Calcium alginate/macrogol ester double-network phase-change energy-storing fiber and preparation method thereof

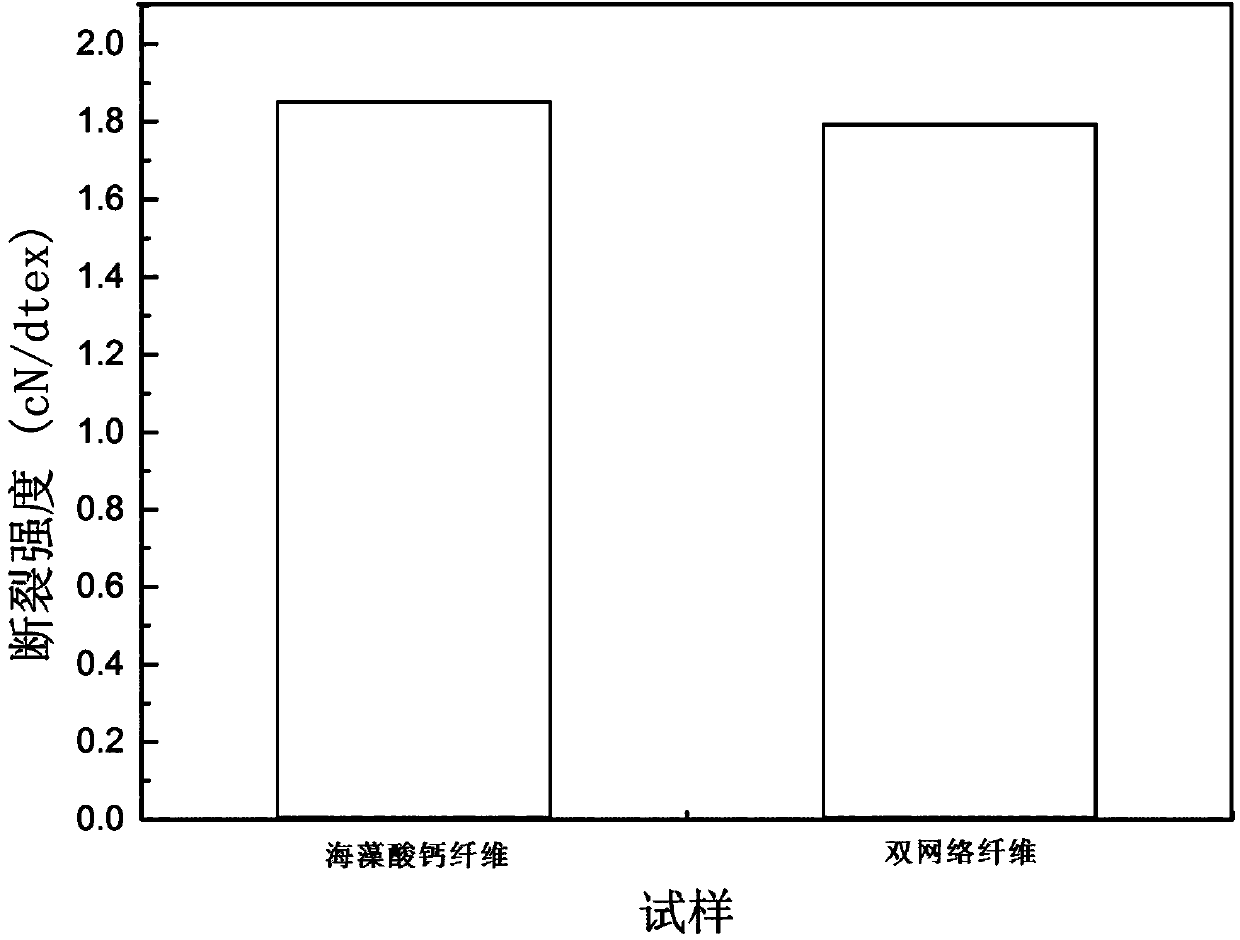

A technology of polyethylene glycol ester and calcium alginate, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, wet spinning method, etc., can solve the problem of low strength of alginate fiber, and achieve the goal of alleviating the imbalance between heat energy supply and demand Contradictory, simple control, effect of reduction in loss of fiber breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example discloses a calcium alginate / polyethylene glycol ester double network phase change energy storage fiber, the preparation method of which is as follows:

[0030] Dissolve 2g of sodium alginate, 0.6g of polyethylene glycol ester, 0.006g of N,N-methylenebisacrylamide, and 0.0024g of ammonium persulfate in 100ml of deionized water, react in a water bath at 60°C for 2.5h, and statically Place it for defoaming, extrude into 2% calcium chloride solution, take out the fiber after 10 minutes of solidification and molding, draw and dry to obtain the double network phase change energy storage calcium alginate fiber.

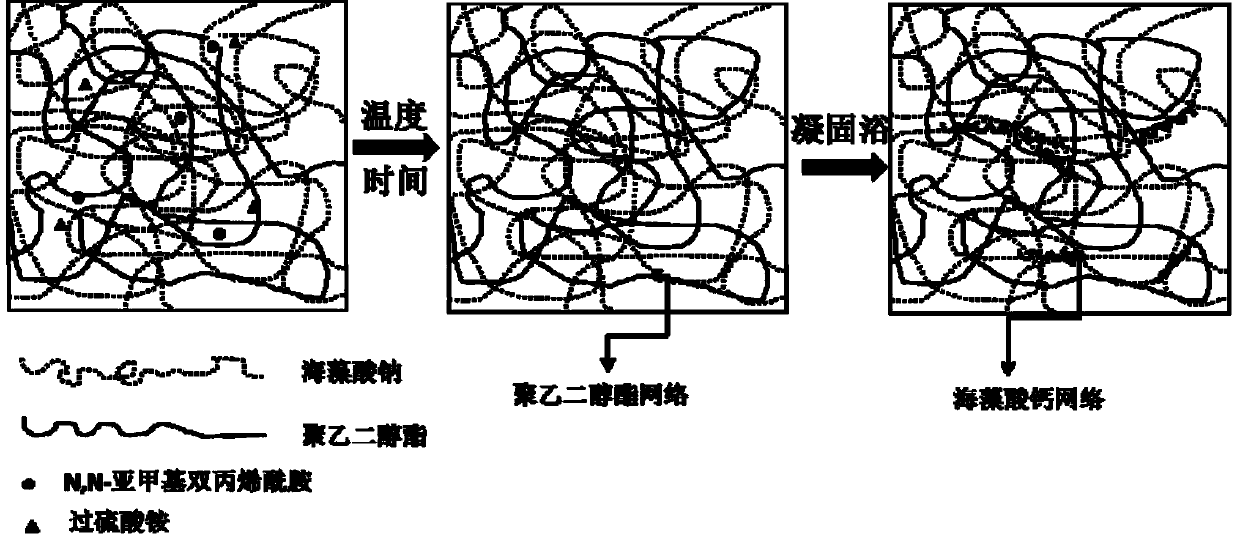

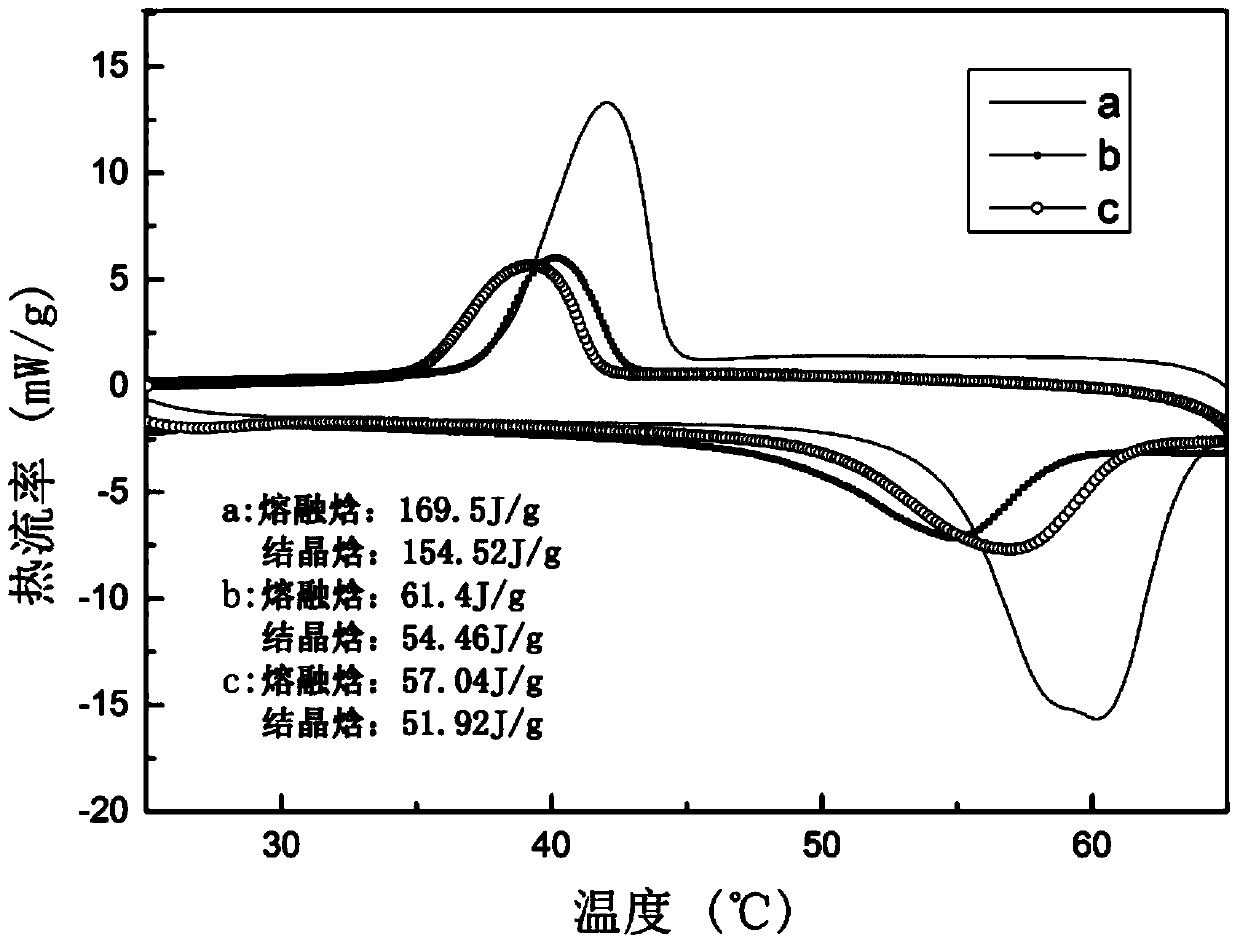

[0031] The structure and preparation process of the calcium alginate / polyethylene glycol ester double network phase change energy storage fiber in this example are as follows: figure 1 As shown, the calcium alginate / polyethylene glycol ester double network phase change energy storage fiber firstly prepares the polyethylene glycol ester covalently crossli...

Embodiment 2

[0035] This example discloses a calcium alginate / polyethylene glycol ester double network phase change energy storage fiber, the preparation method of which is as follows:

[0036] Dissolve 2g of sodium alginate, 0.3g of polyethylene glycol ester, 0.0015g of N,N-methylenebisacrylamide, and 0.0003g of ammonium persulfate in 100ml of deionized water, react in a water bath at 45°C for 2.5h, and statically Place it for defoaming, extrude into 2% calcium chloride solution, take out the fiber after 10 minutes of solidification and molding, draw and dry to obtain calcium alginate / polyethylene glycol ester double network phase change energy storage fiber.

Embodiment 2

[0037] The melting enthalpy of the calcium alginate / polyethylene glycol double network phase change energy storage fiber obtained in Example 2 is 30.94 J / g, the crystallization enthalpy is 11.15 J / g, and the fiber breaking strength is 1.61 cN / dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber breaking strength | aaaaa | aaaaa |

| Fiber breaking strength | aaaaa | aaaaa |

| Fiber breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com