Automatic subpackage machine and method for incense sticks

A technology of subcontracting machines and incense sticks, which is applied in the directions of automatic packaging control, packaging, conveyors, etc., can solve the problems of high labor intensity, low efficiency, labor-intensive, etc., to improve product quality and production efficiency, improve sorting efficiency, The effect of simplifying the device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

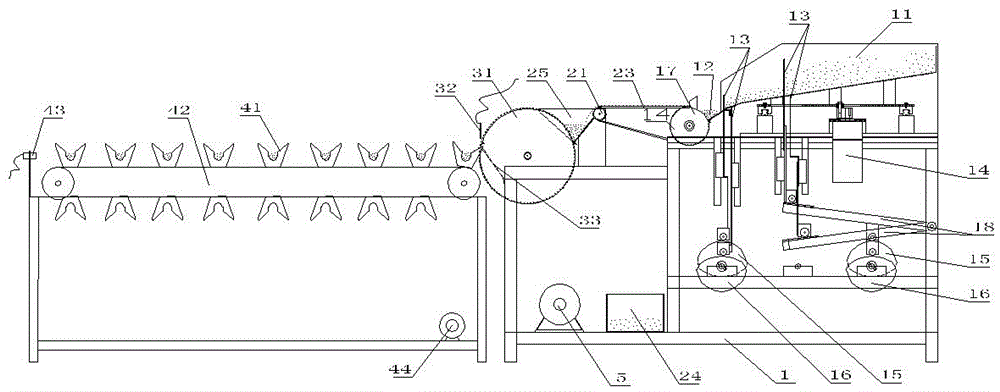

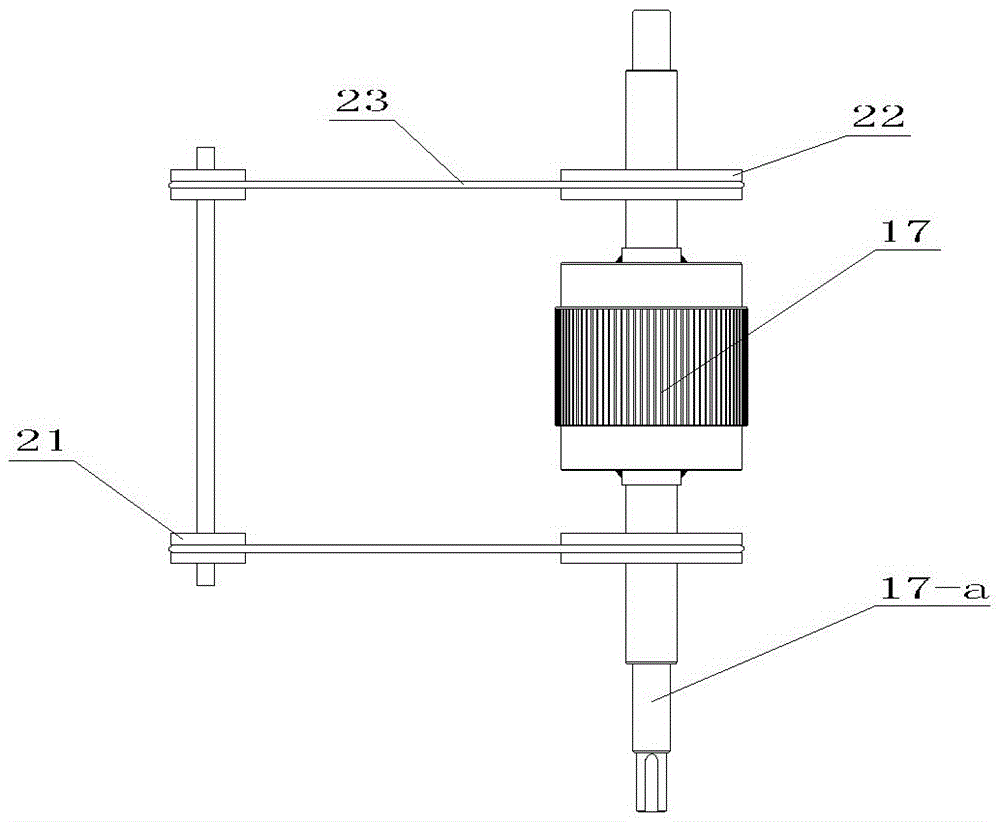

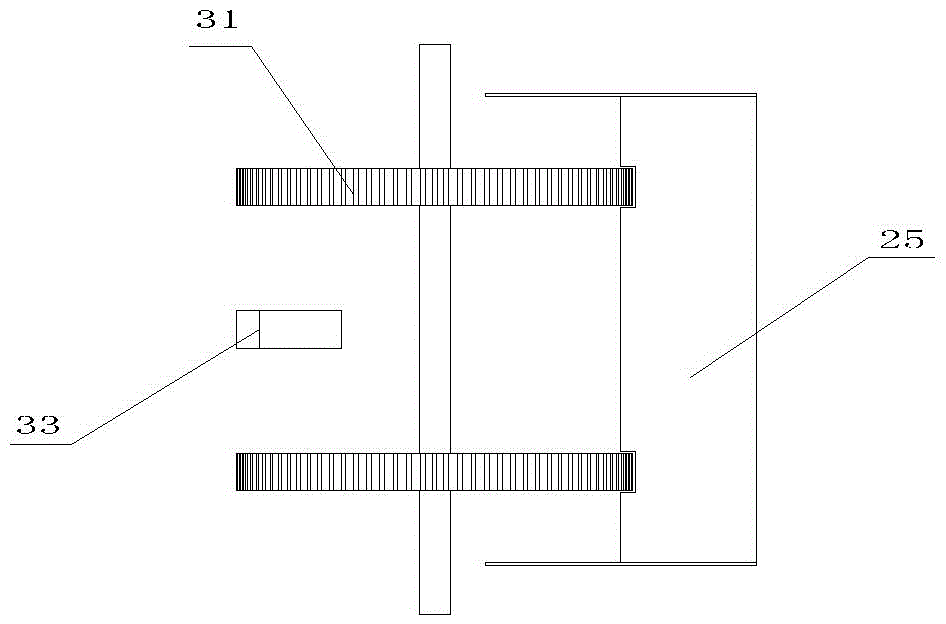

[0025] An automatic packing machine for thread-shaped incense sticks, including a control management circuit and an assembly of sorting and stabilizing flow, breaking incense screening, counting and quantifying, and packing transmission mechanisms designed on the basis of traditional incense stick packaging processes. The breaking incense screening mechanism includes Two parallel transmission belts 23 and supporting pulleys and drives that are arranged in parallel and synchronously run in the same plane. The bottom of the transmission belt 23 is provided with a waste box 24, and the feeding and blanking ends are respectively connected to the steady flow feeding roller 17 and the dispersion. The upper hopper 25, the incense sticks are transported to the conveyor belt 23 in isolation by means of the steady flow feeding roller 17, and the incense sticks placed on the two conveyor belts 23 are sent to the dispersed upper hopper 25, and the unqualified incense sticks fall into the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com