Method for producing compound fertilizer by high tower tubular reactor

A technology of tubular reaction and tubular reactor, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of inability to produce low-nitrogen and high-phosphorus compound fertilizers, product specification restrictions, high energy consumption, etc., and achieve small fluctuations in product nutrients , granulation fluctuation is small, and the effect of optimizing the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

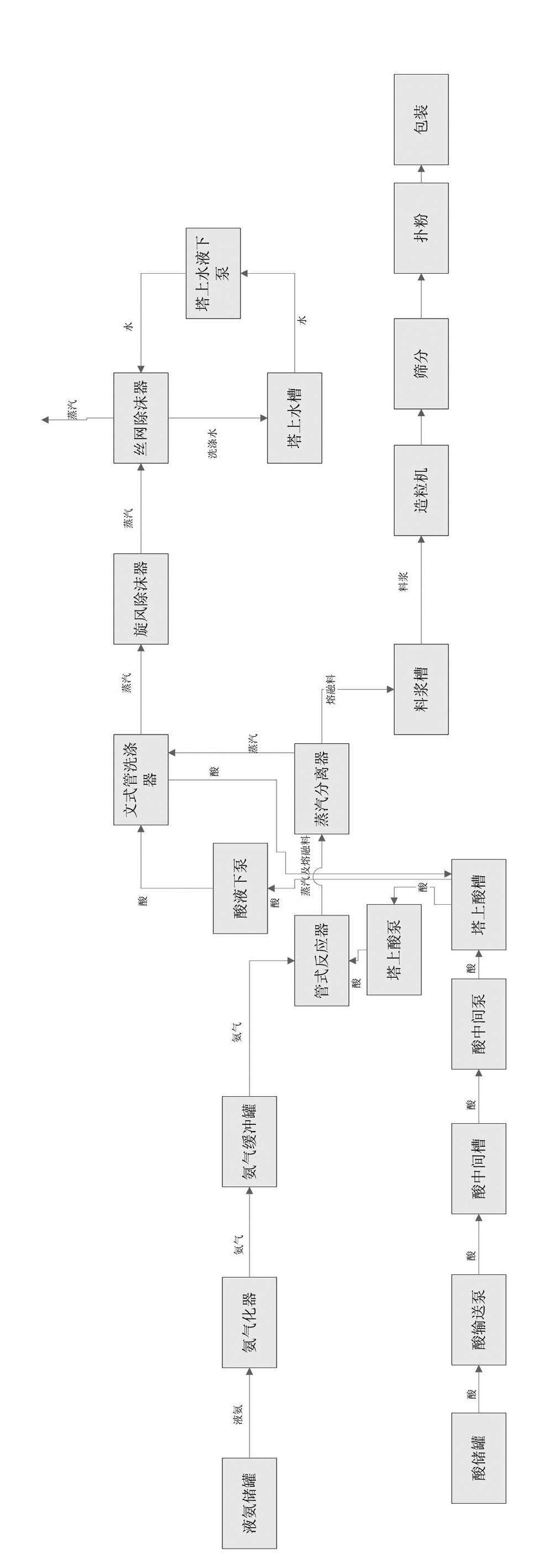

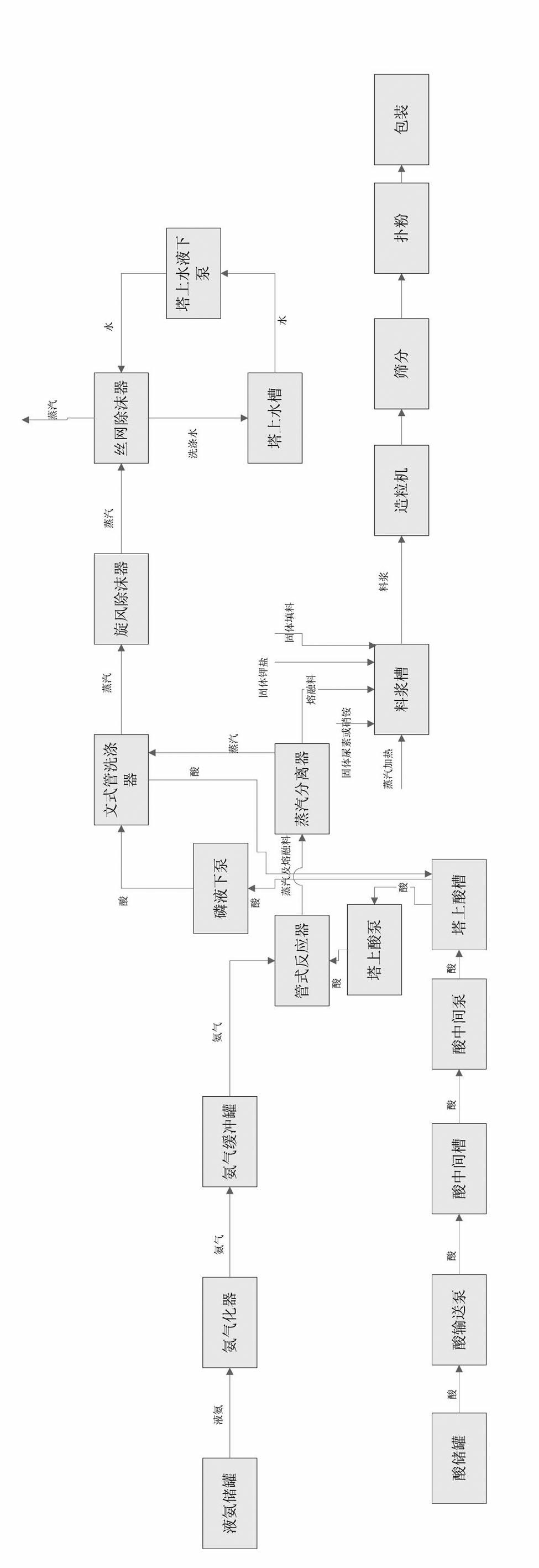

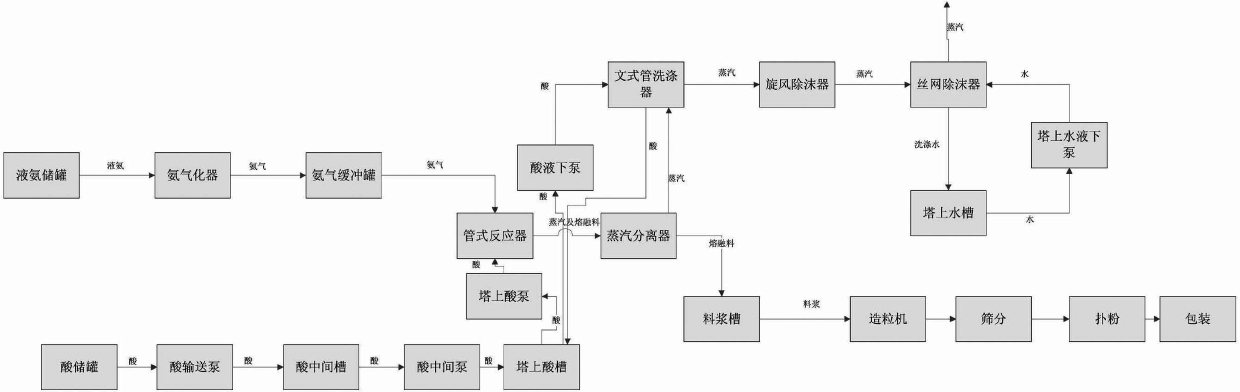

[0036] Embodiment 1: 15-15-15 compound fertilizer

[0037] Step (1): Set the mass concentration to 52% (in P 2 o 5 Wet-process phosphoric acid and ammonia gas are fed into the tubular reactor at the same time, and phosphoric acid reacts with ammonia rapidly in the tubular reactor to obtain ammonium phosphate slurry, and the heat released by the reaction turns water into steam.

[0038] Step (2): Pass the slurry and steam obtained in step (1) into a steam separator to separate the slurry and steam.

[0039] Step (3): Pass the separated slurry into the melt mixer, and add solid raw materials into the melt mixer: urea, potassium chloride, filler, part of the solid raw materials are melted by the heat of the ammonium phosphate slurry itself, and the other A part is melted by the heat of steam to obtain a eutectic slurry.

[0040] Step (4): The eutectic slurry obtained in step (3) is sprayed into the granulation tower through the rotary granulation nozzle on the top of the tower...

Embodiment 2

[0042] Embodiment two: 15-15-15 compound fertilizer

[0043] Identical with embodiment one step, wherein, the mass concentration of phosphoric acid is 52% (in P 2 o 5 Wet-process phosphoric acid in total), and the solid raw materials in step (4) are ammonium nitrate, potassium sulfate and filler.

[0044] The ratio (mass ratio) of phosphoric acid, ammonia gas, ammonium nitrate, potassium sulfate and filler is 0.700:0.087:1.000:0.784:0.194.

Embodiment 3

[0045]Example three: 10-20-20 compound fertilizer

[0046] Identical with embodiment one step, wherein, the mass concentration of phosphoric acid is 47%-54% (in P 2 o 5 In terms of wet-process phosphoric acid), the solid raw materials in step (4) are urea, potassium chloride and filler.

[0047] The ratio (mass ratio) of phosphoric acid, ammonia, urea, potassium chloride and filler is 1.000:0.151:0.290:0.867:0.589.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com