Patents

Literature

610results about How to "Reduce the amount of dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizer coating composite, its making method and multicomponent coated granular fertilizer

InactiveCN1535939AIncrease profitExtend the fertilizer periodFertilizer mixturesOrganic acidAdjuvant

The present invention relates to a coating composite for making coated granular fertilizer and its production method, and the fertilizer made up by using said coating composite. The coating composite is formed from coating agent, solidfying agent, nitrogen synergist, inorganic acid or organic acid, surfactant and adjuvant. As compared with non-coated fertilizer the nitrogen utilization rate of fertilizer produced by adopting said invention can be raised by 6%-10%, the fertilizer can be saved by 15-45%, and its fertilizer efficiency time can be obviously prolonged, and can be reached to 60-120 days.

Owner:陈大顺

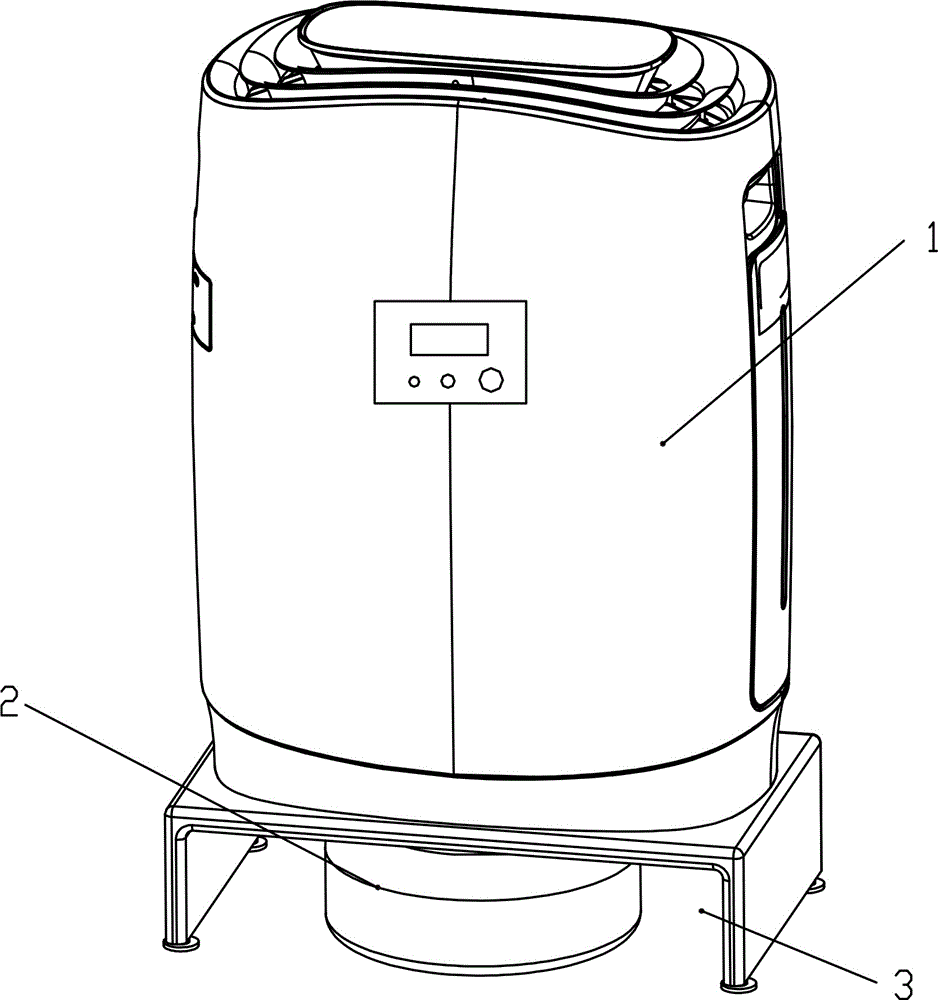

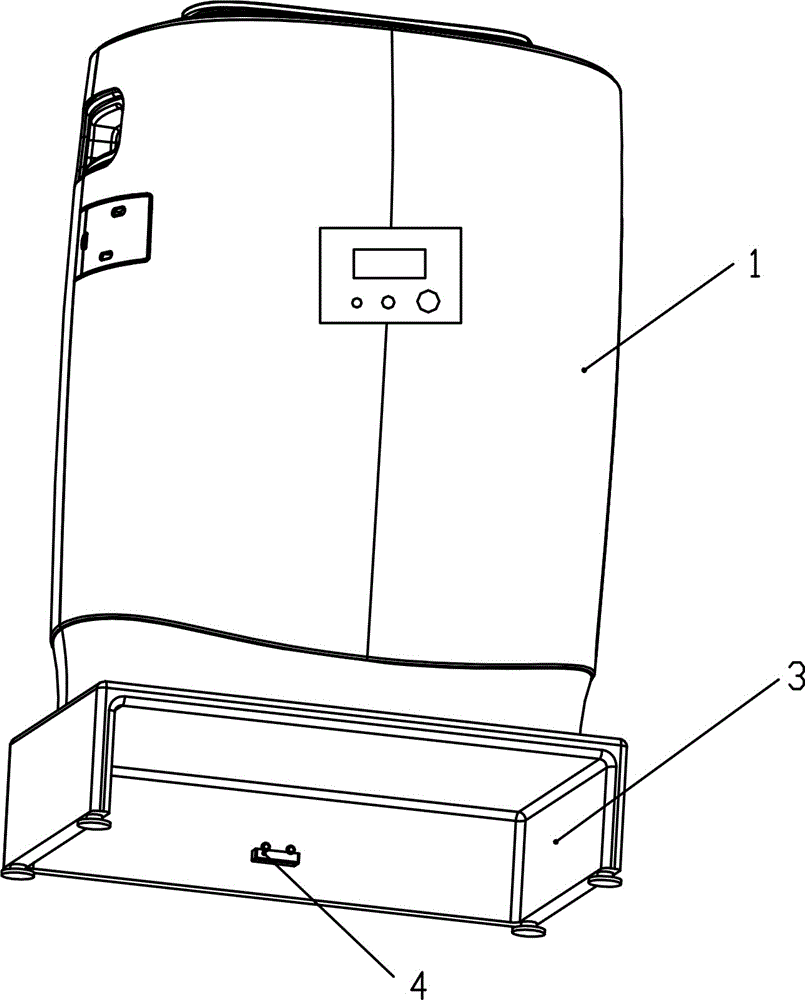

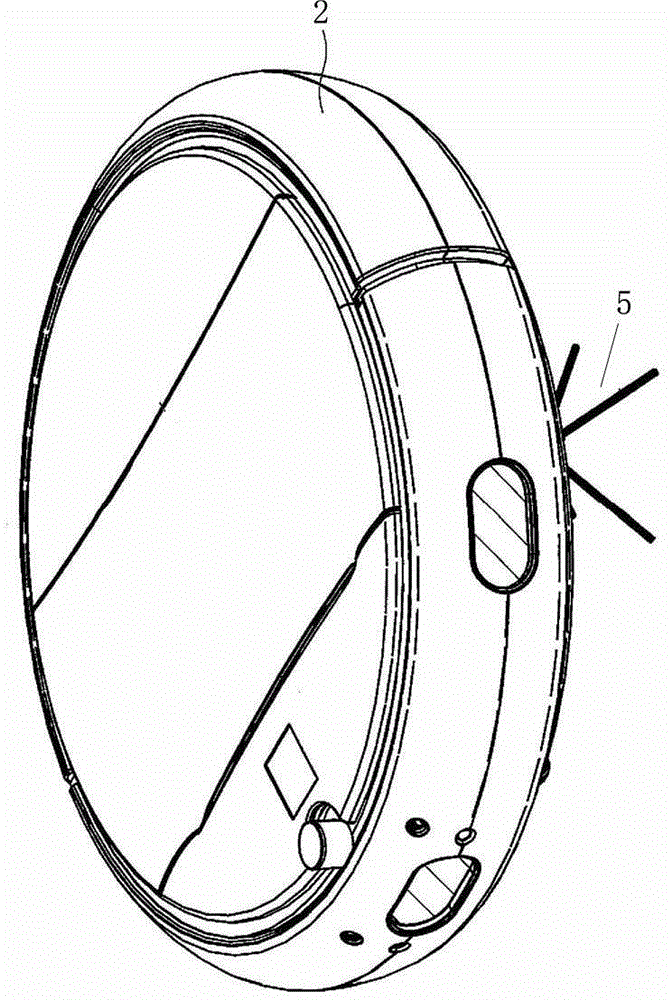

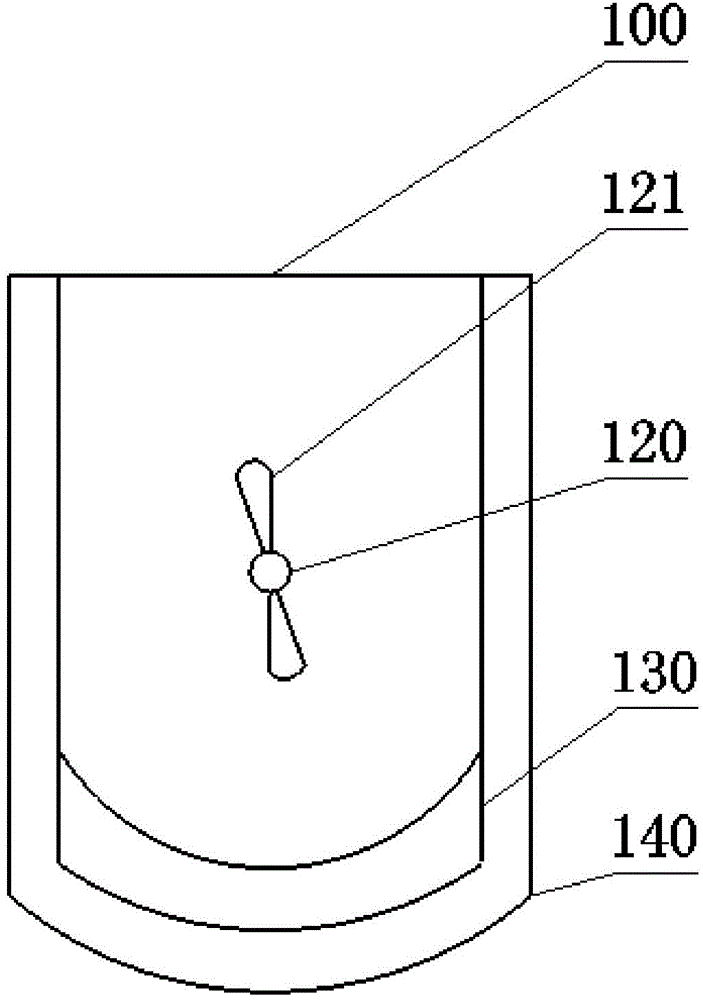

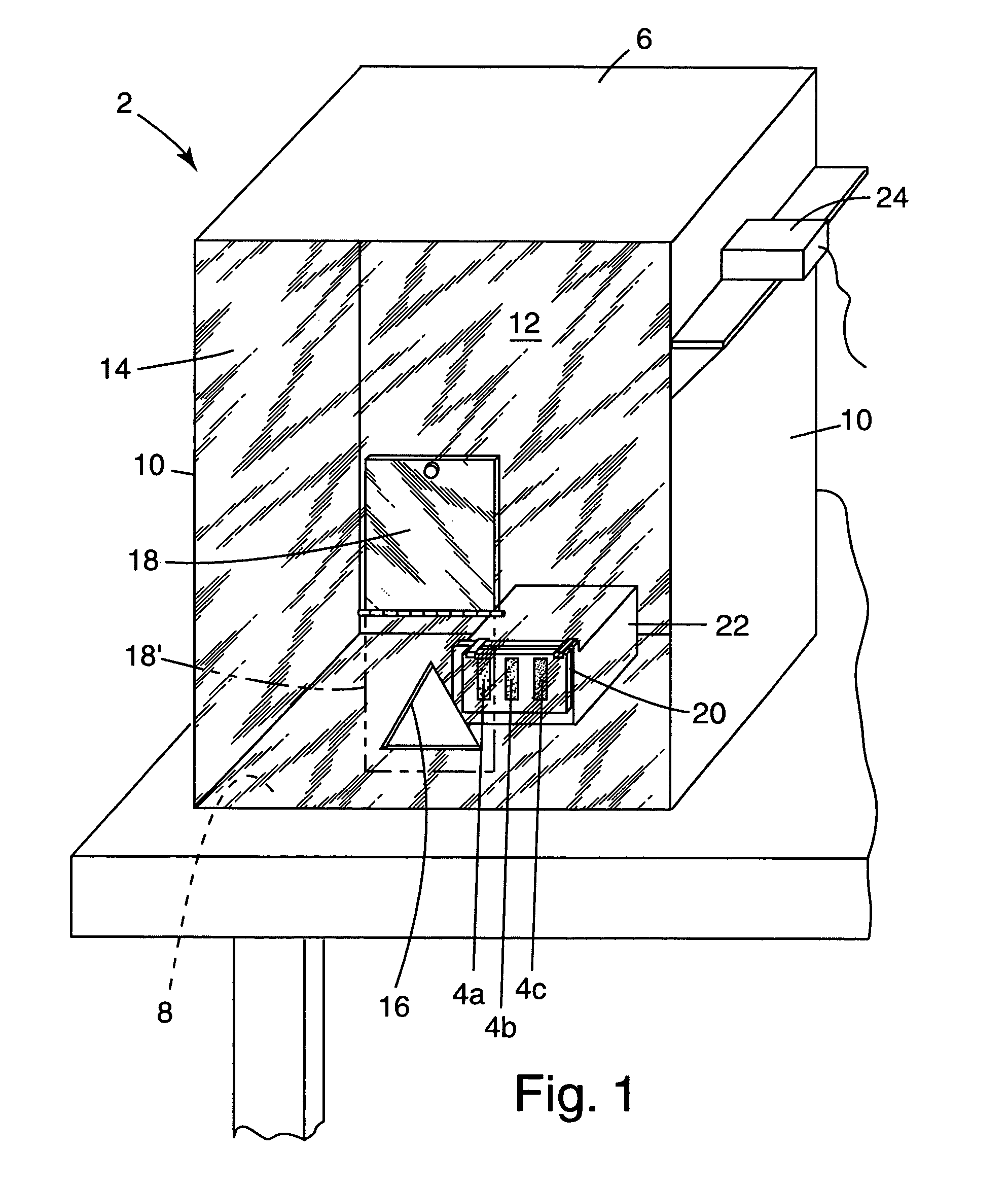

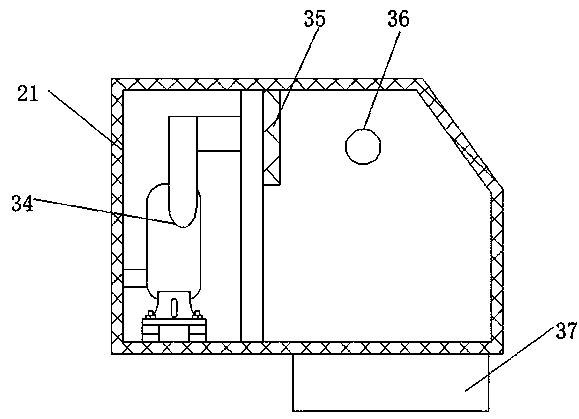

Novel air purification and automatic sweeping integrated machine

ActiveCN104132412ASo neatSave interior spaceCarpet cleanersLighting and heating apparatusEmbedded systemElectricity

The invention relates to a novel air purification and automatic sweeping integrated machine. The integrated machine comprises an air purifier. The air purifier comprises a shell and an electric control device. The integrated machine further comprises an automatic walking sweeping robot used in combination with the air purifier. A containing chamber for containing the automatic walking sweeping robot is formed in the bottom of the shell. A storage battery is arranged on the sweeping robot. A charging socket allowing the sweeping robot to be charged is arranged on the shell. The sweeping robot and the charging socket are connected through a separable electric connector. The electric control device comprises a controlled module arranged on the sweeping robot and a master control module arranged on the air purifier. The master control module and the controlled module are in wireless communication. The novel air purification and automatic sweeping integrated machine has the advantages of being convenient to use and capable of saving energy.

Owner:XIAMEN BRI ENVIRONMENTAL IND CO LTD

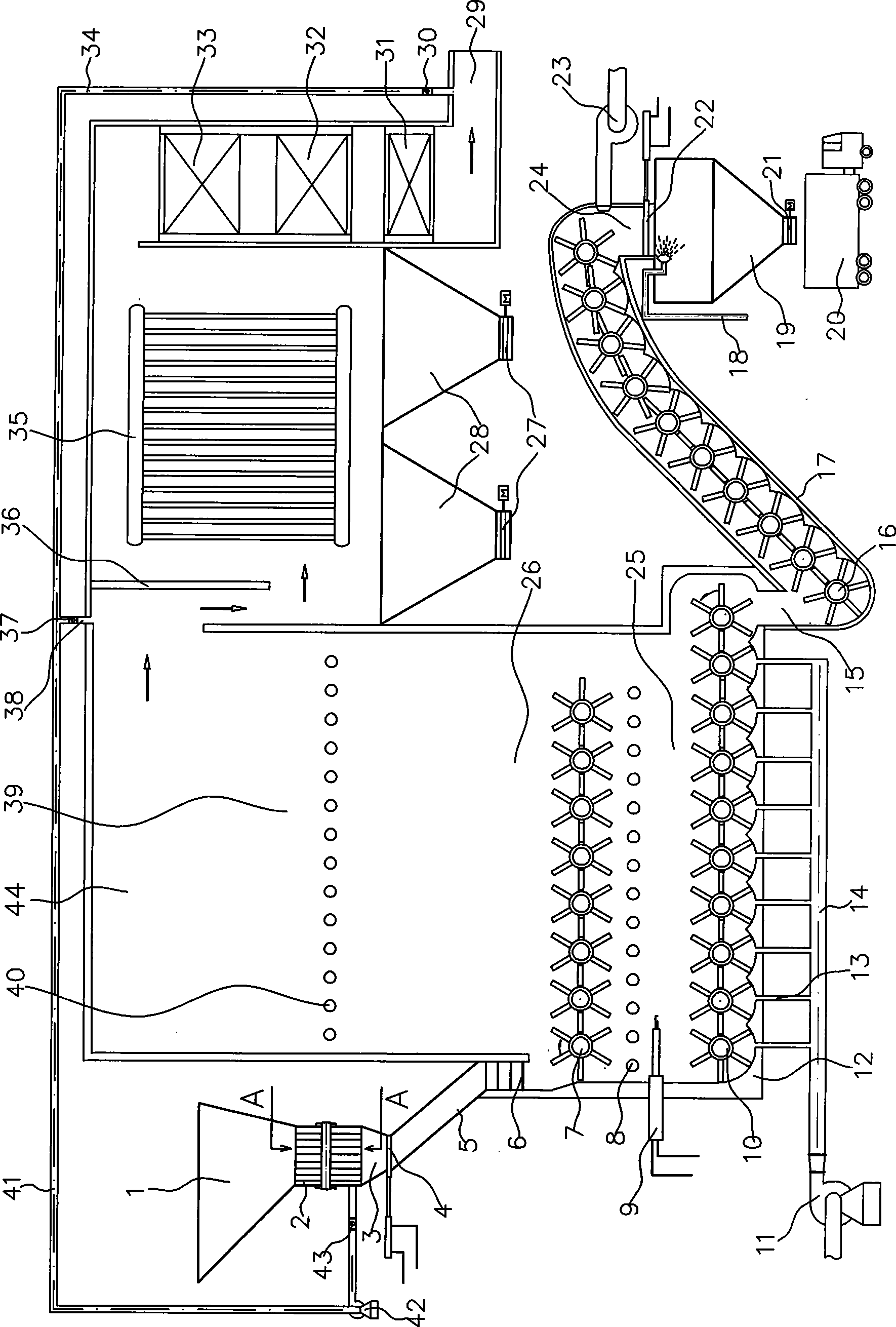

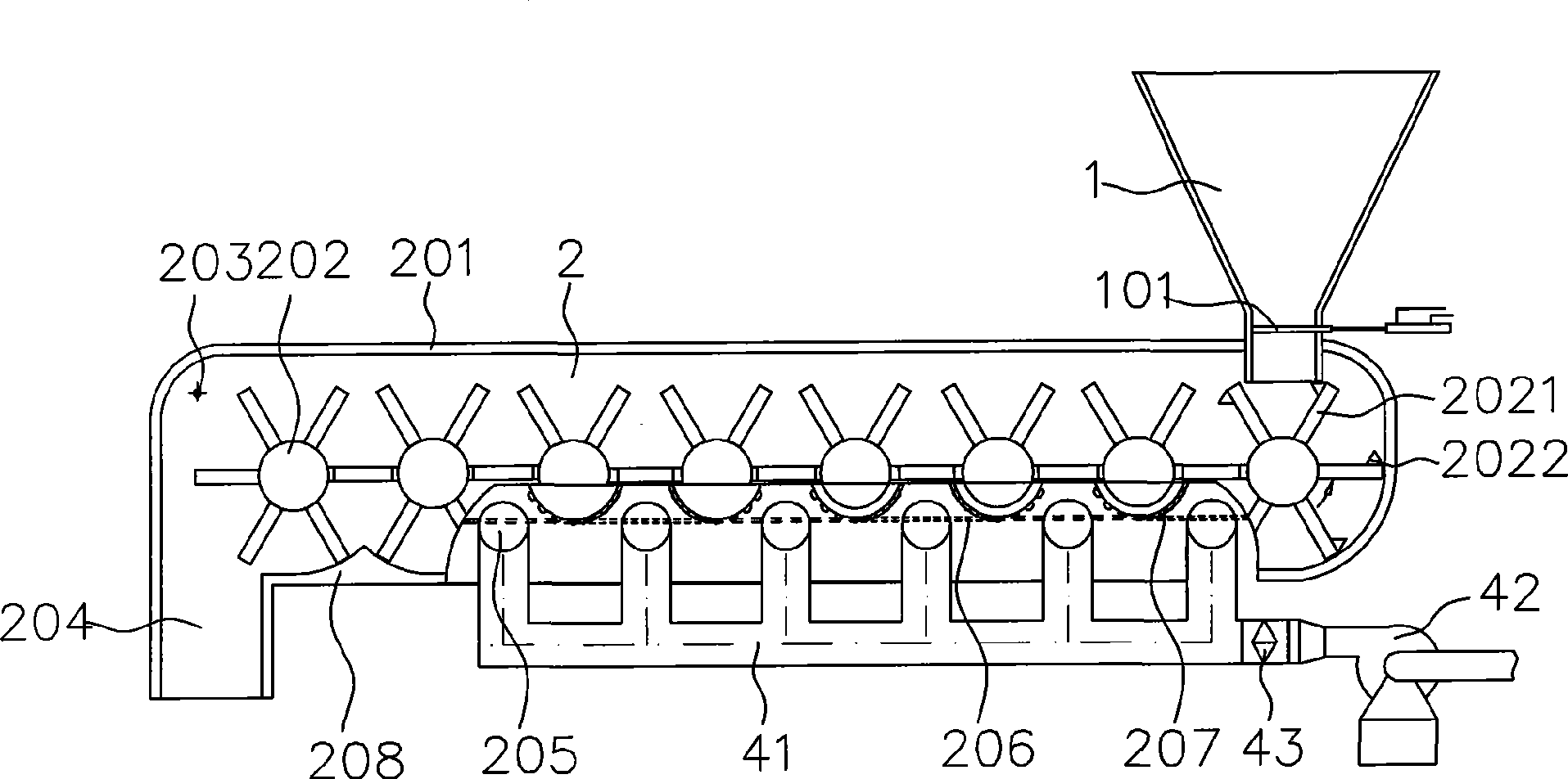

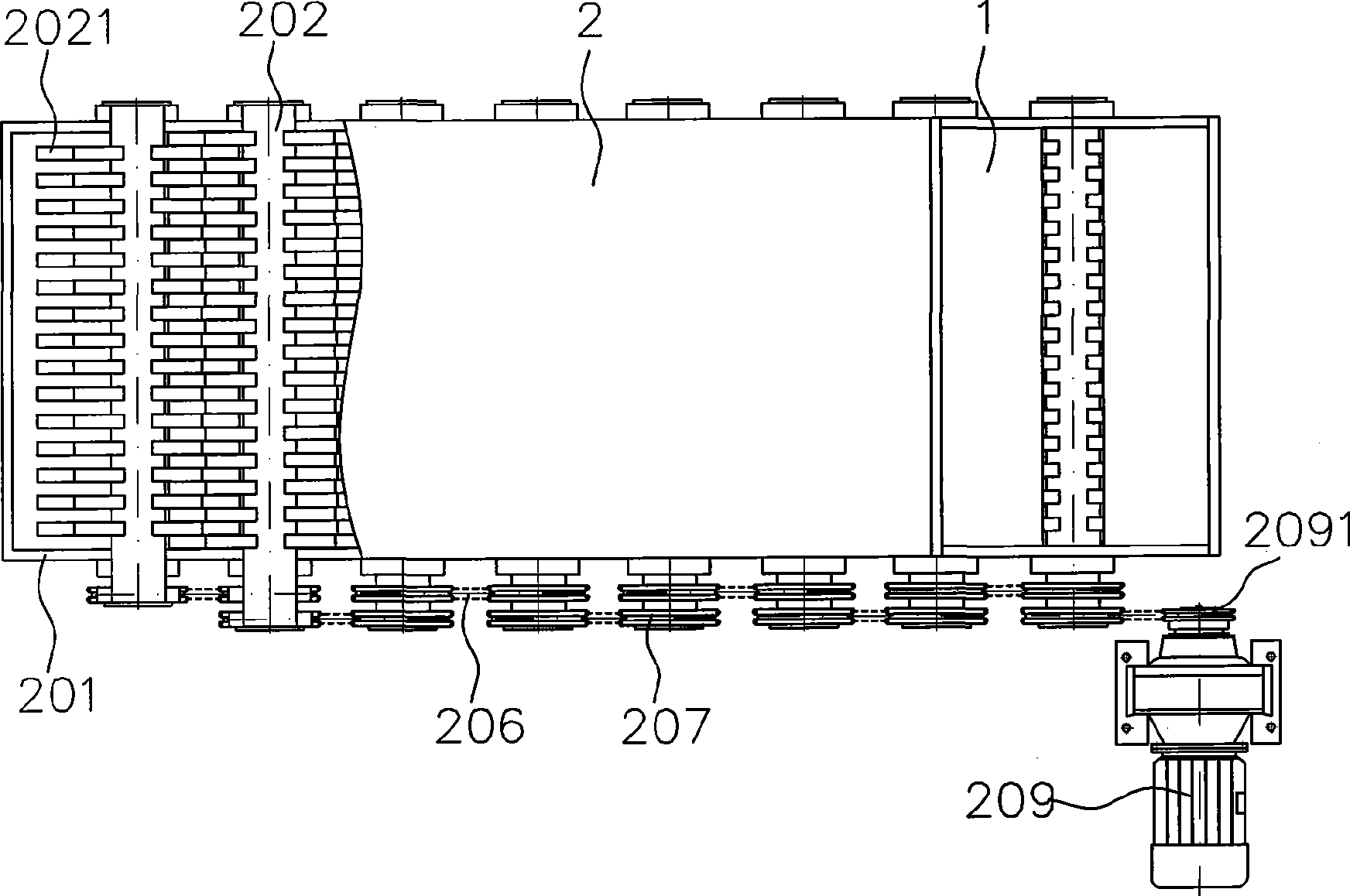

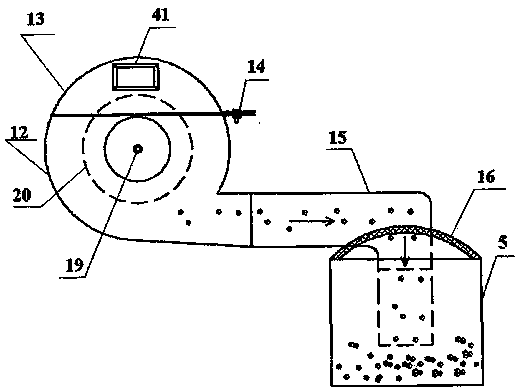

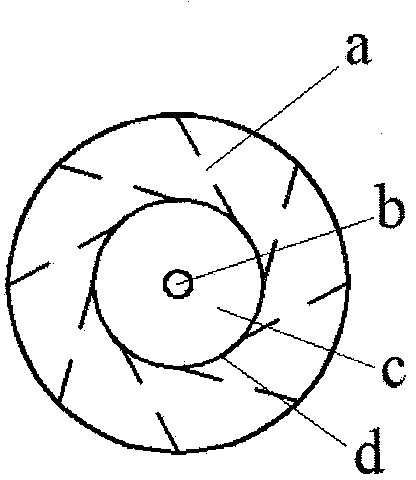

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

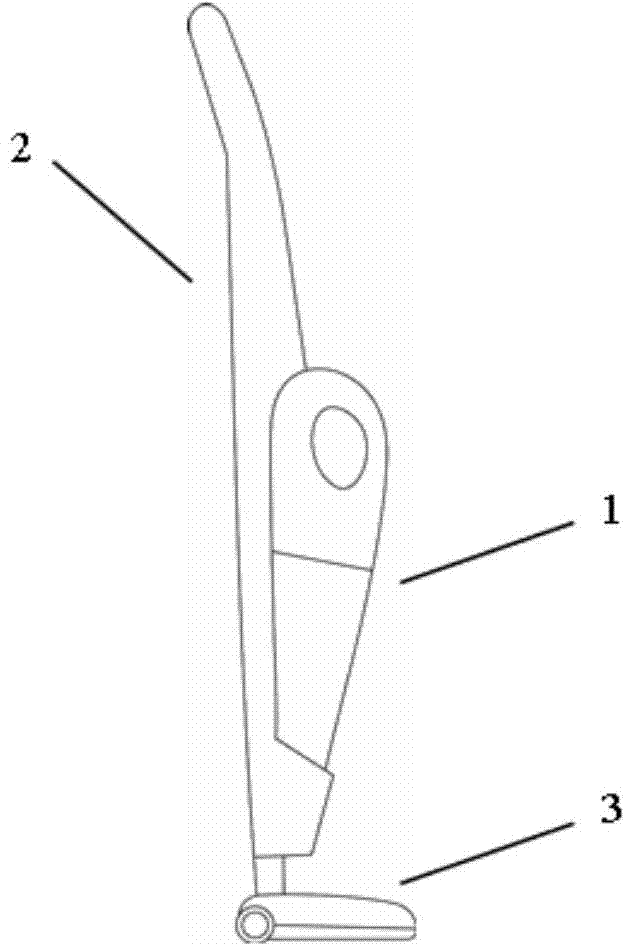

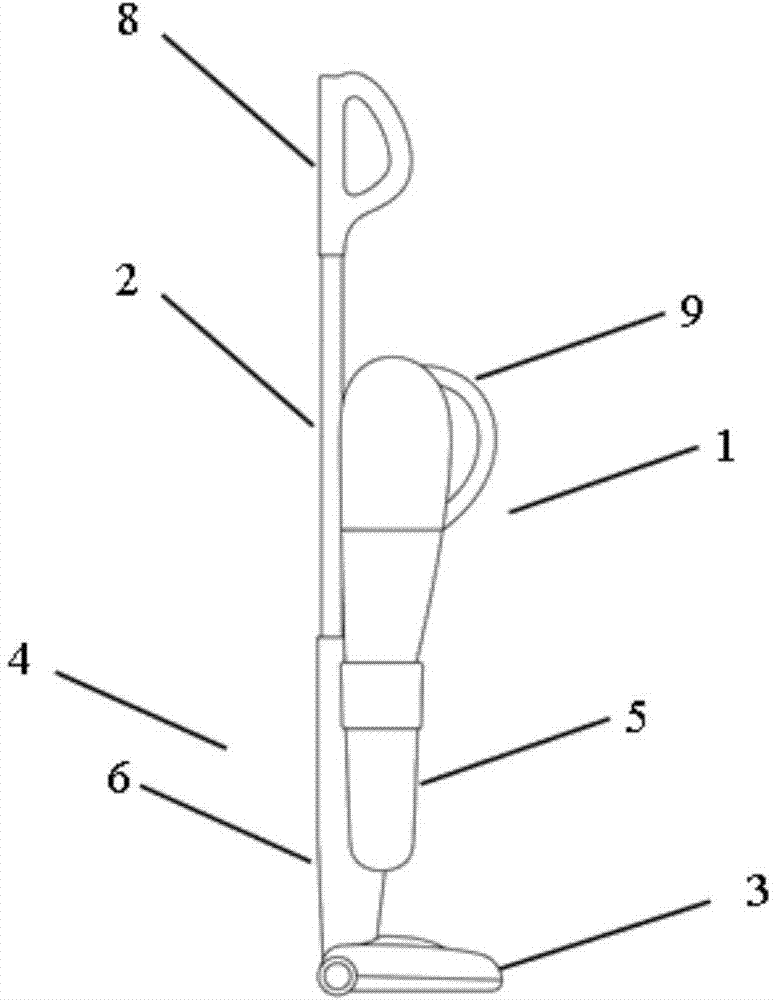

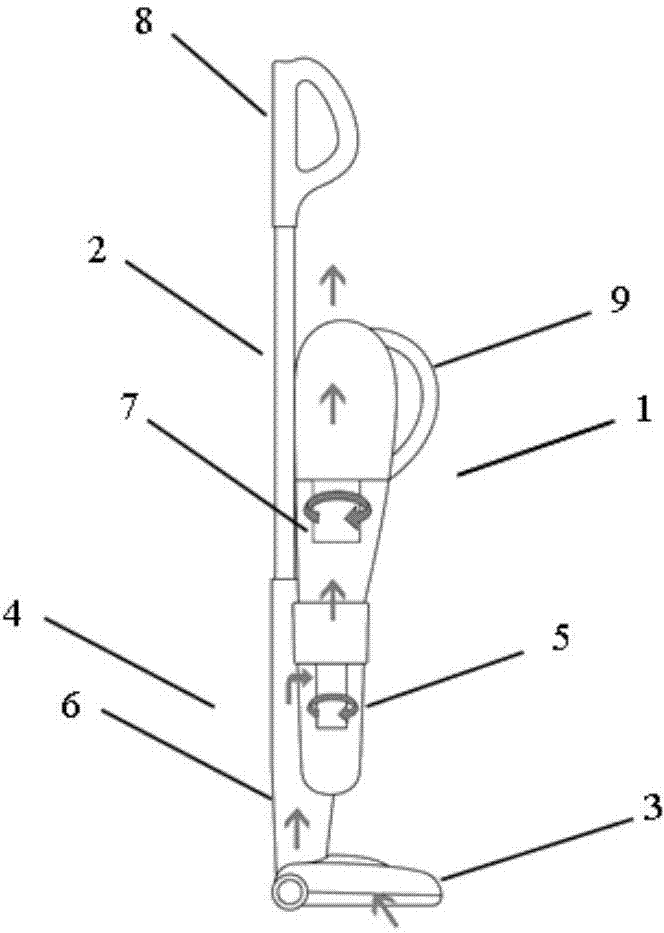

Bar type handheld two-in-one separate dust collector with independent dust and air separation and dust storage device

The invention discloses a bar type handheld two-in-one separate dust collector with an independent dust and air separation and dust storage device. A main unit of the bar type handheld two-in-one separate dust collector is a handheld dust collector, a push rod is a hollow rod, and the independent dust and air separation and dust storage device is arranged on the push rod below the handheld dust collector above a floor brush of the bar type handheld separate dual-purpose dust collector and can be individually taken down, so that dust can be poured. The bar type handheld two-in-one separate dust collector has the advantages that the main unit, the push rod and the floor brush of the bar type handheld two-in-one separate dust collector can be separated from one another and can be assembled with one another, and accordingly the bar type handheld two-in-one separate dust collector can be in different service modes and can work as a mopping dust collector, the handheld dust collector and a handheld dust collector with long connecting pipes.

Owner:KINGCLEAN ELECTRIC

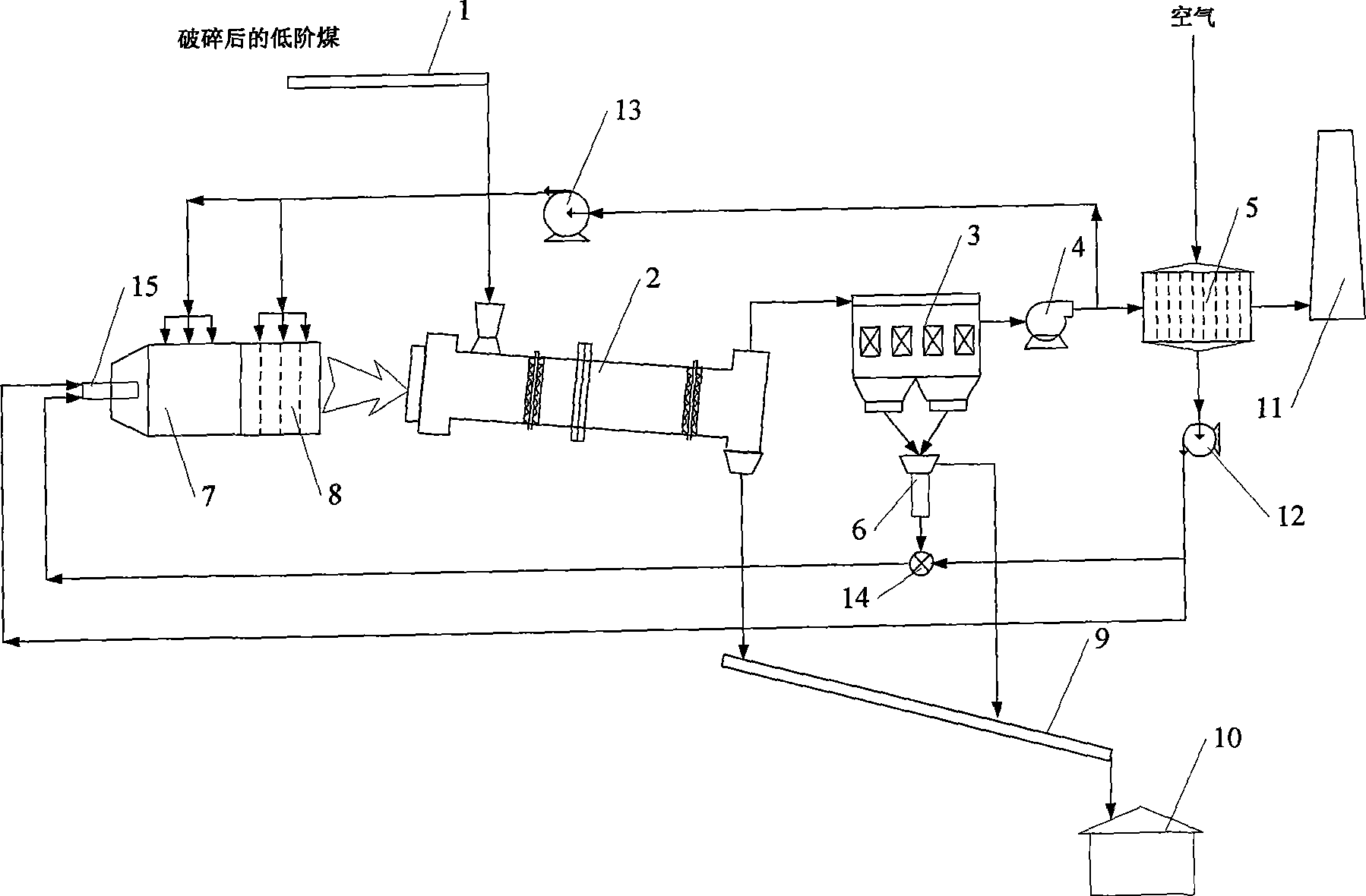

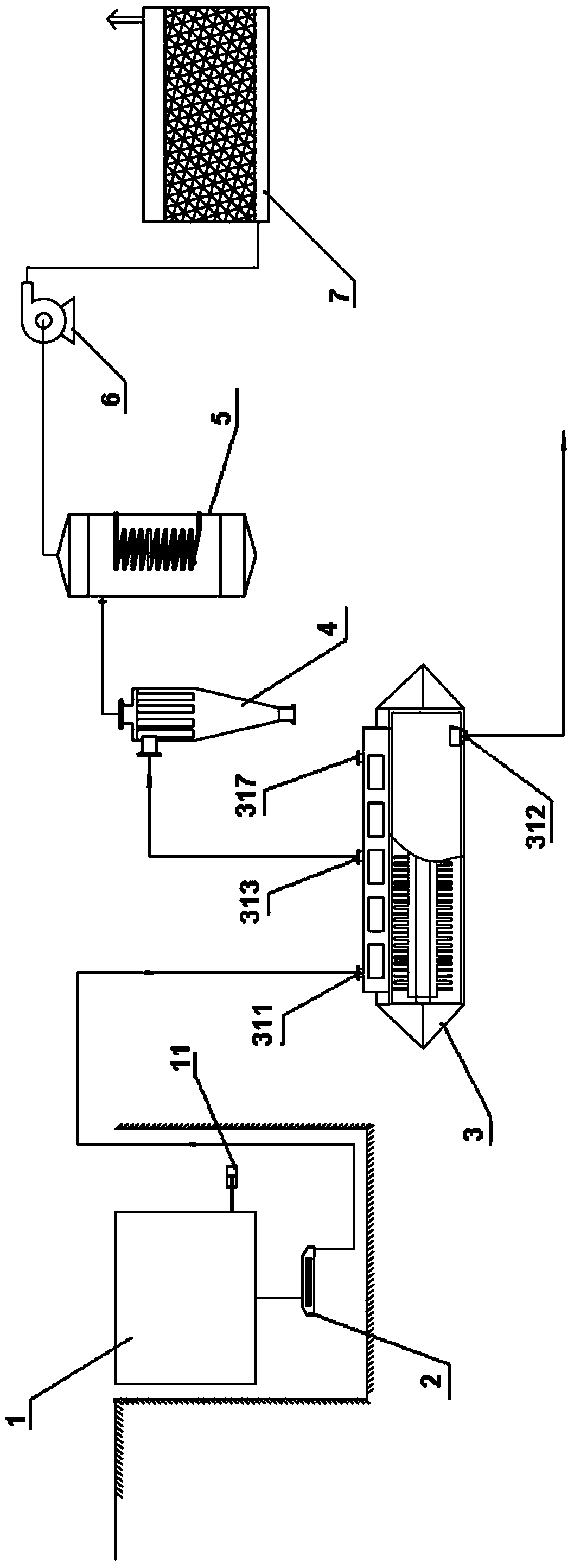

Low-rank coal drying method and system

InactiveCN101476814AReduce pollutionLow costDrying solid materials with heatDrying gas arrangementsComing outAir preheater

The invention discloses a method for drying low-rank coal, which comprises the following steps: (1) the low-rank coal is crushed, and the arrange of a grain diameter of the crushed low-rank coal is between 3 and 50mm; (2) the crushed low-rank coal is sent into a dryer and contacts hot flue gas which comes from a hot flue gas generation device; (3) the low-rank coal which comes out of the dryer is collected, and the hot flue gas discharged by the dryer as well as coal powder and water vapor which are carried by the hot flue gas are aerated into a coal powder treatment and acquisition system at the same time; (4) at least partial coal powder collected by the coal powder treatment and acquisition system is sent to the hot flue gas generation device to serve as a combustion material; (5) the hot flue gas which comes out of the coal powder treatment and acquisition system is divided into two parts, wherein the first part of flue gas circularly returns to the hot flue gas generation device, and the second part of the flue gas is discharged after heating combustion air through an air pre-heater; and (6) the heated combustion air is conveyed to the hot flue gas generation device to take part in the combustion. The invention also provides a low-rank coal drying system with self-supplied fuel, which has the advantages of high energy utilization rate and low production cost.

Owner:DATANG INT CHEM TECH RESINST +1

Method for smelting chromium-nickel-iron alloy from stainless steel dust-removing ash

InactiveCN101126138AEasy to recycleReduce pollutionProcess efficiency improvementChromium nickelFerrosilicon

The invention is a stainless steel ash removing method for smelting inconel. The method comprises the steps as follow; 1 make ash removing block, comprising the following three steps; 1) selective mixing; 2) extrusion molding; 3) natural drying; 2 make the master liquid by melting the normal recycled waste steel or stainless slag steel, pre-treated the molten iron, the ash removing block and the chromate nickel sponge iron inside the electric furnace; 3 batch-by- batch restoring, which comprises the following three steps: 1) add the block and the extra coke or coke breeze to smelt after the raw material used as master liquid is fully melted; 2) supply power with 15 to 20 minutes, then stop for conducting the operations of temperature measuring, exampling and analyzing, and add ferrosilicon breeze and lime; 3) the molten iron is remained between 1550 to 1600 DEG C in the smelting process; 4 finally restoring, and the main components of the metal solution after being finally restored are as follow: C percent is more than or equal to 2.50, Si percent is more than or equal to 0.20, P percent is less than or equal to 0.045, Cr percent is more than or equal to 5.0, and Ni percent is more than or equal to 1.5. The invention has the advantages of reducing environment pollution and increasing the metal yield of the ash removing.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

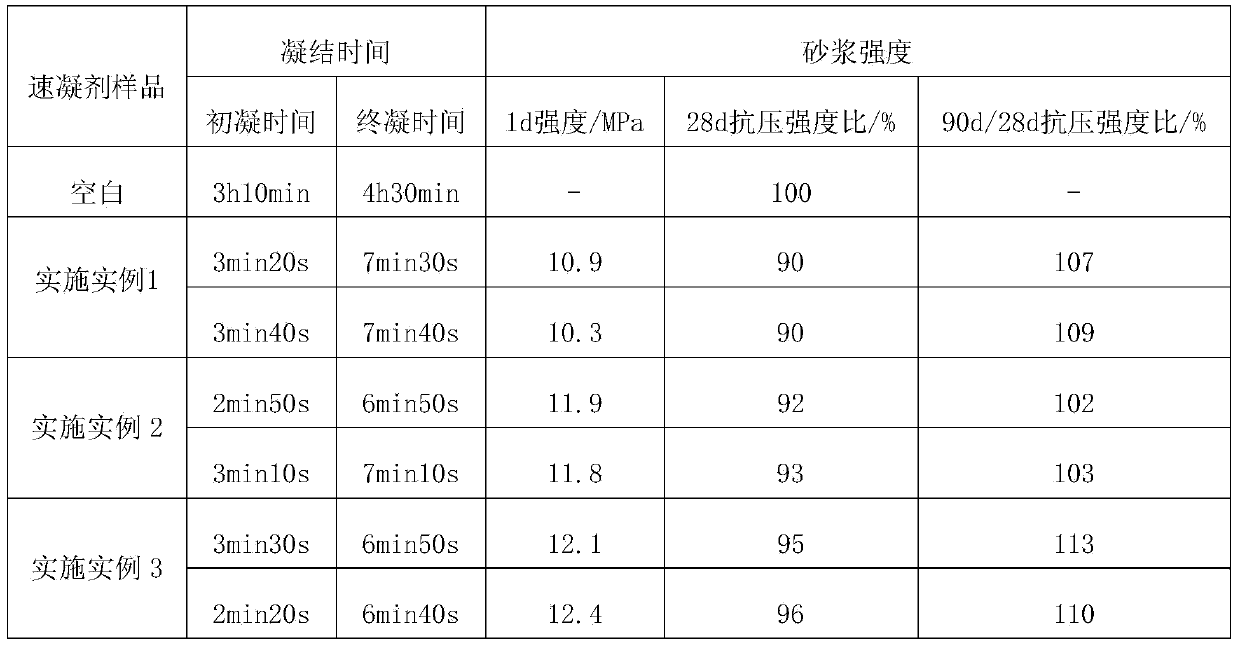

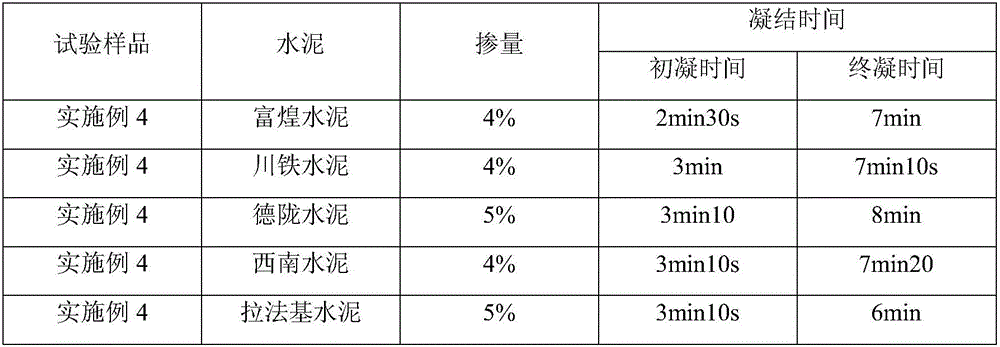

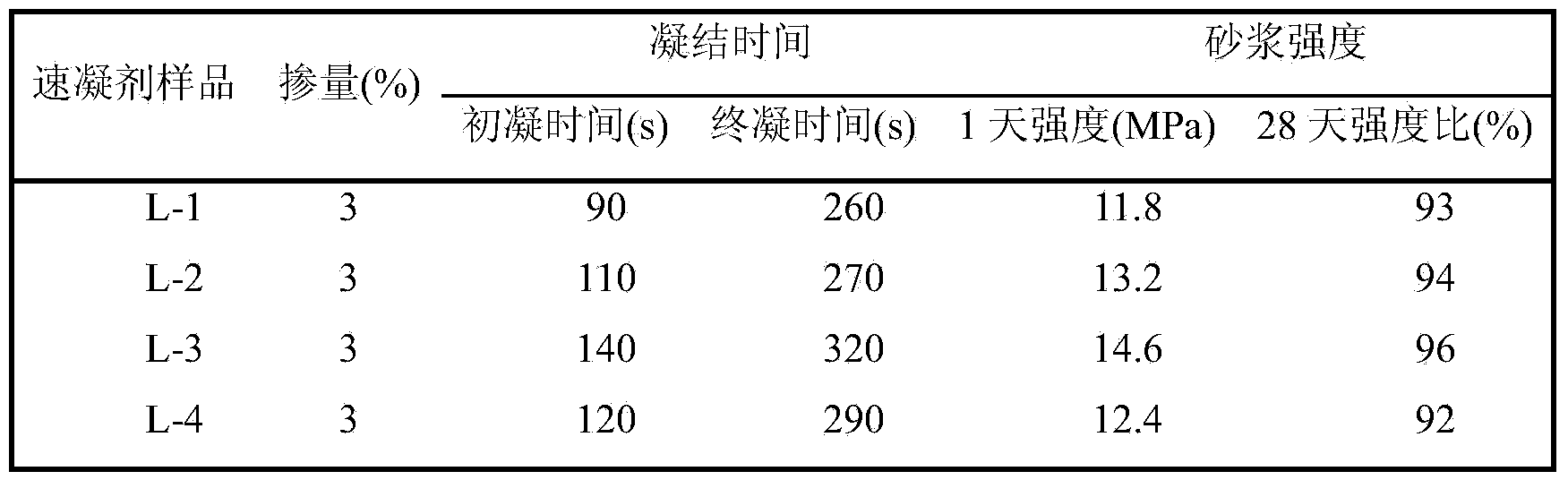

Low-resilience and low-alkaline liquid accelerator for sprayed concrete and preparation method thereof

The invention relates to a low-resilience and low-alkaline liquid accelerator for sprayed concrete and a preparation method thereof. The accelerator is prepared from the following raw materials: an aluminate mother liquid, a modifier, hydramine and a stabilizer, wherein the mass ratio of the modifier and the aluminate mother liquid is 1: (1-5), the dosage of hydramine is 0.5-2.5% of the sum of the modifier and the aluminate mother liquid in mass, the dosage of the stabilizer is 0.3-2% of the sum of the modifier and the aluminate mother liquid in mass; the stabilizer is one of vinylon glue, EDTA (Ethylene Diamine Tetraacetic Acid) and xanthan gum. The preparation method comprises the following steps: preparing the aluminate mother liquid; preparing the modifier; and preparing the low-alkaline liquid accelerator. The adulterate amount of the accelerator provided by the invention is 3-6% mass of cement, the initial setting time is 3 minutes and the final setting time is 8 minutes, and the requirements of JC477-2005 accelerator for sprayed concrete are satisfied. The accelerator is uniform and stable and strong in adaptability with cement, can be used for effectively reducing resilience and dust amount in construction of prayed concrete, and is short in setting time and less in loss of long-term strength.

Owner:刘翠芬

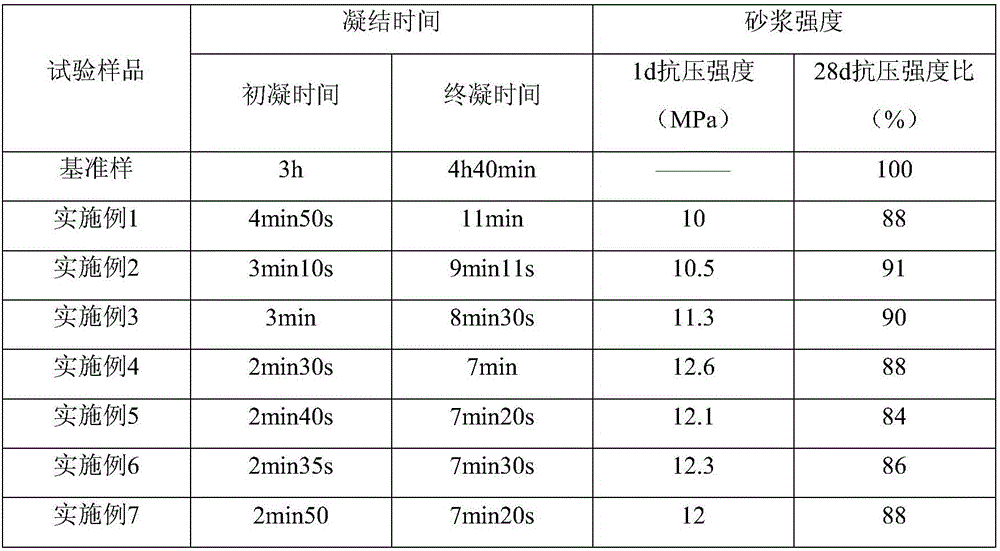

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

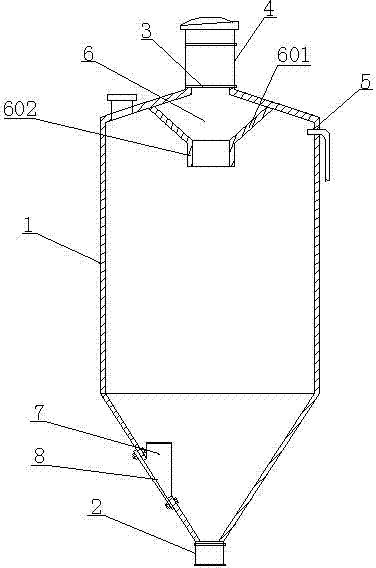

Powder material collecting cabin

The invention relates to a powder material collecting cabin. A dust removing device and a weighing device are arranged in a cabin body, an upper end opening of a conical flow guide tube of the dust removing device is connected with the top surface of the cabin body, a lower end opening of the conical flow guide tube is connected with a cylindrical flow guide tube, an outlet of a material conveying pipe is arranged in the cabin body, the arrangement height of the outlet of the material conveying pipe is greater than the lower end opening of the conical flow guide tube, the arrangement direction of the outlet of the material conveying pipe is parallel to the tangent line direction of the circumference of the cabin body, the weighing device comprises a measuring tube, a support frame, a pressure bearing plate, a sealing rubber cap and at least three pressure sensors, the measuring tube is vertically arranged on the side wall of the funnel-shaped part of the cabin body, the support frame is horizontally arranged in the measuring tube, the pressure sensors are circularly distributed at the upper end of the support frame, the sealing rubber cap is arranged at the upper end opening of the measuring tube, and the pressure bearing plate is arranged between the sealing rubber cap and the pressure sensors. The solid powder body can be separated from the air flow to the furthest degree, the dust quantity of the flowing direction exhaust opening is reduced, in addition, the powder material quantity in the cabin body can be accurately measured, and the production is convenient to control.

Owner:LUOYANG ZHISHENG TECH

Preparation method of low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete

The invention discloses a preparation method of a low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete. The preparation method comprises the following steps: (1) preparing an aluminate mother solution; (2) preparing a modifying agent; (3) preparing a low-alkali polymer high-efficient liquid setting-accelerator. The disclosed low-alkali polymer high-efficient liquid setting-accelerator has a uniform and stable property and strong adaptability; the mixing amount is 2 to 4% of the cement mass, the initial setting time is within 2 minutes, the final setting time is within 5 minutes, the strength loss in the later stage of concrete is within 10%; furthermore, the liquid setting-accelerator can efficiently reduce the dust amount and resilience value during the sprayed concrete construction and improves the strength of sprayed concrete.

Owner:SHANDONG UNIV

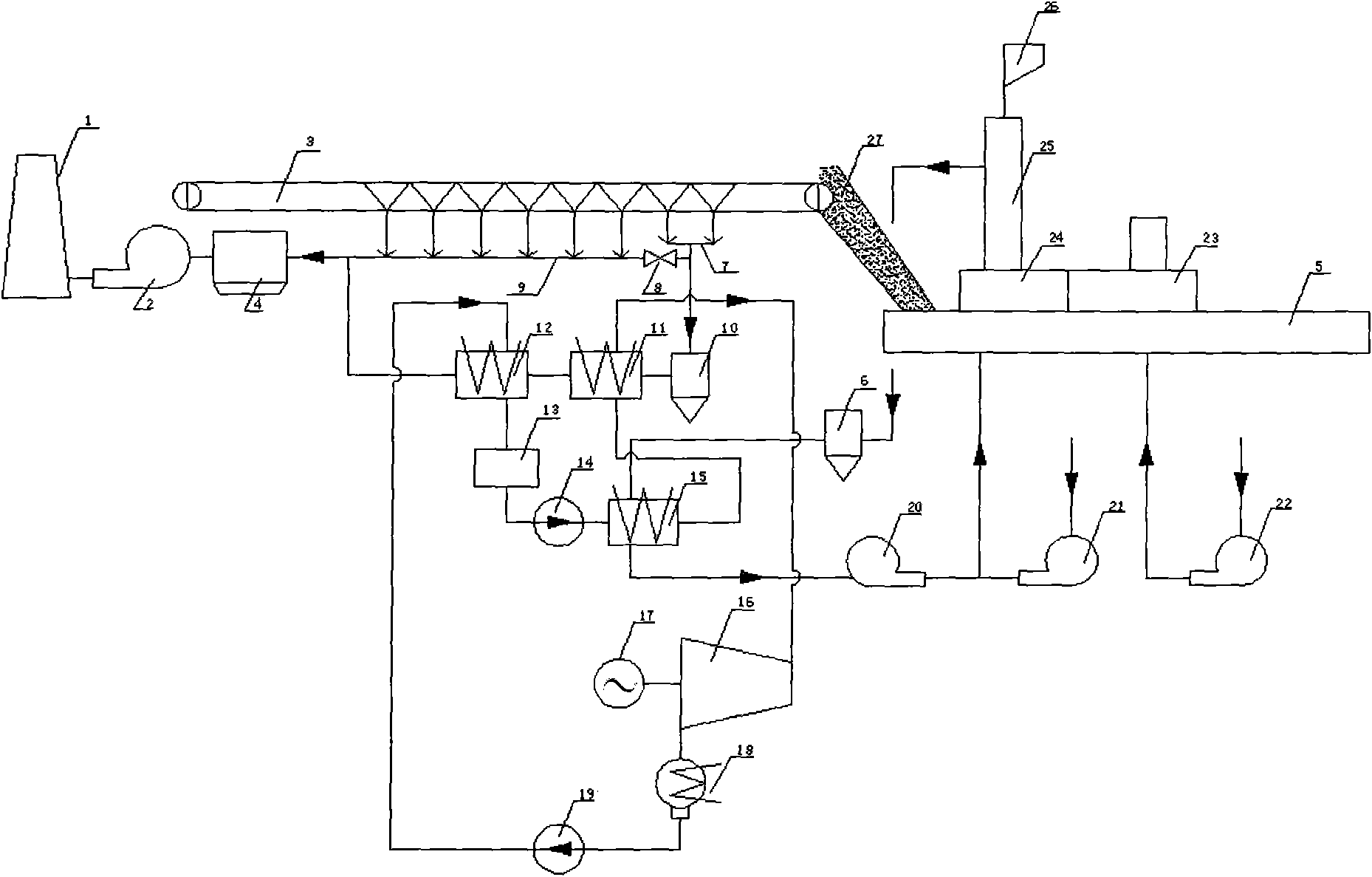

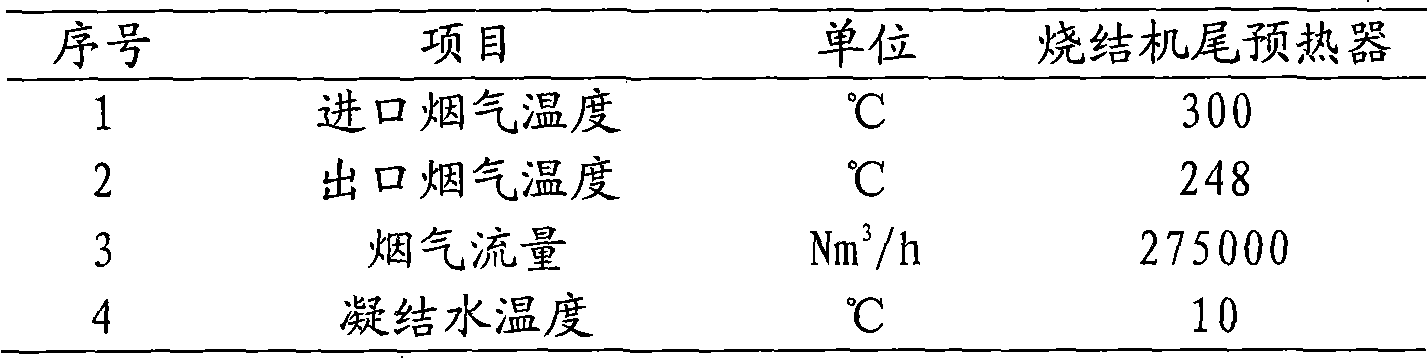

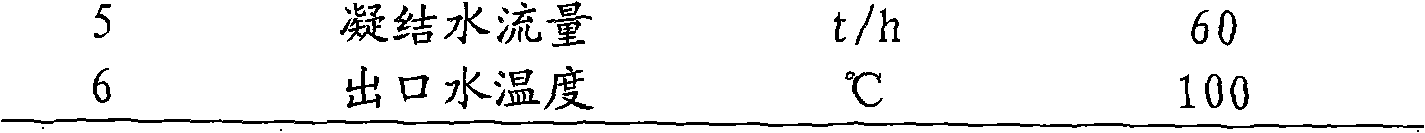

Method and device for power generation by utilizing steam generated from waste heat of steel mill in cascade mode

InactiveCN101915507AIncrease the number ofQuality improvementEnergy industryIncreasing energy efficiencyFlue gasSuperheater

The invention discloses a method and a device for power generation by utilizing steam generated from waste heat of a steel mill in a cascade mode. The device comprises a chimney, a main shaft fan, a sintering machine, a cooling machine, a large flue of the sintering machine, a machine tail flue gas superheater of the sintering machine, a machine tail flue gas preheater of the sintering machine, a deaerator, a feed pump, a waste heat boiler of the cooling machine, a steam turbine, a generator, a condenser, a condensate pump, a circulating fan and the like. Through three process steps of preheating condensed water of the steam turbine by utilizing the preheater in machine tail flue gas of the sintering machine, generating intermediate-temperature steam by heating the waste heat boiler of the cooling machine, heating the intermediate-temperature steam further through the machine tail flue gas superheater of the sintering machine to generate high-temperature steam and the like, the power generation is performed by utilizing the steam generated from the flue gas waste heat of a sintering machine plant fully. The power generation is performed by utilizing the steam generated from the heat of the machine tail flue gas of the sintering machine and the flue gas of the cooling machine of the steel mill, so the quality of the generated steam is improved greatly and meets the requirement of waste heat generation, and a process flow is simple.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

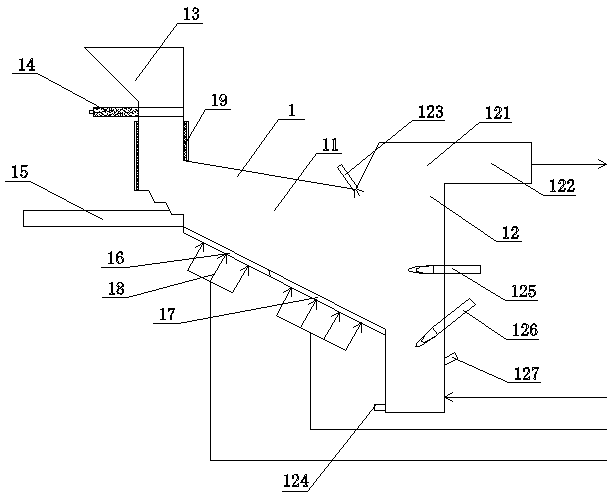

Production system for door leaf of plain batten door

InactiveCN106272856AImproved dust removal designReasonable dust removal designWood working apparatusCo-operative working arrangementsBattenFully automatic

The invention discloses a production system for a door leaf of a plain batten door, and belongs to the field of wood working machinery. The production system for the door leaf of the plain batten door comprises a door leaf blank one-piece flow processing system, wherein the door leaf blank one-piece flow processing system comprises a transfer machine, cutting equipment, edge sealing equipment, hardware processing equipment, frame processing equipment, film covering equipment and a marker printer which are connected in sequence through a conveying platform; a bar code is attached onto a to-be-processed door leaf blank; scanning equipment are arranged on all of the transfer machine, the cutting equipment, the edge sealing equipment, the hardware processing equipment, the frame processing equipment and the film covering equipment. The production system disclosed by the invention has the benefits that a traditional intermittent production mode is changed; through fully-automatic operation, the labor cost is reduced, and the error rate is low; the production system also has the advantages of being strong in processing product compatibility and high in product quality.

Owner:JIANGSHAN OUPAI DOOR IND

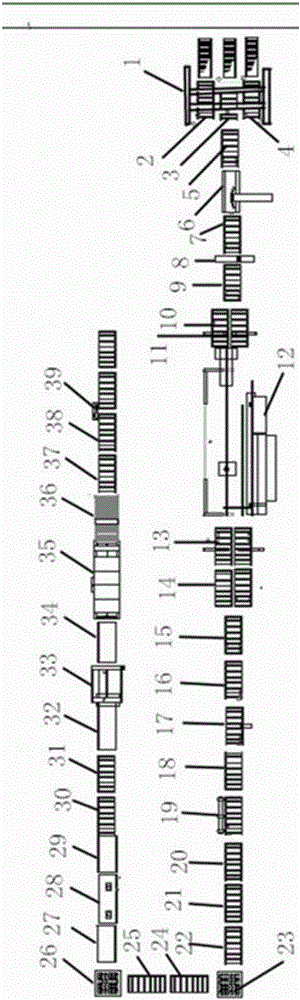

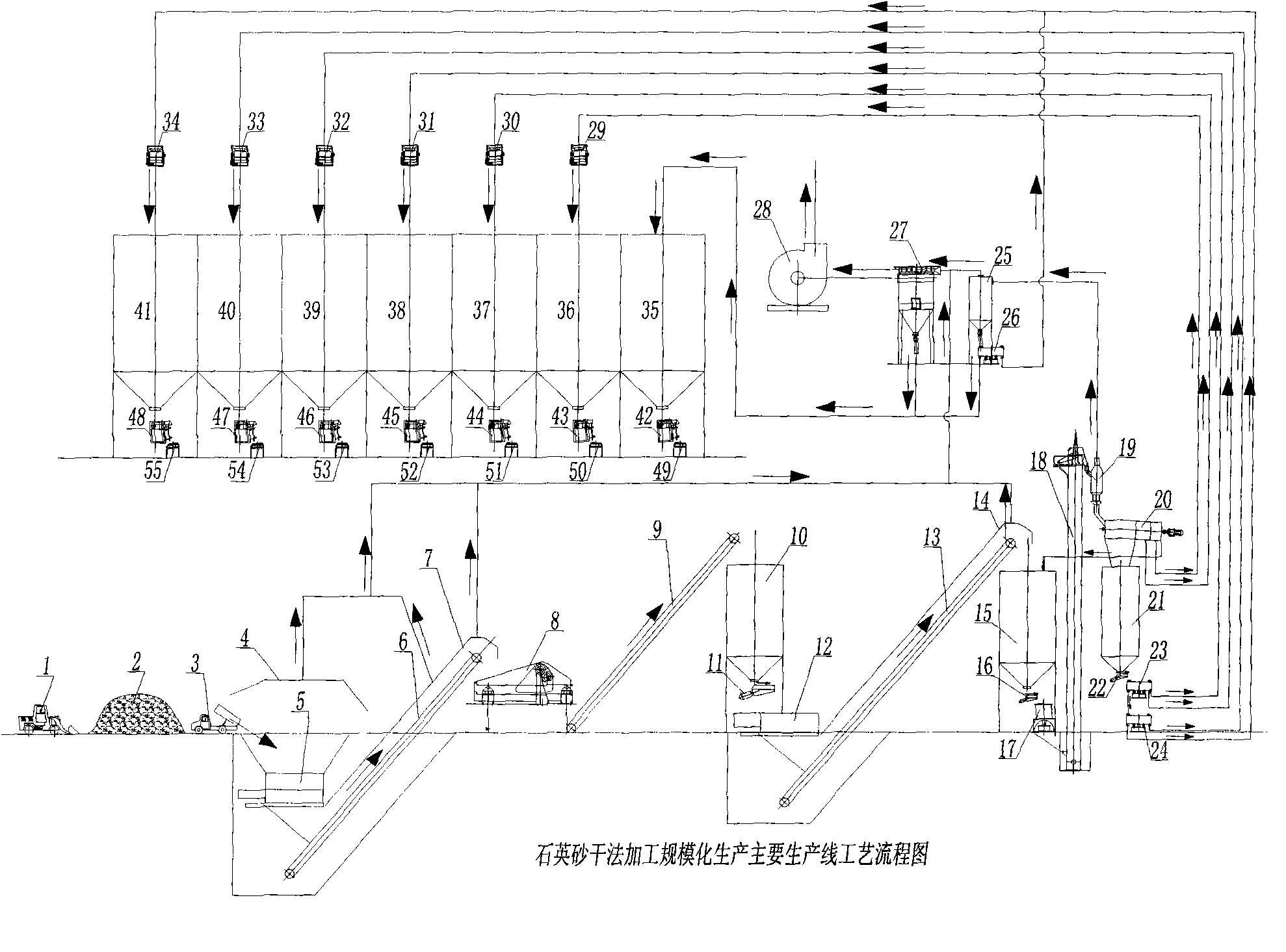

Dry process scale continuous production process of quartz sand

InactiveCN102211854AIncrease productionReduce manual labor intensityGas current separationGlass shaping apparatusProcess scaleProcess engineering

The invention discloses a dry process scale continuous production process of quartz sand, which comprises the process steps of quartz ore breaking and crushing, product grading, packaging and transportation, dust pollution treatment and the like. In the process step of the quartz ore breaking, a two-grade screening type breaker is adopted, and a cleaning dewatering screen and a broken stone drying tower are arranged between two grades of screening and breaking; in the process step of quartz ore crushing, a single-stage HK type sand making machine is adopted, and single-group production or multi-group parallel production can be performed from the HK type sand making machine to the finished product delivery after screening and grading. In the process step of product grading, the mode combining air classification and sieve classification is adopted, namely the process step of single-stage air classification, single-stage drum screen classification and two-stage rotation movable screeningmachine classification is adopted, wherein the air classification adopts negative pressure classification to realize comprehensive functions of separation and dust removal. In the process step of packaging and transportation, a production process in which a plurality of machine sets are connected in parallel is adopted, and the same product is collected and conveyed to a finished product storage bin by the same conveyor to realize the integration of packaging and shipping.

Owner:李立和 +1

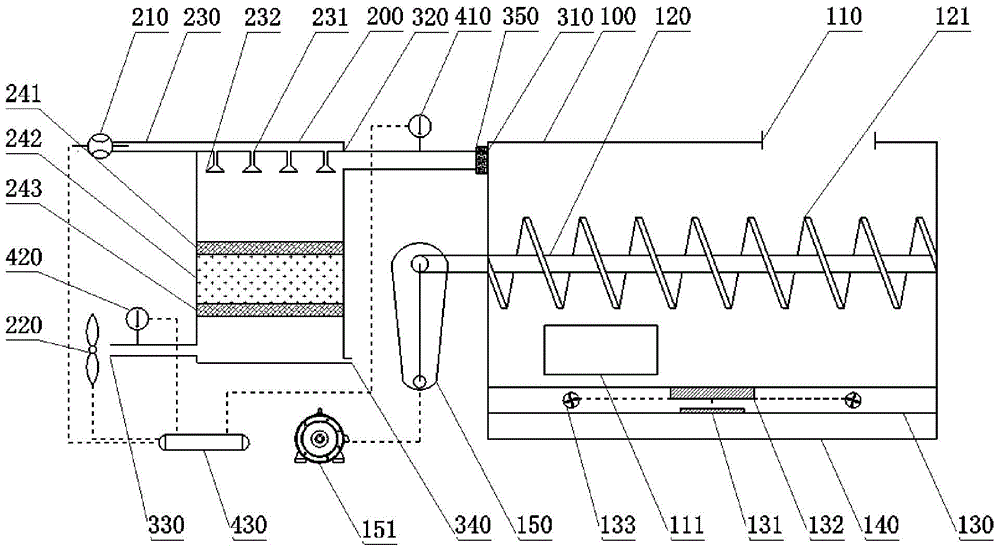

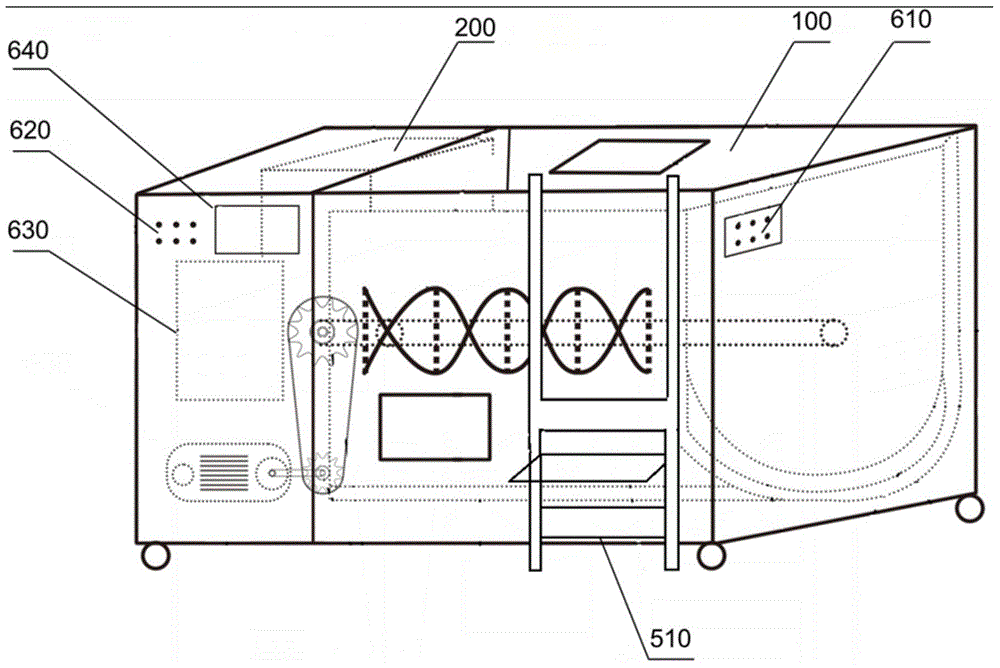

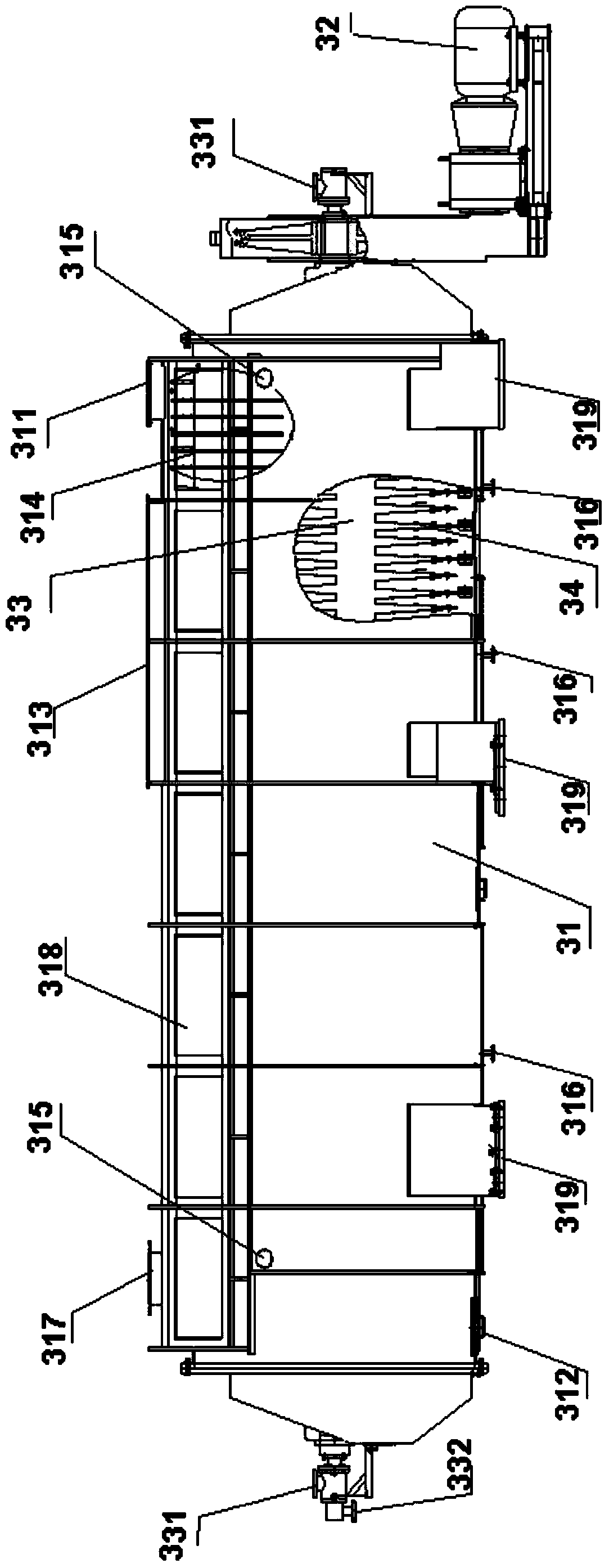

High-temperature biochemical processing machine for kitchen waste and control method thereof

ActiveCN104907320AHigh concentration rateFor subsequent recyclingSolid waste disposalActivated carbonSlag

The invention discloses a high-temperature biochemical processing machine for kitchen waste and a control method thereof. The high-temperature biochemical processing machine comprises a fermentation bin, a dust-removal deodorization purifying tower, temperature sensors and a controller, wherein a feeding hole is formed in the top of the fermentation bin, and a discharging hole is formed in the front face of the fermentation bin; a heating interlayer and a thermal insulation layer are sequentially arranged on the outer side of the fermentation bin, and a waste gas outlet is formed in one end of the fermentation bin; the dust-removal deodorization purifying tower is connected with a water pipe, the water pipe is connected to a plurality of spraying pipes which are arranged on the top end in the dust-removal deodorization purifying tower, and a filter layer, a spraying layer and an activated carbon layer are sequentially arranged in the dust-removal deodorization purifying tower from top to bottom; a waste gas inlet is formed in one end of the top of the dust-removal deodorization purifying tower, an air outlet is formed in one end of the bottom of the dust-removal deodorization purifying tower, a water outlet is formed in the other end of the bottom of the dust-removal deodorization purifying tower, and a draught fan is connected to the air outlet; the temperature sensors are mounted on a gas pipeline and the air outlet; the controller is connected with the temperature sensors and a water pump. The high-temperature biochemical processing machine has the characteristics that the kitchen waste can be processed by virtue of biological fermentation, and the processed waste slag resource can be recycled.

Owner:TIANJIN LINGJUN ENVIRONMENTAL PROTECTION TECH

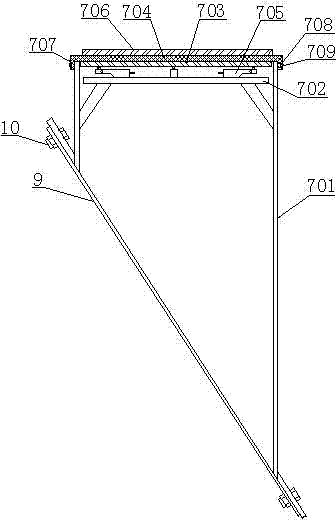

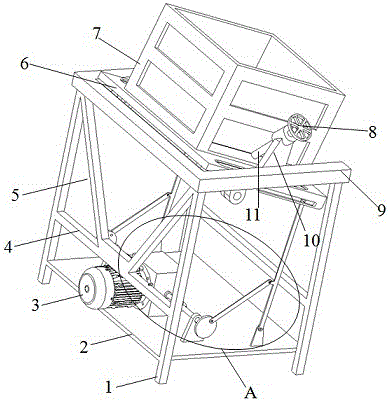

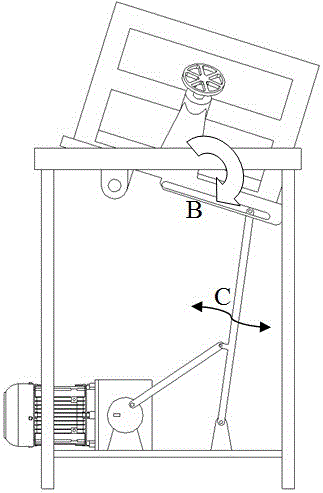

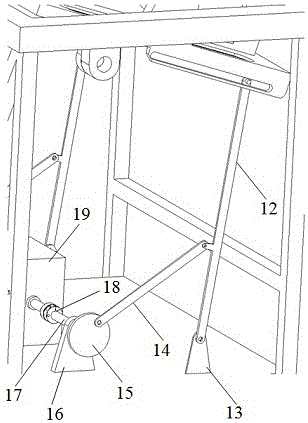

Coarse barium slag discharge overturning table based on crank-link mechanism

InactiveCN106115288ASimple and smart structural designMitigates negative effects of inertial loadsConveyorsBottle emptyingBarium saltSlag

The invention discloses a barium slag removal turning table based on a crank connecting rod mechanism. Before the device works, the crank disc rotates under the action of the turning motor, so that the connecting frame rod is located at one of the limit positions, and this position makes the connecting frame rod vertical On the level ground, so that the turning table is in a horizontal state, then the operator places the hopper on the turning table through the equipment, the operator turns the compression handwheel to make the locking screw press the side of the hopper, and then the turning motor starts, through the two-axis The reducer makes the crank disc rotate until the connecting frame rod is at another limit position. At this time, the turning table tilts, and the materials inside the hopper fall to the ground under the action of its own gravity to complete the unloading process of the barium salt firing hopper. The turning table Lifting equipment removes the material box when it is turned to the horizontal position again. The device can dump the materials in the material box at one time, and the amount of dust generated when the materials fall to the ground is small, which is conducive to maintaining a clean working environment and reducing the physical exertion of operators.

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

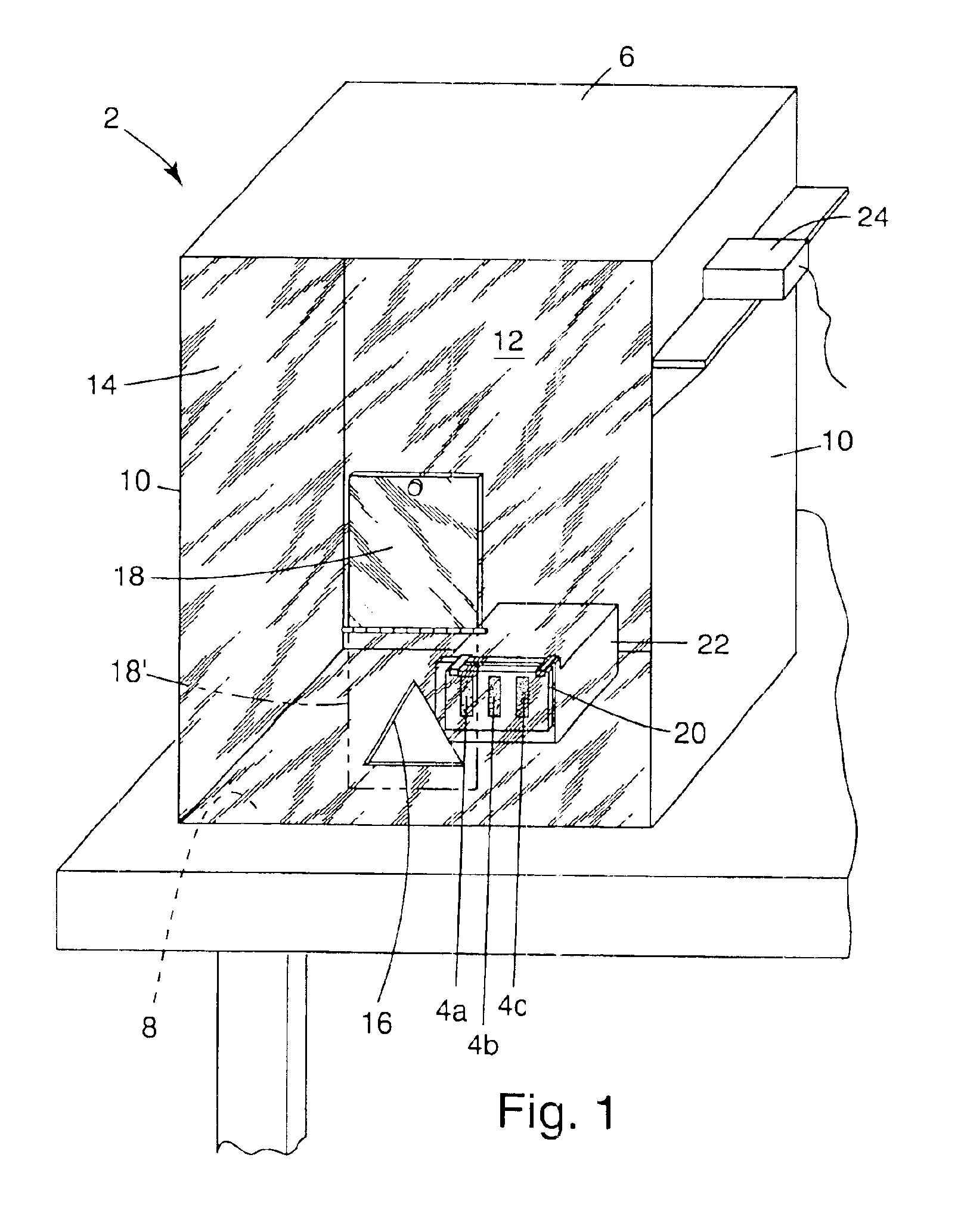

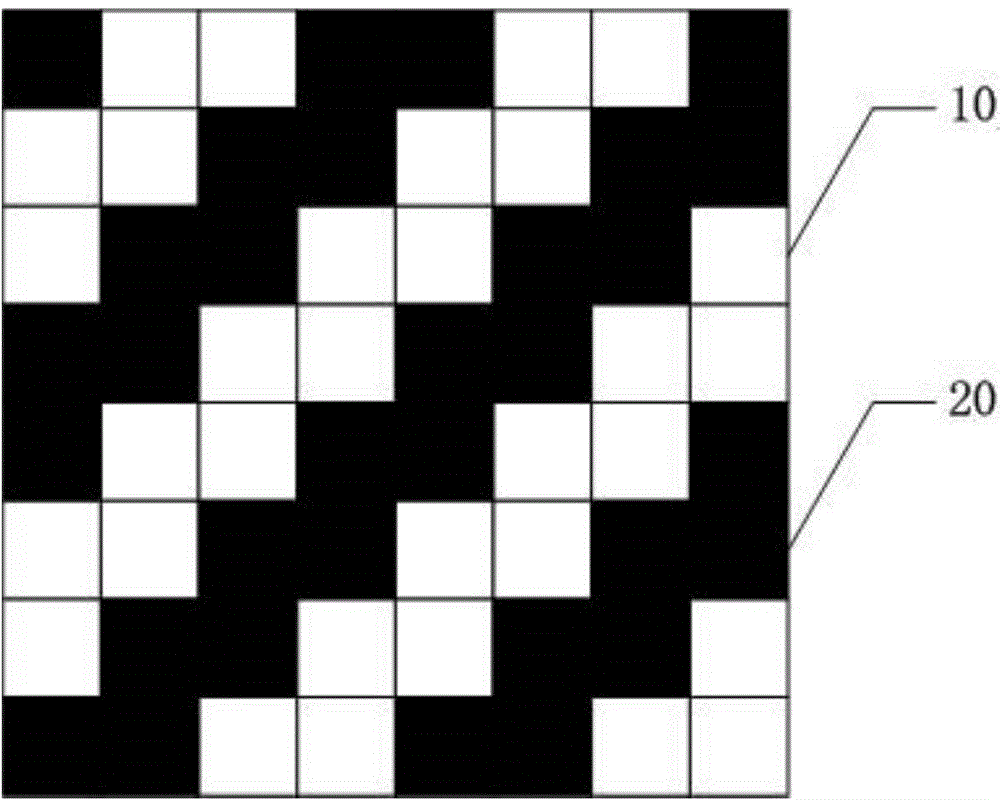

Low dust wall repair compound

InactiveUS6863723B2Reduce in quantityLower Level RequirementsFatty acid chemical modificationPlastic/resin/waxes insulatorsWaxCompound a

A wall repair compound useful for filling and repairing cracks, holes, and other imperfections in a wall surface includes a conventional filler material, a conventional binder material, and a dust reducing additive which reduces the quantity of airborne dust particles generated when sanding the hardened joint compound. Airborne dust reducing additives include oils, surfactants, solvents, waxes, and other petroleum derivatives. The additive can be added to conventional ready-mixed joint compounds and to setting type joint compounds. A method of reducing the quantity of airborne dust generated when sanding a fully hardened joint compound includes mixing a sufficient quantity of the dust reducing additive with the joint compound prior to when the joint compound has been applied to the wall.

Owner:UNITED STATES GYPSUM CO

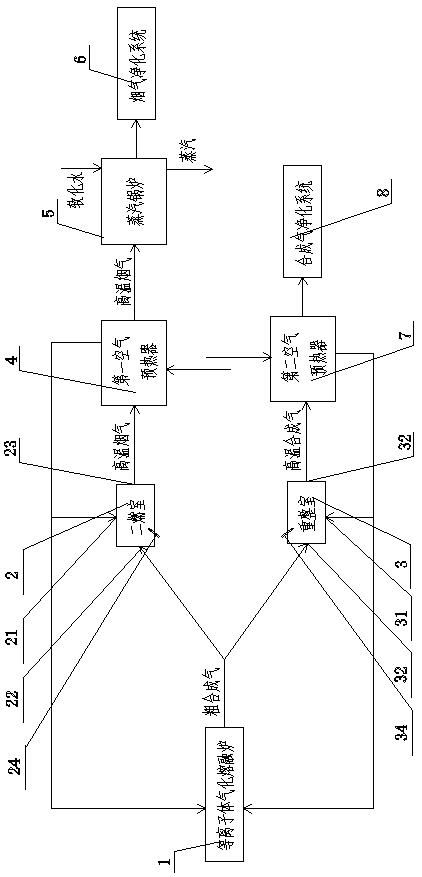

Plasma gasification and melting system for solid waste centralized processing

ActiveCN108097703AReduce the amount of dustPrevent regenerationWaste processingTransportation and packagingFuranCombustion chamber

The invention discloses a plasma gasification and melting system for solid waste centralized processing, and relates to the technical field of solid waste thermochemical treatment. The system comprises a plasma gasification and melting furnace, a synthesis gas outlet of the plasma gasification and melting furnace is connected with a secondary combustion chamber, a high-temperature smoke outlet ofthe secondary combustion chamber is sequentially connected with a waste heat recycling system and a smoke purifying system, and the synthesis gas outlet of the plasma gasification and melting furnaceis further connected with a reforming chamber, a high-temperature synthesis gas outlet of the reforming chamber is sequentially connected with a heat exchange system and a synthesis gas purifying system. The controlled oxygen combustion technology is adopted in the plasma gasification and melting furnace, the excessive air coefficient of primary air is about 0.3 to 0.5, the dust amount in rough synthesis gas can be effectively reduced, re-generation of toxic and harmful substances of dioxin and furan can be restrained, and the production of flying ash amount can be reduced.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Low dust wall repair compound

InactiveUS20050119388A1Reduce in quantityLower Level RequirementsFatty acid chemical modificationPlastic/resin/waxes insulatorsWaxCompound a

A wall repair compound useful for filling and repairing cracks, holes, and other imperfections in a wall surface includes a conventional filler material, a conventional binder material, and a dust reducing additive which reduces the quantity of airborne dust particles generated when sanding the hardened joint compound. Airborne dust reducing additives include oils, surfactants, solvents, waxes, and other petroleum derivatives. The additive can be added to conventional ready-mixed joint compounds and to setting type joint compounds. A method of reducing the quantity of airborne dust generated when sanding a fully hardened joint compound includes mixing a sufficient quantity of the dust reducing additive with the joint compound prior to when the joint compound has been applied to the wall.

Owner:UNITED STATES GYPSUM CO

Quick-setting high-strength alkali-free liquid accelerator

The invention relates to a quick-setting high-strength alkali-free liquid accelerator. Raw materials comprise aluminum sulfate, hydrofluoric acid, aluminum hydroxide, a pre-dispersion reinforcing component, a suspension component, a complexing component, organic acid and water. The accelerator has great adaptability on cement-based materials and dual technical effects of quick setting and high strength are achieved, and the sprayed concrete applying the cement-based material is high in setting speed, high in early strength, low in rebound rate, small in dust amount, good in bonding effect, environmentally friendly and free of corrosion.

Owner:CNBM ZHONGYAN TECH

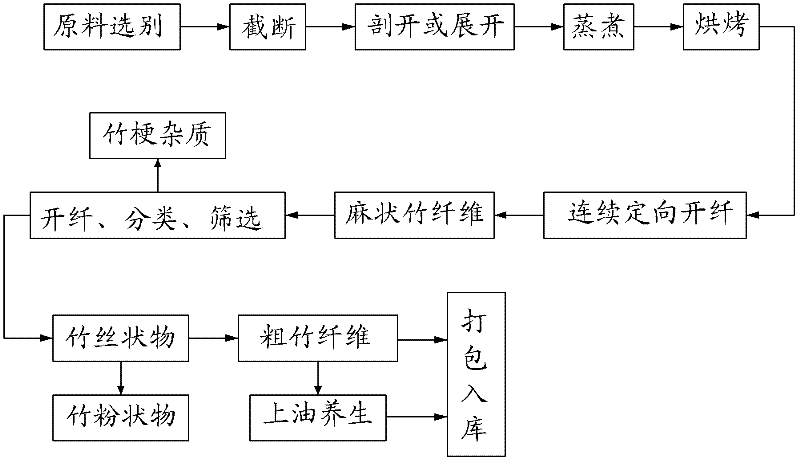

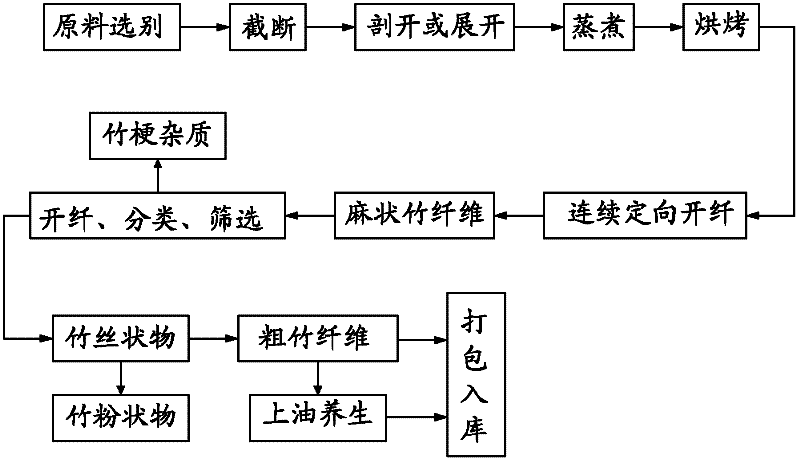

Non-pollution production method of bamboo fibers

ActiveCN102517642AEfficient productionNo harmVegetable materialMechanical fibre separationFiberPollution

The invention provides a non-pollution production method of bamboo fibers, wherein the method is used for producing coarse bamboo fibers with lengths of 60-120 mm and diameters of 0.18-0.35 mm. the method comprises the steps of: firstly, selecting the raw materials; and then, cutting the bamboos into regulated lengths; splitting or flattening the bamboos; adding a reusable neutral softening solution in the bamboos to stew and soften the bamboos; roasting the softened bamboos on a drying machine; directionally opening fibers from the roasted bamboos; drying the bamboos, opening fibers for the second time, classifying and sorting to obtain bamboo fibers with stable quality. The method of the invention has the advantages of non waste liquid drainage during the production process, simple technique, high production efficiency, reliable product quality, and capability of greatly improving the fiber yield and reducing the production cost, so that the method is an ideal method for producing bamboo fibers.

Owner:ZHEJIANG FORESTRY UNIVERSITY

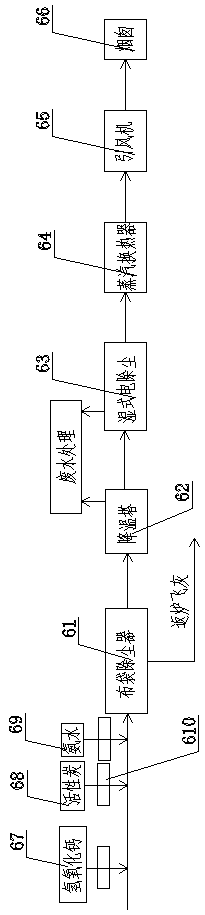

Wet sludge treatment method and equipment thereof

InactiveCN103524013AReduce speedRealize integrationSludge treatment by de-watering/drying/thickeningDeodrantsLand resourcesMunicipal sewage

The invention relates to a wet sludge treatment method and equipment thereof. Wet sludge is conveyed into sludge drying and forming equipment to be dried and formed through a wet sludge conveying pump from a wet sludge cabin; generated tail gas is sucked out through a draught fan, is fed into a dust collector for dust removal, and subsequently is fed into a condenser for condensation; uncondensed gas is fed into a deodorization device for smell gas removal, and is discharged until the gas meets the discharge standard. The wet sludge treatment method has the advantages that the heat conduction efficiency is high, the energy consumption is small, the process is simple, the reliability is high, a land is saved, the operation cost is low, and the like; municipal sewage and sludge can be treated in scale; a land resource is saved; the great significance in energy conservation is achieved.

Owner:天通新环境技术有限公司

Silicon nitride crucible coating and preparation method thereof

InactiveCN103183478AImprove mechanical propertiesMeet oxygen requirementsPolyvinyl alcoholAdhesion strength

The invention provides a silicon nitride crucible coating and a preparation method thereof. The preparation method comprises the following steps: adding adhesive, dispersant and silicon nitride into the deionized water, and uniformly mixing to obtain the sizing agent, wherein weight ratio of silicon nitride to adhesive to dispersant is 100 : (15-28) : (5-12), weight ratio of silicon nitride to deionized water is 1 : (3-4), and the adhesive is one of organosilan, metasilicic acid, polyatomic alcohol, polyvinyl alcohol and acrylate; and spraying or dipcoating the sizing agent to the inner surface of the crucible, and performing calcination and annealing at the temperature of 260 DEG C to 550 DEG C in an inert gas atmosphere, wherein oxygen content of the silicon nitride crucible coating is 1 wt% to 5 wt%. According to the invention, a certain amount of adhesive is added into the sizing agent, and subsequent calcination is controlled to be carried out in the argon gas atmosphere, so that a great amount of dust generated in the spraying process is avoided, and adhesion strength of the coating is enhanced, and as the oxygen content of the coating is controlled to be lower, the requirement of high-quality polycrystalline silicon chip production for the oxygen content of the coating can be met.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

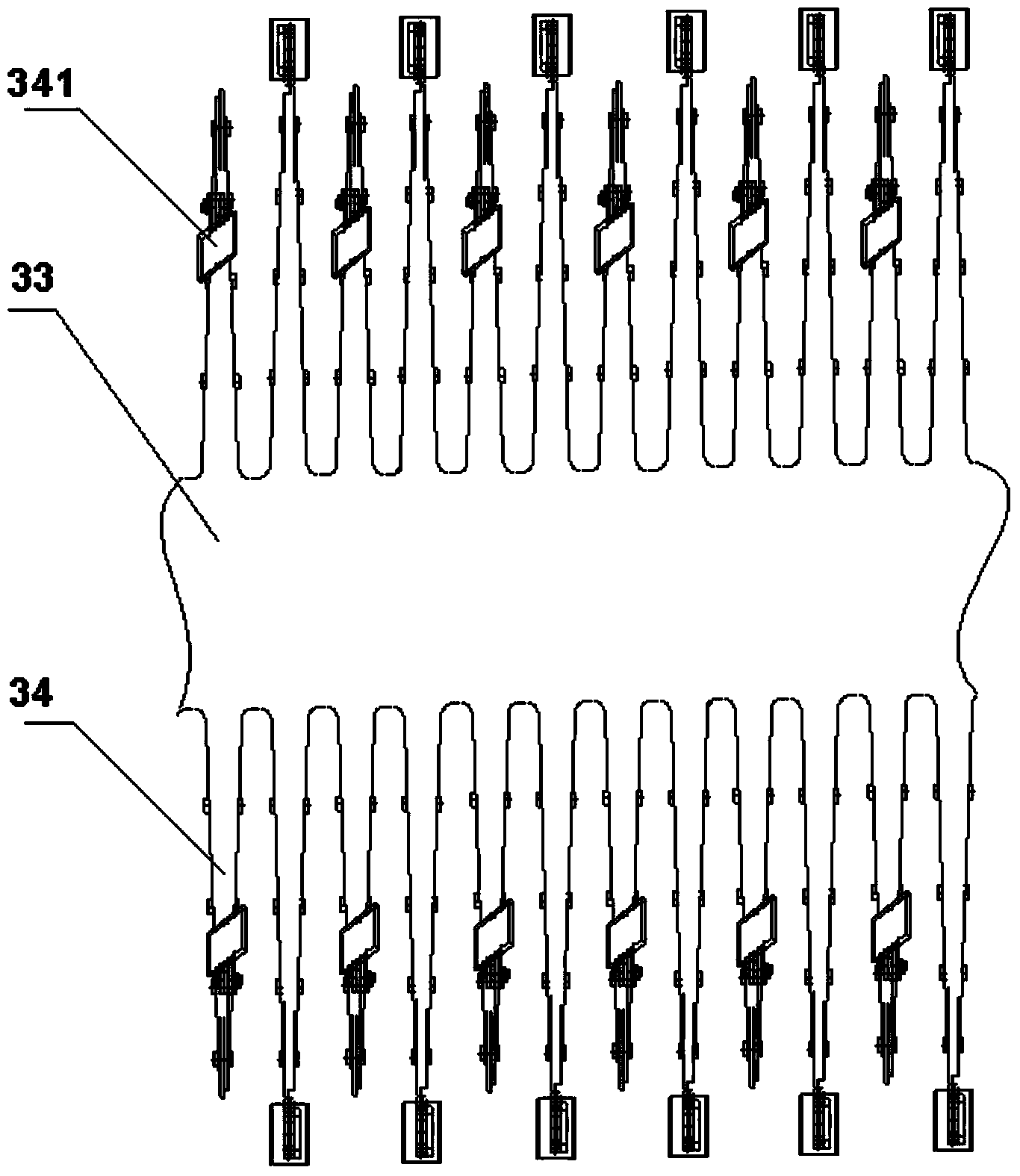

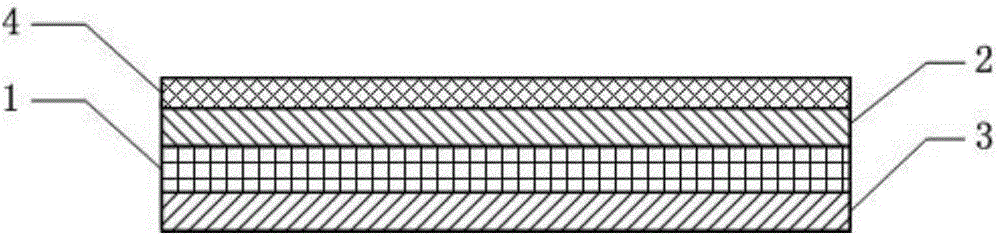

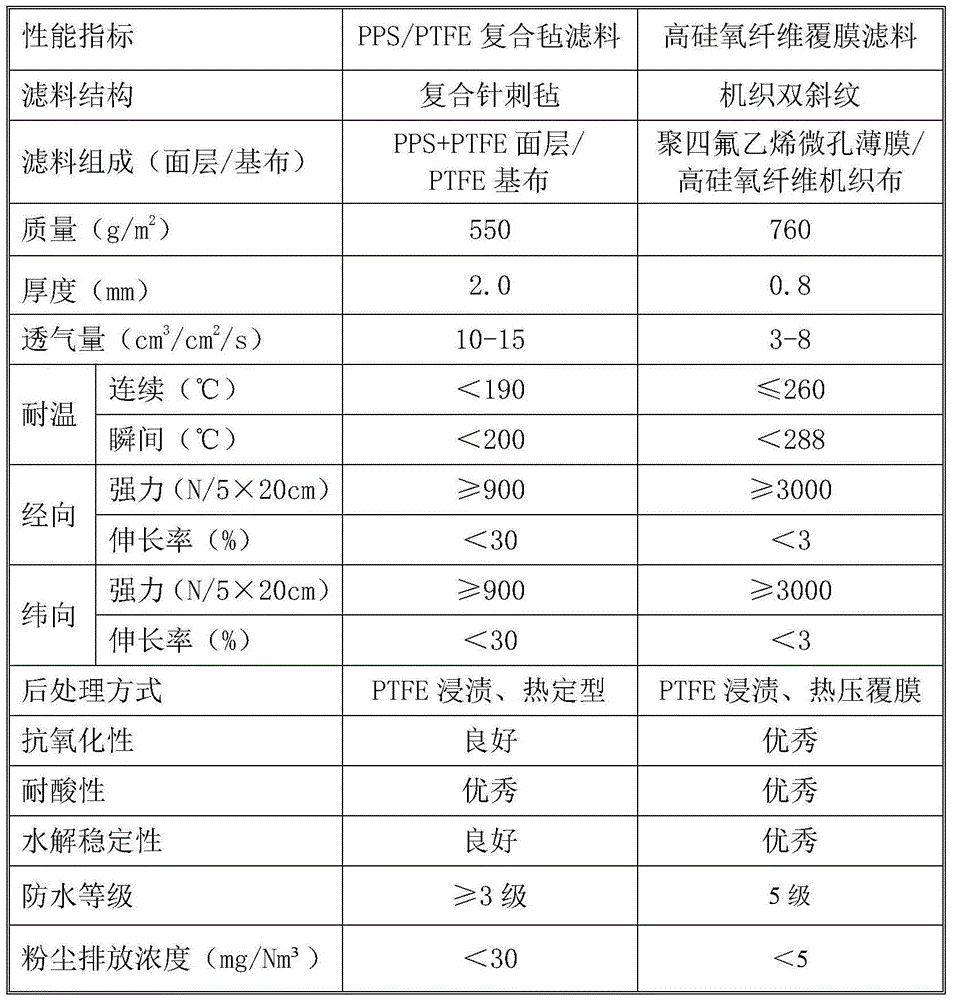

High silica fiber woven tectorial membrane filter material for coal-fired boiler and preparation method of high silica fiber woven tectorial membrane filter material

ActiveCN104623977AHigh filtration precisionGood dimensional stabilitySynthetic resin layered productsLaminationFiberTectorial membrane

The invention provides a high silica fiber woven tectorial membrane filter material for a coal-fired boiler. The high silica fiber woven tectorial membrane filter material for the coal-fired boiler comprises four layer of structures, namely an impregnation treatment protective layer, a high silica fiber expanded fabric layer, an impregnation treatment protective layer and a polytetrafluoroethylene microporous membrane layer sequentially, wherein the high silica fiber expanded fabric adopts double-layer woven fabric woven by adopting a double-layer rearranged twill technology; the whole high silica fiber expanded fabric layer is impregnated in an impregnation liquid, and the impregnation treatment protective layer is formed on the surface of the high silica fiber expanded fabric layer; the high silica fiber expanded fabric layer and the impregnation treatment protective layer form a high silica fiber treatment fabric layer; and the polytetrafluoroethylene microporous membrane layer thermally covers the high silica fiber treatment fabric layer. The high silica fiber woven tectorial membrane filter material for the coal-fired boiler has the characteristics of high filtering accuracy, temperature resistance, corrosion resistance, high strength, low flexibility, low resistance, high efficiency and long service life, PM2.5 dust can be efficiently trapped, and the near zero emission of dust less than 5mg / Nm<3> is realized.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

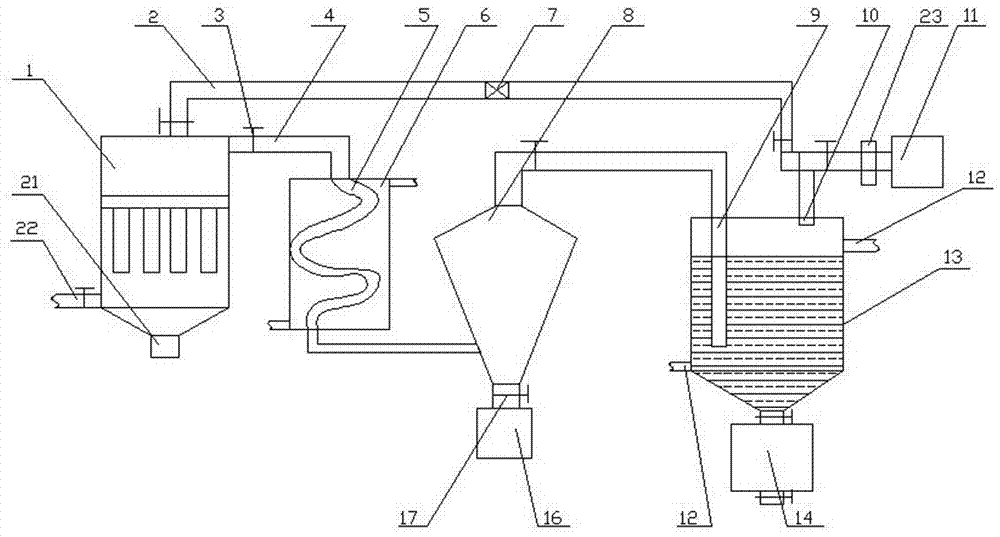

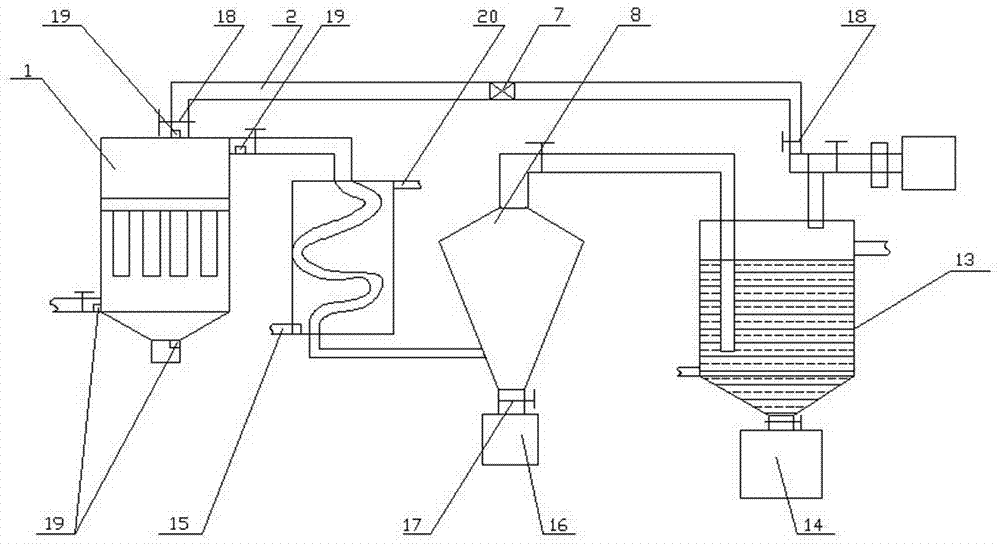

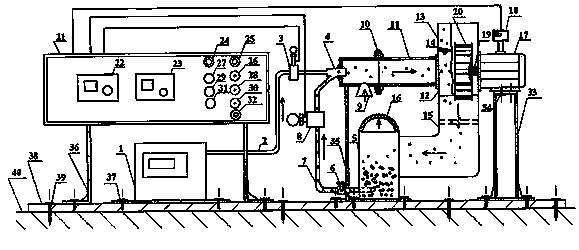

On-line waste gas treatment system of waste cable high-temperature treatment device

InactiveCN107376559AStable and efficient workEfficient recyclingCombination devicesEngineeringHot Temperature

The invention discloses an on-line waste gas treatment system of a waste cable high-temperature treatment device. The on-line waste gas treatment system comprises a first dust collection mechanism, an energy transduction mechanism, a first regeneration mechanism, a settling mechanism, a dust collection module, an absorption mechanism, a discharging mechanism, a circulation mechanism, an unloading module and an adsorption filtering mechanism, wherein the energy transduction mechanism is communicated with the first end of the first dust collection mechanism; the first regeneration mechanism is communicated with the second end of the first dust collection mechanism; the settling mechanism is communicated with the energy transduction mechanism; the dust collection module is arranged below the settling mechanism; the absorption mechanism is arranged behind the settling mechanism; the discharging mechanism is arranged above the absorption mechanism; the circulation mechanism is communicated with the absorption mechanism; the unloading module is arranged below the absorption mechanism; the adsorption filtering mechanism is arranged between the absorption mechanism and the discharging mechanism. Aiming at the phenomena that by using a conventional dust collection system, wastes cannot be efficiently utilized and waste gases is discharged into the natural environment, the modules cooperate with one another, not only are waste gases efficiently recycled, but also substances in the waste gases are recycled, and environment pollution is avoided.

Owner:国网河南省电力公司西峡县供电公司

Device for drying hydrous waste plastic

InactiveCN101825391AGood effectAvoid scorchingDrying solid materials with heatDrying gas arrangementsEngineeringMechanical engineering

The invention relates to a device for drying waste plastic of which the surface carries moisture. The device used together with a waste plastic pyrolysis treatment device. The device of the invention consists of a pedestal, a motor, a drying room, a feed port and a discharge port, wherein the feed port and the discharge port are arranged on the drying room; the drying room is a circular-section cylindrical member of which the cylinder wall is provided with air vents and can rotate around the axis; an included angle between the axis of the drying room and the horizontal plane is between 8 and 15 degree; a sealed outer wall is arranged outside the drying room to form a space between the sealed outer wall and the outer cylinder wall of the drying room; the sealed outer wall is provided with an air inlet pipe and an air outlet pipe; the space between the inside of the outer wall and the outside of the cylinder of the drying room is divided into an air inlet region and an air outlet region; and in the drying room, each pair of an air inlet and an air outlet form a drying unit.

Owner:南通天义环保能源科技发展有限公司

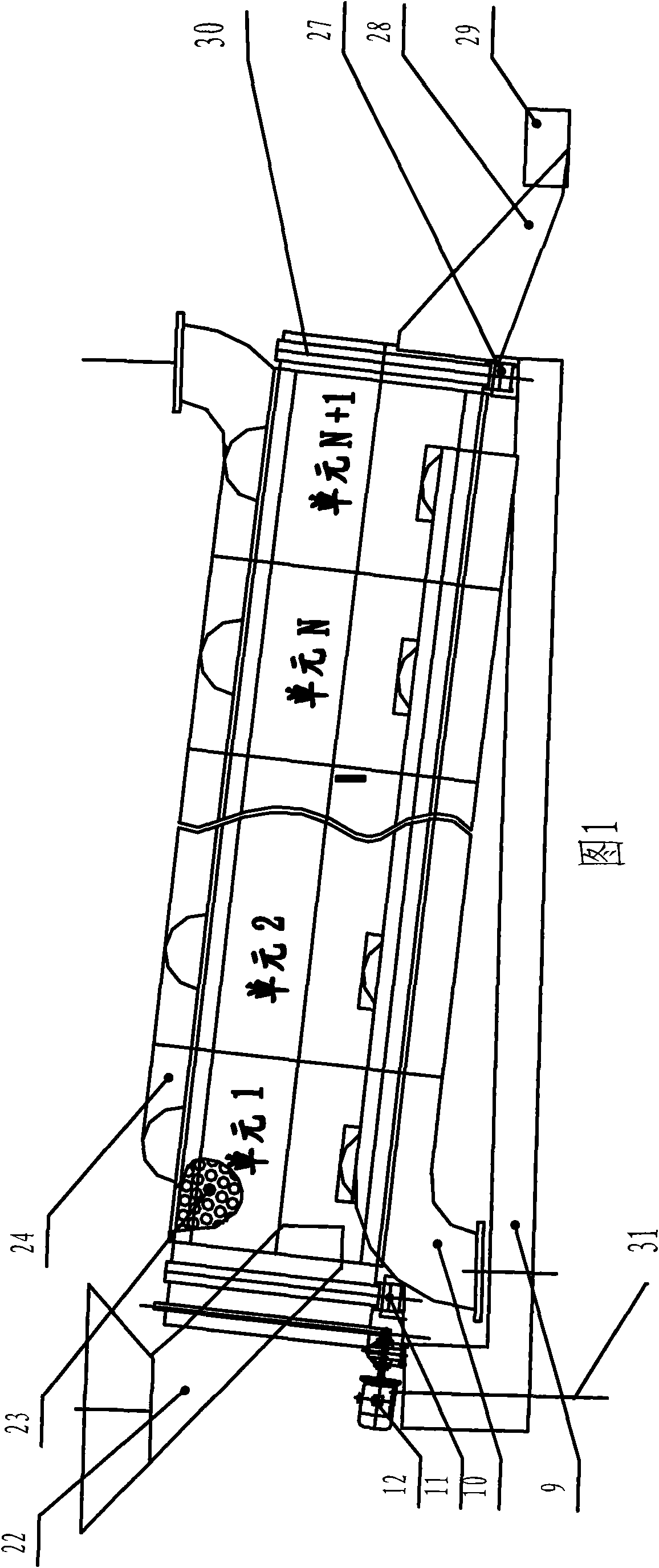

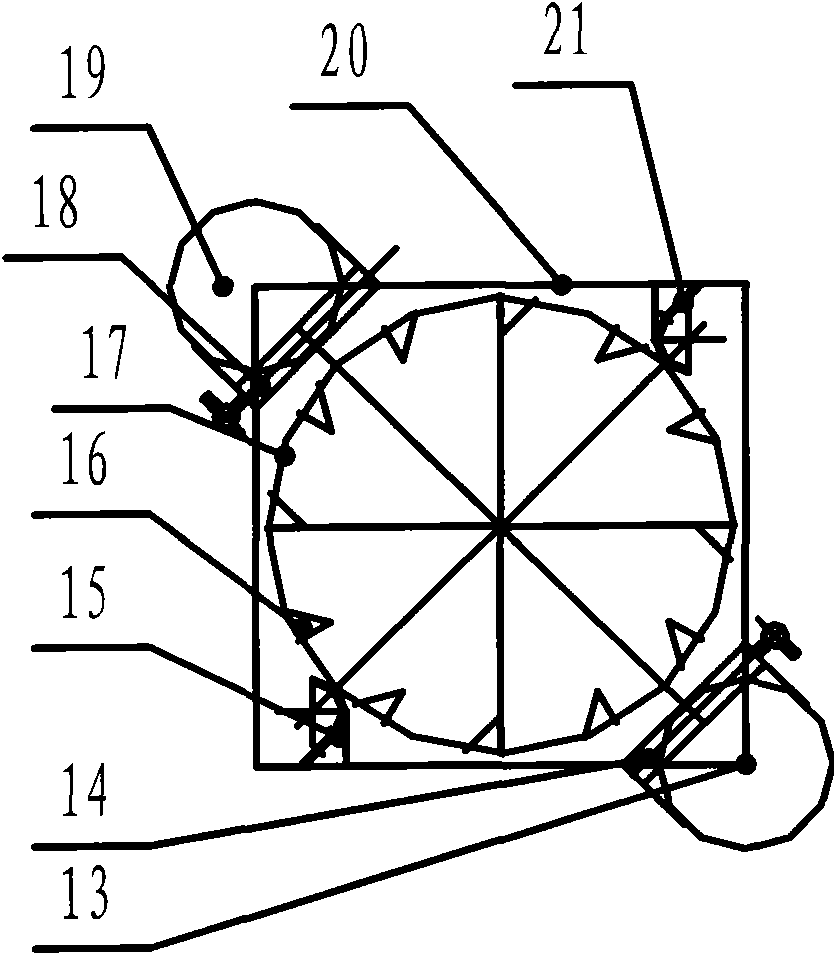

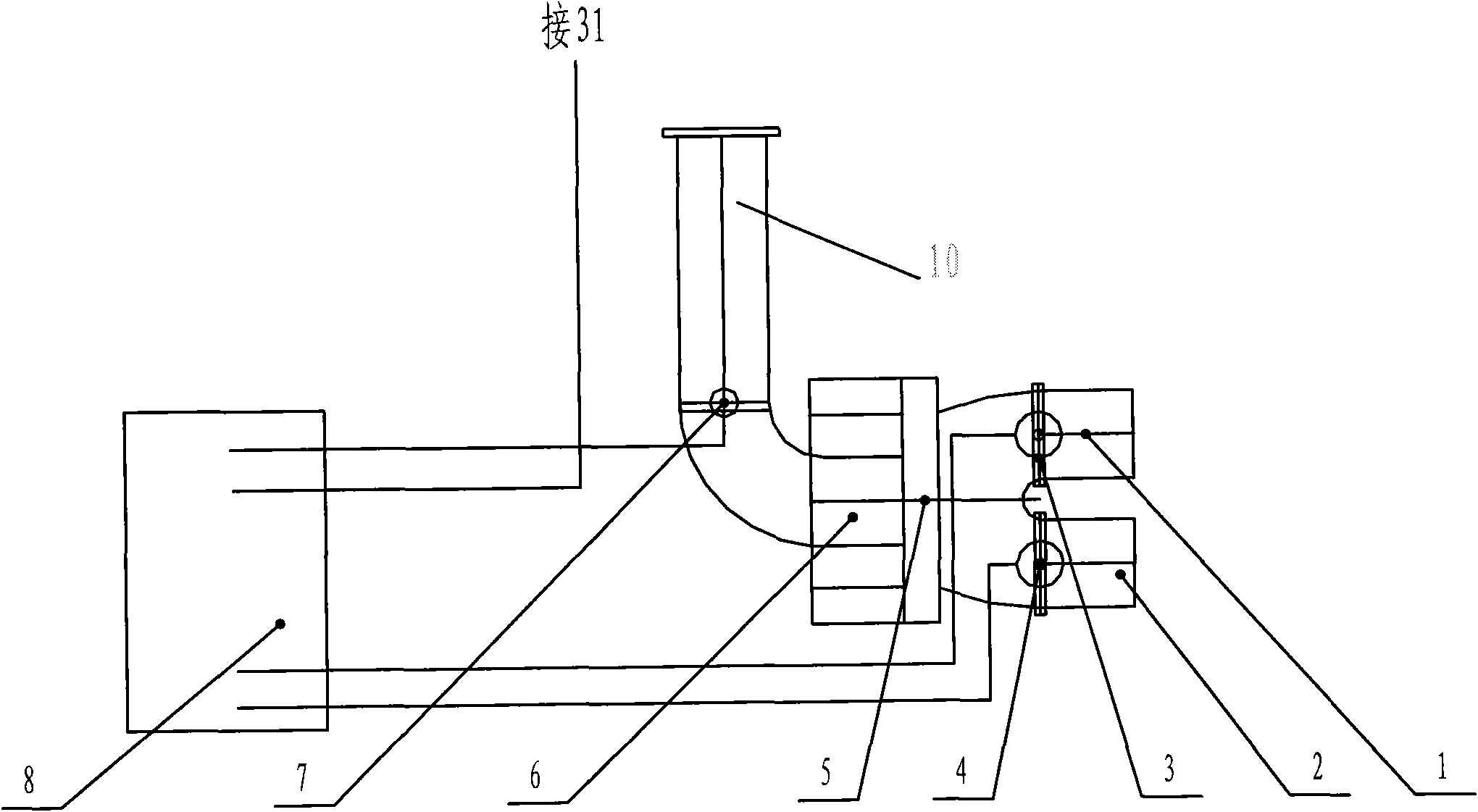

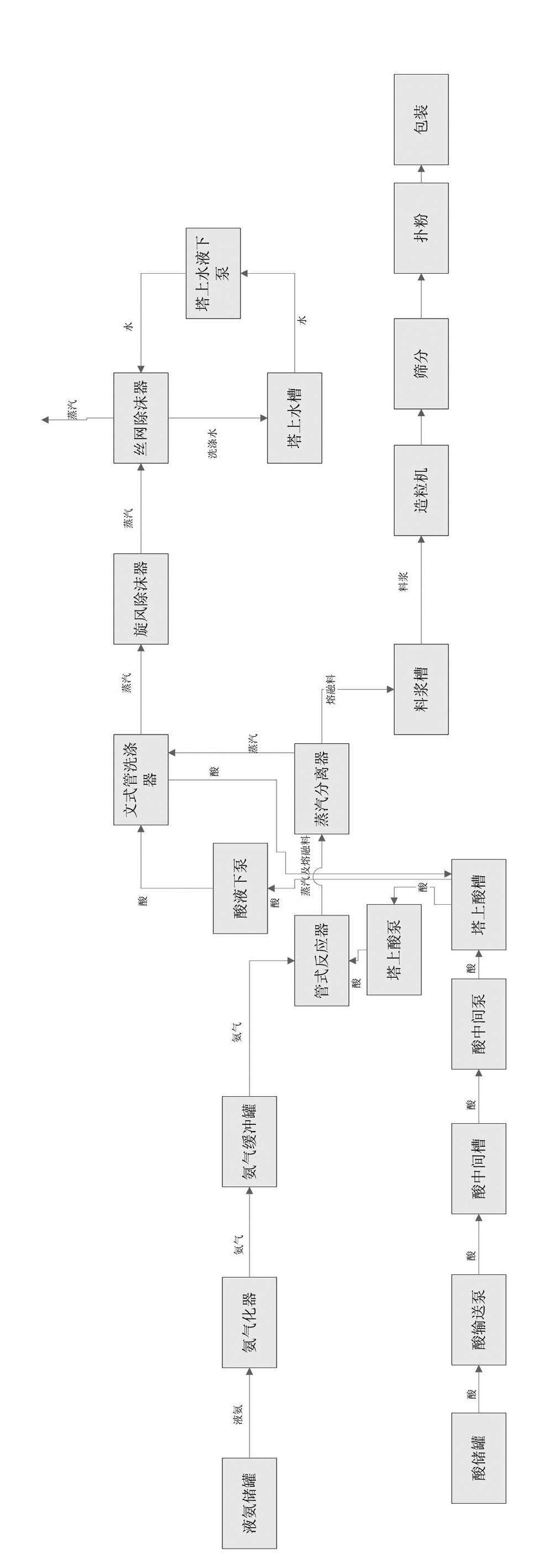

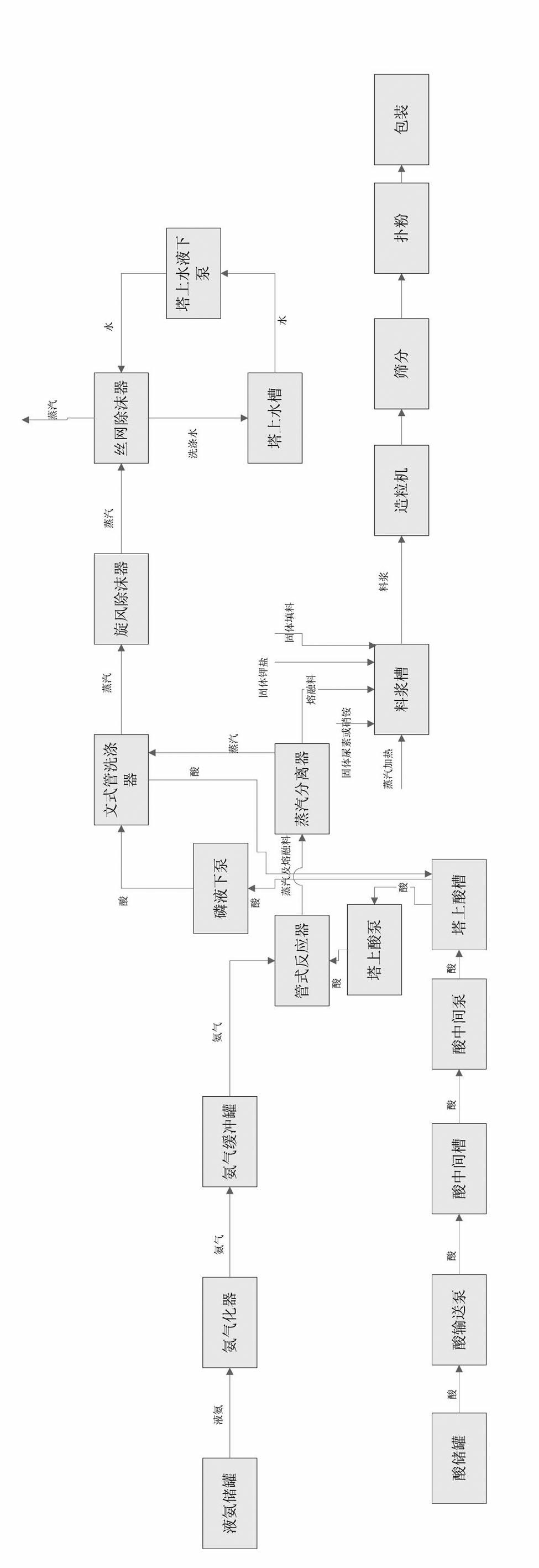

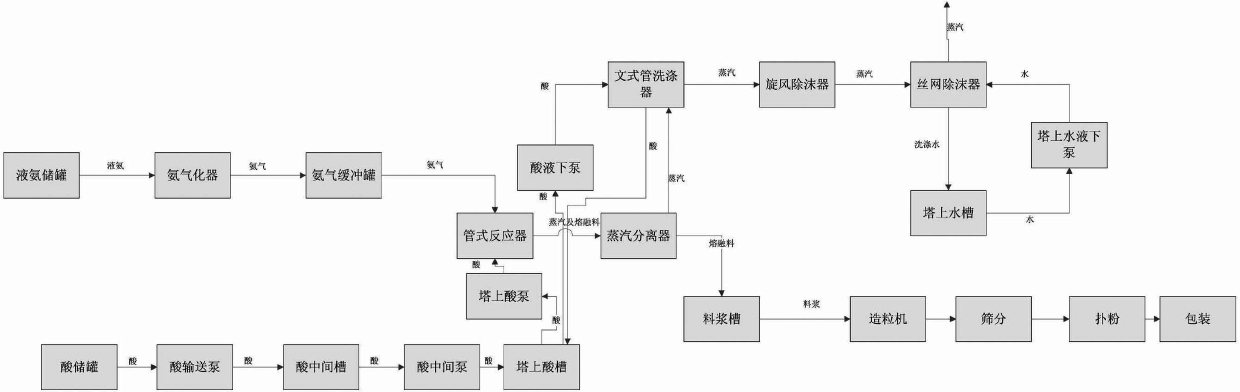

Method for producing compound fertilizer by high tower tubular reactor

The invention relates to a method for producing a compound fertilizer by a high tower tubular reactor, which comprise the following steps of: adding acid and ammonia which are used as raw materials into the tubular reactor to perform the mixing reaction to prepare mixed slurry; separating the mixed slurry from steam by a steam separator; and filling the slurry obtained by separating into a slurry tank, spraying the slurry into a granulation tower by a granulation spray nozzle at the top of a tower, cooling granulation materials by the cold air in the tower to ensure that the granulation materials fall onto the bottom of the tower and sieving to obtain the compound fertilizer. The molten slurry is obtained by utilizing the reaction heat of the acid and the ammonia and a part of solid raw materials can also be molten down, so that energy is saved and the consumption is reduced; the acid and the ammonia which are used as the raw materials are fluid and are more beneficial to mechanical operation, labor is saved, the dust quantity is reduced and the environment is optimized; and the slurry is in a molten state, so that a low-nitrogen high-phosphorus compound fertilizer can be produced by the high-tower granulation.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

A tamping apparatus for road engineering

The invention belongs to the technical field of tamping apparatuses, in particular to a tamping apparatus for road engineering. Aiming to solve problems that local cavities in the road surface, uneventamping, a lot of dust during work and inconvenient movement are likely to occur, the invention proposes the following scheme: the tamping apparatus comprises a bottom plate and a mounting rack; theouter walls on both sides of the top end of the bottom plate are fixed by bolts with vertically arranged positioning posts; the outer wall of one side of the top end of the bottom plate is fixed witha vibration motor by bolts; the side walls of the two positioning posts are sleeved with connecting sleeves; and the two connecting sleeves are respectively fixed by bolts at intermediate positions onthe outer walls of the two sides of the mounting rack; and shock absorbing rods are hinged at positions, close to four corner portions, of the outer wall of the two sides of the mounting rack. The tamping apparatus of the invention can realize graded tamping, improve the tamping effect, make the tamping more uniform, avoid the local cavity phenomenon, collect dust, reduce the amount of dust in the working process and improve the working environment.

Owner:明磊建设集团有限公司

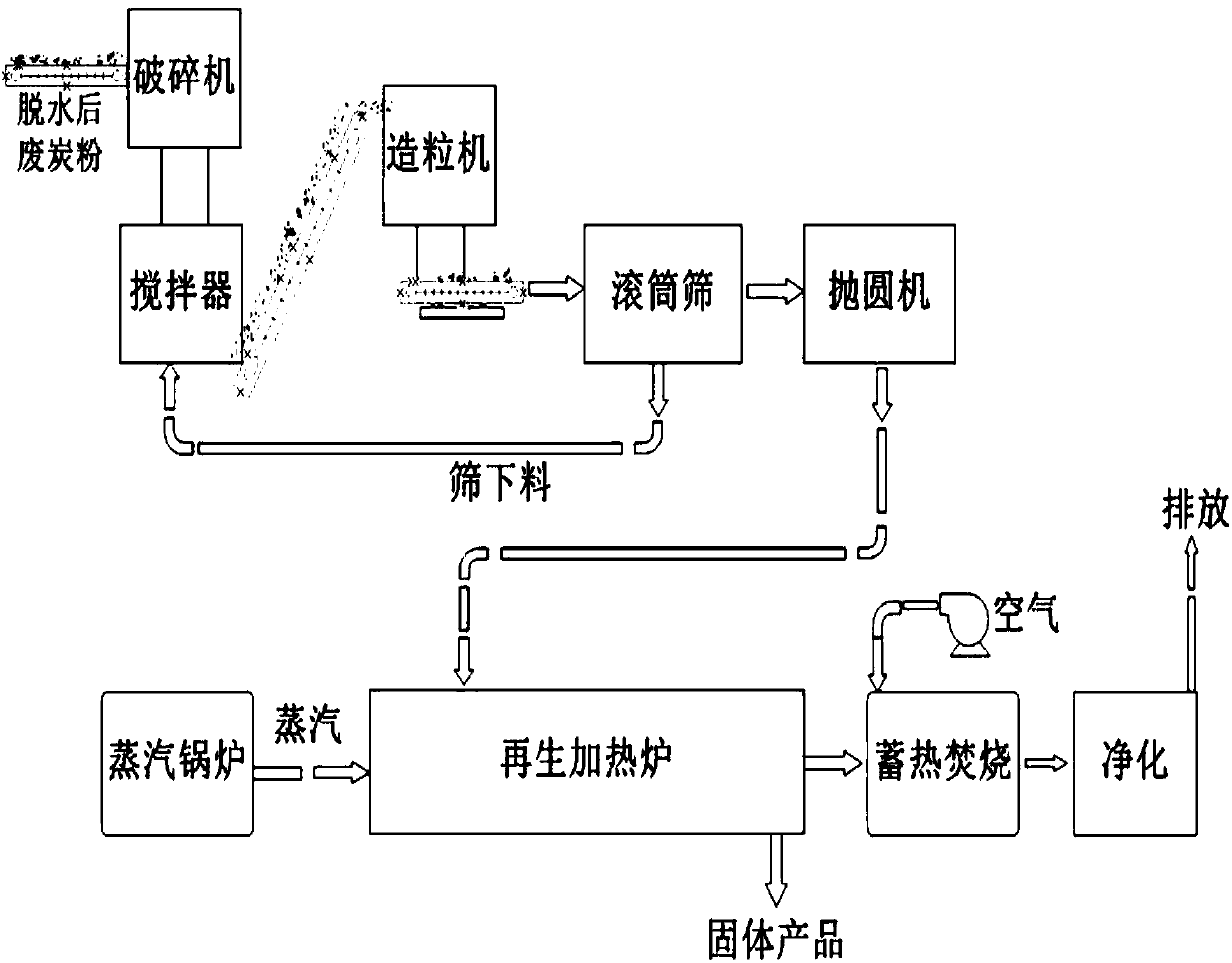

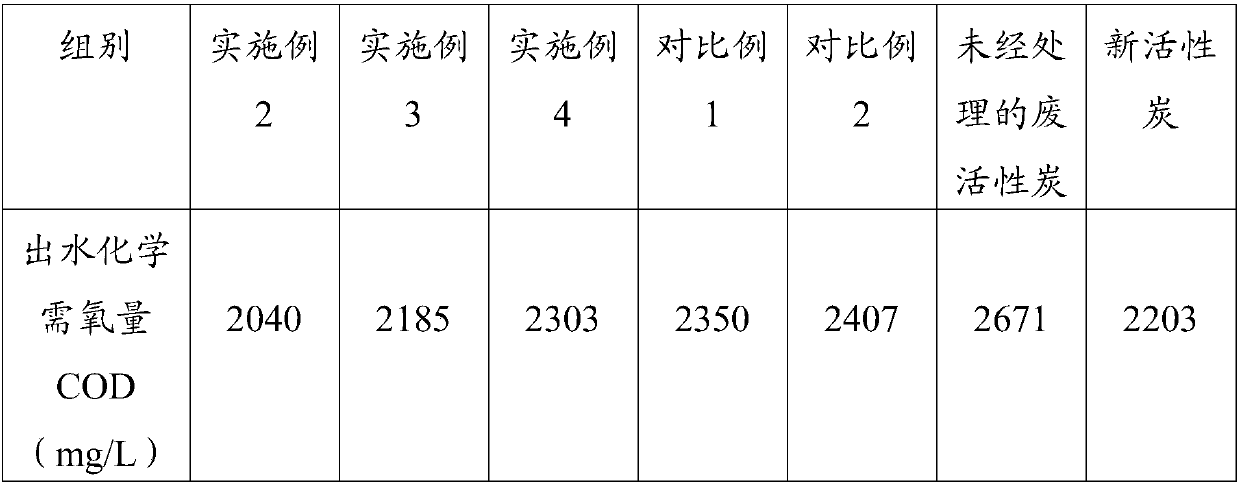

Powdery active carbon regeneration system and powdery active carbon preparation method

ActiveCN107827109AReduce lossesHigh mechanical strengthCarbon compoundsActivated carbonProcess engineering

The invention discloses a powdery active carbon regeneration system and a powdery active carbon preparation method, and belongs to the field of waste treatment. The powdery active carbon regenerationsystem comprises a roller granulating device, a regeneration heating furnace and a gas burning device which are sequentially connected. The system and the method have the advantages of realization ofthe regeneration treatment and cycle use of powdery active carbon, reduction of the pollution to the environment, reduction of the use cost of active carbon, simple process flow, and no secondary pollution in the production process.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Controllable sand flow infinitely variable speed fan blade abrasion testing device

InactiveCN103645103AReduce pollutionKeep healthyInvestigating abrasion/wear resistanceParticle flowWear testing

The invention discloses a controllable sand flow infinitely variable speed fan blade abrasion testing device which consists of an air compressor, a gas delivery pipe, a pressure sensor, a spray gun, a sand storage chamber, a sand flow control valve, a sand pipe, a particle flow sensor, an air inlet pipeline, an erosive wear test chamber, an erosive wear test chamber upper cover, an air outlet pipeline, a deduster, a motor, a frequency converter, a fan propeller, a control cabinet, a motor bracket, an air inlet pipeline bracket, a control cabinet bracket and an angle iron bracket. A series of technical problems that the erosive wear working conditions of a rotary fan blade cannot be really simulated by a conventional erosive wear testing device are overcome.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com