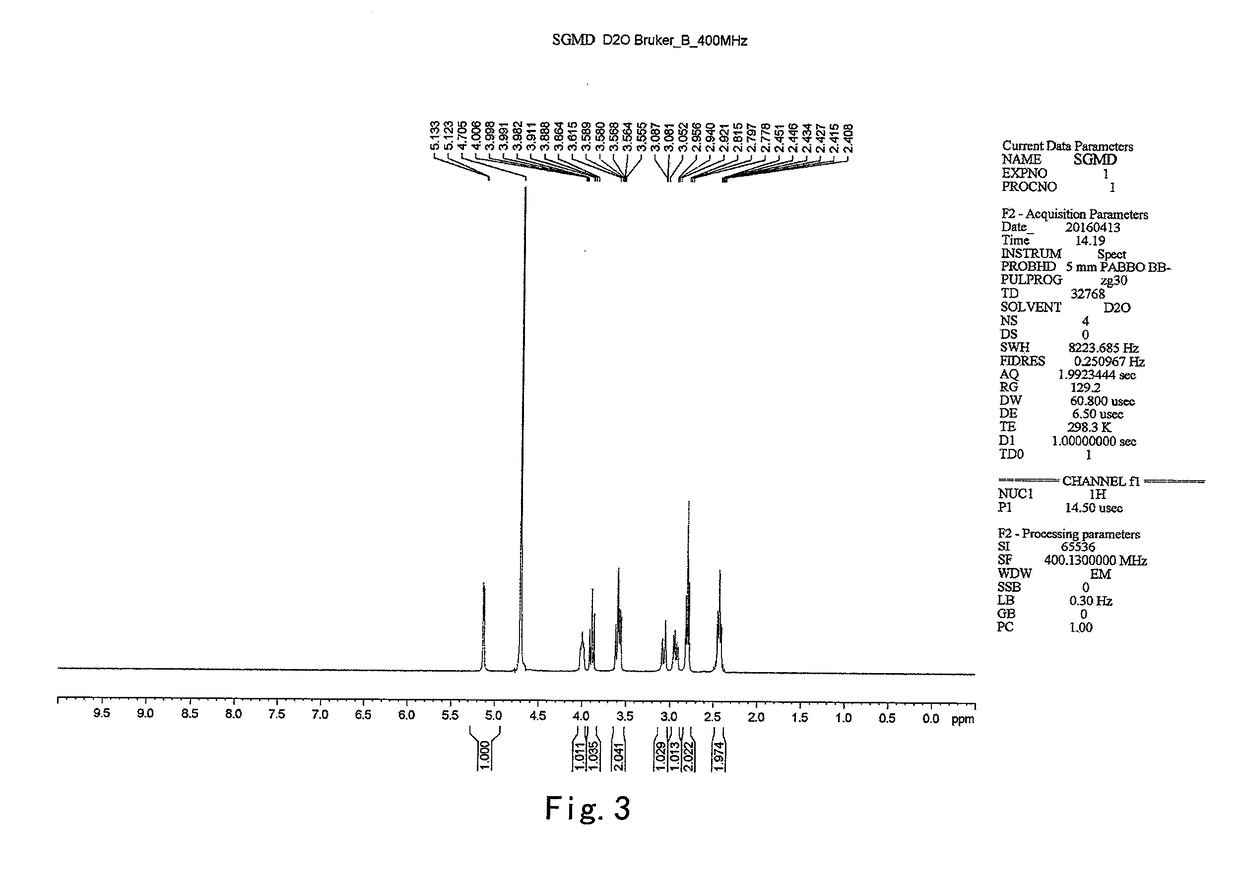

Sugammadex preparation and purification method

InactiveUS20180016359A1Quality improvementSimple processNervous disorderSodium methoxidePurification methods

The present invention provides a process for the preparation of (6-per-deoxy-6-per-(2-carboxyethyl)thio-γ-cyclodextrin) sodium salt, comprising the steps of:reacting γ-cyclodextrin (SM1) with iodine in the presence of triphenylphosphine in an organic solvent to afford an intermediate, 6-per-deoxy-6-iodo-γ-cyclodextrin (abbreviated as SGMD-1);adding methanol solution of sodium methoxide into the reaction system followed by the addition of acetone without removal of the solvent under reduced pressure to obtain the crude SGMD-1 as a solid after filtration;purifying the crude SGMD-1 by recrystallization;reacting a obtained recrystallized intermediate (SGMD-1) with 3-mercaptopropionic acid in basic medium e.g., sodium hydride, to obtain the crude 6-per-deoxy-6-per-(2-carboxyethyl)thio-γ-cyclodextrin sodium salt (abbreviated as SGMD);purifying the crude SGMD by passing through adsorbents followed by recrystallization.

Owner:BEIJING CREATRON INST OF PHARMA RES CO LTD

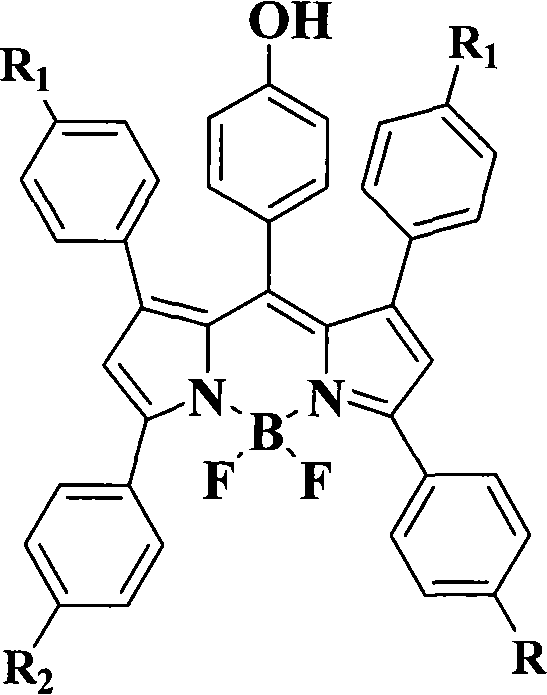

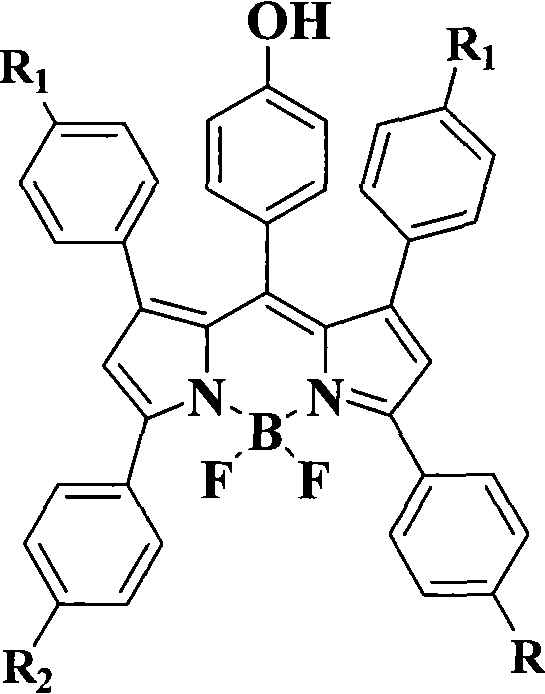

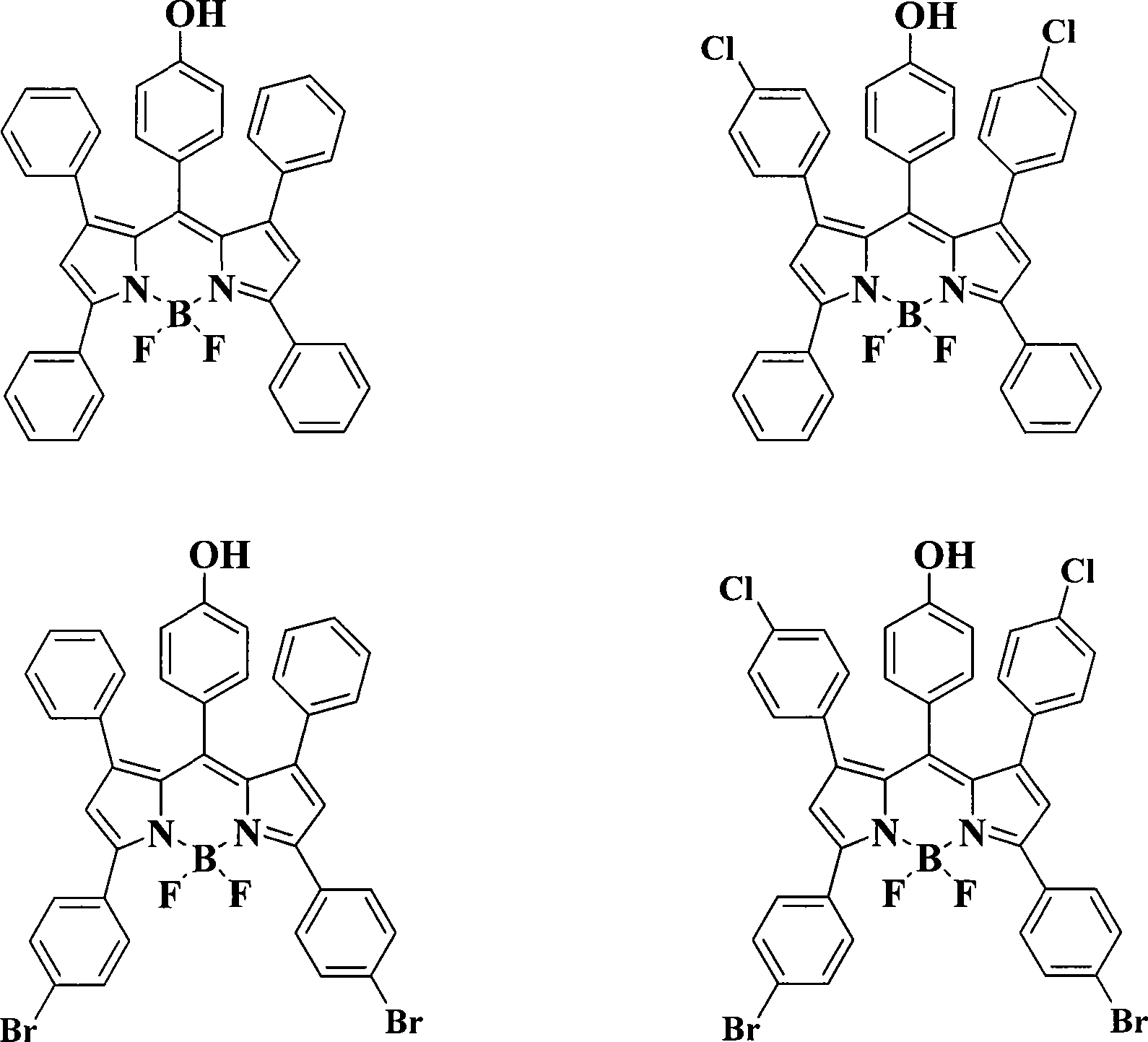

Pyrrole dimethine fluorescent dyes as well as synthetic method and use thereof

InactiveCN101205416ASuitable for excitationSuitable emission wavelengthMethine/polymethine dyesReactive dyesFluorescenceSynthesis methods

The invention provides a pyrrole di-methine fluorescent dye and a synthesis method and application; the synthesis method is as follows: a. preparing 2-phenylaziridine from styrene; b. adding 2-phenylaziridine into acetophenone, and reacting to produce 2, 4-diphenylpyrrole in the presence of sodium hydride under room temperature; c. adding 2, 4-diphenylpyrrole into p-hydroxybenzaldehyde, then adding chloranil according to the weight proportion 2, 4-diphenylpyrrole : chloranil =1:3-7; reacting under room temperature with stirring, removing excessive chloranil after reaction, and spinning dry to get blue solid pyrromethene; d. adding blue solid pyrromethene into dichloromethane for dissolution, then adding boron trifluoride diethyl etherate under the protection of inert gas, and reacting under room temperature; after reaction, adding chloroform and extracting 2 to 3 times; combining extract liquids, water washing, drying by anhydrous magnesium sulfate, spinning dry, and column separation to yield products.

Owner:SHANDONG NORMAL UNIV

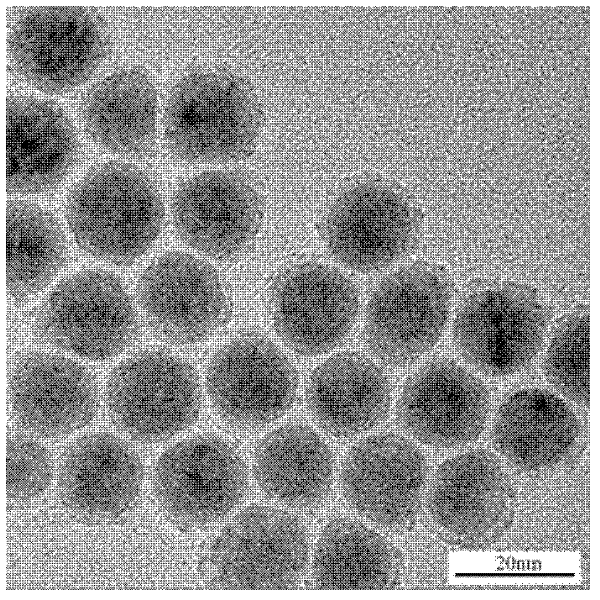

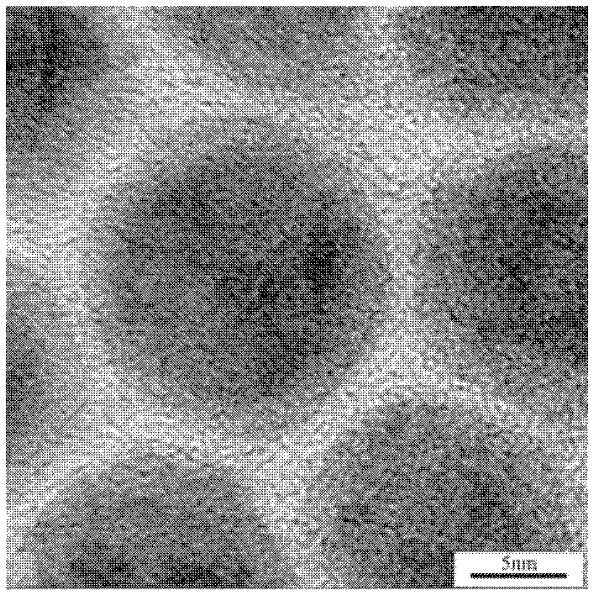

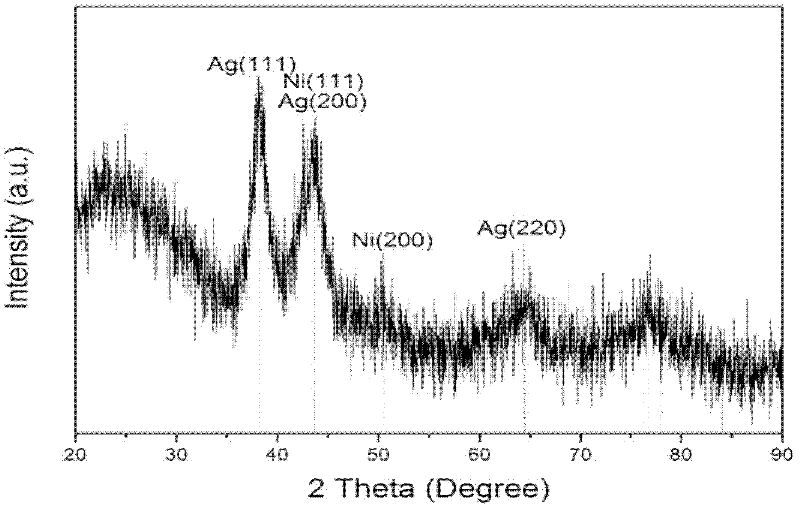

Method for preparing monodisperse silver core-nickel shell nanoparticles

InactiveCN102228994AGood monodispersityTunable Magnetic PropertiesMaterial nanotechnologyHydrogen productionBoiling pointHydrogen production

The invention relates to metal nanoparticles of a core-shell structure and provides a method for preparing monodisperse silver core-nickel shell nanoparticles and application of monodisperse silver core-nickel shell nanoparticles to catalysis of sodium borohydride for hydrolysis hydrogen production, wherein the method has a simple process and can ensure the monodispersity of products. The method comprises the steps of: adding a mixed solution of metal salt of nickel, metal salt of silver, a surface stabilizing agent, alkylamine or alkylamine and a high-boiling-point organic solvent into a reaction vessel under the protection of inert gas, homogenizing the mixture, heating to 170-240 DEG C and preserving the temperature for 20min-3h to obtain a reaction product; and cleaning the obtained reaction product with an organic solvent mixed solution, centrifuging for separation, and vacuum-drying to obtain the monodisperse silver core-nickel shell nanoparticles. The monodisperse silver core-nickel shell nanoparticles can be applied to catalysis of the sodium borohydride for hydrolysis hydrogen production. The method has the advantages of simple preparation process, relatively low cost and convenience for industrial production.

Owner:XIAMEN UNIV

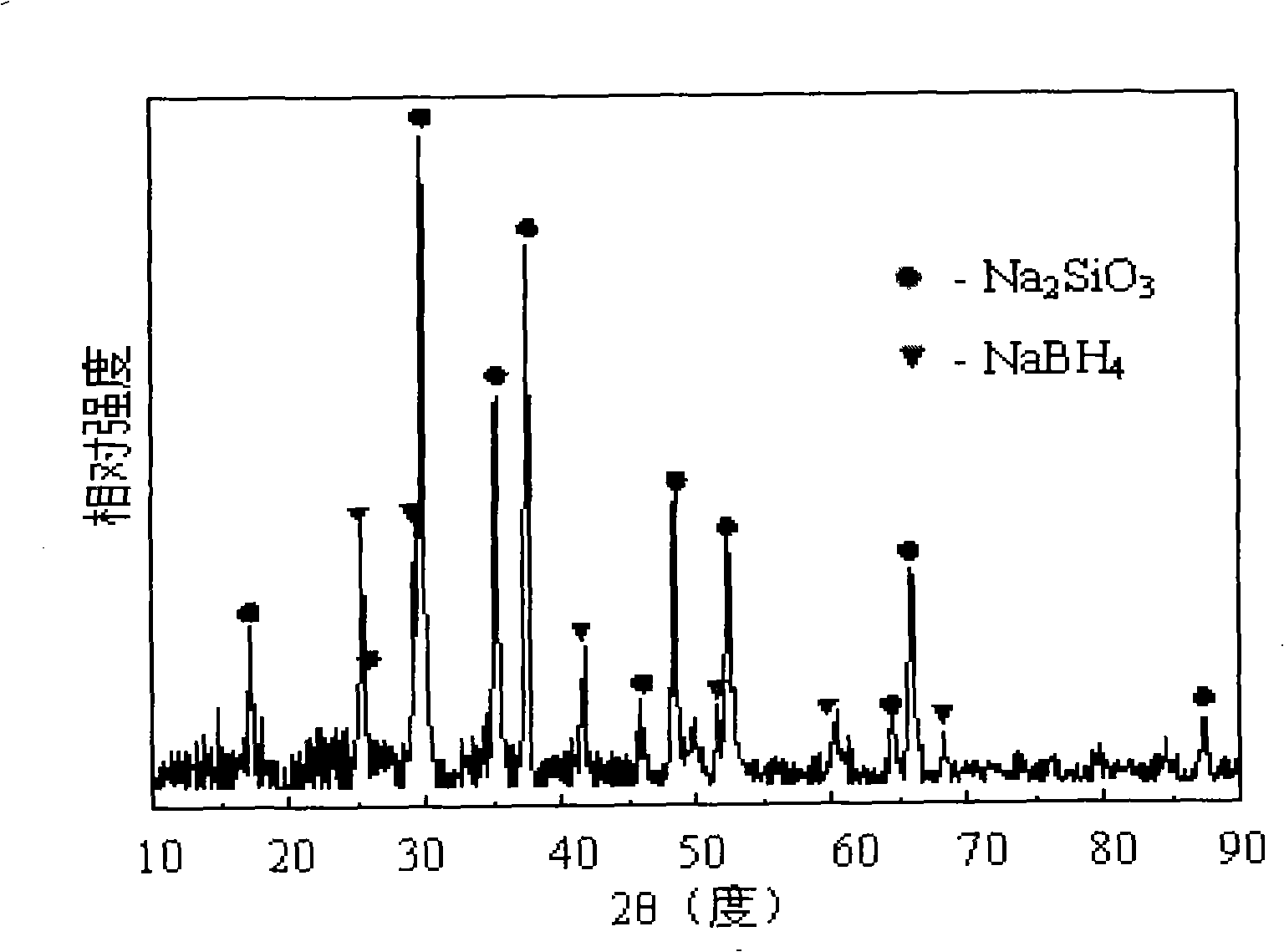

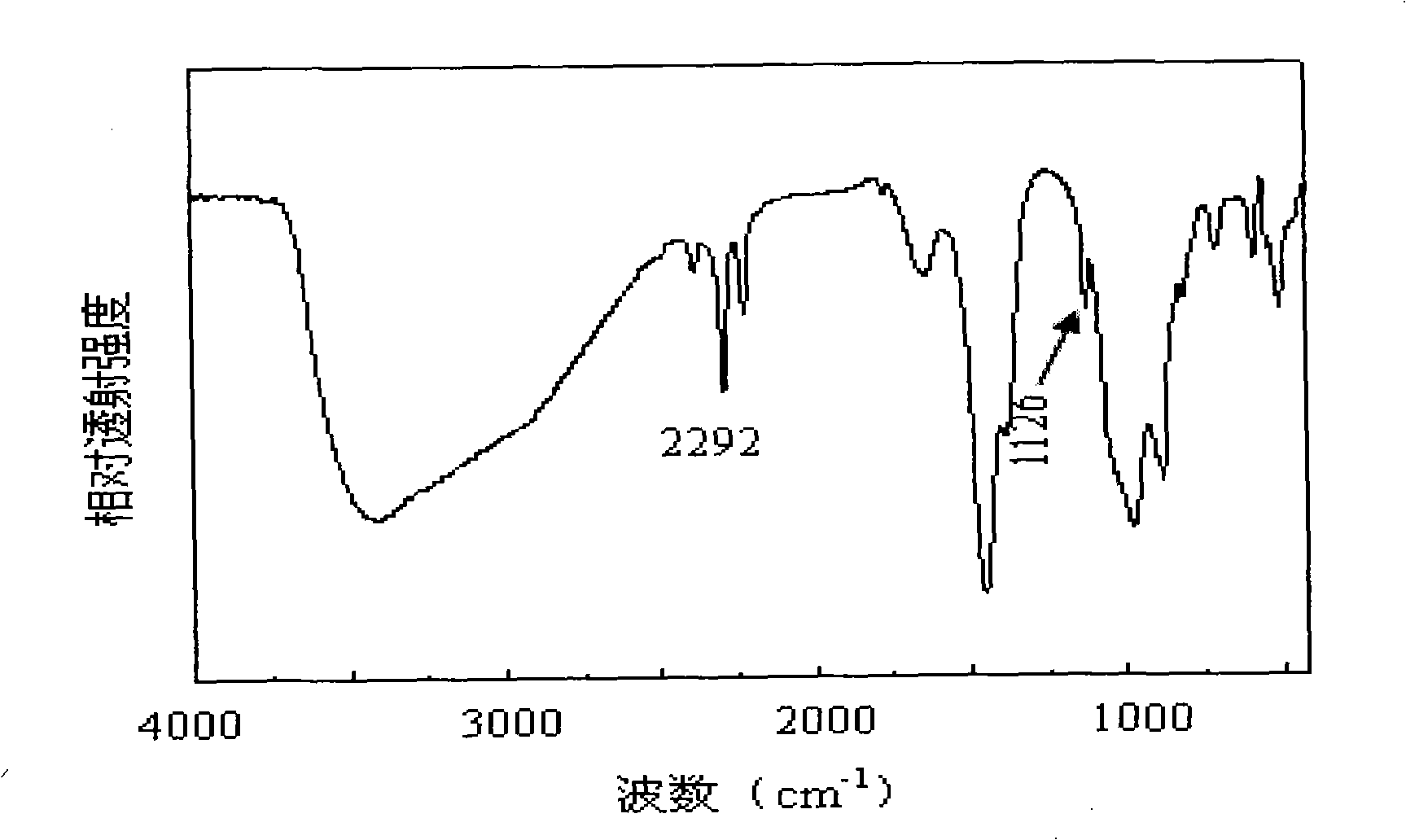

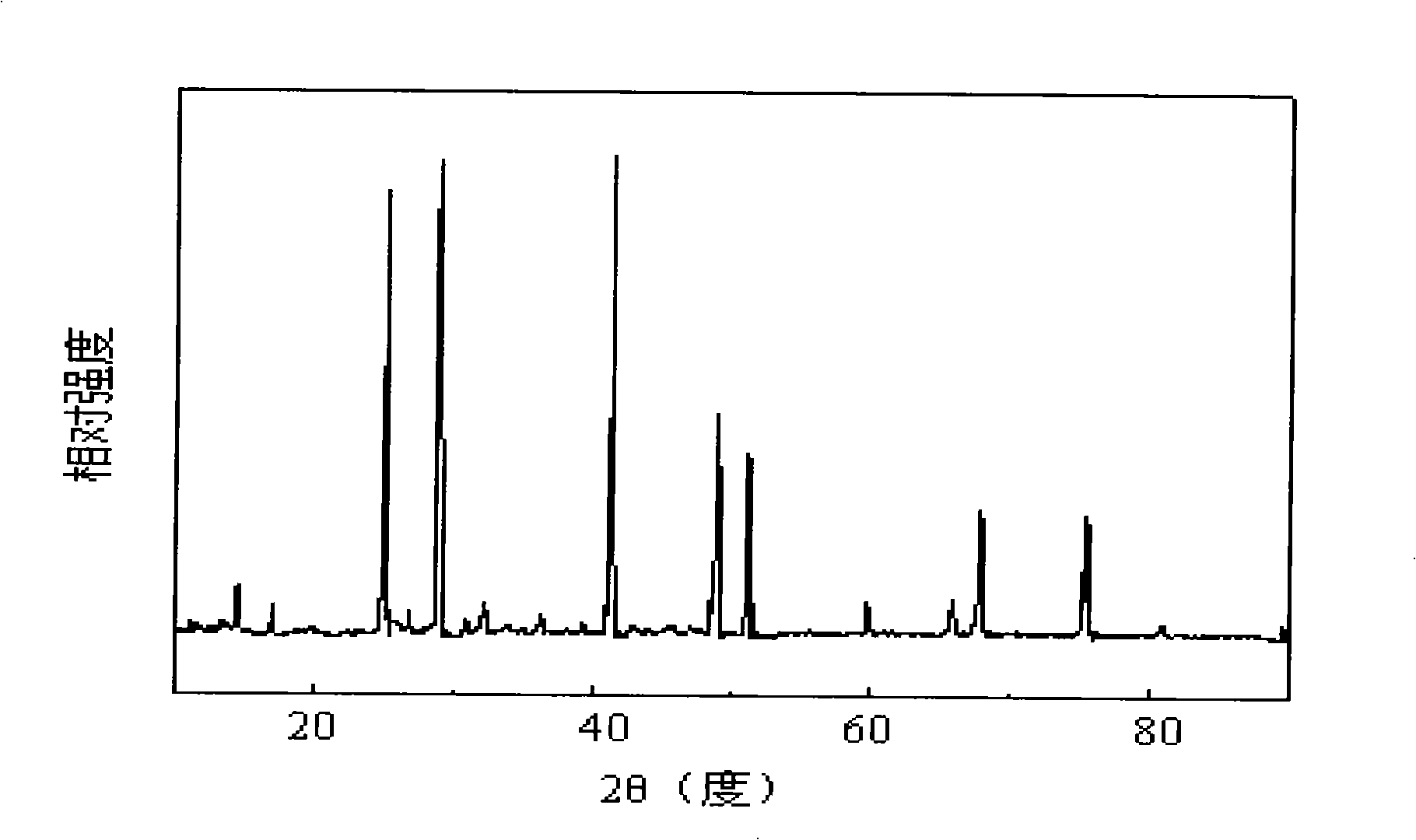

Method for preparing sodium borohydride

InactiveCN101269793AAvoid strict requirementsHigh yieldMonoborane/diborane hydridesHydrogen pressureSolid reaction

The invention belongs to the technical field of compound preparation, in particular relates to a preparation method of sodium borohydride. The invention is different from the traditional gas-solid heterogeneous reaction, and carries out solid-state reaction by a metal hydride and a boron-containing compound, and then the sodium borohydride is prepared. The reaction in the invention is carried out completely at the inner part of solid-state materials, so the sodium borohydride can be obtained under lower hydrogen pressure even in an atmosphere of inert gases, thus, high-pressure hydrogen avoids to be used and the requirement to equipment is reduced. The preparation method has the advantages of simple technical process and easy realization of scale production.

Owner:FUDAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com