Patents

Literature

717results about How to "Realize feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

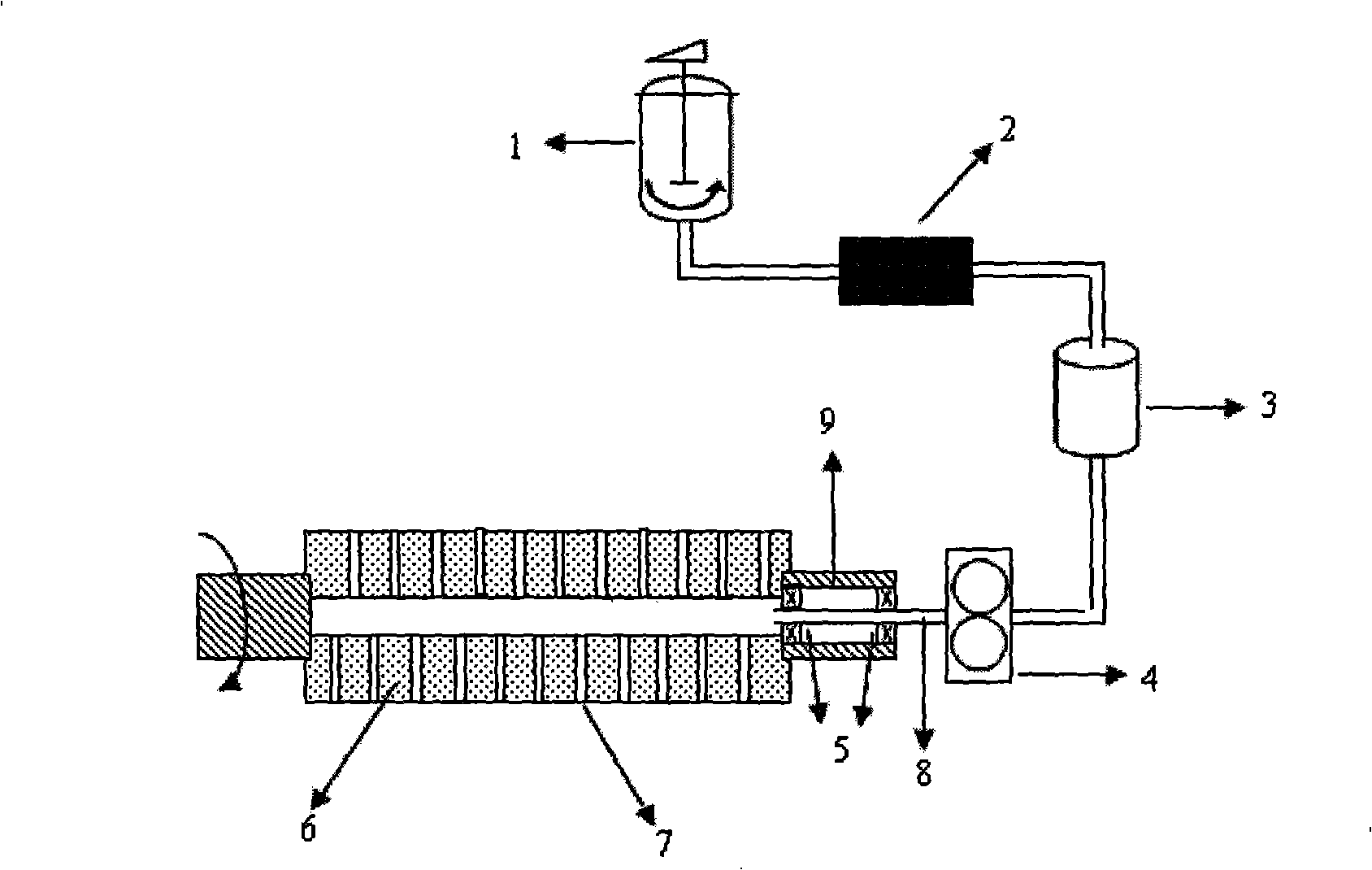

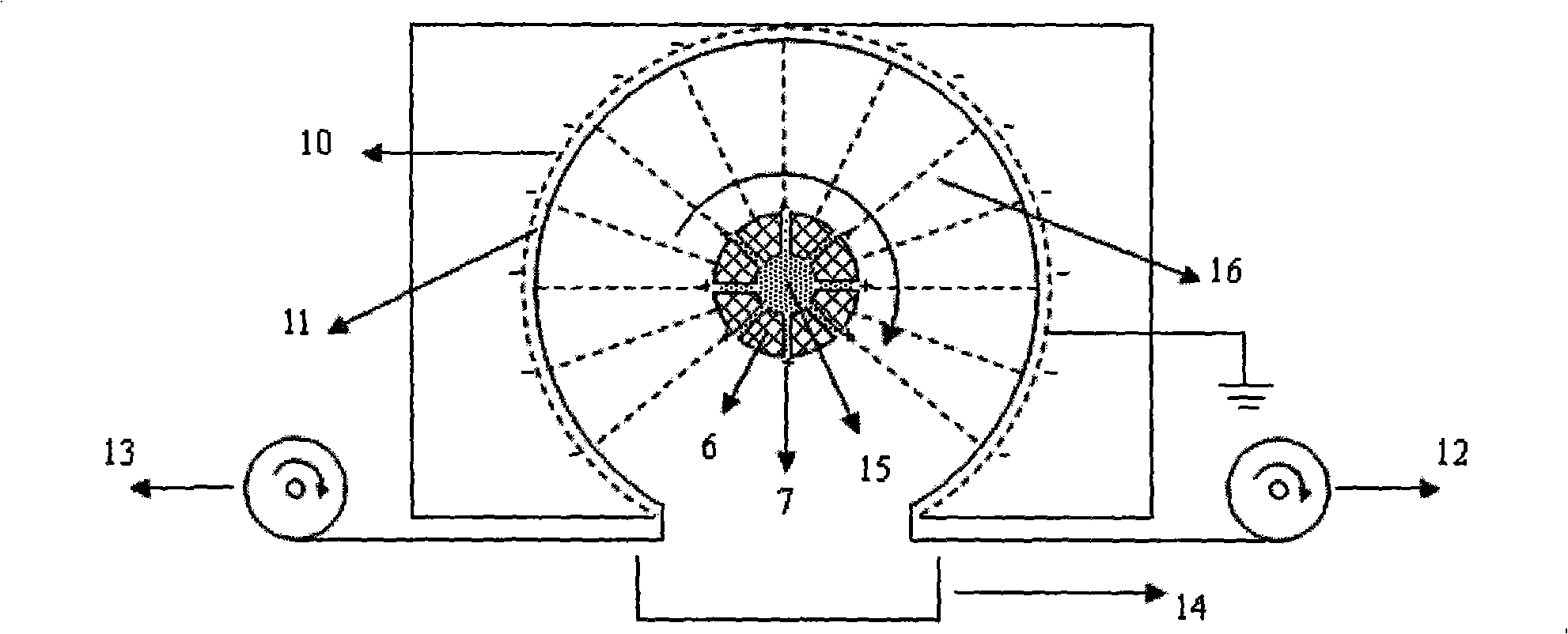

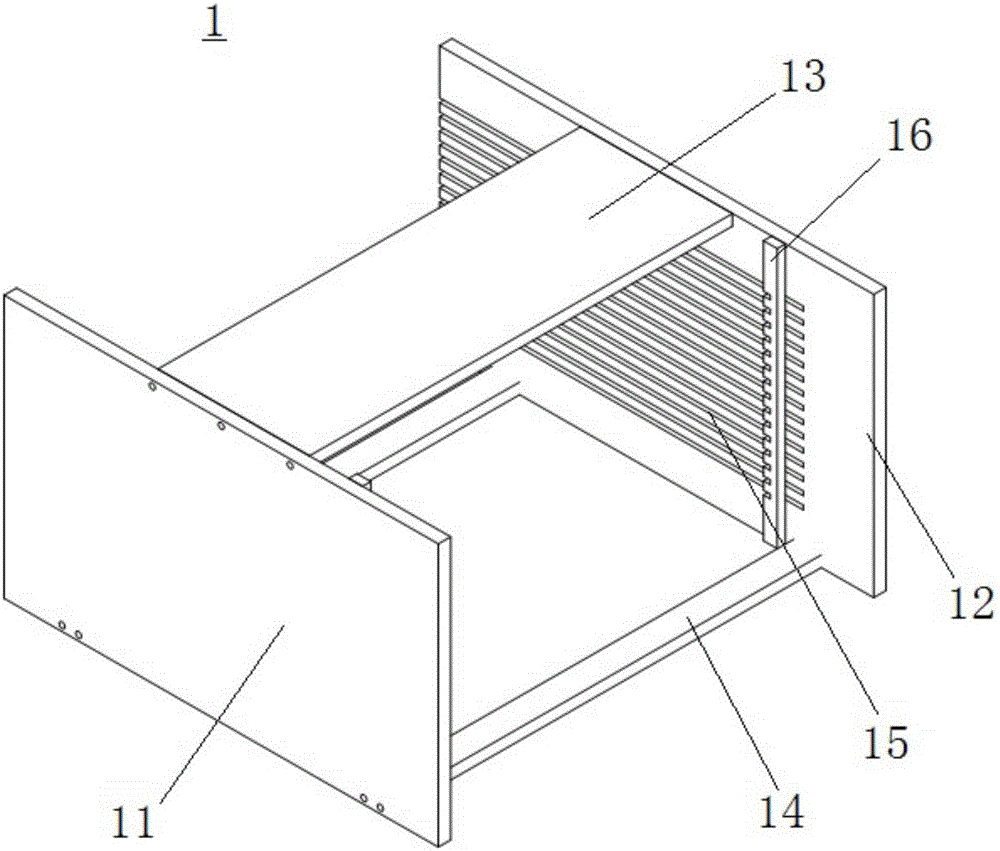

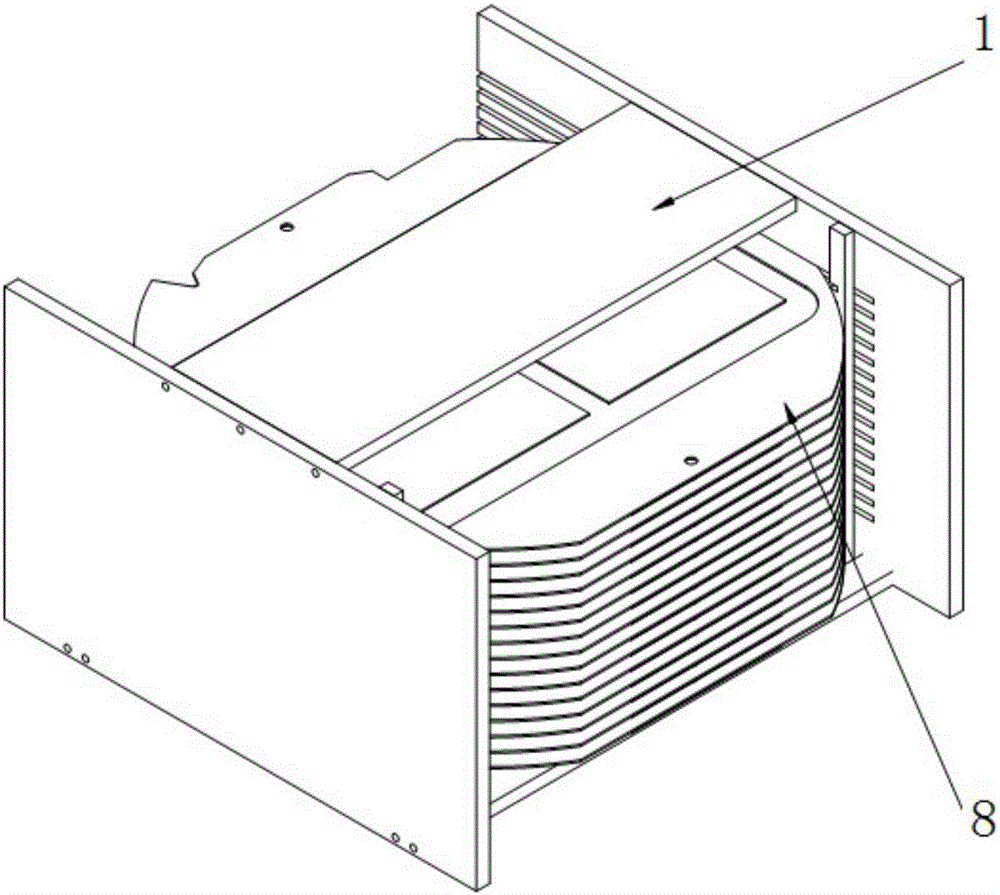

Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

InactiveCN101298724AEvenly distributedAvoid uneven distribution of the jet (16) on the surface of the metal drumSpinnerette packsArtificial filament recoveryElectrospinningNanofiber

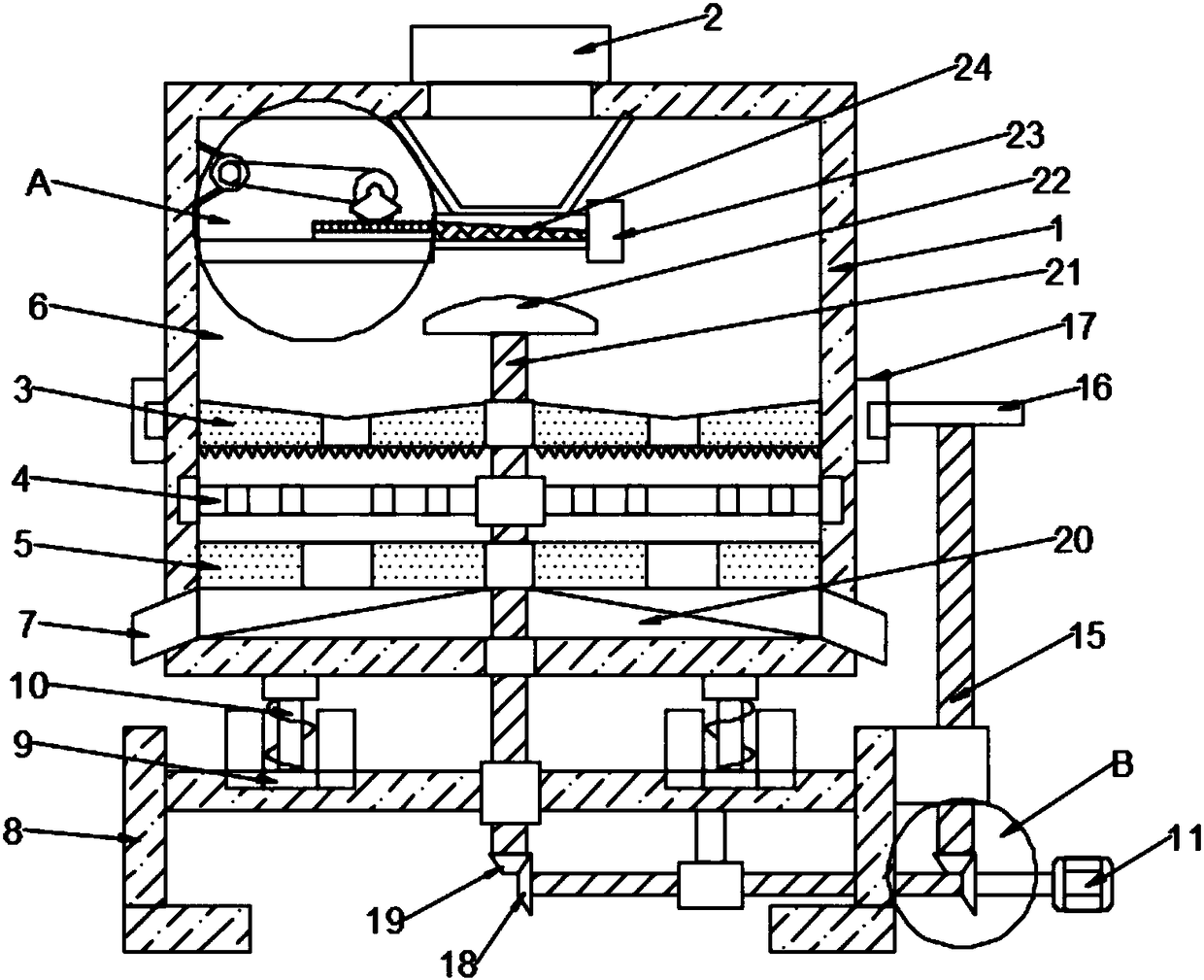

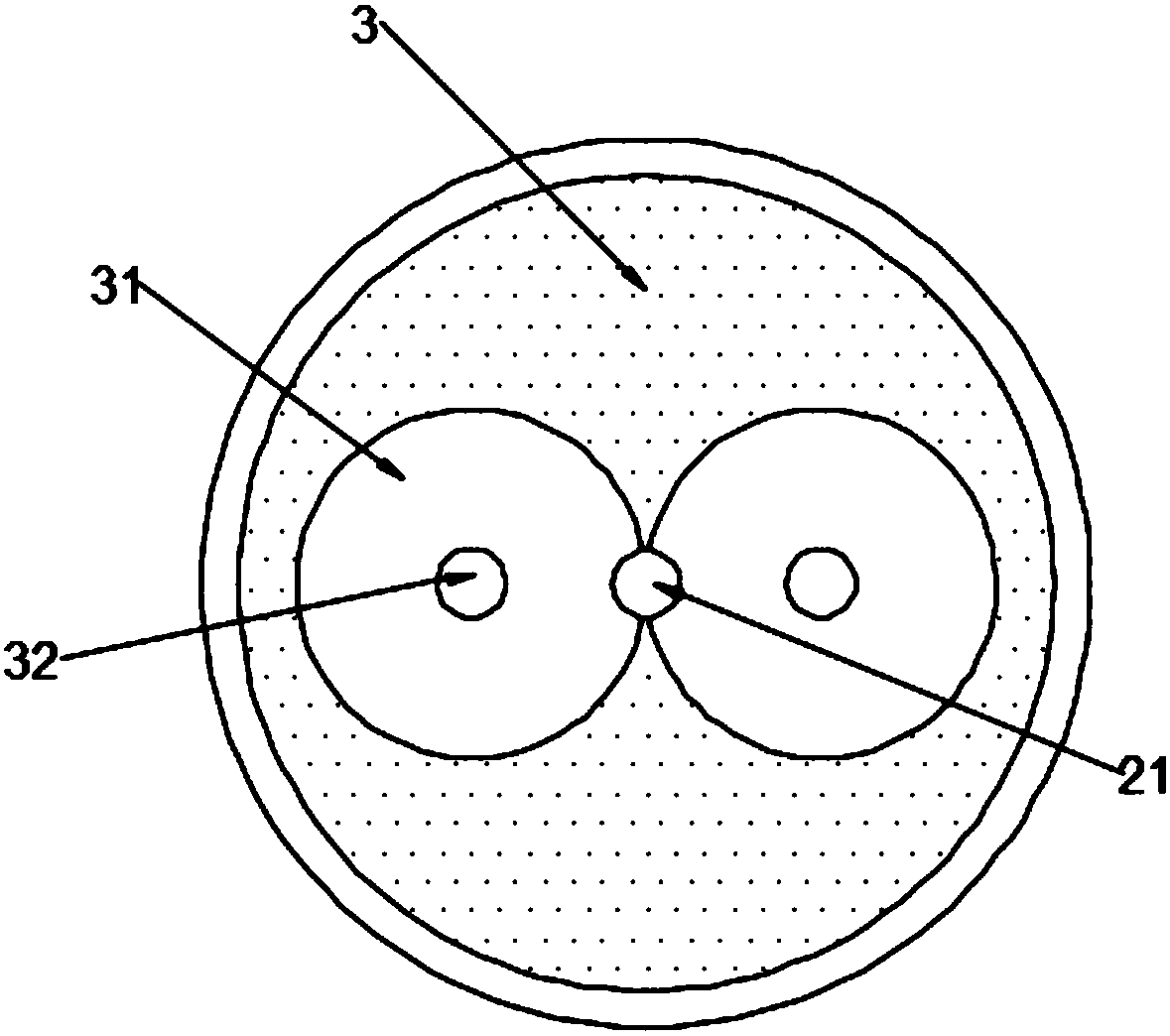

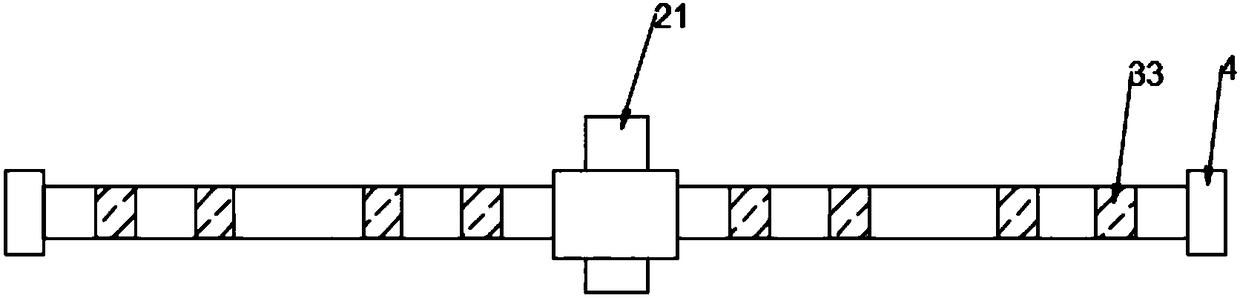

The invention relates to continuous high efficiency nano spinning solution (15), a nanofiber nonwovens manufacturing method and a manufacturing device which not only has high manufacturing efficiency but form better thickness of the nanofiber nonwovens. The manufacturing device comprises a solution supply system, a solution feeding pipe (8), a connecting mechanism and a metal roller (6); a metal strainer (10) and a fiber receiving web (11) which have the same shaft with the metal roller are sequentially arranged on the outside of the metal roller (6), an unreel roller (12) and a winding roller (13) are arranged on the fiber receiving web (11), and pores (7) are cut on the hollow metal roller (6). The manufacturing method includes the steps: (1), polymer spinning solution (15) is prepared; (2), an electric field is arranged between the metal roller (6) and metal strainer (10); (3), the metal roller (6) is revolved at a certain speed; (4) a measuring pump (4) is led to the metal roller (6) for even internal inputting; (5), the nanofiber is received. The invention is good for the scale manufacturing of static spinning.

Owner:DONGHUA UNIV

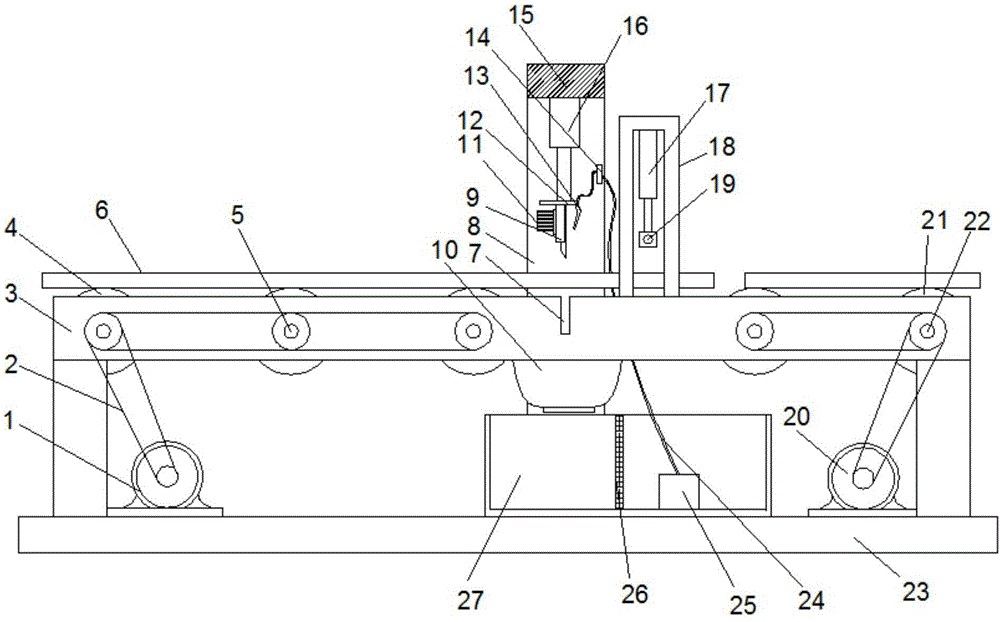

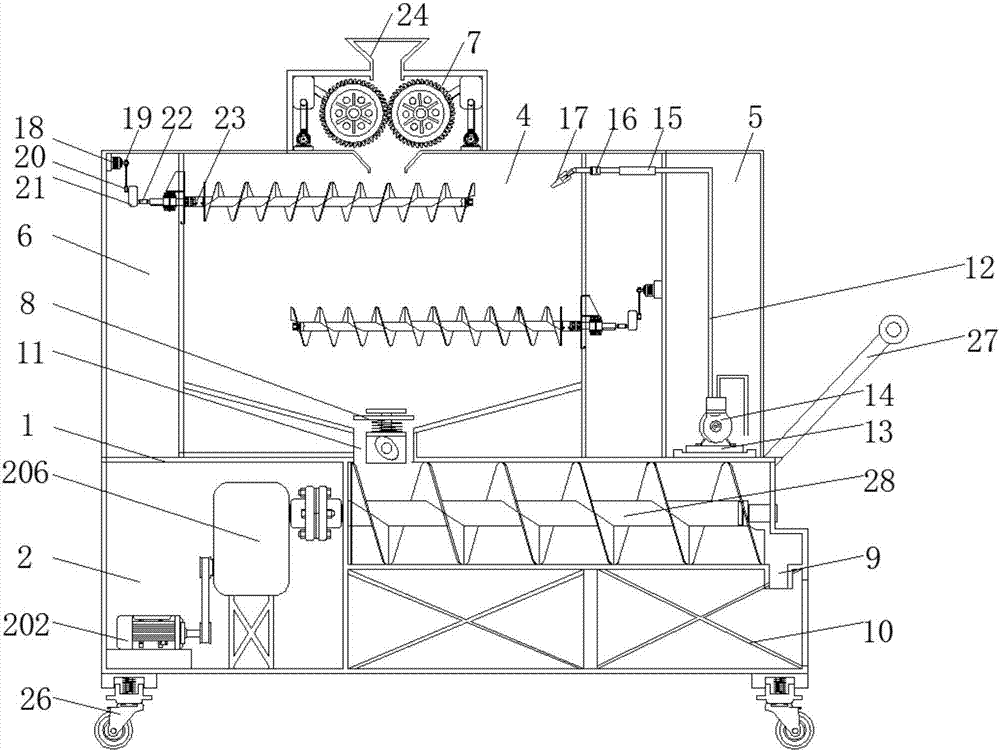

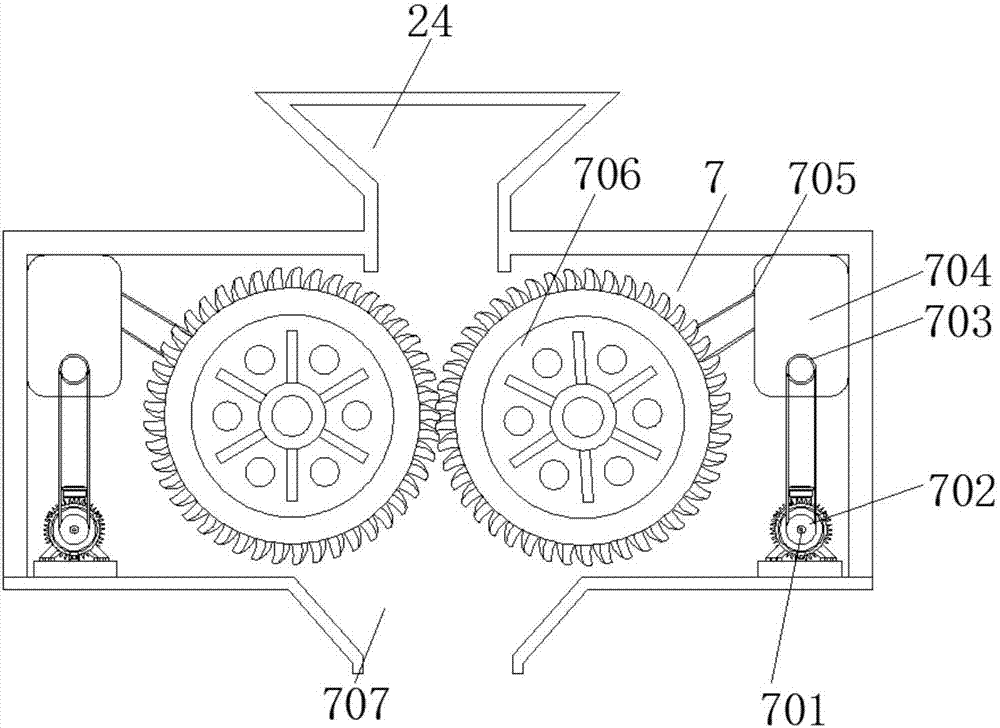

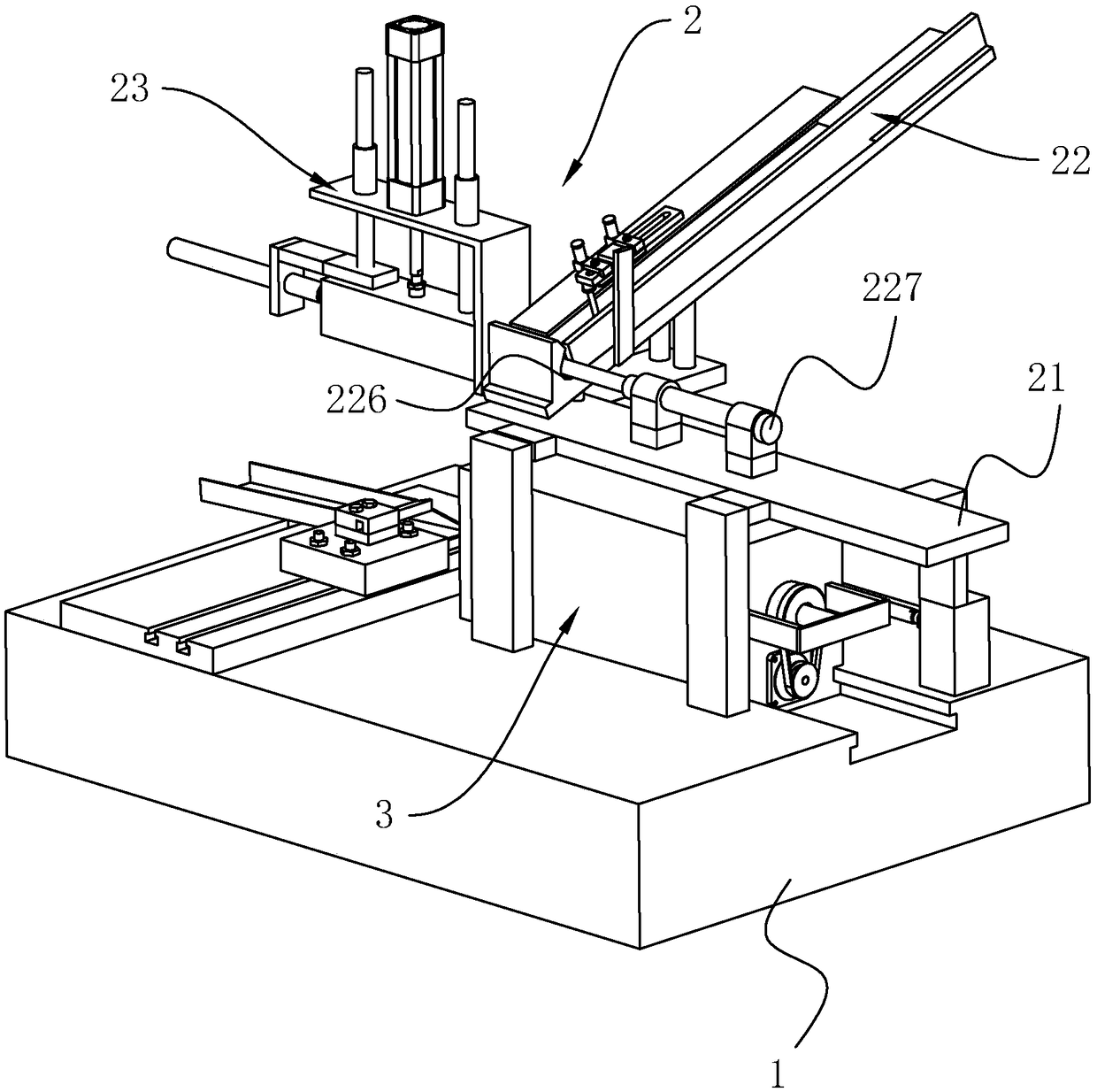

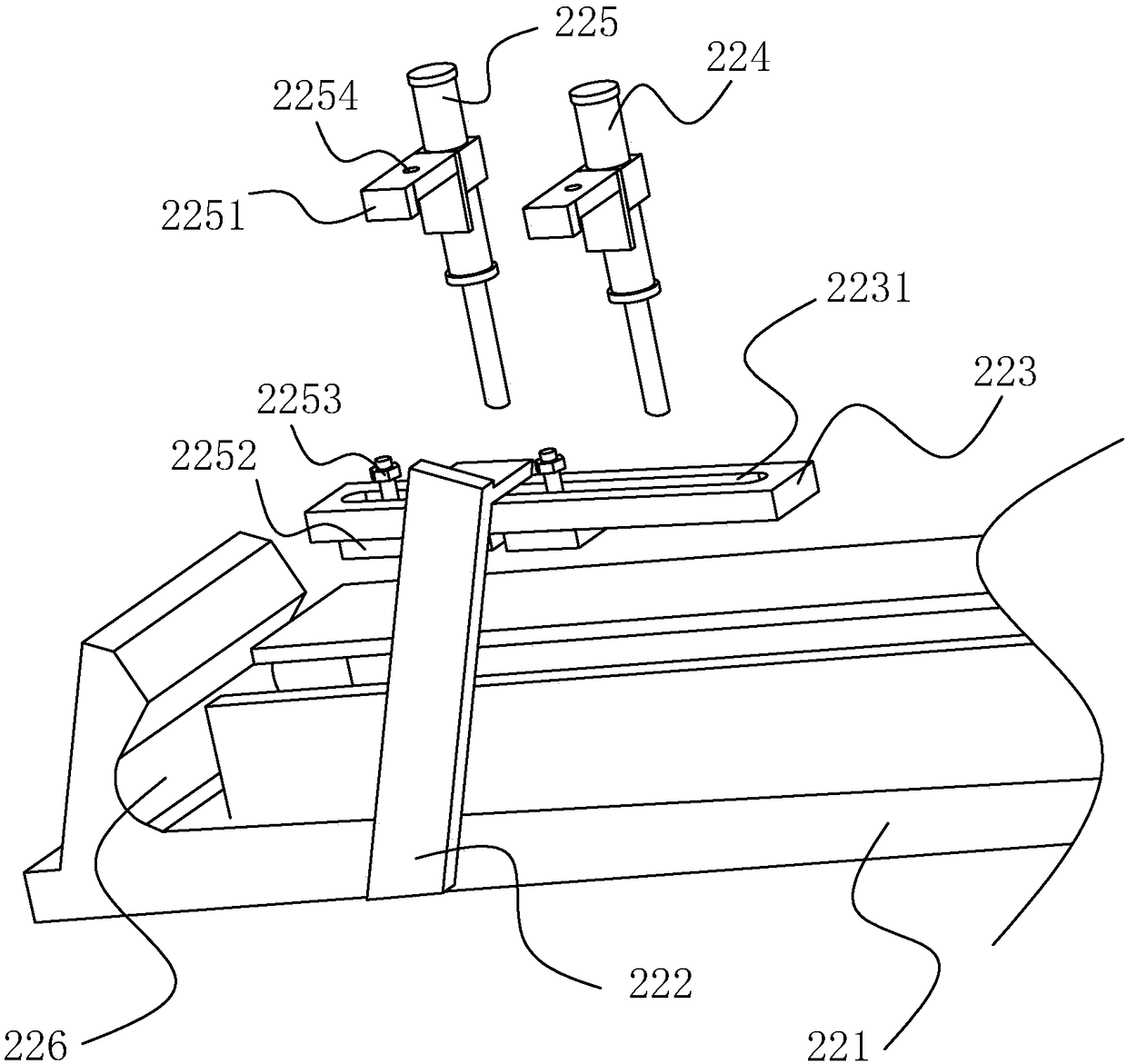

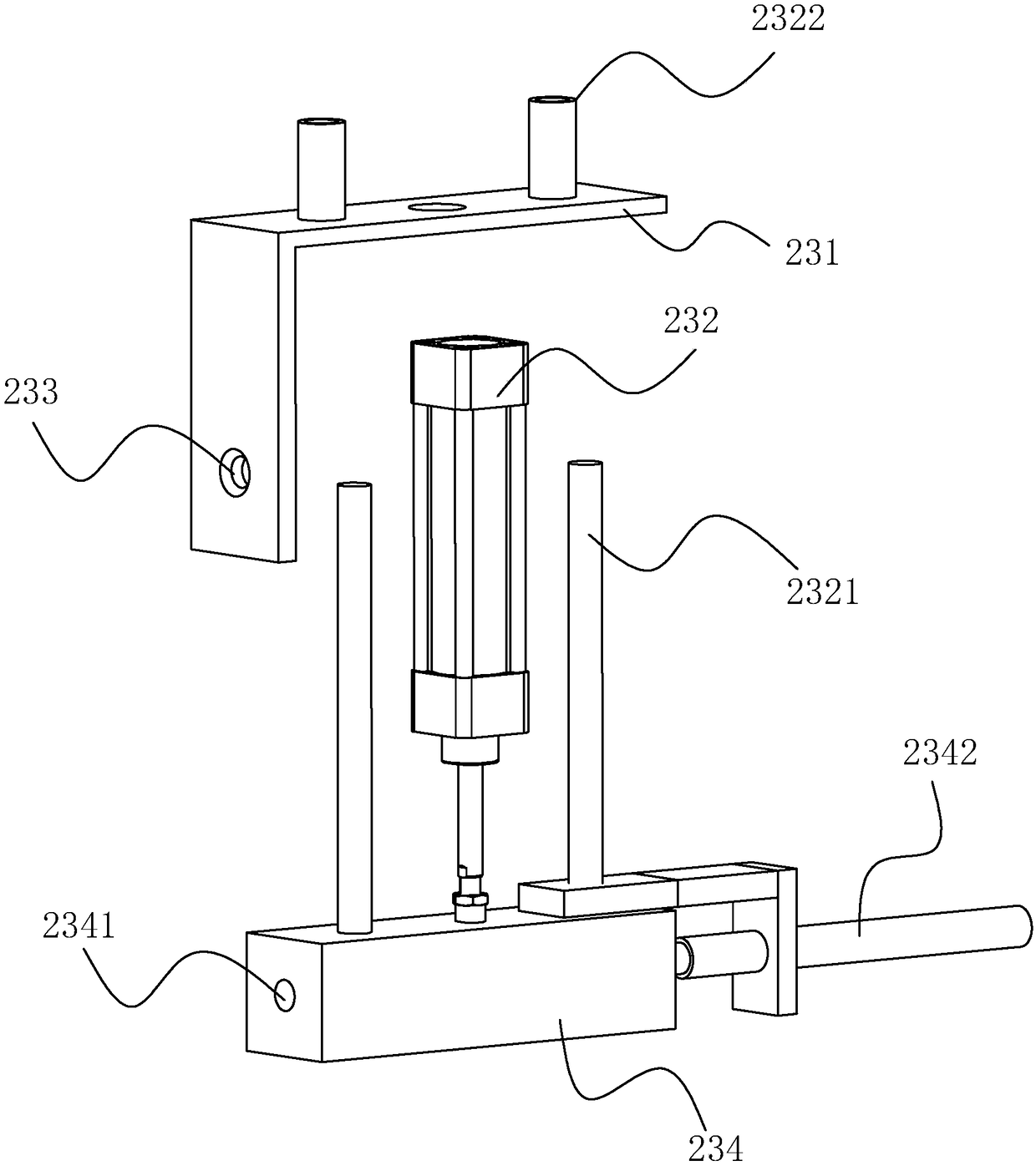

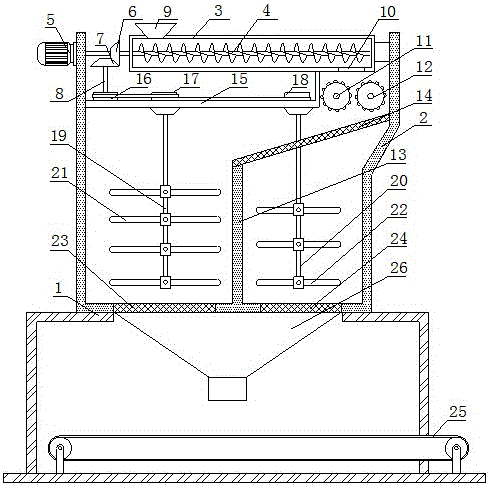

Stainless steel pipe cutting machine

InactiveCN106424899ARealize feedingExtended service lifeWork clamping meansTube shearing machinesEngineeringMechanical engineering

The invention discloses a stainless steel pipe cutting machine which comprises a base and two racks. The racks are arranged at the upper end of the base front and back in parallel. Three sets of upper pipe rolls are arranged between the left ends of the racks at intervals, and the upper pipe rolls are connected with the racks through upper pipe rotary shafts. Belt wheels are arranged at the front ends of the upper pipe rotary shafts, the adjacent belt wheels are in transmission connection through belts, an upper pipe motor is arranged below the left ends of the racks, and the upper pipe motor is in transmission connection with the belt wheel of the upper pipe rotary shaft on the left side through the corresponding belt. The stainless steel pipe cutting machine is reasonable in structural design and convenient to use, and the pipe feeding, pressing, cutting and pipe discharging procedures of stainless steel pipes can be achieved. During cutting, effective cooling can be carried out, heating can be reduced, and the service life of a cutting tool can be prolonged. Sprayed cooling liquid can be recycled and filtered, circulating use is achieved, and cost is reduced.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

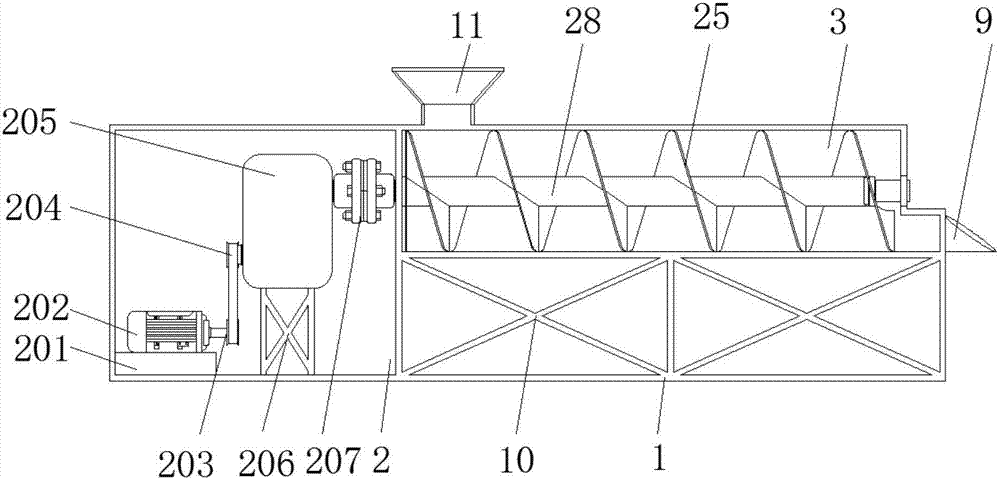

Movable efficient stirring machine used for civil engineering

InactiveCN107225680AQuality assuranceEnsure safetyDischarging apparatusMixing operation control apparatusLeather beltReduction drive

The invention discloses a movable efficient stirring machine used for civil engineering. The movable efficient stirring machine comprises a box body. A transmission device is fixedly connected to one side of an inner cavity of the box body. The top of the outer wall of the box body is fixedly connected with a stirring box. Stirring power boxes are arranged on the two sides of the inner cavity of the stirring box. Stirring motors are fixedly connected to the inner walls of the stirring power boxes and are connected with first belt wheels through output shafts in a rotating manner. The first belt wheels are connected with second belt wheels through belts in a rotating manner. The stirring motors are connected with first speed reducers through the first belt wheels and the second belt wheels in a rotating manner. The invention relates to the technical field of civil engineering machines. The movable efficient stirring machine used for the civil engineering achieves the aim of making concrete more uniform by conducting smashing and then conducting stirring on the to-be-stirred concrete, stable and controllable water addition of the stirring box and stable discharge of a discharge port are achieved, quality of the concrete is ensured, and the aim of moving the stirring machine is achieved.

Owner:中鸿瑞达(厦门)科技有限公司

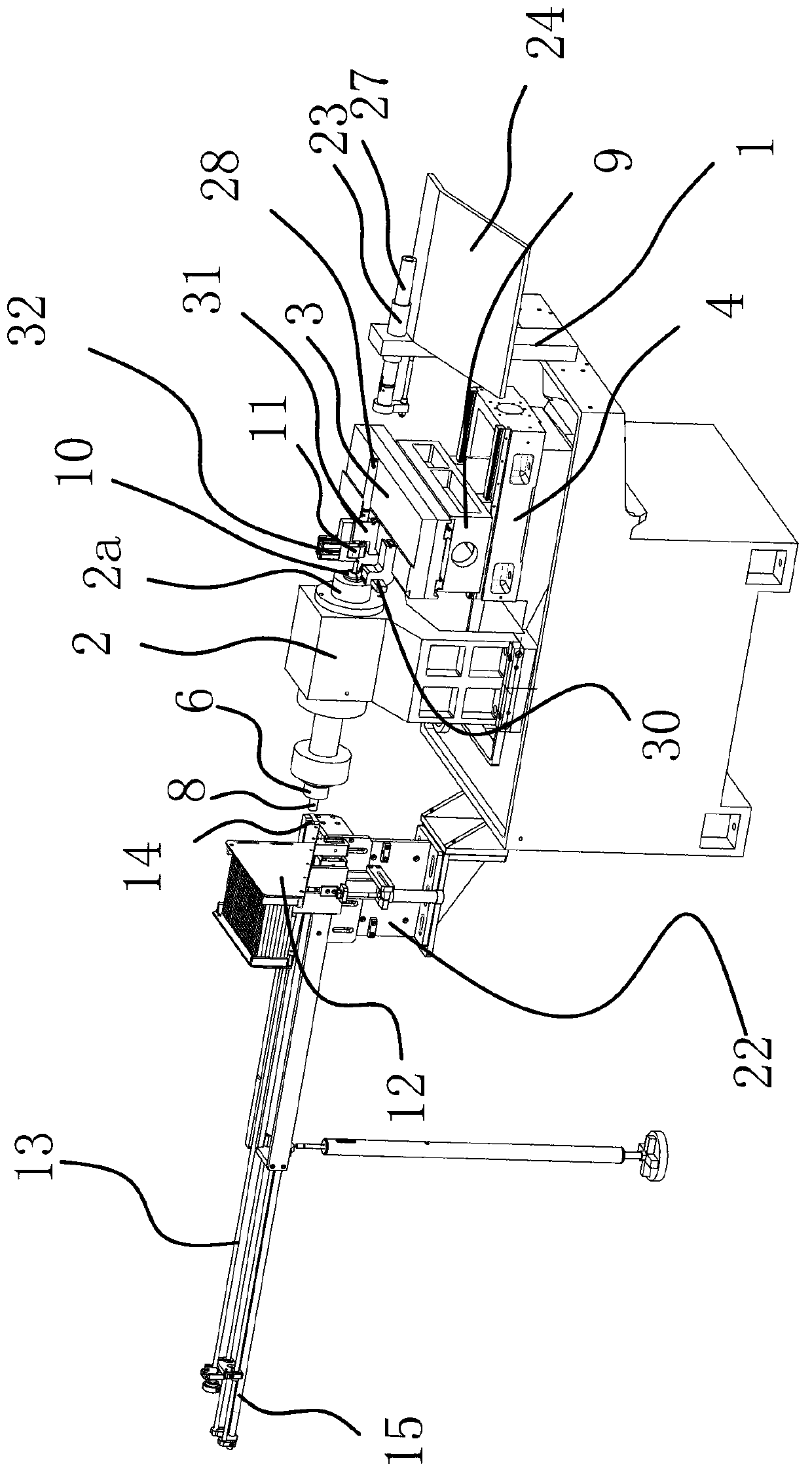

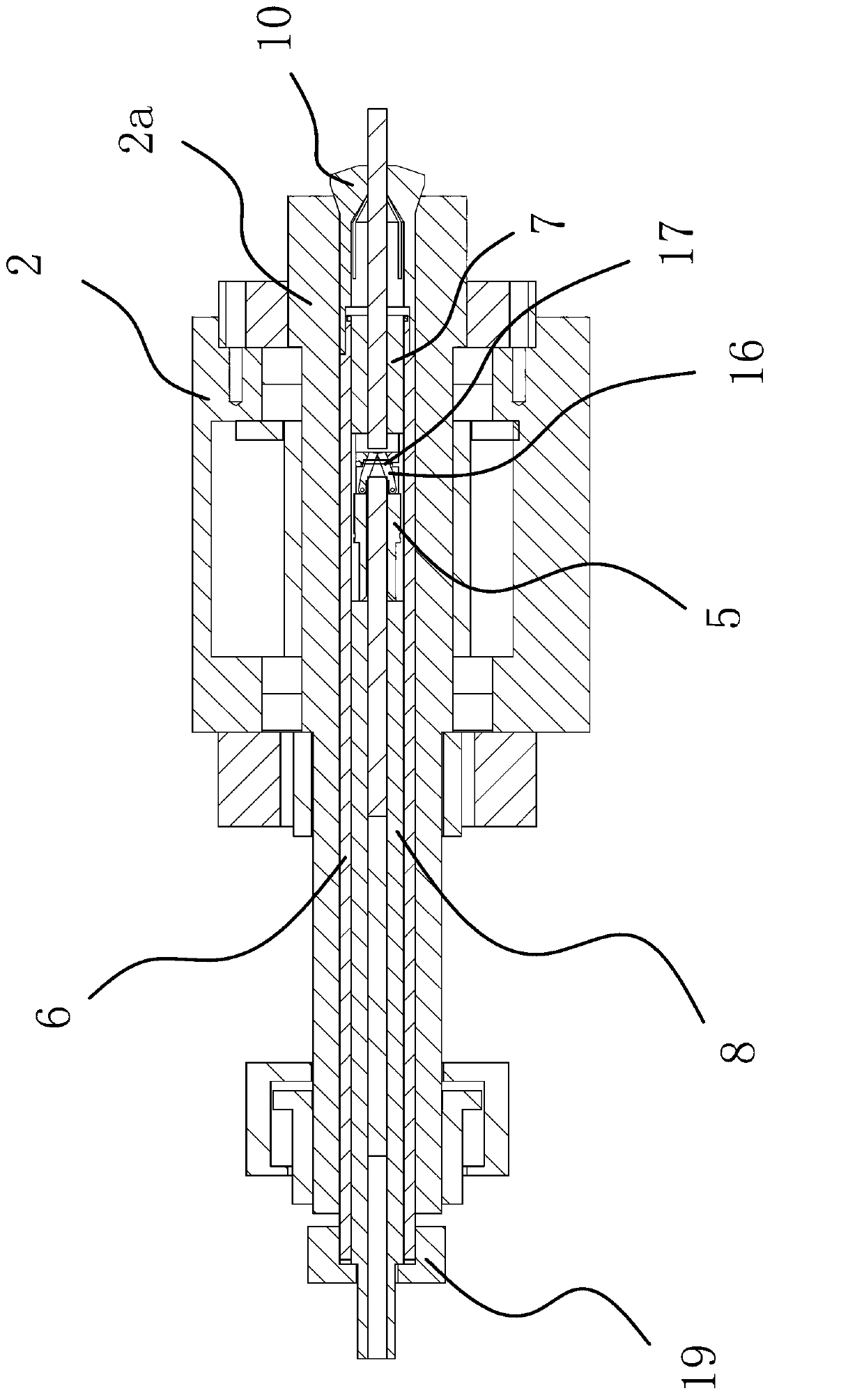

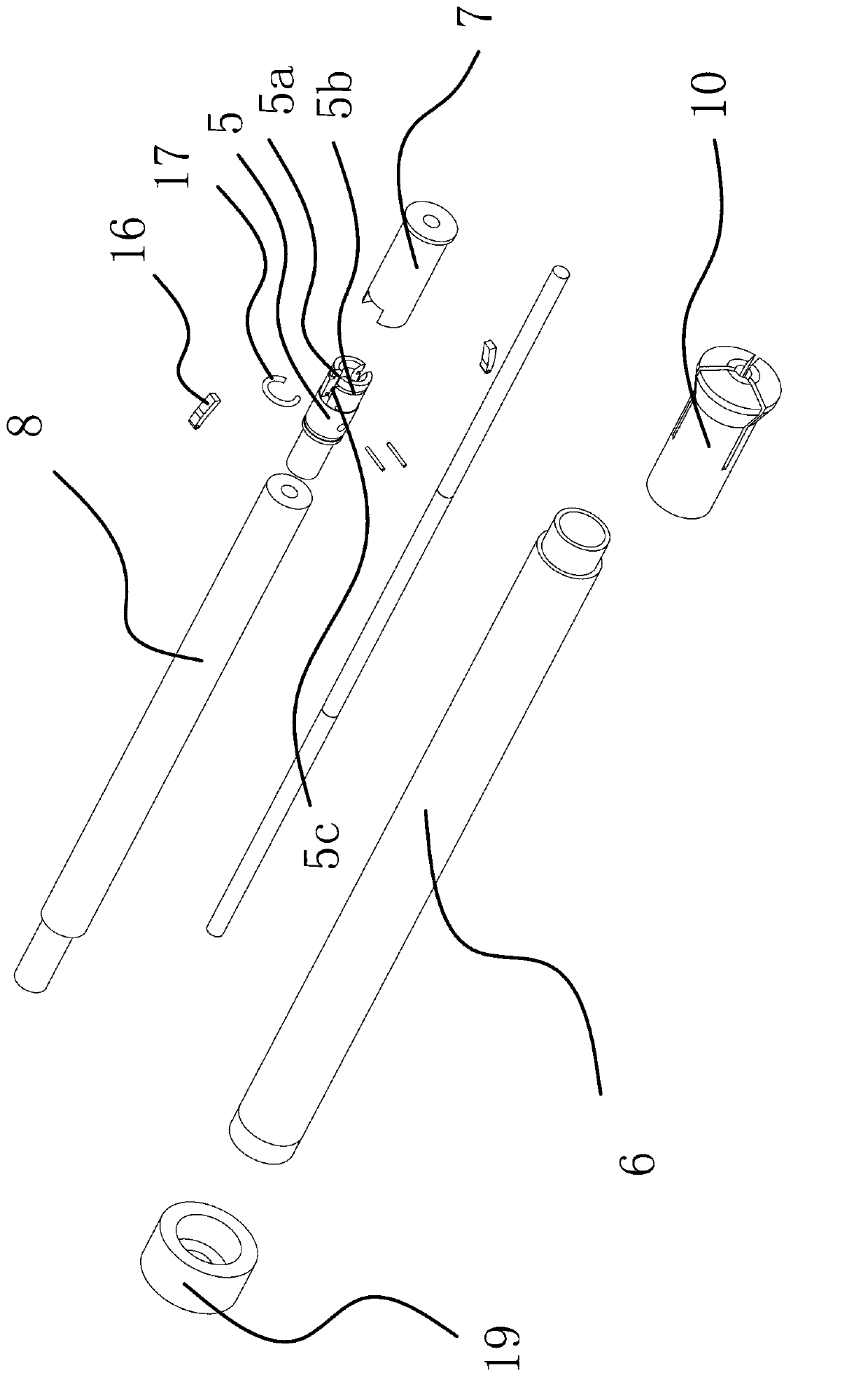

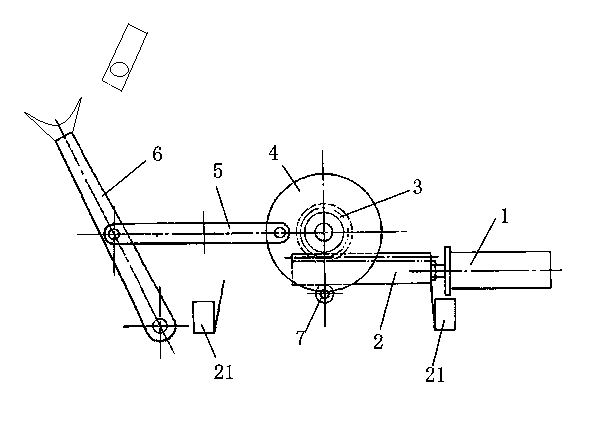

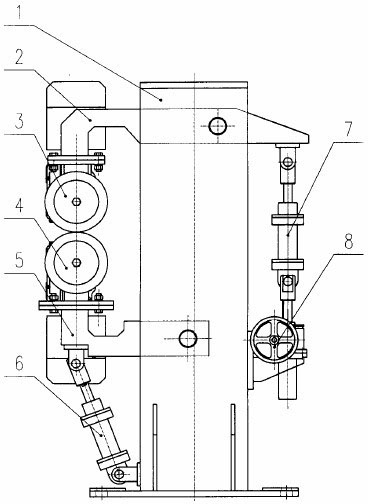

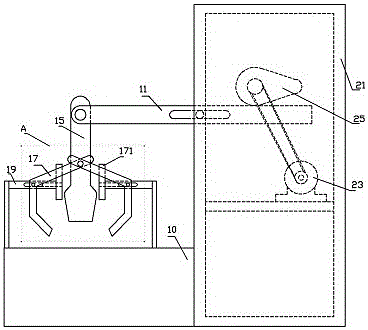

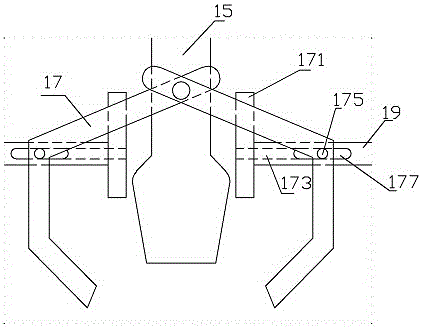

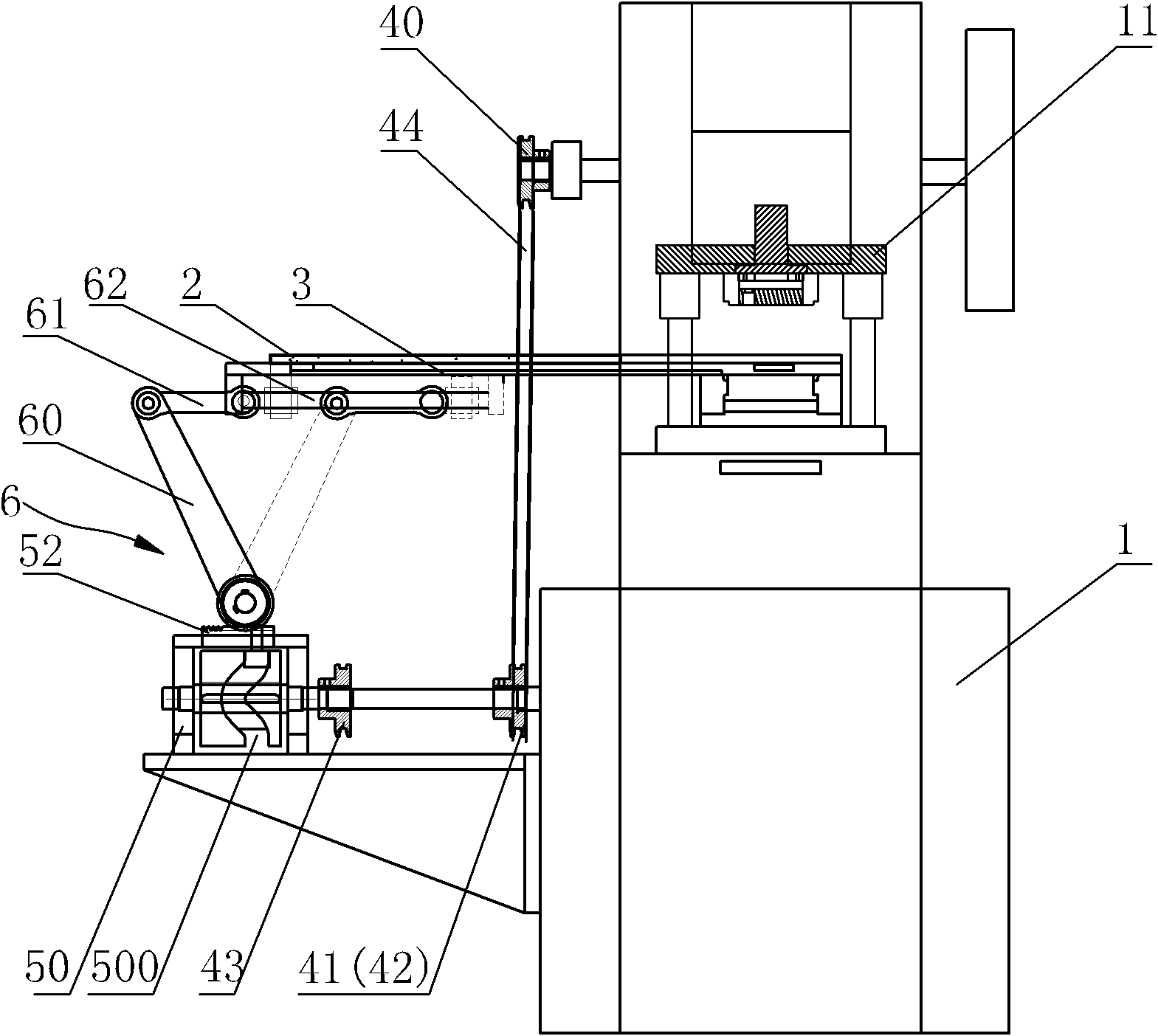

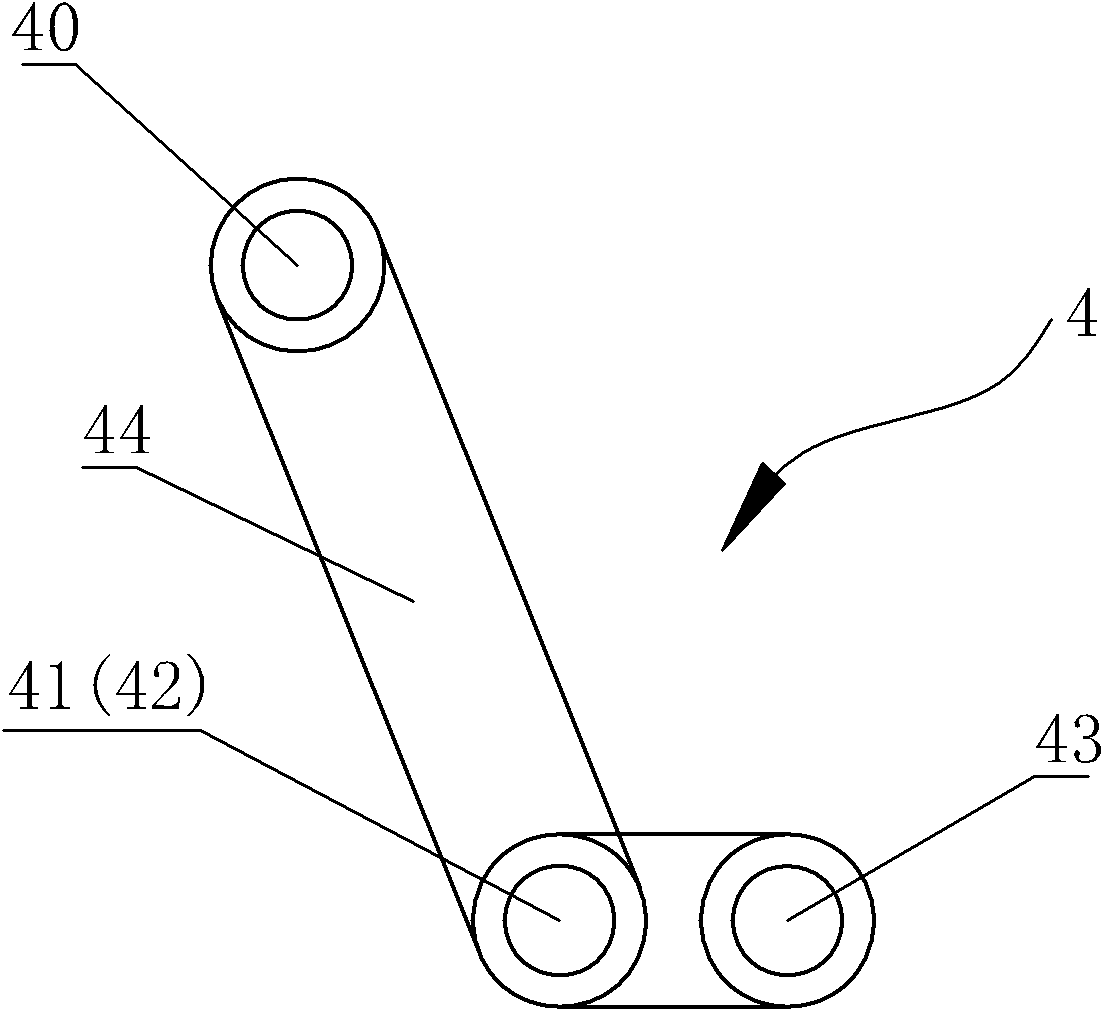

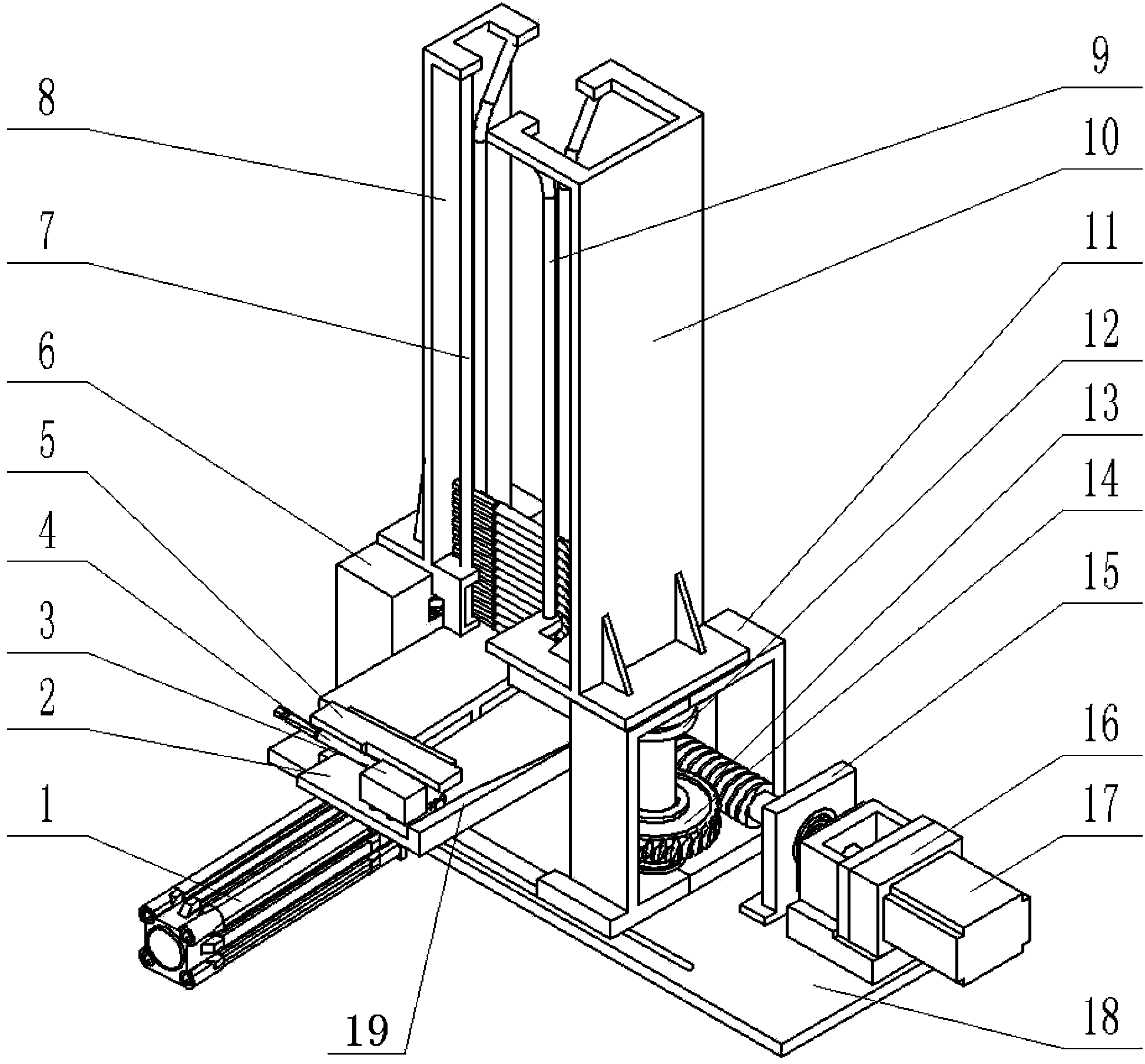

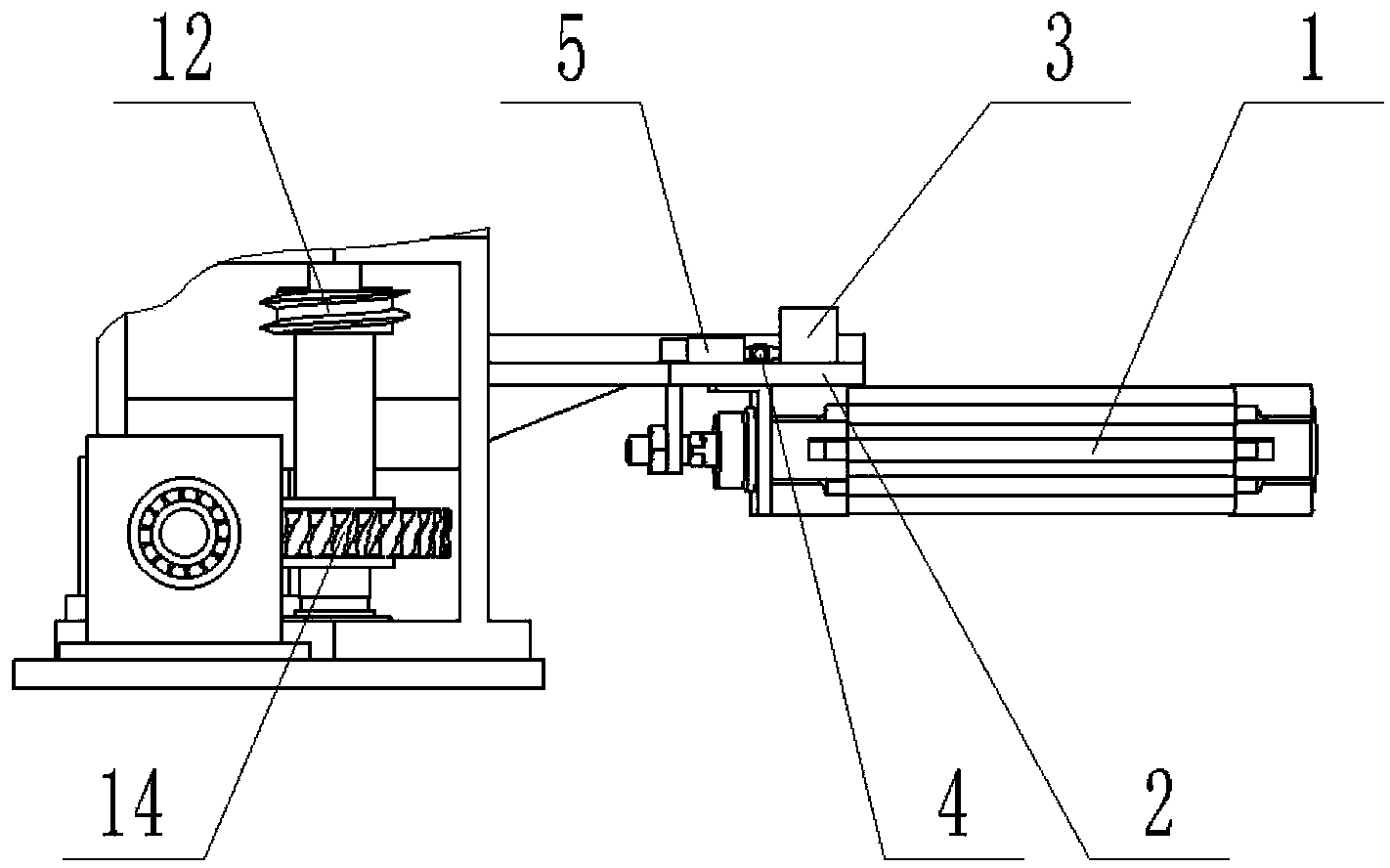

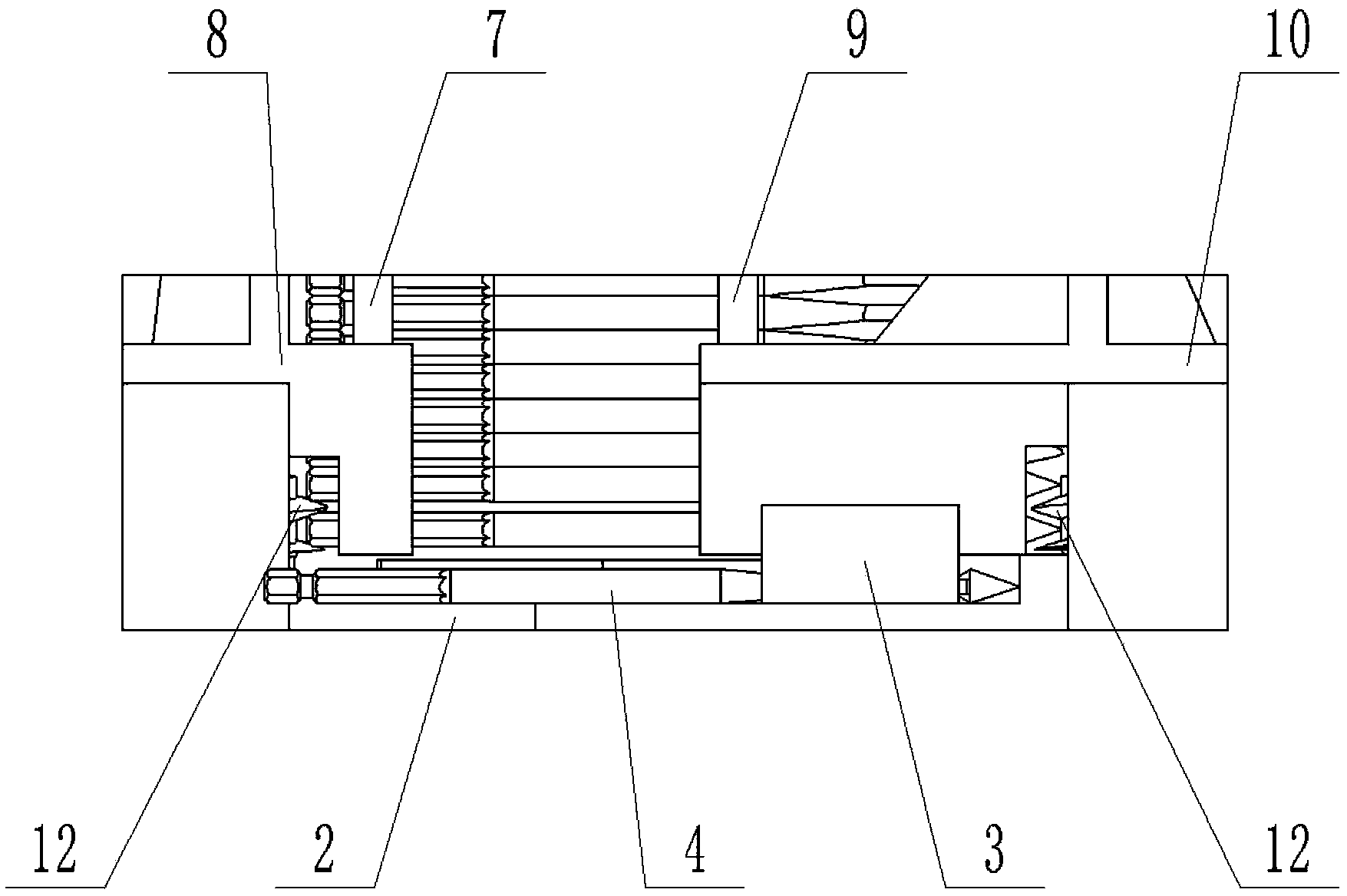

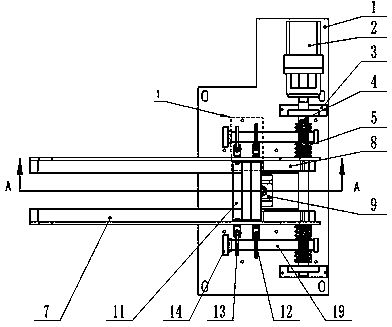

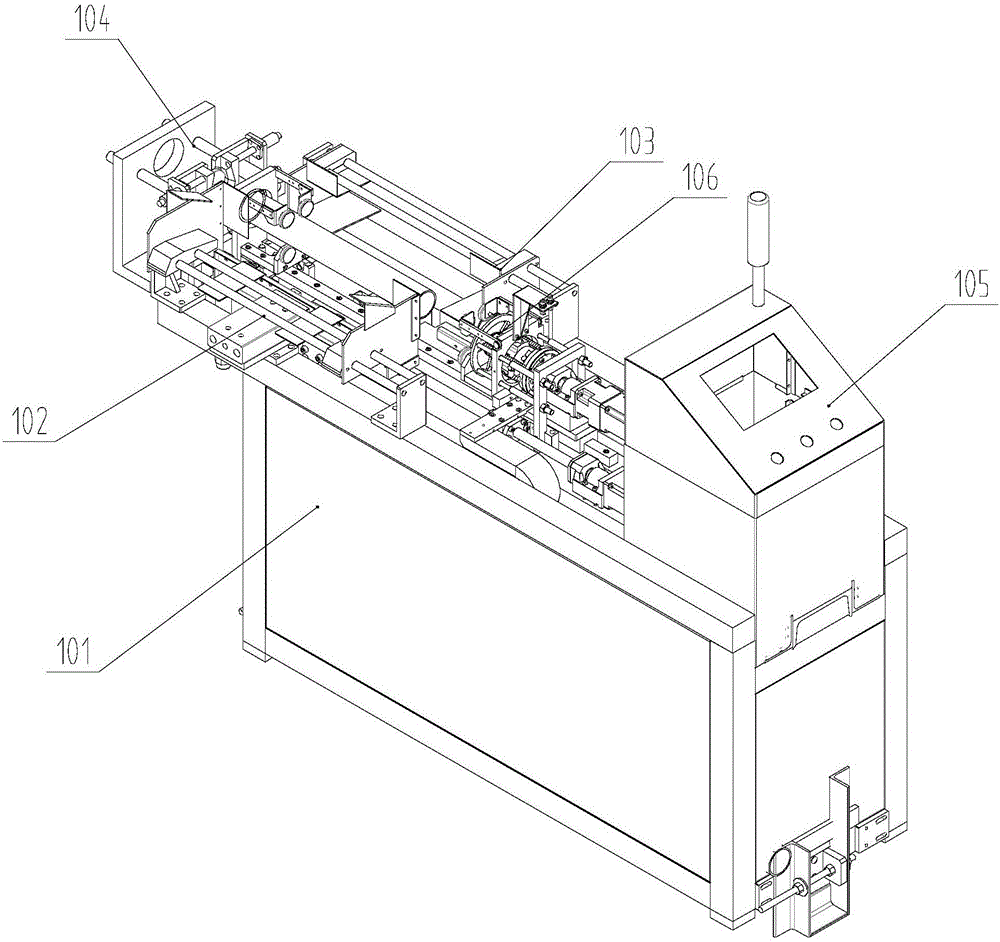

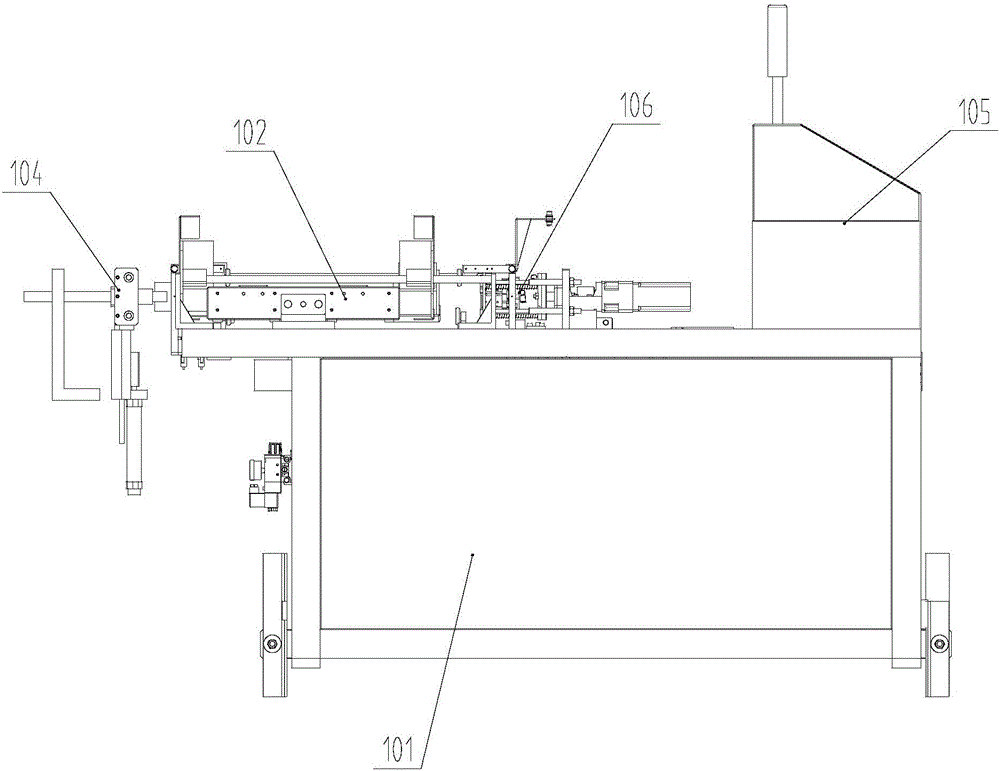

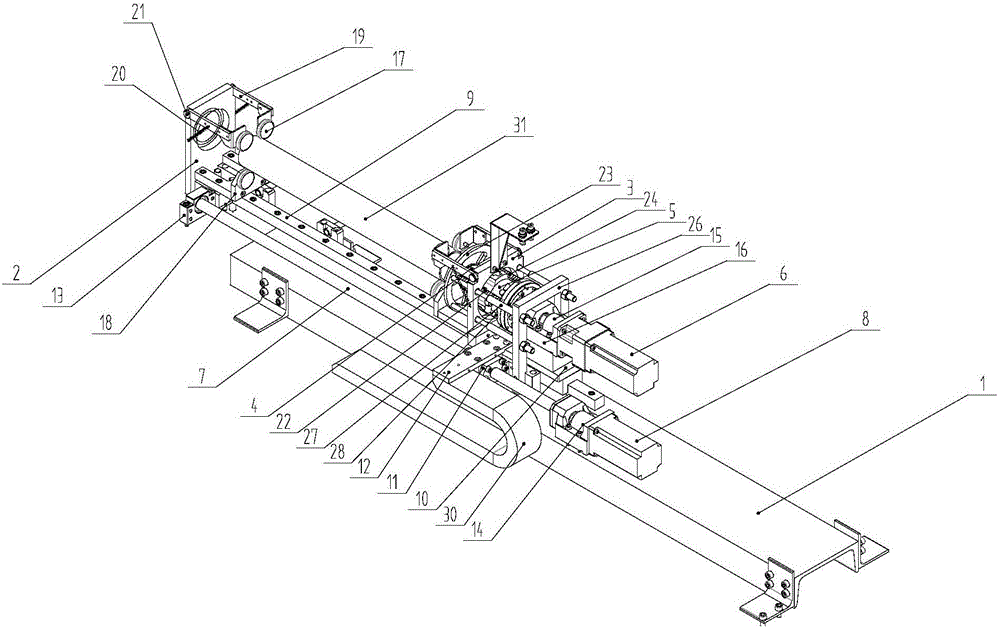

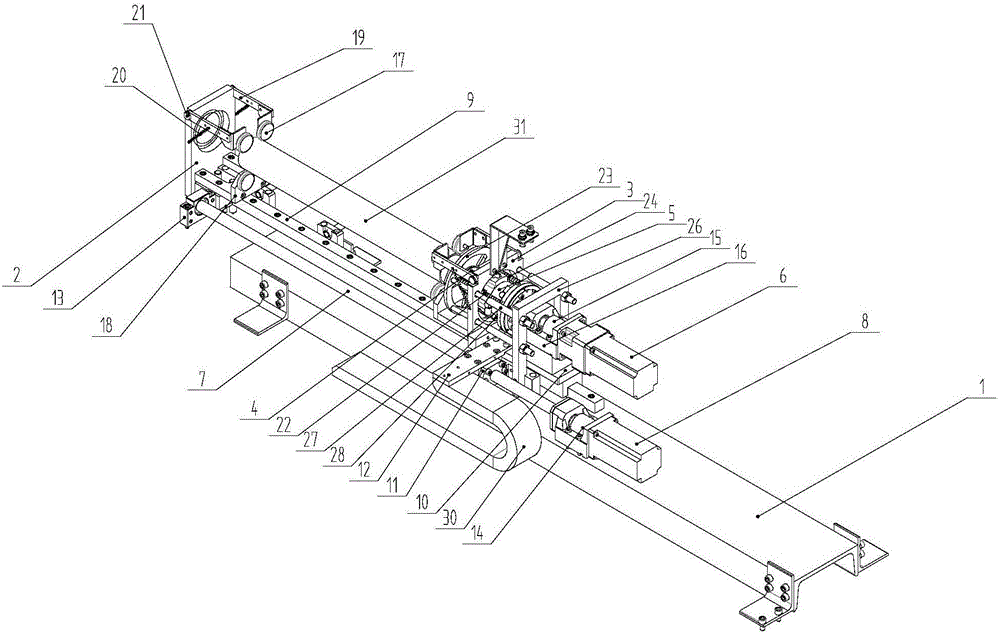

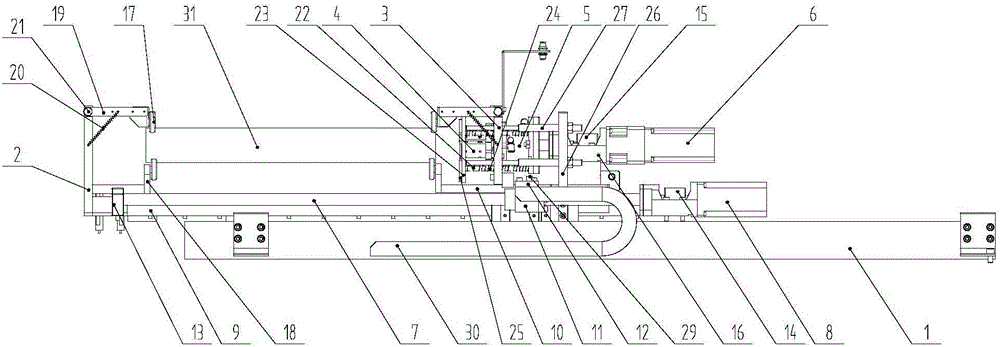

Full-automatic numerically-controlled machine tool for shafts

ActiveCN103273366APrecise positioningImprove work efficiencyMetal working apparatusNumerical controlEngineering

The invention provides a full-automatic numerically-controlled machine tool for shafts, and belongs to the technical field of machinery. The full-automatic numerically-controlled machine tool for the shafts solves the problems that an existing numerically-controlled machine tool for the shafts is low in efficiency because feeding is low in speed, and feeding and blanking are separately carried out. The full-automatic numerically-controlled machine tool for the shafts comprises a working platform, a main machine, a front rack and a rear rack, wherein a material box is installed on the upper side portion of the front rack, a material conveying channel is formed in the front rack, a feeding device is installed on the front rack, a material receiving device is installed on the rear rack, a clamping stay tube is arranged in a spindle, a collet is installed at the front end of the clamping stay tube, a material leading base is installed on the working platform, a double-arm mechanical claw is arranged on the material leading base, a material leading device is arranged between the material leading base and the material receiving device, the material leading device and the spindle are arranged on the same axis line, a locating base is installed in the clamping stay tube, a locating mechanism is installed in the locating base, and a shaft arranged in the locating base can only pass through the locating mechanism under the action of external force. The full-automatic numerically-controlled machine tool for the shafts has the advantages that working efficiency is high, location is accurate, and feeding and blanking are synchronously carried out.

Owner:宁波宫铁智能科技有限公司

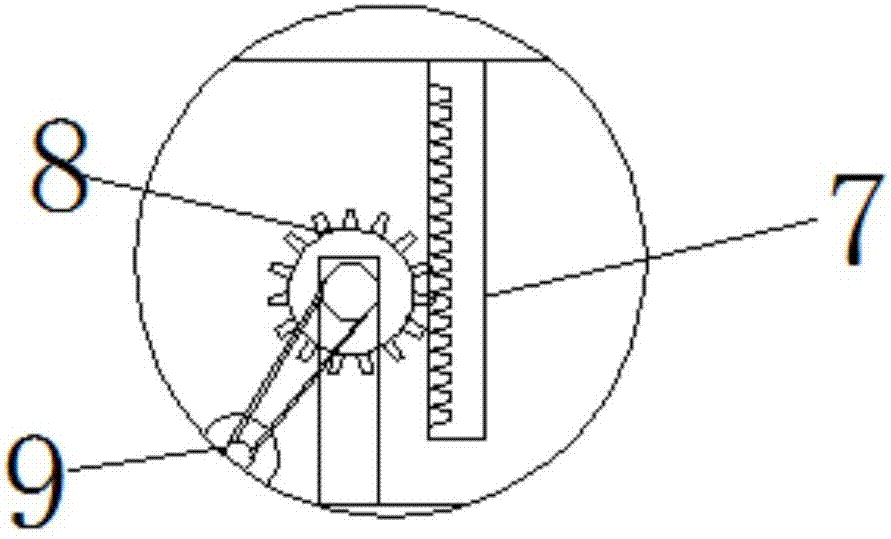

Crank slow-down swinging feeding mechanism

The invention discloses a crank slow-down swinging feeding mechanism comprising a support. An air cylinder is fixed on the support, a piston rod of the air cylinder is fixedly connected with a toothed bar with a tooth surface facing upwards, the tooth surface is meshed with a gear, a crank disc is coaxially arranged on the gear, the crank disc is eccentrically provided with a connecting rod in a hinged manner, the free end of the connecting rod is hinged to the middle of a rocker arm with the fixed end hinged to the support, and the feeding end of the rocker arm is provided with a workpiece clamping groove. Since the piston rod of the air cylinder is linked with the crank disc, linear motion of the air cylinder can be converted into circular motion of the crank disc through the toothed bar and the toothed gear, and manufacturing cost is greatly saved. In addition, according to the characteristics of the structure, motion speed of the rocker arm at biggest swinging positions on both sides is low, workpiece feeding and discharging at the biggest swinging positions on both sides of the rocker arm can be more accurate, and the workpiece can be prevented from flying out of the clamping groove due to excessively high rotation speed of the rocker arm.

Owner:CHONGQING CHENGSHUO TECH

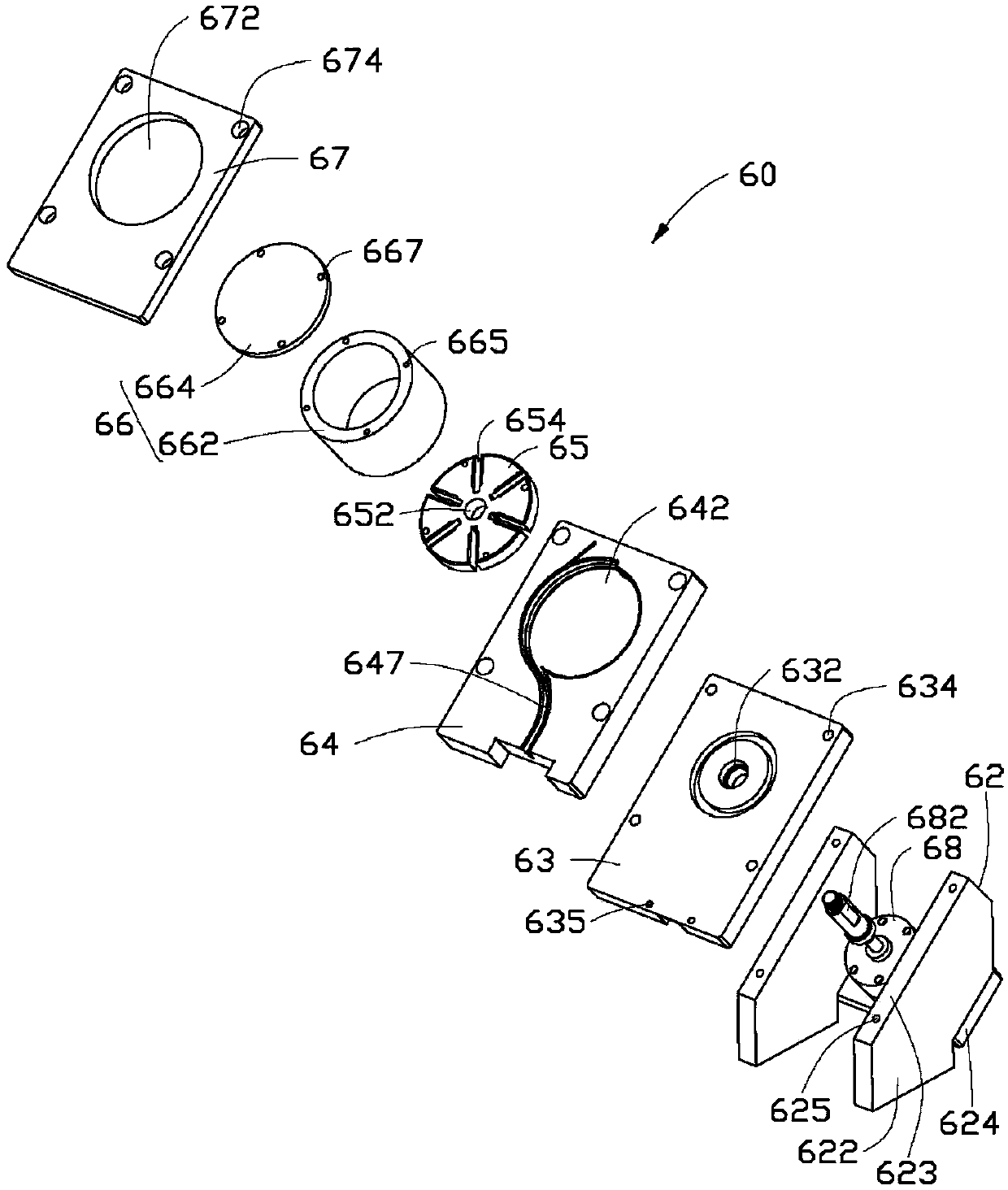

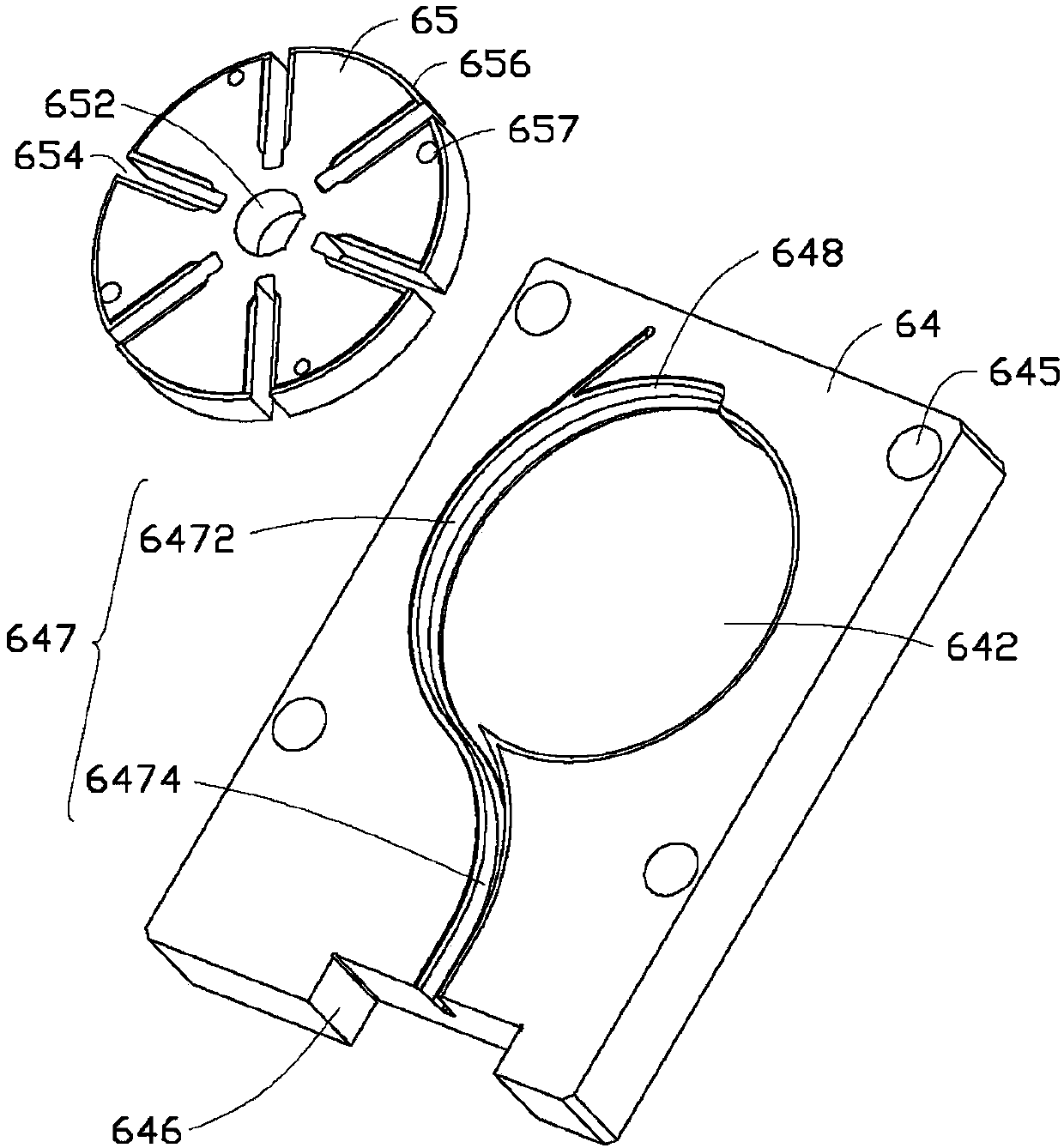

Automatic feed device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

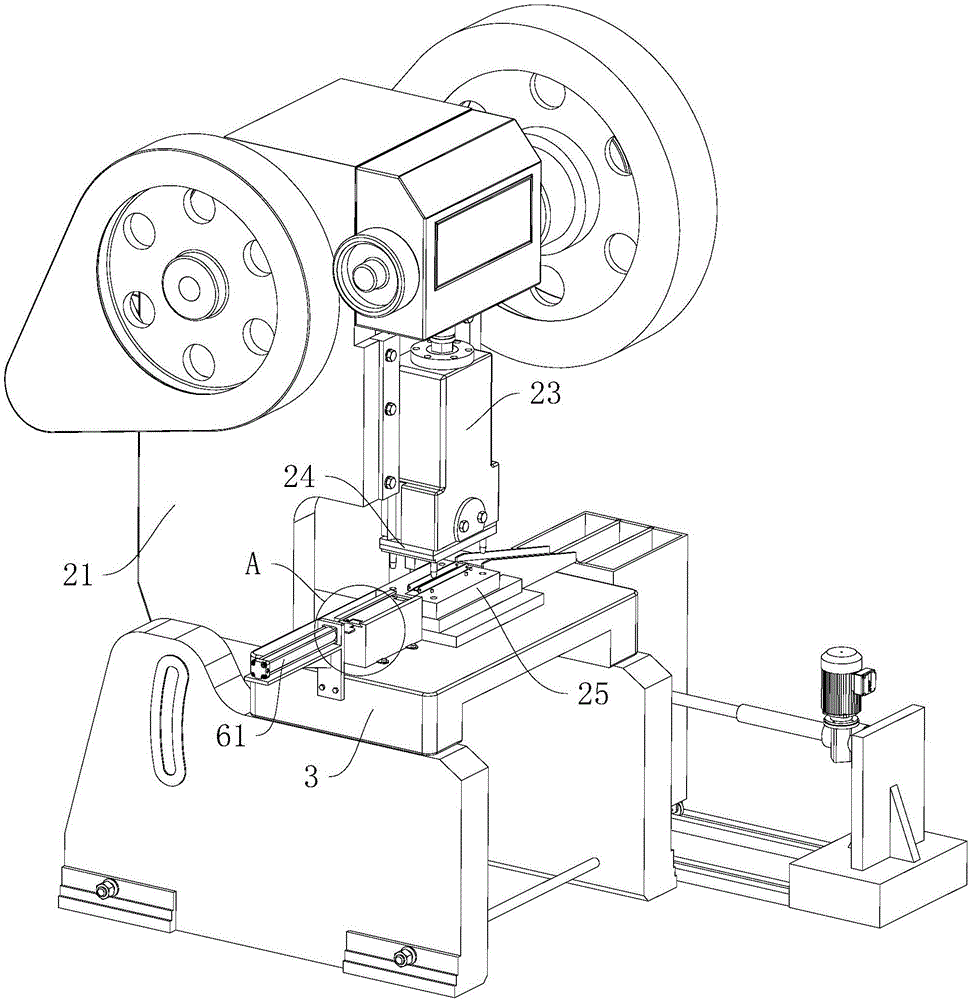

Automatic feeding and discharging punch

ActiveCN107520306AImprove work efficiencyReduce operational riskMetal-working feeding devicesPositioning devicesPunch pressWork in process

The invention discloses an automatic feeding and discharging punch. The problems that in the prior art, manpower is wasted for feeding and discharging of a punch, and potential safety hazards exist are solved. According to the technical scheme, the automatic feeding and discharging punch is characterized in that the automatic feeding and discharging punch comprises a workbench and a punching lower die, a feeding box is arranged on the part, on one side of the punching lower die, of the workbench, the upper end face of the feeding box is flush with the upper end face of the punching lower die, and the feeding box is provided with an elevating mechanism elevating a semi-finished fixing piece; the workbench is further provided with a pushing mechanism pushing the semi-finished fixing piece; the punching lower die is further provided with a first positioning column abutting against the end portion of a side plate of the semi-finished fixing piece in the punching process, and a collecting box for containing a television support fixing piece is arranged on the workbench part on the side, away from the pushing device, of the punching lower die; and according to the punch, semi-finished punched part feeding and television support fixing piece discharging can be achieved without manpower, the manpower is saved, and meanwhile operation risks of operators are reduced.

Owner:宁波臣力五金科技有限公司

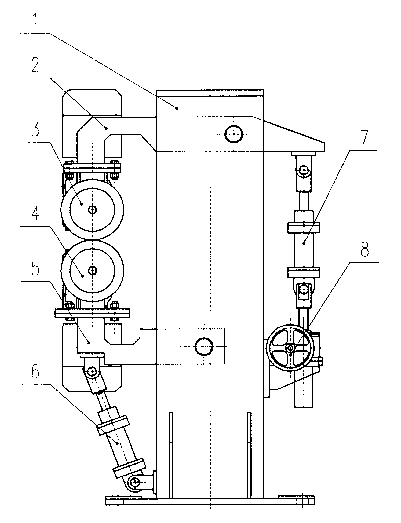

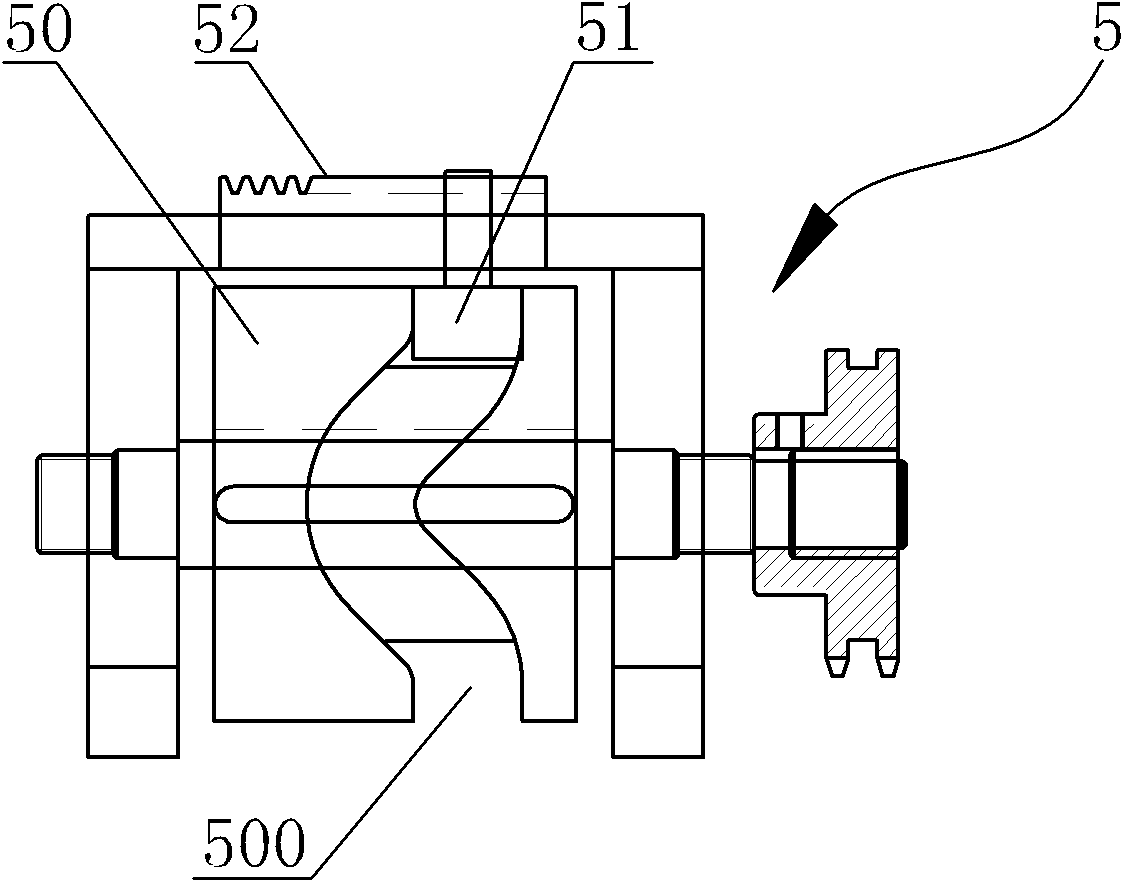

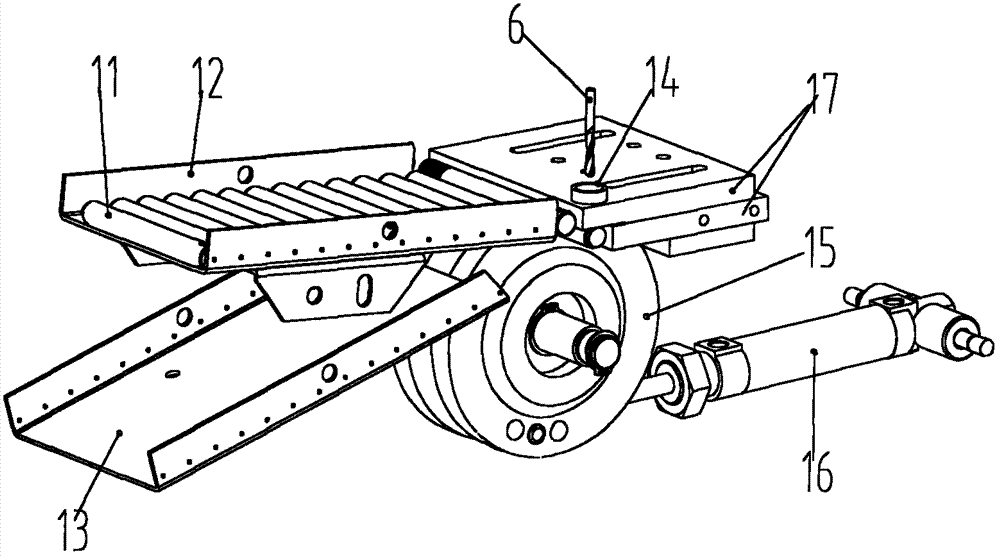

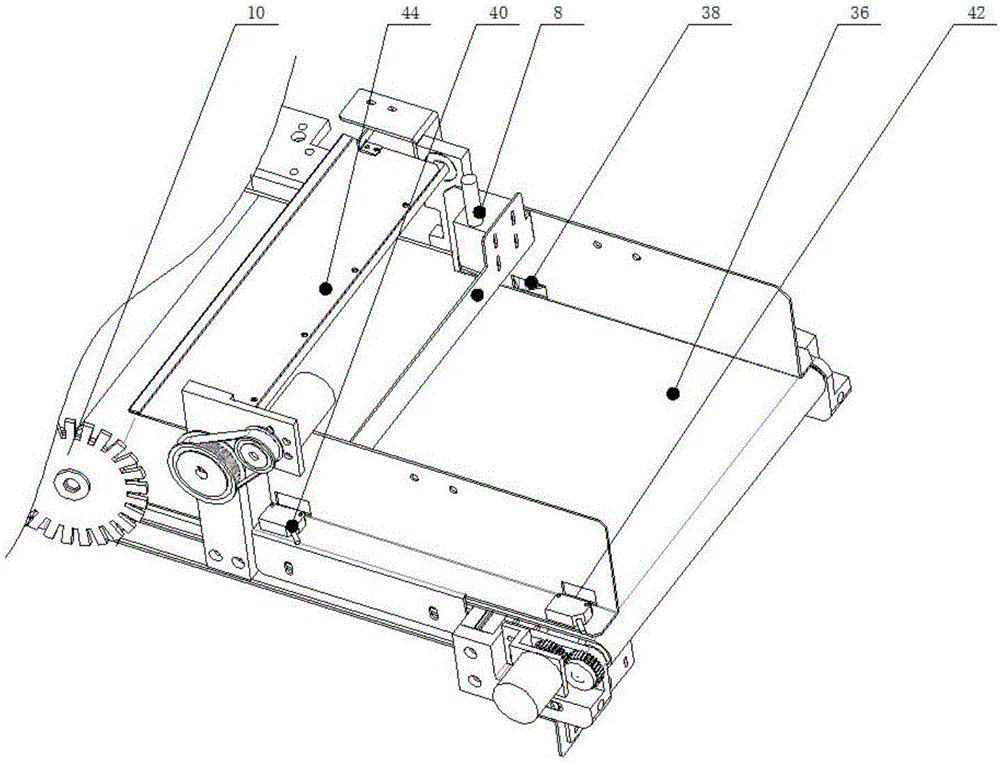

Pinch roll mechanism

ActiveCN102699224ARealize feedingQuick clampingMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention relates to the field of metallurgical mechanical equipment, in particular to a pinch roll mechanism. The pinch roll mechanism at least comprises a rack, an upper oscillating rod, an upper roller driving device, a lower roller driving device, a lower oscillating rod, a lower hydraulic cylinder, an upper hydraulic cylinder and a lifer, and is characterized in that the upper oscillating rod is L-shaped, the length of the upper edge of the upper oscillating rod is larger than the width of the rack, the long edge of the upper oscillating rod is in pin joint with the upper part of the rack through a pin shaft, one end of the upper oscillating rod is fixedly connected with the upper roller driving device, and the other end of the upper oscillating rod is hinged with the upper hydraulic cylinder; the bottom part of the upper hydraulic cylinder is hinged with the lifter, and the lifter is in slide connection with the rack; the lower oscillating rod is in pin joint with the lower part of the rack through a pin shaft, one end of the lower oscillating rod is fixedly connected with the lower roller driving device, the lower oscillating rod is also hinged with the lower hydraulic cylinder, and the bottom part of the lower hydraulic cylinder is fixedly connected with the rack; and the axial lines of the two rollers in the upper roller driving device and the lower roller driving device are located on the same straight line. The pinch roll mechanism provided by the invention can be used for adjusting the openness of the upper roller through the lifter and clamping and loosening the rollers through the upper and lower hydraulic cylinders.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

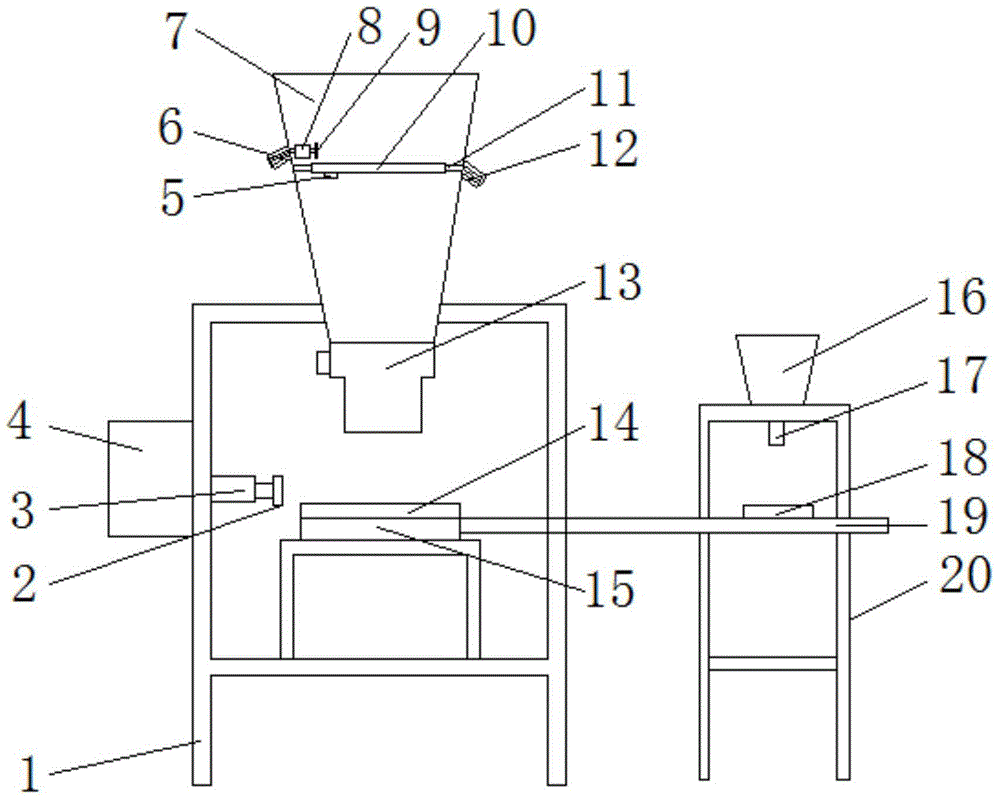

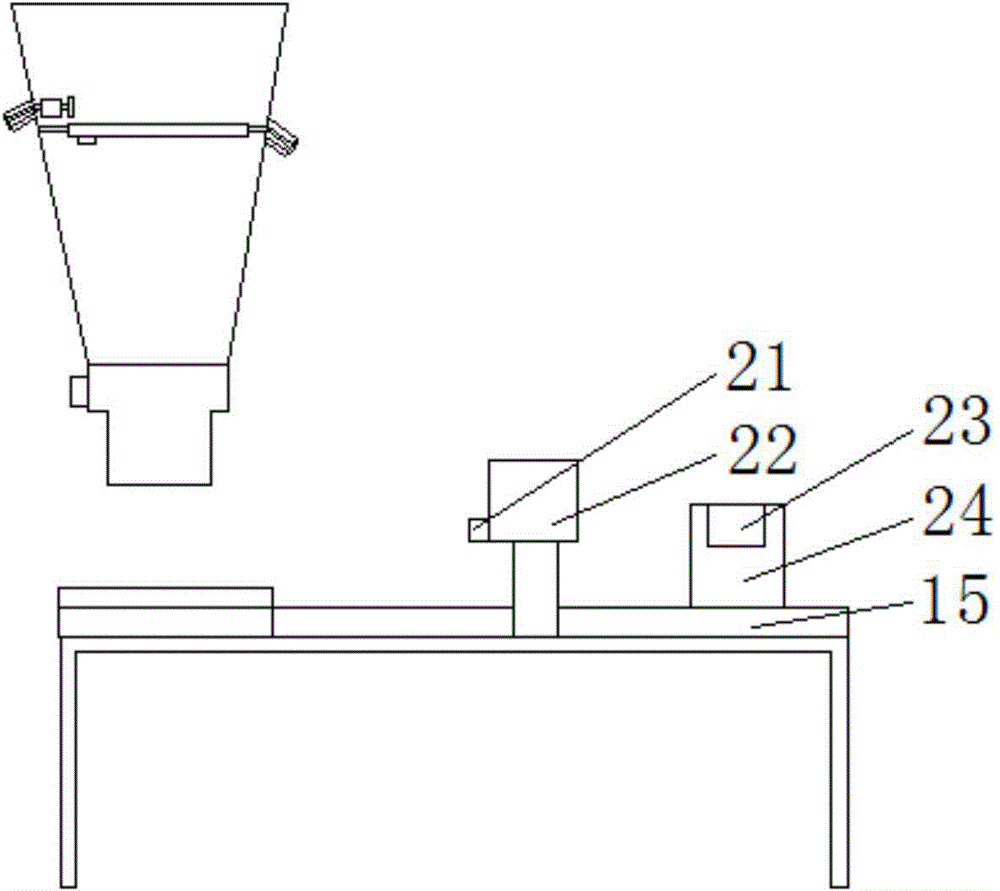

Automatic packer

ActiveCN104691796AAchieve cullingRealize feedingPackaging automatic controlSolid materialPlastic packagingAutomation

The invention discloses an automatic packer. The automatic packer comprises a frame I, a hopper I fixed on the frame I, a qualified product conveying belt, a rejecting device, an unqualified product conveying belt, a frame II and a hopper II fixed on the frame II, wherein an overturning plate is arranged in the hopper I; a weight sensor is arranged on the overturning plate; the lower part of the hopper I is connected with a bagging machine; the rejecting device comprises a cylinder I and a pushing plate connected to a pushing rod; an automatic plastic packaging machine, a labeling machine and a label making machine are arranged on the qualified product conveying belt; an infrared sensor is arranged on the automatic plastic packaging machine; the unqualified product conveying belt penetrates through the frame II. According to the automatic packer, the overturning plate with the weight sensor and the pushing plate are arranged in the hopper I; the materials are fed stably; the uneven stirring and the secondary pollution caused by artistic stirring are avoided; the rejecting device is capable of rejecting unqualified materials and supplementing; the qualified rate of products is ensured; the production efficiency and the automation degree of the equipment are improved.

Owner:天津雍和包装股份有限公司

Beef processing equipment

The invention relates to the field of beef processing, in particular to beef processing equipment. The beef processing equipment comprises a workbench, a power mechanism and a processing mechanism. The processing mechanism comprises a connecting rod, a hammerhead, clamping jaws, hollow transverse rods and storage tubes. The connecting rod is connected to the power mechanism, one end of the connecting rod is abutted against a cam, and the other end of the connecting rod is hinged to the hammerhead. One end of each clamping jaw is hinged to the hammerhead, a hinge column is hinged to the middle of each clamping jaw, and the lower end of each clamping jaw is made of an elastic material and abutted against the workbench in movement. The transverse rods are provided with slide grooves, and the hinge columns are positioned in the slide grooves respectively. Each storage tube is arranged at one end, close to the hammerhead, of the corresponding transverse rod, and the other end of each transverse rod is connected to the workbench through a vertical rod. A retaining plate is slidably connected in a cavity of each transverse rod, one end of each retaining plate is connected to the corresponding hinge column, and the other end of each retaining plate extends into the corresponding storage tube. The beef processing equipment is provided for solving the problem of workload increase caused by moving of a hammer plate in application of existing processing equipment to meat paste processing.

Owner:重庆市长寿区舒福食品有限公司

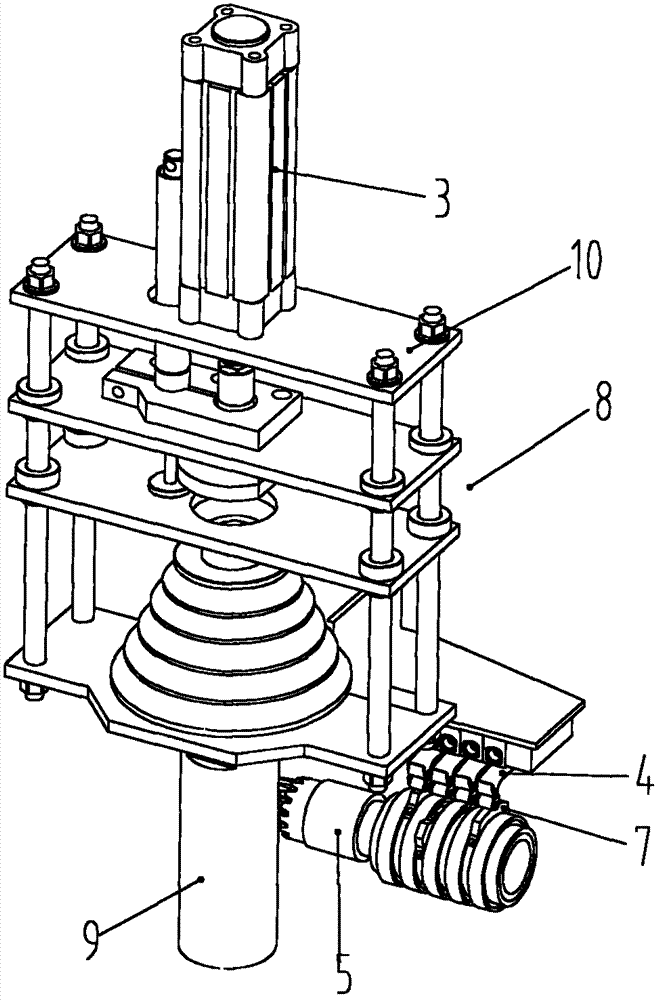

Feeding mechanism for medical needle base assembling

ActiveCN104524662AImprove accuracyReduce confusion errorsInfusion devicesBiomedical engineeringMedical equipment

The invention provides a feeding mechanism for medical needle base assembling and belongs to the technical field of assembling equipment of medical equipment. The feeding mechanism for medical needle base assembling solves the technical problem that existing cylindrical medical needle bases are difficult to feed. The feeding mechanism comprises an installation base and a feeding track capable of conveying needle bases, a through hole is formed in the installation base, a hanging plate is inserted in the through hole movably, the hanging plate is connected with a first driving part capable of driving the hanging plate to move forward and backward in the through hole, one end of the hanging plate can stretch out of the through hole, the edge of the end, stretching out of the through hole, of the hanging plate is provided with notches capable of hanging the medical needle bases, and the feeding track can be used for conveying the needle bases into the notches of the hanging plate. The feeding mechanism further comprises round guide through grooves, and when the front end of the hanging plate stretches out of the through hole, the guide through grooves are located under the notches. Through the feeding mechanism for medical needle base assembling, the needle bases can fall down through the guide through grooves and enter assembling carriers, the moving paths of the needle bases are fixed under the guidance action of the guide through grooves, the accuracy rate is high, confusion errors are reduced, and precision and feeding efficiency are improved.

Owner:MAIDER MEDICAL IND EQUIP

Feeding and returning linkage device

ActiveCN102319823AIncrease productivityHigh feedingMetal-working feeding devicesStripping-off devicesPunch pressMechanical engineering

The invention relates to a feeding and returning linkage device. The device is arranged on a punch press and comprises a feeding channel, a feeding plate, a returning plate and a transmission mechanism, wherein, the feeding channel is simultaneously connected with a conveying belt and a lower die of the punch press; the feeding plate is arranged at the upper part of the feeding channel, the returning plate is arranged at the lower part of the feeding channel, and the length of the returning plate is greater than that of the feeding plate; and the transmission mechanism is simultaneously connected with the feeding plate and the returning plate in a transmission manner. In the invention, when a product to be punched is conveyed to the feeding channel through the conveying belt of the punch press, the feeding plate pushes the product to be punched to the lower die of the punch press and meanwhile the returning plate pushes away the punched product positioned on the lower die of the punch press from the lower die of the punch press. The feeding and returning linkage device has the advantages of high feeding and returning efficiency and accurate feeding and returning positions, thus fully realizing feeding and returning automation and greatly improving the punching production efficiency.

Owner:SUZHOU HYCAN HLDG CO LTD

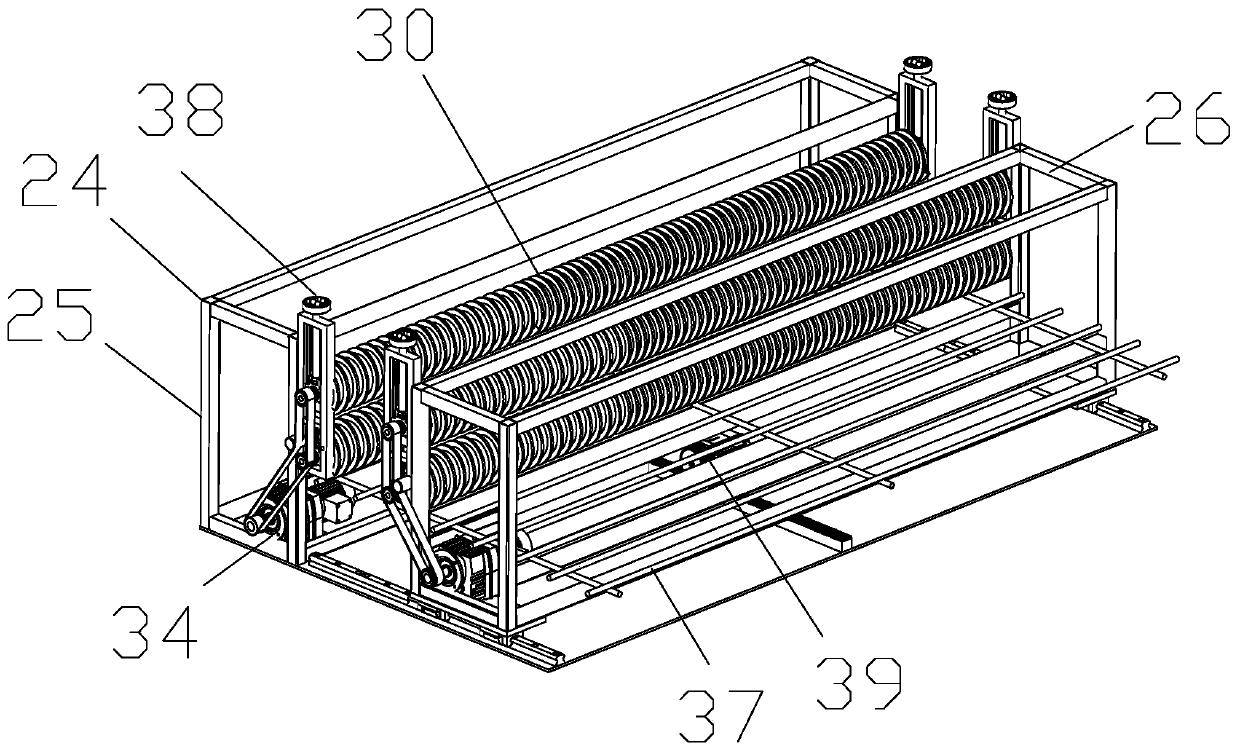

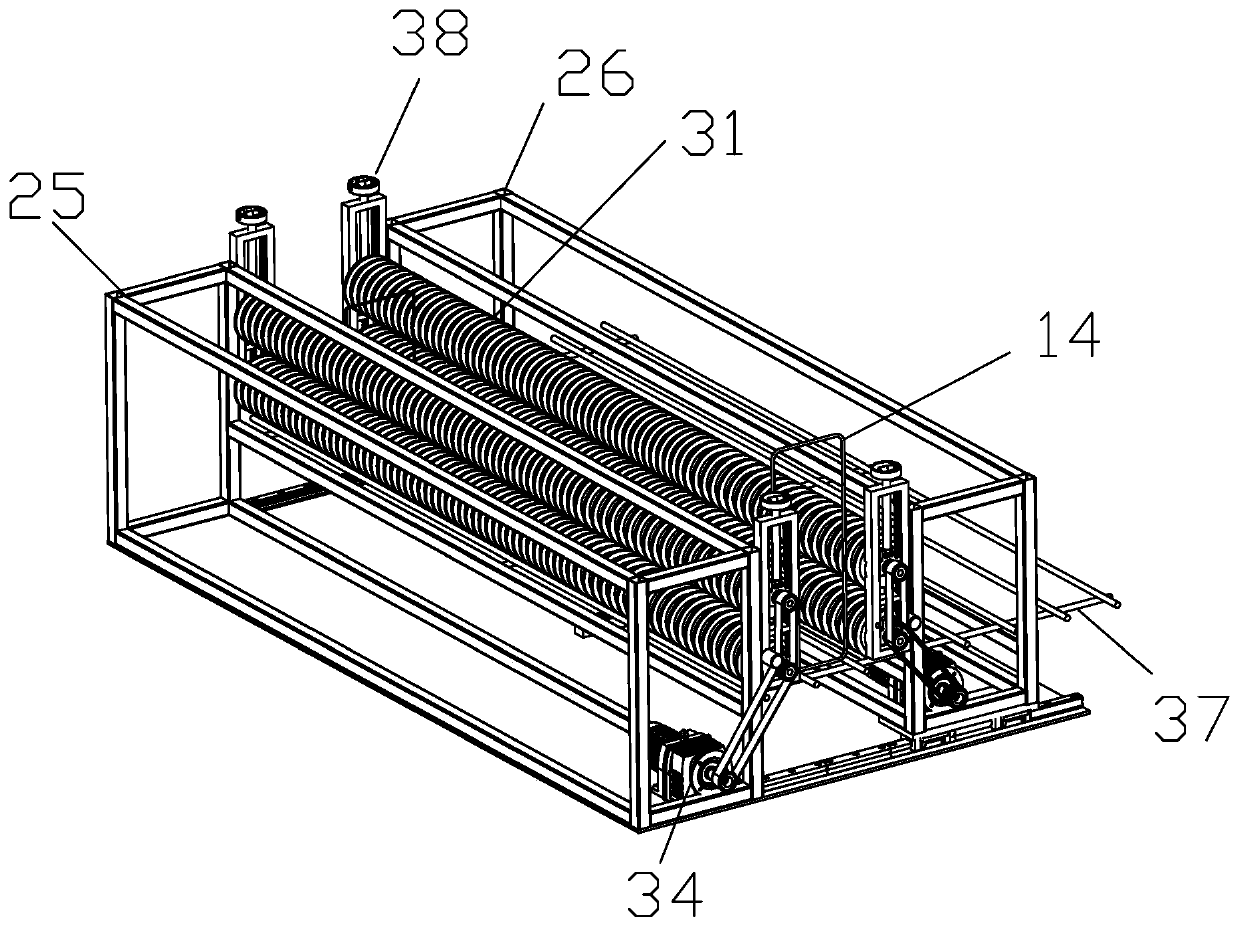

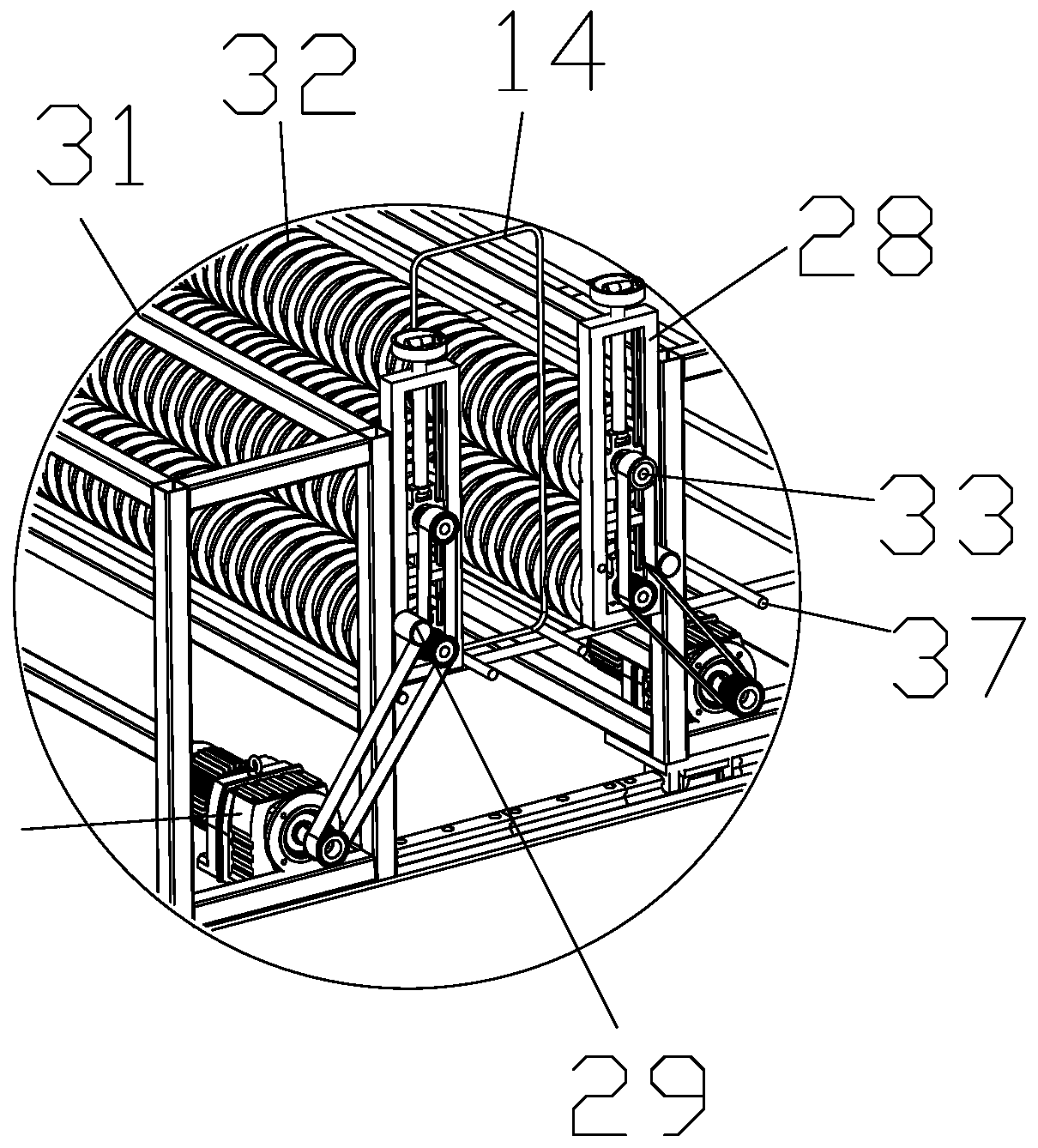

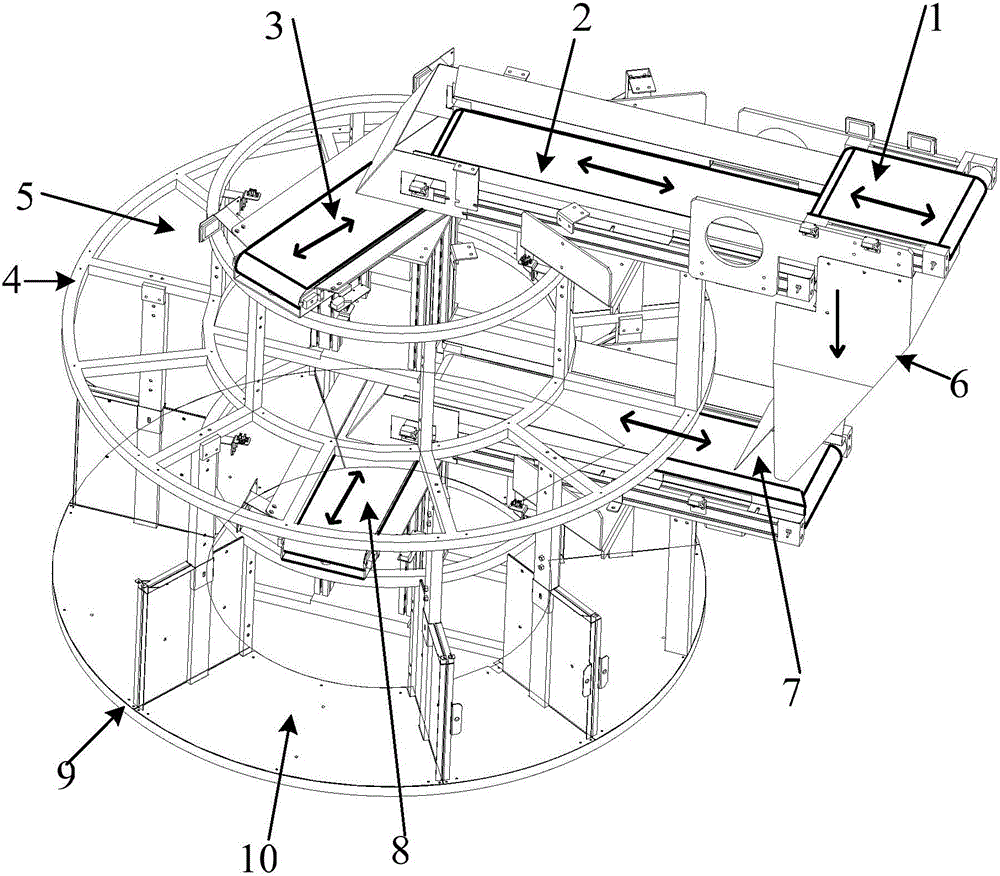

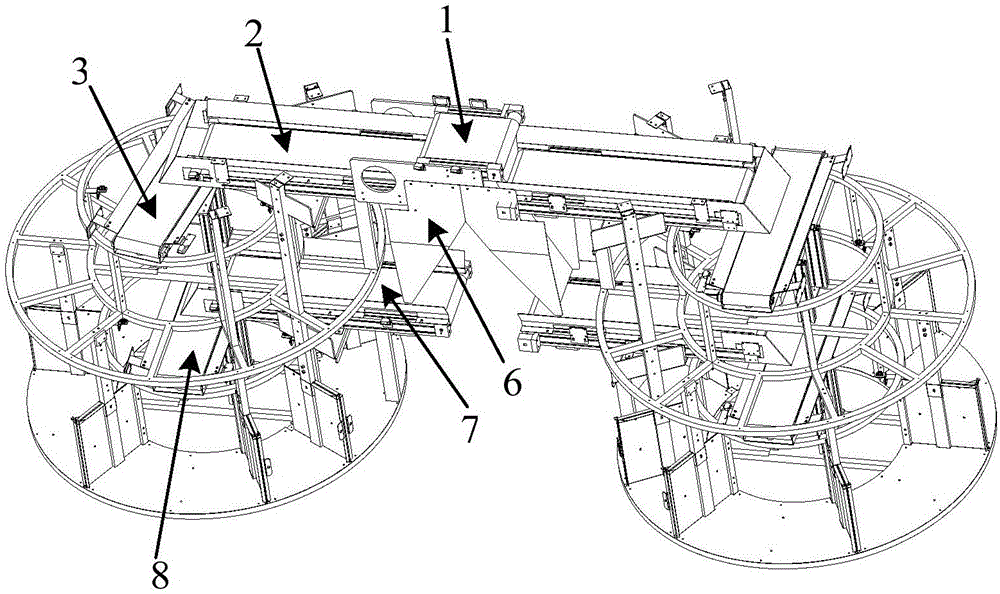

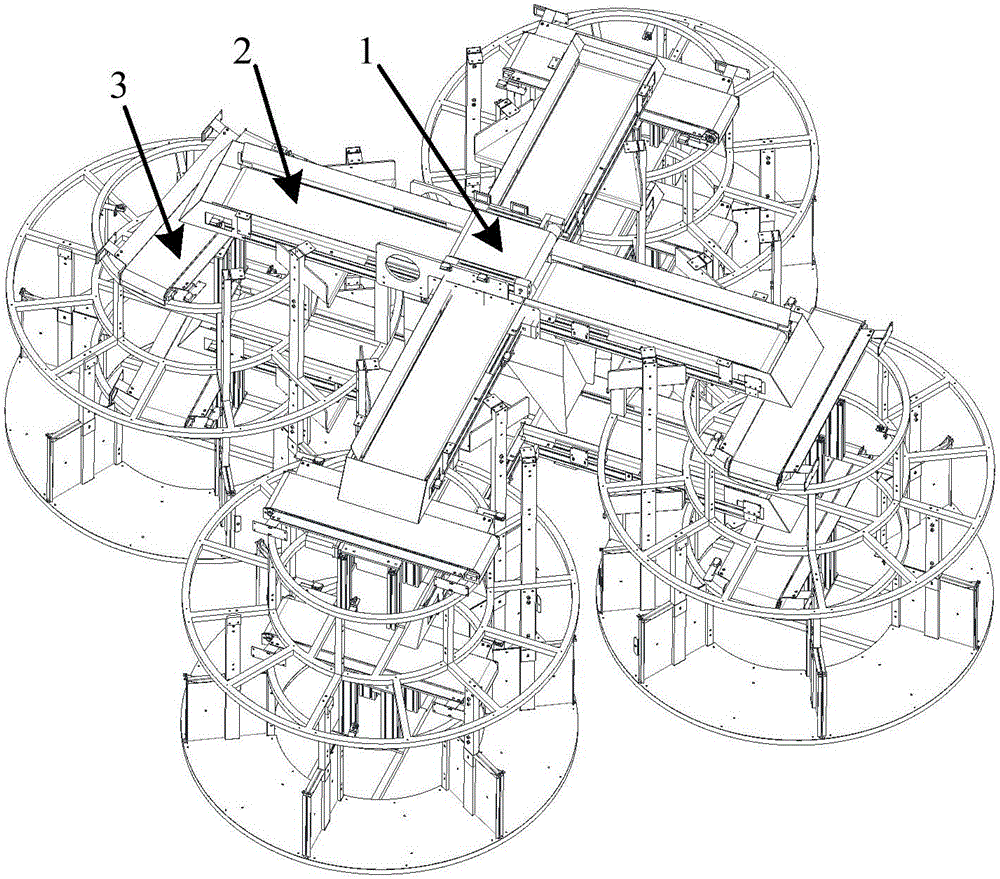

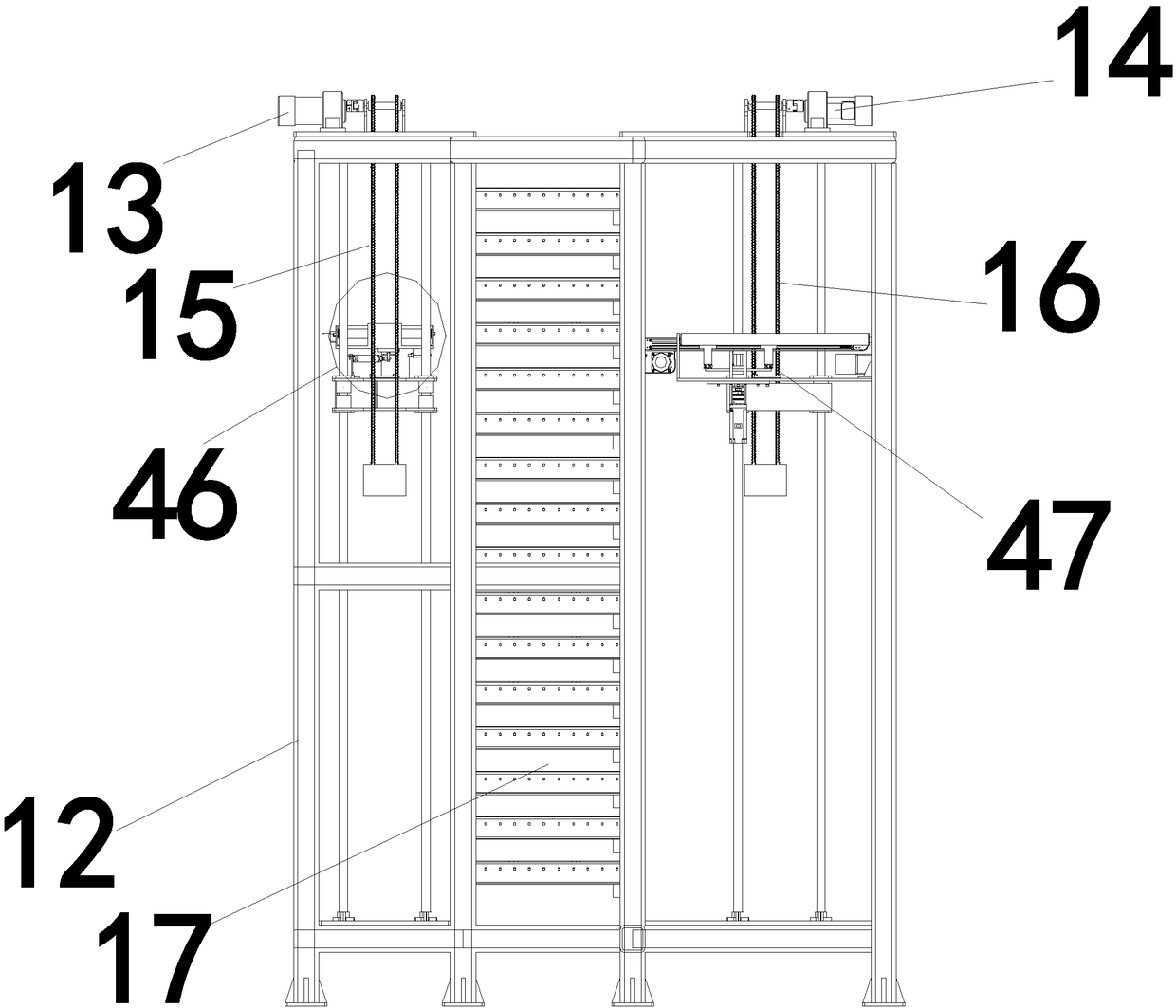

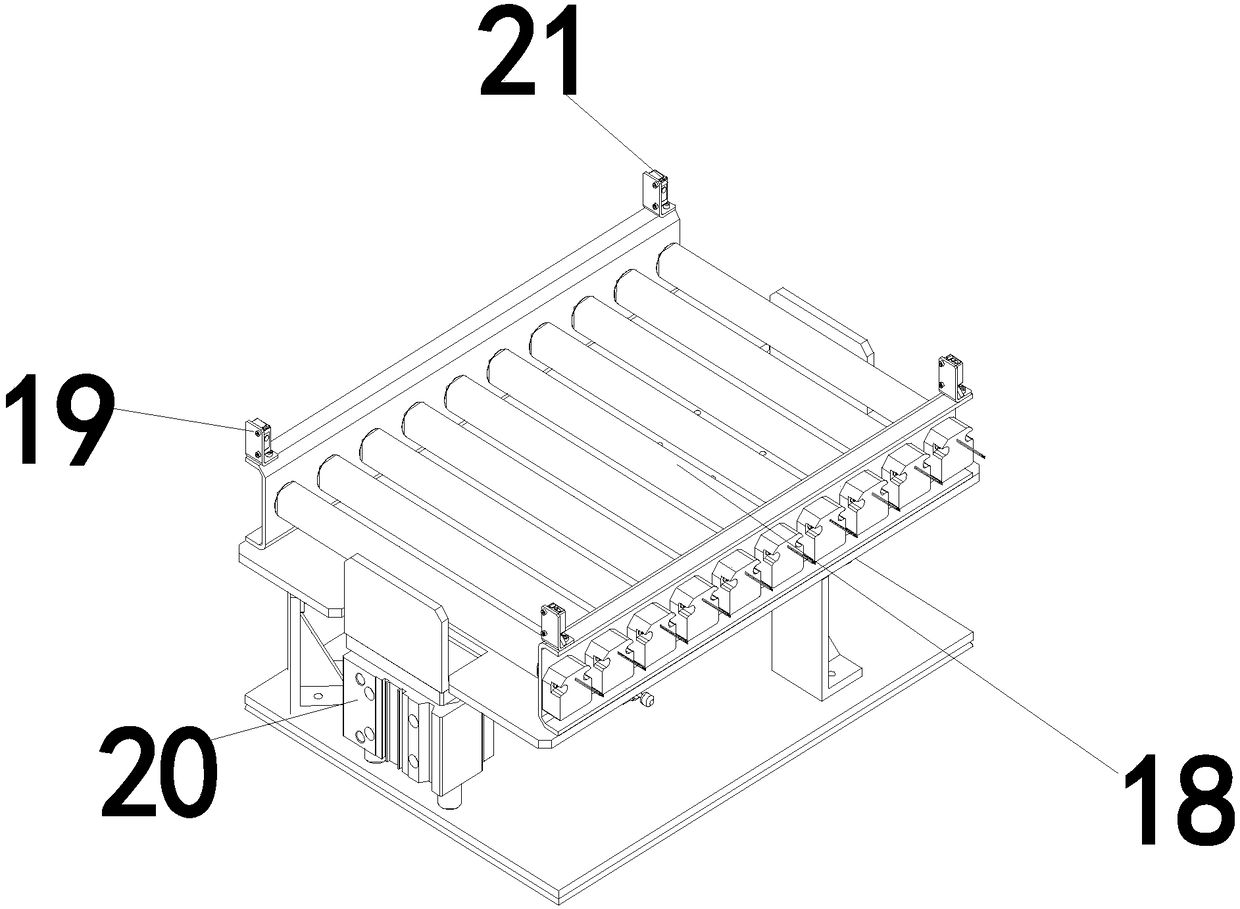

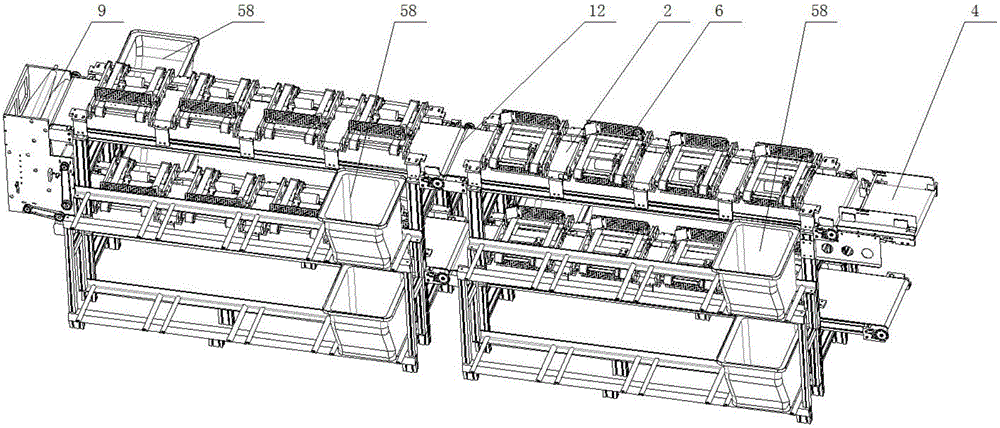

Complete equipment for welding beam or column reinforcement cage

PendingCN109877481ARealize automatic transportationRealize feedingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention provides complete equipment for welding a beam or column reinforcement cage. The equipment comprises a spiral hooping rib feeding device, a longitudinal rib feeding device and a weldingdevice, wherein the spiral hooping rib feeding device, the longitudinal rib feeding device and the welding device are sequentially arranged according to the production process, the spiral hooping ribfeeding device is used for conveying hooping ribs to the welding device, the longitudinal bar feeding device is used for conveying the longitudinal bars to the welding device, the tail ends of the longitudinal bars are inserted into the hooping ribs, and the welding device is used for welding the hooping ribs on the peripheries of the plurality of longitudinal ribs to form the reinforcement cage.According to the equipment, automatic feeding of the hooping ribs and the longitudinal ribs and automatic welding of the reinforcement cage can be realized, manual participation is reduced, the working efficiency is improved, and the automatic and intelligent degree is high.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

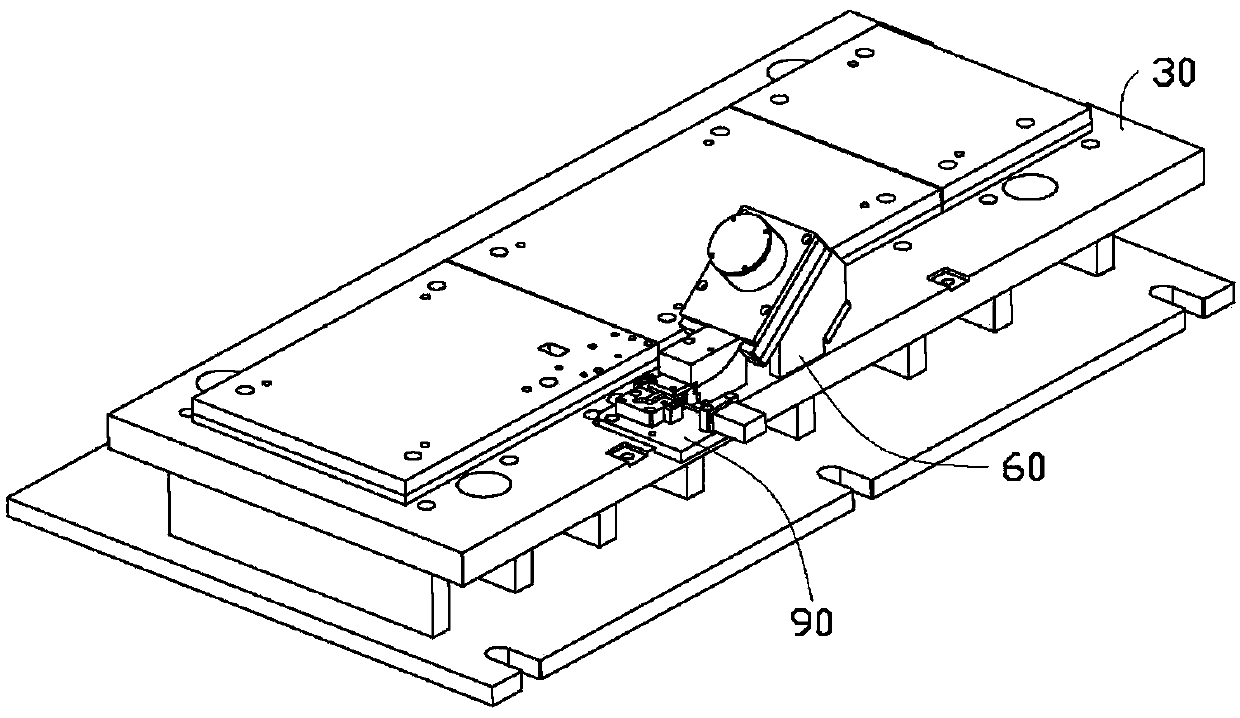

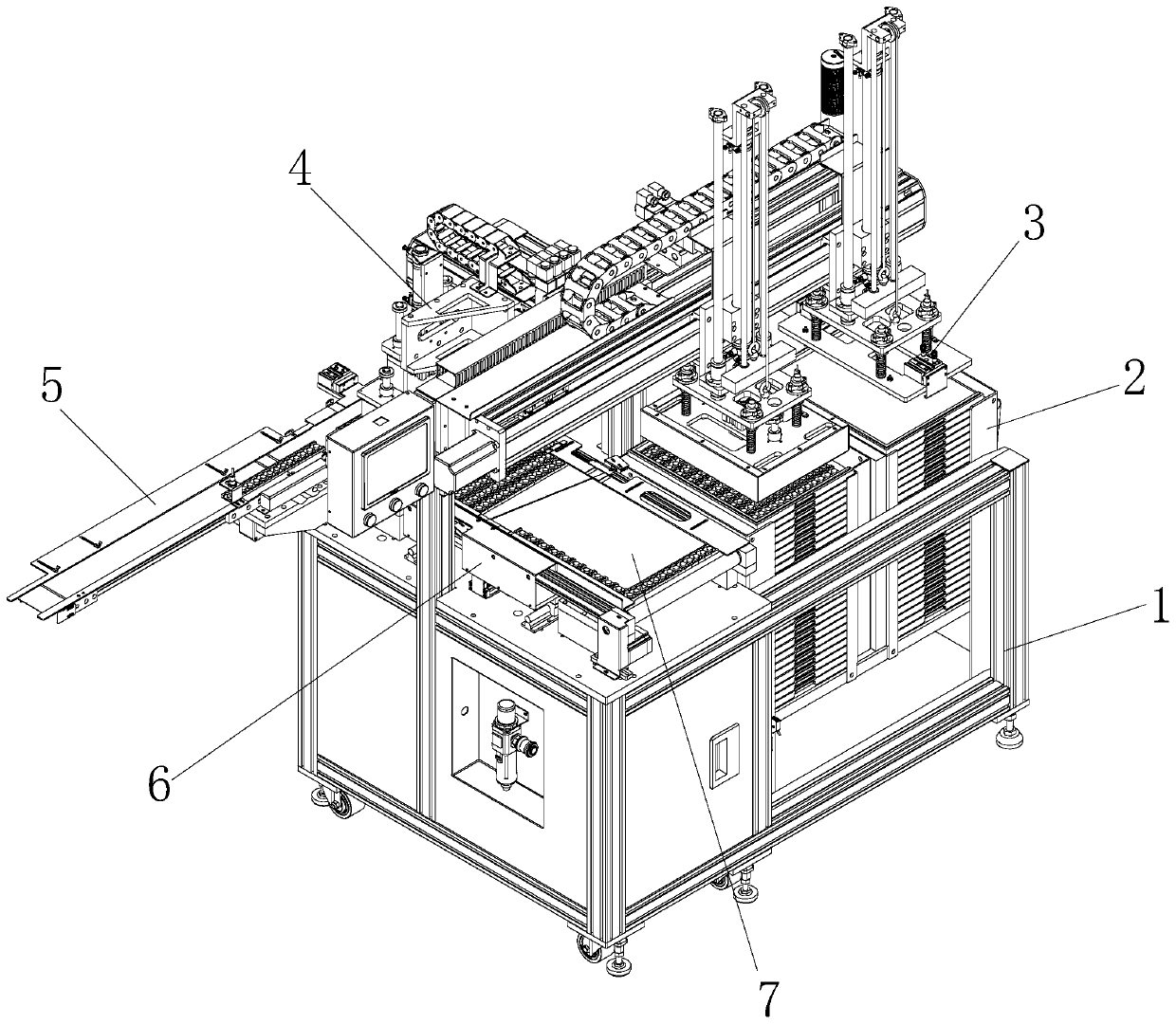

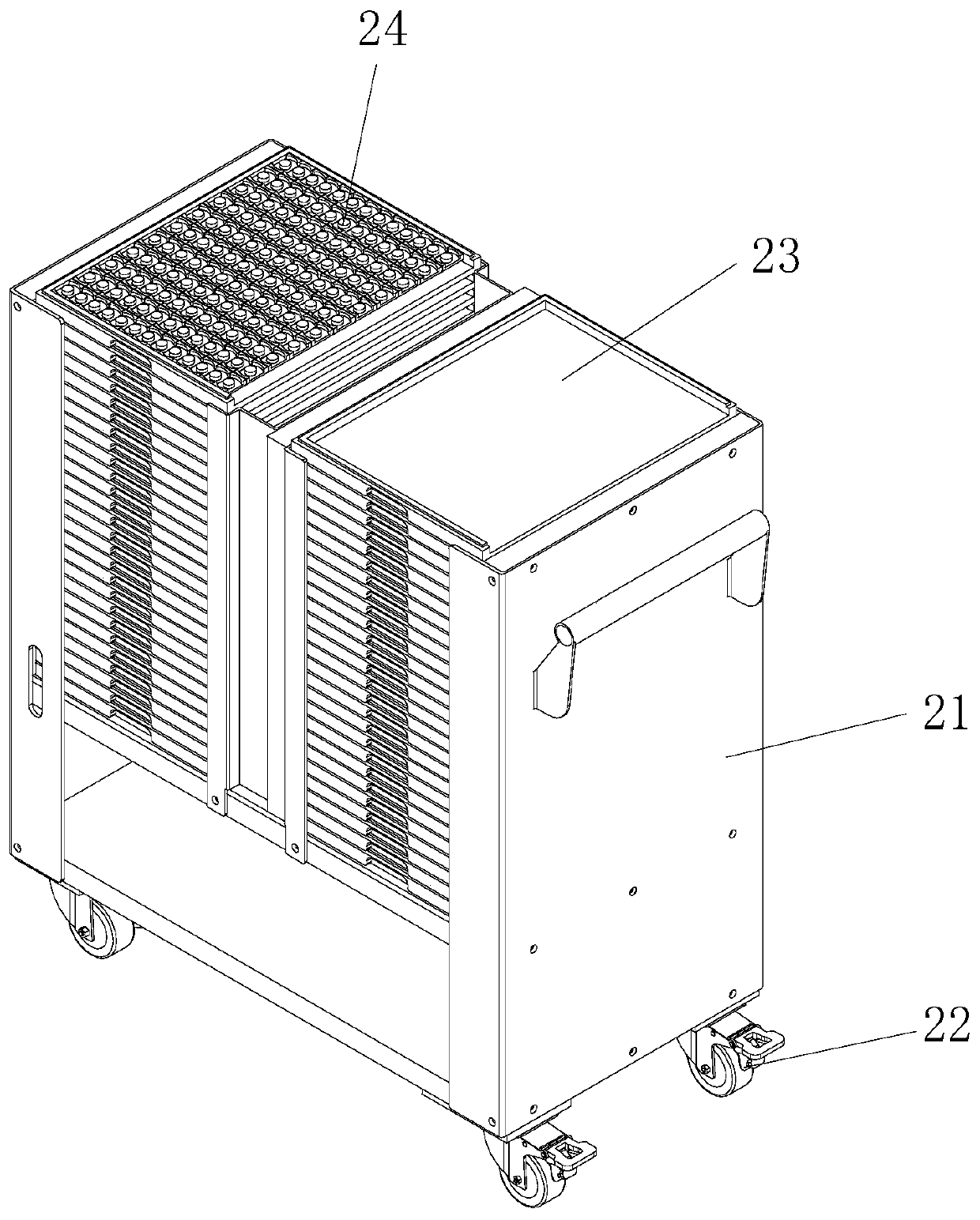

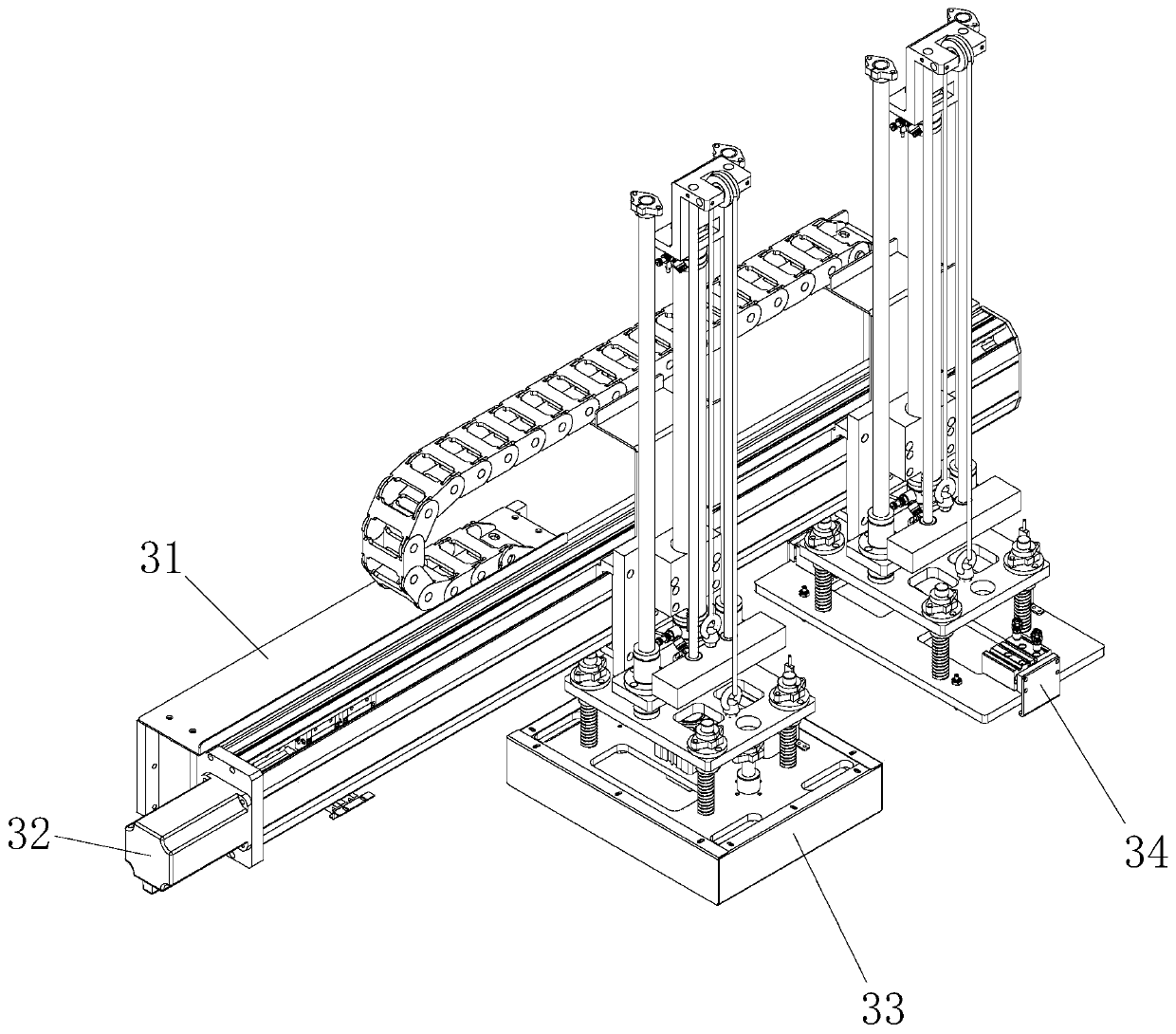

Small product batch feeding device and implementation method thereof

ActiveCN110921322AReduce labor intensityRealize feedingControl devices for conveyorsStacking articlesProcess engineeringWorkbench

The invention discloses a small product batch feeding device. The small product batch feeding device comprises a workbench, wherein a tray storage mechanism is arranged in the workbench; a magnetic attraction feeding mechanism and a transition device are connected to the positions, corresponding to the two sides of the tray storage mechanism, above the workbench; an adjusting mechanism is arrangedon one side of the transition device; a magnetic attraction transplanting mechanism is arranged at one end of the transition device; and a discharging mechanism is arranged on one side of the magnetic attraction transplanting mechanism. The invention further discloses an implementation method of the small product batch feeding device. According to the small product batch feeding device and the implementation method thereof, a linear module of the magnetic attraction feeding mechanism is used for moving a feeding and discharging mechanism and an empty tray clamping mechanism, products in traysare moved to the transition device through the feeding and discharging mechanism, empty trays in a full tray station are clamped into an empty tray station through the empty tray clamping mechanism,and therefore the labor intensity of workers is greatly reduced.

Owner:东阳东磁自动化科技有限公司

Health food material grinding device achieving complete grinding

The invention discloses a health food material grinding device achieving complete grinding. The health food material grinding device achieving complete grinding comprises a shell, a feeding hopper, agrinding cavity, discharging openings and a supporting base. The grinding cavity is arranged in the shell. The feeding hopper is arranged in the middle of the upper surface of the shell. The feeding hopper communicates with the grinding cavity. The discharging cavities are symmetrically formed in the bottom of the side wall of the shell. The grinding cavity communicates with the discharging openings. The supporting base is arranged at the bottom of the shell. The supporting base is rotationally connected with the shell. The health food material grinding device is characterized in that a servomotor is installed on the right side of the supporting base, a first rotating shaft is welded to the left side of an output shaft of the servo motor, a first bevel gear is fixedly installed on the left side of the first rotating shaft, and a second rotating shaft is vertically arranged above the first bevel gear. The health food material grinding device achieving complete grinding has the advantages of quantitative feeding, rapid grinding and time and effort saving. Meanwhile, raw material blockage of raw materials in the grinding process can be avoided, operation is easy, and the health foodmaterial grinding device achieving complete grinding is suitable for application and popularization.

Owner:山西华欣久泰科技有限公司

Feeding device for fish keeping

InactiveCN107027681AReduce labor intensitySimple structureClimate change adaptationPisciculture and aquariaMotor driveEngineering

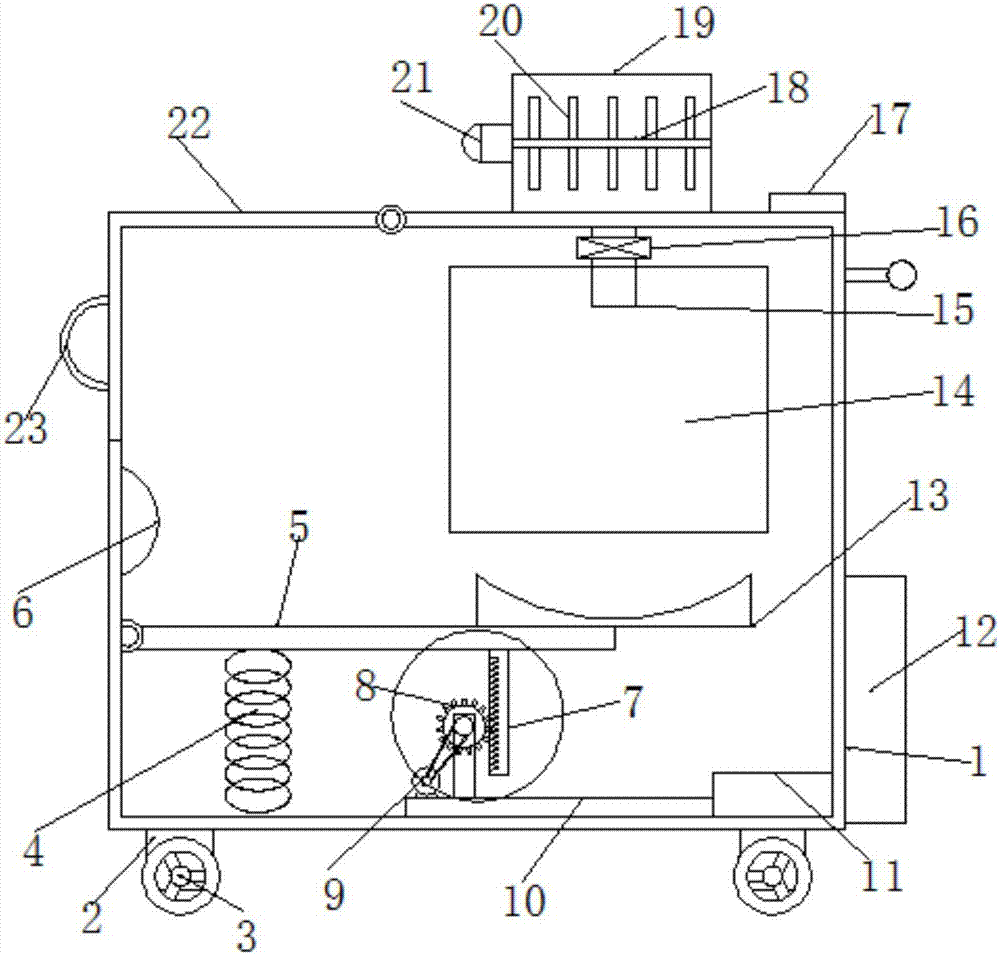

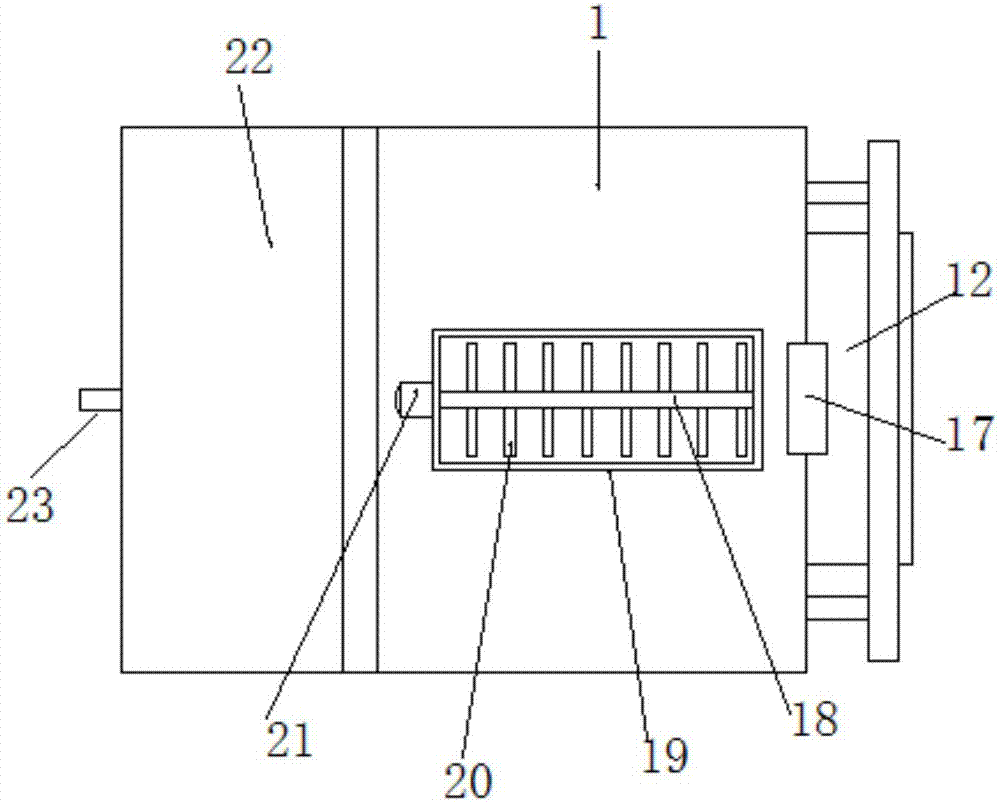

The invention discloses a feeding device for fish keeping. The feeding device for fish keeping comprises a box body, the two sides of the lower end of the box body are symmetrically provided with support legs, the lower ends of the support legs are provided with rollers, the upper end of the box body is provided with a stirring box, the stirring box is a rectangular cylinder which is opened at the upper end, the stirring box is internally horizontally provided with a stirring shaft, the stirring shaft is symmetrically provided with several stirring rods, the left end of the stirring shaft penetrates through the stirring box, and is connected with and fixed to the output end of a stirring motor, the stirring motor drives the stirring shaft and the stirring rods to rotate, stirring of materials in the stirring box is further achieved, the lower end of the stirring box is provided with a blanking pipe, the blanking pipe is provided with a blanking valve, the upper left end of the box body is hinged to a box lid, the outer side of the box lid is provided with a pull ring, the inner wall of the left side of the box body is hinged to a reset plate, and a reset spring is arranged between the lower left end of the reset plate and the bottom of the box body. The feeding device for fish keeping is simple and reasonable in structure and convenient to carry, feed does not need to be spread manually, the work efficiency is improved, the labor intensity of workers is lowered, and the practicability is high.

Owner:合肥蔚然花绿化工程有限公司

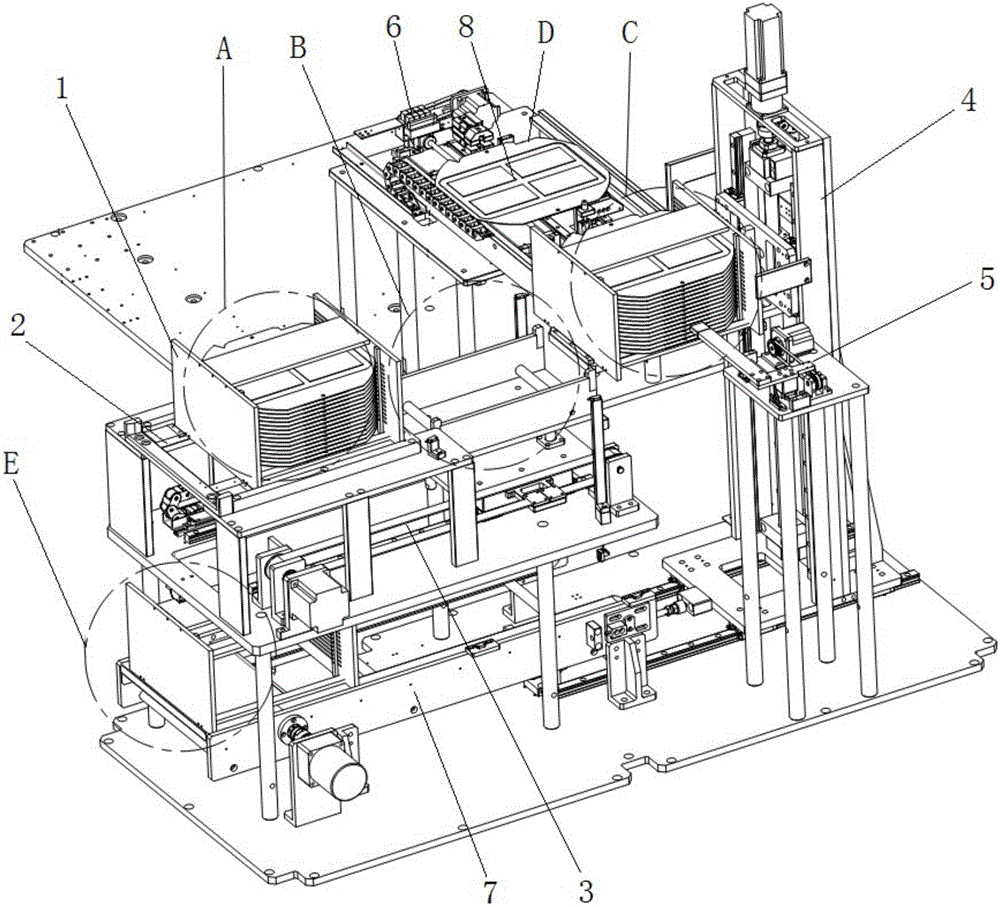

Automatic loading equipment of groove-type material box

PendingCN106783677ARealize automatic transferRealize feedingSolid-state devicesSemiconductor/solid-state device manufacturingRecovery positionEngineering

The invention provides automatic loading equipment of a groove-type material box. The automatic loading equipment comprises the groove-type material box, a loading positioning mechanism, a transport mechanism, a loading / unloading grabbing mechanism, an ejection mechanism, a discharging mechanism and a recovery transmission mechanism, wherein a loading position is arranged on the loading position mechanism, the groove-type material box is arranged on the loading position, the transport mechanism is arranged below the loading positioning mechanism, the groove-type material box is transported to a position to be waited from the loading position by the transport mechanism, the loading / unloading grabbing mechanism can be used for transporting the groove-type material box to a working position from the position to be waited, the ejection mechanism can be used for pulling insertion pieces in the groove-type material box out of the working position one by one, the discharging mechanism can be used for transporting the insertion pieces pulled out of the groove-type material box to a discharging position one by one, and the recovery transmission mechanism is used for transmitting the unloaded groove-type material box to a recovery position. With the adoption of the automatic loading equipment, the groove-type material box can be automatically transported and loaded, the insertion pieces (such as UV film disc) in the groove-type material box are automatically discharged, the unloaded groove-type material box is automatically recovered and transmitted out, labor is saved, and moreover, the product quality is ensured.

Owner:江门格兰达物联装备有限公司

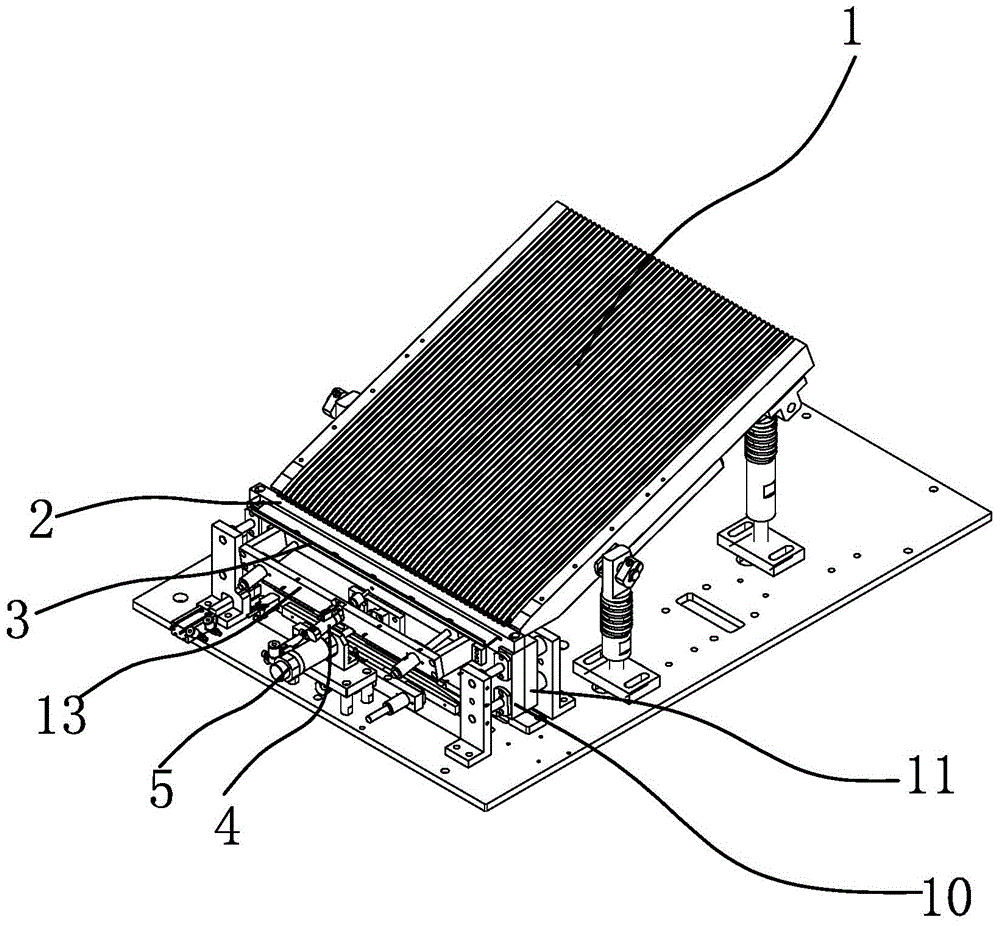

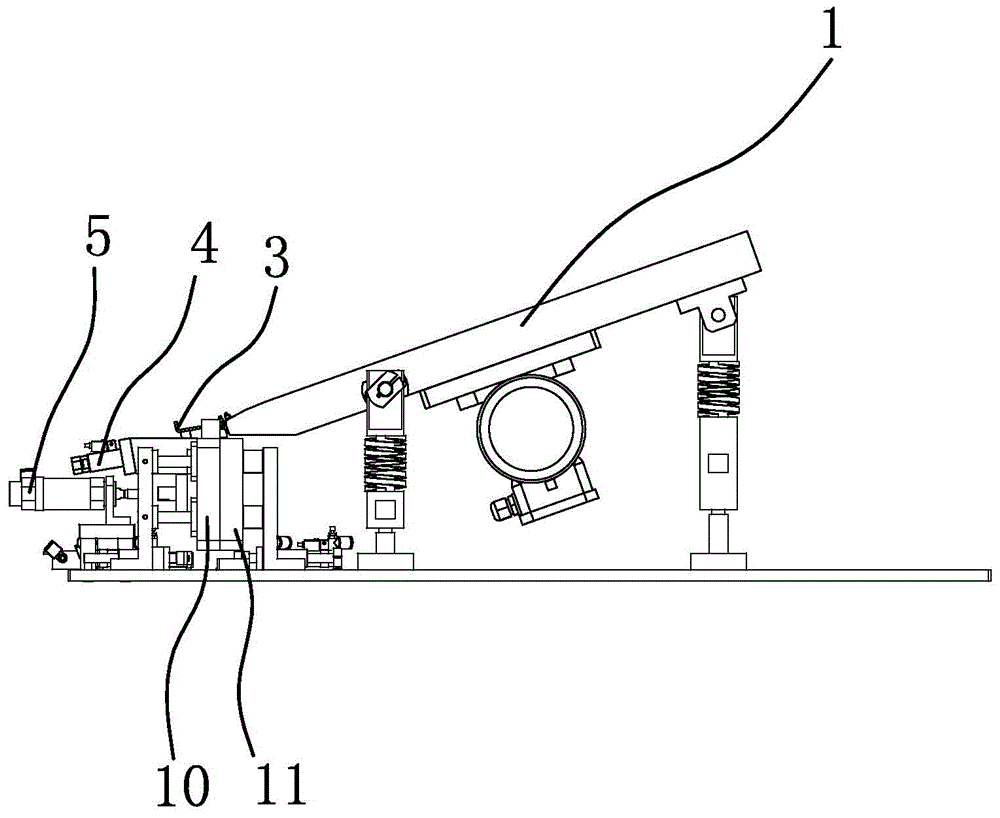

Pipe machining lathe with automatic feeding function

ActiveCN108480661ARealize automatic feeding processRealize feedingAutomatic conveying/guiding stockTool holdersEngineeringMachining

The invention discloses a pipe machining lathe with an automatic feeding function, and belongs to the field of pipe machining. According to the technical scheme, the pipe machining lathe with the automatic feeding function comprises a base, a clamping and cutting device and a feeding device, wherein the clamping and cutting device is arranged on the top of the base; the feeding device is positioned above the clamping and cutting device and comprises a support, a feeding mechanism and a conveying mechanism; the support is fixedly arranged on the upper surface of the base; the feeding mechanismis arranged on the support; the conveying mechanism is connected to one side of the feeding mechanism; the feeding mechanism comprises a feeding groove, a feeding cylinder and a separating cylinder; the feeding groove is obliquely formed in the top surface of the support; the feeding cylinder is detachably and fixedly connected to the side, which is close to the support, of the feeding groove; a groove is formed in the side, which is close to the support, of the feeding groove; and a first pushing cylinder is arranged on one side of the groove. The problem of manual feeding is solved, the effect of improving efficiency is achieved, and the pipe machining lathe with the automatic feeding function is mainly used for pipe machining equipment.

Owner:青岛铭和锐金属有限公司

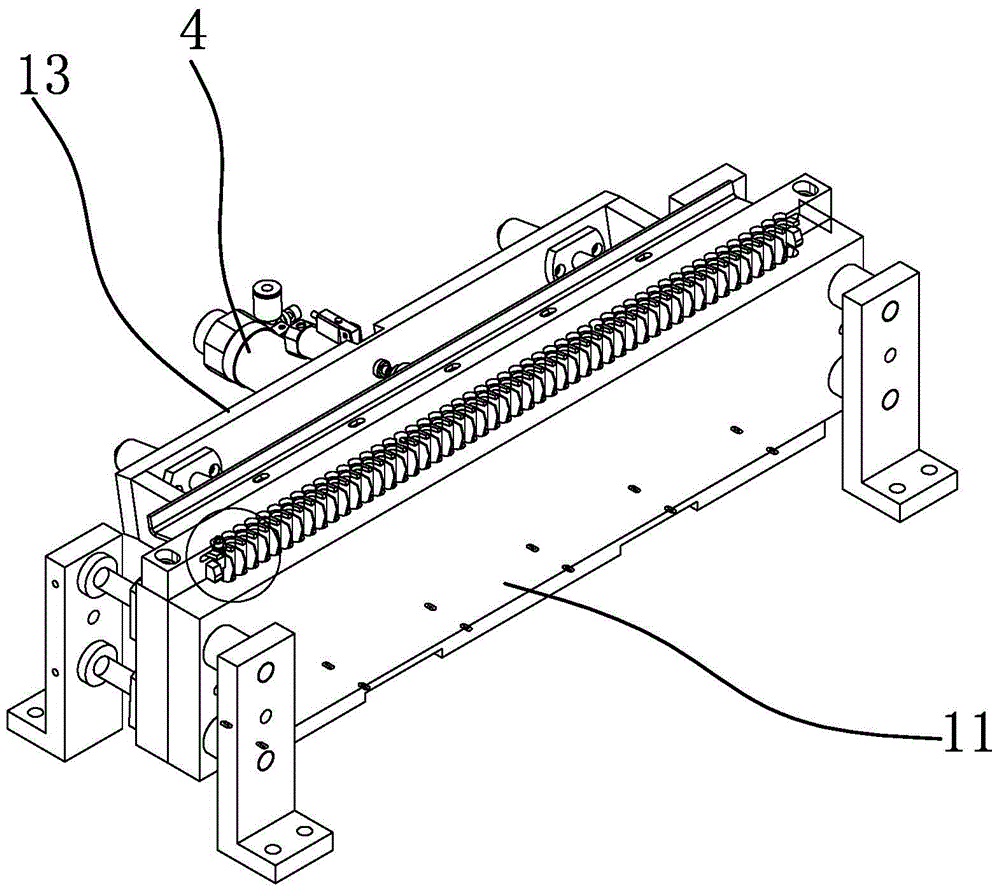

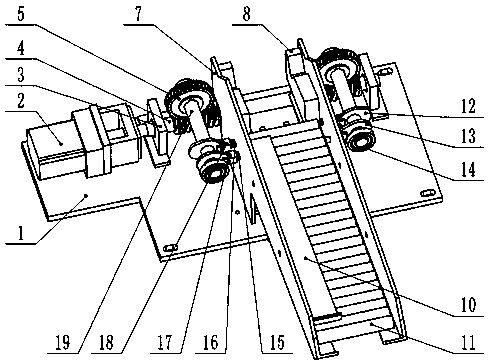

Flexible automatic distribution device for deformed bar materials

ActiveCN103358166AHigh degree of processing automationEasy to operateMetal working apparatusNumerical controlRobot hand

The invention relates to a bar material distribution device, in particular to a flexible automatic distribution device for deformed bar materials. The device comprises a flexible material storage mechanism, a servo distribution mechanism and a pneumatic material pushing mechanism which are used for storing, distributing and pushing the deformed bar materials respectively. Starting from a mechanical-electrical integration design idea, the distribution automation of the deformed bar materials is achieved by a flexible design method according to the characteristics of the deformed bar materials; after the device works with a special mechanical hand and a numerical control special machine, the automatic distributing, feeding and processing of the deformed bar materials can be achieved; the device is simple and reliable to use; the processing automation level of the deformed bar materials is effectively increased; the labor intensity is reduced; the influences caused by human factors are reduced; good cost performance is achieved.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

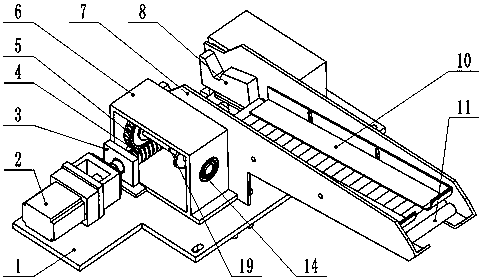

Flexible and automatic distributing device for shaft sleeve workpieces

InactiveCN103878628AOvercome stuckHigh degree of processing automationMetal working apparatusProcess engineeringManipulator

The invention discloses a flexible and automatic distributing device for shaft sleeve workpieces. The device comprises a flexible storage mechanism, a servo distribution mechanism and a pneumatic pushing mechanism arranged under the servo distribution mechanism. The three mechanisms achieve storage, distribution and pushing of the shaft sleeve workpieces respectively. According to characteristics of the shaft sleeve workpieces and by the adoption of a flexible design method, automation of distribution of the shaft sleeve workpieces is achieved, operation is easy, the number of workers is effectively reduced, and recruitment and management difficulty is eased. In specific application, an operator only needs to place a preset number of the shaft sleeve workpieces in the flexible storage mechanism, and other distribution work is finished through the servo distribution mechanism and the pneumatic pushing mechanism automatically. With the combination of a simple manipulator and a numerical control machine tool, automatic distribution, feeding and machining of the shaft sleeve workpieces are achieved, and accordingly influences of human factors are reduced and product quality and production efficiency are improved.

Owner:ZHEJIANG UNIV

Rotating type static allocation infusion bag intelligent sorting system and method thereof

The invention discloses a rotating type static allocation infusion bag intelligent sorting system and a method. The rotating type static allocation infusion bag intelligent sorting system comprises a primary sorting conveying unit and bins. A discharging port of the primary sorting conveying unit is connected with a secondary sorting conveying unit. A discharging port of the secondary sorting conveying unit is connected with a rotating type sorting conveying unit which is located above the first layer of bins, the first layer of bins are provided with multiple bin spaces in the circumferential direction, and the rotating type sorting conveying unit can rotate in the circumferential direction to enable a discharging port of the rotating type sorting conveying unit to correspond to the needed bin space. The other discharging port of the secondary sorting conveying unit is provided with a linear type sorting conveying unit in a connected manner, a discharging port of the linear type sorting conveying unit is provided with a rotating type sorting conveying unit in a connected manner, the rotating type sorting conveying unit is located above a second layer of bins, the second layer of bins are provided with multiple bin spaces in the circumferential direction, and the rotating type sorting conveying unit can rotate in the circumferential direction to enable a discharging port of the rotating type sorting conveying unit to correspond to the needed bin place. The rotating type static allocation infusion bag intelligent sorting device is high in sorting speed, high in accuracy and capable of achieving automatic sorting and feeding of infusion bags.

Owner:SUZHOU IRON TECH

Screw supply device

The invention provides a screw supply device and belongs to the technical field of material supply machines. The screw supply device comprises a stationary hopper, a fan-shaped material fetching plate, an oscillating bar, a guide groove, screws, a material collecting pipe, a support shaft, a gear, a rack, a driving oil cylinder and a material scraping assembly, wherein the fan-shaped material fetching plate is fixed to one end of the oscillating bar, is arranged in the stationary hopper, and can swing up and down; the upper end of the fan-shaped material fetching plate is provided with the guide groove, and the guide groove communicates to one end of the material collecting pipe; the other end of the oscillating bar is mounted on the support shaft, the support shaft is rotatably arranged on a support bracket, and the gear is coaxially fixed to the support shaft; a piston rod of the driving oil cylinder is positioned right below the gear, the rack is fixed to the piston rod, and the gear is meshed with the rack; and a ratchet shaft of the material scraping assembly is rotatably arranged on a material scraping bracket, a ratchet is coaxially mounted on the ratchet shaft, and the driving motor is coaxially connected with the ratchet shaft. The screw supply device realizes the supply of the screws in the same direction, is reasonable in structure and is great in stability.

Owner:ZHEJIANG HONGFENG WARP & WEFT KNITTING

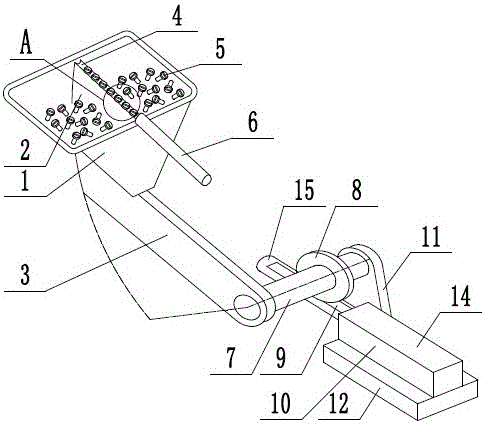

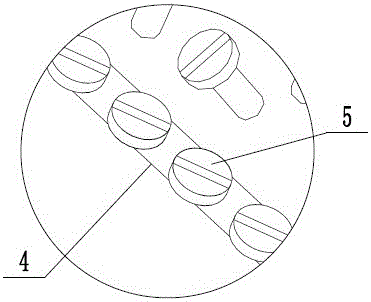

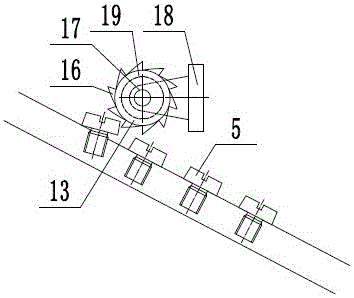

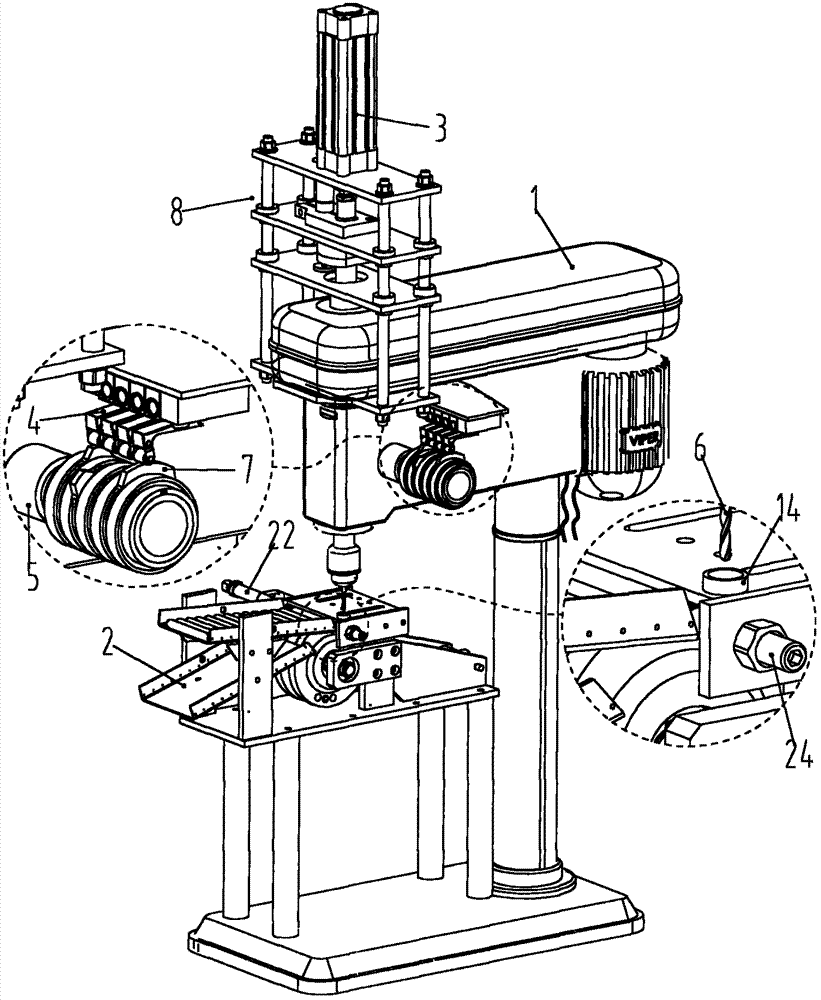

Full-automatic drilling automatic machine

InactiveCN104722793AKeep performance stableLow failure rateWork clamping meansFeeding apparatusManufacturing technologyEngineering

The invention relates to the technical field of the machining and manufacturing technology, in particular to a device for drilling holes in a workpiece. A full-automatic drilling automatic machine comprises a bench mill, an automatic tool and a feed mechanism, wherein the automatic tool is fixedly connected to the bench mill, the feed mechanism is fixedly connected to the bench mill, a mandrel is arranged at the center of a cam, and a groove capable of containing the workpiece is formed in the radial surface of the cam and is of a triangular structure; a baffle is arranged above the cam in the extending direction of a feed hopper. By means of the full-automatic drilling automatic machine, holes are drilled in the workpiece, the bench mill is automatically refitted, the workpiece is machined in a full-automatic and unmanned mode, the automatic feeding, clamping, drilling and discharging are achieved, and the full-automatic drilling automatic machine is compact in structure, small in occupied area, economical and practical.

Owner:WENZHOU POLYTECHNIC

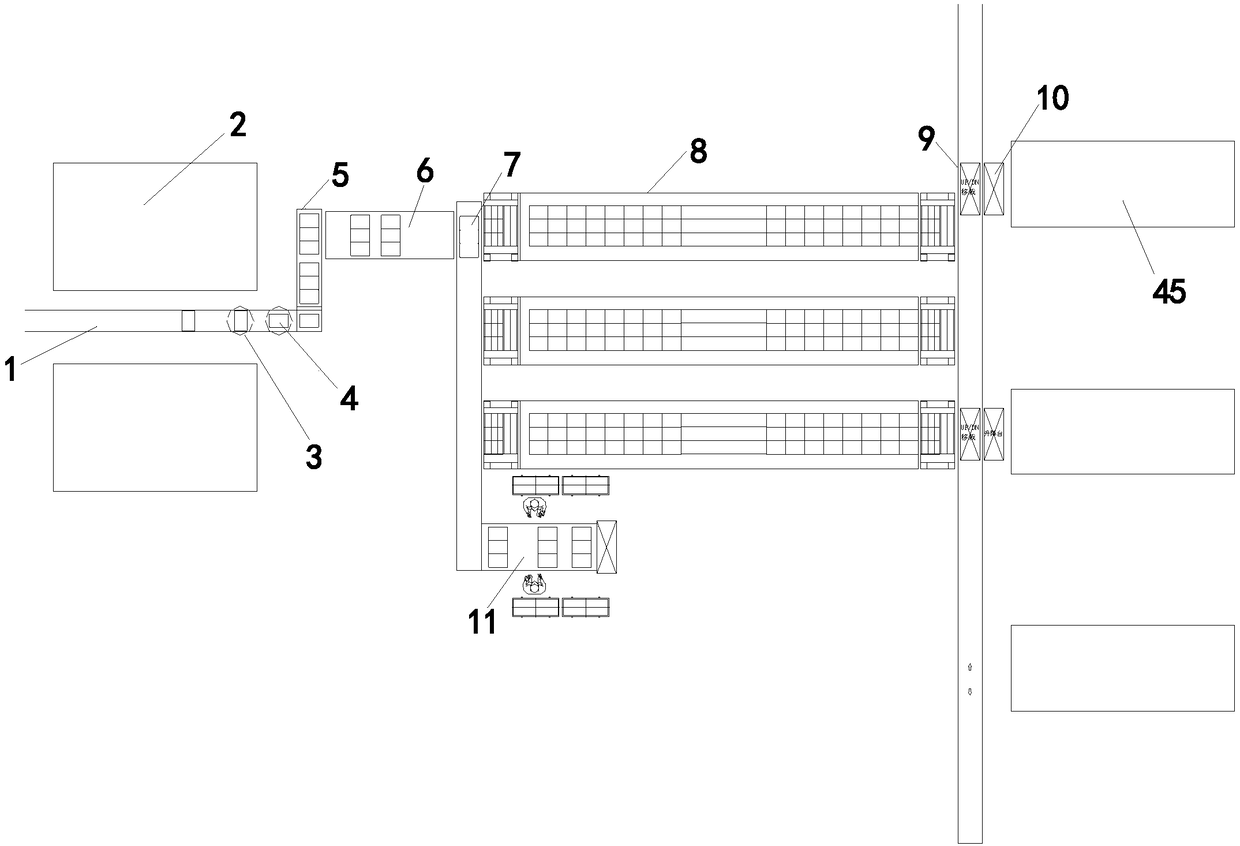

Automatic production line from magnetic tile forming to kiln sintering and realizing method thereof

PendingCN108438795ASimple structureLow costControl devices for conveyorsStorage devicesProduction lineEngineering

The invention discloses an automatic production line from magnetic tile forming to kiln sintering. The automatic production line comprises a forming conveying belt, a plurality of pressing machines, arecognition station, a recognition device and a rotating station. A three-plate integrating bank is arranged on the side edge of the rotating station. A three-plate transition conveying belt is arranged at the outlet end of the three-plate integrating bank. A double-layer transferring conveying trolley is arranged at the outlet end of the three-plate transition conveying belt. A plurality of intelligent warehouses are arranged on the side edge of the double-layer transferring conveying trolley. A warehouse double-layer conveying belt is arranged at the outlet ends of the intelligent warehouses. A plurality of overlap-connected lifting devices are arranged on the side edge of the warehouse double-layer conveying belt. Each overlap-connected lifting device is arranged corresponding to one kiln. A controller is connected with the recognition device, the rotating station, the three-plate integrating bank, the double-layer transferring conveying trolley, the warehouse double-layer conveying belt and the overlap-connected lifting devices. The invention further discloses a realizing method of the automatic production line from magnetic tile forming to kiln sintering. The automatic production line has the beneficial effects of being simple in structure, low in manufacturing cost, high in production efficiency, good in product quality and the like, and saving labor.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

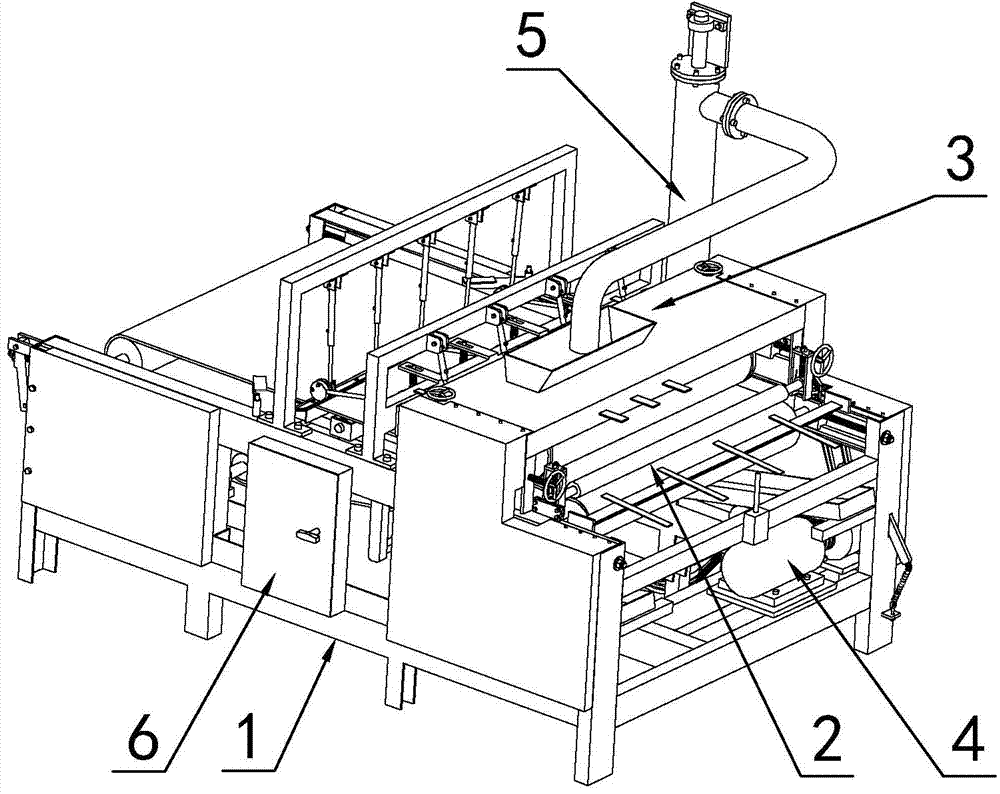

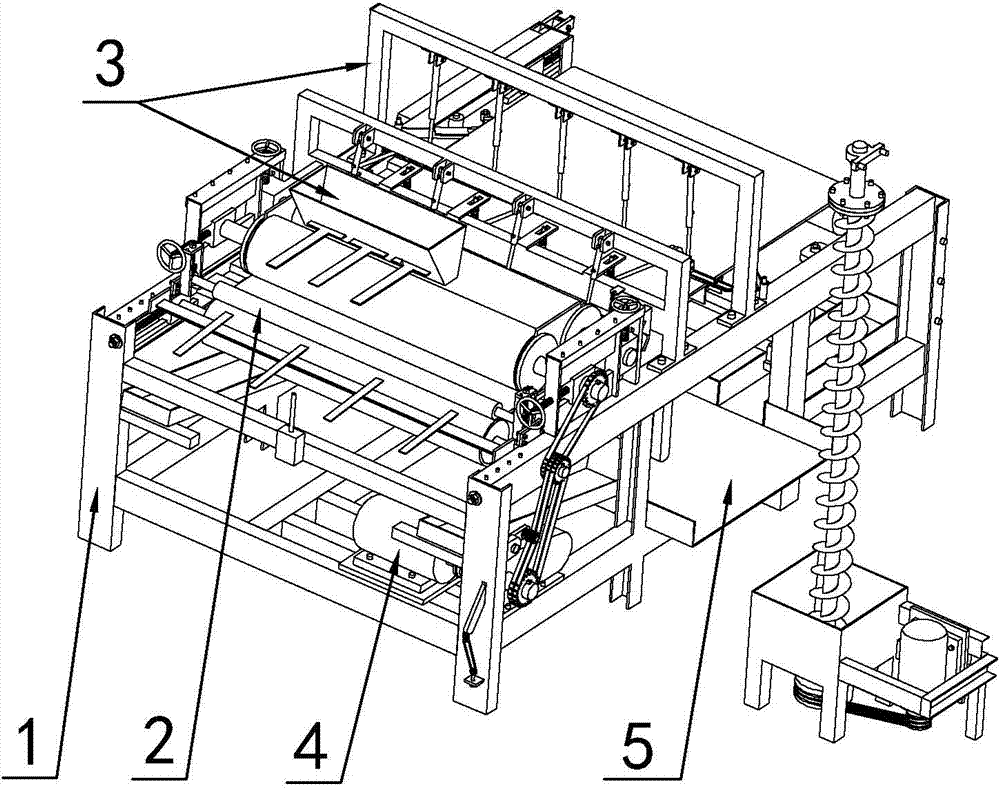

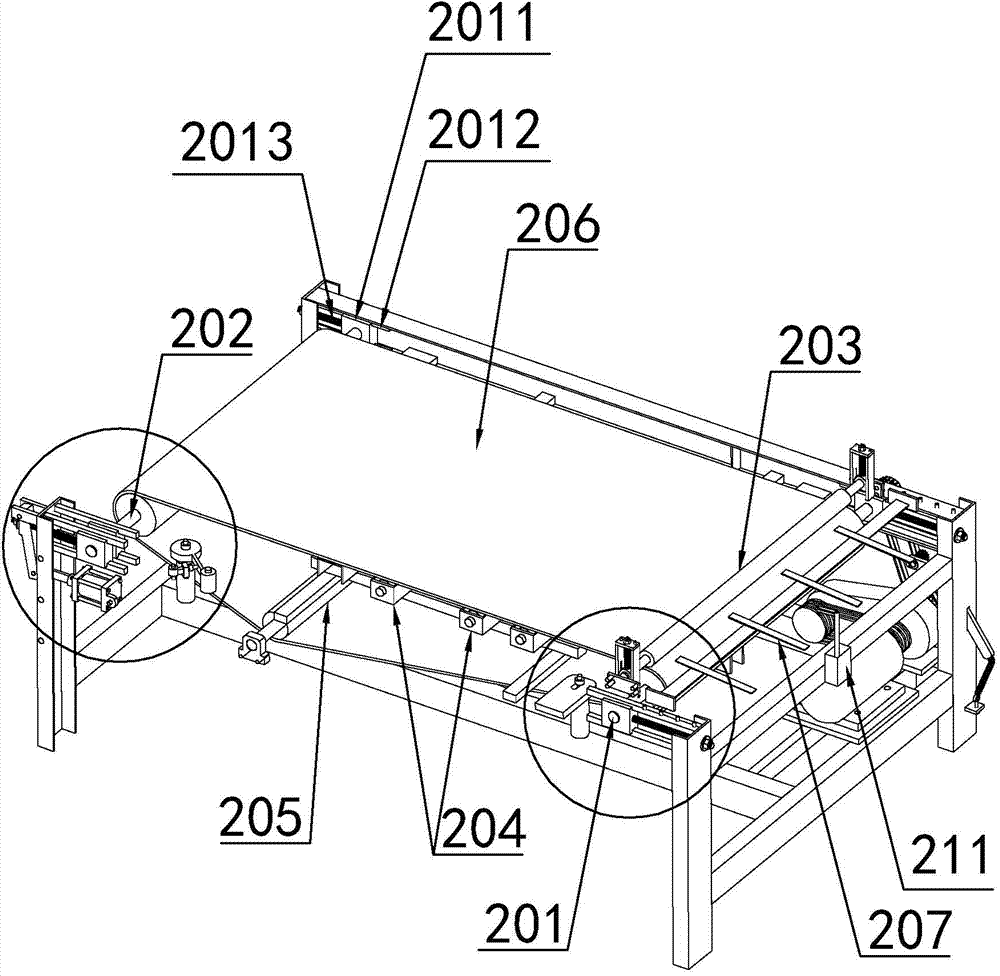

Novel efficient board single-side putty applying machine

ActiveCN104772256AImprove efficiencyQuality improvementLiquid surface applicatorsCoatingsSteel platesOn board

The invention discloses a novel efficient board single-side putty applying machine which comprises a rack, a transmission mechanism, a coating and scraping mechanism and a power mechanism. The rack comprises channel steel, angle steel, a steel plate and square steel, the transmission mechanism comprises a drive roller, a driven roller, a pressure roller, carrier rollers, a tensioning roller and a conveyer belt, the coating and scraping mechanism comprises a putty squeezing roller, a putty coating roller, a support, a double-edged knife and an oblique scraper, and the power mechanism comprises a motor, a speed reducer, an electric control cabinet and chain wheels; sliding bearing seats are arranged on the shaft ends of the drive roller and the driven roller, a screw is arranged on one side of the center of each bearing seat, a nut is arranged on the head of each screw, and the bearing seats are fixedly connected to the rack through the screws and the nuts; the double-edged knife, the putty coating roller and the conveyer belt form a triangle area together, and the rear side of the double-edged knife is provided with the oblique scraper. According to the novel efficient board single-side putty applying machine, automation of applying putty on boards is achieved, the time and the energy are saved, the efficiency is high, and the quality is high.

Owner:孟凡科

Automatic cap welding machine of smoke pipe

ActiveCN105945438ACompact structureReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention discloses an automatic cap welding machine of a smoke pipe. The machine comprises a frame body, a pushing module, a discharge module, a cap welding module, a console and a clamping feeding module; the cap welding module is arranged on the left side of the frame body for clamping and positioning the smoke pipe and automatically feeding the smoke pipe to the clamping feeding module of the cap welding module for fixing on the frame body; the pushing module and the discharge module are respectively arranged on the frame body on two sides of the clamping feeding module; and the console is fixed on the frame body, and is used for controlling motions of the pushing module and the clamping feeding module. The machine is simple and compact in structure, low in production cost and high in automation degree, can finish automatic loading, automatic clamping, automatic positioning and automatic feeding of the smoke pipe, automatic loading of a circular cap, automatic insertion of the circular cap into the smoke pipe, automatic welding of the circular cap with the smoke pipe and automatic unloading, needs no manual operation, and greatly improves the machining efficiency.

Owner:浙江海宁经编产业园区开发有限公司

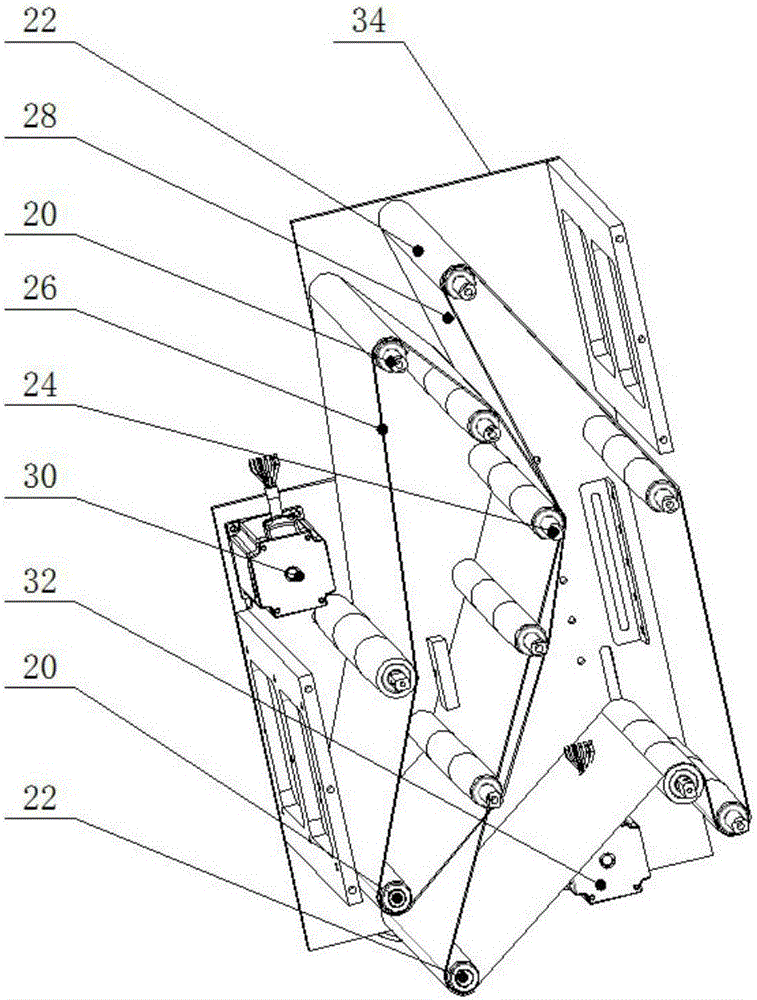

Accurate positioning and feeding device for tubular workpiece single end machining

ActiveCN105858177ASimple and compact structureReduce manufacturing costConveyorsConveyor partsDrive motorEngineering

The invention discloses an accurate positioning and feeding device for tubular workpiece single end machining. The accurate positioning and feeding device for tubular workpiece single end machining comprises a base, a first ached door, a second arched door, a three-jaw chuck, a chuck drive air cylinder, a chuck drive motor, a ball screw, a screw drive motor, a linear guide rail, a sliding base, a screw nut and a screw nut connecting plate. The sides, close to each other, of the first arched door and the second arched door are each provided with two pressing wheels used for clamping the two ends of a tubular workpiece. A push plate is fixed to the front end of the three-jaw chuck. Three screw rods are arranged on the chuck drive air cylinder. A limiting plate is further fixed to the base and provided with a limiting step rod. The accurate positioning and feeding device is simple and compact in structure, low in production cost and high in automation degree. The two ends of the tubular workpiece are pressed through the four pressing wheels, and the three-jaw chuck stretches into one end of the tubular workpiece and clamps the tubular workpiece. When the tubular workpiece horizontally moves, it is still kept that the tubular workpiece is located between the four pressing wheels located at the two ends, the positioning precision is very high, and the feeding accuracy is improved.

Owner:ZHEJIANG UNIV OF TECH

Novel infusion bag sorting system

ActiveCN105151765ARealize automatic sortingRealize feedingSortingStorage devicesAngular displacementPush out

The invention discloses a novel infusion bag sorting system which comprises a conveying mechanism (2), a feeding device (4) and a plurality of pushing mechanisms (6). The conveying mechanism (2) is driven by a first power device to linearly move, the feeding device (4) is arranged at one end of the conveying mechanism (2) and can push infusion bags on the feeding device onto the conveying mechanism (2), and the pushing mechanisms (6) are arranged in the length direction of the conveying mechanism (2) and can push out the infusion bags from the conveying mechanism (2). The system is characterized in that the feeding mechanism (4) is provided with a code scanner (8) capable of reading graphic codes on the infusion bags, and a code disc (10); after the code scanner (8) successfully recognize bar codes on the infusion bags, the code disc (10) is controlled to rotate by a set number of turns and / or angular displacement, and the code disc (10) controls the pushing mechanism (6) closest to the infusion bags to push out the infusion bags. The system solves problems in the prior art, and by means of combination of the conveying mechanism (2), the feeding device (4) and the pushing mechanisms (6), automatic sorting and feeding of medicine are achieved.

Owner:SUZHOU IRON TECH

Crushing device for neodymium iron boron permanent magnet waste residue

The invention discloses a crushing device for neodymium iron boron permanent magnet waste residue. A feeding screw rod is in rotatable connection with the interior of a feeding box; the feeding screw rod is driven to rotate by a motor; a rotating shaft of the motor is sleeved with a first bevel gear; the first bevel gear is meshed with a second bevel gear; a vertical rod is sleeved with the second bevel gear; the vertical rod is vertical to the feeding screw rod; a crushing mechanism is arranged under a discharging port of the feeding box; the vertical rod is in rotatable connection with a support plate; the vertical rod is used for driving a left crushing rod and a right crushing rod to rotate by a conveying mechanism; the left crushing rod and the right crushing rod are respectively arranged in a left crushing chamber and a right crushing chamber; the left crushing rod is sleeved with a left crushing blade; the right crushing rod is sleeved with a right crushing blade; a left filter screen and a right filter screen are respectively connected with the interiors of the left crushing chamber and the right crushing chamber; a conveying device is arranged under a crushing box. The crushing device for neodymium iron boron permanent magnet waste residue, disclosed by the invention, can repeatedly crush the materials; the crushing efficiency is high; the crushing effect is stable; the design is smart; the production cost is low.

Owner:ANHUI JINSANLONG RENEWABLE RESOURCES

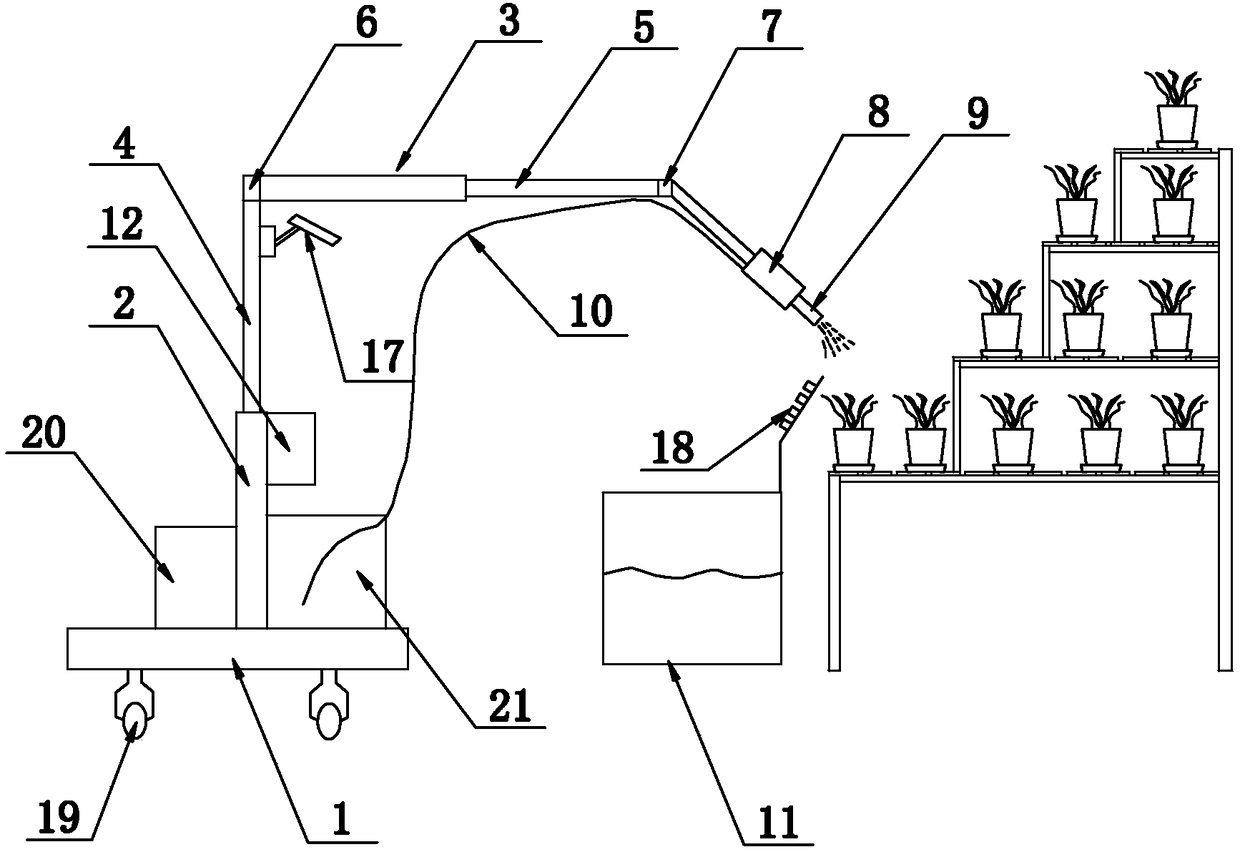

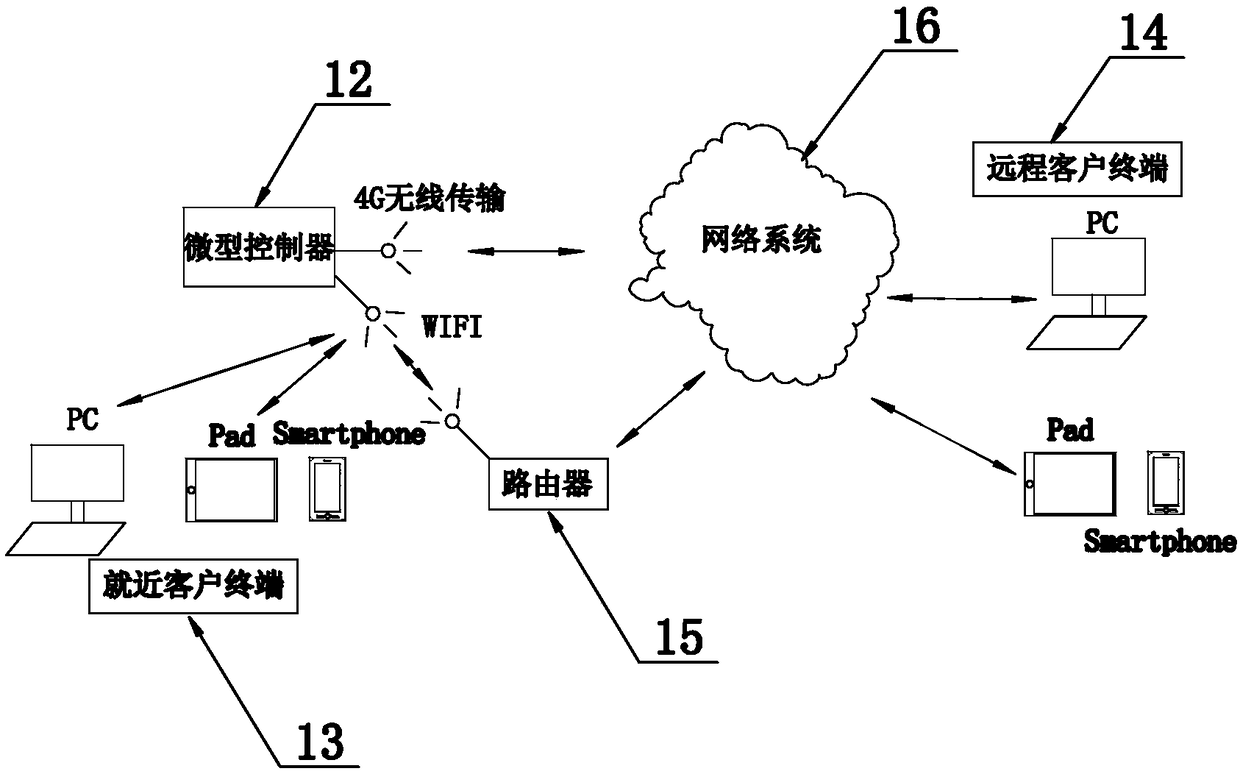

Mobile device for smart home fish culture and plant culture

PendingCN108293941ARealize feedingAdd funSelf-acting watering devicesPisciculture and aquariaWater pipeEngineering

The invention relates to a mobile device for smart home fish culture and plant culture and aims to provide a home fish culture and plant culture device which is simple in structure, high in degree ofintelligence and good in control experience. The device includes a mobile device, a mechanical arm and a microcontroller. The bottom of the mechanical arm is fixed at the top of the mobile device, anda plurality of electric universal wheels are mounted at the bottom of the mobile device. The top of the mobile device is provided with a water tank, a water pumping device is mounted at the top of the mechanical arm, a water pumping port of the water pumping device is connected with one end of a water pipe, the other end of the water pipe extends into the lower portion of the inner liquid surfaceof the water tank, and a watering spray head is connected with a water outlet of the water pumping device. The image signal receiving end of a micro controller is electrically connected to the imagesignal output end of a camera, and the control signal output end of the micro controller is electrically connected to the control signal receiving ends of the mechanical arm, the water pumping device,the watering spray head and the electric universal wheel, respectively.

Owner:石闪东 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com