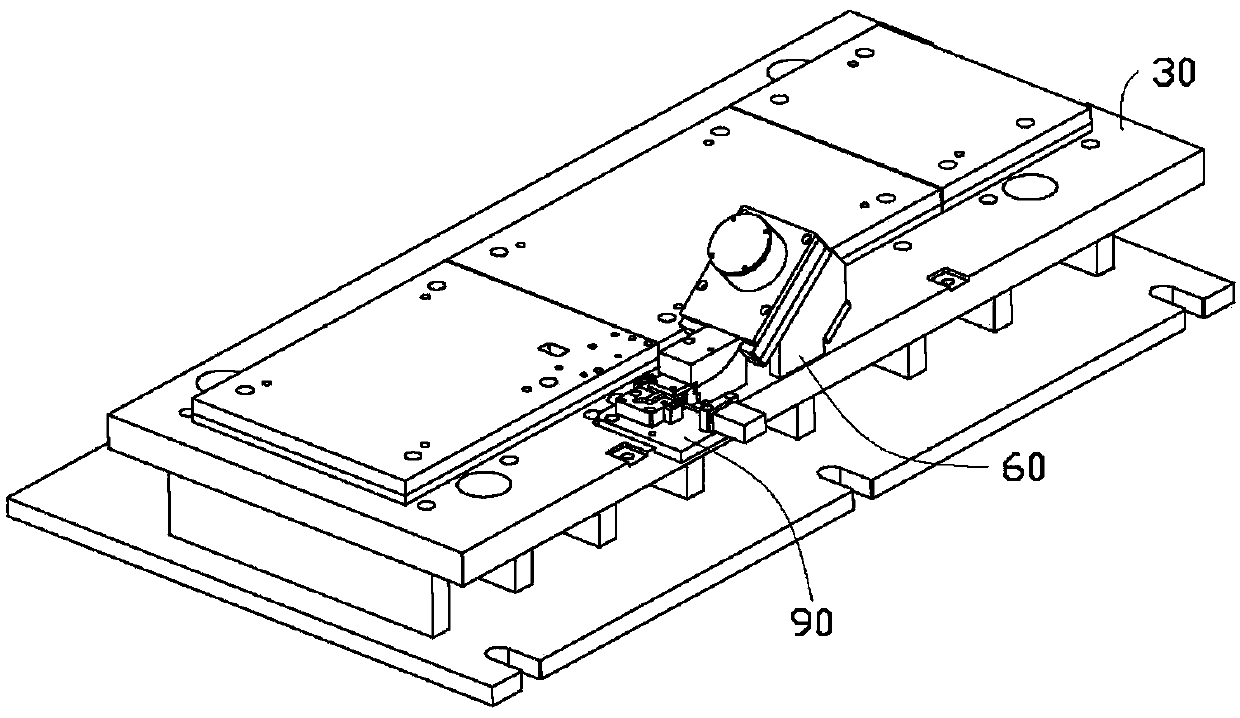

Automatic feed device

A technology of automatic feeding and feeding device, which is applied in the direction of transportation and packaging, conveyor objects, etc., and can solve the problems of low efficiency of rivets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0031] In other embodiments, the mounting plate 63 can also be omitted, and the supporting plate 64 is directly fixed on the supporting surface 623 of the supporting frame 62 .

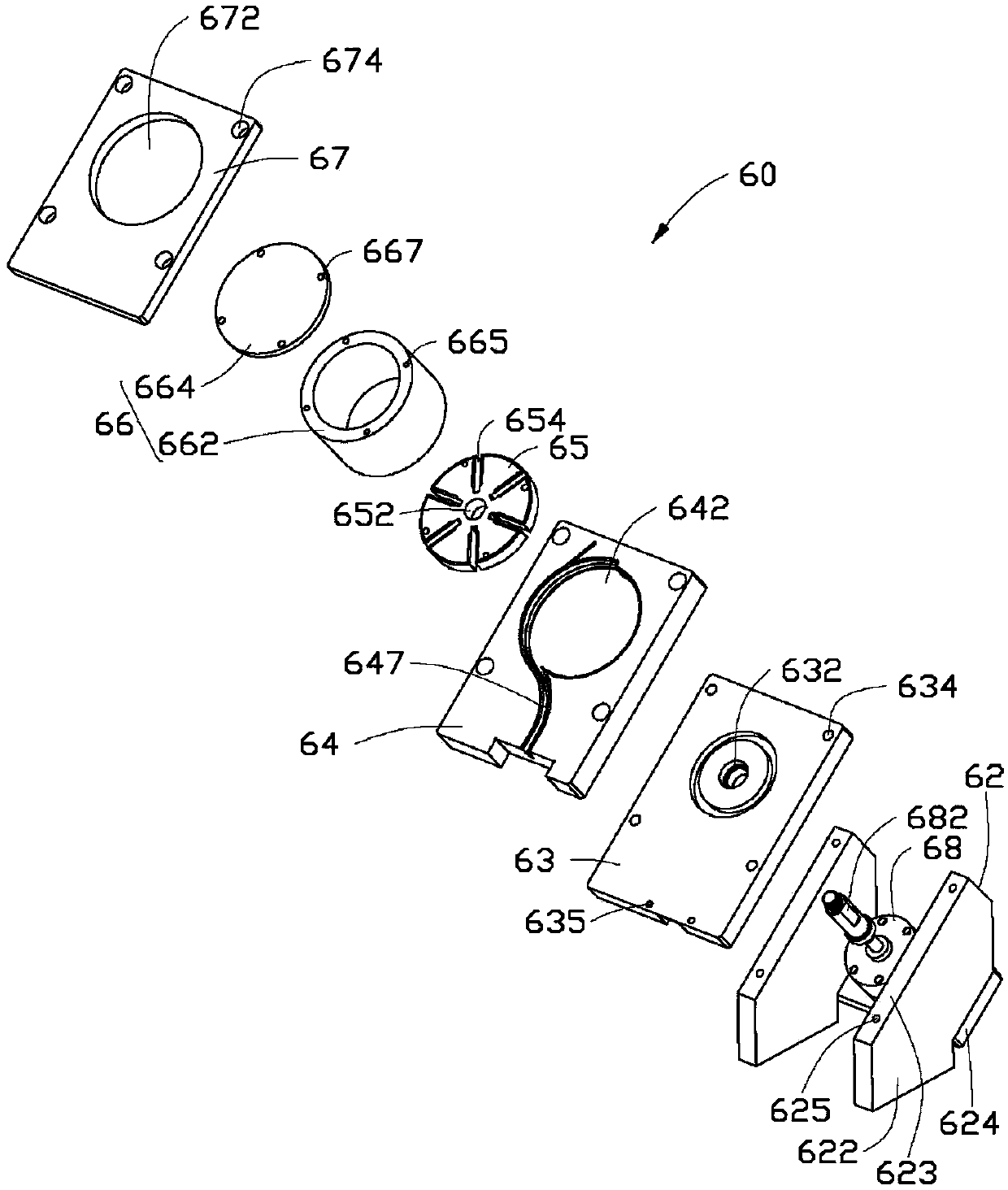

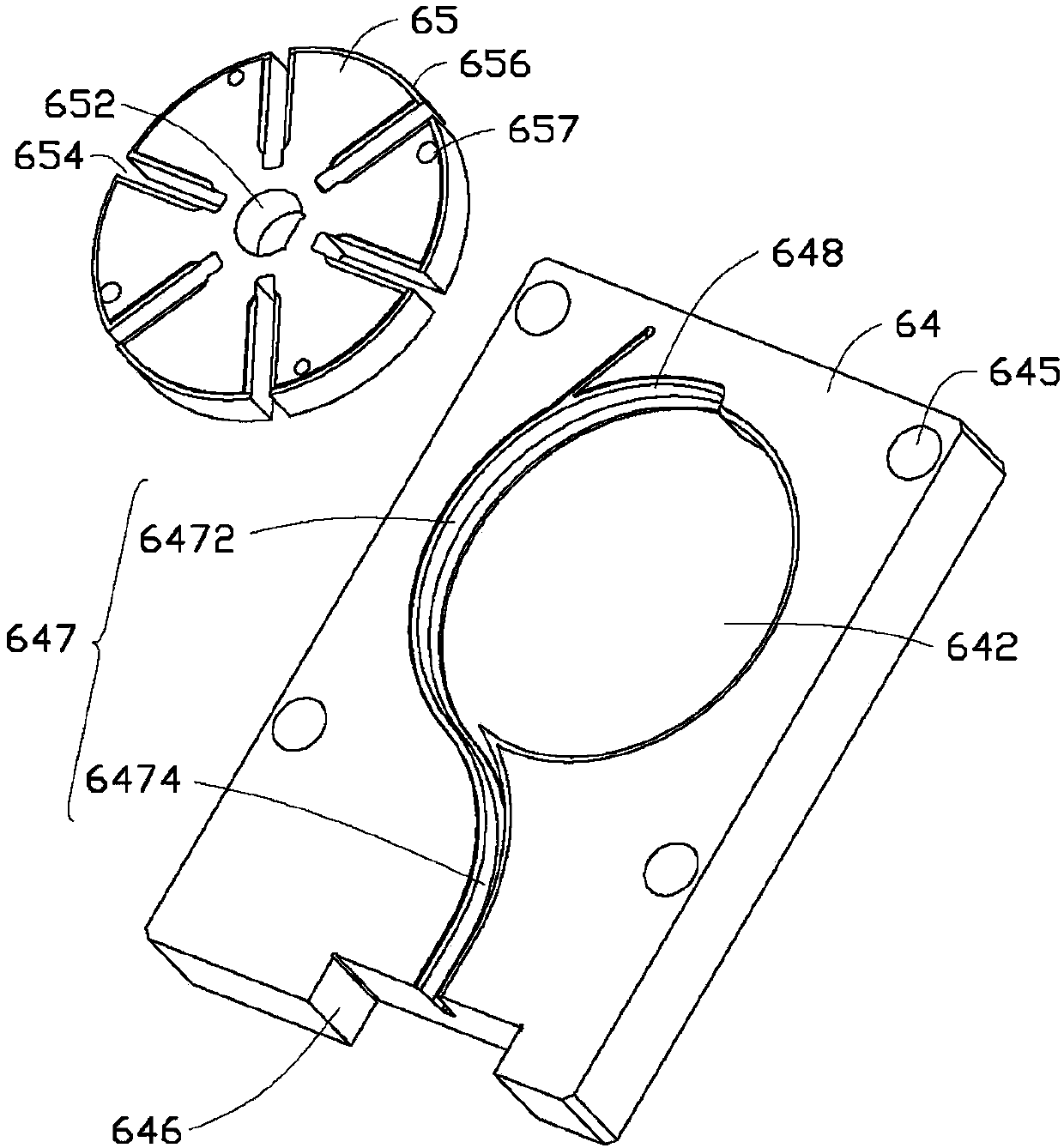

[0032] see Figure 6 to Figure 8, when in use, a number of rivets 200 are placed in the bucket 66, the first driving device 68 drives the distribution pan 65 to rotate, so that the rods of some rivets 200 are inserted into the sieve trough 654 of the distribution pan 65, The head of the rivet 200 is received in the guide groove 656 of the sieving groove 654 . The rod portion of the rivet 200 slides from the sieve trough 654 into the entry portion 6472 of the first trough 647 of the support plate 64, and the head of the rivet 200 slides along the guide groove 648 of the first trough 647 under the action of gravity , through the second chute 964 of the connecting block 96 , and slide into the notch 9462 of the pole 946 . The second driving device 945 pushes the slider 942 to slide along the receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com