Device and method for producing sodium bisulfide by utilizing refinery dry gas

A technology of sodium hydrosulfide, refinery dry gas, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of operator health damage, poor operation safety, harsh production environment, etc., and achieve comprehensive resource utilization. The effect of utilization, no secondary pollution, and efficient resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The dry gas of a refinery is characterized by CH 4 17.82%, C 2 h 6 9.35%, C 2 h 4 8.04%, C 3 h 8 0.52%, C 3 h 6 1.20%, H 2 47.44%, H 2 S is 0.69%, CO 2 0.80% for air and 14.14% for others.

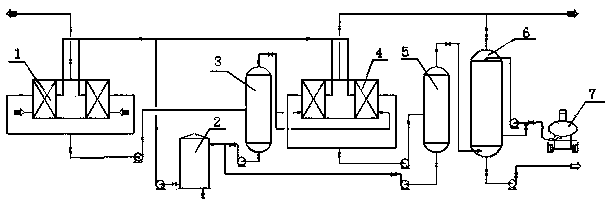

[0029] The dry gas raw material enters the first supergravity machine 1, and contacts with the amine absorbent methyldiethanolamine entering from the upper liquid inlet of the first supergravity machine 1, and the refined dry gas enters the gas pipe from the top of the first supergravity machine The liquid at the bottom of the first supergravity machine 1 enters the first absorbent regeneration tower 3 for absorbent regeneration. The operating pressure in the first supergravity machine is controlled at 1.0MPa, the operating temperature is controlled at 25°C, and the gas is The residence time in the first supergravity machine is 0.5min; after the liquid at the bottom of the first supergravity machine 1 enters the first absorbent regeneration tower 3, the temperature rises ...

Embodiment 2

[0031] The dry gas of a refinery is characterized by CH 4 25.79%, C 2 h 6 10.32%, C 2 h 4 10.04%, C 3 h 8 0.65%, C 3 h 6 1.08%, H 2 32.80%, H 2 S is 0.30%, CO 2 0.20% for air and 18.82% for others.

[0032] The dry gas raw material enters the first supergravity machine 1, and contacts with the amine absorbent methyldiethanolamine entering from the upper liquid inlet of the first supergravity machine 1, and the refined dry gas enters the gas pipe from the top of the first supergravity machine The liquid at the bottom of the first supergravity machine 1 enters the first absorbent regeneration tower 3 for absorbent regeneration. The operating pressure in the first supergravity machine is controlled at 1.2MPa, the operating temperature is controlled at 25°C, and the gas is The residence time in the first supergravity machine is 0.5min; after the liquid at the bottom of the first supergravity machine 1 enters the first absorbent regeneration tower 3, the temperature rise...

Embodiment 3

[0034] The dry gas of a refinery is characterized by CH 4 25.85%, C 2 h 6 11.52%, C 2 h 4 12.44%, C 3 h 8 1.45%, C 3 h 6 1.46%, H 2 31.86%, H 2 S is 0.10%, CO 2 2.86% for air and 12.46% for others.

[0035] The dry gas raw material enters the first supergravity machine 1, and contacts with the amine absorbent methyldiethanolamine entering from the upper liquid inlet of the first supergravity machine 1, and the refined dry gas enters the gas pipe from the top of the first supergravity machine The liquid at the bottom of the first supergravity machine 1 enters the first absorbent regeneration tower 3 for absorbent regeneration. The operating pressure in the first supergravity machine is controlled at 0.8MPa, the operating temperature is controlled at 25°C, and the gas is The residence time in the first supergravity machine is 0.3min; after the liquid at the bottom of the first supergravity machine 1 enters the first absorbent regeneration tower 3, the temperature rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com