Patents

Literature

51results about How to "Small product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

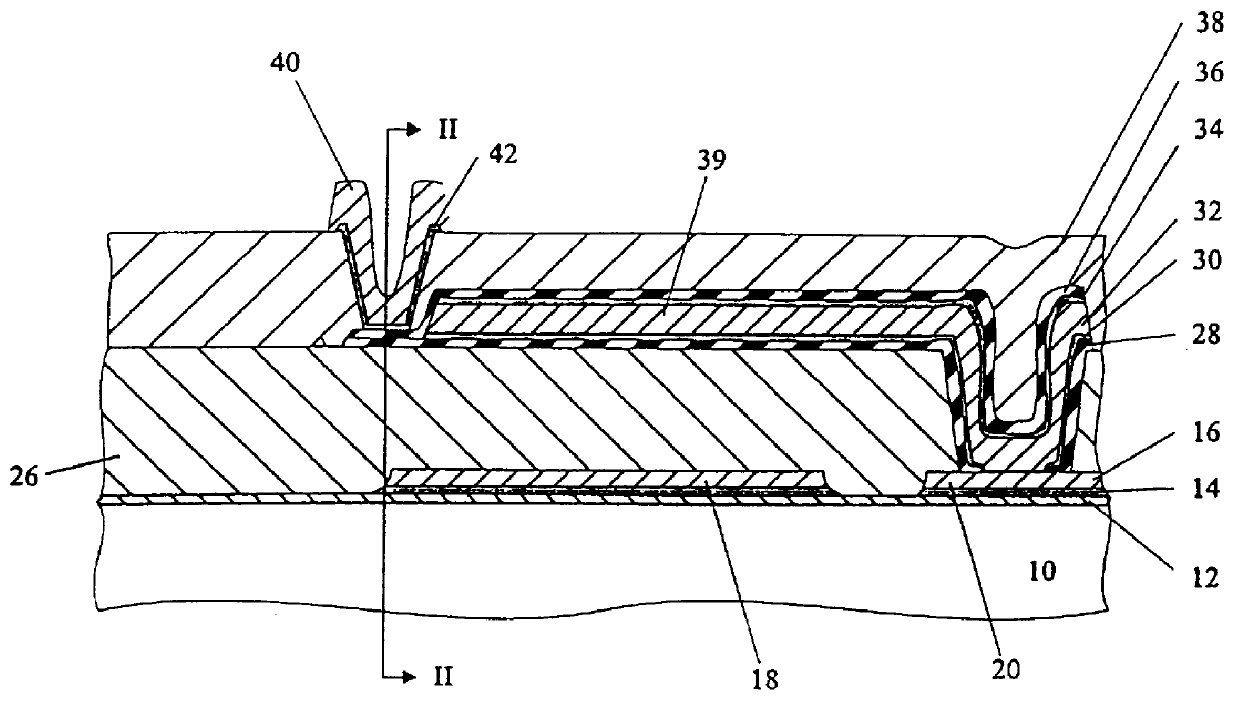

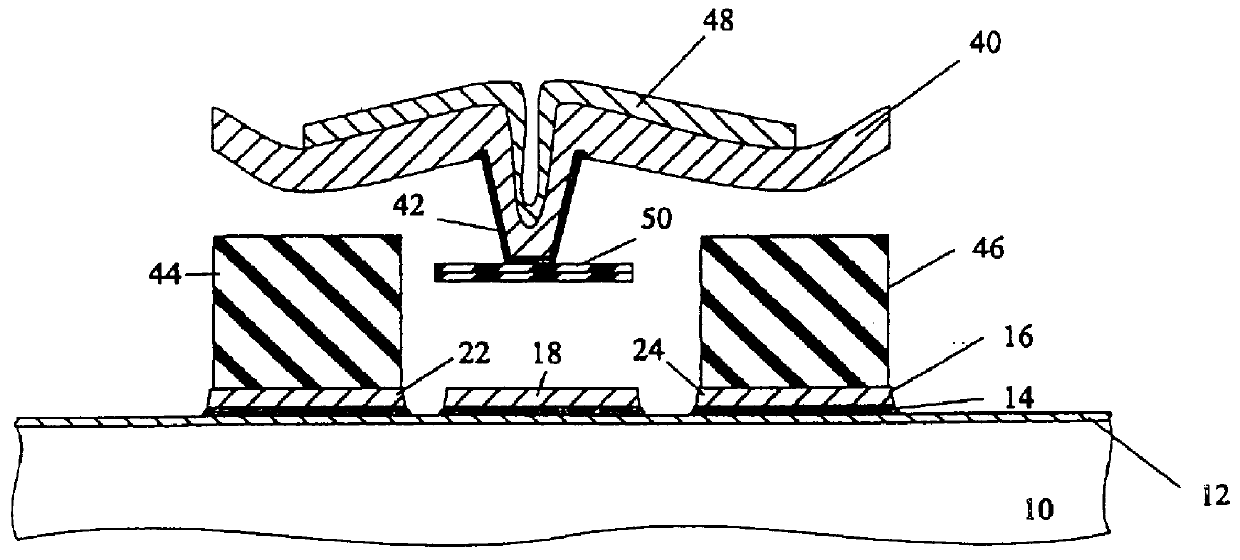

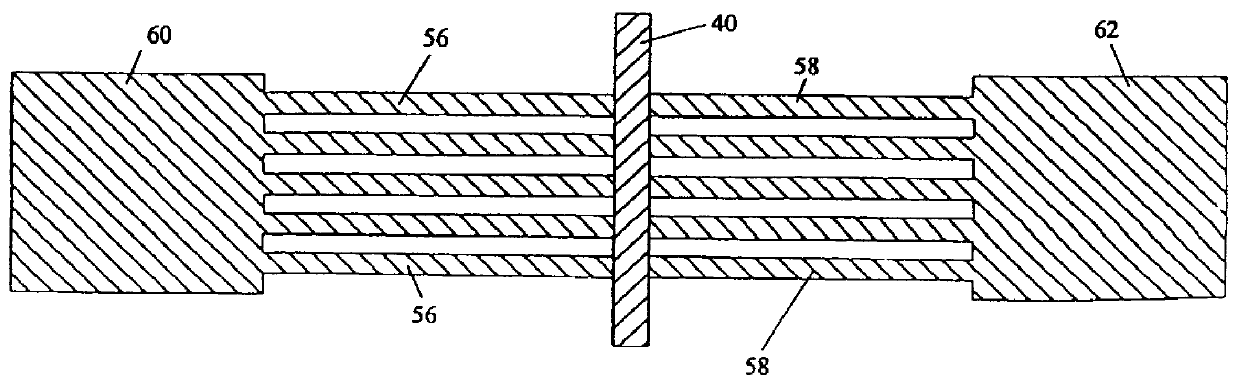

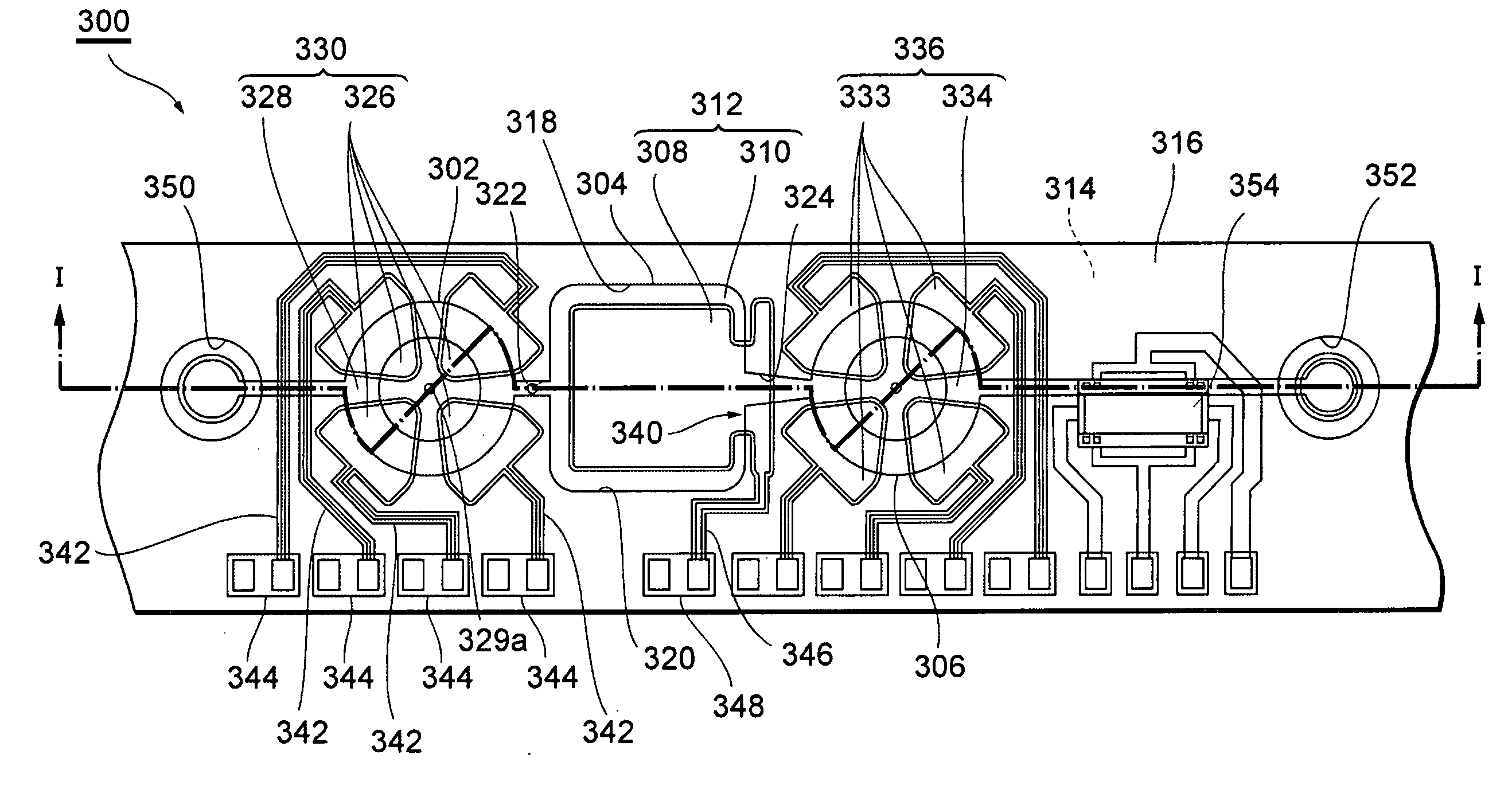

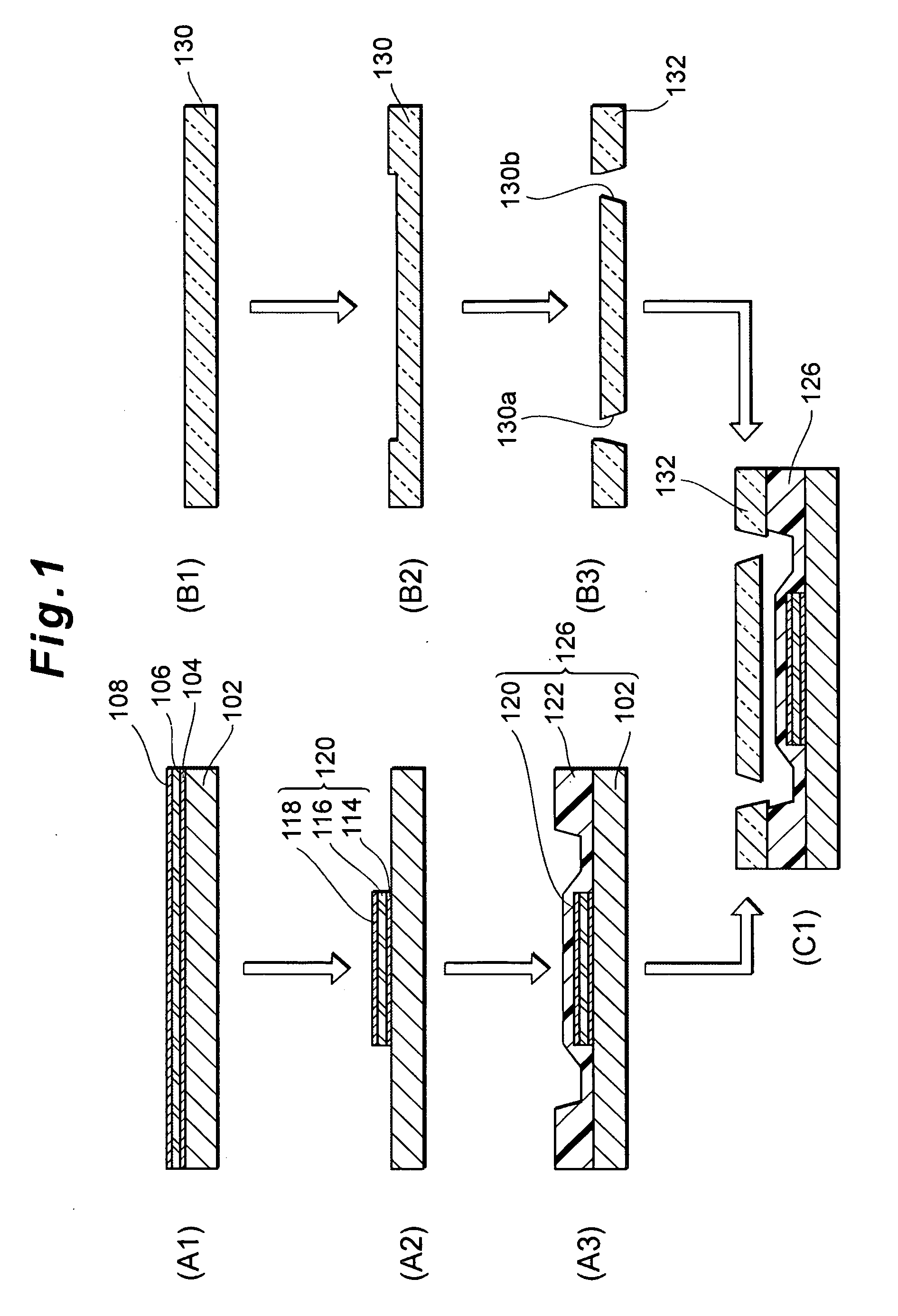

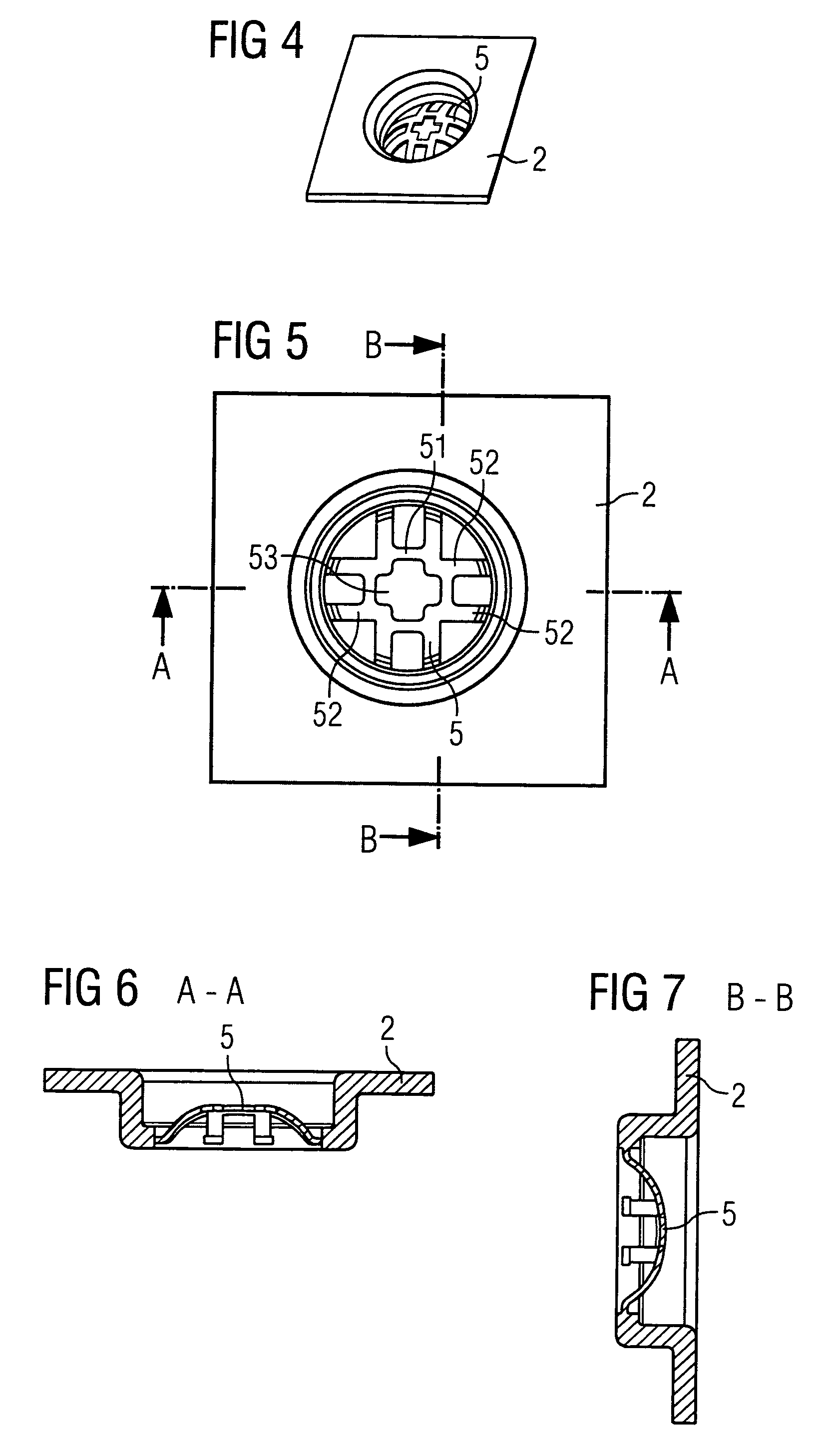

Method for manufacturing a micromechanical relay

InactiveUS6162657ASmall productSmall sizeElectrostatic/electro-adhesion relaysDecorative surface effectsEtchingEngineering

PCT No. PCT / EP97 / 06174 Sec. 371 Date May 11, 1999 Sec. 102(e) Date May 11, 1999 PCT Filed Nov. 6, 1997 PCT Pub. No. WO98 / 21734 PCT Pub. Date May 22, 1998A method of producing a micromechanical relay comprises the steps of providing a substrate including a conductive fixed electrode in or on said substrate. A sacrificial layer and a conductive layer are applied and the conductive layer is structured so as to define a beam structure as a movable counterelectrode opposite said fixed electrode. A contact area is applied, the conductive layer extending between an anchoring region and the contact area and being insulated from said contact area. Subsequently, the sacrificial layer is removed by means of etching so as to produce the beam structure comprising a movable area and an area secured to the anchoring region on the substrate. The beam structure is defined such that etch access openings in said beam structure are structured such that the size of the area covered by the etch access openings used for etching the sacrificial layer increases from the area of the beam structure secured to the substrate to the movable area of the beam structure so that the etching of the sacrificial layer is controlled in such a way that the portion of the sacrificial layer arranged below the movable area of the beam structure is etched faster than the portion of the sacrificial layer arranged in the area of the anchoring region.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

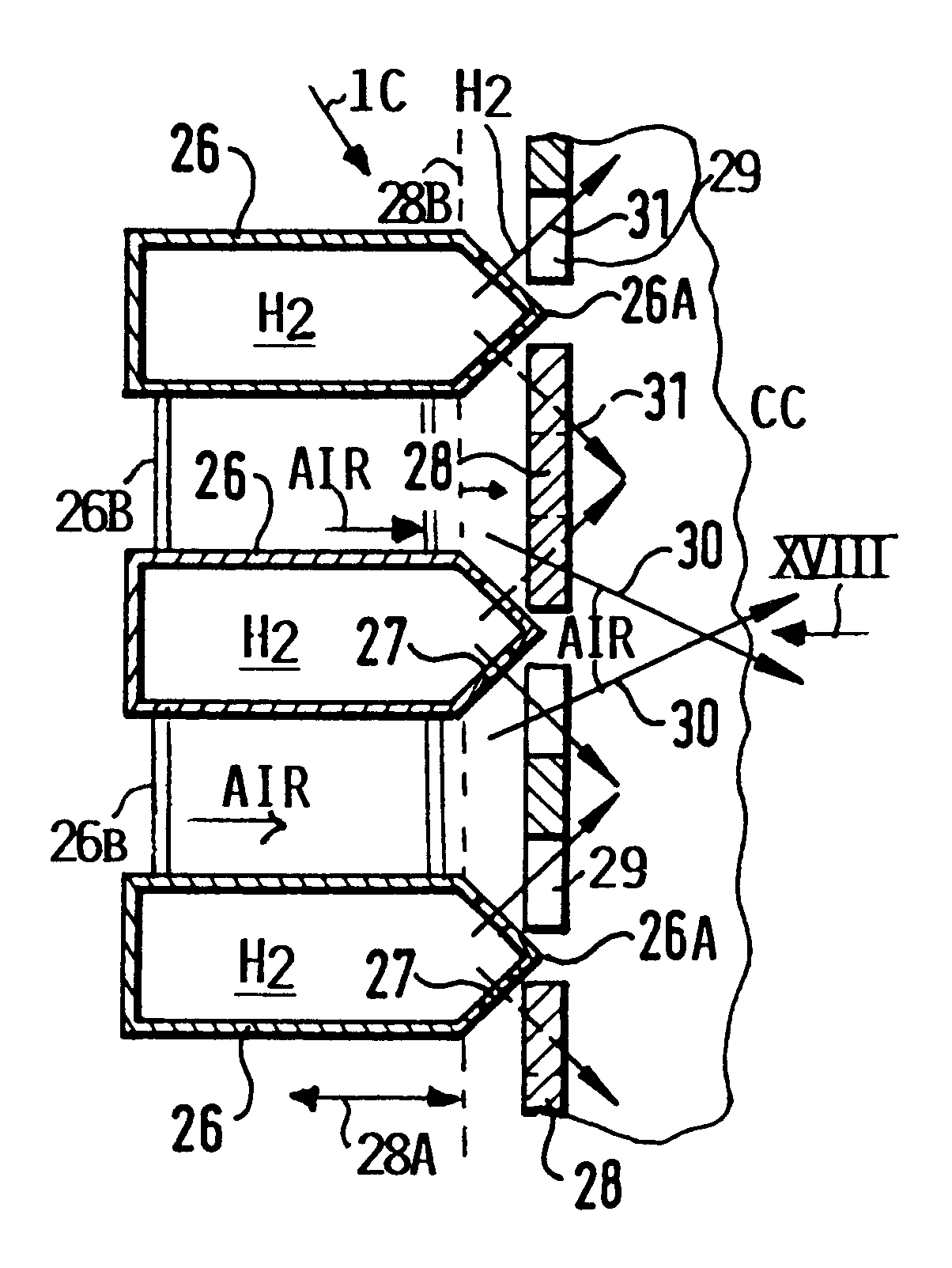

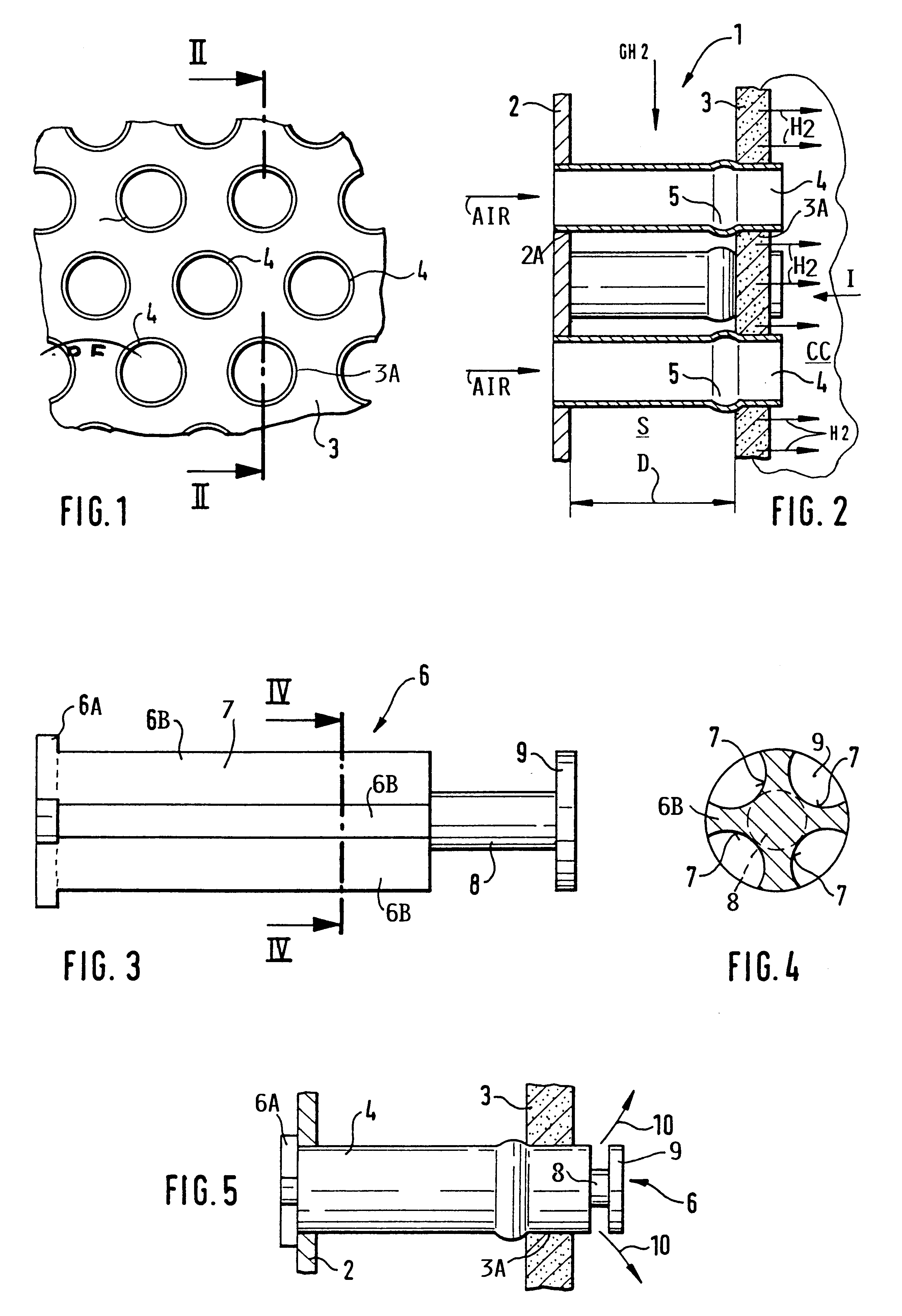

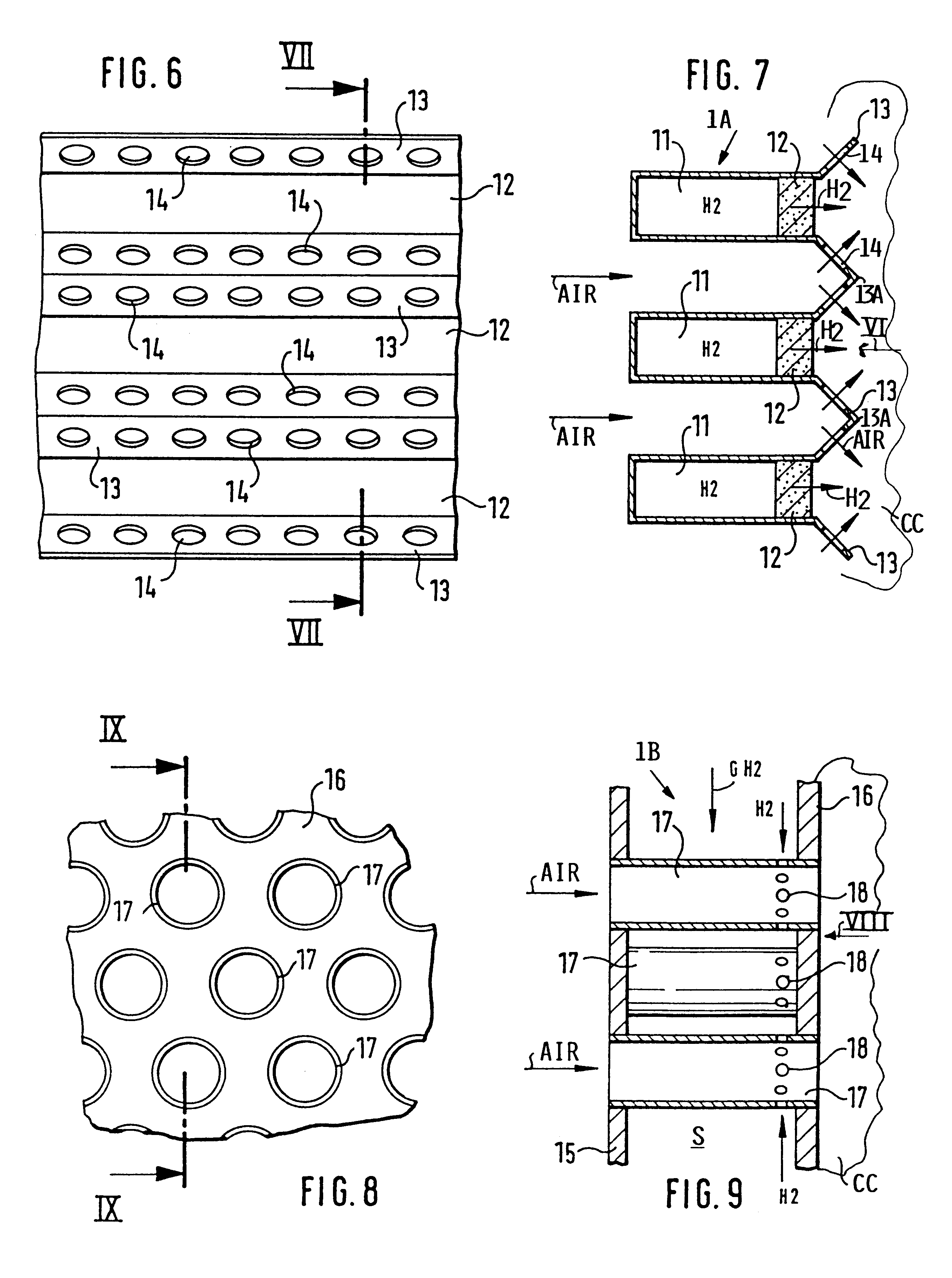

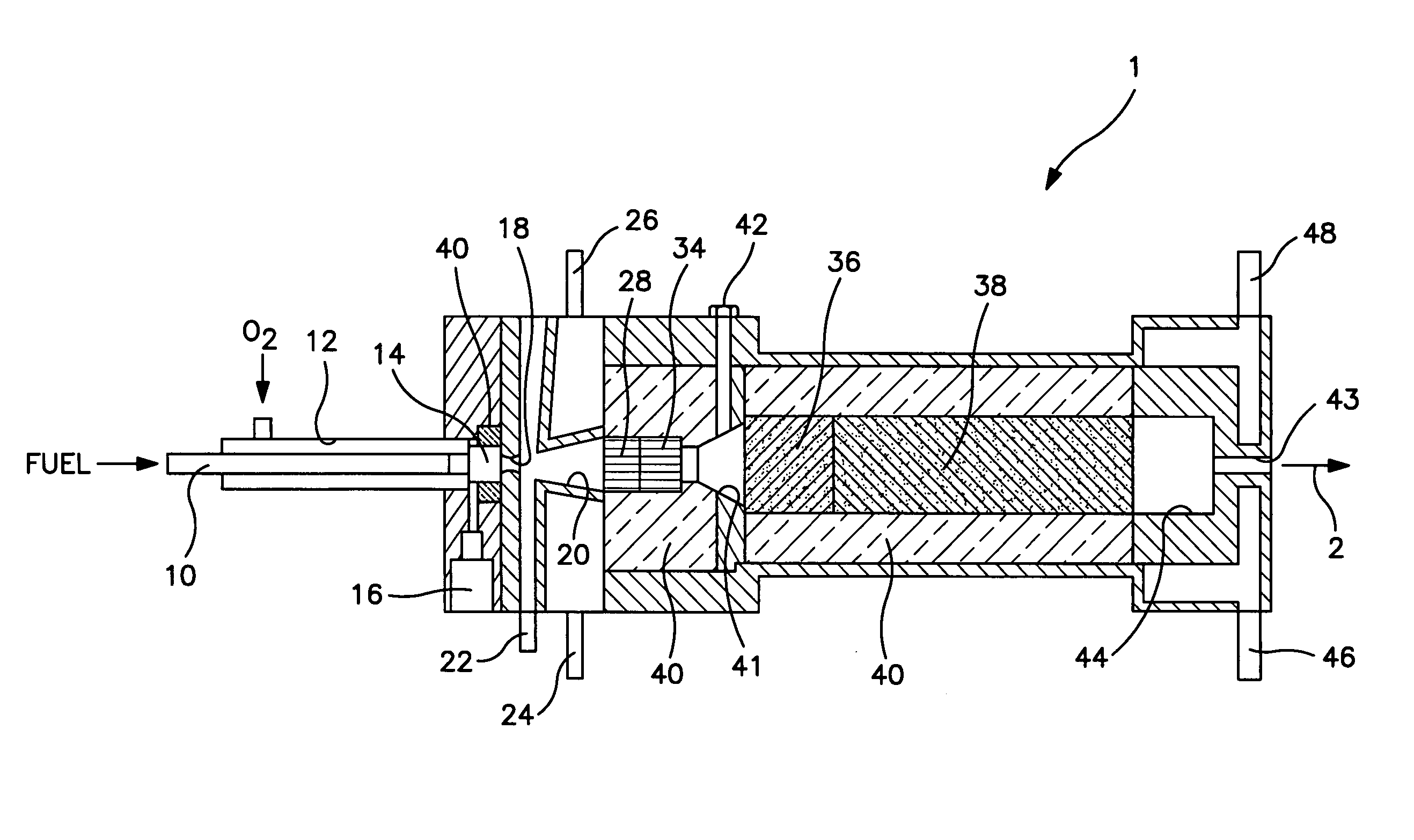

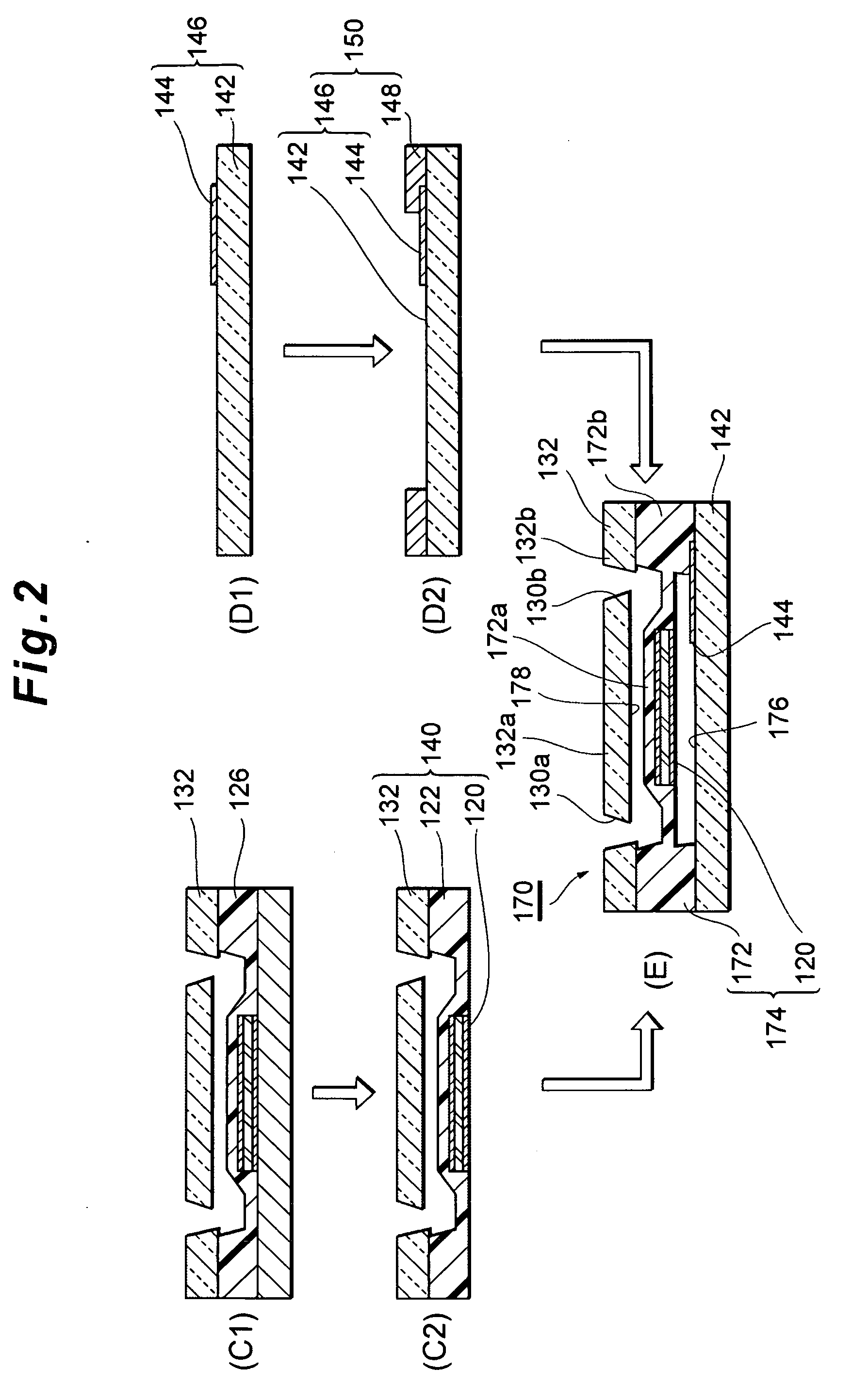

Method and combustor for combusting hydrogen

InactiveUS6267585B1Inhibit combustionSmall mixing scaleCombustion using gaseous and pulverulent fuelBurner safety arrangementsExhaust gasGas turbines

A plate burner for combusting hydrogen with air as an oxidizer forms a wall portion of a combustion chamber for example of a gas turbine. The plate burner is so constructed that air and hydrogen are separately guided to the downstream surface area facing into the combustion chamber for forming a large number of diffusive microcombustion flames, thus achieving a very low mixing scale simultaneously with a high nixing intensity. The number of diffusive micorcombustion flames is so selected that the NOx content in the exhaust gas from the combustion chamber is at the most 10x10-6 cubic foot per cubic foot of exhaust gas. The hydrogen enters the entrance area into the combustion chamber either through a porous wall, and air is injected into the hydrogen environment to form inverse diffusive microcombustion flames or the hydrogen is injected through a multitude of fine holes into high velocity air jets forming regular diffusion flames. In both instances, the formation of NOx in the exhaust gas during combustion is reduced to the above level or below.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

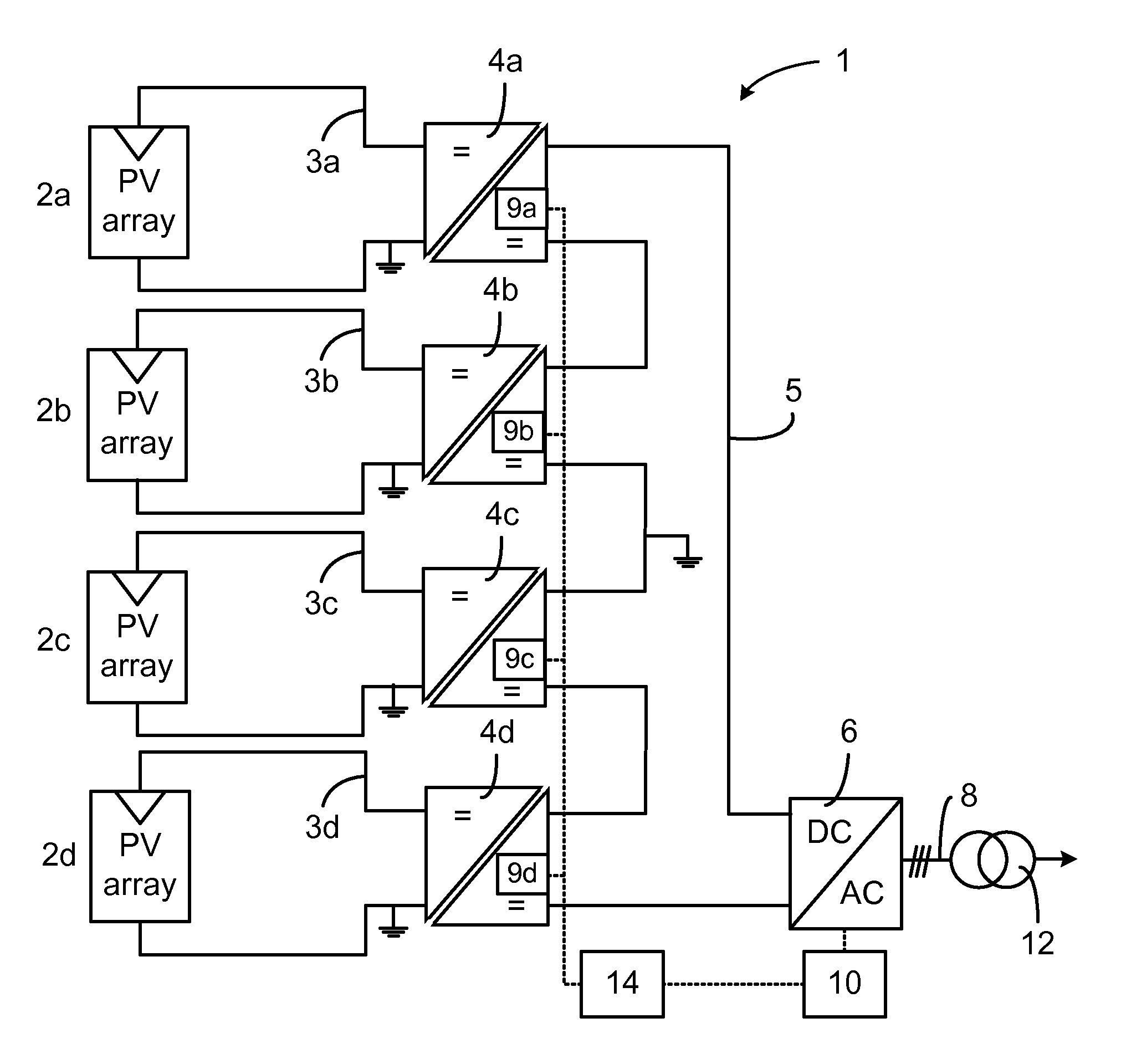

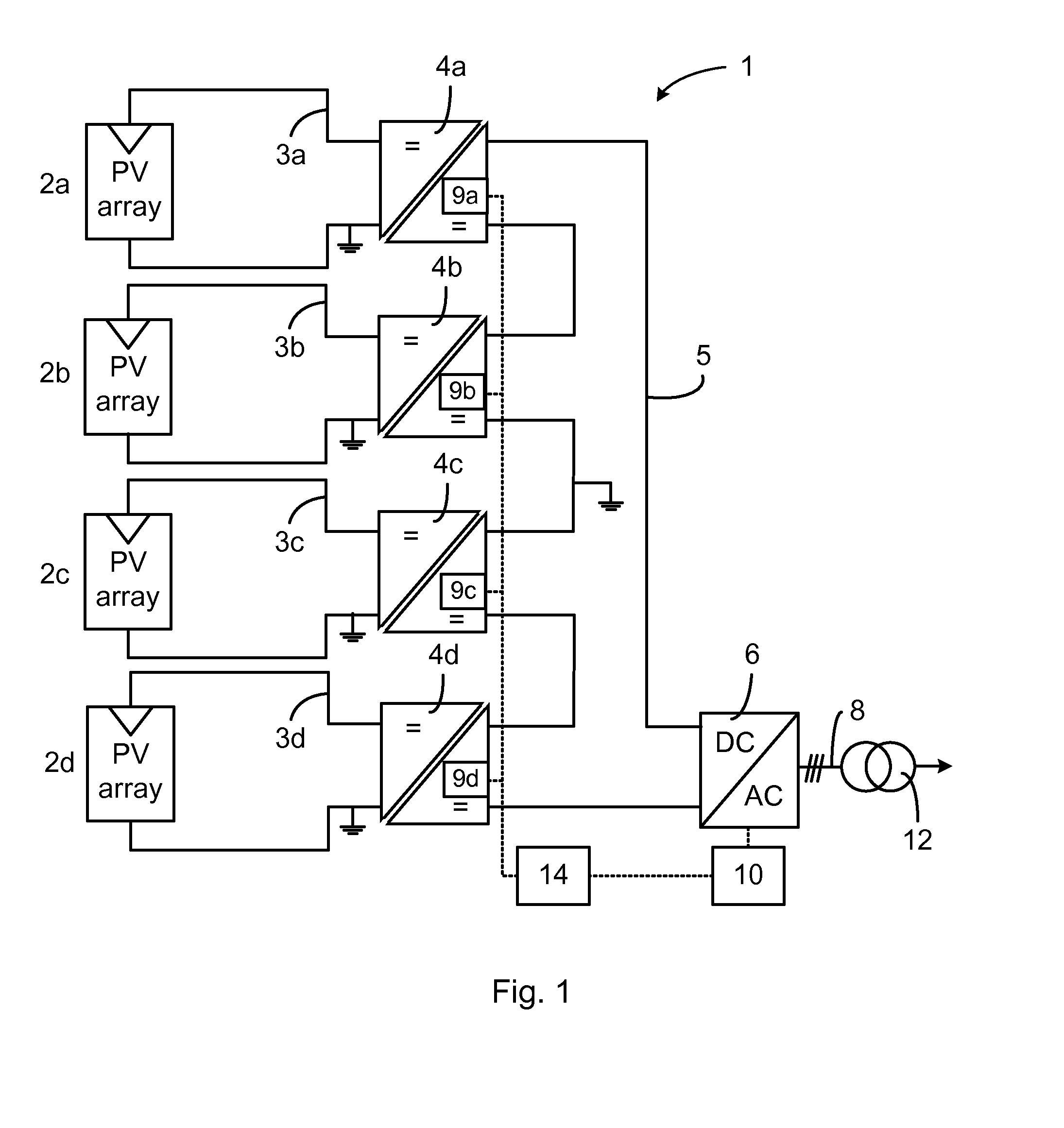

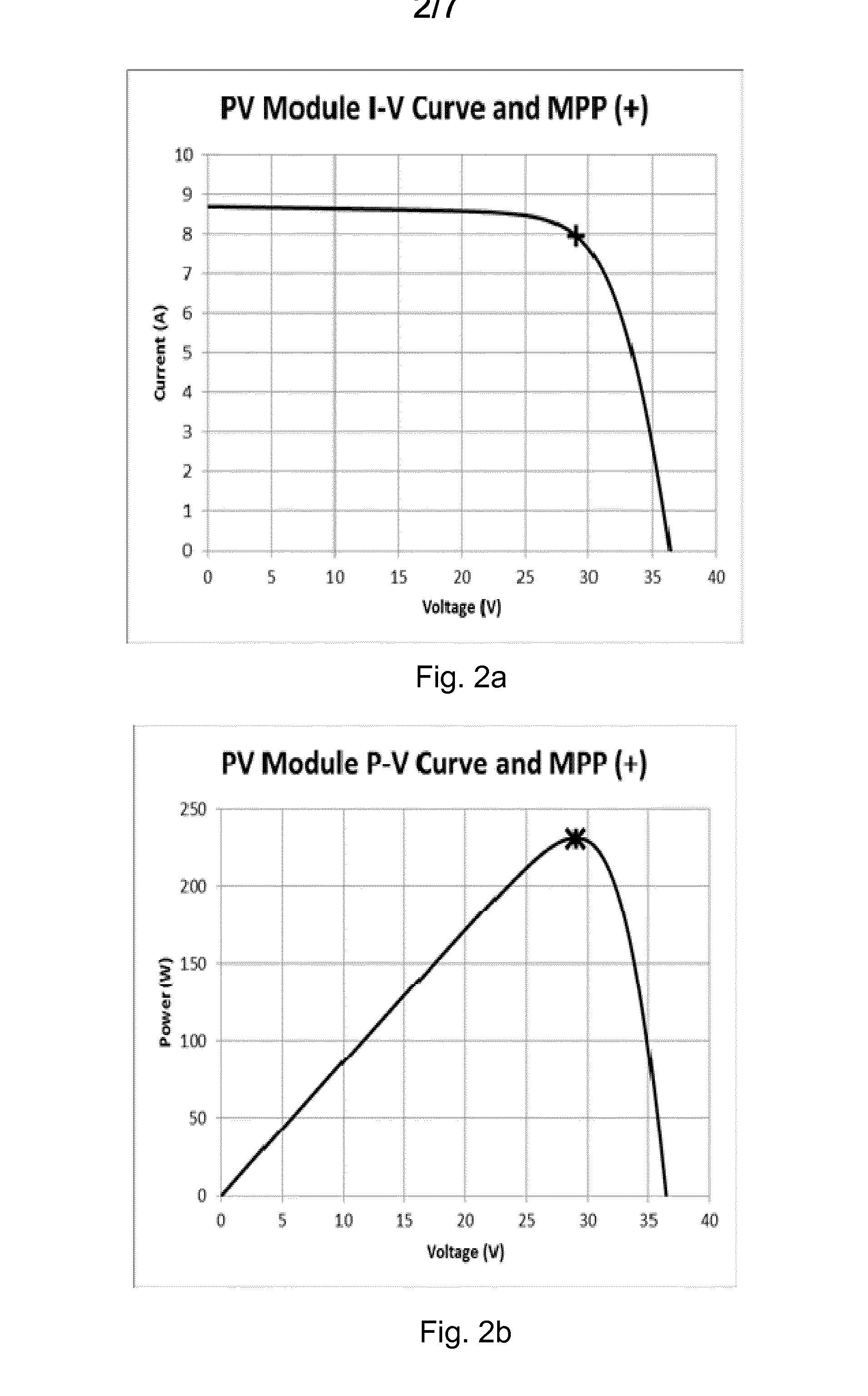

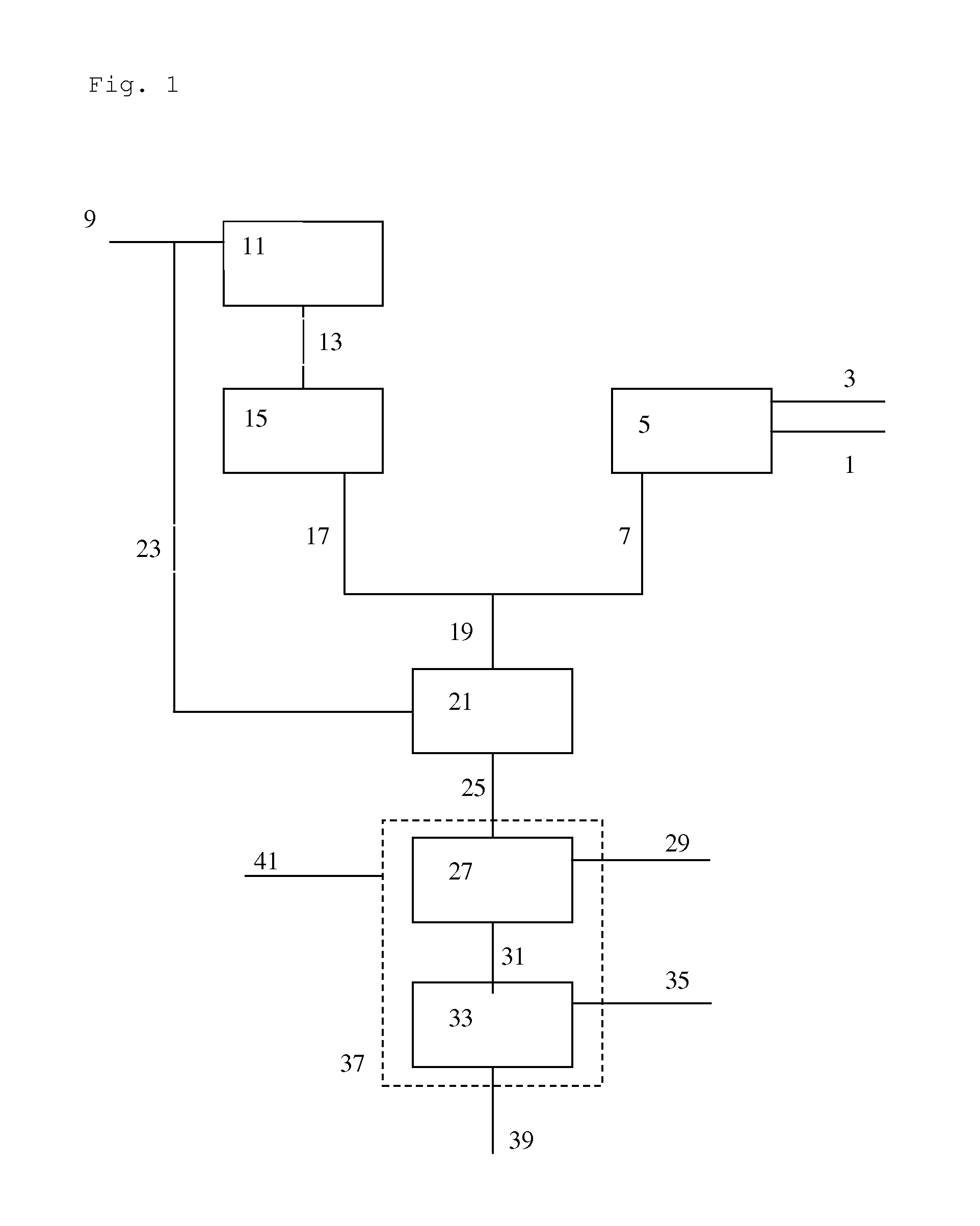

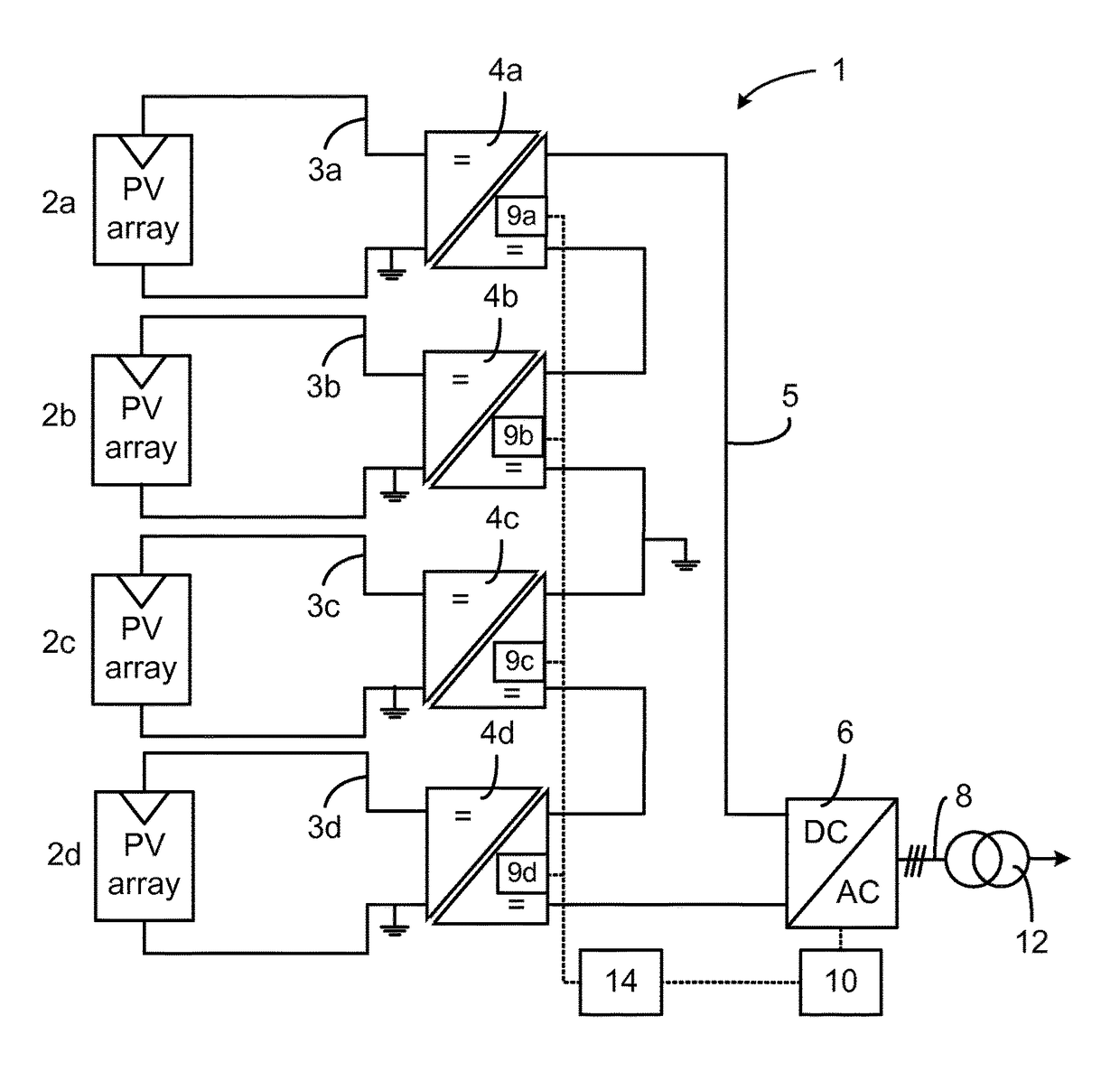

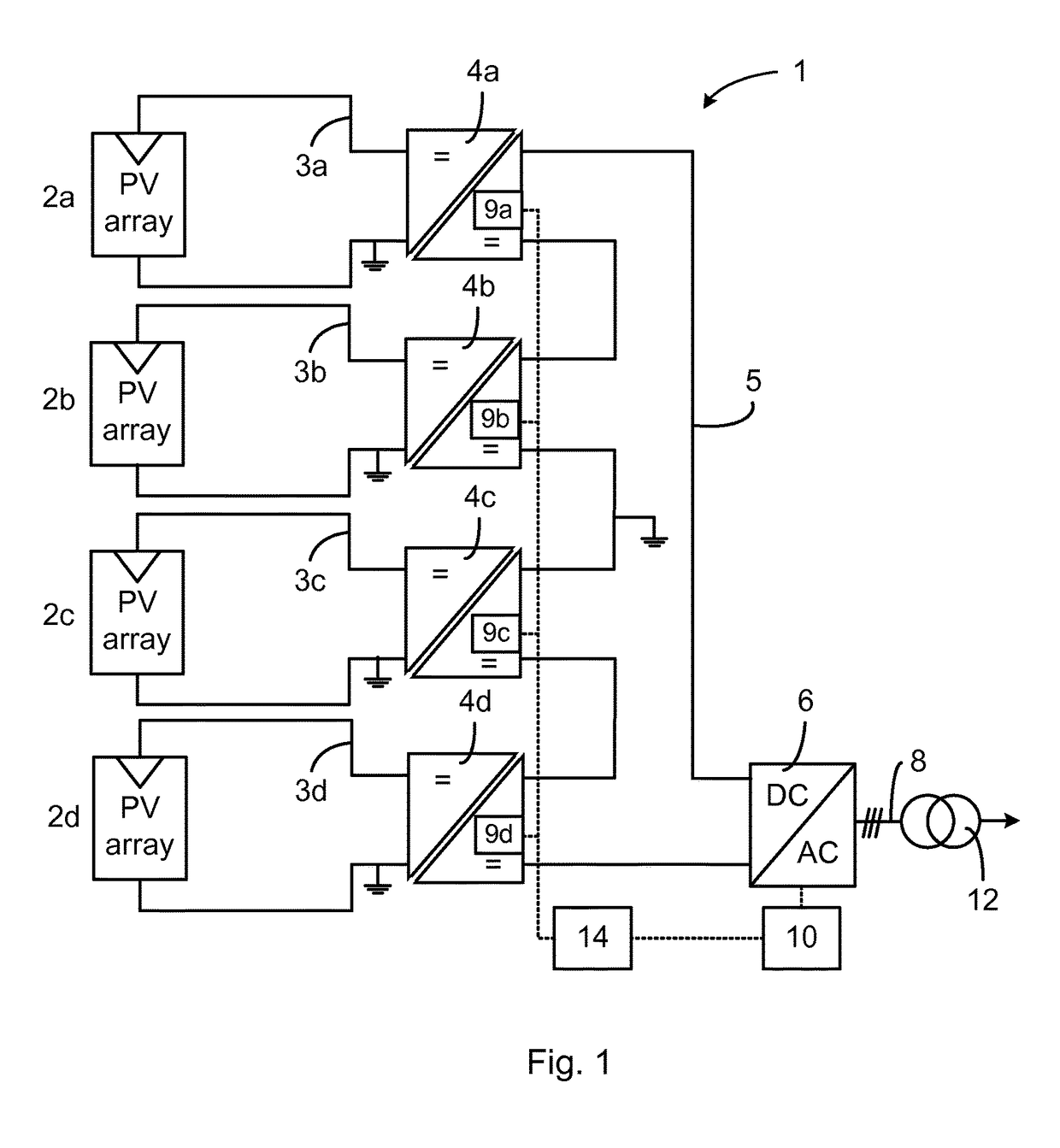

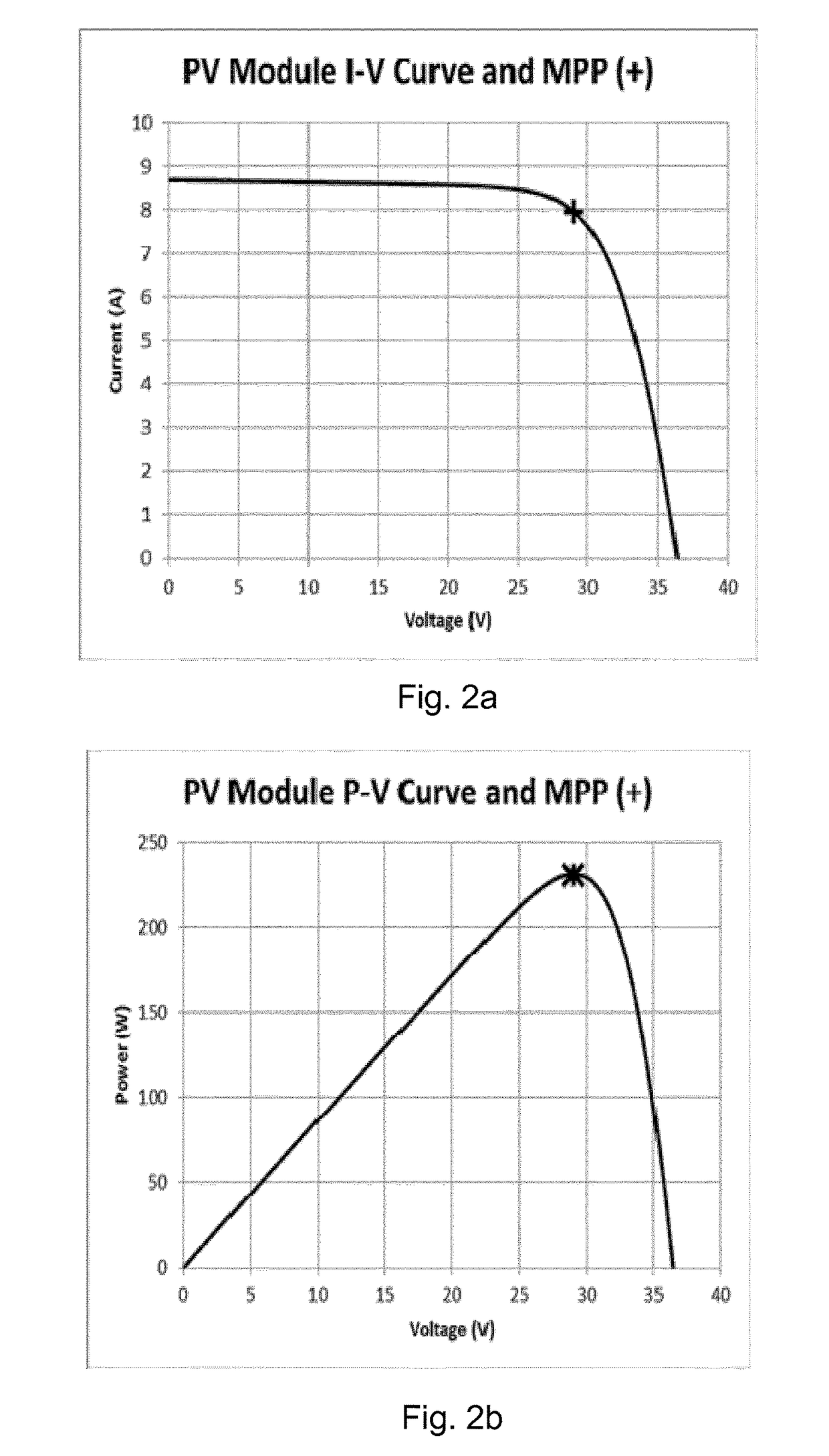

Method of Controlling a Solar Power Plant, A Power Conversion System, a DC/AC Inverter and a Solar Power Plant

ActiveUS20150372490A1Small productElectric signal transmission systemsBatteries circuit arrangementsPower gridGrid interface

A solar power plant including a power conversion system and a method of controlling the power conversion system. Implemented in a DC / AC inverter, the plant includes photovoltaic modules (PV modules) arranged in arrays connected to a respective DC / DC converters. A power collecting grid interfaces between the DC / DC converters and the DC / AC inverter. The method includes monitoring the performance of each PV array by adjusting the voltage level of each interface between a PV array and the corresponding DC / DC converter, and includes monitoring the output power of each DC / DC converter as a feedback for the regulating.

Owner:HITACHI ENERGY SWITZERLAND AG

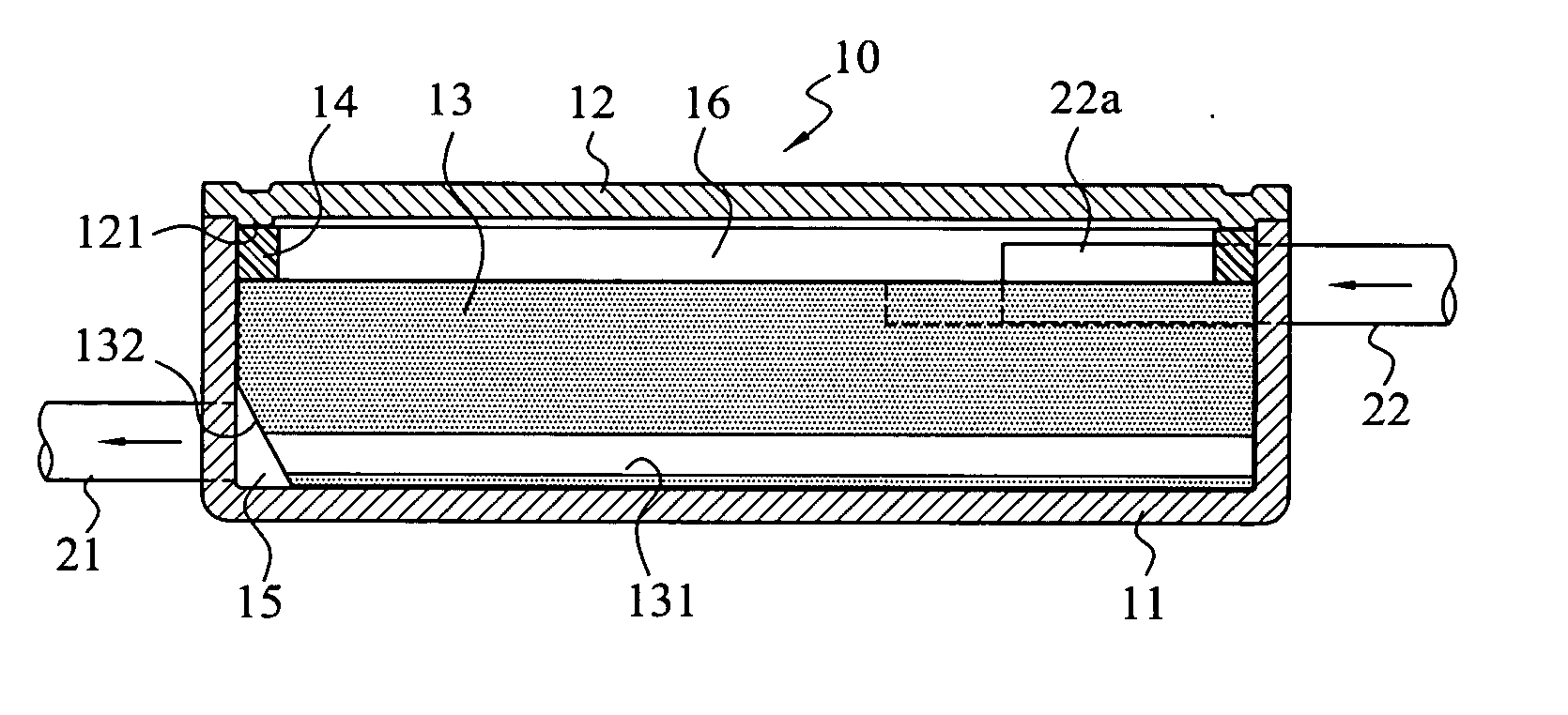

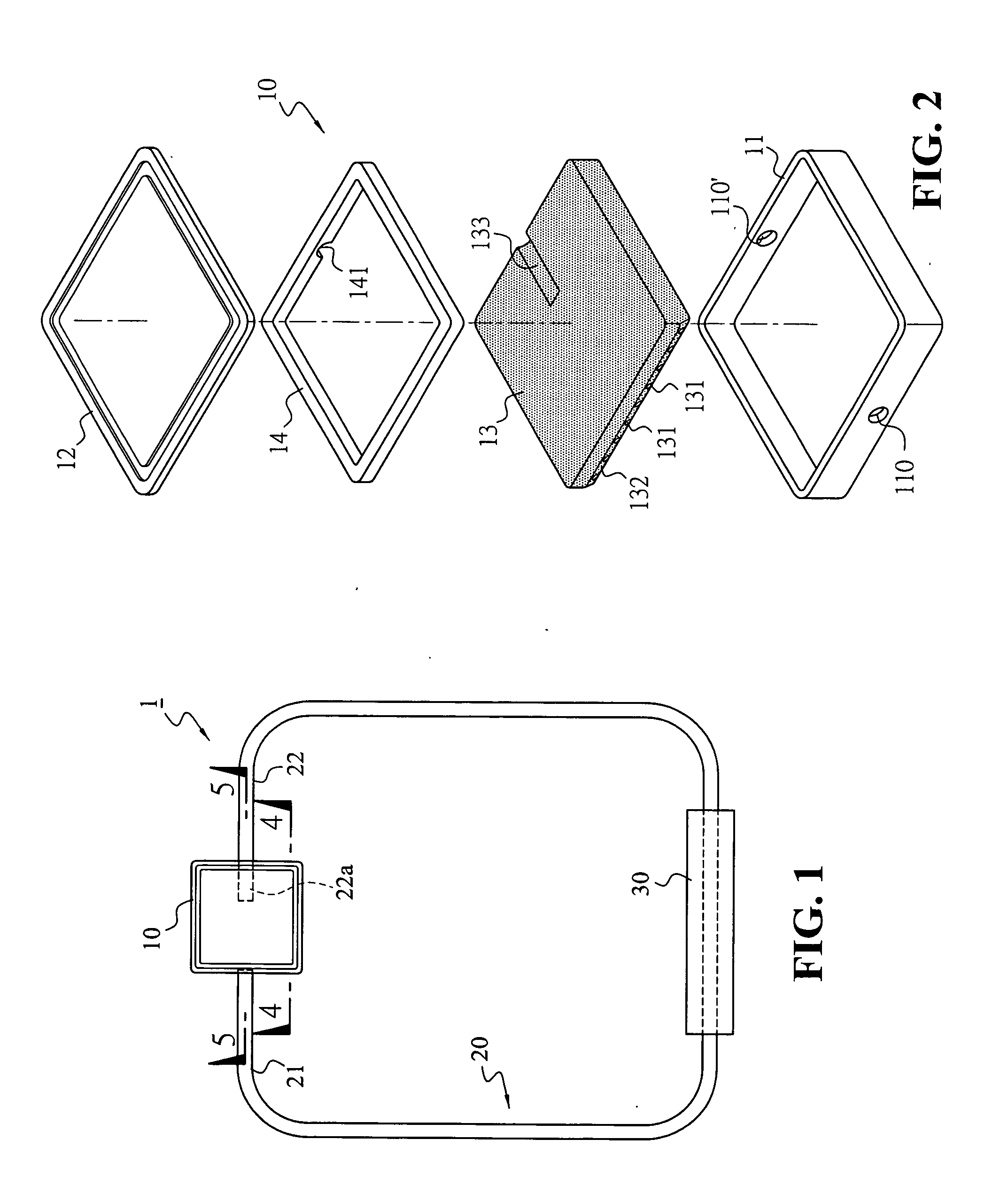

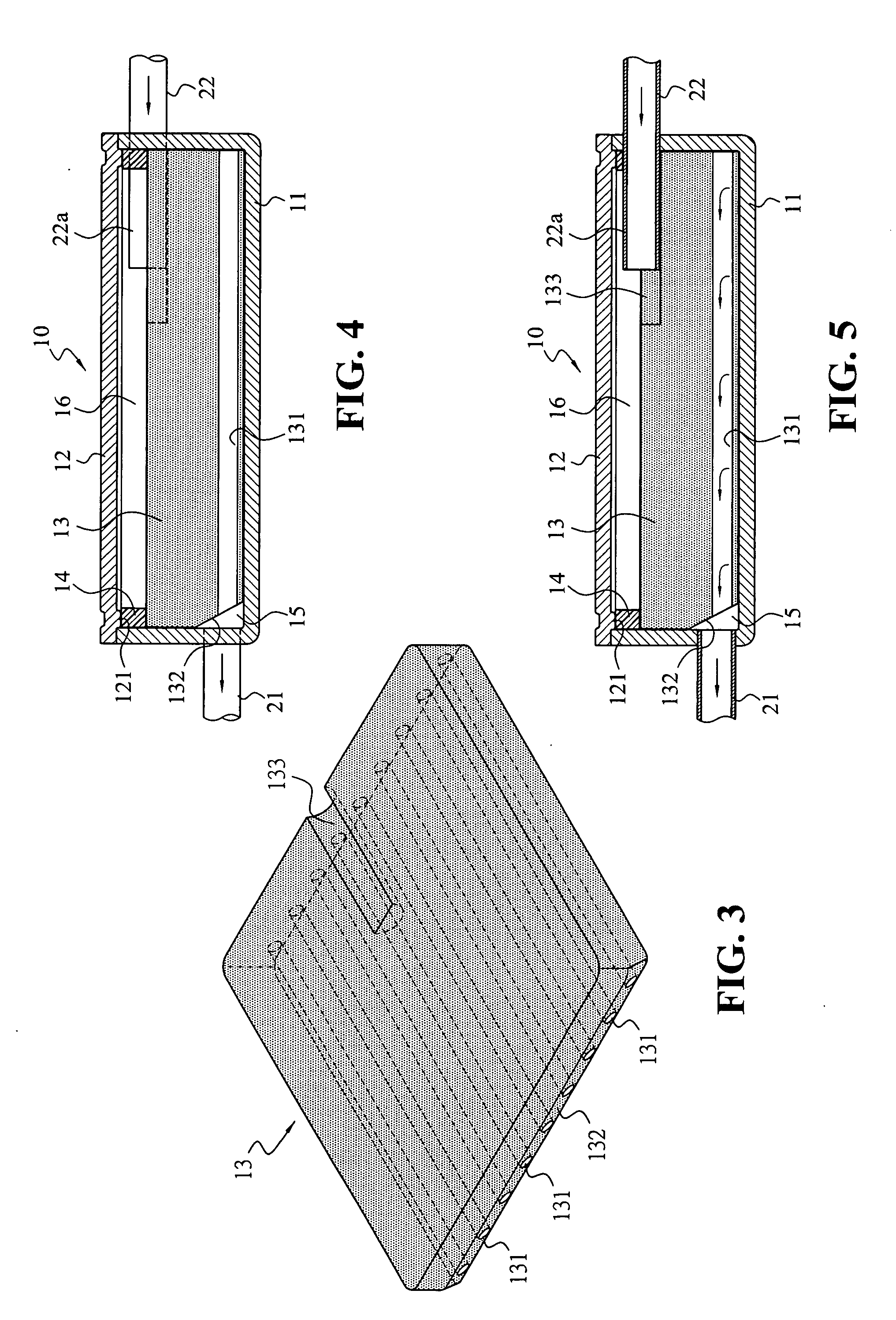

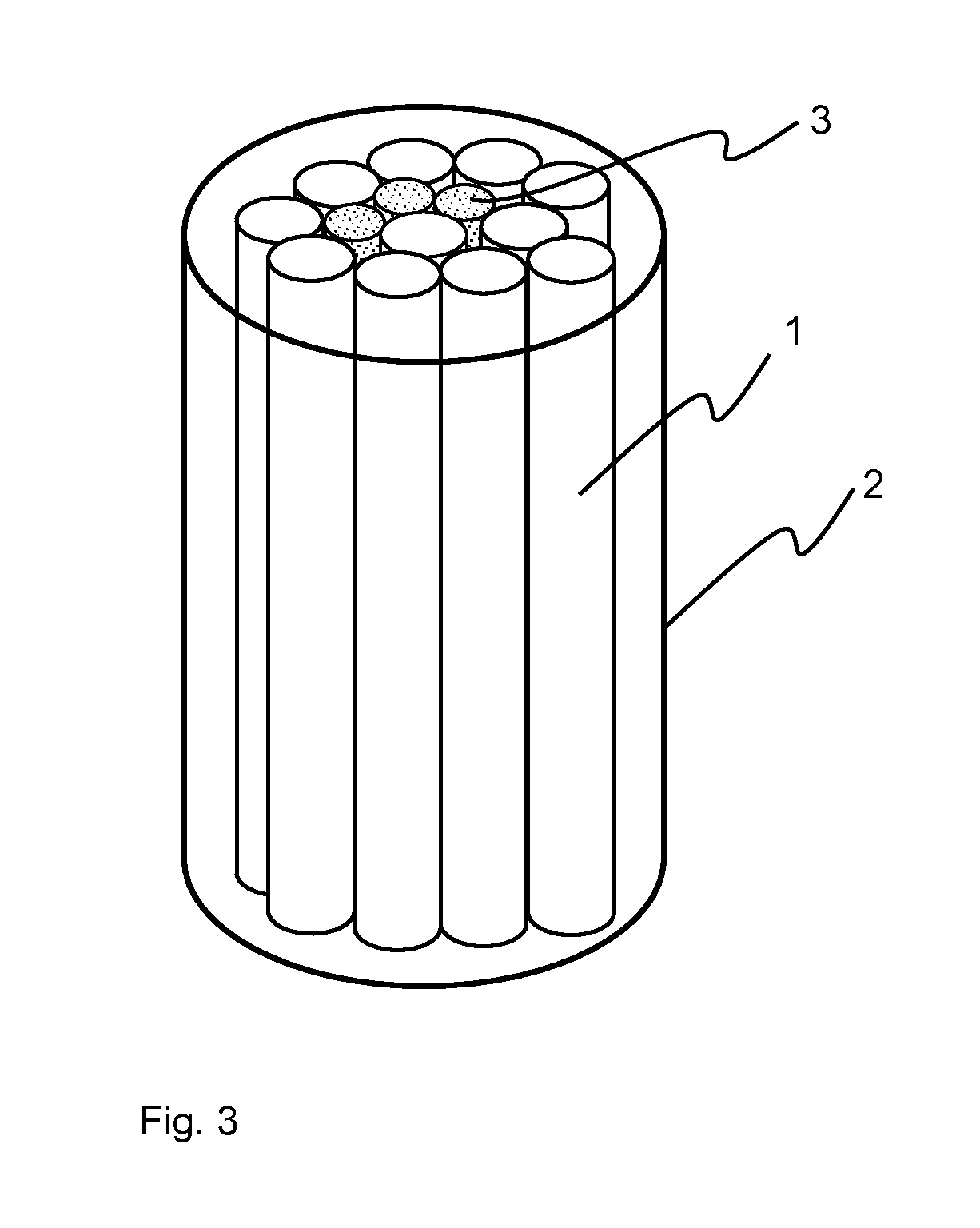

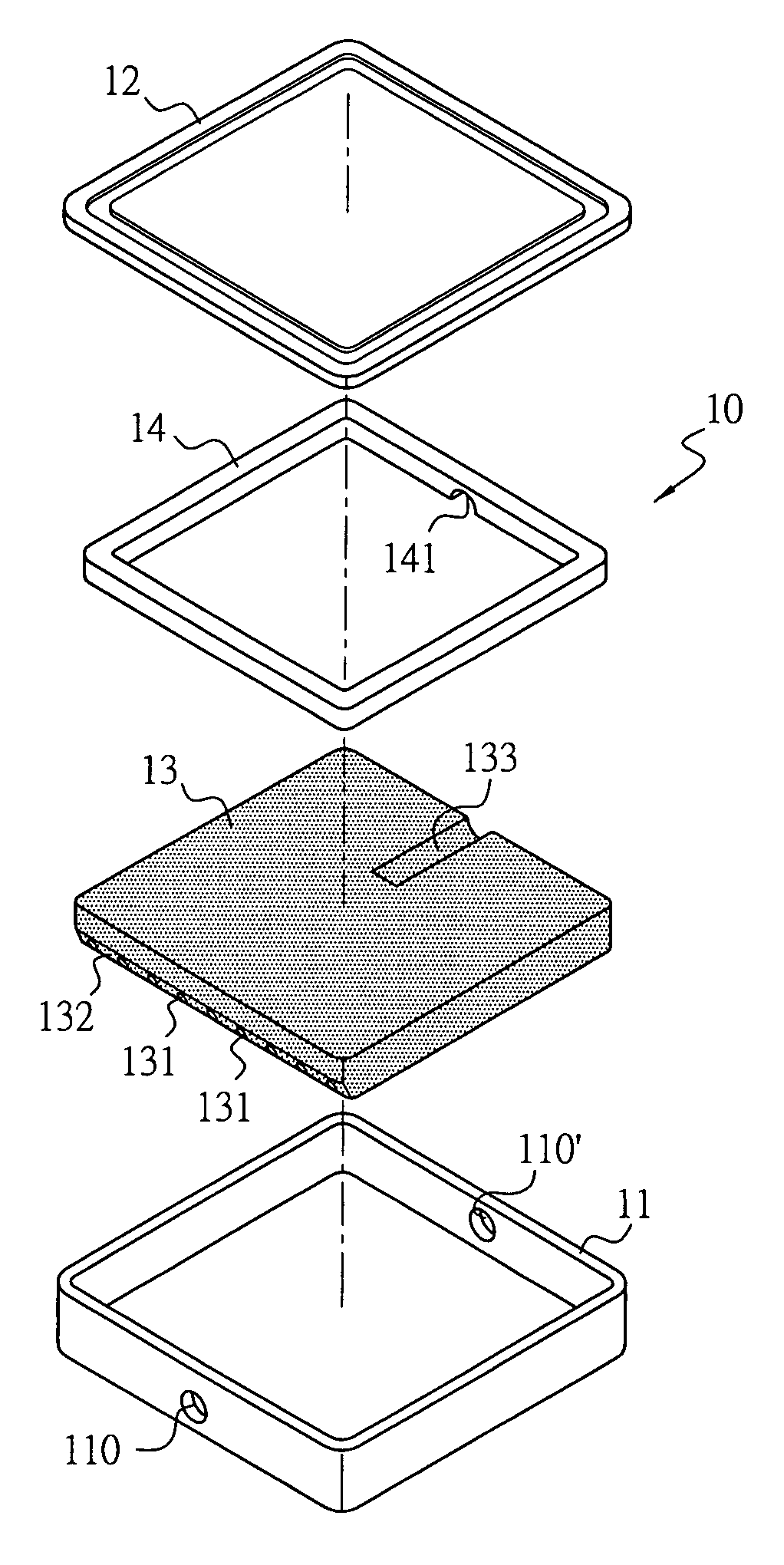

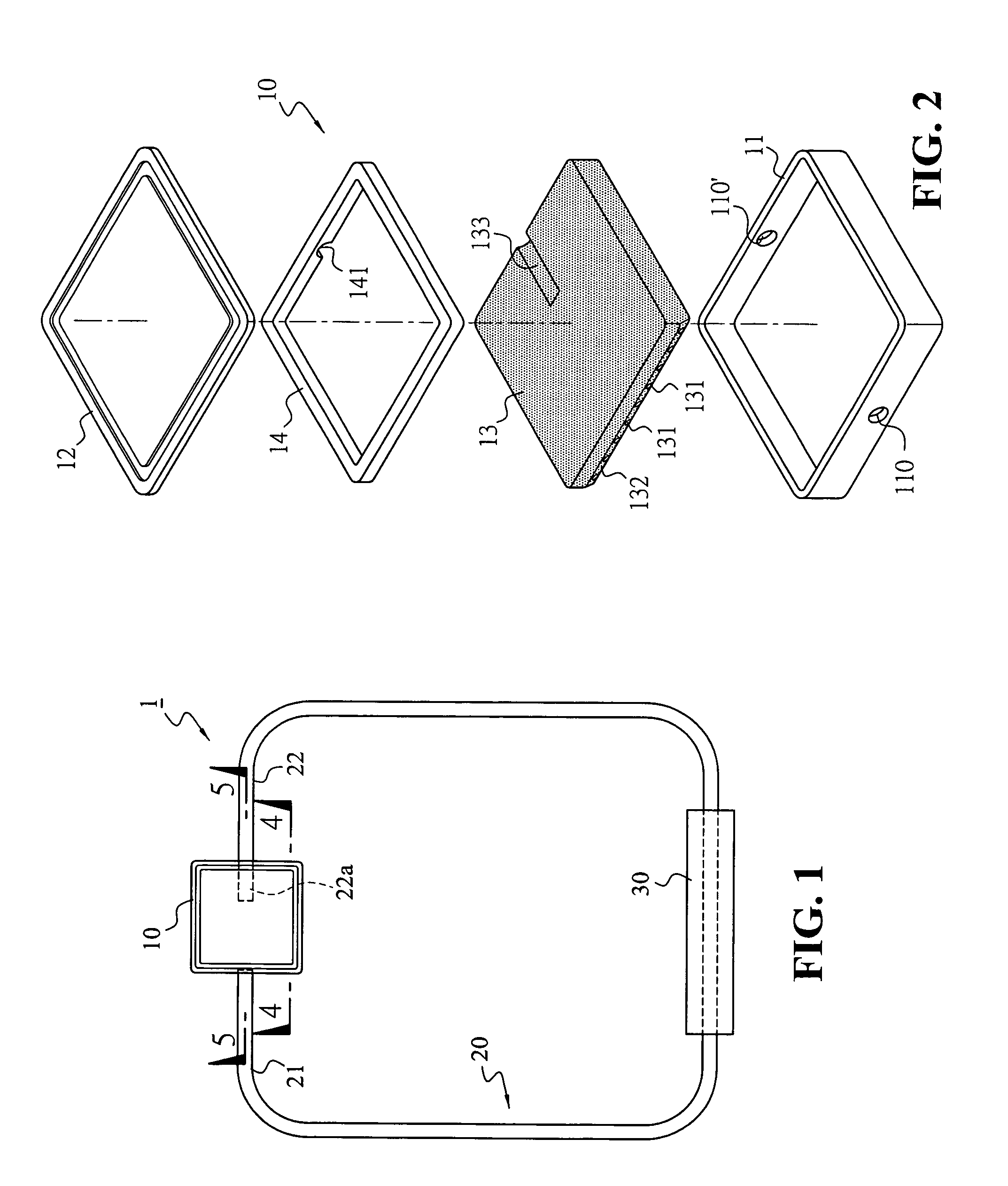

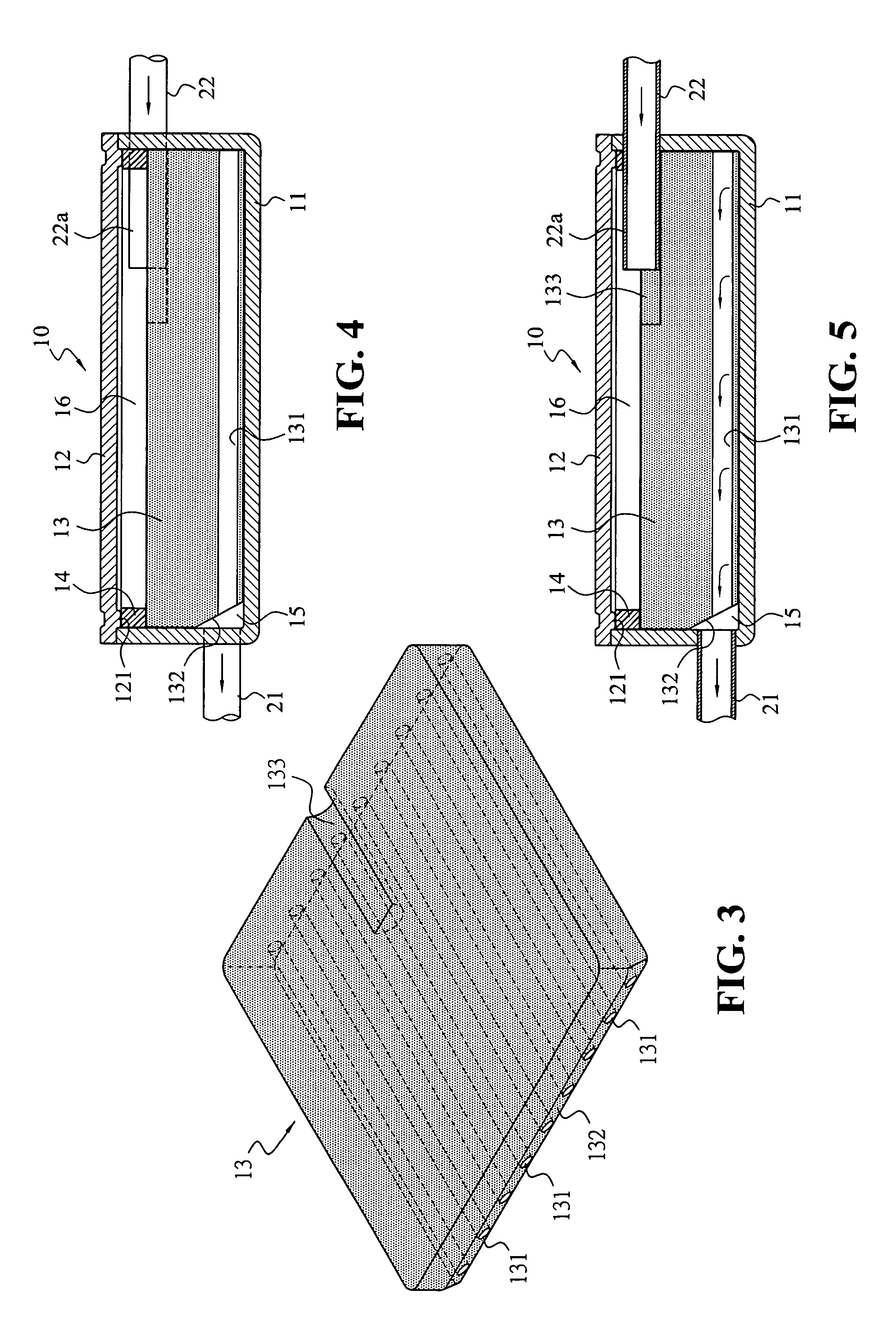

Type of loop heat conducting device

ActiveUS20070187072A1Increase flow resistanceImprove cooling effectIndirect heat exchangersHeat conductingEngineering

This invention relates to a type of loop heat conducting device, comprising an evaporator and a condenser which are connected together by means of a loop pipe, in order to form a cyclic loop for a liquid working medium, wherein the evaporator has a wick network core, and multiple tunnels are formed on the wick network core, and one end of the tunnels converges at a vapor chamber and is connected to a loop pipe to form a gaseous working medium outlet, and the terminal end of the pipe extends into and comes into contact with the internal part of the wick network core, and a compensation chamber for liquid working medium is formed on the upper section of the wick network core. Consequently, the cyclic loop that separates the gas and liquid enables the optimal heat dissipation capacity, and also has a structure that is simplified, thereby allowing for easy mass production.

Owner:YEH CHIANG TECH CORP

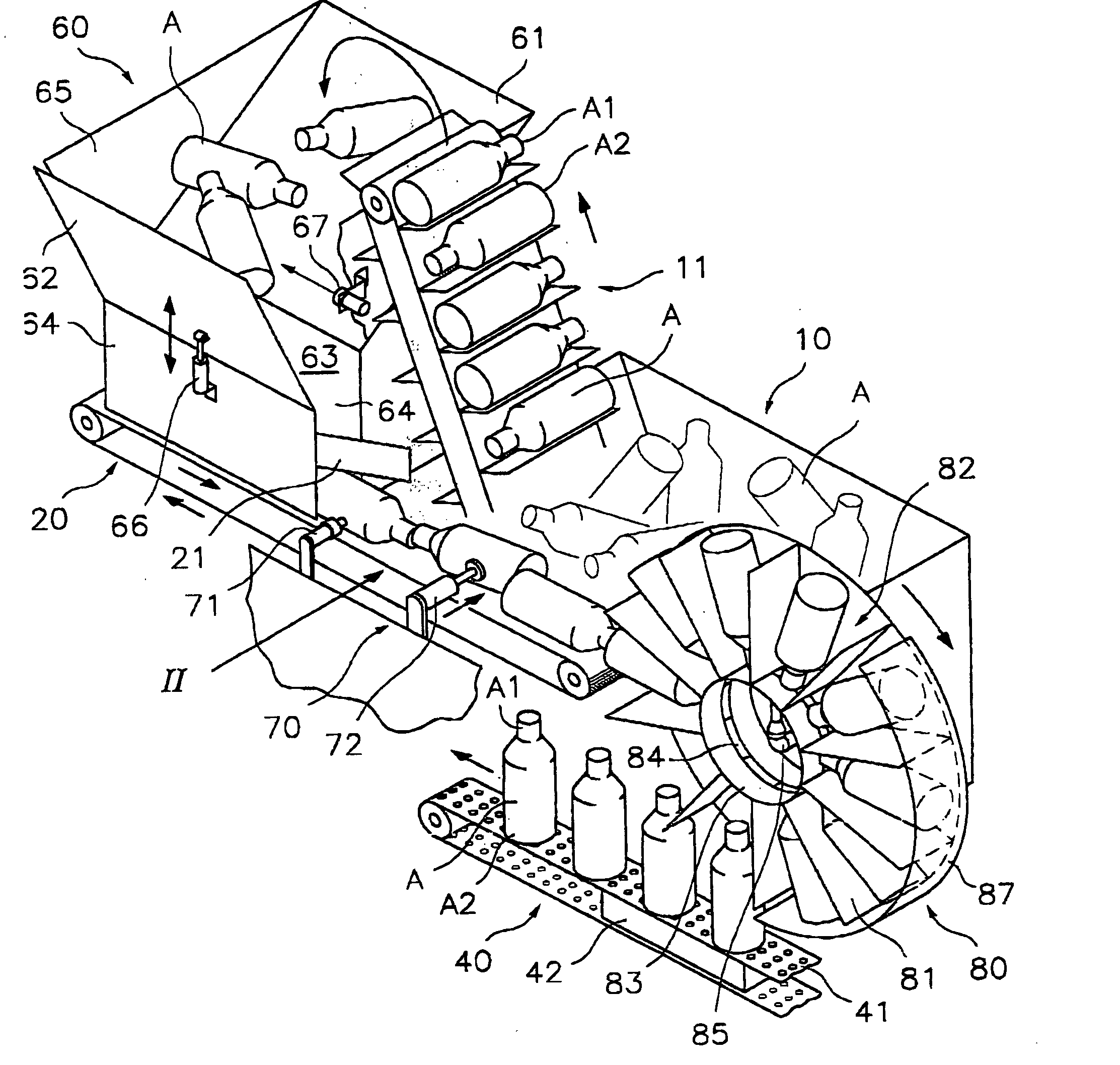

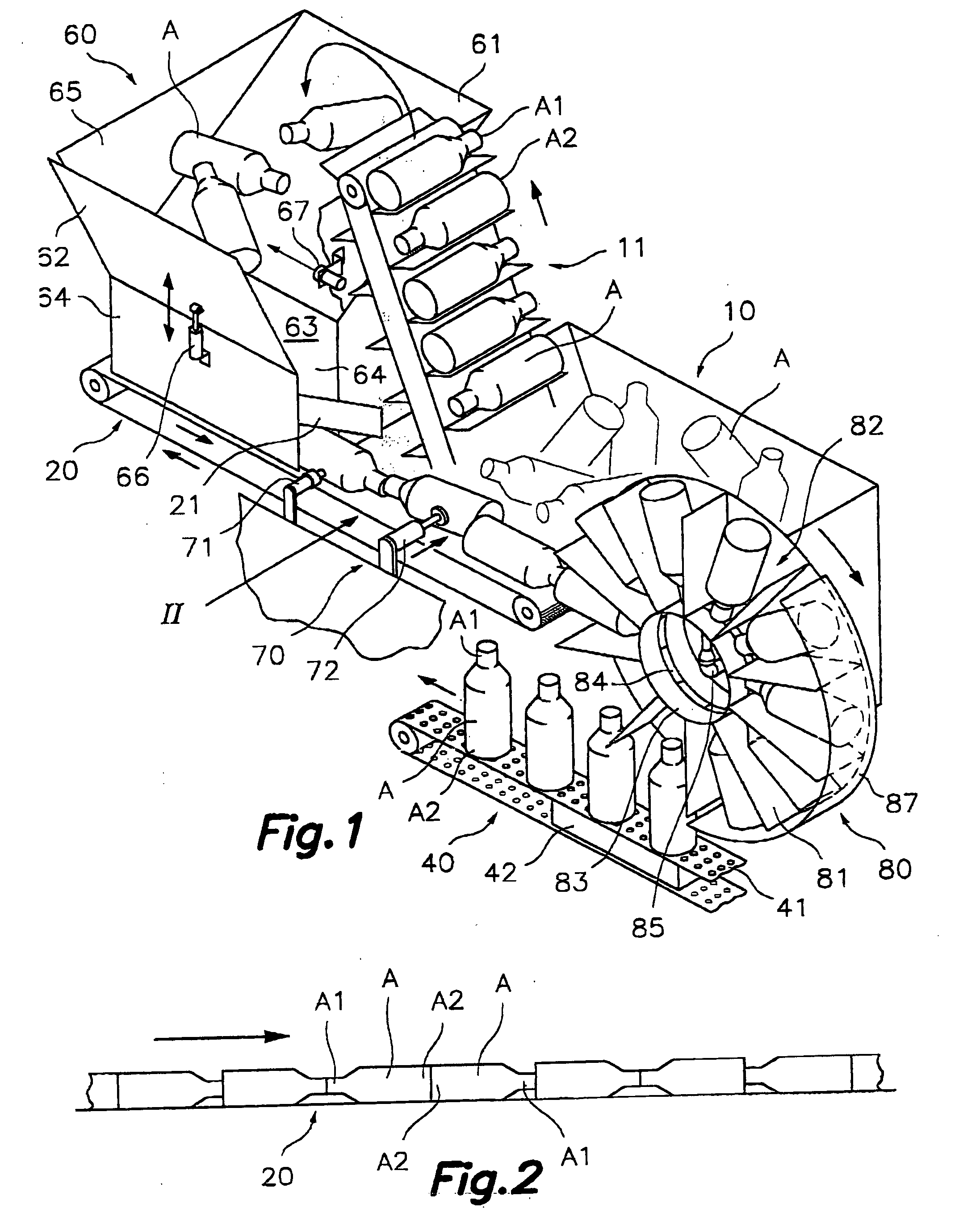

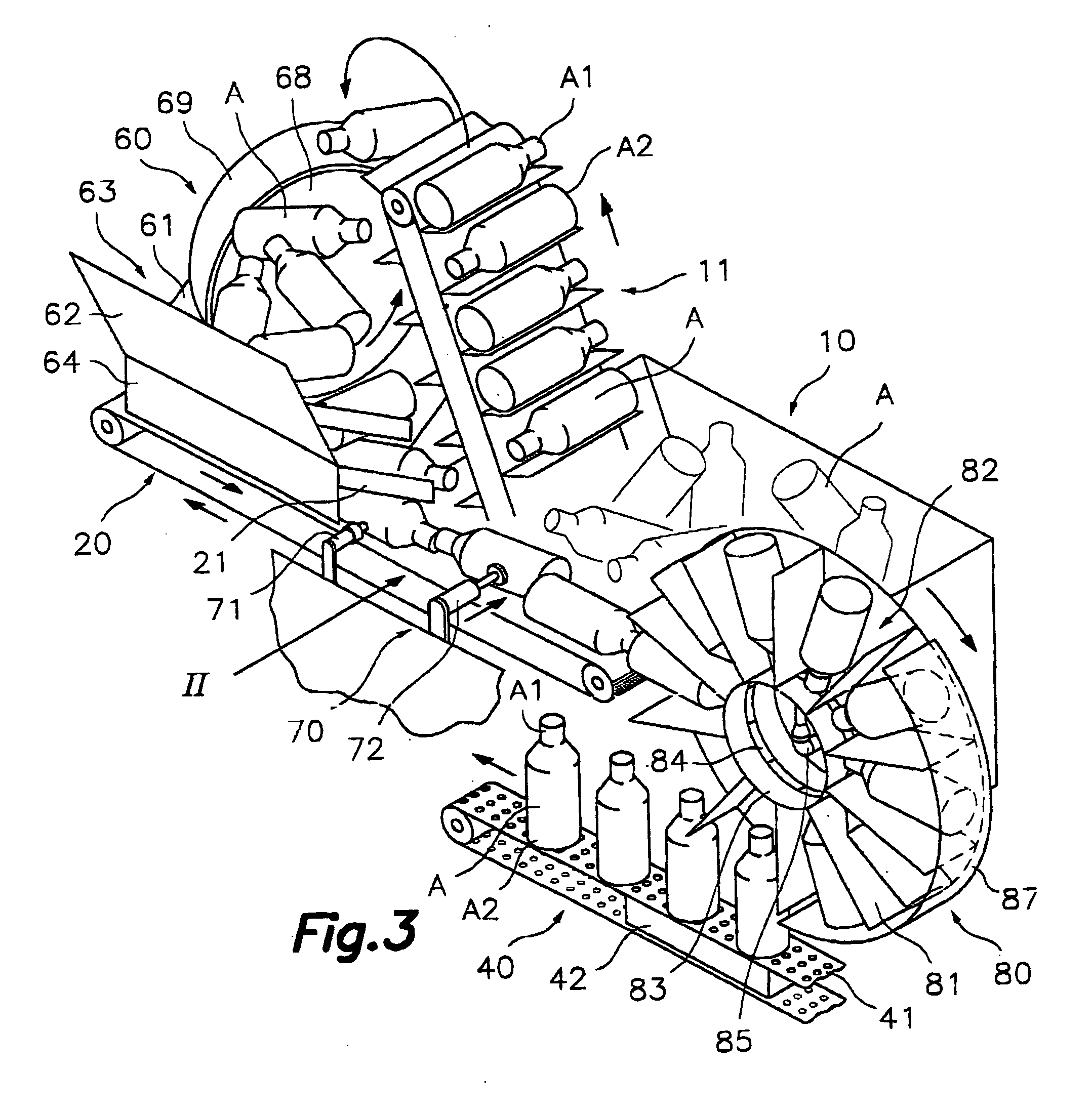

Automatic linear machine for orienting and aligning articles

The machine is intended for articles (A) having a different geometric configuration (A1) on one of their ends. Said machine has a linear transport device (20) for the articles (A) in lying position which has been pre-oriented in longitudinal direction with respect to said different geometric configuration (A1) that is located either in the front or back part relative to the direction of advancement of said transporting device (20). The machine also comprises a positioning station (80) of the articles (A) orienting the articles vertically and associated with the transporting device (20) and output transporting means (40) of the articles (A) that are oriented in vertical position and aligned. The machine also includes lifting means (11) to transfer the articles (A) from a bulk container (10) to a feed device (60) having first and second inclined plane (61, 62), converging in a chute space (63) on the transporting device (20). The positioning station (80) comprises a rotating element (81) provided with cavities (82) for receiving the articles (A) in a substantially radial position and with the geometric configuration (A1) in the desired position.

Owner:SALA JAIME MARTI

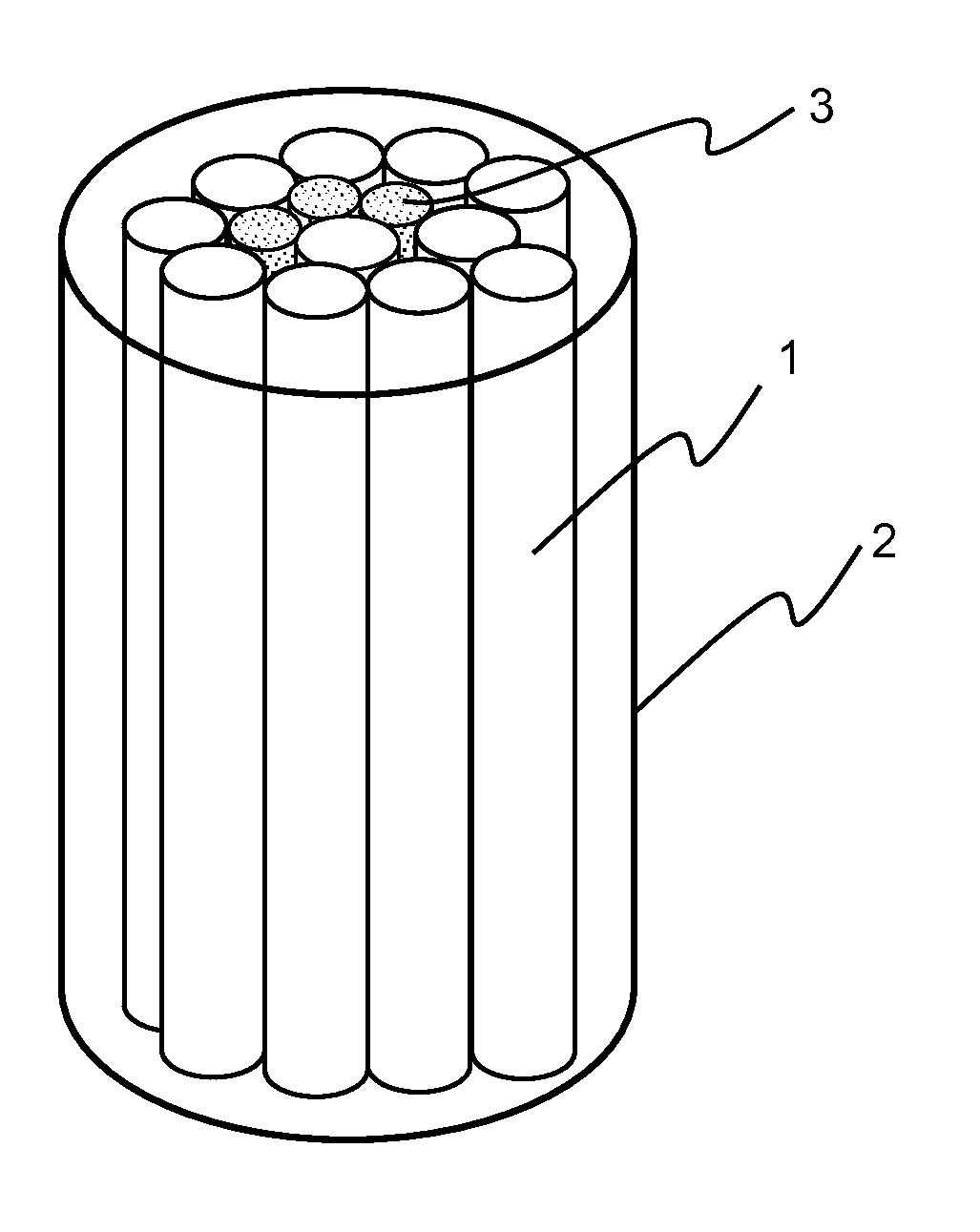

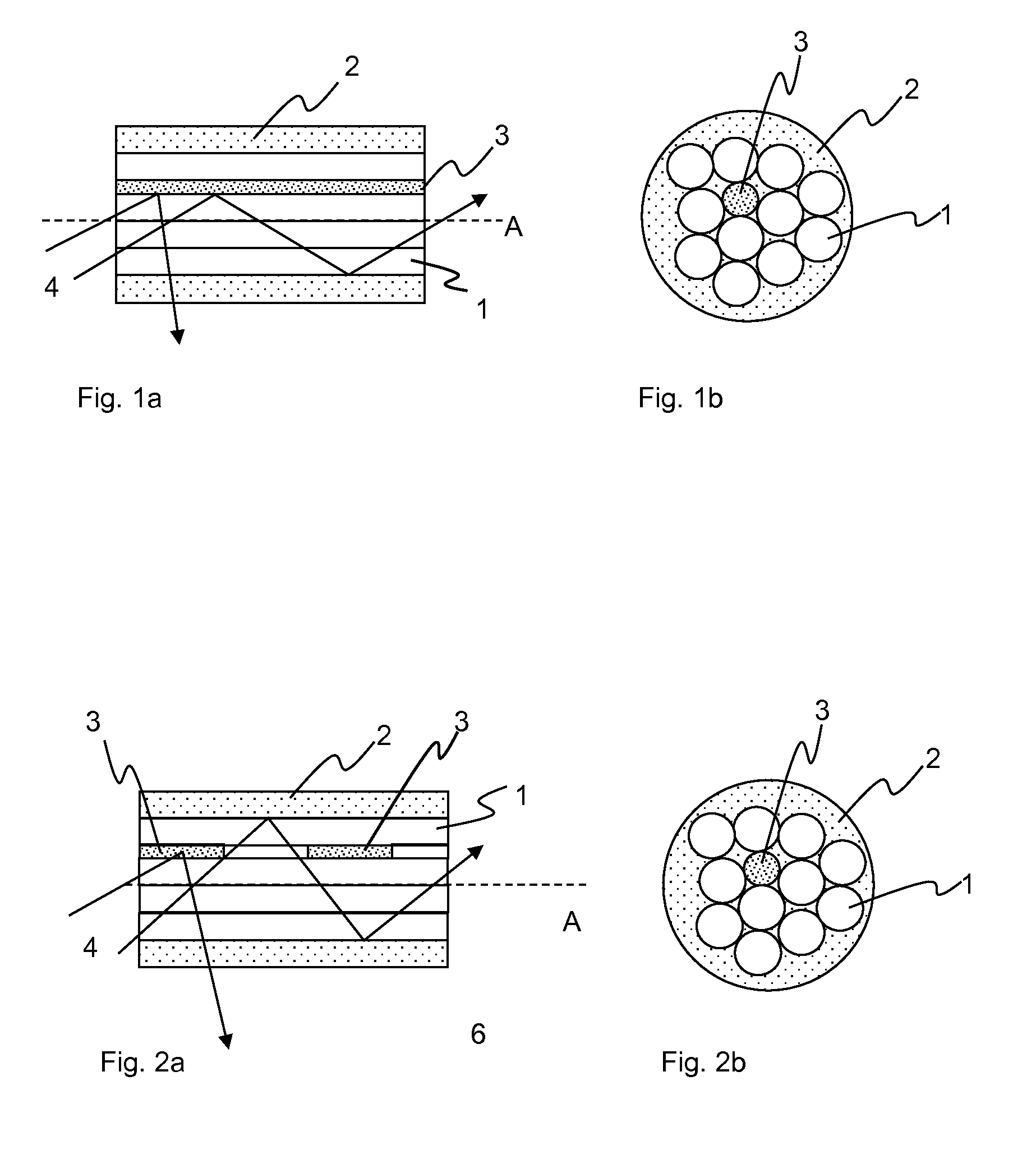

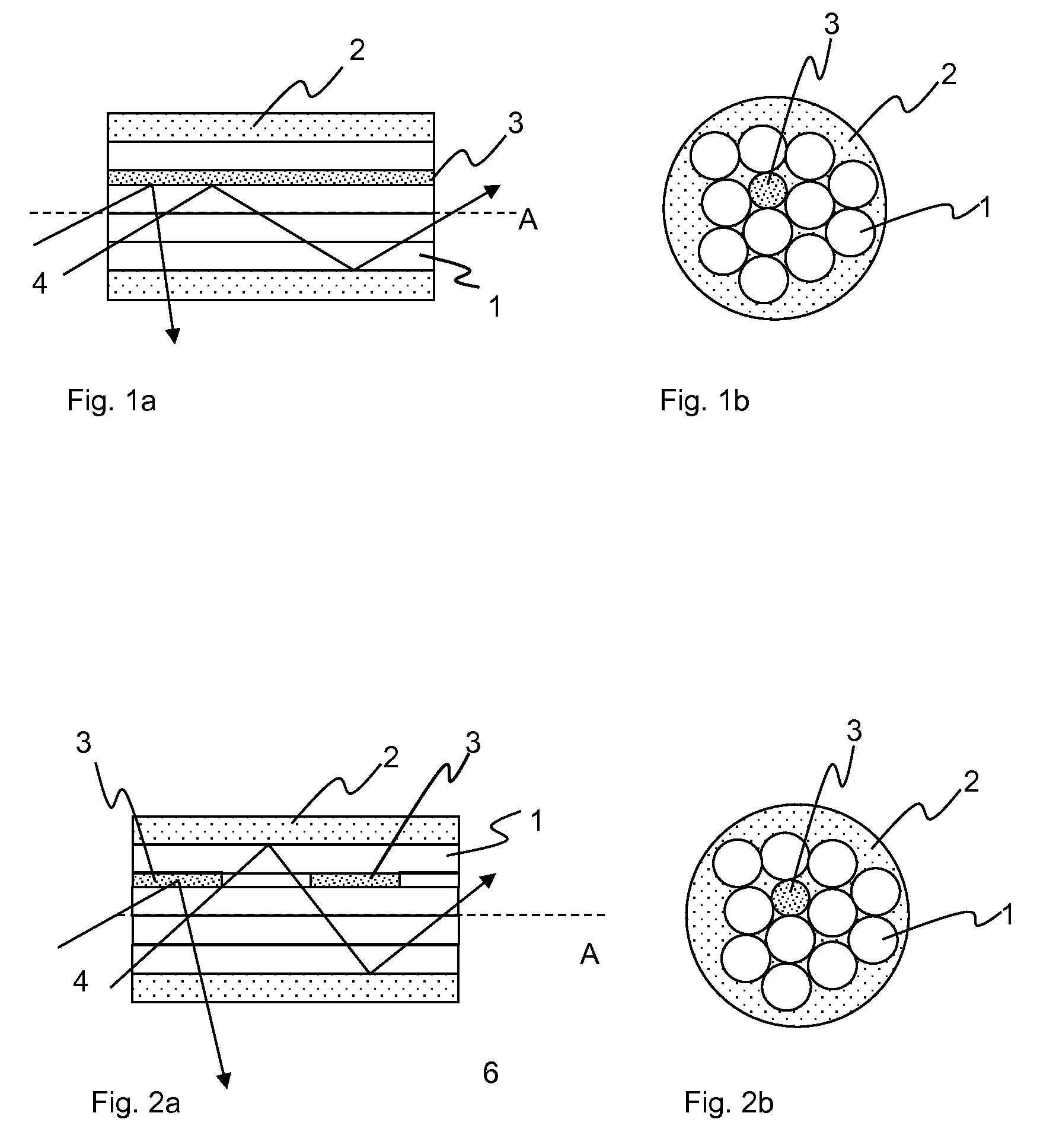

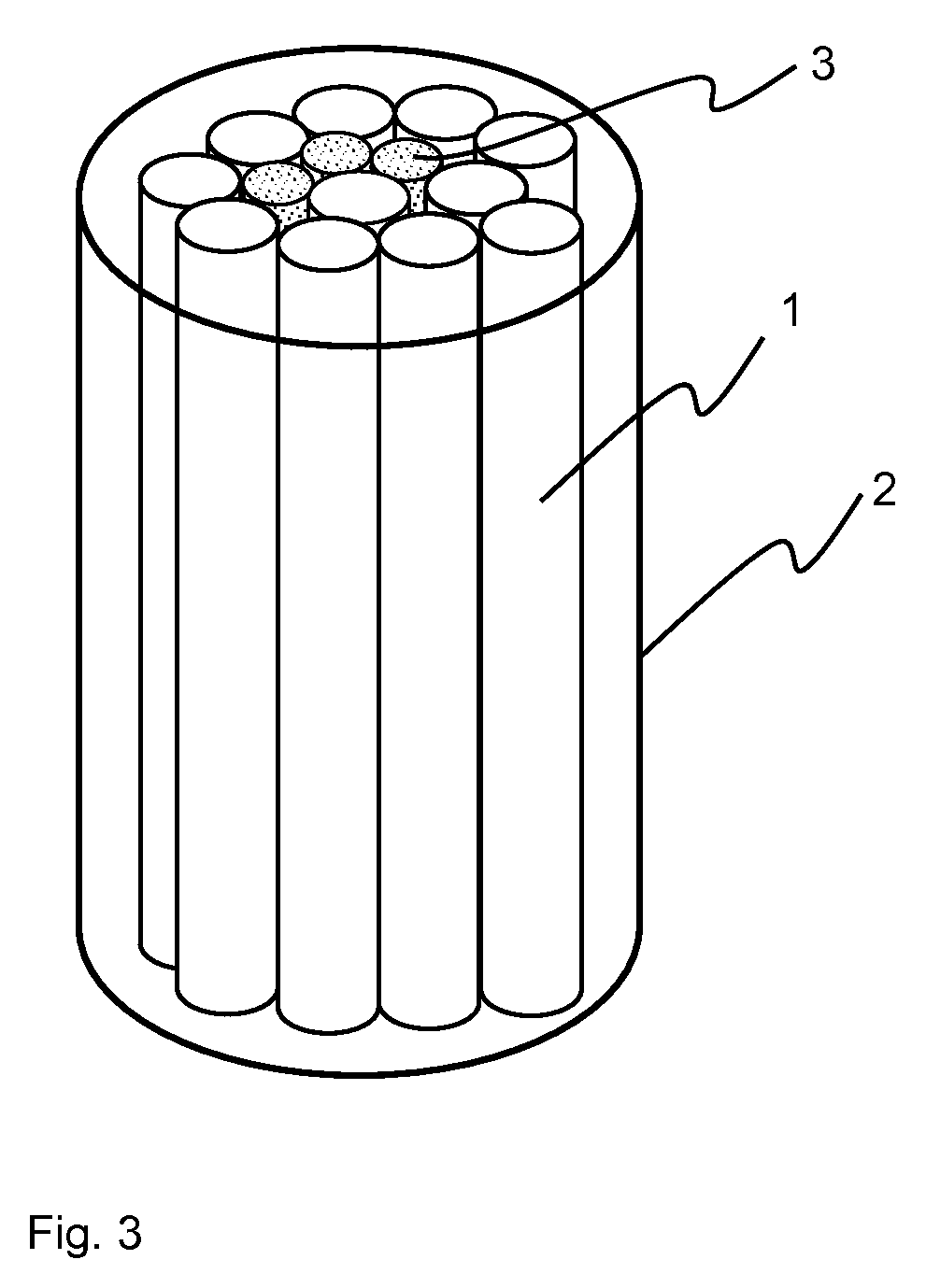

Side emitting glass element

ActiveUS20130314940A1Realize the shapeSuitable for useMechanical apparatusLight guidesLight guideRefractive index

Side emitting glass elements are provided that include a plurality of light guiding elements, which are inseparably connected to one another at their outer circumferential surfaces, and at least one scattering element. The scattering element is inseparably connected to the outer circumferential surface of at least one light guiding element. The light guiding elements have at least one glass with a refractive index n1, wherein the individual light guiding elements are not enclosed by a cladding. A phase boundary is present between the light guiding elements through which the guided light can pass and to reach the scattering element.

Owner:SCHOTT AG

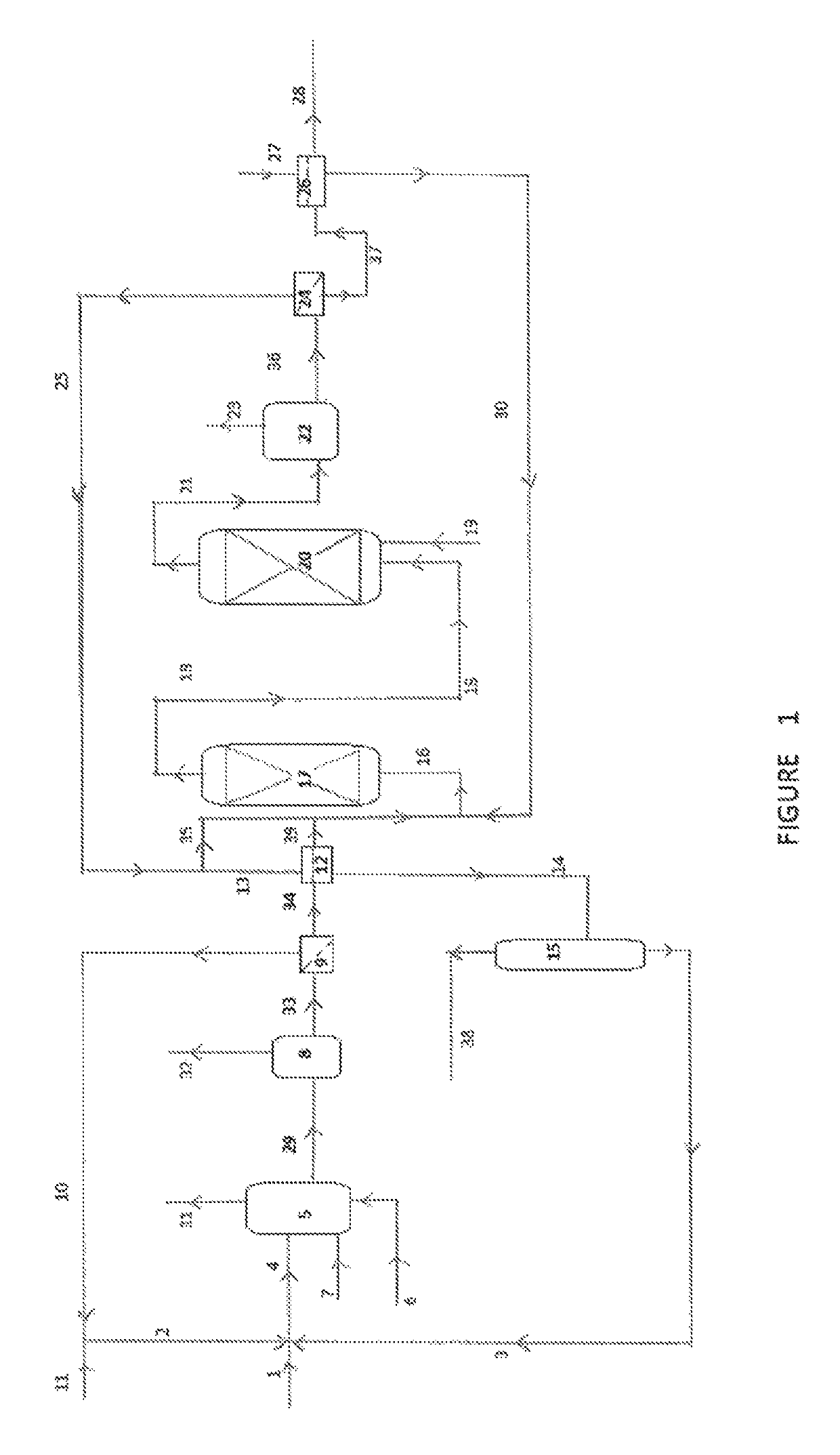

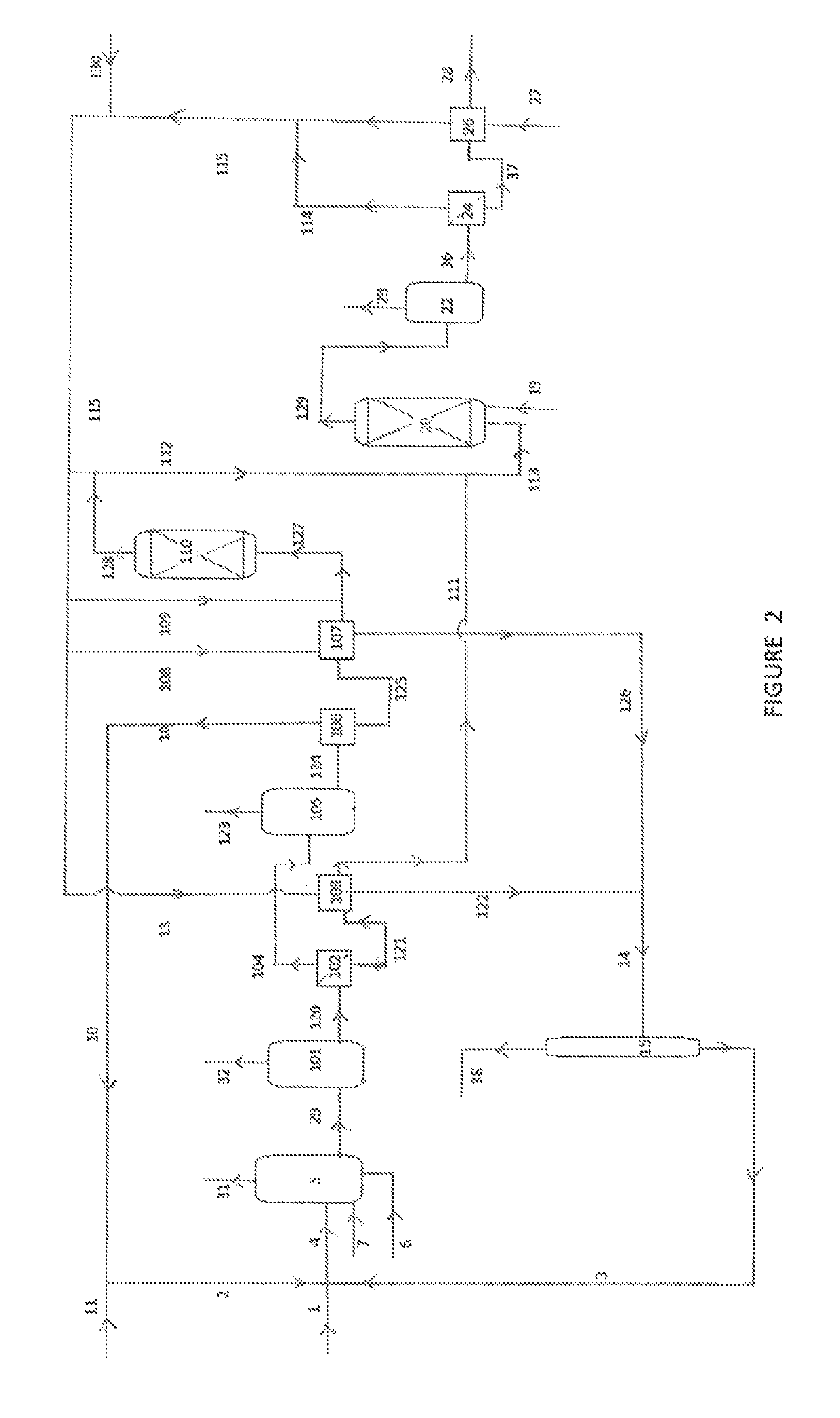

Process for producing olefins

InactiveUS20110112314A1Produce some attenuationReduce needThermal non-catalytic crackingHydroxy compound preparationHydrogenOxygenate

The present invention provides a process for producing olefins, comprising:a. cracking an ethane-comprising feed in a cracking zone under cracking conditions to obtain at least olefins and hydrogen;b. converting an oxygenate feedstock in an oxygenate-to-olefin zone to obtain at least olefins; wherein at least part of the oxygenate feedstock is obtained by providing hydrogen obtained in step a) and a feed containing carbon monoxide and / or carbon dioxide to an oxygenate synthesis zone and synthesizing oxygenates.In another aspect the invention provides an integrated system for producing olefins.

Owner:ACCUFLUX +1

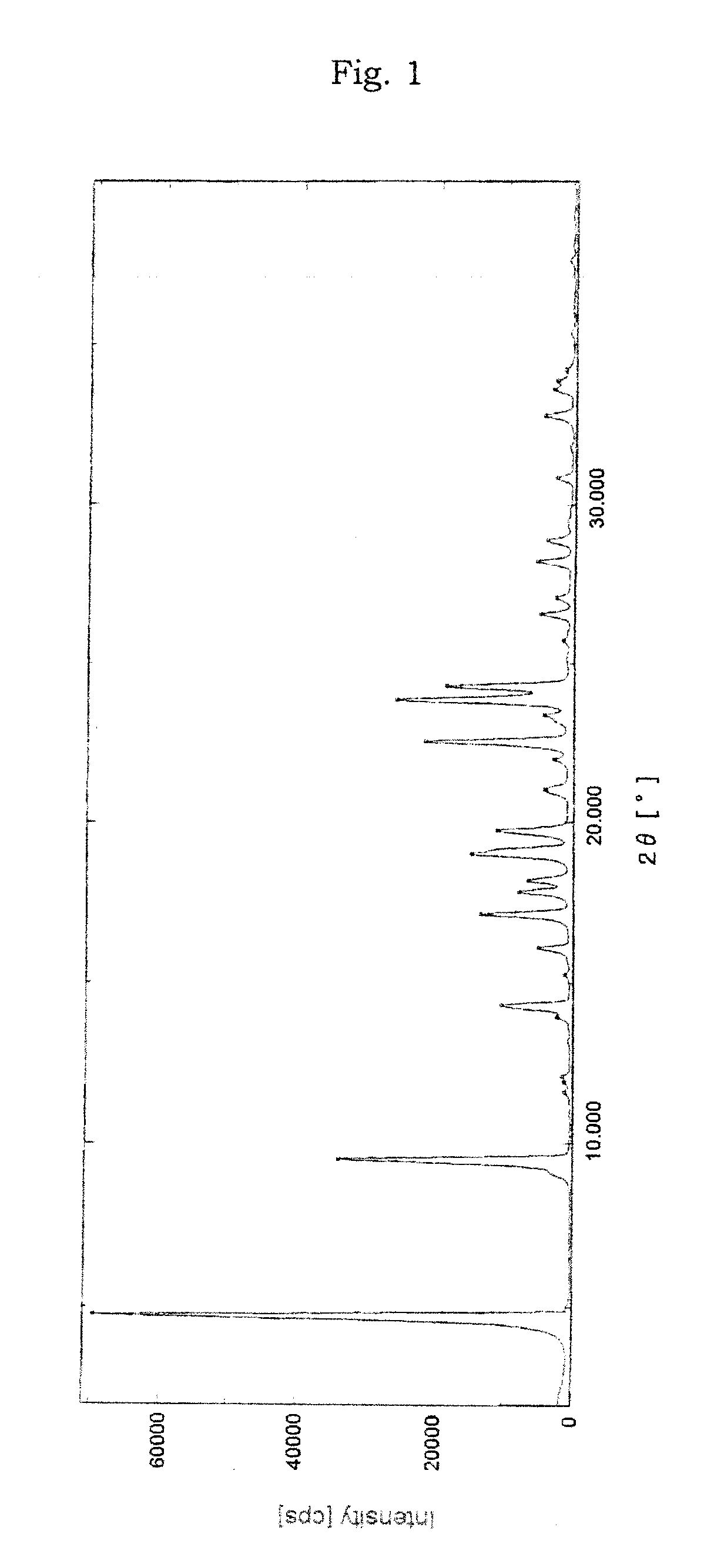

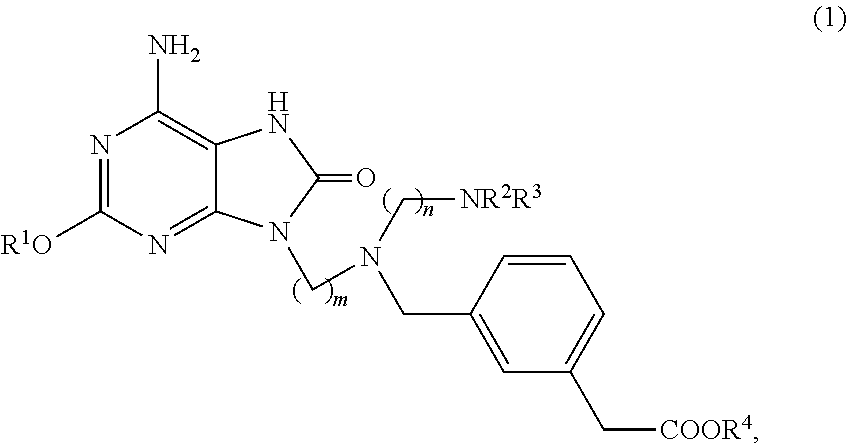

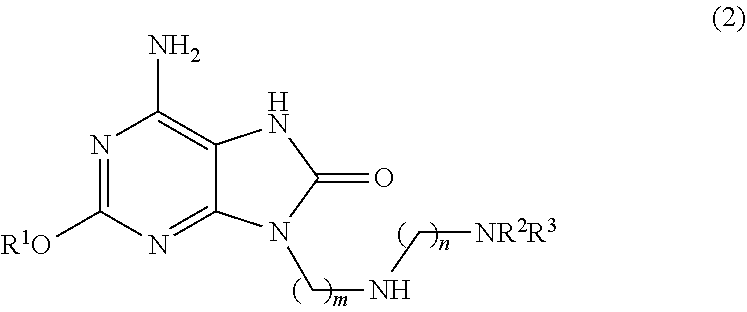

Method for preparing adenine compound

A method for producing adenine compound (1):wherein m and n are independently an integer of 2 to 5, R1 is C1-6 alkyl group, R2 and R3 are the same or different, and hydrogen atom, or C1-6 alkyl group, or R2 and R3 are combined with an adjacent nitrogen atom to form pyrrolidine, morpholine, piperidine, piperazine, etc., and R4 is C1-3 alkyl group,which comprises a step of reacting compound (2):and compound (3):in the presence of a boron-containing reducing agent.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD +1

Type of loop heat conducting device

ActiveUS7543629B2Simple structureEasy to mass produceIndirect heat exchangersCooling/ventilation/heating modificationsHeat conductingEngineering

This invention relates to a type of loop heat conducting device, comprising an evaporator and a condenser which are connected together by means of a loop pipe, in order to form a cyclic loop for a liquid working medium, wherein the evaporator has a wick network core, and multiple tunnels are formed on the wick network core, and one end of the tunnels converges at a vapor chamber and is connected to a loop pipe to form a gaseous working medium outlet, and the terminal end of the pipe extends into and comes into contact with the internal part of the wick network core, and a compensation chamber for liquid working medium is formed on the upper section of the wick network core. Consequently, the cyclic loop that separates the gas and liquid enables the optimal heat dissipation capacity, and also has a structure that is simplified, thereby allowing for easy mass production.

Owner:YEH CHIANG TECH CORP

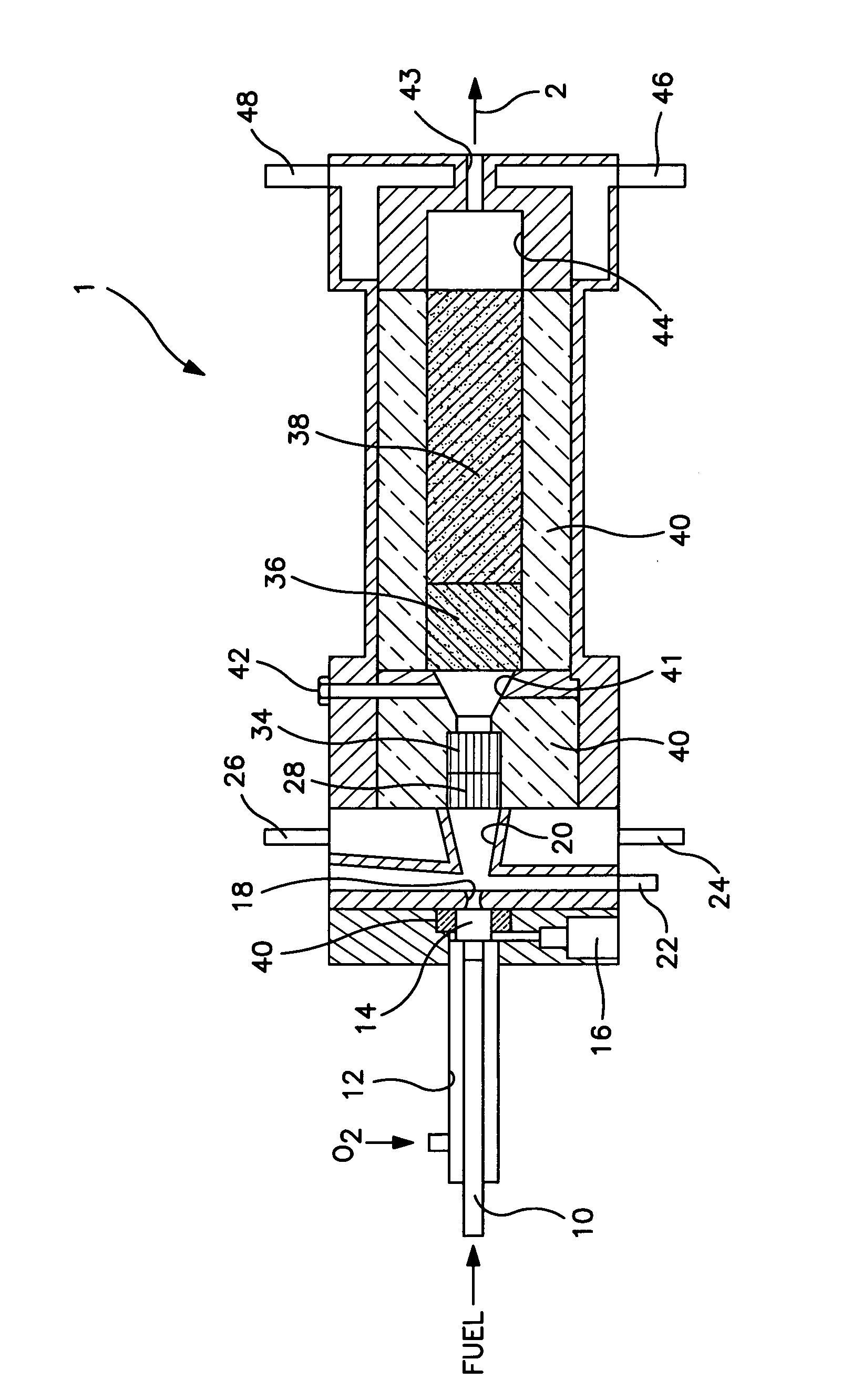

Autothermal reactor and method for production of synthesis gas

ActiveUS7255840B2Quick responseSmall productHydrogenChemical/physical/physico-chemical stationary reactorsPartial oxidationReaction zone

An autothermal reactor and method for producing synthesis gas in which a heated oxygen containing stream is expanded into a mixing chamber to entrain a hydrocarbon containing stream to form a reactant stream without reaction of the oxygen and hydrocarbon contents of the streams. The reactant stream is reacted in a series of sequential catalytic reaction zones to react the hydrocarbon and oxygen contained in the reactant stream to form the synthesis gas. The sequential catalytic reaction zones are configured such that an initial partial oxidation reaction occurs that is followed by endothermic reforming reactions having ever decreasing temperatures. The sequential catalytic reaction zones in which the endothermic reforming reactions occur contain a precious metal catalyst supported on ceramic supports that have successively greater surface areas to compensate for the temperature decrease while remaining stable and without a transform in state.

Owner:PRAXAIR TECH INC

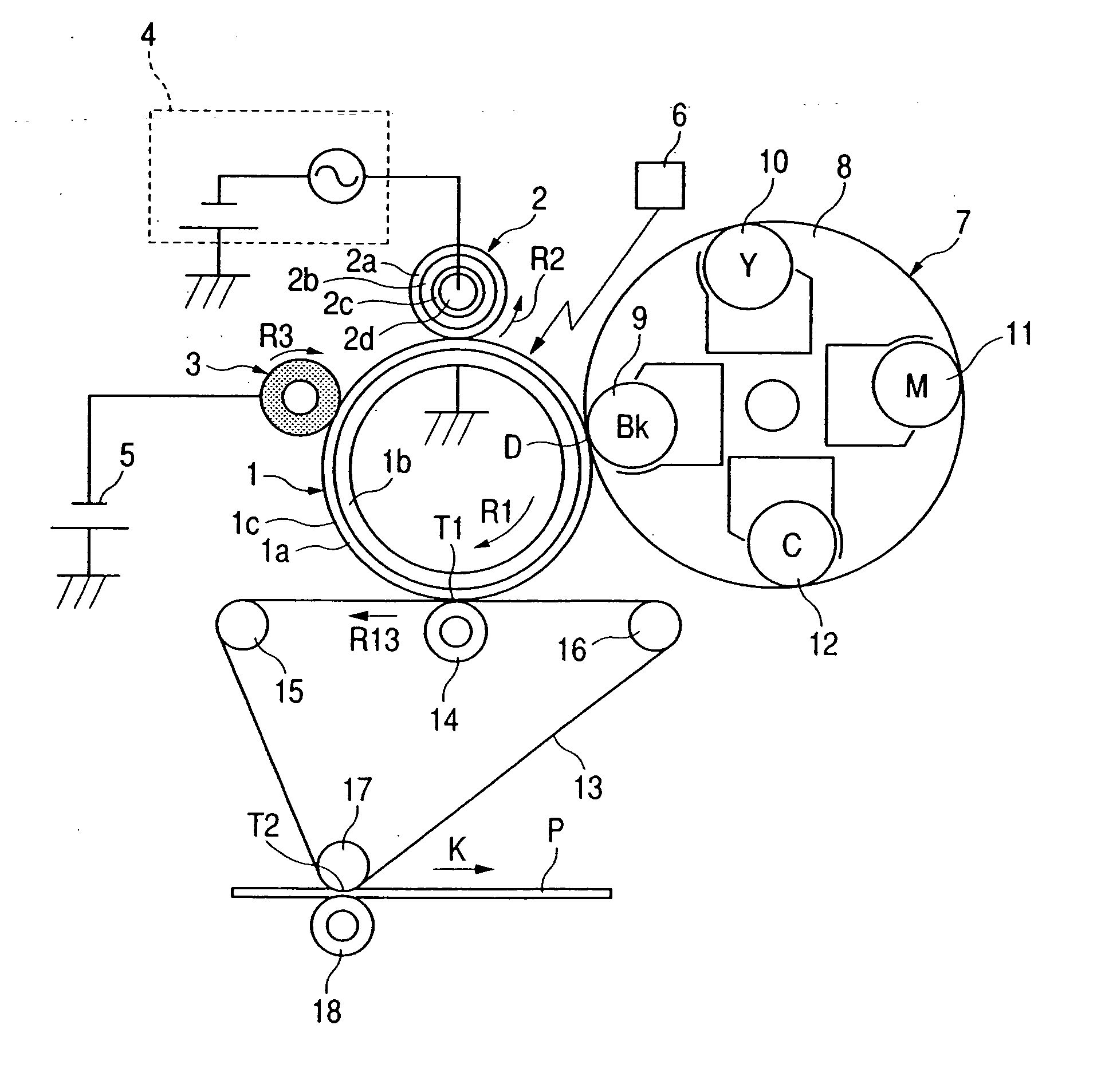

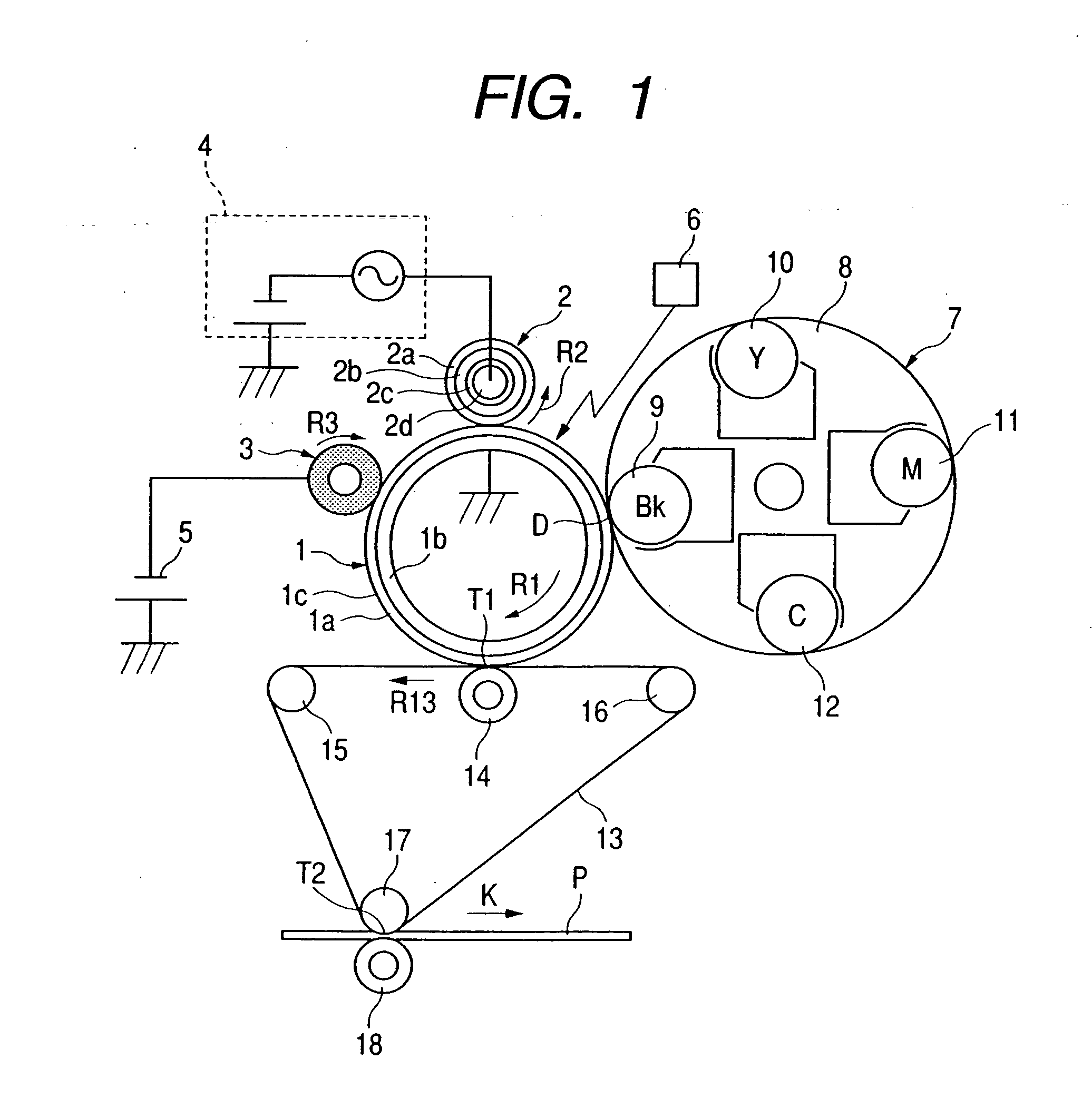

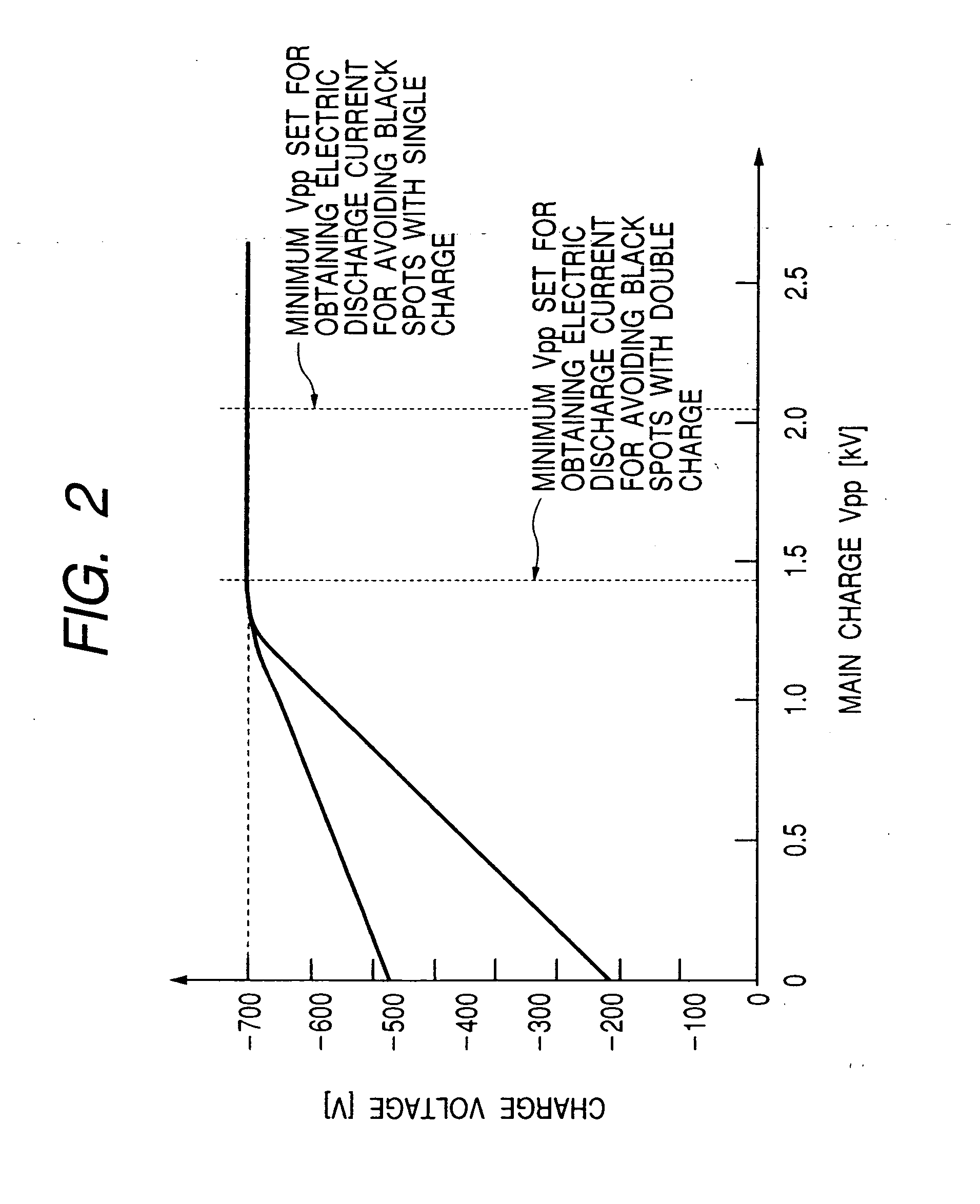

Charging apparatus having auxiliary charger rubbing against image bearing member

InactiveUS20050013631A1Production amount is smallSmall amountRadiation applicationsElectrographic process apparatusEngineeringElectrical and Electronics engineering

A charging apparatus has a movable image bearing member, a first charging member for charging the image bearing member, and a second charging member provided upstream of the first charging member with respect to the direction of movement of the image bearing member, the second charging member having an elastic rotary member rubbing against the image bearing member.

Owner:CANON KK

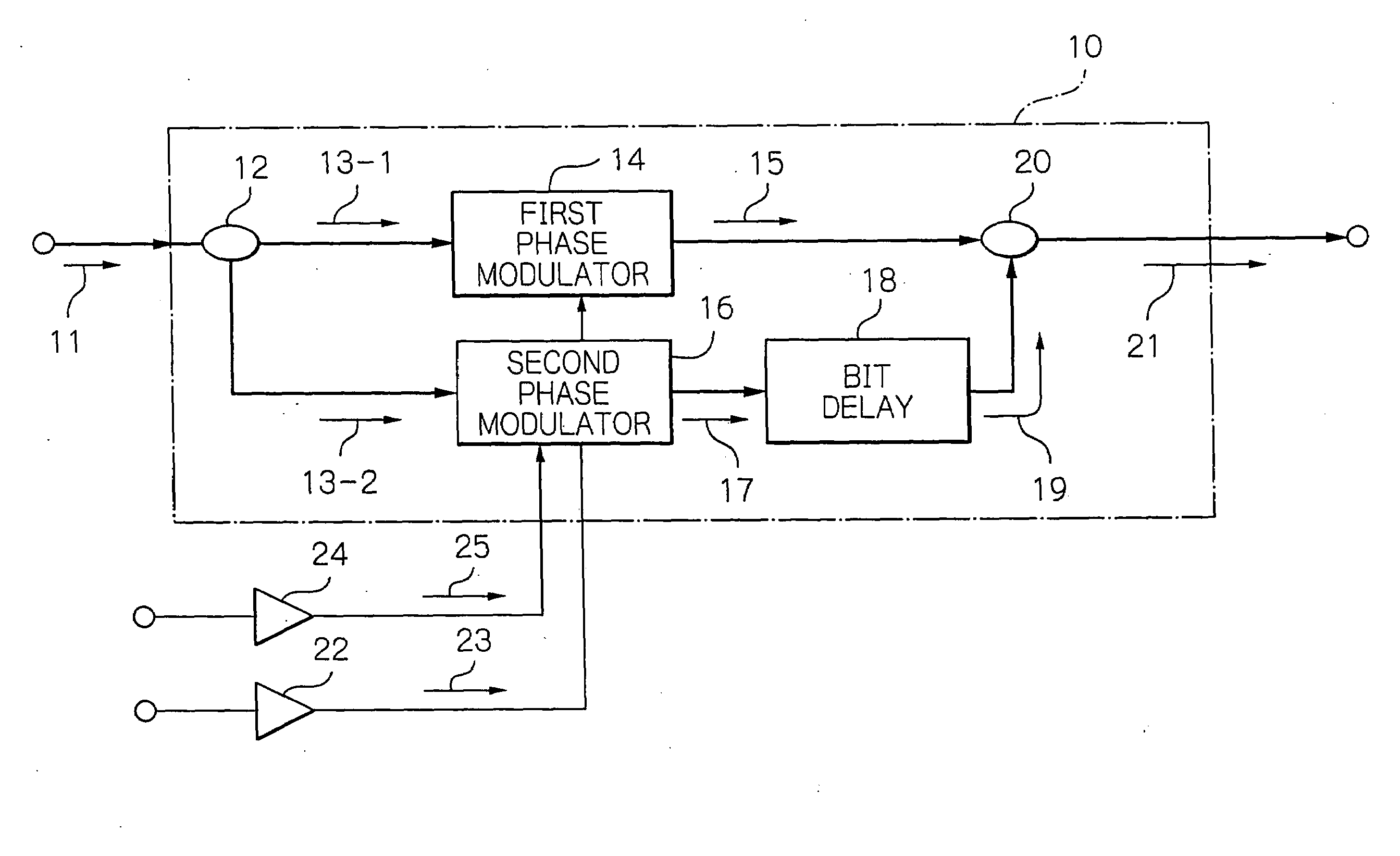

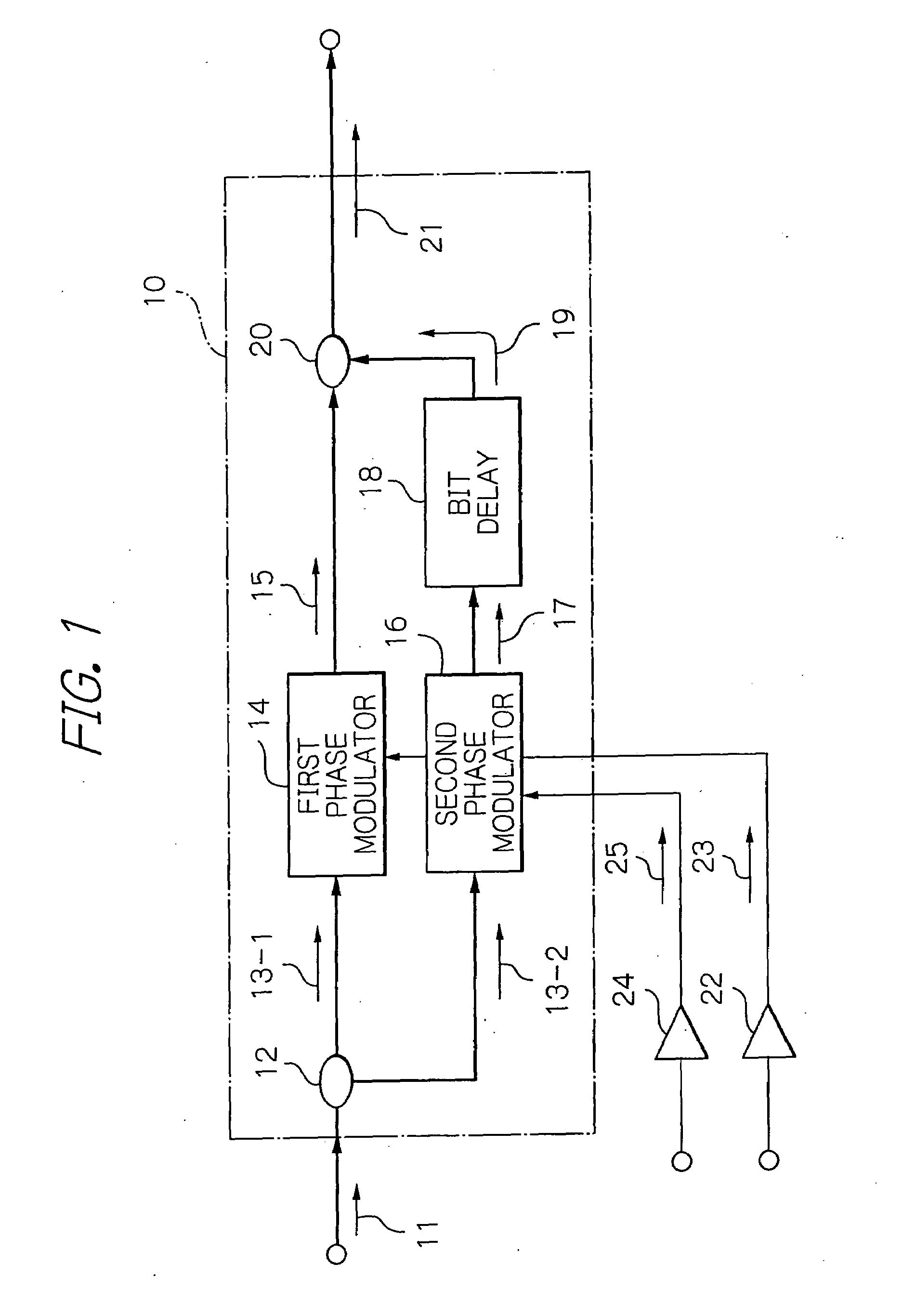

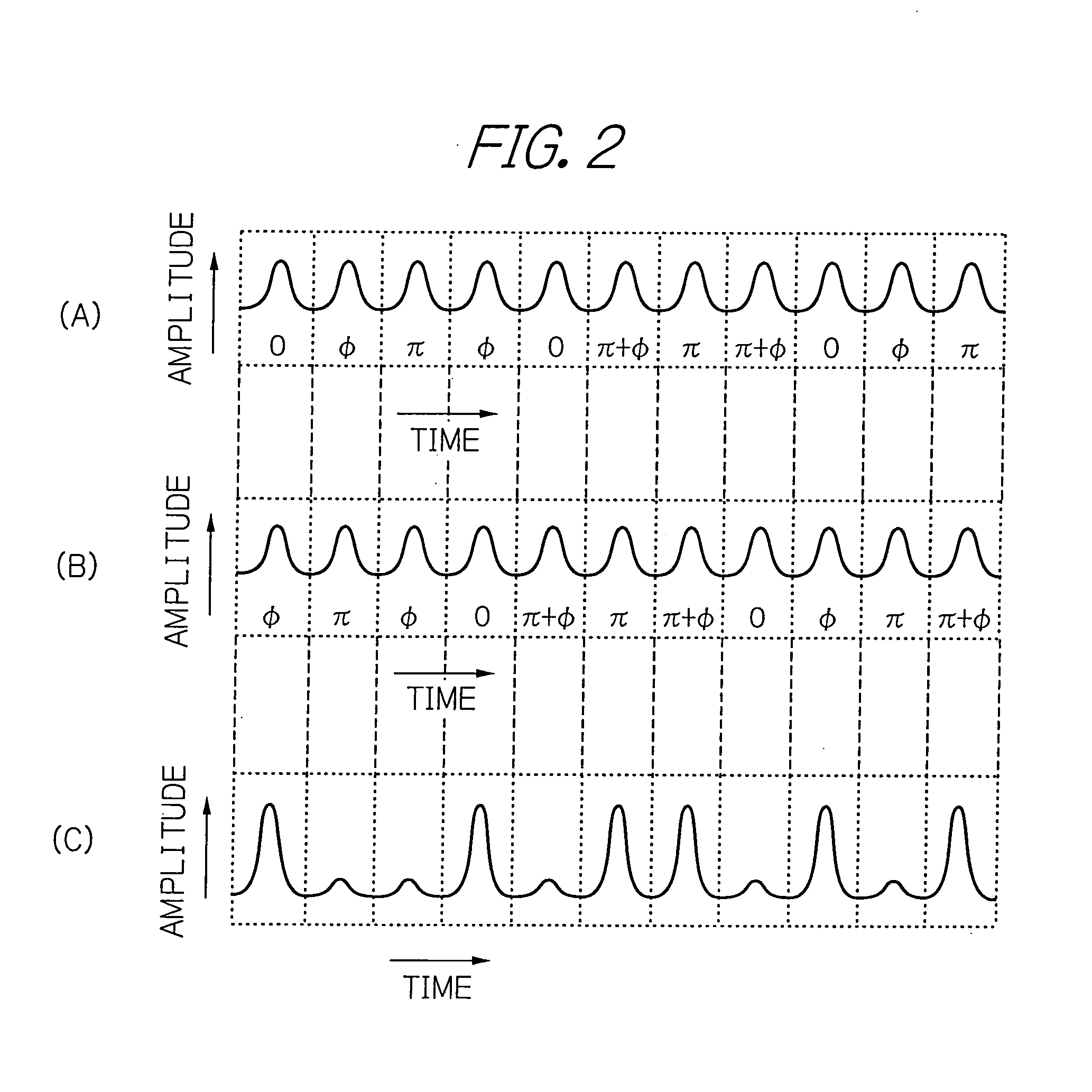

OTDM-DPSK signal generator capable of detecting an optical carrier phase difference between optical pulses

ActiveUS20080080859A1Low costSmall productPolarisation multiplex systemsTime-division optical multiplex systemsSignal generatorOptical coupler

An OTDM-DPSK signal generator includes an optical splitter, a first and a second phase modulator, an optical coupler, and a monitor signal splitter. The optical splitter splits an optical pulse string into a first and a second optical pulse string. The first and second phase modulators generate a first and a second channel DPSK signal, respectively. The DPSK signals are provided with one bit delay to generate another DPSK signal, which enters the optical coupler, which outputs an OTDM-DPSK signal, which enters a monitor signal splitter. The monitor signal splitter splits from the OTDM-DPSK signal a monitor signal and inputs the monitor signal to an optical carrier phase difference detector. The detector generates an optical carrier phase difference detection signal as a function of an optical carrier phase difference between optical pulses. The optical carrier phase difference can thus be detected between optical pulses in an OTDM-DPSK signal.

Owner:OKI ELECTRIC IND CO LTD

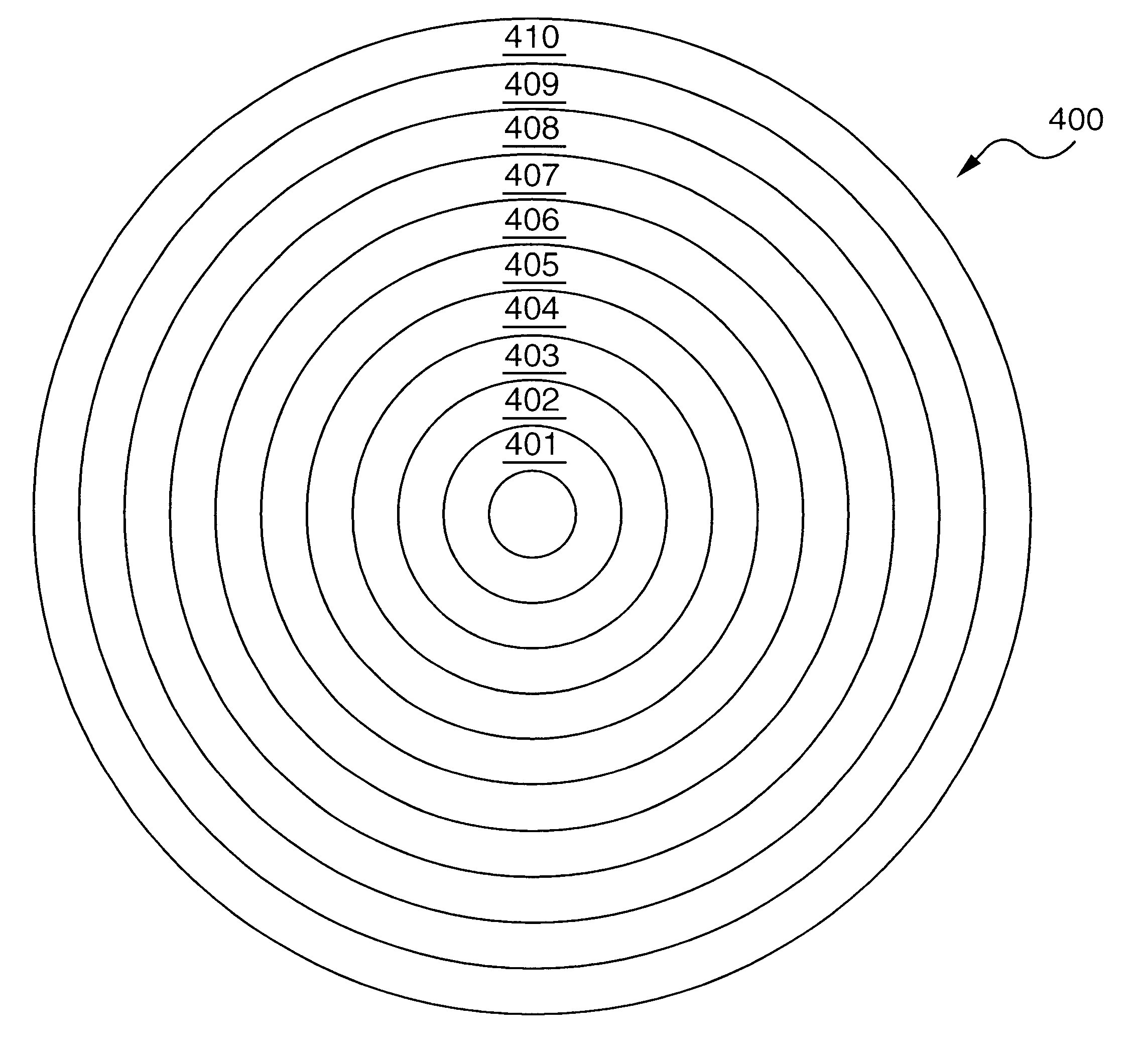

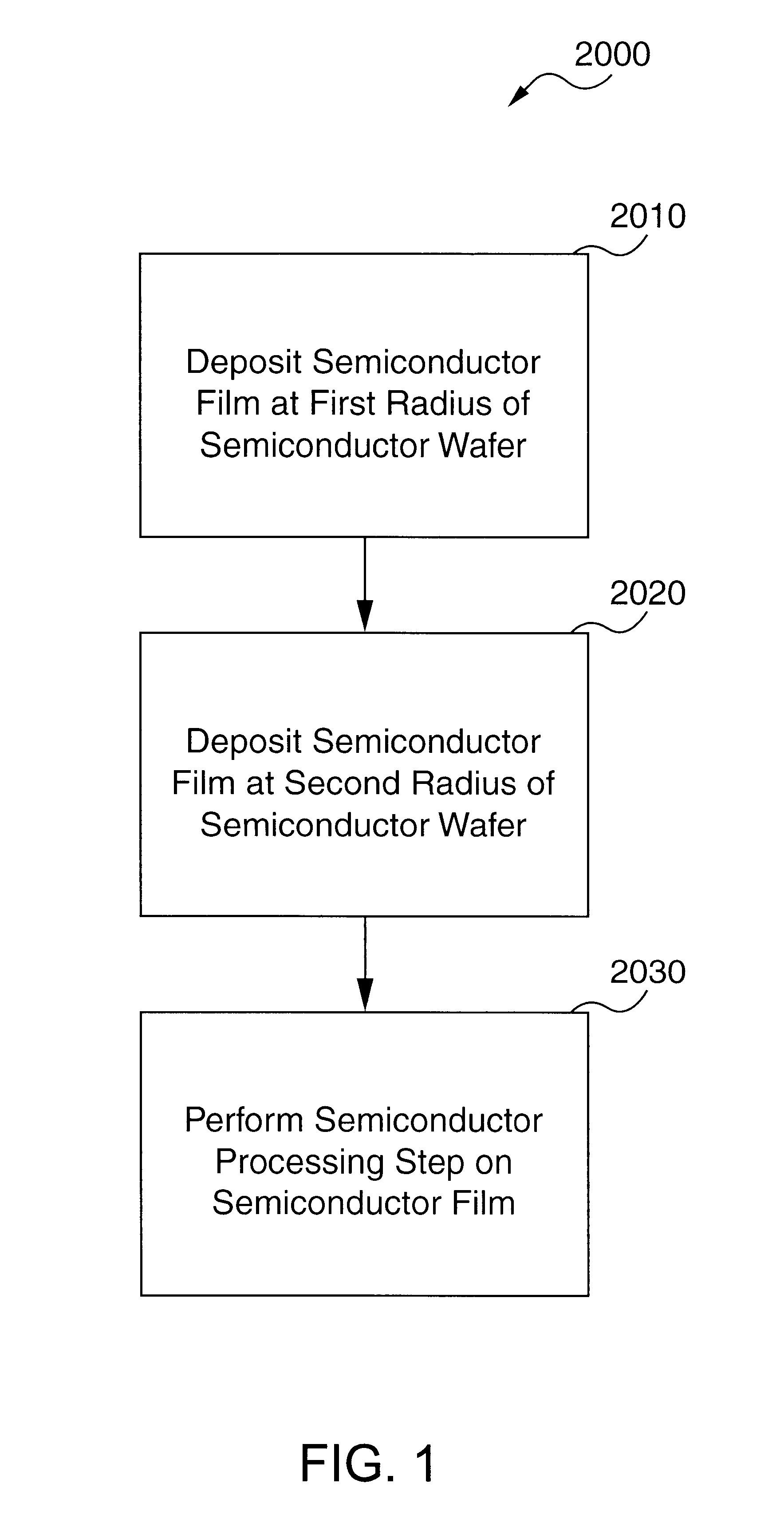

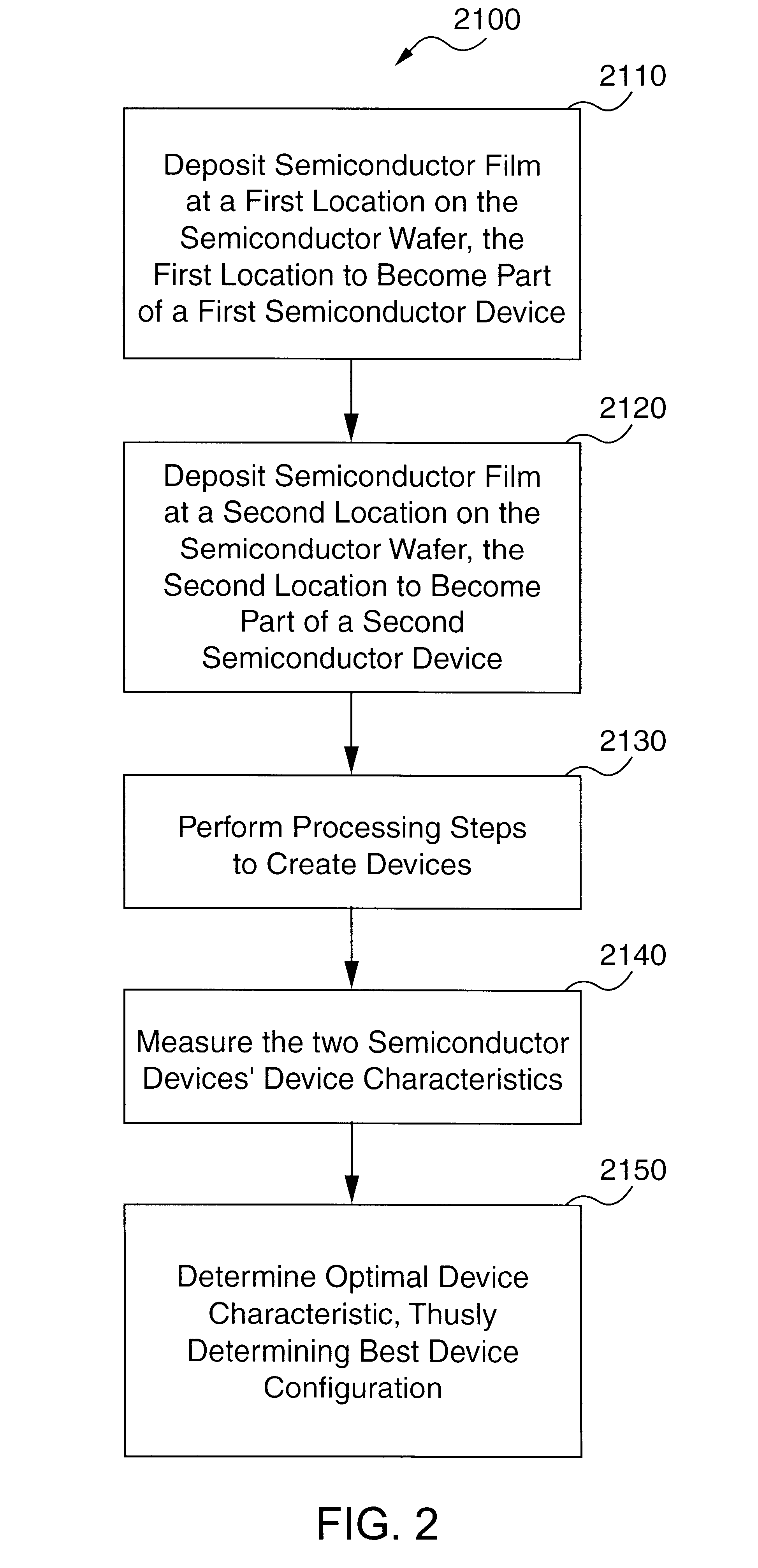

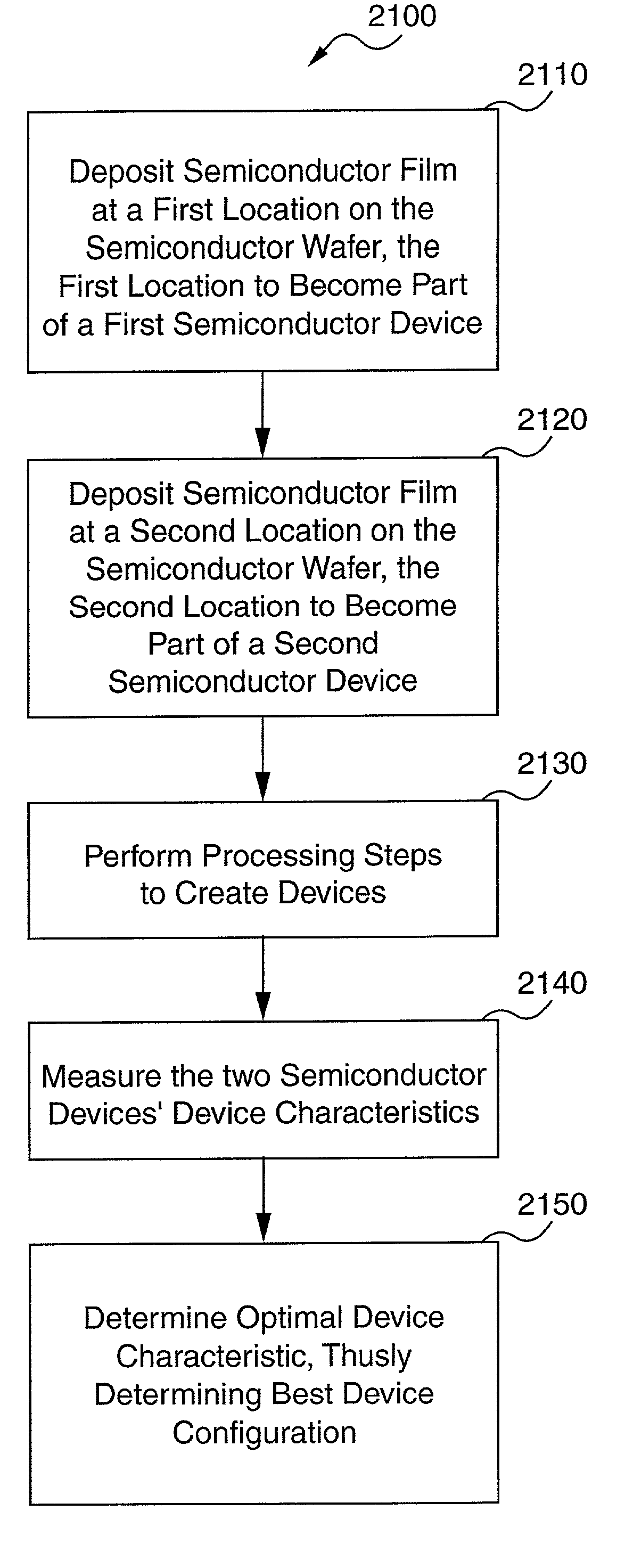

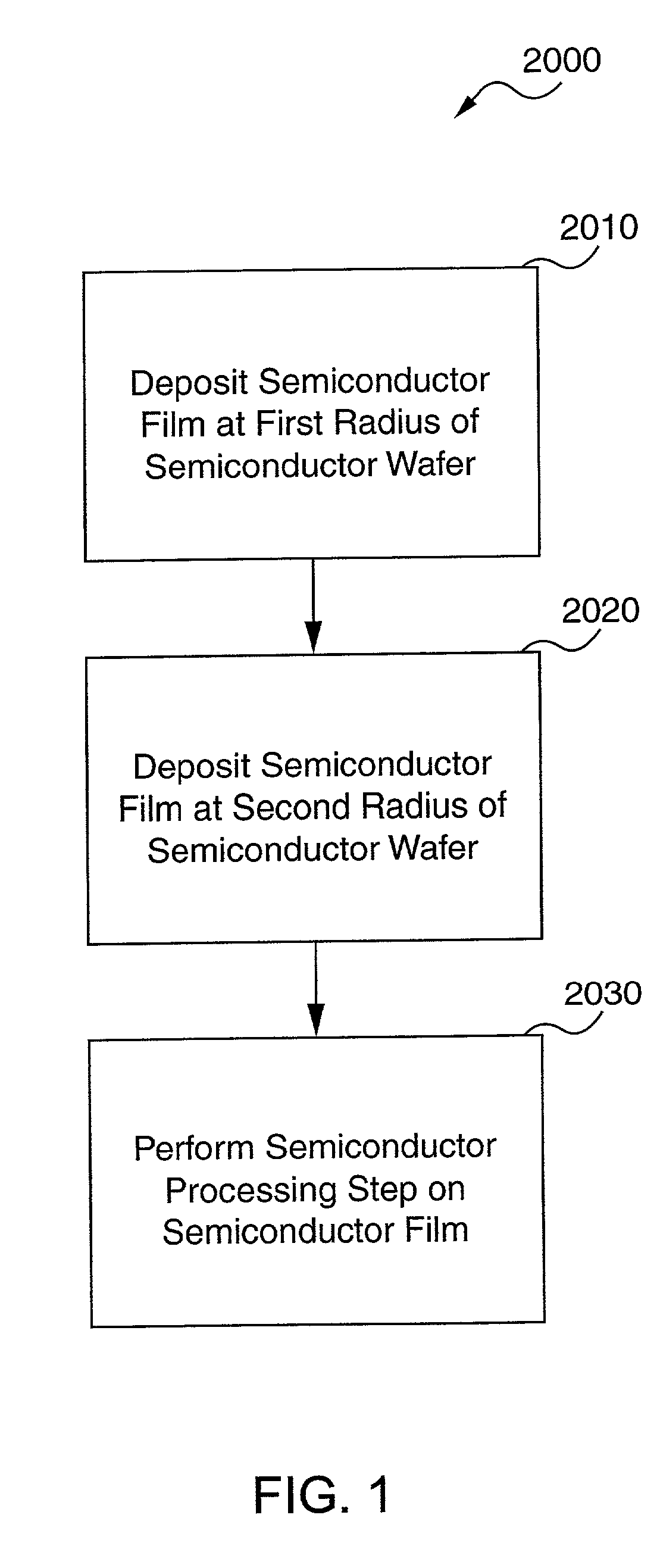

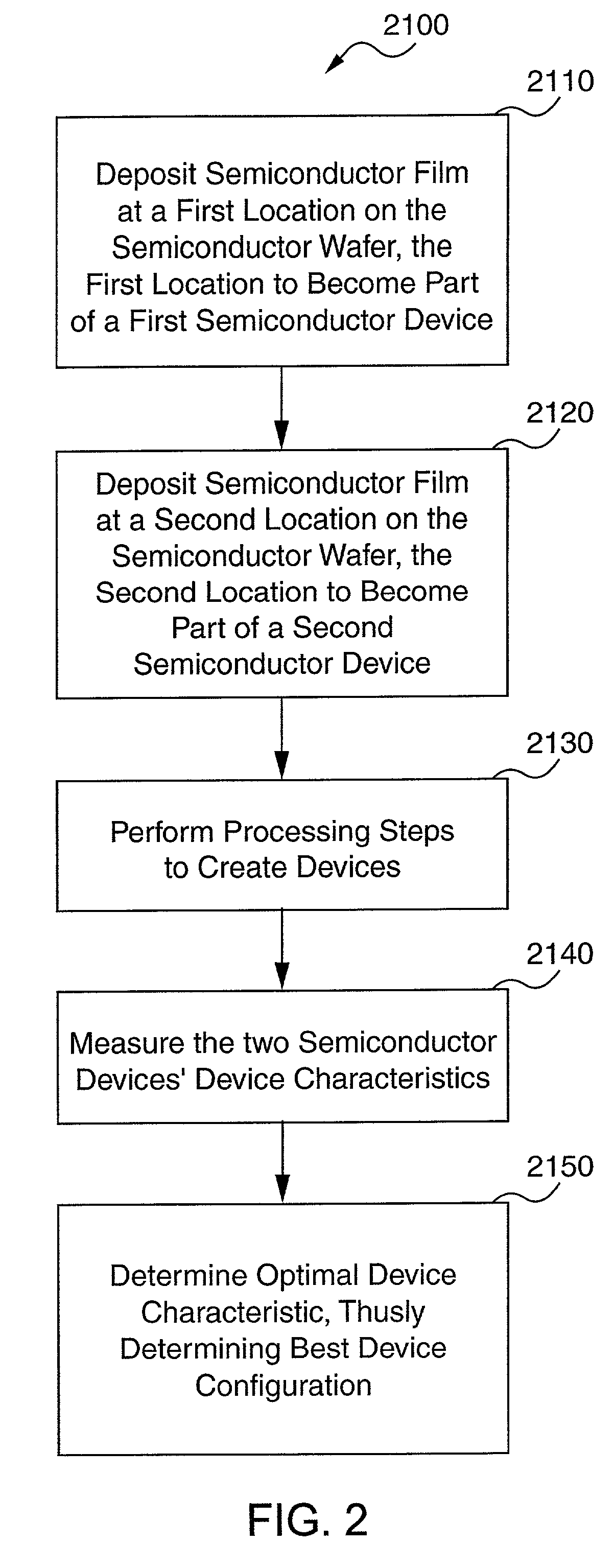

Deliberate semiconductor film variation to compensate for radial processing differences, determine optimal device characteristics, or produce small productions

InactiveUS6344416B1Reduce radial effectImprove featuresSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Methods and apparatuses are disclosed that can introduce deliberate semiconductor film variation during semiconductor manufacturing to compensate for radial processing differences, to determine optimal device characteristics, or produce small production runs. The present invention radially varies the thickness and / or composition of a semiconductor film to compensate for a known radial variation in the semiconductor film that is caused by performing a subsequent semiconductor processing step on the semiconductor film.Additionally, methods and apparatuses are disclosed that can introduce deliberate semiconductor film variations to determine optimal device characteristics or produce small production runs. Introducing semiconductor film variations, such as thickness variations and / or composition variations, allow different devices to be made. A number of devices may be made having variations in semiconductor film. Because the semiconductor film has variations between the devices, device characteristics of the devices should be different. By measuring the device characteristics of devices having the variations, the device with the optimum device characteristic may be chosen, thereby indicating the appropriate semiconductor film thickness and / or composition. Moreover, small production runs of the same devices, having different characteristics, will allow the end user to select the appropriate devices for their needs.

Owner:IBM CORP

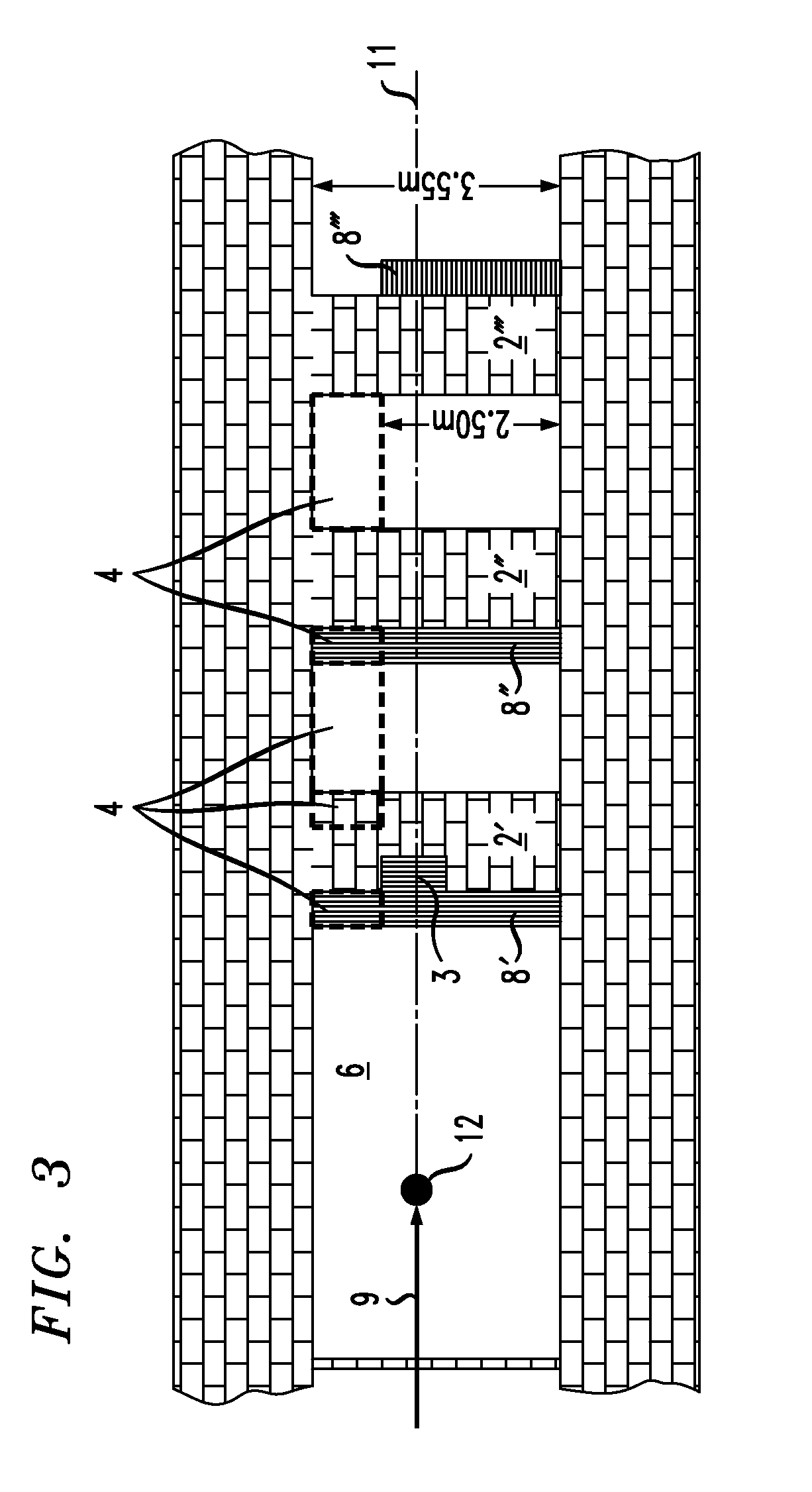

Piezoelectric pump and fluid transferring system

InactiveUS20100059127A1Piezoelectric pumpImprove stabilityFlexible member pumpsPump controlPump chamberEngineering

To provide a piezoelectric pump including: a structure including a piezoelectric element and a support member that supports the piezoelectric element; and a first substrate and a second substrate that sandwich the structure, wherein the piezoelectric pump has: a pump chamber surrounded by the second substrate and the structure; and a first opening and a second opening that are communicated with the pump chamber, and wherein a space is provided so that the structure flexes in a direction opposite to the pump chamber according to an operation of the piezoelectric element.

Owner:TDK CORPARATION

Side emitting glass element

ActiveUS9329318B2Low efficiencyEfficient productionAircraft lightsOptical signallingLight guideRefractive index

Side emitting glass elements are provided that include a plurality of light guiding elements, which are inseparably connected to one another at their outer circumferential surfaces, and at least one scattering element. The scattering element is inseparably connected to the outer circumferential surface of at least one light guiding element. The light guiding elements have at least one glass with a refractive index n1, wherein the individual light guiding elements are not enclosed by a cladding. A phase boundary is present between the light guiding elements through which the guided light can pass and to reach the scattering element.

Owner:SCHOTT AG

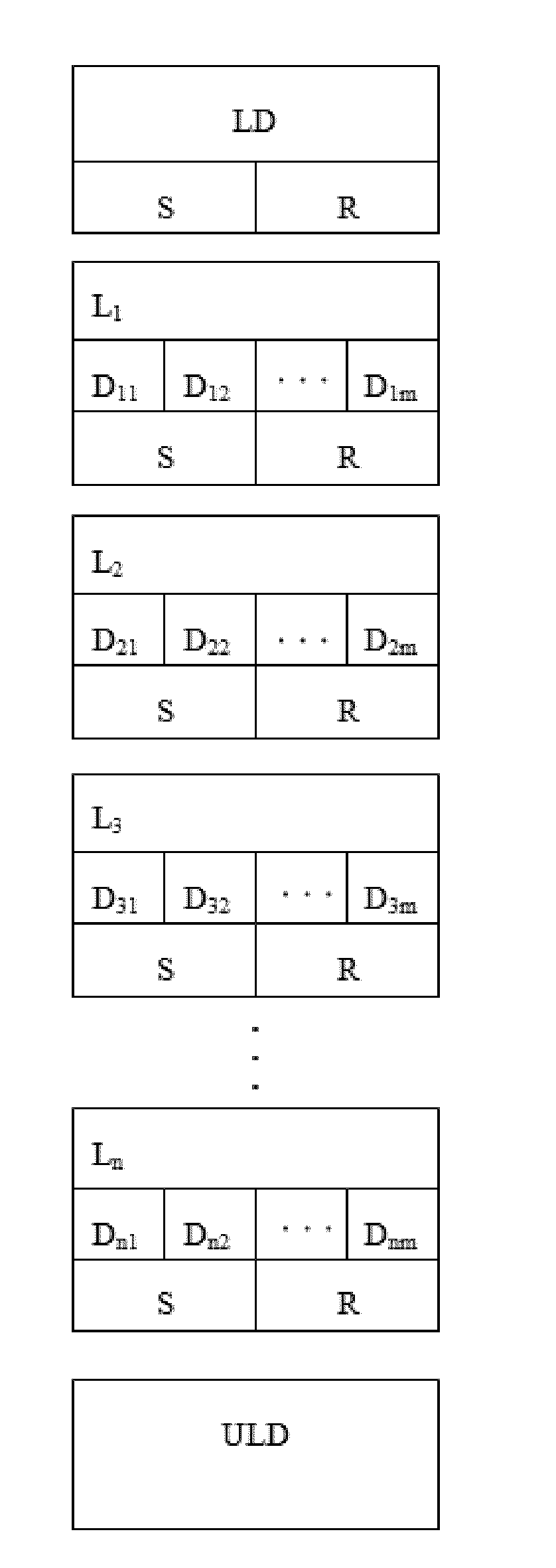

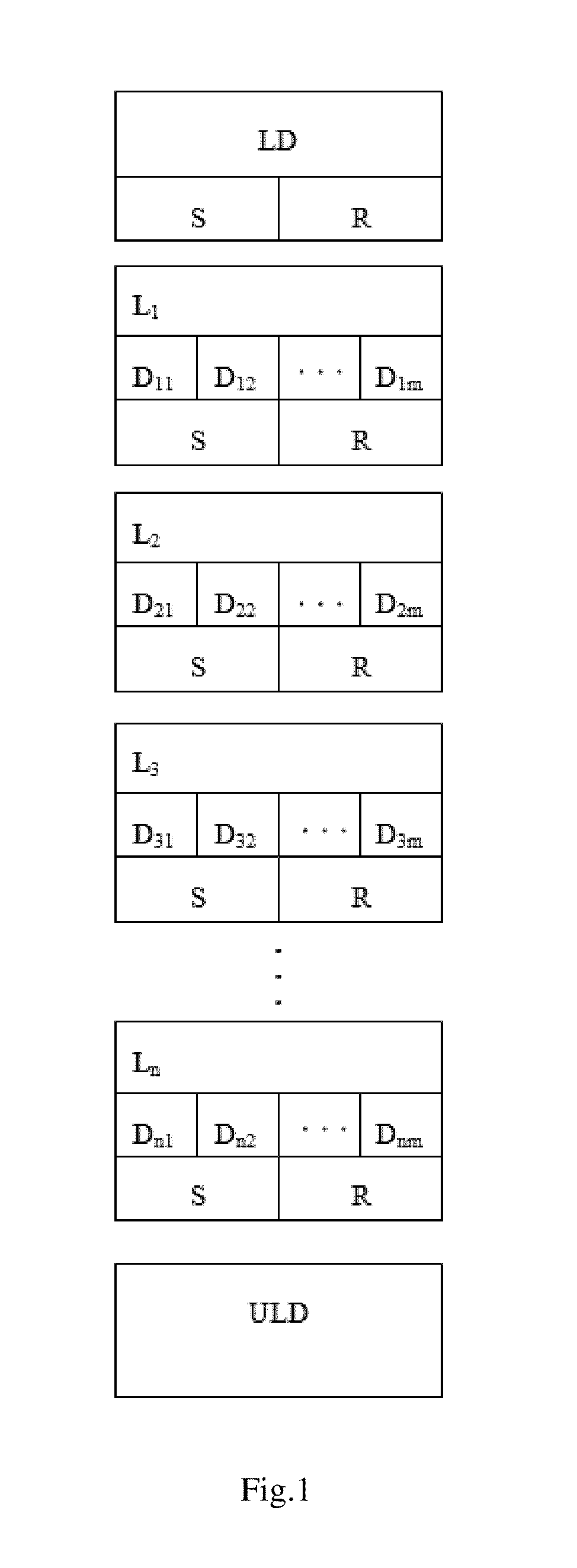

Production Line System and Controlling Method Thereof

ActiveUS20150025669A1Small productEfficient use ofTotal factory controlSpecial data processing applicationsSignal analyzerManufacturing line

A production line system includes n operational stations L1, L2, L3 . . . Ln. Each operational station includes: m operational devices D1, Dn2, Dn3 . . . Dnm in each operational station, and the operational devices used for processing operated products with m specifications, respectively, in which n=1, 2, 3, n and m≧1. An initial terminal of the production line system comprises a signal analyzer and a transport mechanism. The signal analyzer is used for analyzing product information of an operated product and for demanding the transport mechanism to deliver the operated product to a corresponding initial operational station and a corresponding operational device according to the product information The production line system provided can deal with products with more than two different specifications at the same time, and especially can apply to producing a small number of products or an experimental batch of products. The production line system has advantages of saving production time of a small number of products, effectively utilizing devices on the production line, improving production efficiency, and reducing production cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Deliberate semiconductor film variation to compensate for radial processing differences, determine optimal device characteristics, or produce small production runs

InactiveUS20020045357A1Improve featuresSmall productSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Methods and apparatuses are disclosed that can introduce deliberate semiconductor film variation during semiconductor manufacturing to compensate for radial processing differences, to determine optimal device characteristics, or produce small production runs. The present invention radially varies the thickness and / or composition of a semiconductor film to compensate for a known radial variation in the semiconductor film that is caused by performing a subsequent semiconductor processing step on the semiconductor film. Additionally, methods and apparatuses are disclosed that can introduce deliberate semiconductor film variations to determine optimal device characteristics or produce small production runs. Introducing semiconductor film variations, such as thickness variations and / or composition variations, allow different devices to be made. A number of devices may be made having variations in semiconductor film. Because the semiconductor film has variations between the devices, device characteristics of the devices should be different. By measuring the device characteristics of devices having the variations, the device with the optimum device characteristic may be chosen, thereby indicating the appropriate semiconductor film thickness and / or composition. Moreover, small production runs of the same devices, having different characteristics, will allow the end user to select the appropriate devices for their needs.

Owner:IBM CORP

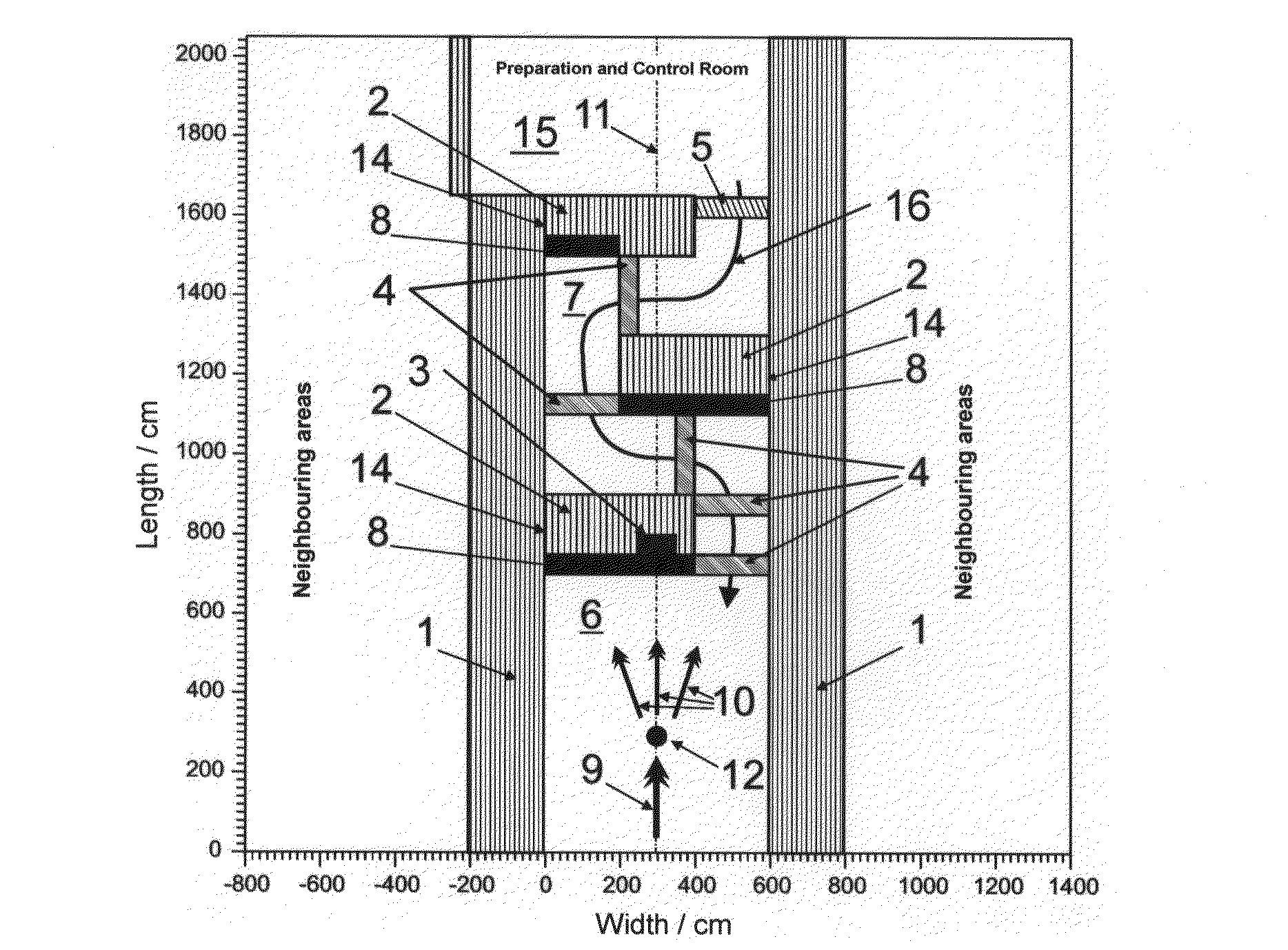

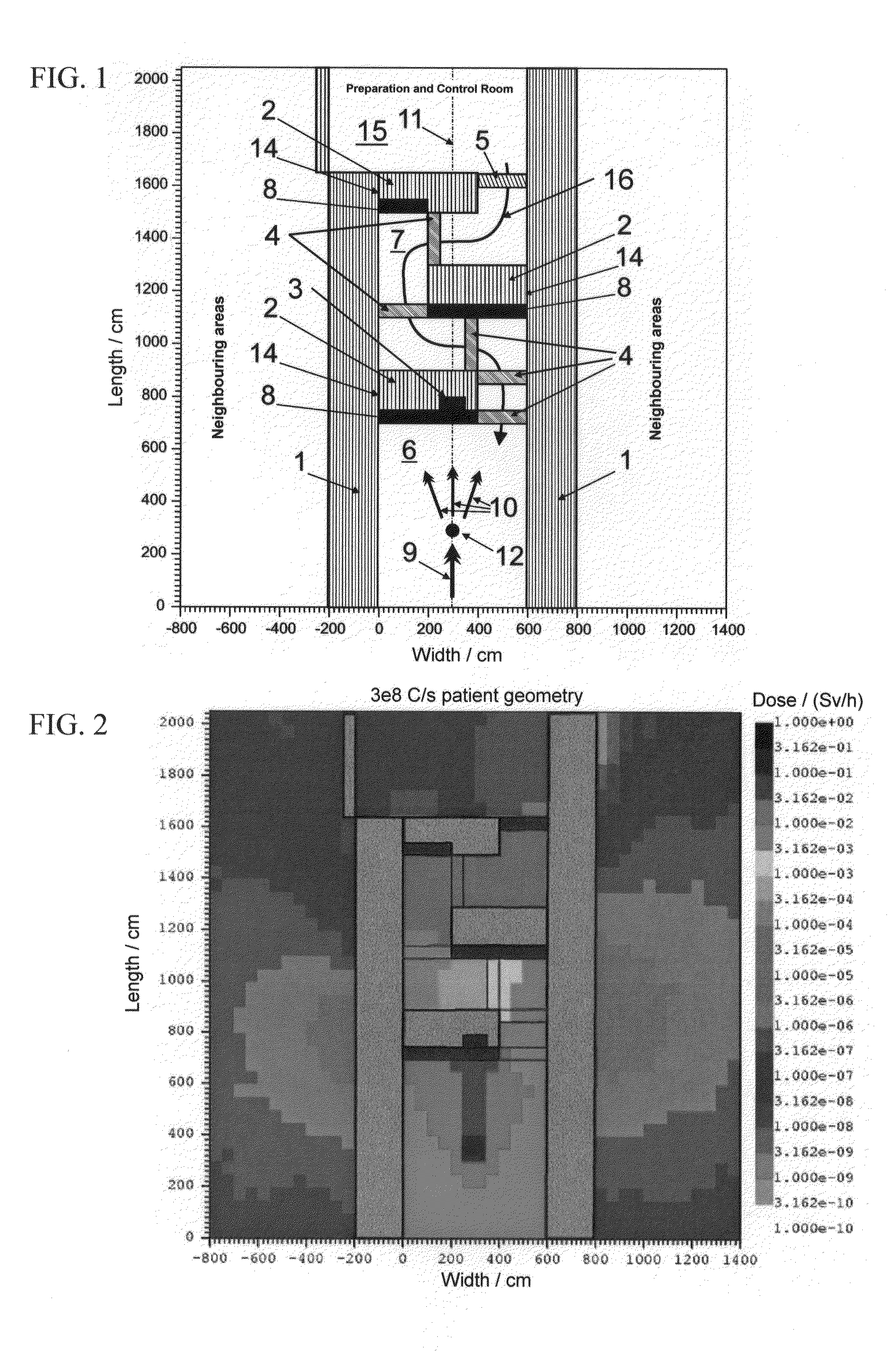

Screened chamber for ion therapy

InactiveUS8139705B2Constant efficiencyConstant interaction probabilitiesConversion outside reactor/acceleratorsNuclear energy generationHigh energyLight beam

In a shielded chamber for neutron therapy including a therapy room which has a central beam axis along which a high-energy therapy beam is introduced into the Chamber through one end wall thereof and which includes at the opposite end a labyrinth entrance with at least two shielding wall sections displaced longitudinally along the central beam axis and extending into the room from opposite side walls, the wall sections include structures for causing spallation to thereby generate from the high energy neutrons in the high energy neutron beam a plurality of low energy neutrons which are then moderated by the wall sections.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

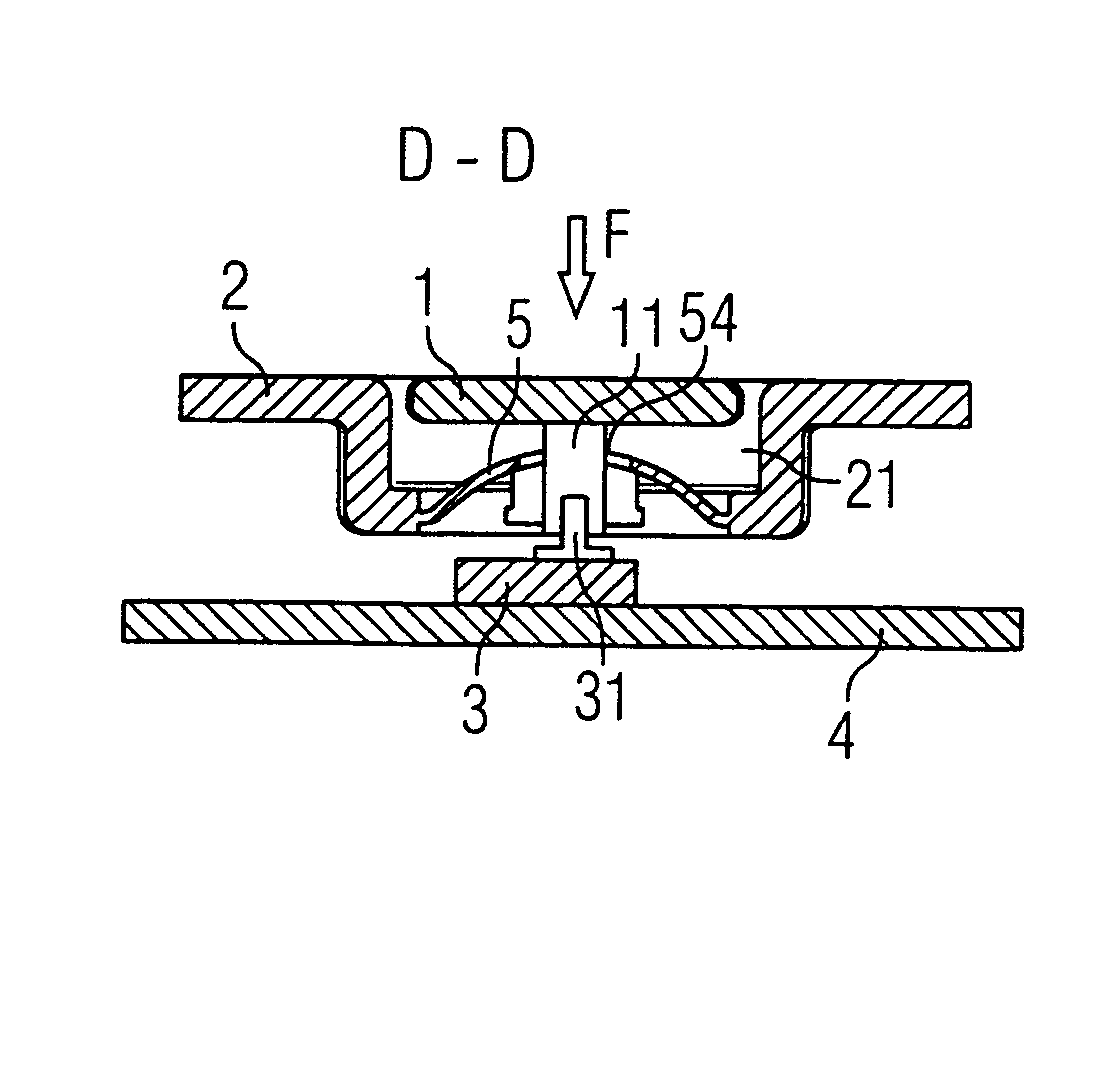

Navigation switch

InactiveUS7436391B2Promote destructionEasy to wearEmergency actuatorsContact mechanismsEngineeringMechanical engineering

Owner:CONTINENTAL AUTOMOTIVE GMBH

Processes for making copolymers using macrocyclic oligoesters, and copolymers therefrom

The invention provides alternatives to traditional polycondensation processes for preparing copolymers. For example, in certain embodiments, the invention provides a process that includes an extrusion step and a solid state polymerization step to prepare high molecular weight block copolymer with a “hard block” contributed by a macrocyclic polyester oligomer (MPO) and a “soft block” contributed by a dihydroxyl-functionalized polymer, an oligoether, and / or a dimerized fatty acid (i.e. a polyol). The invention also provides new copolymer compositions made possible by the new processes—for example, copolymers of higher molecular weight, copolymers with higher weight ratio of soft block units to hard block units, copolymers made with higher molecular weight polyol, and copolymers with hard block units that are themselves random copolyesters of units contributed by a MPO and a cyclic ester.

Owner:LIQUID THERMO PLASTICS

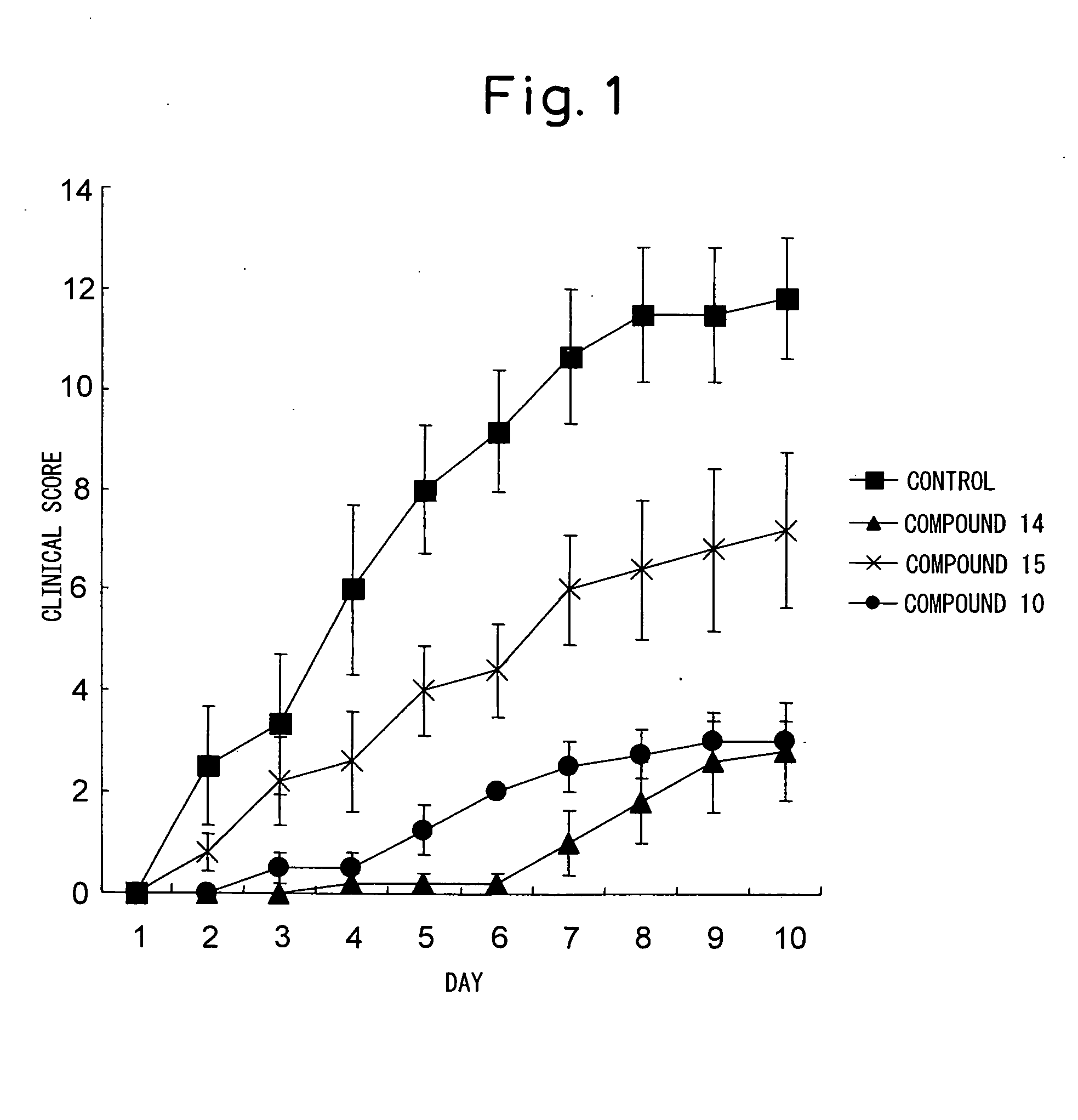

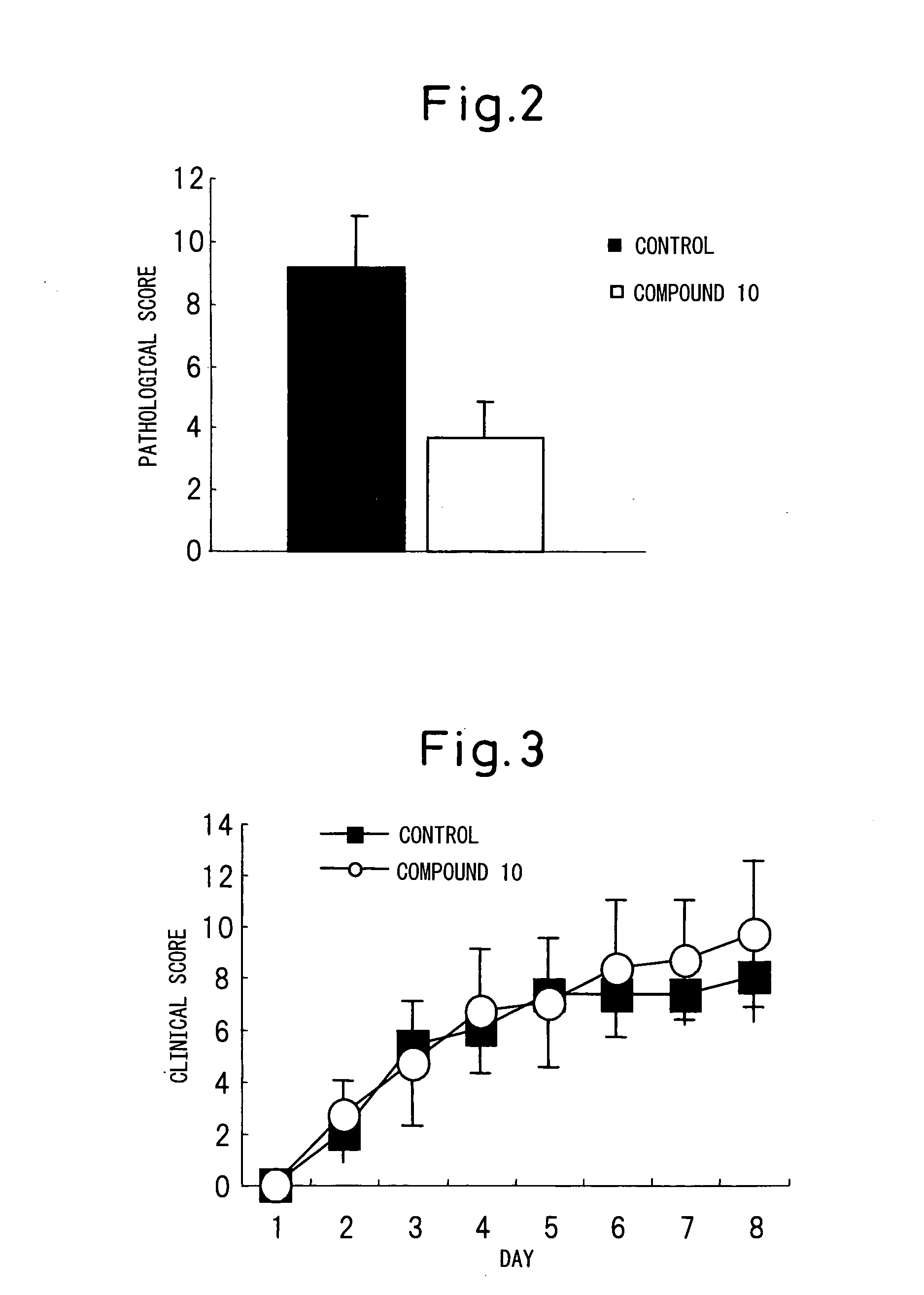

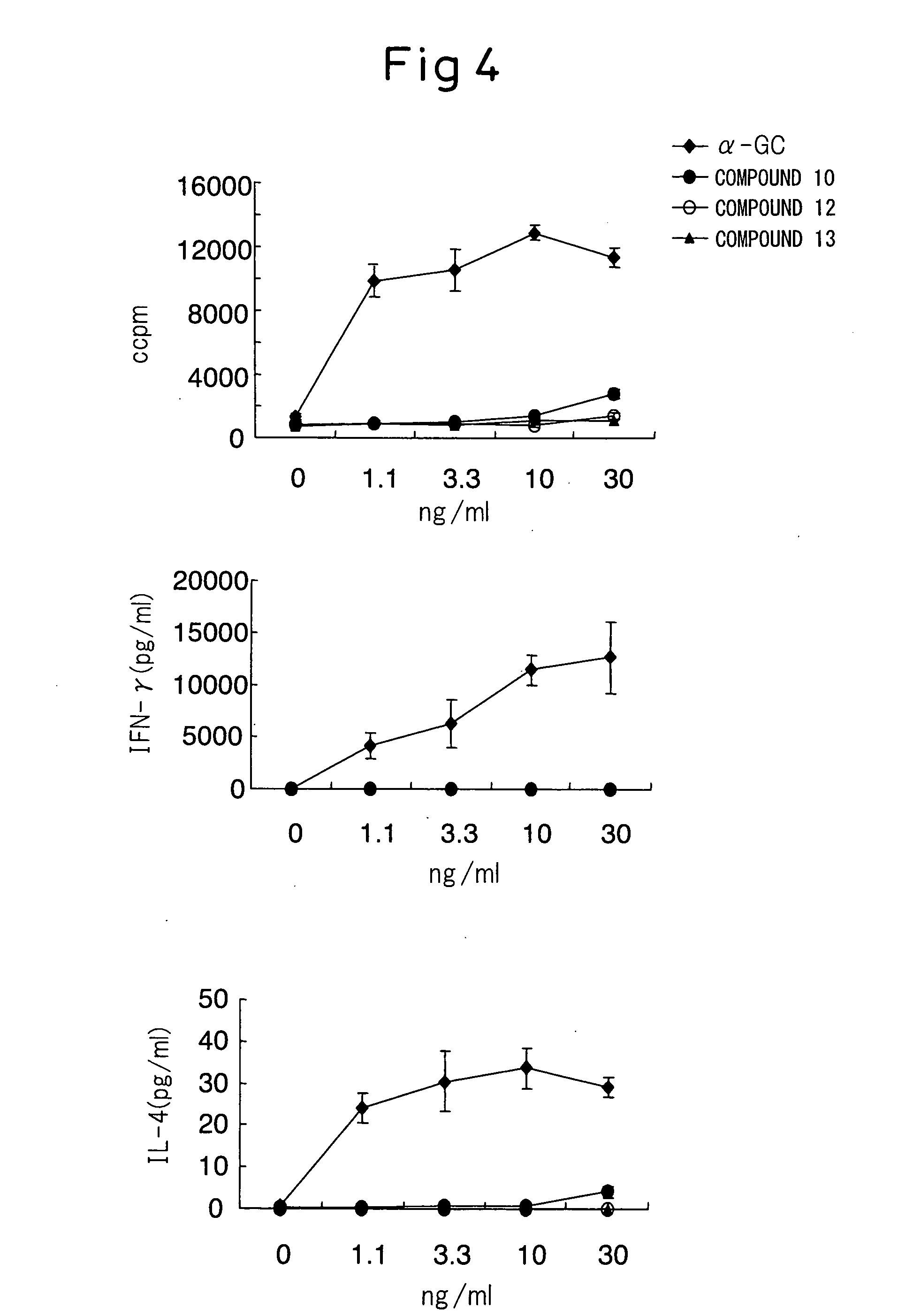

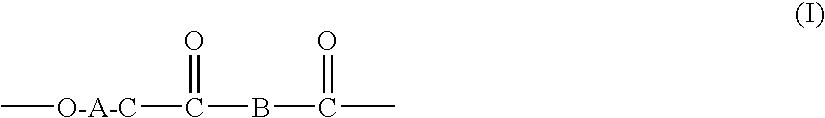

Glycolipid Derivative and Drug Containing the Same as Active Component

InactiveUS20090227781A1Improve securitySuppressing functionSaccharide with heterocyclic radicalsSugar derivativesAutoimmune conditionHydrogen atom

Glycolipid derivatives having the formula (I):wherein R1 indicates an aldopyranose residue, R2 indicates a hydrogen atom or hydroxyl group, A indicates —CH2—, —CH(OH)—CH2— or —CH═CHCH2—, Z indicates —O— or —CH2—, when Z is —O— and x is an integer of 4 to 16, y indicates an integer of 26 to 35, when Z is —O— and x indicates an integer of 17 to 25, y indicates an integer of 0 to 35, when Z is —CH2— and x indicates an integer of 4 to 15, y indicates an integer of 26 to 35, and when Z is —CH2— and x indicates an integer of 16 to 25, y indicates an integer of 0 to 35 and a drug containing the glycolipid derivative for treatment of autoimmune arthritis and other autoimmune disease, bronchial asthma and other allergic diseases or diseases in which NKT cells or stimulation of NKT cells is known to be participating in the deterioration of conditions.

Owner:JAPAN REPRESENTED BY PRESIDENT OF NAT CENT OF NEUROLOGY & PSYCHIATRY KODAIRA +1

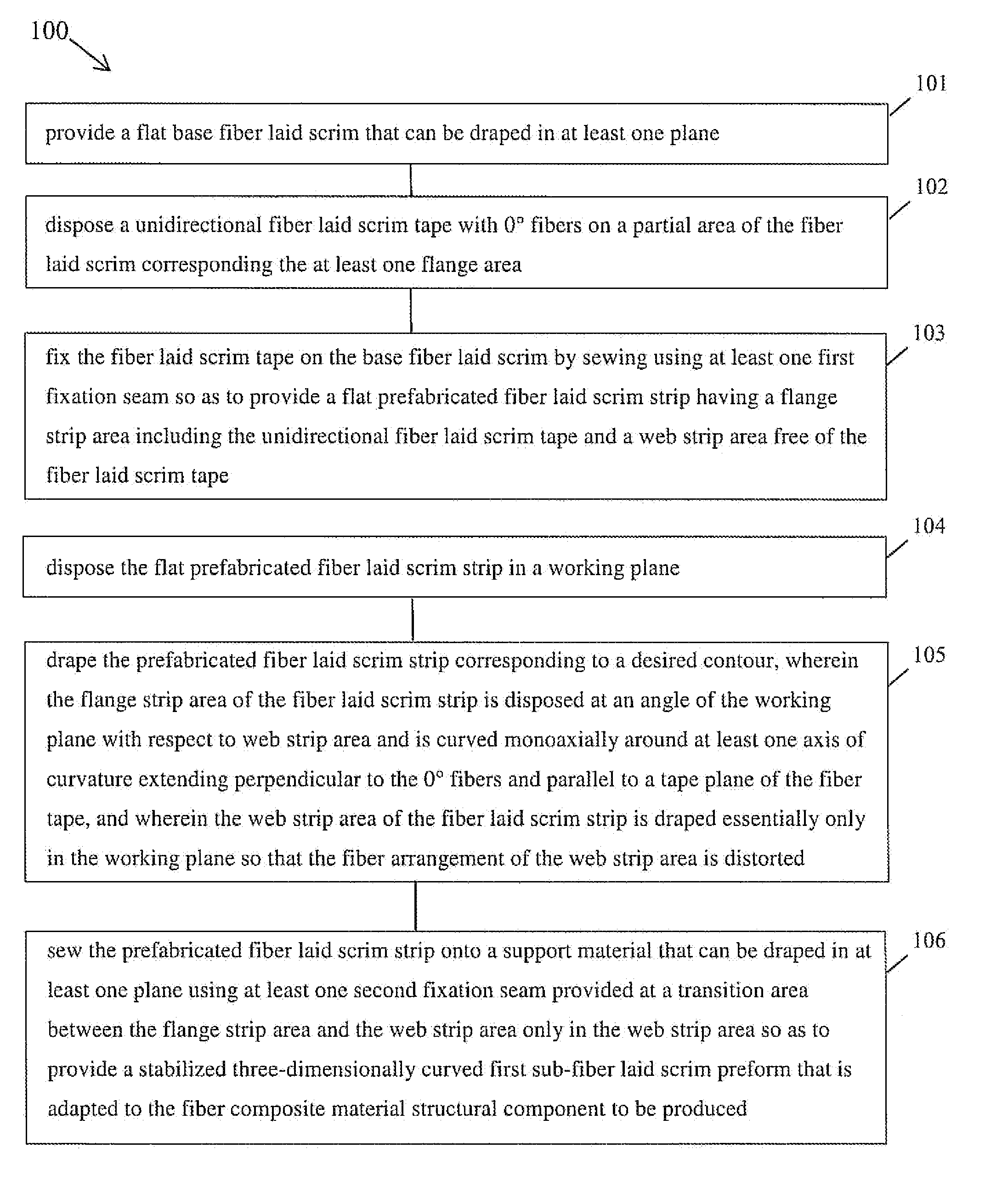

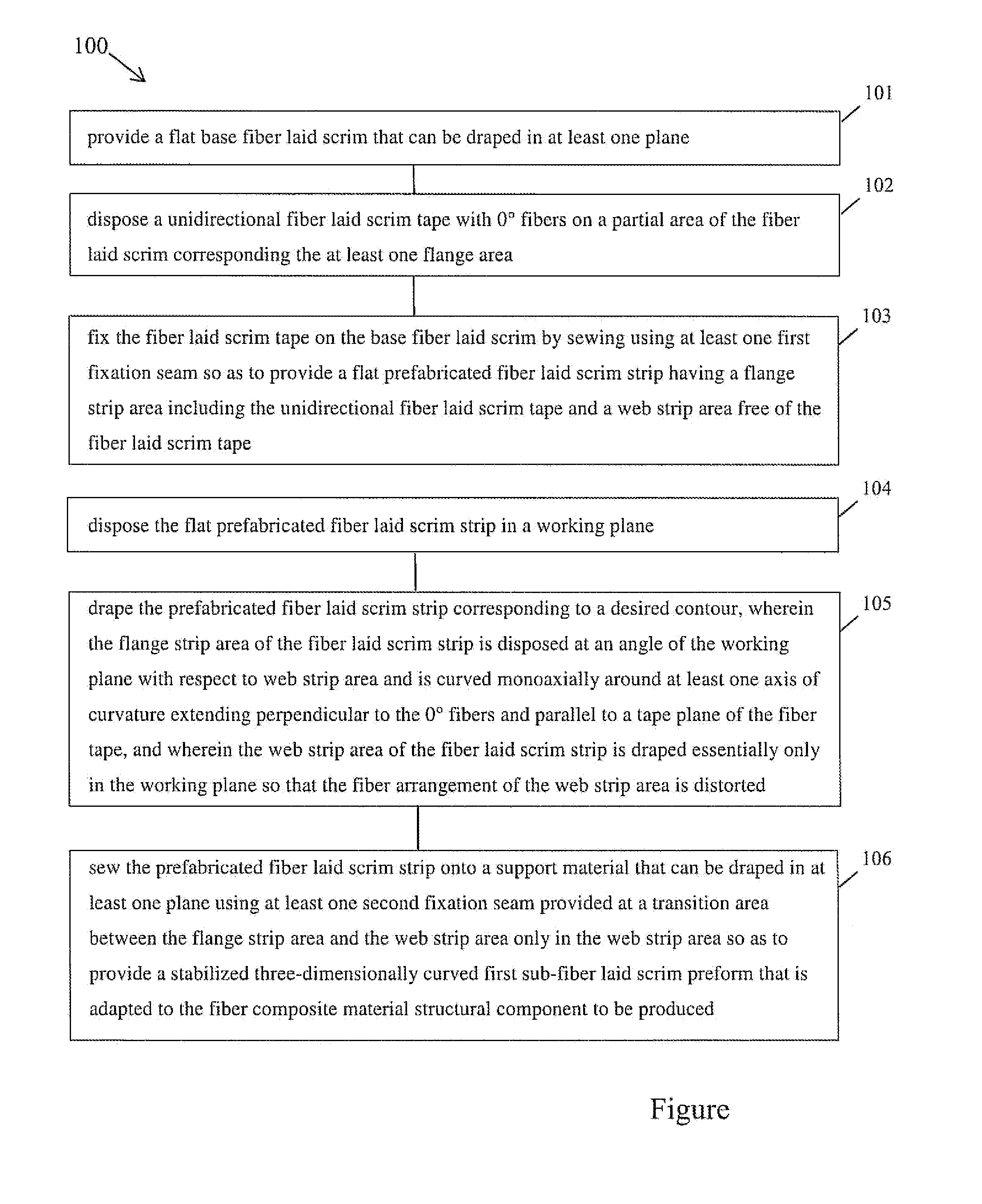

Method for production of a three-dimensional curved fiber composite material structural component

A method for producing a three-dimensionally curved fiber composite material component having a predefined flexural member profile cross section with at least one web area and at least one adjacent flange area, includes providing a flat base fiber laid scrim and disposing a unidirectional fiber laid scrim tape with 0 degree fibers on a partial area of the fiber laid scrim and fixed by sewing so as to provide a flat prefabricated fiber laid scrim strip having a flange area including the unidirectional fiber laid scrim tape and a web strip area free of the fiber laid scrim. The prefabricated scrim tape is draped to a desired contour and is sewn onto a support material so as to provide a stabilized three-dimensionally curved first sub-fiber laid scrim preform adapted to the fiber composite material structural component to be produced.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Processes for making copolymers using macrocyclic oligoesters, and copolymers therefrom

The invention provides alternatives to traditional polycondensation processes for preparing copolymers. For example, in certain embodiments, the invention provides a process that includes an extrusion step and a solid state polymerization step to prepare high molecular weight block copolymer with a “hard block” contributed by a macrocyclic polyester oligomer (MPO) and a “soft block” contributed by a dihydroxyl-functionalized polymer, an oligoether, and / or a dimerized fatty acid (i.e. a polyol). The invention also provides new copolymer compositions made possible by the new processes—for example, copolymers of higher molecular weight, copolymers with higher weight ratio of soft block units to hard block units, copolymers made with higher molecular weight polyol, and copolymers with hard block units that are themselves random copolyesters of units contributed by a MPO and a cyclic ester.

Owner:LIQUID THERMO PLASTICS

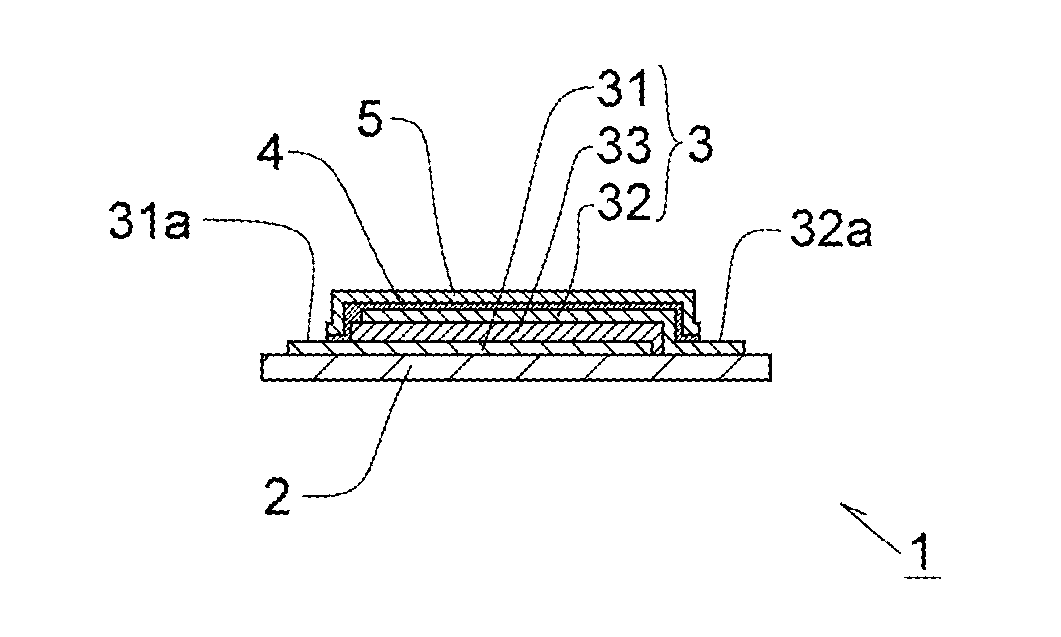

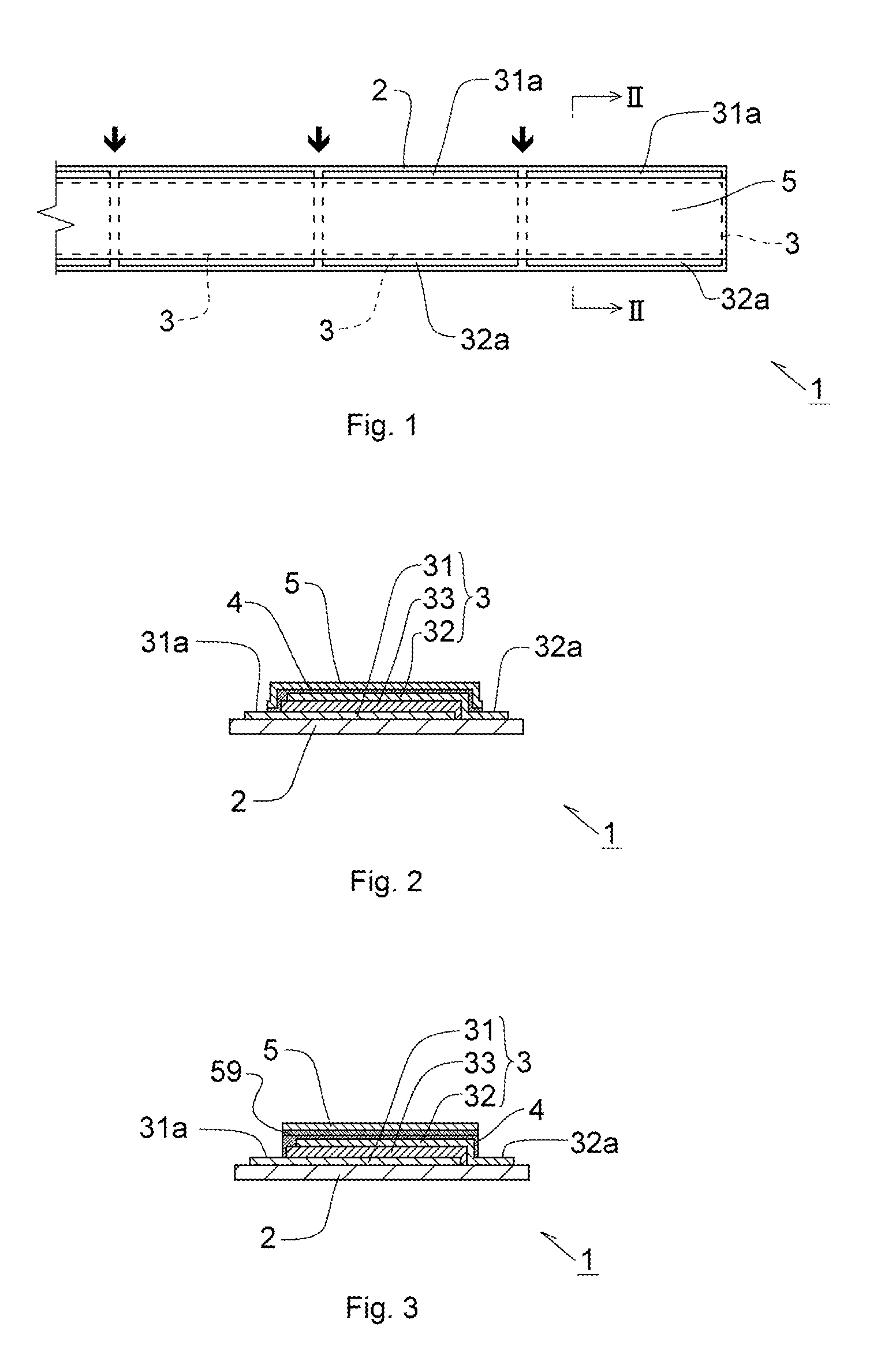

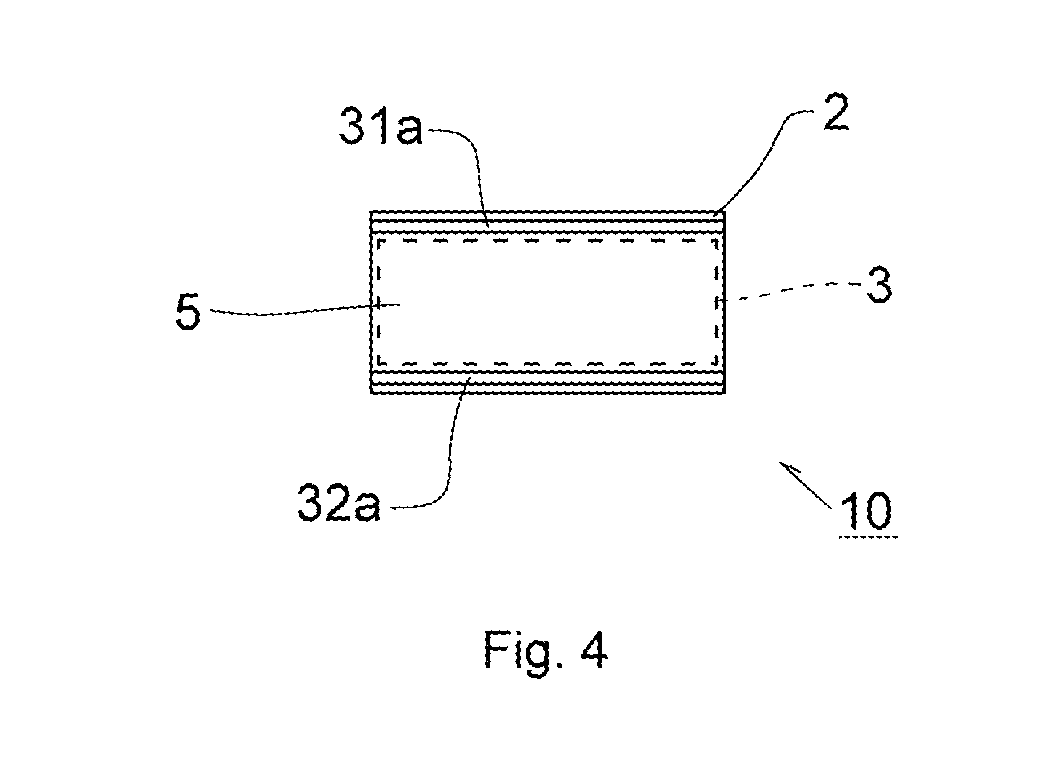

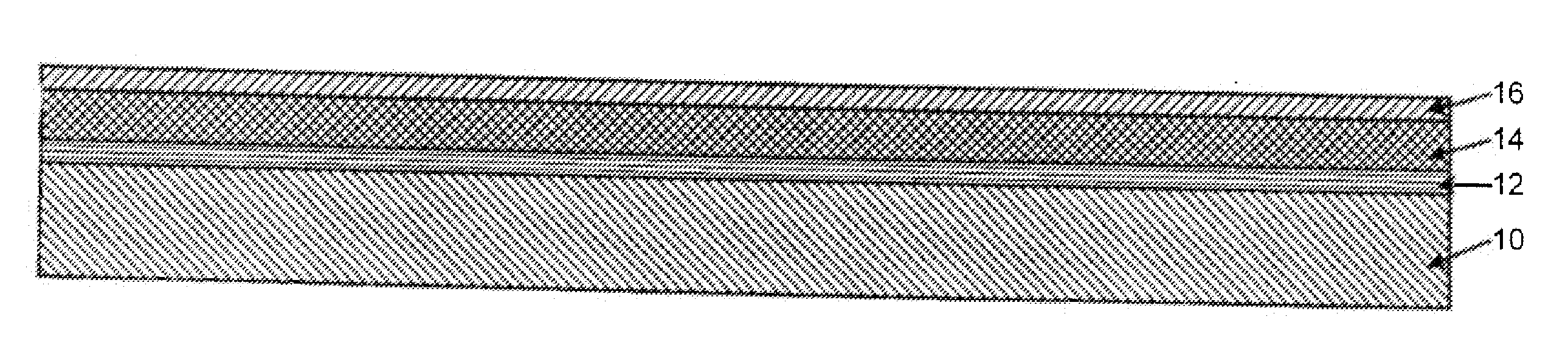

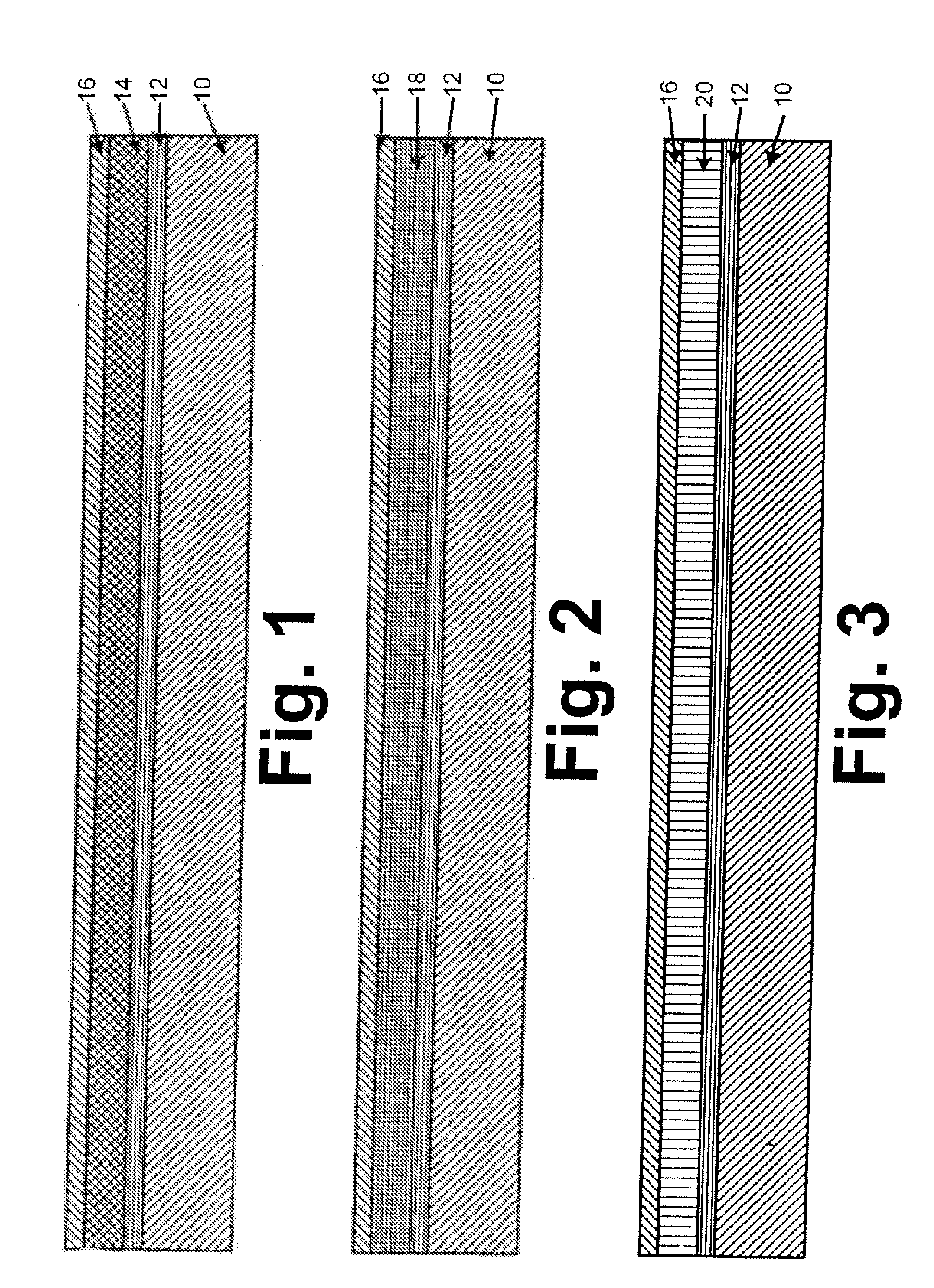

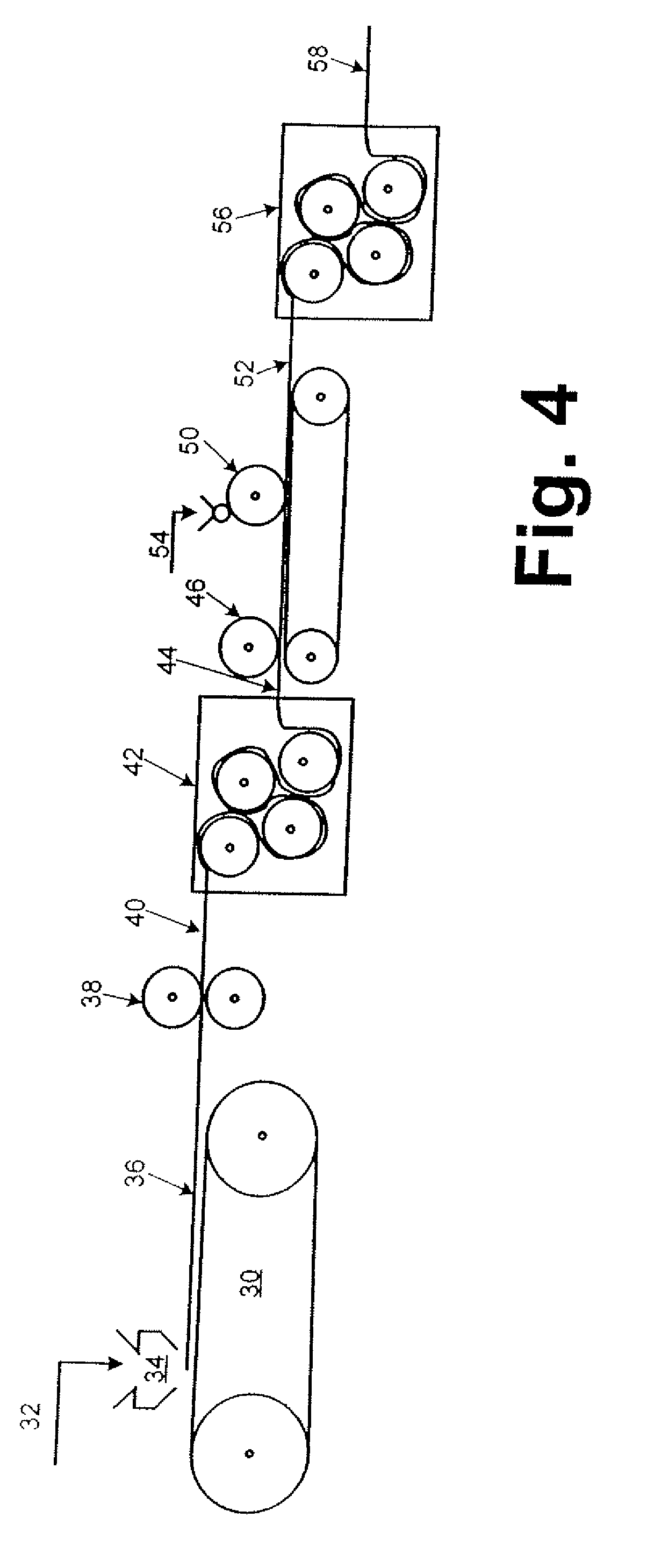

Method for producing organic electroluminescence device

InactiveUS20150357572A1High productivityLow costSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceAdhesive

A method for producing an organic electroluminescence device of the present invention includes a laminating step of laminating a belt-shaped sealing substrate 5 on a belt-shaped supporting substrate 2 on which a plurality of organic EL elements 3 are formed while interposing an uncured thermosetting type adhesive layer 52, a winding step of winding a belt-shaped laminated body 11 having the belt-shaped supporting substrate 2, the organic EL elements 3 and the sealing substrate 5 into a roll, and a curing step of applying heat to the laminated body 11 to perform curing of the adhesive layer 52 while the laminated body 11 remains wound into a roll.

Owner:NITTO DENKO CORP

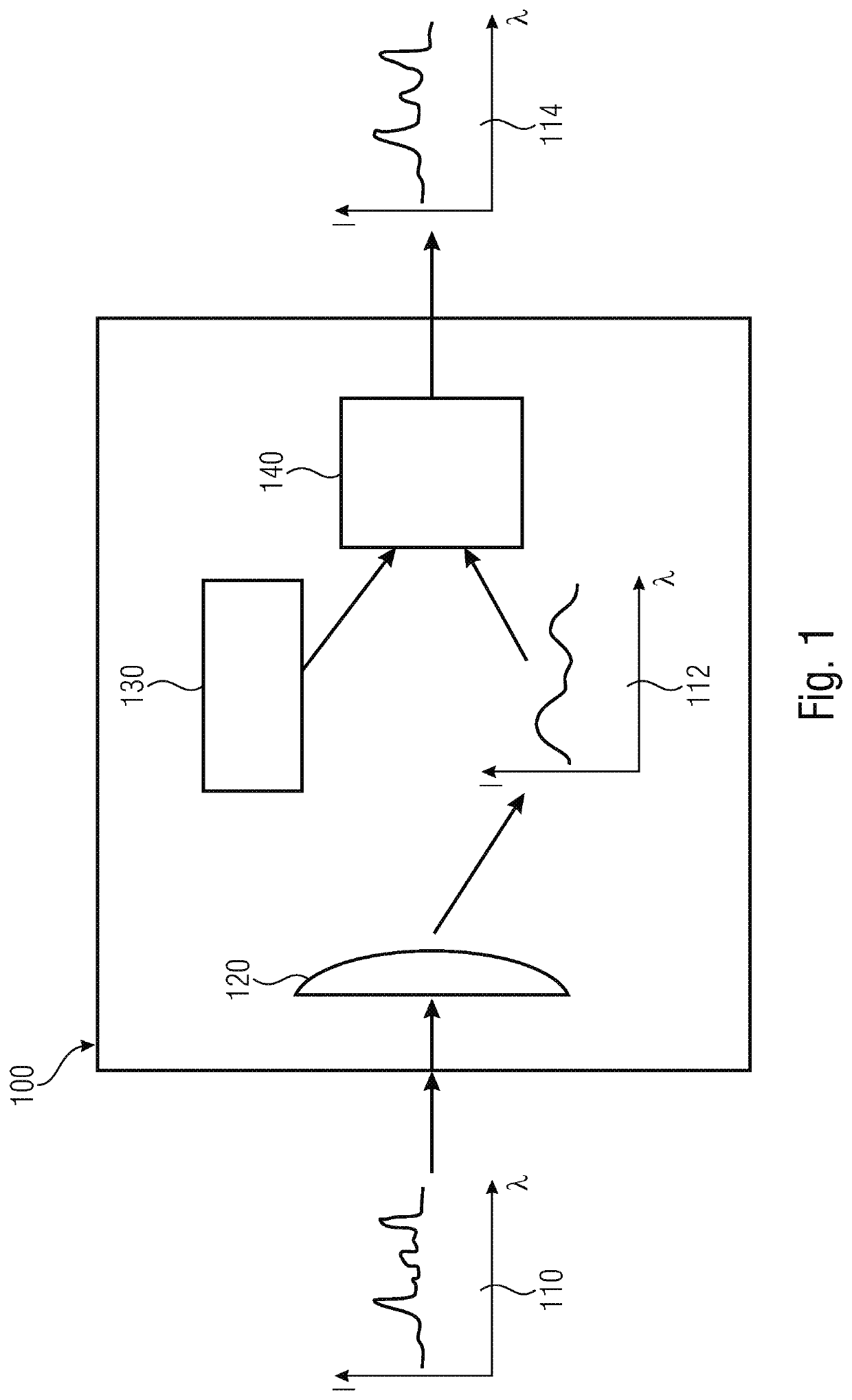

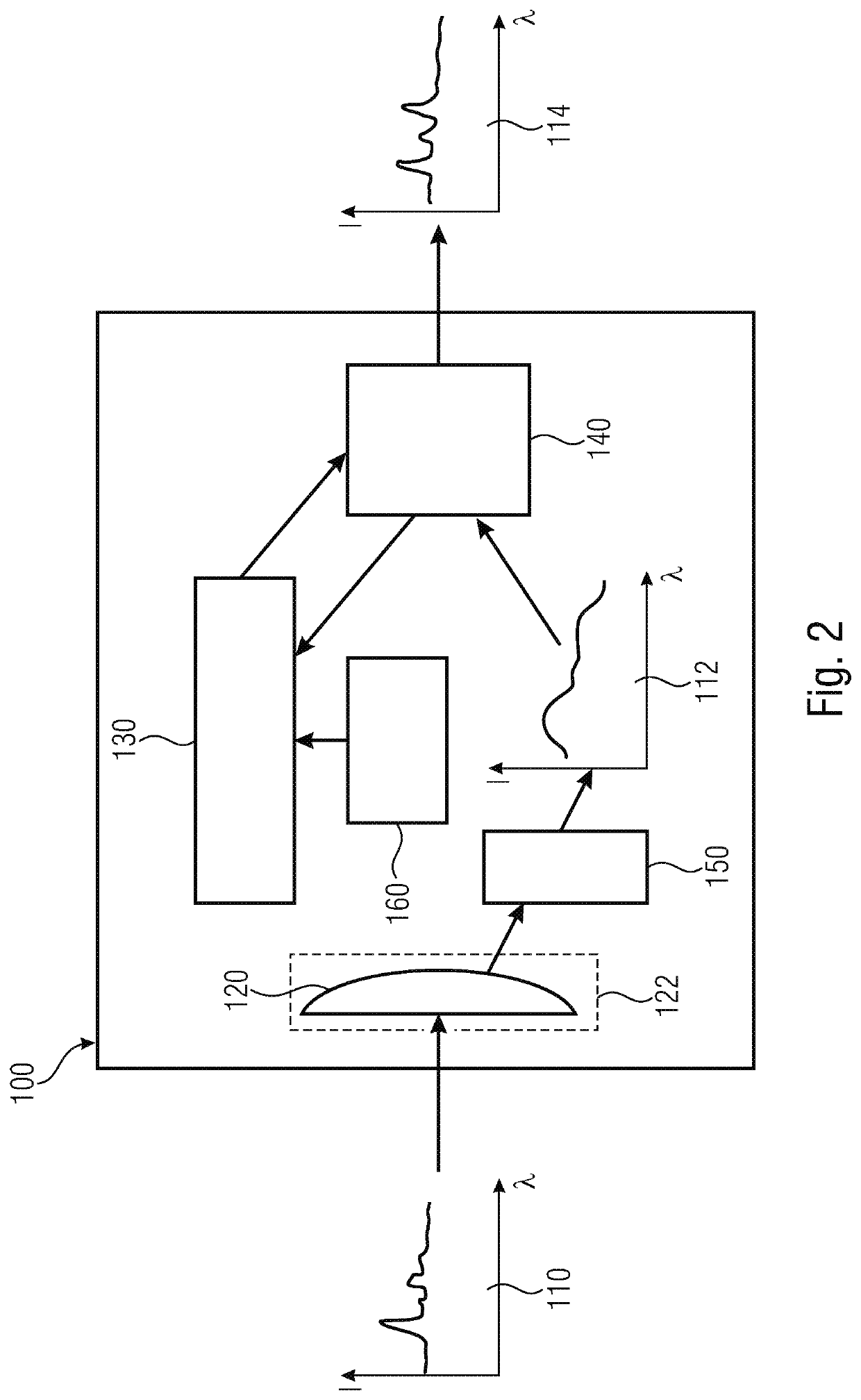

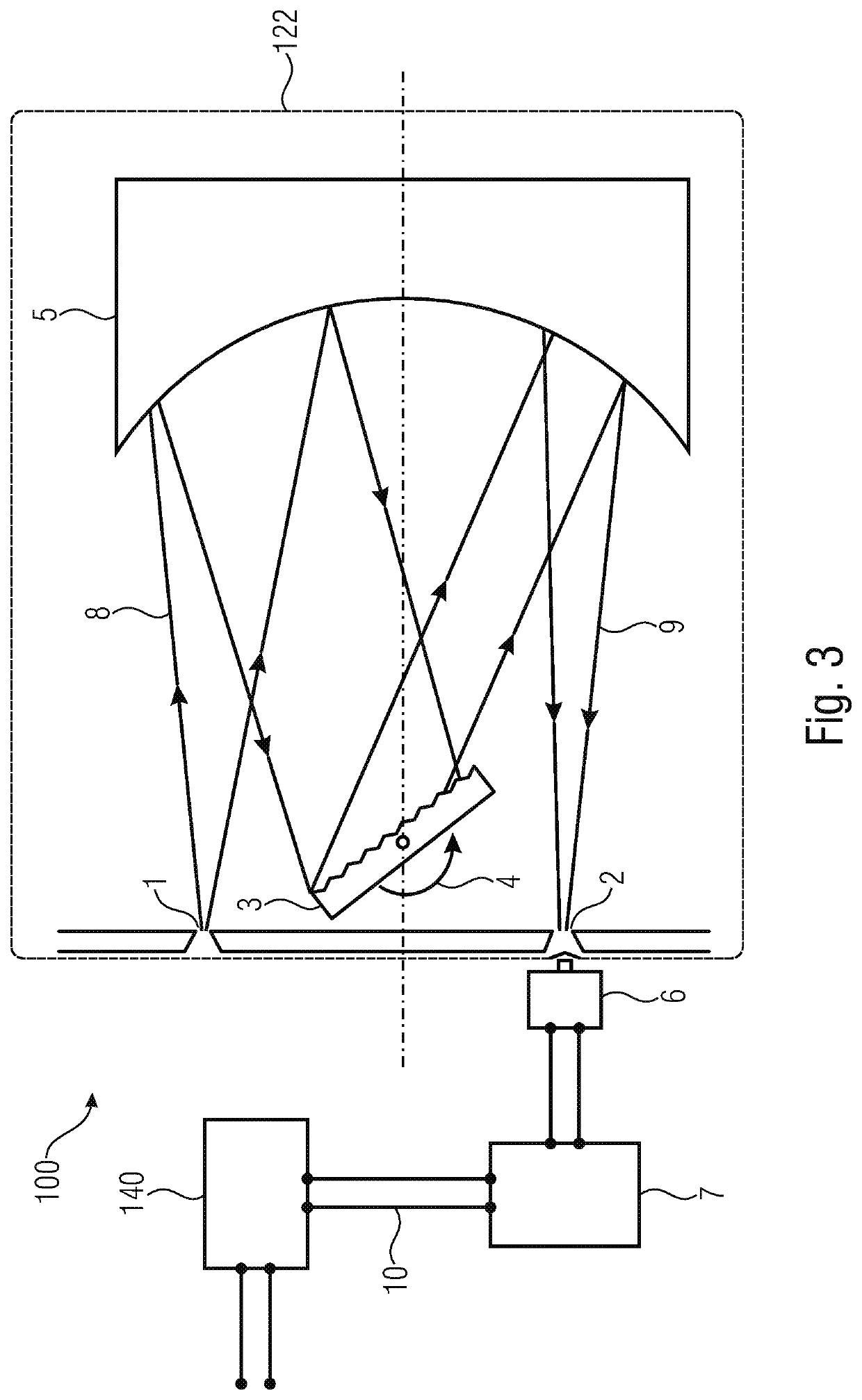

Spectral analysis system, mobile device having a spectral analysis system, method for determining a correction function for the imaging correction of a spectrum captured by a spectral analysis system, and computer program

ActiveUS20210025755A1High spectral resolutionSmall toleranceRadiation pyrometrySpectrum investigationSpectral analysisMobile device

Spectral analysis system for capturing a spectrum with an optic that forms an optical path. The spectral analysis system is configured to apply a correction function to a captured spectrum so as to obtain a modified spectrum.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Process for the preparation of a purified acid composition

ActiveUS10351544B2Increase productionEasy to separateOrganic reductionOrganic compounds purification/separation/stabilisationFuranHydrogen

A purified acid composition including 2,5-furandicarboxylic acid is prepared by a process including a) providing an acid composition solution of a crude acid composition in a polar solvent, the crude acid composition including 2,5-furandicarboxylic acid (FDCA) and 2-formyl-furan-5-carboxylic acid (FFCA); b) contacting the acid composition solution with hydrogen in the presence of a hydrogenation catalyst to hydrogenate FFCA to hydrogenation products, such that the hydrogenation products contain a minor amount of 2-methyl-furan-5-carboxylic acid (MFA) or no MFA, yielding a hydrogenated solution; c) separating at least a portion of the FDCA from the hydrogenated solution by crystallization.

Owner:FURANIX TECH BV

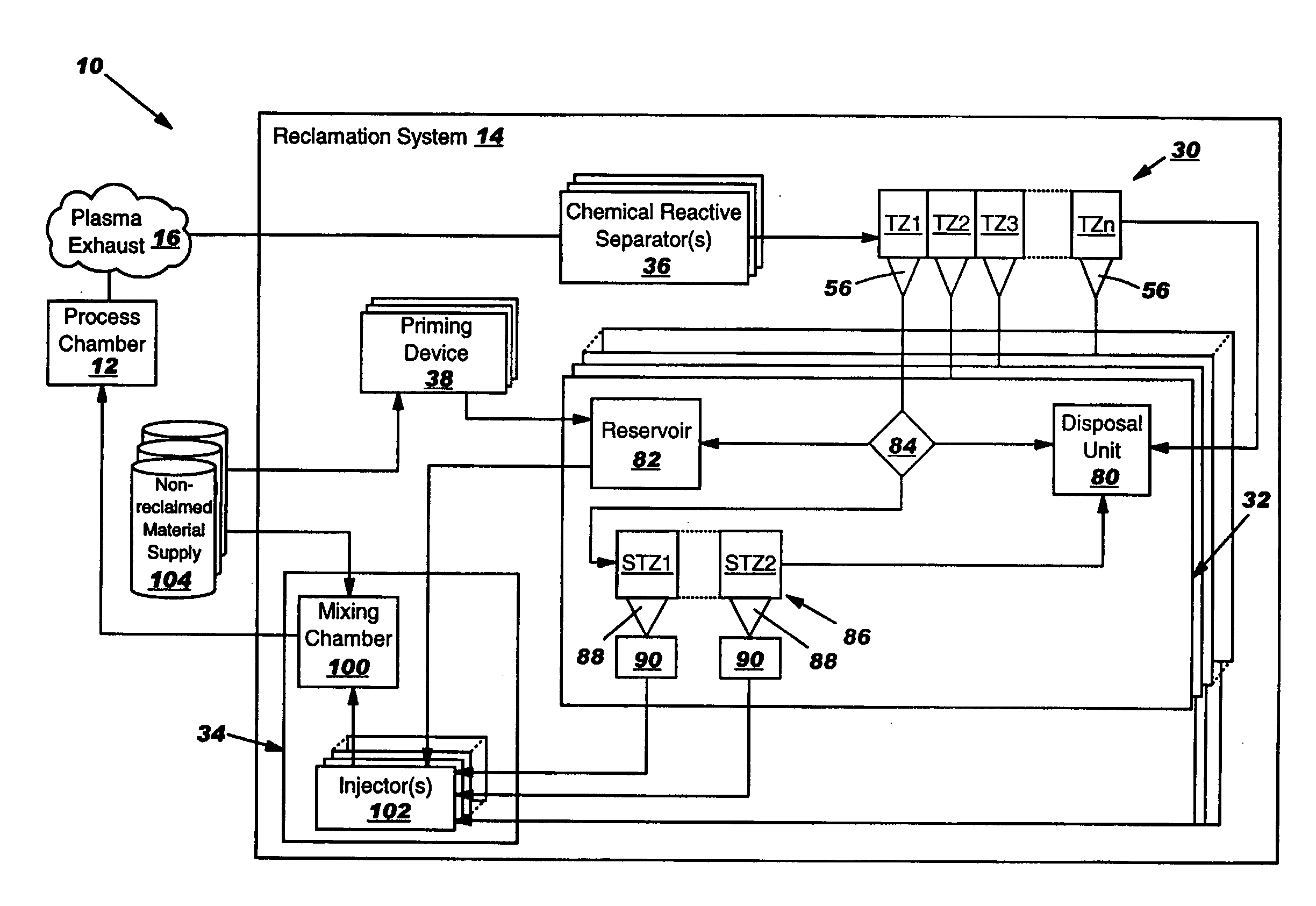

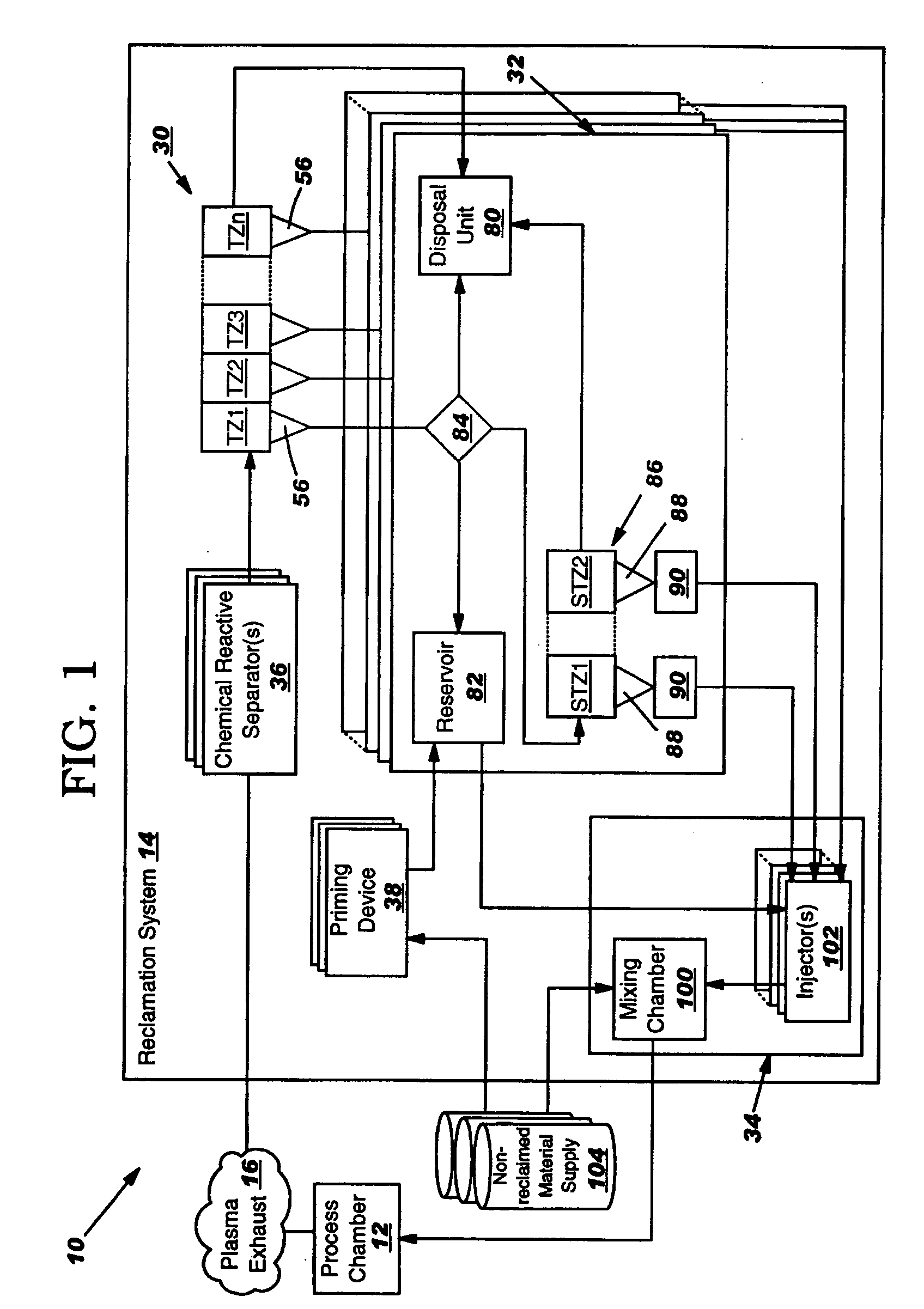

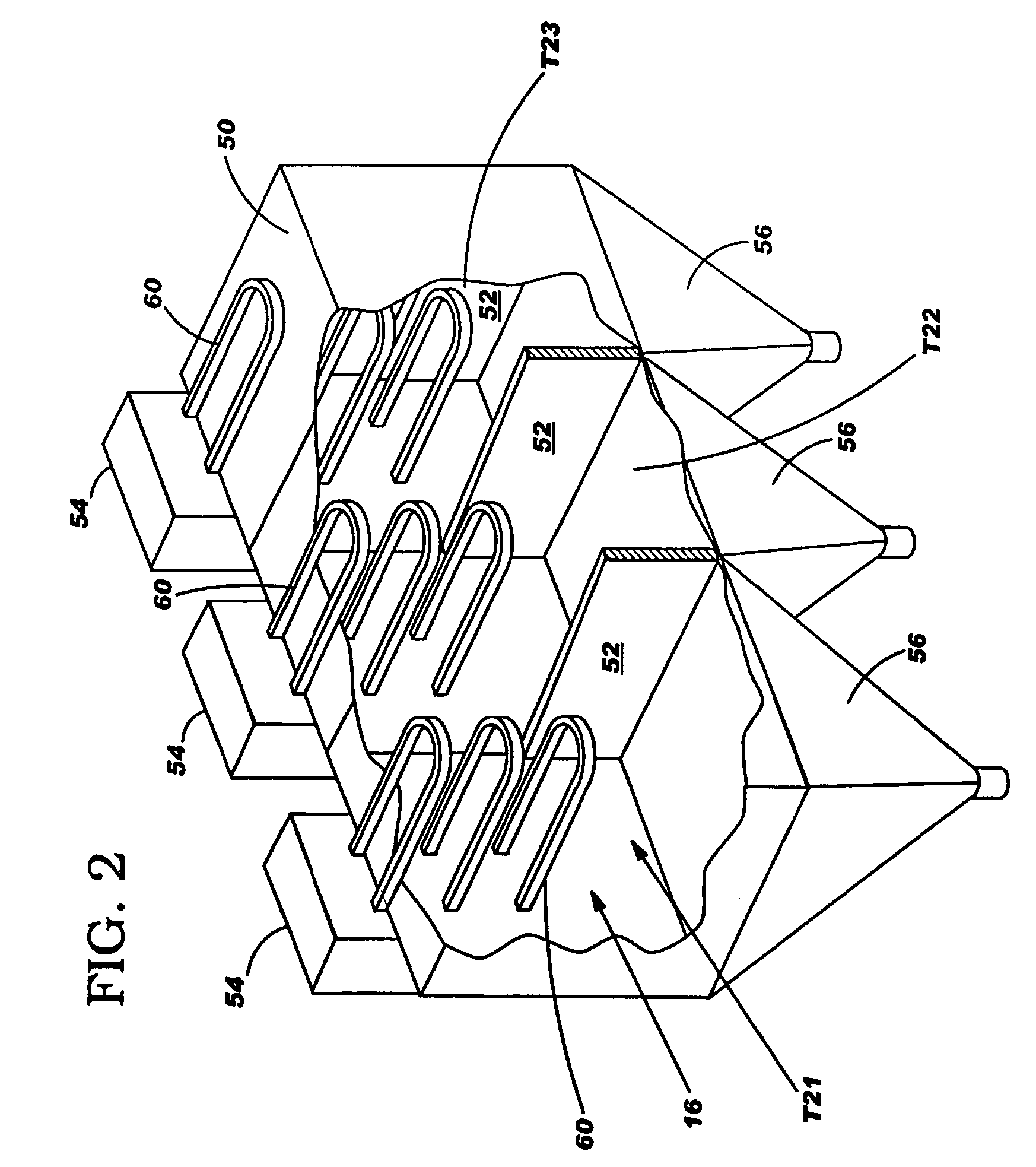

Plasma processing material reclamation and reuse

InactiveUS20050011442A1Little production of wasteLow costElectric discharge tubesPretreated surfacesEngineeringCost savings

An integrated circuit plasma processing system, apparatus and method for reclaiming material, such as a plasma precursor and potentially useful components among their byproducts, from plasma-enhanced exhaust of a plasma process chamber for subsequent reuse in the chamber. The apparatus provides a recycle feedback loop for a plasma process chamber that provides the high purity materials necessary for microelectronic applications. Since the apparatus is in-situ, no byproducts that are not already present are possible. Accordingly, the apparatus guarantees purity of the recycled material. In addition to cost savings, the invention provides an environmentally friendly plasma process chamber and apparatus with very little production of waste.

Owner:IBM CORP

Method of controlling a solar power plant, a power conversion system, a DC/AC inverter and a solar power plant

ActiveUS9748772B2Small productElectric signal transmission systemsSingle network parallel feeding arrangementsPower stationPower grid

A solar power plant including a power conversion system and a method of controlling the power conversion system. Implemented in a DC / AC inverter, the plant includes photovoltaic modules (PV modules) arranged in arrays connected to a respective DC / DC converters. A power collecting grid interfaces between the DC / DC converters and the DC / AC inverter. The method includes monitoring the performance of each PV array by adjusting the voltage level of each interface between a PV array and the corresponding DC / DC converter, and includes monitoring the output power of each DC / DC converter as a feedback for the regulating.

Owner:HITACHI ENERGY LTD

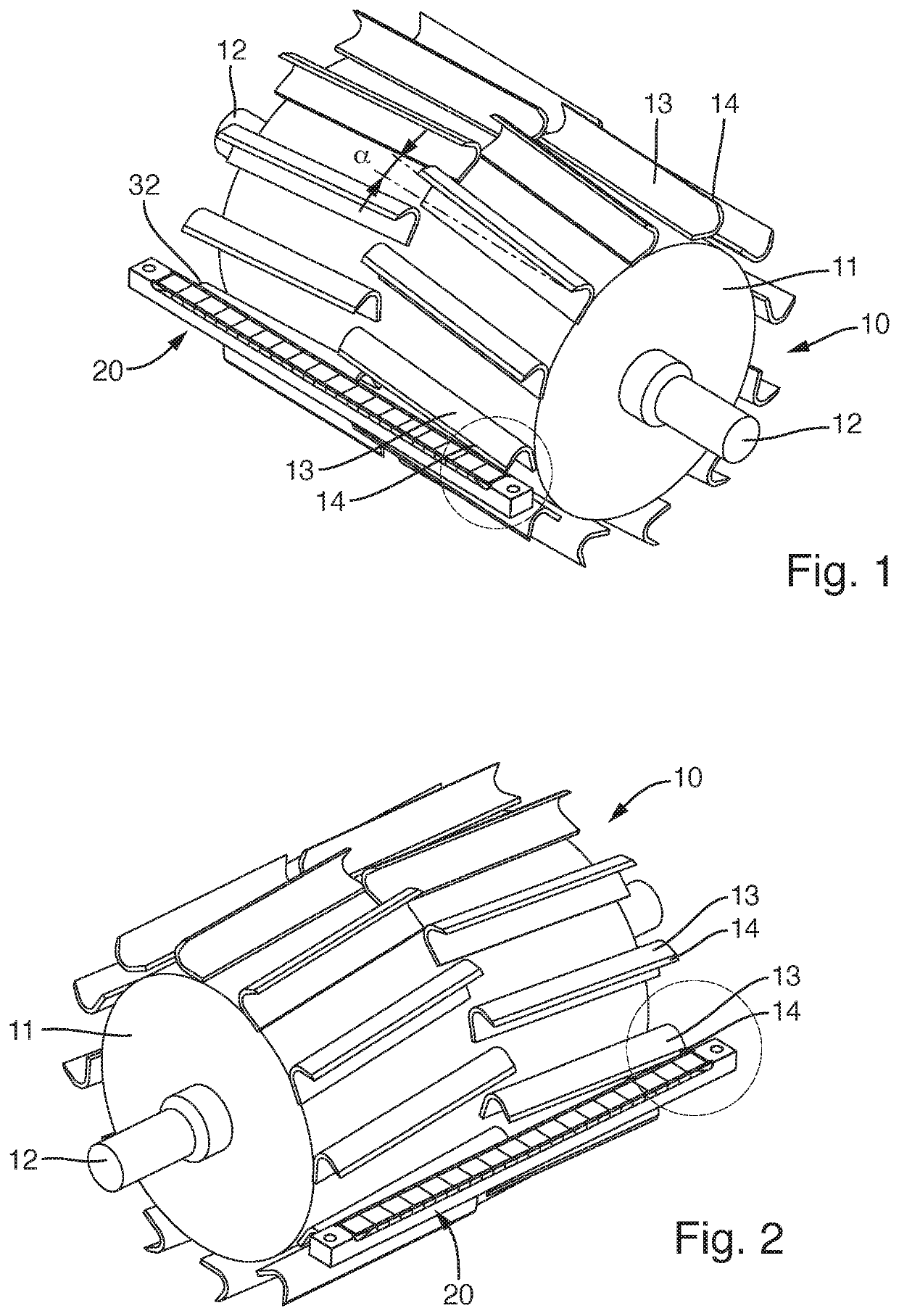

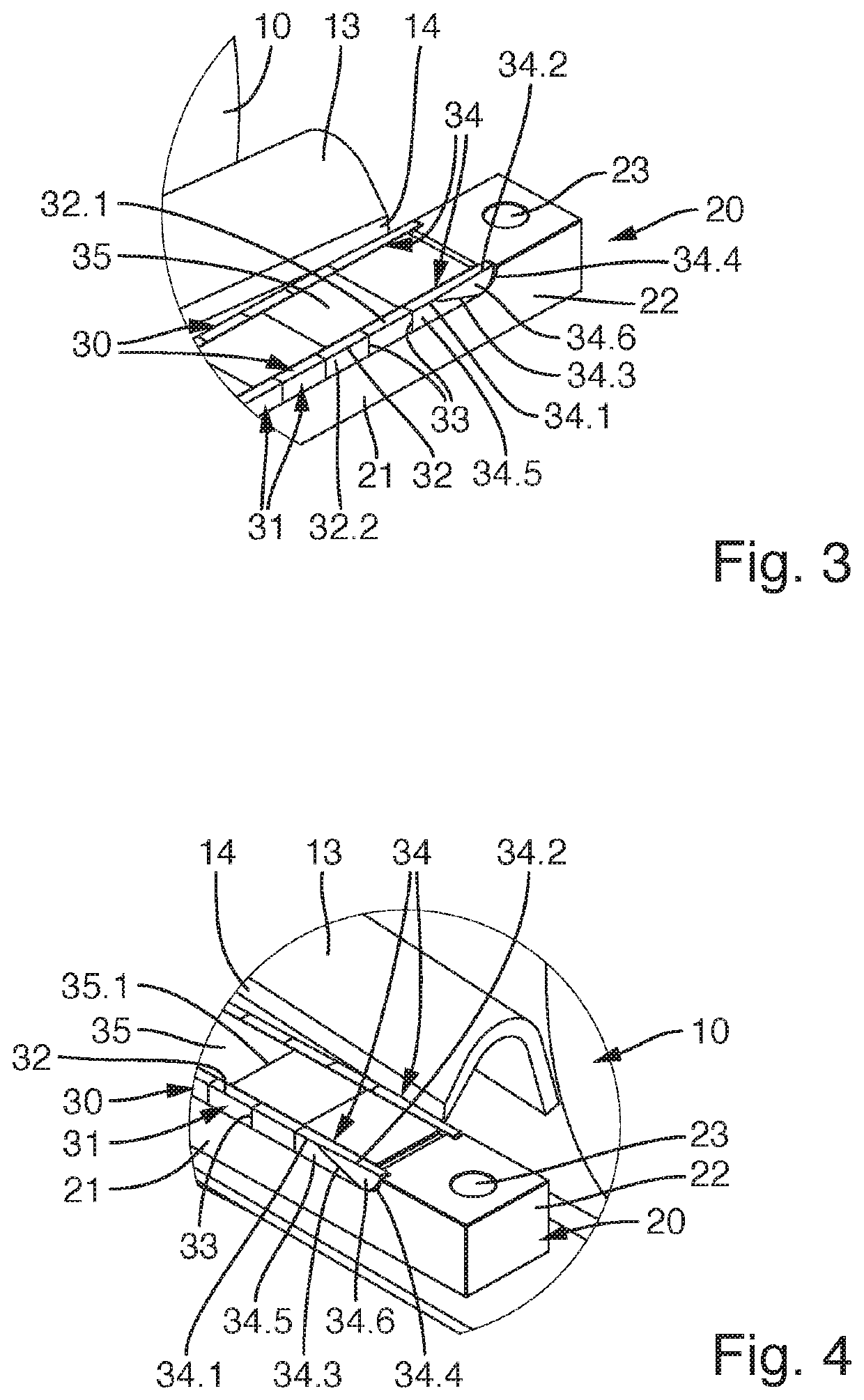

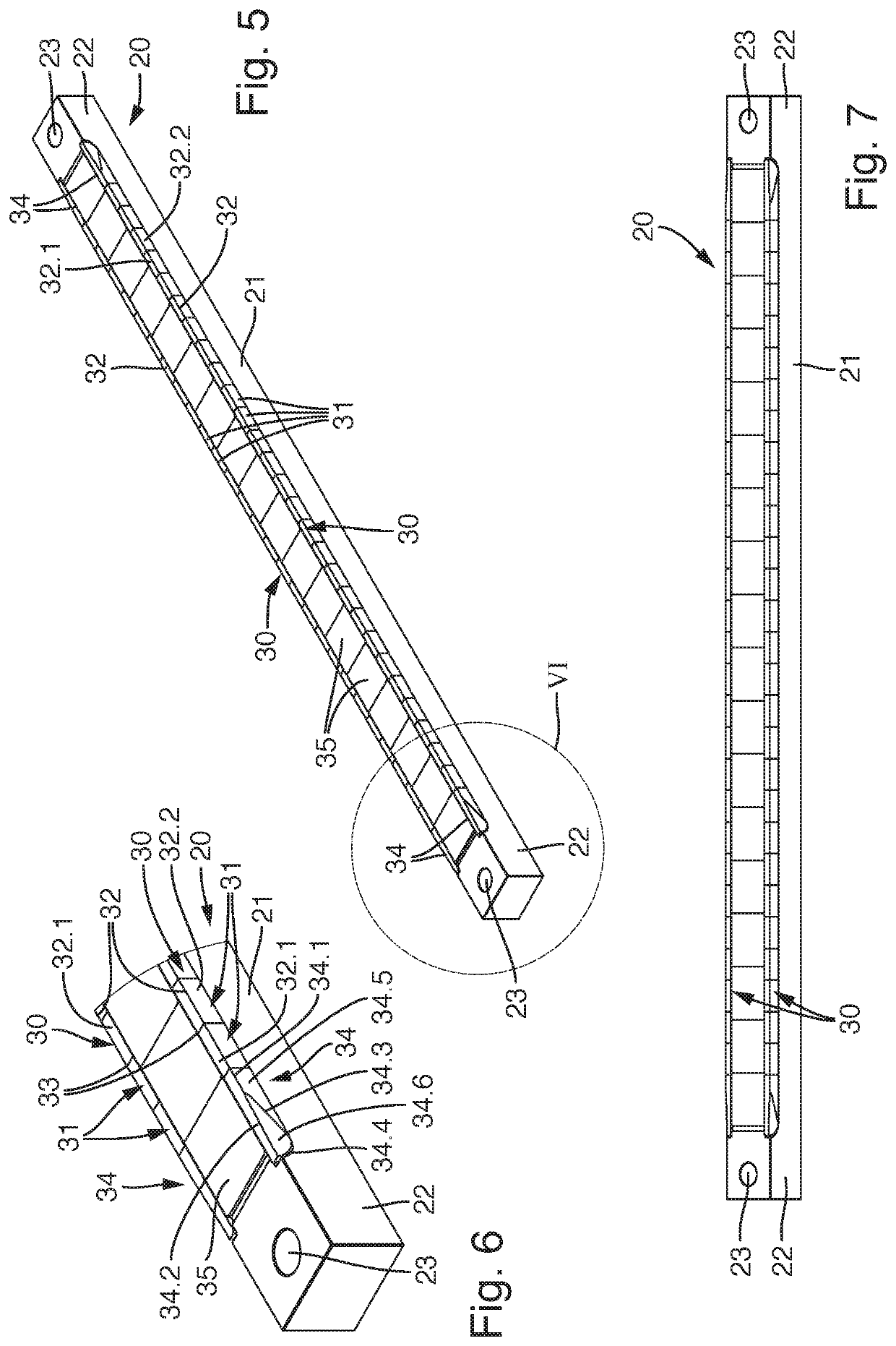

Shear bar

ActiveUS20200396898A1Reduce partComplexity of partMowersCuttersStructural engineeringForage harvester

The invention relates to a shear bar (20), in particular for a forage harvester or another agricultural or silvicultural machine, having a carrier (21) that comprises a cutting region (30); a plurality of cutting elements (31) being set alongside one another in the cutting region (30); the cutting elements (31) comprising a partial edge and at least some of the partial edges forming a cutting edge (32) that is embodied to form, with a knife bar, a cutting engagement for the material to be shredded; the cutting edge (32) forming a transition between a cutting surface (32.1) that is constituted by the cutting elements (31) and extends transversely to the cutting direction, and an exposed surface (32.2) that extends substantially in a cutting direction and indirectly or directly adjoins the cutting edge (32). A shear bar of this kind can be configured to be break-resistant with little complexity in terms of parts and manufacture if provision is made that an infeed element (34), which is embodied as a sintered part made of hard material having an infeed bevel (34.6) profiled on in the sintering process, is provided on or in the row of cutting elements (31); the infeed bevel (34.6) being carried over indirectly or directly into the cutting edge (32); and the infeed bevel (34.6) being arranged at a tilt with respect to the cutting edge (32) in such a way that it is arranged with a setback with respect to the exposed surface (32.2) and toward the cutting surface (32.1).

Owner:BETEK

Paper articles exhibiting long term storageability and method for making same

InactiveUS20110056639A1Less tendency to slideHeavy weightLiquid surface applicatorsNatural cellulose pulp/paperPaperboardCellulose fiber

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com