Patents

Literature

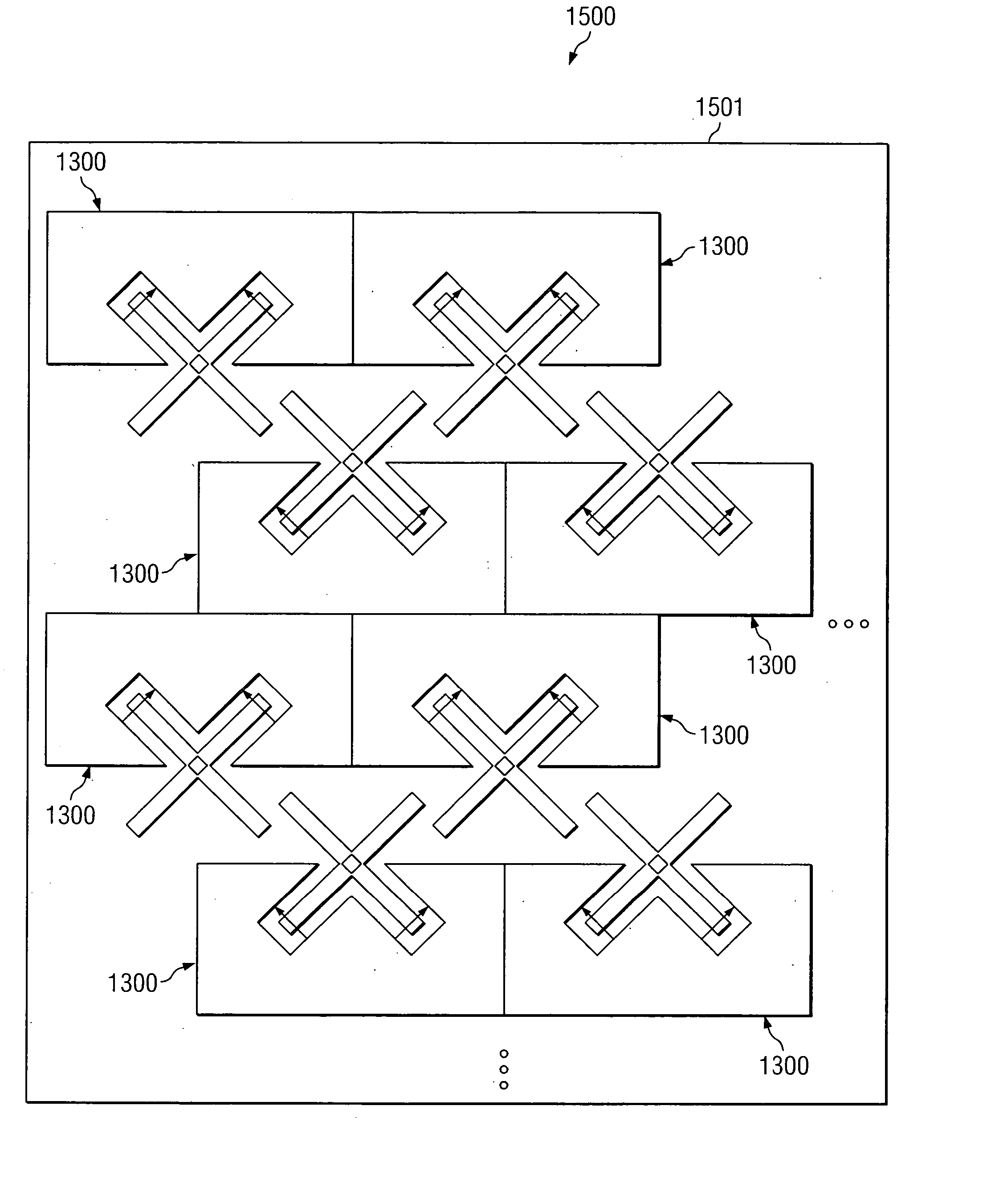

51results about How to "Thin and compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

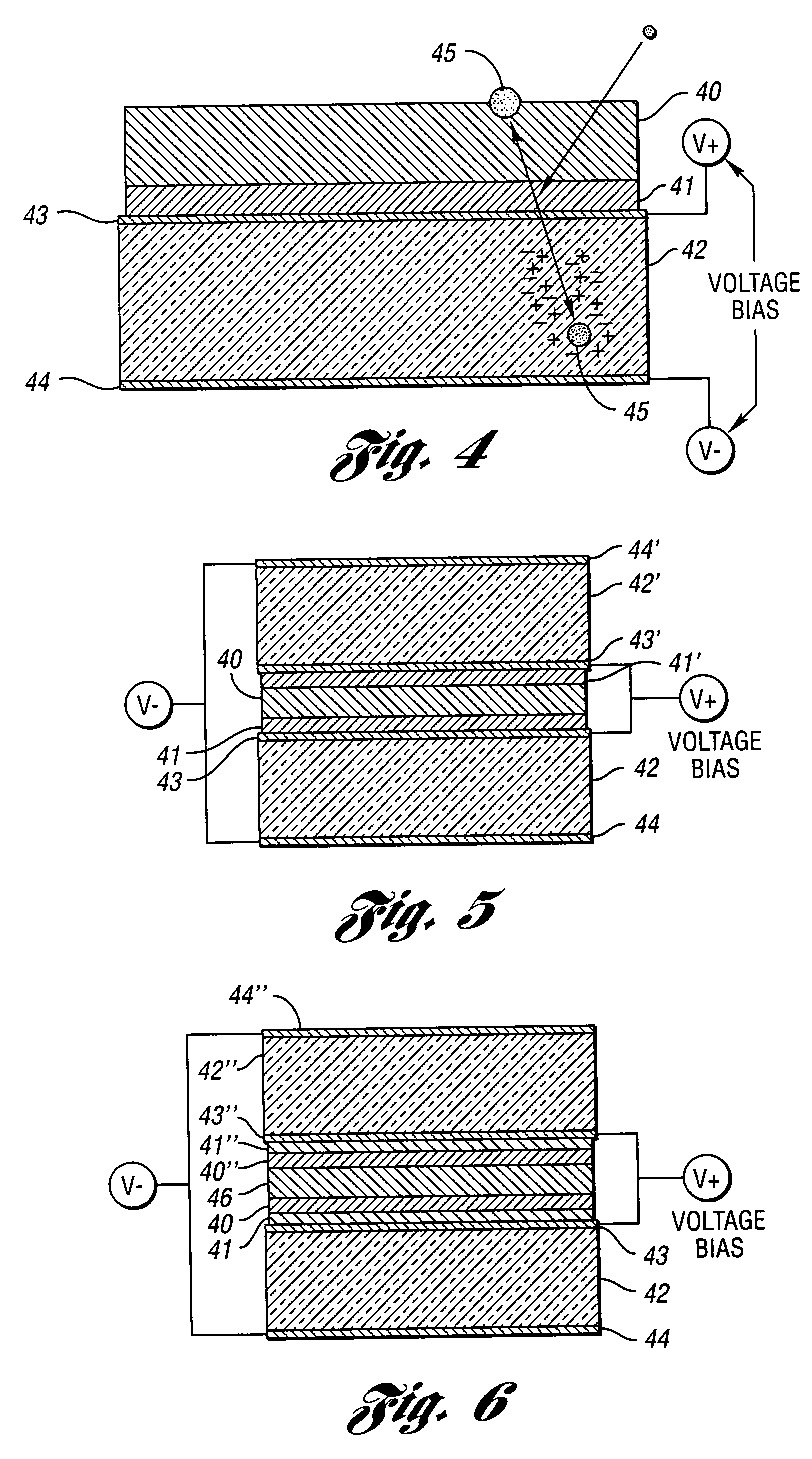

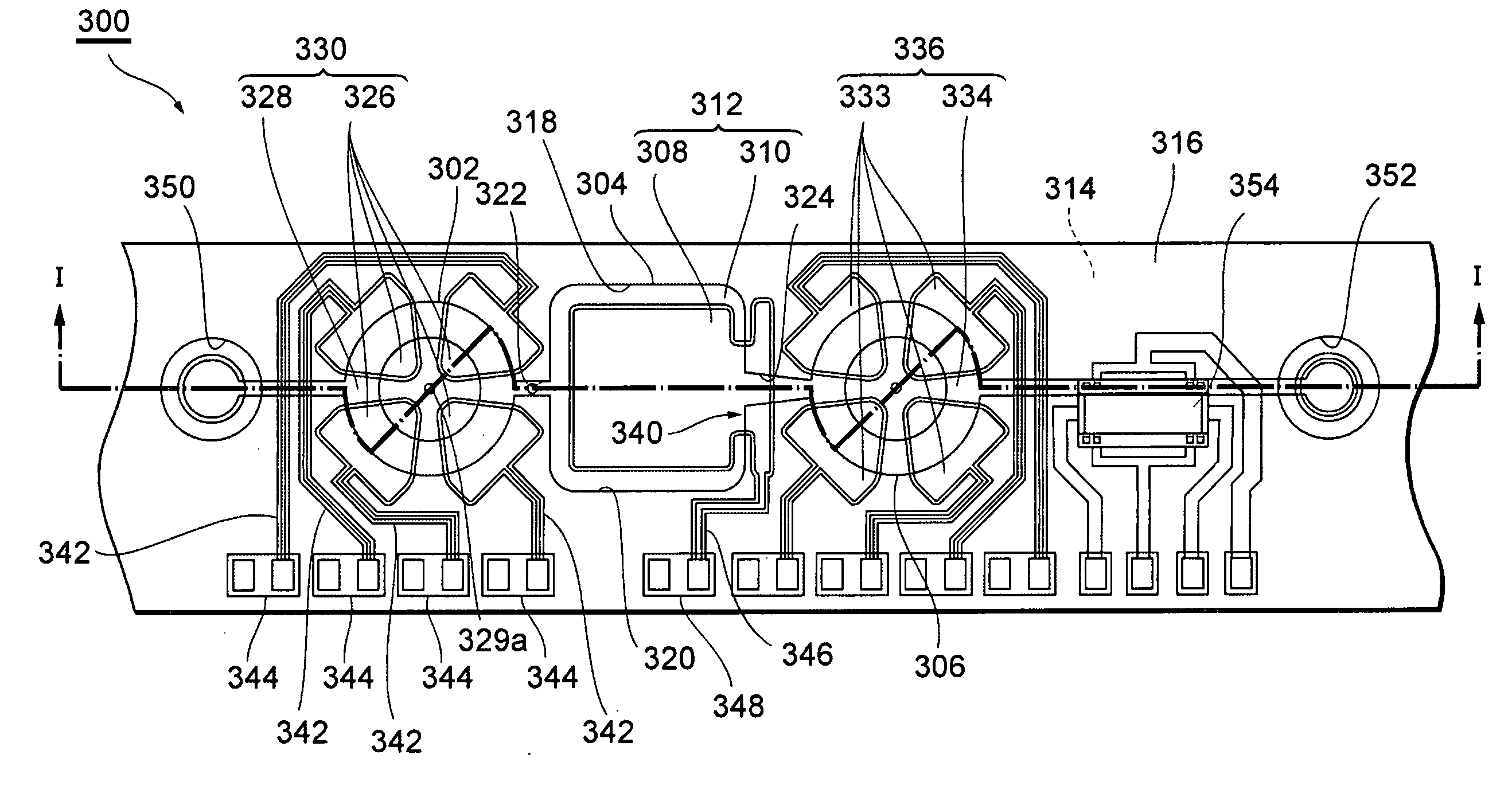

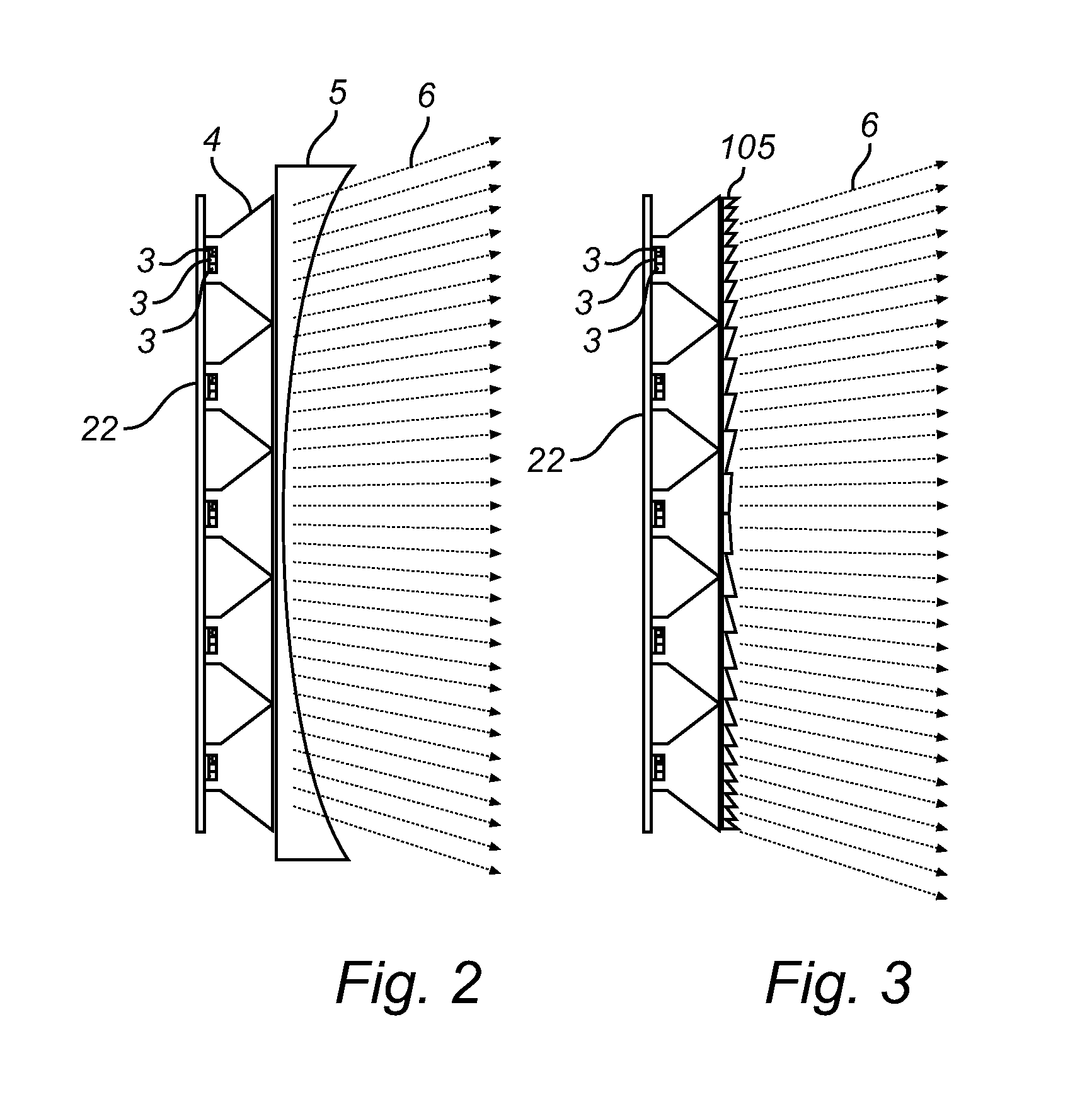

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

ActiveUS7075485B2Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

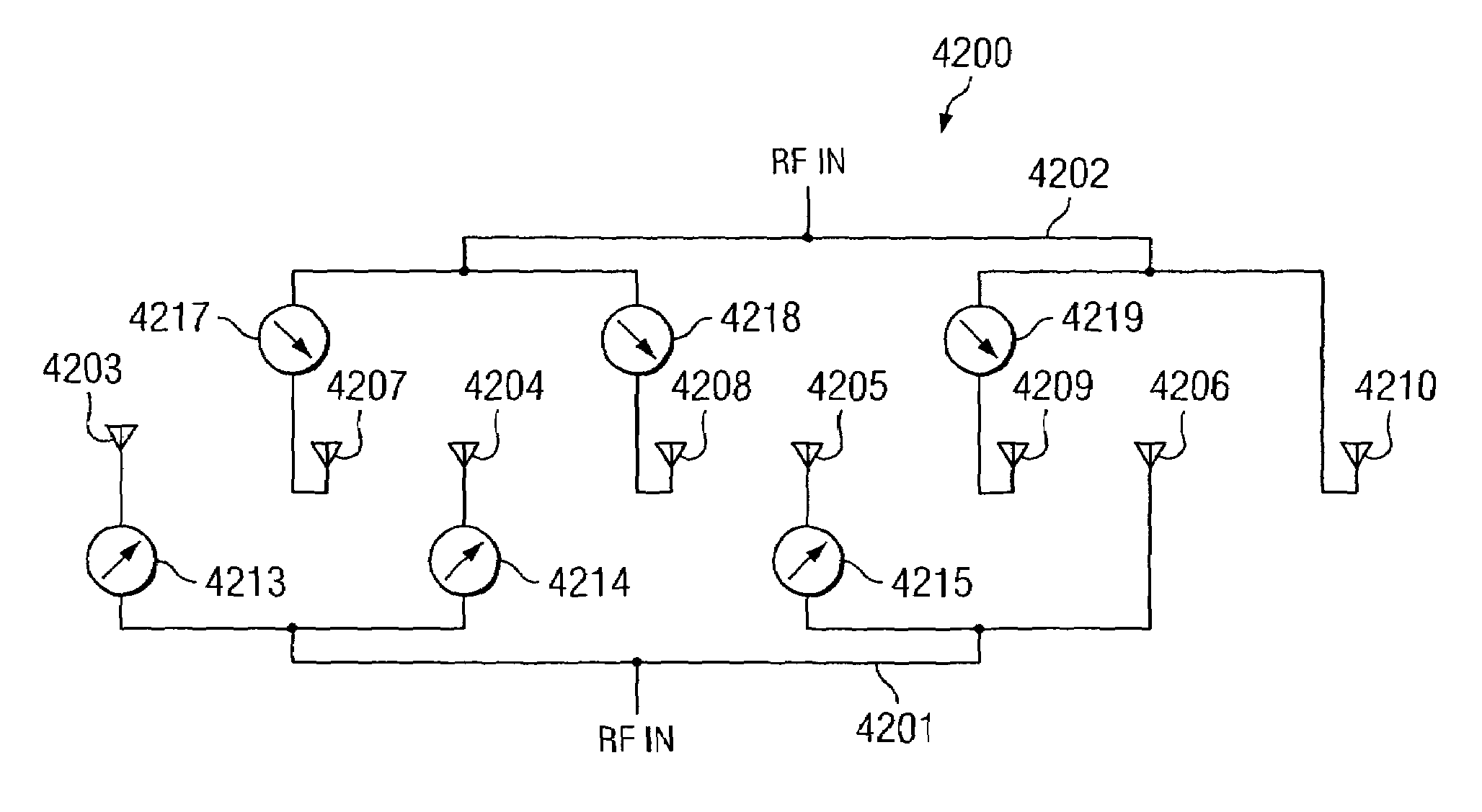

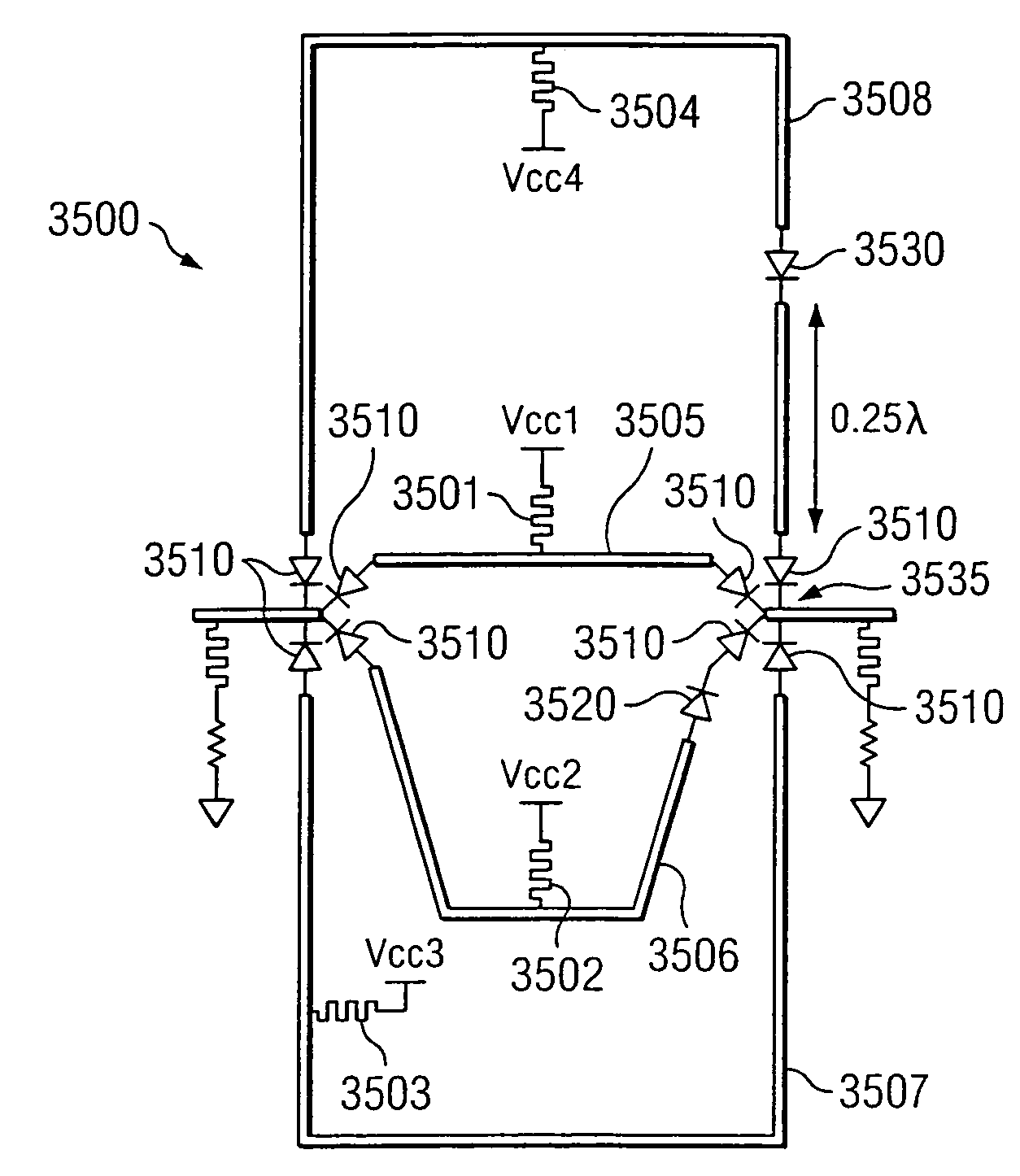

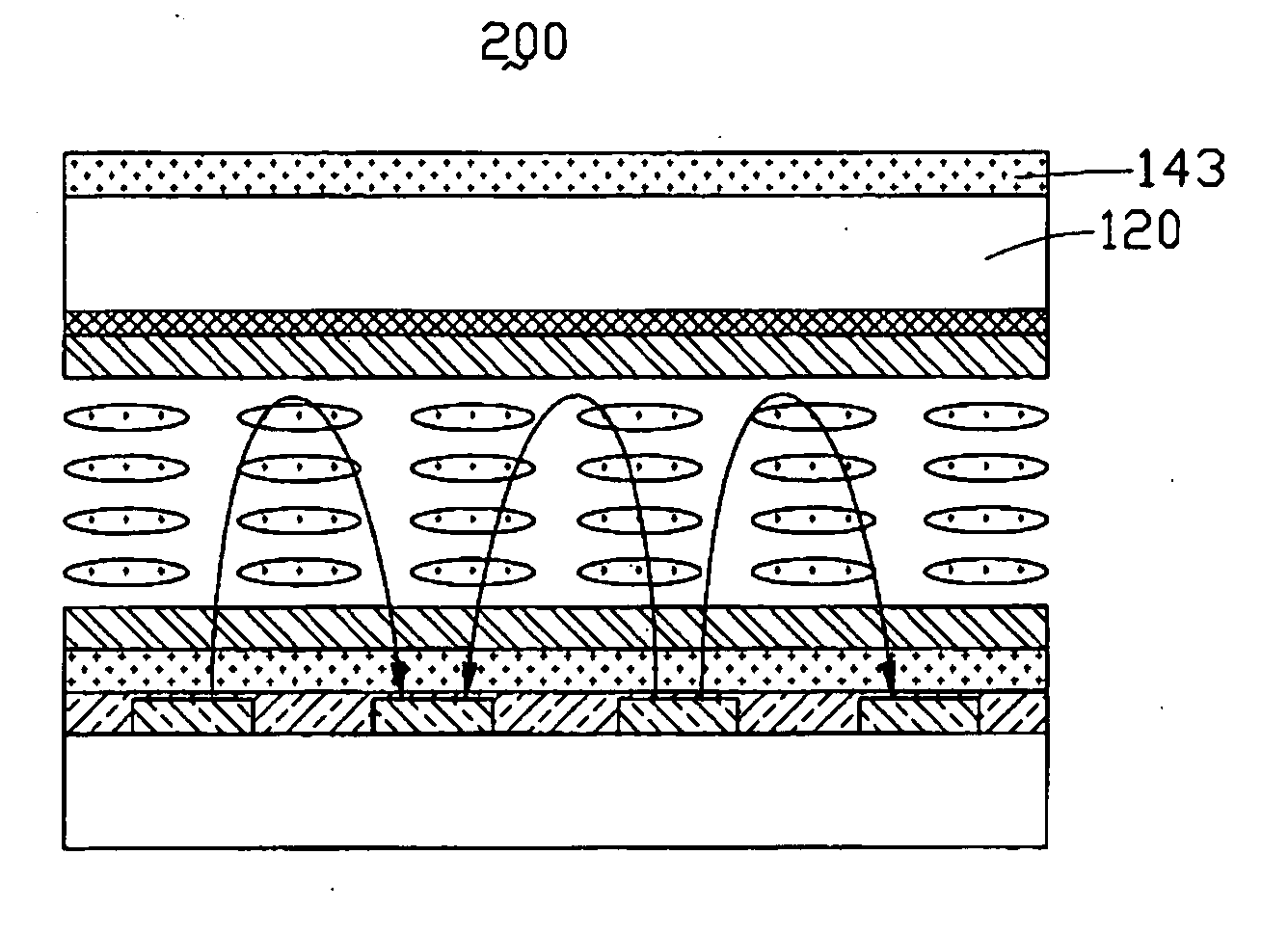

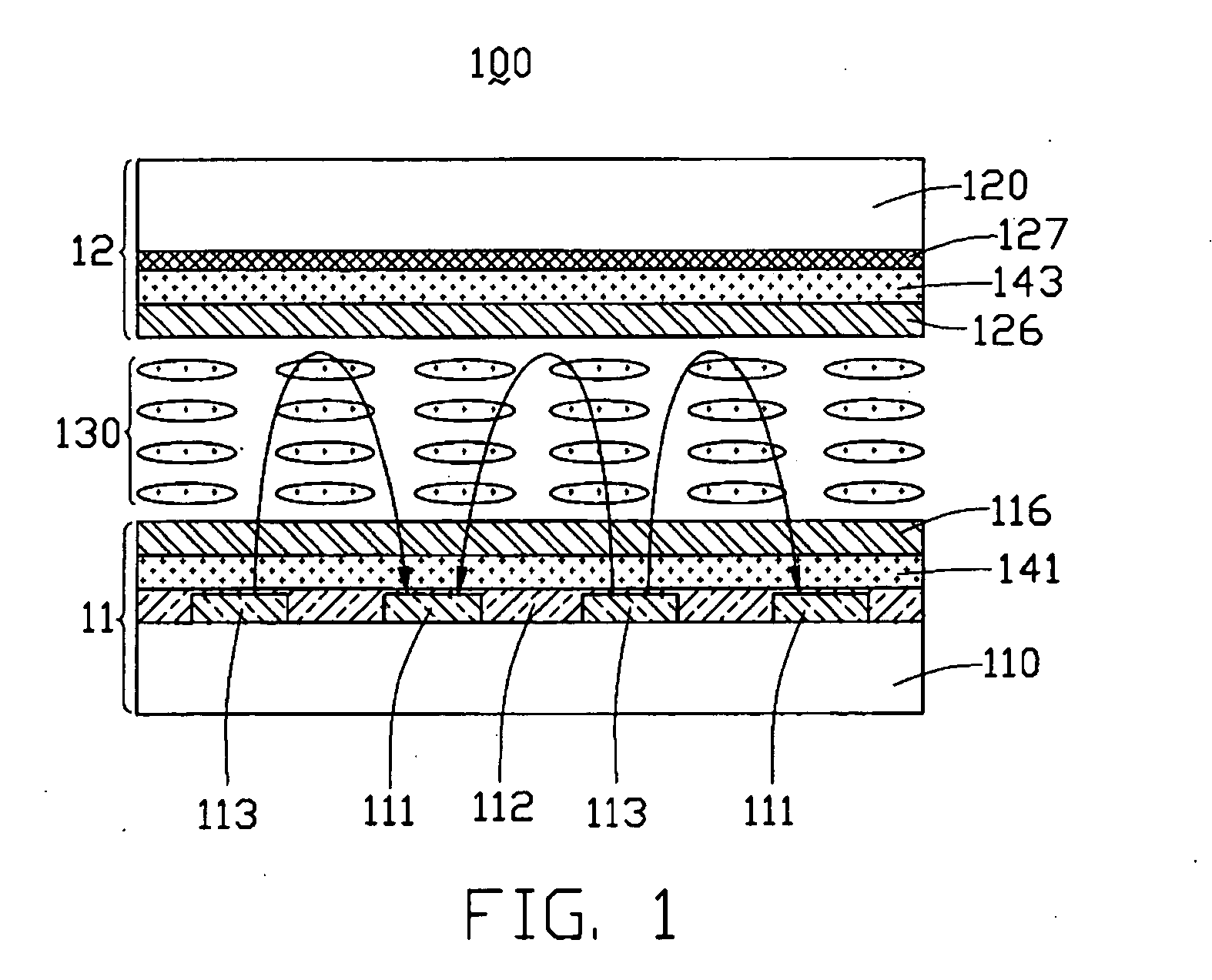

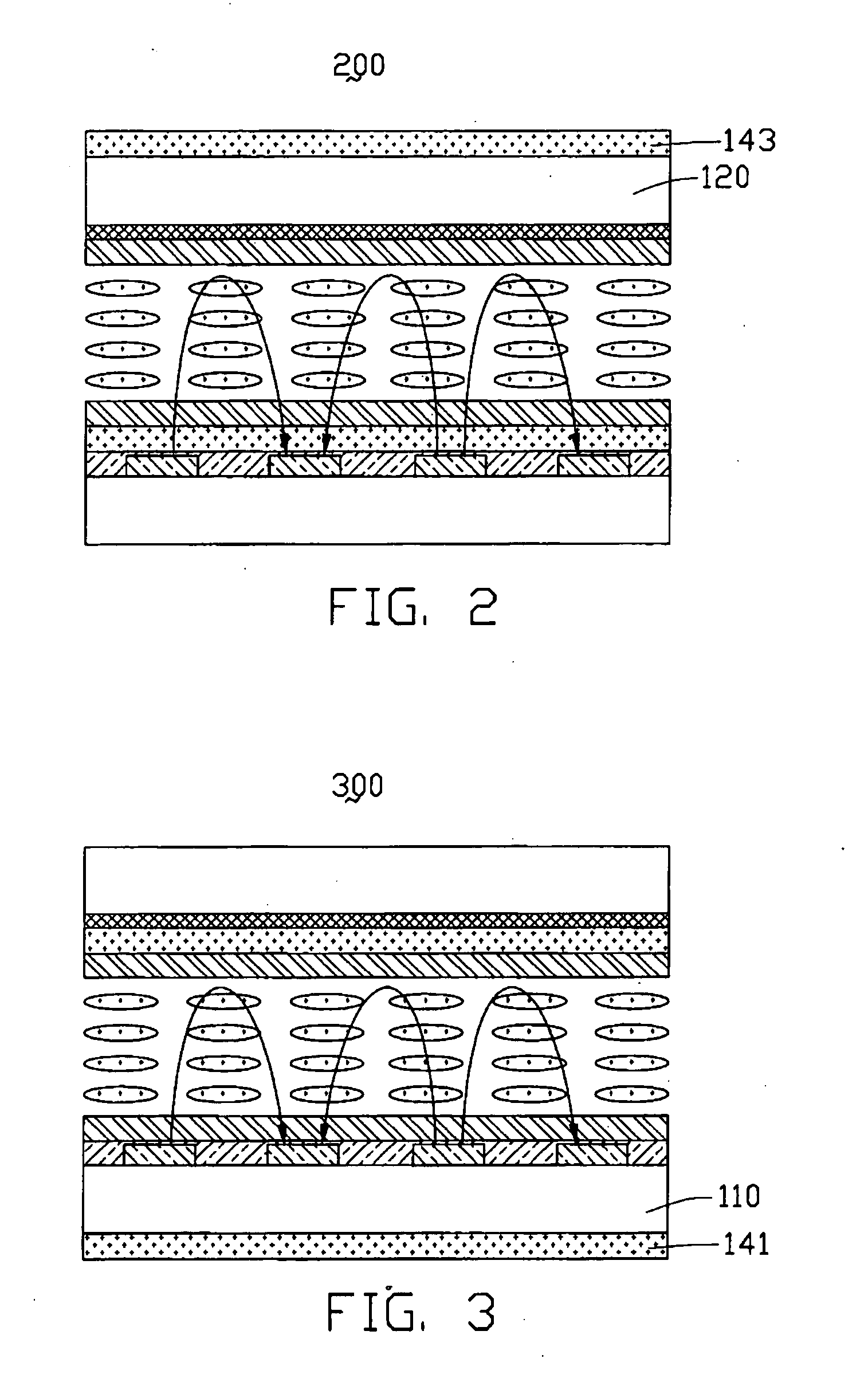

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

InactiveUS7525504B1Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

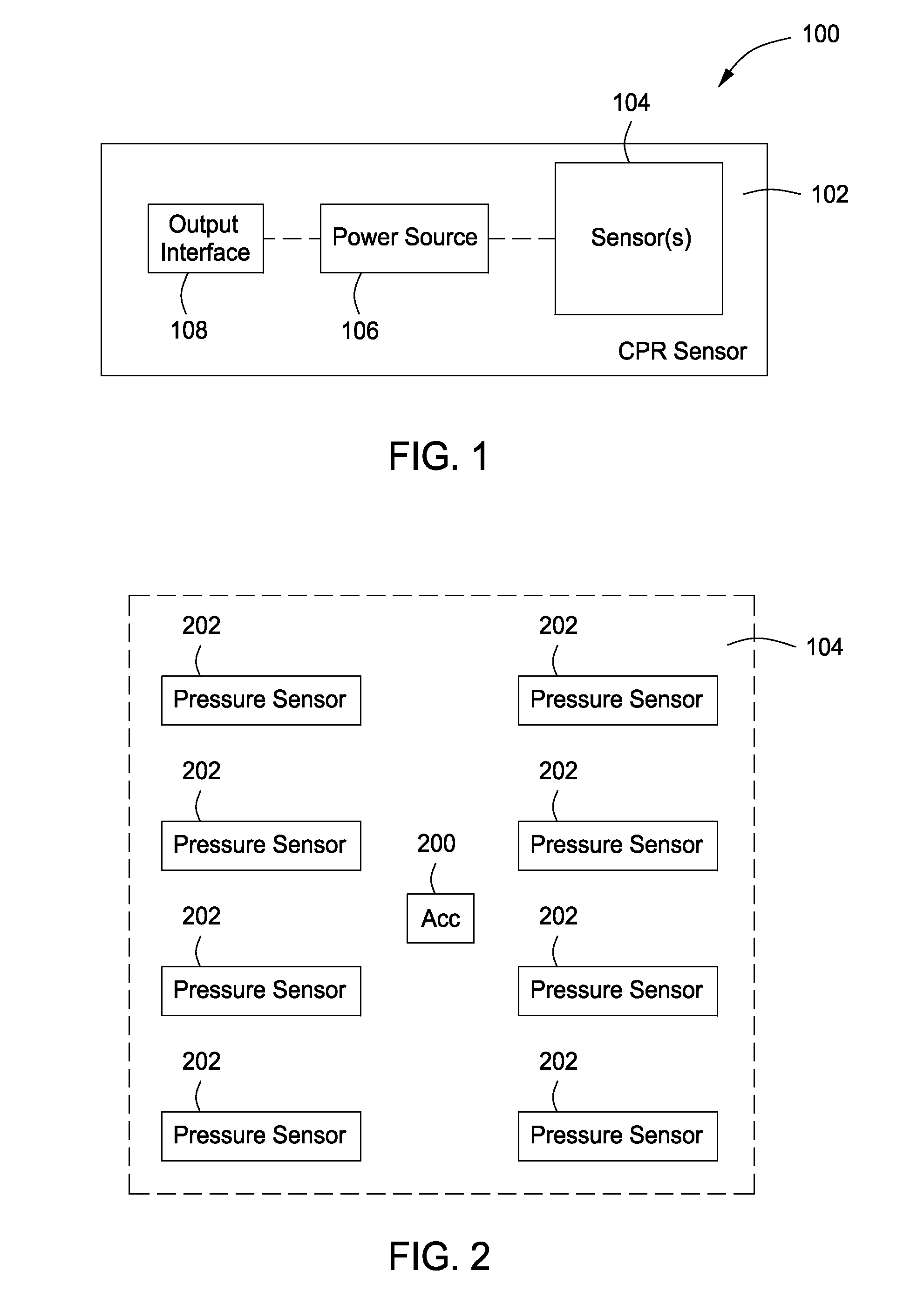

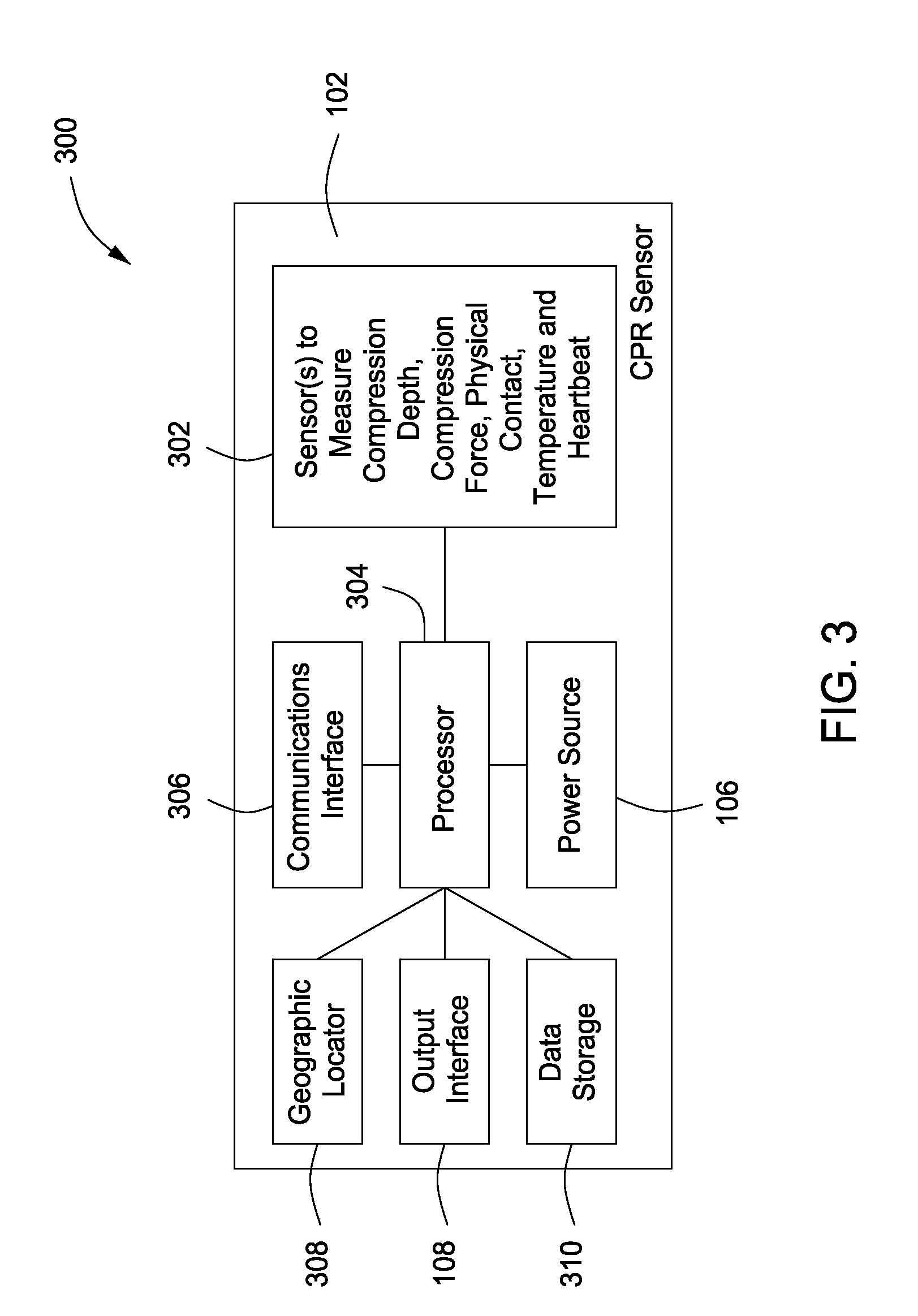

Cardiopulmonary Resuscitation Sensor

ActiveUS20080312565A1Readily availableEasily portableElectrotherapyAcceleration measurement using interia forcesSensor arrayCardiopulmonary resuscitation

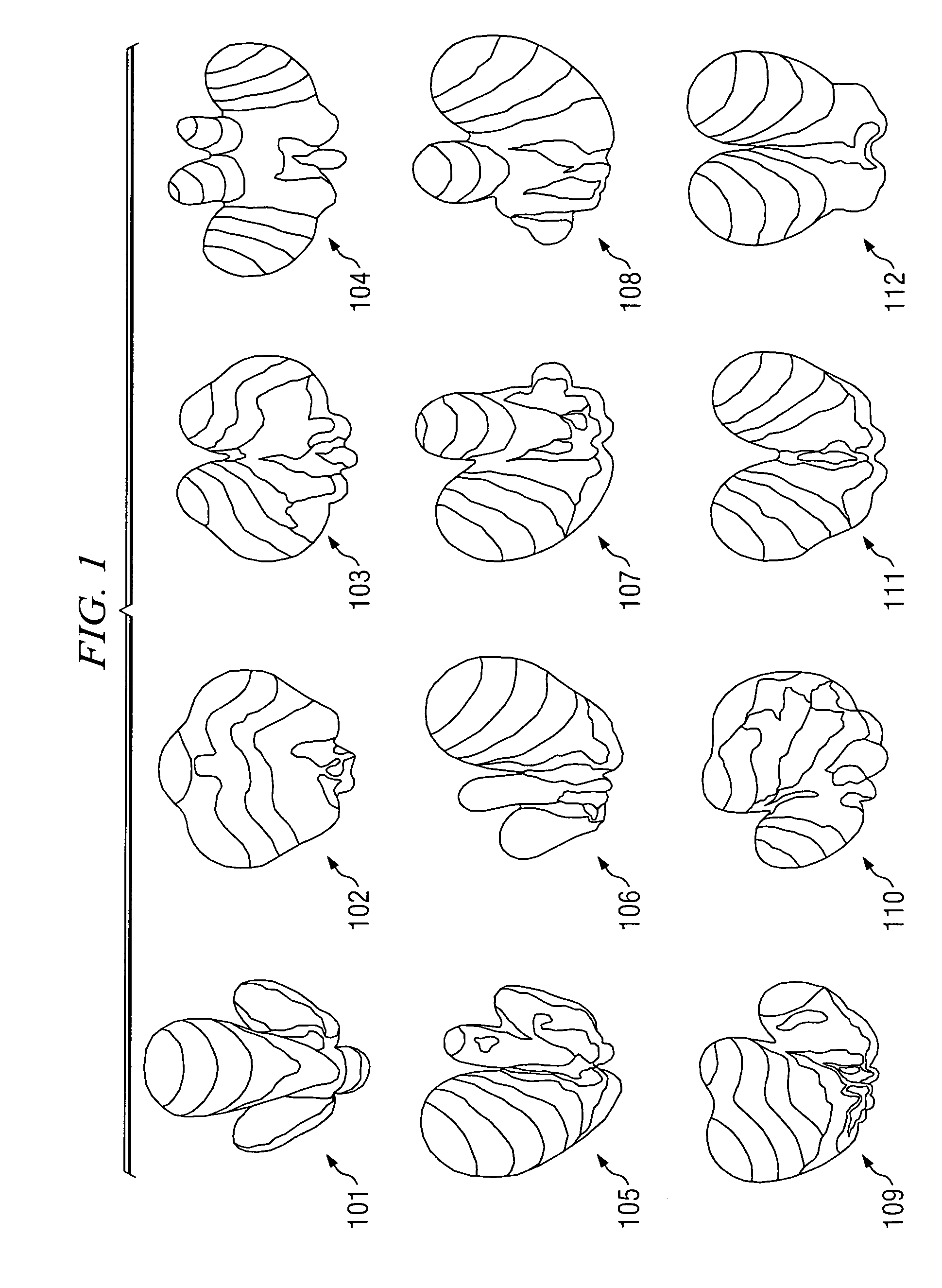

The present invention provides a CPR sensor that includes a thin and substantially flat flexible substrate having one or more sensor arrays, a power source, an output interface and a processor or analog circuit, all of which are disposed on the substantially flat flexible substrate. The substrate can be any shape (e.g., rectangular, circular, a polygon, an irregular shape that is decorative) and made from a polymer, metal film or other suitable material. Note that the substrate can be rigid or semi-flexible instead of flexible. A protective layer may cover the sensor array, the power source, and the processor or analog circuit. Alternatively, a protective covering can be used to encapsulate the device. The one or more sensor arrays measure one or more of the following compressions characteristics: compression depth, compression force, compression frequency and compression acceleration.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

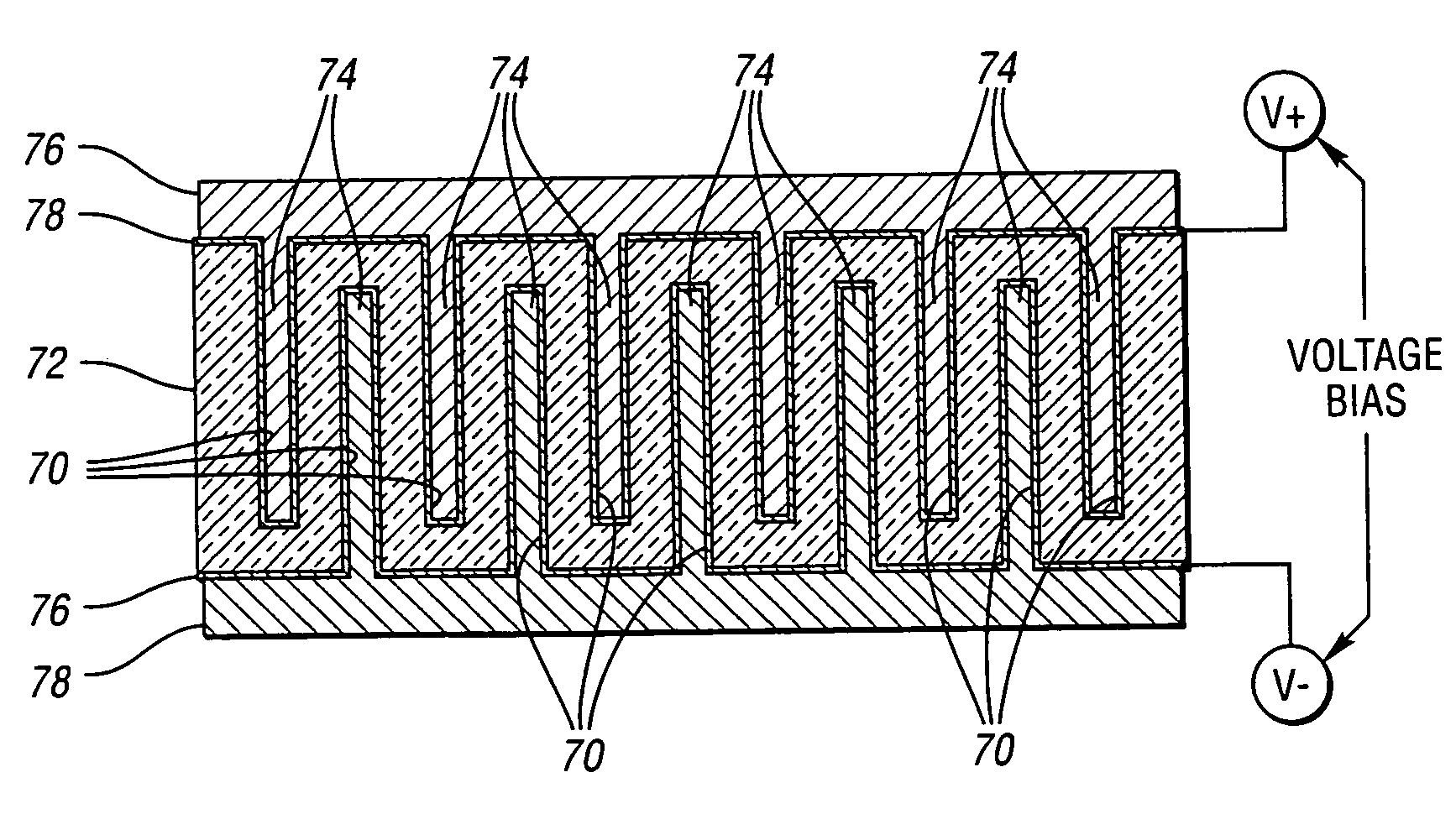

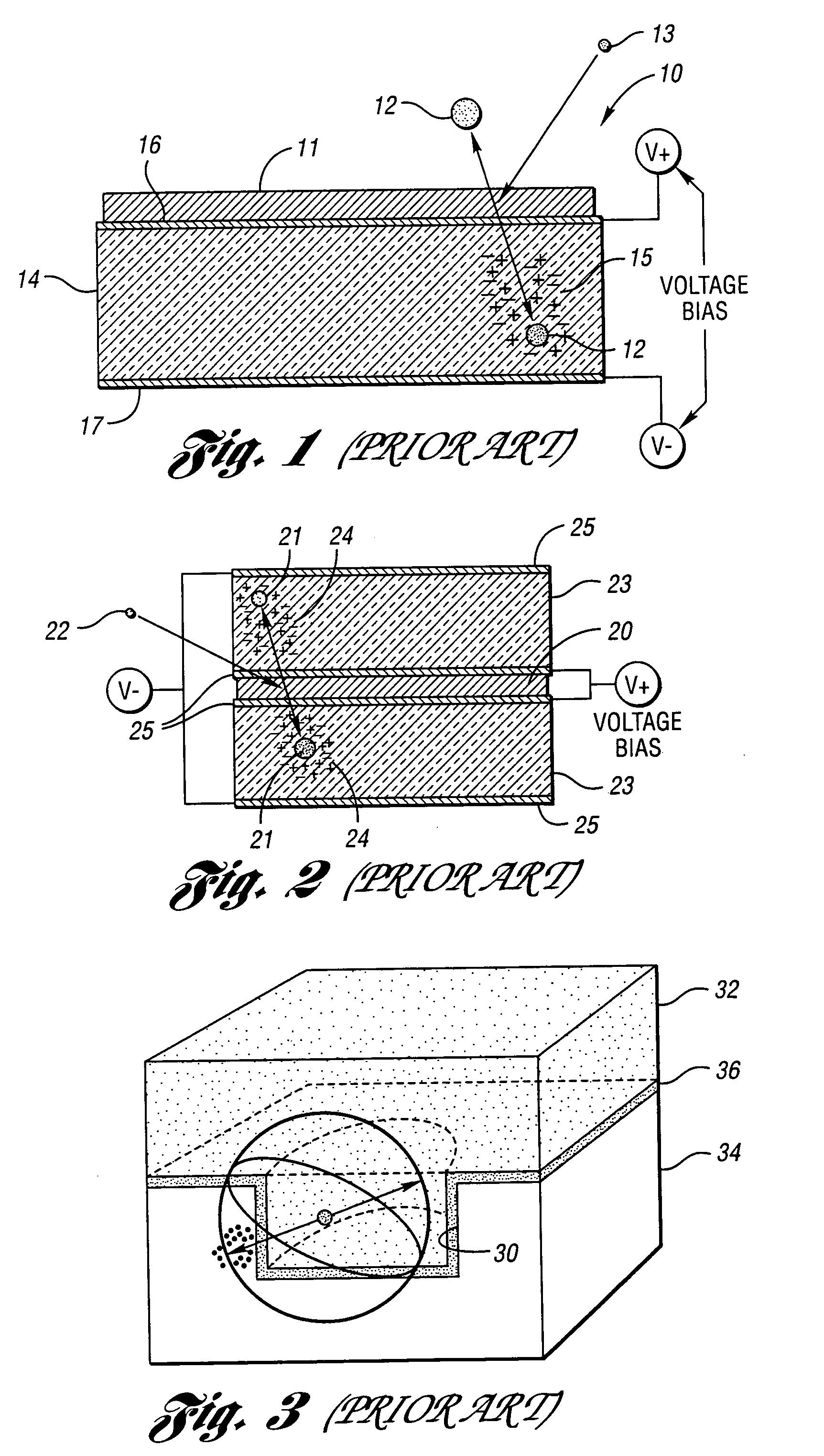

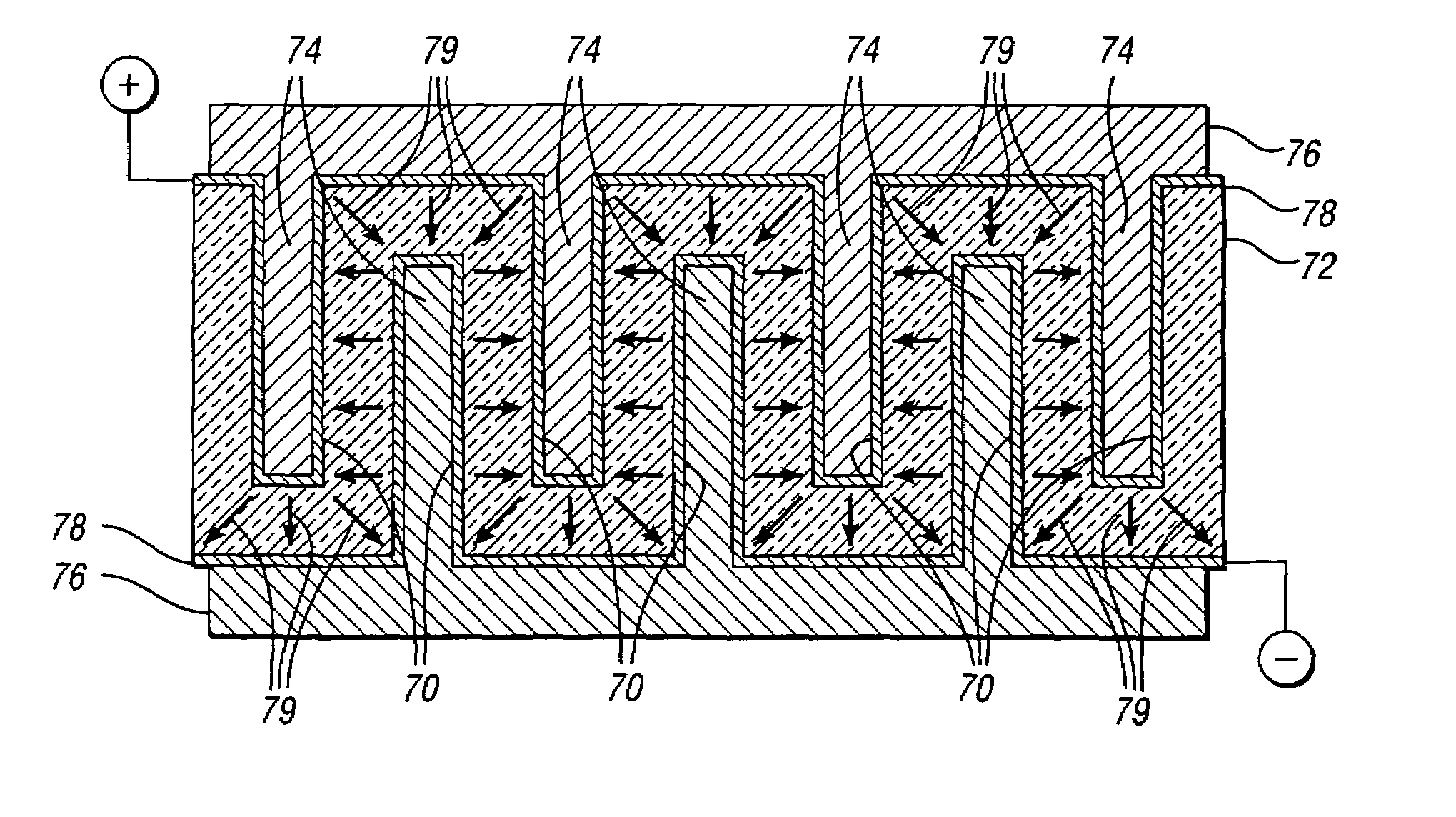

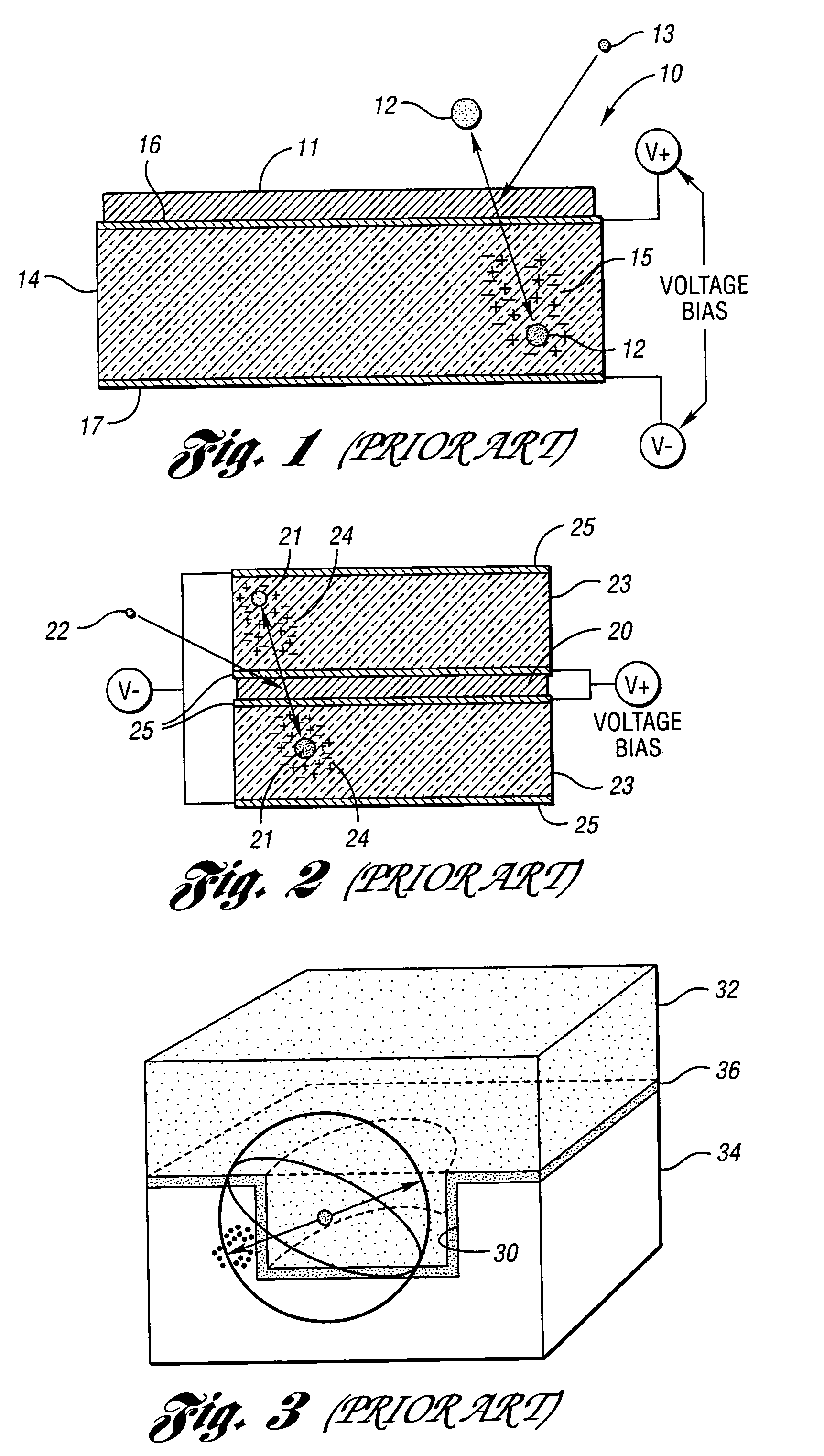

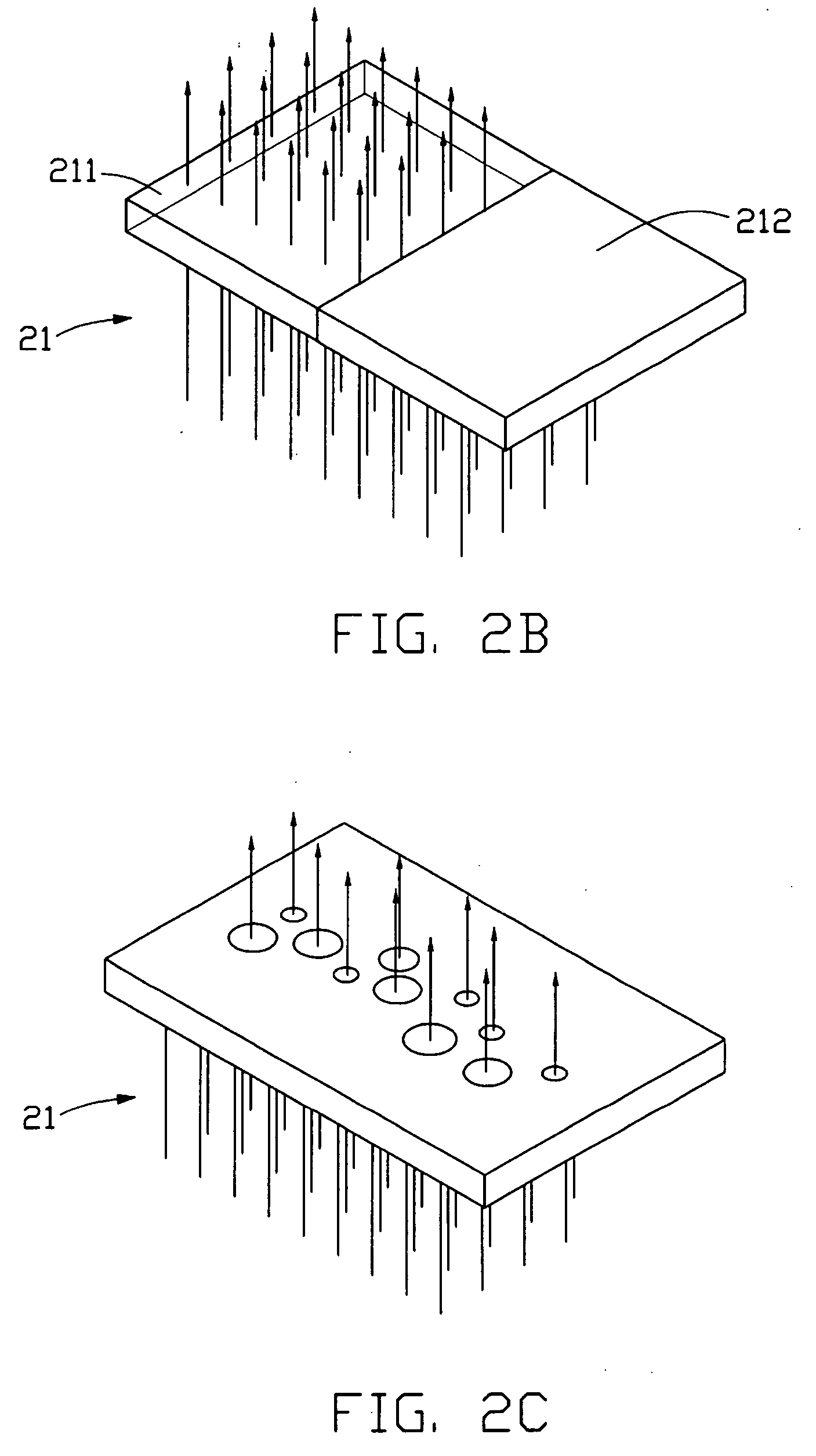

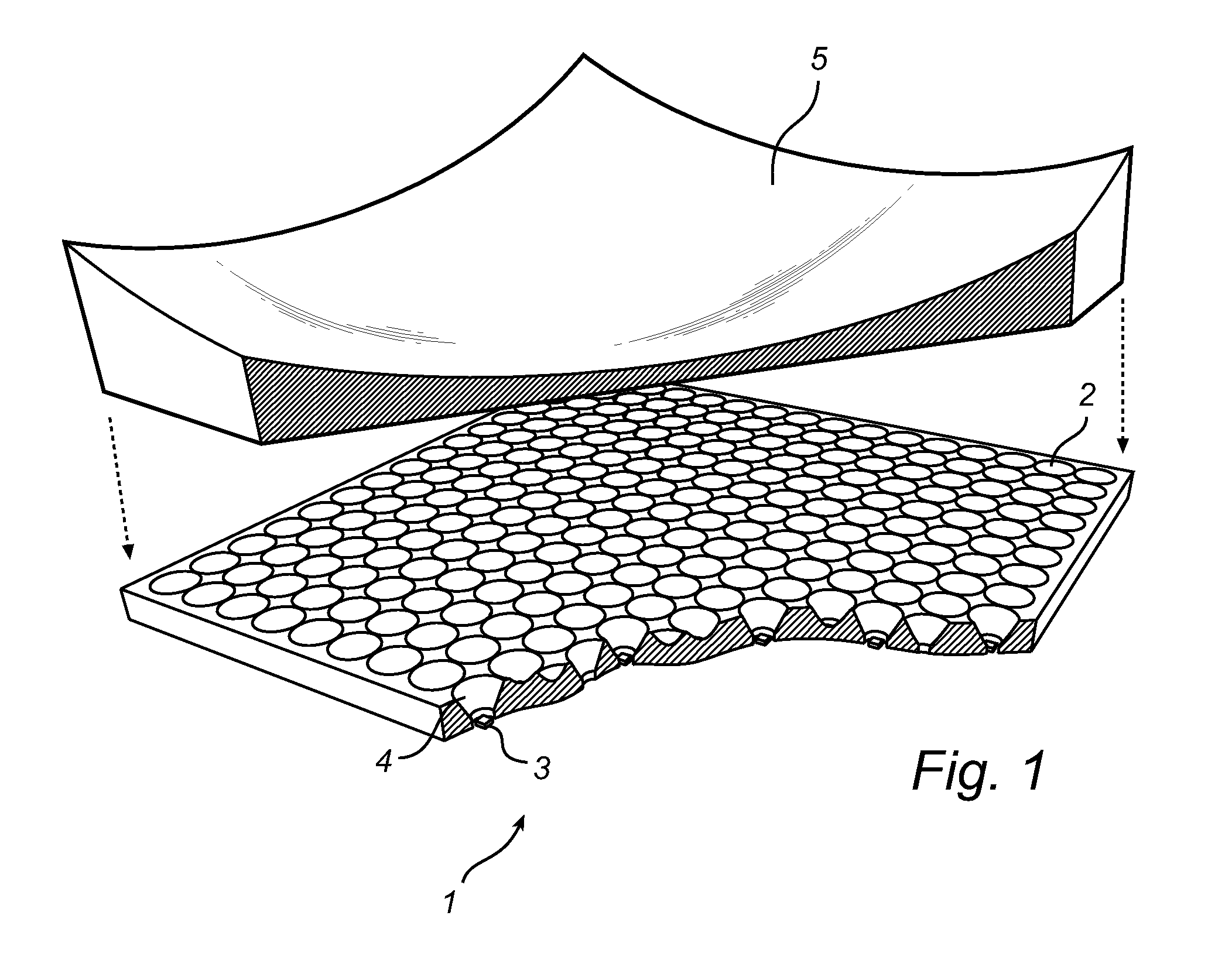

High-efficiency neutron detectors and methods of making same

ActiveUS20050258372A1Efficient detectionThin and compactMeasurement with semiconductor devicesMaterial analysis by optical meansRoom temperatureReactive material

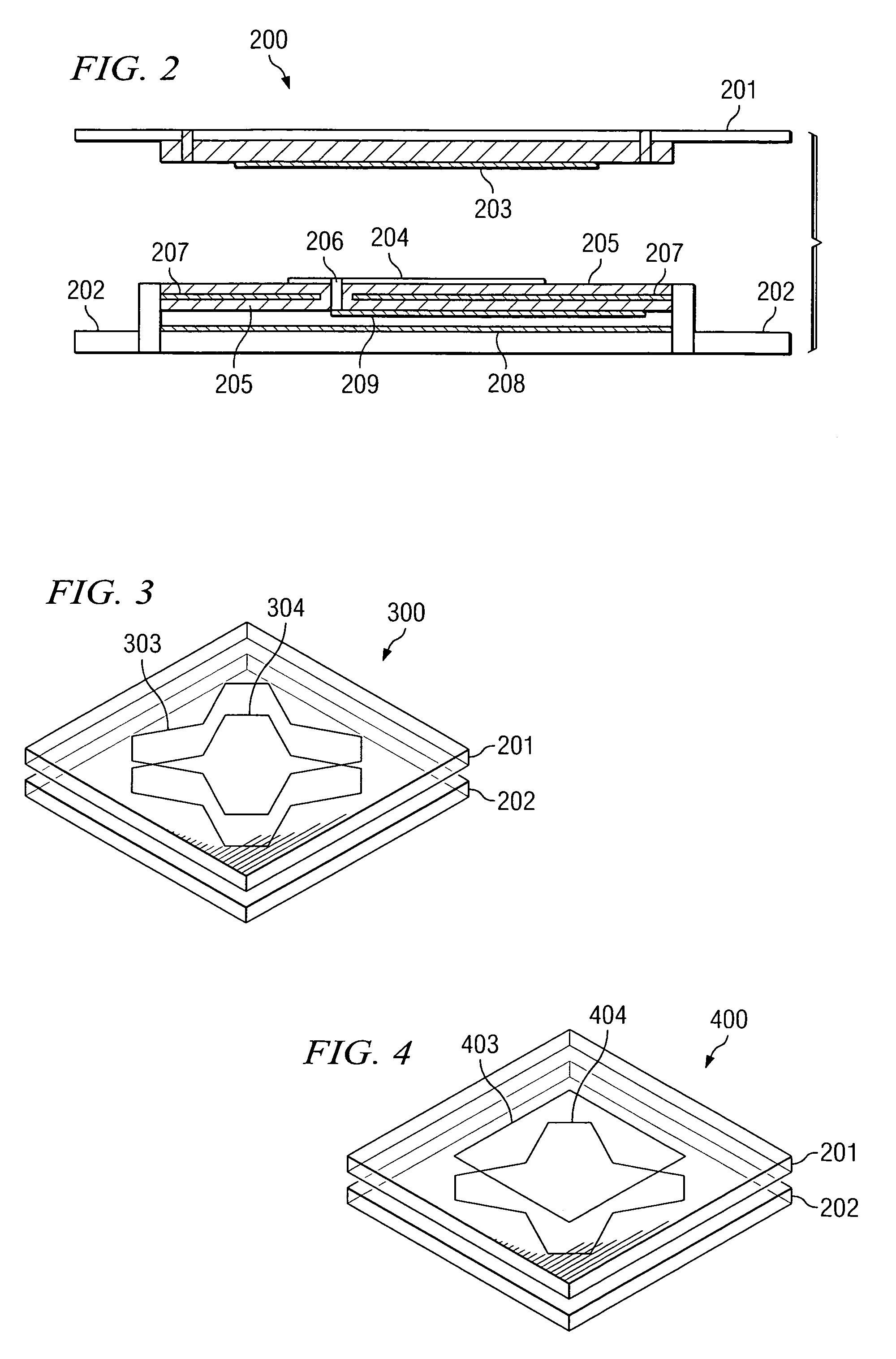

Neutron detectors, advanced detector process techniques and advanced compound film designs have greatly increased neutron-detection efficiency. One embodiment of the detectors utilizes a semiconductor wafer with a matrix of spaced cavities filled with one or more types of neutron reactive material such as 10B or 6LiF. The cavities are etched into both the front and back surfaces of the device such that the cavities from one side surround the cavities from the other side. The cavities may be etched via holes or etched slots or trenches. In another embodiment, the cavities are different-sized and the smaller cavities extend into the wafer from the lower surfaces of the larger cavities. In a third embodiment, multiple layers of different neutron-responsive material are formed on one or more sides of the wafer. The new devices operate at room temperature, are compact, rugged, and reliable in design.

Owner:RGT UNIV OF MICHIGAN

High-efficiency neutron detectors and methods of making same

ActiveUS7164138B2Many timesThin and compactMeasurement with semiconductor devicesMaterial analysis by optical meansRoom temperatureReactive material

Neutron detectors, advanced detector process techniques and advanced compound film designs have greatly increased neutron-detection efficiency. One embodiment of the detectors utilizes a semiconductor wafer with a matrix of spaced cavities filled with one or more types of neutron reactive material such as 10B or 6LiF. The cavities are etched into both the front and back surfaces of the device such that the cavities from one side surround the cavities from the other side. The cavities may be etched via holes or etched slots or trenches. In another embodiment, the cavities are different-sized and the smaller cavities extend into the wafer from the lower surfaces of the larger cavities. In a third embodiment, multiple layers of different neutron-responsive material are formed on one or more sides of the wafer. The new devices operate at room temperature, are compact, rugged, and reliable in design.

Owner:RGT UNIV OF MICHIGAN

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

ActiveUS20050110683A1Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

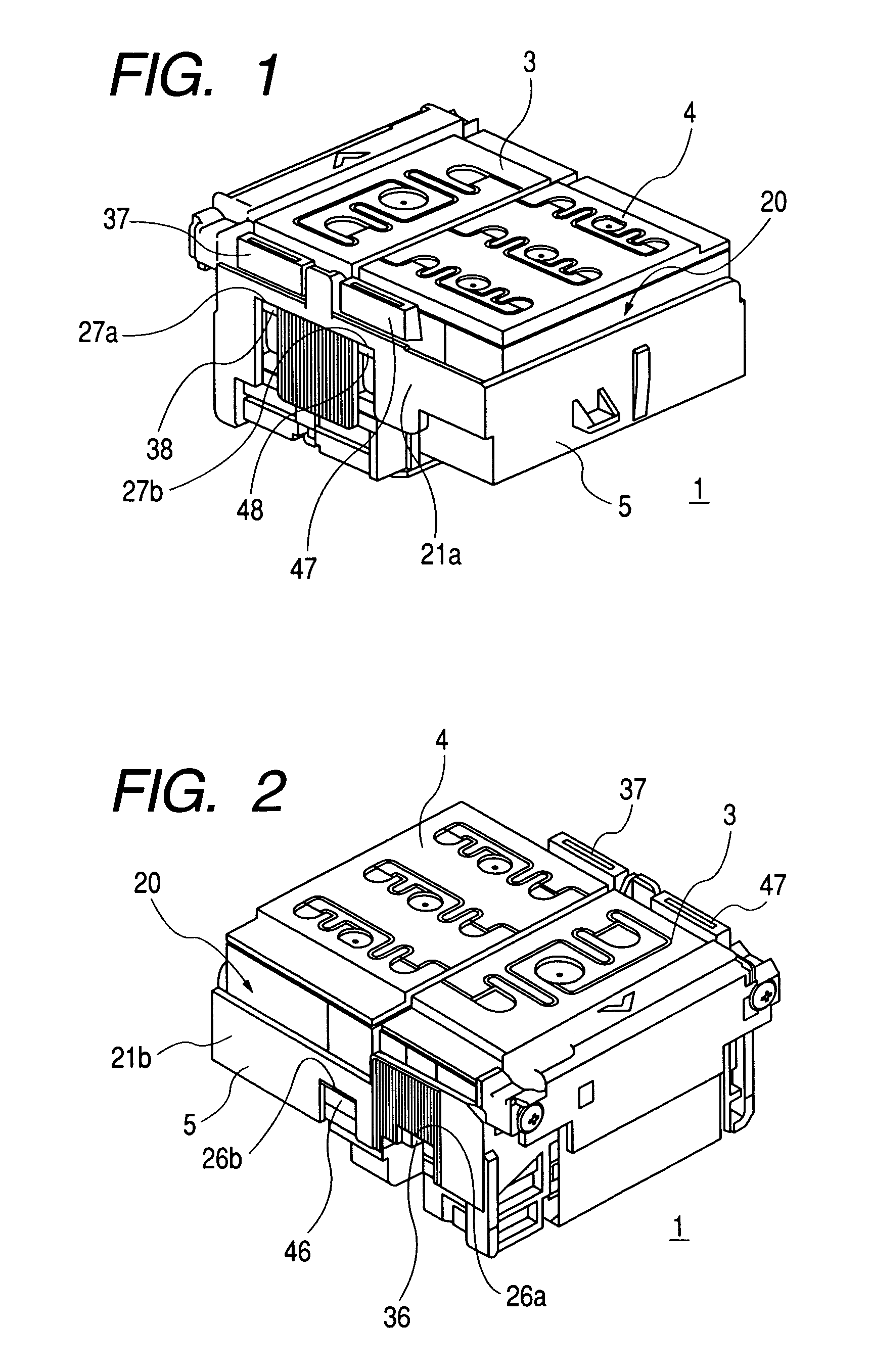

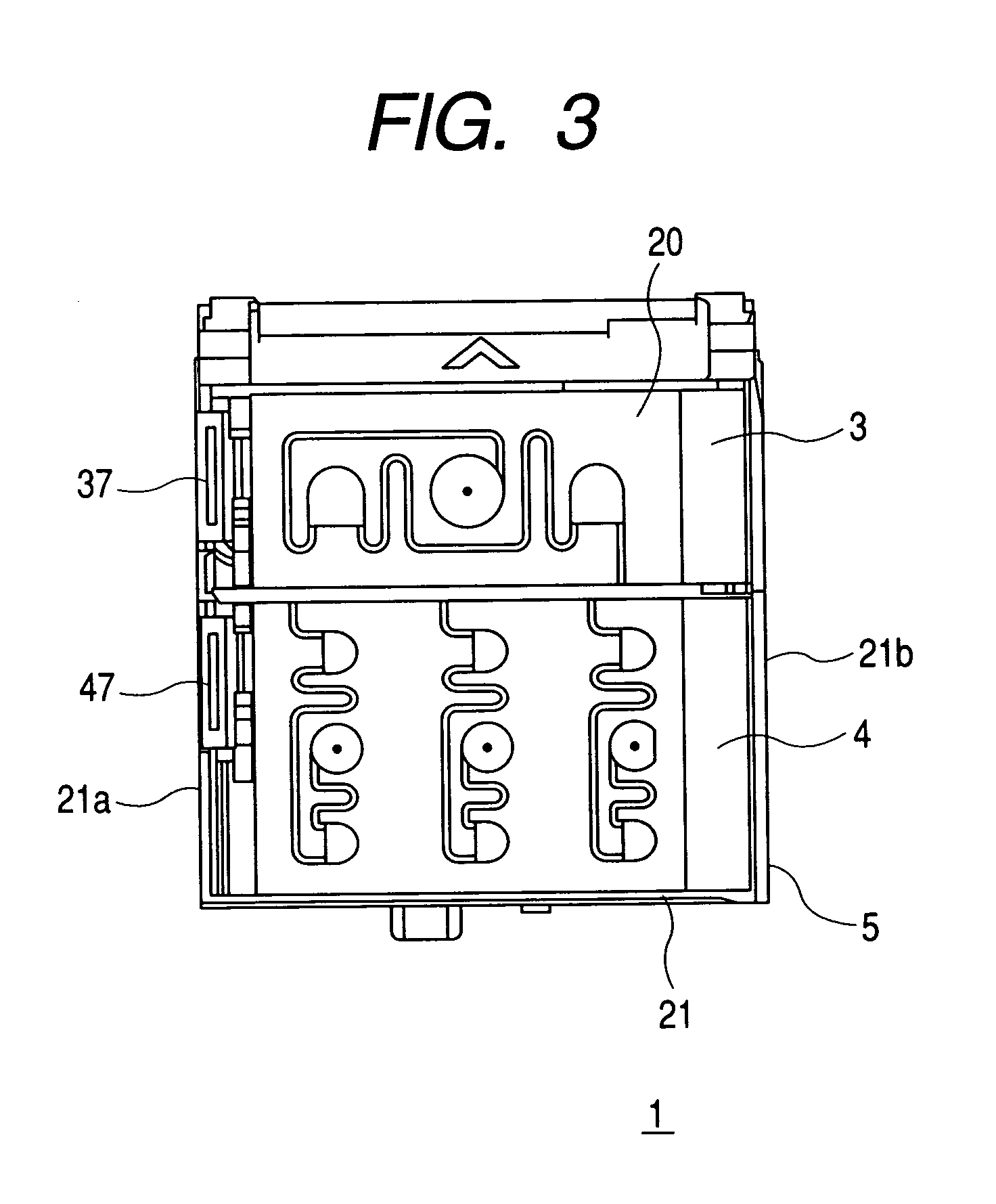

Tank holder, liquid tank and tank attaching and detaching method

InactiveUS6997548B2Eliminate spaceAvoid interferenceElectrographic process apparatusPrintingFuel tankEngineering

A recording head cartridge in which ink tanks include a removal preventing pawl which is provided at a rear surface of an ink container and engages with a tank holder, and a latch lever which is provided at a front surface of the ink container and which has a latch pawl engaging with the tank holder. The height of a rear wall and a side surface of the tank holder are set to be lower than corresponding heights of the ink tank. During removal, the container abuts the upper end of the peripheral wall of the tank holder an dis rotated about this upper end so that a part of the side surface of the container is protruded externally of the holder. Accordingly, a space required to remove the container form the tank holder is placed external of the peripheral wall of the tank holder. Thus, removal space ordinarily wasted by a conventional tank holder can be eliminated.

Owner:CANON KK

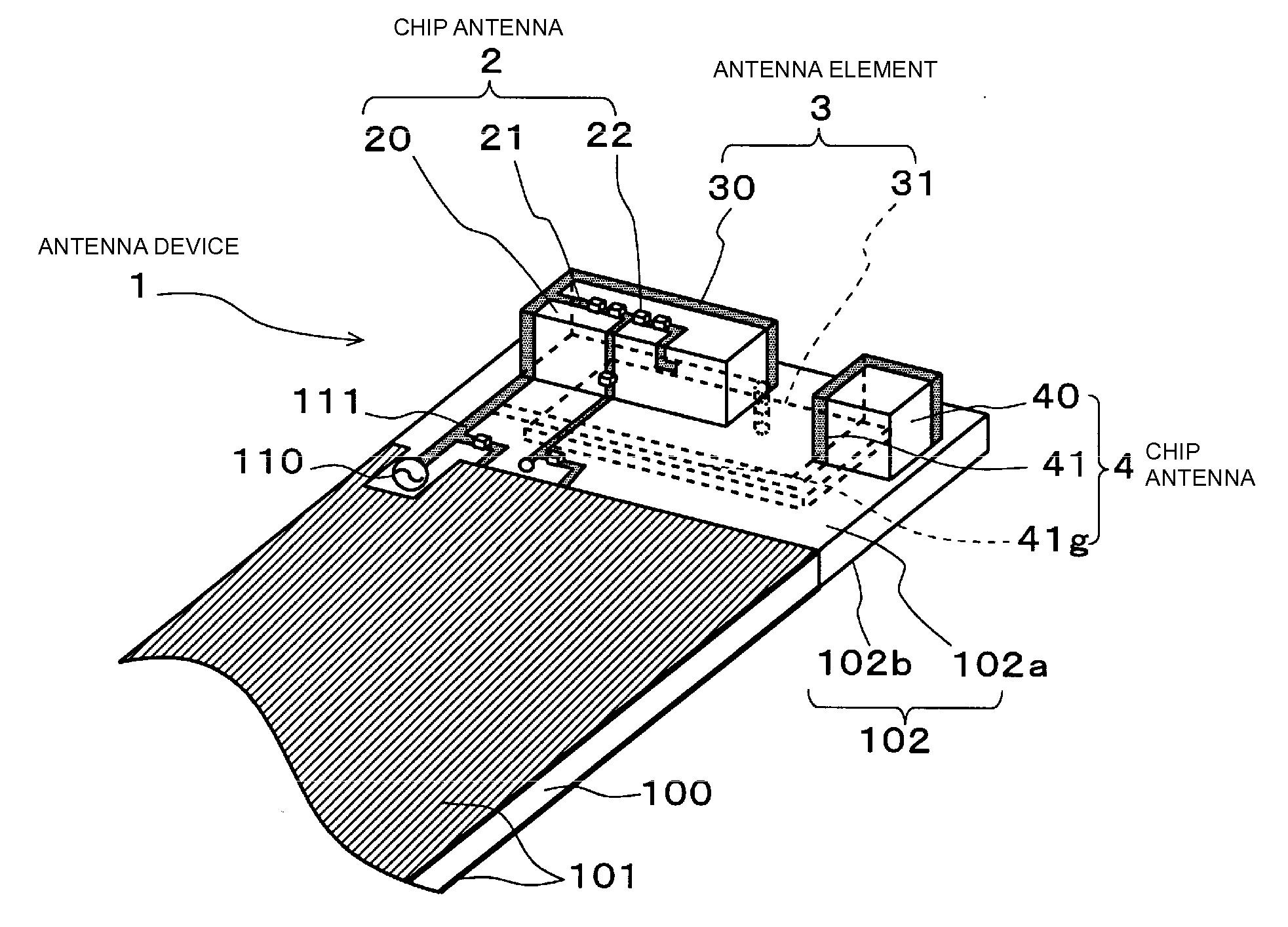

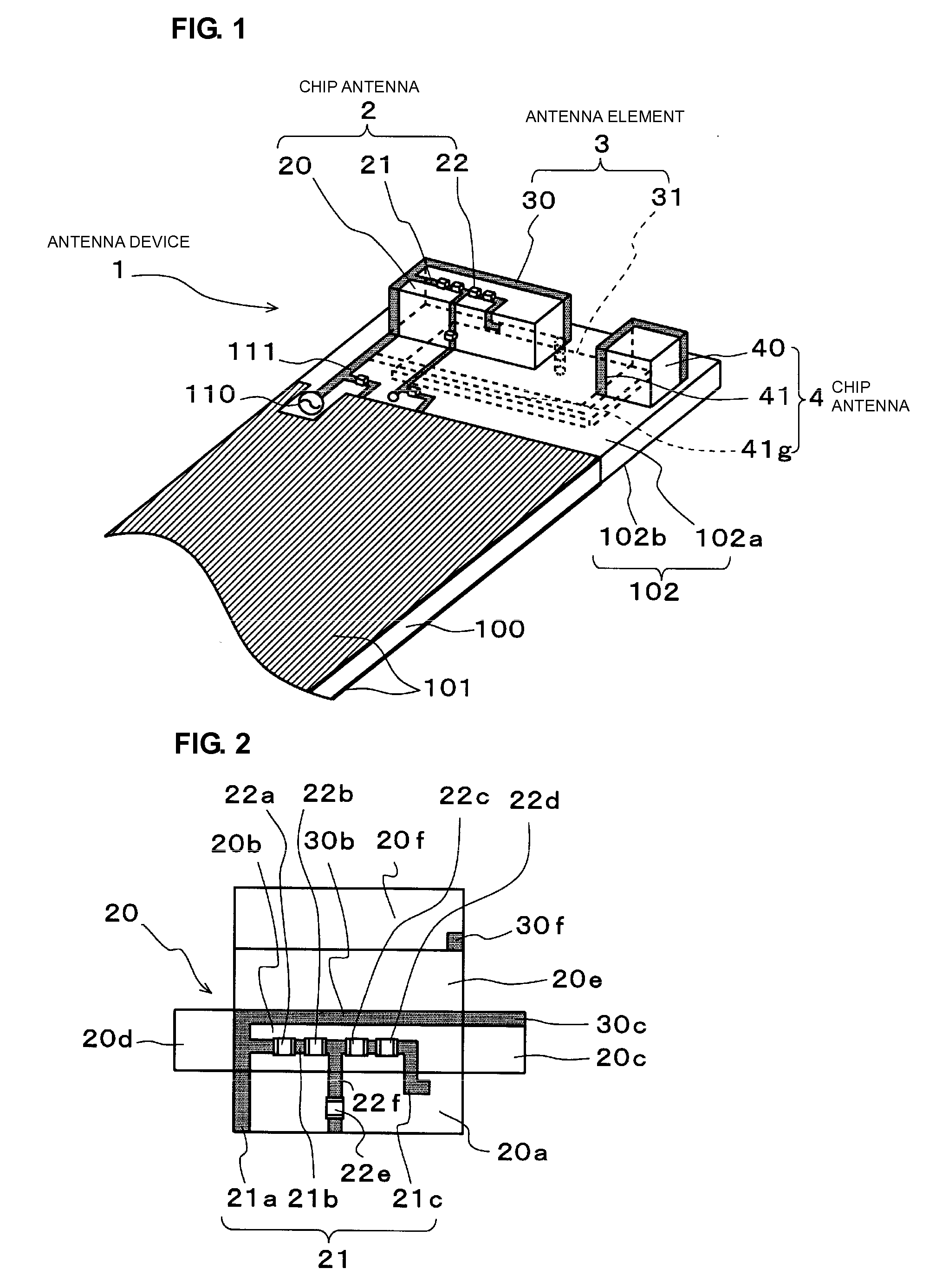

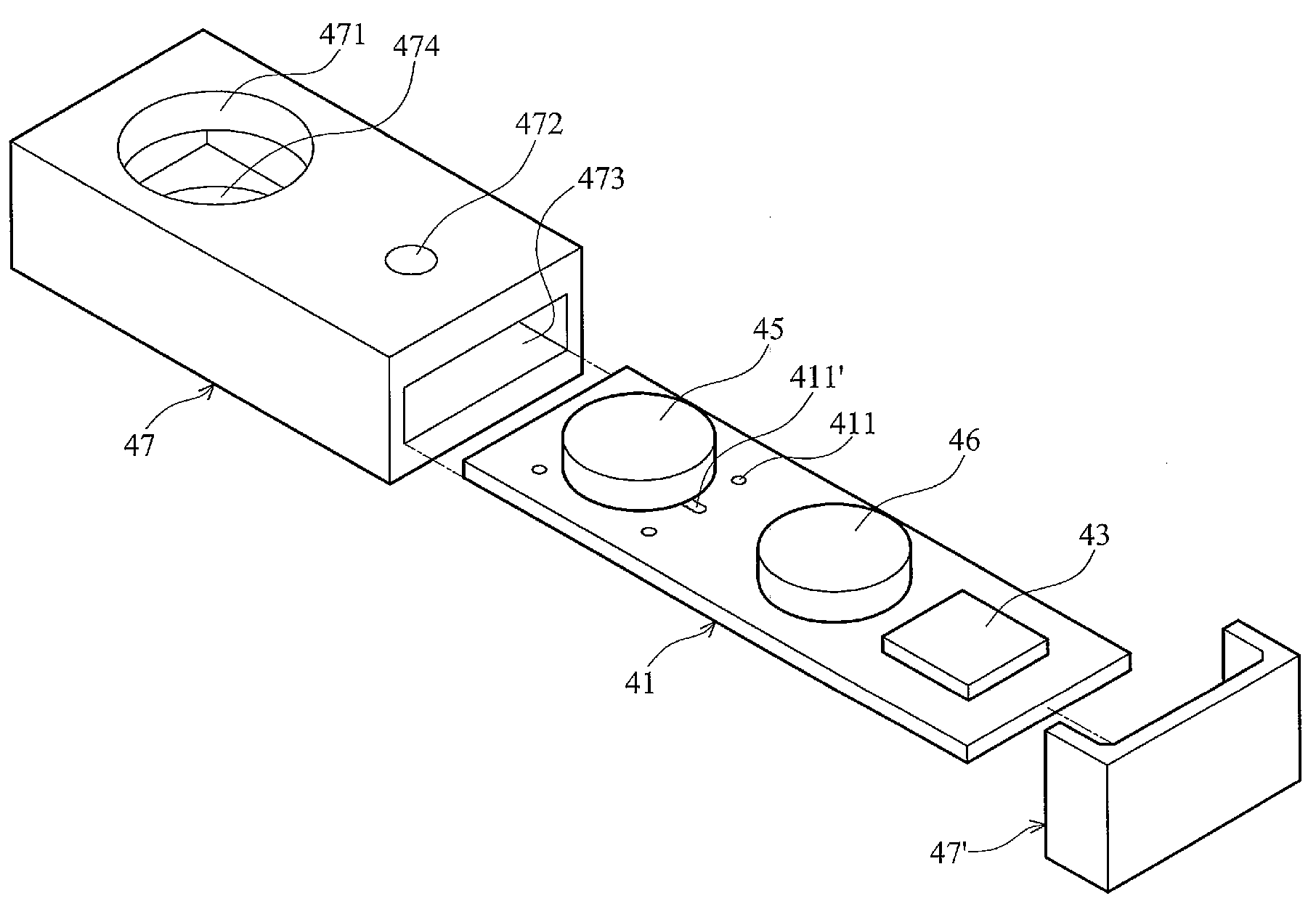

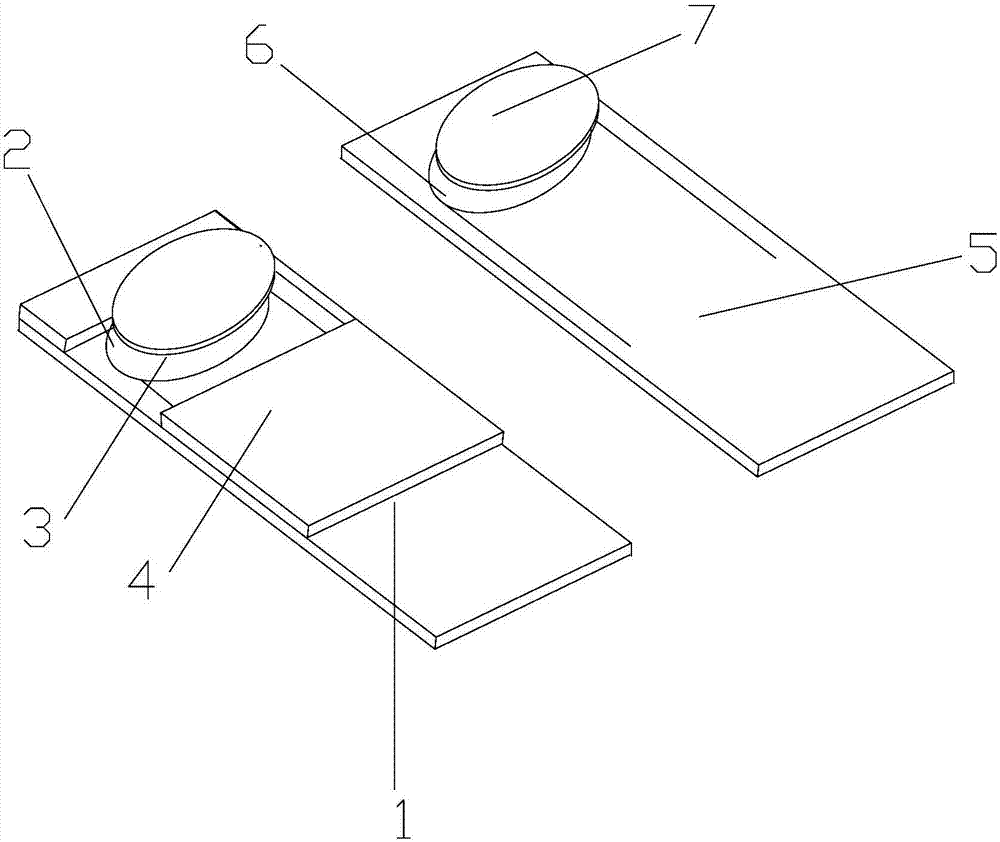

Antenna device and wireless communication apparatus

InactiveUS20080079642A1Thin and compactSimultaneous aerial operationsAntenna supports/mountingsAntenna elementPhysics

A compact and thin antenna device can be mounted in a small area of a substrate and has a multiband capability adaptable to various applications. The antenna device includes a chip antenna, an antenna element, and a chip antenna. The chip antenna is produced by forming a radiation electrode on the surface of a dielectric base, and mounting a frequency variable circuit on the radiation electrode. Thus, it becomes possible to obtain a resonant frequency f1 of the chip antenna and further to vary the resonant frequency f1. The antenna element is produced by adding an auxiliary element to an additional radiation electrode for the chip antenna. The chip antenna includes a radiation electrode on a dielectric base and a conductive pattern. Thus, a resonant frequency f2 and a resonant frequency f3 of the antenna element and the chip antenna, respectively, can be obtained.

Owner:MURATA MFG CO LTD

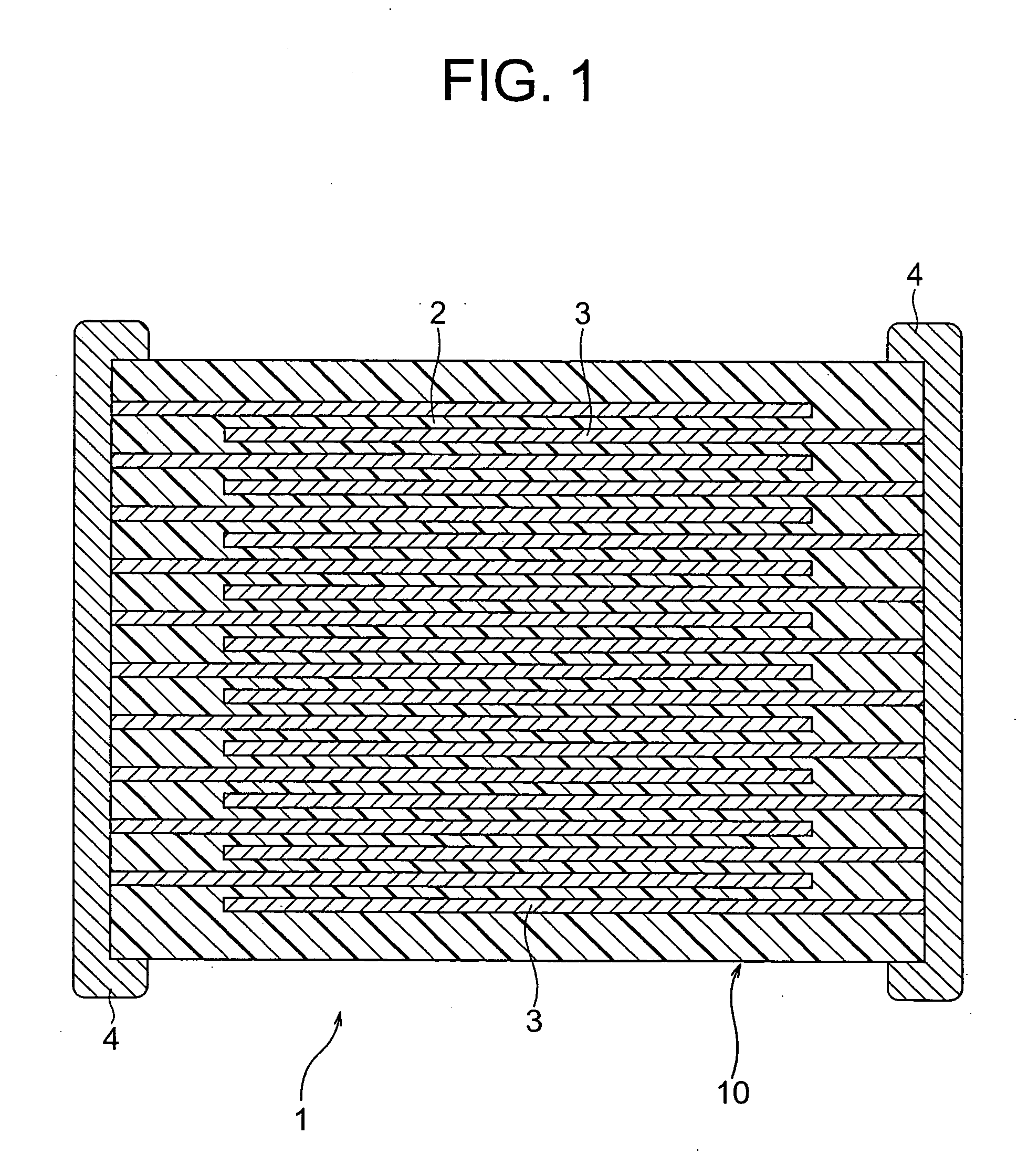

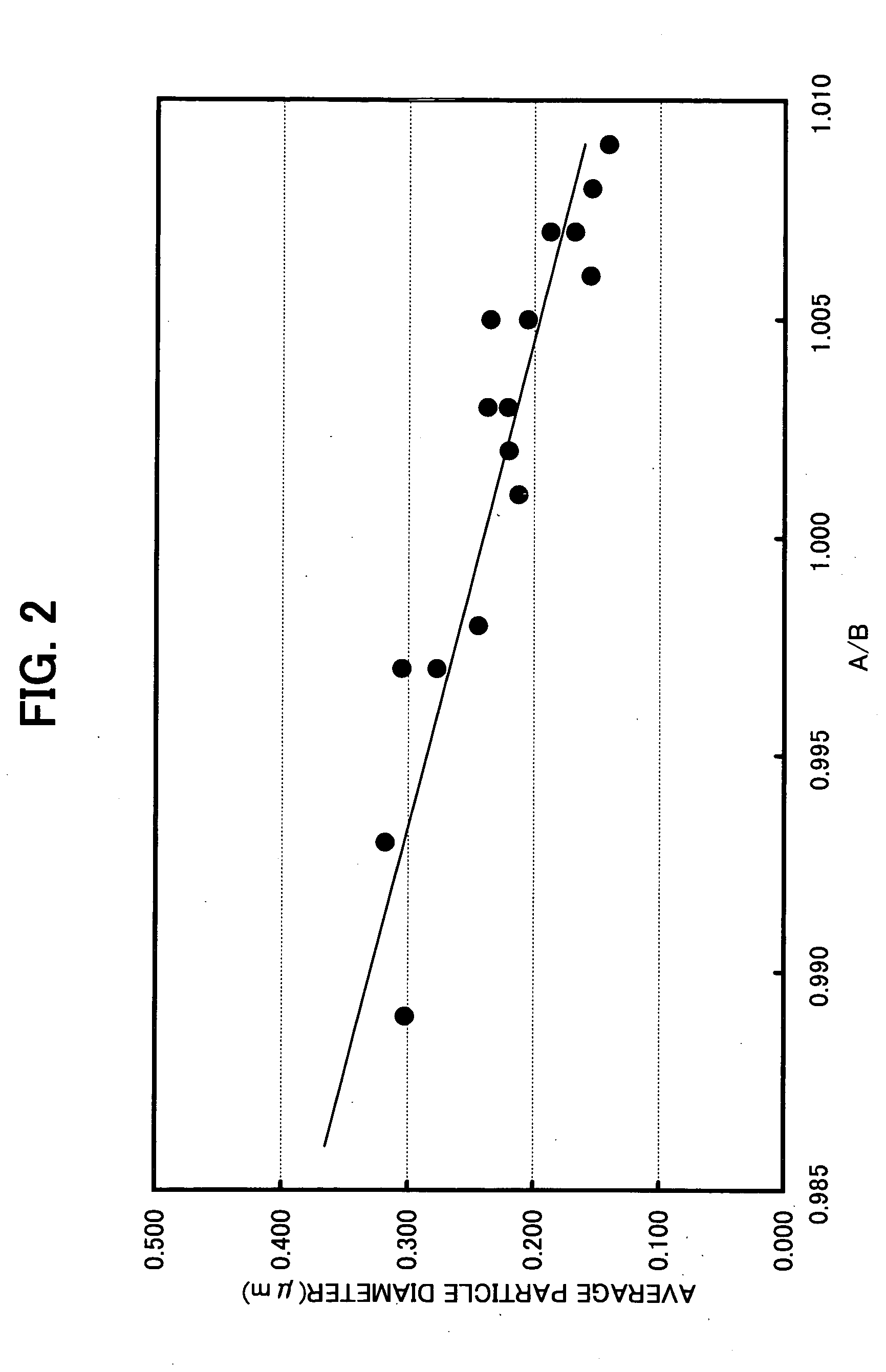

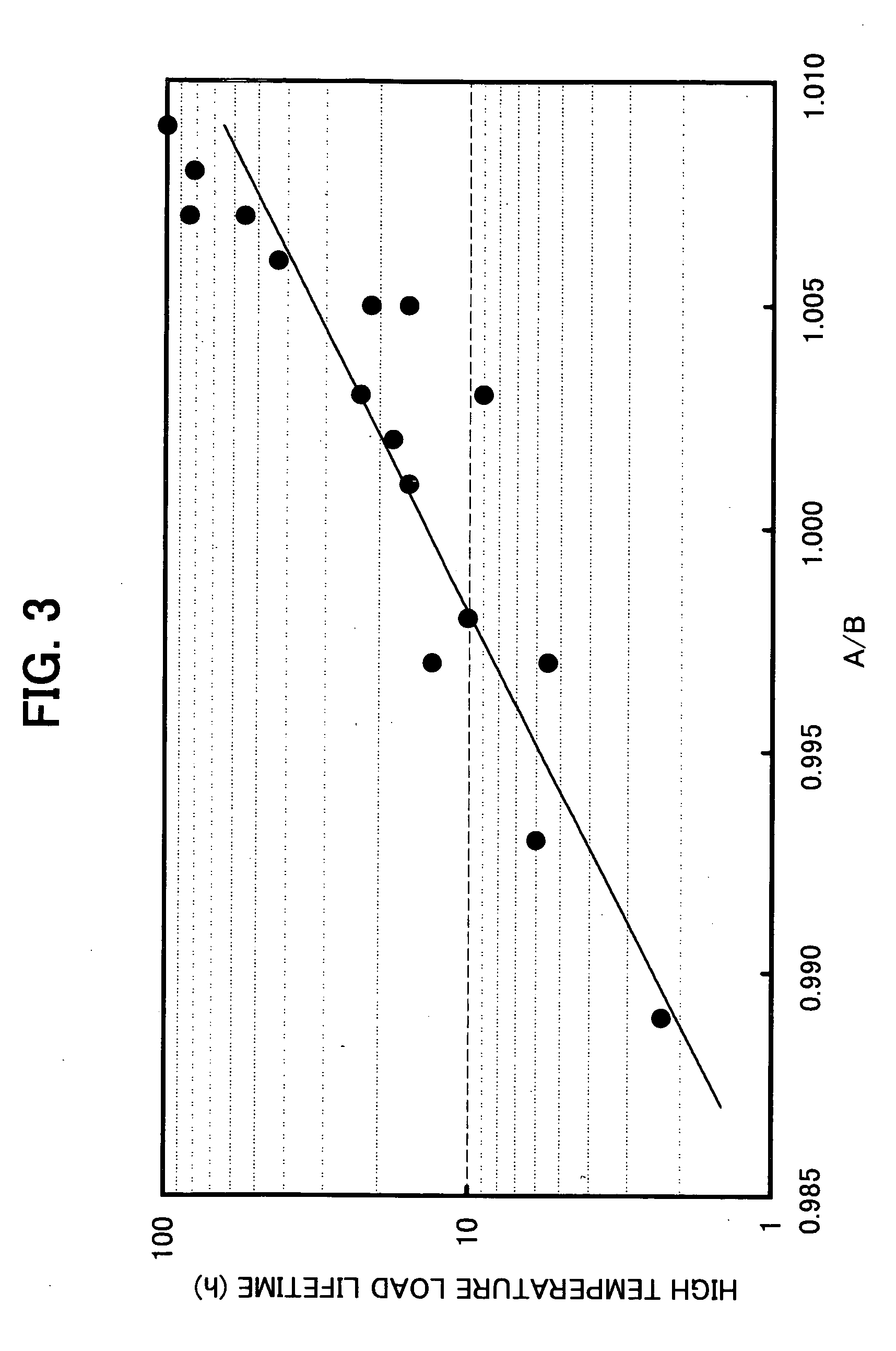

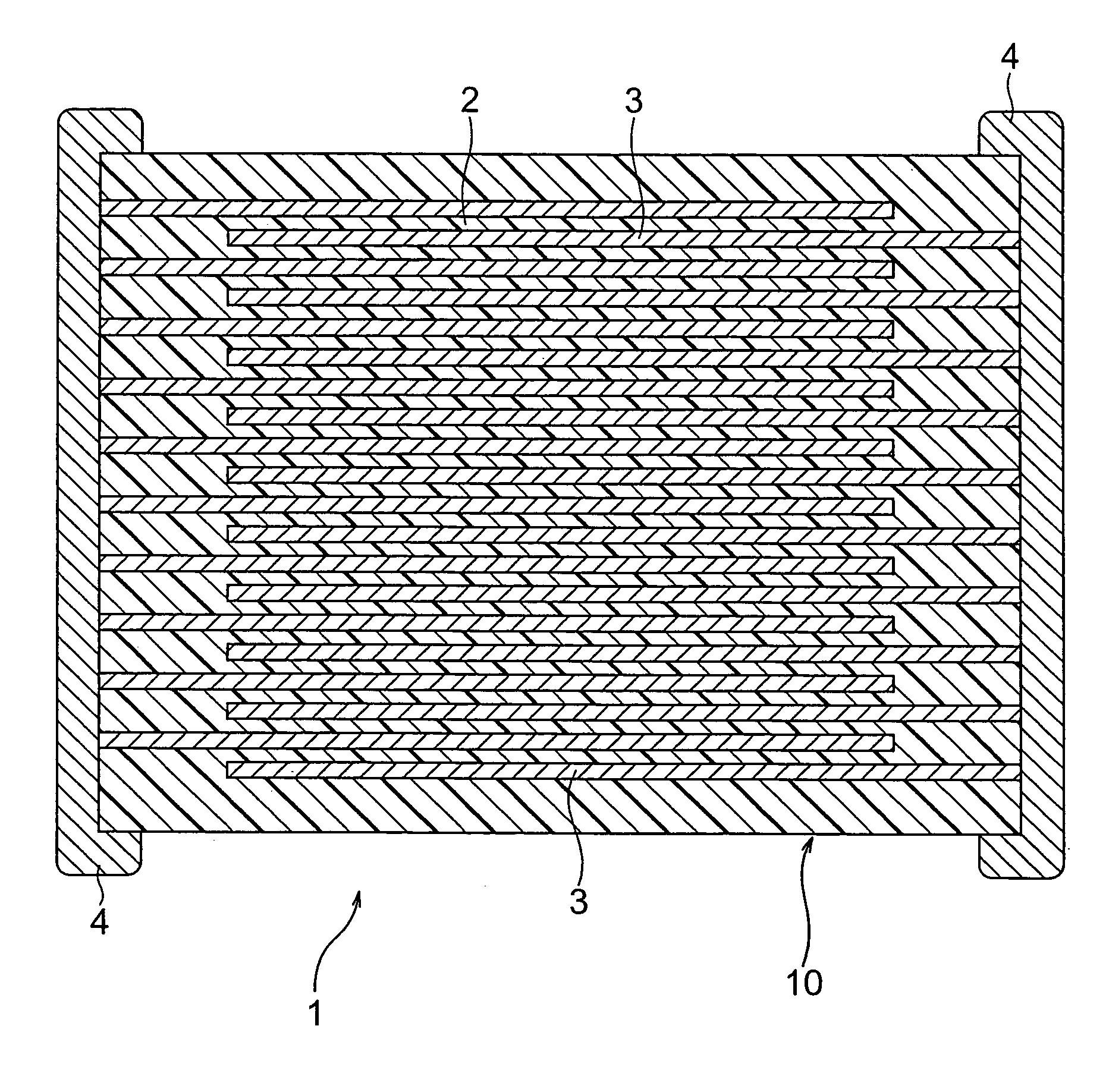

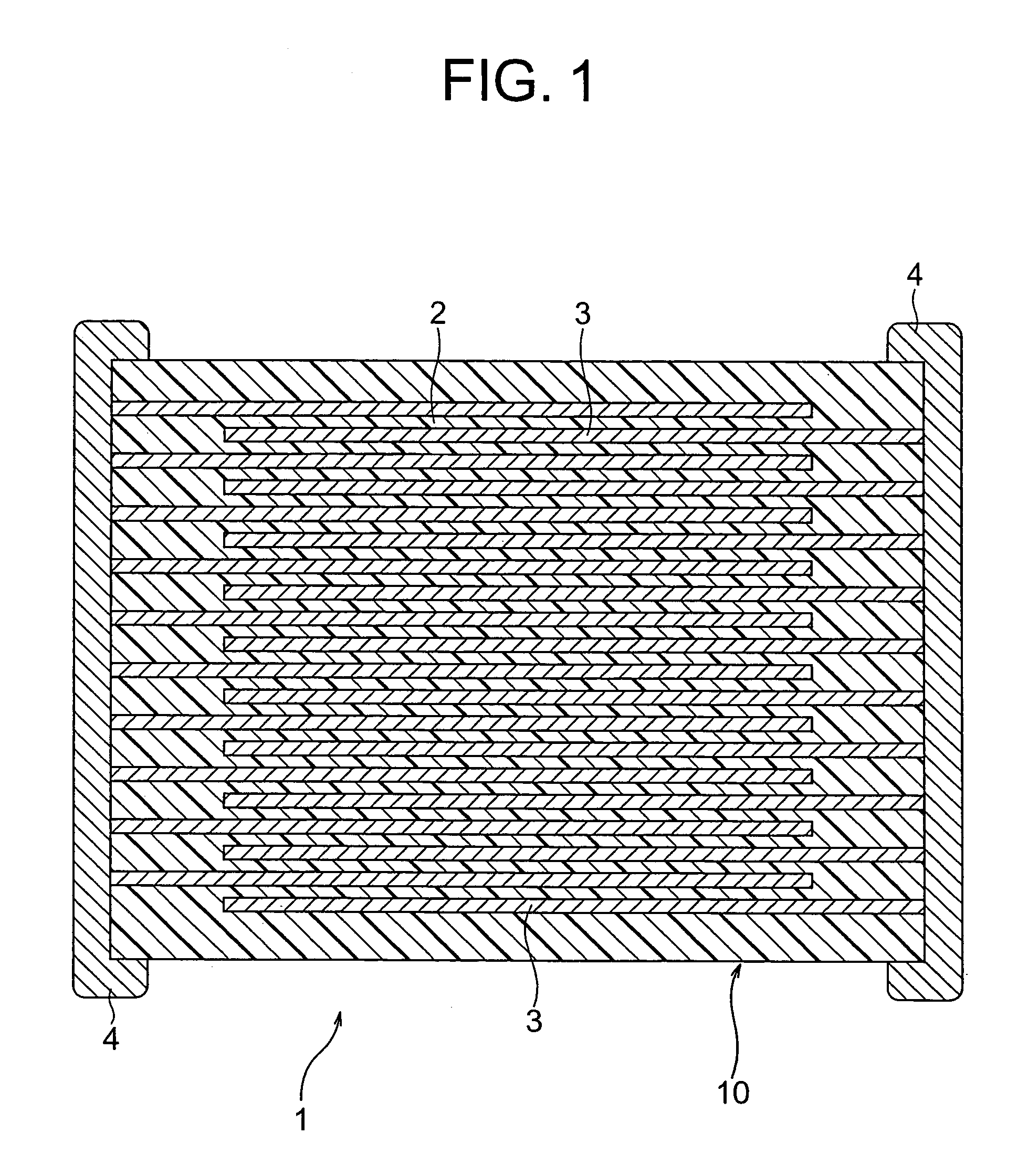

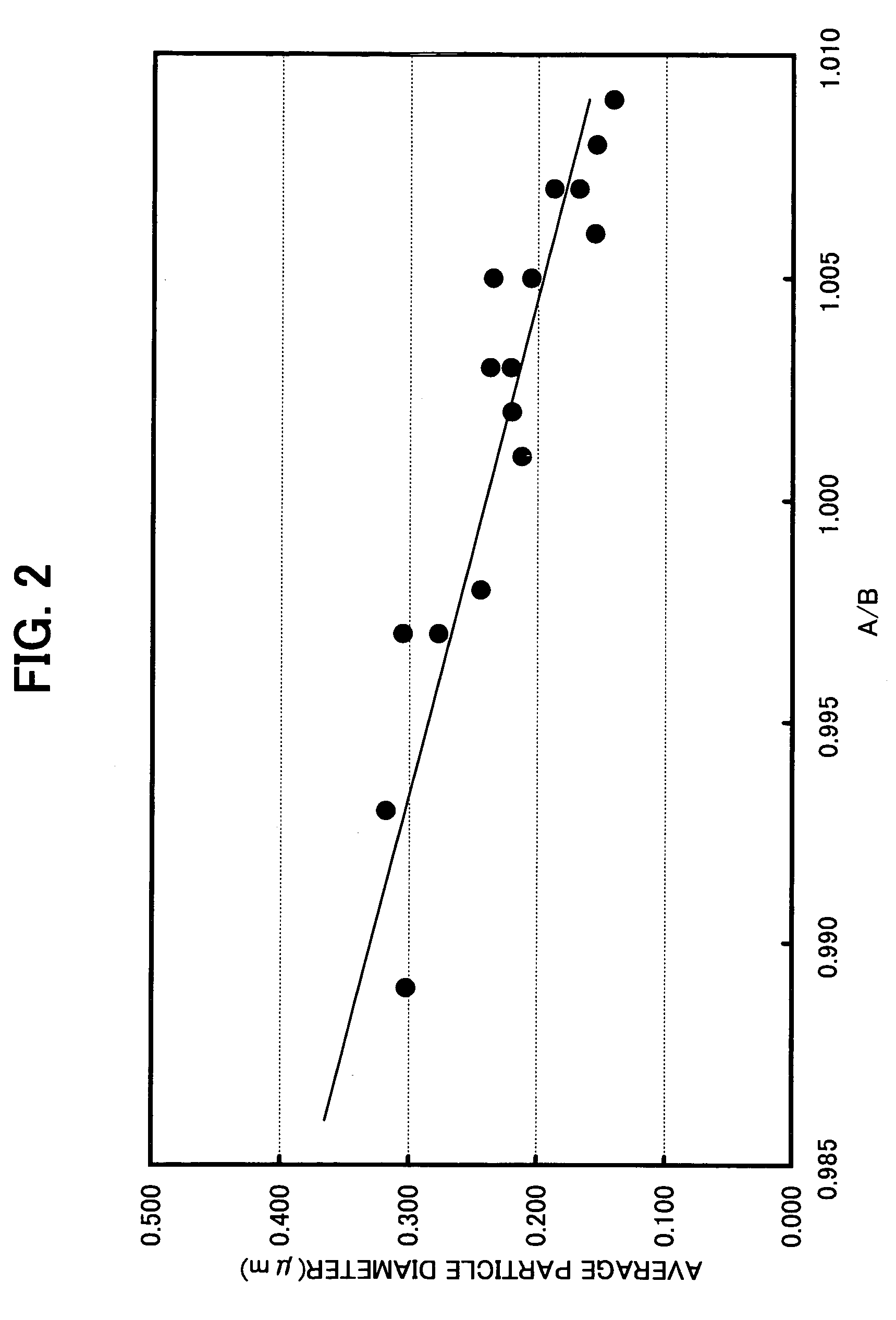

Electronic device, dielectric ceramic composition and the production method

ActiveUS20050107241A1Preferable electric characteristicPreferable characteristic temperatureLayered productsFixed capacitor dielectricBarium titanateAdditive ingredient

A production method of a dielectric ceramic composition having a step of firing dielectric material including a main component ingredient and a subcomponent ingredient, wherein said main component ingredient before firing is barium titanate ingredient powder having the perovskite type crystal structure expressed by ABO3, and a ingredient powder having a ratio A / B of A site components and B site components of 1.006≦A / B≦1.035 and the specific surface area of 8 to 50 m2 / g is used. According to the invention, a dielectric ceramic composition having preferable electric characteristics and temperature characteristic can be provided even in the case of being composed of fine particle and a capacitor made to be a thin layer.

Owner:TDK CORPARATION

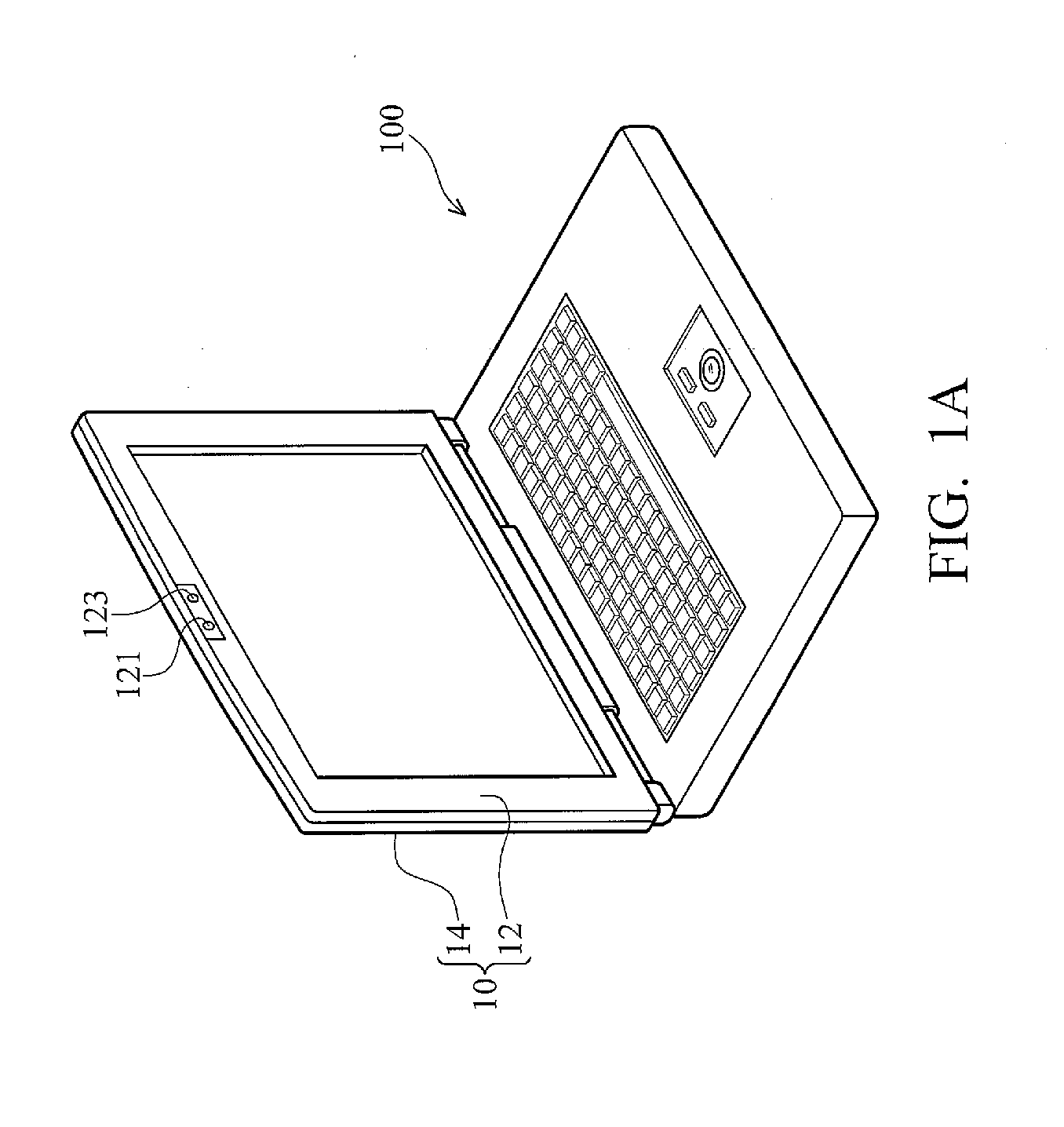

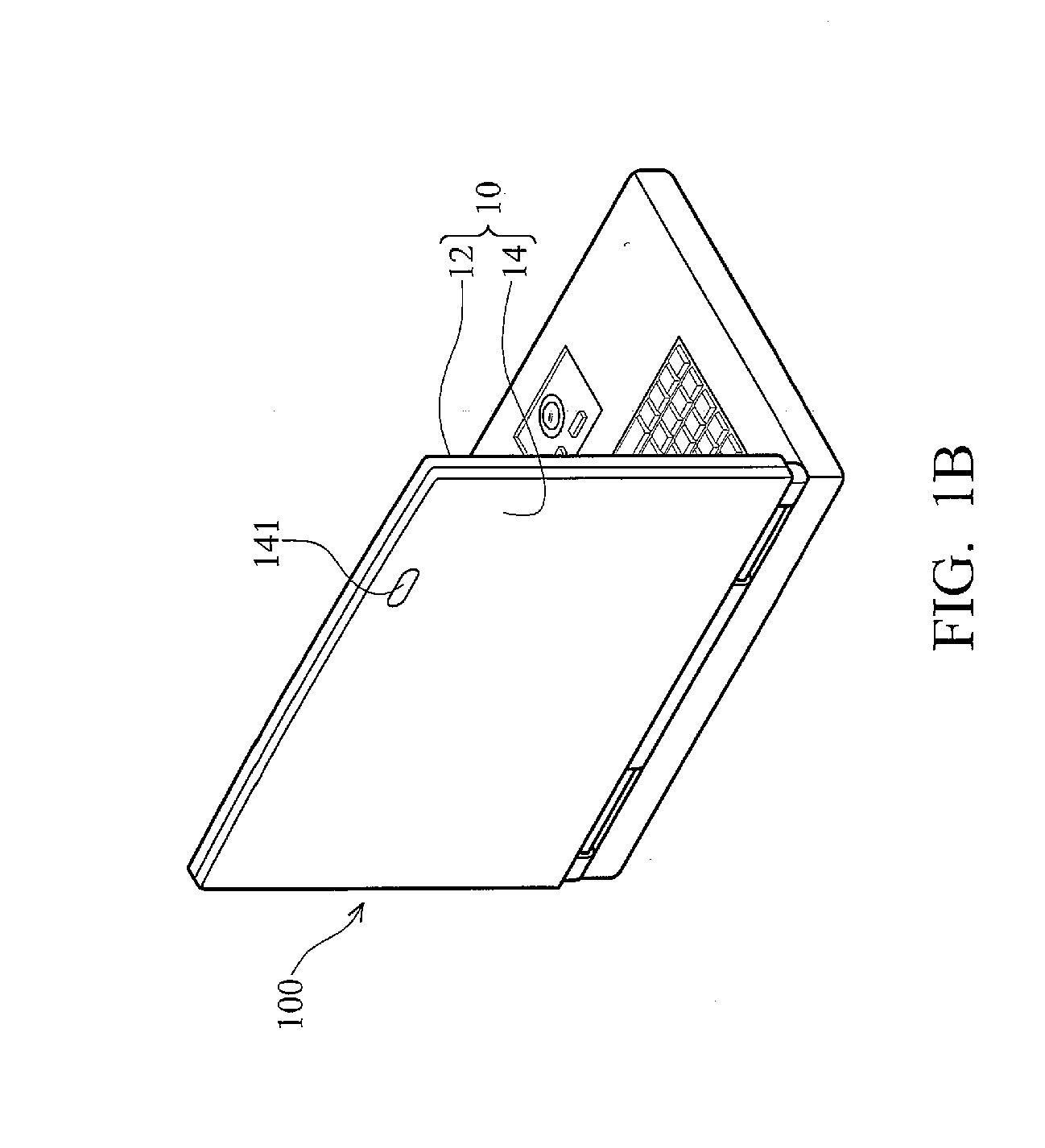

Electronic device including internal microphone array

InactiveUS20080240471A1Enhancing external sound reception capabilityThin and compactMicrophones signal combinationTransducer casings/cabinets/supportsEngineeringMicrophone array

An electronic device includes a housing, a circuit board, and a microphone array. A plurality of acoustic openings is defined in the housing. The circuit board is placed in the housing. The microphone array is placed on the circuit board for receiving external sound via the acoustic openings in the housing.

Owner:FORTEMEDIA

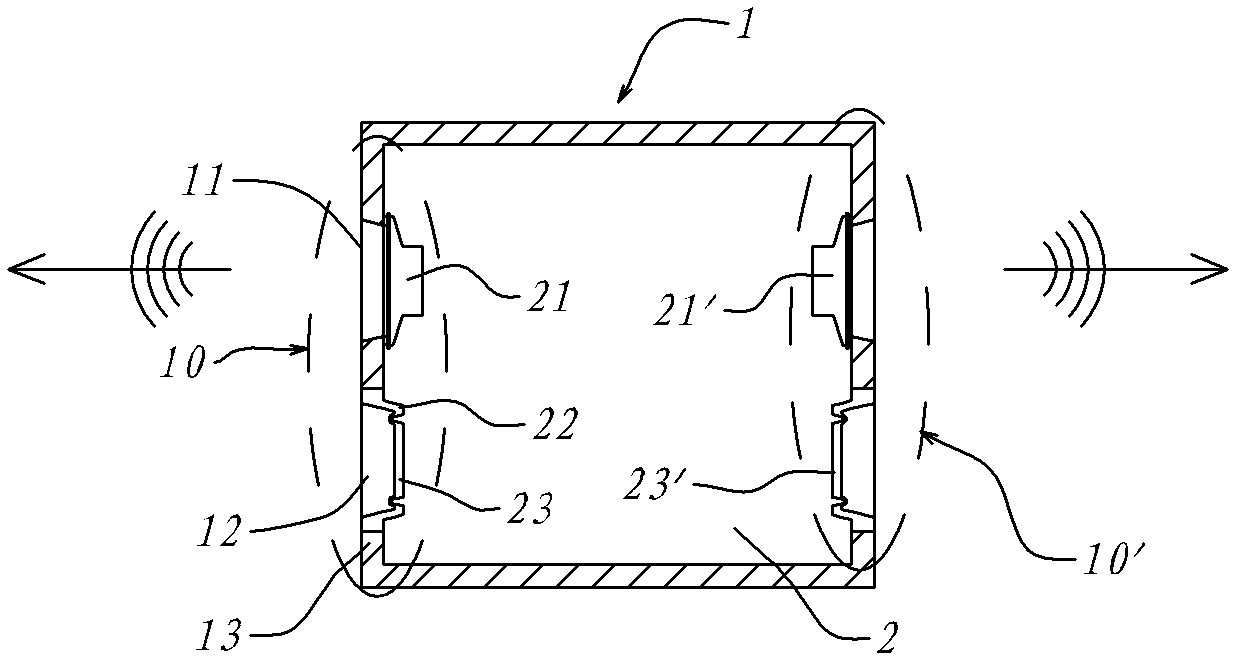

Mirror image vibration type loudspeaker box

InactiveCN102572639AAvoid Extraneous HarmonicsThin and compactFrequency/directions obtaining arrangementsMomentumHarmonic

The invention discloses a mirror image vibration type loudspeaker box, which is characterized by comprising a sealed loudspeaker box body which is provided with an output unit. The output unit comprises at least one cone hole, at least one diaphragm hole, a loud speaker unit and a passive radiation unit. The loudspeaker unit is loaded on the cone hole to be sealed. The passive radiation unit is provided with a passive diaphragm and loaded on the diaphragm hole to be sealed. The vibration direction of the loudspeaker unit is identical with the vibration direction of the passive diaphragm of the passive radiation unit. The mirror image vibration type loudspeaker box further comprises a mirror image unit which is in mirror symmetry with the output unit and the loudspeaker unit and the passive radiation unit which are positioned on the output unit in the reversed direction of the vibration direction. The cone and the passive diaphragm of the loudspeaker unit vibrate in mirror image mode with the same direction and equivalence. The left and right immediate momentums of the loudspeaker box body are balanced; sound coloration, which is caused by a lot of extra unrelated harmonic waves generated by the vibration of the loudspeaker box body, is avoided; and the purpose of small volume and excellent sound effect of the loudspeaker is achieved.

Owner:李世煌

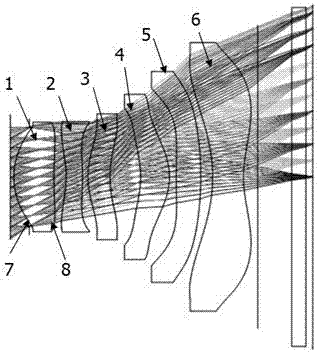

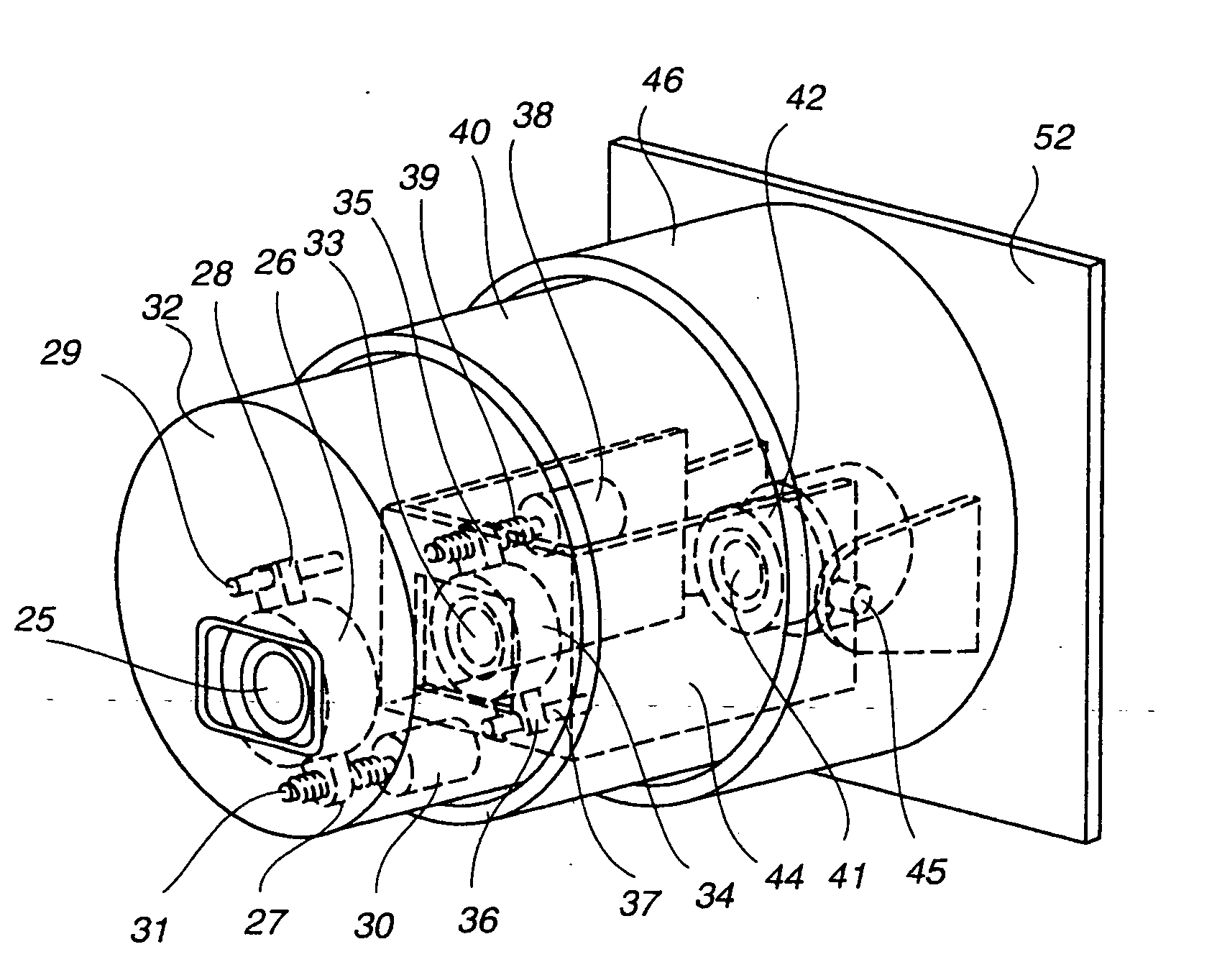

Miniature high-definition lens group and imaging system

The invention relates to the technical field of optical imaging and provides a miniature high-definition lens group. The lens group comprises six lenses arranged from an object side to an image side successively at intervals. The lenses have different refractive power, focal lengths, and concave-convex surfaces. A ratio of the thickness value of the second lens to the thickness value of the third lens is between 0.8 and 1.1. Compared with the prior art, the miniature high-definition lens group provides the lenses with different refractive power and concave-convex surfaces by arranging the six lenses successively at intervals along a direction. Thus, by arranging the six lenses, the miniature high-definition lens group realizes high-quality imaging, takes account of simple and compact structure, and has good market prospect.

Owner:广东省星聚宇光学股份有限公司

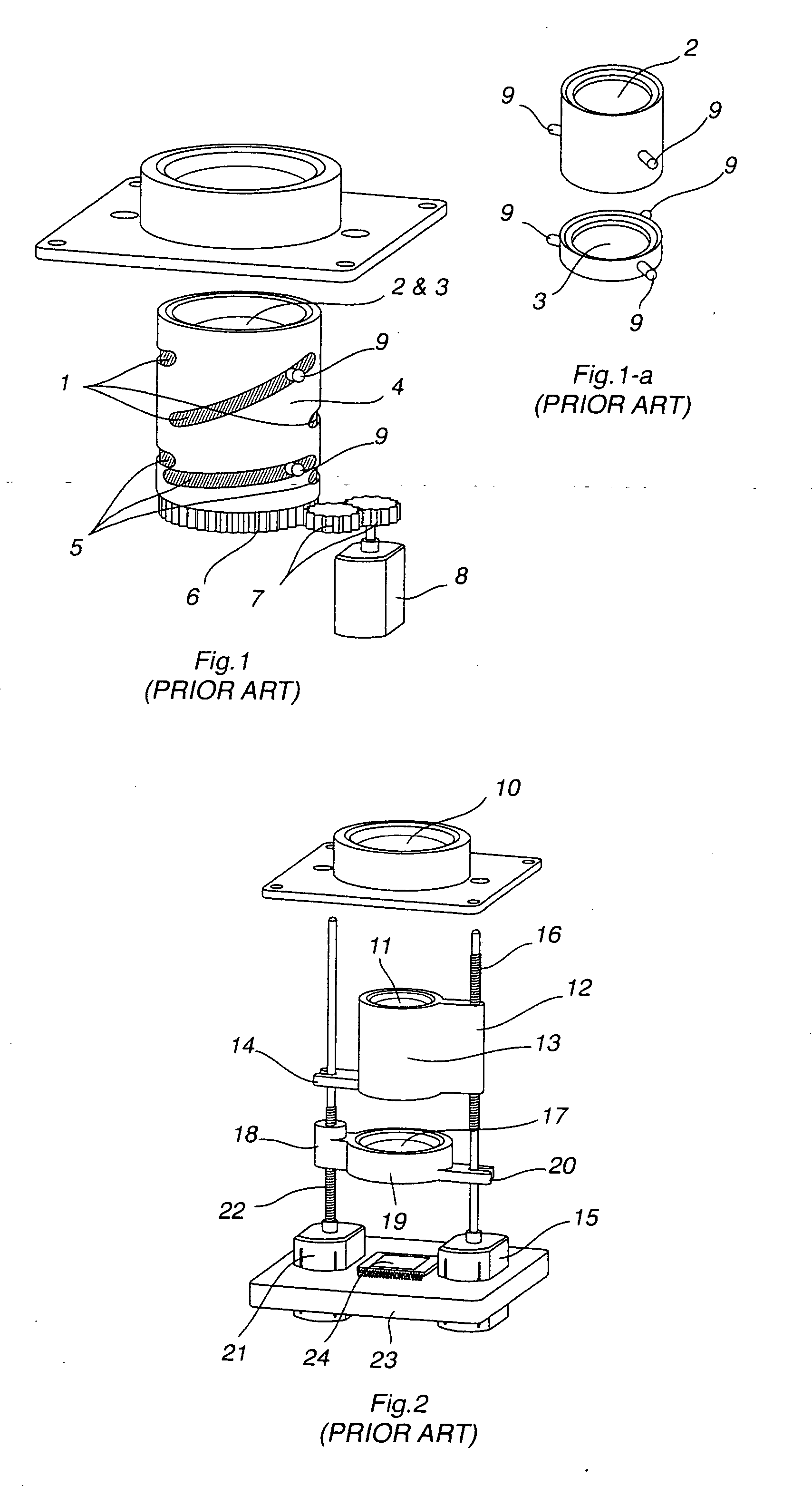

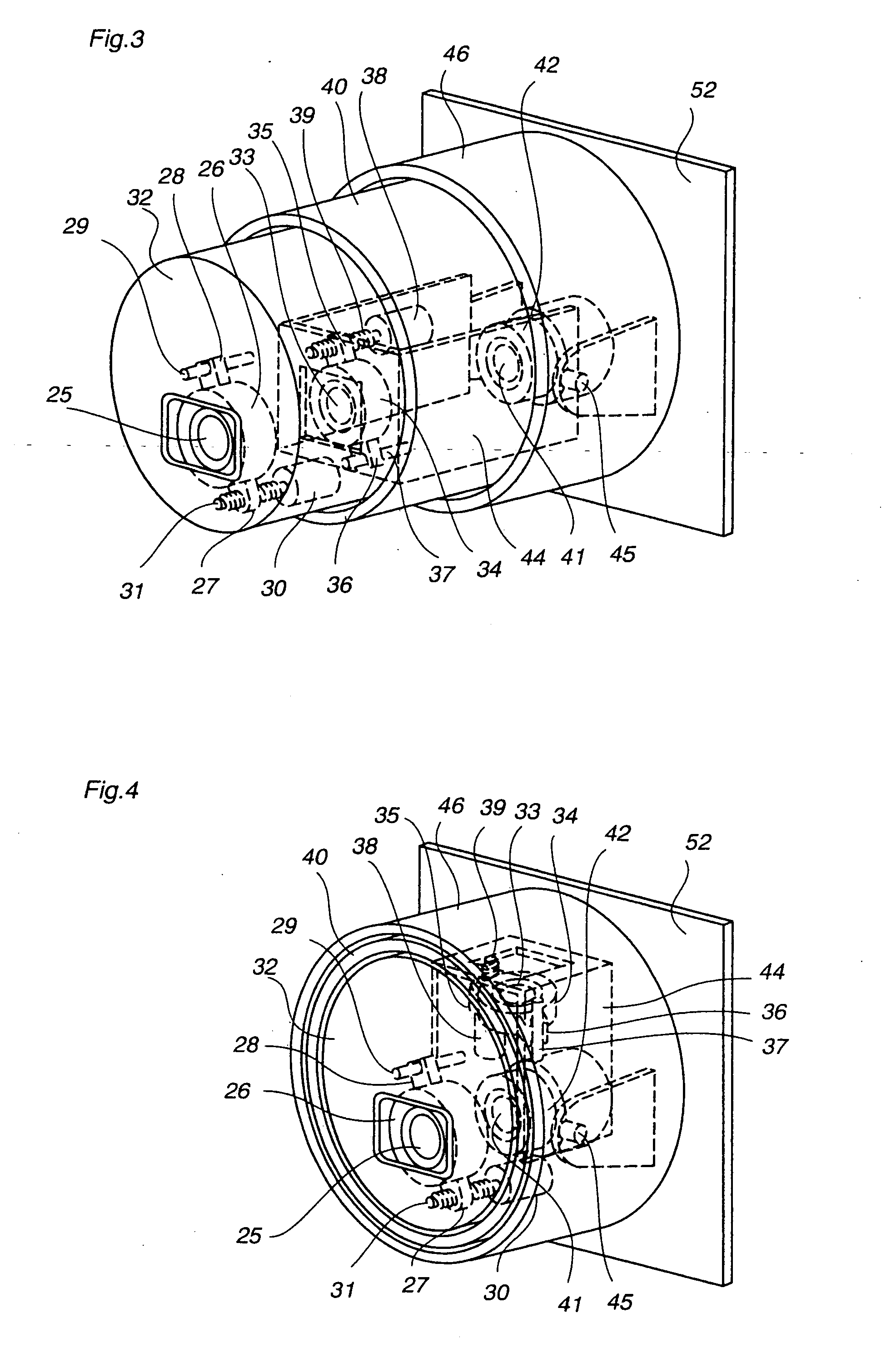

Zoom lens mechanism partly foldable and retractable

InactiveUS20050280903A1Extreme in manufacturingExtreme accuracyPrintersProjectorsEngineeringStill camera

A zoom lens mechanism foldable and retractable to be used in a digital still camera to control zooming of the zoom lens uses programmed data written in a micro controller unit (hereinafter referred to as MCU) instead of the conventional cylindrical grooved cams that are usually used to mechanically control zooming of a zoom lens of a digital still camera, and the assembly of the second lens group is rotatable inside the lens barrel, and the first lens group can be folded and retracted into the space provided by the rotation of the second lens assembly.

Owner:ARC DESIGN +3

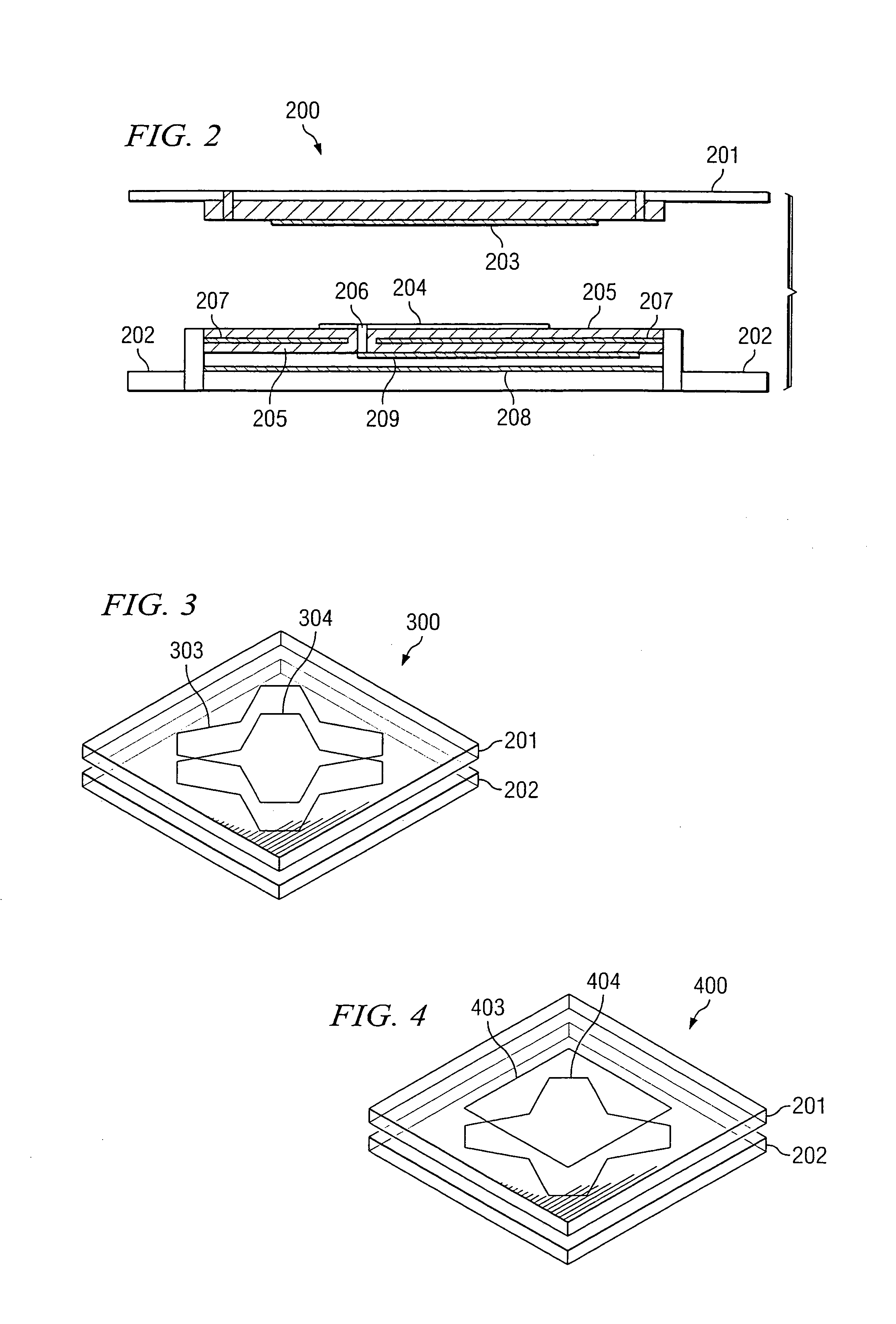

Piezoelectric pump and fluid transferring system

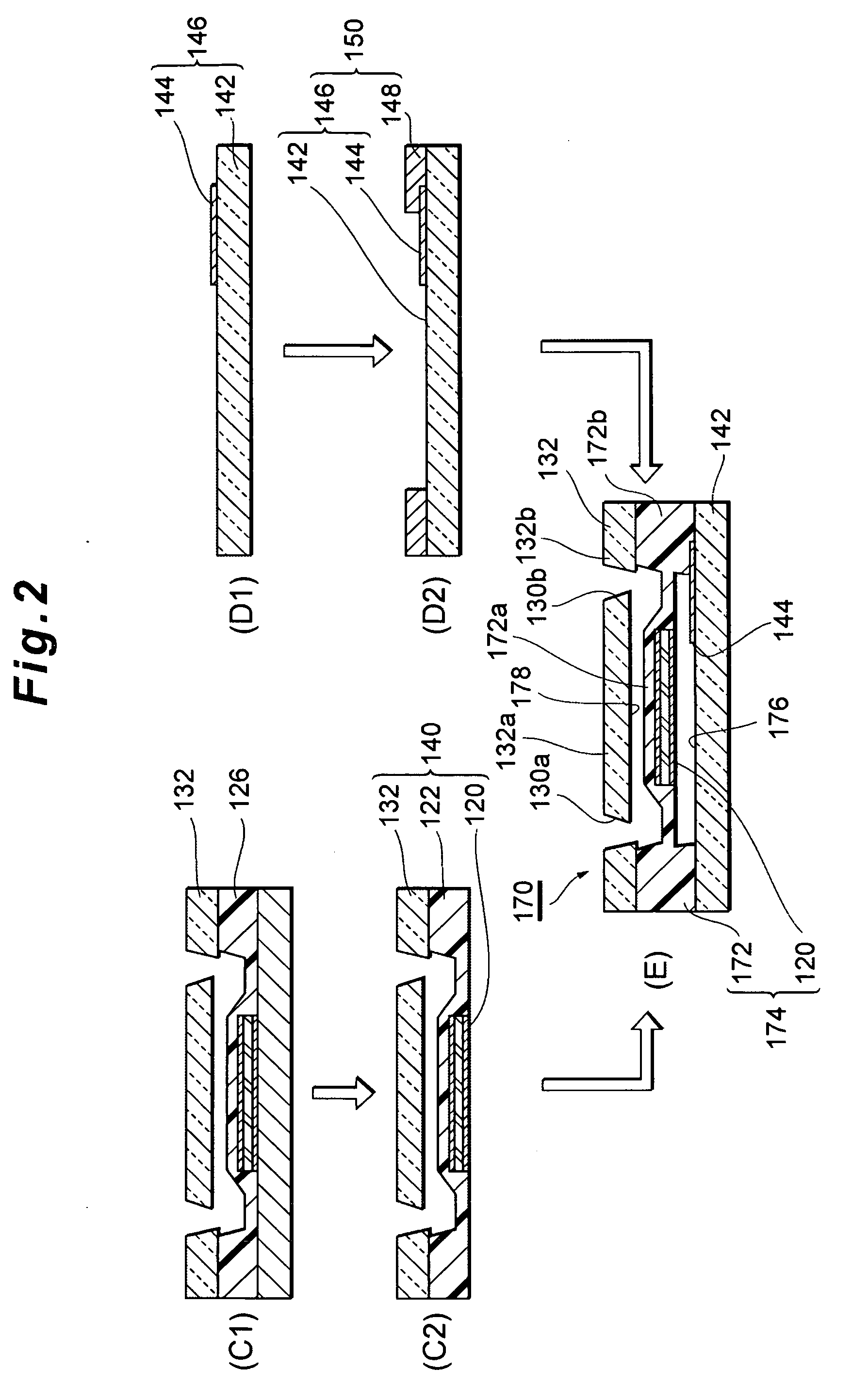

InactiveUS20100059127A1Piezoelectric pumpImprove stabilityFlexible member pumpsPump controlPump chamberEngineering

To provide a piezoelectric pump including: a structure including a piezoelectric element and a support member that supports the piezoelectric element; and a first substrate and a second substrate that sandwich the structure, wherein the piezoelectric pump has: a pump chamber surrounded by the second substrate and the structure; and a first opening and a second opening that are communicated with the pump chamber, and wherein a space is provided so that the structure flexes in a direction opposite to the pump chamber according to an operation of the piezoelectric element.

Owner:TDK CORPARATION

Light emitting device

ActiveUS7888869B2Reliable lightingThin and compactDischarge tube luminescnet screensLamp detailsLight emitting device

A light emitting device, comprises a light emitting element, a plurality of electroconductive layers on which said light emitting element is mounted or which are electrically connected to the light emitting element, and a translucent insulating member that seals the light emitting element and has the electroconductive layers as its bottom surface, wherein the electroconductive layers have a protrusion on part of their side faces, and the upper edges of the protrusion is rounded off.

Owner:NICHIA CORP

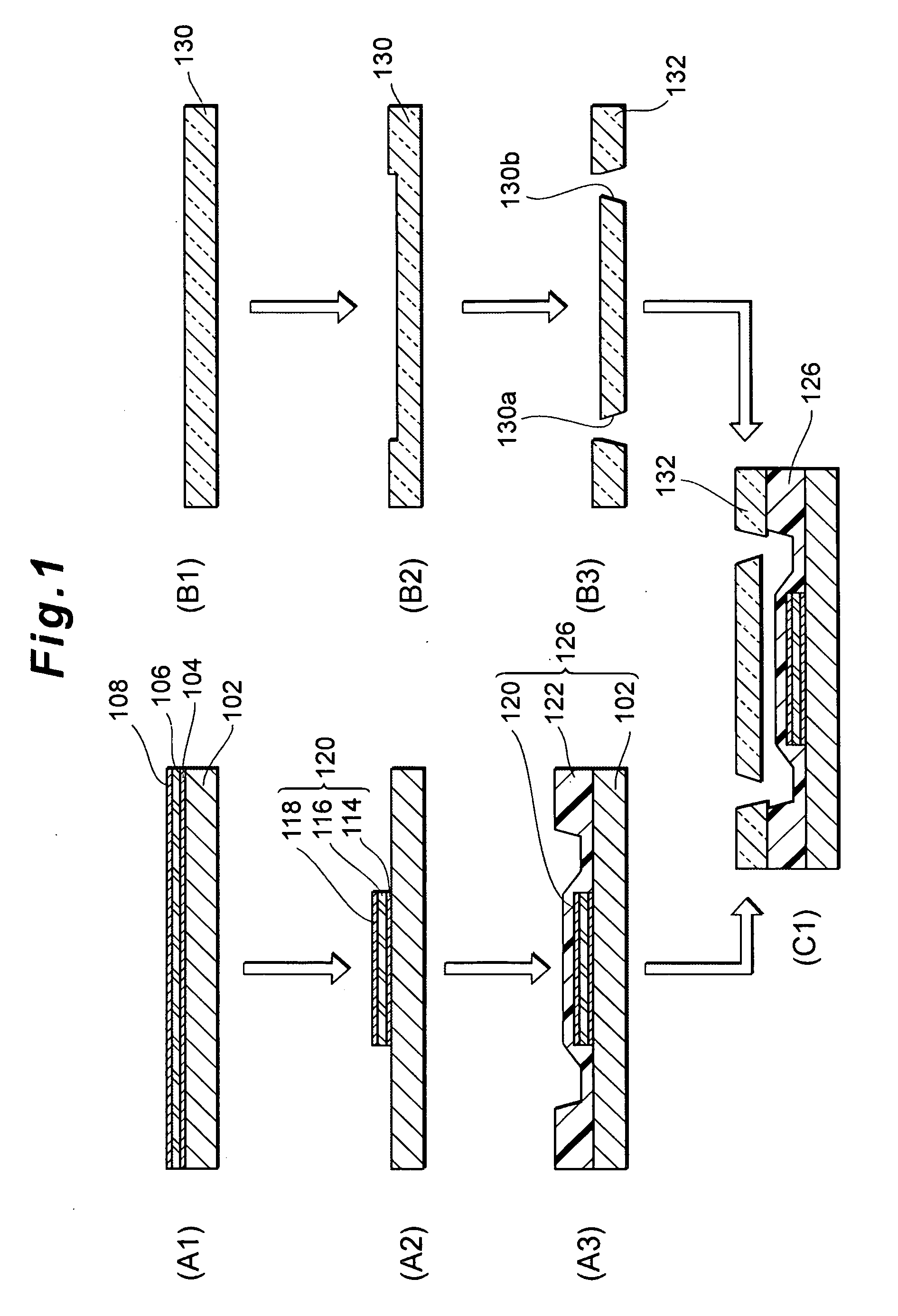

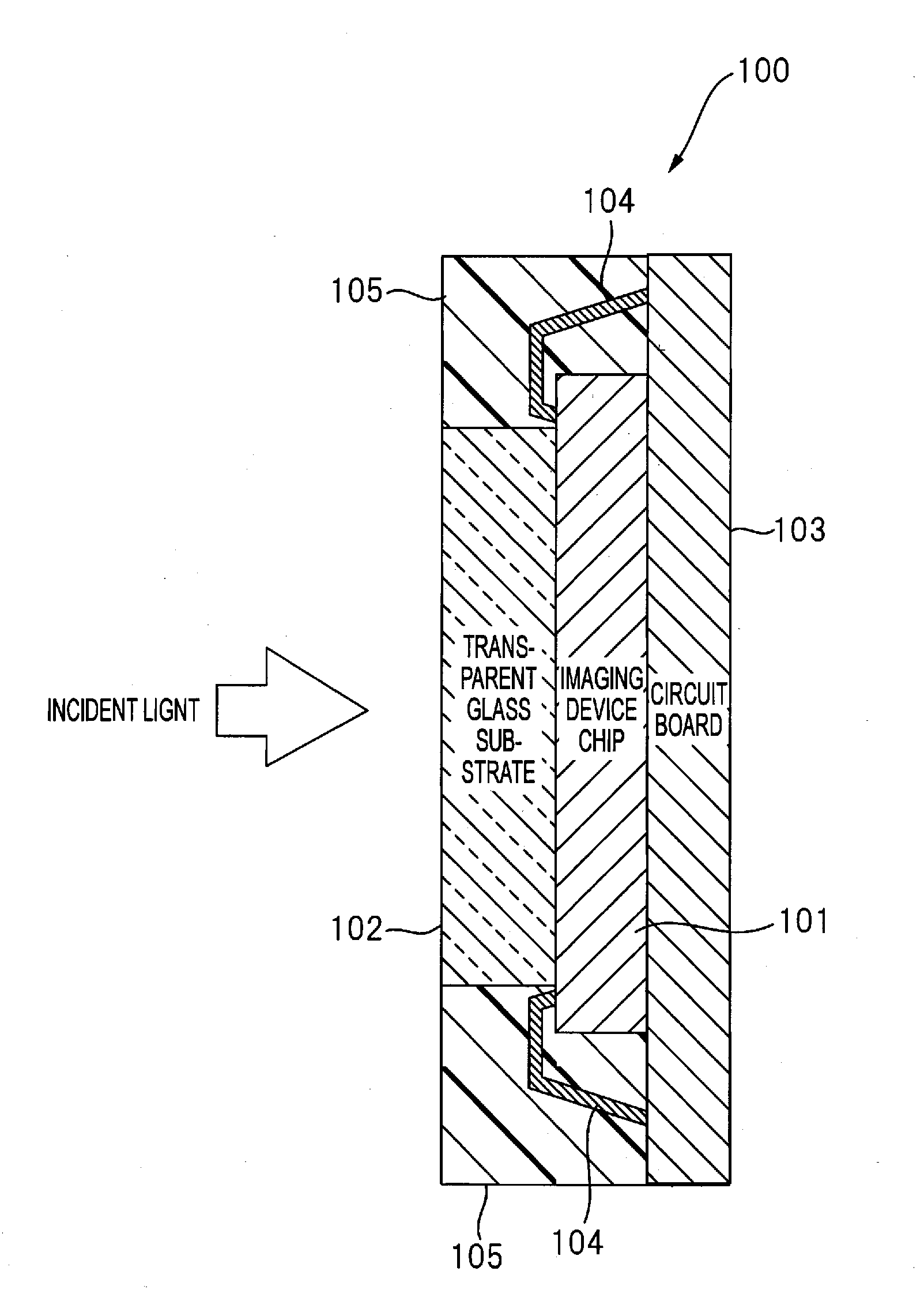

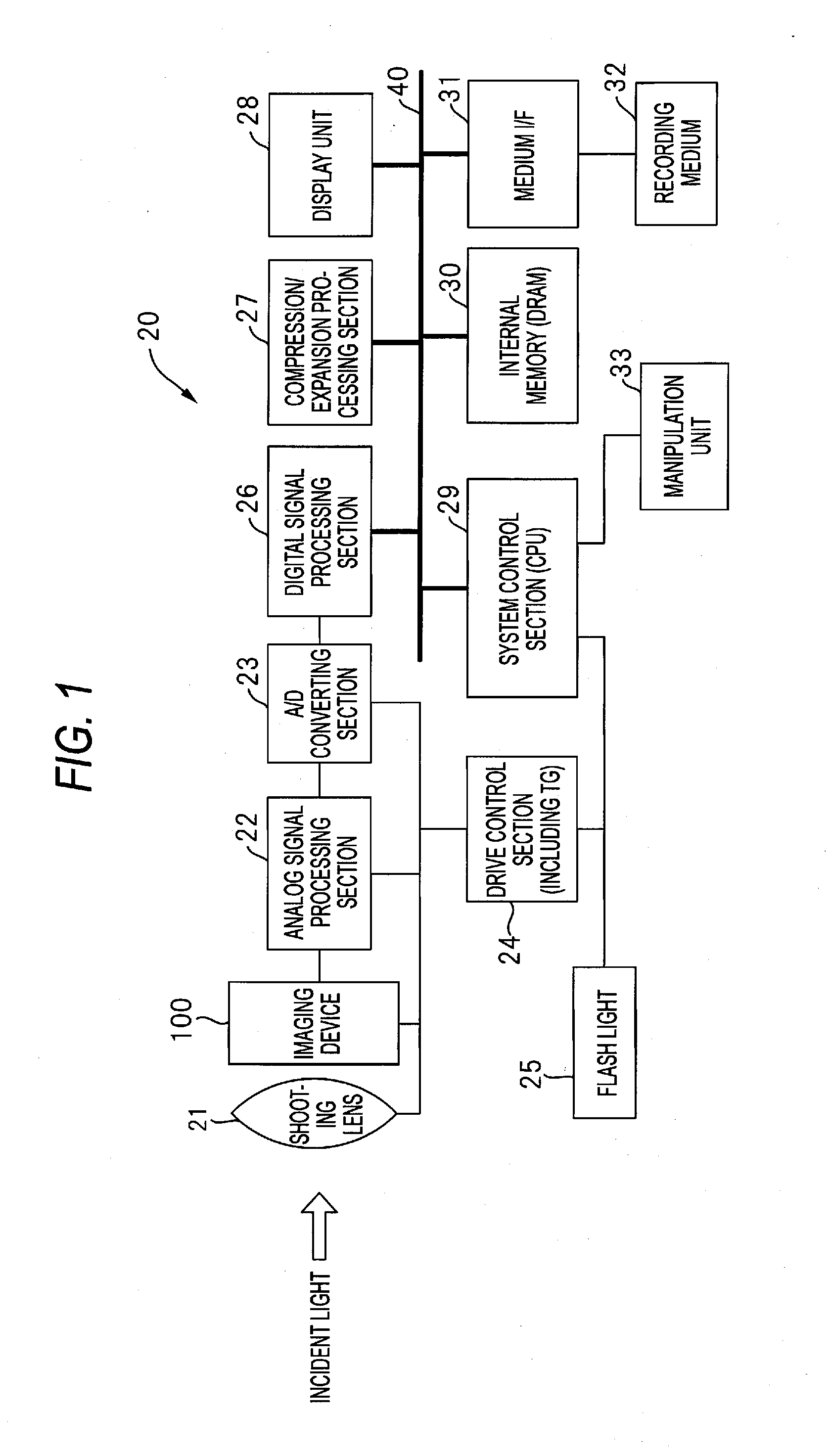

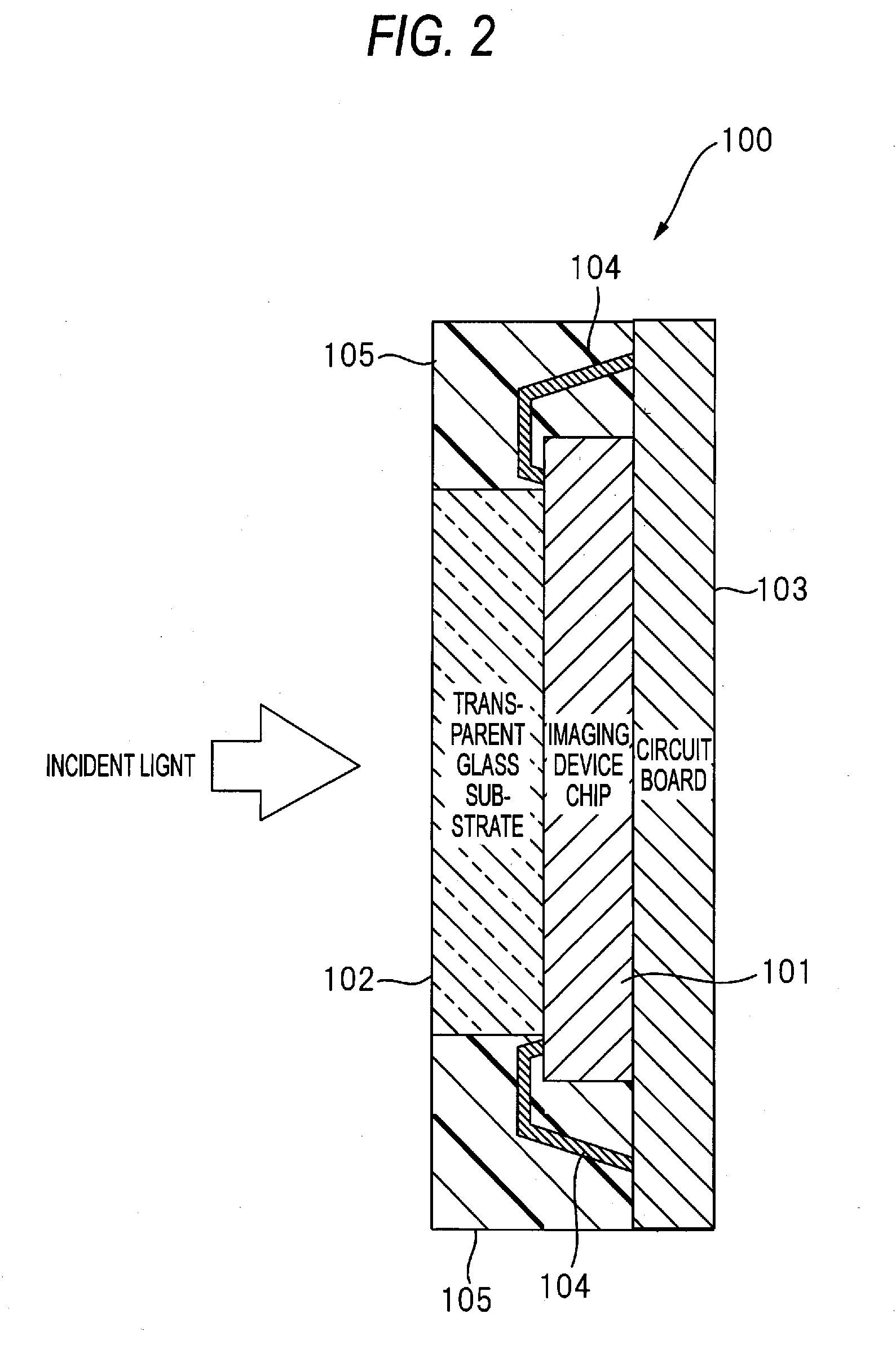

Photoelectric conversion film-stacked solid-state imaging device without microlenses, its manufacturing method, and imaging apparatus

InactiveUS20110227181A1Improve reliabilityThin and compactSolid-state devicesSemiconductor/solid-state device manufacturingPhotoelectric conversionResin adhesive

There are provided a circuit board; a semiconductor substrate bonded to a light-incidence-side surface of the circuit board; a photoelectric conversion film stacked on a layer that is disposed on the light incidence side of the semiconductor substrate; an imaging device chip having signal reading means which is formed in a surface portion of the semiconductor substrate, for reading out, as shot image signals, signals corresponding to signal charge amounts detected by the photoelectric conversion film according to incident light quantities; a transparent substrate bonded to a layer that is disposed on the light incidence side of the photoelectric conversion film with a transparent resin adhesive; and bonding wires which connect connection pads formed on a peripheral portion, not covered with the transparent substrate, of the semiconductor substrate to connection terminals on the circuit board.

Owner:FUJIFILM CORP

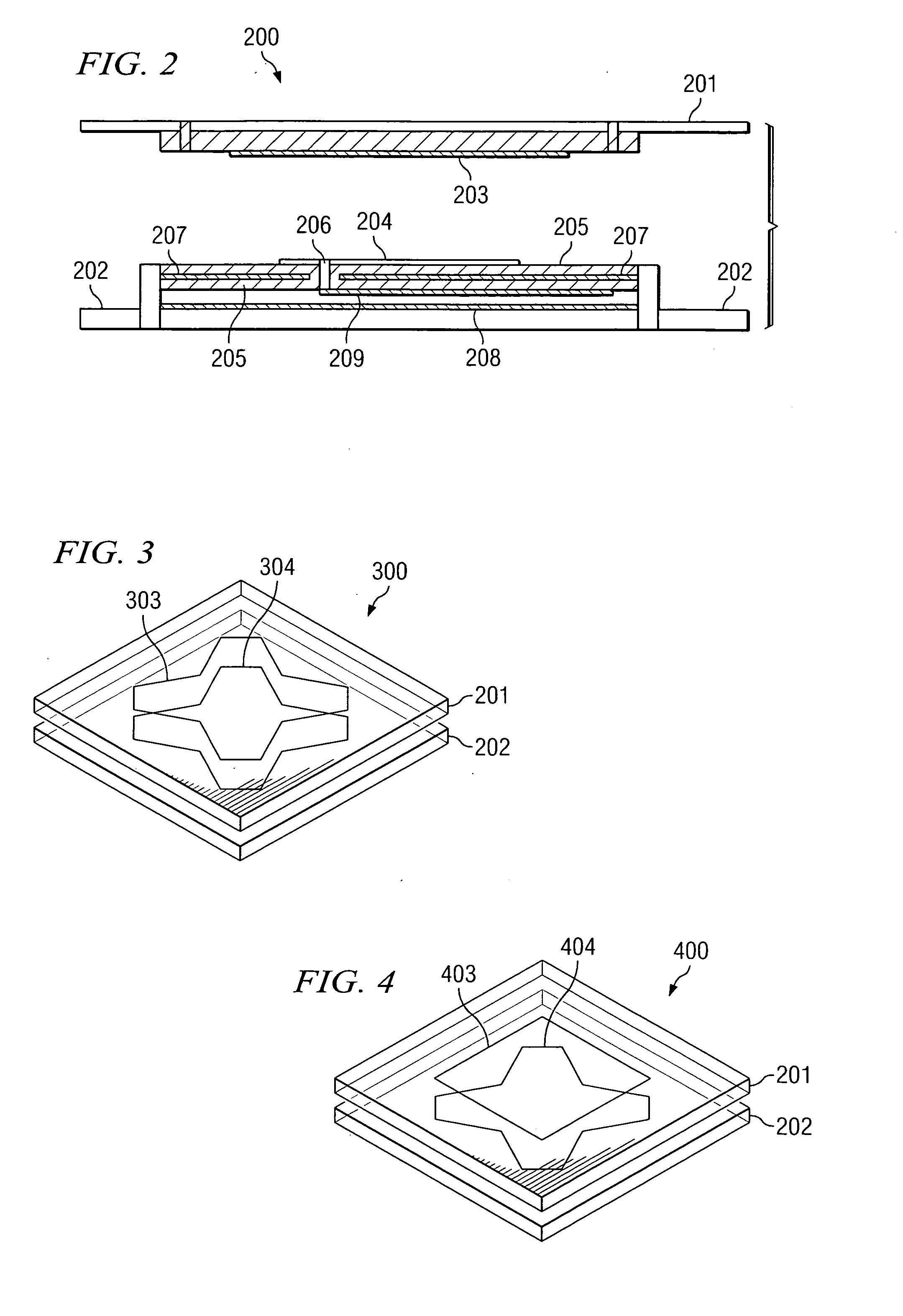

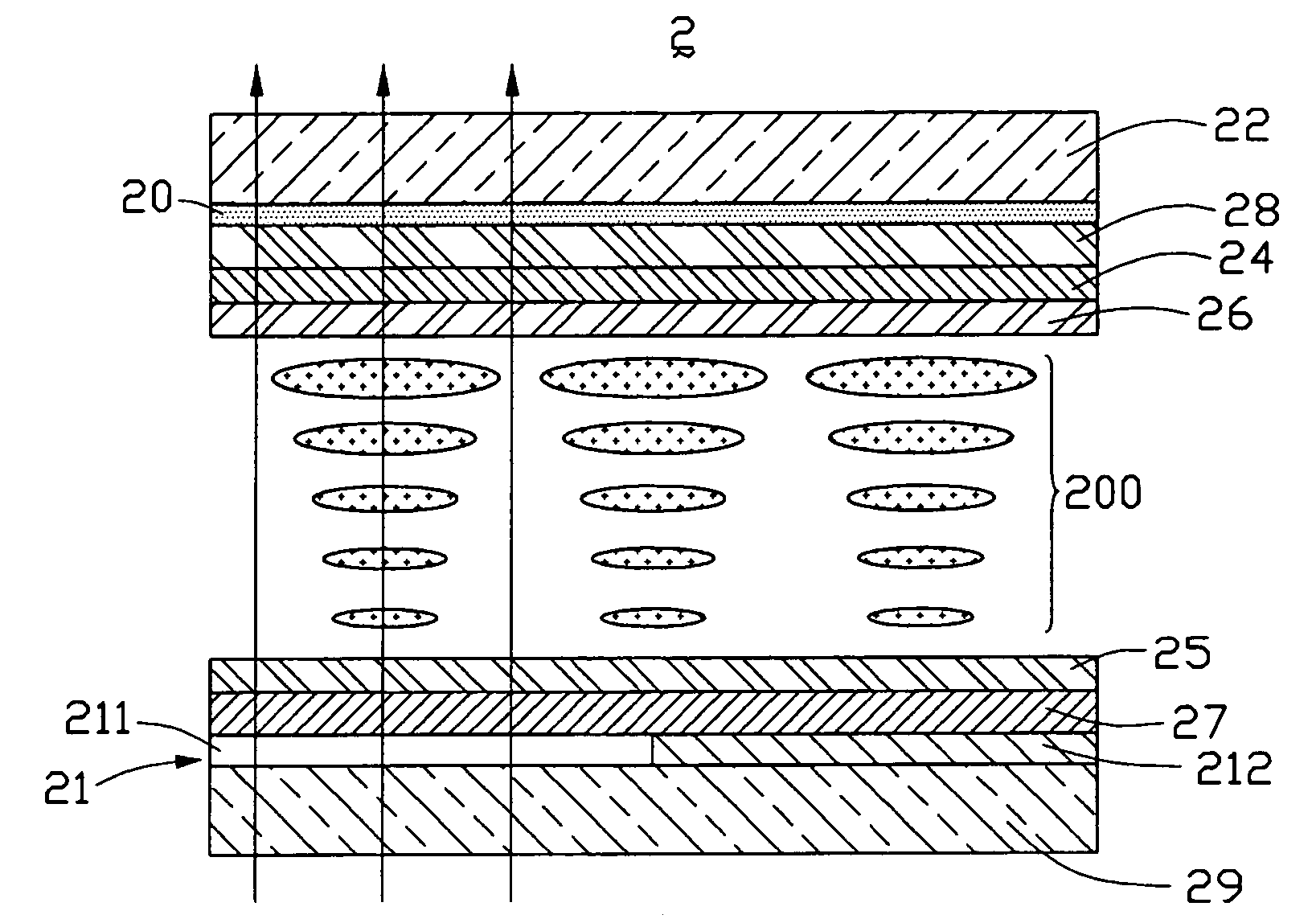

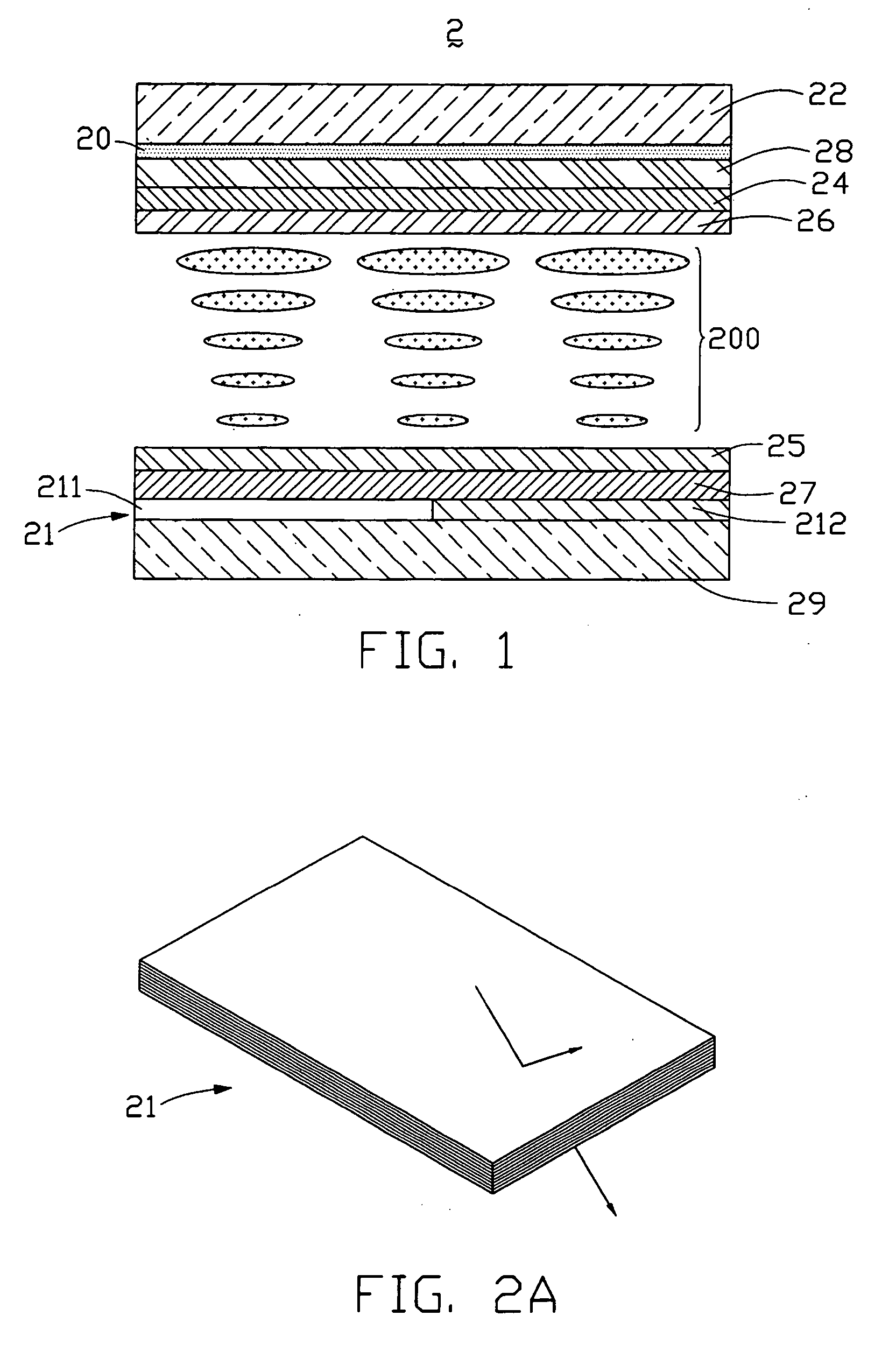

Transflective liquid crystal display device

InactiveUS20050157230A1Thin and compactIncrease contrastNon-linear opticsLiquid crystallineLiquid-crystal display

A transflective liquid crystal display (TR-LCD) (2) includes a first substrate (22) and a second substrate (29) disposed opposite each other and spaced apart a predetermined distance. A liquid crystal layer (200) is interposed between the first substrate and the second substrate. A color filter layer (20), a common electrode (28), a first polarizer (24) and a first alignment film (26) are positioned on an inner surface of the first substrate. A transflective layer (21), a second polarizer (27) and a second alignment film (25) are positioned on an inner surface of the second substrate. The second polarizer is an extraordinary type polarizer. The polarizers are made of a modified organic dye material which exists in a liquid-crystalline phase, thereby enabling the TR-LCD to work in temperatures up to 200 degrees Centigrade.

Owner:INNOLUX CORP

Electronic device, dielectric ceramic composition and the production method

ActiveUS7176156B2Preferable electric characteristic and temperature characteristicPreferable characteristicLayered productsFixed capacitor dielectricBarium titanateCrystal structure

A production method of a dielectric ceramic composition having a step of firing dielectric material including a main component ingredient and a subcomponent ingredient, wherein said main component ingredient before firing is barium titanate ingredient powder having the perovskite type crystal structure expressed by ABO3, and a ingredient powder having a ratio A / B of A site components and B site components of 1.006≦A / B≦1.035 and the specific surface area of 8 to 50 m2 / g is used. According to the invention, a dielectric ceramic composition having preferable electric characteristics and temperature characteristic can be provided even in the case of being composed of fine particle and a capacitor made to be a thin layer.

Owner:TDK CORPARATION

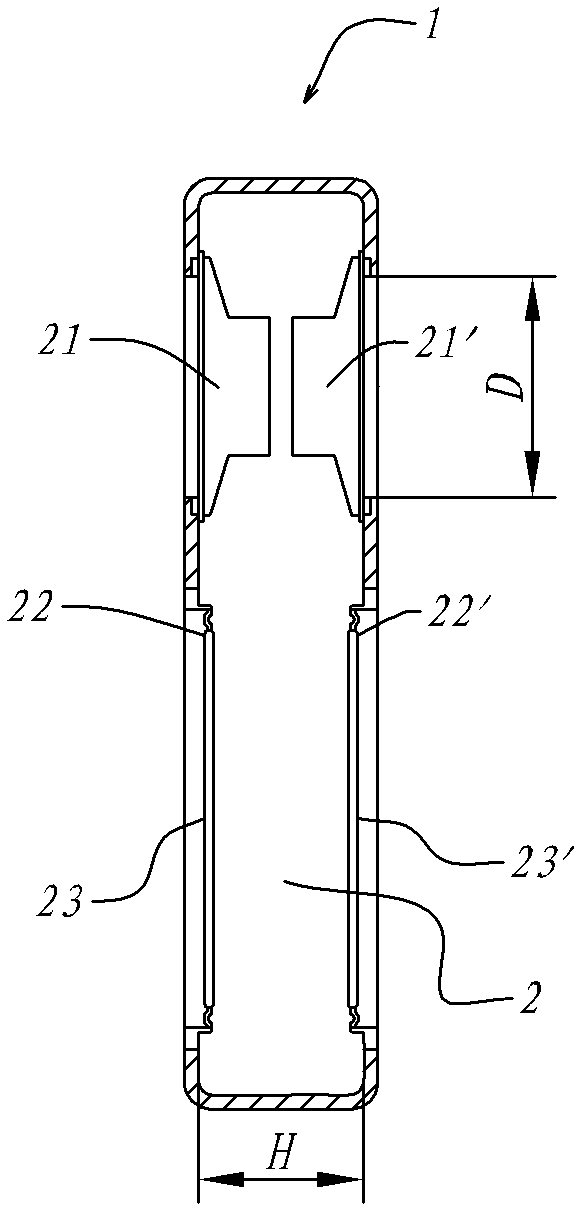

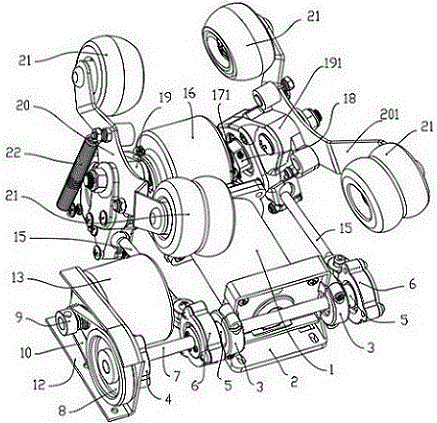

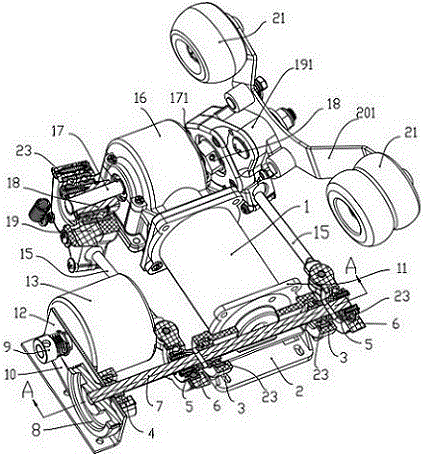

Narrow-and-small kneading and knocking massaging machine core and application

InactiveCN106511047ACompact designSmall sizeVibration massageRoller massageEngineeringMechanical engineering

The invention discloses a narrow-and-small kneading and knocking massaging machine core. The narrow-and-small kneading and knocking massaging machine core is used for reducing the volume of a massager and increasing the massaging journey of a rail massaging apparatus to widening the massaging range. The narrow-and-small kneading and knocking massaging machine core comprises a kneading motor and a knocking motor; a kneading reduction box of a reduction transmission mechanism is arranged at the front end of the kneading motor, output shafts are arranged on the left side and the right side of the a kneading reduction box, and drive a pair of left massaging arm assembly and right massaging arm assembly to knead and massage the body, a knocking driving mechanism is fixed to the back end of the kneading motor, a knocking shaft is movably fixed on a knocking base of the knocking driving mechanism through a bearing, a reduction mechanism of the kneading motor is arranged at one end of the knocking shaft, and the other end and the middle of the knocking shaft drive a pair of left massaging arm assembly and right massaging arm assembly to knock and massage the body. The narrow-and-small kneading and knocking massaging machine core is compact in design, narrow in width, small in volume, suitable for being internally arranged in a hand massager for movably massaging the body and particularly suitable for being internally arranged in the rail massaging apparatus, the massaging range distance is longer and farther, all the parts of the human body are more effectively massaged, and kneading-knocking synchronous or asynchronous massaging is achieved.

Owner:郑纯建

In-plane switching liquid crystal display device having extraordinary polarizers

InactiveUS20050190320A1Thin and compactWide viewing angleNon-linear opticsIn planeLiquid-crystal display

Owner:INNOLUX CORP

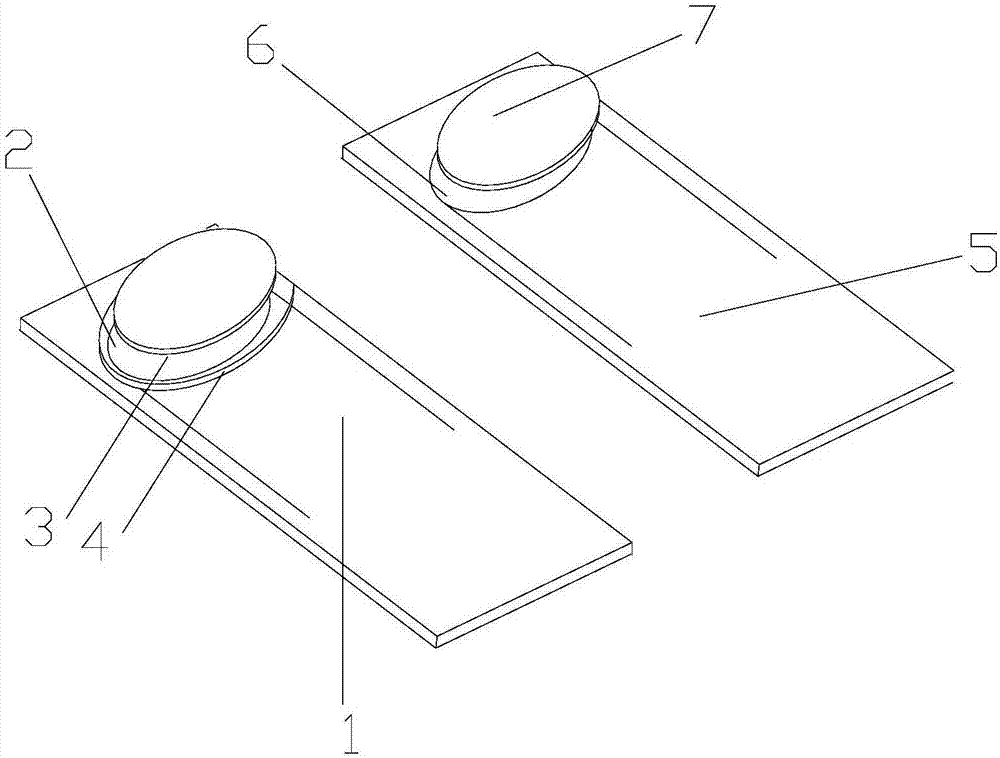

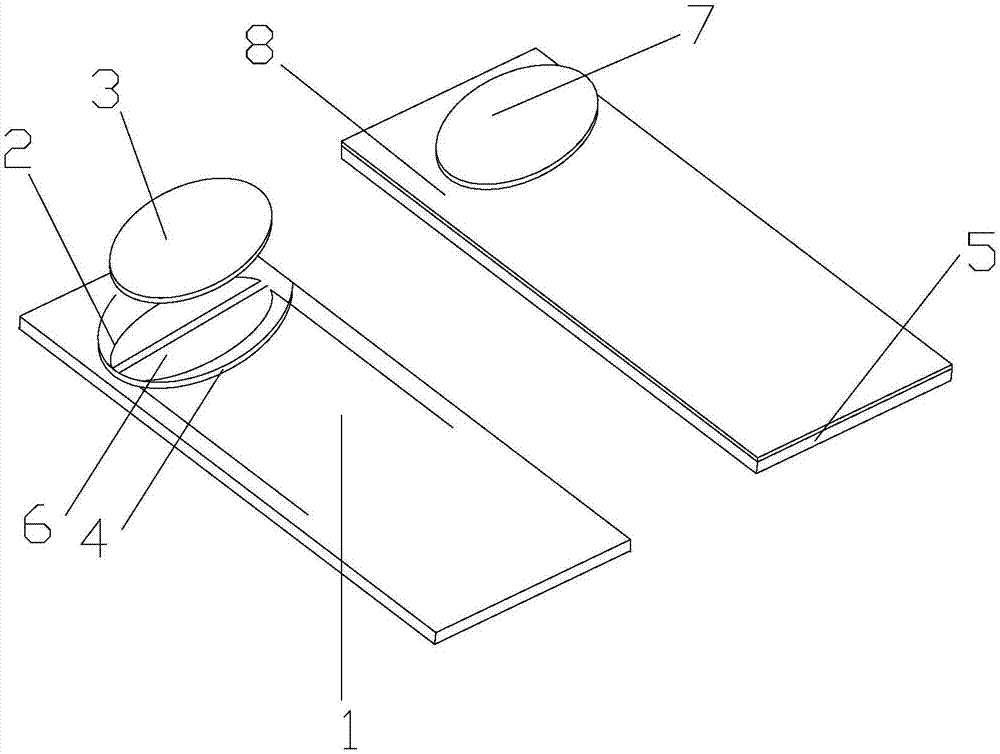

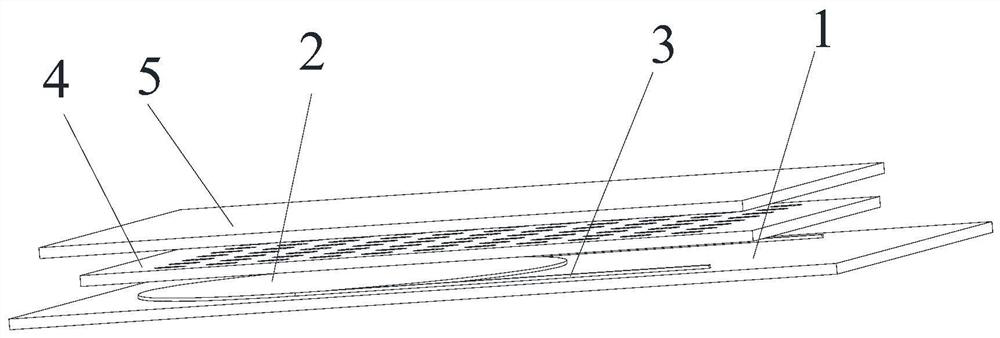

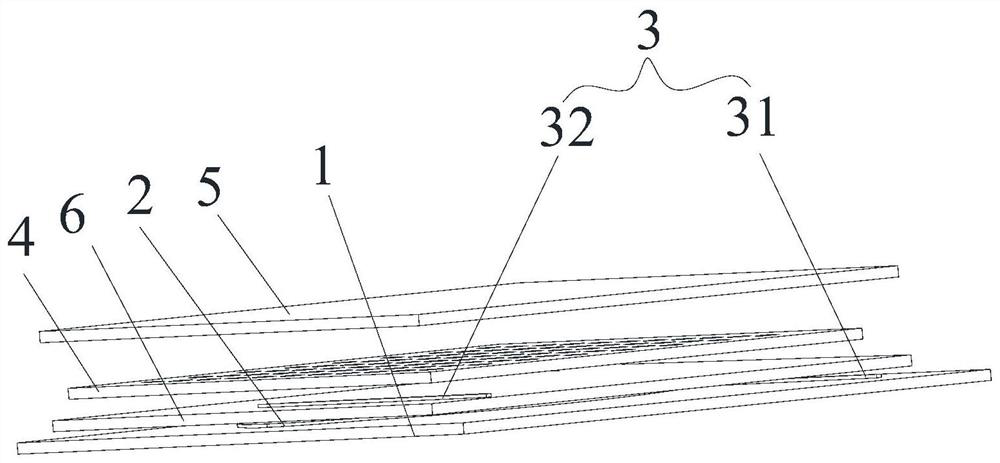

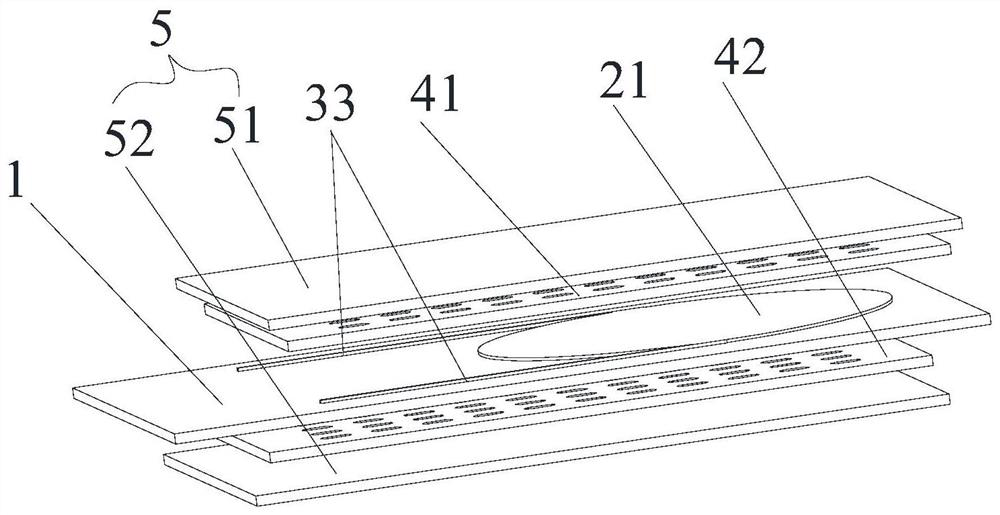

Soft film pressure sensor

PendingCN107340082AHigh sensitivityThin and compactForce measurement using piezo-electric devicesThin membraneForce sensor

The invention relates to a design of a pressure sensor, and particularly relates to a soft film pressure sensor, wherein the sensitivity of the sensor is further improved based on the synergistic effect of changing the resistivity of novel nanometer pressure-sensitive materials and changing the contact area of two pressure-sensitive layers, and the problems of hysteresis effect and poor test repeatability are solved with the assistance of an ultra-thin film substrate having a proper young modulus. The soft film pressure sensor comprises a first flexible substrate, a first electrode layer, a first pressure-sensitive layer, a supporting layer, a second flexible substrate, a second electrode layer and a second pressure-sensitive layer. The first pressure-sensitive layer, the first electrode layer and the first flexible substrate are sequentially connected. The second pressure-sensitive layer, the second electrode layer and the second flexible substrate are sequentially connected. The soft film pressure sensor further comprises the supporting layer positioned between the first soft substrate and the second the flexible substrate and used for fixing the first pressure-sensitive layer and the second pressure-sensitive layer. A gap is formed between the first pressure-sensitive layer and the second pressure-sensitive layer.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

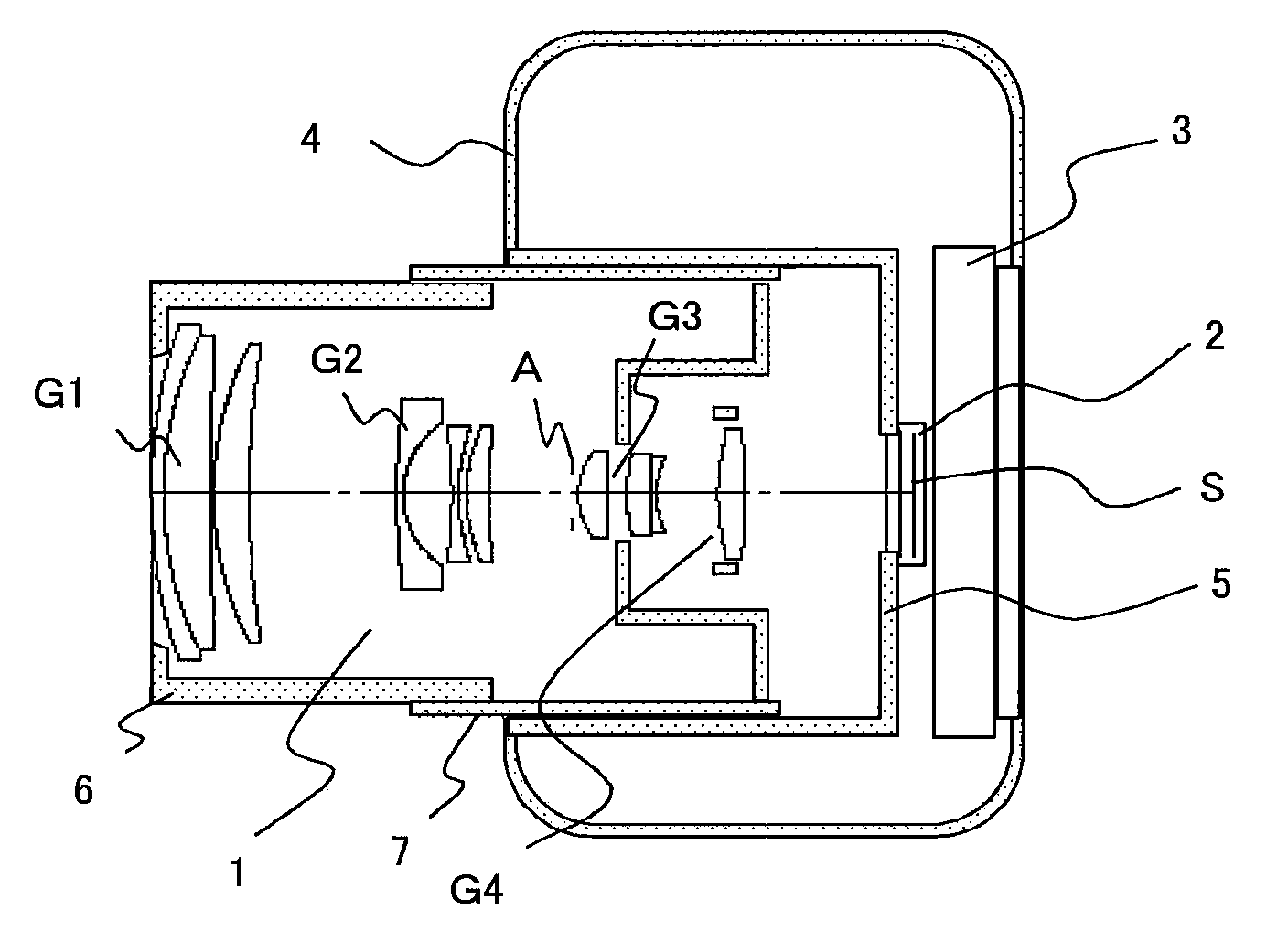

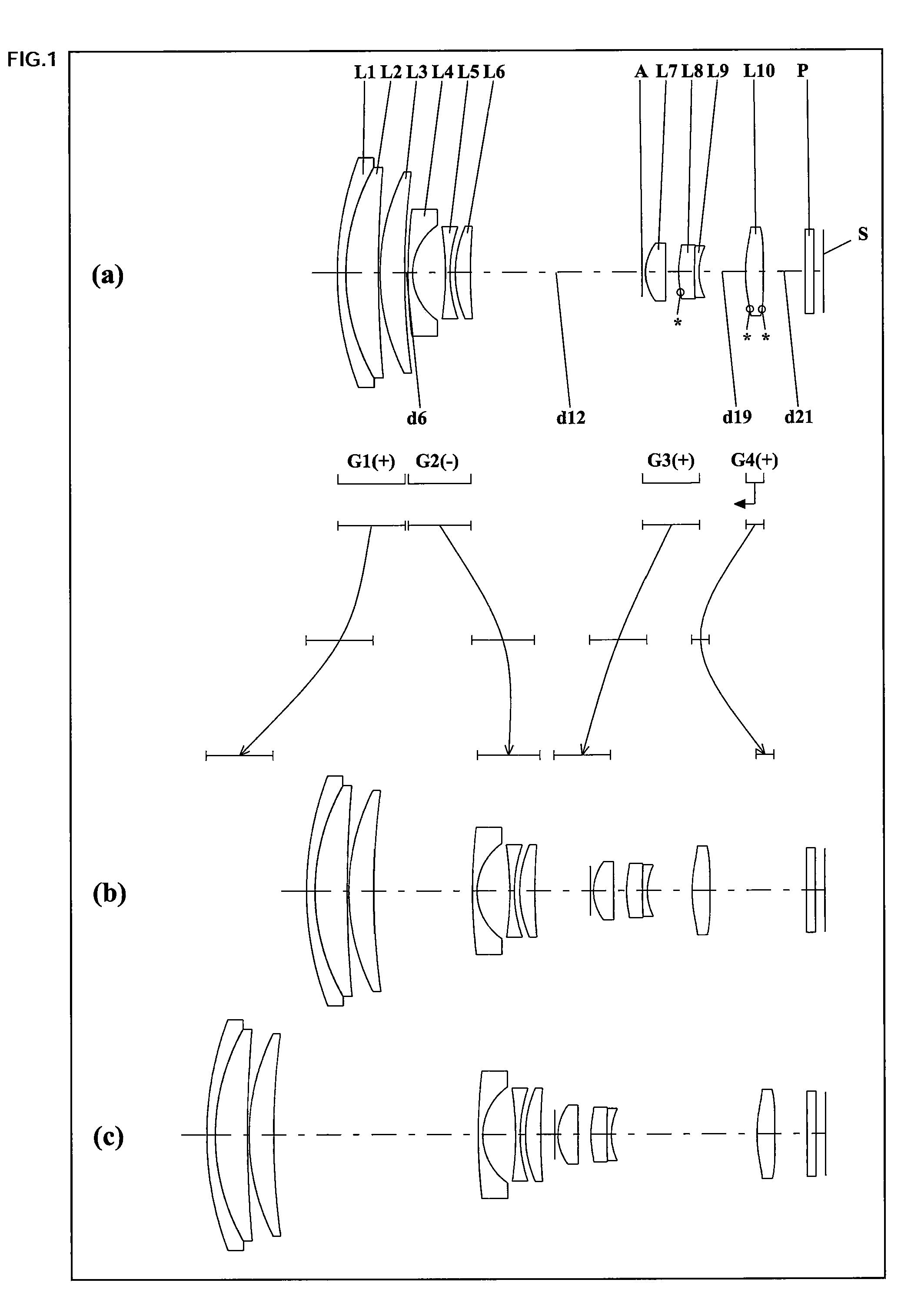

Zoom lens system, imaging device and camera

InactiveUS20100171849A1Small sizeWide viewing angleTelevision system detailsColor television detailsOptical axisNegative power

A zoom lens system, in order from an object side to an image side, comprising a first lens unit of positive power, a second lens unit of negative power, a third lens unit of positive power, and a fourth lens unit of positive power, wherein the first lens unit is composed of three or fewer lens elements, wherein the second lens unit is composed of three lens elements, wherein in zooming, the first to the fourth lens units are moved individually along an optical axis such that air spaces should vary, so that variable magnification is achieved, and wherein the conditions are satisfied: tan 2ωW×m2W≦−1.78, tan 2ωW×|fG2| / fG1≧1.24, ωW≧37 and fT / fW≧10 (m2W is a lateral magnification of the second lens unit at a wide-angle limit, fG1 and fG2 are composite focal lengths of the first and the second lens units, ωW is a half view angle at a wide-angle limit, and fT and fW are focal lengths of the entire system respectively at a telephoto limit and at a wide-angle limit), an imaging device and a camera are provided.

Owner:PANASONIC CORP

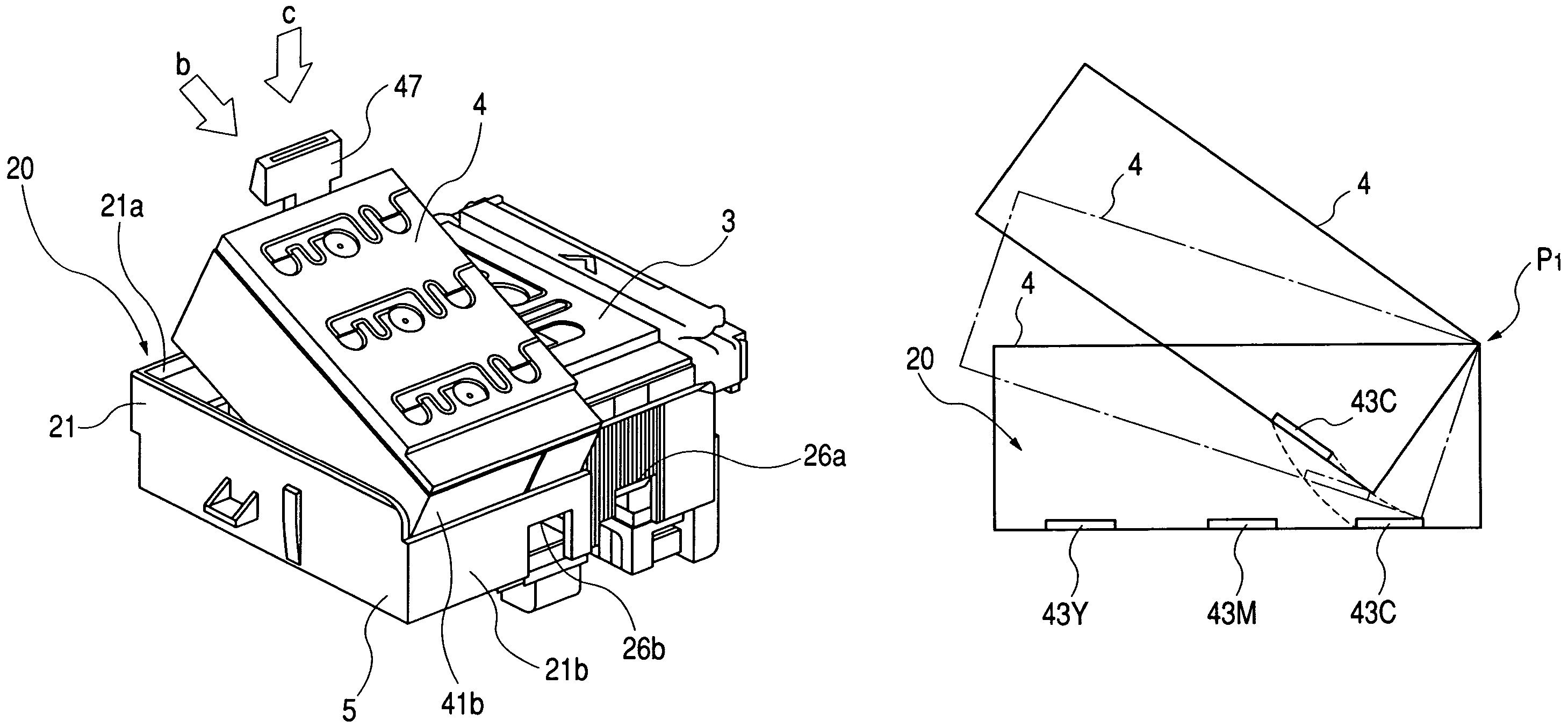

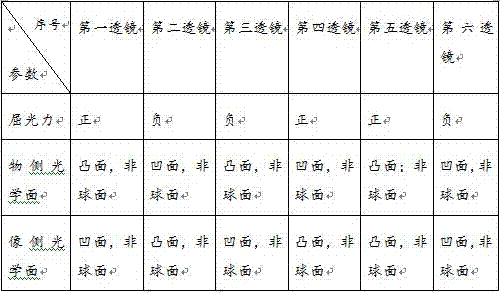

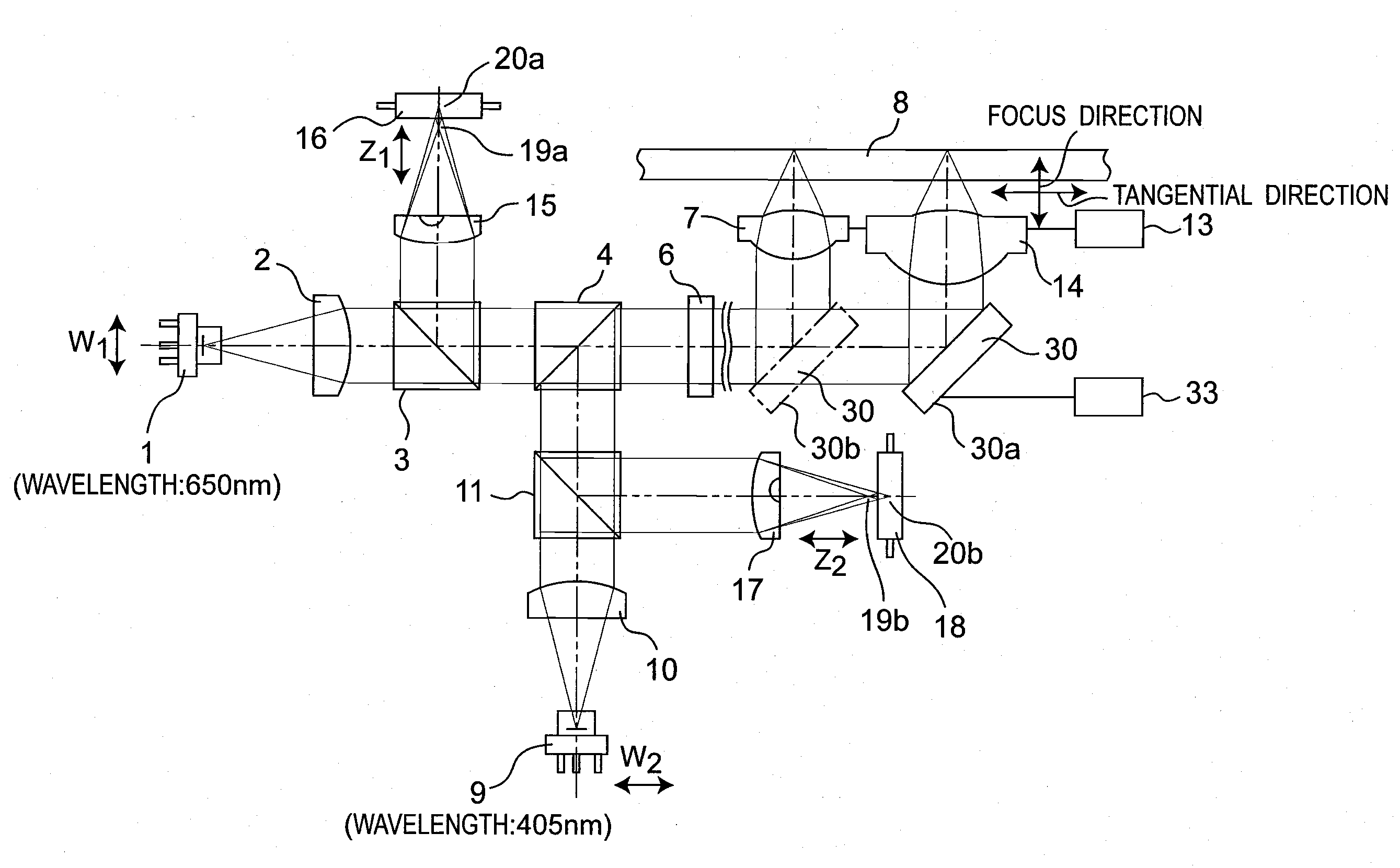

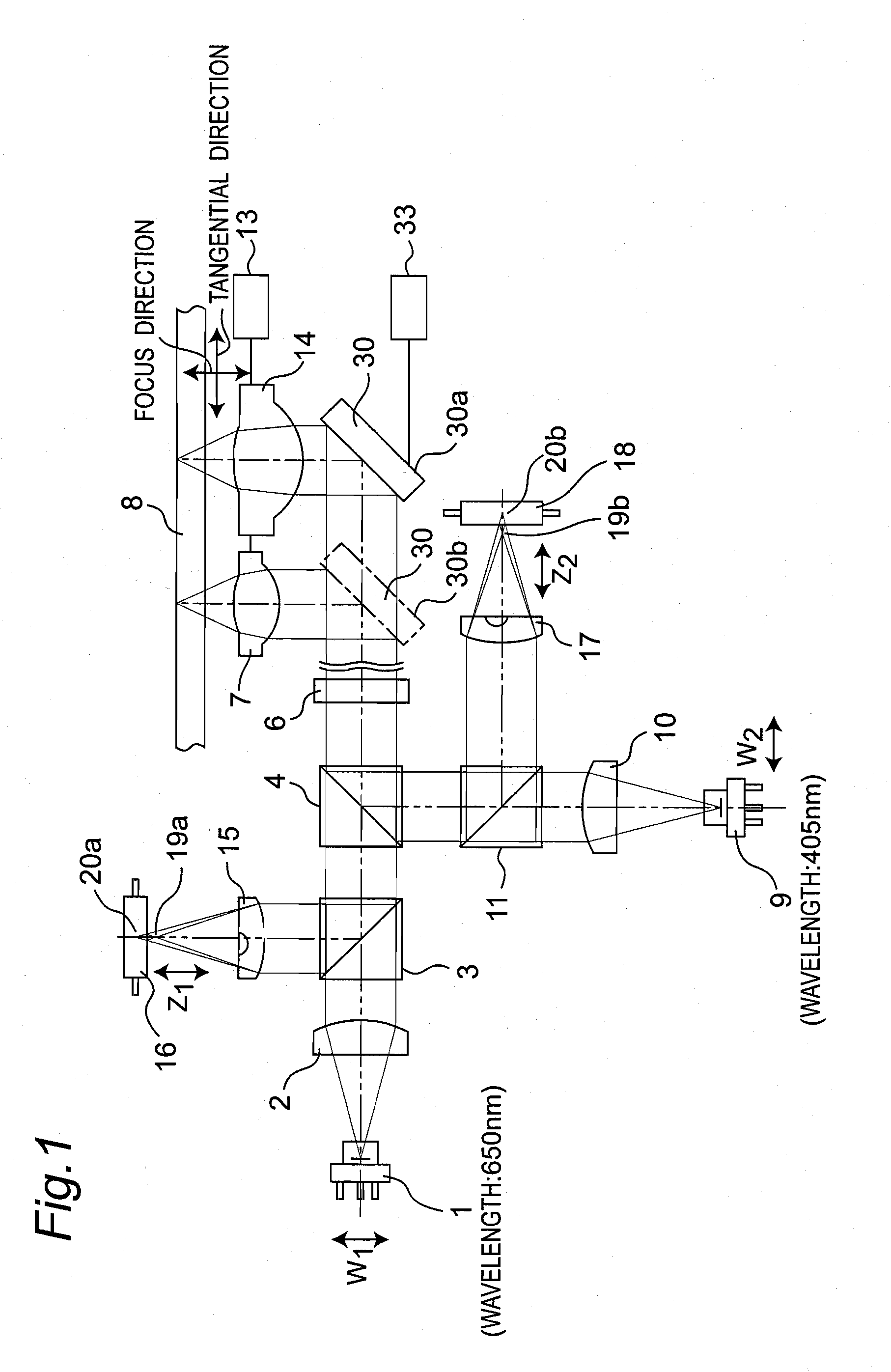

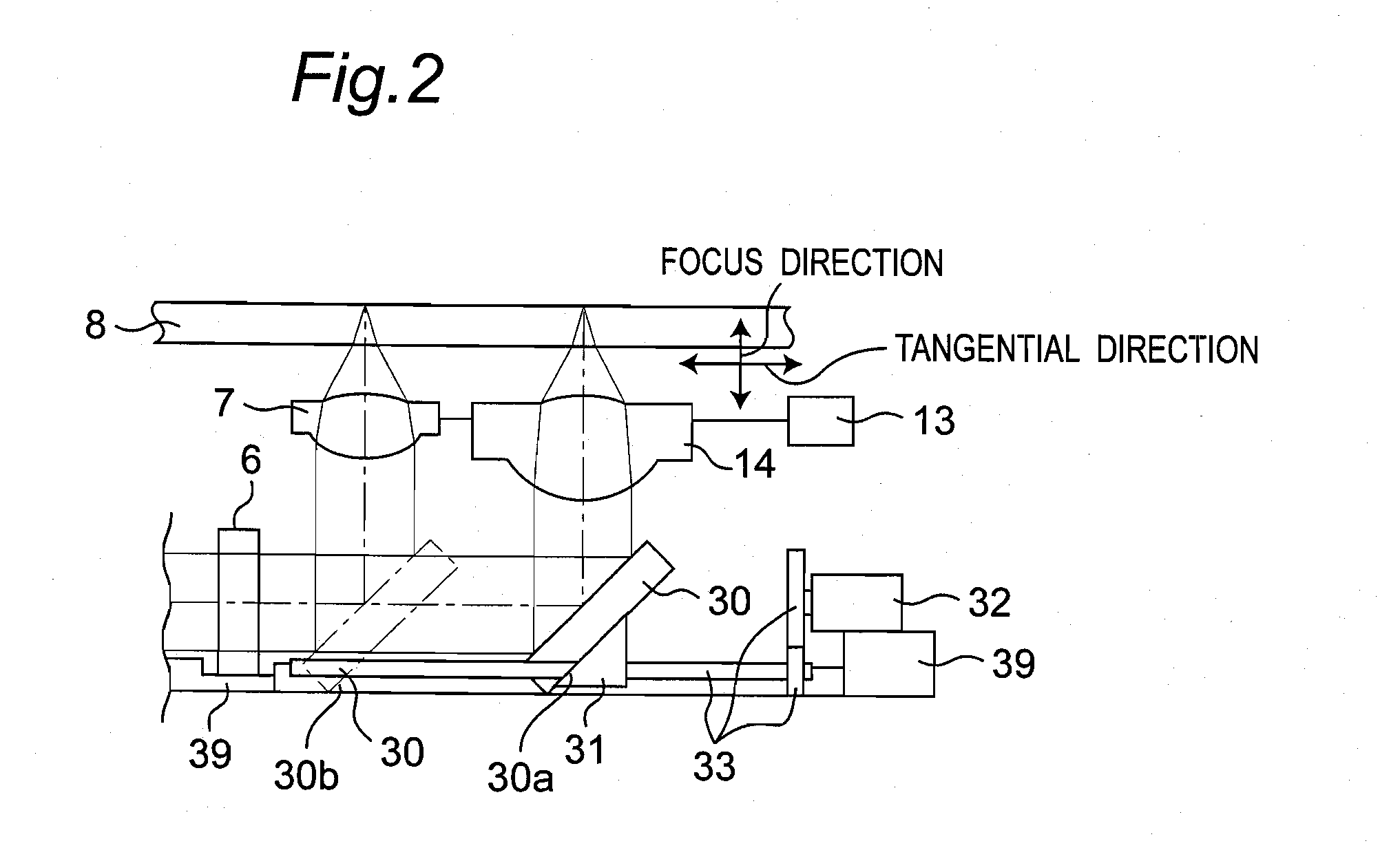

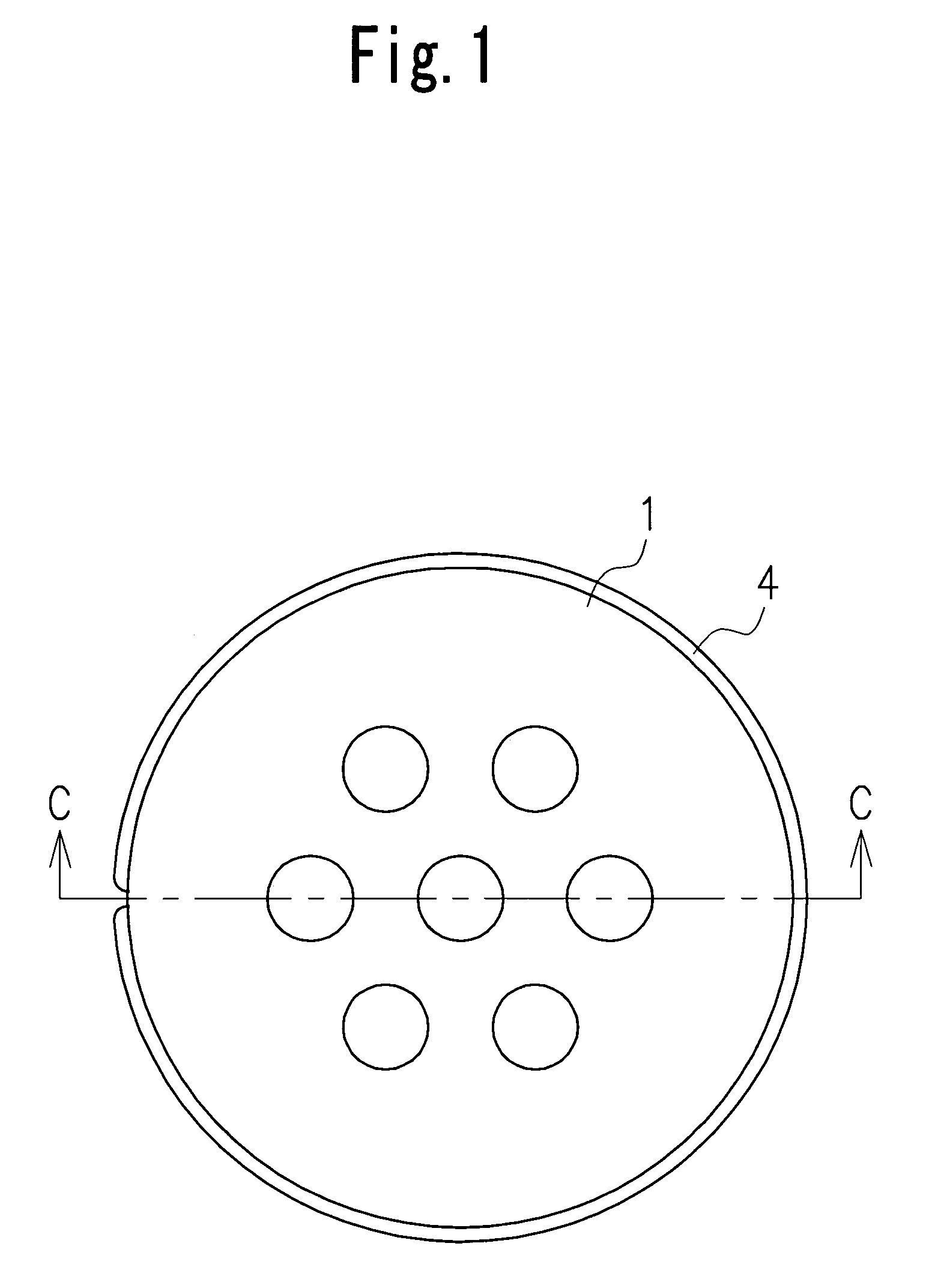

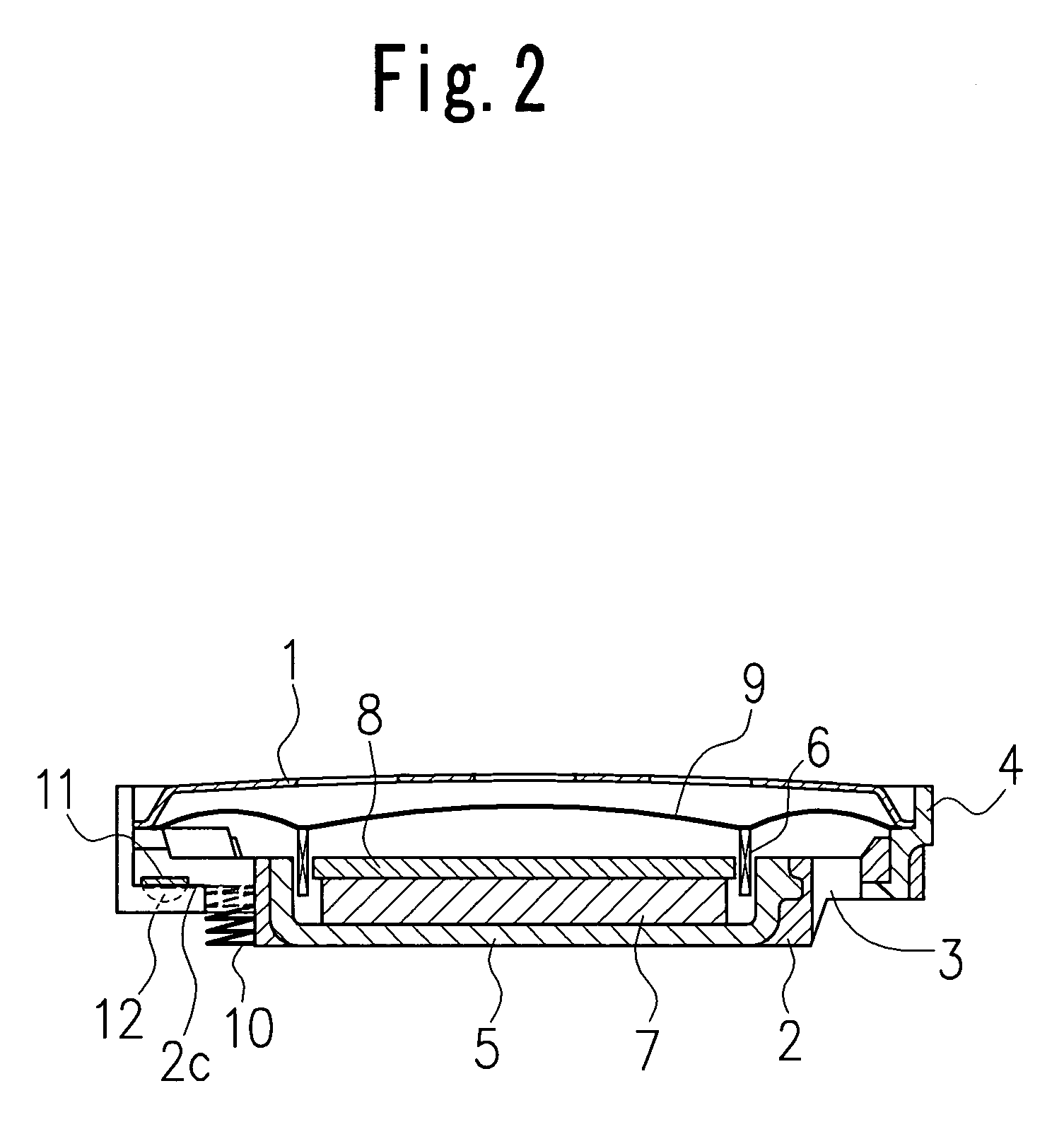

Optical head device for forming light spot on disc-shaped information medium

ActiveUS20090201789A1Increase heightAvoid collisionRecord information storageOptical beam guiding meansLight spotLuminous flux

An optical head device has at least one upward-reflecting mirror, objective lenses, an objective lens actuator, and a moving mechanism. The upward-reflecting mirror receives an incident luminous flux having a wavelength emitted from a semiconductor, and changes its direction. The objective lenses having mutually different numerical apertures condenses the luminous flux whose direction has been changed by the upward-reflecting mirror to radiate a condensed luminous flux onto an information recording medium. The objective lens actuator moves the objective lenses in the focus direction of the information recording medium so that the luminous flux incident on the information recording medium becomes in a focused state. The moving mechanism moves the upward-reflecting mirror so that the luminous flux is incident on the information recording medium via any one of the objective lenses.

Owner:PANASONIC CORP

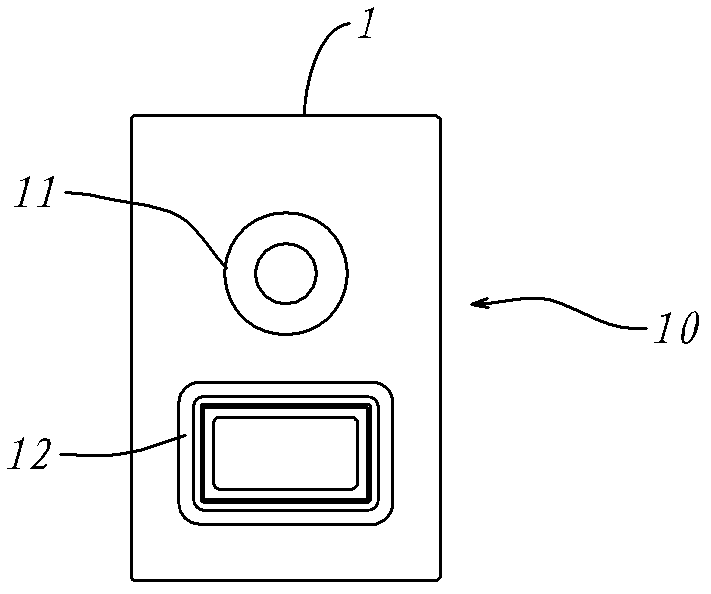

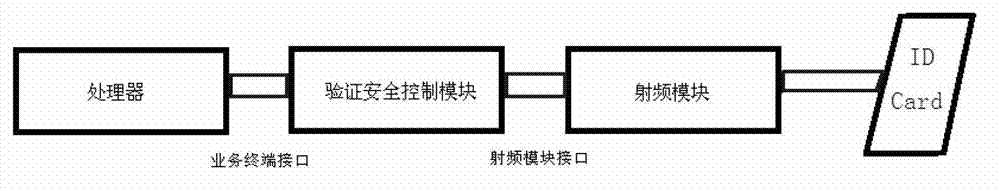

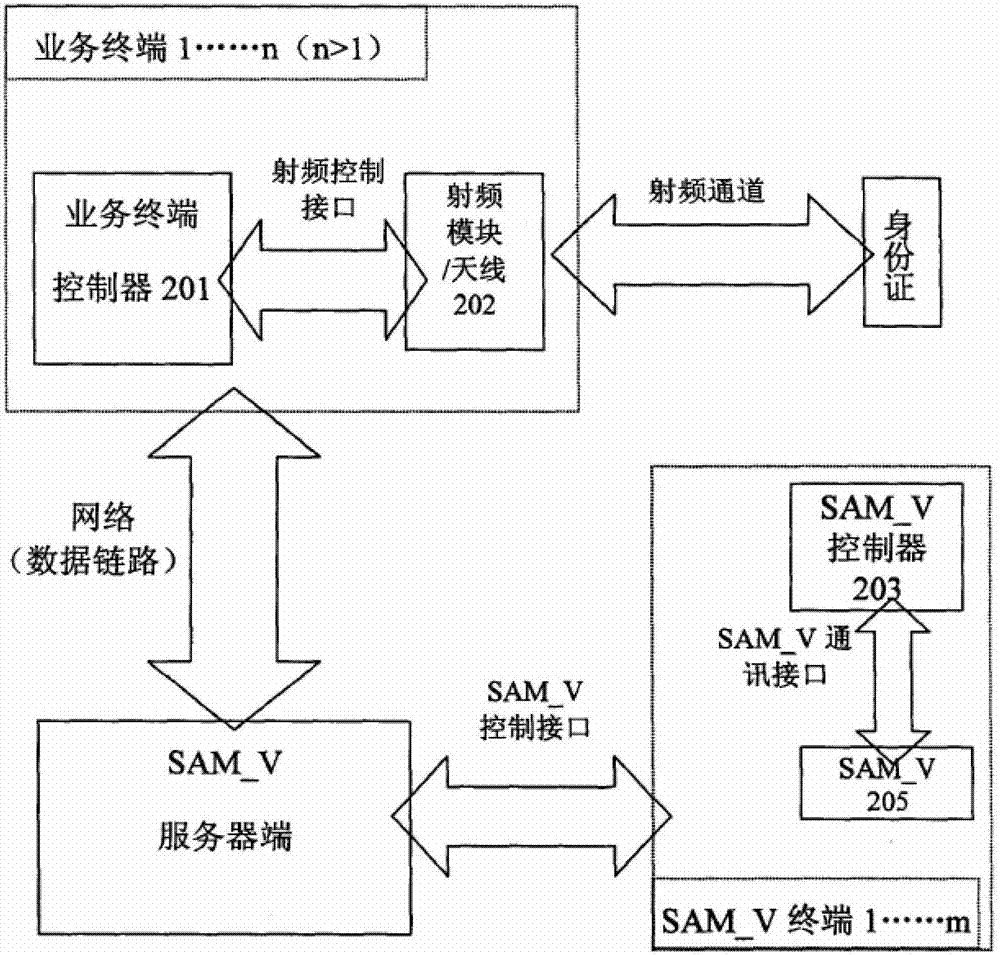

SAM-V side and service side separated identity document reading and testing system and method thereof

InactiveCN103164681AThin and compactLow costSensing record carriersTransmissionComputer moduleVerification system

The invention relates to an SAM-V side and service side separated identity document reading and testing system which comprises an SAM-V side and a service side. The service side comprises a service side processor, a radio frequency module and a display module, wherein the radio frequency module and the display module are connected with the service side processor. The SAM-V side comprises an SAM-V module and an SAM-V side processor connected with the SAM-V module. The SAM-V side processor and the service side processor are connected through a wireless receiving and sending module in an interactive mode. The SAM-V side and service side separated identity document reading and testing system has the advantages that the service side and the SAM-V side are respectively assembled on two products so that the service side is small, exquisite, light and thin in size and convenient to hold, meanwhile, cost of a server is saved, construction and use cost is greatly reduced; and in addition, according to a multi-network interactive mode, the SAM-V side and service side separated identity document reading and testing system is convenient and flexible to use.

Owner:上海盛本智能科技股份有限公司

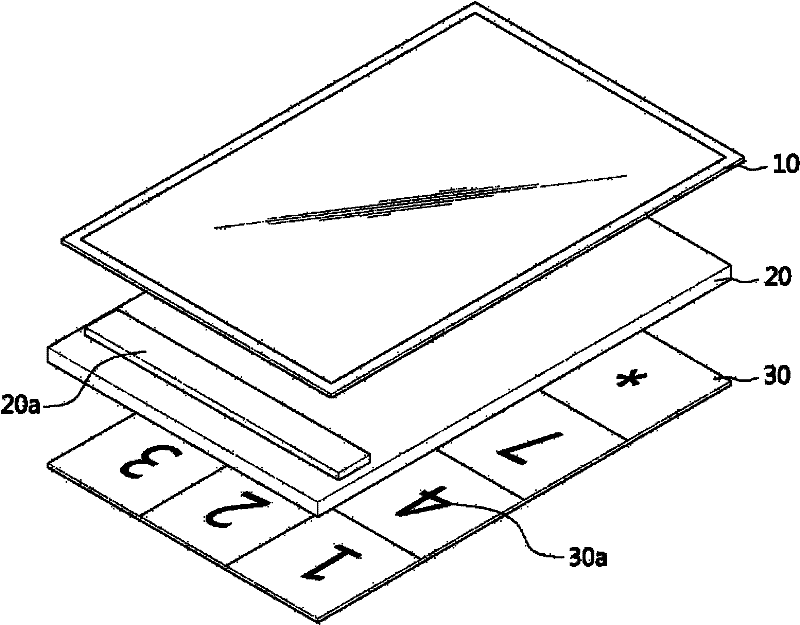

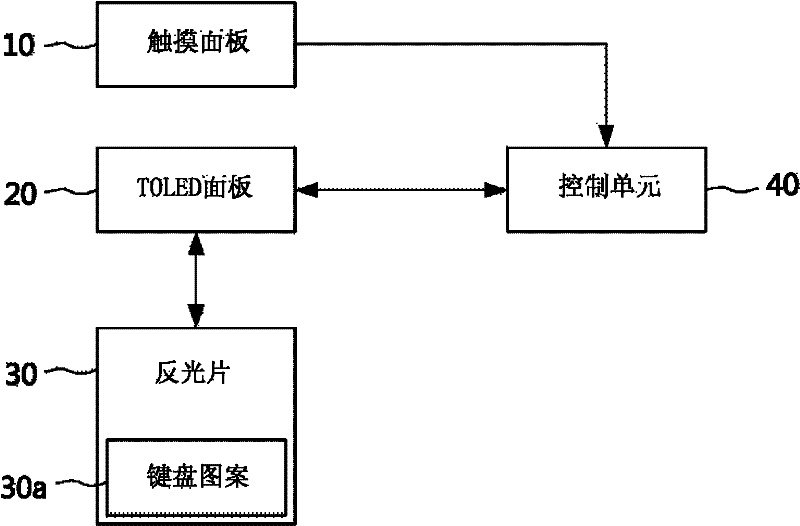

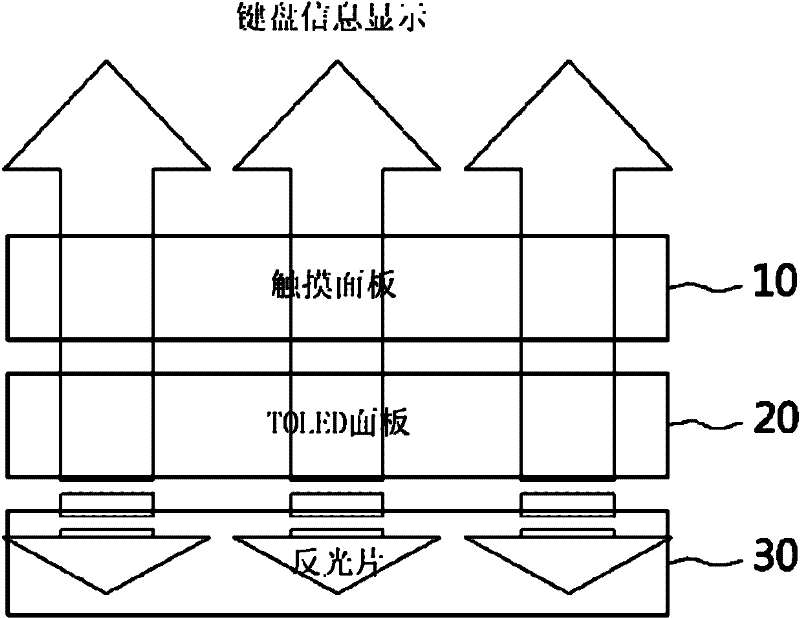

Keypad apparatus, mobile device comprising same, and keypad control method

InactiveCN102177488AThin and compactAchieve double-sided light emissionInput/output for user-computer interactionSolid-state devicesEngineeringMobile device

Disclosed is a keypad apparatus wherein an OLED or a TOLED (Transparent OLED) is employed to make the structure of a product slim and compact. The keypad apparatus of the present invention comprises a TOLED panel which is arranged beneath a touch panel, and a reflection sheet which is arranged beneath the TOLED panel, and which is patterned with keypad information to reflect and display the keypad information corresponding to the pixels of the TOLED panel which have emitted light. The touch panel and the TOLED panel are electrically connected to a controller. The controller senses an electrical signal for a touch point on the touch panel, and emits light from relevant pixels of the TOLED panel corresponding to the touch point.

Owner:NEOVIEWKOLON

Flexible pressure sensor and preparation method thereof

PendingCN113340480AWide linear rangeExpand detection rangeForce measurement using piezo-resistive materialsEngineeringProtection layer

The invention belongs to the technical field of pressure detection, and particularly relates to a flexible pressure sensor and a preparation method thereof. The flexible pressure sensor comprises a flexible substrate, a patterned electrode in close contact with the flexible substrate, a signal transmission electrode electrically connected with the patterned electrode, a pressure-sensitive layer covering the patterned electrode, and a protective layer covering the pressure-sensitive layer or the signal transmission electrode. The preparation method comprises the following steps: S1, selecting a flexible film or a textile fabric as a flexible substrate; S2, manufacturing a patterned electrode layer; S3, preparing a pressure-sensitive layer; S4, preparing a first protection layer; S5, manufacturing a signal transmission electrode; and S6, preparing a second protection layer. The patterned electrode, the pressure-sensitive layer and the protective layer are all directly processed layer by layer through printing or etching, so that the processes of fitting processing, packaging and the like are omitted, the deformation of a film material can be effectively avoided, and the sensor is light, thin, small and exquisite in size, low in power consumption, suitable for application requirements in various occasions and high in universality.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

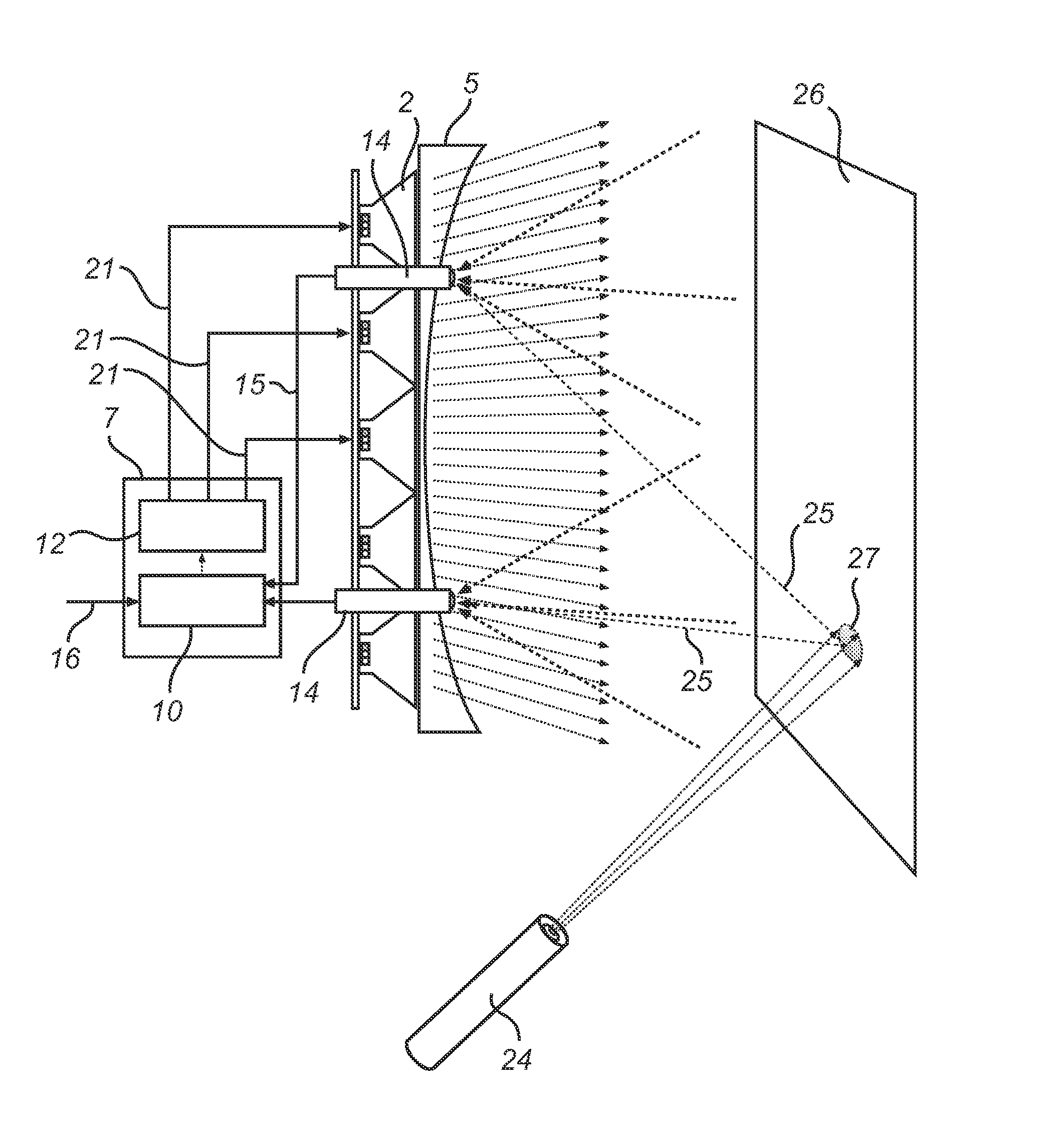

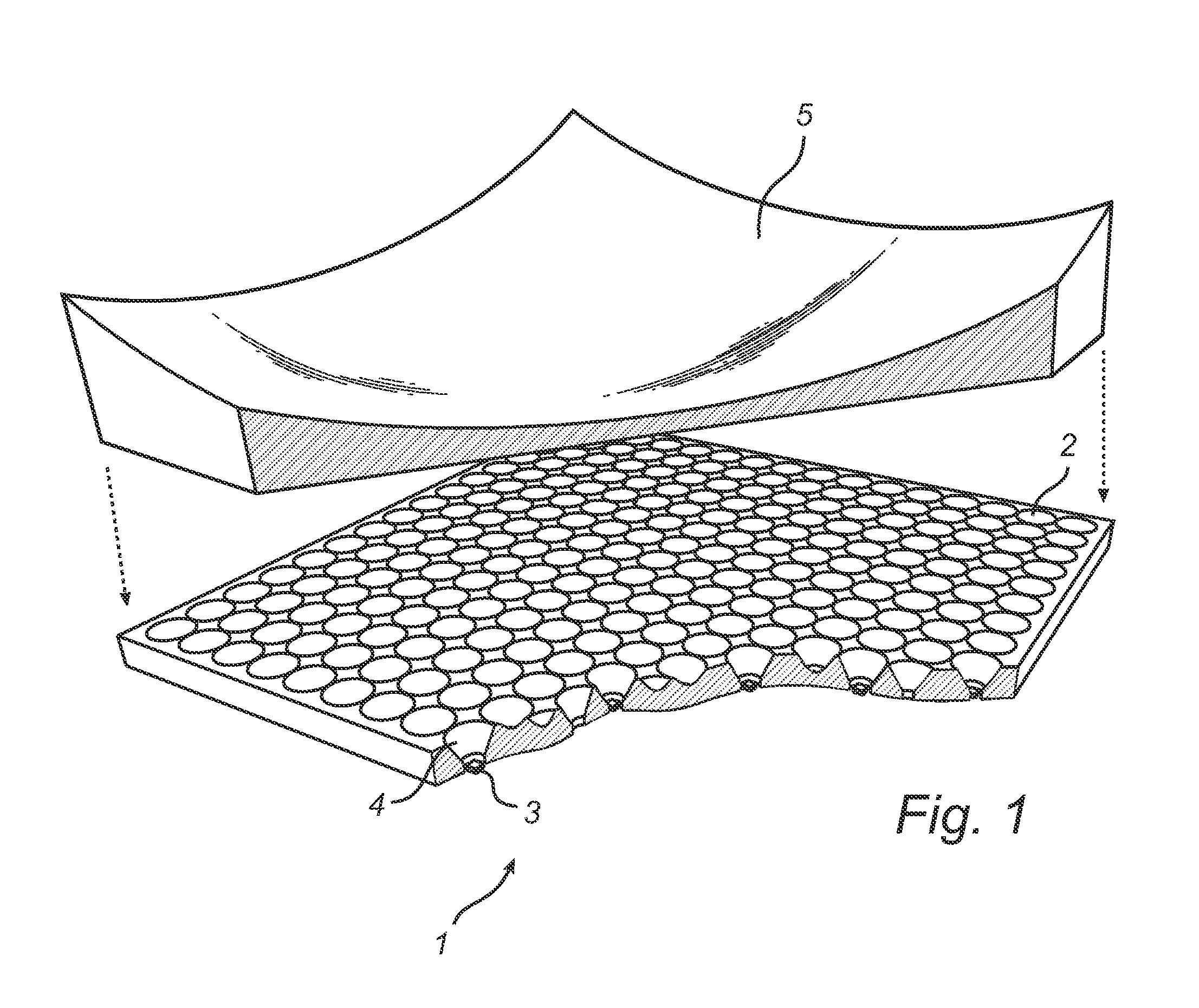

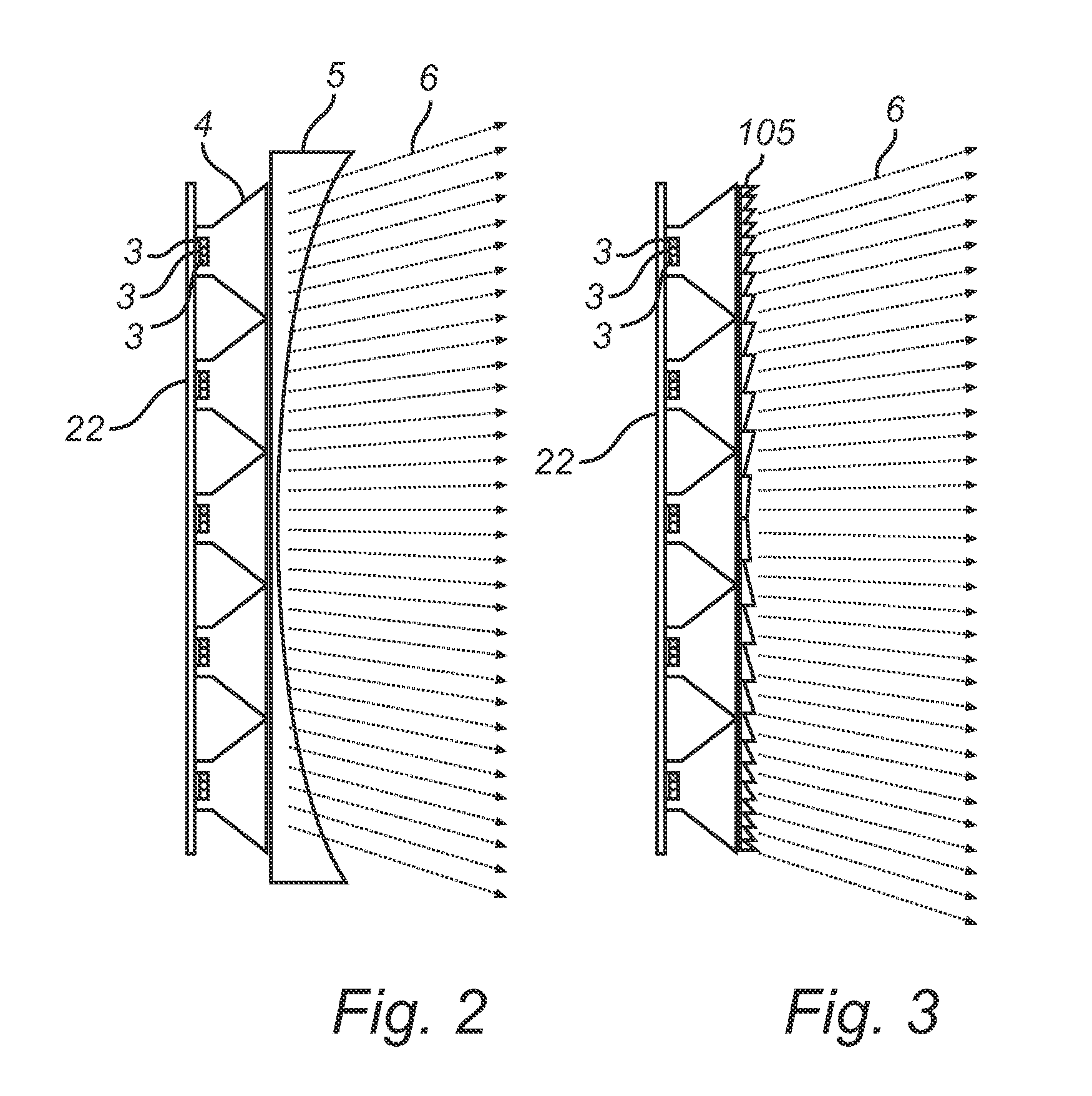

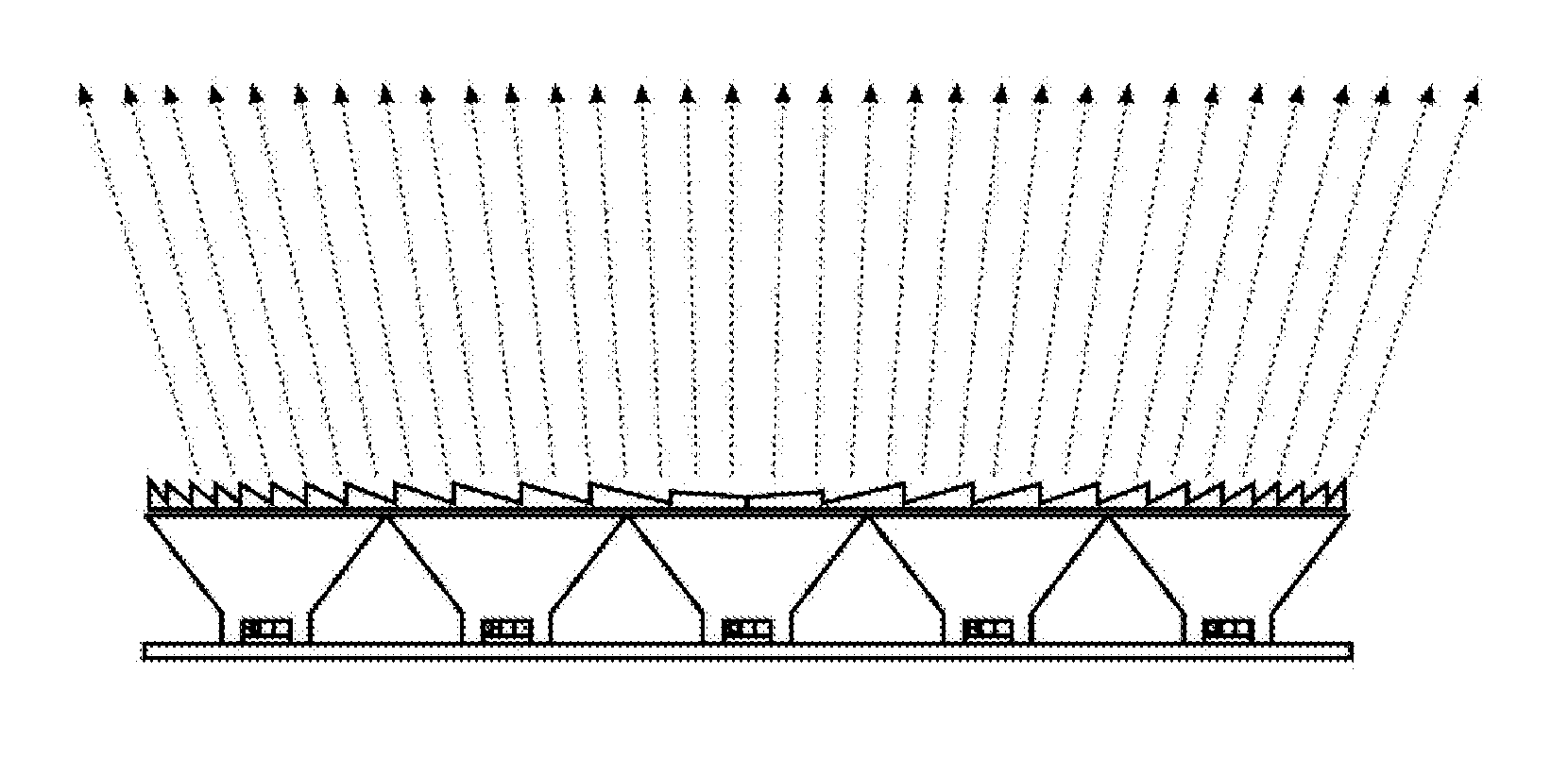

Controllable lighting system

InactiveUS8939605B2Thin and compactAchieve compactPlanar light sourcesLight source combinationsEffect lightEngineering

Owner:SIGNIFY HLDG BV +1

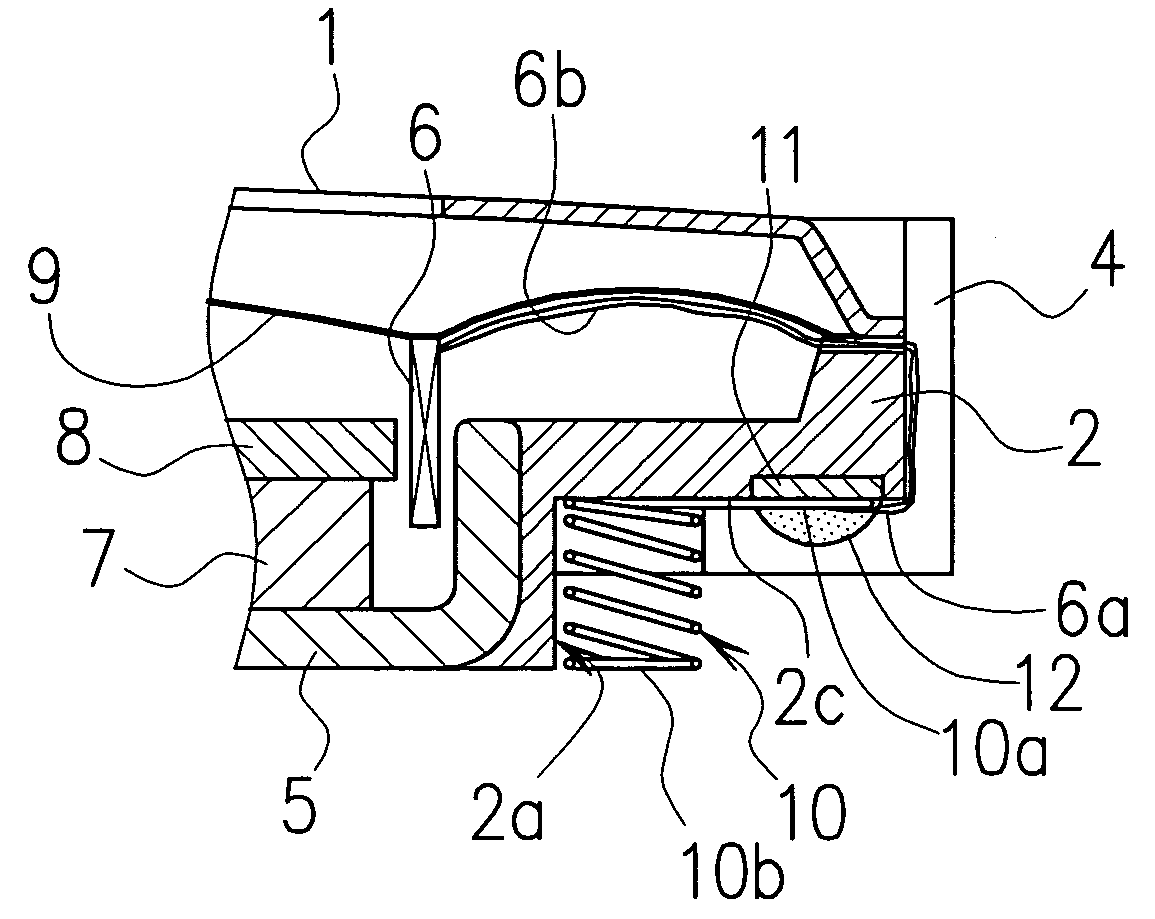

Electrical acoustic converter

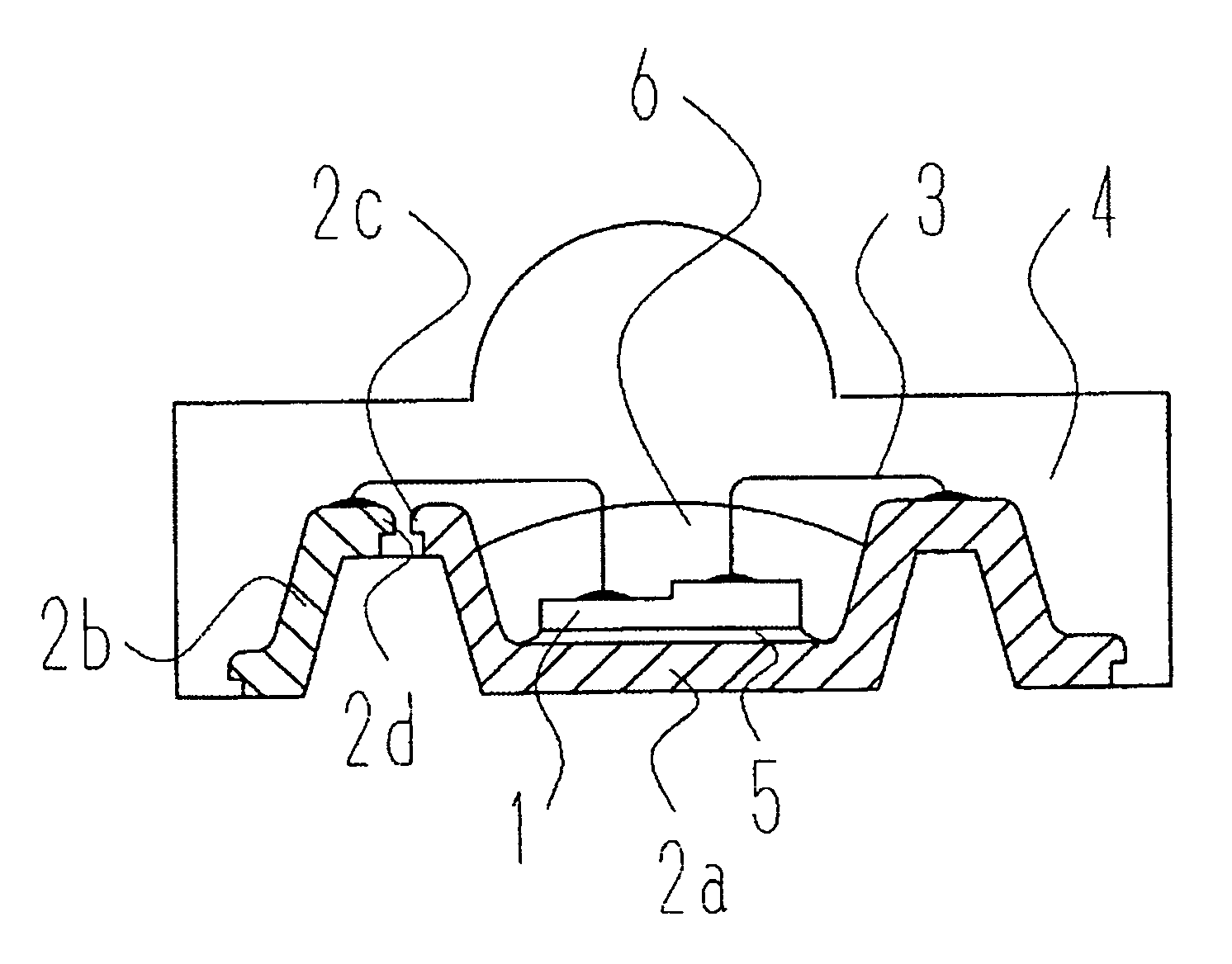

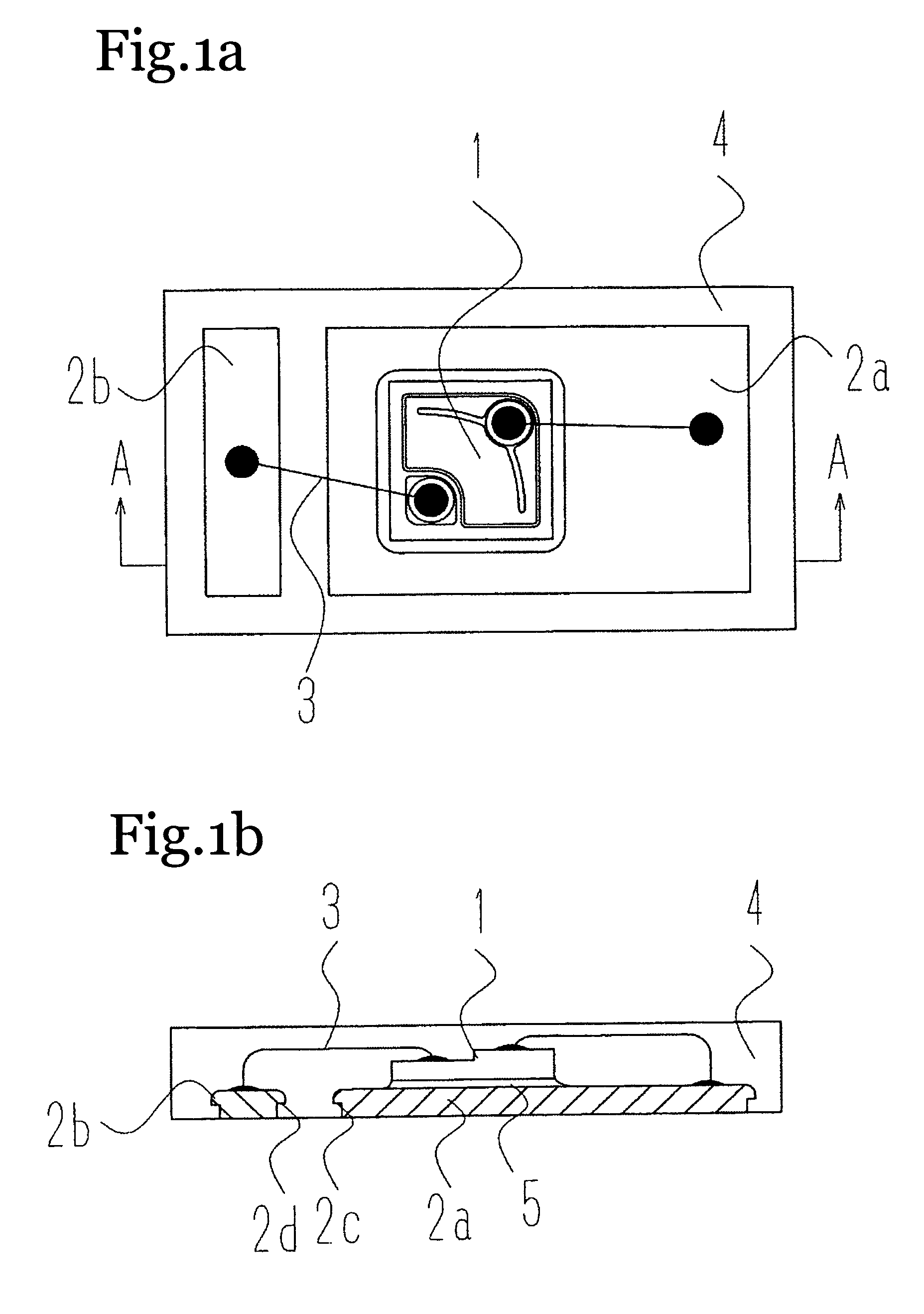

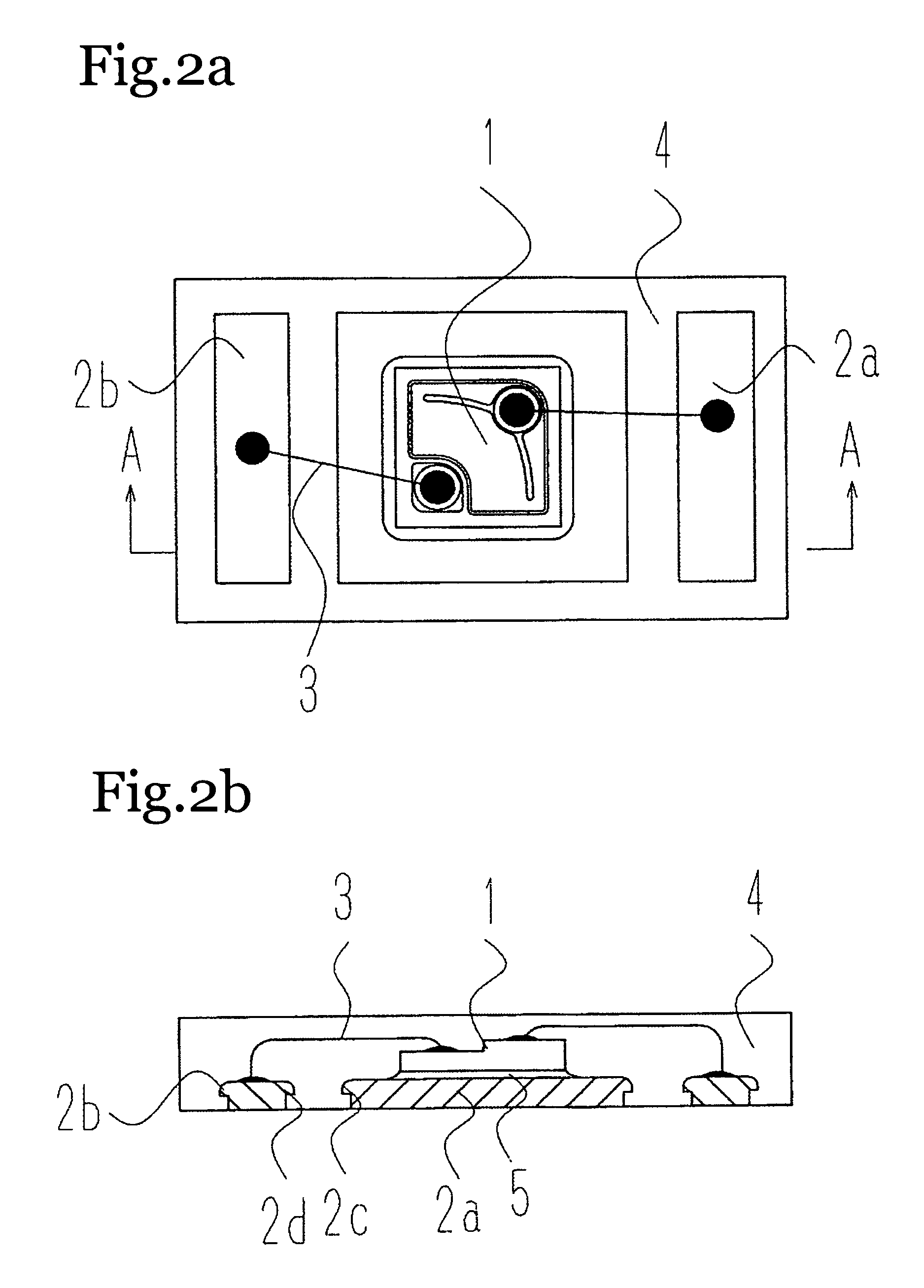

InactiveUS7010142B2Thin and compactSound producing devicesFrequency/directions obtaining arrangementsLead frameMagnet

Disposed within a space formed between a base cover (2) and a top cover (1) attached to the base cover (2) is an electromagnetic sound generating part which has a diaphragm (9) attached to the base cover (2) and a drive part causing the diaphragm (9) to vibrate. The drive part includes a yoke (5) fitted in the base cover (2), a magnet (7) mounted on the yoke (5), a top plate (8) mounted on the magnet (7) and an exciting coil (6) disposed to oppose to side surfaces of the magnet (7) and top plate (8). Coil contact springs (10) are contained into housings (2a) provided on portions of the base cover inside than an outer peripheral edge of the diaphragm. The coil contact springs (10) act to connect the exciting coil (6) with an outside power source. The base cover (2) is provided with a pair of connecting pieces (11) or lead frames which are used to connect the exciting coil (6) and coil contact springs (10). The connecting pieces (11) are embedded in the base cover (2).

Owner:CITIZEN ELECTRONICS CO LTD

Controllable lighting system

ActiveUS20150201476A1Thin and compactAchieve compactPlanar light sourcesLight source combinationsEffect lightEngineering

A lighting system comprising a plurality of controllable light emitting elements is disclosed. The lighting system further comprising a spreading optical element arranged in front of the plurality of light emitting elements to shape the light emitted from the lighting elements, and a controller for varying a light emission angle range of light emitted from the spreading optical element by controlling each of the plurality of controllable light emitting elements. This allows the light emitted from the spreading optical element to be varied without varying any physical parts of the lighting system, because the controller now controls each of the light emitting elements, by e.g. dimming one or more of the light emitting elements or by switching one or more of the light emitting elements off.

Owner:SIGNIFY HLDG BV

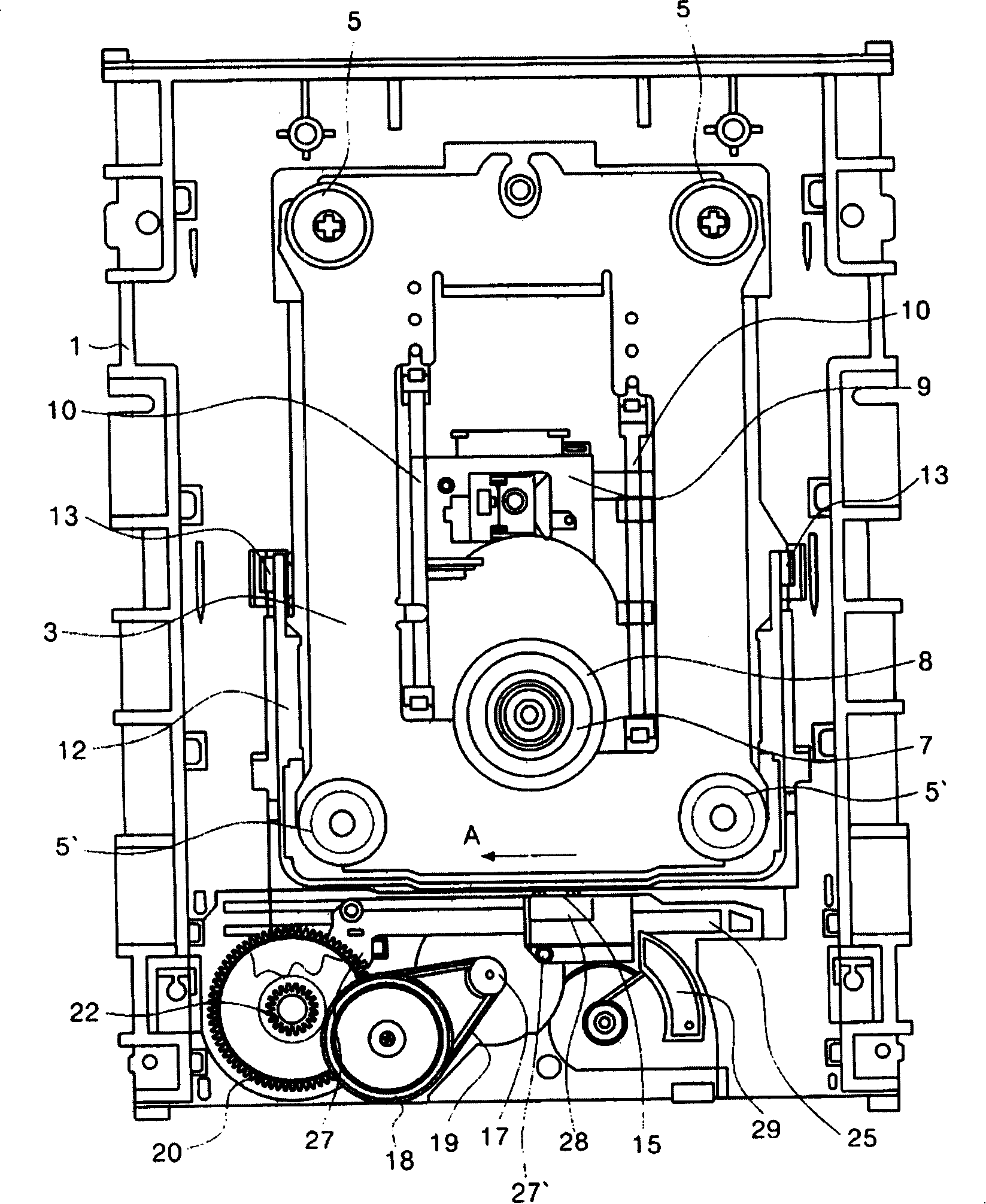

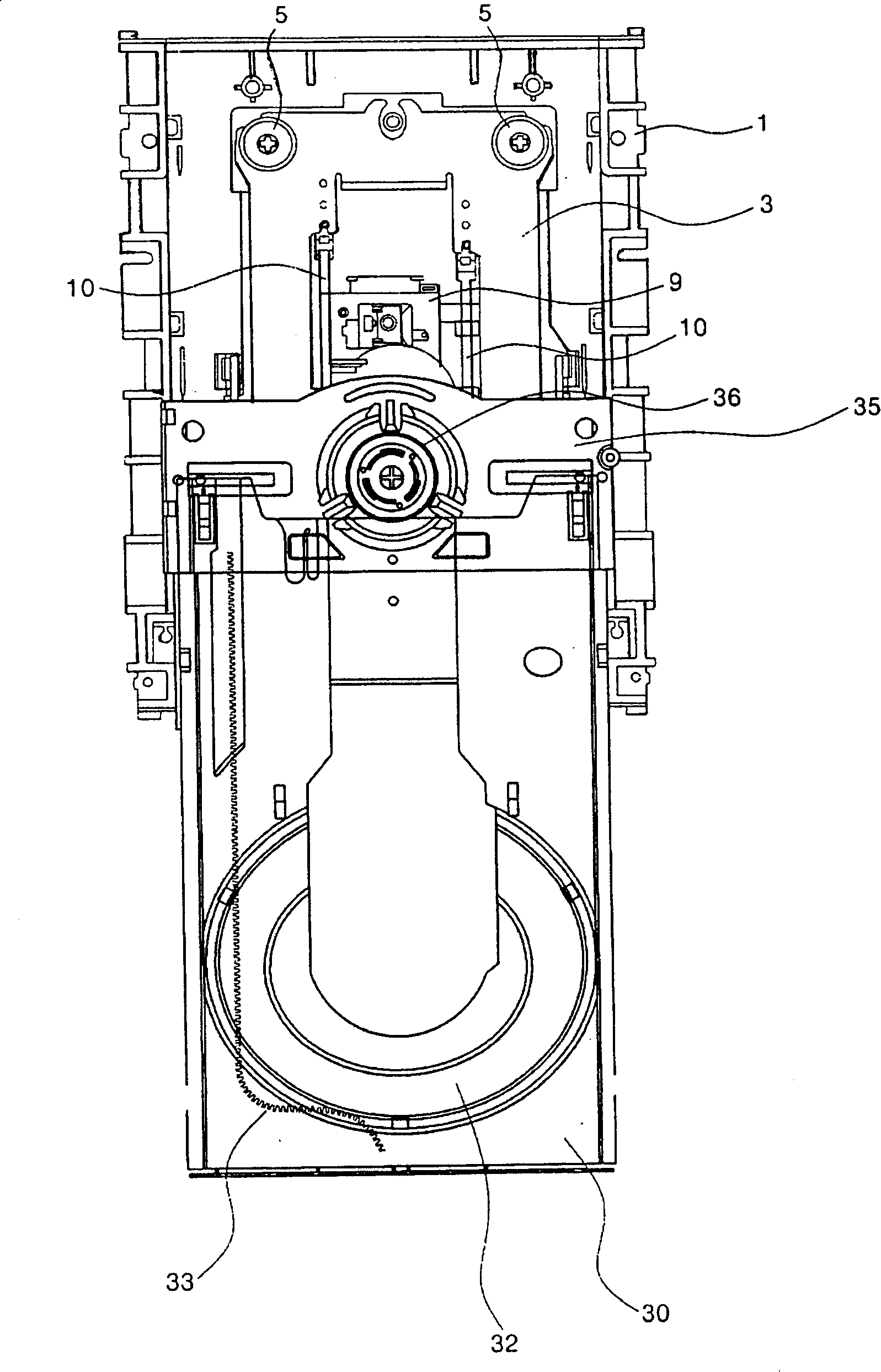

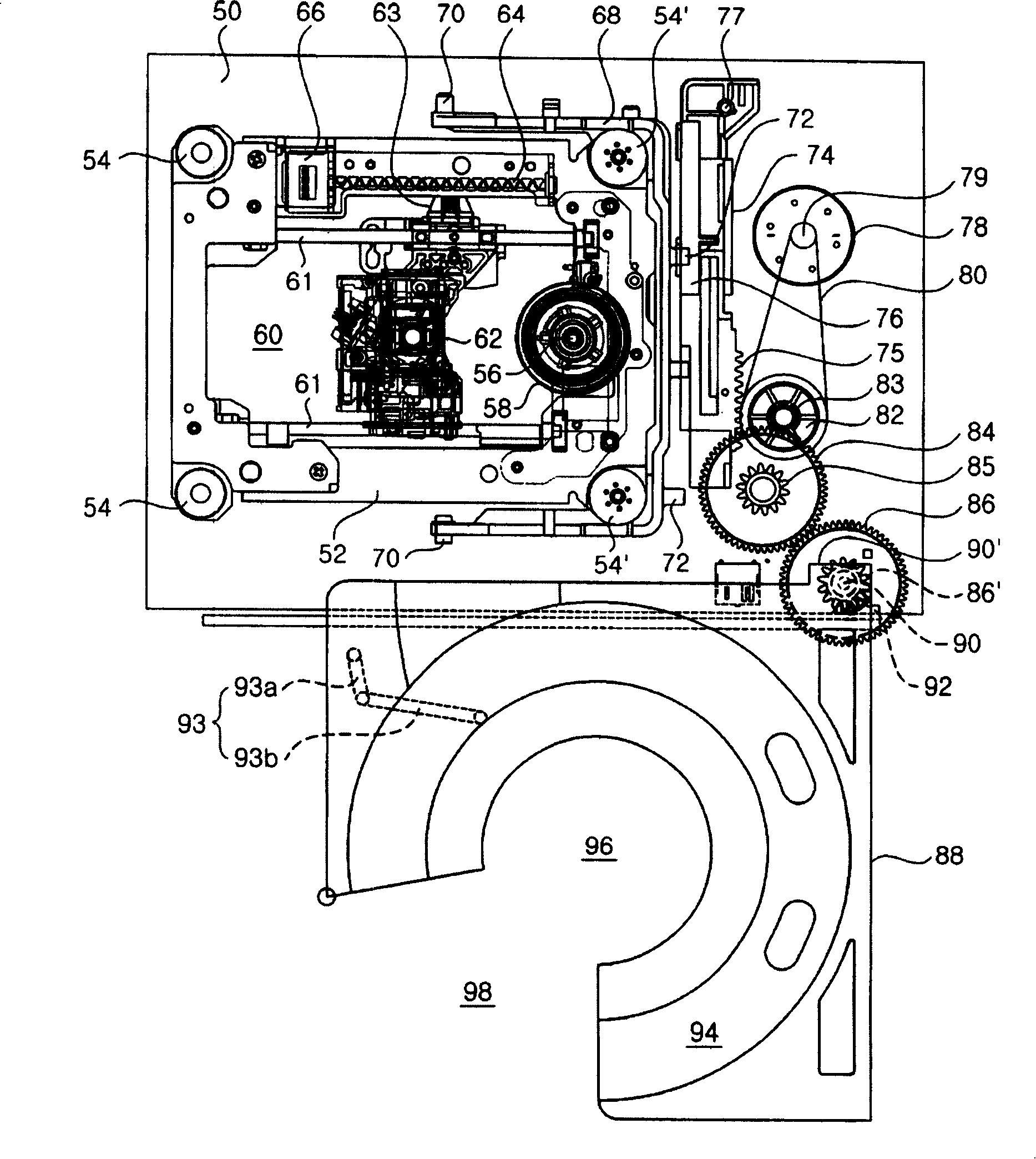

Optical disk drive

The invention relates to a compact disc driver, which comprises a main base, a light picker for allowing the front end of the main base to move left and right, a light picker base with a rotary plate for revolving the compact disc, wherein the light picker base is arranged on one side of the main base to allow itself to rotate, and a tray which loads and unloads the compact disc while moving according to the rotation toward inside and outside of the main base, and a loading electric motor which is arranged on the main base and allows the tray to rotate and the end of the light picker base with the rotary plate to ascend or descend. Compared with the amplitude of the main base in the front and back, the amplitude of the main base on the left and right is larger. The compact disc driver of the invention can minimize the length in the front and back and can be applicable to thin and small electronic products such that the loading time and unloading time of the compact disc are correspondingly reduced.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com