Patents

Literature

436results about How to "Realize automatic sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

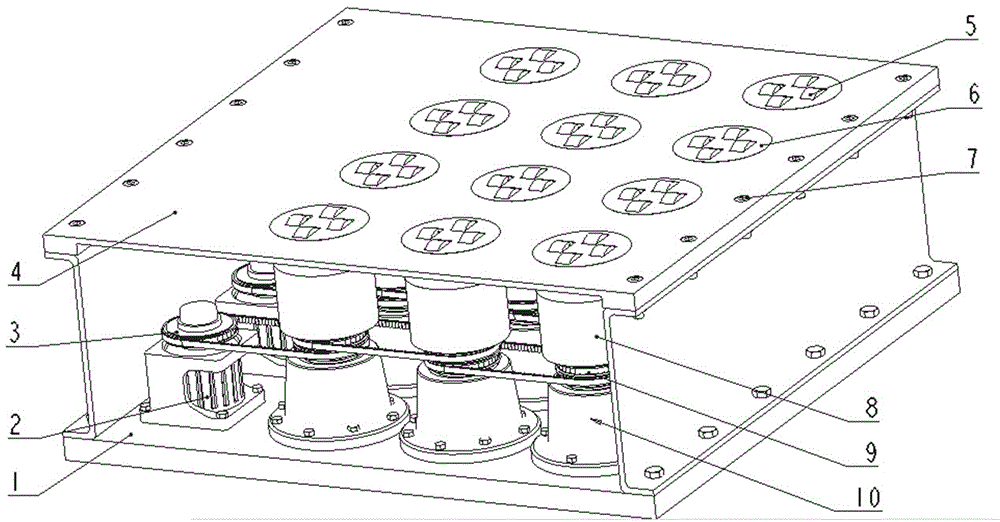

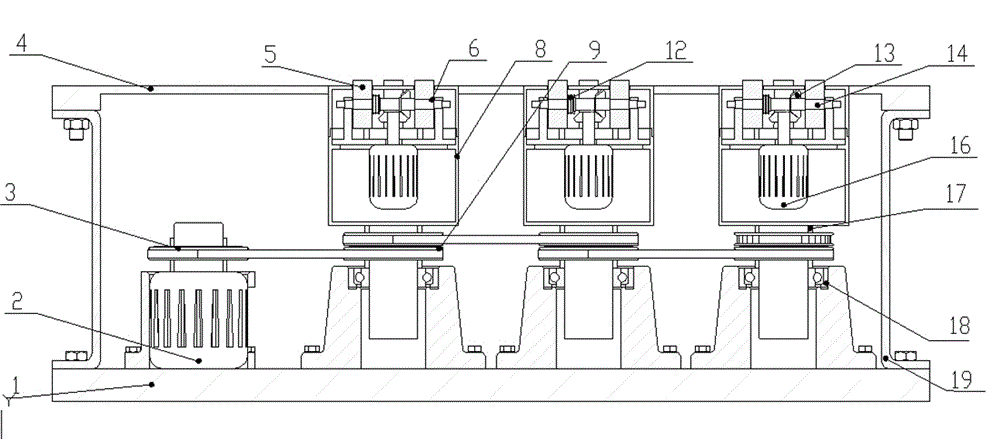

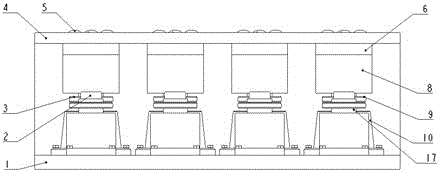

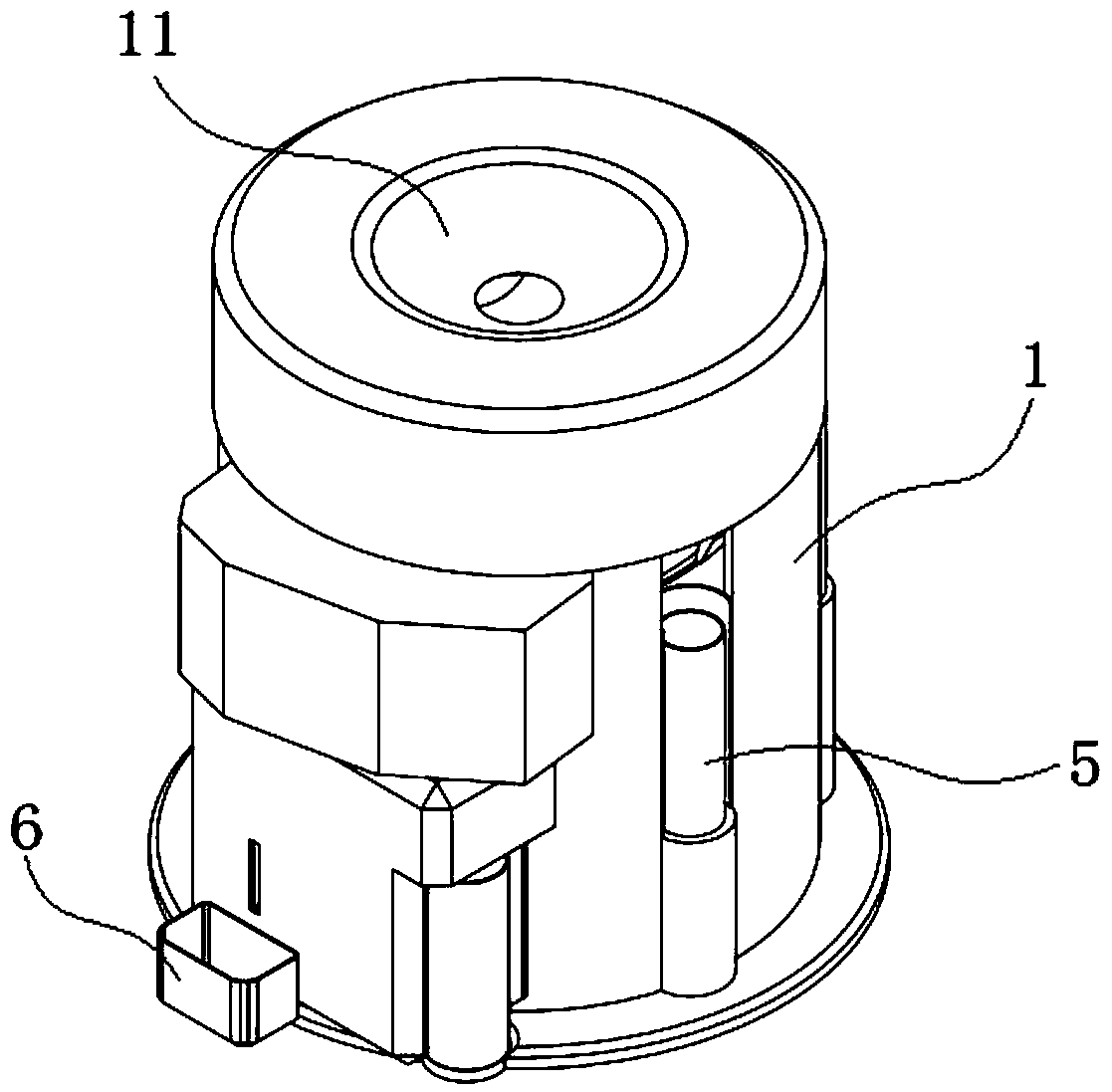

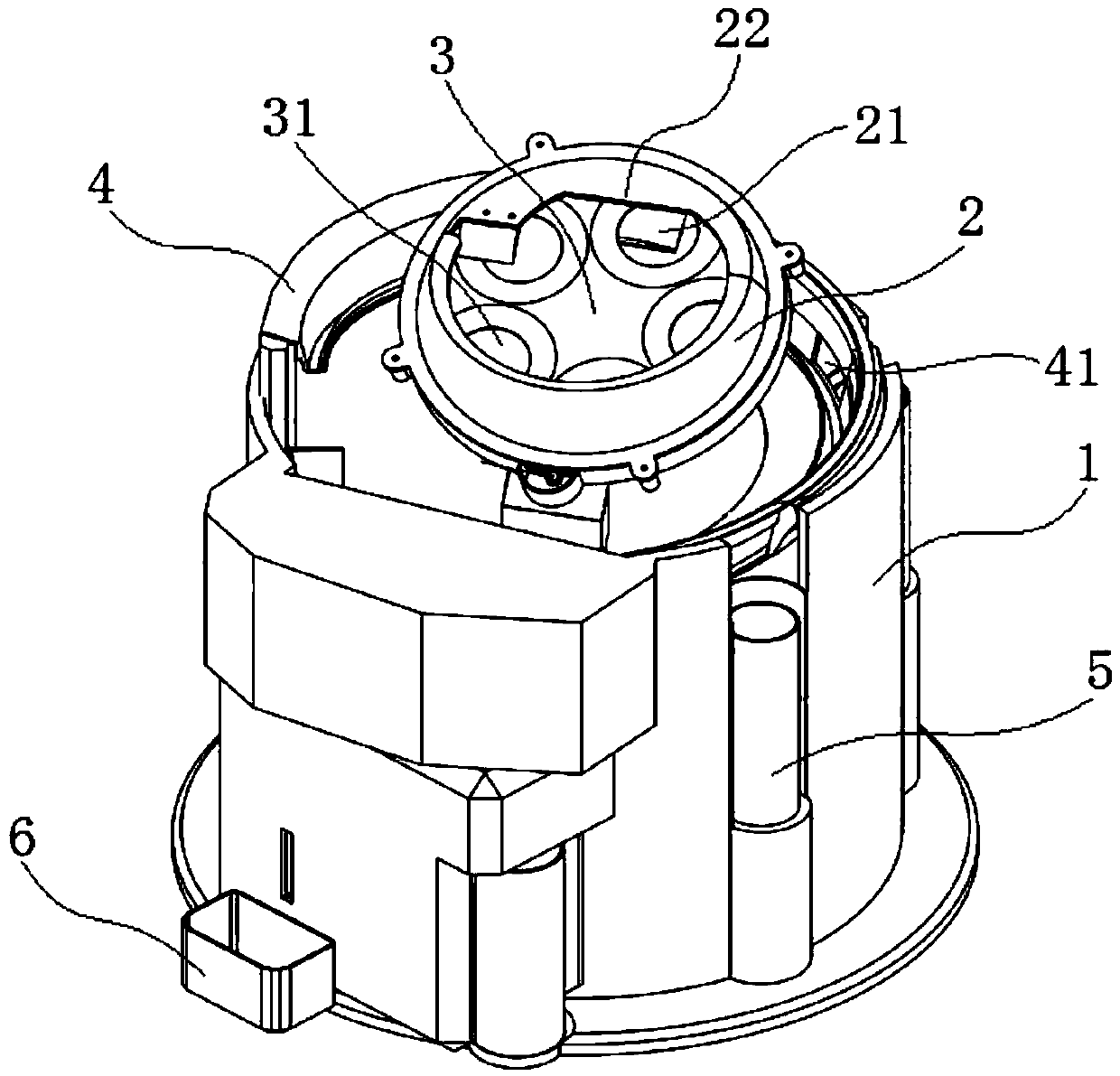

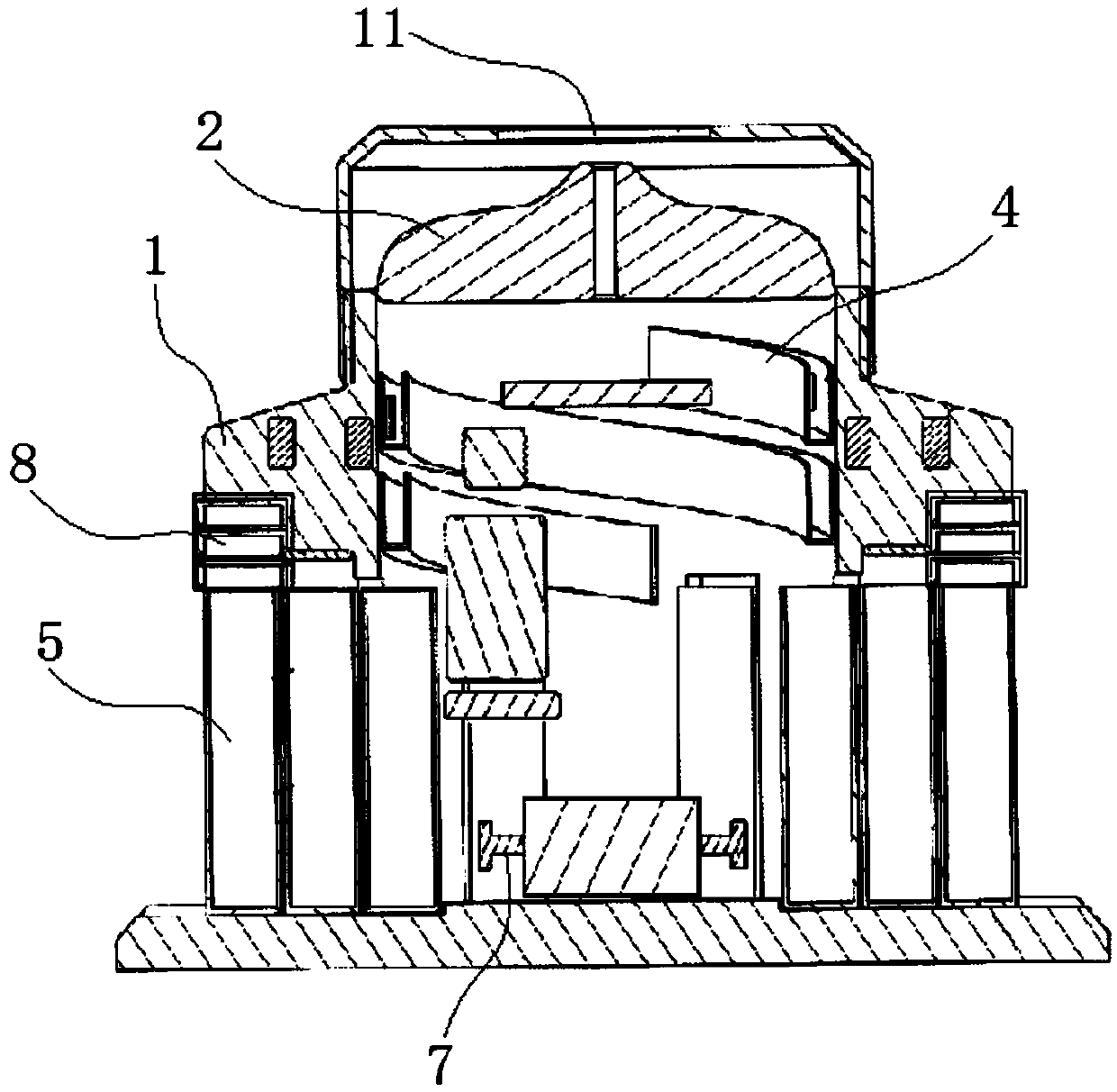

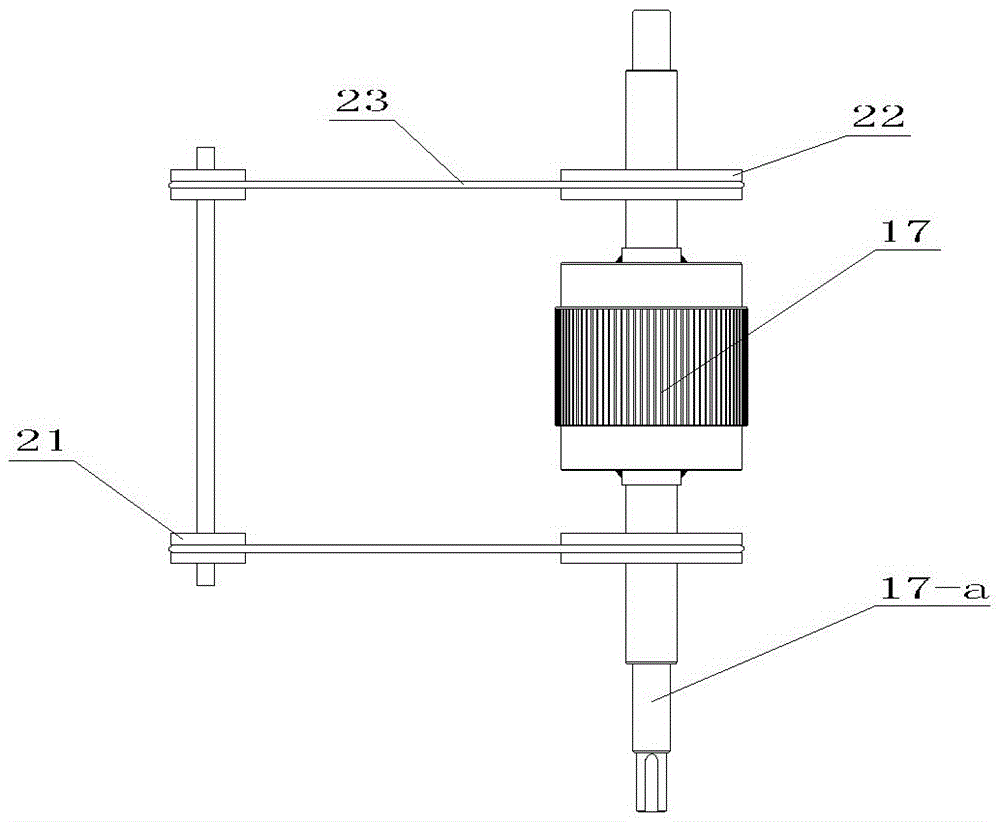

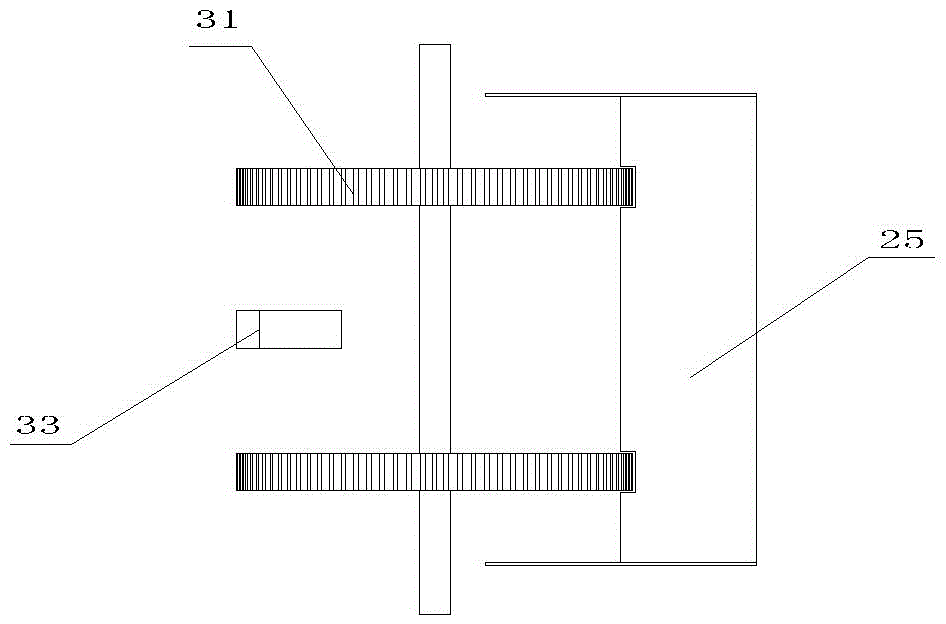

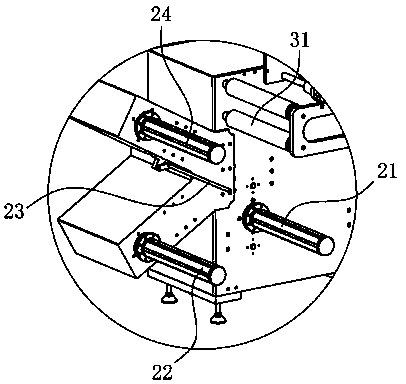

Omnibearing automatic logistics conveying sorting machine

The invention discloses an omnibearing automatic logistics conveying sorting machine. The machine comprises a fixing support and multiple sorting devices, a fixing support panel is provided with multiple rows of and multiple columns of through holes, and the through holes are internally provided with sorting devices; the sorting devices comprise bases and cylindrical cylinder shells; the bottoms of the cylindrical cylinder shells are provided with rotating shafts coaxial to the cylindrical cylinder shells, the rotating shafts are supported on the bases through bearings, and the rotating shafts are connected to servo motors on the fixing supports through first transmission devices; the cylindrical cylinder shells are internally provided with motors and bases, the bases are provided with middle shafts and small shafts, and the middle shafts are connected to the motors through bevel gears; the small shafts are connected to the middle shafts through second transmission devices, and the small shafts are provided with rollers; the rollers are higher than the panels of the fixing supports. The omnibearing automatic logistics conveying sorting machine is easy and convenient to disassembly, assembly and repair and convenient to maintain; different goods can circulate in an omnibearing mode according to types, and the sorting angle is flexible; multiple rollers are adopted, it can be guaranteed that the goods are stably conveyed and the rotation is free of impact, the operation noise is low, and sorting is fast and stable.

Owner:XIANGTAN UNIV

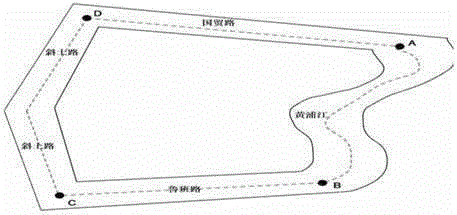

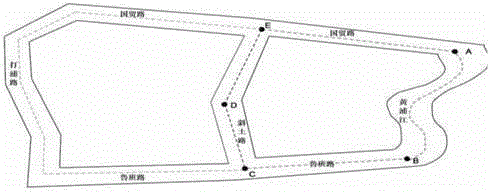

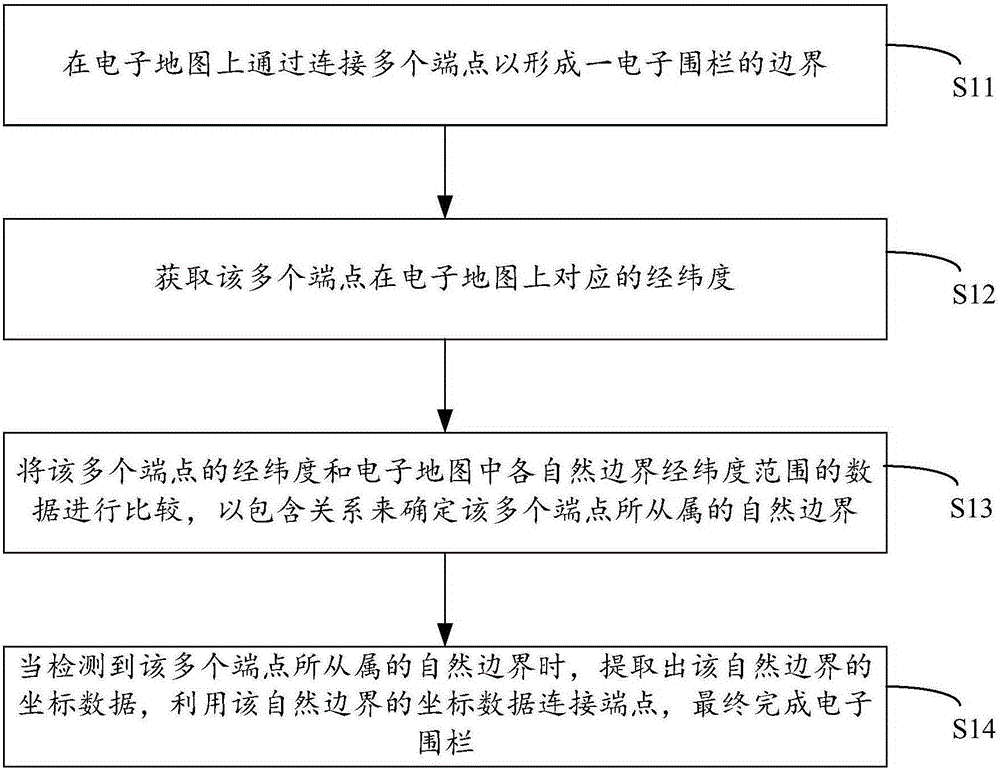

Polygon accurate drawing method based on electronic map and application method thereof

InactiveCN106652756APrecise delineationAvoid overlapping bordersMaps/plans/chartsData connectionInclusion relation

The invention discloses a polygon accurate drawing method based on an electronic map and an application method thereof. Problems that based on the electronic map, during drawing of a single covering, rivers, roads, and fuzzy boundaries cannot be discriminated accurately, and during the drawing of a plurality of polygon coverings, the adjacent boundaries are easy to overlap and are not superposed are solved. The technical scheme provided by the invention is characterized in that by connecting a plurality of endpoints, a boundary of an electronic fence is formed on the electronic map; the corresponding longitudes and the corresponding latitudes of the plurality of endpoints in the electronic map are acquired; the longitudes and the latitudes of the plurality of endpoints are compared with the data of the longitude and latitude ranges of the natural boundaries of the electronic map, and the natural boundaries of the plurality of endpoints are determined by an inclusion relation; when the natural boundaries of the plurality of endpoints are detected, the coordinate data of the natural boundaries is extracted, and the endpoints are connected by using the coordinate data of the natural boundaries, the electronic fence is finally completed.

Owner:YTO EXPRESS CO LTD

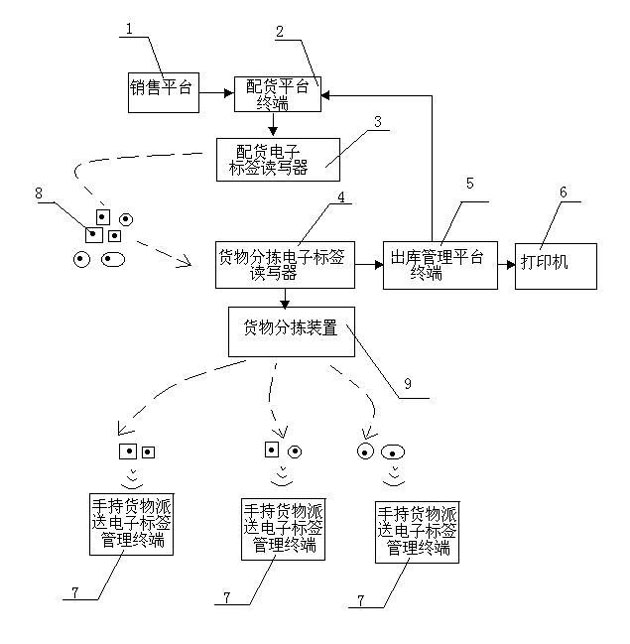

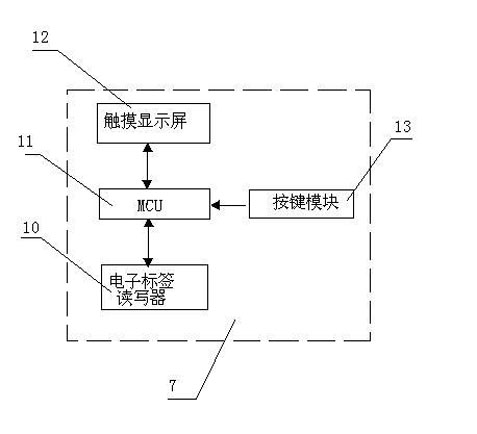

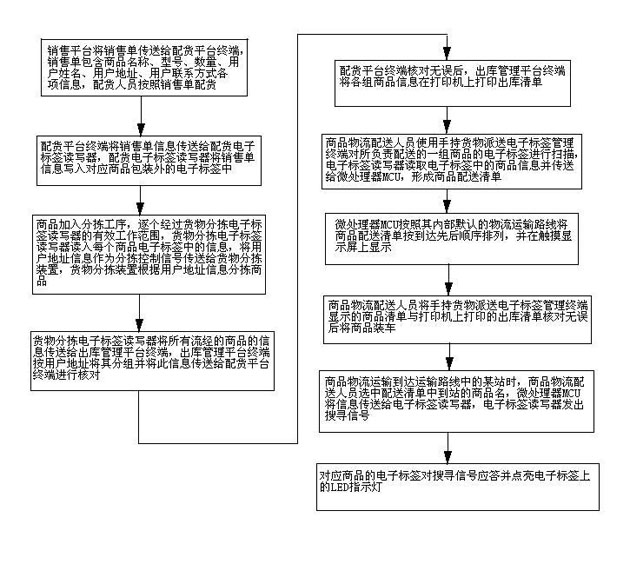

Physical distribution management device and management method for on-line purchased commodities

InactiveCN101976415ARealize automatic sortingCo-operative working arrangementsLogisticsLogistics managementHand held

The invention discloses a physical distribution management device and method for on-line purchased commodities. The device comprises a selling platform, a cargo allocation platform terminal, a cargo allocation electronic tag reader-writer, a cargo sorting electronic tag reader-writer, a delivery management platform terminal, a printer, electronic tags and a cargo sorting device. The system also comprises a hand-held cargo dispatching electronic tag management terminal which comprises an electronic tag reader-writer, a microprocessor MCU, a touch display screen and a key module. When in use, each batch of cargoes are configured with electronic tags on which basic information of commodities and customers is stored, thereby operating and managing physical distribution processes of commodities. The invention can realize the purposes of automatically sorting cargoes and saving cargo sorting information and physical distribution transport information, and can automatically finish the functions of checking cargoes, searching cargoes in the dispatching process and the like. In the invention, the problems that cargo sorting, searching and dispatching works of on-line stores and physical distribution companies make mistakes easily, and the working efficiency is low, are solved.

Owner:JIANGSU KEDA HUIFENG SCI & TECH

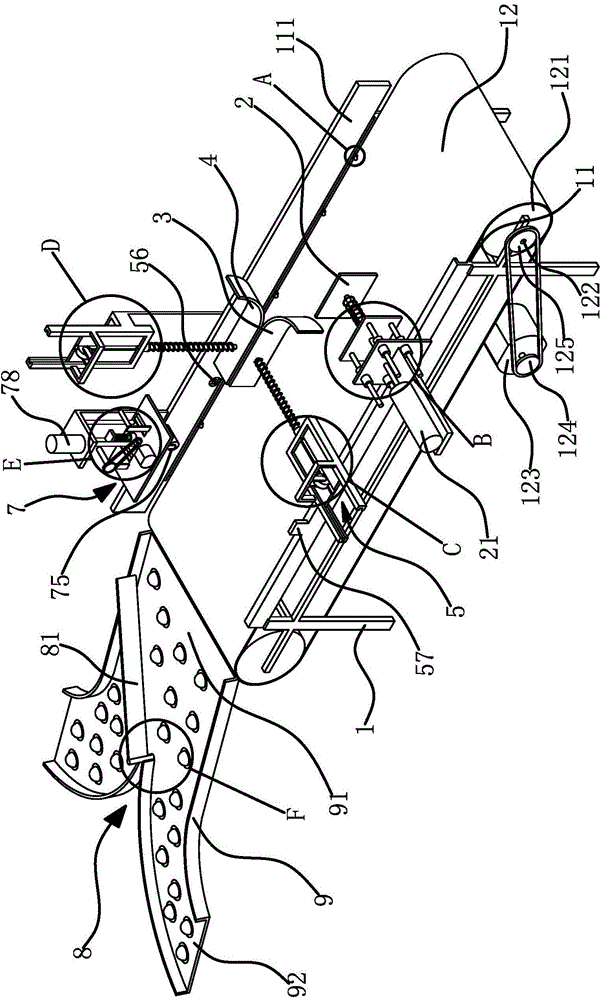

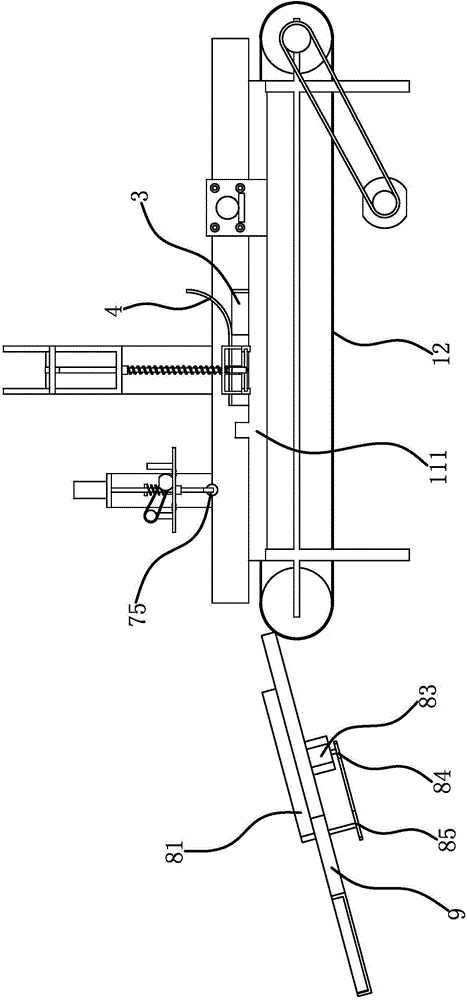

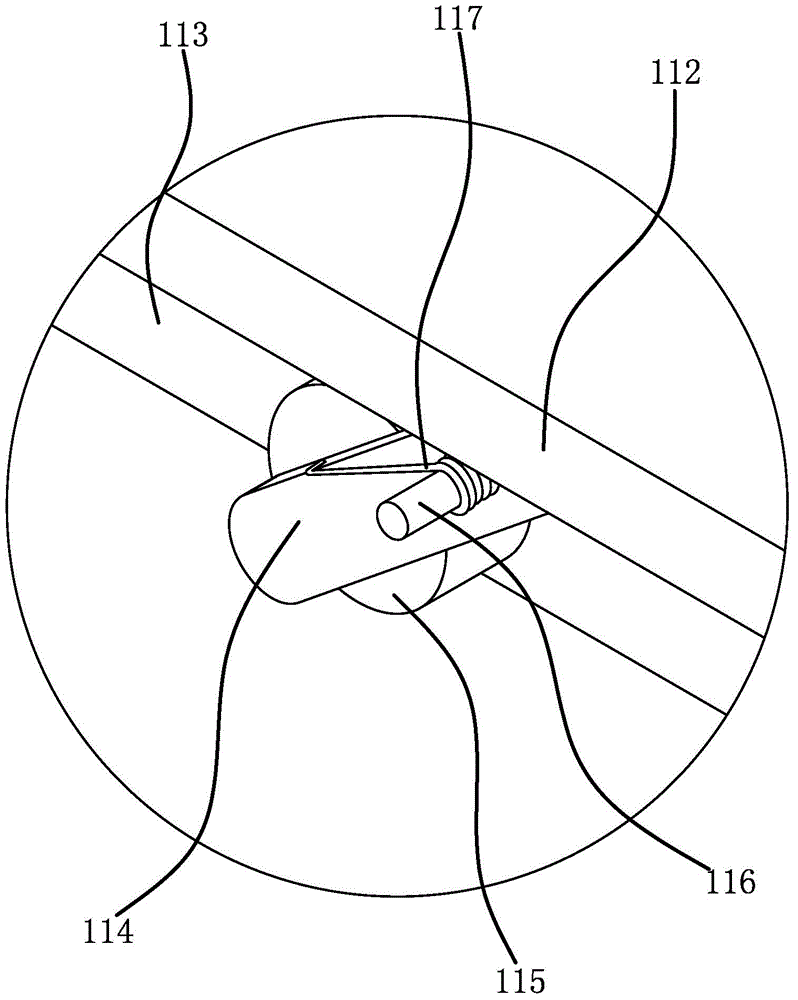

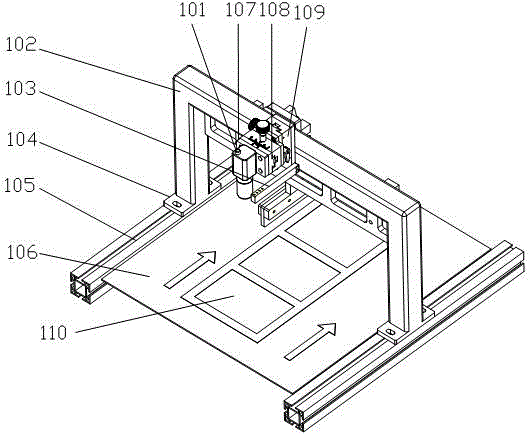

Express item sorter

The invention provides an express item sorter and belongs to the technical field of express item sorters. The express item sorter solves the problem that the existing express item sorter has a low automation degree. The express item sorter comprises a frame, the frame is connected to a conveyor belt, a supporting plate is fixed to the frame, the frame is provided with a compaction member, a transverse detection plate and a vertical detection plate are slidingly connected to the frame, two detection springs are respectively arranged between the transverse detection plate and the frame and between the vertical detection plate and the frame, under the action of the detection springs, two detection devices are respectively arranged between the transverse detection plate and the frame and between the vertical detection plate and the frame, a lifting plate is slidingly connected to the frame, the lifting plate is provided with an express delivery list pasting mechanism and the frame is provided with a dividing mechanism. The express item sorter can orderly realize automatic size measurement, express delivery list pasting and sorting, has a high automation degree and greatly improves express item sorting efficiency.

Owner:ZHEJIANG OCEAN UNIV

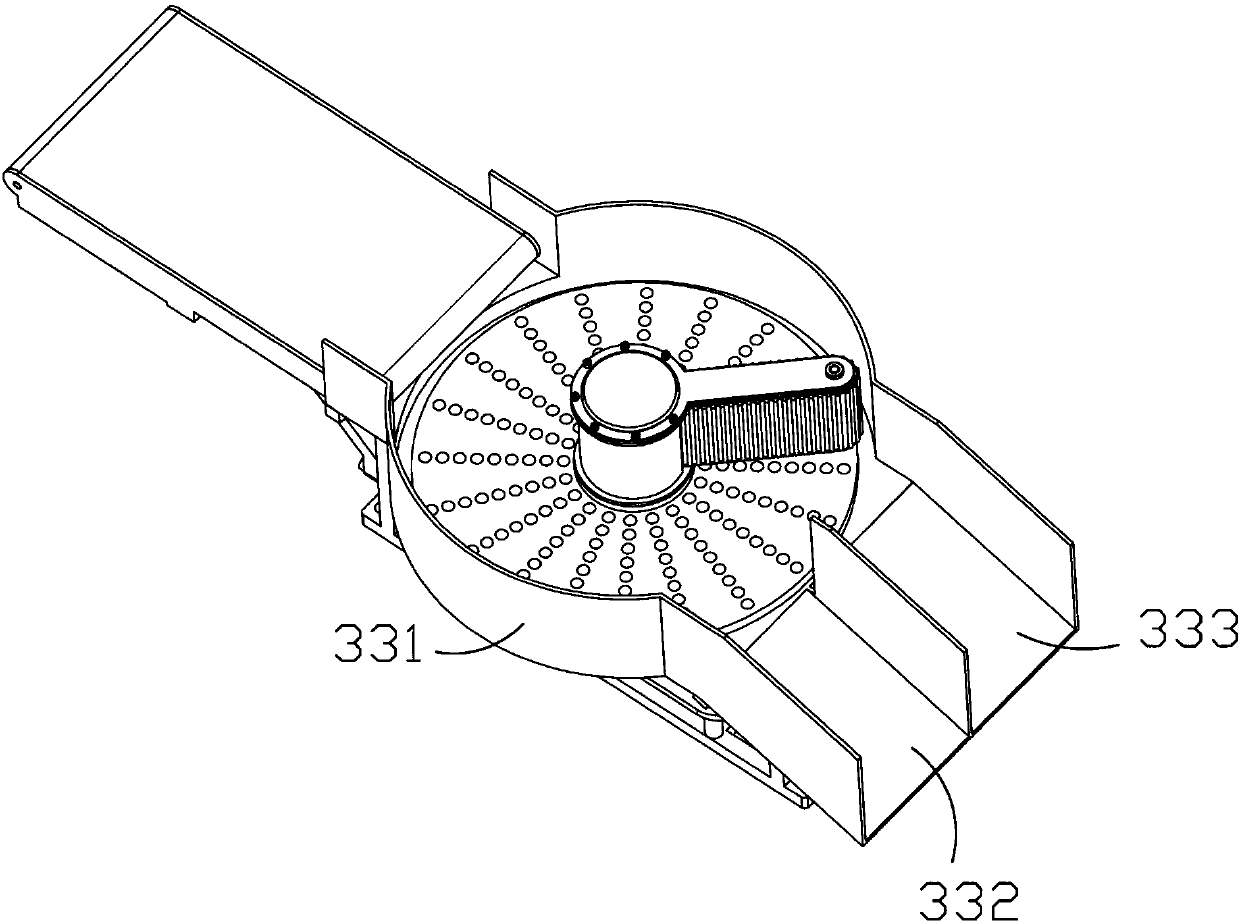

Coin sorting device

InactiveCN105374104ARealize automatic sortingLow costCoin testingCentrifugal forceElectrical and Electronics engineering

The invention discloses a coin sorting device. The coin sorting device comprises a housing, wherein the upper end of the housing is provided with a coin inlet; a coin storage chamber which is arranged in the housing in an inclined manner; a rotary disk, wherein the rotary disk is arranged on the bottom part of the coin storage chamber in a rotary manner, a plurality of coin storage cavities are formed in the rotary disk in a concave manner, the highest part on the bottom part of the coin storage chamber is provided with a coin discharge port corresponding to the coin storage cavities, and the coin discharge port is provided with a coin discharge switch; a rotation mechanism which is used for driving the rotary disk to rotate; a sorting channel, wherein the sorting channel is arranged in the housing and spirally extends downwards, an upper inlet of the sorting channel is corresponding to the coin discharge port, and three coin outlets are formed in the external side wall of the sorting channel; and package cylinders, wherein one package cylinder is arranged below each coin outlet. According to the invention, coins slide downwards in the sorting channels, and centrifugal forces are generated, so that the coins different in size are enabled to be discharged from the three different coin outlets, automatic sorting is realized, and the sorting is accurate and high in efficiency.

Owner:GUANGXI UNIV

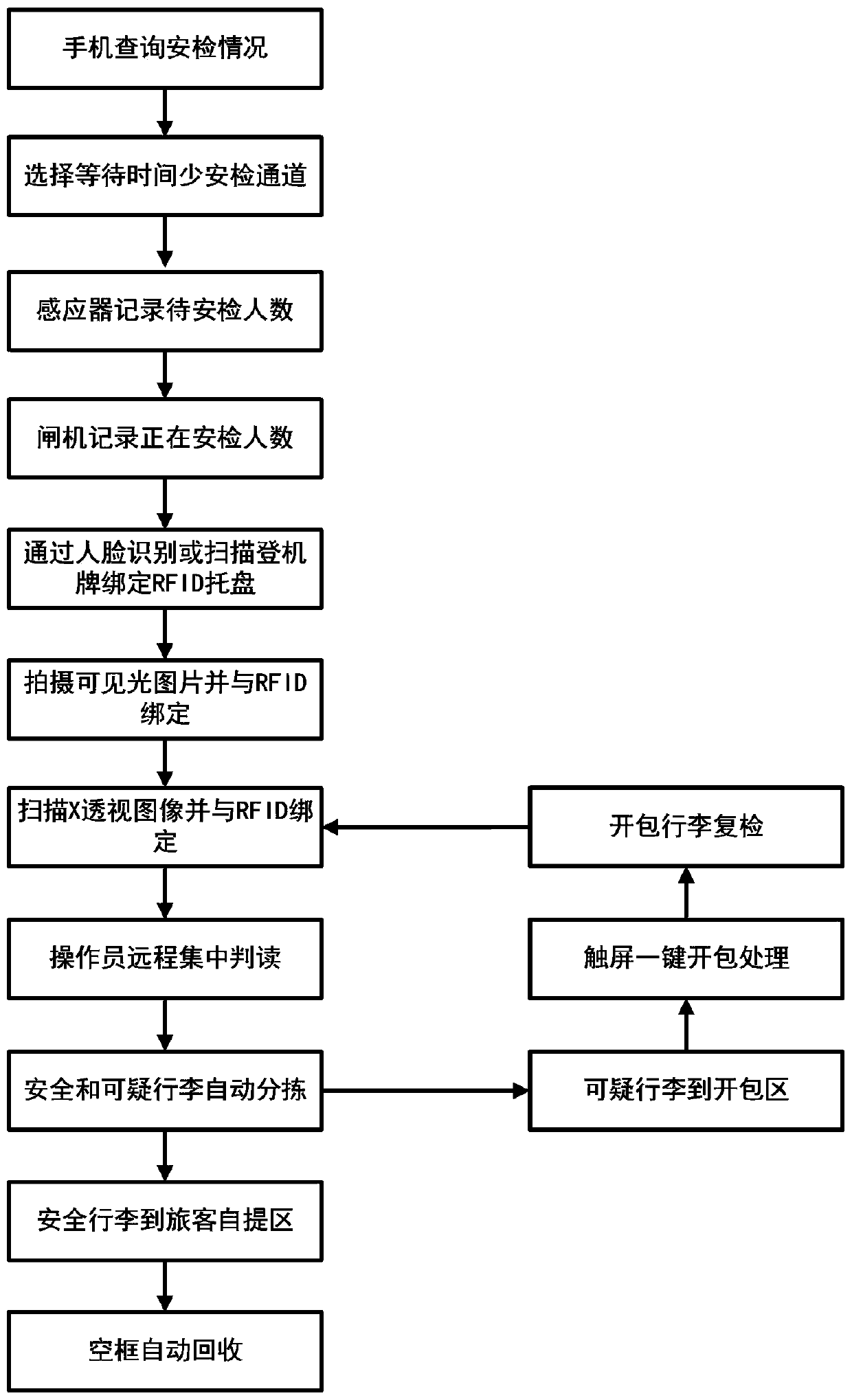

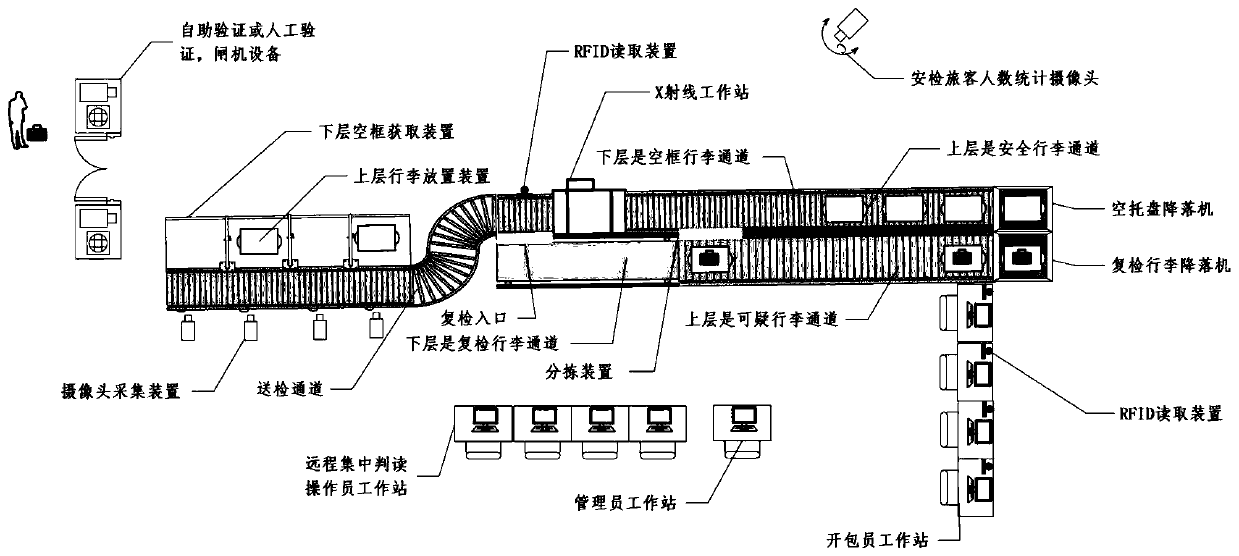

System and method for automatic matching and remote centralized interpretation of intelligent channels for travel inspection

PendingCN110749934ARealize automatic sortingRealize automatic recyclingCharacter and pattern recognitionIndividual entry/exit registersSimulationPassenger information

The invention discloses a system and method for automatic matching and remote centralized interpretation of intelligent channels for travel inspection, and the system comprises an automatic matching and remote centralized interpretation system AMRSS and an automatic basket returning system ABRS that are connected together. The method, by matching uniquely identification tag of the facial feature information and the tray, achieves accurate matching of passenger information, identification tags and image information, realizes the automatic recheck of suspicious luggage and reduces the labor intensity of the security inspectors. Through the design and allocation of multiple basket taking stages, interpretation of multiple operators and recheck of multiple openers, the efficiency of security inspection is improved, the number of passengers and the waiting time of passengers can be predicted, and the waiting time of passengers can be reduced. The cooperation of the automatic matching and remote centralized interpretation system and the automatic transmission subsystem for the travel inspection completes the jobs of people-baggage correspondence, centralized interpretation, baggage sorting and tray recycling, improves the pass rate of passengers in the travel inspection channels, realizes the management of people-baggage correspondence, and reduces the labor intensity of security inspectors.

Owner:ZHONGDUNANMIN ANALYSIS TECH CO LTD BEIJING +2

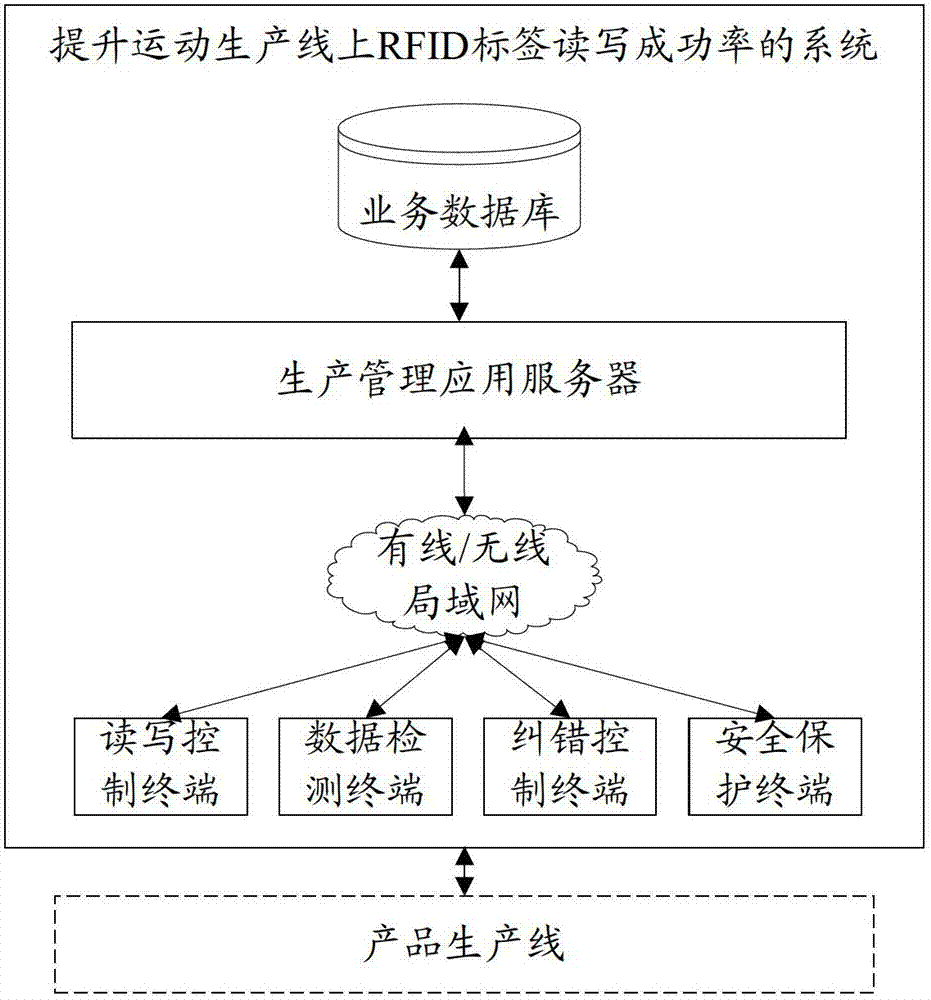

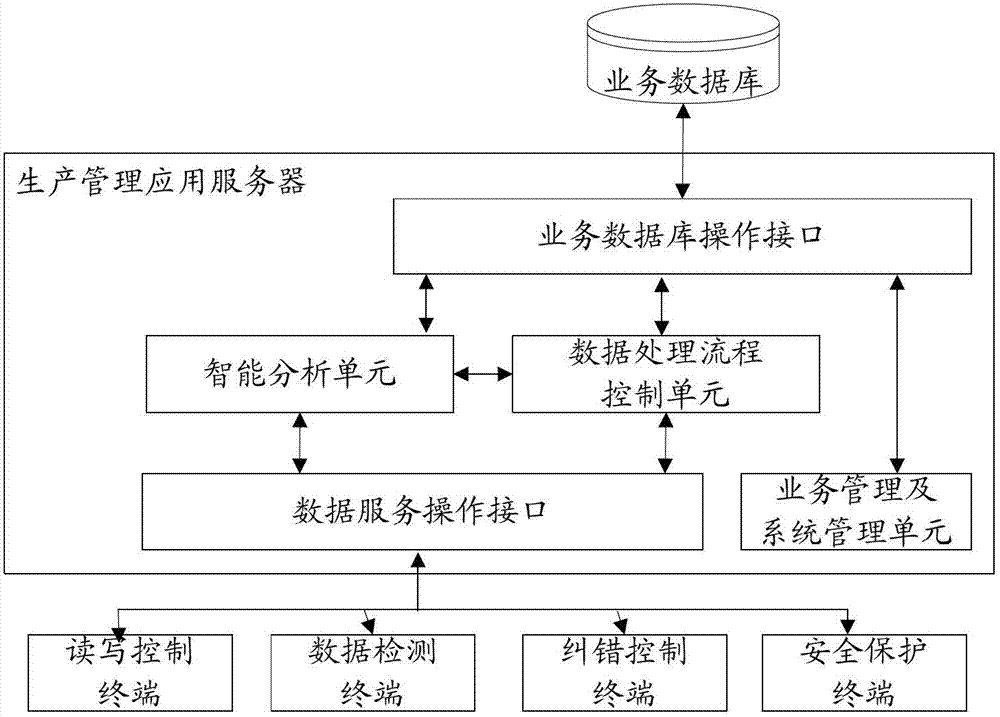

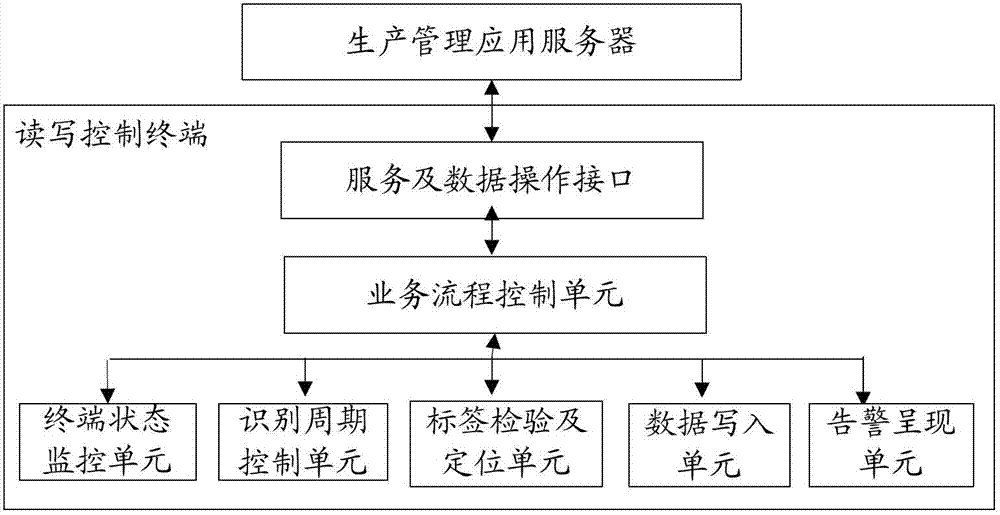

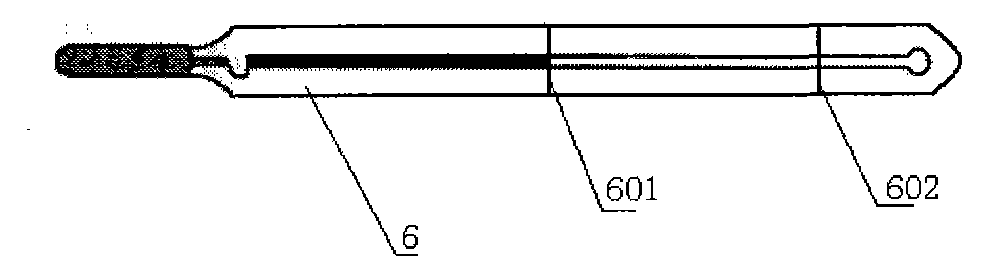

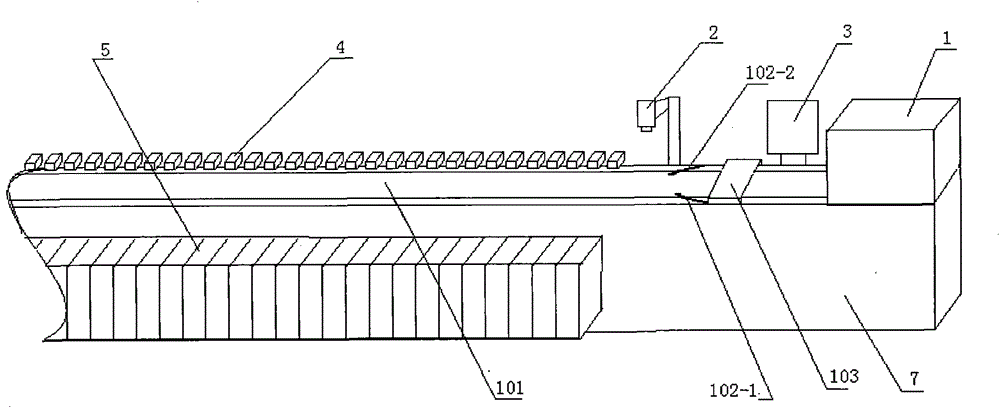

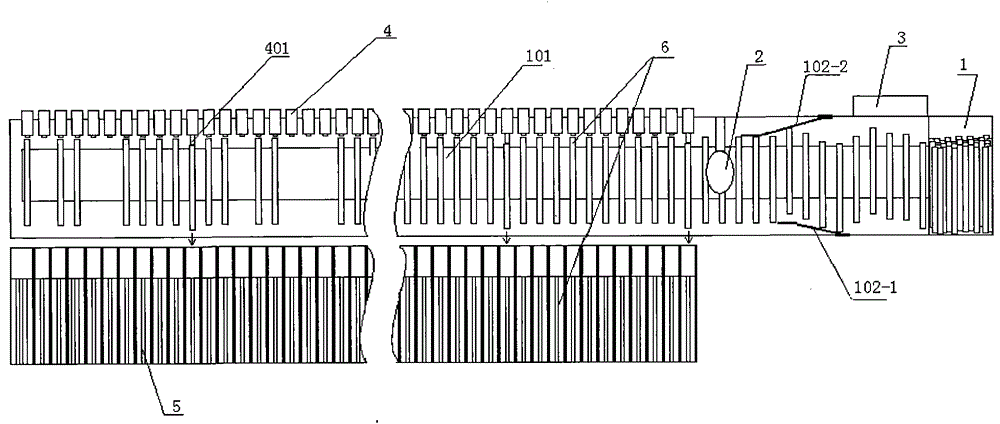

System and method for improving read-write success rate of radio frequency identification tags on movement production line

ActiveCN102819758AWiden the reading angleImprove recognition processing capabilitiesCo-operative working arrangementsResourcesCable networkAutomatic control

The invention relates to a system and a method for improving the read-write success rate of radio frequency identification (RFID) tags on a movement production line. The system consists of a production management application server, read-write control, data detection, error correction control and security protection; the read-write control, the data detection, the error correction control and the security protection are respectively connected with the production management application server through a wired network and / or a wireless network; four different terminals using a computer, RFID, automatic control and the like and the production management application server execute tasks respectively set and are tightly matched; the data in the RFID tags is subjected to the functions, such as precise identification, multiple writing, verification, information protection, and automatic sorting of failure lags on the movement production line; the read-write success rate of the RFID lags data on the movement production line is remarkably improved; the productive efficiency is optimized; and the intelligent management for the production line is realized, so the system and the method provided by the invention have excellent polularization and application prospects on the modern industrial production line.

Owner:上海欣方智能系统有限公司

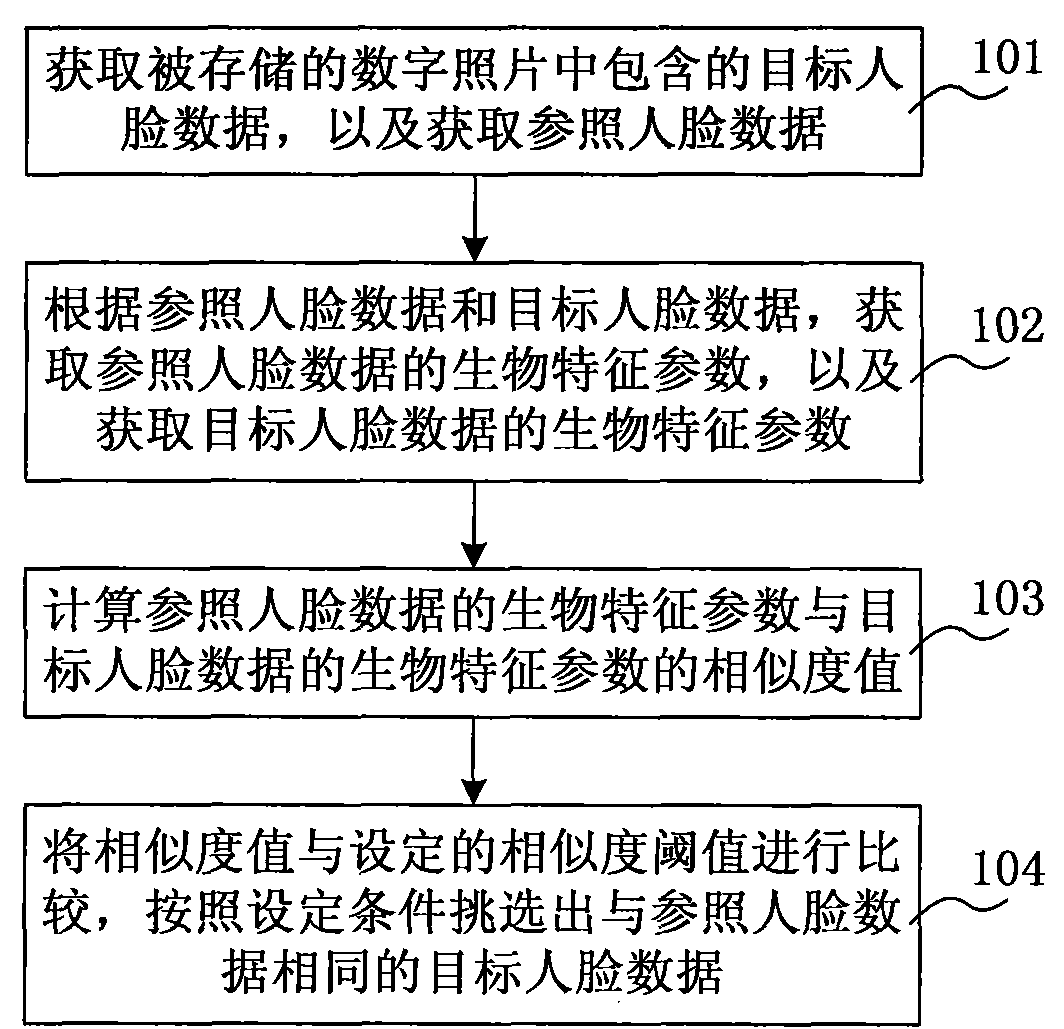

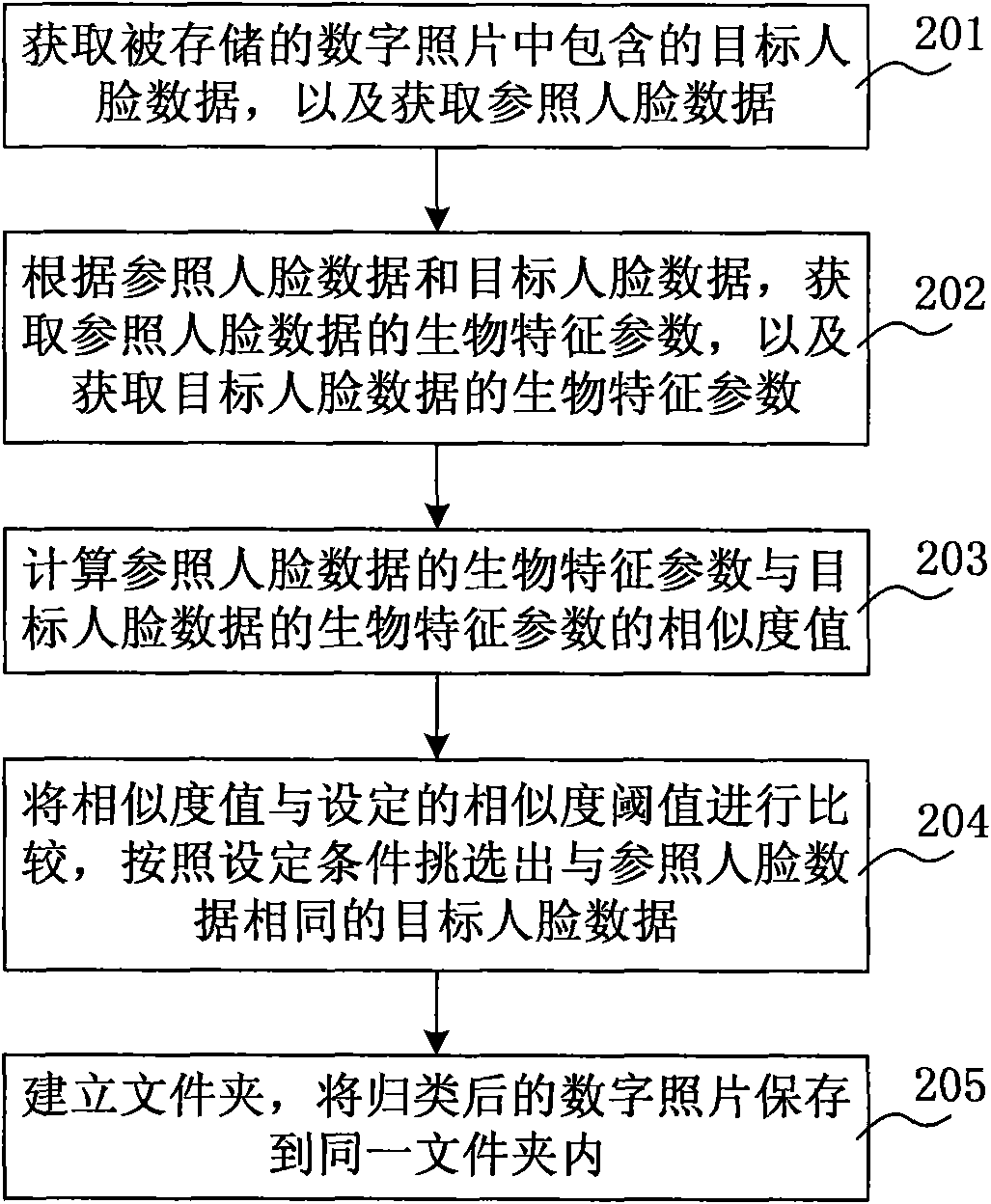

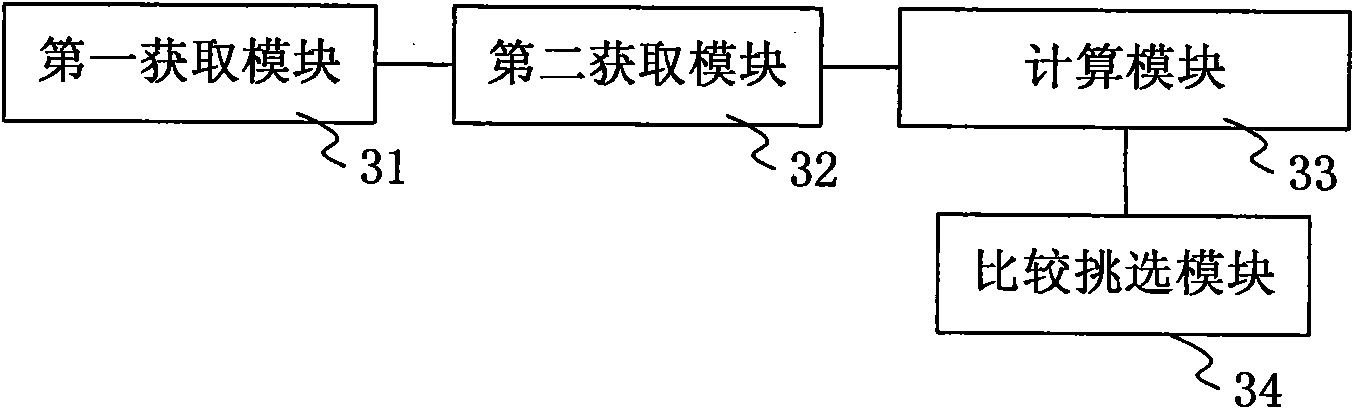

Digital photo sorting method, device and application system thereof

InactiveCN101859367ARealize automatic sortingShorten the timeCharacter and pattern recognitionDigital imagingFeature parameter

The invention relates to a digital photo sorting method, a device and an application system thereof. The method comprises the following steps: acquiring target face data contained in the stored digital photos and reference face data; acquiring the biological feature parameters of the reference face data and the target face data; calculating the similarity value of the biological feature parameters of the reference face data and the target face data; and finally comparing the similarity value with a set similarity threshold, and then selecting out the target face data as the same as the reference face data according to setting conditions. In the invention, by calculating the similarity value of the biological feature parameters of the reference face data and the target face data and selecting out the target face data as the same as the reference face data according to the setting conditions, the digital photo sorting method, the device and the application system thereof can automatically sort and classify the digital photos shot by a digital imaging product, and save time and energy of a user.

Owner:北京算通数字技术研究中心有限公司

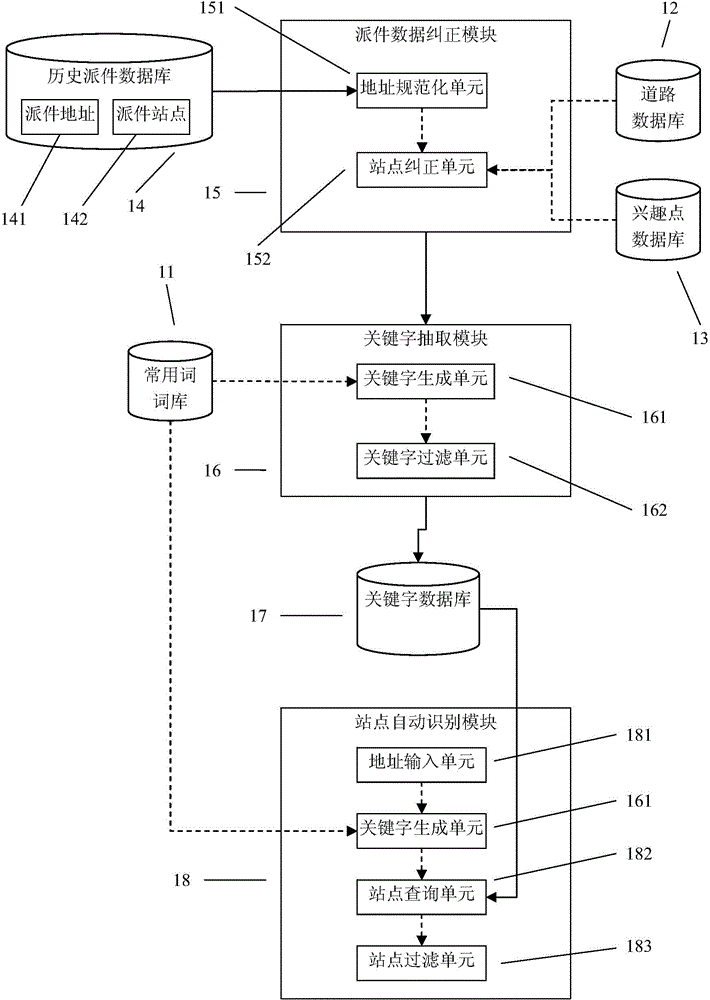

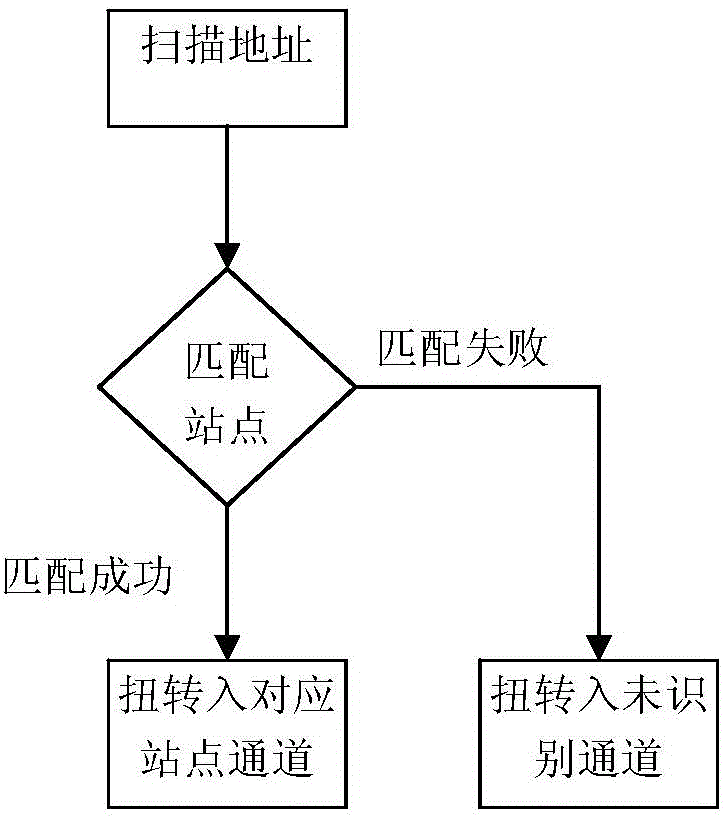

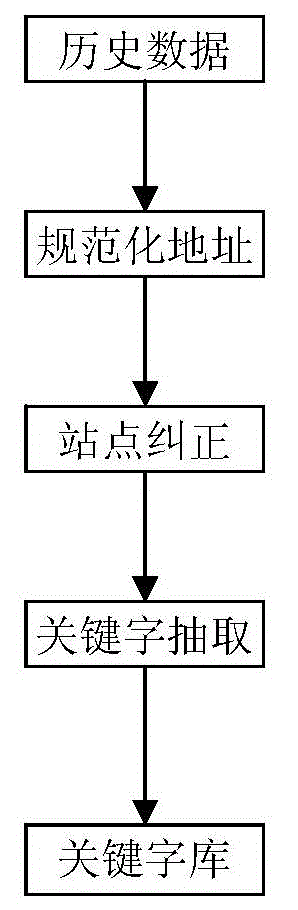

Automatic sorting system and automatic sorting method for express delivery

ActiveCN104624509AAutomatic sorting automatically realizedAutomatic sortingSortingSpecial data processing applicationsSemi automaticComputer module

The invention relates to an automatic sorting system, and discloses an automatic sorting system and an automatic sorting method for express delivery. The automatic sorting system for the express delivery comprises a common word library, a road database, an interest point database, a history delivery database, a delivery data correcting module, a keyword extracting module, a keyword database and an automatic station identifying module. The automatic sorting method comprises the following main steps: keyword database modelling, address scanning and station matching. The invention provides the automatic sorting system and the automatic sorting method for the express delivery, wherein by adopting the automatic sorting system, the identification of delivery stations of the express delivery can be automatically completed without manual interference, sorting of transfer stations and terminal stations of the express delivery can be realized, very high accuracy can be ensured, the problems of easy error occurrence, misoperation, time and labor wasting and the like in a traditional manual sorting method or a semi-automatic sorting method in the express delivery industry are solved, automatic sorting by computers and machines is realized, and the sorting efficiency of the express delivery industry is greatly improved.

Owner:ZHEJIANG BAISHI TECH

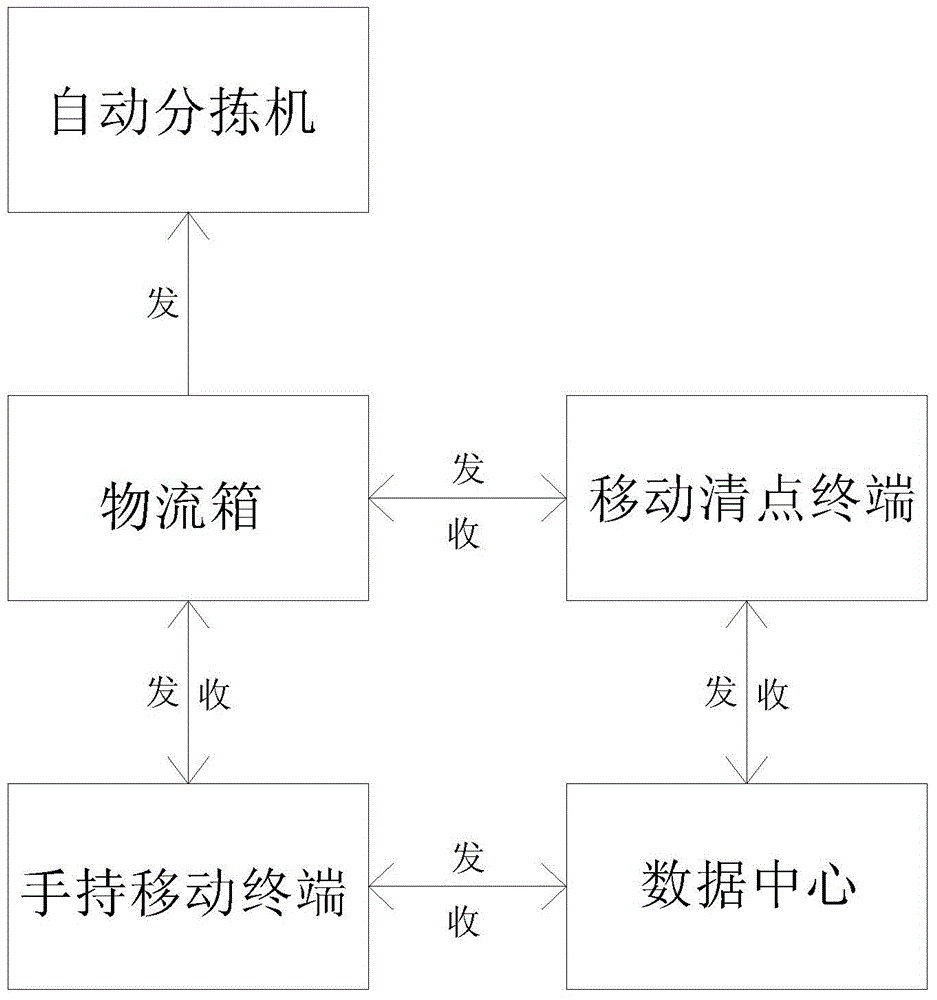

Small standard logistics box, logistics system and express delivery method

InactiveCN104029895ARealize automatic sortingImprove securityContainer/bottle contructionLogisticsLogistics managementPassword

The invention provides a small standard logistics box, a logistics system and an express delivery method. By using a unified size, the logistics box can be repeatedly used while optimizing utility rate of freight space, thus reducing waste and being green and environment-friendly; and by arranging a wireless communication module stored with logistics data on the logistics box, articles can be automatically sorted, and thereby sorting efficiency is greatly improved, and labor cost is effectively reduced; since the logistics data only can be read by special equipment, so that safety of user information can be effectively ensured; in addition, the box is provided with a coded lock controlled by the wireless communication module, so that the safety of cargos in a transportation process are further improved by only sending the password of the coded lock to a consignee.

Owner:SHANGHAI LASERON MICRO ELECTRONICS

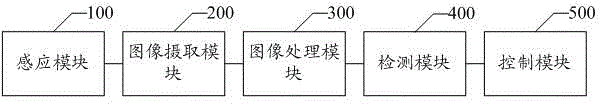

Automatic on-line vision detecting and sorting system and sorting method

ActiveCN103063572AEasy to detectRealize automatic sortingMaterial analysis by optical meansProduction lineProcess engineering

The invention discloses an automatic on-line vision detecting and sorting system and a sorting method. The sorting method comprises the steps of: arranging a sensing module for sensing a product on a production line, shooting a picture only when the product is sensed, and finally removing defective products by using a control module through the follow-up processes of picture processing, defective product detection and the like, thereby automatically detecting and automatically sorting the defective products. The continuous picture shooing does not need, so that a large quantity of memory spaces are saved; and by using the automatic on-line vision detecting and sorting system and the sorting method, the defective products can be removed in real time, so that the real-time performance and the stability of sorting the defective products are improved, the production efficiency is greatly improved and the probability that the defective products enter markets is reduced.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Automatic subpackage machine and method for incense sticks

ActiveCN106314855AControl quantitySmooth connectionConveyorsPackaging automatic controlButt jointContinuous operation

The invention discloses an automatic subpackage machine and method for incense sticks, and belongs to the technical field of incense making. The automatic subpackage machine structurally comprises an arranging and stabilization assembly, a broken incense screening assembly, a counting and quantification assembly, a subpackage and conveying assembly and a control management circuit in sequence. The broken incense screening assembly comprises two parallel conveying belts operating synchronously. A stabilization feeding roller wheel is arranged between the feeding ends of the conveying belts. The receiving position below the feeding roller wheel is in butt joint with a discharging outlet of a vibration feeding hopper, and a discharging point is arranged above the conveying belts to form the linkage of the arranging and stabilization assembly and the broken incense screening assembly. The quantified output automatic subpackage machine is formed by means of the post-processing counting and quantification assembly and the subpackage and conveying assembly. Standard arrangement, broken incense screening, quantified output counting and subpackage of the incense sticks are achieved, and automatic linkage and continuous operation are also achieved. The structure is simple, the efficiency is high, and the repeated operation quality is stable.

Owner:河北古城香业集团股份有限公司

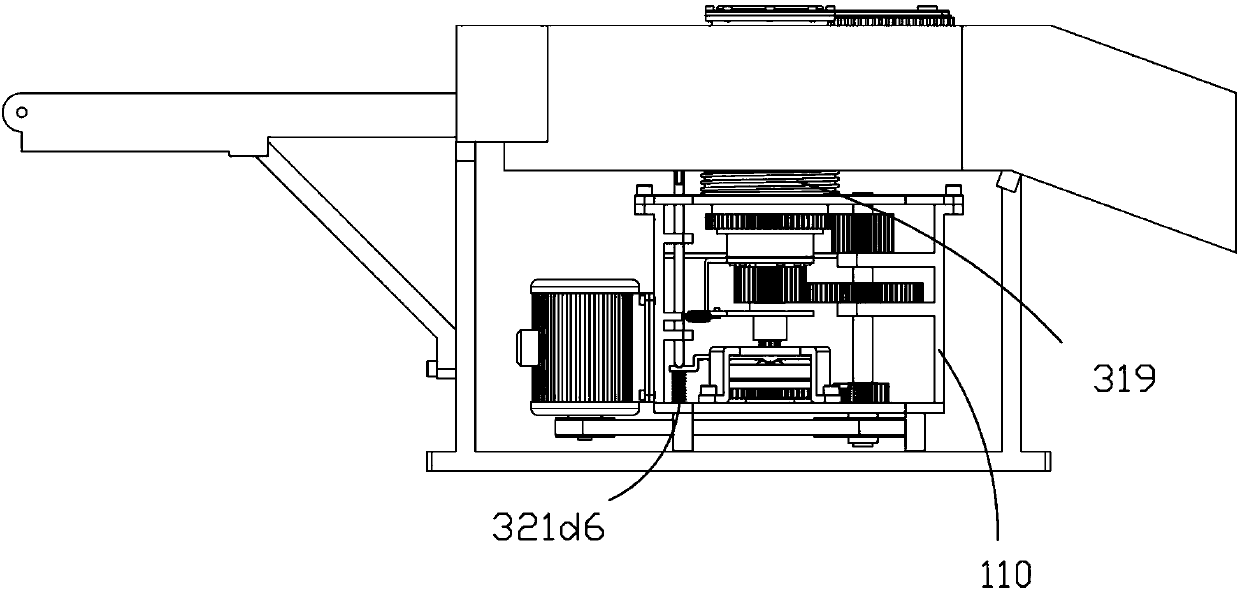

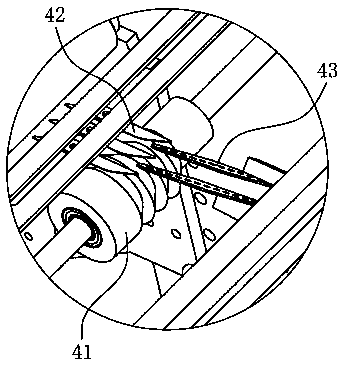

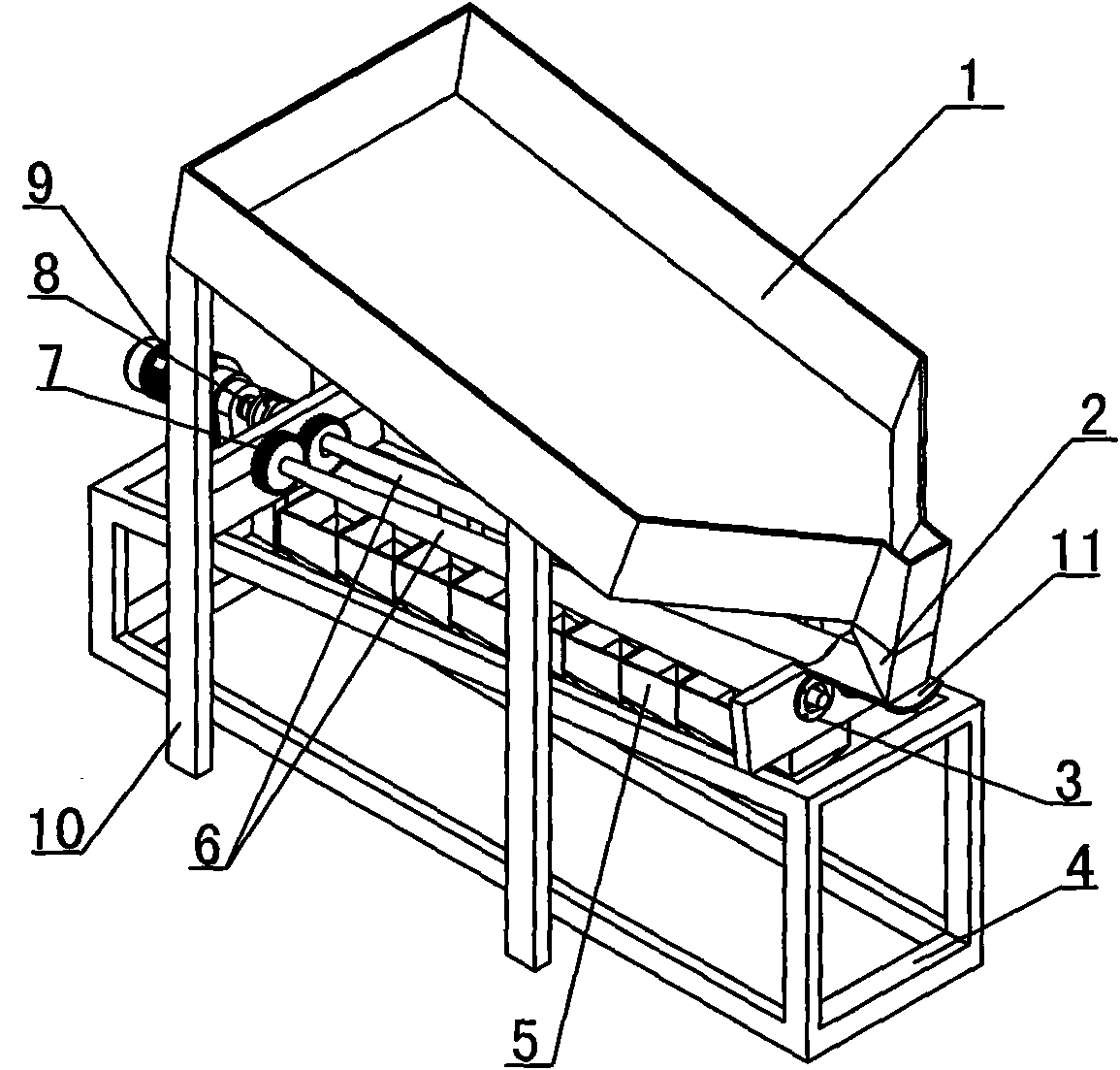

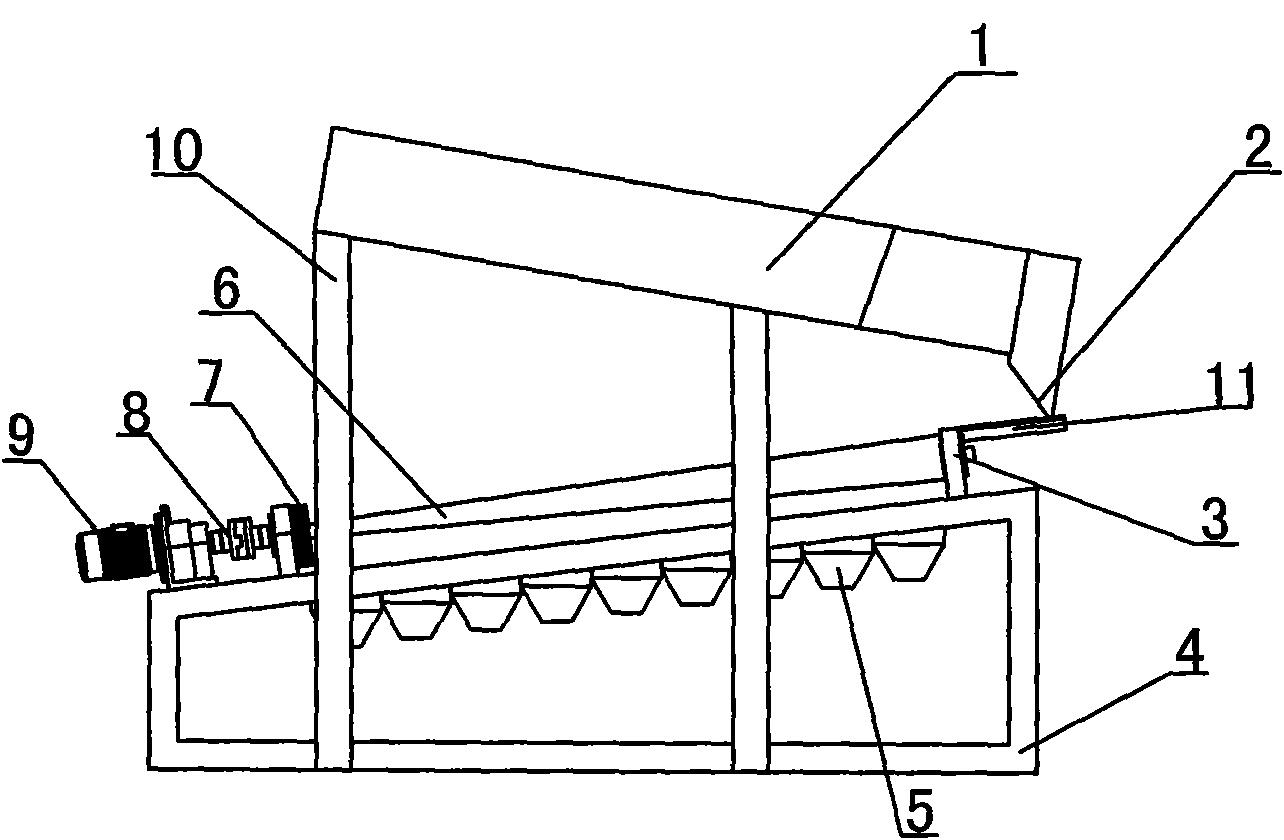

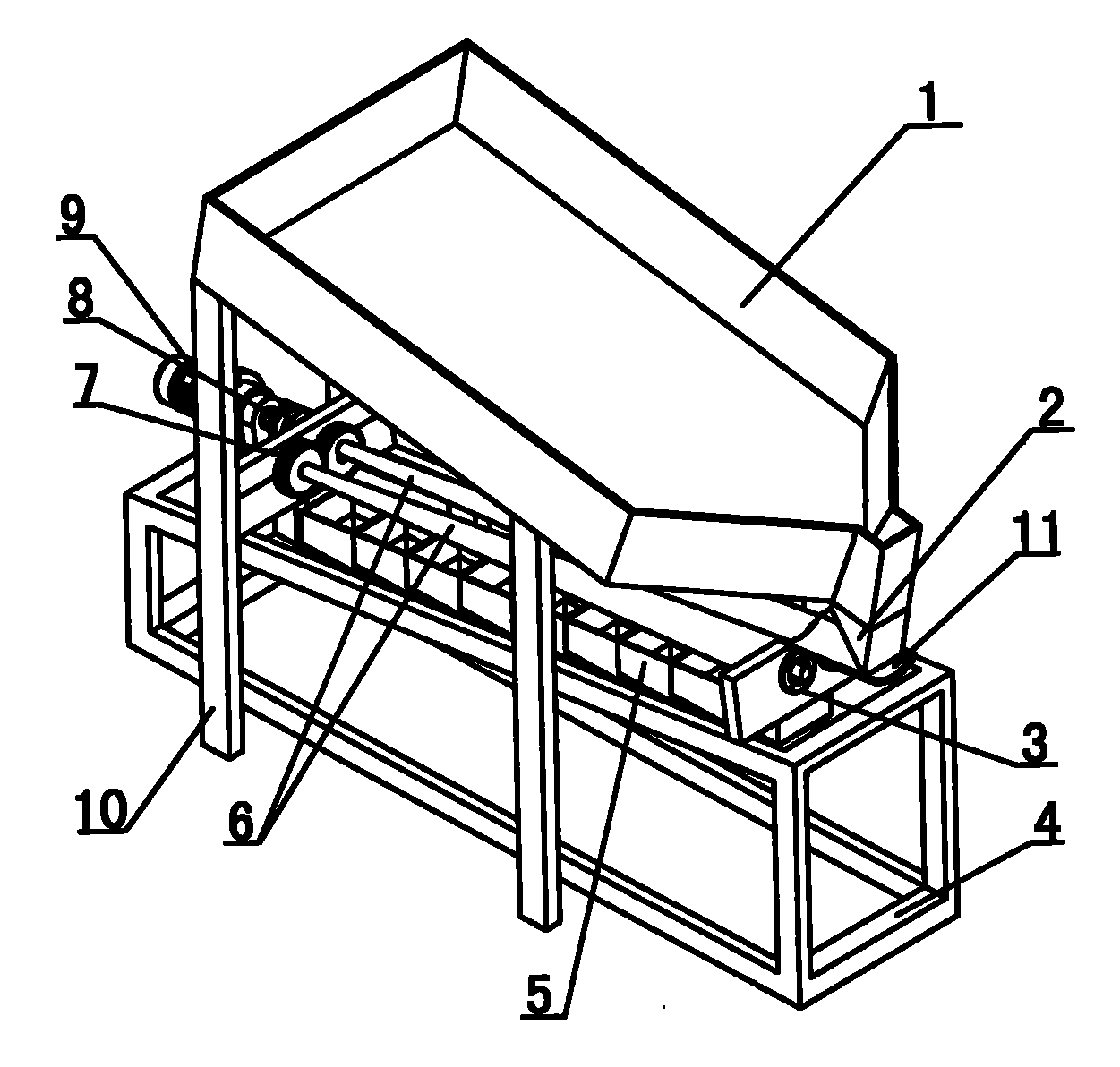

Classification and sorting equipment for logistics transportation piece dynamic weighing

The invention provides classification and sorting equipment for logistics transportation piece dynamic weighing. The classification and sorting equipment comprises a main rack, a conveying mechanism,a power mechanism and a sorting mechanism are arranged on the main rack, the unloading end of the conveying mechanism is connected with the feeding end of the sorting mechanism, the main rack is usedfor providing supporting for the conveying mechanism and the sorting mechanism, the conveying mechanism is used for transporting to-be-sorted objects to the sorting mechanism, and the sorting mechanism is used for sorting the objects with different weights and can be switched to be in different sorting states; and the sorting mechanism comprises a main material guide mechanism, a sorting groove and a sorting state switching mechanism, a feeding opening of the sorting groove is connected with the unloading end of the conveying mechanism, a discharging opening is formed in the discharging end ofthe sorting groove, the main material guide mechanism is used for transporting the to-be-sorted objects at the feeding opening of the sorting groove to the discharging opening of the sorting groove,the sorting state switching mechanism is arranged in the center of the sorting groove, and the sorting state switching mechanism is matched with the main material guide mechanism to achieve sorting ofthe objects with the different weights.

Owner:湖北安捷物流有限公司

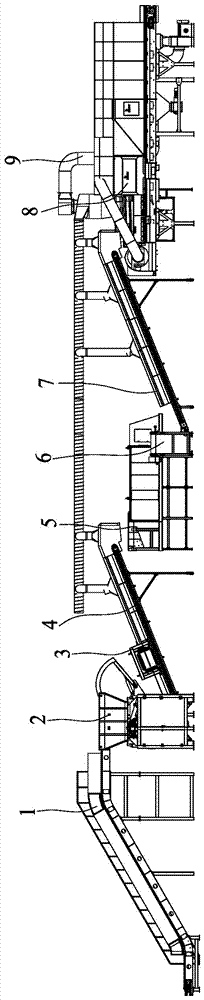

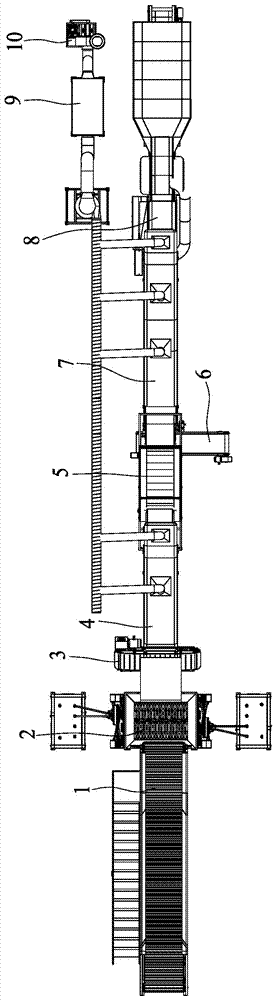

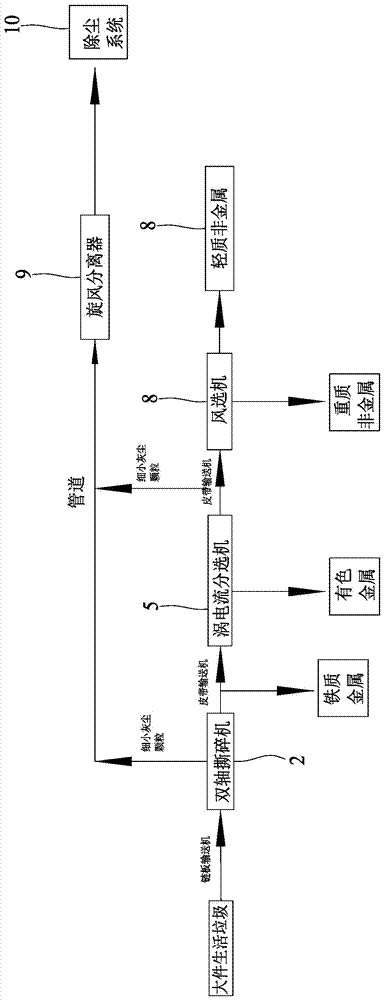

Large-sized garbage crushing and separating equipment and process

PendingCN106903138ASmall sizeRealize automatic sortingTransportation and packagingSolid waste disposalEddy current separatorAir classifier

The invention discloses large-sized garbage crushing and separating equipment and process. The large-sized garbage crushing and separating equipment comprises a chain scraper conveyor, a double-shaft shredder, a first belt conveyor, a magnetic separator, an eddy current separator, a discharged material belt conveyor, a second belt conveyor, an air classifier, a cyclone separator and a dust collector. The chain scraper conveyor, the double-shaft shredder, the first belt conveyor, the eddy current separator, the second belt conveyor and the air classifier are sequentially connected; the magnetic separator is mounted above the first belt conveyor; and the feeding end of the discharged material belt conveyor is connected with non-ferrous metal discharged by the eddy current separator. Large-sized household garbage can be treated by the chain scraper conveyor and the double-shaft shredder, crushed materials can be automatically separated by the magnetic separator and the eddy current separator, and dust produced in the crushing process can be efficiently treated by the cyclone separator and the dust collector, so that no secondary pollution is caused.

Owner:HUANCHUANG XIAMEN TECH

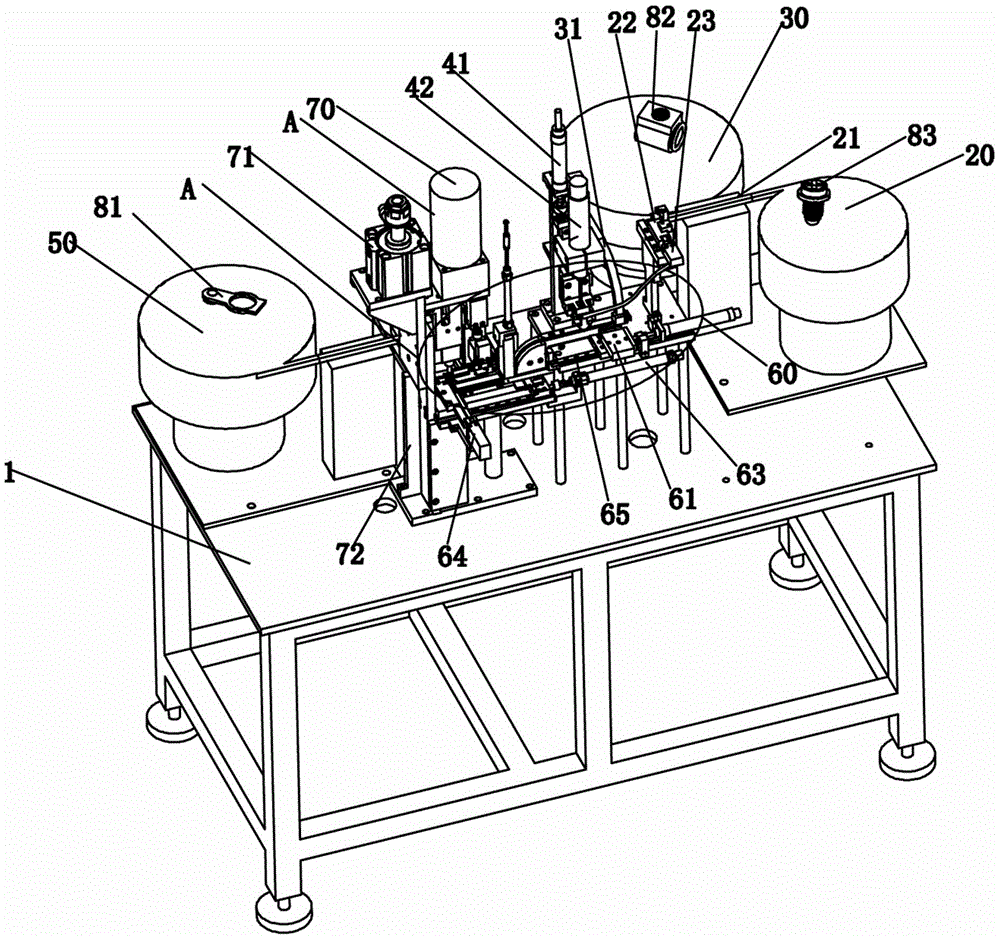

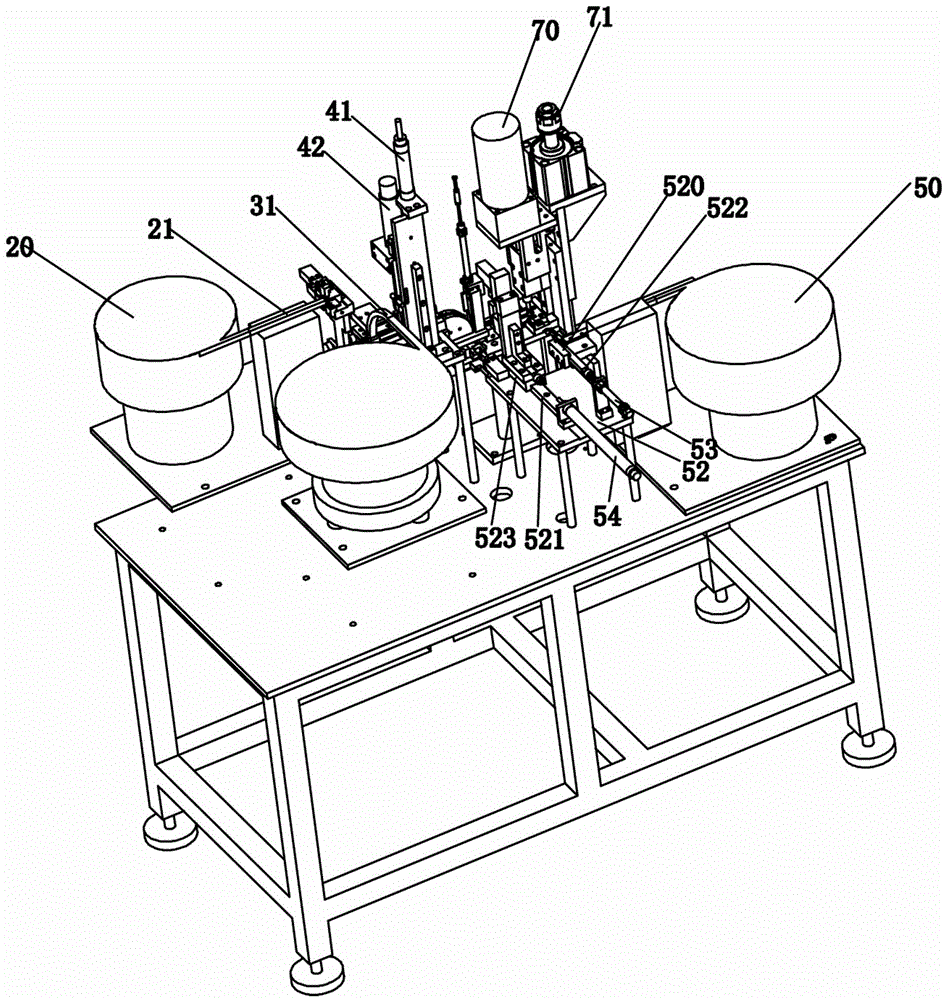

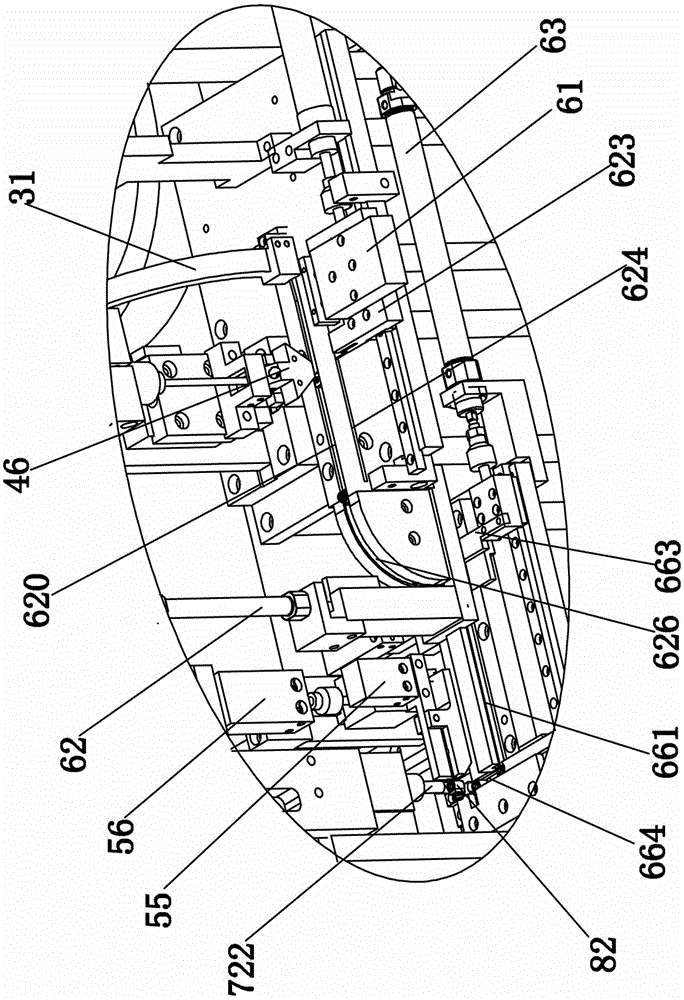

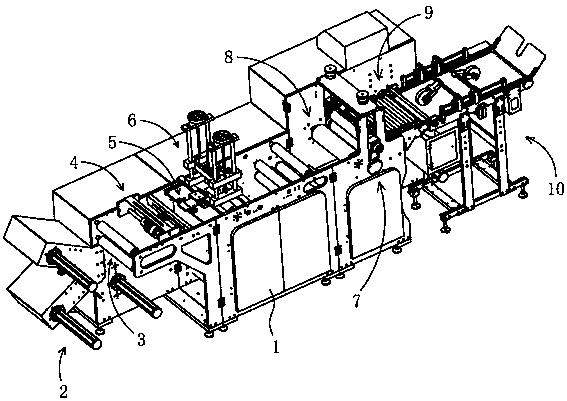

Full-automatic screw locking and sheet riveting feeding machine used for wiring terminal of switch socket

ActiveCN105563084ARealize automatic feedingNo manual operationMetal working apparatusMetal sheetMetal

The invention relates to a full-automatic screw locking and sheet riveting feeding machine used for a wiring terminal of a switch socket. According to the full-automatic screw locking and sheet riveting feeding machine disclosed by the invention, a screw, a metal column and a metal sheet are separately conveyed to a screw turning mechanism through a screw feeding mechanism, a metal column feeding mechanism, a metal sheet feeding mechanism and a material conveying mechanism, and the metal column is screwed up with the screw, and then, the metal column screwed up with the screw is conveyed to a sheet riveting mechanism through the material conveying mechanism for sheet riveting, therefore automatic operation of automatic feeding, automatic screw turning, automatic sheet riveting and the like is realized, so the full-automatic screw locking and sheet riveting feeding machine disclosed by the invention is capable of realizing full-automatic operation from feeding to screw locking to sheet riveting to discharge in a whole process of feeding, screw locking and sheet riveting without manual operation, therefore manual labor is greatly saved, production cost is reduced, and production efficiency is greatly increased.

Owner:FOSHAN SHUNDE MEIZHIMEI APPLIANCE MFG CO LTD

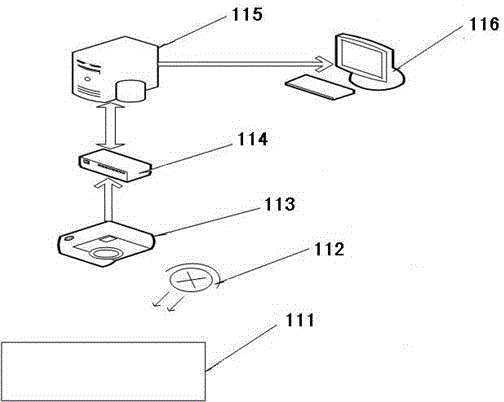

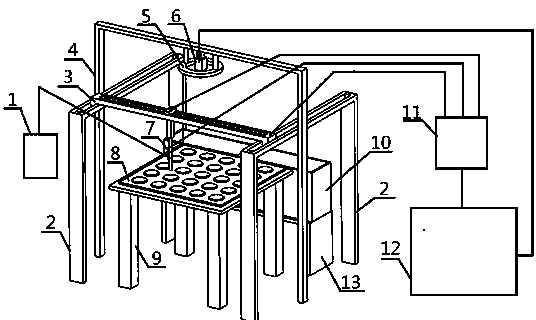

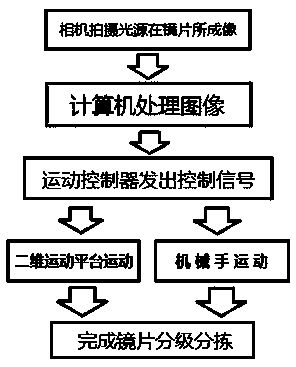

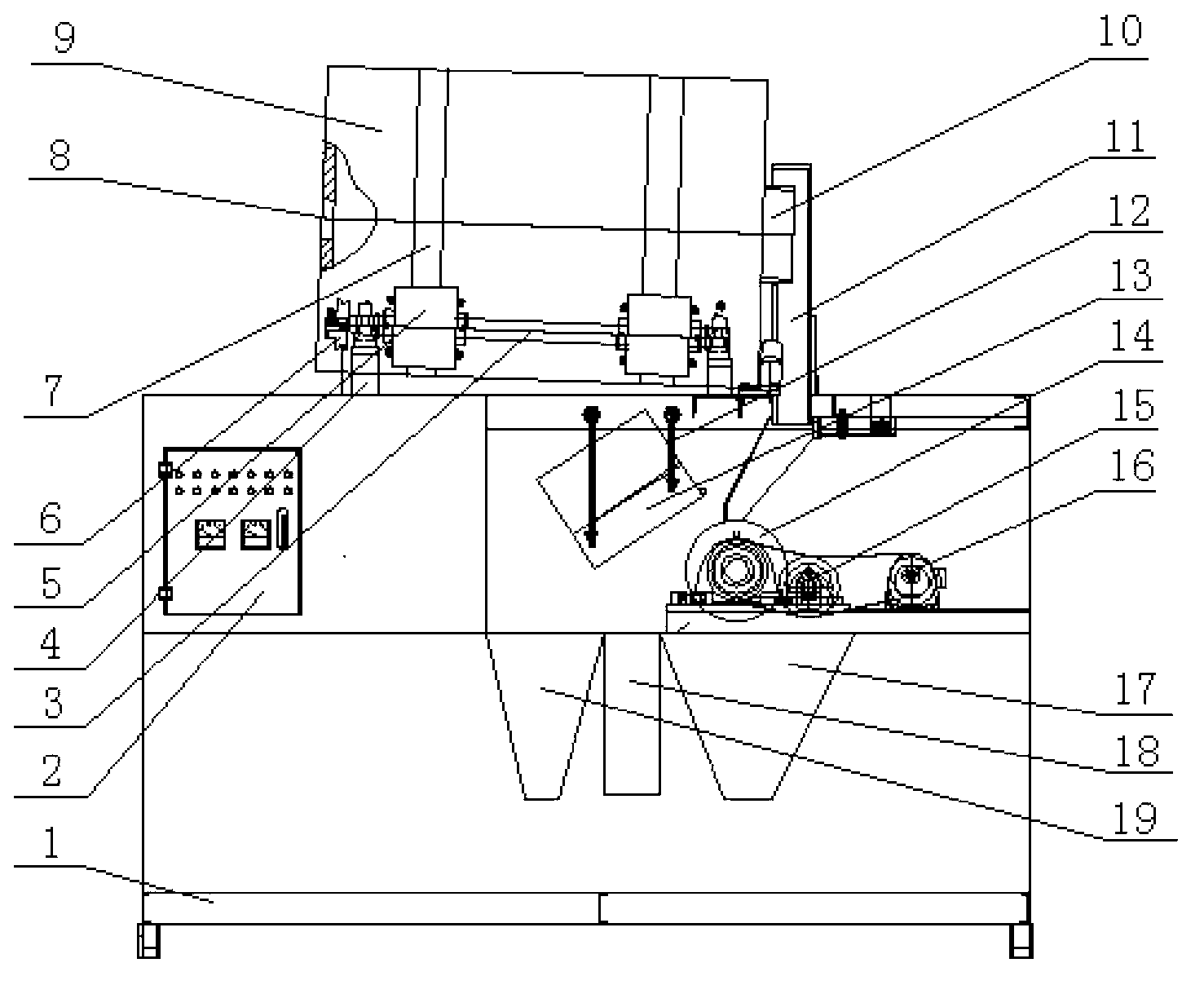

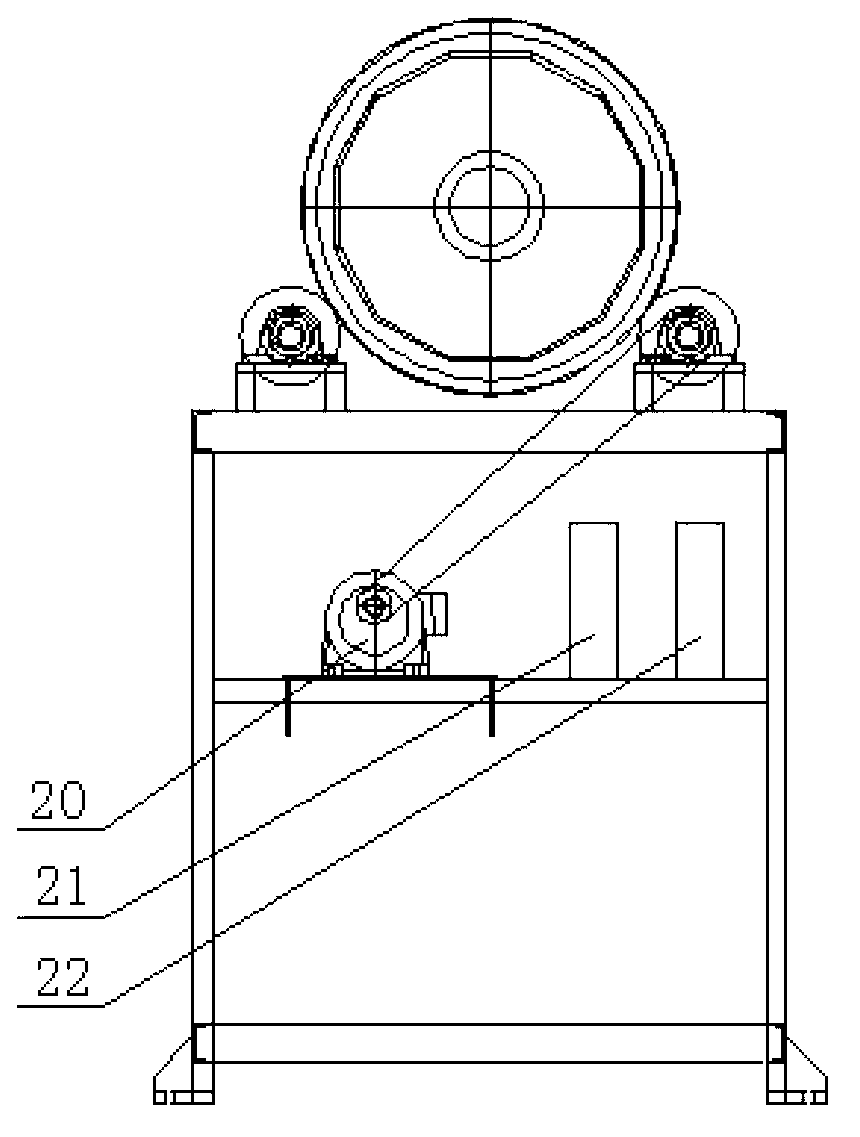

Lens film thickness automatic detection system

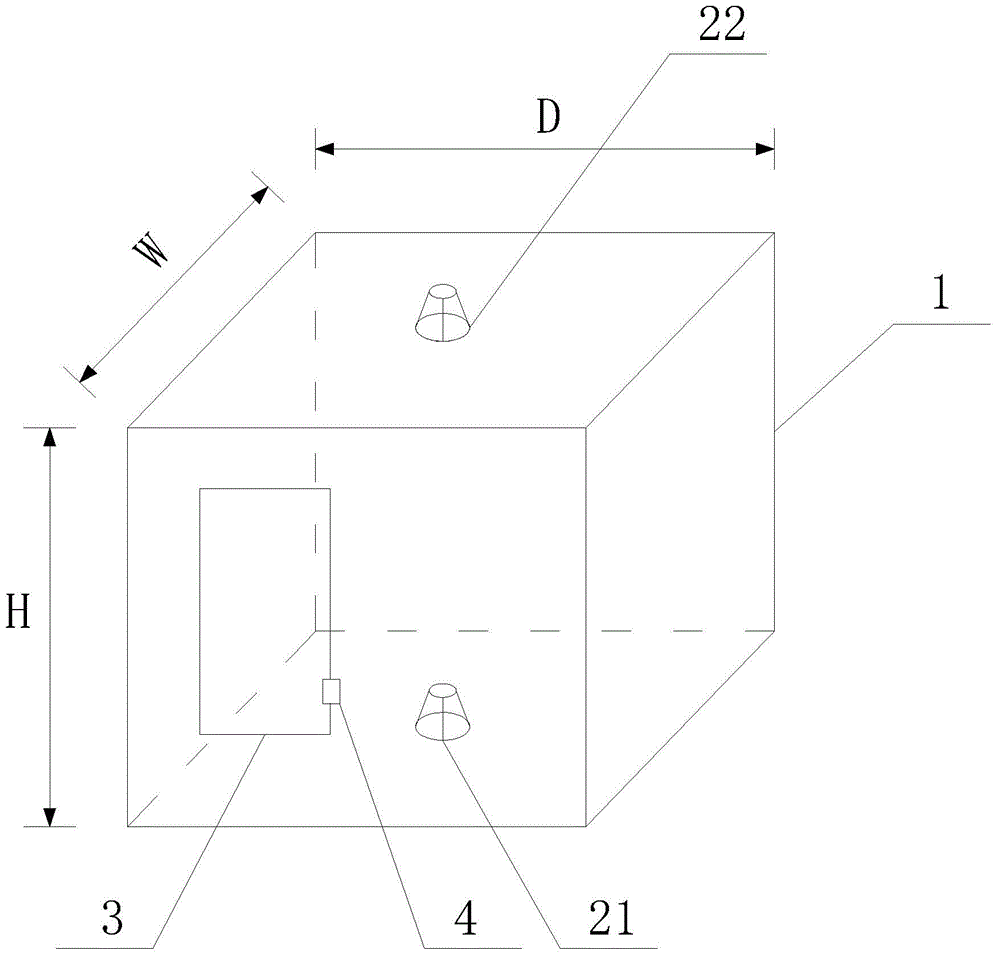

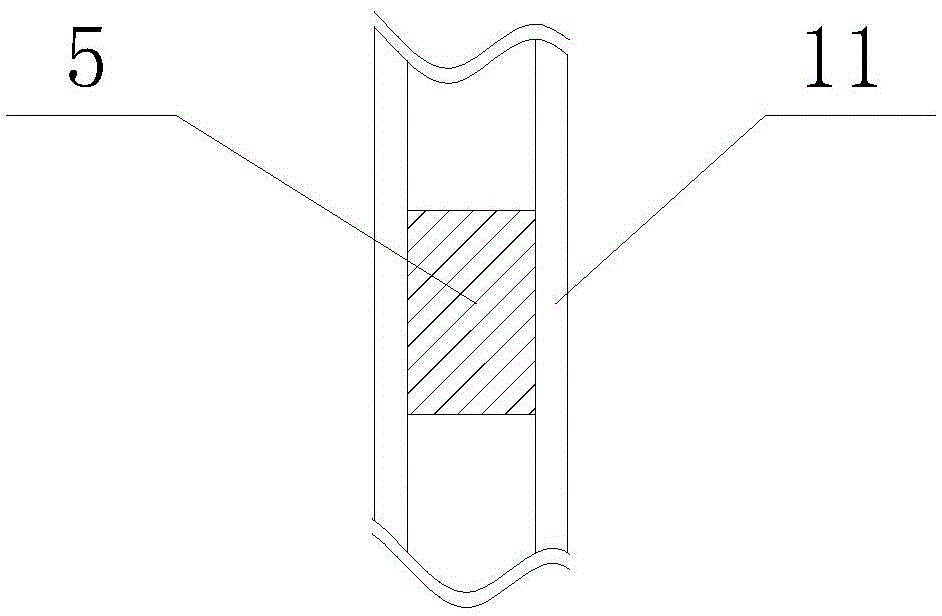

InactiveCN103644852AImprove detection efficiencyReduce thickness detection timeUsing optical meansAir pumpEngineering

The invention relates to an lens film thickness automatic detection system which comprises an air pump 1, a two-dimensional motion platform bracket 2, a two-dimensional motion platform 3, a camera bracket 4, a light source 5, a camera 6, a sucker manipulator 7, a lens tray 8, a lens tray placing platform 9, an inferior grade box 10, a motion controller, a computer 12 and an inferior grade box bracket 13. For plated films with different thickness on a lens, the colors of images generated by the light source at the surface of the lens are different. According to the system, the camera 6 is used to shoot an image generated by the light source 5 on the lens, the computer processes the image through the related software, thus the thickness of the film is determined, and then the sucker manipulator 7 sorts inferior products. According to the system, the automatic batch detection of the lens film thickness is realized, and the detection speed and precision are greatly raised.

Owner:JIANGSU UNIV

Material separation device on basis of friction static electricity

InactiveCN102836786AContinuous operationImprove work efficiencyElectrostatic separationElectricityHigh pressure

The invention relates to a material separation device on the basis of the friction static electricity, which comprises a rack, a drive mechanism, a static generating device, a high voltage electric field separation system and a receiving device. The drive mechanism is arranged on the rack and is connected with the static generating device to drive the static generating device to rotate; the static generating device is arranged above the drive mechanism; the high voltage electric field separation system is arranged below the static generating device; and the receiving device is arranged below the high voltage electric field separation system. According to the invention, by utilizing a principle that different materials have different dielectric constants, the materials are rubbed mutually to respectively generate and carry positive and negative charges and then the positive and negative charges are separated after passing through a high voltage electric field. The material separation device on the basis of the friction static electricity has the advantages of high separating efficiency, low production cost, low labor intensity, no pollution and low energy consumption and can be used for separation operation of various materials, particularly plastics.

Owner:SHANGHAI JIAO TONG UNIV

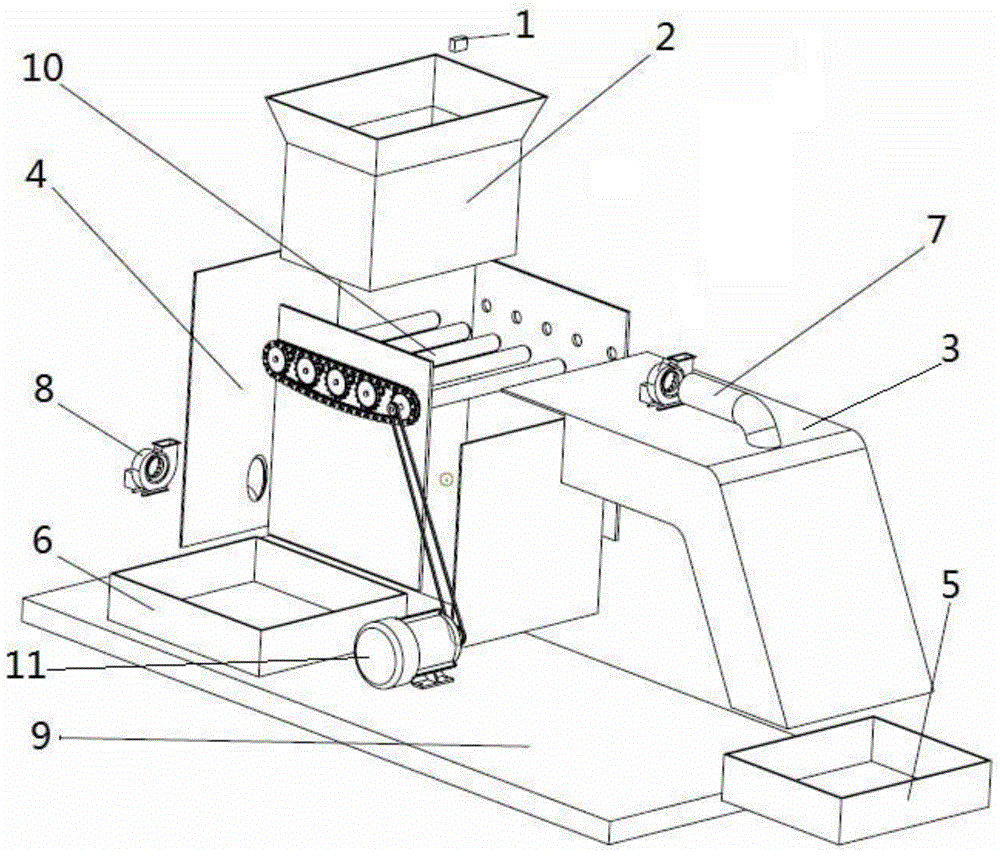

Currency sorting device

The invention discloses a currency sorting device which comprises a frame (9). The frame (9) is provided with an inlet pipe (2), a negative-pressure bank note sorting pipe (3), a coin sorting pipe (4), a bank note collecting box (5) and a coin collecting box (6), wherein the upper end of the inlet pipe (2) serves as a charging port, and the lower end of the inlet pipe (2) is provided with a roller sorting sieve (10) composed of rollers which are arranged separately in parallel; the inlet of the negative-pressure bank note sorting pipe (3) is connected with the inlet pipe, and arranged over the roller sorting sieve, the outlet of the negative-pressure bank note sorting pipe (3) is connected to the bank note collecting box (5), and the negative-pressure bank note sorting pipe (3) is connected with a negative-pressure blower fan (7); and the upper end of the coin sorting pipe (4) is connected to the lower end of the inlet pipe (2), and the lower end of the coin sorting pipe (4) is connected to the coin collecting box (6). The currency sorting device can automatically sort bank notes and coins, and is higher in working efficiency and lower in operation cost.

Owner:GUANGDONG UNIV OF TECH

Flexible AI vision full-automatic mask machine

InactiveCN110897233AQuality assuranceEliminate manual quality inspectionSortingProtective garmentDie cuttingSystems engineering

The invention relates to the technical field of information automation, and discloses a flexible AI vision full-automatic mask machine which comprises a rack, a feeding mechanism, an integration mechanism, a forming mechanism, a flanging mechanism, a welding mechanism, a vision detection mechanism, a die cutting mechanism, a traction mechanism, a receiving mechanism, a receiving mechanism and an AI system. Compared with the prior art, the mask machine is provided with the visual detection mechanism and the material receiving mechanism, so that automatic sorting of defective products and qualified products can be realized, the quality of masks is guaranteed, a manual quality inspection link is omitted, and the labor cost is reduced; meanwhile, the mask machine adopts an AI system to controloperation of all mechanisms, full-automatic production can be achieved, and the production efficiency and productivity of masks are remarkably improved; besides, the mask machine adopts a modular design, is high in openness, and can switch between mask production equipment and traditional coiled material detection equipment or produce masks of different specifications by replacing corresponding operation mechanisms.

Owner:GUANGZHOU PULISI TECH CO LTD

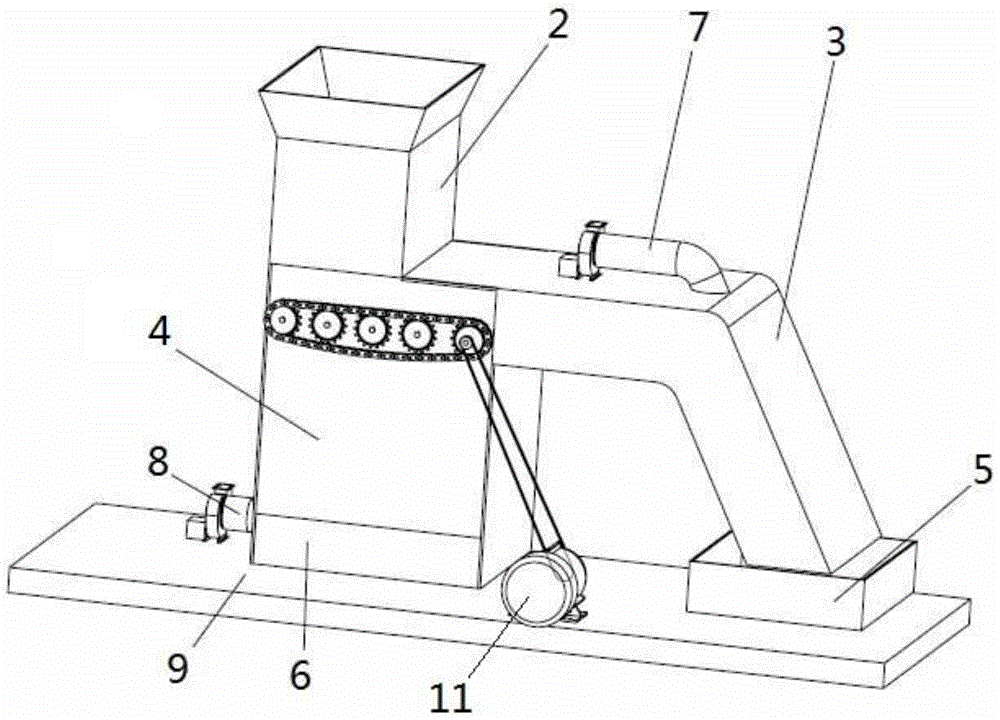

Grinding ball separator

The invention discloses a grinding ball separator. The grinding ball separator comprises a material storage box and a separating mechanism, wherein the material storage box is slantwise arranged on the upper side of a bracket; two conical roll shafts are arranged between two bearing mounting plates on the upper side of a stand at certain intervals; the fine ends of the two conical roll shafts are connected with a coupling through a gear transmission mechanism respectively; and a plurality of receiving hoppers for receiving the steel balls with different sizes are arranged sequentially on the upper side of the stand under the conical roll shafts. The separator has the advantages of realizing automatic separation of the equipment, greatly reducing the labor intensity and improving the production efficiency when the steel balls with various sizes are mixed; the dimensional accuracy of the steel ball with each specification can be controlled by improving the size of a material receiving port; and two shaft rolls can rotate outwards simultaneously through gear transmission so as to prevent the steel balls from being stuck on the shaft rolls.

Owner:宁国市四方钢球模具厂

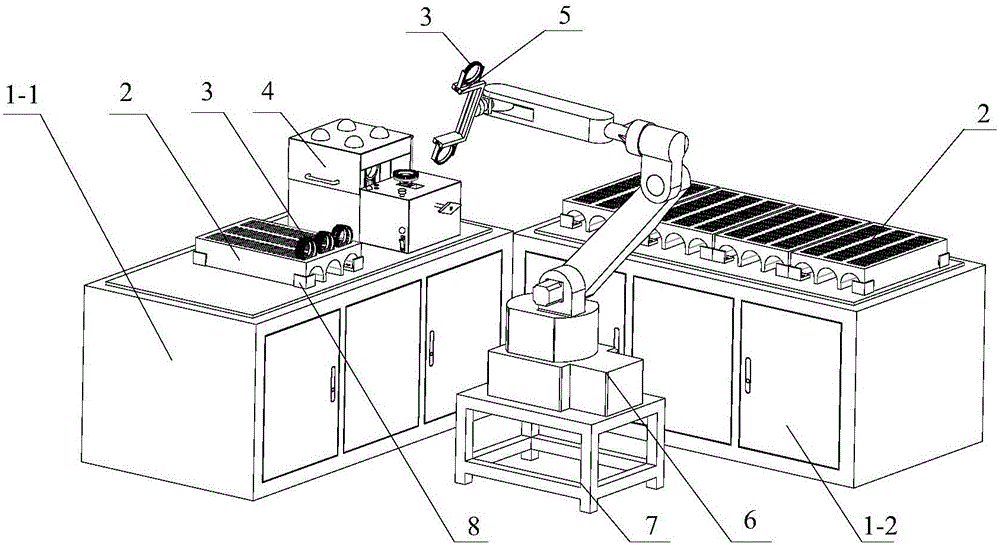

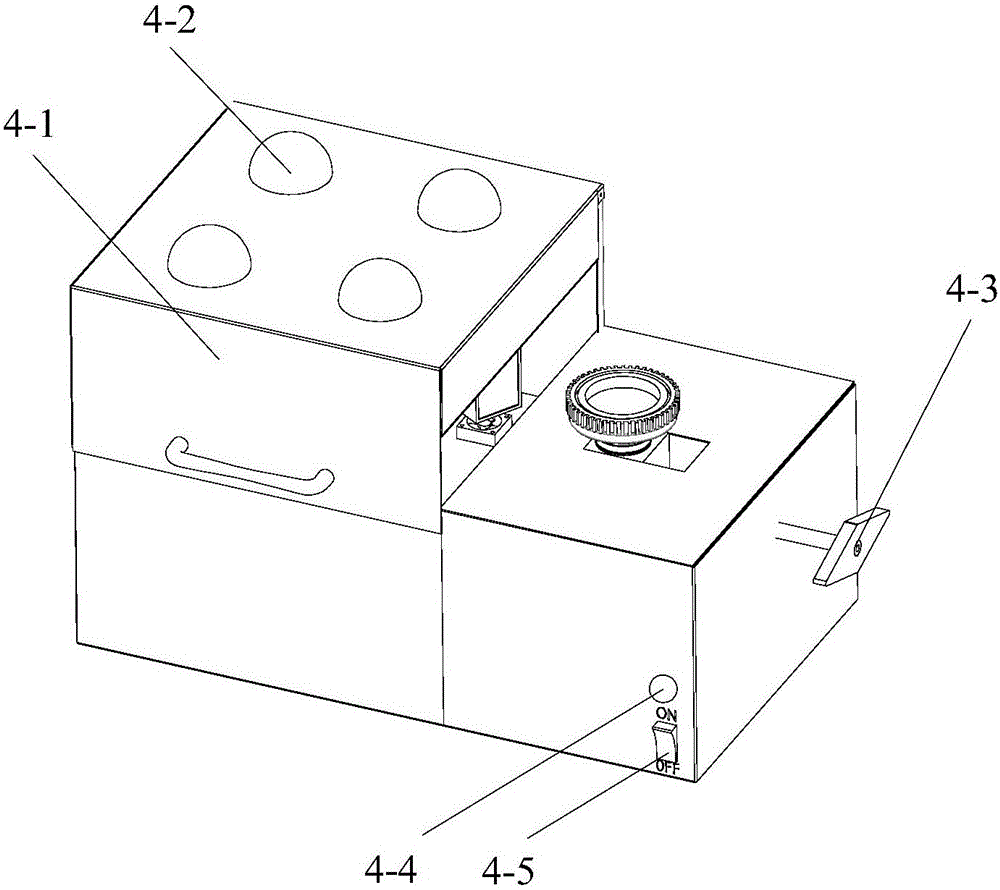

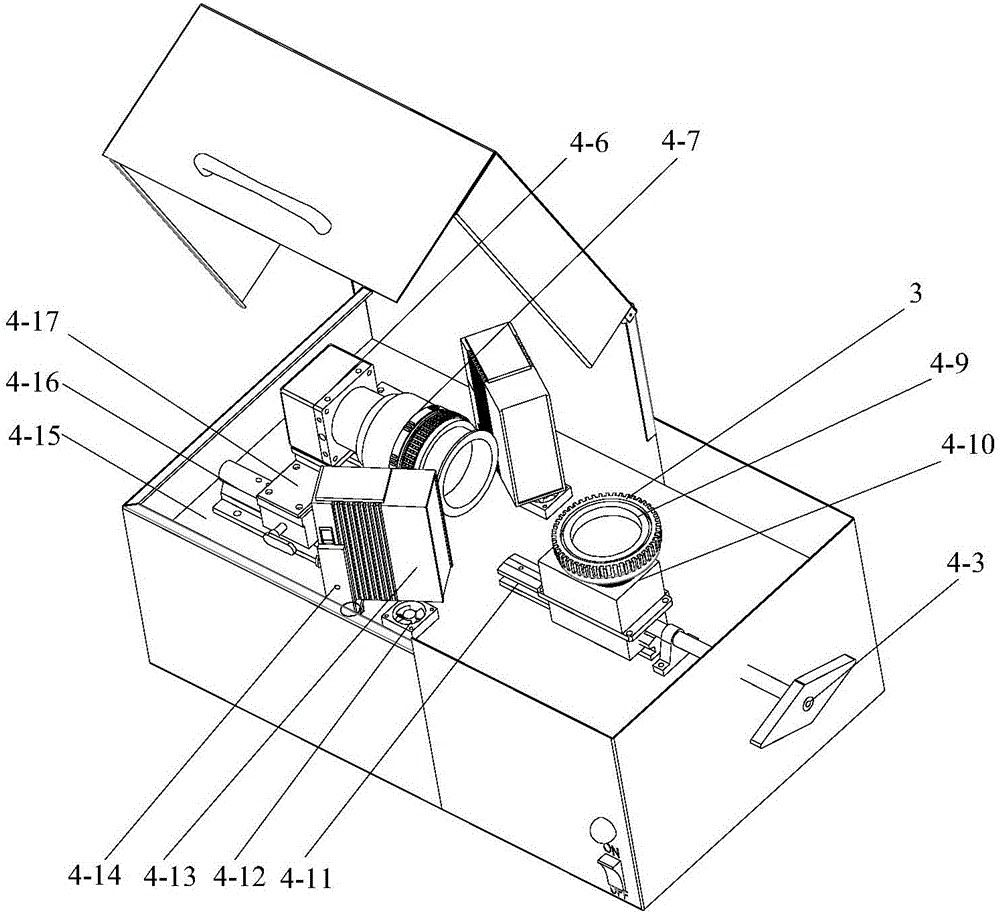

Fully automatic ABS gear ring defect detection system based on machine vision

The invention relates to a fully automatic ABS gear ring defect detection system based on machine vision. Two working tables on the ground are vertically placed in a right-angle form, and a manipulator and a base are located at the center; detection of gear rings is driven by grabbing of the manipulator and manipulator fixtures, defect detection software of an upper computer is used for cooperation, the type of defects of the ABS gear rings is detected, and the gear rings are placed in different material dropping frames according to the types respectively. The system adopts an automatic mode, can greatly reduce the investment of manpower and financial resources in the detection step, and improves the detection efficiency and the detection success rate.

Owner:CHINA JILIANG UNIV

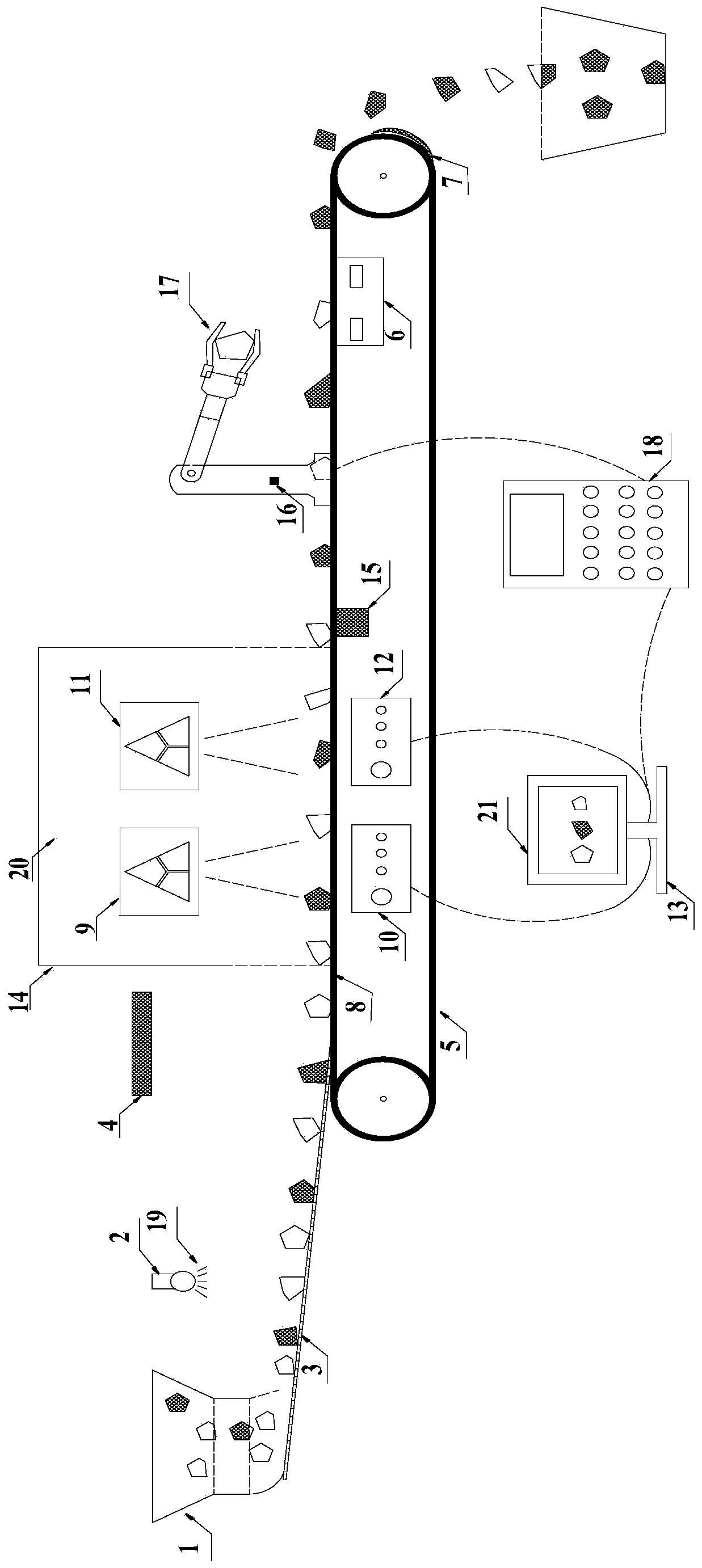

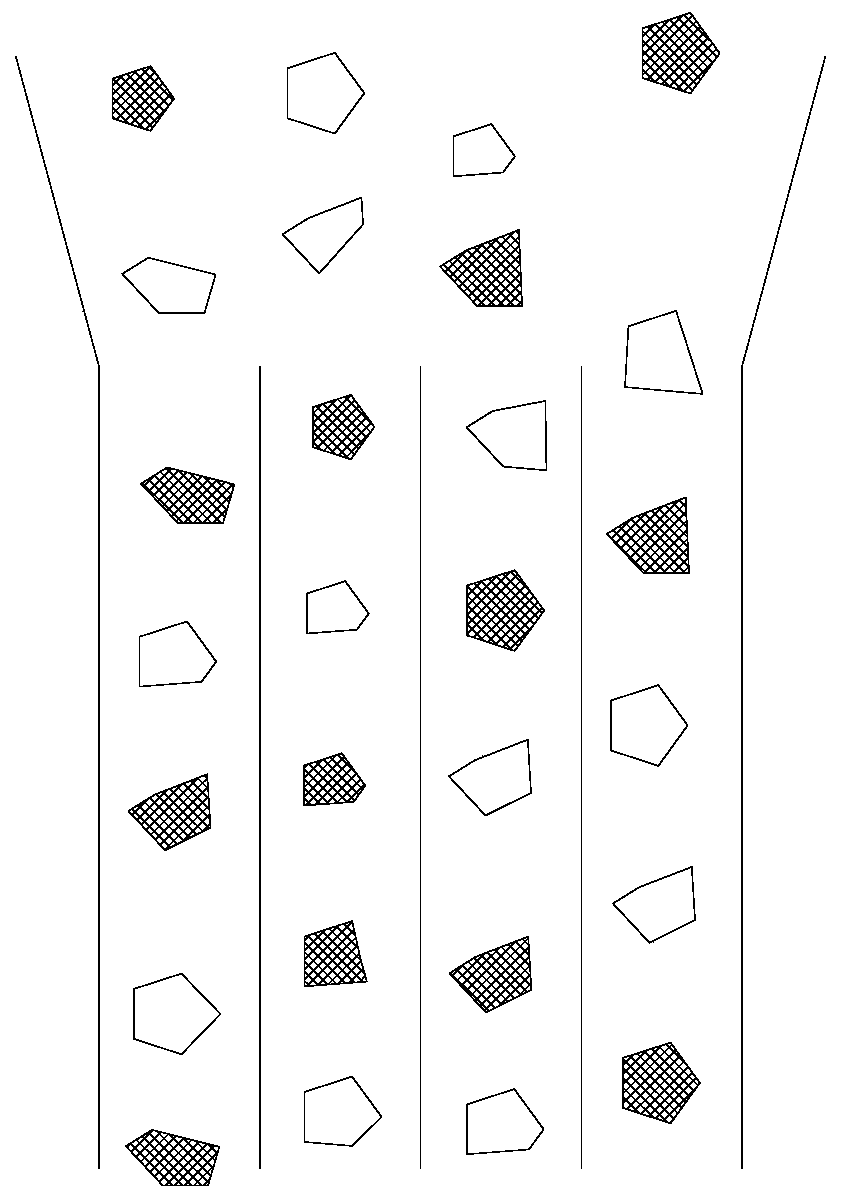

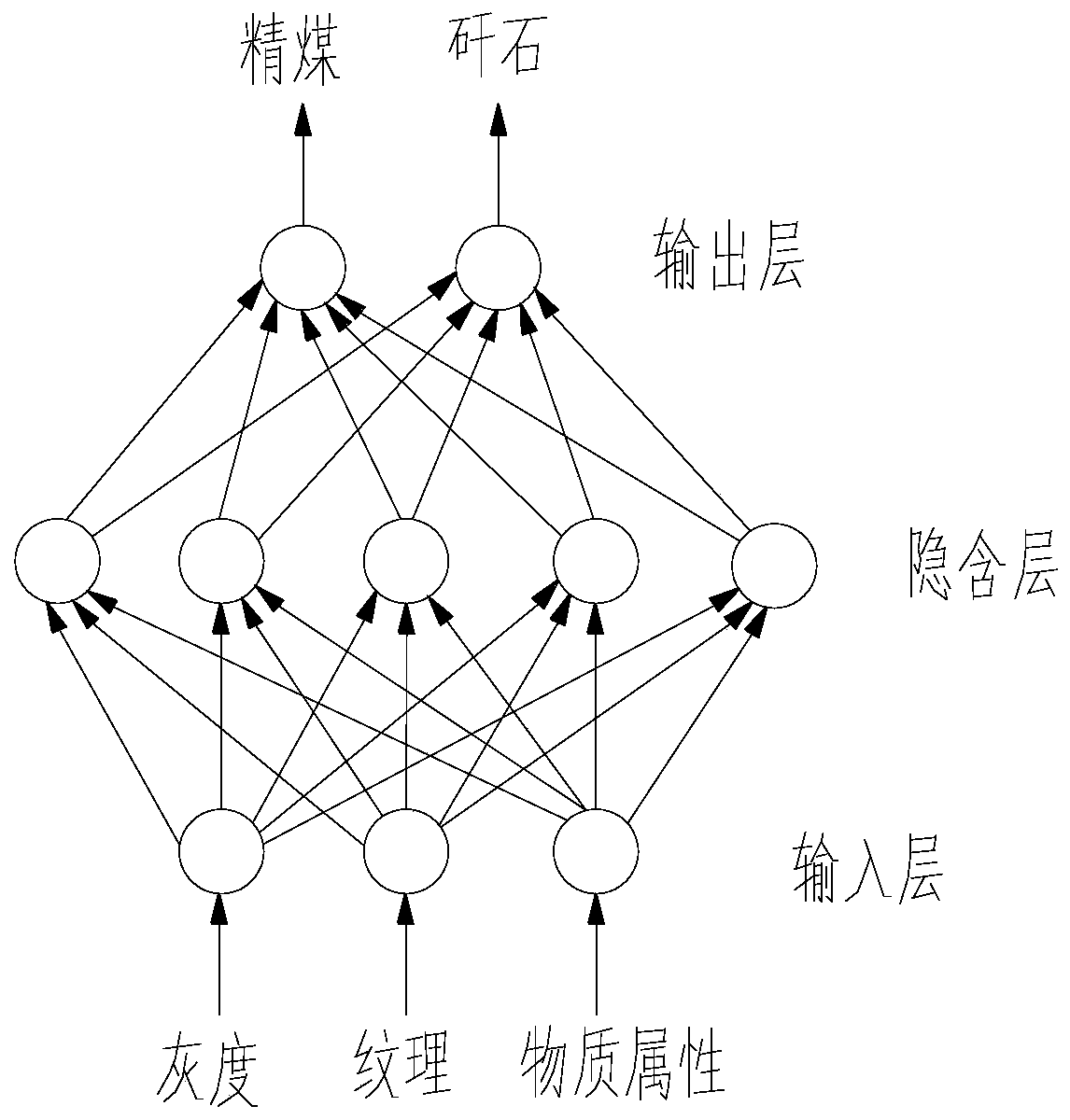

Intelligent dry waste discharge system based on true dual energy X-rays

InactiveCN110773454AStrong adaptabilityReduce manpower inputMagnetic separationSortingProcess engineeringManipulator

The invention relates to the field of coal preparation and waste discharge, in particular to an intelligent dry waste discharge system based on true dual energy X-rays. The intelligent dry waste discharge system includes a feeding mechanism, a conveying mechanism, a recognition mechanism and a sorting mechanism. The feeding mechanism is composed of a feeding funnel and a spray desliming device, the outer part of the feeding funnel is in an inverted cone shape, and the inner part of the feeding funnel is laid with wear-resistant porcelain plates which can reduce the abrasion of funnel wall surfaces; the spray desliming device is composed of spray pipes and a high-frequency sifter; the conveying mechanism is composed of an electronic belt scale which can monitor the feeding quantity in realtime, an electromagnetic iron remover which can reduce the contamination of sundries, a belt cleaner which can clean fine materials, and a lining-up device capable of forming a plurality of regular coal flows; the recognition mechanism is composed of an X-ray generator generating the X-rays with different intensity, a detector receiving the X-rays, an imaging upper computer, a BP neural network, and a lead isolation room; and the sorting mechanism is composed of a positioning device, a manipulator, and a PLC control cabinet. According to the intelligent dry waste discharge system based on thetrue dual energy X-rays, adaptability to coal is strong, intelligent recognition is realized, therecognition accuracy is high, and at the same time, coal-dust pollution is reduced.

Owner:ANHUI UNIV OF SCI & TECH

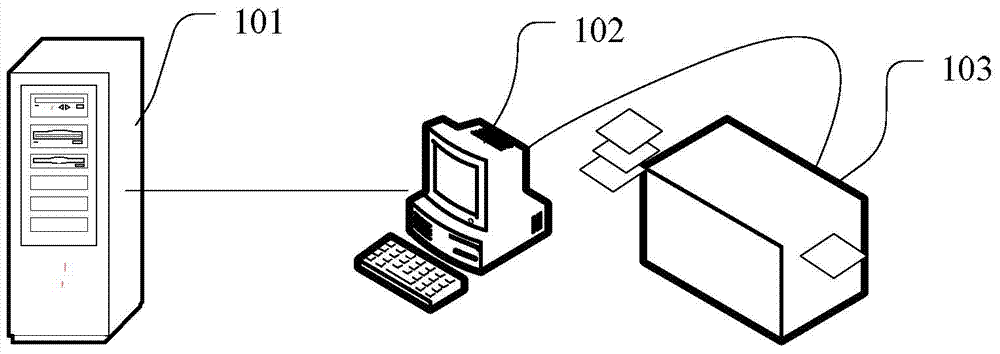

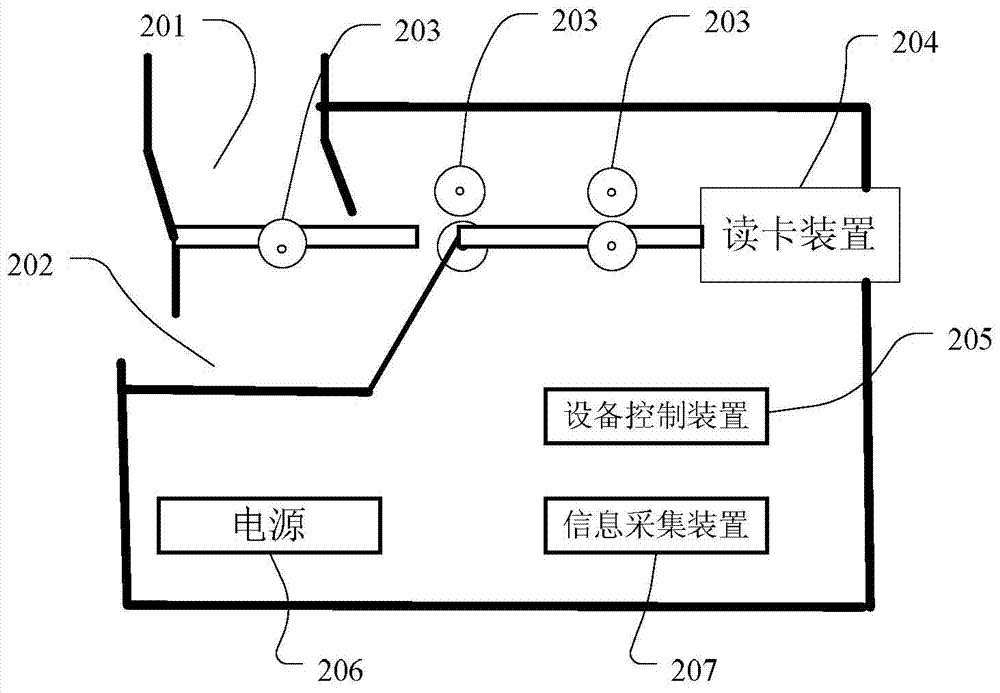

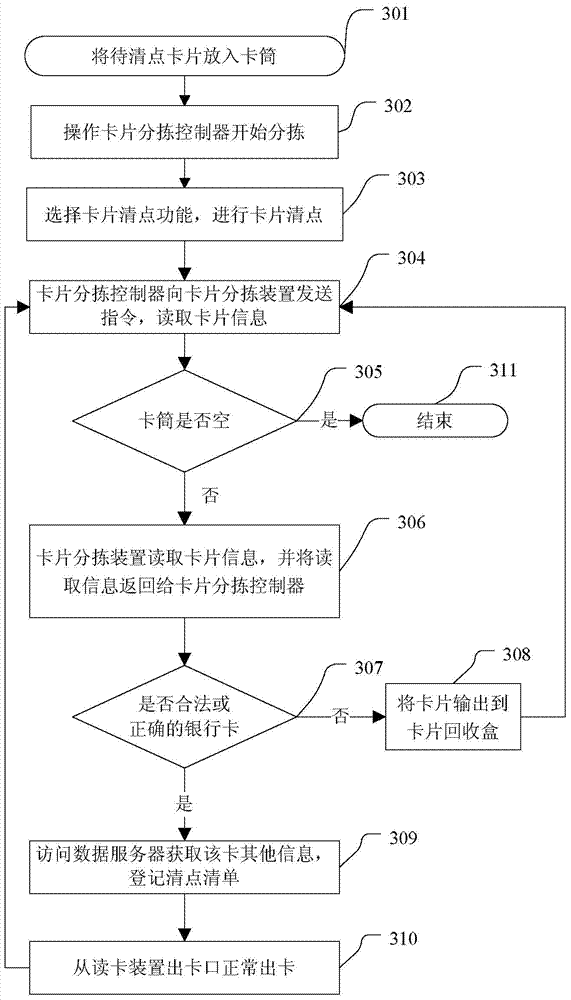

Device and system for sorting cards

The invention discloses a device and a system for sorting cards. The device for sorting cards comprises a card cylinder, a card transporting device, a card reading device, a card recovery box and an equipment control device, wherein the card cylinder is used for placing cards to be sorted, the card transporting device is composed of a step motor and a mechanical device and used for completing moving and transporting of cards in the device for sorting cards, the card reading device is used for completing the reading work of cards and dispensing cards according to instructions of the equipment control device, the card recovery box is used for holding cards needing to be recovered, and the equipment control device is used for reading the information of cards through the card reading device and controlling the card transporting device to transport cards to the card recovery box based on the information of cards, or controlling the card reading device to dispense cards. The device and the system for sorting cards are capable of realizing automatic and intelligent sorting of cards.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

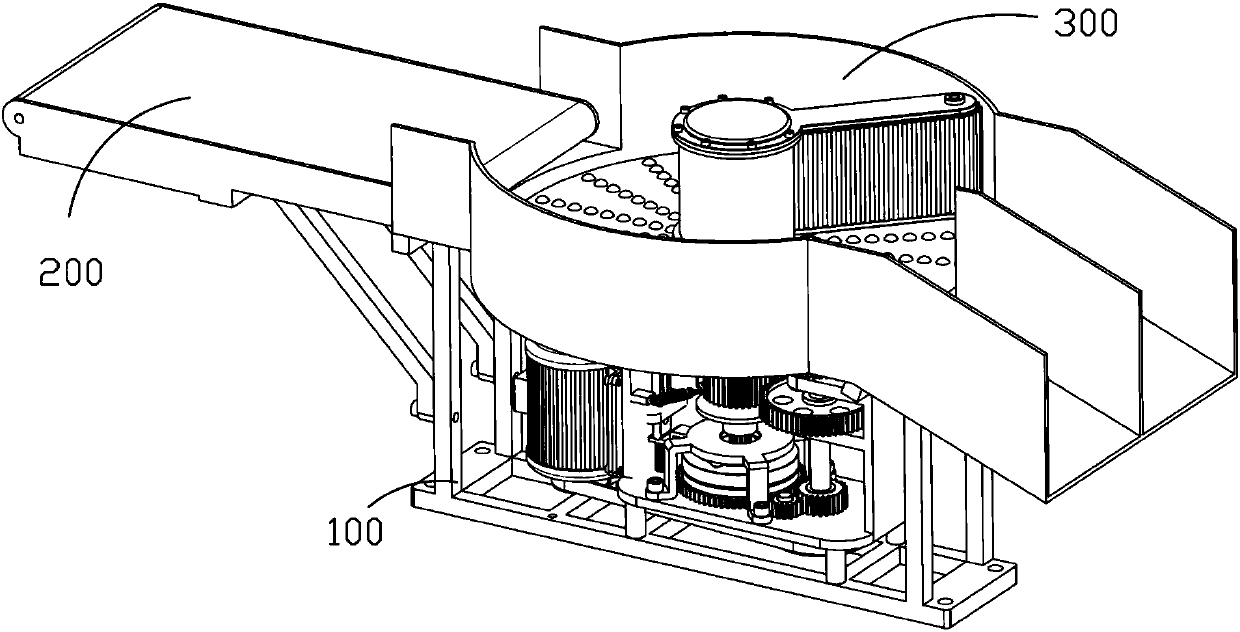

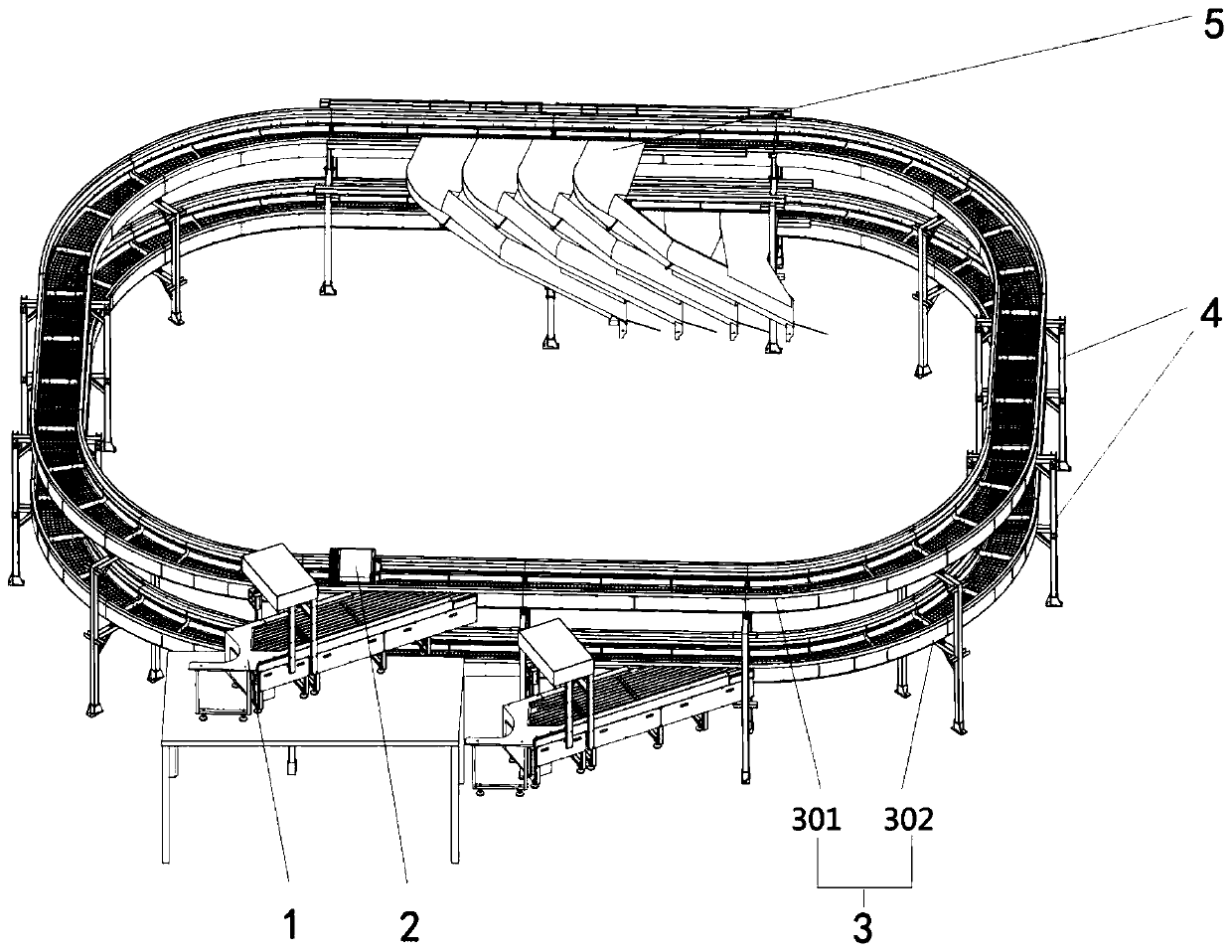

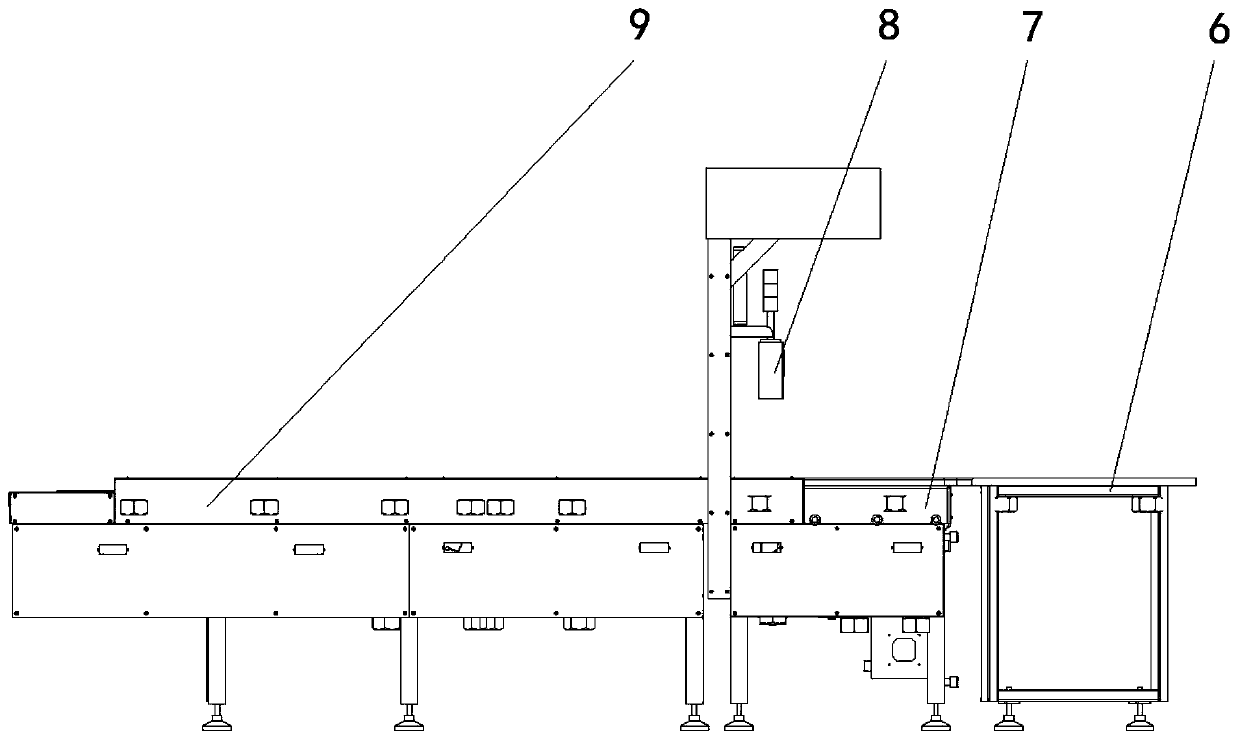

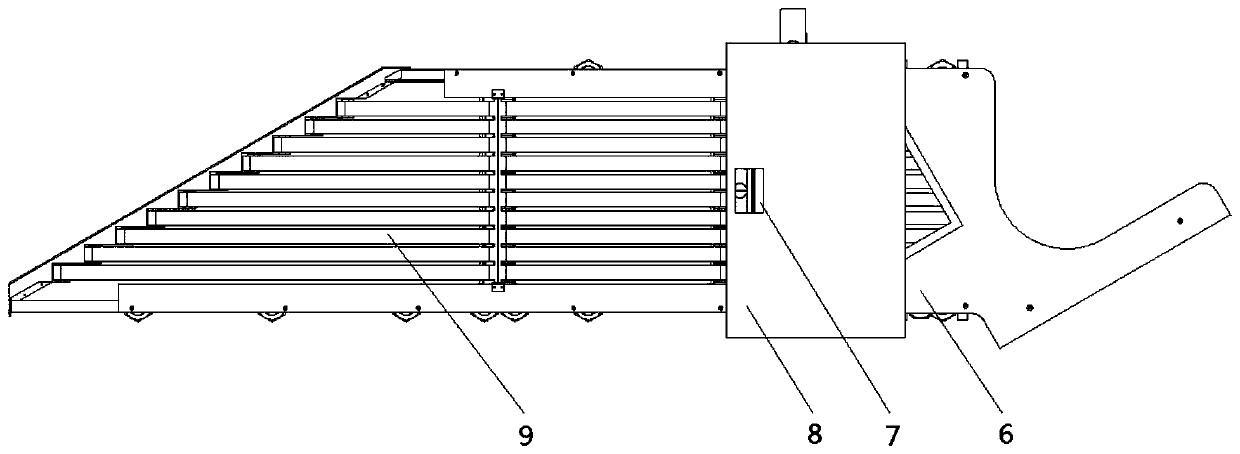

Double-layer ring-shaped cross belt sorting mechanism based on network model control

ActiveCN110077793AImprove sorting efficiencyAutomatic Sorting GuaranteeControl devices for conveyorsSortingNetwork modelEngineering

The invention relates to a double-layer ring-shaped cross belt sorting mechanism based on network model control. The double-layer ring-shaped cross belt sorting mechanism based on network model control comprises a loading mechanism, a sorting trolley, a rail device, a portal frame and a sorting outlet device, wherein the bevel edge of the loading mechanism is connected to the outer wall of the rail device; the sorting trolley moves at uniform speed in the rail device; the portal frame is connected to two mutually independent ring-shaped rails in the rail device; and the sorting outlet device is connected to the inner part of the rail device. Motion and sorting of the sorting trolley are realized by a WCS sorting control system, high-speed 5G cellular communication and industrial 5G multi-point distribution layout based on an MESH technology are adopted, a wireless signal generated by a wireless signal emitter is automatically connected to be a network module, and a control terminal automatically selects a point with highest signal strength to communicate; and meanwhile, the whole sorting mechanism is located in a hotspot coverage area to achieve the point-to-point transmission purpose and the point-to-multipoint purpose. The double-layer ring-shaped cross belt sorting mechanism based on network model control is high in sorting efficiency, is accurate and stable in sorting method, and has a very great market prospect and a very gas popularization value.

Owner:江苏浩智智能科技有限公司 +1

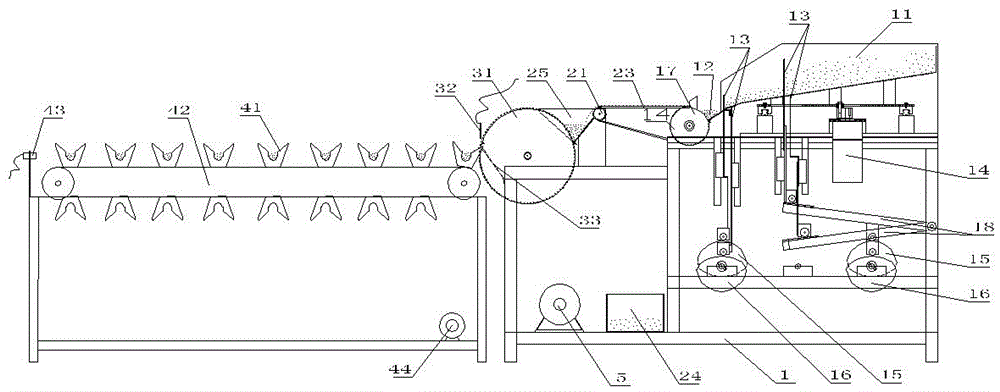

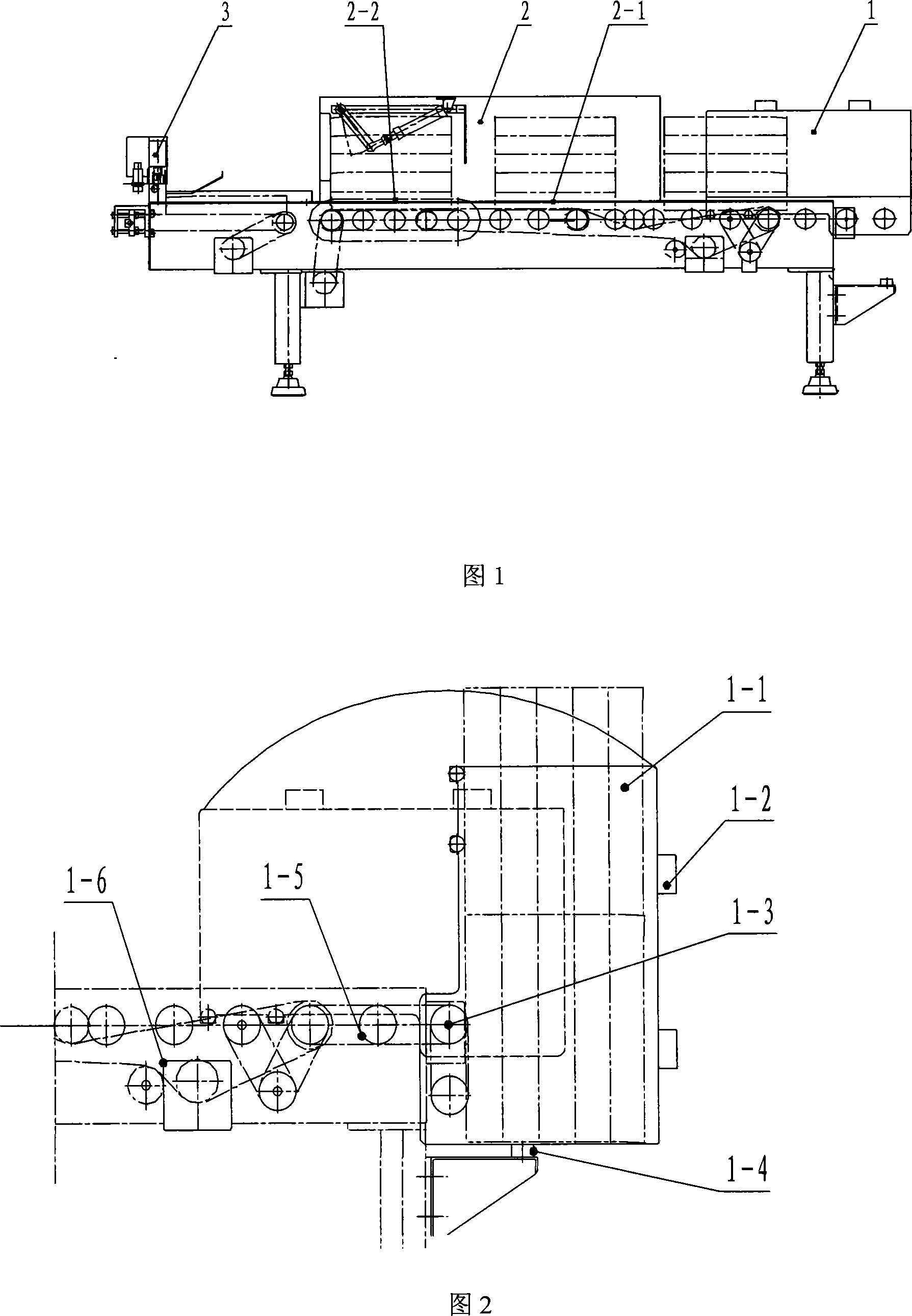

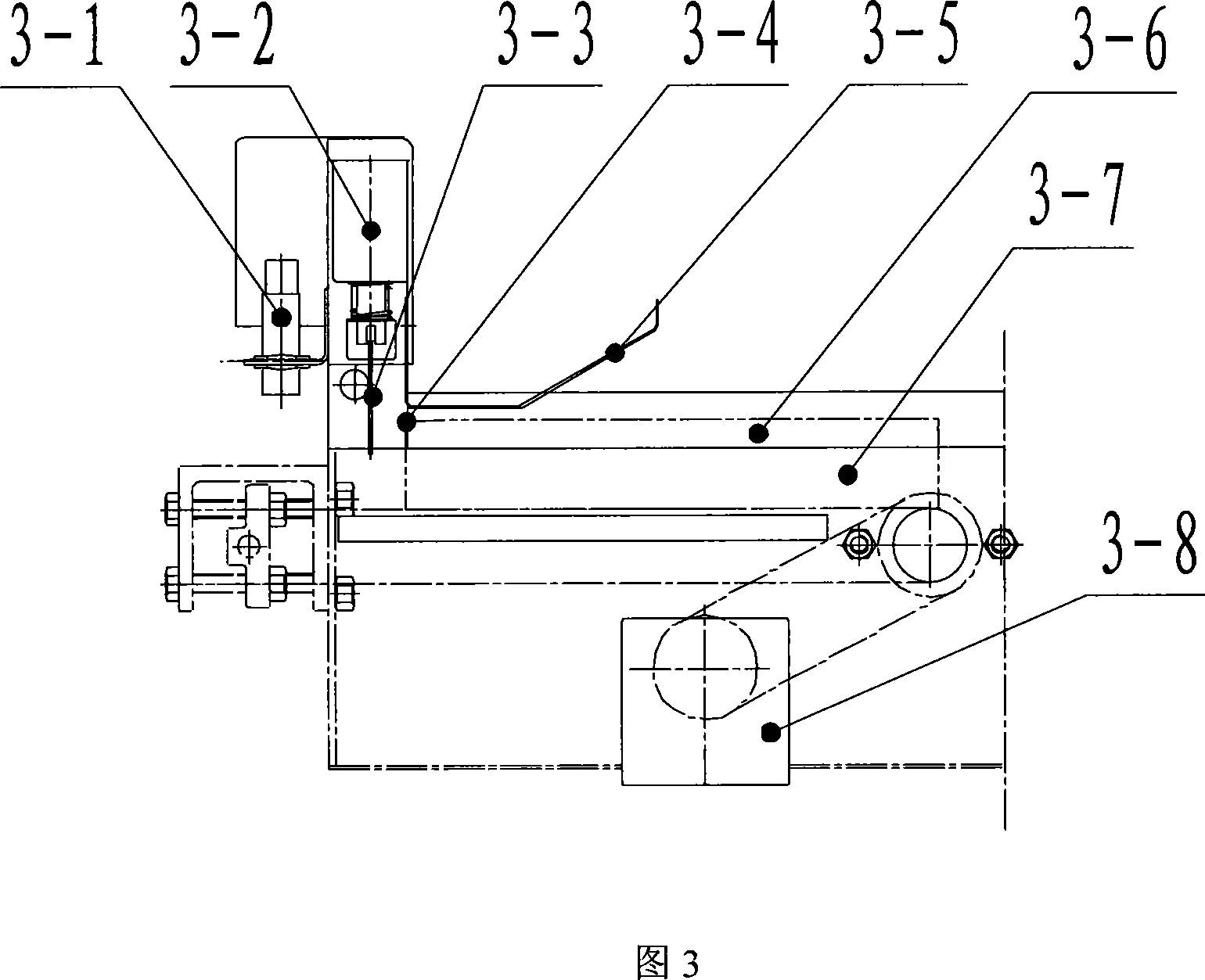

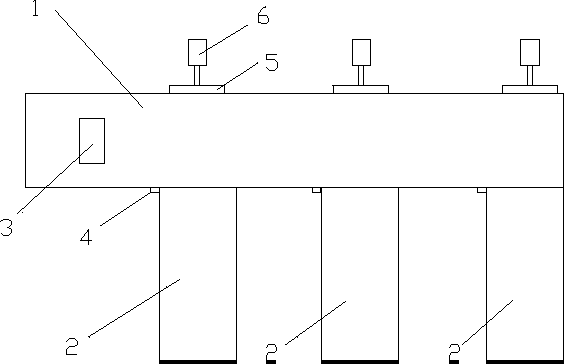

Horizontal carton packaged cigarette sorter

ActiveCN101185927ANot suitable for damageRealize automatic sortingSortingLogistics managementControl system

The invention which belongs to the field of logistics equipment technology relates to a horizontal tobacco carton sorting machine used in tobacco carton delivery operation, comprising a turn-over tobacco supplement device, a tobacco carton delivery mechanism which includes a conveying passage and a separated transportation mechanism, a tobacco carton sorting mechanism and a control system. The turn-over tobacco supplement device is arranged at the start end of the conveying passage of the tobacco carton delivery mechanism. The tobacco carton sorting mechanism is arranged at the terminal end of the separated transportation mechanism of the tobacco carton delivery mechanism. The whole structure of the machine is simple and reasonable. The style of tobacco supplement is simple, rapid and labor-saving, which reduces labor intensity and improves working efficiency. The sorting is flexible with a reliable precision, which seldom damages the tobacco carton and improves the sorting package quality. According to the requirements of the sorting business, the sorting system can be arbitrarily combined and installed by utilizing the horizontal tobacco carton sorting machine, so as to realize the automatic sorting of tobacco carton and high adaptability.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Conveyor belt with sorting function

The invention provides a conveyor belt with the sorting function. The conveyor belt comprises a main conveyor strip and at least two auxiliary conveyor strips connected with the main conveyor strip. A bar code scanner is arranged above a feed inlet of the main conveyor strip, one side of the main conveyor strip is provided with pushing plates with the number corresponding to the number of the auxiliary conveyor strips, and the pushing plates are used for pushing materials to the auxiliary conveyor belts and driven by a driving device. A sensor electrically connected with the driving device is arranged on one side of feed inlets of the auxiliary conveyor belts, and the sensor is electrically connected with the bar code scanner. Due to the fact that the bar code scanner is arranged above the main conveyor belt, the category of a product is judged according to the scanned bar code information, then the sensor on the inlets of the corresponding auxiliary conveyor belts is triggered, the sensor triggers the driving device to drive the corresponding pushing plates to push the product to the corresponding conveyor belt after the product passes through the sensor, and automatic sorting of products is achieved.

Owner:赵立军

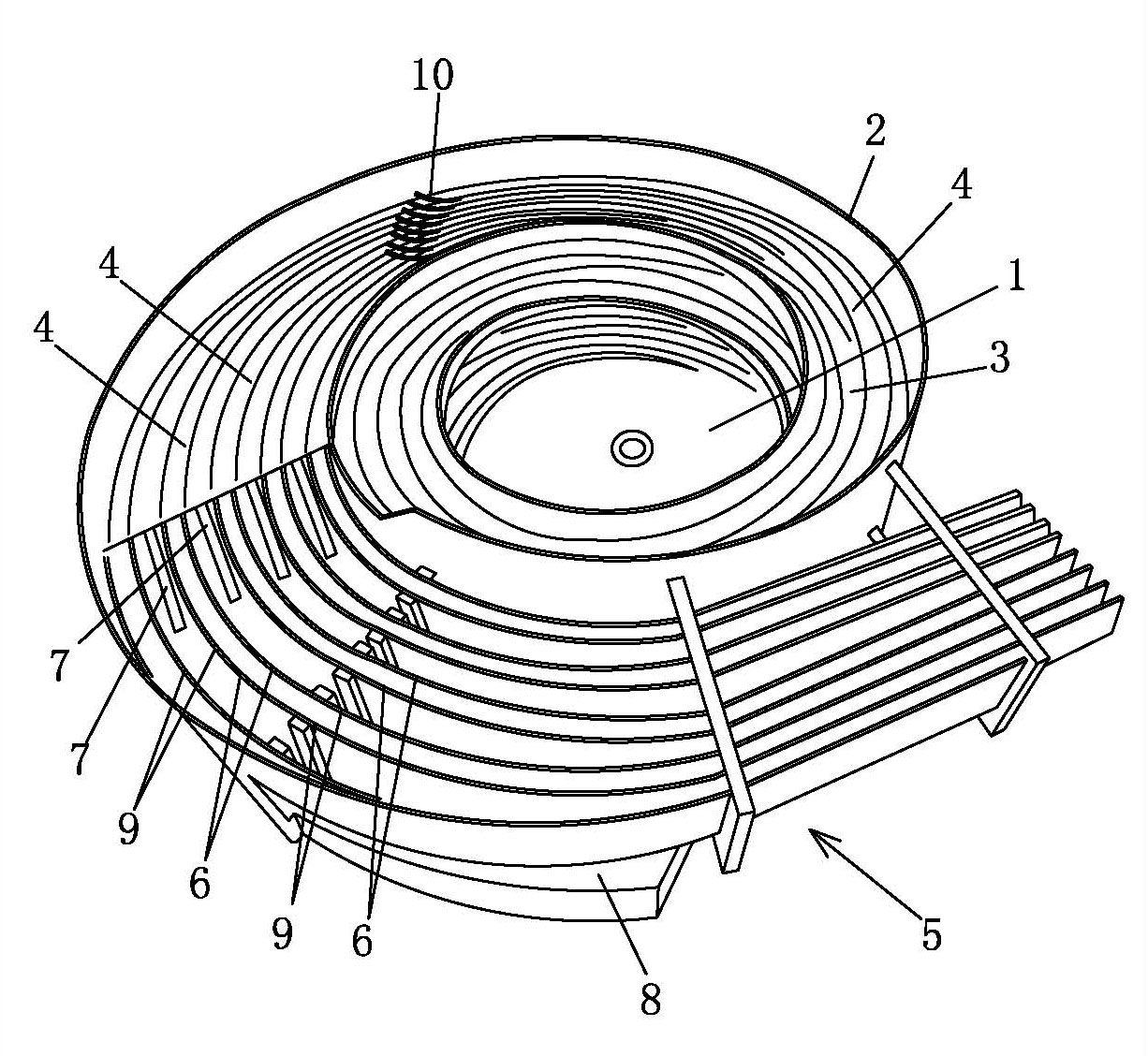

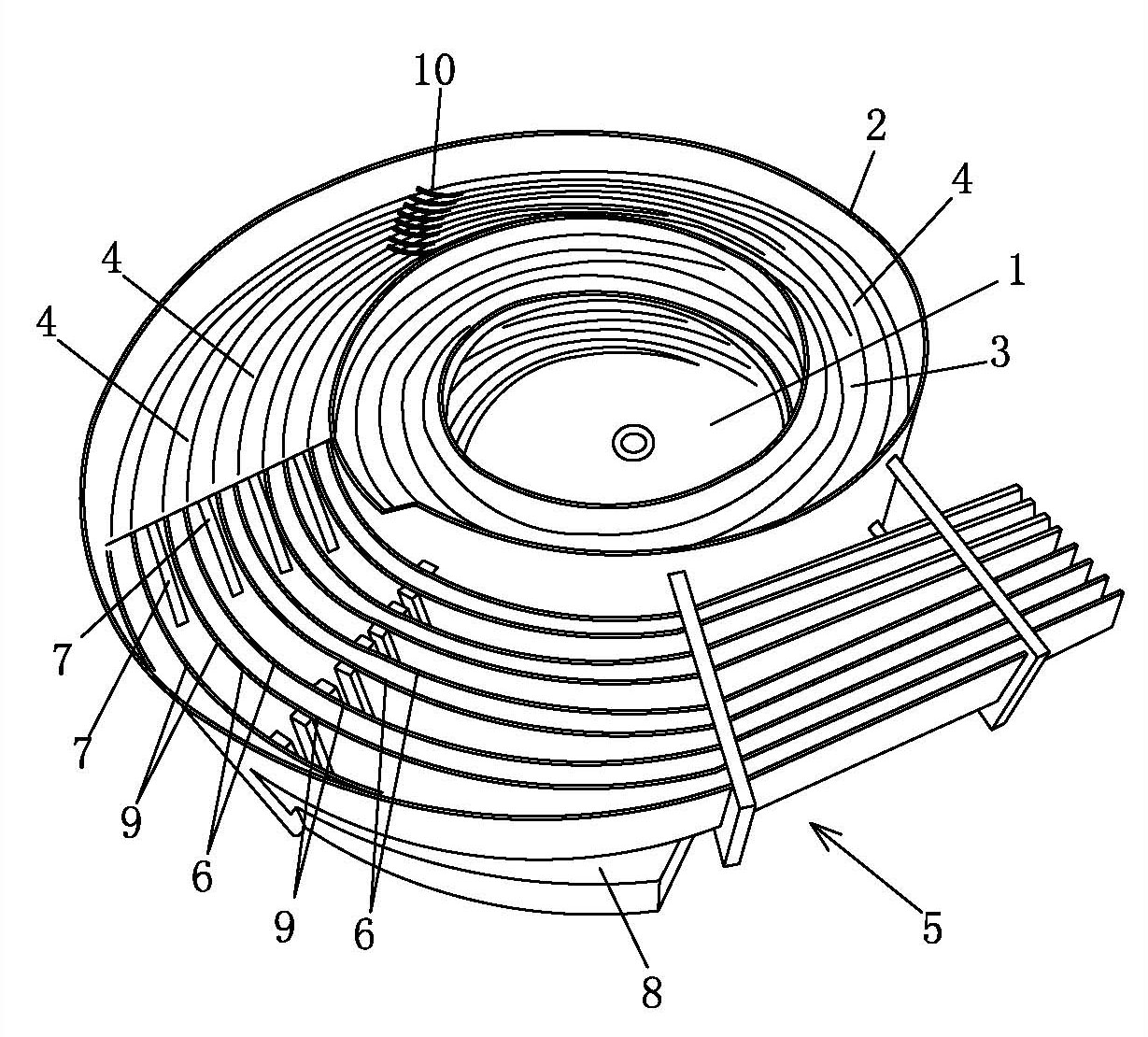

Material disc of automatic material feeding device

InactiveCN102424245AImprove dynamic performanceThe differential coefficient KD is largeJigging conveyorsWhole bodySpare part

The invention relates to a material disc of an automatic material feeding device, which comprises a disc surface and a side wall around the disc surface, wherein the inner side of the side wall is provided with a spirally-risingen charge track, a charge end of the charge track is arranged at a lower place of the disc surface, a plurality of isolating ways are arranged on the surface of the charge track side by side, a discharge end of the charge track is connected with an integrated material track, the integrated material track comprises a plurality of suspending ways and a plurality of material falling ways, a plurality of charge openings of the suspending ways and a plurality of discharge openings of the isolating ways are correspondingly connected with one another one by one, the material falling ways are arranged among the adjoining suspending ways, the charge track or the integrated material track is provided with a sensor capable of sensing the moving speed of spare parts, and the sensor is connected with a voltage controller by a signal controller. The periphery of the integrated material track is provided with a collecting groove, the collecting groove is connected with the material disc into a whole body, and the collecting groove is communicated with an inner cavity of the material disc by an opening on the side wall of the collecting groove. The material disc has the advantages of being adjustable in speed, and autonomic in sequencing for the spare parts.

Owner:GUANGDONG GALANZ GRP CO LTD

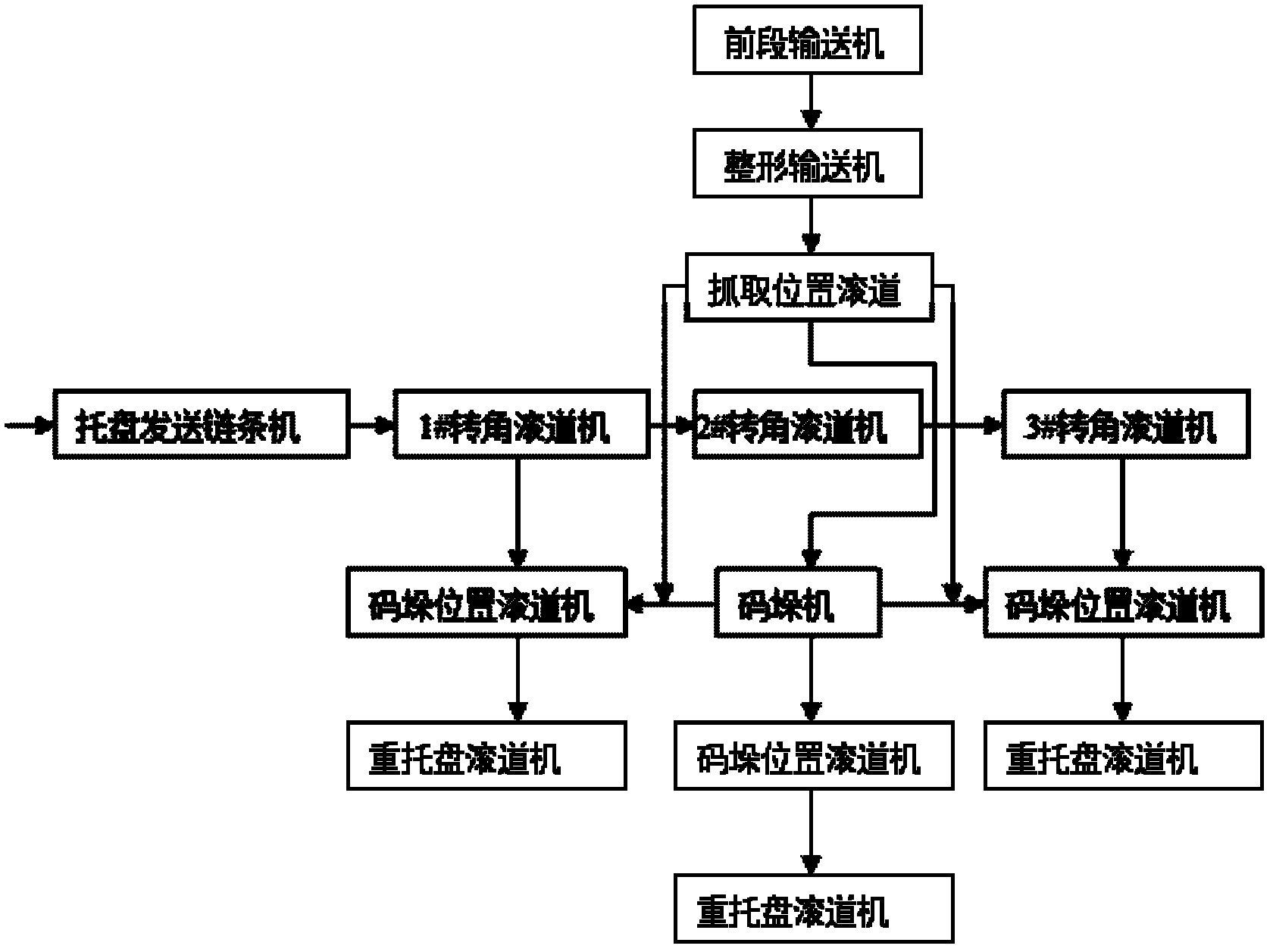

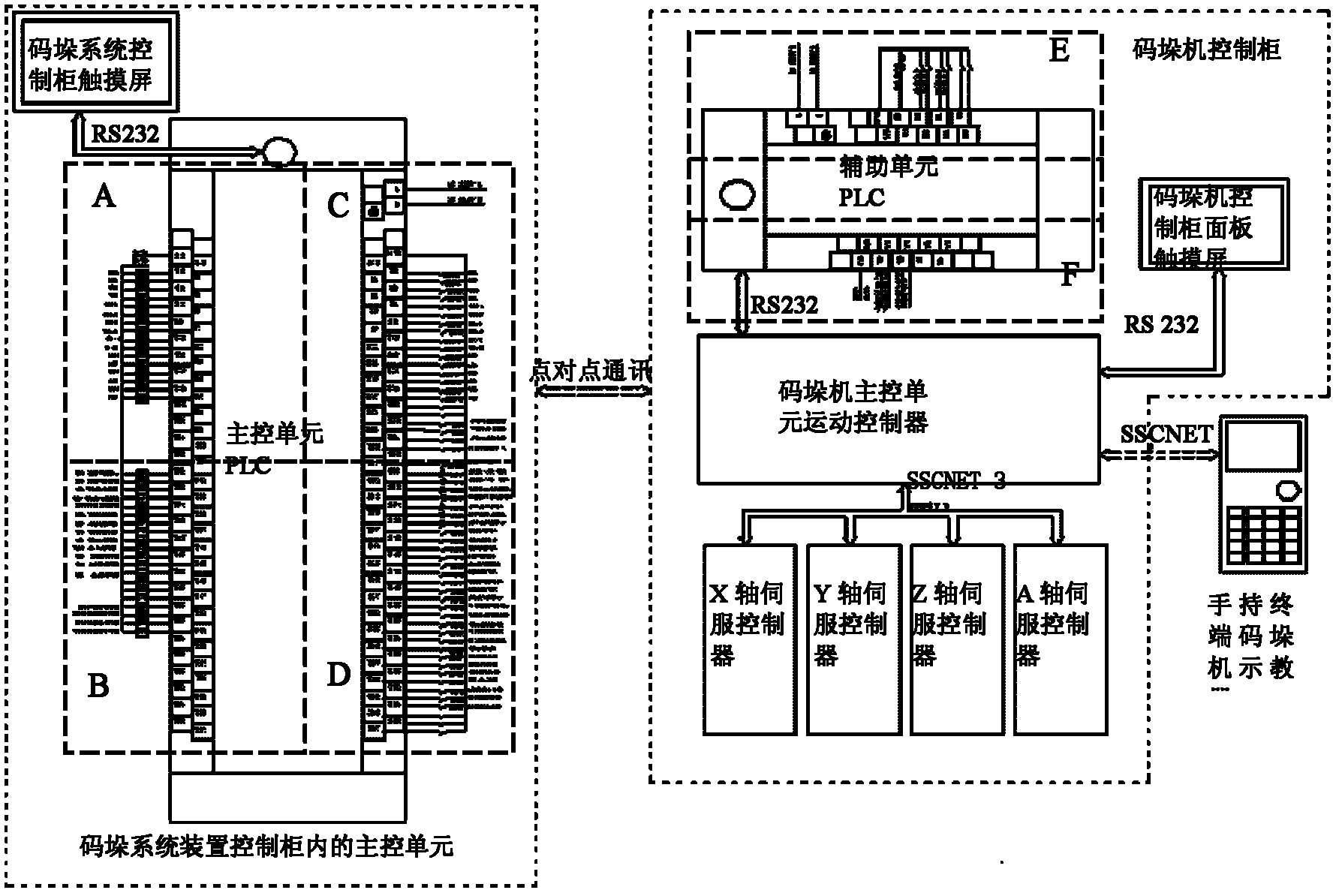

Intelligent joint robot stacking system and control system thereof

InactiveCN102633129ARealize automatic sendingRealize automatic sortingStacking articlesDe-stacking articlesPhysical hard workStack machine

The invention provides an intelligent joint robot stacking system and a control system thereof. The intelligent joint robot stacking system comprises a front-section conveyor, a reshaping conveyor, a fetching position raceway, a stacking position raceway machine, a stacking rear heavy tray raceway machine, a tray sending chain machine positioned on a tray library, a corner raceway machine on a tray library, an intelligent joint robot stacking machine and a device control system, wherein the device control system adopts a PLC (Programmable Logic Controller) control technology; equipment, such as an intelligent stacking machine, the intelligent tray transmitter, a conveying belt machine, a power raceway and the like, is organically combined with various detection elements and pneumatic elements; and under the control of a main control unit, one joint robot stacking machine is adopted to distinguish and automatically stack different products. According to the intelligent joint robot stacking system and the control system thereof, manpower can be saved, heavy manual work is liberated, and various possible errors which possibly appear during manual operation are avoided. The production efficiency is improved, the system can stably and reliably work, the equipment use ratio is improved, the equipment investment is saved, and the energy consumption is lowered.

Owner:WUXI DADONG MACHINERY MFG

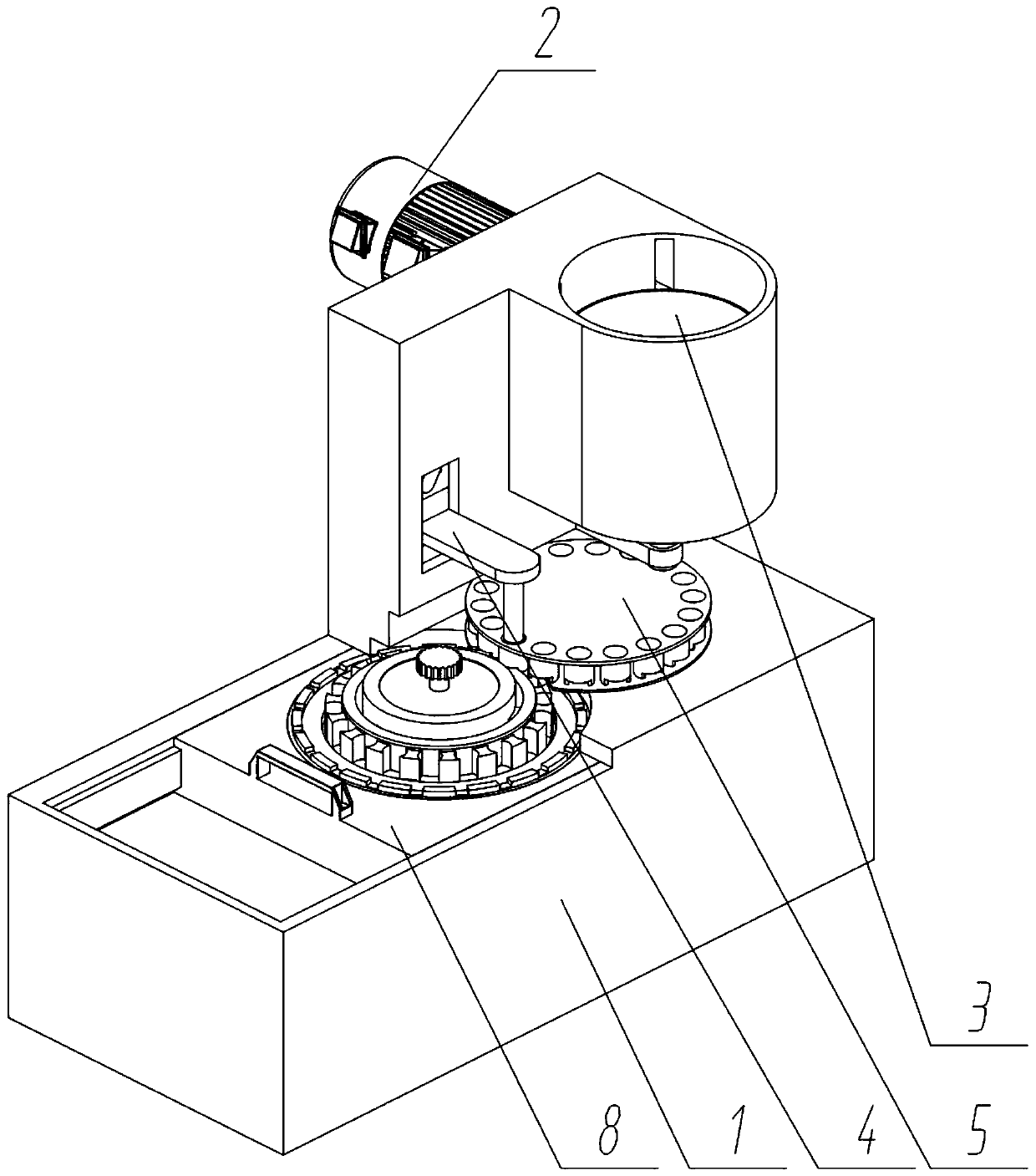

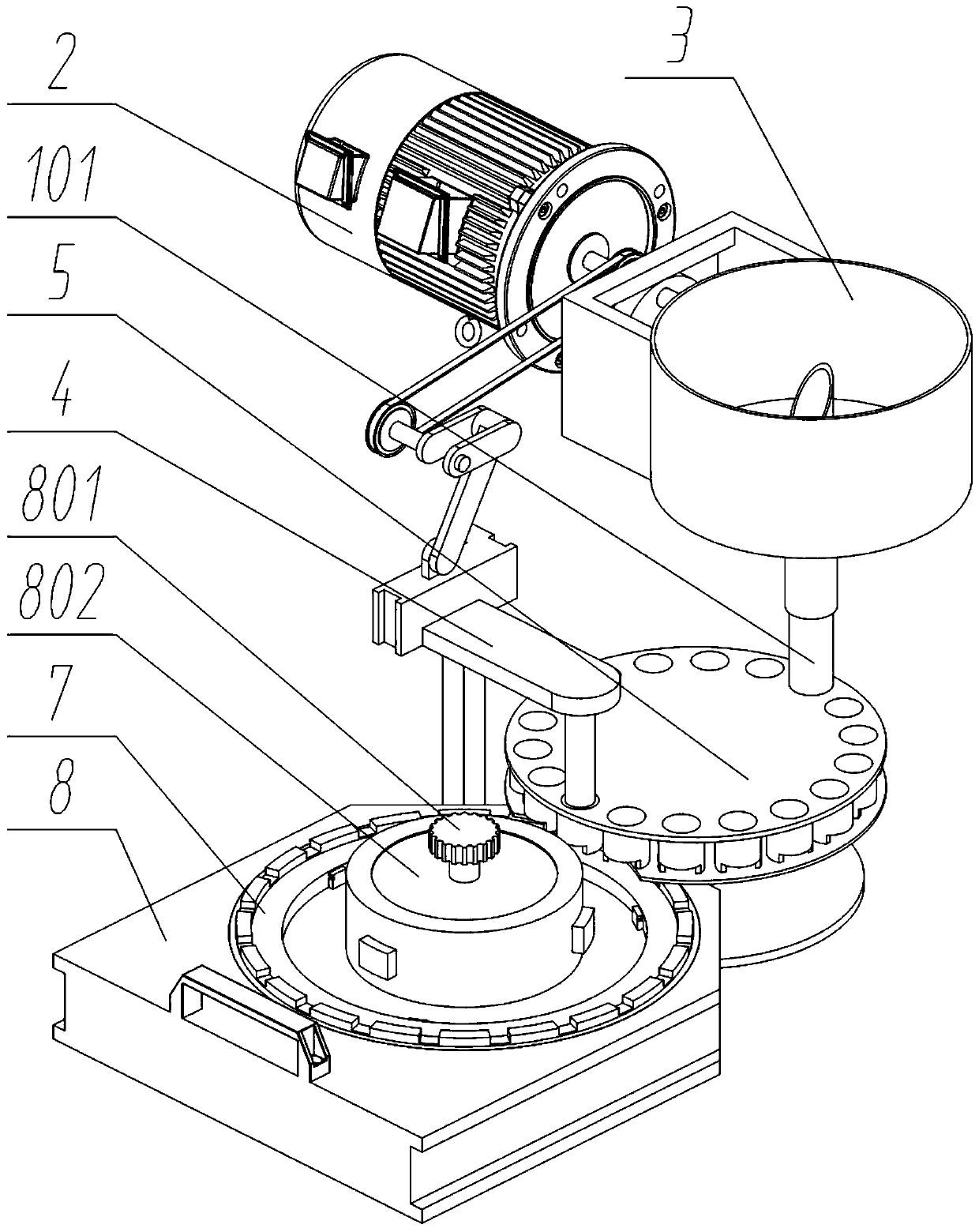

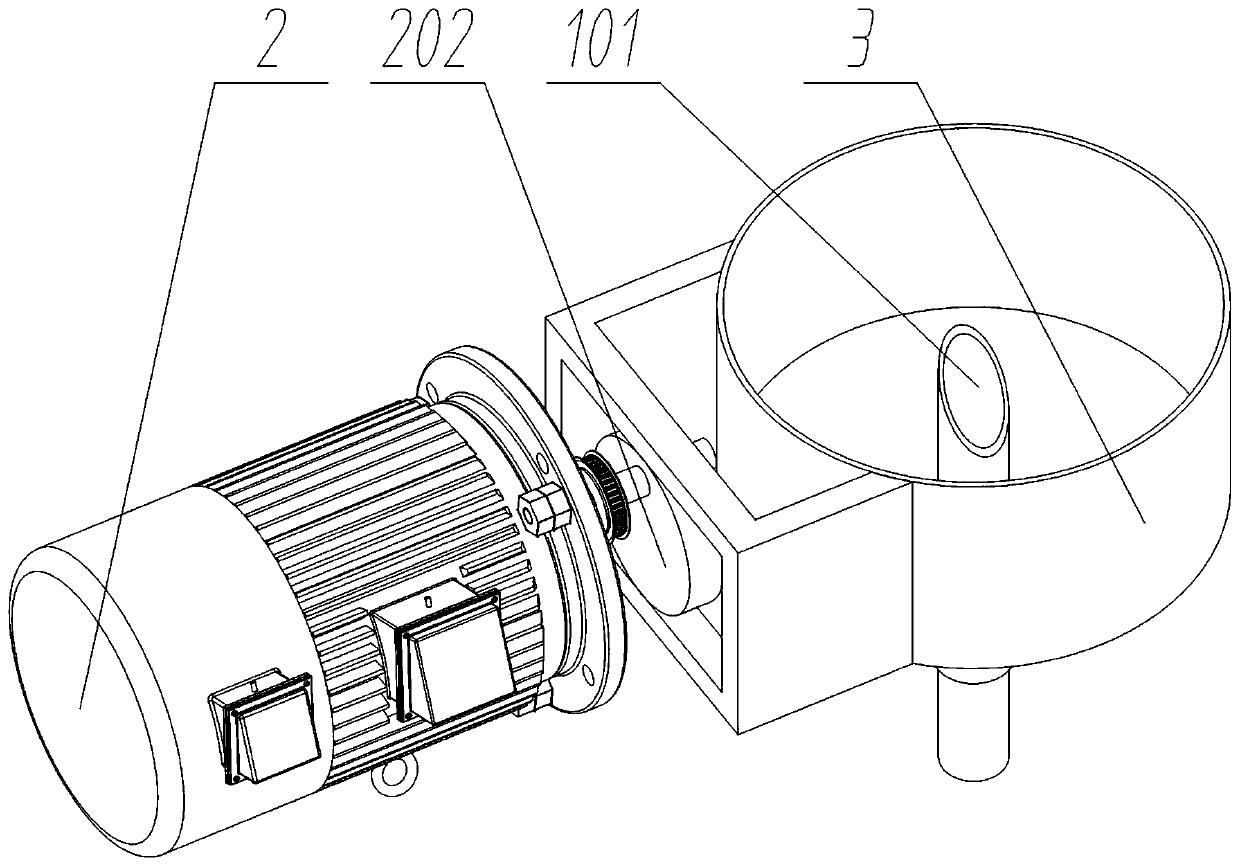

Large bearing roller press-in assembling device for bearing production

InactiveCN111571180AReduce labor intensityEasy to useAssembly machinesBearing componentsDrive shaftElectric machinery

The invention discloses a large bearing roller press-in assembling device for bearing production, and relates to the technical field of the bearing production. The large bearing roller press-in assembling device solves the problem that in an existing bearing roller press-in mode, the actions of roller placing, knocking and retainer rotating need to be repeatedly carried out for mounting and assembling, the operation is troublesome, the large labor force needs to be consumed, and the production efficiency is low. The large bearing roller press-in assembling device comprises a main body, whereina driving motor is fixedly connected to the rear end surface of the main body; a roller sorting hopper is slidably connected to the upper part of the right side of the main body; a feeding transmission shaft is rotationally connected to the rear part of the inner side of the main body; a mounting sliding block is slidably connected to the upper end surface of the left side of the main body; and aretainer mounting seat is rotationally connected to the upper end surface of the mounting sliding block. According to the large bearing roller press-in assembling device, the operations such as automatic sorting, feeding, press-in, and transposition of rollers are achieved, the previous manual knock-in action of the rollers is replaced, the labor intensity of workers is low, the use is easy, theoperation is convenient, and the working efficiency can be greatly improved.

Owner:杨 昆鹏

Glass clinical thermometer automatic sorting device

The invention belongs to the technical field of medical apparatus and instruments, and relates to a glass clinical thermometer automatic sorting device which comprises a machine frame and a feeding device, an image acquisition device, a single-chip microcomputer, a push shot device and a material collecting device which are mounted on the machine frame; the feeding device achieves automatic continuous feeding; the image acquisition device shoots and acquires pattern information of glass clinical thermometer tube materials each scratched with a datum line; the single-chip microcomputer divides clinical thermometers into groups according to the datum line separation distance obtained by the image acquisition device, and calculates a conveying position of each tube material on a conveying belt; the push shot device is composed of a plurality of electromagnetic launchers arranged side by side, and each electromagnetic launcher corresponds to a group of image signals; when the glass clinical thermometer tube materials reach corresponding positions of the electromagnetic launchers, the single-chip microcomputer controls the push shot device to push and shoot the glass clinical thermometer tube materials into corresponding material collecting boxes. Through adopting a quite simplified structure, automatic sorting of the glass clinical thermometers is achieved, and the sorting accuracy and the sorting efficiency are effectively improved.

Owner:东阿阿华医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com