Hot ironing machine

A technology of hot ironing machine and hot ironing, which is applied in printing presses, rotary printing machines, printing and other directions, can solve the problem that the hot ironing machine cannot automatically transfer in batches, etc., and achieves the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

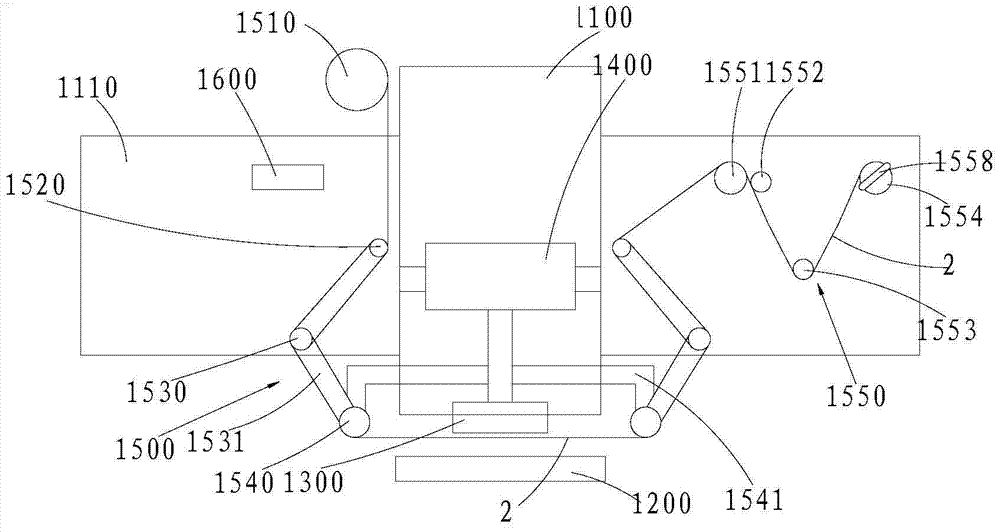

[0025] Such as figure 1 As shown, a hot stamping machine includes a frame 1100, a hot pressing platform 1200, a hot pressing block 1300, a cylinder 1400, a hot stamping label paper conveying mechanism 1500, and a label paper sensor 1600.

[0026] Two supporting arms 1110 are respectively provided on both sides of the frame 1100, and the two supporting arms 1110 on each side are arranged at intervals in the horizontal direction.

[0027] The hot pressing platform 1200 is arranged under the frame 1100 and is used to place the transfer target objects, such as cloth.

[0028] The hot pressing block 1300 is located above the hot pressing platform 1200, and the hot pressing block 1300 is drivingly connected to a cylinder 1400, which is vertically arranged in the frame 1100.

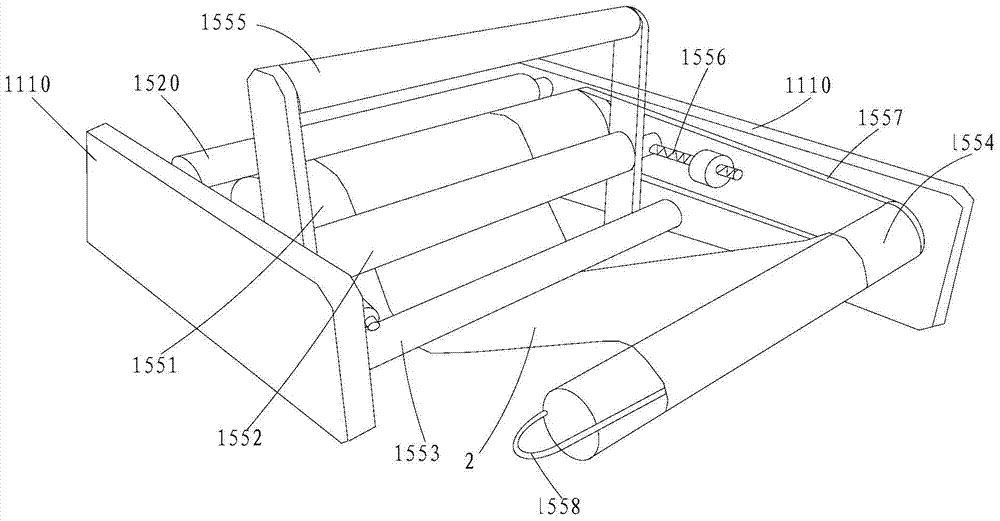

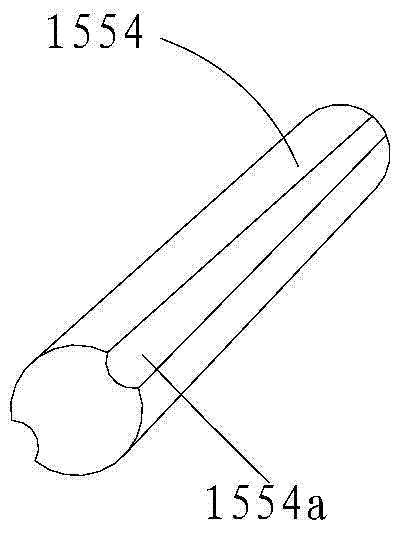

[0029] The hot label paper conveying mechanism 1500 includes an unwinding roller 1510 for fixing the hot label paper roll, two first rollers 1520, two second rollers 1530, two third rollers 1540, and a winding unit 1550...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com