Bast fiber separating device

A bast fiber and separation device technology, applied in the directions of fiber mechanical separation, fiber processing, textile and papermaking, etc., can solve the problems of large fiber loss, high labor intensity, and reduced fiber strength, and achieve the effect of uniform skin and bone separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are preferred embodiments of the present invention.

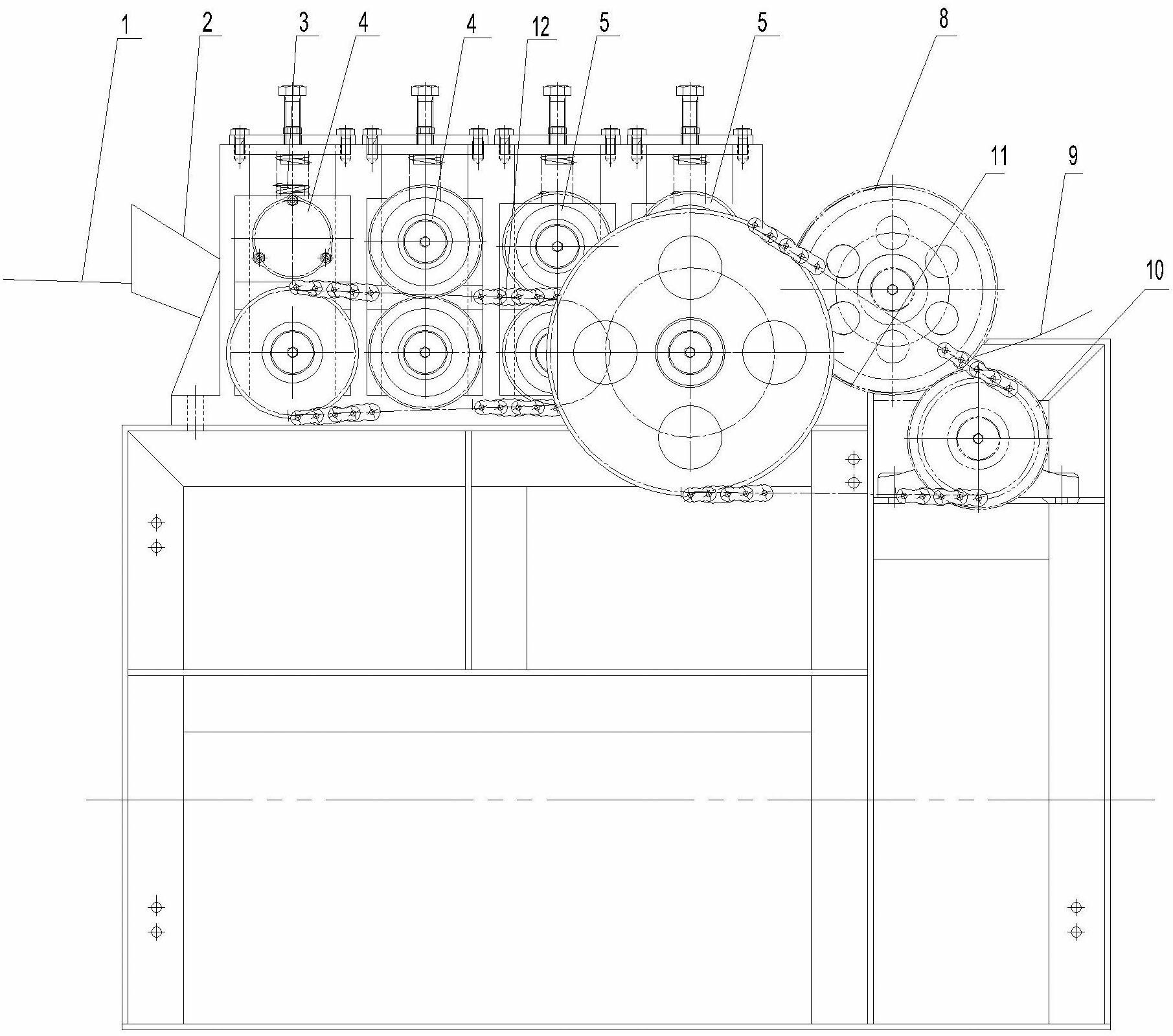

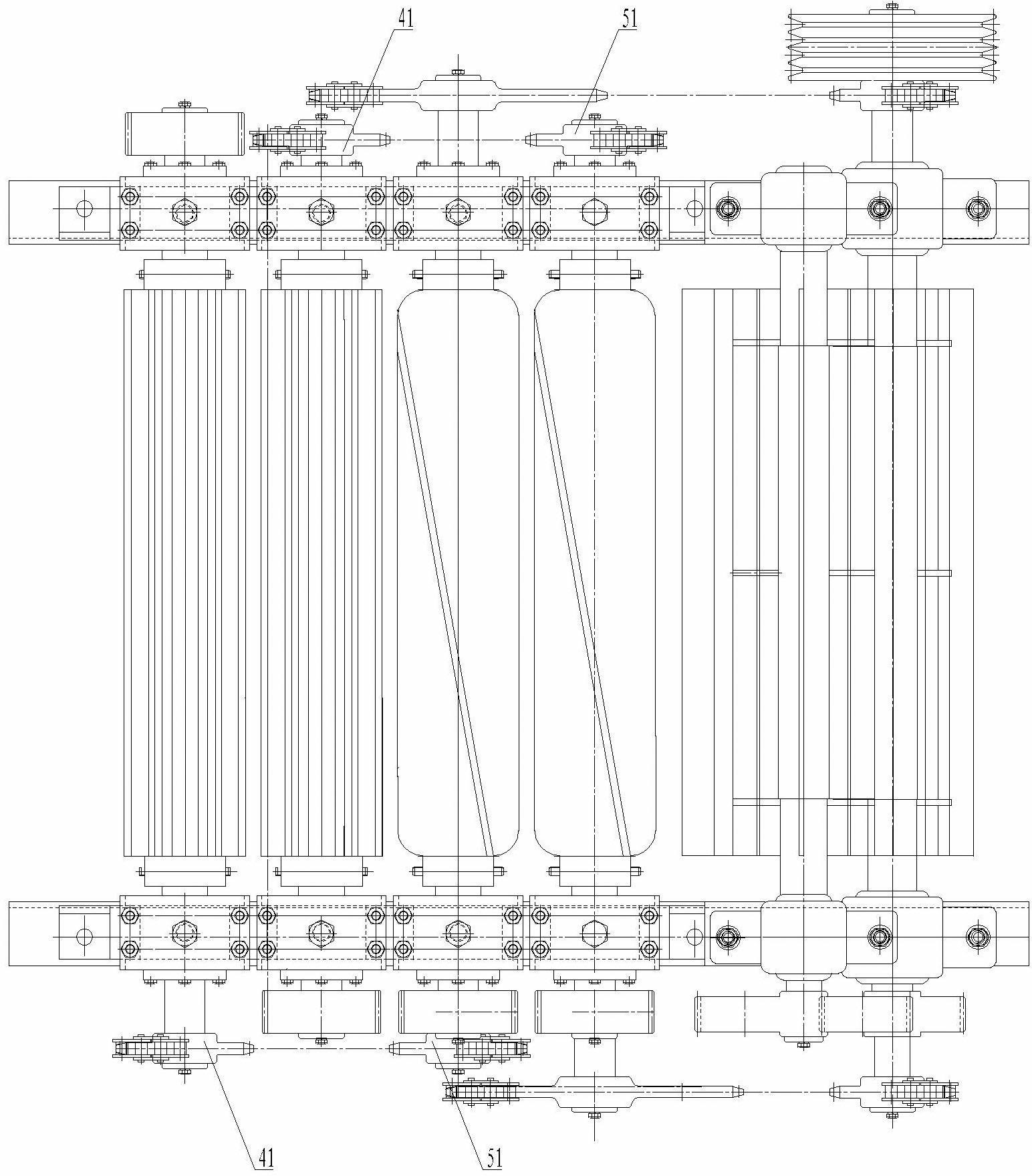

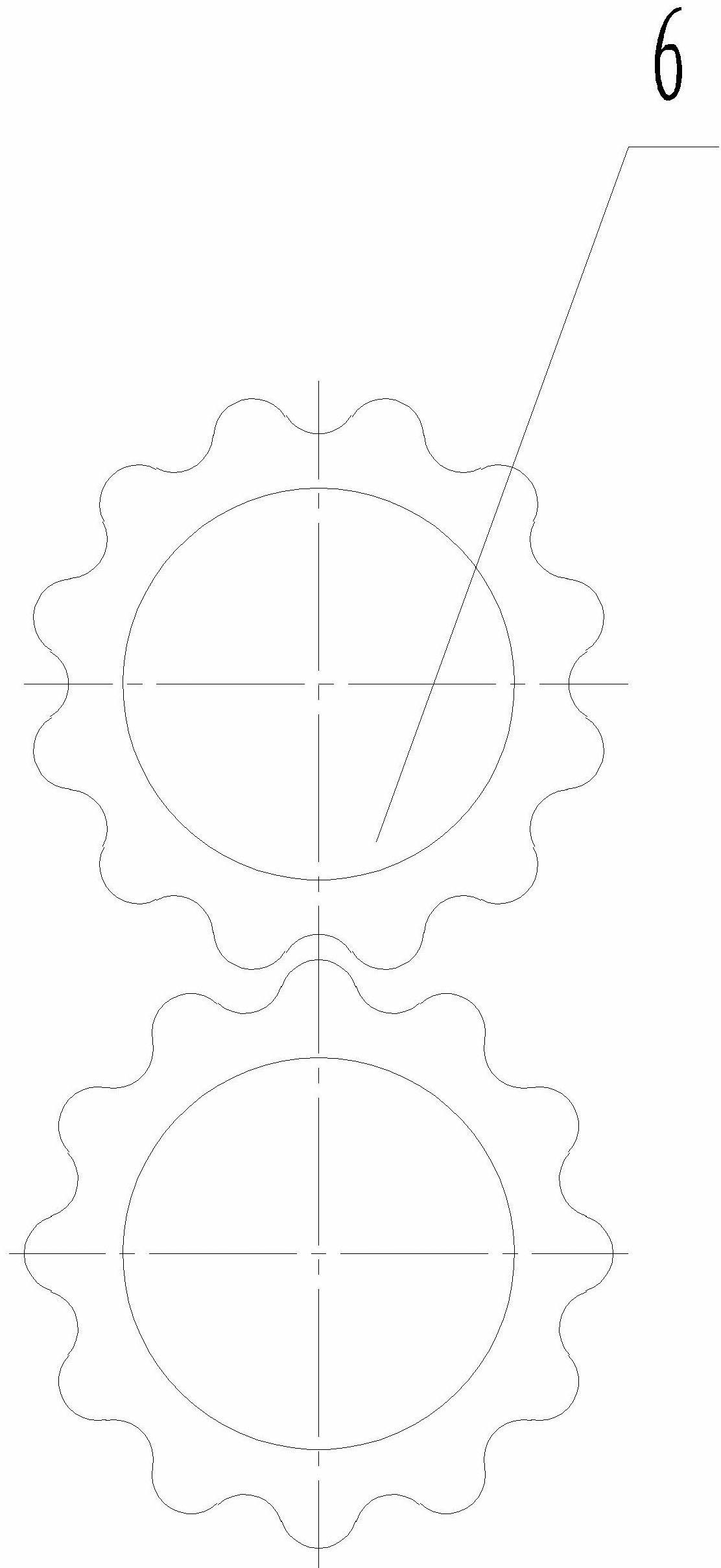

[0015] Such as Figure 1-Figure 4 Shown, the hemp class bast fiber separation device provided by the present invention is installed on the frame, and it mainly comprises rolling roller 4 and rubbing roller 5, and rubbing roller 4 is positioned at the back of rolling roller 5, and their outer diameters are equal, The rolling roller 4 and the kneading roller 5 are all arranged in pairs up and down, and each pair of rollers has the same structure and meshes with each other. There are two pairs of rolling rollers 4 and rubbing rollers 5, and rolling rollers 4 are arranged at the inlet end of the hemp stem 1, and their surfaces are axially evenly distributed with twelve semicircular grid bars 6, and the upper and lower rolling rollers 4 The meshing gap between them is 8 mm, and the surface of the kneading roller 5 is evenly distributed along the axial direction with twelve flat racks 7 arranged in a spiral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com