Patents

Literature

64 results about "Hammermill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers.

Slotted hammermill hammer

An improved hammermill hammer is provided wherein the hammer body has an interlocking slot, to receive one of a pair of retaining rods, and a rod hole through which a second rod is interfitted to lock the hammer securely to the hammermill rotor.

Owner:DZ GRINDERS LLC

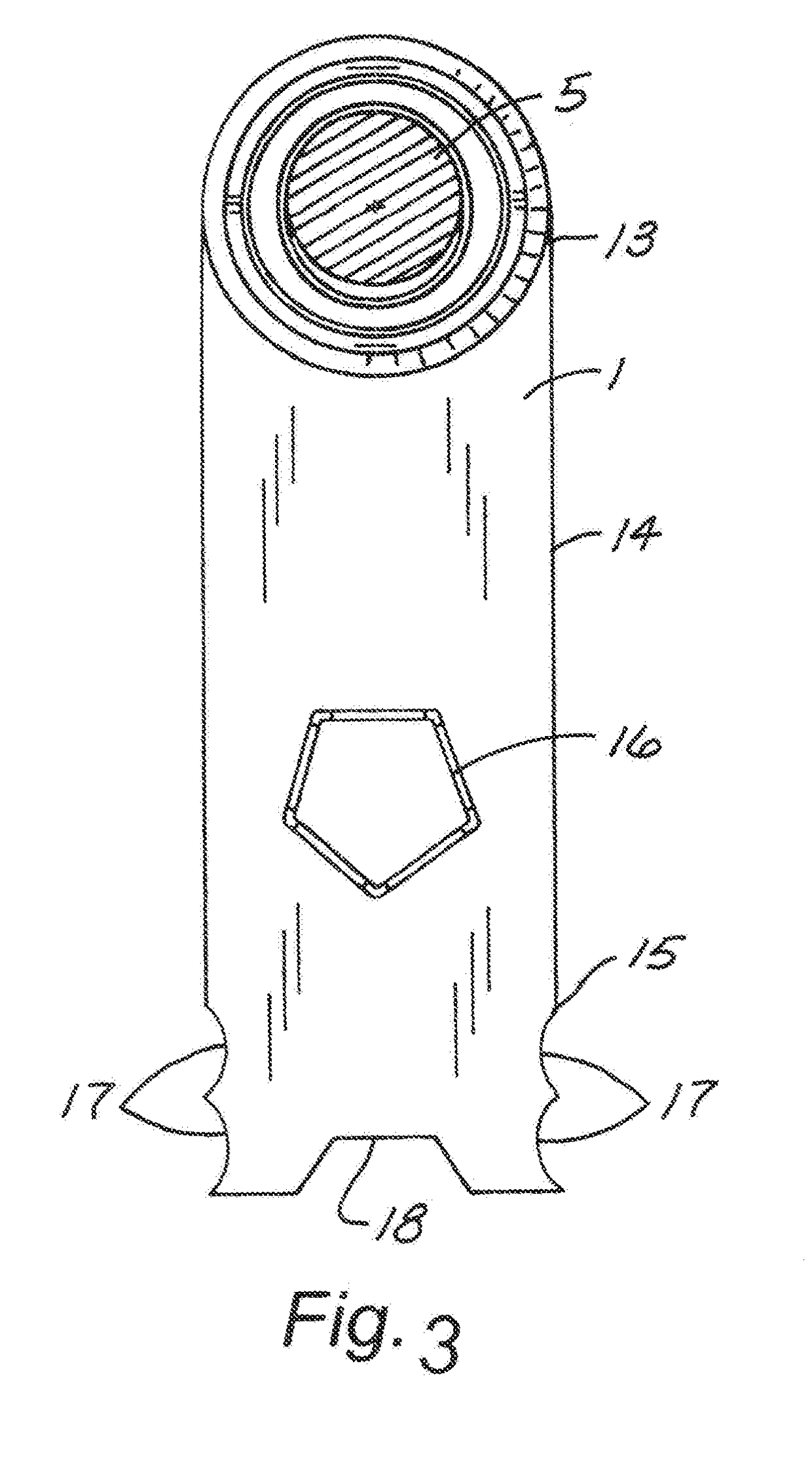

Forged hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The design as disclosed and claimed is forged increasing the strength of the hammer. The shape of hammer as disclosed and claimed uses this improved strength to reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design incorporates comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

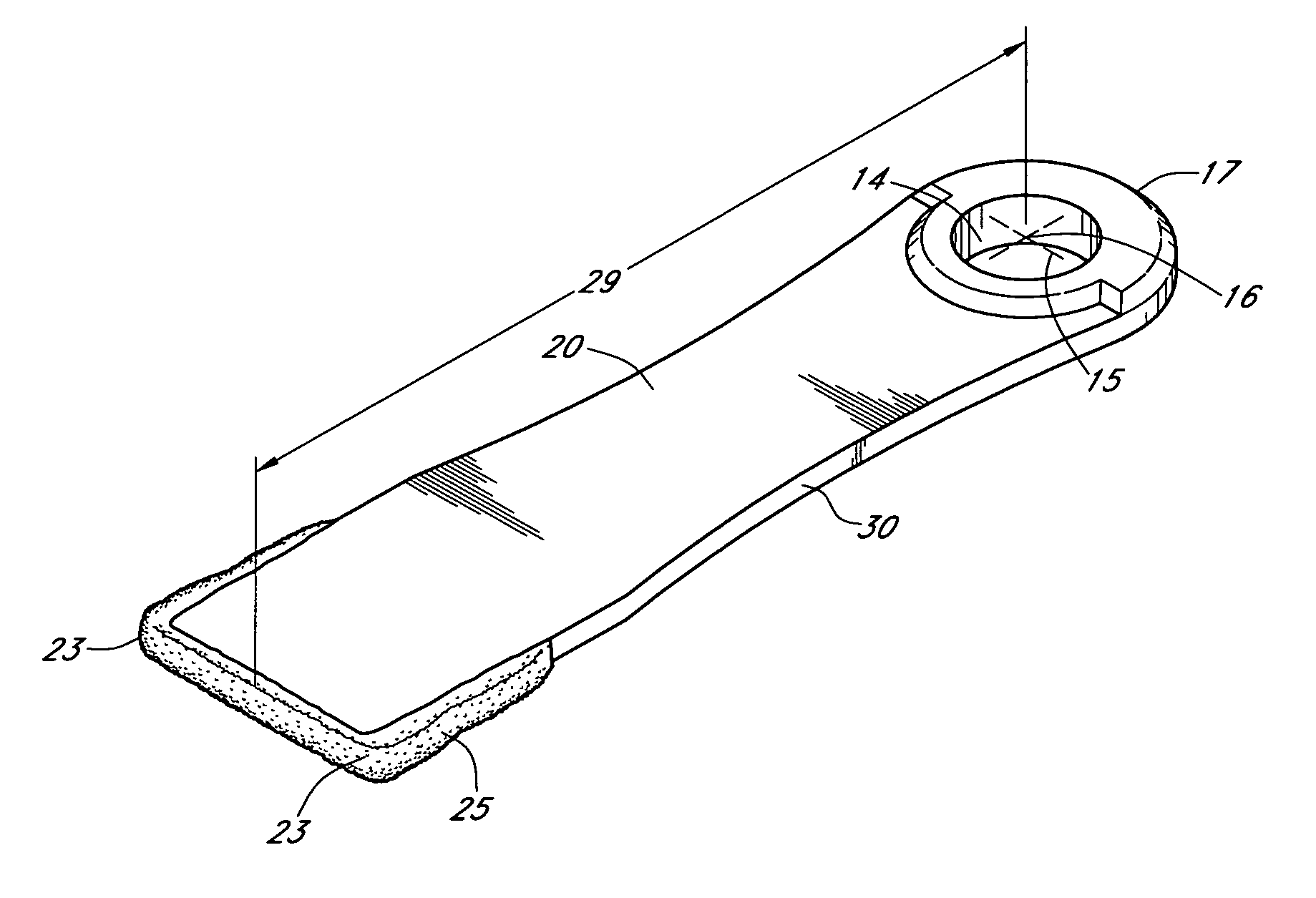

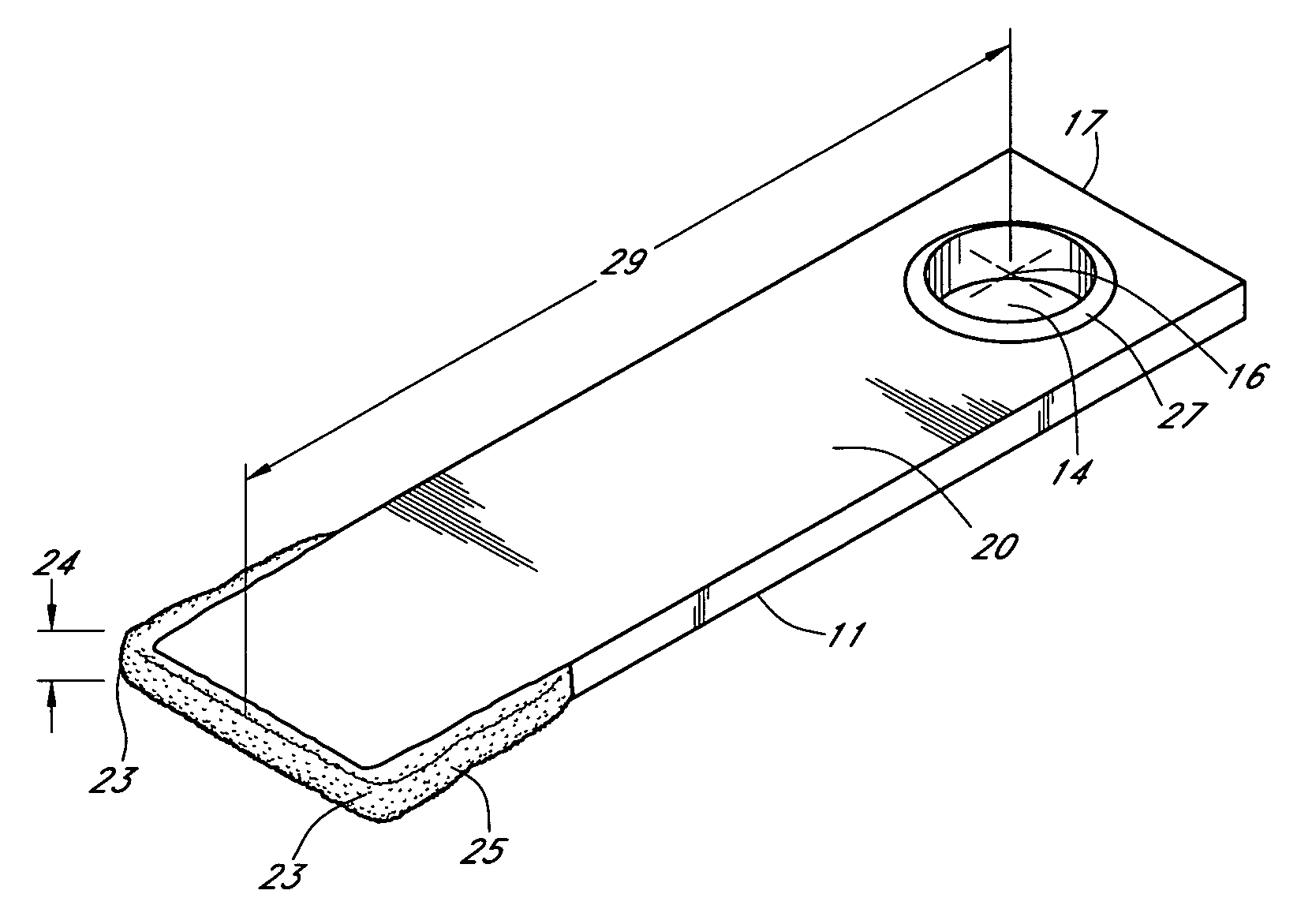

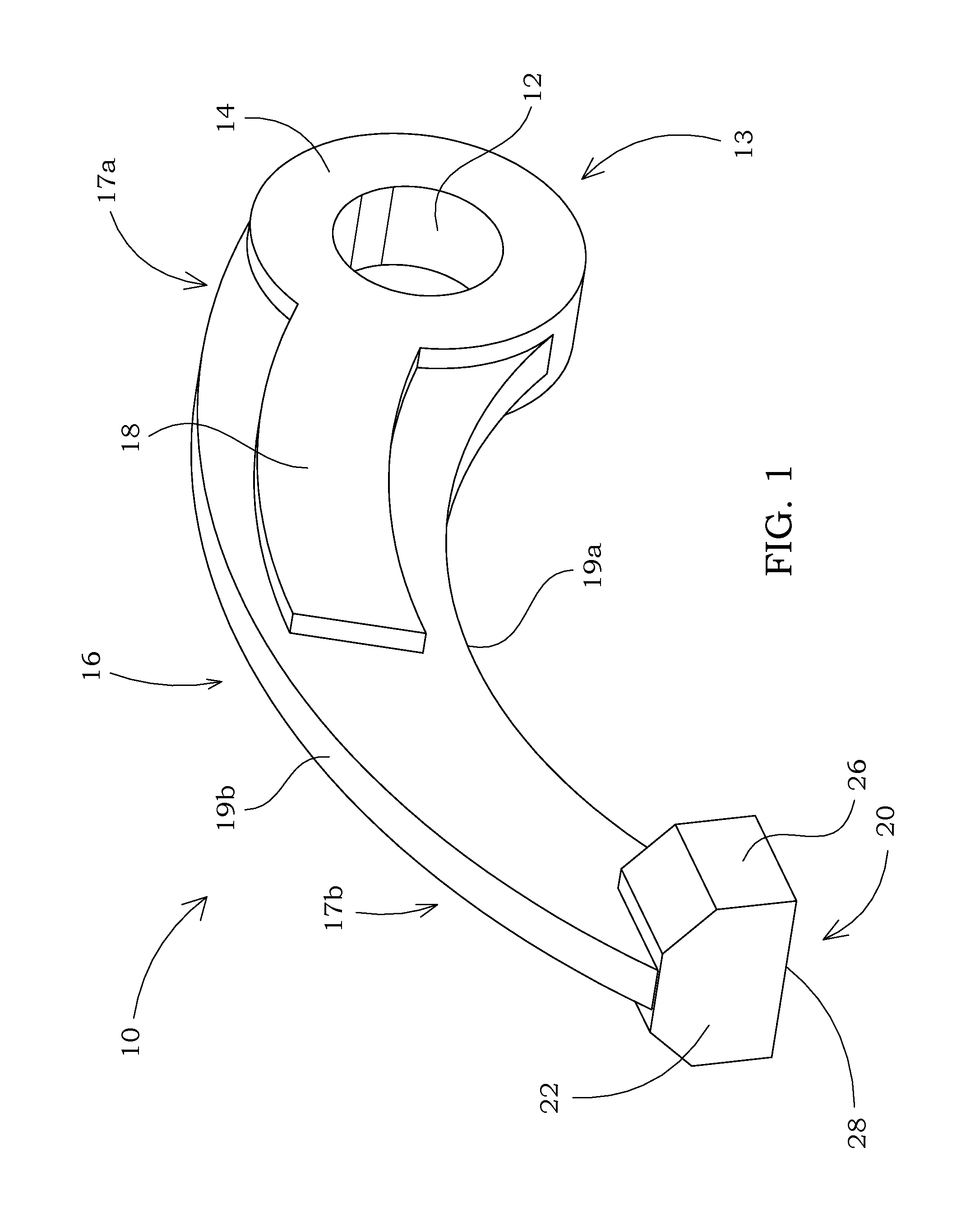

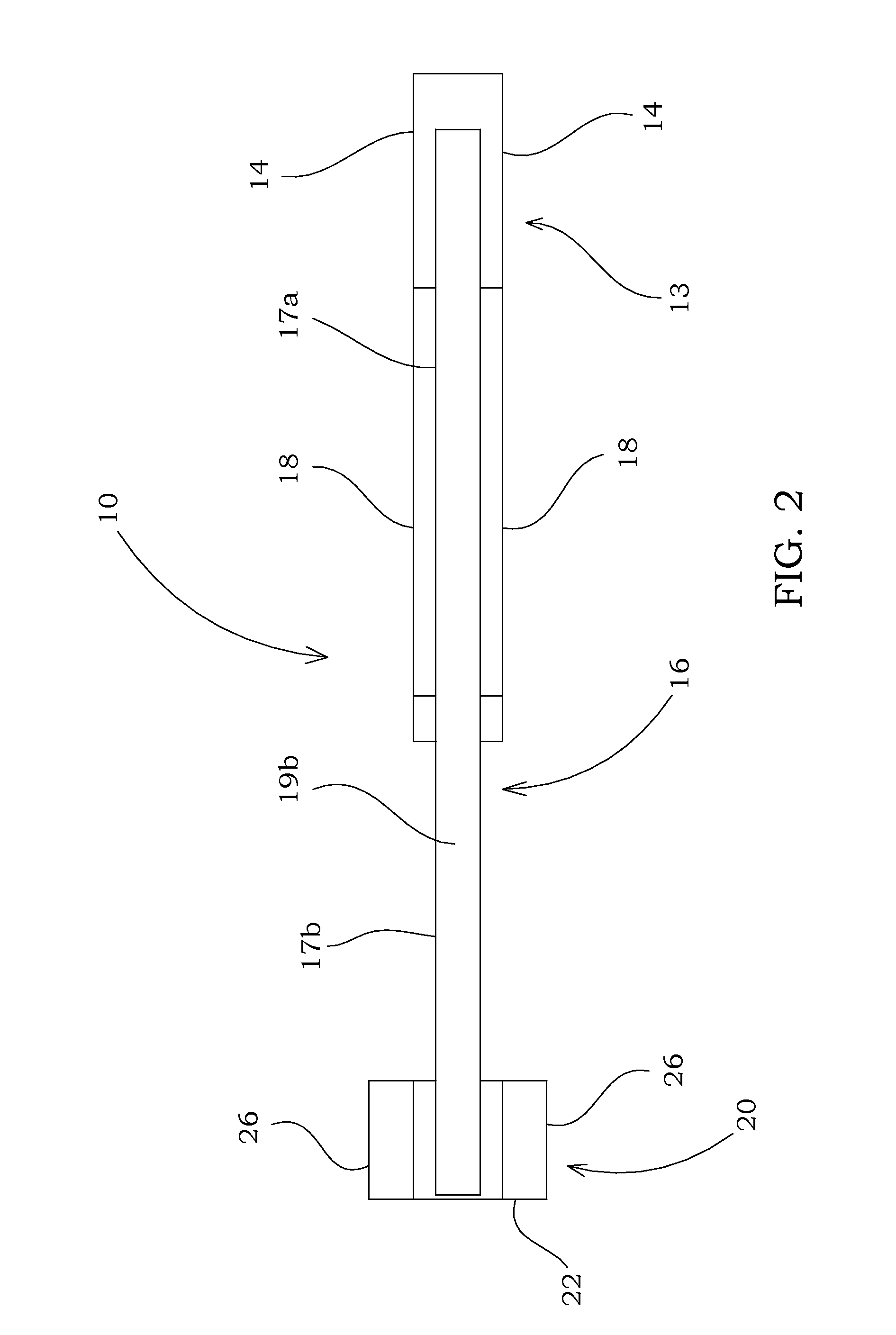

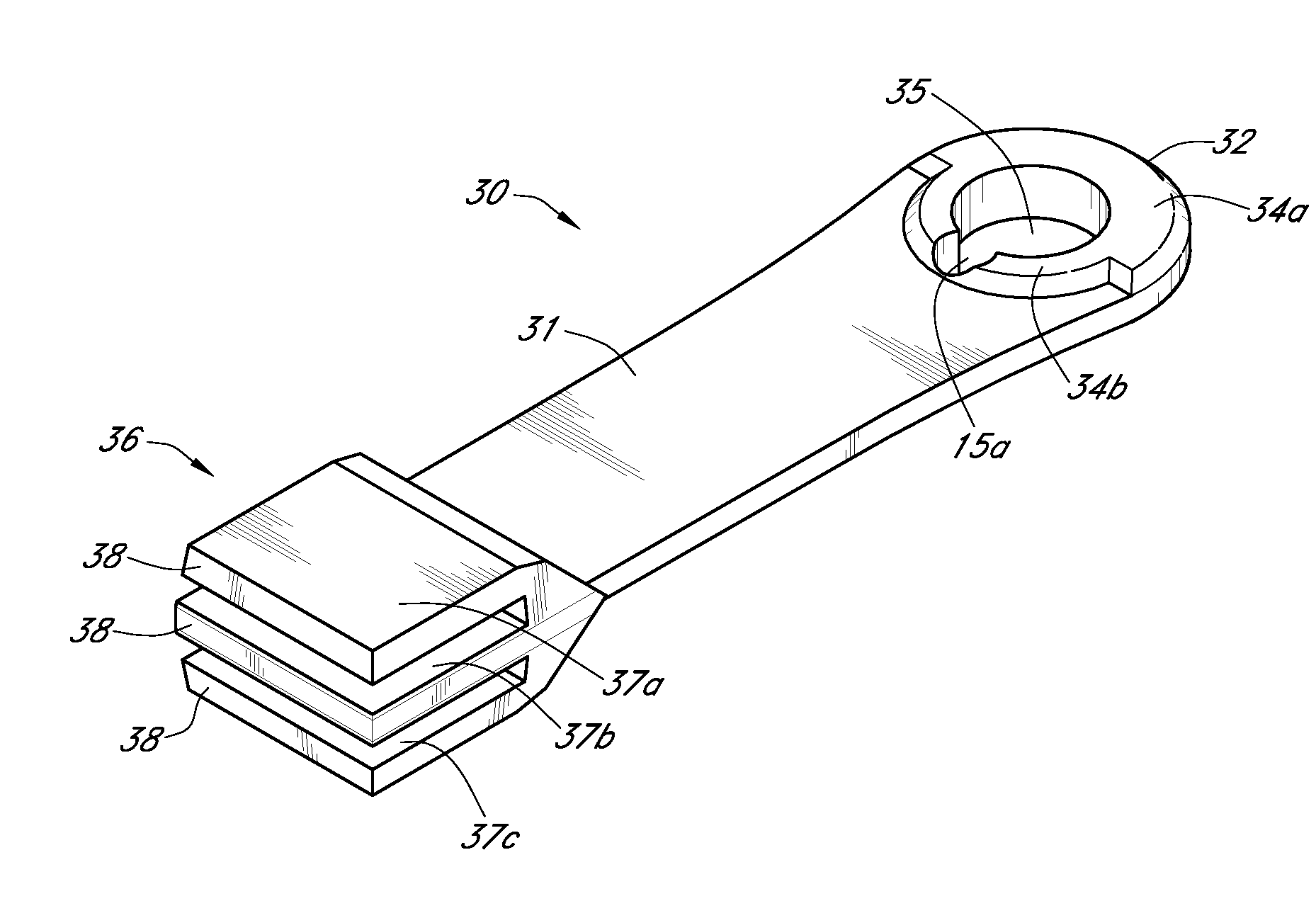

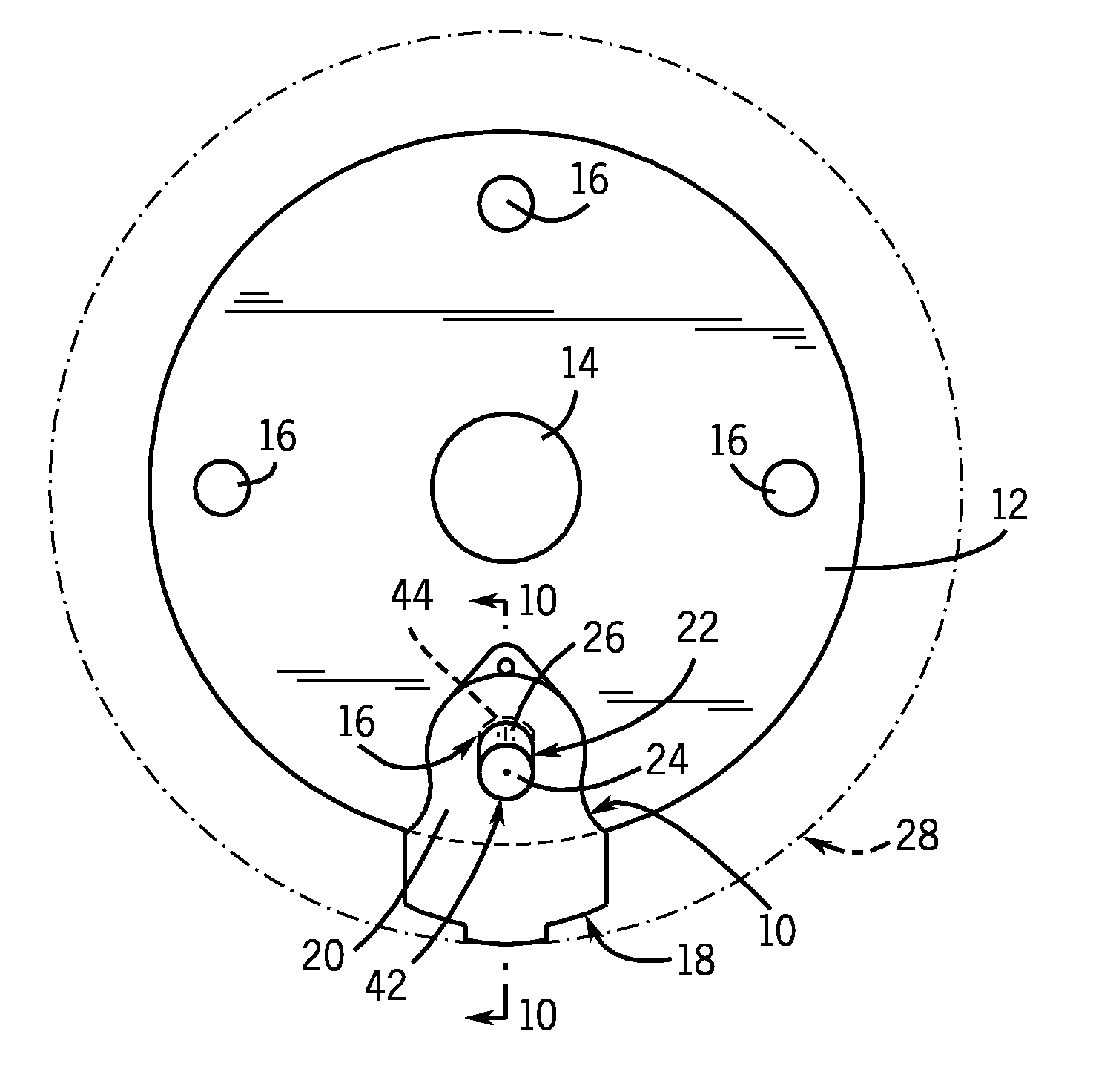

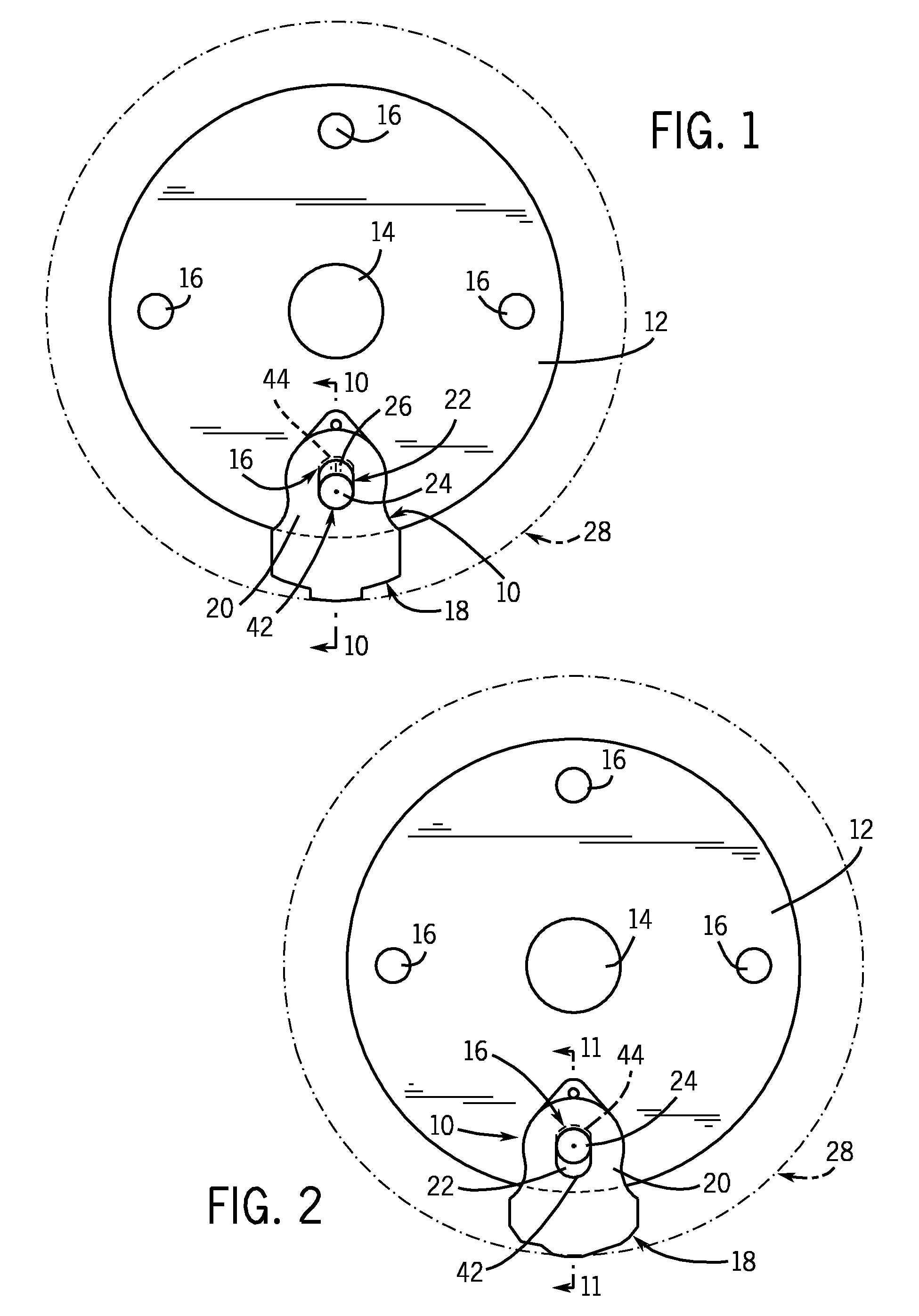

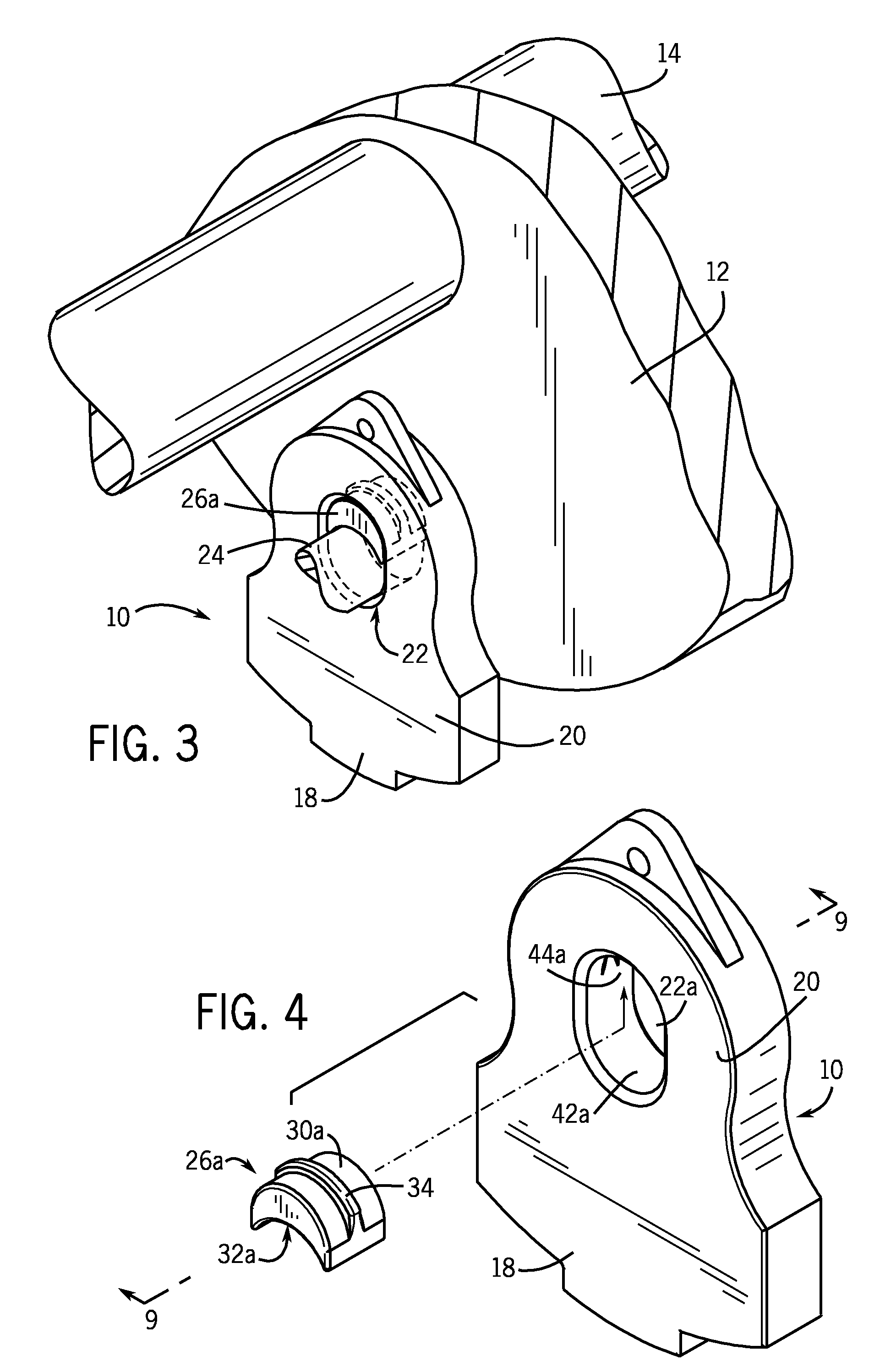

Hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

Hammermill hammer

ActiveUS20070023554A1Excellent hardness propertiesIncrease torqueGrain treatmentsEngineeringHardness

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The improved hammermill hammer may incorporate multiple comminution edges for having increased hardness for longer operational run times. The design as disclosed and claimed may be forged to increase the strength of the hammer. The shape of the hammer body may be varied, as disclosed and claimed, to improve the hammer strength reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design may also incorporate comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

Hammer

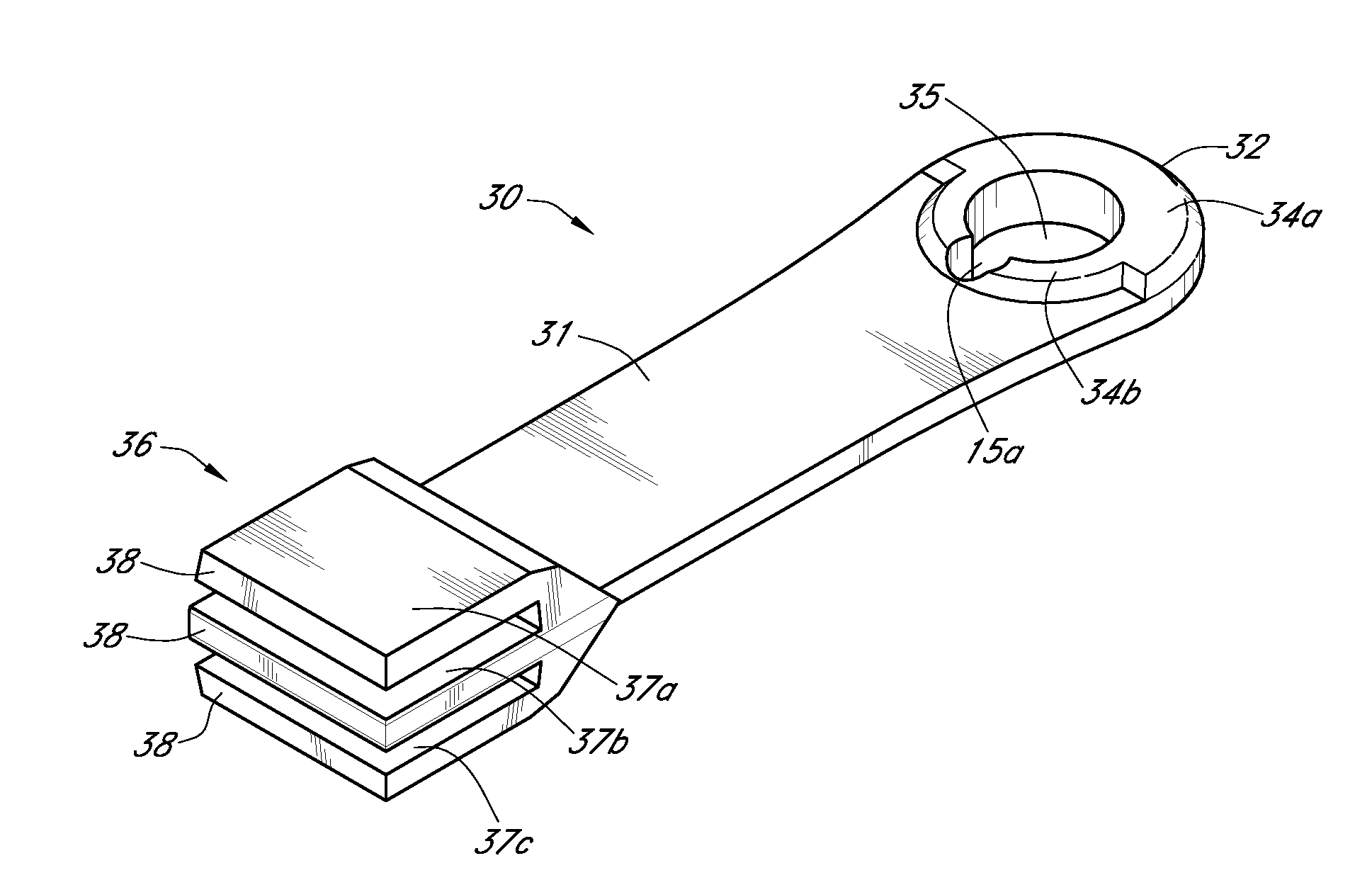

A hammer for use in a rotatable hammermill assembly comprising a first end for securement within a hammermill assembly, wherein a rod hole is formed in the second end, wherein the rod hole is centered in the first end for engagement with and attachment to the hammermill assembly is disclosed. The hammer also has a second end for contact and delivery of momentum to material to be comminuted, wherein the second end includes at least two blades. A neck connects the first end to the second end. In some embodiments the thickness of the neck may be less than the thickness of the first end or of any of the blades. In some embodiments the rod hole is surrounded by one or more rod hole shoulders. In other embodiments a notch is positioned in the rod hole along the longitudinal axis thereof.

Owner:GENESIS III

Forged hammermill hammer

ActiveUS20060032958A1High strengthDecrease susceptibility to rod hole elongationGrain treatmentsEngineeringHardness

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The design as disclosed and claimed is forged increasing the strength of the hammer. The shape of hammer as disclosed and claimed uses this improved strength to reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design incorporates comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

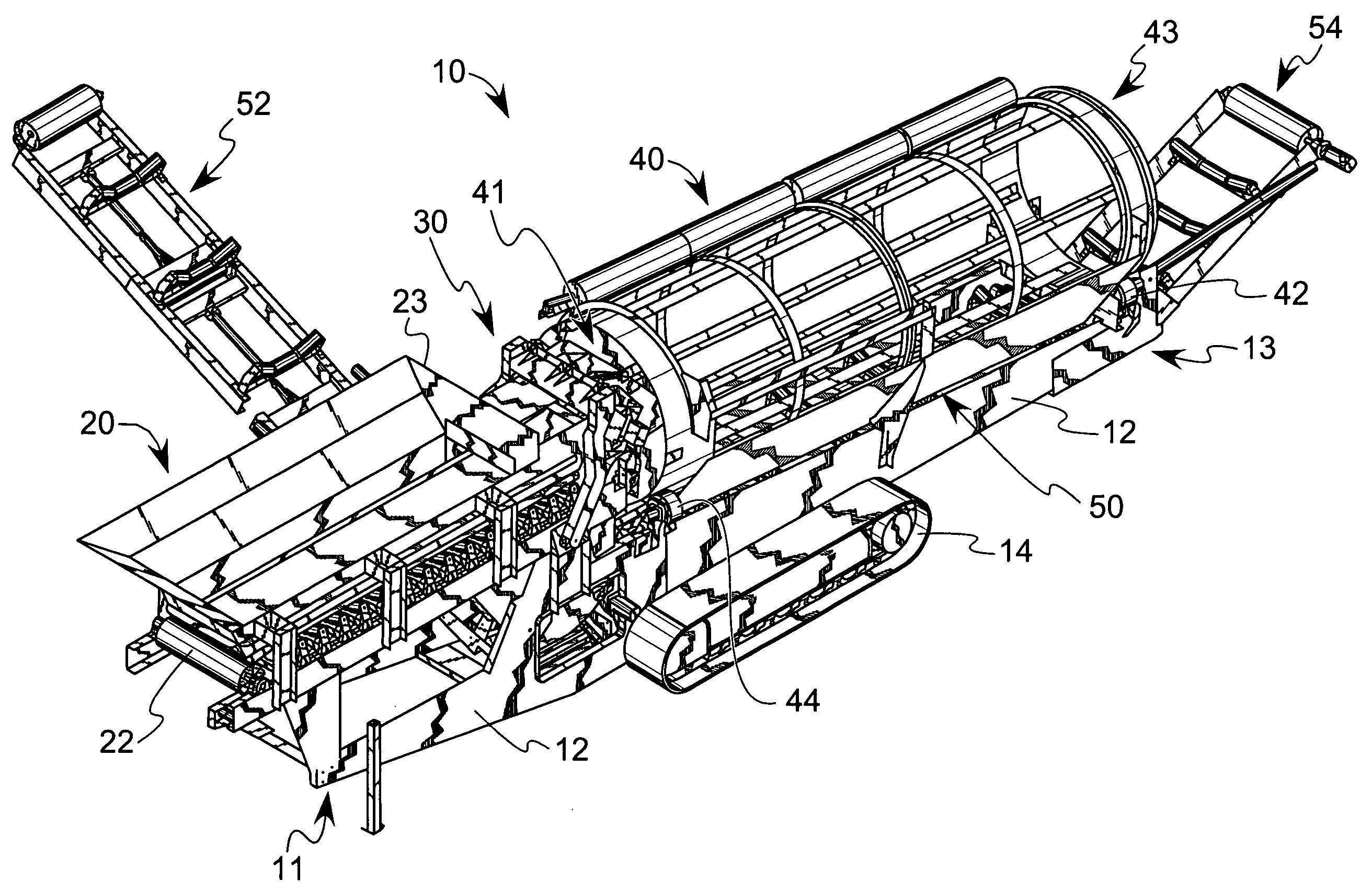

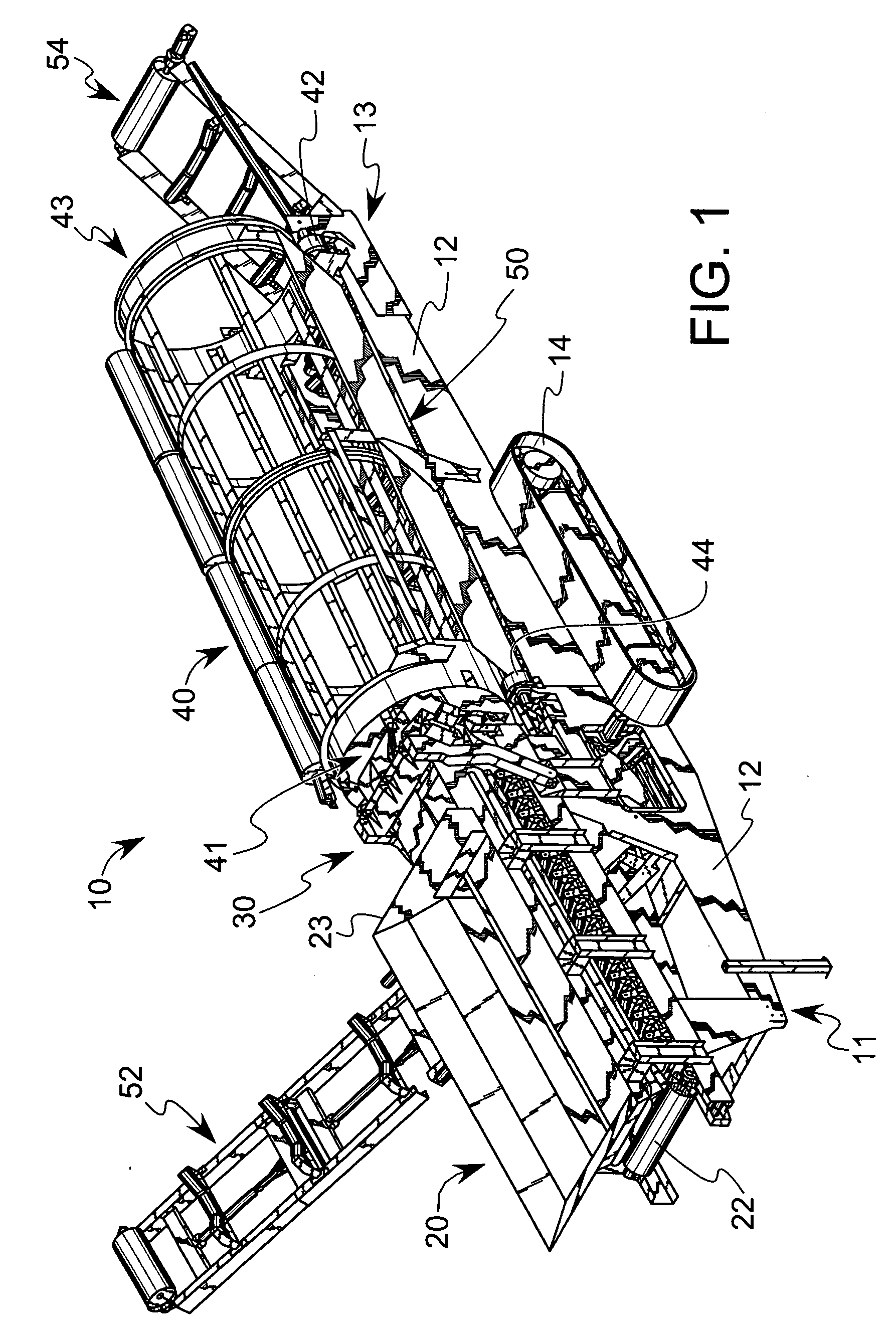

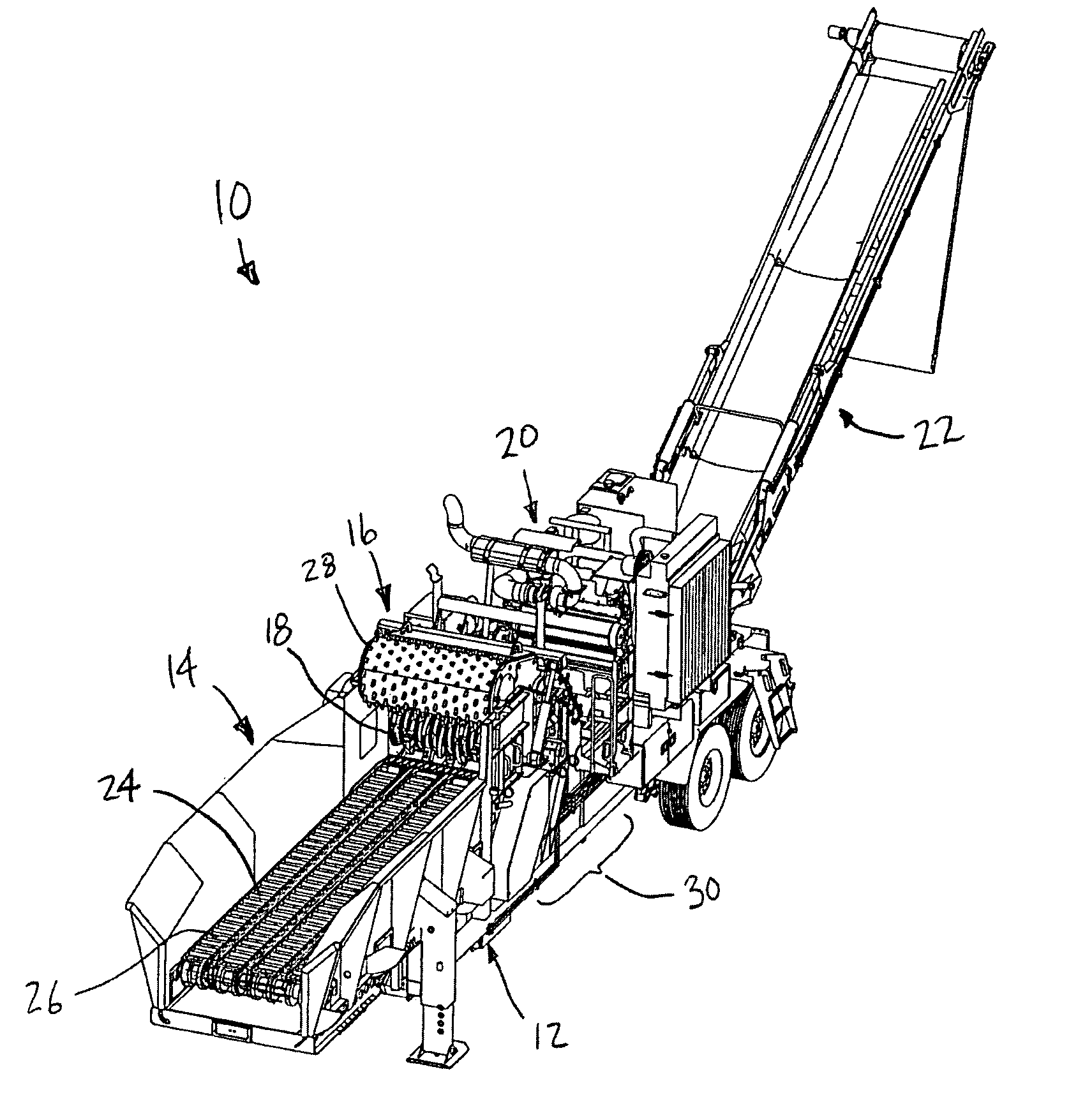

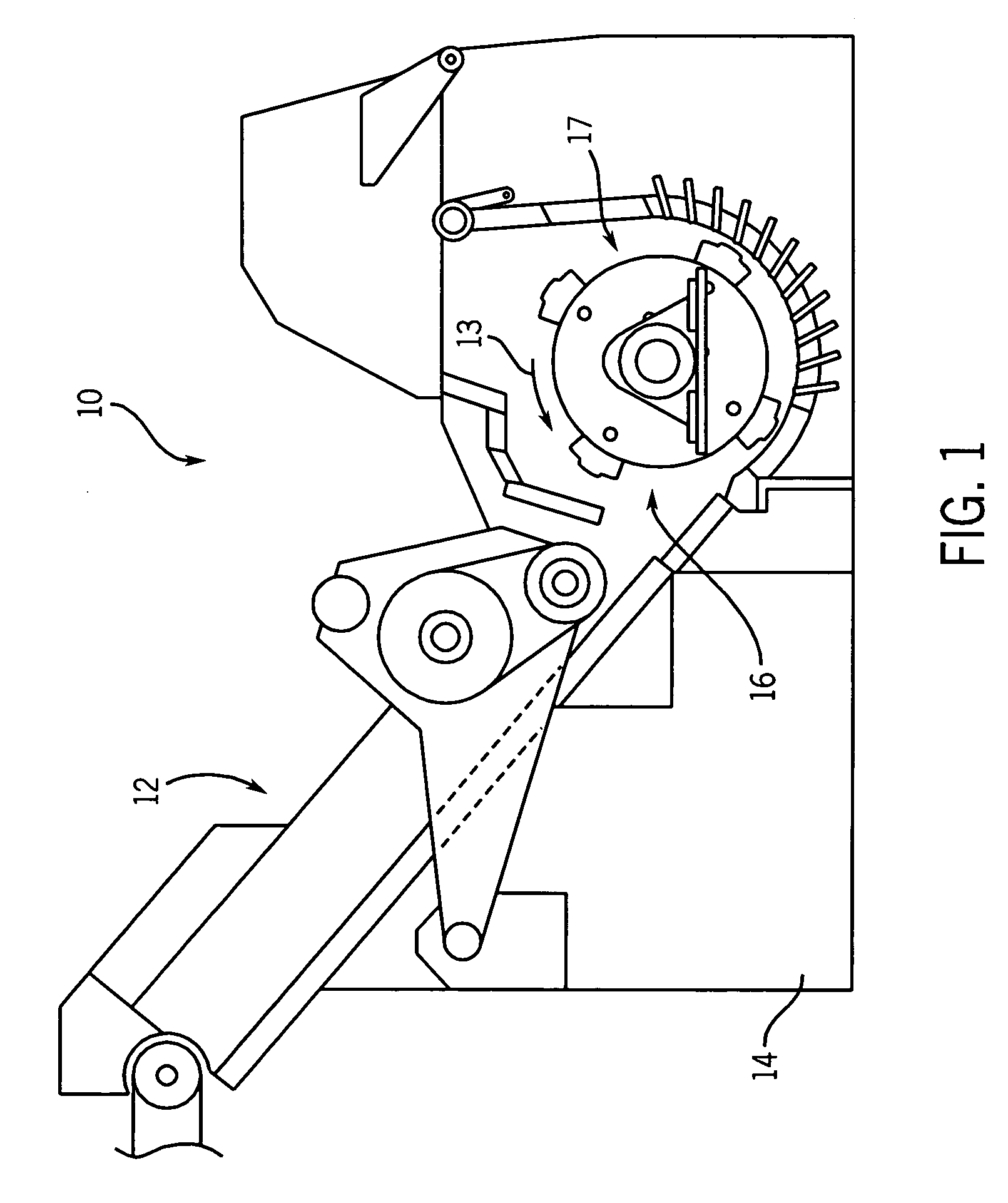

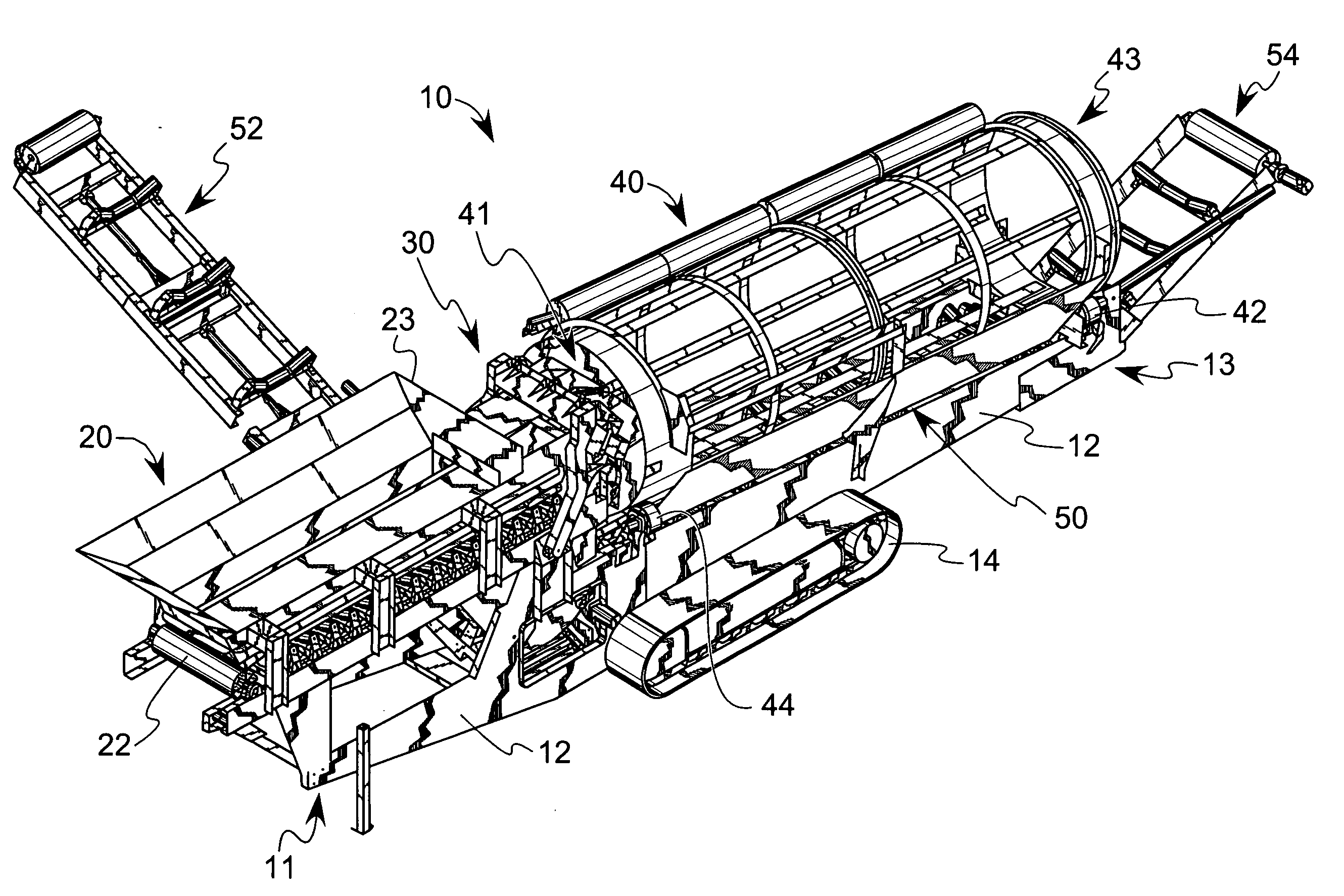

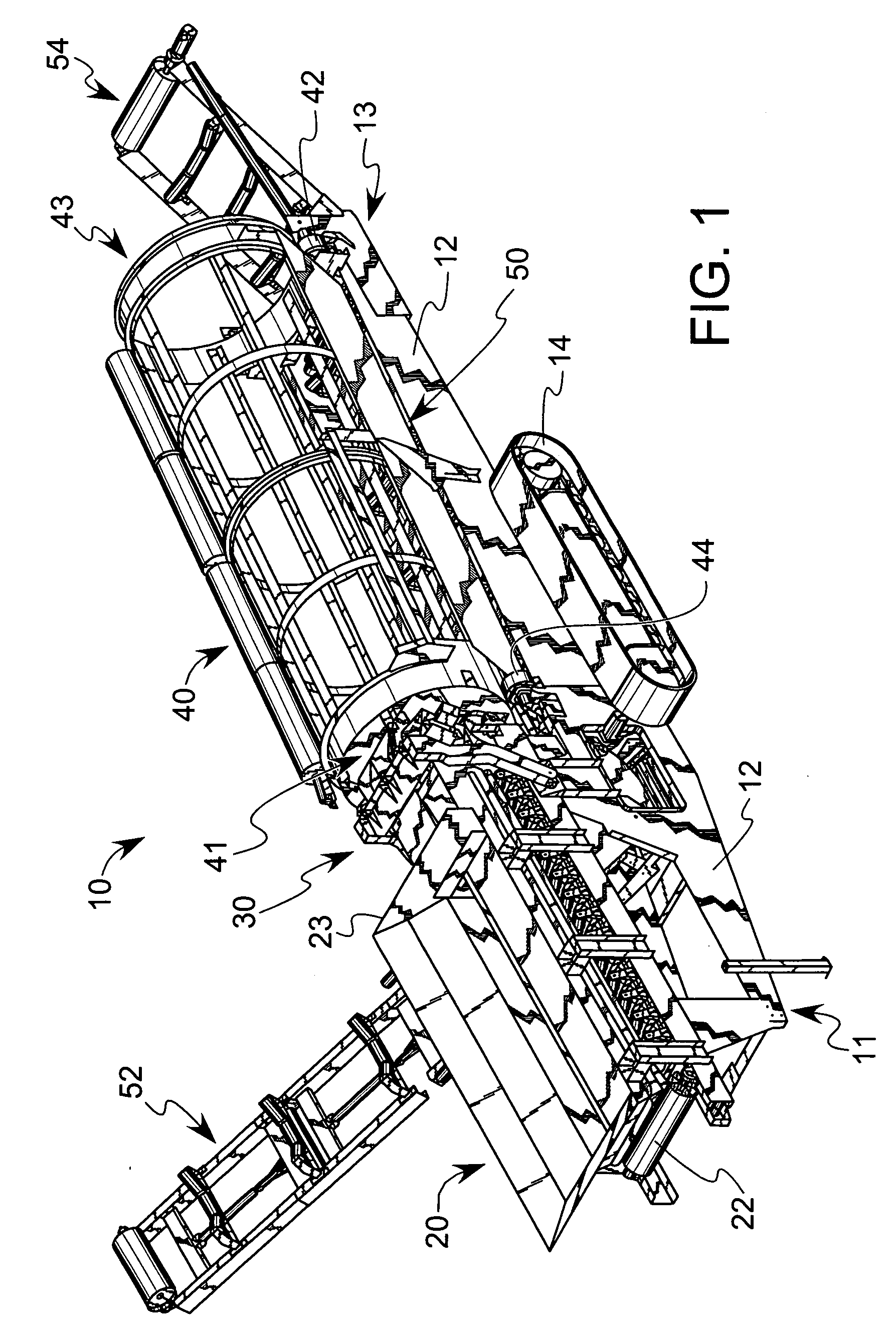

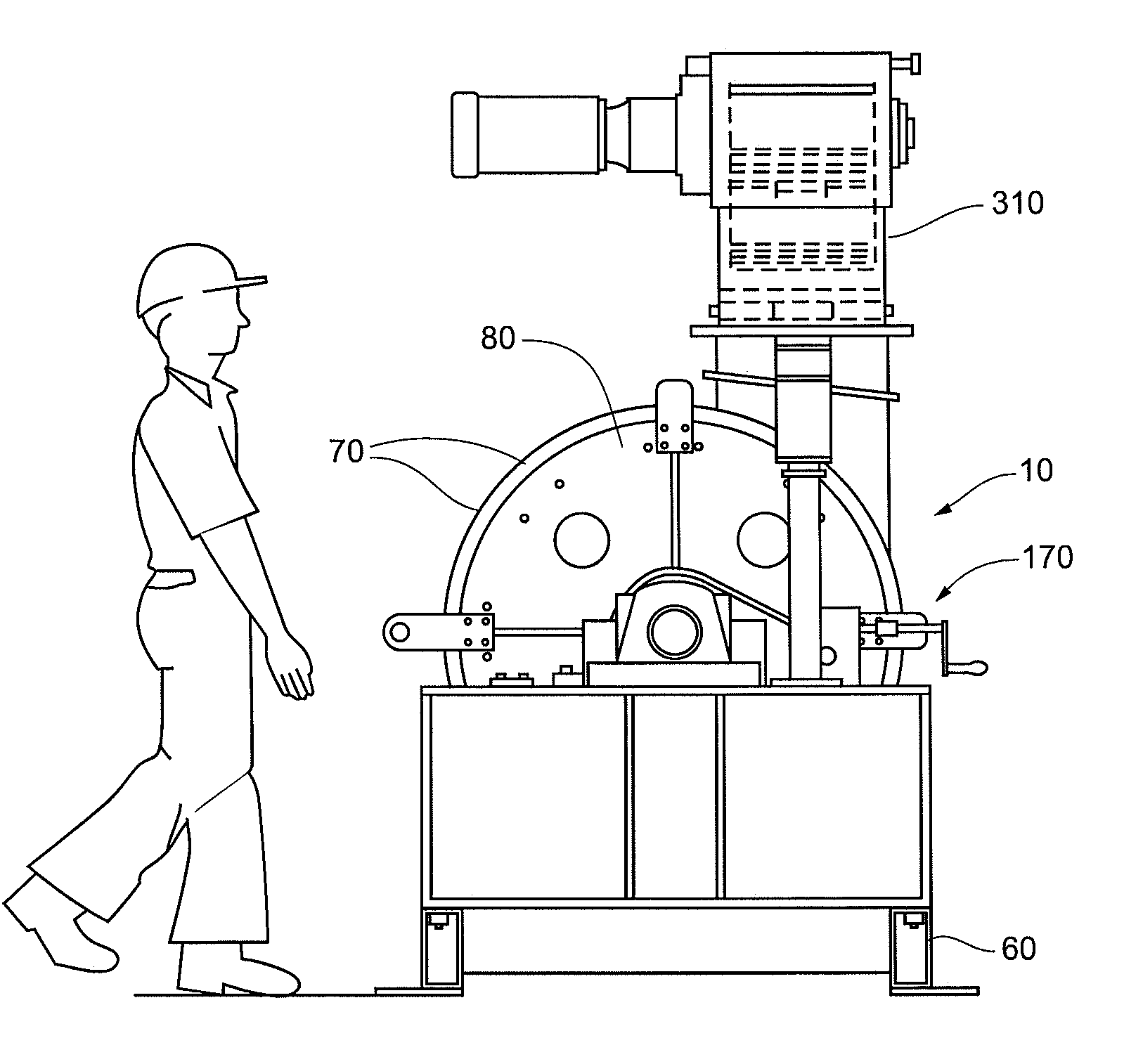

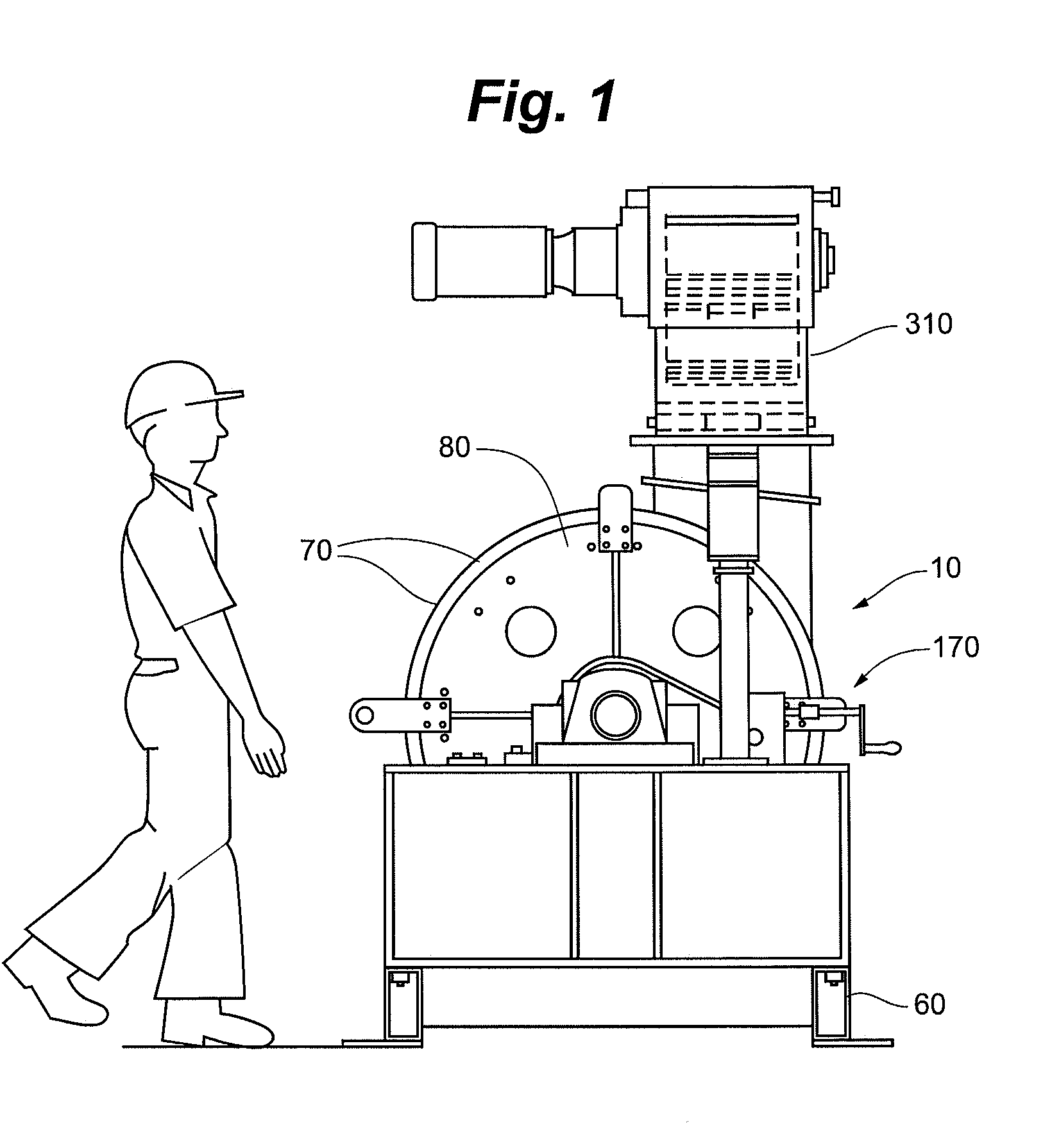

Screening apparatus with hammermill

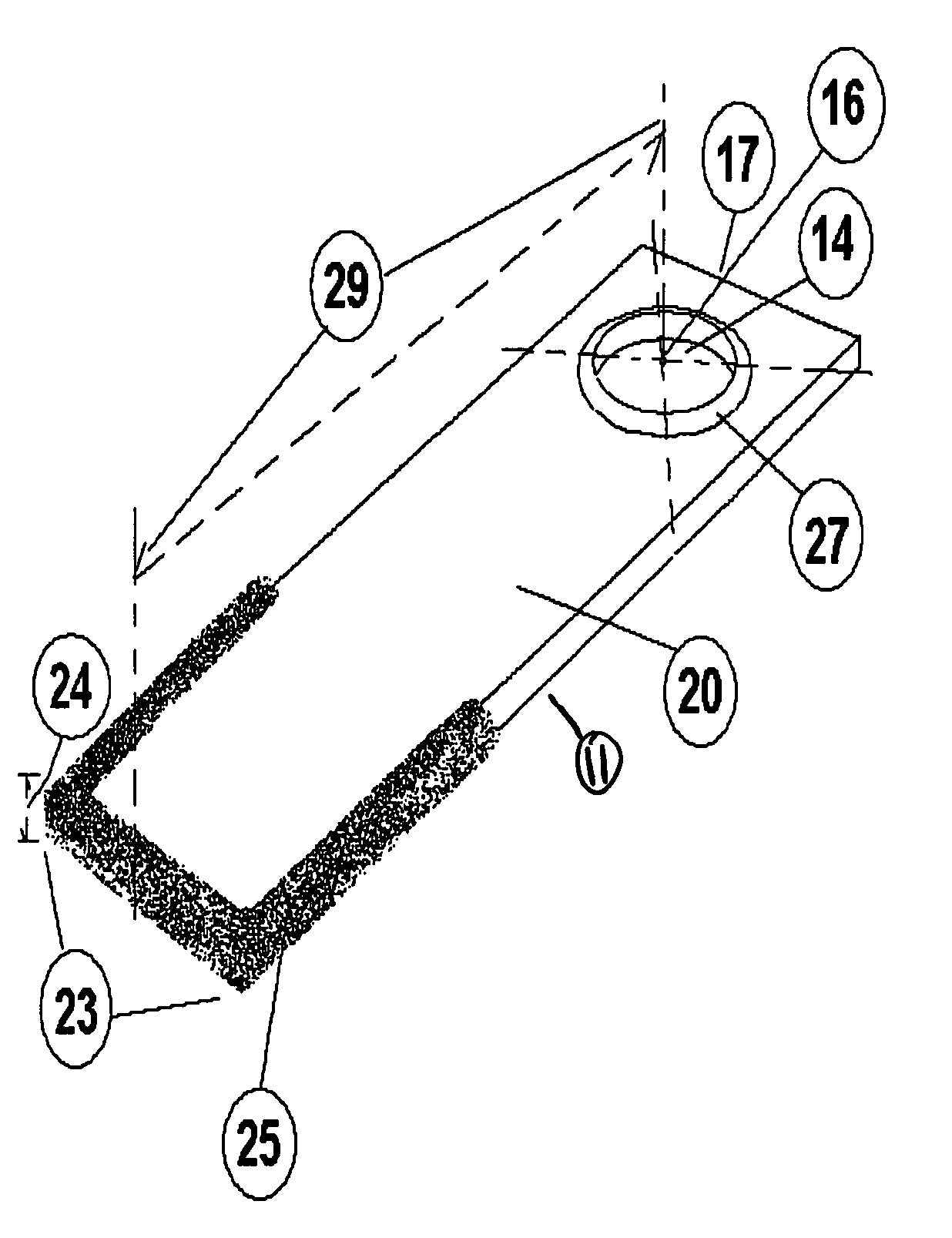

A screening machine on a frame with a hopper having a conveyor belt. The conveyor belt discharges particulate material poured into the hopper into a rotating barrel screen or vibrating planar screen for sifting the material. A hammermill apparatus is pivotably mounted on a hood member to an arm that is pivotably mounted to the frame of the machine. The hammermill is positioned above the conveyor belt at the discharge end. The hammermill can pivot upwardly relative to the arm upon striking a large object on the conveyor belt, and a spring mounted to the arm and the hood biases the hammermill back to its original position. A hydraulic ram is drivingly linked to the arm for manually or automatically displacing the hammermill relative to the conveyor belt.

Owner:SCREEN MACHINE IND

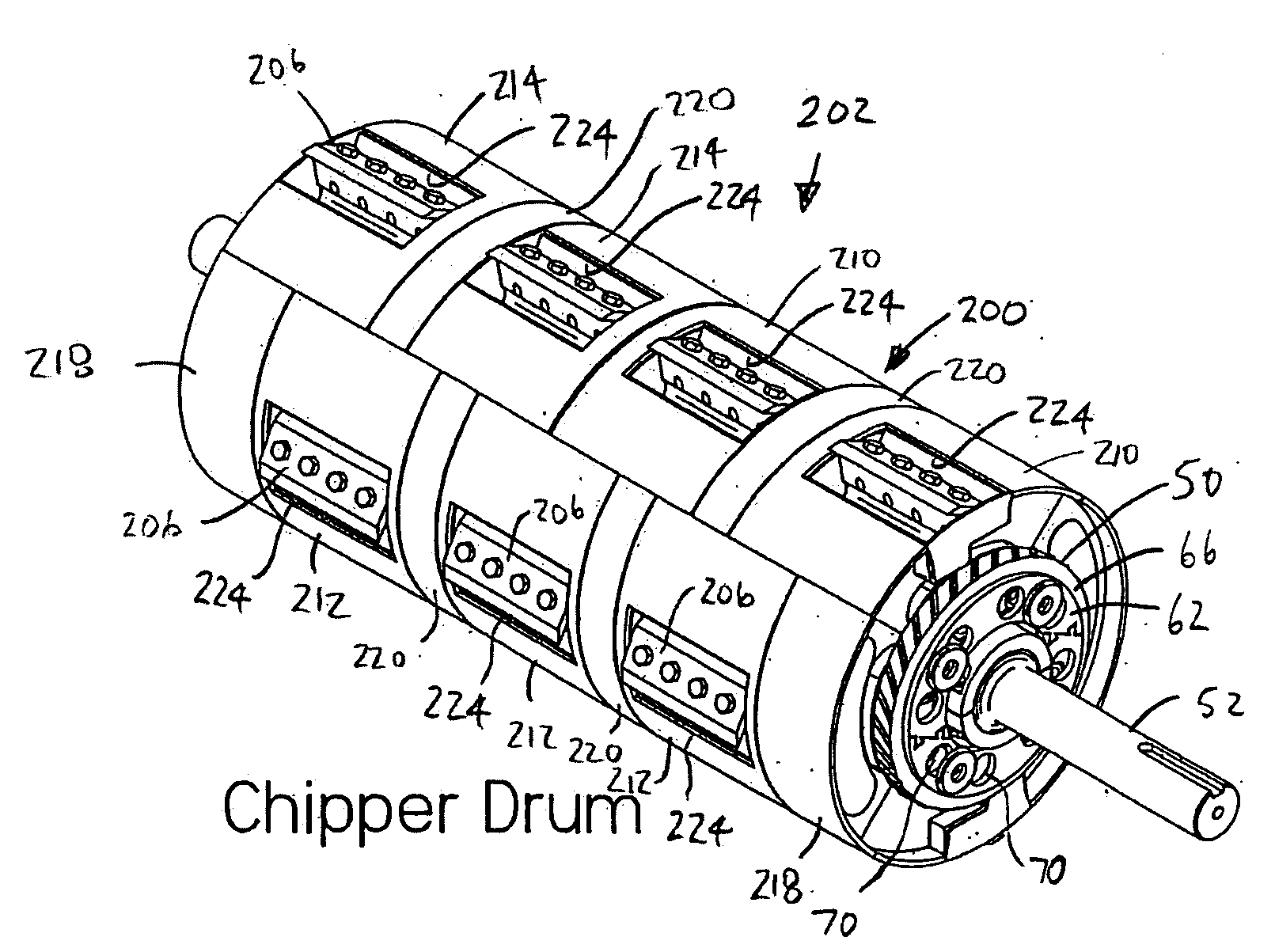

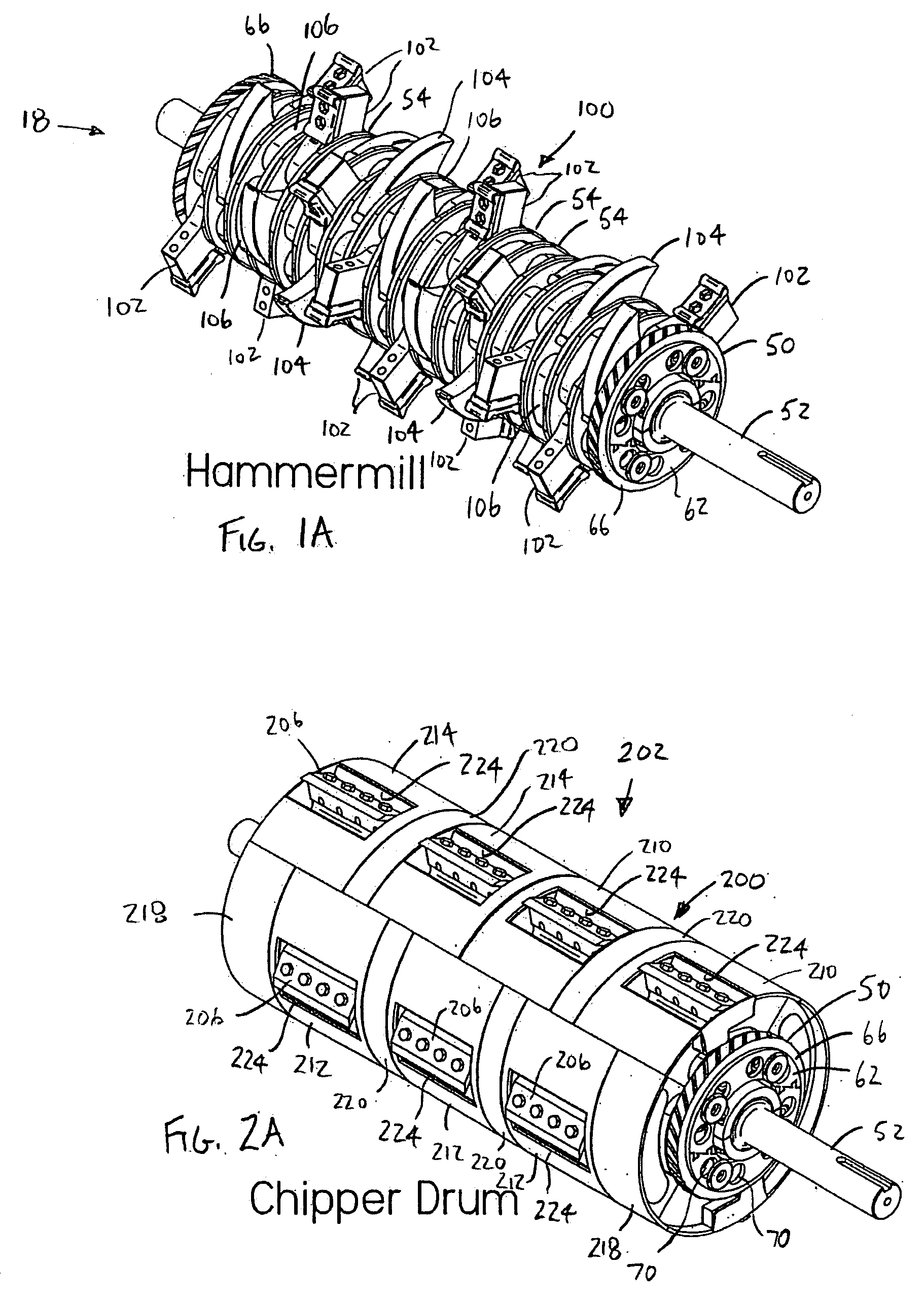

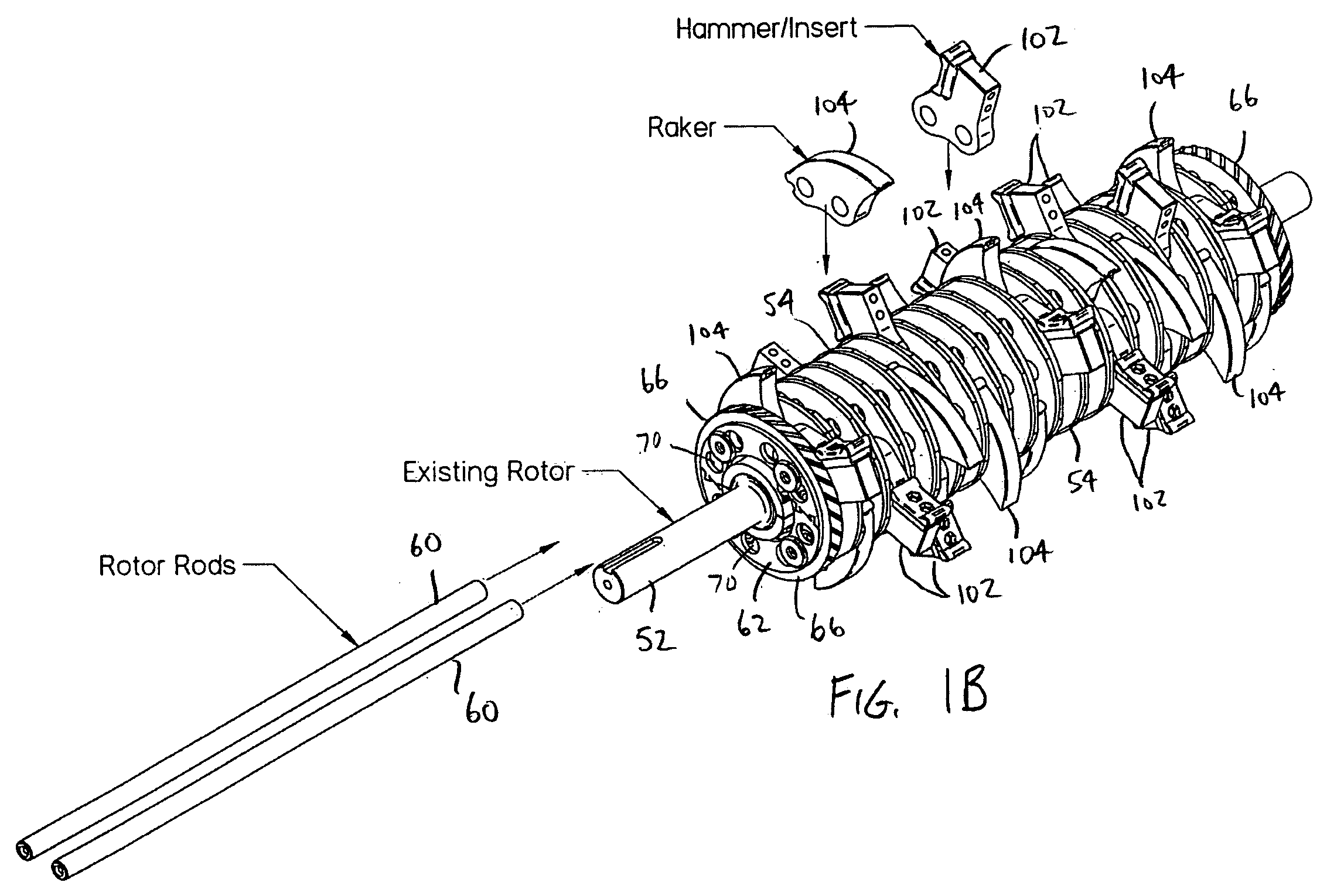

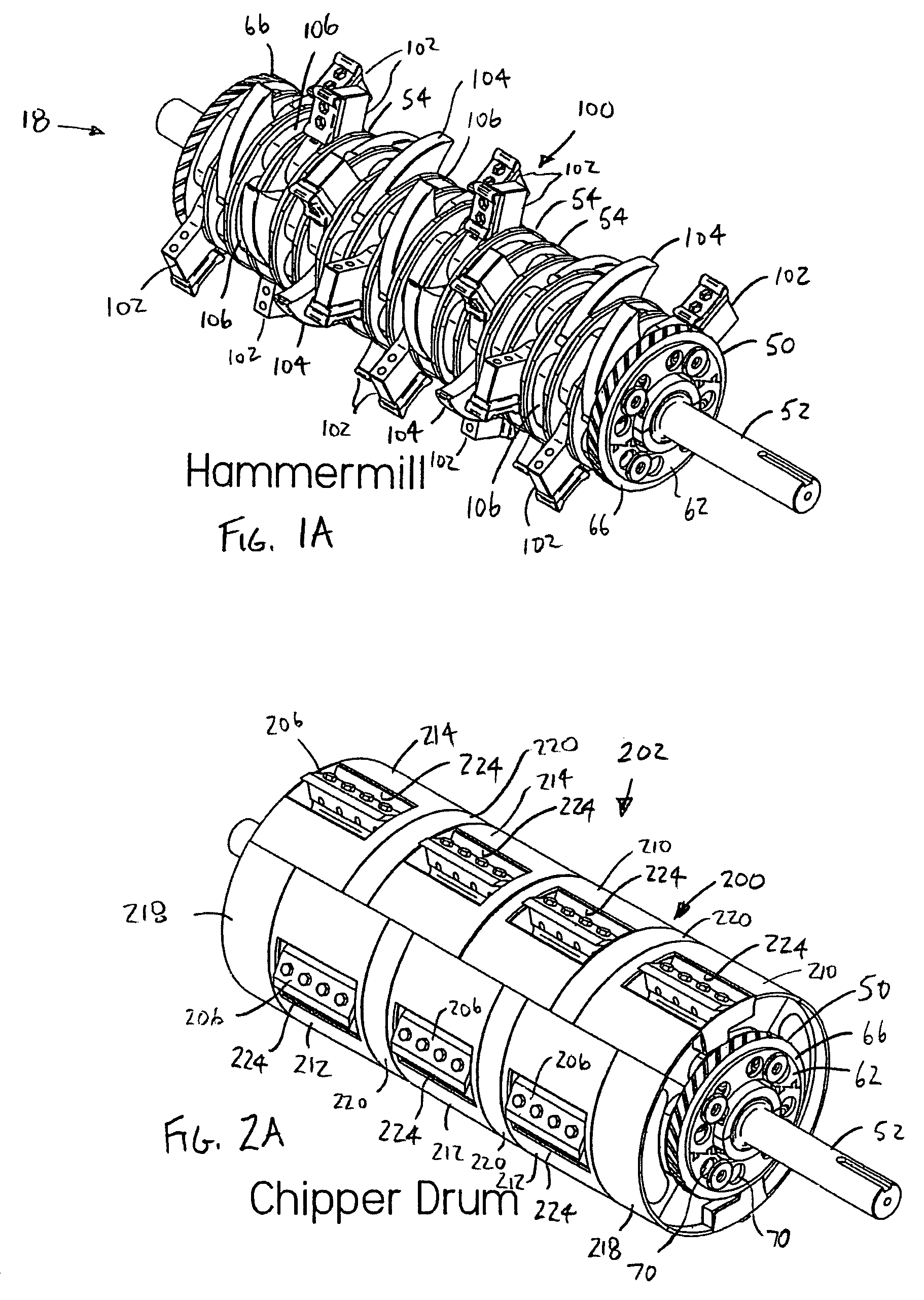

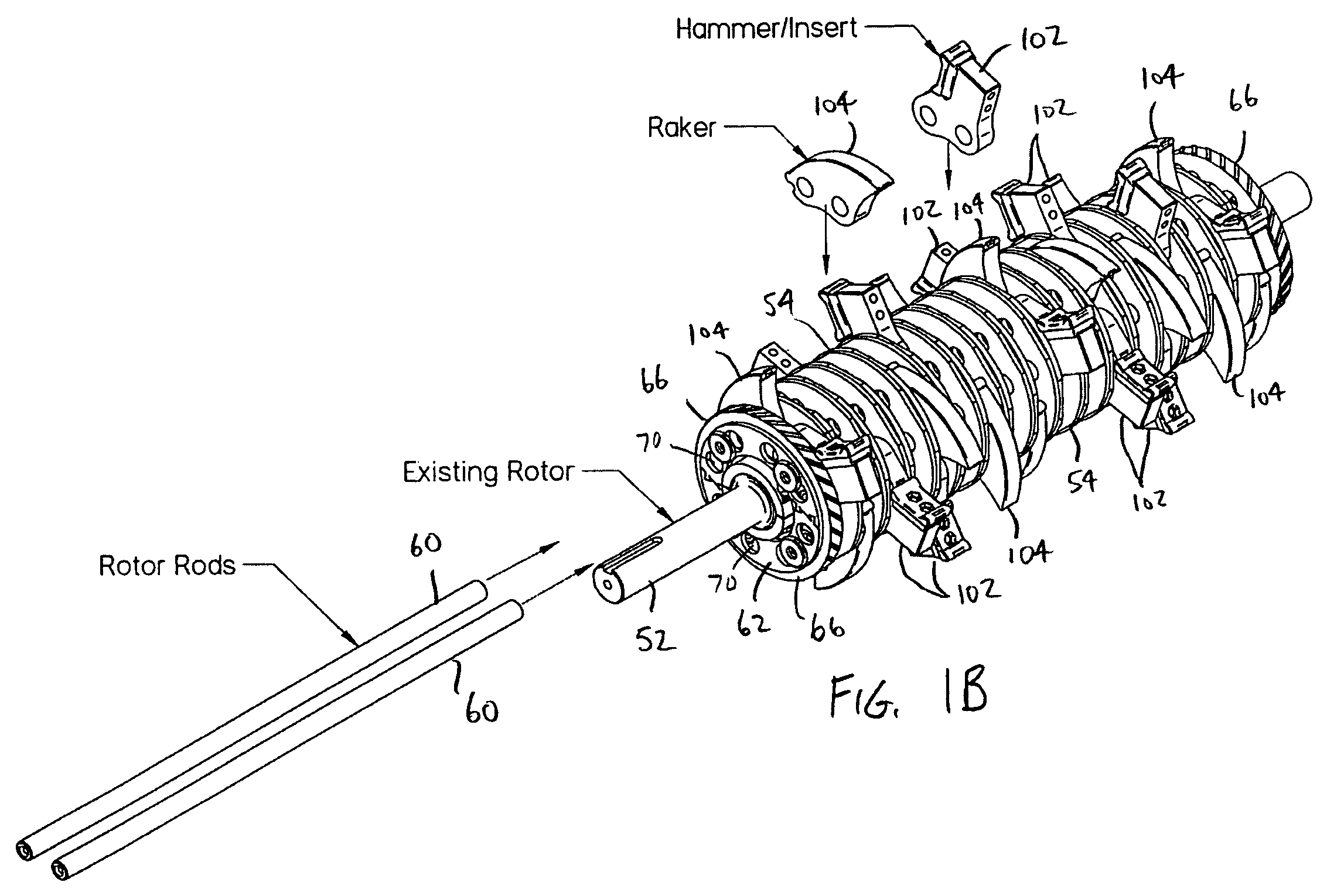

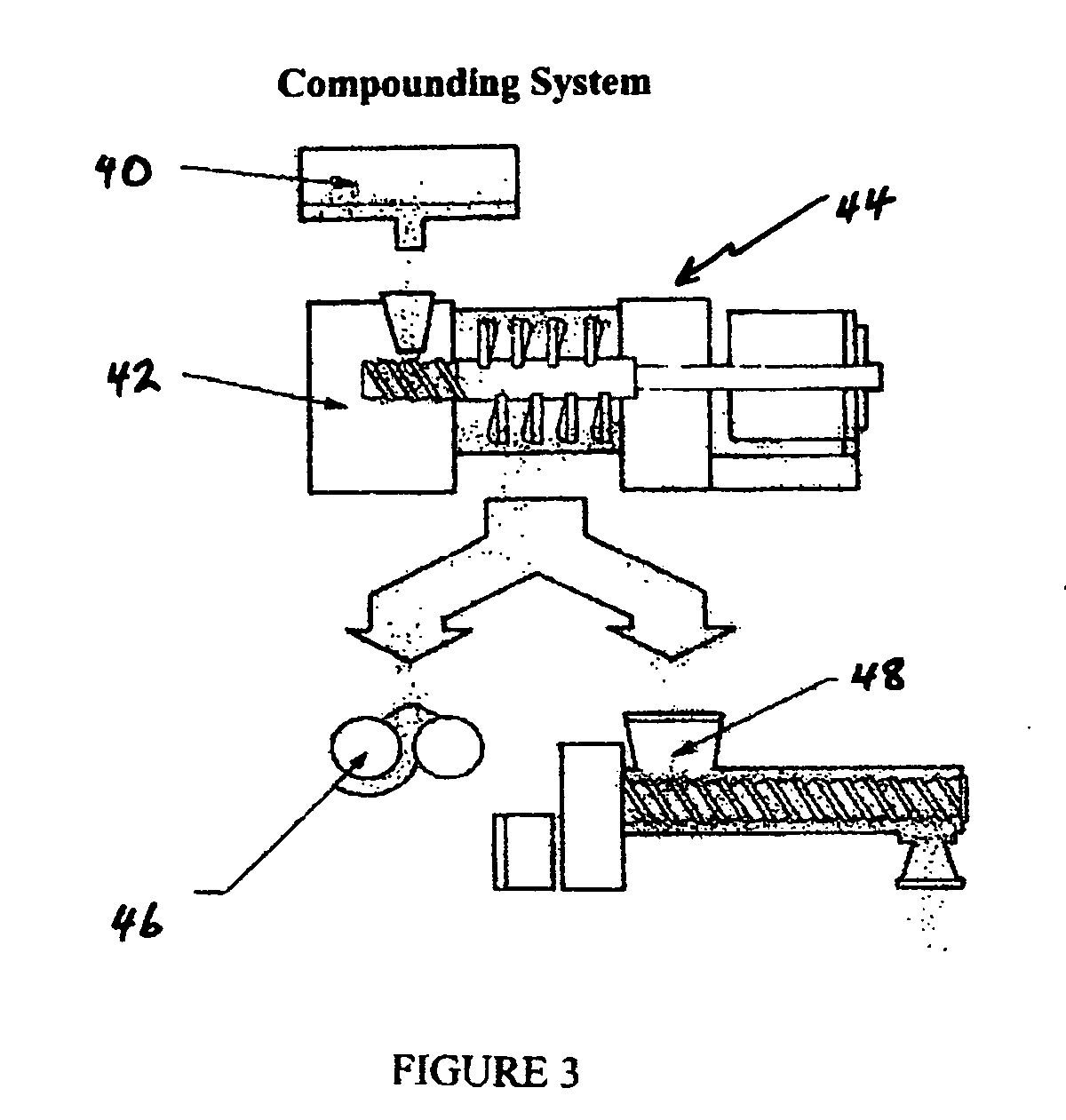

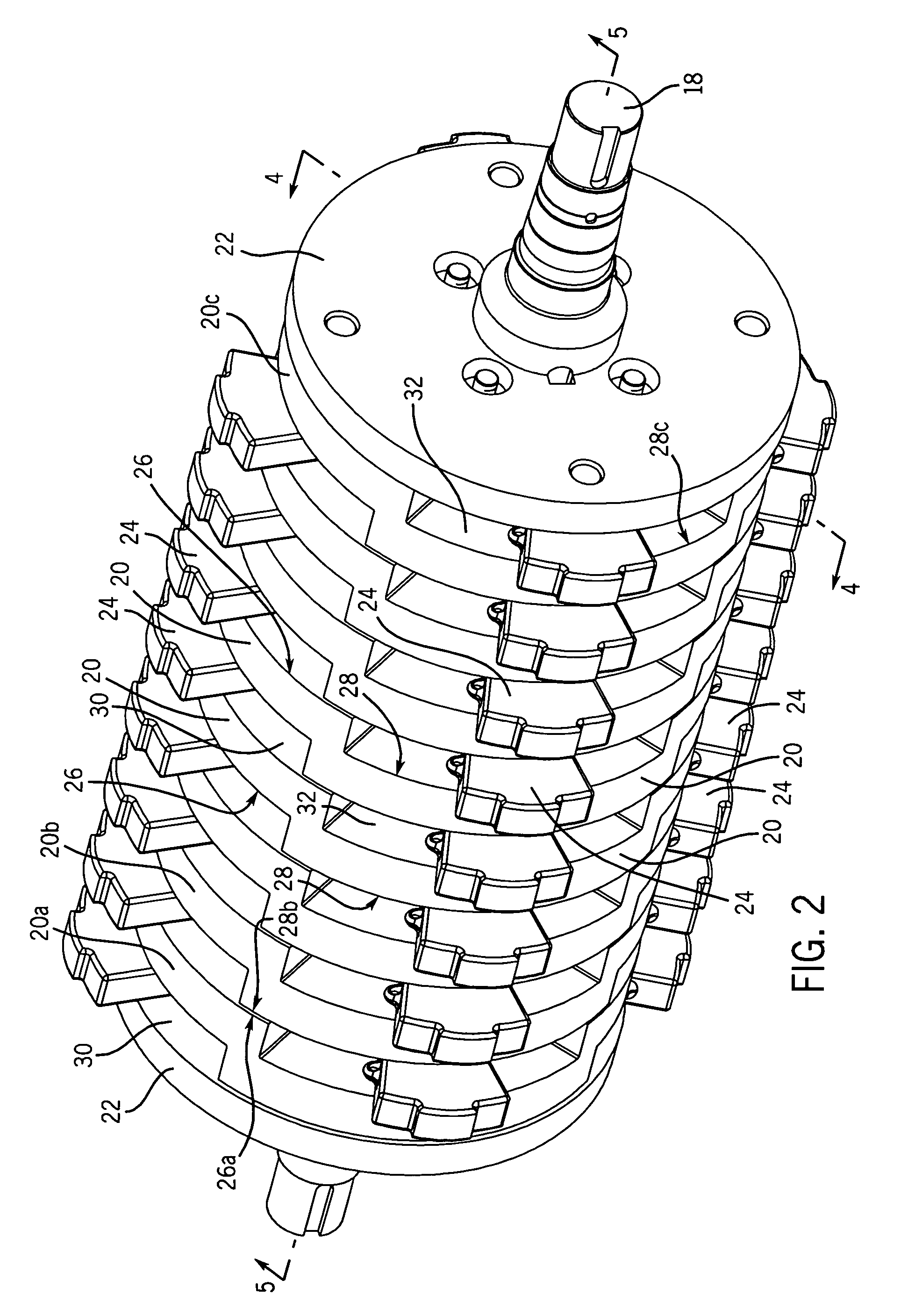

Interchangable chipper inserts for wood grinder

ActiveUS20100206973A1Facilitate quick and easy reversing and replacementEasy to installMetal sawing devicesShearing machinesWood grinderKnife blades

A plurality of chipper inserts that may be installed on a hammermill rotor in place of the hammer inserts to selectively convert the rotor to a chipper. The chipper inserts include drum surfaces that cooperatively define a chipper drum. The chipper inserts may include cutter inserts that have a cutter disposed in a cutter pocket. The chipper drum may be a generally continuous cylindrical interrupted essentially only by the cutter pockets. The cutters and cutter pockets may be positioned in essentially any desired pattern around the drum. The chipper inserts may include a left cutter insert, a center cutter insert, a right cutter insert and three different size spacer inserts. The different types of cutter inserts and spacer inserts may be installed about the rotor with at least one left cutter insert mounted on the left end of the chipper drum and at least one right cutter insert mounted on the right end of the chipper drum. The chipper inserts may be configured in quadrant sections, such that it takes four inserts to extend around the rotor.

Owner:ALAMO GROUP

Interchangable chipper inserts for wood grinder

ActiveUS8061640B2Facilitate quick and easy reversing and replacementEasy to installMetal sawing devicesShearing machinesWood grinderEngineering

Owner:ALAMO GROUP

Hammer

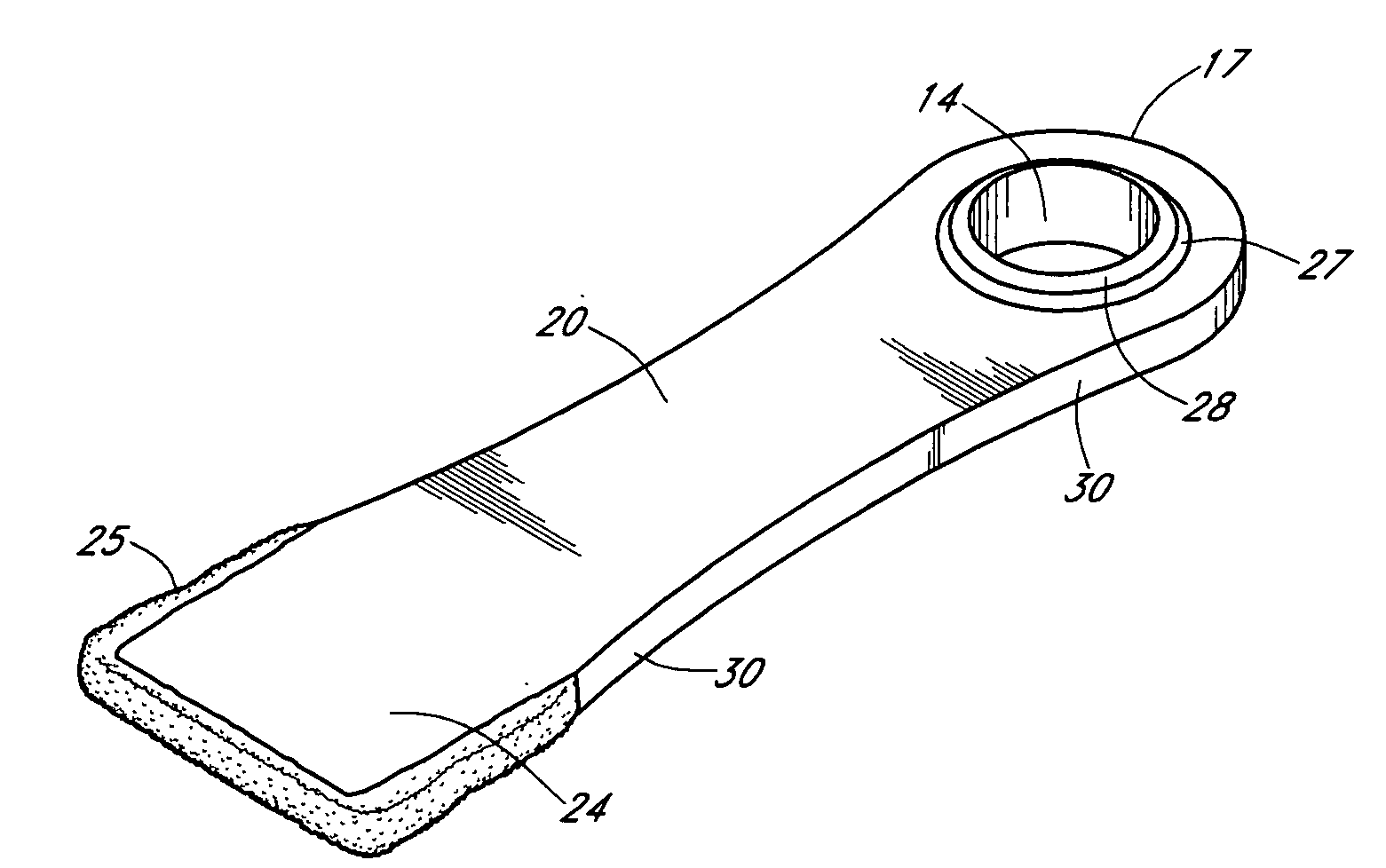

The various embodiments disclosed and pictured illustrate a hammer for comminuting various materials. The embodiments pictured and described herein are primarily for use with a rotatable hammermill assembly. The hammer includes a connector end having a rod hole therein, a contact end for delivery of energy to the material to be comminuted, and a neck affixing the connector end to the contact end. The neck is formed with at least one neck recess therein. In other embodiments, one or more shoulders are positioned around the periphery of the rod hole for added strength. In still other embodiments, the contact end is configured with more than one contact surface.

Owner:GENESIS III

Hammermill hammer

ActiveUS20080011890A1Improve efficiencyExcellent hardness propertiesGrain treatmentsEngineeringComminution

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

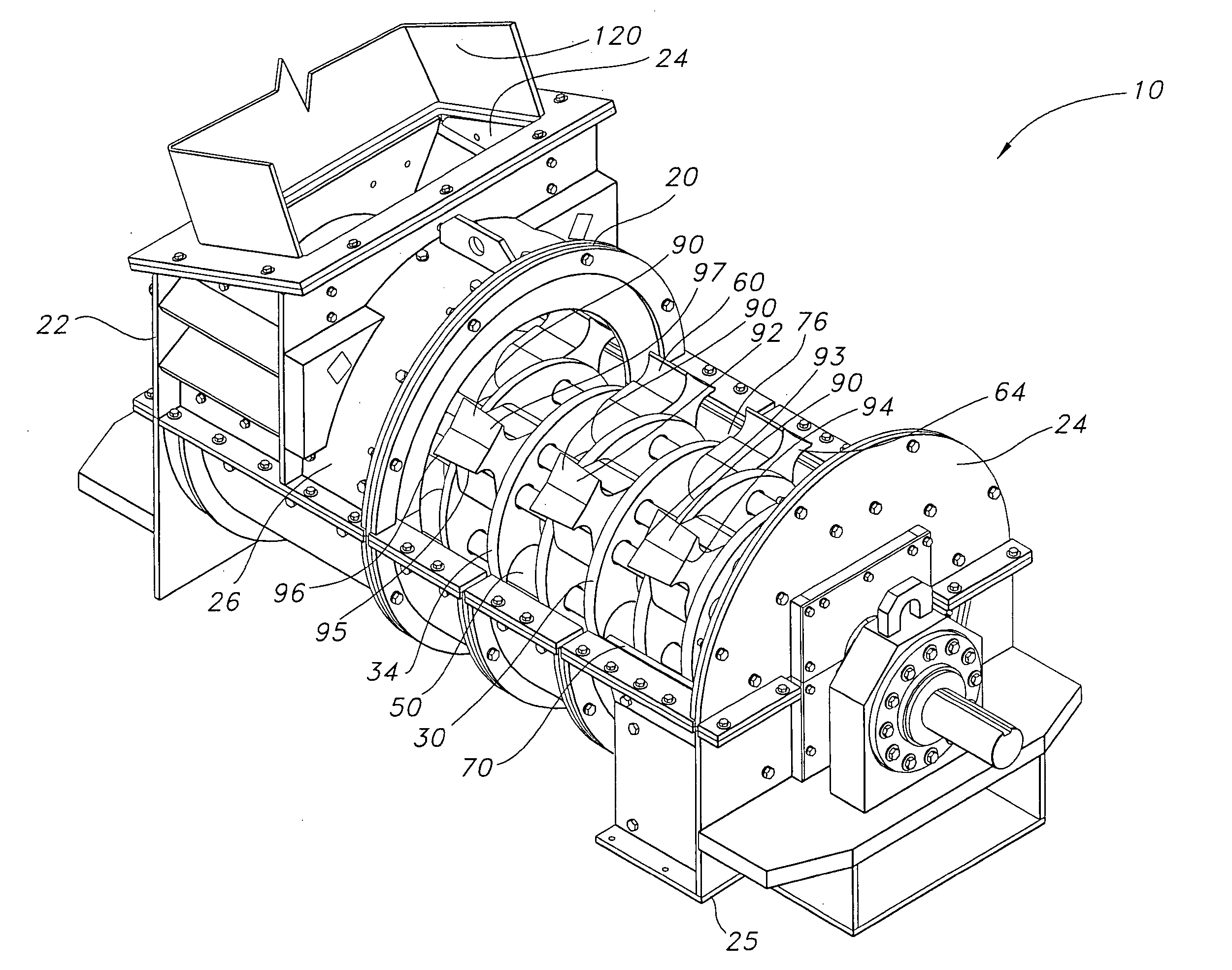

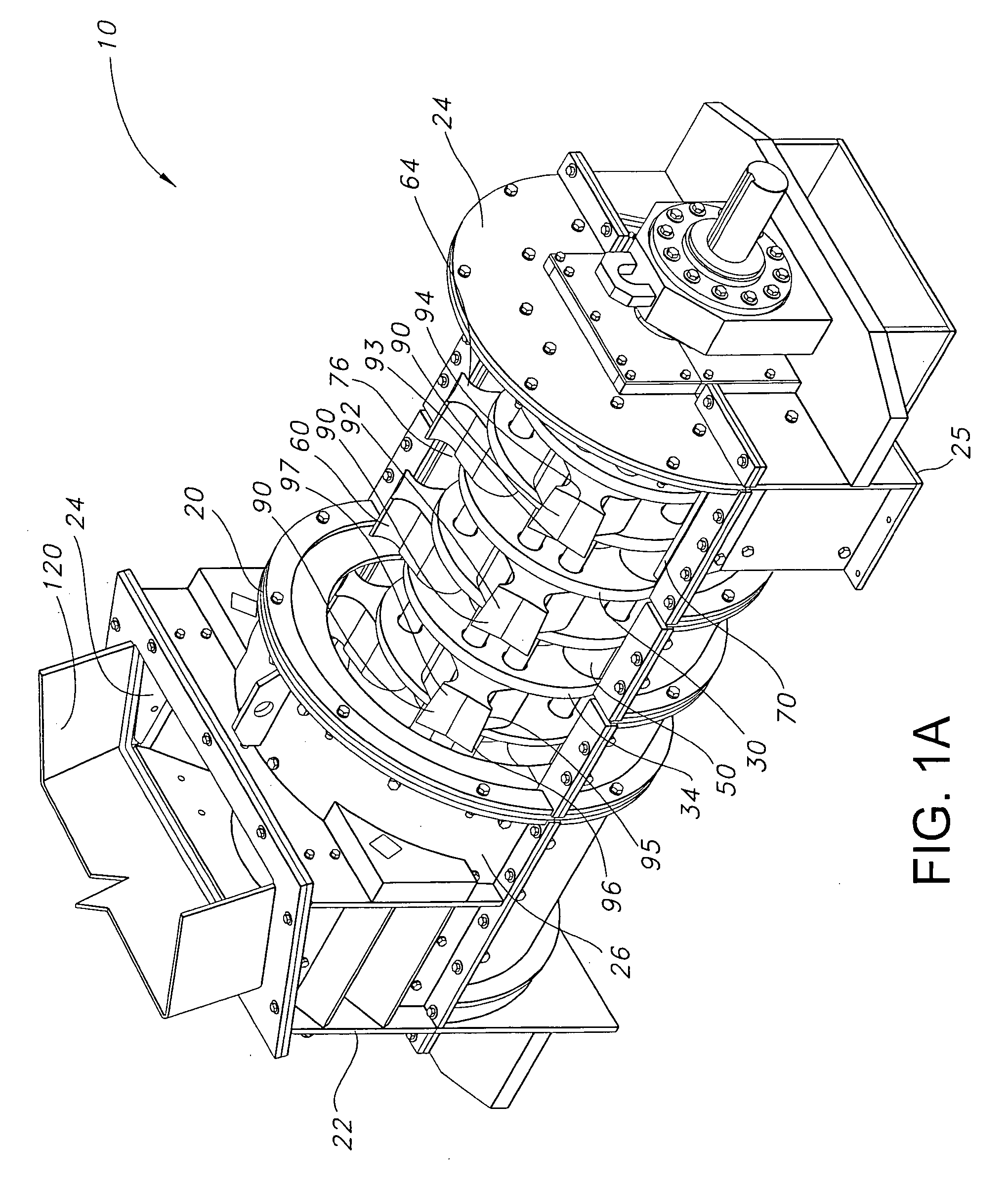

Hammermill

A hammermill having a housing, a rotor assembly, a first plurality of hammers, and a first attrition plate assembly is provided to reduce oversized particulate material to a desired size. The housing has a sidewall that extends between an inlet end and an discharge end which defines an enclosed work space. The rotor assembly is disposed within the housing for rotation about a longitudinal axis of the housing. The first plurality of hammers is coupled to the rotor assembly and is disposed within the enclosed work space. The first attrition plate assembly has a generally circular configuration and is removably secured to the sidewall within the enclosed work space of the housing. The first attrition plate assembly is arranged such that at least a portion of each hammer of the first plurality of hammers is spaced from and overlies a portion of the first attrition plate assembly so that the hammers and the attrition plate assembly cooperate to reduce particulate material to a desired size and to urge the particulate material toward the discharge end of the housing.

Owner:REGIONS BANK

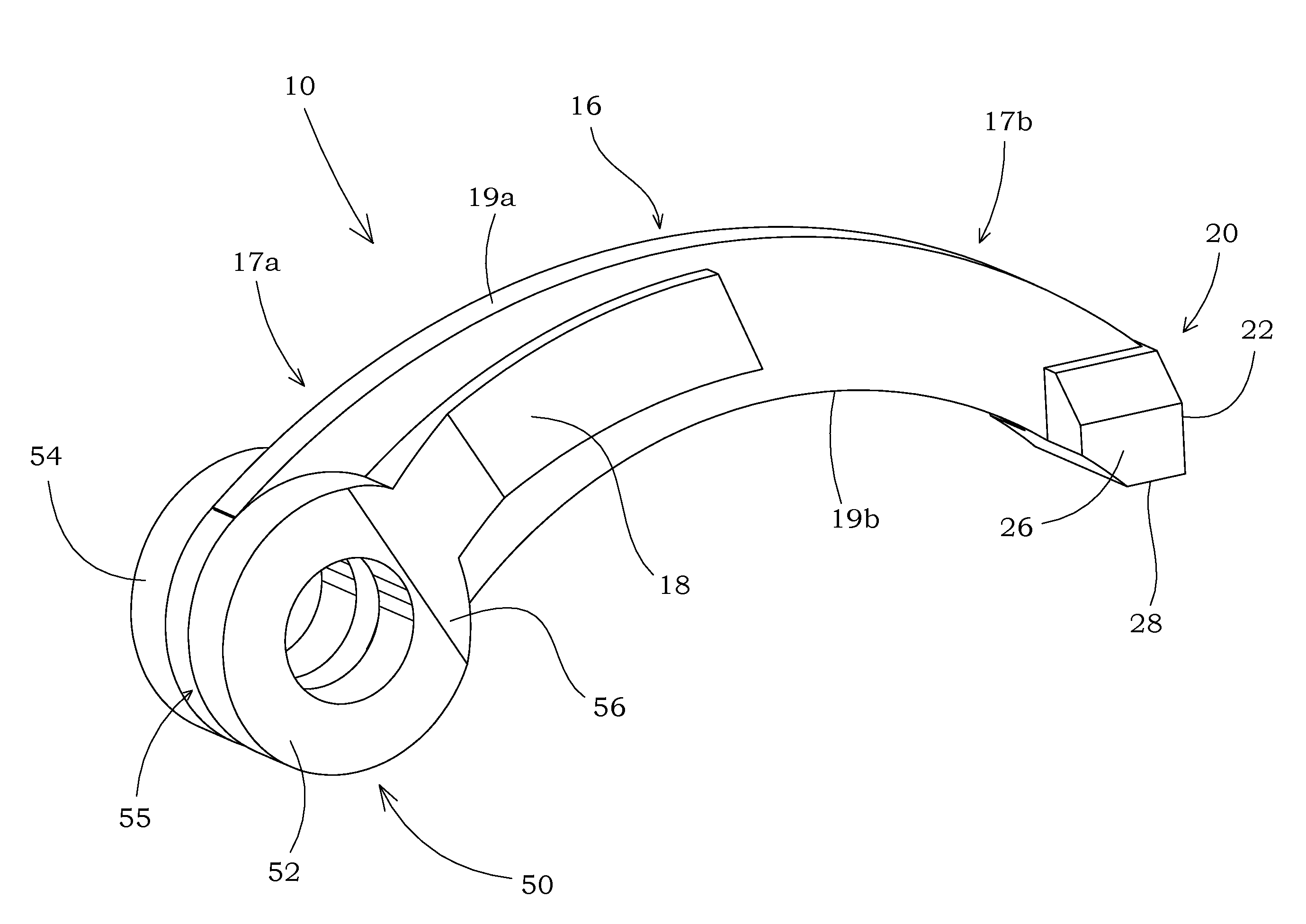

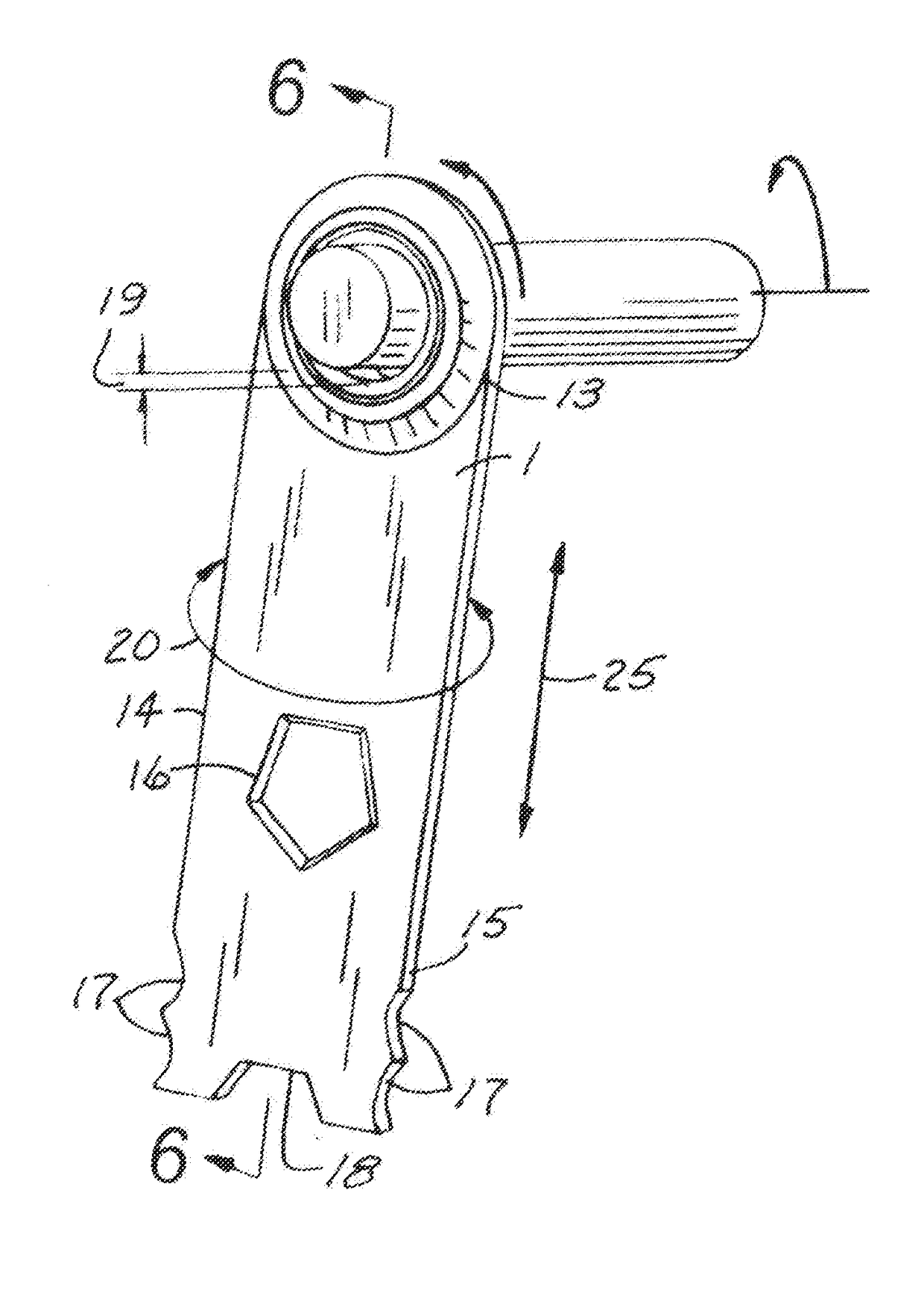

Curved hammer

The various embodiments disclosed and pictured illustrate a curved hammer for comminuting various materials. The illustrative embodiments pictured and described herein are primarily for use with a rotatable hammermill assembly. The curved hammer includes a connection portion having a rod hole therein, a contact portion for delivery of energy to the material to be comminuted, and a curved neck portion affixing the connection portion to the contact portion. In other embodiments, a shoulder is positioned around the periphery of the rod hole for added strength. In still other embodiments, a neck reinforcement is positioned along a portion of the neck for increased strength. A weld or plurality of welds may be affixed to various surfaces of the contact portion to aide in comminuting and / or longevity of the curved hammer.

Owner:GENESIS III

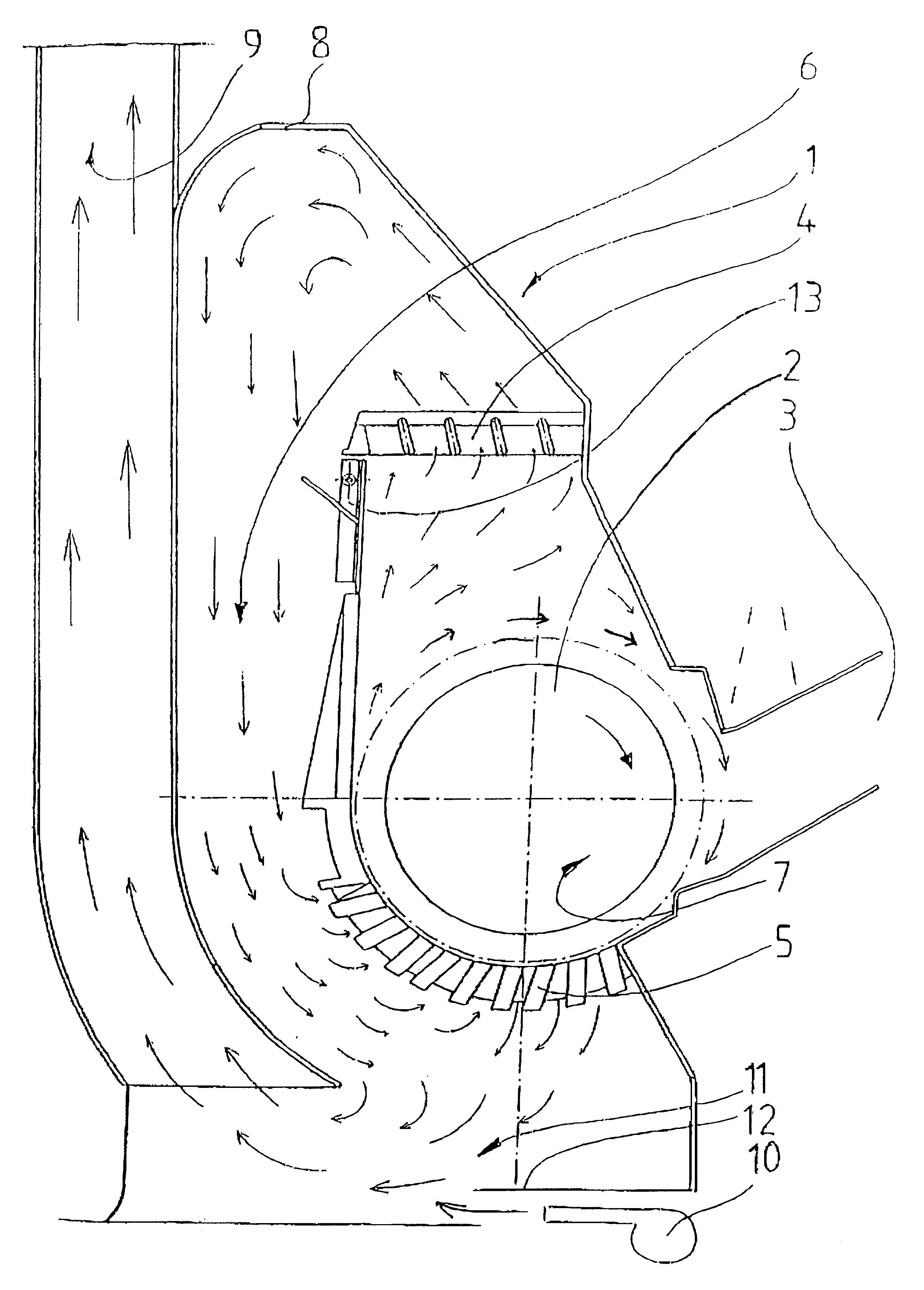

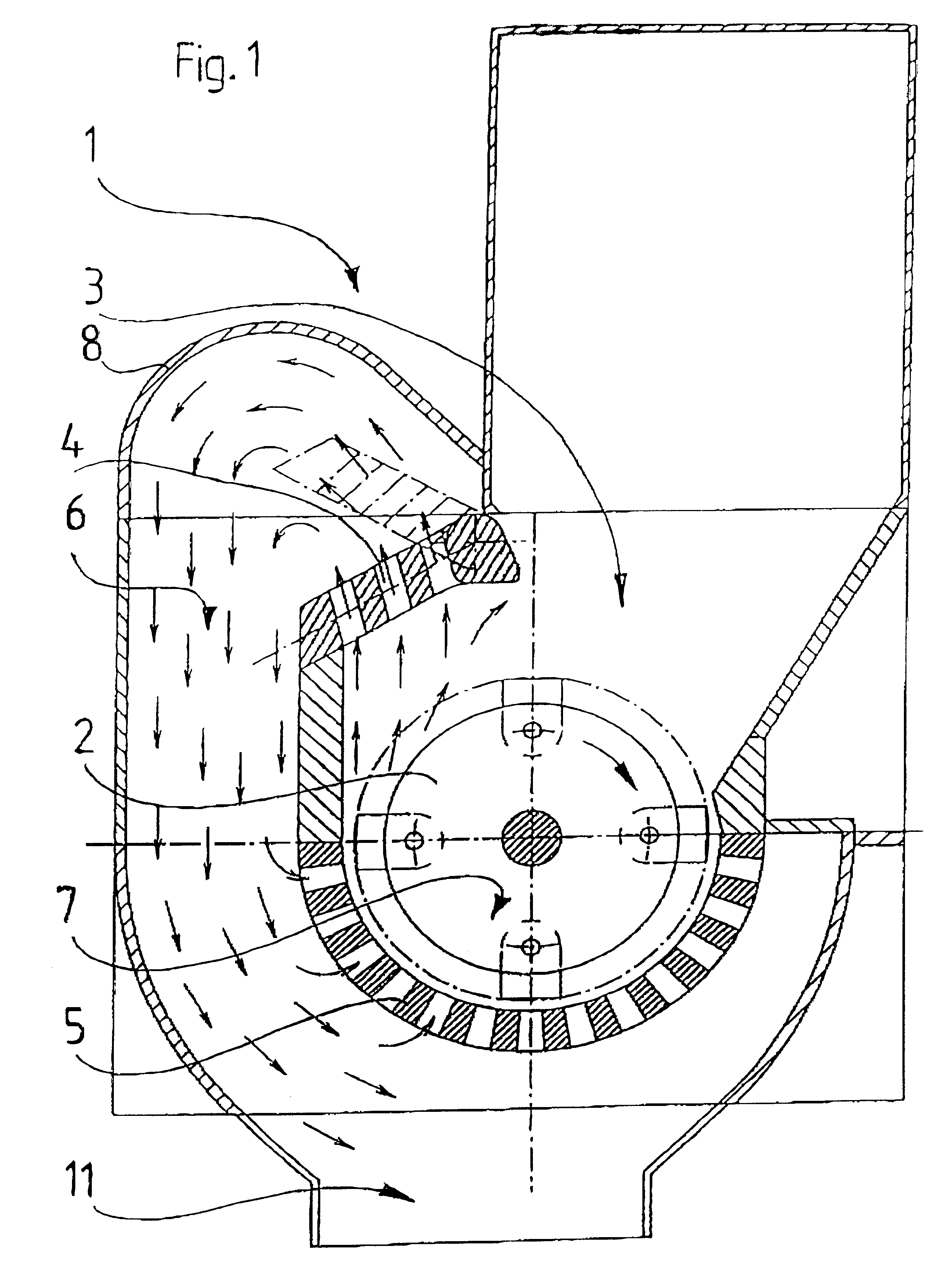

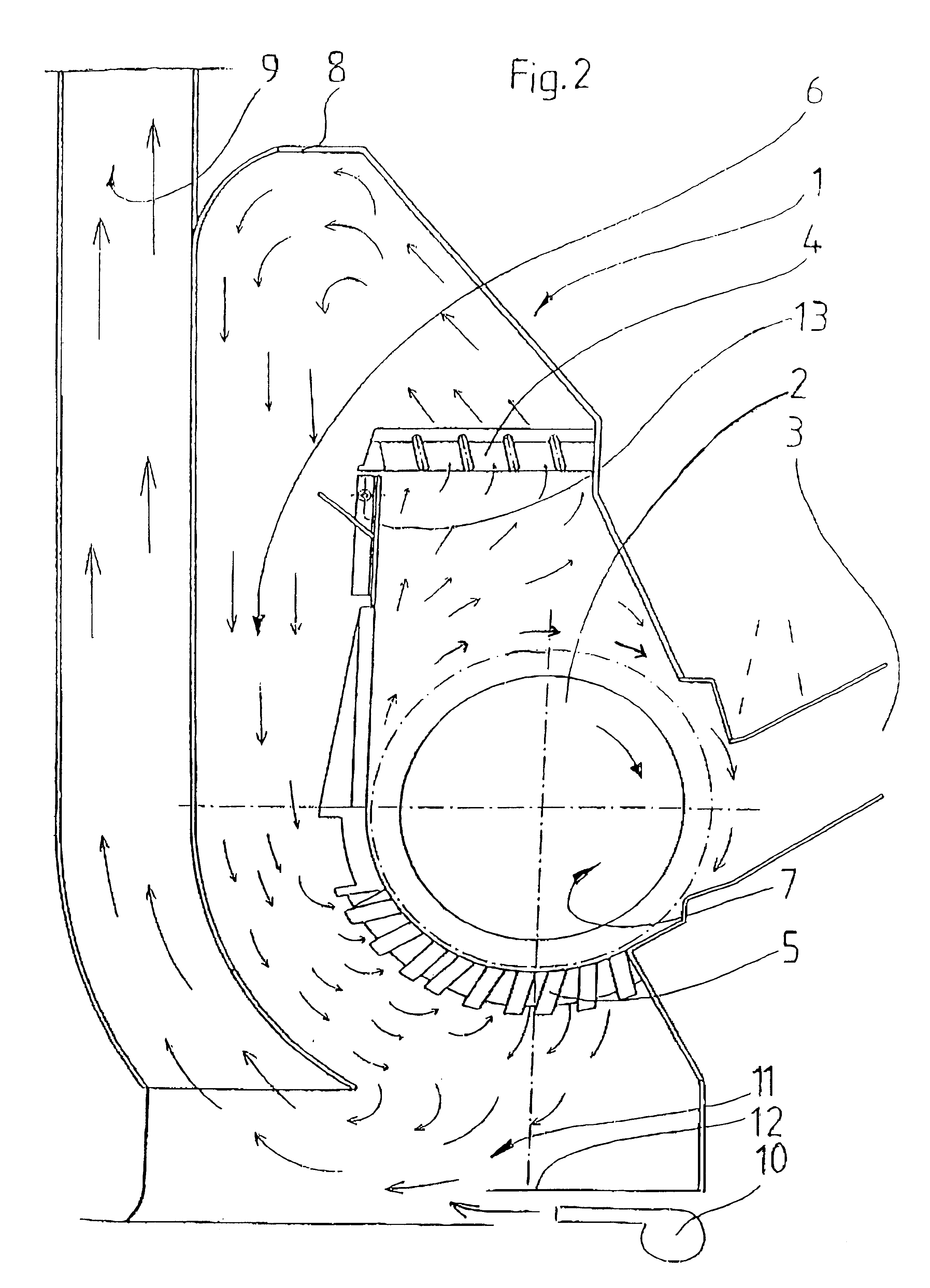

Method for operating the air circuit and conveying stock flow in the casing of a hammer mill

InactiveUS6648253B1Constant air volumeAir capacity of the dust exhaust device can be reducedGas current separationSolid waste disposalAir cycleEngineering

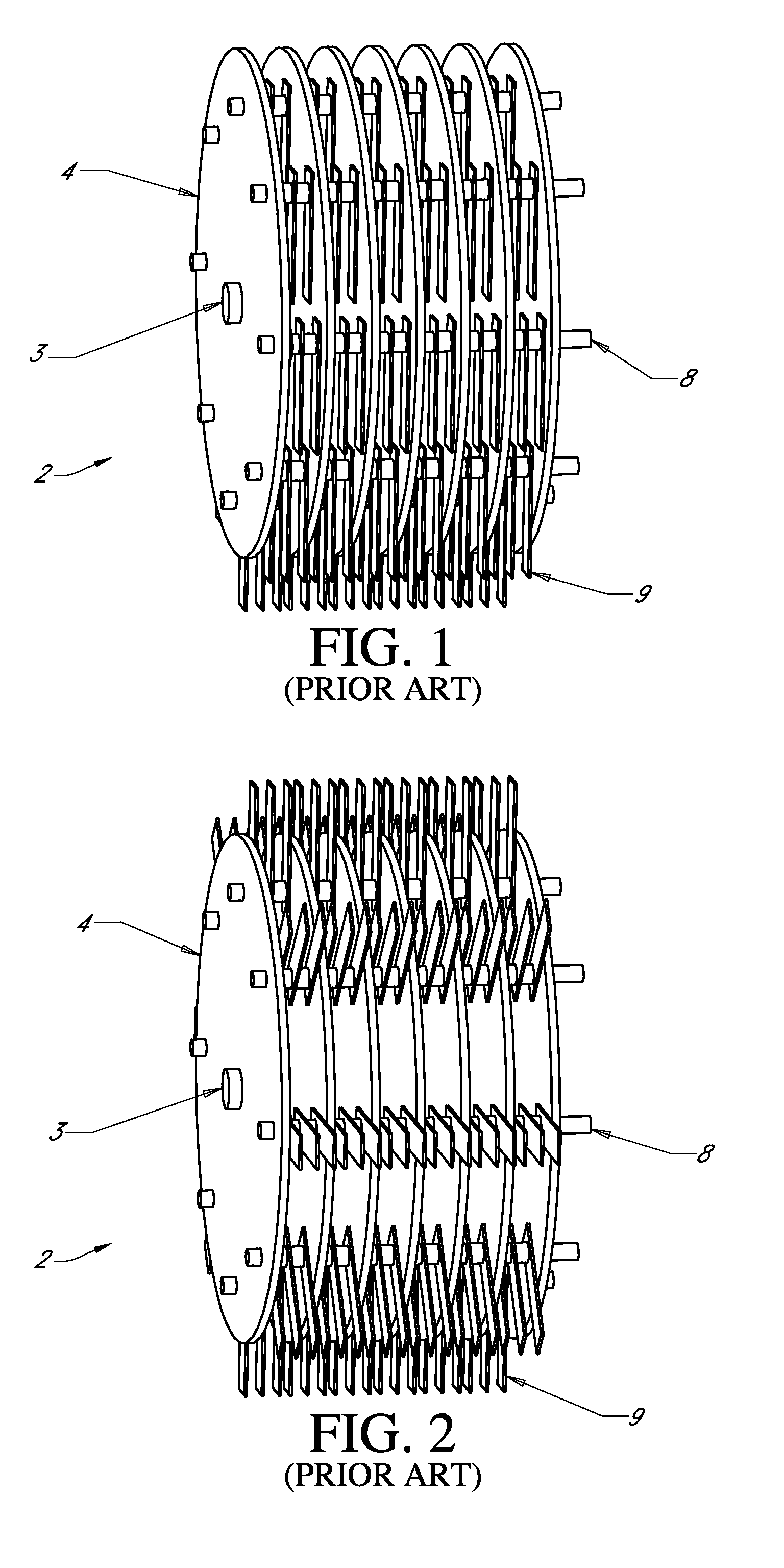

To operate the air circulation and convey the stock flow of scrap material comminuted in the housing (1) of a hammer mill, the airflow generated by the blower effect of a rotor (2) and the stock flow passing through an upper classifying grate (4) are diverted by a deflector hood (8) and guided vertically downwards into a duct (6) that is separate from the housing (1). The stock flow is combined with the stock flow classified in the area of a lower classifying grate (5). The air flow is then guided in the circulating air and the combined stock flow is conveyed to a device (11) for further processing, sorting and / or conveyance.

Owner:METABO LINDEMANN GMBH

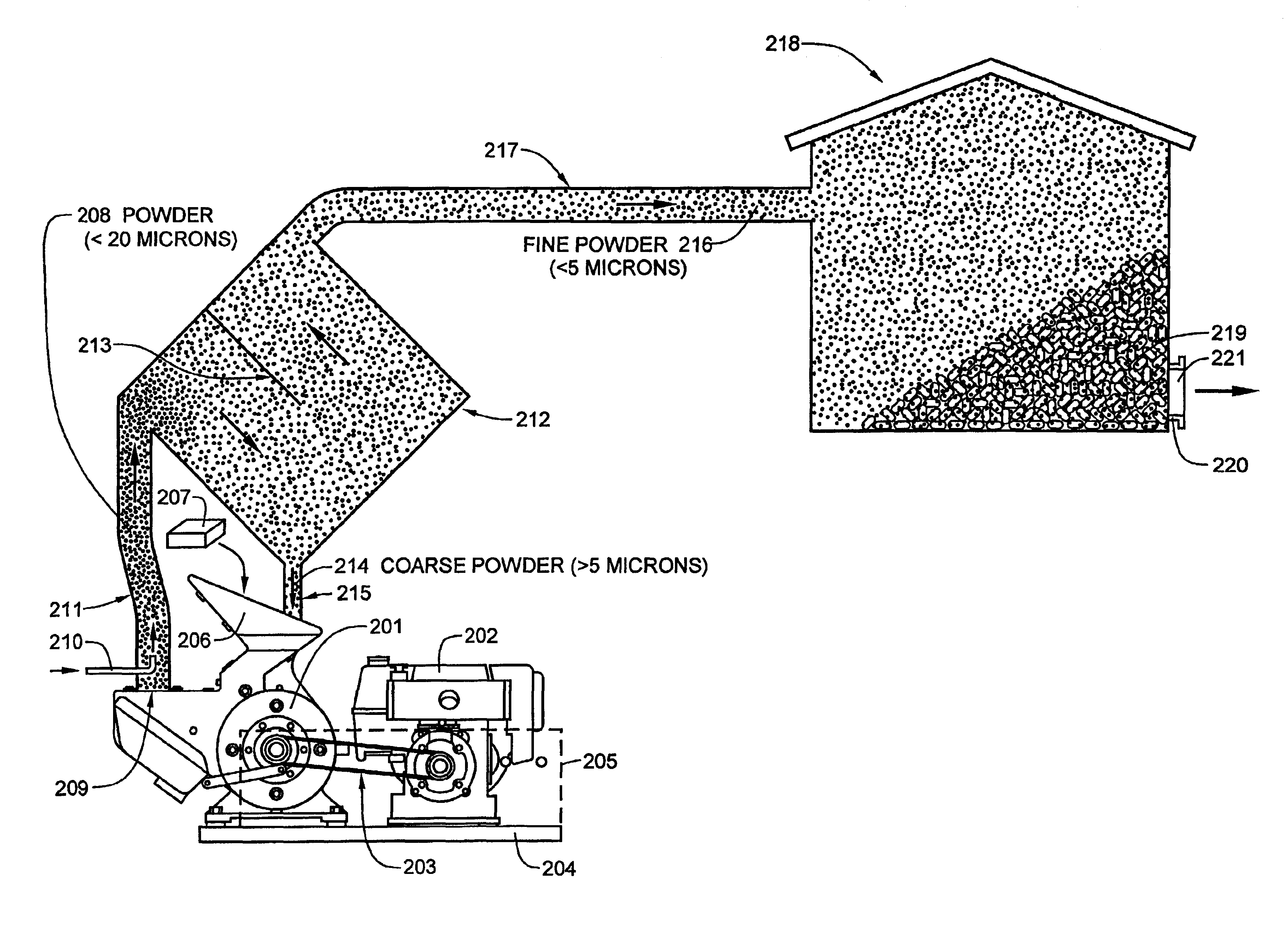

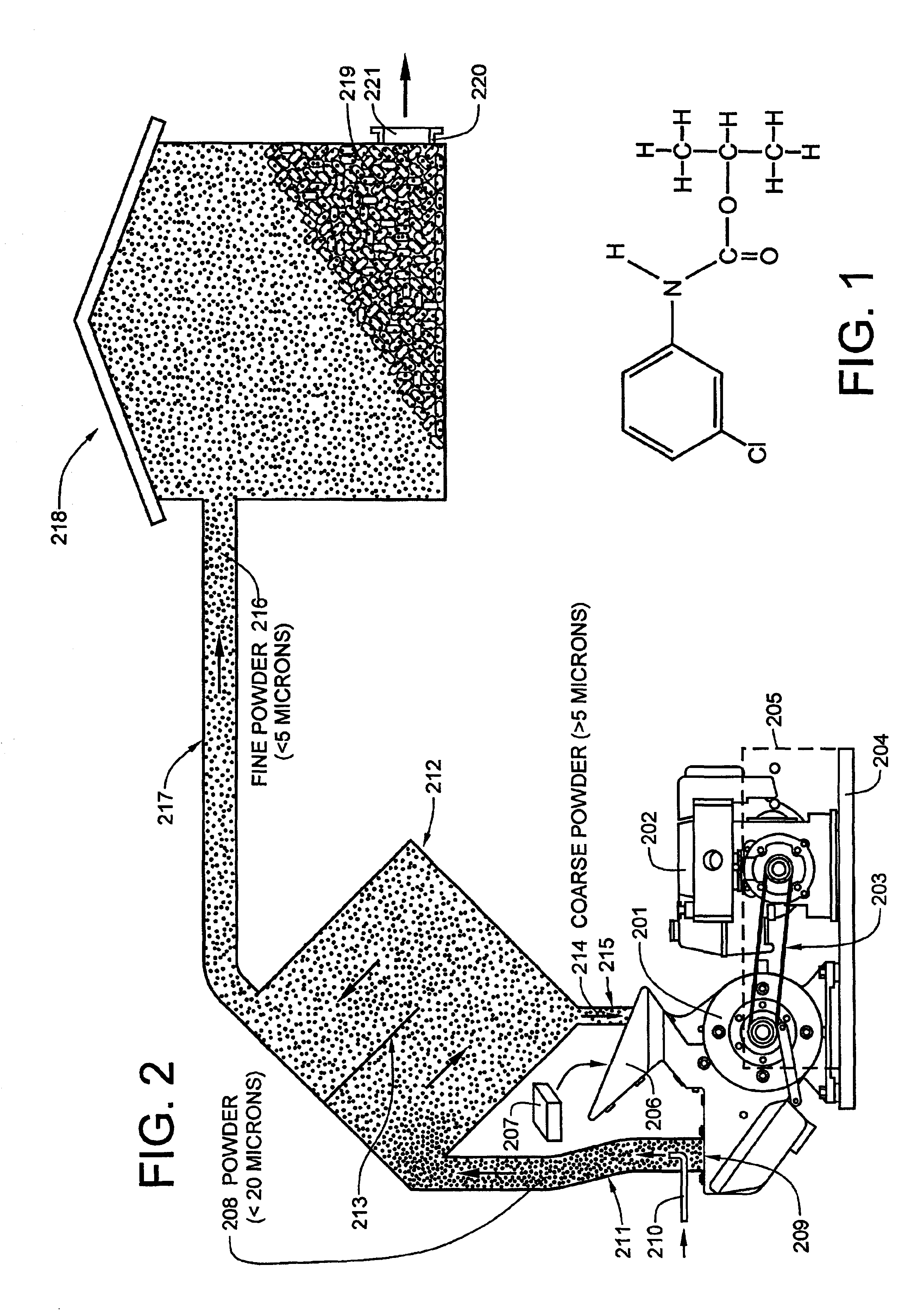

Method and apparatus for treating tubers with a powdered organic compound

The present invention provides both a process and apparatus for treating tubers in storage with chlorpropham (CIPC) dust or the dust of any other similar organic compound. The process includes the steps of forming minute particles of solid CIPC particles from a larger block or chunks of solid CIPC, and inducting the particles into an airstream which transports the particles to a tuber storage shed. For a preferred embodiment of the invention, the blocks or chunks of solid CIPC are fed into a hammer mill or like apparatus, which pulverizes the solid CIPC. Insufficiently fine particles are returned to the mill for further pulverization. Fine powder consisting of particles, each of which has a major dimension of less than about 5 micrometers, is transported by the ducted airstream from the separator to a storage shed containing a pile of tubers. The powder filters through the pile and coats exposed surfaces of the exposed tubers.

Owner:INDAL VENTILATION

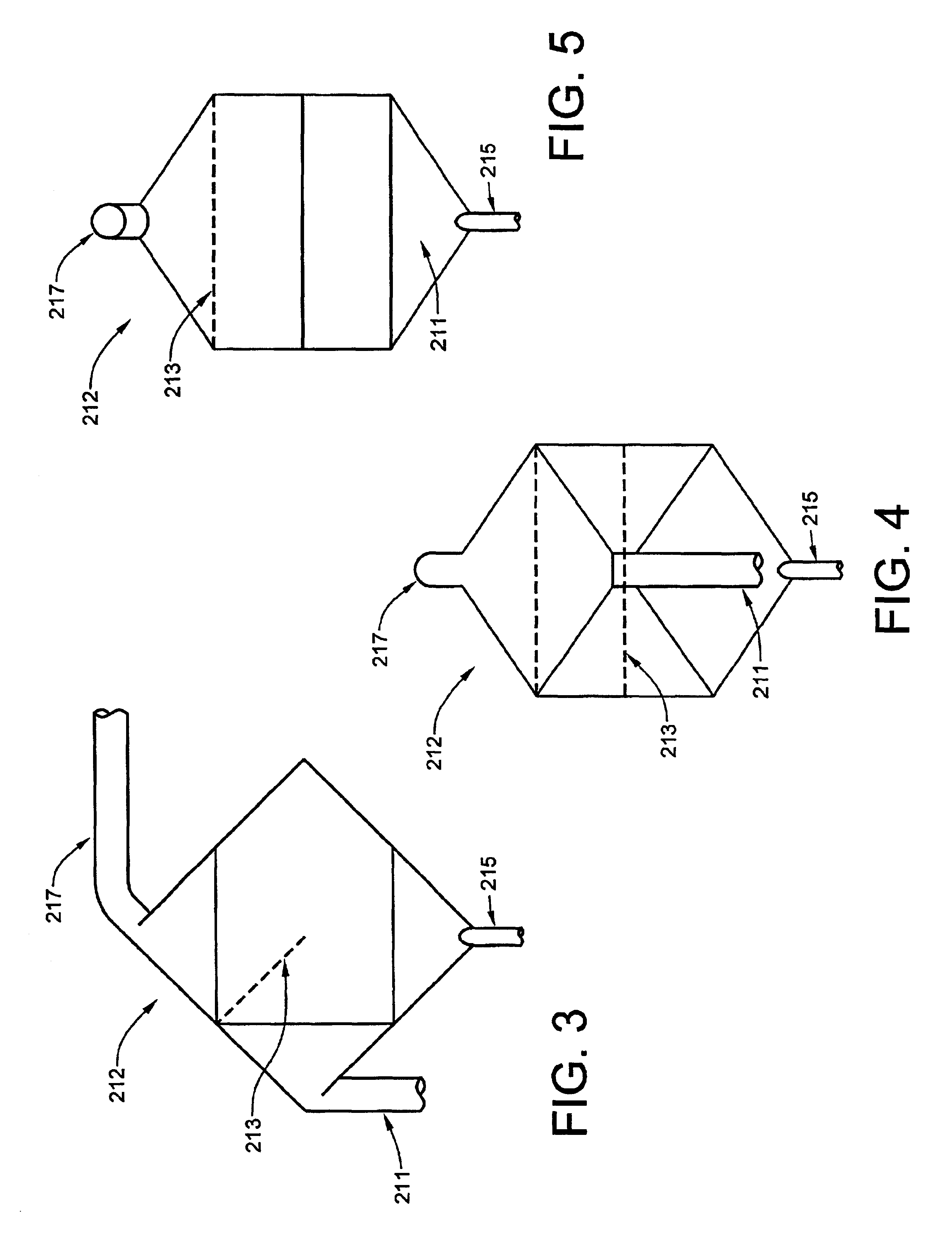

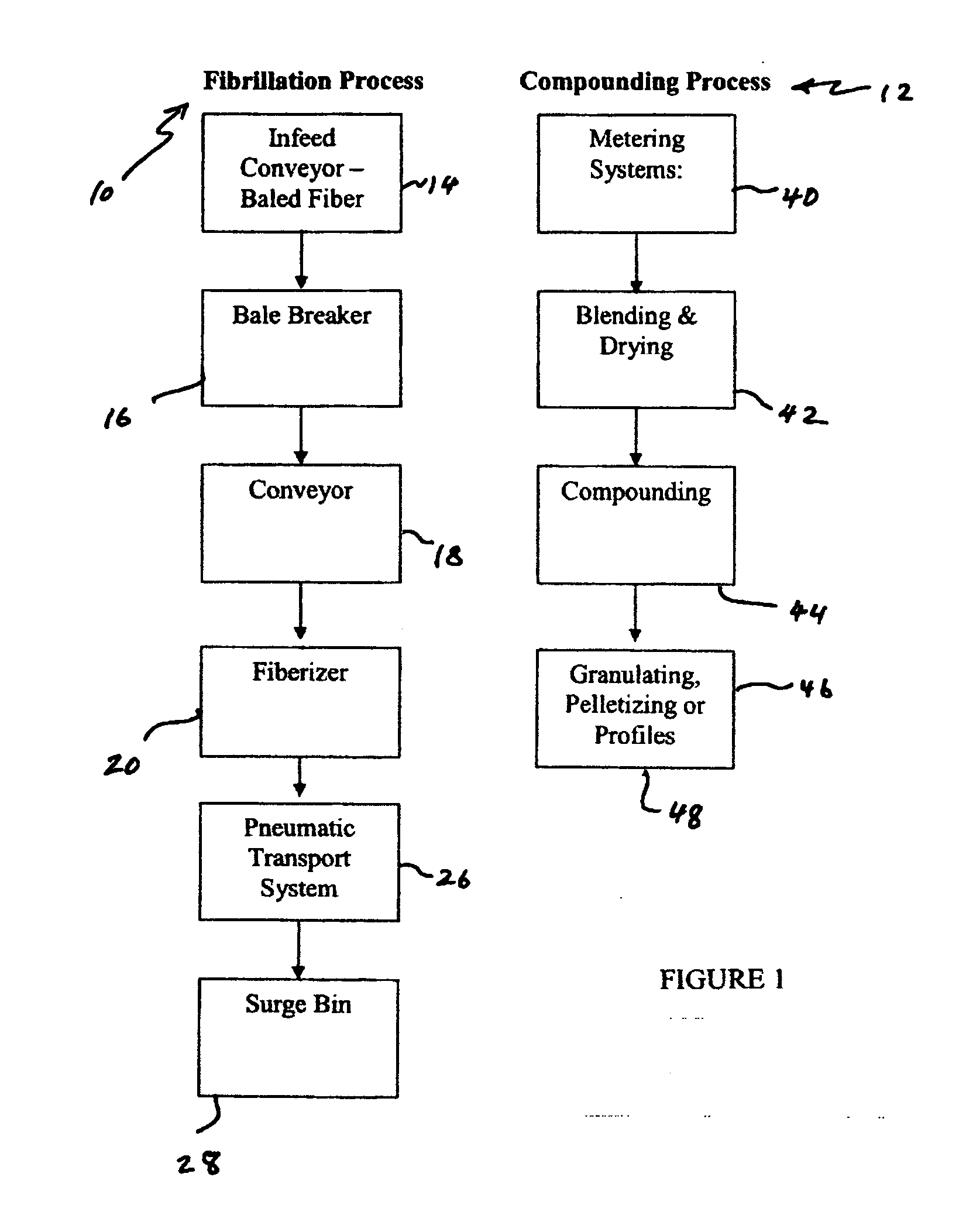

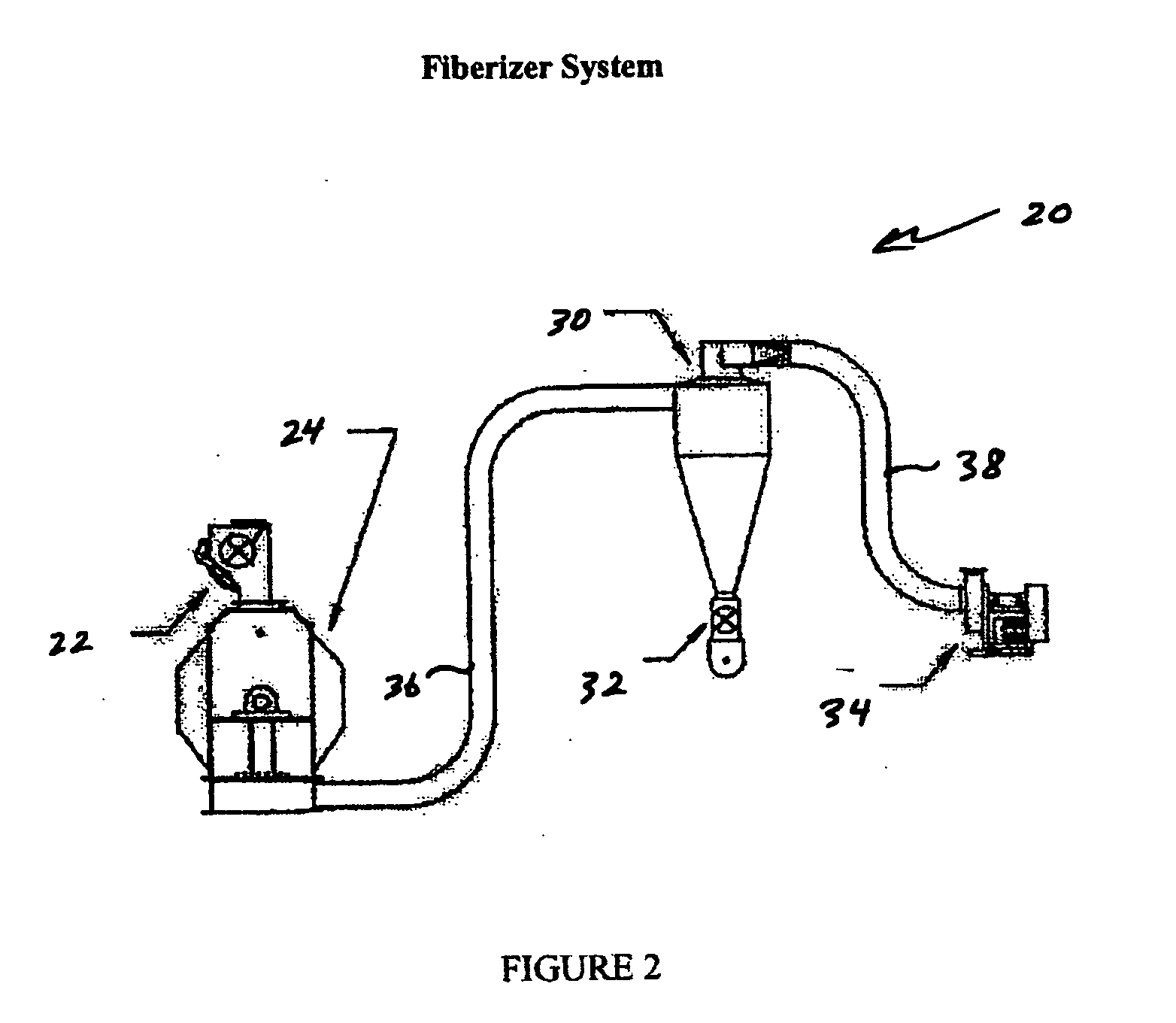

Compounding of fibrillated fiber

InactiveUS20060162879A1Fats/resins/pitch/waxes removal in pulpVegetable materialPolymer scienceNatural fiber

A process for the preparation of natural fibers for use in forming reinforced polymer composites. The process comprises fiberizing or fibrillating the natural fibers by introducing them to a hammermill that includes a rotor with hammers affixed which uses hammers to force the material against a set of perforated screens. The size of the screen prevents the material from leaving the process until it is ground to the predetermined size. The process also includes compounding the natural fibers by discharging the fibrillated natural fibers into a high speed drying and blending device and a compounding device to mix and dry the fibers and to discharge the mix as a generally soft dough.

Owner:CUATRO

Process for singulating cellulose fibers from a wet pulp sheet

A hammermill for singulating cellulosic fibers from a wet pulp sheet includes a cylindrical housing, a feed slot with a breaker bar positioned therein and a rotor mounted for rotation in the housing. Feed rolls are provided to feed a sheet of pulp into the feed slot upstream of the breaker bar. A plurality of hammers are mounted on the rotor. Air is introduced into the hammermill housing tangentially downstream from the second feed slot. An air outlet is positioned tangentially on the housing downstream from the air inlet to allow air and singulated fibers to escape. A process for producing singulated fibers includes wetting a fiber sheet, milling the fibers in the hammermill, and drying the fibers. The singulated fibers have a low knot content.

Owner:INT PAPER CO

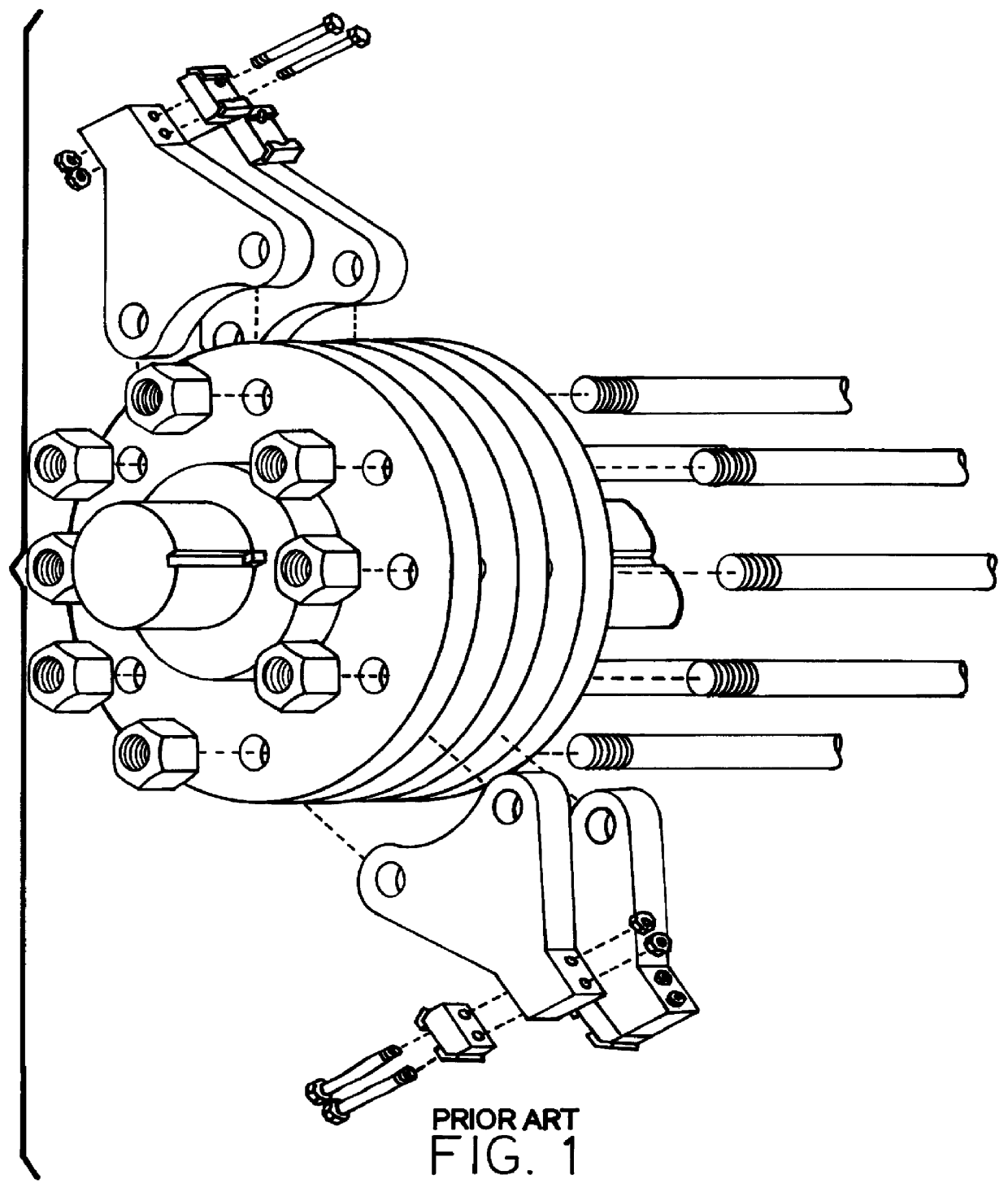

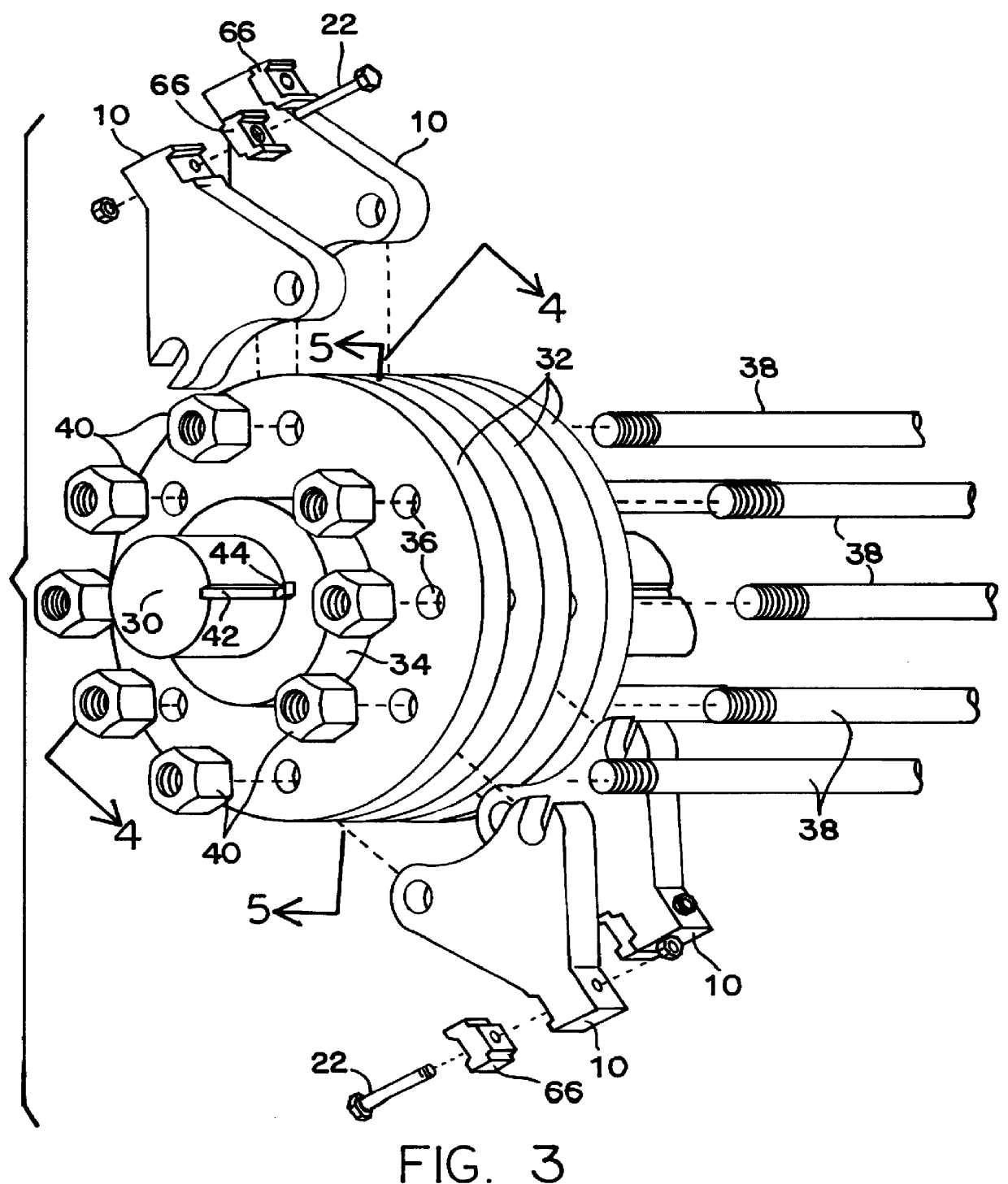

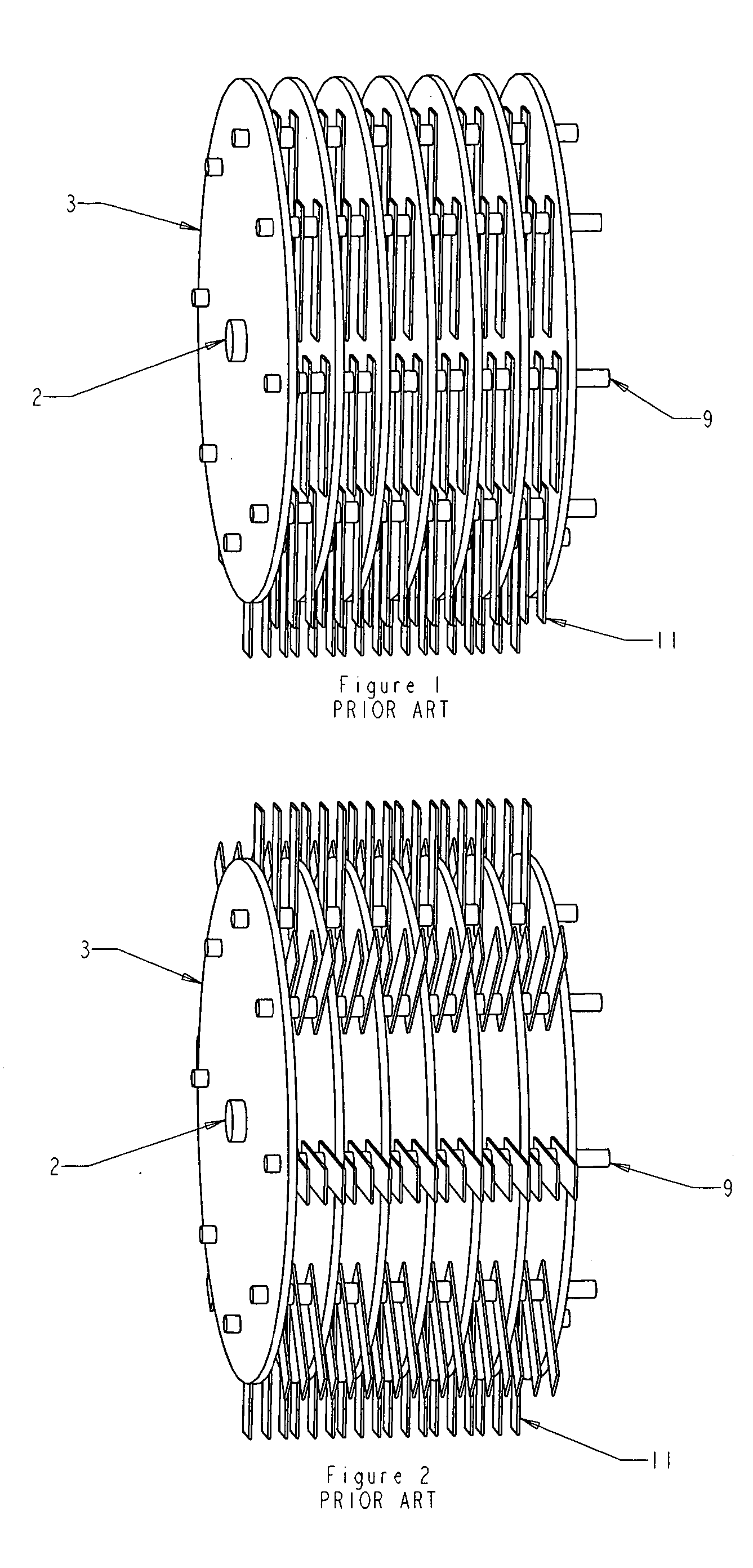

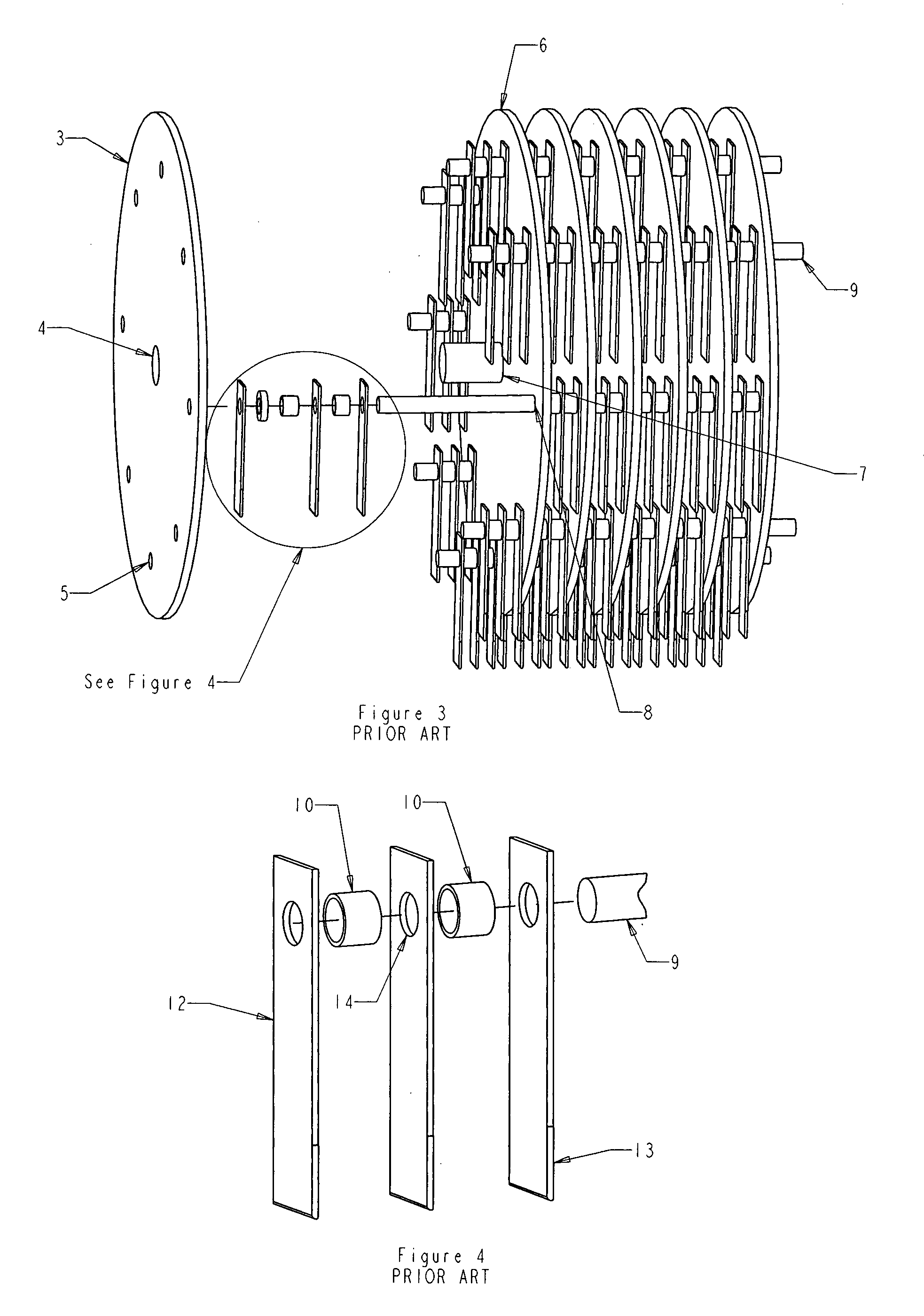

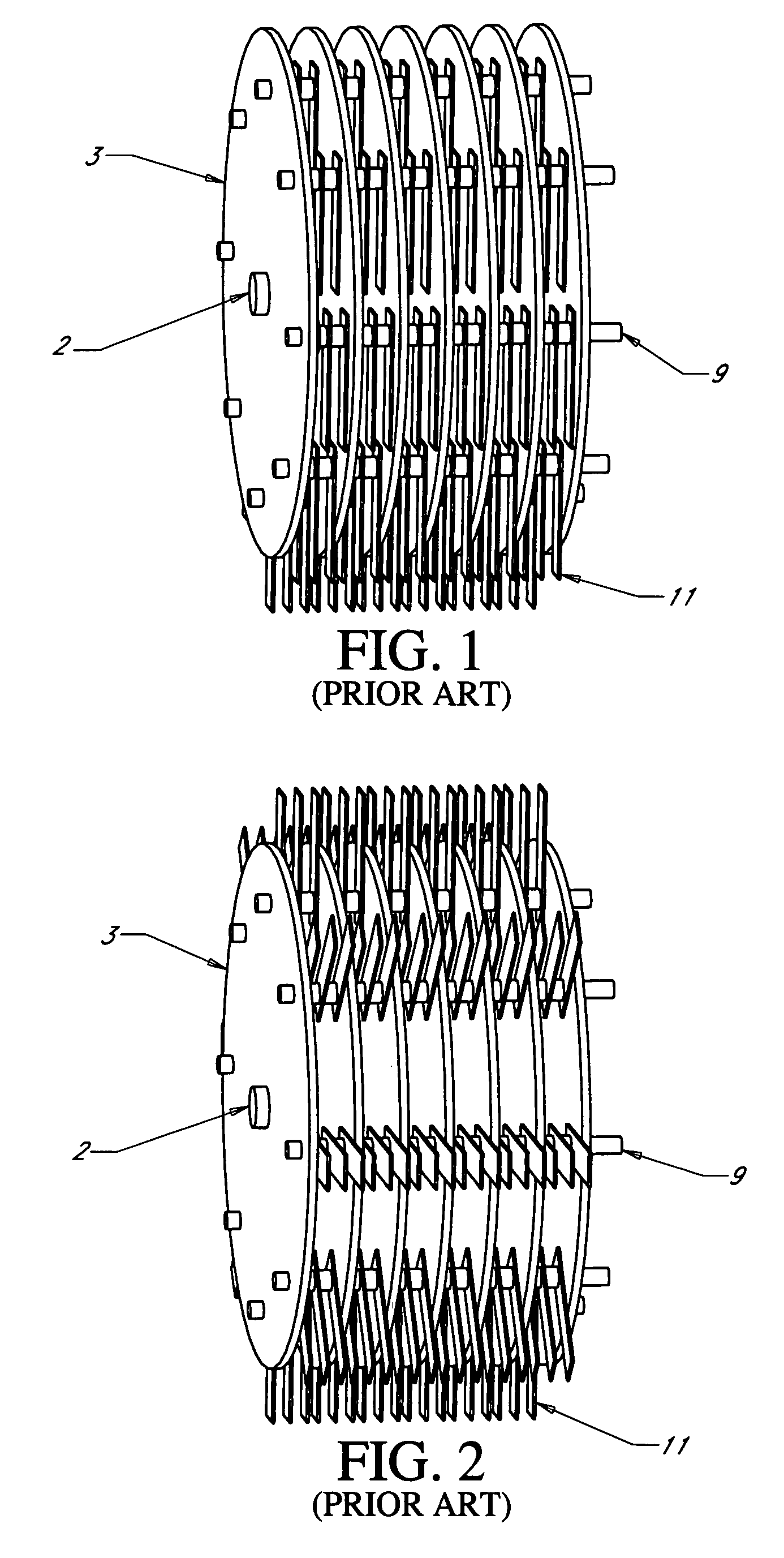

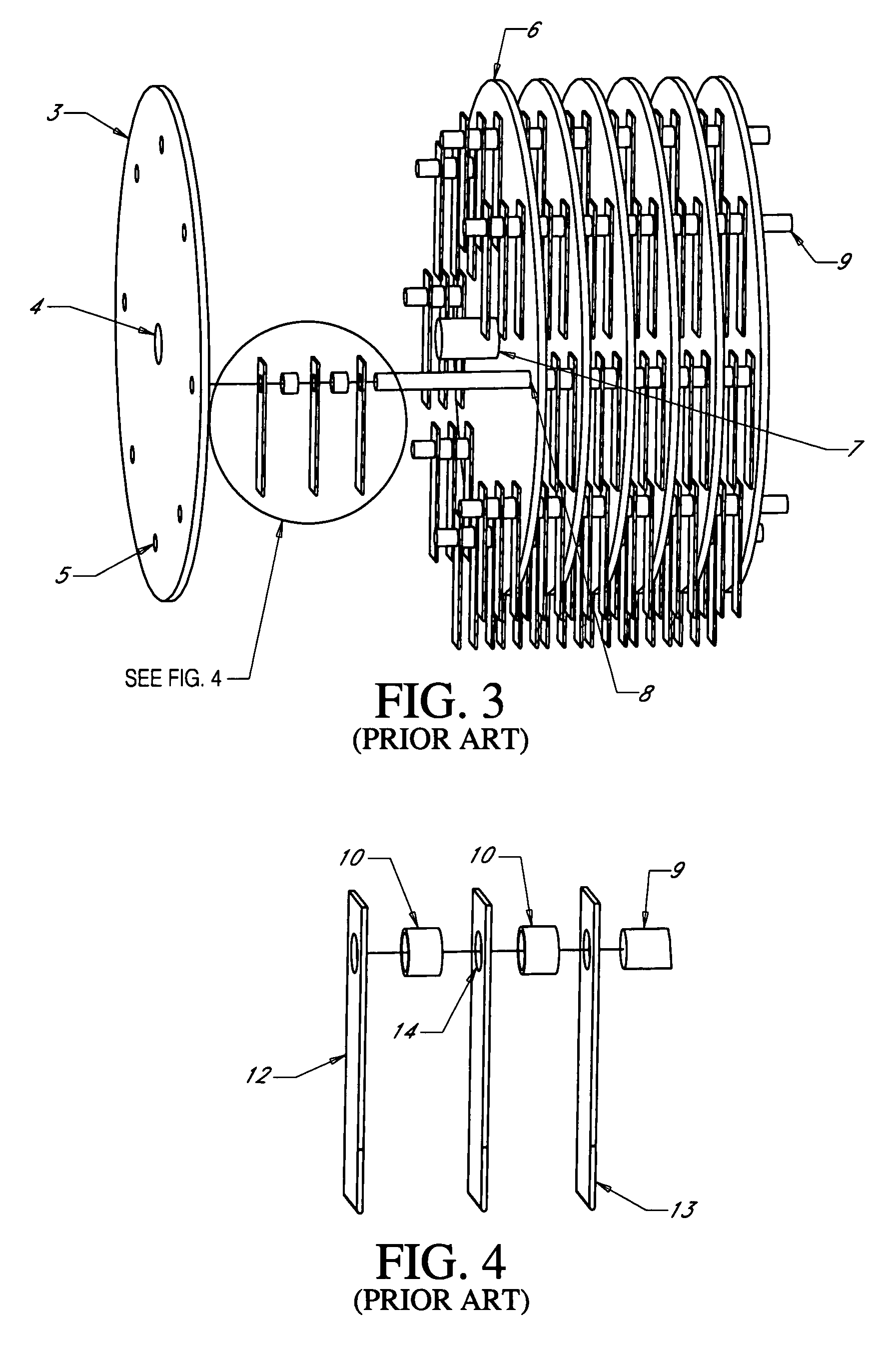

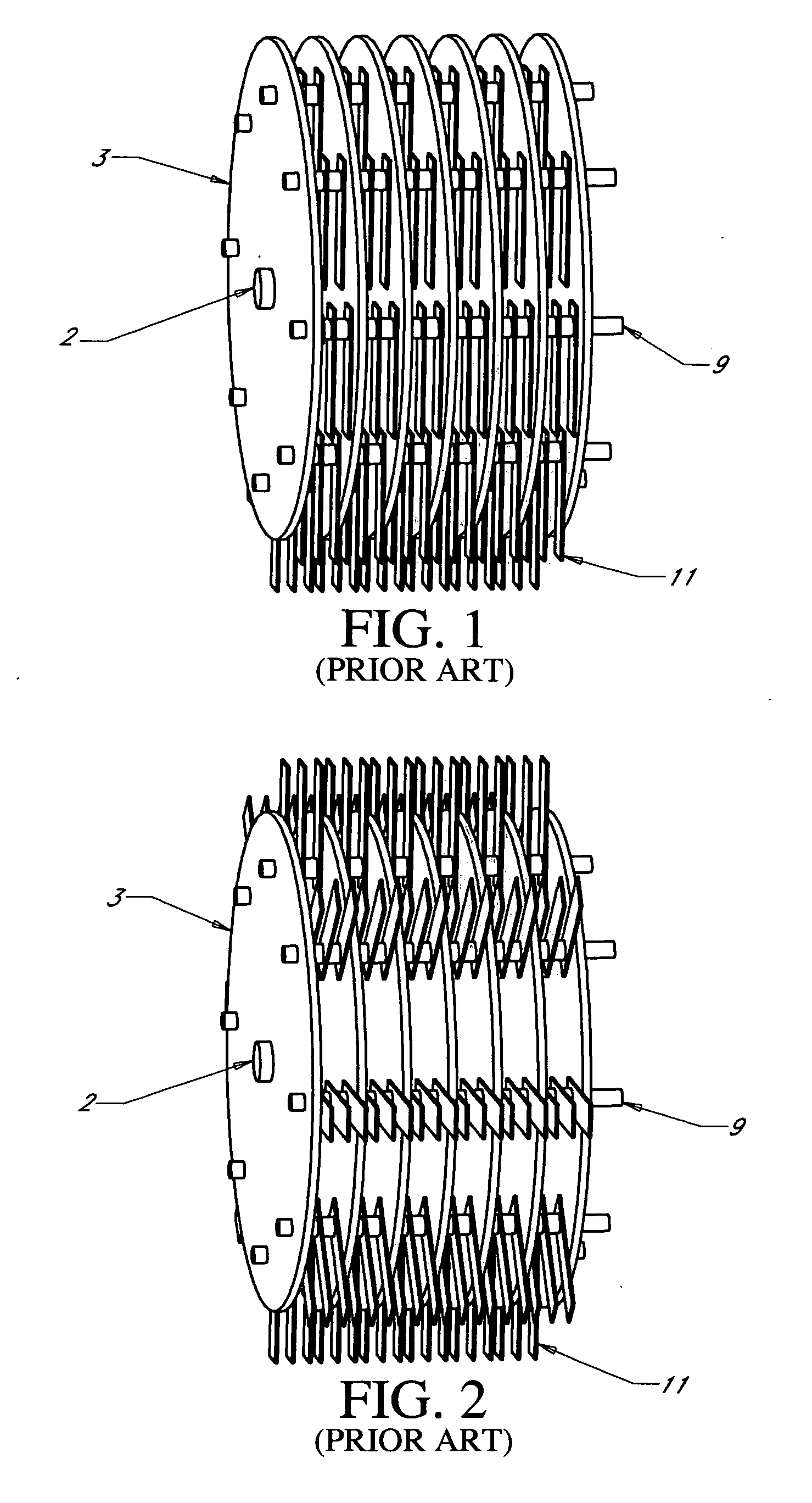

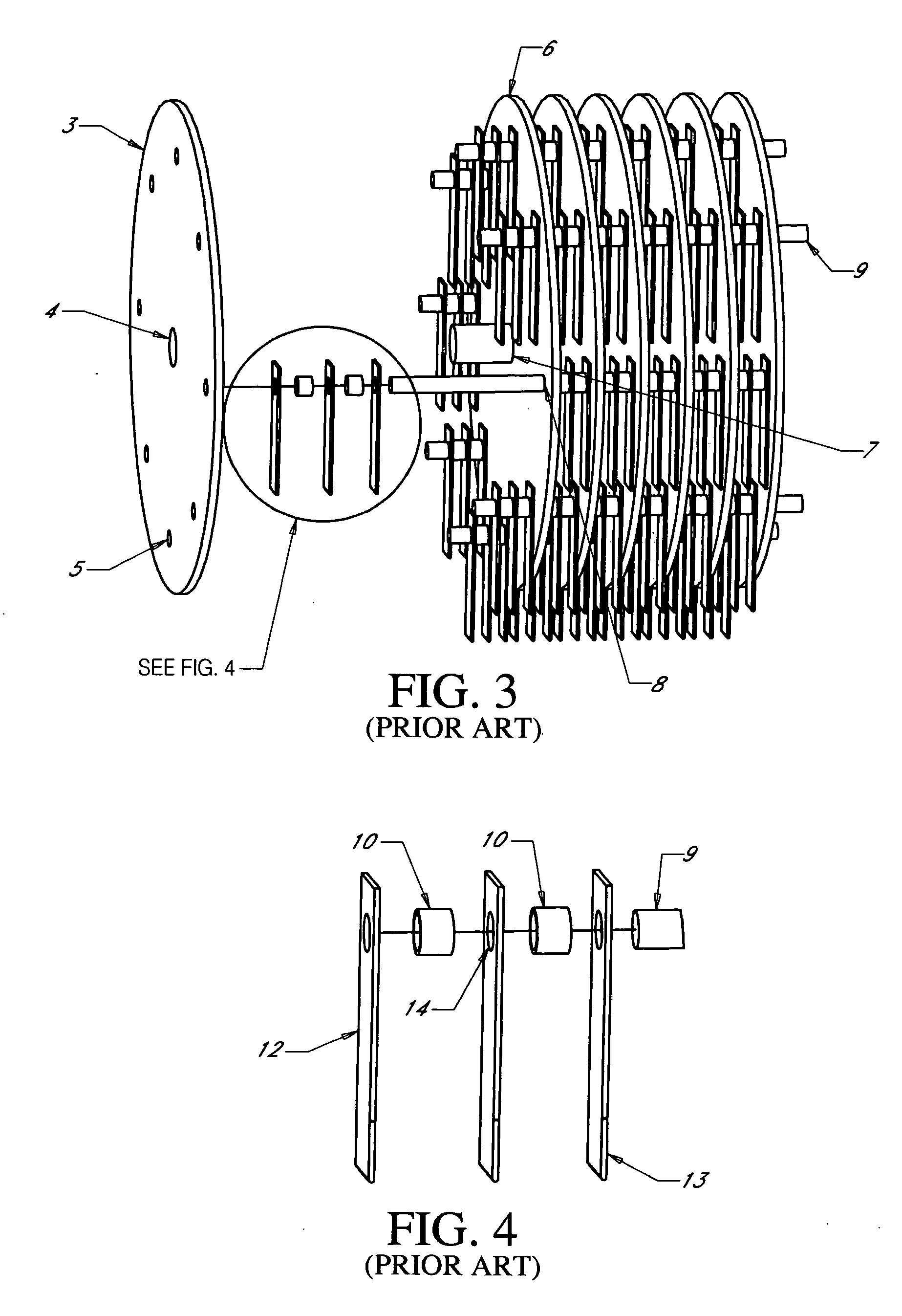

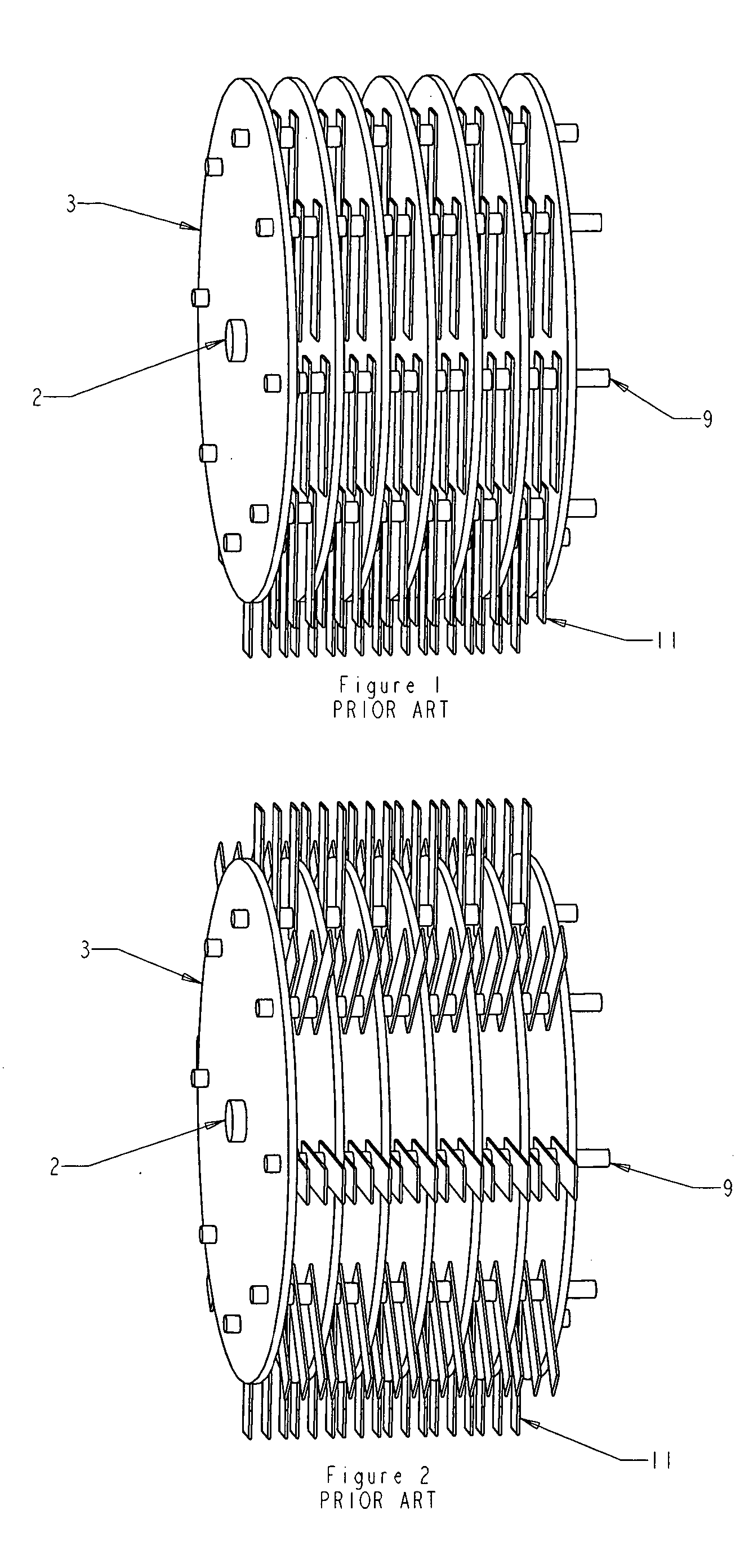

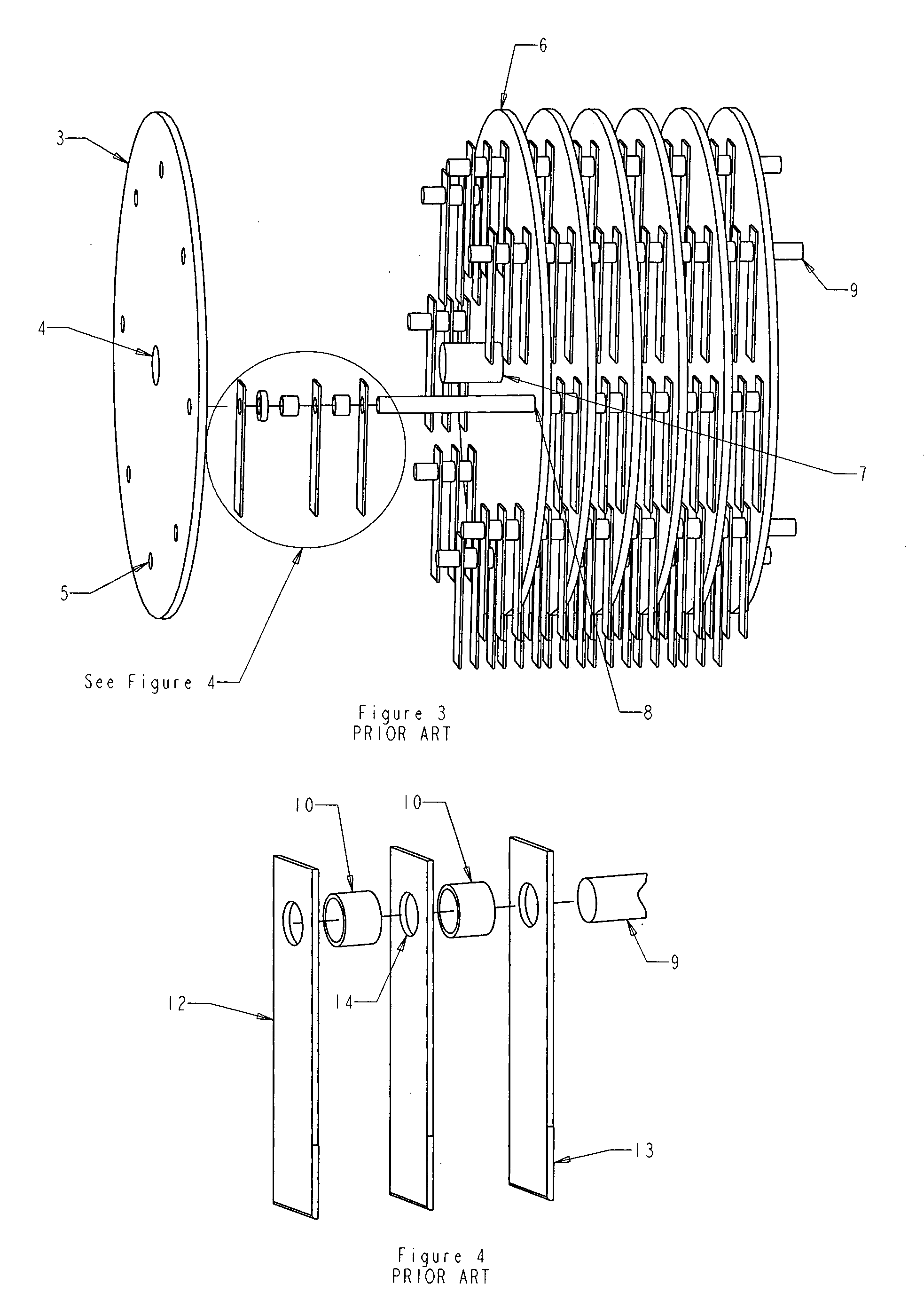

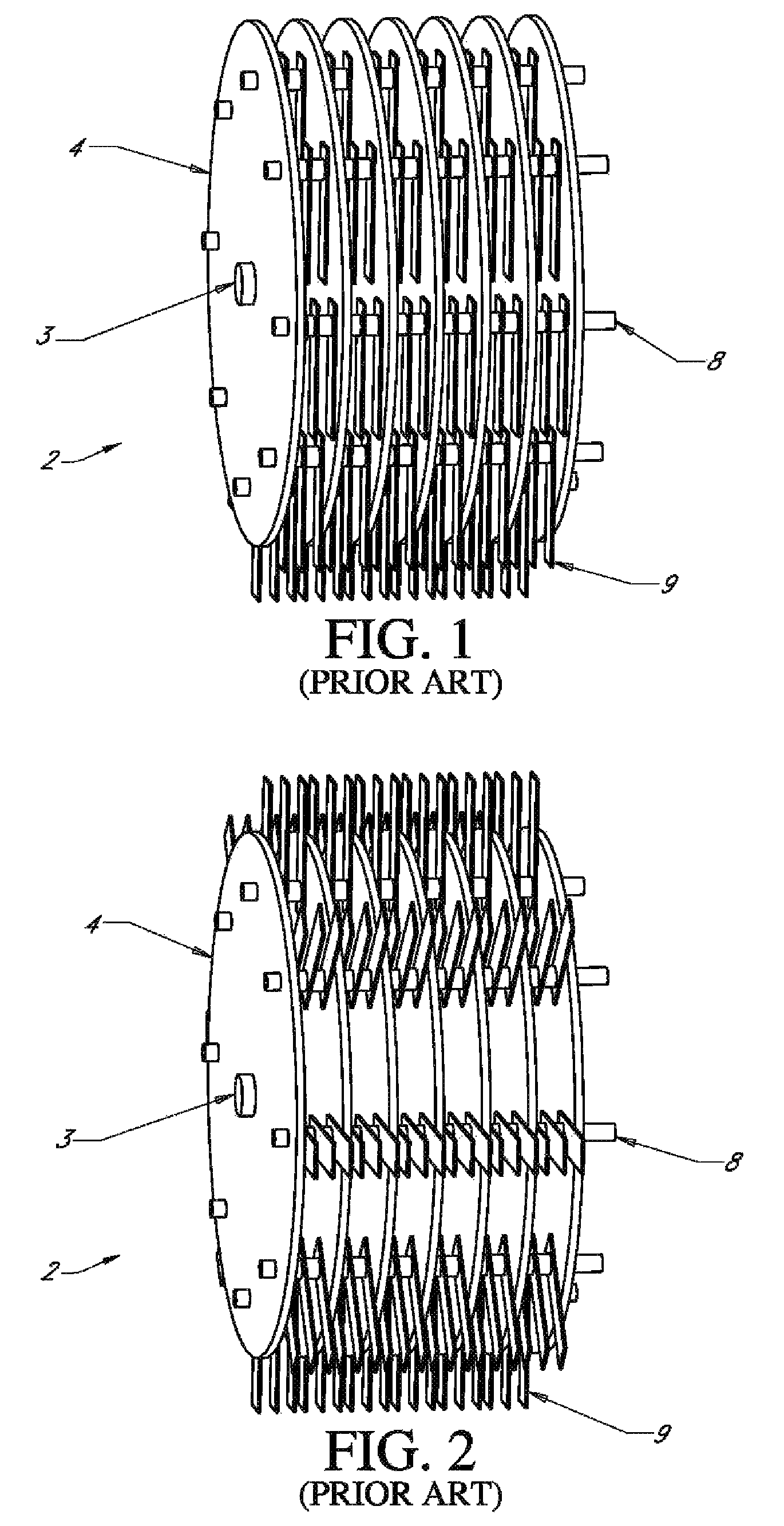

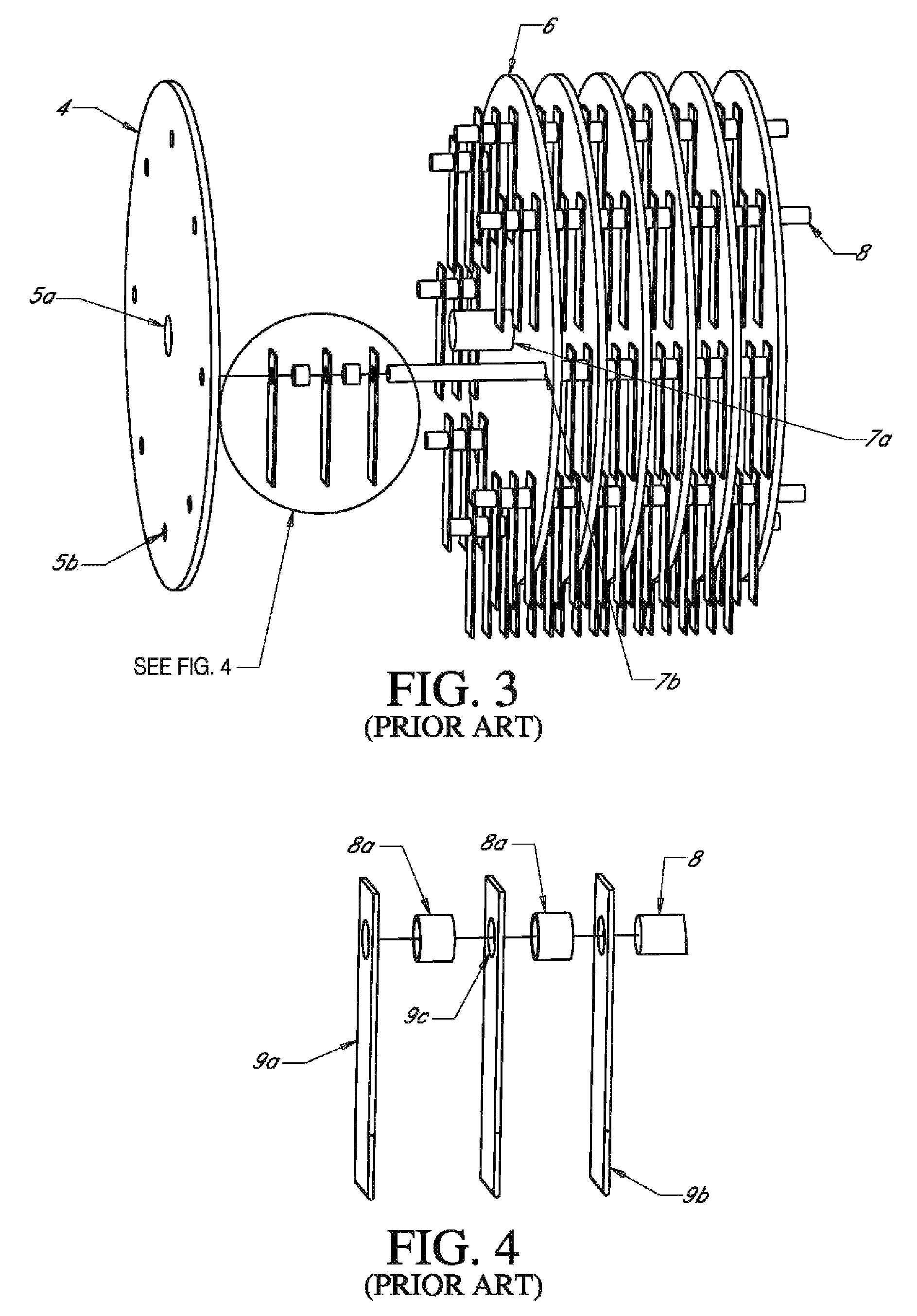

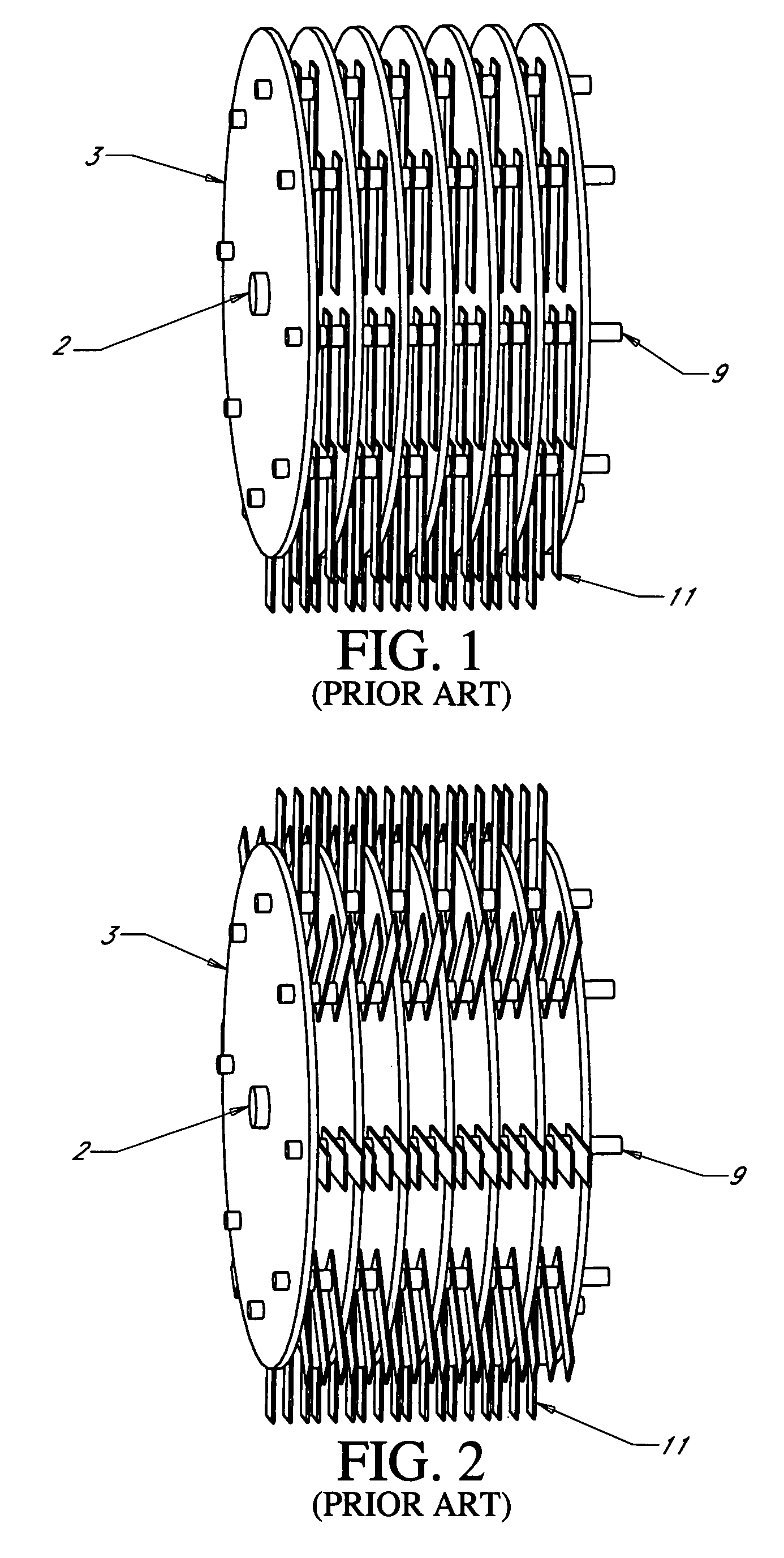

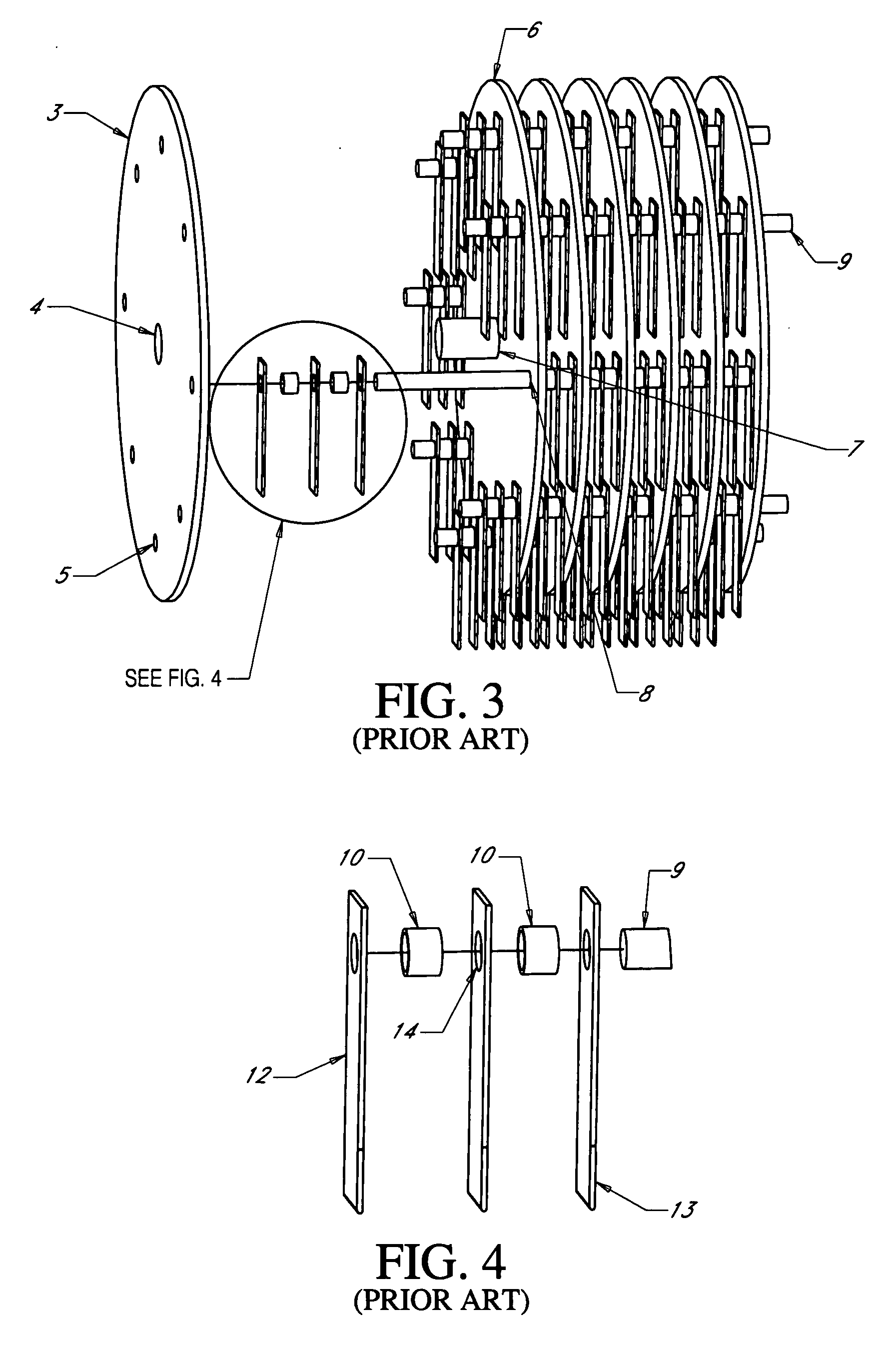

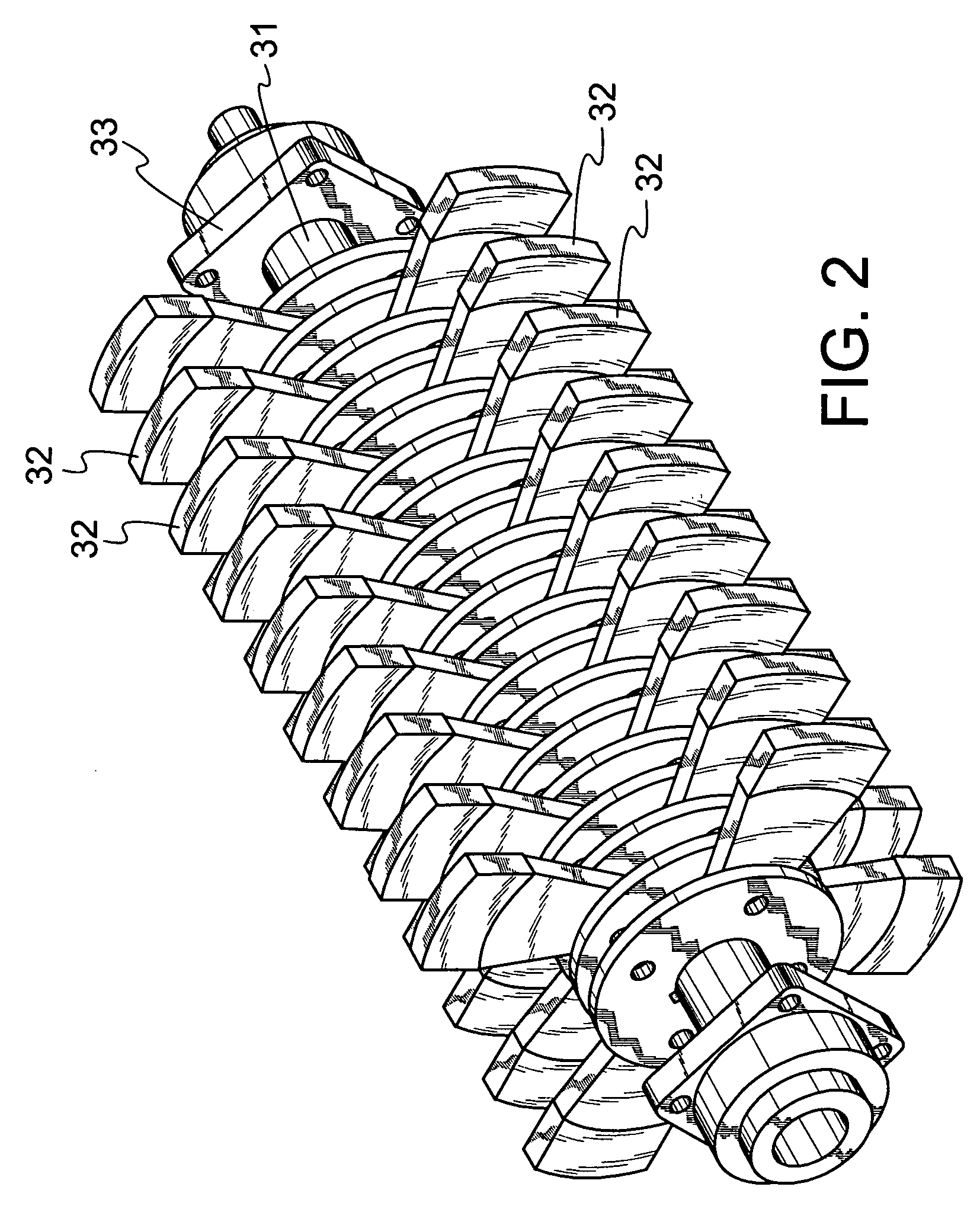

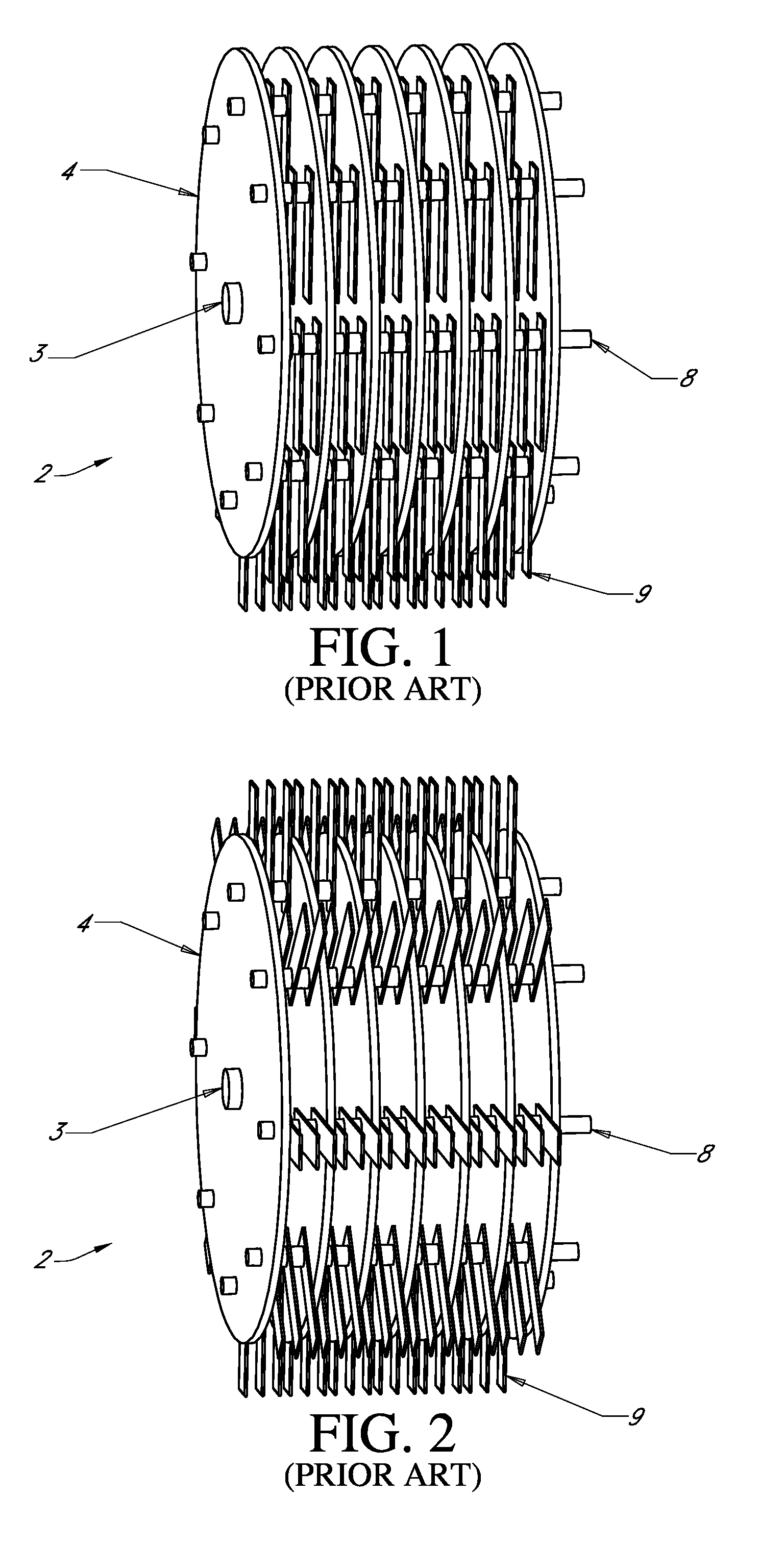

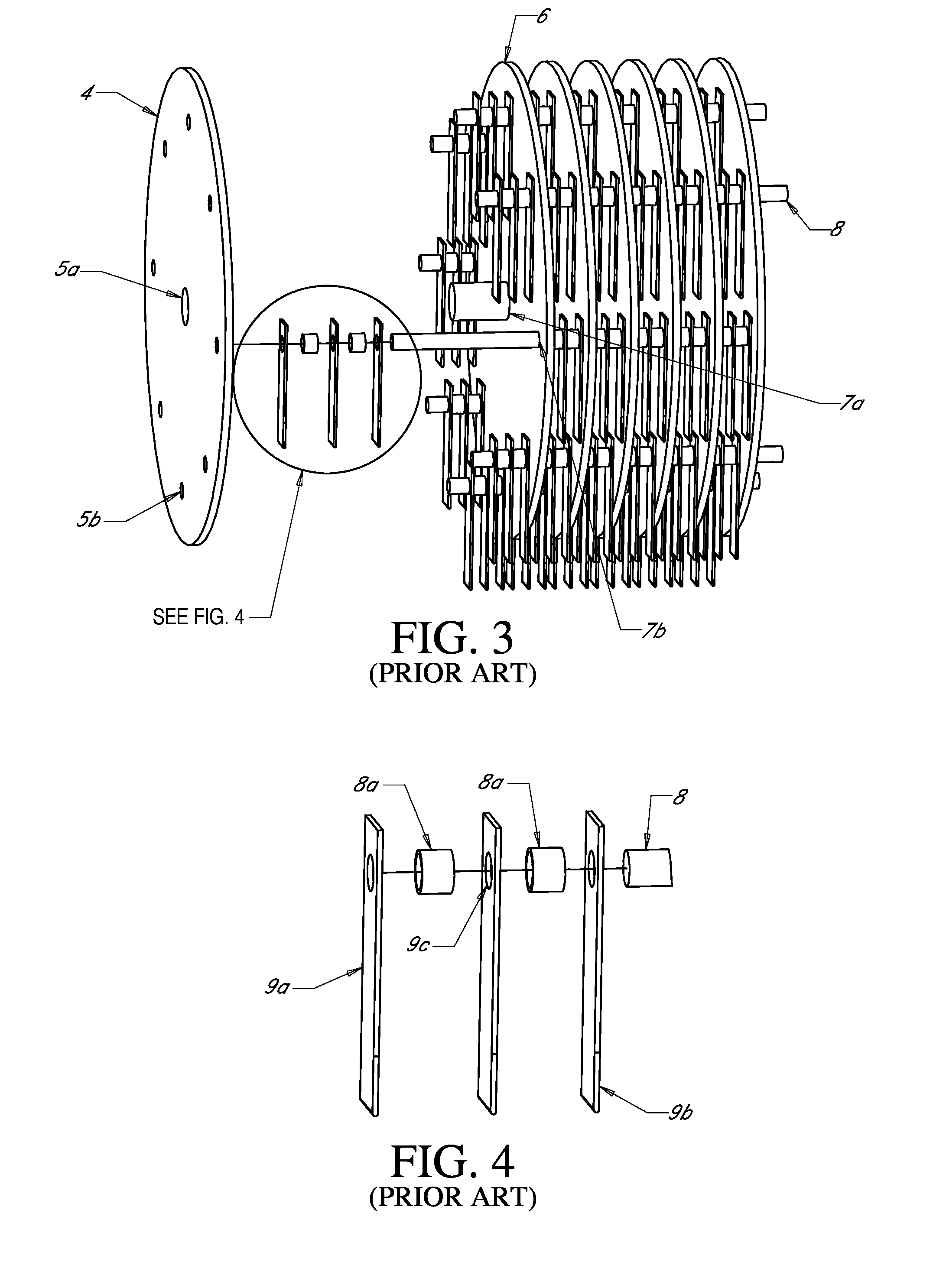

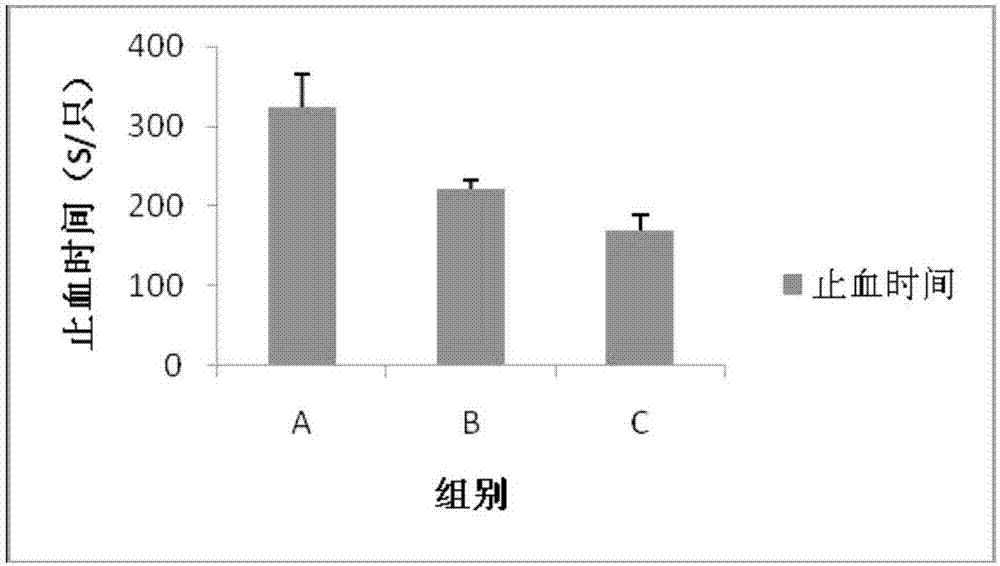

Offset disc hammer assembly for a hammermill

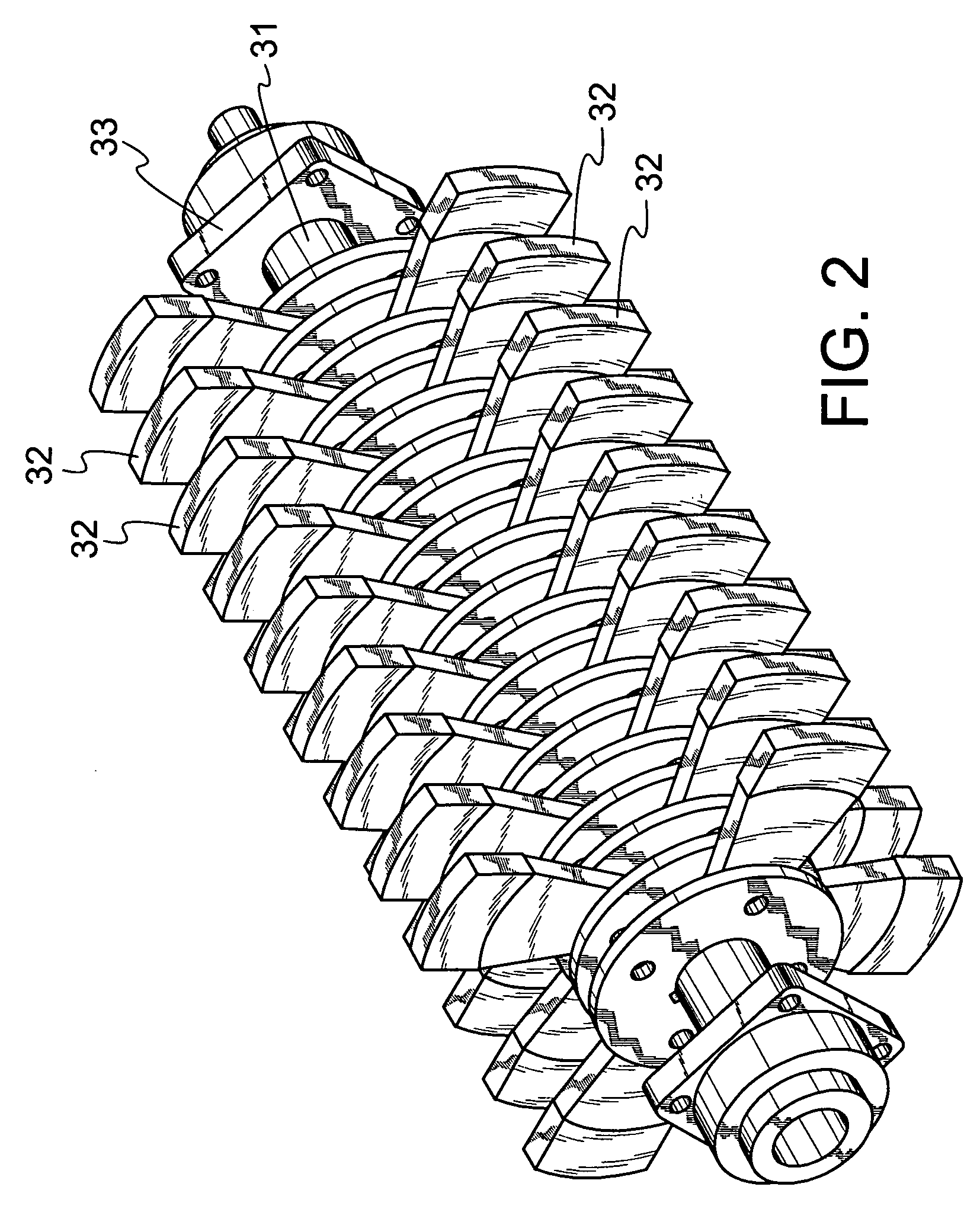

InactiveUS20060226269A1Efficient processingReduce in quantityGrain treatmentsCircular discDrive shaft

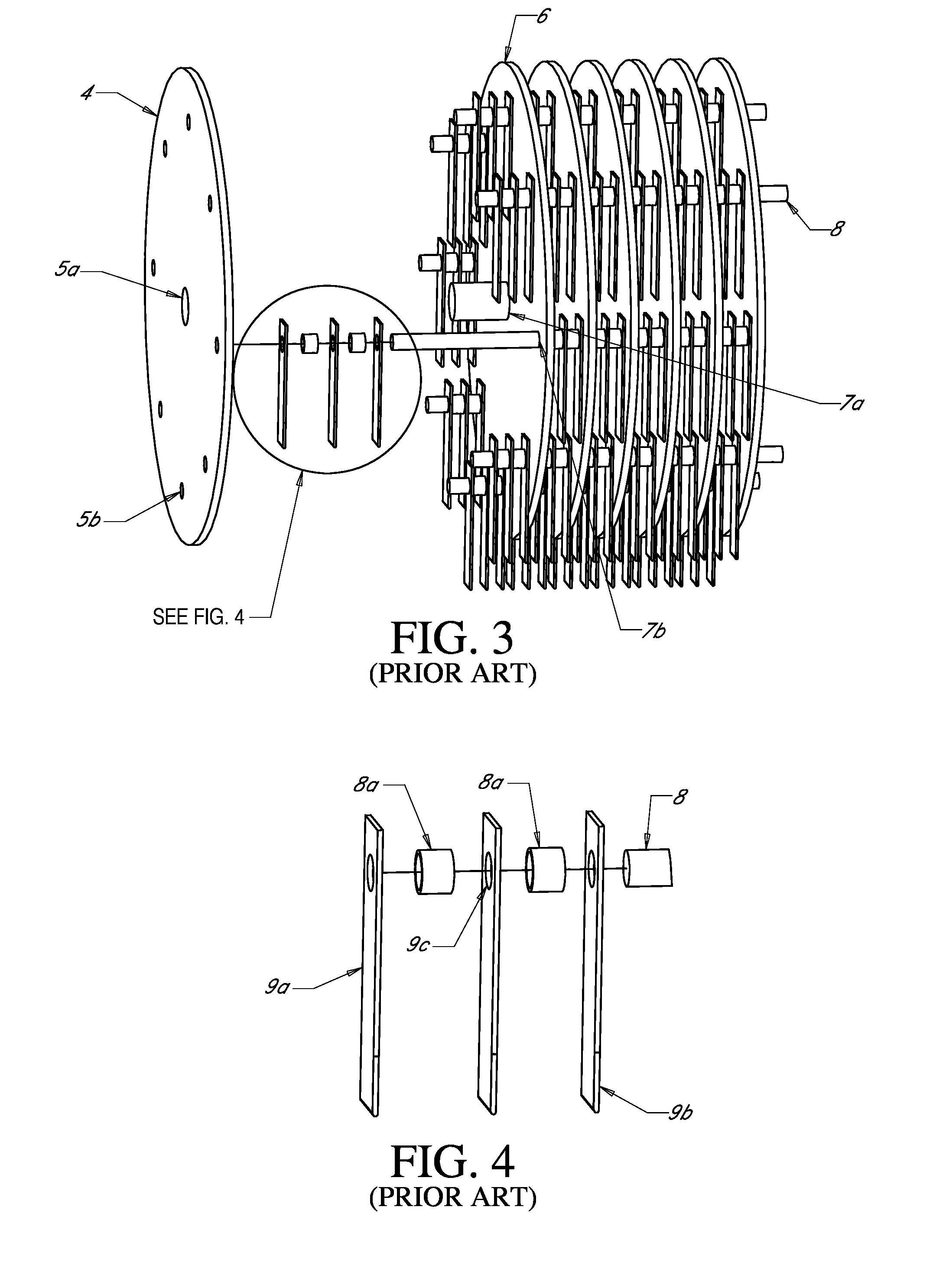

A hammer assembly for a hammermill is disclosed. The hammer assembly includes a drive shaft, a plurality of offset discs arranged in axial alignment about the drive shaft, and a plurality of hammers. Each offset disc is placed along the drive shaft adjacent to at least one other offset disc. The arrangement of the discs defines a plurality of alternately offset mounting spaces such that a hammer may be mounted in the offset mounting spaces.

Owner:RIVERSIDE ENG

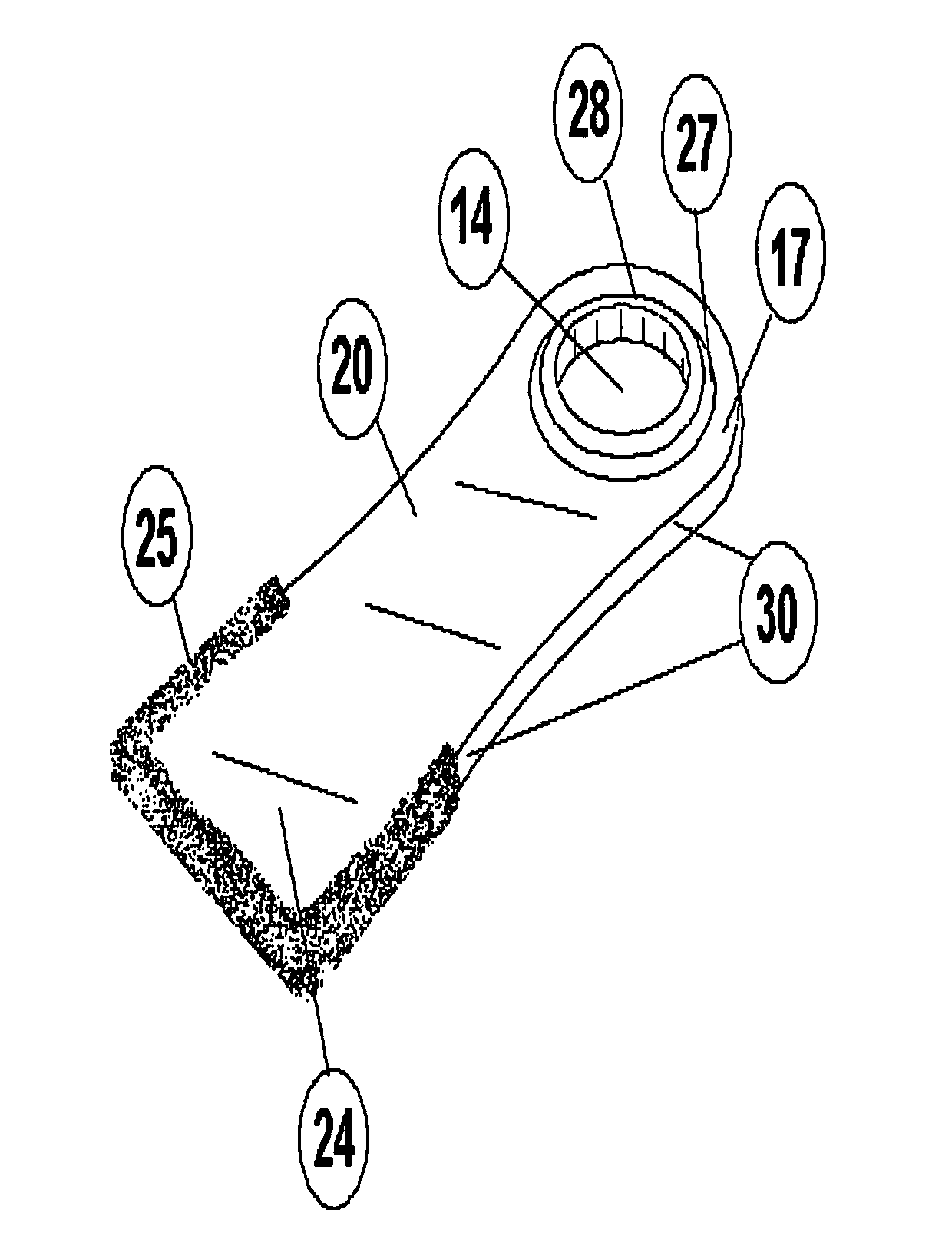

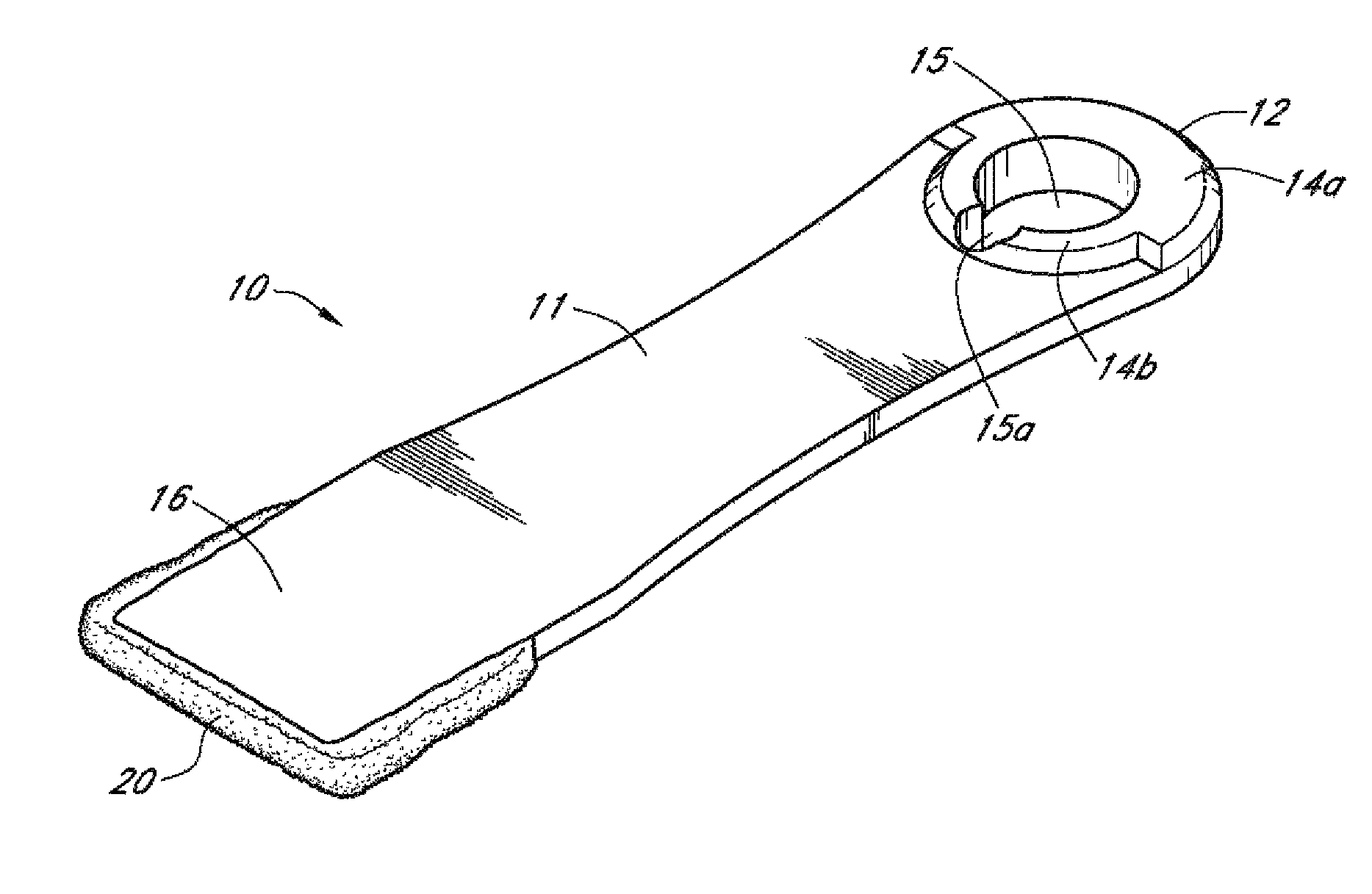

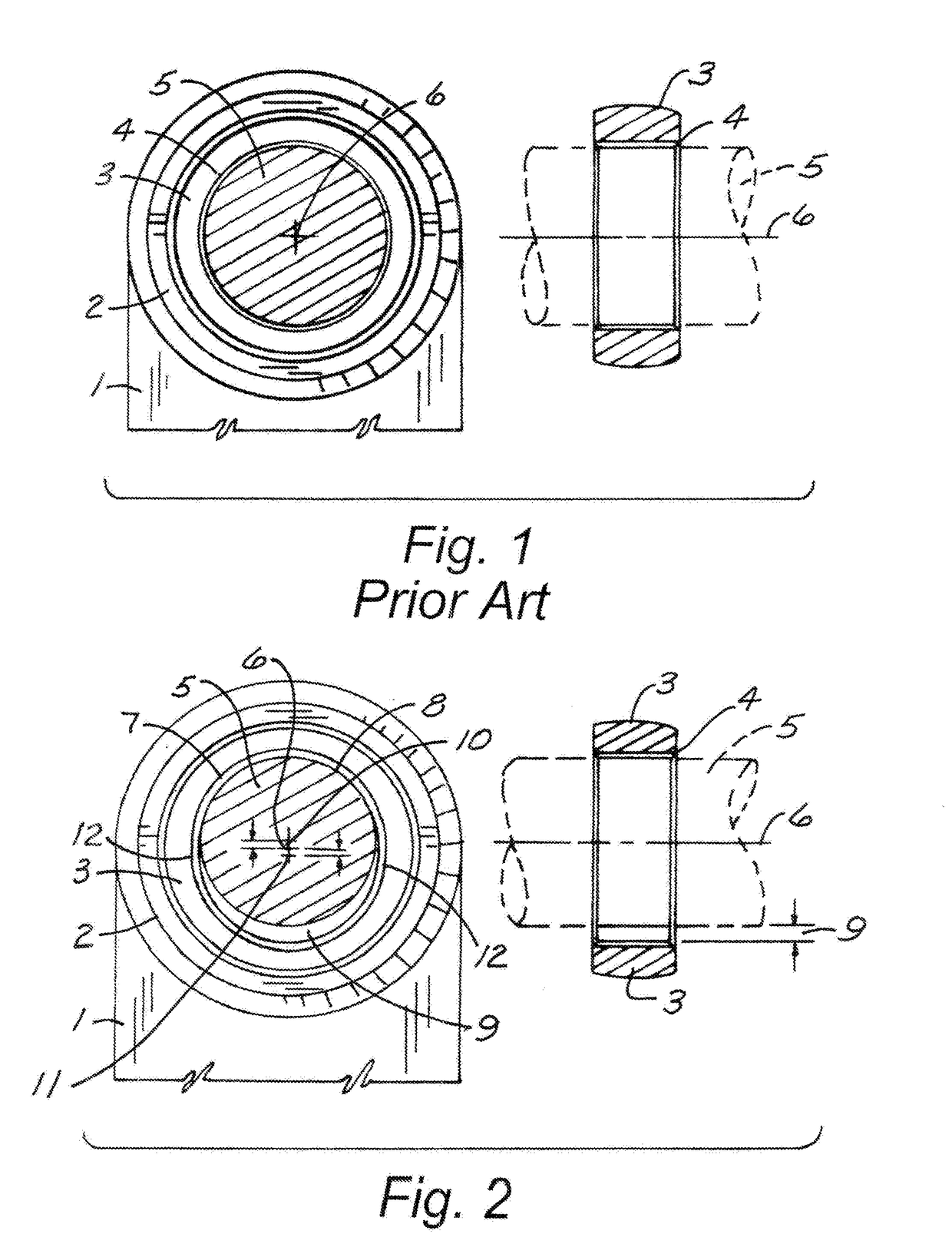

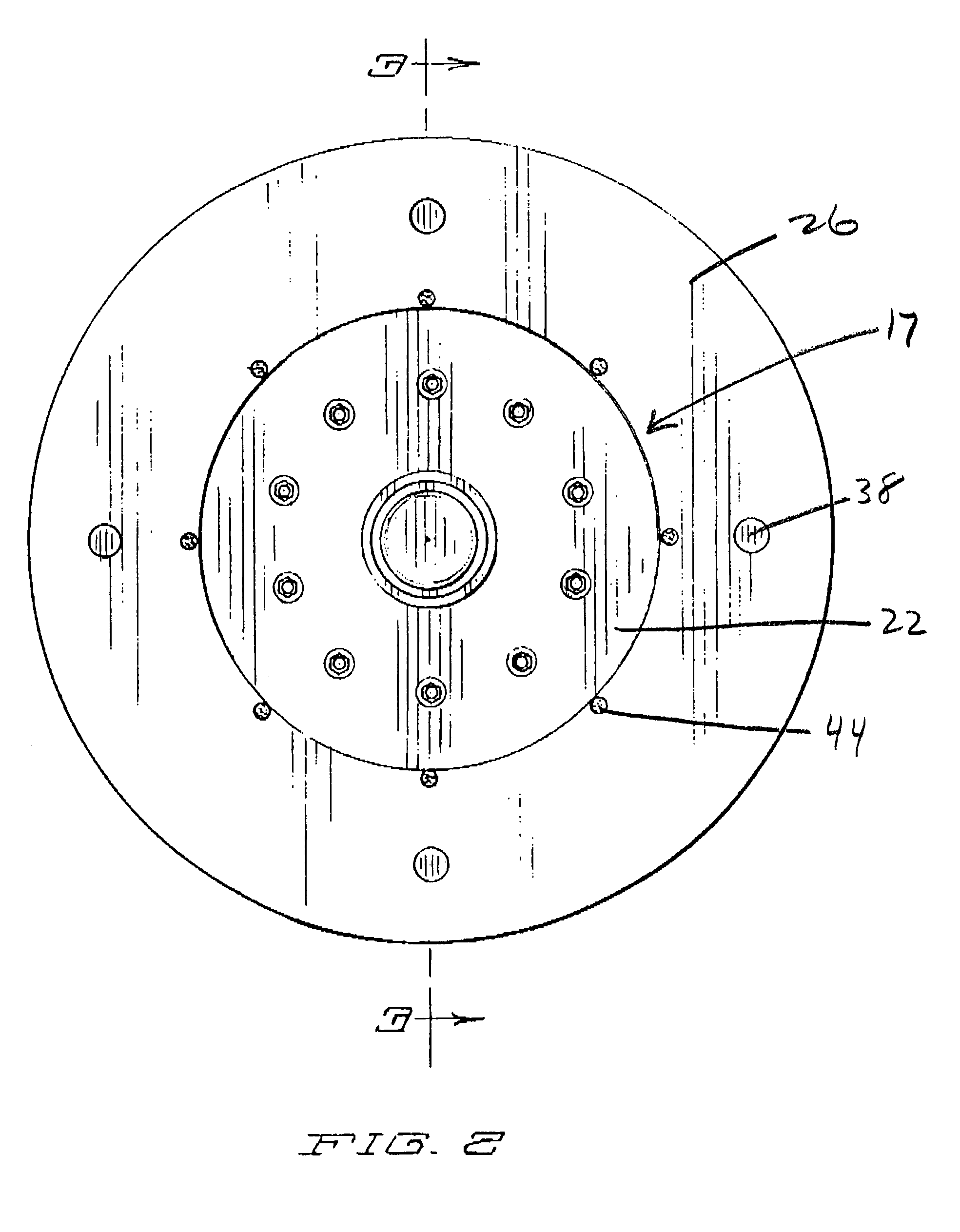

Hammer Mill Hammer With Non-Circular Rod Hole in Inner Bearing Race

An improved hammermill hammer with a connection end having a bearing race in the hammer body and a bearing received in said bearing race, the bearing having a non-circular, elongated, elliptical, oval or egg shaped inner bearing surface for receiving a hammer rod there through to prevent the hammer from sticking to the hammer rod.

Owner:JACOBS CORP

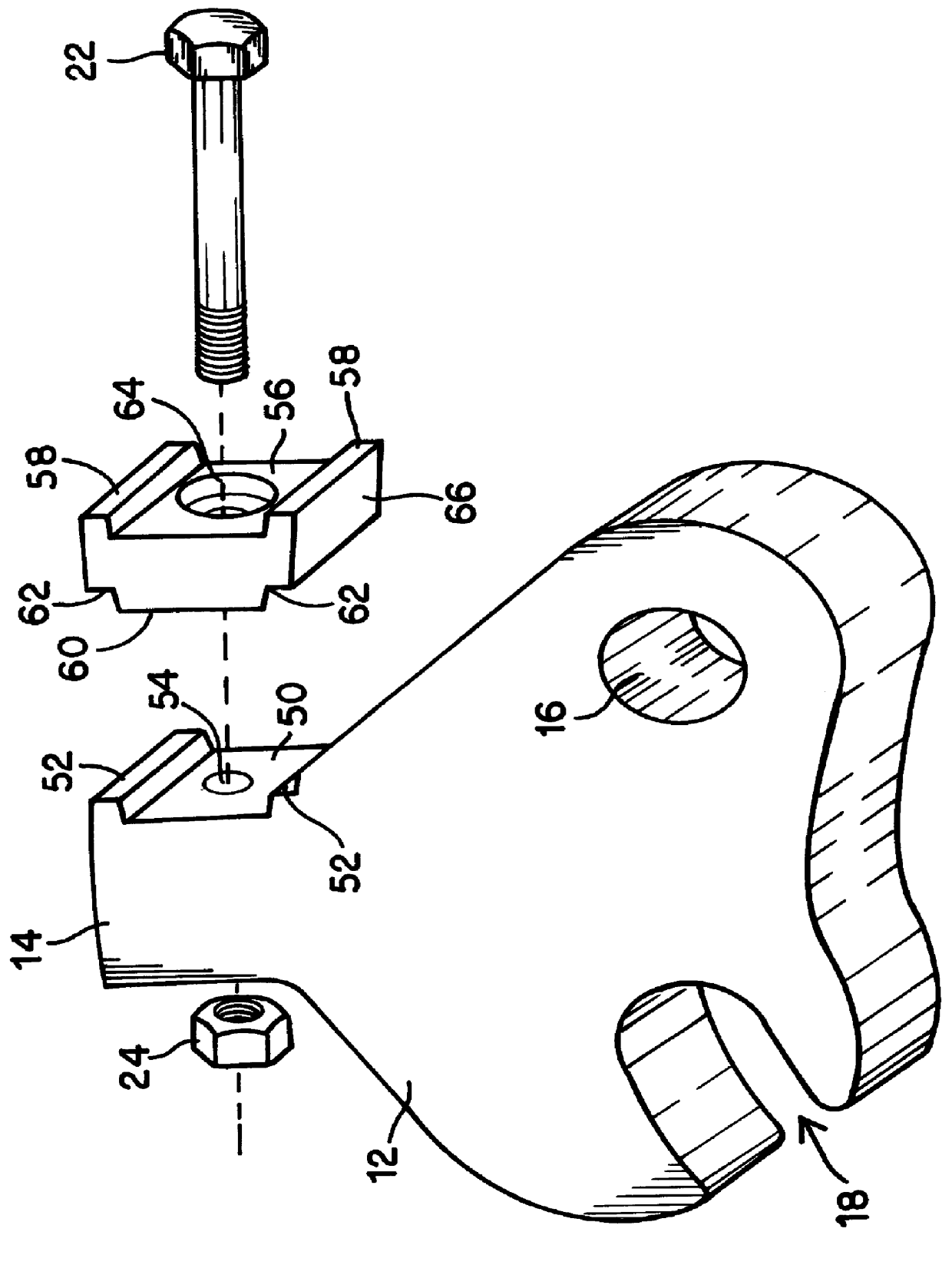

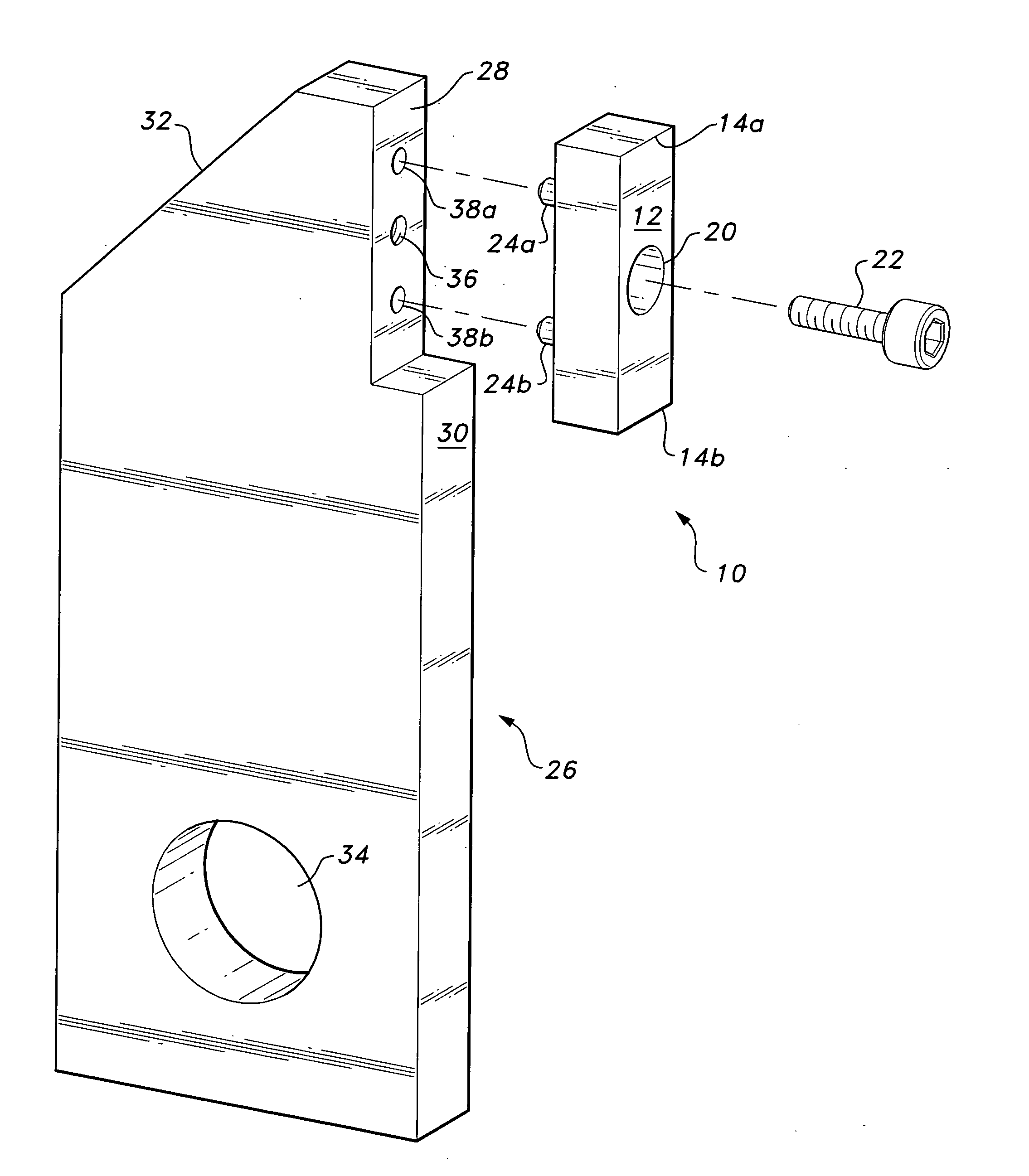

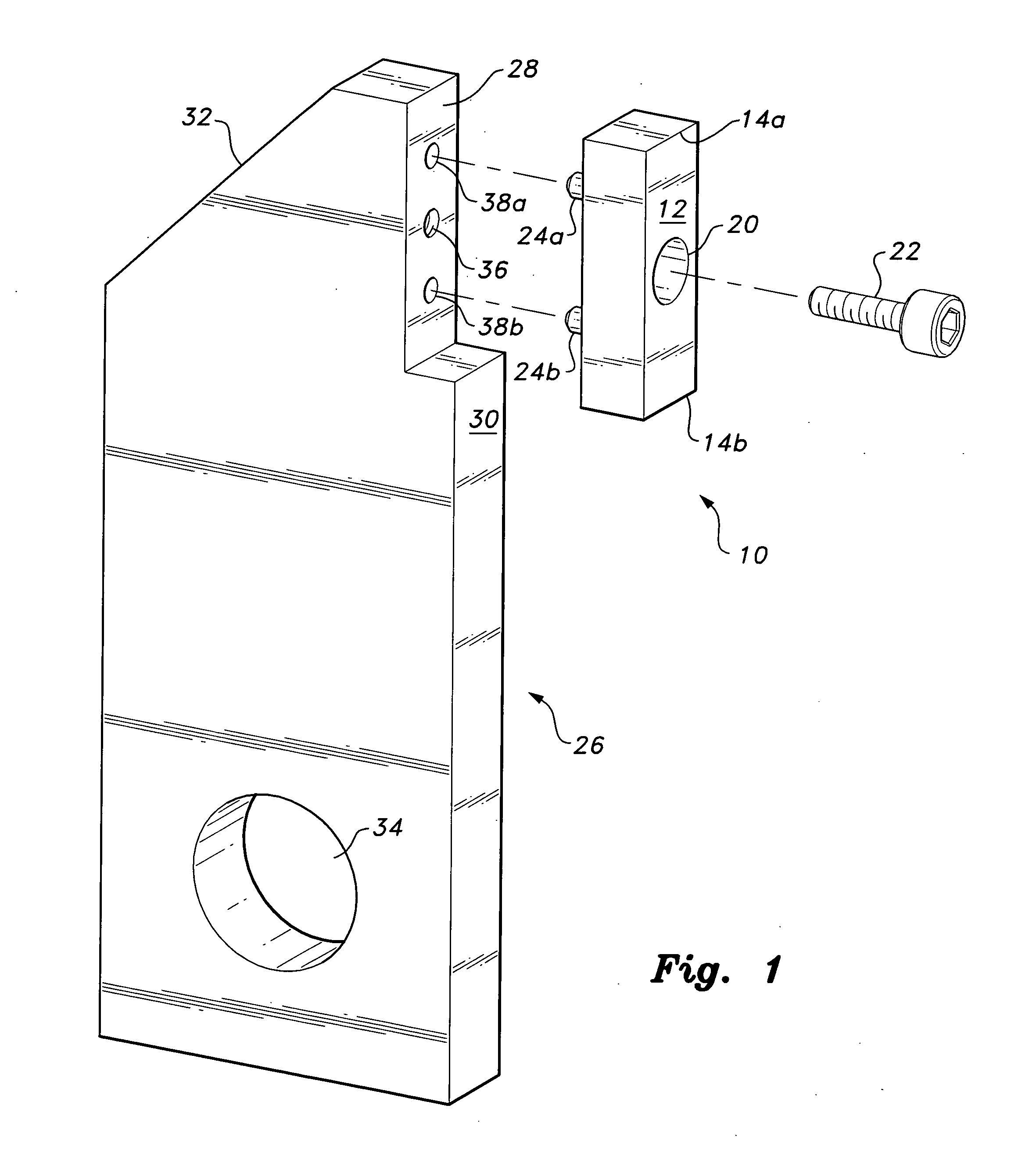

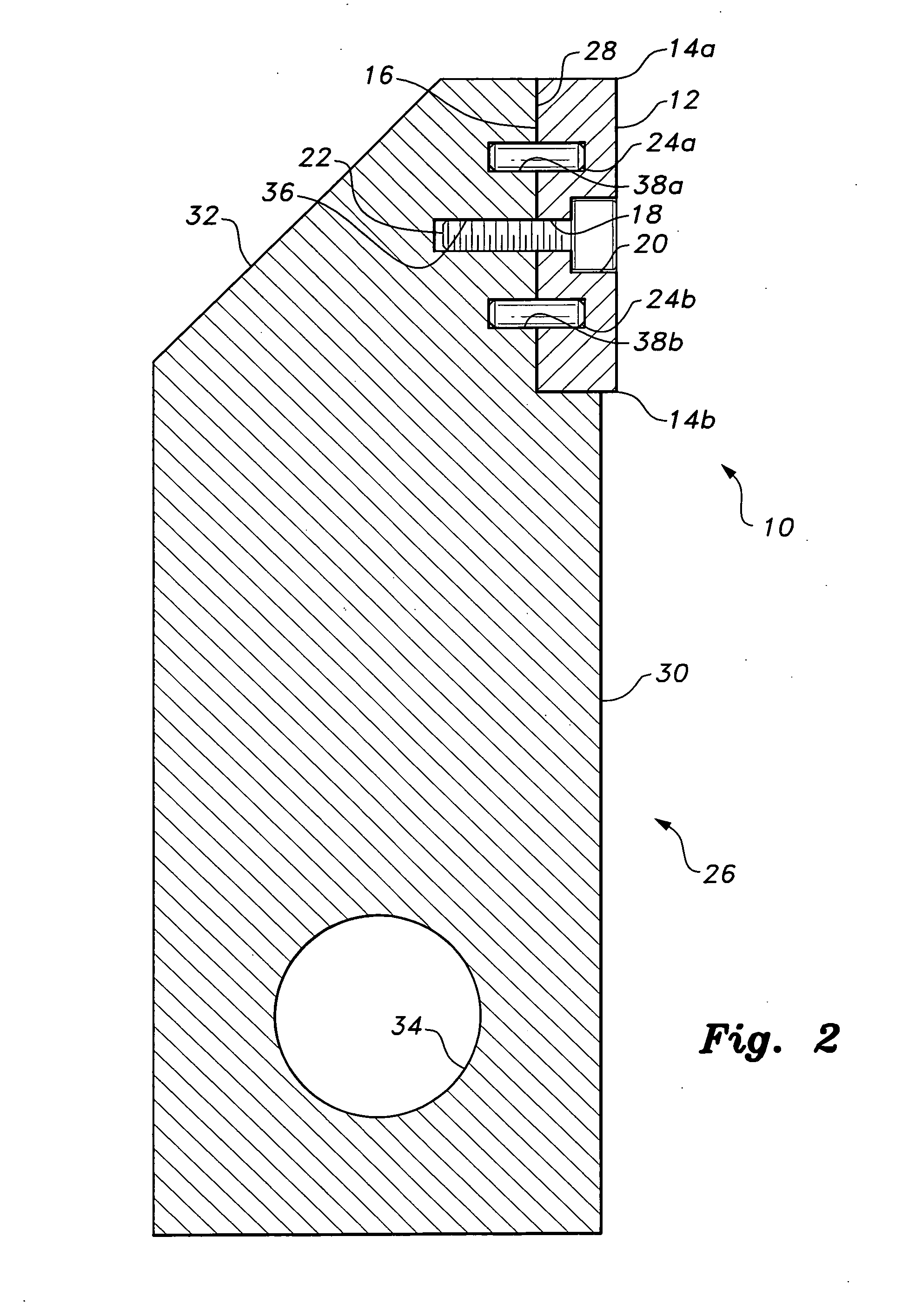

Replaceable insert for a hammermill hammer

The replaceable insert for a hammermill hammer enables the insert to be removed and replaced by the removal and installation of a single bolt in the leading face or edge of the hammer, rather than requiring partial disassembly of the hammermill for the removal of a damaged hammer and hammer shank from its retaining rod. The insert is formed of hard and tough metal, e.g., tool steel, carbide alloy, etc., as a longitudinally and laterally symmetrical rectangular parallelepiped, the hammer shank having a cooperating relief formed therein. The symmetrical configuration allows the insert to be reversed through 180° in its installation, thereby exposing a fresh insert face after the first face has been worn or damaged. A pair of indexing pins extends from the insert, the pins fitting closely within cooperating receptacles in the hammer shank relief to secure the insert precisely within the relief.

Owner:CRAVEN MATT H

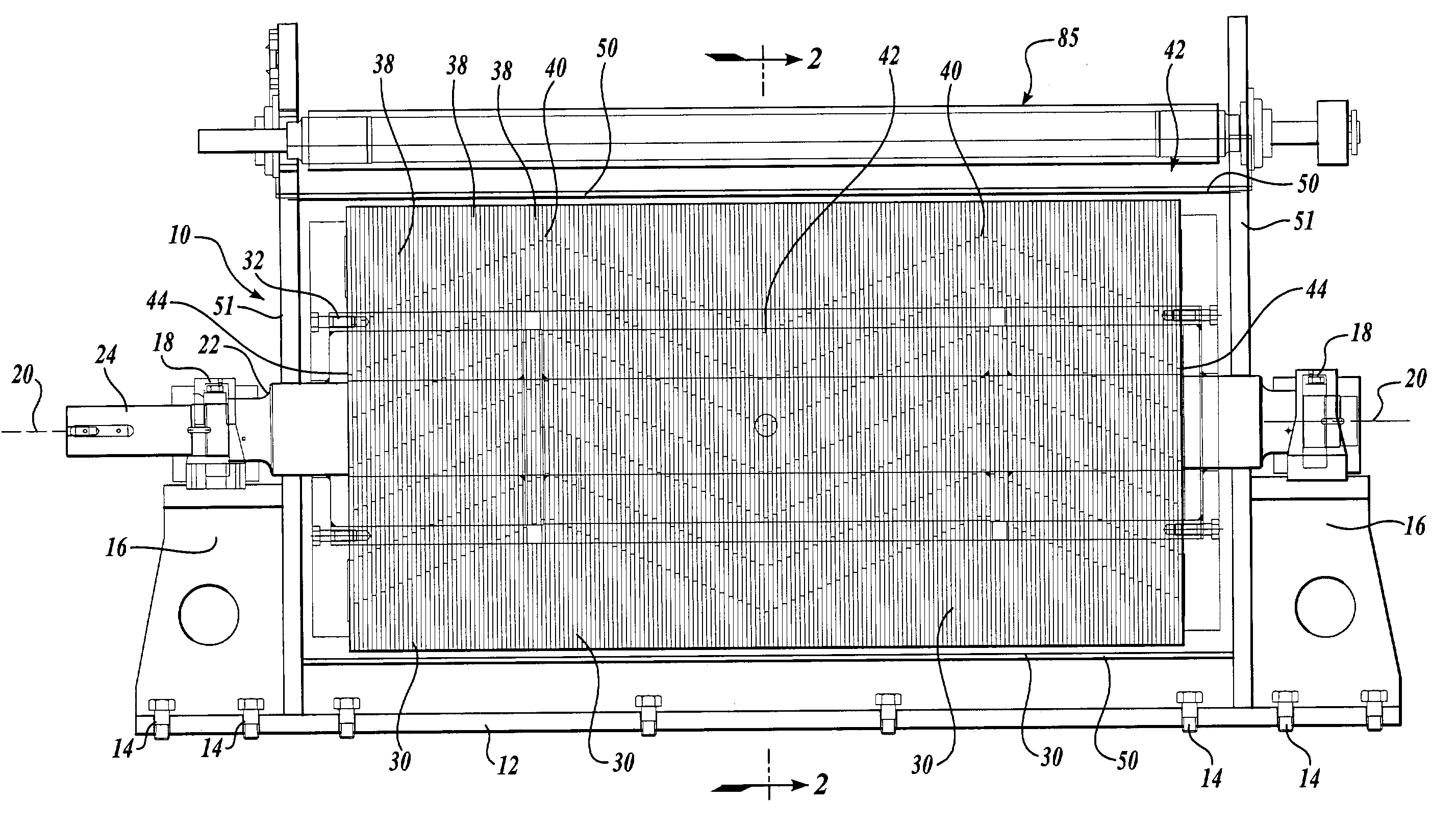

Screening apparatus with hammermill

A screening machine on a frame with a hopper having a conveyor belt. The conveyor belt discharges particulate material poured into the hopper into a rotating barrel screen or vibrating planar screen for sifting the material. A hammermill apparatus is pivotably mounted on a hood member to an arm that is pivotably mounted to the frame of the machine. The hammermill is positioned above the conveyor belt at the discharge end. The hammermill can pivot upwardly relative to the arm upon striking a large object on the conveyor belt, and a spring mounted to the arm and the hood biases the hammermill back to its original position. A hydraulic ram is drivingly linked to the arm for manually or automatically displacing the hammermill relative to the conveyor belt.

Owner:SCREEN MACHINE IND

Hammer

A hammer for use in a rotatable hammermill assembly comprising a first end for securement within a hammermill assembly, wherein a rod hole is formed in the second end, wherein the rod hole is centered in the first end for engagement with and attachment to the hammermill assembly is disclosed. The hammer also has a second end for contact and delivery of momentum to material to be comminuted, wherein the second end includes at least two blades. A neck connects the first end to the second end. In some embodiments the thickness of the neck may be less than the thickness of the first end or of any of the blades. In some embodiments the rod hole is surrounded by one or more rod hole shoulders. In other embodiments a notch is positioned in the rod hole along the longitudinal axis thereof.

Owner:GENESIS III

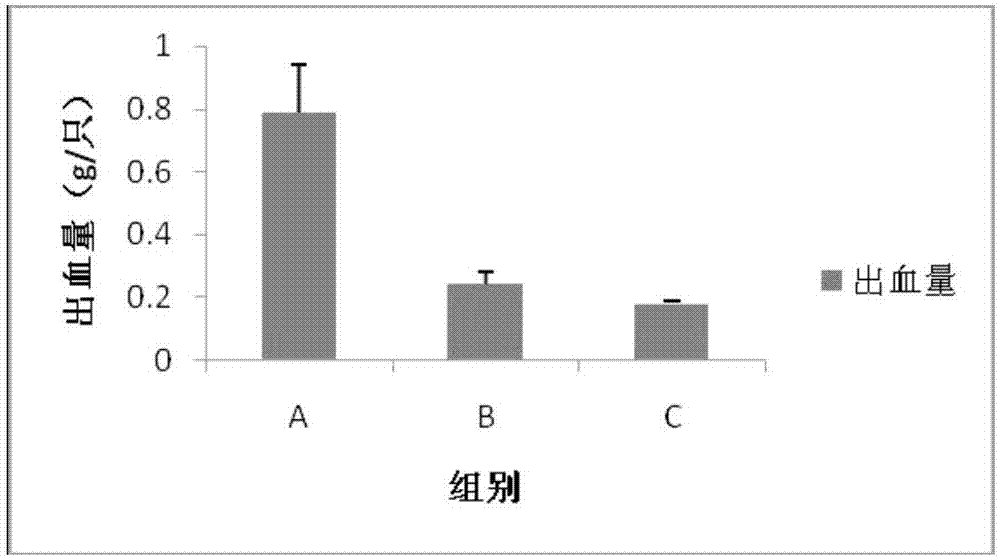

Microfiber collagen hemostatic material and preparation method thereof

ActiveCN107137758ASufficient tensile strengthGood hemostatic effectSurgical adhesivesHeatFibrosisRadiation Sterilization

The invention relates to a microfiber collagen hemostatic material and a preparation method thereof. The preparation method of the material includes the first step of sodium sulfide unhairing, the second step of shredding and fibrosis, the third step of swelling control, the fourth step of drying, the fifth step of depolymerisation and fluffing, and the sixth step of Co60 radiation sterilization, wherein in the fifth step, the obtained fasciculus is treated using a hammer mill to obtain a microfiber collagen product. According to the method, the use concentration of sodium sulphide is reduced, the efficiency of unhairing is improved, and degreasing and impure protein removal are effectively conducted; collagen materials are not oxidized and degenerated, the activity of microfiber collagen is easy to maintain, and the hemostatic effect is improved. Acid is introduced in the treating process, the degreasing and protein removal are more effective, and the adhesion property of the hemostatic material is guaranteed.

Owner:林贵梅

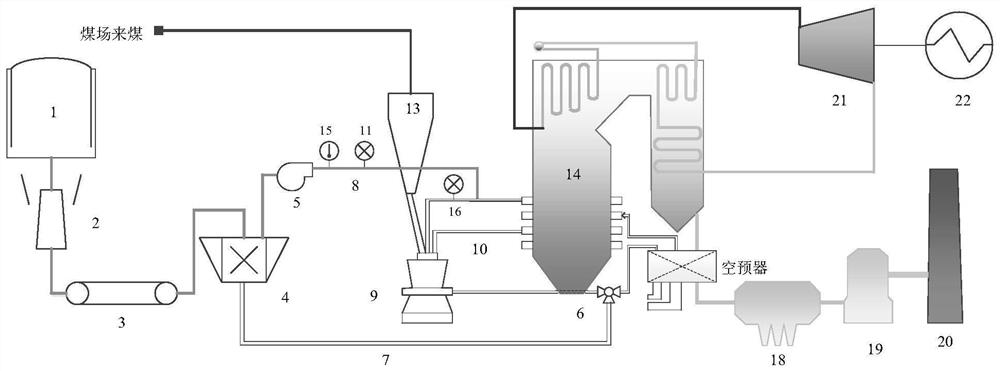

Coal-fired unit coupling biomass power generation system and method

PendingCN113154432AThe overall impact is smallEfficient couplingAir supply regulationDrying gas arrangementsProcess engineeringHammermill

The invention discloses a coal-fired unit coupling biomass power generation system and method. The coal-fired unit coupling biomass power generation system comprises a crushing mill, a conveyor, a hammer mill and a booster fan. An outlet of the crushing mill is connected to the input end of the conveyor, the output end of the conveyor is connected to a biomass powder inlet of the hammer mill, the hammer mill is further connected with a primary air bypass pipeline, and a biomass powder outlet of the hammer mill is connected to a primary powder pipe of the boiler through a biomass powder pipeline and the booster fan arranged on the biomass powder pipeline. The coal-fired unit coupling biomass power generation system and method are simple and efficient, large influences on the output of a unit coal mill in a co-grinding or forming blending combustion process is avoided, and the system investment of an independent spraying combustion process and the transformation influence on a boiler can also be reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

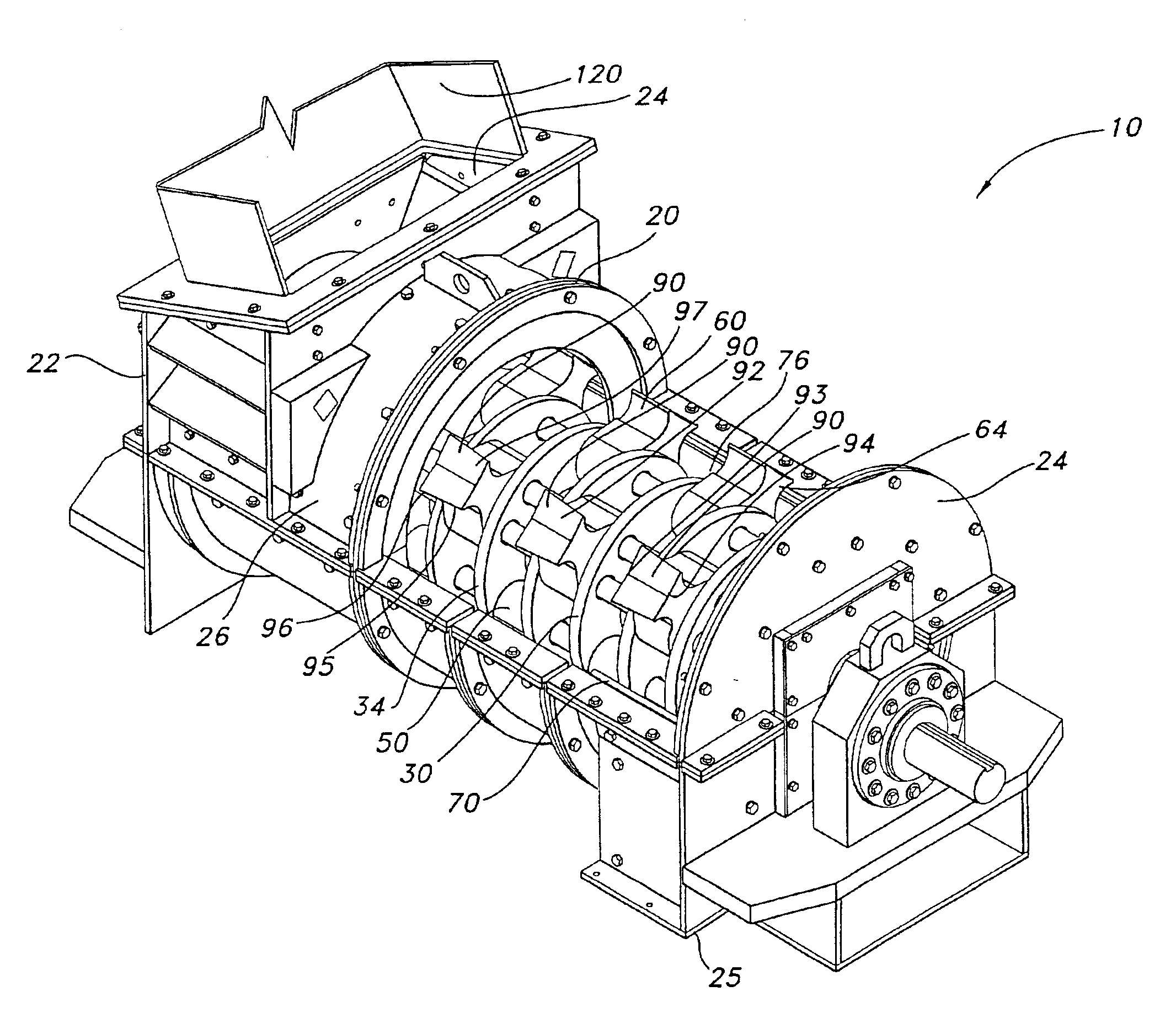

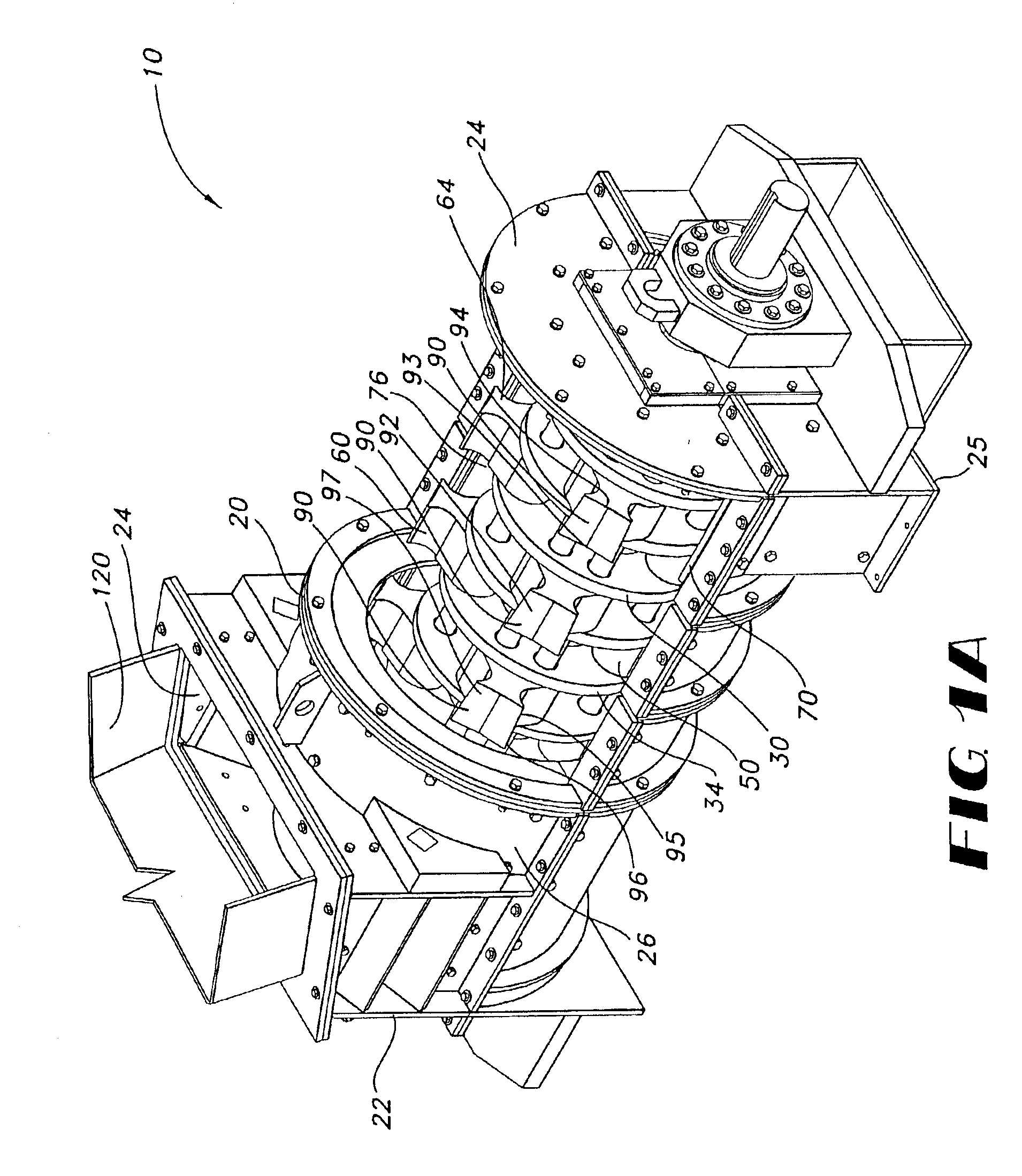

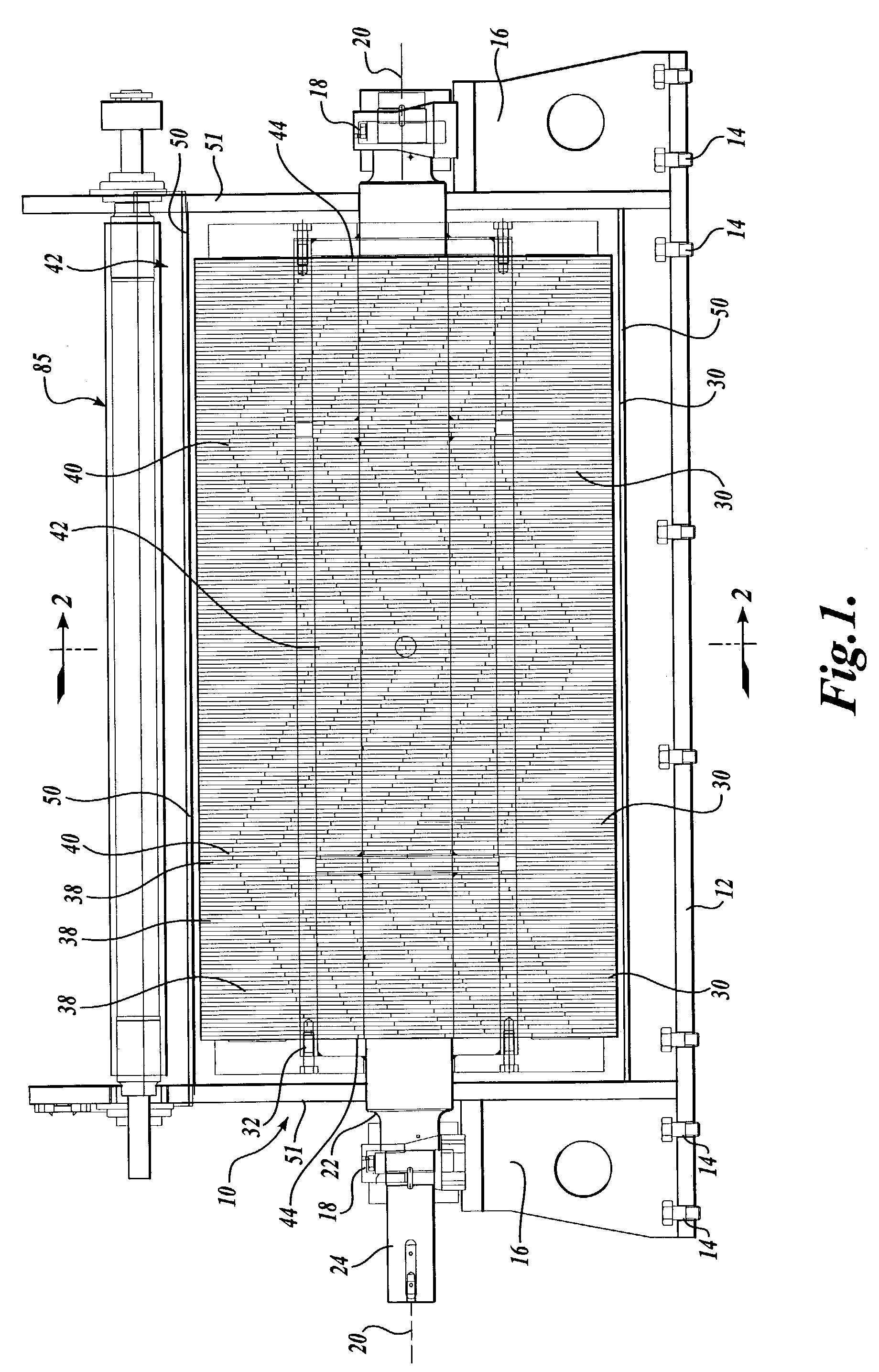

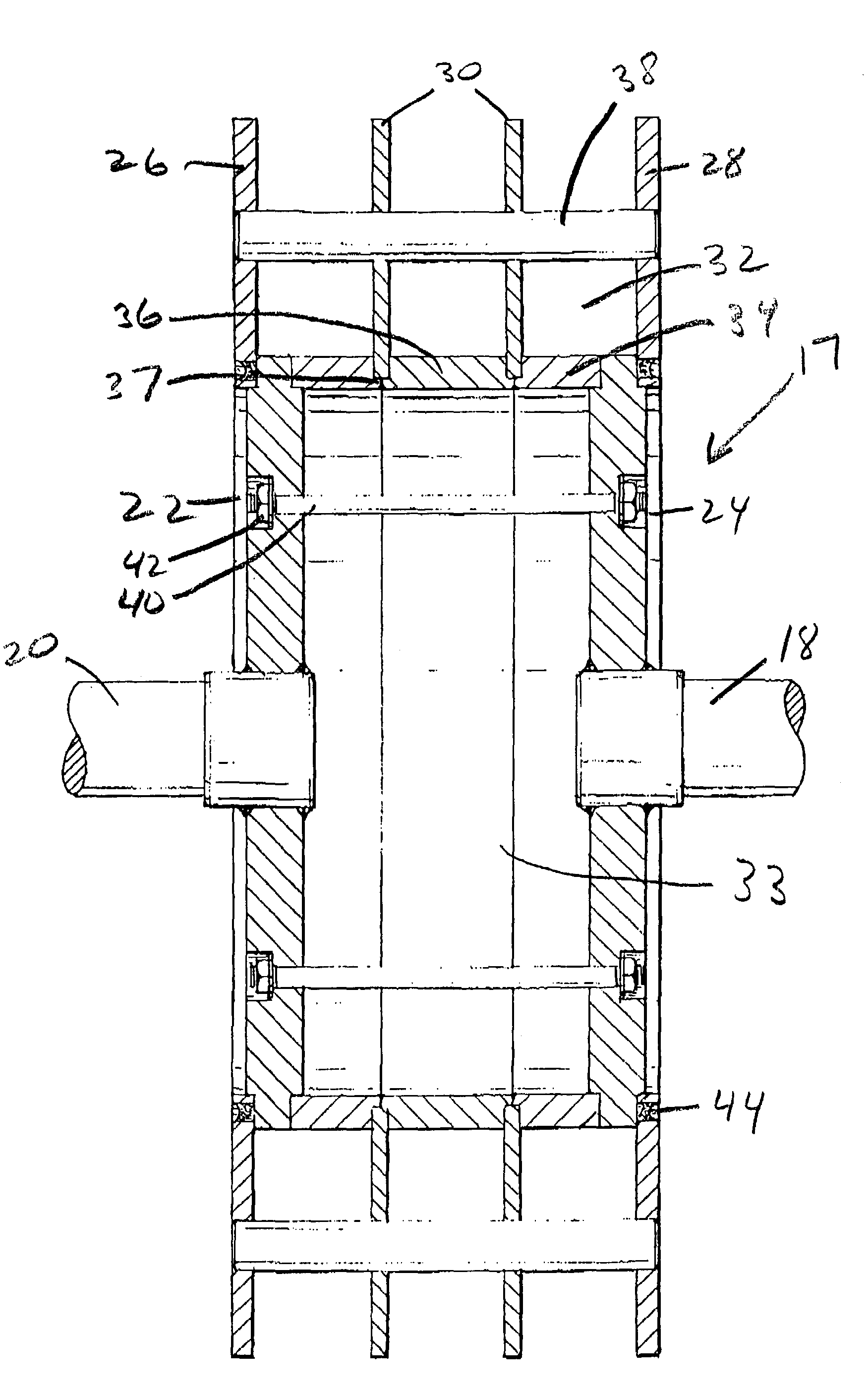

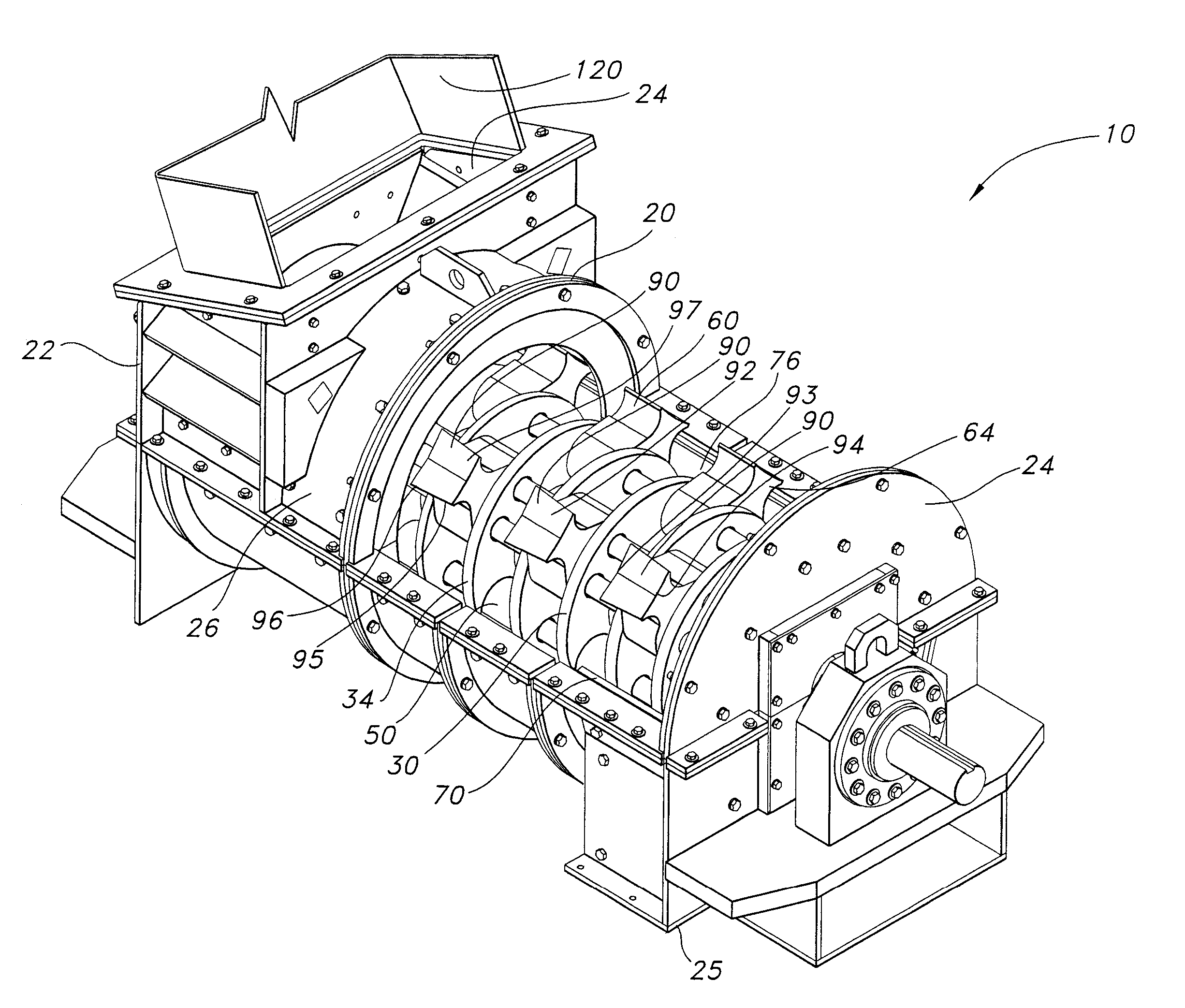

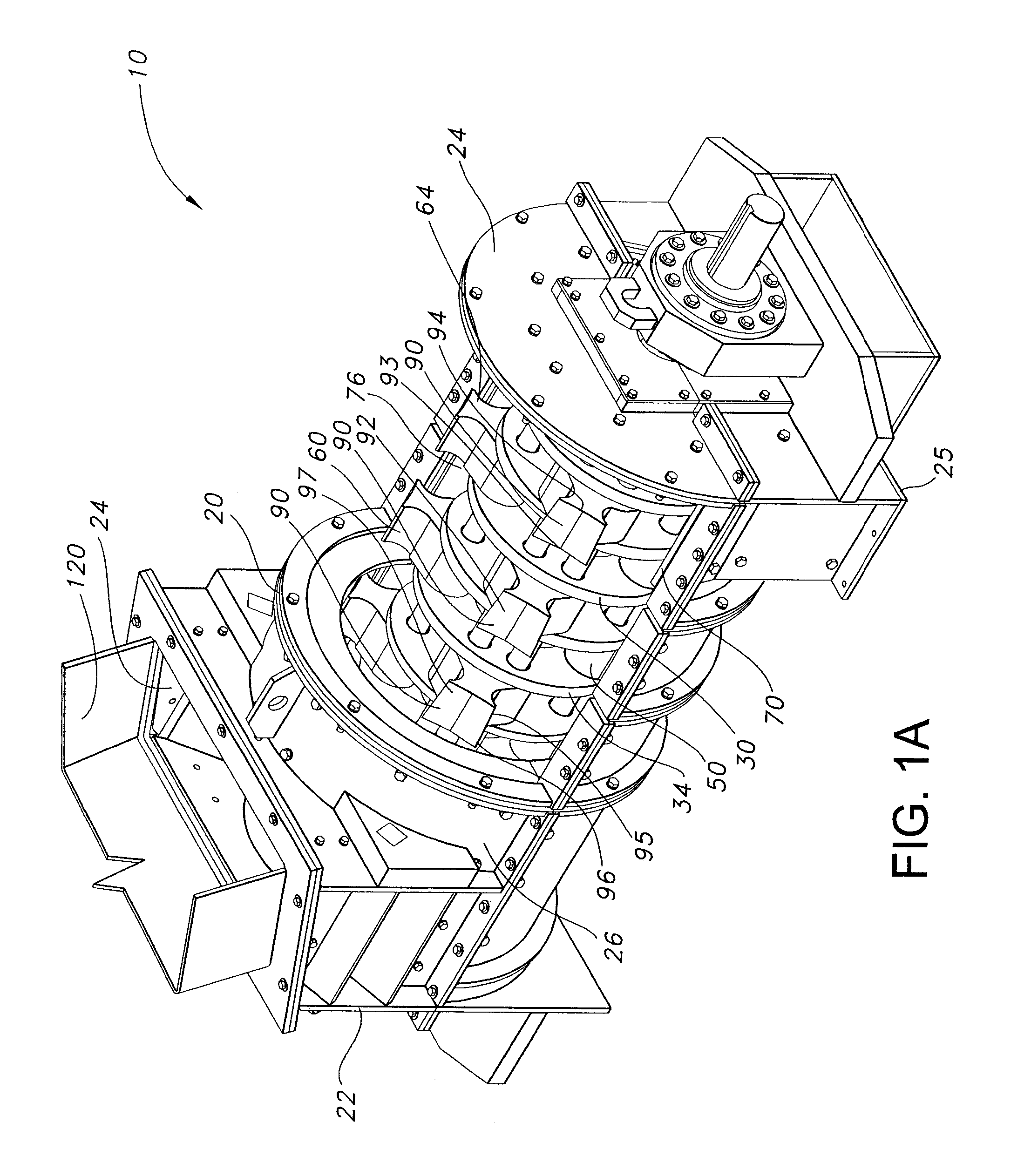

Hammermill with stub shaft rotor apparatus and method

ActiveUS7025294B2Efficient structural designReduced maximum bending stressGrain treatmentsEngineeringHammermill

An improved rotor design for hammermills. The invention eliminates the solid rotor shaft and replaces it with a tubular structure comprised of two stub rotor shafts with plate flanges and grooved spacer rings therebetween. End head disks, attached to the plate flanges, and intermediate disks are concentrically positioned with the axis of rotation of the assembly. The intermediate disks are held in alignment by the pilot groove located in the spacer rings. The flanges, stub shafts, spacer rings and intermediate disks are supported and held in proper alignment by tension rod compression. The resulting tubular rotor shaft assembly is less massive, more stiff, less susceptible to vibration, has a reduced bending stress, is less expensive to startup and operate and less expensive and more flexible in terms of component inventory than known solid through-shaft rotors.

Owner:CARTER DAY INDS

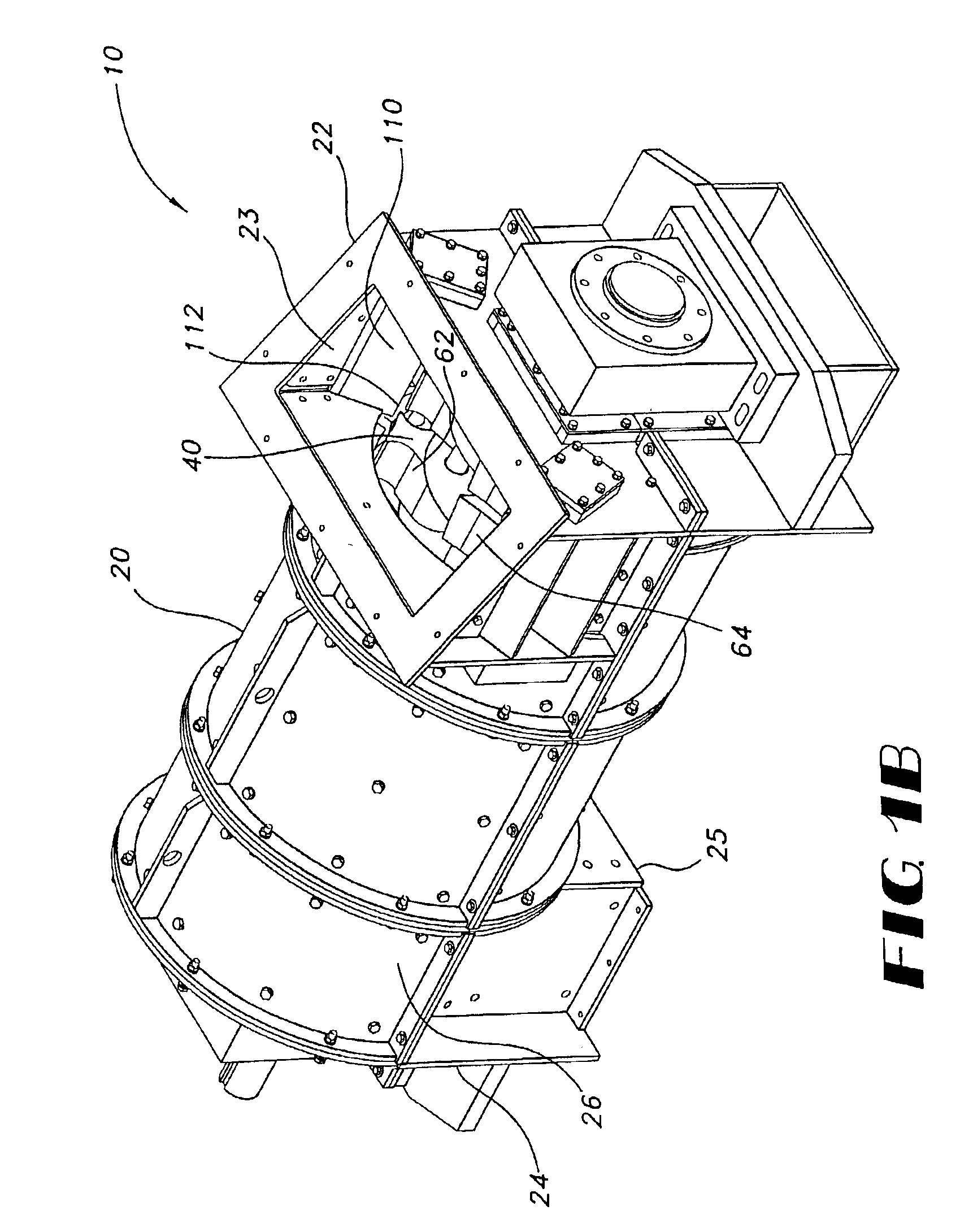

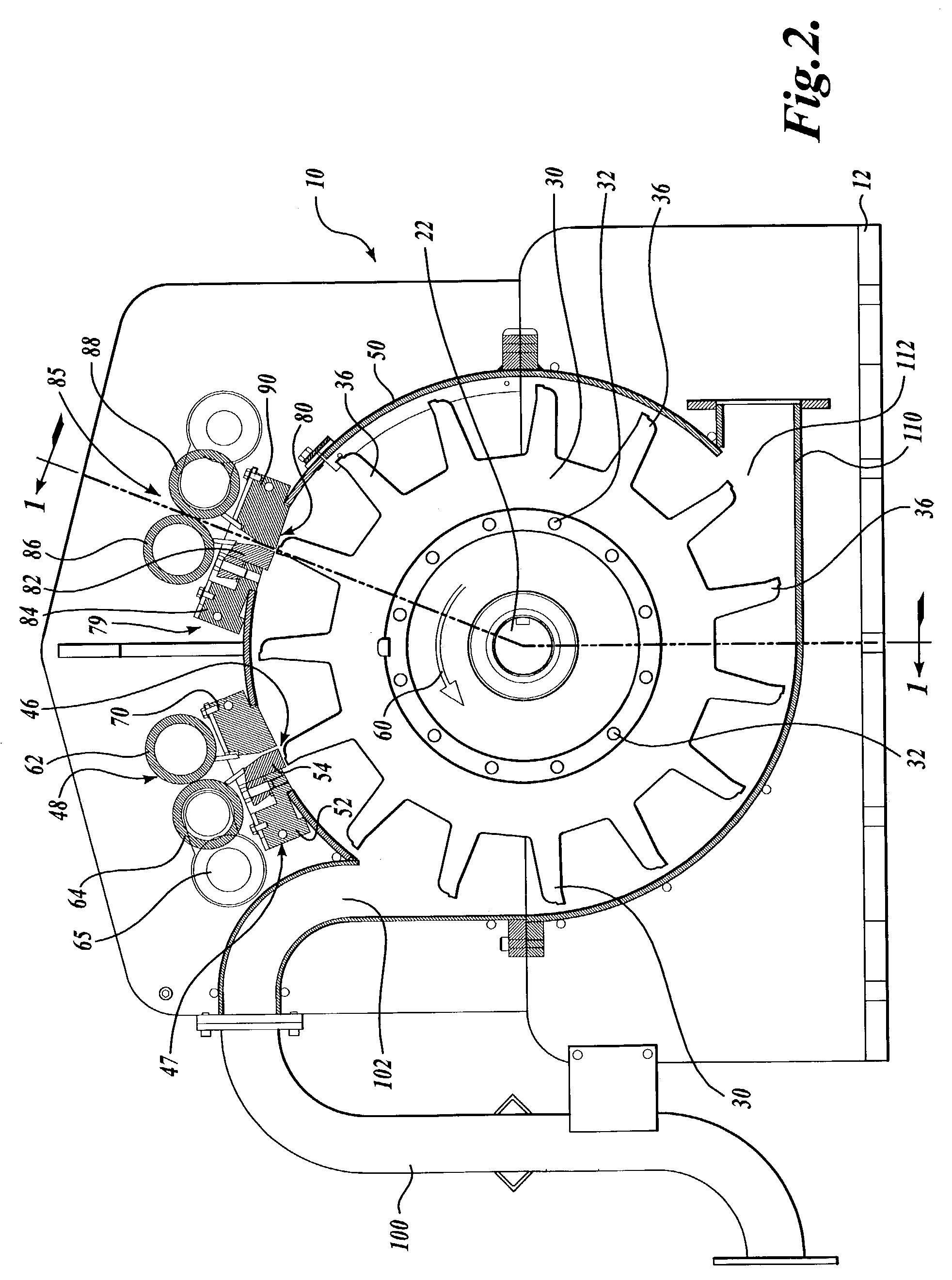

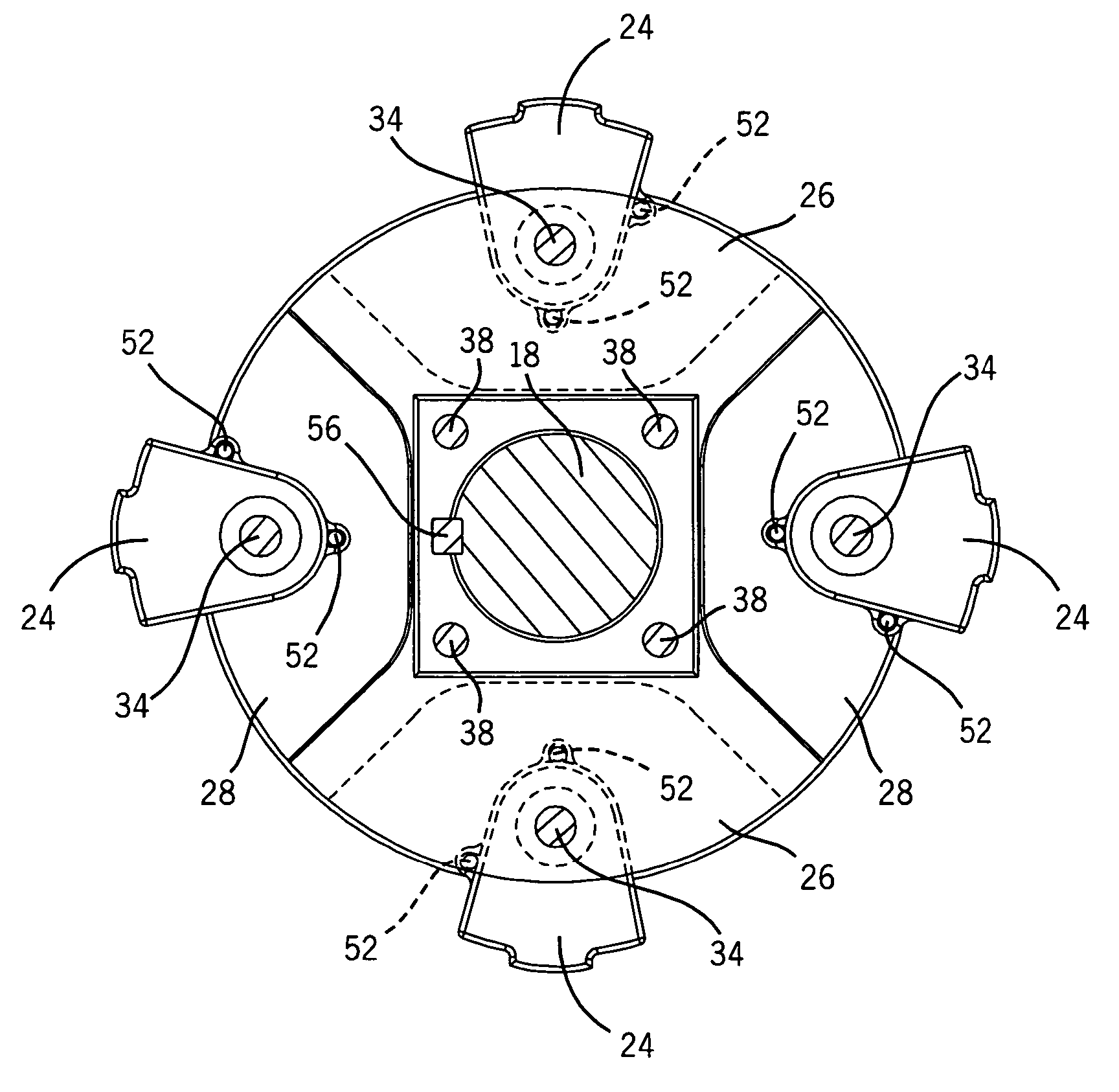

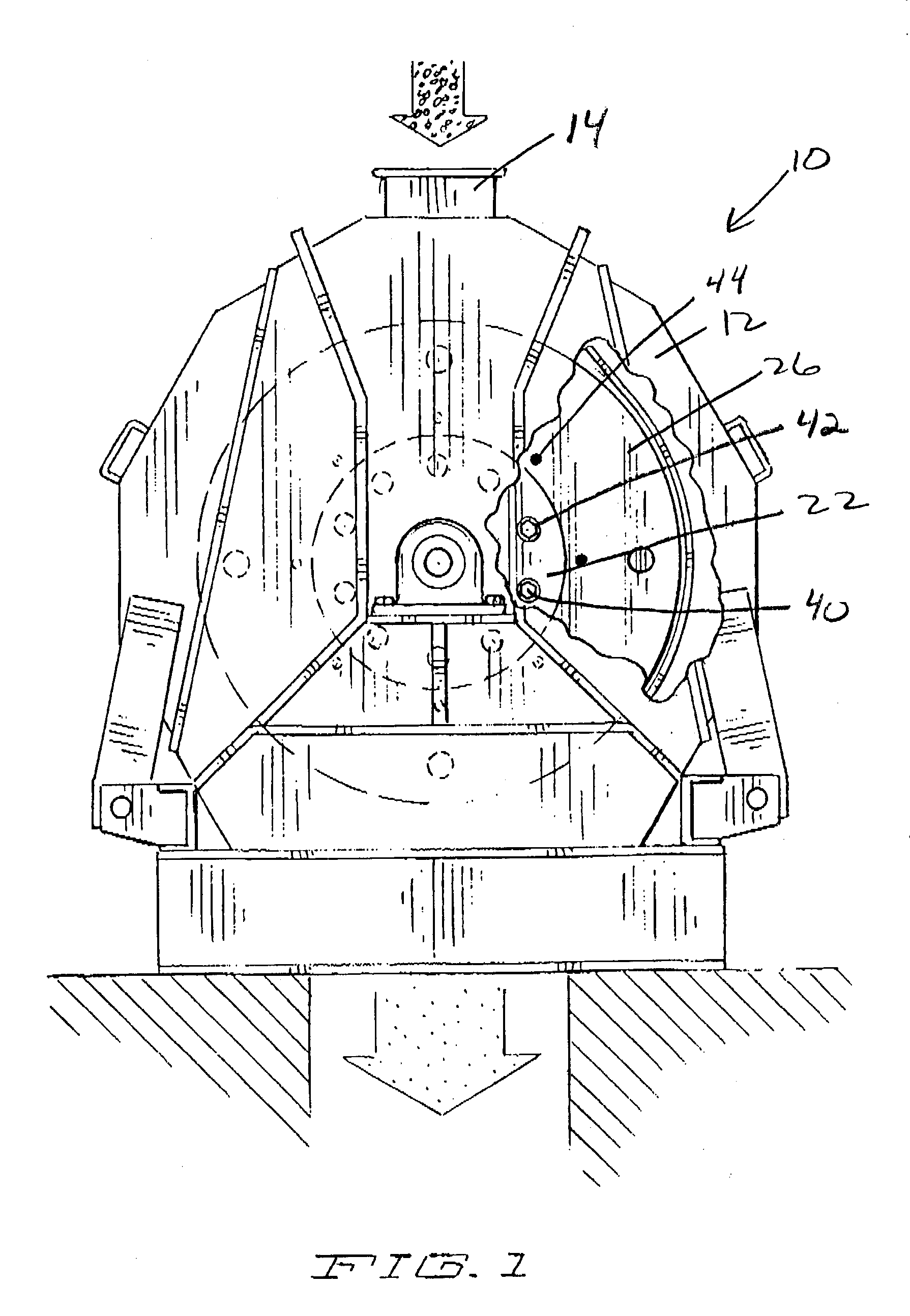

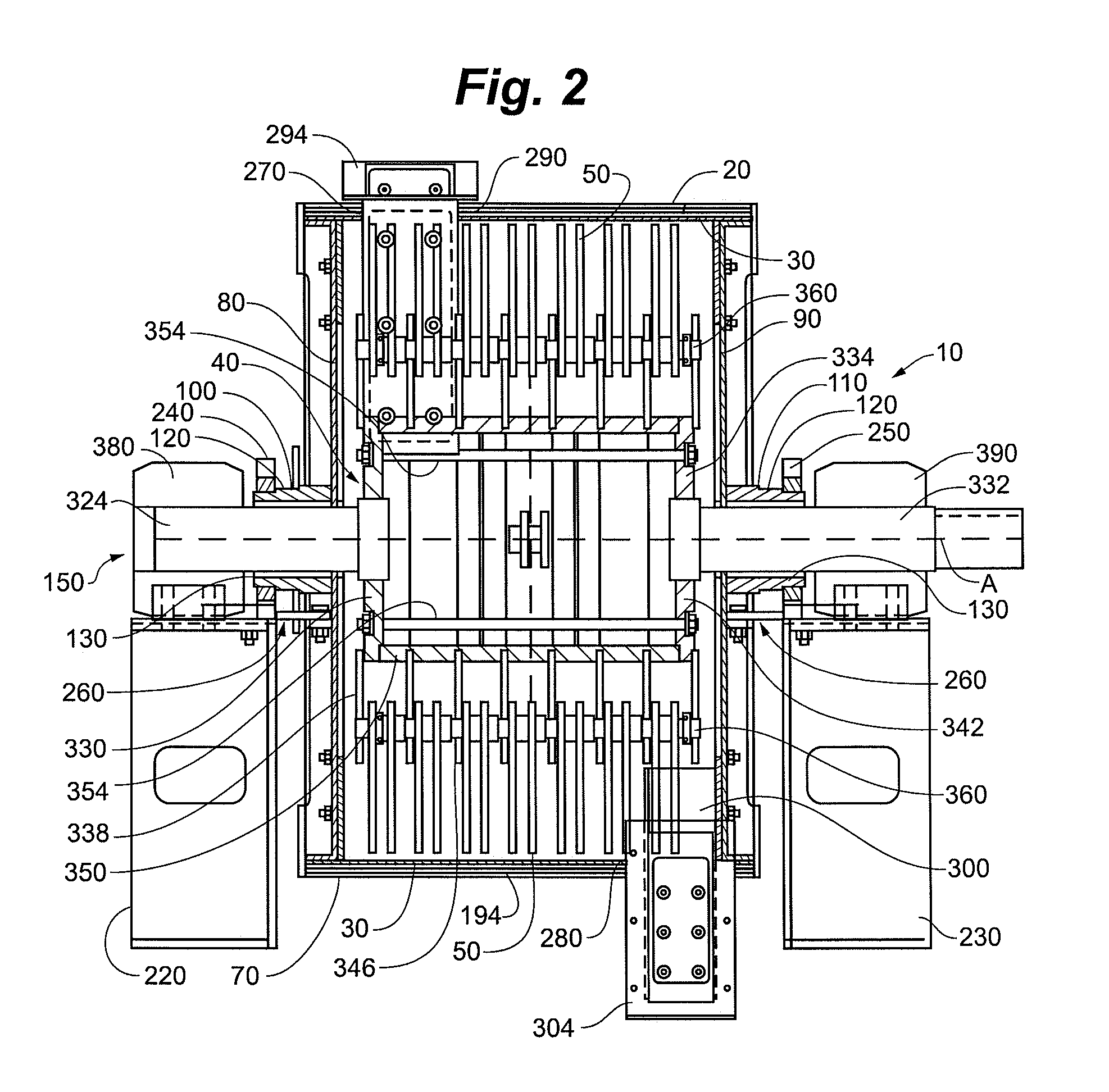

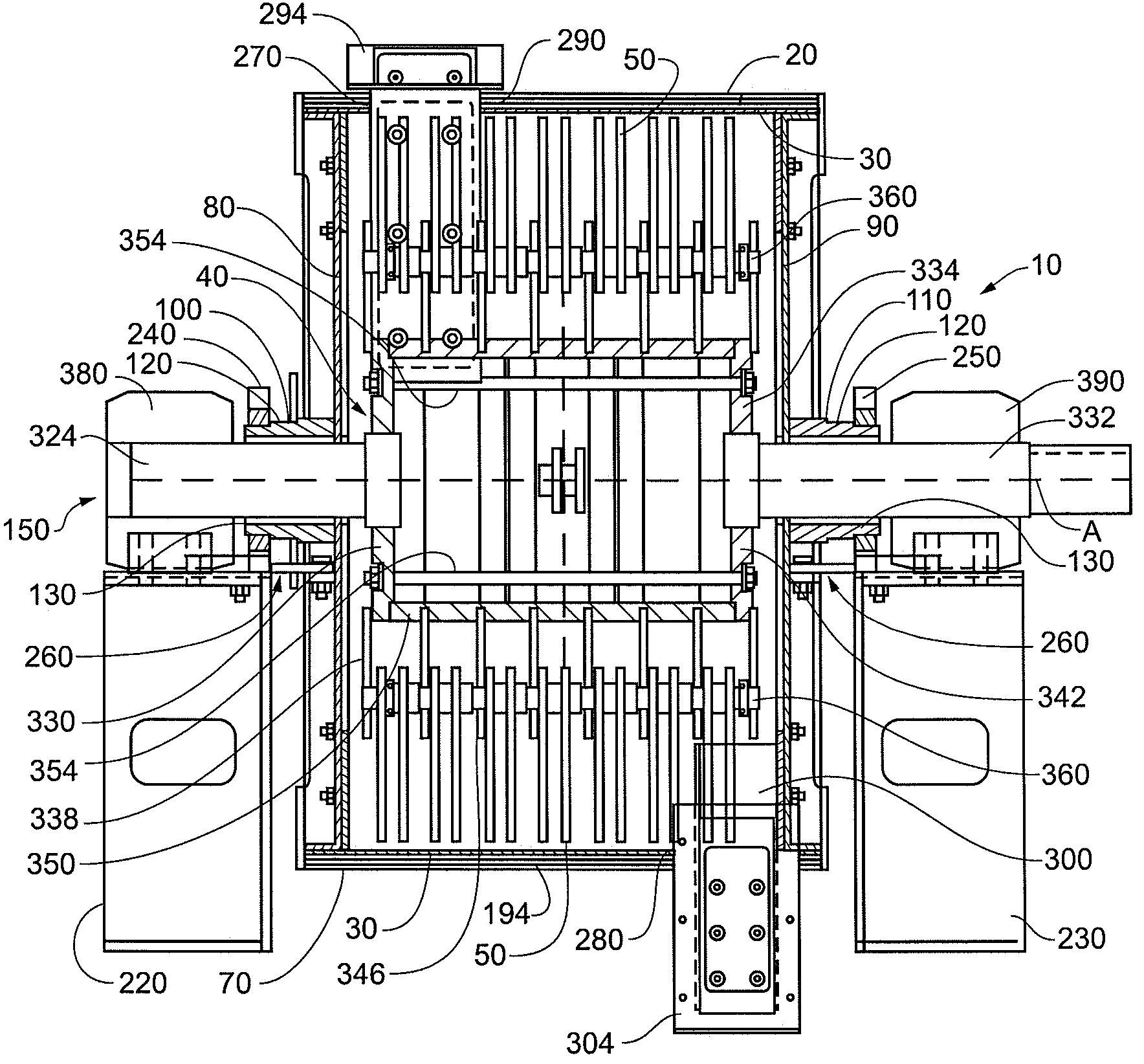

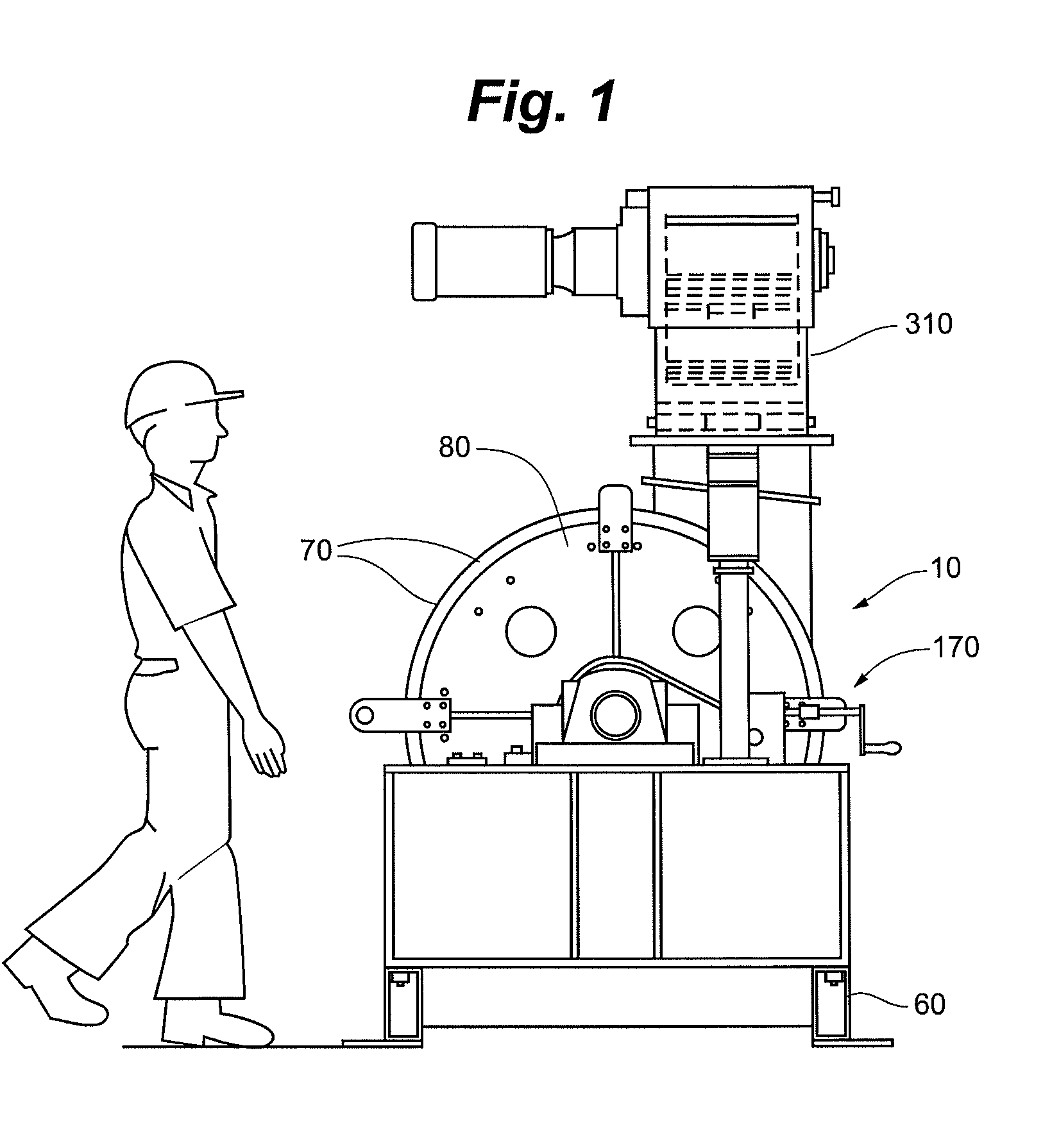

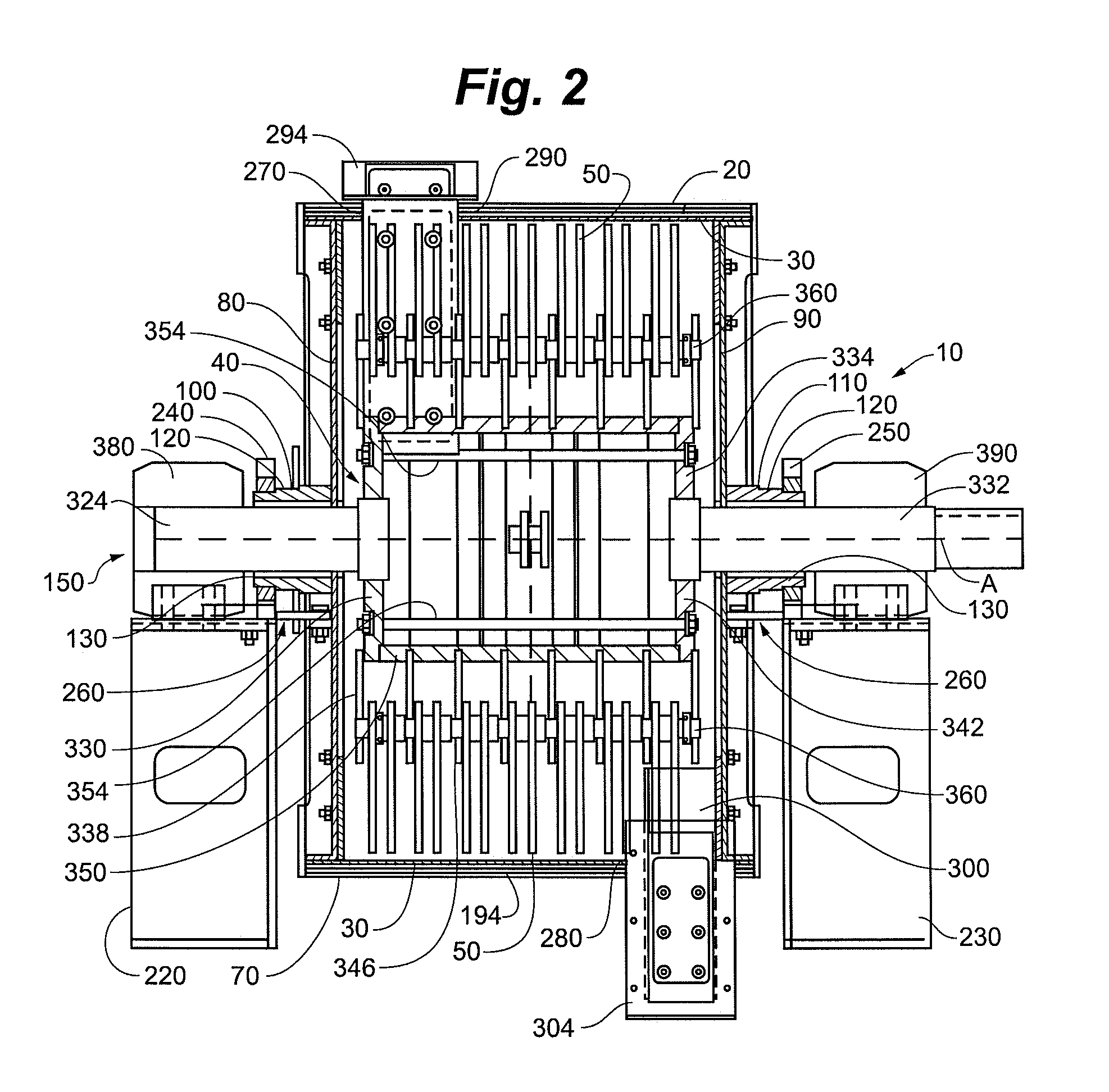

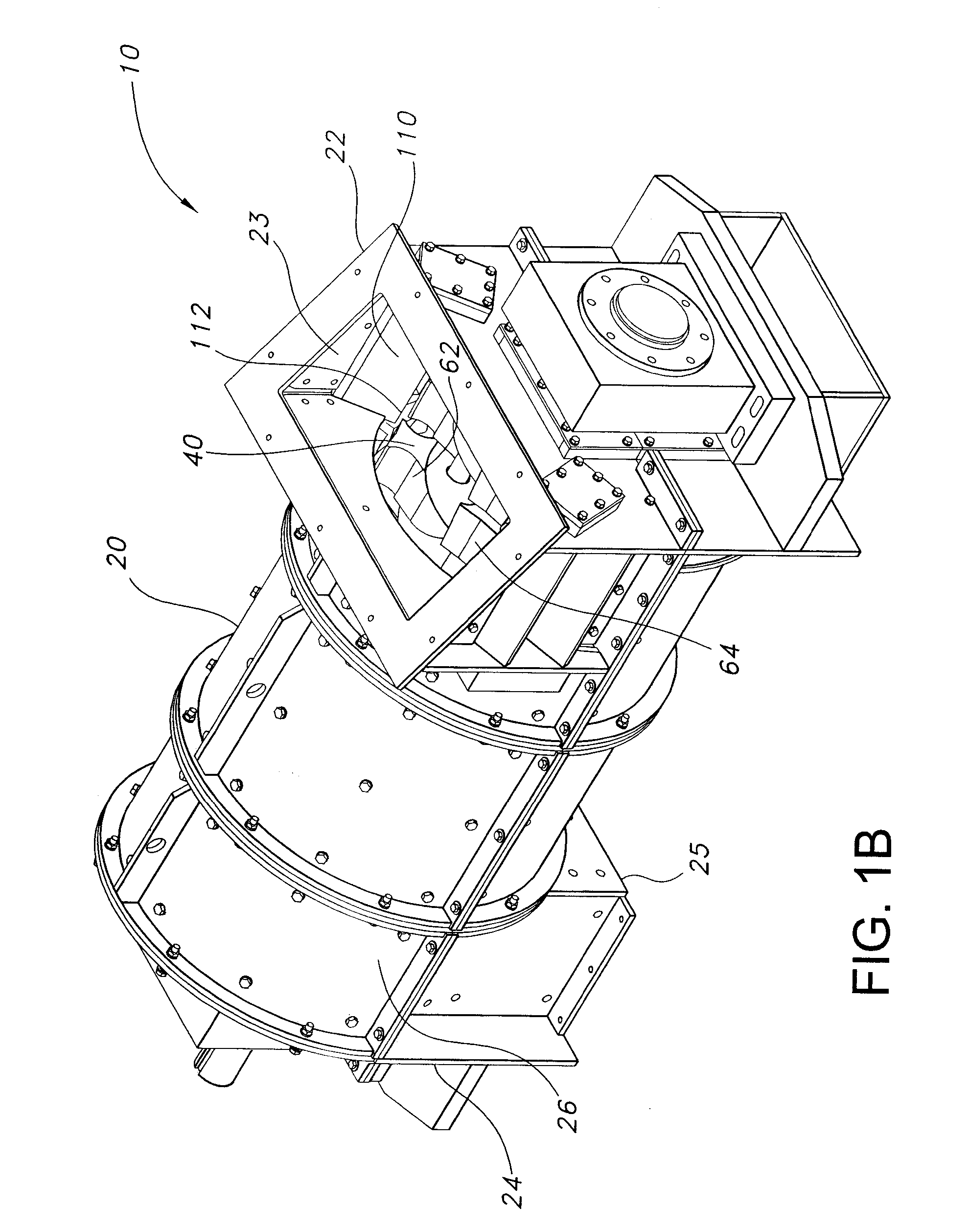

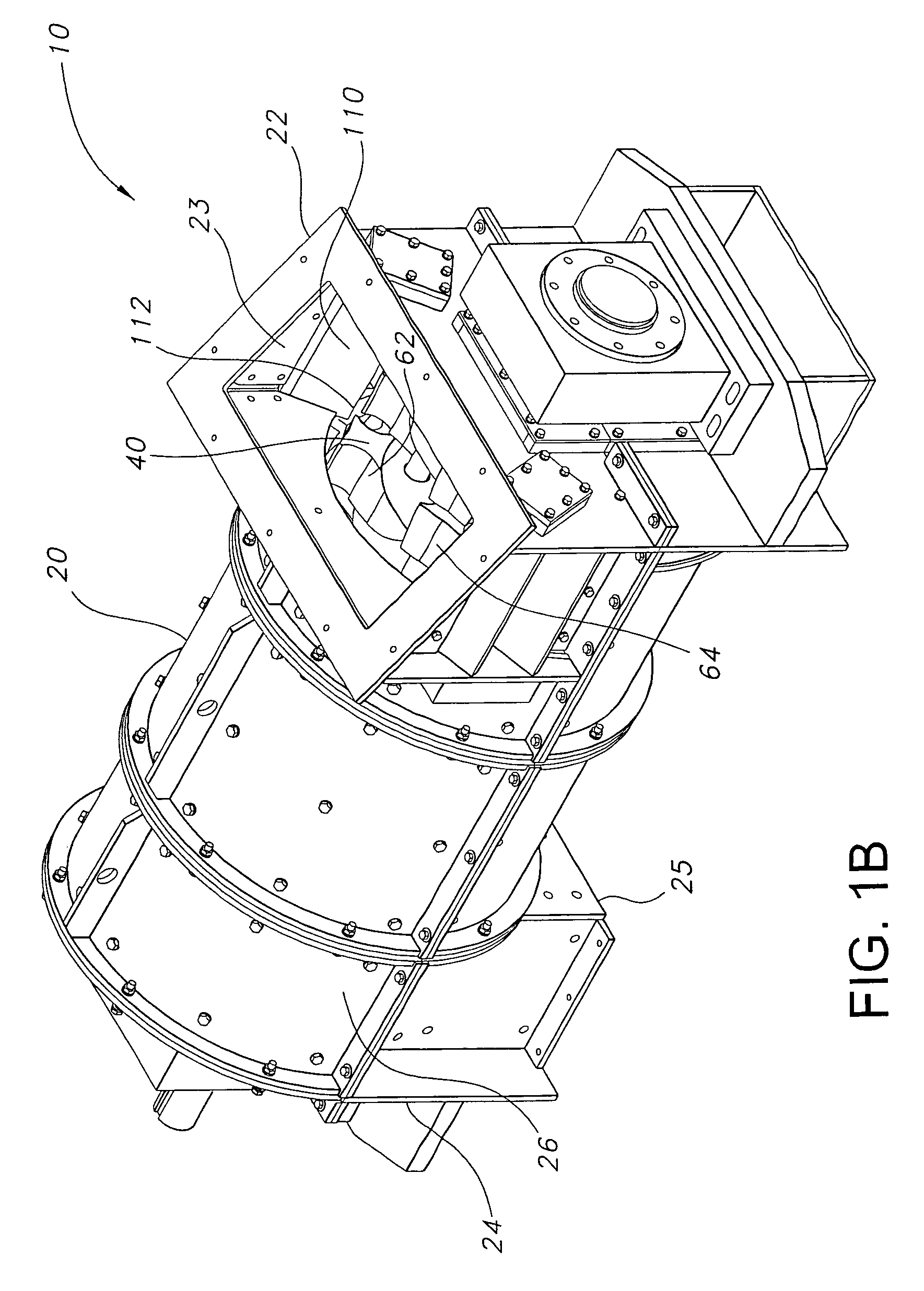

Hammermill with rotatable housing

InactiveUS20080277515A1Easy accessEasy to removeGrinding machine componentsSupporting apparatusRotational axisHammermill

The invention includes a hammermill for comminuting material. The hammer includes a housing and a cutting plate disposed within the housing. A rotor assembly is rotatably mounted within the housing about an axis of rotation and a plurality of hammers are functionally coupled to the rotor assembly. The housing is rotatable about the axis of rotation.

Owner:CARTER DAY INDS

Hammermill with rotatable housing

InactiveUS7775468B2Easy accessEasy to removeGrinding machine componentsSupporting apparatusRotational axisEngineering

The invention includes a hammermill for comminuting material. The hammer includes a housing and a cutting plate disposed within the housing. A rotor assembly is rotatably mounted within the housing about an axis of rotation and a plurality of hammers are functionally coupled to the rotor assembly. The housing is rotatable about the axis of rotation.

Owner:CARTER DAY INDS

Hammer for a hammermill

A hammermill having a housing, a rotor assembly, a plurality of hammers, and an attrition plate assembly is provided to reduce oversized particulate material to a desired size. The housing defines an enclosed work space. The rotor assembly is disposed within the housing for rotation about a longitudinal axis of the housing. The plurality of hammers is coupled to the rotor assembly and is disposed within the enclosed work space. Each hammer having an impact end, a connection portion adapted to couple to a portion of the rotor assembly, and a shank portion extending between the impact end and the connection portion.

Owner:ELLIOTT JAMES C

Hammermill hammer with pin-hole insert

A hammer for a hammermill includes an elongated pin hole and a pin-hole insert that allows the hammer to be mounted in a first position and a second position on a rotor of a hammermill to prolong the useful life of the hammer. The insert is installed in the pin hole using corresponding mating features. A hammer assembly and method for prolonging the life of hammers in a hammermill are also described.

Owner:RIVERSIDE CO LLC

Hammermill

Owner:REGIONS BANK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com