Patents

Literature

88results about How to "Constant efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

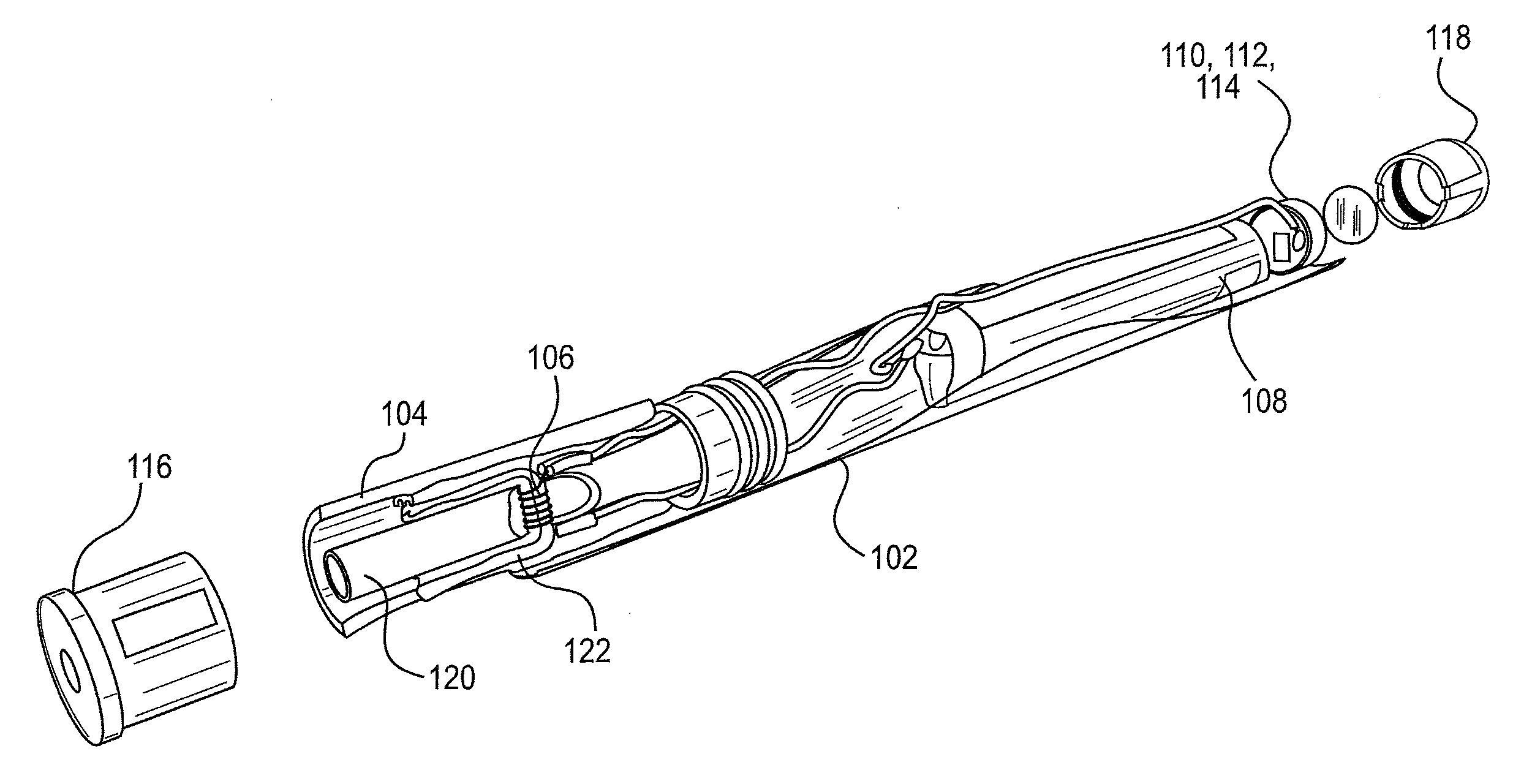

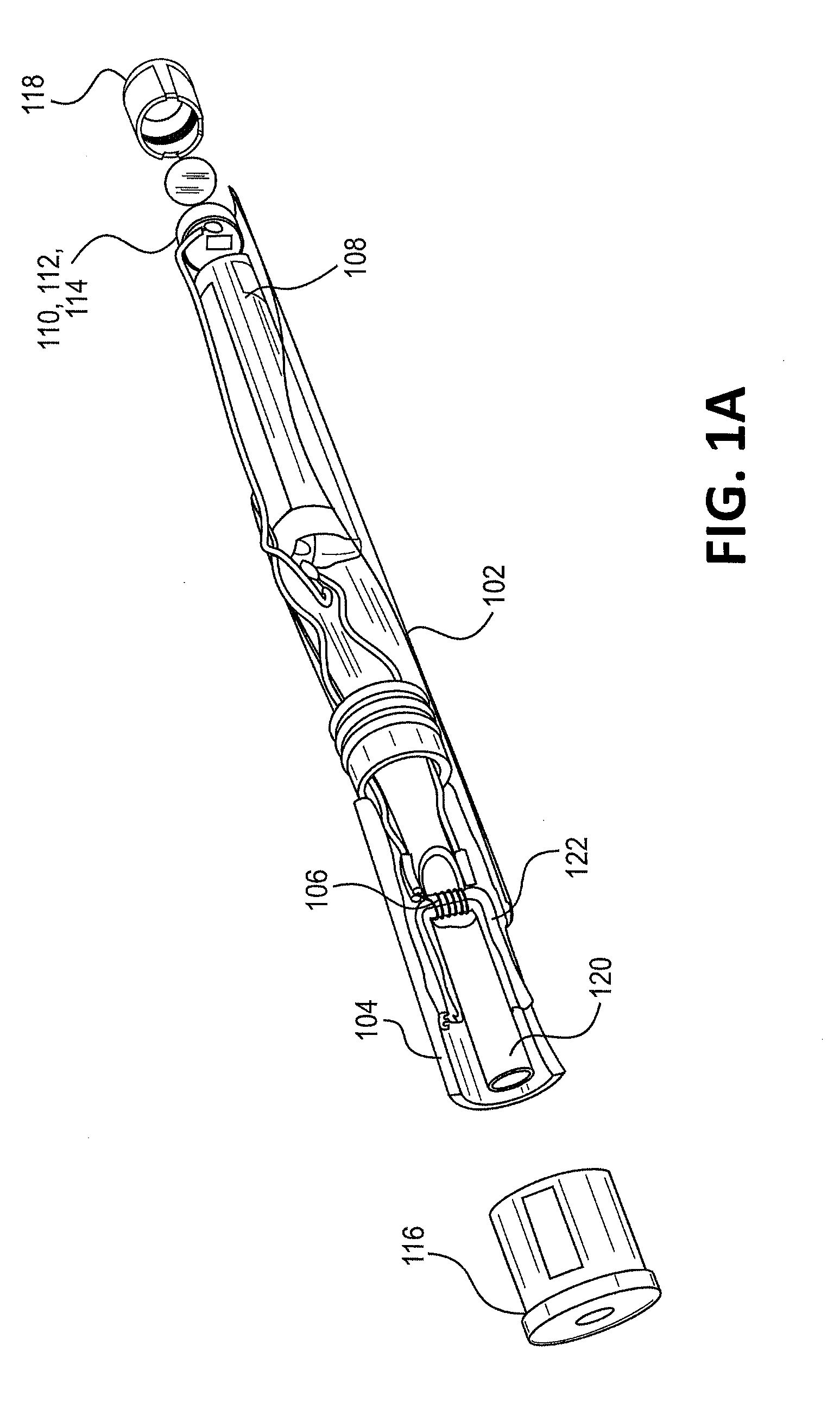

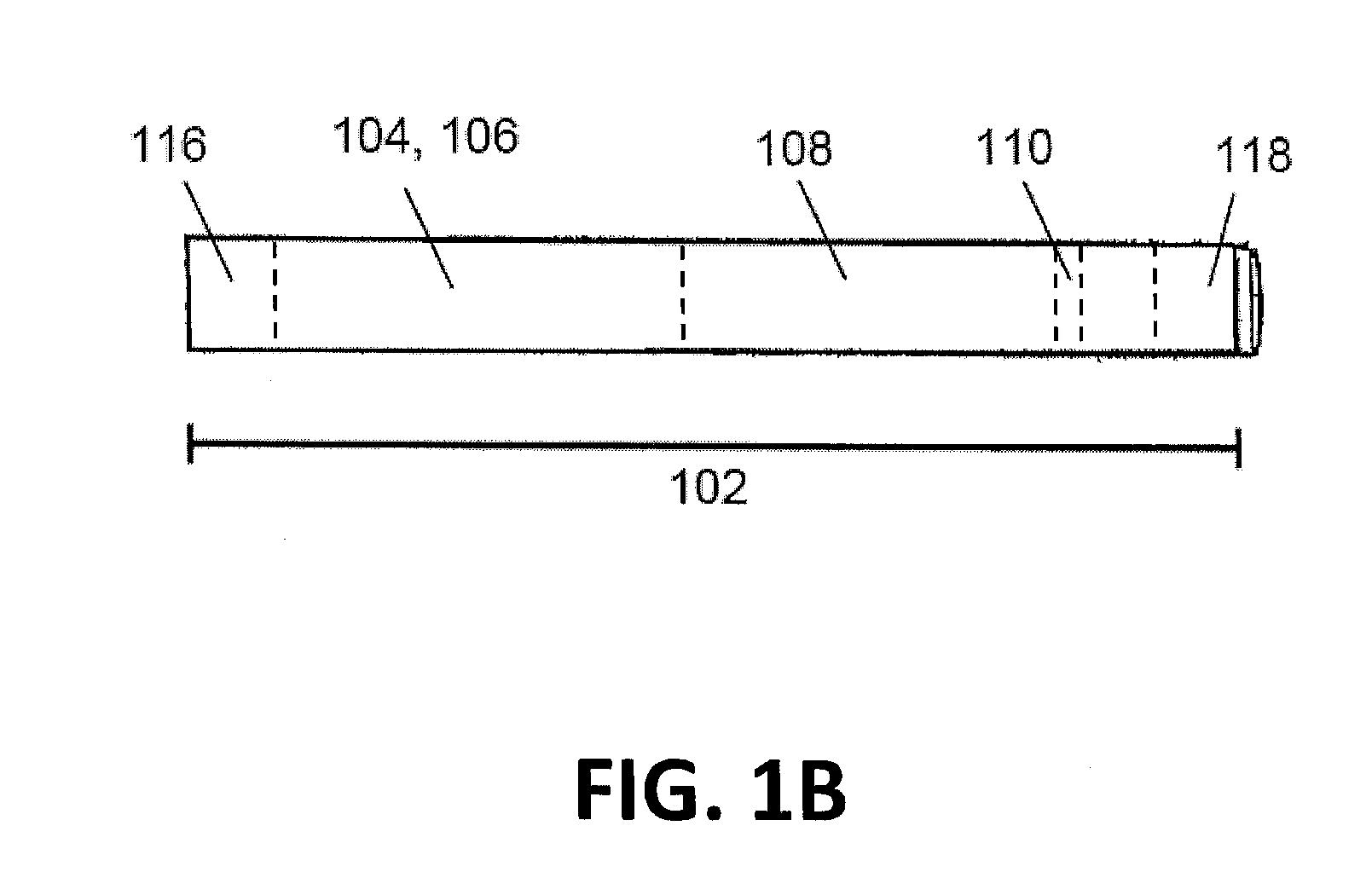

Compositions, devices, and methods for nicotine aerosol delivery

ActiveUS20140345635A1Reduce degradationConstant efficiencyTobacco treatmentTobacco devicesSolventElectron

The present disclosure generally relates to compositions, and related devices and methods, useful in vaporizing devices such as electronic cigarettes. The composition may comprise nicotine, at least one solvent, and at least one ion pairing agent, and may be vaporized to form a condensation aerosol, wherein inhalation of the aerosol allows for deposition of nicotine with the respiratory system, including deep lung deposition. The vaporizing device may comprise a vaporization unit, a battery, and an integrated circuit coupled to the battery, wherein the integrated circuit is configured to control the battery for rapid initial vaporization without overheating, producing thermal degradation products, or draining battery energy. The battery may operate with pulse width modulation for at least a portion of the time the vaporizing device is being used.

Owner:NJOY LLC

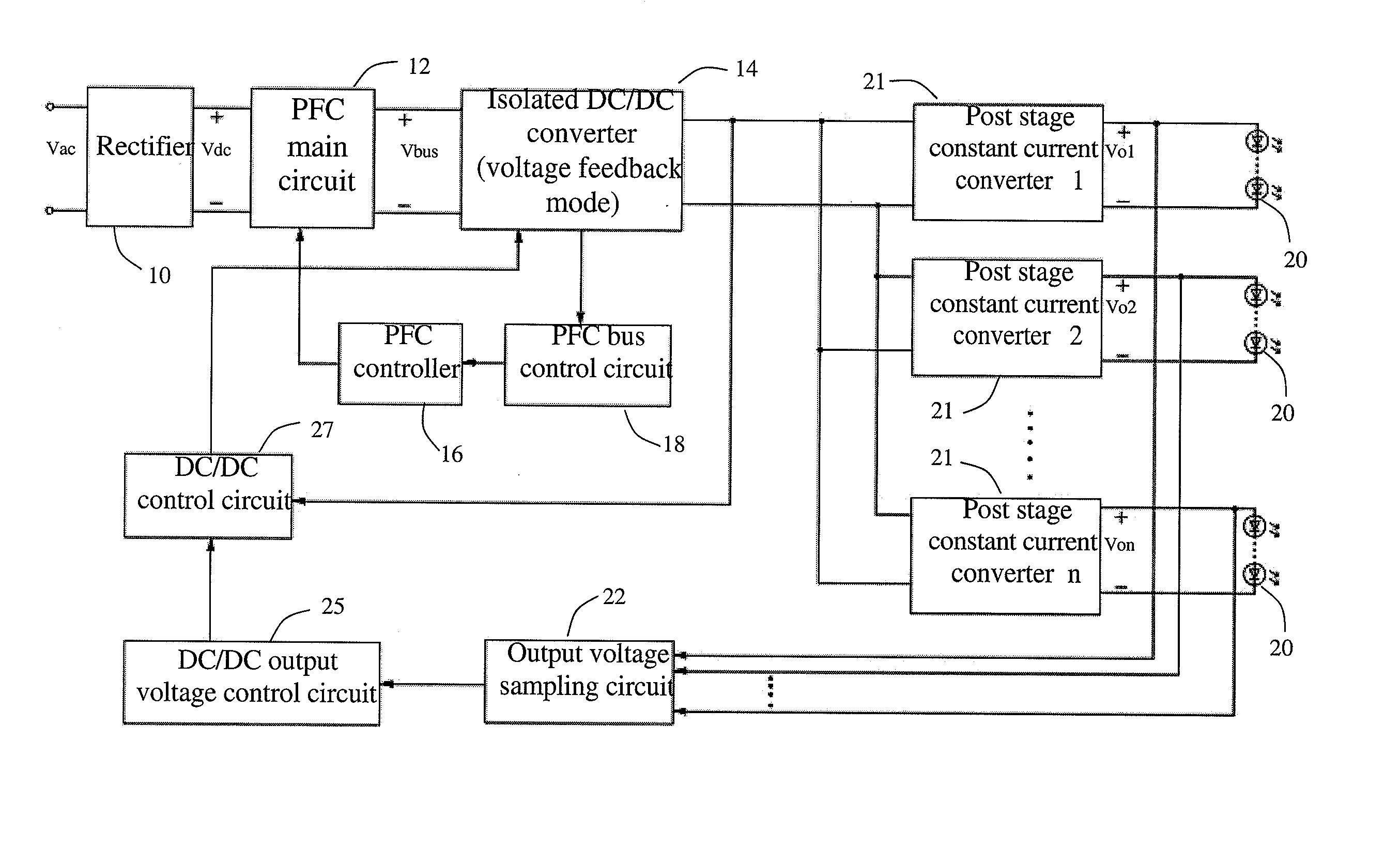

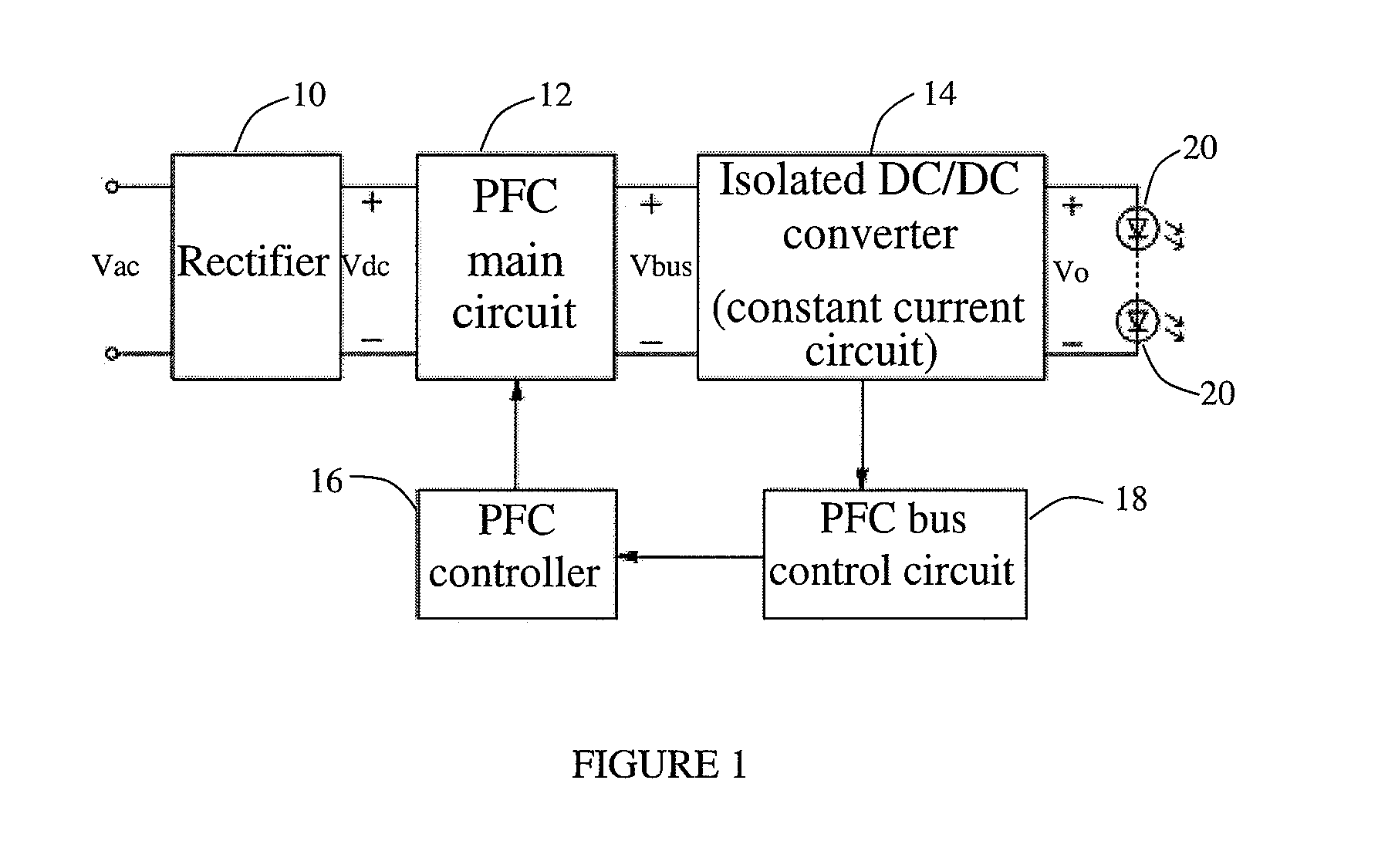

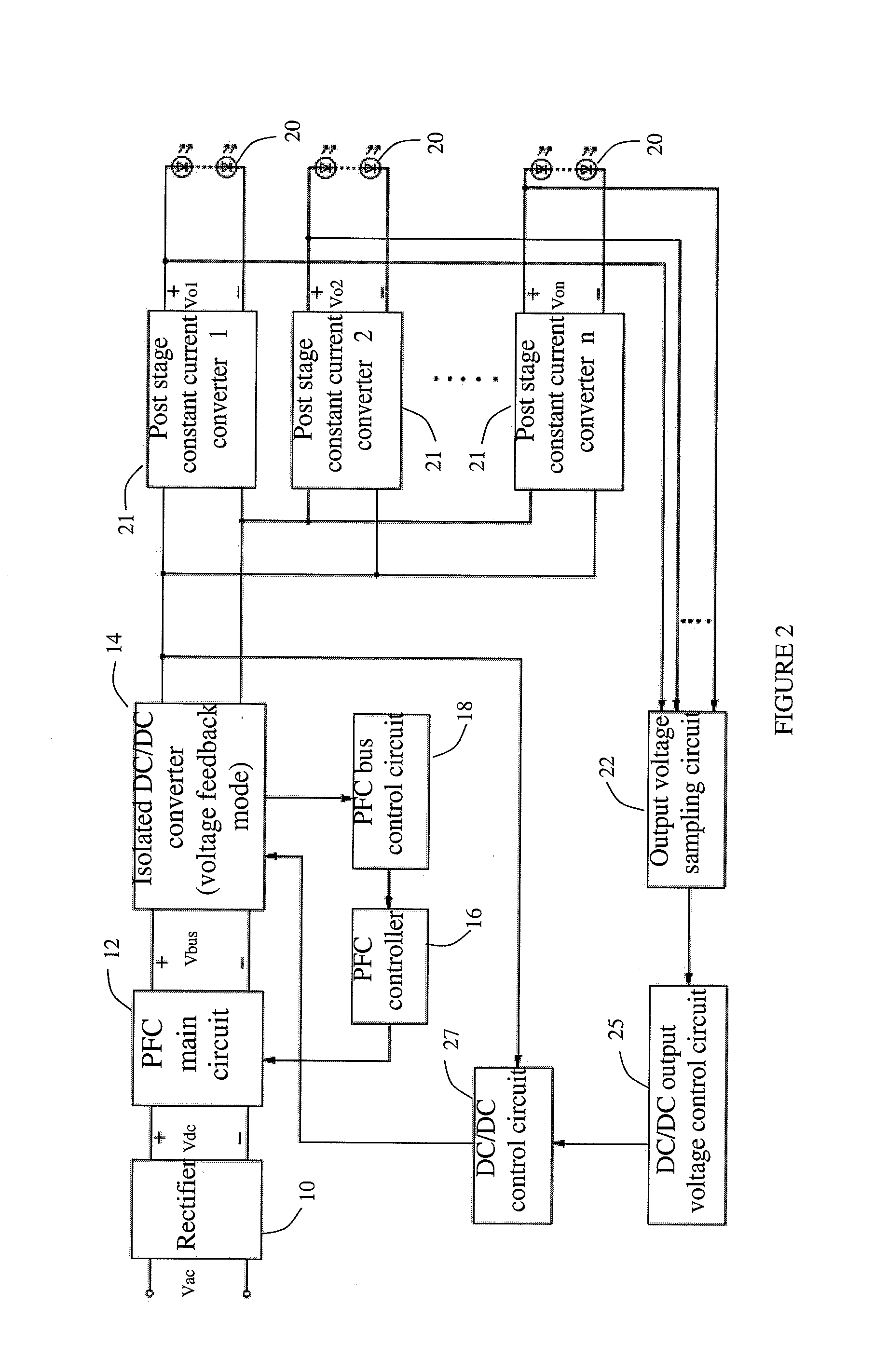

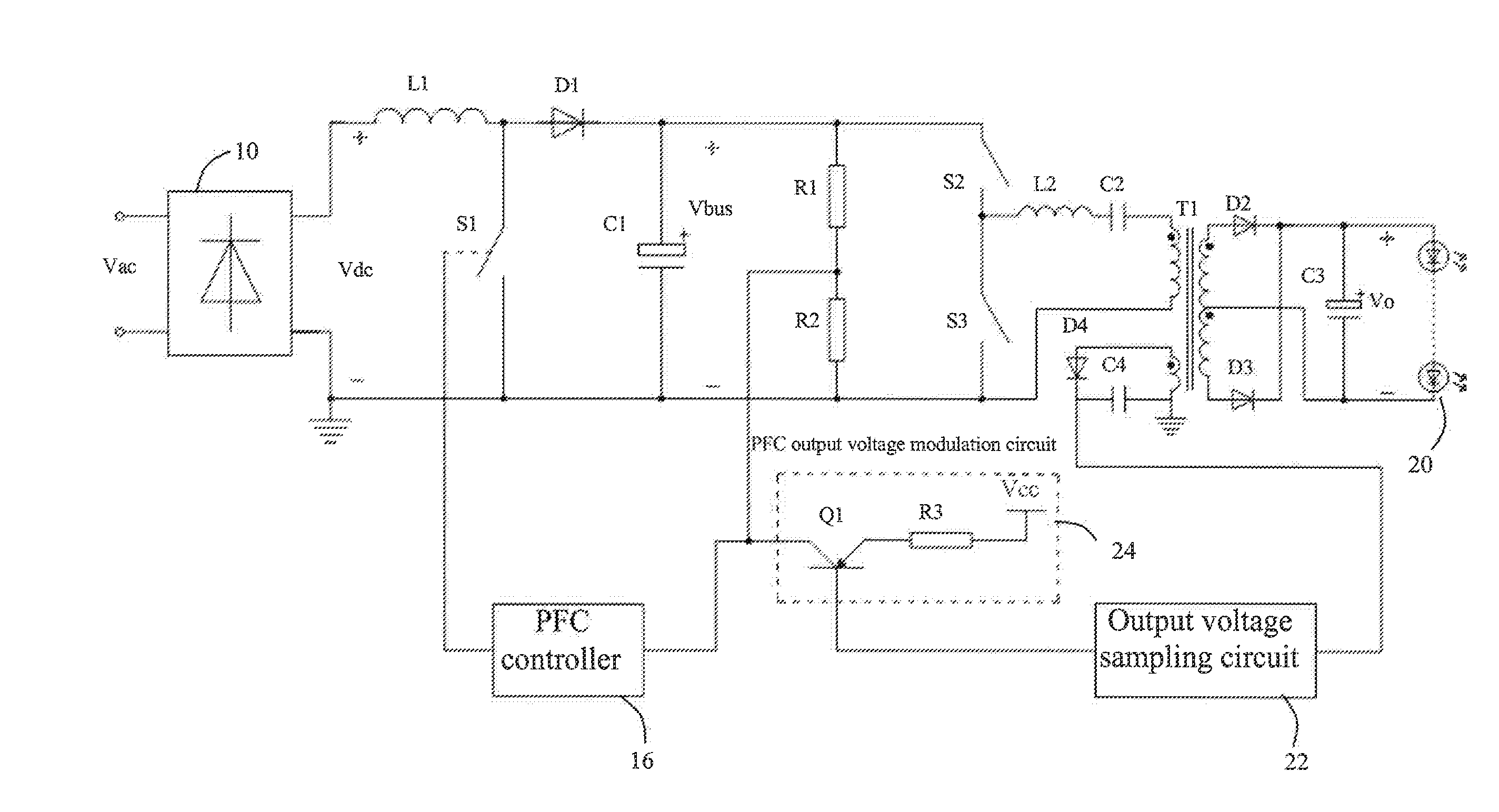

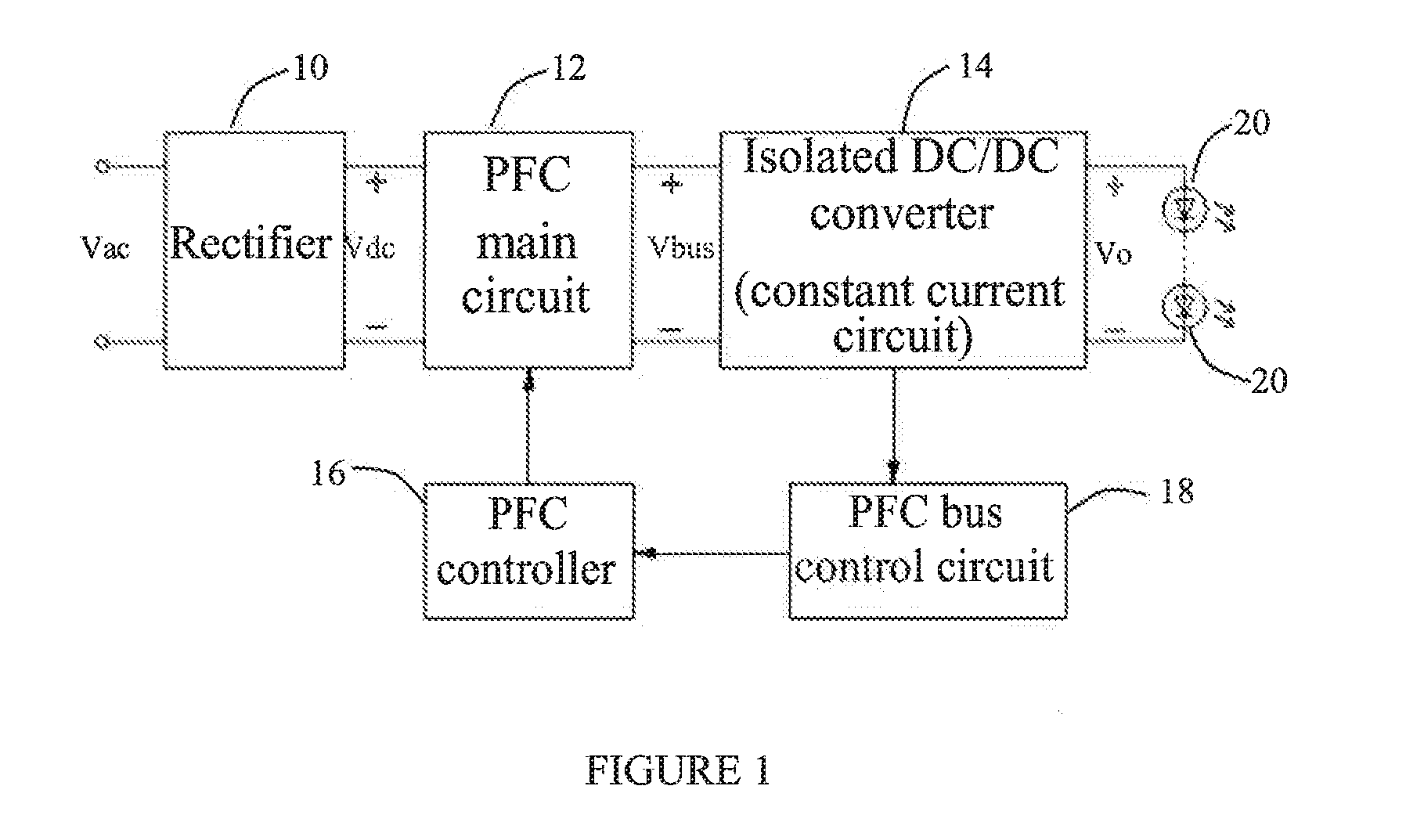

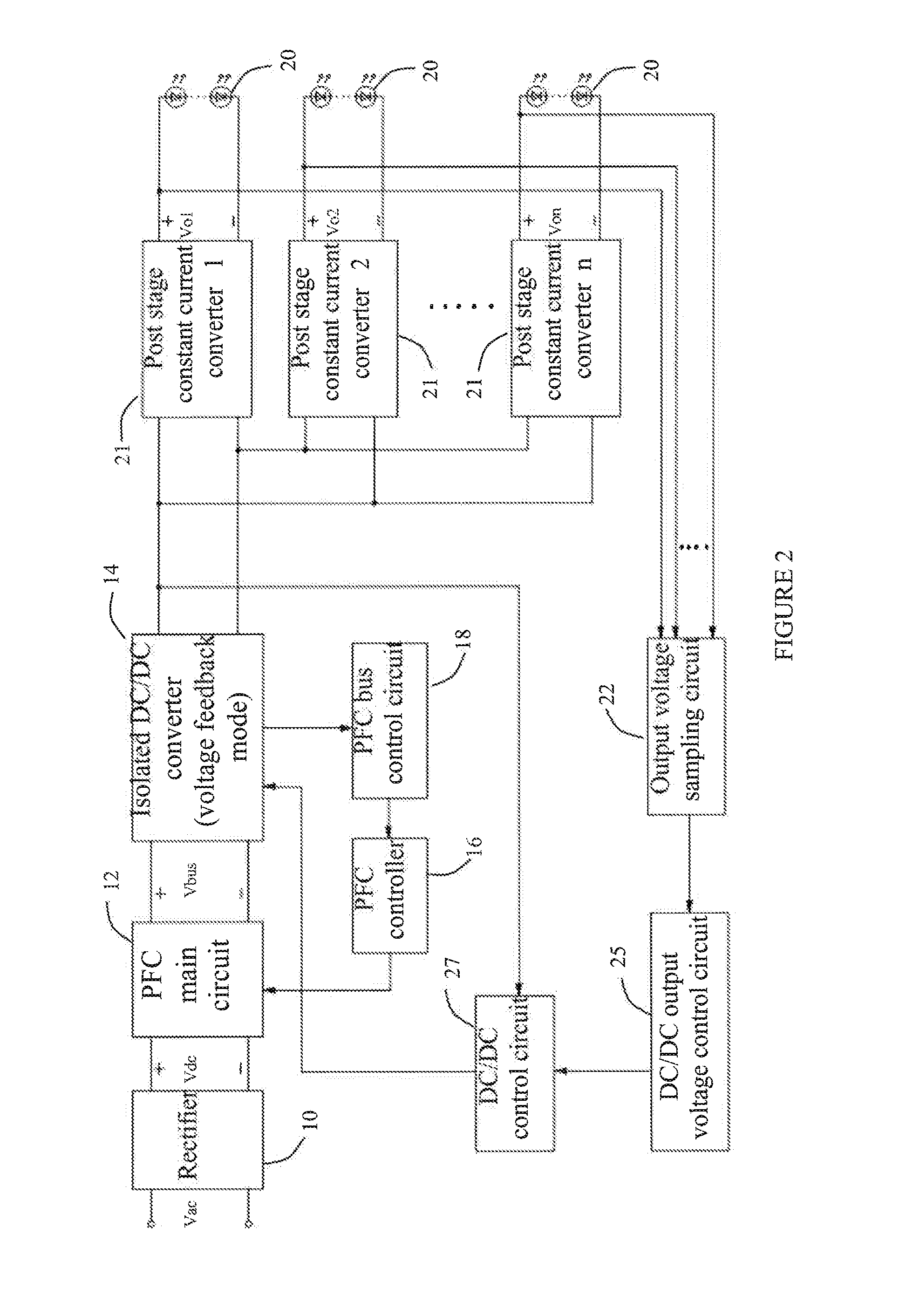

High efficiency constant current LED driver

InactiveUS20110080102A1Improve efficiencyLarge gainEfficient power electronics conversionElectroluminescent light sourcesFull bridgeEngineering

The present invention discloses a high efficiency constant current LED driver, which comprises a rectification bridge, a PFC main circuit, an isolated DC / DC converter, a PFC controller and a PFC bus control circuit. Since the input voltage is an intermediate PFC bus voltage, which varies with the output voltage of the DC / DC converter. When the isolated DC / DC converter is an LLC resonant circuit, the operating frequency of the LLC circuit is close to the resonant frequency within a wide output voltage range. Thus, the gain range and the operating frequency is narrow, and can enable the constant current module to work with a high efficiency at a wide output voltage range. When the isolated DC / DC converter is a symmetric half bridge, or an asymmetric half bridge or a full bridge circuit, the duty cycle of DC / DC circuit is close to 50% within a wide output voltage range. Thus, the changing range of the duty cycle of the DC / DC converter will be narrow and can improve the efficiency dramatically.

Owner:INVENTRONICS HANGZHOU

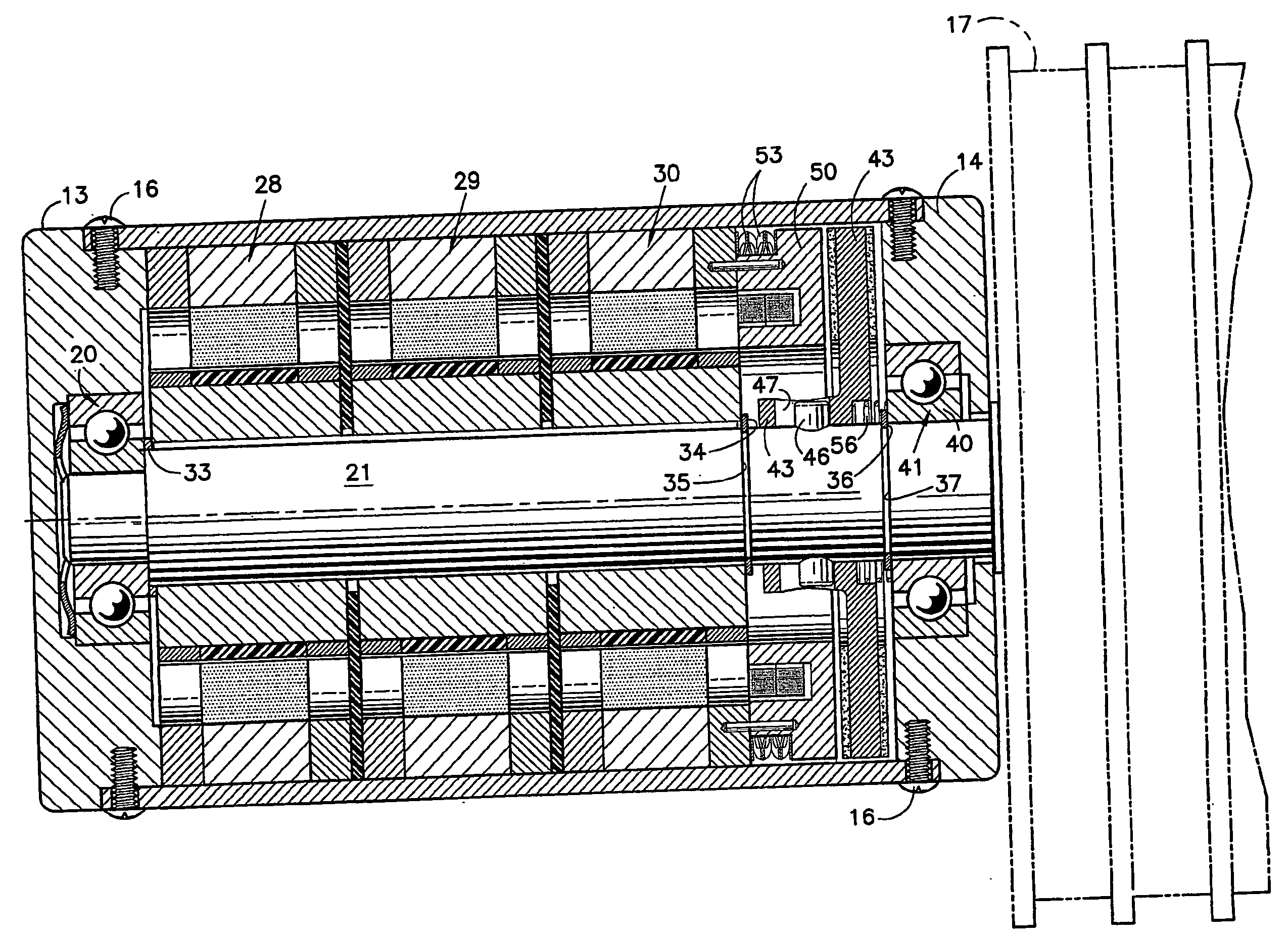

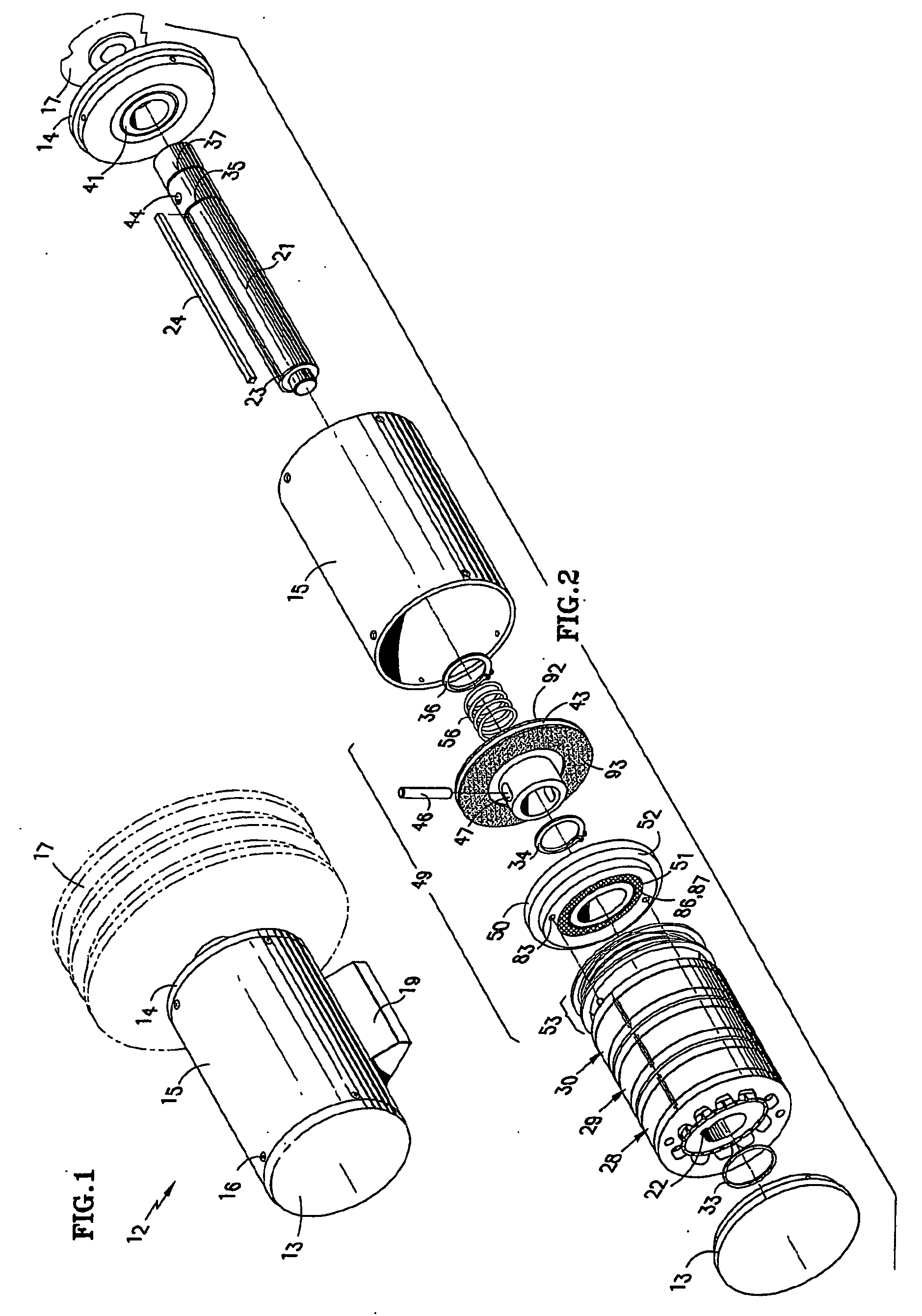

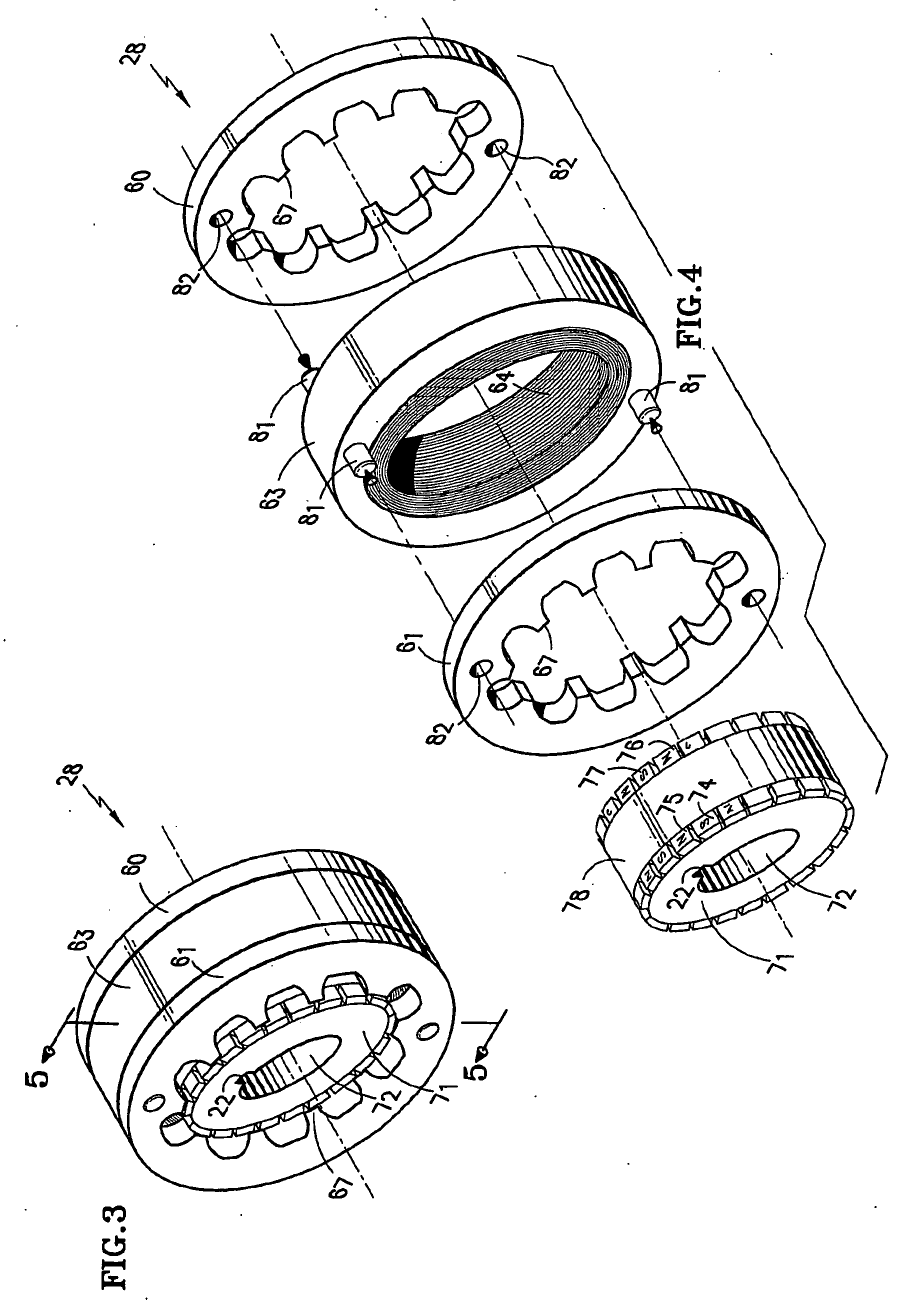

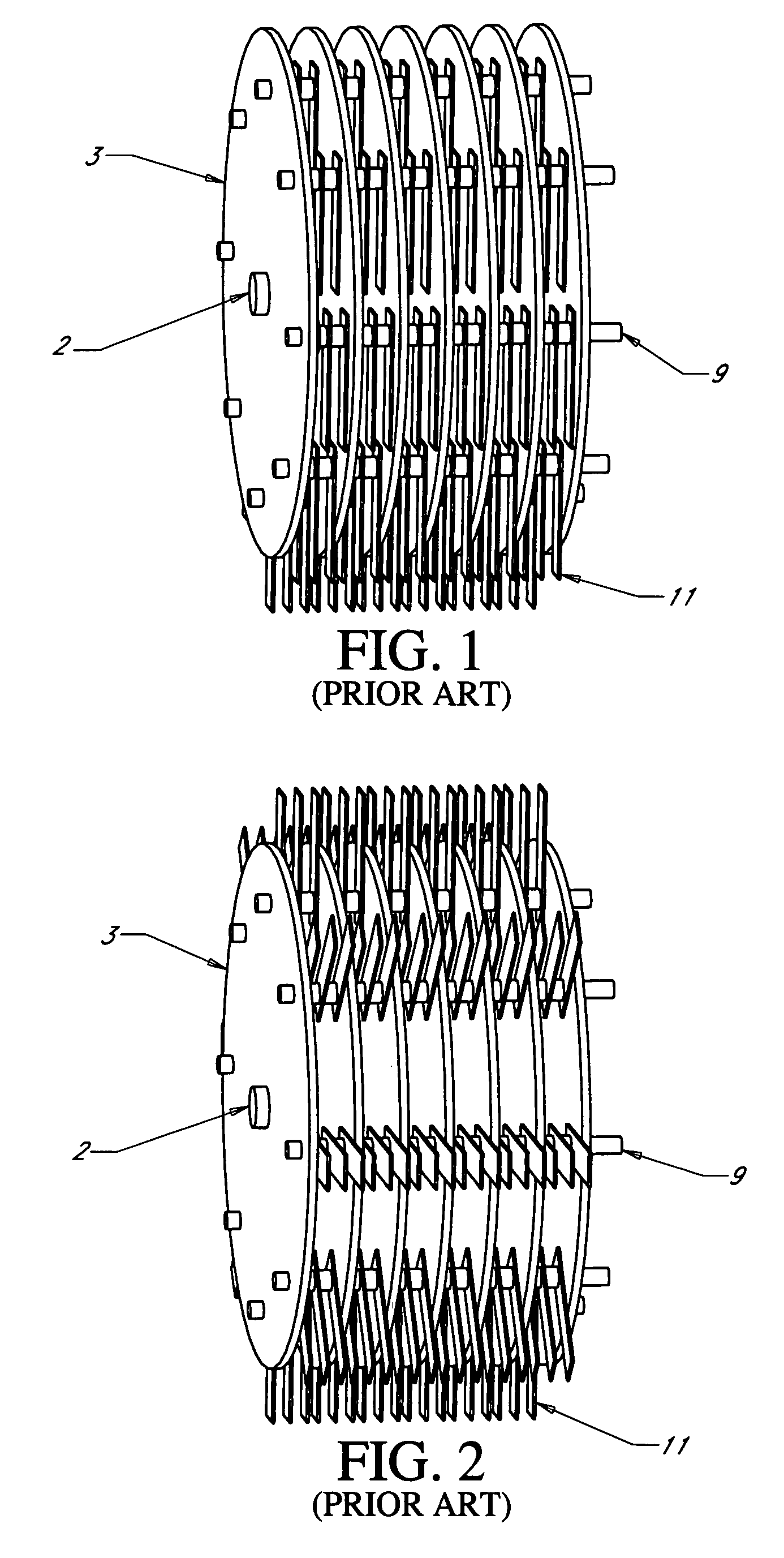

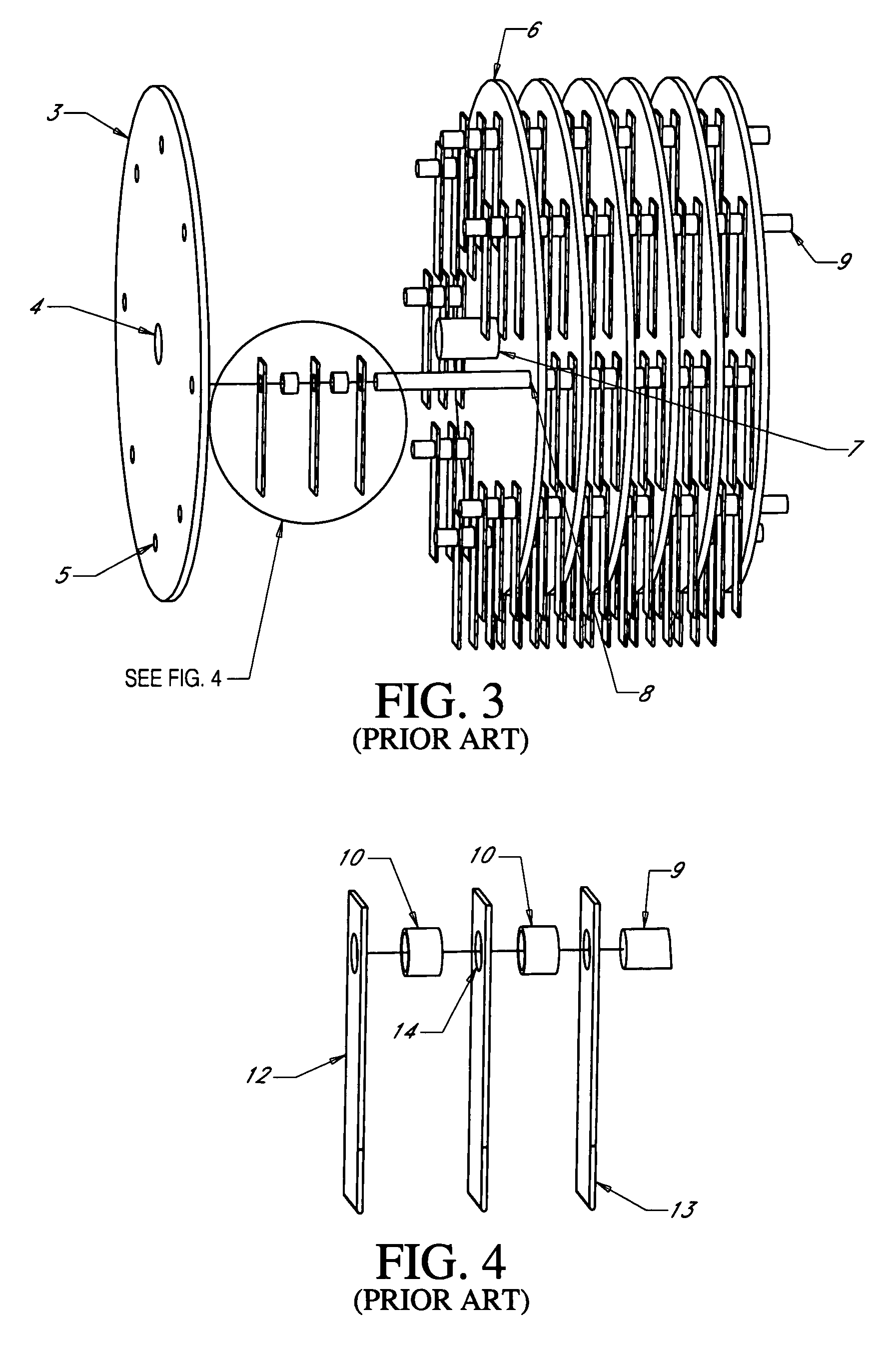

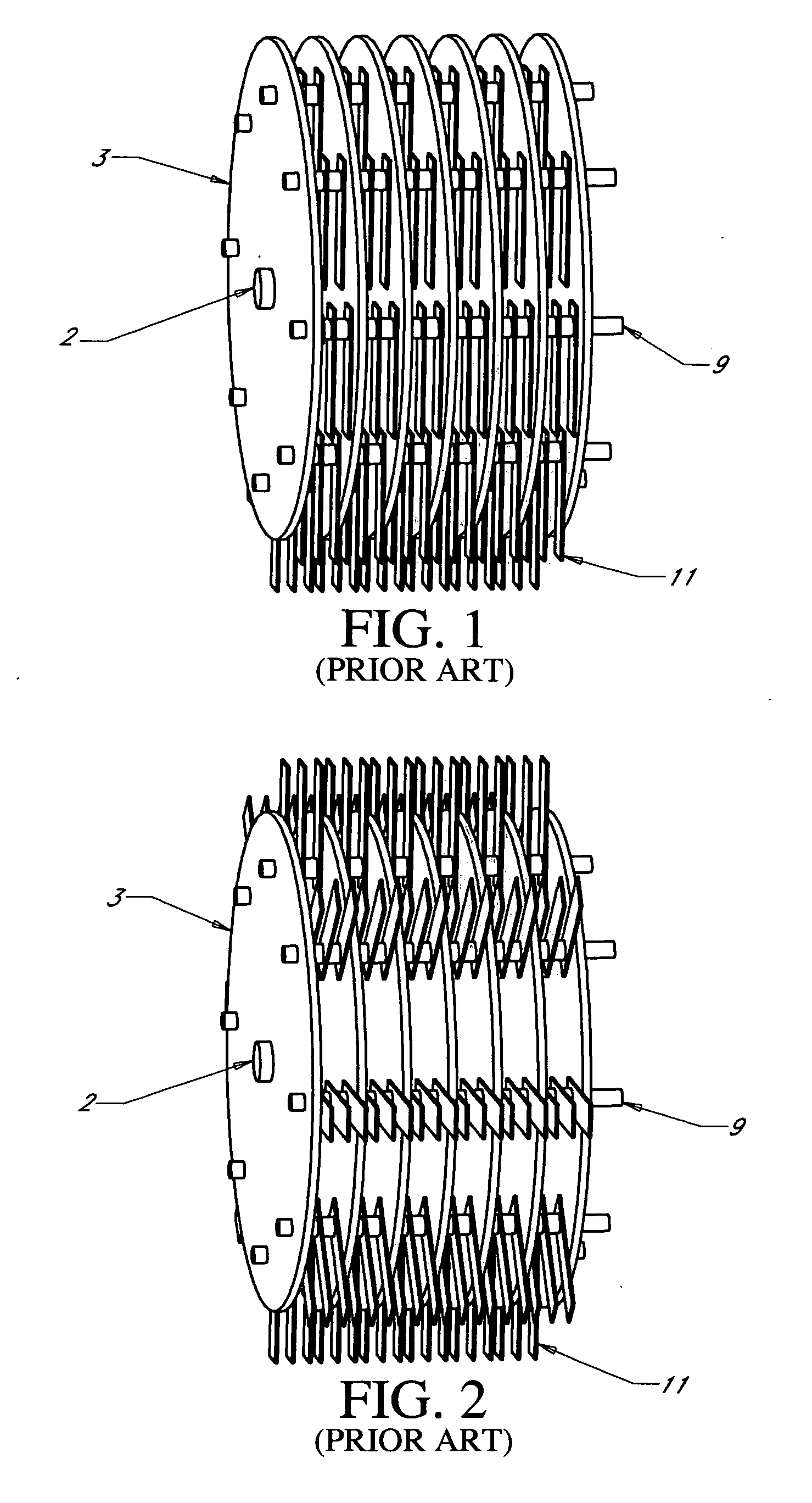

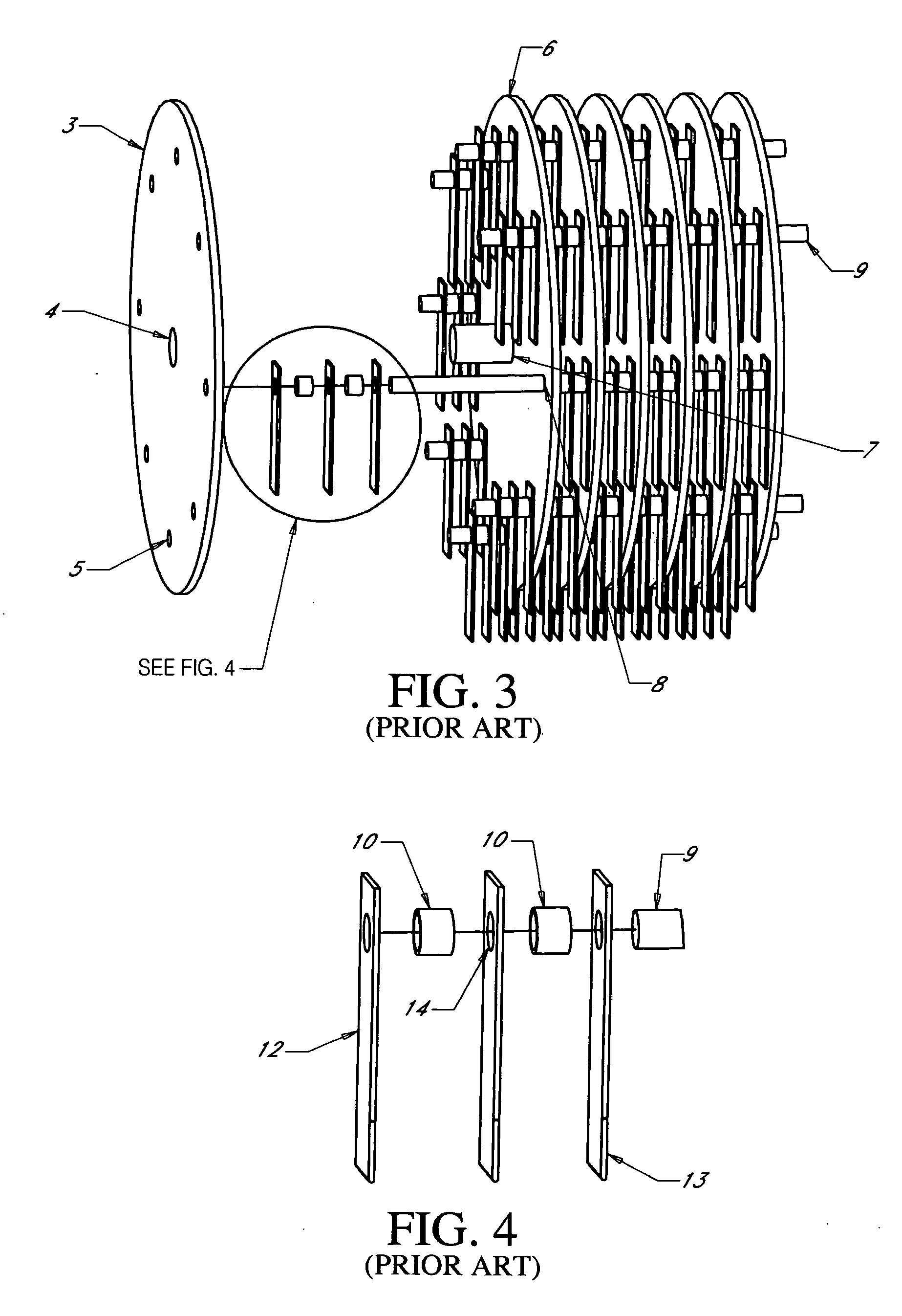

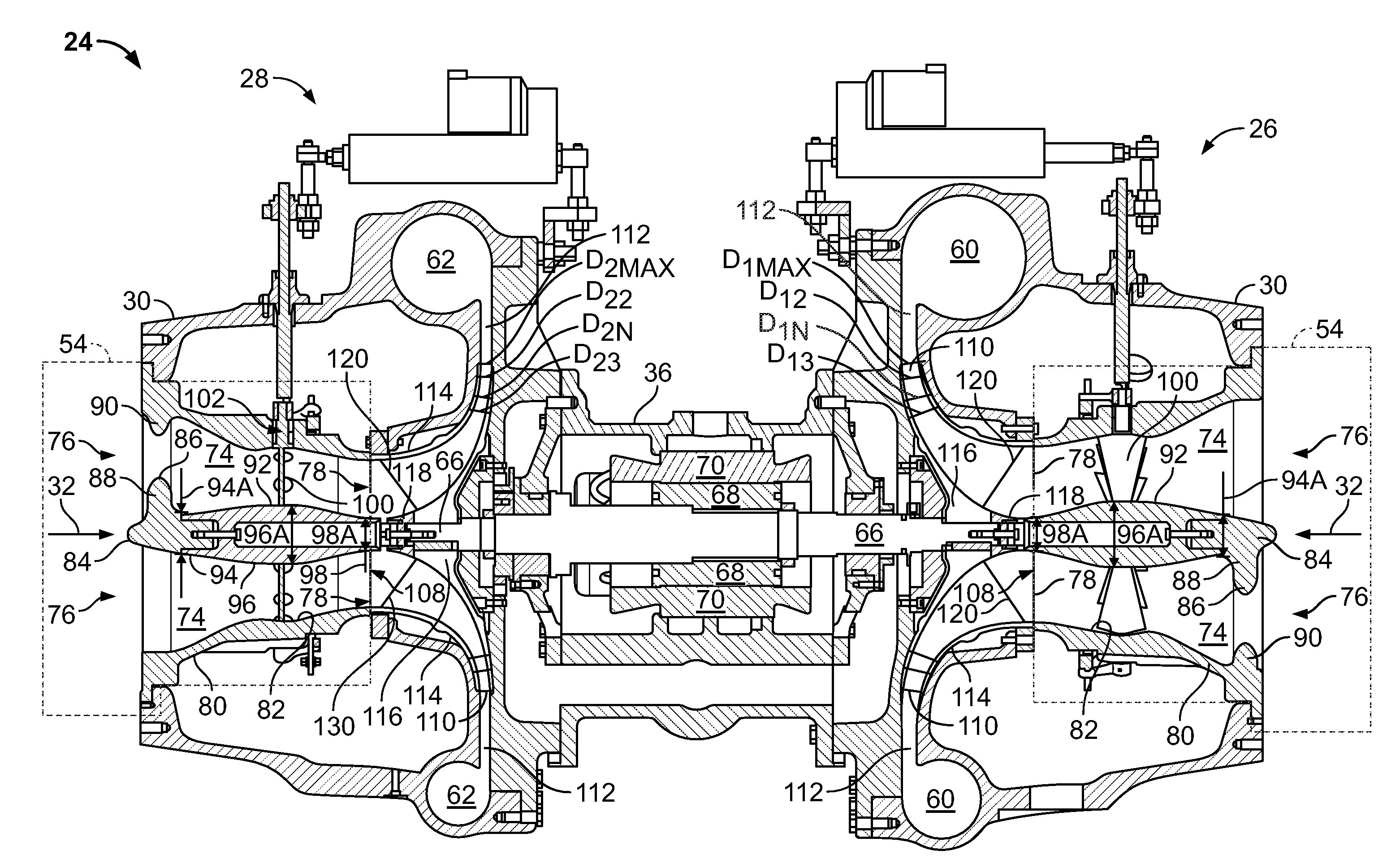

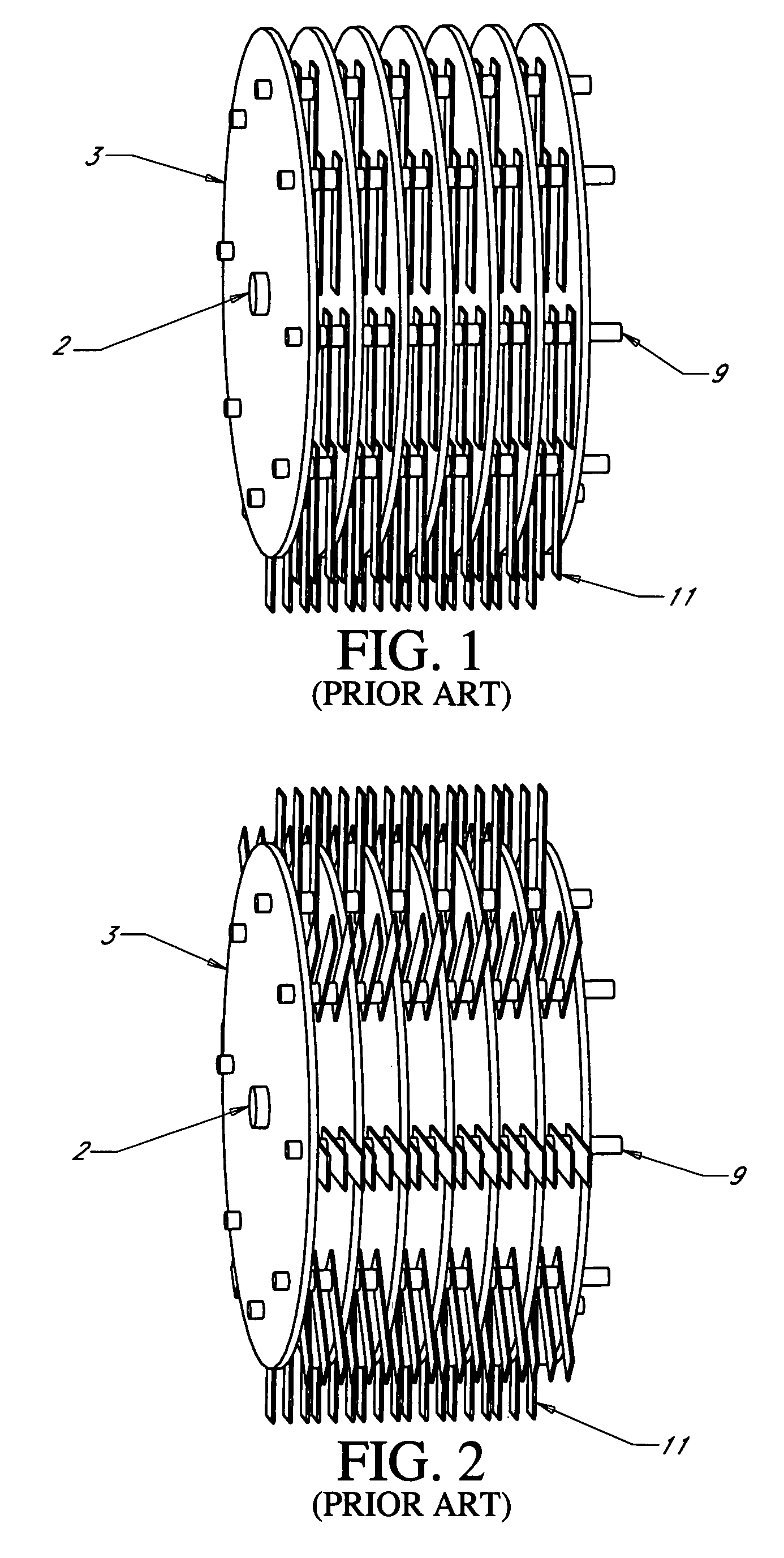

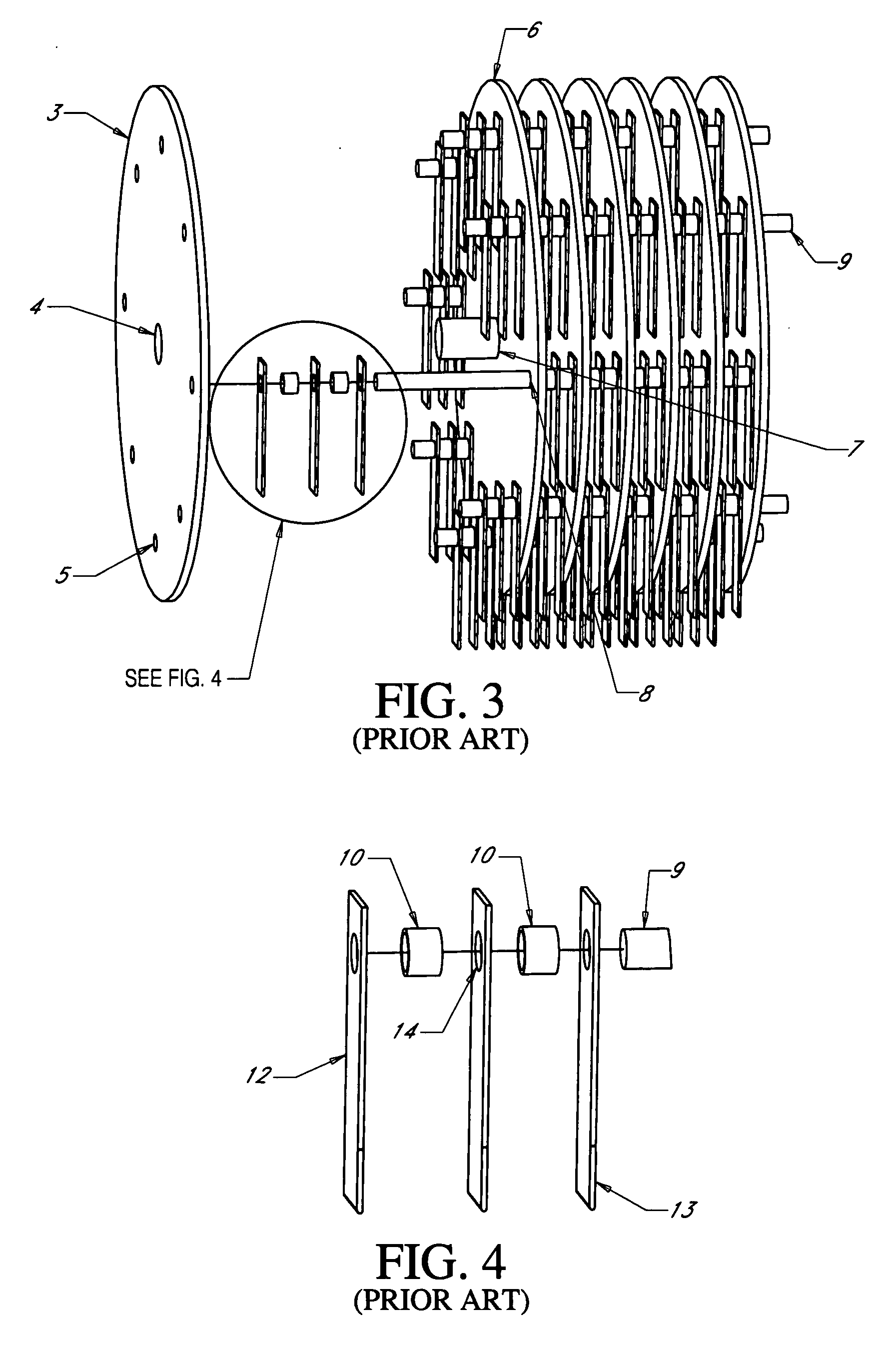

Modular transverse flux motor with integrated brake

InactiveUS20060192453A1Increased torque densityImprove efficiencySynchronous generatorsDynamo-electric brakes/clutchesTransverse fluxMotor end plates

An elevator machine (12) has a plurality of identical transverse flux rotor / stator modules (28-30) of a generally cylindrical configuration arranged contiguously on a common shaft (21) to provide torque to the shaft equal to the torque capability of the modules times the number of modules. A disc brake (49) is integrated with the motor; a two-sided brake disc (49) has friction pads (92, 93) on both sides, braking force being applied to motor end plate (14) and through the brake disc to a stator (60) of one phase (30) of the motor. A process (113) forms variously-sized motors from identically sized modular components, in various configurations (12, 100, 110).

Owner:OTIS ELEVATOR CO

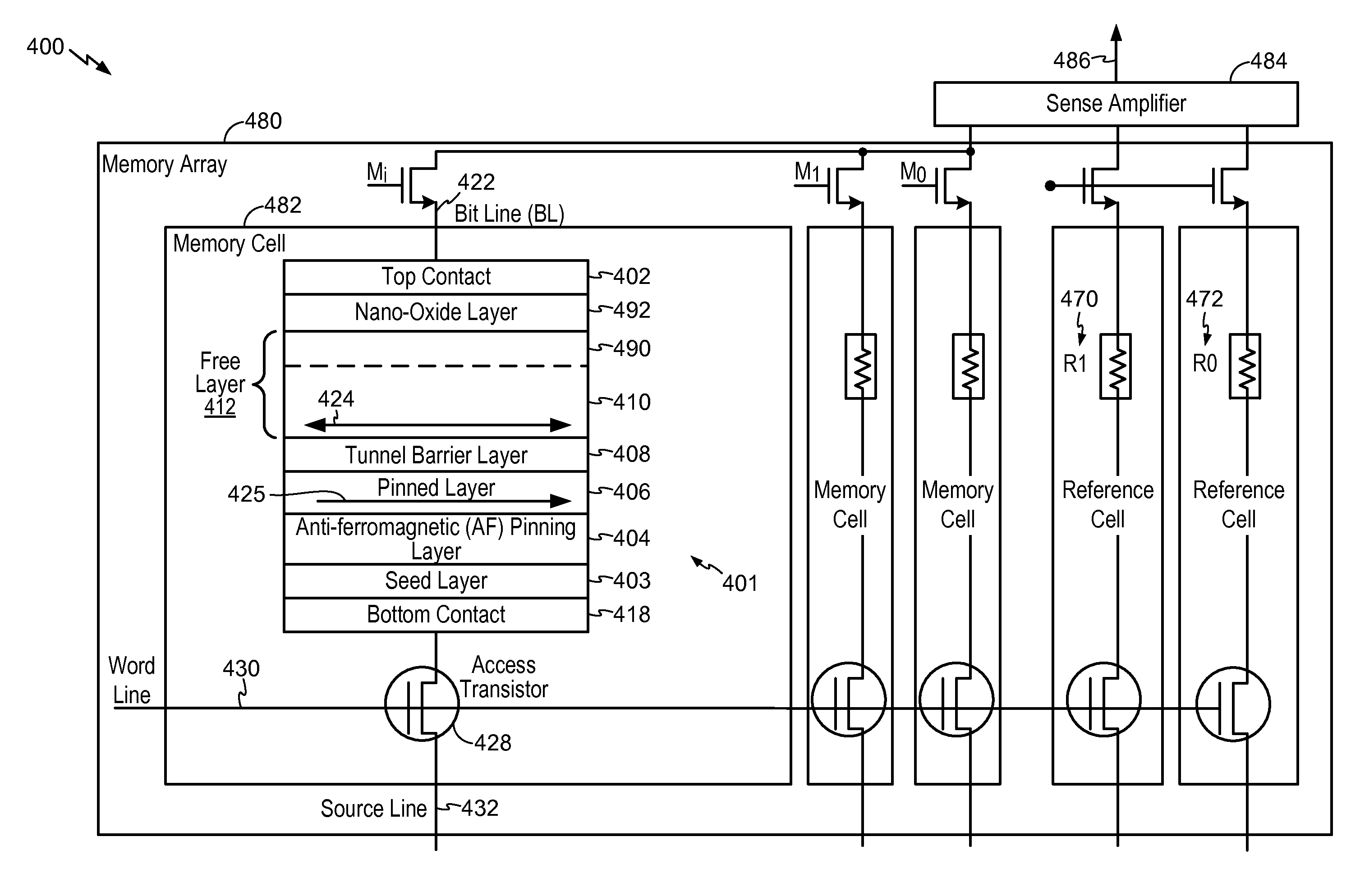

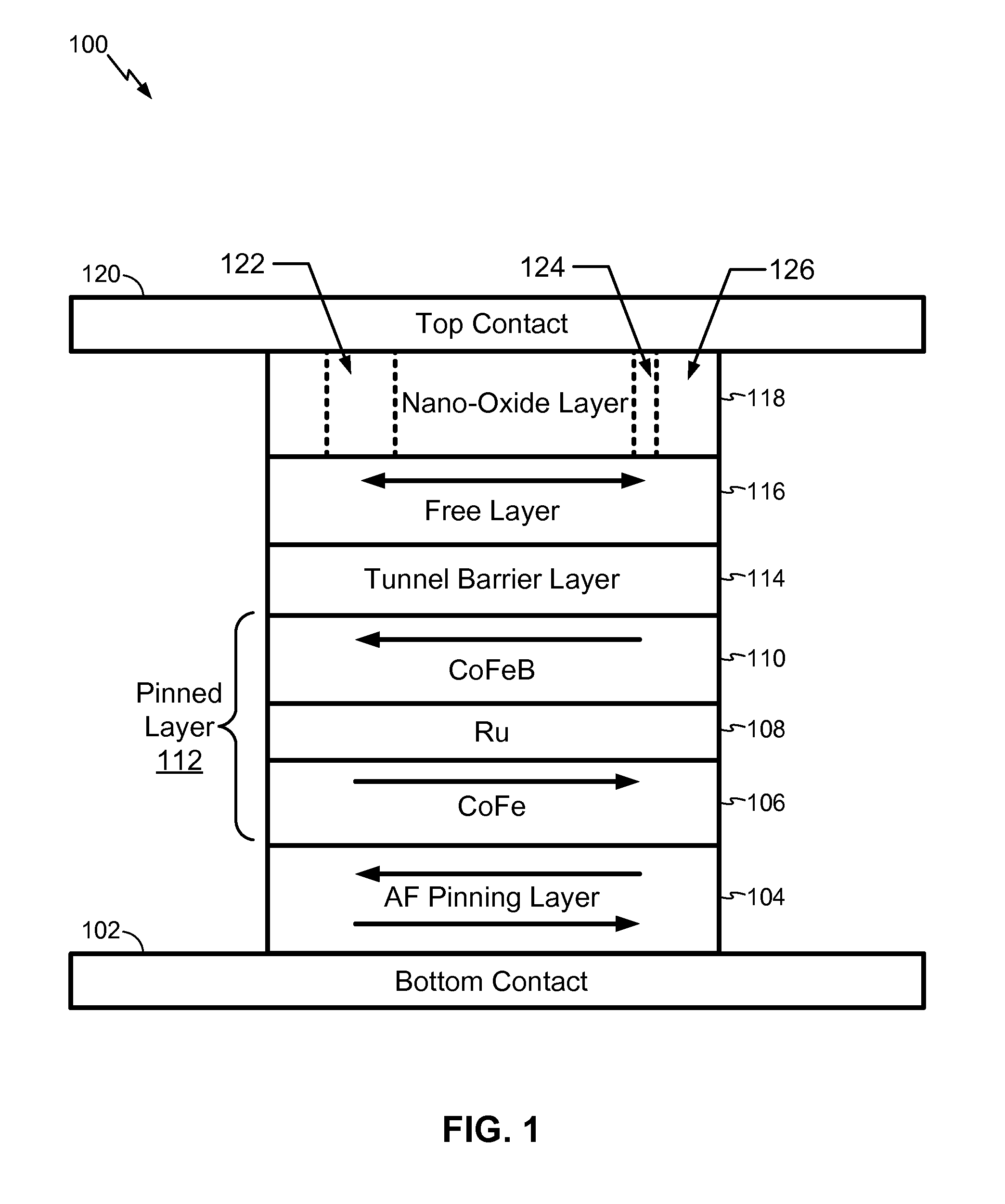

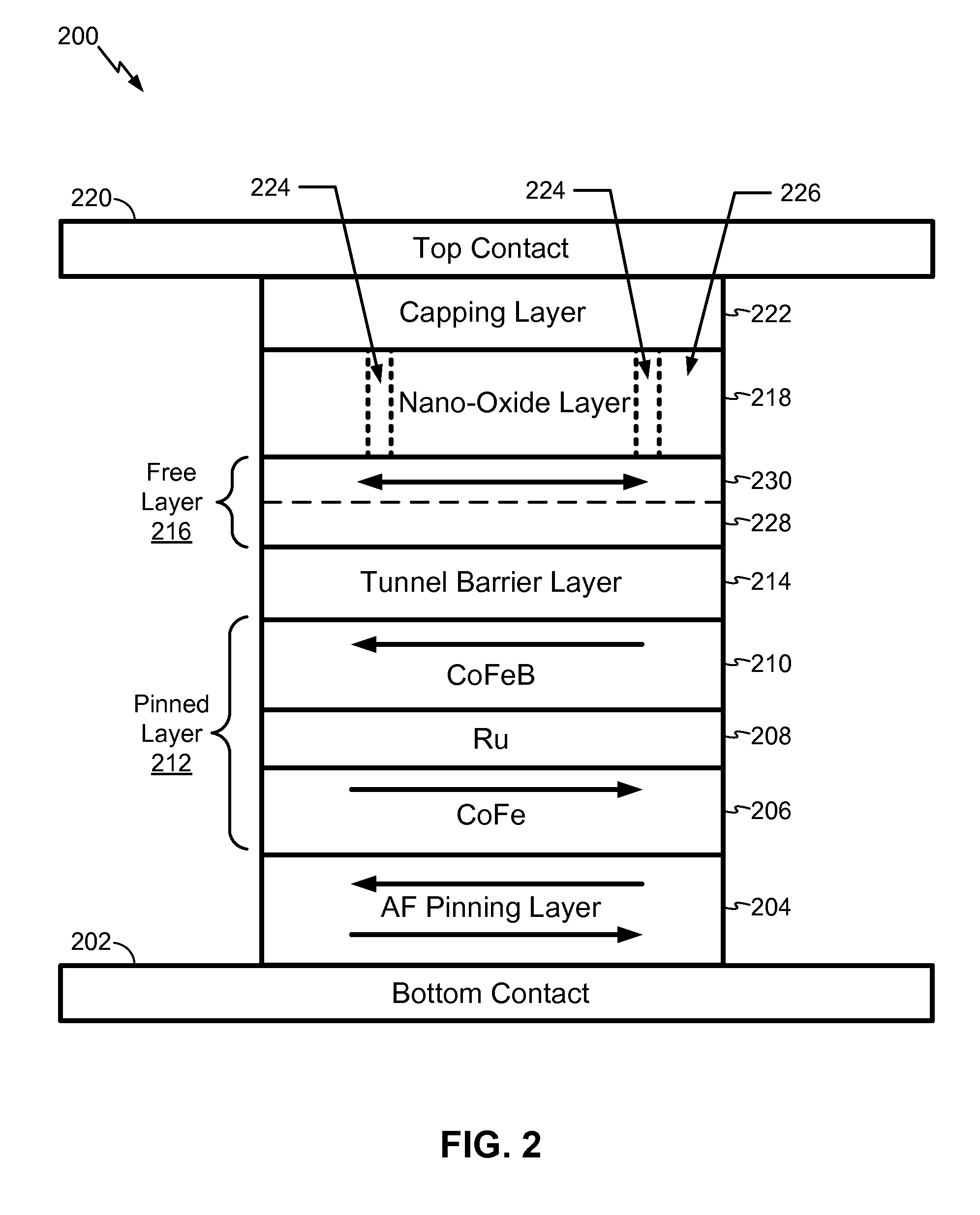

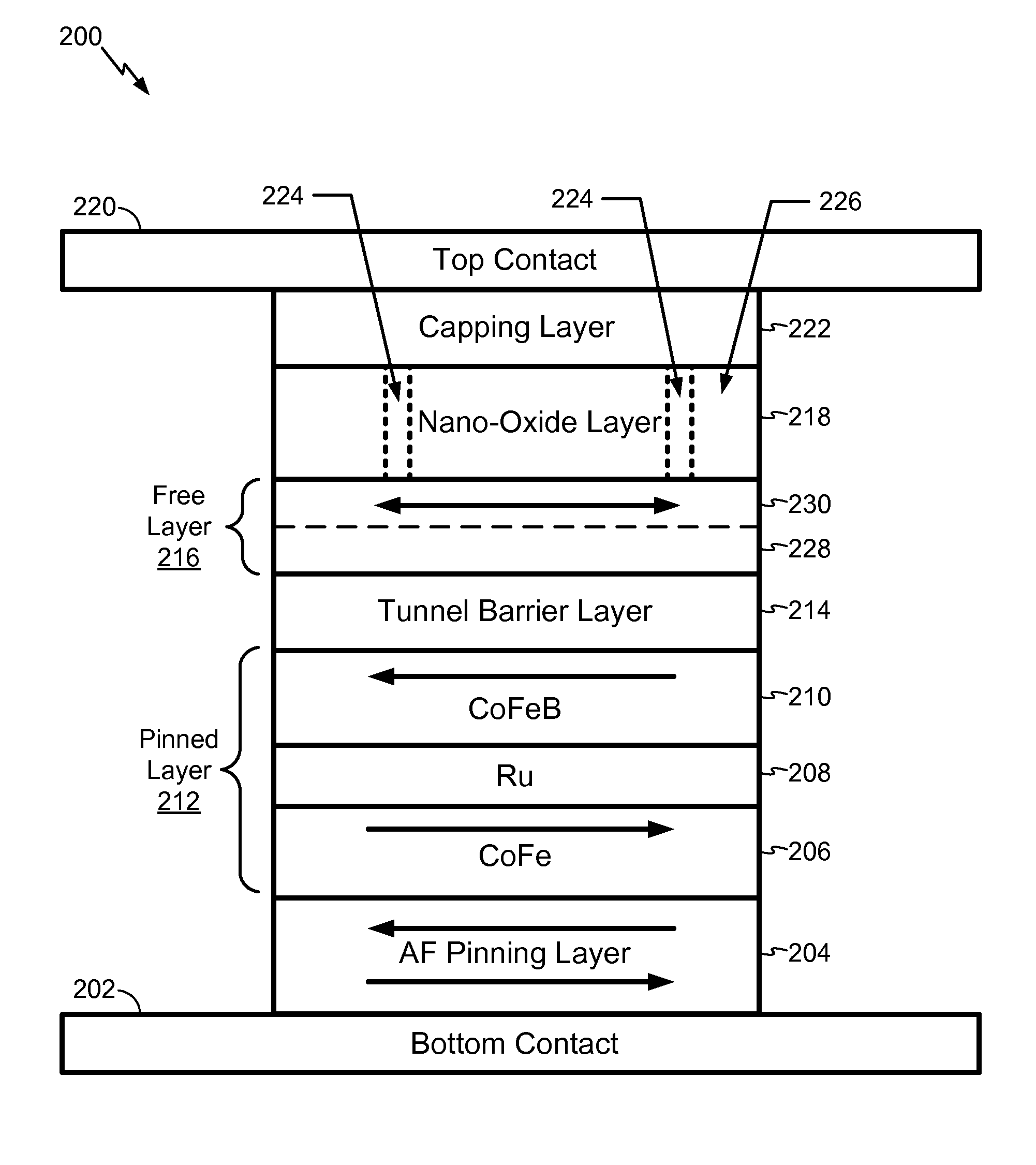

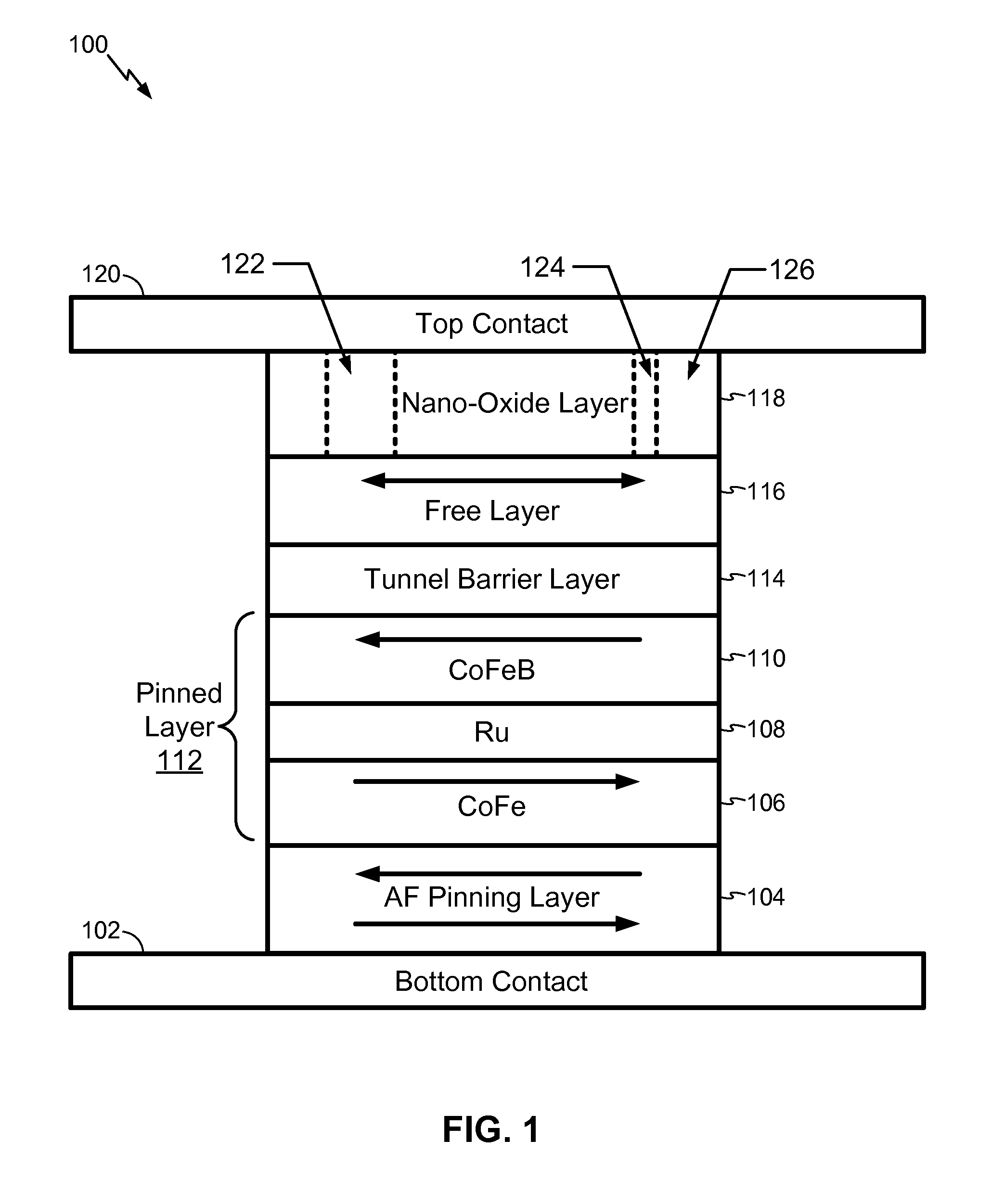

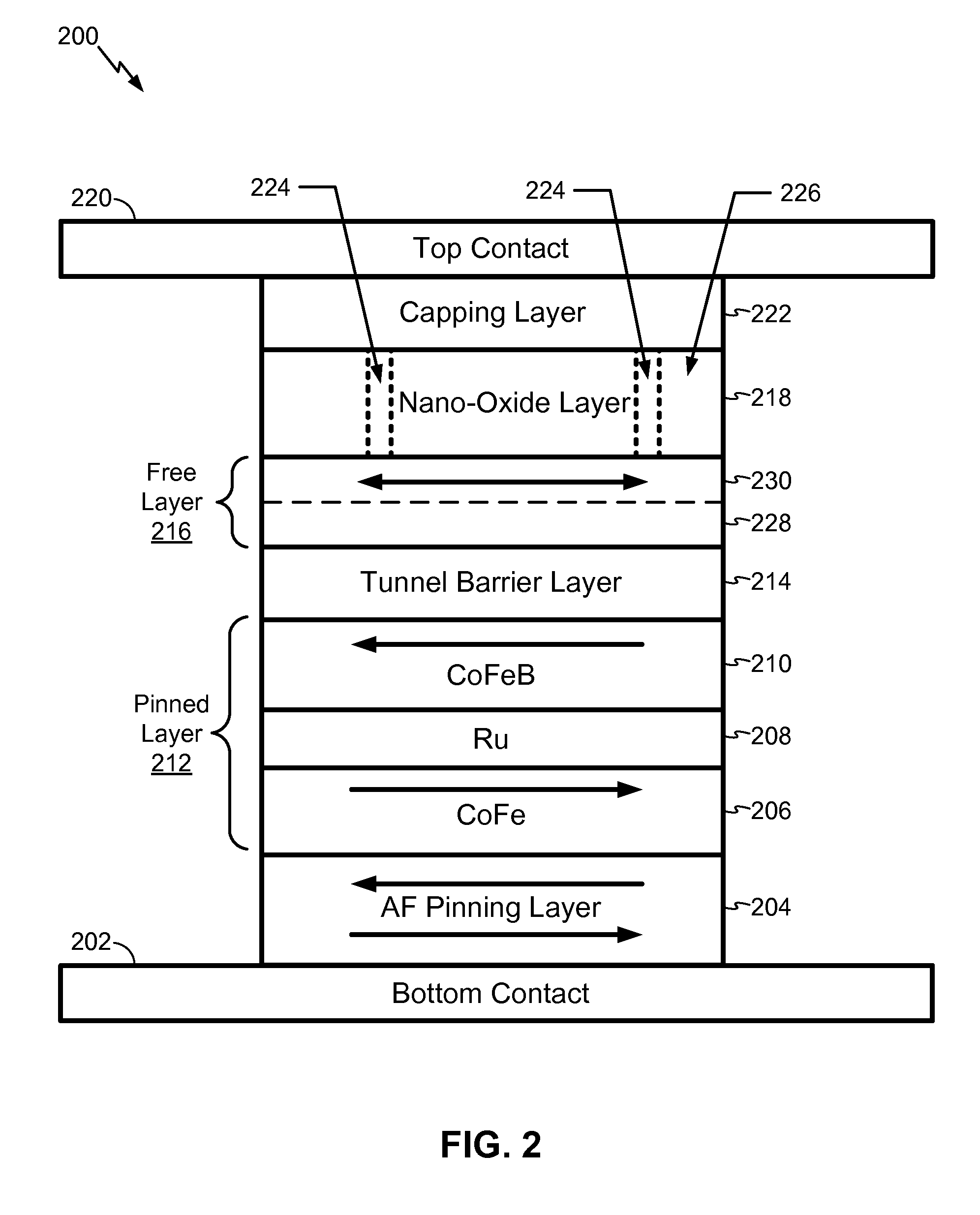

Magnetic Tunnel Junction Device and Fabrication

ActiveUS20100315863A1Constant efficiencyLow densityNanomagnetismMagnetic measurementsEngineeringTunnel junction

A magnetic tunneling junction (MTJ) device and fabrication method is disclosed. In a particular embodiment, an apparatus is disclosed that includes an MTJ device. The MTJ device includes a free layer and a spin torque enhancing layer. The spin torque enhancing layer includes a nano-oxide layer.

Owner:QUALCOMM INC

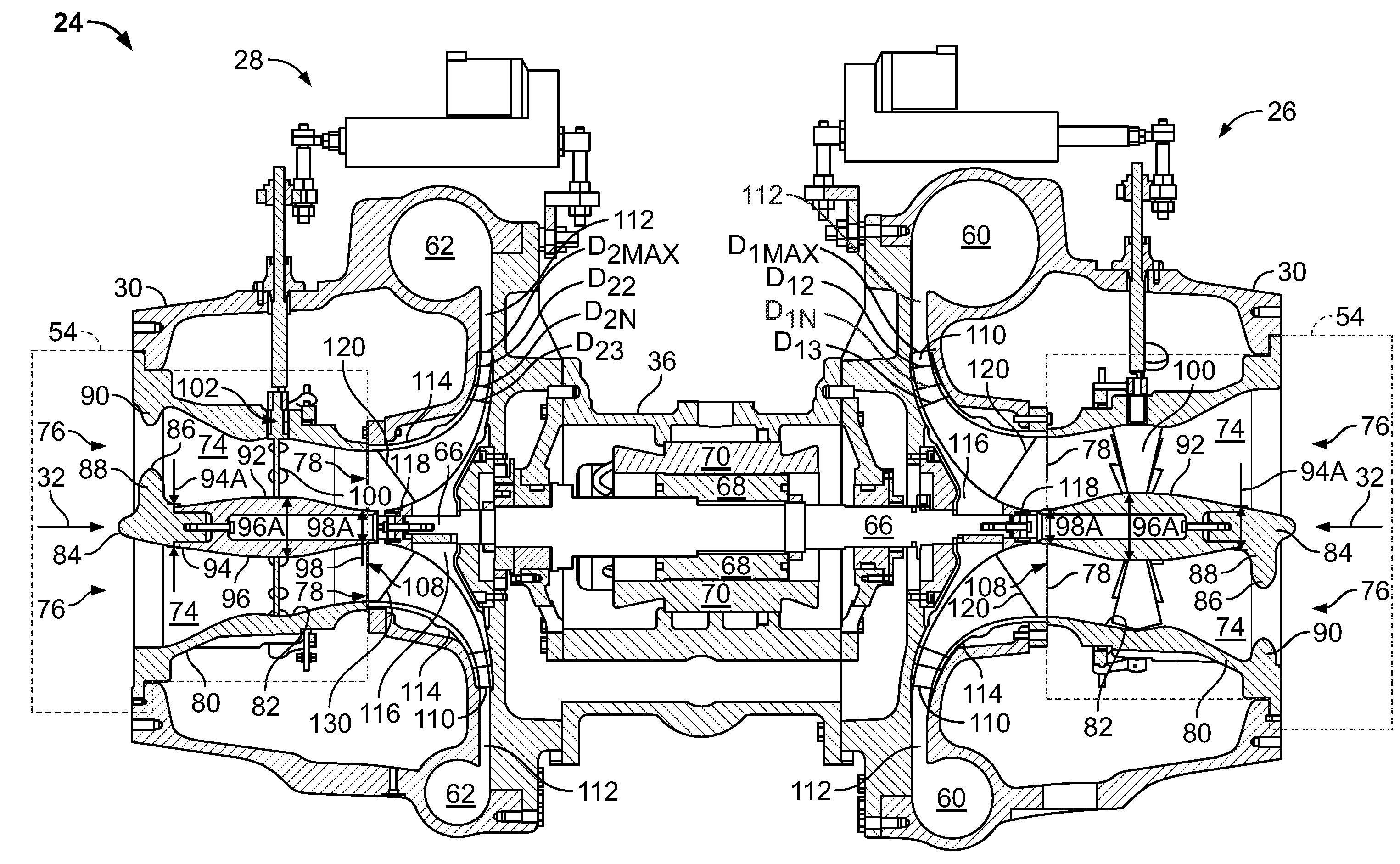

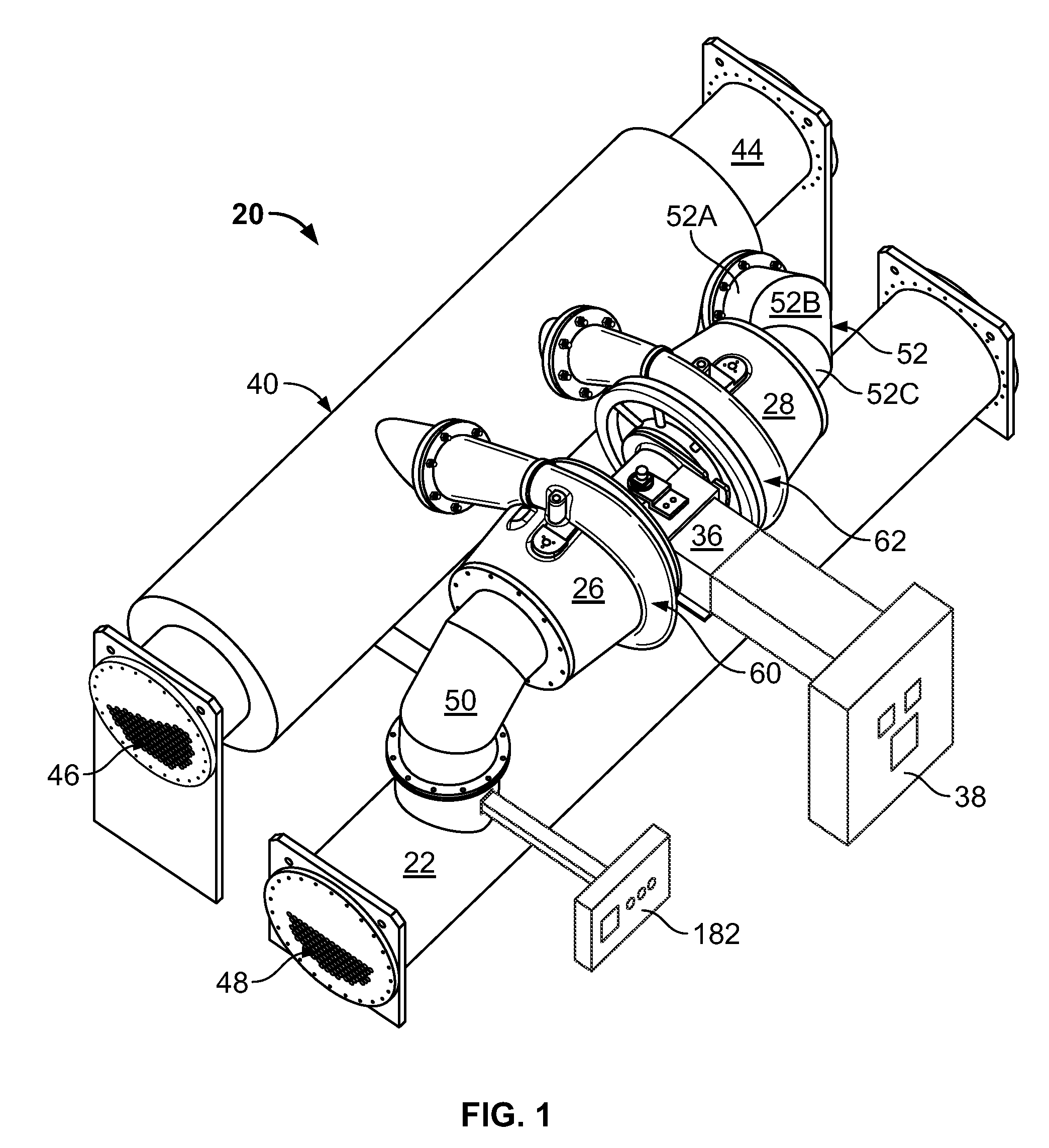

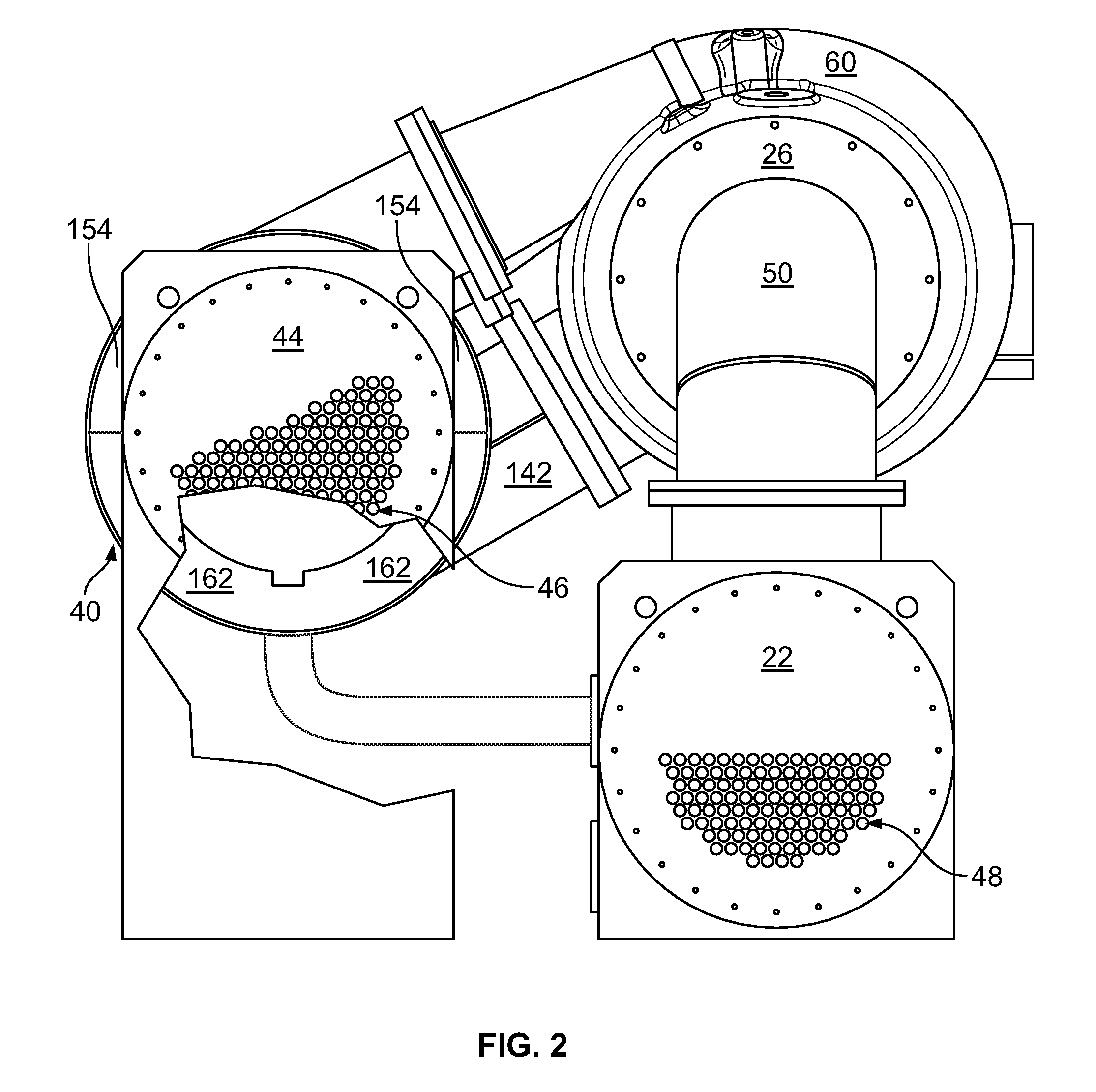

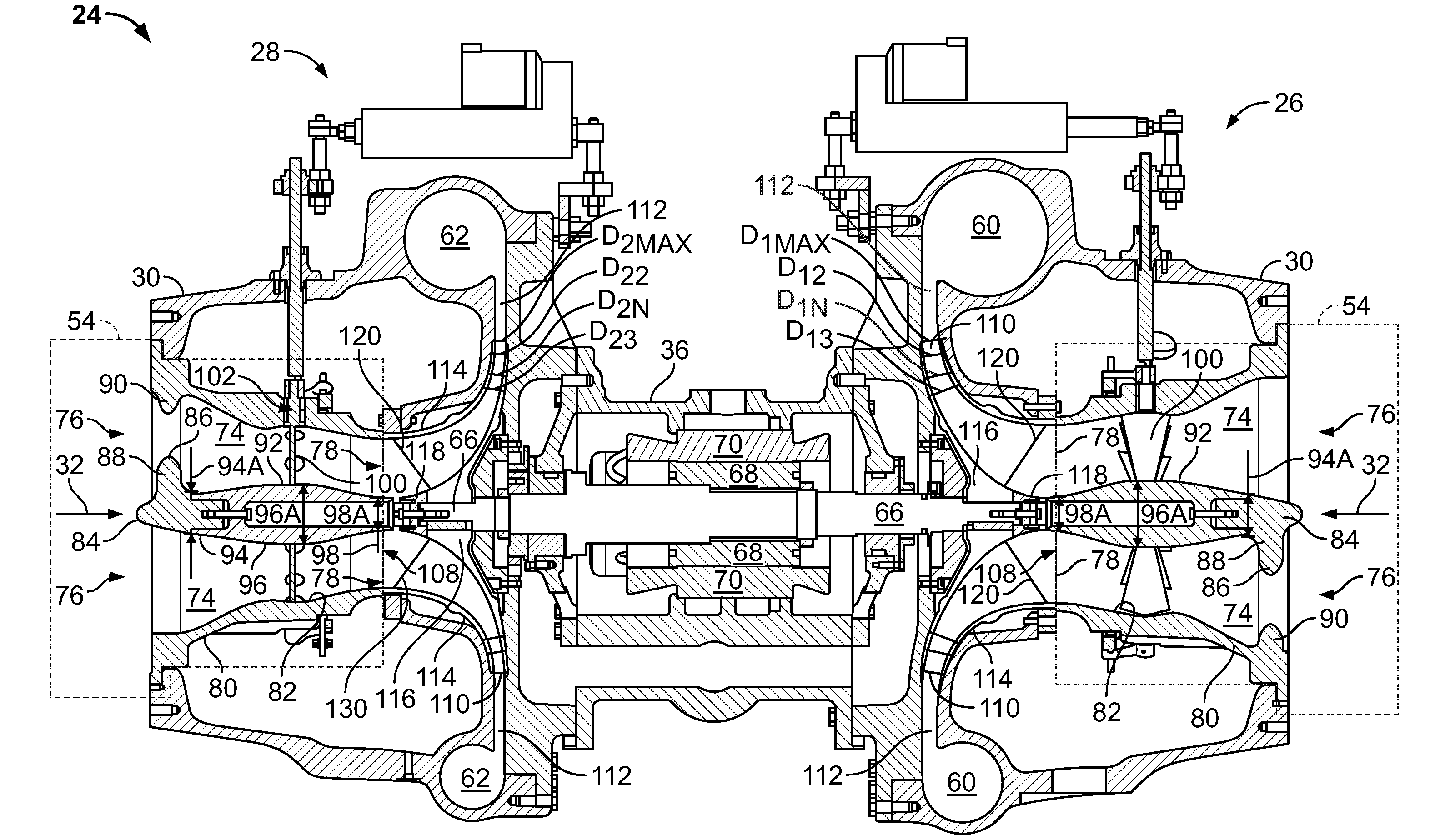

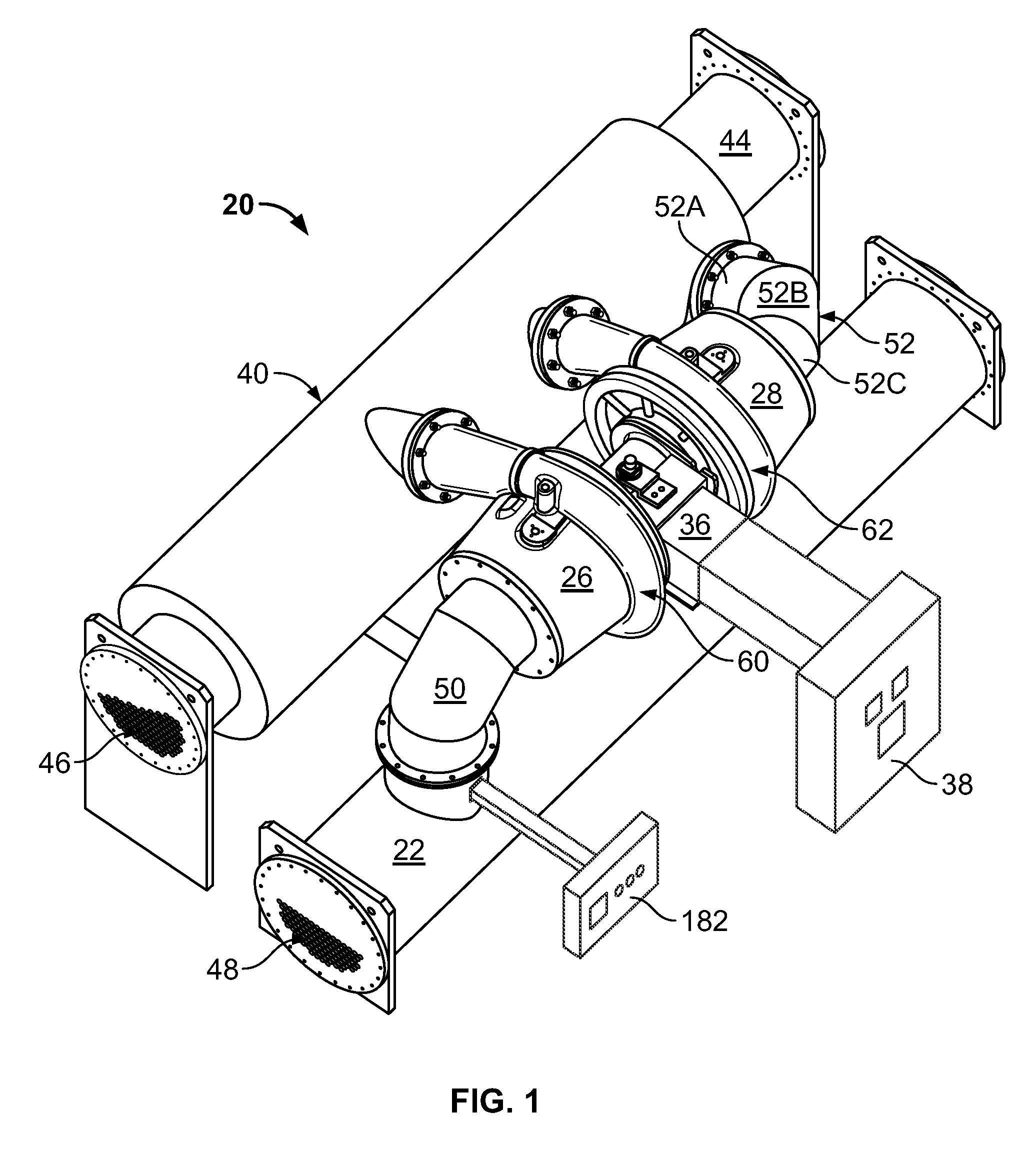

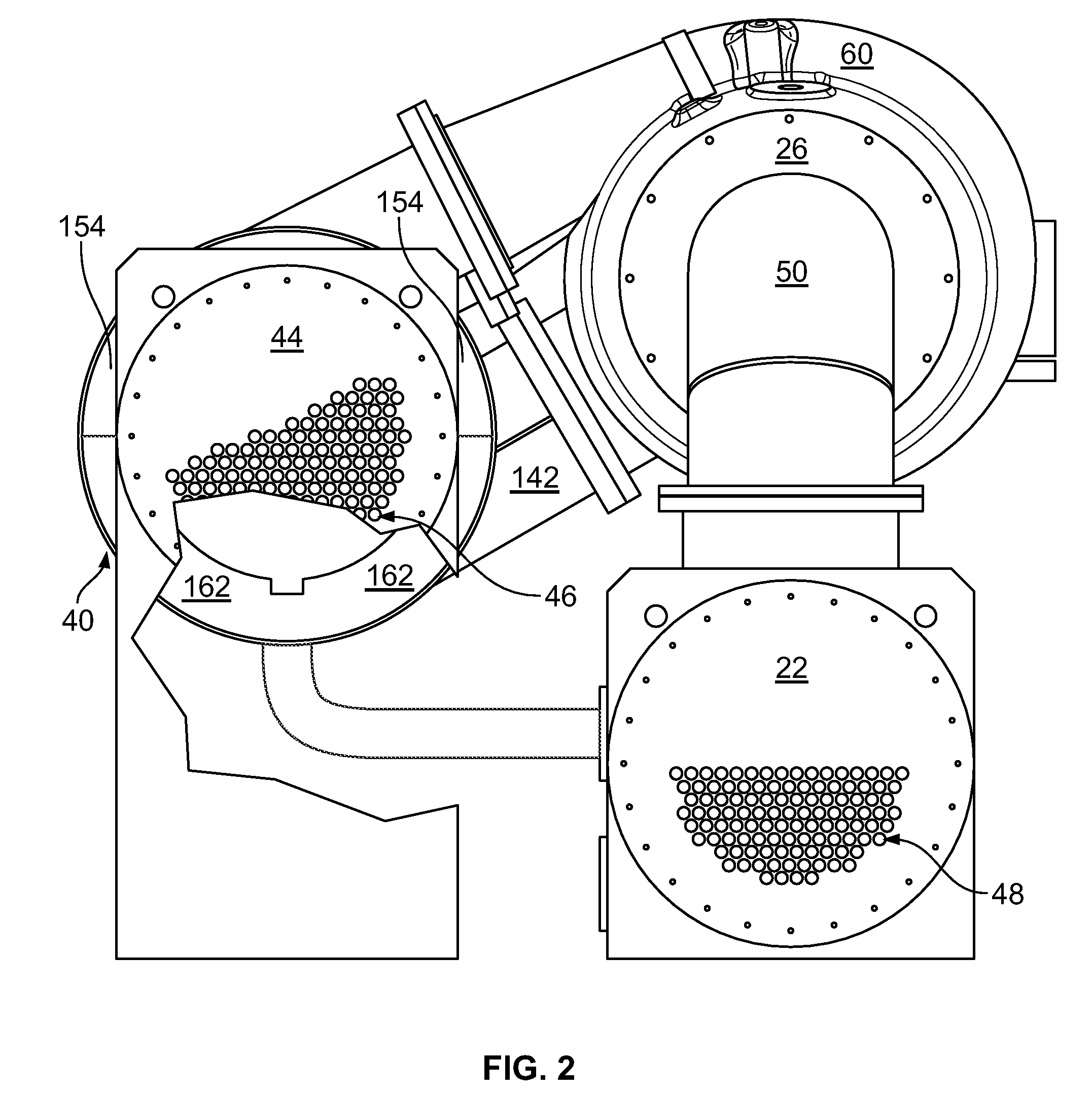

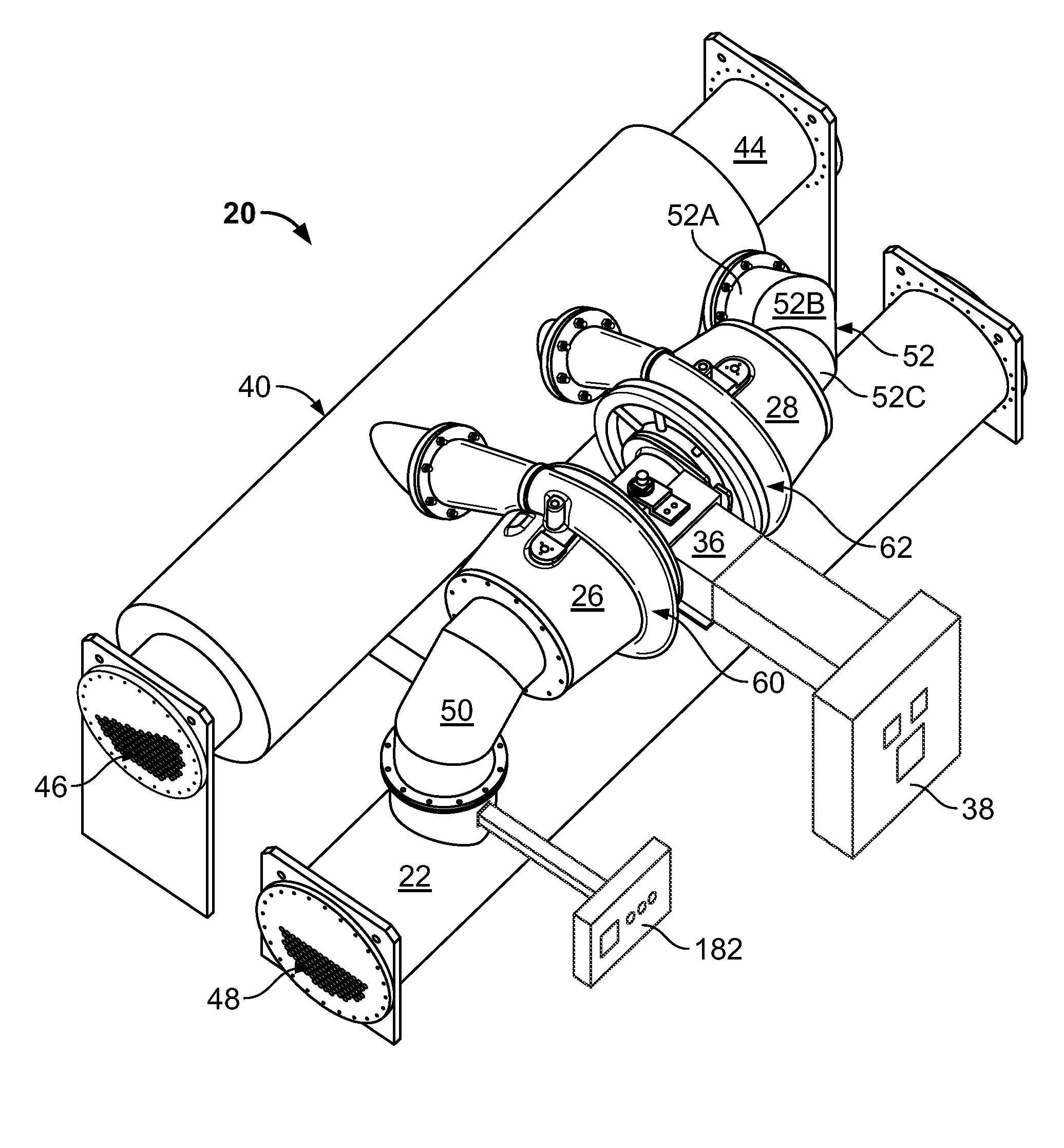

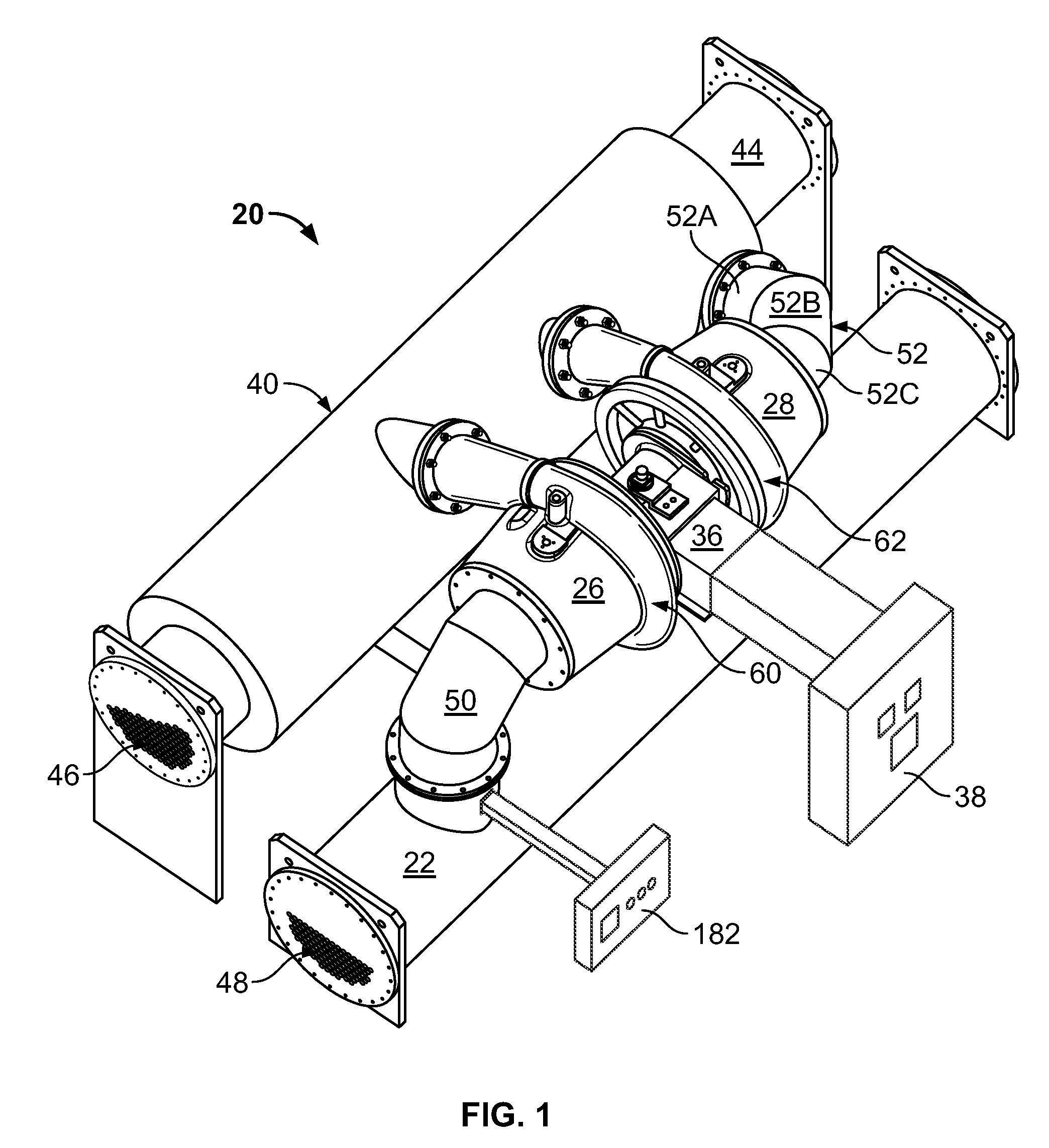

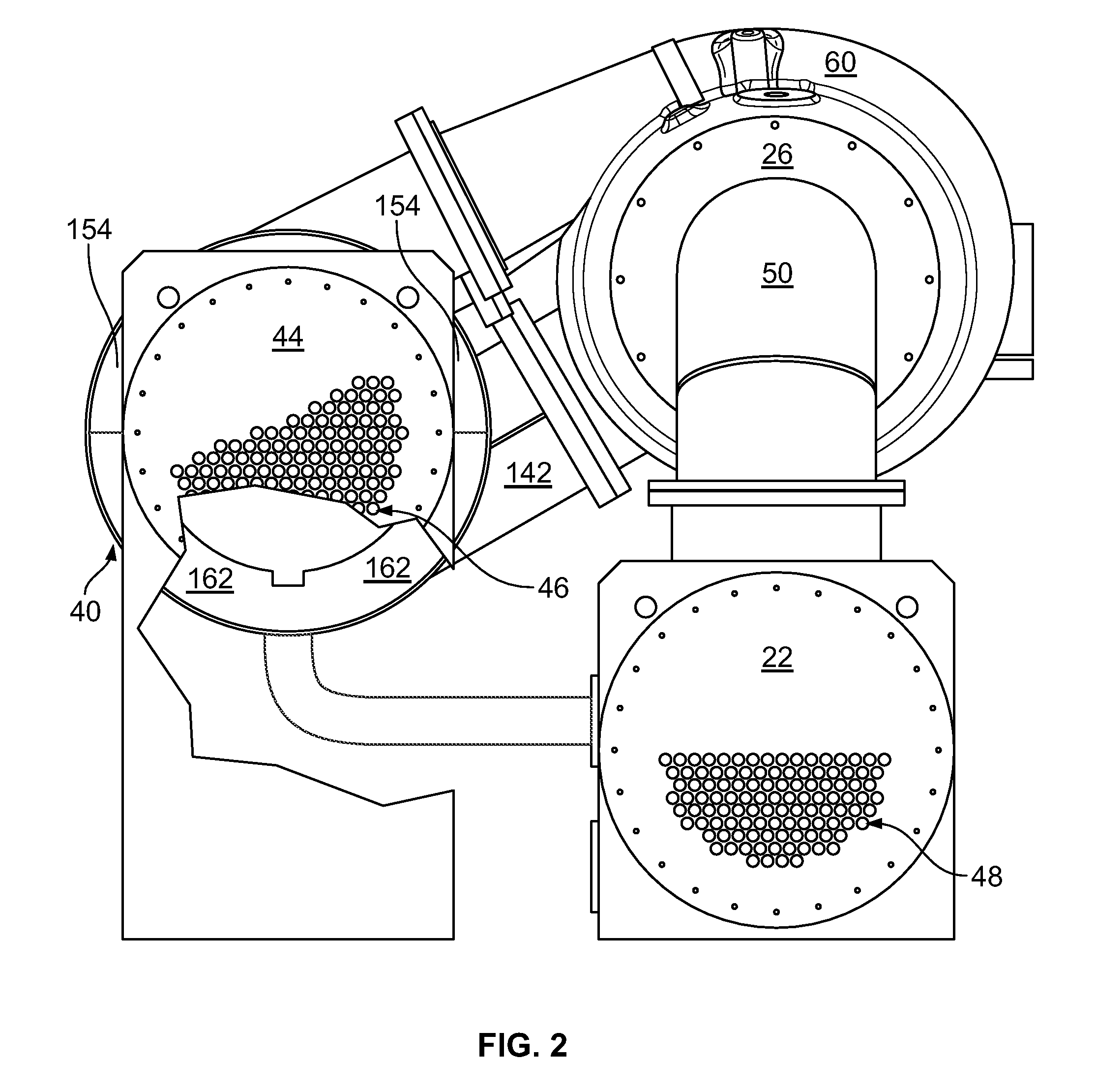

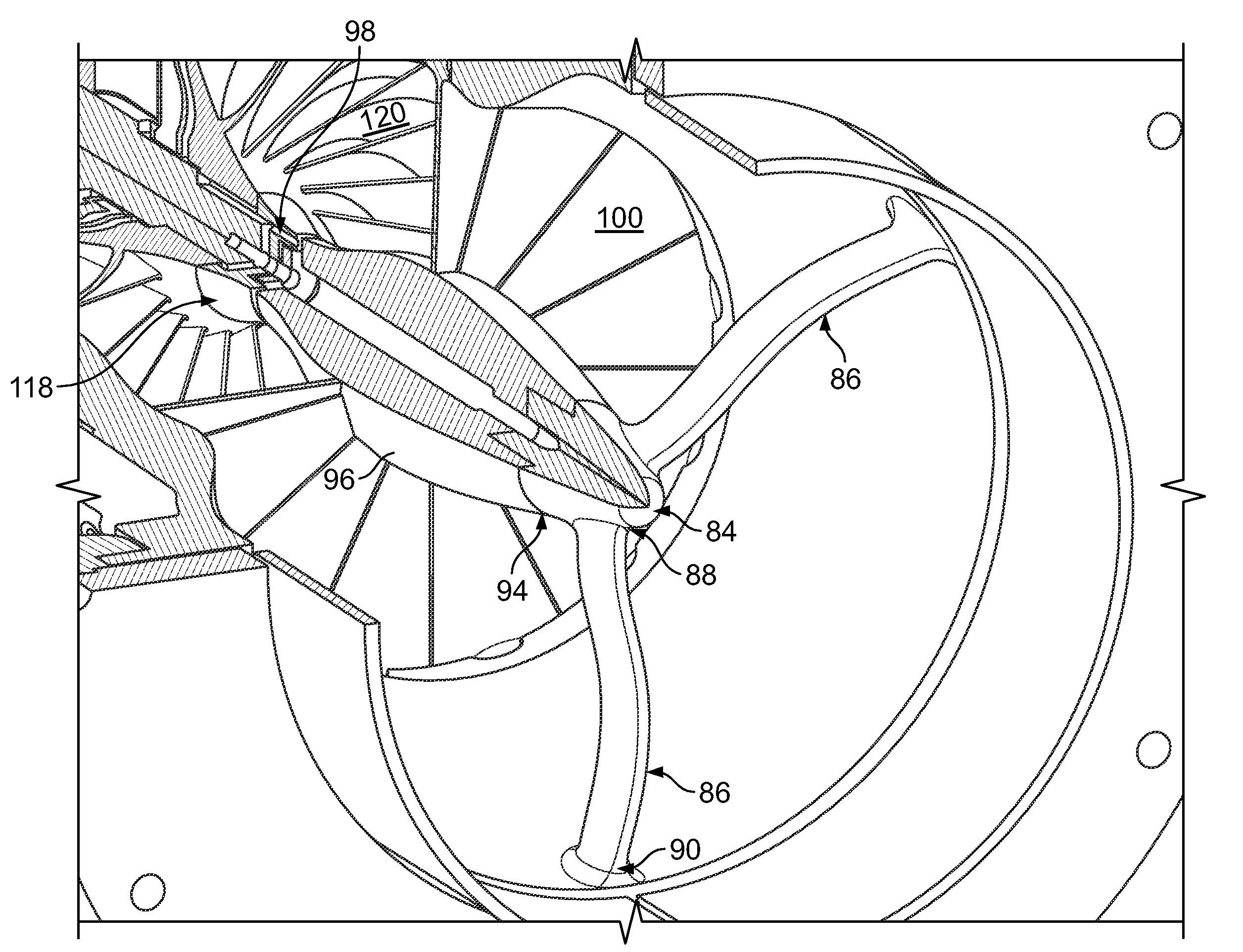

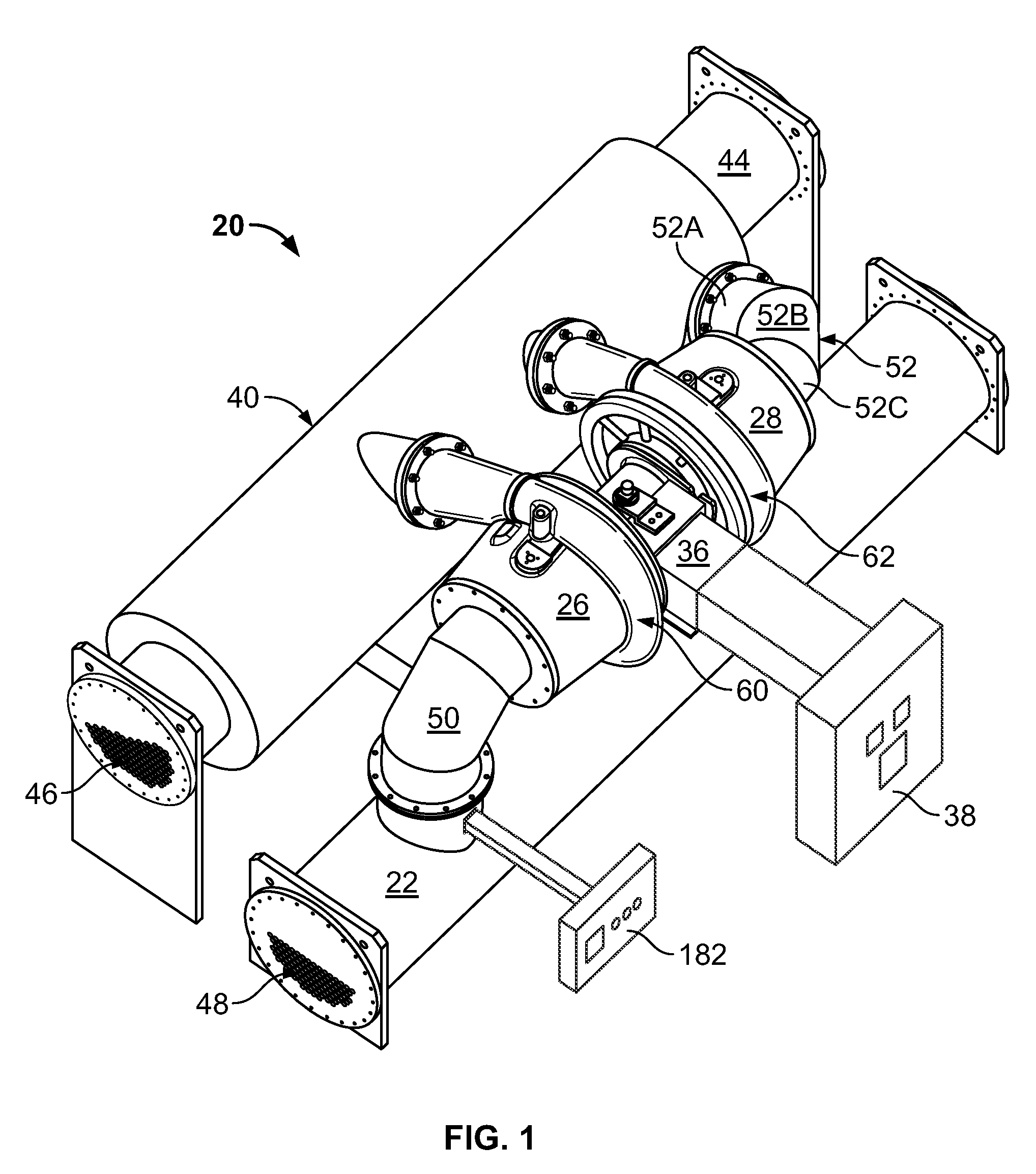

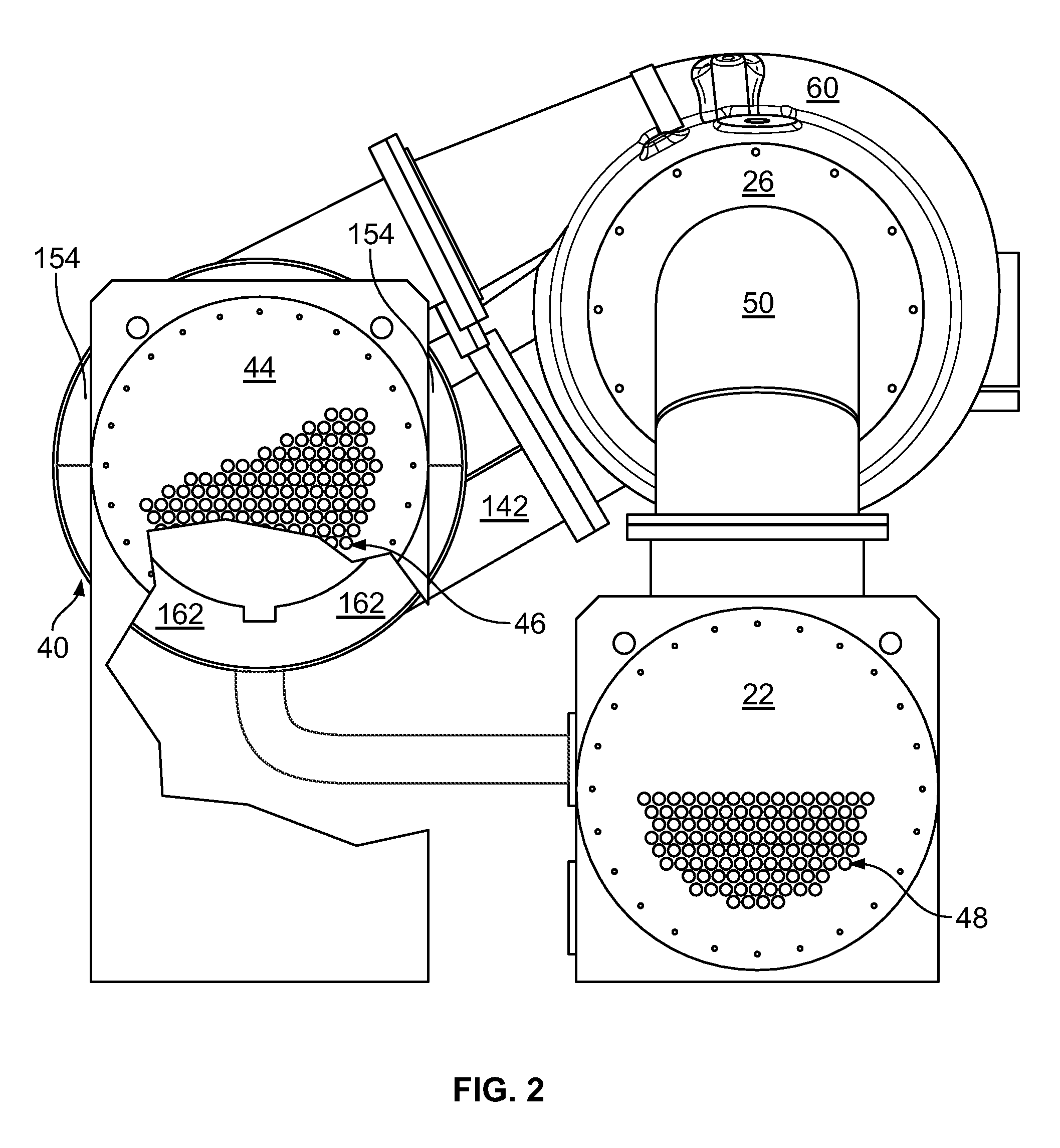

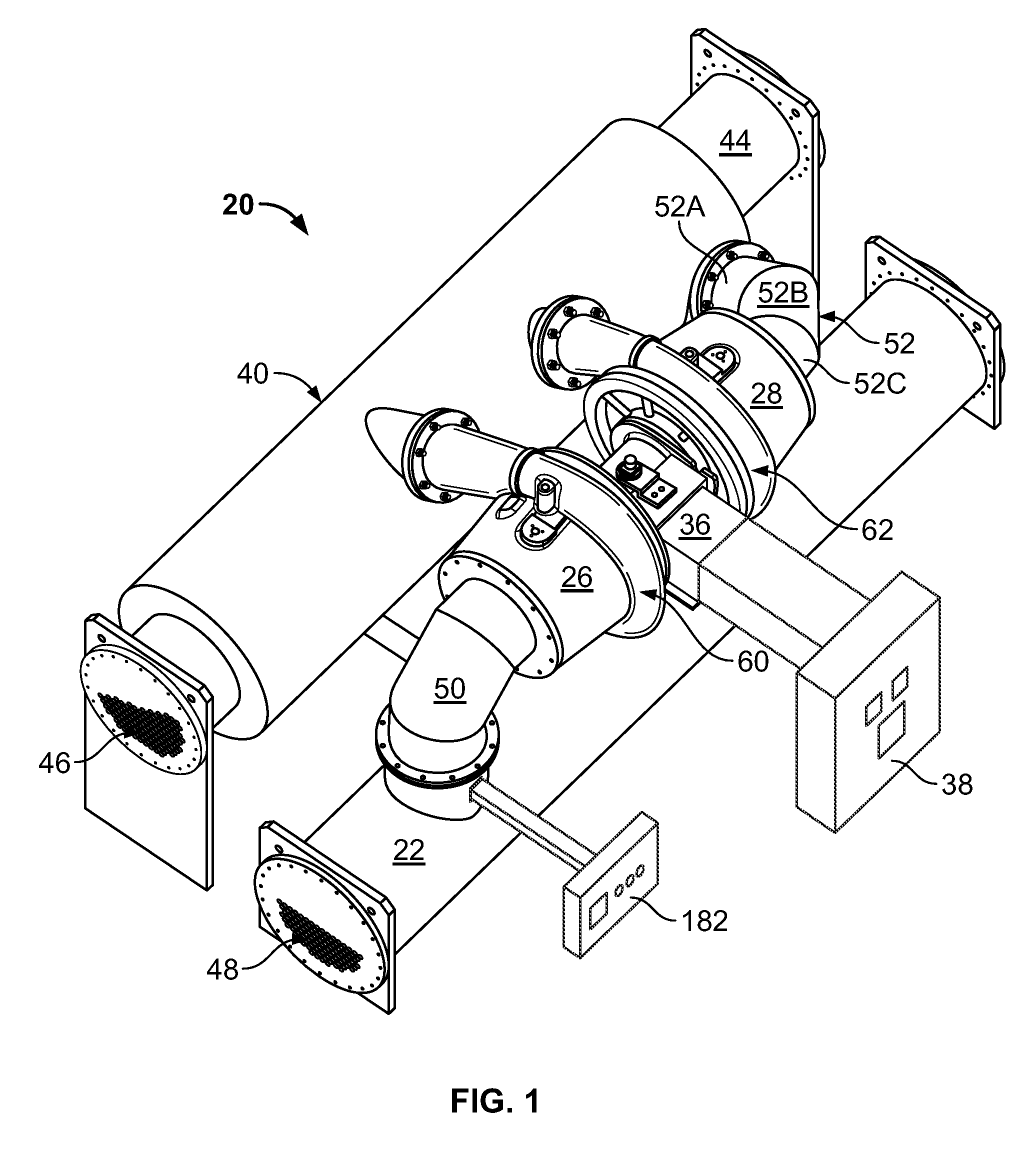

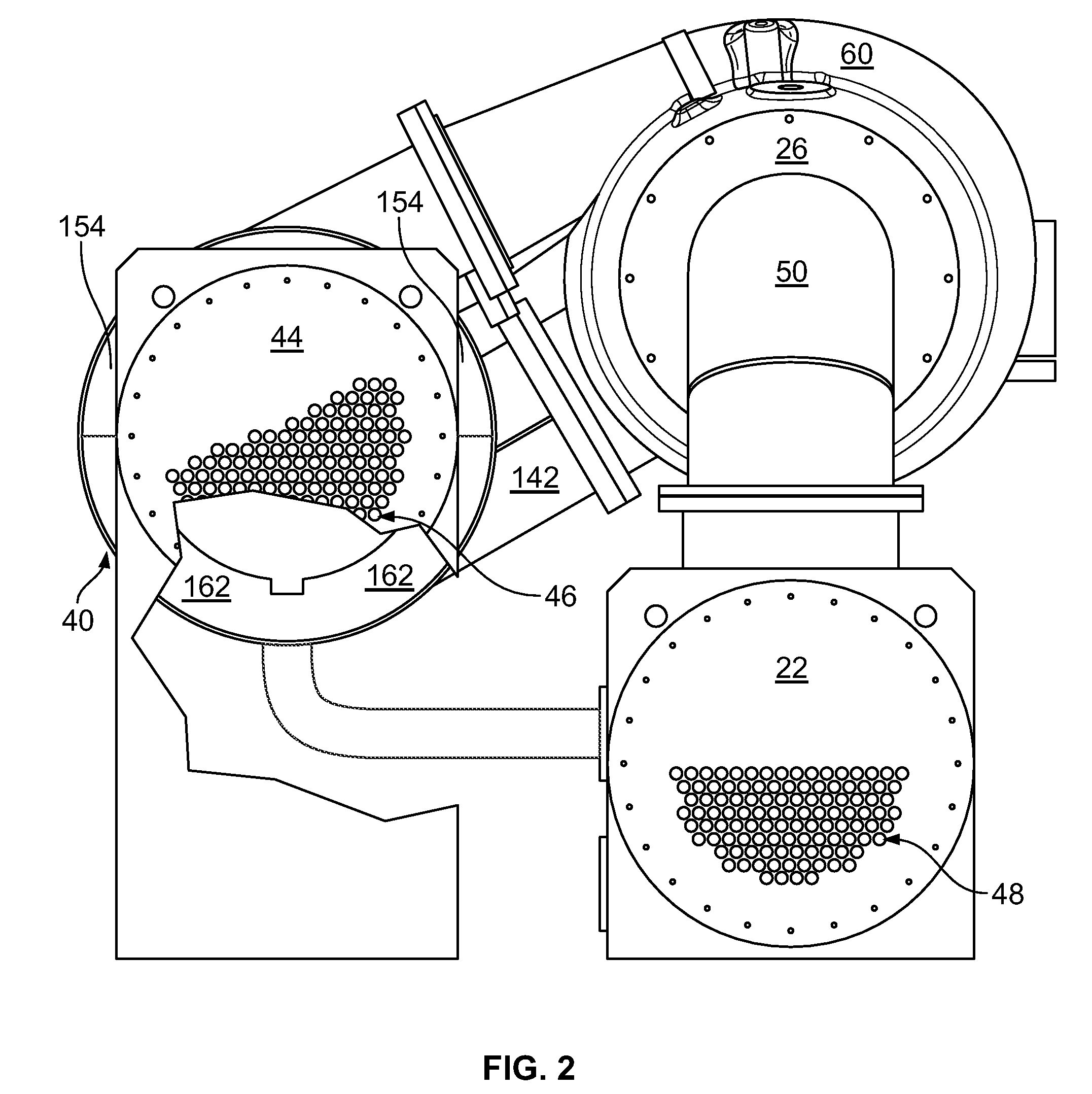

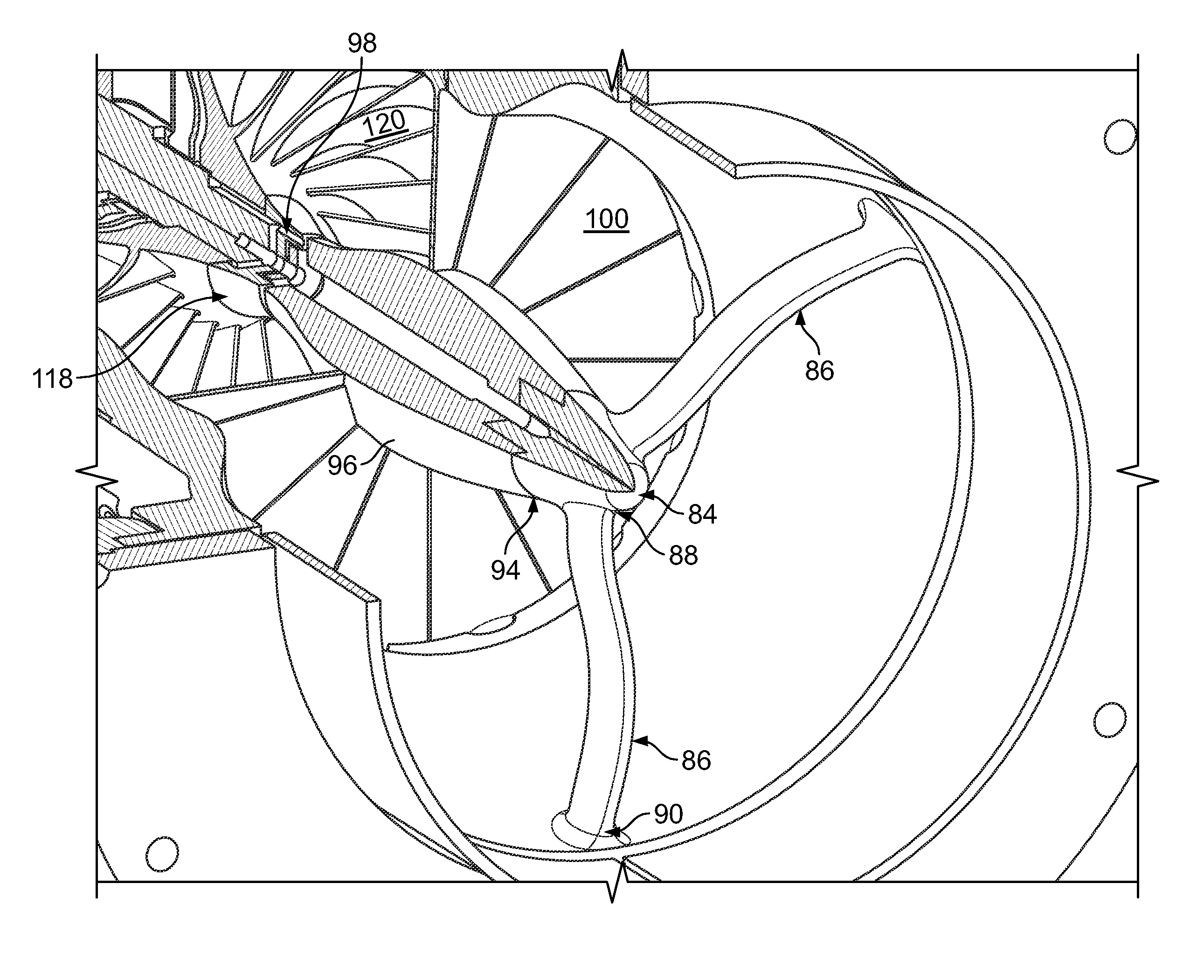

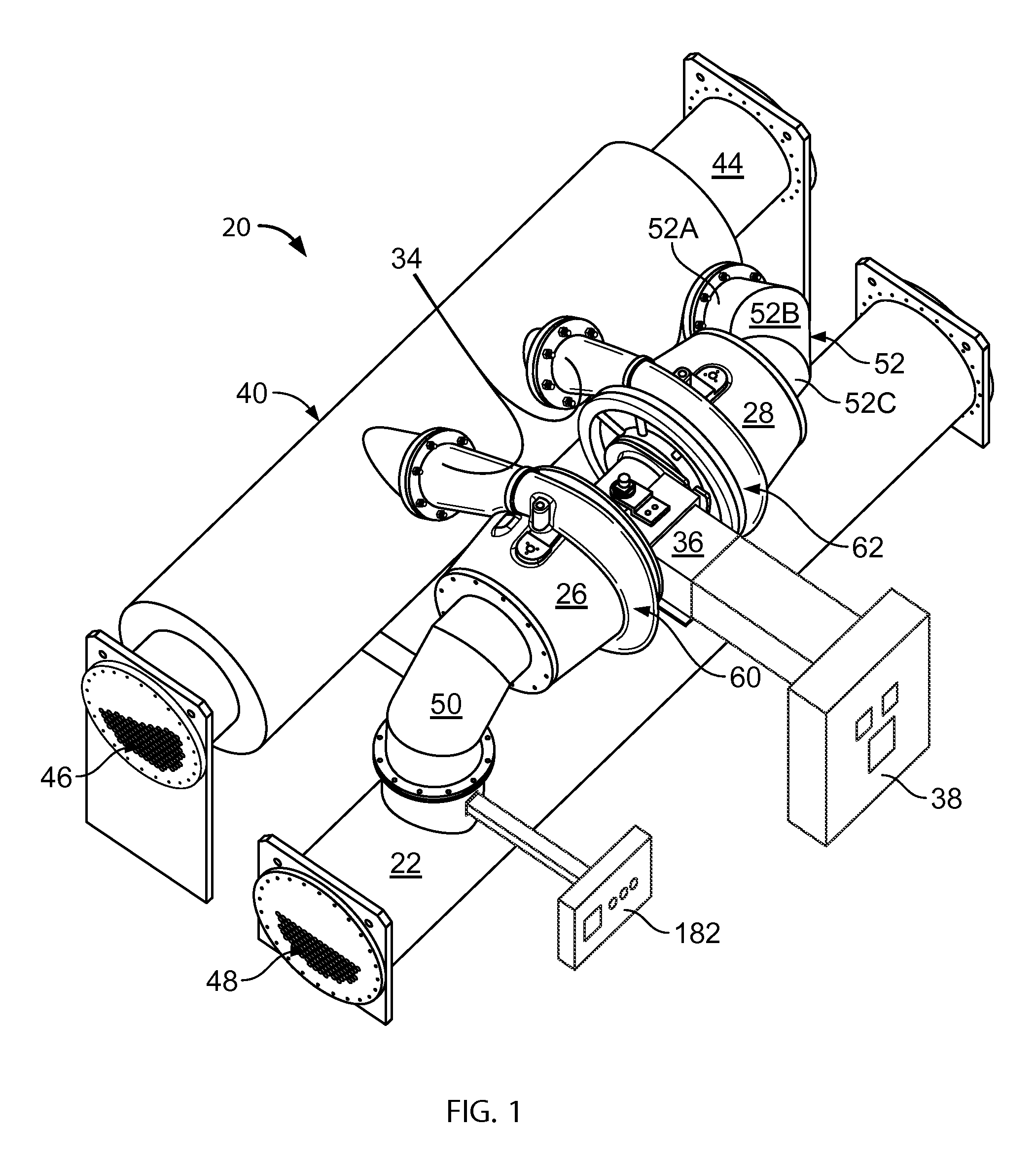

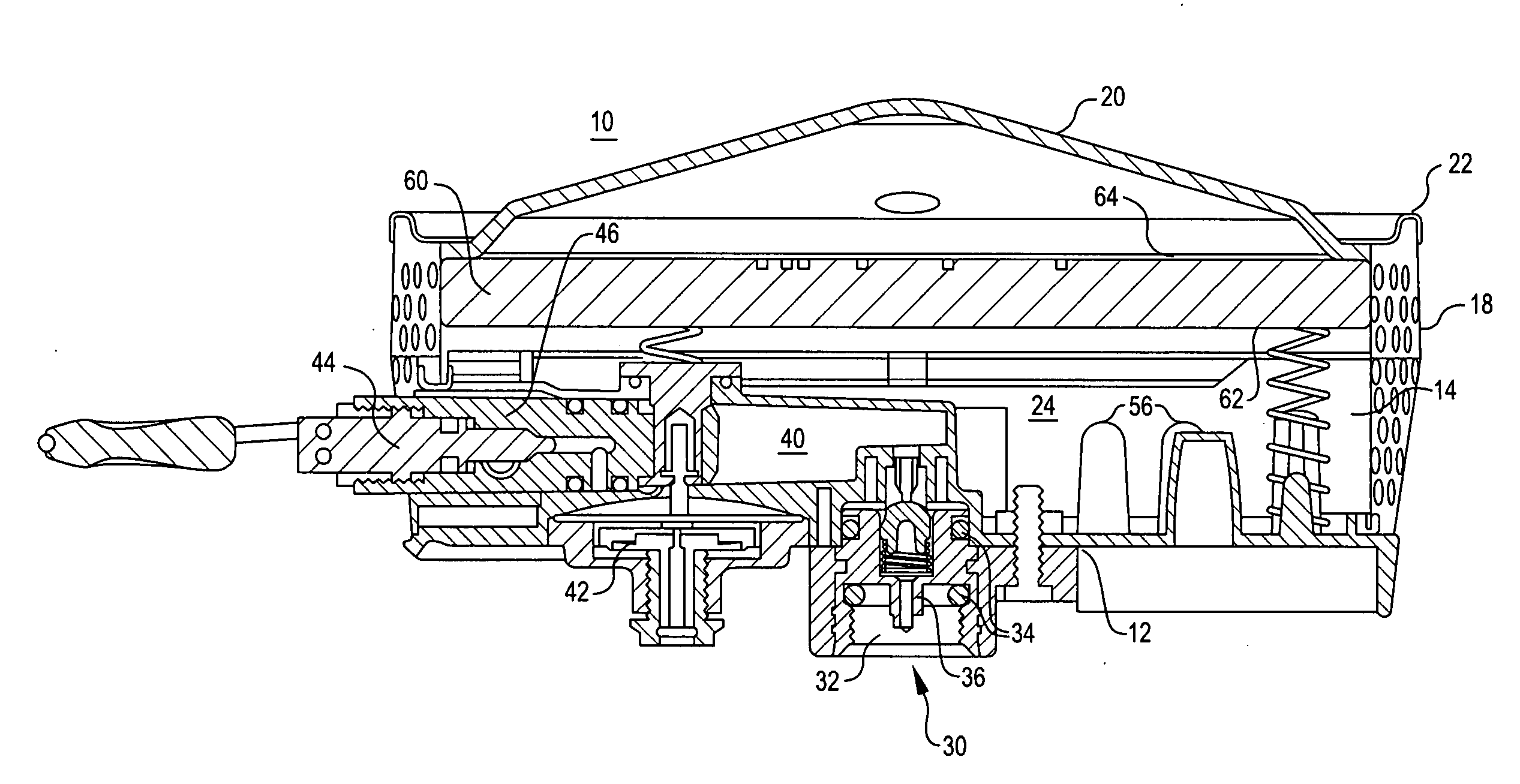

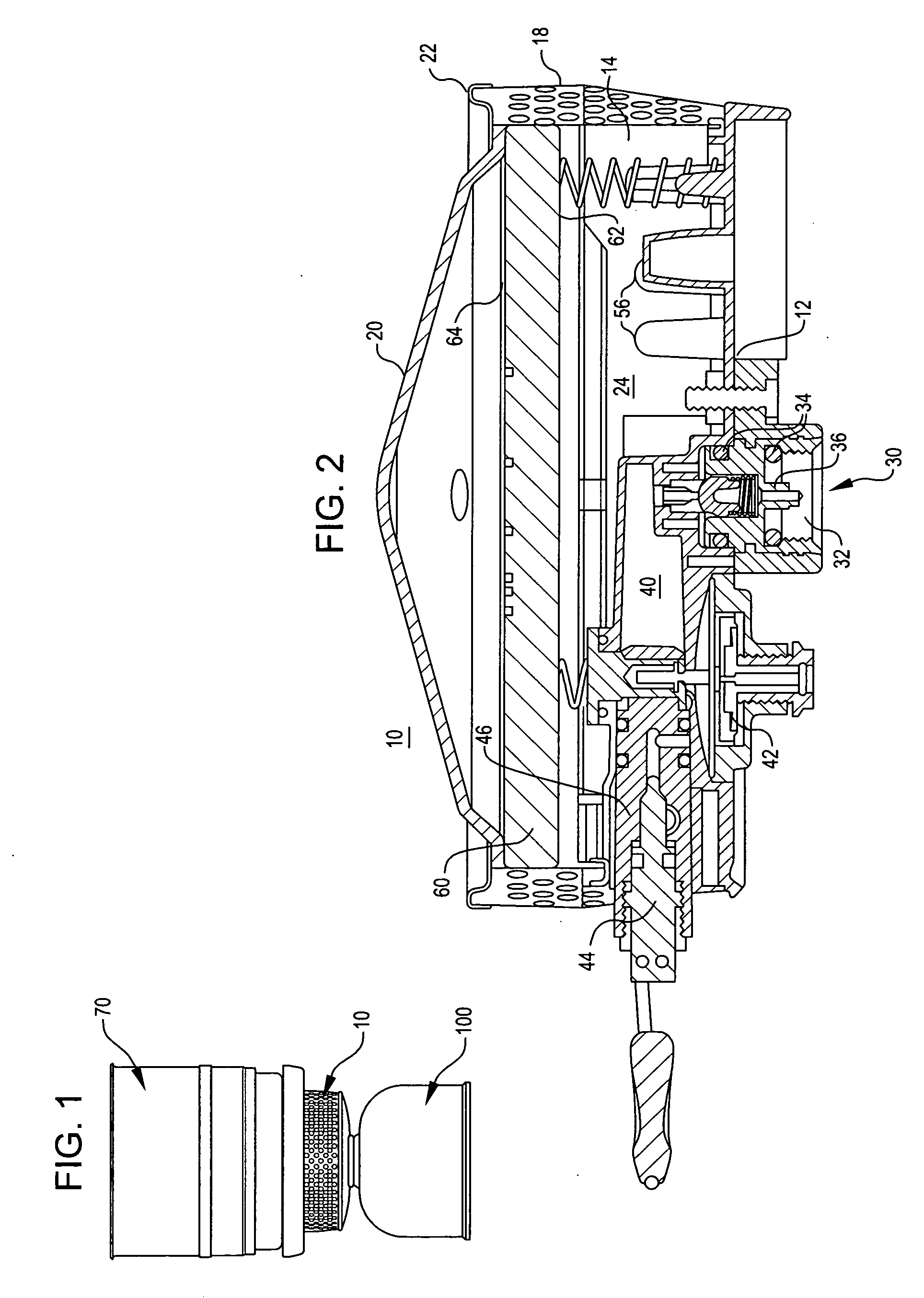

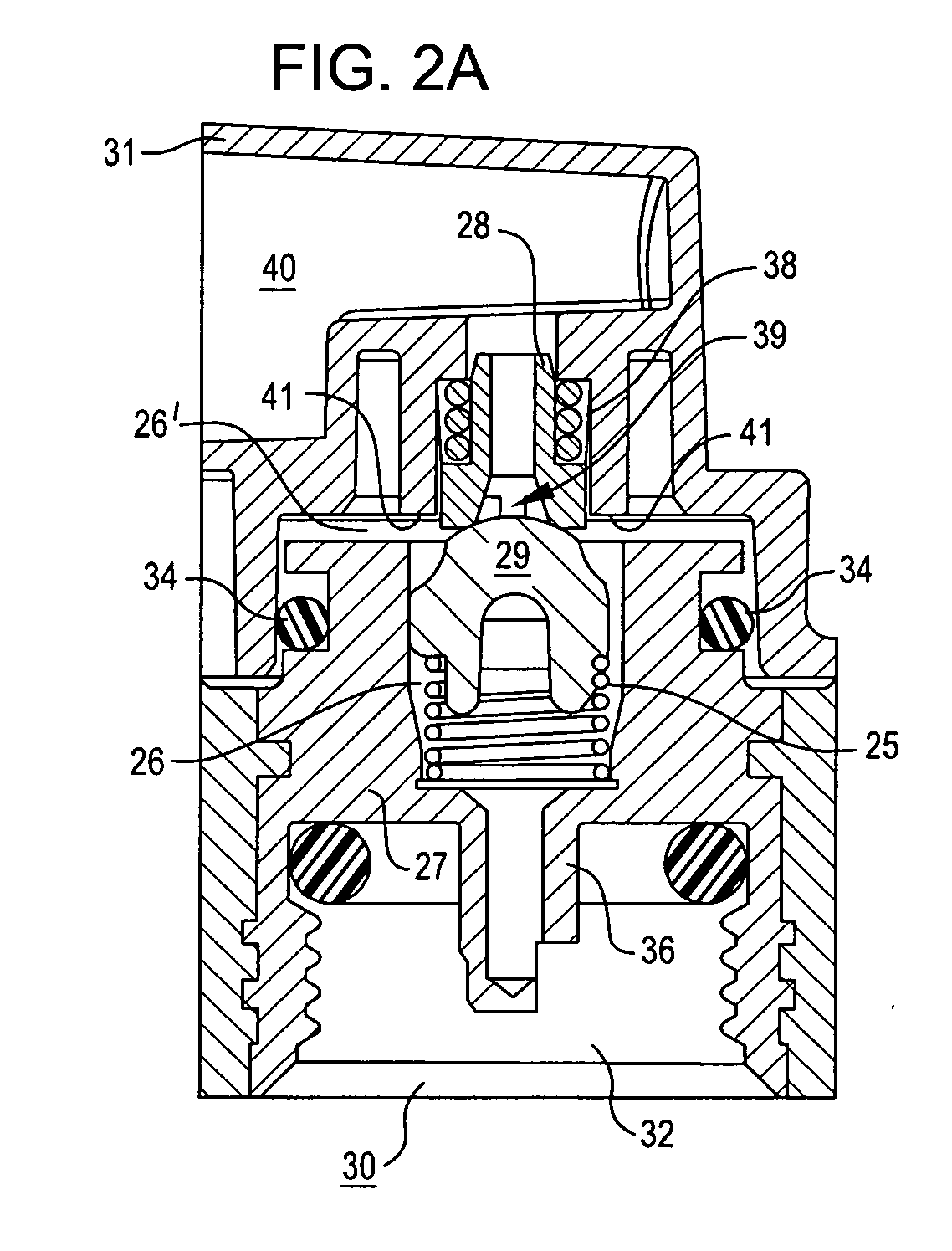

Centrifugal compressor assembly and method

ActiveUS20090205360A1High energy densityImprove performancePump componentsRotary non-positive displacement pumpsConstant angleHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS7856834B2Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

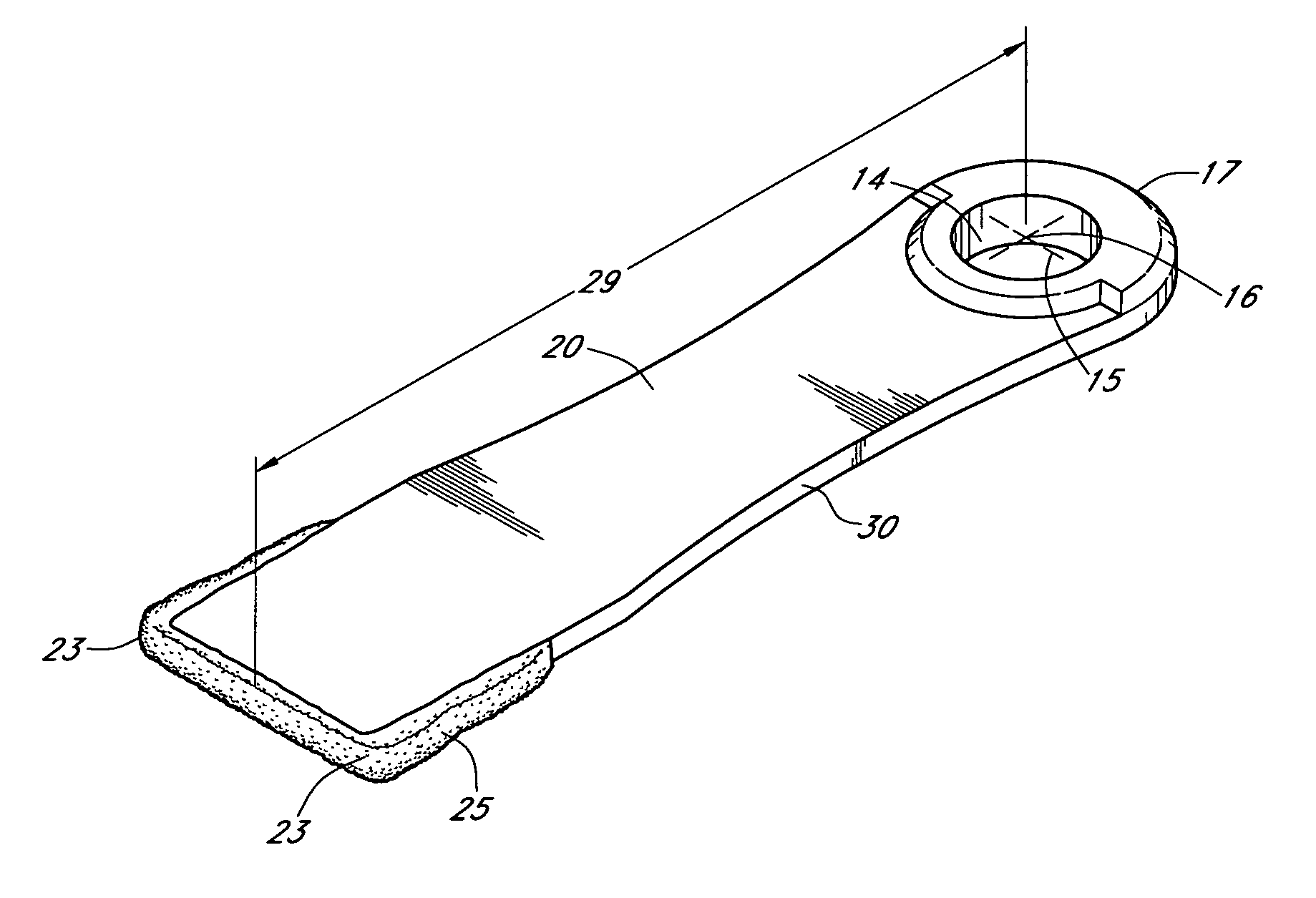

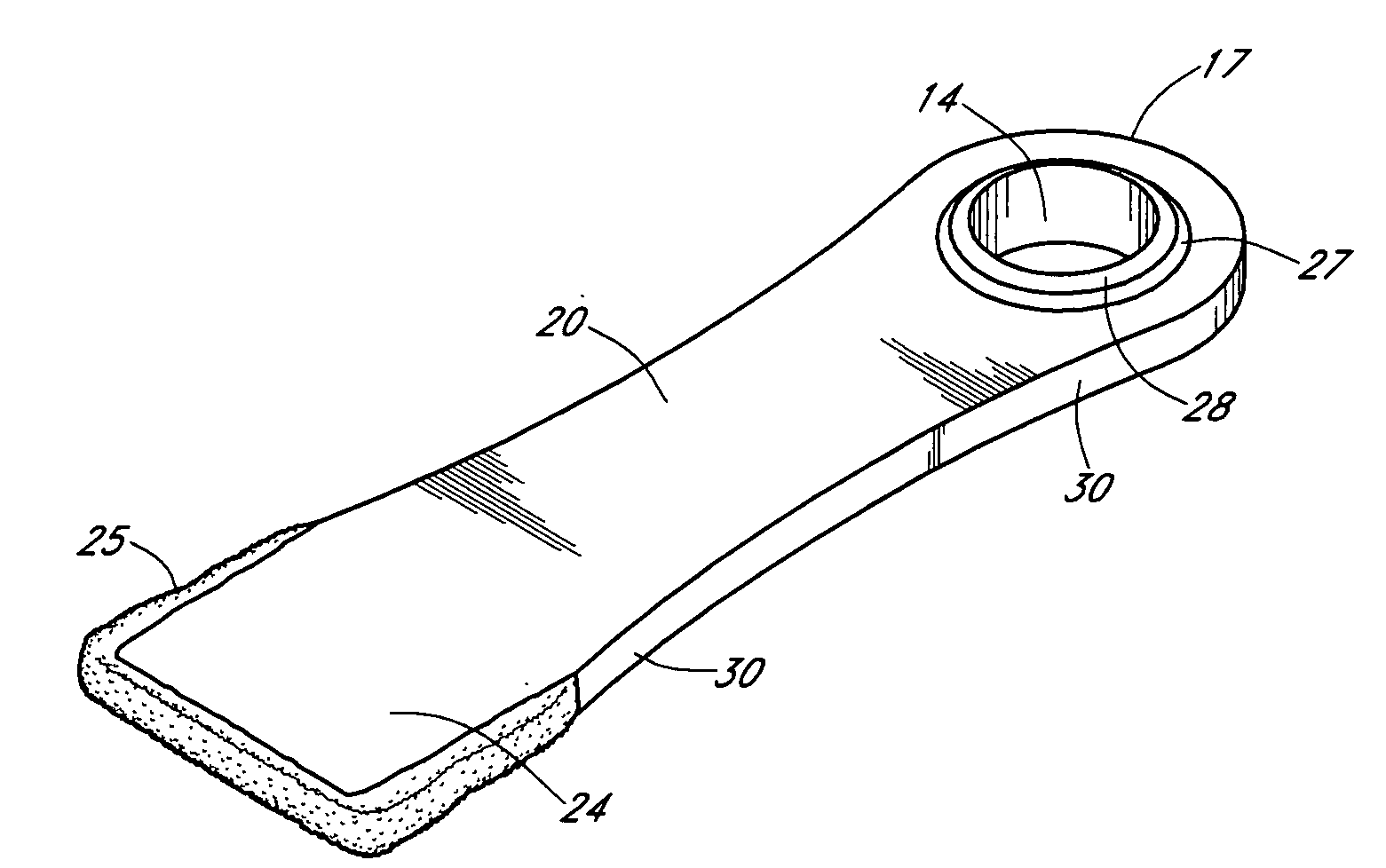

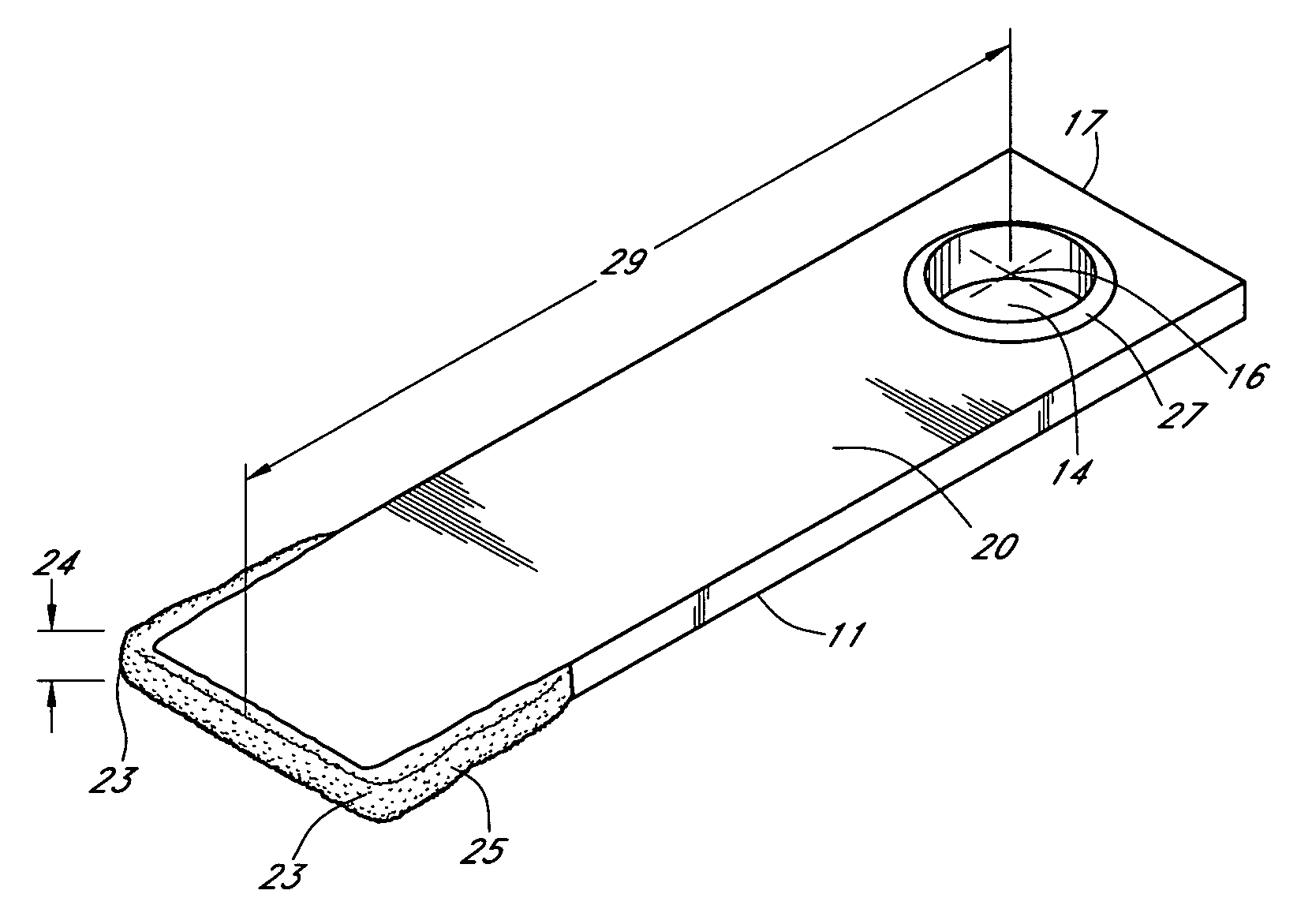

Hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

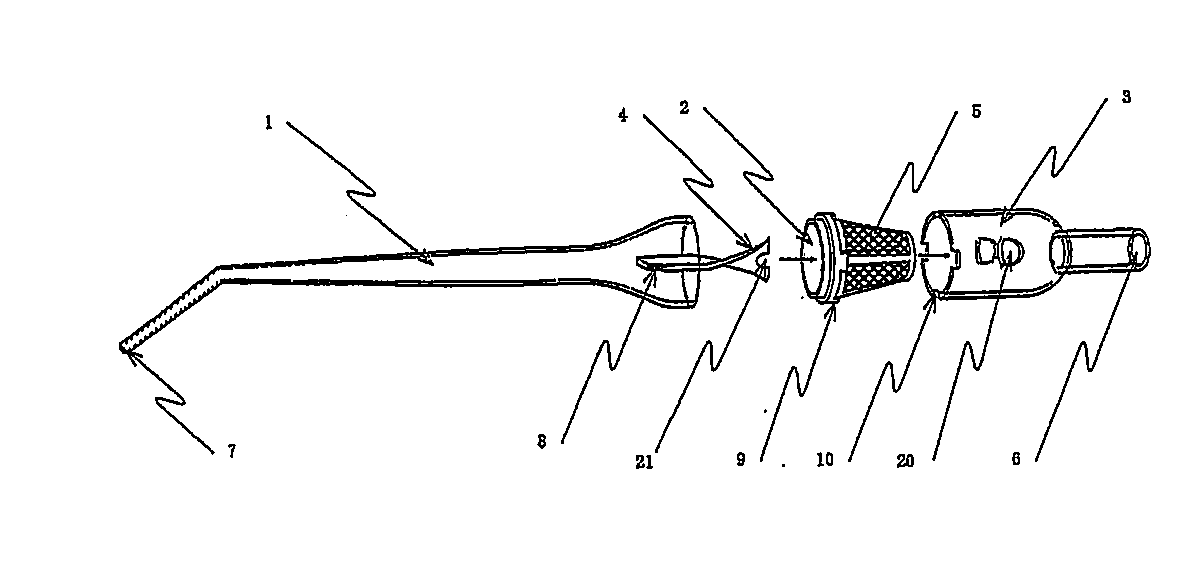

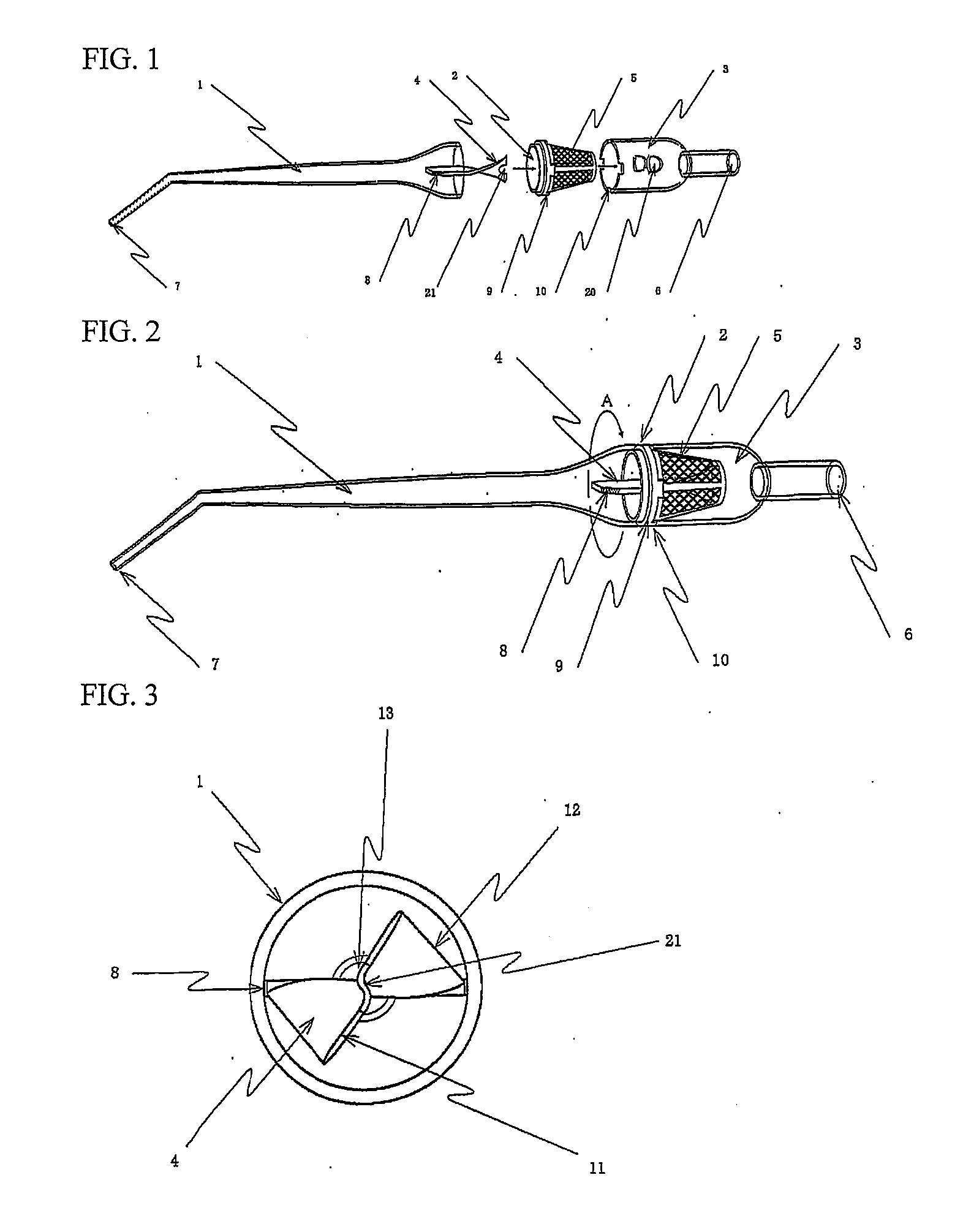

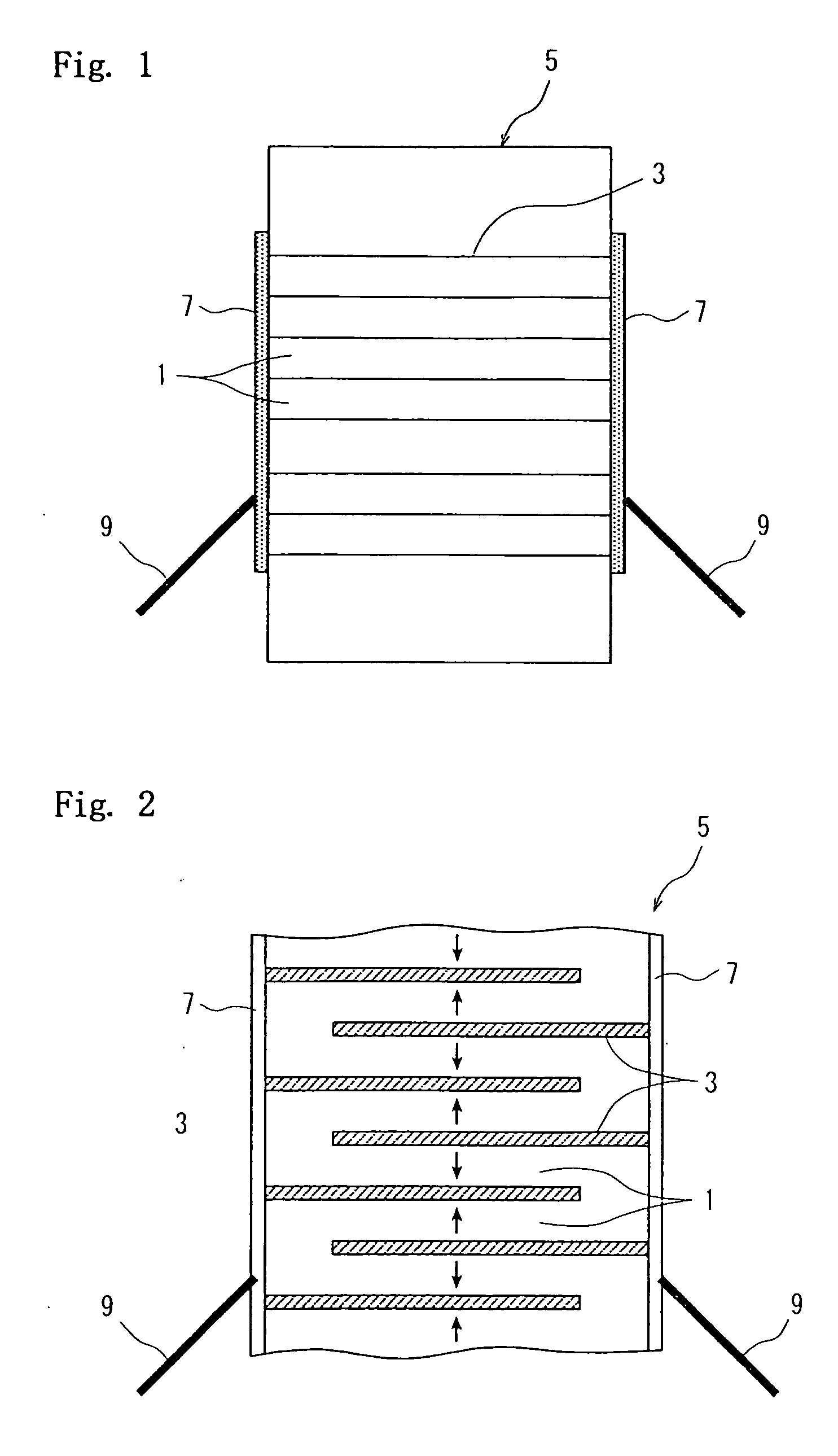

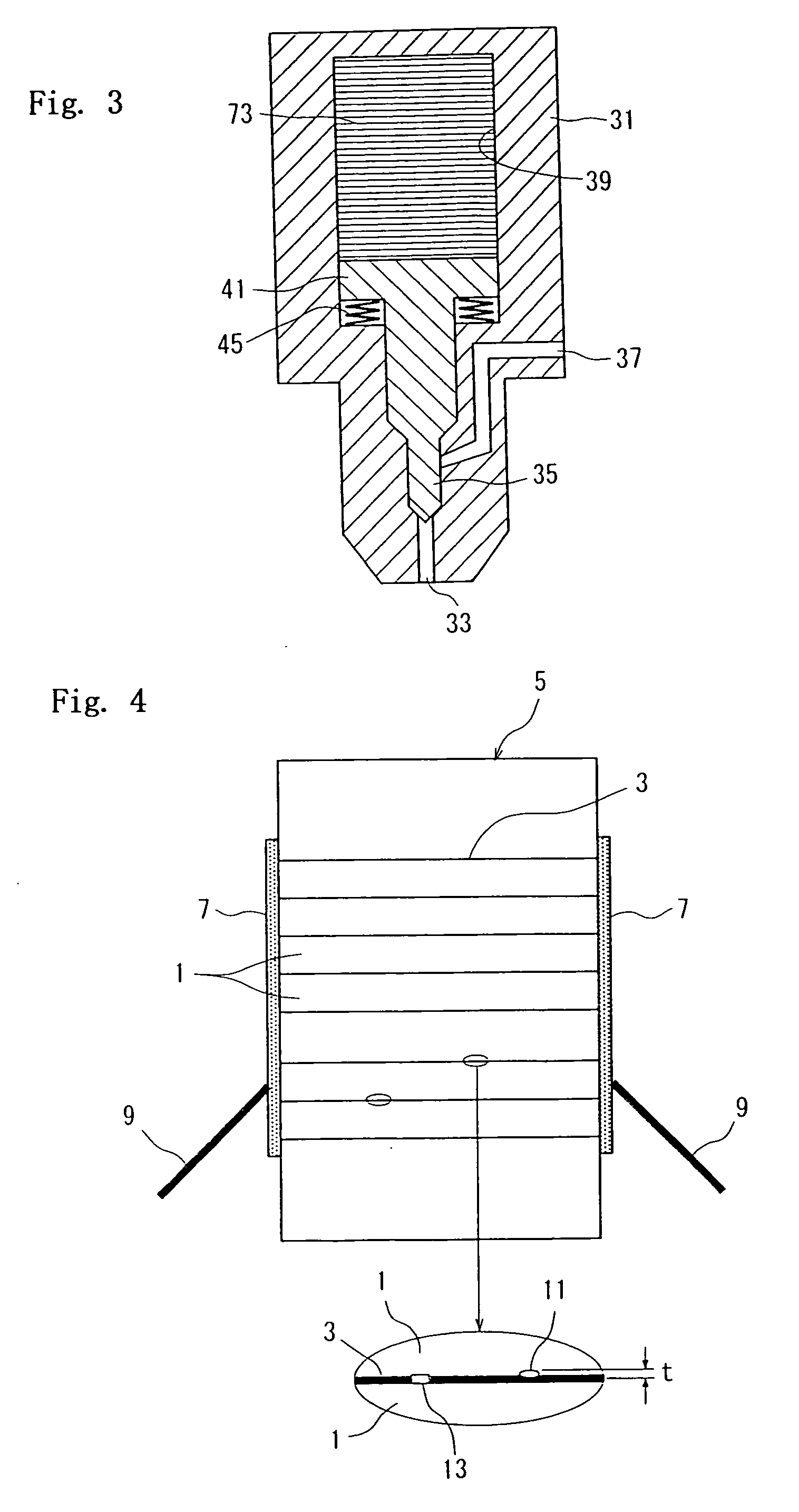

Autologous bone collection device having enhanced suction efficiency

InactiveUS20090306669A1Constant suction efficiencySuction efficiency is maximizedSurgeryVaccination/ovulation diagnosticsMotor driveBone chip

A bone piece collector wherein a blade (4) coming into tight contact with the surface of a filter (2) under an appropriate pressure is provided in order to prevent lowering in the efficiency of suction work due to sampled bone chips adhering to the surface of the filter (2) in the bone piece collector provided in a suction line in order to sample a bone, i.e. a transplantation material in autologous bone transplantation, the blade (4) is rotated while being pressed against the surface of the filter (2) with a finger pressure or a motor drive force, and the sampled bone chips are moved in a certain direction so that clogging of the filter (2) is eliminated and the suction efficiency can be recovered at any time.

Owner:TAKAHASHI ATSUSHI

Hammermill hammer

ActiveUS20070023554A1Excellent hardness propertiesIncrease torqueGrain treatmentsEngineeringHardness

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The improved hammermill hammer may incorporate multiple comminution edges for having increased hardness for longer operational run times. The design as disclosed and claimed may be forged to increase the strength of the hammer. The shape of the hammer body may be varied, as disclosed and claimed, to improve the hammer strength reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design may also incorporate comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

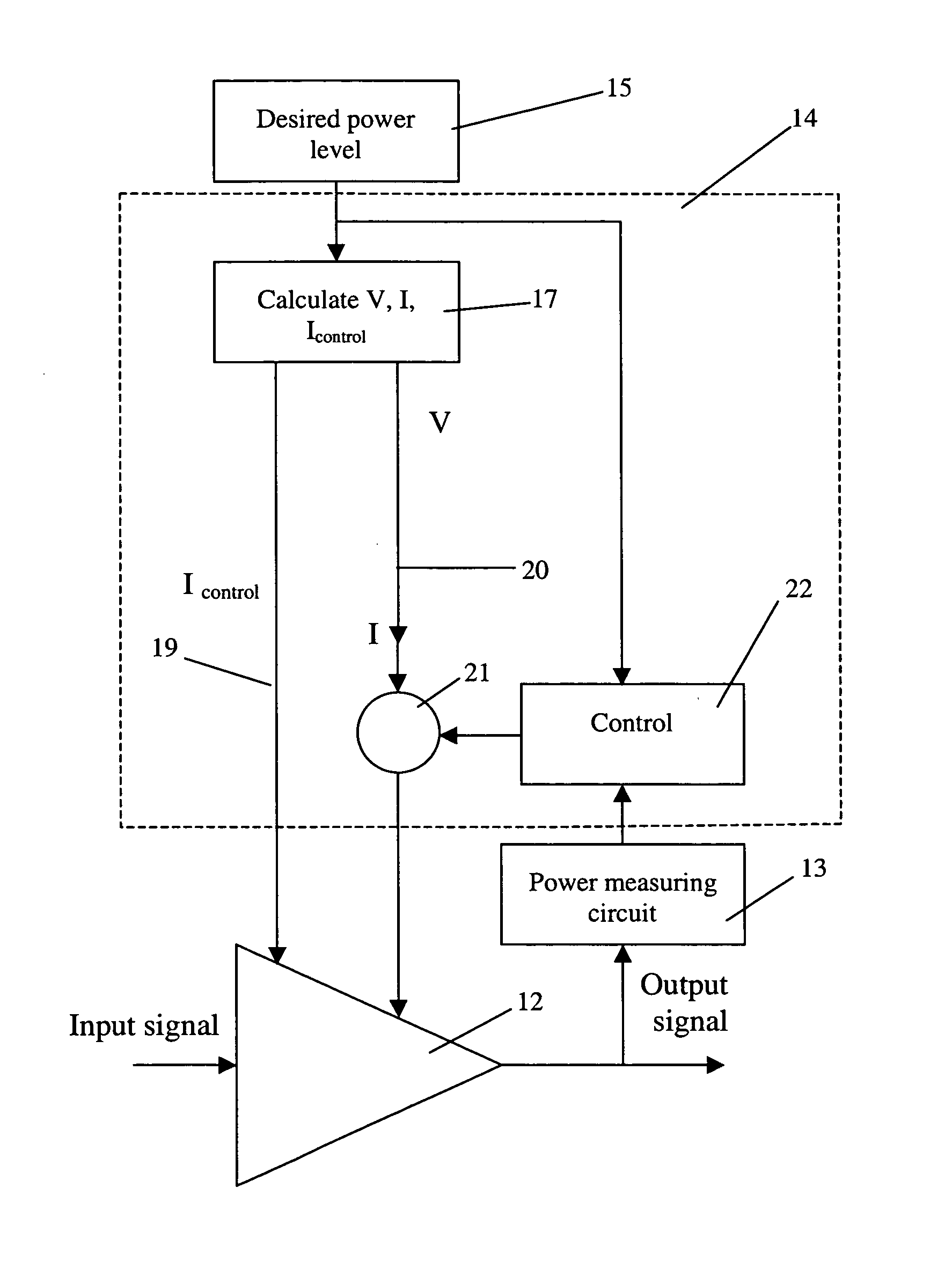

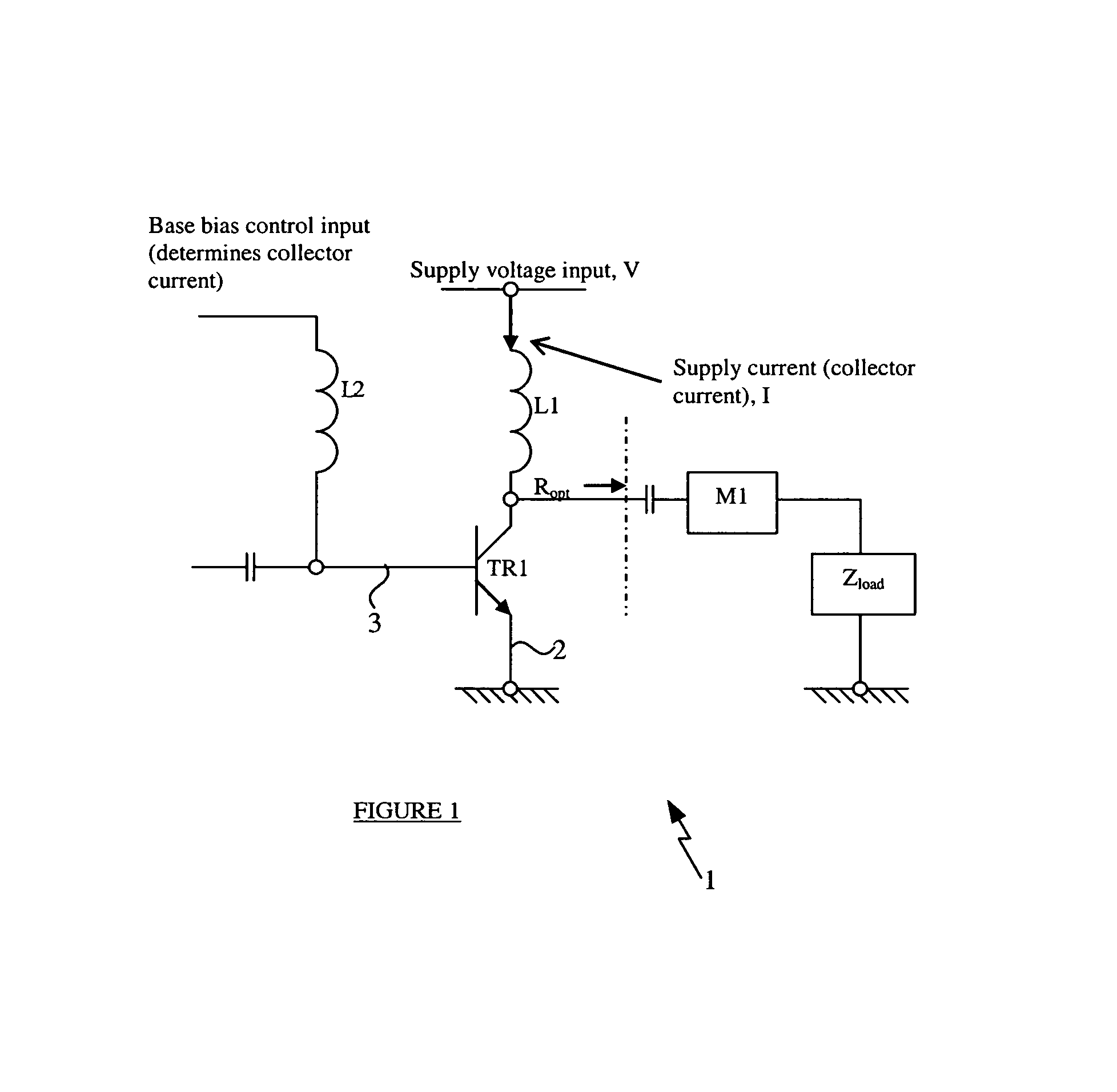

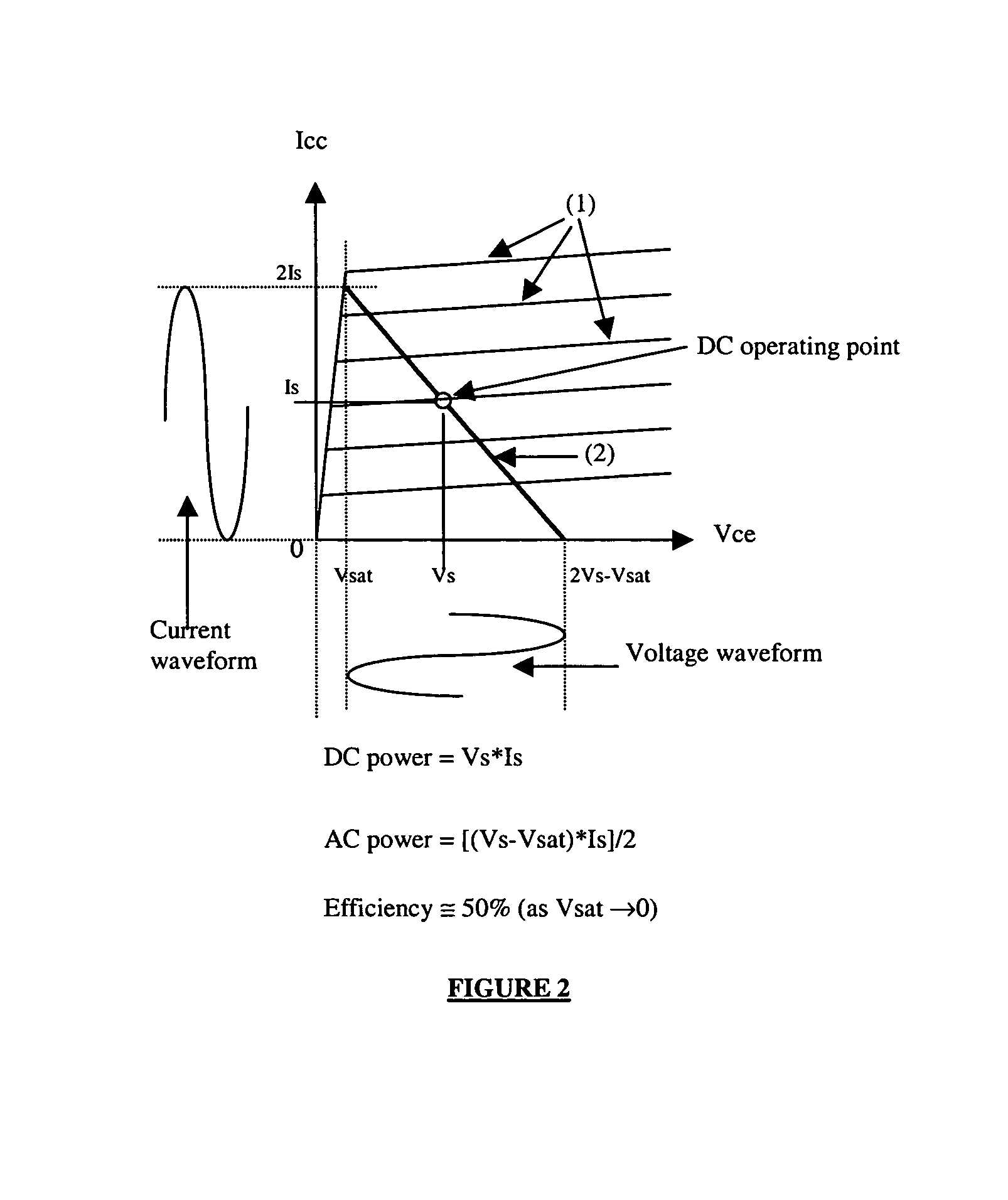

Amplifier circuit

ActiveUS7196584B2Optimise amplifier efficiencyMaximize efficiencyGain controlAmplifier modifications to raise efficiencyPower controlPower level

An amplifier circuit 11 comprises an amplifier 12, an indicator of desired power 15, a power control circuit 14 and a power measuring circuit 13. The amplifier 12 amplifies an input signal to produce an output signal, and has an input for controlling a supply current I and an input for receiving a supply voltage V and supply current I, for driving the amplifier. The power control circuit calculates and applies values of both a supply voltage V and a supply current I, according to any one of a plurality of desired power levels, in order to operate the amplifier with maximum efficiency over a wide range of power levels. The power control circuit may further comprise a power control loop whereby adjustment of the output power can also be effected according to a measurement of output power and a desired level of output power.

Owner:QUALCOMM INC

Centrifugal compressor assembly and method

ActiveUS8037713B2Improve performanceReduce physical sizePump componentsRotary non-positive displacement pumpsMixed flowHigh energy

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS20090208331A1Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Centrifugal compressor assembly and method

ActiveUS20090205362A1Improve performanceReduce physical sizePropellersBlade accessoriesMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

Fluid catalytic cracking catalyst with low coke yield and method for making the same

InactiveUS20100298118A1Zeolite content be increaseHigh activityMaterial nanotechnologyCatalytic crackingIon exchangeMetakaolin

A method is provided for making a fluid catalytic cracking catalyst with a low coke yield from kaolin, including: dividing kaolin into two portions, mixing one portion of kaolin with chemical water and a dispersant to make a slurry, and spraying the slurry to produce kaolin microspheres, calcining the kaolin microspheres at a high temperature to obtain spinel-containing calcined microspheres; calcining the other portion of kaolin to form metakaolin, which is subjected to ultrafine pulverization to obtain metakaolin ultrafine powder; mixing the calcined microspheres with the metakaolin ultrafine powder in a certain proportion, subjecting the resultant mixture to in-situ crystallization on the hydrothermal condition and then to centrifugal separation to obtain an in-situ crystallized product containing zeolite NaY with a high Si / Al ratio; and subjecting the in-situ crystallized product to ion exchange and deep ultrastable hydrothermal treatment to obtain an in-situ crystallized fluid catalytic cracking catalyst.

Owner:TAN ZHIPING

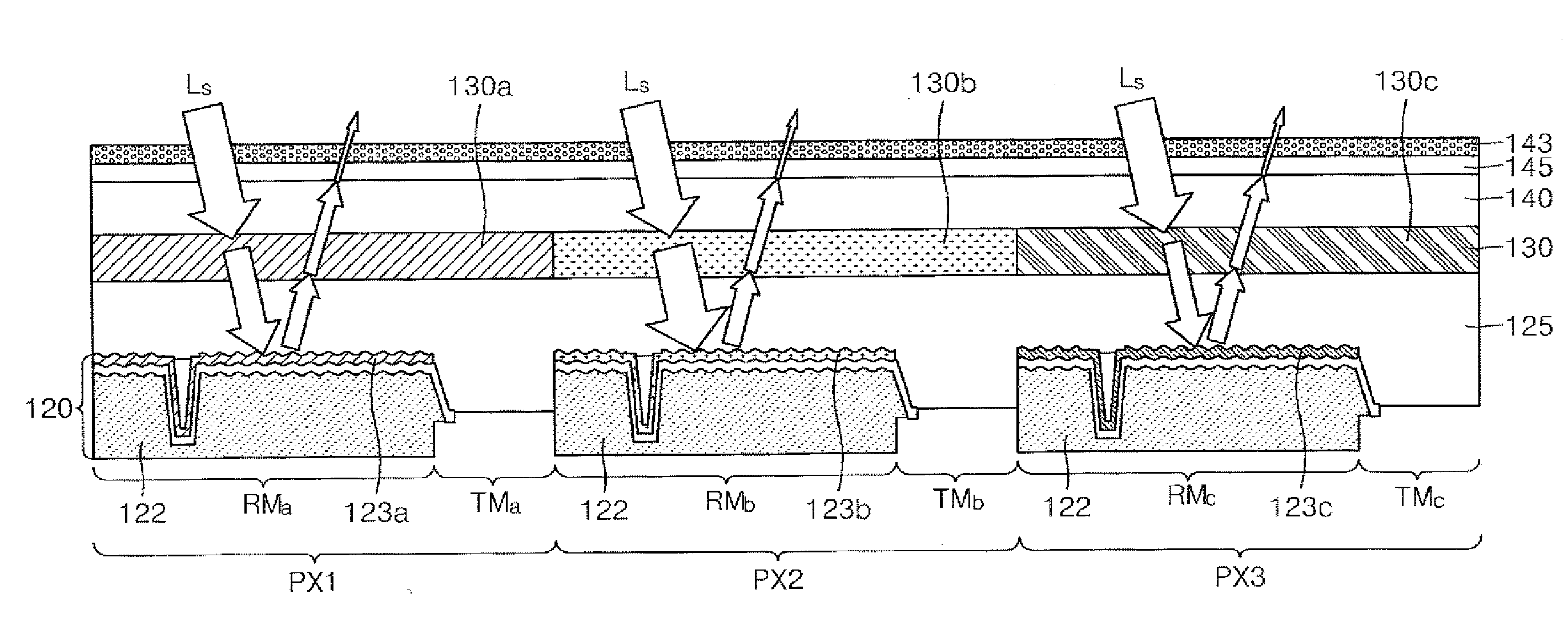

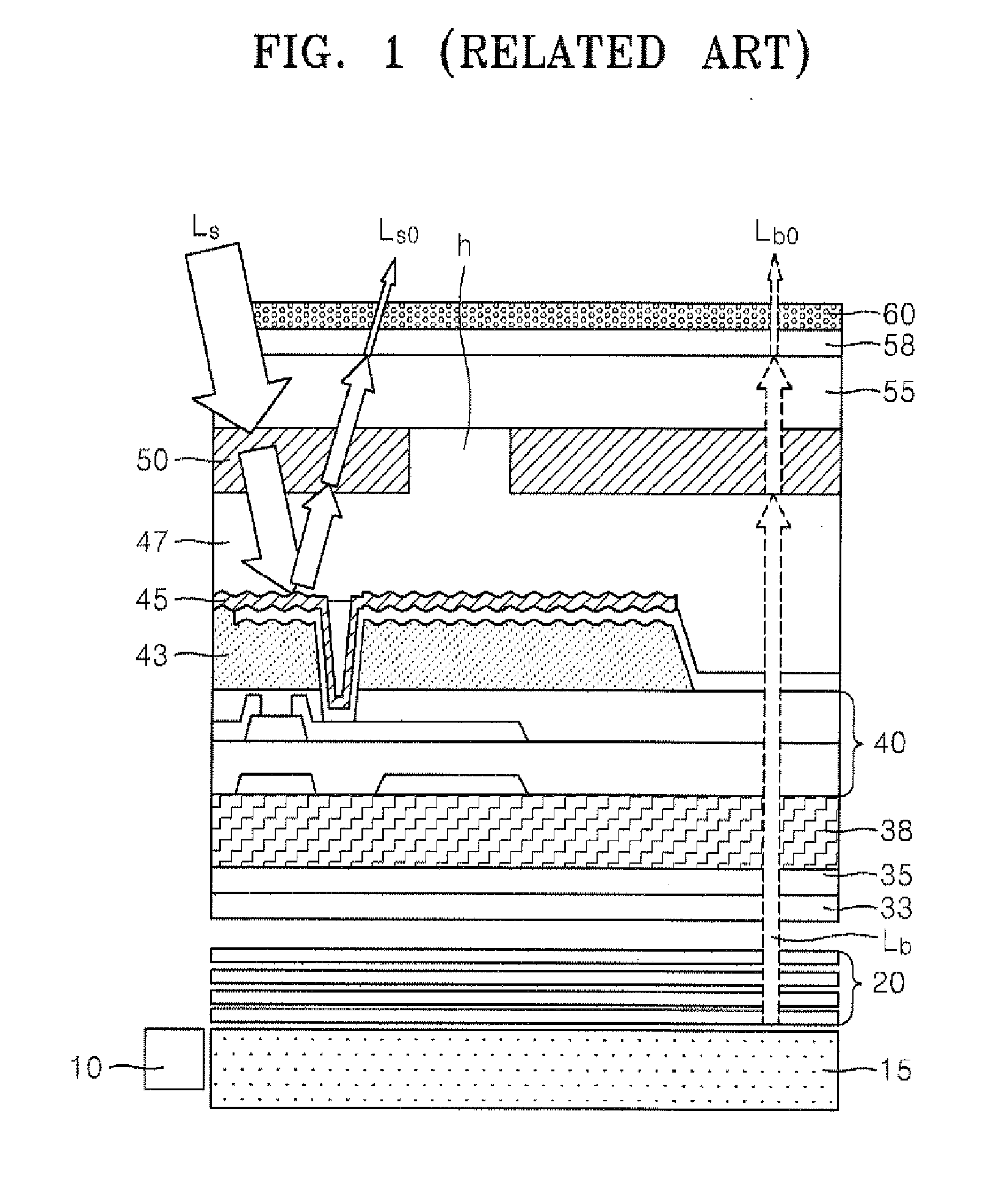

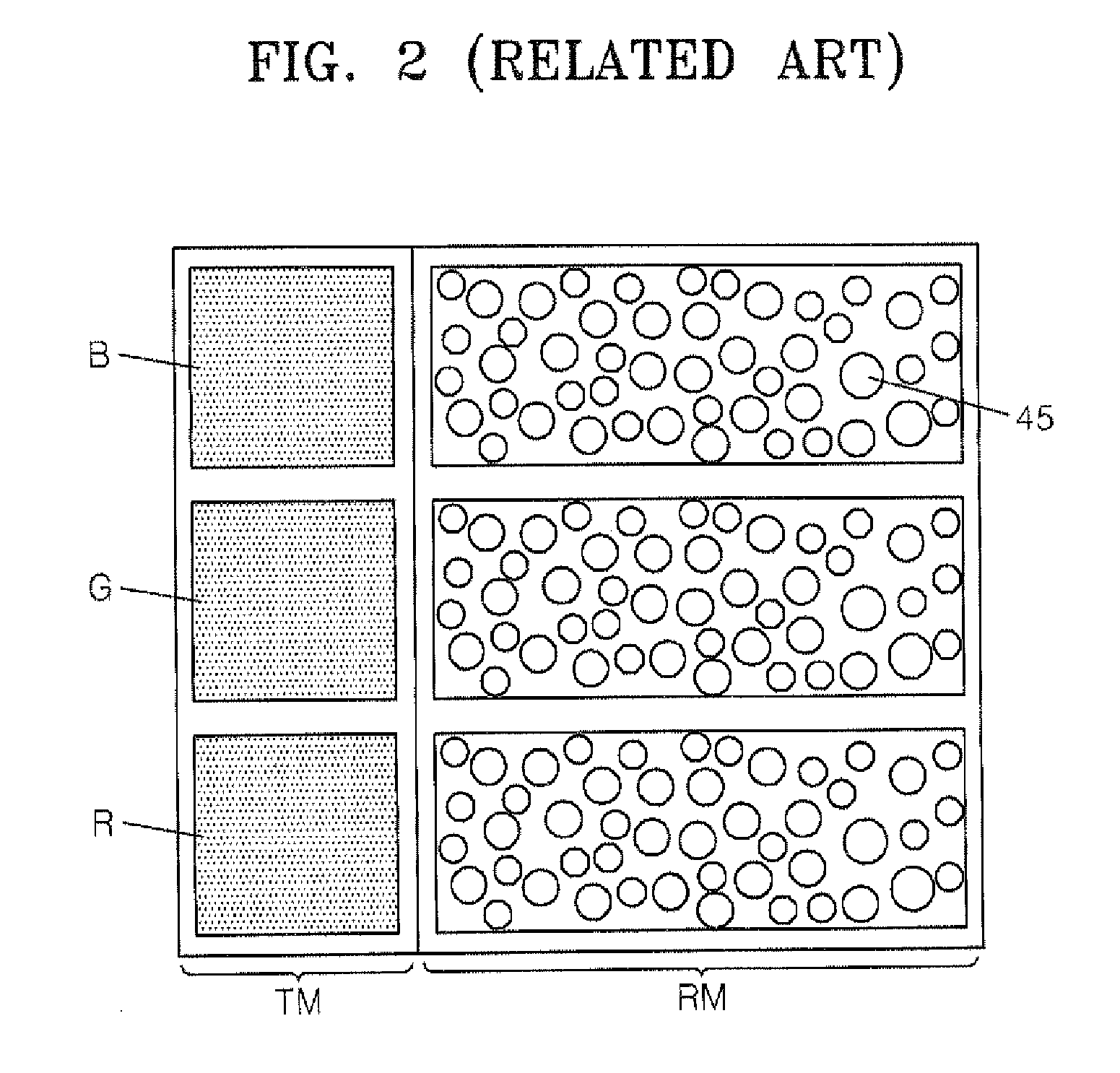

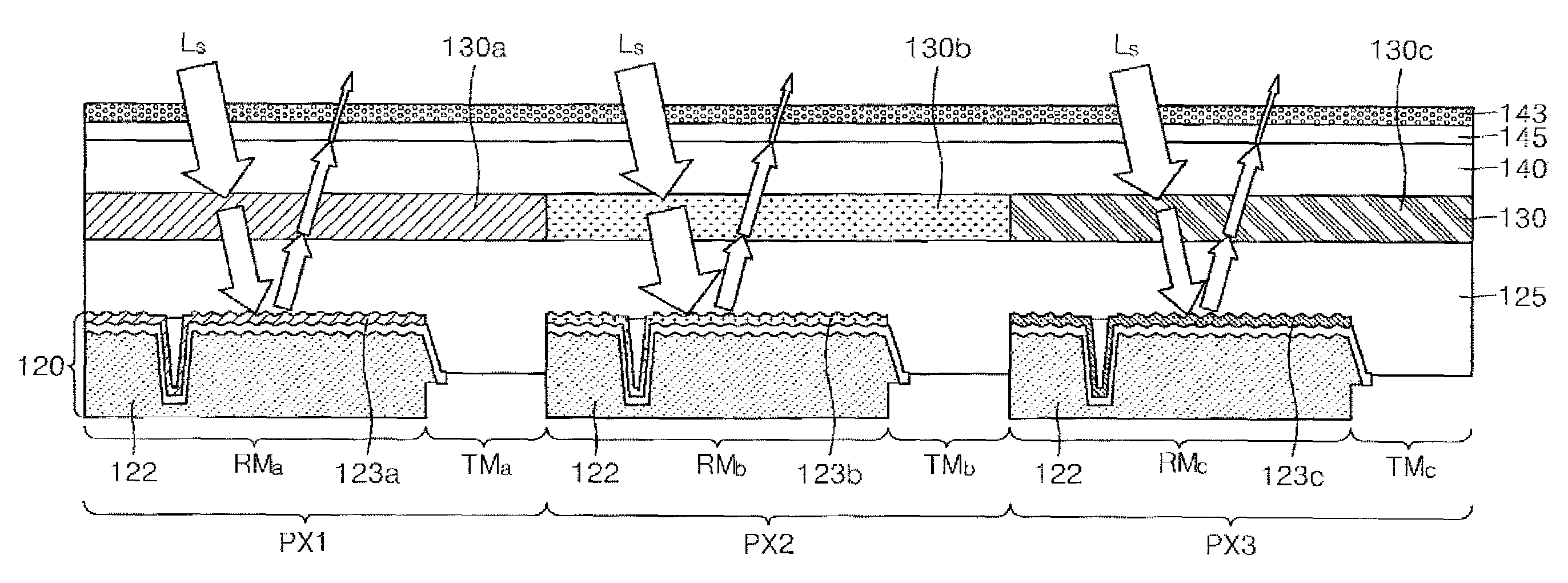

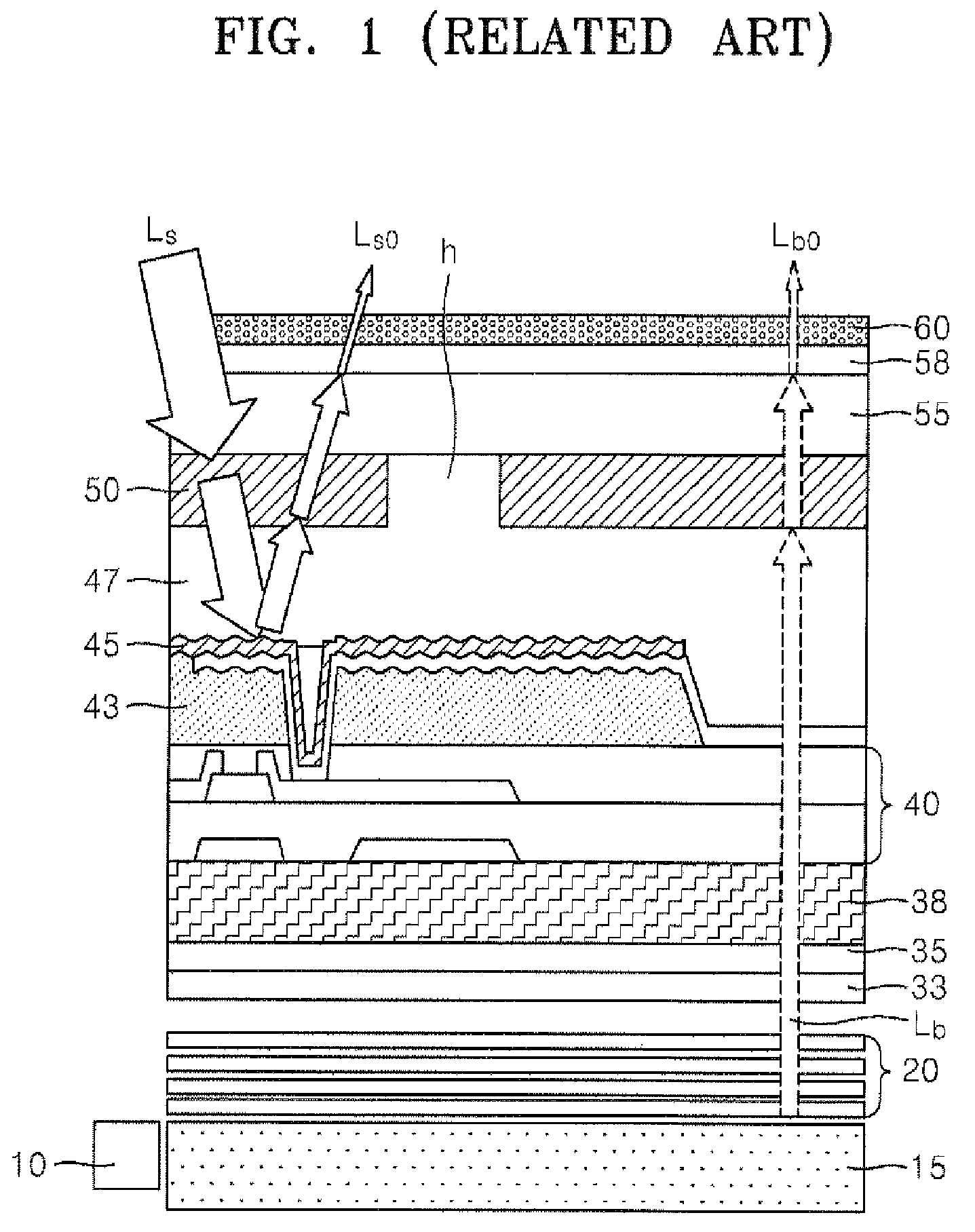

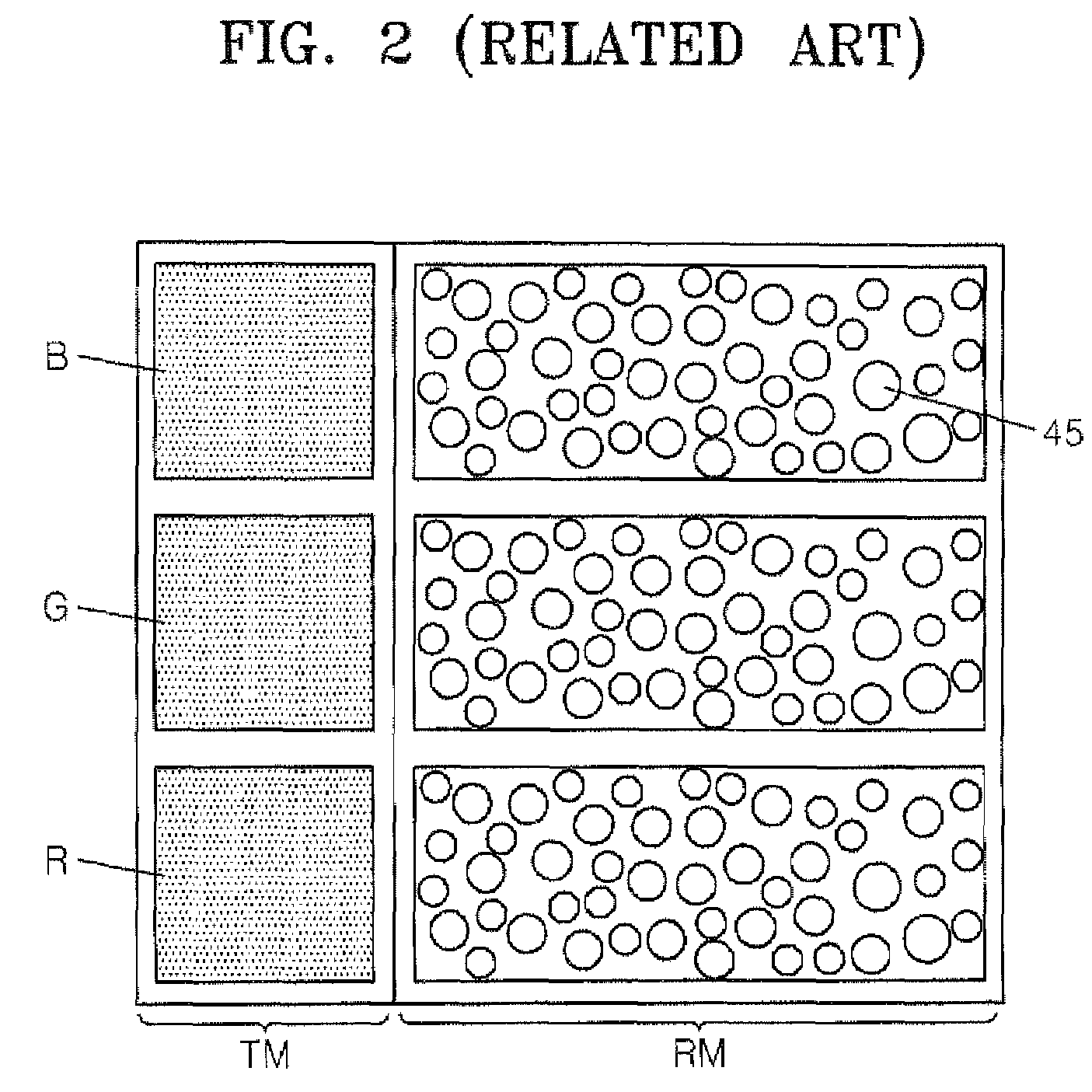

Transflective display panel and display apparatus using the same

InactiveUS20080158486A1High-brightness color reproductionHigh reflective brightnessNon-linear opticsTransmittanceLiquid crystal

A transflective display panel and a display apparatus using the same are provided. The display panel includes a plurality of pixels arranged in a matrix. Each of the pixels includes a plurality of subpixels, and each subpixel within a pixel outputs a different color of light. In addition, each of the subpixels includes a transflective mode region which has a reflection mode region with a diffraction grating and a transmission mode region; a liquid crystal layer which adjusts a transmittance of incident light through electric control; and a sub color filter which transmits light within a wavelength band of the incident light. Because the display panel includes the reflection mode region where the diffraction grating is formed, it can display a high-quality image with good white balance, even while outdoors or under bright illumination.

Owner:SAMSUNG DISPLAY CO LTD

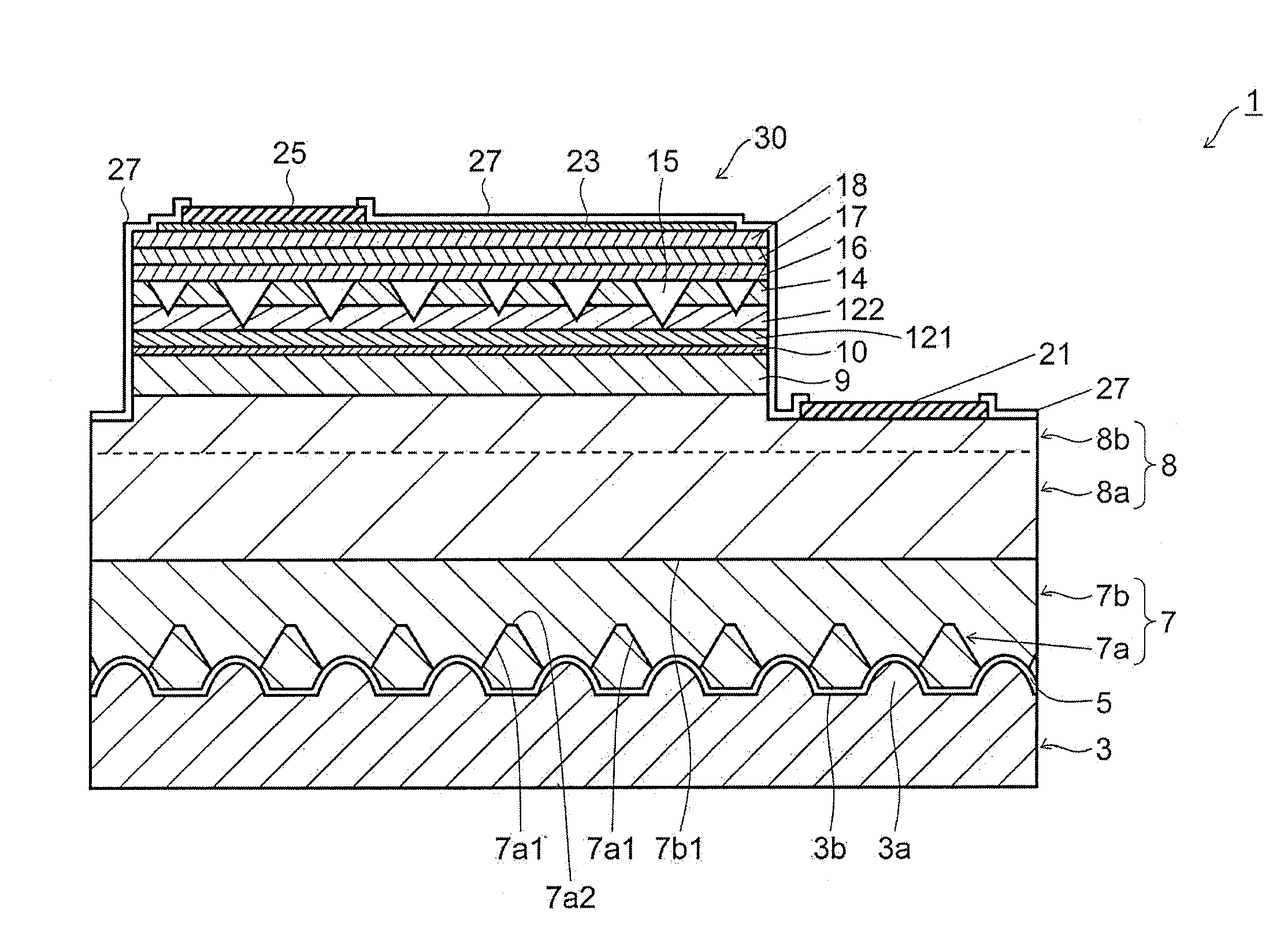

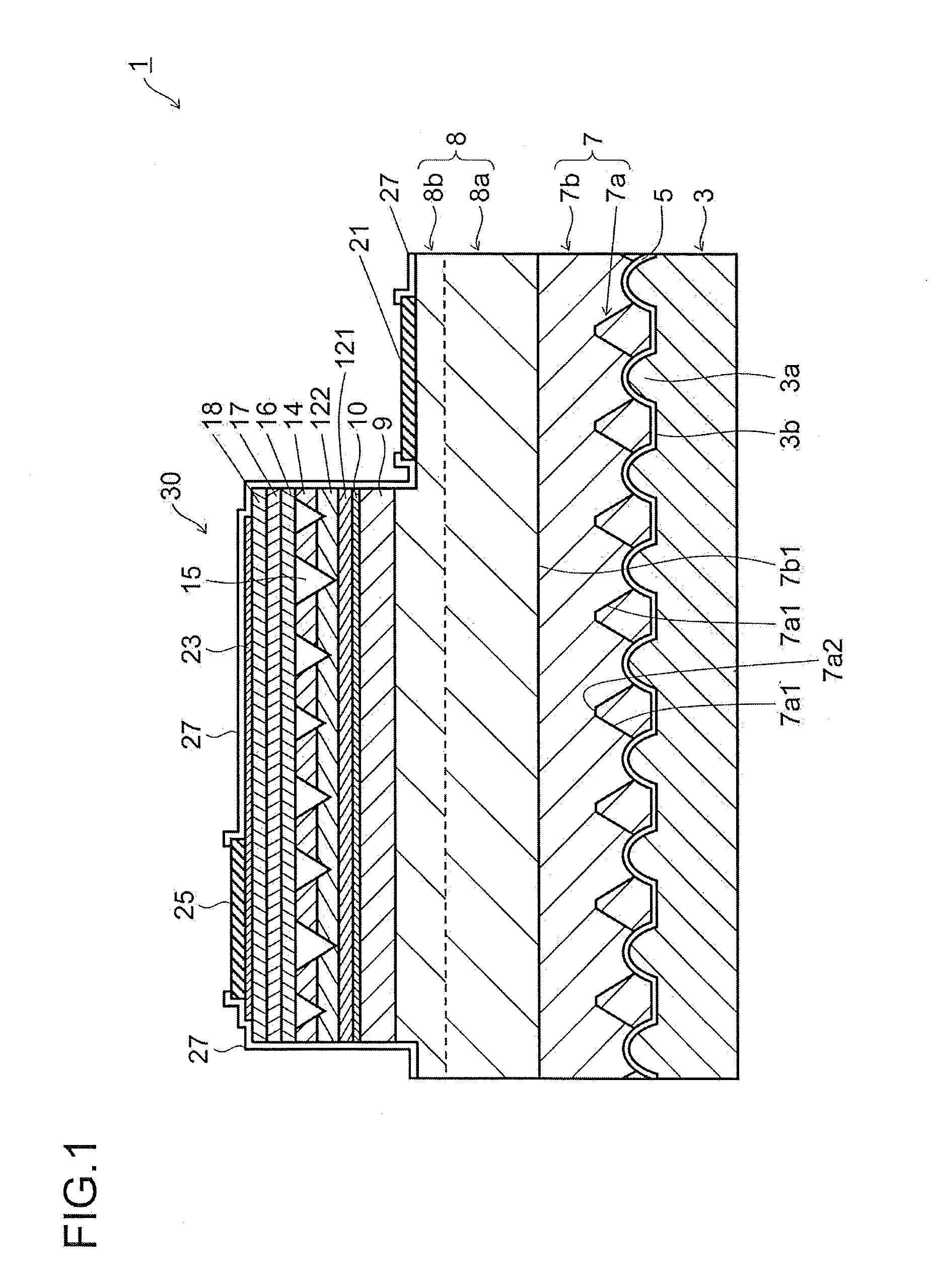

Nitride semiconductor light emitting element and method for manufacturing same

ActiveUS20150171263A1Reduce decreaseConstant efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal planeMaterials science

A nitride semiconductor light emitting element is provided with: a substrate; a buffer layer that is provided on the substrate; a base layer that is provided on the buffer layer; an n-side nitride semiconductor layer that is provided on the base layer; an MQW light emitting layer that is provided on the n-side nitride semiconductor layer; and a p-side nitride semiconductor layer that is provided on the MQW light emitting layer. An x-ray rocking curve half-value width ω (004) with respect to a (004) plane, i.e., the crystal plane of the nitride semiconductor, is 40 arcsec or less, or the x-ray rocking curve half-value width ω (102) with respect to a (102) plane is 130 arcsec or less, and the rate P (80) / P (25) between light output P (25) at 25° C. and light output P (80) at 80° C. with a same operating current is 95% or more.

Owner:SHARP FUKUYAMA LASER CO LTD

Centrifugal compressor assembly and method

ActiveUS9353765B2Improve performanceReduce physical sizeEngine manufacturePump componentsMixed flowHigh energy

A centrifugal compressor assembly for compressing refrigerant in a 250-ton capacity or larger chiller system comprising a motor, preferably a compact, high energy density motor or permanent magnet motor, for driving a shaft at a range of sustained operating speeds under the control of a variable speed drive. Another embodiment of the centrifugal compressor assembly comprises a mixed flow impeller and a vaneless diffuser sized such that a final stage compressor operates with an optimal specific speed range for targeted combinations of head and capacity, while a non-final stage compressor operates above the optimum specific speed of the final stage compressor. Another embodiment of the centrifugal compressor assembly comprises an integrated inlet flow conditioning assembly comprising a flow conditioning nose, a plurality of inlet guide vanes and a flow conditioning body that positions inlet guide vanes to condition flow of refrigerant into an impeller to achieve a target approximately constant angle swirl distribution with minimal guide vane turning.

Owner:TRANE INT INC

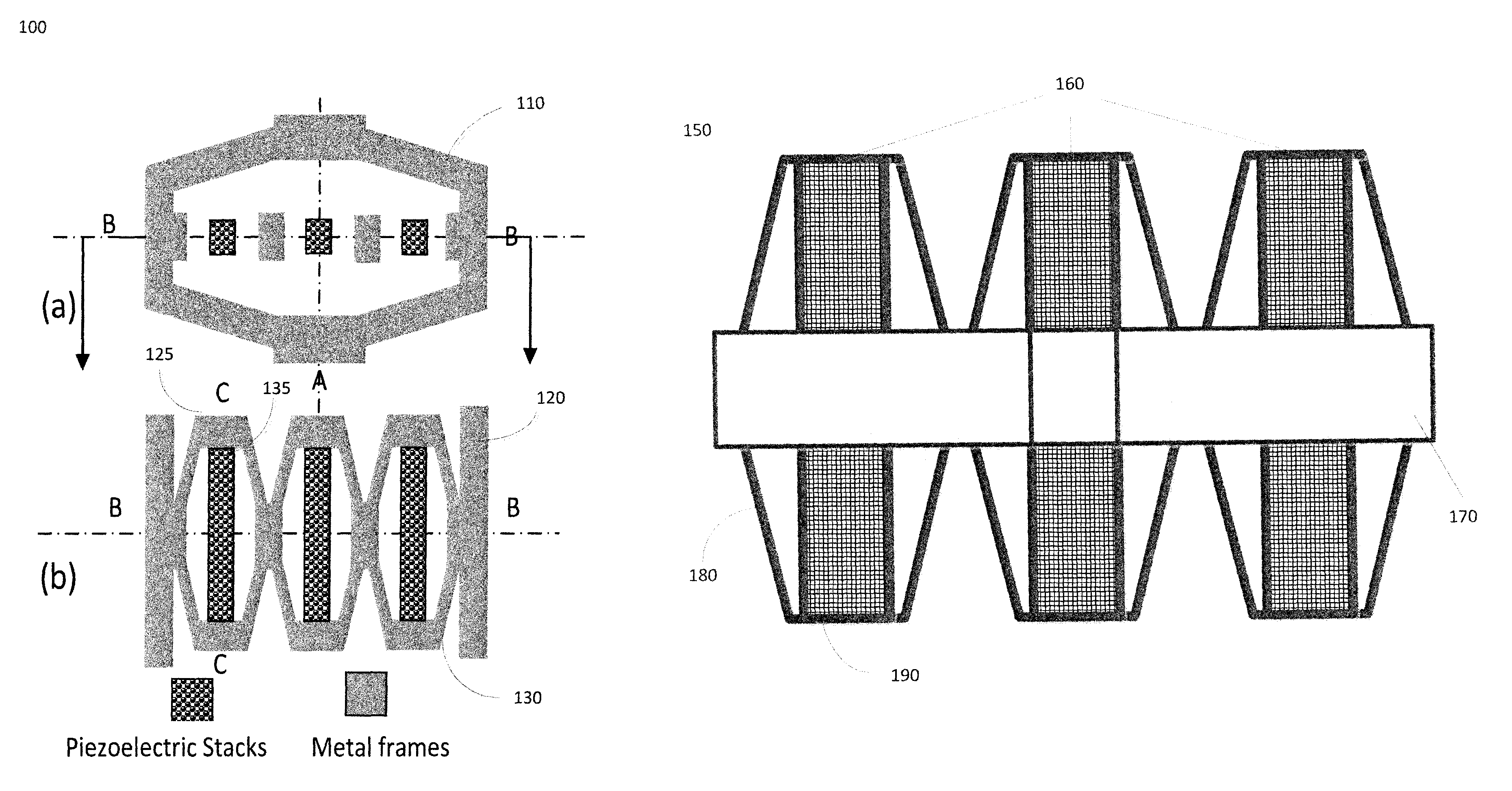

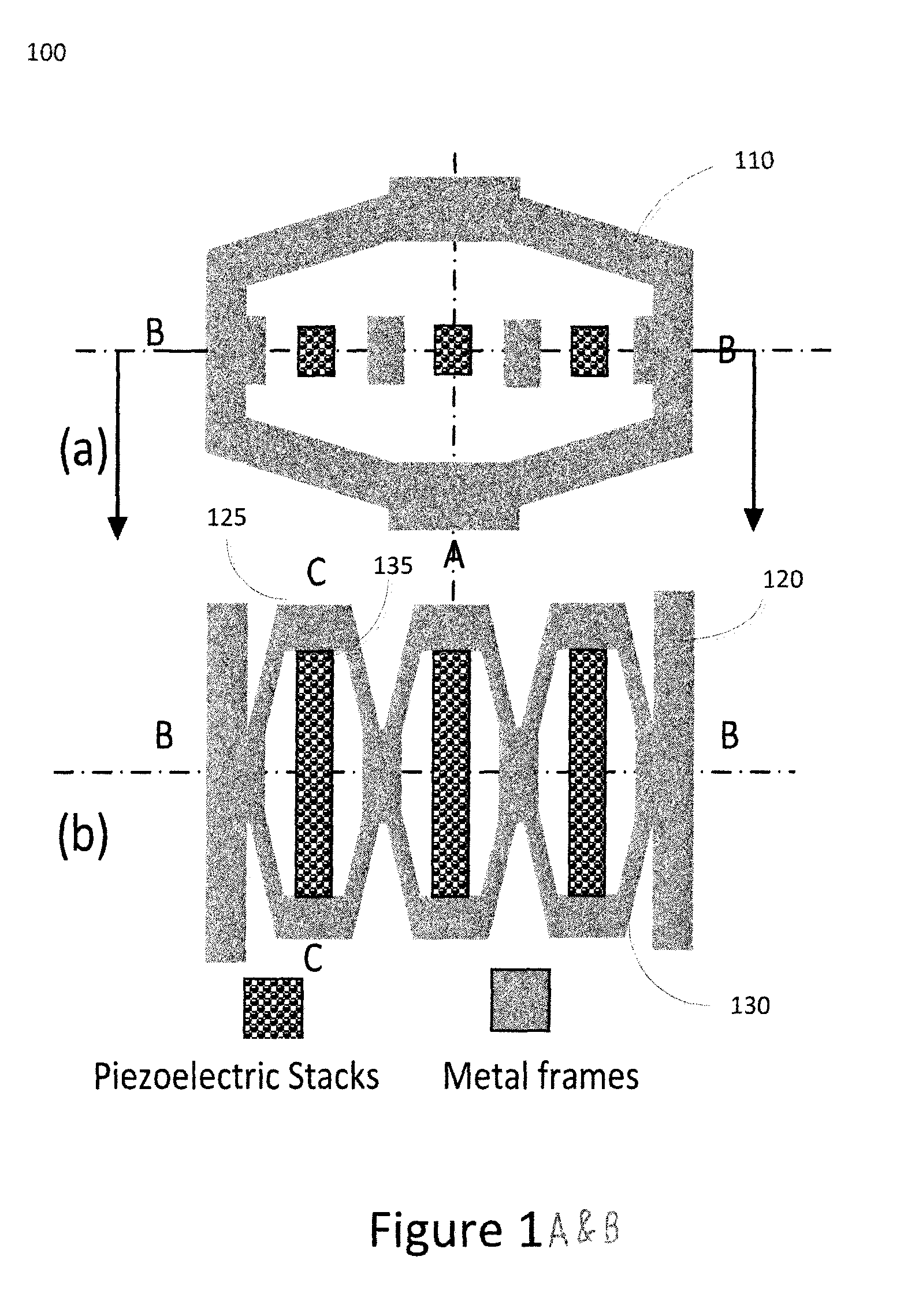

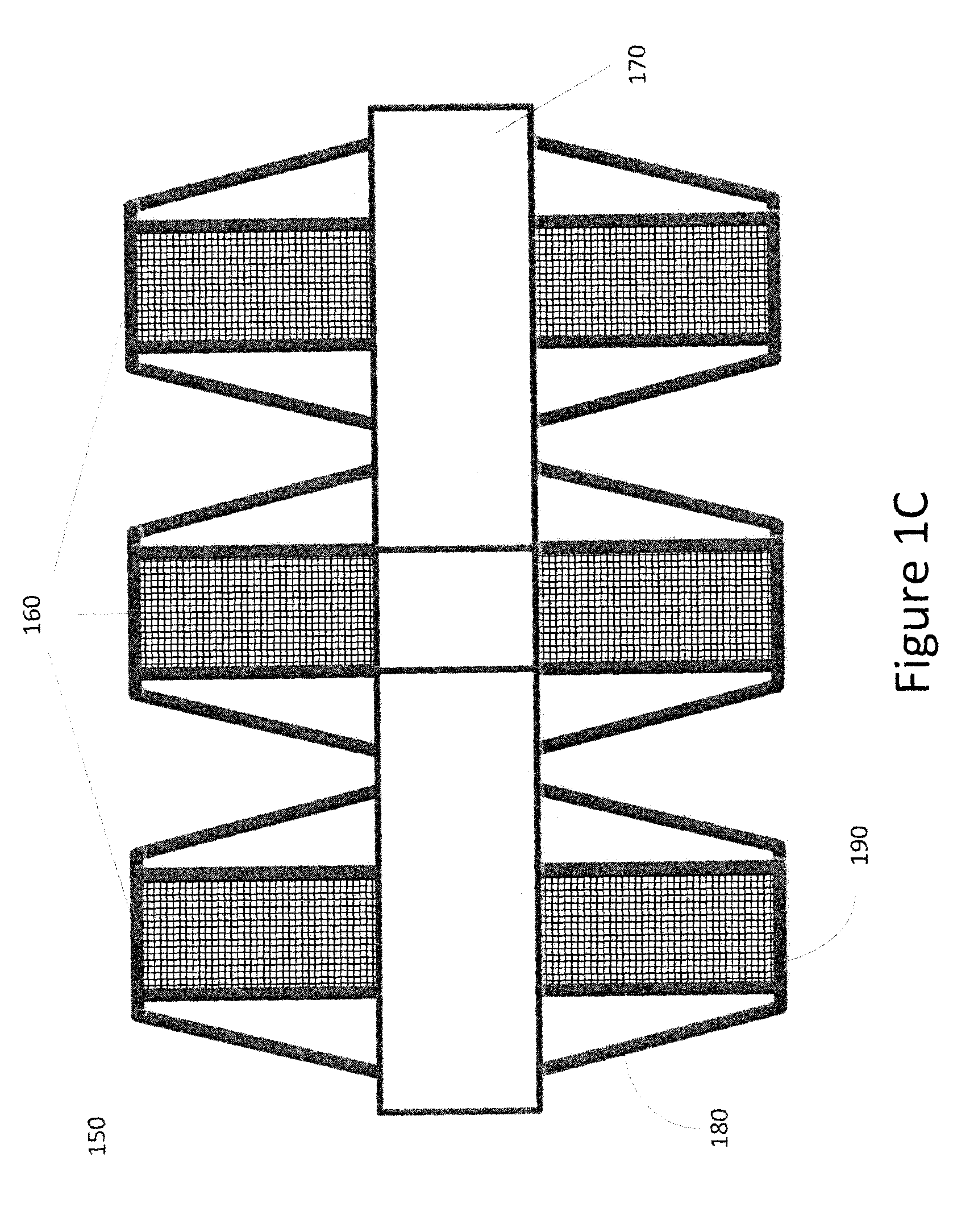

Multistage force amplification of piezoelectric stacks

ActiveUS9048759B2Constant efficiencyReduce stiffnessPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityEnergy based

Embodiments of the disclosure include an apparatus and methods for using a piezoelectric device, that includes an outer flextensional casing, a first cell and a last cell serially coupled to each other and coupled to the outer flextensional casing such that each cell having a flextensional cell structure and each cell receives an input force and provides an output force that is amplified based on the input force. The apparatus further includes a piezoelectric stack coupled to each cell such that the piezoelectric stack of each cell provides piezoelectric energy based on the output force for each cell. Further, the last cell receives an input force that is the output force from the first cell and the last cell provides an output apparatus force In addition, the piezoelectric energy harvested is based on the output apparatus force. Moreover, the apparatus provides displacement based on the output apparatus force.

Owner:NASA

High efficiency constant current LED driver

ActiveUS20130320871A1Improve efficiencyLarge gainEfficient power electronics conversionElectroluminescent light sourcesFull bridgeVoltage range

Owner:INVENTRONICS HANGZHOU

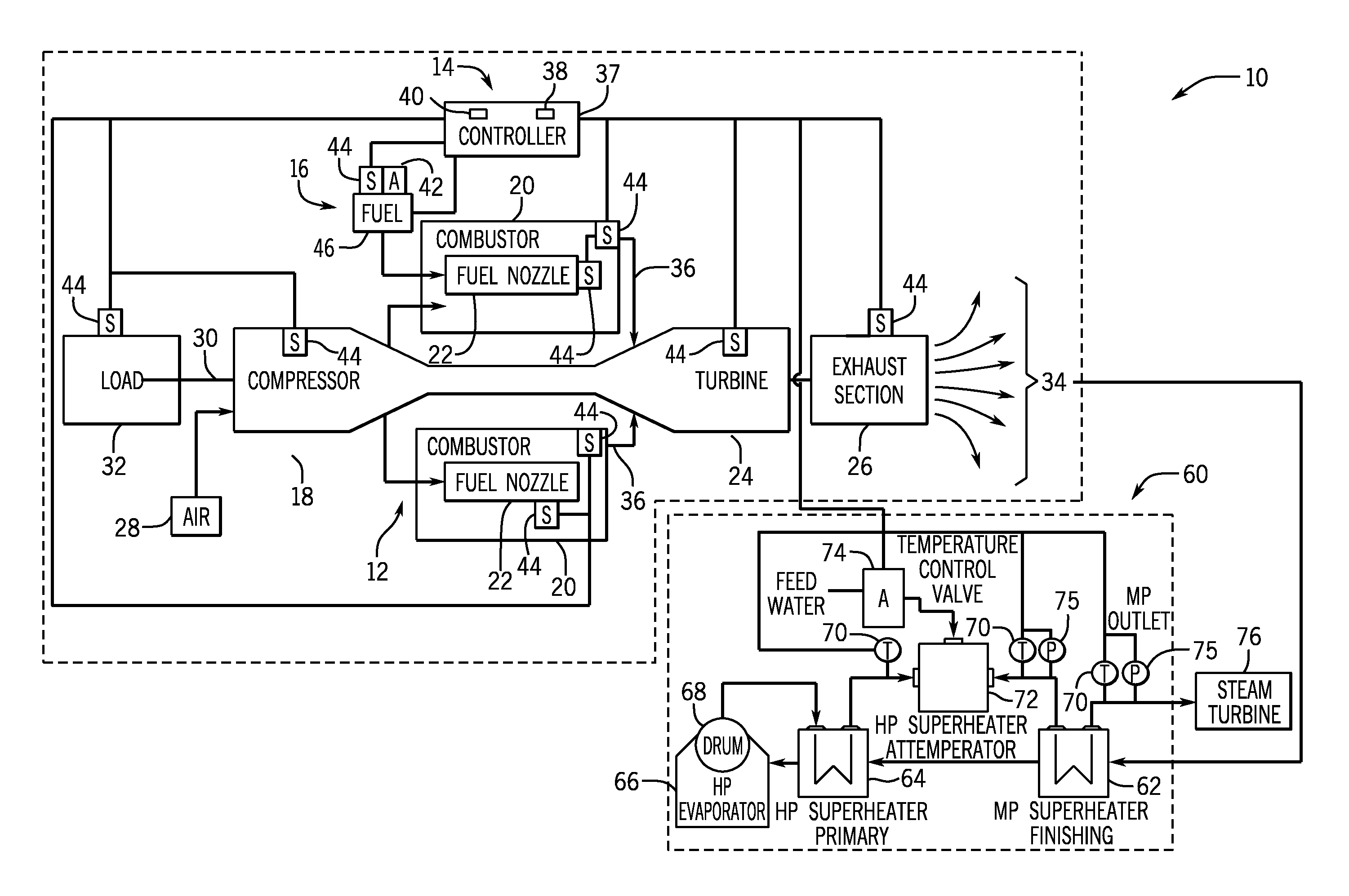

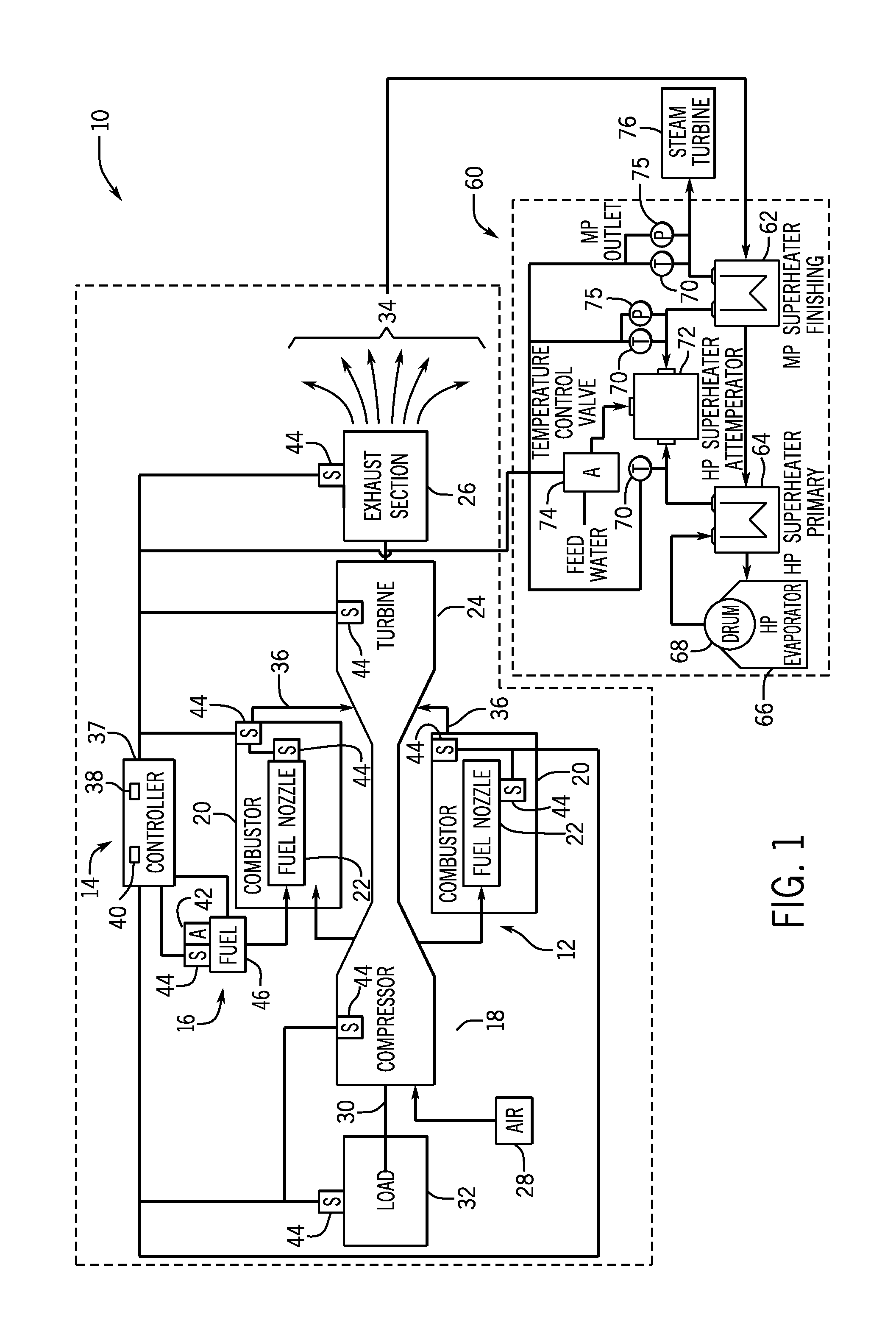

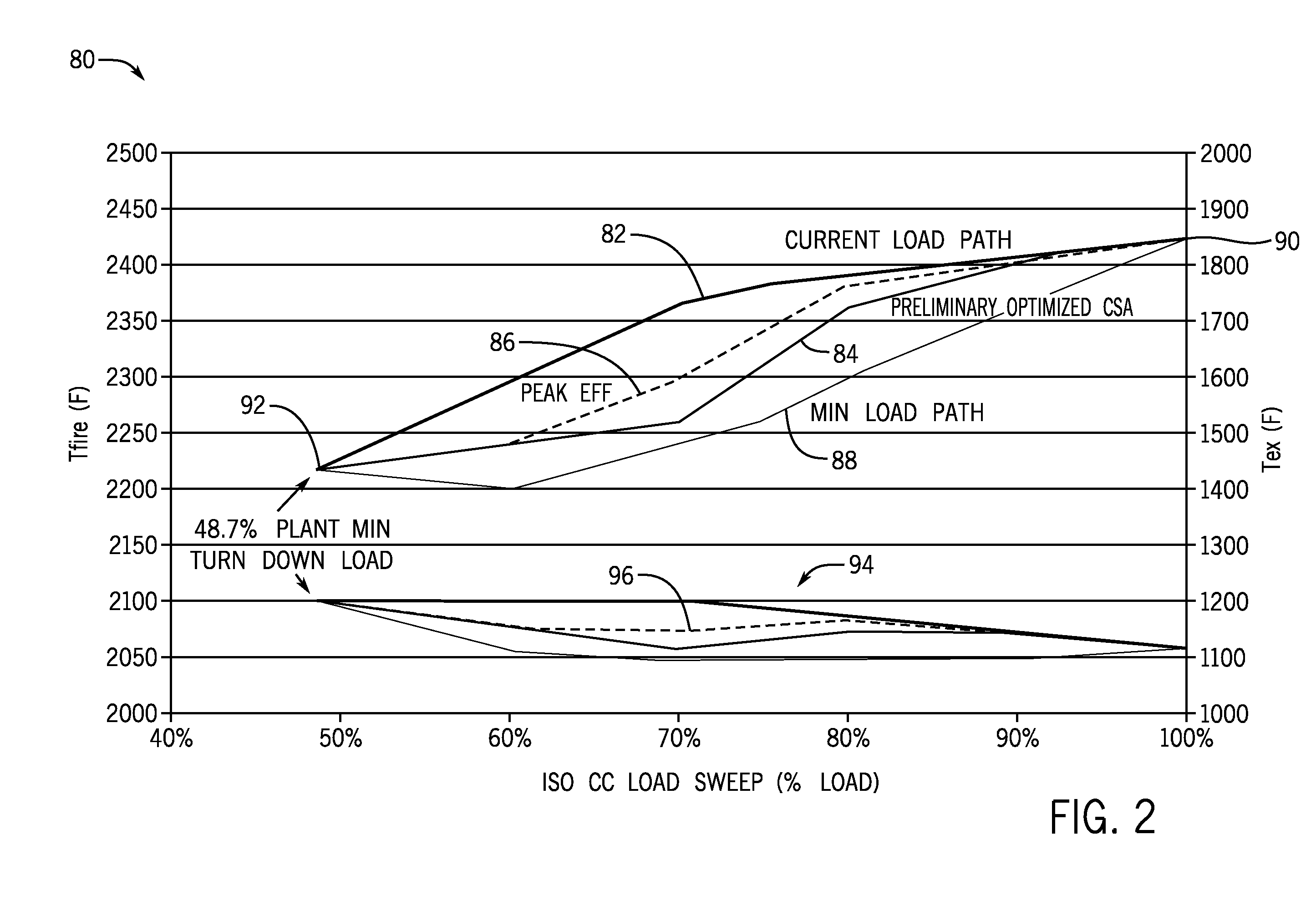

Systems and methods for improved combined cycle control

ActiveUS20150247464A1Constant efficiencyConstant load pathLevel controlEngine fuctionsCurrent loadCycle control

Systems and methods for improved control of a turbomachine system with a bottoming cycle system are presented. The systems and methods include a controller that utilizes modeling techniques to derive a plurality of load path curves. The controller utilizes a current load path, a minimum load path, and a constant efficiency load path. The systems and methods include a control process configured to receive a user input representative of a life cycle control modality and to execute a control action based on deriving a load efficiency by applying the current load path, the minimum load path, the constant efficiency load path, or a combination thereof, and the life cycle control modality. The control action is applied to control the turbomachine system and the bottoming cycle system fluidly coupled to the turbomachine system. Further, the life cycle control modalities may be selected by a user based upon known tradeoffs.

Owner:GENERAL ELECTRIC CO

Hammermill hammer

ActiveUS20080011890A1Improve efficiencyExcellent hardness propertiesGrain treatmentsEngineeringComminution

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

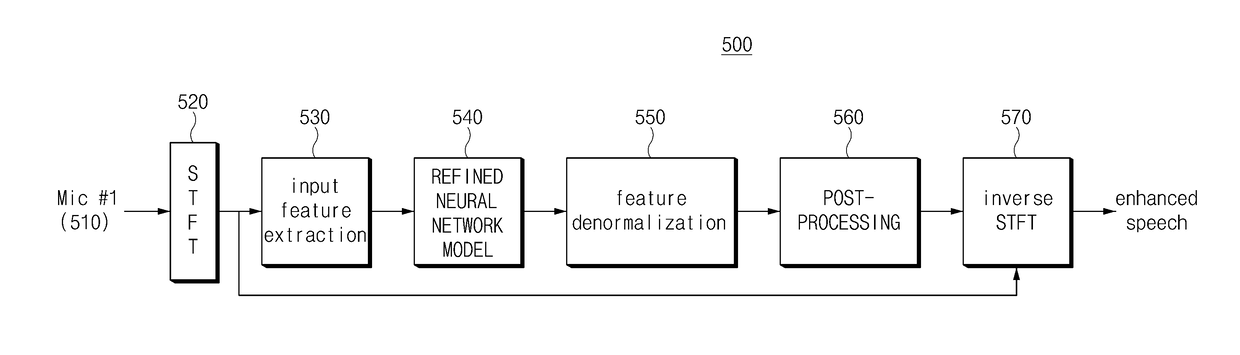

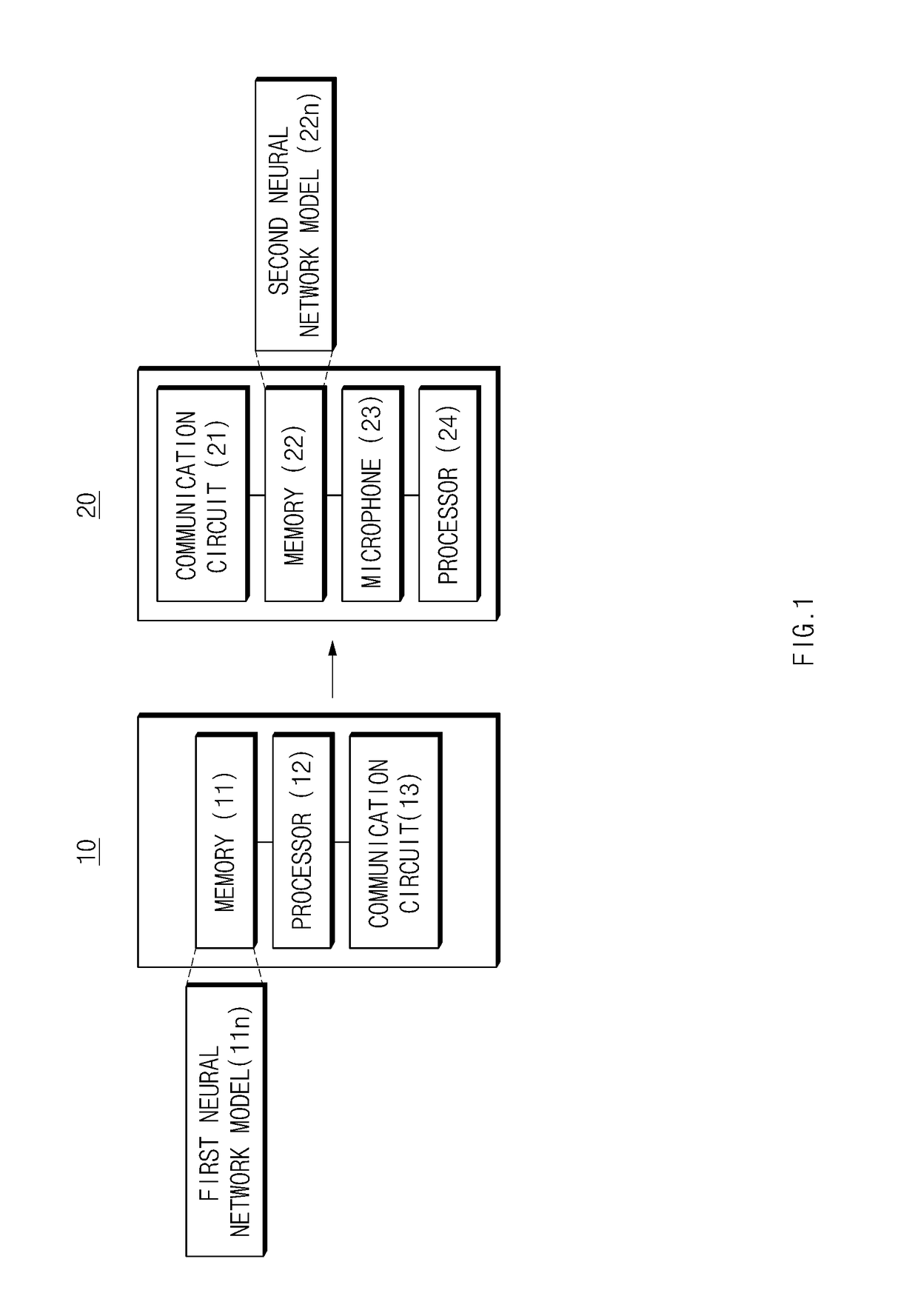

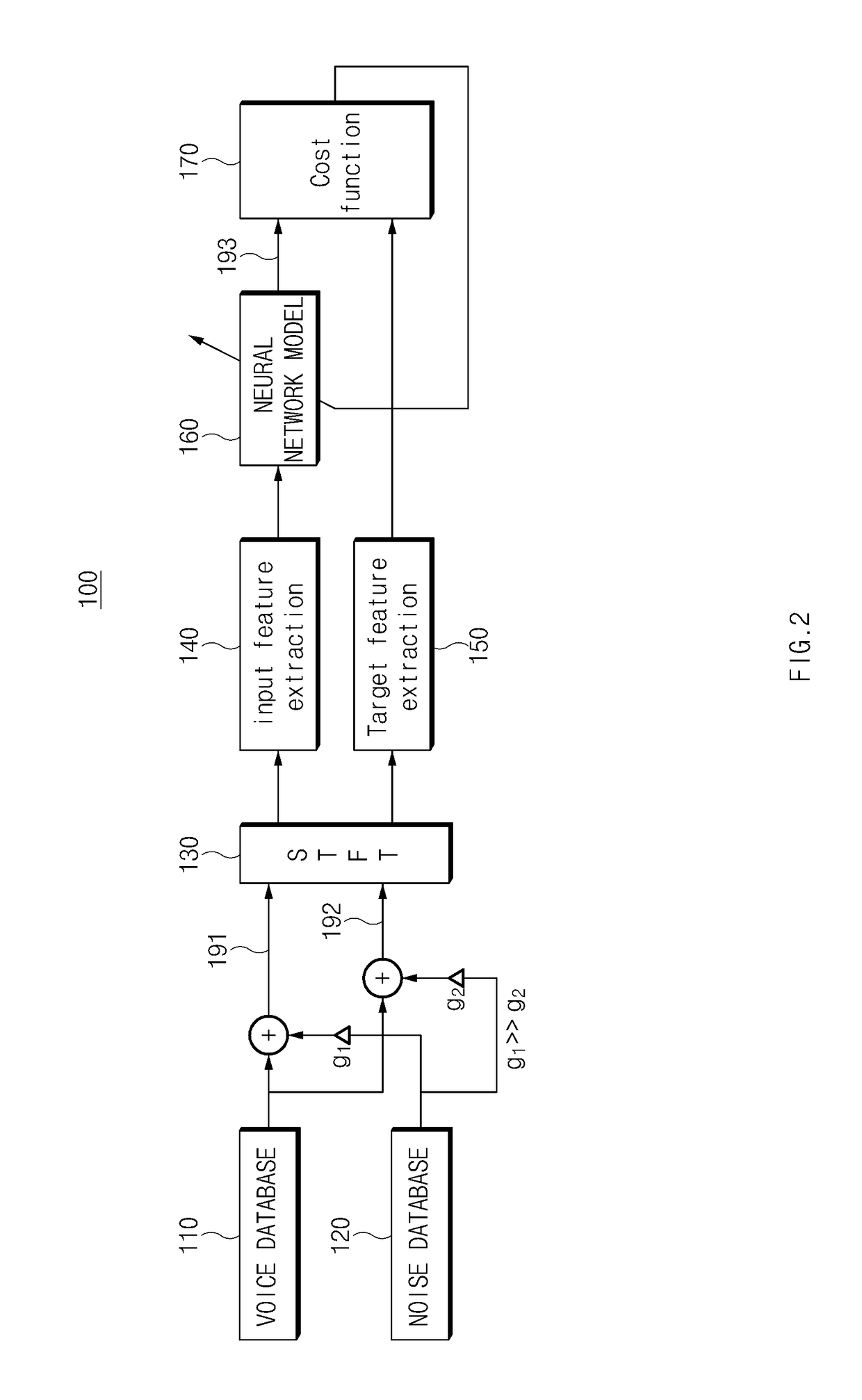

Method and device for removing noise using neural network model

ActiveUS20180286425A1Constant efficiencyImprove removal efficiencySpeech analysisBiological neural network modelsNetwork modelInput device

A portable electronic device includes an audio input device and a processor. The processor is configured to obtain audio input data including a noise signal having an audio feature through the audio input device, to filter the audio input data using a neural network model to generate first audio output data, and to filter the first audio output data without using the neural network model to generate second audio output data. The first audio output data has a first changed audio feature corresponding to the audio feature and the second audio output data has a second changed audio feature corresponding to the audio feature.

Owner:SAMSUNG ELECTRONICS CO LTD

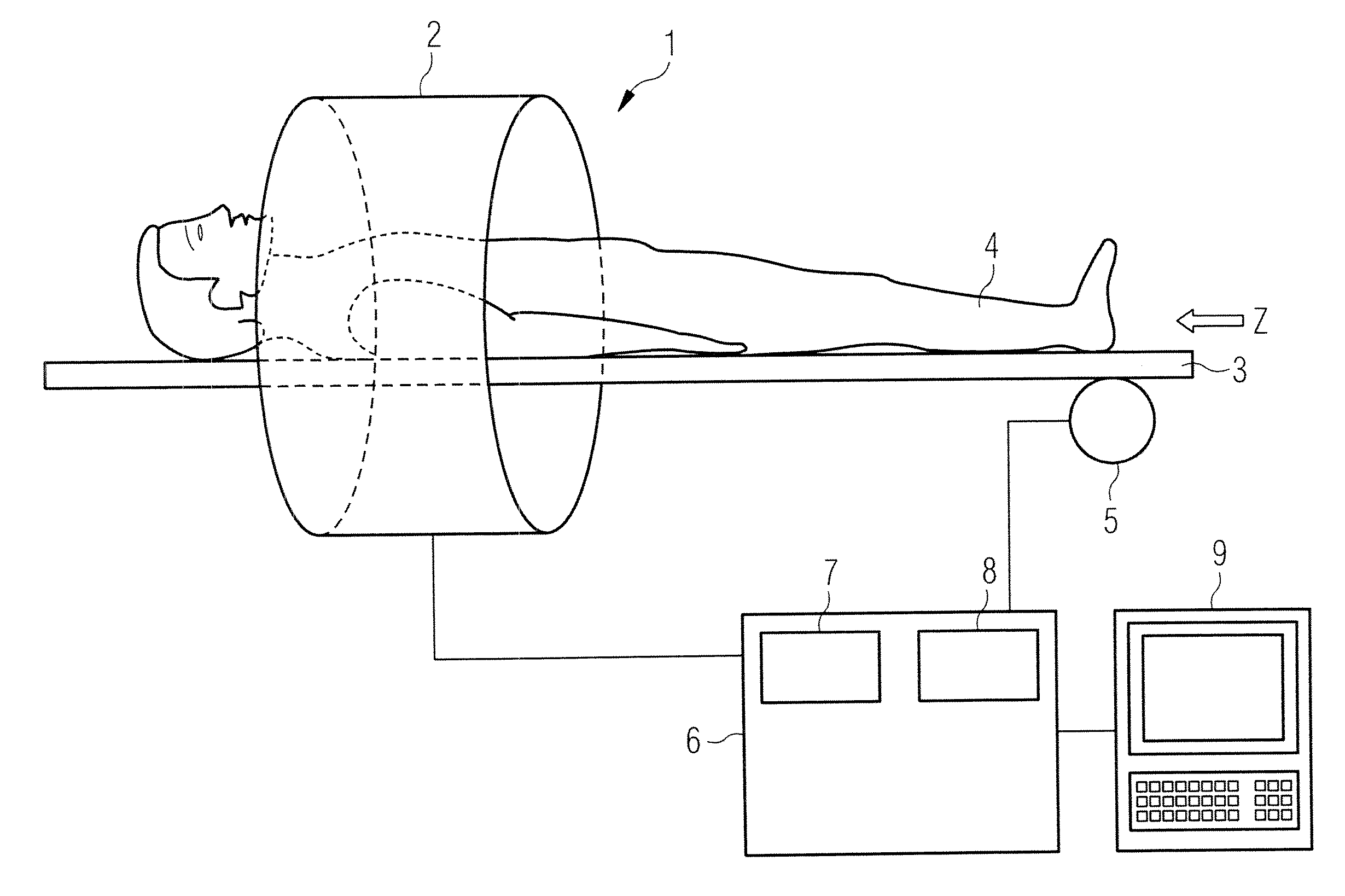

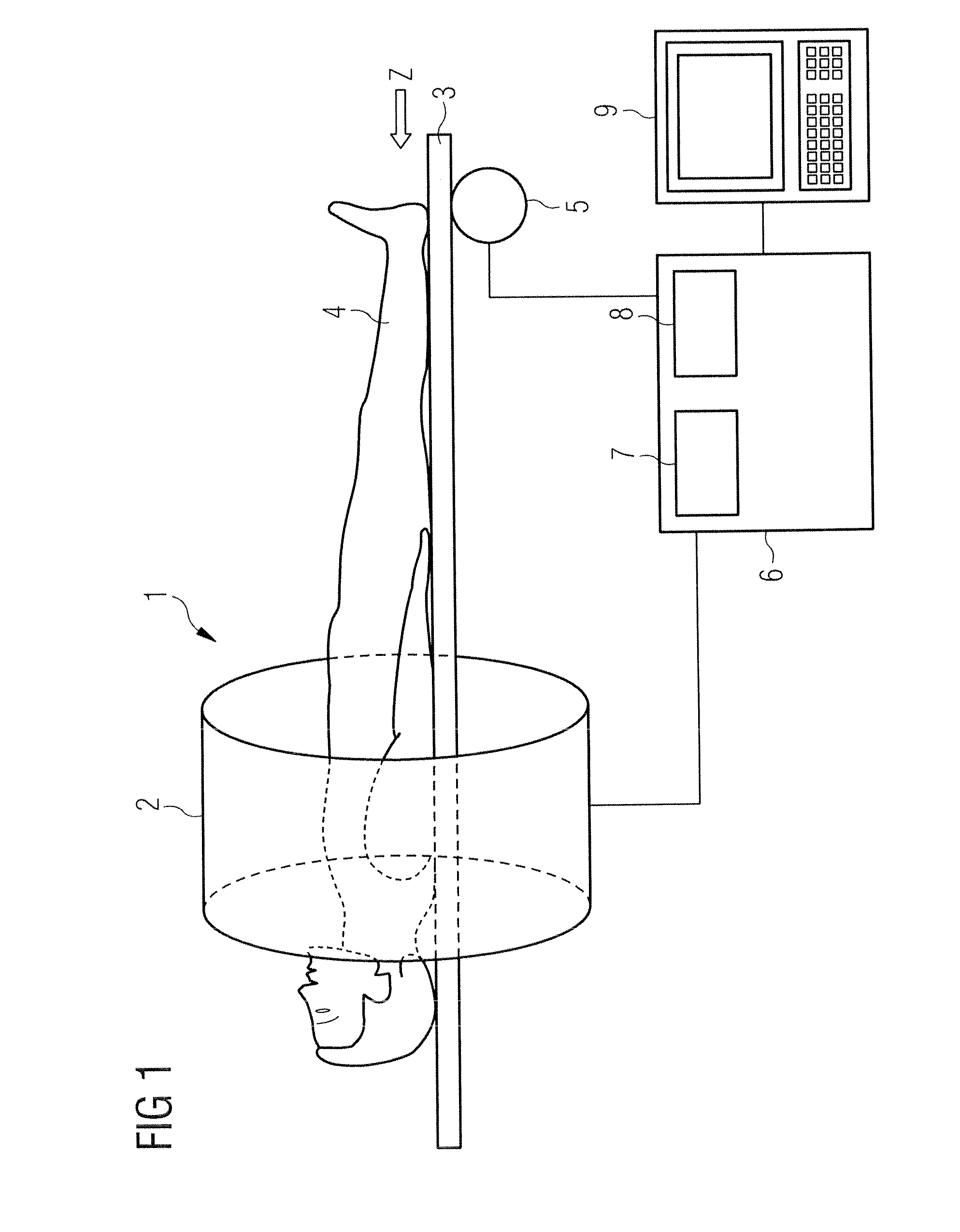

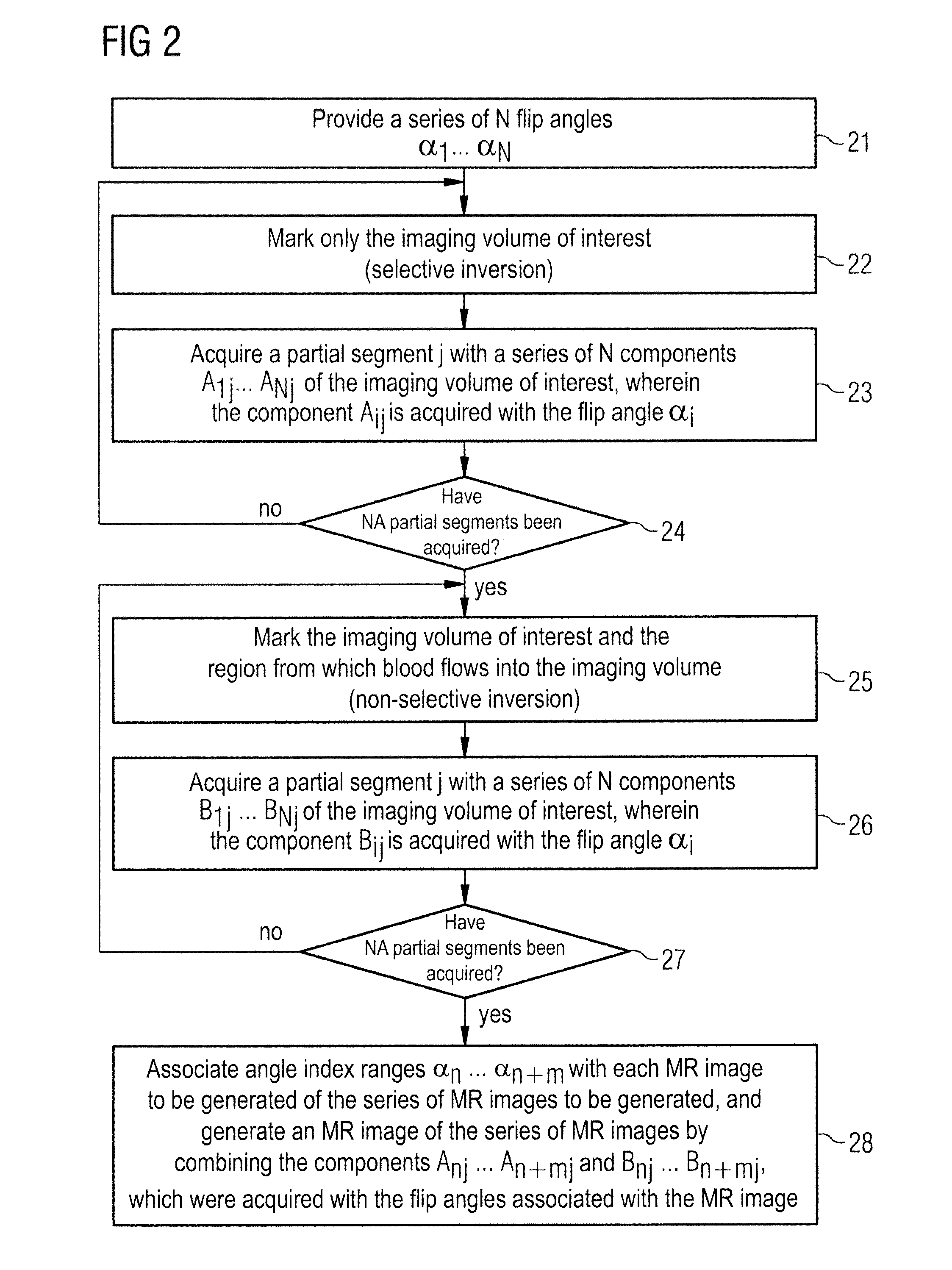

Method and apparatus to generate angiographic magnetic resonance images

ActiveUS20110251477A1Constant efficiencyLess additionally acceleratedMagnetic measurementsDiagnostic recording/measuringResonanceSpins

In a magnetic resonance system and operating method to generate a series of temporally successive angiographic magnetic resonance images of an examination region, a series with a predetermined number of flip angles is established. The first flip angle at the beginning of the series is smaller than the last flip angle at the end of the series, and an arbitrary flip angle is greater than or equal to the preceding flip angle in the series. First and second magnetic resonance data are determined by acquiring a predetermined number of partial segments of k-space belonging to the first and second magnetic resonance data. Each partial segment is acquired over a respective first or second time interval and respectively has a series of components. Each component is acquired according to a gradient echo method with a flip angle that exists at a position in the series of flip angles, which position corresponds to the component. A fluid flowing into the examination region is given a first predetermined spin marking at the beginning of the first time intervals and a second predetermined spin marking, different than the first spin marking, at the beginning of the second time intervals. The series of temporally successive angiography magnetic resonance images is generated by combining the first and second magnetic resonance data.

Owner:SIEMENS HEALTHCARE GMBH

Transflective display panel and display apparatus using the same

InactiveUS7675591B2High-brightness color reproductionHigh reflective brightnessNon-linear opticsElectricityTransmittance

Owner:SAMSUNG DISPLAY CO LTD

Piezoelectric ceramic and laminated piezoelectric element

InactiveUS20070125977A1High curie temperatureIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCurie temperatureCeramic

A piezoelectric ceramic comprising a perovskite composite oxide of an ABO3 composition containing Pb in the A-site and Zr and Ti in the B-site, wherein when the total amount of the element species constituting the B-site of the perovskite composite oxide in the ceramic is set to be one mol, an average valency of the element species constituting the B-site is in a range of from 4.002 to 4.009. The piezoelectric ceramic can be fired at a low temperature, has a high Curie temperature and a high piezoelectric distortion constant, as well as excellent durability and reliability against high temperatures.

Owner:KYOCERA CORP

High efficiency radiant burner

InactiveUS20080213715A1Increasing burner efficiencyImprove efficiencyGaseous fuel burnerCombustion regulationInjectorProduct gas

A naturally aspirated, fully aerated radiant burner and optional heat exchanger arrangement where the radiant burner has a generally enclosed cavity defined, at least in part, by fuel gas impermeable surroundings and a lower surface of fuel gas permeable burner element, wherein cavity preferably has two opening exposed to an oxidizer source. Sealingly coupled to openings are mix tubes, each having respective first ends and second ends, wherein first ends occupy openings and second ends extend into and are exposed to cavity. Fuel gas injectors, which during use are in fluid communication with fuel gas, are positioned to introduce fuel gas into mix tubes and entrain only slightly more air than needed for stoichiometric combustion. Pre-combustion gasses migrate to upper surface where stable stoichiometric combustion occurs, resulting in low CO and NOx emissions, increased wind resistance and elevated combustion gas temperatures Connecting the heat exchanger directly to the burner further increases its wind resistance and prevents dilution of the combustion gases by wind or free convection.

Owner:CASCADE DESIGNS INC

Magnetic tunnel junction device and fabrication

Owner:QUALCOMM INC

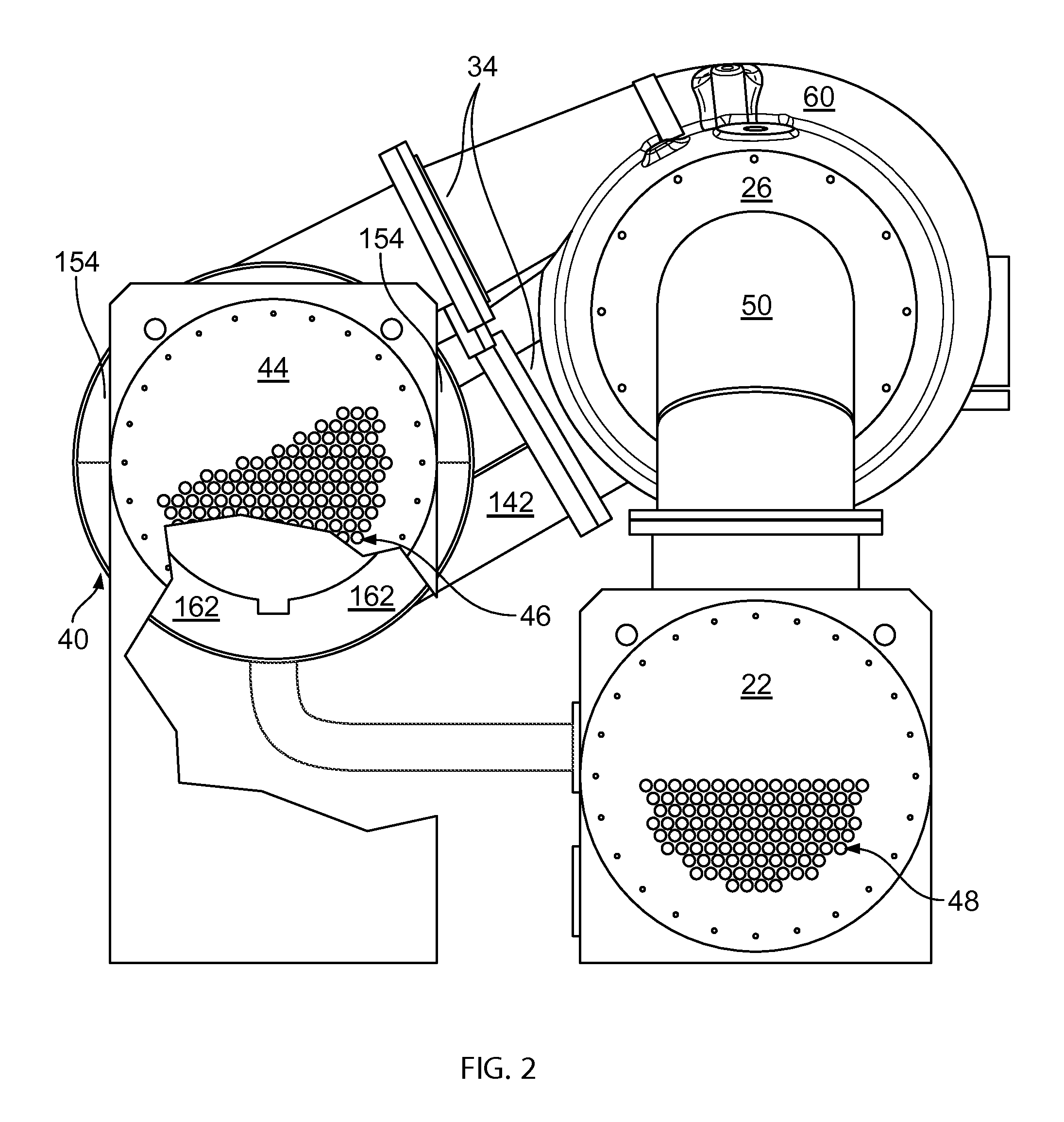

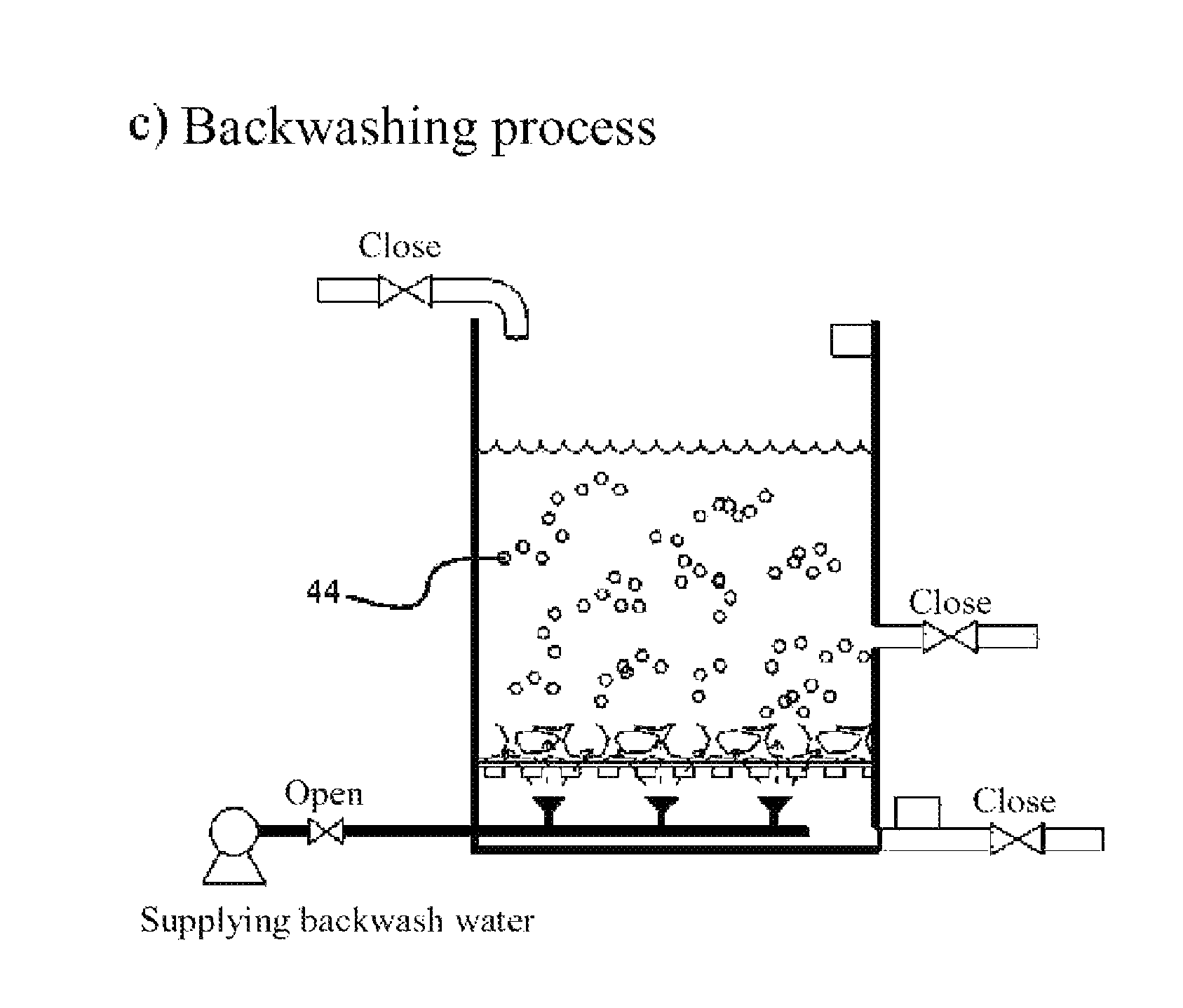

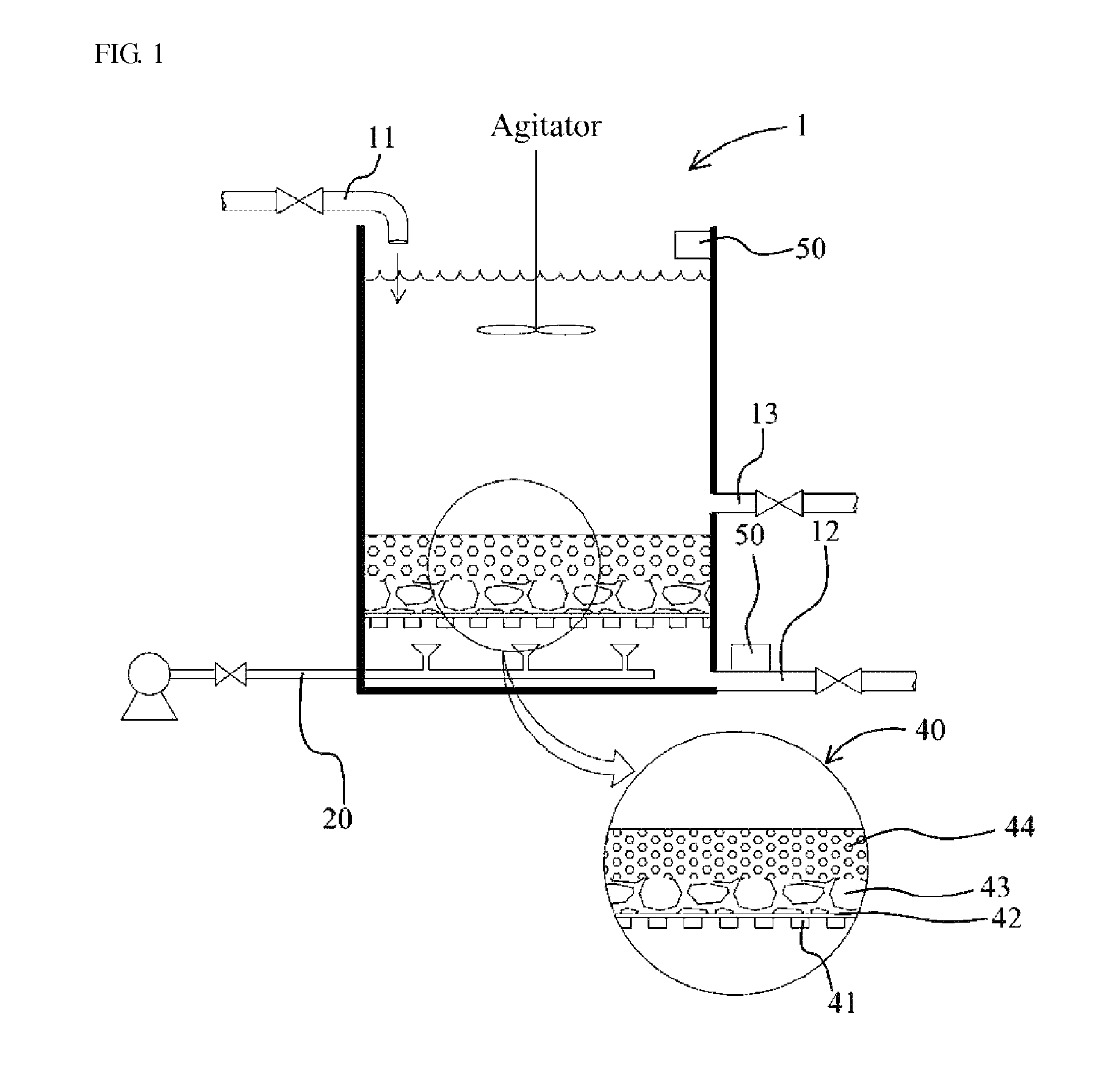

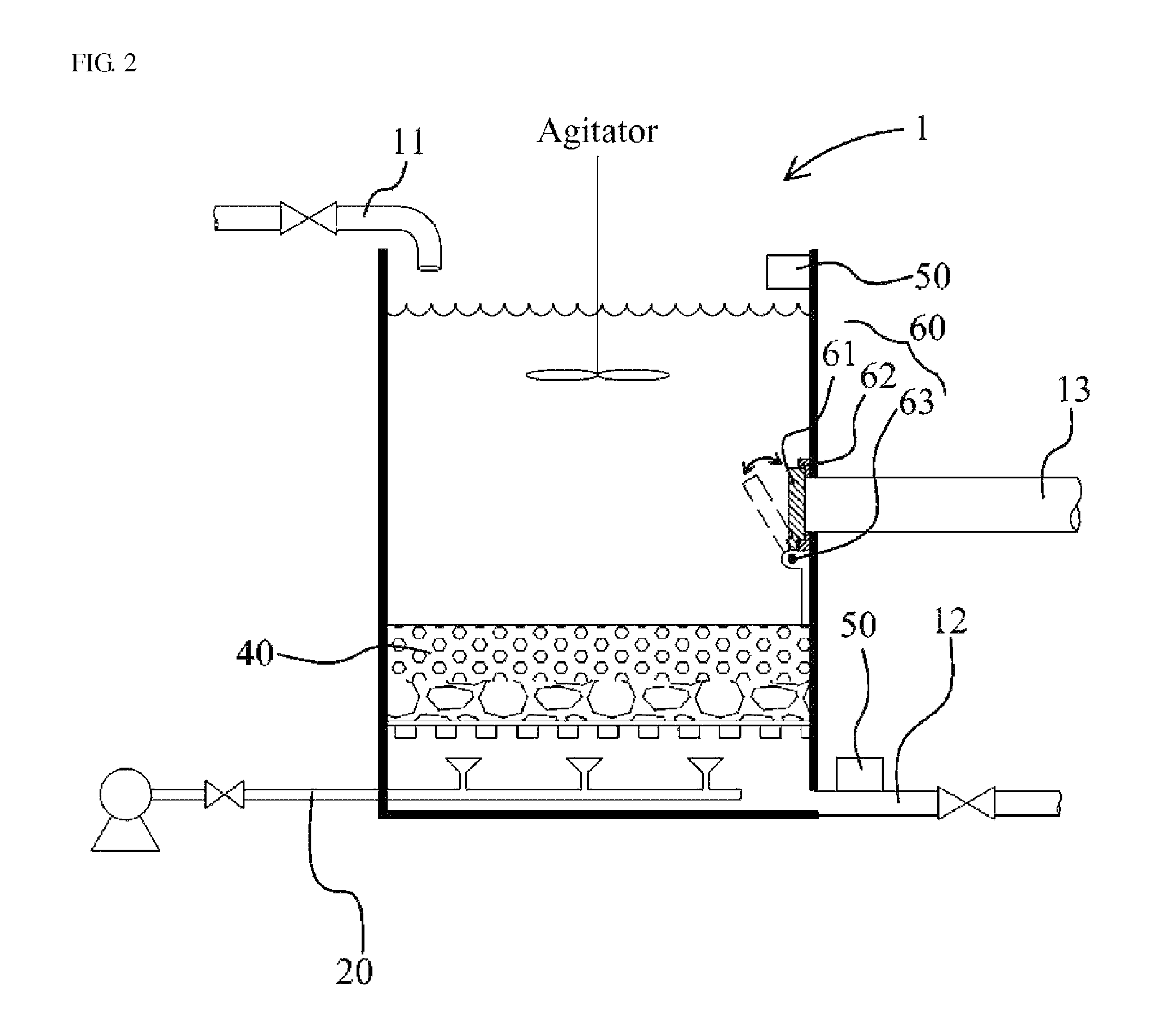

High speed filtration device using porous media, and backwash method thereof

InactiveUS9149746B2Enhance effective removalConstant efficiencyGeneral water supply conservationSpecific water treatment objectivesFiltrationWater flow

The present invention relates to a porous media-mediated high speed filtration device for easy backwash, wherein the inflow water to be filtered is guided to an upper portion of the high speed filtration device and is filtered by downflow and porous media are backwashed for maintaining optimum filter efficiency by blocking the flow of inflow water and water to be treated after sensing the level of the inflow water or the change in the flux of the water to be treated, supplying backwash water and / or air by upflow through a backwash equipment to separate pollutants in the porous media by the collision and friction between the porous media by flowing of the porous media through the stream of the backwash water, placing the porous media in a stationary location, and discharging the pollutants through a discharge pipe of the high speed filtration device before the pollutants settle. In addition, the present invention comprises a backwash method of the high speed filtration device using porous media.

Owner:SUNG PIL CHOI

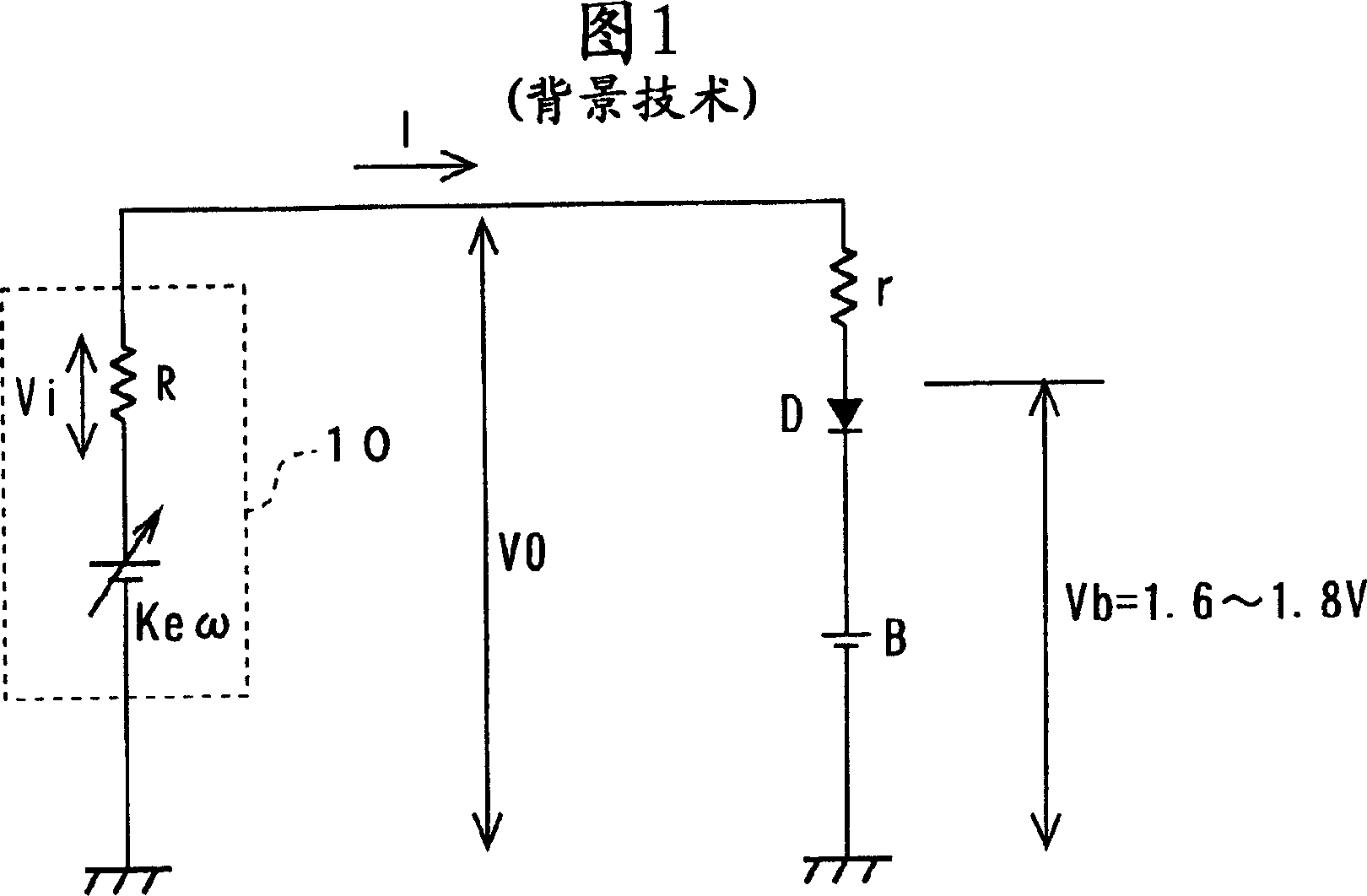

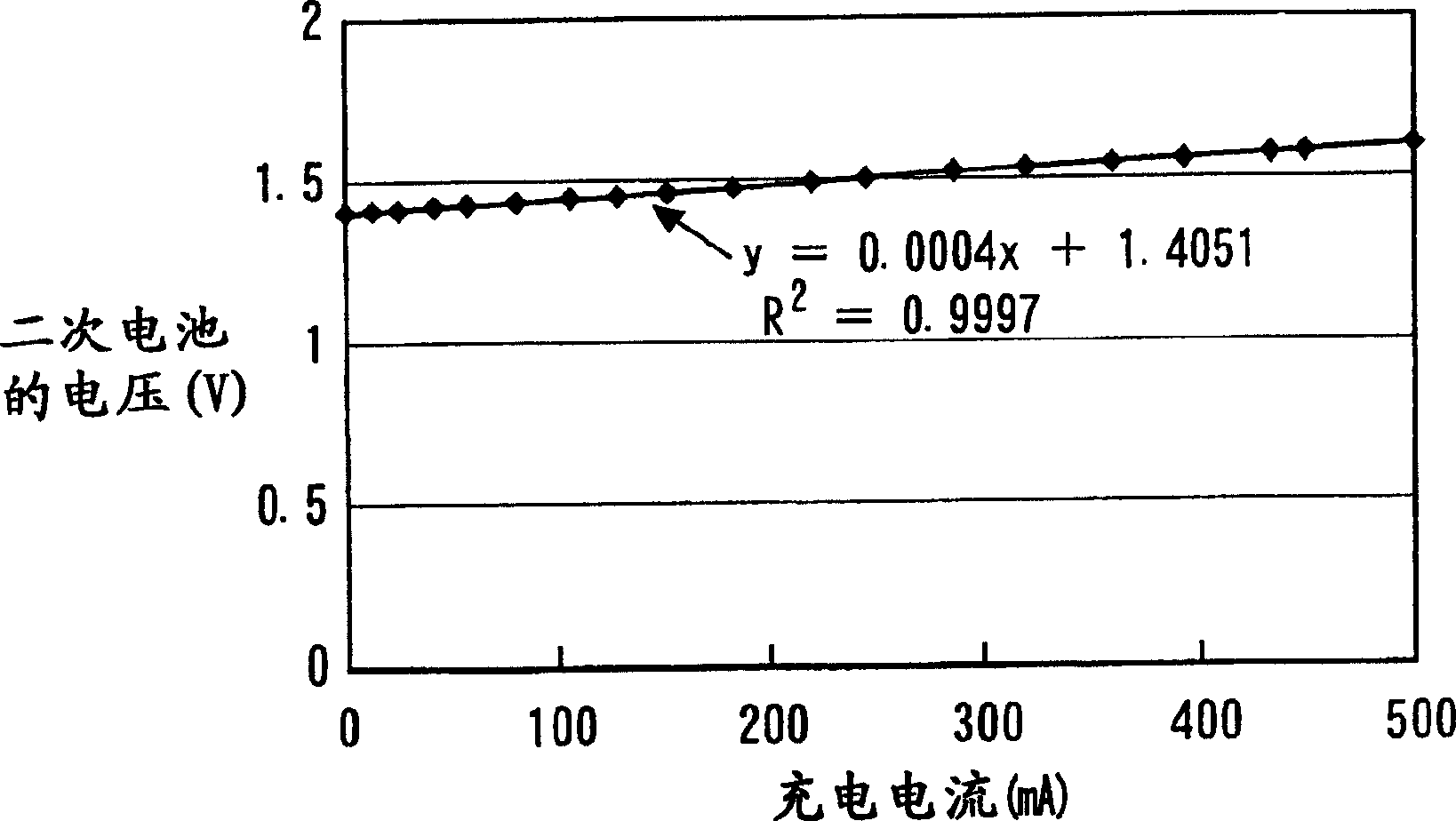

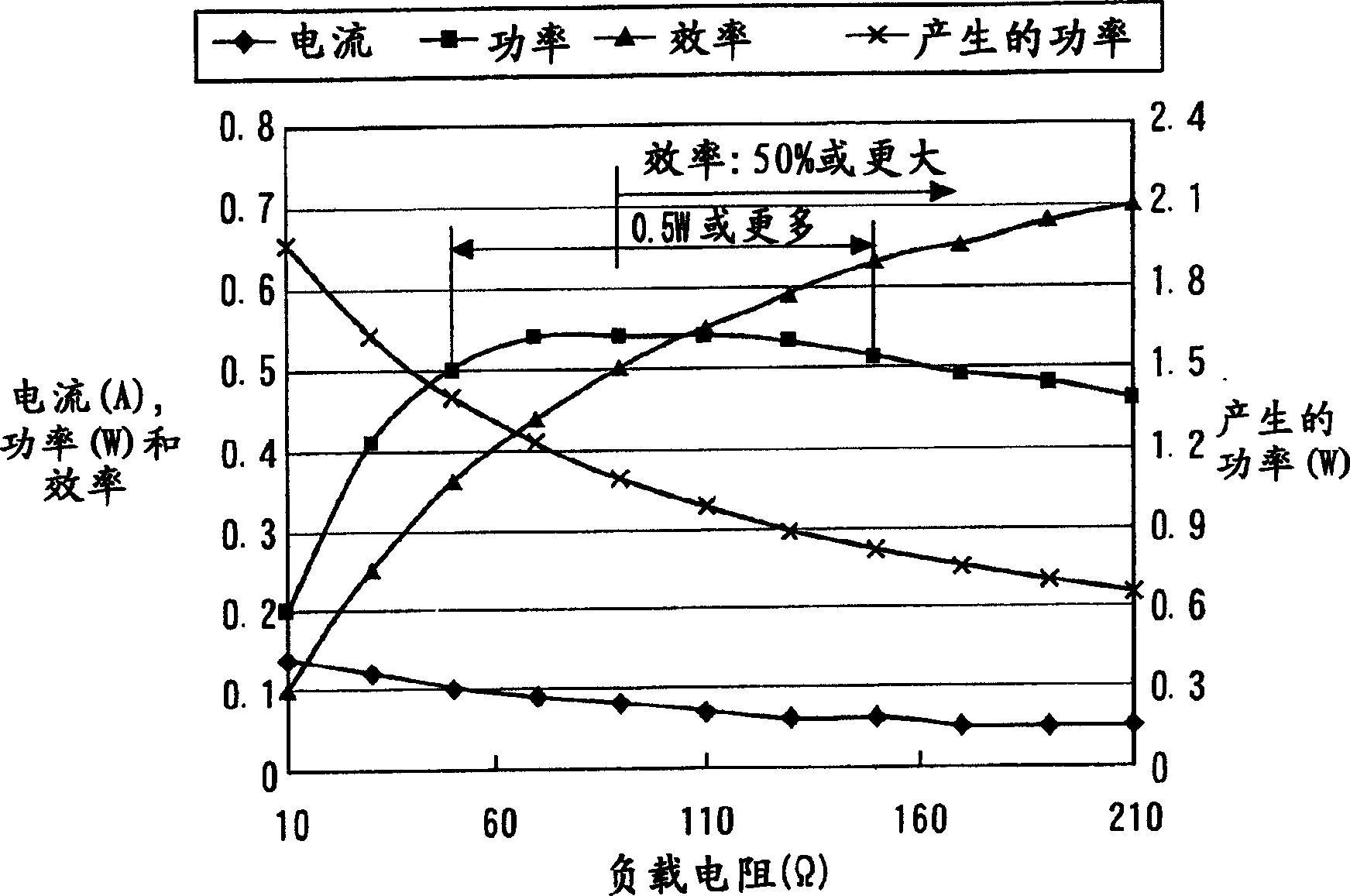

Charging circuit and charger using the same

InactiveCN1578046AAchieve Impedance MatchingEffective take outBatteries circuit arrangementsElectric powerCharge currentLow voltage

The invention discloses a charging circuit and a charger using the charging circuit, comprising a generator; a voltage reducing circuit, a current controller, a mode selector, and a monitor. The invention is characterized in that the voltage reducing circuit reduces the output voltage of the generator to predetermined voltage; the current controller controls the charging current supplied to a secondary battery by the voltage reducing circuit according to the electric quantity produced by the generator; the mode selector selects charging mode; the monitor monitoring the stored electric quantity; in the process of charging, the voltage reducing circuit receives the output of the generator by high voltage and small current, and charges the secondary battery by low voltage and high current.

Owner:SONY CORP

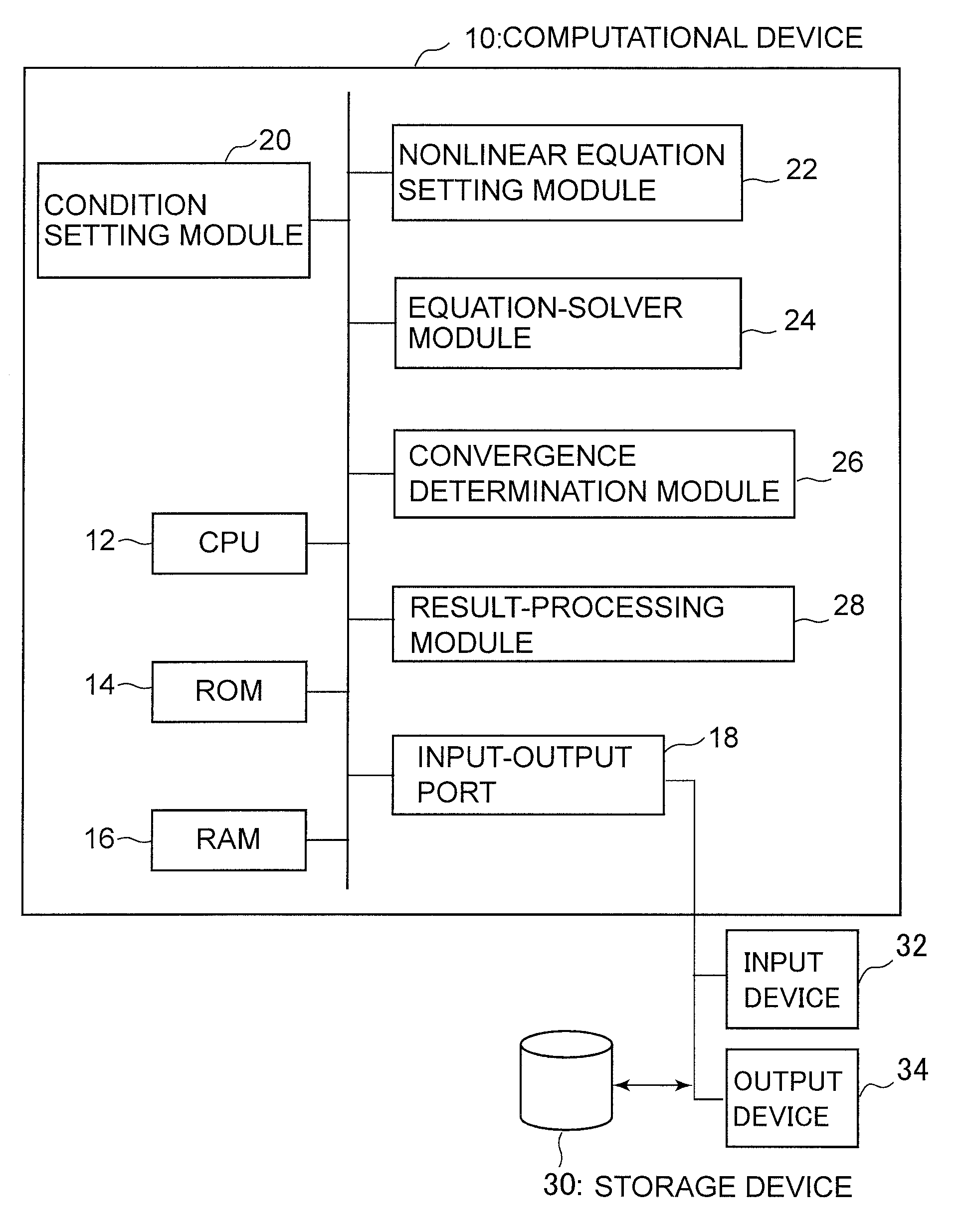

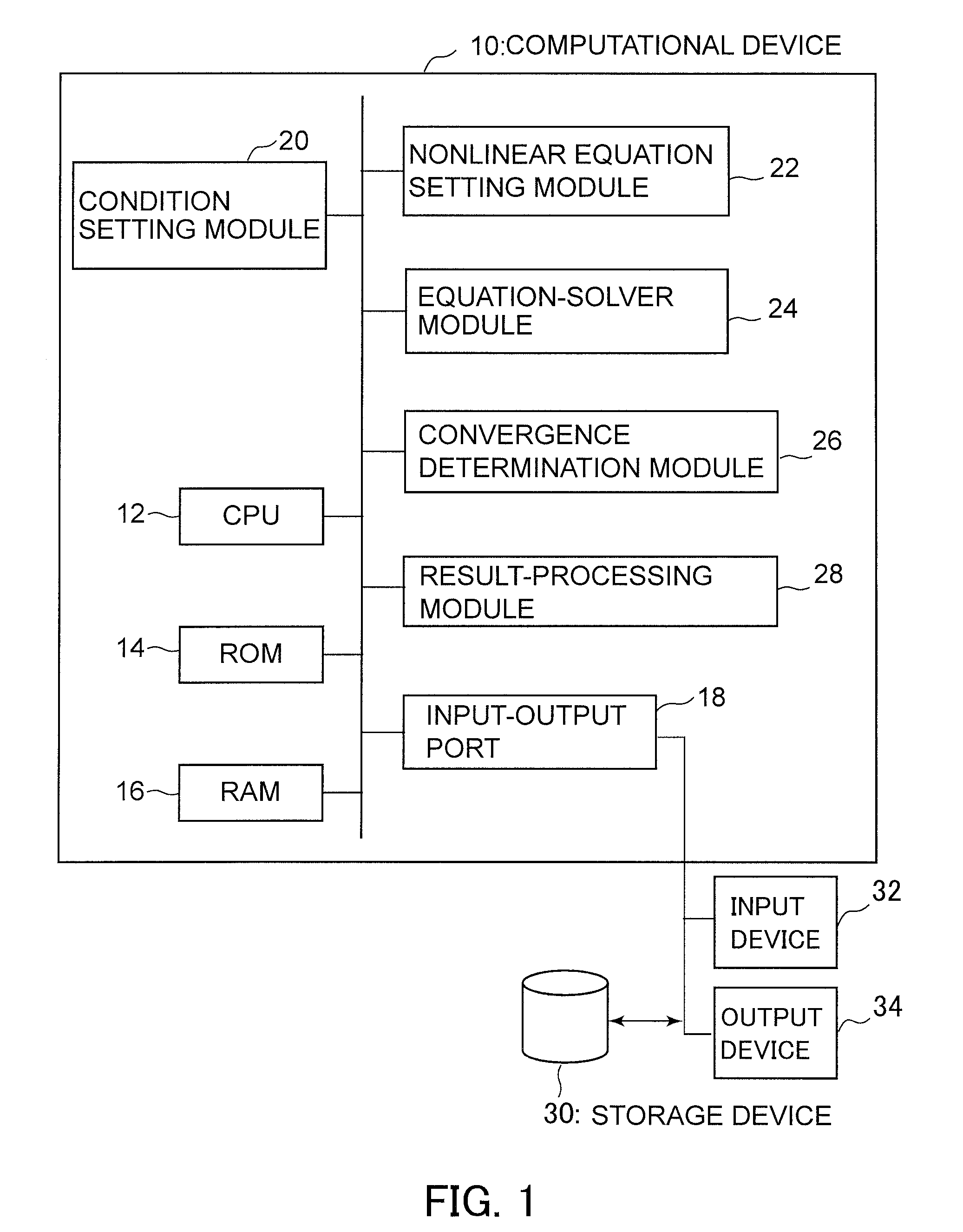

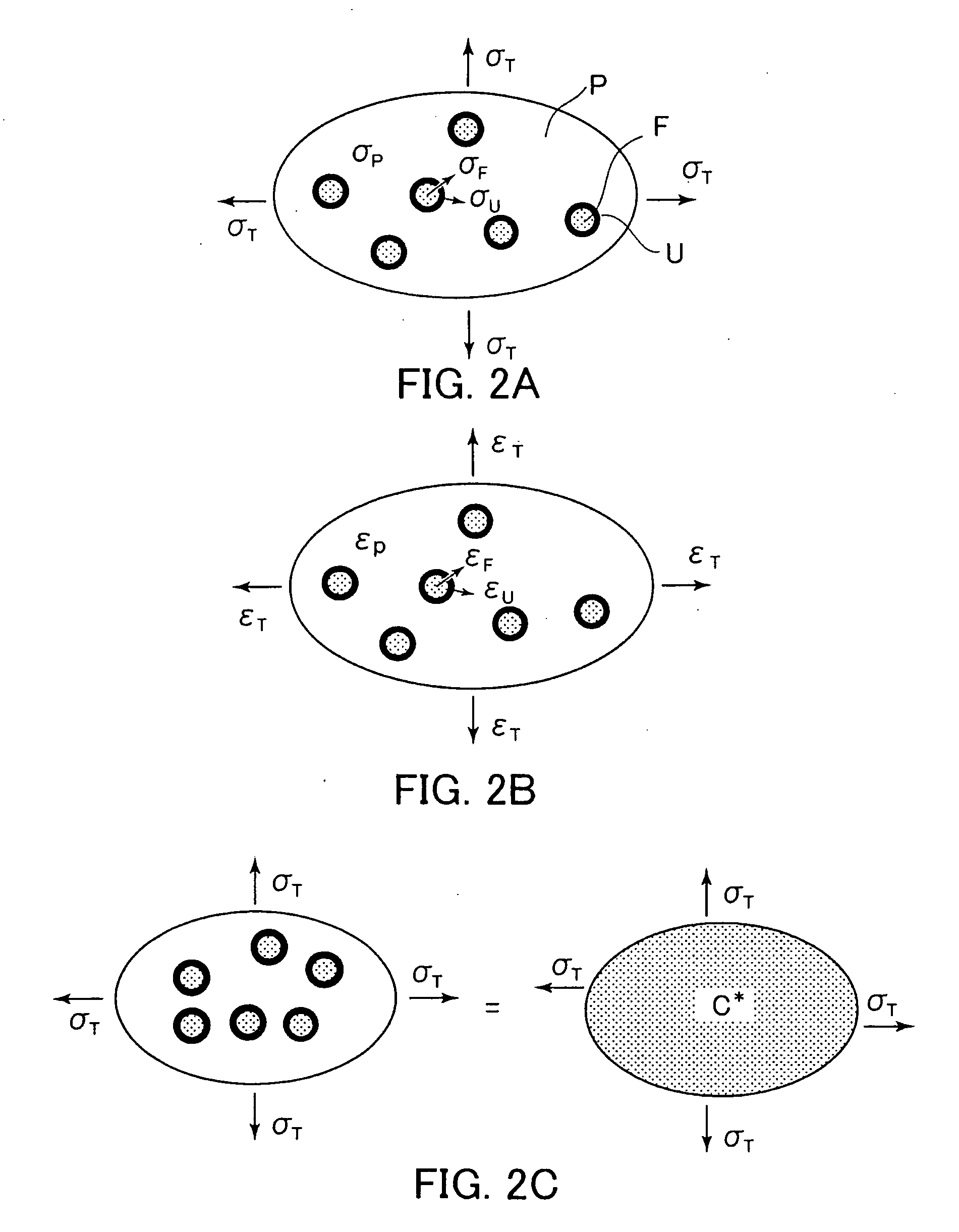

Computation method of mechanical material constant of composite material and volume fraction of material component in composite material, and recording medium

InactiveUS20100262407A1Constant efficiencyShort timeComputation using non-denominational number representationDesign optimisation/simulationCalculation methodsMaterial constants

In a method of computing the overall material constant of a composite material, a virtual composite material is defined as the one that a first material component is dispersed in a form of inner spherical particles in a matrix phase and each of the inner spherical particles is enveloped by the second material component, in a form of outer shell layers, as a coating layer. Based on this, a nonlinear equation is prepared, which has the material constant of the virtual composite material as an unknown. Next, the material constant of the virtual composite material is computed by solving the equation. In the equation, the material constant in each of the surrounding areas of the outer shell layers coating the inner spherical particles is defined as the overall material constant of the virtual composite material to be computed. The volume fractions of the material components in the composite material are computed using the equation.

Owner:YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com