CrNiMo high-strength pinion steel and preparation method thereof

A gear steel, high-strength technology, applied in the direction of improving process efficiency, can solve the problems of inability to meet the performance requirements of heavy-duty automobiles and large shaft tooth parts, unsatisfactory hardenability control, and large fluctuations in end hardenability. , to achieve the effect of improving process performance and heat treatment, low band structure level, and improving heat treatment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The following examples are used to illustrate the present invention, but the protection scope of the present invention is not limited to the following examples.

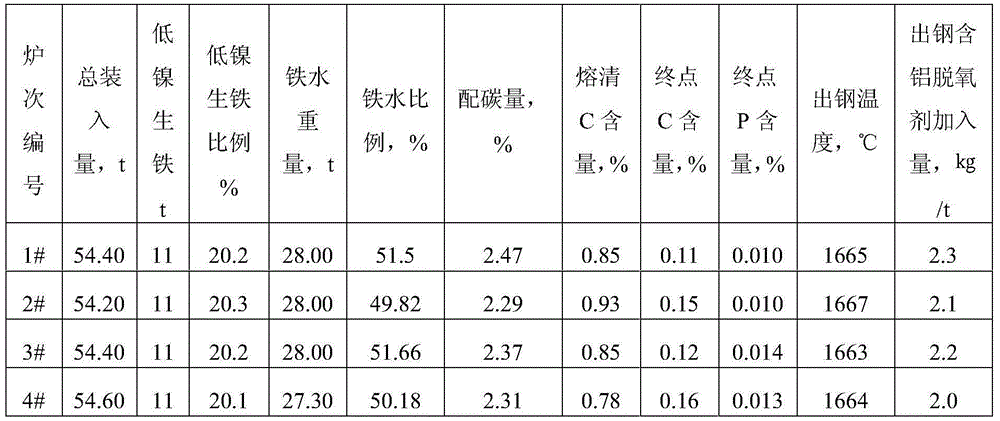

[0040] The production process is: batching→electric arc furnace smelting→LF refining furnace refining→VD vacuum refining furnace refining→bloom continuous casting→semi-continuous rolling mill rolling.

[0041] In order to ensure the economy of low-nickel pig iron electric furnace smelting, optimize the batching structure, increase the amount of low-nickel pig iron added, and adopt the solid batching mode; low-nickel pig iron is blended according to the middle and lower limits of the nickel element specification of the steel grade, and the nickel yield is calculated as 100%. Arrangement of charging The low-nickel pig iron cloth is placed around the large material and close to the bottom of the material frame, but avoids the furnace door to prevent splashing during melting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com