Patents

Literature

873 results about "Fiber strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber Strength is very often the dominating characteristics. This can be seen from the fact that the nature produces counties fibers, most of which are not usable for textiles because of inadequate strength. The minimum strength for a textile fiber is approximately 6 CN/tex. Some significant breaking strength of fibers:

Bamboo-carbon viscose fibre and its production

ActiveCN101029420AEvenly dispersedHarm reductionMonocomponent cellulose artificial filamentArtifical filament manufactureViscose fiberFiber strength

A bamboo-carbon viscose fiber and its production are disclosed. It consists of bamboo pulp dregs and nano-bamboo carbon 4-30wt%, the grain size is 75-150nm, final-product fiber strength is 1.7-3.0cN / dtex, extensibility is 9-18%. It adopts viscose coagulation bath composite modifying technology, it has excellent antibacterial, far-infrared health care and deodorization functions. It has better fiber strength and spinning handling property. It's cool, refined and no environmental pollution and can be used for summer clothing production and non-woven industries.

Owner:潍坊欣龙生物材料有限公司

Preparation method of ultra-high molecular weight polyethylene fiber

ActiveCN102002769ANo force lossHigh strengthSpinning head liquid feederArtificial filament washing/dryingEnvironmental resistanceYarn

The invention relates to a novel production method for preparing a high-strength and high-elongation polyethylene fiber at low energy consumption and low cost. The method comprises the following two steps: 1, preparing a polyethylene modified master batch; and 2, uniformly mixing ultra-high molecular weight polyethylene resin with the prepared polyethylene modified master batch to prepare an ultra-high molecular weight polyethylene melt spinning yarn, wherein the fiber strength of the prepared ultra-high molecular weight polyethylene fiber is 15-25 CN / dtex, and the breaking elongation is 5-8%. The invention has the advantages of short production flow, low energy consumption, environment friendliness, low manufacturing cost and high single-machine productive capacity. Besides, the product can be widely used in various fields such as the cable twisting and weaving field, the fishnet knitting field, the industrial cloth and belt weaving field and the like and the effective use of the fiber strength can be maintained.

Owner:宁波大盛新材料有限公司

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

Novel production process of high-strength breathable socks

The invention discloses a novel production process of high-strength breathable socks. The novel production process sequentially includes the following steps of yarn manufacturing, sock weaving, scouring and bleaching treatment, arrangement and dyeing, seam allowance treatment, reinforcing treatment, shaping treatment, water-curing treatment, drying treatment and inspecting and packaging. According to the production process, the method that hydroscopic cotton natural fibers and cotton-type hydrophilic polyester fibers are staggered is adopted, the high strength characteristic of the cotton-type hydrophilic polyester fibers is fully utilized, flat structures are adopted in soles of the socks, and then fabric can meet the requirement for high strength, breathability and comfortableness; the cotton-type hydrophilic polyester fibers are high in strength and good in shape preservation and have abrasive resistance and good moisture absorption, and therefore good hand feeling and good appearance can be obtained by staggering the hydroscopic cotton natural fibers and the cotton-type hydrophilic polyester fibers. The produced socks have the excellent performance of spandex, are capable of freely expanding and contracting when being worn, comfortable and capable of fitting feet, and have good moisture absorption, good breathability and good abrasive resistance compared with the prior art.

Owner:浙江丰悦针纺有限公司

Ultra-High Molecular Weight Polyethylene (UHMWPE)Inorganic Nanocomposite Material and High Performance Fiber Manufacturing Method Thereof

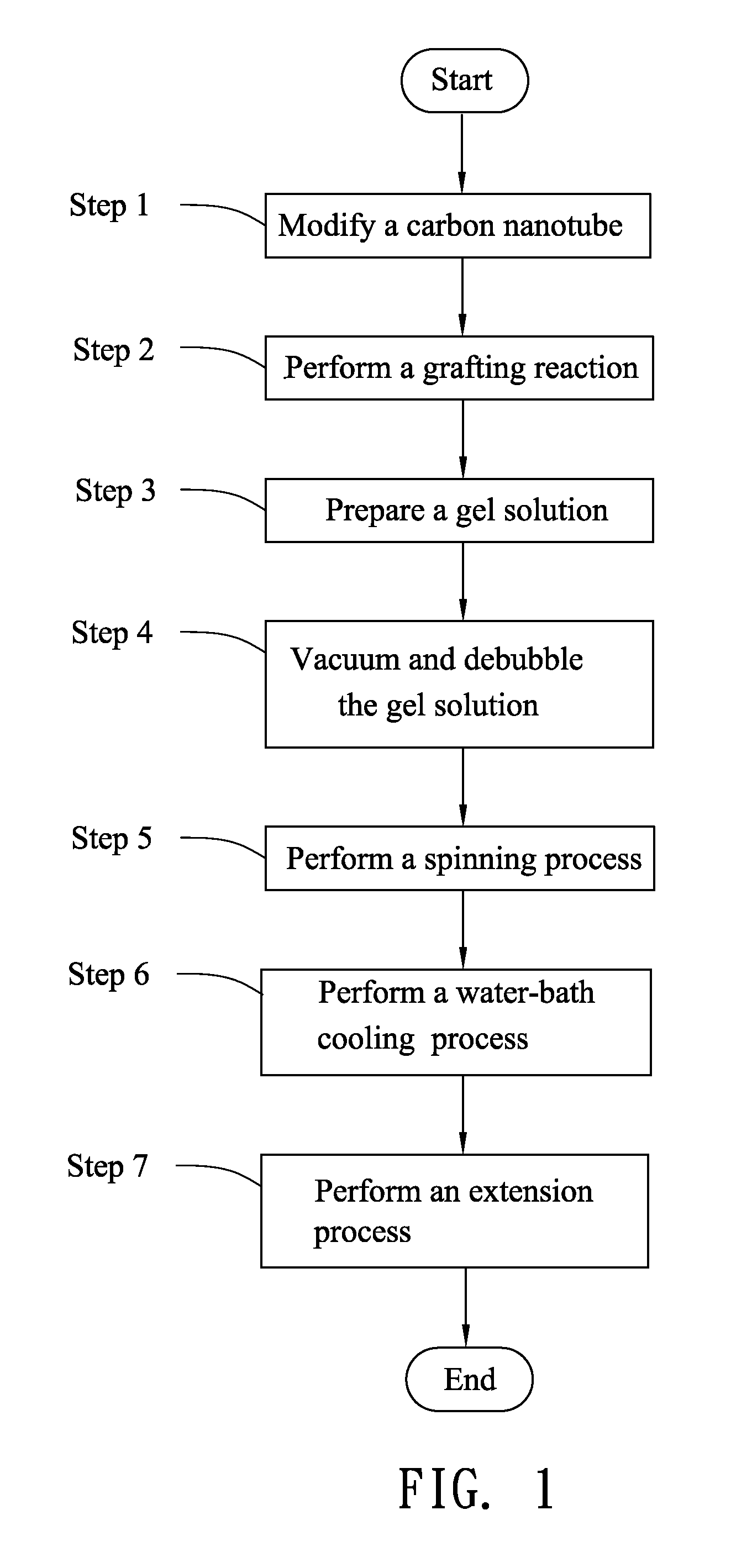

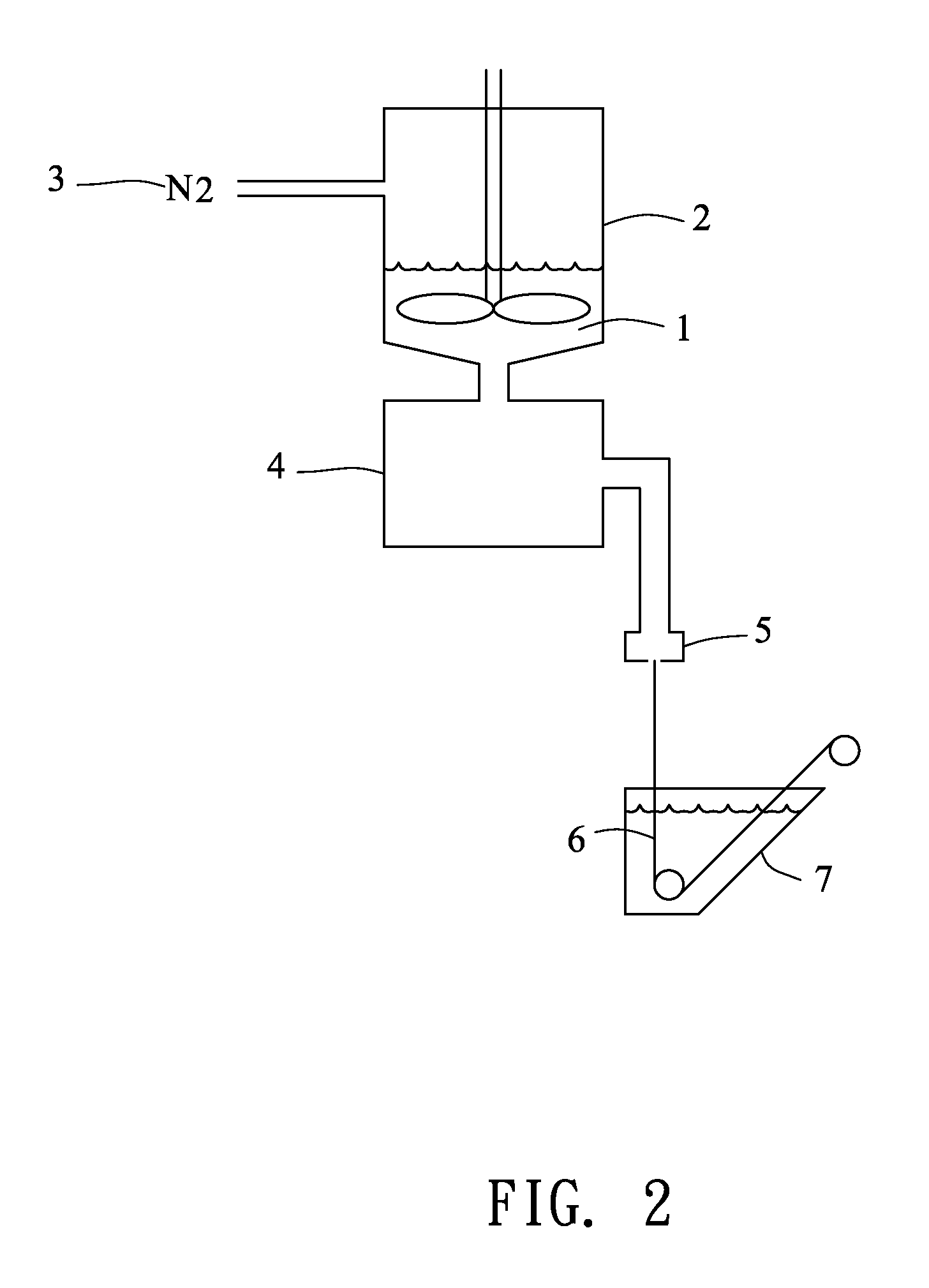

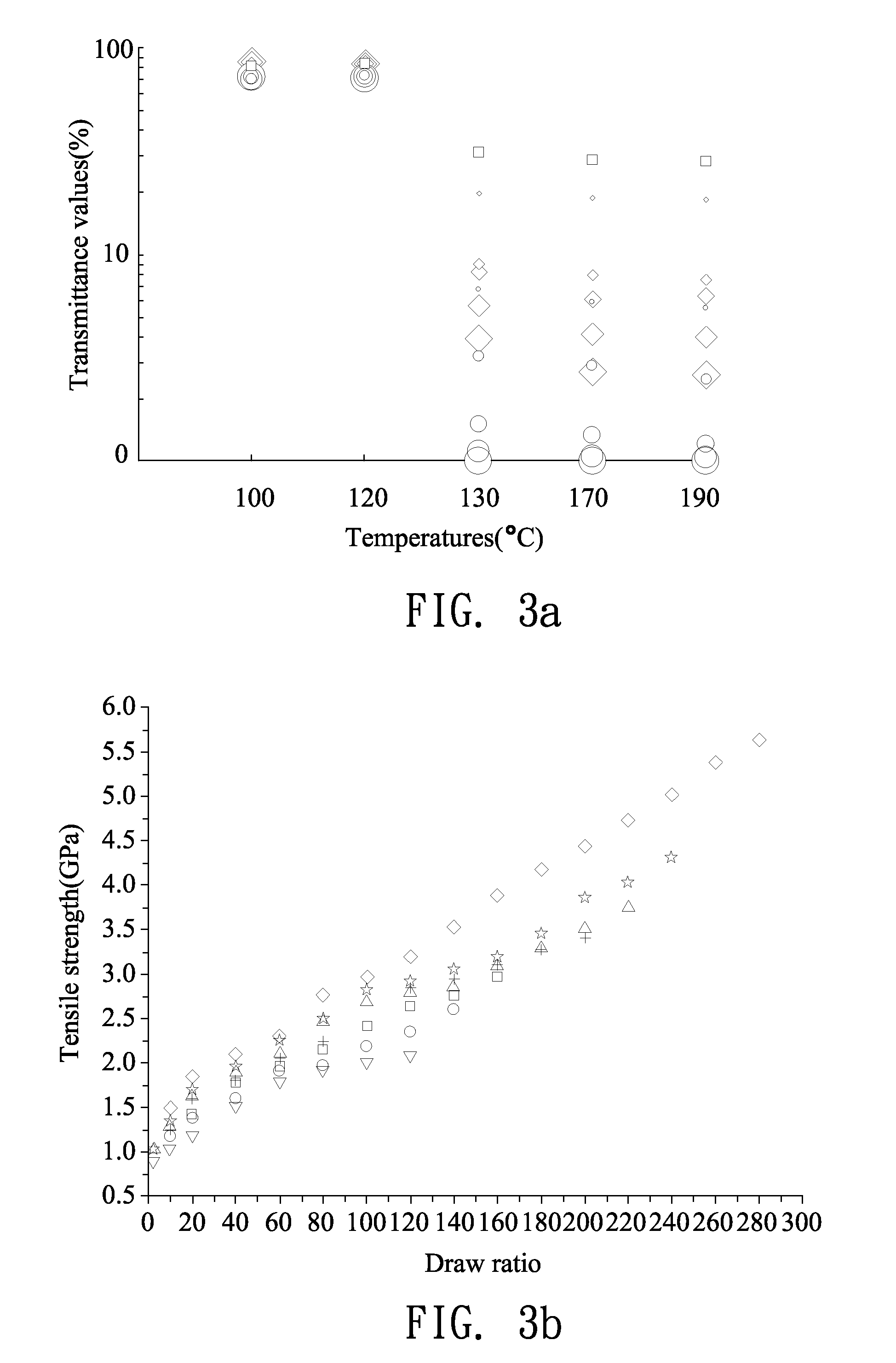

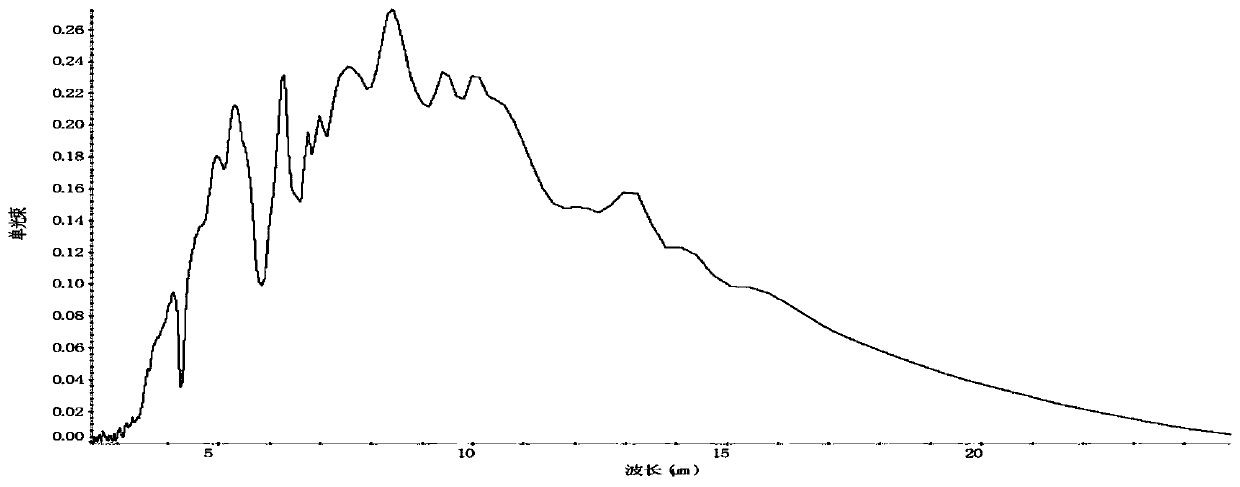

The present invention discloses an ultra-high molecular weight polyethylene (UHMWPE) / inorganic nanocomposite material and a high performance fiber manufacturing method using UHMWPE and a dispersed inorganic nano substance (such as attapulgite, carbon nano-tube, sepiolite, wollastonite and montmorillonite) to prepare a gel solution. The gel solution having a light transmittance approaching zero at a certain concentration is heated, dissolved and gone through processes including vacuum debubbling, sudden air cooling, water-phase solidification, and multi-stage temperature-change drawing for a spinning by using different conditions of a spinneret (including different spinneret angles, in-feed lengths and out-feed lengths) to obtain a composite material composed of high-tenacity fibers and having a light transmittance approaching to zero, so as to increase the fiber strength and modulus of the UHMWPE and overcome the drawbacks of high crimp, creep, and light transmission of the high molecular weight polyethylene fiber.

Owner:YEH JEN TAUT +1

A kind of production method of superfine high-strength high-modulus viscose fiber

InactiveCN102296373AIncrease contact areaIncreasing the thicknessSpinnerette packsArtificial filaments from viscoseCellulosePolymer science

The invention discloses a production method of ultra-fine, high-strength and high-modulus viscose fibers. The cellulose xanthate polymer spinning viscose which is still in a viscous flow state is provided with viscose ejection holes and coagulation baths respectively. The composite spinneret of the spray hole is sprayed out, and is solidified and formed by a low-acid, high-zinc, low-salt and low-temperature coagulation bath, and then combined with bath stretching and air stretching, and drawn by nozzles with different ratios , inter-disk drafting and plasticizing drafting, and then post-treatment to obtain a fineness of 0.44~0.78dtex, dry strength ≥ 3.1cN / dtex, wet strength ≥ 2.1cN / dtex, wet modulus ≥ 0.5cN / dtex, whiteness ≥82.0% ultra-fine high-strength high-modulus viscose fiber. The invention realizes the effective coordination of the ultrafine denier fiber spinning forming process and drafting, and the normal implementation of the spinning process, and the produced ultrafine high-strength high-modulus viscose fiber has a uniform structure, and the fiber strength and modulus are 50% higher than conventional varieties. %above.

Owner:CHTC HELON

Bamboo fiber composite base material and method for manufacturing automotive interior trim part

InactiveCN102896843APromote growthIncrease productionLamination ancillary operationsSynthetic resin layered productsVascular bundlePolyester

The invention relates to a composite material for manufacturing an automotive interior trim part. The bamboo fiber composite base material for manufacturing the automotive interior trim part is prepared by taking thermoplastic synthetic fibers (polypropylene PP, polyethylene PE or polyester PET and the like) as a bonding substrate and bamboo fibers as a reinforcing material through hot pressing. The bamboo fiber composite base material is characterized in that the bamboo fibers are prepared by sawing natural bamboo into pieces with length required by production, removing parenchyma from the bamboo by mechanical, physical, chemical and biological methods and directly extracting vascular bundle bamboo fibers from the bamboo, and have the length of 60 to 150mm, the diameter of 0.3 to 1.5mm, the strength of 60 to 120MPa and the water content of 10 to 12 percent. The automotive interior trim part can be subjected to press forming when the bamboo fiber composite base material covers artificial leather, leather or a knitted or non-woven fabric for surface decoration.

Owner:喻云水

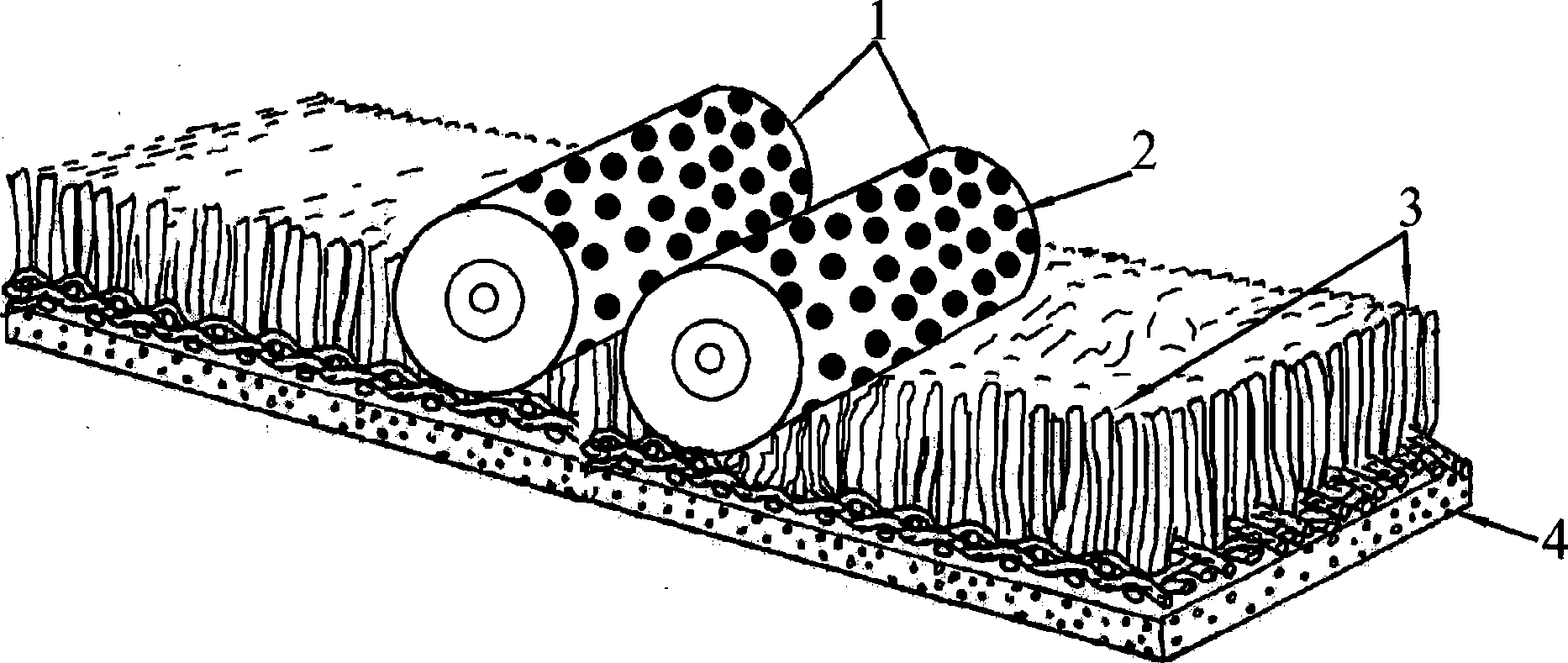

Enhanced artificial lawn fibre and preparation thereof

ActiveCN101476174AHigh strengthGood flexibilityGround pavingsMelt spinning methodsArtificial turfFiber strength

The invention discloses an enhancing type artificial turf fibre and a preparing method thereof which belongs to the artificial turf technique field. Fibre intension and flexible of the enhancing type artificial turf fibre are increased greatly and is suitable for occasion with great intensity movement and vehement that can reduce probability of influencing movement caused by turf fibre hurting. The enhancing type artificial turf fibre is composed of matrix resin, enhancing master batch and functional material that each component has weight percentage as follows: 60-94% matrix resin, 5-30% enhancing master batch and 0.1-10% functional material.

Owner:COCREATION GRASS CO LTD

Method for producing hemp yarns through vortex spinning

ActiveCN102108574AImprove efficiencyImprove flexibilityContinuous wound-up machinesOpen-end spinning machinesYarnFibril

The invention provides a method for producing hemp yarns through vortex spinning. The method comprises the following steps: curing pretreatment of hemp fibers, a bale plucker, a bending and opening machine, an opening machine, a vibrating feed box, a lap machine, a carding machine, a pre-draw frame, a draw frame and lap machine combined, a combing machine, a draw frame and a vortex spinning machine, wherein in the step of curing pretreatment of hemp fibers, the addition of an oil feeding and conditioning soft penetrating agent is 6-8% of hemp fibrils by weight; the oil feeding and conditioning soft penetrating agent comprises 12-16% of emulsifying agent, 6-10% of softening agent and 75-79% of soft water; and the moisture regain is controlled between 12% and 15%. The method has the following advantages: the maximum count of the weaved hemp yarns can be 50; the noil rate is reduced; the flexibility, parallel straightness, spinnability and strength of the fibers are improved; the finished product rate is high; the hemp fibers are protected by adopting the methods of more opening and fewer beating and jogging; and the method lays the foundation for normal production through vortex spinning.

Owner:JIANGSU YUEDA HOME TEXTILE

Cotton stalk peel fiber cleaning and deguming method

InactiveCN101008108AQuality improvementReduce concentrationFibre treatment to obtain bast fibrePulp and paper industryHigh pressure

The invention discloses a method for cleaning and degumming cotton stalk bark fiber, combining flash explosion, high pressure and high pressure. The inventive method comprises that: washing cotton stalk bark in water, drying, flash explosion, washing in hot water, washing in water, degumming with high pressure and high temperature, washing in water, feeding oil to soften, removing oil, drying and ultra drying cotton stalk bark fiber. The invention first utilizes flash explosion technique to degrade part of semi-cellulose and lignin, utilizes high-temperature high-pressure technique to treat cotton stalk bark deeply in order to remove the lignin and semi-cellulose and obtain white soft cotton stalk bark fiber. Since the cotton stalk bark fiber is similar to prior estopa fiber, it has high lignin content and high strength; since the inventive method uses flash explosion and high-pressure high-temperature low-alkali technique, it can effectively remove lignin and reduce fiber strength to effectively degum, without pollution.

Owner:ZHEJIANG SCI-TECH UNIV

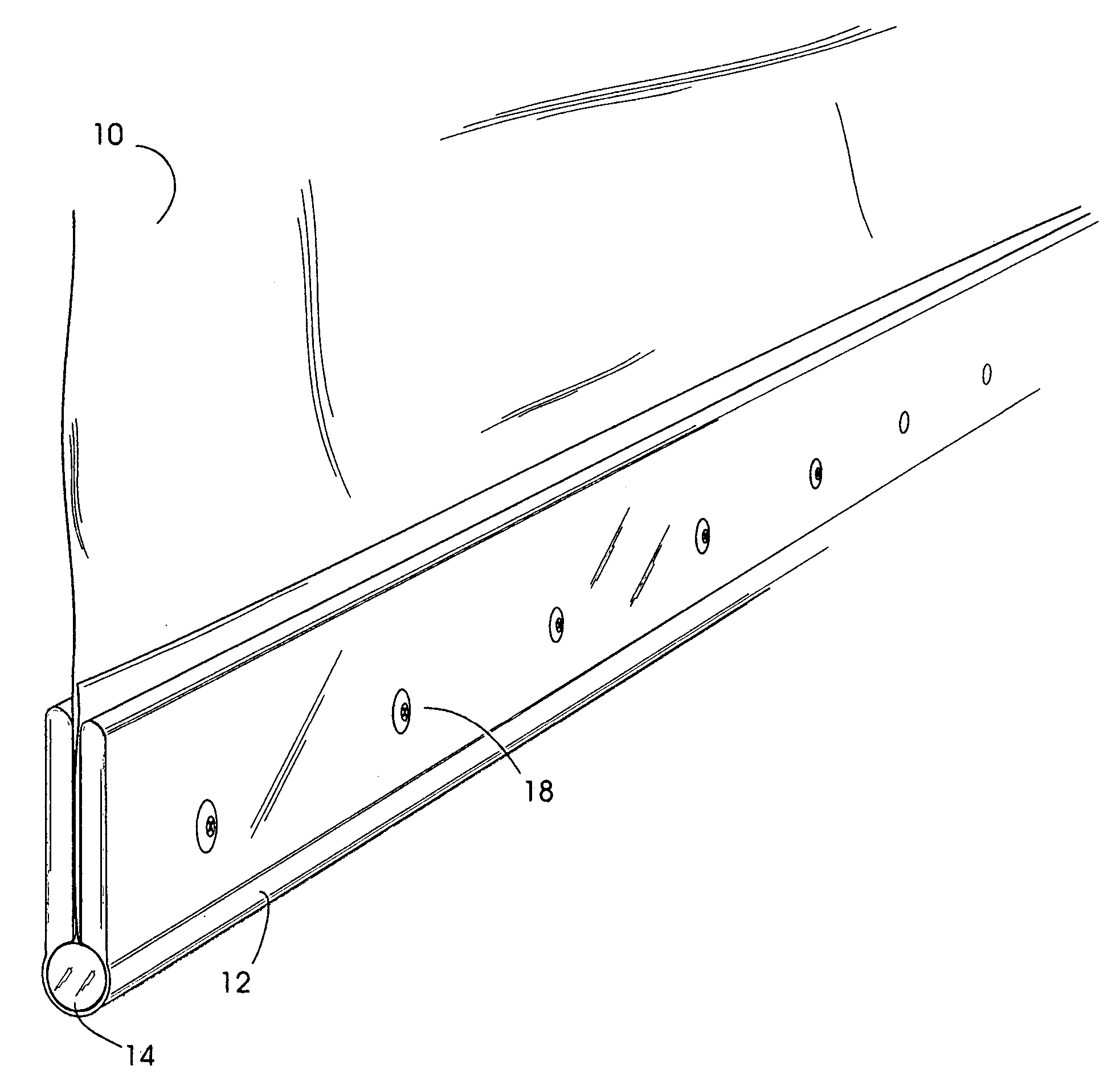

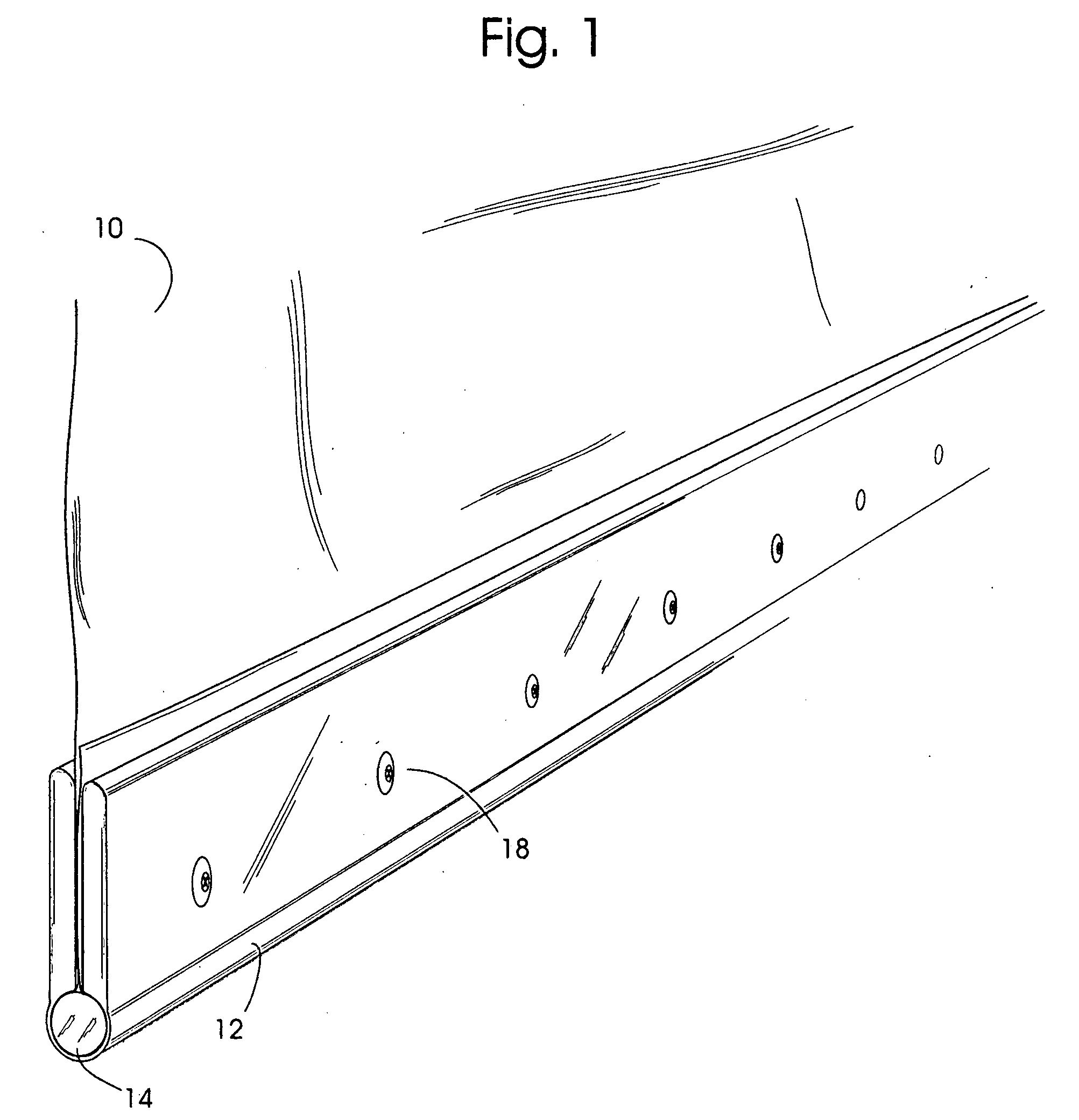

Load bearing textile clamp

InactiveUS20080000056A1Heavy loadImprove load transfer efficiencySnap fastenersTents/canopiesEngineeringUltimate tensile strength

An invention where a removable load bearing textile clamp comprised of an outer compressive sleeve configured to accept an internally positioned removable rod such that a textile can be led around the rod and positioned inside the compressive sleeve and said sleeve once fastened can form a clamp assembly between the sleeve, rod, and textile to create a load bearing textile clamp that can be attached to a secondary structure such that the fiber strength of the textile is retained and the textile panel can perform work.

Owner:MURRAY MICHAEL EDWARD

Method of improving surface cohesion performance of relative molecular weight polyethylene

InactiveCN1693544AGood adhesionImprove surface adhesionFilament-forming treatmentStretch-spinning methodsPolymer scienceUltimate tensile strength

The invention discloses a method for improving surface bonding performance of ultrahigh molecular polyethylene filter (UHMWPE), including the steps as follows: (1) dissolving polar polymer in a routine extractant of ultrahigh weight-average relative molecular weight polyethylene jelly glue filter with a relative molecular weight of 1,000,000-5,000,000 to make a composite extractant, where the polar polymer accounts for 0.1wt%-10wt% (weight percent); (2) extracting the said jelly glue fiber at 0.4-5 atmospheres at 0-80 deg.C in the composite extractant for 0.1-20 min, and then by the postprocessing procedures, such as stretching, making an ultrahigh relative molecular weight polyethylene fiber with the surface bonding performance has been improved to a higher extent. The advantages of the invention are that it maximumly holds original fiber strength and the surface bonding performance of UHMWPE has a relatively outstanding improved effect.

Owner:DONGHUA UNIV

Method for producing high whiteness cotton pulp by using cotton linter

InactiveCN101105012AReduce pollutionReduce dosagePaper material treatmentMaterials preparationMaterial consumption

The invention discloses a simple method for producing high-whiteness cotton pulp from cotton linters as raw materials. The method comprises the steps of material preparation, prehydrolysis, boiling, loosening, desanding, concentration, chloridization, alkali purification, bleaching, acid treatment, desanding, concentration, paper making, and oven-drying. A mixture of NaOH and green oxygen is used in the boiling step. The invention has the advantages of simple and controllable process, low processing load posterior to the boiling step, reduced material consumption, less waste discharge, and low environmental pollution. The produced cotton pulp has high pulping fiber strength, yield and whiteness.

Owner:CHTC HELON

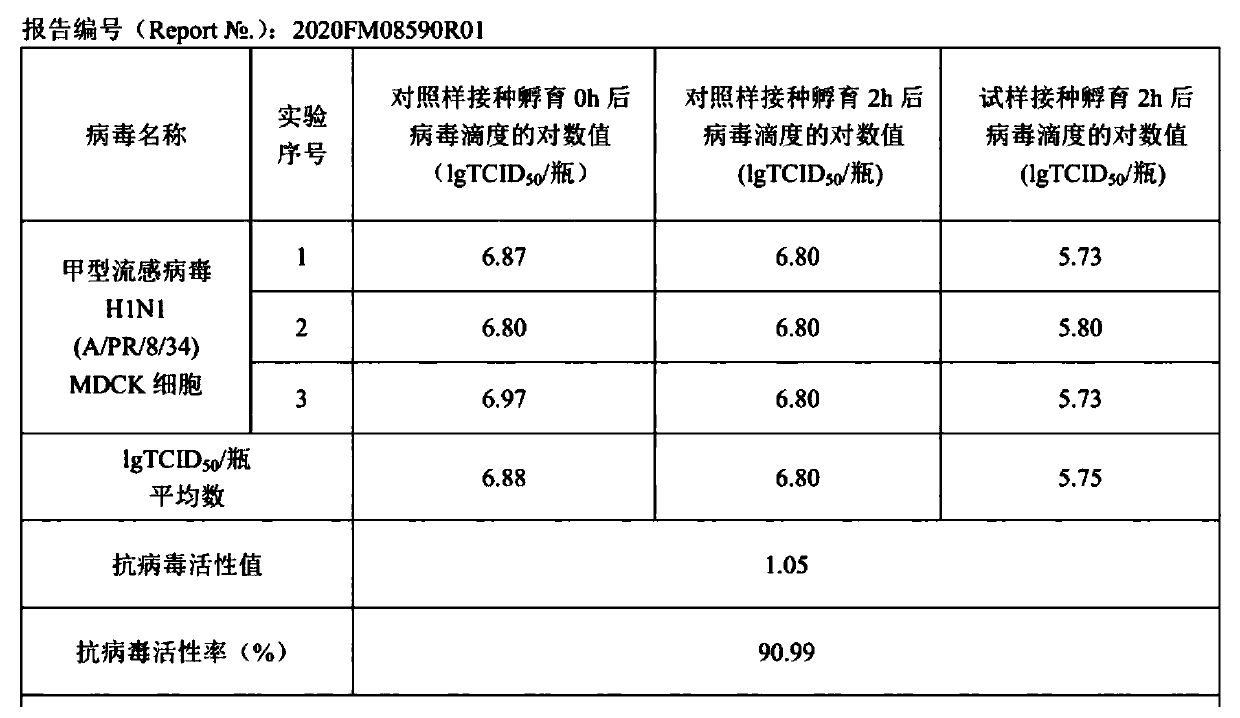

Compound antiviral and antibacterial multifunctional PP, PE and PET non-woven fabric and preparation and application thereof

The invention belongs to the field of functional fiber materials, and discloses compound antiviral and antibacterial multifunctional PP, PE, PET non-woven fabric and preparation and application thereof. The preparation method comprises the steps that silica aerogel microspheres are used to load inorganic antiviral and antibacterial metal / oxides and antiviral and antibacterial components of traditional Chinese medicine correspondingly through a specific method, and then mixed with fiber slices and extruded to obtain master batch; and the master batch and the fiber slices are blended and spun and woven into shapes to obtain the compound antiviral and antibacterial multifunctional PP, PE, PET non-woven fabric. Through the adoption that the silica aerogel microspheres with a specific structureare used to load the inorganic and traditional Chinese medicine antiviral and antibacterial components correspondingly through the specific method, the components are added into fiber substrate, theobtained functional fiber material has long-lasting antiviral and antibacterial effects and is washable, the fiber strength and heat preservation effect are improved to a certain extent, and other health care functions of the fiber such as negative ions and far-infrared effects are not affected.

Owner:芯安健康科技广东有限公司

Technological process of producing fire retardant antiflux fiber

ActiveCN1847476AHigh strengthGuaranteed alkali resistanceFlame-proof filament manufactureMonocomponent cellulose artificial filamentCellulose pulpFire retardant

The present invention discloses technological process of producing fire retardant antiflux fiber. The fire retardant antiflux fiber is produced with cellulose pulp as material, and the production process includes the steps of: dipping, squeezing, crushing, ageing, sulfidizing, maturating, spinning, refining and stoving. The refining step includes washing, cross-liking and dewatering and oiling; and in the sulfidizing step, the silicon fire retardant is compounded into solution added into the alkali cellulose through stirring for dissolving and mixing to produce viscose of fire retardant fiber. The fire retardant antiflux fiber of the present invention has high fire retardant antiflux effect, high fiber strength and excellent filtering performance.

Owner:潍坊欣龙生物材料有限公司

Leveling agent for wool and real silk and preparation method thereof

The invention discloses a leveling agent for wool and real silk and a preparation method thereof. The leveling agent for the wool and the real silk comprises the following raw materials in parts by mass: 8-10 parts of fatty amine polyoxyethylene ether, 5-8 parts of benzyl sulphonic acid sodium salt, 2-4 parts of polyvinylpyrrolidone, 4-7 parts of stearic acid, 6-8 parts of urea, 15-18 parts of water and 30-35 parts of glycol. The leveling agent enables the wool and the real silk to be uniformly coloured during dying and have good uniform dying performance, improves the dying ratio of a dye, meanwhile is reasonable in formula, relatively mild for the wool and the real silk, and enables the wool to retain the original fiber strength after uniform dying.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Method for producing fiber non-woven fabric superfine fiber synthetic leather

ActiveCN102561050AGood physical and mechanical propertiesIncrease elasticityFabric breaking/softeningLamination ancillary operationsPolyamideSlurry

The invention relates to a method for producing fiber non-woven fabric superfine fiber synthetic leather, belonging to the technical field of production of synthetic leather. The method comprises the following steps of wet-method impregnating, coating, solidifying, water washing, drying shaping, dry-method veneering and line rubbing to obtain the fiber non-woven fabric superfine fiber synthetic leather, wherein a special fiber adopted by the method is mucilage glue and PA (Polyamide), mucilage glue fiber has soft hand feeling and good elasticity, the softness of the the mucilage glue fiber isnot basically influenced but the fiber strength of the mucilage glue fiber is worse after the mucilage glue fiber is impregnated in a dimethylformamide solution of polyurethane resin slurry. The PA has better physical mechanical performance, and the softness of the PA is not increased excessively after the PA is impregnated in the dimethylformamide solution of the polyurethane resin slurry. The mucilage glue fiber and the PA both are complemented, and a majority of advantages of superfine fiber synthetic leather can be realized through utilizing a reasonable formula and the technique operation above during a dry-wet method; therefore, the fiber non-woven fabric superfine fiber synthetic leather produced by the method disclosed by the invention has the advantages of soft and thick hand feeling, smooth and full grains and attractive appearance and further has better physical mechanical properties such as strong force, tearing strength and peeling strength.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL

In-situ growth method for carbon nano tubes (CNTs) on carbon fiber surface

InactiveCN104532548ALittle loss of strengthEvenly distributedCarbon fibresElectrolytic agentCarbon fibers

The invention belongs to the technical field of composite materials. An in-situ growth method for carbon nano tubes (CNTs) on a carbon fiber surface is that the controlled surface treatment is carried out on carbon fibers by adopting an electrochemical process, so as to control the quantity and the distribution of active points on the carbon fiber surface; a catalyst is loaded by adopting a solution infiltration method, so that the catalyst can be uniformly distribute on the carbon fiber surface. The in-situ growth method for the (CNTs) on the carbon fiber surface comprises the steps of treating the surfaces of the carbon fibers; loading the catalyst; reducing the catalyst; promoting the growing of the CNTs; the surfaces treatment of the carbon fibers is carried out by adopting the electrochemical process; the electrolyte concentration is 1 to 10wt.%, the electrolyzing current is 0.1 to 1.5A, and the electrolyzing is carried out for 1 to 15min. The method is mild in processing condition, simple to operate and easy to control; the fiber intensity is lost little; the damage ratio of multifilament tensile strength is less than 10%; the CNTs are uniformly and densely distributed on the carbon fiber surface, and the loading quantity and the distribution density are controllable; the interlayer scission strength of a composite material can be improved by more than 13%; the method is applicable to the field of processing of carbon fiber reinforced resin based composite materials, and particularly applied to the field of processing of the carbon fiber reinforced resin based composite materials with high requirements on interlayer adhering performances.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP +1

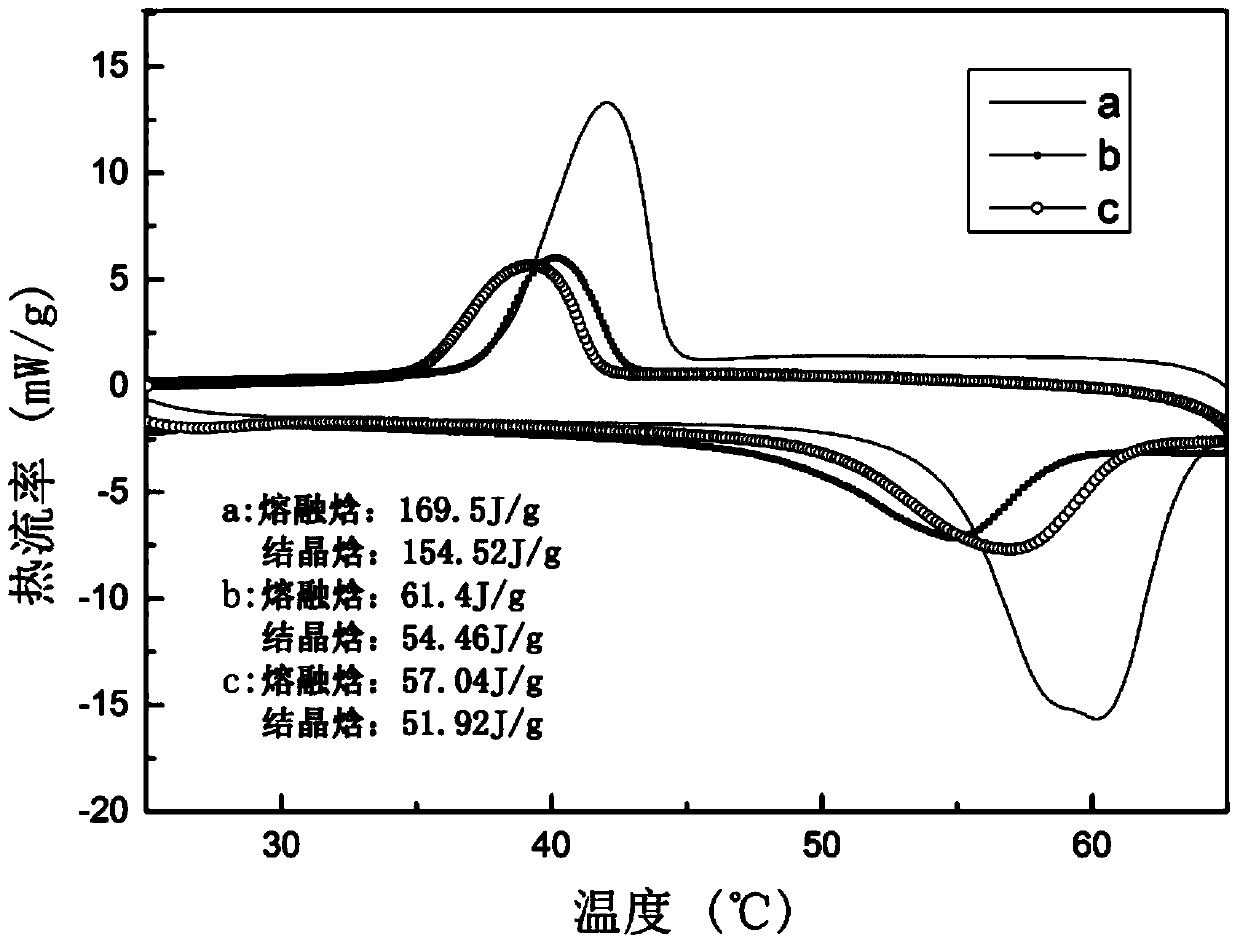

Polypropylene fiber, method of producing the same and utilization of the same

ActiveUS20100173547A1High crystallinityImprove heat resistanceWarp knittingMonocomponent polypropylene artificial filamentPolymer scienceHeat resistance

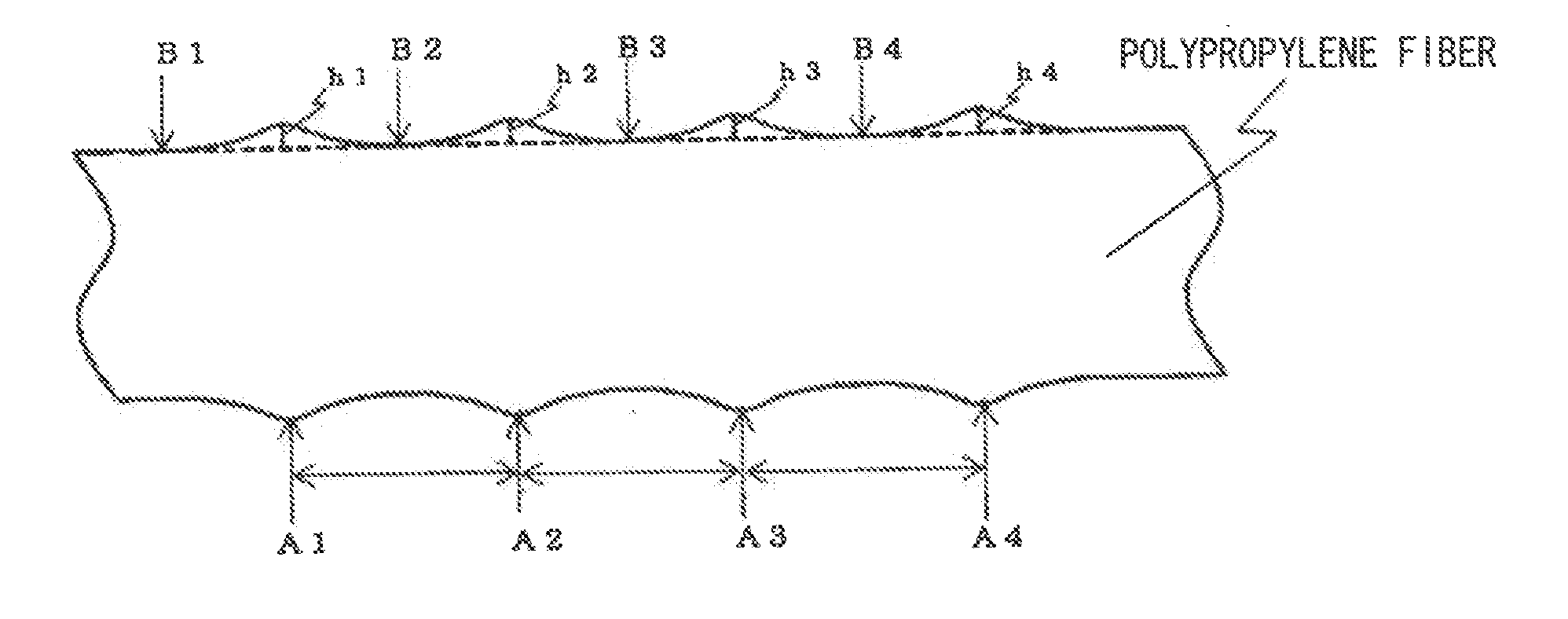

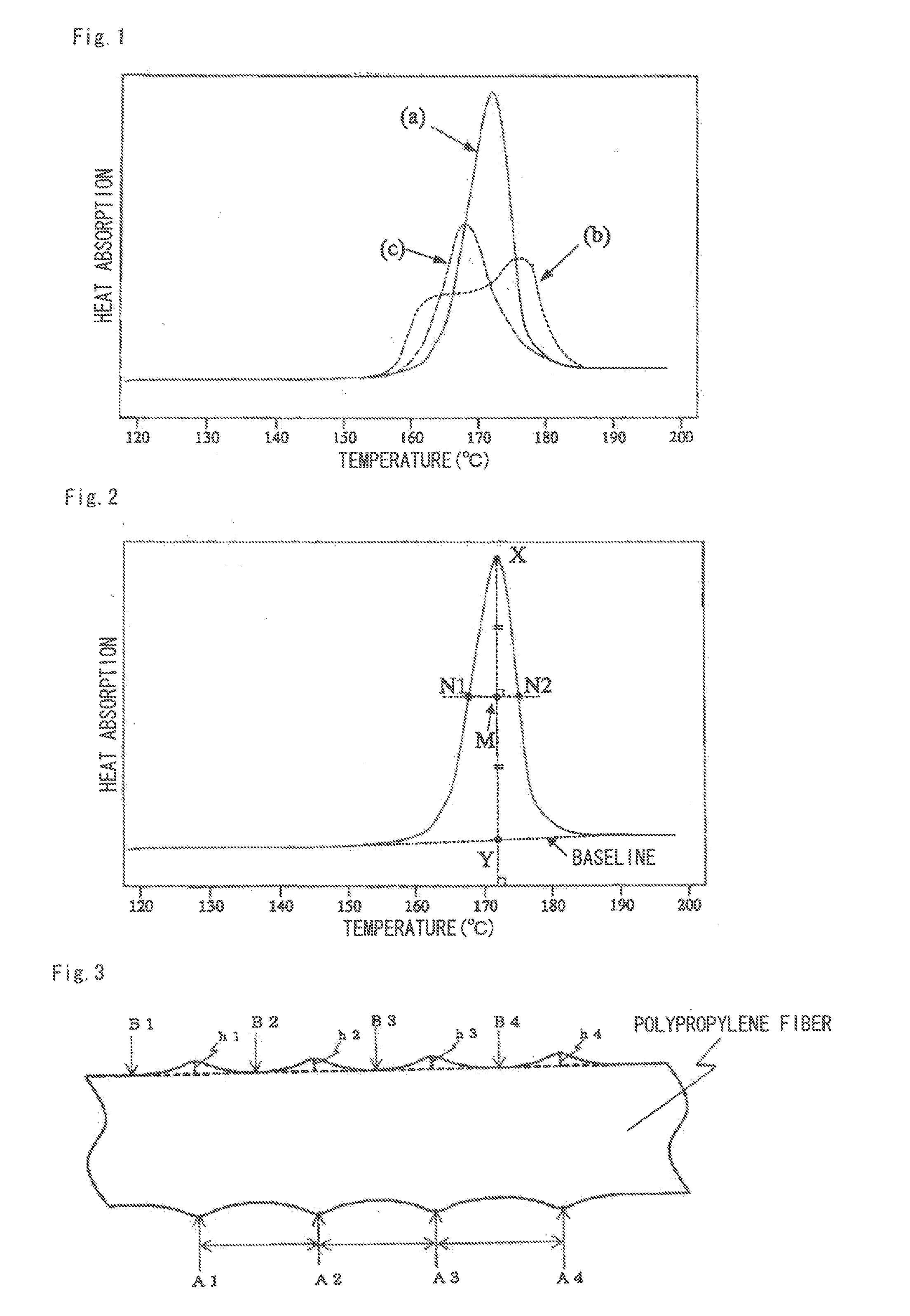

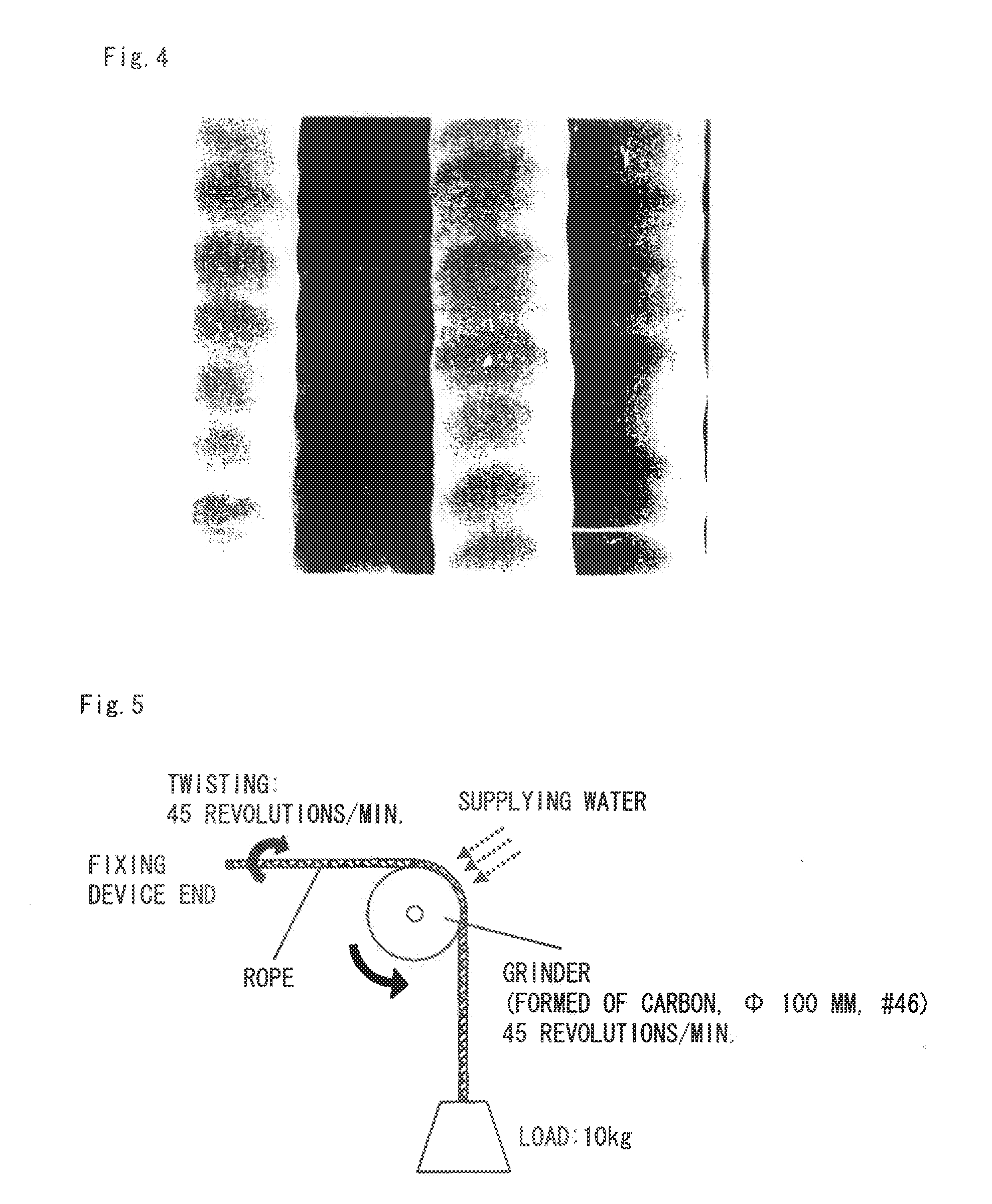

The present invention aims to provide a polypropylene fiber (PP fiber) excellent in strength, heat resistance, and water-absorption properties, a method of producing the same, and a hydraulic composition, a rope, a sheet-shaped fiber structure, and a composite material with an organic polymer each using the PP fiber. The present invention provides: a PP fiber having a fiber strength of 7 cN / dtex or more and having either or both of (i) DSC properties such that the endothermic peak shape by DSC is a single shape having a half width of 10° C. or lower and the melt enthalpy change (AH) is 125 J / g and (ii) irregular properties such that the single fiber fineness is 0.1 to 3 dtex and irregularities are formed on the surface, the irregularities having an average interval of 6.5 to 20 μm and an average height of 0.35 to 1 μm as a result of alternate presence of a protruded portion having a large diameter and a non-protruded portion having a small diameter along its fiber axis; a method of producing the PP fiber by pre-drawing an undrawn PP fiber having an IPF of 94% or more at 120 to 150° C. at a drawing magnification of 3 to 10 times, and then post-drawing the resultant at 170 to 190° C. and a drawing magnification of 1.2 to 3.0 times under the conditions of a deformation rate of 1.5 to 15 times / min and a draw tension of 1.0 to 2.5 cN / dtex; and a hydraulic composition, a rope, a sheet-shaped fiber structure, and a composite material with an organic polymer each using the PP fiber.

Owner:KURARAY CO LTD

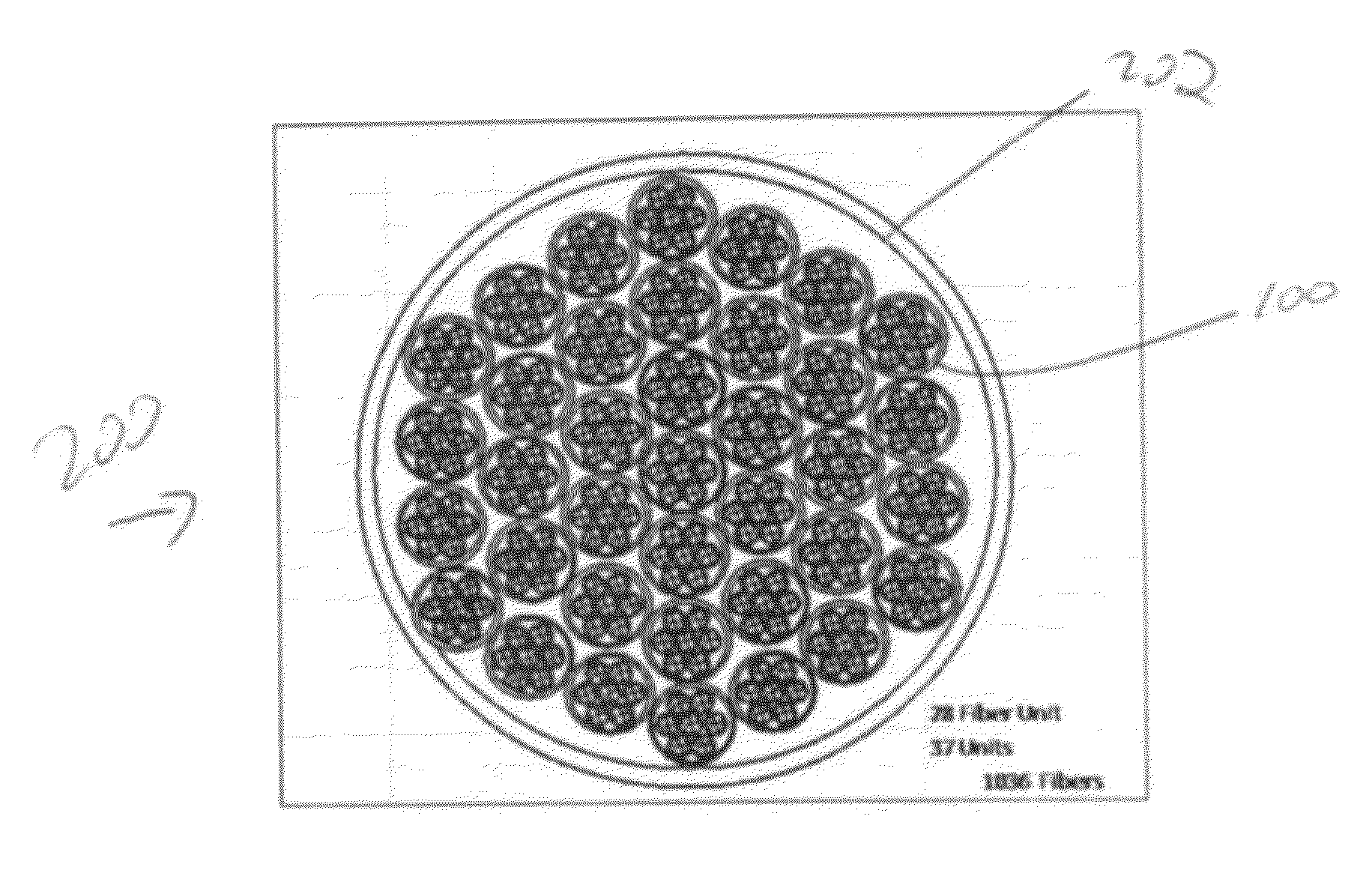

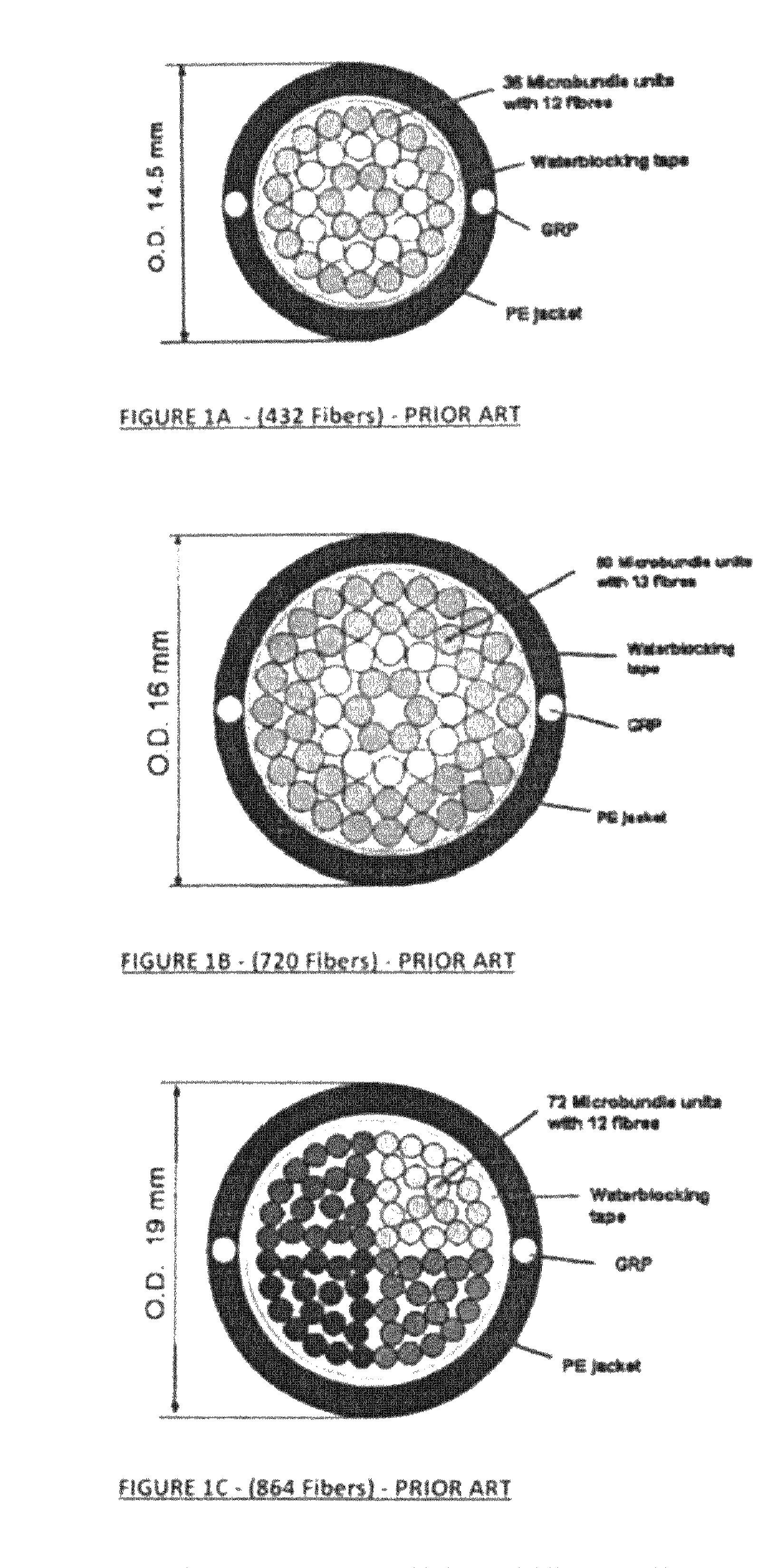

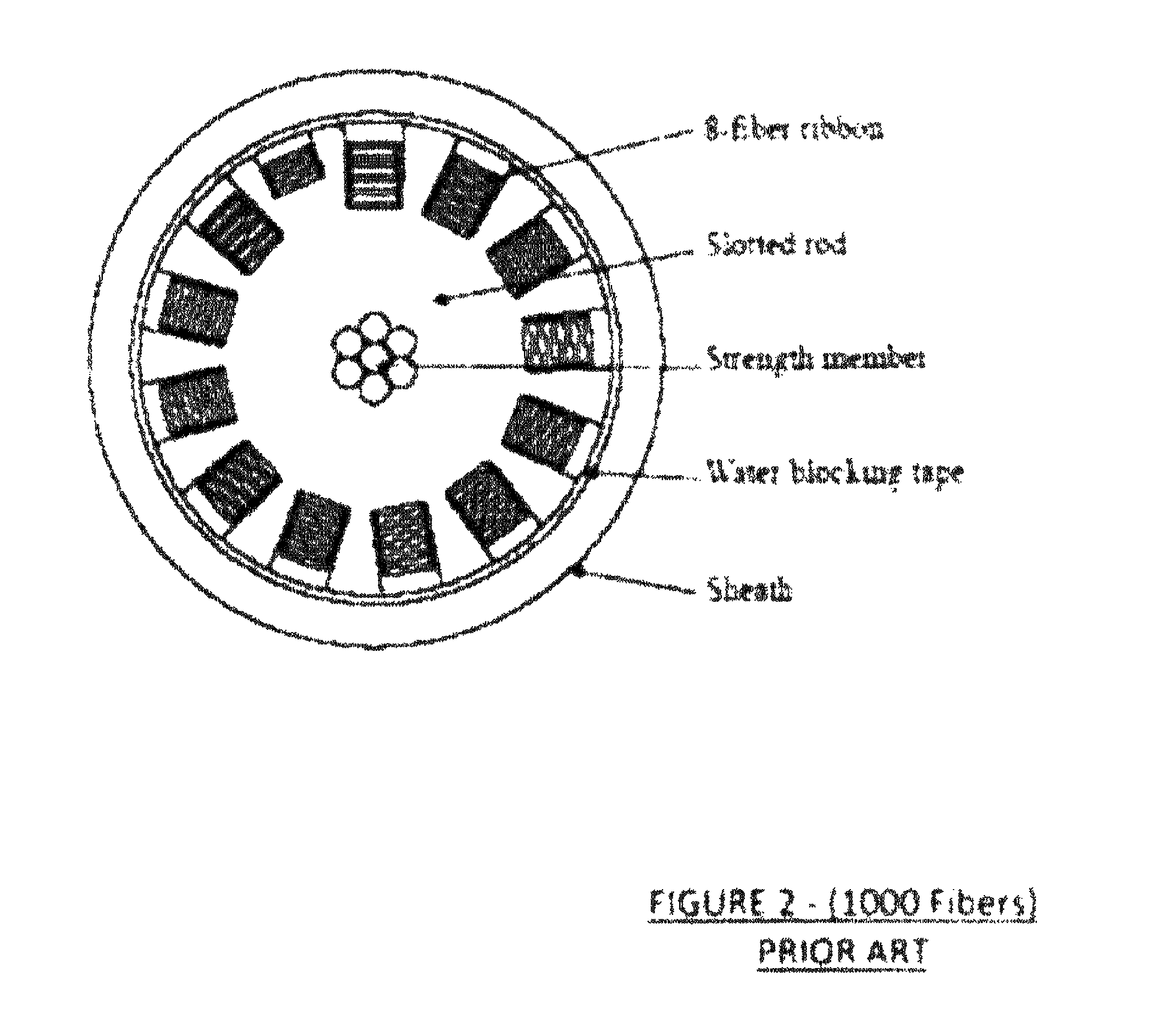

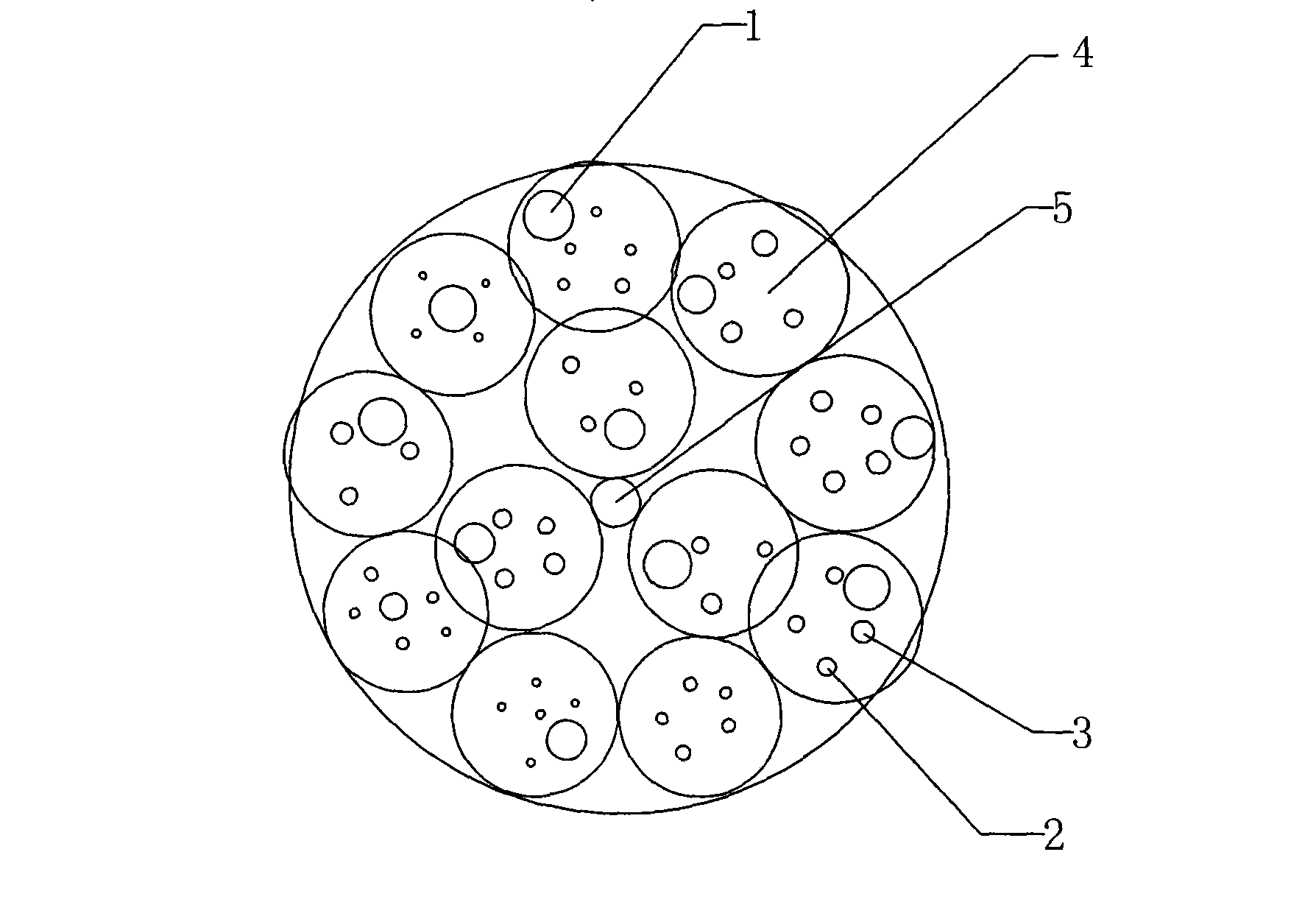

Expanded four fiber unit cable for increased fiber count cables having increased flexibility and fiber strength utilization

ActiveUS8494327B2Increase flexibilityReduce stiffnessFibre mechanical structuresEngineeringUltimate tensile strength

Owner:BERK TEK

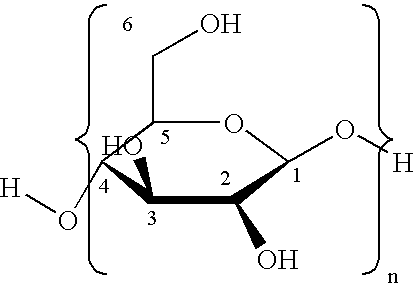

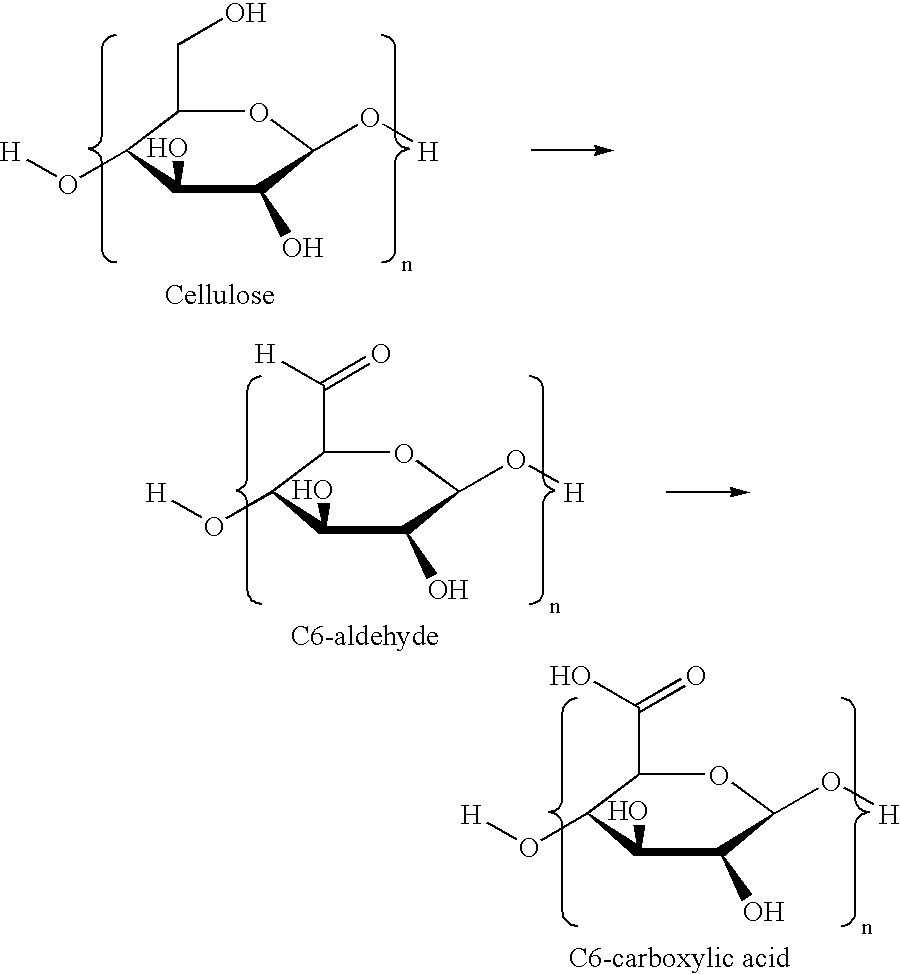

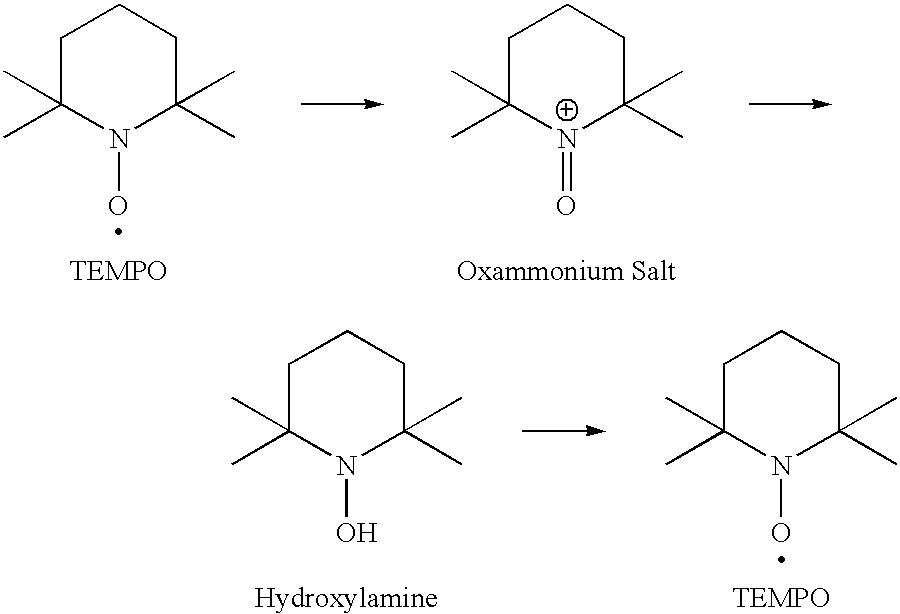

Hypochlorite free method for preparation of stable carboxylated carbohydrate products

InactiveUS6919447B2Low costEnvironmental lossPulp properties modificationSugar derivativesHydroxylamineHypochlorite

Owner:INT PAPER CANADA PULP HLDG ULC

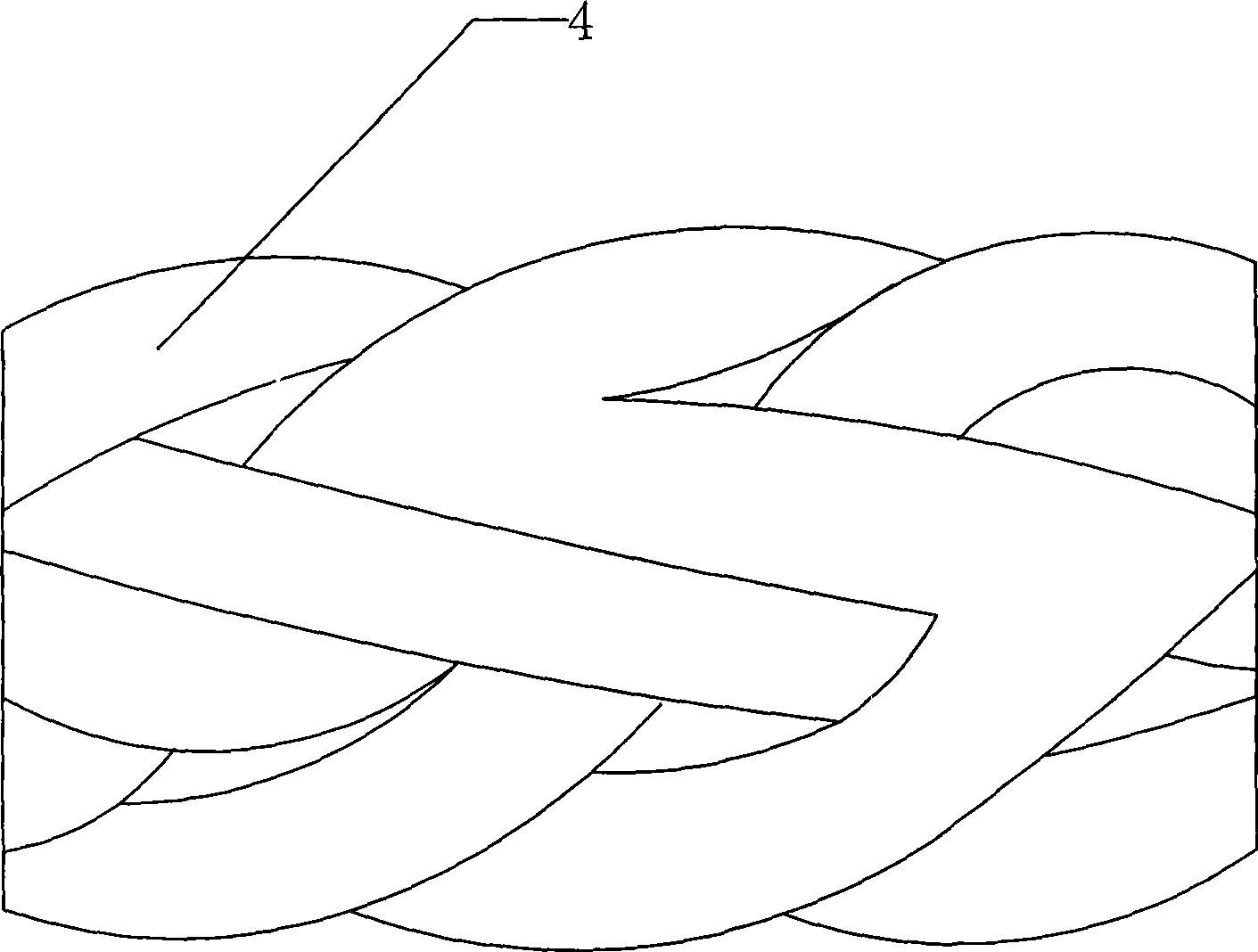

12 strand composite rope of nylon monofilament

The invention relates to a nylon monofilament twelve-strand composite rope which comprises a nylon spindle strand and twelve strands which are braided into a unit. The nylon spindle strand is arranged on the center of the twelve strand rope. The twelve strands are made of six left stranding strands and six right stranding strands in a braiding way. The strands comprise nylon monofilaments, nylon multifilaments and rope yarns which are twisted into a unit. The preparation method comprises the following steps: 1) raw materials selection; 2) threads twisting; 3) strand preparation; 4) rope preparation. The nylon monofilament twelve-strand composite rope has the beneficial effects that the braiding distance of the rope and the twisting degree of the strands are matched mutually, therefore, the trend of the rope yarns and the stress direction of the rope are identical, and the torque at the inside of the rope during the process of stress is zero; and the utilization rate of the fiber strength is effectively improved. The nylon monofilament twelve-strand composite rope has the advantages of strong wear resistance, safety, convenience and long service life.

Owner:浙江四兄绳业有限公司

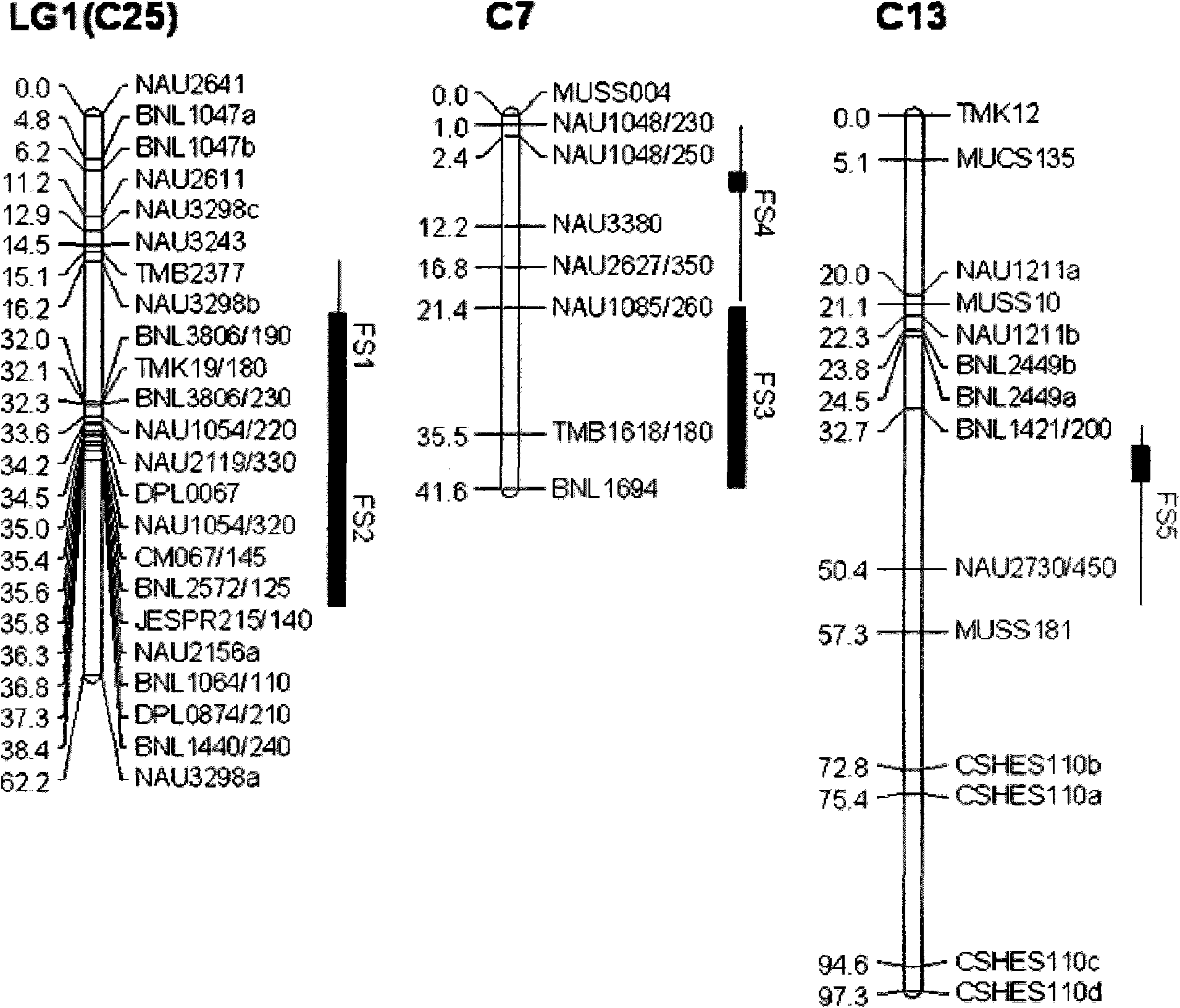

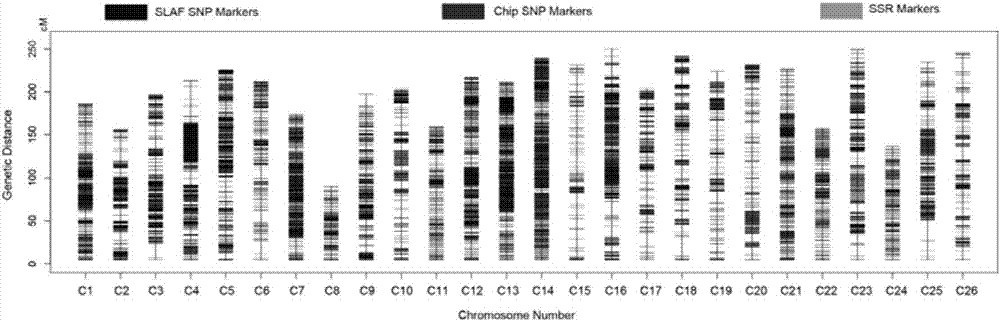

SSR markers lined with major gene of cotton fiber strength

InactiveCN101613761AImprove selection efficiencyGood effectMicrobiological testing/measurementFermentationAgricultural scienceA-DNA

The invention discloser SSR markers lined with major genes of cotton fiber strength, which is obtained by the following steps: generating F2 and F2:3 populations by using a cotton search 41 line sGK9708 selected from cultivated varieties of gossypium hirsutum and a high quality line 0-153 of gossypium hirsutum as parents; allowing generation within the family of the F2:3 population to self cross till the F2:6 generation, performing within-family individual selection of the F2:6 generation once, and planting two generation till F6:8; performing polymorphism screening of the parents by using SSR primers and creating an RIL population linkage map; and performing the multi-environment major QTL screening of the cotton fiber strength to screen 6 QTLs of a cotton fiber strength character from line 0-153, wherein 5 QTLs are multi-environment stable QTLs and are FS1 linkage marker NAU2119330, FS2 linkage markers BNL2572125, BNL1064110 and DPL0874210, FS4 linkage markers are NAU1048250 and NAU2627350, and FS5 linkage markers BNL1421200 and NAU2730450. The SSR markers lined with the major genes of the cotton fiber strength are screen from high fiber quality materials and used as molecular markers to perform early auxiliary selection on a DNA level to improve the selection efficiency of the cotton fiber strength.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

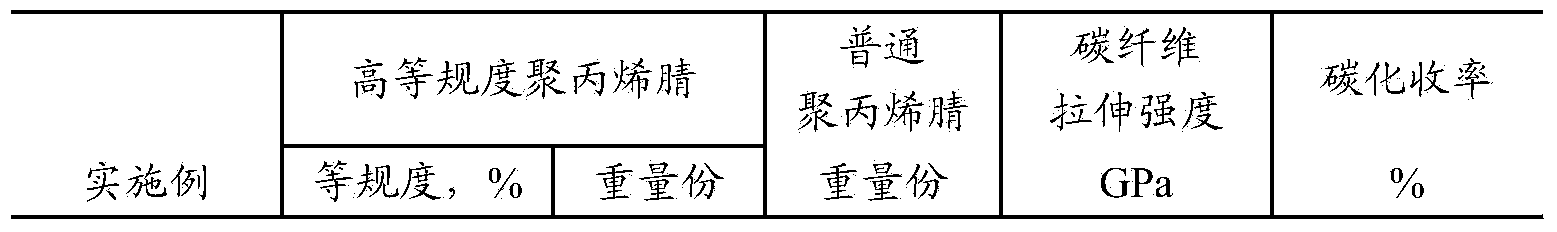

Production method of carbon fiber

InactiveCN103409854AHigh yieldHigh crystallinityWet spinning methodsMonocomponent synthetic polymer artificial filamentCarbon fibersCarbonization

The invention relates to a production method of a carbon fiber. The production method comprises the following steps of: preparing a spinning solution; carrying out wet spinning; solidifying; previously oxidizing primary polyacrylonitrile resin fibers; carrying out low-temperature carbonization; carrying out high-temperature carbonization, and the like. The production method disclosed by the invention can be used for enhancing the regularity of a fiber molecular chain by mixing high-regularity polyacrylonitrile resin and common polyacrylonitrile resin, thereby enhancing the fiber crystallinity, enhancing the fiber compact degree, increasing the carbon network length of the final fiber molecular chain and enhancing the fiber strength. Compared with the carbon fiber in the prior art, the carbon fiber obtained by adopting the production method has the advantage that the tensile strength and the carbonization yield are respectively improved by more than 19.7% and 26.0%.

Owner:THE NORTHWEST RES INST OF CHEM IND

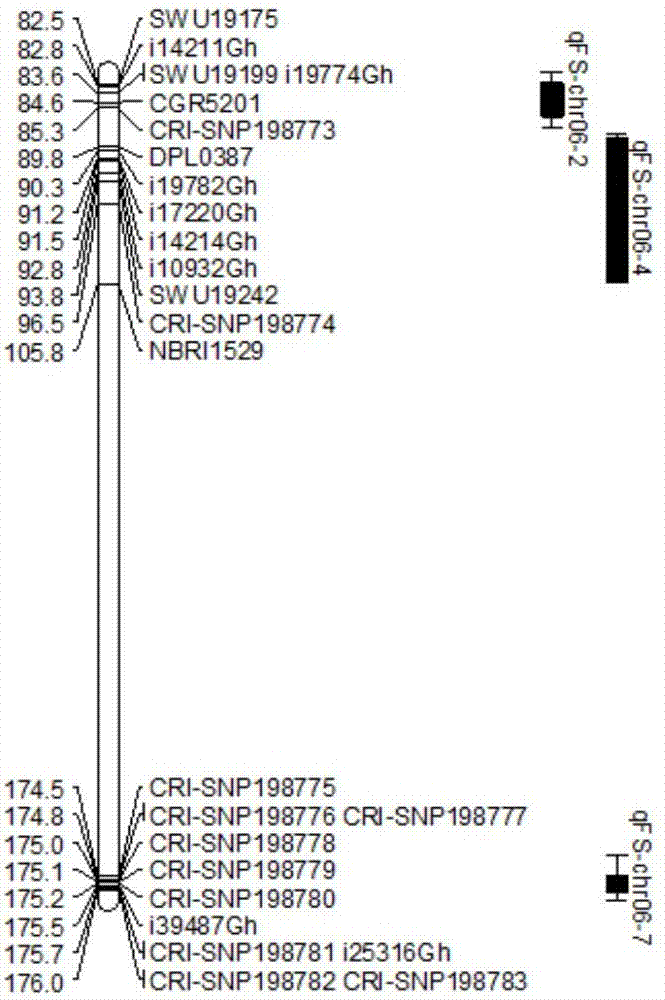

SNP molecular marker associated with chromosome 6 and fiber strength of upland cotton

ActiveCN106868131AShorten the breeding cycleImprove breeding efficiencyMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceMolecular breeding

The invention belongs to the technical field of molecular breeding of cotton and discloses an SNP molecular marker associated with fiber strength of upland cotton as well as detection and application thereof. The SNP molecular marker is obtained by taking stable RIL group of cotton as the material through a genome resequencing method. When the SNP markers are used for carrying out molecular marker-assisted breeding selection, the breeding period can be greatly shortened; the breeding efficiency of the cotton can be improved; the cotton fiber strength can be improved.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Degumming process for kudzu vine

InactiveCN103835006AReduce usageReduce hard bar rateFibre treatment to obtain bast fibreProcess chemistryEngineering

The invention provides a degumming process for a kudzu vine. Directed at the problems of a great usage amount of chemicals, a high fiber strength damage rate, severe environmental pollution and the like in conventional chemical degumming process, the invention provides a degumming method for the kudzu vine through low temperature refrigeration and vacuum technology. The process comprises the following steps: changing the interior structure of a raw kudzu vine by using low temperature vacuum technology so as to form considerable micropores, thereby increasing the surface area of a fiber; and then fully injecting dilute alkali lye and a low-concentration hydrogen peroxide solution into the interior of the fiber by using vacuum negative pressure technology so as to allow alkali lye and hydrogen peroxide to exert maximum efficacy. The process provided by the invention substantially reduces the usage amount of chemicals, shortens degumming flow and has a high gum and lignin removal rate and a low fiber damage rate.

Owner:姜著川

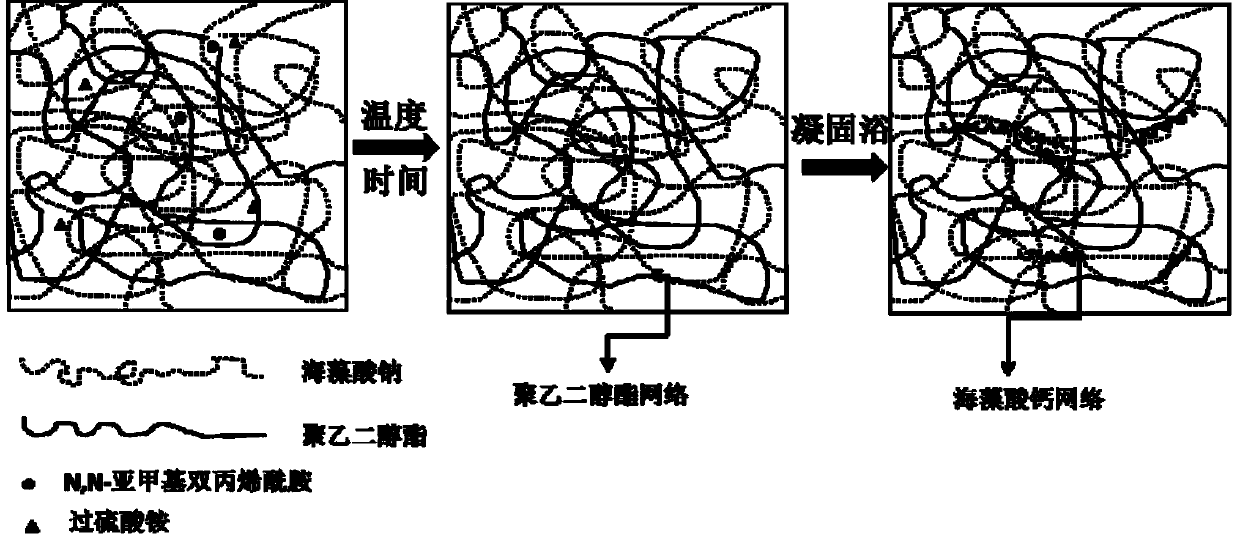

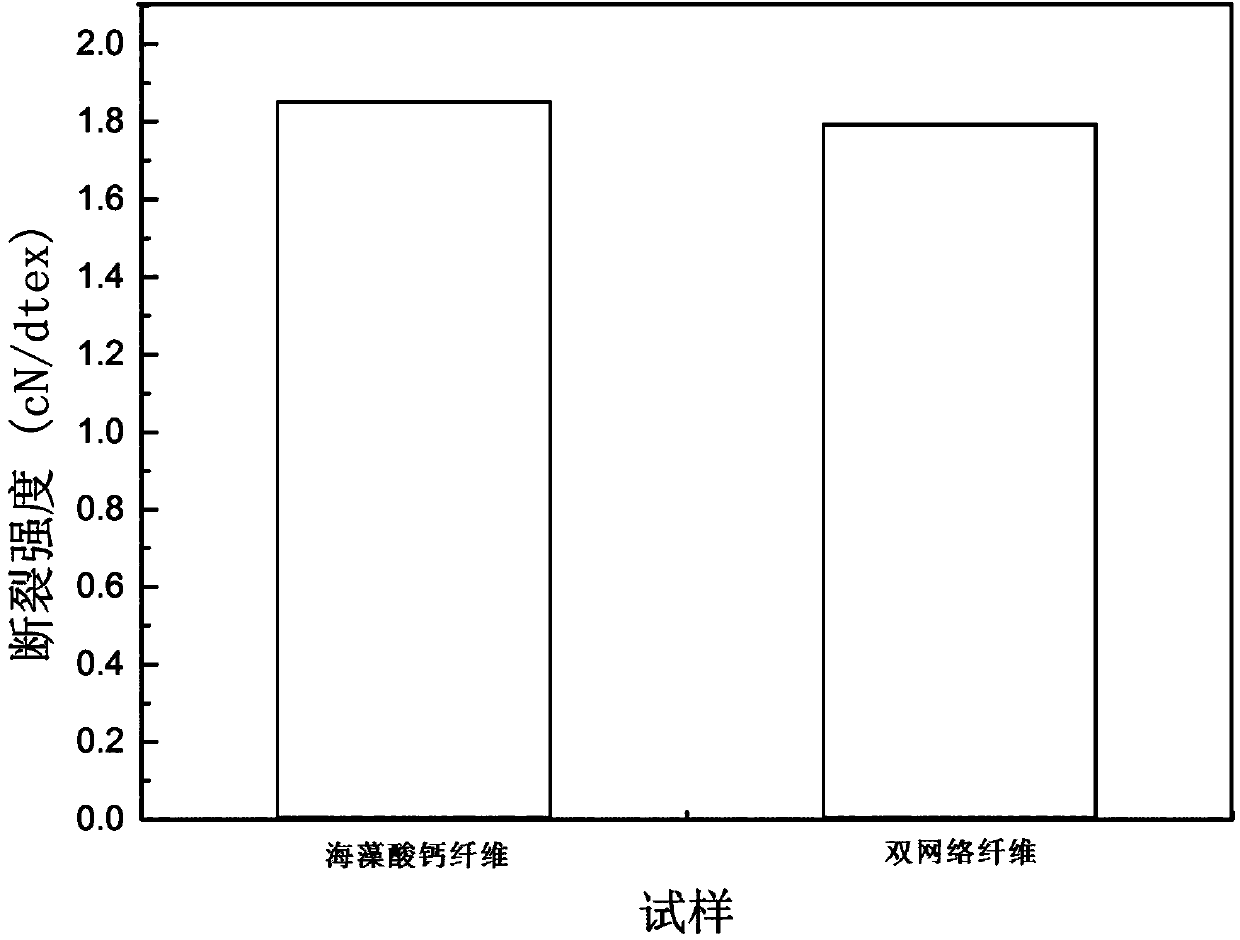

Calcium alginate/macrogol ester double-network phase-change energy-storing fiber and preparation method thereof

ActiveCN103741261AGuaranteed mechanical propertiesFunctionalization of good phase change thermoregulation performanceWet spinning methodsConjugated synthetic polymer artificial filamentsBreaking strengthDouble network

The invention provides a calcium alginate / macrogol ester double-network phase-change energy-storing fiber and a preparation method thereof. The calcium alginate / macrogol ester double-network phase-change energy-storing fiber is formed by copolymerizing sodium alginate and a phase-change material in the presence of a cross-linking agent and an initiating agent and solidifying, wherein the mass ratio of the sodium alginate to the phase-change material is (100:15) to (100:30); the mass ratio of the cross-linking agent to the phase-change material is (0.5:100) to (2:100); the mass ratio of the initiating agent to the phase-change material is (0.1:100) to (0.8:100). According to the calcium alginate / macrogol ester double-network phase-change energy-storing fiber disclosed by the invention, due to a double-network structure, the phase-change material is fixed in the fiber; the double-network structure ensures functionalization and also reduces loss of the break strength of the fiber; by controlling the reaction condition, the cross-linking degree of macrogol ester networks is changed to regulate the balance among the phase-change energy-storage temperature regulation performance of the fiber, the fiber strength and the spinning solution processability so as to meet the requirements on practical processing and application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Flame-proof fusion-resistant viscose fiber and production method thereof

InactiveCN101161878AImprove strength and elongationGuaranteed filtering effectMonocomponent cellulose artificial filamentCelluloseFiltration

The present invention discloses a flame-retardant anti-melting viscose fiber. According to mass ratio, the viscose fiber mainly comprises the following components: 60-80 percent of cellulose, 15-26 percent of silicon series flame retardant (metered through silicon dioxide) and 3-20 percent of water. The present invention also discloses a production method for flame-retardant anti-melting viscose fiber, and the technical essential is that: in the adding step of flame retardant, the silicon series flame retardant is added into cellulose sulphonic acid ester in a yellowing step or viscose prepared after the yellowing step is over, and the addition amount is 20-45 percent of cellulose if metered through silicon dioxide. The flame-retardant anti-melting fiber produced by using the method is good in flame-retardant anti-melting effect and high in fiber strength, can lead viscose to keep good filtration performance in production process, reduces the production pause caused by that viscose clogs filter screens, and improves production efficiency. The viscose fiber can be widely used for the manufacturing of non-woven fabrics and so on.

Owner:CHTC HELON

Process for producing towel fabric containing bamboo fiber garn

InactiveCN1458332AReduce quality lossMaintain strong performanceFibre treatmentYarnAdditive ingredient

The technological process of producing towel fabric containing bamboo fiber yarn includes the steps of: warping, sizing, weaving, desizing and degreasing, bleaching, dyeing and post-finishing. It features the regulated glue size ingredients with PAV in 0.2-0.6 % and wheat starch in 0.8-1.2 %, the sizing process at 96-100 deg.c for 28-32 sec, the make-up of desizing and degreasing liquid with reduced NaOH amount of 1.2-1.5 g / L, and regulated desizing and degreasing process at 93-97 deg.c for 55-65 min. The said technological process makes the bamboo fiber yarn possess raised strength and lubricating performance for fluent weaving. The fabric is soft, high in fiber strength, and color fast, and will not become sticky and mildewy.

Owner:SHANGHAI JINLE TEXTILE DECORATIONS

Preparation method of graphene/thermotropic liquid crystal wholly aromatic polyester composite material

ActiveCN103333324AEvenly dispersedImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolymer scienceResin-Based Composite

The invention relates to a preparation method of a graphene / thermotropic liquid crystal wholly aromatic polyester composite material. According to the invention, 6-alkyl-2-naphthoic acid non-covalent bond modified graphene oxide is obtained through the pi-pi interaction of the naphthalene ring structure of 6-alkyl-2-naphthoic acid and graphene oxide, and the modified graphene oxide is subjected to hot reduction in the polycondensation process of a wholly aromatic polyester monomer to generate graphene, so that the graphene is uniformly dispersed in the thermotropic liquid crystal wholly aromatic polyester resin, thus overcoming the problems that the graphene is difficult to disperse and the lamellar structure is easy to agglomerate when the graphene is directly blended with the thermotropic liquid crystal wholly aromatic polyester. After being processed into fiber, the prepared composite resin has favorable conductivity and mechanical performance. Tests prove that the composite material has stable mechanical performance, the strength of the fiber formed by spinning the composite material is increased by 60% or so in comparison with the simple thermotropic liquid crystal wholly aromatic polyester, the fiber has favorable conductivity, and the mechanical performance of the fiber is even superior to that of the simple TLCP (thermotropic liquid crystal polymer) fiber.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com