Method for automatically packaging tubular product

An automatic packaging and pipe technology, applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of low work efficiency, high cost, time-consuming and labor-intensive material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

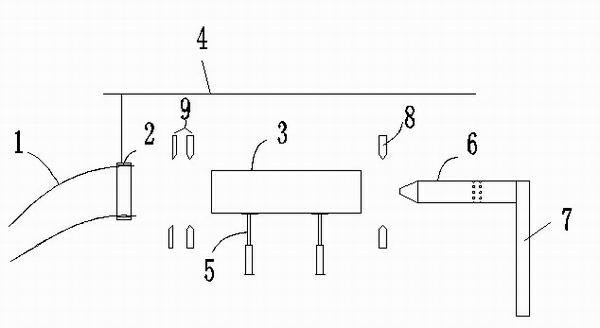

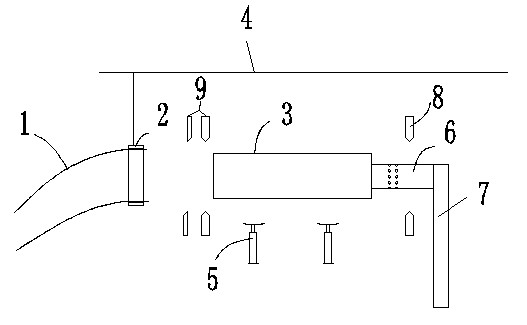

[0028] Such as figure 1 As shown, the material required for packaging the pipe 3 is a plastic film 1, and the plastic film 1 is in a roll shape. When packaging the pipe 3, the plastic film 1 is wrapped on the pipe 3 and heat-sealed at both ends. The pipe support 5 is used to support the pipe 3, and the pipe support 5 is telescopic, and its height can be adjusted as required. The vacuum ring 2 is located on the left side of the pipe support 5, and can move left and right under the drive of the vacuum ring cantilever 4. The intubation tube 6 is located on the right side of the pipe support 5, and can move left and right under the drive of the intubation support arm 7, and the tube wall of the intubation tube 6 has air holes. The axes of the vacuum ring 2 and the cannula 6 are approximately at the same height, the inner diameter of the vacuum ring 2 is larger than the outer diameter of the pipe 3 , and the outer diameter of the cannula 6 is smaller than the inner diameter of the...

Embodiment 2

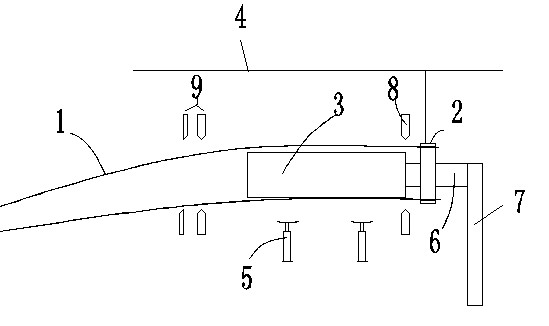

[0041] Such as Figure 5 As shown, the vacuum ring 2 is located on the left side of the pipe support 5 and can move left and right driven by the vacuum ring cantilever 4 . The intubation tube 6 is positioned at the right side of the pipe support 5, and the tube wall of the intubation tube 6 has an air passage hole. The inner diameter of the vacuum ring 2 is larger than the outer diameter of the pipe material 3 , and the outer diameter of the cannula 6 is smaller than the inner diameter of the pipe material 3 . The vacuum ring 2 is circular. Its structure and arrangement differ from Embodiment 1 in that: the pipe support 5 has a fixed height, and the intubation tube 6 can move not only left and right but also up and down driven by the intubation support arm 7 . The heat sealing machine 8 is arranged between the intubation tube 6 and the pipe material 3 to heat seal the plastic film 1; the heat sealing cutting machine 9 is arranged between the vacuum ring 2 and the pipe materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com