Patents

Literature

784results about "Rod-shaped articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

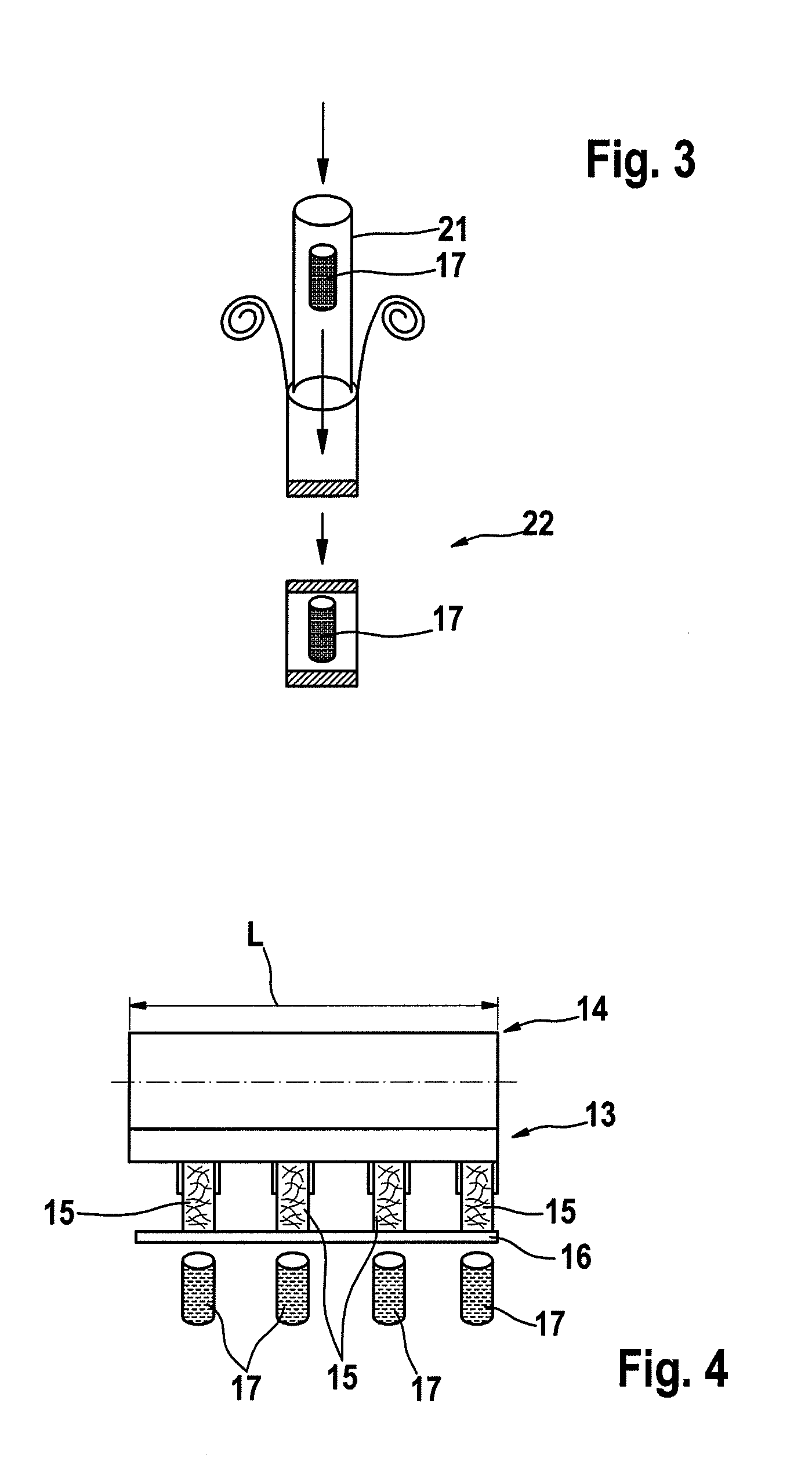

Parallel cigarette filter combining techniques with particle filling of cavities

ActiveUS20060157070A1Quality improvementFast processingCigarette manufactureTobacco smoke filtersEngineeringMechanical engineering

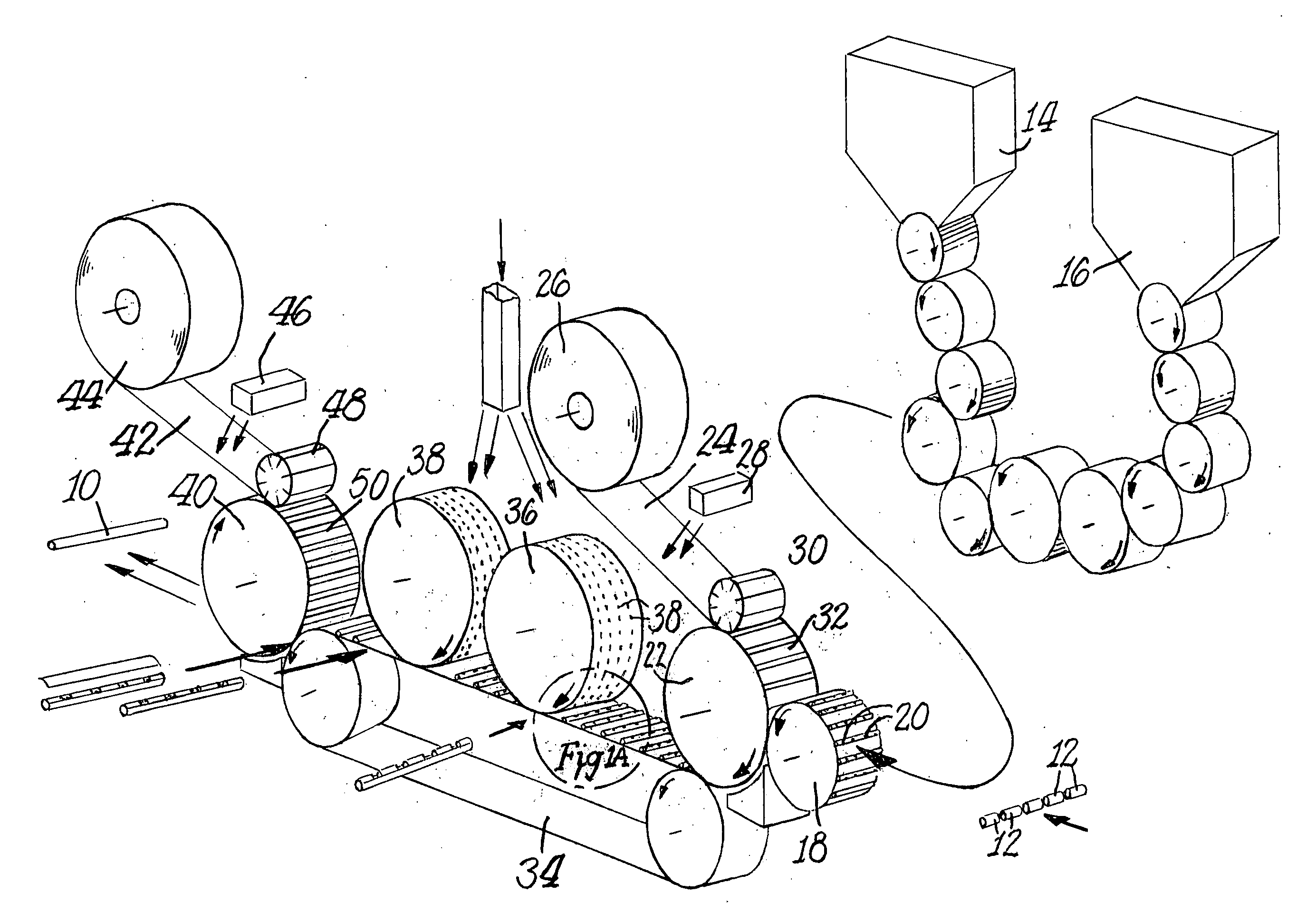

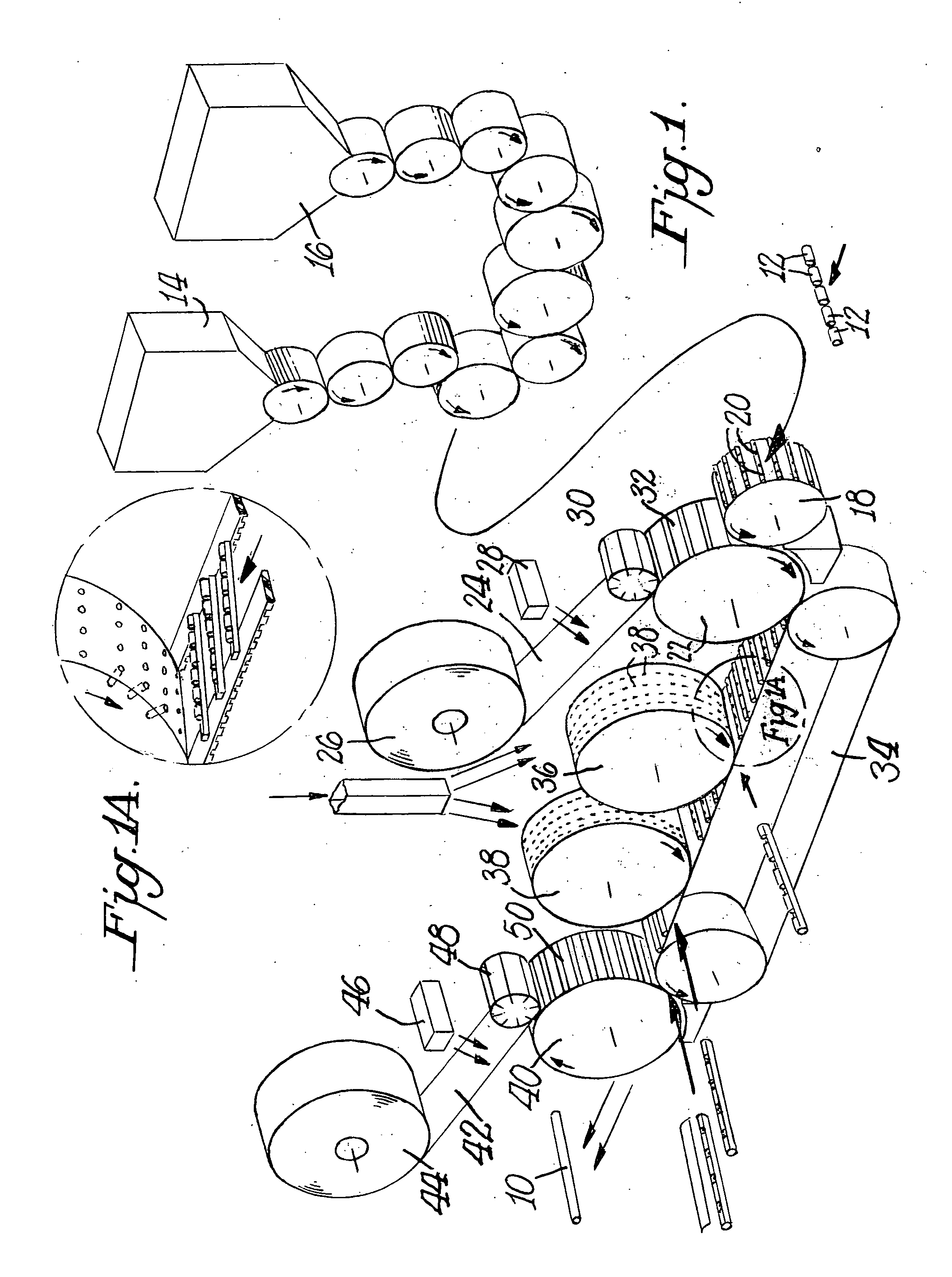

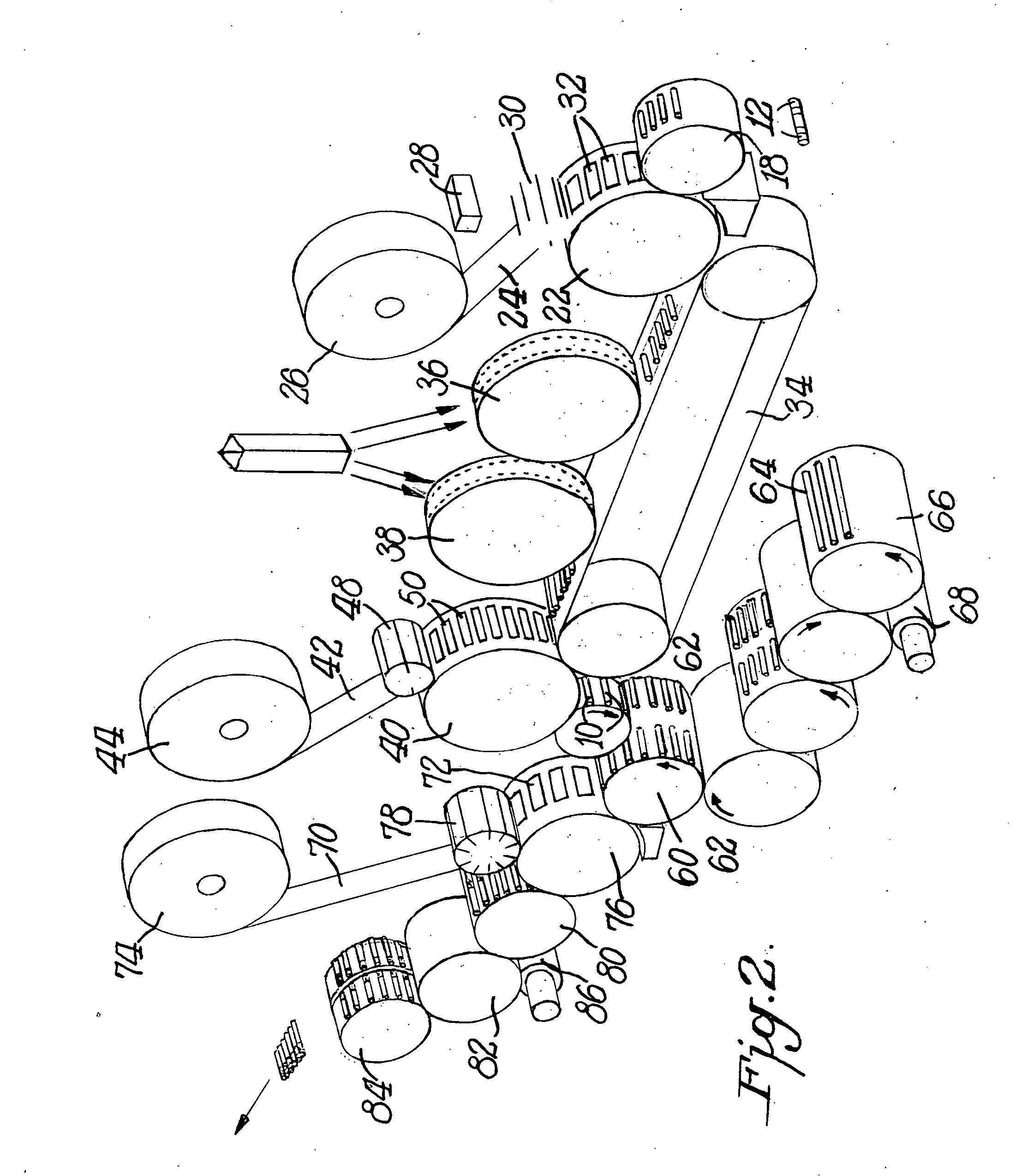

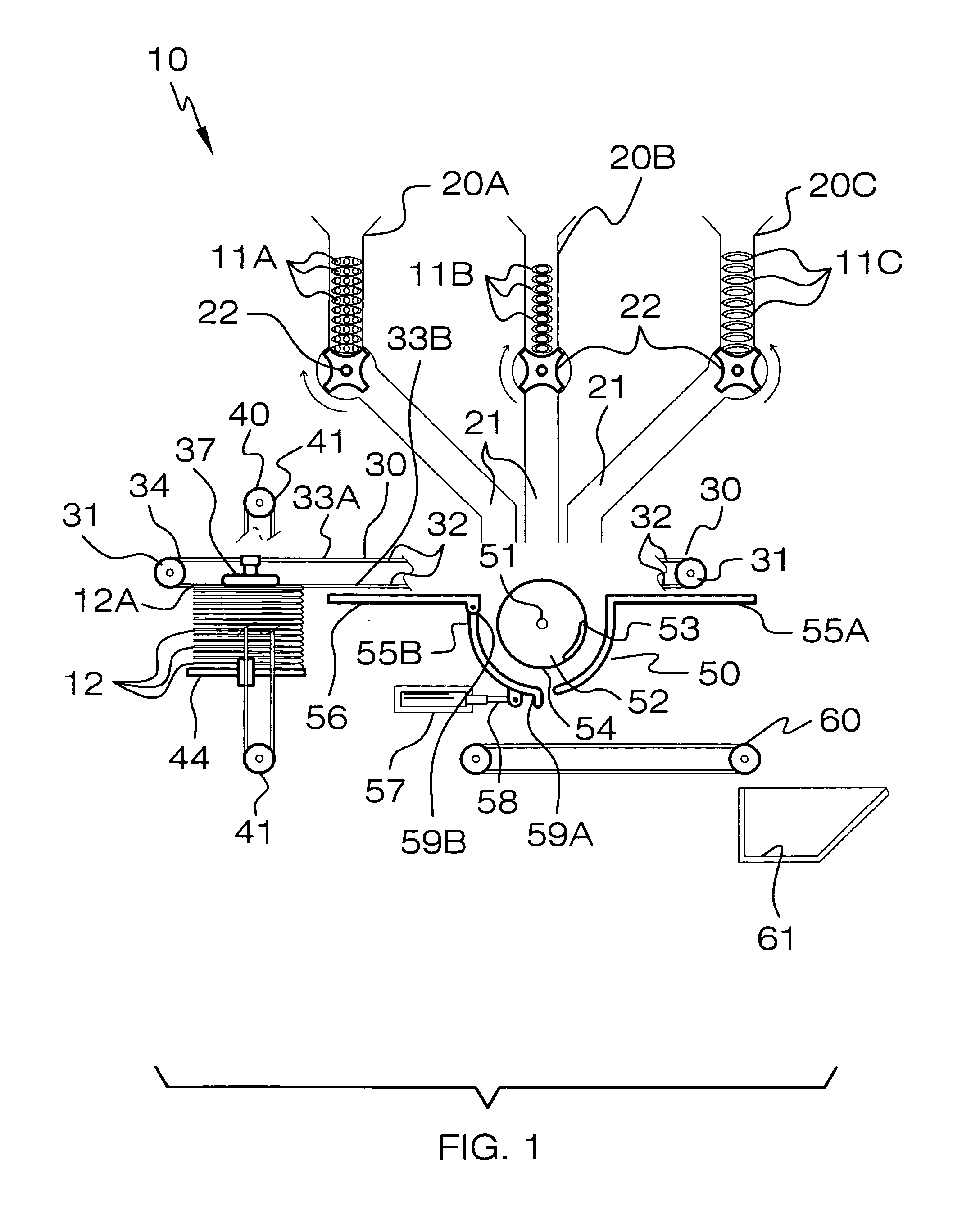

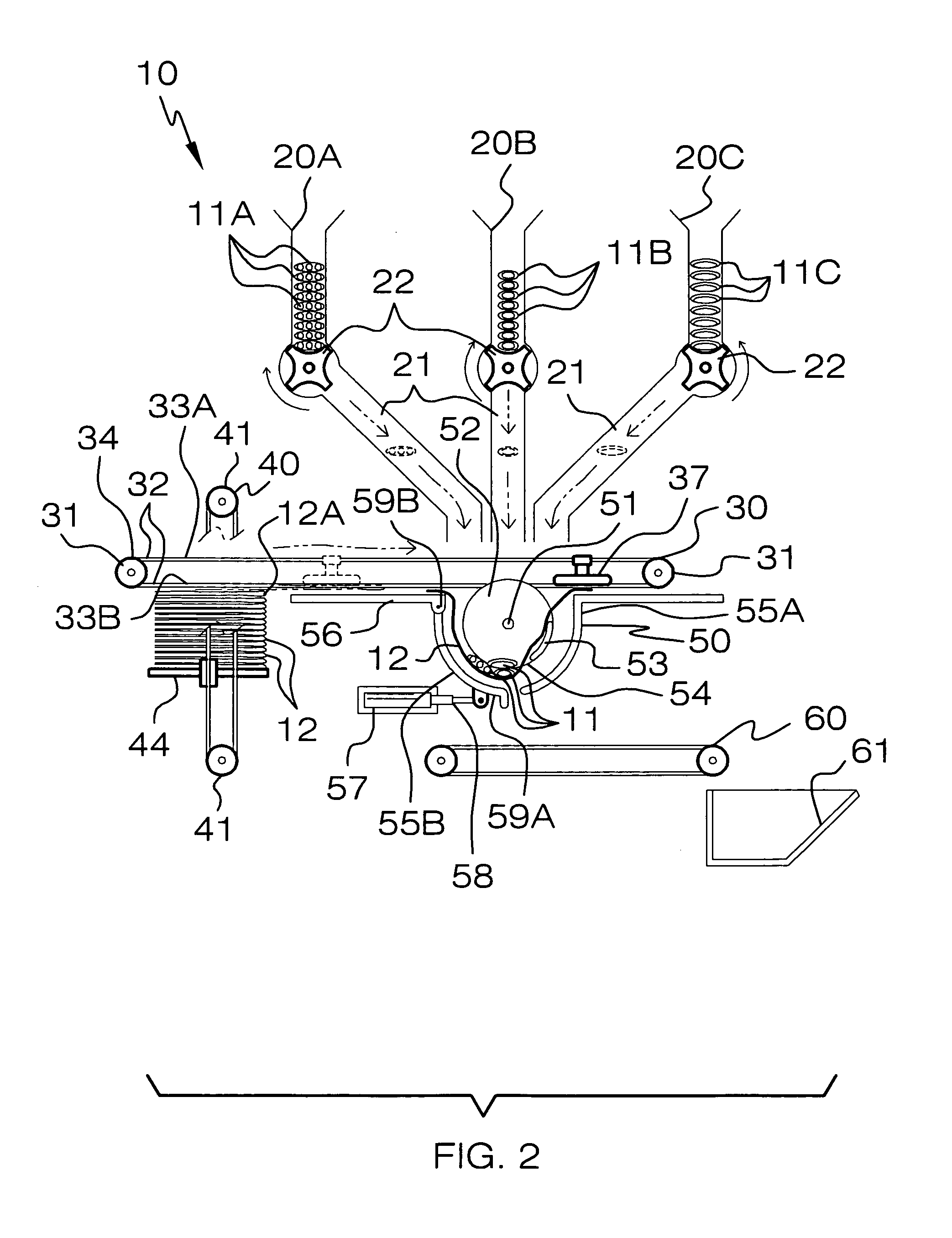

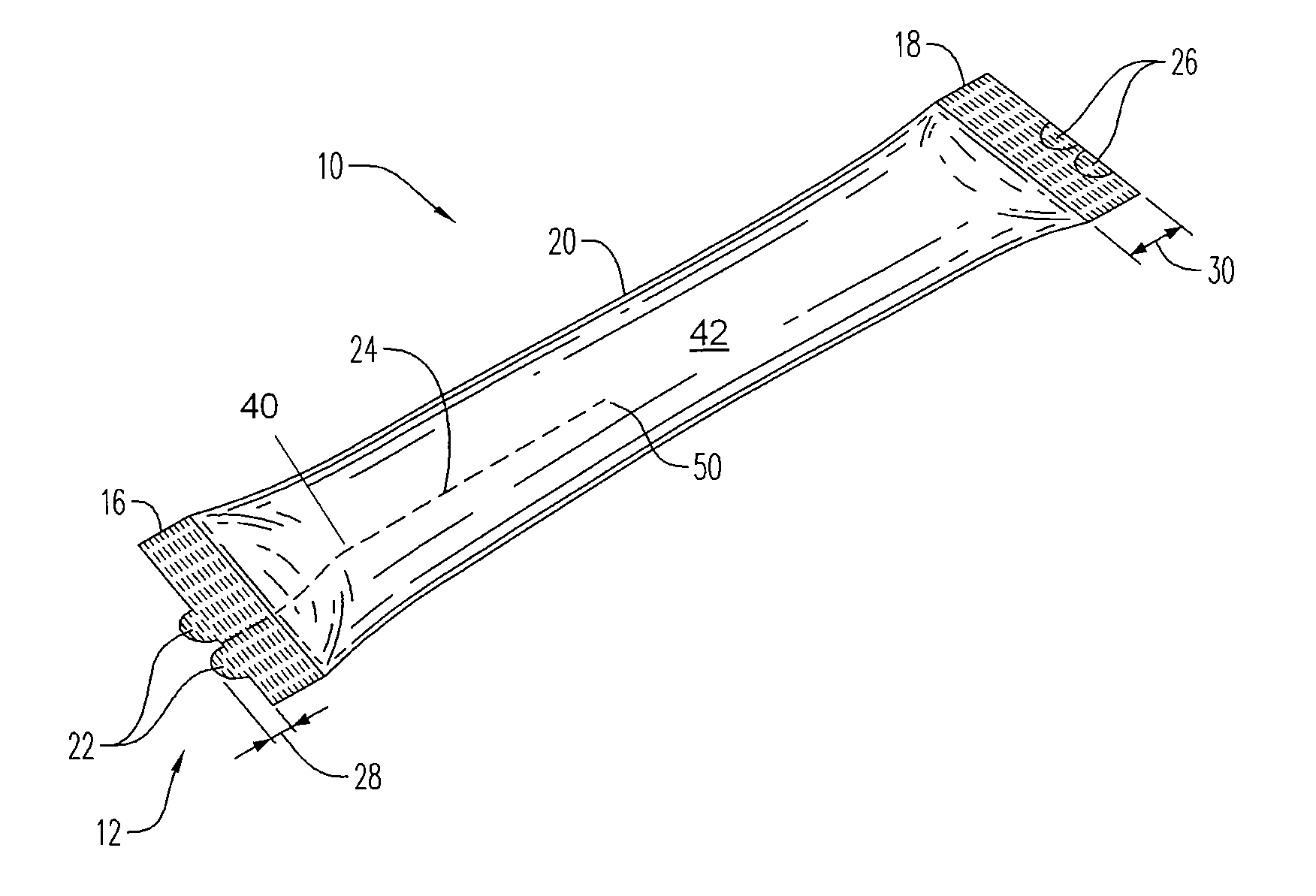

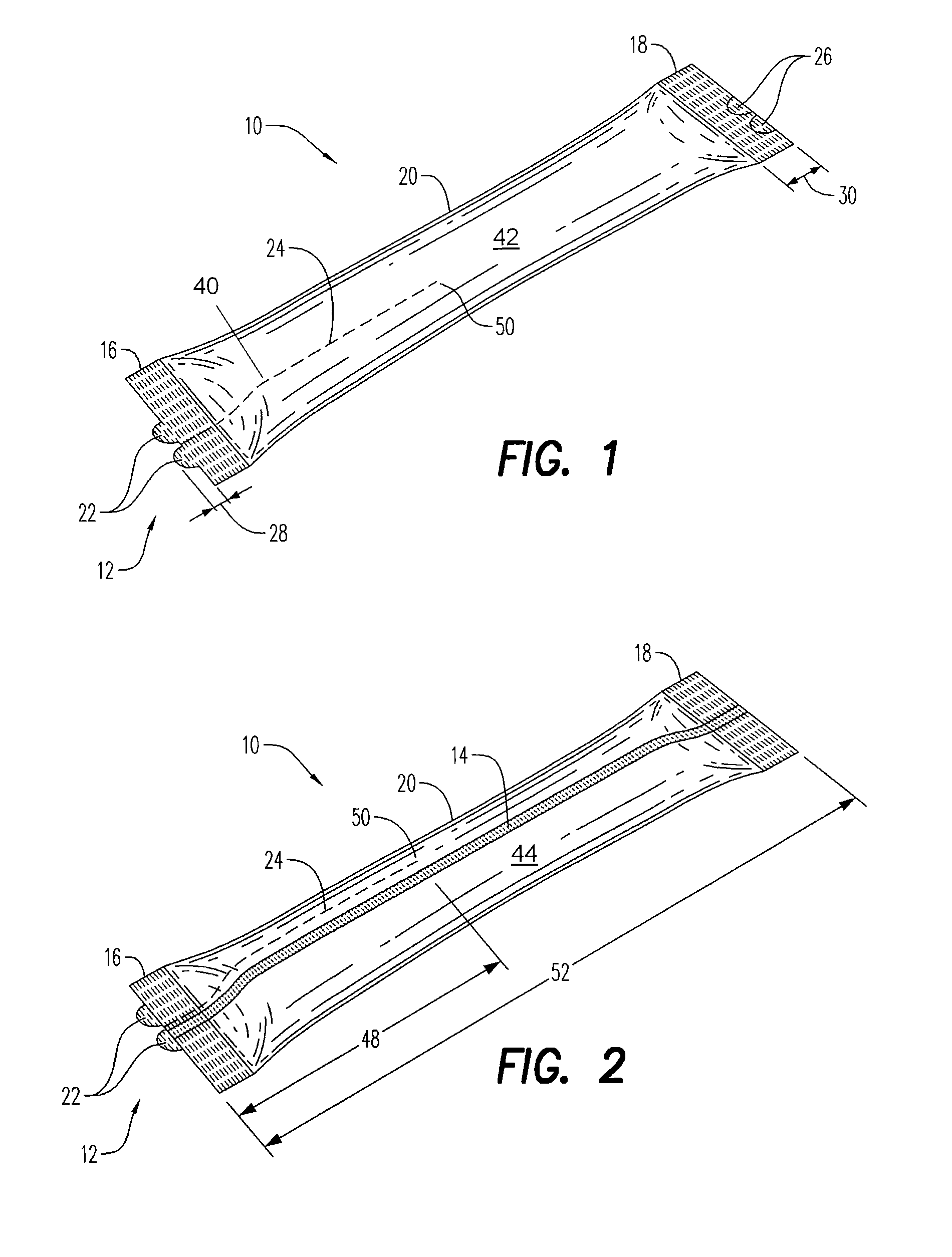

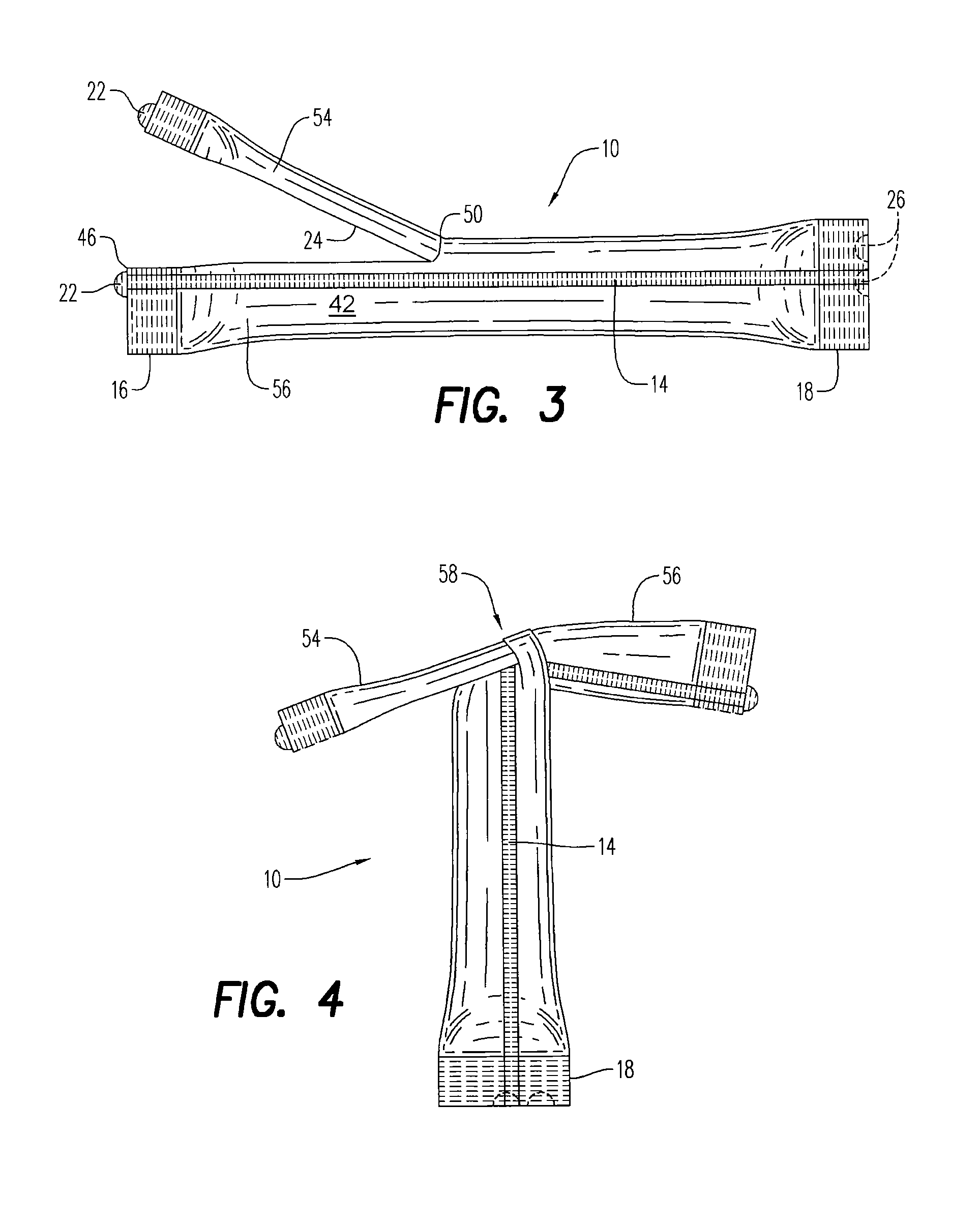

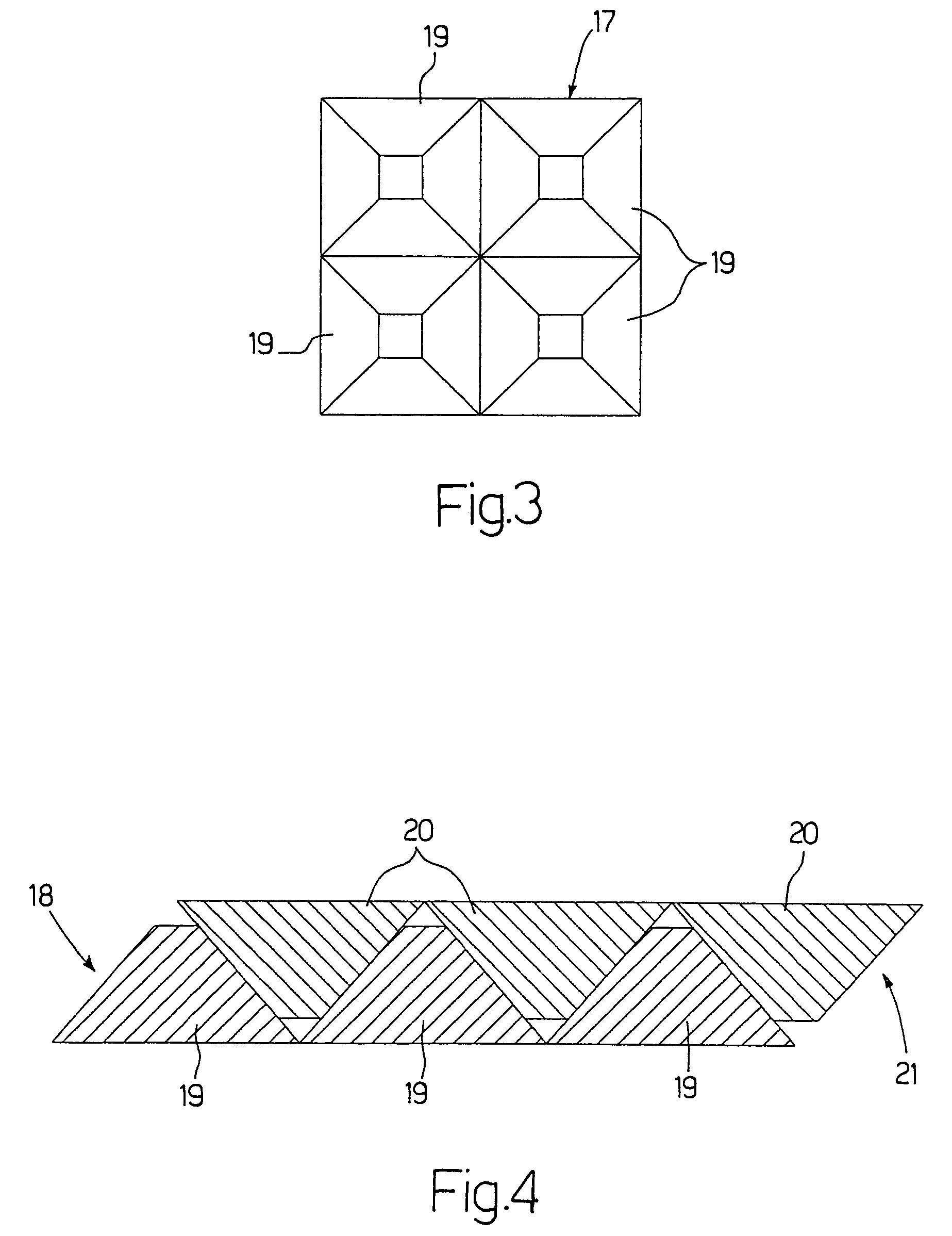

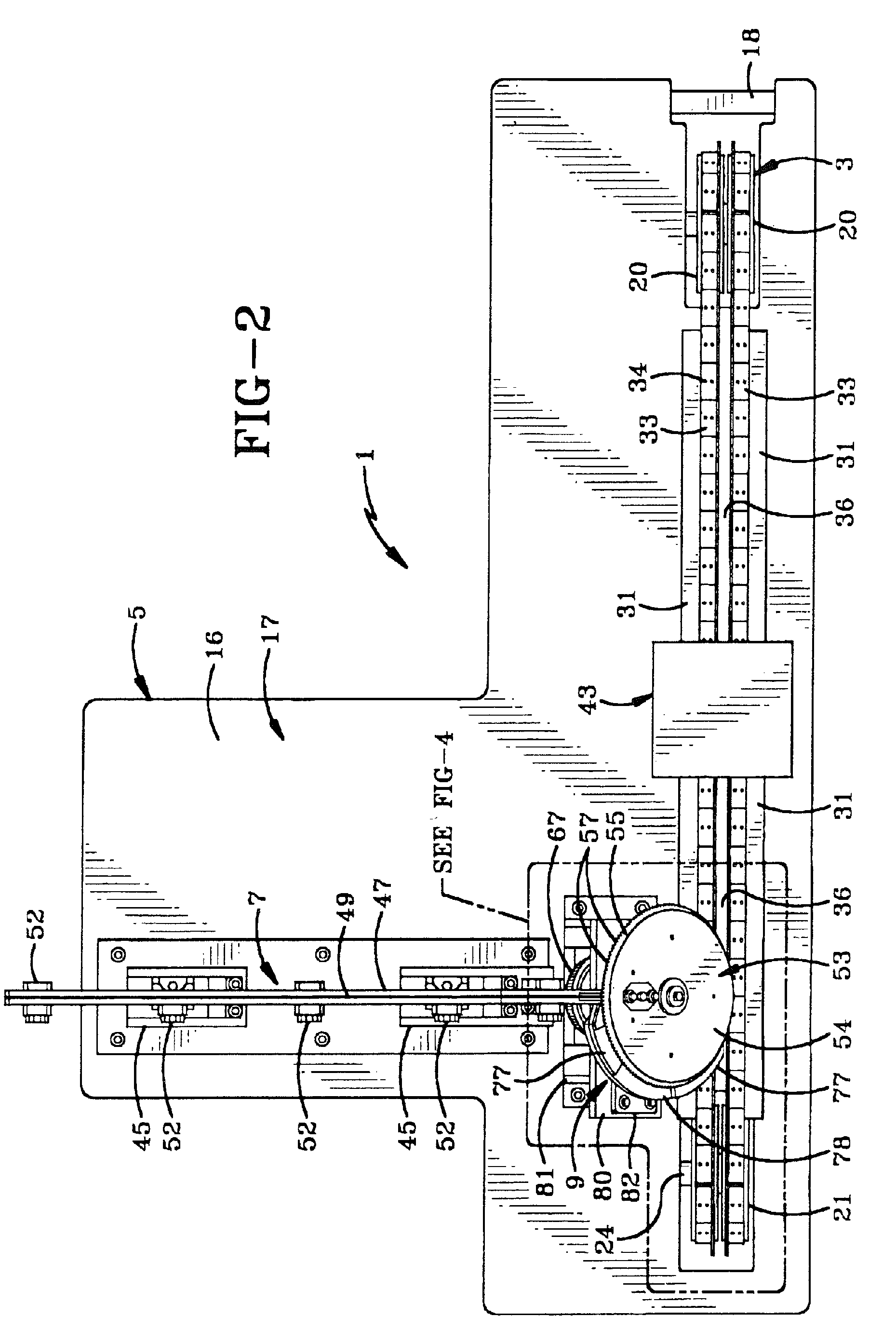

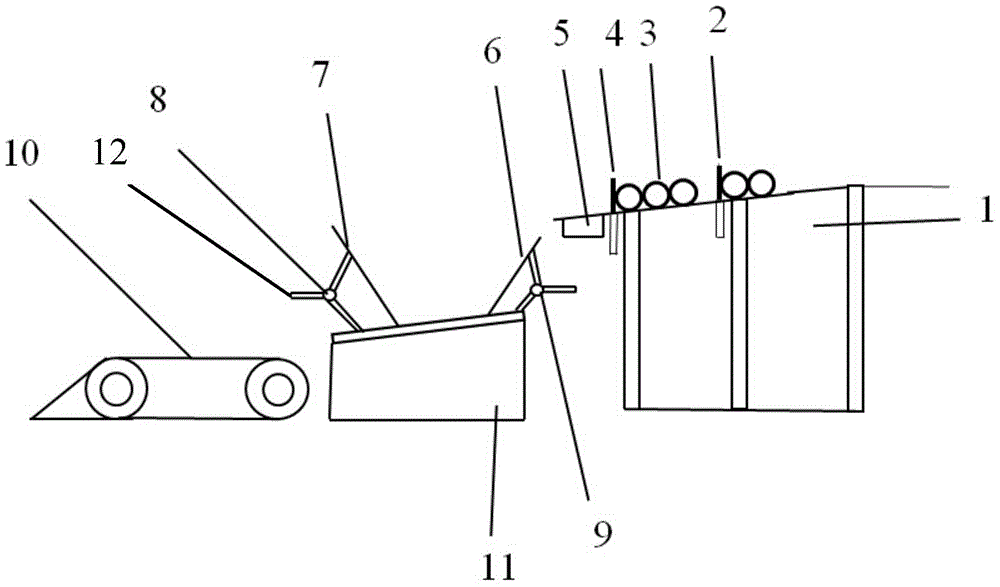

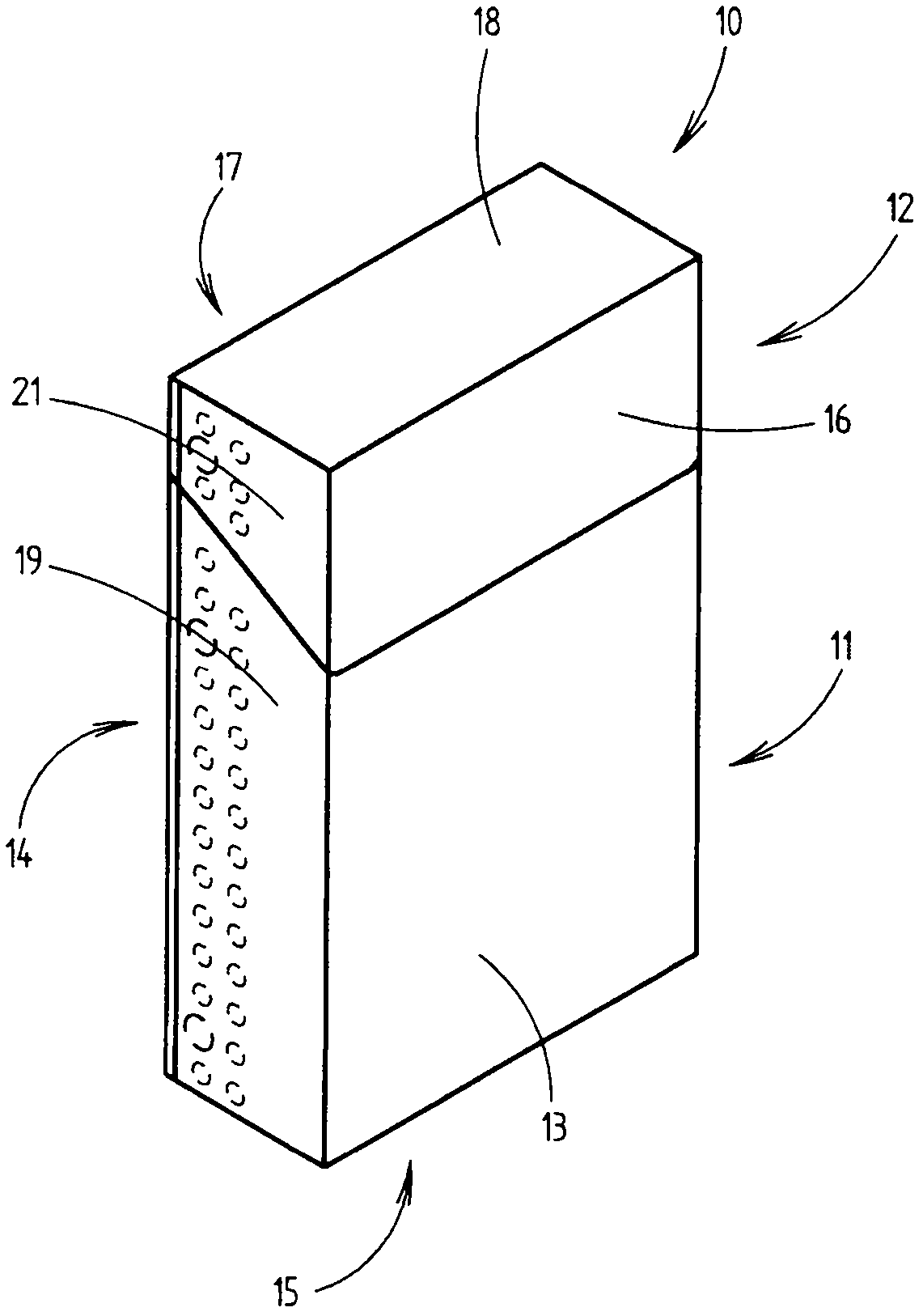

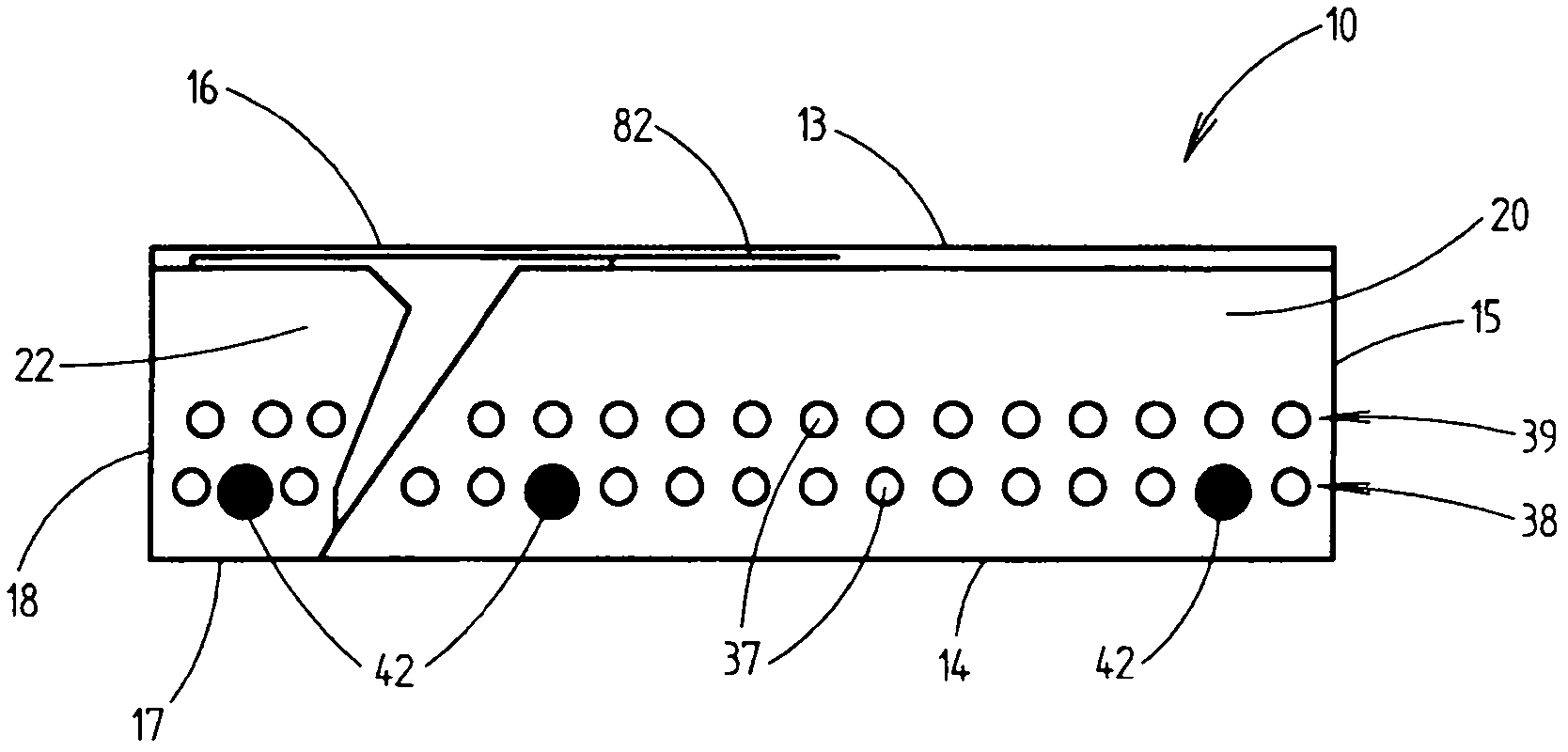

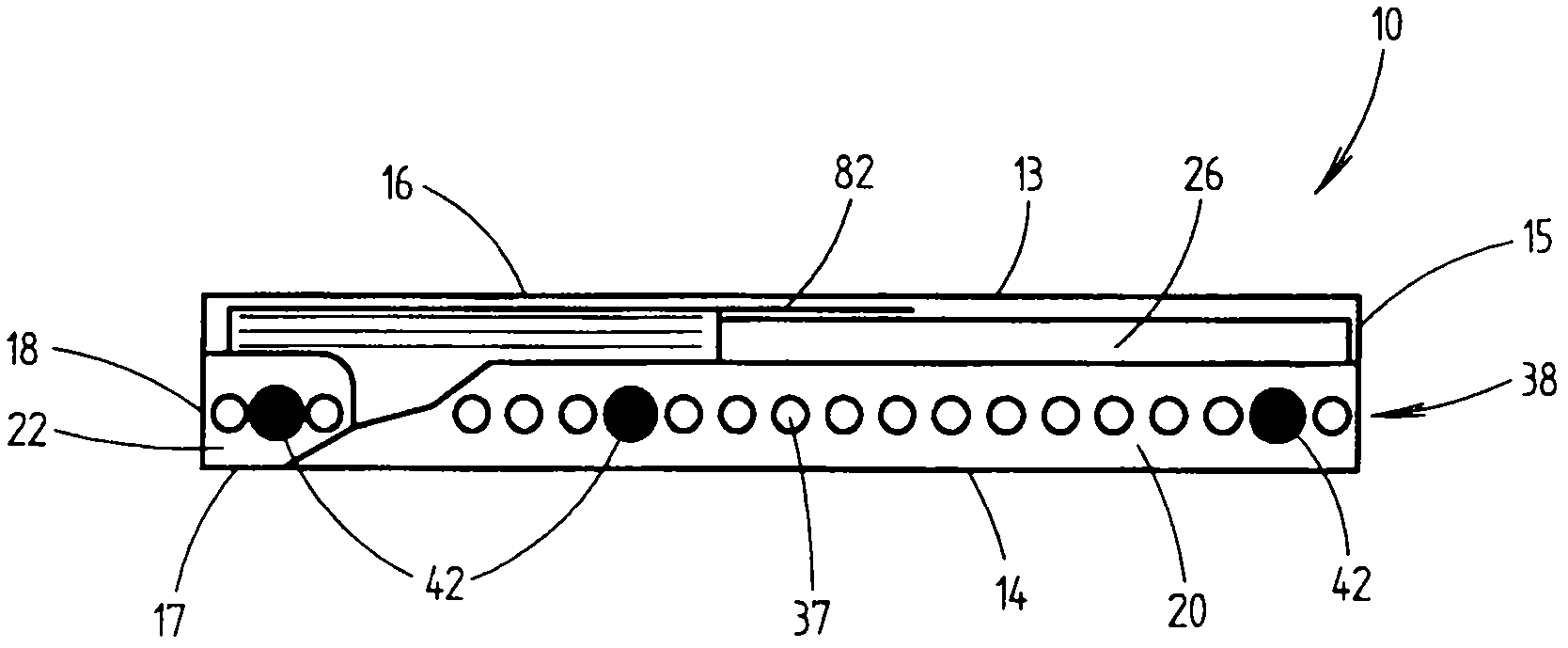

Apparatus and method for forming cigarette filters comprise a single or multiple hopper system for forming filter components of single or multiple sizes. The filter components with spaces therebetween are partially wrapped and then conveyed to at least one media applying wheel where media is deposited into the spaces between the filter components. A cover cap is formed and placed over the partially wrapped filter components downstream of the media wheel to thereby completely wrap the filter components. Subsequently, the completely wrapped filter components are joined to tobacco rods with tipping paper.

Owner:PHILIP MORRIS USA INC

Device for wrapping a napkin about silverware and associated method

InactiveUS7210279B1Efficient extractionEfficient transferWrapping material feeding apparatusWrapper folding/bending apparatusEating UtensilsEngineering

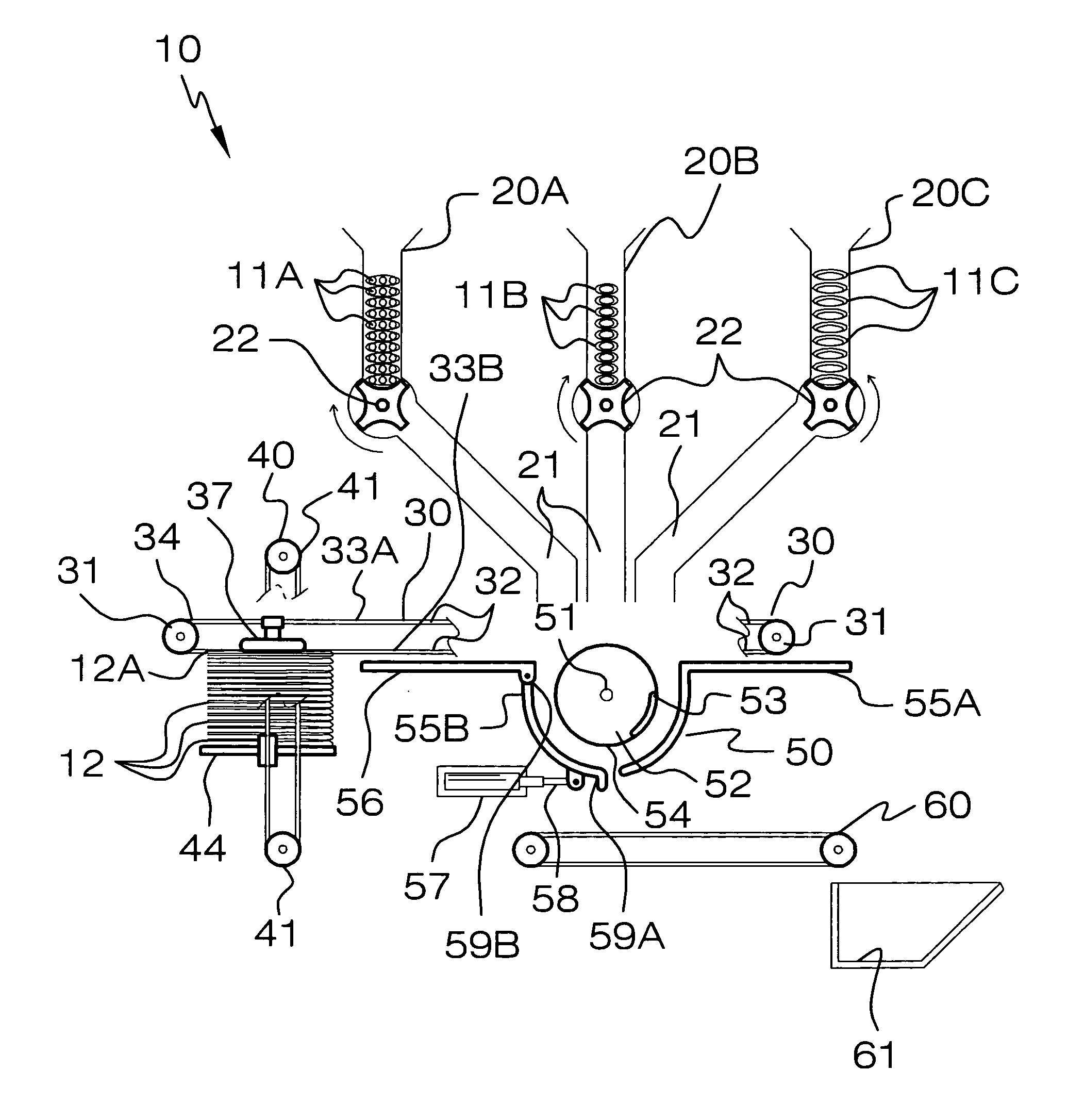

A device includes isolated hoppers defining independent passageways converging downwardly towards a central and unitary area. A conveyor belt assembly is disposed subjacent to the hoppers, traverses the passageways, and travels along a linear path passing through the unitary area. A mechanism is included for depositing a napkin onto the conveyor belt. The napkin depositing mechanism is connected to the conveyor belt assembly and is spaced adjacent to one end portion thereof. A mechanism is included for simultaneously folding the napkin and horizontally stacking the eating utensils such that the napkin becomes folded about the eating utensils before being ejected from the simultaneous folding mechanism. A receiving conveyor belt assembly is disposed beneath the simultaneous folding mechanism for transporting the combined napkin and eating utensils. A storage bin is laid adjacent to the receiving conveyor belt and houses the combined napkin and eating utensils for transit.

Owner:AHMED IBRAHIM A +1

Apparatus and method for metering oral tobacco in portions suitable for consumption

InactiveUS20100252056A1Transport stableImprove reliabilityTobacco preparationCigar manufactureEngineeringOral Tobacco

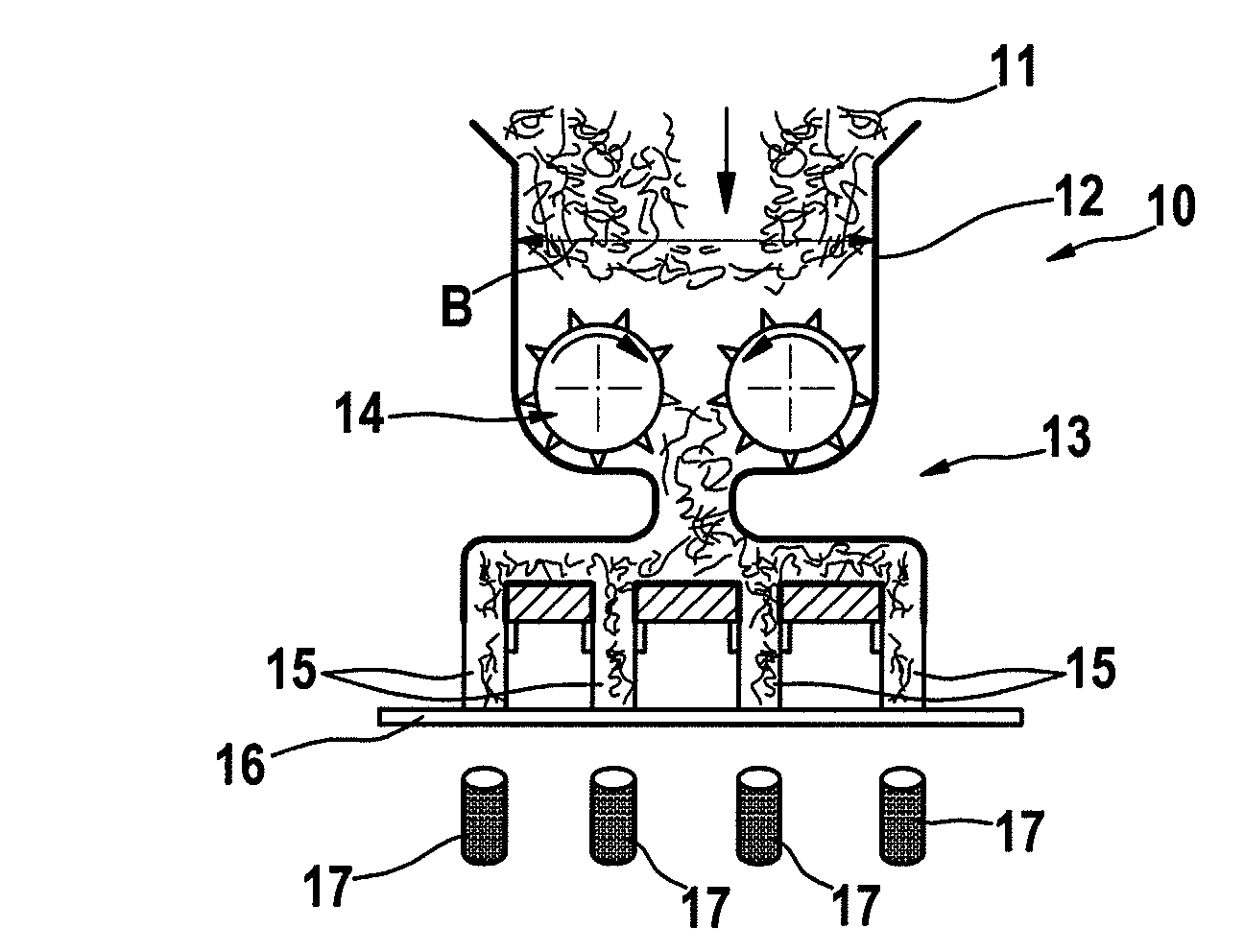

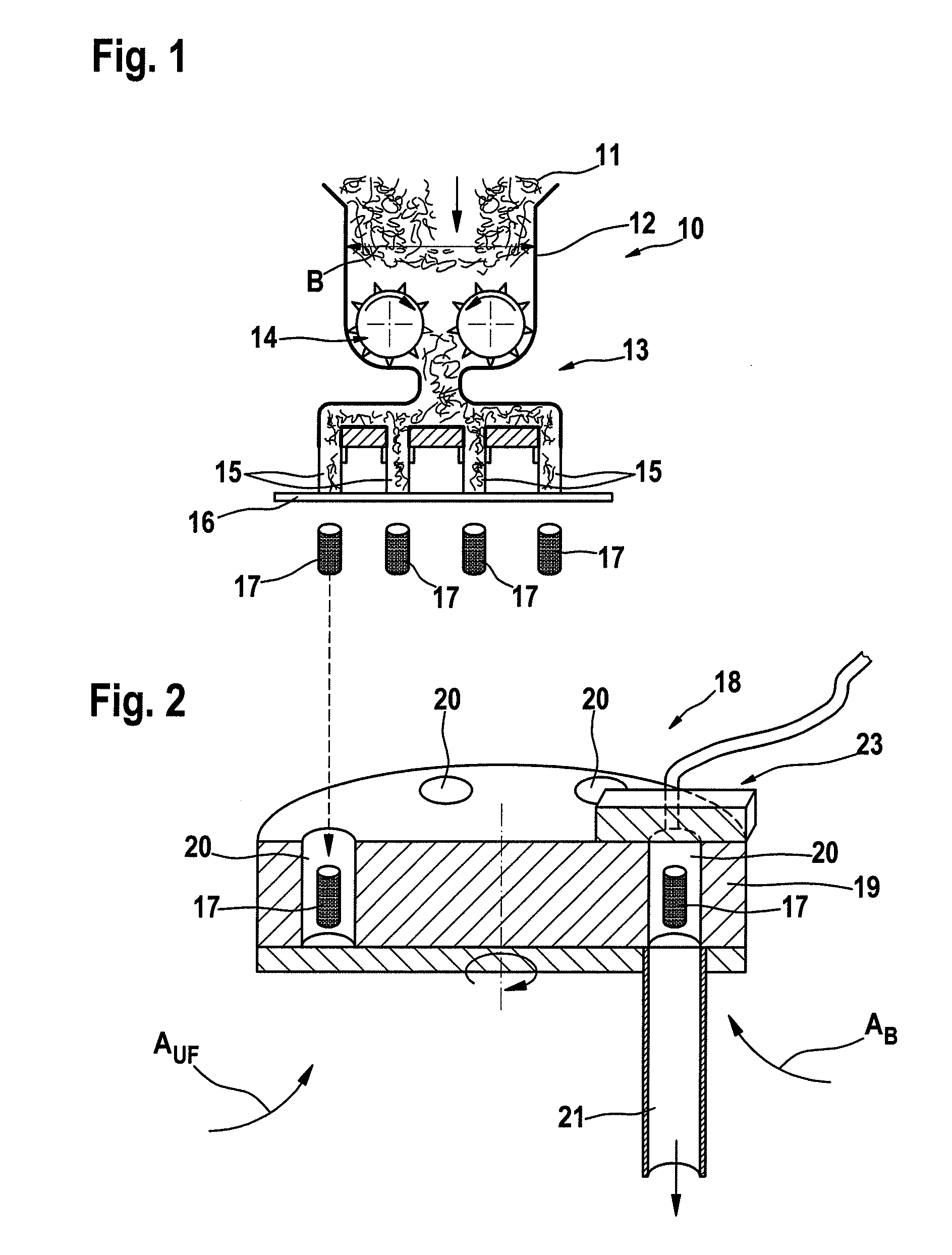

An apparatus for metering oral tobacco into portions suitable for consumption including a delivery device to hold and deliver the tobacco and a metering device to receive the tobacco from the delivery device. The metering device includes a shaping component operative to shape and press the tobacco into at least one endless tobacco rod and a slicing component operative to slice the endless tobacco rod into pre-defined tobacco portions with respect to shape and weight and to discharge the tobacco portions for subsequent processing. Further, a method for metering oral tobacco in portions suitable for consumption, includes the steps of delivering the tobacco, continuous shaping and pressing the tobacco into at least one endless tobacco rod, slicing the endless tobacco rod into pre-defined tobacco portions with respect to shape and weight, and conveying the tobacco portions to a subsequent processing station.

Owner:HAUNI MASCHINENBAU AG

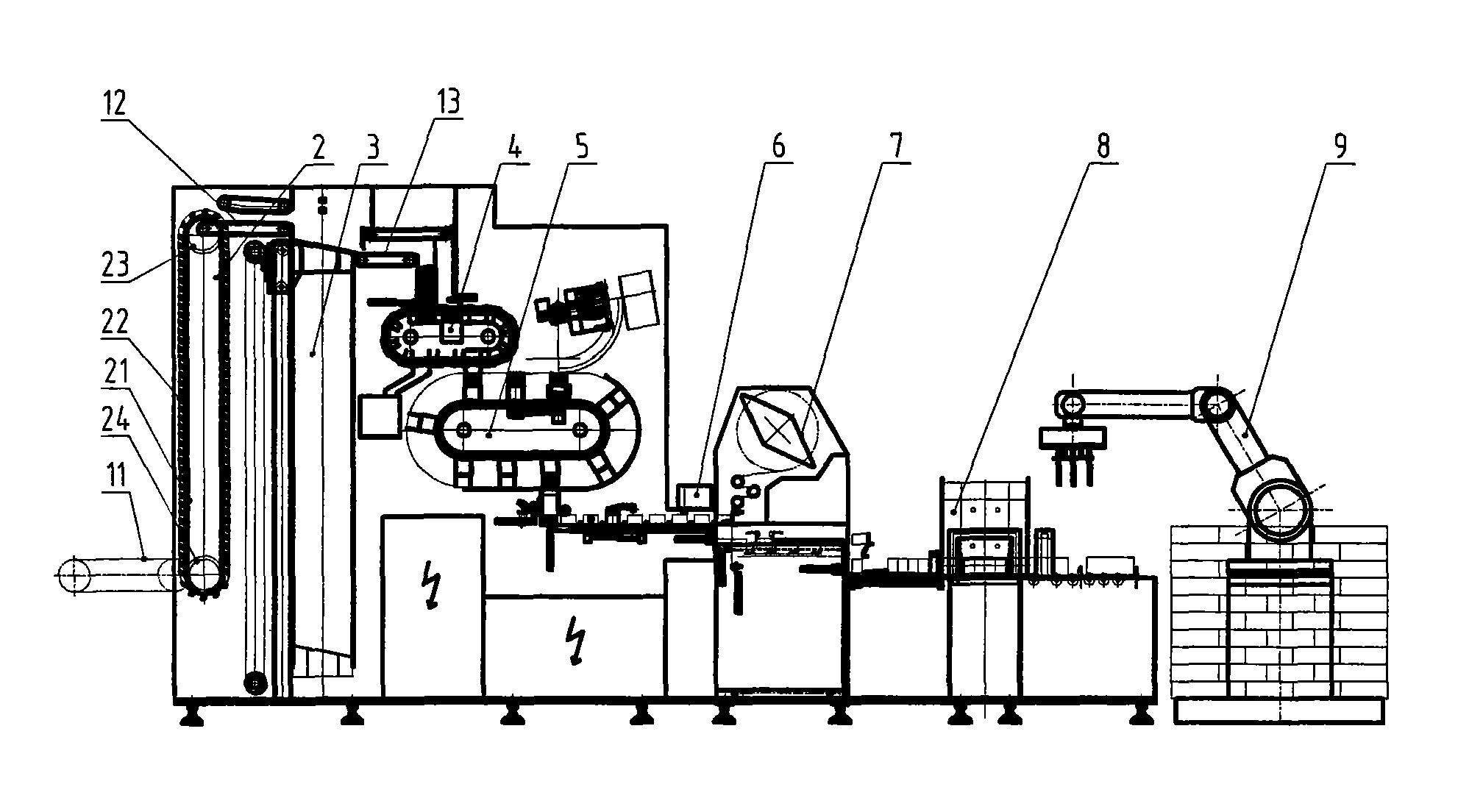

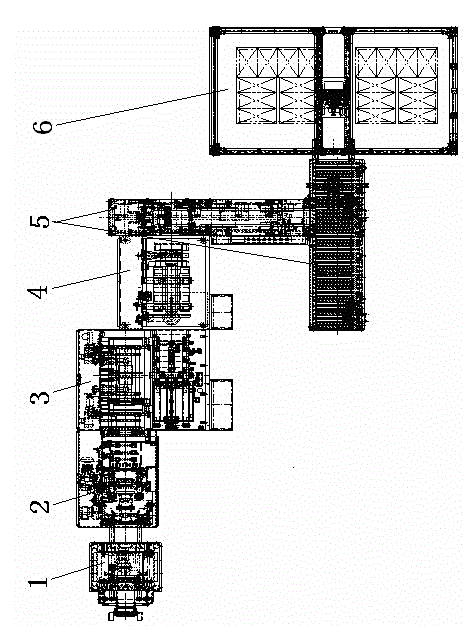

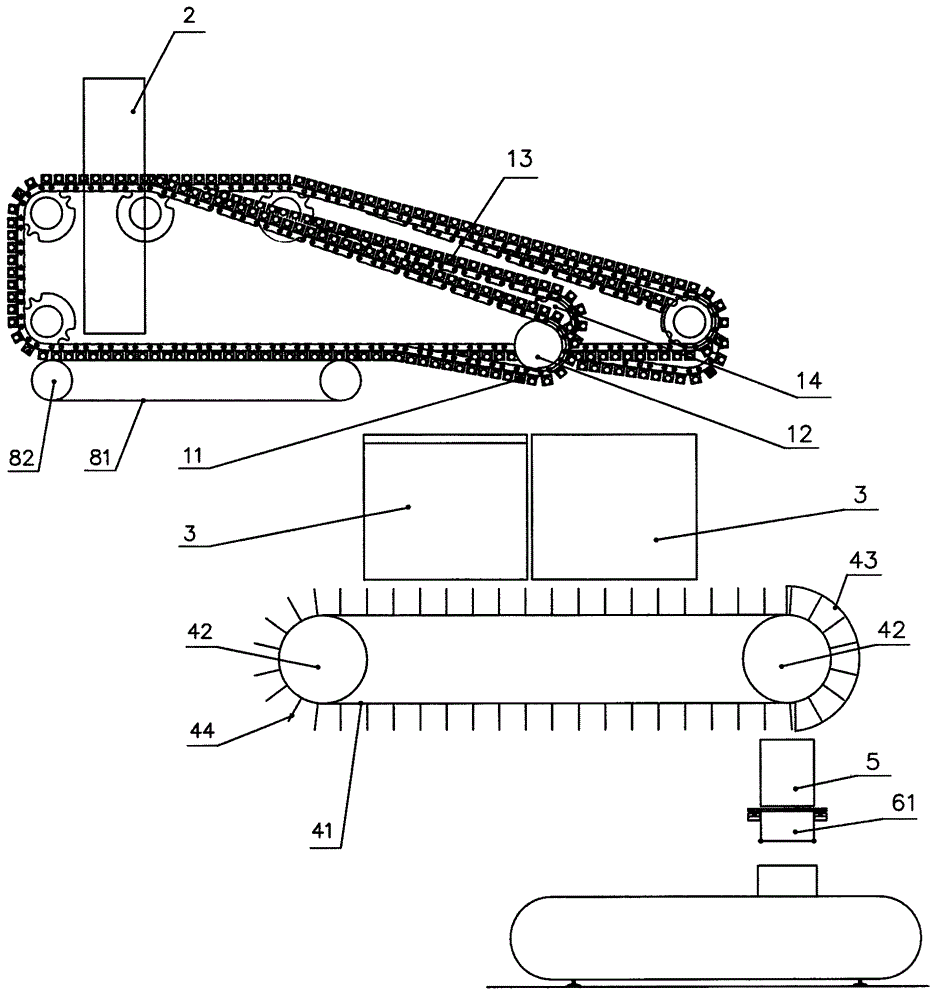

Automatic packaging machine

InactiveCN101525056AReduce laborQuality improvementWrapper twisting/gatheringSolid materialEngineeringManufacturing line

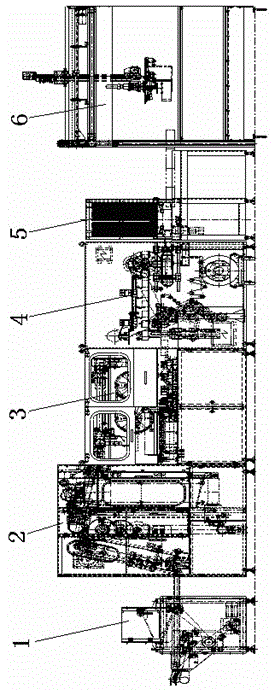

The invention provides an automatic packaging machine, comprising a conveying mechanism. The automatic packaging machine is characterized by also comprising a lifter, a storing machine, a sub-boxing weigher and a boxing and packaging machine. The materials to be packaged are conveyed by the lifter to the storing machine for temporary storage so as to maintain continuous normal operation of production lines and packaging lines, or the materials are conveyed directly to another conveyer by the storage machine, then conveyed into a material-collecting box of the sub-boxing weigher, subpackaged into a material box by a discharging channel of the lower part of the material-collecting box, weighed, measured and conveyed into a charging box of the boxing and packaging machine; packaging box paper is placed on the materials by a paper box supply mechanism, firstly box edge folding, edge ear folding and edge end folding of the packaging box paper are finished, then the rest box edge folding and edge end folding are finished in the discharging process of separation of the materials from the charging box, thus realizing full automatic sub-boxing, measuring, boxing and packaging of materials, reducing the labor of workers to a greater degree, improving working efficiency and enhancing level and quality of products. The boxing and packaging machine has compact structure and reasonable layout and does not occupy space.

Owner:KUNMING DINGCHENG TECH

Protective wrappers for consumer products and methods of making

A protective wrapper is provided that includes a film having a first sealed end, a longitudinal seal, and a second sealed end with a first height, as well as an opening mechanism. The opening mechanism includes a pair of protrusions extending outward from the first sealed end by a first height, a line of weakness extending inward from a starting point where the pair of protrusions meet, and a pair of indentations extending inward from the second sealed end. The first height of the pair of protrusions is equal to or less than the second height of the second sealed end.

Owner:EVEREADY BATTERY CO INC

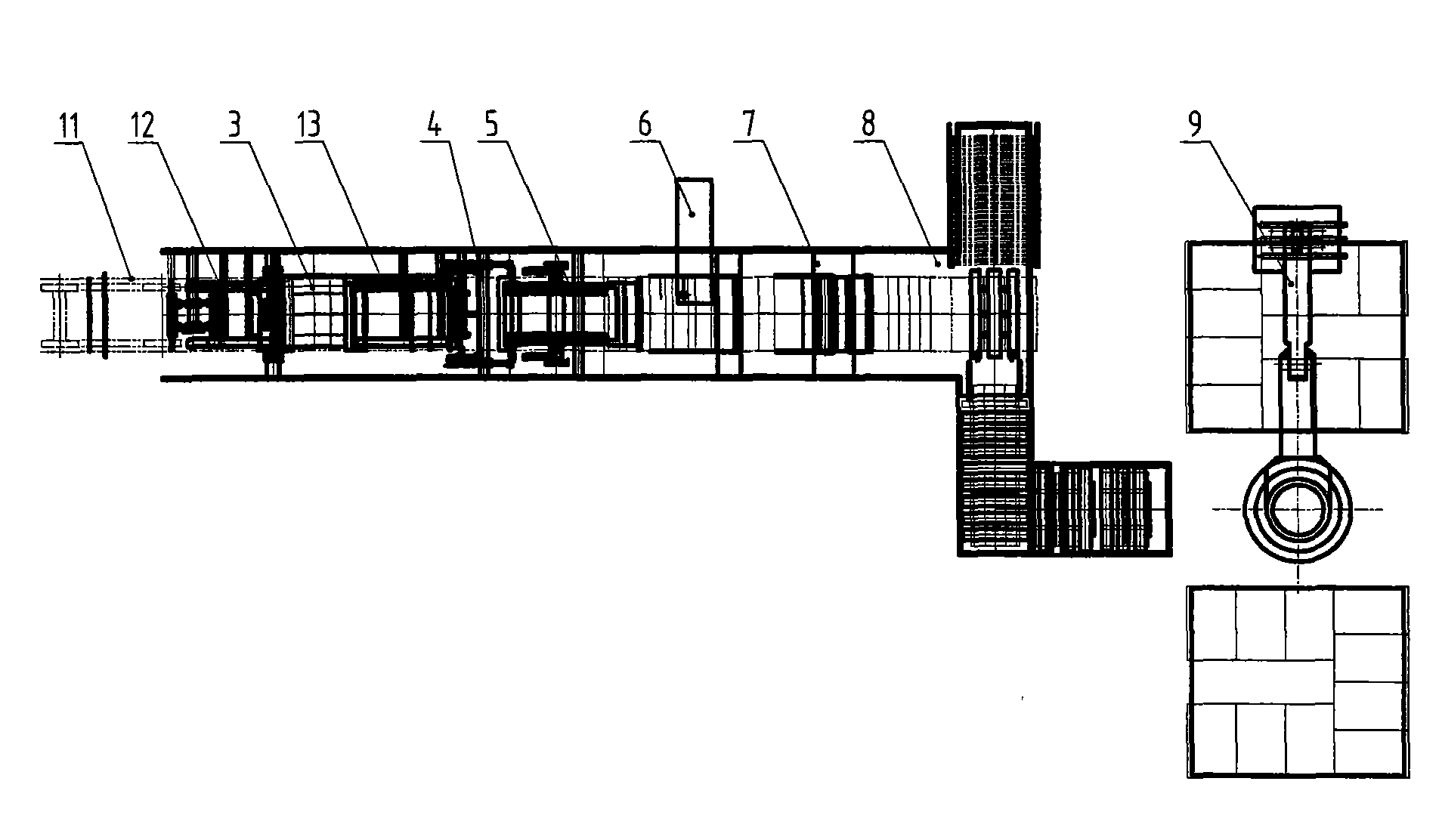

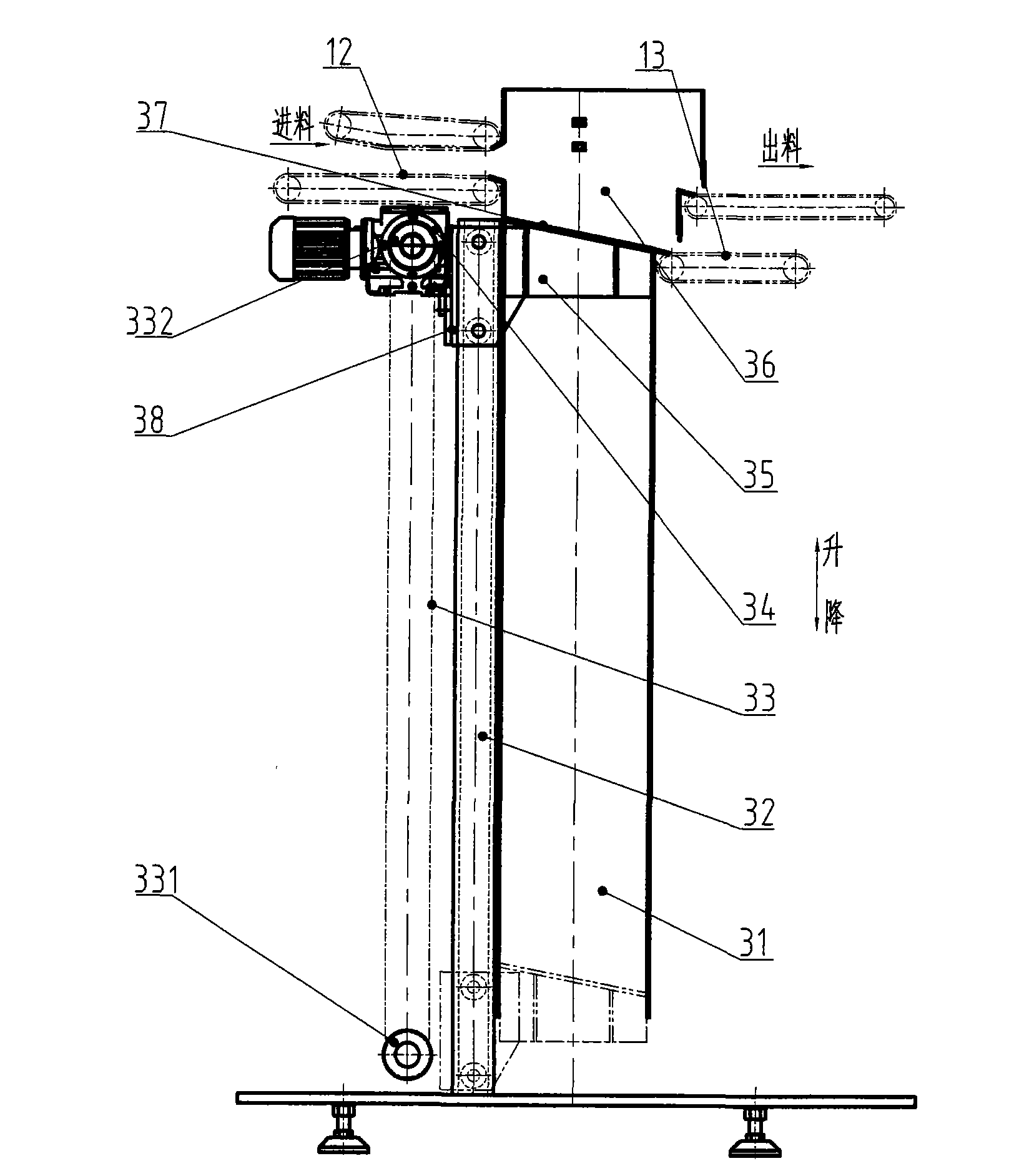

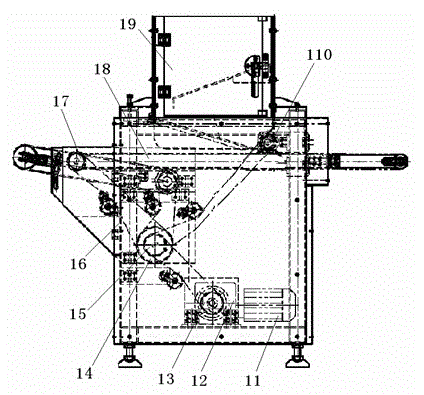

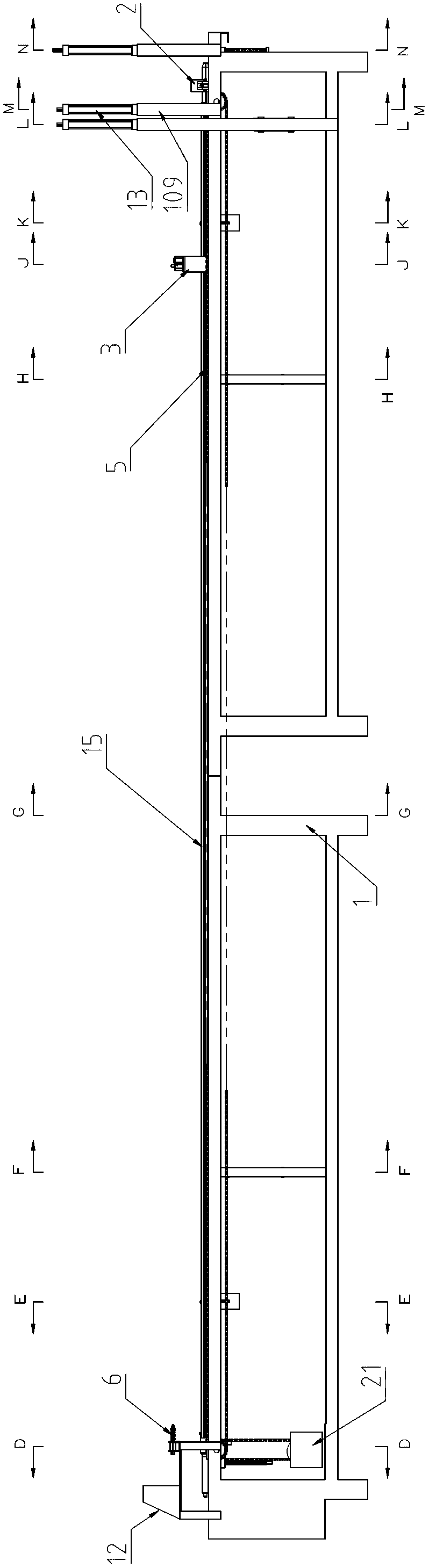

Automatic packaging unit

InactiveCN102717912AFull performanceAutomate the packaging processWrapping material feeding apparatusWrappingManufacturing lineStacker

The invention provides an automatic packaging unit which comprises a feeding machine, an automatic buffer lifting machine, an automatic barrel packaging machine, an automatic film packaging machine, a boxing machine and a stacker crane that are sequentially connected with one another. When a production line has abnormal conditions, strip-shaped materials are continuously sent to the automatic buffer lifting machine through the feeding machine; on one hand, the strip-shaped materials are directly sent to the automatic barrel packaging machine in a subsequent procedure through the automatic buffer lifting machine, on the other hand, when the equipment in the subsequent procedure fails, the strip-shaped materials in the equipment in the former procedure are temporarily stored in a bin; when the equipment in the former procedure fails, the strip-shaped materials stored in the bin can be conveniently sent to the equipment in the subsequent procedure; and therefore, the whole production line and the whole process cannot stop due to local maintenance. The strip-shaped materials to be packaged are simultaneously sent to barrels to be packaged through the automatic barrel packaging machine while being automatically counted, and films wraps the barrels through the automatic film packaging machine, so that the strip-shaped materials are packaged with good quantity and quality, and the grade of the products is improved. The automatic packaging unit realizes autonomic packaging and counting of the strip-shaped materials, and is suitable for packaging any strip-shaped material.

Owner:KUNMING DINGCHENG TECH

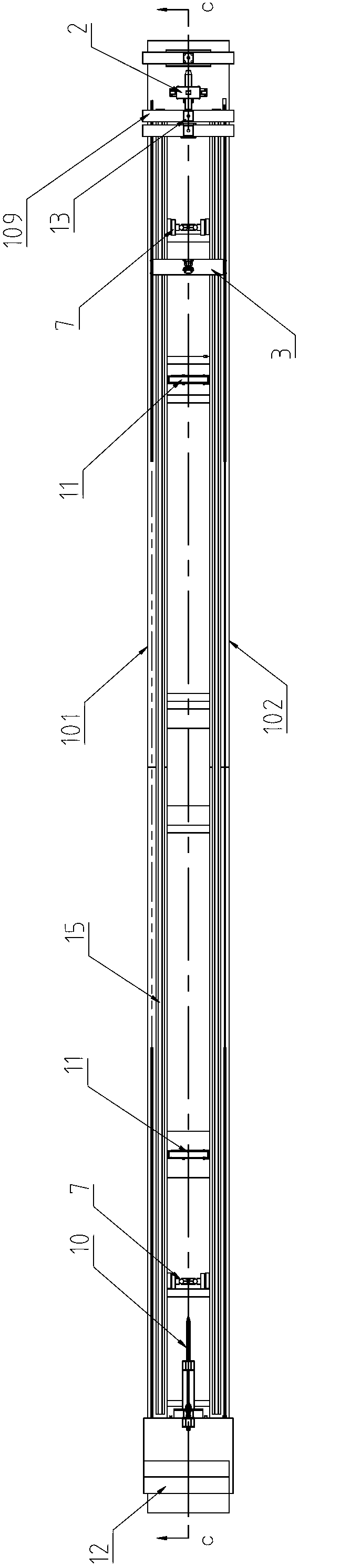

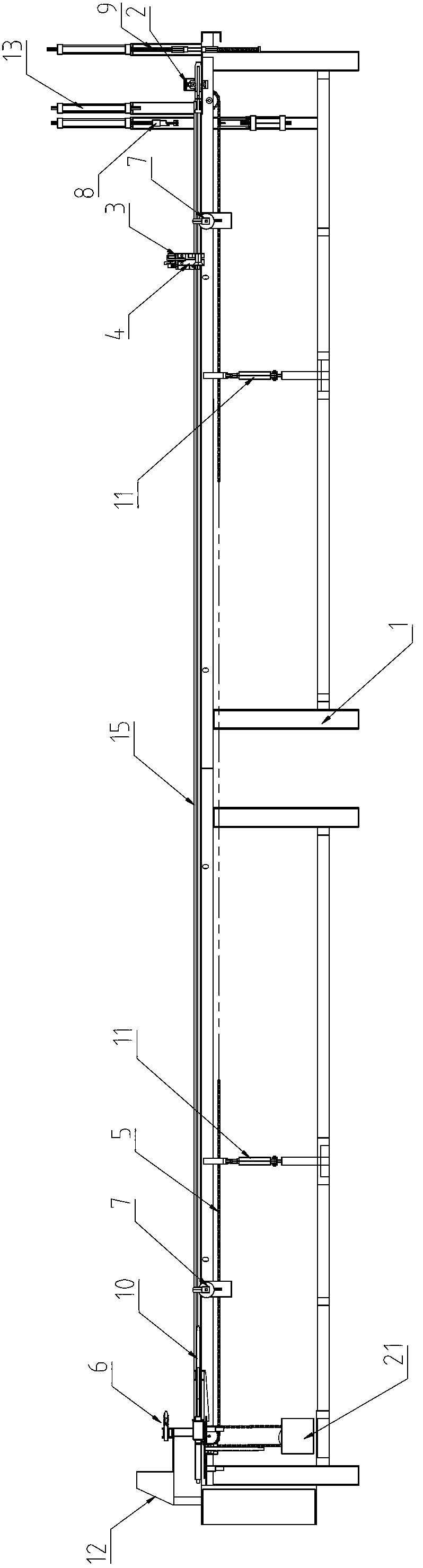

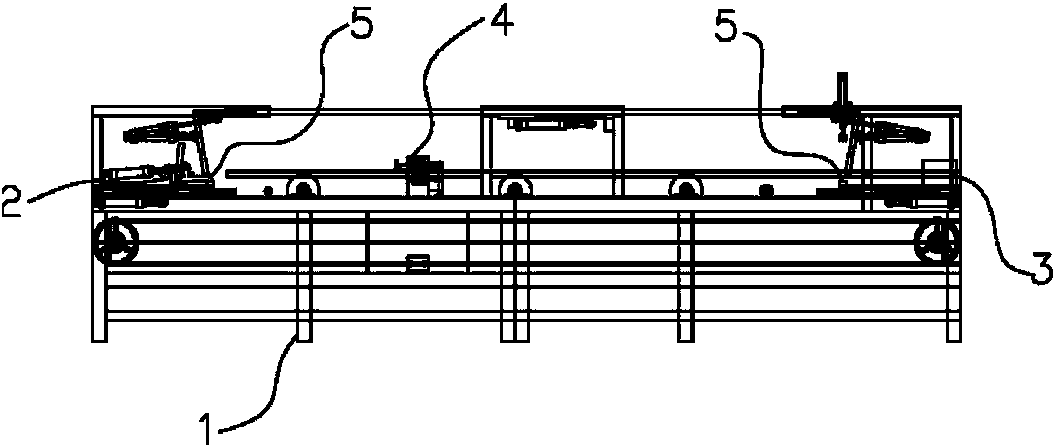

Bagging packaging method for long material and bagging packaging machine for long material

InactiveCN102700752AHigh degree of automationImprove packaging efficiencyRod-shaped articlesReciprocating motionEngineering

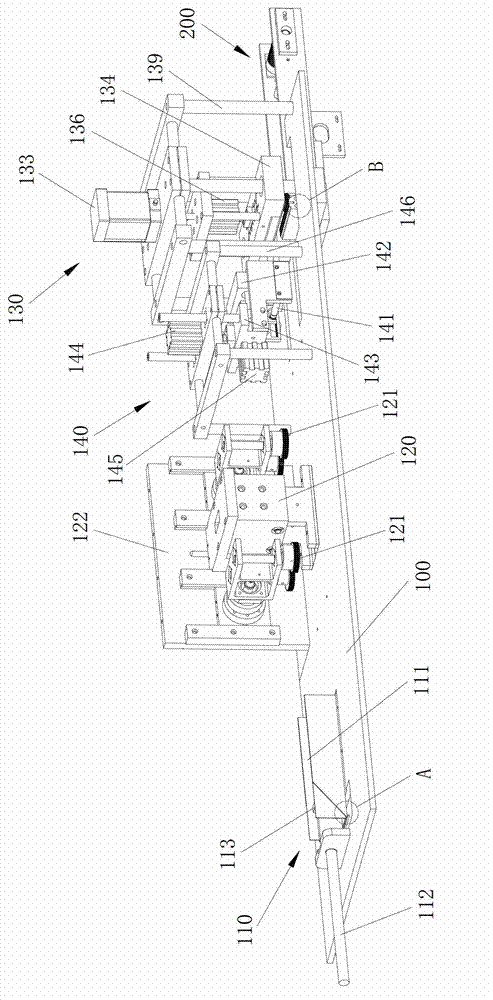

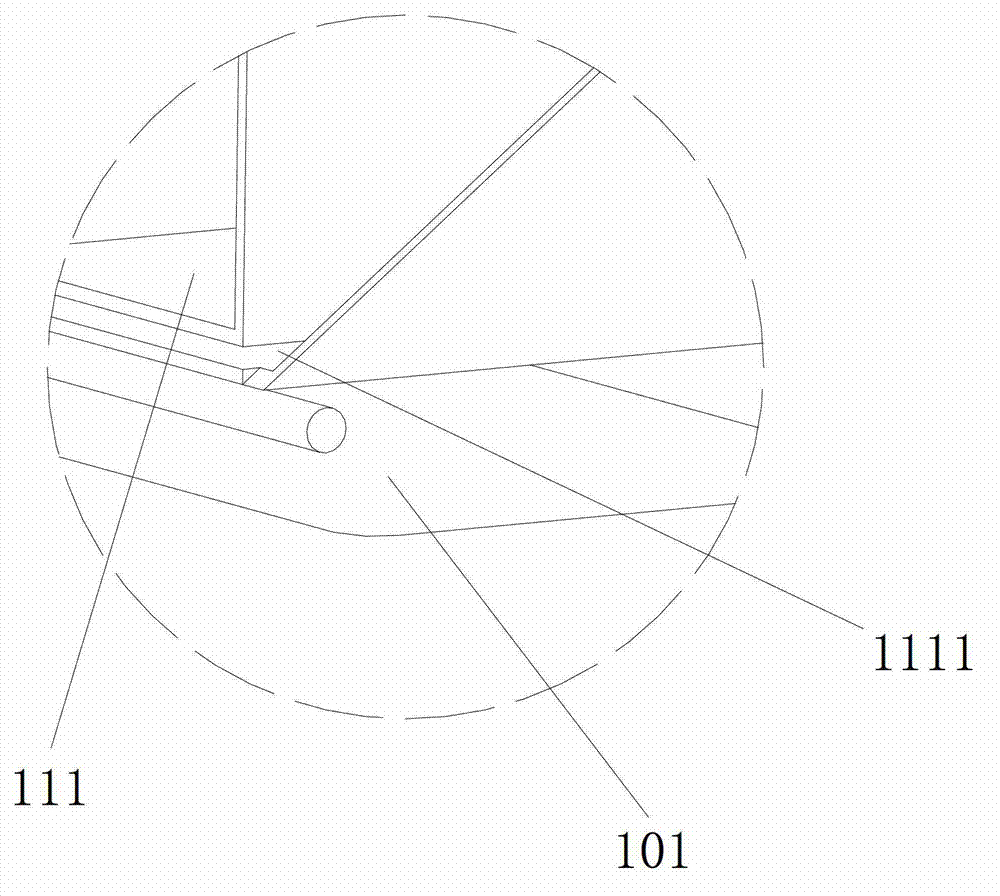

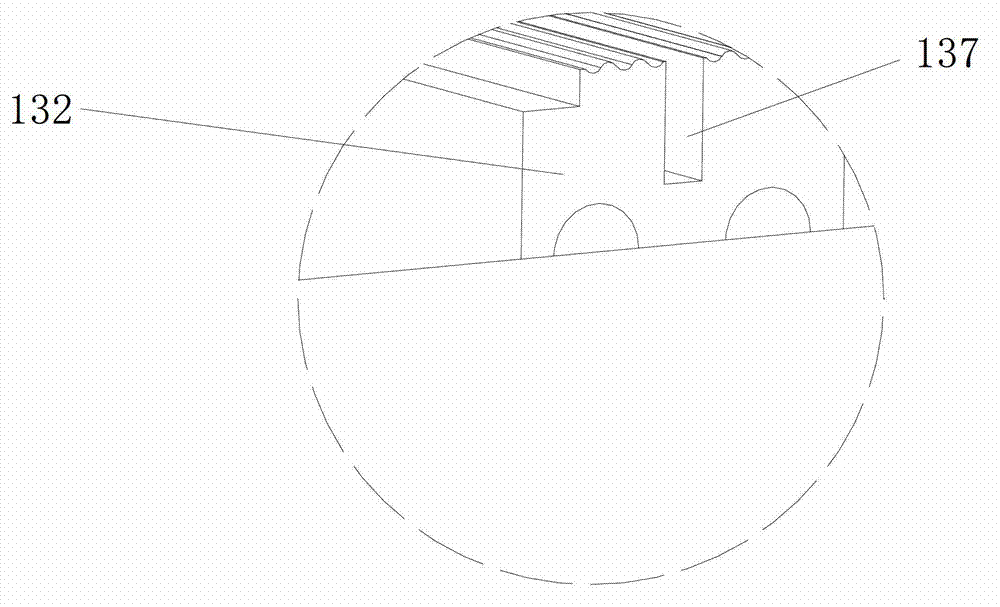

The invention discloses a bagging packaging method for a long material and a bagging packaging machine for the long material. The bagging packaging machine for the long material comprises a frame, a bag-opening device, a bagging trolley, a bag-clamping device, a guide rail pair, a trolley driving mechanism and a long material bearing mechanism, wherein the bag-clamping device is fixed on the bagging trolley; the bag-opening device is mounted on the front part of the frame; guide rails of the guide rail pair are fixed on the frame along the longitudinal direction of the frame; the bagging trolley is fixed on a slide block of the guide rail pair; and the bagging trolley is driven by the trolley driving mechanism to move back and forth along the guide rails on the frame. The bagging packaging method for the long material comprises the following steps: opening a tubular film bag by the bag-opening device; forward moving the bagging trolley; clamping a bag head of the opened film bag by the bag-clamping device on the bagging trolley; causing the long material to enter into a packaging position; driving the bag-clamping device to move backward by the bagging trolley till the film bag is sleeved on the exterior of the long material through the rear end of the long material; cutting off the film bag in front of the long material; and detaching the packaged long material. The bagging packaging method provided by the invention has the advantages of high degree of automation, high packaging efficiency, low labor cost and convenience for an enterprise to perform large-scale production.

Owner:兰信庭

Method for automatically packaging tubular product

InactiveCN102180281AIncrease production capacityImplement packagingConveyor wrappingRod-shaped articlesProduction linePunching

The invention discloses a method for automatically packaging a tubular product. By steps of punching bags, installing tubes, inserting the tubes, lifting, wrapping the tubes, exchanging air, thermally encapsulating and cutting, emptying a position and the like, automation is realized in the whole process, complicated carrying work in manual packaging operation is avoided, production and working efficiency is improved, labor intensity of packaging is reduced, and production cost is lowered greatly; therefore, the method is matched with a tubular product extrusion production line, so that automatic continuous production and packaging of the tubular product can be realized.

Owner:陈蕴

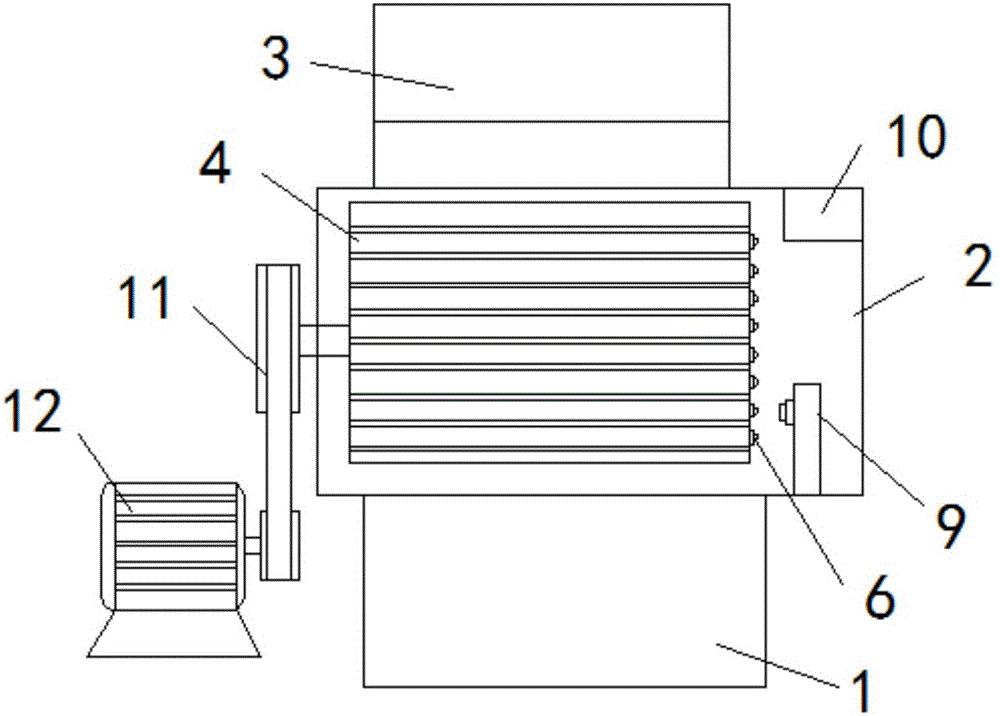

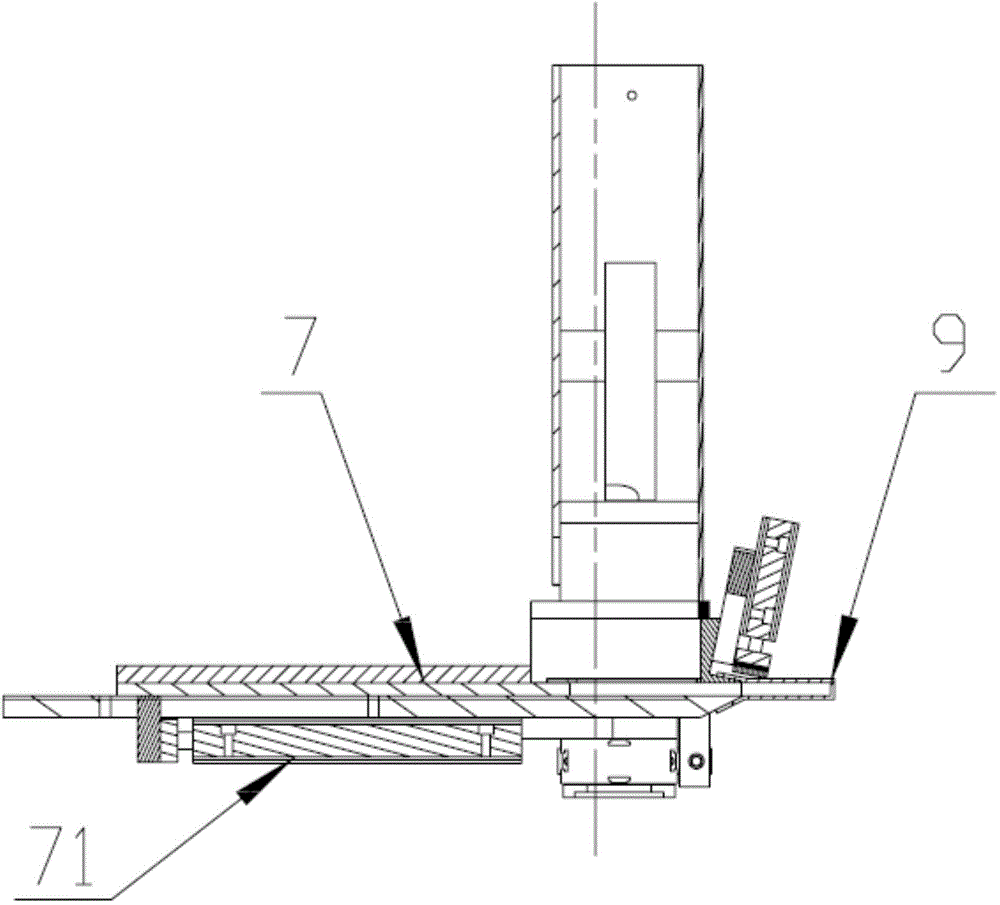

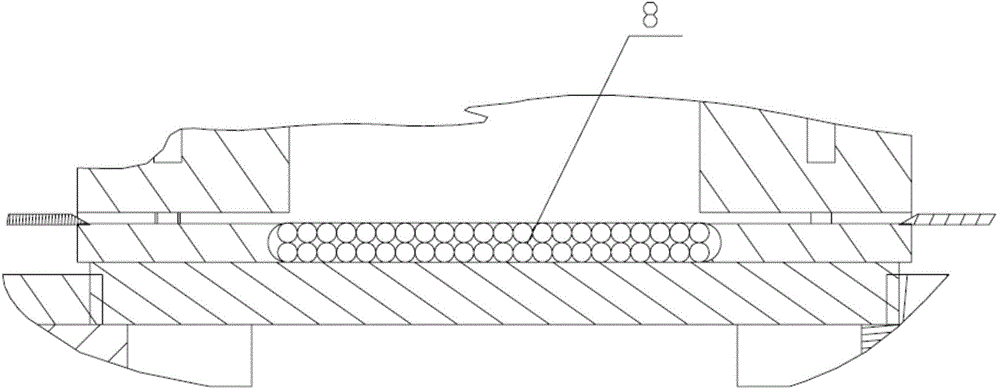

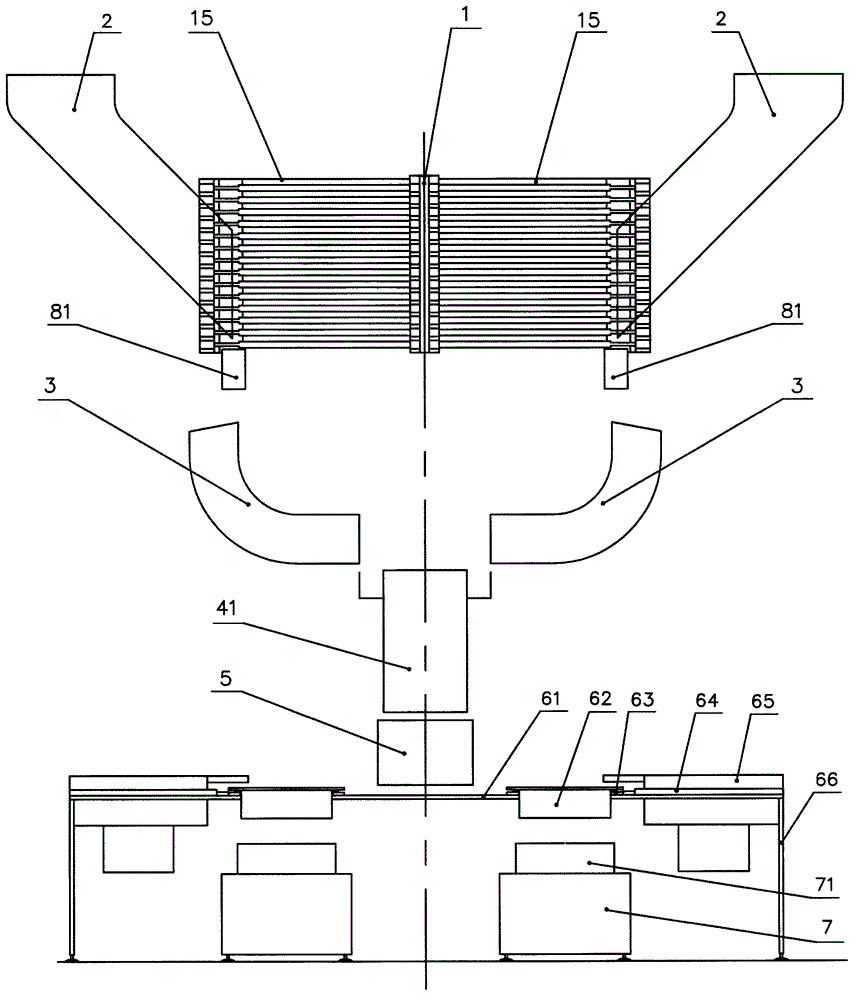

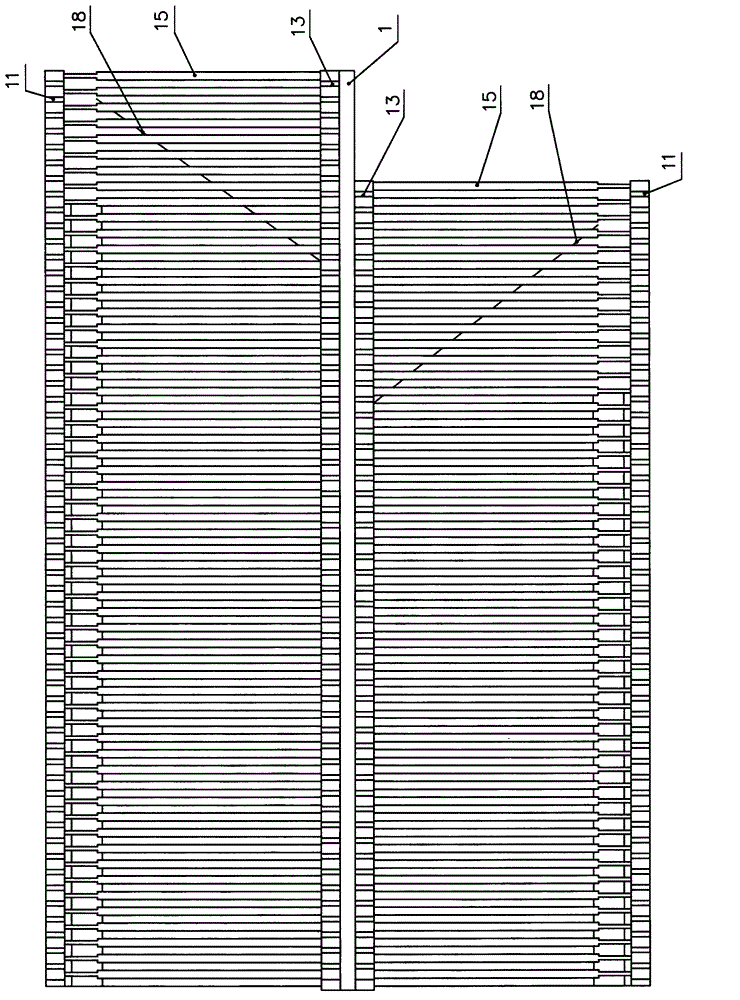

Full automatic pencil lead filling machine and filling technology thereof

ActiveCN108146687ARealize automatic fillingIncrease productivityRod-shaped articlesEngineeringMechanical engineering

The invention relates to the field of pencil lead manufacturing, in particular to a full automatic pencil lead filling machine. The full automatic pencil lead filling machine comprises a pencil lead barrel charging and locating device, a conveying device, a pencil lead charging and locating device, a pencil lead barrel cover charging device, a press-fitting device and a finished product conveyingbelt; the pencil lead barrel charging and locating device, the conveying device and the finished product conveying belt are arranged in the conveying direction of the conveying device; the pencil leadcharging and locating device is perpendicular to the conveying device; the pencil lead barrel cover charging device is located on the side of the pencil lead charging and locating device; the conveying device comprises a first rack and a conveying mechanism; a mounting groove is formed in the top of the first rack; the conveying mechanism is fixed in the mounting groove; the press-fitting deviceis fixed in the mounting groove and is located between the conveying mechanism and the finished product conveying belt; a first supporting block and a second supporting block are arranged on the firstrack symmetrically; and a first slideway is arranged on one side, facing the second supporting block, of the first supporting block. Automatic filling of pencil leads is realized, the production efficiency is improved and the technology is simple and reliable.

Owner:陈信发

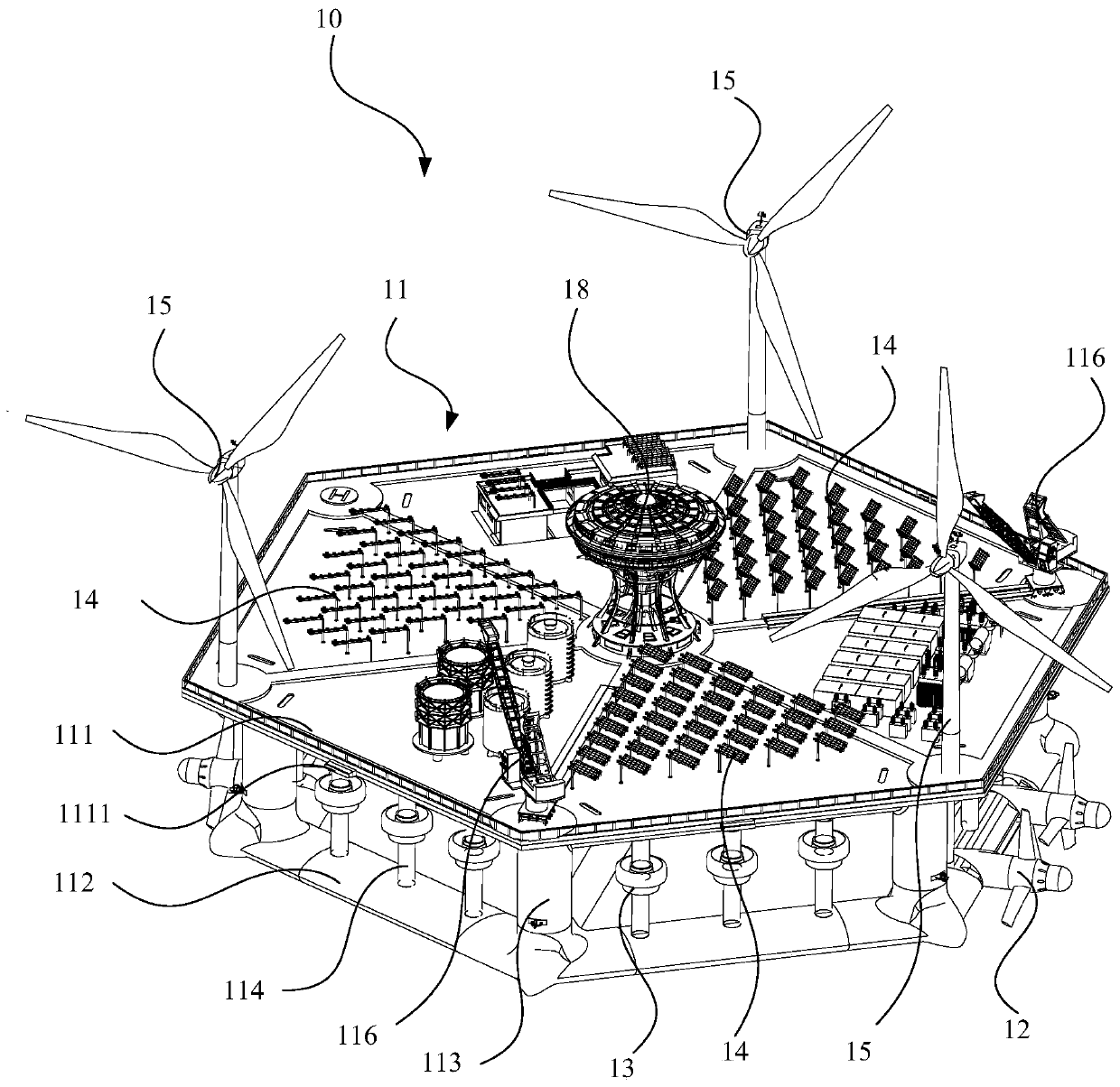

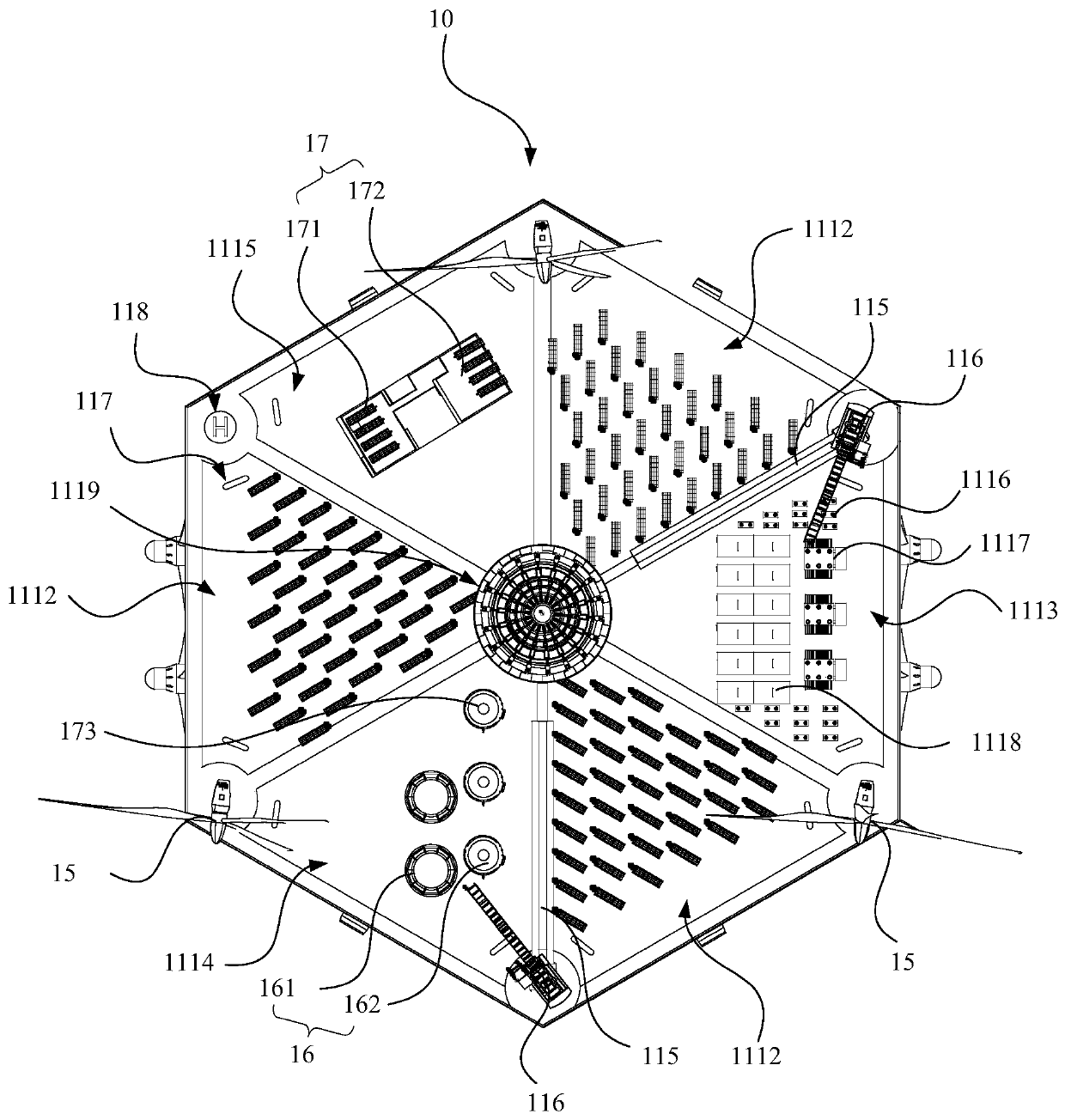

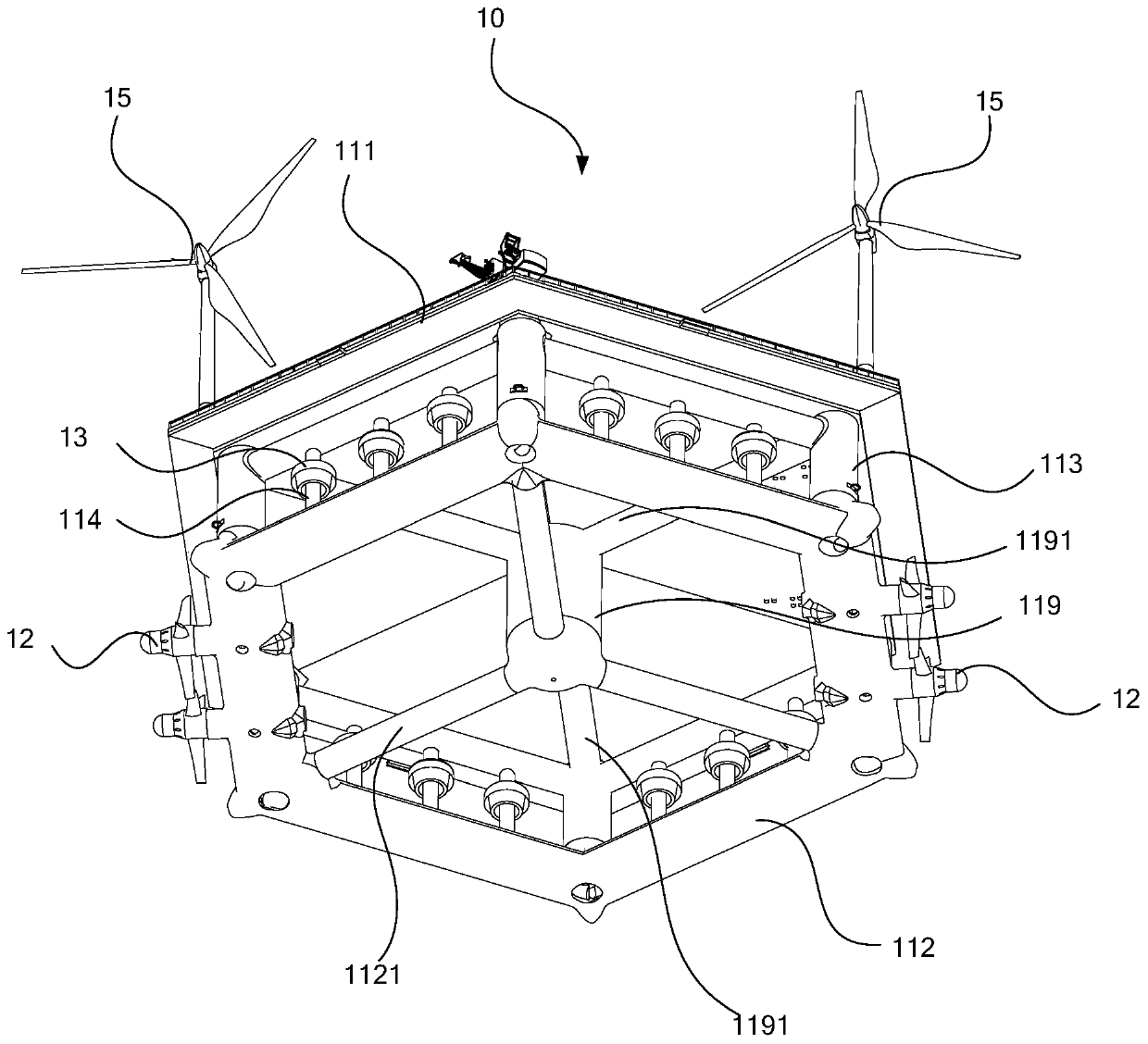

Offshore energy island device

ActiveCN110945234APhotovoltaic supportsGeneral water supply conservationEngineeringAtmospheric sciences

The invention relates to an offshore energy island device, comprising: an offshore platform, wherein a tidal current energy power generation device, a wave energy power generation device, a photovoltaic power generation device, a wind energy power generation device, a hydrogen production device and a seawater desalination device are all arranged on the offshore platform; the tidal current energy power generation device, the wave energy power generation device, the photovoltaic power generation device and the wind energy power generation device are all electrically connected with the hydrogen production device and used for providing electric energy for the hydrogen production device; and the tidal current energy power generation device, the wave energy power generation device, the photovoltaic power generation device and the wind energy power generation device are all electrically connected with the seawater desalination device and used for providing electric energy for the seawater desalination device. Various renewable resources in the sea are fully utilized and provide electric energy for the operation of the seawater desalination device and the hydrogen production device, the stability of the power supply process is ensured and the input-output ratio is improved.

Owner:SUN YAT SEN UNIV

Automatic pipe packing machine

ActiveCN103359309AImprove packaging efficiencyImprove packaging qualityWrappingWrapper twisting/gatheringEngineeringMechanical engineering

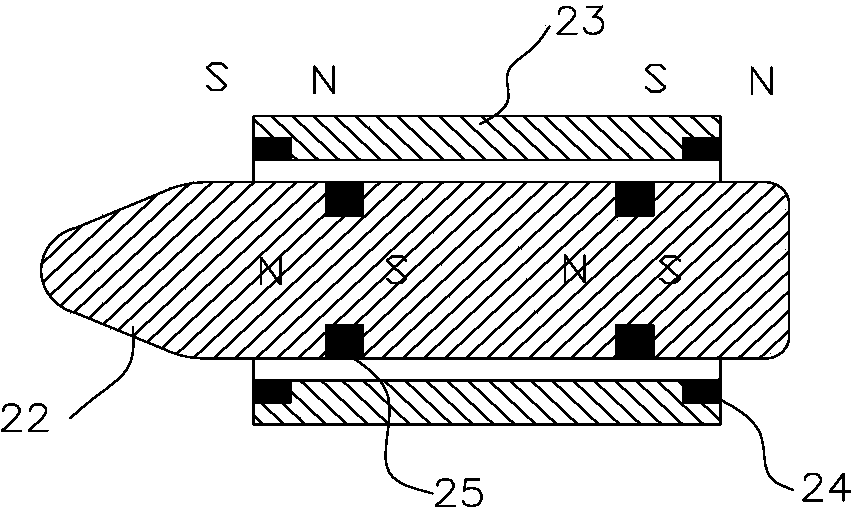

The invention discloses an automatic pipe packing machine which comprises a machine frame and a magnetic suspension device arranged at the front end of the machine frame and used for strutting a packing film, an inflation device arranged at the rear end of the machine frame and used for enabling the strutted packing film to float above a pipe, an automatic film clamping device arranged on the machine frame, moved in the placing direction of the pipe and used for clamping a packing film wrapping pipe, and an edge cutting and sealing devices respectively located at the front end and the rear end of the machine frame and used for performing edge cutting and sealing of the packing film. The automatic pipe packing machine is mainly applied in the packing field of pipes, and optimizes the packing process of the packing machine, effectively improves pipe packing efficiency and pipe packing quality; in addition, the automatic pipe packing machine is simple and reasonable in structure, division of work of the components is clear, the operation is easy, and the manufacturing cost is relatively lower.

Owner:佛山汉深科技有限公司

Hinged-lid package, and packing method and machine for producing a hinged-lid package

InactiveUS8671648B2Cheap and easy to implementWrapper folding/bending apparatusMultiple wrapper applicationEngineeringMechanical engineering

Owner:GD SPA

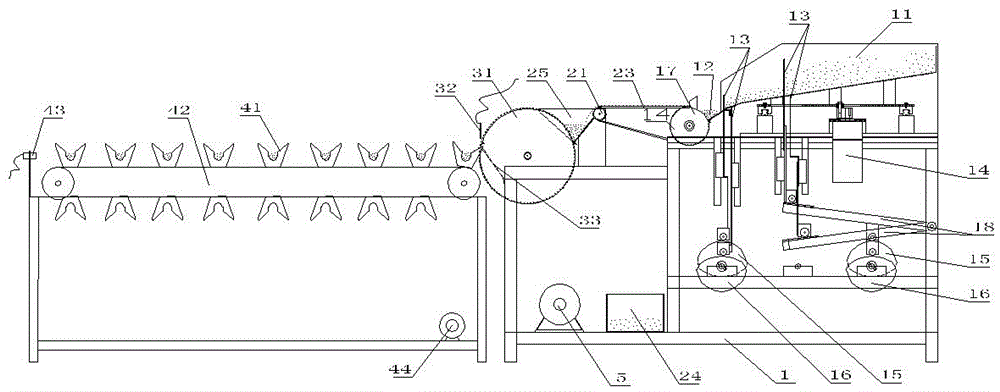

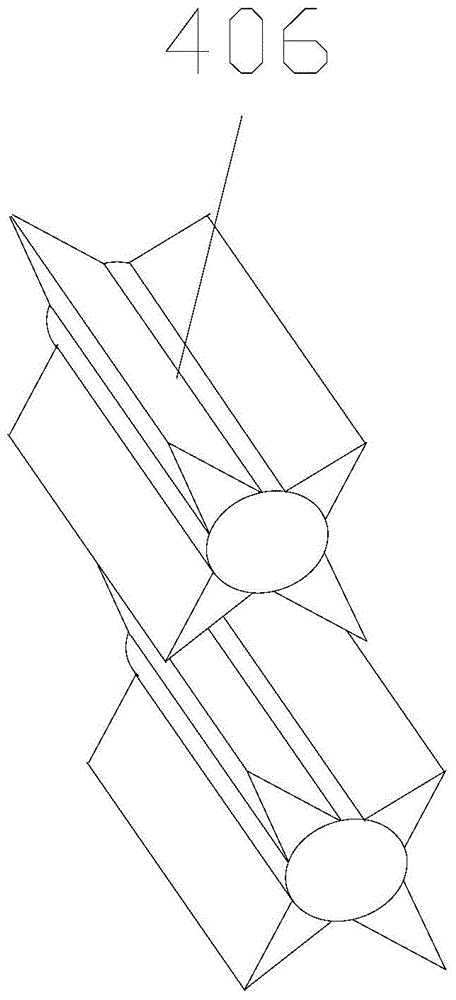

Automatic subpackage machine and method for incense sticks

ActiveCN106314855AControl quantitySmooth connectionConveyorsPackaging automatic controlButt jointContinuous operation

The invention discloses an automatic subpackage machine and method for incense sticks, and belongs to the technical field of incense making. The automatic subpackage machine structurally comprises an arranging and stabilization assembly, a broken incense screening assembly, a counting and quantification assembly, a subpackage and conveying assembly and a control management circuit in sequence. The broken incense screening assembly comprises two parallel conveying belts operating synchronously. A stabilization feeding roller wheel is arranged between the feeding ends of the conveying belts. The receiving position below the feeding roller wheel is in butt joint with a discharging outlet of a vibration feeding hopper, and a discharging point is arranged above the conveying belts to form the linkage of the arranging and stabilization assembly and the broken incense screening assembly. The quantified output automatic subpackage machine is formed by means of the post-processing counting and quantification assembly and the subpackage and conveying assembly. Standard arrangement, broken incense screening, quantified output counting and subpackage of the incense sticks are achieved, and automatic linkage and continuous operation are also achieved. The structure is simple, the efficiency is high, and the repeated operation quality is stable.

Owner:河北古城香业集团股份有限公司

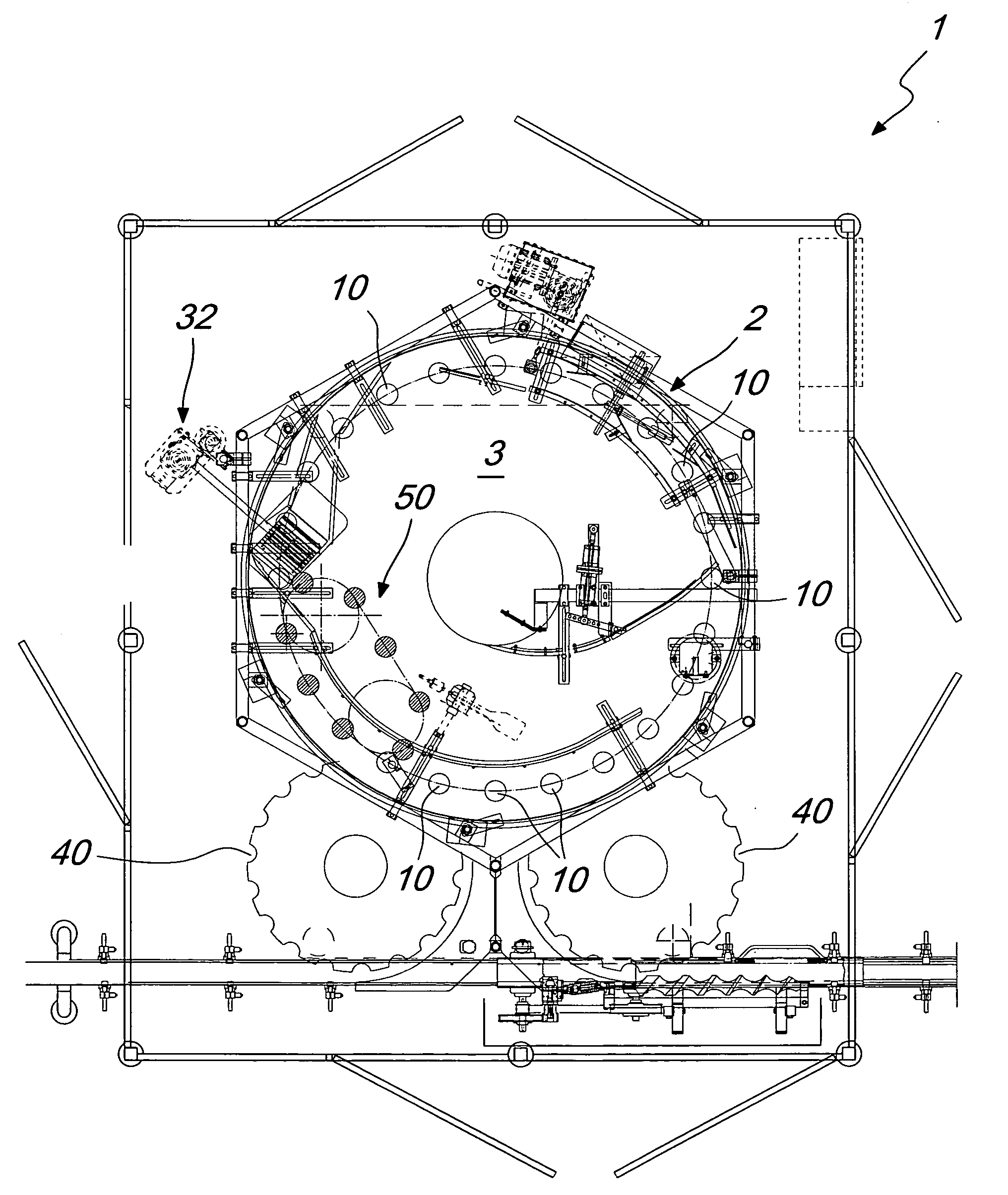

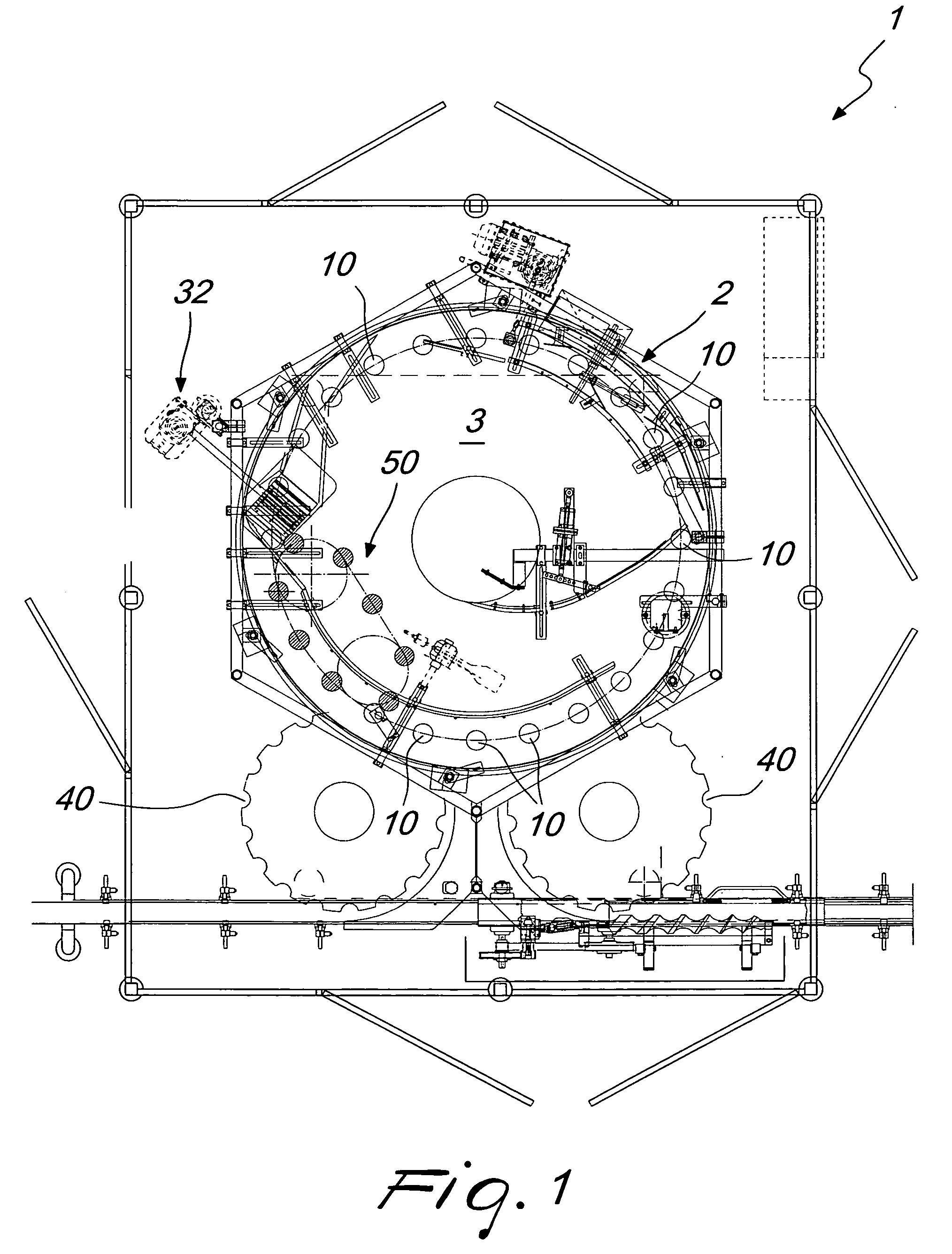

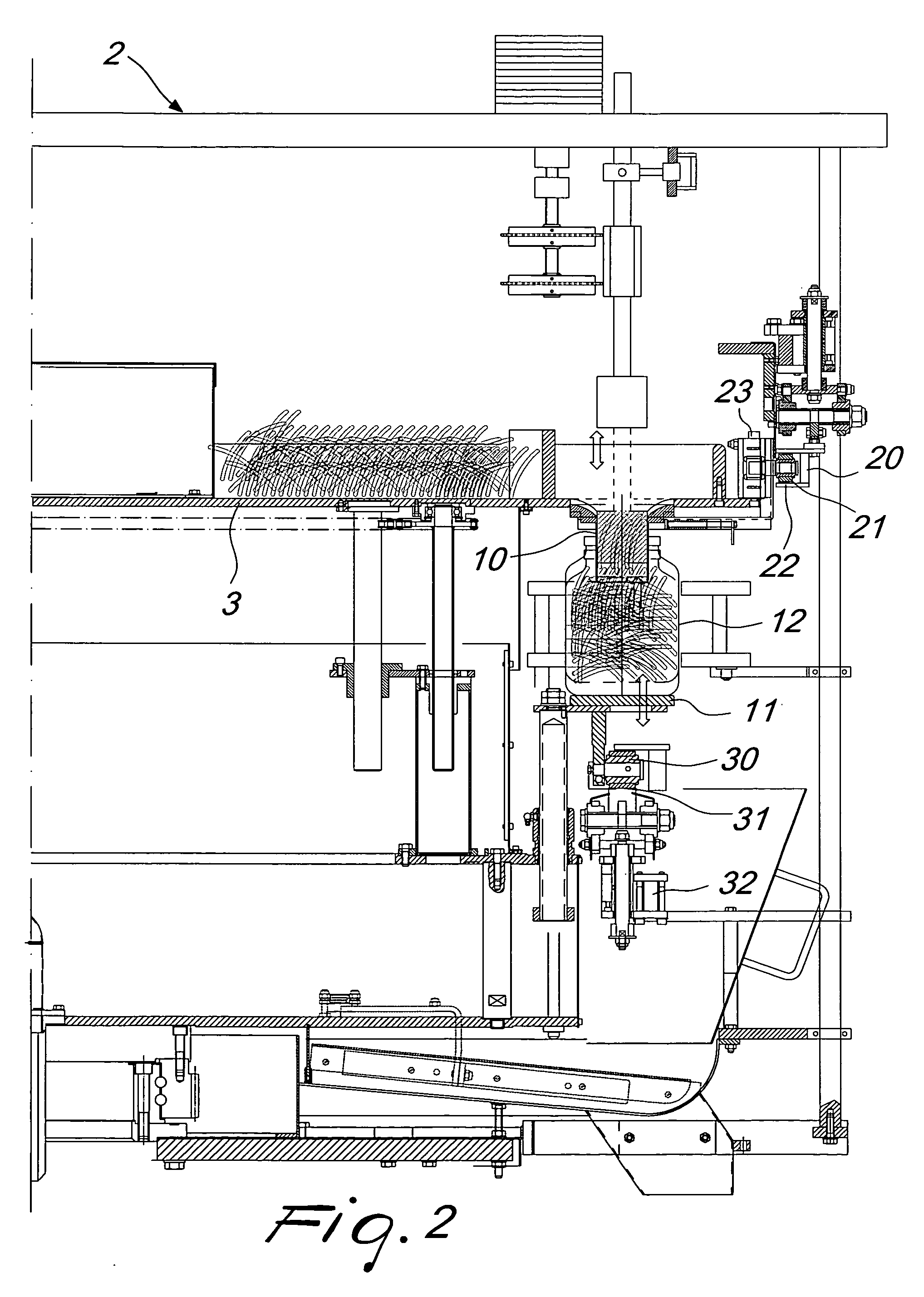

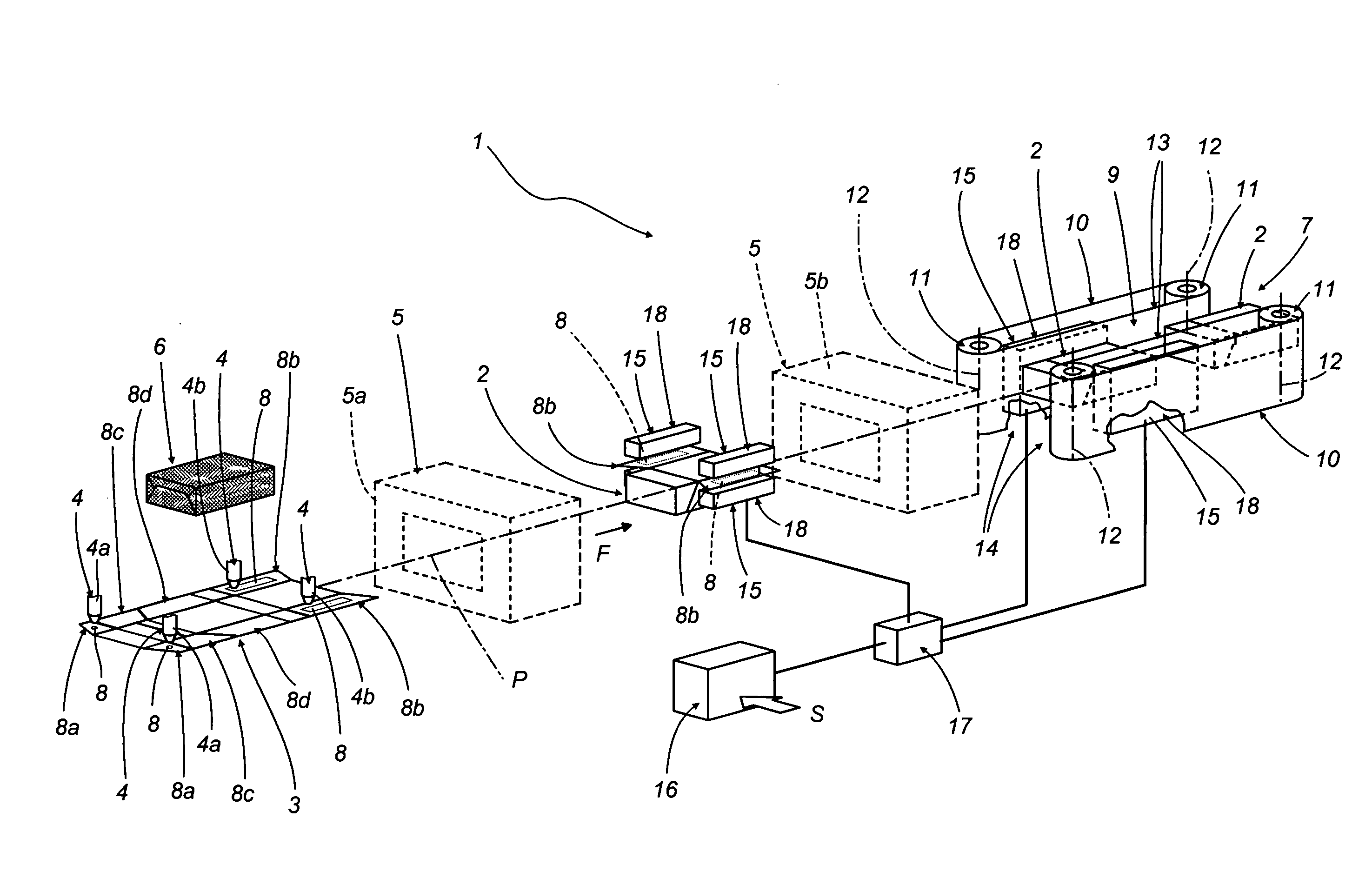

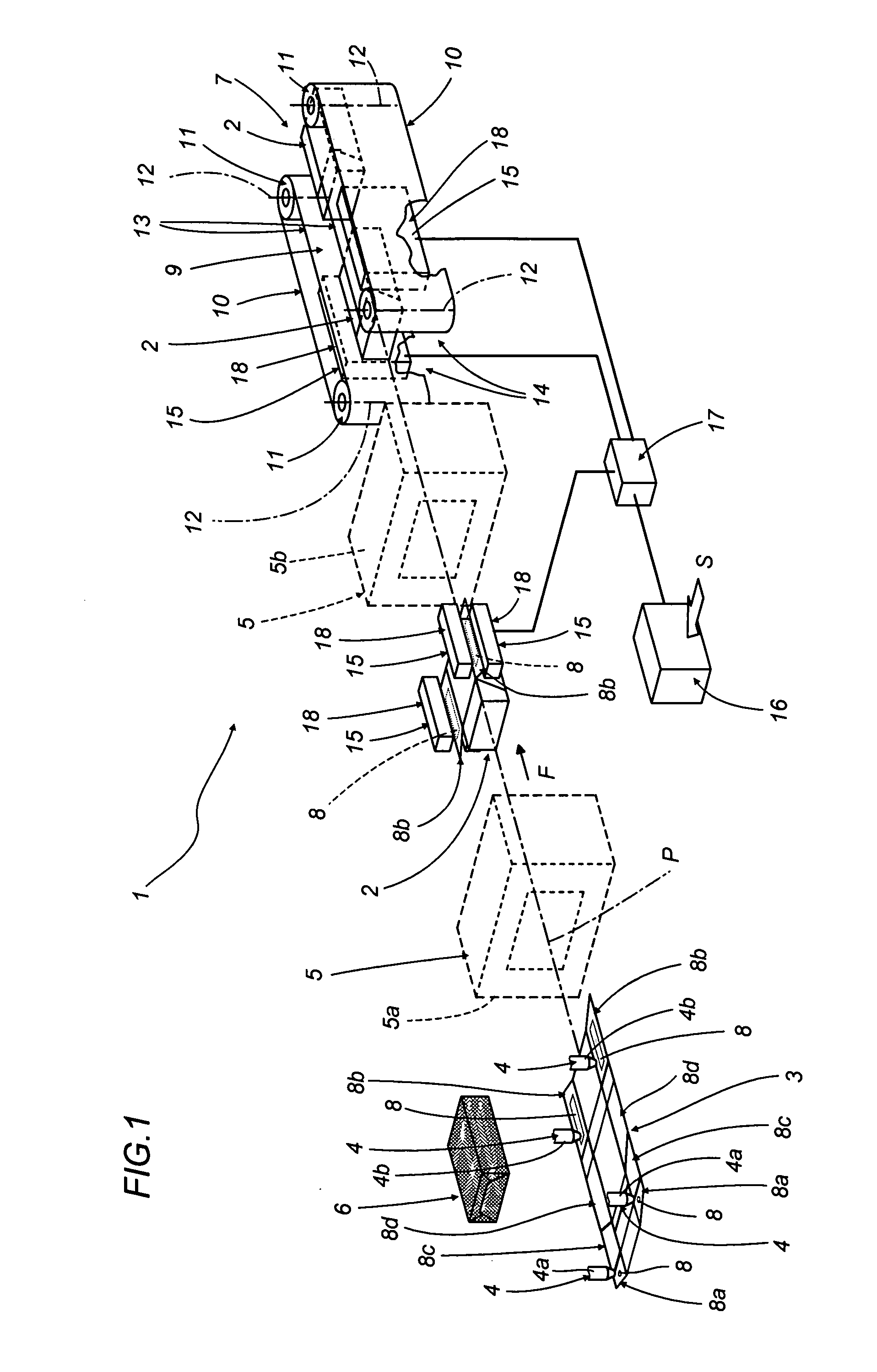

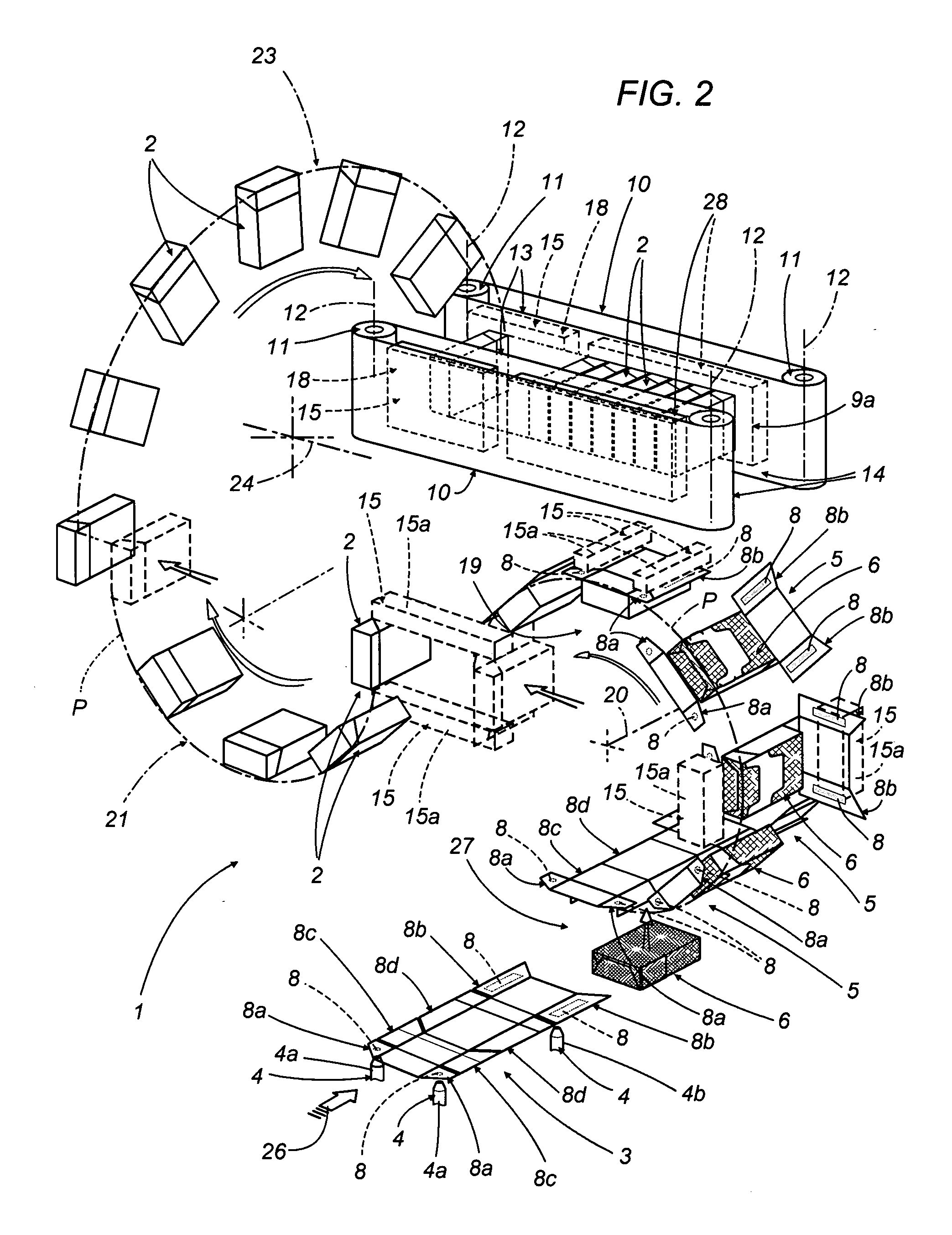

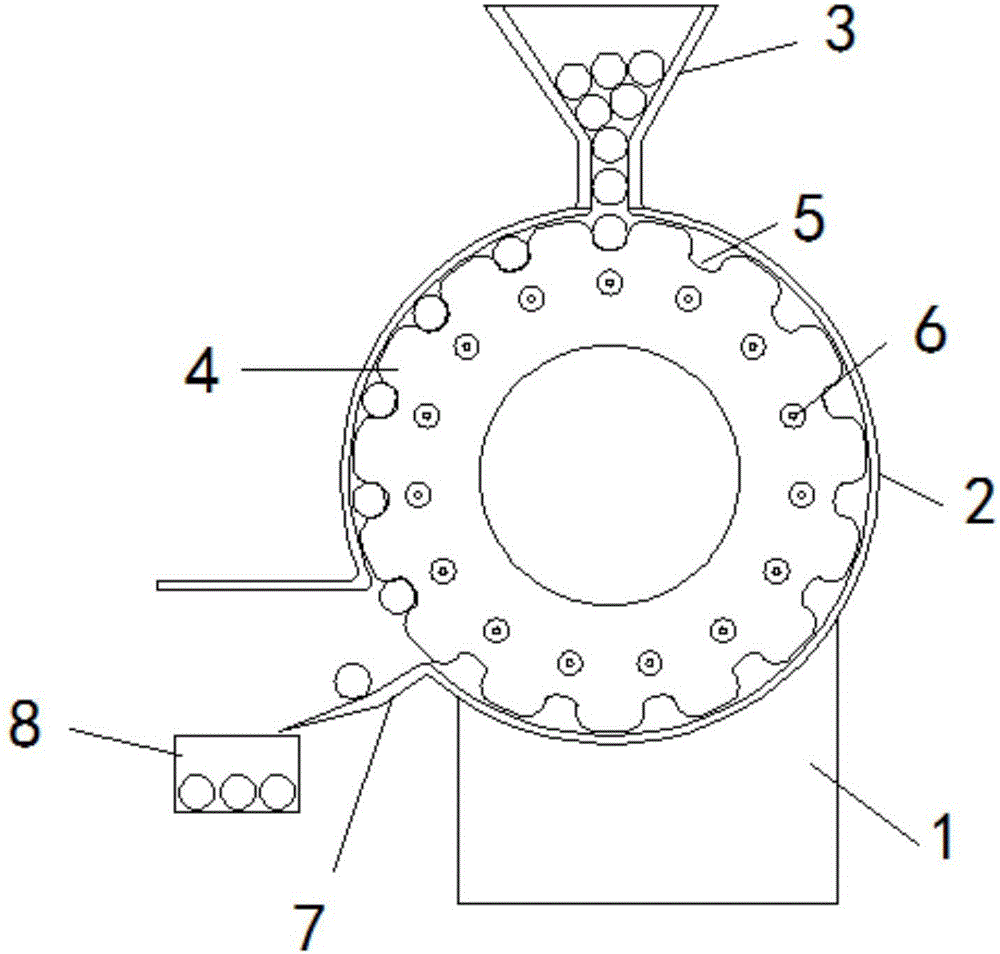

Circular filling machine particularly for slender and elongated products

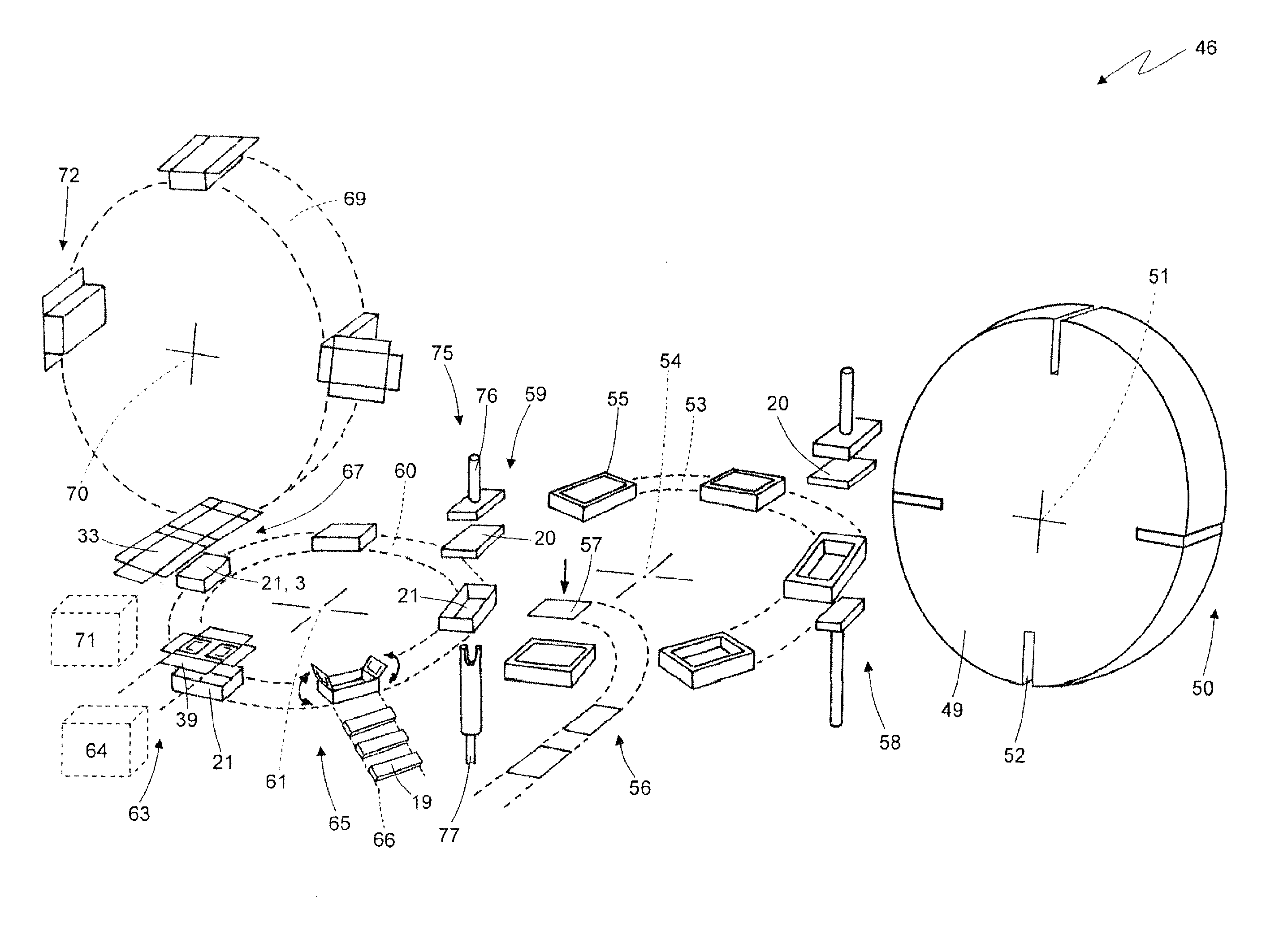

ActiveUS20090288375A1Inhibition formationEasy to getSolid materialRod-shaped articlesEngineeringMechanical engineering

A circular filling machine particularly for slender and elongated products, comprising a carousel assembly which supports a plurality of filling funnels which can be inserted in corresponding containers supported by transfer pans, the filling machine further comprising vibration elements for the funnels, vibration elements for the containers, and a tamping assembly for the insertion and final packing of the product in the containers.

Owner:ZANICHELLI MECCANICA

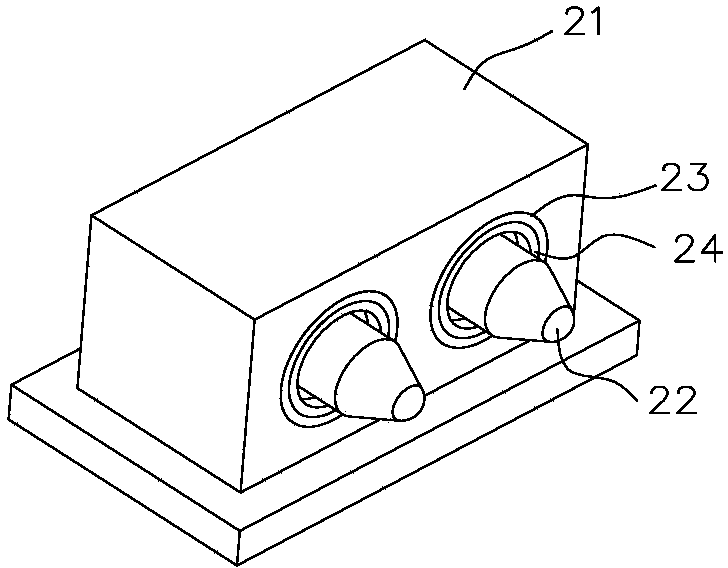

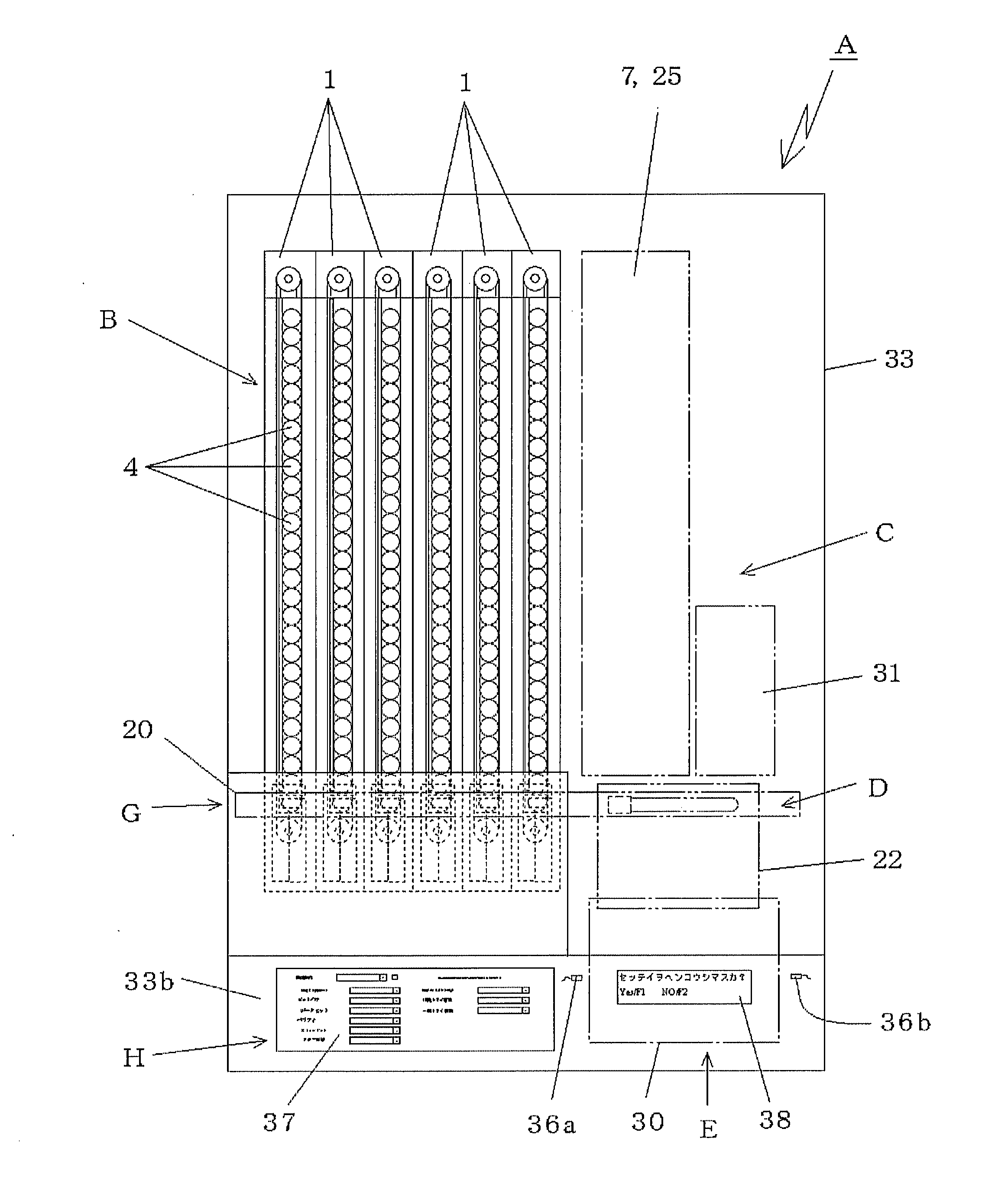

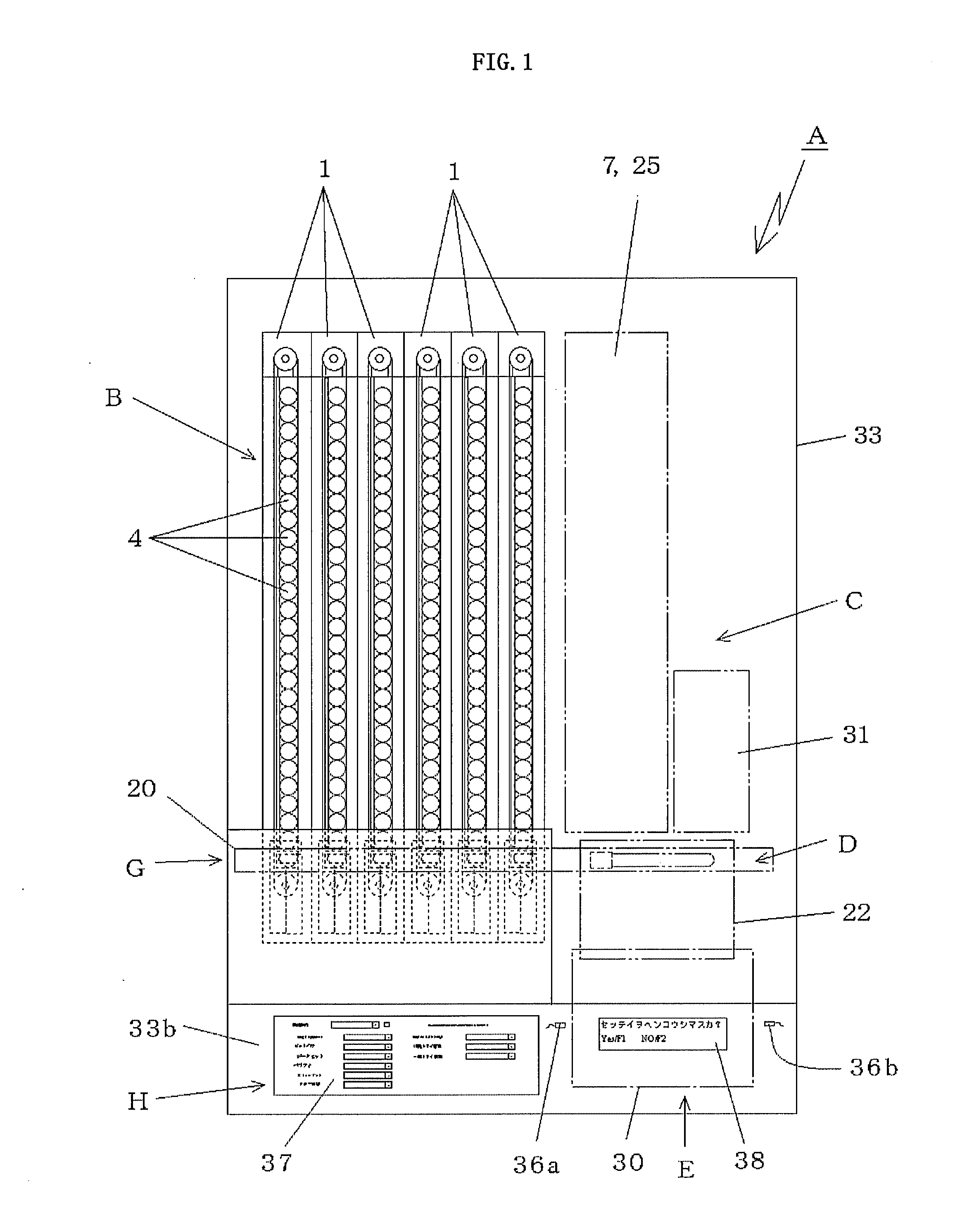

Blood collection tube storage box and blood collection tube preparing apparatus

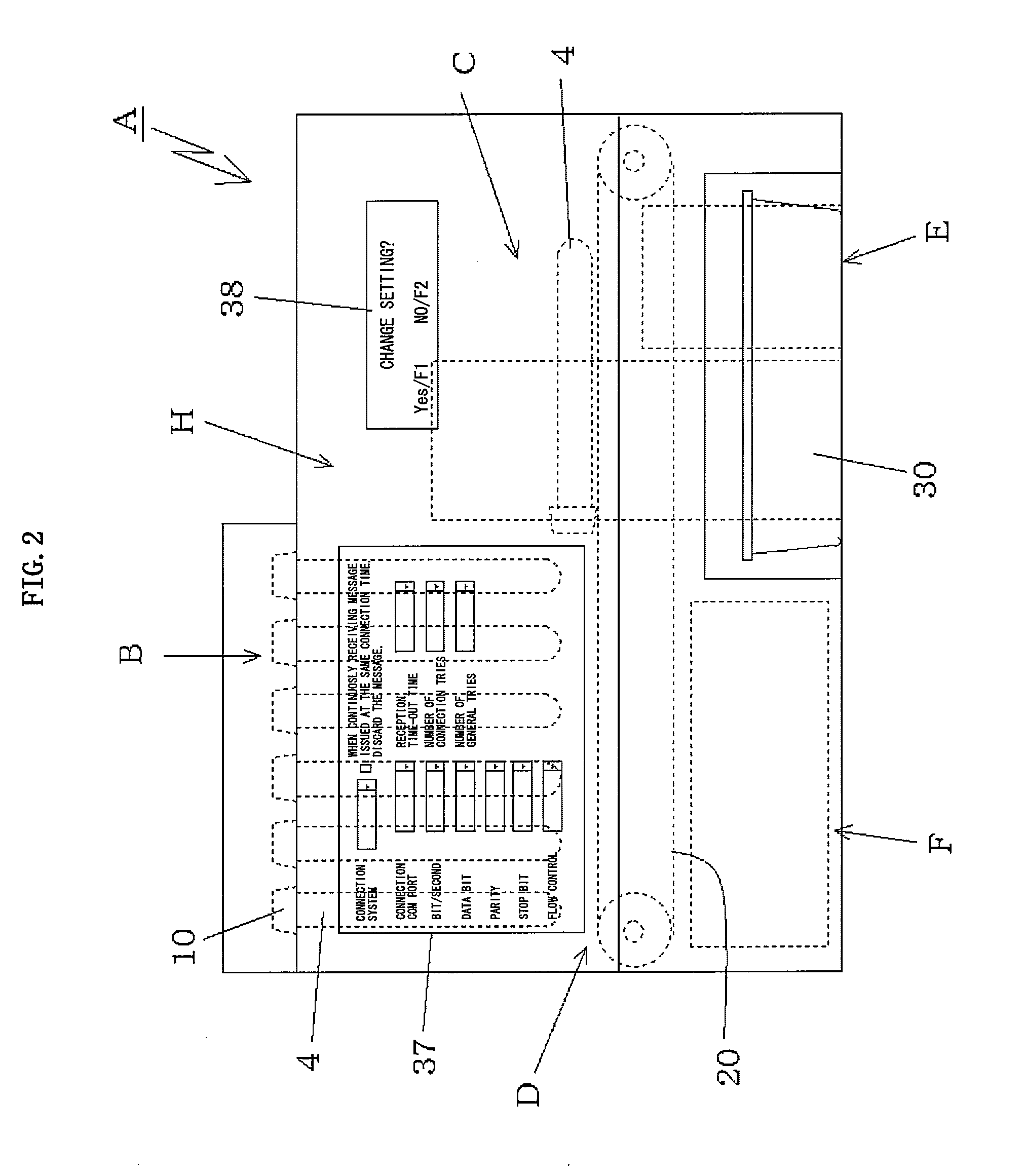

InactiveUS20110173927A1Reduce width sizePharmaceutical product form changeSolid materialBlood Collection TubeMedicine

Provided is a blood collection tube preparing apparatus which is simple, downsized, portable, capable of being easily placed on a desk or the like, excellent in responding to an emergency such as a disaster, and capable of preparing various kinds of blood collection tubes depending on a blood collection instruction from a doctor. A blood collection tube holding member is arranged along one transferring belt and between a forward-side transferring belt and a backward-side transferring belt of the one transferring belt, and lower end surfaces of a cap of a blood collection tube is supported on upper end surfaces of the blood collection tube holding member and the forward-side transferring belt. The forward-side transferring belt applies a transferring force to the blood collection tube through the cap. Further, the members constituting a storage box are accommodated in one module, and the storage box is detachably mounted onto a mounting portion of an apparatus main body. Further, the storage box is in the form of module, and hence an operation in the case of failure or during maintenance is significantly facilitated.

Owner:AFC MINNESOTA

Method and a device for the assembly of packets for tobacco products

Cigarette packets are assembled by a method that involves dabbing or spraying a cold-setting adhesive onto selected areas of a blank fed along the wrapping line of a packaging machine, whereupon the blank is folded to form a packet; should there be a break in operation of the machine following the application of the adhesive, persisting for a certain length of time, the method includes a heat-reactivation step whereby the adhesive applied previously to the blank is warmed to a given temperature so as to restore its bonding properties and guarantee the ultimate stability of the assembled packet.

Owner:GD SPA

Candle moulding counting device

InactiveCN105923416AReduce processingRealize continuous productionConveyorsPackaging automatic controlDisplay deviceCandle

The invention discloses a candle moulding counting device. The candle moulding counting device comprises a base and a box, wherein the box is fixed on the base and is of a cylindrical hollow structure; a material inlet hopper is arranged above the box and communicates with the inner part of the box; a roller is arranged in the box; a motor is arranged on the outer side of the base; the motor is connected with the roller through a belt wheel group; material grooves are uniformly distributed on the outer side surface of the roller; one end surface, of the roller, is provided with infrared emitters corresponding to the material grooves; an infrared receiving device is arranged on the left side of the roller in the box; the infrared receiving device corresponds to the infrared emitters; a counting display is arranged on the upper part of the outer part of the box; and the infrared receiving device is connected with the counting display; a material guiding plate is arranged on the left and lower part of the box; and a package box is arranged right below the material guiding plate. By adopting the candle moulding counting device, continuous production can be realized; labor intensity is lowered; counting processing does not need to be performed manually; the amount of processed data is reduced; and the production efficiency is improved.

Owner:重庆市荣昌区鸿强工艺蜡烛厂

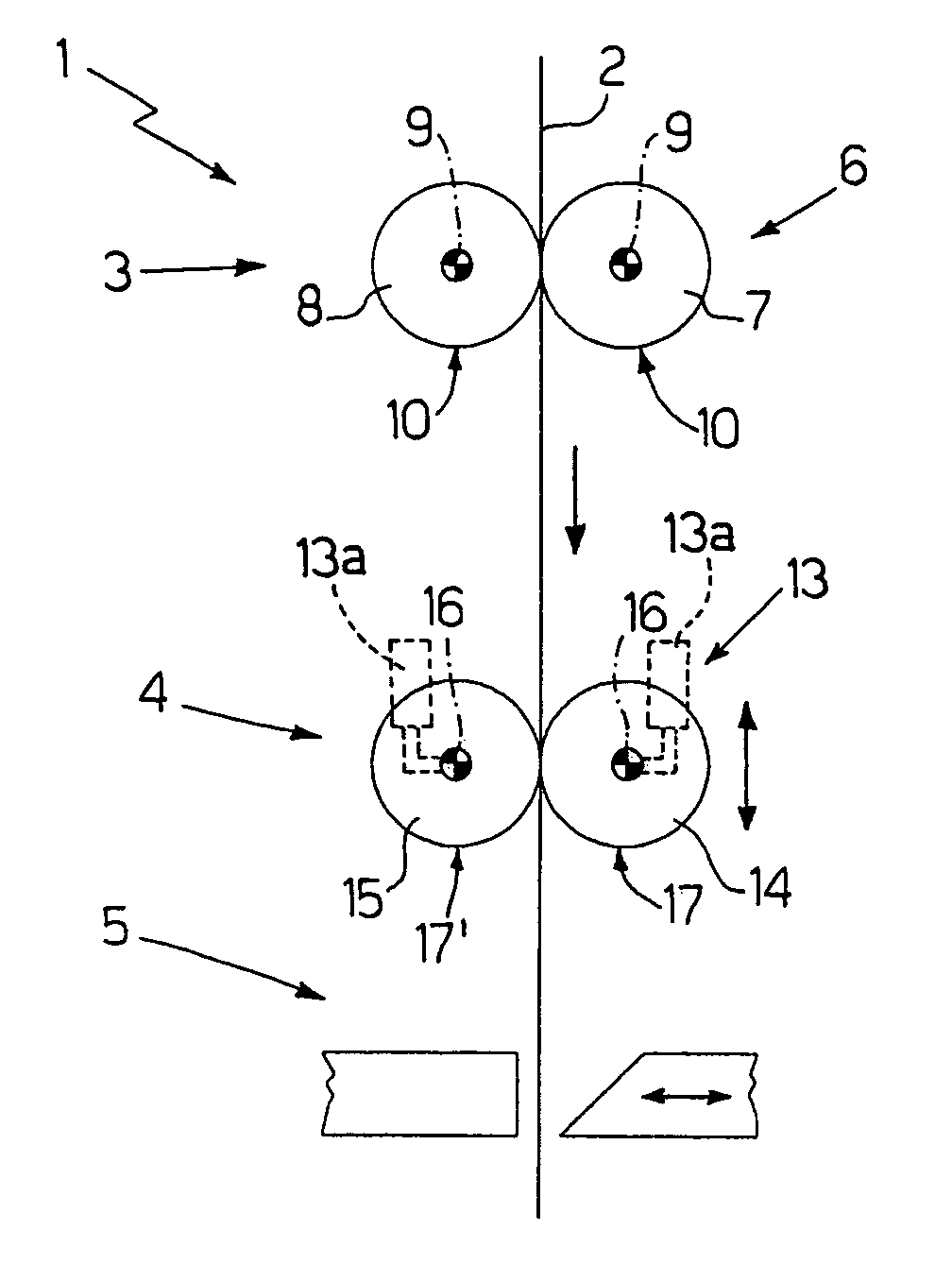

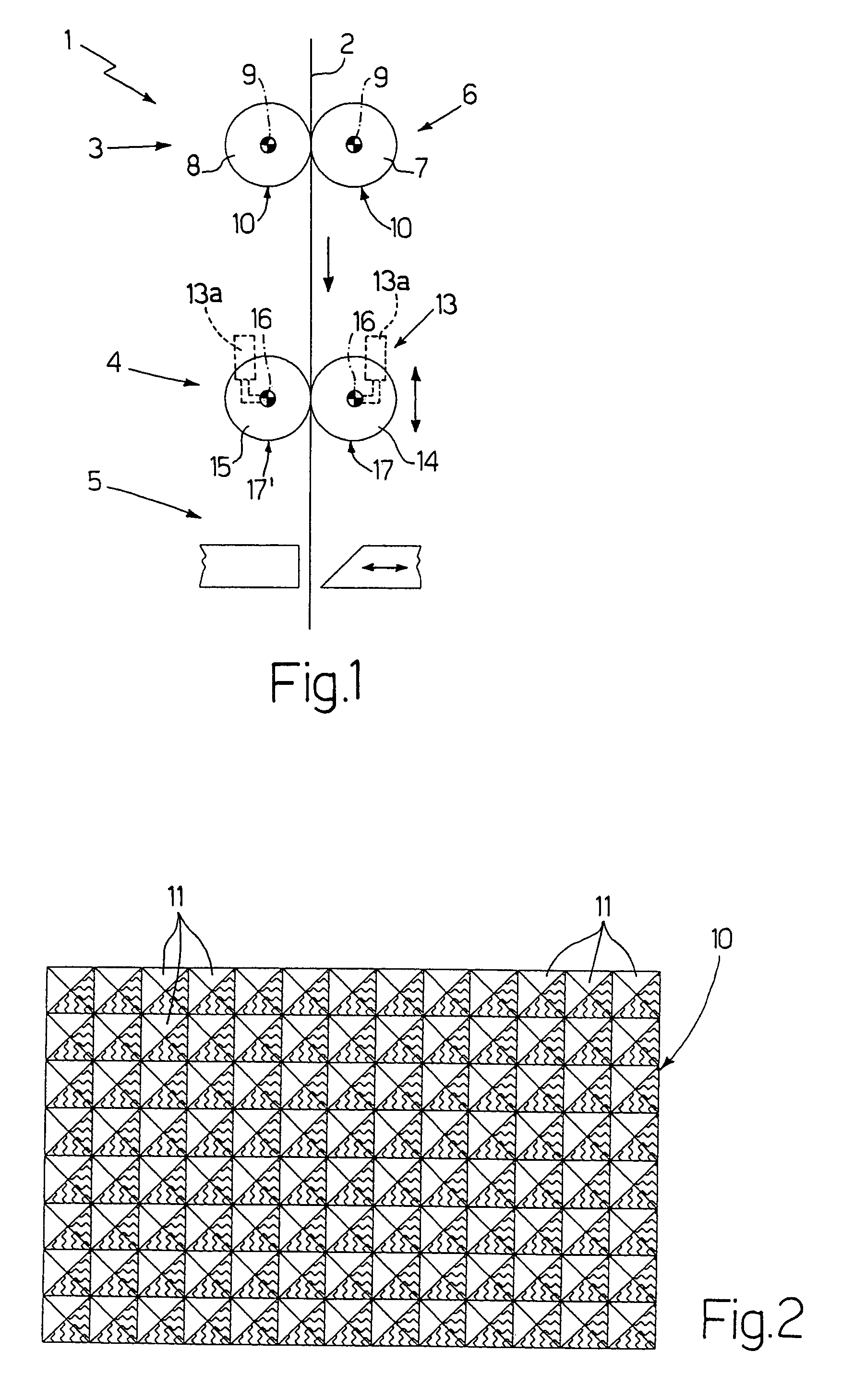

Embossing device

InactiveUS7426886B2Drawback can be obviatedNon-fibrous pulp additionNatural cellulose pulp/paperGraphicsPack material

An embossing device having a first embossing unit for satin finishing a strip of packing material, and a second embossing unit for impressing graphics on the strip of packing material; the second embossing unit has two embossing rollers, at least one of which only has embossing pins in areas for impressing the graphics.

Owner:GD SPA

Bag forming machine with straw inserting mechanism

A machine for making sealed liquid pouches with a free-floating straw inside the pouch is described. The machine comprises a vertical pouch former which forms a continuous plastic film tube from a film sheet with the plastic film tube disposed about a liquid dispensing spout. A straw convecting tube also extends to one side of the liquid dispensing spout inside the tube. A straw is released through the convecting tube at predetermined intervals in synchronism with a transverse sealer which forms a bottom and top edge seal of pouches as liquid is continuously dispensed through the liquid dispensing tube. The plastic film tube is maintained in a transversely expanded condition during the filling of the pouch and is advanced by an engagement mechanism between the sealing cycles.

Owner:LARSON GRP +2

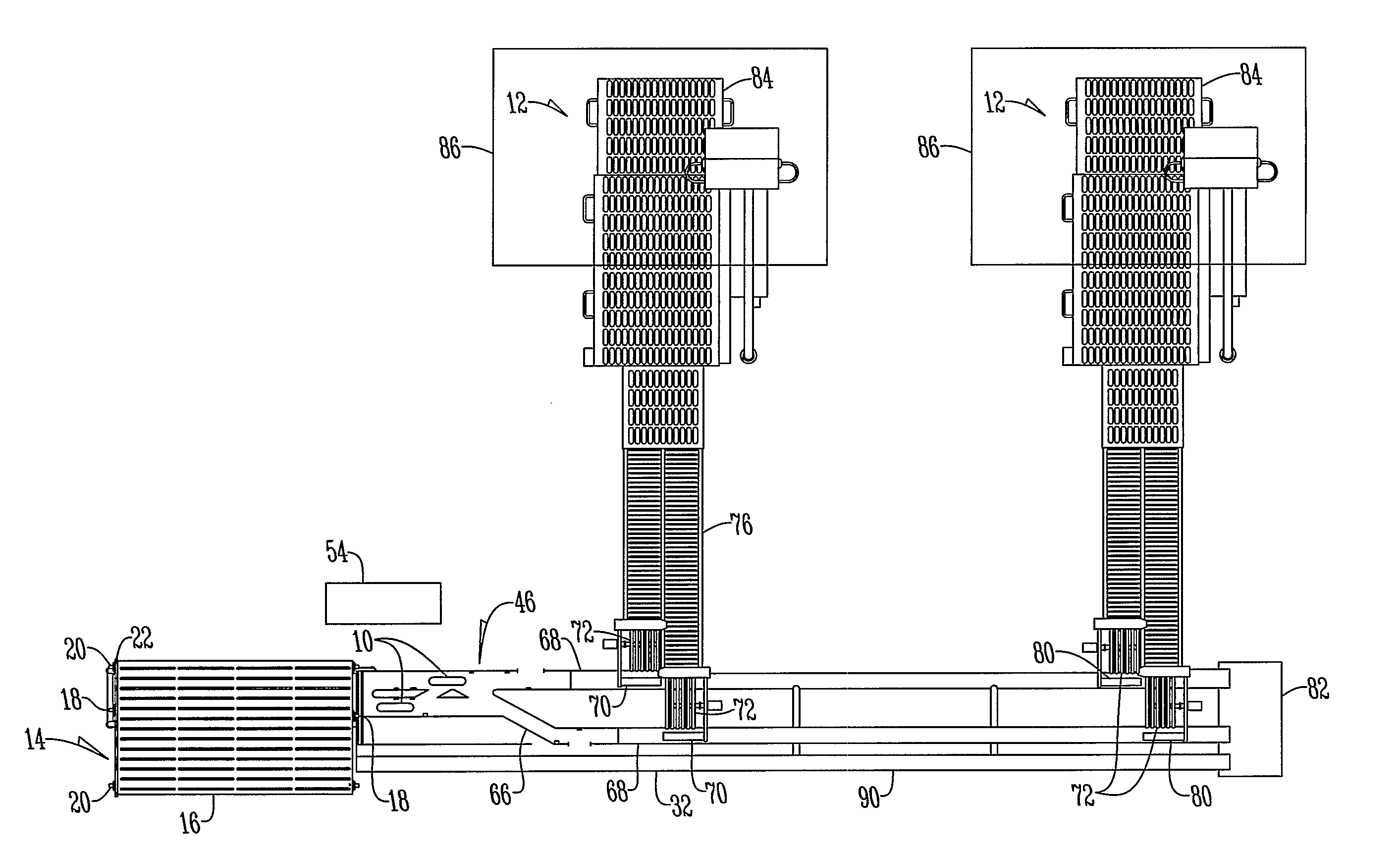

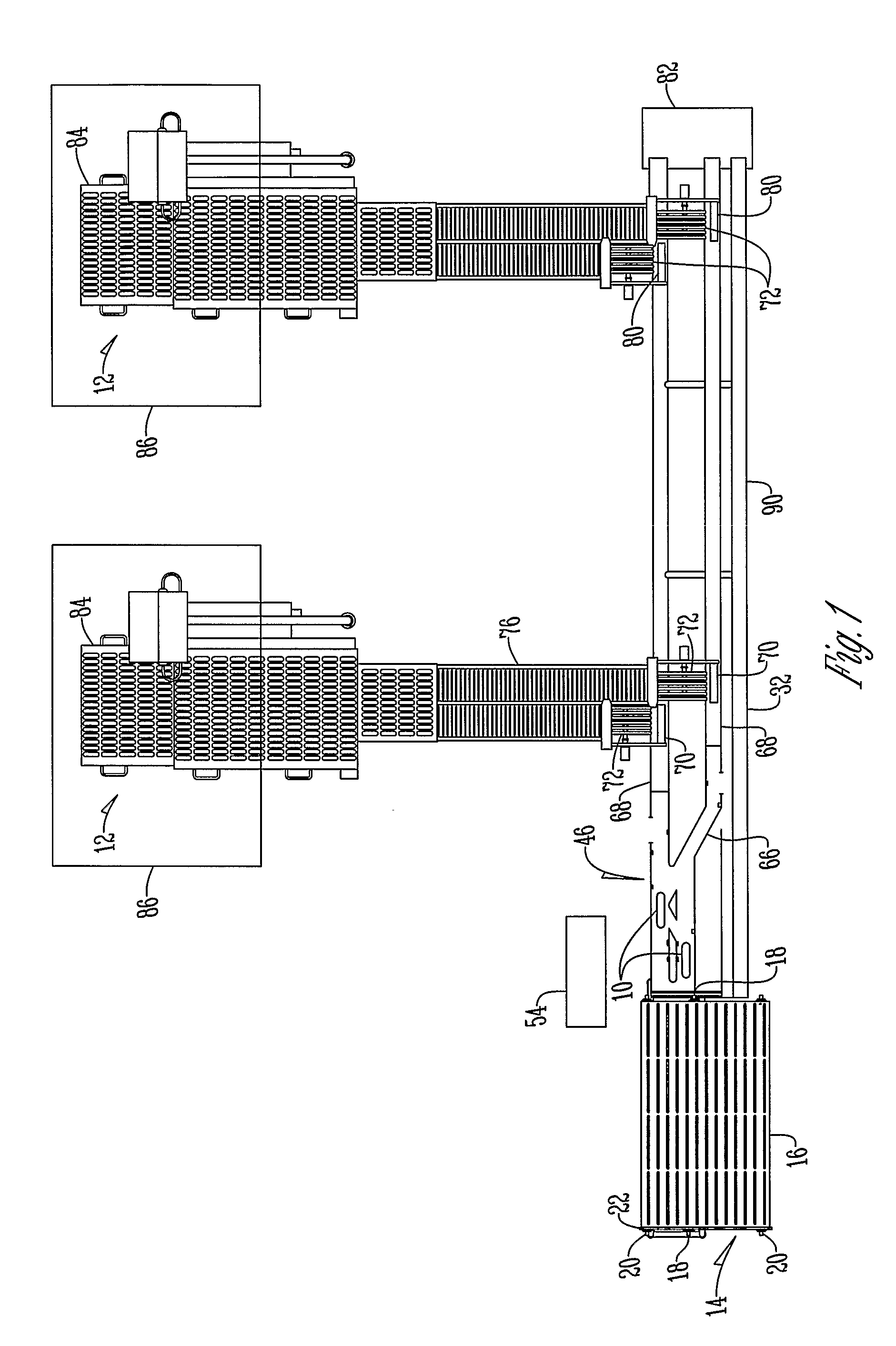

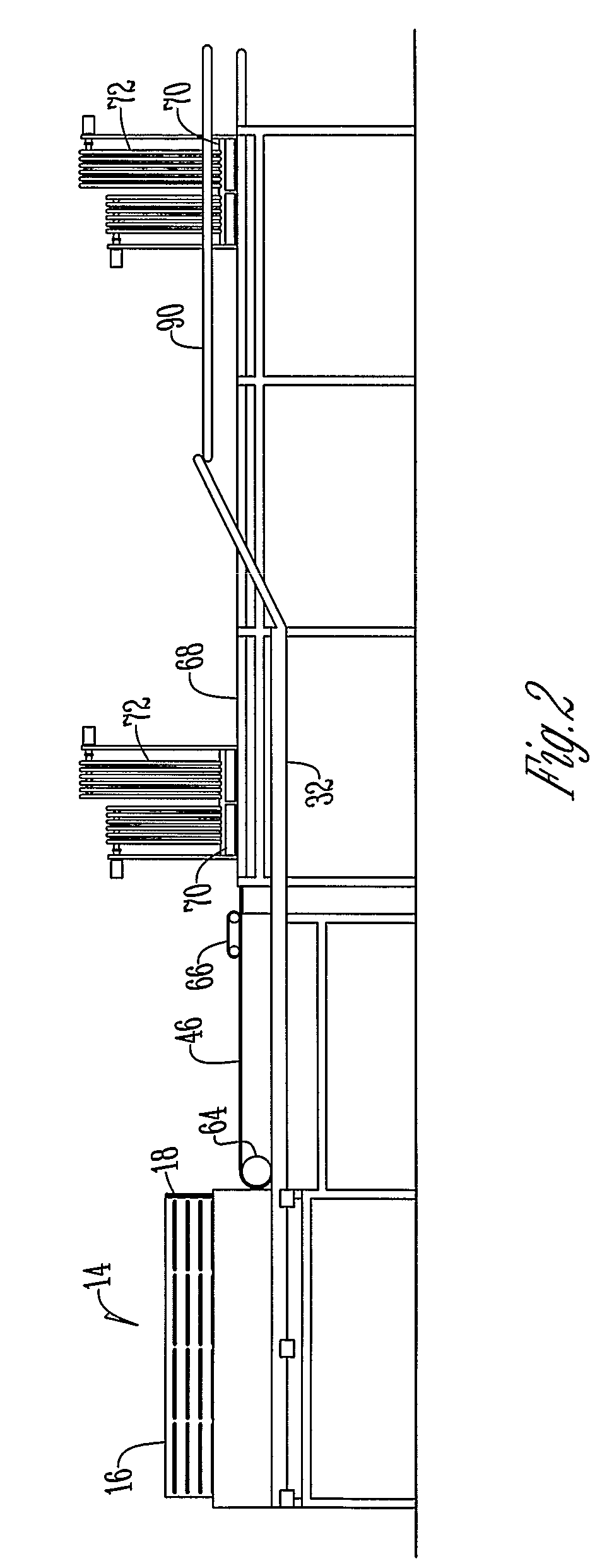

Apparatus and method of transporting food products to a loading head

An apparatus and method of transporting food products (10) to a loading station (12) having a cooling conveyor (14) that selectively drops food product into a distributor (34). The distributor (34) separates product into at least two lanes (48, 50) and drops product onto a conveyor. A balancing and diverting conveyor (46) monitors and counts product in each lane (48, 50) and diverts product selectively based upon the sensed product. An orienter (70, 80) transfers product from a loading conveyor (68) to a buffer conveyor (72). The buffer conveyor (72) transfers product to a main conveyor (76) which transfers product to a loading head (84).

Owner:MAREL MEAT PROCESSING

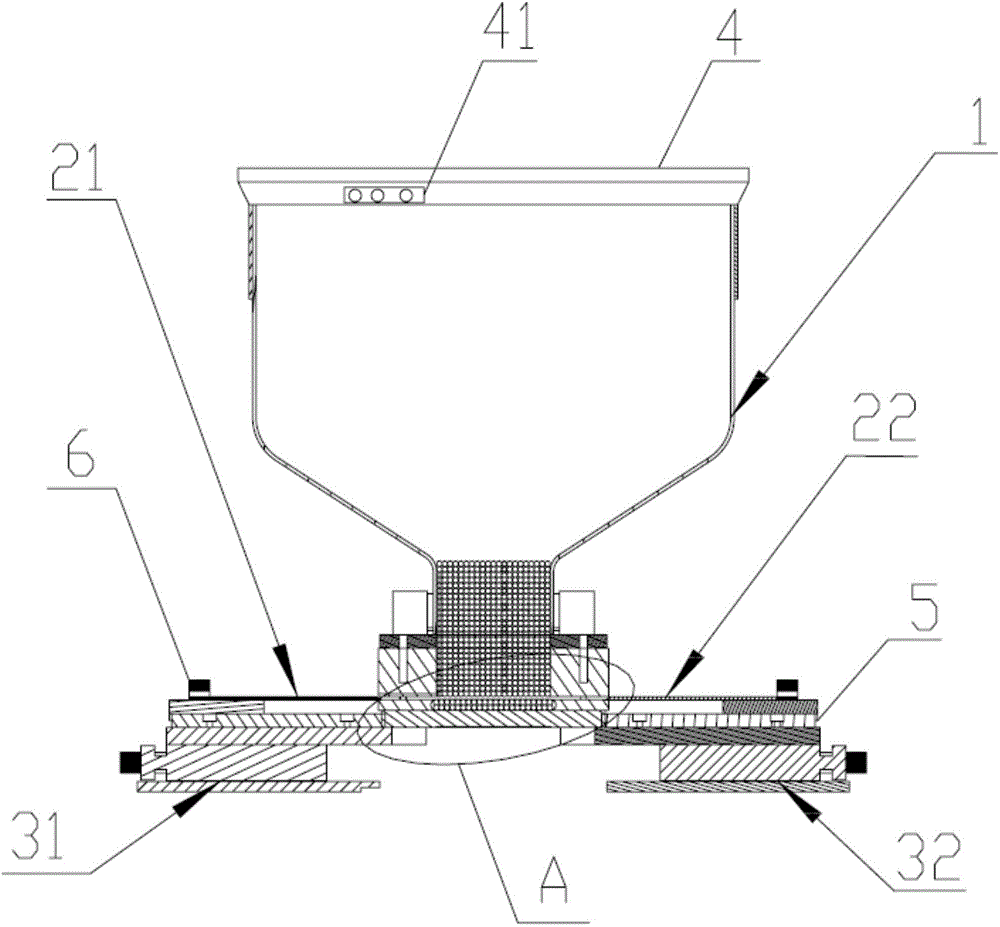

Automatic weighing and subpackaging device for welding rods

The invention relates to an automatic weighing and subpackaging device for welding rods. The automatic weighing and subpackaging device is characterized by comprising an automatic weighing mechanism and an automatic subpackaging mechanism, wherein the automatic weighing mechanism comprises a first frame, a first transmission device, a first driving device and a counting device; and the automatic subpackaging mechanism comprises a second frame, a second transmission device and a second driving device which is a stepping type driving device. According to the automatic weighing and subpackaging device, the automatic weighing mechanism performs quantitative weighing and separating on continuously-conveyed welding rods, and the automatic subpackaging mechanism performs independent subpackaging on the separated welding rods. Compared with the existing manual weighing and subpackaging mode, the automatic weighing and subpackaging device only needs one to two packaging workers, so that quantity of workers and labor intensity are reduced, production efficiency of welding rod package is improved, and cost of welding rod production is reduced.

Owner:TIANJIN DAQIAO XINGWANG WELDING ELECTRODE

Material arrangement mechanism of automatic toothpick packer

InactiveCN104908994AAvoid secondary pollutionEnsure safetyPackage sterilisationRod-shaped articlesEngineeringModel Number

The invention discloses a material arrangement mechanism of an automatic toothpick packer. The mechanism comprises a material storage device, a positioning device and a power device, wherein the material storage device consists of a bin and a sealing cover; the positioning device consists of a positioning left plate and a positioning right plate; the power device comprises a left pneumatic actuator and a right pneumatic actuator; the positioning device is fixed in a chute of a working tabletop; the power device is mounted at the lower part of the working tabletop; a material pushing plate is arranged between the working tabletop and the positioning device; and the pneumatic actuators control the material pushing plate to move. Toothpicks are positioned through the positioning device; after being fully arranged in an accommodating cavity, the toothpicks are pushed into a packing film bag by the material pushing plate, so that the secondary pollution of the toothpicks can be prevented in the packing process, and the safety of diners is guaranteed; the whole material arrangement procedure is controlled by the pneumatic actuation mechanisms, and the control is precise and reliable to prevent the generation of empty bags; and the size of the accommodating cavity is voluntarily adjusted to apply to automatic packing of the toothpicks with multiple different model numbers.

Owner:ZHEJIANG SHENGZHOU HONGDA MACHINERY

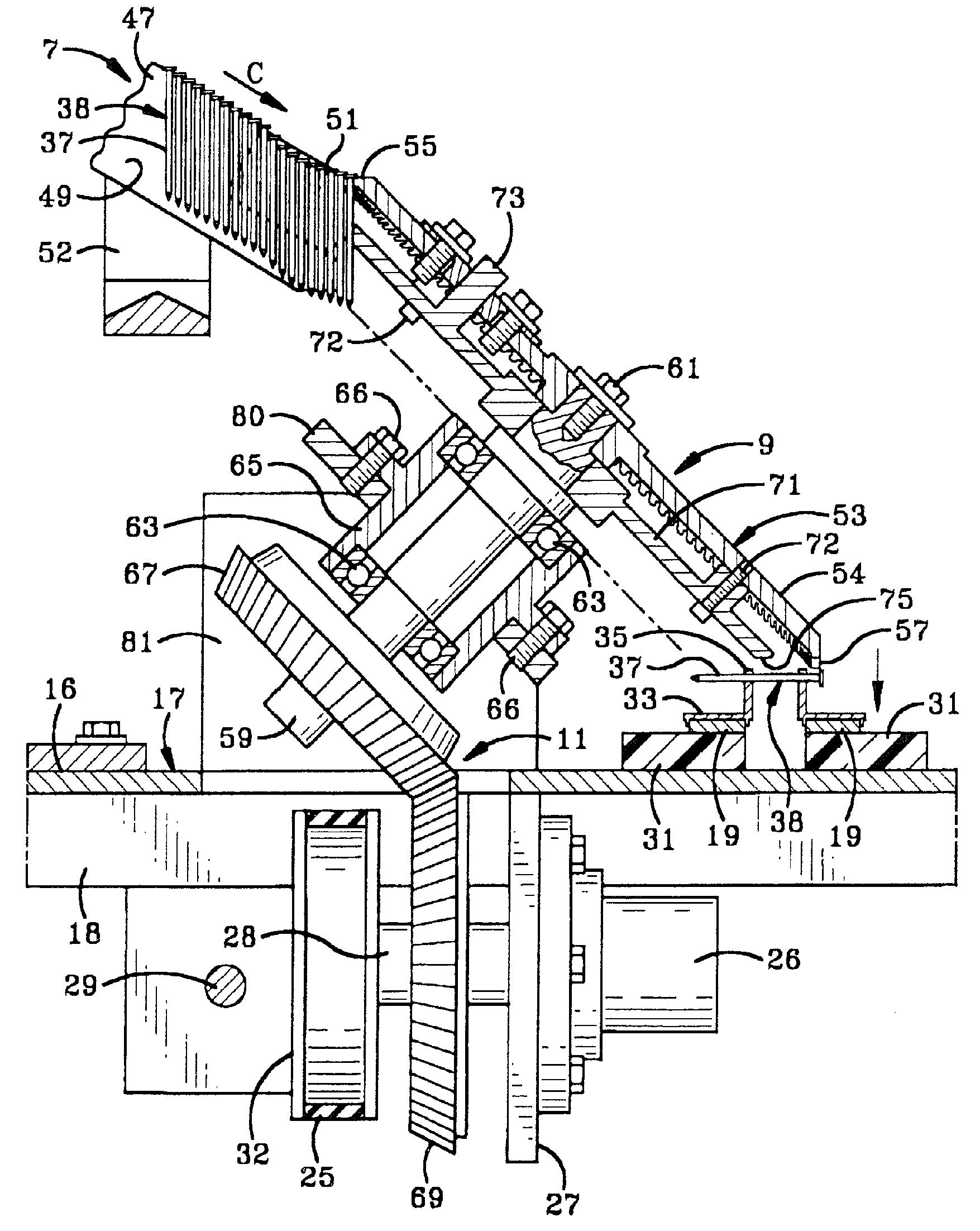

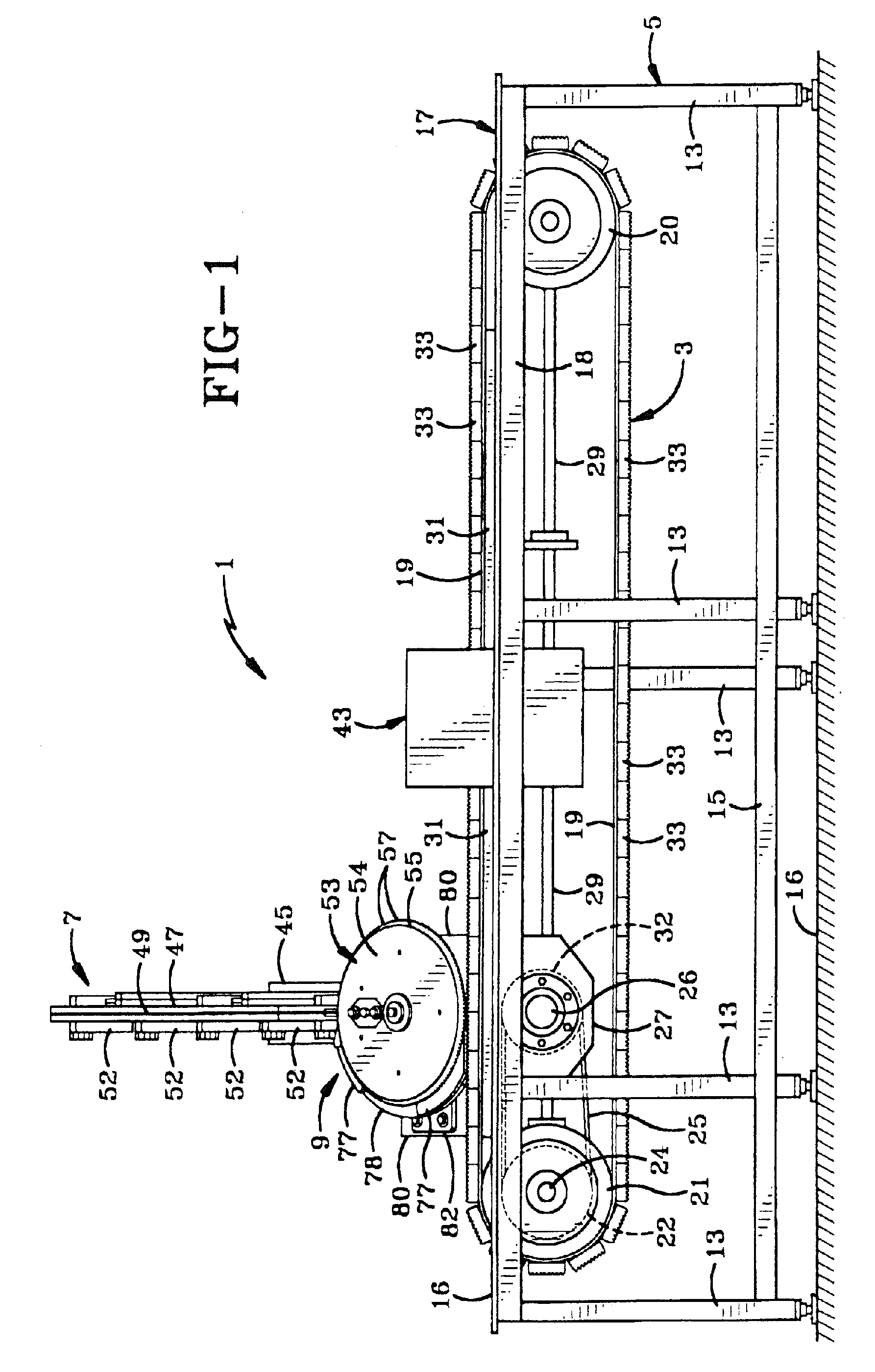

Method and apparatus for collating nails

An apparatus and method for collating nails wherein round head nails are fed by gravity along an inclined rail to a periphery of a rotating indexing and feed wheel. The nails are deposited into circumferentially spaced grooves formed in the periphery of the feed wheel in a vertical orientation. The feed wheel is inclined at an angle of approximately 45° and upon 180° rotation of the feed wheel the nails assume a horizontal orientation. A conveyor has a plurality of spaced segments attached to a pair of moving belts. Each segment is formed with spaced notches for receiving the nails in a horizontal spaced relationship from the feed wheel and then transporting the horizontally spaced nails to a collator for forming into a continuous strip. Rotation of the feed wheel is synchronized with movement of the conveyor by a motor, a gear train and drive shafts extending between the feed wheel and conveyor.

Owner:KIM CHI HYUN

Packaging mechanism of automatic packaging machine for medical cotton swabs

InactiveCN103112610ASimplify the packaging processImprove production and packaging efficiencyWrapper twisting/gatheringRod-shaped articlesCotton swabHot press

The invention relates to the technical field of cotton swab packaging equipment, in particular to a packaging mechanism of an automatic packaging machine for medical cotton swabs. The packaging mechanism of the automatic packaging machine for the medical cotton swabs comprises a conveying platform, wherein a material pushing device, an upper edge sealing device and a hot pressing sealing and trimming device are arranged on the conveying platform in sequence. The hot pressing sealing and trimming device comprises a hot pressing sealing upper mold, a hot pressing sealing lower mold, a first cylinder, a first movable plate, a sealing cutter, a fixing device and a second cylinder. When the packaging mechanism of the automatic packaging machine for the medical cotton swabs works, the upper edge sealing device is capable of sealing the upper edge of a packaging film bag which contains the medical cotton swabs to be packaged and is conveyed by material pushing device, and then sealing and trimming of the packaging film bag with the upper edge well sealed and conveyed by the upper edge sealing device are achieved through the hot pressing sealing and trimming device. The sealing process and the trimming process are carried out at the same time, and therefore packaging processes are enabled to be simple and production and packaging efficiency is high.

Owner:东莞市万江鸿浩五金电器厂

Steel pipe bundling and conveying device

InactiveCN105460315AAccurate countGood degree of automationPackaging automatic controlRod-shaped articlesSteel tubeEngineering

The invention provides a steel pipe bundling and conveying device. The steel pipe bundling and conveying device is characterized by comprising a bearing device, a bundling device and a conveying device. The bearing device comprises a first stopper, a second stopper, steel pipes and an optical grating counter. The bundling device comprises a first baffle, a second baffle, a first angle regulator and a second angle regulator. By means of the technical scheme, during usage, the two stoppers act respectively, the steel pipes of a specific number can be bundled, and the steel pipes can be accurately counted by the aid of the optical grating counter; the manpower cost is reduced; the counting by the bundling and conveying device is more accurate than that by people; the automation degree is good. The steel pipes are bundled and conveyed through the steel pipe bundling and conveying device, the bundling shape is regular so as to facilitate storage and conveying, and moreover the appearance is attractive. The steel pipe bundling and conveying device has the advantages of being simple in structure, easy to operate, high in work efficiency and the like.

Owner:天津腾飞钢管有限公司

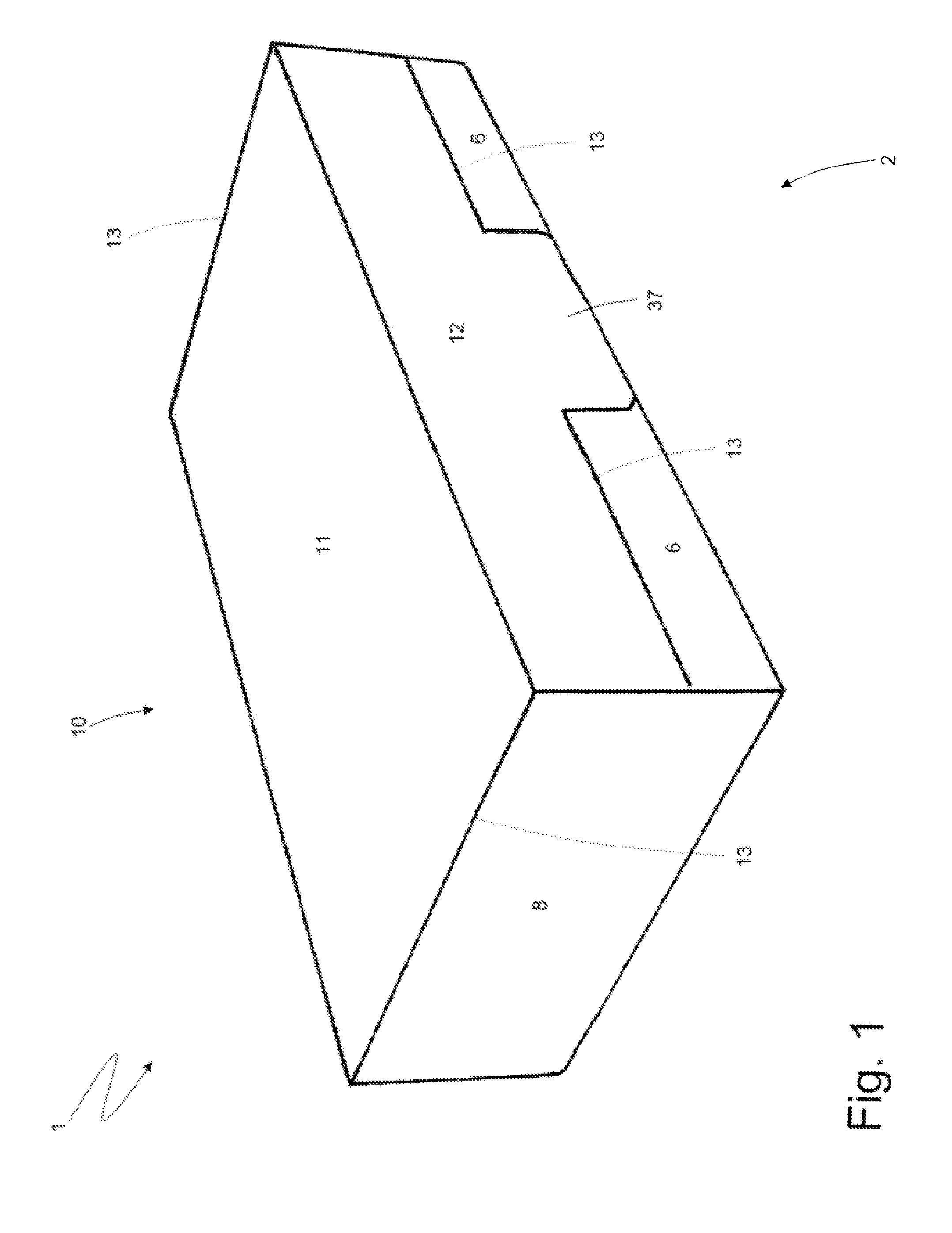

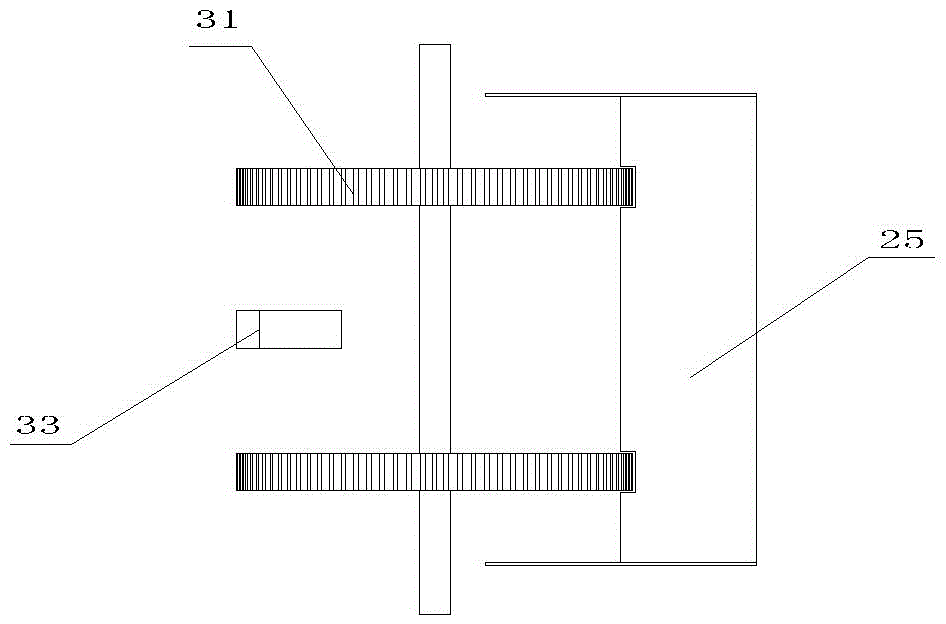

Method and device for manufacturing packaging for cigarettes

The device has a folding device i.e. folding turret (23), for folding blanks from a package material i.e. thin card board. A transport line (24) i.e. packing line, is connected to the turret. Glue application stations (32, 33) with glue assemblies (34, 35, 40, 41) i.e. flue nozzles, are arranged in the transport line for applying glues on folding arms of the blank. The glue assemblies are arranged in a glue application position on both sides of the transport line in a height of the folding arms. The glue assemblies are movable in a cleaning position for cleaning the glue assemblies. An independent claim is also included for a method for manufacturing cigarette packages i.e. folding box-type cigarette packages.

Owner:FOCKE & CO (GMBH & CO KG)

Automatic iron nail packing machine

InactiveCN104670556AGood nail row effectSimple structureSolid materialRod-shaped articlesEngineeringSprocket

The invention relates to an automatic iron nail packing machine, which is characterized by comprising a collating device and a conveying device; the collating device comprises a support, a feeding hopper, a vibrator, a steering bent hopper and two groups of chain net nail arranging mechanisms arranged on the support; the vibrator is used for vibrating the support; the chain net nail arranging mechanisms comprise power sources, outside chains, outside chain wheels meshed with the outside chains, inside chains, inside chain wheels meshed with the inside chains and multiple cross rods arranged side by side. The chain net nail arranging mechanisms vertically collate disordered iron nails in sequence in a mechanical manner, the vertically arranged iron nails are turned into two groups of iron nails in opposite directions and are horizontally arranged on a conveyor belt by the steering bent hopper, the conveying device conveys the well arranged iron nails for boxing, the nail arranging effect is good, the structure is simple, durability is realized, the manufacturing cost is low, and operation, maintenance and repair are convenient.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

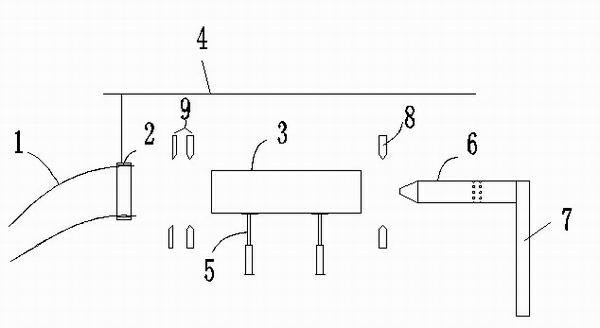

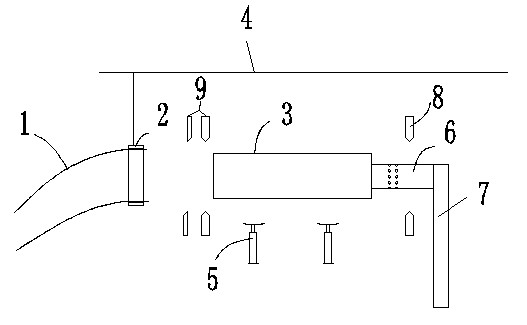

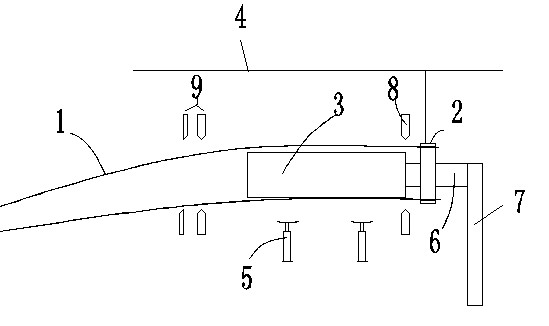

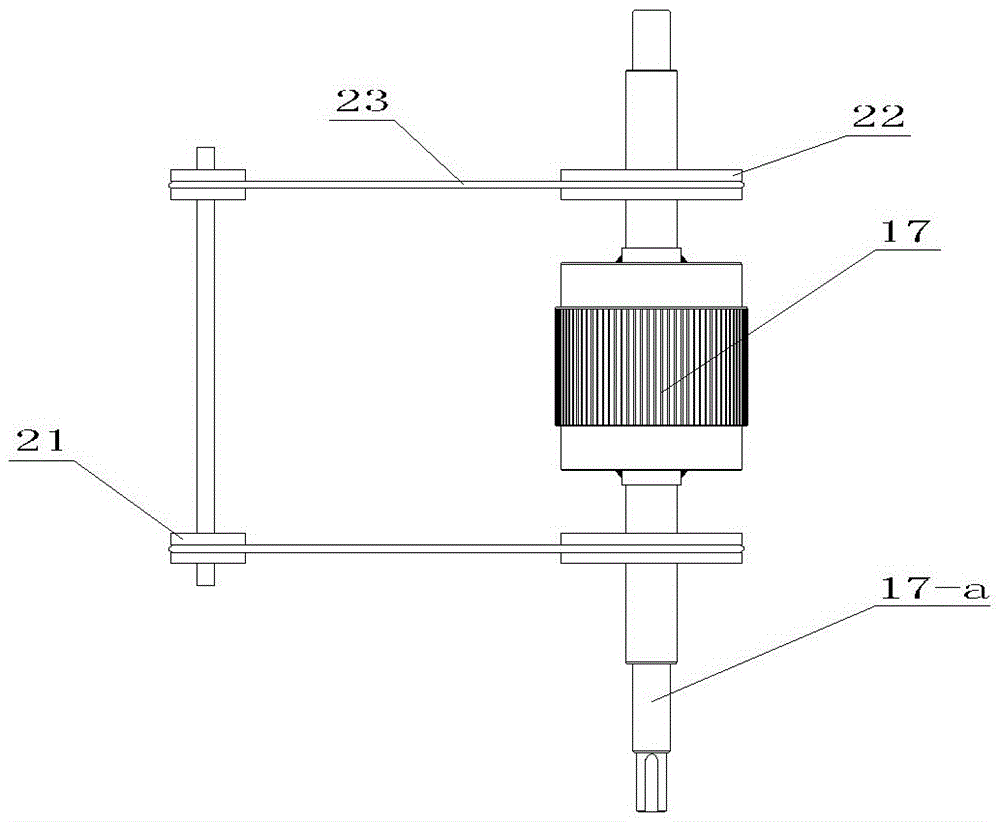

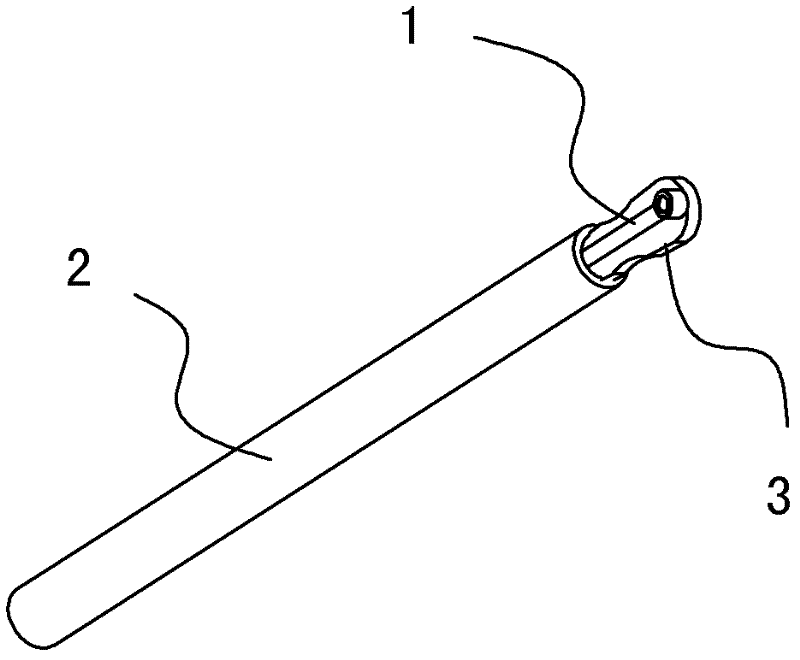

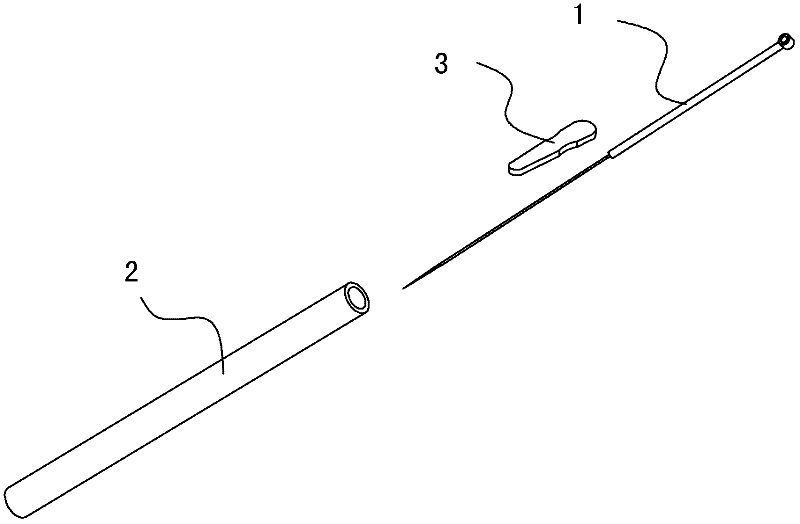

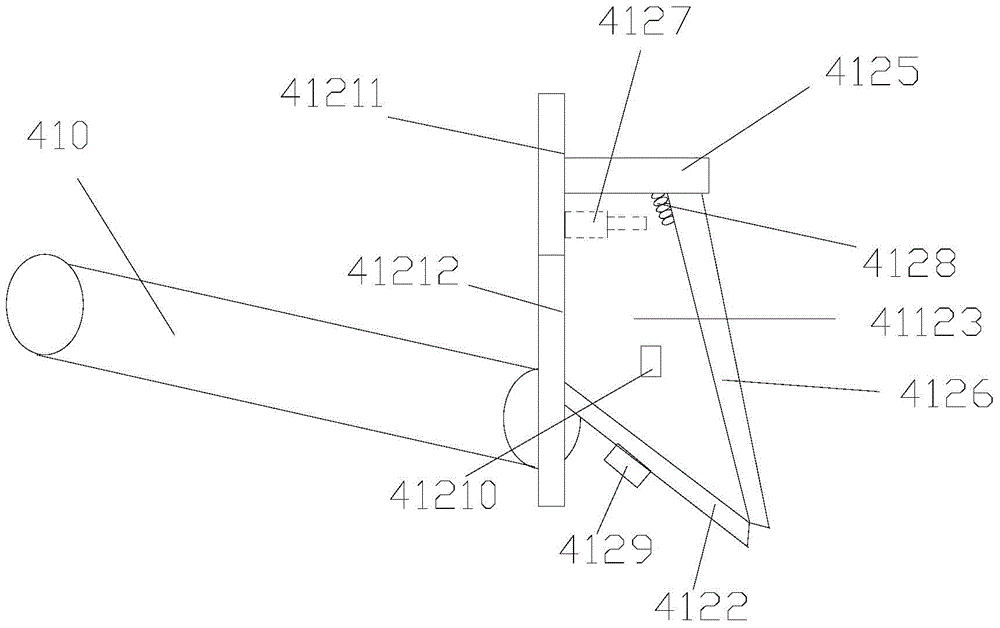

Automatic acupuncture needle tubing packaging machine

The invention discloses an automatic acupuncture needle tubing packaging machine, which comprises a circular feed mechanism, a tube pushing mechanism, a needle pushing mechanism, and a sheet delivery mechanism. The circular feed mechanism in which a group of V-shaped grooves, a material transfer plate, a first linear driving mechanism and a second linear driving mechanism are matched is designed;and the tube pushing mechanism, the needle pushing mechanism, and the sheet delivery mechanism are arranged beside the circular feed mechanism. After an acupuncture needle and a plastic tube are parallelly fed into the first V-shaped groove, the material transfer plate transfers the acupuncture needle and the plastic tube stage by stage to the next V-shaped groove, and in the stage-by-stage transfer process, the needle pushing mechanism pushes the needle stage by stage through needle pushing rods with different lengths, so that the acupuncture needle is gradually inserted into the plastic tube to reach a proper position; and under the cooperation of the sheet delivery mechanism, the needle pushing mechanism and the tube pushing mechanism, a plastic sheet is inserted into the plastic tube to clamp and position the needle body finally. By the matching of the group of V-shaped grooves and the material transfer plate, and a design of pushing the needle stage by stage, the tubing packagingis stable and reliable, and the machine is suitable for acupuncture needles with different lengths.

Owner:SUZHOU MEDICAL SUPPLY FACTORY CO LTD

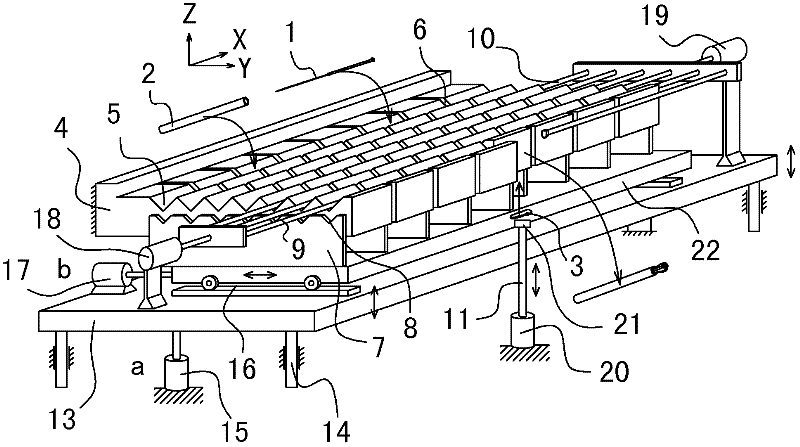

Integral noodle processing and packaging device

ActiveCN104886465AReduce lossSave floor spaceMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsNumerical controlSmall footprint

The invention discloses an integral noodle processing and packaging device. The integral noodle processing and packaging device comprises an input device, a numerical control device, a servo system, a machine tool mainframe device, a water supply system and a discharging device. The machine tool mainframe comprises a dough kneading device, a pre-rolling device, composite rolls, mill rolls, noodle cutters, cutoff tools, a first conveying device, an automatic weighing device, a second conveying device, a third conveying device, an alignment device, a packaging bag supply device, a packaging bag middle sealing device and a packaging bag end sealing and shearing device. The water supply system supplies water to the dough kneading device, and the discharging devices collects products processed by the packaging bag end sealing and shearing device. The integral noodle processing and packaging device has the advantages of high machining precision, small floor space, sufficient water supply power, uniformity in discharging after dough kneading and prevention of side leakage in noodle processing.

Owner:HUAIBEI XUYUAN FOOD CO LTD

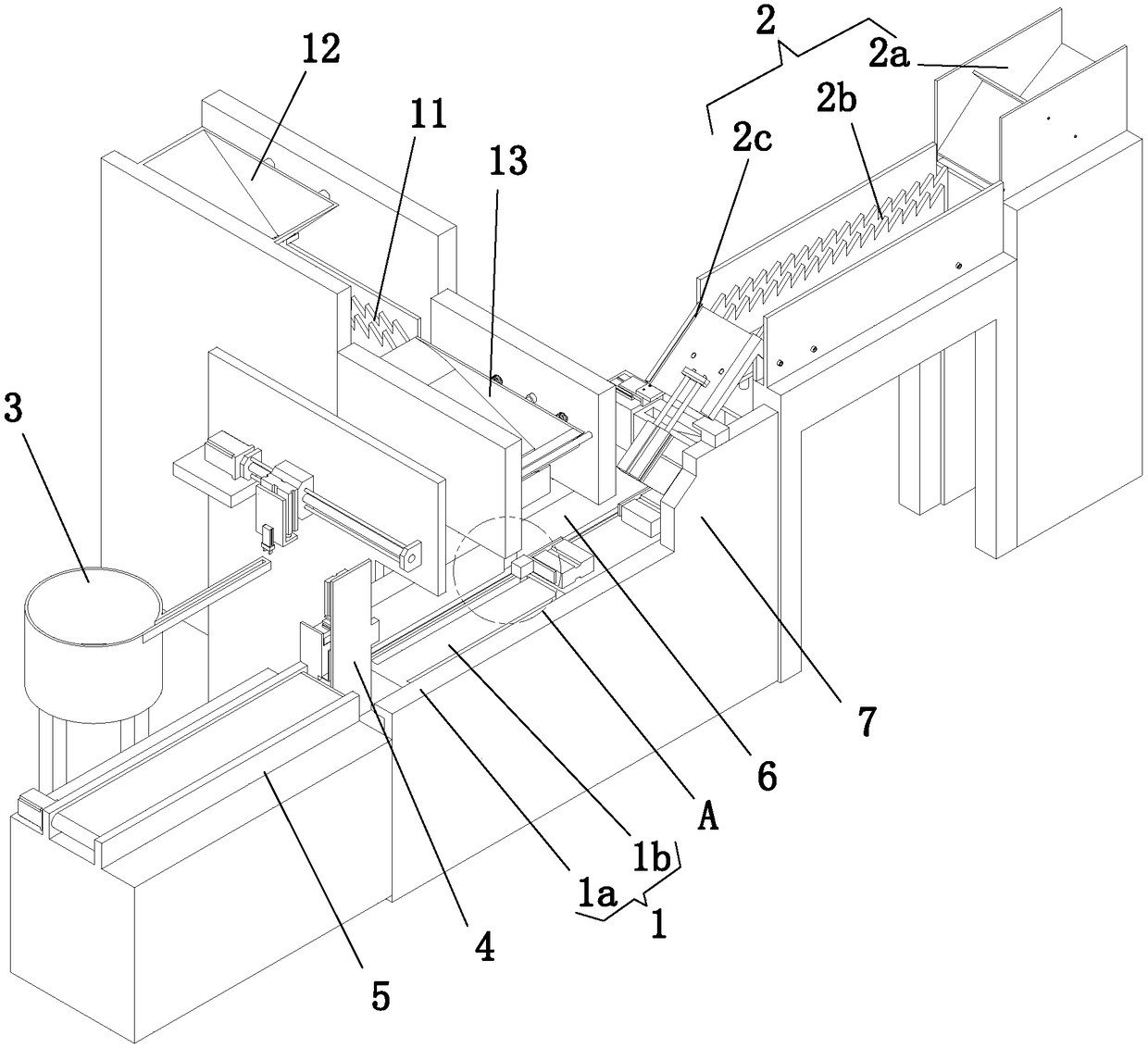

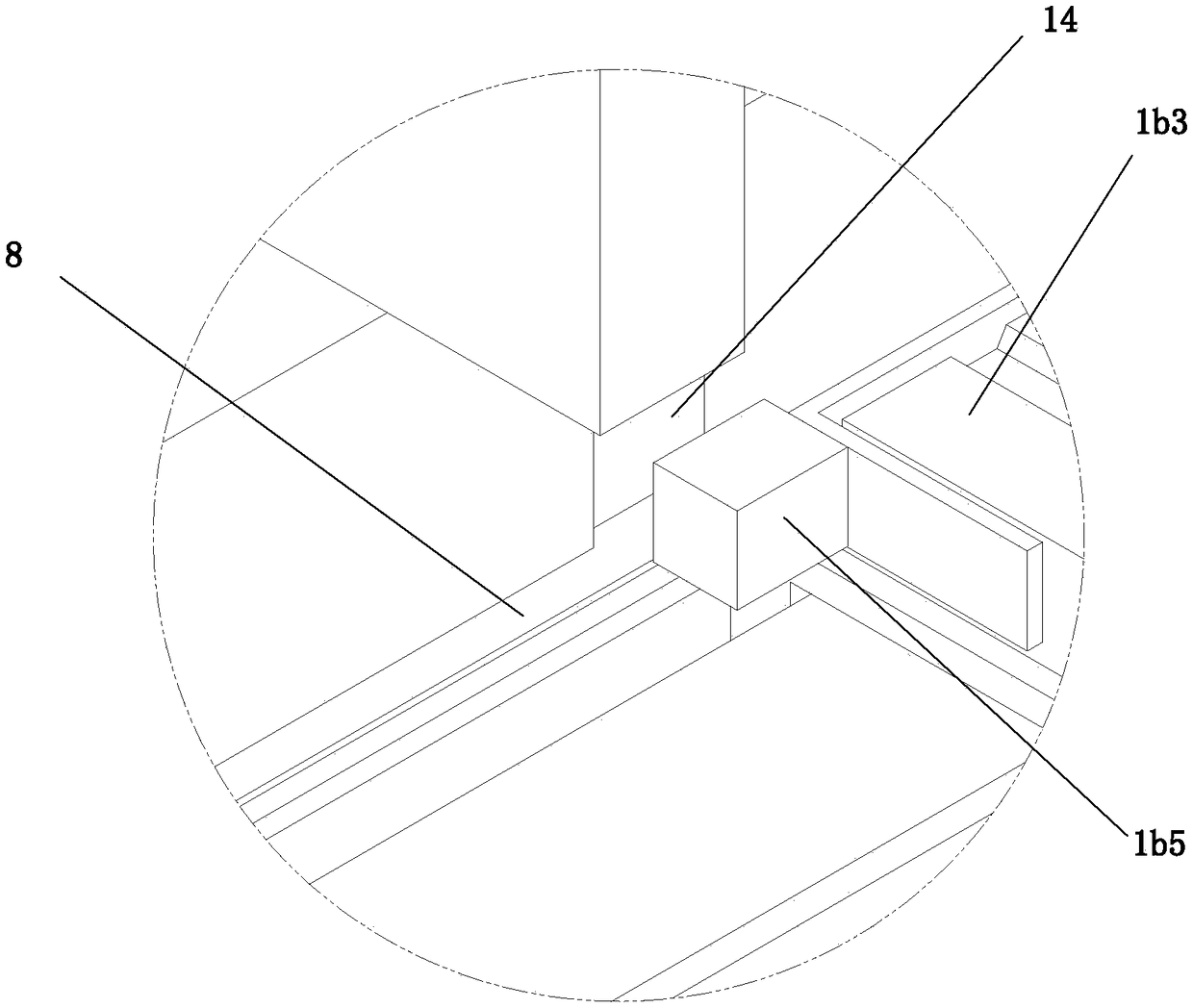

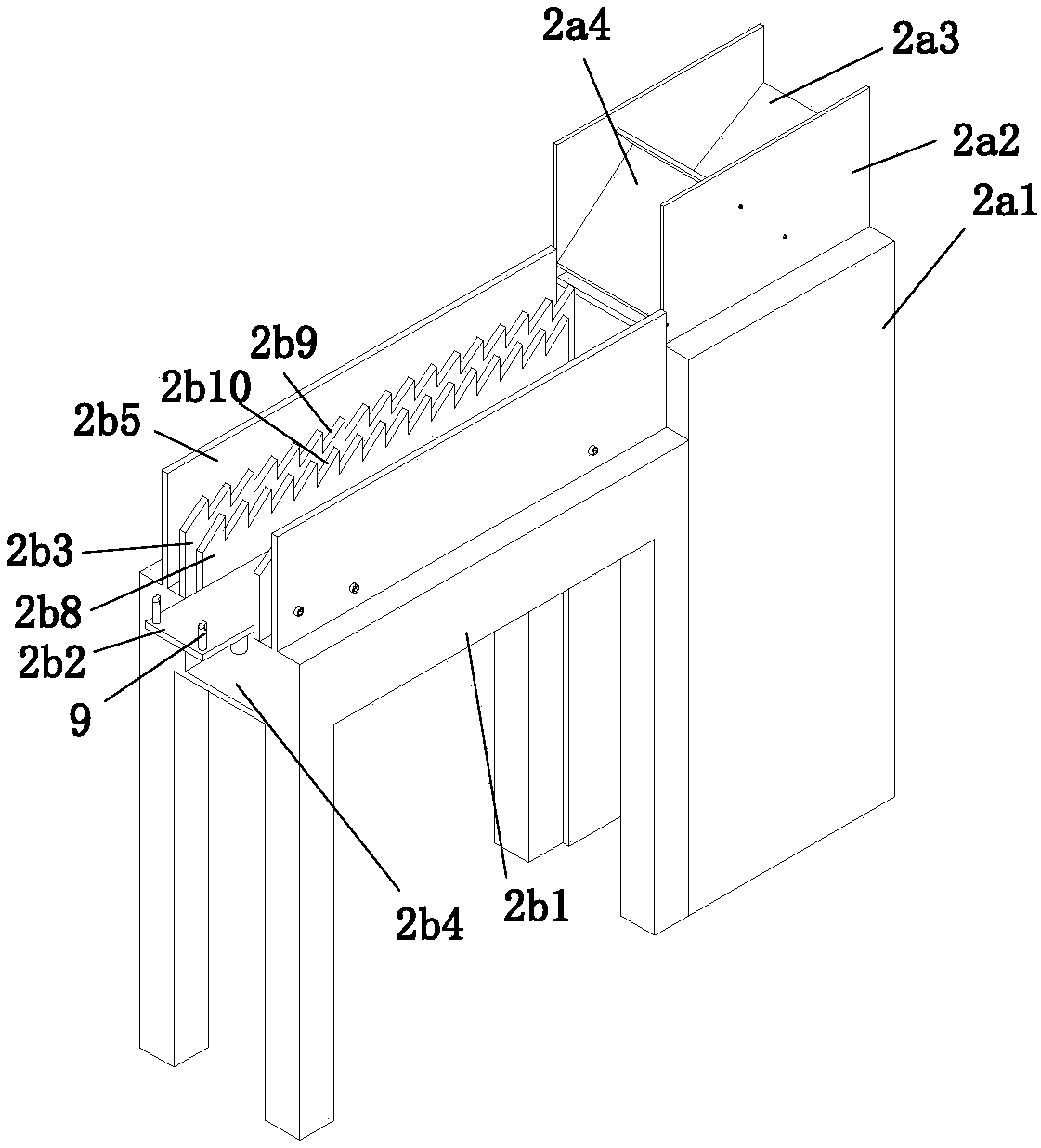

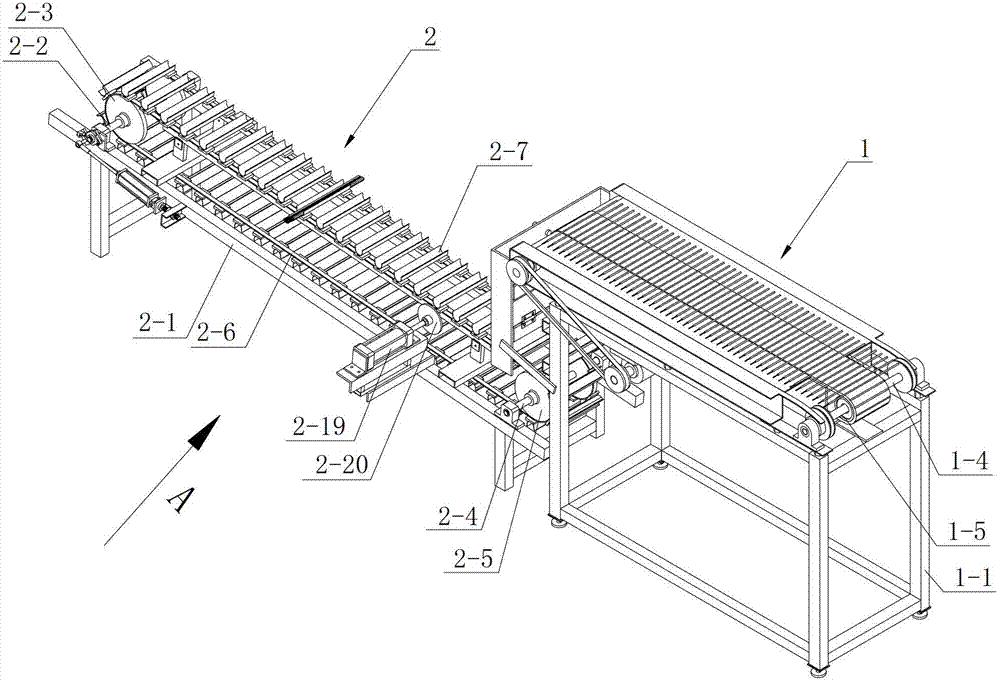

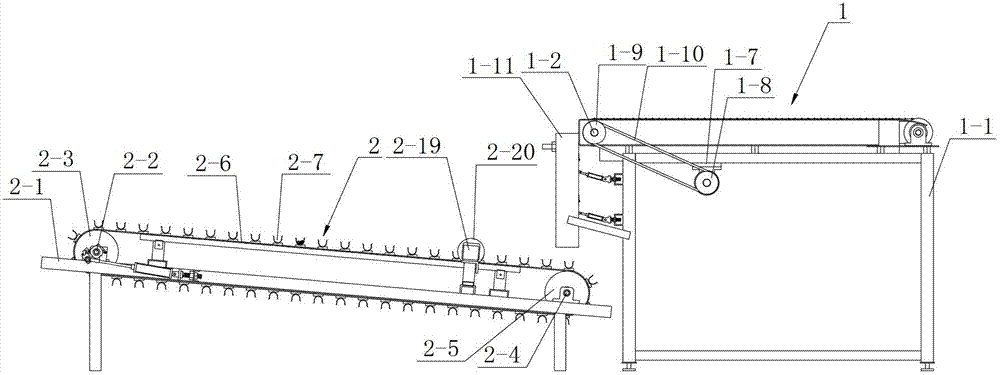

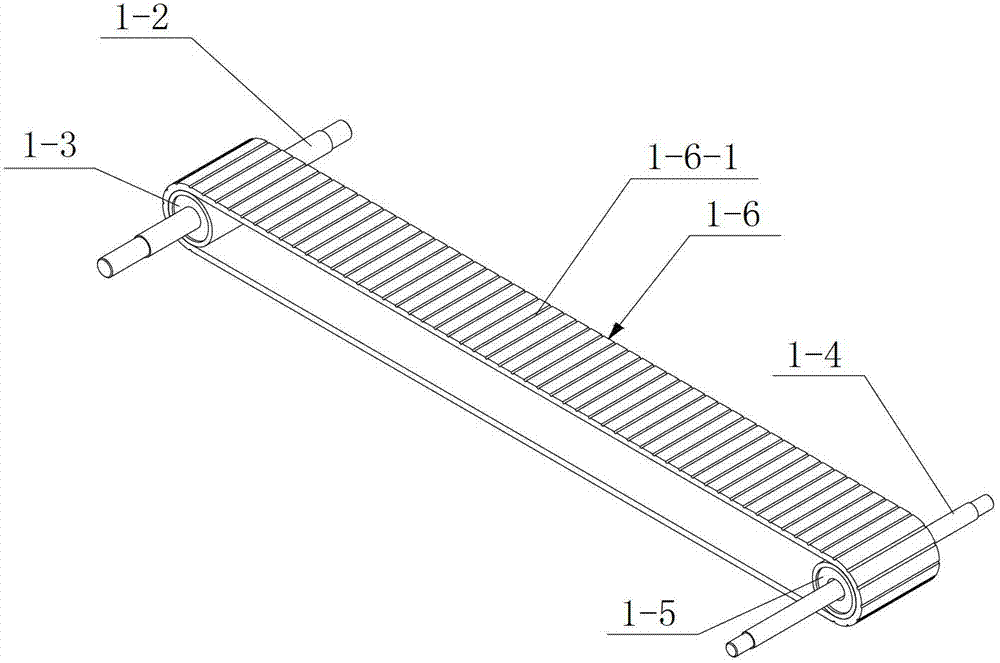

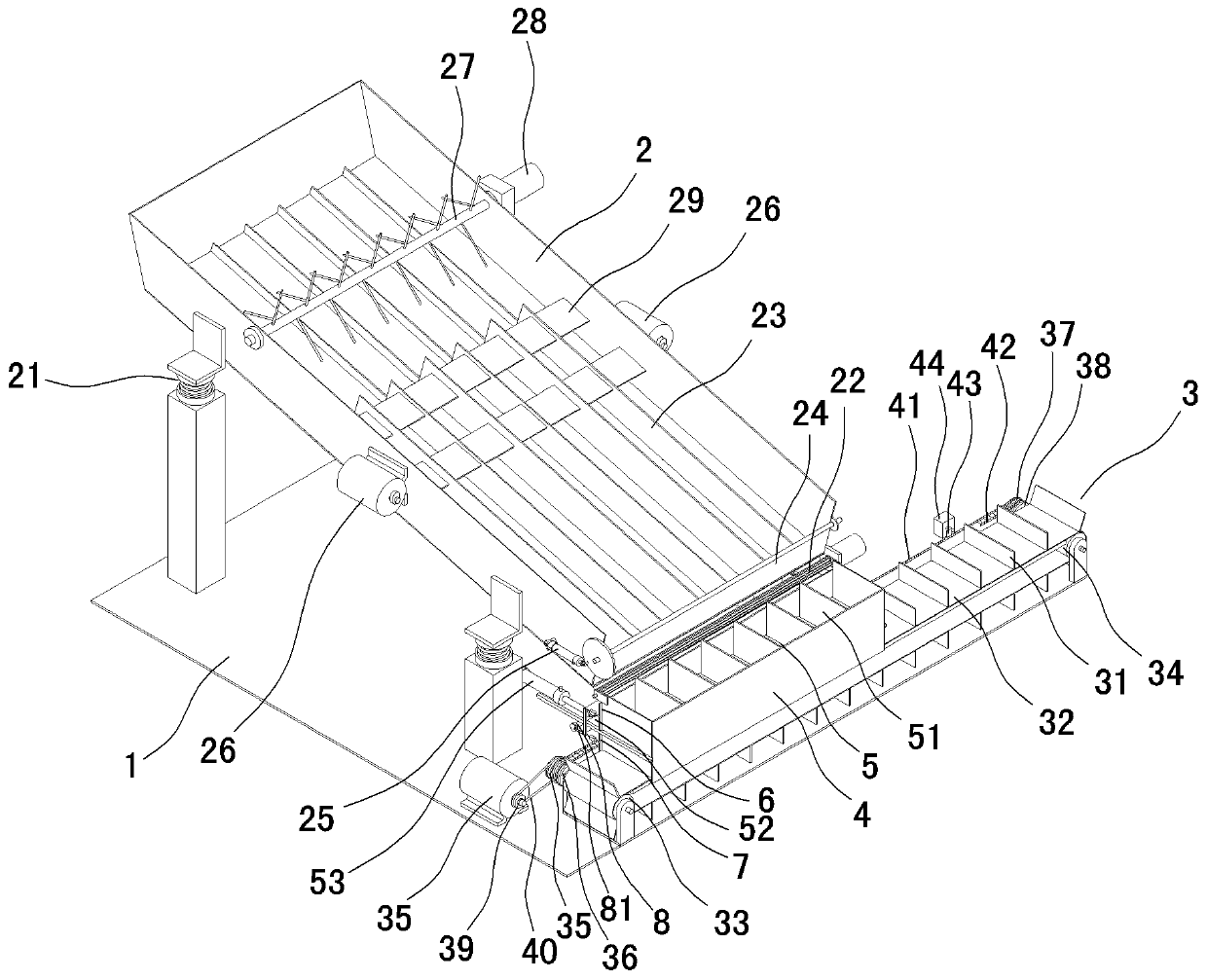

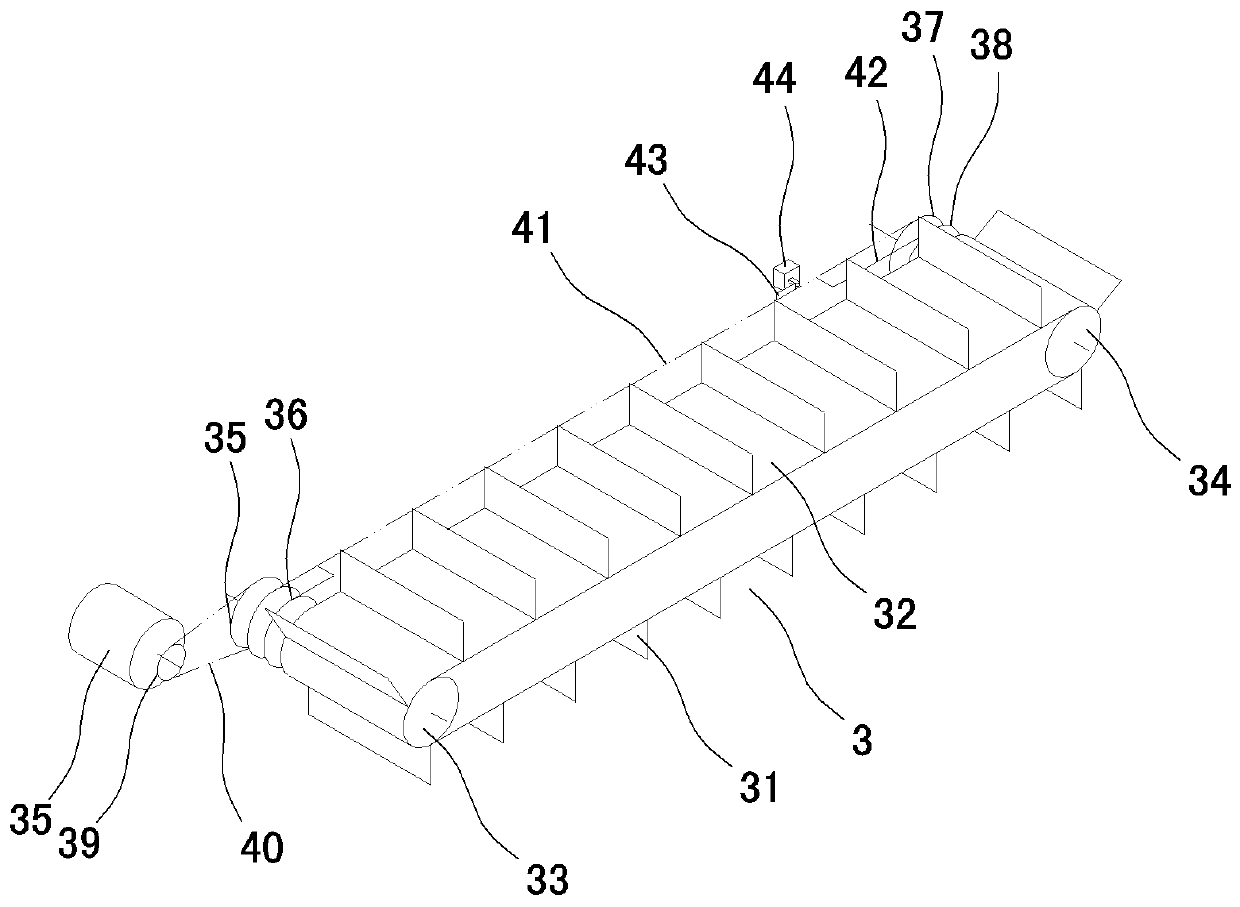

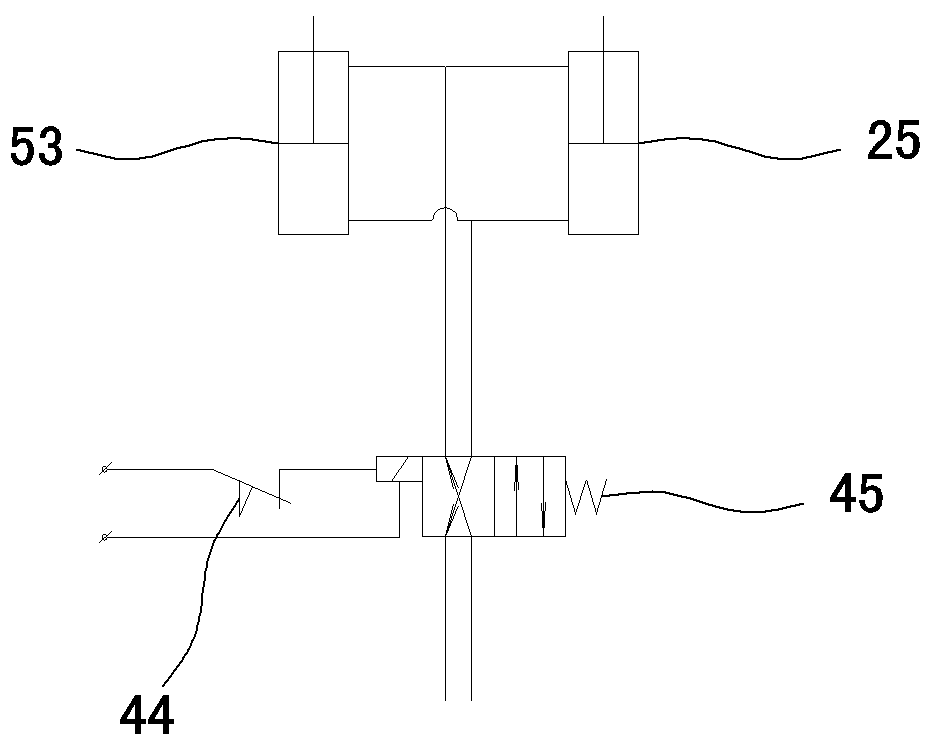

Wood rod and stick orderly arrangement device

InactiveCN107600497AStraighten outEasy to storeRod-shaped articlesFailure ratePulp and paper industry

The invention relates to a wood rod and stick orderly arrangement device. The wood rod and stick orderly arrangement device comprises a machine base (1), a vibrating guiding apparatus (2), a conveyingbelt (3) and a material blocking plate (4), wherein an intermittent material arrangement chamber (5) is disposed between the discharging side of the vibrating guiding apparatus (2) and the conveyingbelt (3); a bottom inserting plate (52) of the intermittent material arrangement chamber (5) serves as the chamber bottom of the intermittent material arrangement chamber (5); a sliding air cylinder (53) is disposed between the bottom inserting plate (52) and the machine base (1), and then the bottom inserting plate (52) is driven to open or close the bottom of the intermittent material arrangement chamber (5); a material blocking turnover plate (24) is arranged on the discharging side of the vibrating guiding apparatus (2); and a turnover air cylinder (25) is arranged between the material blocking turnover plate (24) and the vibrating guiding apparatus (2) and drives the material blocking turnover plate (24) to turn over. By means of the wood rod and stick orderly arrangement device, woodrods and wood sticks can be more orderly arranged, boxing is more convenient, manpower and labor work are further reduced, and the production cost can be reduced. The wood rod and stick orderly arrangement device is simple in structure, convenient to use, good in effect, low in failure rate and capable of reducing production procedures and shortening production time.

Owner:刘新涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com