Patents

Literature

330 results about "High Gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

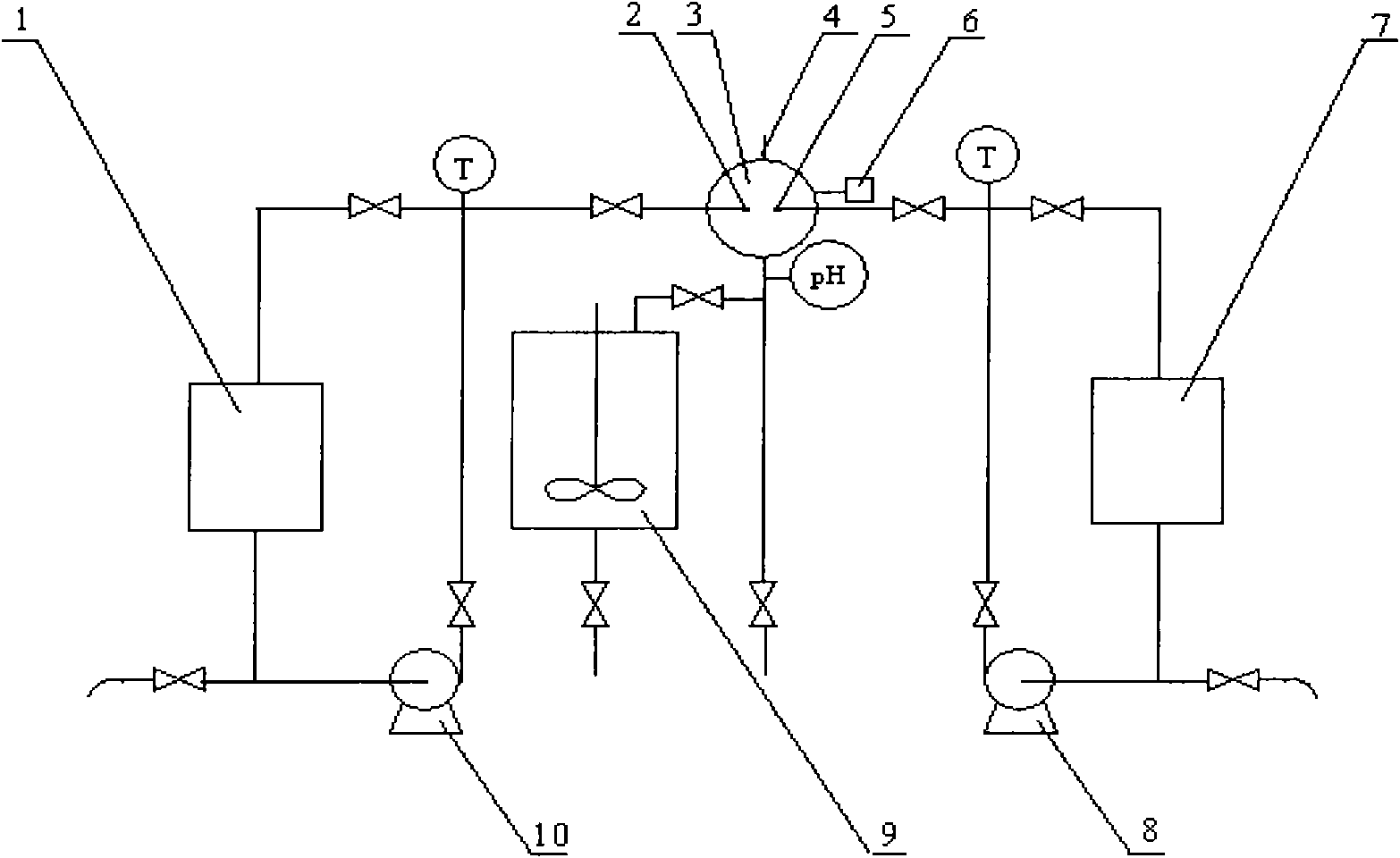

Method for removing hydrogen sulfide in gas phase through oxidization under high gravity field

InactiveCN102151476AShort regeneration timeSmall sizeDispersed particle separationGas phaseDefoaming Agents

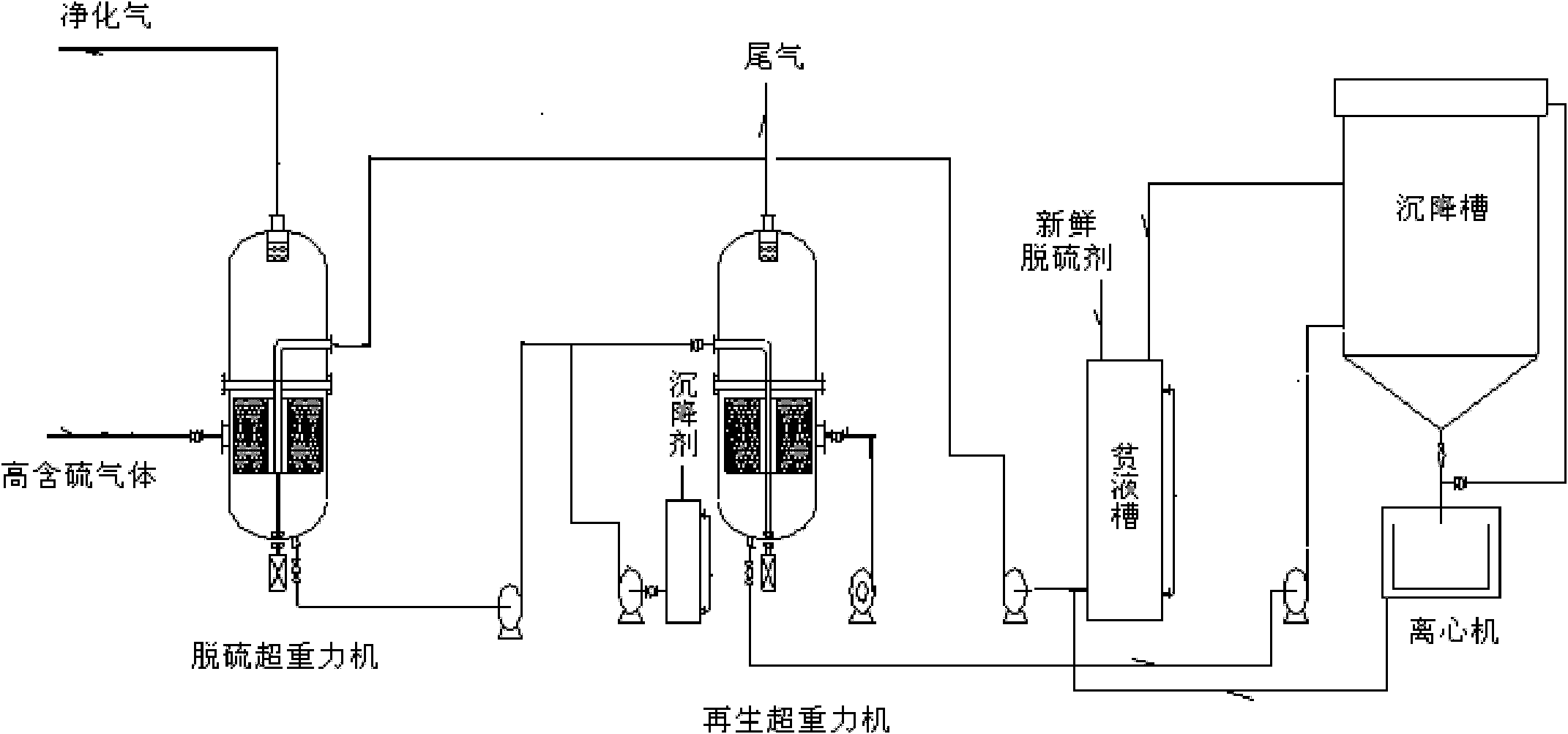

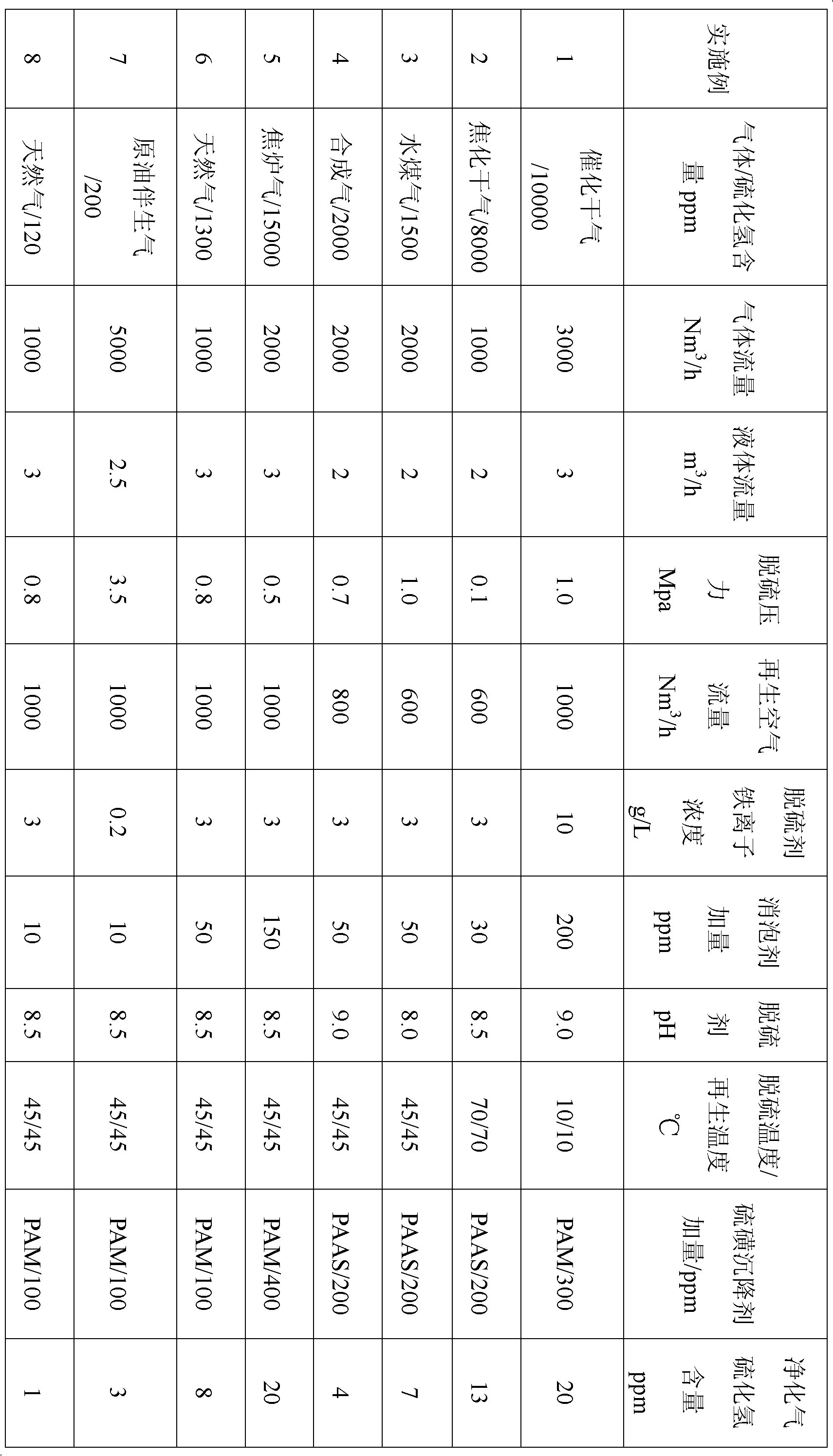

The invention discloses a method for removing hydrogen sulfide in a gas phase through oxidization under a high gravity field, which comprises the steps of: enabling a desulfurizing agent to be in a countercurrent or cross current contact with a hydrogen sulfide containing gas in a desulfurizing high gravity machine; and then adding the desulfurizing agent rich in sulphur in a sulphur sedimentation agent and then enabling the desulfurizing agent added with the sulphur sedimentation agent to be in a countercurrent or cross current contact with air in a regeneration high gravity machine, whereinthe desulfurizing agent is a mixed solution consisting of complex iron, aqueous alkali, a sulphur modifying agent and a defoaming agent, and in the mixed solution, the concentration of iron ions is 0.1-10g / L, pH is 8.0-9.2, the concentration of the sulphur modifying agent is 10-200ppm, and the concentration of the defoaming agent is 5-50ppm. The high gravity machine is used for replacing the traditional low-transfer-efficiency reactor, and a high gravity rotary packed bed reactor is adopted during hydrogen sulfide oxidization and catalyst regeneration, thus process transfer efficiency is greatly strengthened, and time of oxidization desulfurization and regeneration of a desulfurizing agent is shortened; in addition, the sedimentation agent is adopted in a sulphur sedimentation stage and acts together with the sulphr modifying agent, thus the sulphur sedimentation time is also greatly shortened.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD +1

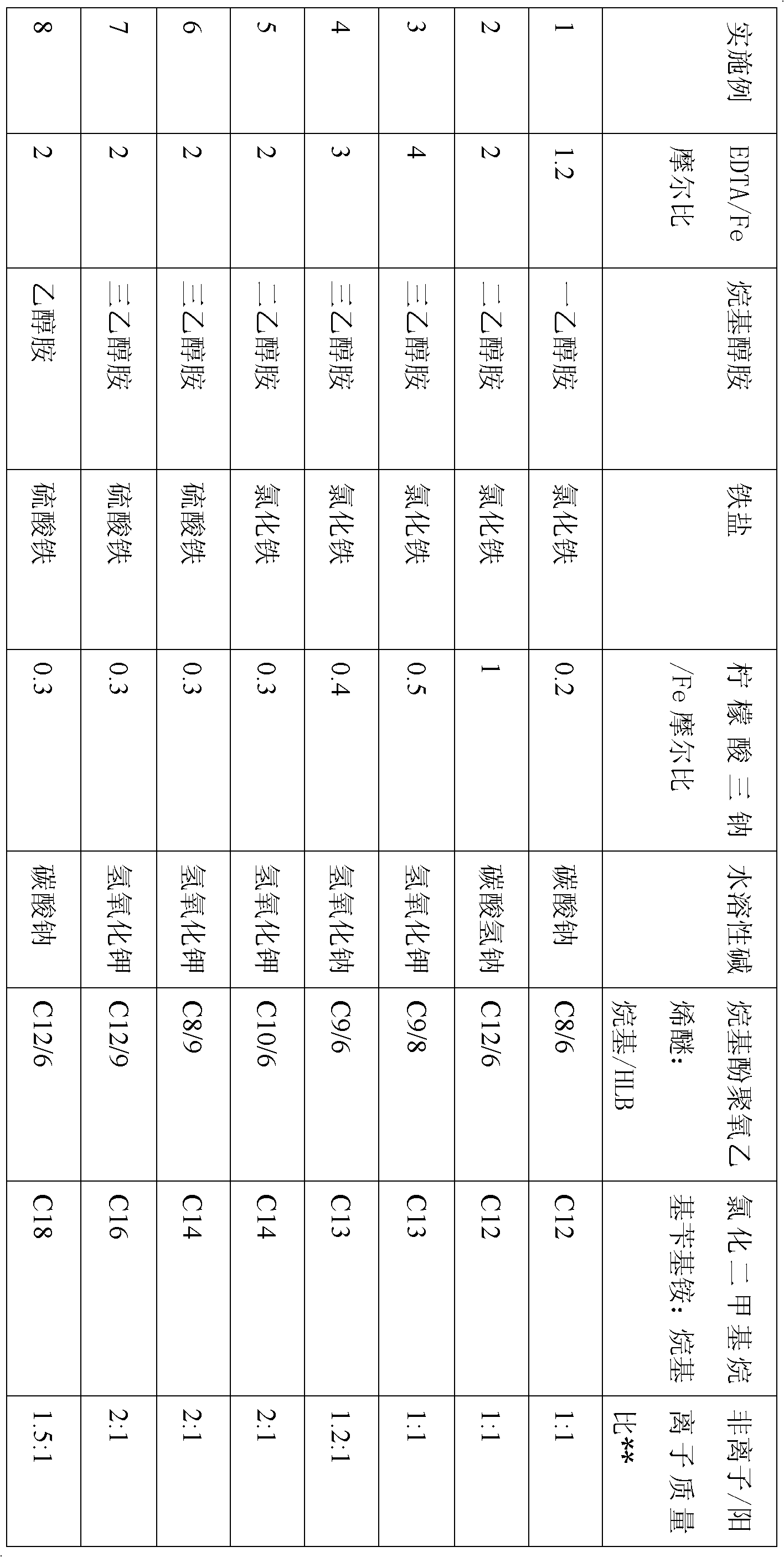

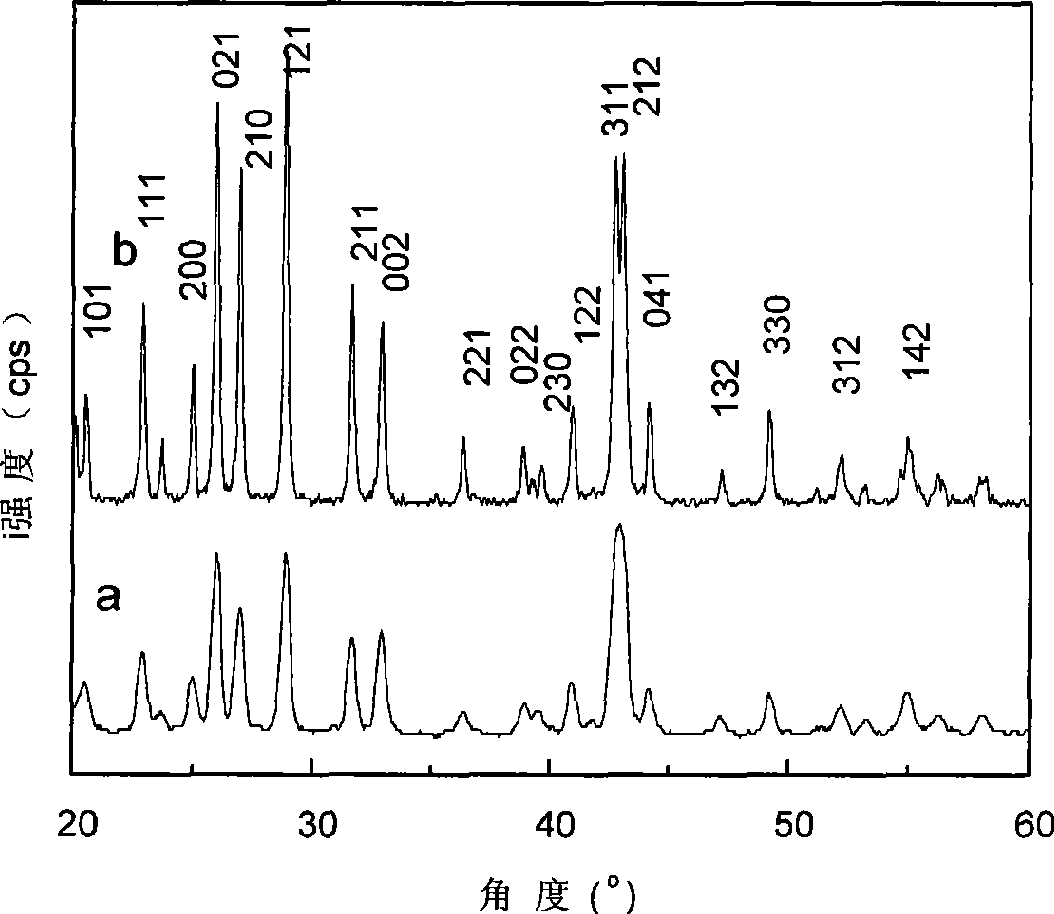

Process for preparing perovskite-type crystalline compound powders

InactiveUS20060045840A1Alkaline earth titanatesMaterial nanotechnologyRare earthParticle-size distribution

A process for preparing perovskite-type compound Ax(BO3)y powders involving reacting a solution containing A and a solution containing B, or a combined solution comprising A and B, with an alkaline solution in a high-gravity reactor at a temperature ranging from about 60° C. to about 100° C. A is one or more metal elements selected from the group consisting of Li, Na, K, Mg, Ca, Sr, Ba, Pb, Sm, La, Nd, Bi, and other rare-earth metal elements. B is one or more metal elements selected from the group consisting of Ti, Zr, Sn, Hf, Nb, Ce, Al, Zn, Mn, Co, Ni, Fe, Cr, Y, Sc, W, Ta, and the like. The resulting mixture is then filtered, rinsed and dried to obtain the desired powders. The obtained perovskite-type compound Ax(BO3)y powders have a small average particle size with a narrow particle size distribution, a perfect crystal form and a uniform particle shape, and is suitable for use as raw material for making dielectric, piezoelectric, anti-ferroelectric, pyroelectric, pressure-resisting, sensing, microwave media, and other ceramics.

Owner:BEIJING UNIV OF CHEM TECH +1

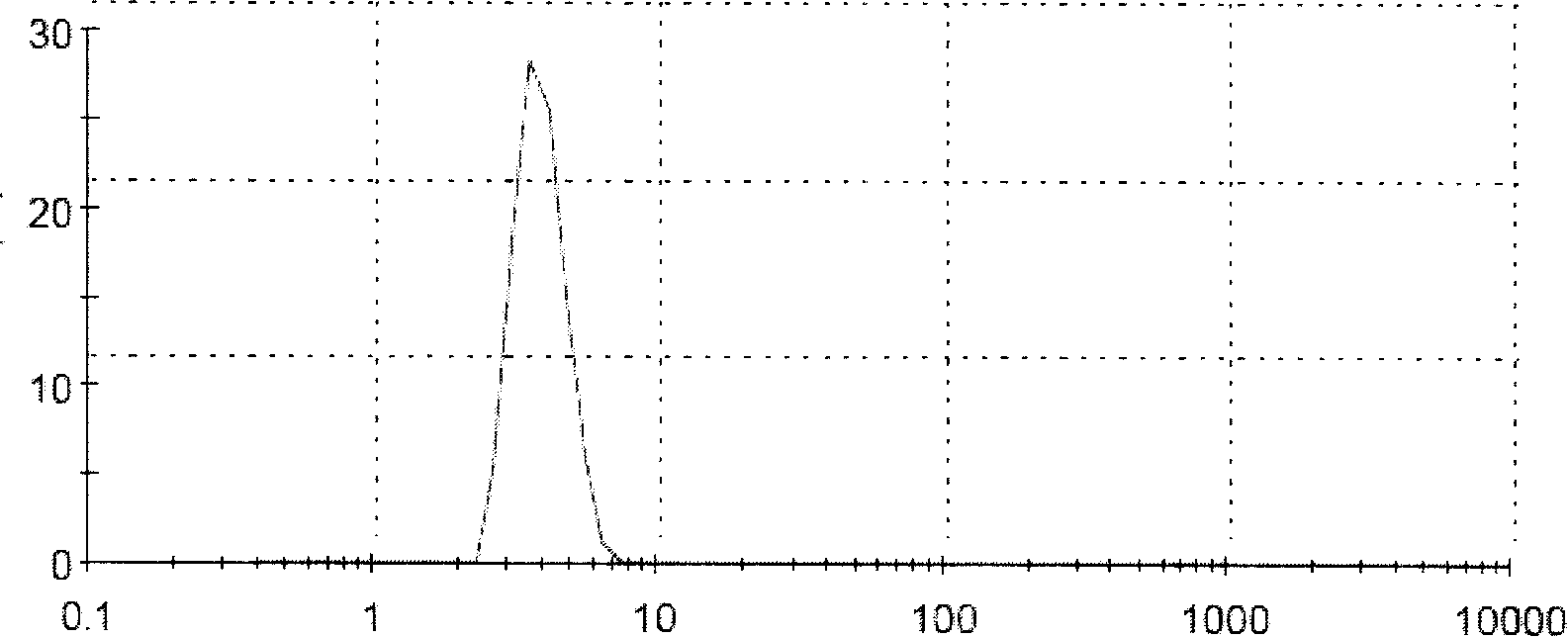

Method for preparing nano barium sulfate with controllable particle size distribution

InactiveCN101423239APrecise control of particle sizeInhibit growthCalcium/strontium/barium sulfatesEmulsionSlurry

The invention provides a preparation method of nano barium sulfate with the controllable particle size distribution. The preparation method takes BaCl2 and Na2SO4 as raw materials, respectively prepares two types of solution and then simultaneously adds the two types of solution into a rotary liquid membrane reactor with the high-speed rotation at the same flow rate for carrying out nucleation reaction, and centrifugal washing and drying are carried out to the obtained slurry to obtain the nano BaSO4 with the particle size of 30-120nm and the narrower particle size distribution. The purpose of precisely controlling the particle size of the product can be achieved by regulating and controlling the rotational speed, the gap and other operation parameters of the reactor, thereby being capable of preparing the BaSO4 with the particle size of 30-40nm. The method combines the advantages of a micro-reactor and a high gravity reactor and simultaneously avoids the shortcomings of the micro-emulsion method, the complex method and the like, thereby having small reaction space and high preparation speed and being capable of meeting the requirements on the industrial preparation of the nano BaSO4.

Owner:BEIJING UNIV OF CHEM TECH

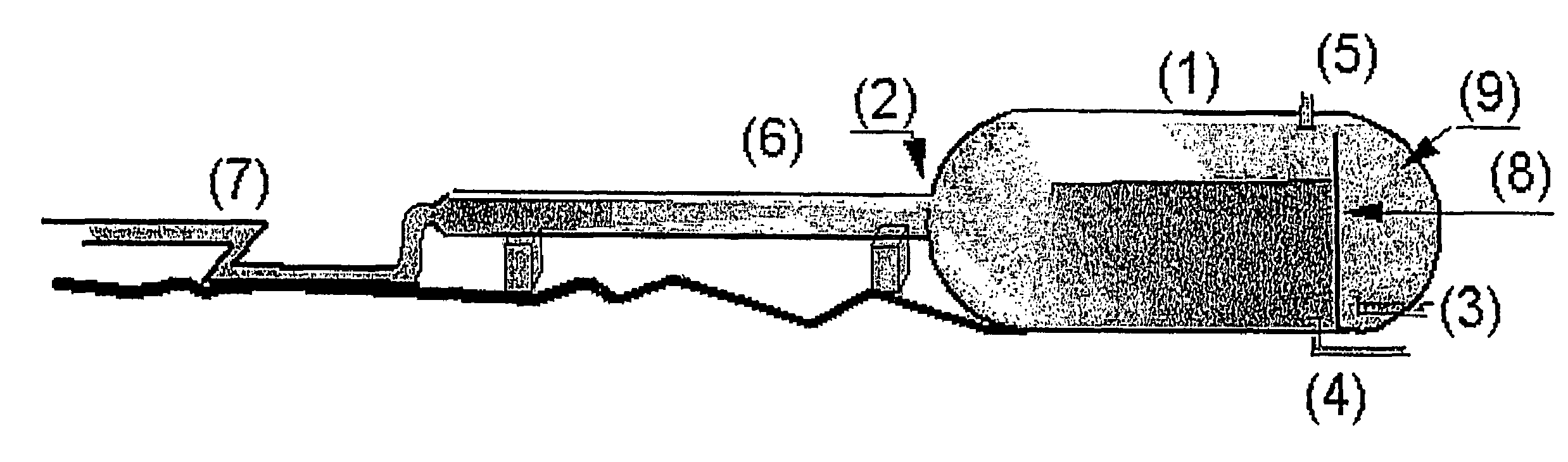

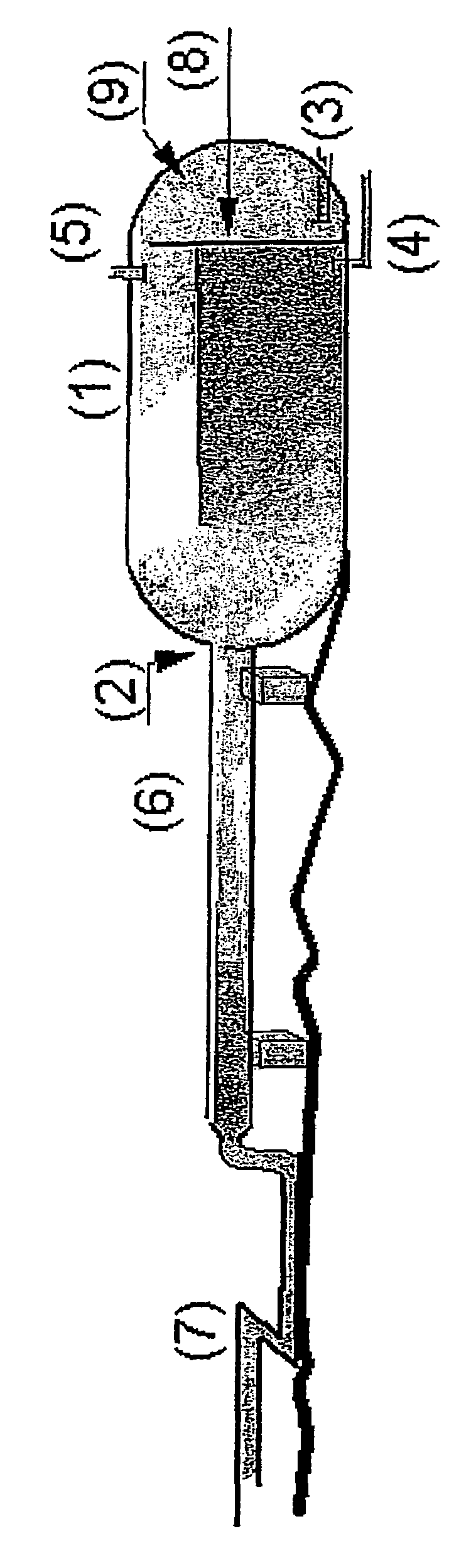

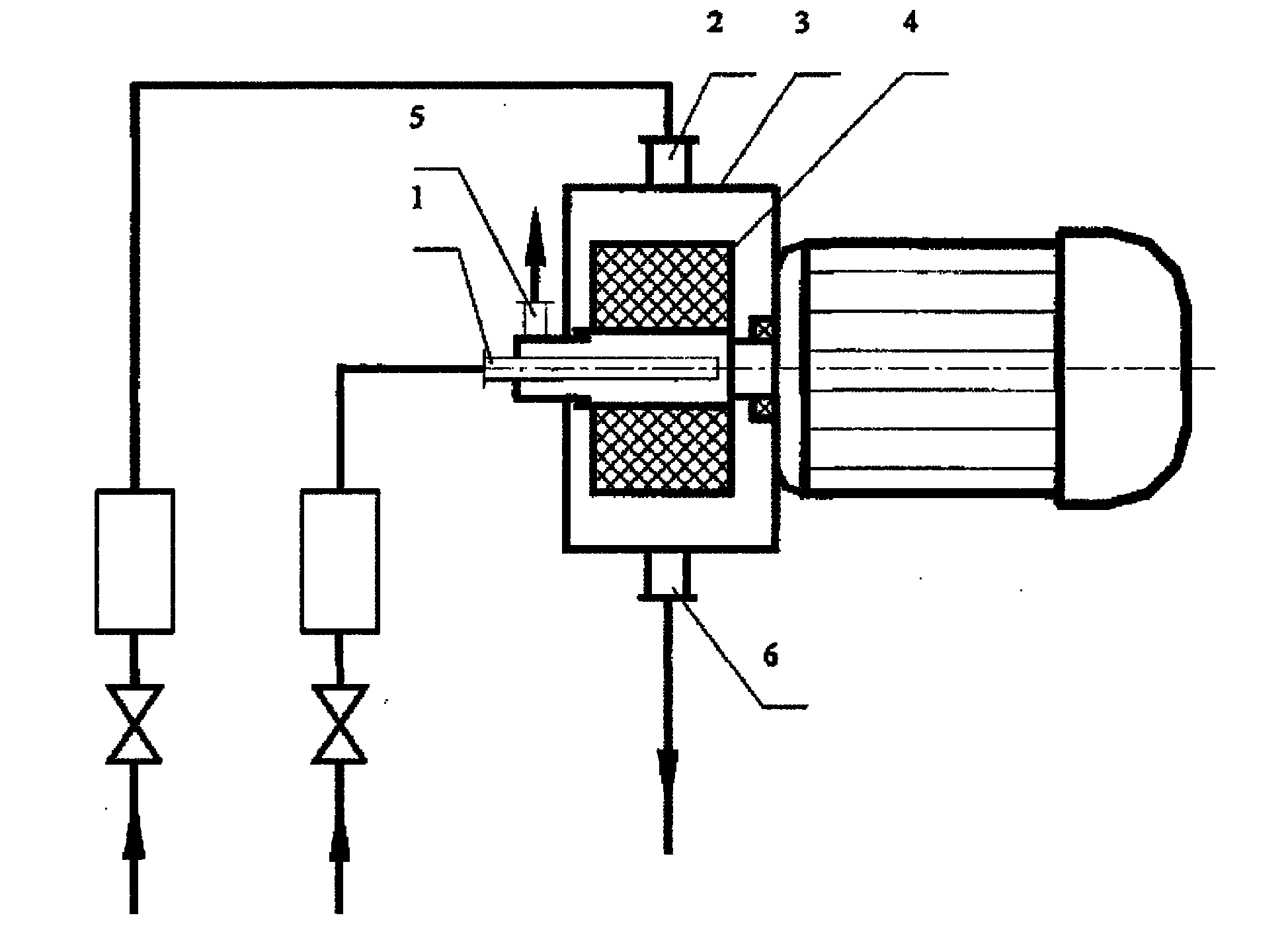

Device for separating multi-phase fluids

ActiveUS7278543B2Improve performanceLower the volumeLiquid degasificationFluid removalEngineeringMulti phase

A device in connection with a separator for separation of a multiphase fluid, including a preferably cylindrical container (1) with an inlet (2), a first outlet (3) for liquid with a higher gravity (for example water), a second outlet (4) for liquid with a lower gravity (for example oil) and a third outlet (5) for gas. A pipe separator (6) is connected to the inlet (2) of the container (1). The pipe separator (6) constitutes a continuation of a supply pipe (7) for supplying the fluid to be separated and extends partially into the container (1).

Owner:DEN NORSKE STATS OLJESELSKAP AS

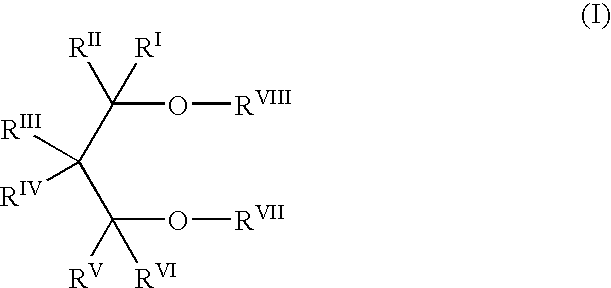

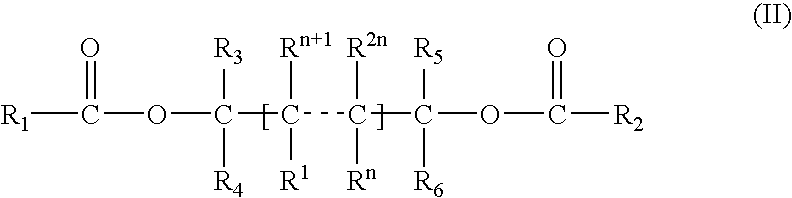

Magnesium halide/alcohol adduct, its preparation and use

ActiveUS7361621B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlcoholLiquid medium

The present invention provides a process for preparing particles of magnesium halide / alcohol adduct, said process comprising: preparing a melt of magnesium halide / alcohol adduct in an inert liquid medium, dispersing the mixture of the inert liquid medium and the melt of the magnesium halide / alcohol adduct by high-speed rotation under a high-gravity field to obtain a dispersion of magnesium halide / alcohol adduct melt; and the cooling the dispersion of the melt to form the particles of magnesium halide / alcohol adduct. The present invention further relates to the particles of magnesium halide / alcohol adduct prepared by the process of the present invention and the use thereof in the preparation of catalysts for olefin polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

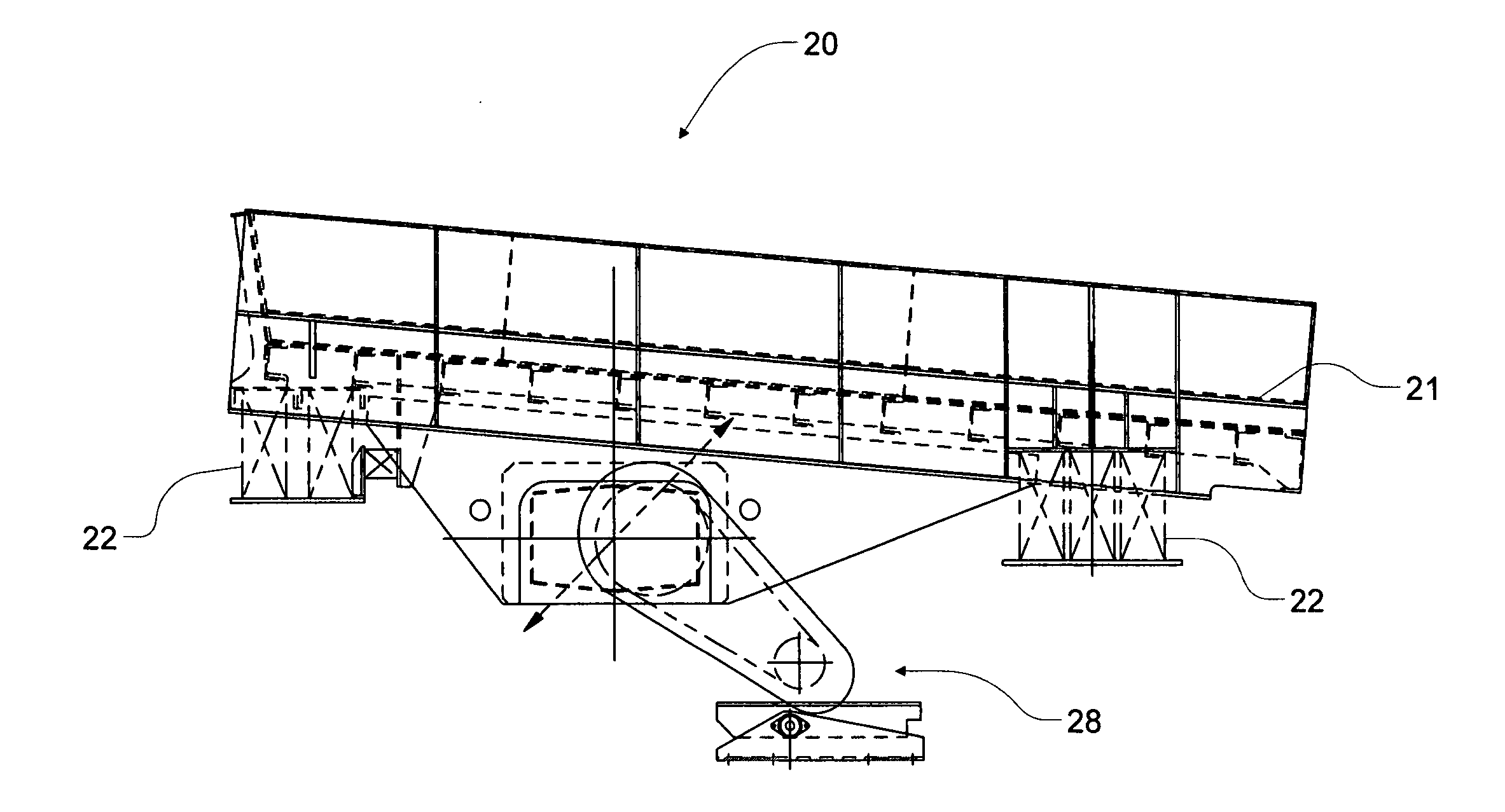

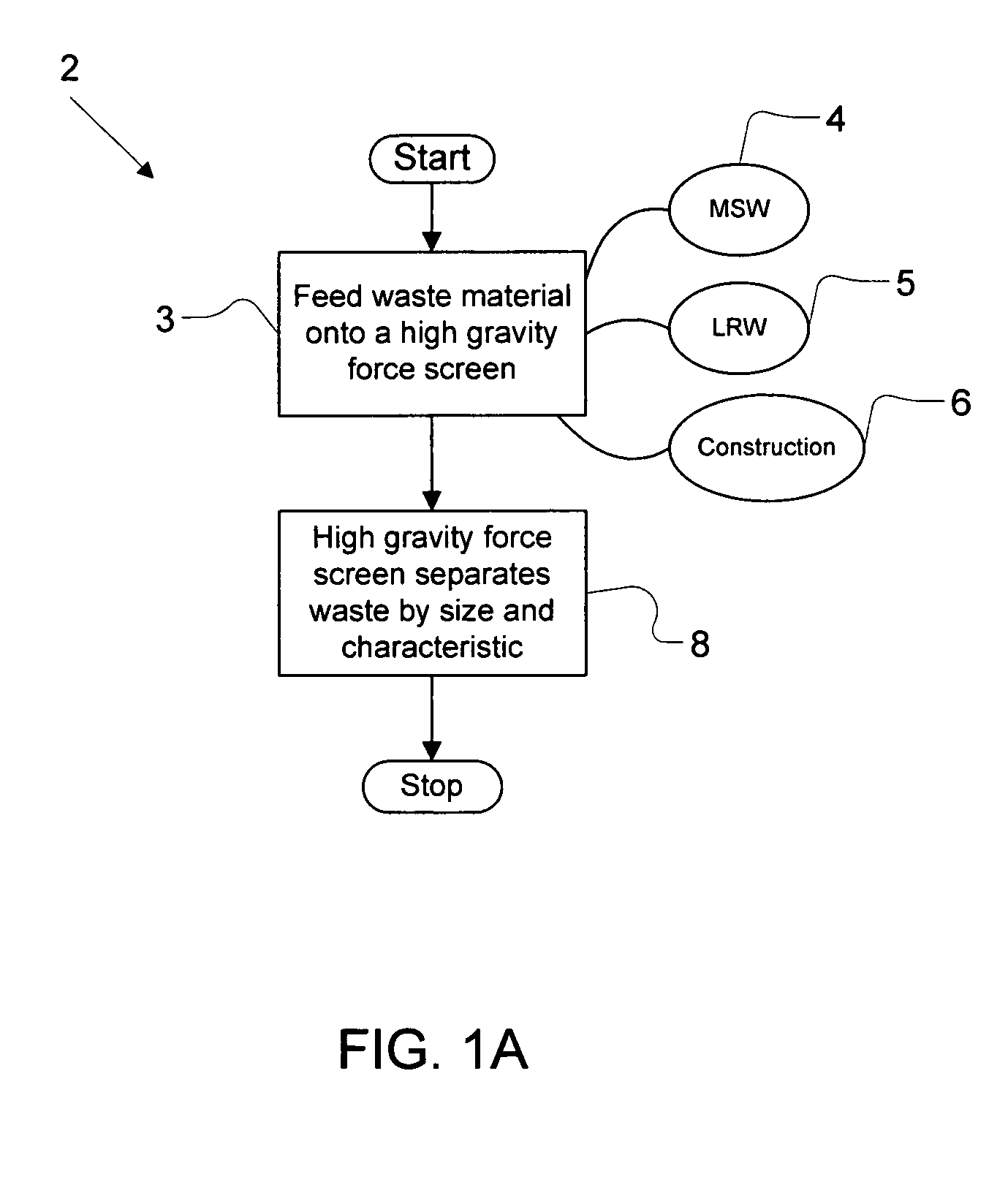

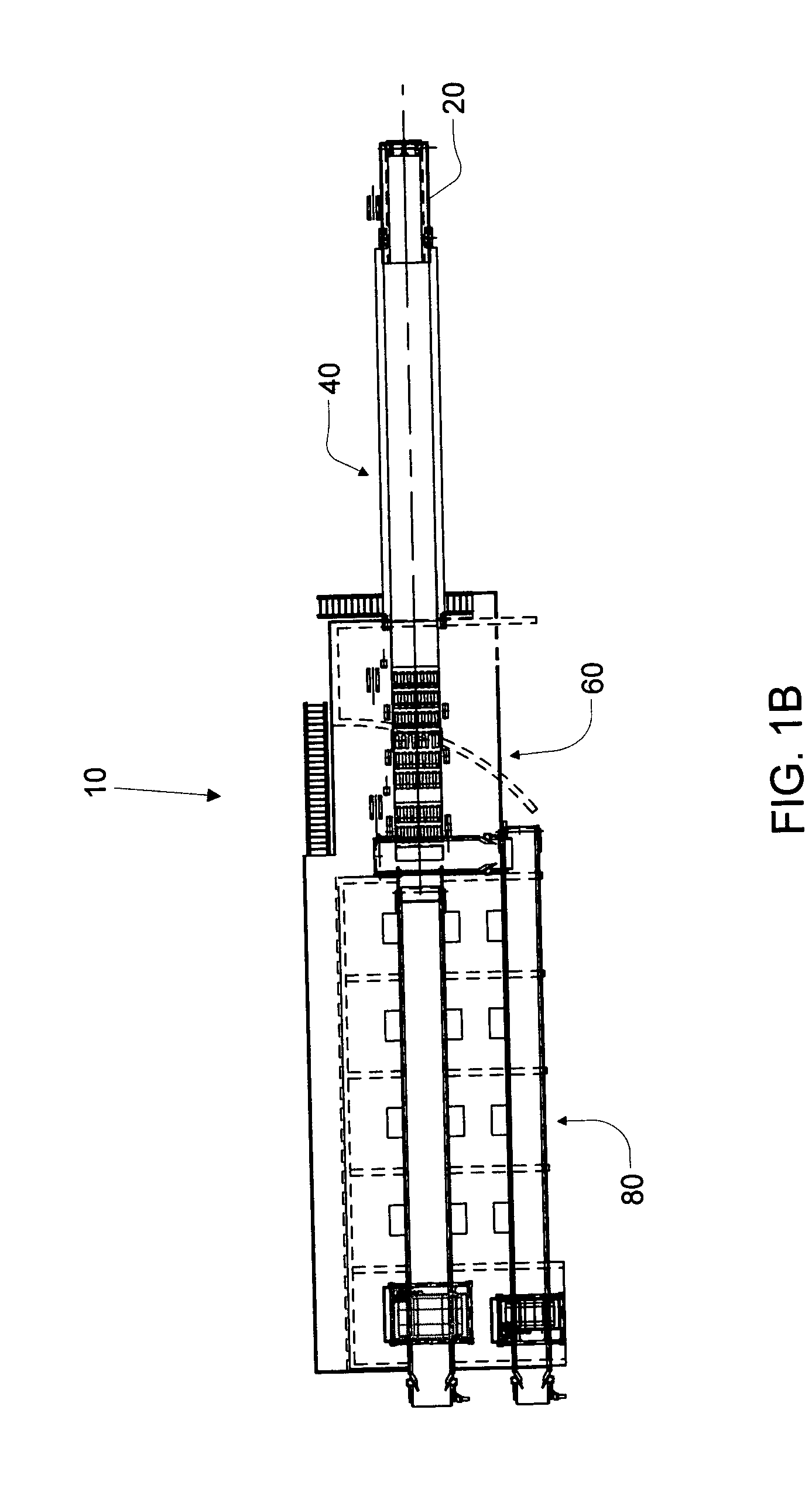

System and method for processing waste and recovering recyclable materials

A system and method is provided for recovering recyclable materials from waste material. In general, the method includes the steps of feeding the waste material onto a high gravity force and separating the waste material by size and characteristic using the high gravity force. The system and method can be used to recover recyclable materials from municipal solid waste, landfill reclamation waste, and / or construction waste.

Owner:MCGEE DAVID P

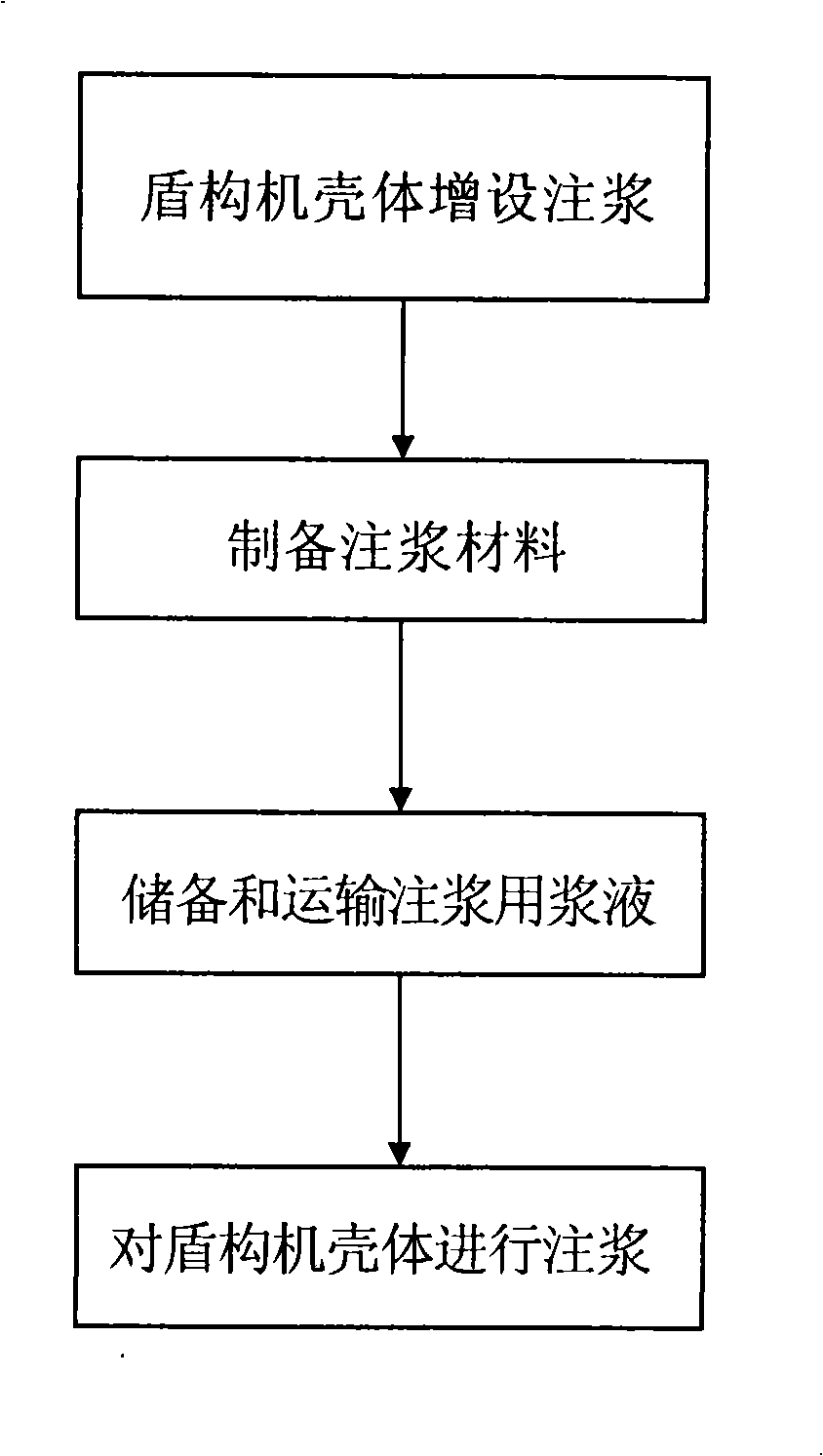

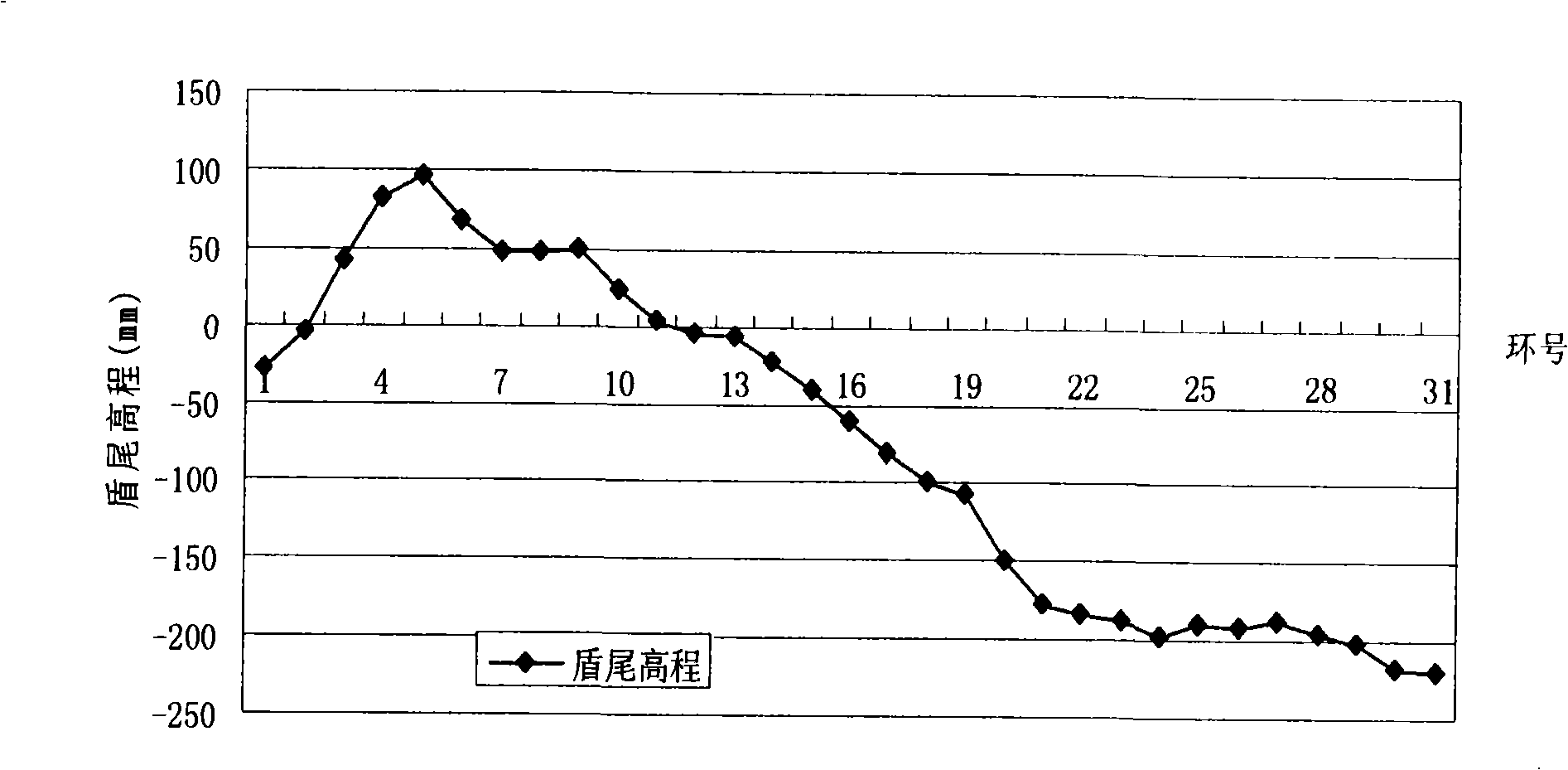

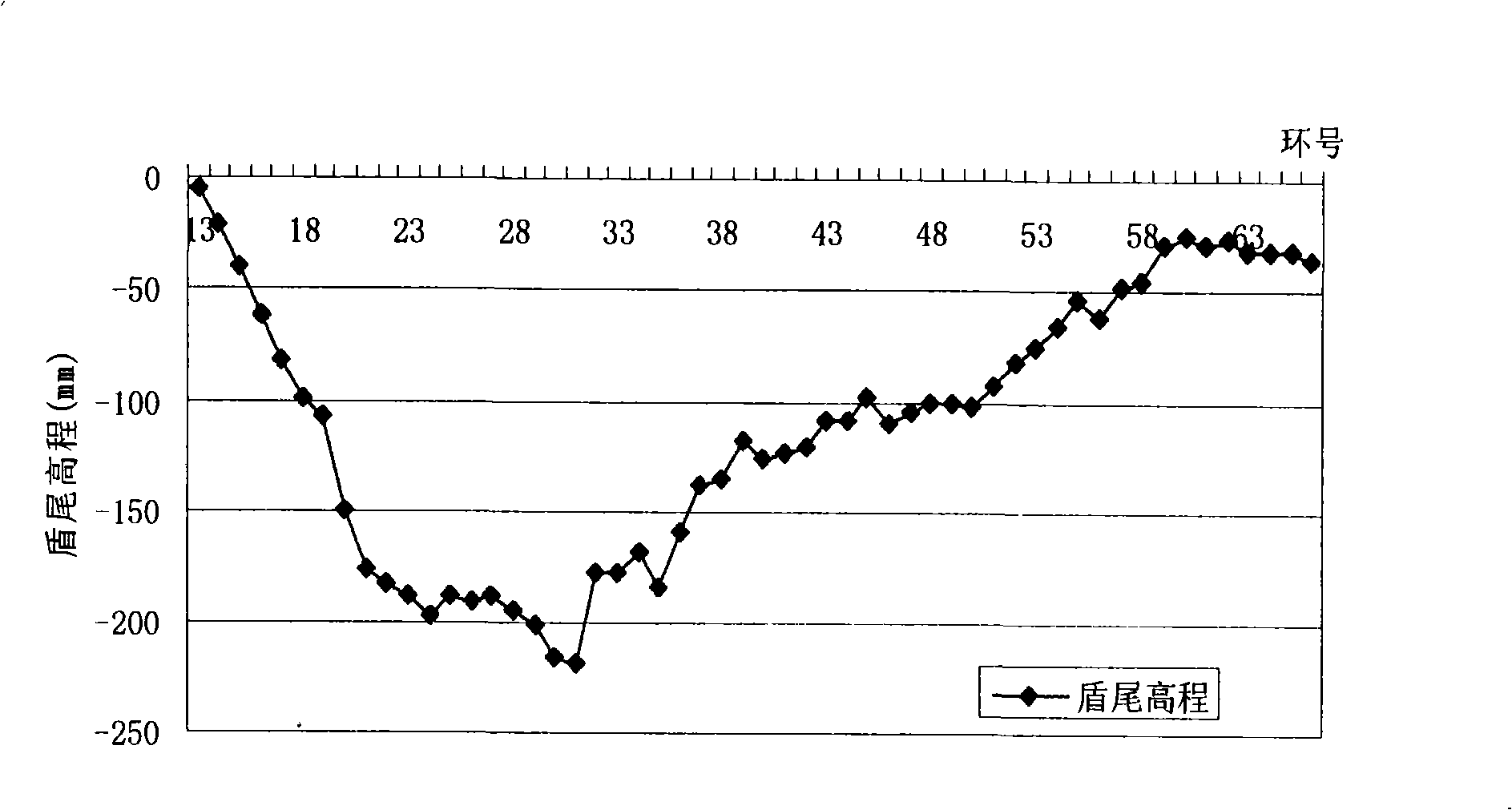

Slip casting control shield attitude and deviation correcting construction method

The invention discloses a construction method for controlling the posture of a shield by grouting, and for deviation rectification. The method comprises the following steps: first, grouting holes are additionally arranged on a shield shell body; second, grouting material is prepared; third, grout used for grouting is stored and transported; fourth, grouting is performed to the shield shell body. The method adopts shearing resistant high gravity single slurry mainly including sand as the grouting material, grouting is performed through the grouting holes of the shield shell body, and the purposes of shield posture adjustment and deviation rectification can be achieved. The method has the advantages that the method is simple and feasible, the effect is obvious, and meanwhile, the influence of the shield construction to the periphery environment can be reduced. Therefore, the method is especially suitable for the tunnel construction of the large-scale shield, and can particularly be used for shield posture adjustment and deviation rectification during the construction of the shield with ultra large diameter larger than 11 m.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

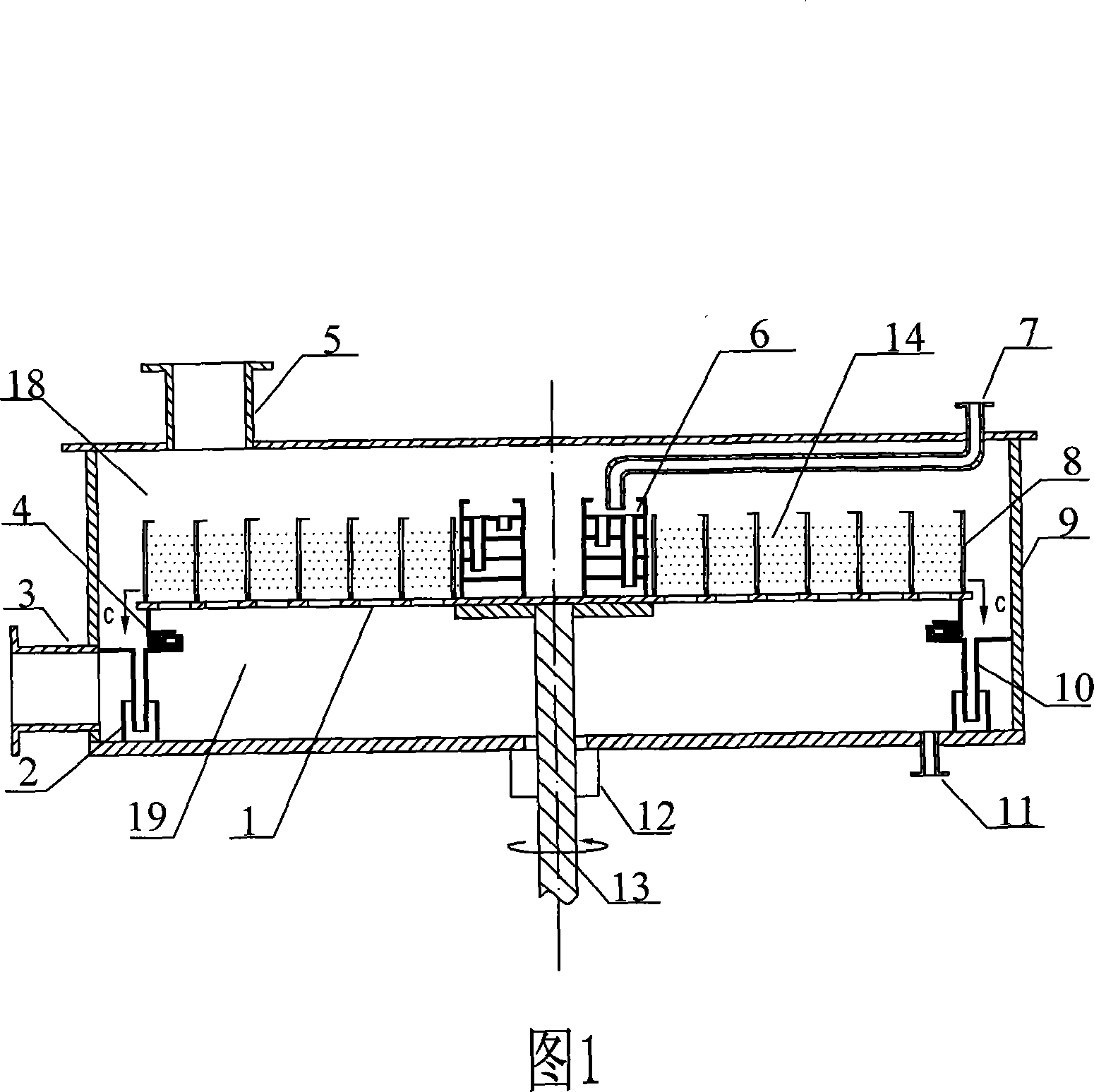

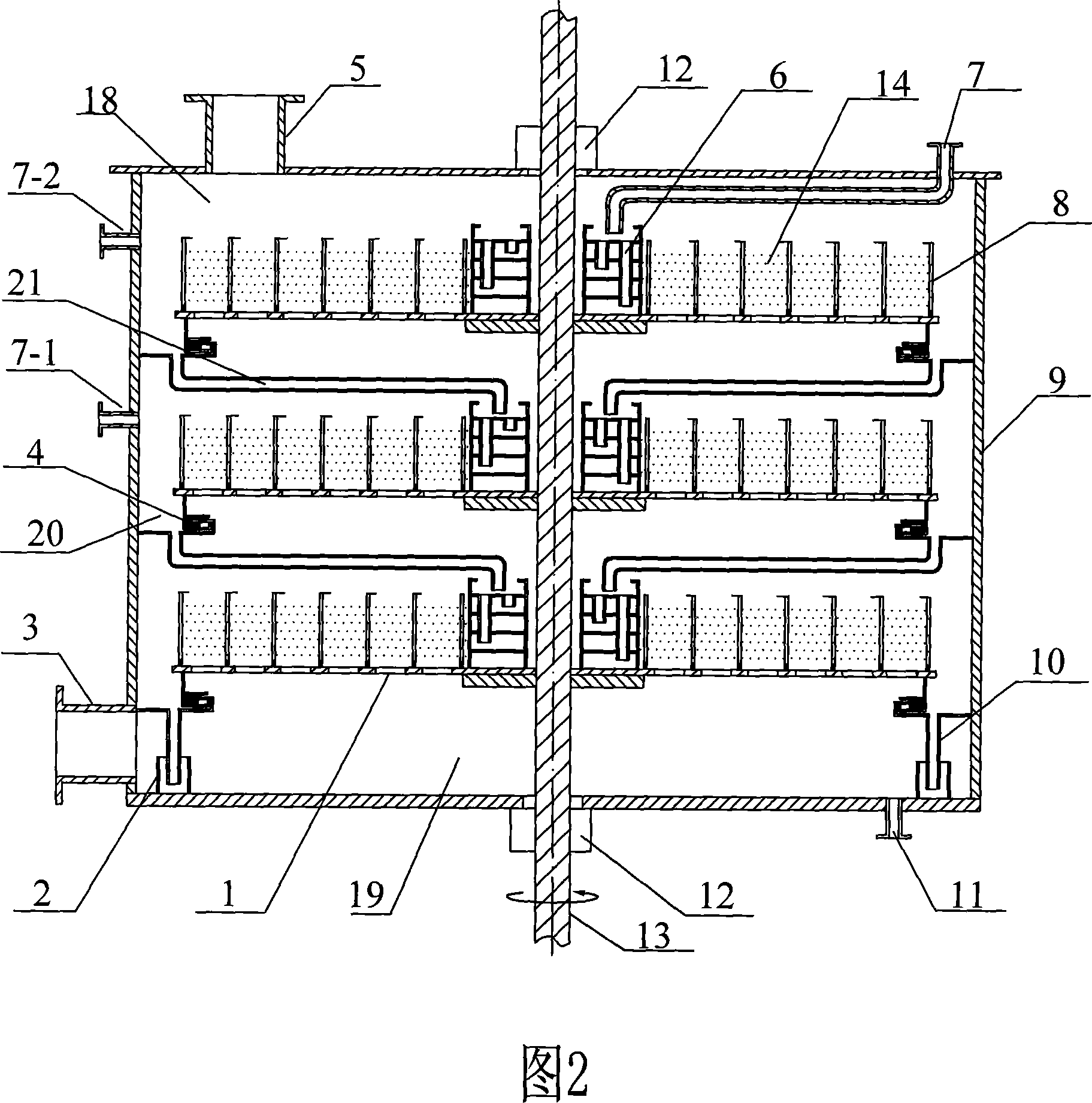

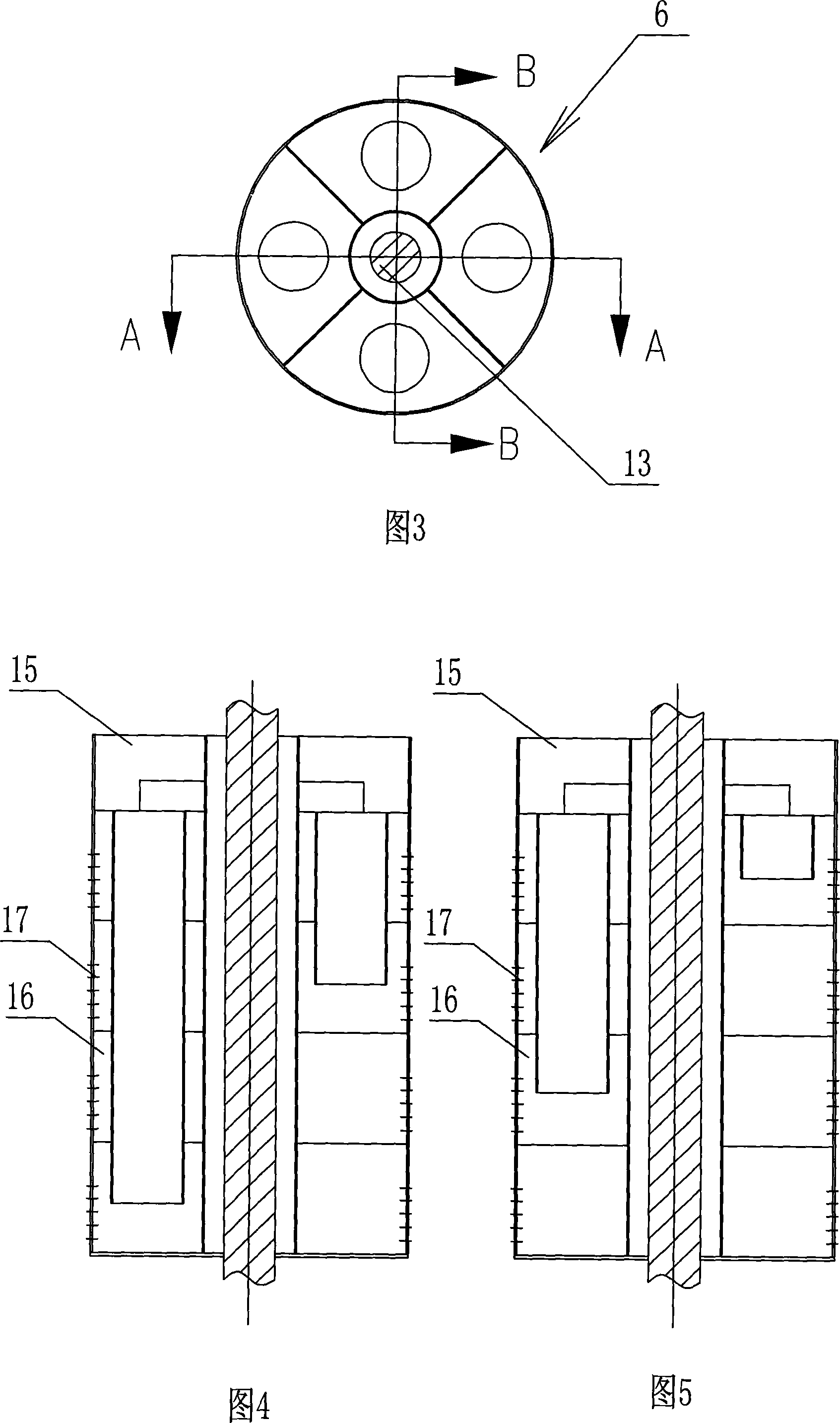

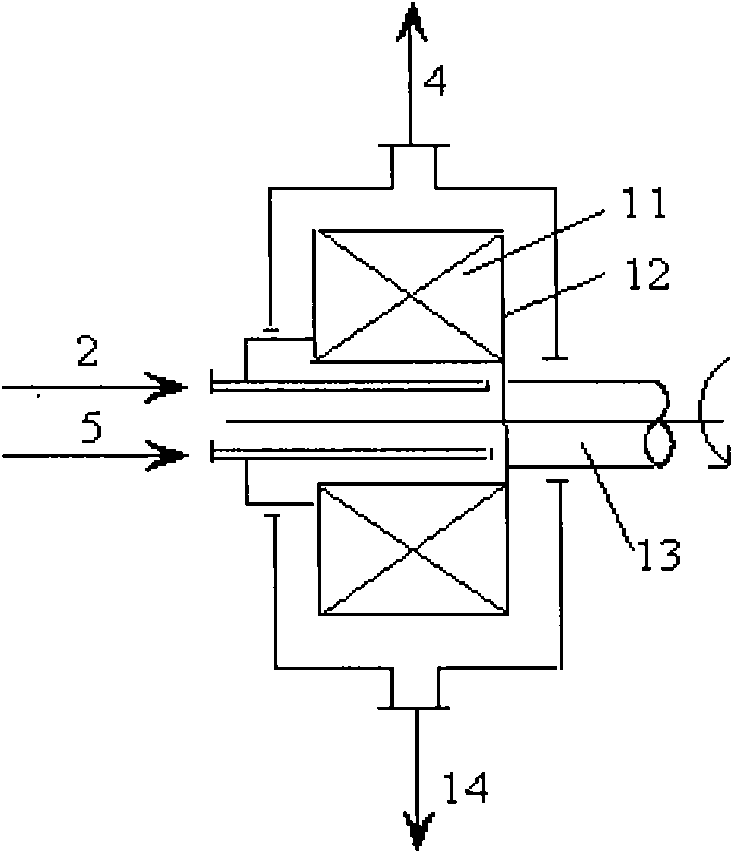

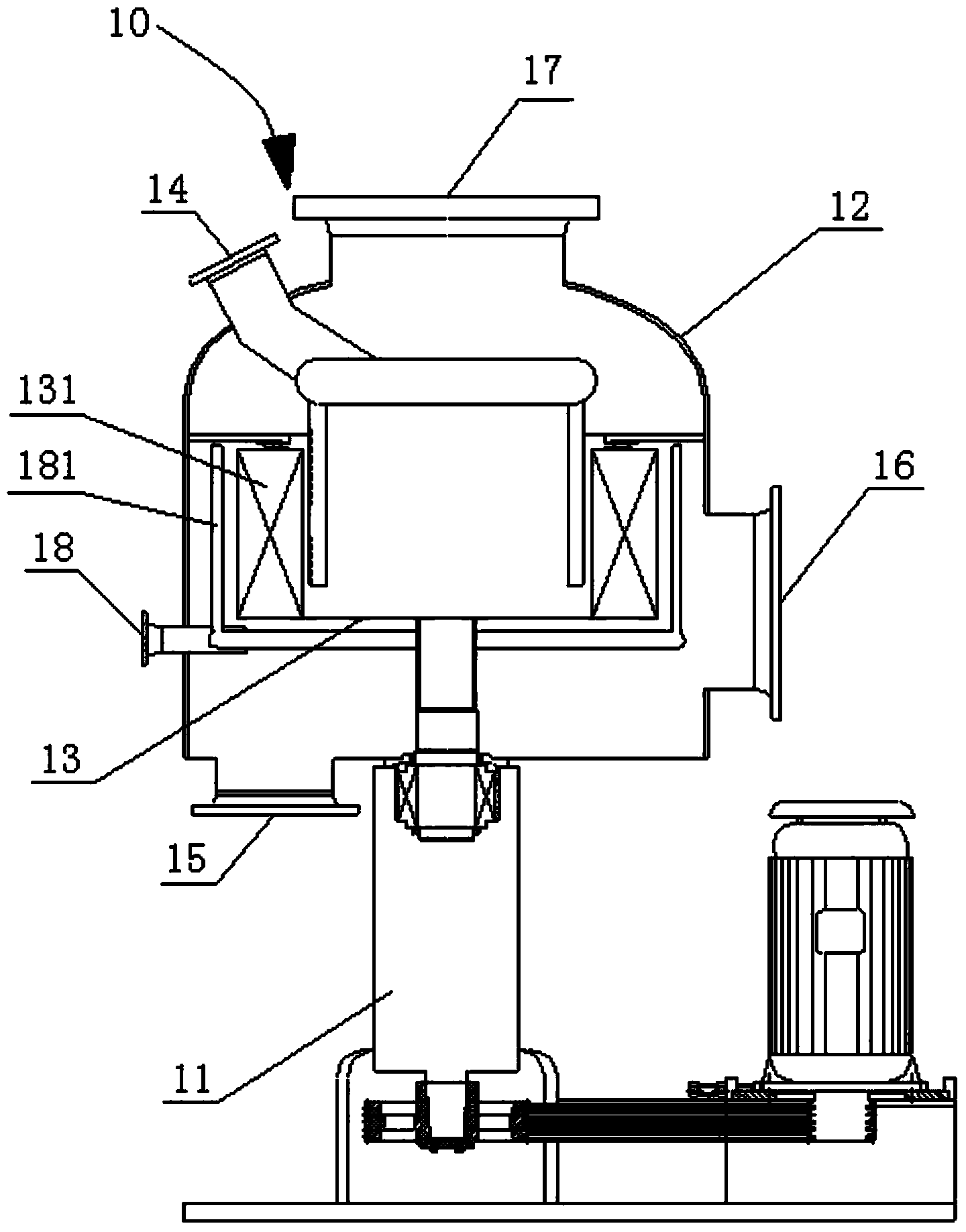

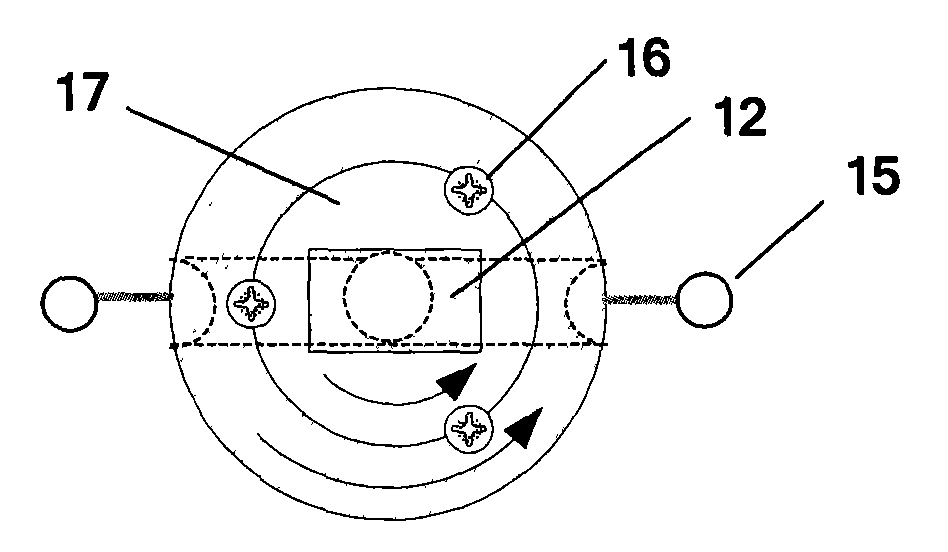

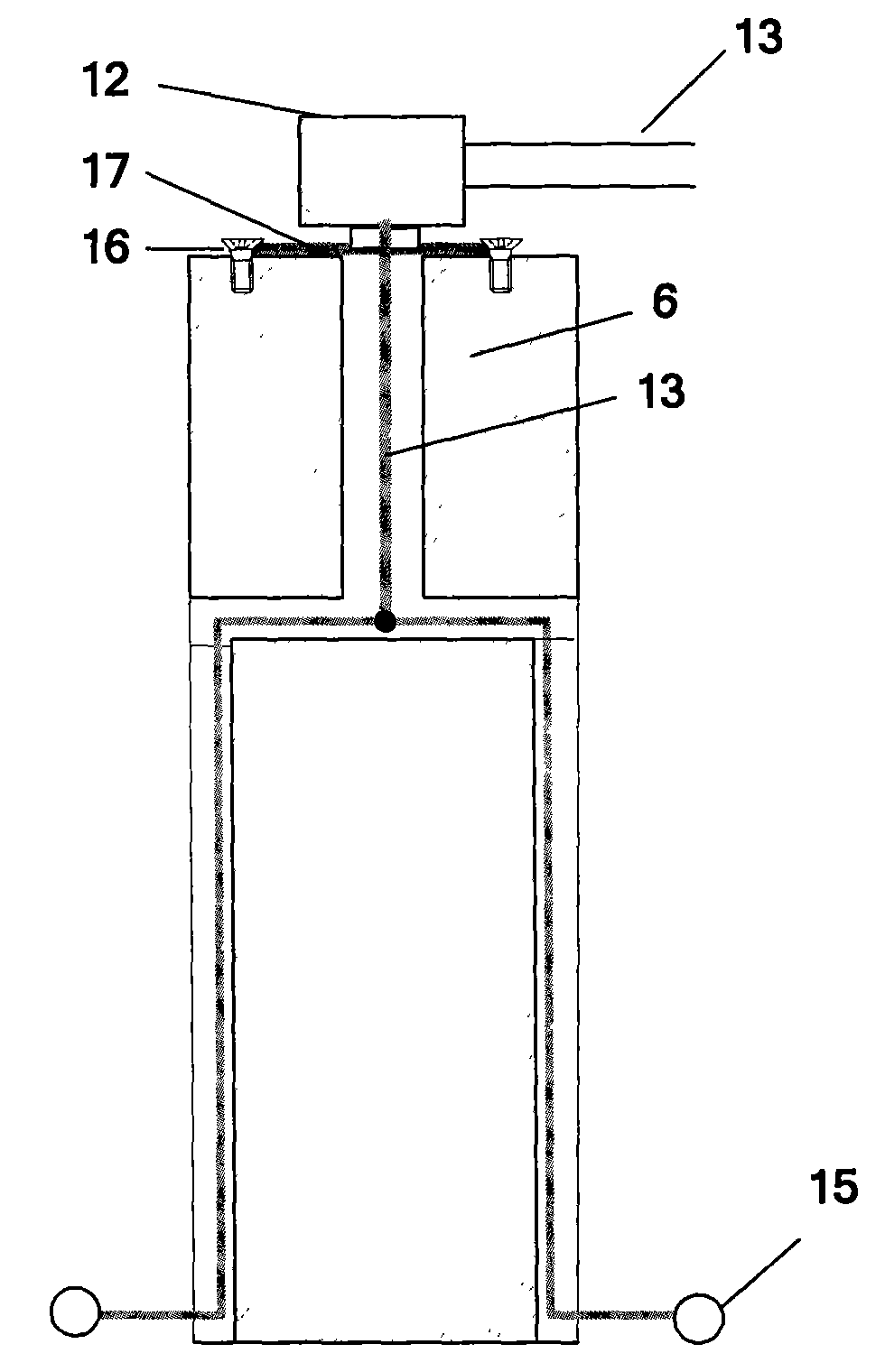

Concentric ring type cross current type hypergravity field swinging bed device

ActiveCN101234261AUniform cross sectionSimple structureChemical/physical/physico-chemical moving reactorsFractional distillationHypergravityEngineering

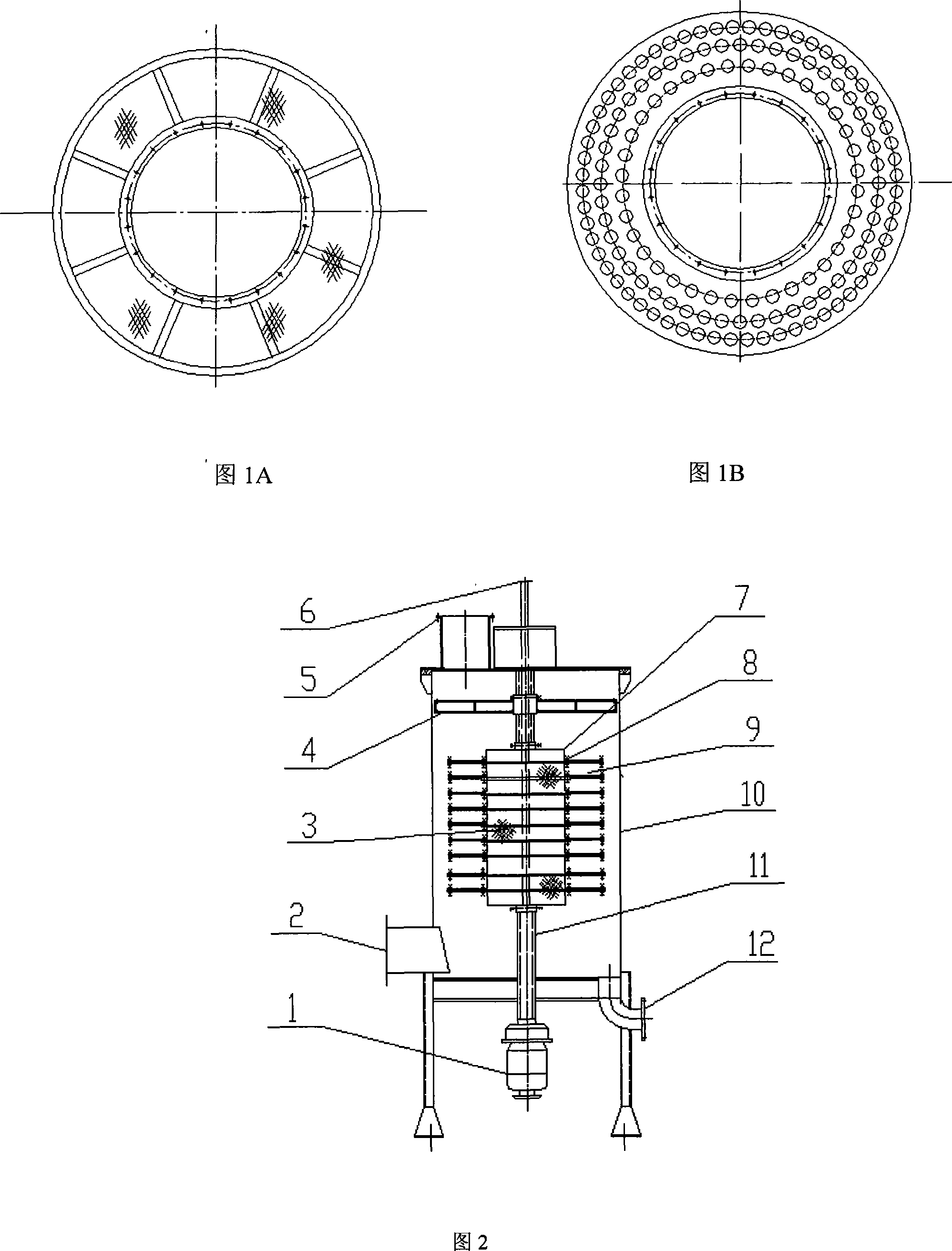

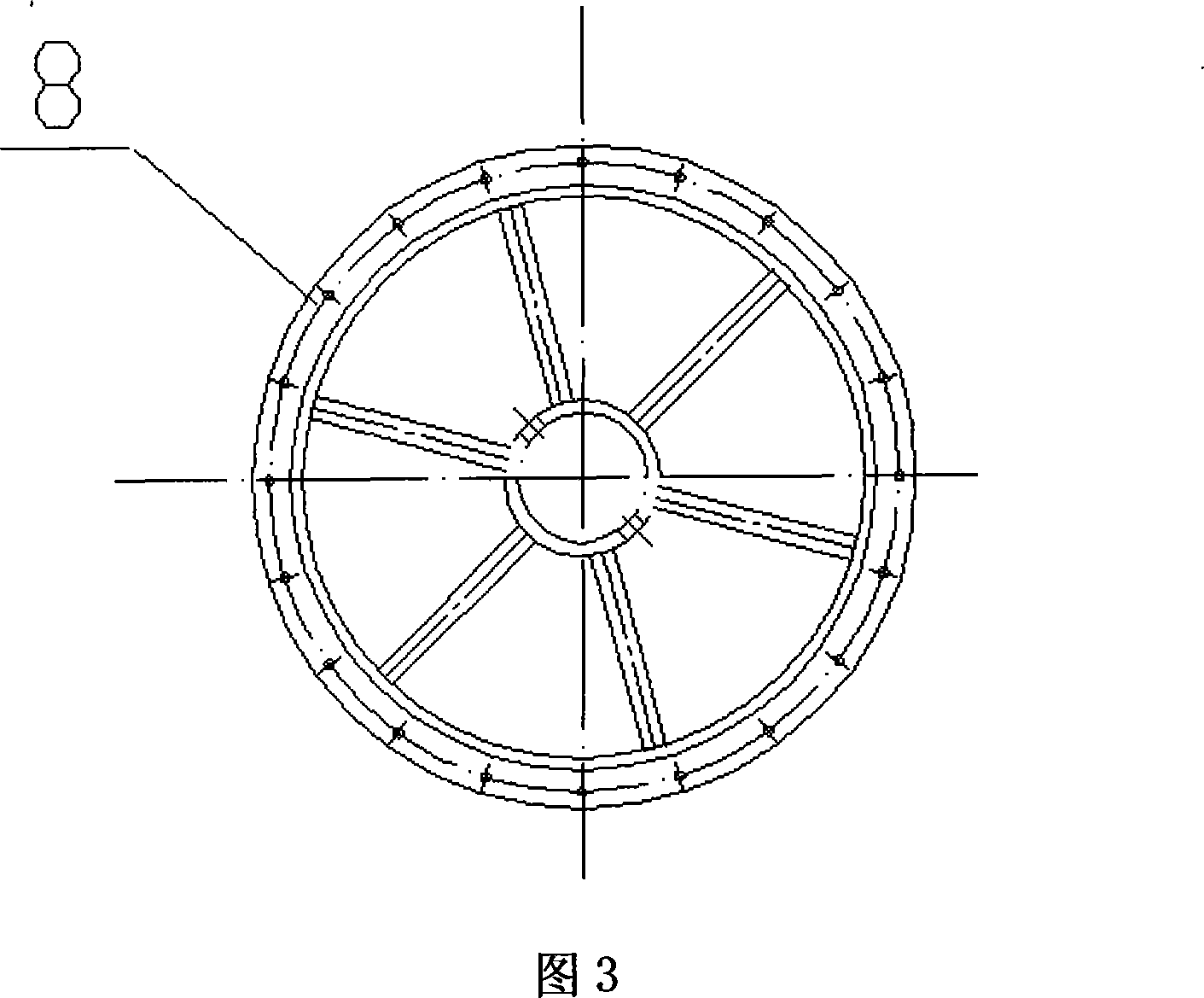

The invention relates to concentric cross-flow type rotating packed bed in high-gravity field , comprising a shell, a rotating disc, a rotating shaft and a liquid redistributor, the shell is provided with a medium a inlet pipe, a medium b outlet pipe, a medium d outlet pipe and a fluid bath, a concentric ring and the liquid redistributor are fixedly connected with the rotating disc, the center of which is in fixed connection with the rotating shaft, the end of labyrinth seal is in connection with the shell, the lower end is in connection with a guiding pipe which is inserted in the fluid bath, the labyrinth seal and the rotating disc divide the shell into an upper cavity and a lower cavity, the medium b outlet pipe is in communication with the upper cavity, the medium a inlet pipe and the medium d outlet pipe are separately in communication with the lower cavity, one end of a medium c inlet pipe is in communication with the upper end of a liquid distributor, while the other end surpasses the shell and is sealed together with the shell. The beneficial effect of the rotating packed bed is that the rotating packed bed of the invention has the simple and reasonable structure so as to be easily installed, the little gas resistance, the low equipment pressure drop, and the higher efficiency and the better effect of gas-liquid mass transfer.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of high-gravity spherical cobalt carbonate

InactiveCN101973592AHigh degree of sphericityProportionally largeCobalt carbonatesPh controlReaction temperature

The invention relates to a preparation method of high-gravity spherical cobalt carbonate, comprising the following steps of: with a water-soluble cobalt salt as a raw material and ammonium hydrogen carbonate as a precipitant adding a cobalt salt aqueous solution and an ammonium hydrogen carbonate aqueous solution into a reactor at the same time by adopting a first-slow and rear-quick stage feeding manner at reaction temperature of 60-90DEG C under a stirring condition, wherein a feeding speed ratio of the cobalt salt aqueous solution of a slow feeding stage to a quick feeding stage is 1:2.5-1:10, and the feeding volume of the slow feeding stage occupies 25-60 percent of the total feeding volume; controlling pH of a reaction solution between 7.0 and 7.5; then, reducing the temperature to carry out heat preservation reaction; and filtering, drying and washing a reaction product to obtain the high-gravity spherical cobalt carbonate. Under the condition of high temperature, a first-slow and rear-quick stage speed-control feeding manner is adopted to prepare cobalt carbonate which has the advantages of high spherical degree, high gravity, controllable grain diameter, good dispersive property and good flow property and can satisfy different product requirements; meanwhile, the invention has short reaction time and is beneficial to the increasing of the production efficiency.

Owner:安徽寒锐新材料有限公司

Method for preparing CuO/ZnO/Al*O* catalyst

InactiveCN101579629AGranularity can be adjusted arbitrarilyImprove efficiencyCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentCopper

The invention relates to a method for preparing a CuO / ZnO / Al2O3 catalyst. Mixed solution containing Cu, Zn and Al reacts with precipitant in a high-gravity rotating-bed reactor at a temperature of between 50 and 90 DEG C, wherein the molar ratio of the mixed solution containing Cu, Zn and Al is 3 / 2-8 / 0.5-1.5; the aqueous-solution molar concentration of the mixed solution is 0.5 to 1.5 mol / L; the aqueous-solution molar concentration of the precipitant is 1.0 to 3.0 mol / L; the rotating speed of the high-gravity rotating-bed reactor is 200 to 1,500 r / min; and the volume-flow ratio of the mixed solution containing Cu, Zn and Al to the precipitant is 1 / 1-1 / 2. The method can improve production efficiency by 30 percent, freely adjusts the particle size of copper as an active component in a range between 5 and 20 nm, and is capable of continuous production.

Owner:PETROCHINA CO LTD +1

Device and method for producing sodium bisulfide by utilizing refinery dry gas

ActiveCN103754833ARaise the possibilityRealize resource utilizationSulfur compoundsResource utilizationGas composition

The invention relates to a device and method for producing sodium bisulfide by utilizing refinery dry gas. Aiming at the gas composition characteristics of the refinery dry gas, the dry gas refining desulphurization process is processed by utilizing an ultra-high gravity technology, and H2S in acid tail gas after dry gas refining desulphurization is selectively removed, so that the content of the purified H2S is over 99 percent, the purified and refined H2S is absorbed for preparing high-purity NaHS by adopting a continuous alkali liquor cycle, the concentration purity is over 42 percent, the process technology is greatly innovated, the investment is saved, secondary pollution is avoided, a process of a traditional out-dated NaHS product can be replaced, the device has a certain economic benefits and high-efficiency resource utilization rate, the H2S in the acid gas is almost recycled completely, the requirements of environment friendliness and emission are met, high social benefits are achieved, and recycling comprehensive utilization of refinery acid tail gas is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

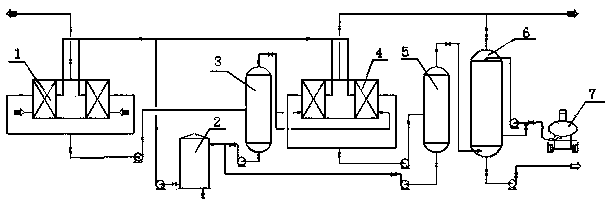

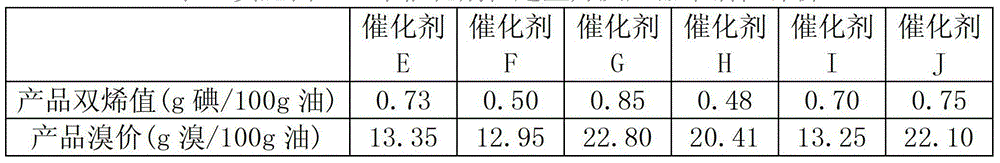

Method for selective hydrogenation of pyrolysis gasoline

ActiveCN104419454ALarge specific surface areaEasy to processHydrocarbon oils refiningChemistryHigh Gravity

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device foraging white spirit

InactiveCN101250474APromote formationMaintain flavor profileAlcoholic beverage preparationEngineeringHigh Gravity

The invention provides a method for aging liquor and a special device thereof. The method for aging comprises: simulating a natural traditional aging process and the environment of the liquor on the basis of conversion behavior of various components in the liquor in the natural traditional aging process, utilizing a high efficient mass-transfer technique of a high gravity rotating packed bed to age the liquor, and not changing the style and the characteristics of any pure grain brewed liquor in the whole aging process, the method for aging has low cost and convenient operation, and is suitable for various liquor and industrial production with various scales. The liquor which is processed has color, fragrant and sapor which can be compared with the liquor which has be aged for half a year to two years or longer time naturally.

Owner:SHANXI UNIV

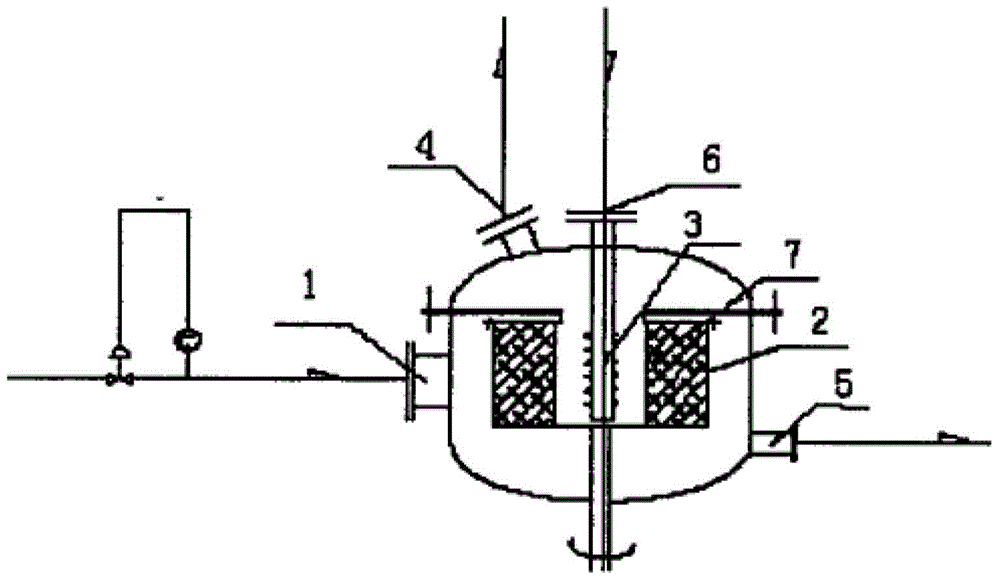

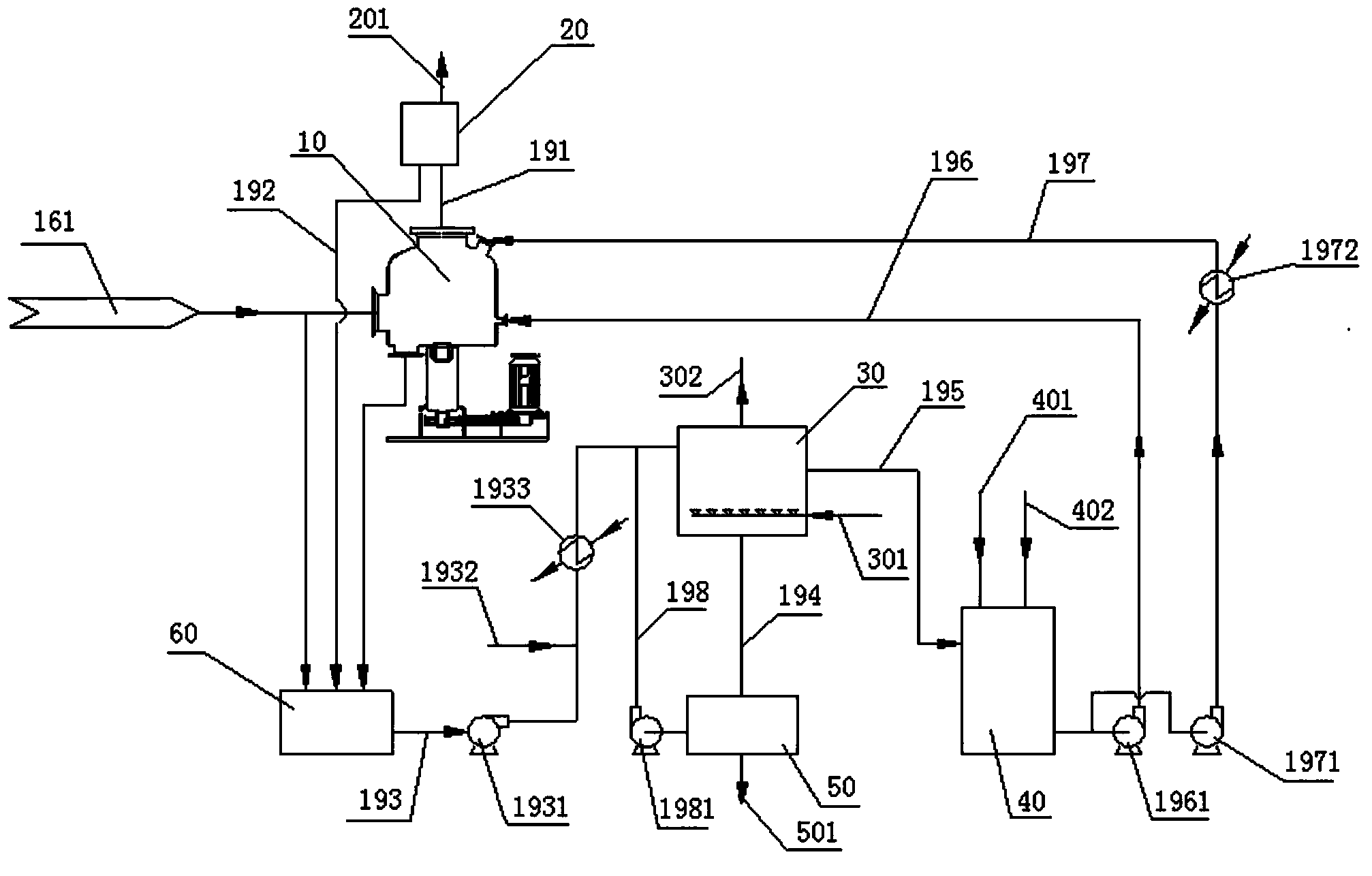

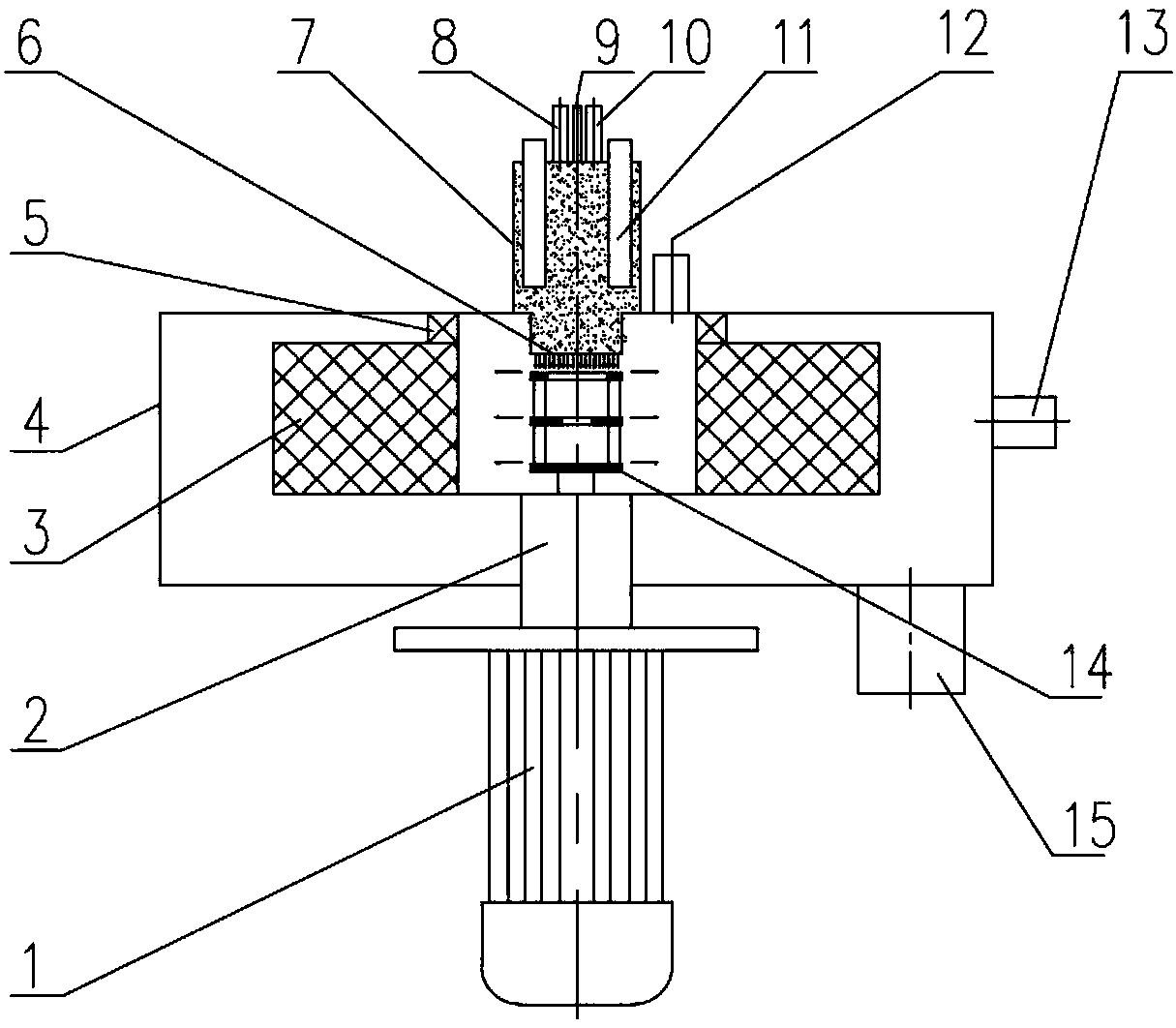

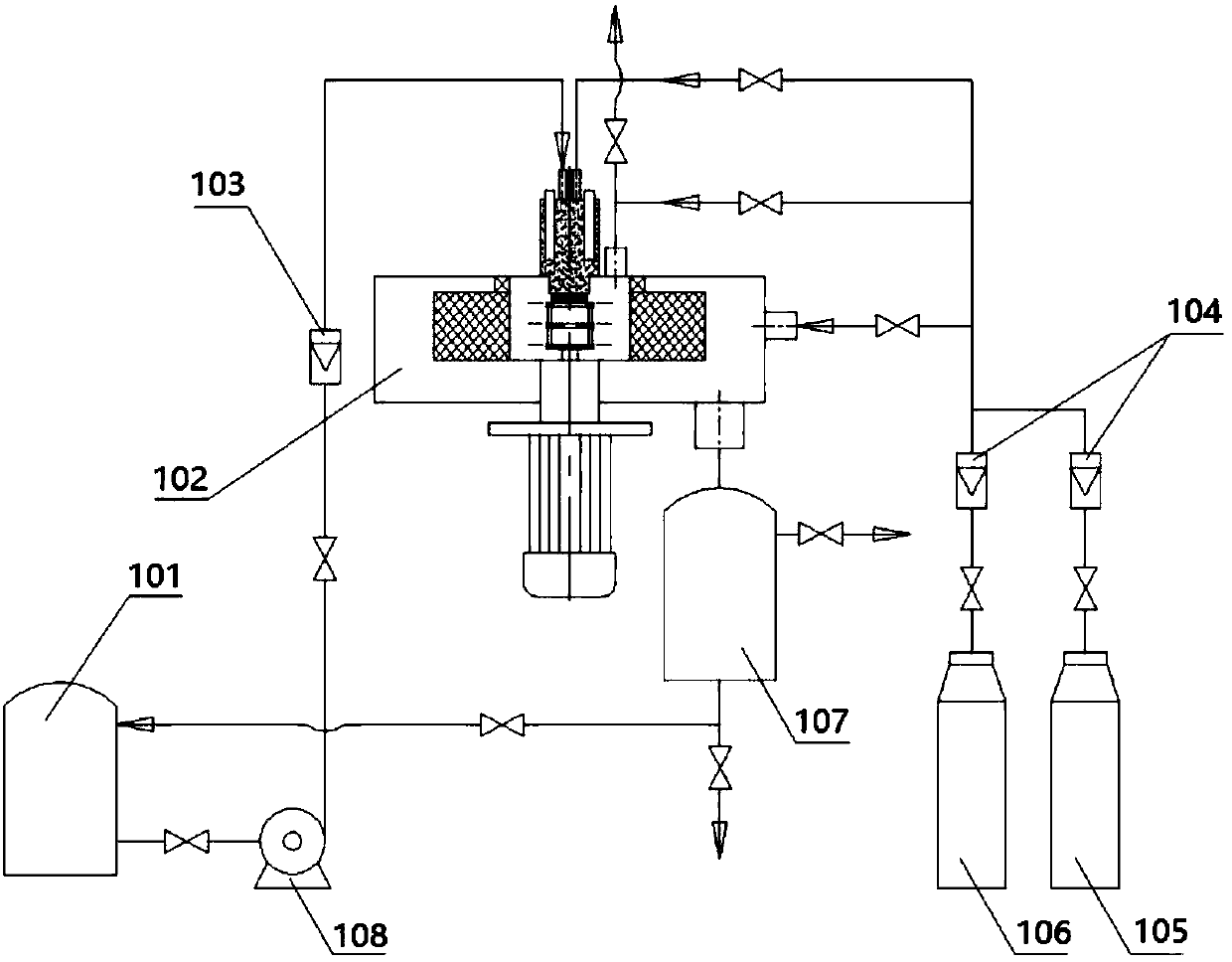

Apparatus for high gravity removal of hydrogen sulfide of novel industrial gas, and technology thereof

ActiveCN104043326AAvoid cloggingImprove mass transfer efficiencyDispersed particle separationSulfur preparation/purificationIndustrial gasHigh concentration

The invention discloses an apparatus for the high gravity removal of hydrogen sulfide of a novel industrial gas. The apparatus comprises a high gravity machine, a gas-liquid separation device, an oxidation tank, a lean liquid tank, a rotary drum vacuum filter and a rich liquid tank; the high gravity machine comprises a power device, a shell, a rotor, a liquid inlet, a liquid outlet, a gas inlet, a gas outlet and a flushing liquor inlet; the output shaft of the power device stretches into the shell and is fixedly connected with the rotor, the upper end surface of the shell is provided with the liquid inlet and the gas outlet, and the lower end of the shell is provided with the liquid outlet and the gas inlet; and the rotor is provided with a filler, the external layer of the rotor filler is provided with a backwashing device, and the backwashing device is connected with the flushing liquor inlet. The adoption of a backwashing high-gravity rotary filler bed greatly prevents the obstruction of the high gravity filler by sulfur particles. The adoption of the drum air regeneration oxidation tank substantially simplifies the process flow and substantially reduces the cost. The apparatus and the method can be used for the desulphurization of high concentration hydrogen sulfide gases in order to prevent the obstruction of the rotor filler by sulfur.

Owner:BEIJING UNIV OF CHEM TECH +2

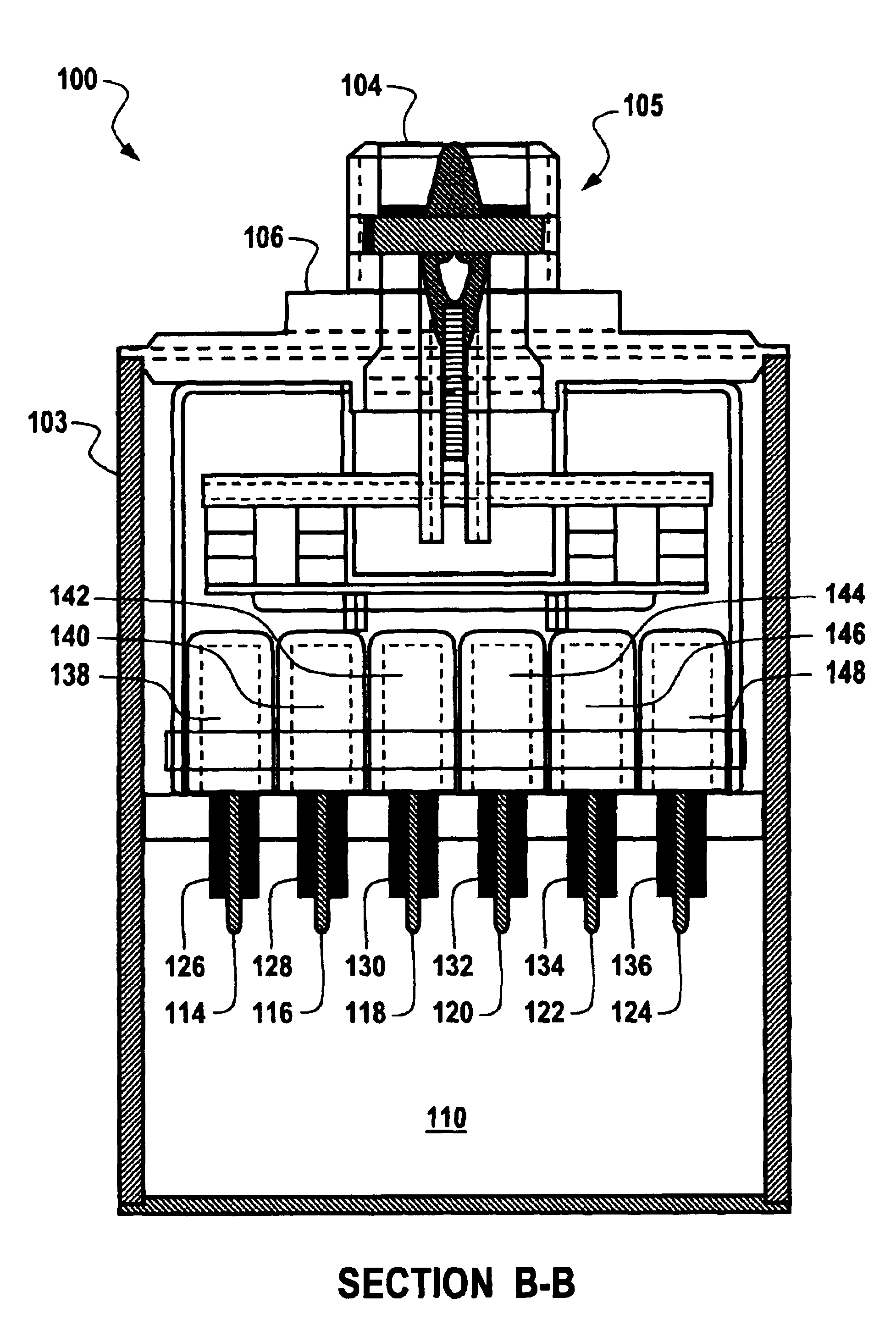

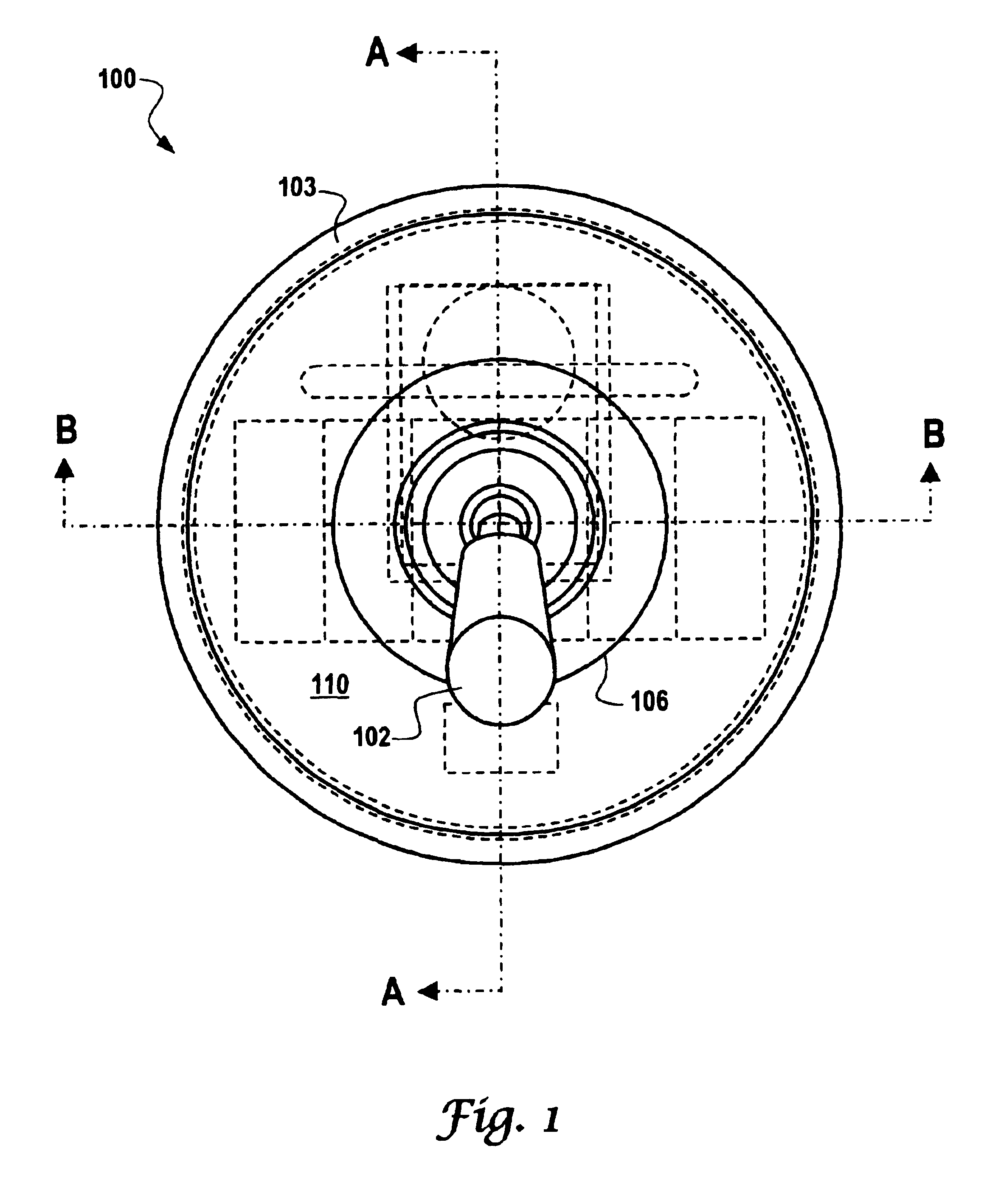

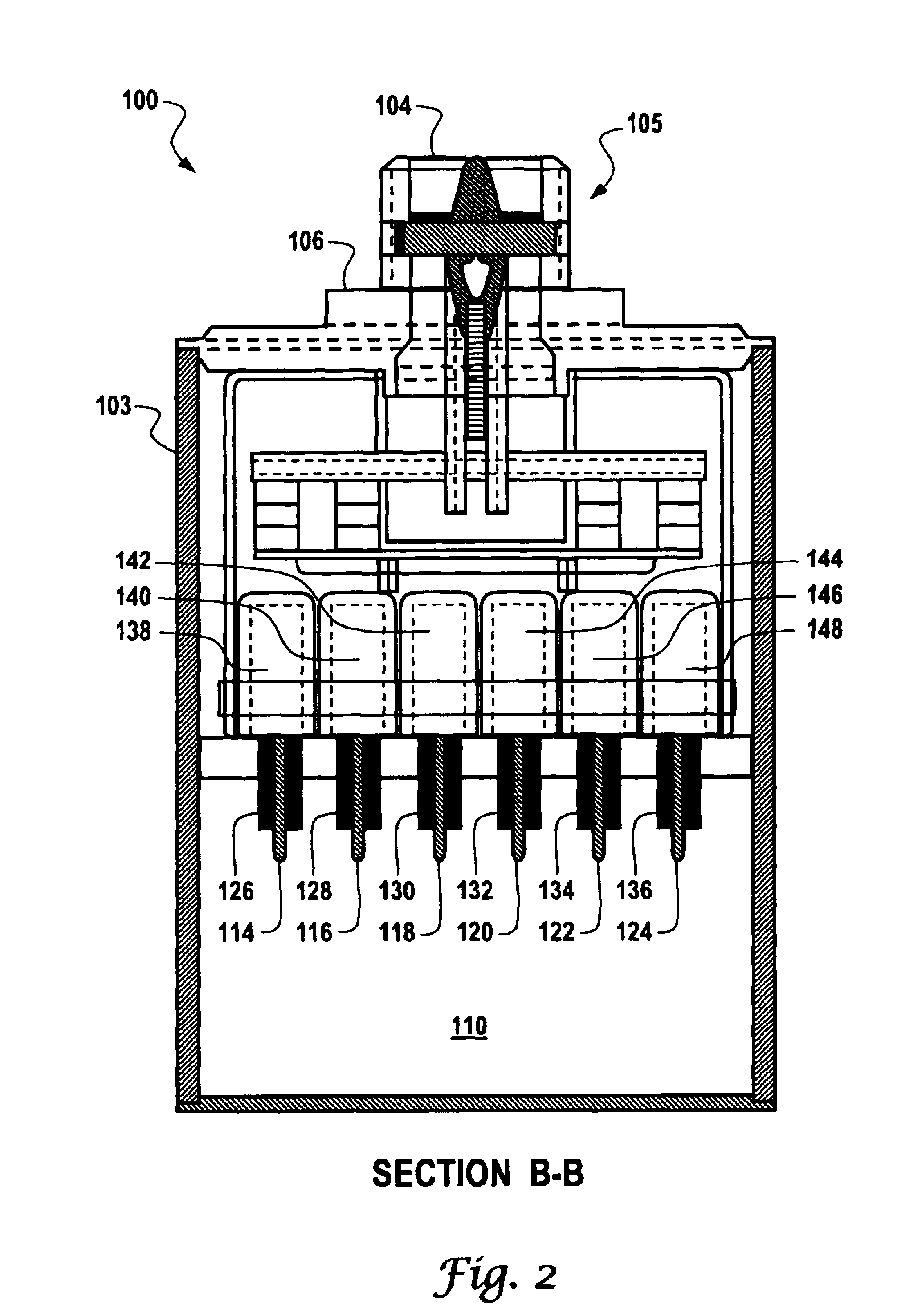

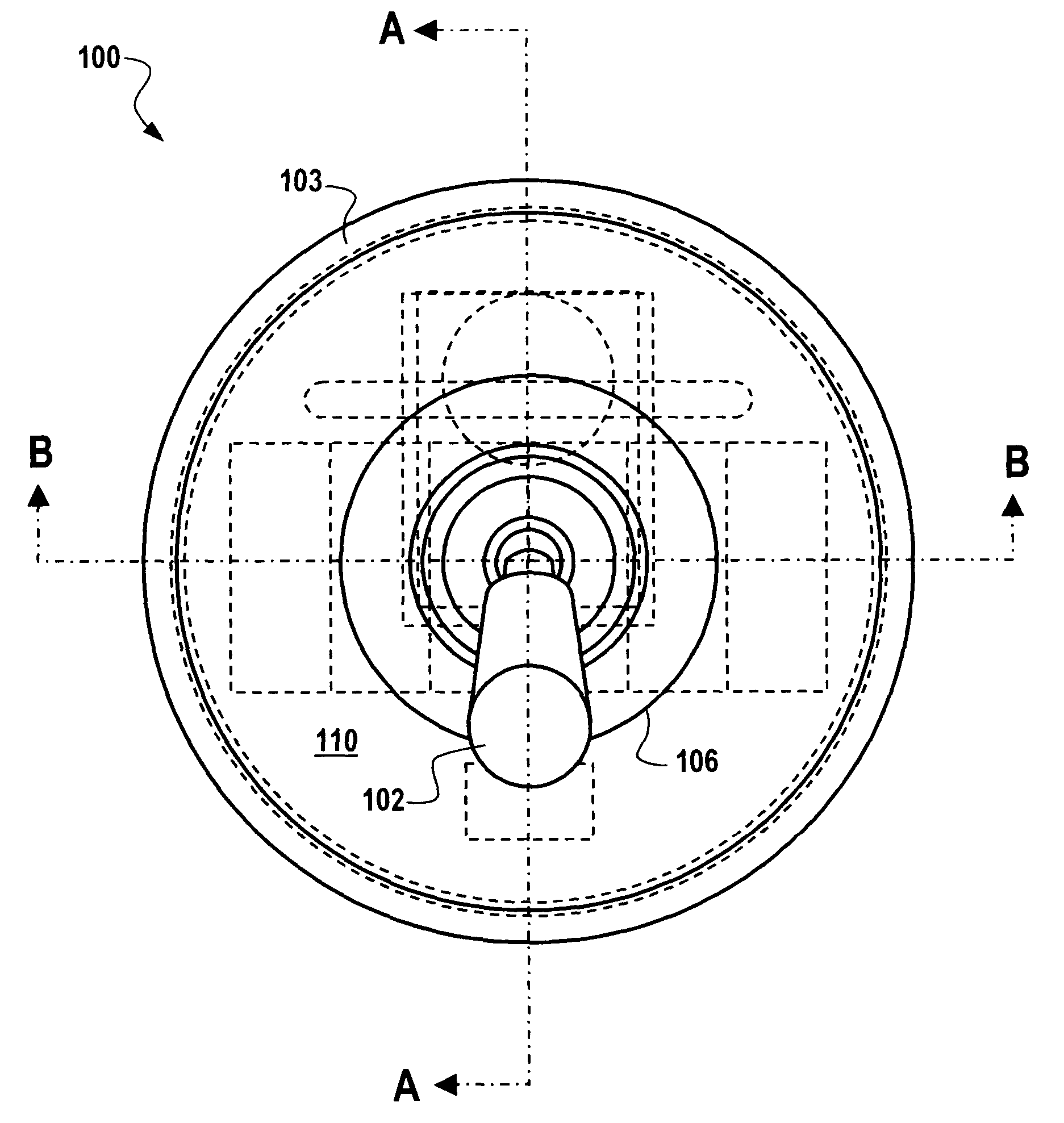

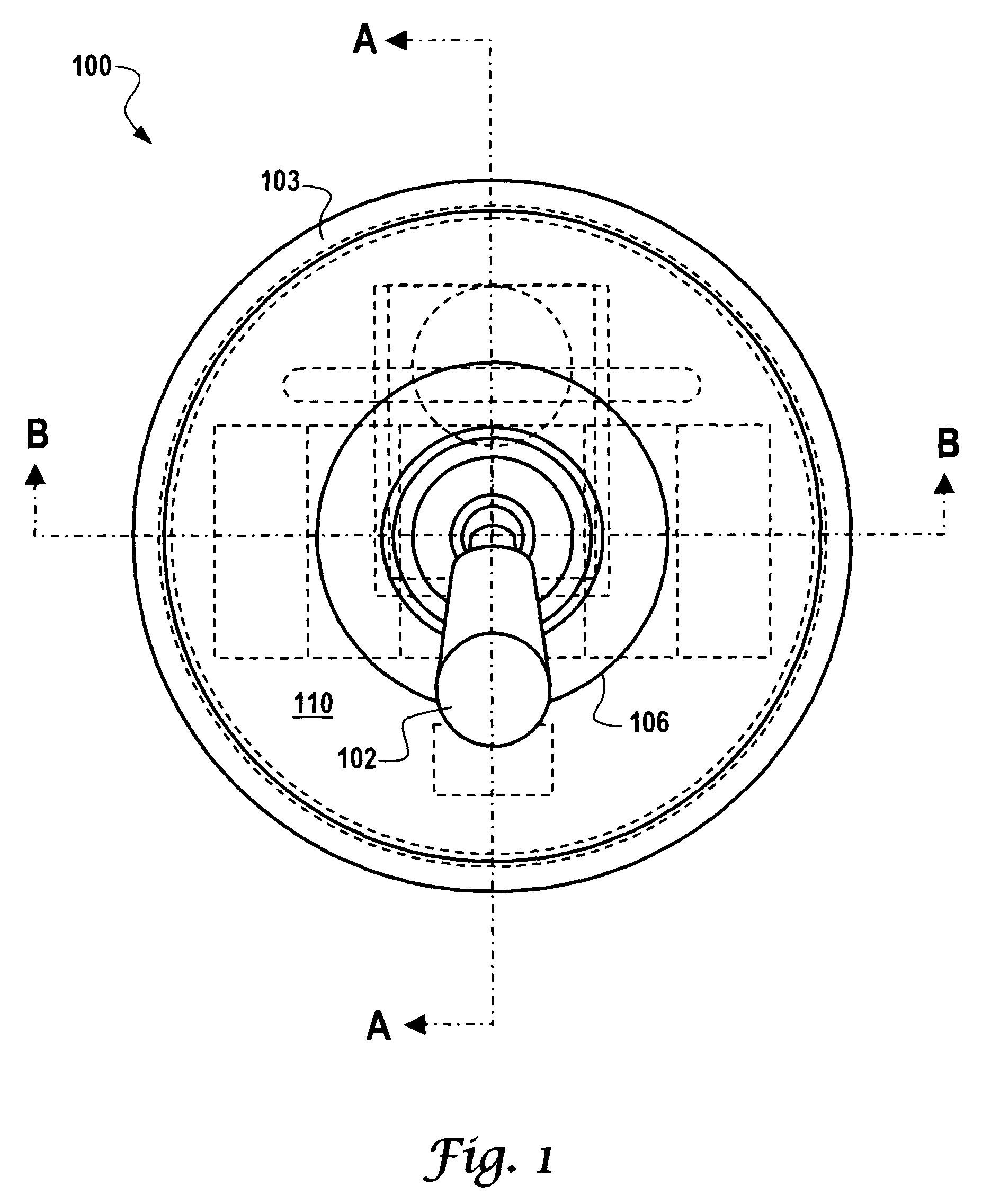

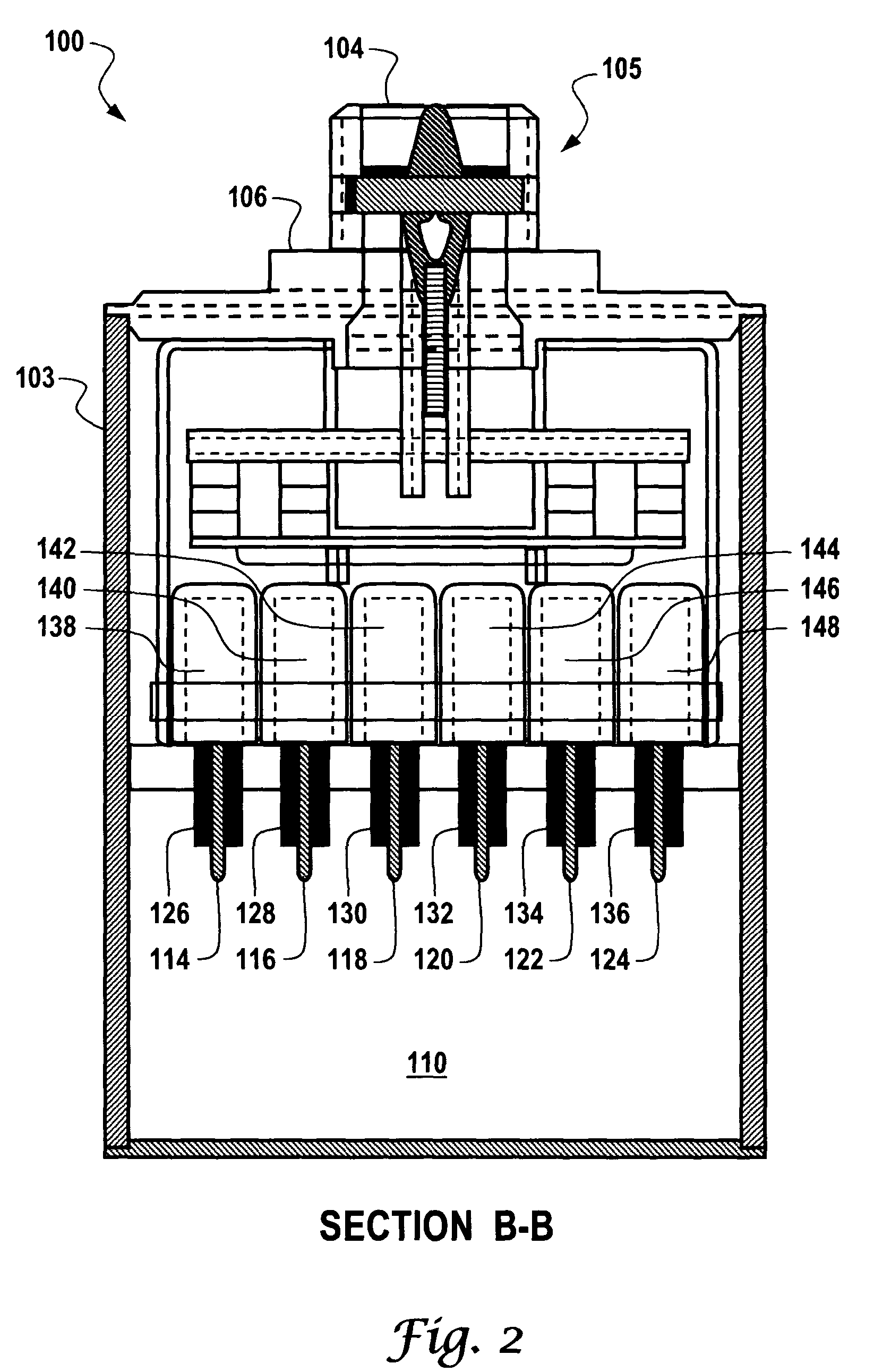

Toggle switch apparatus

InactiveUS6943310B2Additional componentContact mechanismsContact electric connectionToggle switchActuator

A toggle switch apparatus is disclosed, which includes a toggle mechanism and a plurality of basic switches maintained within a tubular housing. An actuator is associated with at least one spring which together can serve to actuate the plurality of basic switches. A lead wire termination assembly can also be configured within the tubular housing, wherein the lead wire termination assembly comprises a plurality of lead wires attached to a plurality of pin contacts that exit through a cover of the tubular housing, thereby permitting the toggle switch apparatus to be actuated manually in a maintained position during high gravity conditions. The tubular housing can be configured as a sealed metal tube. A header can also be sealed into the tubular housing utilizing a glass-to-metal seal.

Owner:HONEYWELL INT INC

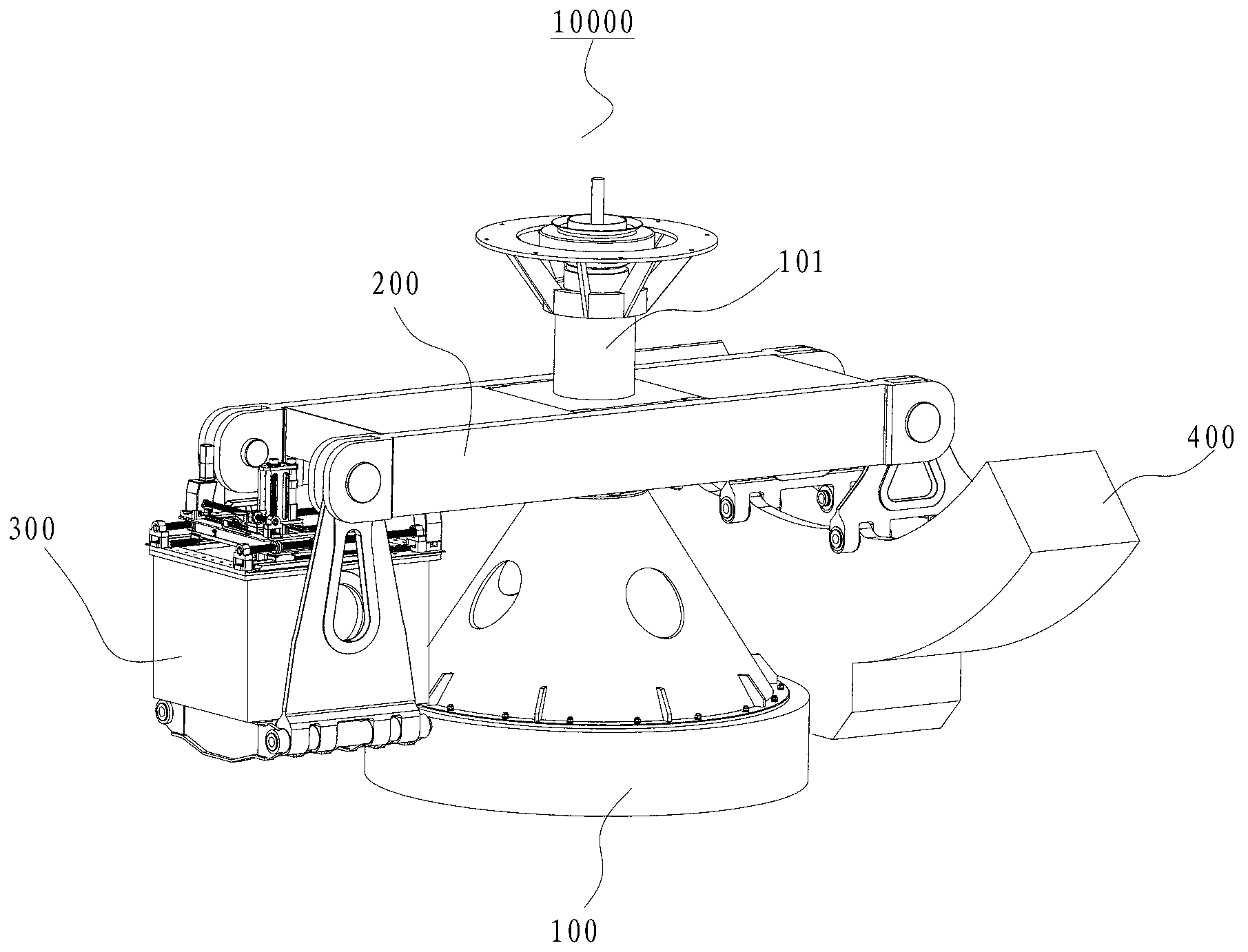

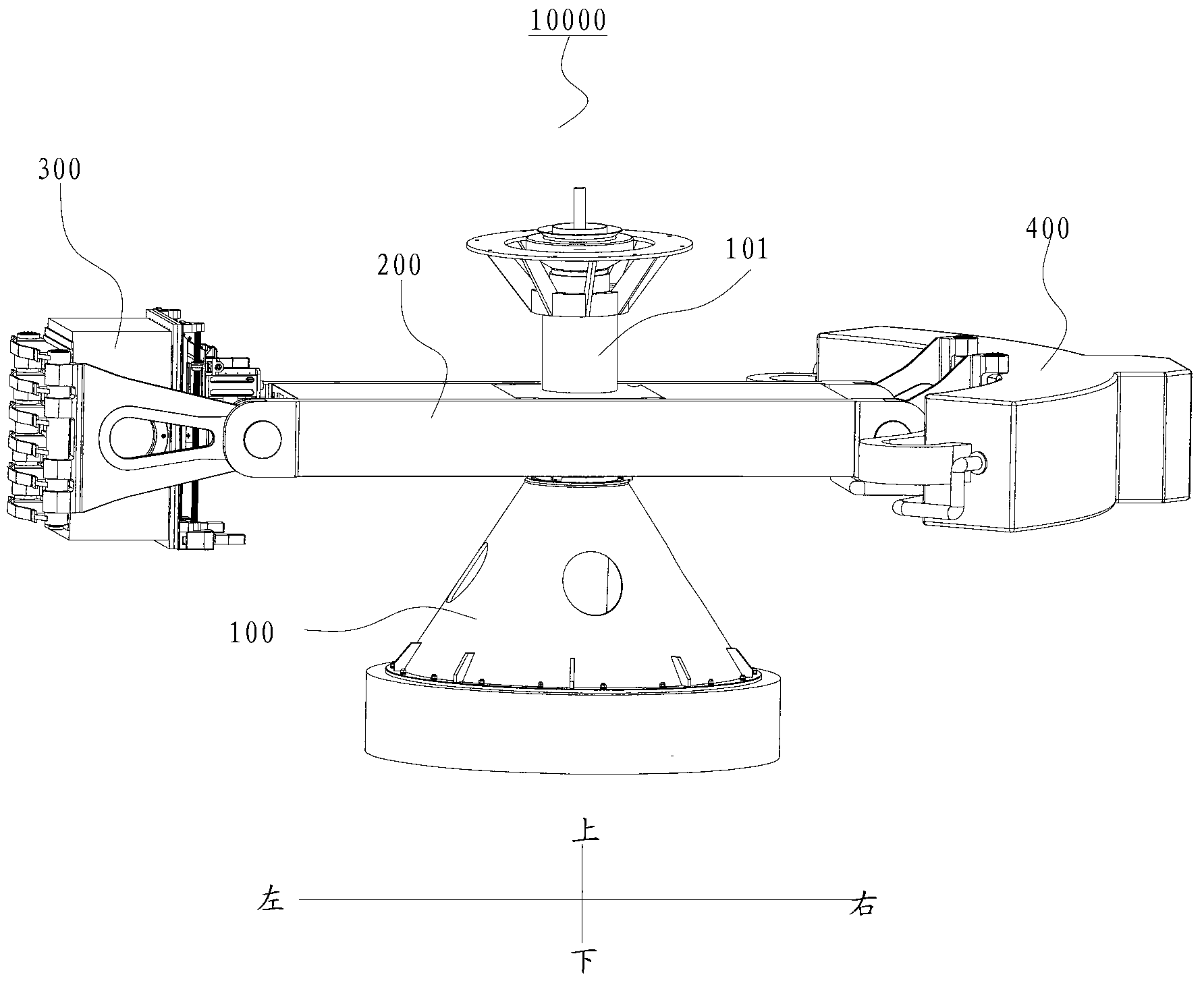

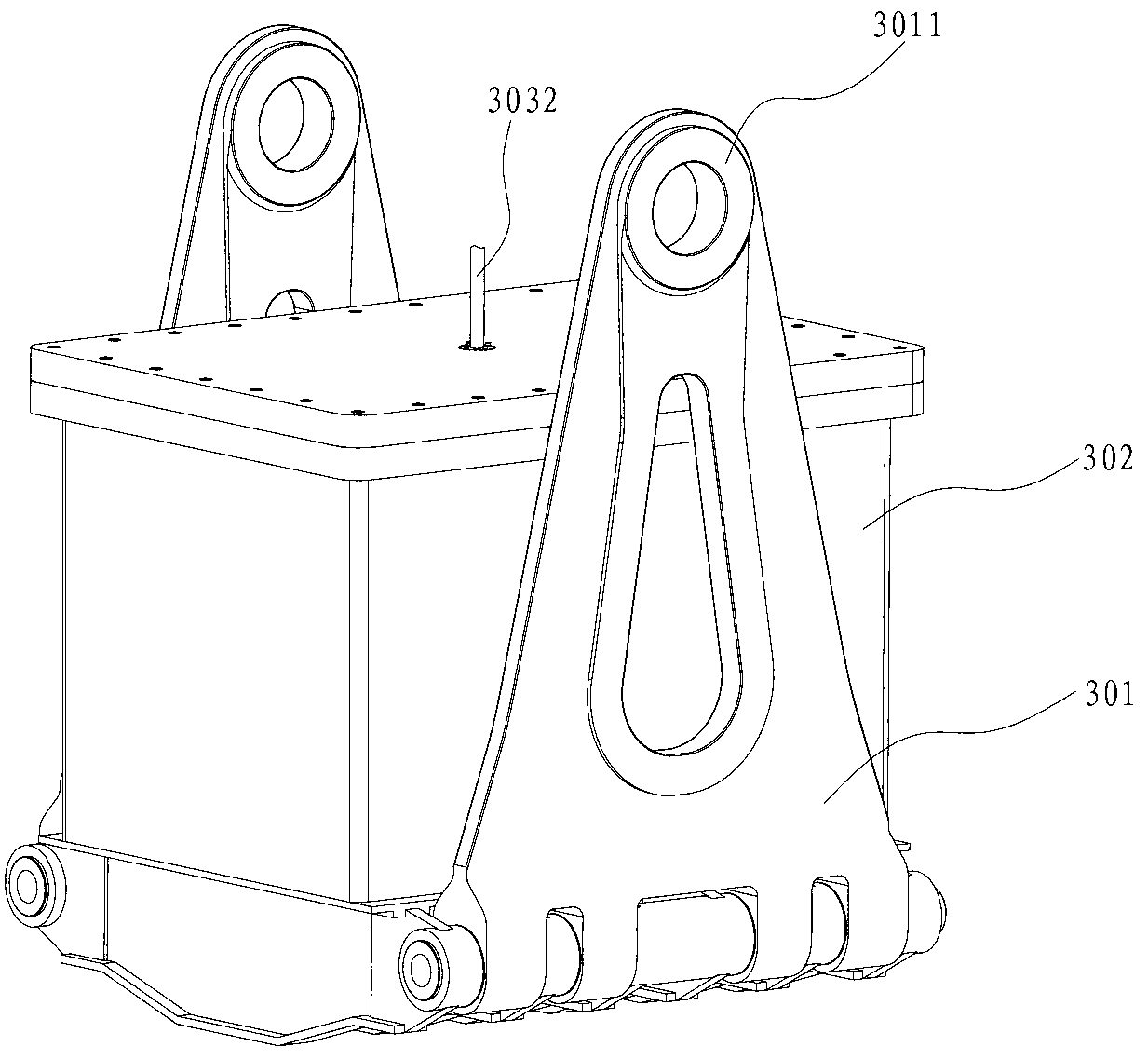

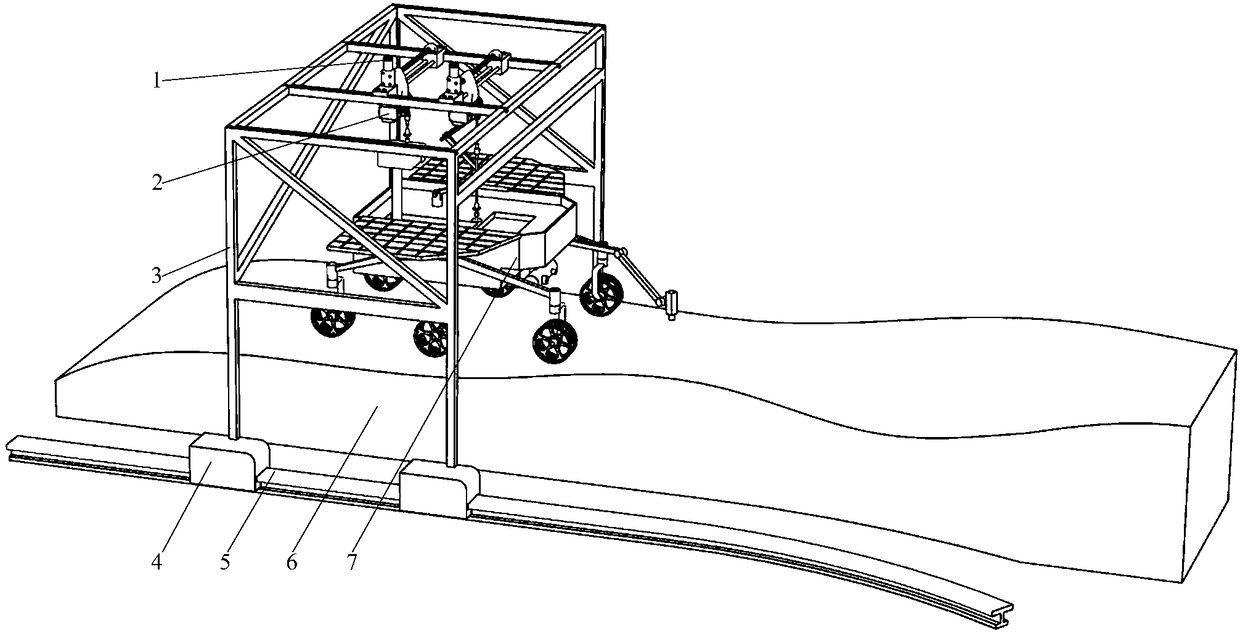

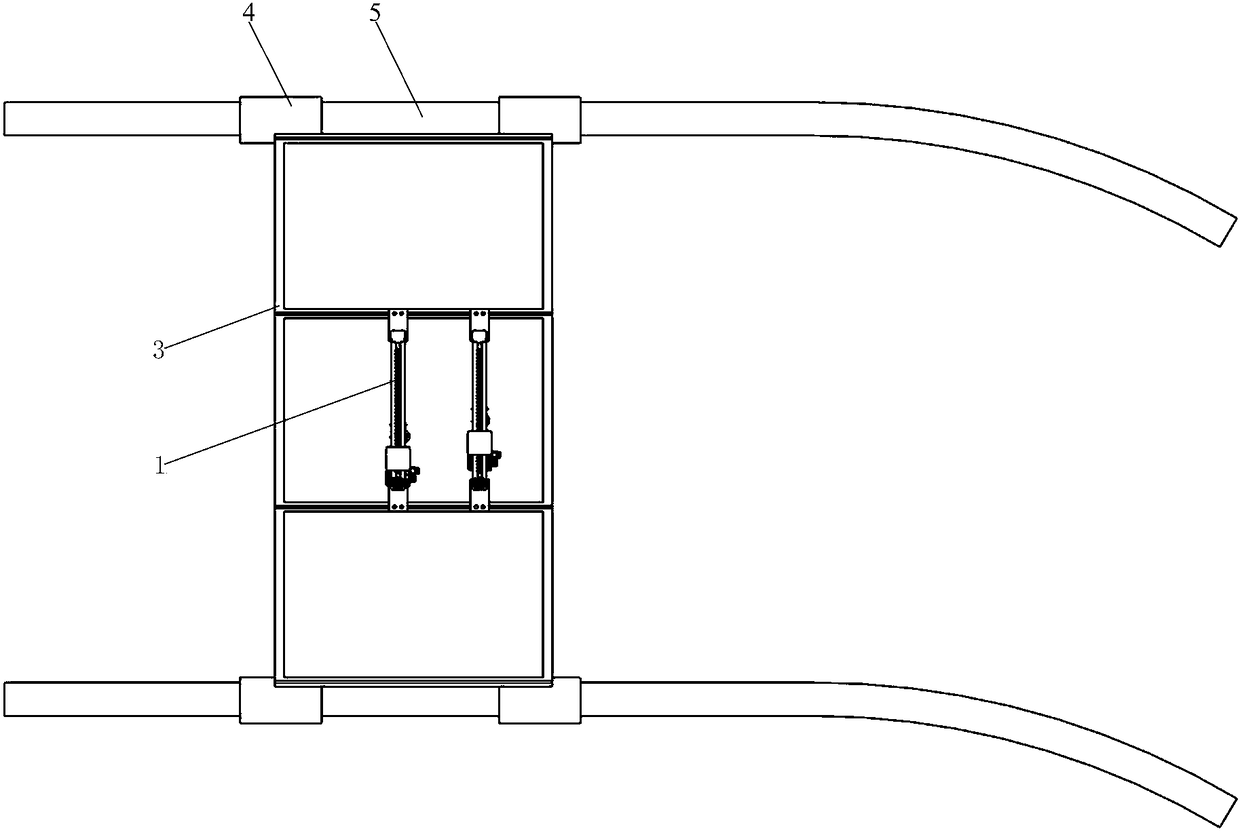

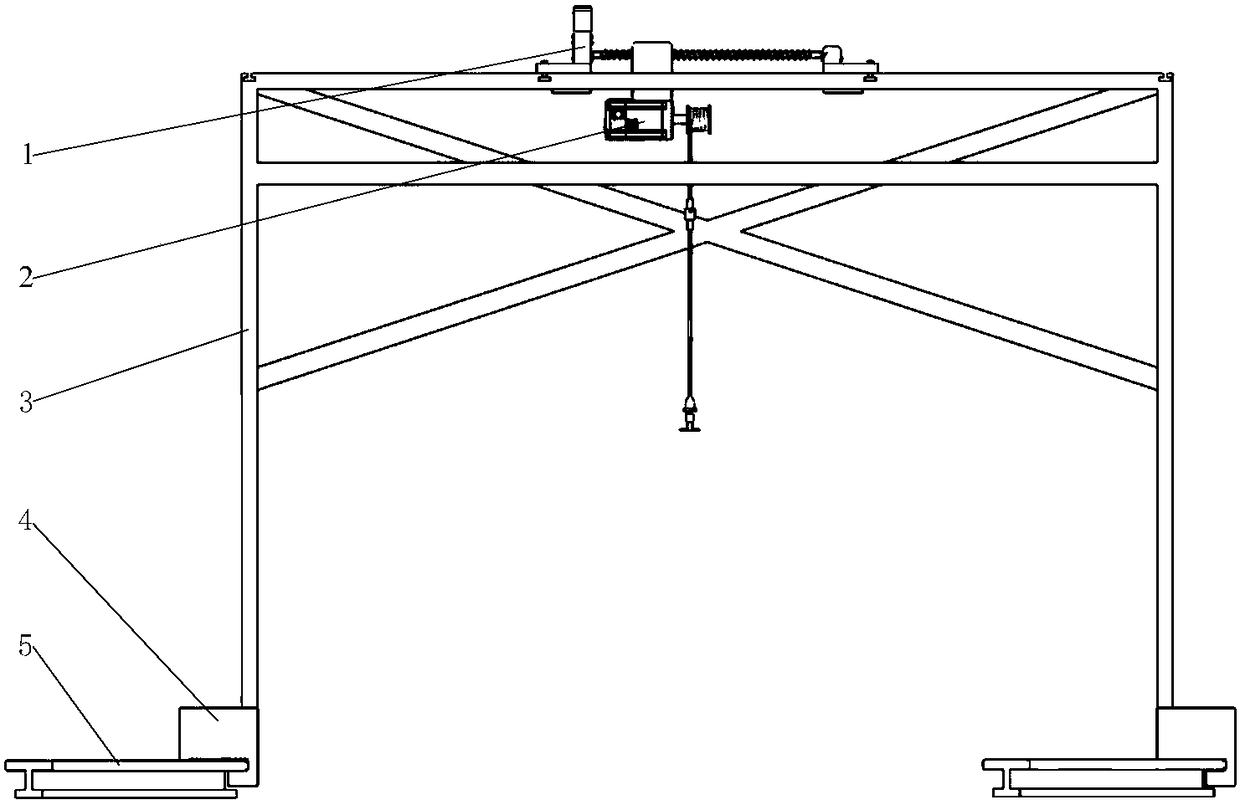

Giant maritime work centrifugal machine

The invention discloses a giant maritime work centrifugal machine which comprises a stander, a rocker arm, a first maritime work suspension basket, a second maritime work suspension basket, a vibration table model box, a vibration table, a windstorm generating component, an ocean current generating machine and a wave generating machine, wherein the first maritime work suspension basket and the second maritime work suspension basket are connected onto the rocker arm, the second maritime work suspension basket is provided with an arc maritime work suspension basket model box, the maritime work suspension basket model box is internally provided with a groove cavity, and a maritime work structure is placed in the middle section of the maritime work suspension basket model box. The vibration table is used for generating the vibration and applying the vibration onto a vibration table model box. The windstorm generating component is used for generating windstorm within the groove cavity. The ocean current generating machine is used for generating the ocean current within the groove cavity. The wave generating machine is used for generating the wave within the groove cavity. After the giant maritime work centrifugal machine disclosed by the invention is used, the marine environment simulation technique from shallow sea to deep sea can be realized, and the wave, ocean current, windstorm and earthquake process under the marine environment within a high gravity field can be realized.

Owner:TSINGHUA UNIV +1

Follow-up overhanging gravity compensation device based on magnetic suspension

ActiveCN108382616ASolve the accuracy problemSimple structureCosmonautic condition simulationsElectric energy managementConstant forceComputer module

The invention provides a follow-up overhanging gravity compensation device based on magnetic suspension. The device mainly comprises a magnetic suspension drive compensation system and an overhangingcompensation system, the magnetic suspension drive compensation system comprises magnetic suspension drive modules and a magnetic suspension guide rail, and two magnetic suspension drive modules are respectively arranged on the magnetic suspension guide rail; the overhanging compensation system comprises an overhanging frame, overhanging constant force control modules and position servo modules, four supporting legs of the overhanging frame are respectively fixedly connected with the magnetic suspension drive modules, and two position servo modules are arranged on a sliding rail of the overhanging frame and respectively perpendicularly connected with two overhanging constant force control modules; each position servo module comprises two moving sliding blocks of an X direction, a moving sliding block of a Y direction, a servo motor, a screw and two auxiliary guide rods; each overhanging constant force control module comprises a direct current motor, a winding reel, a steel wire rope, an angle sensor and a tension sensor. The device has better comprehensive properties of simple structures, high gravity compensation precision, strong universality and good expandability.

Owner:YANSHAN UNIV

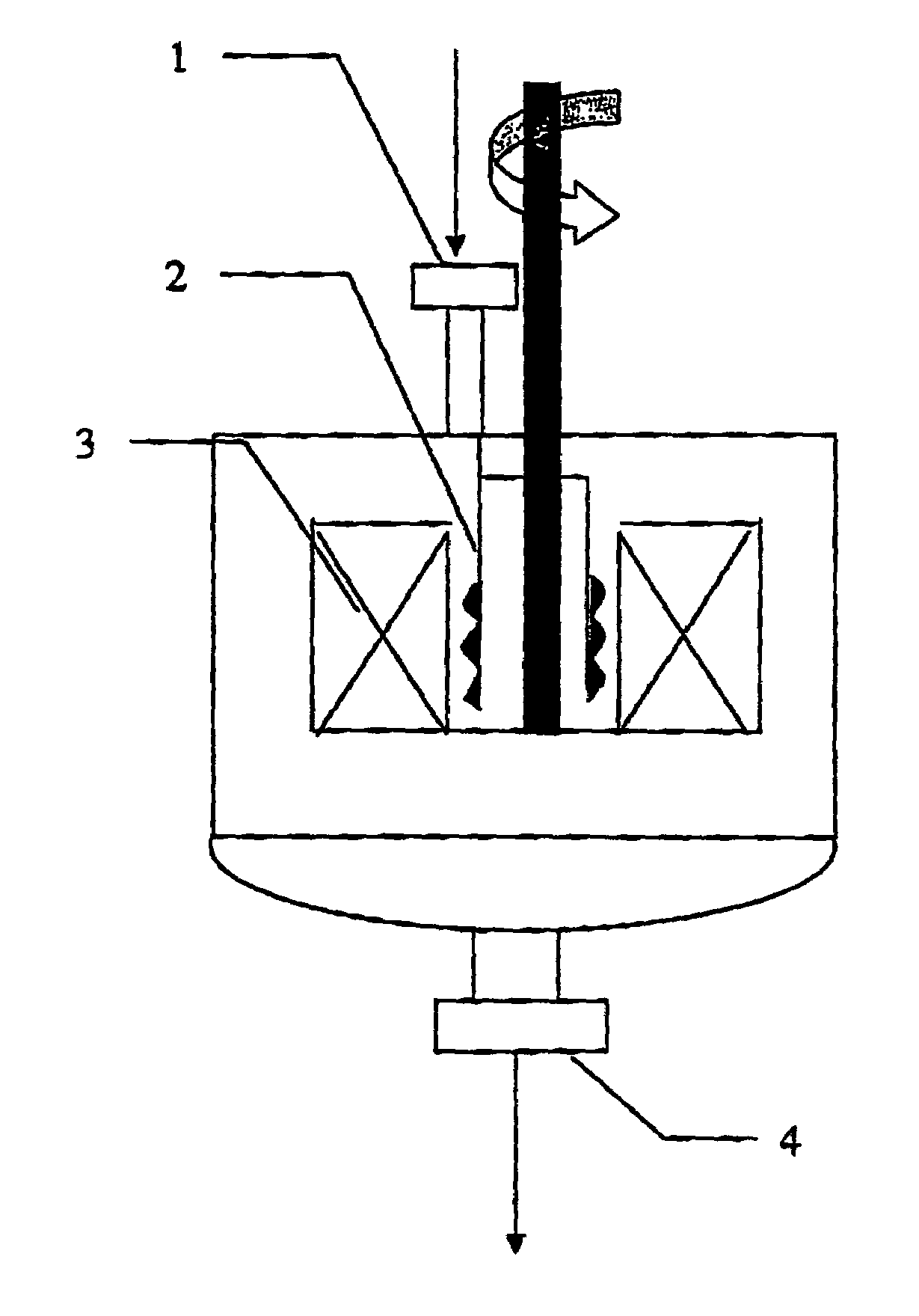

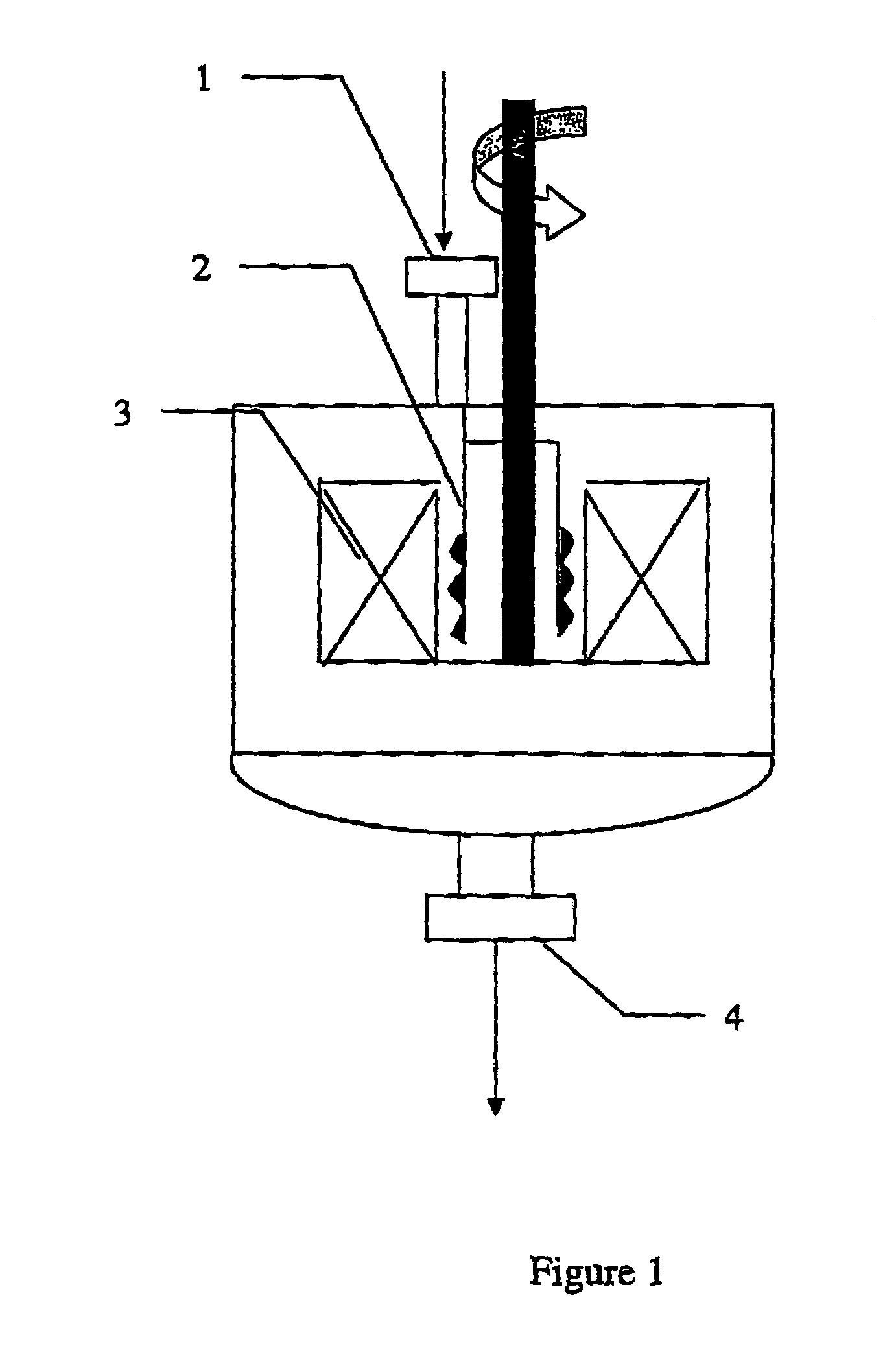

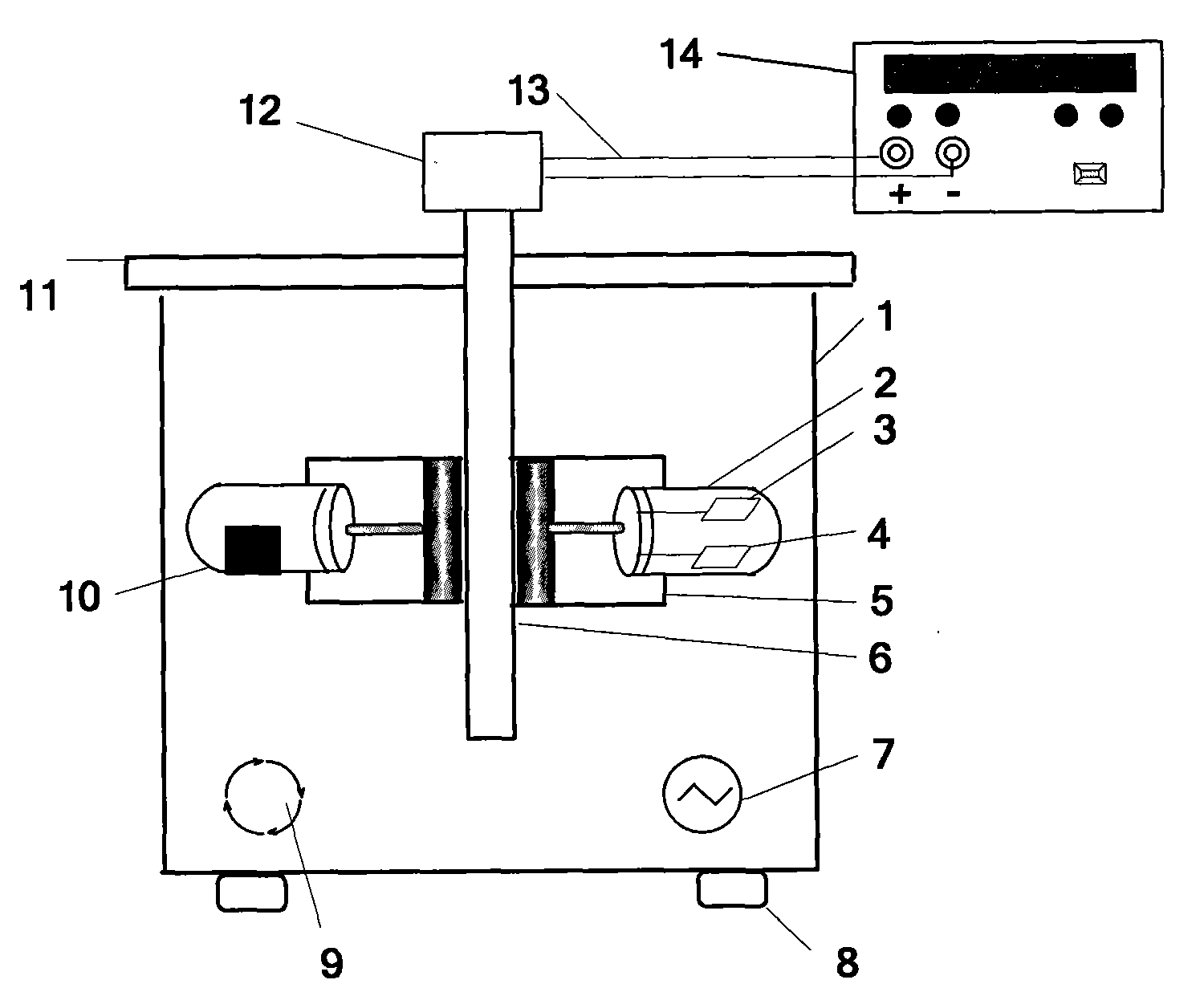

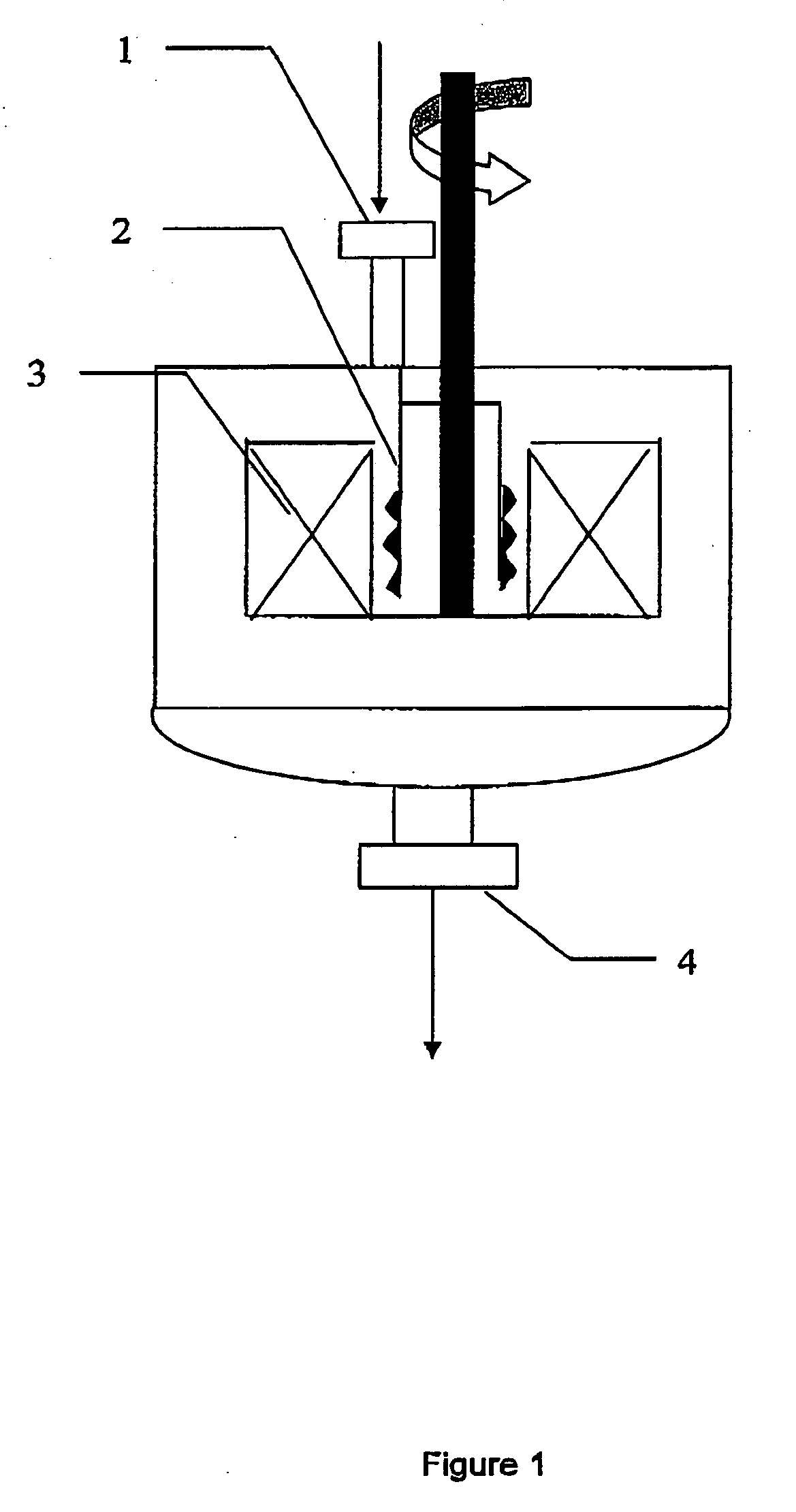

Method and device for preparing copper powder by intensified electrolysis

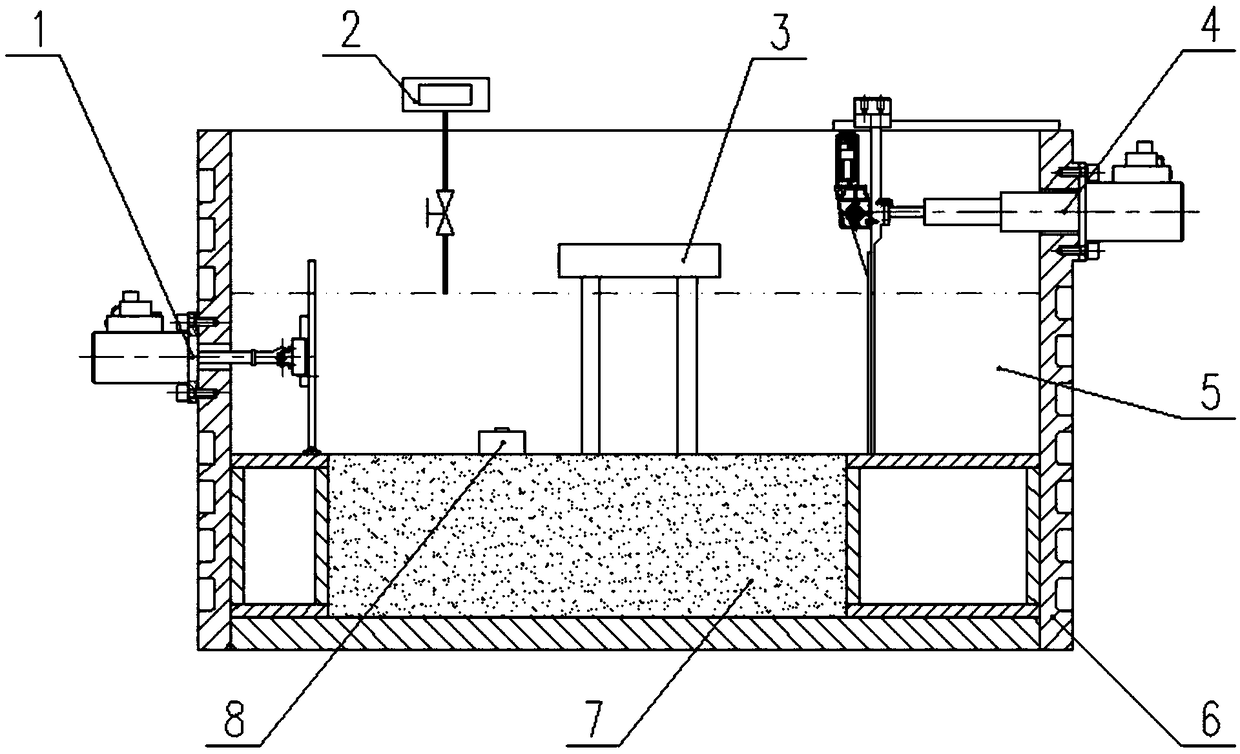

InactiveCN101560674AAccelerated disengagementAvoid growing upCellsElectrochemical responseHigh current density

The invention provides a method and a device for preparing copper powder by intensified electrolysis, and belongs to the technical field of metal electrolysis under special conditions. The method adopts hypergravity fields to intensify the electrolysis of the copper powder. The hepergravity electrolyzer comprises a centrifuge, an electric signal transmission system, an electrolyic bath system and an electrochemical reaction control system. The hypergravity fields are generated in a test cup by utilizing the rotation of a rotor of the centrifuge, and the copper powder electrolysis reaction is carried out in the high gravity fields; an electrolytic reaction signal is transmitted by a conductive ring of the electric signal transmission system; and the electrolytic copper powder reaction is carried out in the electrolytic bath. The method and the device have the advantages of greatly improving the current efficiency of the electrolytic copper powder and lowering the particle size of the copper powder; moreover, the electrolysis under a high current density is realized, and the particle size of the copper powder is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Toggle switch apparatus

InactiveUS20050045464A1Easy to optimizeAdditional componentContact mechanismsContact electric connectionToggle switchEngineering

A toggle switch apparatus is disclosed, which includes a toggle mechanism and a plurality of basic switches maintained within a tubular housing. An actuator is associated with at least one spring which together can serve to actuate the plurality of basic switches. A lead wire termination assembly can also be configured within the tubular housing, wherein the lead wire termination assembly comprises a plurality of lead wires attached to a plurality of pin contacts that exit through a cover of the tubular housing, thereby permitting the toggle switch apparatus to be actuated manually in a maintained position during high gravity conditions. The tubular housing can be configured as a sealed metal tube. A header can also be sealed into the tubular housing utilizing a glass-to-metal seal.

Owner:HONEYWELL INT INC

Method for preparing stable-type vitamin a microcapsules continuously

ActiveUS20140001662A1Easy to embedNot easy to absorb moistureHydroxy compound active ingredientsMetabolism disorderEmulsionAntioxidant

A method for continuously preparing stable-type vitamin A microcapsules is disclosed. The method comprises the following steps: adding vitamin A crystals and an antioxidant into a crystal melter continuously according to a certain ratio under the protection of nitrogen to prepare vitamin A melting oil containing the antioxidant; pumping the above melting oil into a high gravity rotary packed bed emulsifier with a liquid distributor by a pump, and pumping aqueous solution containing gellable modified starch into the above high gravity rotary packed bed emulsifier after deoxidation treatment to obtain vitamin A emulsion at the outlet of the high gravity rotary packed bed emulsifier; and atomizing and spraying the emulsion continuously in a cooled starch bed for granulating, and performing fluidization drying and gelation treatment in a fluidized bed by taking nitrogen as a drying medium to obtain the stable-type vitamin A microcapsules. Above method has the advantage of capability of continuous production, and has good embedding effect due to adopting the gellable modified starch, granulating and gelation treatment, thus the product has good storage stability.

Owner:ZHEJIANG NHU CO LTD

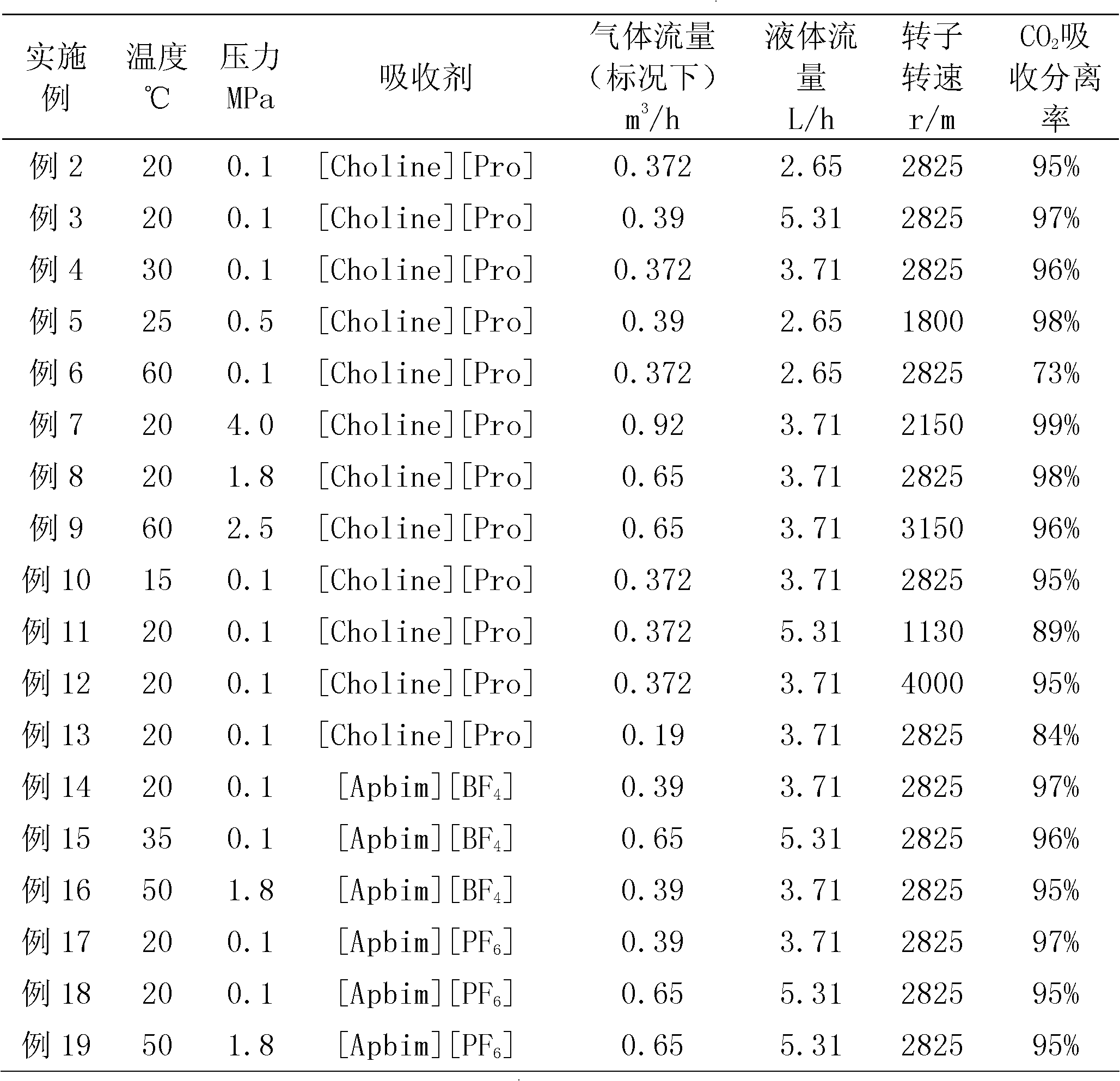

Novel method for capturing and separating carbon dioxide

ActiveCN102580462AEffective separation and captureLess investmentProductsReagentsGas to liquidsProcess industry

The invention discloses a novel method for capturing and separating carbon dioxide, which is applicable to capturing and separating CO2 from tail gas in gas purification, emission reduction of greenhouse gas and process industry and from oil field gas. According to the method, with a high-gravity rotating bed as a rotator and ionic liquid as an absorbent, the absorbent and a mixed gas containing CO2 are in countercurrent or cross-current contact in the high-gravity rotating bed to capture CO2, and the volume-flow ratio of gas to liquid is (50-500):1; the rotating speed of the high-gravity rotating bed is 100-400 rpm; the absorbent is the ionic liquid including amino functional groups or mixture thereof; the pressure in absorption is 0.1-4.0 MPa and the temperature is 15-60 DEG C; and the removal rate of CO2 in raw gas can reach more than 95% (volume). The novel method disclosed by the invention has the advantages of low investment of equipment, small occupied area, low energy consumption, environment friendliness and no corrosion to equipment and the like.

Owner:BEIJING UNIV OF CHEM TECH

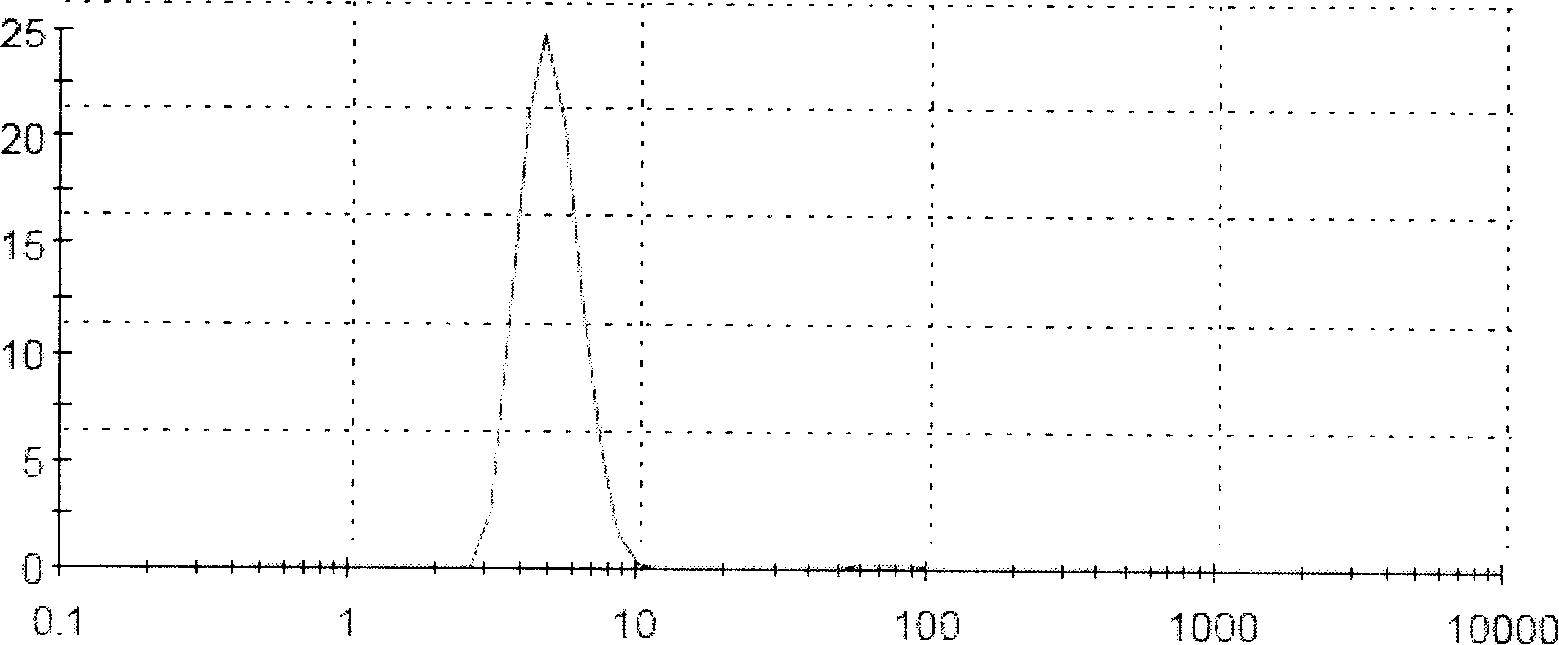

Method of preparing nano-dispersed high-all-trans-carotenoid microcapsules

ActiveUS20120018912A1Easy to operateEasy to controlCosmetic preparationsPowder deliveryAntioxidantDesolvation

A method of preparing nano-dispersed high-all-trans-carotenoid microcapsules is provided, comprising: preparing 10-20% carotenoid suspension by milling the high-all trans-carotenoid crystals with dichloromethane until the particle size thereof is in the range of 2-5 μm, then supplying the suspension together with preheated dichloromethane of another pass into a dissolving tank to obtain a solution of 0.5-2%; delivering the solution together with ethanol or isopropanol into a crystallization device having high gravity rotating packed bed simultaneously and continuously, and then into a wiped-film evaporator for desolvation until the solid content is 10-20%, then a transparent alcohol dispersion of carotenoid is obtained; mashing the alcohol dispersion together with an aqueous solution containing an antioxidant and protective colloid and spray drying to obtain nano-dispersed high-all-trans-carotenoid microcapsules. As the crystals are nano-dispersed and the content of trans-isomer is more than 90%, the carotenoid microcapsules of present inventions exhibit high bioavailability.

Owner:ZHEJIANG NHU CO LTD +2

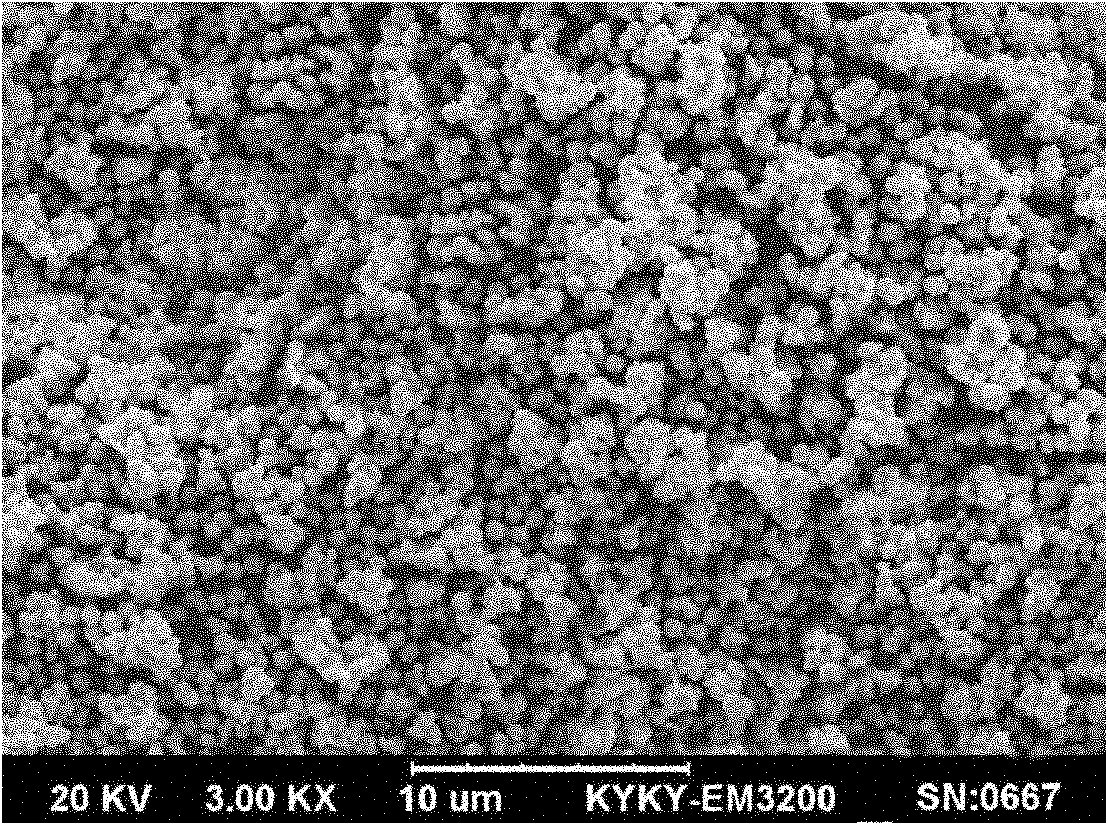

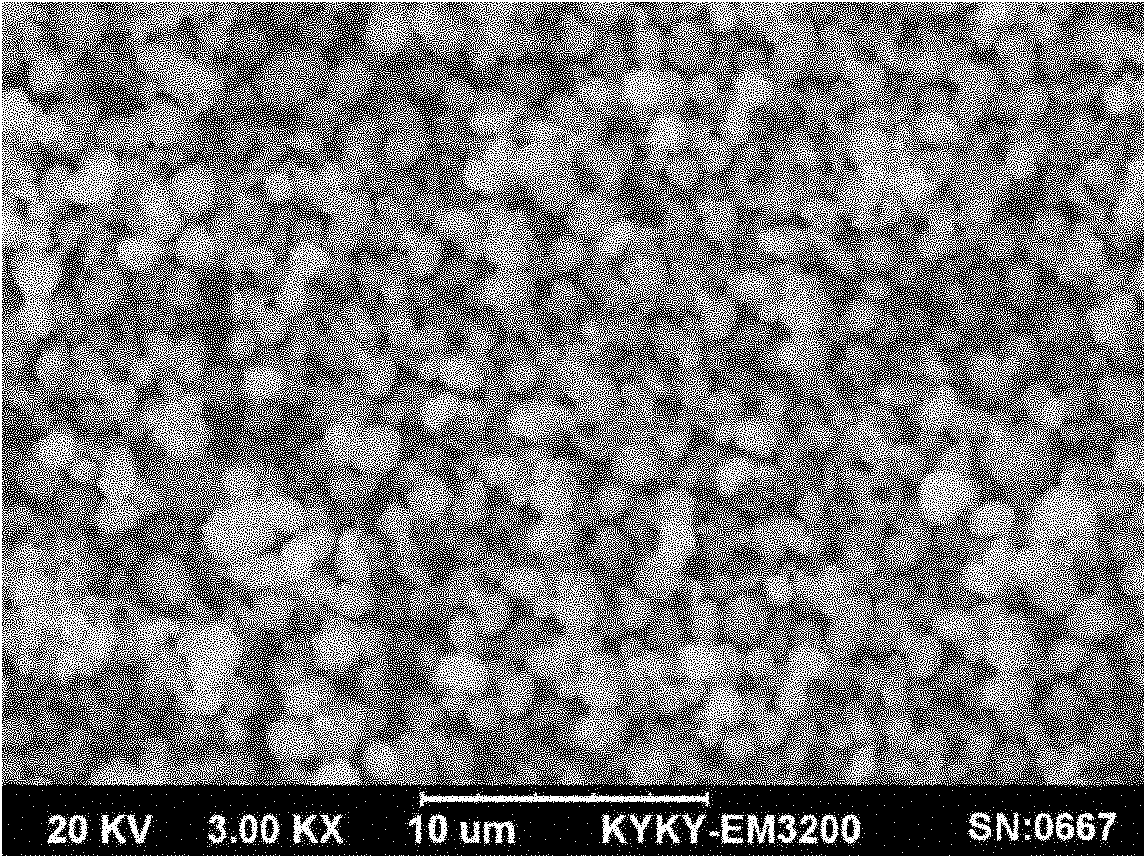

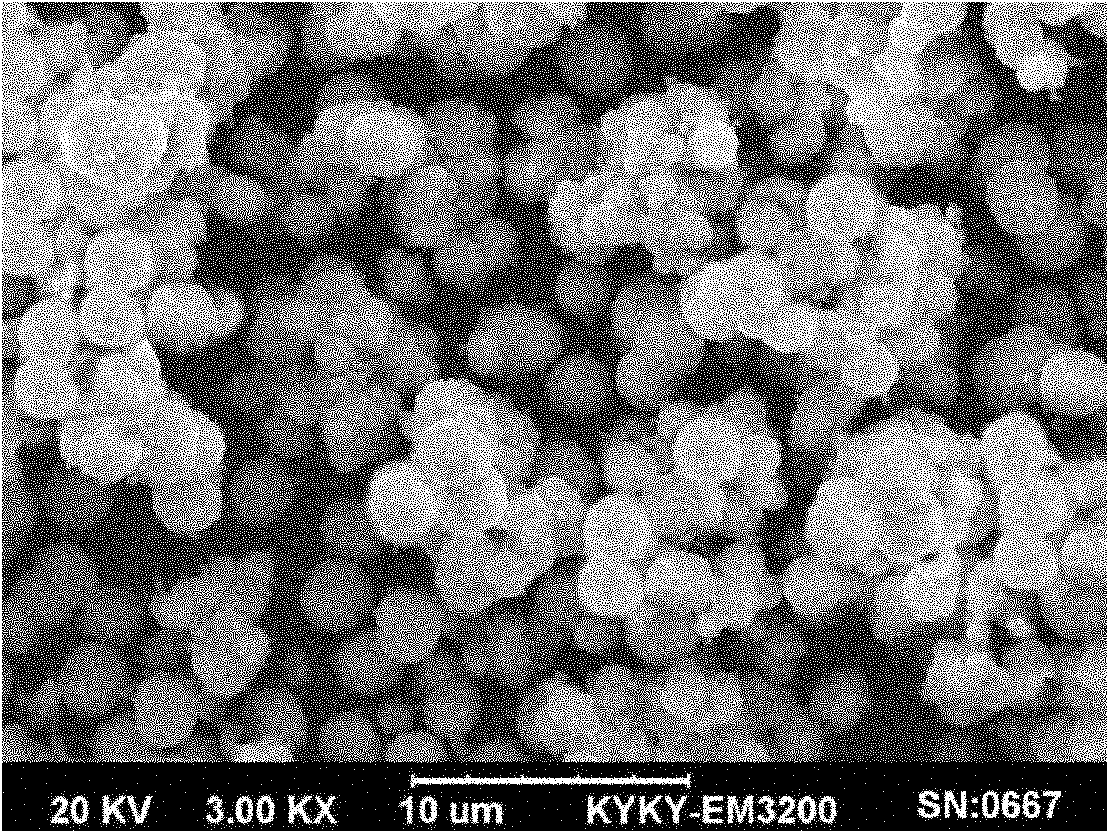

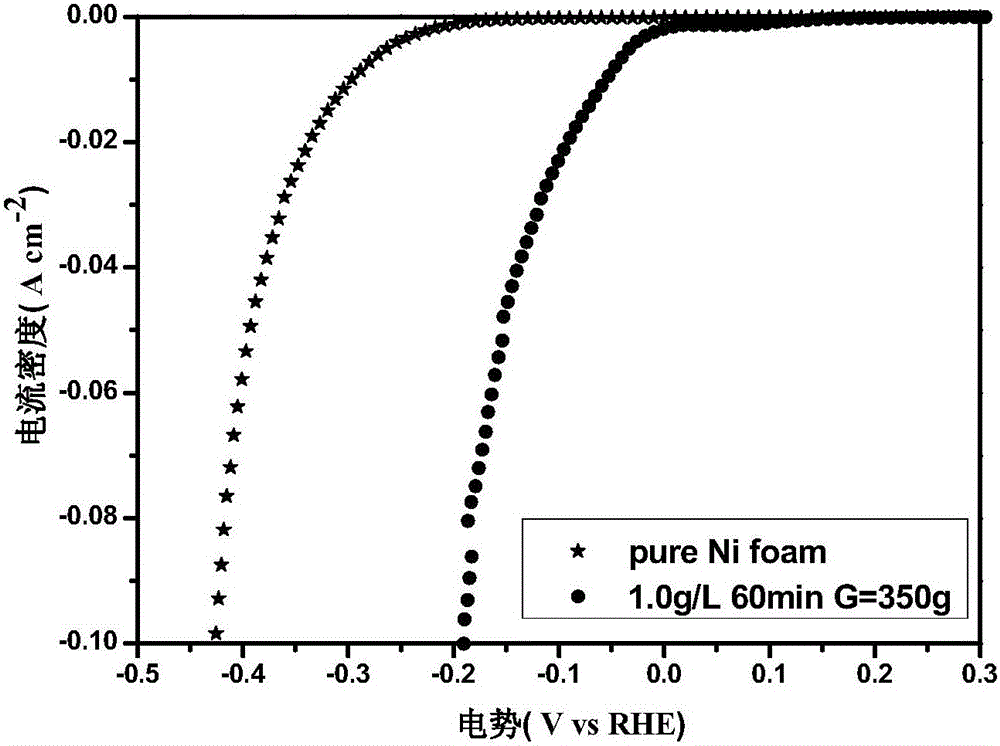

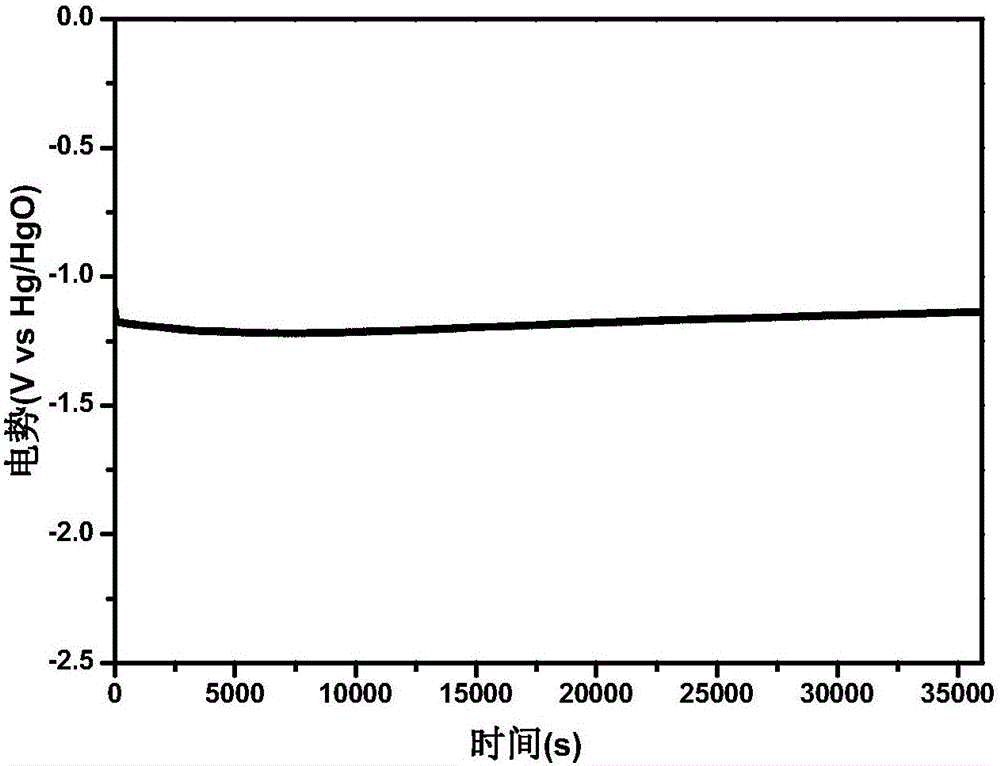

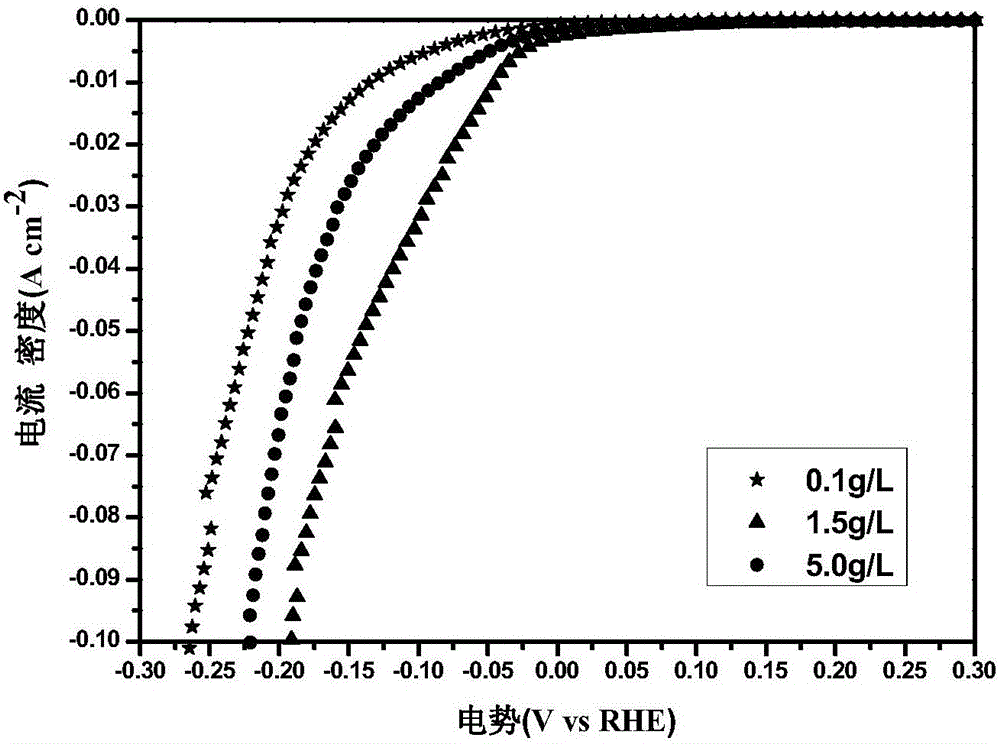

Preparing method of 3D-structuer Ni/rGO composite hydrogen evolution electrode

ActiveCN106087002ALarge specific surface areaPass throughElectrolytic coatingsElectrode shape/formsOverpotentialGraphite oxide

The invention discloses a preparing method of a 3D-structuer Ni / rGO composite hydrogen evolution electrode. The preparing method mainly comprises the steps that graphite oxide is added into deionized water, and ultrasonic treatment is carried out to obtain graphene oxide dispersion liquid; nickel aminosulfonate, nickel chloride and ammonium chloride are added into the graphene oxide dispersion liquid, ultrasonic treatment is carried out to obtain a composite plating solution, a foam nickel substrate subject to ultrasonic and acidification treatment serves as an electro-deposition cathode, a pure nickel pipe serves as an electro-deposition anode, the strength G of a high gravity field is 350 g, the electro-deposition time ranges from 10 min to 100 min, the electro-deposition temperature is 45 DEG C, the electro-deposition current density is 3 A / dm<2>, and a composite coating obtained through preparing is washed with deionized water to be neutral and is dried; and the prepared Ni / rGO composite electrode has the considerable specific surface area, a uniform and stable coating structure and the excellent hydrogen evolution performance. When the current density is 100.0 mA / cm<2>, the hydrogen evolution reaction overpotential is reduced to 190 mV from 240 mV obtained through conventional electro-deposition preparing.

Owner:BEIJING CEI TECH

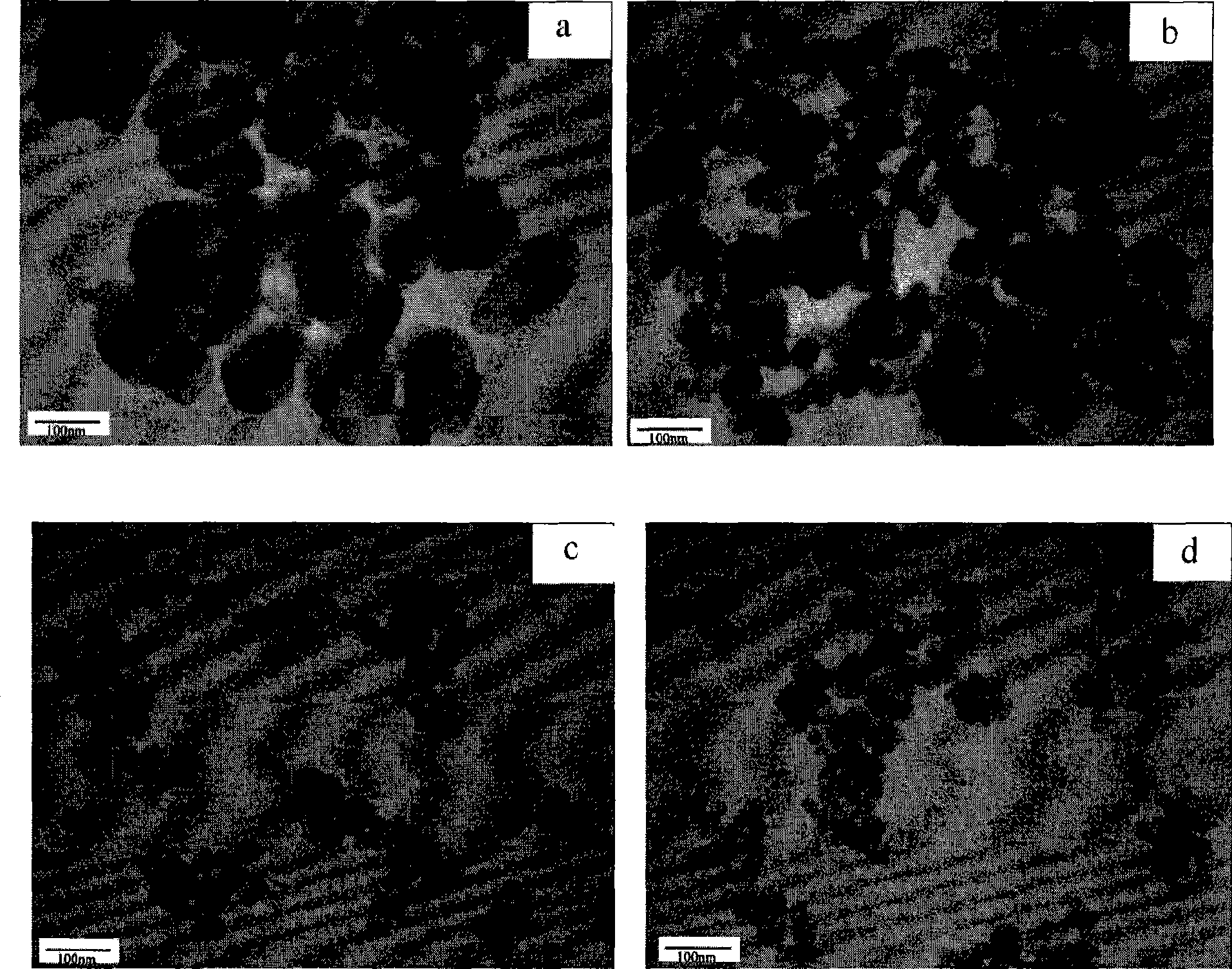

Spheric catalyst component for olefin polymerization and catalyst comprising the same

InactiveUS20060003888A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorSolid particle

The present invention provides a spheric catalyst component as well as a catalyst for olefin polymerization. The spheric catalyst component comprises at least one titanium compound and optionally at least one electron donor compound supported on an active magnesium halide spheric carrier, wherein the active magnesium halide spheric carrier is solid particles obtained by dispersing a melt of magnesium halide / alcohol adduct by rotation under high-gravity field. The catalyst has good particle morphology and narrow particle size distribution, and when used in olefin polymerization, especially in propylene polymerization, exhibits relatively high activity and stereoelectivity, and gives polymers having good particle morphology and high bulk density.

Owner:CHINA PETROCHEMICAL CORP +1

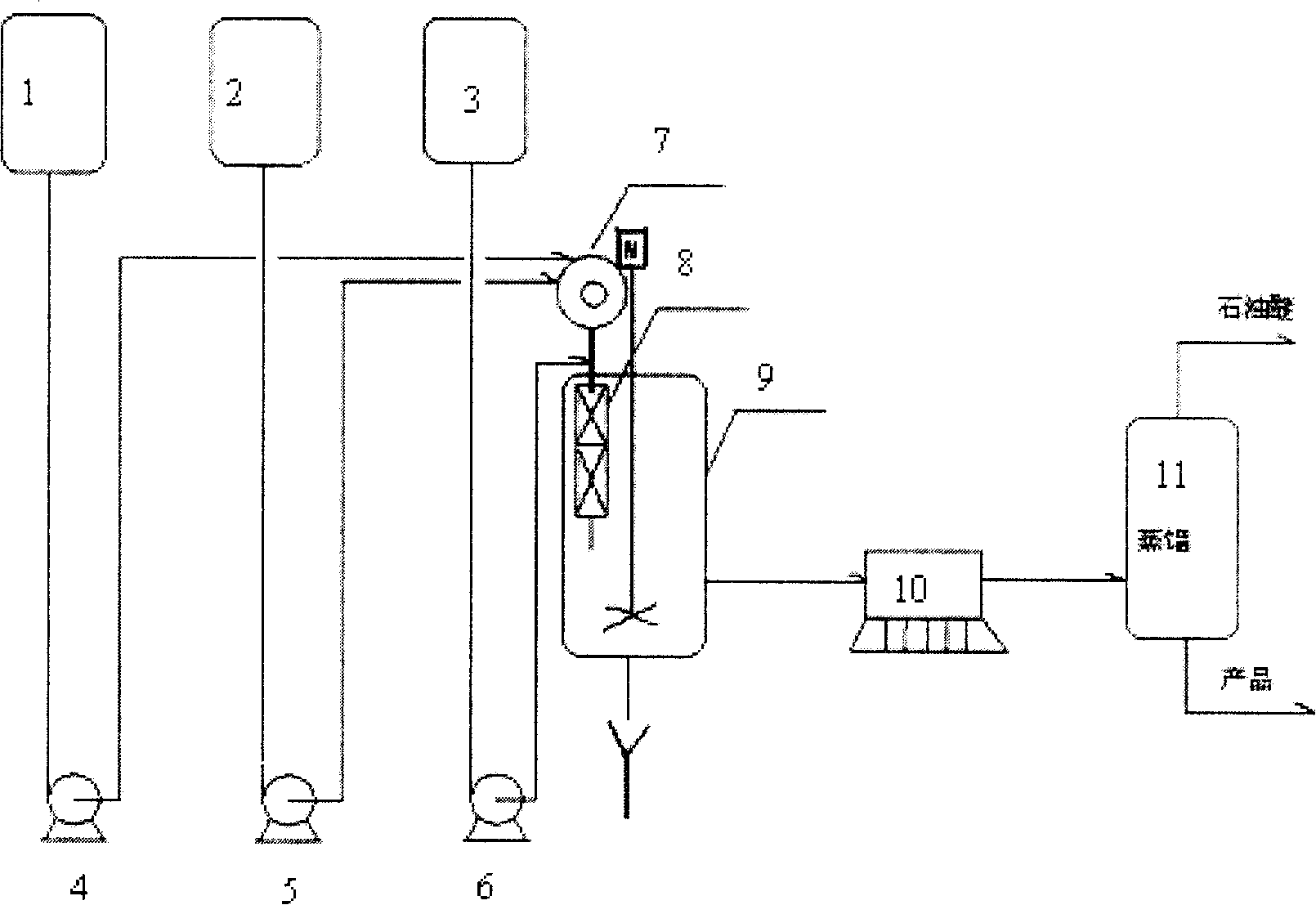

Method for preparing nano copper lubricating oil additive

ActiveCN101200667AOvercoming rapid nucleationOvercoming the Need for MicromixingAdditivesDispersion stabilityDistillation

The present invention provides a method of preparing nanometer copper lubricant additive by a high gravity technology. Copper salt solution and reducer solution are processed for the liquid phase reduction reaction of cupric salt inside a high gravity machine, the solution after the reaction and extractant are mixed inside a static mixer and then stirred inside a reaction vessel for complete mixing reaction and the surface modification during the process of extraction and to be processed for standing and being layered, oil phase at the upper layer is obtained for pressure reduction and distillation to obtain a final product. The reaction speed of the method of the present invention is fast; the repeat reproducibility of the products between batches is good; the nanometer copper lubricant additive is prepared directly by a wet method, which does not require vacuum drying for preparing for nanometer copper dry powder, avoids the occurrence of agglomeration, simplifies the technical flow and has high product quality, high yield and short production period; the granularity of prepared nanometer copper powder reaches the nanometer grade (is less than 20nm) and is distributed quite narrowly, and the nanometer copper powder has very good dispersion stability in the lubricant.

Owner:PETROCHINA CO LTD +1

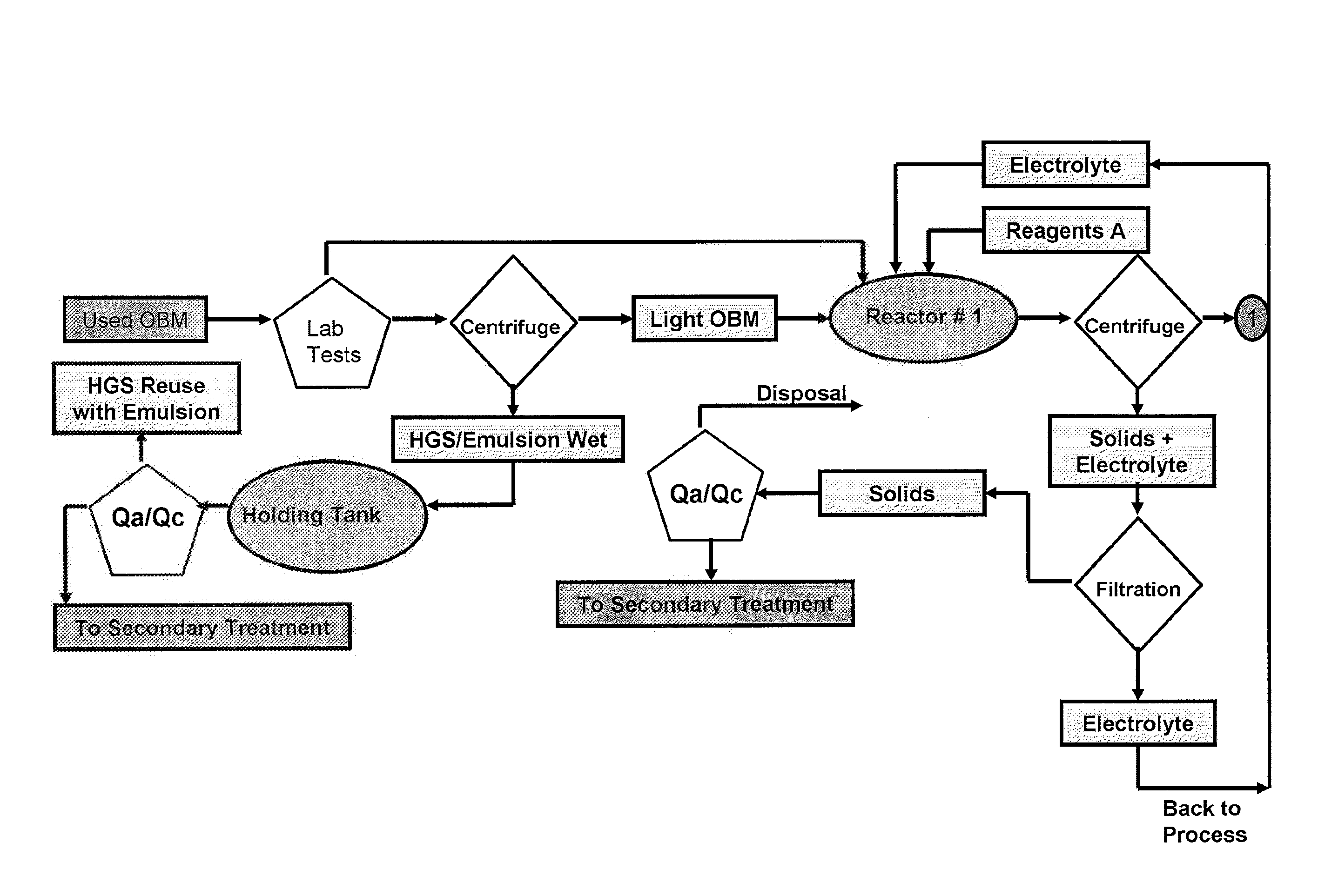

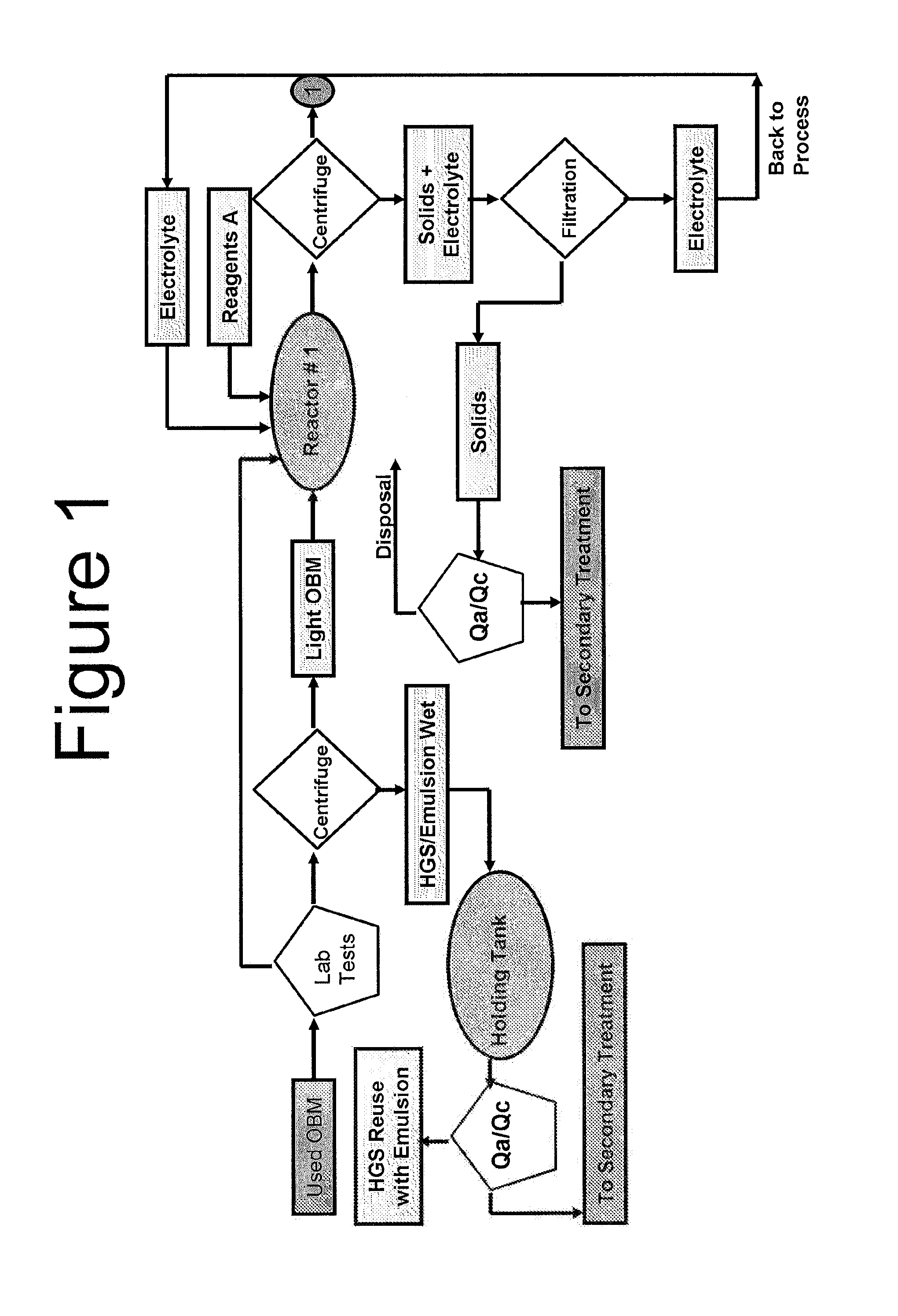

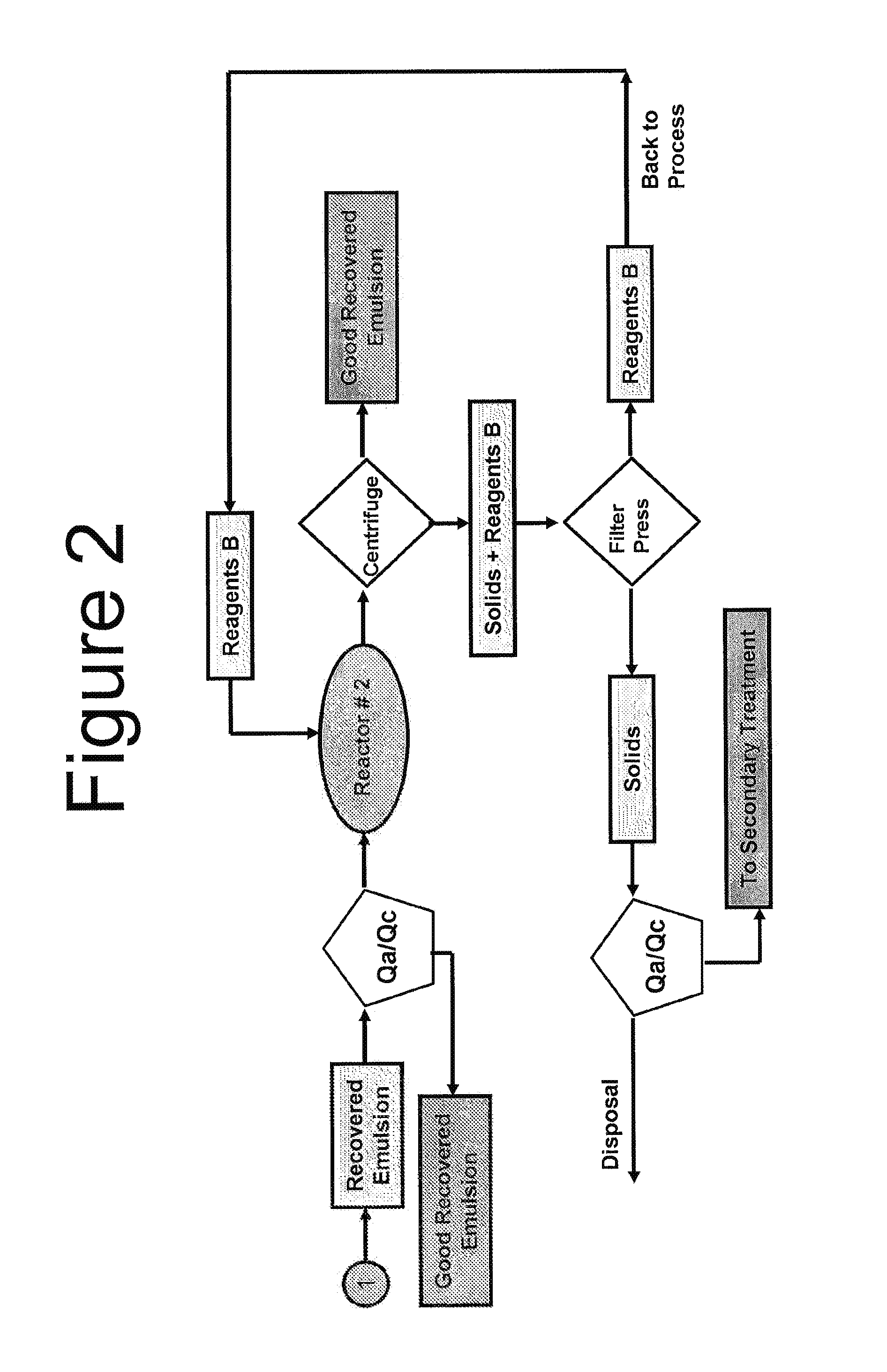

Method and system to recover usable oil-based drilling muds from used and unacceptable oil-based drilling muds

A system for treating spent / used Oil Based Drilling Muds (OBM's) to recover High Gravity Solids (HGS) for further reuse and to separate the invert emulsion from the Light Gravity Solids (LGS) with good characteristics also for further reuse. Separated LGS is processed to extract the remaining oil in order to render an environmentally safe solid fraction. The overflow of a screening or centrifugation of spent OBM enters a reactor where reagents are added and mixed to control the oil / water ratio of the recovered emulsion and to reduce the LGS concentration. A catalyst is added before adding a final reagent that initiates the reaction. Upon centrifuging the reacted mix, the recovered emulsion is the overflow and a thin layer of LGS forms slightly below the emulsion. The underflow of this separation is further sedimented by gravity and the phase dispersant layer is decanted and sent for reuse.

Owner:SCOMI ECOSOLVE

Wave simulation generating device under high gravity field

ActiveCN109141819AGuaranteed similarityImprove absorbing performanceHydrodynamic testingWave shapeReflected waves

The invention discloses a wave simulation generating device under a high gravity field. The adoption of a wave absorbing unit can enhance the wave absorbing effect, reduce the influence of a reflectedwave on a waveform, and ensure the similarity of a wave simulation experiment to real environment simulation. The wave absorbing unit can adjust the position of a wave absorbing plate and the size ofa grating opening according to the waveform generated by a wave generating unit so as to ensure an optimal wave absorbing effect. The wave generating unit realizes force transfer and the decoupling of motion in a simple structure. Compared with a transmission structure with a long transmission path and a complicated structure, the wave simulation generating device is less affected by mechanism jamming caused by deformation of a centrifugal field and ensures the rigidity and stability of a transmission mechanism more easily. Different from a conventional way of moving a push plate as a whole,only the upper part of the push plate is pushed, and so the load on the push plate is small and required power is small. The wave simulation generating device under a high gravity field is suitable for simulation of waves with high water depth and large amplitude.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

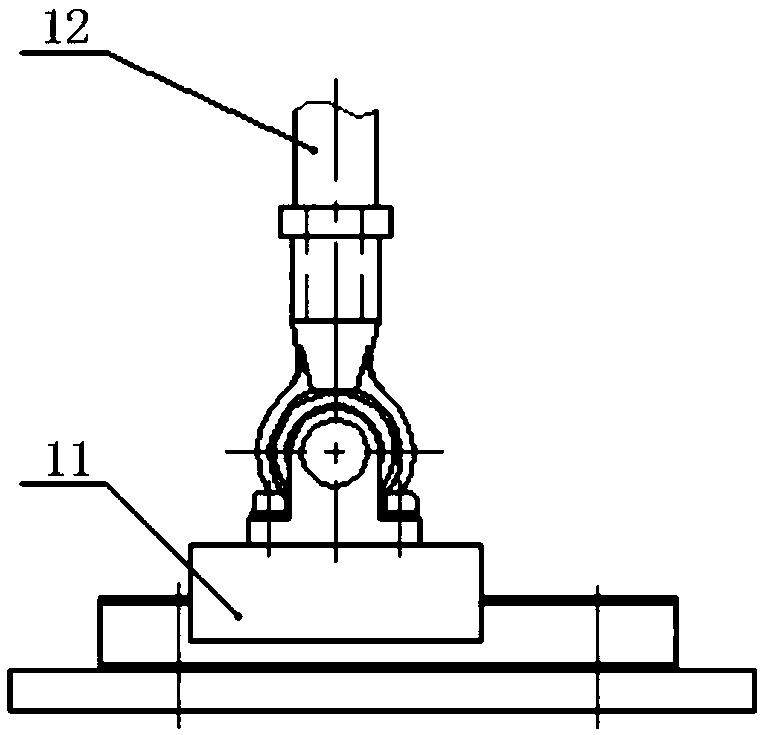

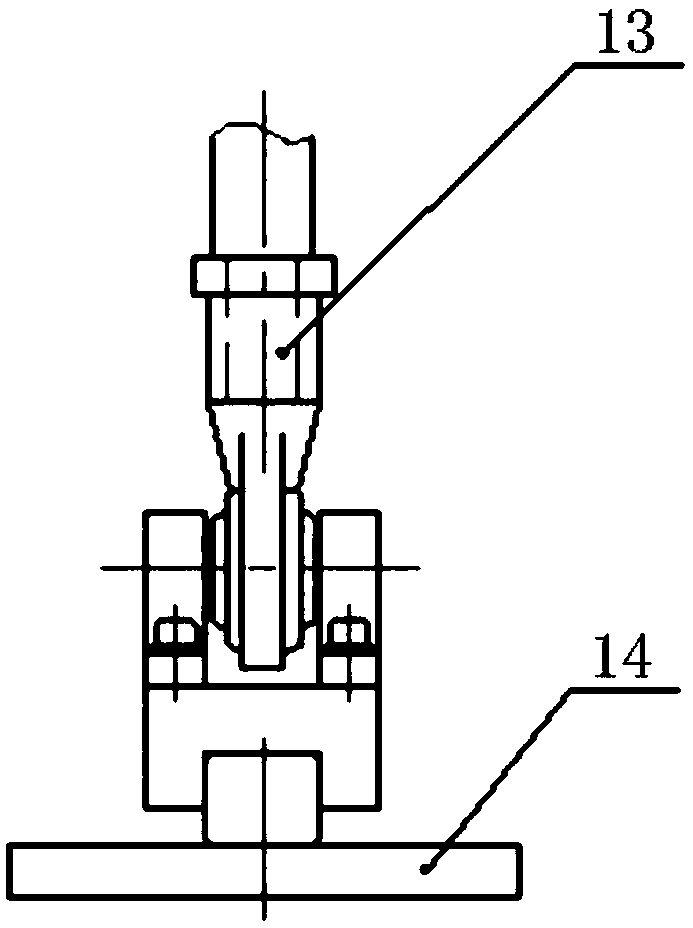

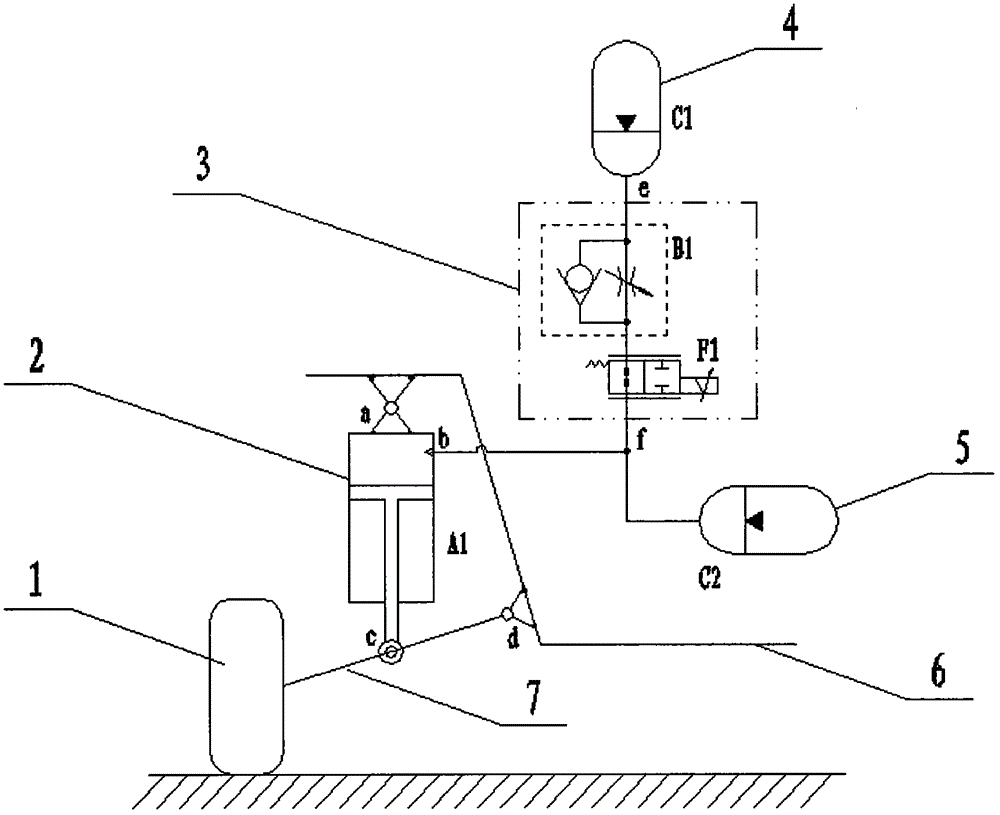

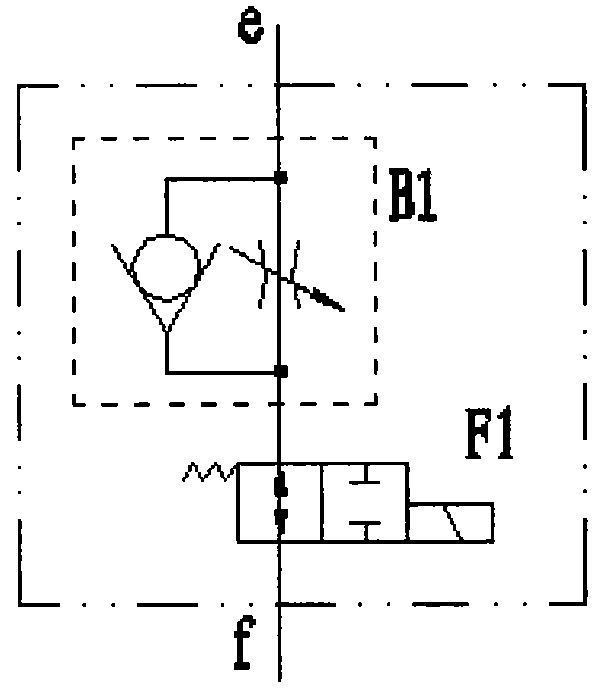

Vehicle side-turn-prevention suspension device

The invention belongs to the technical field of vehicle suspensions, and discloses a vehicle side-turn-prevention suspension device. The vehicle side-turn-prevention suspension device comprises a suspension oil cylinder, a cross arm, a damping valve group, a low-voltage energy accumulator and a high-voltage energy accumulator, wherein the suspension oil cylinder is used for supporting the weight of a vehicle body, the upper portion of the suspension oil cylinder is hinged to the vehicle body, a lower portion piston rod is hinged to the middle of the cross arm, one end of the cross arm is connected with a wheel, and the other end of the cross arm is hinged to the vehicle body; the damping valve group is used for attenuating the vibration of the vehicle body, one end of the damping valve group is communicated with an upper cavity of the suspension oil cylinder and the high-voltage energy accumulator through oil pipes, the other end of the damping valve group is communicated with the low-voltage energy accumulator through an oil pipe, the damping valve group has resistance on oil liquid passing in the damping valve group, and the vibration energy carried by the oil liquid is dissipated in a temperature rise mode. By controlling the rigidity and damping of the suspension device, side turning in the steering process of a vehicle is restrained, and therefore the driving safety of the vehicle is improved. The vehicle side-turn-prevention suspension device plays an important role especially for large buses, heavy trucks and concrete mixers with a high gravity center on the aspect of preventing side turning of vehicles.

Owner:CHINA NORTH VEHICLE RES INST

Multilevel atomizing hypergravity swinging bed with plane reticular lamina reinforced and uses thereof

InactiveCN101234260AReduce resistanceStrong mass and heat transferChemical/physical/physico-chemical moving reactorsFractional distillationHypergravityEngineering

The invention discloses a reinforced multi-stage spraying high-gravity rotating packed bed with a flat netted board and the application thereof, the rotating packed bed comprises a rotating bed shell, a motor and a rotating shaft which is arranged inside the shell, the peripheral of the shaft is provided with a hollow tumbler, a middle pipe with a hole is inserted into the middle of the shaft which is provided with hollow structure, the pipe is provided with a liquid inlet port, a rotating shaft inside the tumbler is provided with small holes, the tumbler corresponding to the rotating shaft is also provided with small holes, at least two flat netted boards are fixedly arranged on the tumbler, which are arranged horizontally, and an axial distance is kept between the flat netted boards. The reinforced multi-stage spraying high-gravity rotating packed bed with the flat netted board can not only strengthen the mass-transfer and heat-transfer between gas-liquid two phase, and improve dedusting efficiency, but also can avoid high gas resistance loss, so in the condition of low gas resistance, high heat-transfer and mass-transfer coefficient and high dedusting efficiency can be obtained, and in industry, the invention has the value of being widely spread and applied.

Owner:SOUTH CHINA UNIV OF TECH

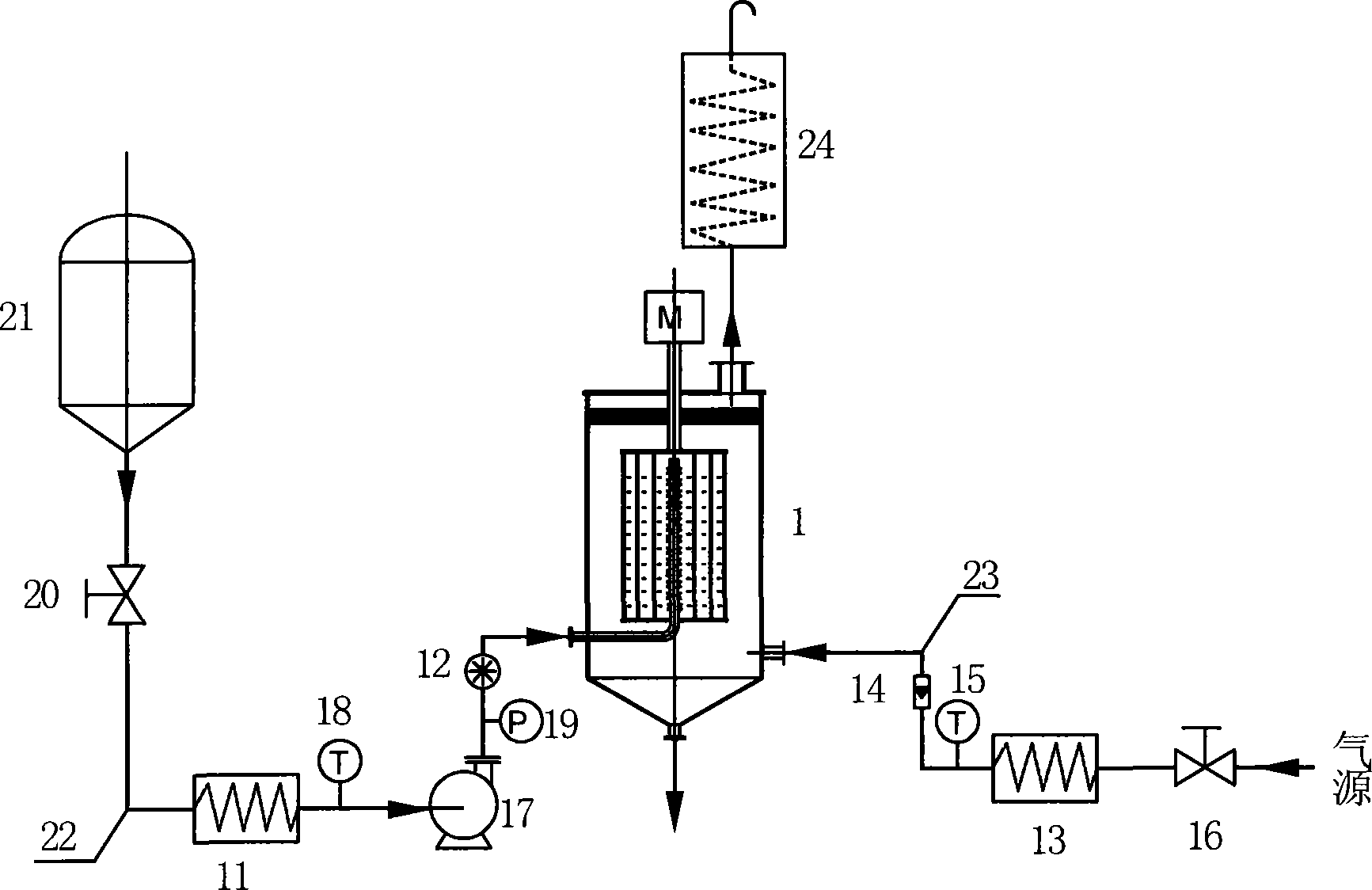

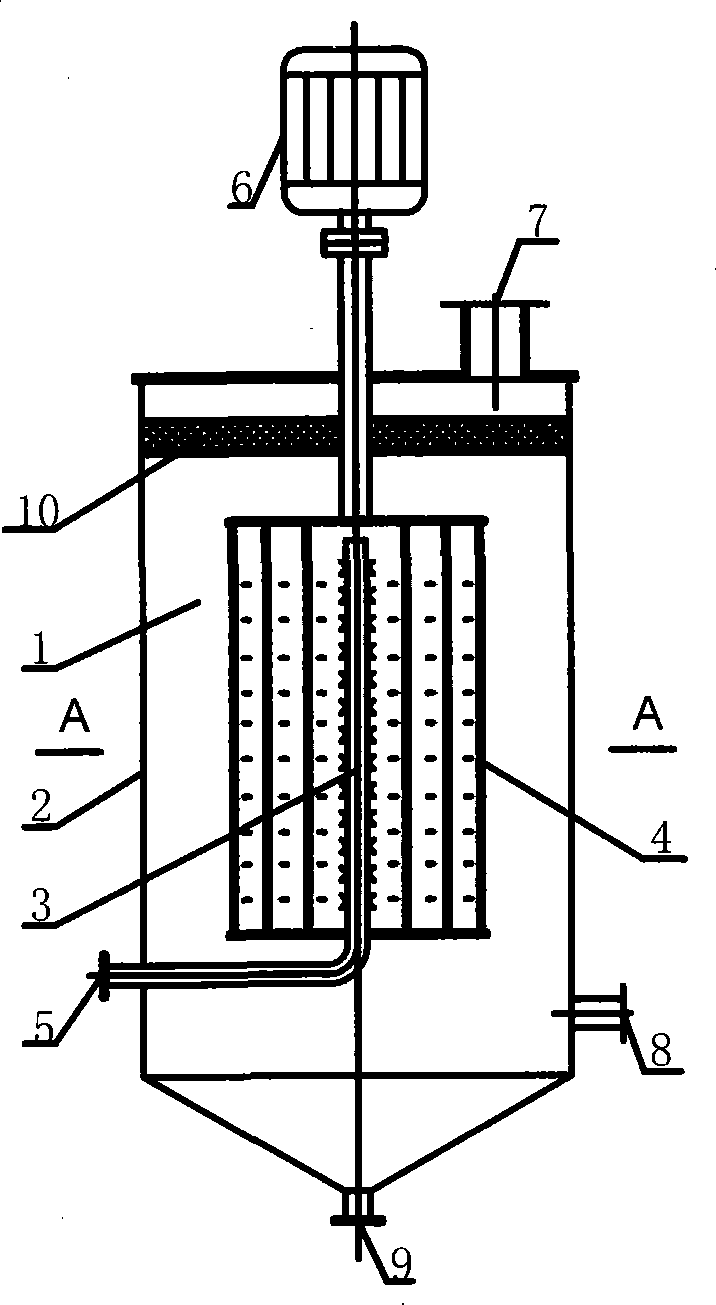

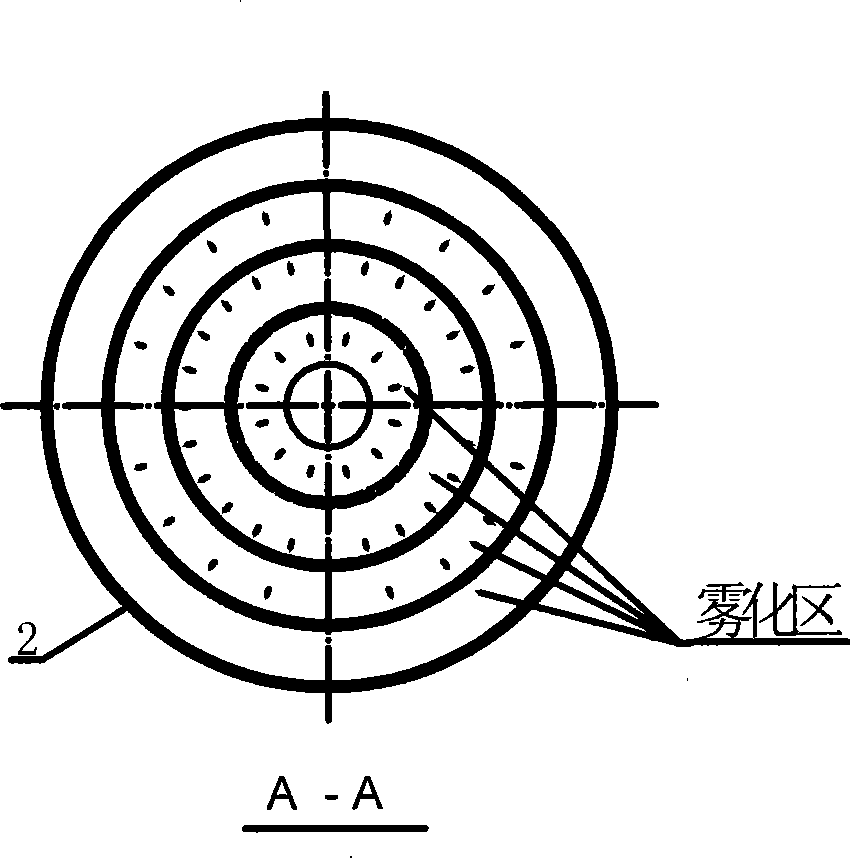

Method for performing residual oil hydrogenation reaction in high gravity reactor

ActiveCN107686742AExtension of timeSlow ascentEnergy based chemical/physical/physico-chemical processesHydrocarbon oils treatmentSolubilityHydrogenation reaction

The invention discloses a method for performing a residual oil hydrogenation reaction in a high gravity reactor. The method comprises the following steps: selecting a high gravity reactor; starting amotor of the high gravity reactor to drive a rotary disk to rotate, meanwhile turning on an ultrasonic probe in a charging cavity; conveying hydrogen and residual oil into the charging cavity to perform efficient gas-liquid mixing, so that insoluble hydrogen is dispersed into a large quantity of nano-micronair bubbles in residual oil, and the solubility of the hydrogen in the residual oil is up toan over-saturated sate to form a gas-liquid mixture; spraying the gas-liquid mixture onto the rotary disk from a lower end of the charging cavity under the actions of gas pressure and gravity, throwing the gas-liquid mixture onto an inner edge of a rotor by using centrifugal force of the rotary force, and making the gas-liquid mixture flow through a catalyst to finish a gas-liquid-solid hydrocracking reaction process. By adopting the method disclosed by the invention, the desulfurization rate of the residual oil can be larger than or equal to 85 percent, the denitrification rate can be largerthan or equal to 25 percent, the vanadium content can be less than or equal to 0.55mug / g, and the nickel content can be less than or equal to 45mug / g.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com