Piezoelectric pump and fluid transferring system

a fluid transfer system and piezoelectric pump technology, applied in water installations, thin material processing, construction, etc., can solve the problems of difficult to accurately manufacture a piezoelectric pump capable of stable fluid transfer, difficult to integrate high density, and difficult to combine the use of piezoelectric pump and component, so as to achieve stable fluid transfer, maintain uniform stress in the motion part, and achieve the effect of piezoelectric pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0185]The following describes the present invention in more detail by way of examples, though the present invention is not limited to these examples.

[0186](Effect Verification Test Based on Differences in First Substrate Making Method)

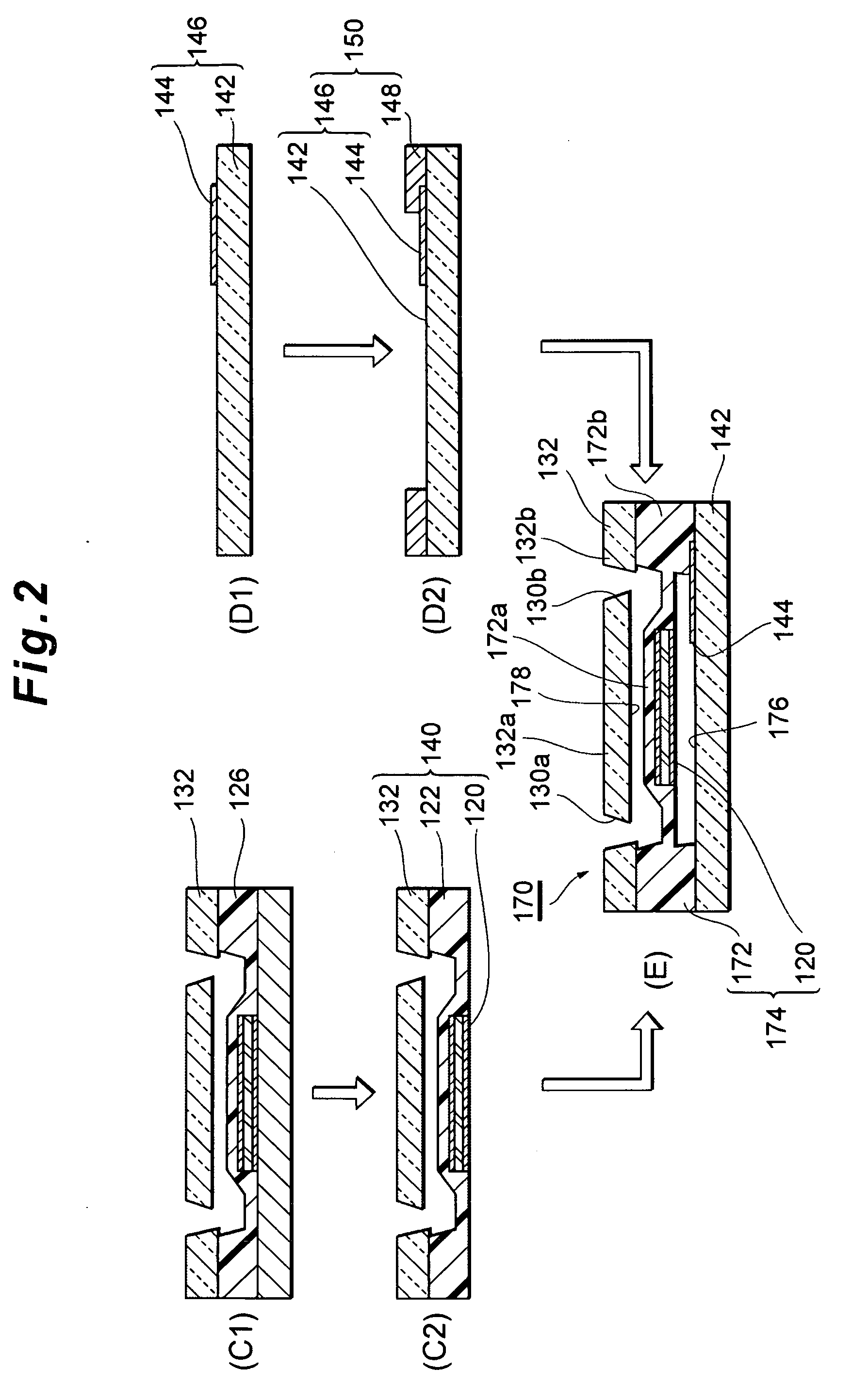

[0187]In this test, to verify the displacement amount of the piezoelectric element in the piezoelectric pump, samples shown in FIGS. 15A and 15B were made. First, the making of the sample shown in FIG. 15A according to an example was started by laminating a lower electrode layer (not illustrated, Pt as a material, 0.1 μm in thickness), a piezoelectric body layer (not illustrated, PZT as a material, 2 μm to 2.5 μm in thickness), and an upper electrode layer (not illustrated, Pt as a material, 0.1 μm in thickness) on a Si substrate of 400 μm in thickness by vapor deposition and sputtering, in this order. Next, the lower electrode layer, the piezoelectric body layer, and the upper electrode layer were patterned to a planar shape shown in FIG. 15C by ion m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com