Method for preparing nano copper lubricating oil additive

A lubricating oil additive, nano-copper technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of difficult speed control, uneven mixing, wide range of nano-copper particle size, etc. Efficiency, time saving effect in drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

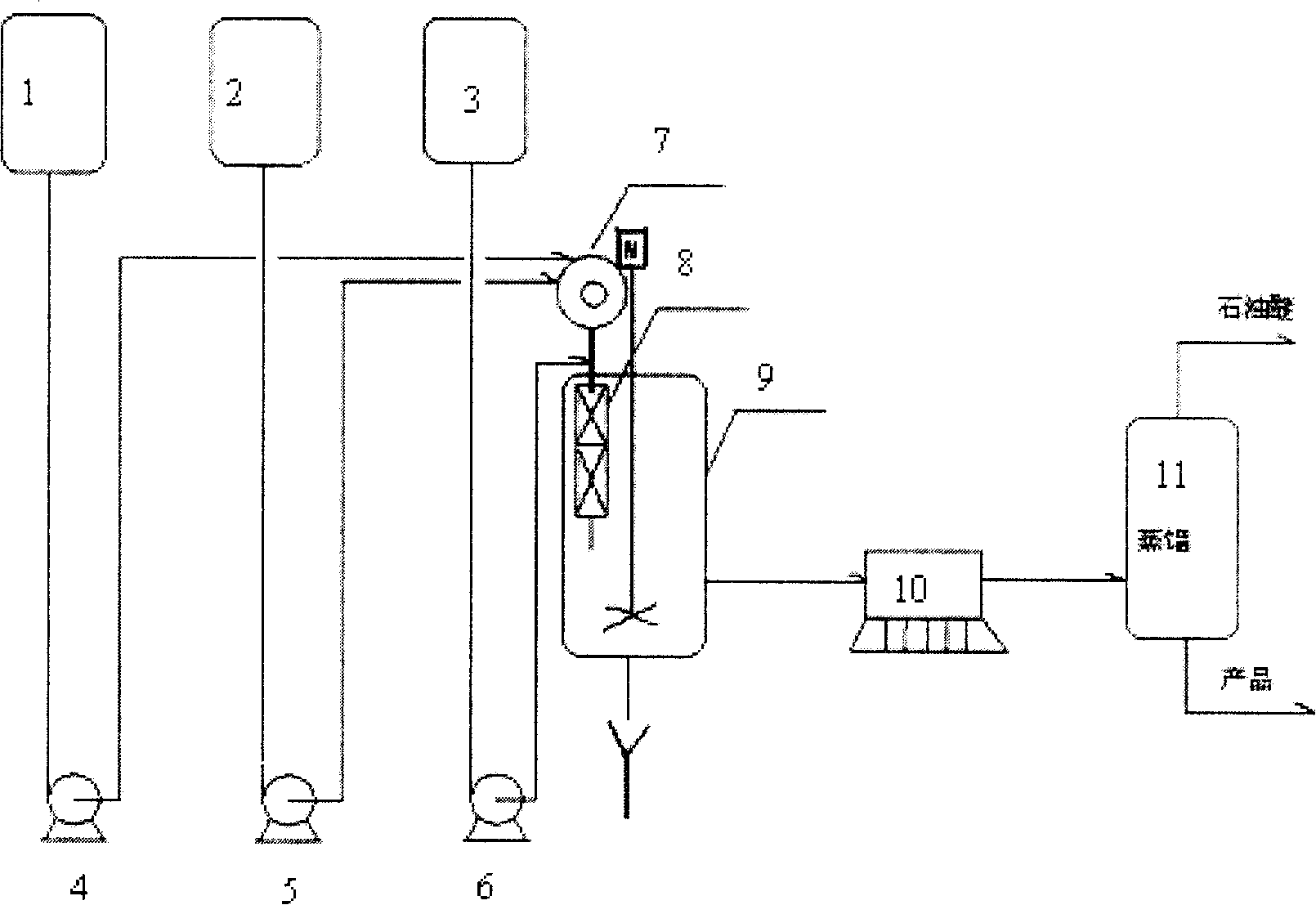

[0021] Example 1: In figure 1 in the process shown

[0022] (1) Weigh 3.133kg of CuSO 4 ·5H 2 O powder, dissolve and dilute to 25L with normal temperature industrial water (about 30°C), and filter impurities to prepare a CuSO4 solution with a concentration of 0.50mol / L; weigh 12.5kg of hydrazine hydrate, and use normal temperature industrial water (about 30°C) Dissolve and dilute to 25L to prepare a hydrazine hydrate reducing agent solution with a concentration of 8.5mol / L; weigh 7.5kg of liquid sulfuric acid, dissolve it with petroleum ether (distillation range 60-90°C) at normal temperature (about 30°C) and Dilute to 25L and prepare a modified extractant solution with a concentration of 0.846mol / L.

[0023] (2) Turn on three centrifugal pumps at the same time, the copper salt solution and reducing solution enter the supergravity machine, the modified extract directly enters the reaction kettle, adjust the rotameter, and control the flow rate of the three materials to be 1...

Embodiment 2

[0027] (1) Take 2.5kg of copper acetate powder, dissolve and dilute it to 25L with normal temperature industrial water (about 30°C), and filter impurities to prepare a copper acetate solution with a mass percentage concentration of 0.5mol / L; weigh 6.25kg of Hydrazine hydrate, dissolved with normal temperature industrial water (about 30°C) and diluted to 25L to prepare a hydrazine hydrate reducing agent solution with a concentration of 4.25mol / L; weigh 3.75kg of liquid sulfuric acid, and use Petroleum ether (distillation range 60-90°C) was dissolved and diluted to 25 L to prepare a modified extractant solution with a concentration of 0.423 mol / L.

[0028] (2) Turn on 3 centrifugal pumps at the same time, the copper salt solution and the reducing solution enter the supergravity machine, the modified extract directly enters the reaction kettle, adjust the rotameter, and control the flow rate of the three materials to be 160L / h for the copper salt solution and the reducing agent T...

Embodiment 3-7

[0032] The basic steps are the same as in Example 1, and the present invention is implemented under different process conditions.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com