Non-pollution production method of bamboo fibers

A bamboo fiber, pollution-free technology, applied in the chemical post-processing of fibers, fiber processing, fiber mechanical separation, etc., can solve problems such as difficulty in meeting the requirements of sustainable green production concepts, environmental problems of pollutants, and increased production costs, etc. Achieve high softening efficiency, short softening time and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

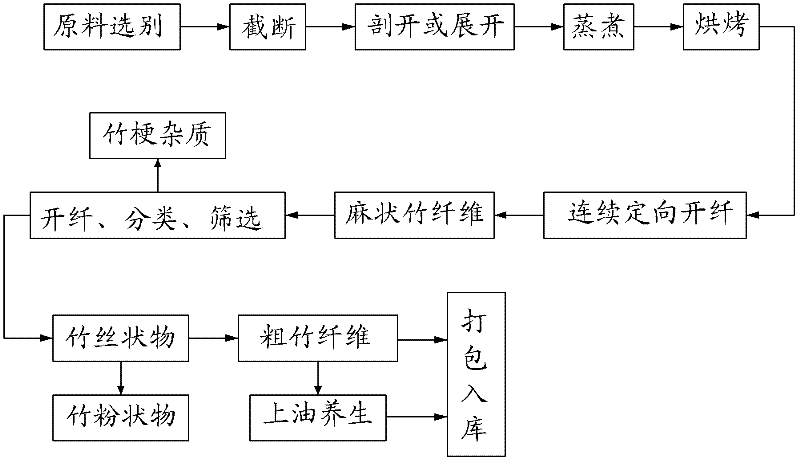

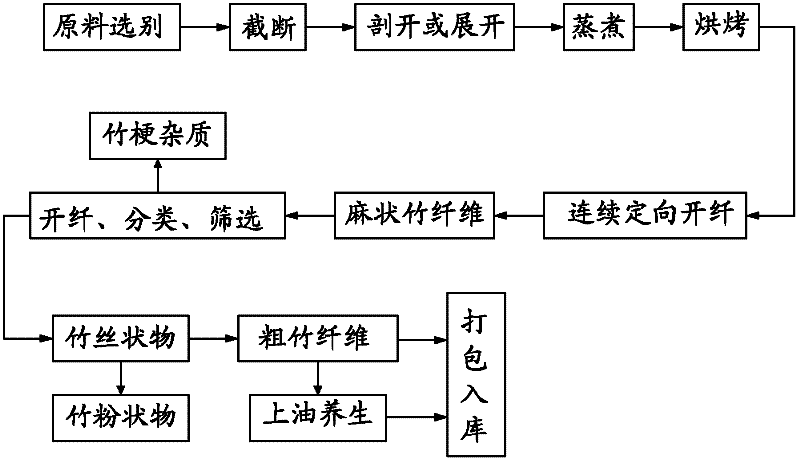

[0026] Such as figure 1 Described, a kind of pollution-free production bamboo fiber method that the present invention relates to, comprises the following steps:

[0027] Step 1 Raw materials are selected, and each batch of bamboo is classified according to the place of origin and bamboo age, and stored in each designated area;

[0028] Step 2. Cutting off, sawing off the tip, middle and head of the bamboo according to the specified length. Generally, the sawing length can be within the range of 1-6 meters;

[0029] Step 3. Cutting or flattening, the truncated bamboo is cut in half or divided into 1 / 4 pieces, or the bamboo is directly unfolded into sheets with a flattening machine;

[0030] Step 4. Cooking. Send the split or flattened bamboo to a special high-temperature and high-pressure cooking pot, add water or secondary softening solution, and completely immerse the bamboo in the solution. The cooking temperature is controlled at 100-130°C. Press to 2-3kg / cm2, cook for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com