Method and equipment for detecting batched products

A technology for testing equipment and batch products, applied in sorting and other directions, can solve the problems of slow speed and low detection efficiency, and achieve the effect of increasing mobile efficiency, realizing packaging and efficient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to help those skilled in the art to accurately understand the subject matter claimed by the present invention, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

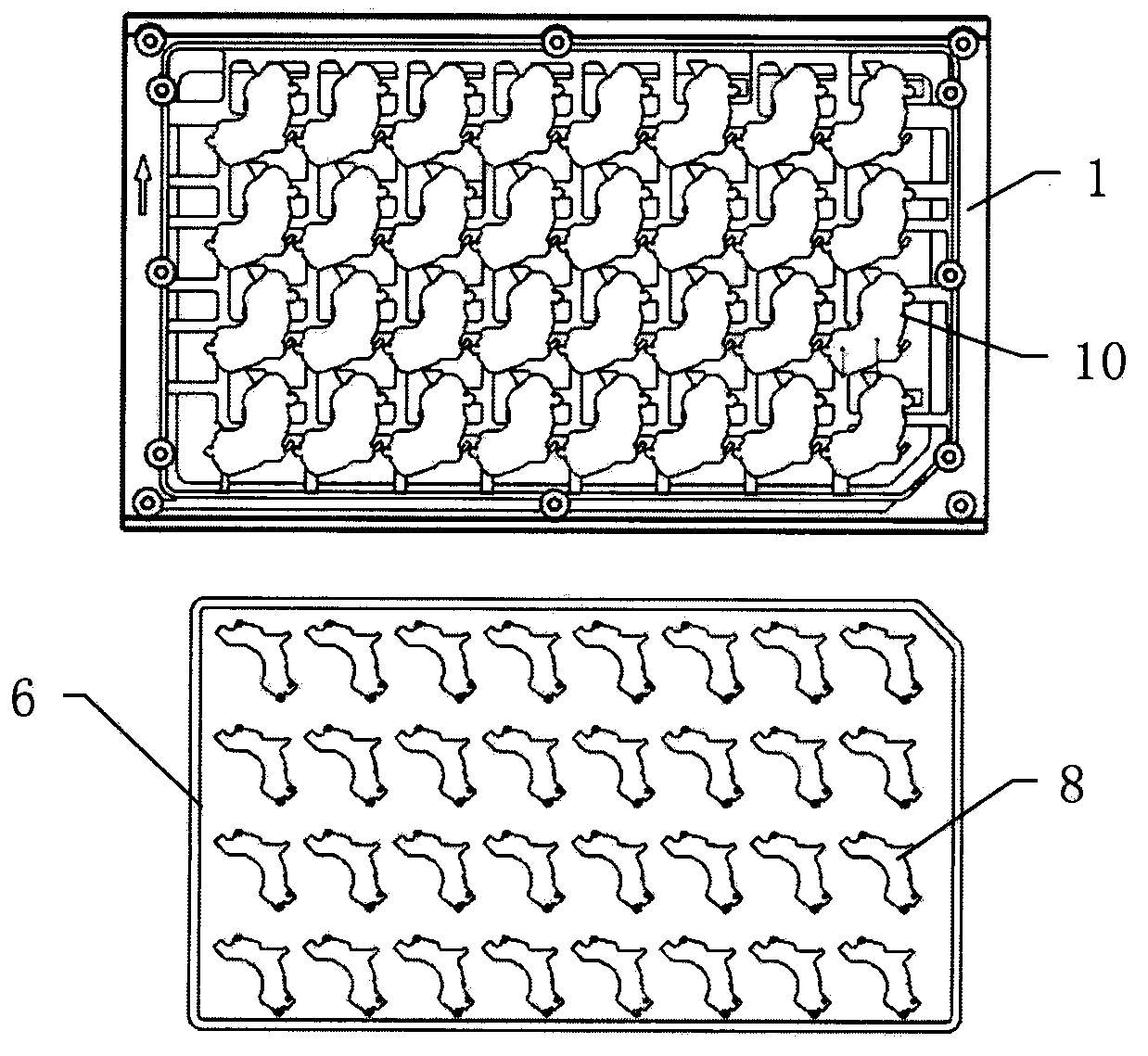

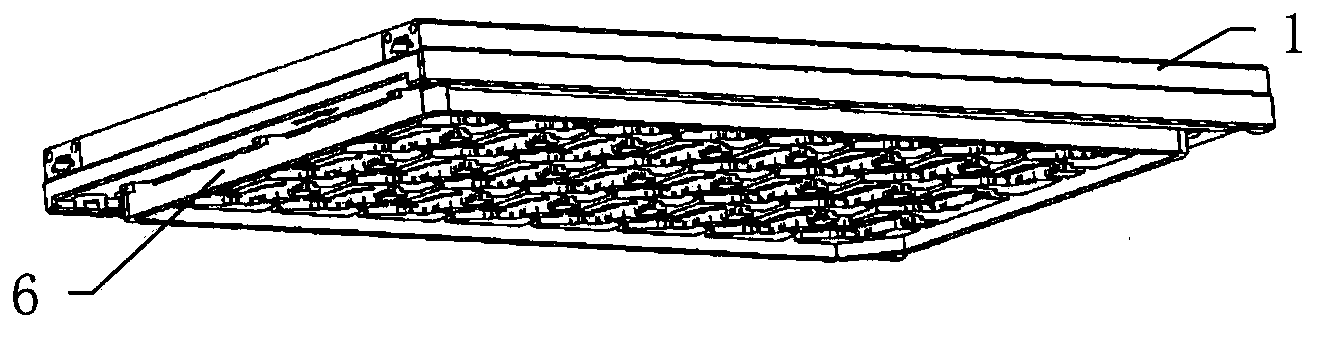

[0030] Those of ordinary skill in the art know that multiple products can usually be contained in one package. For example, see figure 2 As shown, the product packaging includes a tray 6 containing a plurality of products 8, and the plurality of products 8 are positioned on the tray 6. Specifically, a total of 32 products 8 in 8 rows and 4 columns are arranged in one tray 6.

[0031] Different from the traditional method, the inventor of this application has innovatively invented a method for efficient detection.

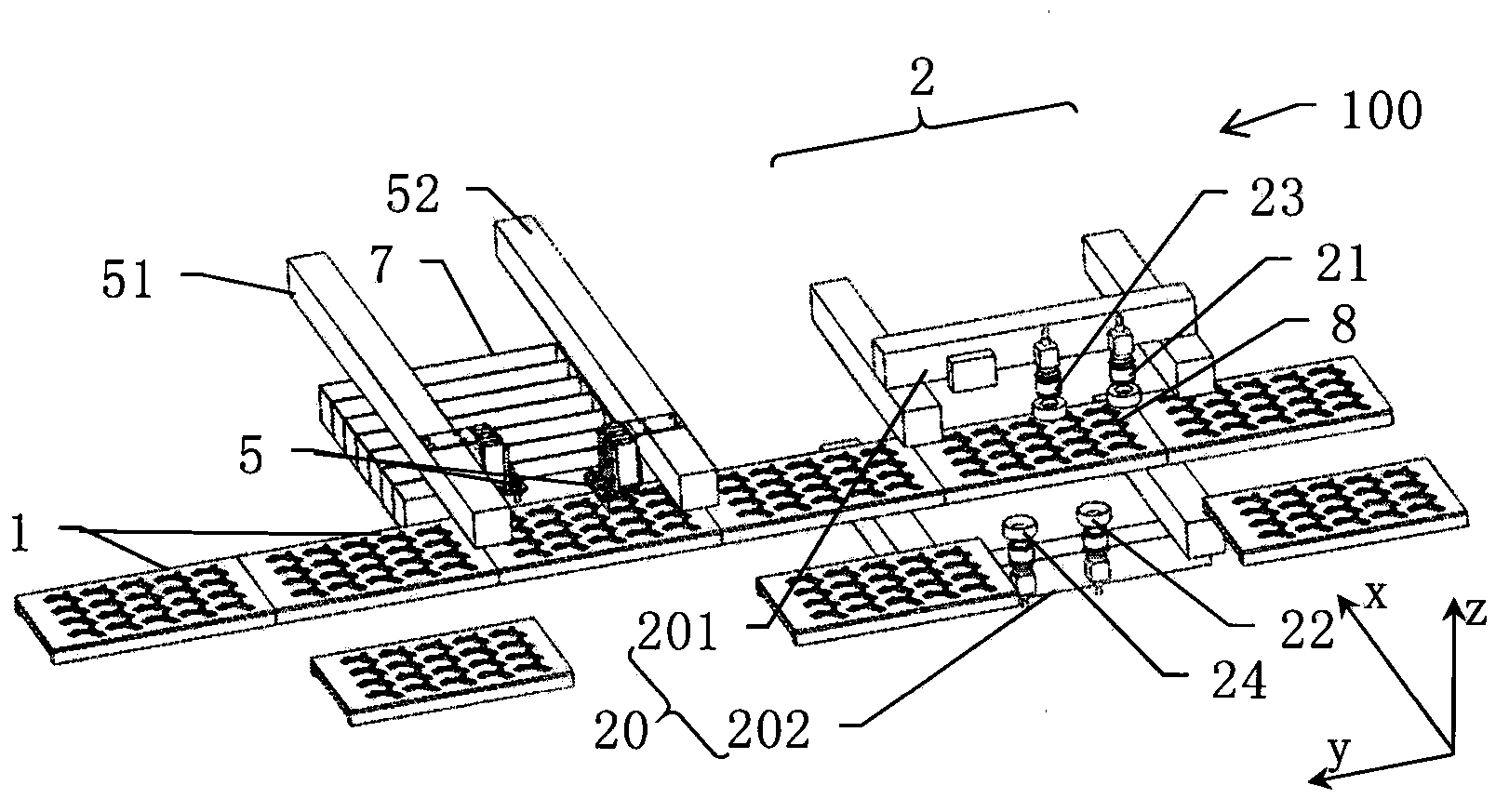

[0032] See first figure 1 A detection device 100 for this method is shown. The inspection device 100 includes a carrier 1, an image pickup section 2, a defective product container 7, a pickup 5, and the like. The carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com