Patents

Literature

232results about How to "Implement packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

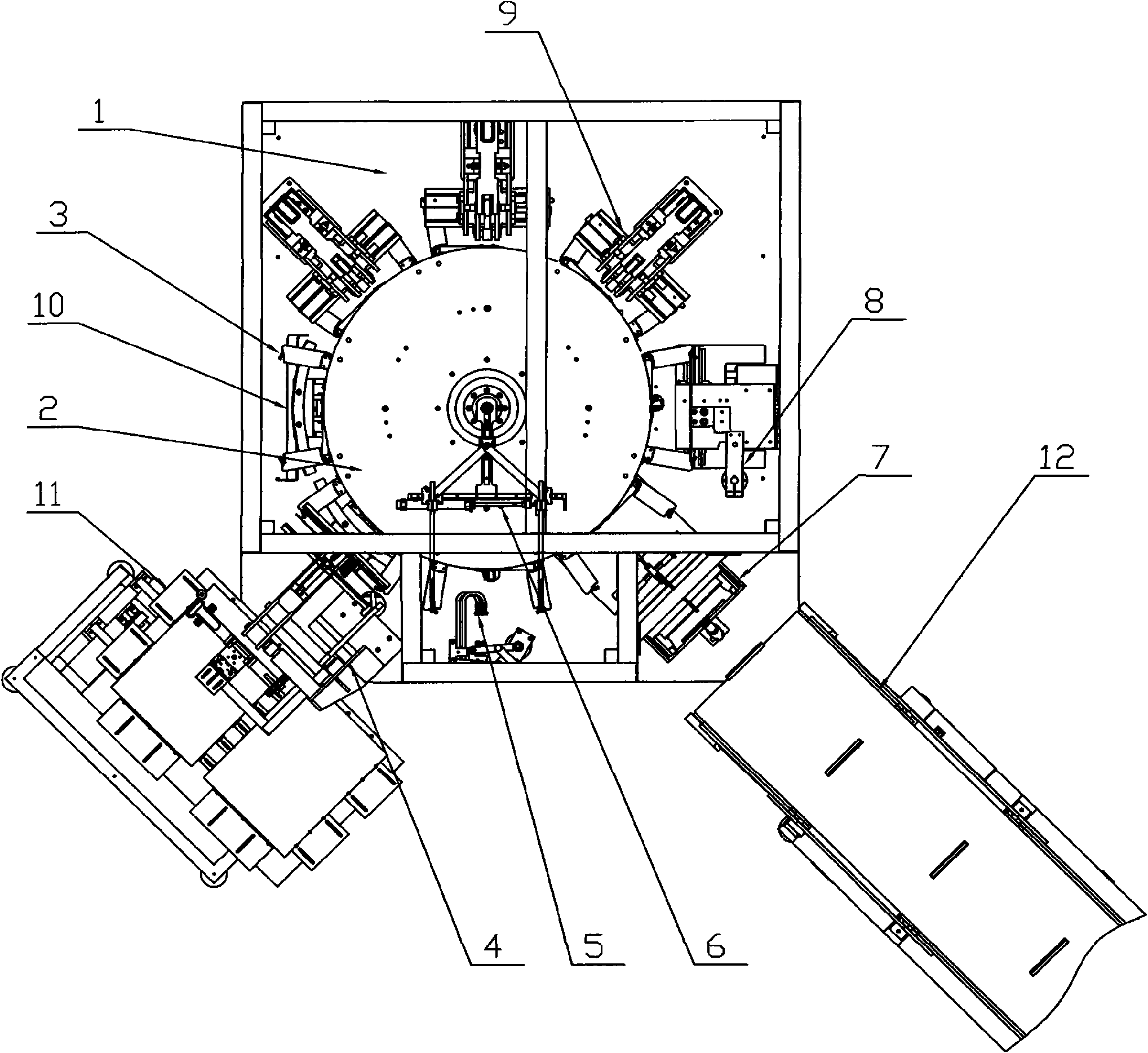

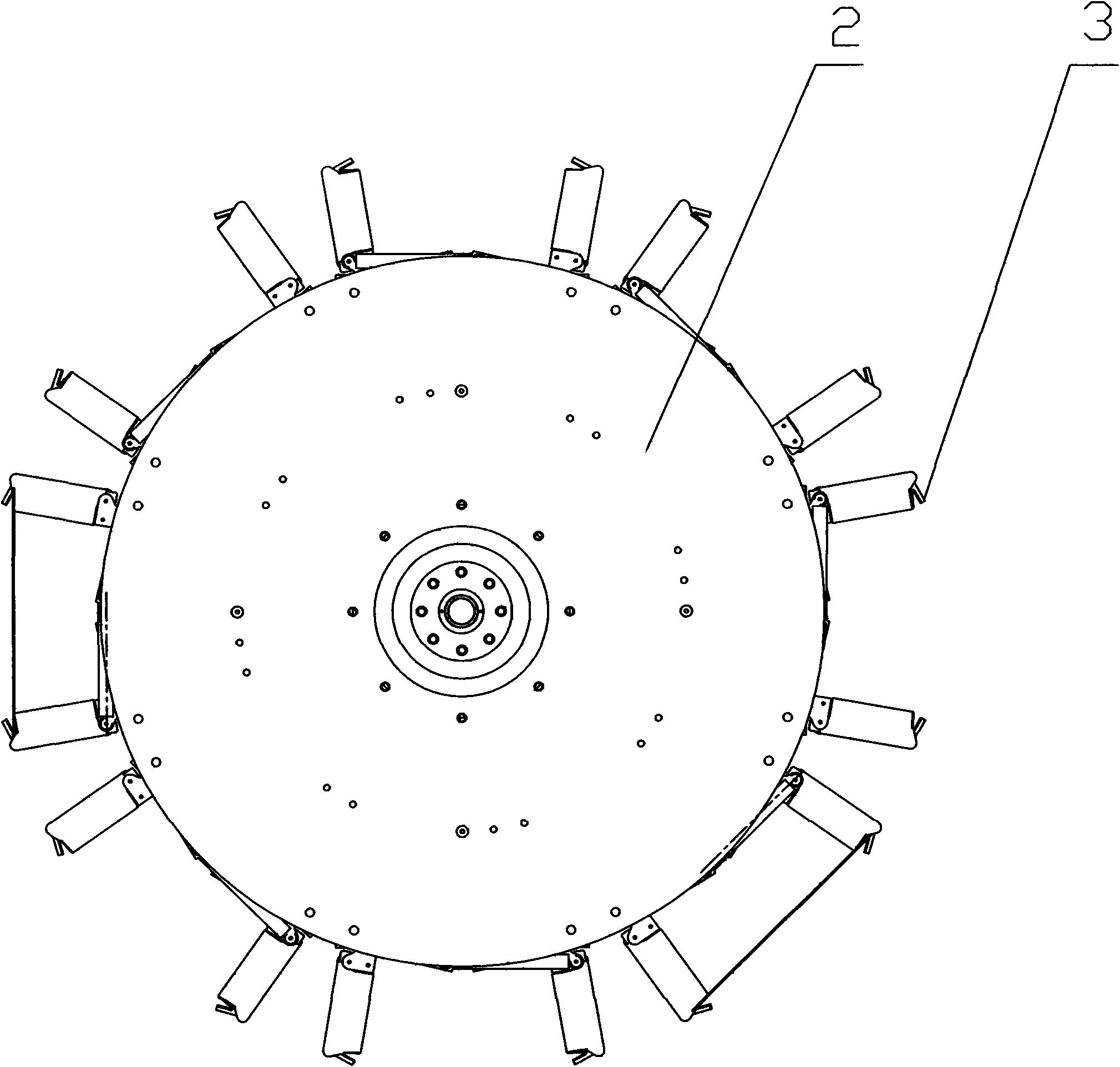

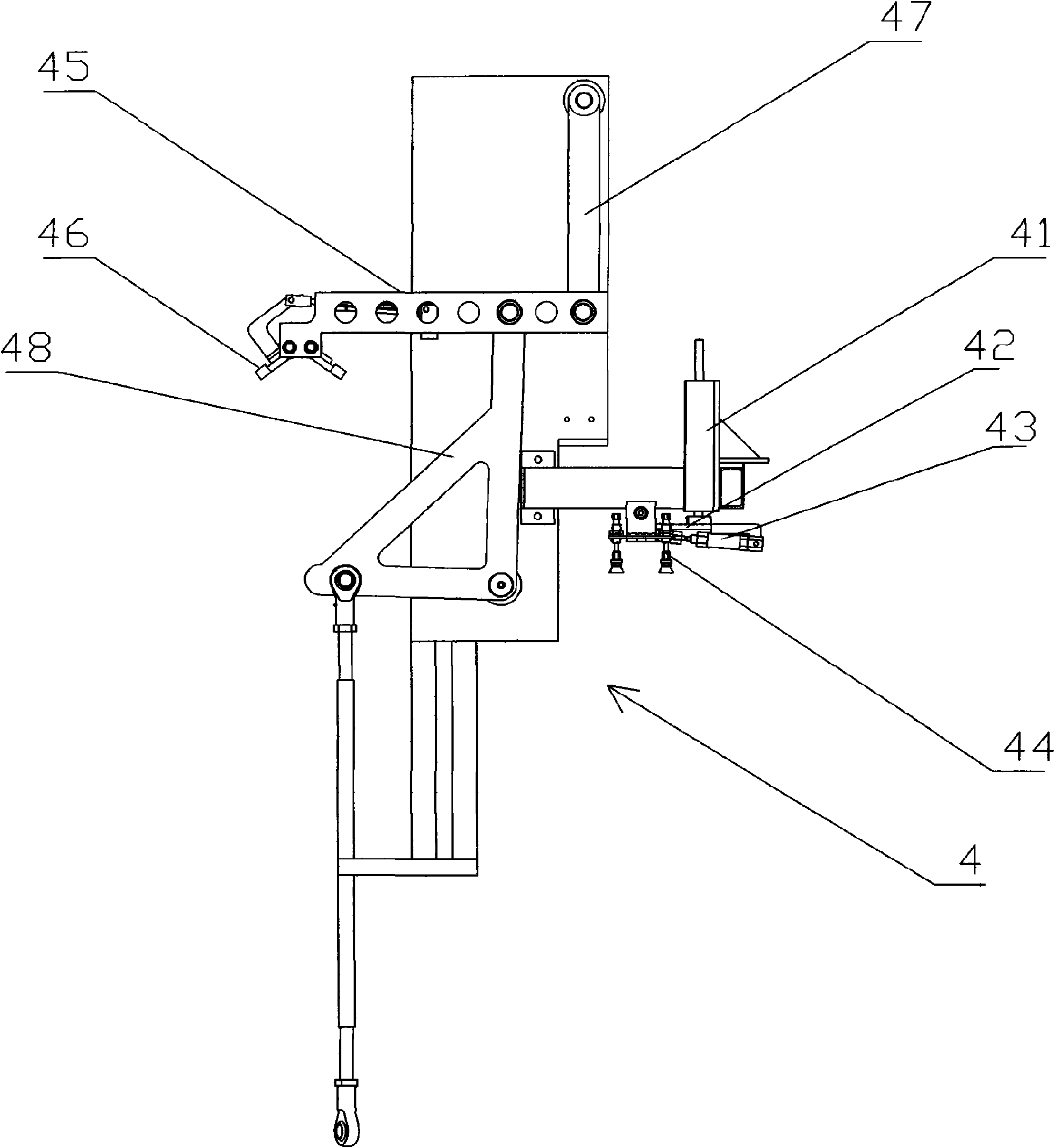

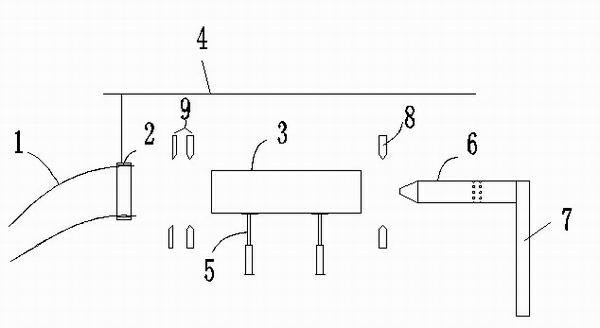

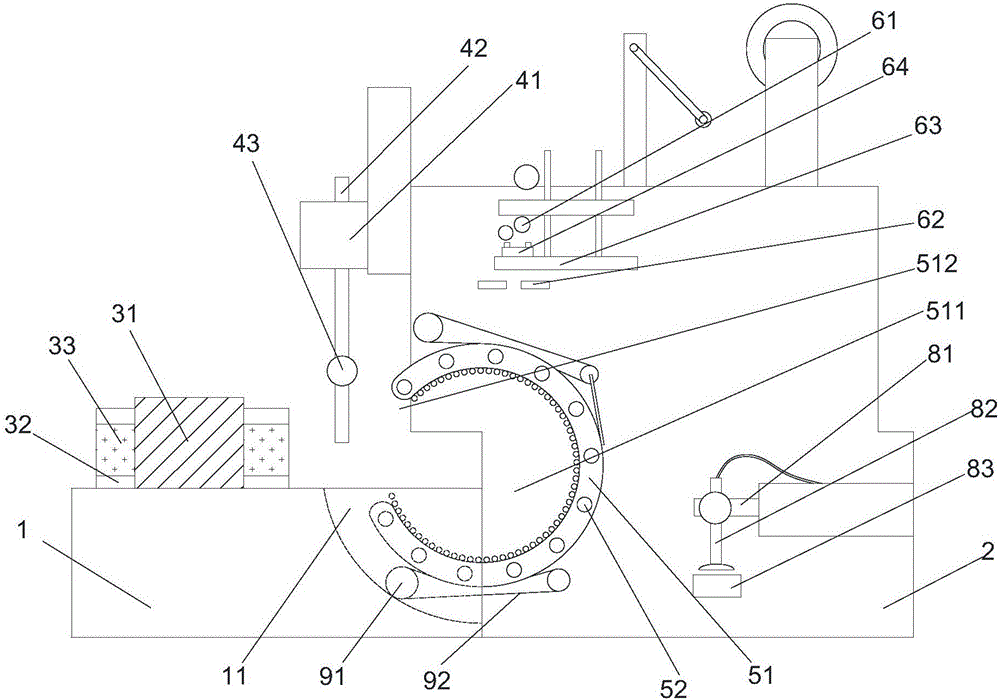

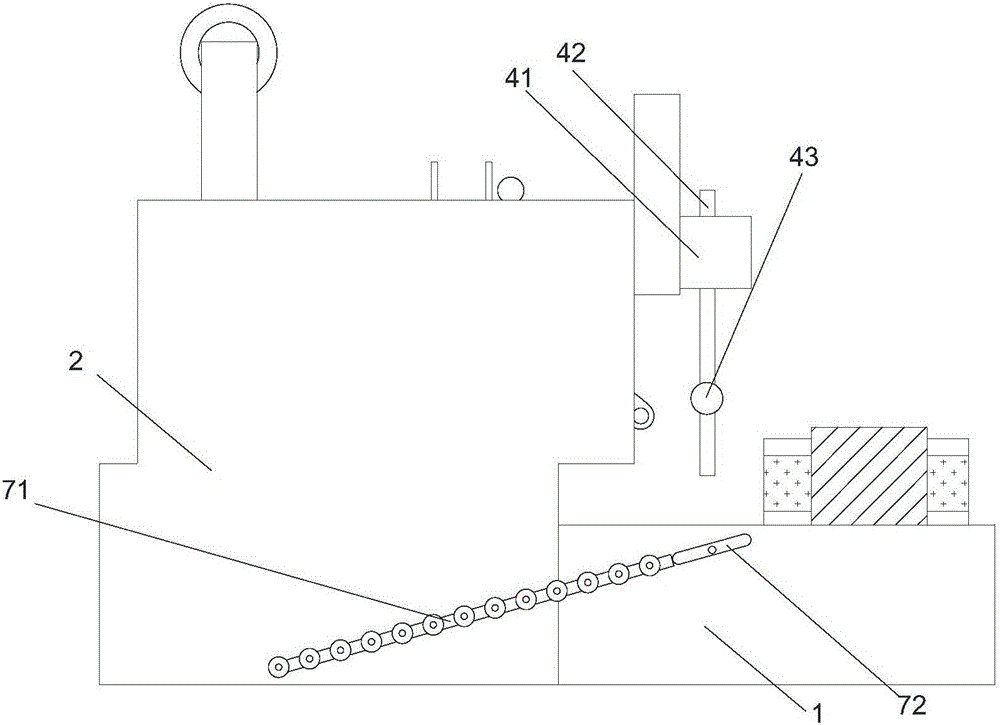

Method for packaging large flatbreads and fully-automatic flatbread packaging machine for achieving same

InactiveCN101590920ASimple methodImprove processing efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringPlastic bagEngineering

The invention relates to a method for packaging large flatbreads and a fully-automatic flatbread packaging machine for achieving the same. The method comprises the following steps: taking bags: picking up packaging bags; opening the packaging bags: opening bag openings of the packaging bags; keeping the packaging bags open: using a mechanism to keep the bag openings of the packaging bags in an open state; filling the large flatbreads: filling the large flatbreads into plastic bags smoothly by using a conveying belt and a charge mechanism; vacuumizing the plastic bags: discharging the air in the plastic bags to the outside by using a vacuumizing pipe; and sealing the plastic bags: sealing the bag openings of the plastic bags to finish the packaging. The fully-automatic flatbread packaging machine comprises a stander, a turntable arranged on the stander, and a plurality of pairs of clips arranged on the periphery of the turntable. The periphery of the turntable is provided with a bag-delivering mechanism, a bag-opening mechanism, an oscillating bag-opening mechanism and the charge mechanism in turn, and then the periphery of the turntable is provided with a vacuumizing sealing mechanism for vacuumizing the air in the plastic bags and sealing the bag openings preliminarily, a sealing mechanism for completely sealing the bag openings of the plastic bags, and a shedding mechanism for taking down the plastic bags from the clips in turn.

Owner:ZHONGSHAN NCA

Method for automatically packaging tubular product

InactiveCN102180281AIncrease production capacityImplement packagingConveyor wrappingRod-shaped articlesProduction linePunching

The invention discloses a method for automatically packaging a tubular product. By steps of punching bags, installing tubes, inserting the tubes, lifting, wrapping the tubes, exchanging air, thermally encapsulating and cutting, emptying a position and the like, automation is realized in the whole process, complicated carrying work in manual packaging operation is avoided, production and working efficiency is improved, labor intensity of packaging is reduced, and production cost is lowered greatly; therefore, the method is matched with a tubular product extrusion production line, so that automatic continuous production and packaging of the tubular product can be realized.

Owner:陈蕴

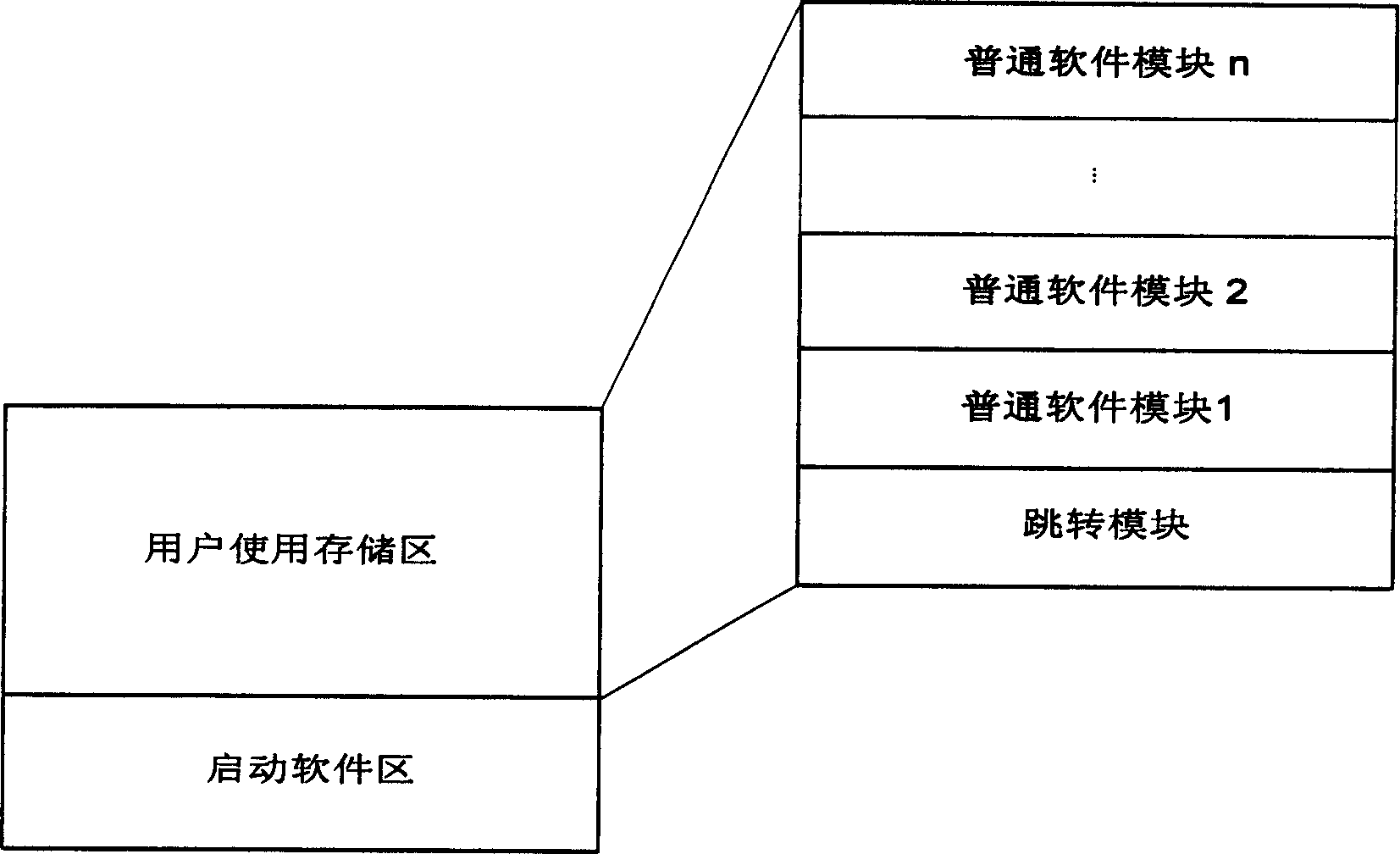

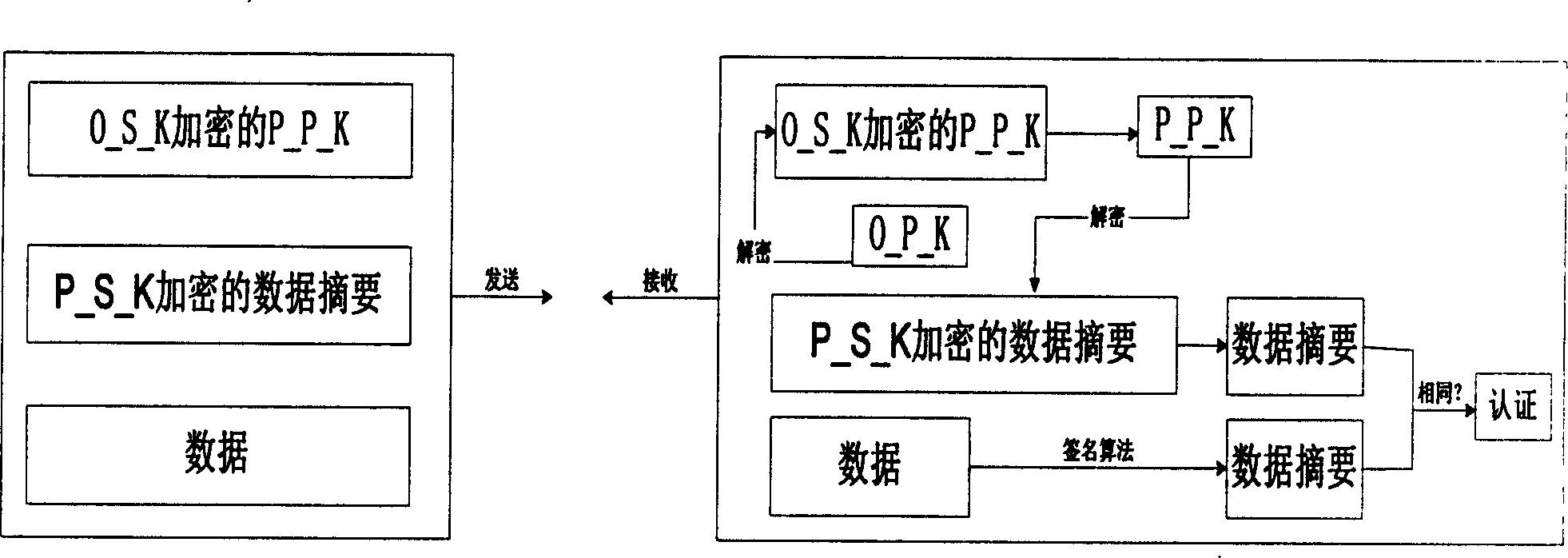

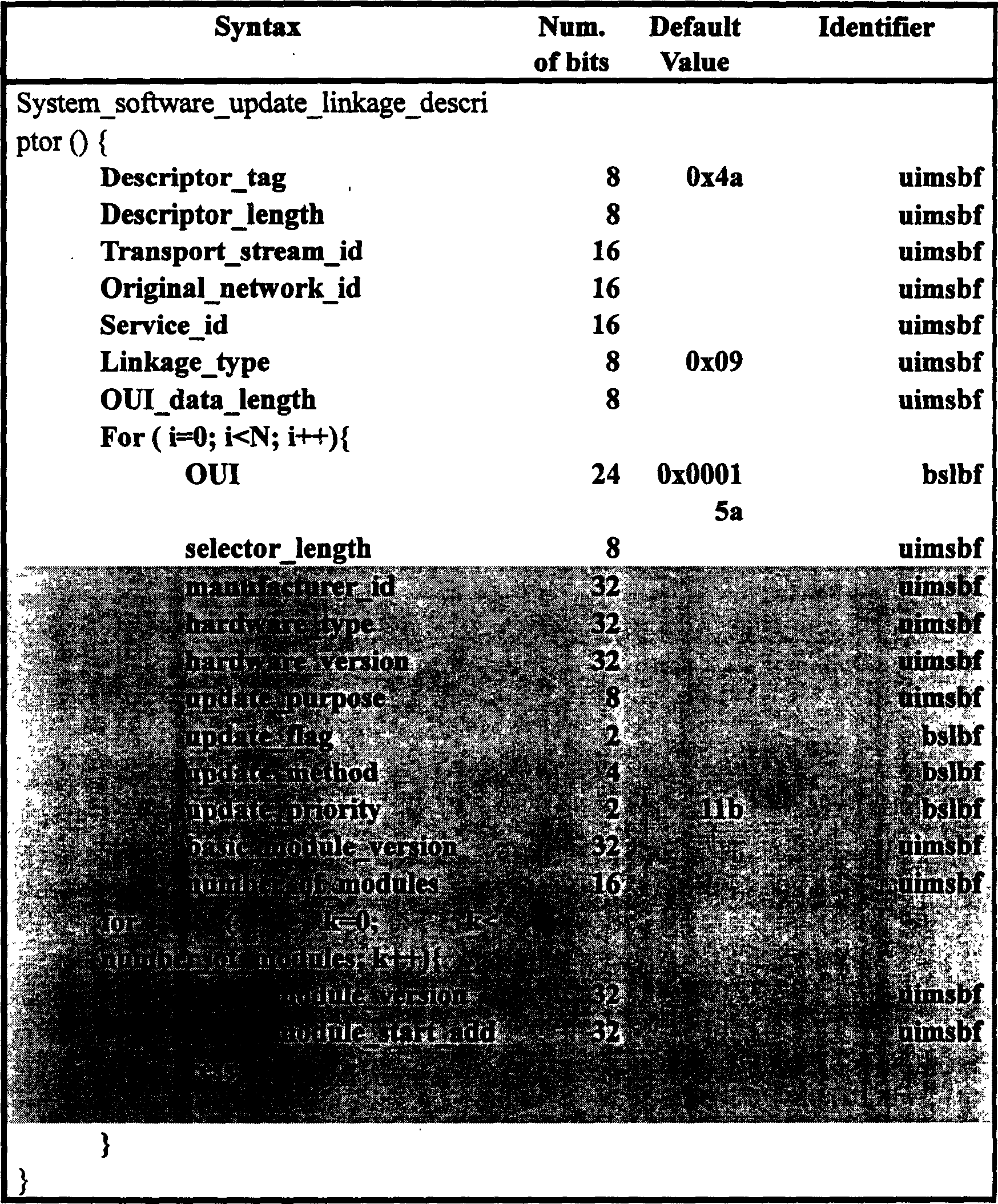

Method for upgrading software of digital terminal system in DVB system

InactiveCN1798034AIncrease flexibilityImplement packagingProgram loading/initiatingData switching networksSoftware engineeringComputer module

Method for upgrading system software of digital terminal in DVB system includes steps: partitioning the system software into multiple software modules, and dividing up storage space of digital terminal into multiple storage zones, each software module occupies one piece of storage zone; upgrading system software by using software as unit; when software module in system software is needed to upgrade, the method only transfers upgrading module, which is corresponding to the software module to be upgraded, to the digital terminal; in the digital terminal, the upgrading module replaces the corresponding software module. Allocation of storage space in digital terminal strengthens flexibility for upgrading system software. Advantages are: in time of transferring data, only software module to be upgraded is transferred; in time of upgrading system software; only some necessary software modules are upgraded without need of upgrading all software module.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

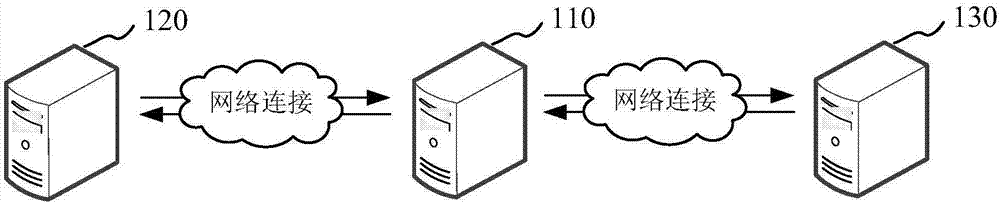

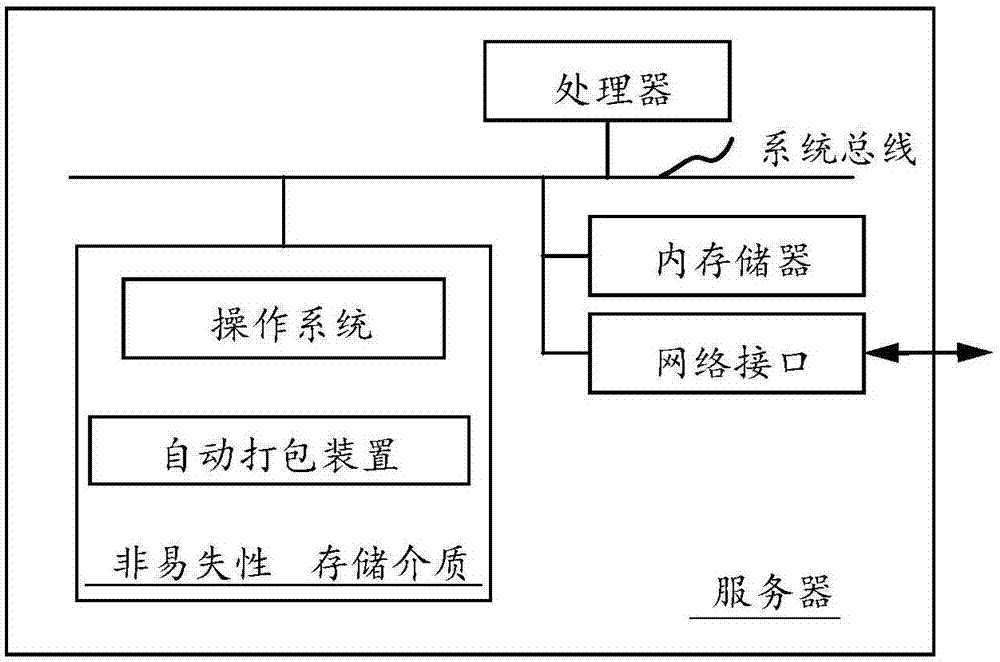

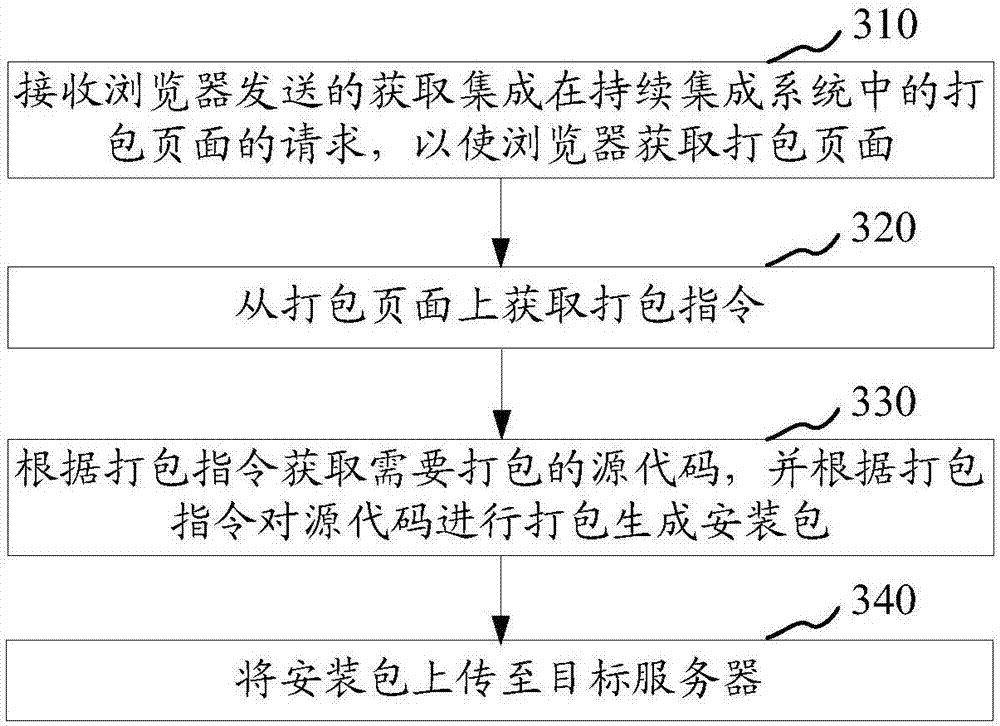

Automatic packaging method and device, storage medium and computer equipment

InactiveCN107450941AImplement packagingSave time and effortProgram loading/initiatingSoftware deploymentComputer equipmentSource code

The invention relates to an automatic packaging method and device, a storage medium and computer equipment. The method comprises the steps of receiving a request for obtaining a packaging page integrated in a continuous integration system sent from a browser, to enable the browser to obtain the packaging page; obtaining a packaging instruction from the packaging page; obtaining a source code to be packaged based on the packaging instruction; and packaging the source code for generation of an installation package based on the packaging instruction and uploading the installation package to a target server. According to the method, the packaging function is integrated in the continuous integration system, and the packaging page integrated in the continuous integration system can be accessed via the browser for packaging. The computer in the invention finishes packaging only by the browser without installation of a special packaging tool; and during packaging, packaging of the source code is realized simply by inputting the packaging instruction according to packaging requirements on the packaging page, without contact of the source code and developers for packaging, so as to save time and energy of the developers.

Owner:深圳市小牛在线互联网信息咨询有限公司

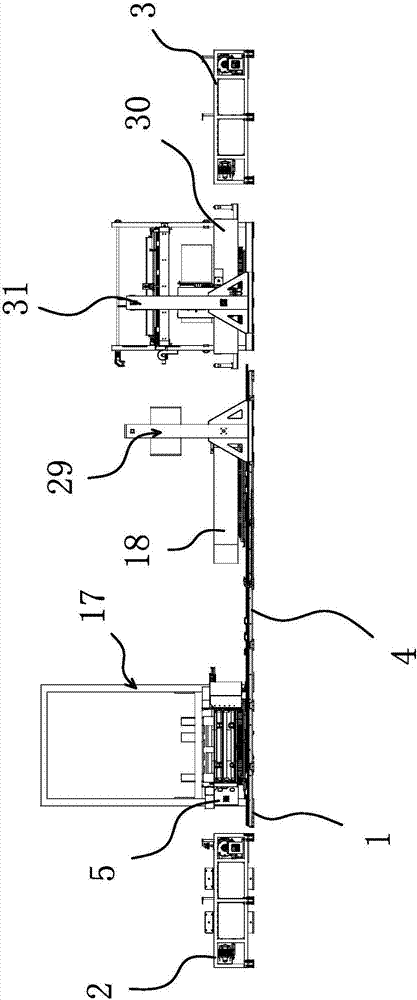

Automatic silk stocking packaging production line

InactiveCN105584666ARealize automatic linerAchieve foldingWrapper twisting/gatheringIndividual articlesCardboardEngineering

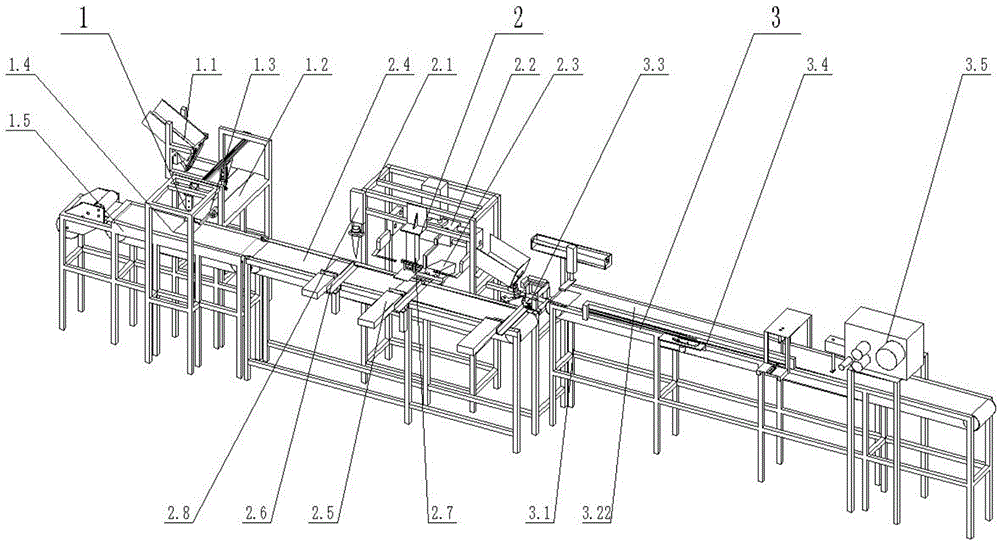

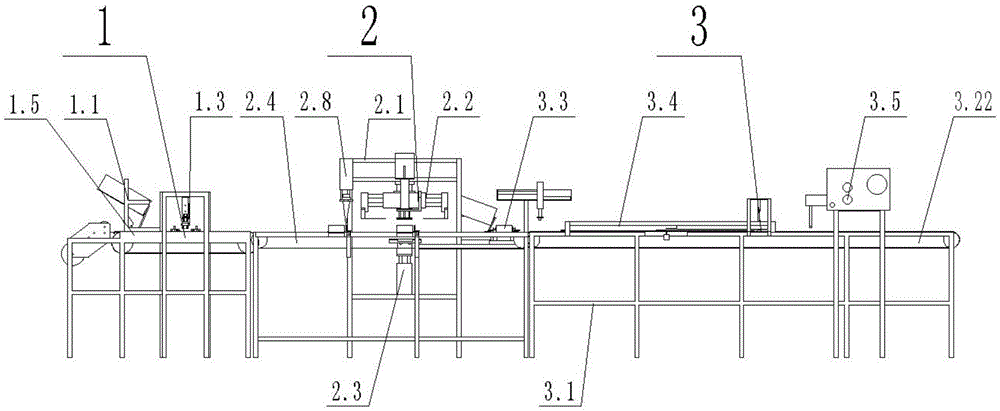

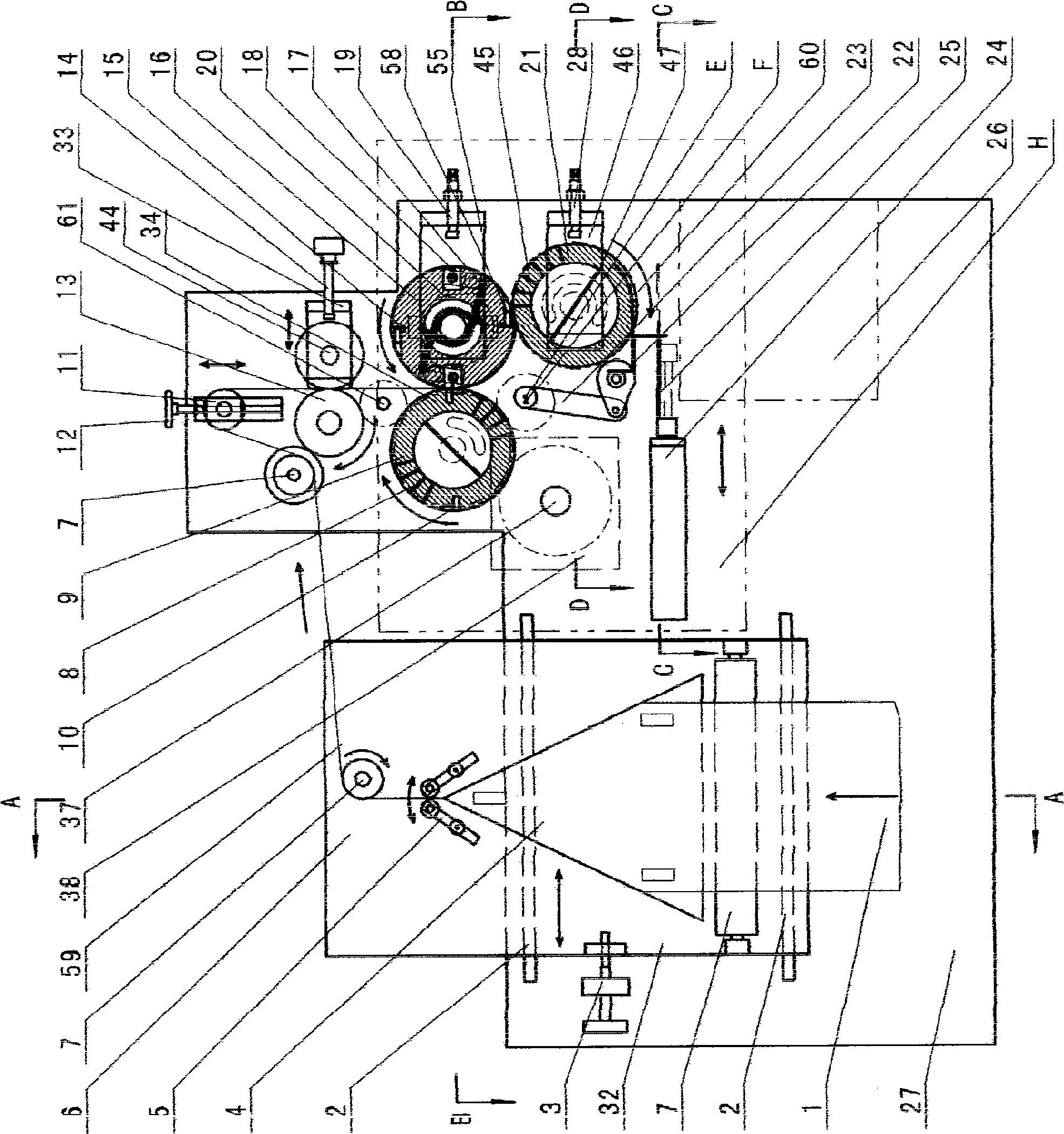

Provided is an automatic silk stocking packaging production line. The automatic silk stocking packaging production line comprises an automatic bagging mechanism, an automatic glue injection and sealing mechanism and an automatic boxing and sealing mechanism. Silk stockings sequentially pass through all the mechanisms on a conveying belt, the automatic bagging mechanism is used for automatically conveying the silk stockings into packaging bags after folding the silk stockings on a paper board, and the automatic glue injection and sealing mechanism is used for injecting glue to bag openings of the packaging bags containing the silk stockings and automatically sealing the bag openings. The automatic bagging and sealing mechanism is used for automatically putting the packaging bags containing the silk stockings into paper boxes and automatically sealing openings.

Owner:HEBEI UNIV OF TECH

Technique for folding and producing adsorption type napkin paper and device thereof

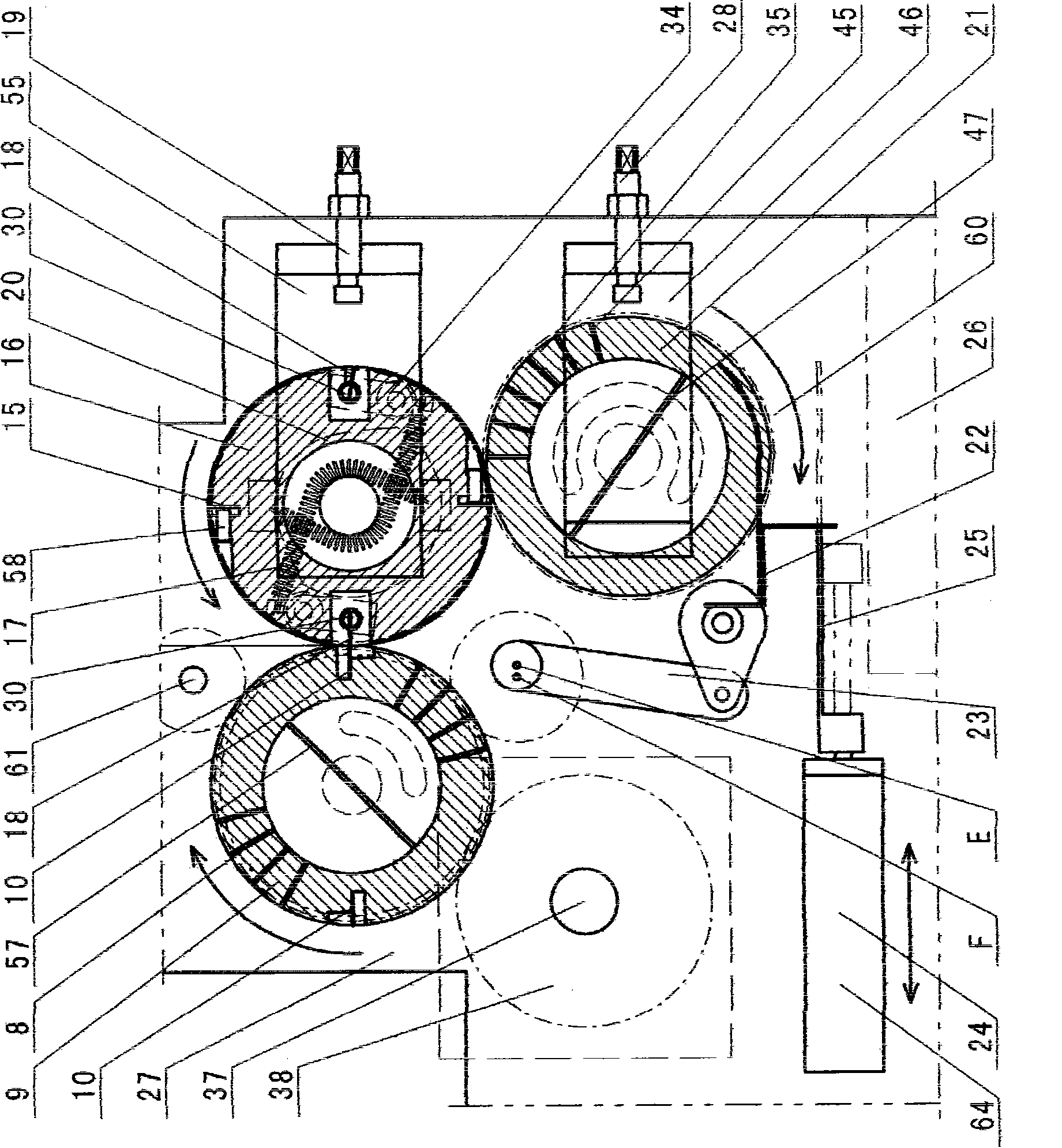

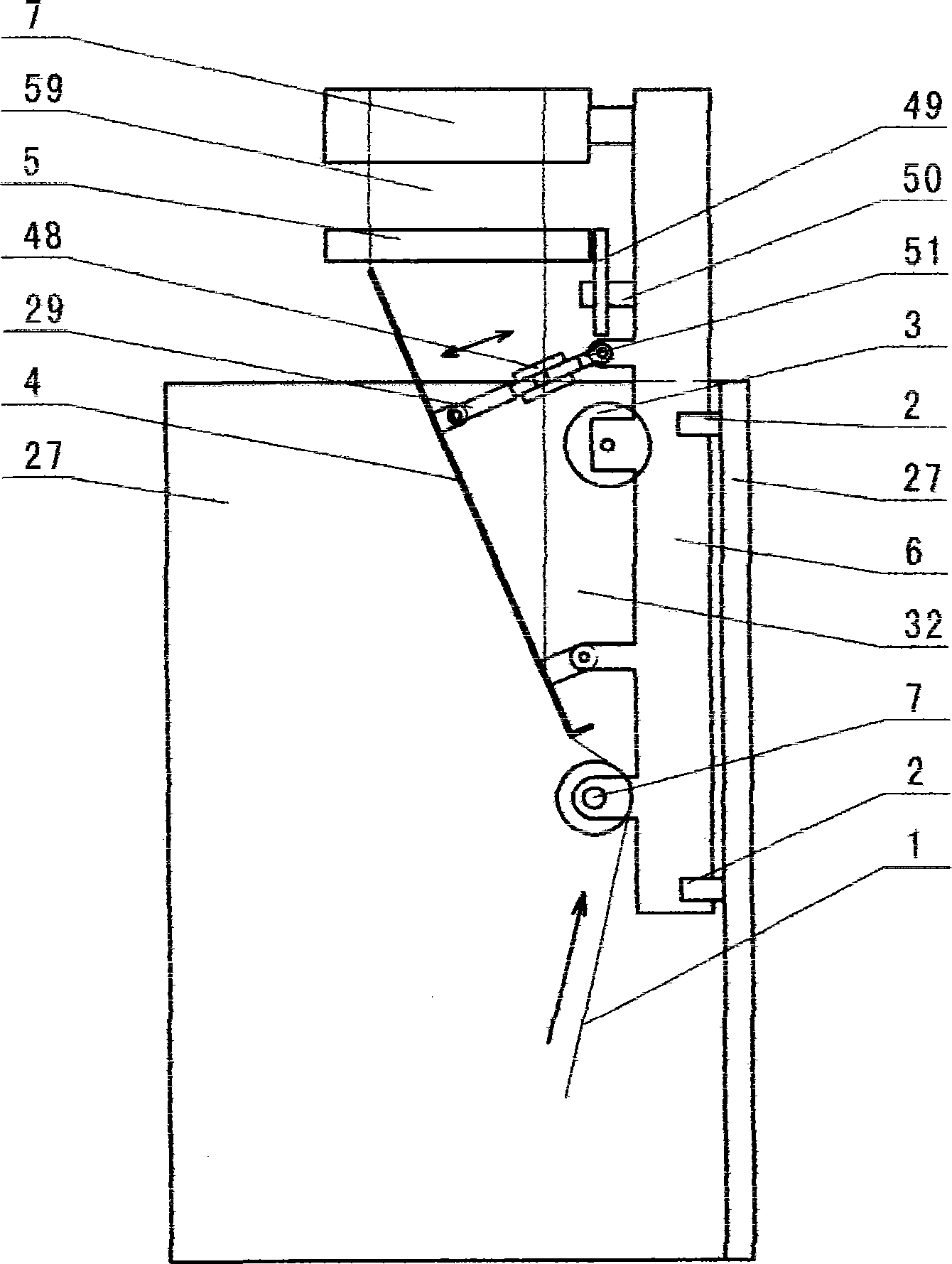

InactiveCN101474891ARealize in-line printingRealize the collectionPaper/cardboard articlesHigh ratePulp and paper industry

The invention relates to a high-speed adsorption napkin paper folding and manufacturing process and device needing wire printing and folding. The prior adopted mechanical linkage vertical folding structure has the defects of complex structure, low folding accuracy, more fault points, low rate of finished products, low production efficiency, and the like. Therefore, the invention designs the adsorption napkin paper folding and manufacturing process and device. The process comprises that: the napkin paper is pulled by a traction mechanism, aligned and longitudinally folded by a longitudinal folding mechanism, smoothed by a compression roller and then aligned by an aligning mechanism, fed into an adsorption transversely folding mechanism through the traction mechanism and then aligned and transversely folded; and then the longitudinally folded paper is cut by a cutting knife roll, and manufactured into finished products by an adsorption counting mechanism and a collecting and packaging mechanism. The process and the device achieve wire printing and folding of the napkin paper conveniently and reliably, have the advantages of high folding accuracy, few fault points, high rate of finished products, high production efficiency, stable quality of the products and low production cost, and are suitable for large-scale industrialized production.

Owner:李玉龙

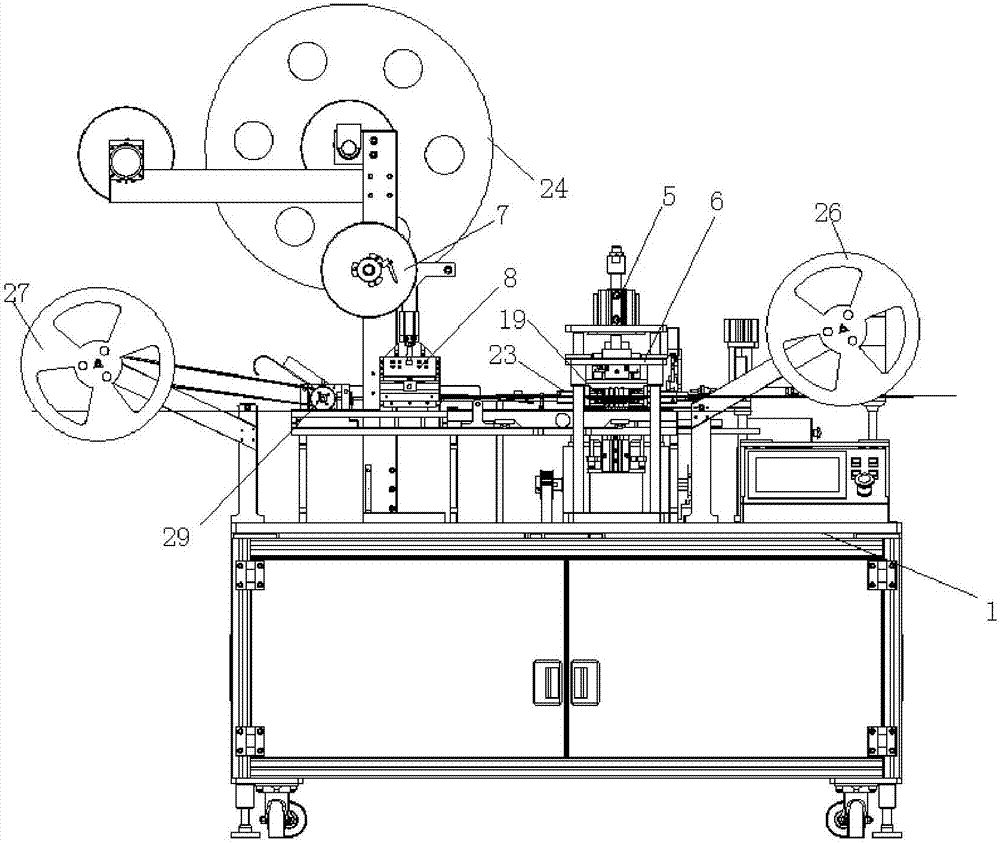

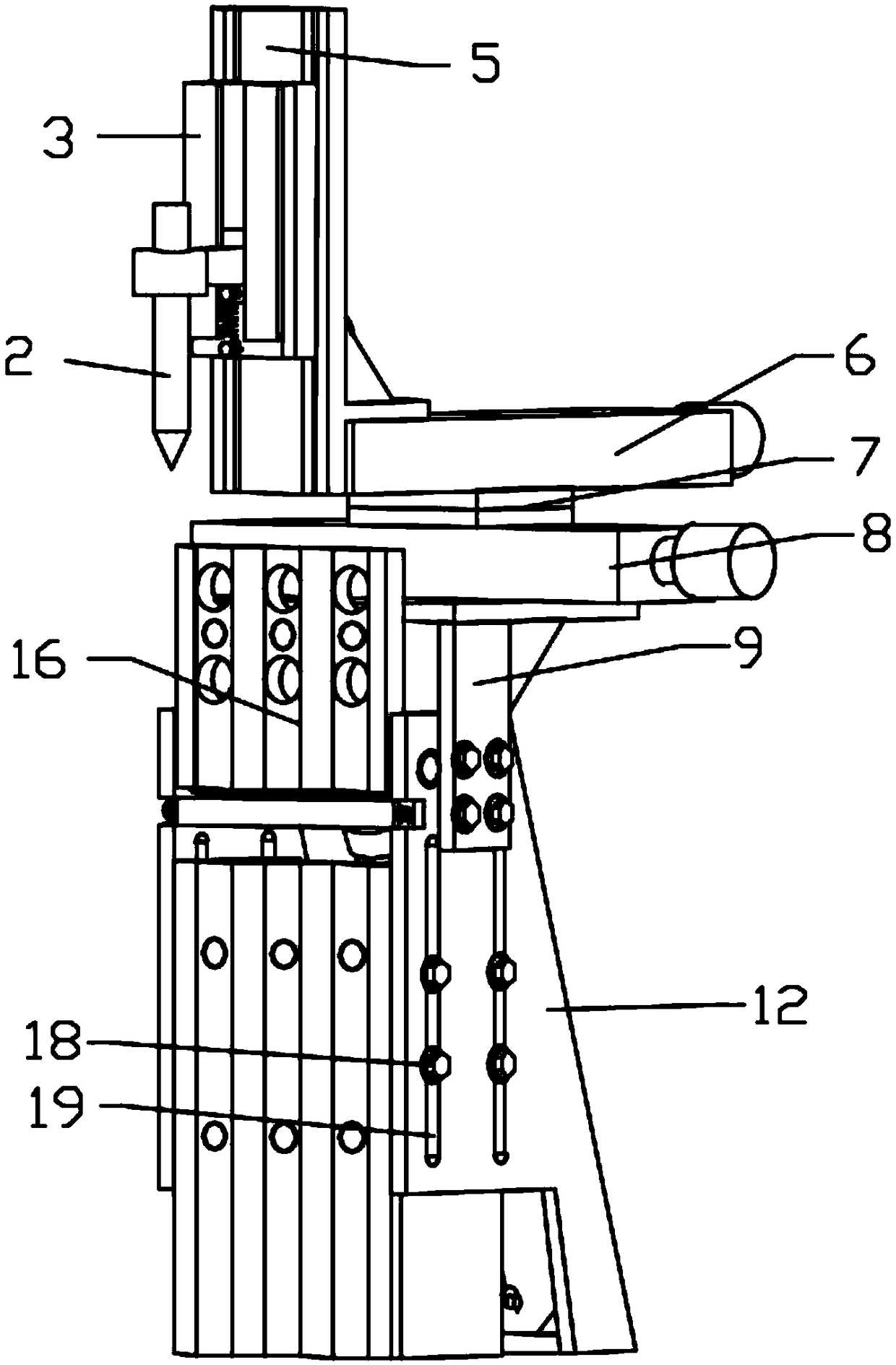

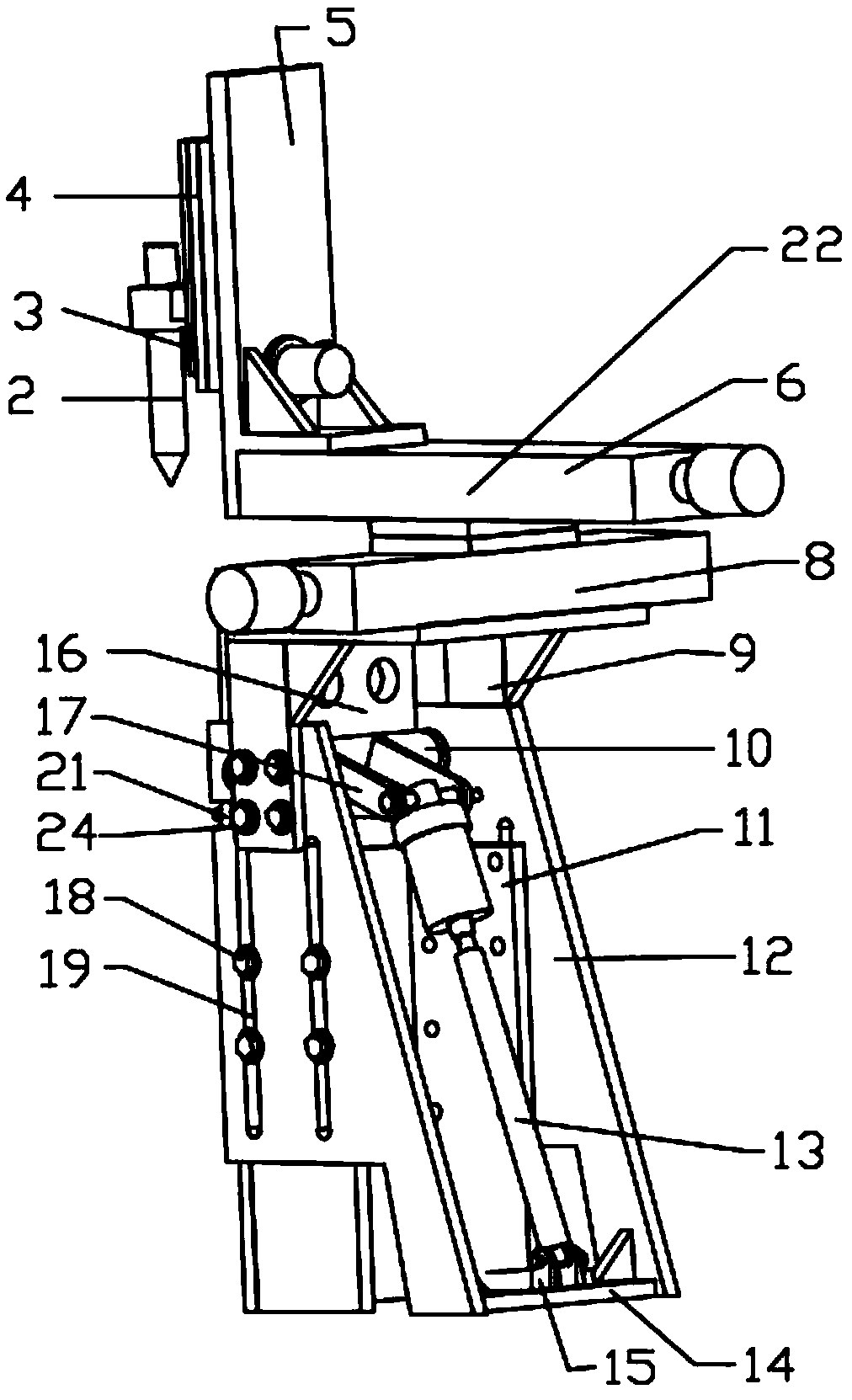

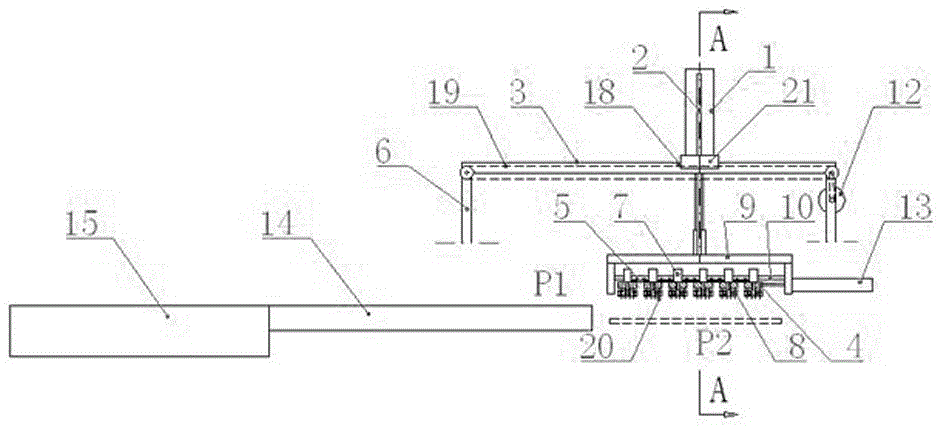

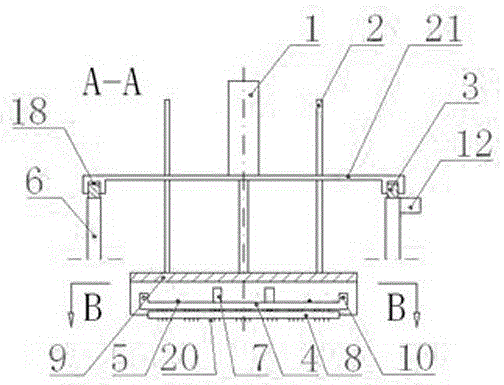

Reinforcement steel sheet cutting belt-carrying packaging machine

ActiveCN106944529AImplement packagingAvoid pollutionMetal-working feeding devicesPackagingEngineeringAutomation

The invention discloses a reinforcement steel sheet cutting belt-carrying packaging machine. A material box material belt conveying channel and a steel sheet cutting die are located at the two ends of a divider module. A material box material belt feeding device conveys a material box material belt to slide along the material box material belt conveying channel. A hot sealing belt led out from a hot sealing belt material disc and the material box material belt are subjected to hot sealing through a hot sealing module. A steel sheet material belt feeding device conveys a steel sheet material belt to the steel sheet cutting die. The steel sheet cutting die can cut off a steel sheet product on the steel sheet material belt. A first steel sheet grabbing device can put the cut steel sheet on a positioning device at the other end of the divider module, and a second steel sheet grabbing device can put a steel sheet at one end of the divider module into a material box. The divider module rotates to achieve alternate position changing of the tow ends, and the hot sealing module achieves hot sealing packaging of the material box material belt and a hot sealing film. By means of the reinforcement steel sheet cutting belt-carrying packaging machine, full-automatic blanking and packaging of the steel sheet are achieved, the automation degree is high, and labor is saved.

Owner:昆山金群力精密组件有限公司

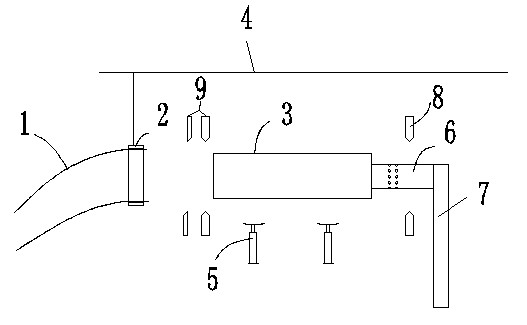

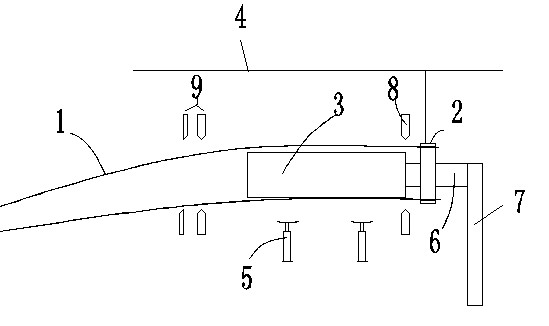

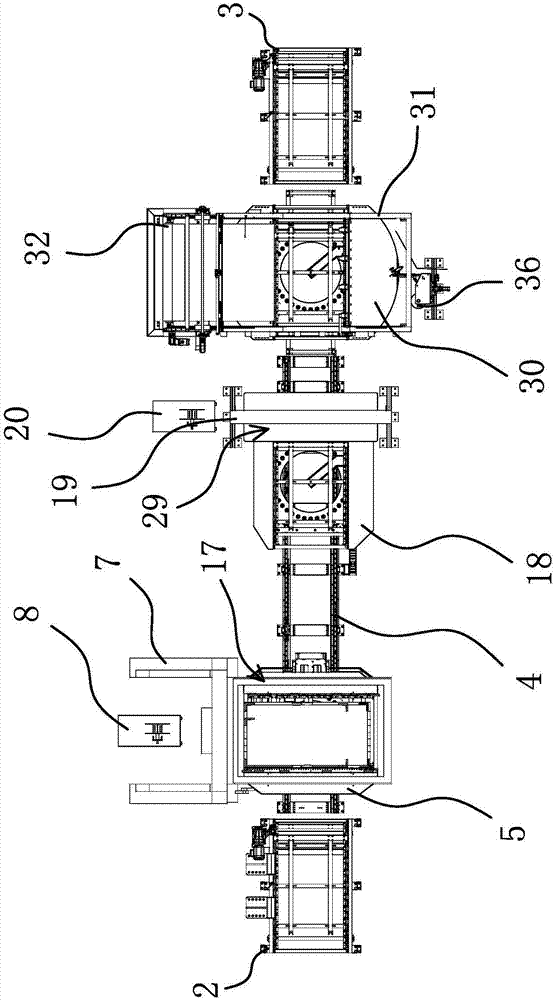

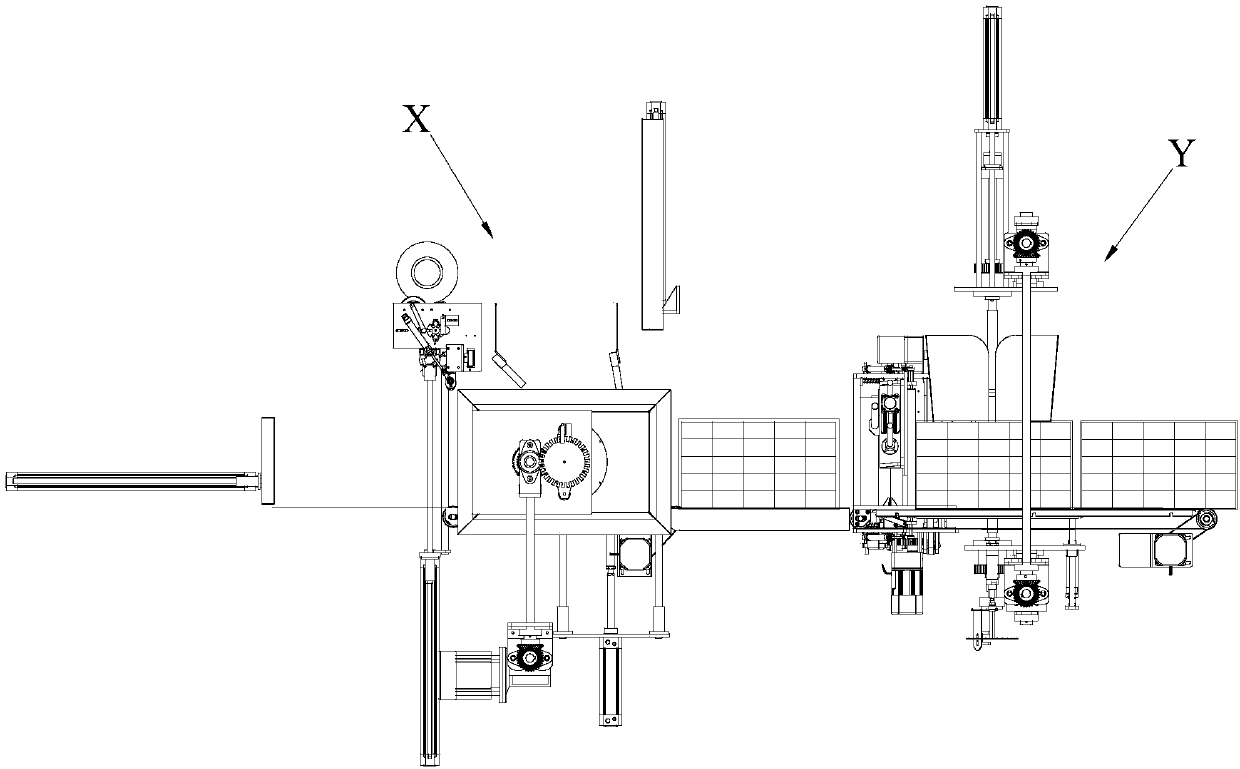

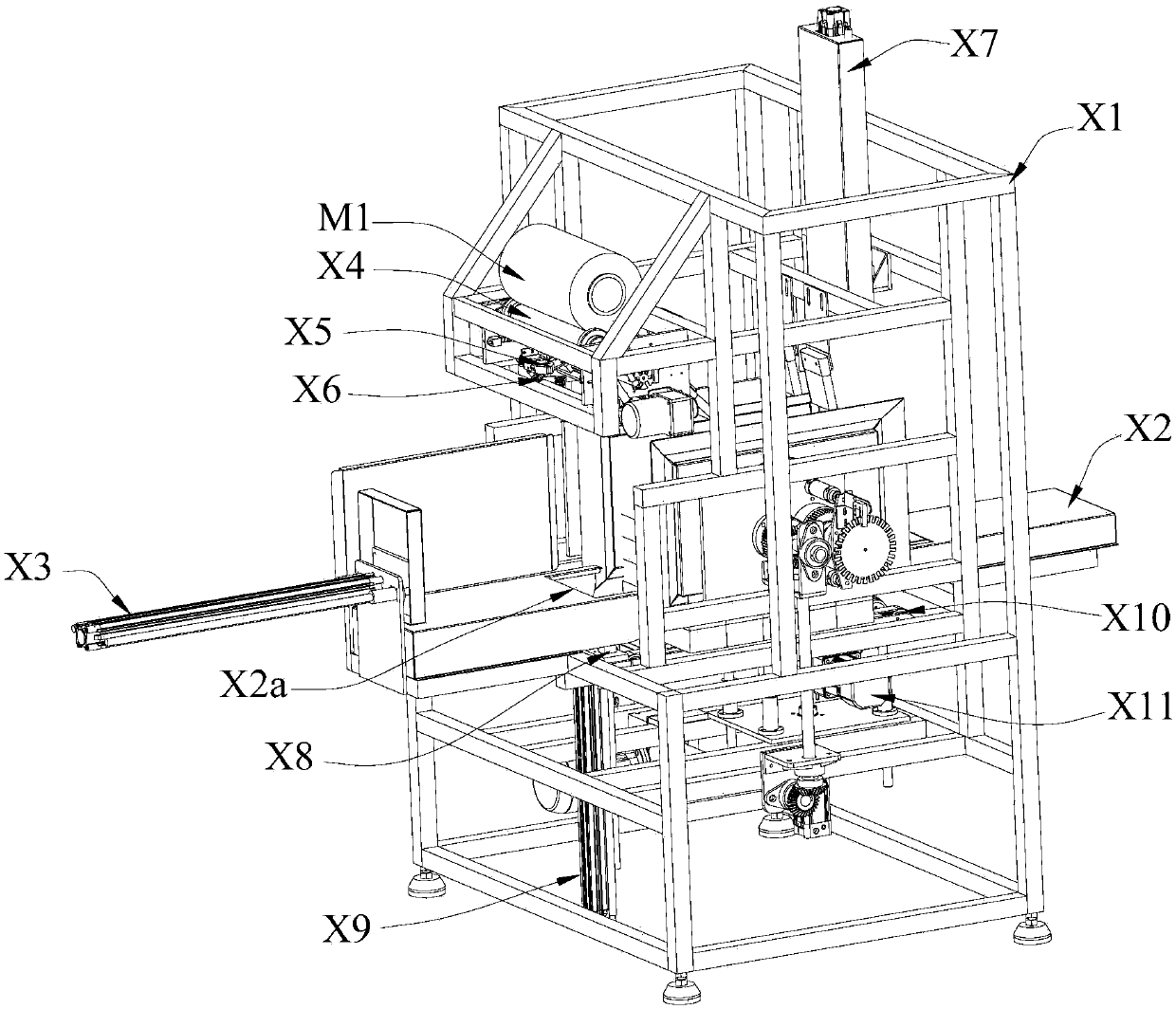

Fully automatic packaging device for photovoltaic glass

PendingCN106976610ARealize horizontal beltingRealize longitudinal beltingConveyor wrappingWrapping with article rotationStrappingThin membrane

The invention provides a fully automatic packaging device for photovoltaic glass, and belongs to the technical field of machinery. The fully automatic packaging device for the photovoltaic glass comprises a machine frame and ground rails, and a transverse packaging station, a longitudinal packaging station and a film winding station are sequentially arranged on the ground rails; a rotating conveying table I is arranged at the transverse packaging station, a protecting plate positioning mechanism is arranged on the rotating conveying table I, wherein the protecting plate positioning mechanism enables protecting plates to abut against the edges of the photovoltaic glass, and a horizontal strapping machine is arranged at one side of the rotating conveying table I; a rotating conveying table II is arranged at the longitudinal packaging station, and a saber strapping machine is arranged at one side of the rotating conveying table II; and a rotating conveying table III is arranged at the film winding station, a supporting seat is further fixed to the machine frame and located above the rotating conveying table III, and a film coating mechanism and a film winding mechanism are arranged on the supporting seat. The fully automatic packaging device can conduct transverse strapping and longitudinal strapping on stacked photovoltaic glass, can conduct film coating on strapped photovoltaic glass and has the high degree of automation.

Owner:FLAT GLASS GROUP CO LTD

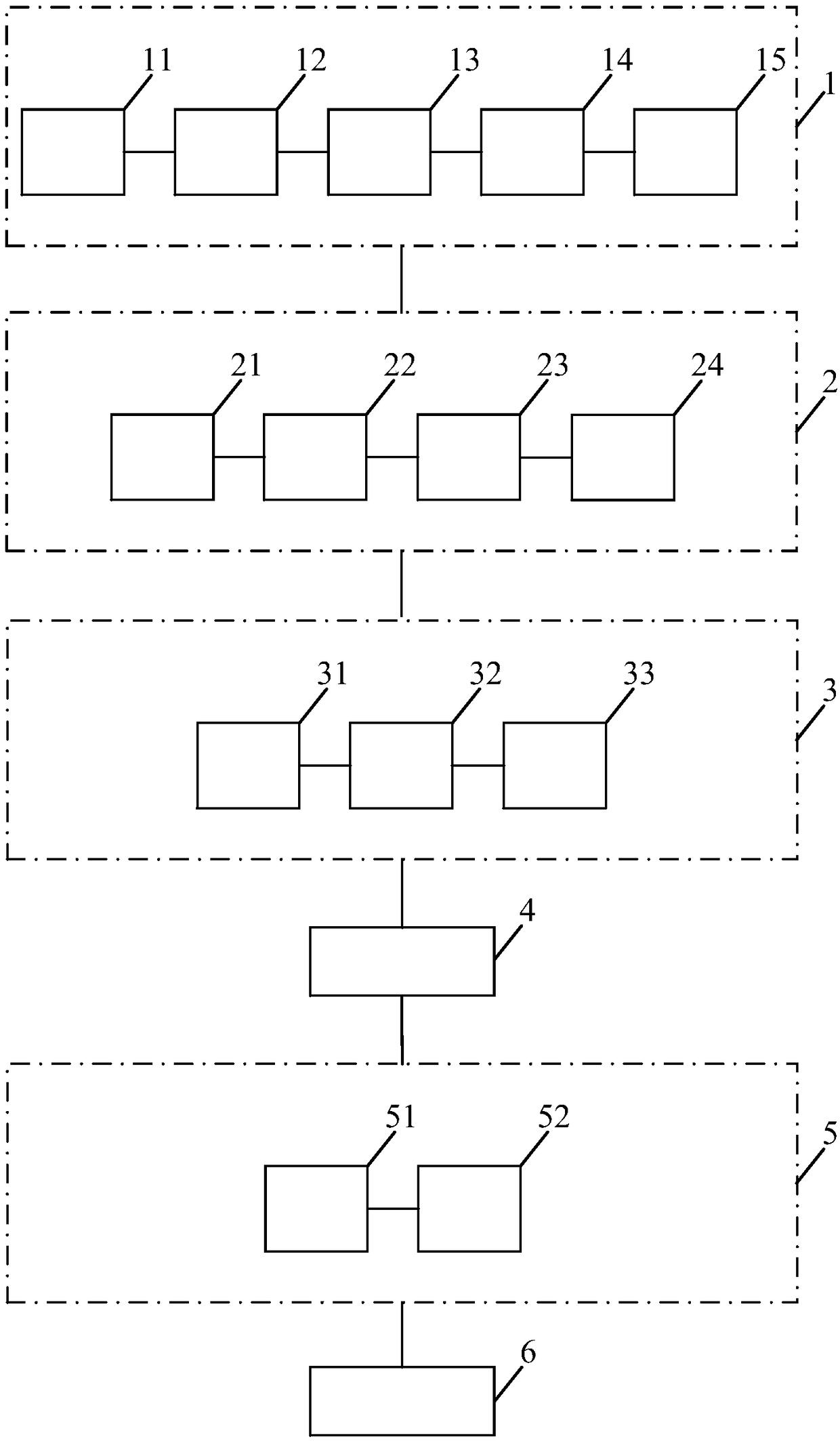

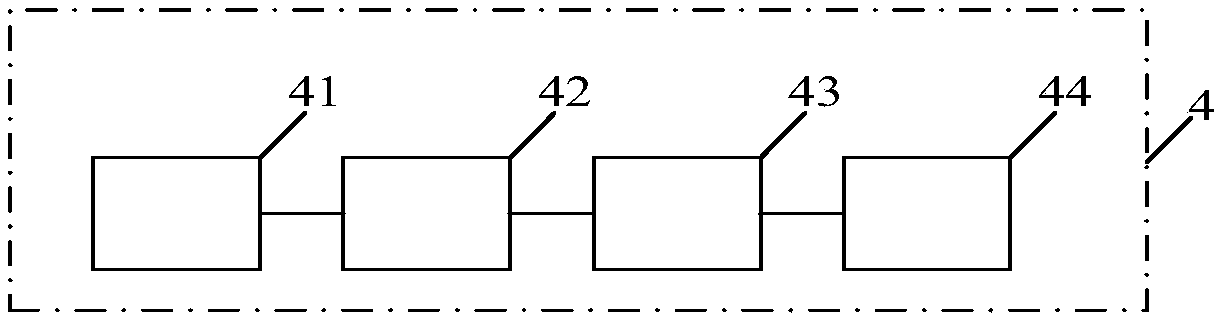

Automatic cigarette sorting system

ActiveCN108423251AImprove accuracyRealize automatic separationMultiple wrapper applicationPackaging automatic controlControl signalEngineering

The invention provides an automatic cigarette sorting system. The automatic cigarette sorting system comprises a box opening subsystem, a cigarette replenishment subsystem, a sorting subsystem, a coding subsystem and a packaging subsystem; the box opening subsystem automatically opens a cigarette box and takes out cigarettes in the cigarette box from the cigarette box to a cigarette temporary storage mechanism of the box opening subsystem; the cigarette replenishment subsystem conveys the cigarettes from the cigarette temporary storage mechanism to a horizontal cigarette bin of the sorting subsystem according to a cigarette replenishment control signal and performs automatic replenishment on the sorting subsystem; the sorting subsystem automatically sorts the cigarettes in the horizontal cigarette bin according to the order information sorted to households and conveys the sorted cigarettes sorted to households to the coding subsystem; the coding subsystem performs coding on the cigarettes sorted to households and comprises a conveying mechanism, an identification mechanism, a query mechanism and a laser coding mechanism; and the packaging subsystem packages the coded cigarettes. According to the automatic cigarette sorting system, by means of a method, automatic box opening, automatic replenishment, automatic sorting and automatic packaging in the whole sorting process of the cigarettes can be achieved, automatic collinear sorting and packaging of the standard cigarettes and the fine cigarettes can be realized.

Owner:中国烟草总公司北京市公司物流中心

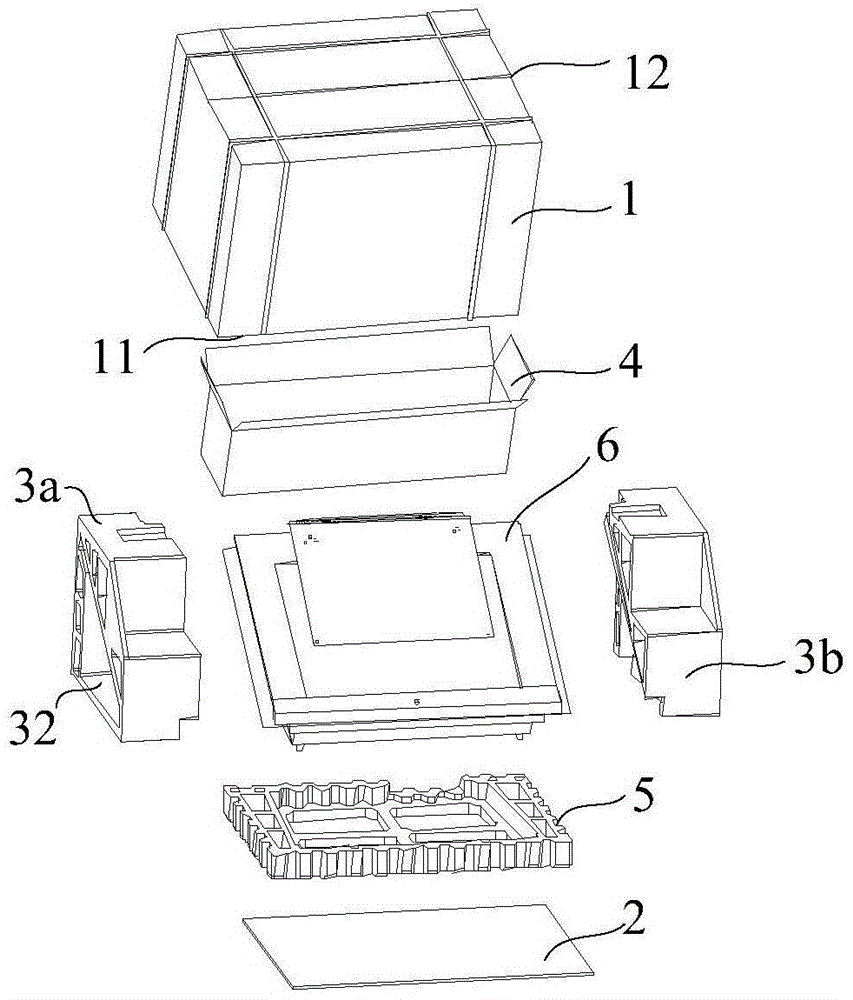

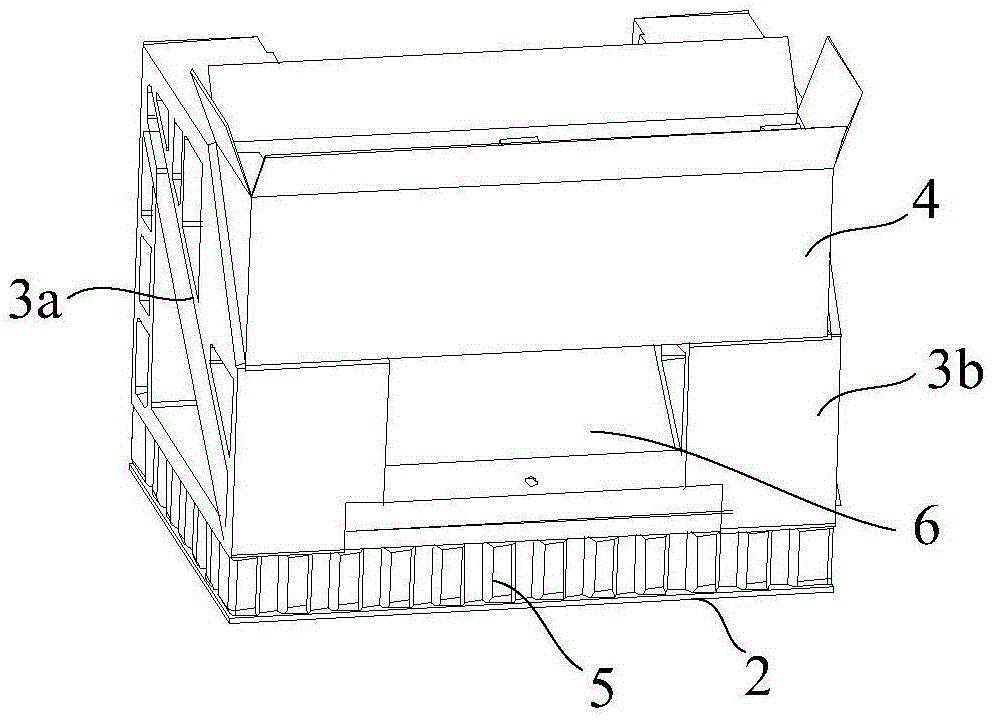

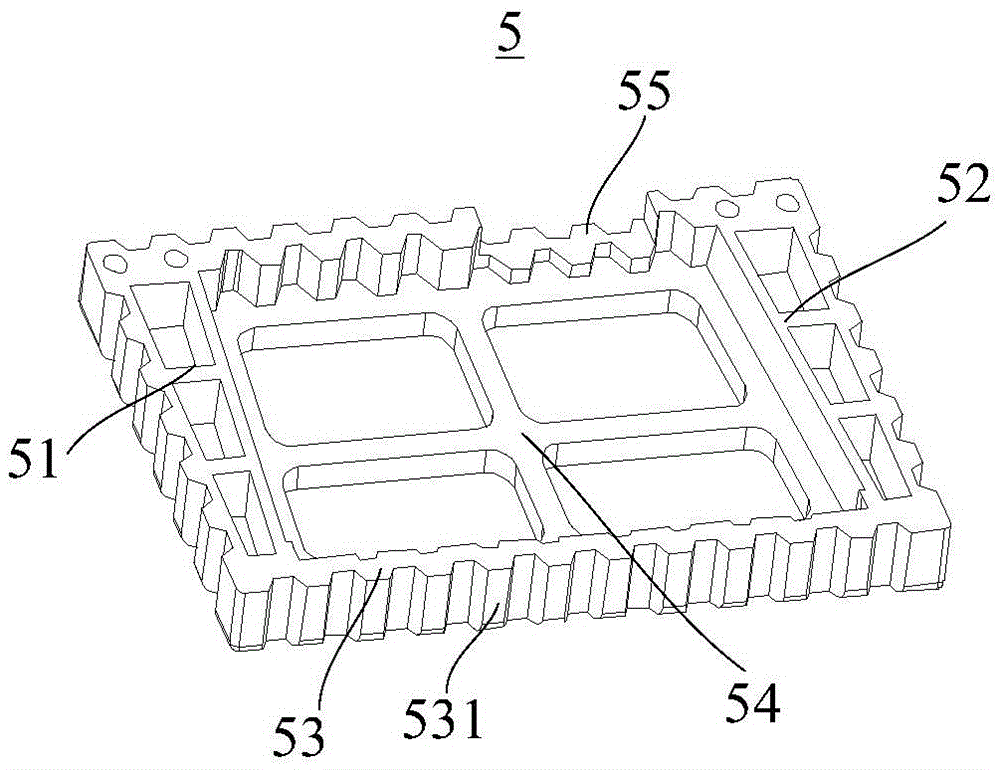

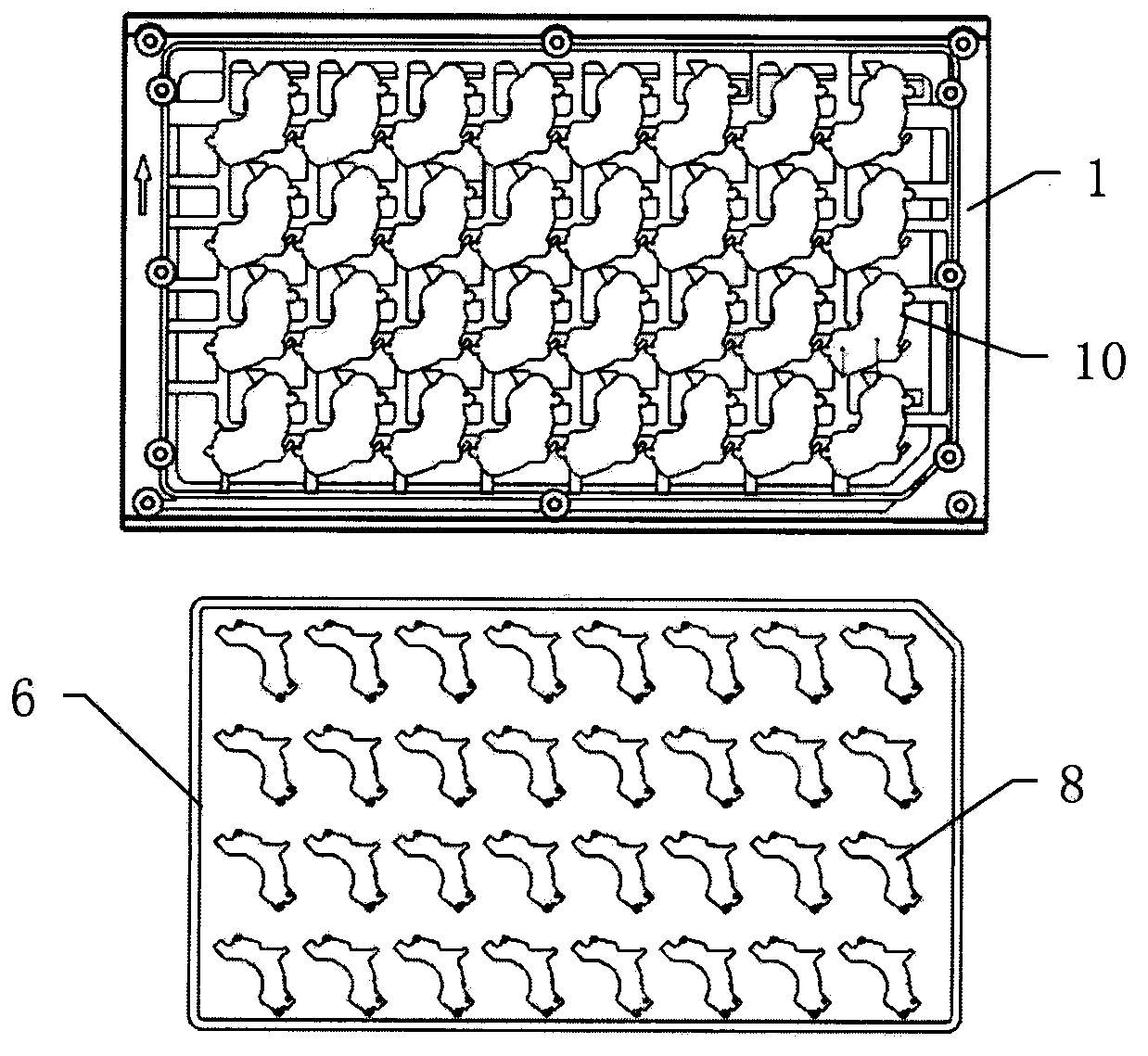

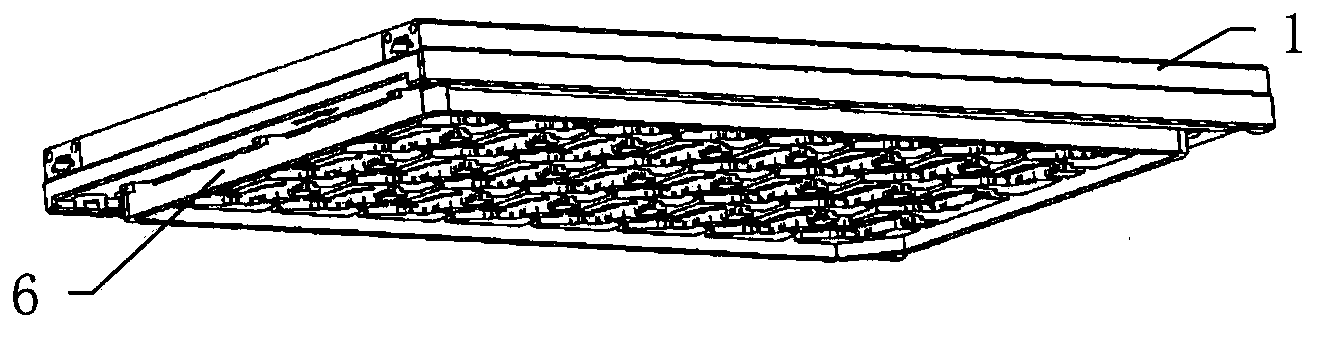

Packaging structure and side-draft type range hood

ActiveCN105460426AReduce packing or unpacking timeImprove packaging efficiencyPackaging vehiclesContainers for machinesEngineering

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

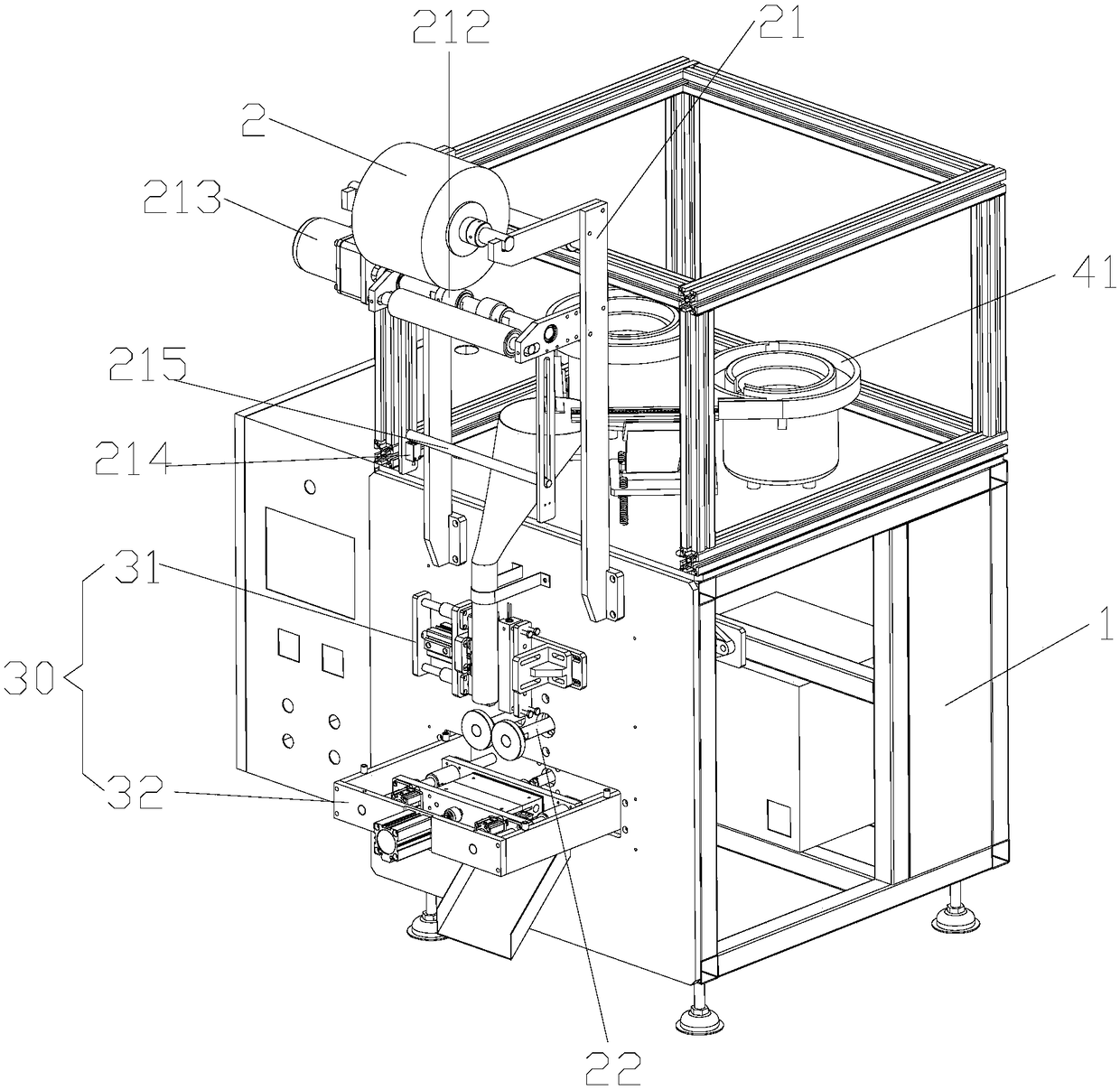

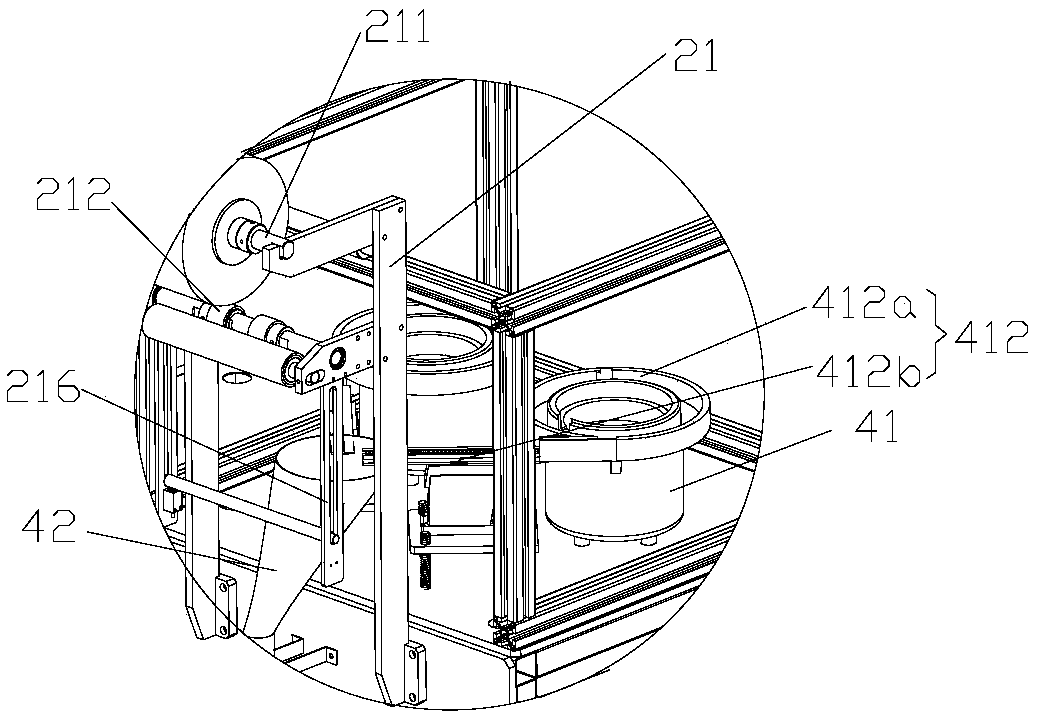

Packing device

PendingCN109502093ANo wasteRealize automatic material distributionWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

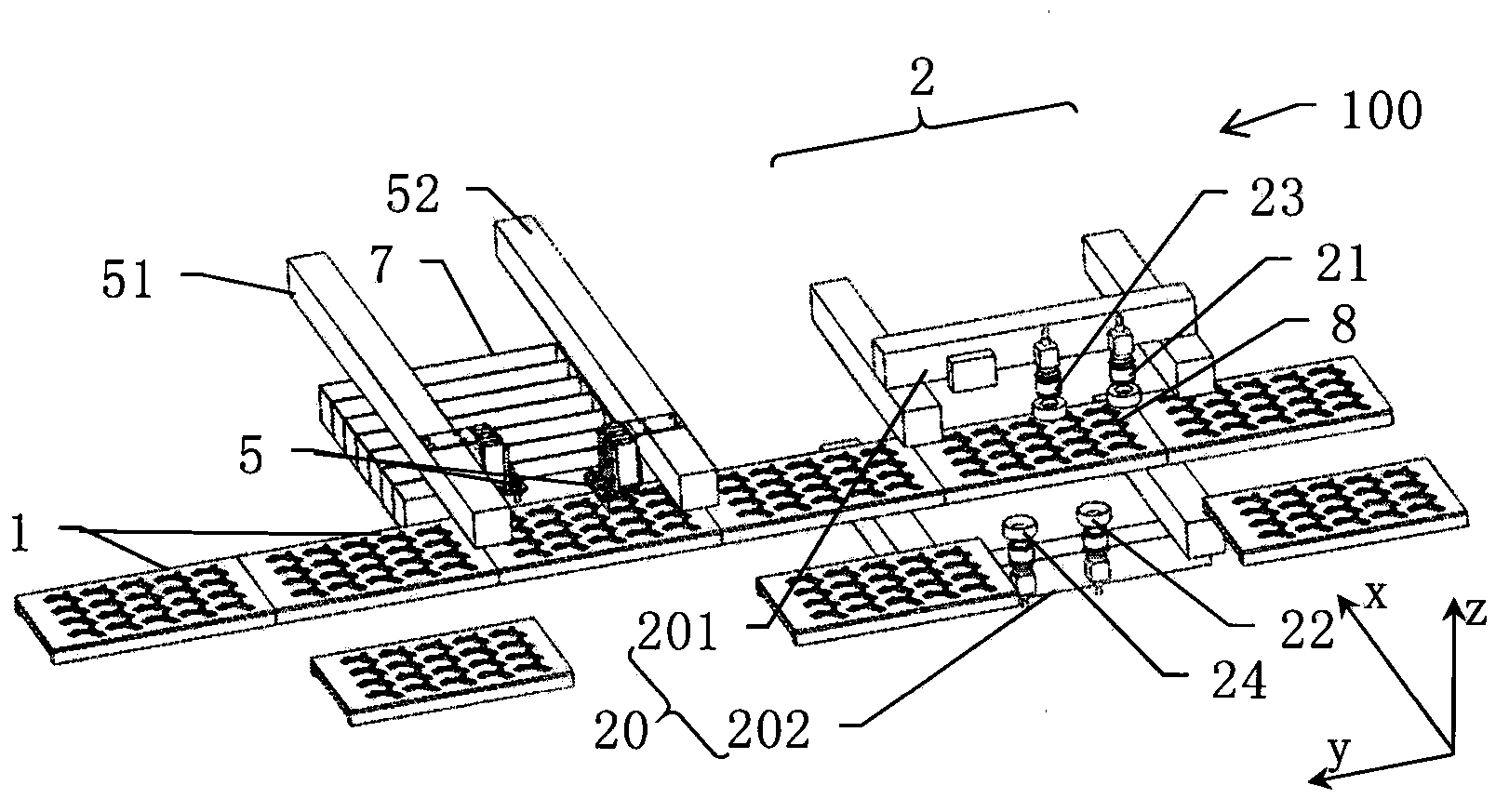

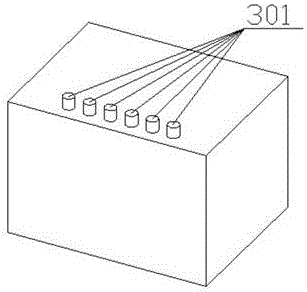

Method and equipment for detecting batched products

The invention relates to a method and equipment for detecting batched products. In the method, a carrier loaded with a plurality of products is sent into an image pickup working section of detecting equipment; a plurality of image pickup devices in charge of different optical detection works respectively are arranged in the image pickup working section of the detecting equipment; the image pickup devices move synchronously and separately pick up product images of each group of products synchronously; the detecting equipment automatically judges out unqualified products according to the picked images, automatically picks up the unqualified products by using a picker and puts the unqualified products into an unqualified product container. Through the method and the equipment, the batched products can be efficiently detected automatically.

Owner:李志红

Wire packing and classifying equipment

ActiveCN105799966AImplement packagingImplement classificationBundling machine detailsEngineeringMechanical engineering

The invention provides wire packing and classifying equipment which comprises a workbench, a mounting rack, two clamping mechanisms, a wire feeding mechanism, a packing mechanism, a belt feeding mechanism and a classifying mechanism. A work groove is formed in one side of the workbench. The mounting rack is mounted on the other side of the workbench and corresponds to the position of the work groove. Each clamping mechanism comprises a sliding seat, two clamping blocks and two conveying belts. The wire feeding mechanism comprises a moving seat, a moving rod and at least one pressing roll. The packing mechanism comprises a C-shaped frame and a plurality of belt feeding rolls. The belt feeding mechanism comprises a belt guide roll, a shear knife, a mounting seat and a clamping device. The classifying mechanism comprises a wire conveying frame, a wire dividing plate and a gravity sensor. The wire packing and classifying equipment is convenient to use, and wires can be efficiently packed and classified.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

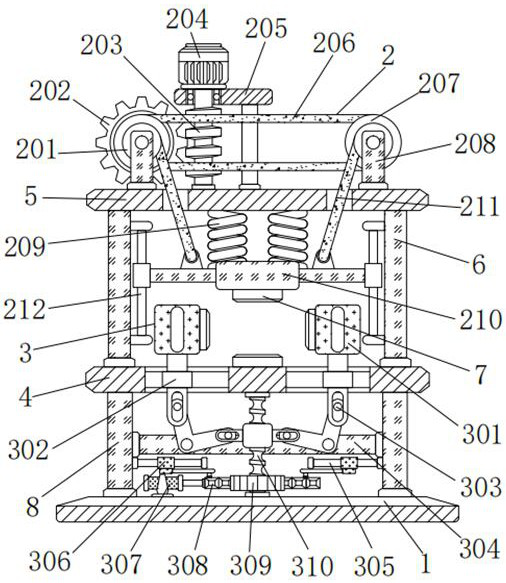

Metal stamping structural part waste cleaning and packaging device

InactiveCN111216398AFast packing processImprove sufficiencyGrain treatmentsPressesReciprocating motionElectric machinery

The invention discloses a metal stamping structural part waste cleaning and packaging device, and particularly relates to the technical field of metal waste treatment. The metal stamping structural part waste cleaning and packaging device comprises a material pressing bin, a material crushing bin is fixedly installed at the top of the material pressing bin, a material conveying bin is fixedly installed at the top of the material crushing bin, a material conveying mechanism is arranged in the material conveying bin, wherein a material crushing mechanism is arranged in the material crushing bin,a material pressing mechanism is arranged in the material pressing bin, the material conveying mechanism comprises a first pressing roller and a second pressing roller, and a feeding hopper is fixedly installed at the top of the material conveying bin. By starting the gear motor, the first compression roller is driven to rotate, the waste plate is driven to move downwards, the transmission motoris controlled, the movable cutter is driven to achieve periodic reciprocating motion in the empty groove plate, the original long-strip-shaped waste plate is crushed into small-block-shaped waste, thewaste is conveniently pressed into blocks through the material pressing mechanism, and the waste treatment sufficiency is improved.

Owner:昆山全泰信息科技服务有限公司

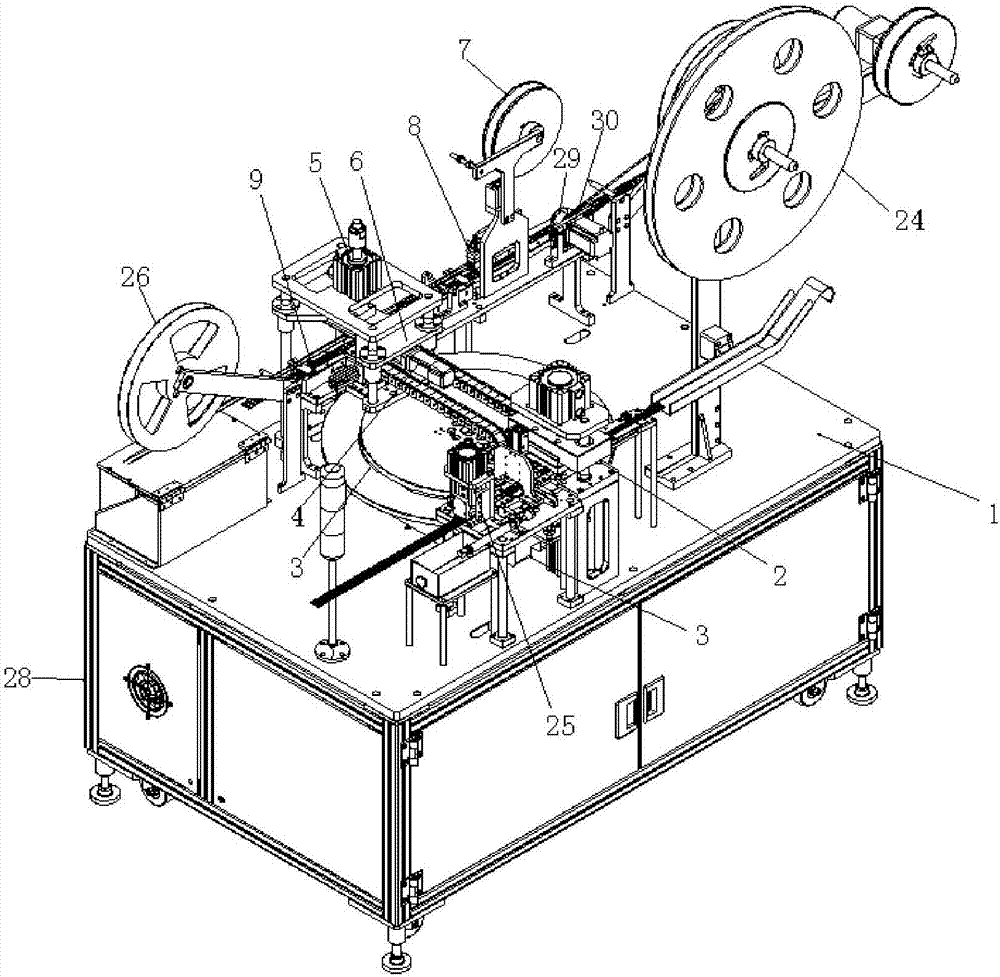

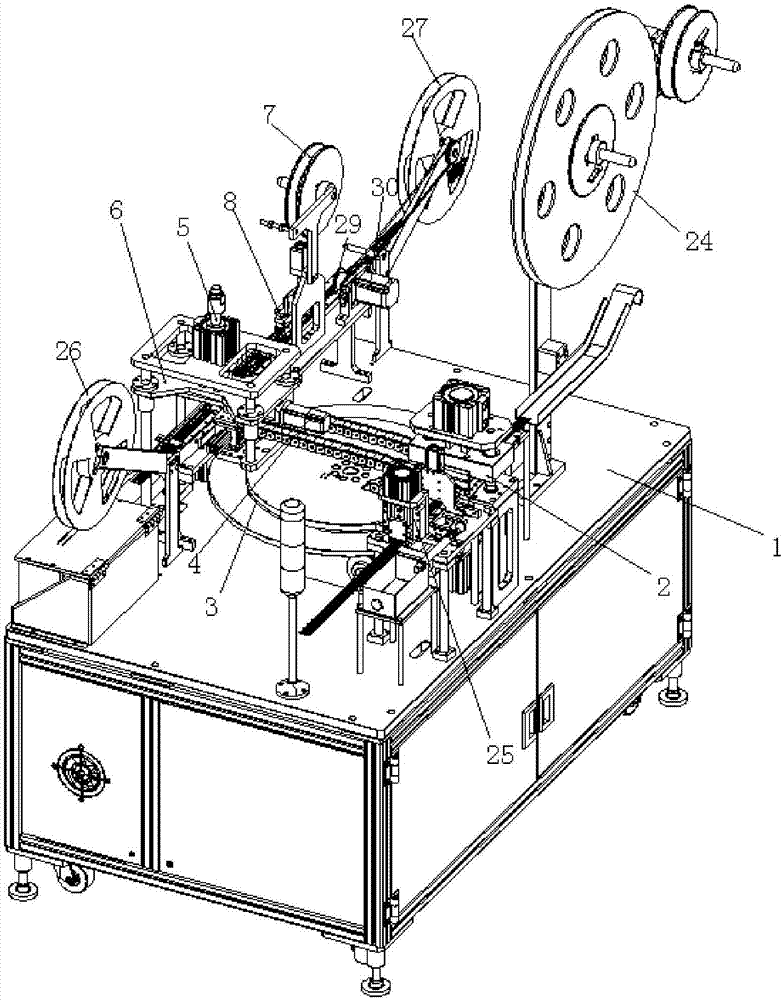

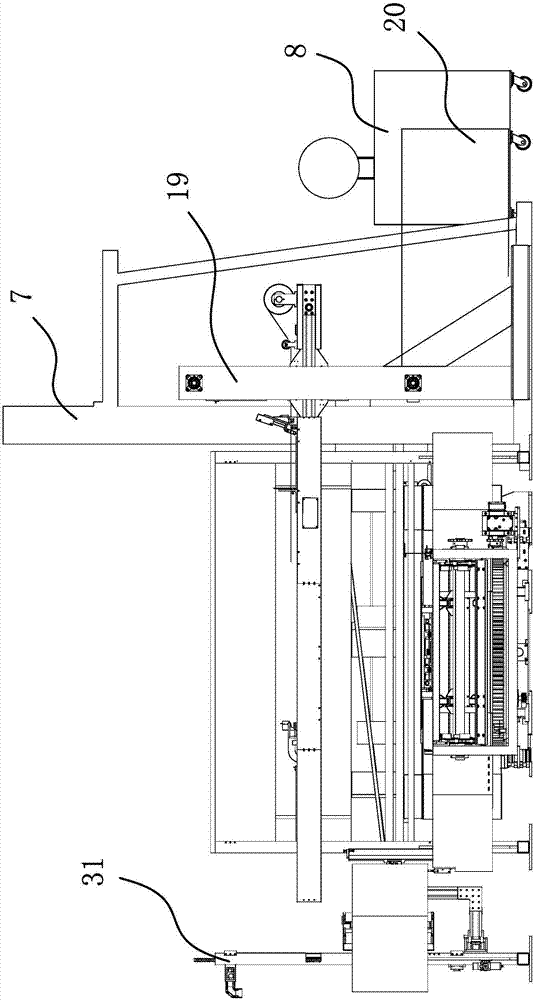

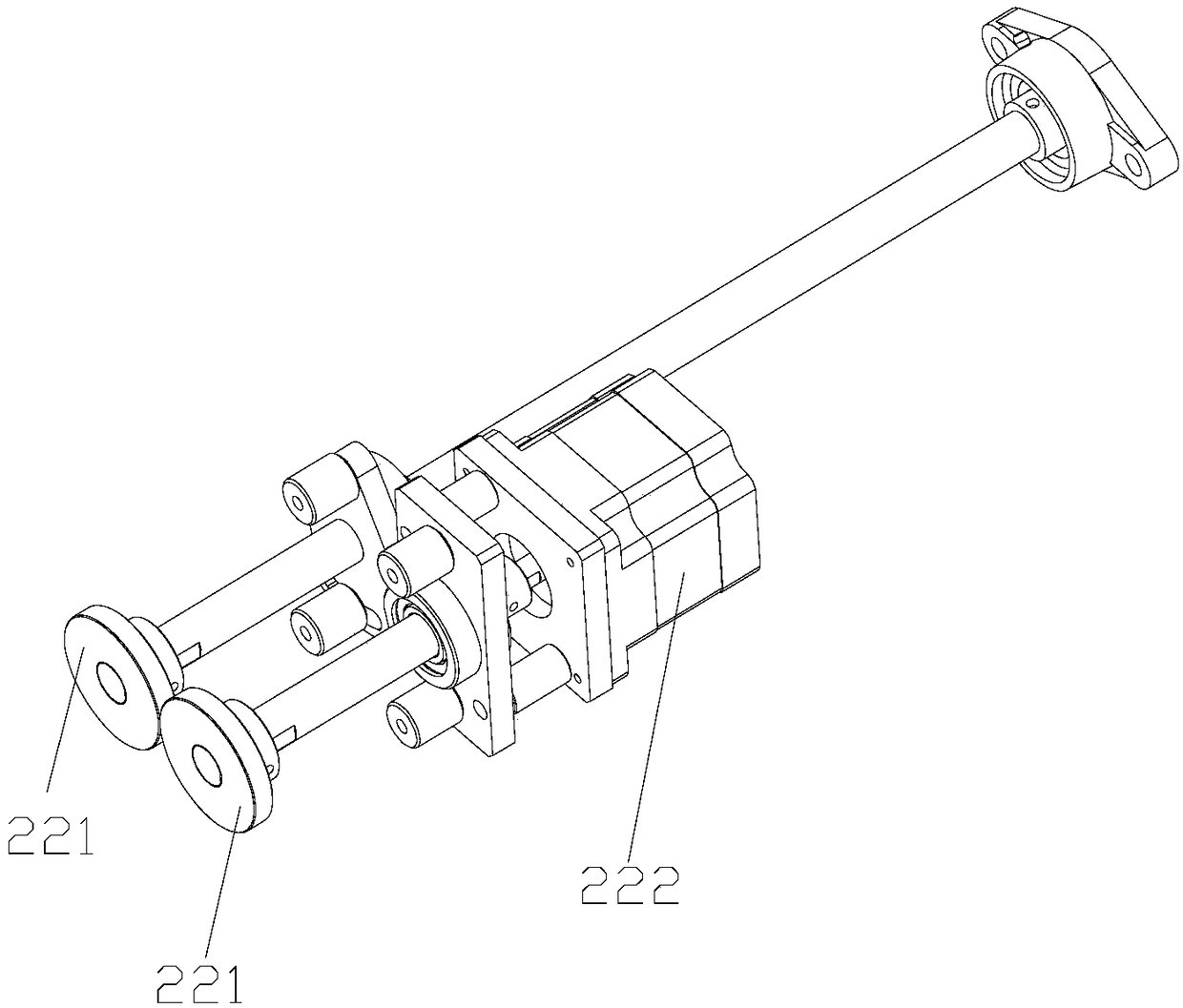

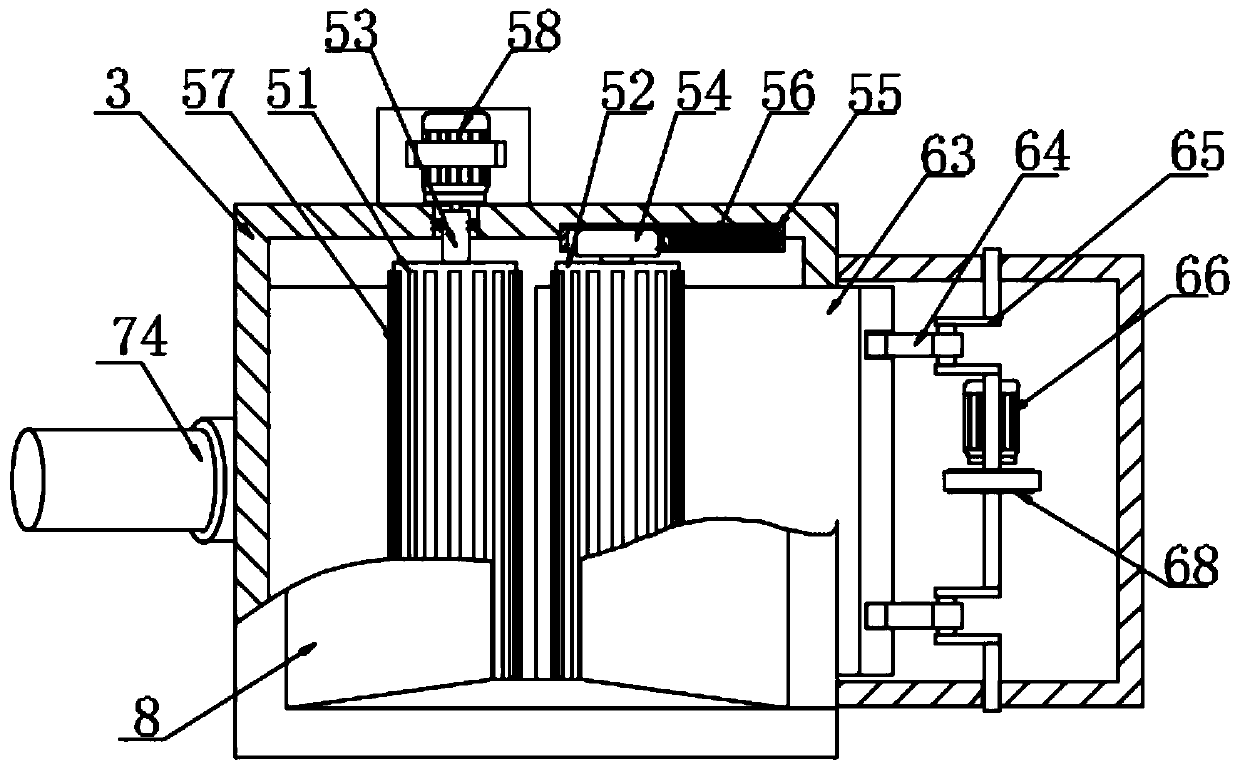

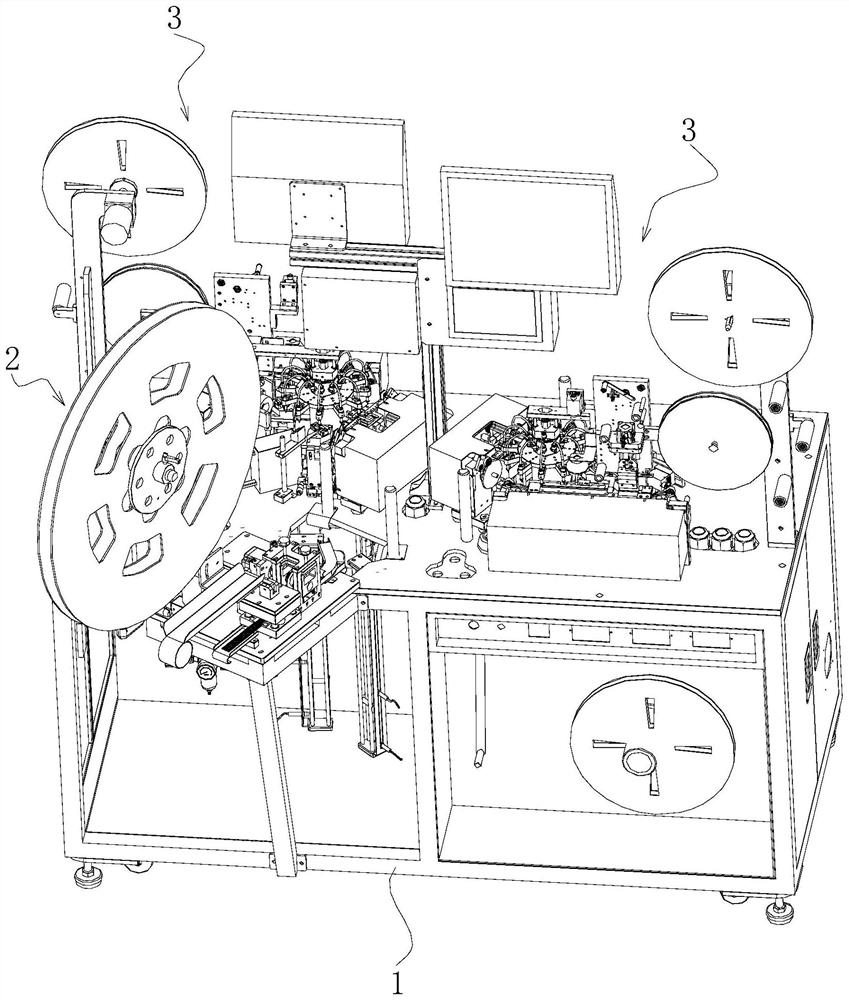

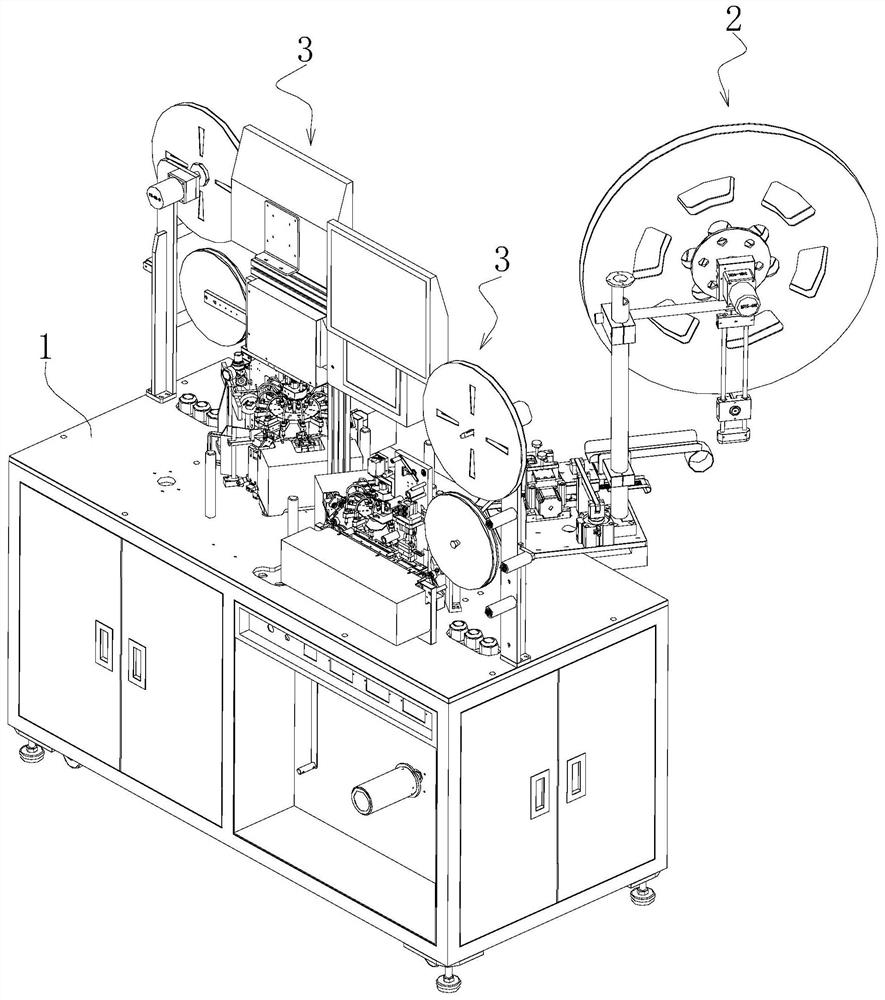

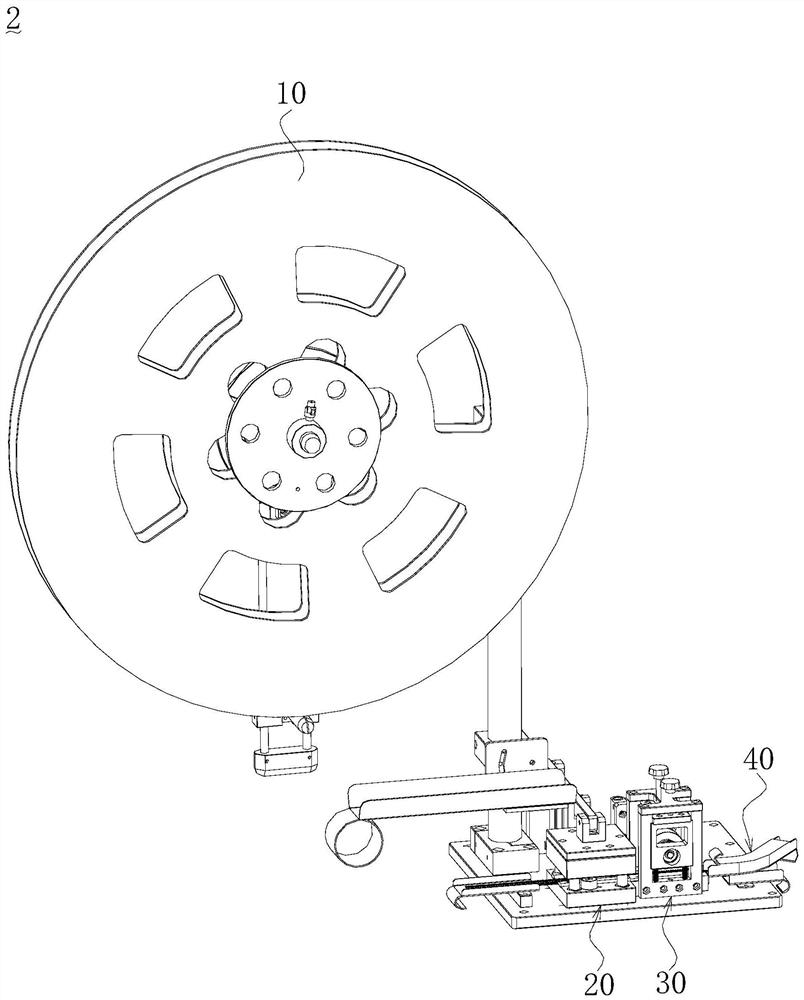

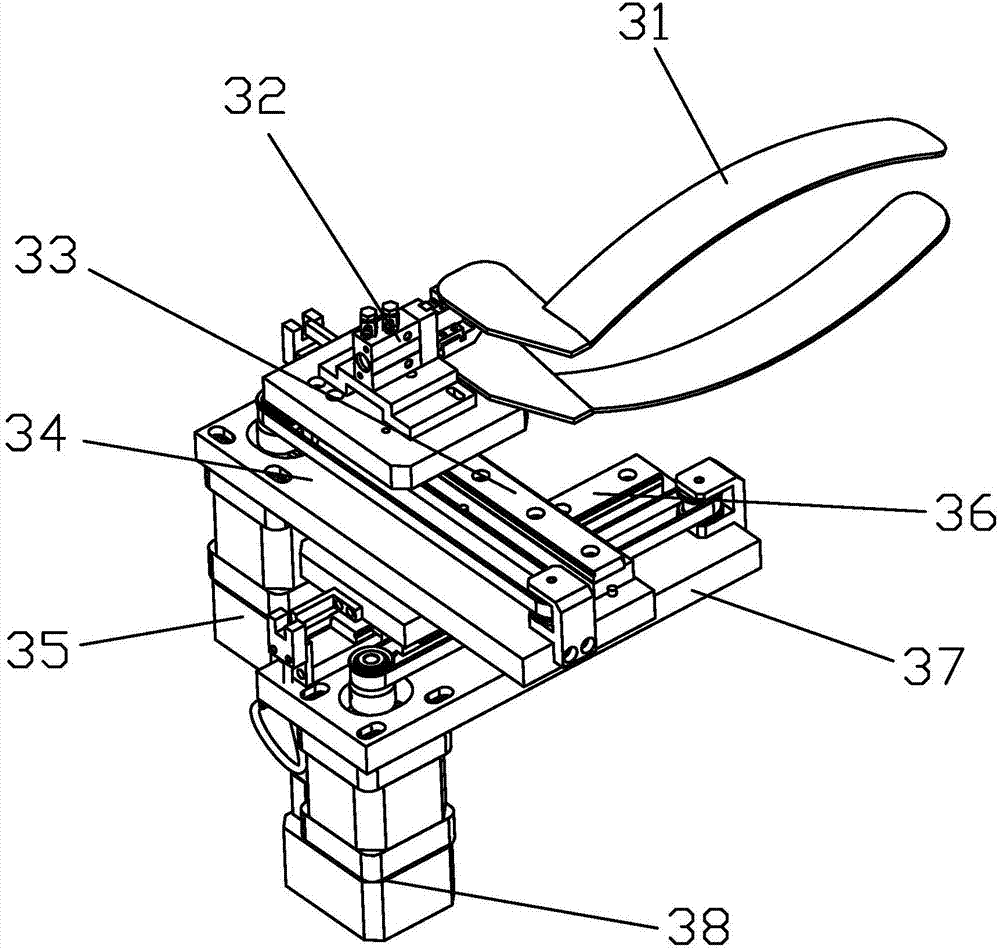

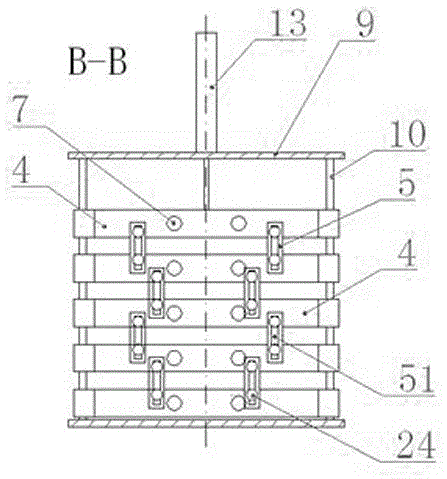

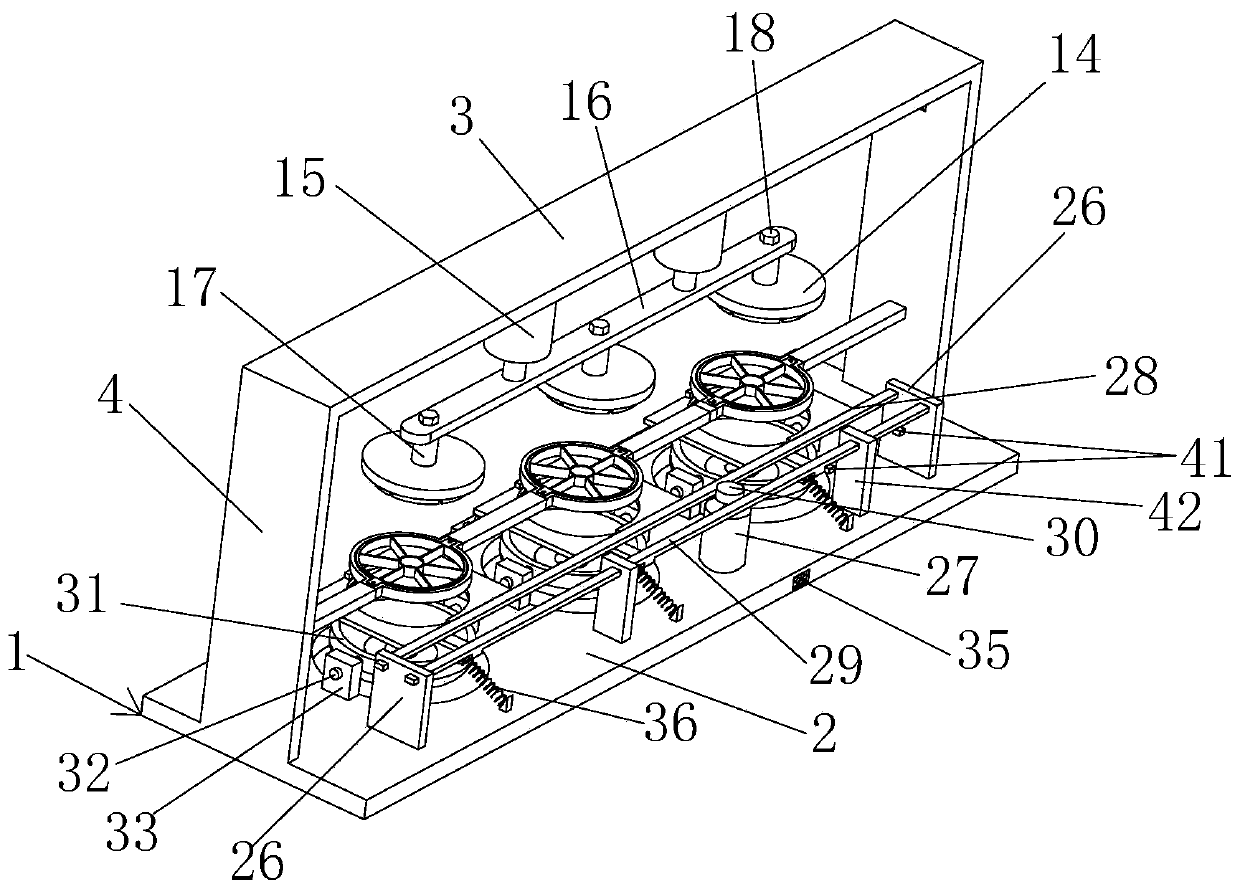

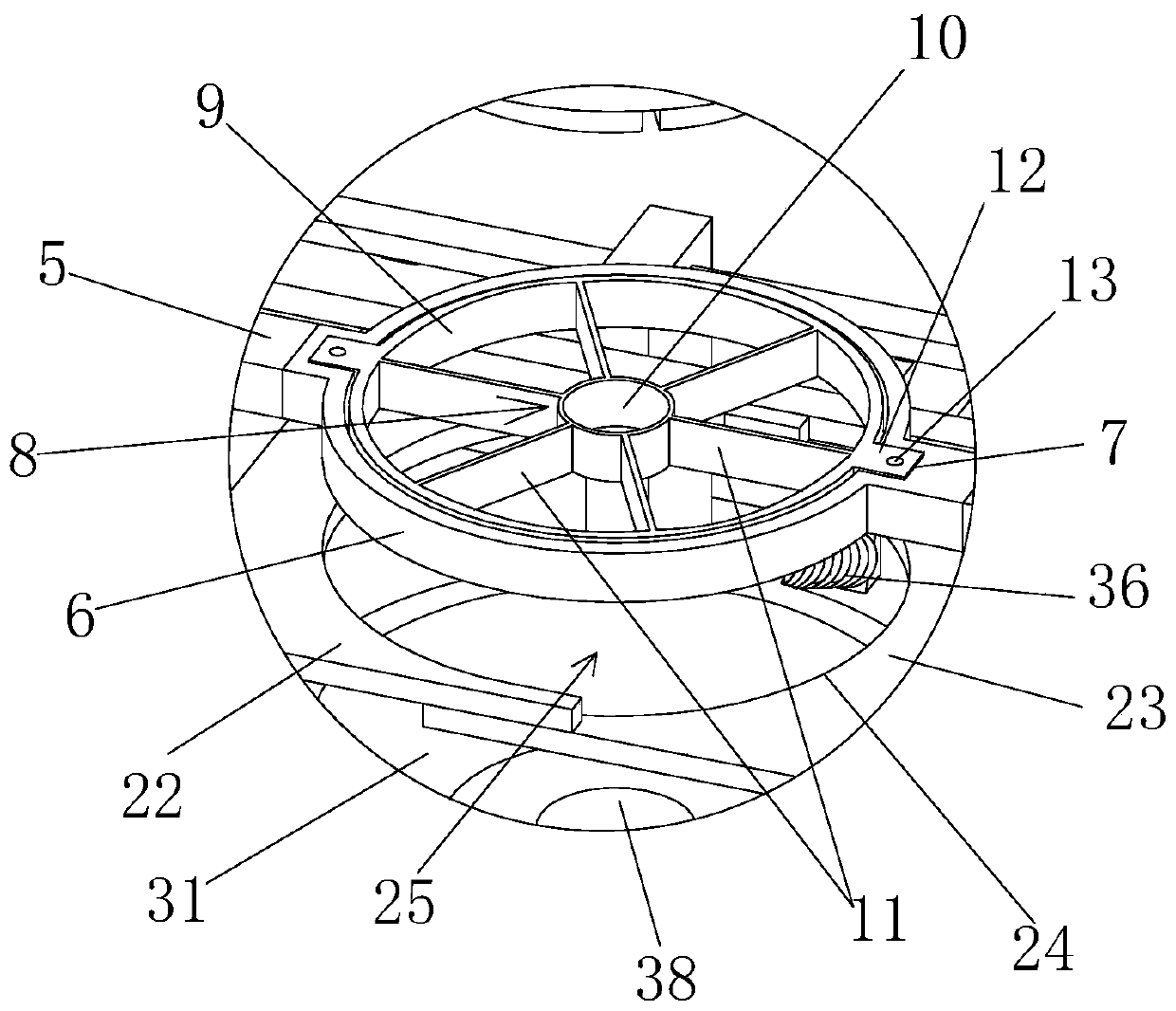

Elastic piece double-material-belt packaging machine

The invention belongs to the technical field of elastic piece packaging equipment, and particularly relates to an elastic piece double-material-belt packaging machine which comprises a rack, an elastic piece distributing device and elastic piece packaging devices, and the elastic piece distributing device is installed on the rack and used for slitting a double material belt into two single material belts. The two elastic piece packaging devices are installed on the rack in a spaced mode and used for machining the two single material belts respectively. Each elastic piece packaging device comprises an elastic piece cutting mechanism, a multi-station rotating mechanism, a clamping and guiding mechanism, a carrying belt conveying mechanism and a film belt packaging mechanism. According to theelastic piece double-material-belt packaging machine, in the working process of elastic piece packaging, automatic operation is achieved in the whole process, in this way, the production efficiency can be greatly improved, meanwhile, due to the fact that manual operation is not needed, the problem of manual errors is avoided, and then the quality of packaged elastic pieces can be improved.

Owner:JITS COMM CO LTDGD

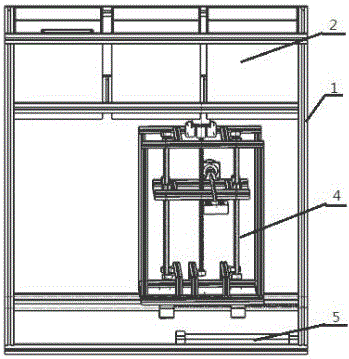

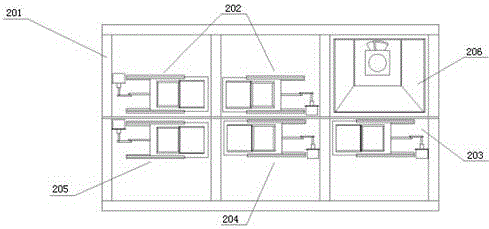

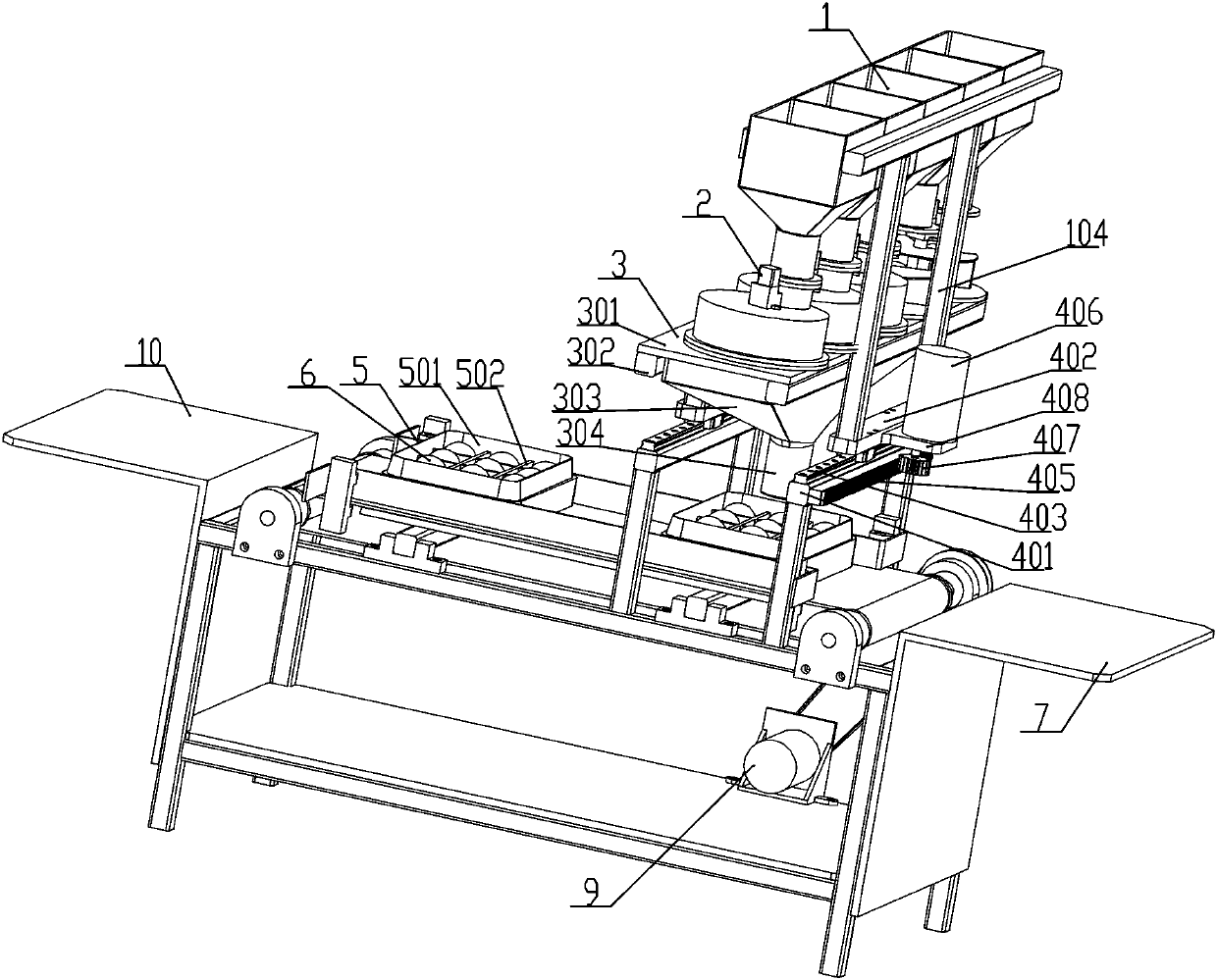

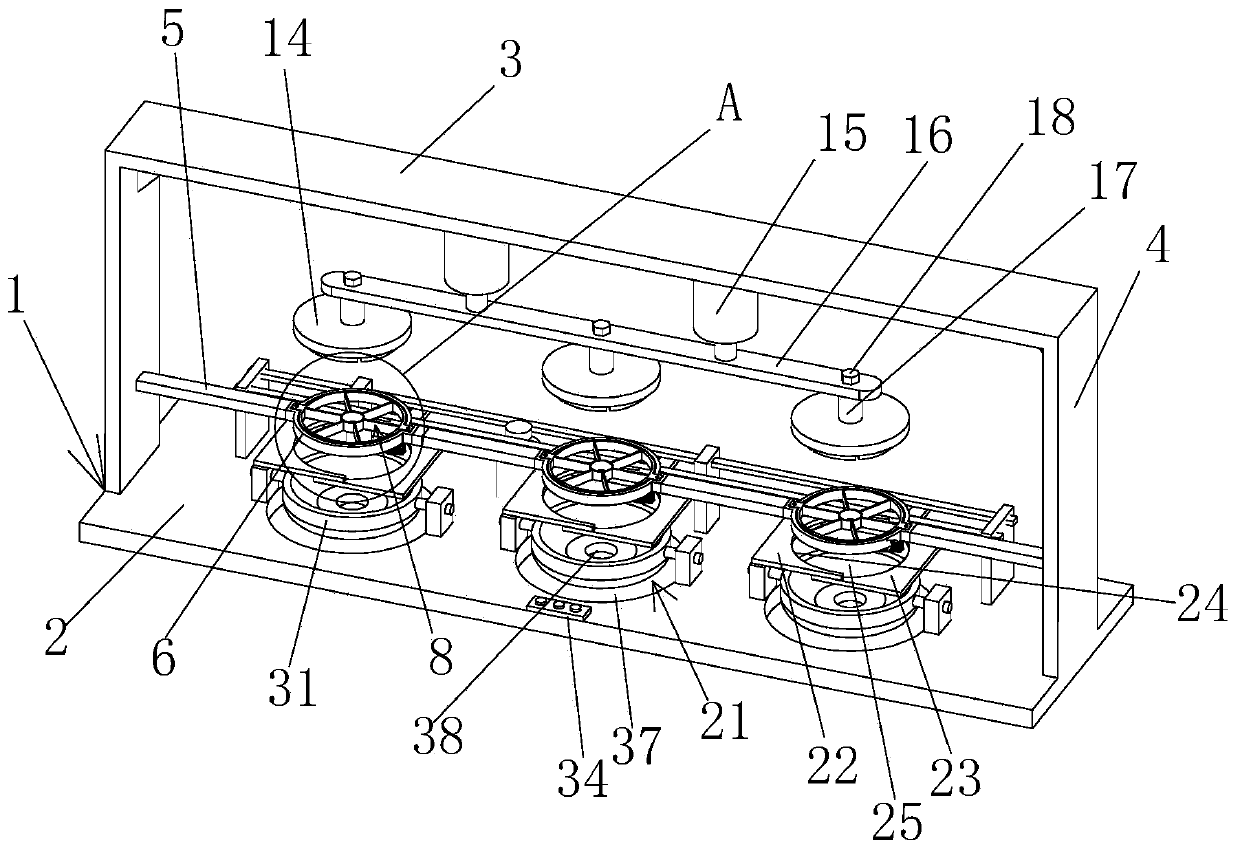

Modular automatic fast food packing machine

The invention relates to a modular automatic fast food packing machine. The modular automatic fast food packing machine comprises an outer frame, a modular dish discharging mechanism, an operating platform, a meal box conveying mechanism and a plastic packing mechanism. The modular dish discharging mechanism is arranged at the upper end of the outer frame. The operating platform is located at the position, on the rear side of the modular dish discharging mechanism, on the outer frame. The meal box conveying mechanism is arranged on the outer frame through transverse lead screws below the operating platform. The plastic packing mechanism is located at the position, below the modular dish discharging mechanism, on the outer frame. The modular dish discharging mechanism, the meal box conveying mechanism and the plastic packing mechanism are in circuit connection with the operating platform. A control system is arranged in the operating platform. The modular automatic fast food packing machine has the advantages that the control system is adopted to control automatic packing, the packing efficiency is improved, the meal supplying capacity is greatly improved, labor force and cost are saved, and the sanitation degree of products is improved.

Owner:ZHEJIANG UNIV OF TECH

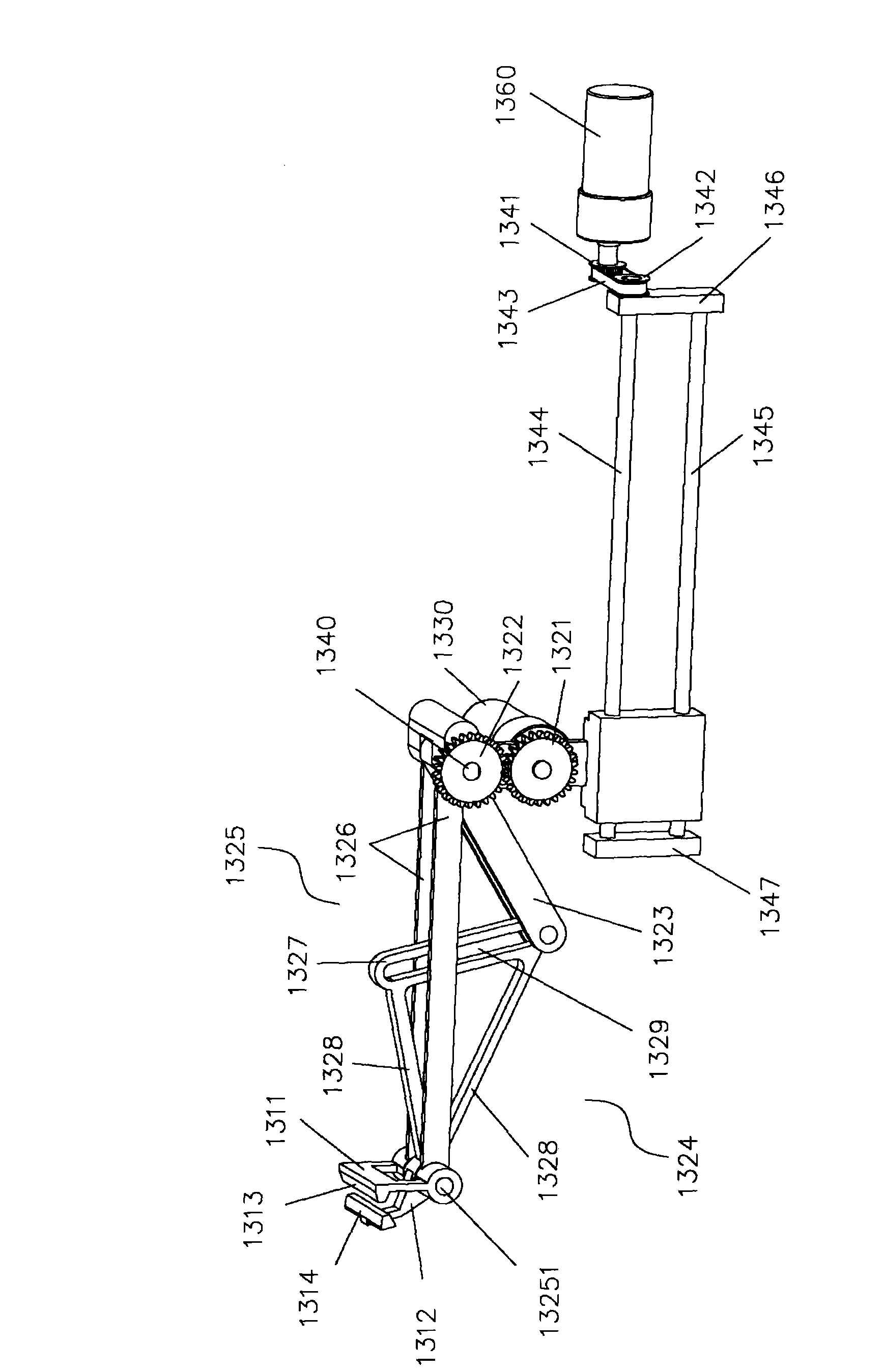

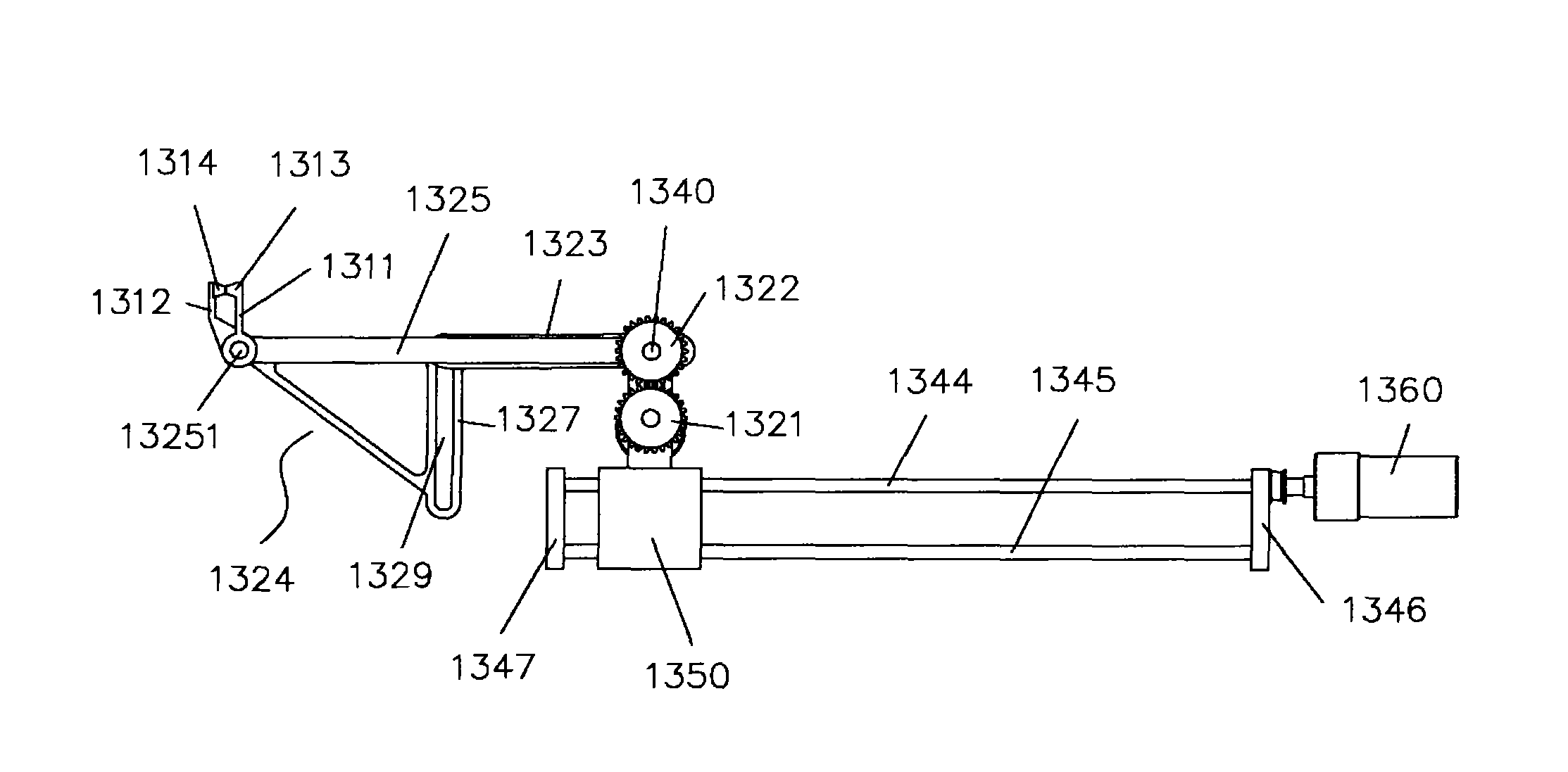

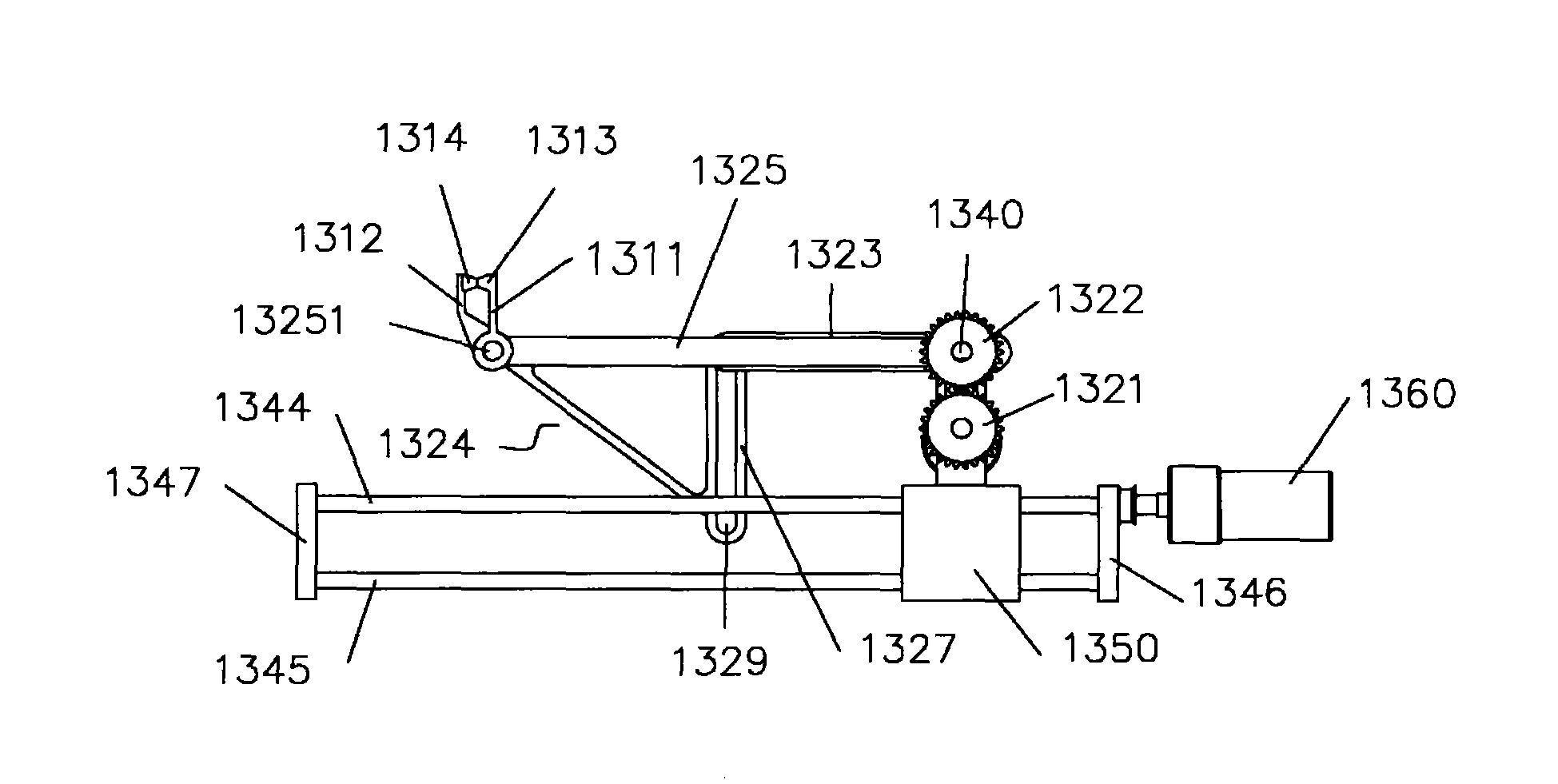

Clamping, pouring and conveying mechanism and cooking material feeding system and method

ActiveCN103211503ARealize automated productionImplement packagingCooking vesselsAdditive ingredientEngineering

The invention provides a camping, pouring and conveying mechanism, which comprises a clamping and pouring device and an inter-station conveying device, wherein the clamping and pouring device is used for clamping a material bag which contains cooking materials, limiting the shape of the material bag and automatically pouring the cooking materials in the material bag into a cooking pot; and the inter-station conveying device is used for moving the material bag which is clamped by the clamping and pouring device between a material bag clamping station and a feeding station. The invention additionally provides a cooking material feeding system and method based on the camping, pouring and conveying mechanism. The effect of automatically cooking the materials which are contained in the material bag is realized, the clamped material bag can be accurately moved to a feeding position, the cooking materials are prevented from being scattered and / or spilt in clamping, conveying, pouring and feeding processes, the structural layout avoids mechanism interference which is possibly caused due to complex structural layout around the cooking pot, spaces are provided for further stir-frying the cooking materials and feeding other minor ingredients, and the goal of enabling the cooking process to be convenient, rapid and simplified is achieved.

Owner:AIC ROBOTICS TECH

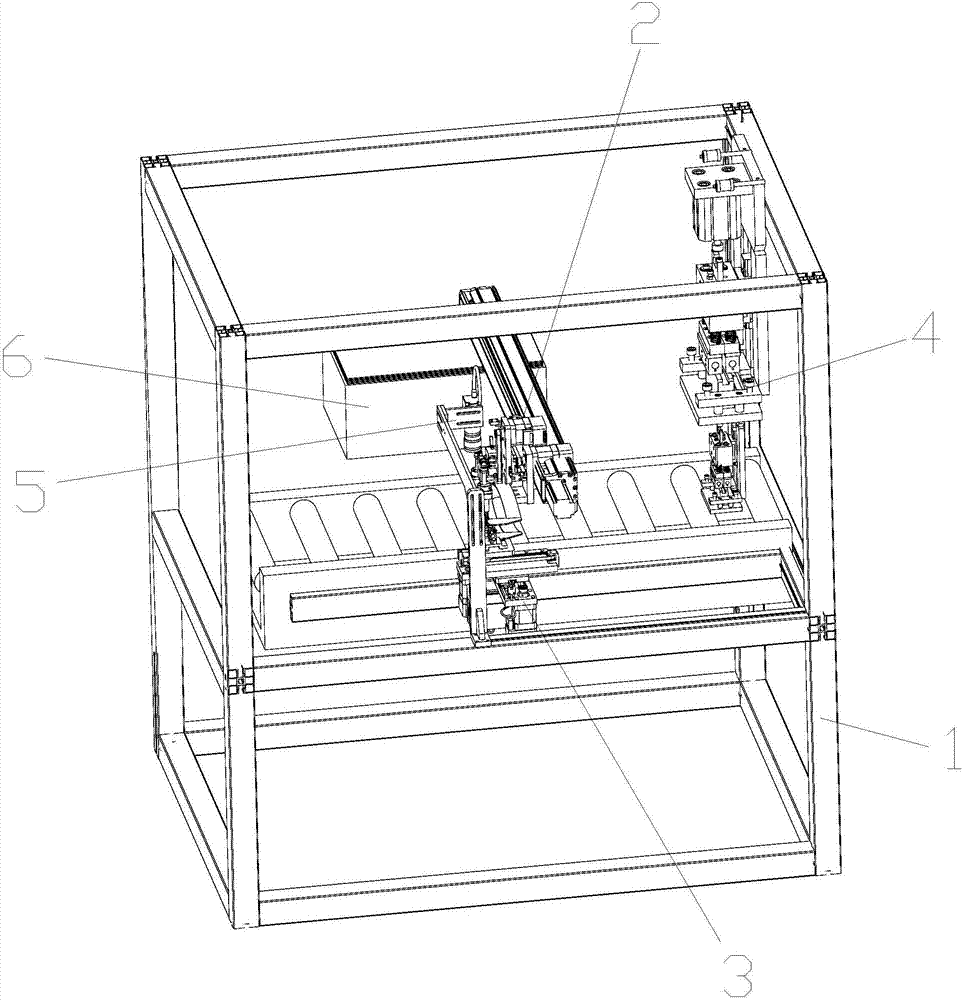

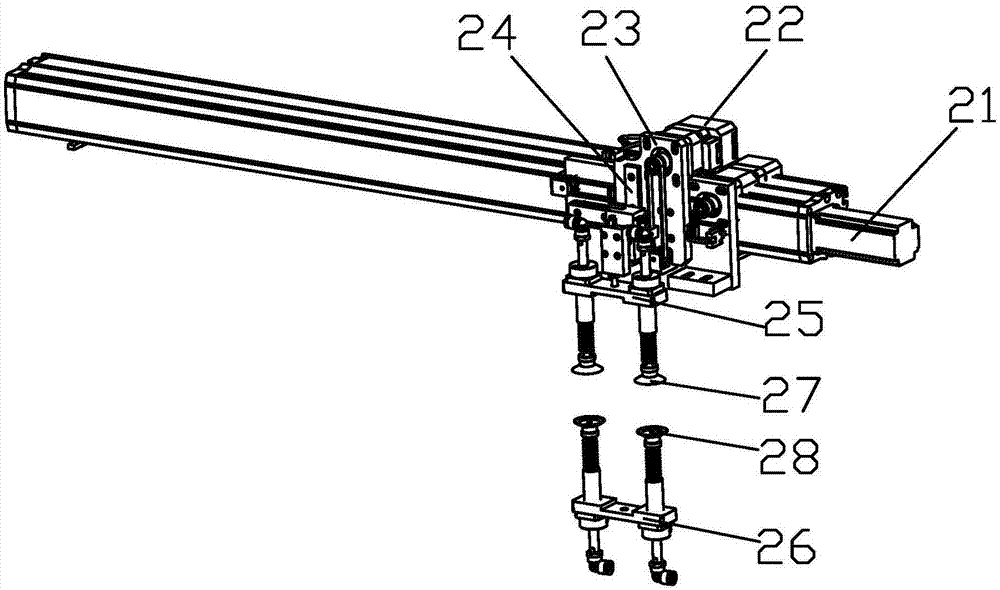

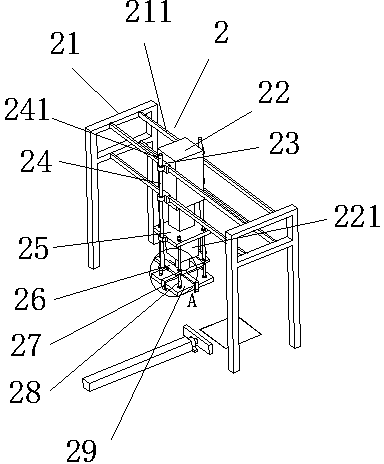

Bagging module of peritoneal dialysis solution bags

PendingCN107054753AImprove efficiencyImplement packagingWrapper twisting/gatheringPackaging automatic controlPeritoneal membranePeritoneal dialysis solutions

The invention discloses a bagging module of peritoneal dialysis solution bags. The bagging module comprises a bagging rack, a suction mechanism, a mouth opening mechanism, a roller wheel conveying line, a heat sealing machine and a bagging visual inspection mechanism. The roller wheel conveying line is fixed to the bagging rack. A packaging bag containing box is arranged at the position, located on the side face of the roller wheel conveying line, of the bagging rack. The heat sealing machine is fixed to one side of the bagging rack. The suction mechanism comprises an upper suction cup mechanism and a lower suction cup mechanism. The upper suction cup mechanism and the lower suction cup mechanism are arranged above and below the roller wheel conveying line correspondingly. The mouth opening mechanism is arranged at the position of the side face of the roller wheel conveying line and corresponds to the upper suction cup mechanism. The bagging visual inspection mechanism is arranged at the position, corresponding to the suction mechanism, of the bagging rack. In this manner, according to the bagging module, empty bags and full bags can be contained in outer bags, and automatic peritoneal dialysis solution bag packaging is achieved.

Owner:SUZHOU DALIKE AUTOMATION TECH

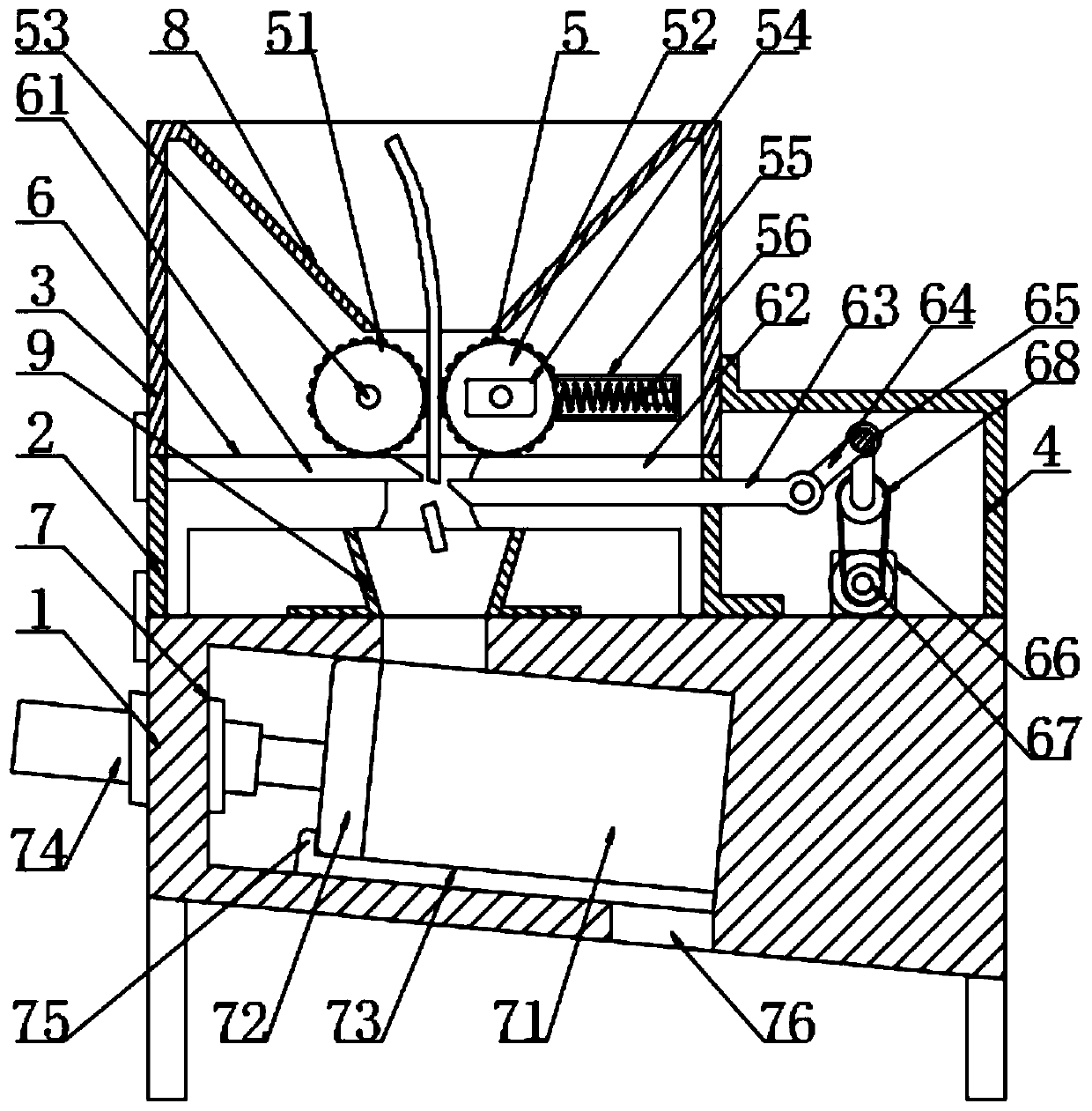

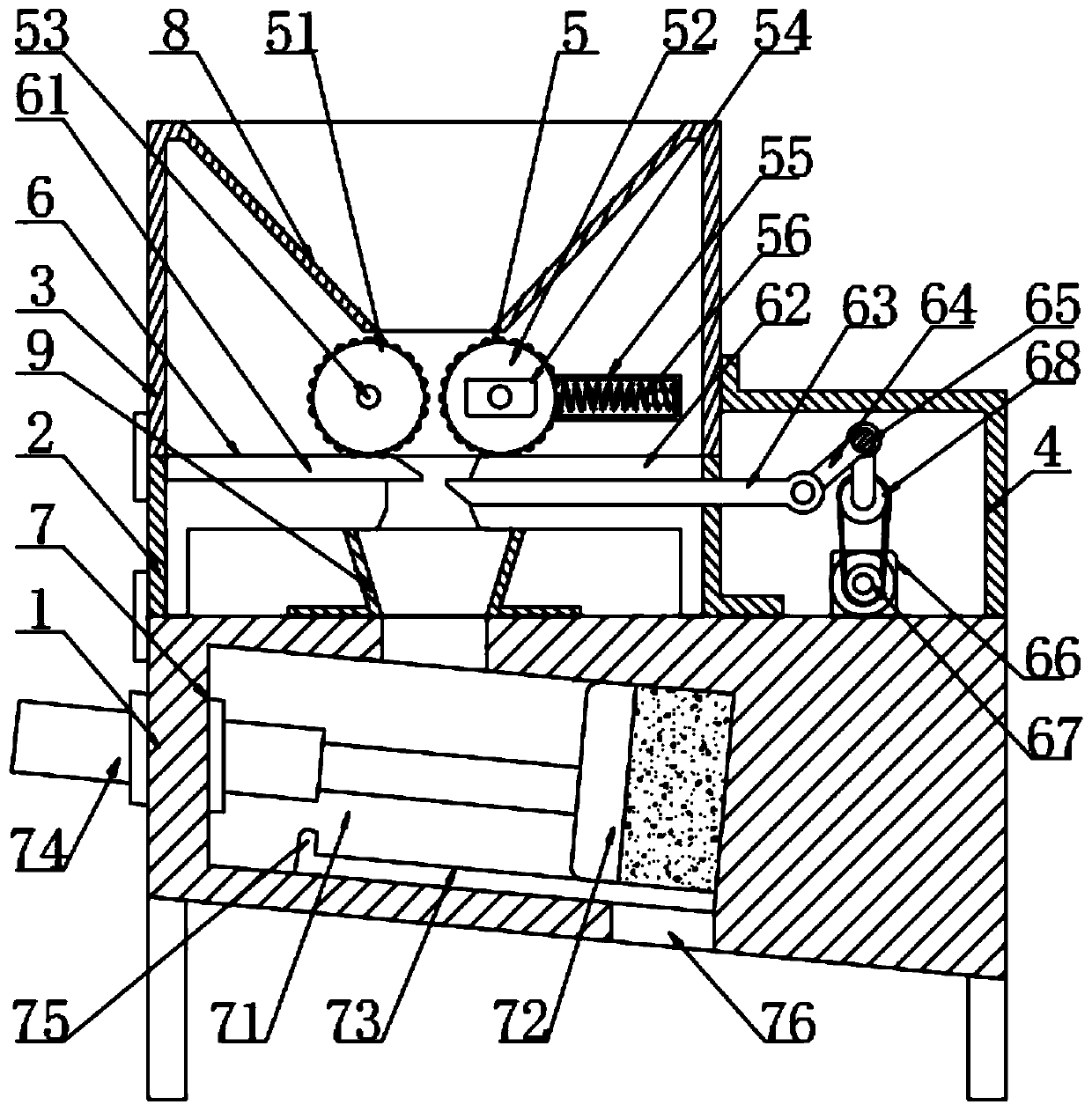

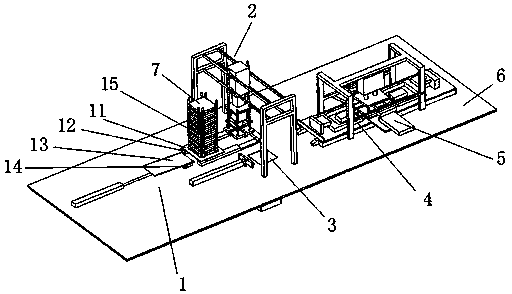

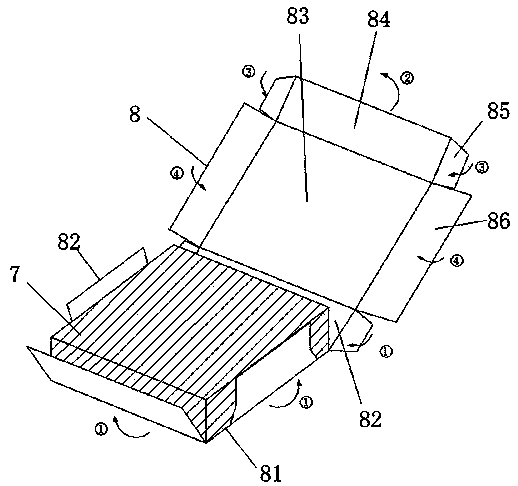

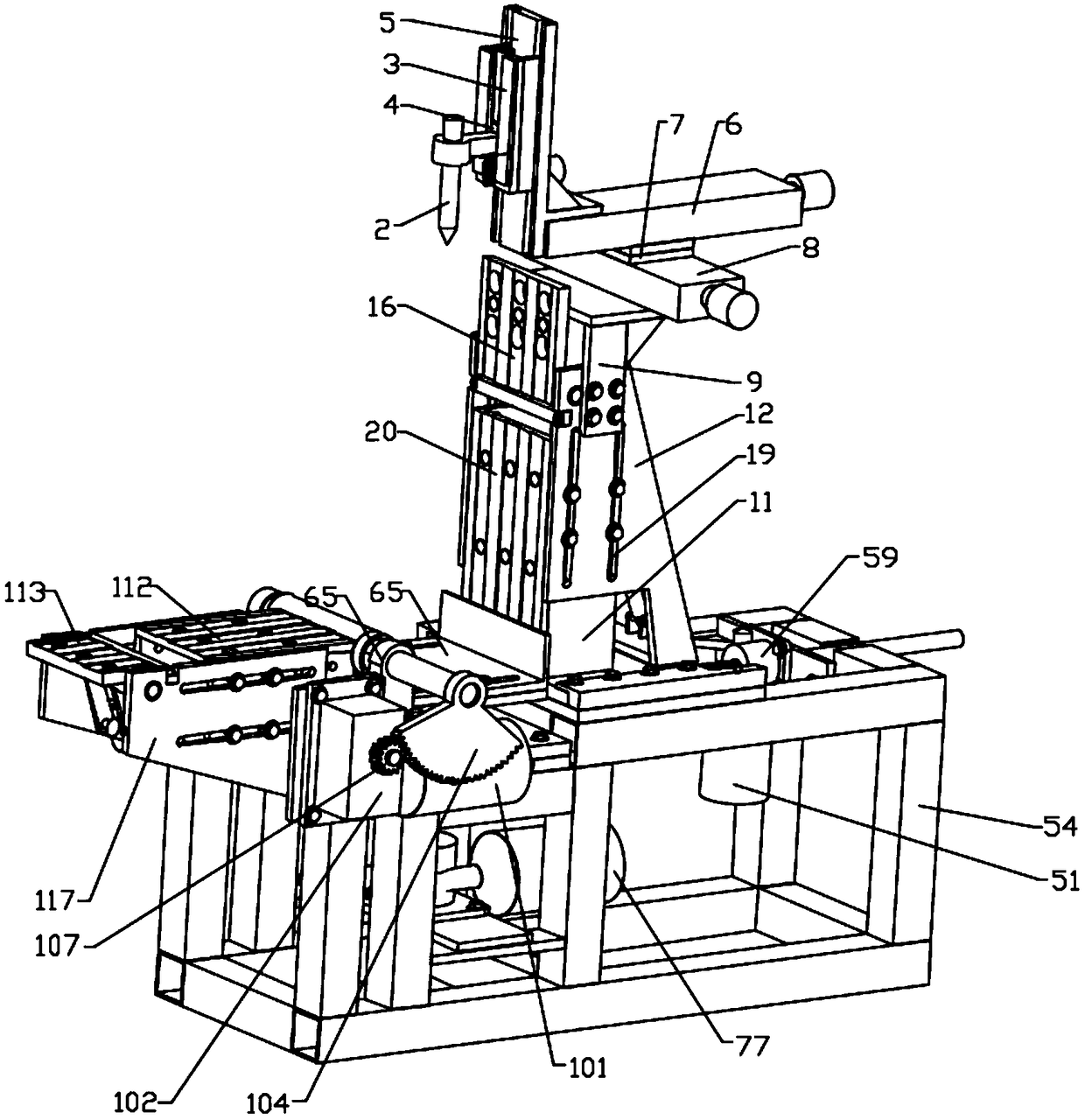

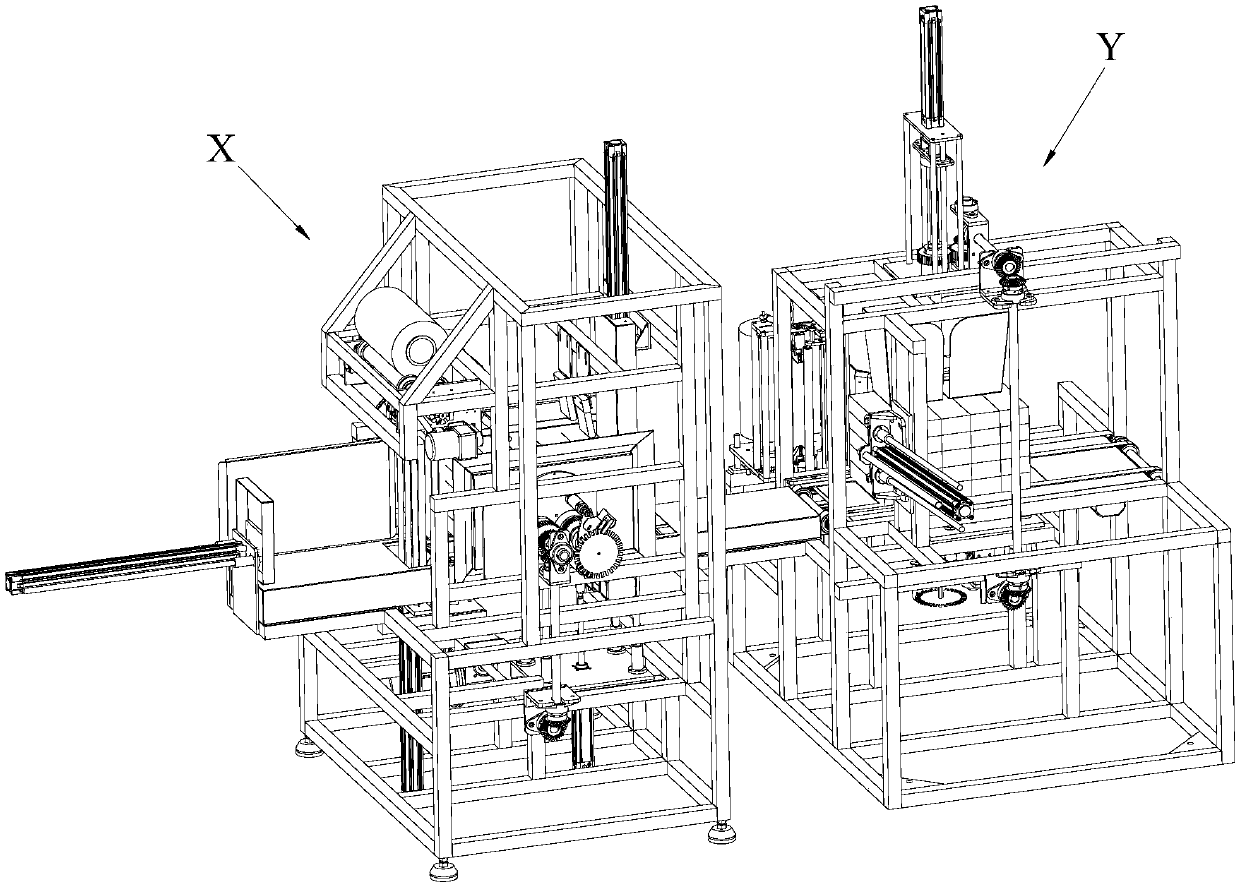

Quick packaging machine for box body

ActiveCN104354929AAvoid overlap in structural location designReduce complexityWrapper folding/bending apparatusConveyor wrappingLinear operationBiomedical engineering

The invention discloses a quick packaging machine for a box body. The quick packaging machine comprises a base, a material placing device for placing box bodies, a taking device for separately taking one box body each time, a primary packaging device for packaging the box body by using packing paper, a secondary packaging device used for packaging the remaining surface area of the box body and a material discharging device. According to the quick packaging machine for the box body, through partitioning of an edge banding mechanism, precise control of a packaging part every time can be realized, the part structure is greatly simplified, and through the linear movement of the box body and the linear operation of the packaging machine, the packaging process of the box body by using packaging papers is realized. The quick packaging machine is simple in structure, convenient to operate, is suitable for packaging box bodies with different sizes.

Owner:临清市经开实业有限公司

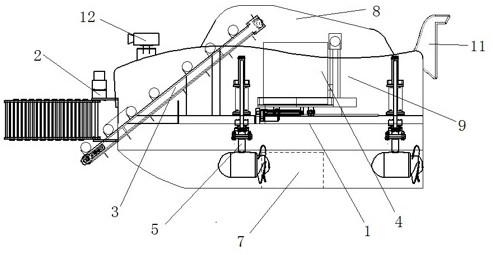

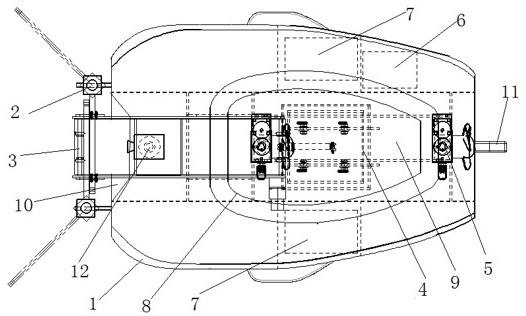

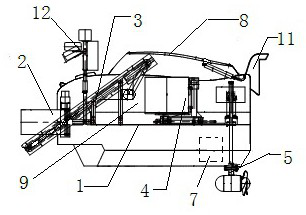

Intelligent water cleaning robot

PendingCN111945691AAvoid Waterlogging ProblemsWork lessWater cleaningWaterborne vesselsControl systemElectrical battery

The invention relates to the technical field of water garbage clearing, in particular to an intelligent water cleaning robot which comprises a mother ship floating body, a salvage conveying mechanism,a garbage storage device and at least one propelling device. An electric control cabinet and a power supply battery are arranged in the mother ship floating body, and an electrical control system isarranged in the electric control cabinet. According to the technical scheme, all composition structures are matched with one another under the control of the electrical control system to form a set ofcomplete water surface garbage salvaging process, wherein the propelling devices control the navigational speed and the navigational direction of salvage equipment in water, a material gathering mechanism gathers garbage to be matched with the salvage conveying mechanism to improve the salvage efficiency, and the salvage conveying mechanism smoothly conveys the garbage into a frame body, and theframe body automatically packages the garbage; the whole salvage process can completely break away from manual assistance, and safe, efficient and intelligent full-automatic unmanned salvage operationcan be truly achieved.

Owner:SICHUAN ORIENT HYDROELECTRIC ENG

Automatic packaging welding machine

PendingCN109317884AAvoid delayReduce manual hazardsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive motor

The invention provides an automatic packaging welding machine, and belongs to the technical field of packaging welding. The automatic packaging welding machine comprises a welding pressing plate assembly, a work bottom plate assembly and a turnover pressing plate assembly which are all fixedly arranged on a main support. The welding pressing plate assembly and the turnover pressing plate assemblyare arranged on the two sides of the work bottom plate, a welding gun achieves three-dimensional movement relative to a vertical plate, an electric push rod drives a stand column pressing plate to rotate relative to a special-shaped plate, a vertical rotating shaft drives a second vertical plate and a pressing plate through a motor to rotate, a second motor push rod controls the pressing plate torotate for the second time, a spiral lead screw elevator drives a lower base through a driving motor to ascend and descend, one end of a spiral lead screw mover is connected with a welding installation plate, and the spiral lead screw mover drives a welding machine installation plate through a second driving motor to horizontally move. The components are electrically controlled to move, automaticwelding is adopted, manual labor is reduced, the cost is reduced, and welding quality is improved.

Owner:天津源泰德润钢管制造集团有限公司

Slice material automatic feeding device

Disclosed is a slice material automatic feeding device. The slice material automatic feeding device comprises a spiral vibration disc and a plate vibrator. One end of the plate vibrator is connected with the spiral vibration disc in a butt joint mode. The slice material automatic feeding device is characterized in that a material grabbing device is arranged above the other end of the plate vibrator. The material grabbing device comprises a translation assembly and a grabbing assembly which is installed on the translation assembly. The translation assembly drives the grabbing assembly to move in the moving direction of materials on the plate vibrator 14. The slice material automatic feeding device has the advantages that automatic cloth packing is achieved, labor is saved, and the work efficiency is improved greatly; and the structure is simple, the manufacturing cost is low, operation is reliable, and usage and maintenance are convenient.

Owner:郑汝升

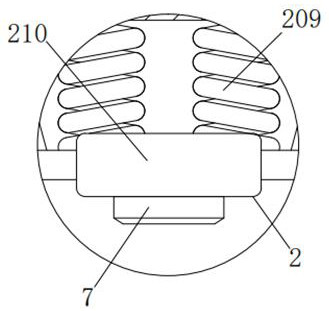

Medicine particle packaging machine

InactiveCN111332514ADosage is the sameAvoid problemsWrapper twisting/gatheringSolid materialPhysicsEngineering

The invention discloses a medicine particle packaging machine. The medicine particle packaging machine comprises supporting legs, a case body, a quantitative feeding mechanism, a support body, a longitudinal edge sealing mechanism, an opening sealing mechanism, bag walking wheels, a packaging film roll and a controller. According to the medicine particle packaging machine, the quantitative feedingmechanism is arranged, in the feeding process, a push rod of a first air cylinder drives a feeding plate to contract downwards, an arc trough in the top of the feeding plate is filled with particlesin a hopper at the moment, then the first air cylinder pushes the feeding plate to move upwards, the feeding plate stops when the feeding plate and an arc material conveying trough is flushed, the particles in the feeding plate fall into a packaging bag through the arc material conveying trough at the moment, particle medicine is scrapped and rolled in no step in the process, the particle medicineis effectively prevented from being rolled into powder, and dust is avoided.

Owner:严白双

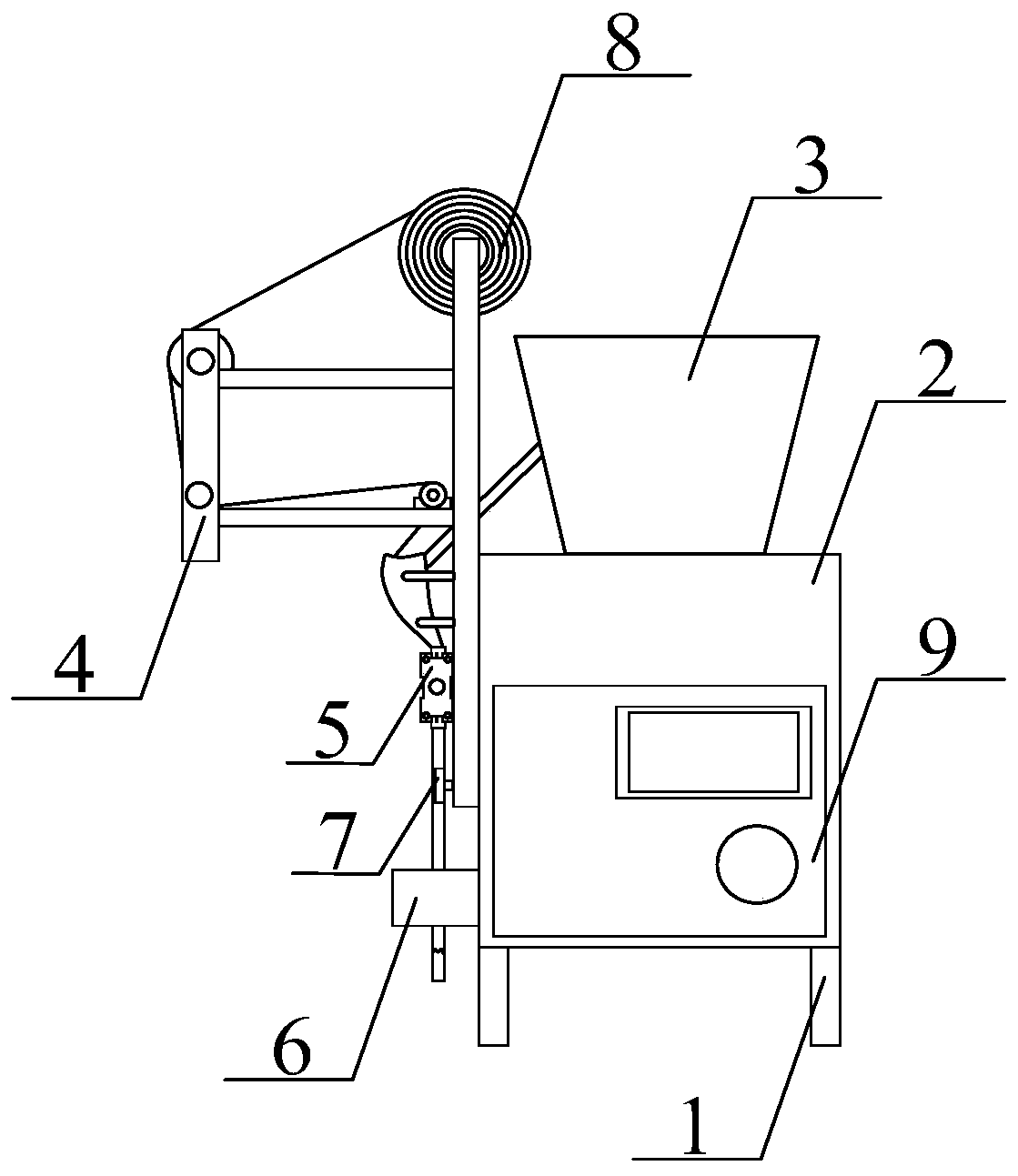

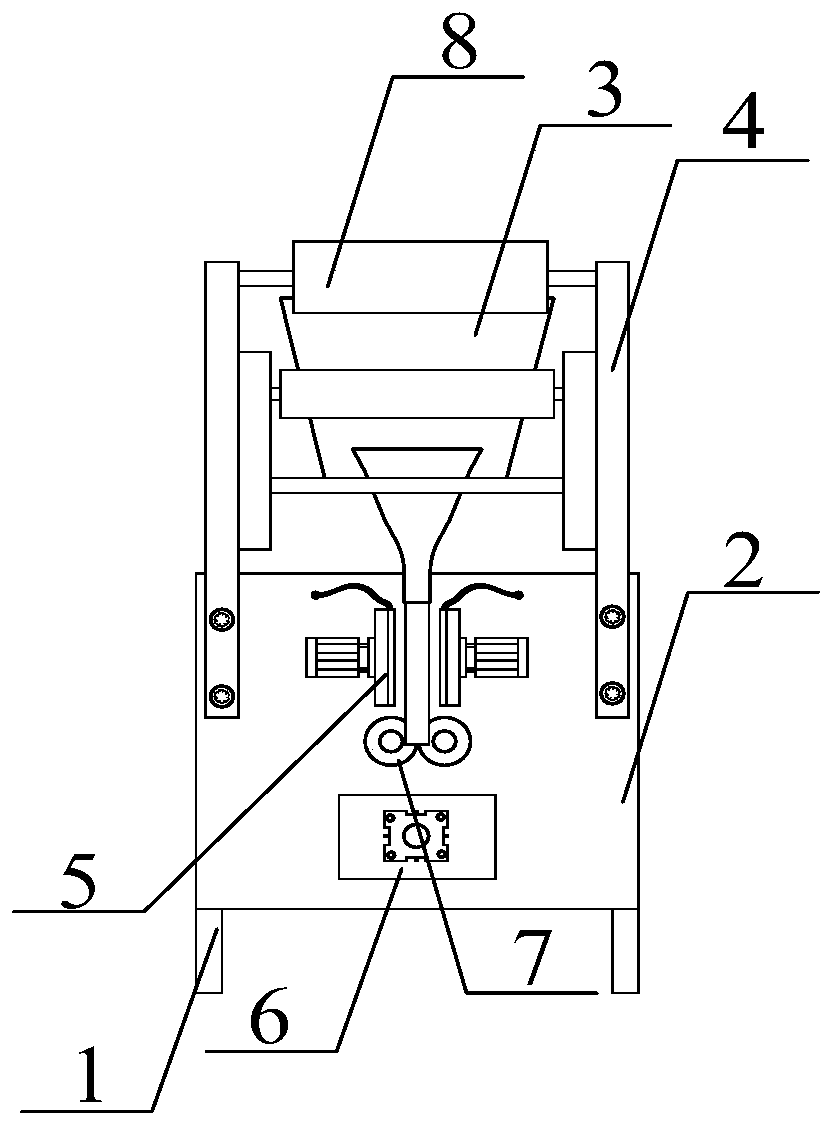

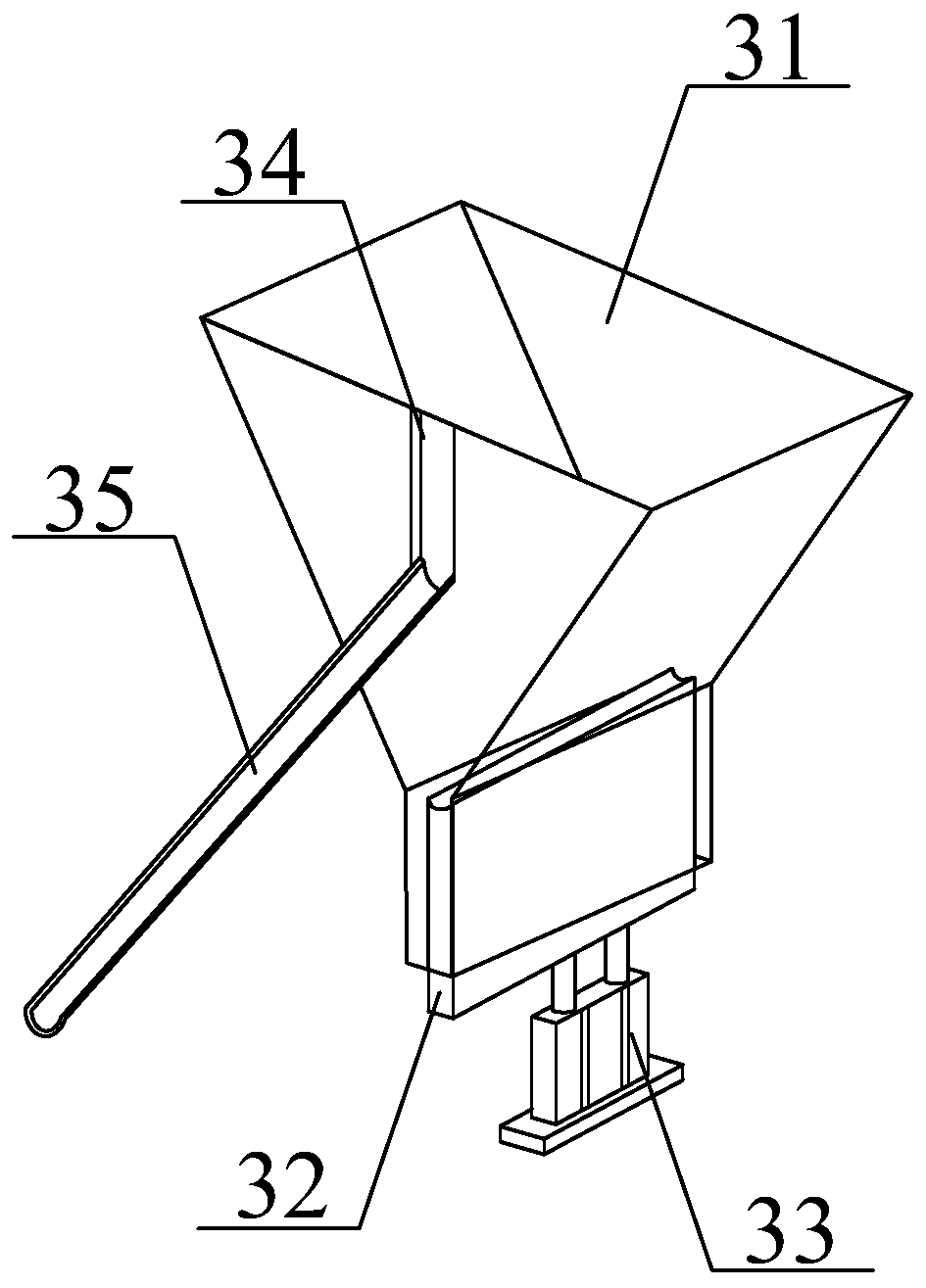

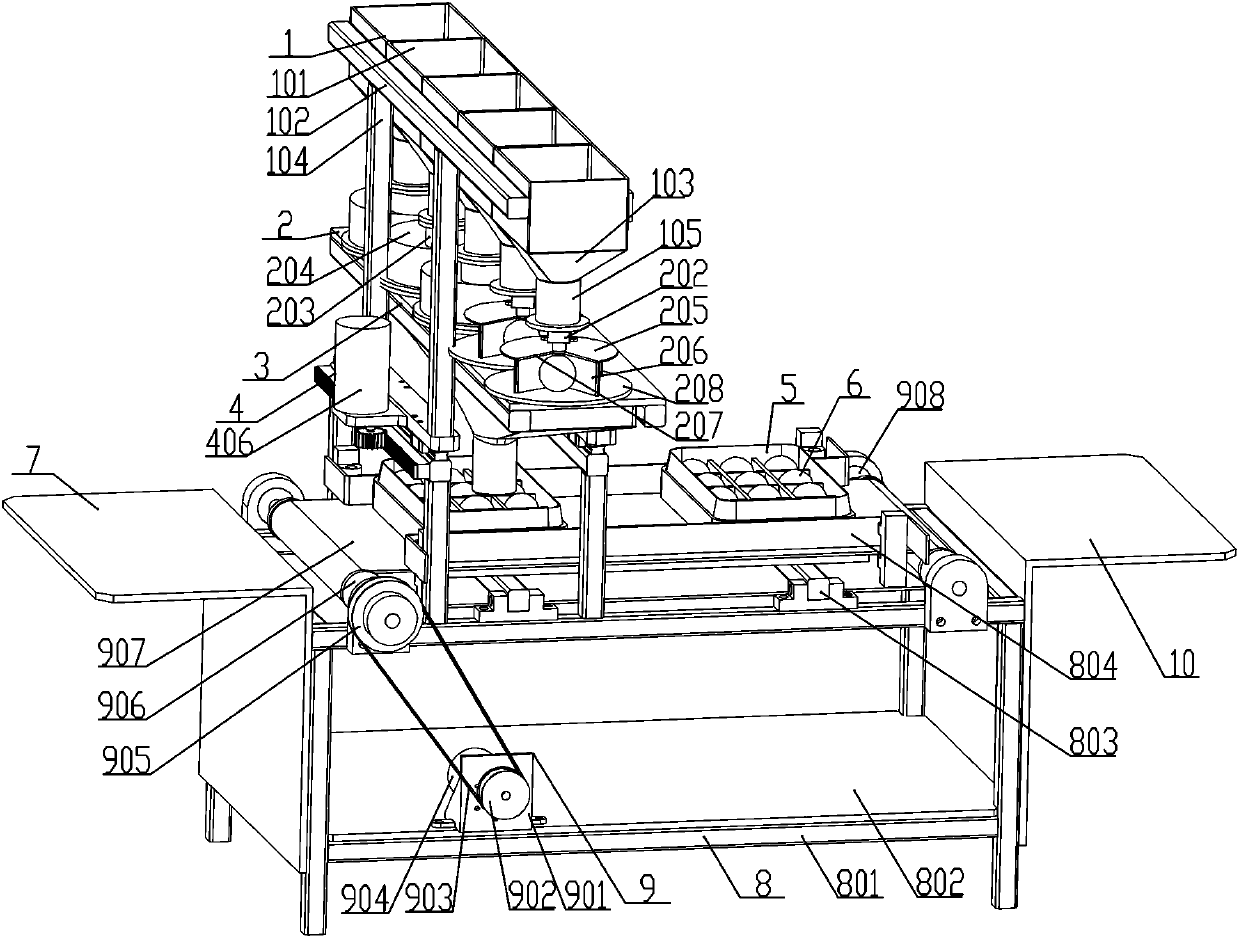

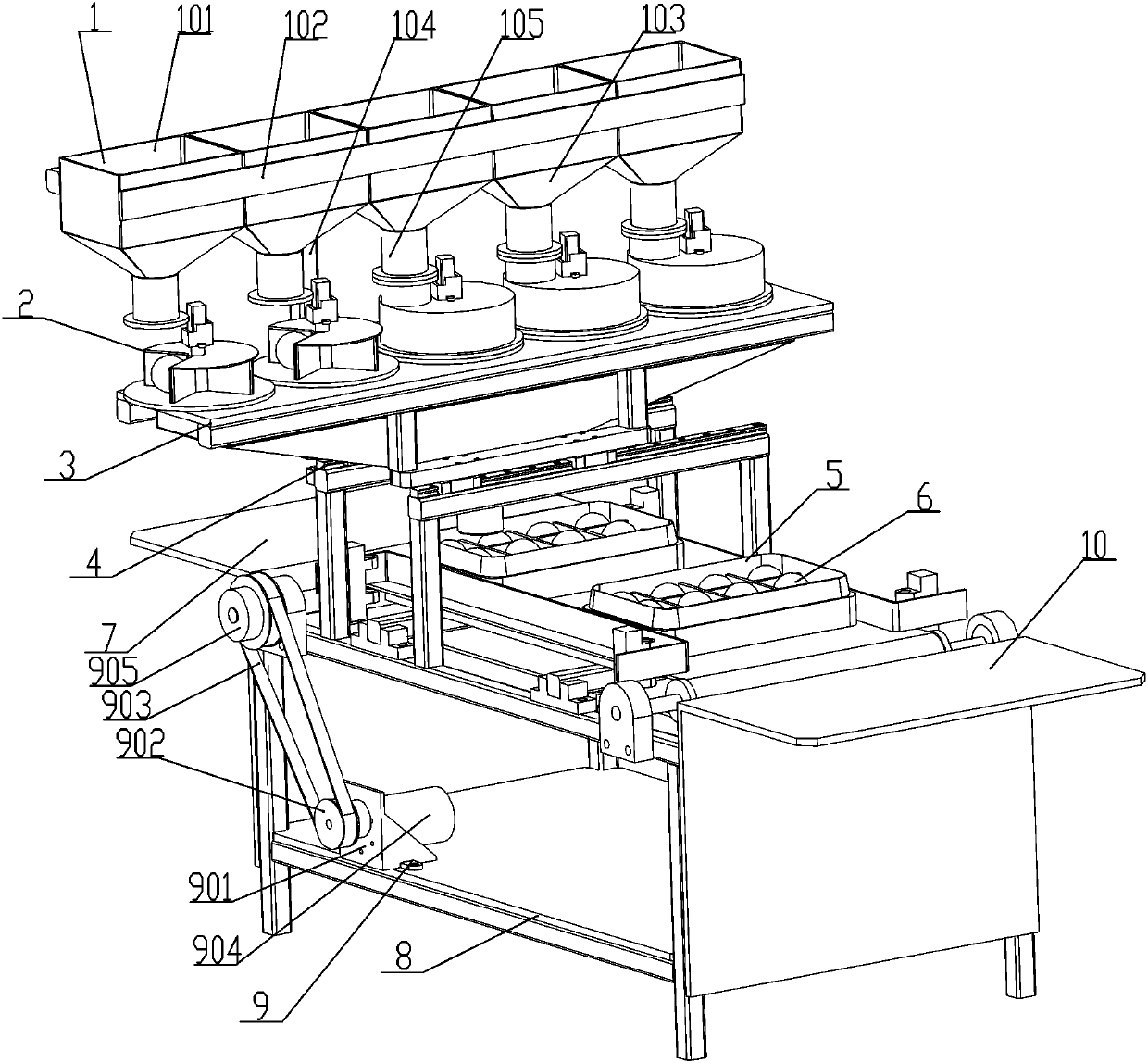

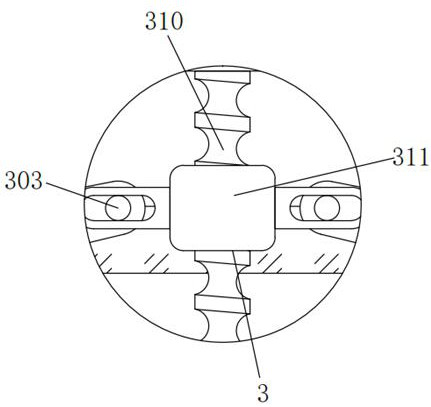

Machine capable of automatically and quantitatively packaging spherical fruits and operation method

InactiveCN107600503ARealize automatic packaging operationsRealize quantitative automatic cuttingPackaging fruits/vegetablesProcess engineeringDistributor

The invention provides a machine capable of automatically and quantitatively packaging spherical fruits and an operation method. The machine comprises a general discharging device for containing the fruits, wherein discharging ports of the general discharging device are provided with distributors for realizing sequential discharging of the fruits correspondingly in a butted mode, and discharging holes of the distributors are provided with a bottom discharging device; the general discharging device, the distributors and the bottom discharging device are all supported on a translation mechanismfor moving the whole device; the translation mechanism is fixedly arranged on a conveyor frame, and a conveyor belt device used for conveying fruit boxes is arranged on the conveyor frame; the bottomdischarging device is arranged right above the conveyor belt device; and the translation direction of the translation mechanism is perpendicular to the conveying direction of the conveyor belt device.The automatic discharging mechanism can ensure that only one object is discharged at each time, so that quantitative packaging is realized, the defects of traditional packaging are overcome, and thepackaging efficiency is guaranteed.

Owner:CHINA THREE GORGES UNIV

Packaging method for cigarettes in carton

ActiveCN107892009AImplement packagingLow costWrapping with article rotationWorking environmentCarton

The invention discloses a packaging method for cigarettes in carton. The packaging method comprises a step of twining and coating the to-be-packaged cigarettes in carton with a wrapping film, whereinthe twining film is stretchable and adhesive. According to the packaging method, the film needs no thermal shrinkage, so the problems about peculiar smell, power consumption and high cost generated ina thermal shrinkage process when a thermal sealing film is used for packaging the cigarettes in carton in the prior art can be avoided, and the packaging method has the advantages of being low in cost and friendly to working environment.

Owner:林辅钦

Method for rapidly packaging android application on APP development platform

InactiveCN104503776APacking operations are reducedFast packingProgram loading/initiatingSignature fileApplication software

The invention discloses a method for rapidly packaging android application on an APP development platform. The method comprises steps that an APP master program template is arranged on the APP development platform, and an APP configured signature file module is further arranged on the APP development platform which is combined with the master program template to form an APP application program, an android development tool is mounted on the APP development platform, which pre-executes android package operation on the master program template, while a user only develops the configured signature file module; after the completion of development, the android development tool carries out android package operation on the configured signature file module developed by the user; finally two packaging results are synthesized, so as to form a complete android packaging program for APP application. The user only needs to package the configured signature file module, and the method is more intelligent and efficient, reduces packaging operation of the user, and accelerates the packaging speed.

Owner:BEIJING JINHER SOFTWARE

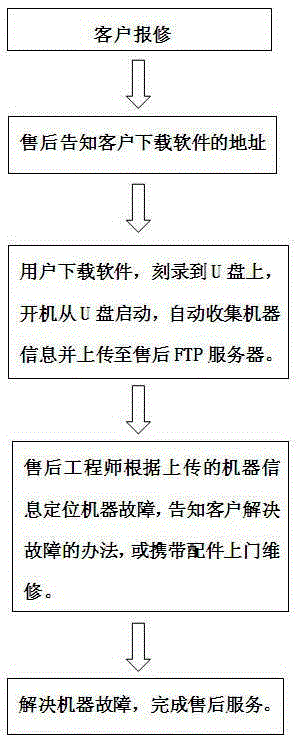

Fault machine information collection method used for server after-sales service

InactiveCN105306604AEasy to useUse auto-implementationTransmissionCommerceWeb siteOperational system

The invention discloses a fault machine information collection method used for server after-sales service, comprising the steps of 1) a client reporting reparation; 2) an after sale party telling the client of a software downloading address; 3) the client downloading software, recording the software on a USB flash disk, and starting up from the USB flash disk to automatically collect machine information, and to upload the machine information to an after sale FTP server; 4) according to the uploaded machine information, an after sale engineer positioning a machine fault, and notifying the client of a fault solution method or carrying fittings to perform on-site repair; and 5) solving machine faults and completing after sale service. For current server after sale on-site repair, fault positioning before visiting a site is difficult, current information grabbing software depends on a client operating system, information grabbing is uncomprehensive, and the client has to upload grabbed information to an after sale website by oneself, and the fault machine information collection method can solve the problems; the after sale engineer can be more targeted before visiting a client, and avoid fault detection at the site, thereby saving time and labor; the client does not need to upload information by oneself; the fault machine information collection method realizes automation, and is simple and fast.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Packaging device for diaper production

ActiveCN112693688AImplement packagingHigh degree of automationWrapper twisting/gatheringPackaging machinesElectric machineryWorm drive

The invention discloses a packaging device for diaper production. The packaging device comprises a long plate, wherein vertical plates are fixedly connected to the left side and the right side of the top of the long plate, the tops of the vertical plates are fixedly connected with the left side and the right side of the bottom of a transverse plate, the top of the long plate is fixedly connected with a heating plate located below the long plate, and a lifting device is arranged above the long plate. According to the packaging device for diaper production, by means of the cooperation of a bottom plate, the long plate, the transverse plate, the vertical plates, the heating plate, round rods and the lifting device, a motor drives a worm to rotate, the worm drives a worm wheel to rotate, the worm wheel drives a grooved wheel on the left side to rotate, the grooved wheel drives a wire wheel to rotate, the wire wheel enables a steel wire rope to extend, and springs drive a straight plate to move downwards, the straight plate drives the heating plate on the upper portion to move downwards, then packaging of diapers is achieved, the automation degree is high, the labor is saved, and the working efficiency is improved; and an electric push rod drives a rack to move leftwards and rightwards, then second bent rods can be rotated, then sliding blocks can drive clamping plates to move leftwards and rightwards, and then fixing of the diapers is achieved.

Owner:李月红

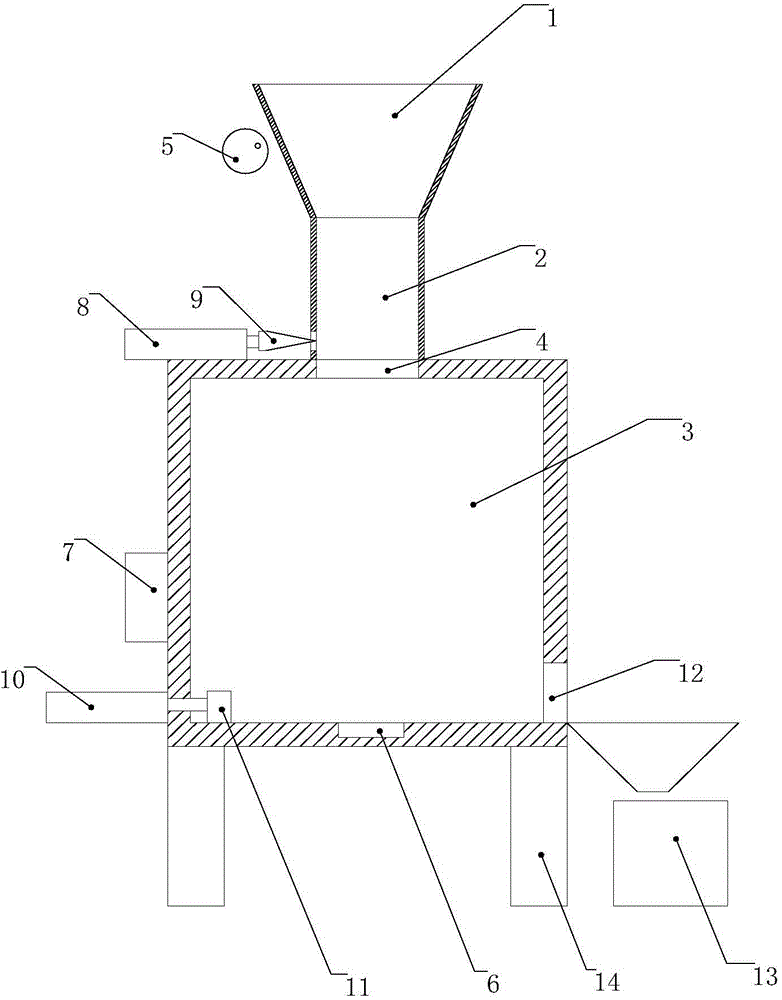

Packing machine

The invention discloses a packing machine and relates to the technical field of food packing machinery. The packing machine can automatically weigh food and can prevent food from adhering to the inner sidewall of a material inlet. The packing machine comprises the material inlet, a material guide hole and a weighing chamber. An inner cavity is arranged in the weighing chamber. A material falling hole is formed in the position, corresponding to an outlet of the material guide hole, of the upper surface of the weighing chamber. The packing machine further comprises a vibrating device, a pneumatic cutter, a pressure sensor, a pneumatic push plate and a control device. The vibrating device is installed on the outer side face of the material inlet. The pneumatic cutter comprises a first cylinder and a cutter body. The pressure sensor is installed in the bottom wall of the weighing chamber. The pneumatic push plate comprises a second cylinder and a push plate body. The control device is installed on the outer sidewall of the weighing chamber and is fixedly connected with the first cylinder and the second cylinder through electromagnetic valves. A material outlet is formed in the sidewall, opposite to the push plate body, of the weighing chamber. A sealing machine is arranged at the material outlet.

Owner:尚素平

Onion cutting device

PendingCN109877905ARealize automatic cuttingProcess effortWrapper folding/bending apparatusWrapper twisting/gatheringMechanical engineeringPiston rod

The invention provides an onion cutting device, aims at overcoming the defects of manual onion cutting in black onion production process and strength consuming and low efficiency in onion packaging process, and belongs to the technical field of onion processing. The device comprises a rack, cutter tools are fixed to the rack, pressing plates are arranged above each cutter tool, air cylinders whichare used for driving the pressing plates to push the pressing plates to the cutter tools, piston rods of the air cylinders are connected with push rods, and the pressing plates are fixedly arranged below the push rods and can be moved along with the push rods; outer package wrapping devices are arranged below each cutter tool. The device has the advantages that onions can be automatically cut, cut onions can be automatically packaged to prepare for further processing, the whole process is extremely strength-saving, and the production efficiency can be improved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com