Patents

Literature

81results about How to "Excellent caking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colored glaze mixed type ink for ceramic ink-jet printing and preparation method thereof

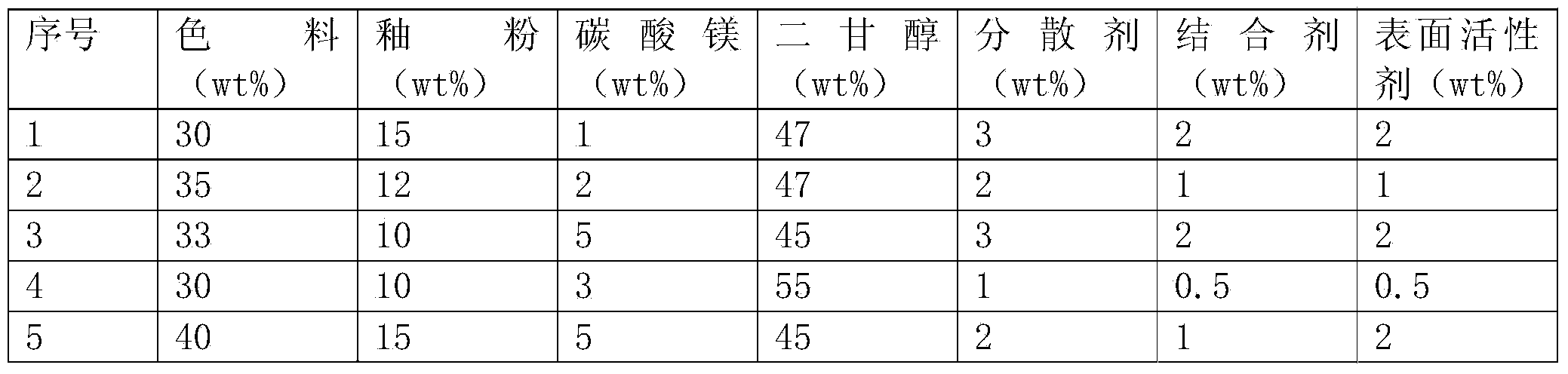

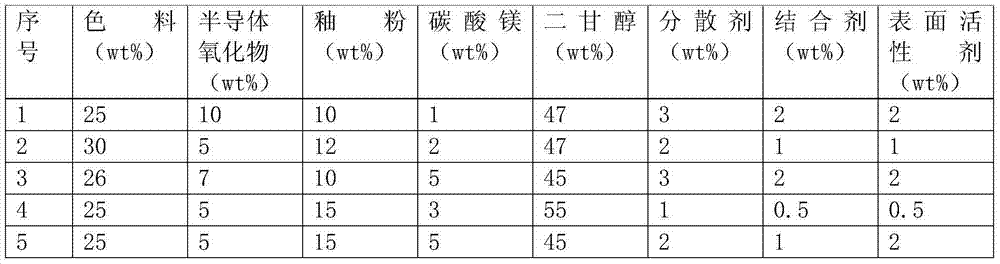

The invention provides colored glaze mixed type ink for ceramic ink-jet printing and a preparation method thereof, belonging to the technology of ceramic tile decoration. The ink comprises the following components by mass percent: 30%-40% of pigment, 10%-15% of glaze powder, 1%-5% of magnesium carbonate, 45%-55% of diethylene glycol, 1%-3% of dispersing agent, 0.5%-2% of binding agent, and 0.5%-2% of surfactant. When the colored glaze mixed type ink for ceramic ink-jet printing is used for producing ceramic tiles for wall and floor, after ink-jet printing, the ceramic tiles can be directly sintered at high temperature without being applied with transparent protective glaze; the glaze in the ink is melted in sintering, so that the color development component of the ink is uniformly dispersed in the melted glaze, the formed ink-jet printing layer has good abrasion resistance, the production technology of the ink-jet printed ceramic tiles is greatly simplified, the production cost is lowered, and the production efficiency is improved.

Owner:LIXIAN XINPENG CERAMIC +1

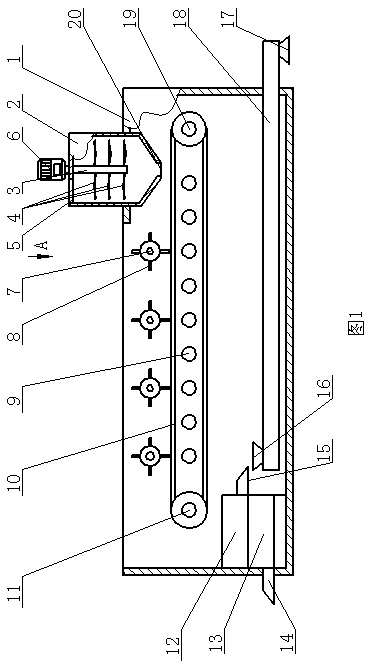

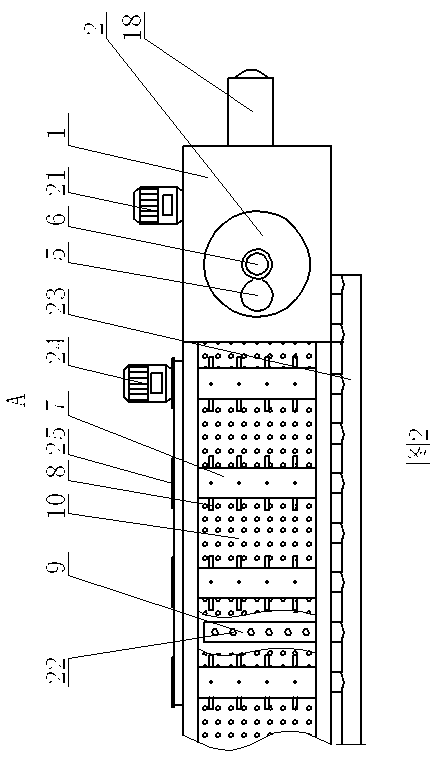

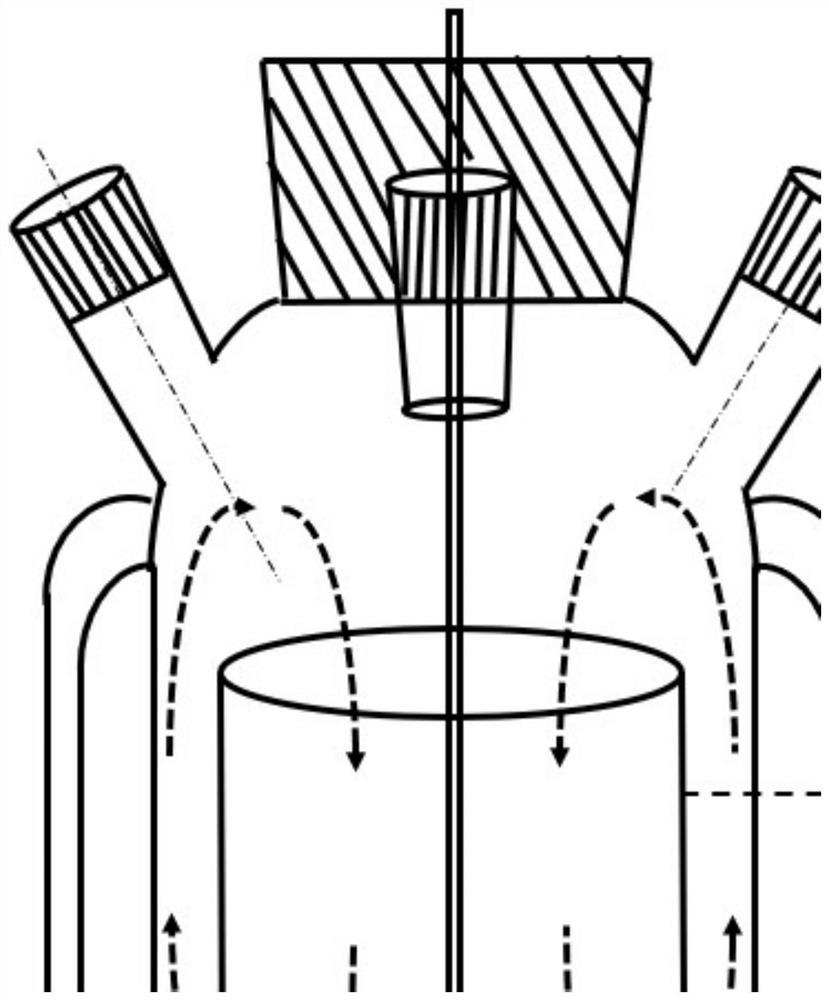

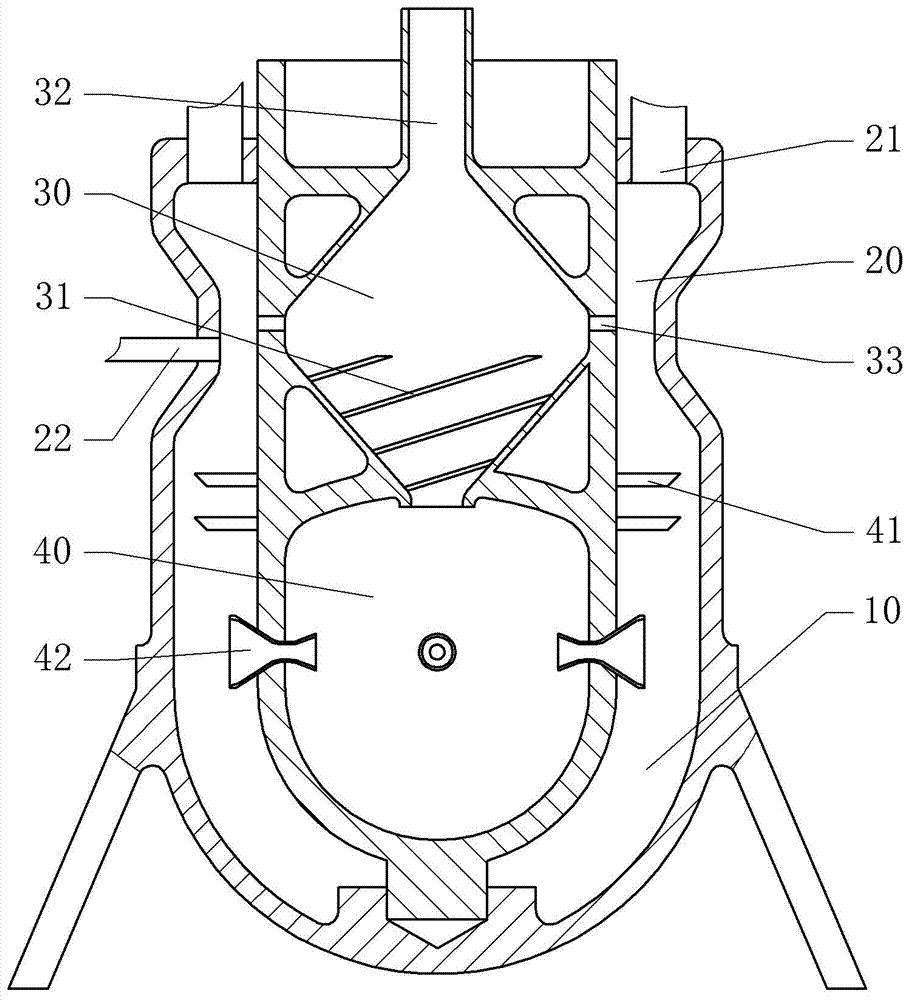

Method for producing compound fertilizer by high tower tubular reactor

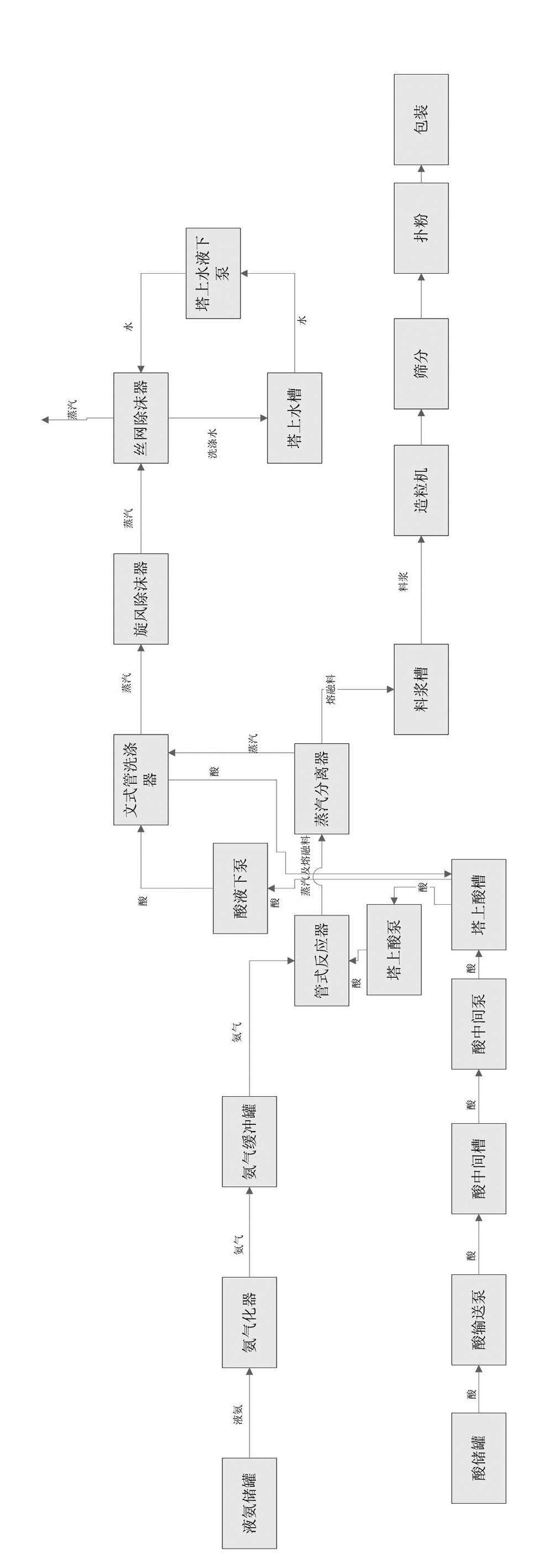

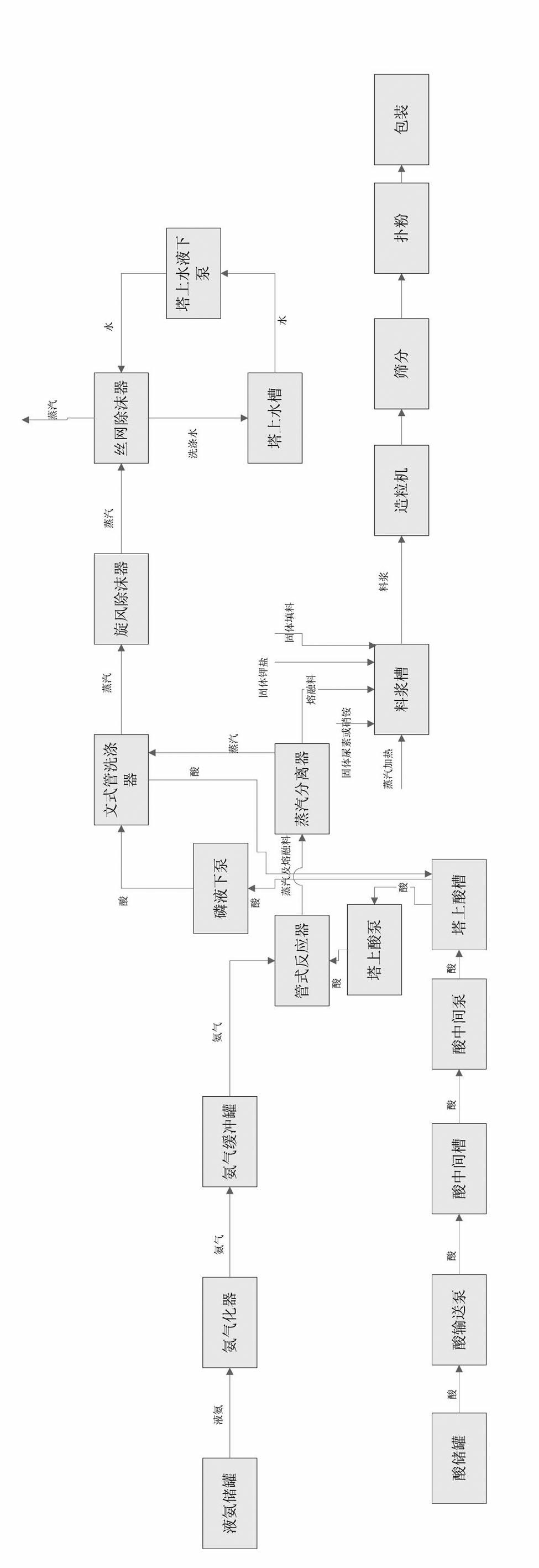

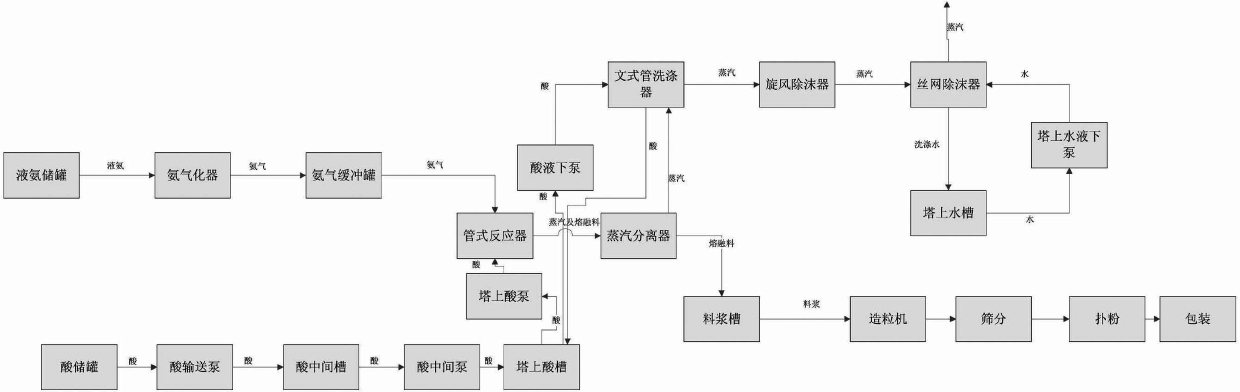

The invention relates to a method for producing a compound fertilizer by a high tower tubular reactor, which comprise the following steps of: adding acid and ammonia which are used as raw materials into the tubular reactor to perform the mixing reaction to prepare mixed slurry; separating the mixed slurry from steam by a steam separator; and filling the slurry obtained by separating into a slurry tank, spraying the slurry into a granulation tower by a granulation spray nozzle at the top of a tower, cooling granulation materials by the cold air in the tower to ensure that the granulation materials fall onto the bottom of the tower and sieving to obtain the compound fertilizer. The molten slurry is obtained by utilizing the reaction heat of the acid and the ammonia and a part of solid raw materials can also be molten down, so that energy is saved and the consumption is reduced; the acid and the ammonia which are used as the raw materials are fluid and are more beneficial to mechanical operation, labor is saved, the dust quantity is reduced and the environment is optimized; and the slurry is in a molten state, so that a low-nitrogen high-phosphorus compound fertilizer can be produced by the high-tower granulation.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

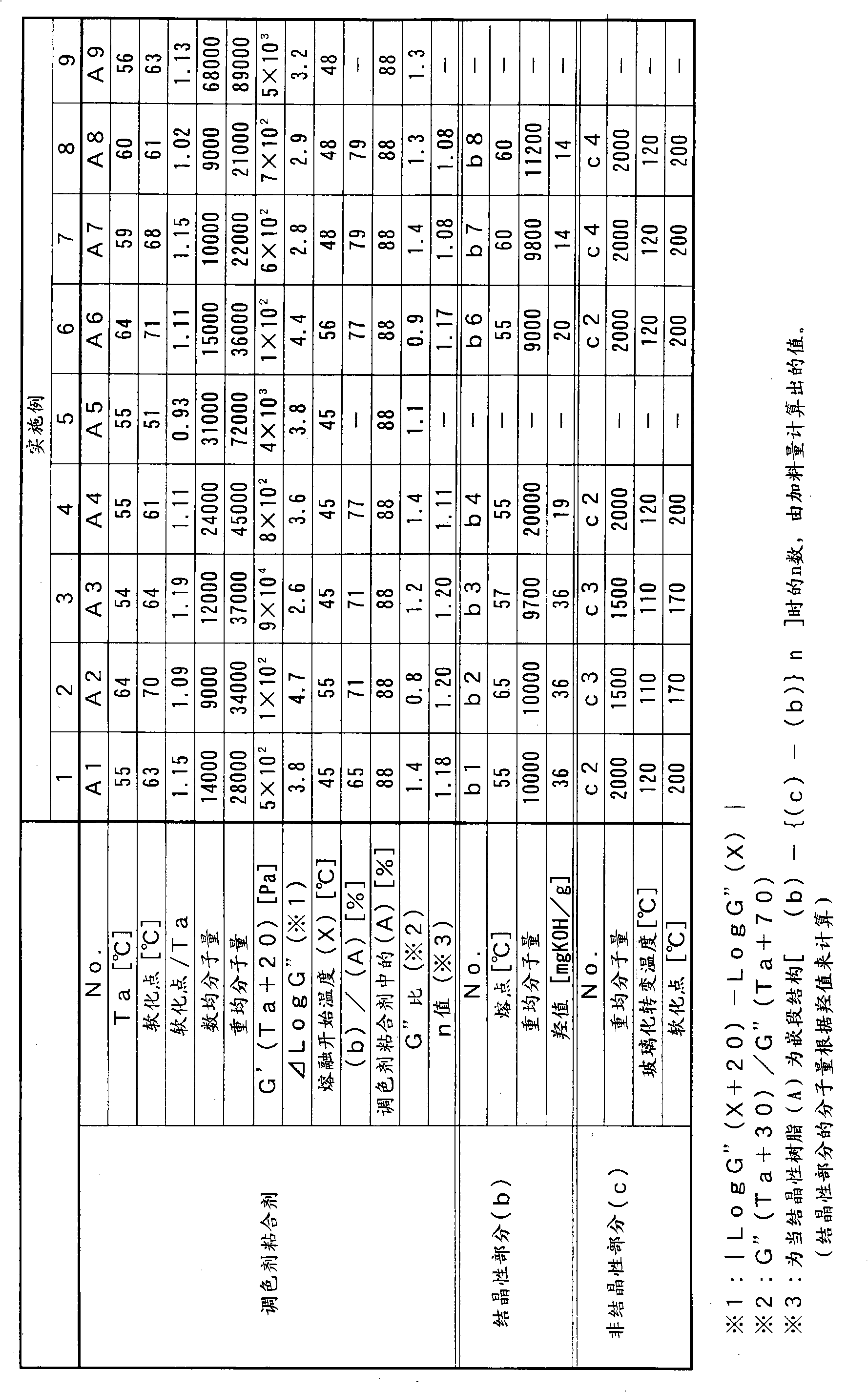

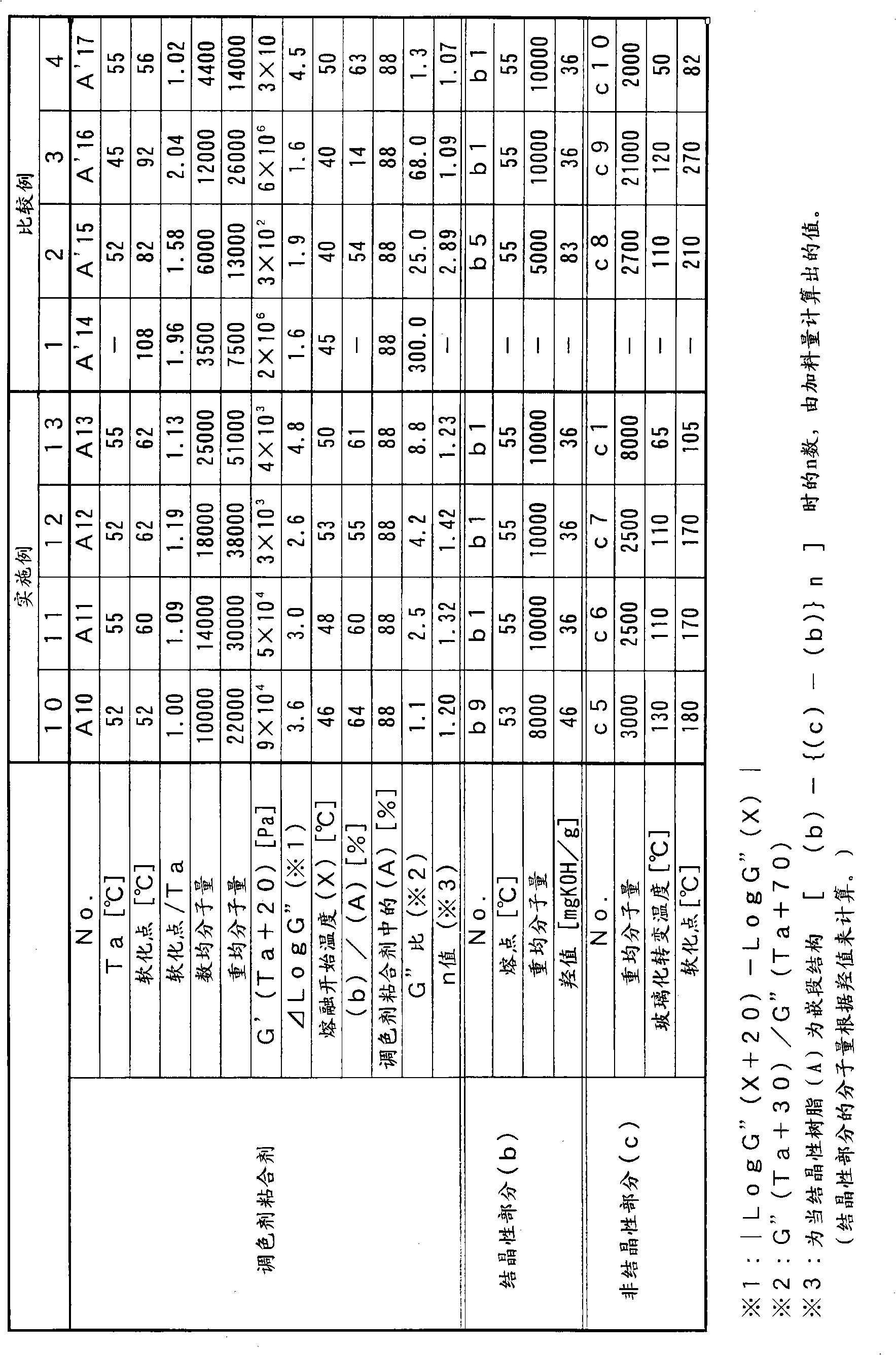

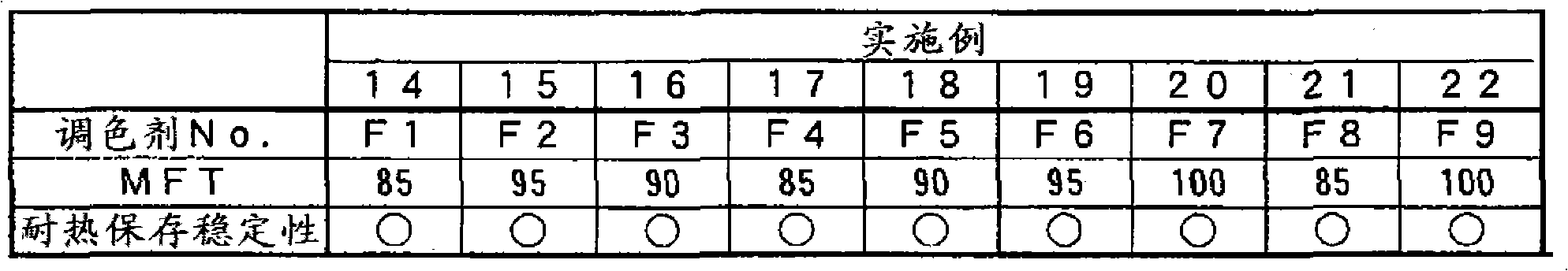

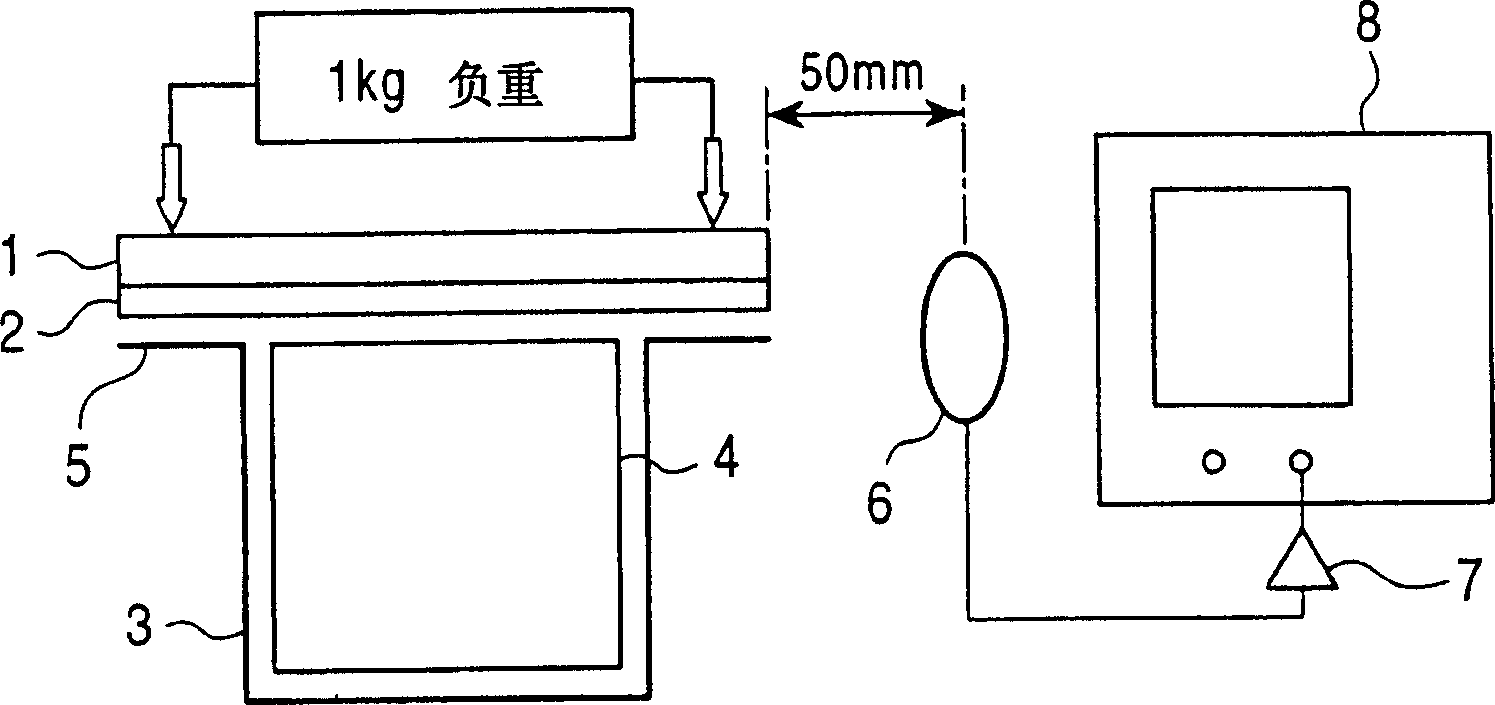

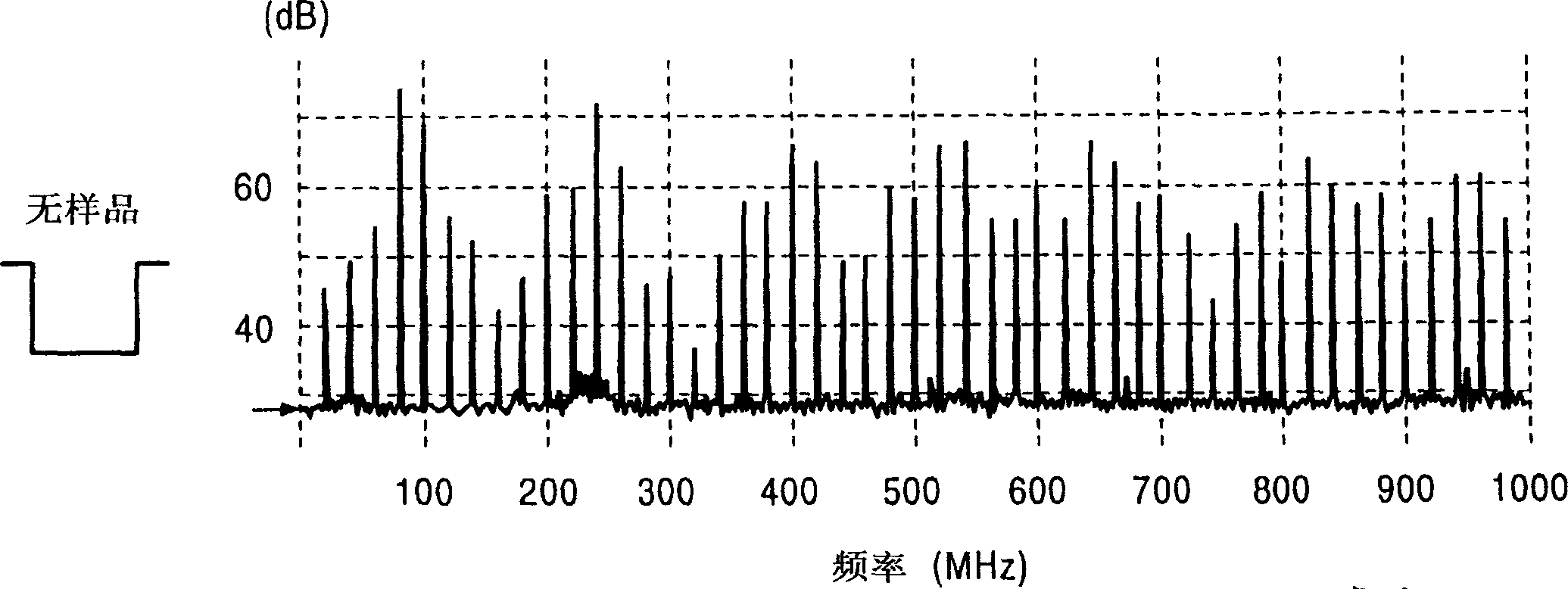

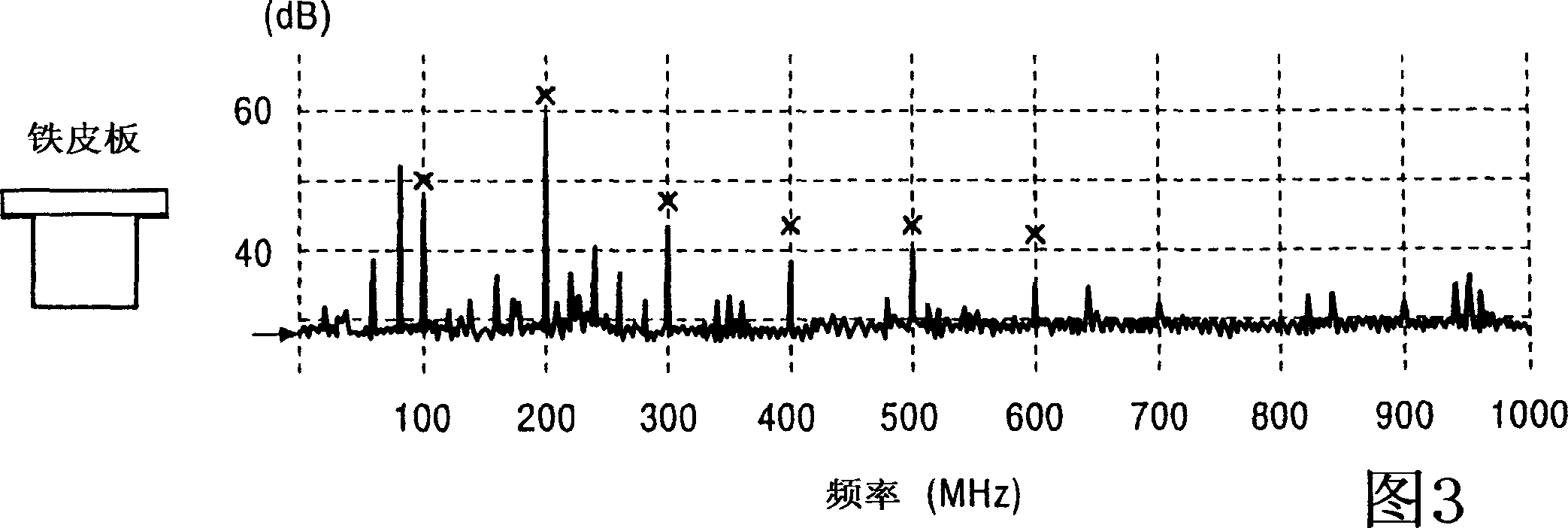

Toner binder and toner

ActiveCN101981516AExcellent low temperature fixabilityExcellent caking resistanceDevelopersEngineeringColoring agents

Owner:SANYO CHEM IND LTD

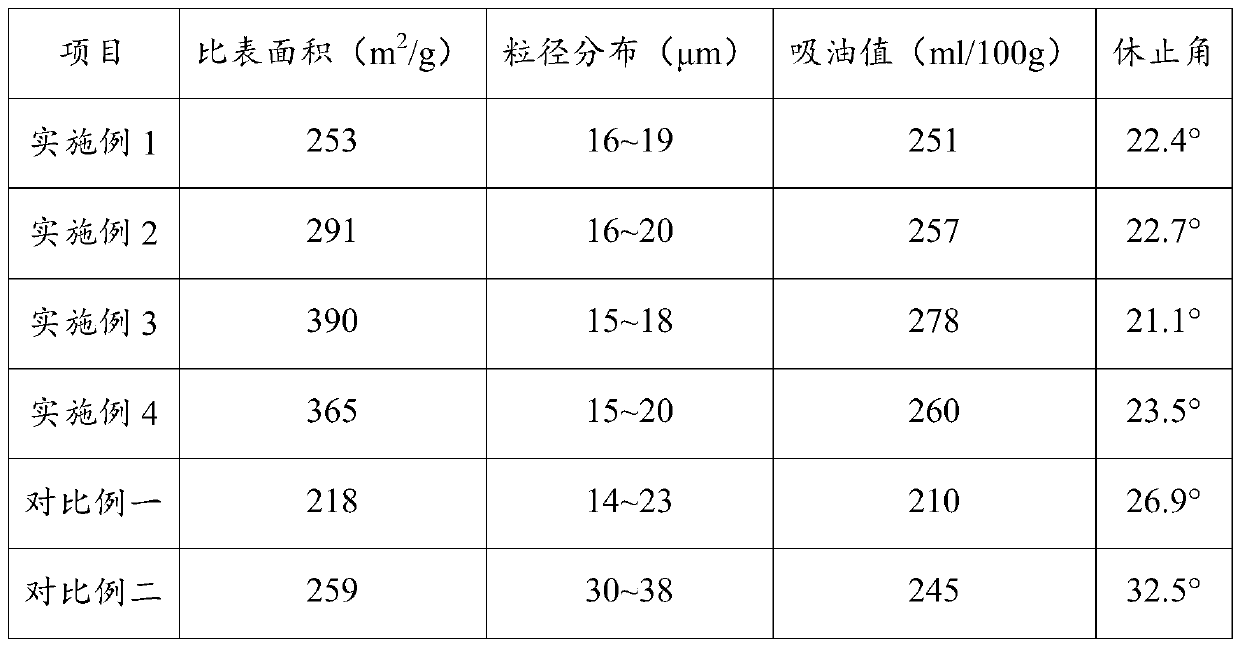

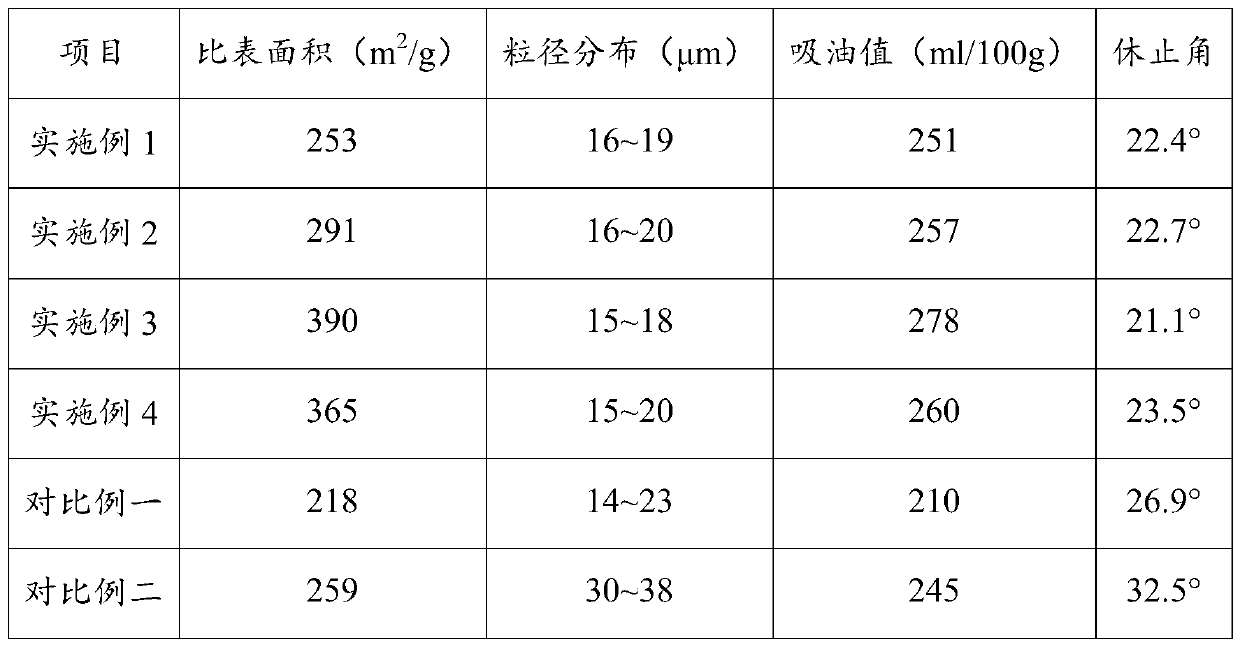

Silica with high fluidity and high oil absorption value for washing powder and preparation method thereof

ActiveCN110395740AHigh oil absorption valueUniform particle sizeInorganic/elemental detergent compounding agentsSilicaFiltrationSODIUM SILICATE SOLN

The invention belongs to the technical field of silica preparation, and particularly relates to silica with high fluidity and high oil absorption value for washing powder and a preparation method thereof. The preparation method of silica comprises the following steps: S1, adding water into a reaction kettle, adding a sulfuric acid solution under stirring, performing heating, dropwise adding a sodium silicate solution until a pH value is 3.5-4.5, then simultaneously dropwise adding the sodium silicate solution and the sulfuric acid solution to carry out a cocurrent neutralization reaction, controlling a pH value to be 3.0-5.0, simultaneously stopping addition of the sulfuric acid solution when drop addition of the sodium silicate solution is completed, and further performing stirring; S2, continuously adding the sodium silicate solution, stopping drop addition of the sodium silicate solution when a pH value is 7.0-8.0, and performing maturing; and S3, performing pressure filtration andwashing on the formed silica, and performing spray drying treatment to obtain the silica. The silica has uniform particle size distribution, large specific surface area, high oil absorption value andhigh fluidity, and has good application prospects in washing powder.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

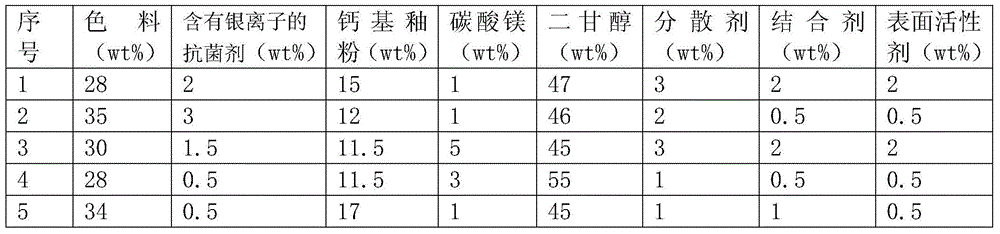

Ceramic ink-jet printing colored glaze mixed type antibacterial ink and preparation method thereof

ActiveCN103602144ASimple processing technologyPracticalInksSurface-active agentsAntibacterial effect

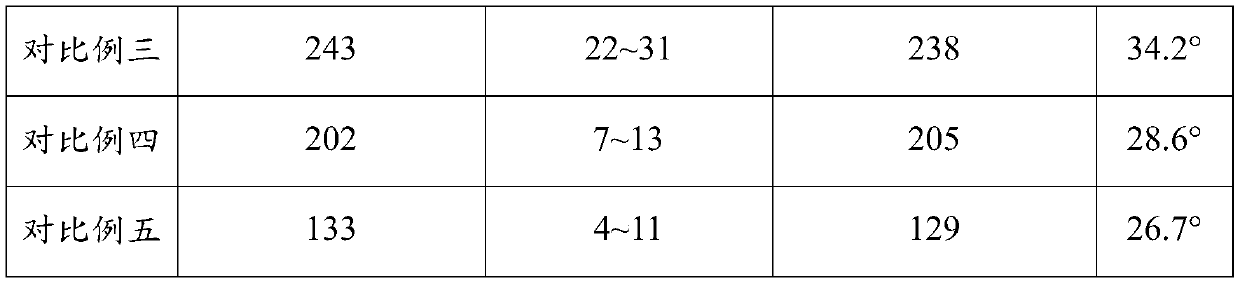

The invention provides a ceramic ink-jet printing colored glaze mixed type antibacterial ink and a preparation method thereof, and belongs to the ceramic brick decoration technology. The ceramic ink-jet printing colored glaze mixed type antibacterial ink provided by the invention comprises the components by the mass percentage: 28%-35% of a coloring material, 11.5%-17% of a calcium-based glaze powder, 0.5%-3% of an antibacterial agent containing silver ions, 1%-5% of magnesium carbonate, 45%-55% of diethylene glycol, 1-3% of a dispersant, 0.5%-2% of a bonding agent, and 0.5%-2% of a surface active agent. An ink-jet printing layer formed after ink-jet printing of the ink on a ceramic brick blank has good antibacterial effect after sintering, and moreover, the printing layer is resistant to wear and lasting in antibacterial effect, and is especially suitable for bottom surface decoration of public space having urgent antibacterial requirements.

Owner:FOSHAN DONGPENG CERAMIC +2

Zeolite controlled-release fertilizer and manufacturing method for same

The invention provides a zeolite controlled-release fertilizer and a manufacturing method for the same. The zeolite controlled-release fertilizer comprises the following raw materials in the parts by weight: 5-15 parts of biochemical potassium fulvate, 30-50 parts of urea, 10-40 parts of monoammonium phosphate, 15-40 parts of inorganic potassium salt, 1-4 parts of magnesium sulphate, 1-4 parts of calcium nitrate, 1-4 parts of zinc sulphate, 10-30 parts of modified zeolite, 2-5 parts of ammonium ferric citrate, 2-5 parts of emathlite, and 1-4 parts of calcium sulphate. The manufacturing method comprises the following steps of: (1) adding the raw materials aforementioned in a crusher, and crushing; (2) performing the operations of steam humidification, granulation and drying on the crushed raw materials to obtain a zeolite controlled-release fertilizer crude product; and (3) screening the zeolite controlled-release fertilizer crude product obtained in the step (2), wherein the oversize product is the zeolite controlled-release fertilizer. Zeolite is used as a carrier for the active ingredients, and the modified zeolite has multi-channel adsorbability, metal ion exchange property, water absorption and water retention property, acid resistance, alkali resistance, heat resistance, potassium fulvate rapid dissolution property, and the like, as well as achieves controlled release by being matched with proper nitrogen, phosphorus, potassium, calcium, magnesium, zinc and the like.

Owner:山东华粮生物工程集团股份有限公司

Explosive cladding explosive and preparation method and applications thereof

ActiveCN103058800ALow costExcellent caking resistanceExplosivesNon-electric welding apparatusExplosive claddingExplosive Agents

The present invention provides an explosive cladding explosive prepared from expanded ammonium nitrate explosive, calcium nitrate, graphite and magnesium stearate according to a certain ratio. The present invention also provides a method for preparing the explosive, and the method comprises weighing all raw materials and placing the raw materials in an automatic drug mixing machine to mix uniformly to obtain an explosive cladding explosive. Further, the present invention also provides a method for preparing explosive clad plates by using the explosive, and the method comprises: laying a clad plate on the top of a baseplate, and laying support columns between the clad plate and the baseplate; positioning an explosive frame on the clad plate, overlying the explosive inside the explosive frame, and placing a detonating primer on the explosive; and detonating the explosive by using the detonating primer to obtain the explosive clad plate. The explosive cladding explosive of the invention is good in formula design, simple in a blending method, low in cost, excellent in performance and anti-caking performance; and the explosive clad plate prepared by using the explosive cladding explosive of the invention has a high interlaminar bonding rate and high combination strength, and is for large-scale industrial production.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Tryptophan premix

ActiveCN101700098ATo promote metabolismLess starchFood processingAnimal feeding stuffLiquid mediumTryptophan

The invention belongs to the technical filed of fodders and particularly relates to a tryptophan premix; the processing method of the tryptophan premix comprises the following steps: (1) fermenting: mycelia are cultured in liquid medium to obtain matured seeds, and the matured seeds are transplanted to acidification nutrient medium of a fermentation cylinder to be fermented and metabolized to obtain tryptophan fermentation liquid; (2) separation: the tryptophan fermentation liquid carries out solid-liquid separation to obtain clear liquid and thick slurry; (3) mixing: while the thick slurry is stirred, corn cob powder is added, so as to obtain mixture with 0.5-4 percent of tryptophan content; (4) drying: the mixture is dried to control the water content to be 1-10 percent. The tryptophan premix has good palatability to lead animals to like to eat and good feeding effect.

Owner:浙江拜克生物科技有限公司

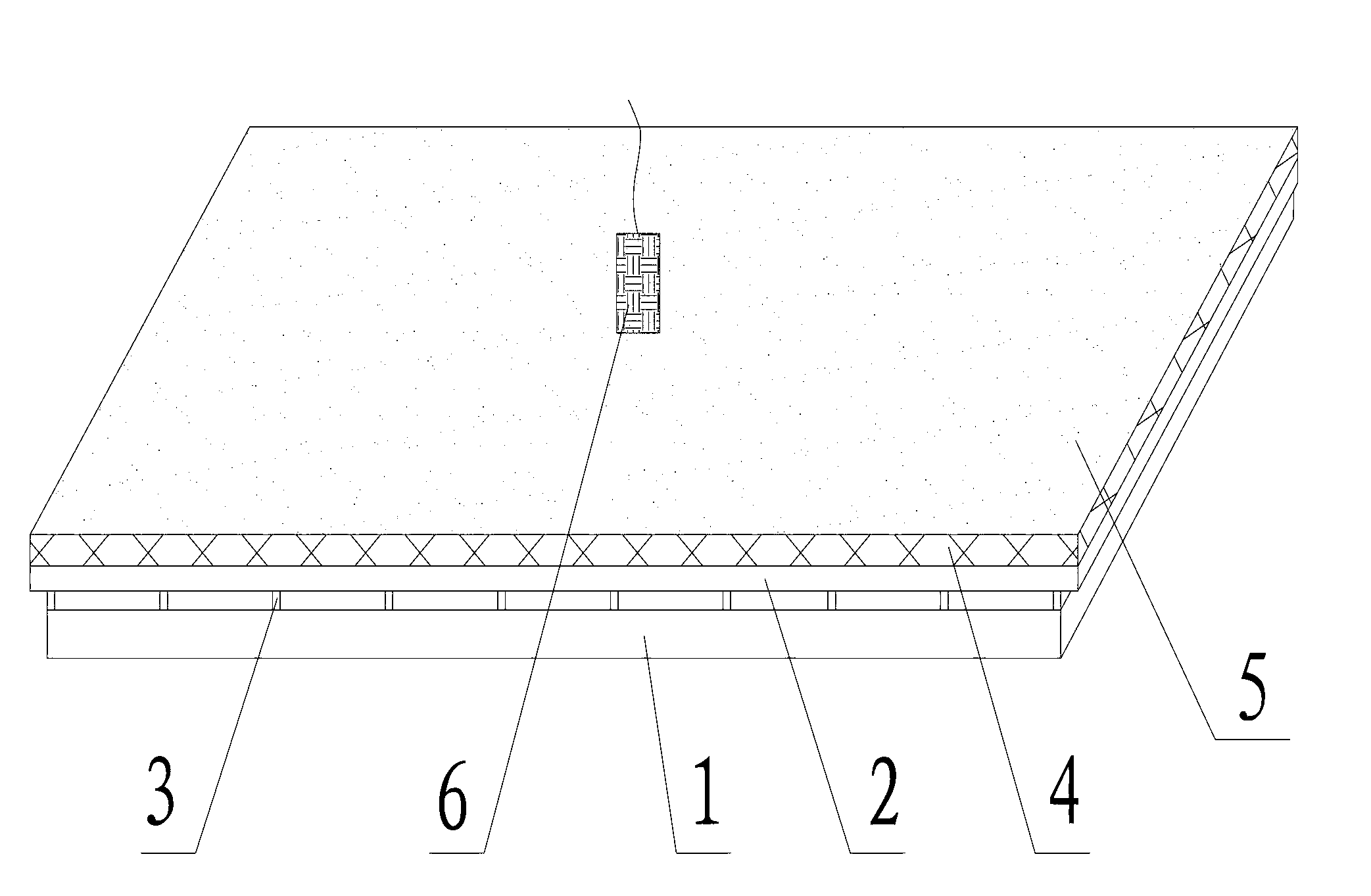

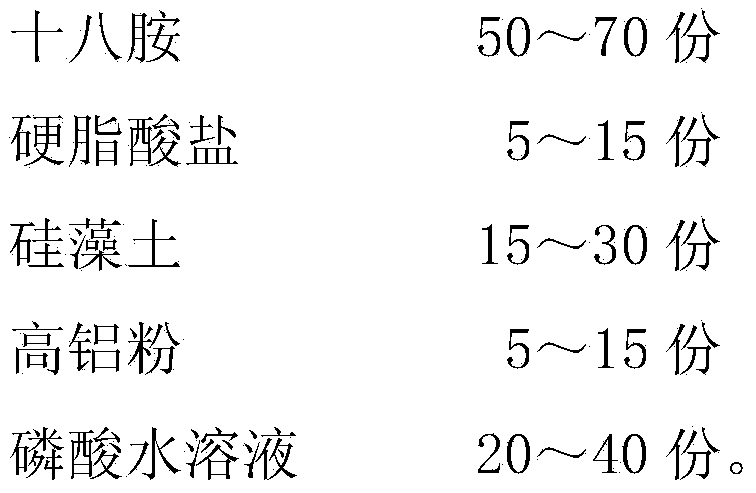

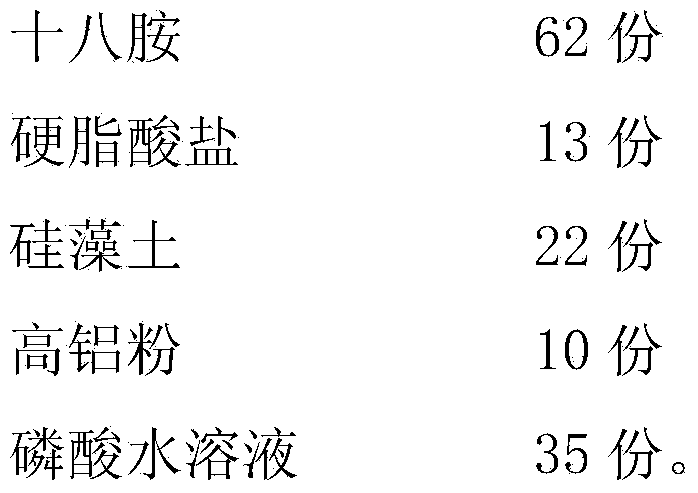

Civil ammonium nitrate modifier

InactiveCN103641668AImprove performanceSteady hotNon-explosive/non-thermic compositionsPhosphoric acidMoisture absorption

The invention discloses a civil ammonium nitrate modifier, which is composed of the following components in parts by weight: 50 to 70 parts of octadecylamine, 5 to 15 parts of stearate, 15 to 30 parts of diatomite and kaolin, 5 to 15 parts of high aluminum powder, and 20 to 40 parts of phosphoric acid water solution. Stearate and diatomite are scientifically and reasonably added so as to prevent secondary moisture absorption and agglomeration; and high aluminum powder is added at the same time in order to improve the explosion temperature and explosion powder of the explosive. The civil ammonium nitrate modifier has the advantages of reasonable and scientific formula and prominent improvement on the anti-dampness performance and anti-agglomeration performance of industrial ammonium nitrate explosive.

Owner:ANHUI HUAIHUA

Anti-static colored glaze mixed ink for ceramic ink-jet printing and preparation method thereof

The invention provides anti-static colored glaze mixed ink for ceramic ink-jet printing and a preparation method thereof, belonging to the technical field of ceramic tile decoration. The ink provided by the invention comprises the following components in percentage by weight: 25%-30% of pigment, 10%-15% of glaze powder, 1%-5% of magnesium carbonate, 45%-55% of diethylene glycol, 1%-3% of dispersing agent, 0.5%-2% of binding agent, 0.5%-2% of surfactant and 5%-10% of semiconductor oxide. A printed layer formed by the ink provided by the invention has a good anti-static effect, and an anti-static ceramic product produced by utilizing the ink is suitable for special engineering purposes.

Owner:FOSHAN DONGPENG CERAMIC +2

A kind of drying method of citric acid monohydrate crystal and obtained citric acid crystal monohydrate

ActiveCN102260166AImprove the ability to bind crystal waterImproved anti-caking abilityCarboxylic compound separation/purificationCitrate monohydrateRelative humidity

The invention provides a method for drying citrate monohydrate crystals and the citrate monohydrate crystals obtained by the method. The method comprises the following steps of: 1) performing solid-liquid separation on crystal slurry containing the citrate monohydrate crystals to obtain wet citrate monohydrate crystals and a crystallized citrate mother solution; and 2) drying and cooling the wet citrate monohydrate crystals obtained in the step 1) at the temperature of between 15 and 36.6DEG C and the relative humidity of less than 65 percent. The citrate monohydrate crystals obtained by the drying method have bright color, the crystal particles have high capacity of bonding crystal water, the anti-caking capacity is obviously improved.

Owner:COFCO BIOTECHNOLOGY CO LTD

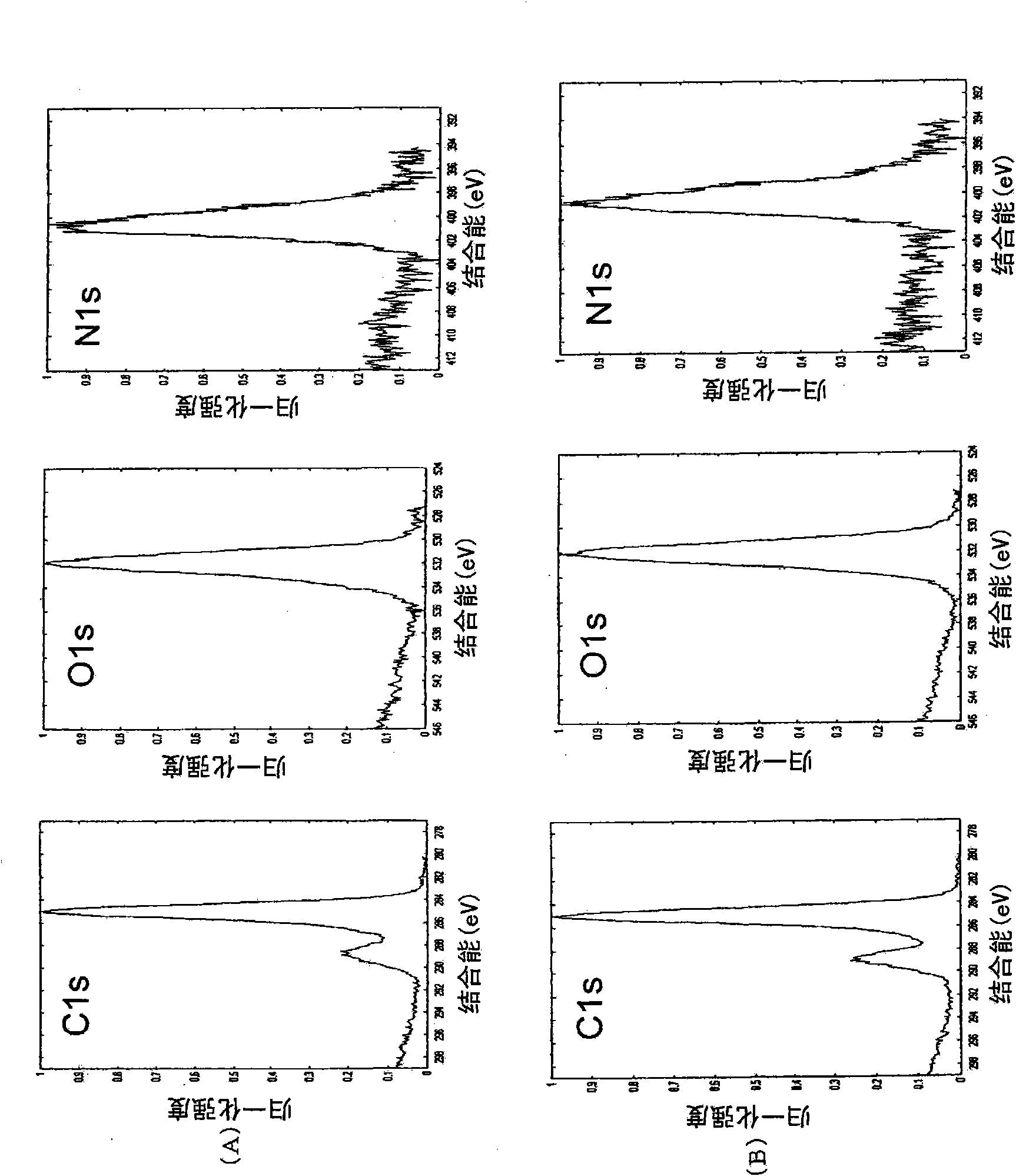

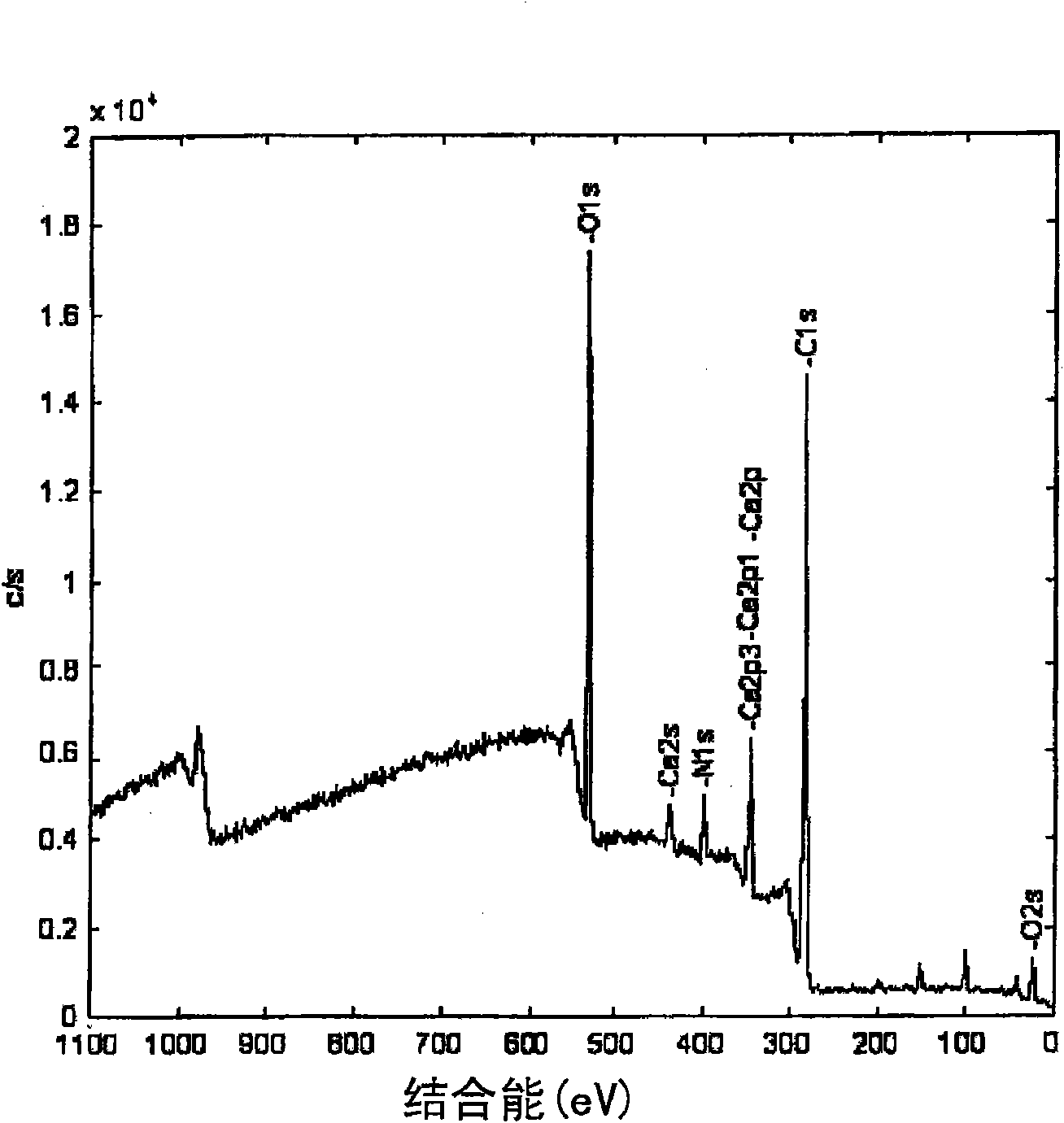

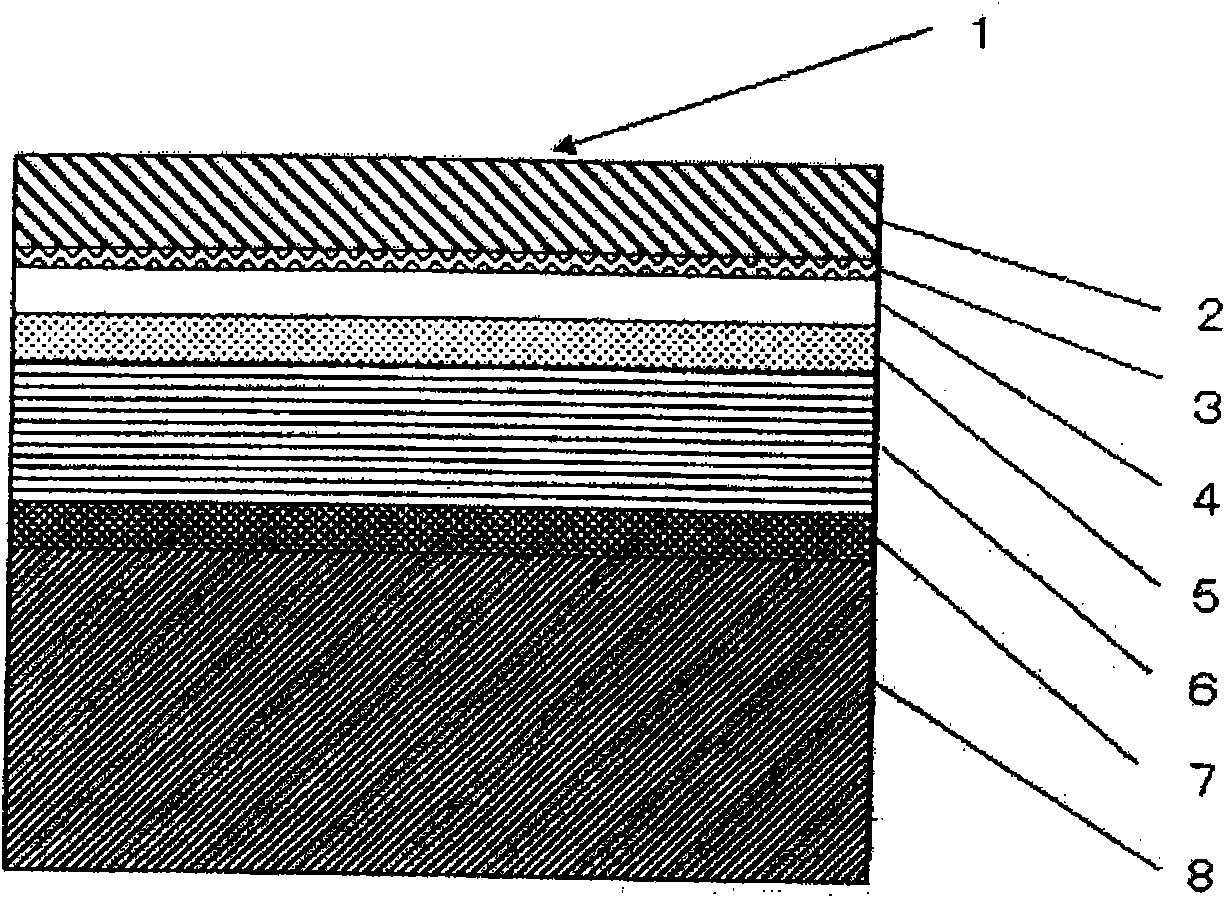

Gas-barrier material with excellent blocking resistance and process for producing the same

InactiveCN101808822AExcellent caking resistanceAchieve anti-caking effectSynthetic resin layered productsCoatingsHydrogenSurface layer

A gas-barrier material which has a gas-barrier layer comprising a polycarboxylic acid polymer. It is characterized in that the gas-barrier layer includes a surface layer which has isocyanate-group-derived chemical bonds formed therein, and that the surface layer has a nitrogen content of at least 1 at.% based on the sum of carbon, oxygen, and nitrogen in the surface layer. This gas-barrier material, which employs the polycarboxylic acid polymer which is a polymer having a high tendency to combine with hydrogen, has excellent blocking resistance regardless of the degree of crosslinking.

Owner:TOYO SEIKAN KAISHA LTD

High density polyethylene plastic container

InactiveCN104861267AIncrease resistanceImprove high temperature resistanceLow-density polyethyleneTetrafluoroborate

The invention discloses a high density polyethylene plastic container, which comprises components with parts by weight: high density polyethylene 82-90, aminocyclopropane carboxylic acid 0.1-0.2, tetraethylammonium tetrafluoroborate 0.4-1, ethylparaben 2-3, expanded perlite 6-10, 2-ethylhexyl acrylate 3-4, triallyl isocyanurate 0.1-0.3, manganese oxide 1-2, ricinoleic acid 0.3-0.7, polyethyleneimine 0.8-2, cyclohexanhexol 0.2-0.4 and fluorinated rubber 10-13. The high density polyethylene plastic container uses the high density polyethylene as main materials, has excellent insulativity, impact resistance and low temperature resistance, can be suitable to store goods in cold regions, is not easy to damage, and is long in service life.

Owner:ANHUI YIJIA COMMODITY

Additive premixing feed

ActiveCN101700099APromote absorptionScattering is goodFood processingAnimal feeding stuffFodderChemistry

The invention belongs to the feed technical field, in particular to an additive premixing feed. A processing method of the additive premixing feed comprises the following steps: (1) concentrating: fermenting feed liquid containing tryptophan is concentrated to obtain concentrated feed liquid containing 8%-15% tryptophan; (2) crushing: corn cob is crushed to obtain corm cob particles with 20-80 meshes; (3) mixing; the corn cob particles are added into the concentrated feed liquid in the stirring state to obtain wet mixed feed containing 5%-10% tryptophan; (4) drying: the wet mixed feed is dried. The additive premixing feed has better feeding effect.

Owner:浙江拜克生物科技有限公司

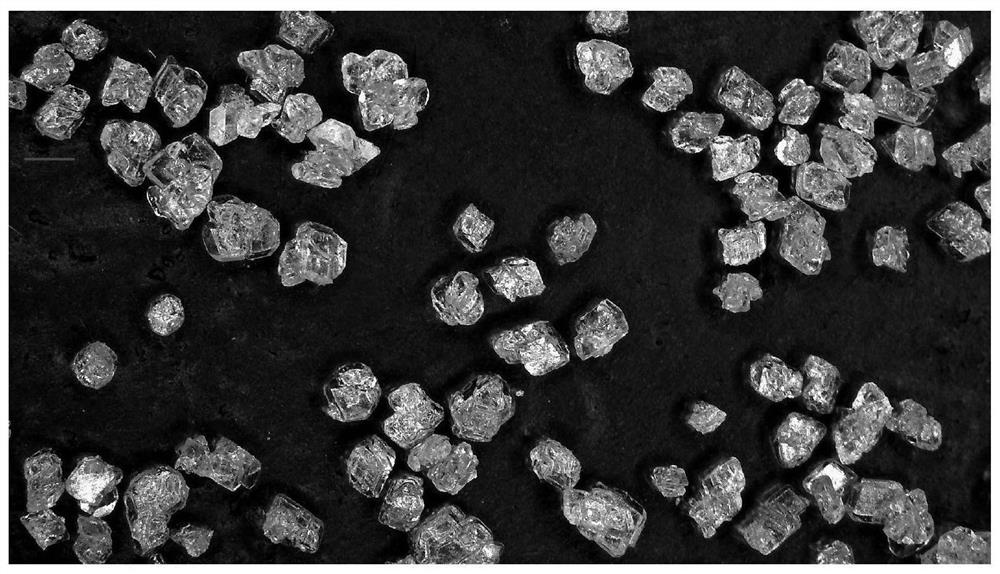

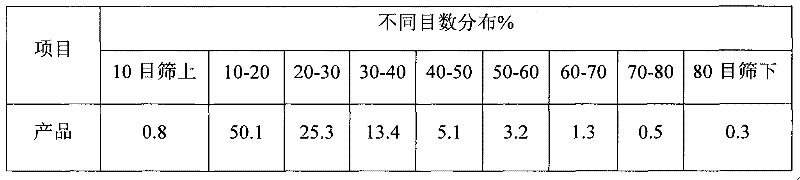

Preparation method of ammonium persulfate crystal

ActiveCN112678779AEasy to controlHigh purityPeroxyhydrates/peroxyacidsPhysical chemistrySeed crystal

The invention provides a preparation method of an ammonium persulfate crystal. The preparation method comprises the following steps of: adding an ammonium persulfate seed crystal into a mixed solution of ammonium persulfate and ammonium sulfate at 25-35 DEG C under the stirring action of a push-type stirrer with a guide cylinder to carrying out seeding; slowly heating to 0.5-1 DEG C; and cooling to -3 to -10 DEG C at a cooling rate of 3-18 DEG C / h, and carrying out cooling crystallization to obtain the ammonium persulfate crystal. The average particle size of the ammonium persulfate crystal is greater than 800 microns. According to the preparation method of the ammonium persulfate crystal of the present invention, the push-type stirrer with the guide cylinder is used, the micro-amplitude 0.5-1 DEG C heating process is performed, and a cooling range is extended; and the growth and crystallization process of the crystal can be well controlled through the synergistic effect of a plurality of factors, and therefore, the purity, the uniformity and the average particle size of the crystal can be increased, the anti-caking performance of the ammonium persulfate crystal can be improved, and the application range of the product is greatly extended.

Owner:TIANJIN UNIV

Tryptophan additive premix

ActiveCN101700100AEvenly distributedUniform compositionFood processingAnimal feeding stuffSprayerTryptophan

The invention belongs to the technical filed of fodders and relates to a tryptophan additive premix; the processing method of the tryptophan additive premix comprises the following steps: (1) powdering: fermented feed liquid containing tryptophan is spray-dried to obtain powder; (2) crashing: core cobs are crashed into core cob particles with 40-80 meshes; (3) drying: the core cob particles are rapidly dried to obtain the particles with less than 5 percent of water content at 50-60 DEG C; (4) water spraying and mixing: the core cob particles and the powder are placed in a closed space according to weight ratio with 3-4:1, a water sprayer is arranged at the upper part of the closes space for spraying water, and air flows in the closes space to lead the core cob particles and the powder to be stirred. The tryptophan additive premix has high stability and good feeding effect.

Owner:浙江拜克生物科技有限公司

Production method for citric acid monohydrate crystal

ActiveCN102234225AIncrease crystallization rateExcellent caking resistanceCarboxylic compound separation/purificationCrystallization temperatureCitric Acid Monohydrate

The invention provides a production method for a citric acid monohydrate crystal. The method is characterized in that: the method comprises the following steps: (1) carrying out heating and condensing for a citric acid solution at a temperature of 50-100 DEG C until a citric acid concentration of the citric acid solution is 68.5-84 wt% to obtain a citric acid concentrated solution; (2) cooling the citric acid concentrated solution from the step (1), adding anhydrous citric acid crystal seed to the citric acid concentrated solution during the cooling process, wherein the citric acid concentrated solution is in a supersaturated state and has a temperature higher than 36.6 DEG C; continuously cooling and adding citric acid monohydrate crystal seed, wherein the temperature of the citric acid concentrated solution is lower than a crystallization temperature of the citric acid monohydrate, and is higher than or equal to a temperature of 10 DEG C; (3) carrying out a solid-liquid separation for the resulting products from the step (2) to obtain a citric acid monohydrate wet crystal and a citric acid crystal mother solution. According to the method provided by the present invention, the produced citric acid monohydrate crystal has a characteristic of uniform and massive particles, and a crystallization ratio is up to 70%.

Owner:COFCO BIOTECHNOLOGY CO LTD

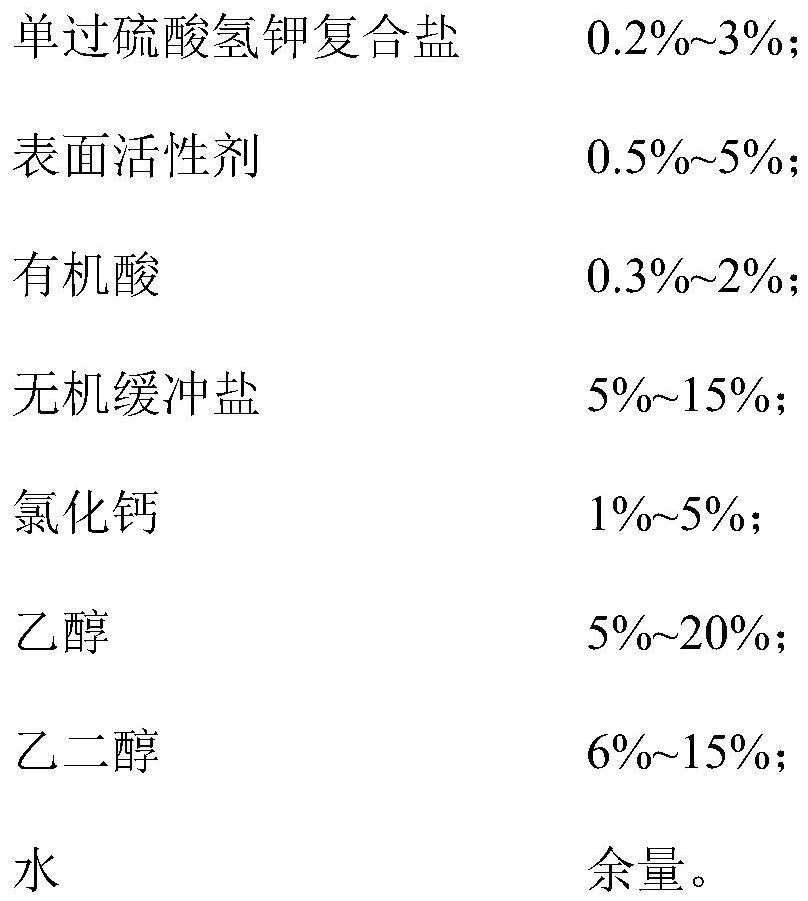

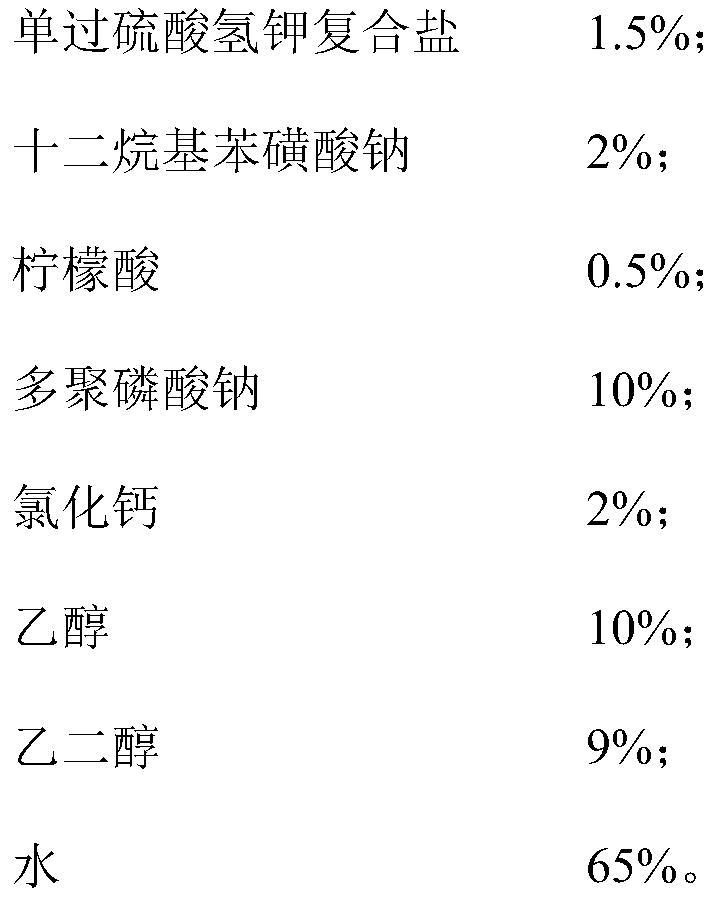

Potassium monopersulfate low-temperature disinfectant and preparation method thereof

ActiveCN113854313AStrong disinfection abilityGuaranteed disinfection effectBiocideDisinfectantsBacterial virusDisinfectant

The invention belongs to the technical field of low-temperature disinfectants, and discloses a potassium monopersulfate low-temperature disinfectant and a preparation method thereof. The low-temperature disinfectant comprises a liquid single-component system or a double-component system composed of powder and a solution; and the disinfectant comprises the following components: potassium monopersulfate composite salt, a surfactant, organic acid, inorganic buffer salt, calcium chloride, ethanol, ethylene glycol and water. The low-temperature disinfectant disclosed by the invention can be kept in a liquid state at minus 40 DEG C, does not solidify or freeze, can still be sprayed for disinfection, and can still keep a disinfection effect. Sterilization tests are carried out under the normal temperature conditions of 25 DEG C, -18 DEG C and -40 DEG C respectively, and the average killing logarithm values on bacteria and viruses are all larger than 4.00 after the action time of 10 min. The disinfectant has good disinfection capability under the conditions of normal temperature and low temperature.

Owner:惠州市栢诗新材料有限公司

Blackening-treated steel plate

InactiveCN1890087AImprove corrosion resistanceGood solvent resistanceLiquid surface applicatorsMagnetic/electric field screeningGlycolurilWater dispersible

A black steel sheet comprising a Zn-Ni plated steel sheet having undergone a blackening treatment and, superimposed on the surface thereof, a coating formed by application of a coating composition comprising (a) metal ions, (b) a water soluble organic resin, (c) a water dispersible organic resin, (d) a glycoluril resin and (e) an acid.

Owner:JFE STEEL CORP

Production technology of edible salt

The invention discloses a production technology of edible salt, and relates to the processing technology of the table salt. The processing technology mainly comprises six steps of taking salt pulp, performing crystal cultivation, performing washing, performing centrifugal separation, performing crushing and performing packaging, wherein the steps of taking the salt pulp, performing crystal cultivation and washing are conventional steps existing in the prior art; in the steps of performing centrifugal separation and performing drying, the water ratio of table salt crystal grains needs to be reduced to 0.5% or below; and in the crushing step, the edible salt crystal grains are crushed into fine particles of which the diameter is 2[mu]m through air compression pressure crushing equipment. The particle size of the table salt is reduced, the surface area can be enlarged, the contact area of the table salt and dishes can be enlarged, and the dishes can be quickly tasteful through the table salt, so that the intake of the table salt is reduced. The table salt is packaged in a manner that the weight of each bag of the table salt is 4-6g, and the weight of each bag of the table salt is the intake of table salt of each person one day, so that control on the intake of the table salt every is facilitated; and in addition, each bag of the table salt can be run out at a time, so that the situation that the table salt is agglomerated due to being in contact with air can be avoided.

Owner:重庆飞亚实业有限公司

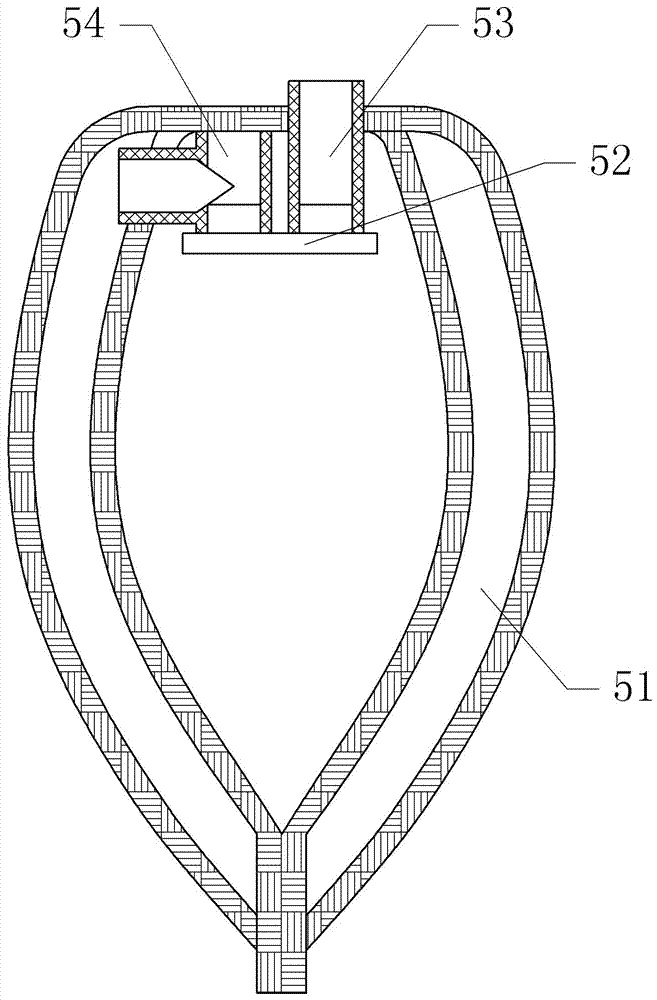

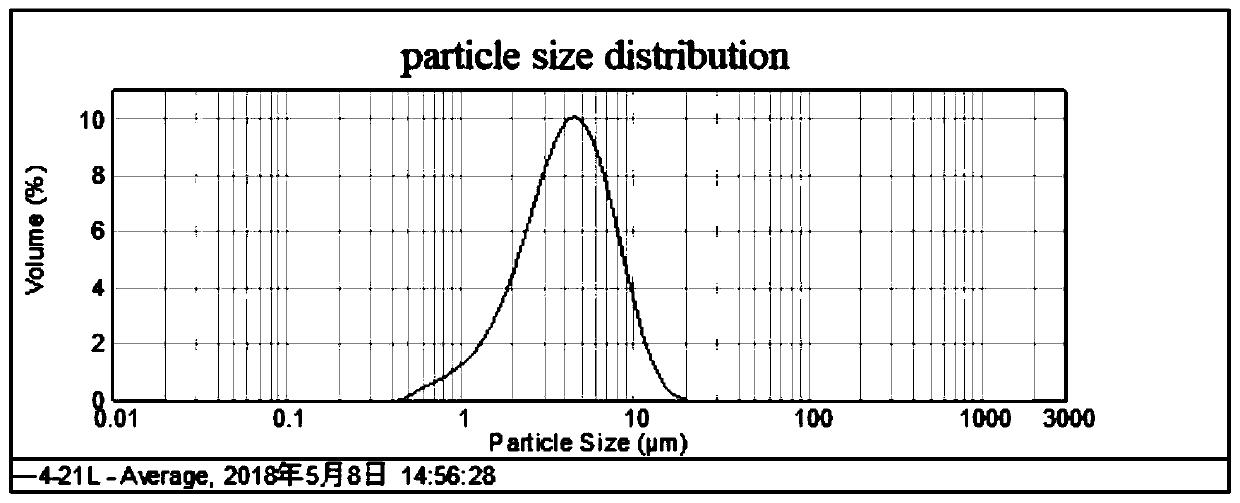

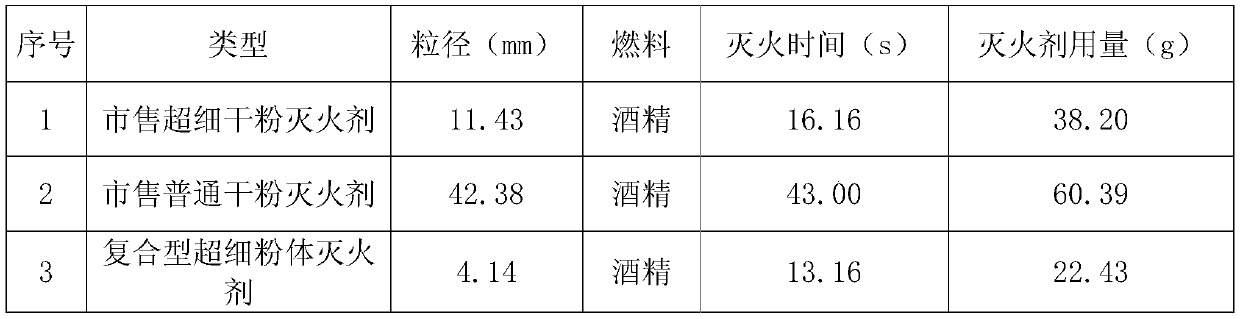

Composite superfine powder fire extinguishing agent and preparation method thereof

InactiveCN110393885ASmall particle sizeHigh fire extinguishing efficiencyFire extinguisherAluminium hydroxideMagnesium stearate

The invention relates to a composite superfine powder fire extinguishing agent which comprises 30-40% of magnesium hydroxide, 20-30% of aluminum hydroxide, 20-30% of ammonium dihydrogen phosphate, 4-6% of talcum powder, 2-3% of mica powder, 4-5% of white carbon black, 3-4% of activated clay, 2-3% of hydrogen-containing silicon oil and 1-1.5% of magnesium stearate. The preparation method comprisesthe following steps: uniformly mixing the substances so as to obtain a base material; and performing ball milling stirring, heat preservation, wet milling, drying and ball milling crushing on the mixed base material in a ball mill, so as to obtain the composite superfine powder fire extinguishing agent. As the amounts of the magnesium hydroxide and the aluminum hydroxide in the dry powder fire extinguishing agent are increased, and the magnesium hydroxide and the aluminum hydroxide have the advantages of being simple in preparation process, rich in raw material source, low in cost, free of equipment corrosion, and the like, the composite superfine powder fire extinguishing agent has wide application prospects and market potential.

Owner:TIANJIN CHENGJIAN UNIV

Preparation method of high-efficiency fire extinguishing ABC superfine dry powder extinguishing agent

InactiveCN107823833AImprove fire extinguishing effectGood water repellencyFire extinguisherGlass fiberPhosphate

The invention discloses a preparation method of a high-efficiency fire extinguishing ABC superfine dry powder extinguishing agent. The preparation method of the high-efficiency fire extinguishing ABCsuperfine dry powder extinguishing agent comprises the following steps of mixing and drying ammonium dihydrogen phosphate and monoammonium phosphate, adding an alum compound, and stirring the ammoniumdihydrogen phosphate, the monoammonium phosphate and the alum compound to obtain a prefabricated material A; adding alkaline residues, glass fibers and magnesium stearate into the prefabricated material A, mixing the alkaline residues, the glass fibers, the magnesium stearate and the prefabricated material A uniformly, and then obtaining a prefabricated material B through ball milling; and dropwise adding silicon oil into the prefabricated material B in a stirring state, stirring the silicon oil and the prefabricated material B uniformly, adding fumed silica for continuous stirring, and crushing the mixture to obtain the high-efficiency fire extinguishing ABC superfine dry powder extinguishing agent. The high-efficiency fire extinguishing ABC superfine dry powder extinguishing agent is high in fire extinguishing efficiency, the fire extinguishing efficiency is 10 times that of a common dry powder extinguishing agent, and meanwhile, compared with other superfine dry powder extinguishing agents, the high-efficiency fire extinguishing ABC superfine dry powder extinguishing agent is not only good in water repellency and liquidity, not prone to be agglomerated and capable of being stored for a long period of time, but also simple in preparation process, low in production cost, pollution-free and suitable for large-scale production.

Owner:BENGBU LONGTAI FIRE FIGHTING

Easily degradable plastic container

The invention discloses an easily degradable plastic container, comprising the following materials in parts by weight: 80 to 90 parts of polyethylene glycol terephthalate, 0.1 to 0.2 parts of agar, 1 to 2 parts of polylactic acid, 10 to 15 parts of ethylene vinyl acetate copolymer, 0.5 to 1 part of sodium chloride, 2 to 3 parts of borax, 0.8 to 1 part of konjac glucomannan, 2 to 4 parts of milltailings, 3 to 4 parts of dioctyl sebacate, 5 to 6 parts of wollastonite in powder, 0.3 to 1 part of titanyl sulfate, 0.3 to 0.7 parts of origanum oil, 10 to 15 parts of modified adhesive material and 1 to 2 parts of tetrapropylammonium bromide. The plastic container is better in decomposability, is easy to decompose by being buried, is residue-free, low in combustion heat and good in environmental protection property as toxicants are not generated in a combustion process.

Owner:安徽省佳艺休闲用品有限公司

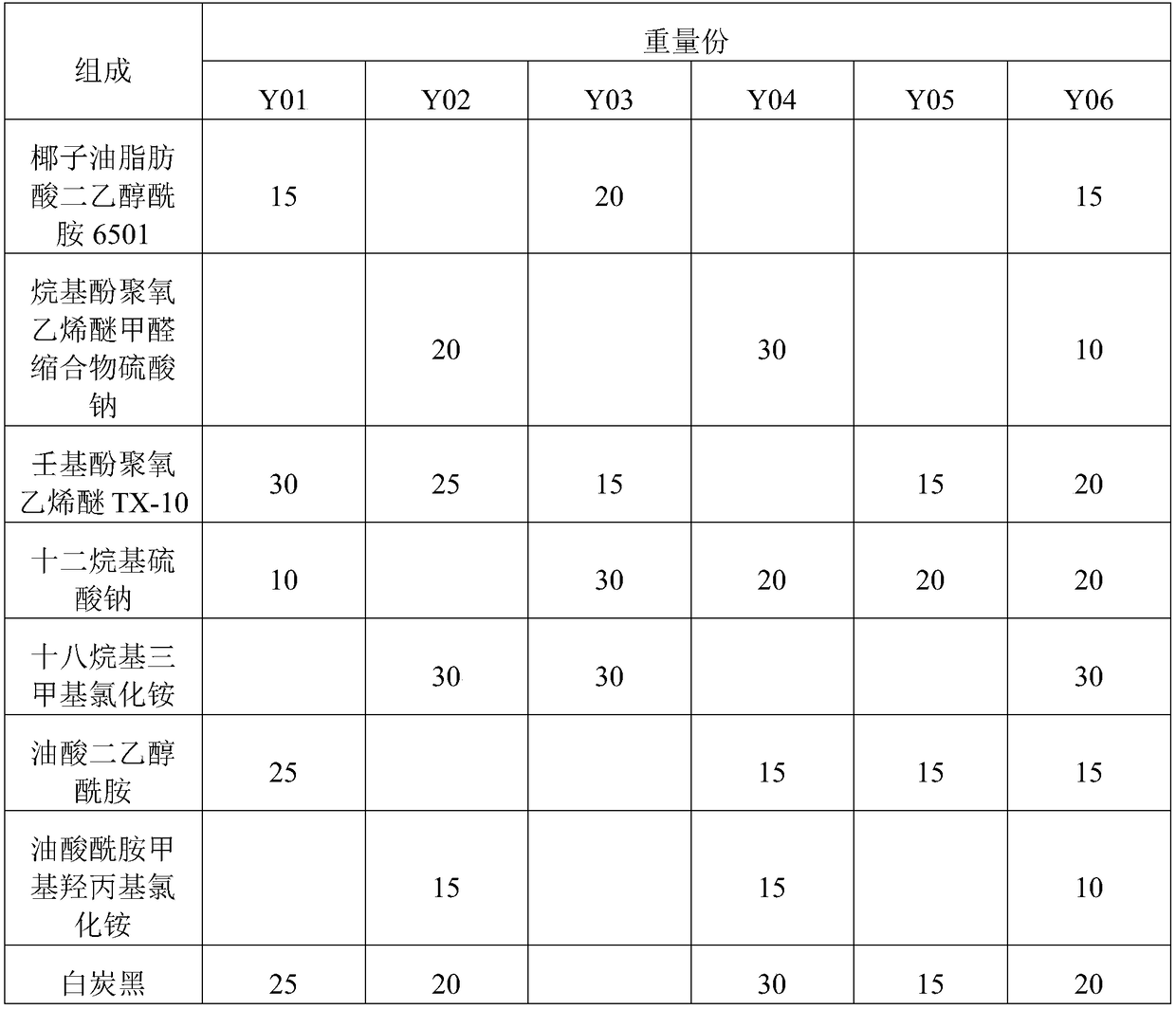

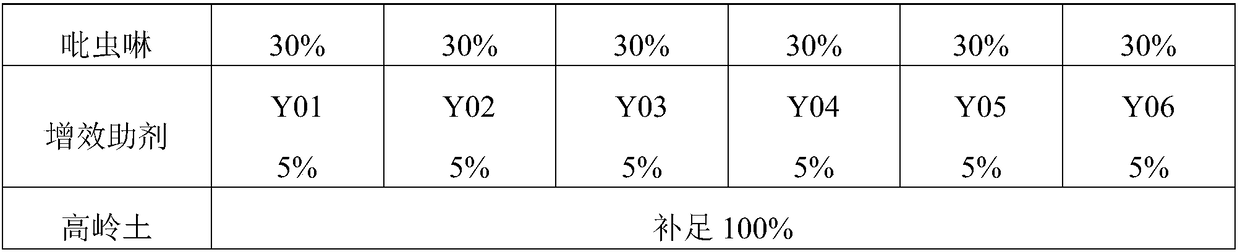

Special additive composition for wettable powder

InactiveCN108902137AImprove wettabilitySolve the problem of low suspension rateBiocideFungicidesCoconut oilEther

The invention belongs to the field of pesticide preparations, and particularly provides a special additive composition YZ-01 for wettable powder. The special additive composition consists of the following components in parts by weight: 10-65 parts of coconut oil fatty acid diethanolamide 6501, 10-60 parts of polyoxyethylene nonylphenyl ether TX-10, 10-40 parts of sodium dodecyl sulfate, 10-30 parts of oleic diethanolamide and 10-50 parts of white carbon black. The special additive composition YZ-01 for wettable powder can be used to solve the problem of poor wettability and low suspension rateof wettable powder, the fluidity and the anti-caking property of a preparation can be improved, and the prevention and treatment effects of active ingredients can be enhanced.

Owner:薏舟(上海)化工科技有限公司

Silica for washing powder with high fluidity and high oil absorption value and preparation method thereof

ActiveCN110395740BHigh oil absorption valueUniform particle sizeInorganic/elemental detergent compounding agentsSilicaFiltrationPhysical chemistry

The invention belongs to the technical field of silica preparation, and particularly relates to silica with high fluidity and high oil absorption value for washing powder and a preparation method thereof. The preparation method of silica comprises the following steps: S1, adding water into a reaction kettle, adding a sulfuric acid solution under stirring, performing heating, dropwise adding a sodium silicate solution until a pH value is 3.5-4.5, then simultaneously dropwise adding the sodium silicate solution and the sulfuric acid solution to carry out a cocurrent neutralization reaction, controlling a pH value to be 3.0-5.0, simultaneously stopping addition of the sulfuric acid solution when drop addition of the sodium silicate solution is completed, and further performing stirring; S2, continuously adding the sodium silicate solution, stopping drop addition of the sodium silicate solution when a pH value is 7.0-8.0, and performing maturing; and S3, performing pressure filtration andwashing on the formed silica, and performing spray drying treatment to obtain the silica. The silica has uniform particle size distribution, large specific surface area, high oil absorption value andhigh fluidity, and has good application prospects in washing powder.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Redispersable emulsion powder-modified antiblocking agent, preparation method thereof and application thereof

ActiveCN101824164ARedispersion properties are not affectedExcellent caking resistanceEmulsionFatty acid

The invention discloses a redispersable emulsion powder-modified antiblocking agent, a preparation method thereof and application thereof. The modified antiblocking agent comprises the following components based on parts by weight: 100 parts of anhydrite, 3-5 parts of fatty acid, 0.5-1.5 parts of titanate coupling agent and 3-5 parts of cation etherifying agent. The redispersable emulsion powder-modified antiblocking agent can be used for the redispersable emulsion powder. The invention compositely modifies the anhydrite powder with the fatty acid and the titanate coupling agent, so that the redispersable performance of the emulsion powder in cement plaster can not be influenced, thereby improving the antiblocking performance of the emulsion powder, and stabilizing the quality of the product.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

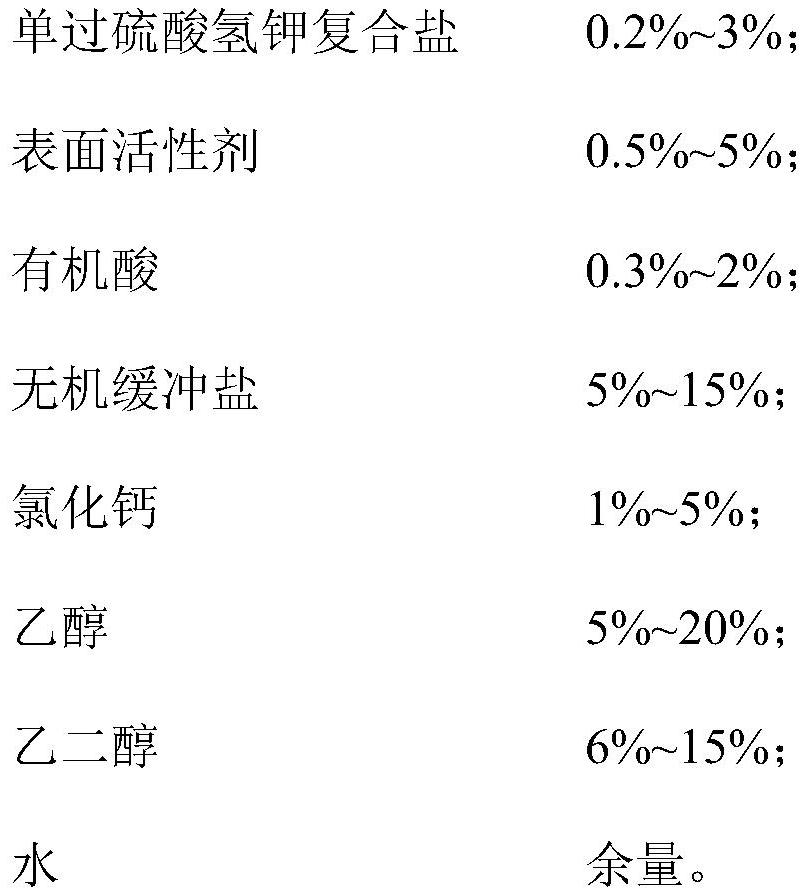

Anti-caking high-stability potassium hydrogen persulfate active salt disinfectant and preparation method thereof

ActiveCN113767900APromote crystallizationExcellent caking resistanceBiocideDisinfectantsActive agentPotassium hydroxide

The invention belongs to the technical field of disinfectants, and discloses an anti-caking high-stability potassium hydrogen persulfate active salt disinfectant and a preparation method thereof. The preparation method comprises the following steps: reacting hydrogen peroxide with fuming sulfuric acid in the presence of a stabilizer under a low-temperature condition to obtain a peroxidation reaction solution, then adding a potassium carbonate or potassium hydroxide solution for a neutralization reaction to obtain a neutralization solution, then adding liquid sodium silicate, performing stirring and dissolving uniformly, performing concentrating in vacuum, performing cooling and crystallizing, and performing centrifugal drying to obtain a potassium monopersulfate composite salt; and finally, uniformly performing stirring and mixing with a surfactant, organic acid and inorganic buffer salt to obtain the potassium hydrogen persulfate active salt disinfectant product. A certain amount of liquid sodium silicate is added in the concentration and crystallization process of the potassium monopersulfate composite salt, so that the product yield, the caking resistance and the stability can be remarkably improved. The method has the advantages of low cost and good product performance.

Owner:惠州市栢诗新材料有限公司

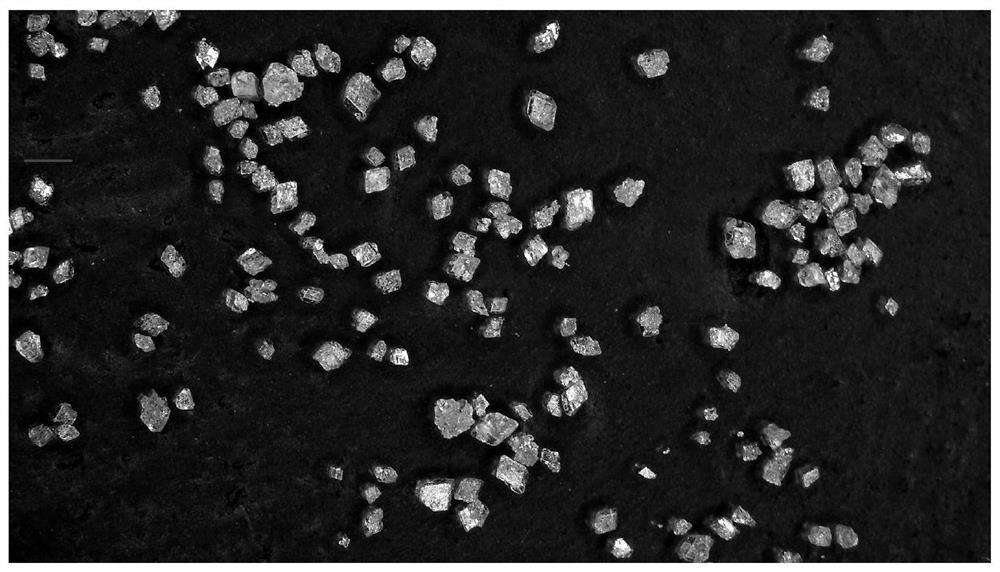

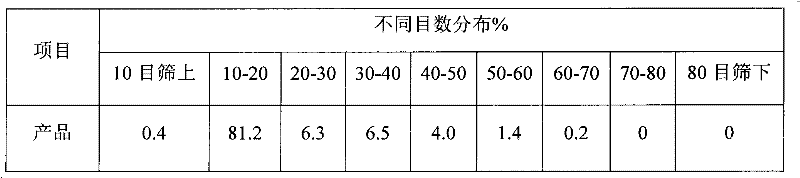

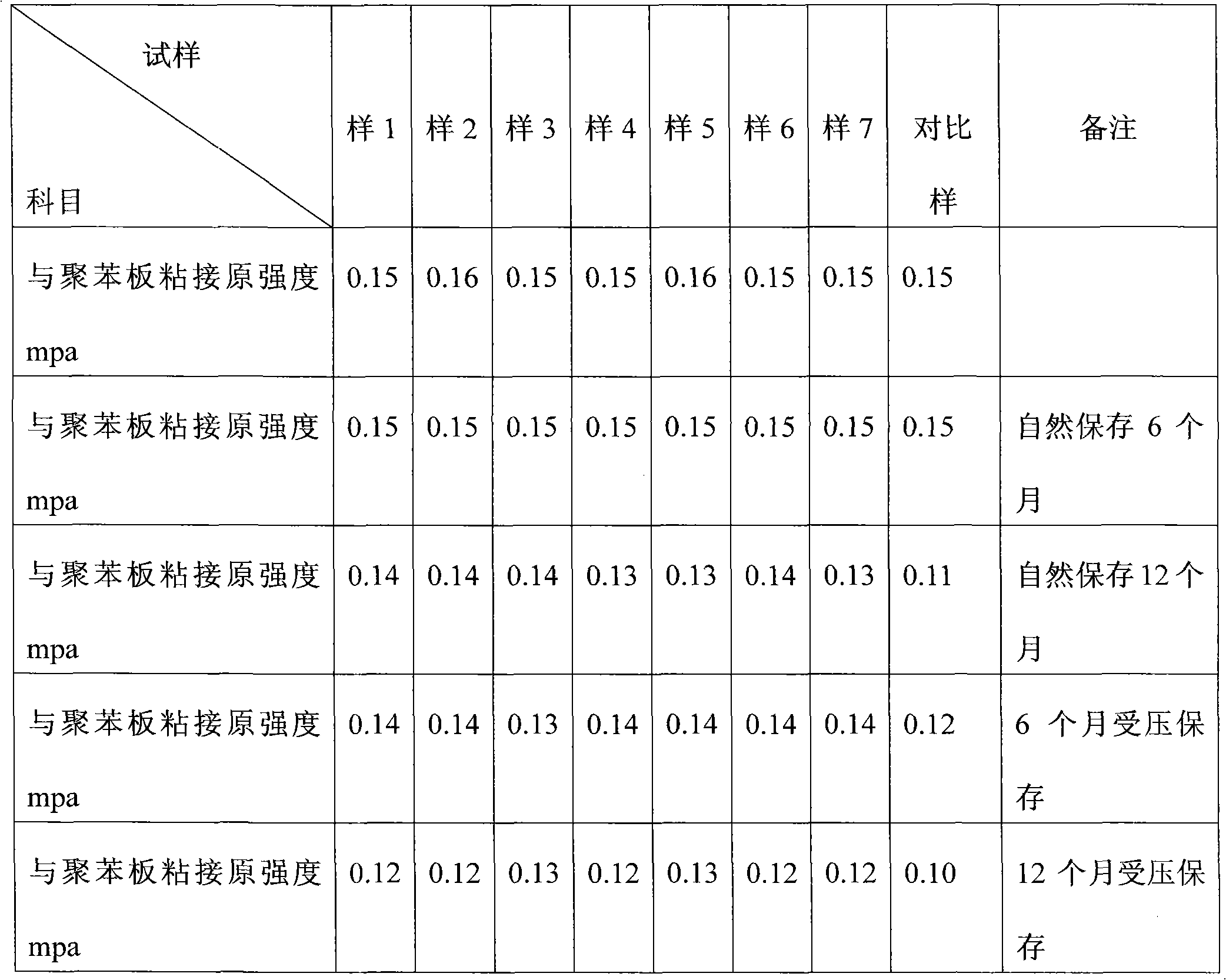

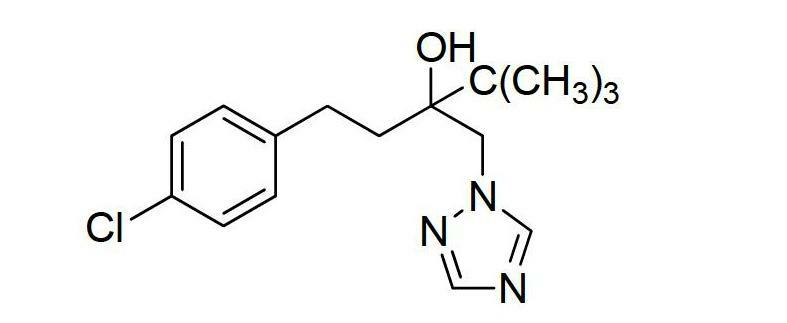

Method for improving anti-caking property of tebuconazole

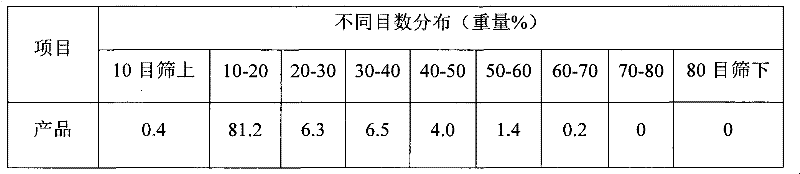

ActiveCN102659696AOvercoming the problem of poor caking resistanceExcellent caking resistanceOrganic chemistryOrganic solventGranularity

The invention discloses a method for improving anti-caking property of tebuconazole, wherein the method comprises the following steps: dissolving tebuconazole in an organic solvent, thereby obtaining a tebuconazole solution, and then cooling and crystallizing the tebuconazole solution, wherein the particle size of the obtained crystal is D90 from 250 to 305 microns due to the cooling and crystallizing condition. The caking problem during transportation and storage processes is effectively overcome by the tebuconazole product obtained according to the method provided by the invention.

Owner:北京颖泰嘉和分析技术有限公司

Preparation method of efficient fire extinguishing superfine dry powder extinguishing agent

The invention discloses a preparation method of an efficient fire extinguishing superfine dry powder extinguishing agent. The preparation method comprises the following steps of uniformly mixing monoammonium phosphate, ammonium chloride, light calcium carbonate, dolomite powder, dicyandiamide, phenolic resin, magnesium chloride, borax, copper acetate and trimethyl ethyoxyl silane, carrying out warming, spraying methyl phenyl silicone oil in a stirring state, and uniformly stirring the mixture to obtain a mixed material; and crushing the mixed material, adjusting the temperature, and stirring and drying the mixed material to obtain the high-efficiency fire extinguishing superfine dry powder extinguishing agent. According to the preparation method of the efficient fire extinguishing superfine dry powder extinguishing agent, the water repellent property, fluidity, the jetting property and the anti-caking property of the obtained dry powder extinguishing agent are excellent, the price is low, furthermore, the specific surface area is large, fire extinguishing efficiency is high, the use amount is less during the extinguishing process of the fire disaster with the same level, and the fire extinguishing cost is low.

Owner:安徽云联知识产权运营有限公司

Light stable-type plastic container

InactiveCN104845294AImprove anti-agingExcellent caking resistancePolyethylene glycolPolyethylene terephtalate

The invention discloses a light stable-type plastic container, which consists of the following raw materials in parts by weight: 0.1 to 0.2 parts of benzophenone, 6 to 10 parts of graphene, 3 to 4 parts of sulfonated-pheno-formoldehyde resin, 0.5 to 1 part of hydroxypropyl methyl cellulose, 0.3 to 0.4 parts of mercaptoacetic acid, 0.7 to 1 part of butynediol, 1 to 2 parts of magnesium oxide, 0.8 to 2 parts of sodium dihydrogen phosphate, 1 to 2 parts of dimethyl succinate, 1.5 to 2 parts of ammonium molybdate, 0.4 to 1 part of butylmercaptooxo stannane, 90 to 96 parts of polyethylene glycol terephthalate, and 10 to 17 parts of modified sizing materials. The plastic container provided by the invention has the advantages of light weight, good stability, high weather ability, good adaptation to environment, and high corrosion resistance, and can be used for containing medicine raw materials and the like.

Owner:安徽省佳艺休闲用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com