Method for preparing powdery polycarboxylic acid hyperdispersant

A technology of hyperdispersant and polycarboxylic acid, which is applied in the field of preparation of powdery hyperdispersant, can solve the problem of high product packaging and transportation costs, easy water absorption and agglomeration, and affect the storage stability of powdery polycarboxylate hyperdispersant products Performance and ease of use and other issues, to achieve the effect of excellent dispersion stability, excellent dispersion, excellent anti-caking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

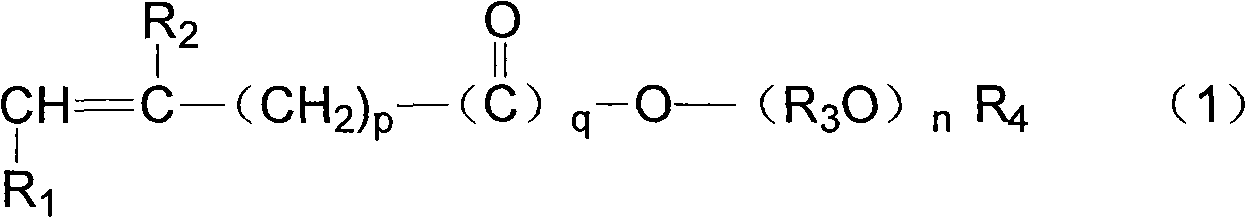

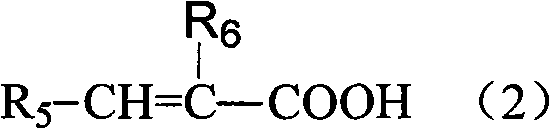

Method used

Image

Examples

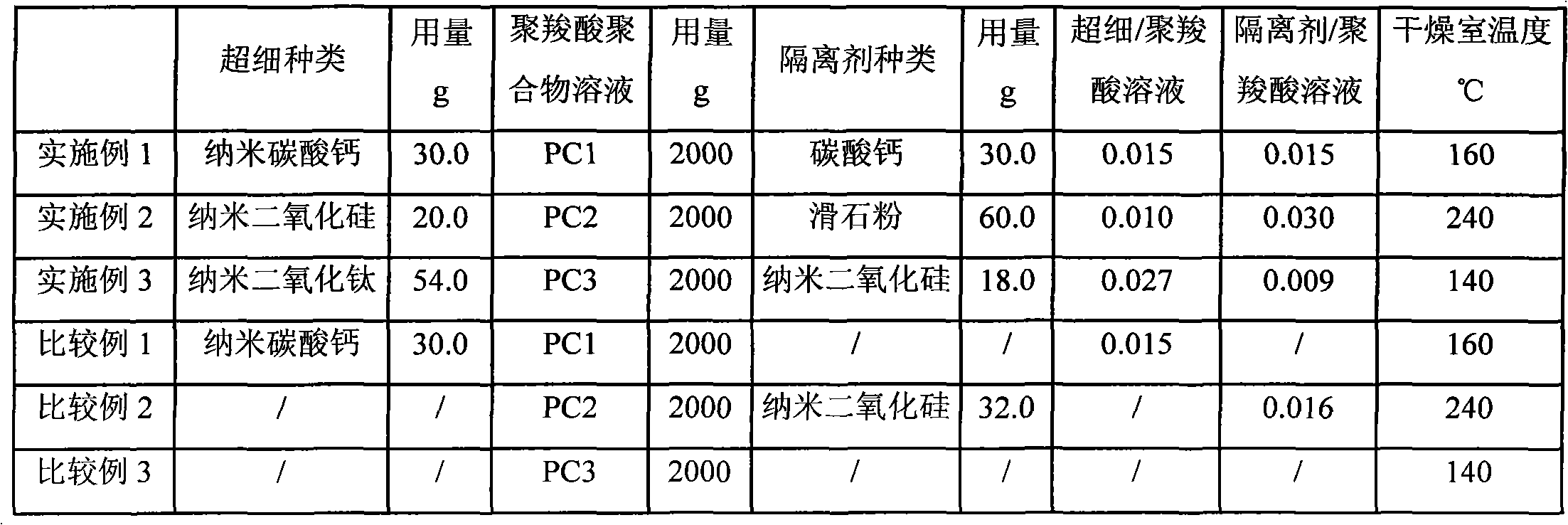

Embodiment 1

[0038] In the case of stirring, gradually make the specific surface area to 30.0g 25.0m 2 The nano calcium carbonate powder of / g is added gradually in the polycarboxylate polymer solution PC1 of 2.0kg 30.0% solid content, and continue to stir until the polycarboxylate slurry is even. Then the obtained polycarboxylate slurry is atomized by a high-speed centrifugal atomizer at 30,000 rpm, and enters a drying tower with an inlet air temperature of 160° C. for drying and dehydration. At the same time, 30.0 g of 1250 mesh calcium carbonate is blown into the drying tower to separate agent, the speed of adding the polycarboxylate slurry is controlled so that the outlet air temperature of the drying tower is around 85°C. Collect and filter the powder with a 20-mesh square sieve to obtain a powdery polycarboxylate hyperdispersant, denoted as SDP-1.

Embodiment 2

[0040] In the case of stirring, gradually make the specific surface area to 20.0g 300.0m 2 The nano silicon dioxide powder powder of / g is added gradually in the polycarboxylate polymer solution PC2 of 2.0kg 40.0% solid content, and continue to stir until the polycarboxylate slurry is even. Then the obtained polycarboxylate slurry is atomized by a high-speed centrifugal atomizer at 35,000 rpm, and enters a drying tower with an inlet air temperature of 240° C. for drying and dehydration. At the same time, 60.0 g of 1250-mesh talcum powder release agent is blown into the drying tower , The speed of adding the polycarboxylate slurry is controlled so that the outlet air temperature of the drying tower is around 100°C. Collect and filter the powder with a 10-mesh square sieve to obtain a powdery polycarboxylate hyperdispersant, denoted as SDP-2.

Embodiment 3

[0042] In the case of stirring, gradually the specific surface area is 54.0g 50.0m 2The nano titanium dioxide powder of / g is added gradually in the polycarboxylate polymer solution PC3 of 2.0kg 45.0% solid content, and continue to stir until the polycarboxylate slurry is even. Then the obtained polycarboxylic acid slurry is atomized by a 30000rpm high-speed centrifugal atomizer, and enters a drying tower with an inlet air temperature of 140°C for drying and dehydration. At the same time, 18.0g300.0m 2 / g of nano-silica powder powder, the speed of adding the polycarboxylate slurry is controlled to make the outlet air temperature of the drying tower around 70°C. Collect and filter the powder with a 20-mesh square sieve to obtain a powdery polycarboxylate hyperdispersant, designated as SDP-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com