Patents

Literature

811results about "Mechanical fibre separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

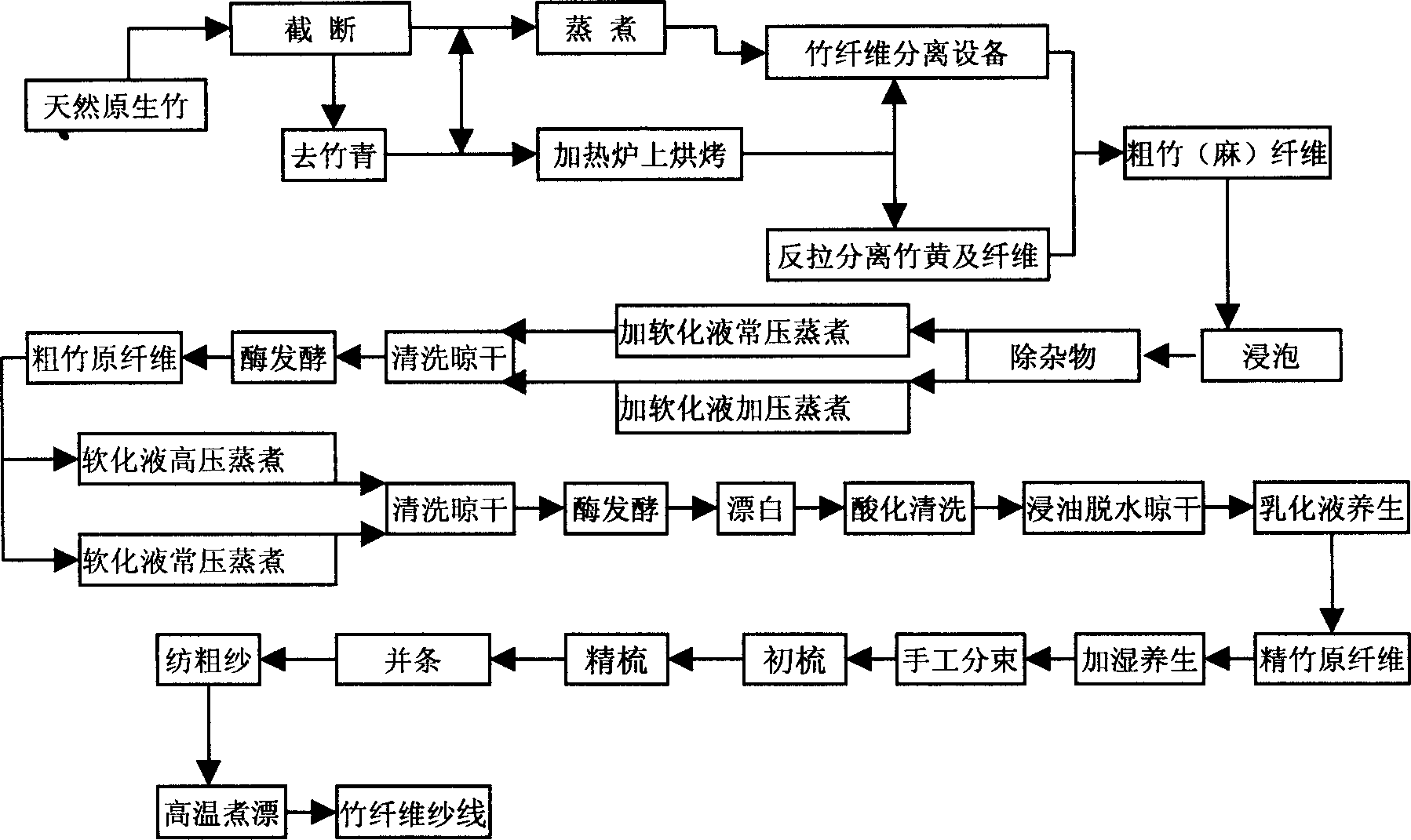

Method for making bamboo fiber

InactiveCN1621580ASolve the problem of excessive lignin contentHigh strengthWood working apparatusMechanical fibre separationCardingToughness

The present invention is preparation process of bamboo fiber, including coarse bamboo fiber, refined bamboo fiber and spinnable bamboo fiber. The coarse bamboo fiber is prepared through cutting bamboo, separating bamboo fiber, steaming inside the No. 1 softening liquid and enzyme fermentation; the refined bamboo fiber is prepared through steaming inside the No. 2 softening liquid, enzyme fermentation, rinsing and bleaching, acid treatment, and oil soaking and drying; and the spinnable bamboo fiber is prepared through emulsifying, initial carding, combing and drawing. The bamboo fiber has lignin content lower than 5 %, and has the features of being natural and green, high in strength, high toughness, high brightness and high elasticity.

Owner:临安力源竹纤维技术开发有限公司

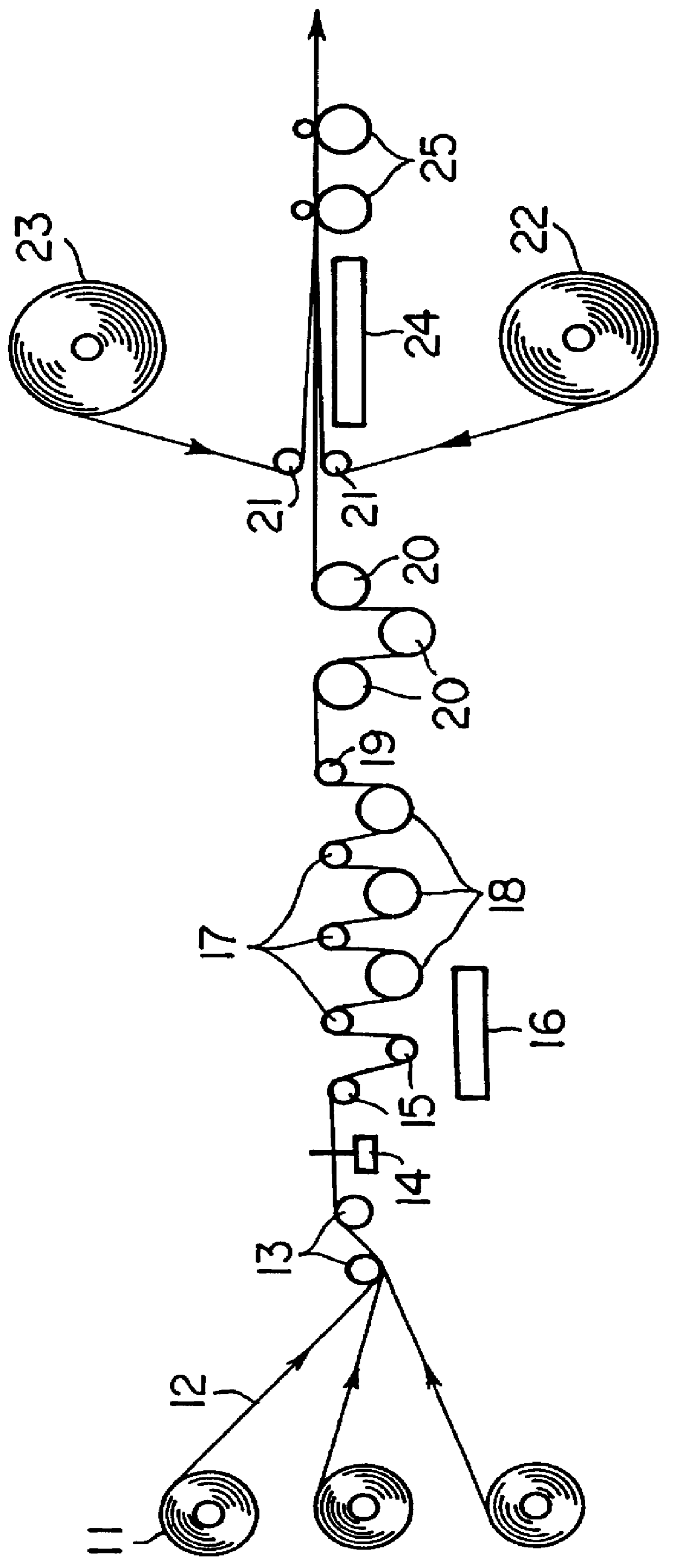

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Preparation method of ko-hemp

The invention relates to a preparation method of ko-hemp, which comprises the following steps: pueraria lobata is collected after leaves fall down in the end of fall and prepared into the ko-hemp through stewing, immersion, rolling, kneading, brushing and drying. The prepared ko-hemp is pure white, glossy and soft and has good toughness, thereby being used as materials of mattresses, seat cushions, wall papers and pillows.

Owner:汪盛明

Glassware cleaning and drying equipment for medical experiments

InactiveUS20200108426A1Continuous cleaningIncrease flexibilityHollow article cleaningDrying gas arrangementsGlass vesselElectric machinery

The invention discloses a glassware cleaning and drying equipment for medical experiments, which includes a device cabinet, wherein a cleaning space is provided in the device cabinet, a brushing space communicating with the cleaning space is provided on a bottom wall of the cleaning space, and a water pump is fixedly installed in the left inner wall of the brushing space. The nozzle is fixedly installed on the output pipe. The brushing motor is started. The brushing motor drives the gear shaft to rotate. The brush cylinder and the washing brush that the gear shaft rotates rotate. The medical glassware is cleaned and disinfected. The effect of individual treatment is better and the disinfection is more thorough. The chuck can be changed according to the size of the clamped utensils. There is no need to change the mold for clamping the utensils.

Owner:WU MEIJUN

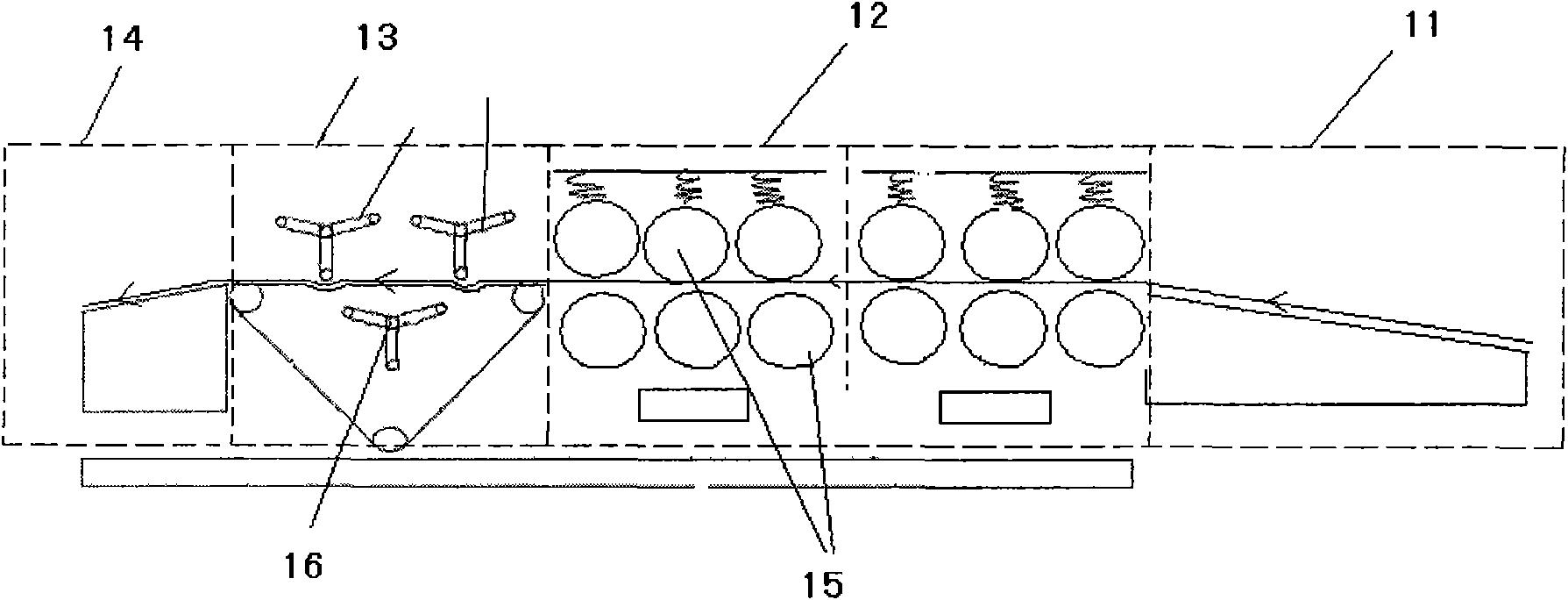

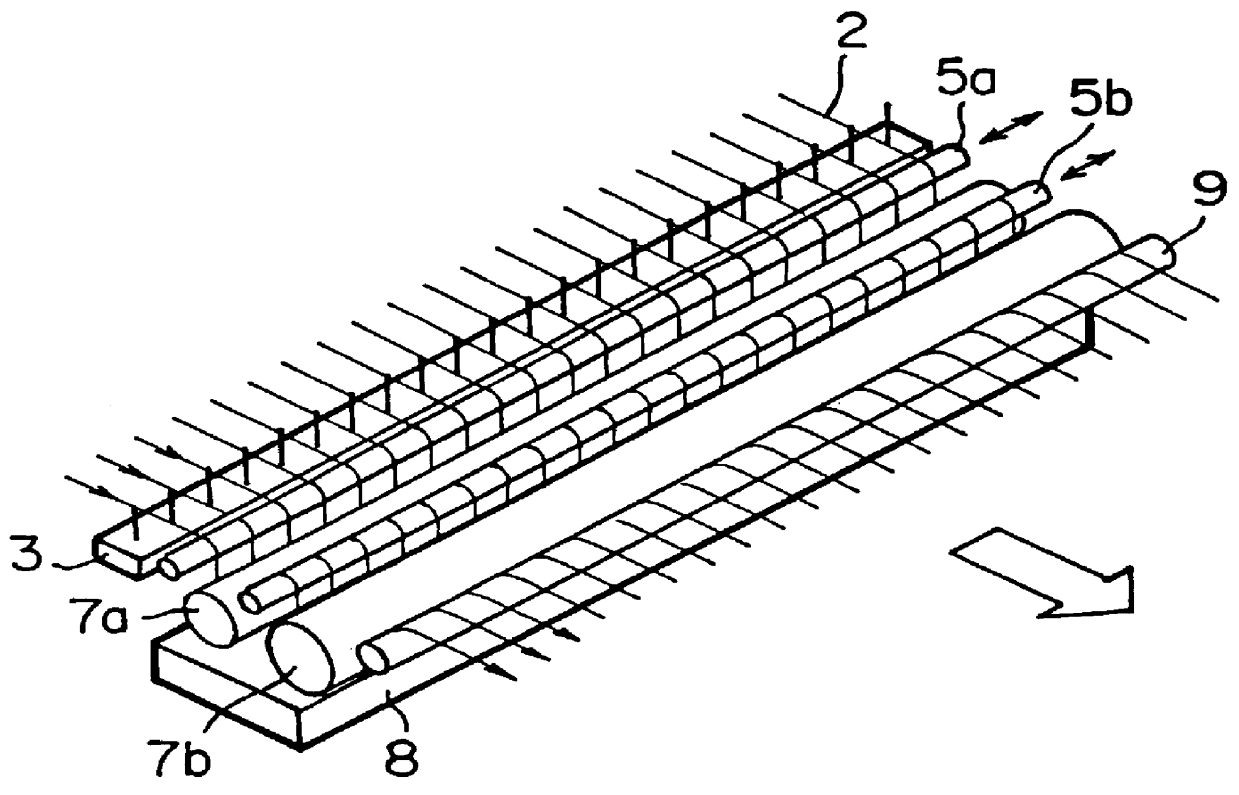

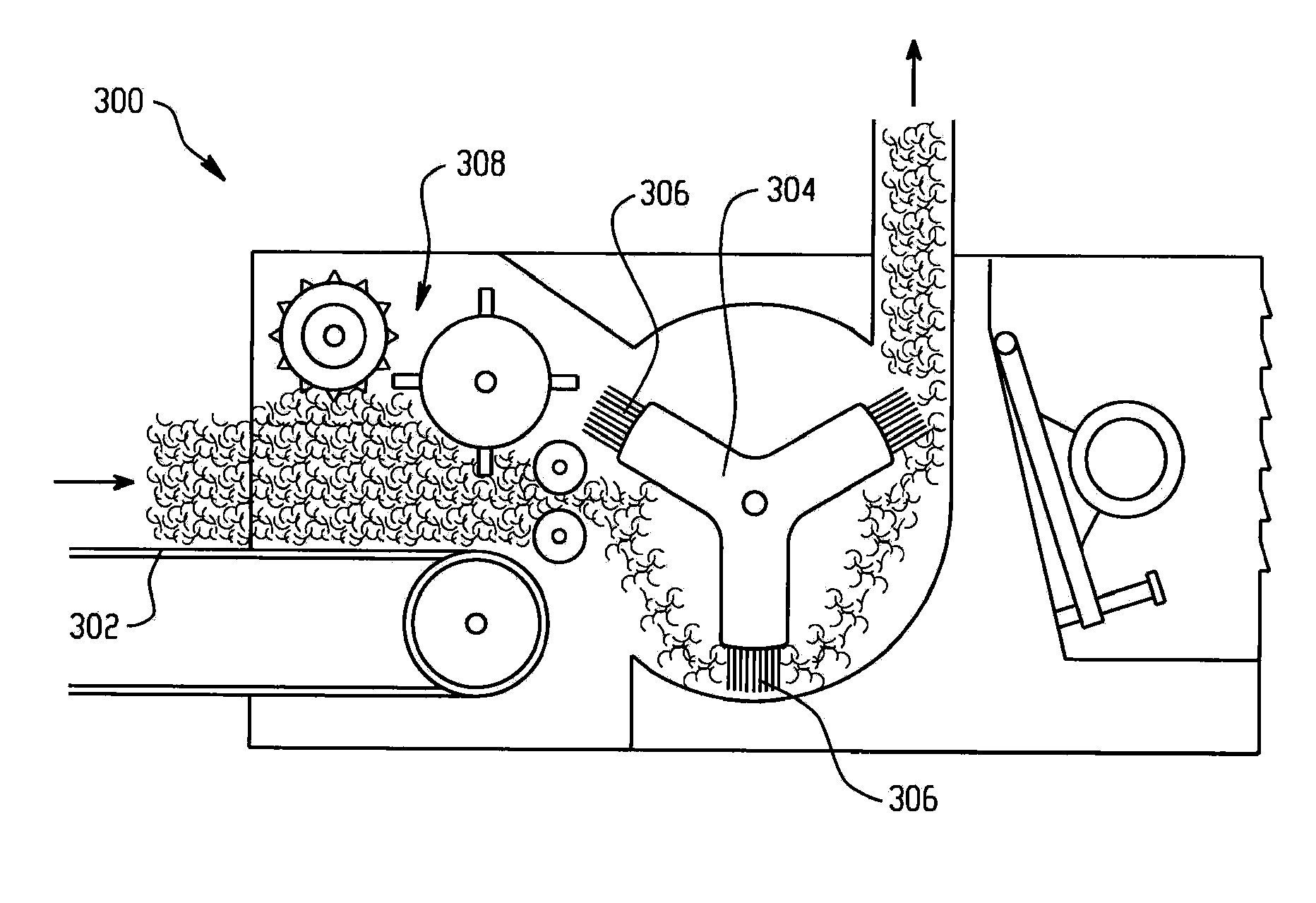

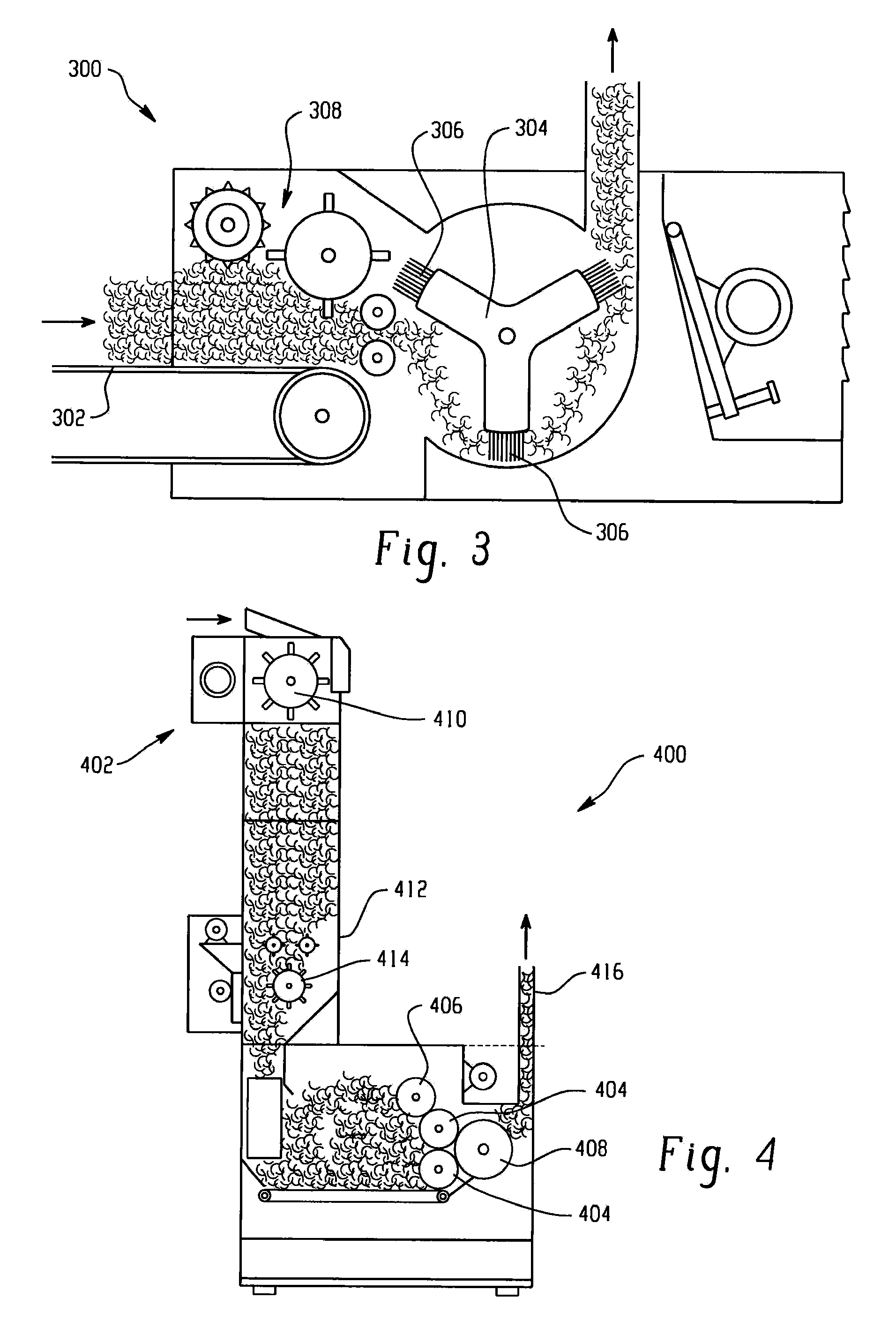

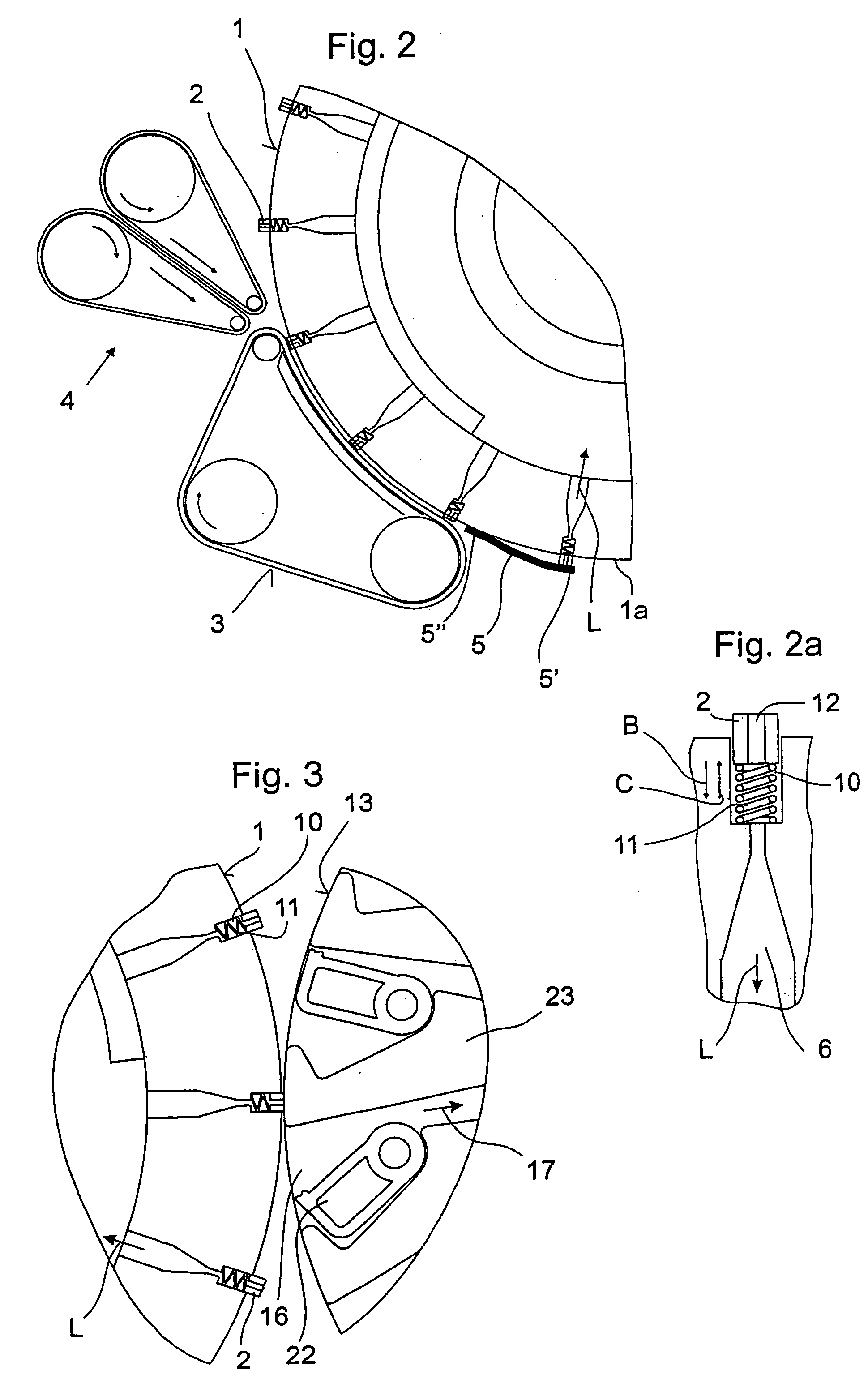

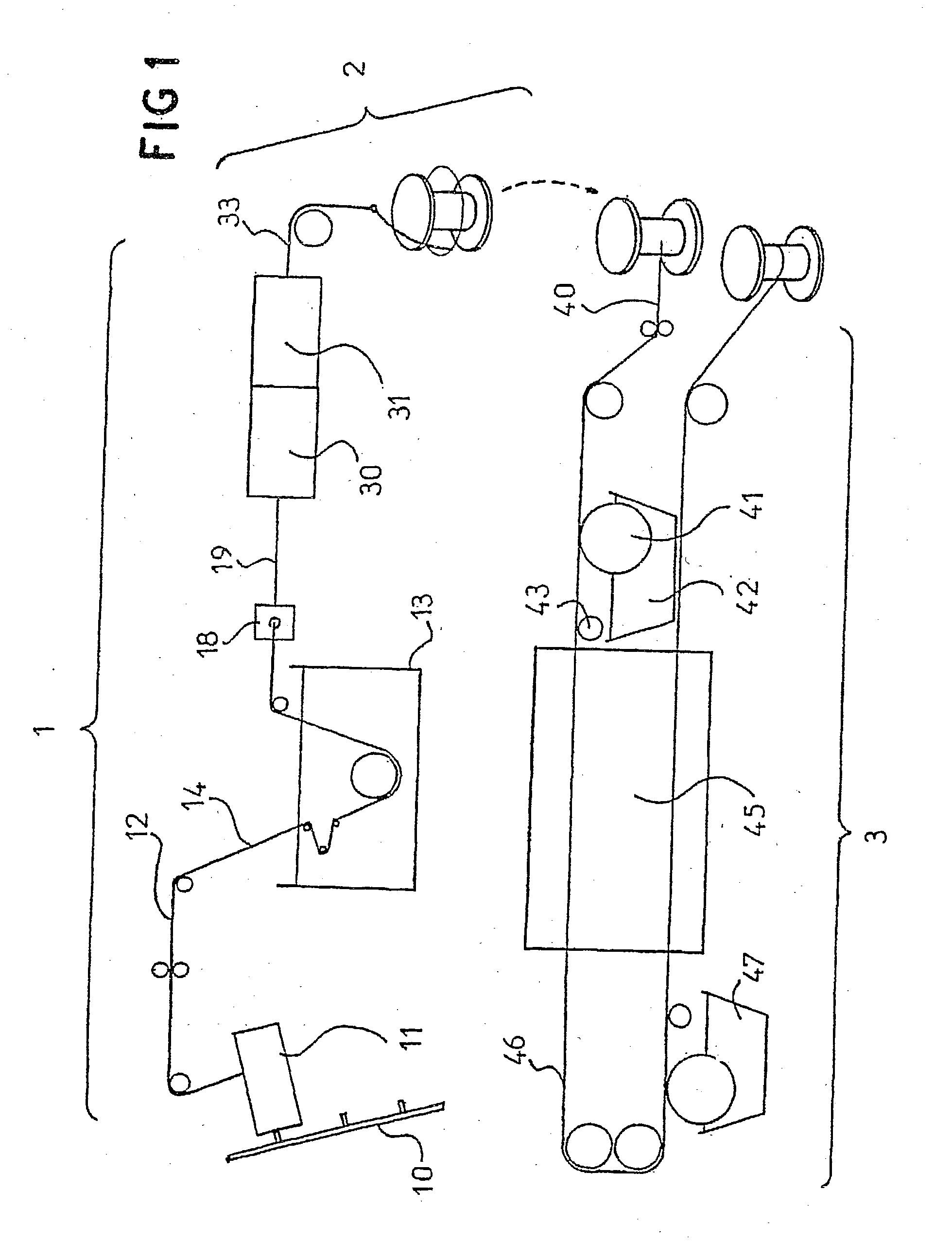

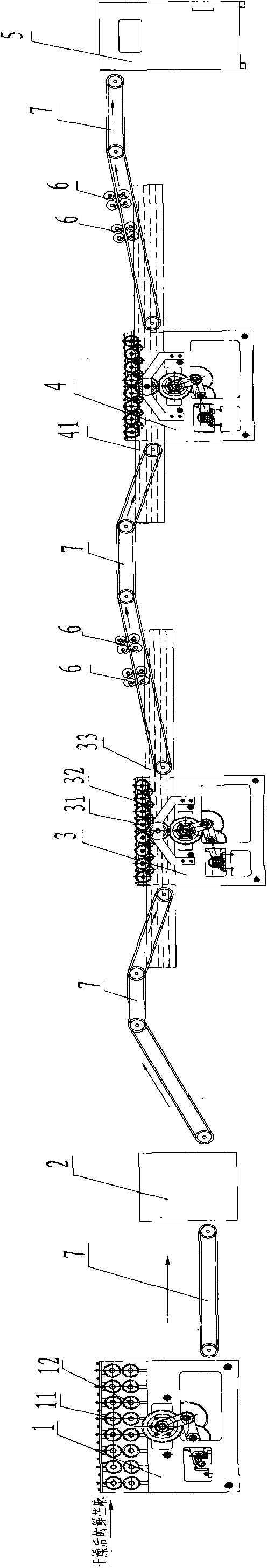

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

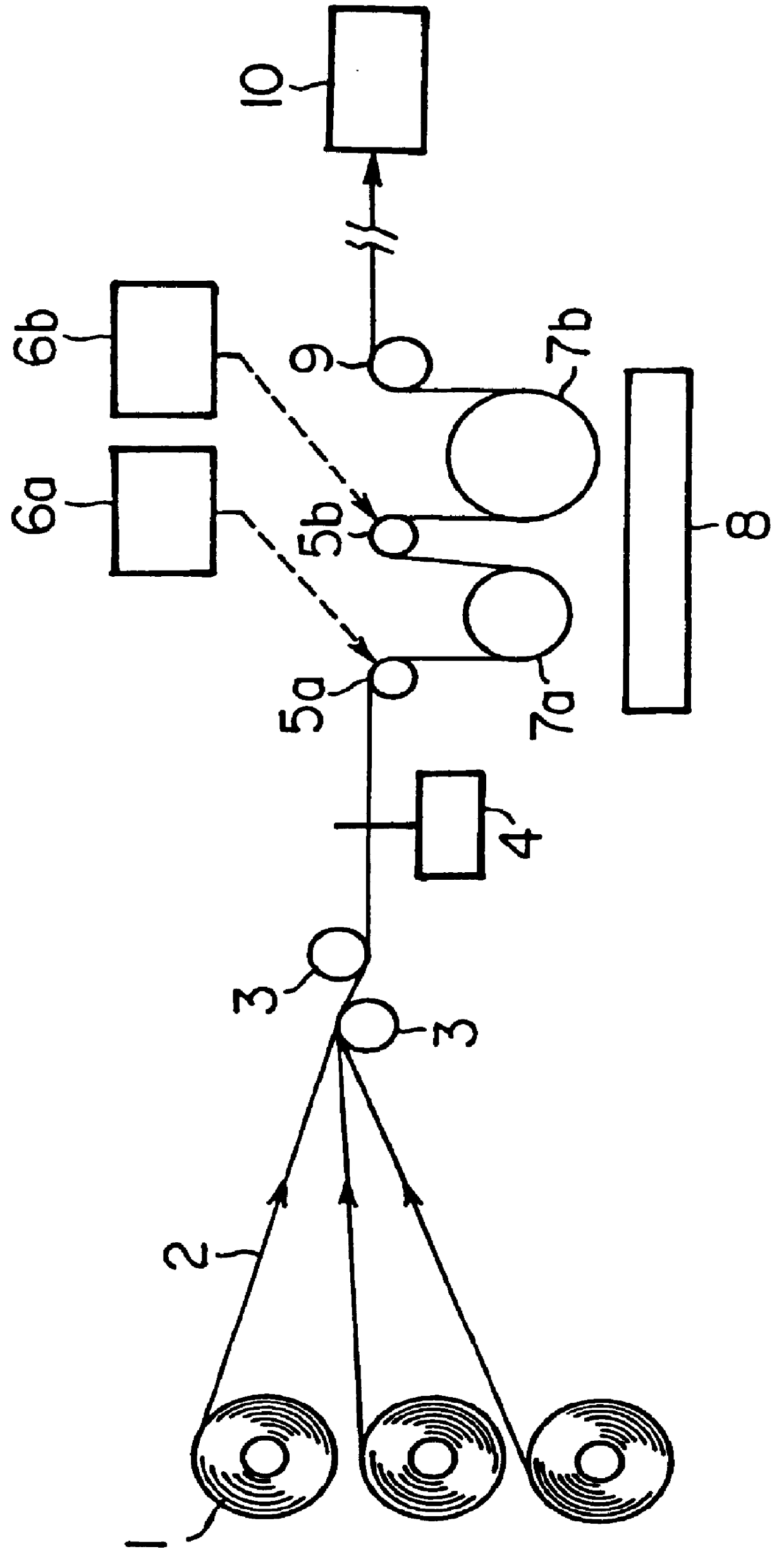

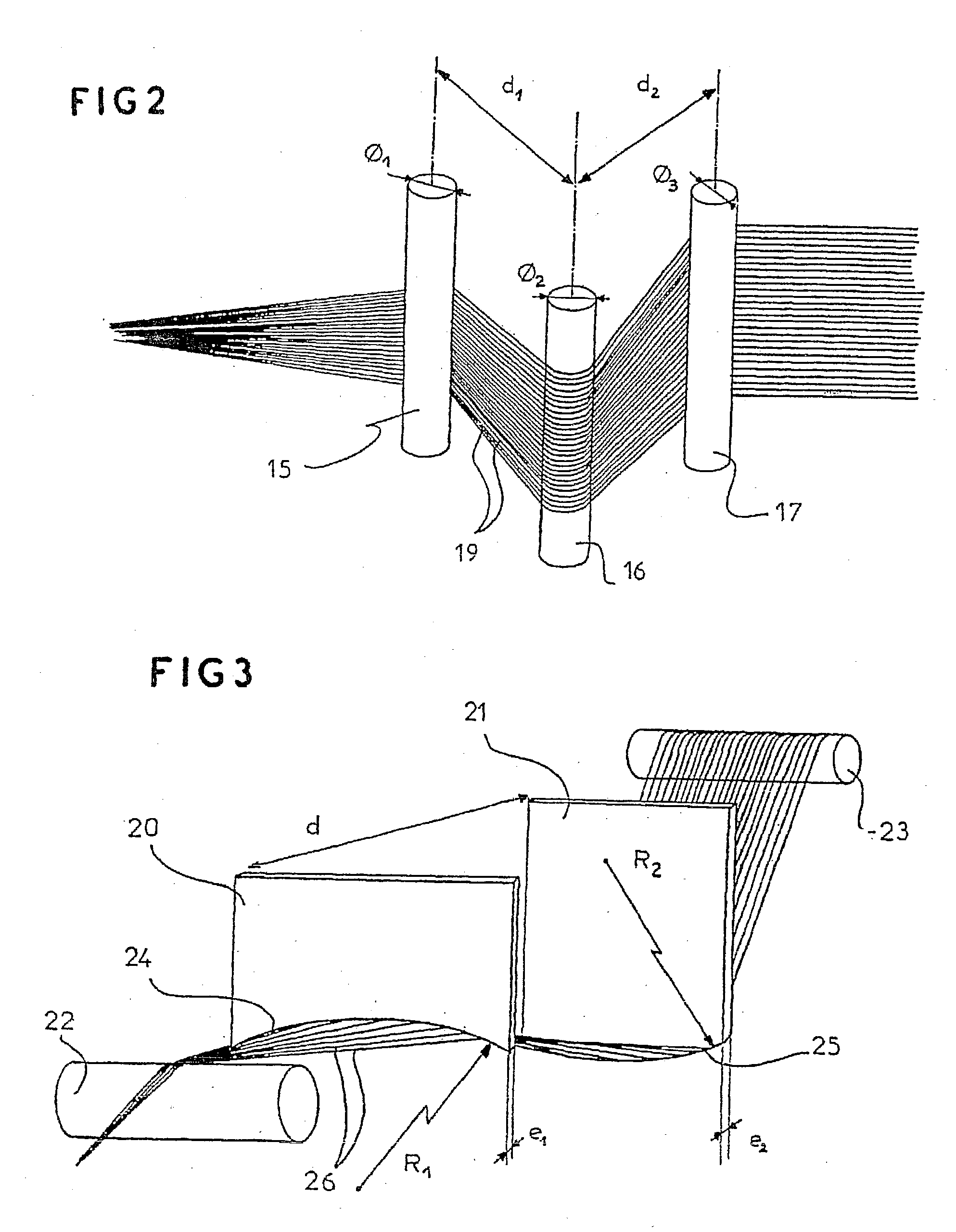

Method and apparatus for opening reinforcing fiber bundle and method of manufacturing prepreg

PCT No. PCT / JP97 / 04541 Sec. 371 Date Dec. 18, 1998 Sec. 102(e) Date Dec. 18, 1998 PCT Filed Dec. 10, 1997 PCT Pub. No. WO98 / 45515 PCT Pub. Date Oct. 15, 1998The present invention provides a method and apparatus, in which a reinforcing fiber bundle consisting of a plurality of paralleled single fibers is or a plurality of mutually paralleled reinforcing fiber bundles respectively consisting of a plurality of paralleled single fibers are driven to run through a plurality of rolls while being bent to open the fiber, and in which the opened reinforcing fiber bundle is impregnated with resin to produce a prepreg, comprising vibrating at least one of the rolls in the axial direction of the roll, to open the reinforcing fiber bundle(s), pressing the reinforcing fiber bundle(s) to the peripheral surface of a roll located immediately downstream of the vibrating roll without vibrating the roll, and bringing the opened reinforcing fiber bundle(s) into contact with the peripheral surface of the non-vibrating roll with a contact length of not less than twice the contact length of the reinforcing fiber bundle(s) on the vibrating roll, for retaining the opened state of the reinforcing fiber bundle(s). The present invention allows the reinforcing fiber bundle(s) to be opened stably with little fuzzing caused, for producing a uniform and thin reinforcing fiber sheet, and from the uniform and thin reinforcing fiber sheet, a uniform and thin crack-less prepreg with a good grade can be obtained.

Owner:TORAY IND INC

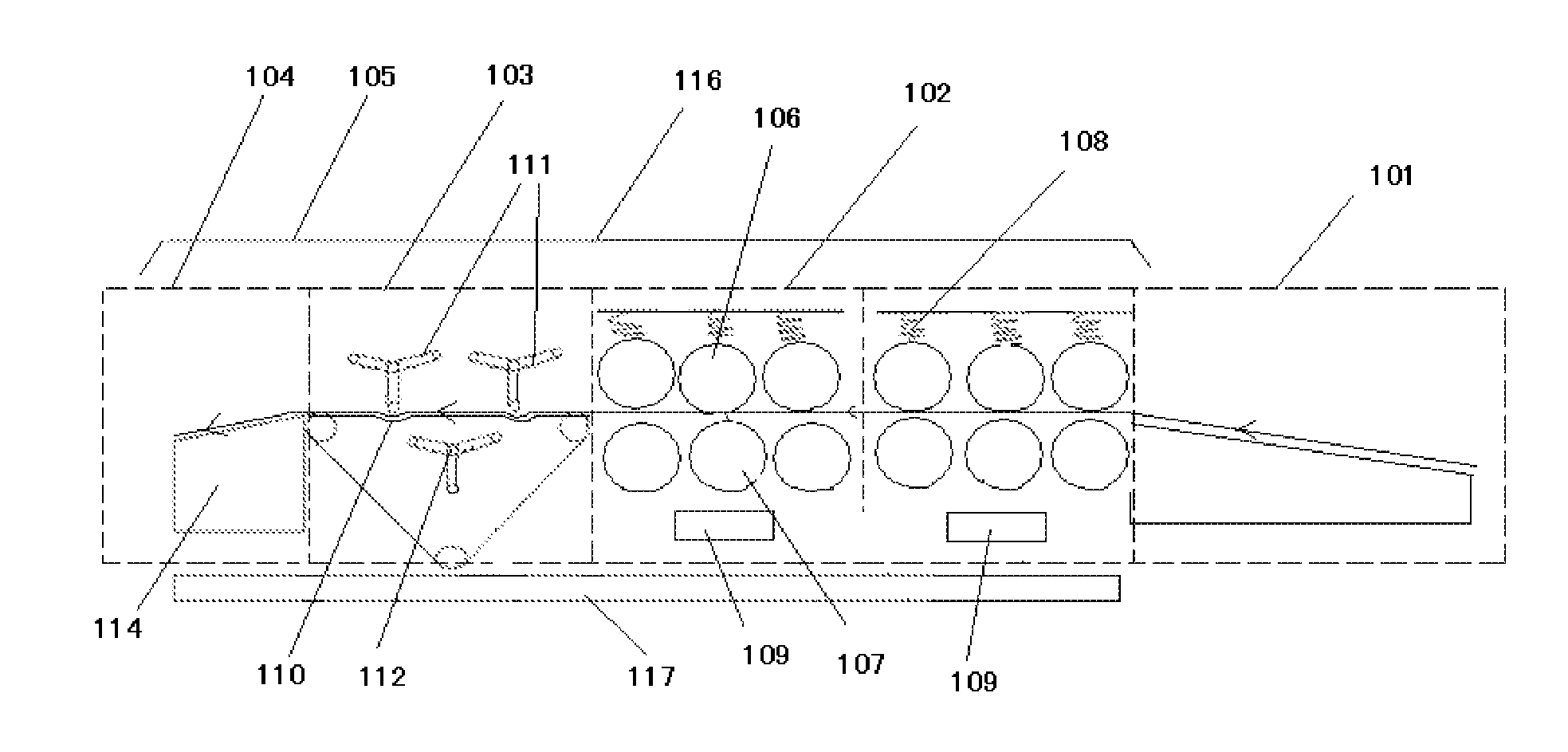

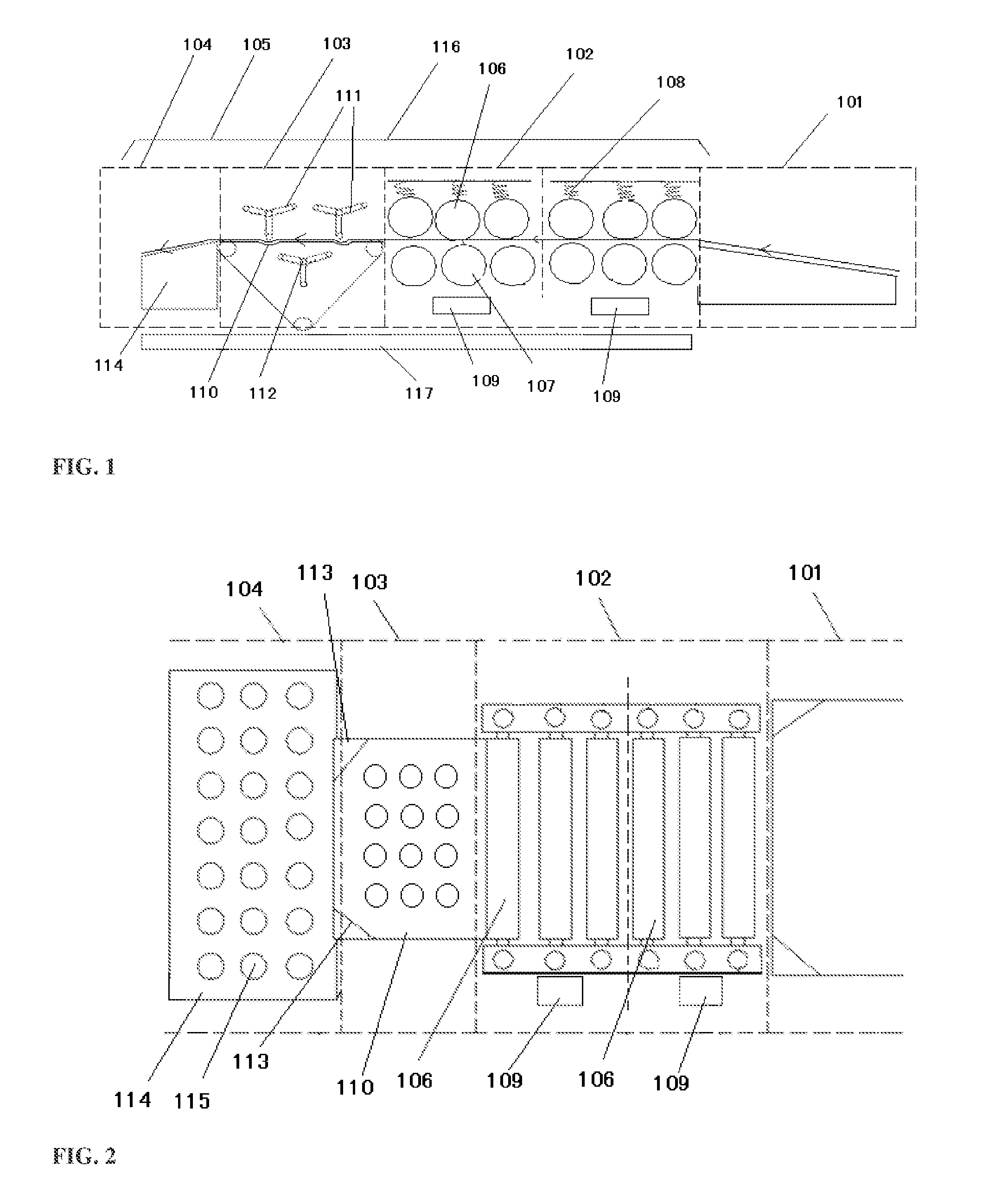

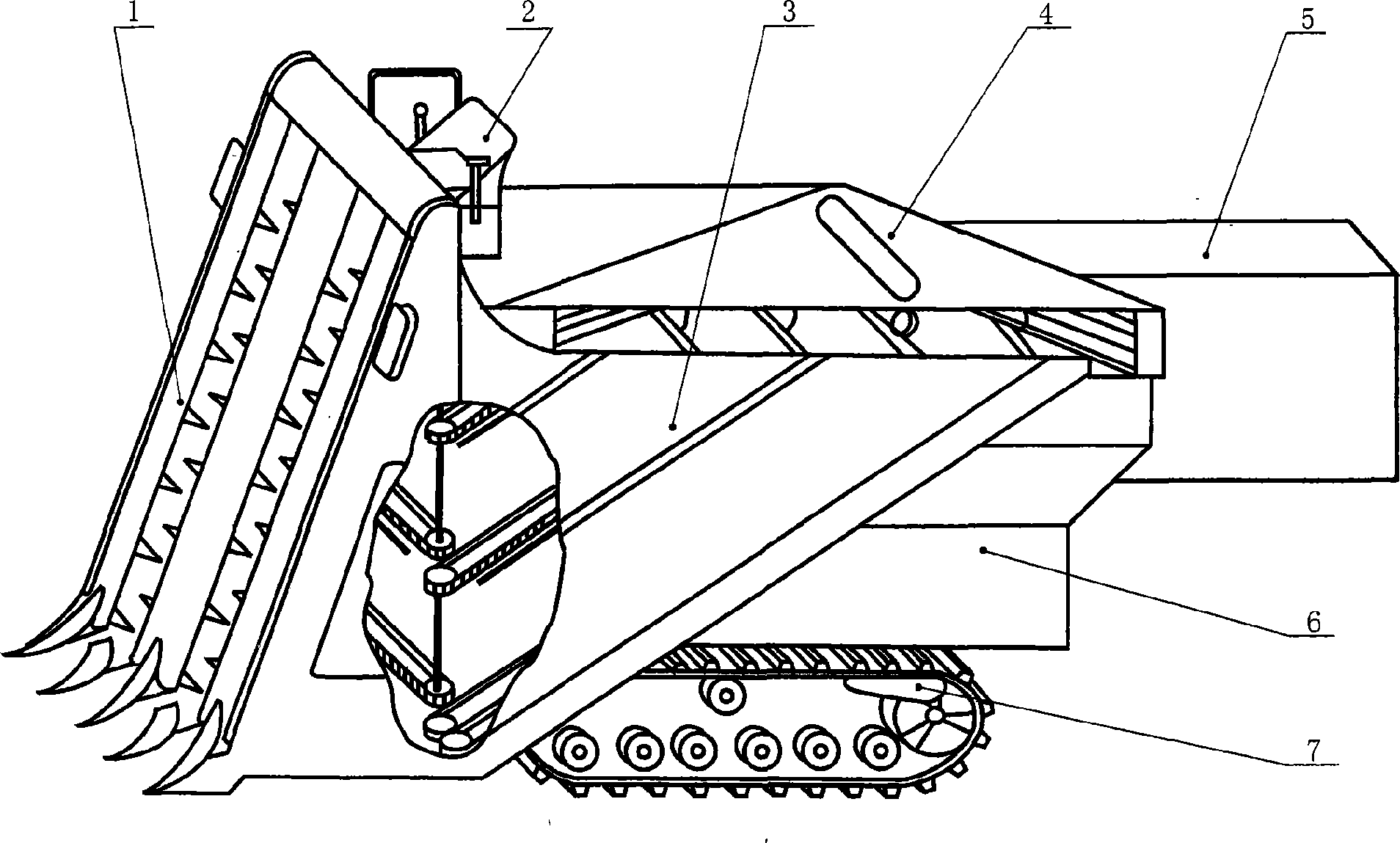

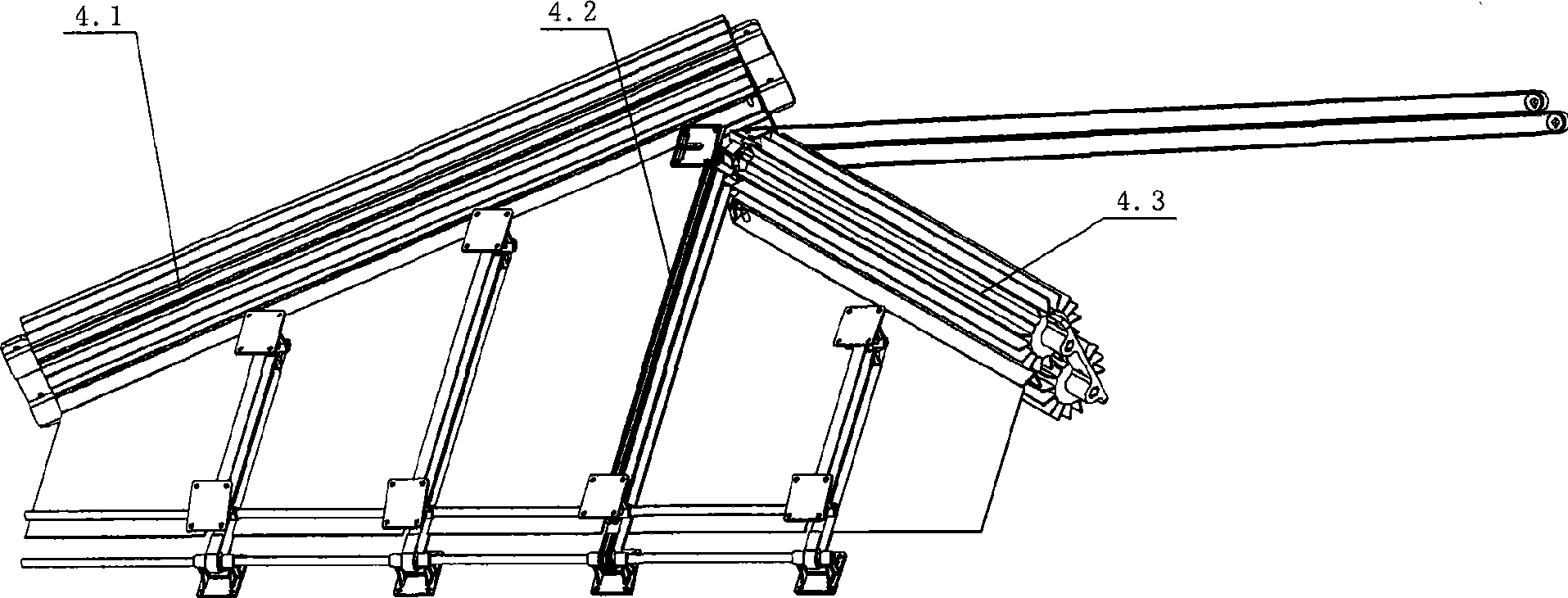

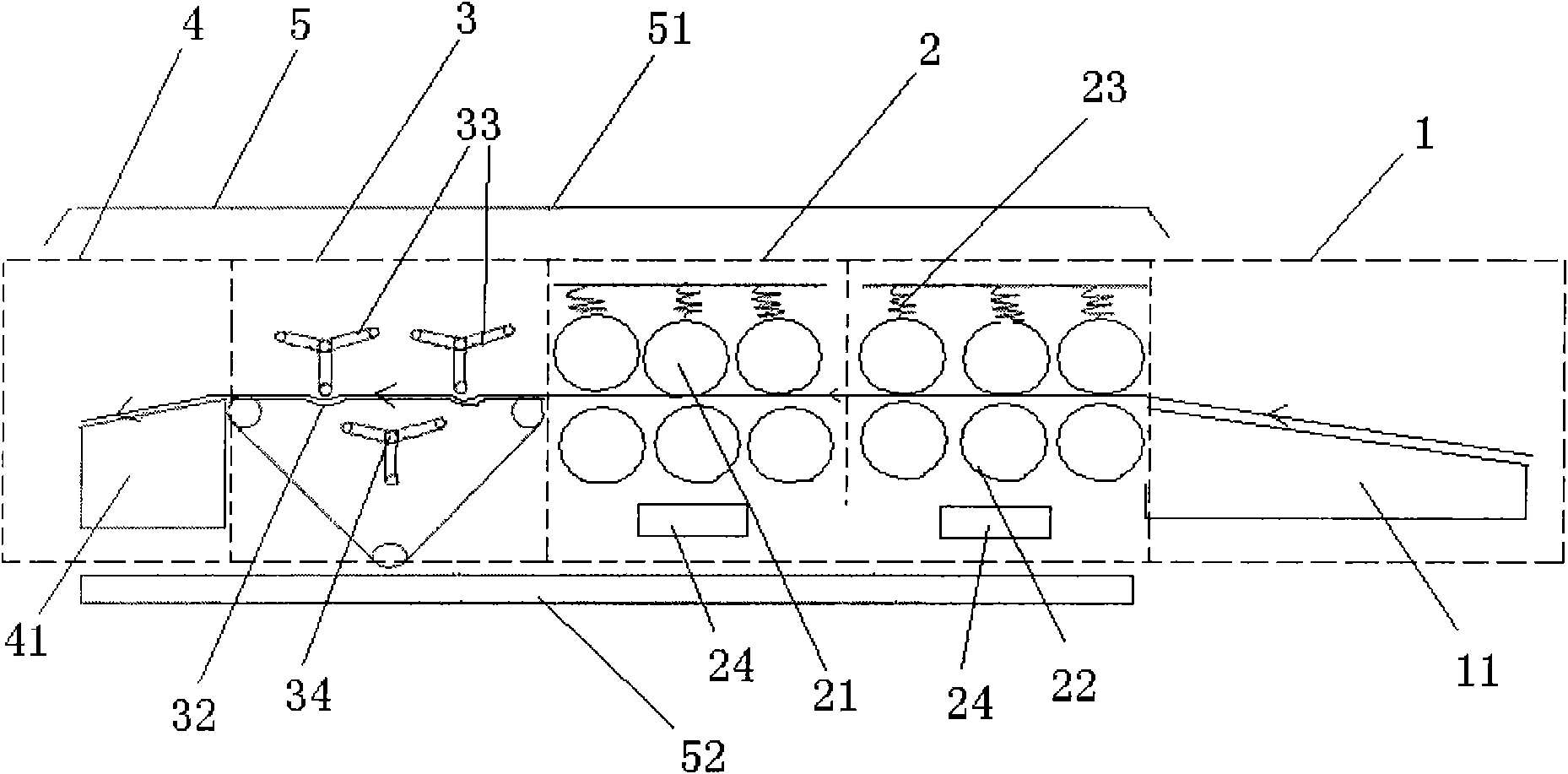

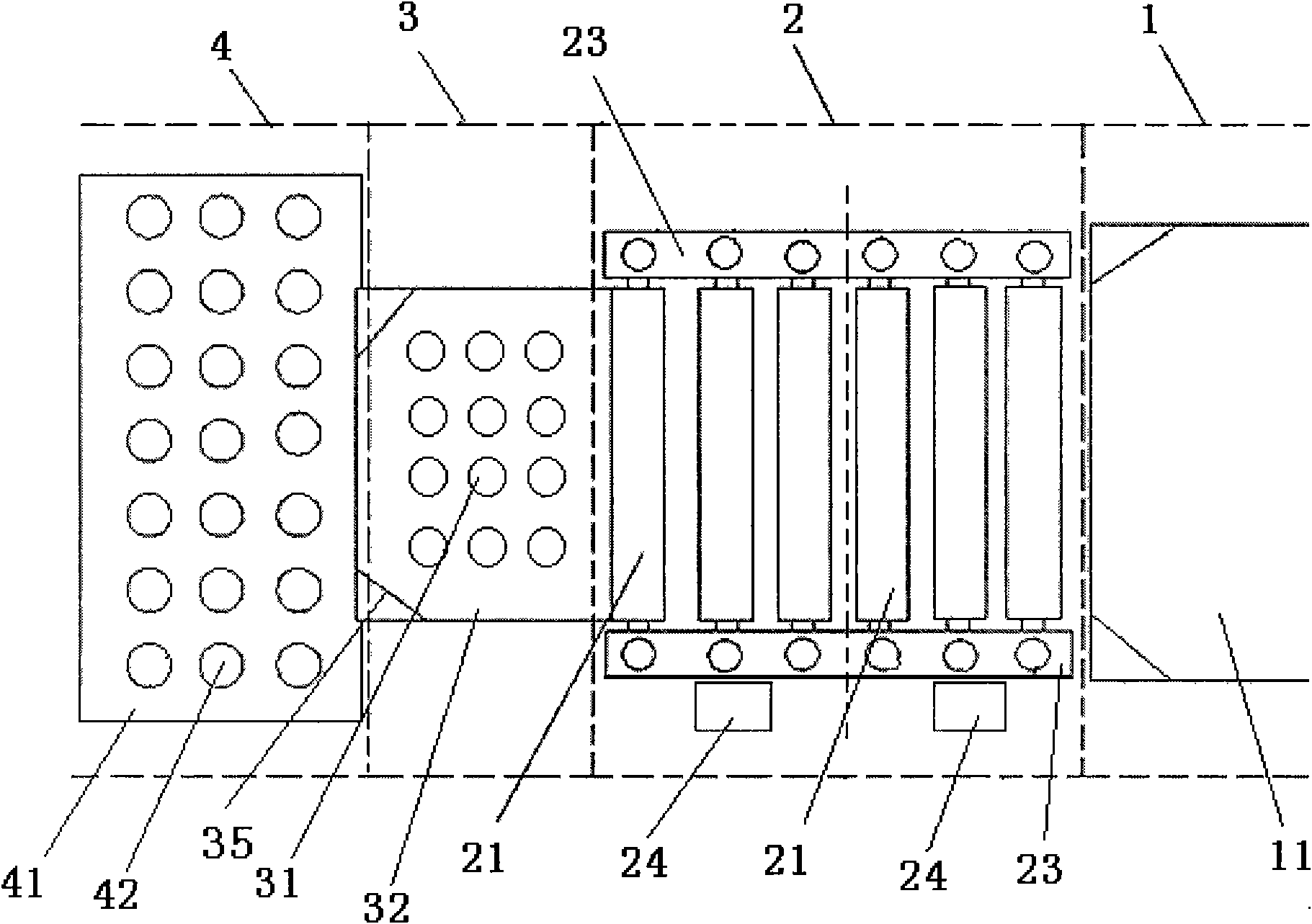

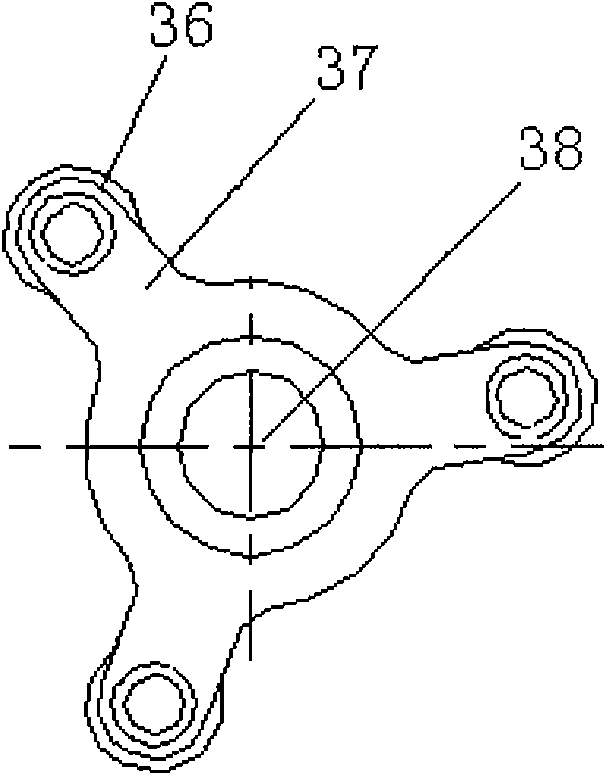

Ramie combine harvester

InactiveCN101518182AReduce impurityIncrease productivityHarvestersMechanical fibre separationEngineeringMechanical equipment

The invention relates to a ramie combine harvester which is applicable to combining harvest of ramie, namely completes ramie cutting and fiber primary processing by one time continuously, belonging to agricultural mechanical equipment. The ramie combine harvester consists of a vertical cutting table, an operating mechanism, a middle conveyor, a two-way automatic ramie removing machine, a mechanism which integrates ramie bin, power and transmission mechanism and a walking device. A bottom plate part is universal with a half head-feed grain combine harvester. A holding conveying belt is a synchronous belt; and the outer surfaces of the two belts are coupled with a longitudinal convex-concave bar groove, one belt at the inner side is a fixed support and the other belt is an elastic pressing support. The two-way ramie removing machine has two sets of ramie removing mechanisms at the front and back which are arranged in a reversed-V shape. After being cut, the ramie stalks are conveyed in a vertical and lateral mode, conveyed by a holding base part in a rotatable and upward mode, continuously fed into two sets of ramie removing mechanism for processing the base part and the tip part in a horizontal mode and the obtained ramie stalks are wound at a ramie blocking pin with an extruding and scratching machine at the tail ends of the ramie removing mechanisms, and the fiber is drawn, thus realizing removing of skin, skeleton and glue. The mechanical equipment has high production efficiency and good ramie removing quality and thoroughly solves the scutching difficulty which restricts the development of the ramie industry.

Owner:咸宁市农业机械化研究所

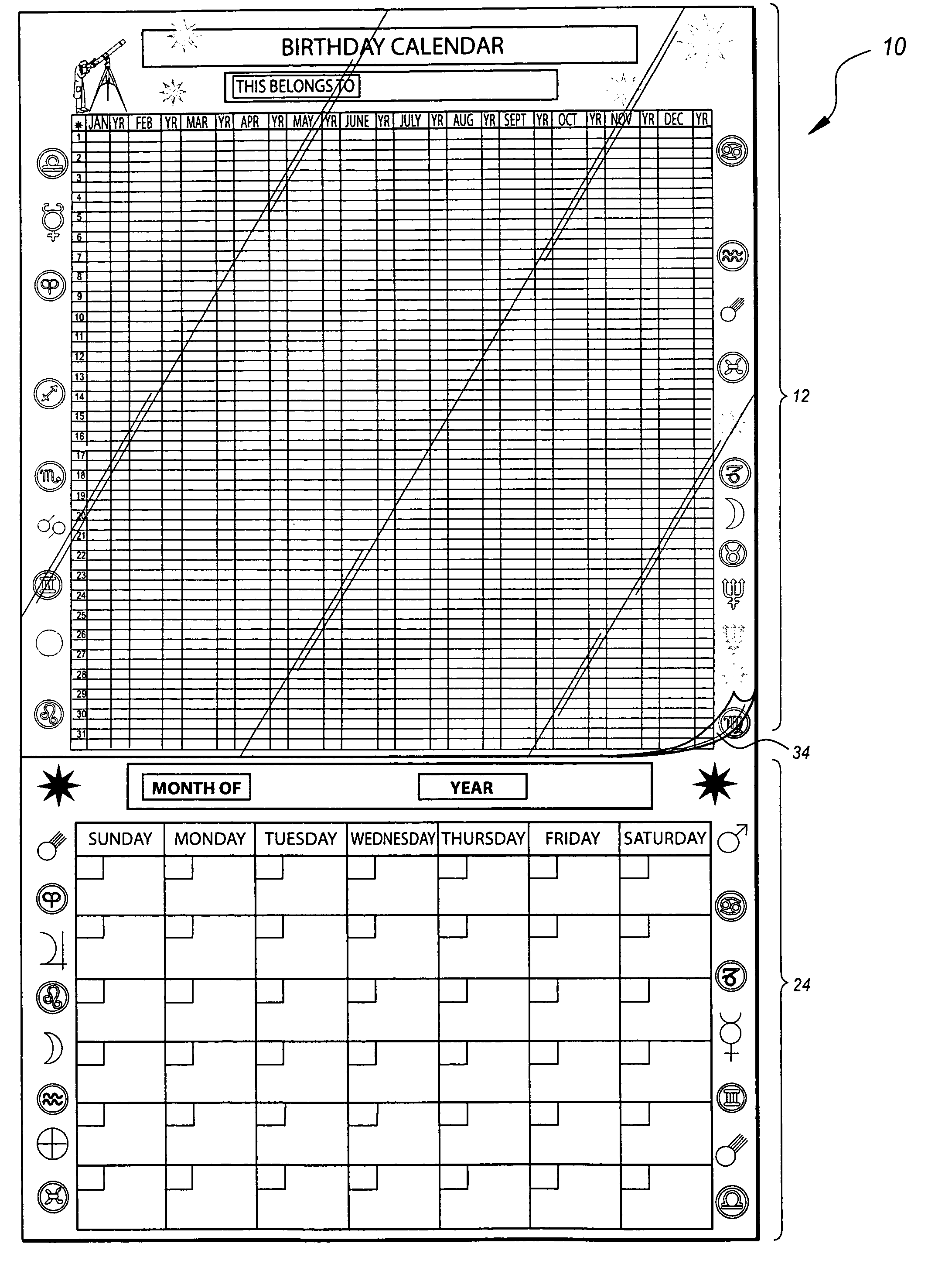

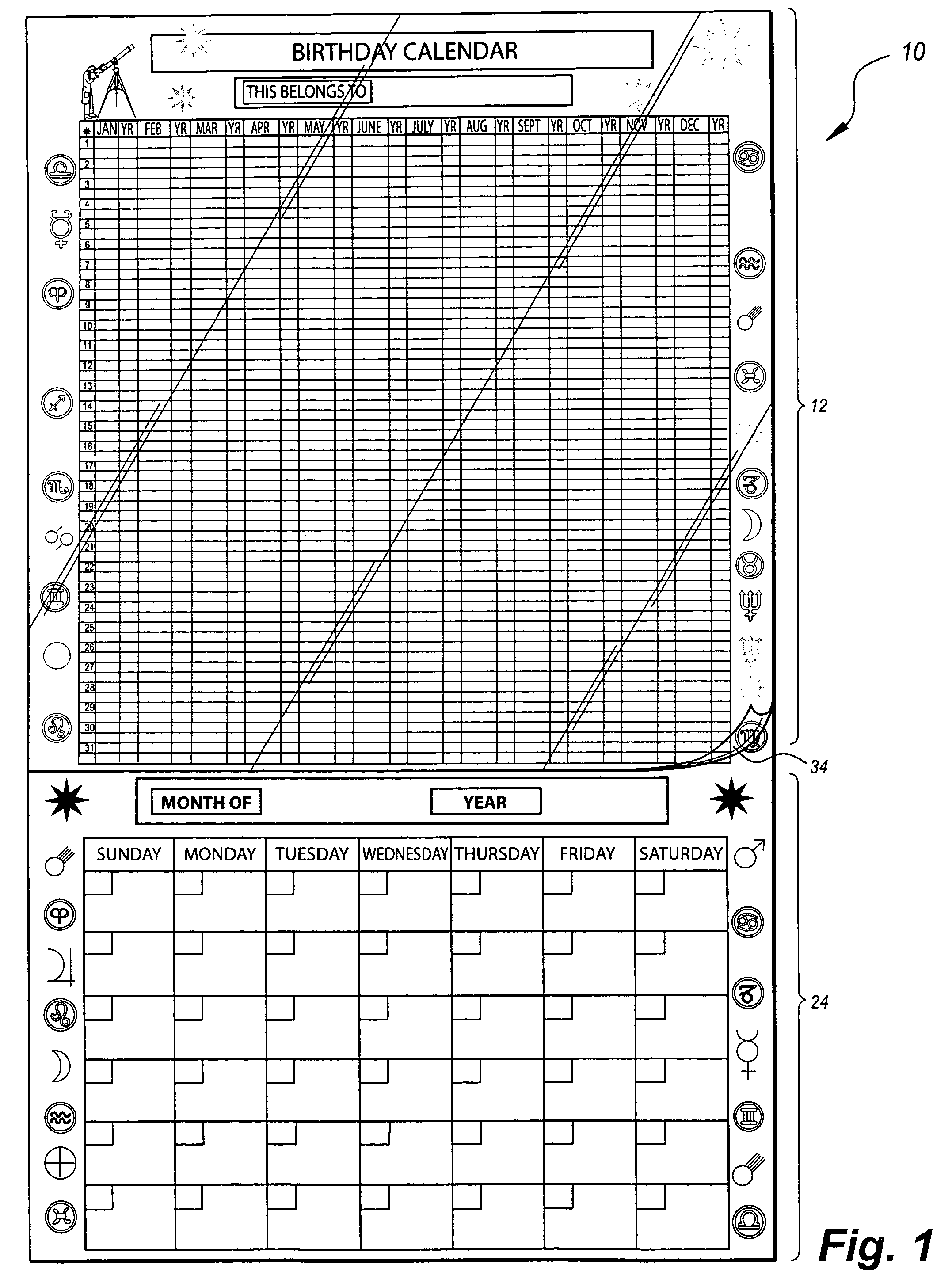

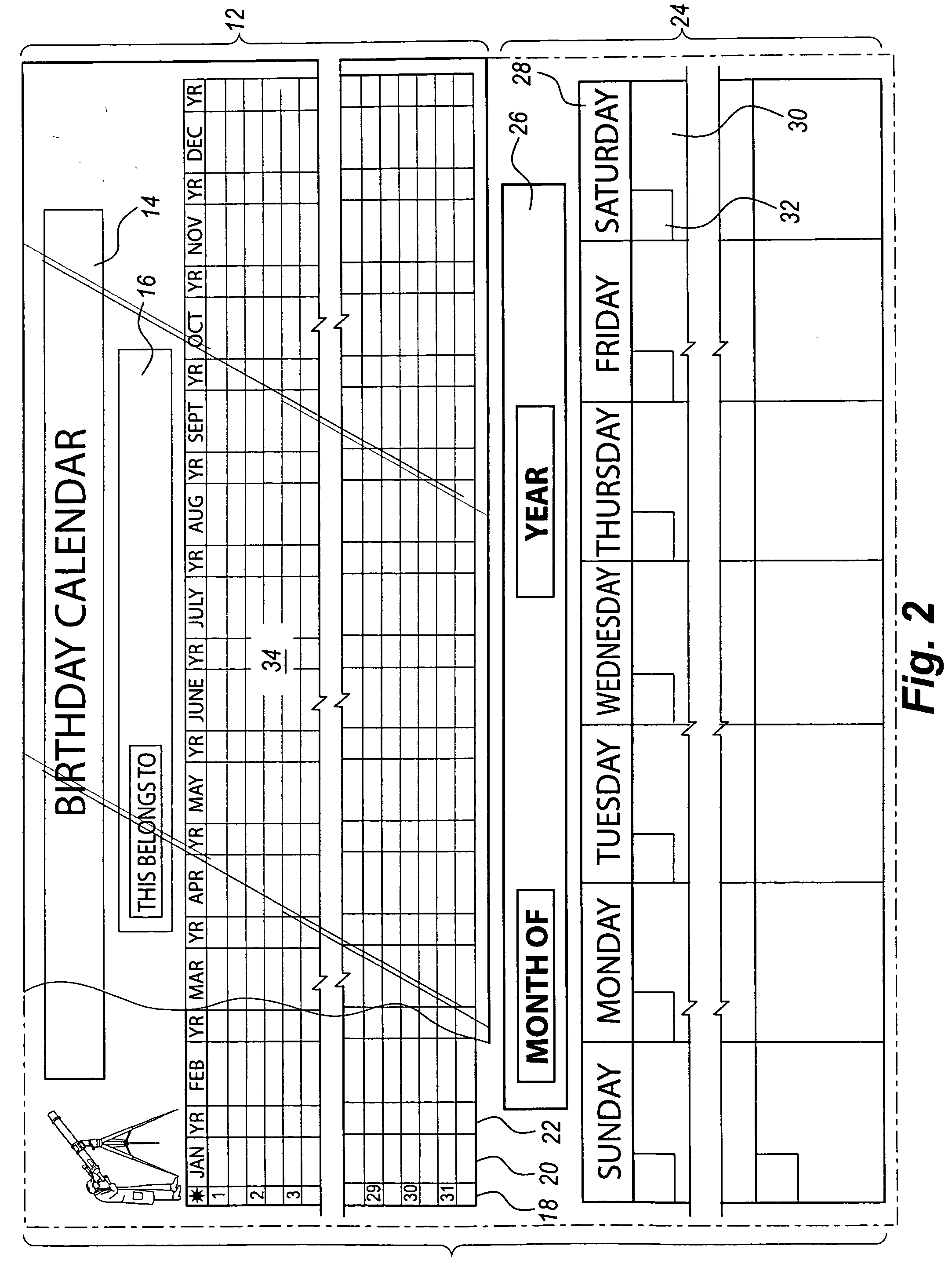

Birthday calendar

The birthday calendar is a dual monthly calendar and twelve-month chart. The calendar is perpetual in that it is not designated for any particular year or month. The monthly calendar is made of a dry-erase board displaying a month grid that is filled in with erasable ink for any particular month. The chart is a grid used to permanently record and display birth dates and other annual dates such as anniversaries and holidays. The chart displays columns intersected by rows. The columns are grouped in twelve sets of two having a month column adjacent to a year column. The rows display the dates of each month down the left side of the chart, numbered from 1–31. An event is recorded in the chart by writing the event's name in the appropriate month and date space and the year in the adjacent year space.

Owner:MARTIN JUDY A

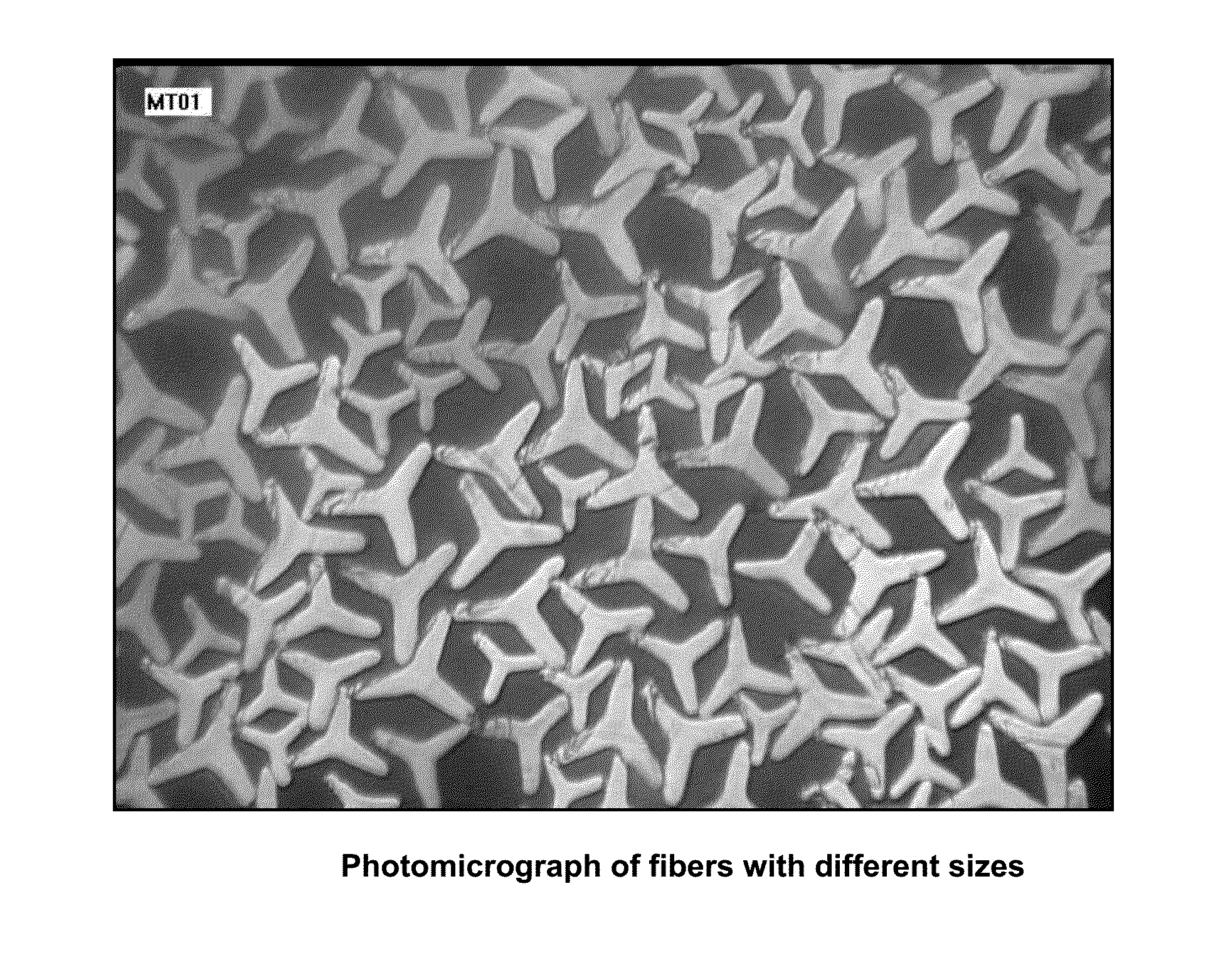

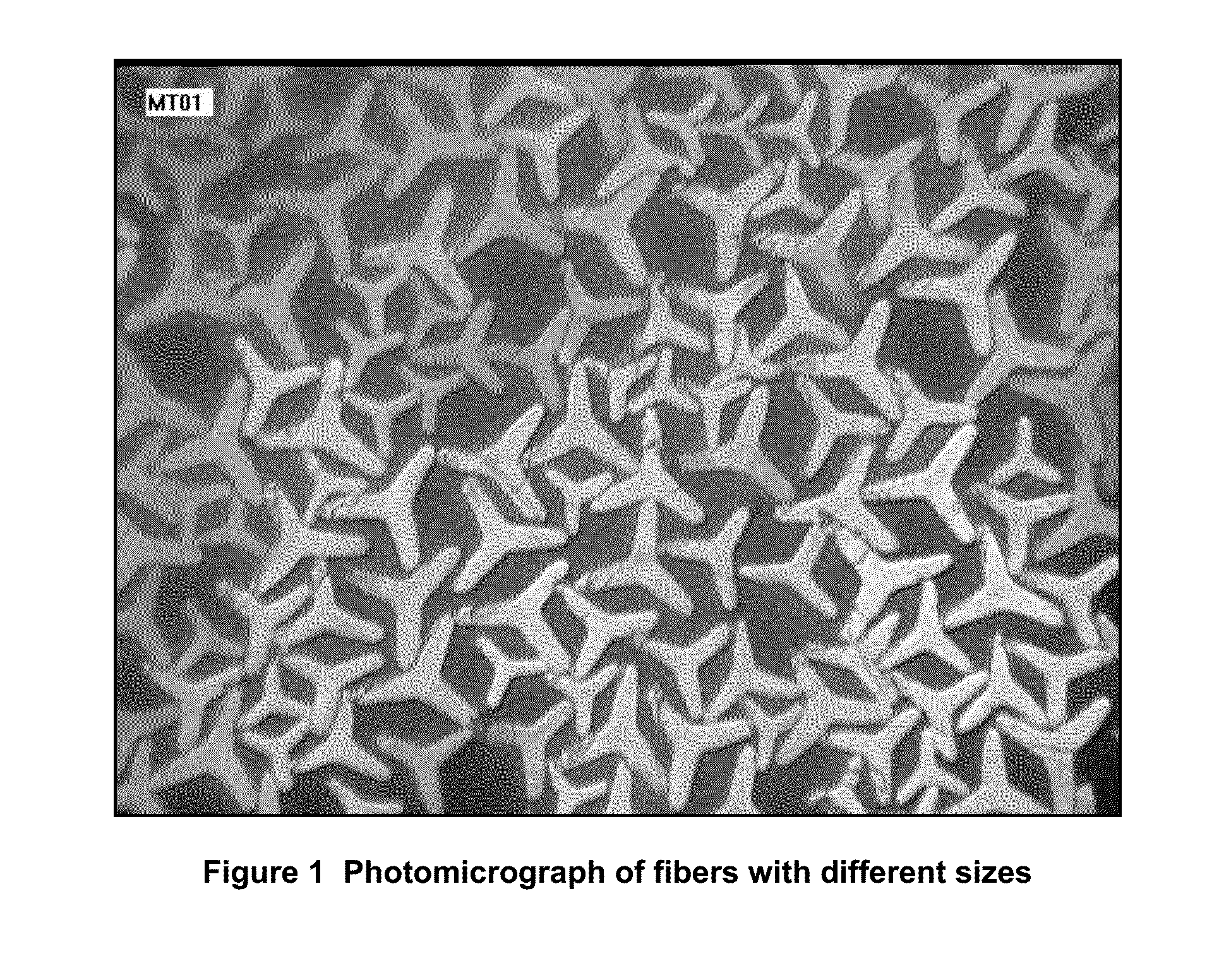

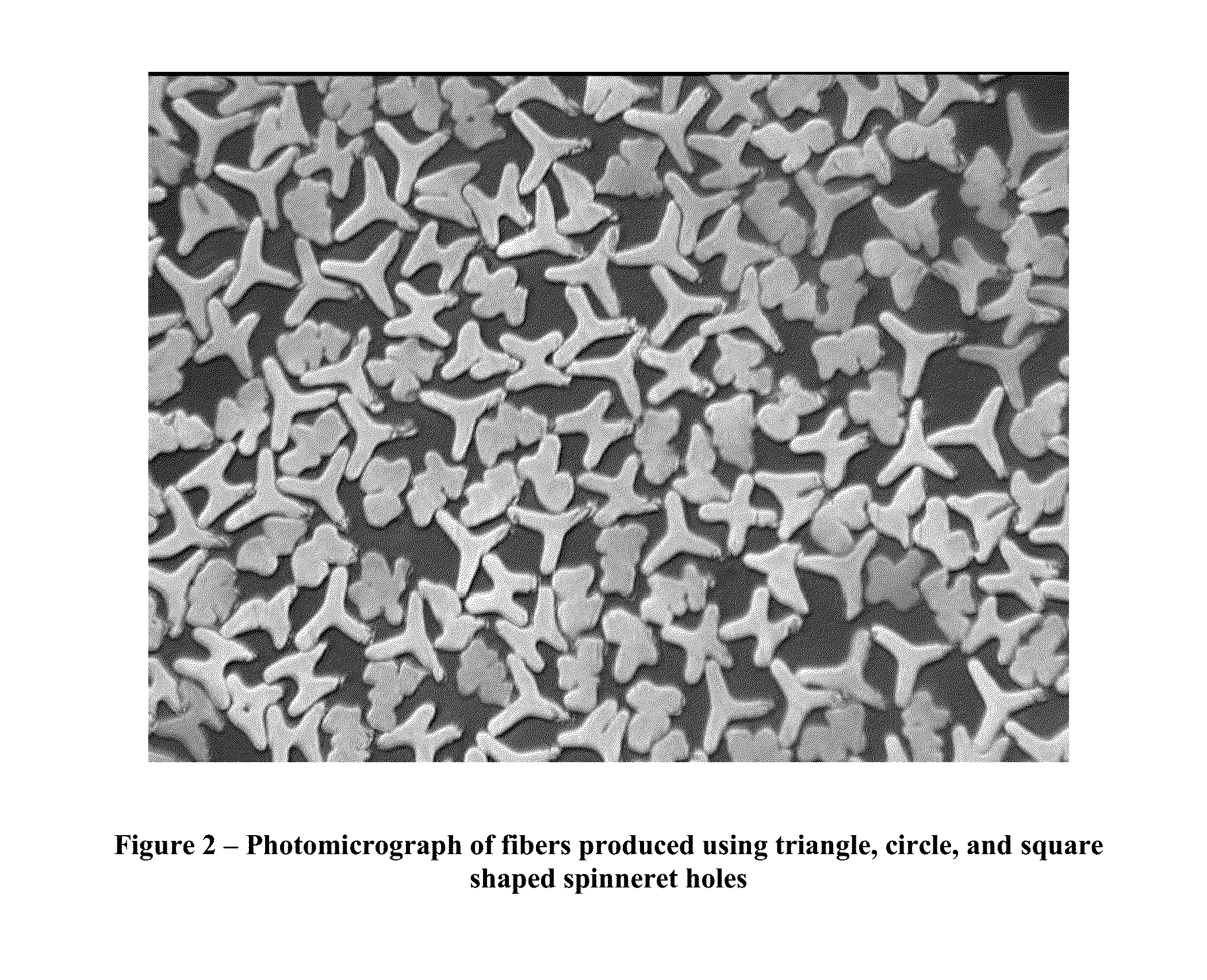

Method for making an acetate tow band with shape and size used for coding

Disclosed is a method of making an acetate tow bands comprising identification fibers which can be used for tracking and tracing the acetate tow band through at least part of the supply chain. Each identification fiber exhibits at least one distinct feature. Each group of distinguishable identification fibers can exhibit a taggant cross-section shape, a taggant cross-section size, or combination of the same taggant cross-section shape and same taggant cross-section size. The distinct features and the number of fibers in each group of distinguishable identification fibers can represent at least one supply chain component of the acetate tow band, including the manufacturer of the acetate tow band and the customer of the acetate tow band. The identification fibers can be produced on a cellulose acetate tow line using one or more spinnerets with spinneret holes to produce the taggant cross-section shapes and / or taggant cross-section sizes.

Owner:EASTMAN CHEM CO

Bamboo fiber composite base material and method for manufacturing automotive interior trim part

InactiveCN102896843APromote growthIncrease productionLamination ancillary operationsSynthetic resin layered productsVascular bundlePolyester

The invention relates to a composite material for manufacturing an automotive interior trim part. The bamboo fiber composite base material for manufacturing the automotive interior trim part is prepared by taking thermoplastic synthetic fibers (polypropylene PP, polyethylene PE or polyester PET and the like) as a bonding substrate and bamboo fibers as a reinforcing material through hot pressing. The bamboo fiber composite base material is characterized in that the bamboo fibers are prepared by sawing natural bamboo into pieces with length required by production, removing parenchyma from the bamboo by mechanical, physical, chemical and biological methods and directly extracting vascular bundle bamboo fibers from the bamboo, and have the length of 60 to 150mm, the diameter of 0.3 to 1.5mm, the strength of 60 to 120MPa and the water content of 10 to 12 percent. The automotive interior trim part can be subjected to press forming when the bamboo fiber composite base material covers artificial leather, leather or a knitted or non-woven fabric for surface decoration.

Owner:喻云水

Bookmarks

Owner:J LEA

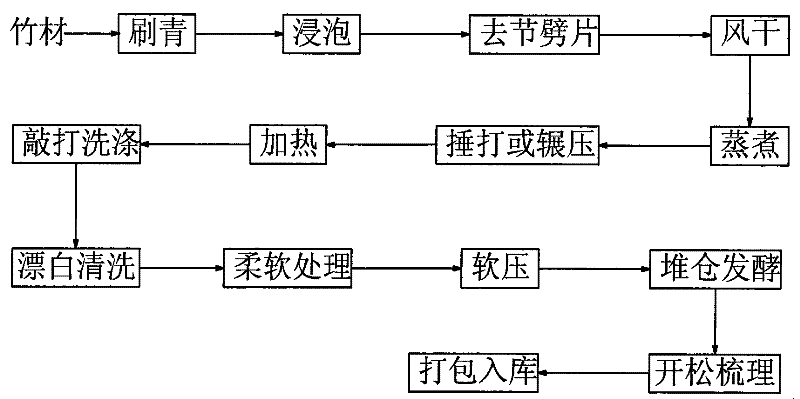

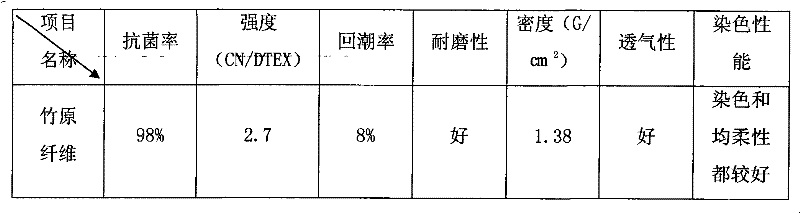

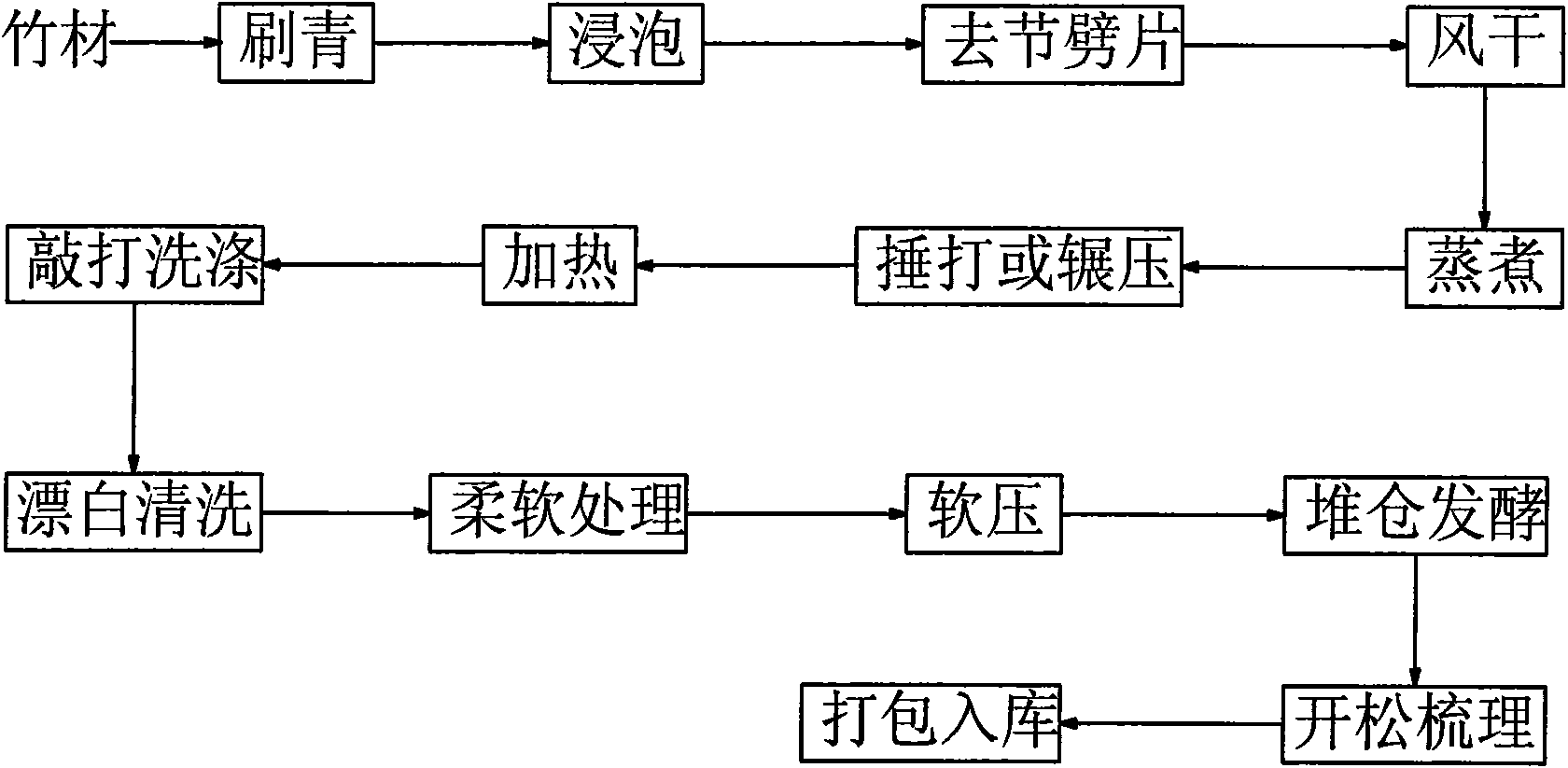

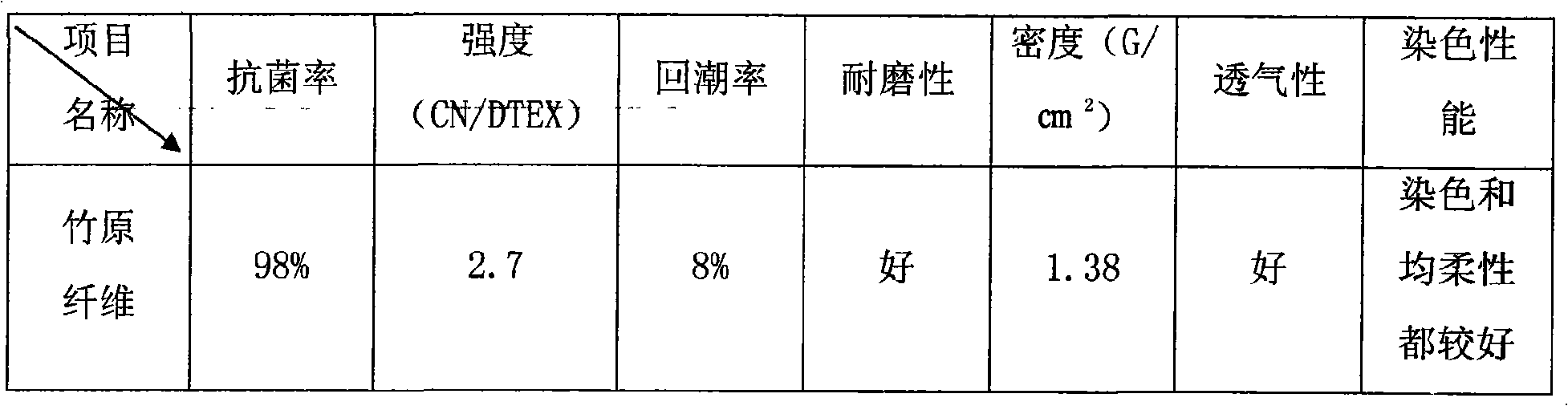

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

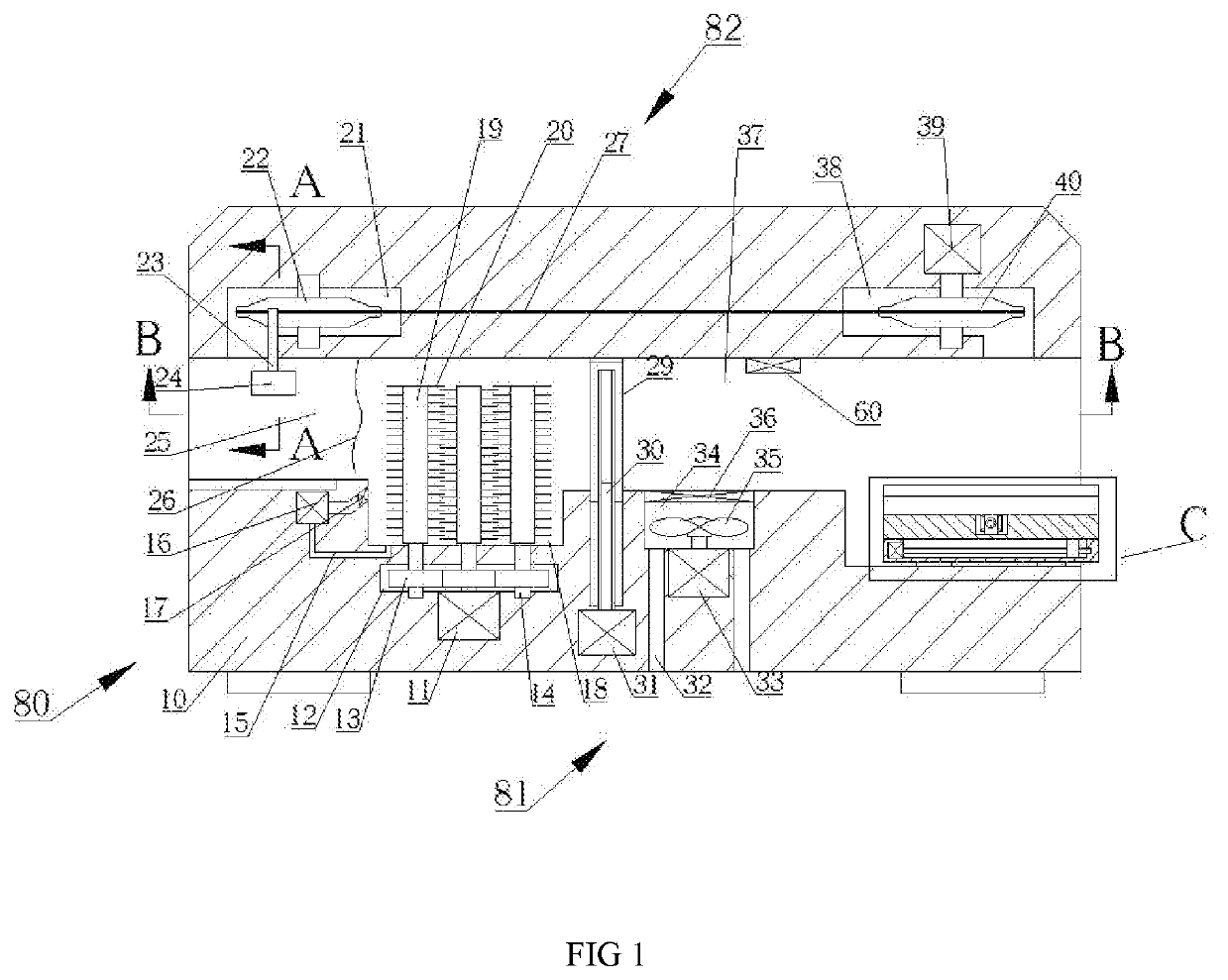

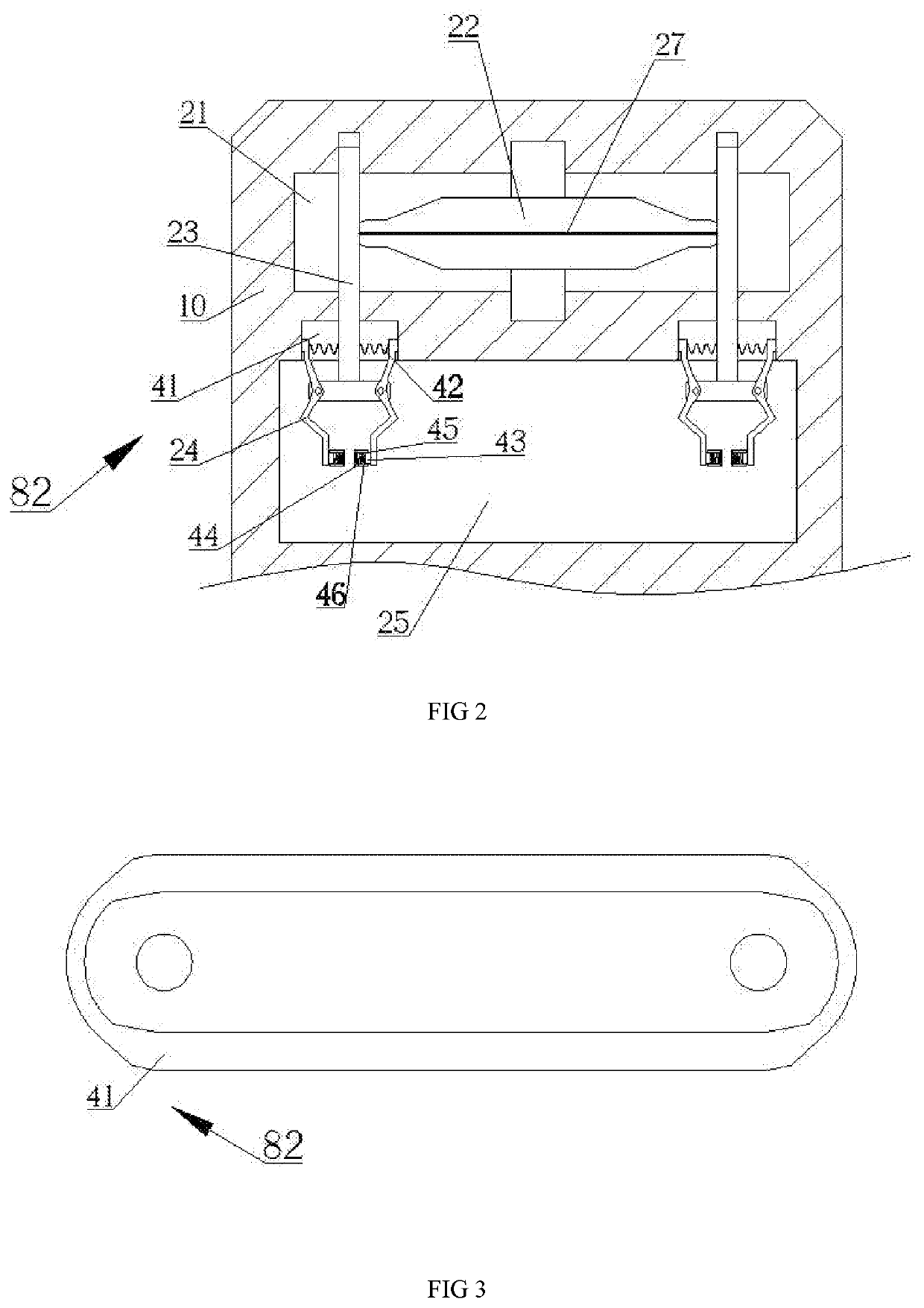

Cotton stalk skin-core mechanical separation method and special equipment

InactiveCN101230491ALow impurity contentAvoid damageMechanical fibre separationRaw material pretreatmentEngineeringSkin core

The invention relates to a processing method of separating a cotton stalk skin from a cotton stalk core mechanically as well as special equipment. Firstly, the cross section of a cotton stalk is squeezed to be of a flatly cracked shape and caused to present a continuous shape along the longitude direction; secondly, the flatly-cracked cotton stalk is struck every a certain length to be bent 85 to 90 degrees rapidly, thus leaving the skin separated from the core preliminarily. A free high-frequency strike is conducted to the strap-shaped cotton stalk skin to remove the broken core residue; and finally, the strap-shaped cotton stalk skin is conducted a cross free strike with a frequency higher than the frequency in the second step to eliminate the remaining attached core residue and obtain an eligible cotton stalk skin. The special equipment consists of a squeezing device, a vertical striking device, a diverted striking and skin separating device together with a wallboard and a stand that are used for fixing the devices and all the devices are arranged in sequence. The mandrel of each device is arranged in parallel, supported and fixed by the wallboard and driven by a drive mechanism. The special equipment can realize a mechanical separation of a cotton stalk skin from a cotton stalk core. The processed cotton stalk skin takes the shape of a continuous strap and can be processed further. The processed cotton stalk core takes the shape of millimeter-level crumbs and is an excellent material for pulping and paper making.

Owner:凌受明 +1

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

Natural antibacterial material and its use

InactiveCN1461827ANo side effectsGood antibacterial effectAbsorbent padsNon-woven fabricsFiberCuticle

A natural antibacterial material is prepared from natural bamboo fibre pulp through weaving. It can be used as medical dressing, gauze, bandage, and the substrate able to directly contact with human skin. Its advantages are high antibacterial effect and no toxic by-effect.

Owner:余钢纲 +1

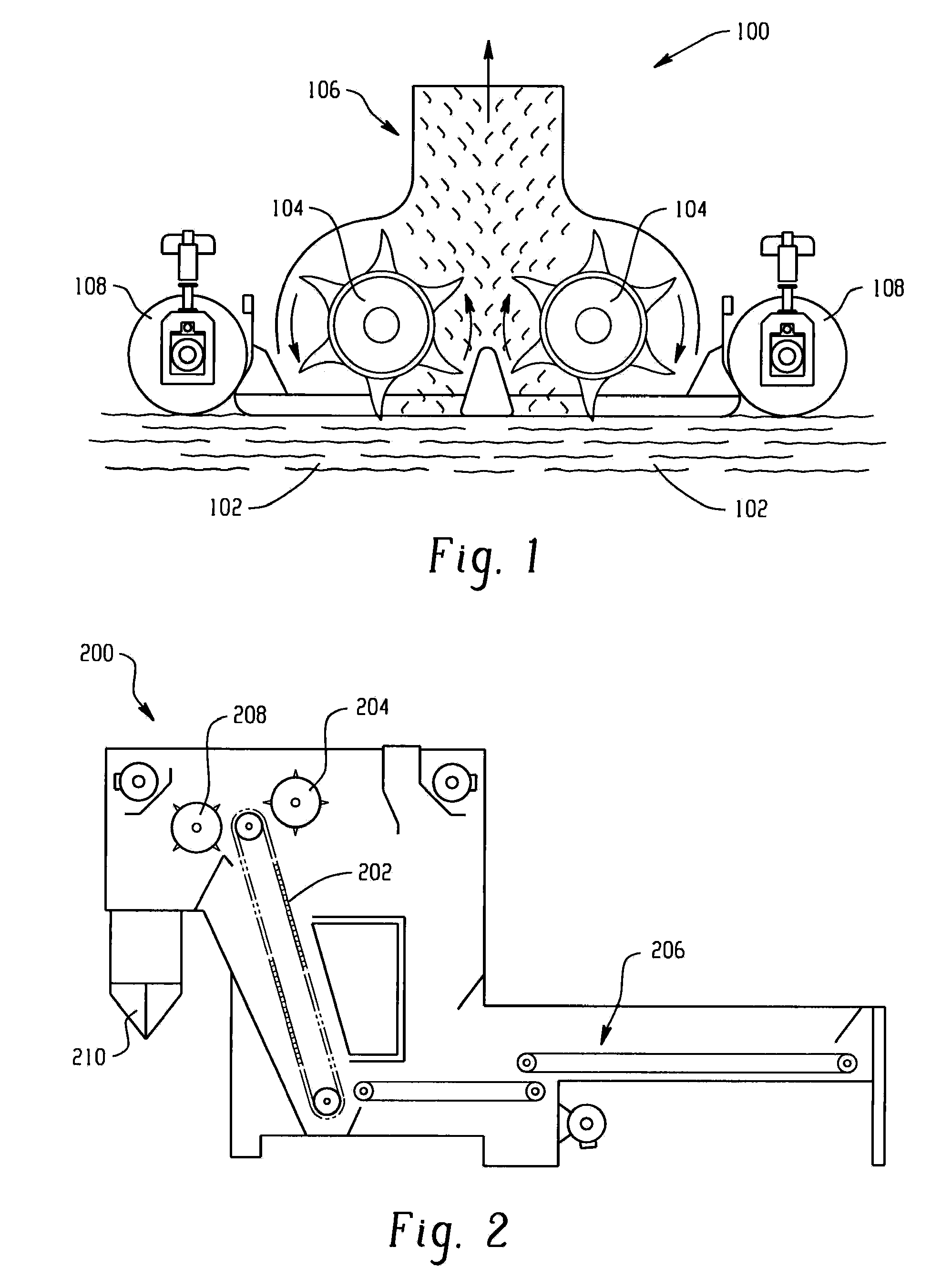

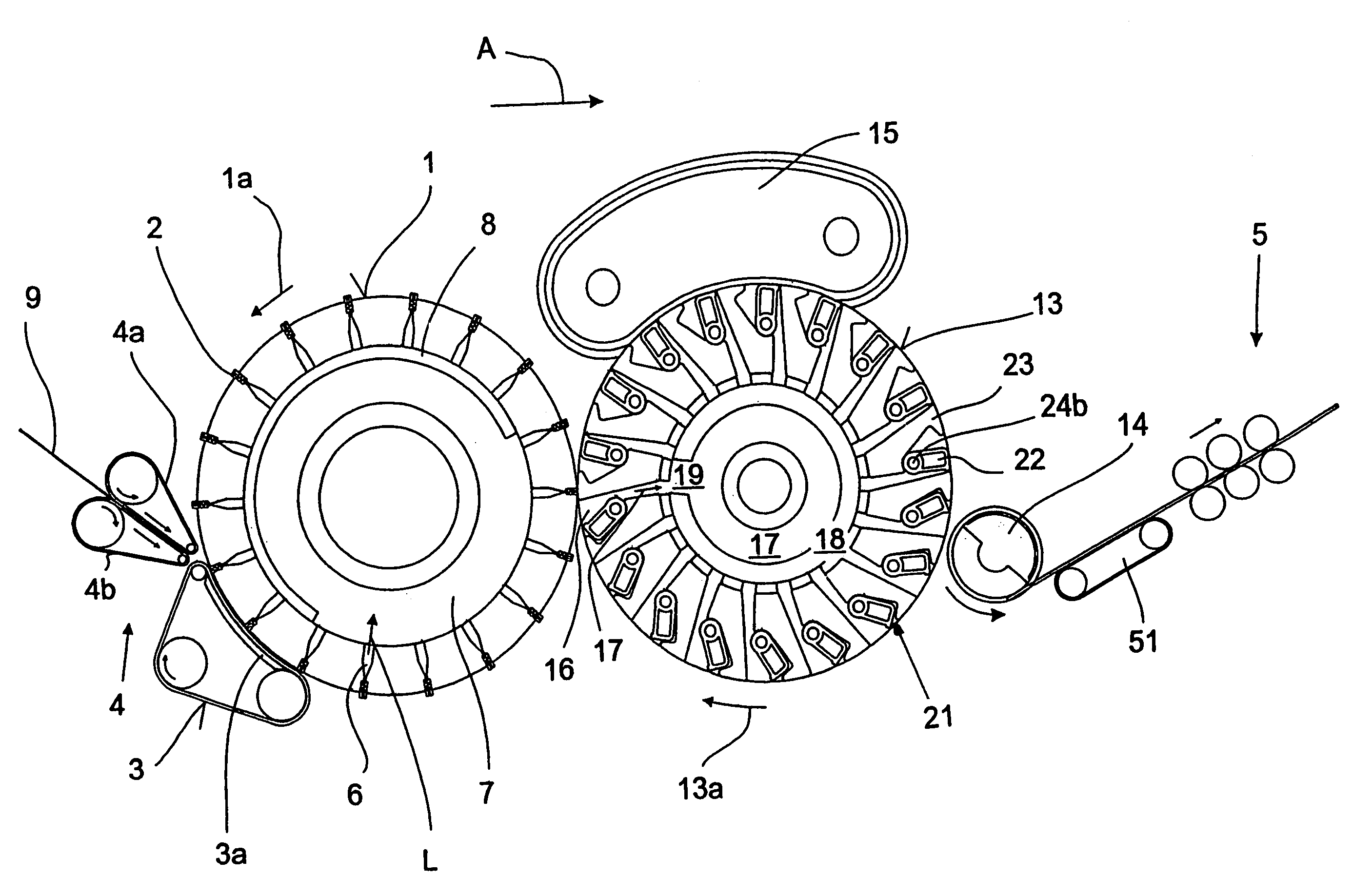

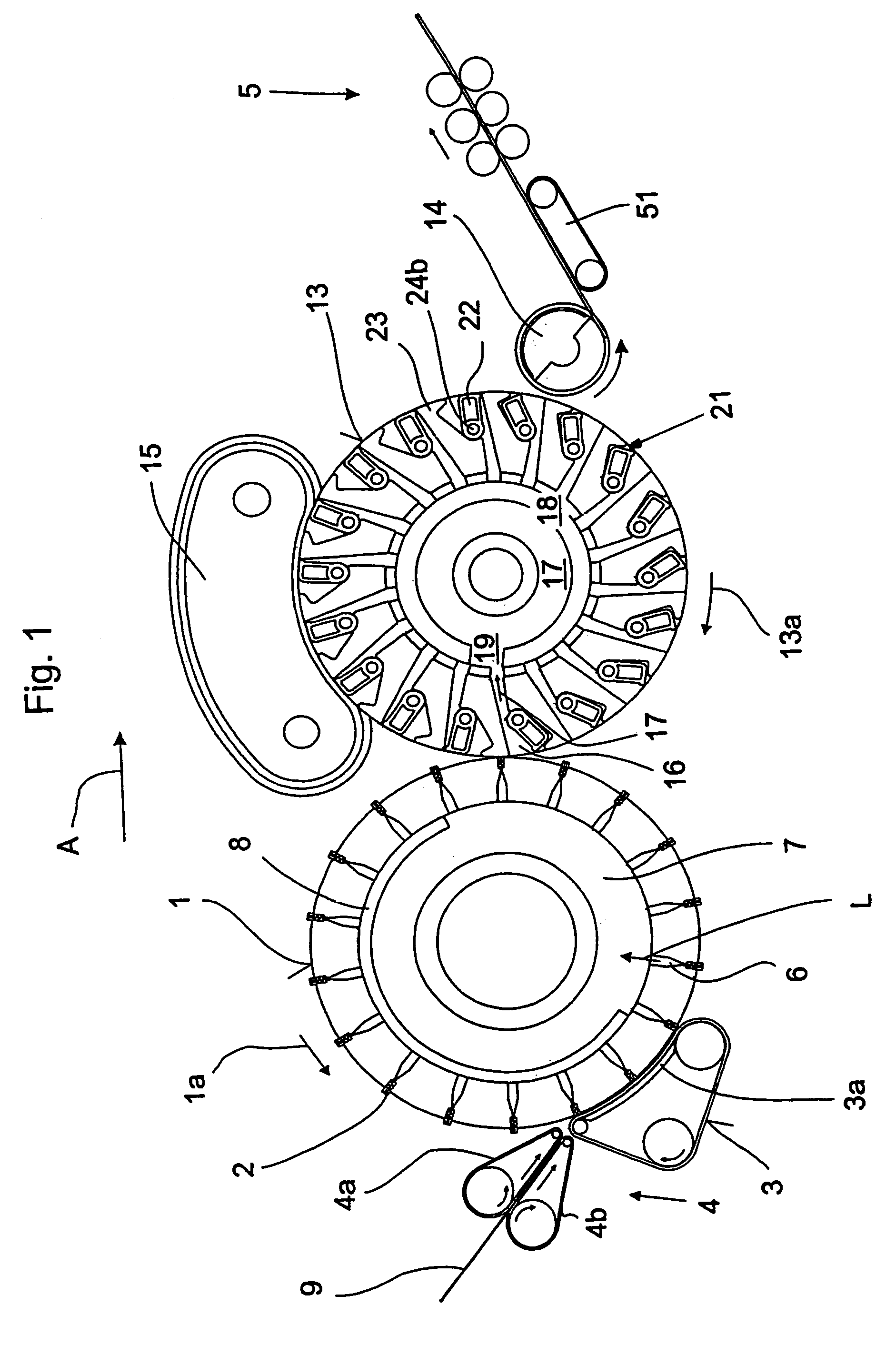

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000079A1Improved sliverIncrease volumeCombing machinesFibre separationProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device, in which a mechanical device is present which generates a combing action to loosen and remove non-clamped constituents, and a clamping element is present for transfer of the supplied fibre material. To enable productivity to be increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged two rotatably mounted rollers, which are provided with clamping devices for the fibre material having clamping elements that are distributed spaced apart in the region of the roller periphery and co-operate with counter-elements, the counter-elements in the case of the first roller being arranged opposite the roller periphery and in the case of the second roller on or in the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Method for the production of a carbon fiber-based reinforcing element for tires

InactiveUS20040043213A1Reduce riskImprove the lubrication effectCarbon fibresFilament handlingFiberCarbon fibers

A method for the production of a multifilament carbon fibre-based longitudinal reinforcing element, designed to be incorporated in a rubber-based item. Said method comprises the following steps, whereby untwisted carbon fibres are plunged into an impregnating bath contained a solution of resorcinol-formaldehyde resin and rubber latex, the impregnated fibres are then dried and the dried fibres are subsequently twisted. The inventive method is characterised by the fact that it also comprises a step, during the impregnation step, consisting in opening out the carbon fibres by spreading out the constituent filaments thereof in such a way that each fibre has an increased surface area on which the impregnation can be performed.

Owner:SOVOUTRI SOC VOULTAINE DE TRANSFORMES INDS

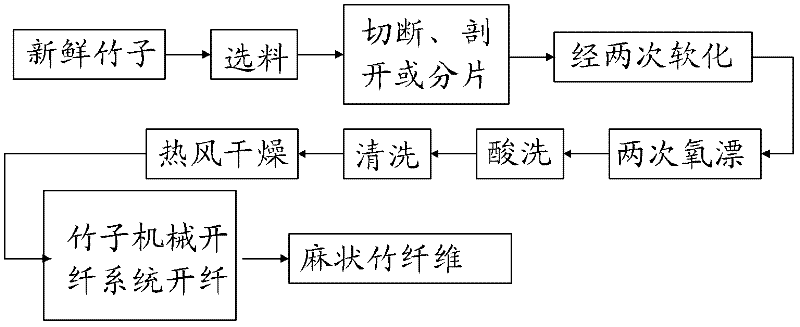

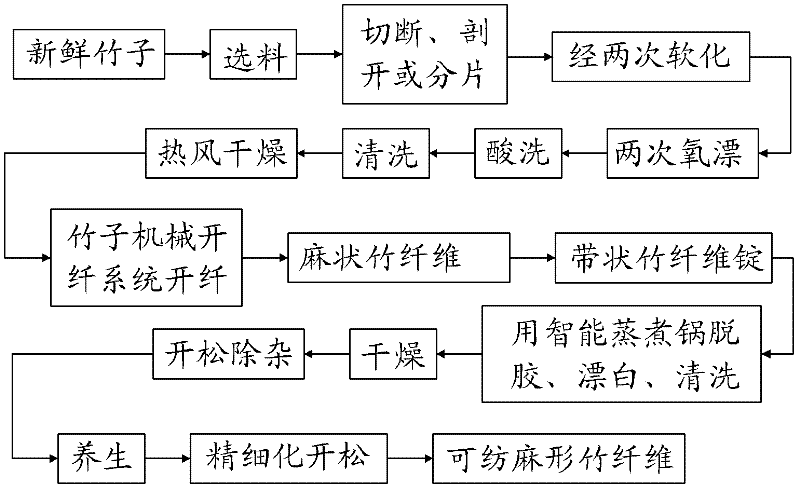

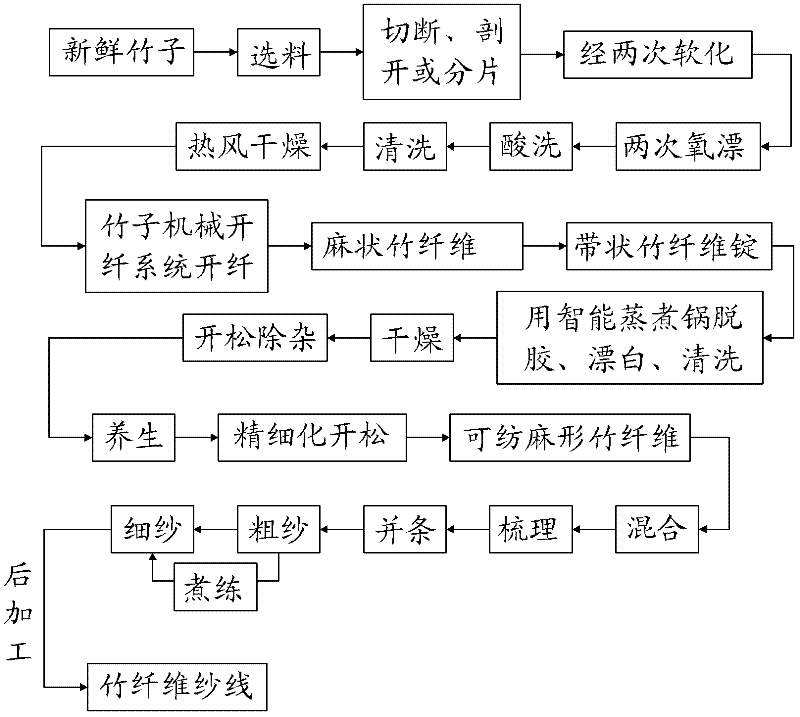

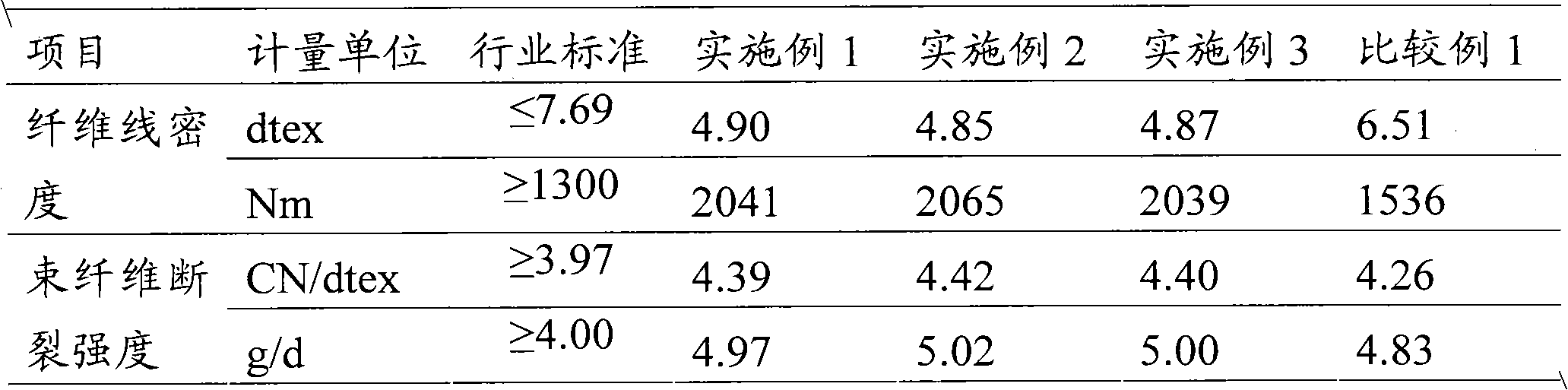

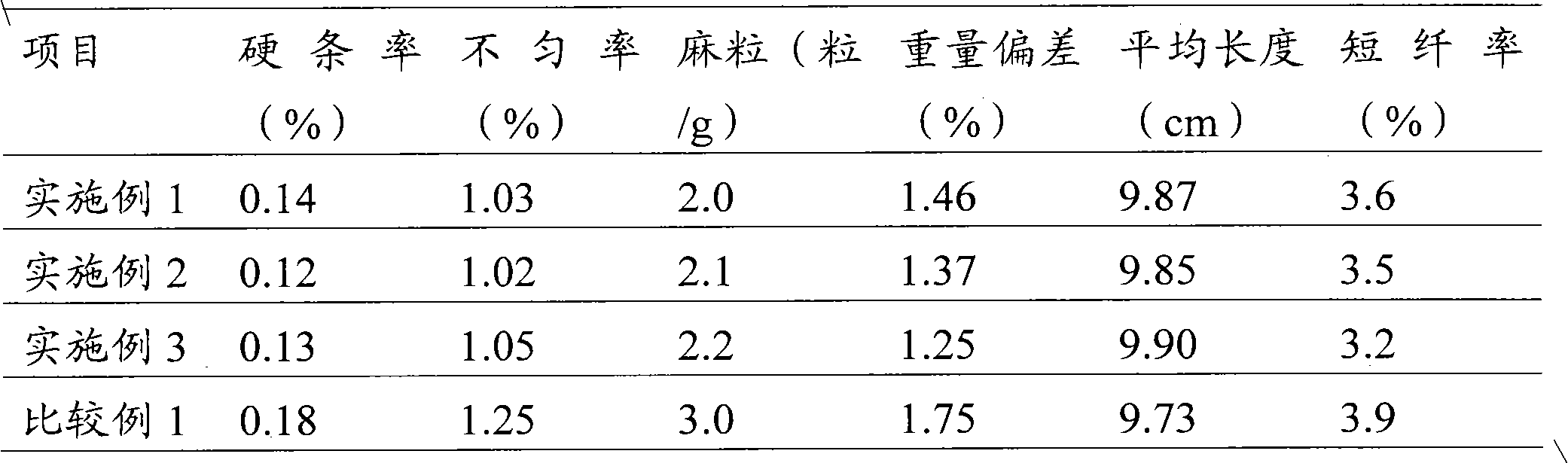

Production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns

ActiveCN102242403AQuality improvementHigh strengthVegetable materialMechanical fibre separationYarnSoftening

The invention relates to a production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns. The production process comprises the following steps: sawing a fresh bamboo into pieces according to a certain length and then respectively soaking the pieces in different biologic softening solutions or cooking the pieces in specially prepared softening solutions at high temperature; after cleaning the pieces, heating and airing the pieces, and then feeding the pieces into a bamboo mechanical splitting system, thereby preparing the linen bamboo fibers; processing the linen bamboo fibers into strip-shaped bamboo fiber spindles; putting the strip-shaped bamboo fiber spindles into an intelligent steam cooker in turn, thereby degumming, bleaching and cleaning the strip-shaped bamboo fiber spindles; after drying the strip-shaped bamboo fiber spindles, opening and removing impurities, thereby acquiring the spinnable linen bamboo fibers; and sending the spinnable linen bamboo fibers into a yarn-forming integrated system, and performing the processes of opening, cotton-blending, carding, drawing and yarn-forming, thereby finally acquiring the bamboo fiber yarns. The bamboo fibers prepared by using the production process are linen, longer, thinner, more uniform and softer. The average fineness of the bamboo fibers can reach 400-600 metric counts. The bamboo fibers can be purely spun or fully blended with fibers such as cotton, linen, and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY +1

Physical preparation method of natural bamboo fibers

ActiveCN102560695AImprove the bactericidal effectFineness slenderVegetable materialMechanical fibre separationDeodorantHigh pressure

The invention provides a physical preparation method of natural bamboo fibers. Through original bamboo cutting, rolling and slicing, dipping, primary high temperature and high pressure cooking, water washing, rolling and splitting, secondary high temperature and high pressure cooking, secondary water washing, ultrasonic vibratory splitting, bamboo fibers combing as well as screening and drying procedures, the natural bamboo fibers are prepared by using middle materials of Hunan annual moso bamboos as raw materials for preparing the natural bamboo fibers. By using the physical preparation method of the natural bamboo fibers, provided by the invention, the bactericidal capability of the bamboo fibers are improved while natural antibacterial, bacteriostatic, mothproofing, deodorant and ultraviolet resistant functions of the bamboo fibers are kept; and obvious breakthrough are made in fineness, strength, residual gum content and other aspects of the made 100% natural bamboo fibers.

Owner:湖南欧林雅服饰有限责任公司

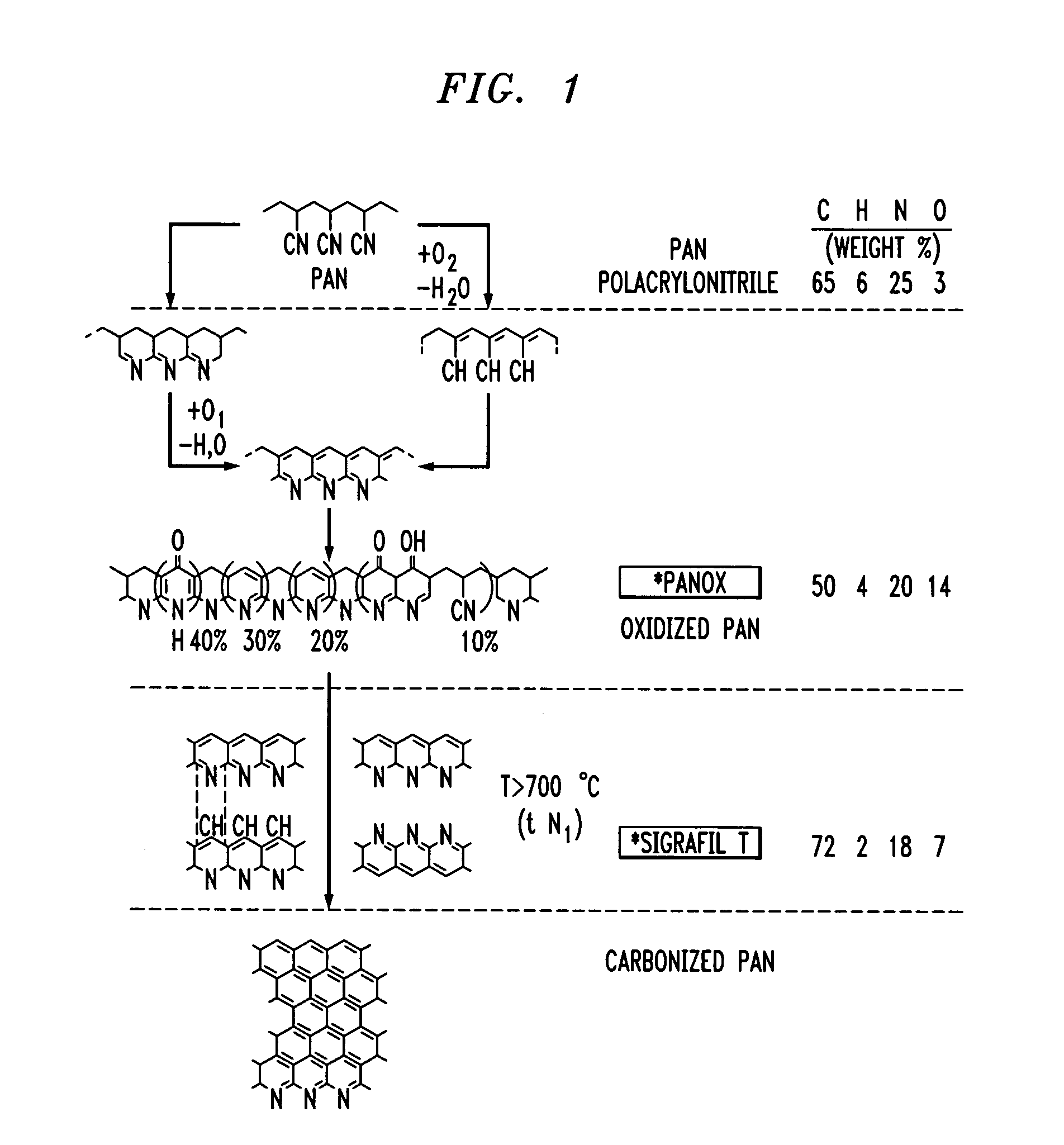

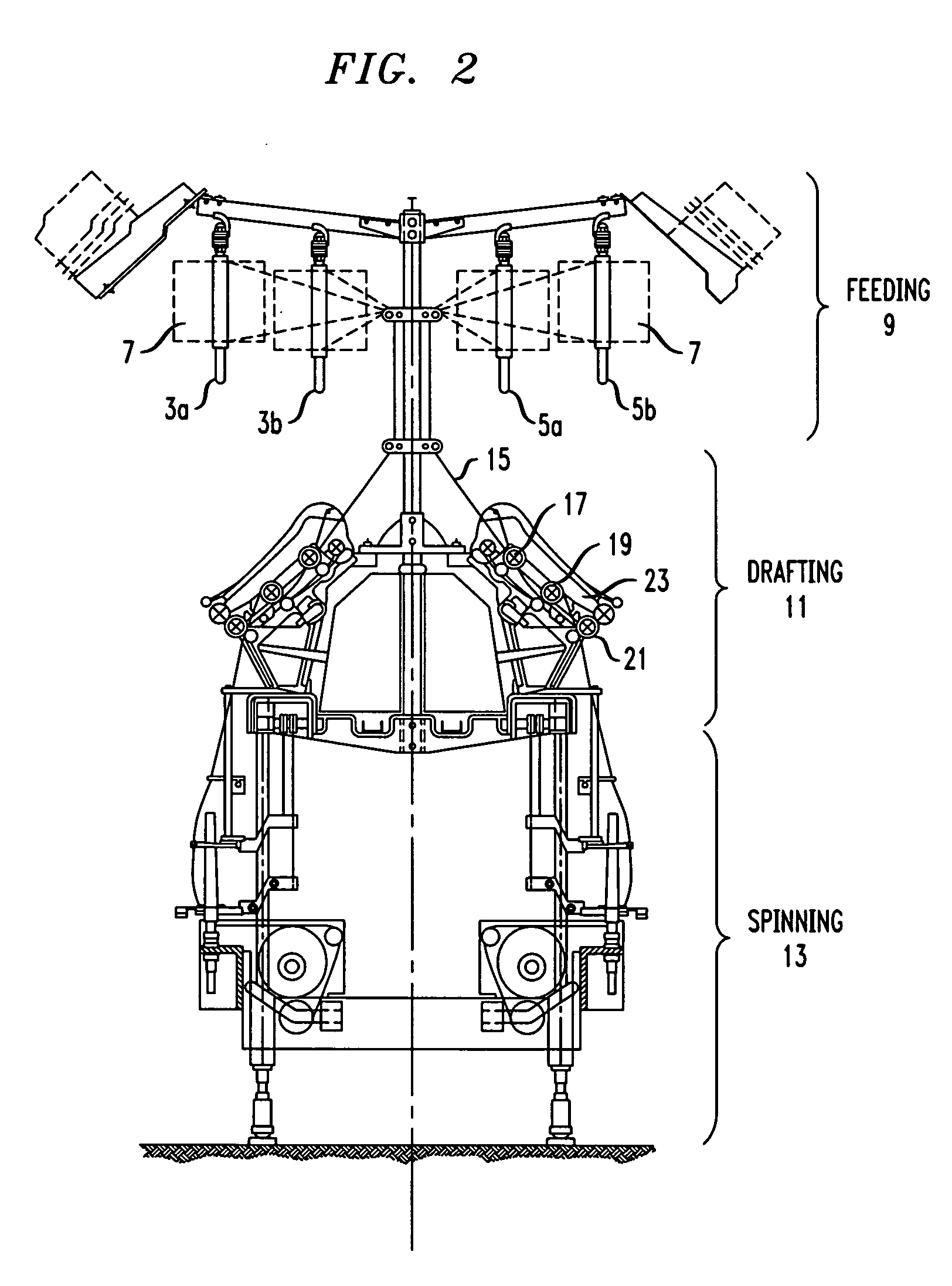

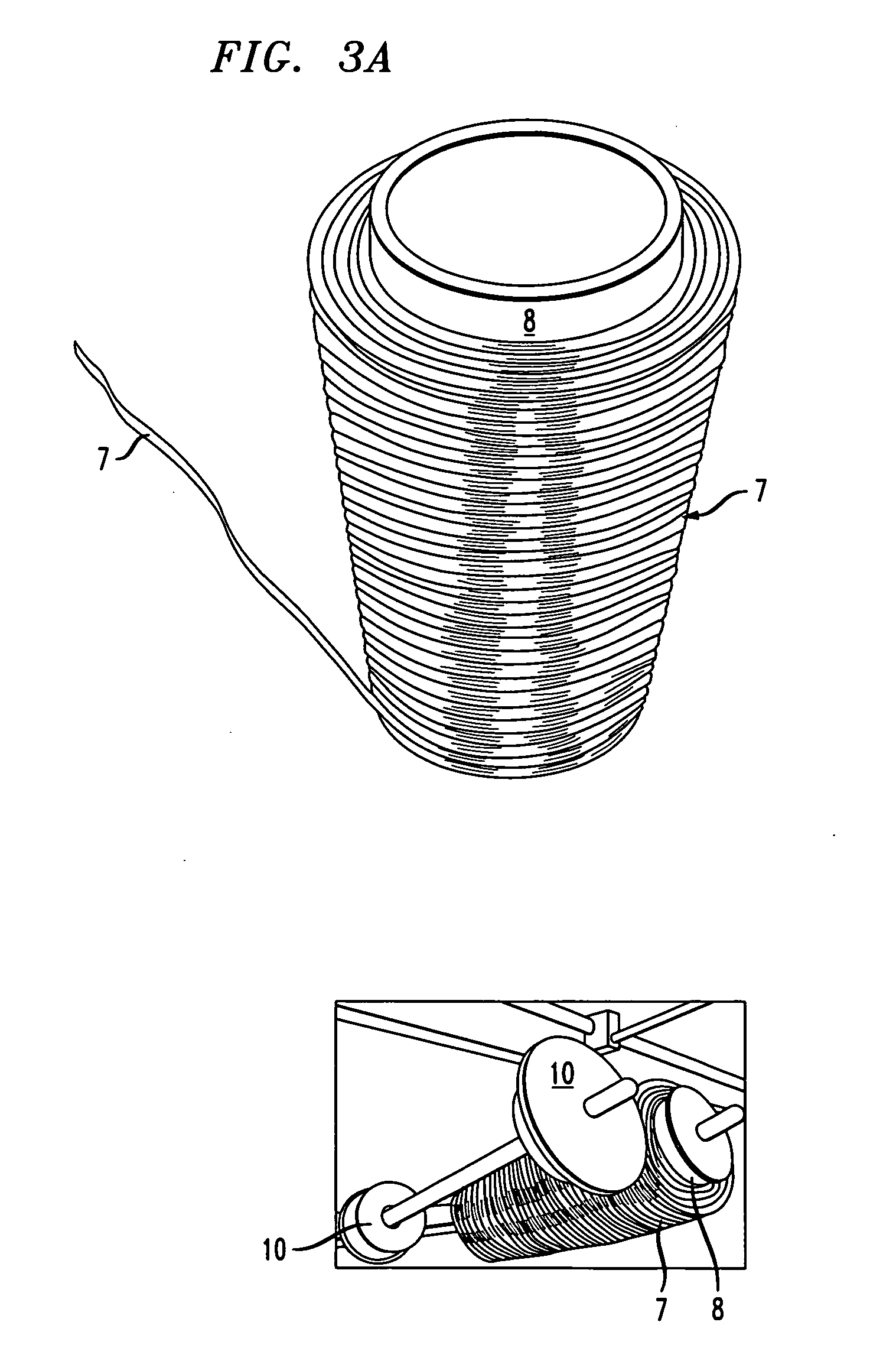

Fire retardant compositions and methods and apparatuses for making the same

A method for forming yarn provides for forming an intermediate product being a fire retardant and heat resistant cohesive elongated network of fibers in a single operation by stretching and breaking filaments of a ribbon like tow starting material of longitudinally aligned filaments. The intermediate product may be wool-like with wavy and randomly oriented fibers formed by from the fragmented filaments. The single drafting operation includes directing the tow through first and second pairs of rollers, the second pair rotating faster than the first. The intermediate product may be spun directly into yarn in one spinning / twisting operation. The fire retardant and heat resistant yarn so produced may include 100% oxidized polyacrylonitrile fibers having an average length greater than about 15 cm. The yarn may be knitted or otherwise formed into fire-retardant and heat resistant fabrics or other products used in various applications.

Owner:LORICA INT

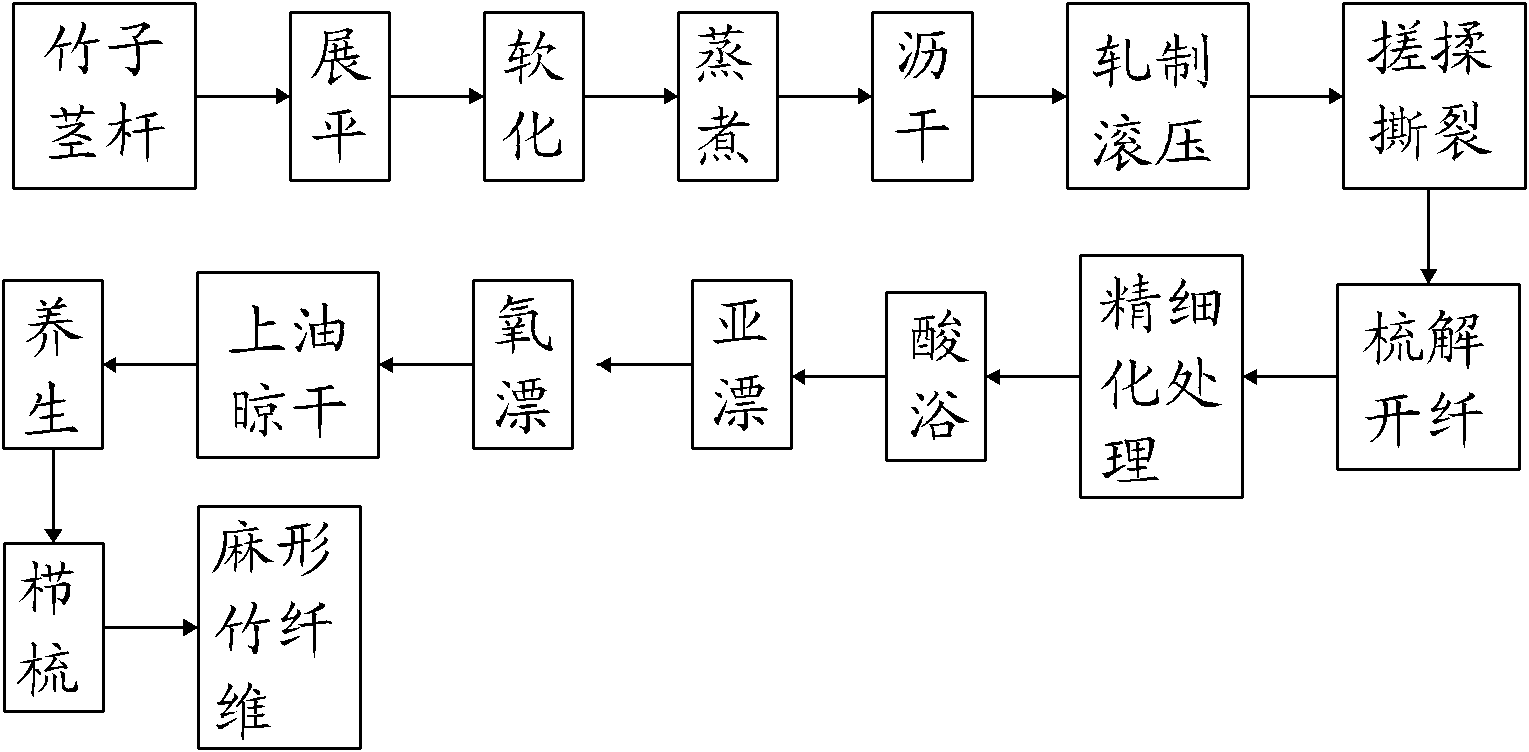

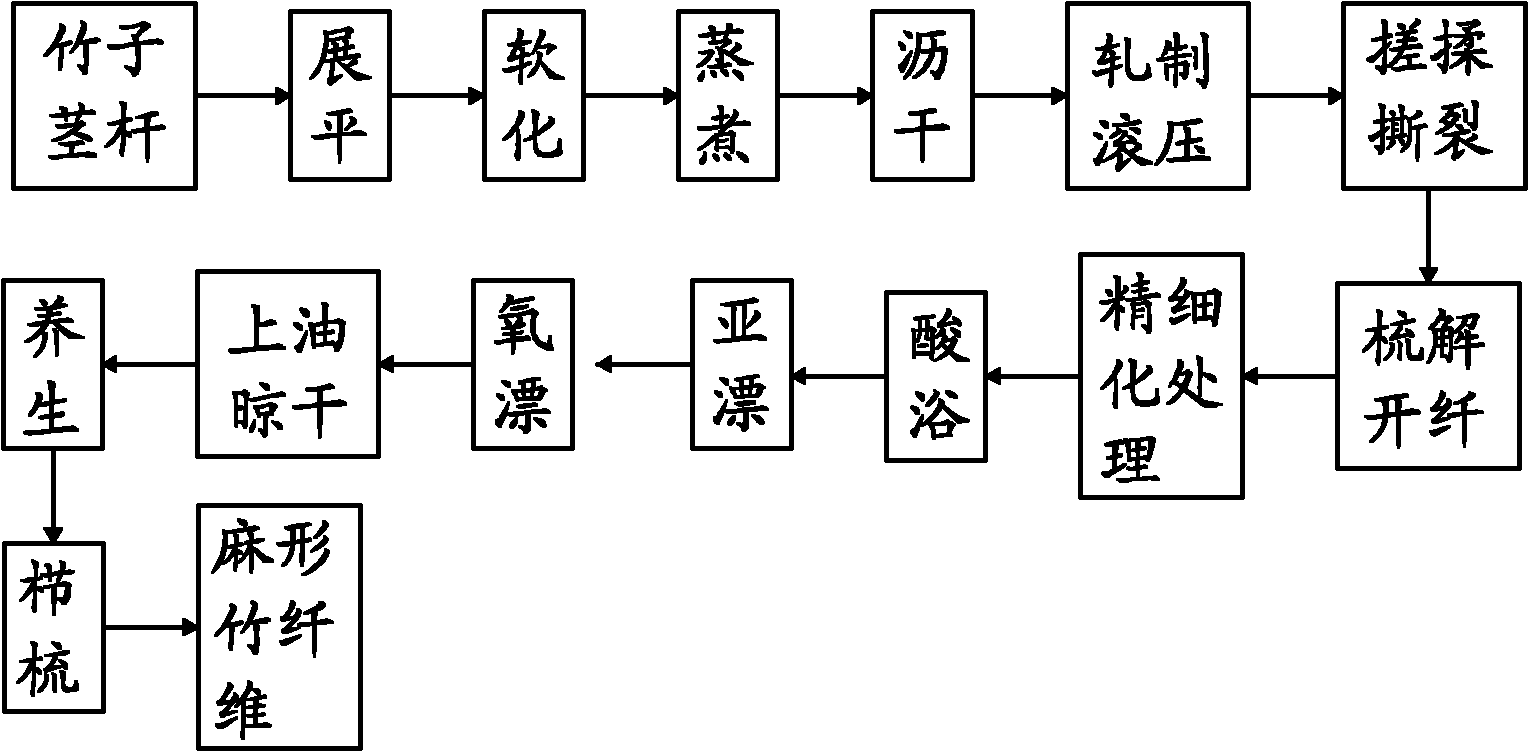

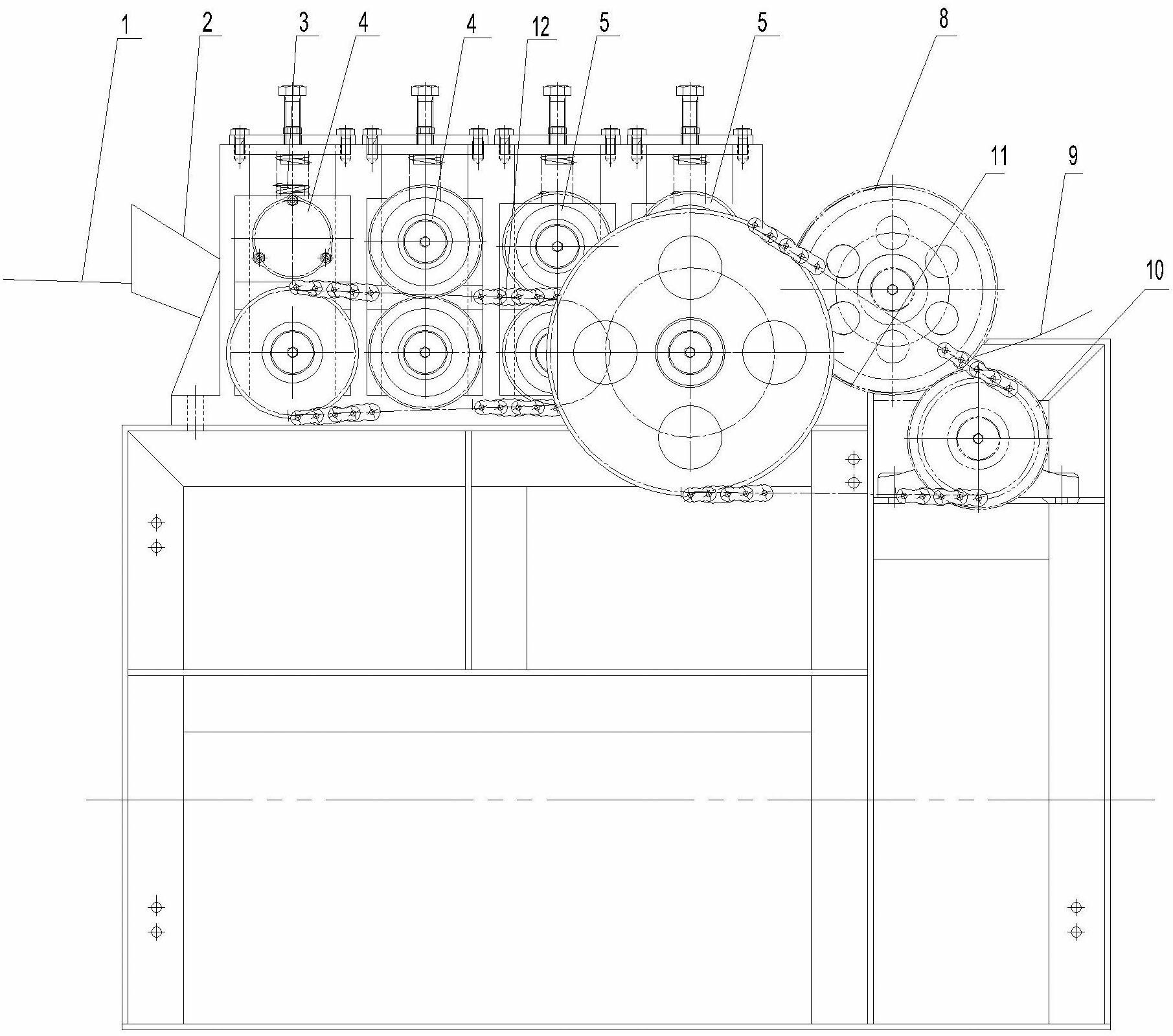

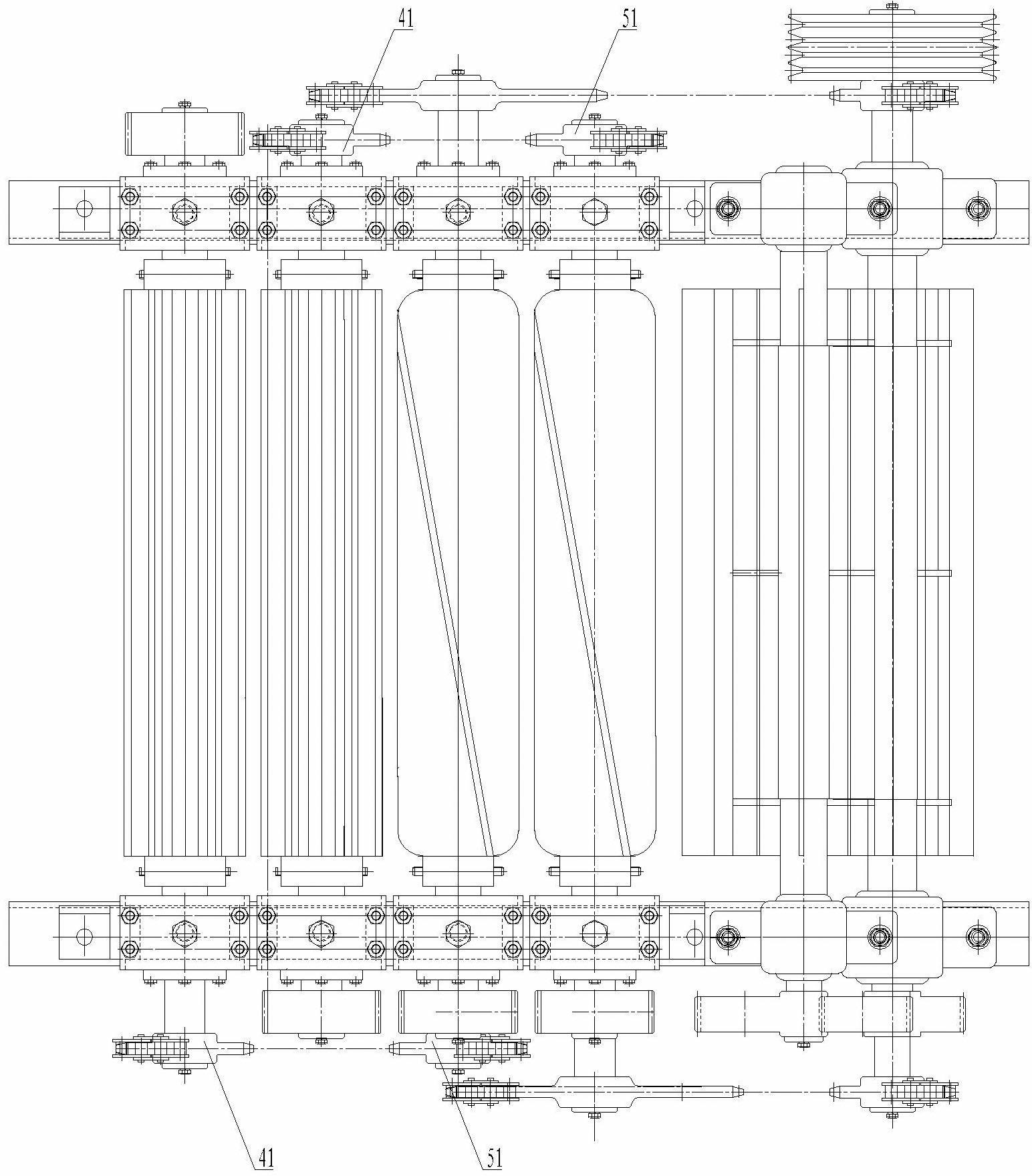

Process for producing hemp-like bamboo fibers

ActiveCN102206873AStable separationGood flexibilityVegetable materialMechanical fibre separationHigh pressureFlax fiber

The invention relates to a process for producing hemp-like bamboo fibers, which comprises the following steps of: sawing bamboo according to certain length, flattening, soaking in intermediate temperature softening solution for 3 to 24 hours or cooking by using tailor-made softening solution at a high temperature under high pressure for 15 to 60 minutes, draining, feeding into a fiber separator, rolling, kneading, tearing, combing, opening and the like to prepare the hemp-like bamboo fibers; putting the hemp-like bamboo fibers into a bamboo fiber purifying reactor, performing alkali boiling, bleaching, cleaning and curing; and opening, decontaminating and regularly combing the hemp-like bamboo fibers by using a hackling machine or a middle cutting machine to prepare hemp-like spinnable bamboo fibers. By the method, the hemp-like bamboo fibers can be produced; and the fibers are regular, uniform and soft, have the characteristics of large length, high strength, low fineness and the like, and have spinnability similar to that of hemp and flax fibers.

Owner:ZHEJIANG FORESTRY UNIVERSITY

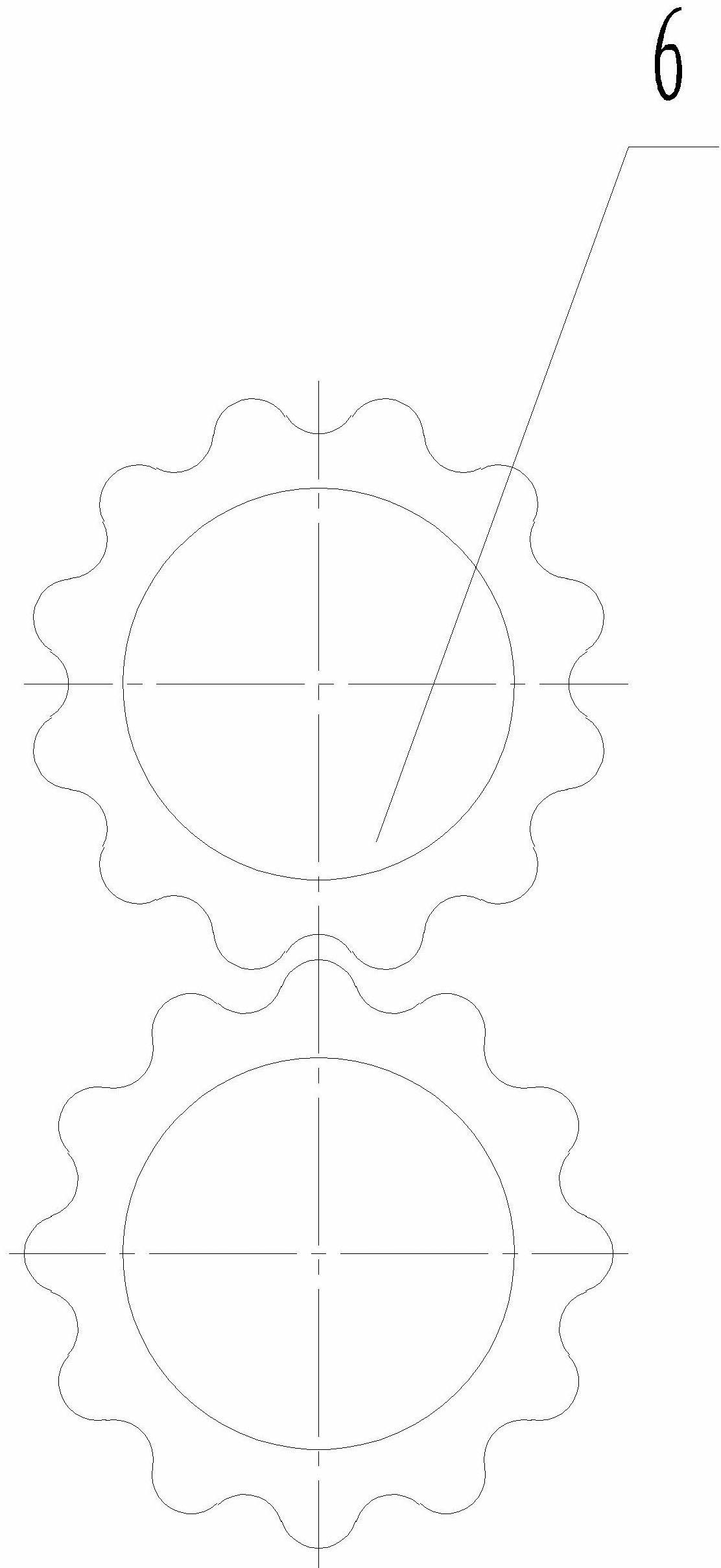

Bast fiber separating device

The invention discloses a bast fiber separating device, which comprises grinding rollers and kneading rollers positioned behind the grinding rollers. The outer diameter of each grinding roller is equal to that of each kneading roller, the grinding rollers and the kneading rollers are respectively vertically aligned pairwise, and the rollers in each pair are the same in structure and are engaged with each other. Semicircular grid bars on the surfaces of the grinding rollers are used for evenly grinding sticks of hemp stems, so that the sticks are primarily separated from bast fibers. Spirally arranged racks on the surfaces of the kneading rollers are used for kneading while further grinding the hemp stems, so that the bast fibers are thoroughly separated from the sticks. As the kneading rollers and the grinding rollers have linear speed difference, both longitudinal acting force and transverse acting force are applied to the hemp stems, and skins and the sticks of the hemp stems are separated more evenly while the bast fibers are not damaged. In addition, gaps among the semicircular grid bars and gaps among the flat racks are all arc grooves, namely contact surfaces of the hemp stems and each pair of kneading rollers are smooth arc surfaces, the strength of the bast fibers cannot be reduced, and the bast fibers cannot be lost.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

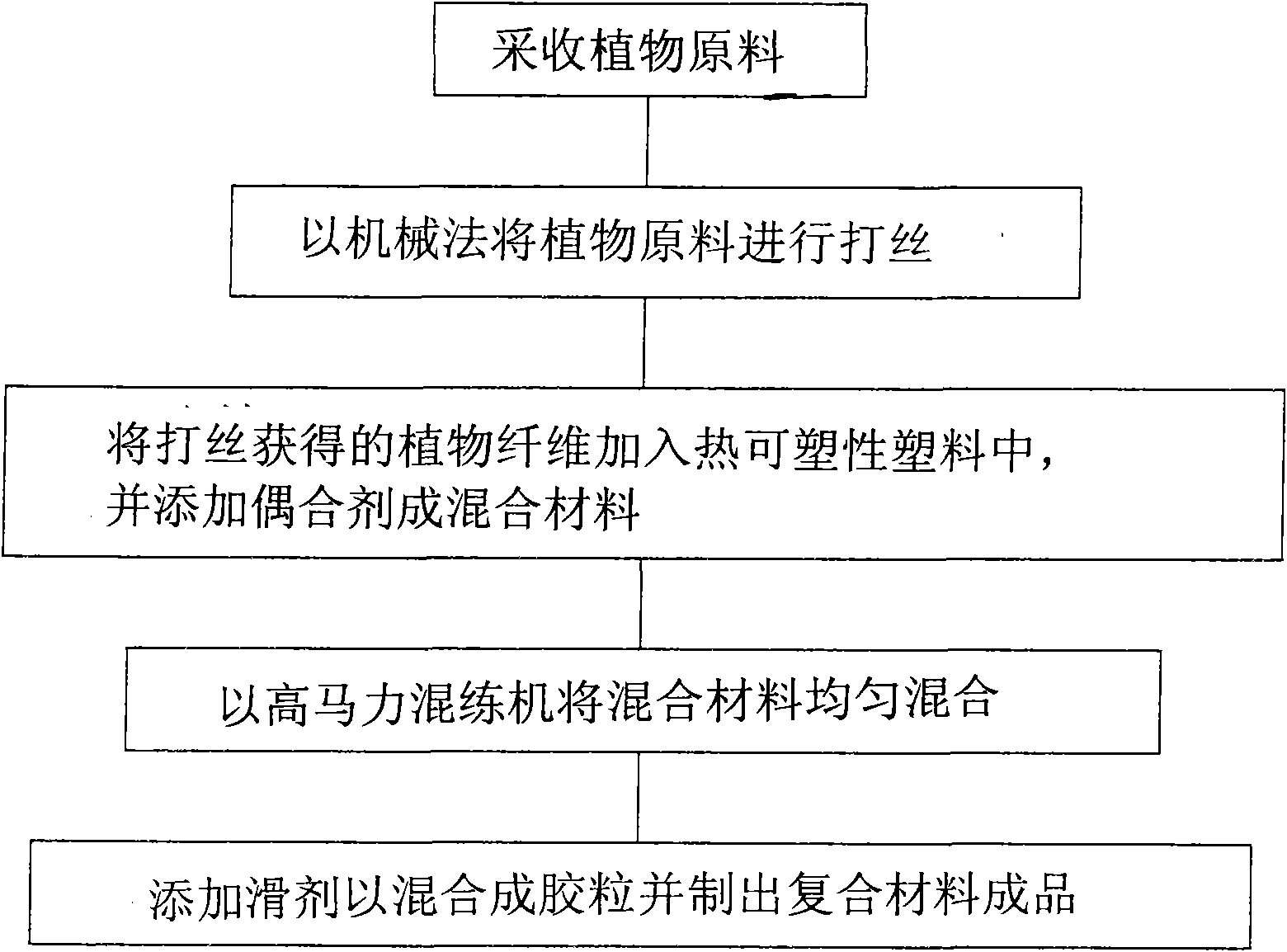

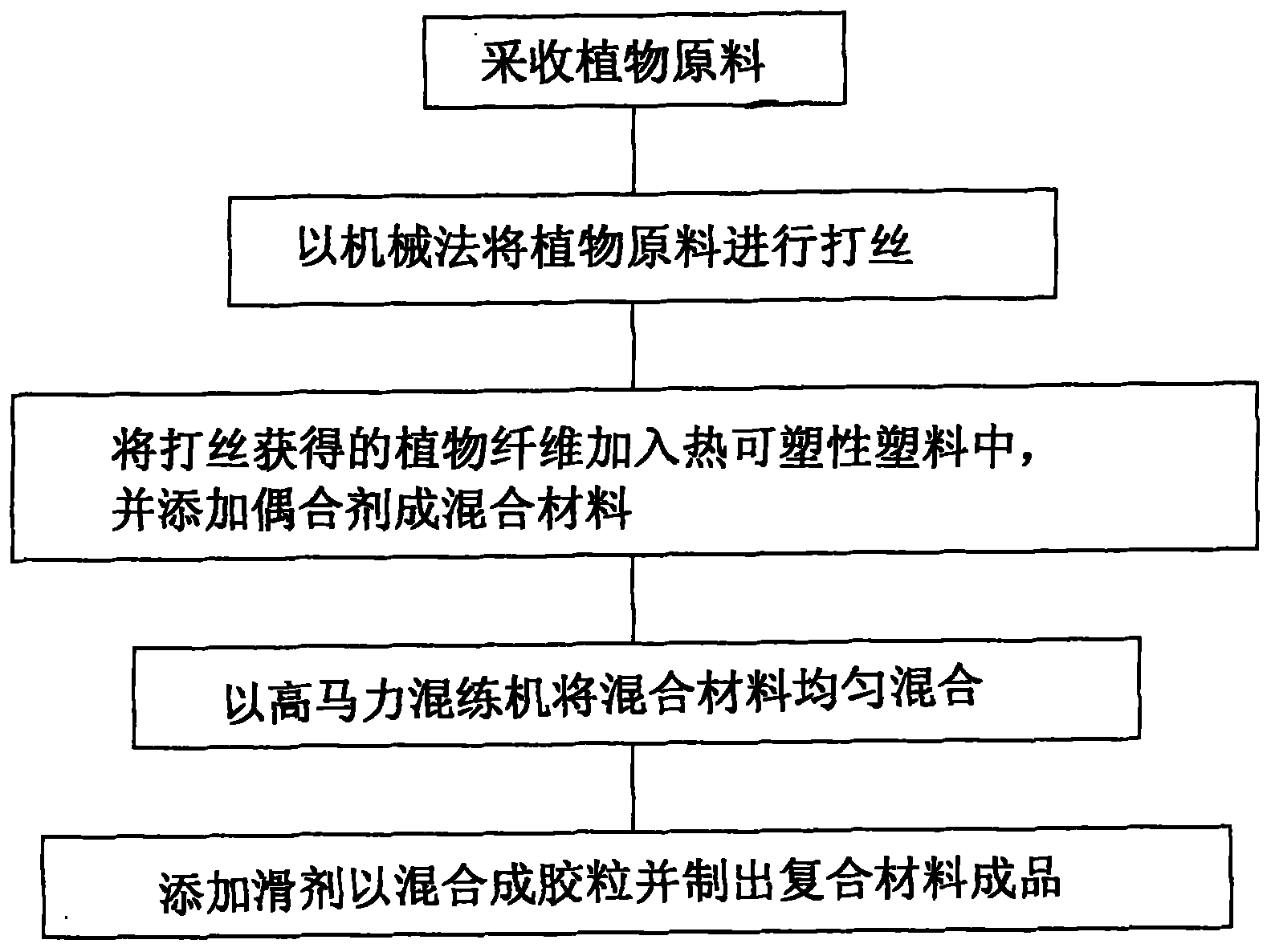

Preparation process of plant fiber composite materials

InactiveCN101781472AImprove flexural strengthReduce weightMechanical fibre separationManufacturing cost reductionFiber

The invention provides a preparation process of plant fiber composite materials, which comprises the following steps: collecting plant raw materials; using a mechanical method for cutting the plant raw materials into threads; adding the plant fiber obtained after the thread cutting into thermoplastic plastics and adding coupling agents to obtain mixed materials; using a high-horsepower calendaring machine for uniformly mixing the mixed materials; and adding lubricating agents to be mixed into colloidal particles and preparing finished products of composite materials. Because of the plant fiber composite materials, the prepared finished products have the characteristics of high bending resistance intensity, weight reduction, difficult thermal distortion, small thermal contraction force, manufacture cost reduction and the like.

Owner:詹德威

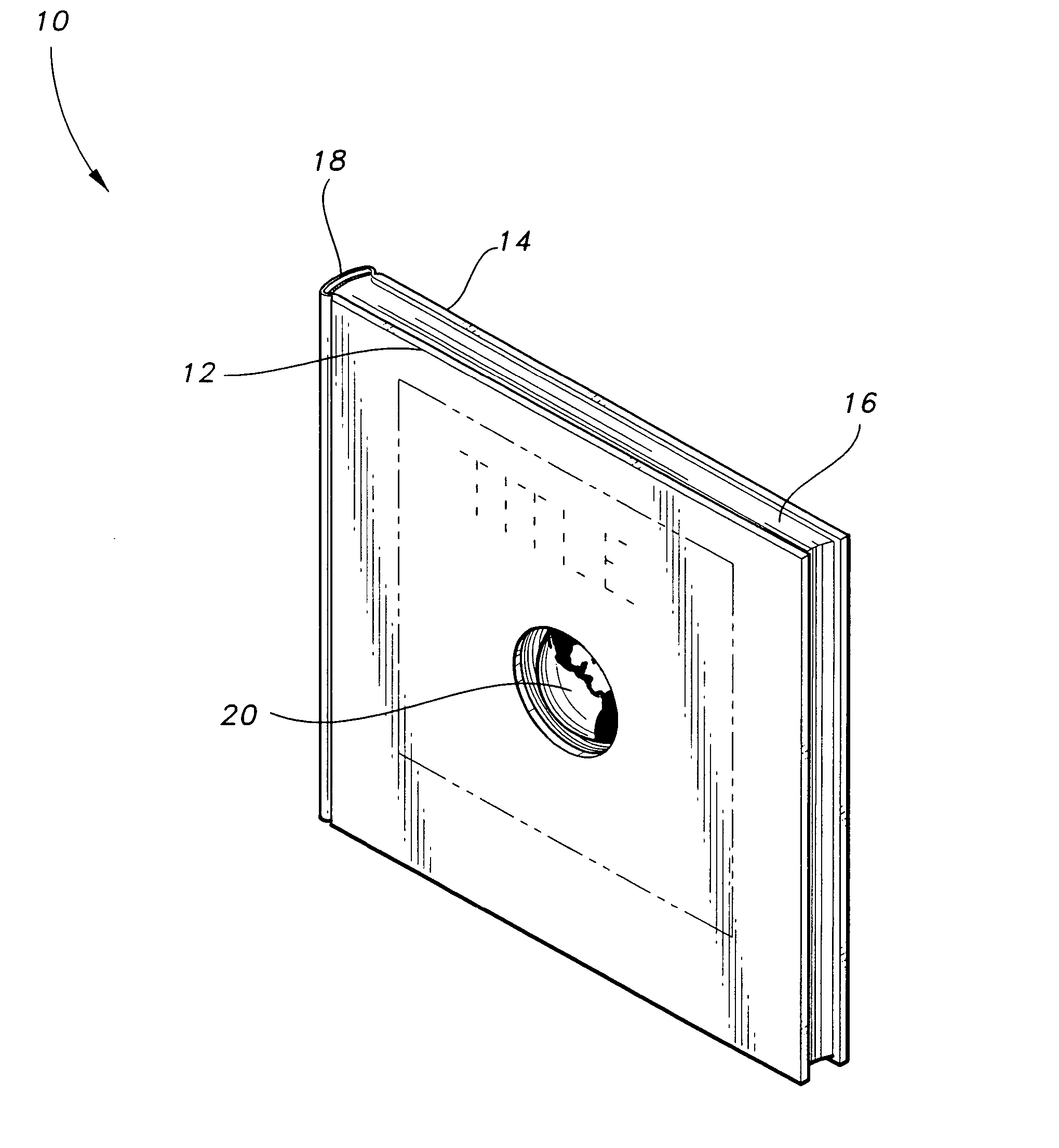

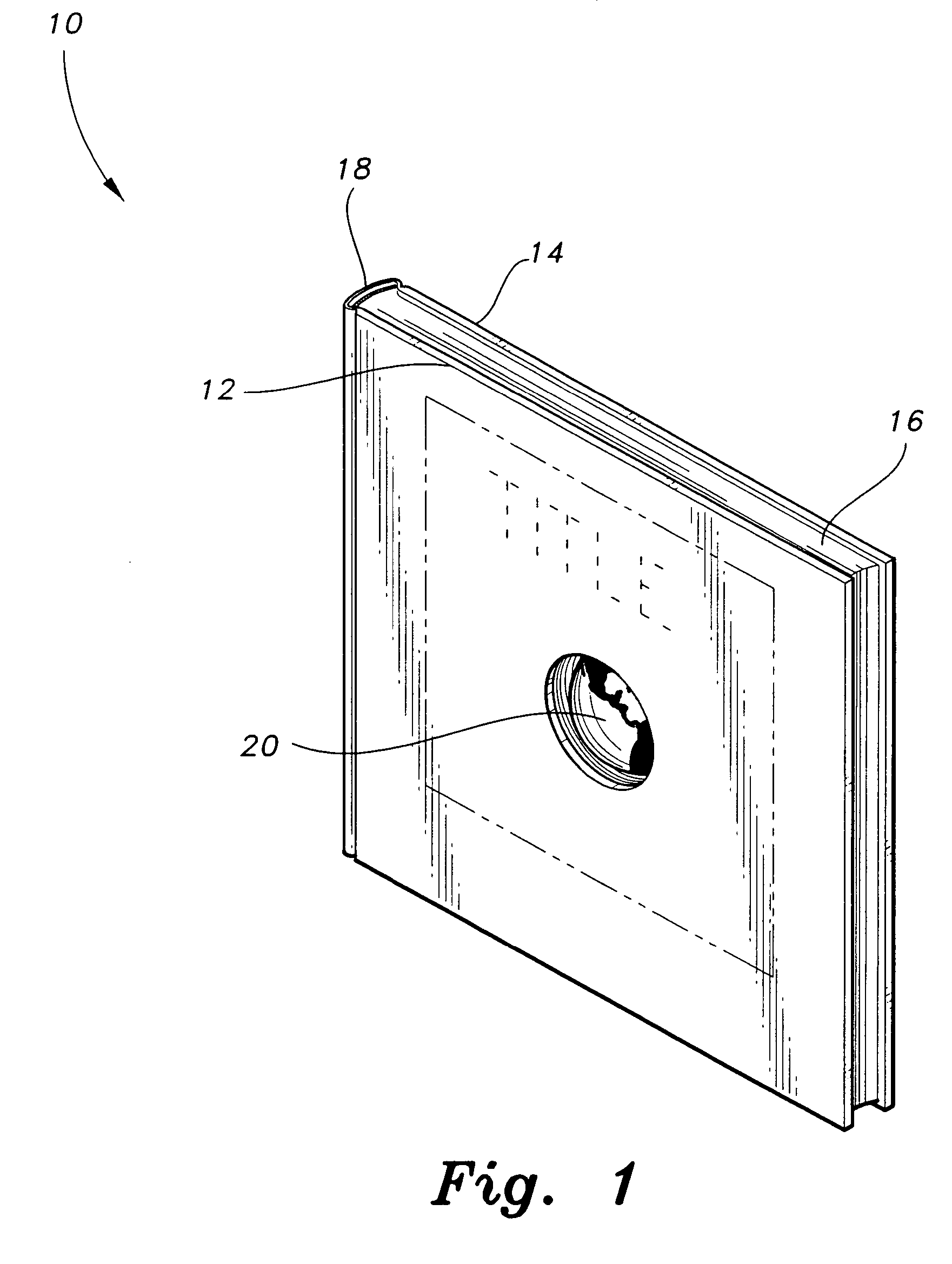

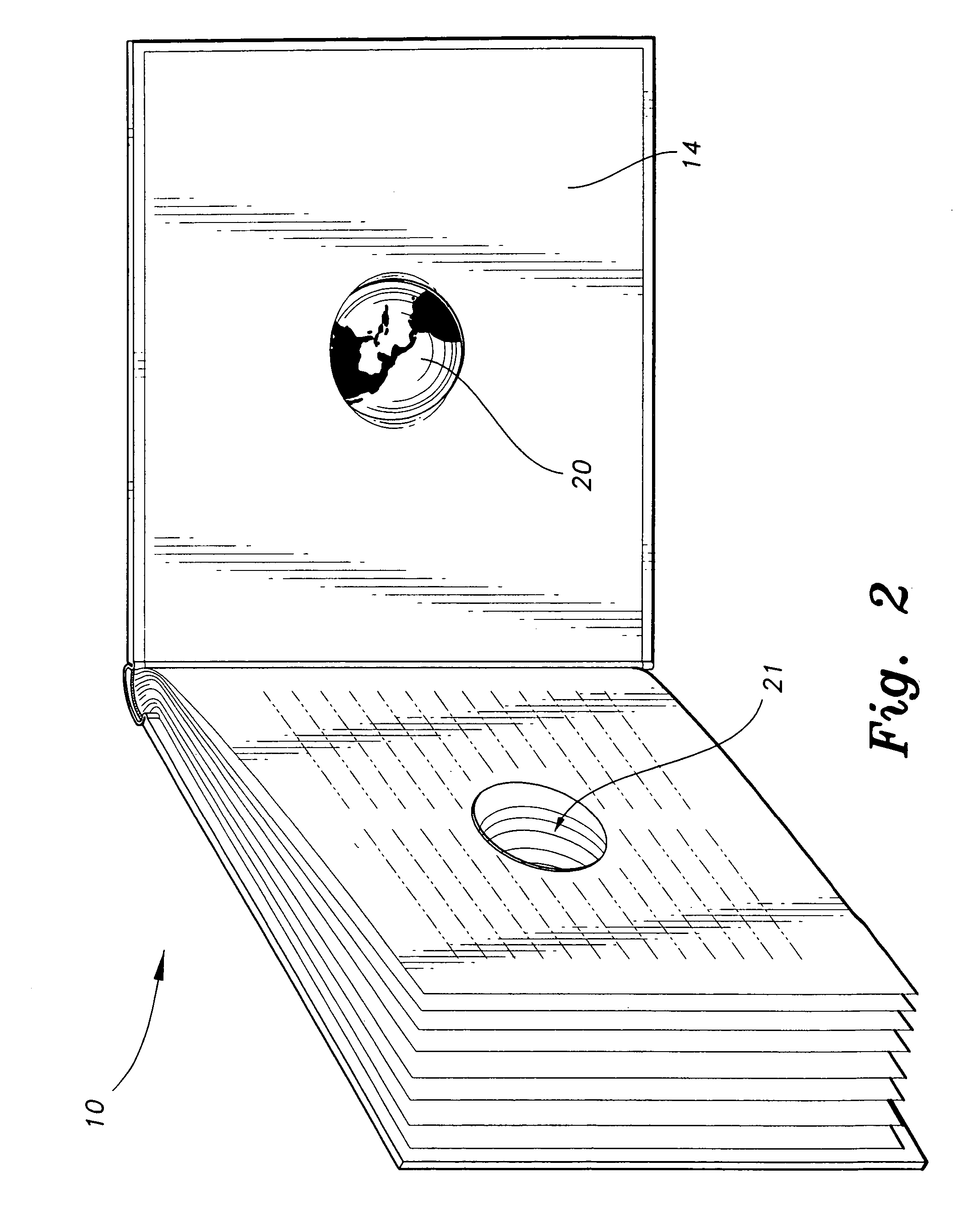

Book with spinning globe

The book with spinning globe has a front cover, a back cover, and a spine or binding portion which binds the front cover, and the back cover. An earth globe is rotatably connected to a front cover, back cover, or spine so that the globe is rotatable about an axis extending along a plane of the front cover, back cover, or spine to which the globe is connected. The book may optionally include at least one leaf positioned between the front and the back cover. The globe may also be rotatably connected to the leaf. The globe is configured to represent the earth, and has outlines representing the continents and at least larger countries or geographical regions, and may have contours representing mountains or other features.

Owner:DUPREY JOHN F

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743AHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Process for producing sisal fiber

InactiveCN101294309AImprove finenessGood flexibilityMechanical fibre separationFibre treatment to obtain bast fibreColloidHemicellulose

The method for preparing sisal fiber is characterized in that the method comprises the following steps: (1) scraping colloid in sisal leaf pulp by mechanical knocking or rolling, and removing partial lignin, hemicellulose and pectin therein; (2) pre-soaking fiber material in sulfuric solution at 30 to 80 DEG C for 1 to 3 h; (3) cleaning with circulating water to adjust pH value to 6.8 to 7.2; (4) adding the fiber material in a boiler with pressure of 0.1 to 0.2 MPa, and boiling with sodium hydroxide solution for 2 to 6 h; (5) cleaning with circulating water to adjust pH value to 6.8 to 7.2; and (6) post-treating to obtain sisal fiber. The method has the advantages that the fineness and the flexibility of sisal fiber prepared by the method are improved greatly in comparison with unprocessed crude sisal.

Owner:DONGHUA UNIV

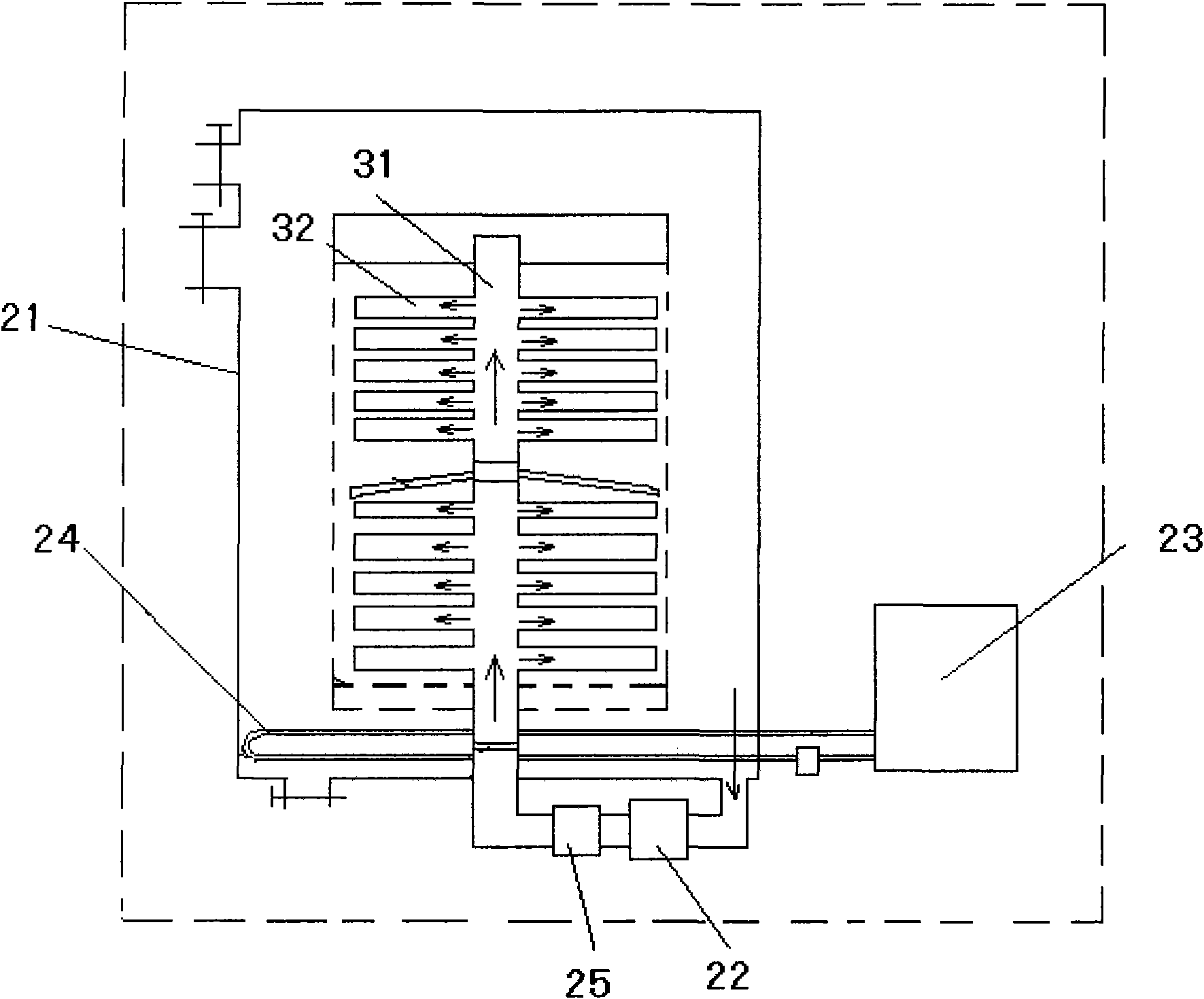

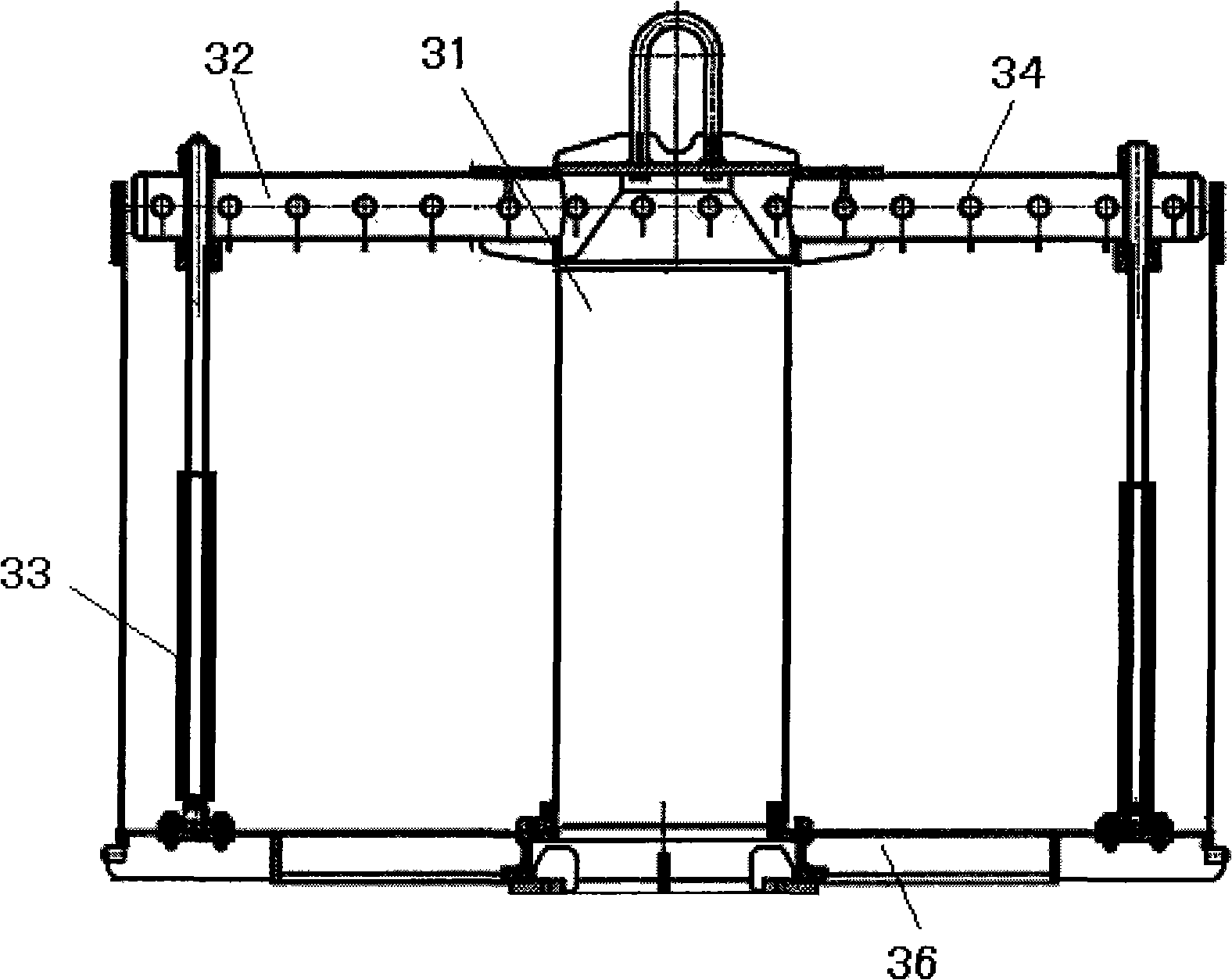

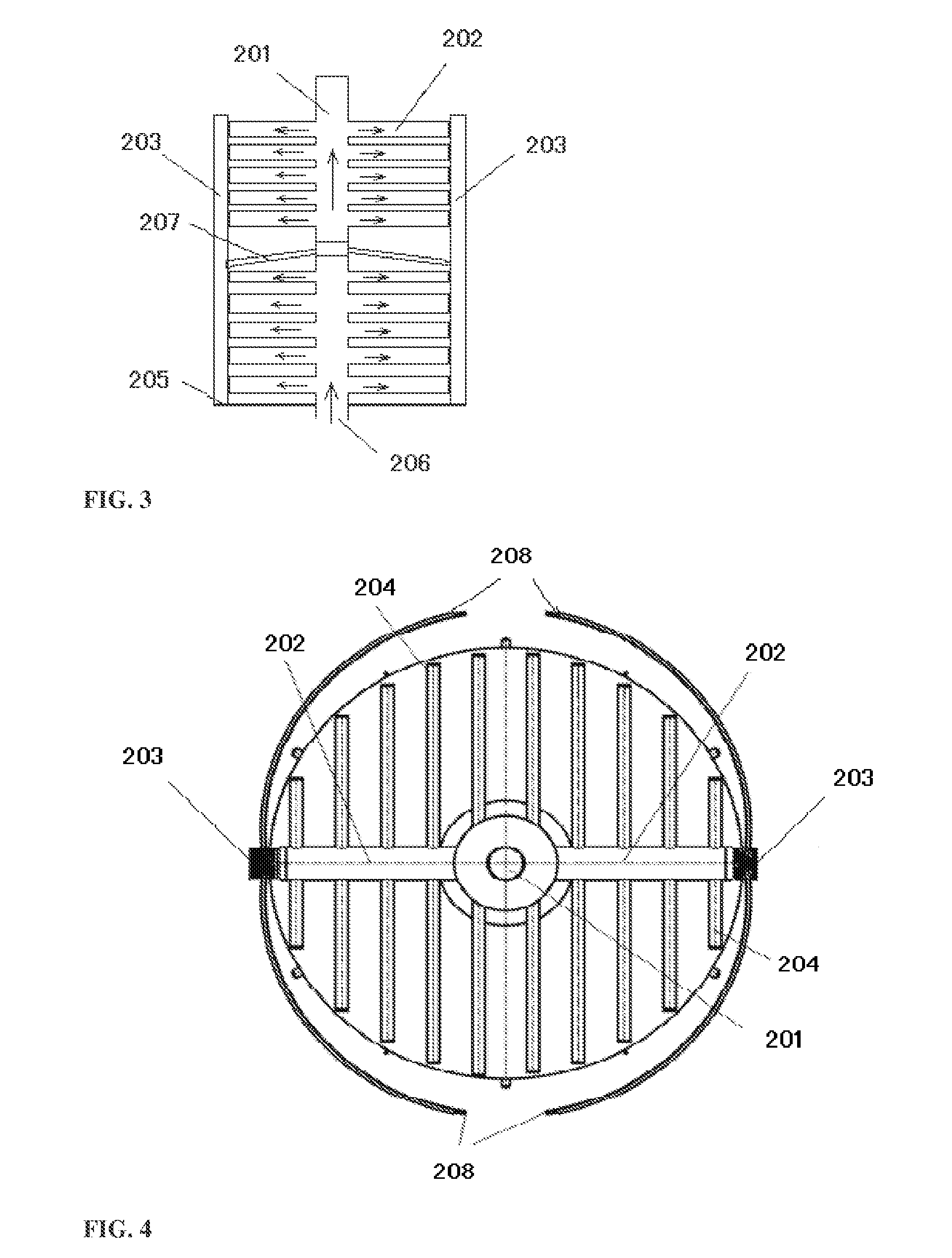

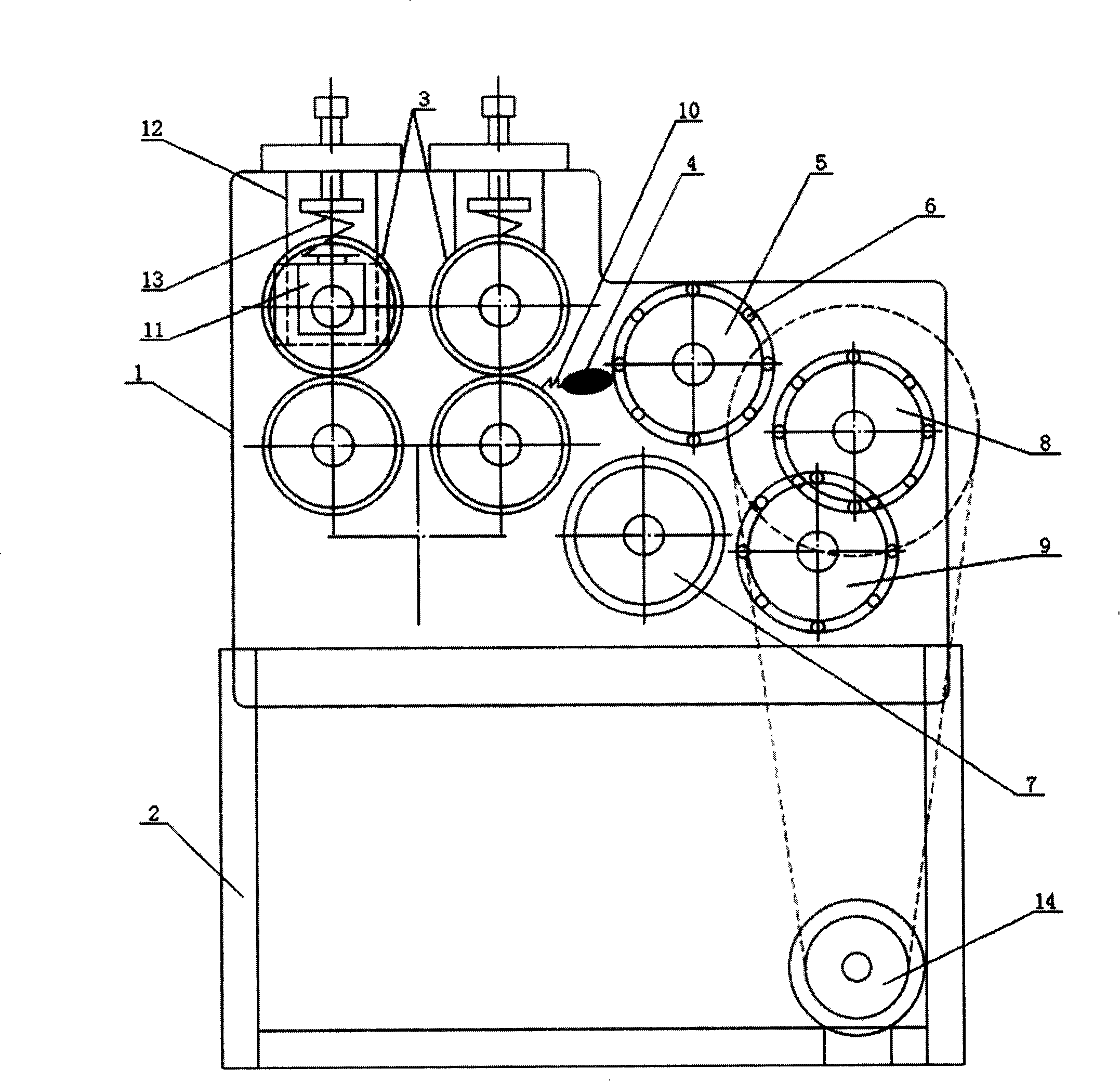

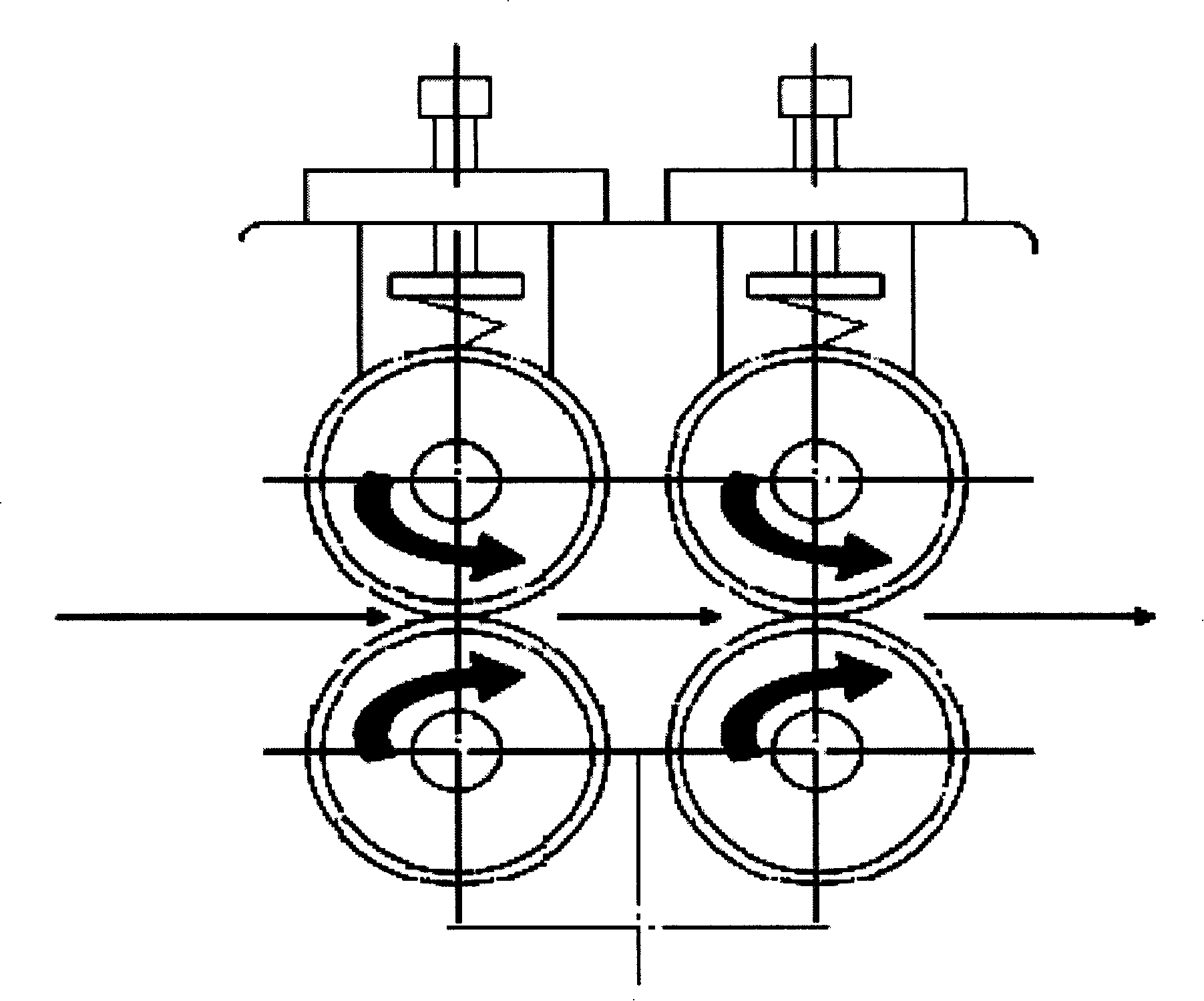

Mechanical degluing method and device of phloem fiber

ActiveCN101824657AHas penetrationUniform degummingMechanical fibre separationElectric machineryEngineering

The invention relates to a mechanical degluing method and a device of phloem fiber. The method of the invention comprises the following steps: 1) spreading and flatly paving phloem fiber in bundles, manually or mechanically feeding the phloem fiber between two rows of upper rollers and lower rollers in arrangement in pairs; 2) driving the upper rollers and the lower rollers to do alternating movement in the positive direction and the reverse direction through a motor, in addition, ensuring that the movement time in the positive direction is longer than the movement time in the reverse direction, and repeatedly extruding, kneading and forwards conveying the phloem fiber; 3) carrying out manual or mechanical oscillation and impurity removal through flapping on colloidal particles and dust on the phloem fiber at the same time of conveying the processed phloem fiber in the second step by a conveying belt; and 4) carrying out manual and mechanical shaking for further impurity removal on the processed phloem fiber in the third step, and then, packing the phloem fiber into bundles. The invention has the advantages of reasonable structural design, ideal degluing effect, small degluing pollution and safe and reliable operation, and can be widely used in the degluing process of phloem fiber, leaf fiber and gramineae fiber raw materials and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

Pineapple leaf fiber preparation method

InactiveCN101307502AGood physical and mechanical propertiesImprove dyeing effectCellulose/protein filament chemical after-treatmentMechanical fibre separationHemicelluloseMechanical property

The invention provides a method for preparing arghan, which comprises the following steps that: pineapple leaves are subject to mechanical treatment, acid preimpregnation, washing, basic boiling, alkali cooking, washing, dehydration, loosing and oiling. The method has the advantages that: the provided arghan has high cellulose content, and other compositions such as hemicellulose, lignin and pectin have lower content, so the arghan provided by the method has good physical and mechanical properties, the fiber length of the arghan can reaches between 3 and 38cm, the fiber fineness reaches between 1000 and 5000 metric counts, the strength is between 5 and 6.8cN / dtex, and the softness reaches between 65 and 85 twirl / 25cm. In addition, the arghan provided by the method has good dyeing property as well as anti-ultraviolet performance and sound wave resistant performance.

Owner:DONGHUA UNIV

Method and device for biological degumming of ramie

InactiveCN101857974ALarge specific surface areaFully contactedVegetable materialMechanical fibre separationCelluloseUltimate tensile strength

The invention provides a method for the biological degumming of ramie, which comprises the following steps of: c peeling and pre-opening fibers of the dried fresh ramie to obtain raw ramie; soaking and inoculating degumming bacteria subjected to amplification culture in the raw ramie and carrying out oscillation fermentation on the mixture at a rotation speed of 50 to 200 revolutions per minute to obtain fermented ramie; carrying out washing and fiber opening on the fermented ramie to obtain primary ramie; and carrying out oil soaking, dehydration and drying on the primary ramie to obtain fine ramie. The invention also provides a device for the degumming on the ramie. Compared with the prior art, the method provided by the invention combines a mechanical processing method with a biological degumming method, firstly carries out fiber pre-opening to improve the efficiency of subsequent biological degumming and then carries out washing and fiber opening after completing biological degumming to realize complete separation of gelatinous substance and cellulose, shortens degumming time and improves degumming efficiency. The obtained fine dried ramie has stable quality and higher fiber strength.

Owner:湖南润久科技有限公司

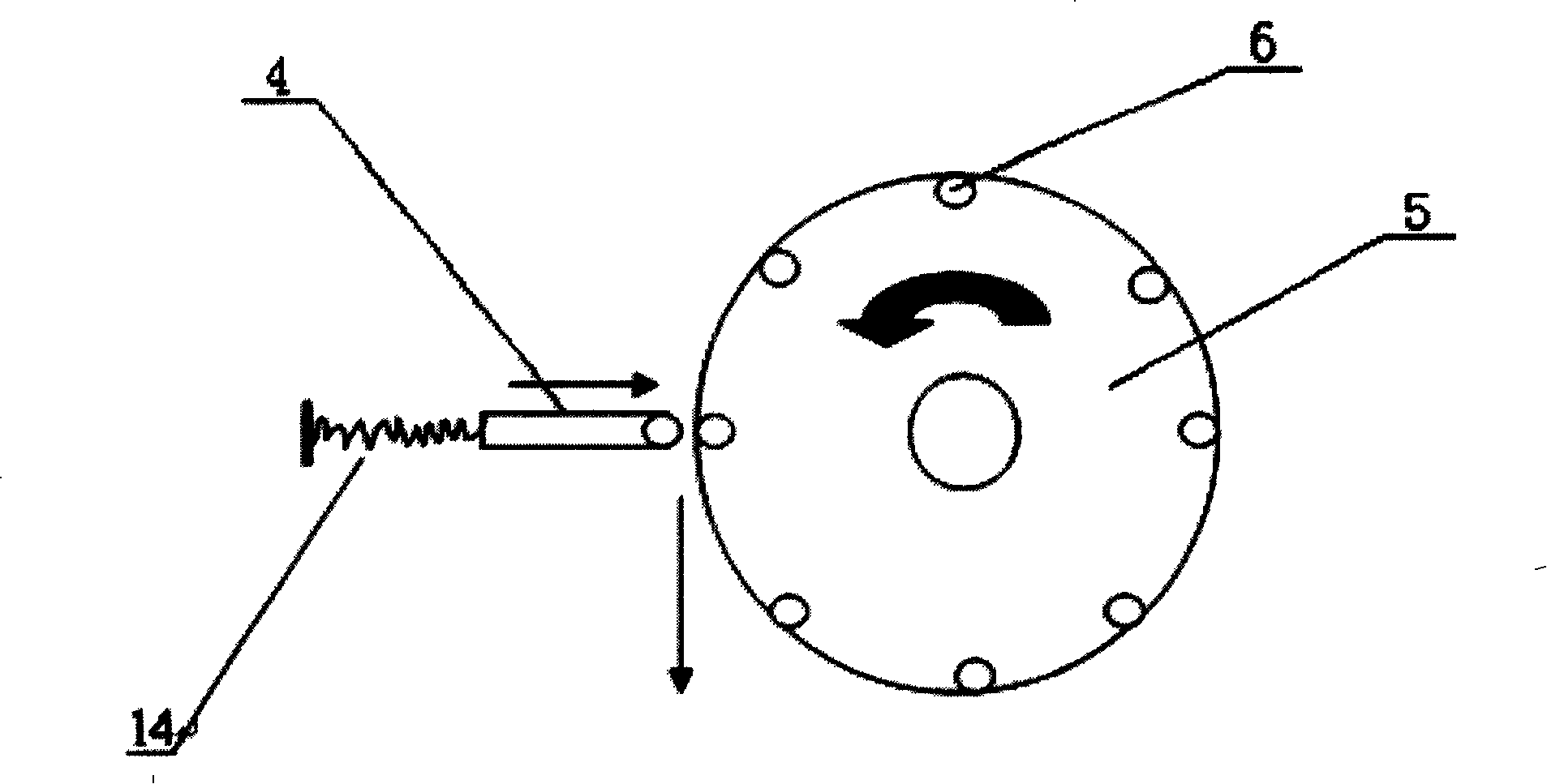

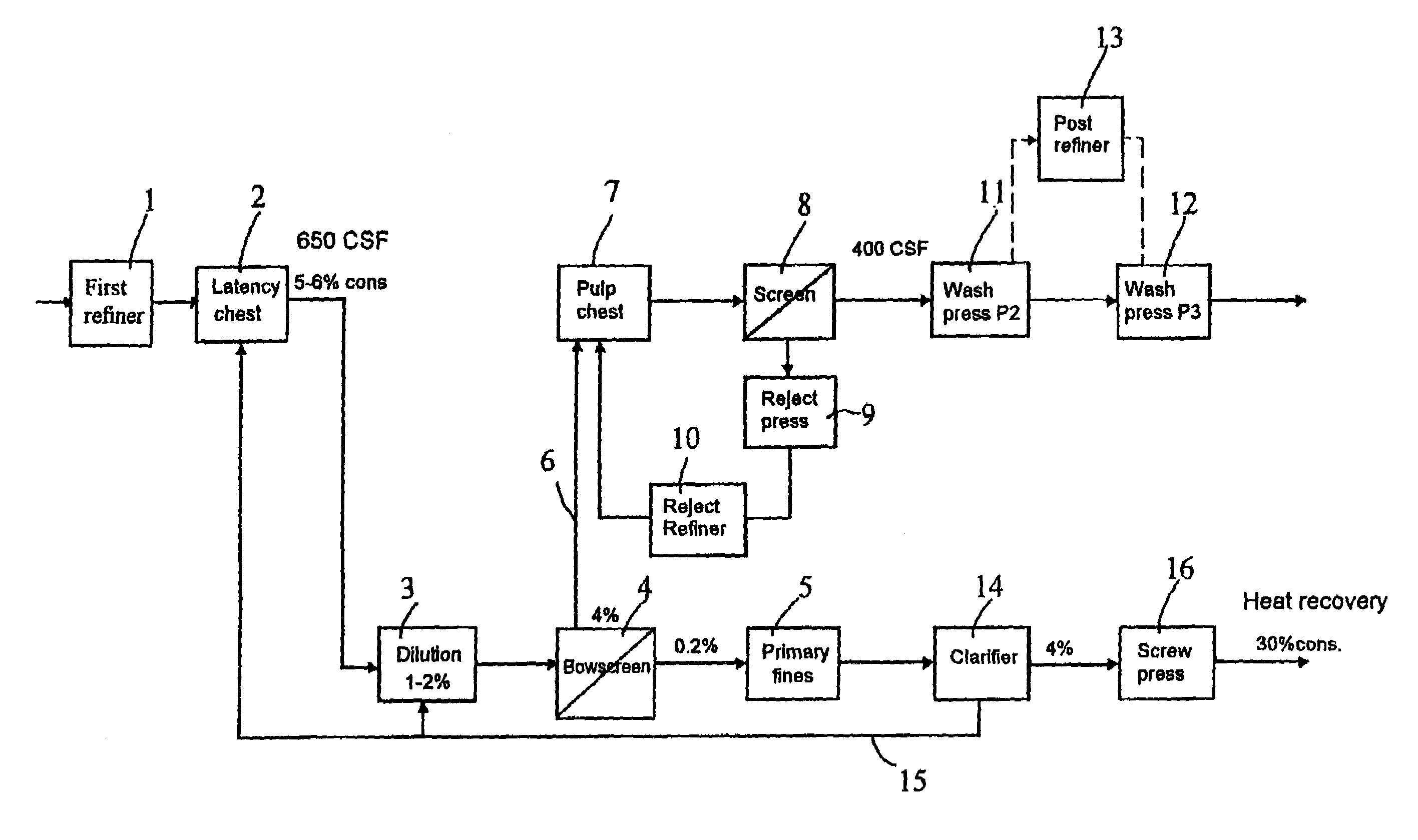

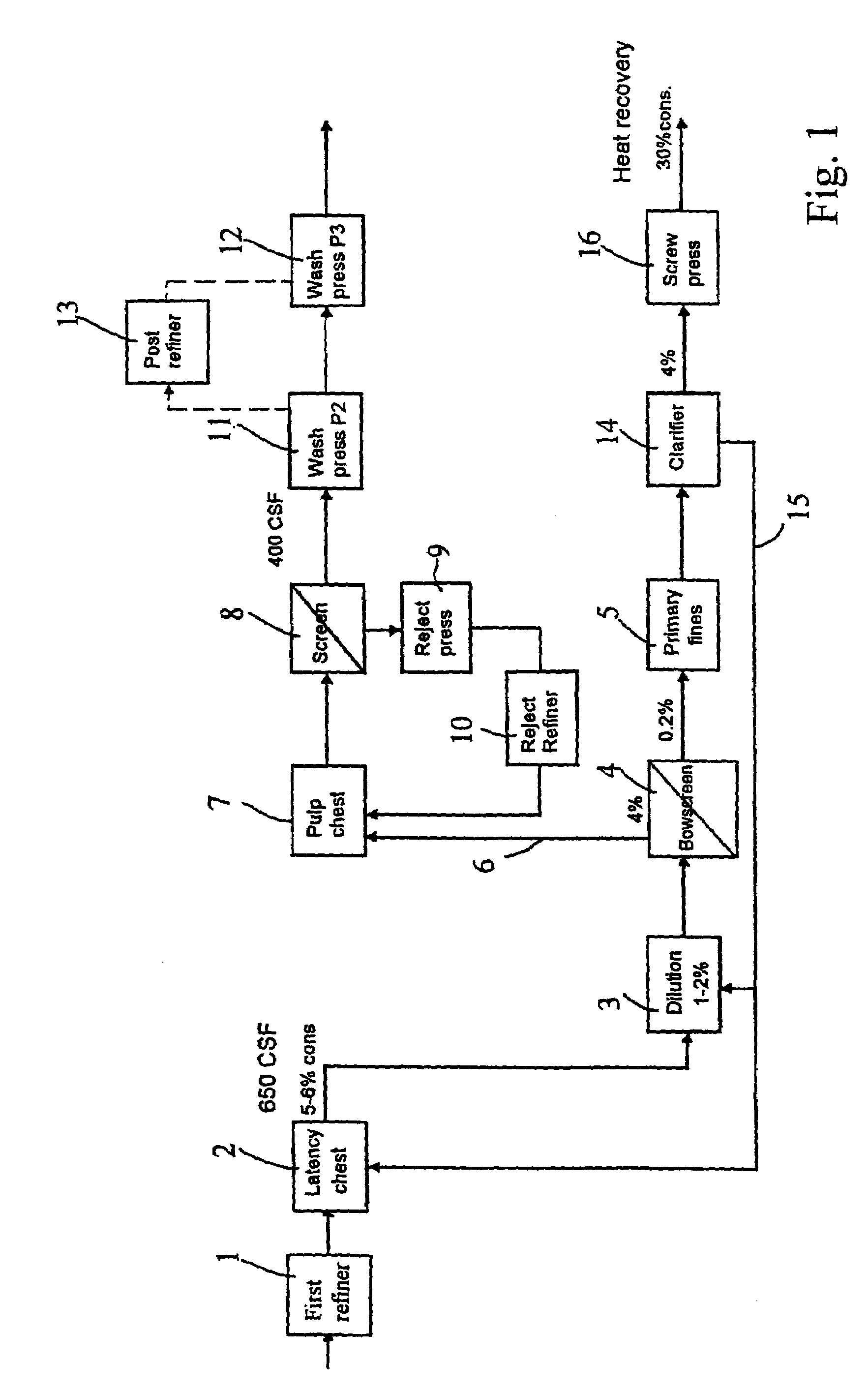

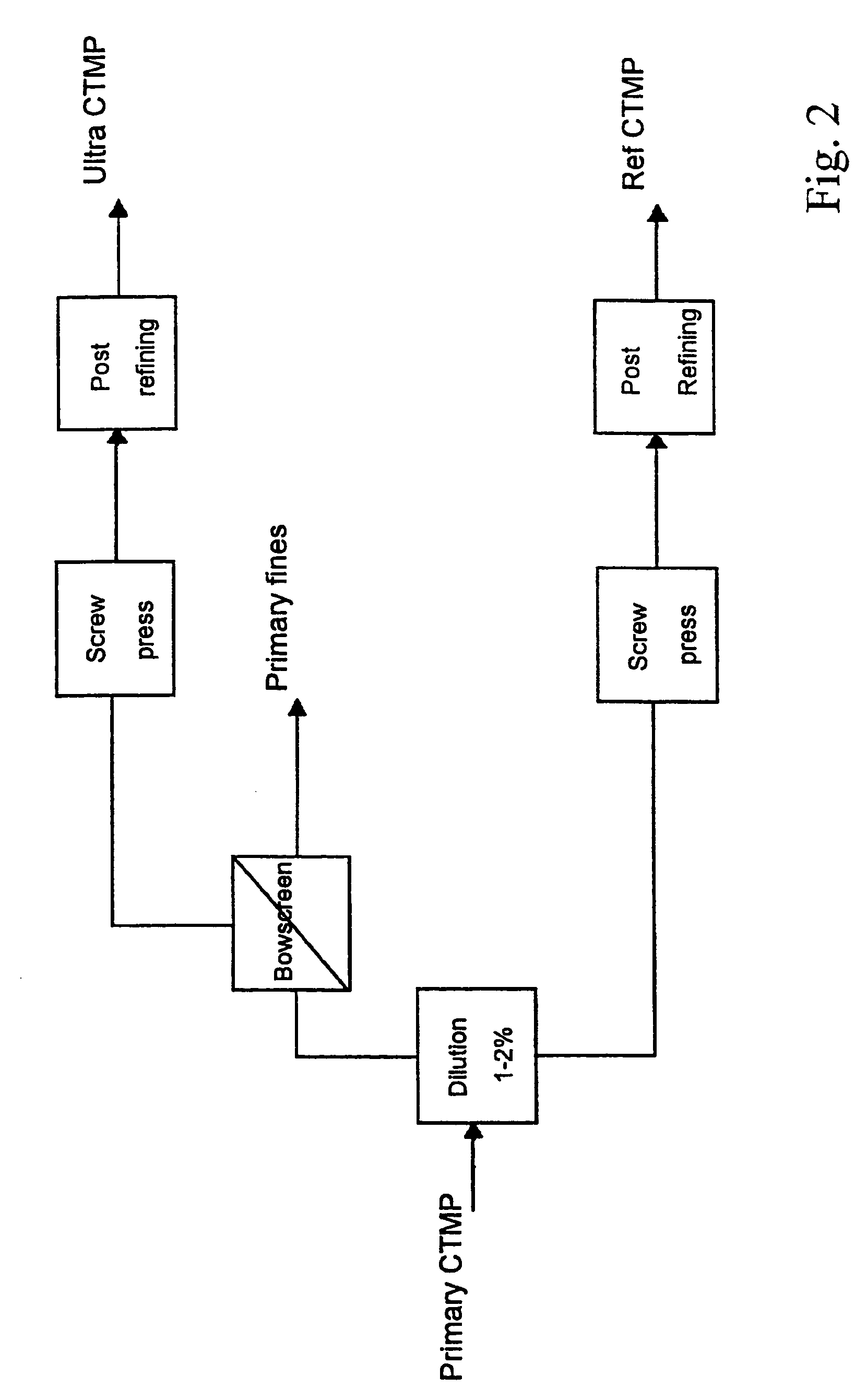

Method in connection with the production of mechanical pulp

InactiveUS7005034B1Reduce consumptionGood removal effectFats/resins/pitch/waxes removal in pulpDigestersCellulosePaperboard

A method in connection with the production of mechanical pulp from a cellulose containing material wherein the material is processed in at least one refining step to produce pulp. According to the invention, the pulp is fractionated (4), after a first refining step (1), in order to separate primary fines (5) from the pulp. The invention also relates to a mechanical pulp, produced by the method, and to a paperboard, which at least partly consists of such mechanical pulp.

Owner:STORA ENSO AB

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com