Patents

Literature

180results about How to "Realize automatic transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

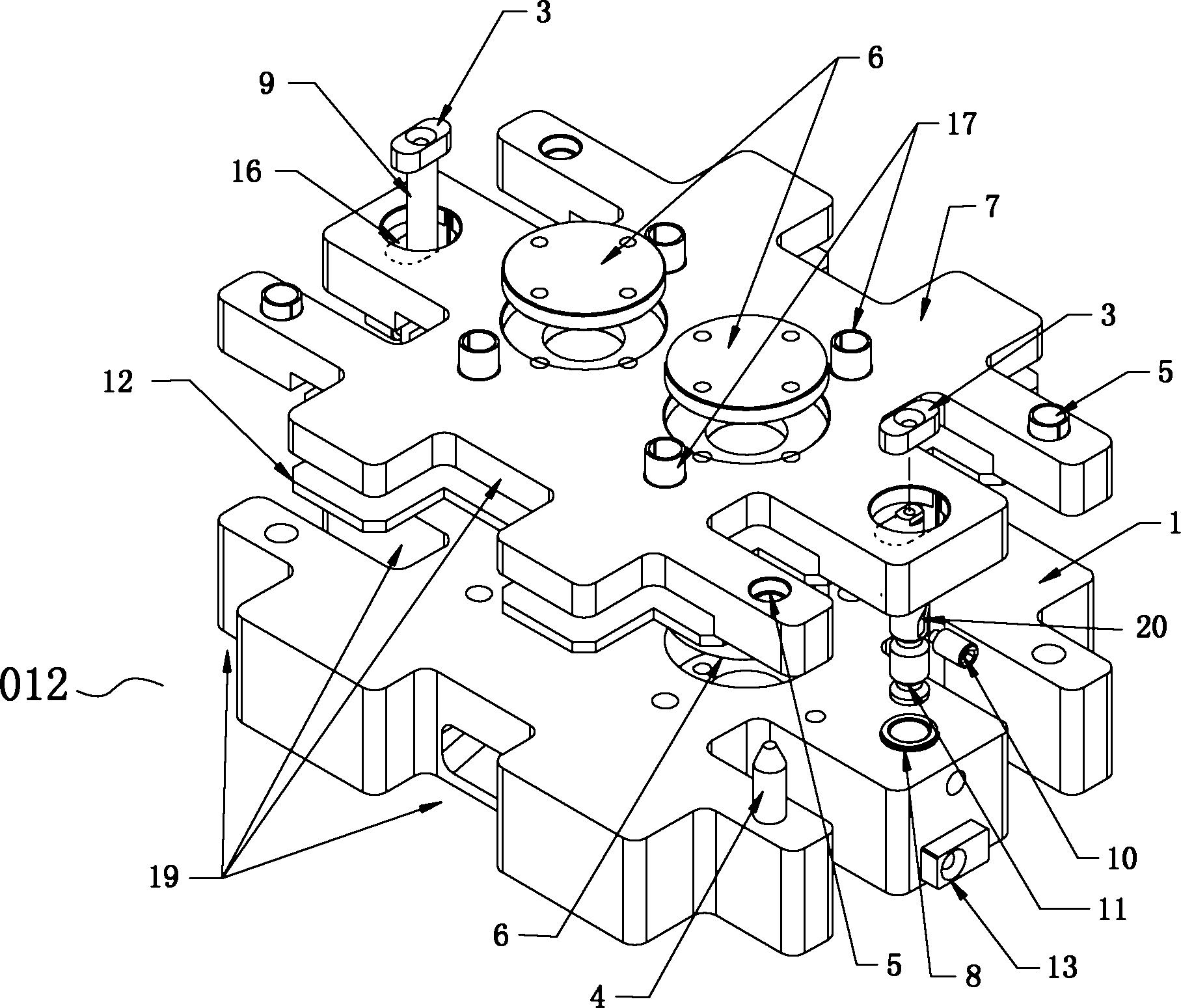

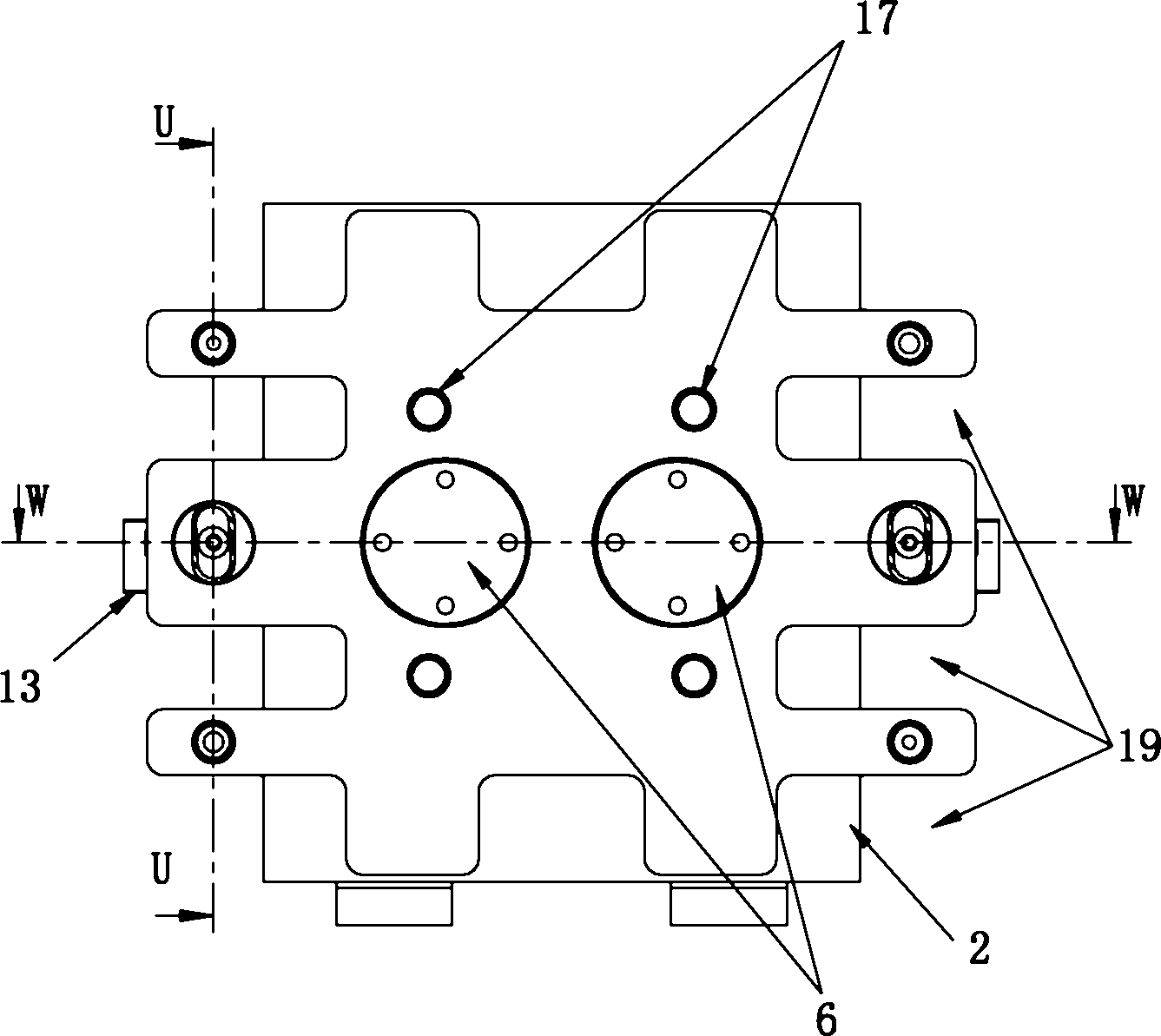

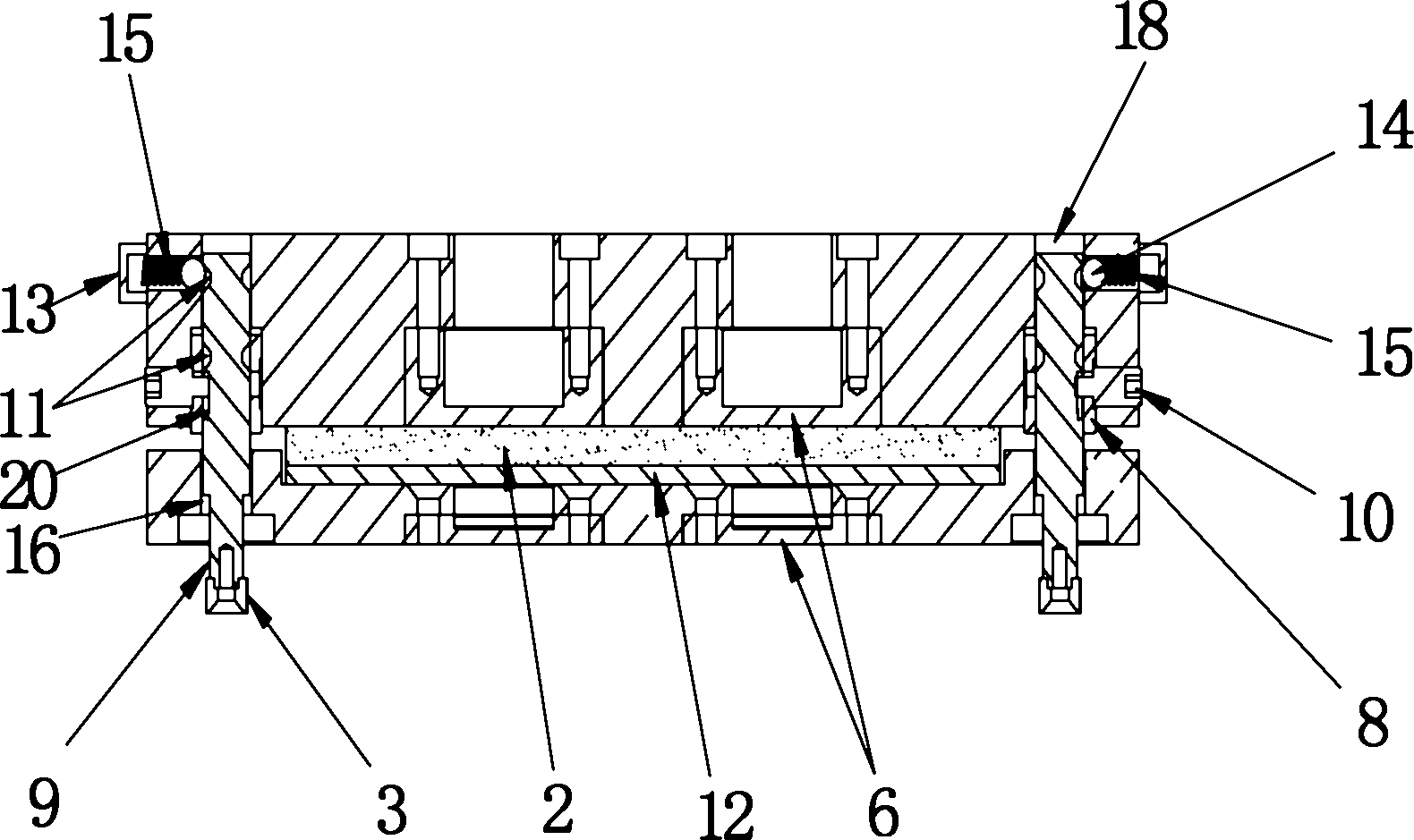

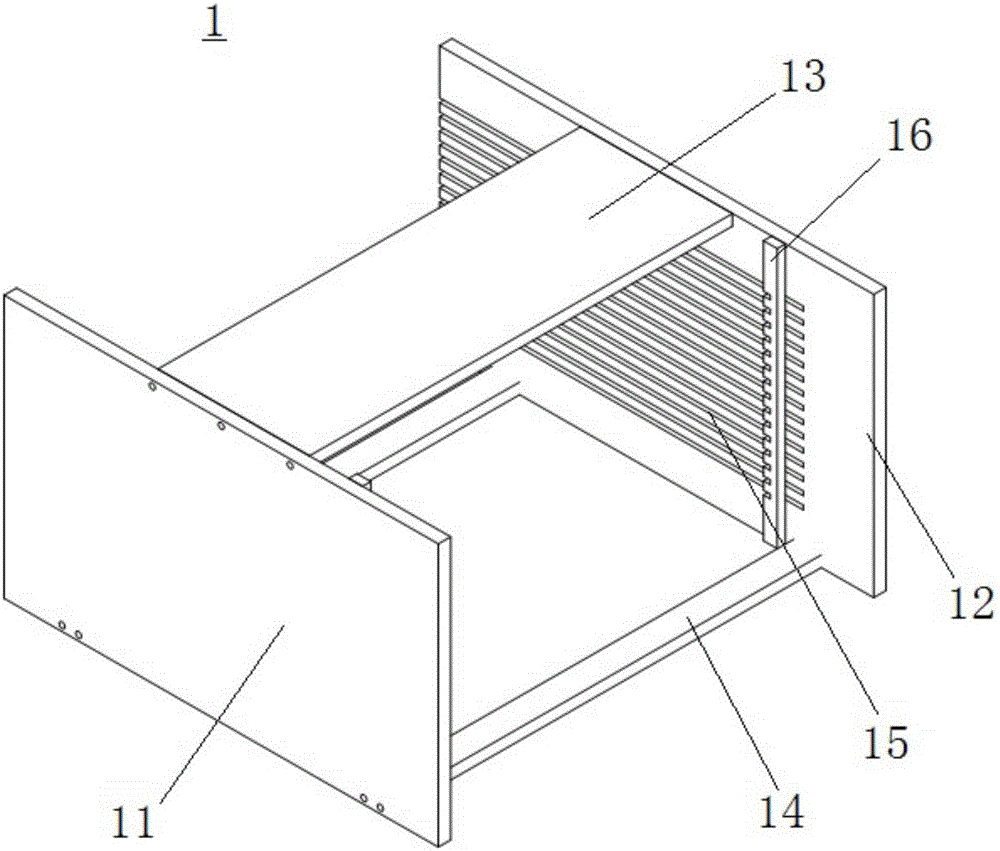

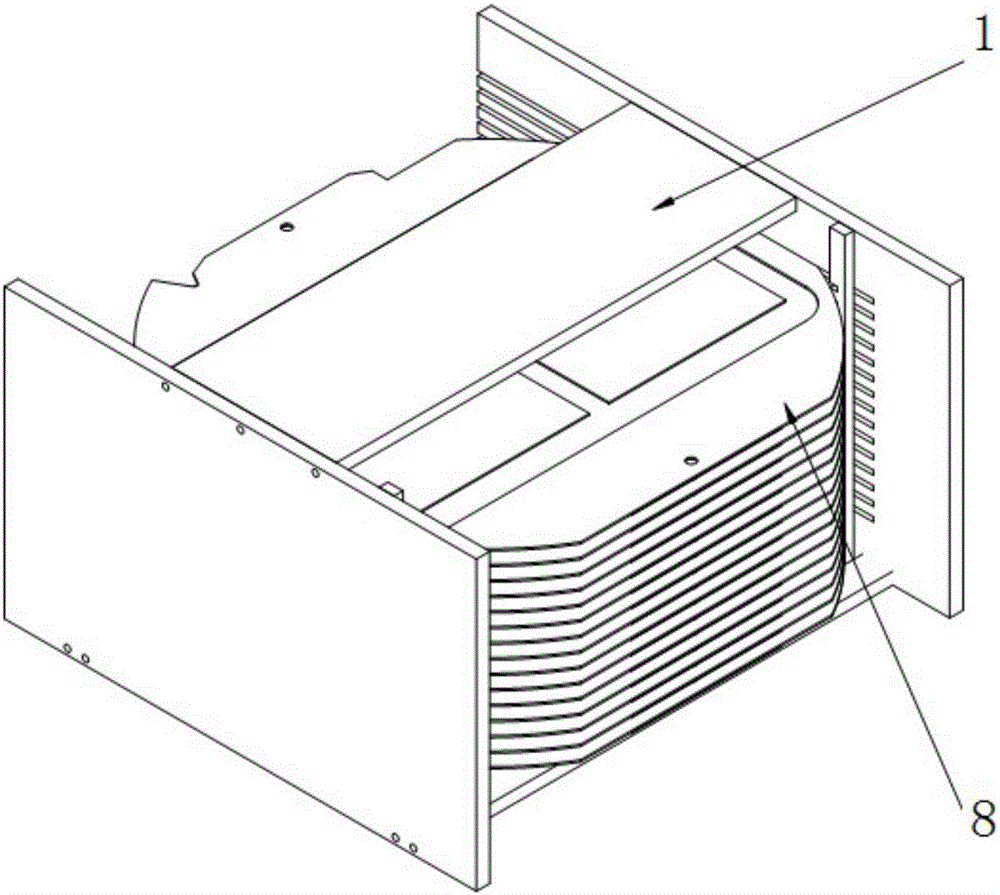

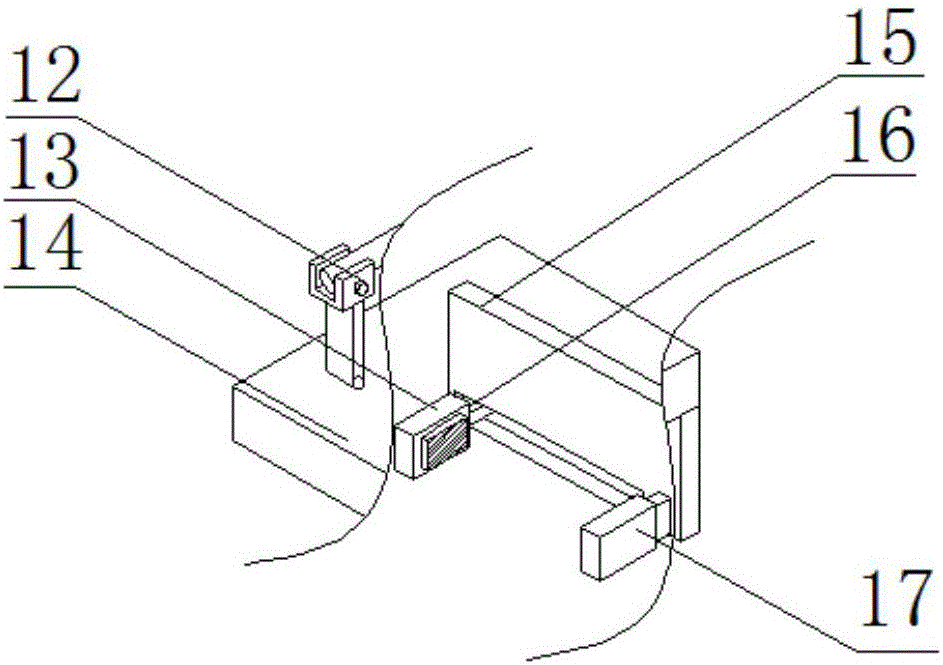

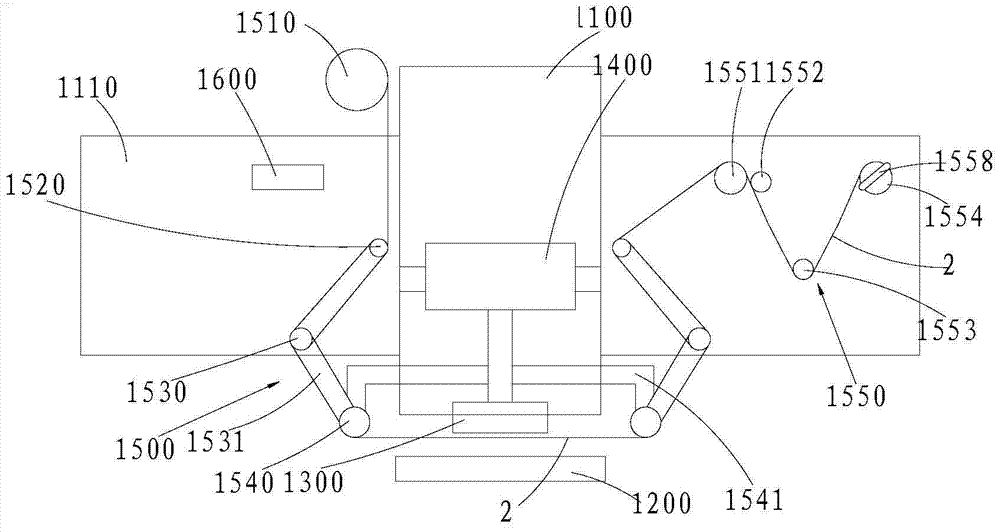

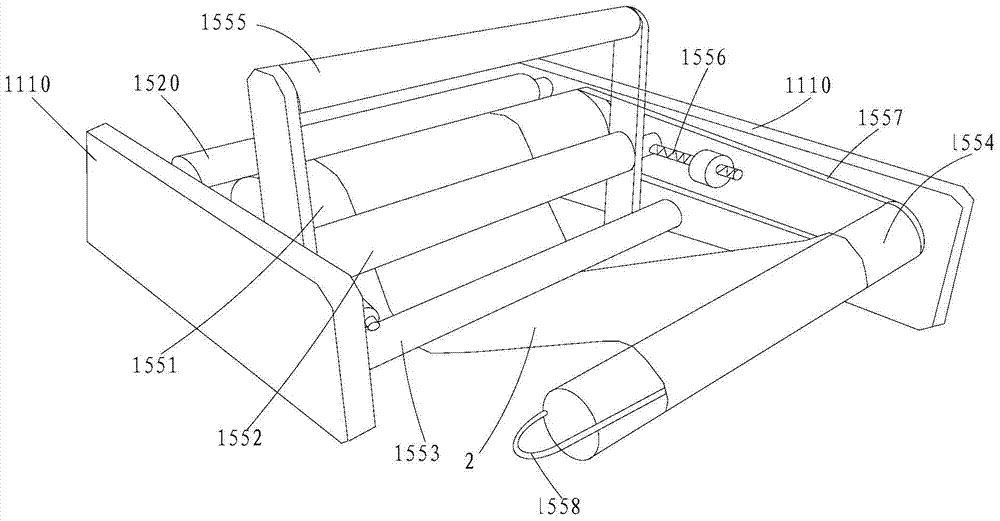

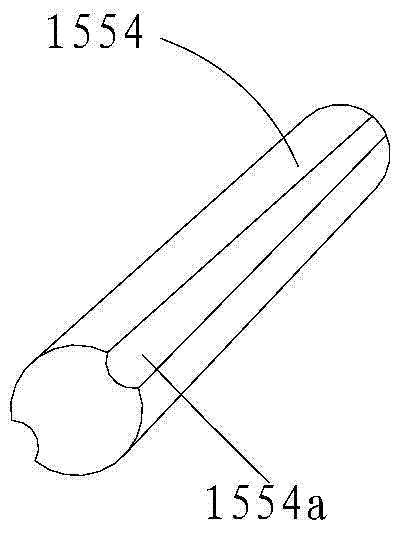

Turnover fixture, power battery assembling method and equipment

ActiveCN102376982AReduce positioning deviationRealize automatic transferAssembling battery machinesFinal product manufacturePower batteryProduction line

The invention discloses a turnover fixture, a power battery assembling method and equipment which can be applied in the field of power battery soft packaging. The turnover fixture is composed of a base plate, an upper cap and a buffering mechanism. The fixture is coupled with a battery core, and is used for positioning the battery core. During a transportation process, the turnover fixture can beused for protecting the battery core, and for improving the battery core positioning precision. With the turnover fixture provided by the invention, positioning deviation during battery core transportation is reduced, and the battery core is prevented from being directly contacted. The invention also provides the equipment comprising a conveyor, a cap fixing machine, a cap opening machine, and a conveyer manipulator. The invention establishes a production line with the turnover fixtures as battery core carriers. With the production line, automatic transportation can be carried out by using the fixtures, such that the battery cores are prevented from being repeatedly transported by using human hands or manipulators, such that the consistency of the battery cores can be endured.

Owner:GEESUN AUTOMATION TECH

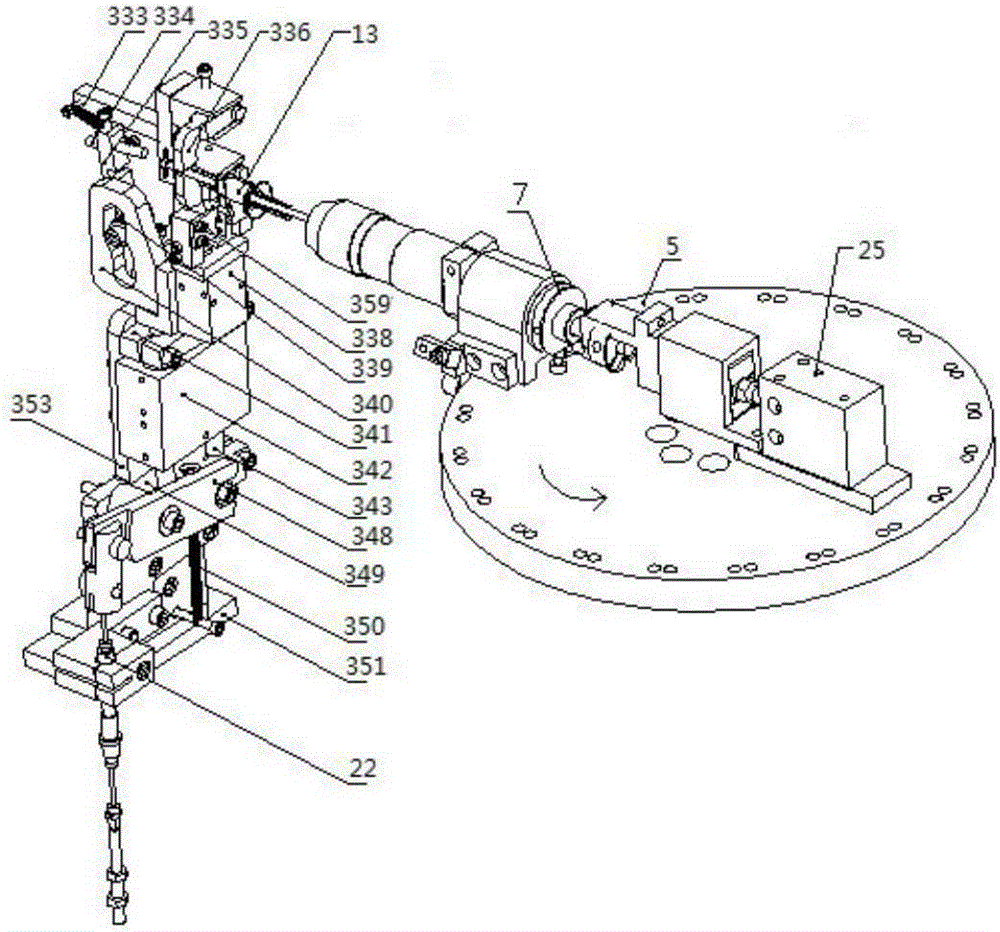

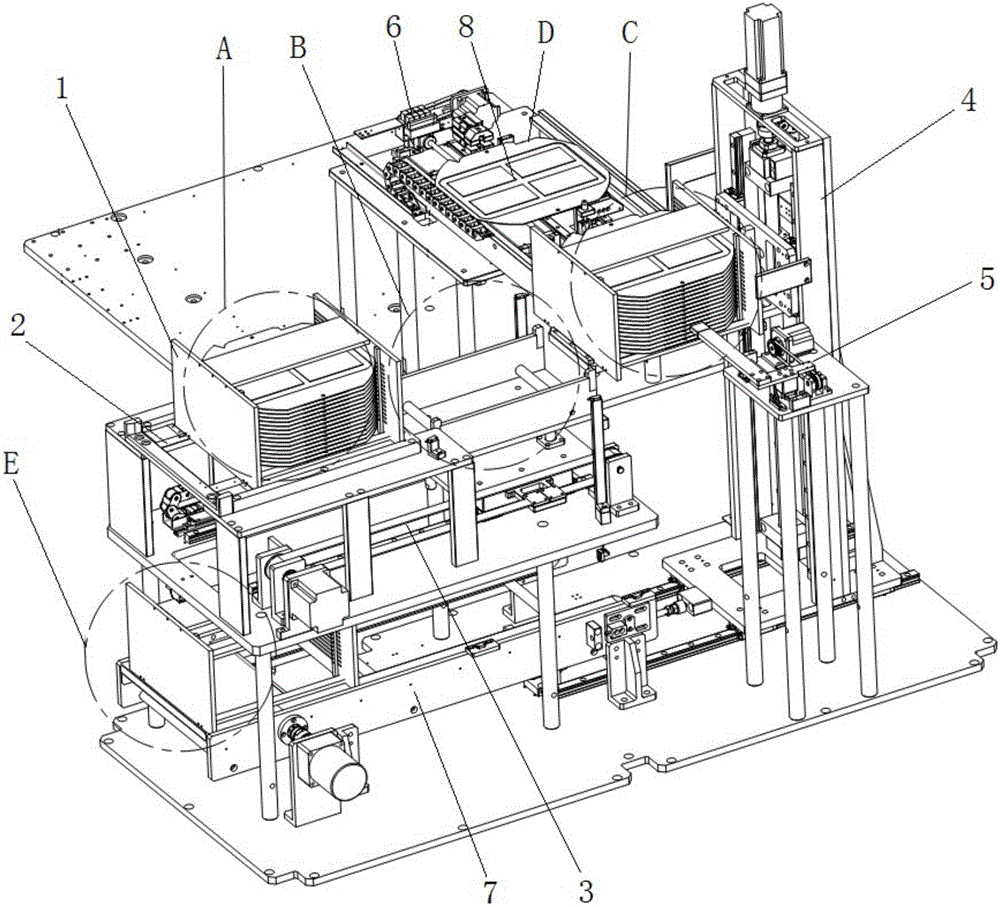

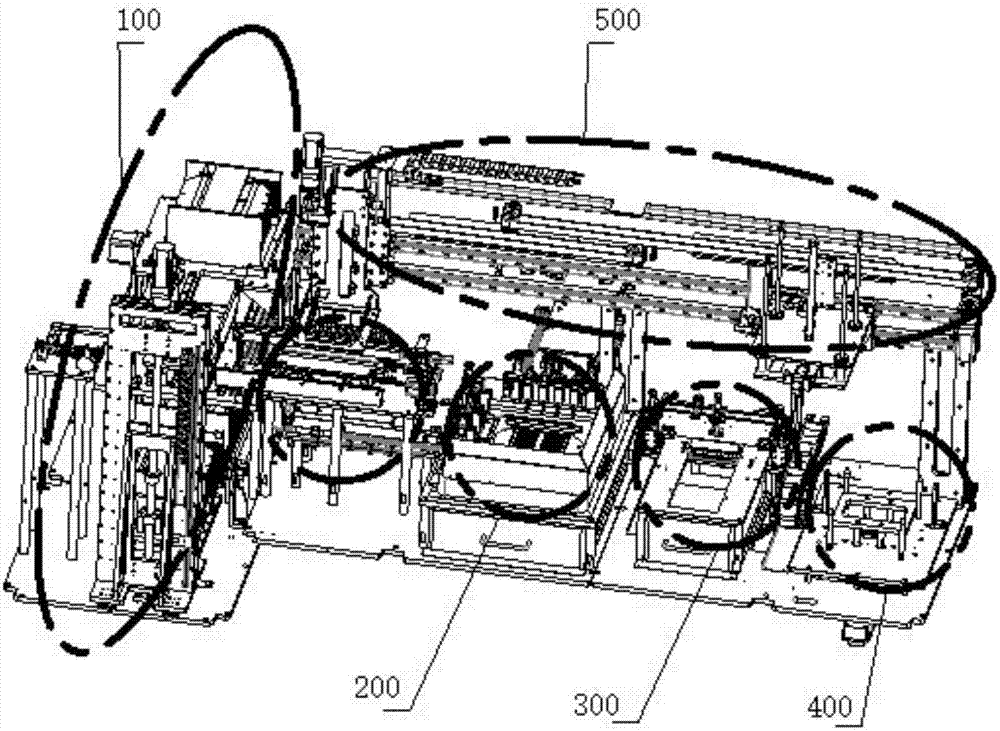

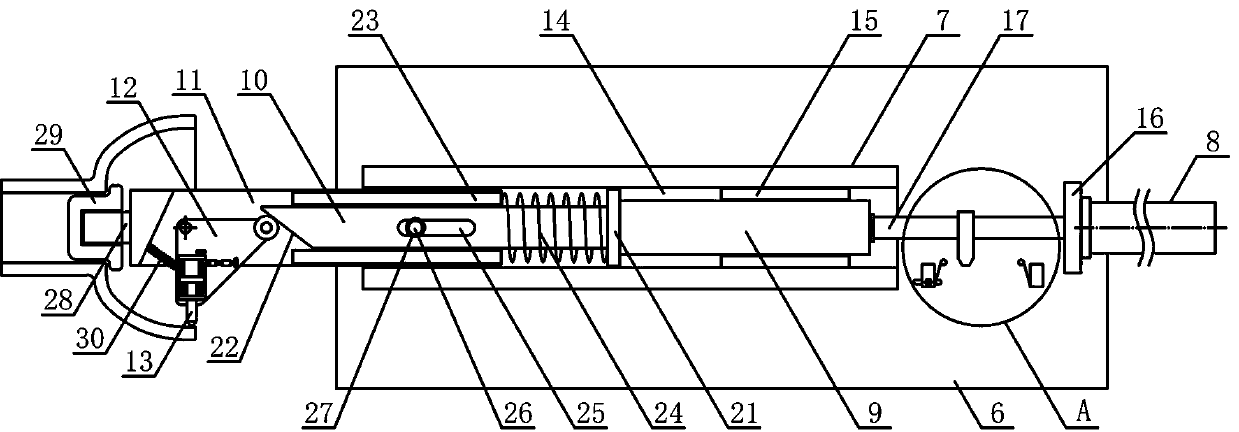

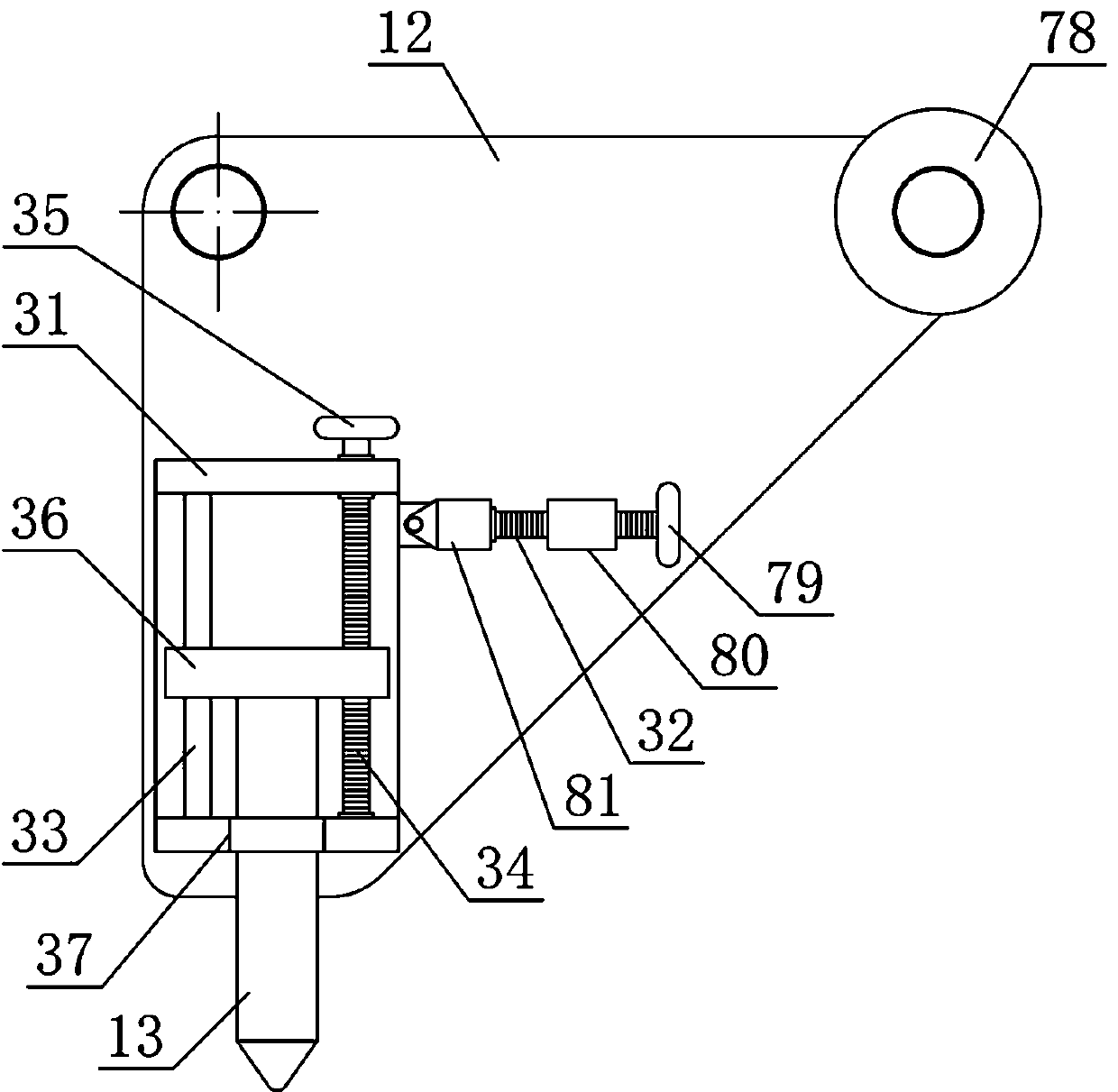

Full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration

ActiveCN105345470AFacilitate automated processing operationsEasy to operateOther manufacturing equipments/toolsCircular discReduction drive

The invention discloses full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration. The full-automatic production equipment comprises a main bottom plate, a platen and an upper bracket, wherein the upper end of the main bottom plate supports the platen through four thick bracket legs. A discharging mechanism and a buffering conveying mechanism are arranged on the left and the right of the side surface of the platen respectively, and a feed mechanism is arranged at the end of the buffering conveying mechanism. The platen is provided with a gap divider. An index plate rotates anticlockwise and is provided with a stem clamp. The main bottom plate is provided with a speed reducer, a station main shaft and a cam mechanism. A stem locating mechanism, a long foot arranging mechanism, a short foot poking mechanism, a 45-degree long foot poking assembly mechanism, a 45-degree short foot poking assembly mechanism, a foot straightening mechanism, an LED light strip shearing and conveying mechanism, an automatic LED light strip rotating and conveying mechanism and a welding mechanism are sequentially arranged on the platen from the front end of the feed mechanism and surround the index plate. The full-automatic production equipment is high in automation degree, high in welding and shaping efficiency and high in shaping accuracy.

Owner:南通睿博电器有限公司

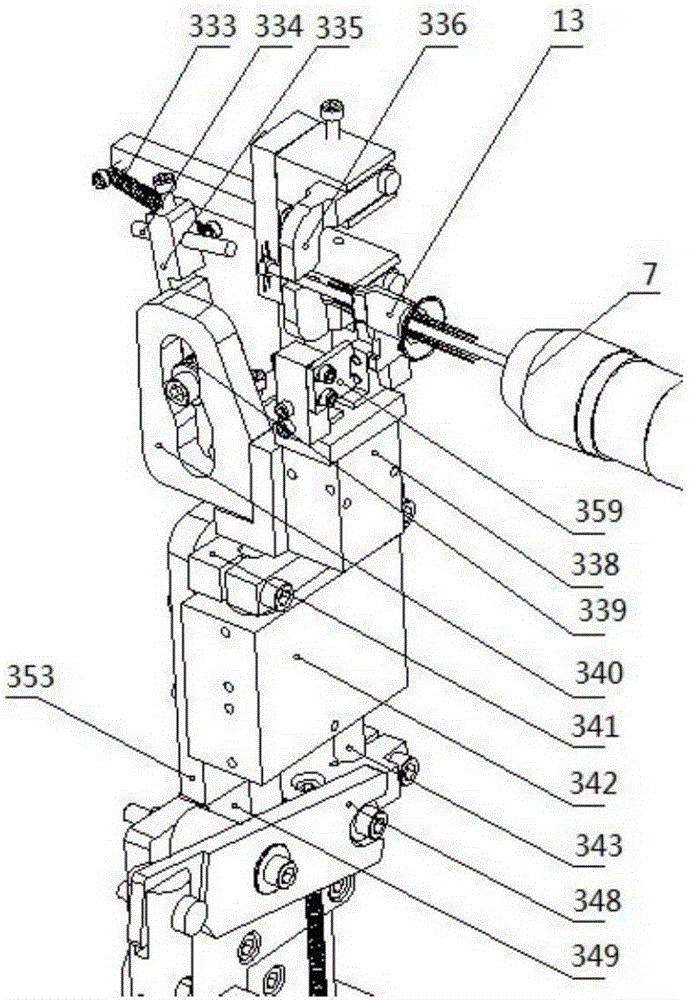

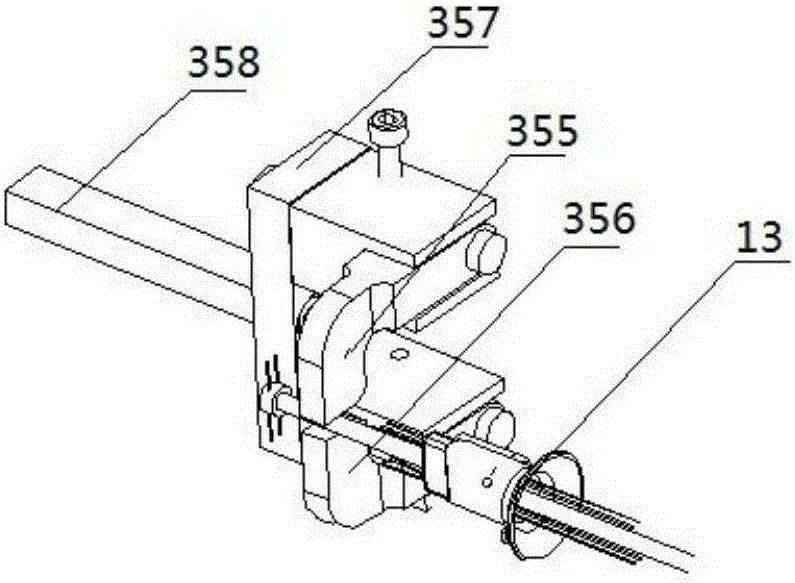

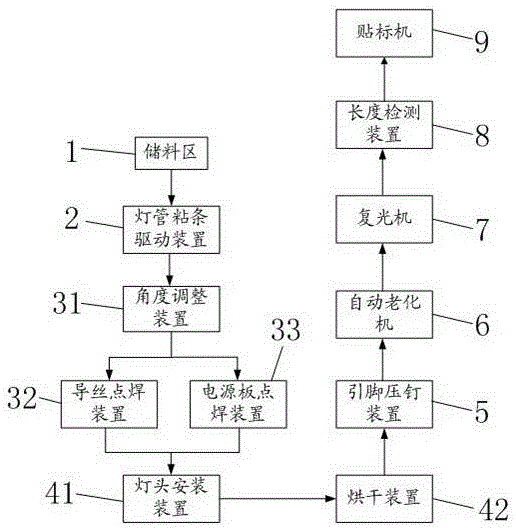

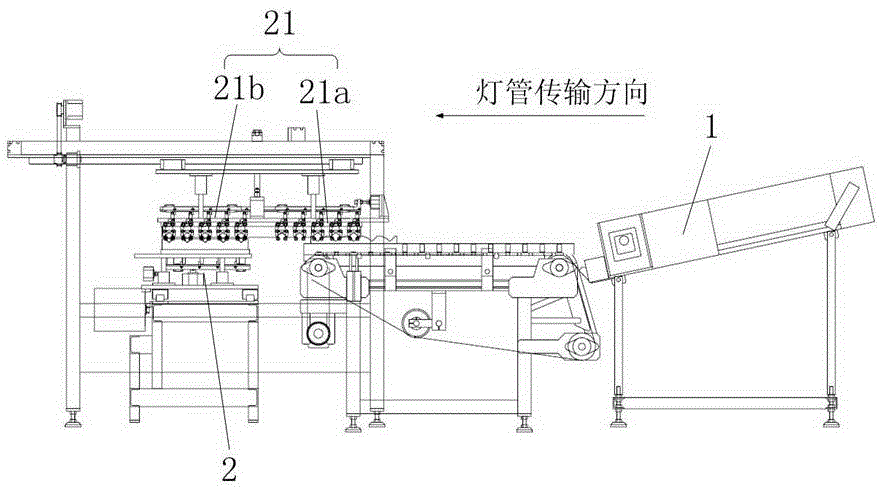

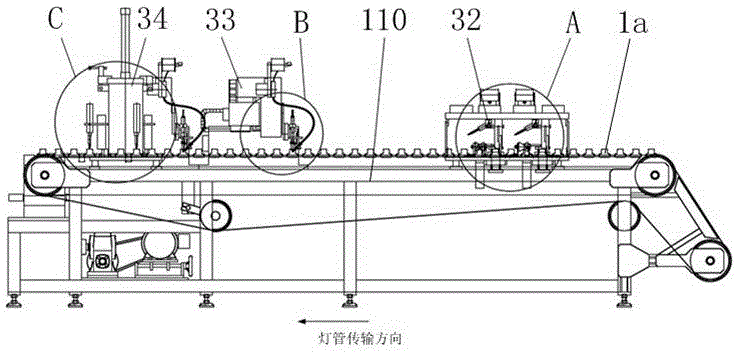

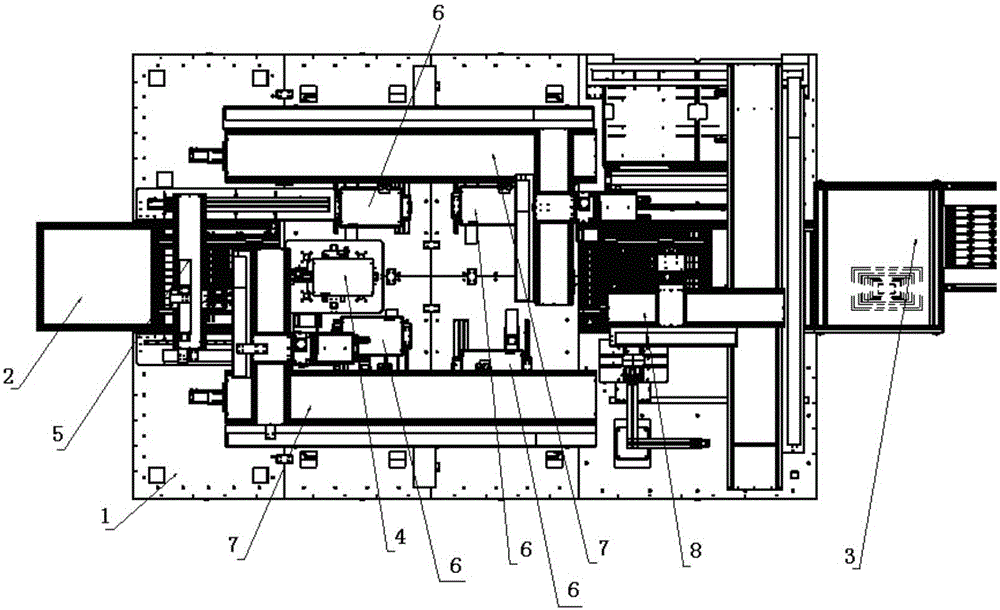

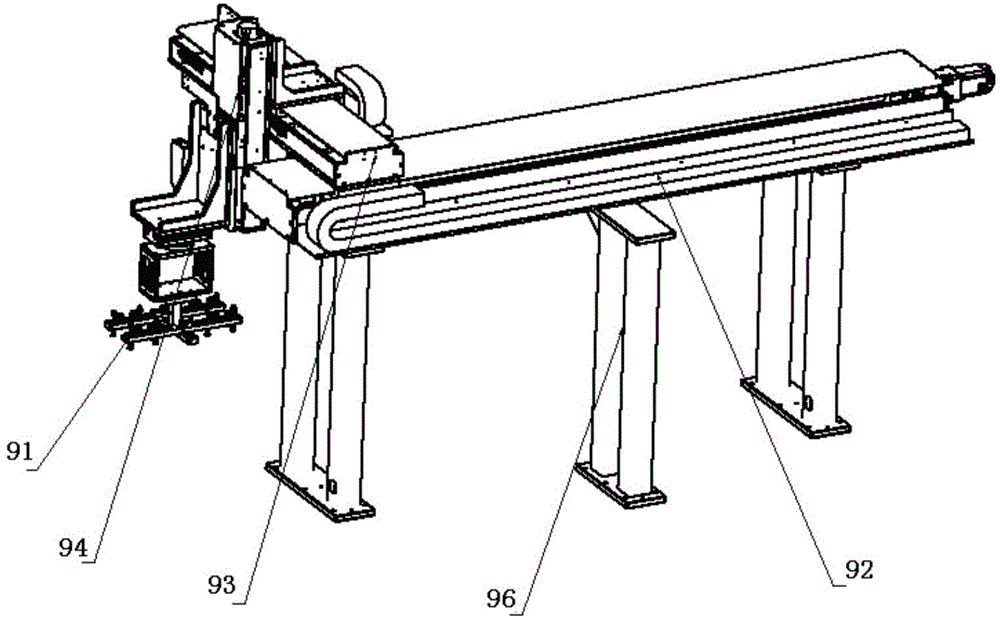

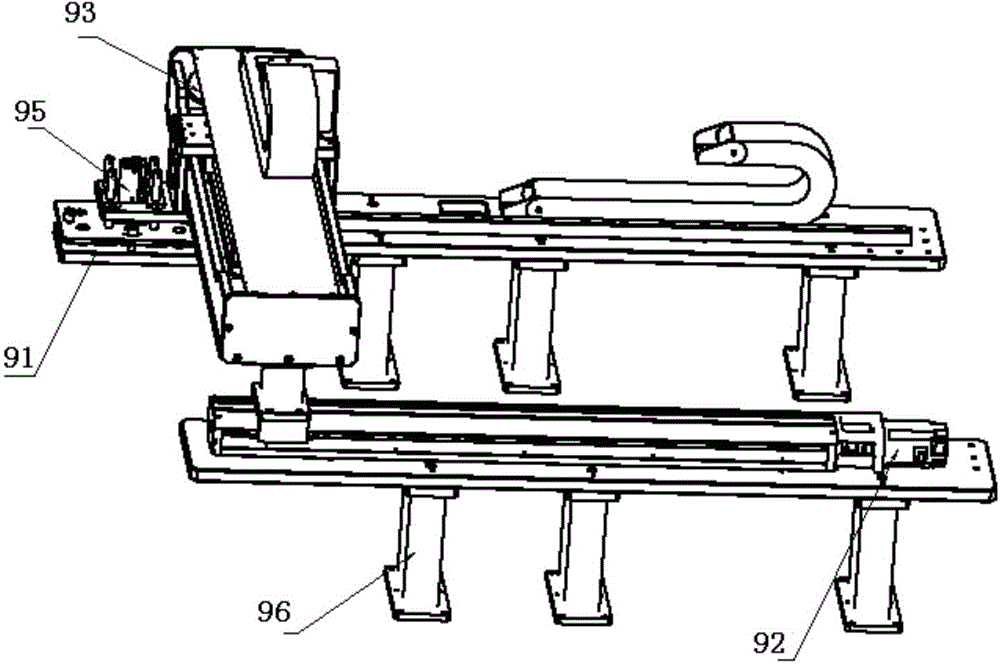

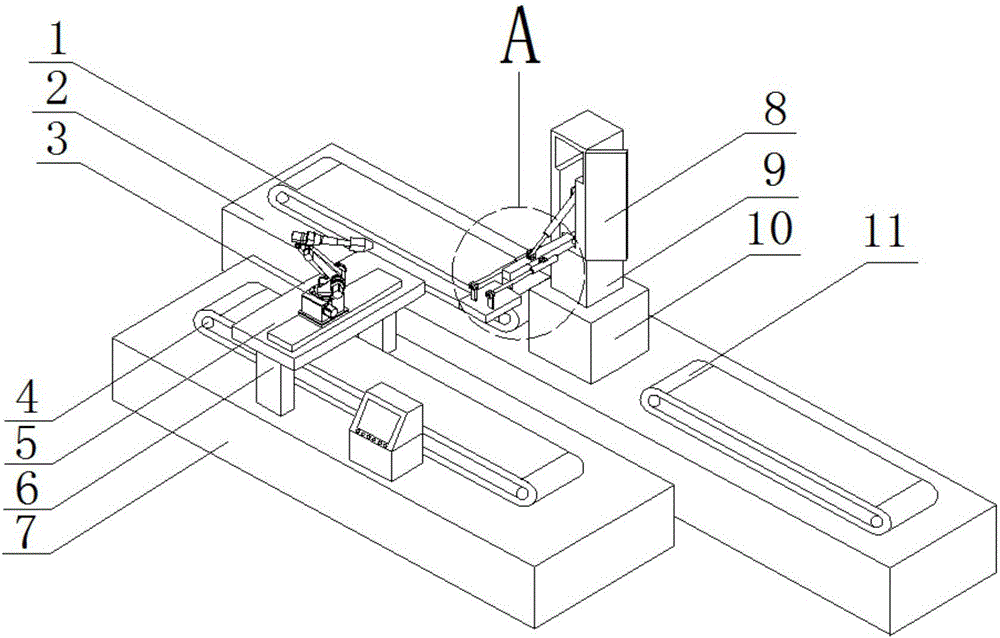

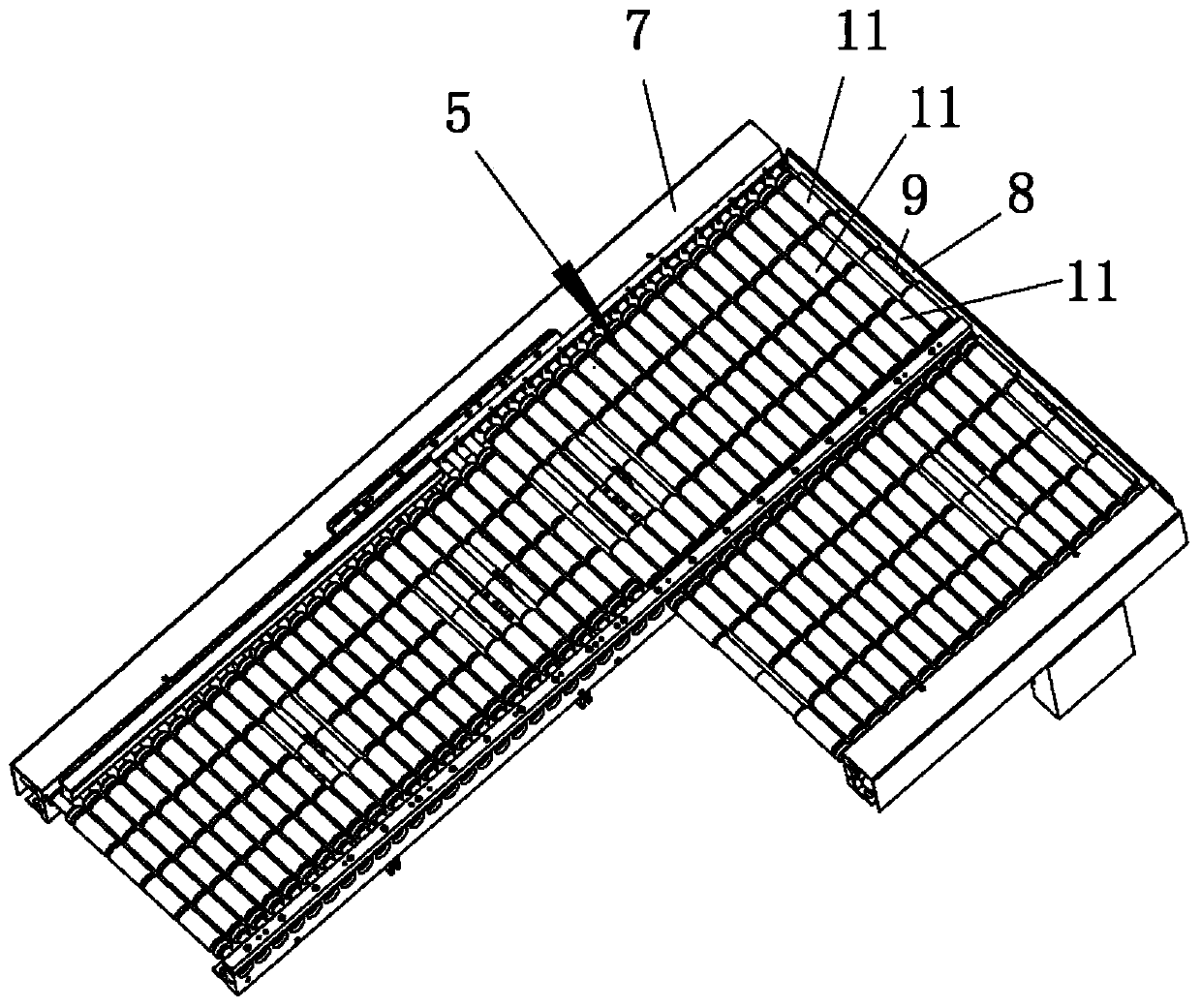

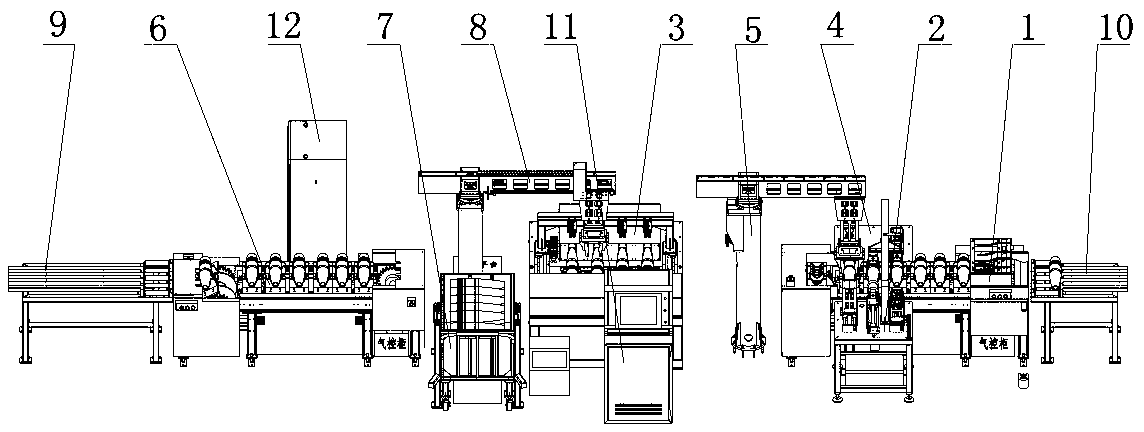

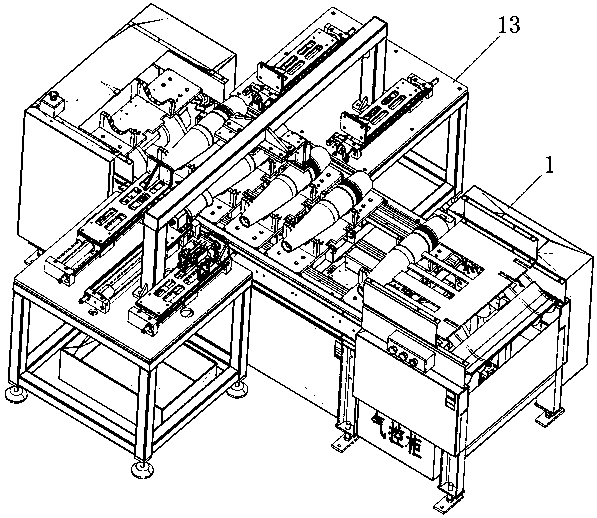

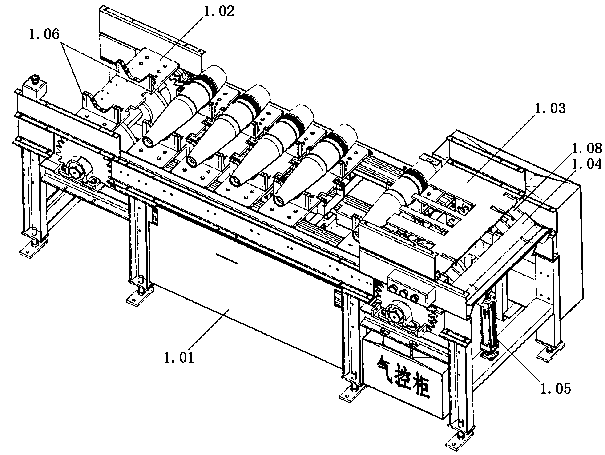

Full-automatic production line for LED lamp tube

ActiveCN106112317ARealize automatic transferImprove Spot Welding EfficiencyLiquid surface applicatorsWelding/cutting auxillary devicesProduction lineAdhesive

The invention discloses a full-automatic production line for an LED lamp tube. The full-automatic production line comprises a conveying chain, a material storage area, a lamp strip dispensing tube sticking area, a spot welding area and a lamp head installation area, wherein the conveying chain is used for conveying the lamp tube, and the material storage area, the lamp strip dispensing tube sticking area, the spot welding area and the lamp head installation area are sequentially arranged along the conveying chain. The lamp strip dispensing tube sticking area comprises a lamp strip dispensing device used for conducting glue feeding on the upper surface of a lamp strip, a lamp tube adhesive tape driving device used for driving the lamp tube to move back and forth in the length direction of the lamp strip and a lamp tube feeding and discharging device. The lamp tube spot welding area comprises a first angle adjusting device, a guide wire spot welding device and a power board spot welding device. The first angle adjusting device drives the lamp tube entering the lamp tube spot welding area to rotate till the lamp strip is located at the bottom of the lamp tube. The lamp head installation area comprises a lamp head installation device and a drying device. The lamp head installation device comprises a transfer mechanical arm and a leading wire alignment mechanism. The drying device comprises a lamp tube feeding and discharging mechanism, a lamp tube rotating mechanism used for conveying the lamp tube and a lamp tube heating mechanism which is arranged on the lamp tube rotating mechanism and used for heating and curing a lamp head. The full-automatic production line for the LED lamp tube is high in efficiency.

Owner:FOSHAN ELECTRICAL & LIGHTING

Automatic detecting device of touch screen

ActiveCN104459439AImplement automatic detectionRealization of automatic alignment and deviation correctionResistance/reactance/impedenceElectrical testingEngineeringTransfer mechanism

The invention discloses an automatic detecting device of a touch screen. The automatic detecting device comprises a rack with at least one detecting position. A feeding conveying mechanism and a discharging conveying mechanism are arranged on the peripheral side of the rack. An automatic aligning mechanism, a first transferring mechanism, a detecting device body, a second transferring mechanism and a third transferring mechanism are arranged on the upper side of the rack. The detecting device body comprises a conveying mechanism, a detecting mechanism and an observing mechanism. The automatic aligning mechanism can carry out automatic aligning and deviation correcting on a to-be-detected touch screen conveyed to the part in front of the detecting position. The first transferring mechanism can convey the to-be-detected touch screen to the automatic aligning mechanism. The detecting mechanism can adjust the relative position of the to-be-detected touch screen and the detecting mechanism. The second transferring mechanism can convey the to-be-detected touch screen to the conveying mechanism from the automatic aligning mechanism. The third transferring mechanism can convey the detected touch screen to a defective product centralizing area or a discharging conveying mechanism. The touch screen can be automatically conveyed, aligned and detected, and the automatic detecting device has the advantages of being high in detecting efficiency, safe and convenient in detecting process and the like.

Owner:SUZHOU JINGLAI OPTO CO LTD

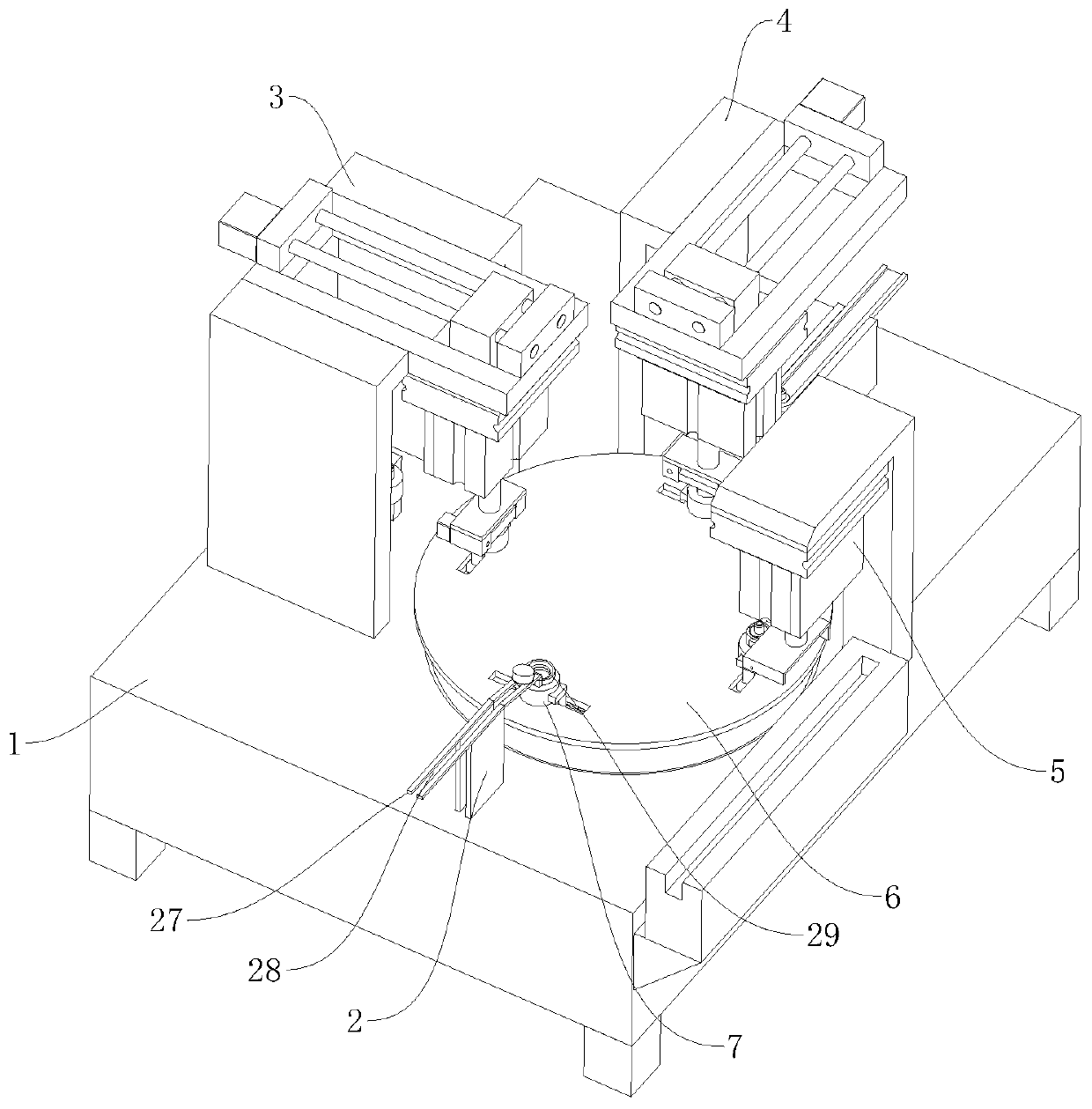

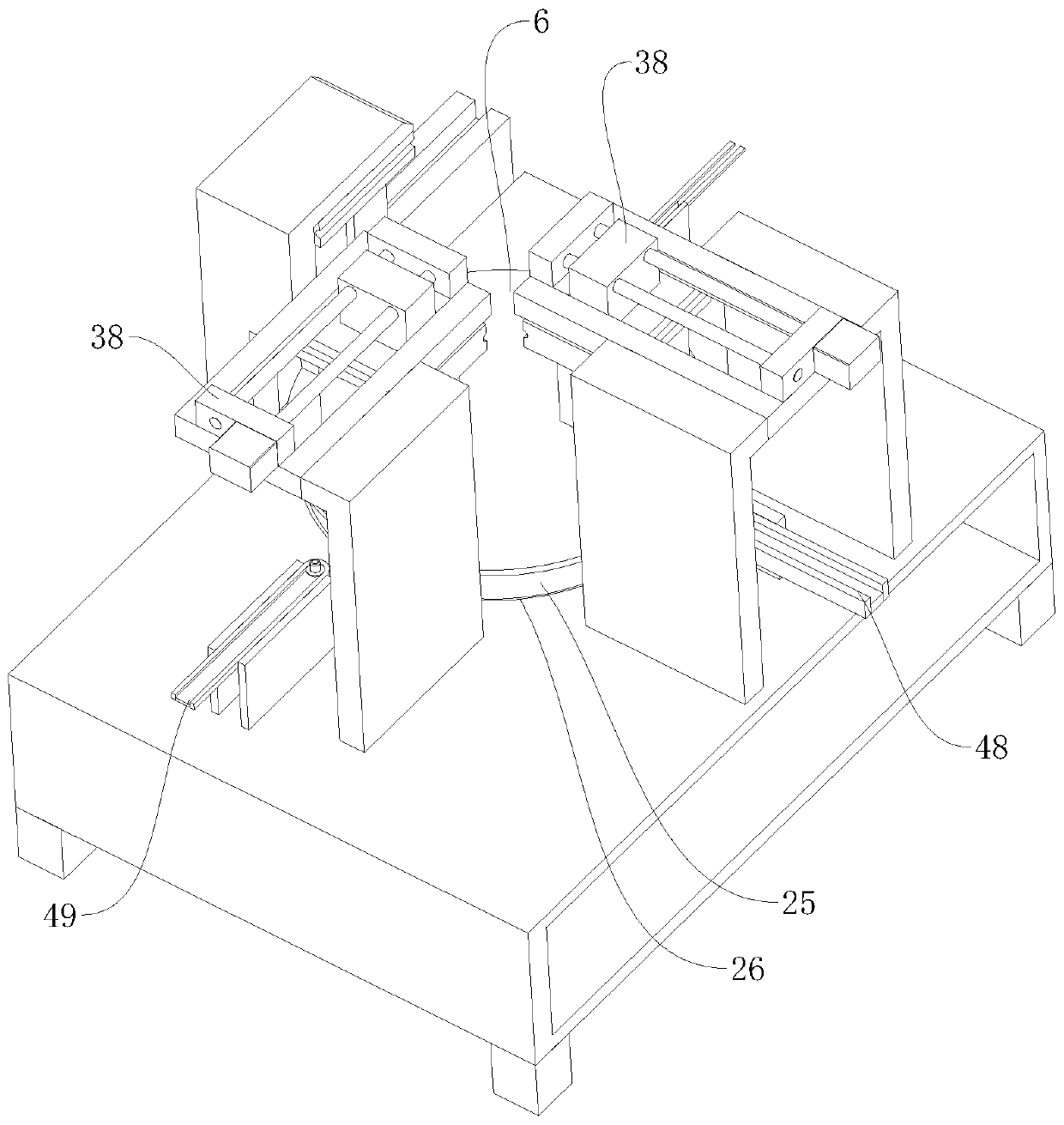

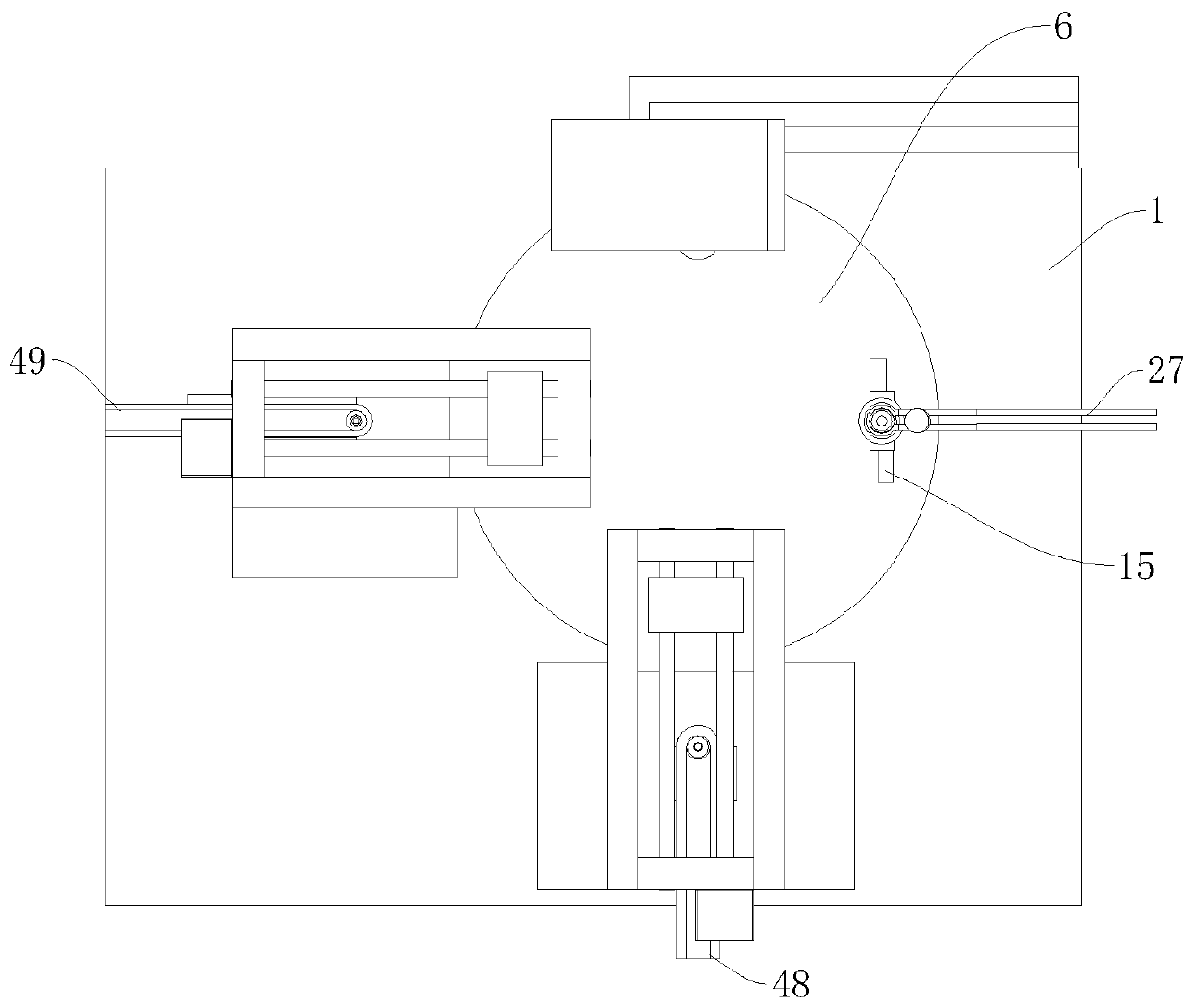

Assembling equipment for electronic cigarette atomization head

ActiveCN110181267APlay the role of orientationRealize automatic transferAssembly machinesTobaccoElectronic cigaretteRotating disc

The invention relates to the field of electronic cigarettes, in particular to assembling equipment for an electronic cigarette atomization head. The assembling equipment comprises a workbench and further comprises a rotary locating mechanism, a first procedure mechanism, a second procedure mechanism, a third procedure mechanism and a fourth procedure mechanism, wherein the rotary locating mechanism, the first procedure mechanism, the second procedure mechanism, the third procedure mechanism and the fourth procedure mechanism are mounted on the workbench. The rotary locating mechanism comprisesa carrying rotating disc and a rotary driving assembly. The carrying rotating disc is provided with four locating assemblies used for being in contact with a workpiece in an abutting manner. The first procedure mechanism comprises a first feeding assembly. The second procedure mechanism comprises a second feeding assembly, a first material shifting assembly and a first tool assembly. The third procedure mechanism comprises a third feeding assembly, a second material shifting assembly and a second tool assembly. The fourth procedure mechanism comprises a discharging track and a rotary discharging assembly. The discharging track is fixedly mounted at one side of the workbench through a support. The rotary discharging assembly is located above the discharging track. By means of the equipment, the electronic cigarette atomization head can be assembled automatically; and the equipment is simple in structure, and the efficiency is improved.

Owner:北京明博互通信息技术有限公司

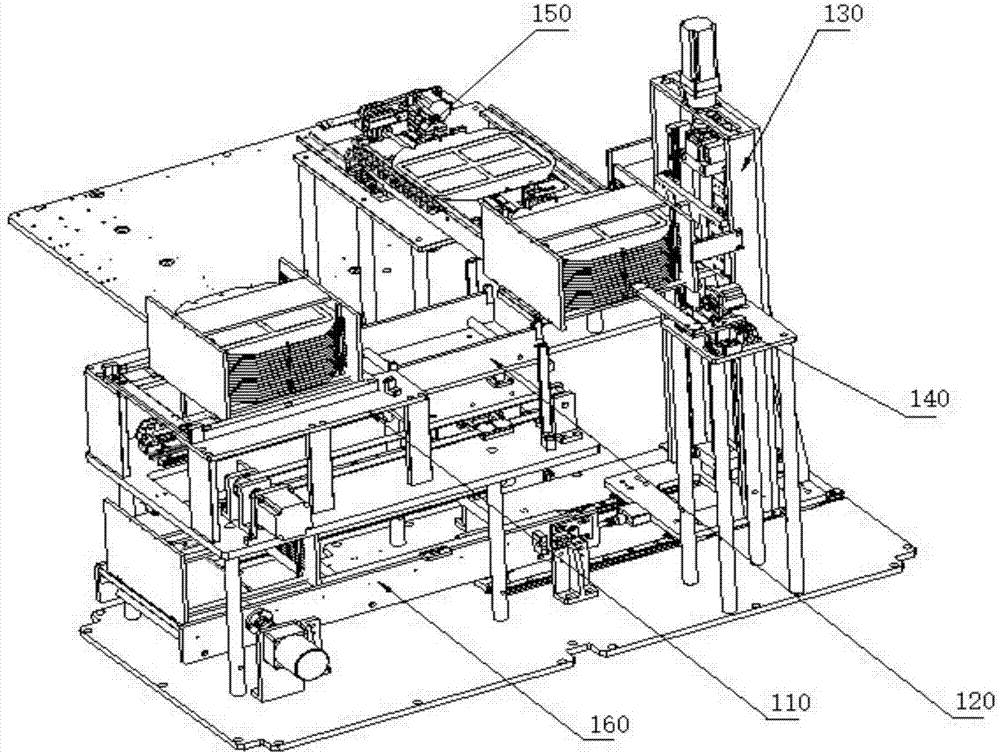

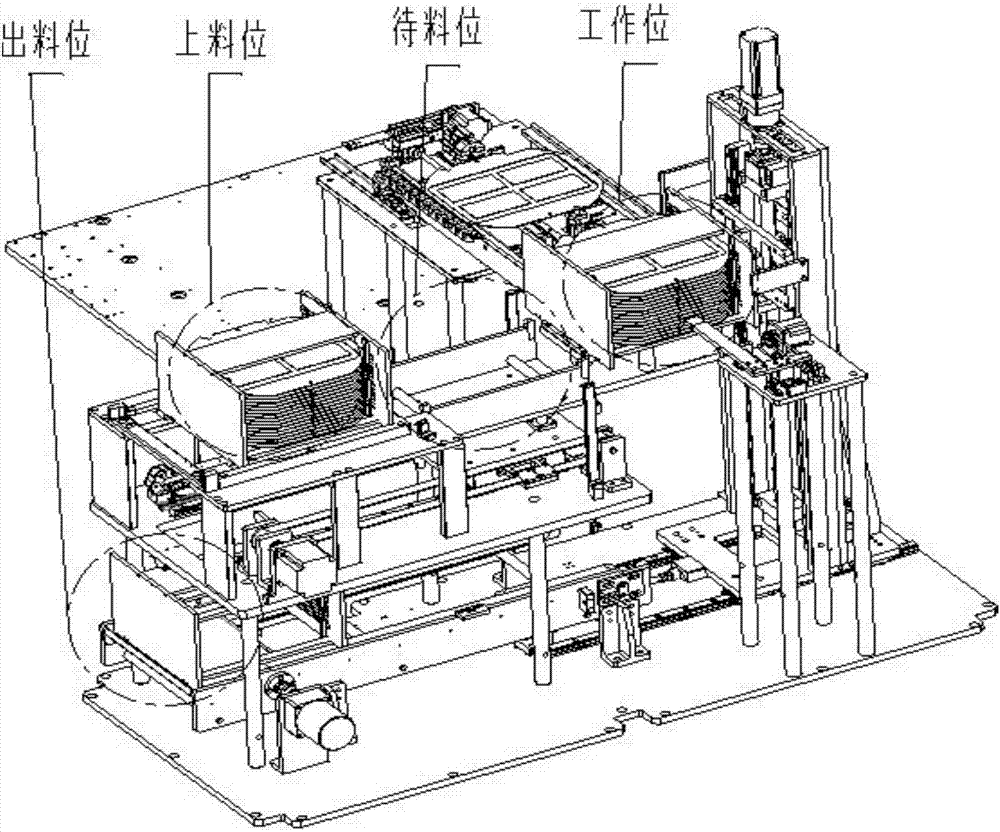

Automatic loading equipment of groove-type material box

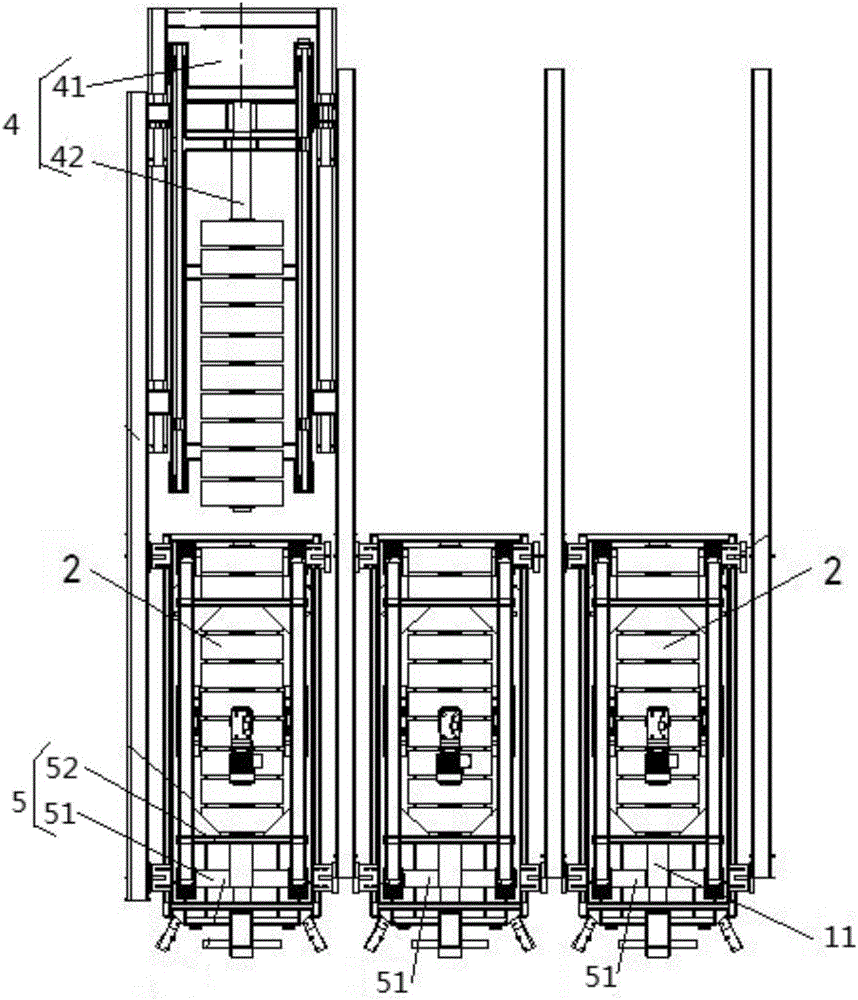

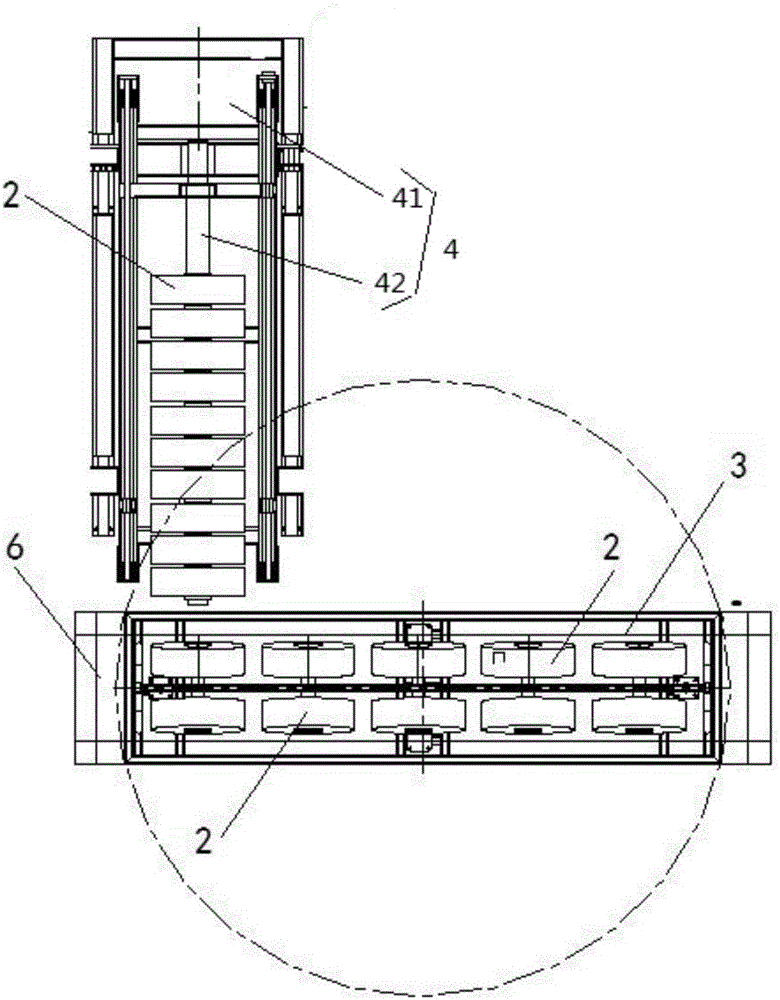

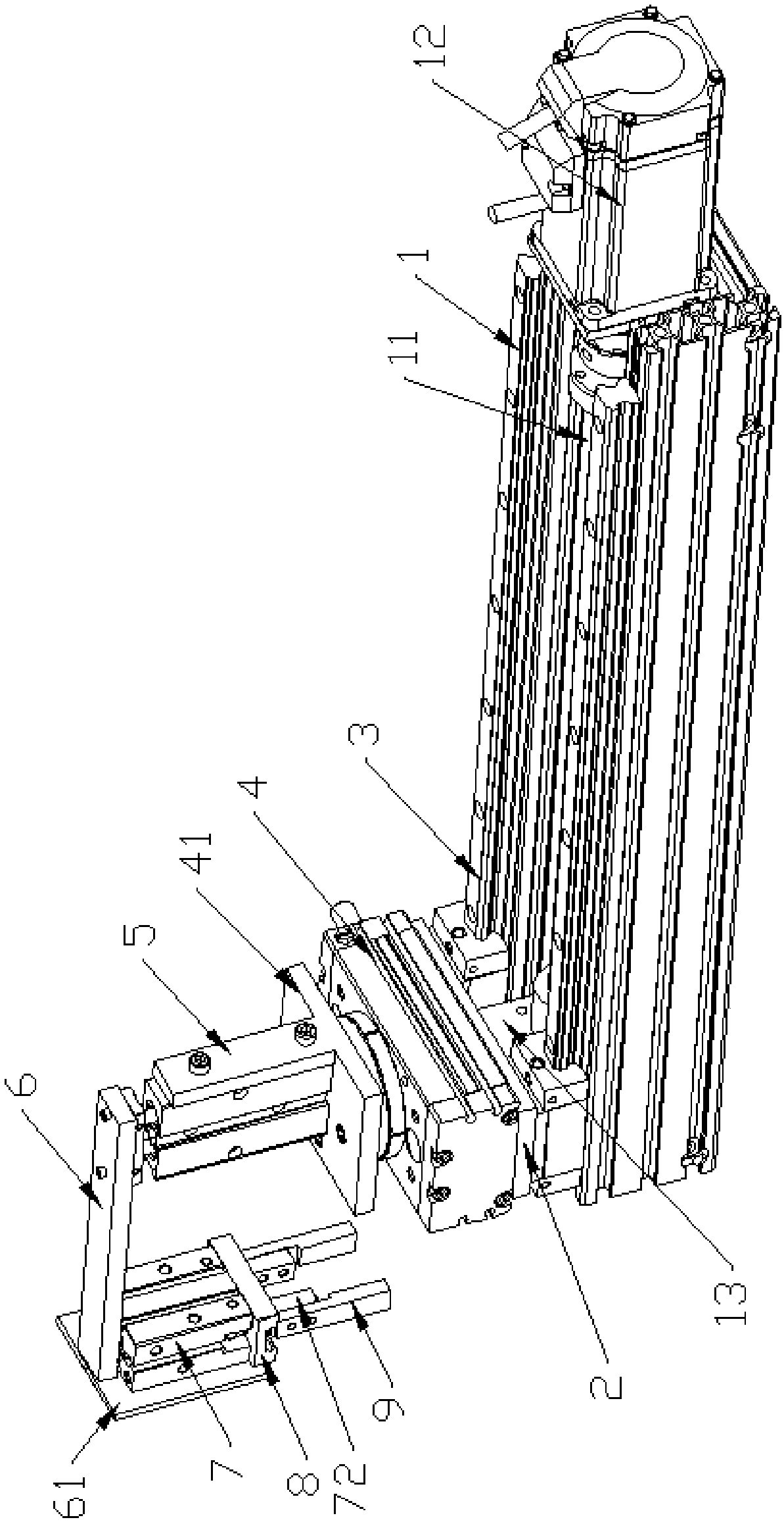

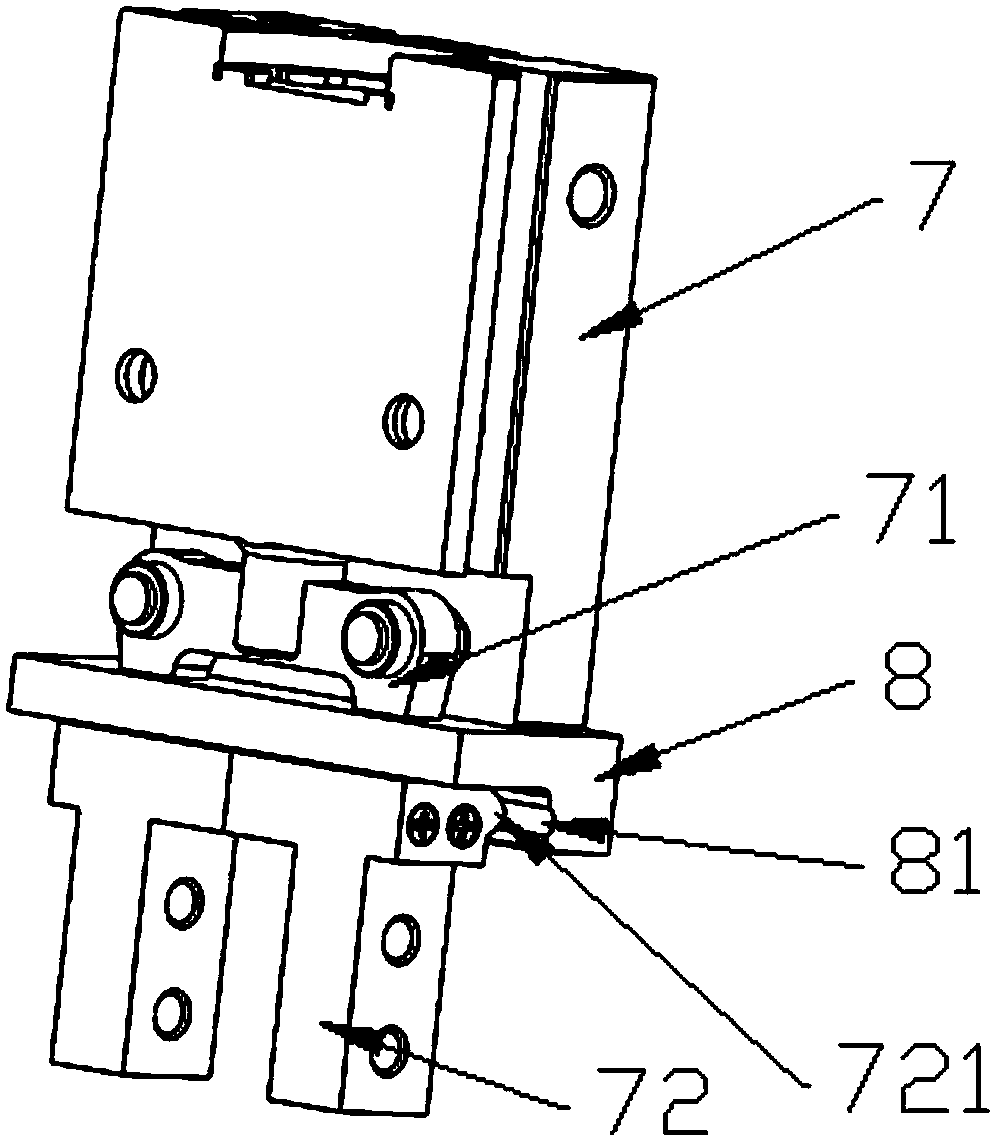

PendingCN106783677ARealize automatic transferRealize feedingSolid-state devicesSemiconductor/solid-state device manufacturingRecovery positionEngineering

The invention provides automatic loading equipment of a groove-type material box. The automatic loading equipment comprises the groove-type material box, a loading positioning mechanism, a transport mechanism, a loading / unloading grabbing mechanism, an ejection mechanism, a discharging mechanism and a recovery transmission mechanism, wherein a loading position is arranged on the loading position mechanism, the groove-type material box is arranged on the loading position, the transport mechanism is arranged below the loading positioning mechanism, the groove-type material box is transported to a position to be waited from the loading position by the transport mechanism, the loading / unloading grabbing mechanism can be used for transporting the groove-type material box to a working position from the position to be waited, the ejection mechanism can be used for pulling insertion pieces in the groove-type material box out of the working position one by one, the discharging mechanism can be used for transporting the insertion pieces pulled out of the groove-type material box to a discharging position one by one, and the recovery transmission mechanism is used for transmitting the unloaded groove-type material box to a recovery position. With the adoption of the automatic loading equipment, the groove-type material box can be automatically transported and loaded, the insertion pieces (such as UV film disc) in the groove-type material box are automatically discharged, the unloaded groove-type material box is automatically recovered and transmitted out, labor is saved, and moreover, the product quality is ensured.

Owner:江门格兰达物联装备有限公司

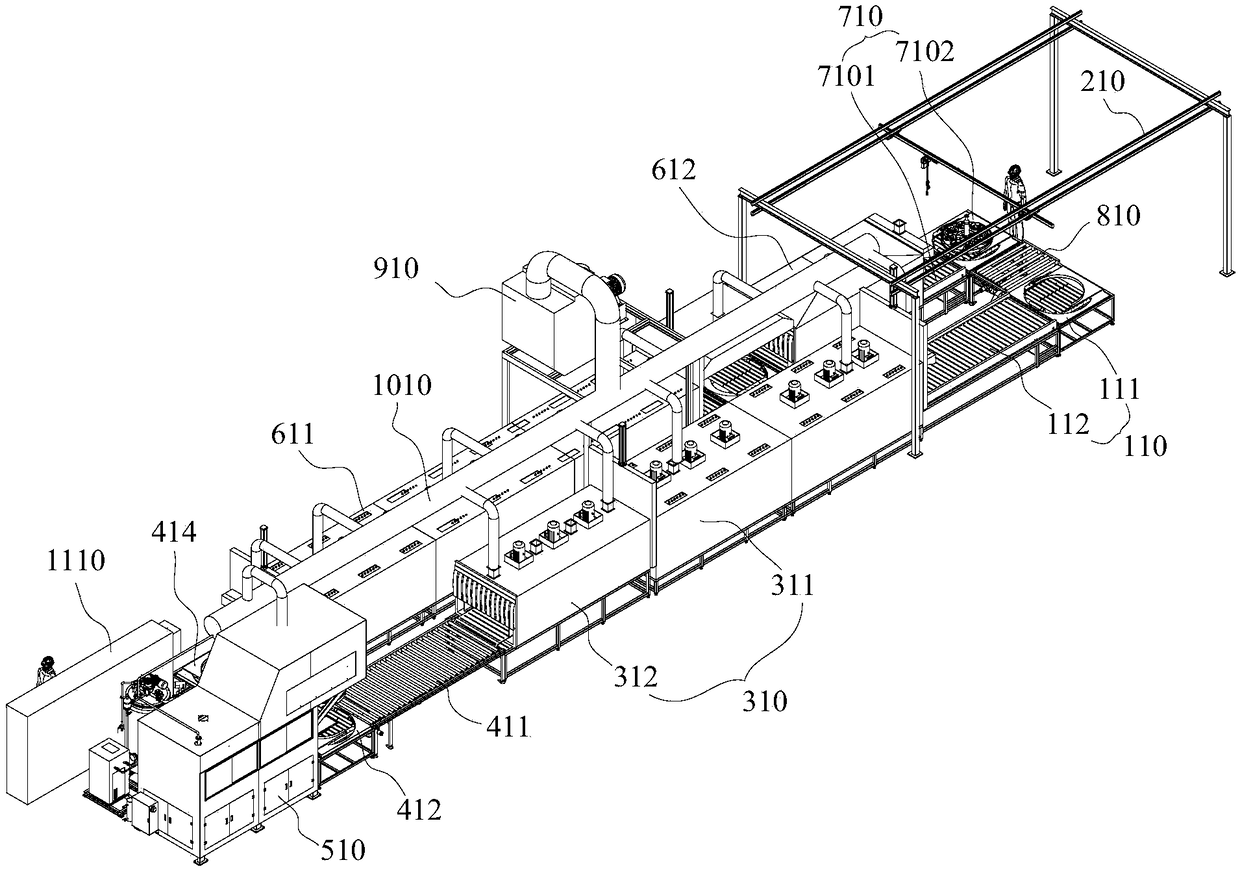

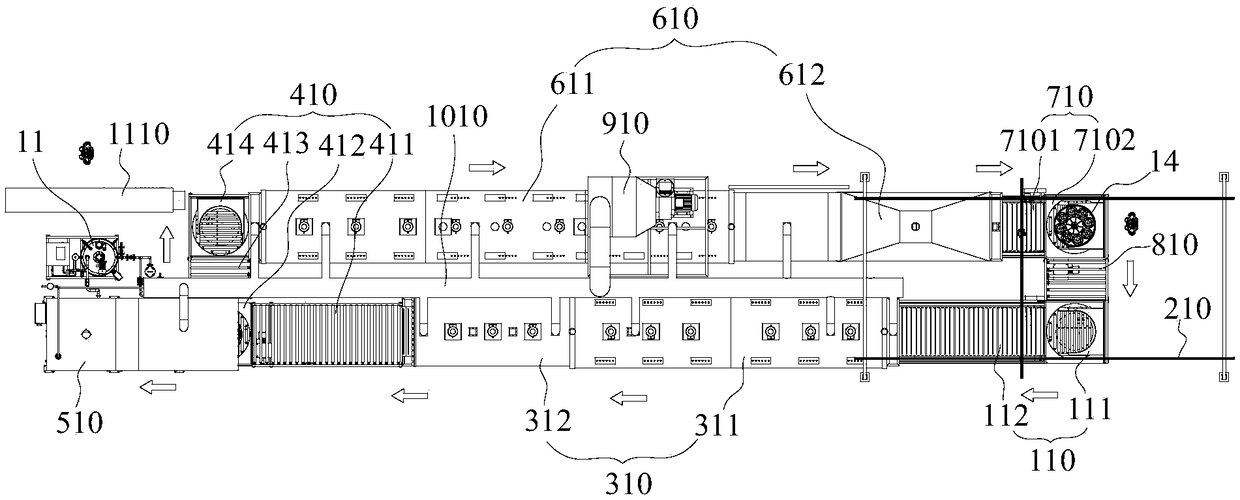

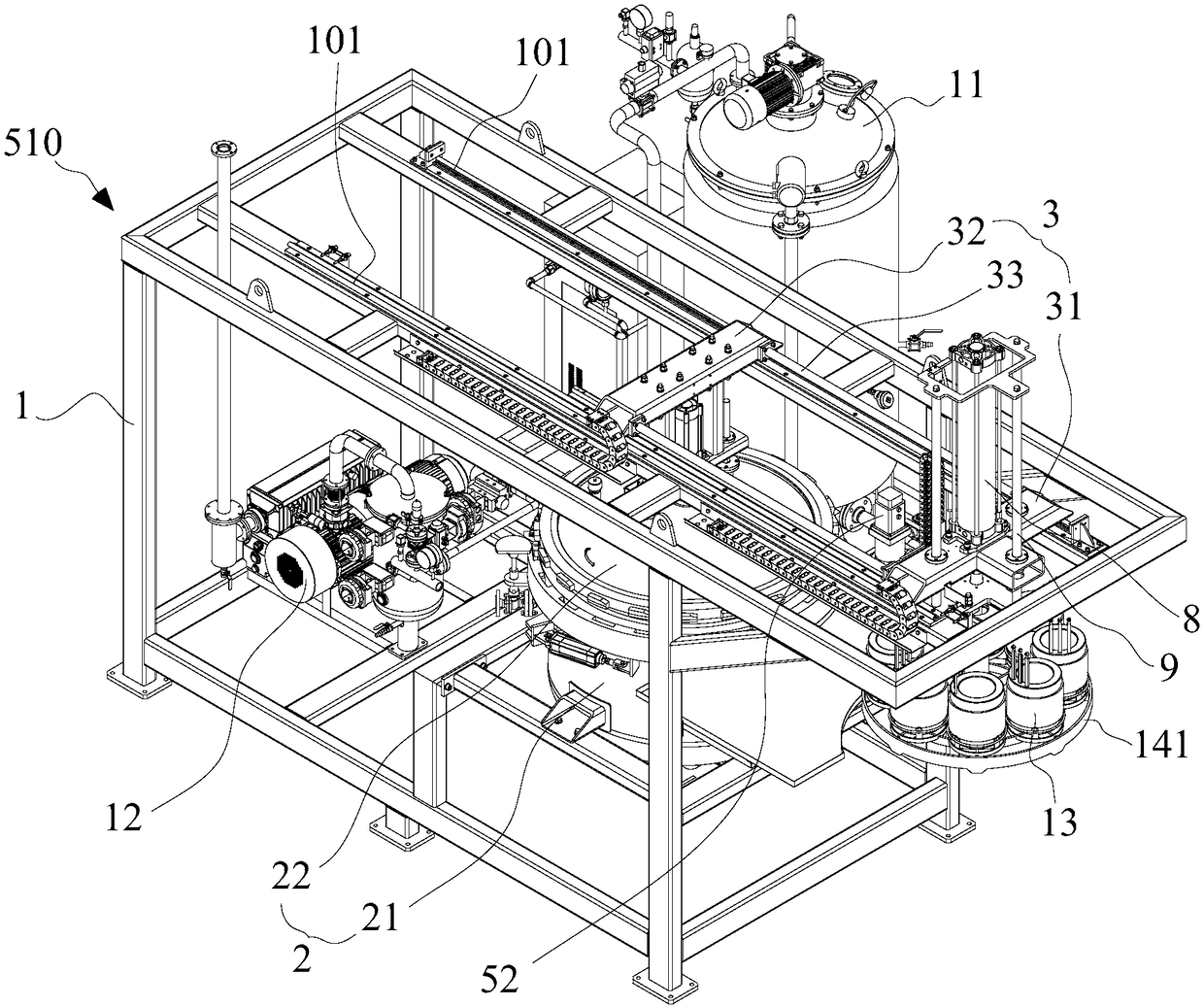

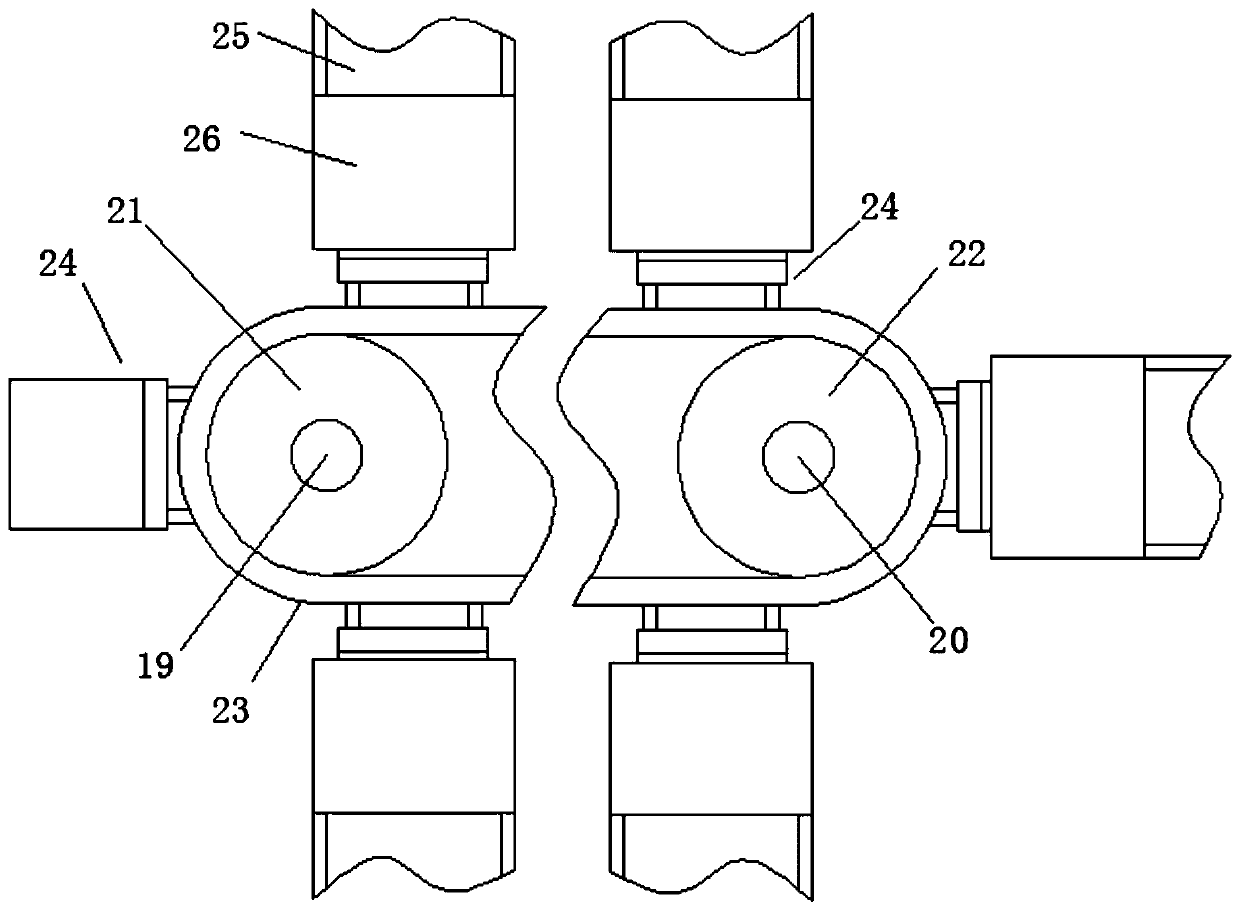

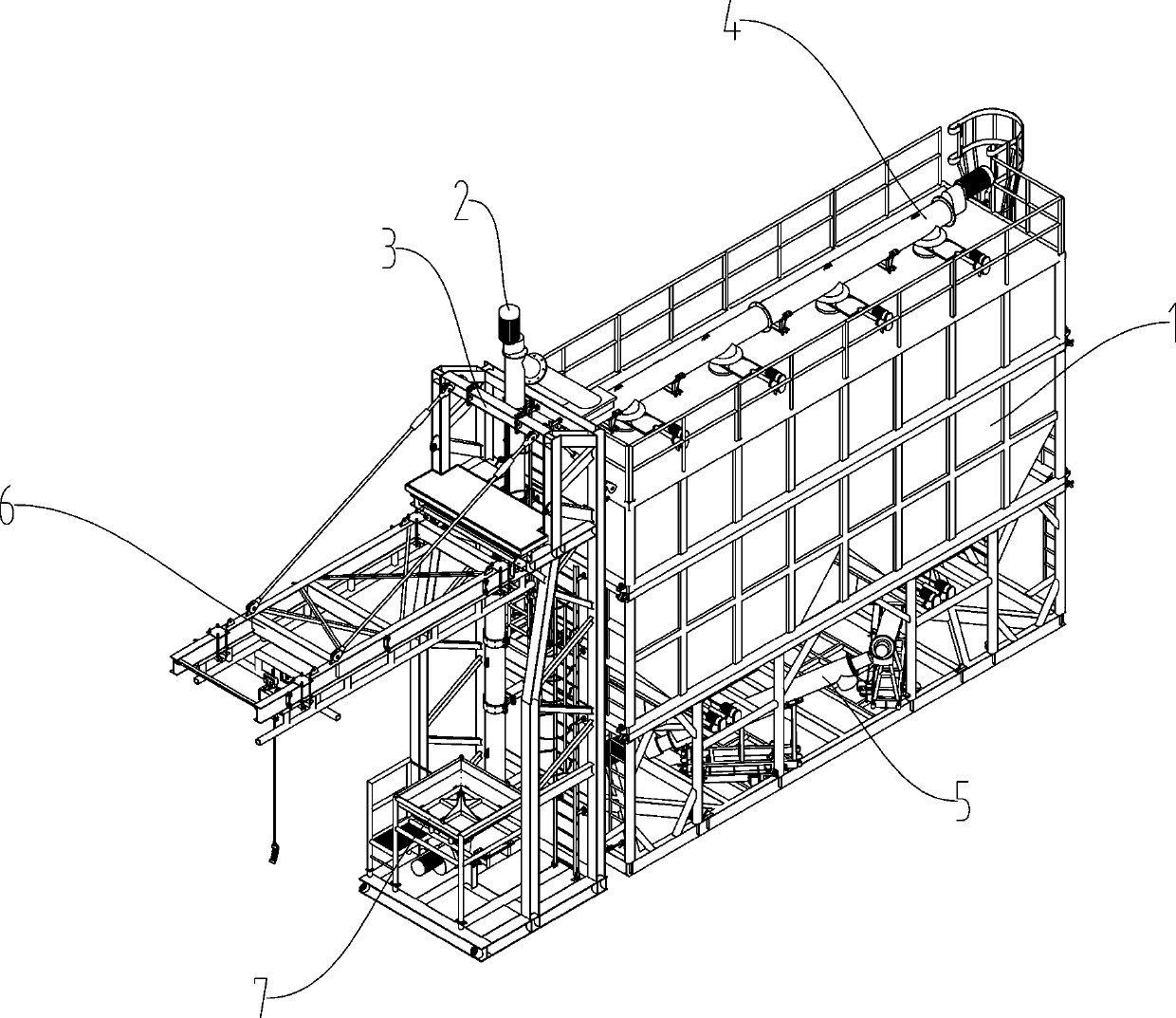

Continuous vacuum dip-painting production line

PendingCN108321997ARealize automatic transferAvoid manual handlingLiquid surface applicatorsManufacturing dynamo-electric machinesProduction lineLacquer

The invention discloses a continuous vacuum dip-painting production line. The continuous vacuum dip-painting production line comprises a crane device, a vacuum dip-coating system as well as a first conveying device, a preheating heat insulation device, a second conveying device, a cured cooling device and a third conveying device which are sequentially connected, wherein the preheating heat insulation device and the cured cooling device are arranged in parallel; the crane device is used for loading a stator on the first conveying device and unloading a stator of a hanging basket on the third conveying device; the vacuum dip-coating system is arranged on one side of the second conveying device and used for hoisting away the hanging basket on the second conveying device and putting the hanging basket subjected to dip-coating treatment back to the second conveying device.

Owner:ZHONGSHAN KAIXUAN VACUUM SCI & TECH CO LTD

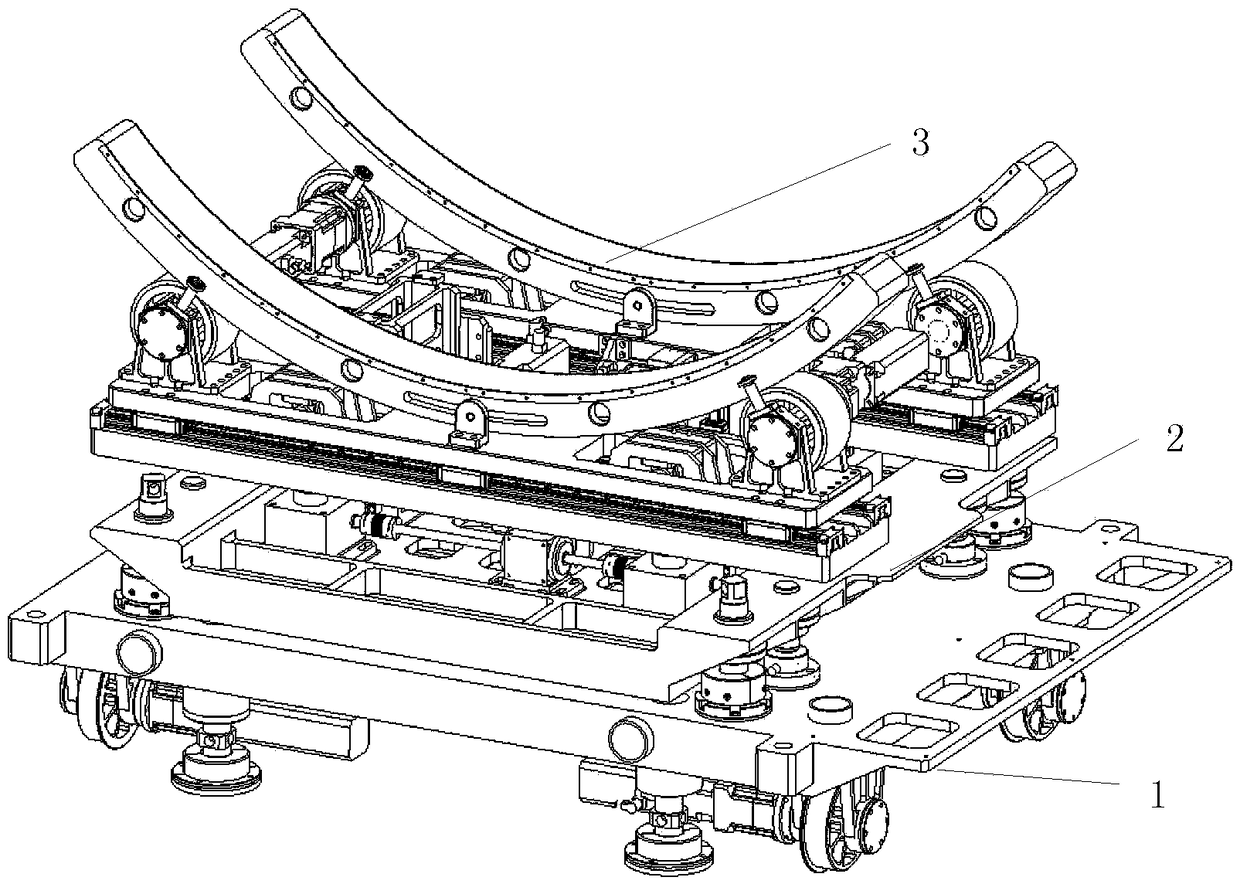

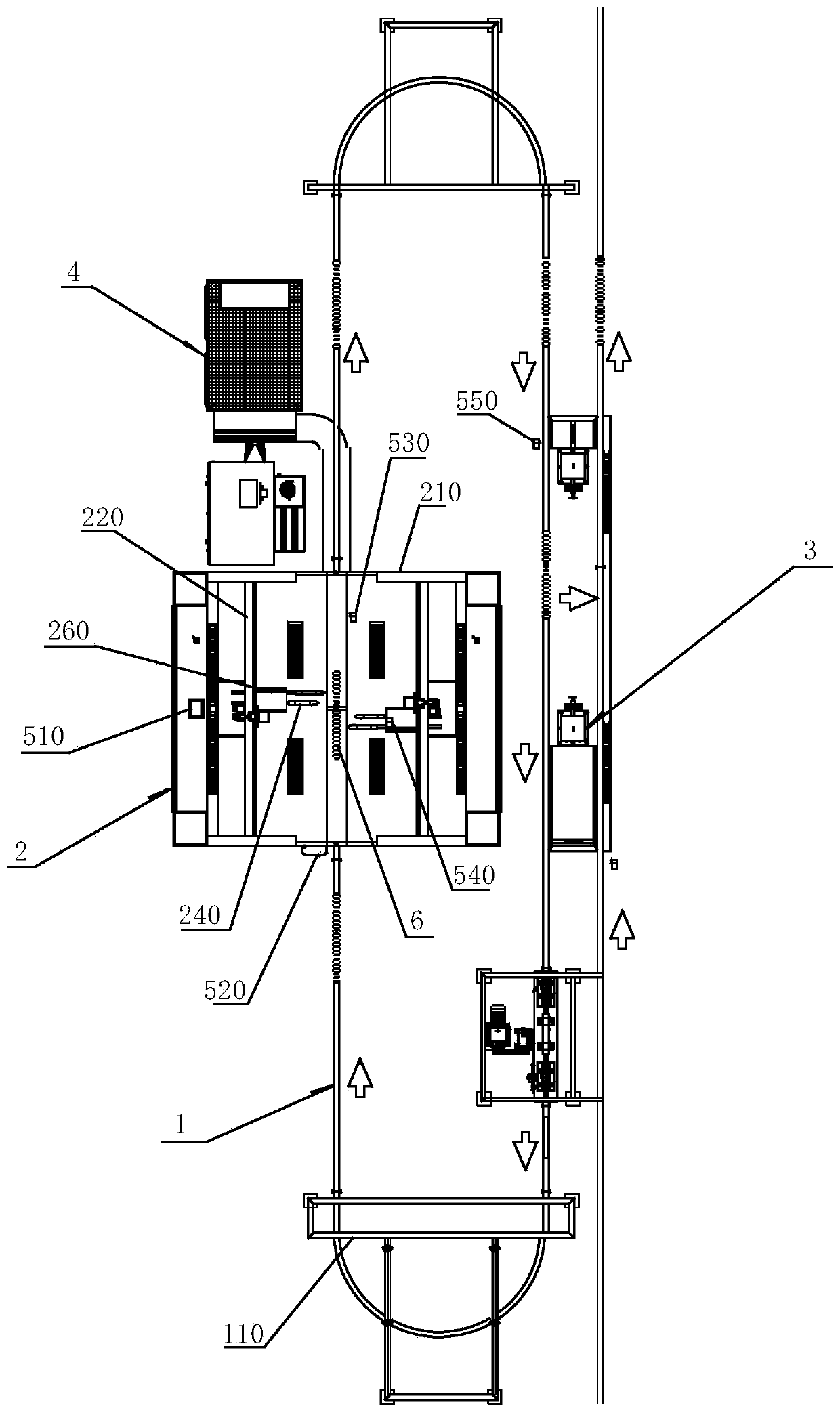

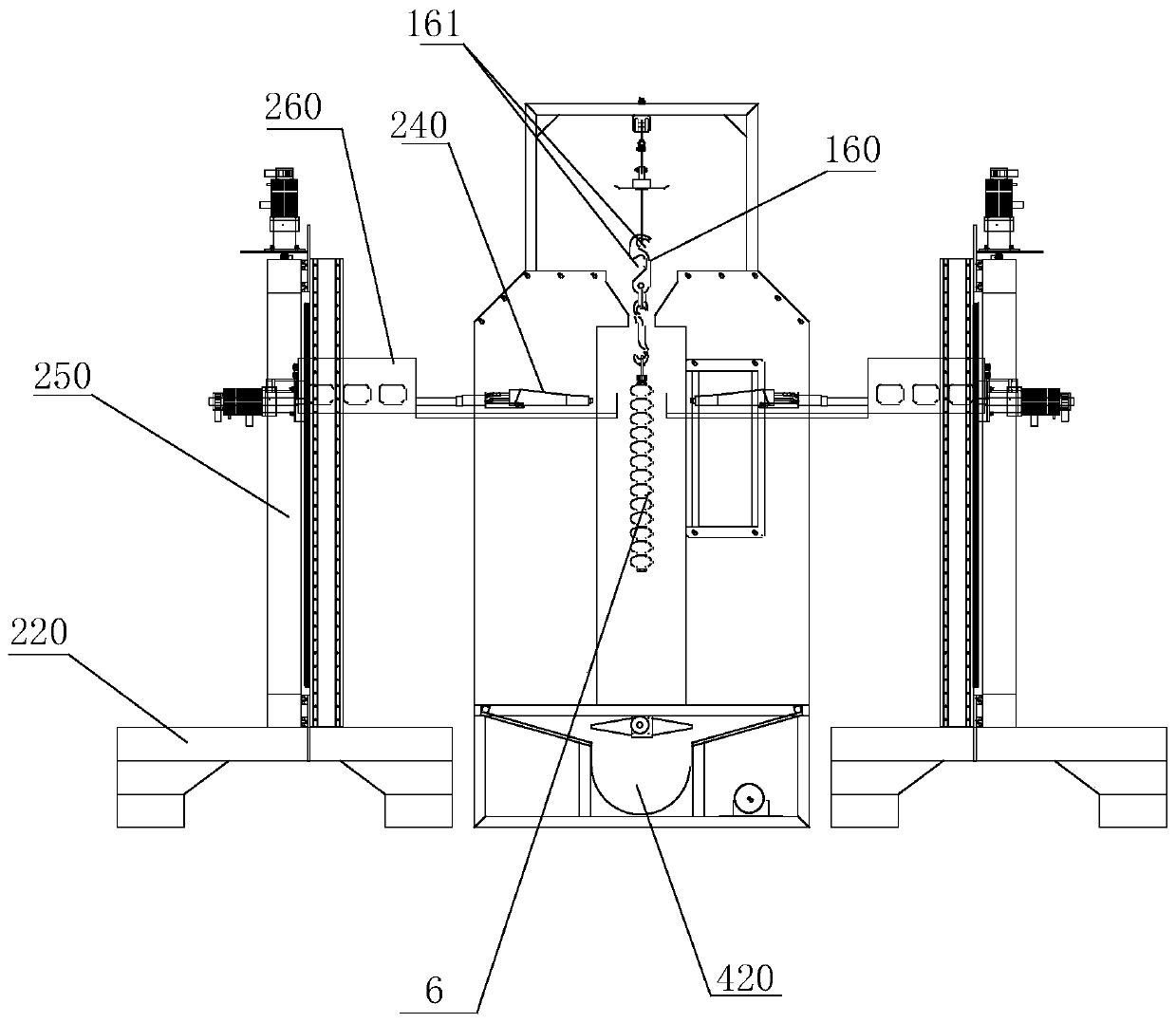

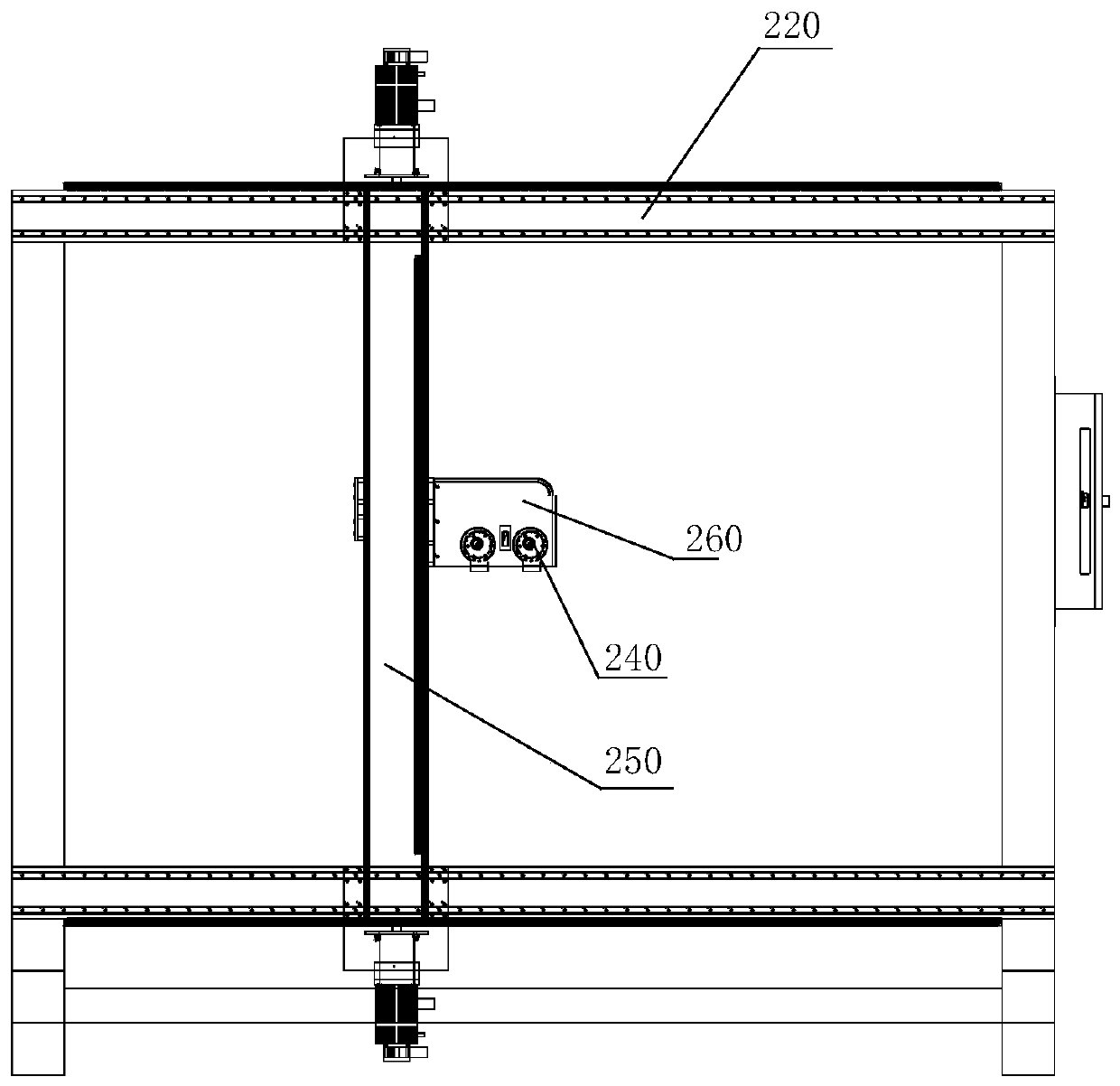

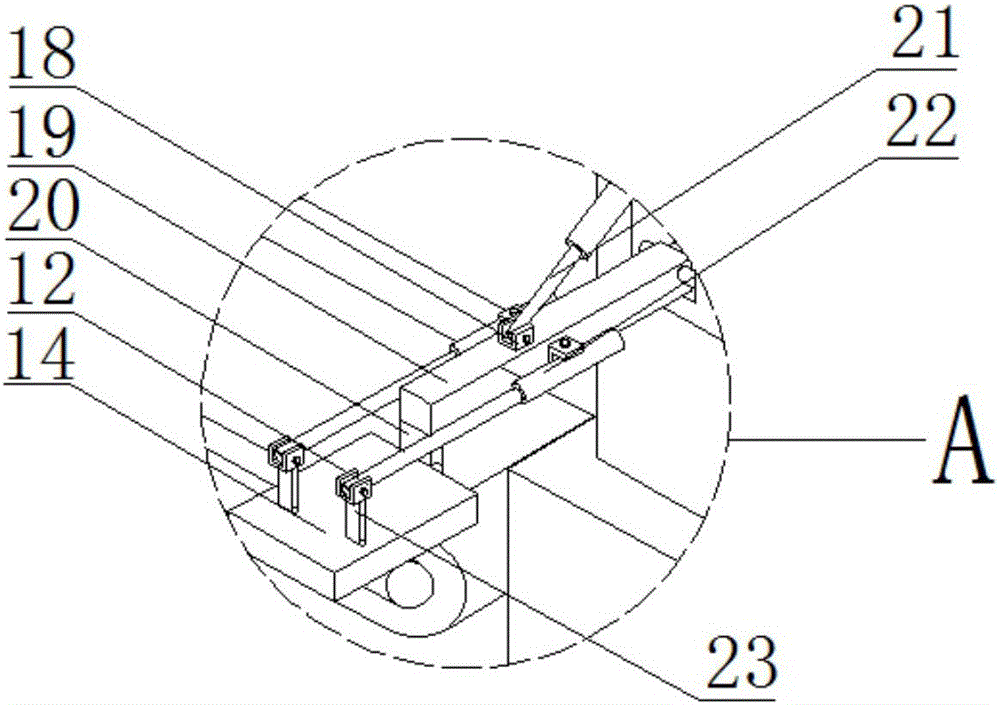

On-line quality and mass center measurement platform for assembly butt-joint scene

InactiveCN109489901ARealize automatic transferAutomated attitude adjustmentStatic/dynamic balance measurementEngineeringMass center

The invention discloses an on-line quality and mass center measurement platform for an assembly butt-joint scene. The on-line quality and mass center measurement platform comprises a chassis assembly,a quality and mass center measurement assembly and a posture adjusting assembly; the posture adjusting assembly is installed on the quality and mass center measurement assembly, and the quality and mass center measurement assembly is installed on a chassis. Through the on-line quality and mass center measurement platform, portions can be automatically transferred in a factory, and meanwhile automatic posture adjustment can be realized with high precision for horizontal movement, lifting, pitching, yawing and rolling of the portions, and at any station, the quality, an axial mass center and aradial mass center are measured without assembling and disassembling supporting portions of the portions.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

Heating radiator spraying production line

PendingCN110420788ARealize automatic transferStable sprayingPretreated surfacesCoatingsProduction lineDrive shaft

The invention belongs to the technical field of heat radiator electrostatic powder spraying, and particularly relates to a heating radiator spraying production line. The heating radiator spraying production line comprises a suspension chain conveyor, a spraying device and a rotary hanging device. The spraying device comprises spraying guns which are oppositely arranged, the positions of the spraying guns can be adjusted up and down, front and back and left and right, and the spraying device can rotate. The rotary hanging device comprises a rotary hanging base, and a walking support driven by asynchronous walking driving mechanism is slidably arranged on the rotary hanging base. Two oppositely arranged synchronous rocker arms driven by a rotary hanging mechanism are rotationally mounted onthe walking support. Rotary hanging parts are arranged on the synchronous rocker arms. According to the heating radiator spraying production line, spraying can be automatically controlled to replacemanual spraying, and spraying is stable; the production efficiency and the spraying precision can be improved, and automatic workpiece rotary hanging operation is achieved; and manpower is saved, andthe production efficiency is improved.

Owner:临朐浩伟电子设备有限公司

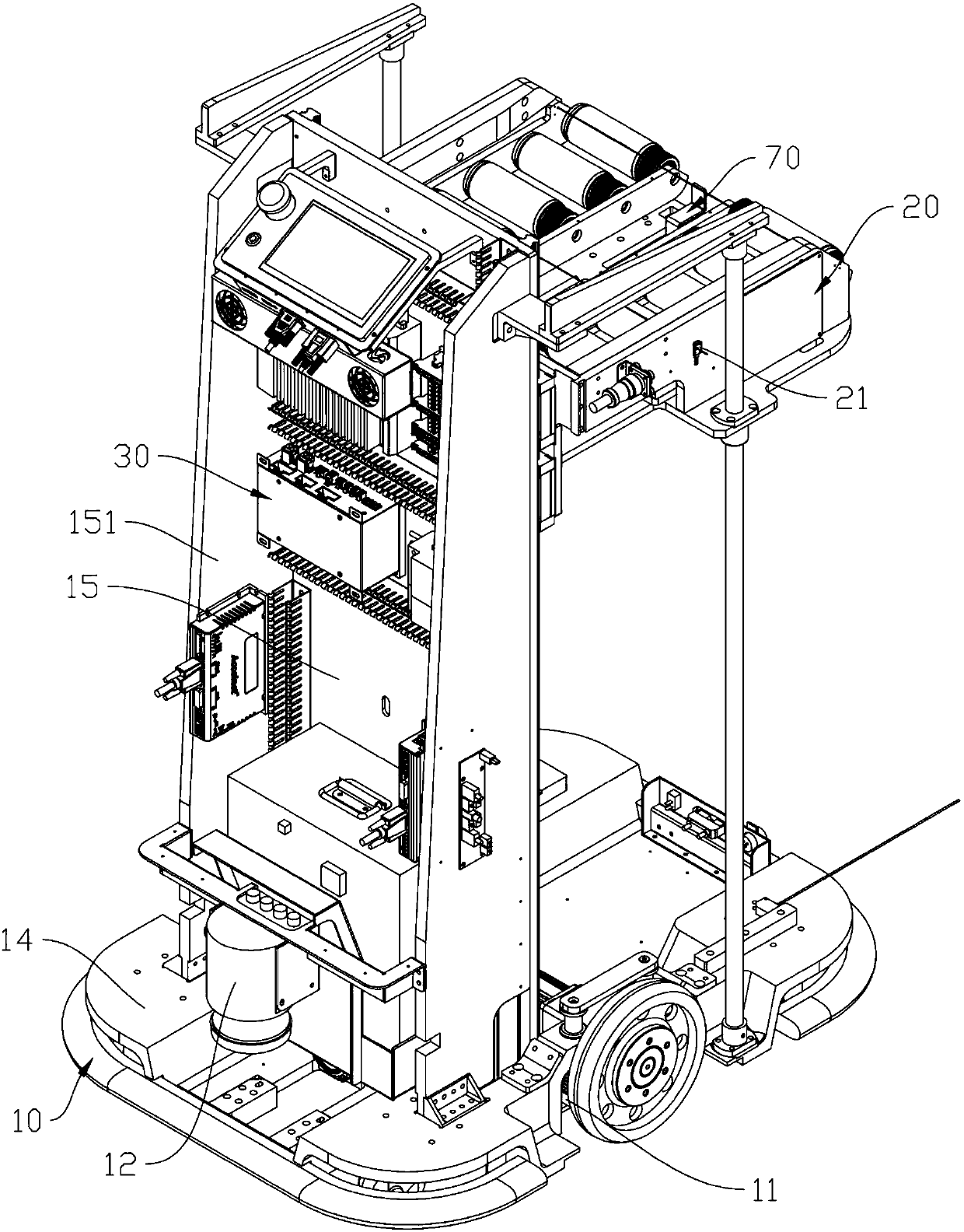

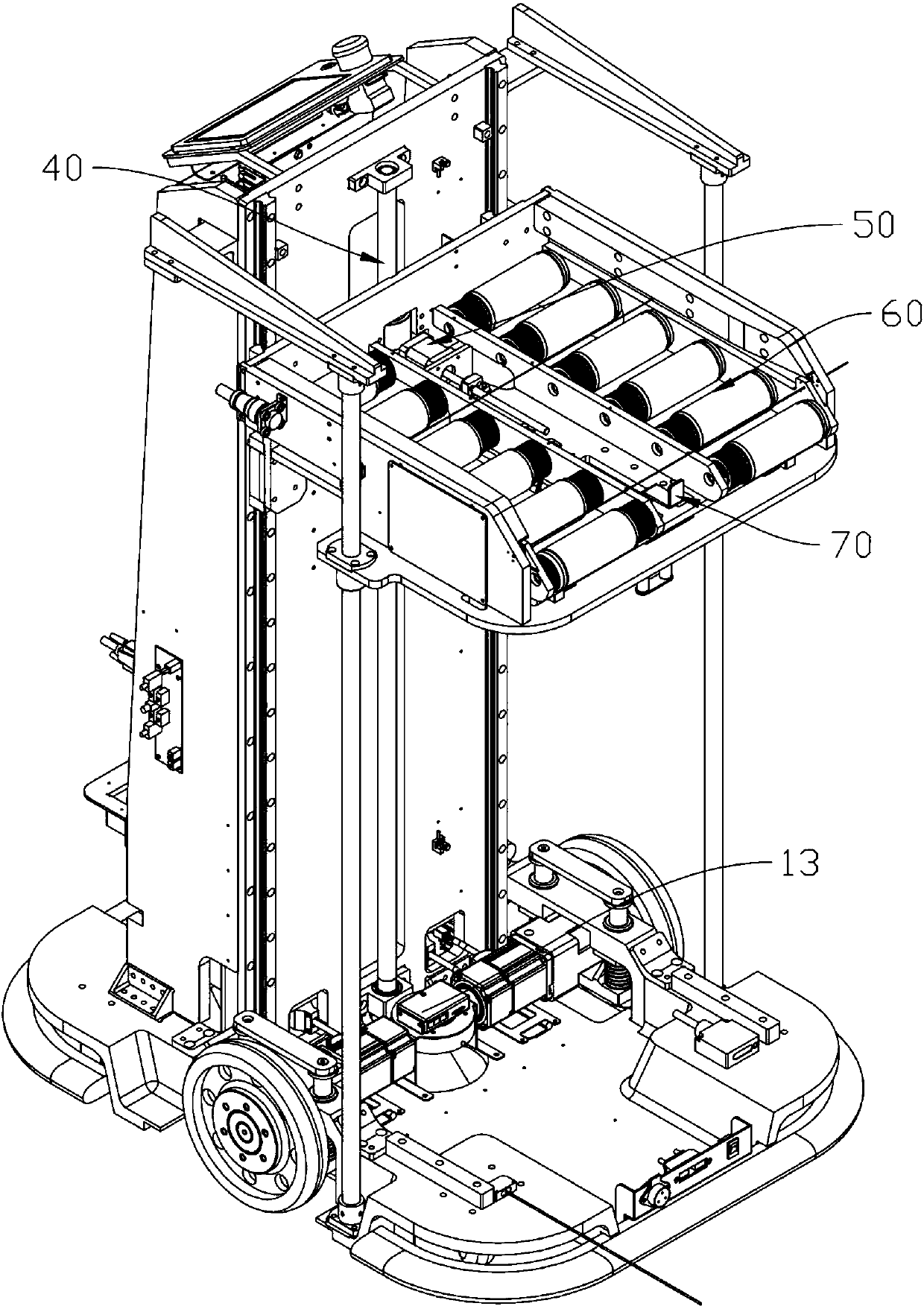

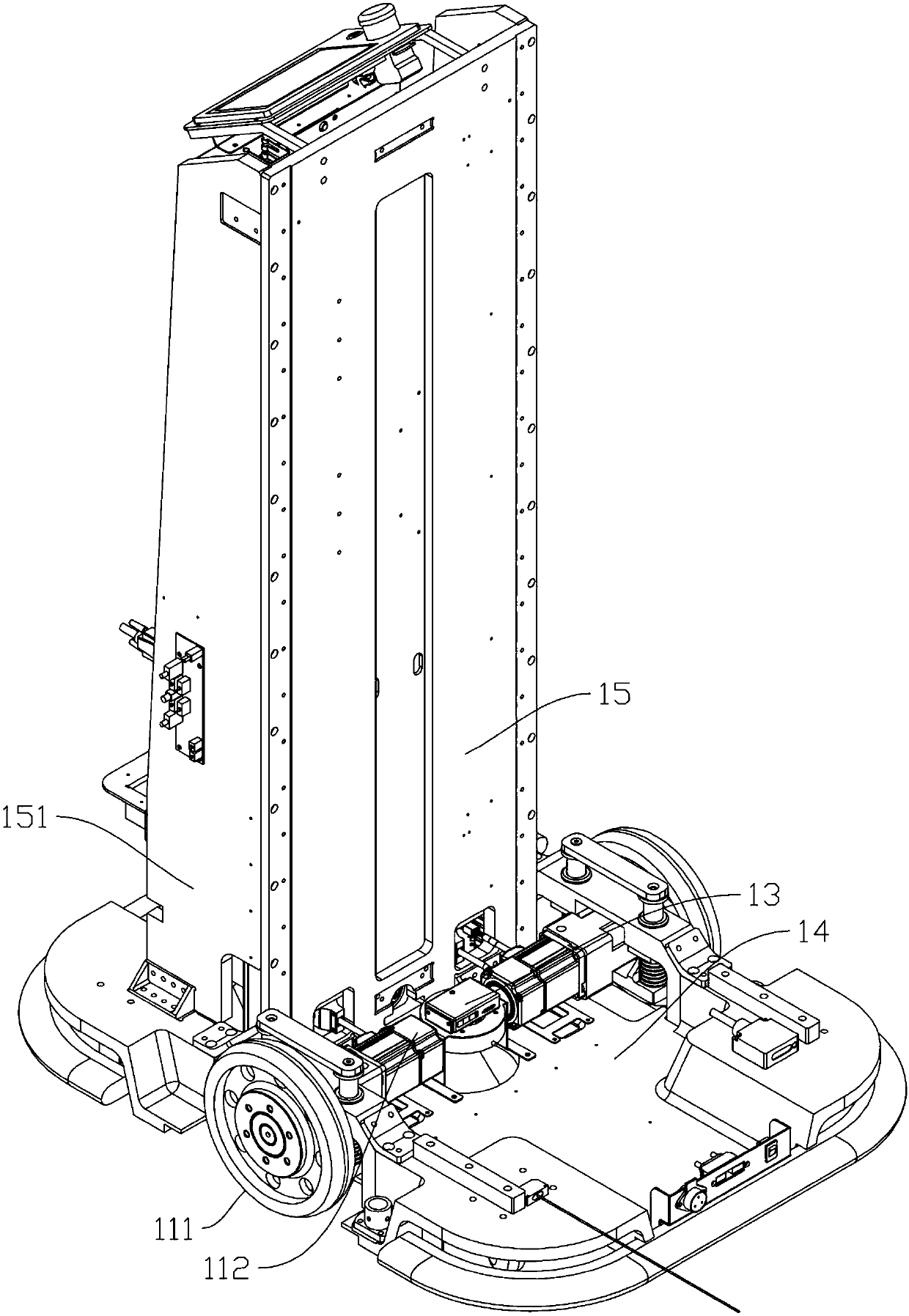

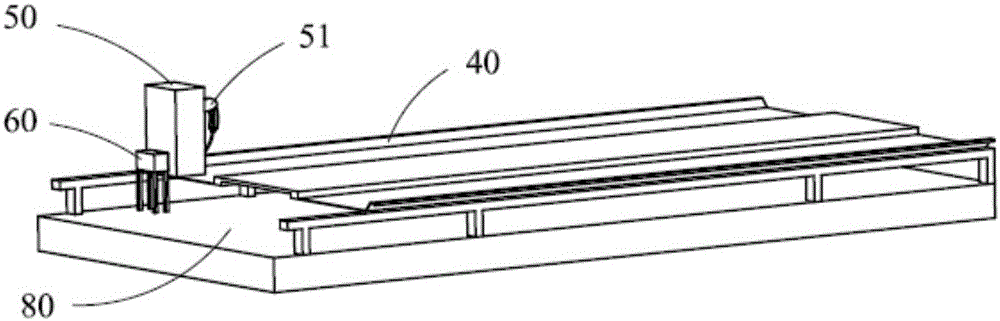

Workbin handling AGV, handling method and automatic docking system for SMT production line

PendingCN107813882ACompact sizeCompact bodyElectric/hybrid propulsionTotal factory controlEngineeringProduction line

The invention discloses a workbin handling AGV, a handing method and an automatic docking system for an SMT production line, comprising a vehicle body, a workbin loading and unloading device arrangedon the vehicle body and a control center. The control center is used for controlling the workbin loading and unloading device to perform corresponding actions. The workbin loading and unloading deviceis arranged on the rear part of the vehicle body, the workbin loading and unloading device comprises a workbin transportation mechanism used for receiving and transporting a workbin, the workbin receiving and transporting direction of the workbin of the workbin transportation mechanism is parallel to the moving direction of the vehicle body. The SMT workbin automatic handling machine has the advantages of being quick, accurate and high-efficient, manpower can completely be replaced, and a smart factory is perfectly suited.

Owner:NANJIANG ROBOT

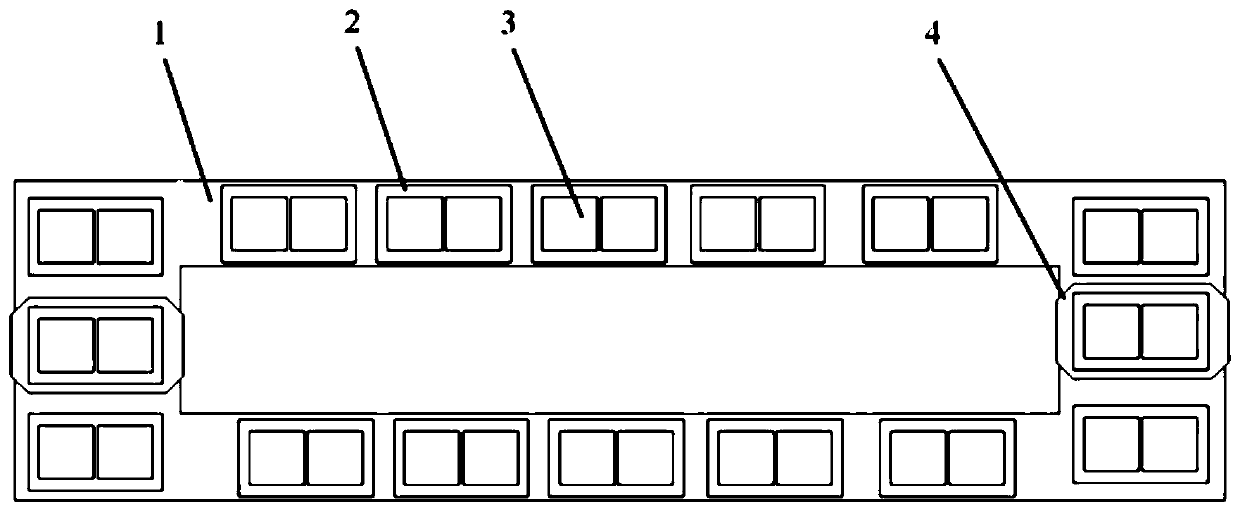

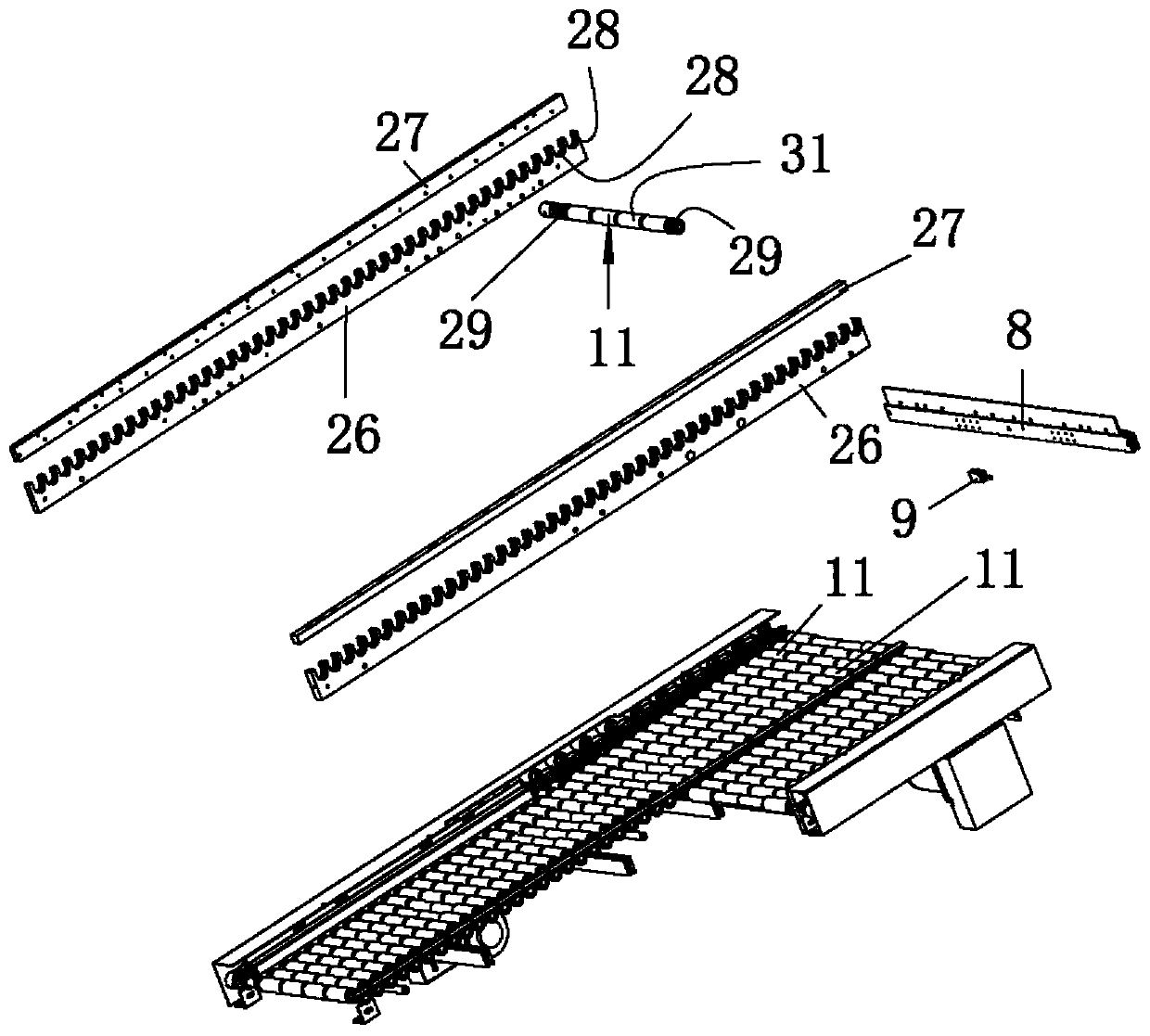

Buffer storing and conveying system and method

ActiveCN110641971ARealize automatic transferWith temporary cache functionConveyor partsComputer hardwareProcess engineering

The invention discloses a buffer storing and conveying system and method and belongs to the technical field of equipment manufacturing. The buffer storing and conveying system operates to transfer multiple types of parts between the working procedures under the condition of mixed line production and also has the temporary buffer storing function. The buffer storing and conveying system comprises trays, locating tools, fixing working positions and a control module. The locating tools are placed on the trays. The trays are provided with chips. The locating tools can meet the requirement for temporary storing of multiple types of parts. Different tools are compatible with different types of parts. The same kind of parts is placed on the same type of tools. The locating tools include the locating tools A and the locating tools B. Each fixing working position is provided with a reading and writing head which can read chip information and write information into the chips. The read and write-in information includes the information of the locating tools on the trays are idle or not and identity information of the parts on the locating tools. The method comprises two kinds of control contents, namely, the stepping mode and the quick position selection mode. The buffer storing and conveying system operates to automatically transfer products between the working procedures under the condition of mixed line automatic production and also has the temporary buffer storing function. The upstream and downstream working procedures are effectively connected, and the transfer mode is independently selected and judged. the buffer storing and conveying system and method have the characteristics of high flexibility and high automation control degree.

Owner:内蒙古第一机械集团股份有限公司

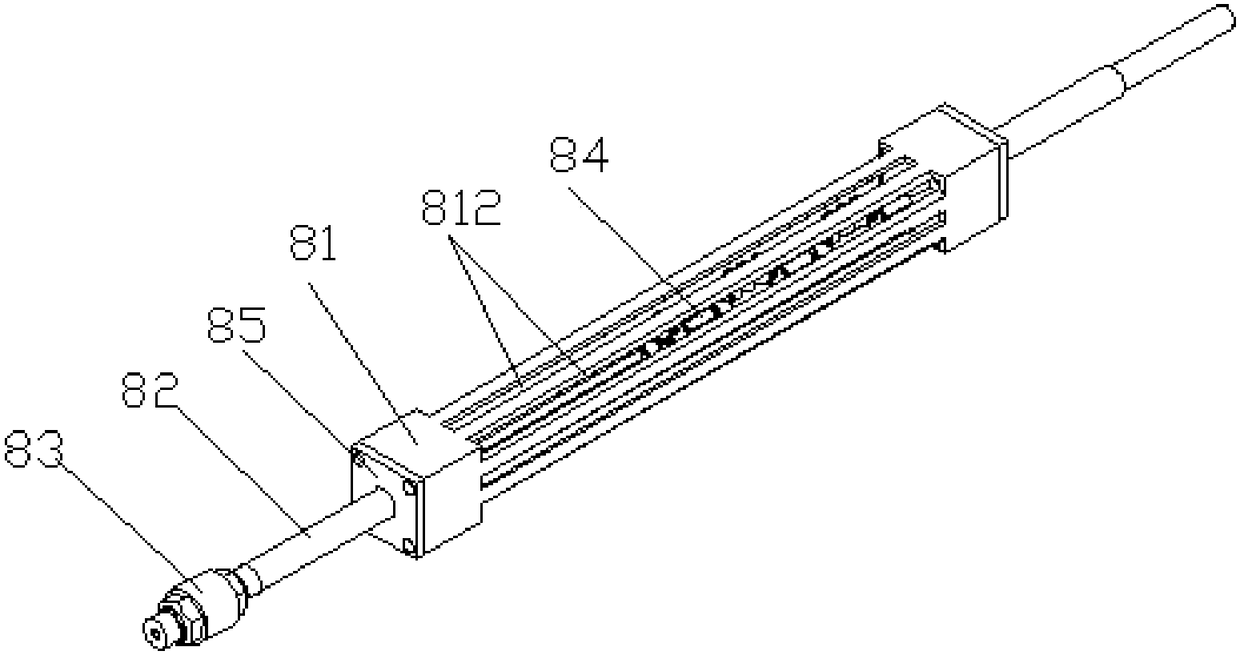

Truck loading equipment for spinning cakes

ActiveCN105905683ARealize automatic transferReduce labor intensityFilament handlingMechanical conveyorsTruckPush out

The invention provides truck loading equipment for spinning cakes, and relates to automatic truck loading equipment. The truck loading equipment comprises a wire falling truck, an assembly device and a truck loading machine, wherein one end of a first shaft body is fixed on the wire falling truck, and the other end of the first shaft body is opposite to one end of the first shaft body and suspended; multiple spinning cakes can annularly coat the outer wall of the first shaft body from the other end of the first shaft body; the assembly device is used for driving the wire falling truck to lift and pushing out the multiple spinning cakes put on the wire falling truck; the truck loading machine is used for assembling the multiple spinning cakes pushed out by the assembly device thereon; and a wire frame truck is used for hanging the spinning cakes. On the one hand, the equipment is fewer in number of automatic transfer parts, and reduces the equipment cost; and on the other hand, the equipment provides a completely different solution.

Owner:ZHEJIANG FIELD INTELLIGENT EQUIP CO LTD

Component transfer tool

PendingCN108032279ARealize automatic transferImprove positionProgramme-controlled manipulatorGripping headsDrive motorForce output

The invention provides a component transfer tool, and belongs to the field of component processing equipment. The component transfer tool comprises a base, a movable seat, a rotary cylinder and a lifting cylinder. A mounting groove is formed in the middle of the base, a lead screw is erected in the mounting groove, the axis of the lead screw is parallel to the longitudinal center line of the base,a driving motor is arranged at an end of the base, a force output shaft of the driving motor is fixedly connected with an end of the lead screw, and a nut is fittingly arranged on the lead screw andis fixedly connected with the movable seat by a connecting plate which is vertically arranged. The component transfer tool has the advantages that components at different locations can be quickly transferred by the component transfer tool, and the component transfer tool is high in precision and efficiency.

Owner:TIANJIN KAIDA HEAVY HYDROPOWER EQUIP MFG

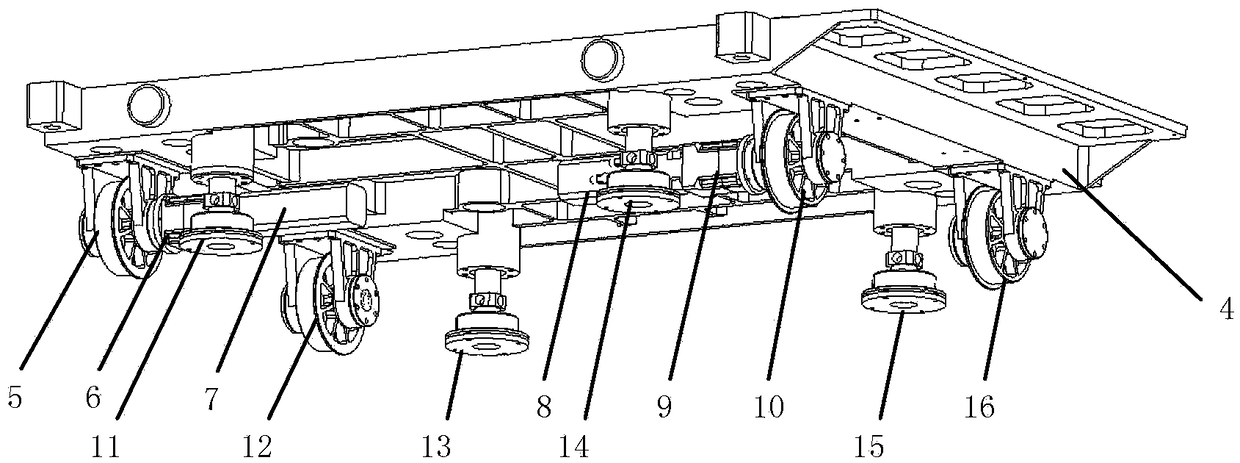

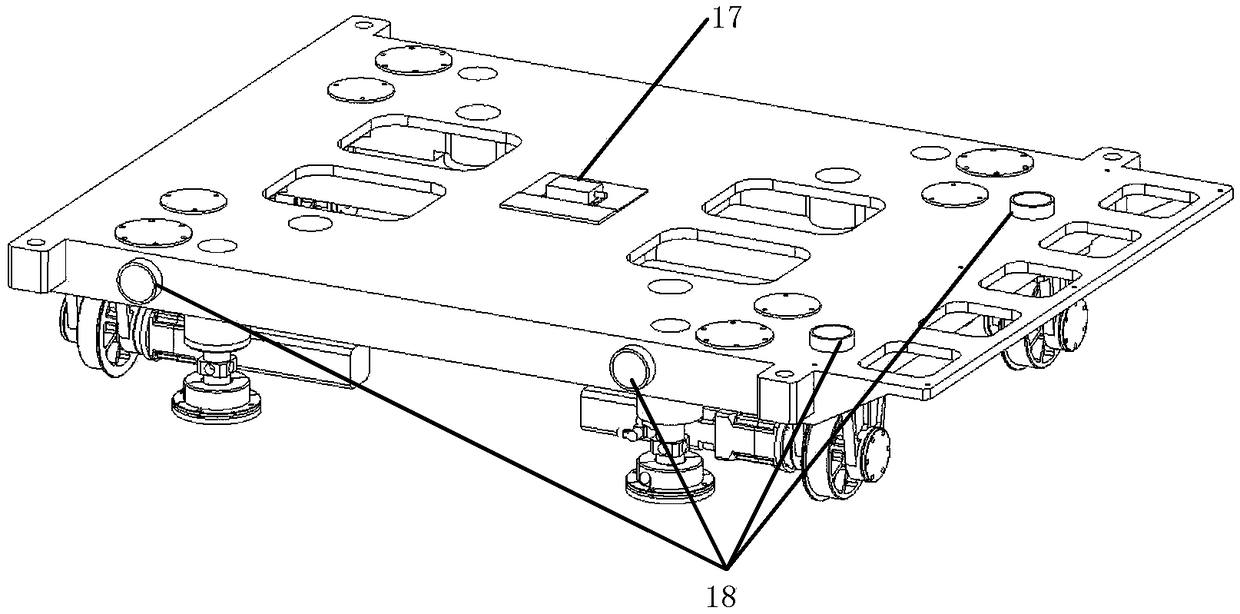

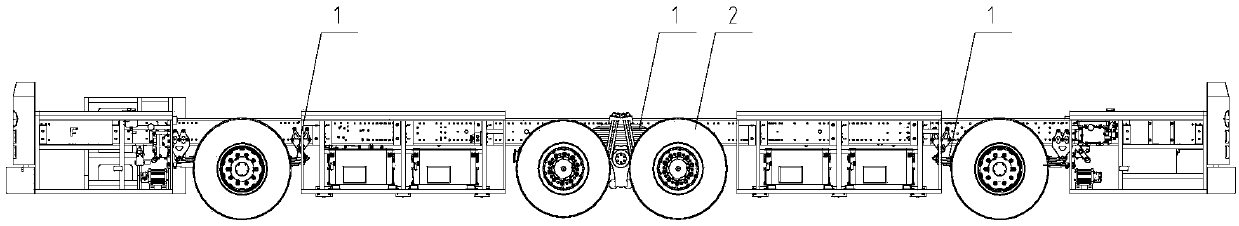

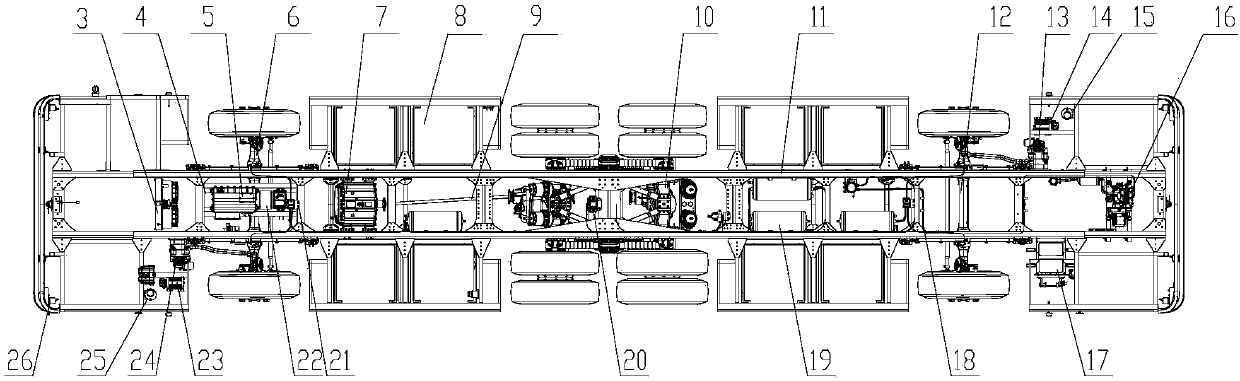

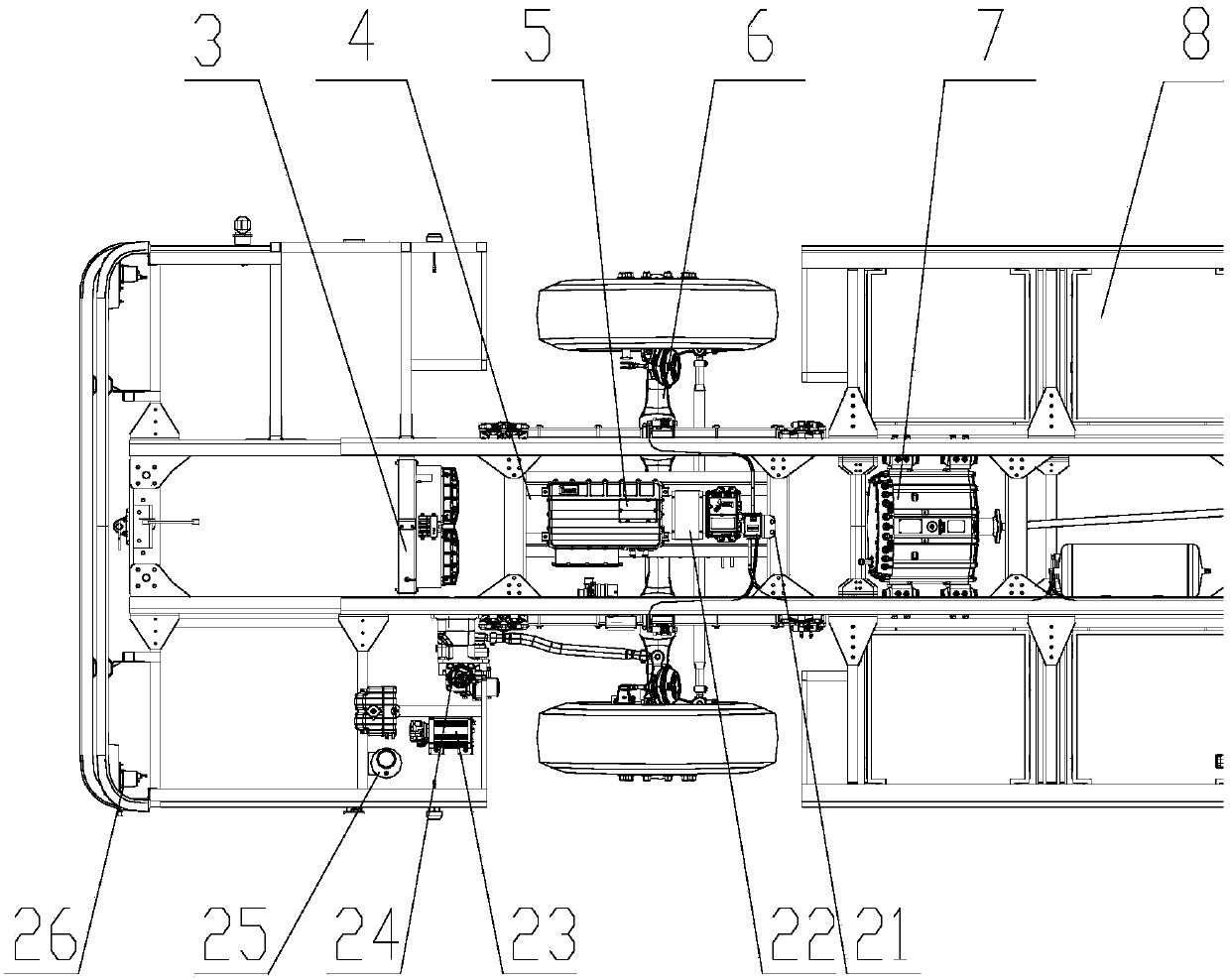

Chassis of automatic container guiding vehicle

PendingCN107791928AImprove mobilityThe positive and negative effects are the sameElectric propulsion mountingFluid steeringAutomated guided vehicleControl theory

The invention provides a chassis of an automatic container guiding vehicle. The chassis is provided with a front steering shaft, a rear steering shaft and two driving axles. The front steering shaft and the rear steering shaft are arranged at the front end and the rear end of the chassis in a mode of being symmetric in the front-rear direction relative to the center of the vehicle. The two drivingaxles are arranged in the middle of the chassis side by side. Single tires are arranged at the two ends of the front steering shaft and the rear steering shaft correspondingly. Double tires are arranged at the two ends of the driving axles correspondingly. The chassis of the automatic container guiding vehicle adopts a 8x4 driving mode, the forward-rotation effect and the reverse-rotation effectof the vehicle are consistent, and distinguishing of advancing or backing-up is not needed; steering of the front steering shaft and steering of the rear steering shaft are coordinated and consistent,so that the turning radius is decreased, and vehicle maneuverability is promoted; and the bearing loads of the tires of the chassis are consistent basically, and thus the large-bearing requirement ismet.

Owner:CHINA FIRST AUTOMOBILE

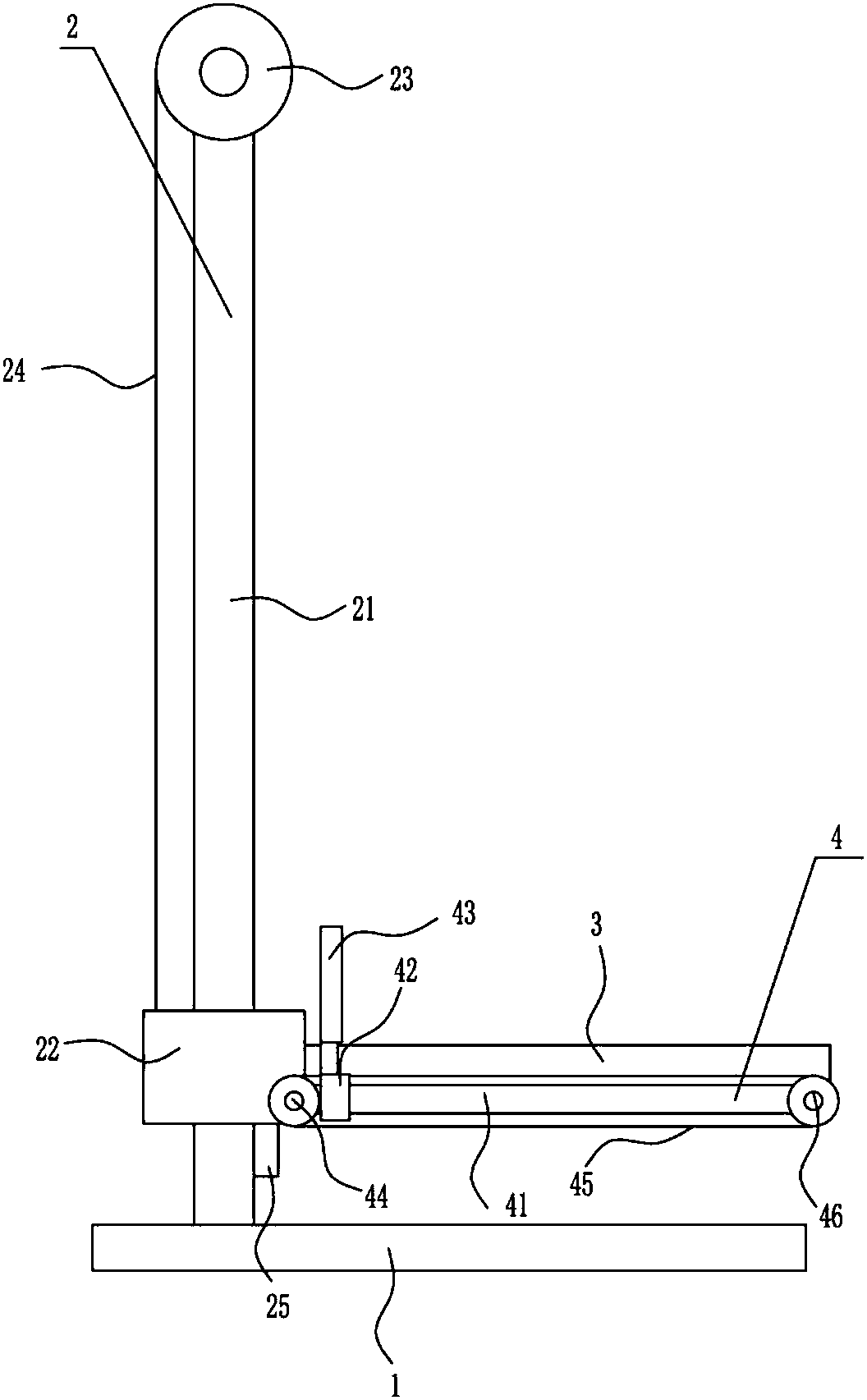

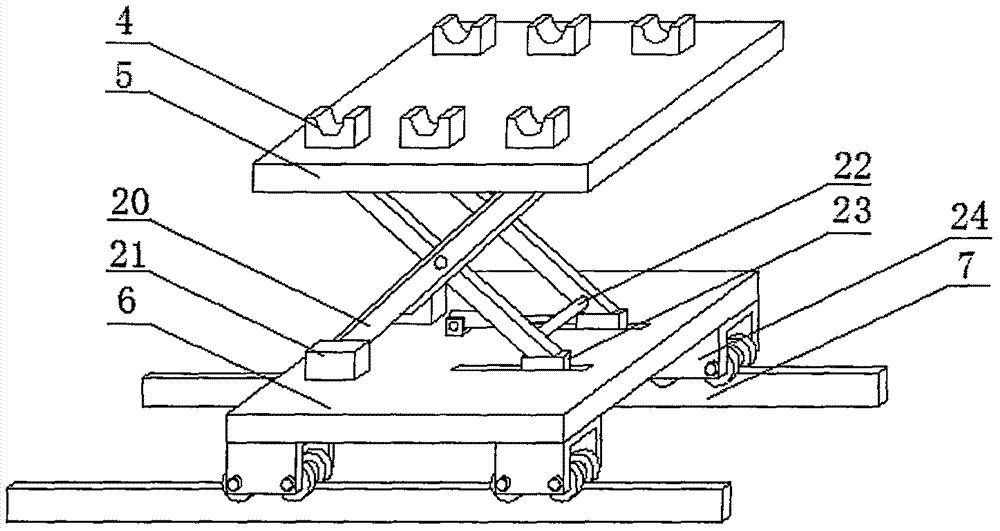

Brick conveying device for building construction

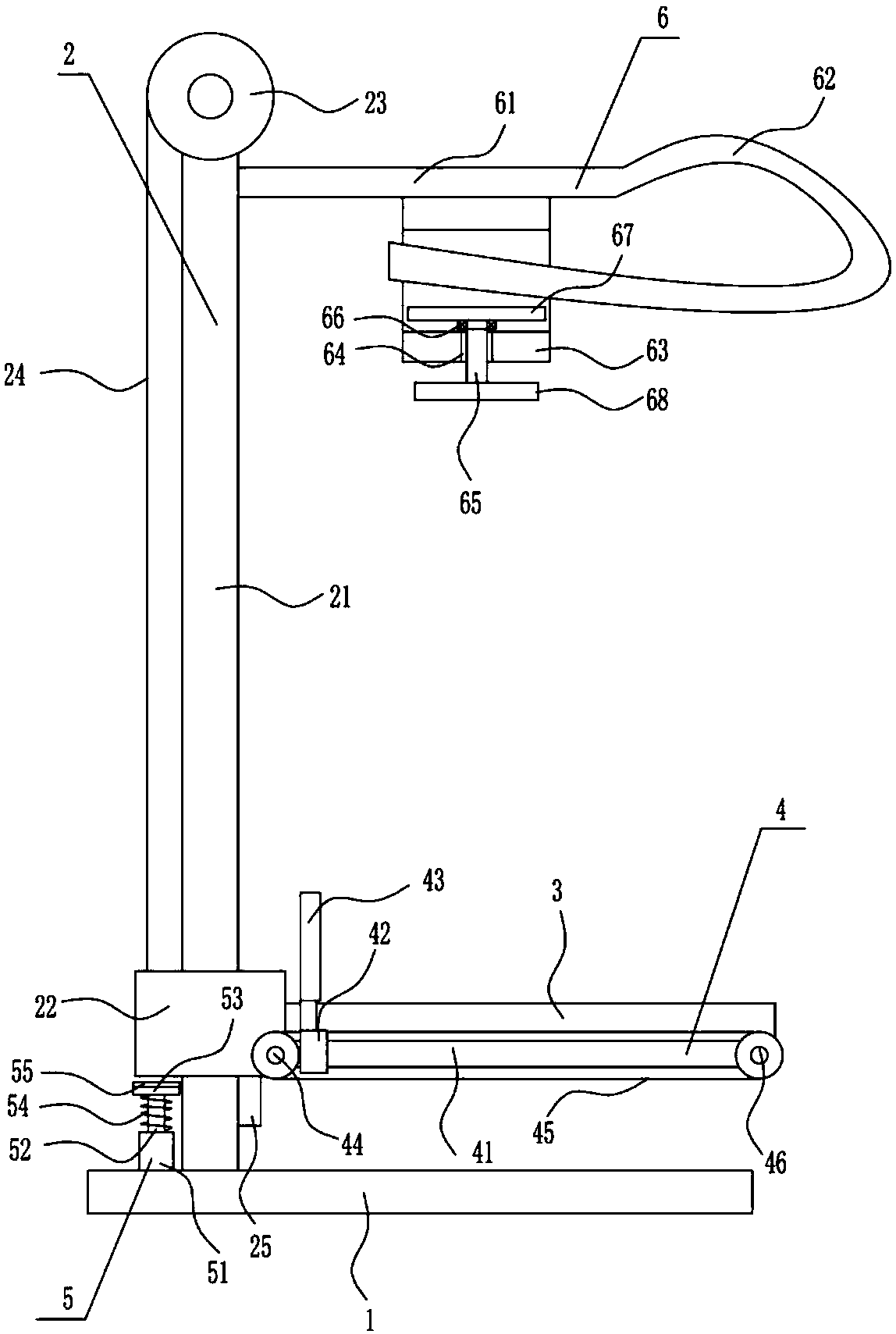

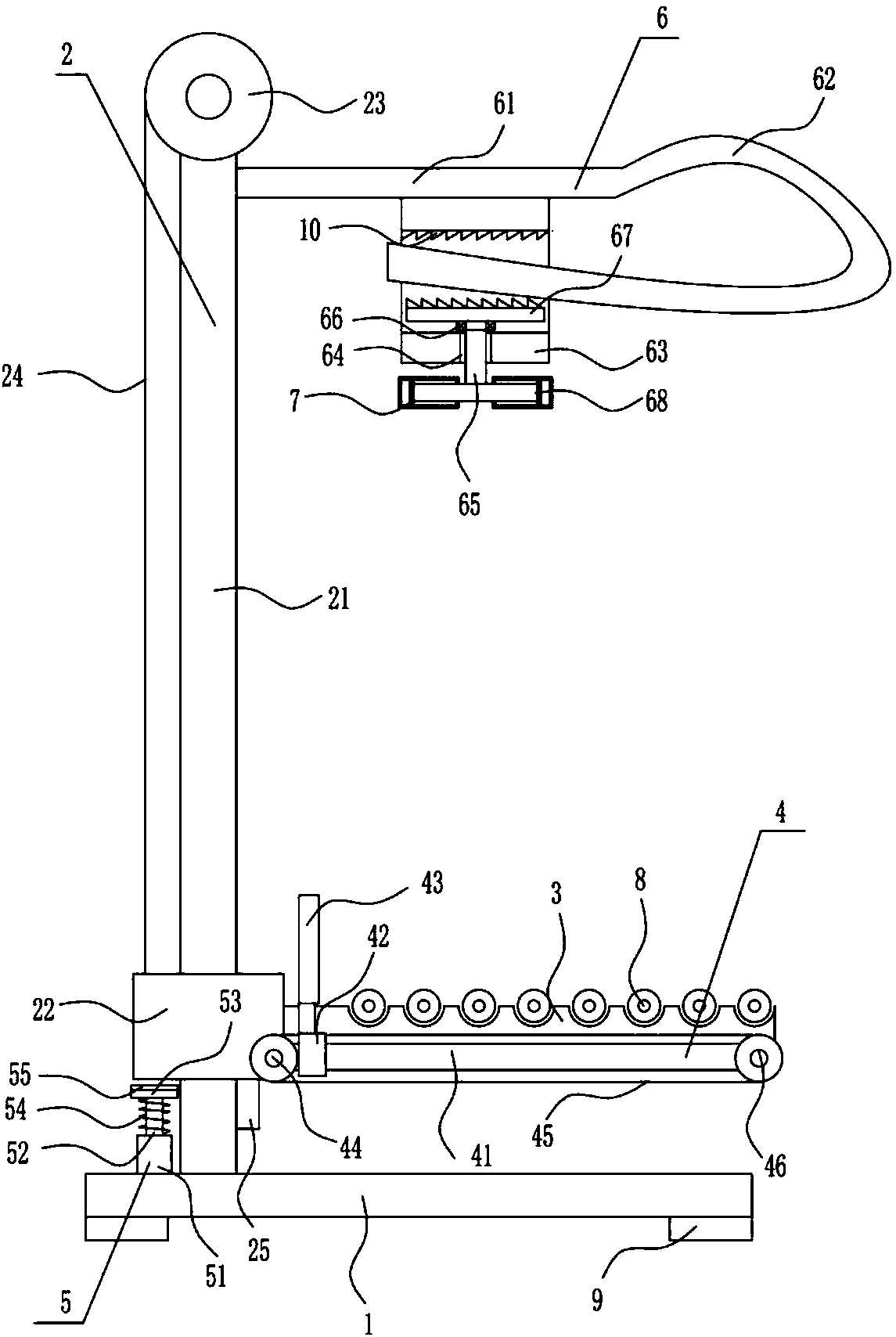

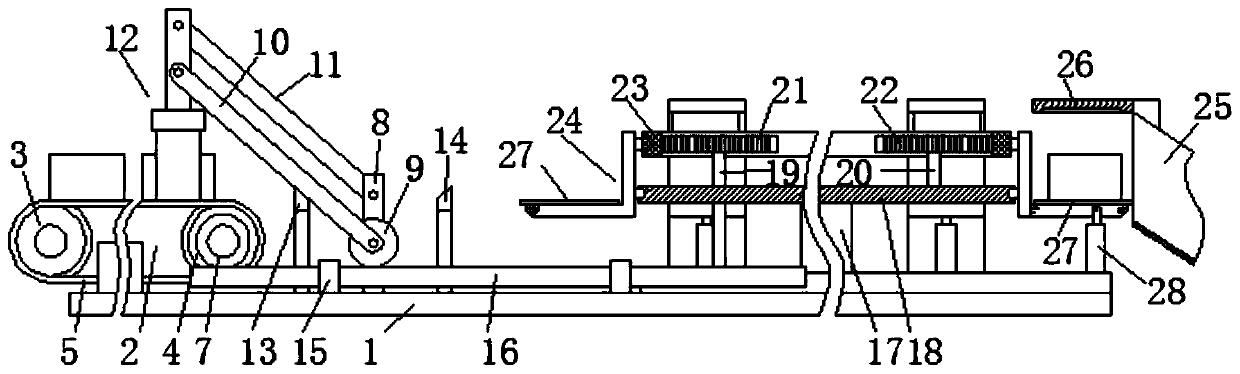

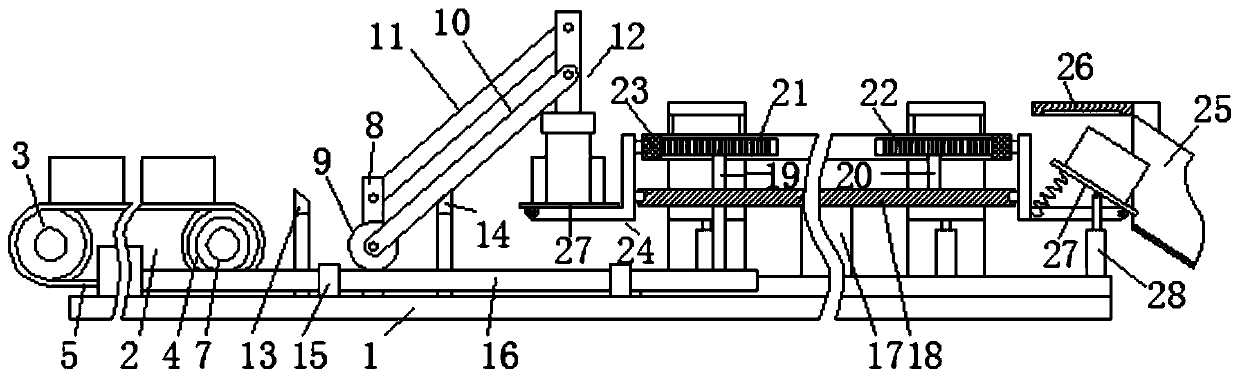

The invention relates to a construction site construction device, in particular to a brick conveying device for building construction. The brick conveying device for the building construction is characterized by being capable of achieving automatic transferring, high in conveying efficiency and good in reliability. The brick conveying device for the building construction comprises a bottom plate and the like, a lifting mechanism is arranged at the top of the bottom plate, an operating table is arranged on a moving part of the lifting mechanism, and a pushing mechanism is arranged on the frontside of the operating table. According to the brick conveying device for the building construction, bricks placed on the operating table are transferred through mutual cooperation of the lifting mechanism and the pushing mechanism, and meanwhile, through optimization of a buffer mechanism and a protection mechanism, the effects of being capable of realizing automatic transfer, high in conveying efficiency and good in reliability are achieved.

Owner:良求机械有限公司

Special automatic sorting device for logistics express delivery and application method thereof

InactiveCN111215338ARealize automatic transferImprove work efficiencySortingElectric machineryTransfer mechanism

The invention relates to the field of logistics sorting equipment, in particular to a special automatic sorting device for logistics express delivery and an application method of the special automaticsorting device for logistics express delivery. The special automatic sorting device for logistics express delivery comprises a base. A transferring mechanism which moves express packages is arrangedon the left side of the base, a sorting mechanism which sorts the express packages is arranged on the right side of the base, and the transferring mechanism and the sorting mechanism are connected ina transmission mode. The transferring mechanism comprises a goods conveying frame and a motor. A conveying belt which is used for conveying the express packages is arranged on the goods conveying frame, the output shaft end of the motor is connected with a clamping mechanism in a driving mode, and the clamping mechanism transfers the express packages on the conveying belt to the sorting mechanism.The sorting mechanism comprises a chain. Multiple sorting frames are arranged on the chain at equal intervals, and multiple material guide plates are arranged on the periphery of the chain. By the adoption of the special automatic sorting device for logistics express delivery and the application method of the special automatic sorting device for logistics express delivery, automatic transferringoperation of the express packages is achieved, the circulating and intermittent type work is adopted, the express packages are conveniently sorted one by one, the manpower output is greatly reduced, and the working efficiency and the sorting accuracy rate are improved.

Owner:林知寒

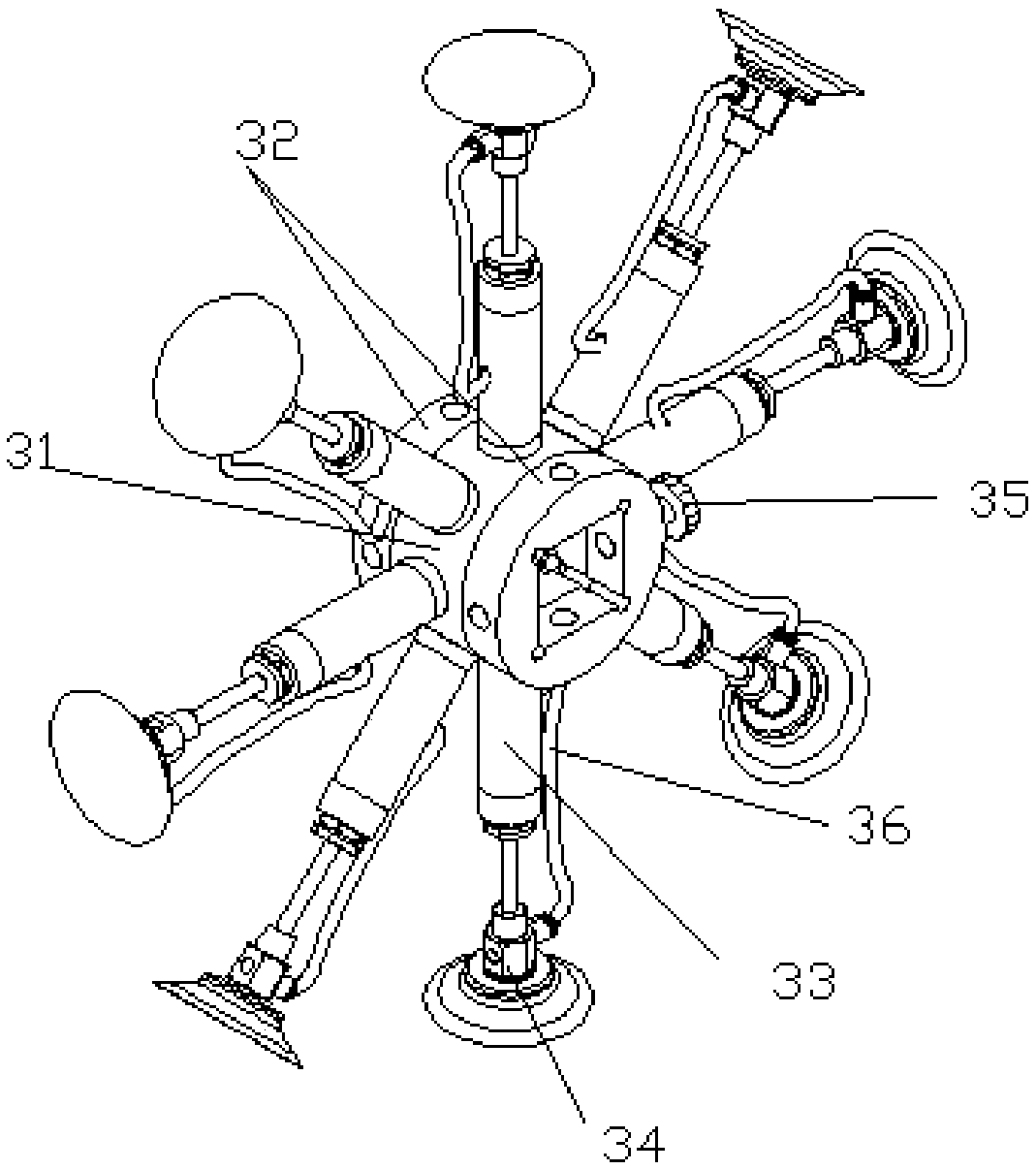

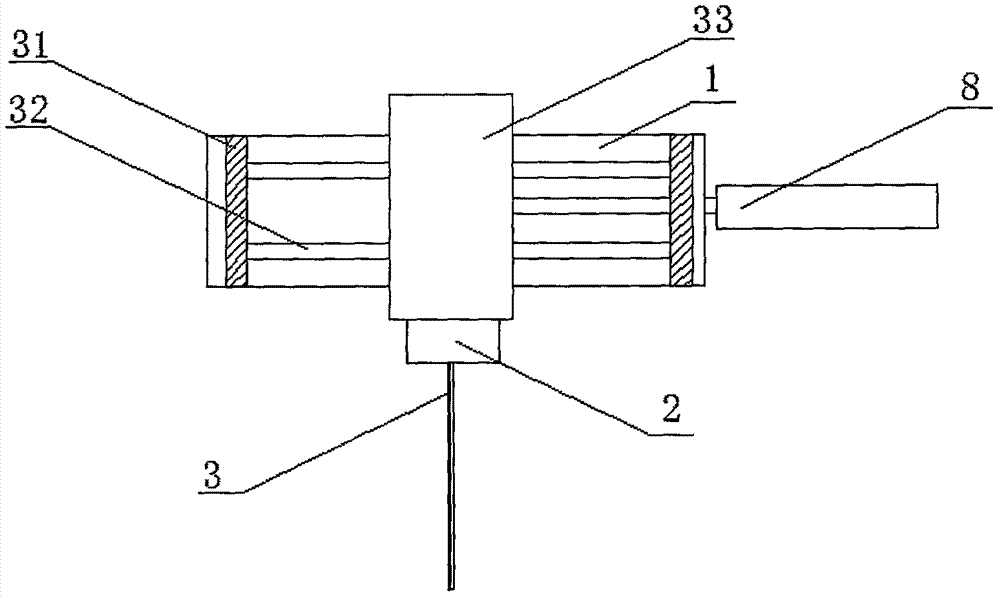

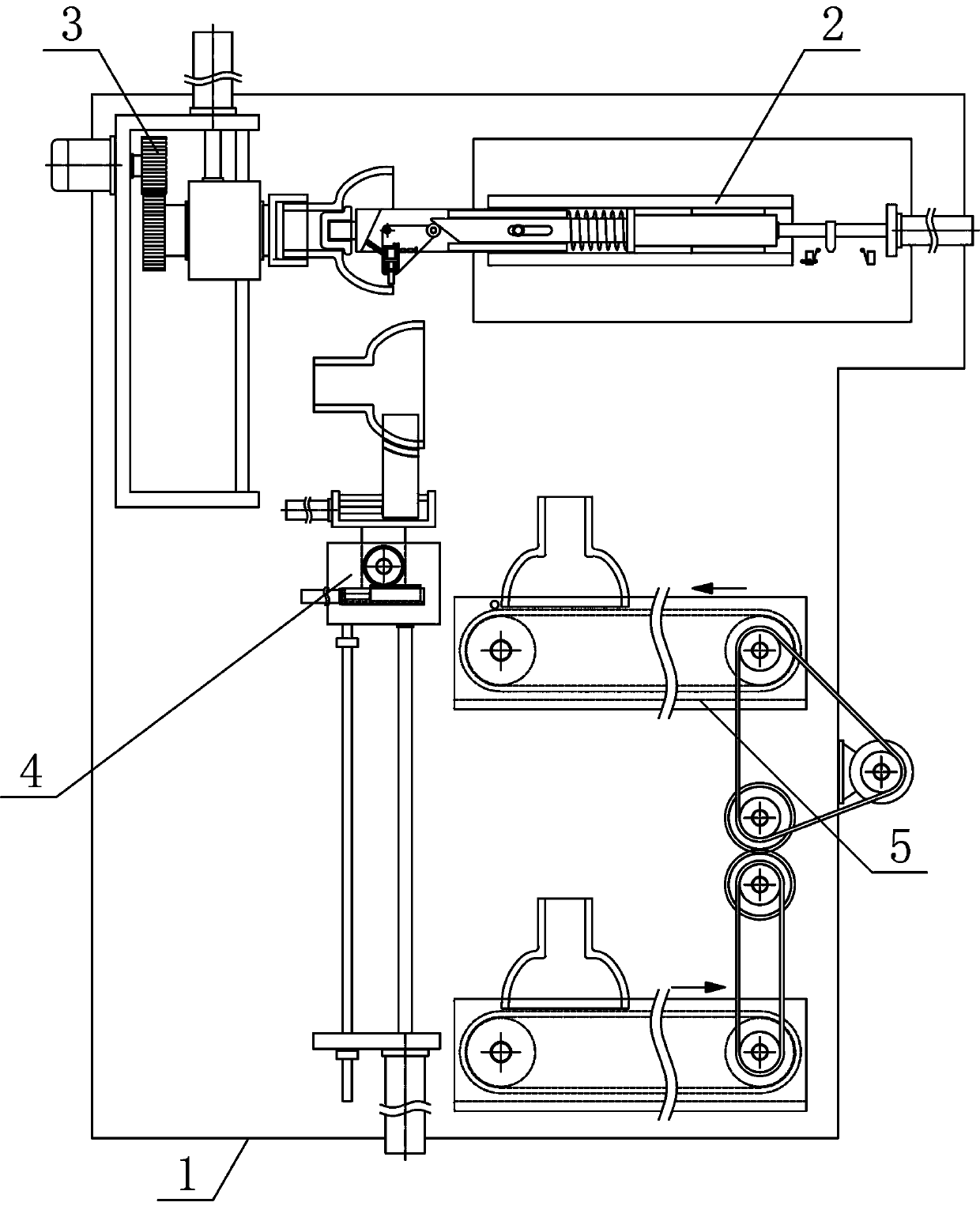

Rubber piece automatic reverse head-delivery equipment

The invention provides rubber piece automatic reverse head-delivery equipment. The rubber piece automatic reverse head-delivery equipment is arranged between the discharging end of a horizontal conveying mechanism and the feeding end of an uphill conveying mechanism and comprises a bracket, a gas supply shaft, and a material picking and conveying device for picking materials of the horizontal conveying mechanism and reversely conveying the materials to the uphill conveying mechanism; the material picking and conveying device comprises a shaft sleeve and a plurality of vacuum suction cups evenly arranged on the outer circumferential surface of the shaft sleeve in the circumferential direction of the shaft sleeve; the shaft sleeve is fixedly mounted on the gas supply shaft in a sleeving mode, gas inlets of the vacuum suction cups are connected with gas inlet hoses, and each gas inlet hose communicates with a gas outlet of a gas distributor. According to the rubber piece automatic reversehead-delivery equipment, the gas supply shaft drives the multiple vacuum suction cups on the shaft sleeve to rotate around the axis, thus rubber pieces are automatically transferred from the discharging end of the horizontal conveying mechanism to the feeding end of the uphill conveying mechanism, a conventional manual transferring mode is changed through the transferring mode, the material transferring process of the vacuum suction cups are completed through control of a controller, and the accuracy of the transferring position is ensured.

Owner:TIANJIN VOCATIONAL & TECHNICAL COLLEGE OF MECHANICAL & ELECTRICAL ENG

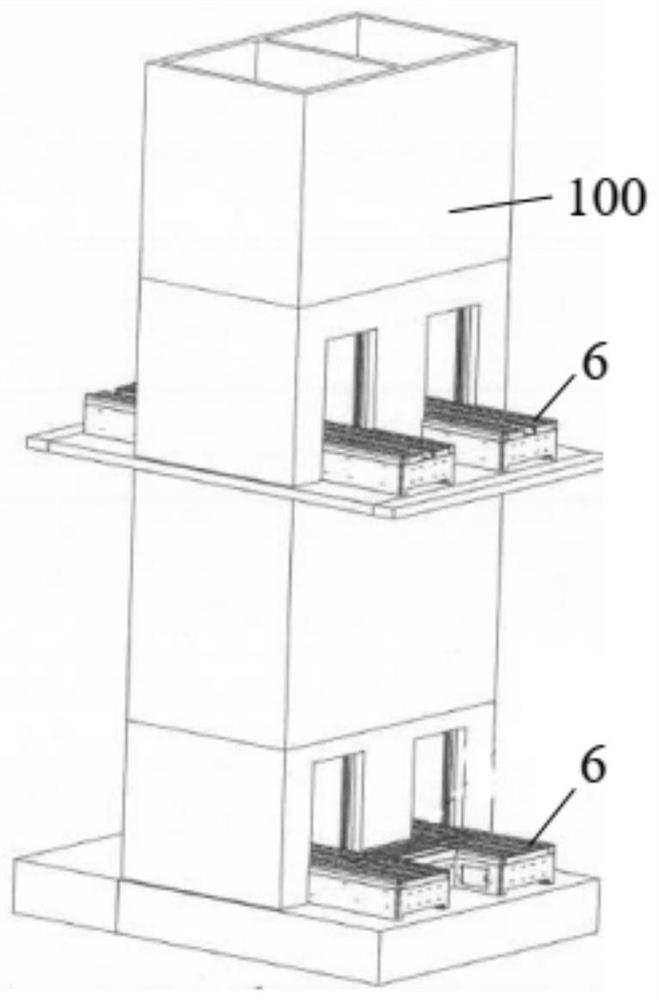

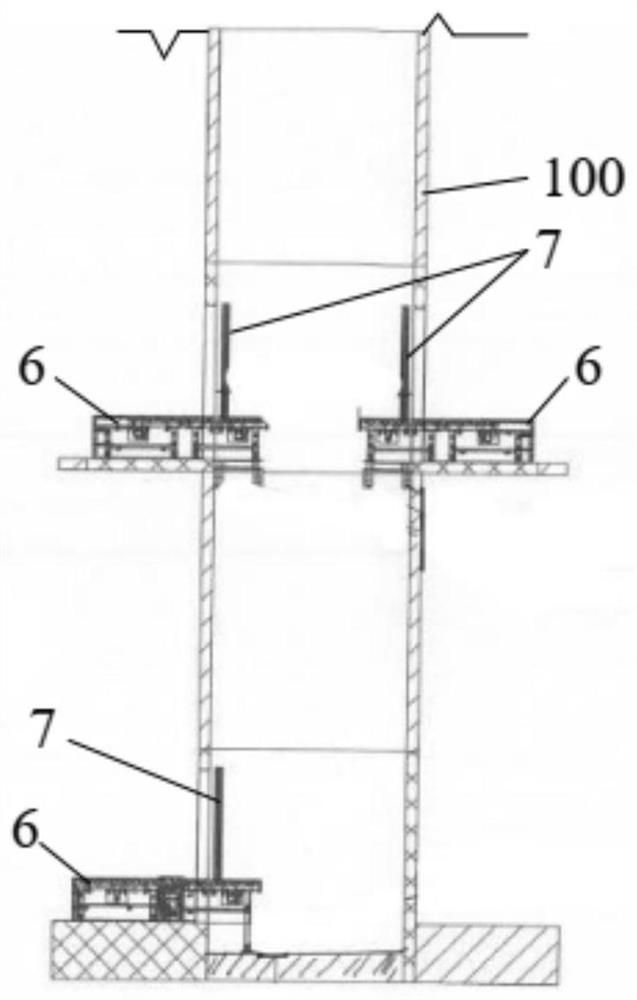

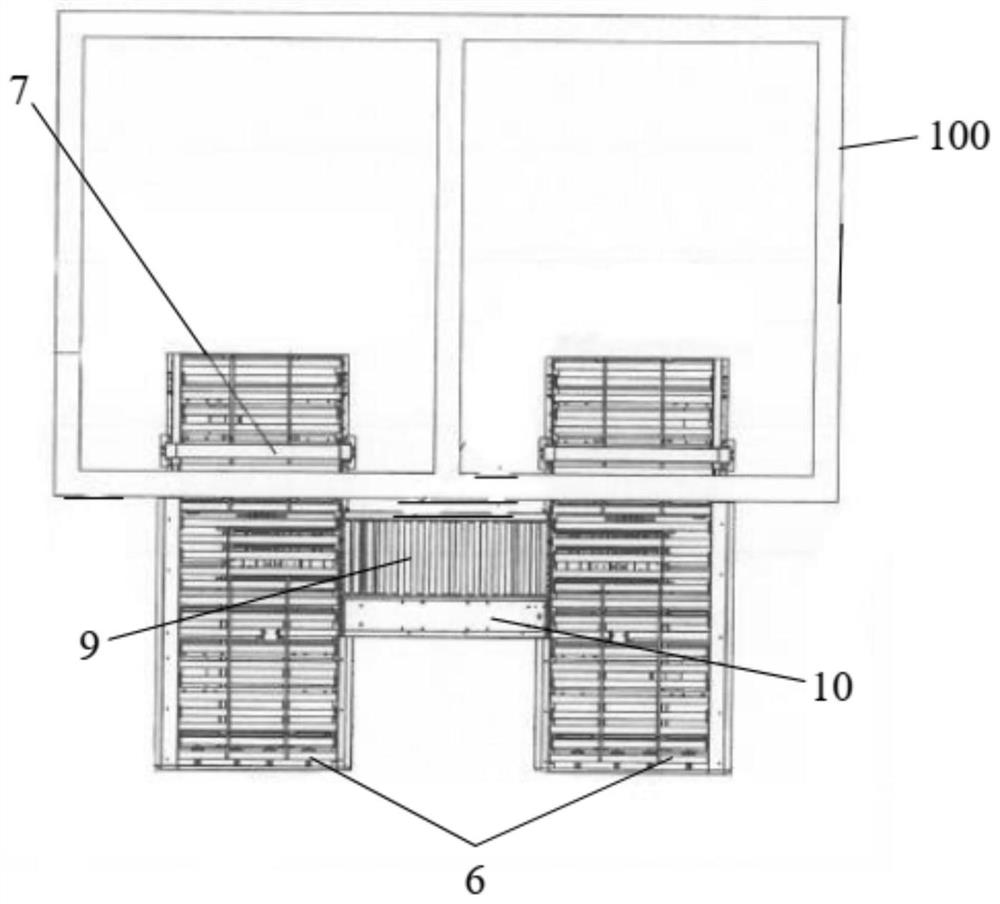

Warehouse material lifting and conveying device

PendingCN112408155ARealize automatic transferImprove delivery efficiencyElevatorsBuilding liftsLogistics managementControl engineering

The invention relates to the field of logistics transportation, and discloses a warehouse material lifting and conveying device which is used for conveying materials to a designated floor. A translation conveying mechanism used for transferring materials is arranged on a lifting mechanism, and the lifting mechanism drives the translation conveying mechanism to ascend and descend; a position detection mechanism is in signal connection with a control mechanism and used for detecting the floor position of the translation conveying mechanism; a loading detection mechanism is in signal connection with the control mechanism and is used for detecting the loading state of the translation conveying mechanism; and the control mechanism is in control connection with the translation conveying mechanism and the lifting mechanism so as to control the lifting mechanism to move to a specified floor and control transfer starting and stopping of the translation conveying mechanism. According to the warehouse material lifting and conveying device, whether the translation conveying mechanism bears materials or not and the floor where the translation conveying mechanism is located are detected in realtime through the position detection mechanism and the loading detection mechanism, the translation conveying mechanism is made to ascend and descend to the designated floor under the control of the control mechanism to automatically complete material conveying, automatic material transferring between floors can be achieved, flexibility is high, and the conveying efficiency is high.

Owner:MAKINO MACHINE TOOL CHINA CO LTD

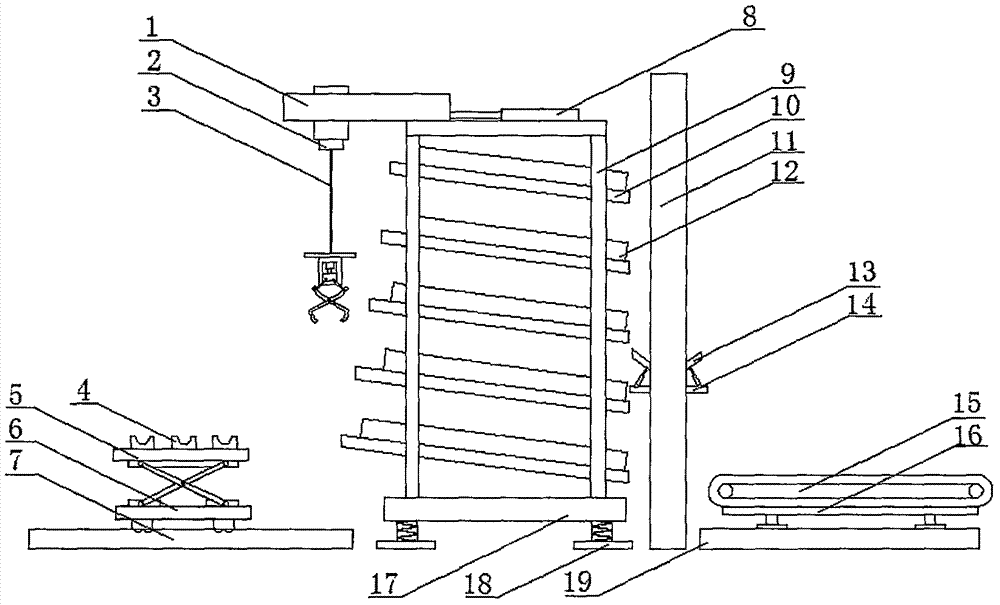

Automatic feeding device

ActiveCN106914789ARealize automatic transferRealize deliveryMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic feeding device which comprises a base, wherein a damping device is arranged at the lower end of the base, and a placing rack is arranged at the upper end of the base; a plurality of placing plates are arranged on the placing rack along a vertical direction at equal interval, and the lengths of the placing plates are decreased progressively in order from top to bottom; baffle plates are arranged at the two ends of each placing plate, and a sealing door is arranged on one side of the placing plate and is rotationally connected between the two baffle plates; a driving device is arranged on one side of one baffle plate, and an output shaft of the driving device penetrates through the baffle plate and is fixedly connected with one end of the sealing door. The automatic feeding device realizes automatic steel pipe transfer and transport through the combination of a pipe placing mechanism, a clamping device, a transfer device, etc., increases the storage capacity by the arrangement of the placing rack, can take materials as required, improves the production efficiency, reduces the cost, reduces dangerous accidents, and is suitable for popularization.

Owner:无锡诚勇自动化技术有限公司

Laser welding quality monitoring device

ActiveCN106624419ARealize deliveryRealize automatic transferLaser beam welding apparatusVision sensorLaser

The invention discloses a laser welding quality monitoring device comprising a first operating platform and a second operating platform parallel to each other. A first conveying belt used for conveying a part to be welded is arranged on the first operating platform. A welding device is arranged on the first operating platform. A second conveying belt used for conveying an unqualified welded part is arranged on one side of the upper end of the second operating platform. A third conveying belt used for conveying a qualified welded part is arranged on the other side of the upper end of the second operating platform. A bearing platform is arranged between the second conveying belt and the third conveying belt, and the lower end of the bearing platform is fixed on the second operating platform. Through the combination of the multiple conveying belts, a welding robot, an electric sliding rail and the like, automatic welding and conveying of the part are achieved. An automatic transfer is achieved through the arrangement of a transfer device. Automatic identifying and clamping are achieved through the combination of a visual sensor and a clamping device. Not only is the labor cost reduced, but also the production efficiency is improved, and the laser welding quality monitoring device is suitable for being popularized.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

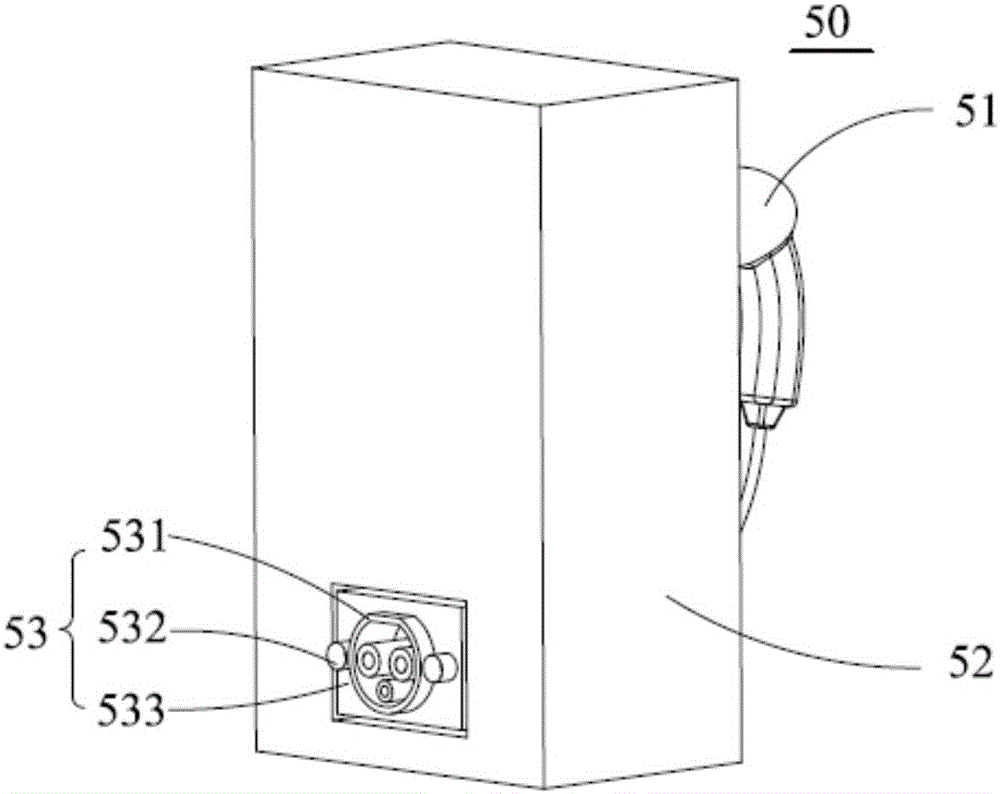

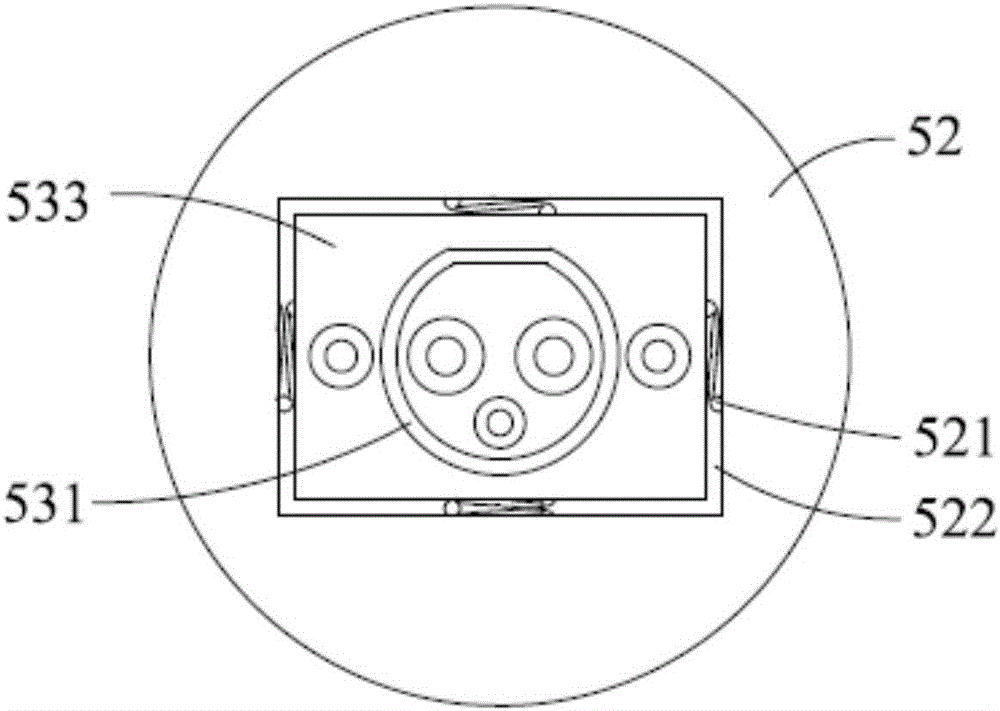

Automatic plugging charging device, intelligent stereo garage, and charging method

PendingCN106560966ARealize automatic transferIntelligent chargingBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringData transmission

The invention discloses an automatic plugging charging device, an intelligent stereo garage with the automatic plugging charging device, and a charging method. The device comprises a bottom plate, a vehicle bedplate moving relative to the bottom plate, a charging pile, a charging gun, and a plug assembly. The plug assembly is disposed at one side of the bottom plate, and the charging pile is disposed at one end of the vehicle bedplate. The charging gun is connected to the charging pipe, and one of the vehicle bedplate and the charging pile is provided with a first communication module. The plug assembly is provided with a second communication module. The first communication module and the second communication module carry out data transmission, and the plug assembly achieves the connection or disconnection with the charging pile after receiving a data instruction. The device provided by the invention solves a technical problem of the automatic plugging connection between the charging pile and the plug assembly. The intelligent stereo garage with the automatic plugging charging device solves a problem of parking and charging of an electric car, and guarantees the intelligent operation of the charging process of the electric car.

Owner:ZTEV

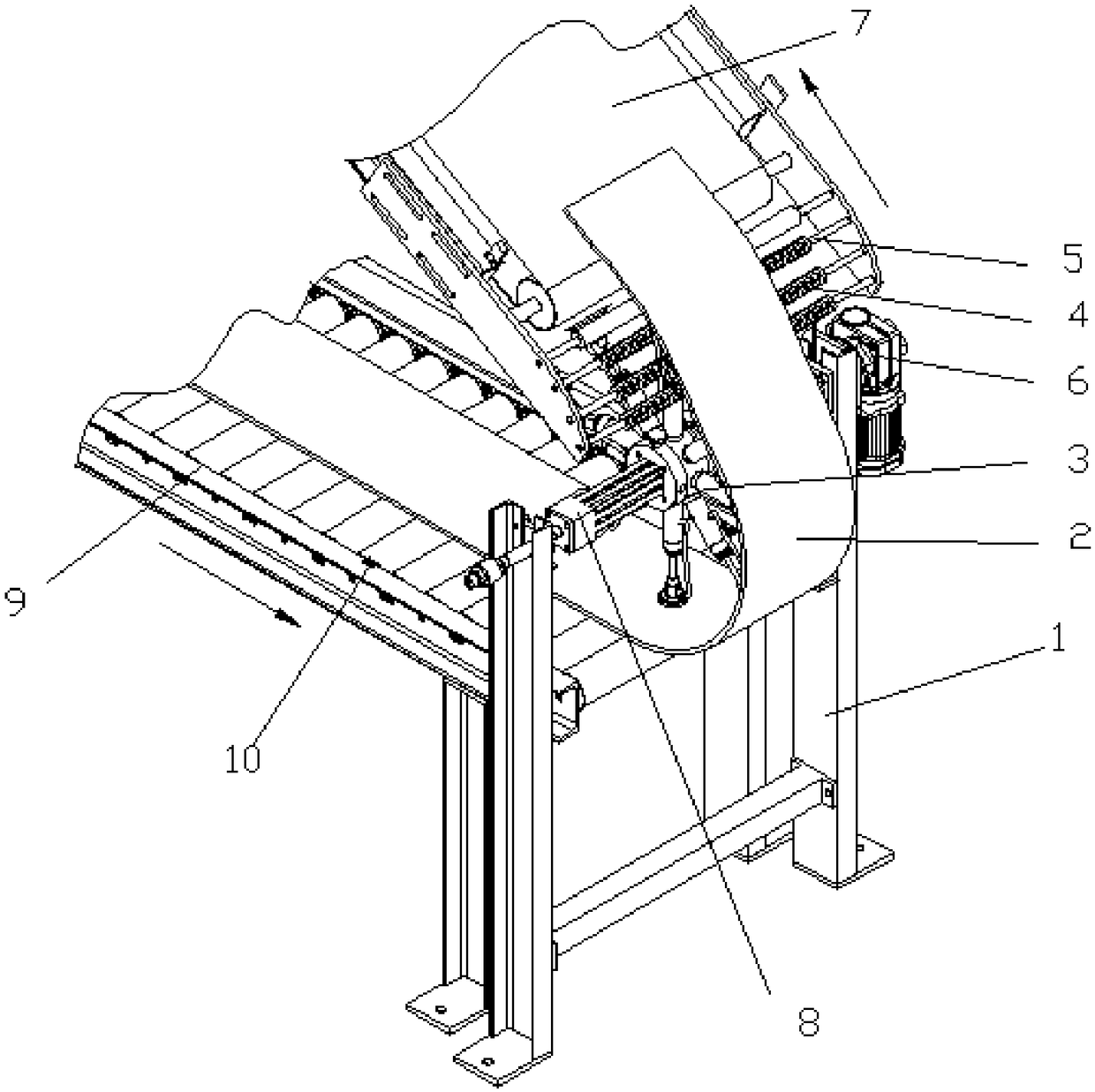

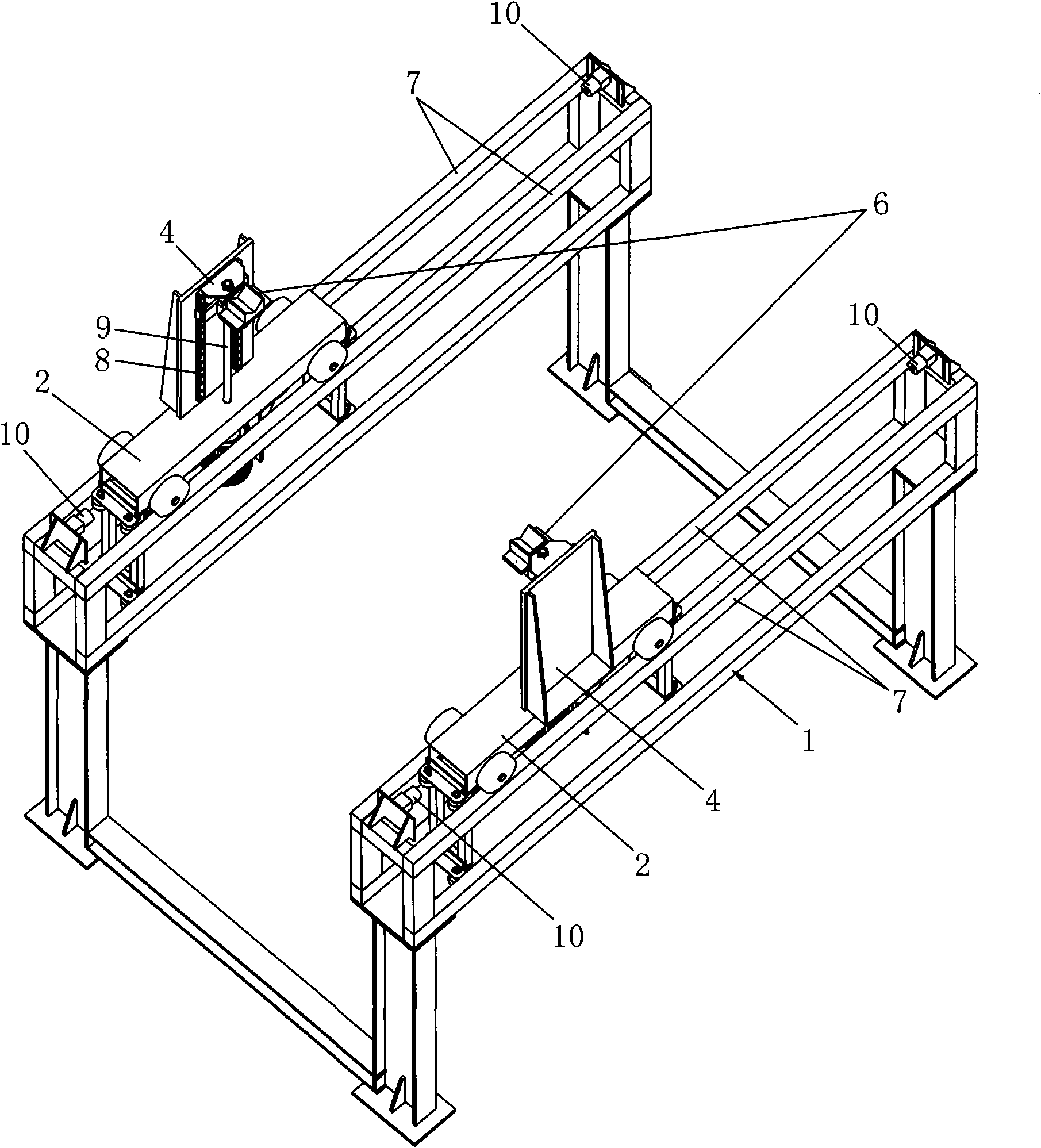

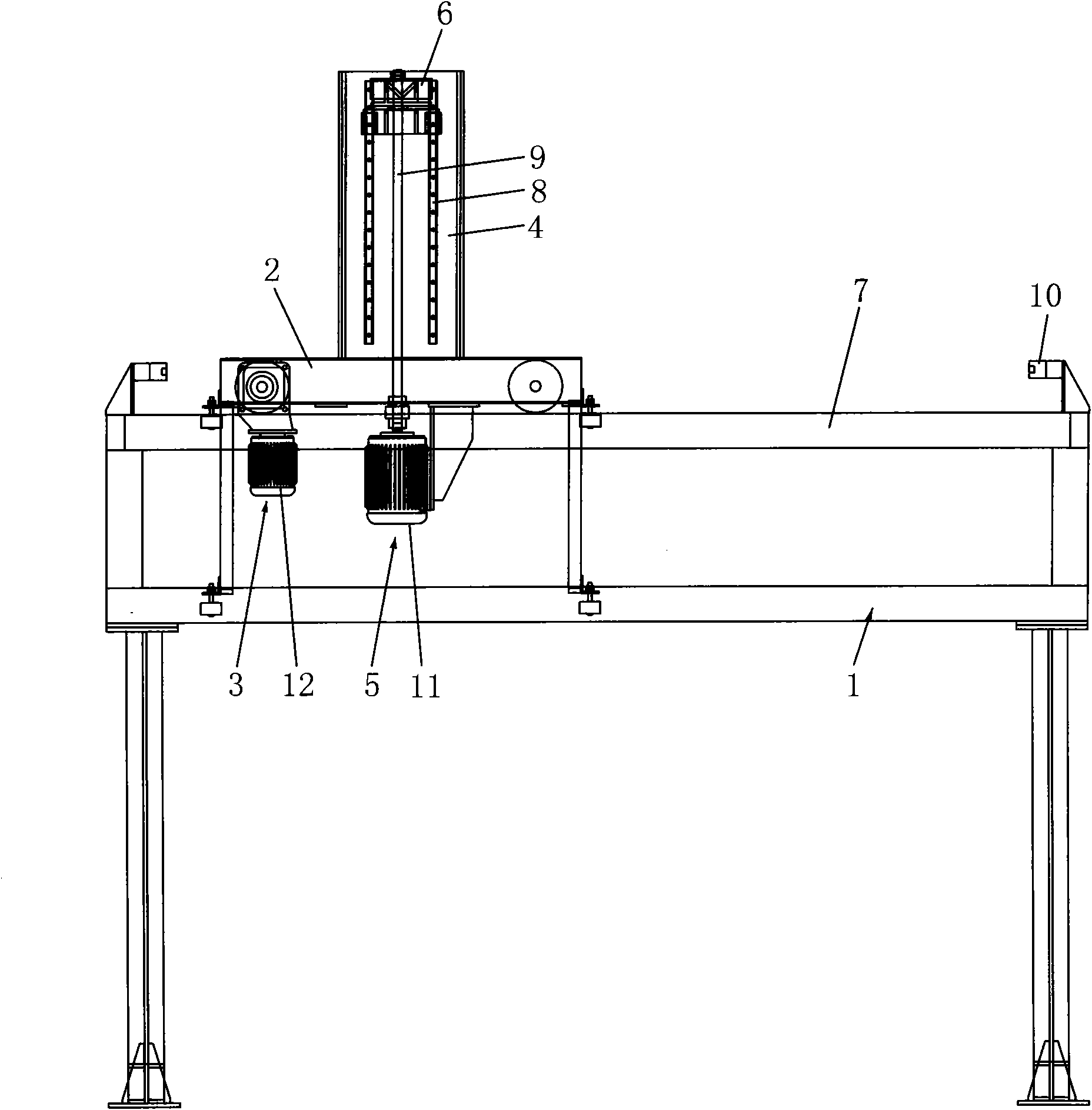

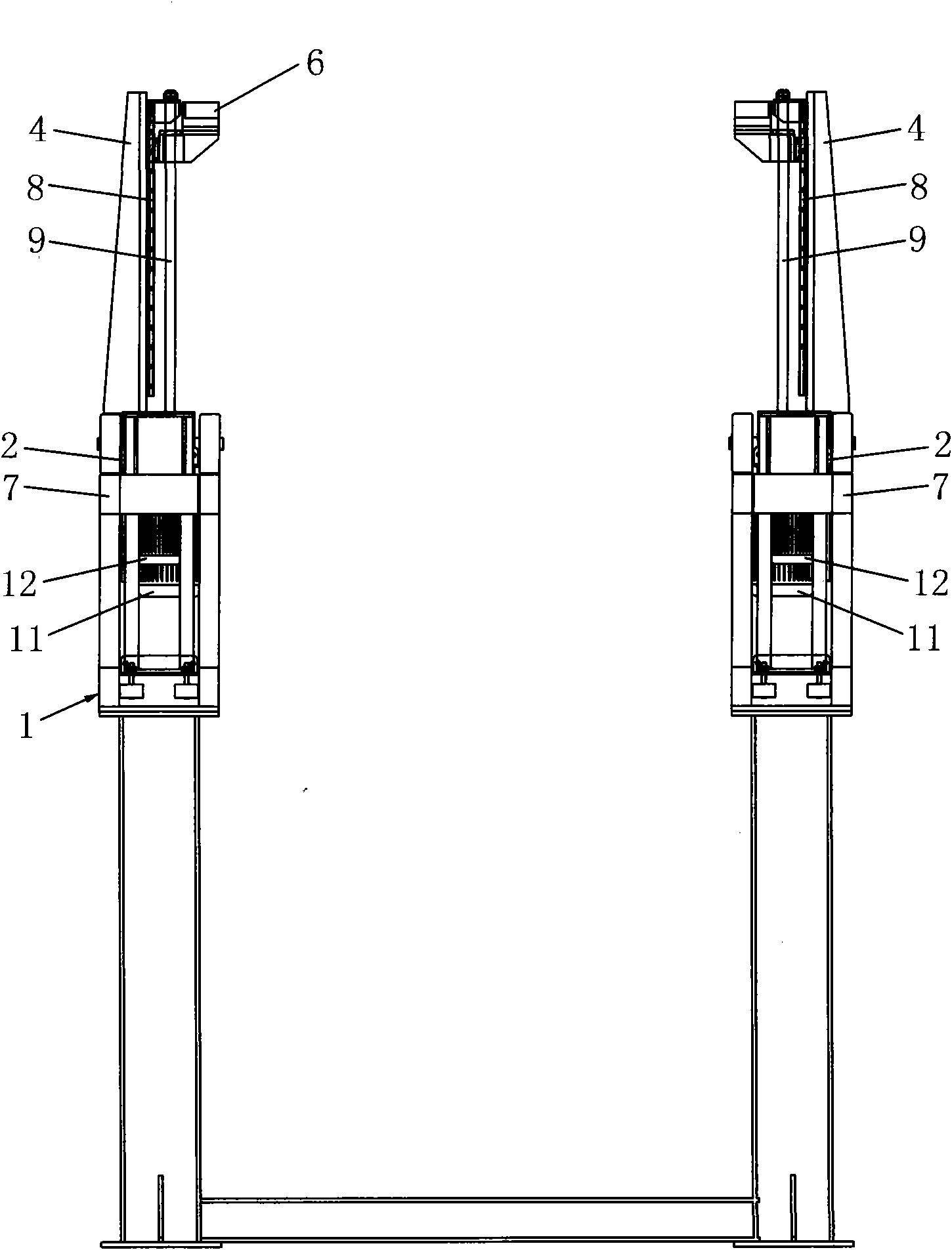

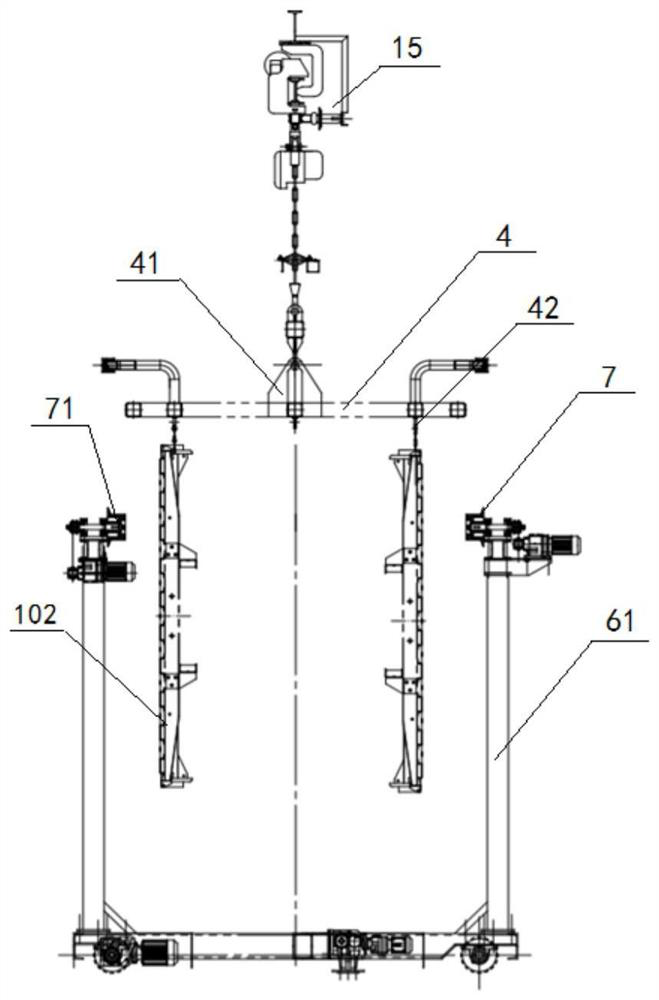

Rotationally hanging device for small spraying equipment

ActiveCN101850325ANot to be collidedRealize automatic transferLiquid surface applicatorsCoatingsEngineeringHooking

The invention discloses a rotationally hanging device for small spraying equipment, which comprises an underframe, a rotationally hanging mechanism and a workpiece bearing device, wherein the rotationally hanging mechanism comprises a traversing frame, a traversing driving device, a lifting frame and a lifting driving device; the traversing frame capable of transversely moving relative to the underframe can be carried on the underframe; the traversing driving device is connected with the traversing frame; the lifting frame is fixed on the traversing frame; the workpiece bearing device capable of lifting relative to the lifting frame can be carried on the lifting frame; and the lifting driving device is connected with the workpiece bearing device. In the device, a workpiece is lifted by the workpiece bearing device and moved by moving the traversing frame to be transferred from a hook of a power and free chain to the hook of another power and free chain, so the automatic hooking transfer of the workpiece can be realized without manual operation. Thus, the working efficiency is improved, the production cost is reduced. In addition, the device is simple in structure and stable and reliable in operation, guarantees that the workpiece is not impacted and guarantees spraying quality.

Owner:DONGGUAN FIRSTOP M & E EQUIP

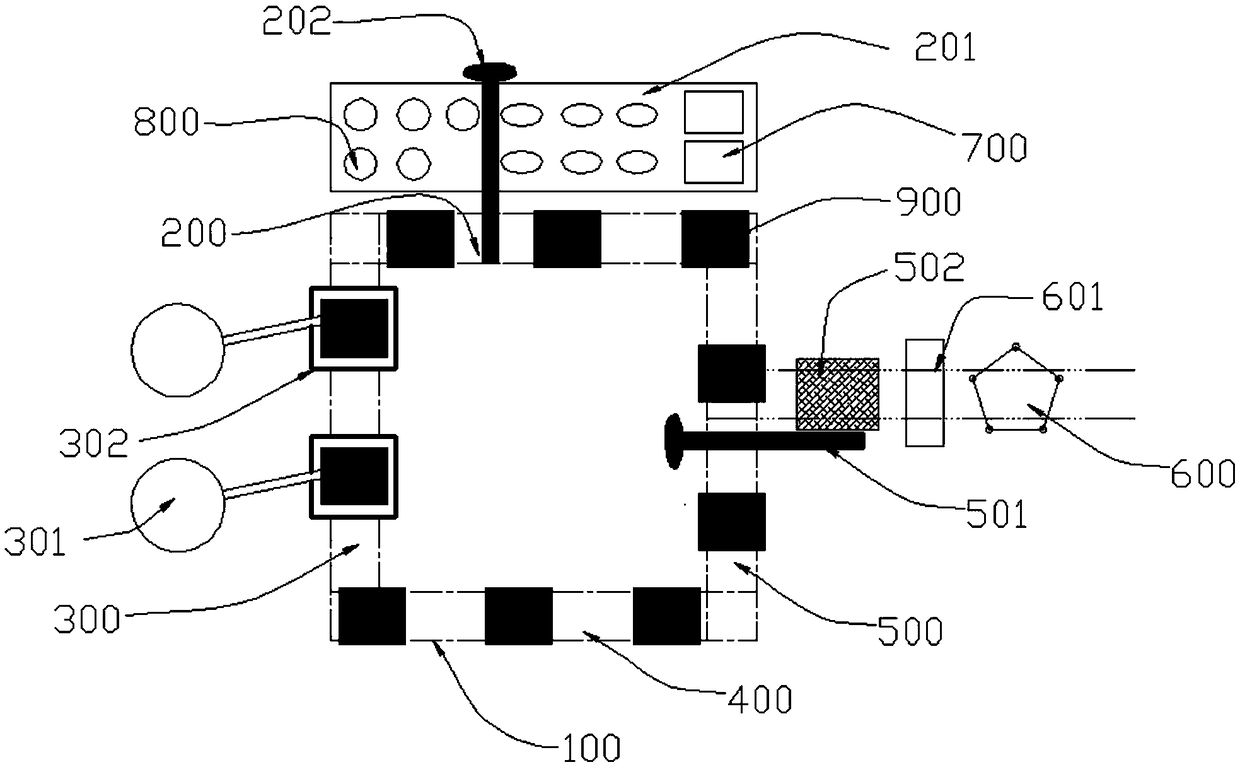

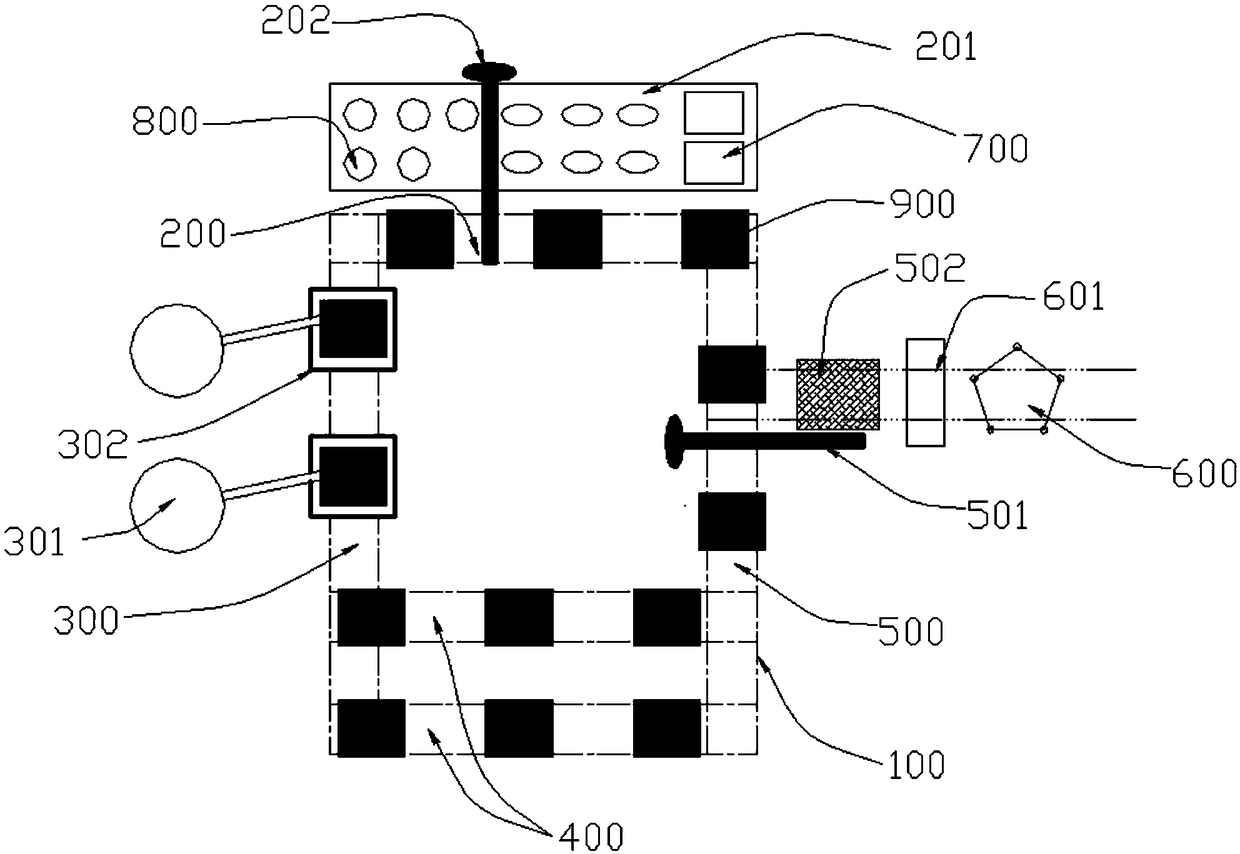

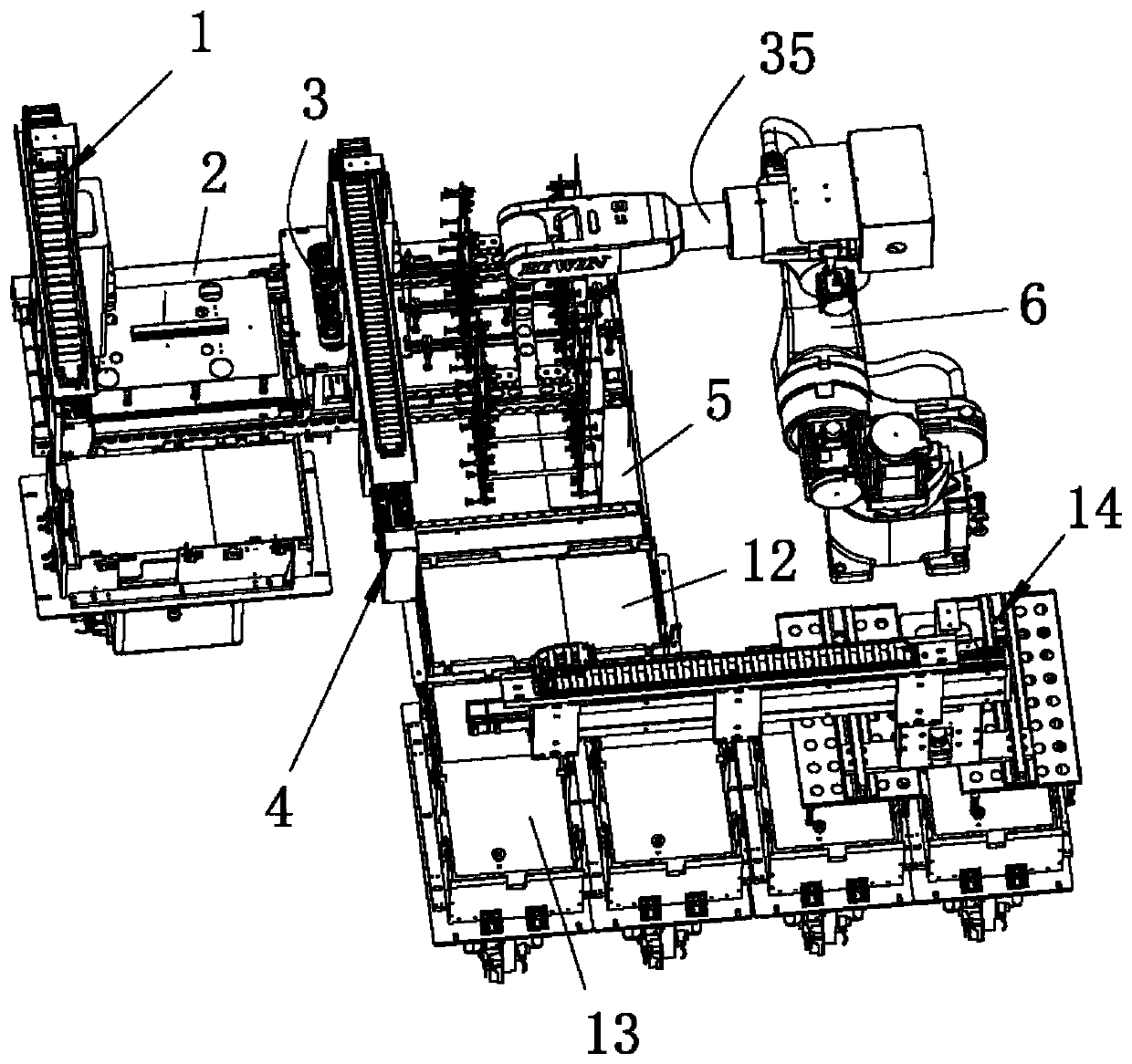

Fully automatic chip stripping machine and working method thereof

ActiveCN107170699AAvoid scratchesAvoider damageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFully automatic

The invention discloses a fully automatic chip stripping machine. The stripping machine comprises a groove type material box loading mechanism, a boundary material stripping mechanism, a chip stripping mechanism, a hollow disc collection mechanism and a film disc multi-station moving and turning mechanism, which are arranged on the same platform. The groove type material box loading mechanism, the boundary material stripping mechanism, the chip stripping mechanism and the hollow disc collection mechanism are successively arranged on the same side with the film disc multi-position moving and turning mechanism side by side. The invention also discloses a working method of the fully automatic chip stripping machine. According to the invention, the fully automatic chip stripping machine is suitable for stripping chips with big areas and thin thicknesses and capable of cleaning boundary materials of chips, stripping the chips, preventing chips from being scratched or damaged and effectively protecting the chips, so working efficiency is greatly improved.

Owner:SHENZHEN GRAND INNOSYS CORP

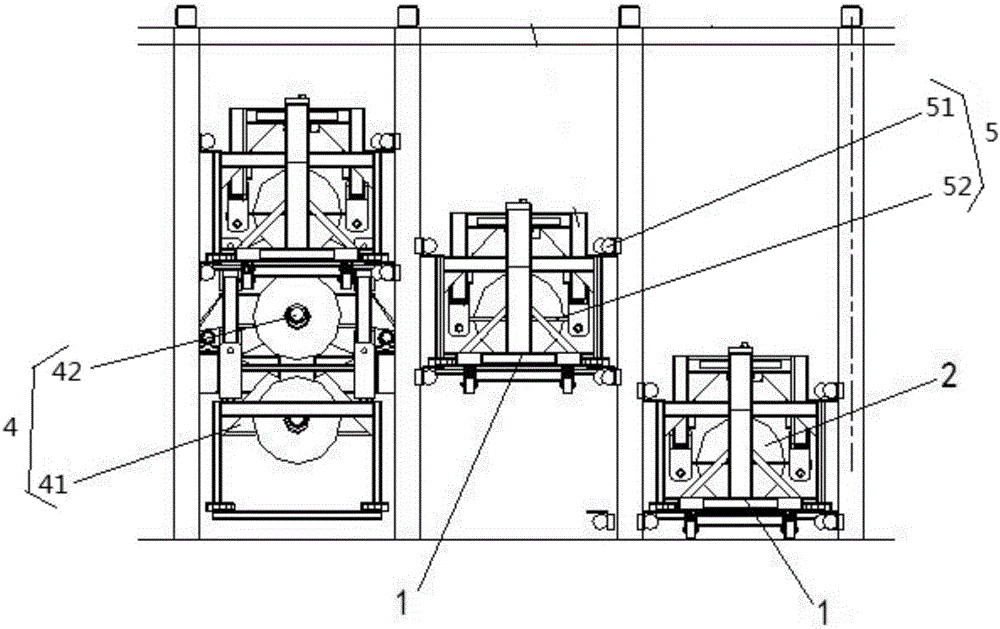

Sand box molding line and working method thereof

ActiveCN109226699AGuaranteed continuityShorten the takt timeMoulding plantsIntelligent control systemManipulator

The invention relates to a sand box molding line. The sand box molding line comprises a free-running multi-rate conveying line, a box locking workstation, a filling sand compaction workstation, a hardening workstation and a demolding workstation; the box locking workstation, the filling sand compaction workstation, the hardening workstation and the demolding workstation are connected in sequence to form a rectangular sand box molding line by virtue of the free-running multi-rate conveying line; the box locking workstation comprises a storage library and a box locking manipulator; the filling sand compaction workstation comprises a sand feeding apparatus and a vibration compaction table; the hardening workstation is used for hardening a sand mold in the sand box; and the demolding workstation is provided with a box overturning manipulator and a fixing mechanism. According to the sand box molding line, the box locking workstation, the filling sand compaction workstation, the hardening workstation and the demolding workstation are reasonably distributed, so that the consistence in production can be ensured, the working efficiency can be improved, the use of overhead cranes can be reduced by utilizing the manipulator and an intelligent control system, the automatic warehousing is realized, the automatic transshipping is realized, the production efficiency is improved, and the laborintensity is alleviated.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

Hot ironing machine

ActiveCN103802456ASimple structureEasy to useTransfer printingWebs handlingEngineeringMechanical engineering

A hot ironing machine comprises a rack, a hot press platform, a hot press block, a hot ironing label paper conveying mechanism and a label paper sensor, wherein the two sides of the rack are respectively provided with two supporting arms, and the two supporting arms on each side are horizontally arranged at intervals; the hot press platform is used for placing transfer print target objects and arranged below the rack; the hot press block is located above the hot press platform and in transmission connection with an air cylinder, and the air cylinder is vertically arranged in the rack; the hot ironing label paper conveying mechanism comprises a pay-off roller used for fixing a hot ironing label paper coil, two first rollers, two second rollers, two third rollers and a take-up unit; the label paper sensor is arranged in a conveying path of the hot ironing label paper conveying mechanism. The hot ironing machine is simple in structure, convenient to use and capable of achieving automatic transfer print in batches.

Owner:MAXIM SMART MFG CO LTD

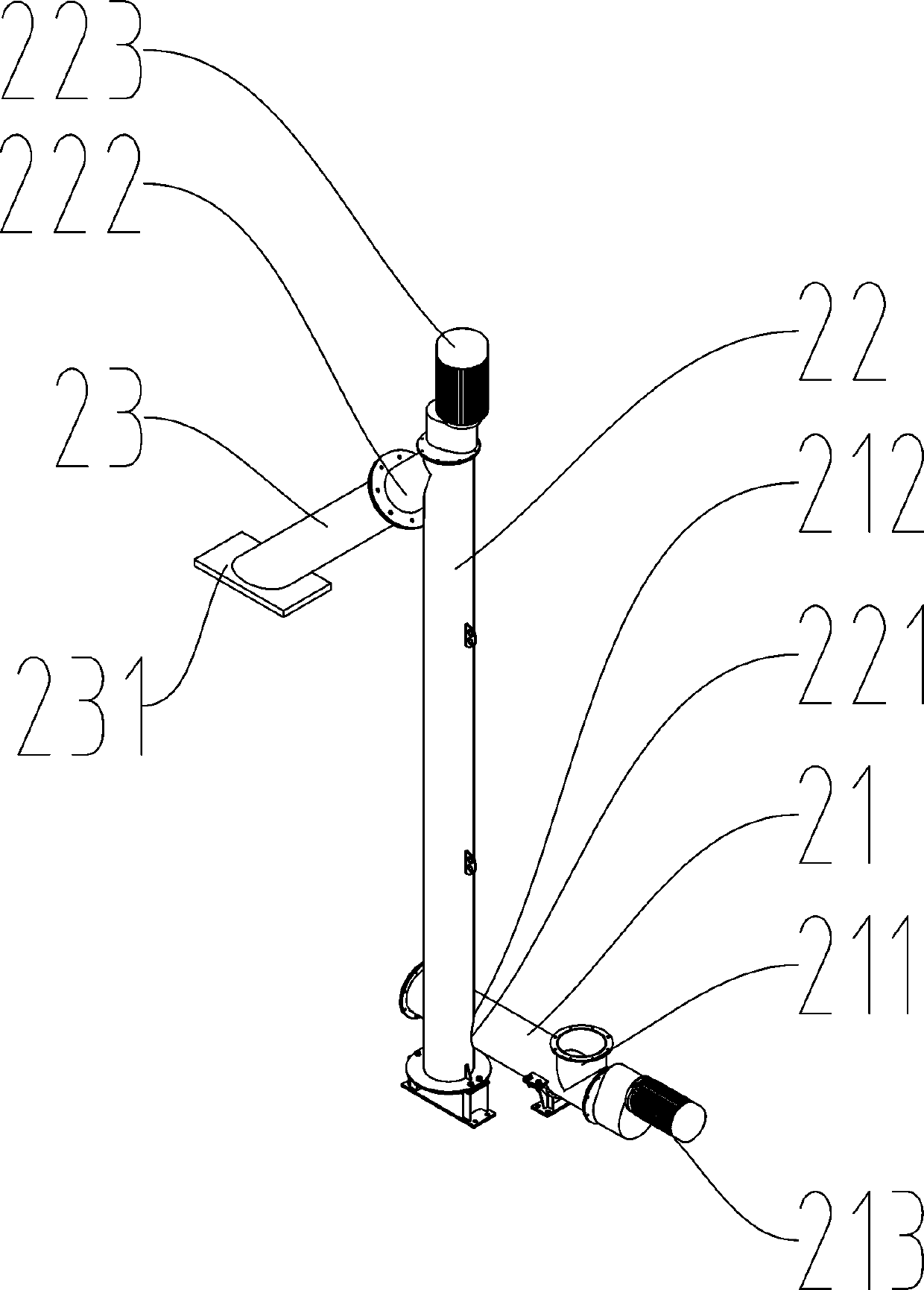

Automatic sand conveying system

PendingCN110482250ARealize automatic transferAchieve finishingConveyorsFlexible bulk container emptying systemsEngineeringPetroleum

The invention relates to the field of petroleum drilling and mining equipment, and particularly relates to an automatic sand conveying system for carrying out modular conveying and full-closed automatic sand conveying. The automatic sand conveying system involves a sand storage device assembly connected with a foundation, a vertical spiral sand conveying assembly fixedly connected with the sand storage device assembly, a mounting frame assembly used for fixing the vertical spiral sand conveying assembly, a horizontal spiral sand conveying assembly fixedly connected with the top of the sand storage device assembly, a spiral sand outlet assembly fixedly connected with the inner bottom of the sand storage device assembly, a sand bag lifting device fixedly connected with the upper part of themounting frame assembly, and a bag breaking device fixedly connected with the mounting frame assembly, and further comprises a rain shielding device fixedly connected with the sand bag lifting device.According to the automatic sand conveying system, the structure is adopted, so that the conveying modularization and the propping agent fully-closed conveying can be realized, and meanwhile, the automatic operation is carried out in the whole process.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

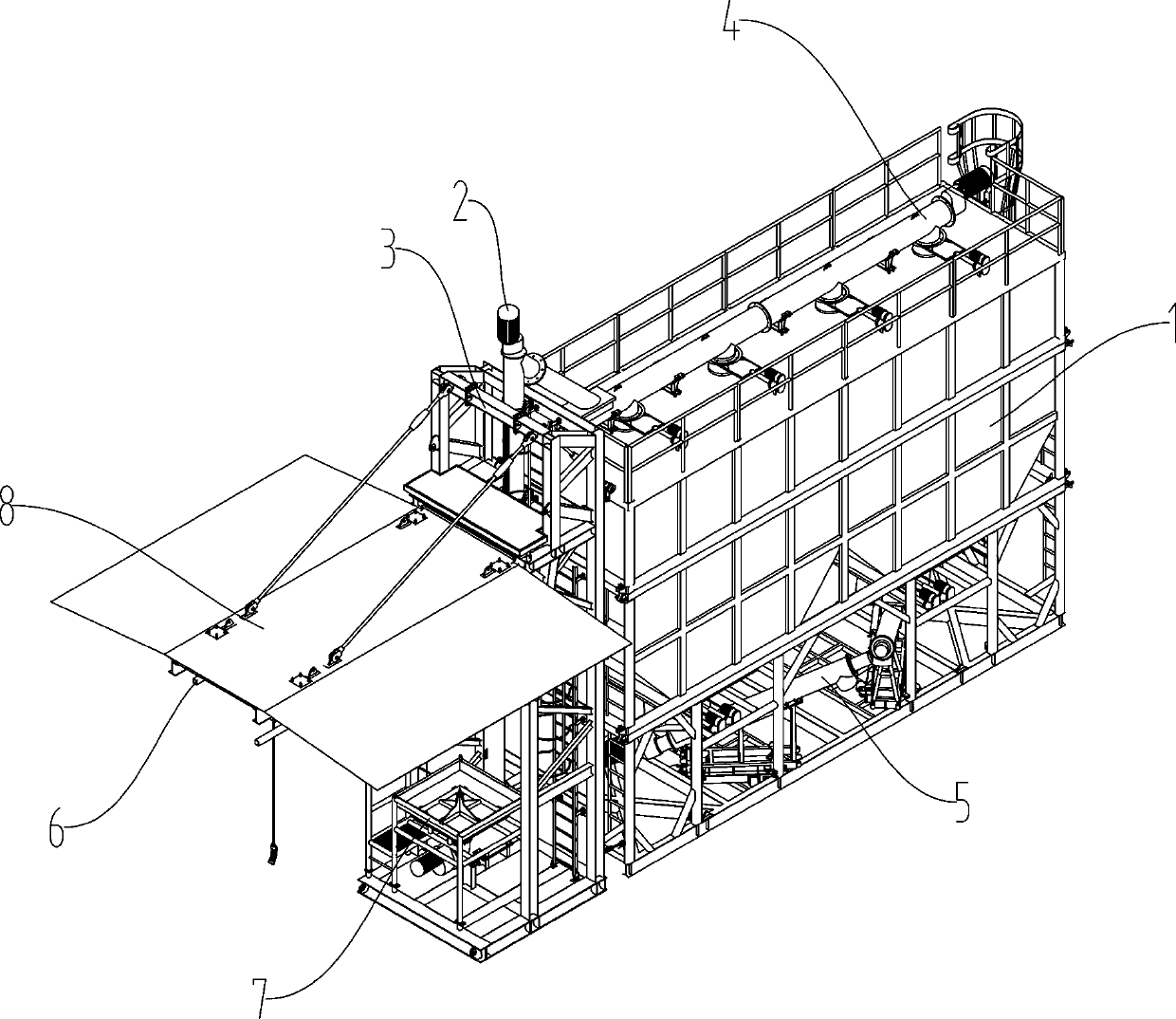

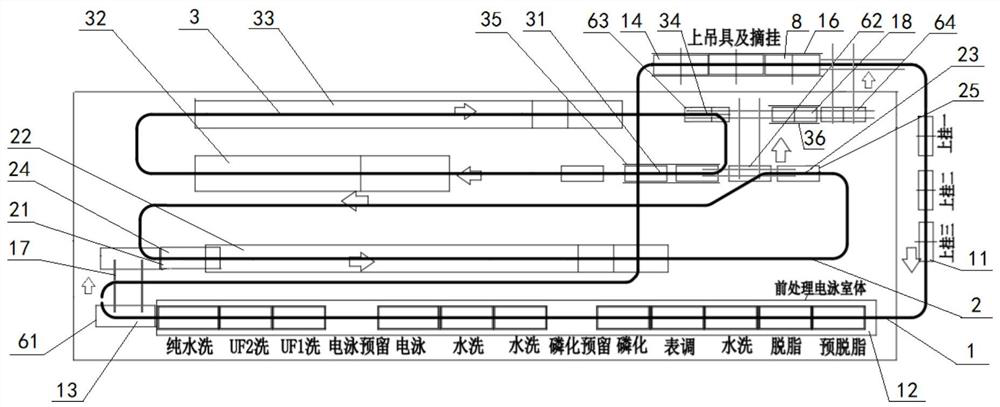

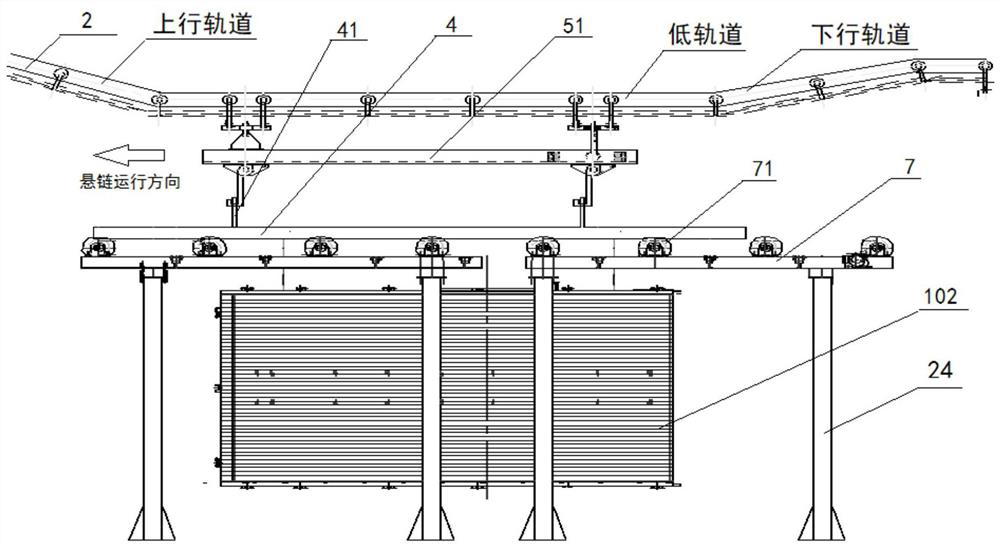

Mixed flow coating line and mixed flow coating method for standard compartment and van vehicles

The invention relates to a mixed flow coating line and a mixed flow coating method for standard compartment and van vehicles. The mixed flow coating line comprises an annular pretreatment track, a primer treatment suspension chain and a finish treatment suspension chain, wherein a hanging station, a pretreatment electrophoresis chamber, a pretreatment discharging station and a picking and hangingstation are sequentially arranged below the pretreatment track in the running direction of an electric hoist; a primer feeding station, a primer drying furnace and a primer discharging station are sequentially arranged below the primer drying suspension chain in the rotating direction of a suspension chain track; a finish feeding station, a paint spraying chamber, a finish drying furnace and a finish discharging station are sequentially arranged below the finish treatment suspension chain in the rotating direction of the suspension chain track; and to-be-coated parts are suspended on a movablehanging bracket for conveying and a high-position roller way and a transverse moving trolley are matched through a descending track, a low track and an ascending track which are arranged on the suspension chains for rotary hanging and feeding and discharging. According to the design, mixed flow production of the standard compartment and van vehicles is realized through unique coating line arrangement and suspension conveying and rotary hanging modes.

Owner:DONGFENG AUTOMOBILE COMPANY

Automatic plate taking and putting device with mechanical arms matched with code reading

PendingCN110271872ARealize automatic transferImprove efficiencyStacking articlesDe-stacking articlesEngineeringTransfer mechanism

The invention relates to the technical field of plate code reading machining, in particular to an automatic plate taking and putting device with mechanical arms matched with code reading. The automatic plate taking and putting device with the mechanical arms matched with code reading comprises a first feeding mechanism, a conveying mechanism, a code reading mechanism, a material transferring mechanism, a positioning mechanism and a transferring mechanism. The first feeding mechanism transfers a plate to the conveying mechanism. The conveying mechanism conveys the plate transferred by the first feeding mechanism to the code reading mechanism. The code reading mechanism carries out code reading processing on the plate conveyed by the conveying mechanism. The material transferring mechanism transfers the plate subjected to code reading of the code reading mechanism to the positioning mechanism. The positioning mechanism positions the plate transferred by the material transferring mechanism. The transferring mechanism transfers the plate positioned by the positioning mechanism. In the using process of the automatic plate taking and putting device, the transferring mechanism transfers the plate positioned by the positioning mechanism to operating equipment to be subjected to automatic machining treatment, automatic code reading and automatic transferring of the plate are achieved, the code reading efficiency and the transferring efficiency of the plate are improved, and the production manufacturing efficiency of the plate is improved.

Owner:XUNDE MACHINERY DONGGUAN CO LTD

Full-automatic detection line for size of inner cavity of rotatory body

PendingCN110940274AImprove efficiencyImprove detection accuracyUsing optical meansSortingPhysicsInternal cavity

The invention provides a full-automatic detection line for the size of an inner cavity of a rotary body, which belongs to the technical field of detection of the size of the inner cavity of the rotarybody and comprises a feeding conveying line, an opening and inner cavity cleaning device, a primary shaping device, a feeding transfer device, a size detection device, a discharging transfer device,a discharging conveying line and an unqualified product buffer trolley. According to the full-automatic detection line for the size of the inner cavity of the rotary body, automation of the detectionprocess is achieved, manual detection is replaced, efficiency is improved, and detection precision is improved.

Owner:SHANXI DIMAI WOKE PHOTOELECTRIC IND CO LTD

Cutting machining device for spherical-surface workpieces

ActiveCN110586962ARealize automatic transferSmooth rotationAutomatic control devicesFeeding apparatusMechanical equipmentTransfer mechanism

The invention discloses a cutting machining device for spherical-surface workpieces, and belongs to the field of workpiece machining mechanical equipment. The cutting machining device comprises a machining conveying support, a horizontal moving and cutting mechanism, a clamping and lifting mechanism, a turning and transferring mechanism and a workpiece conveying mechanism, wherein the horizontal moving and cutting mechanism is horizontally and fixedly arranged on one side above the machining conveying support, the clamping and lifting mechanism is vertically arranged at the position, on one side of the horizontal moving and cutting mechanism, of the machining conveying support, the turning and transferring mechanism is vertically arranged at the position, on one side below the clamping andlifting mechanism, of the machining conveying support, and the workpiece conveying mechanism is horizontally arranged at the position, on one side of the turning and transferring mechanism, of the machining conveying support in a mode of being adjacent to the turning and transferring mechanism. The cutting machining device has the advantages that the structural design is reasonable, the spherical-surface workpieces can be efficiently and stably cut and machined one by one, moreover, automatic transferring feeding and pushing of the spherical-surface workpieces can be achieved, the machining automation degree is high, and the workpiece machining and use requirements are met.

Owner:昆山勖盟工业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com