Patents

Literature

93results about How to "Sufficient tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite core conductors and method of making the same

InactiveUS20120186851A1Sufficient tensile strengthNon-insulated conductorsPower cablesElectricityEngineering

Electrical cables for the transmission of electricity between power poles or towers with at least one of a cooling feature and a fail safe feature and methods of producing the same.

Owner:GIFT TECH LLC

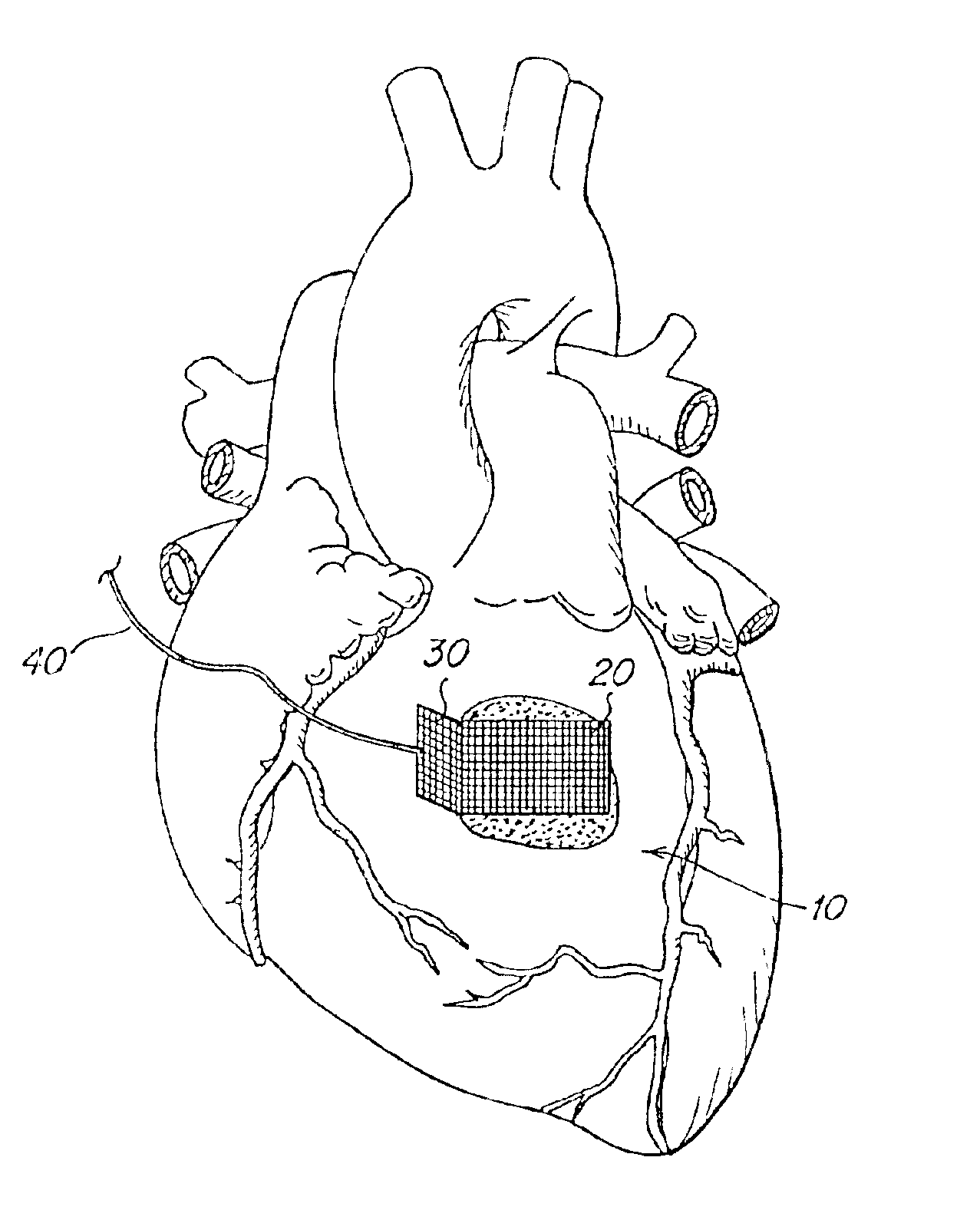

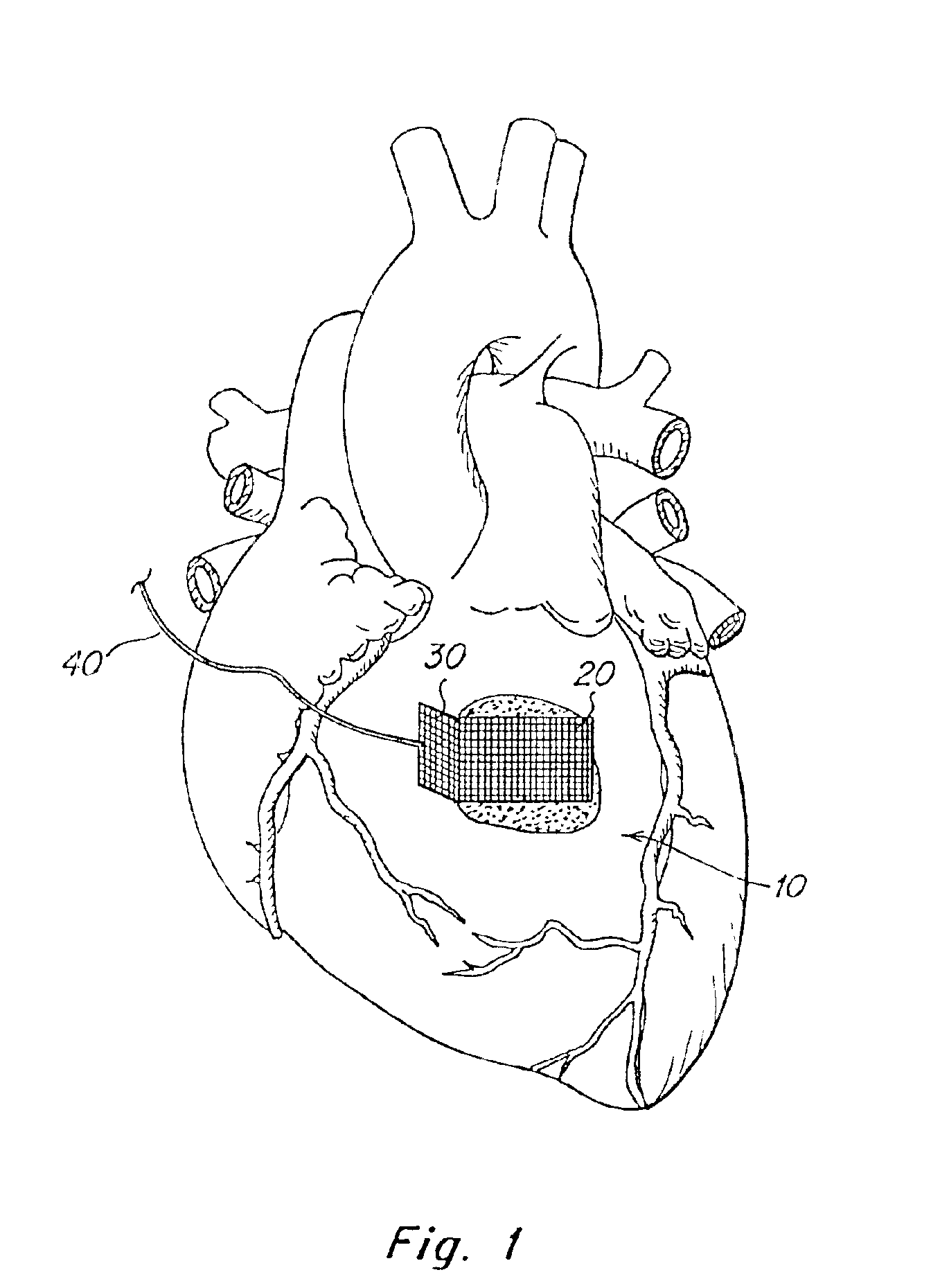

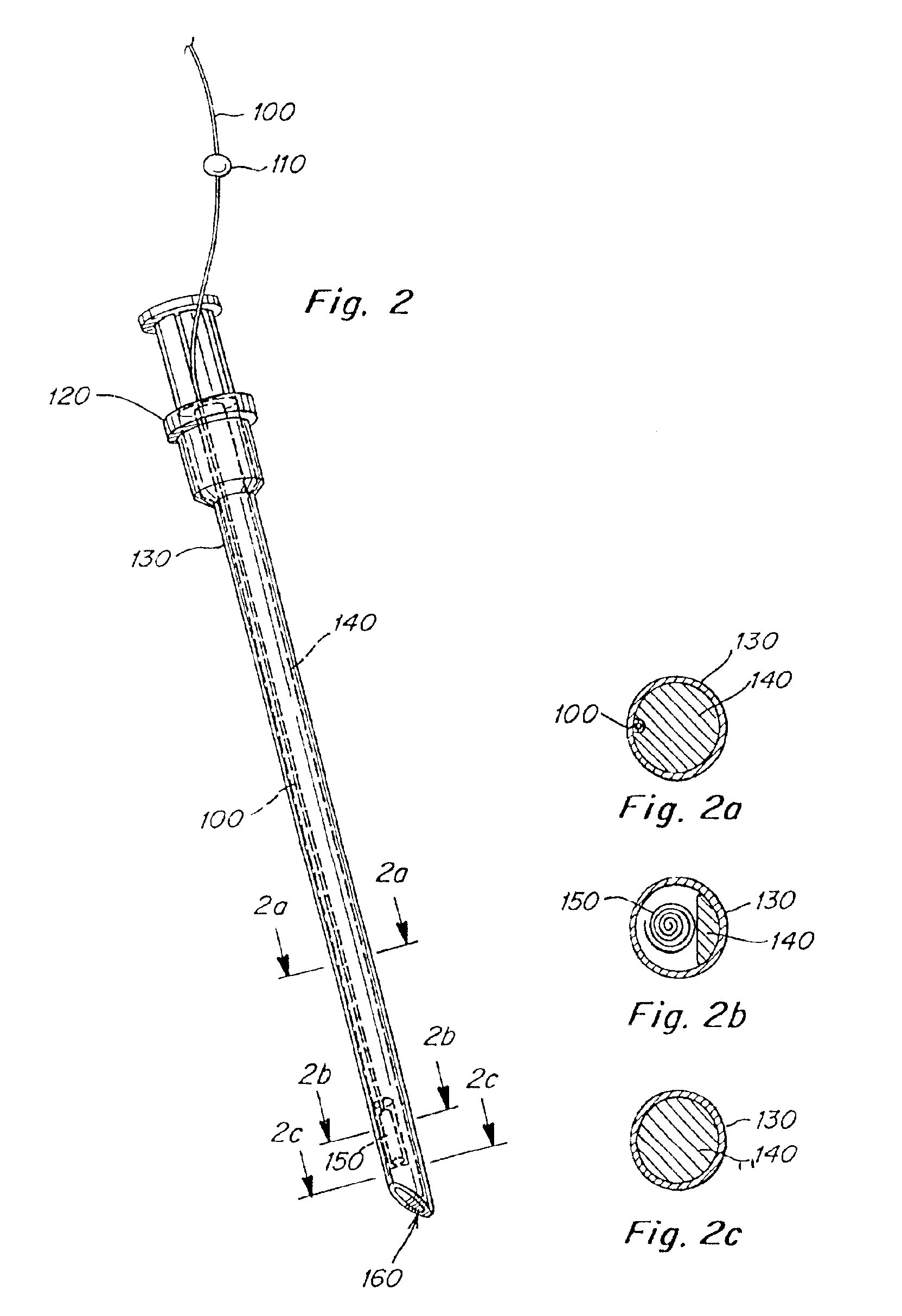

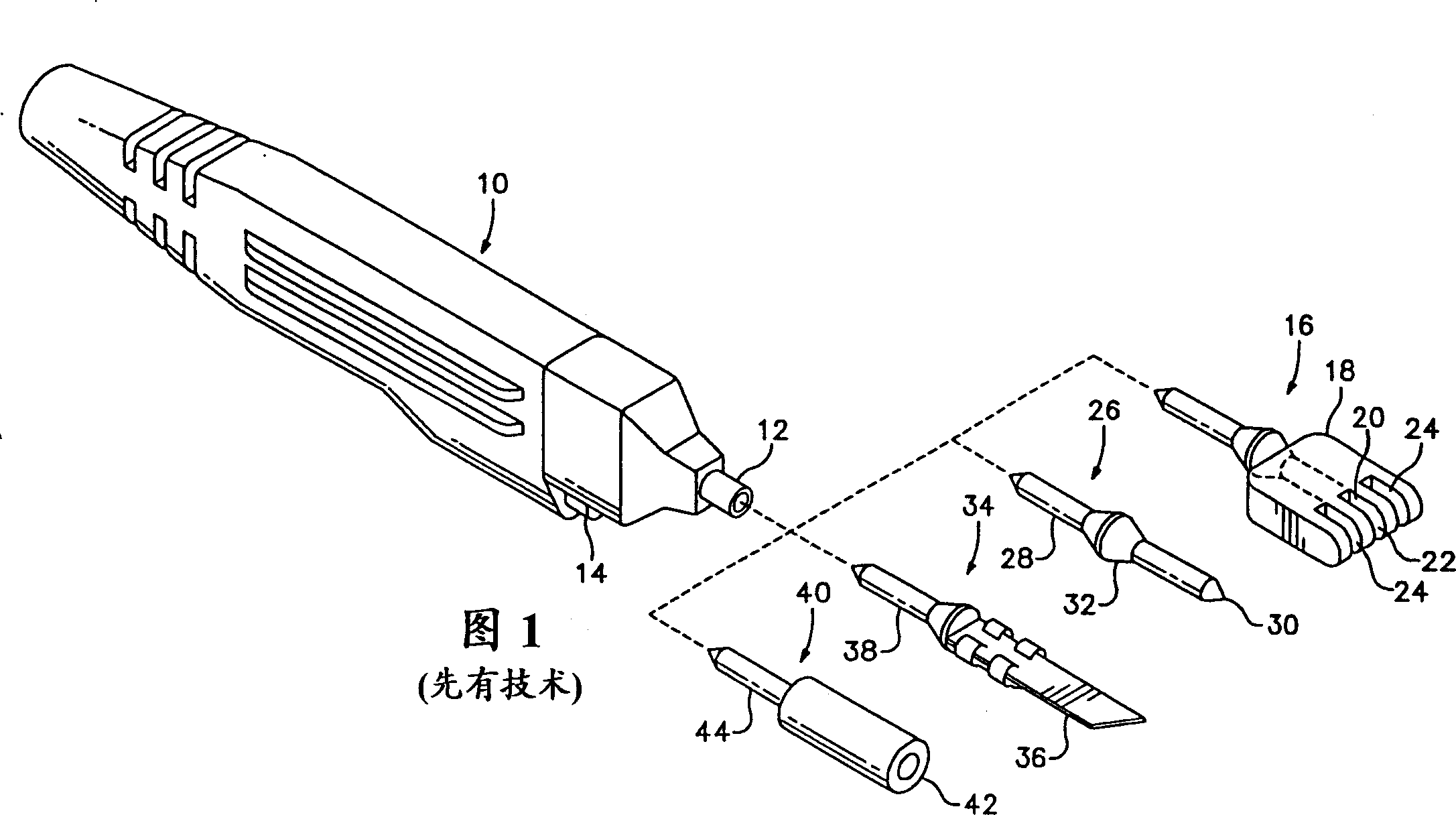

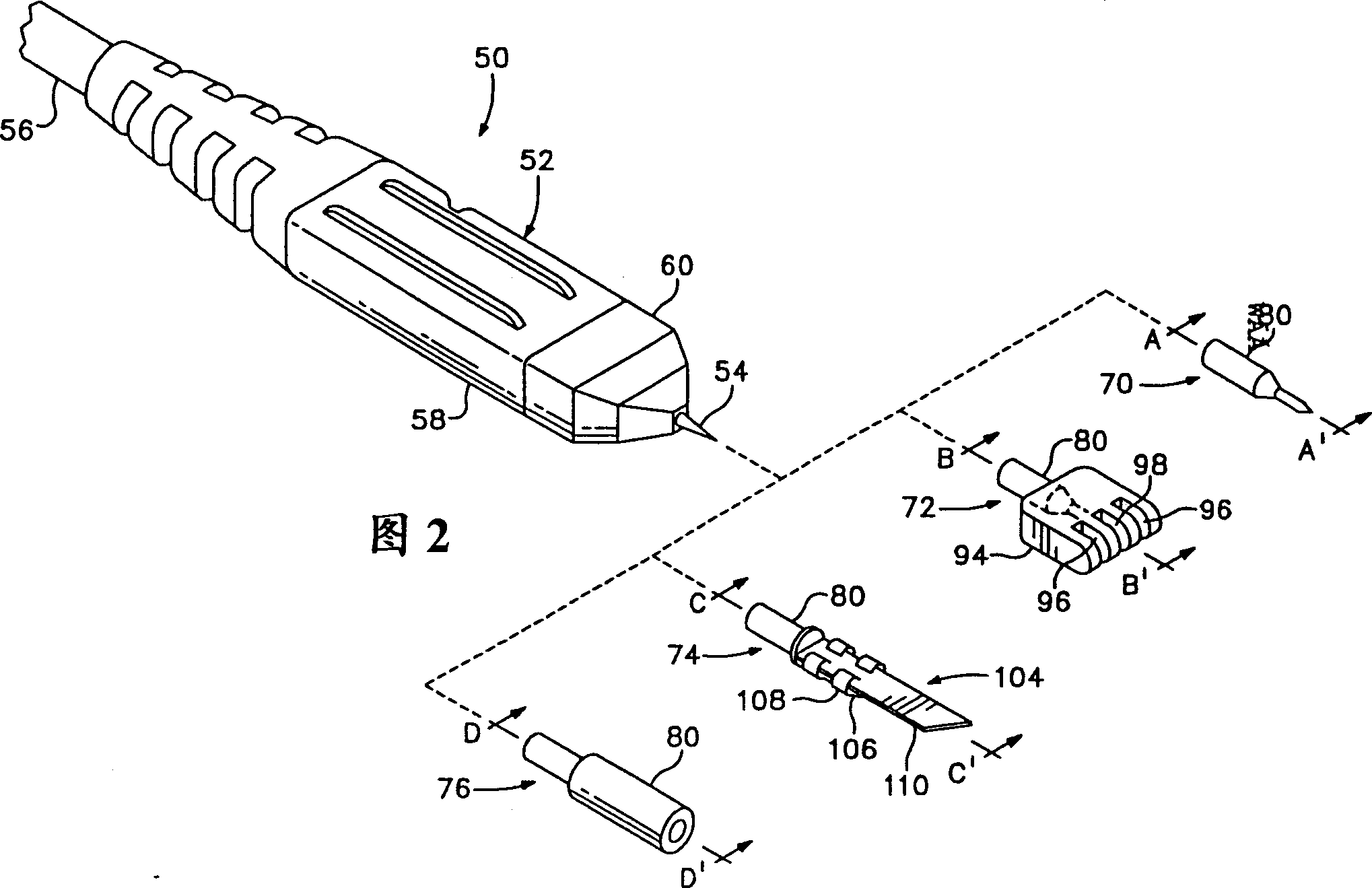

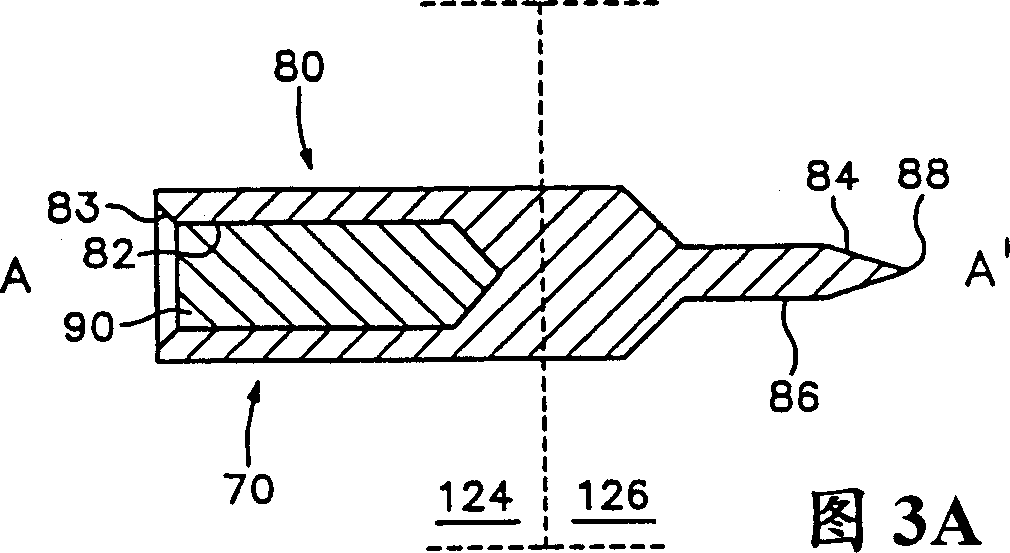

Biodegradable tissue retractor

InactiveUS6936005B2Easily grasp and move and stabilizeSufficient tensile strengthSuture equipmentsSurgical needlesForcepsInvasive surgery

This invention describes novel methods and devices for stabilizing and retracting tissue during surgery, in particular internal tissue. Patches of material, preferably biodegradable, are adhered to tissue surfaces. By manipulation of the patches, for example directly with forceps, or via sutures attached to the patches, tissues can be retracted or otherwise manipulated with minimal trauma to the tissues. The method is especially useful in minimally-invasive surgery.

Owner:FOCAL

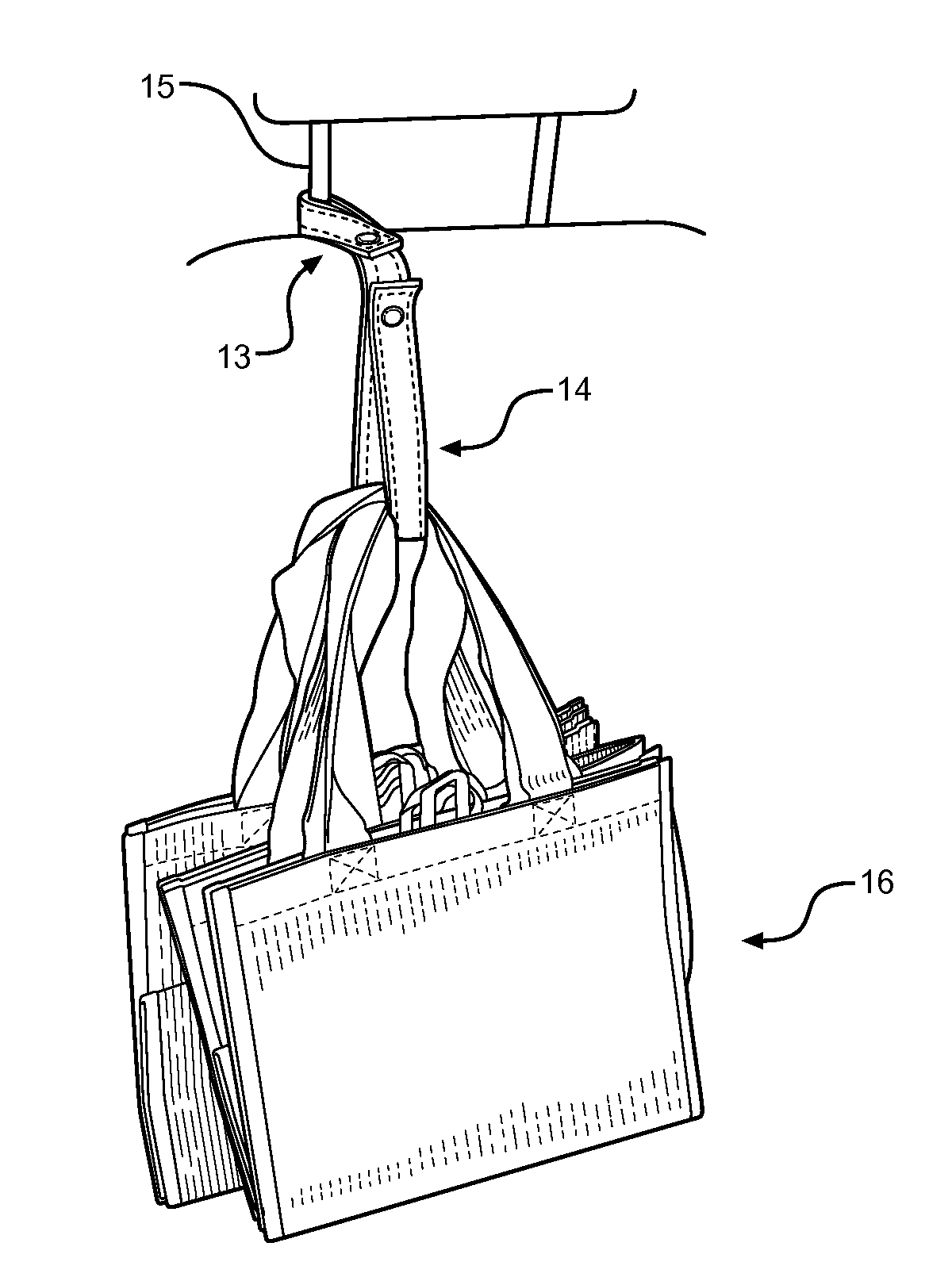

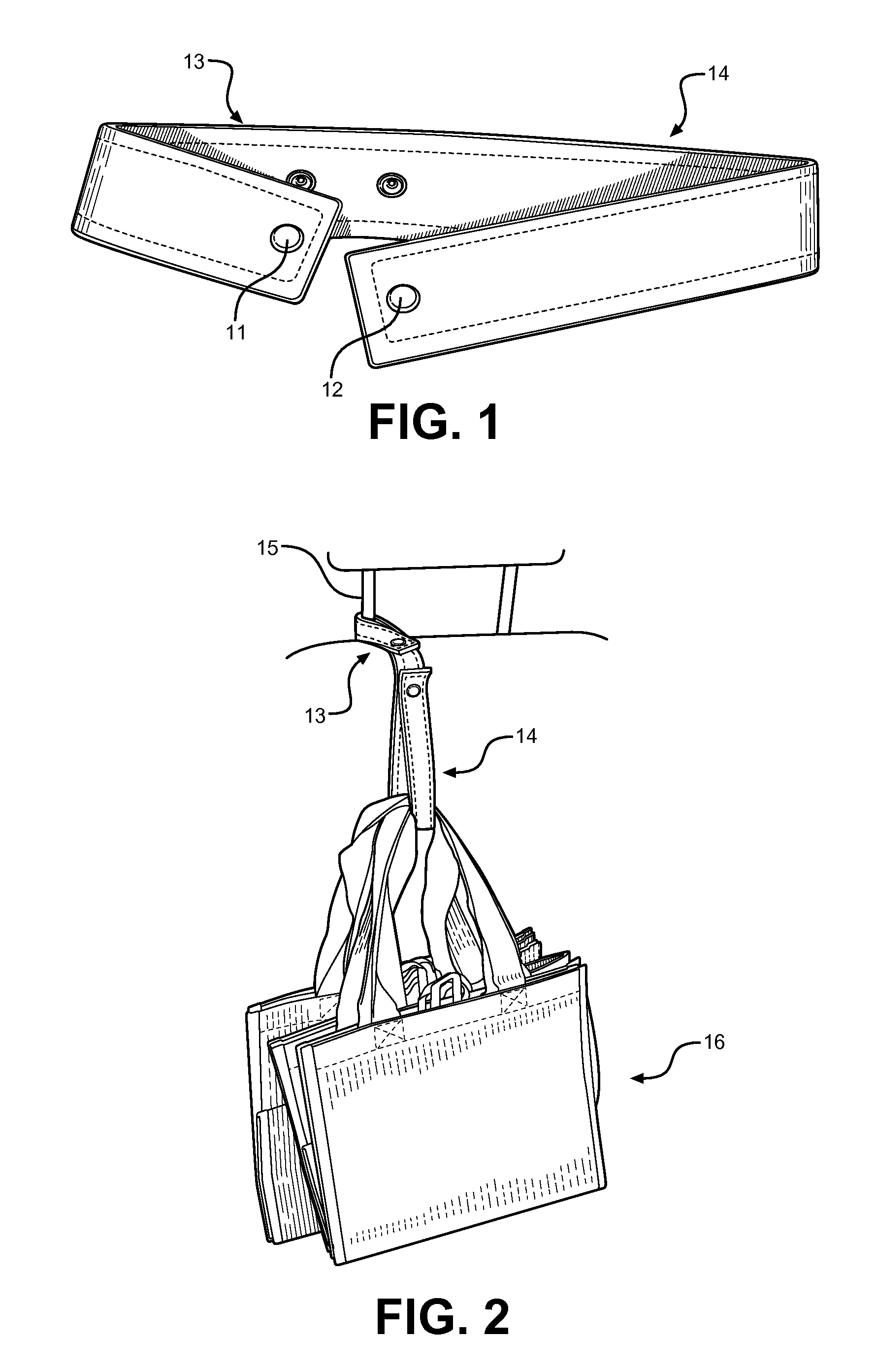

Tote Tether

InactiveUS20110248057A1Simplistic structureSufficient tensile strengthTravelling carriersHoldersCartEngineering

An elongated strap with a first and second connecting snap to support one or a plurality of hanging items. Each end of the strap is folded on itself and snapped in position along the interior of the strap, forming two closed loops. The first loop may be secured by hand or to an external support, such as a vehicle seat headrest, a shopping cart or similar structure. The second loop passes through the handles of reusable grocery bags, hand bags or totes to securely hold and organize the items. The strap itself is a high strength material that can support the load of the suspended items and is adorned with a decorative pattern or color on its outer surface. In use, the device is intended to organize empty grocery totes along the outer rim of a grocery cart while shopping, as well as organize and store empty totes on the backside of a vehicle seat.

Owner:SCHMITZ PATRICIA

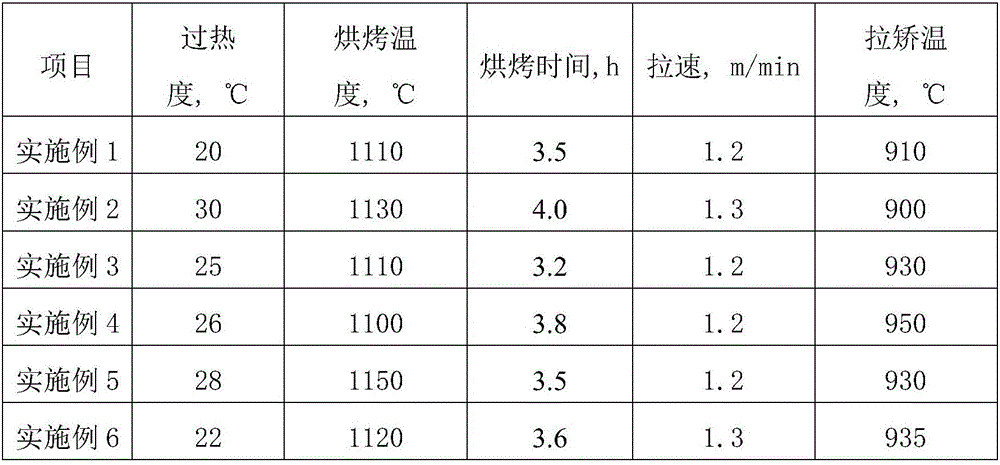

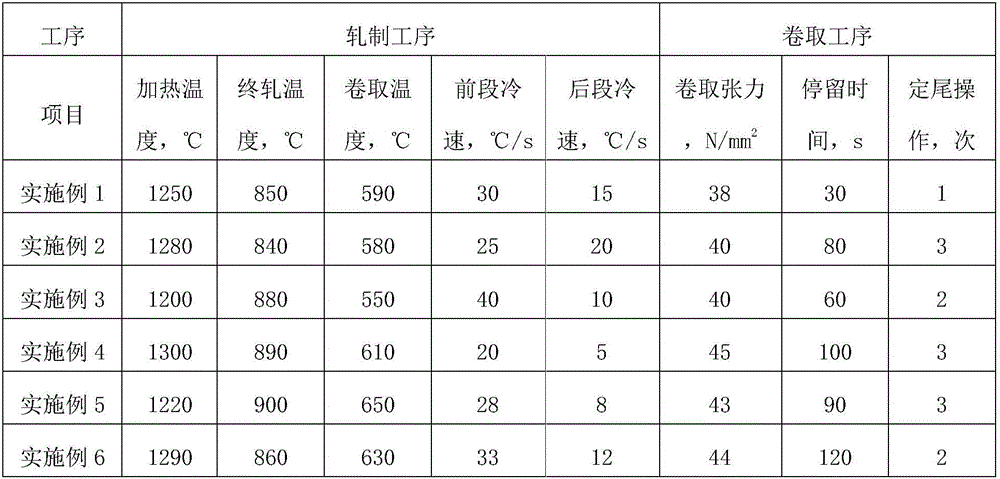

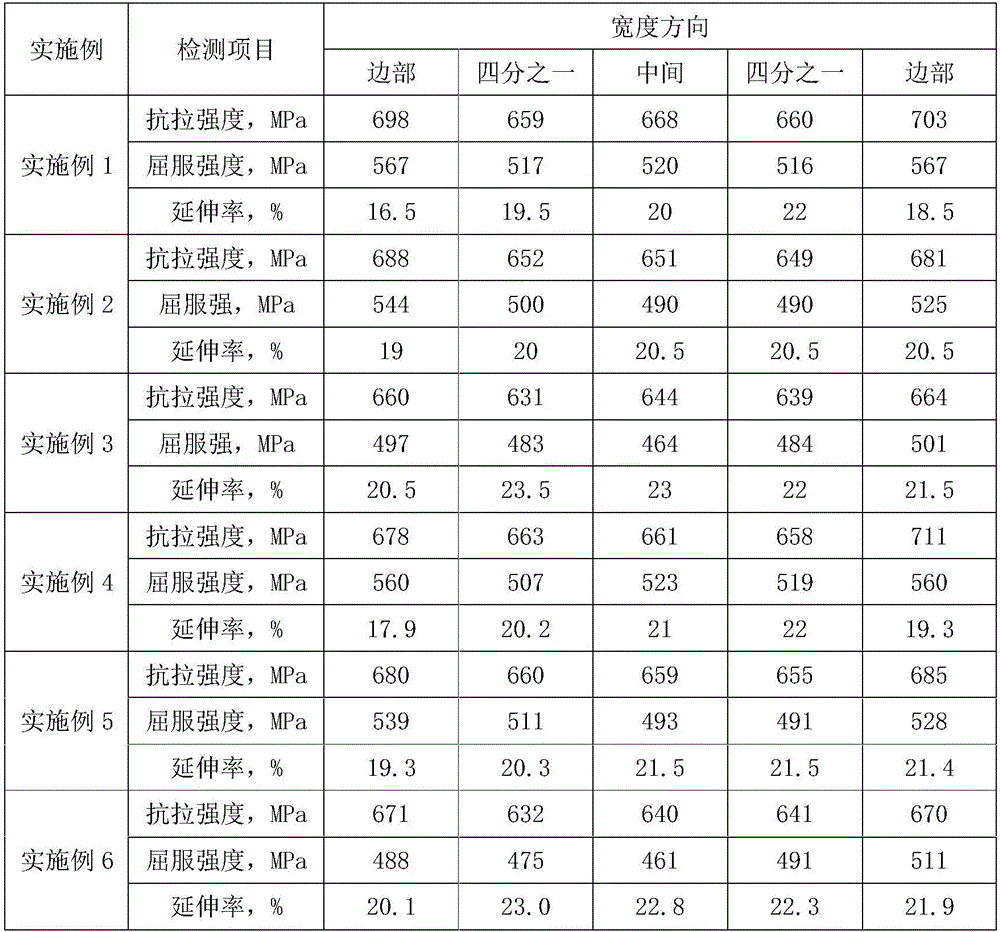

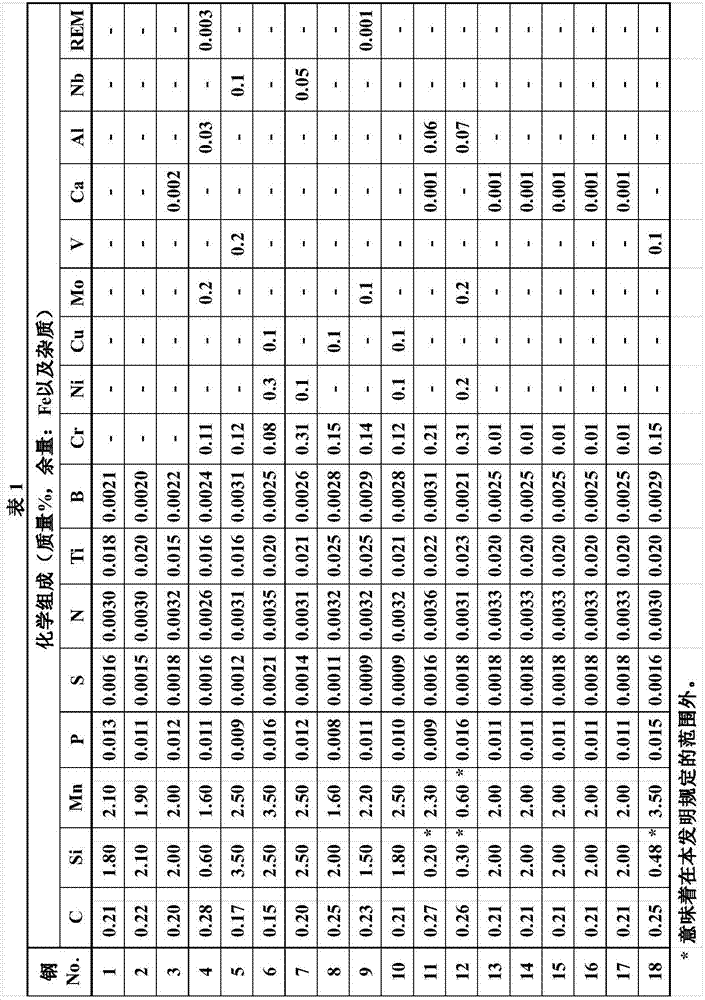

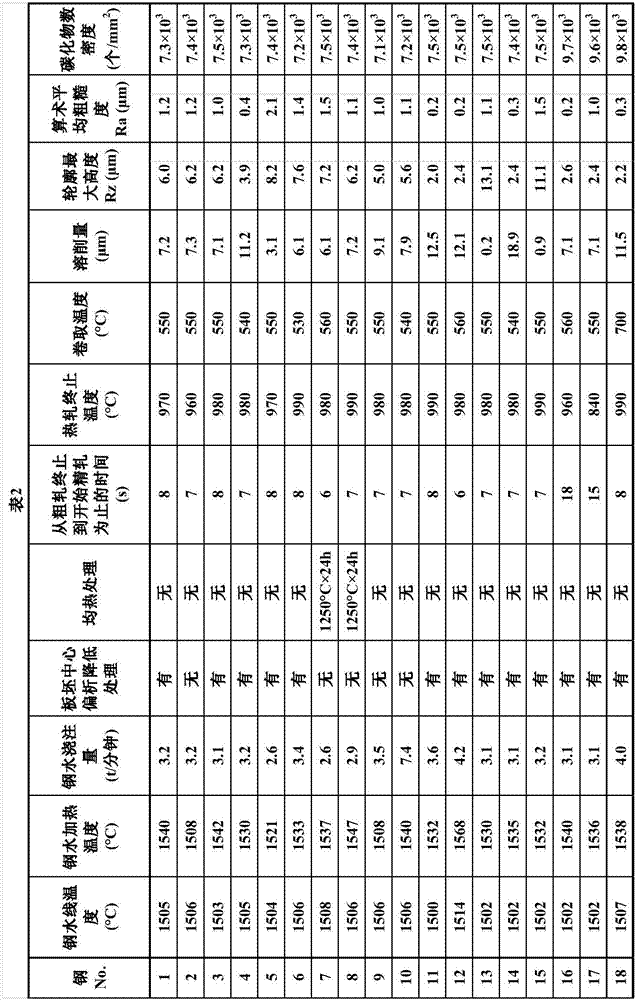

Hot rolled steel strip for heat stamping and shaping and production method thereof

ActiveCN106086624AReduce the amount addedImprove hardenabilityFurnace typesHeat treatment furnacesSheet steelPre treatment

The invention discloses a hot rolled steel strip for heat stamping and shaping and a production method thereof. The hot rolled steel strip is prepared from the following components according to mass percent: 0.20 to 0.25% of C, 0.15 to 0.35% of Si, 1.20 to 1.50% of Mn, 0.10 to 0.50% of Cr, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.030 to 0.050% of Als, 0.030 to 0.050% of Ti, less than or equal to 0.0060% of N, 0.0020 to 0.0050% of B and Fe and inevitable impurities as the rest. The production method comprises the following steps of pretreating hot metal, smelting with a converter, performing LF refining and slab continuous casting, heating, rolling, cooling and coiling; steel plate components and processes are optimized, slow cooling after rolling is adopted, and the coiling temperature and the coiling tension are set. The problems of casting slab cracks, flat coils and the like are solved, and the steel strip with good mechanical homogeneity for the heat stamping and shaping is obtained.

Owner:TANGSHAN IRON & STEEL GROUP

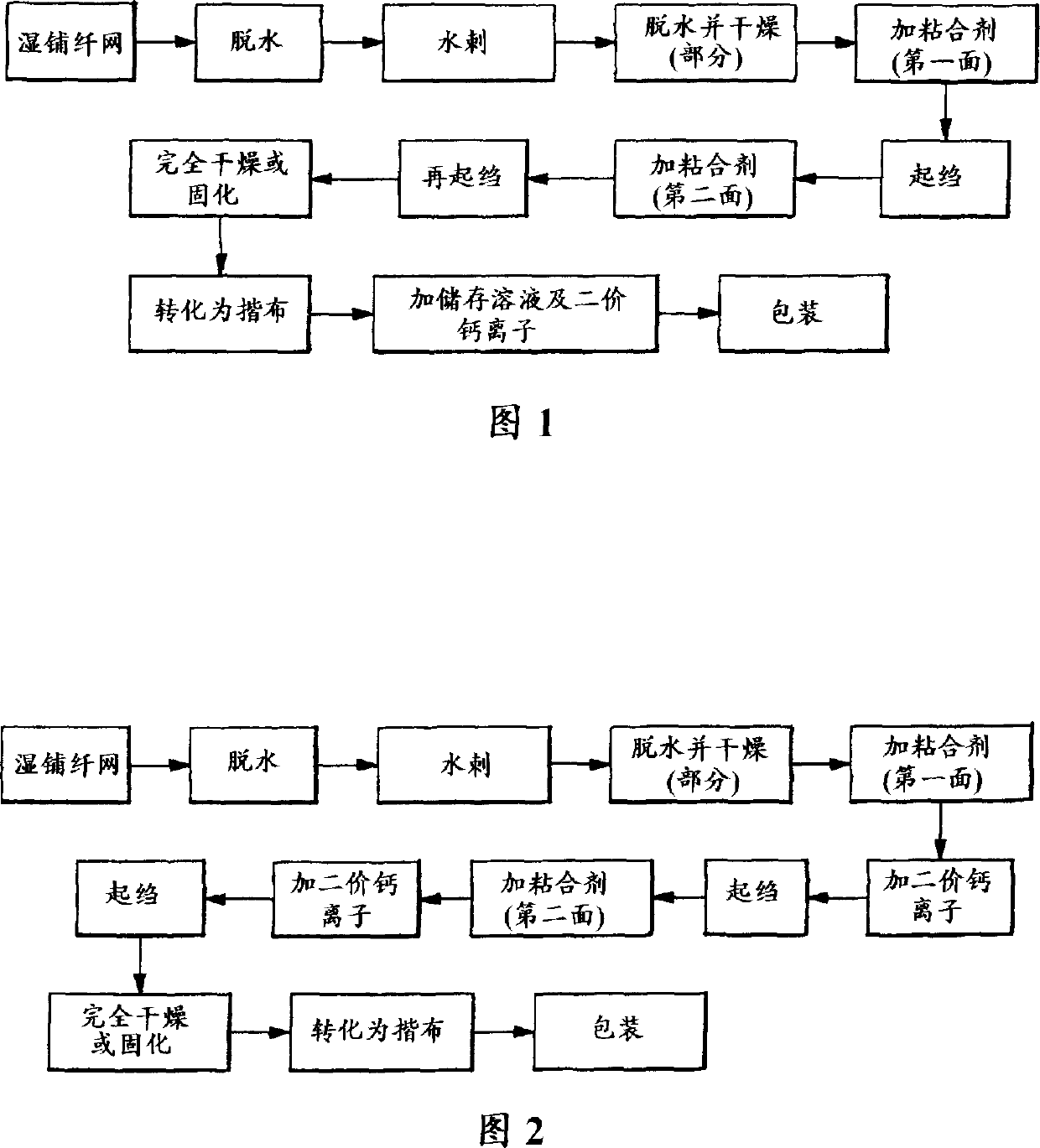

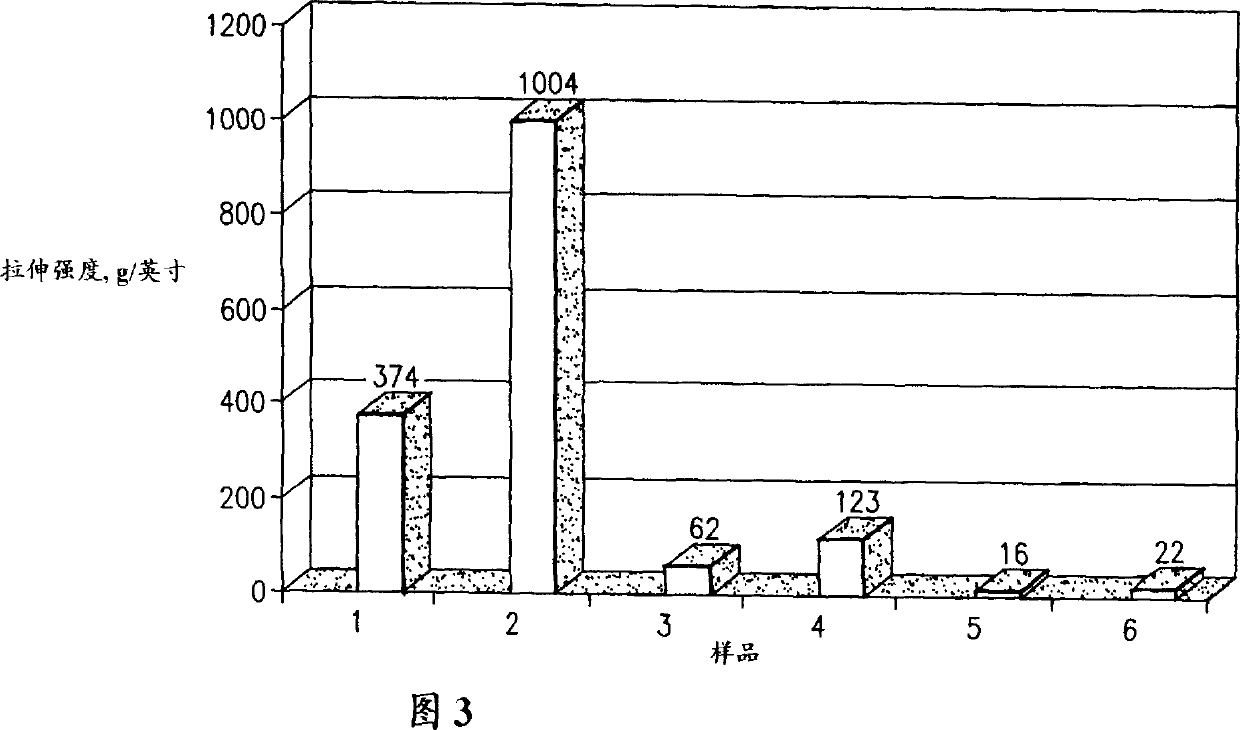

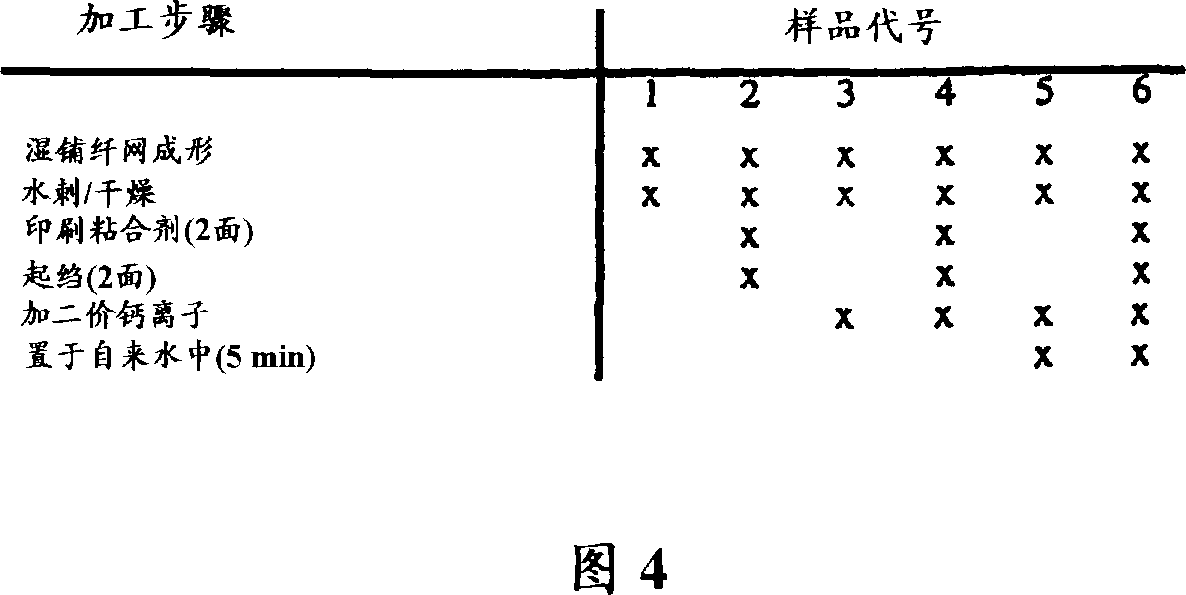

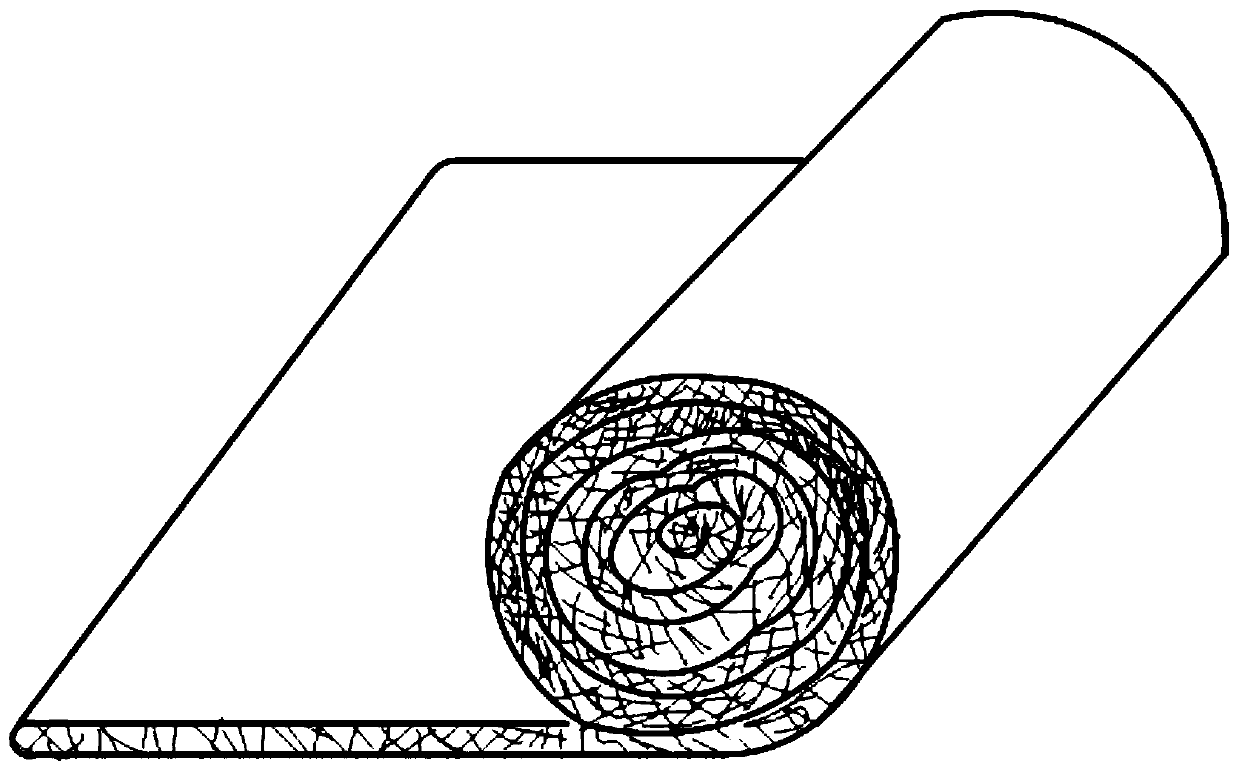

Dispersible nonwoven fabric and production thereof

InactiveCN1252109ASufficient tensile strengthMechanical paper treatmentPaper/cardboardPolymer scienceWet wipe

A soft, absorbent nonwoven fibrous web, such as a wet wipe, capable of dispersing in an aqueous environment into unrecognizable pieces, made by a method comprising the steps of forming a wet-laid nonwoven web from an aqueous slurry of fibers; hydraulically needling the wet-laid nonwoven web; partially drying the hydraulically needled web; applying a binder composition to one side of the web; creping the web such that interfiber adhesion is disrupted and z-direction fiber orientation is introduced; optionally applying a binder composition to the second side of the web; recreping the web; drying and curing the web; and, converting the dried and cured web into a wet wipe, dry wipe, or other absorbent article. In the case of a wet wipe, a solution containing about 100 ppm of calcium ion is applied to the web, such as in a preserving solution. In the case of a dry wipe, the calcium ion is added after the binder is added to the web, and the final product is stored in a dry state. The combination of processes produces a web having a desirable tensile strength, bulk and softness during storage and use, yet will disperse in an aqueous environment into unrecognizable pieces.

Owner:KIMBERLY-CLARK WORLDWIDE INC

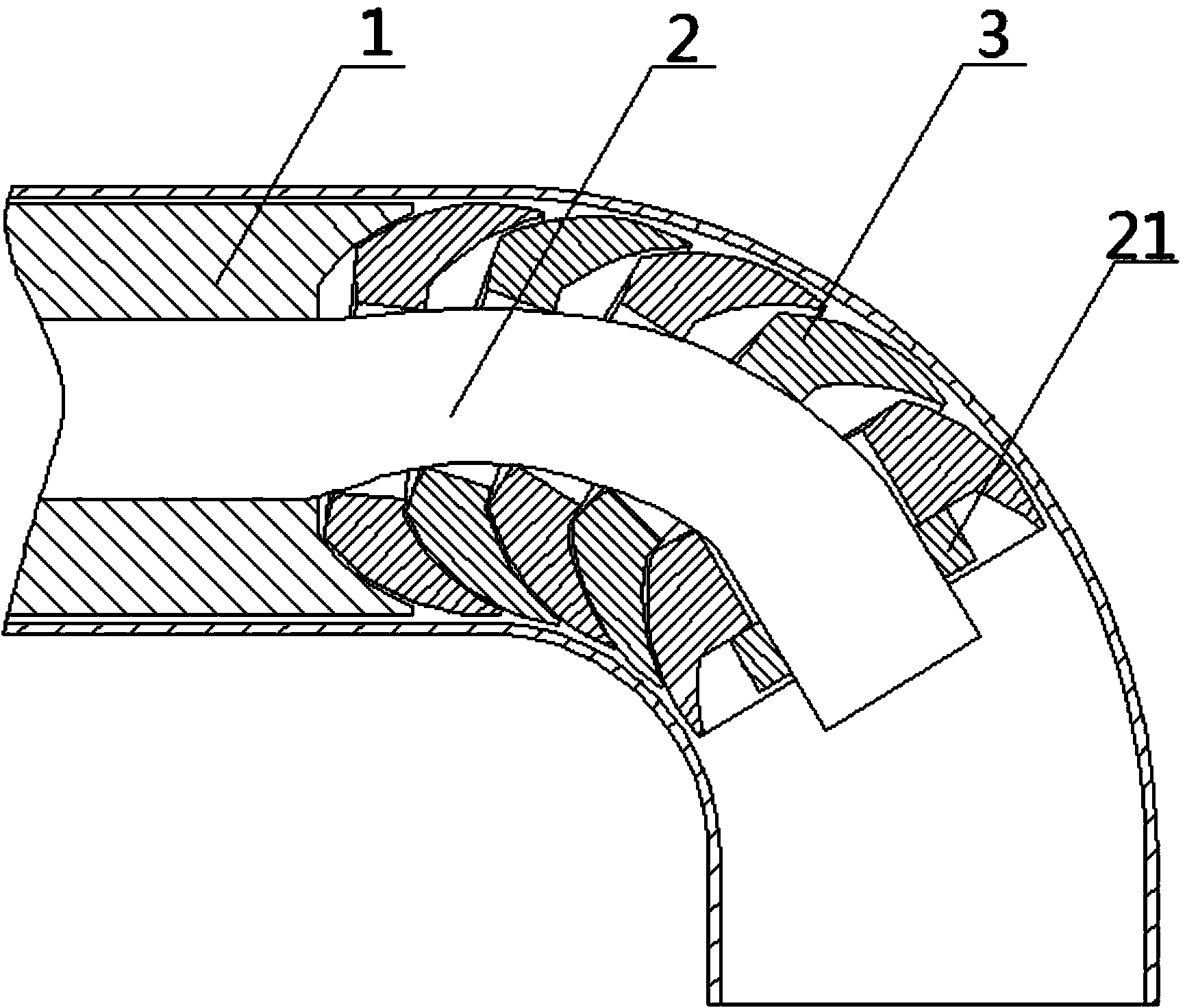

Elastic core bar for bent pipe

An elastic core bar for a bent pipe comprises a core shaft used for supporting a straight pipe section and a plurality of core balls used for supporting a bent pipe section. The core shaft and the core balls are connected through an elastic body. The fixed end of the elastic body is fixed into the core shaft. The free end of the elastic body penetrates through the core balls in sequence, and a clamping positioning block limiting the displacement of the core balls is arranged at the end of the free end. The distance between two end faces of the core balls is defined as the thickness of the core balls. The thicknesses of the core balls are not consistent. The characteristics of a squillid body structure are used for reference, the spherical core balls are designed and connected through the elastic body, the wall of a pipe fitting can be more stably supported when small bent radius bending forming is carried out on the thin-wall pipe fitting, the friction force with the pipe fitting is smaller, and the quality of the bent pipe fitting is better.

Owner:ZHEJIANG UNIV OF TECH

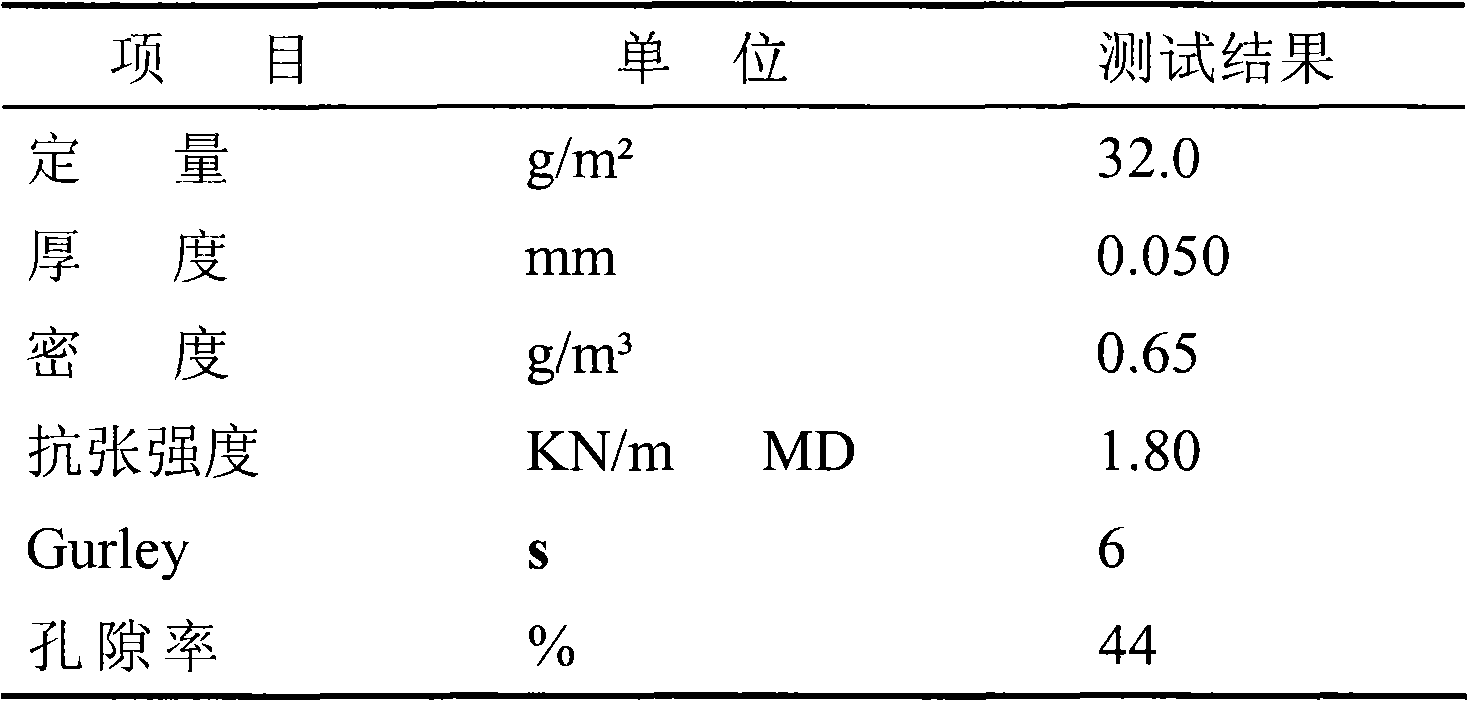

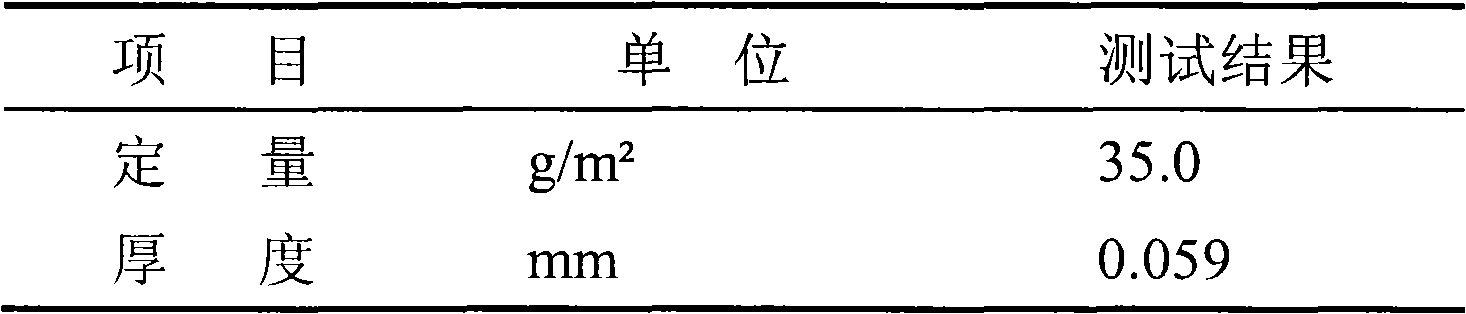

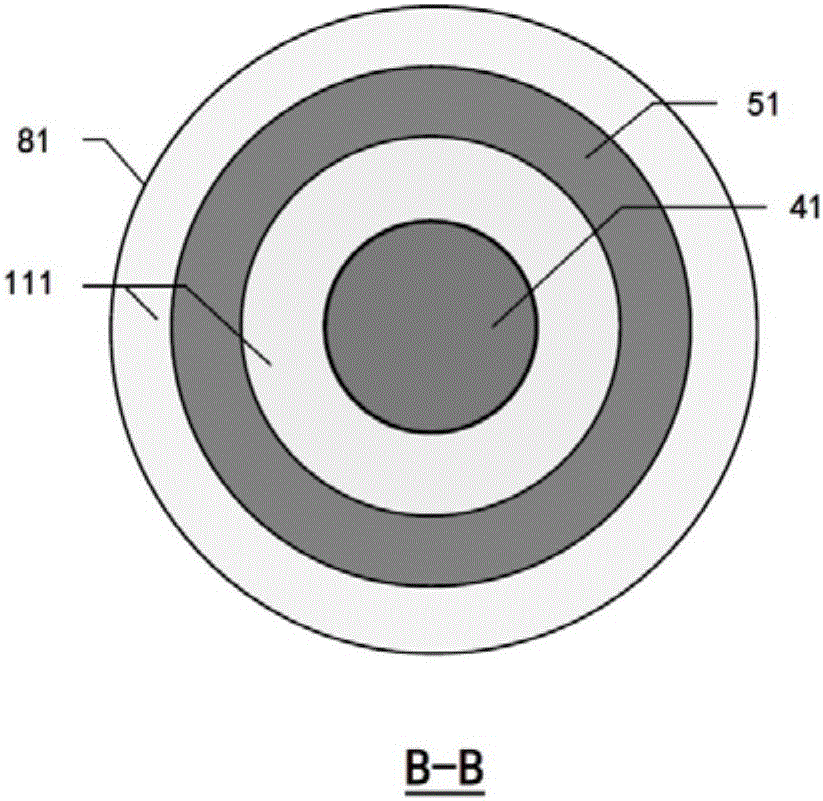

Battery diaphragm based on aramid fibre

InactiveCN101867030AOvercome the weakness of heat intoleranceProne to liquid-solid phase separationCell component detailsPorosityElectrical resistance and conductance

The invention discloses a battery diaphragm based on aramid fibre. The battery diaphragm is manufactured mainly from ultra-short aramid fibre in match with aramid fibre fibrid, and the specific requirements of air permeability and porosity of the battery diaphragm can be satisfied through adjusting fibre formula and molding process. The battery diaphragm can realize mechanical isolation function of the positive and negative poles of the battery, ensures low resistance and high ion electrical conductivity simultaneously, and has enough electrochemistry stability. Compared with traditional plastic diaphragm, the battery diaphragm in the invention has more excellent comprehensive properties, i.e. excellent heat resistance performance, high strength, fatigue resistance performance, low deformation, fire-resistant and flame retardant performance, chemical-corrosion resistance performance and the like. The battery diaphragm in the invention can be widely applied to the manufacturing of various ion batteries.

Owner:深圳昊天龙邦复合材料有限公司

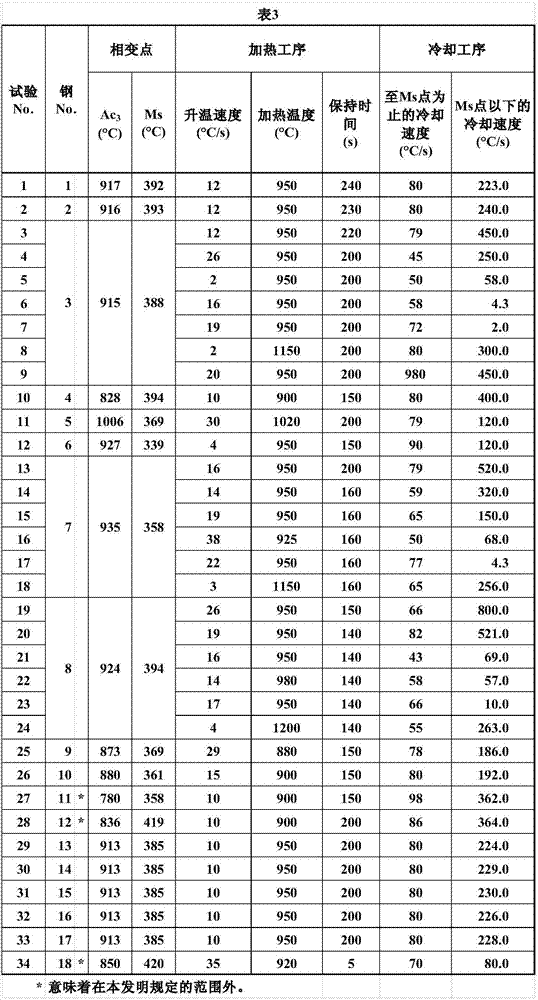

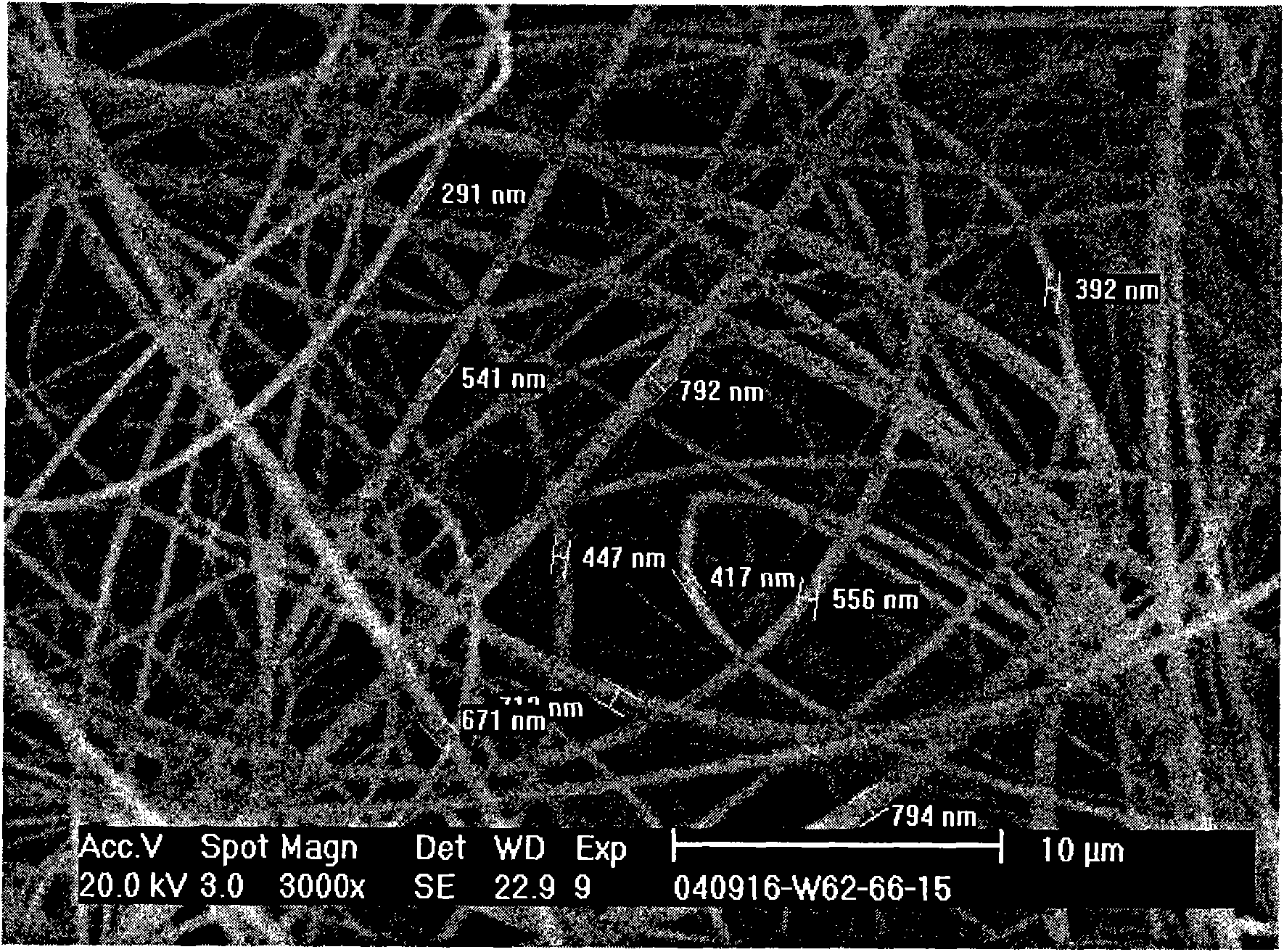

Heat-treated steel sheet member, and production method therefor

ActiveCN107532255ASufficient tensile strengthHigh yield ratioFurnace typesHeat treatment furnacesChemical compositionSheet steel

Owner:NIPPON STEEL CORP

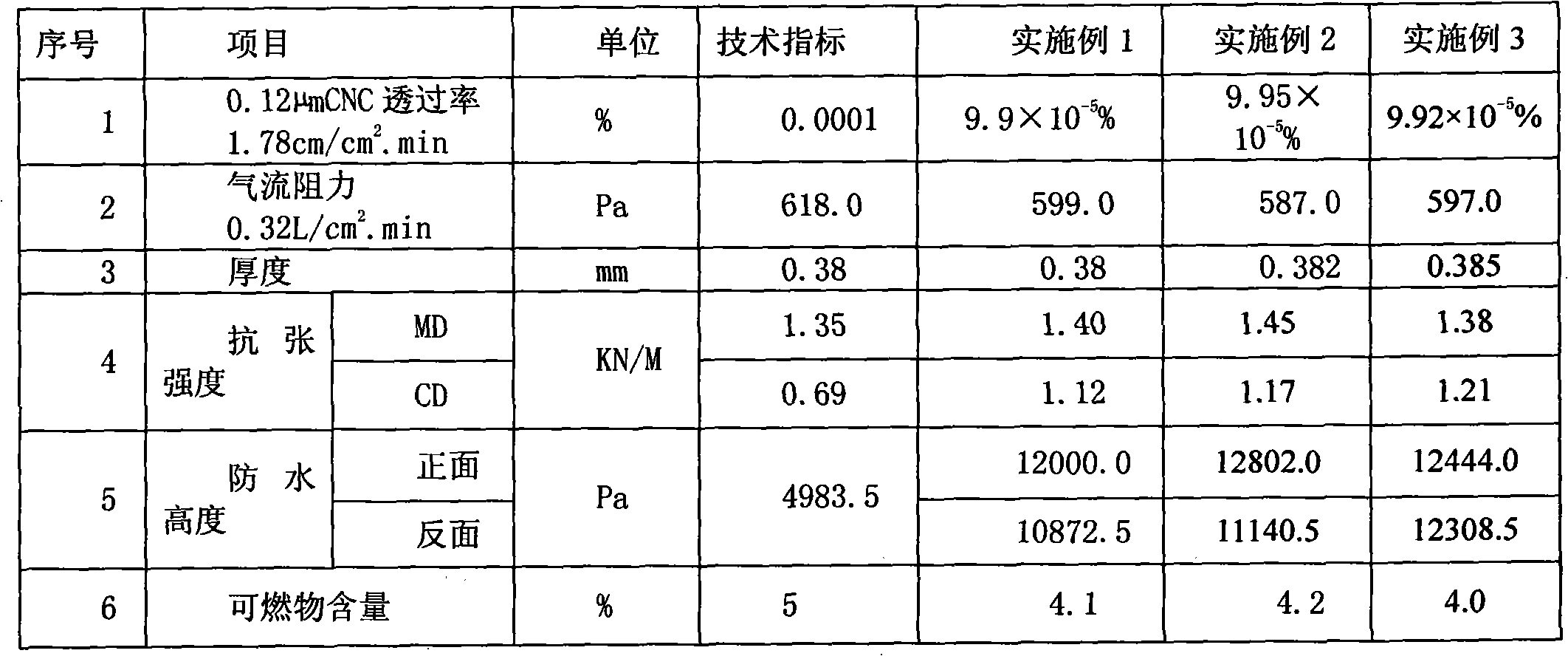

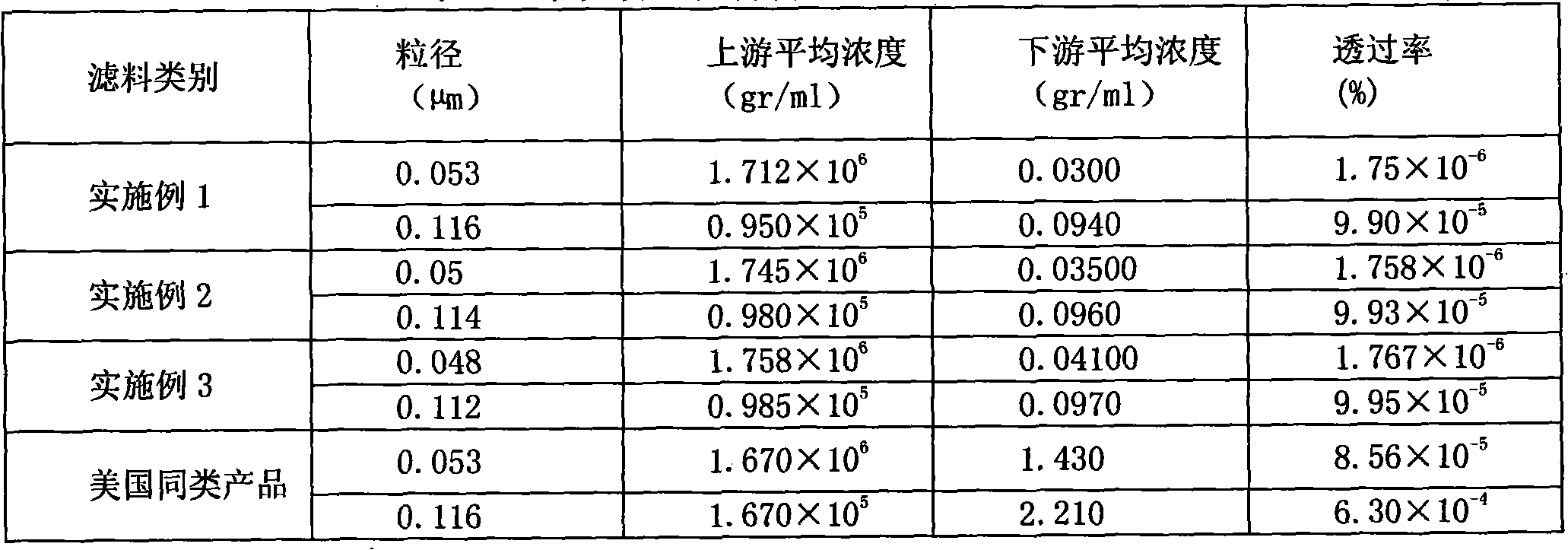

Preparation method of ULPA ultra performance air filter material

ActiveCN101644012AIncrease effective spaceLarge aperture rangeWater-repelling agents additionPulp beating methodsSizingAverage diameter

The invention discloses a preparation method of ULPA super performance air filter material, including the following steps: step (1), 20-30wt% of glass fiber with average diameter of 0.1-0.3 Mum, 28-35wt% of glass fiber with average diameter of 0.4-1 Mum, 15-20wt% of glass fiber with average diameter of 5-7 Mum and 20-30wt% of long glass fiber with average diameter of 15-20 Mum are dispersed in water by beating, mass concentration of size is controlled to be 4.5-5.5%, acidity is controlled to be pH 2.1-2.6, and time of beating is controlled to be 40-48min; step (2), size obtained by the step (1) is diluted and stored; step (3), paper is made; step (4), sizing is carried out; step (5), drying is carried out. The invention has the advantages of high poriness, high clogging capacity and high efficiency.

Owner:CHONGQING ZAISHENG TECH CORP

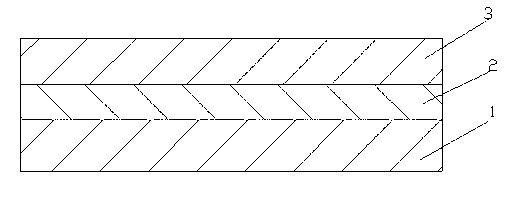

Heat seal cover tape and preparation method of heat seal cover tape

InactiveCN103273714ASimple production processLow requirements for production equipmentSynthetic resin layered productsPolyethylene glycolPolystyrene

The invention discloses a heat seal cover tape and a preparation method of the heat seal cover tape, belonging to the package field of electronic parts and components. A bottom coating is arranged above a base material film layer of the heat seal cover tape; a heat seal layer is arranged above the bottom coating; and the heat seal cover tape is prepared by coating through a coating machine. According to the heat seal cover tape, the production technology is simple and the requirement on production equipment is low. The heat seal cover tape has excellent heat seal property, proper peel strength, even peeling force, high light transmittance, anti-bonding property, high temperature resistance, high humidity resistance, anti-aging performance and enough tensile strength. The heat seal cover tape is suitable for being arranged on a carrier tape made from polystyrene, polycarbonate, polyethylene glycol terephthalate plastic and the like in a way of heat seal. According to the heat seal cover tape and the preparation method of the heat seal cover tape, the problems that the product has dependence on import, high in price and the like can be solved.

Owner:JINGJIANG RUITAI ELECTRIC MATERIAL

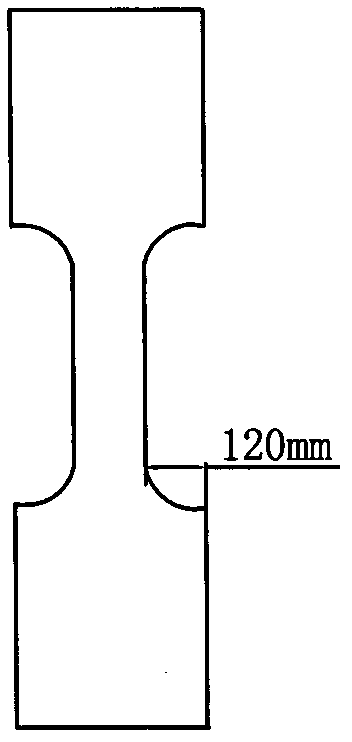

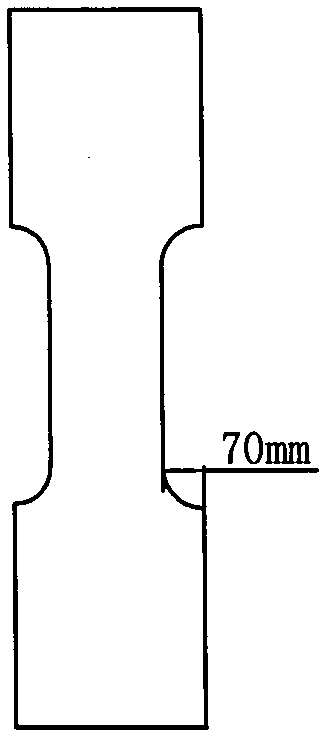

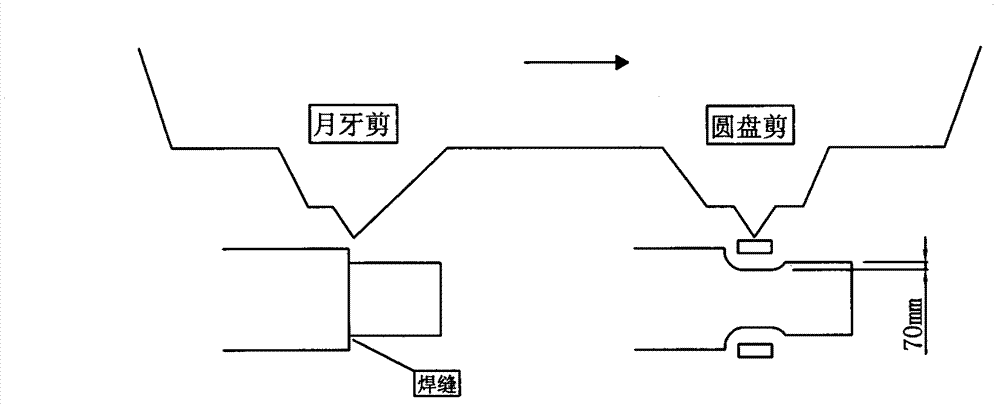

Cold tandem mill strip steel edge trimming controlling method

ActiveCN102784803APut an end to broken beltAvoid broken beltRoll mill control devicesMetal rolling arrangementsEngineeringBack-stripping

The invention relates to a cold tandem mill strip steel edge trimming controlling method and belongs to the technical field of cold tandem rolling devices. According to the method, based on existing cold tandem mill lines, a small crescent punched edge with a punched edge depth of 70mm and a large crescent punched edge with a punched edge depth of 120mm are set; when the width difference of strip steel in the front and rear of a welding seam is in a range from 0mm to 75mm, a notcher is controlled to perform a small crescent edge punching at a position of the welding seam, and a circle shear is controlled to perform an edge trimming at the position of the welding seam; when the width difference of strip steel in the front and rear of the welding seam is larger than 75mm and the front and back strip steel is narrow in front and wide in back, the notcher is controlled to perform the small crescent edge punching at a position 1050+ / -30mm in the front of the welding seam, and the circle shear is controlled to perform the edge trimming at a position 1150+ / -30mm in the front of the welding seam; if the front and back strip steel is wide in front and narrow in back, the notcher is controlled to perform the small crescent edge punching at a position 850+ / -30mm in the rear of the welding seam, and the circle shear is controlled to perform the edge trimming at a position 750+ / -30mm in the rear of the welding seam; and otherwise existing processes are performed. According to the method, the small crescent edge punching is innovated, the edge punching position and depth of the notcher and the edge trimming position of the circle shear are respectively judged and adjusted according to the width difference of strip steel in the front and rear of the welding seam, and thereby a sufficient tensile strength of the strip steel at the position of the welding seam can be guaranteed so as to prevent strip breakage.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

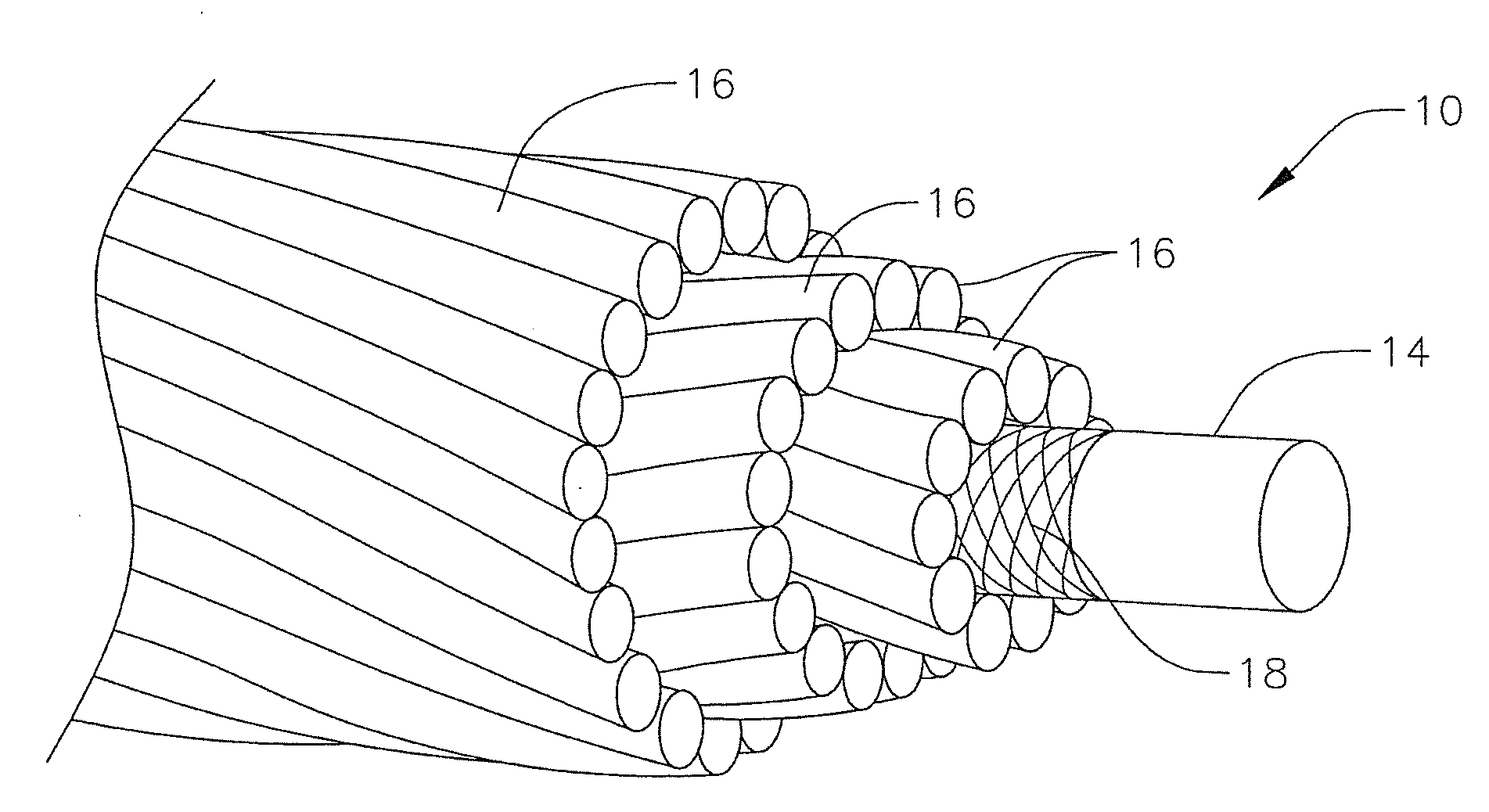

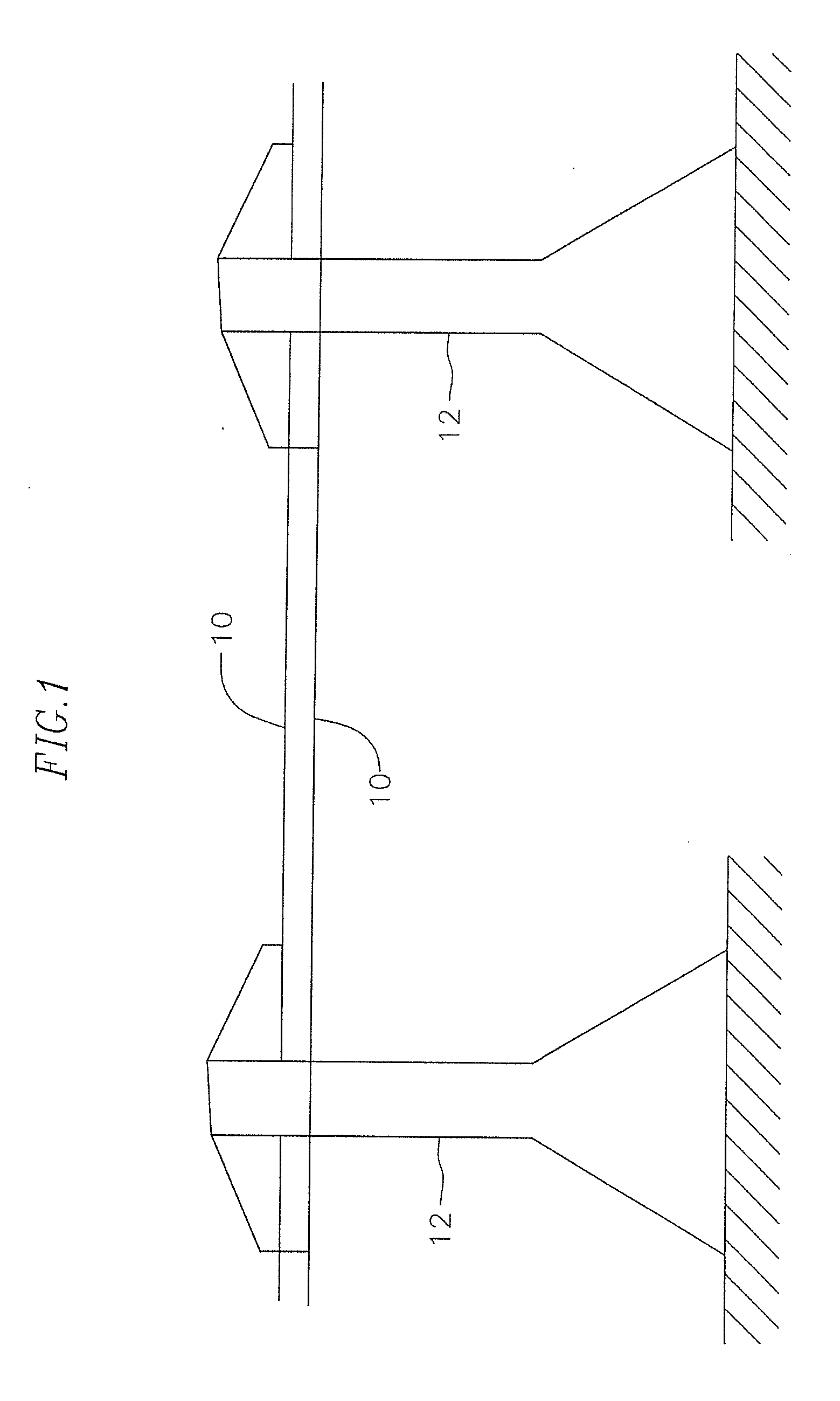

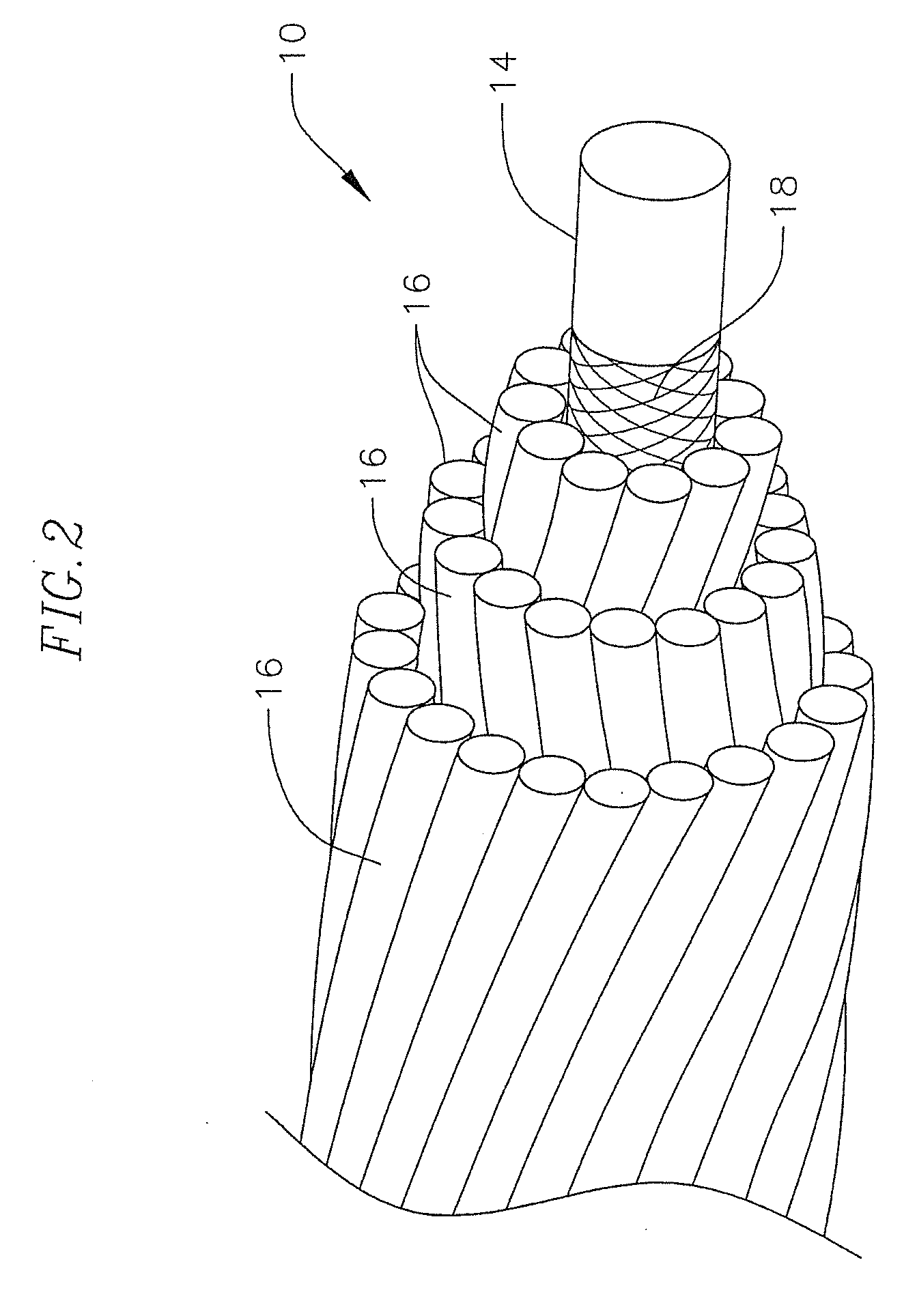

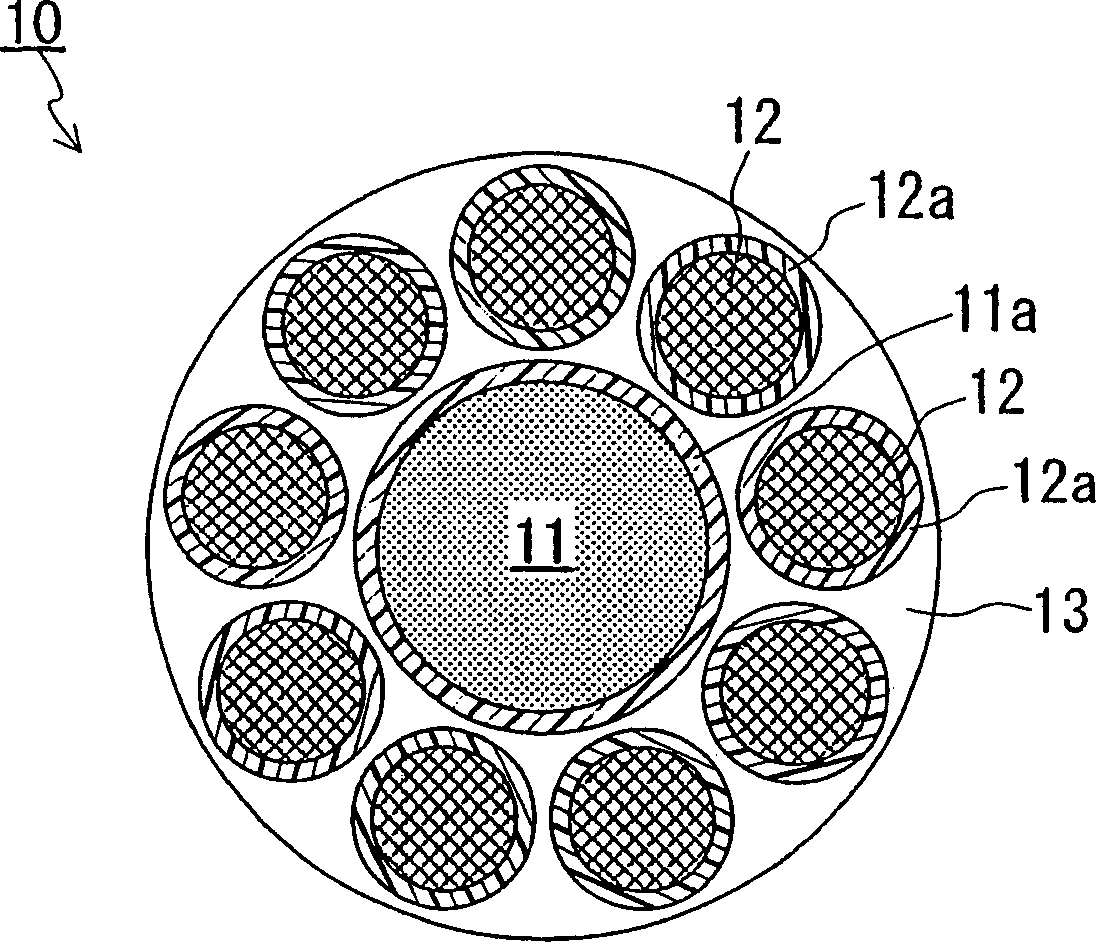

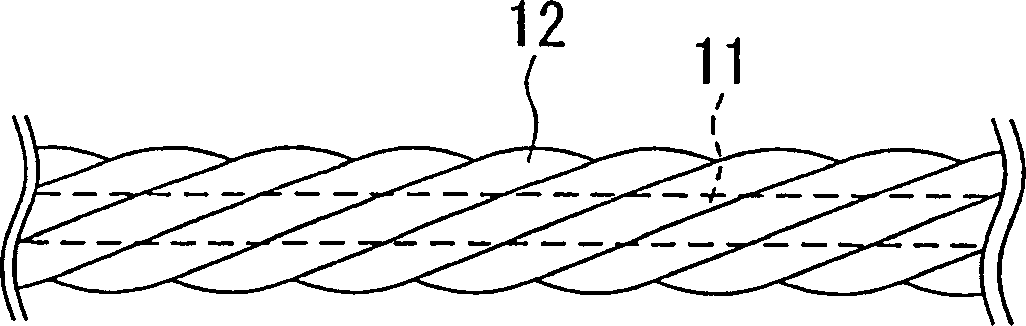

Reinforcing cord for reinforcing rubber and rubber product using the same

The reinforcing cord of the present invention is a reinforcing cord for reinforcing rubber, and includes a carbon fiber strand (11) and a plurality of glass fiber strands (12) arranged around the carbon fiber strand (11). According to the present invention, a reinforcing cord having sufficient tensile strength to reinforce rubber products and having high dimensional stability and bending fatigue resistance can be obtained.

Owner:NIPPON SHEET GLASS CO LTD

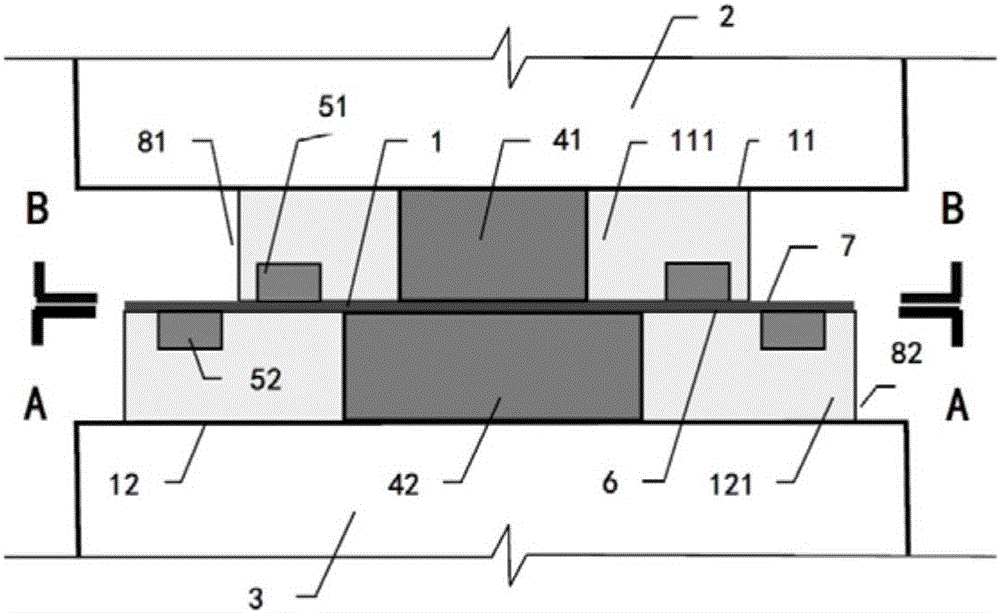

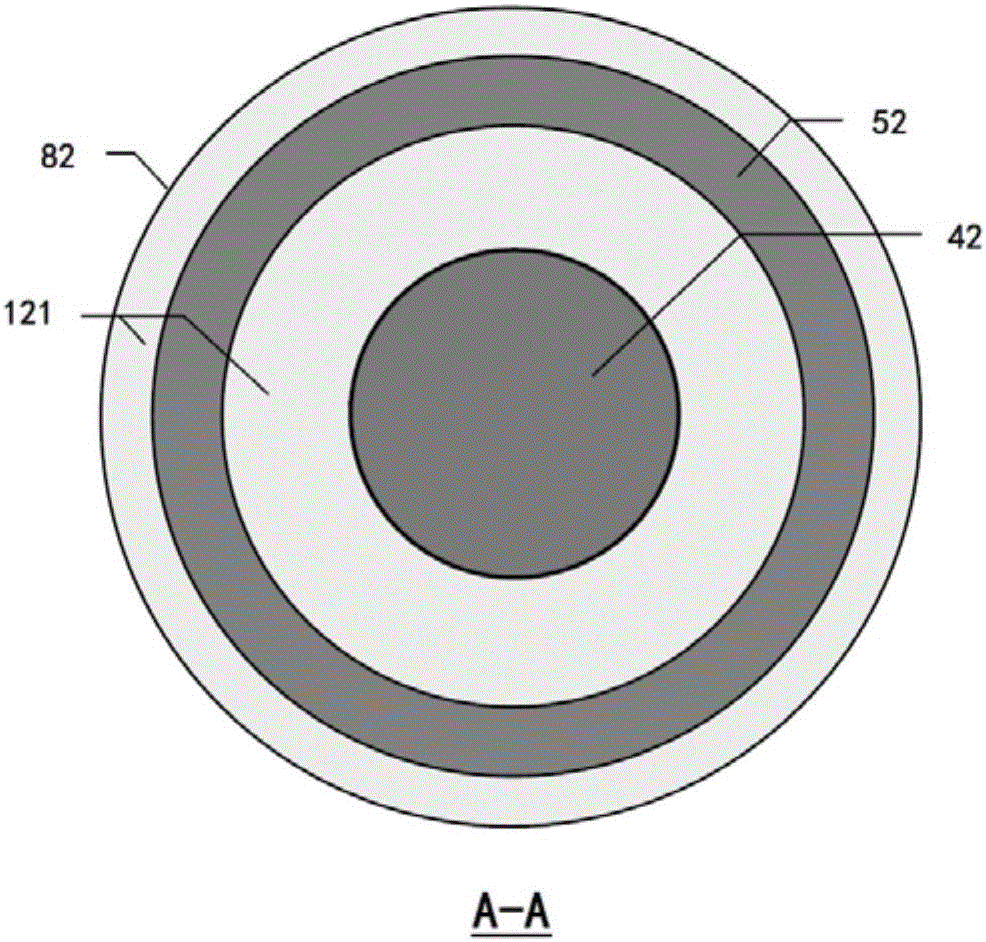

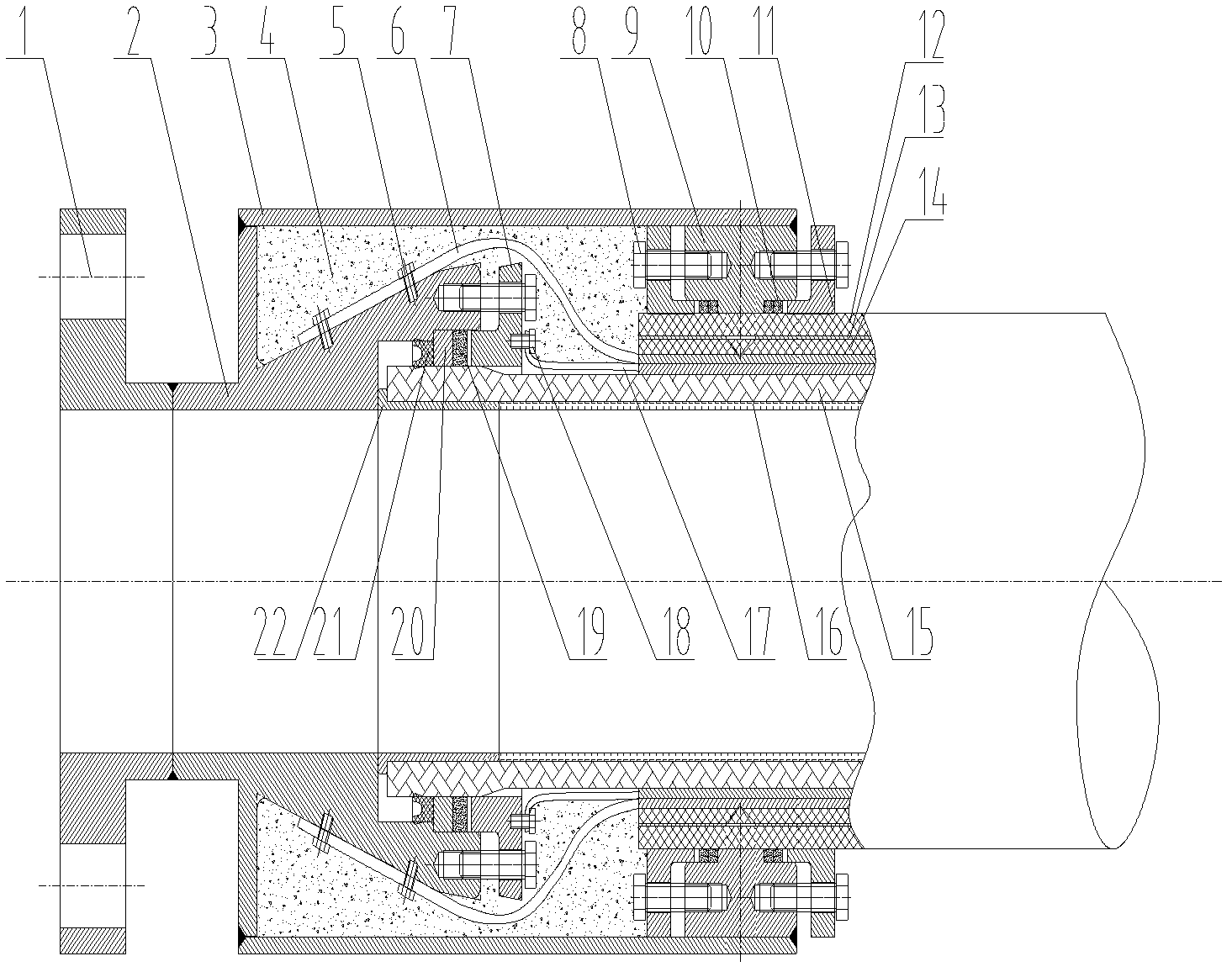

Slip vibration isolation support

ActiveCN105804263AHigh sensitivityGood filtering performanceBridge structural detailsShock proofingMagnetStructural engineering

The invention discloses a slip vibration isolation support which comprises an upper support and a lower support. The upper support is supported by the lower support, and interlayer surfaces are arranged between the upper support and the lower support; the upper support and the lower support are both filled with lead core rubber and internally provided with annular permanent magnets in a staggered mode, and the upper permanent magnet and the lower permanent magnet are both arranged to be close to the interlayer surfaces so as to provide sufficient magnetic induction intensity; the vibration support adopts aluminum plates as the interlyaer surfaces, outer sealing is conducted through annular steel tanks, and the interlayer surfaces are covered with polytetrafluoroethylene plates. Compared with a traditional vibration isolation support, the internally arranged magnet type vibration isolation support has the advantages of being small in abrasion, high in sensitivity, good in filtering property, high in energy consumption, small in impact effect, high in self reset capacity, capable of saving space, good in tensile property and the like, and important significance in solving the technical problems that deformation of the vibration isolation support of the area with high seismic intensity is too large, the impact effect is significant, and the tensile property is weak is achieved.

Owner:TONGJI UNIV

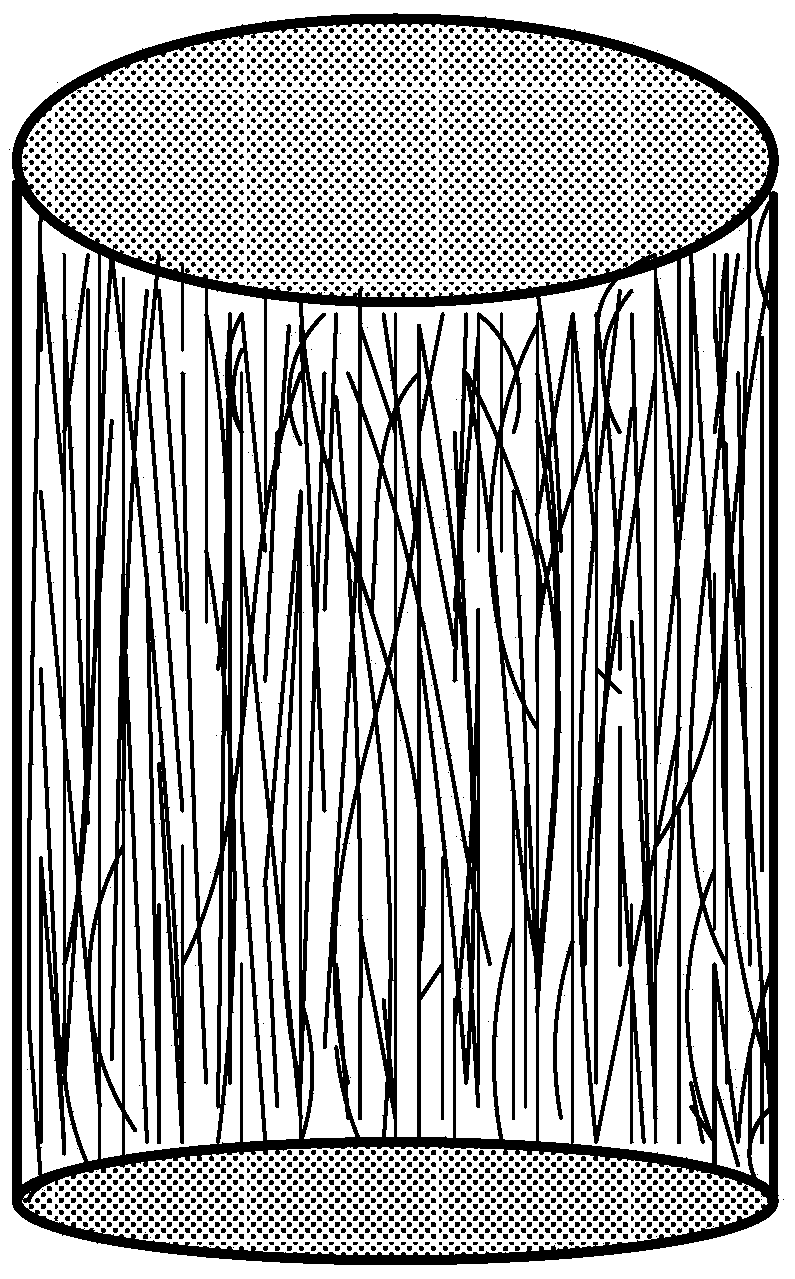

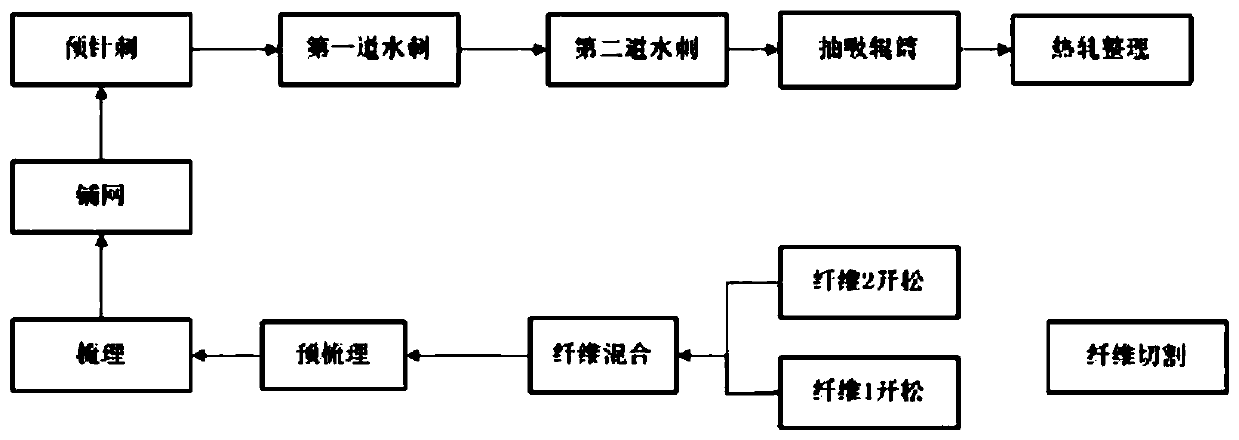

Composite acetate fiber non-woven material applicable to cigarette filters and preparation method and application of composite acetate fiber non-woven material

PendingCN110616505AHigh tensile strengthStrong heat conduction and heat absorption capacityCarbon fibresTobacco smoke filtersAbsorption effectPolylactic acid

The invention relates to a composite acetate fiber non-woven material applicable to cigarette filters and a preparation method of the composite acetate fiber non-woven material. The composite acetatefiber non-woven material is prepared by mixing acetate fiber and other fibers, wherein the other fibers is one, two or three of polylactic acid fibers, metal fibers and carbon fibers. The composite acetate fiber non-woven material comprises 5-99wt% of cellulose acetate fibers and 1-95wt% of non-acetate-fiber material. The preparation method includes: opening the cellulose acetate fibers, mixing with the non-acetate-fiber material, carding, lapping, and performing spunlace to obtain the acetate fiber non-woven material. The acetate fiber non-woven material has a certain heat absorption effect and certain filtering performance and can lower smoke temperature and filter harmful components in smoke. After fiber mixing, the tensile strength of the non-woven material is enhanced, and the strength requirement of the cigarette filters produced by the non-woven material can be satisfied. The composite acetate fiber non-woven material can be used to produce incombustible cigarette filters.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

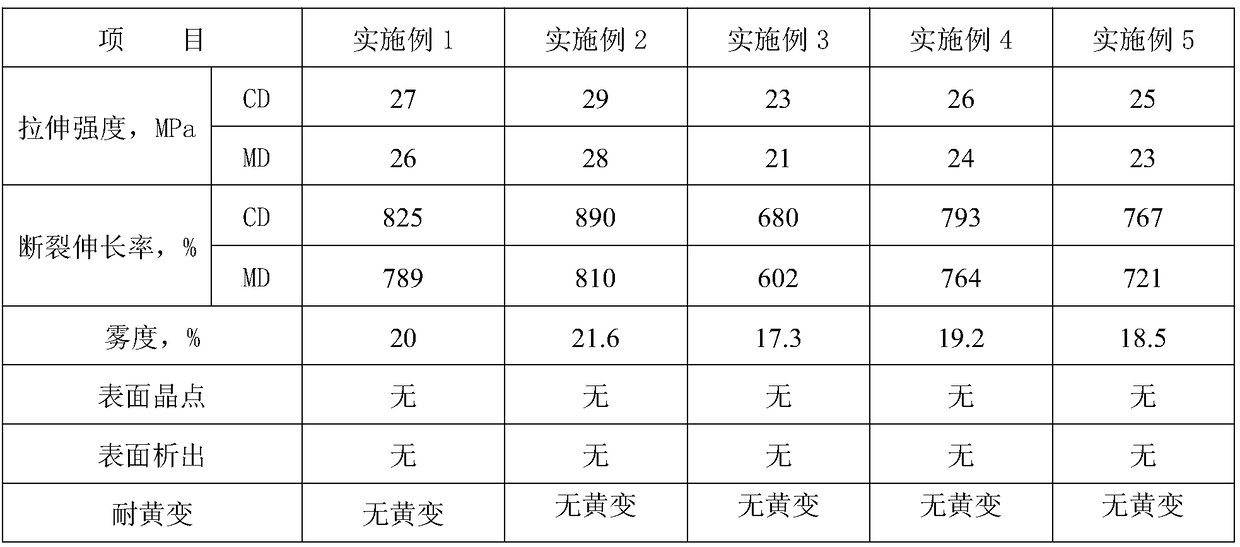

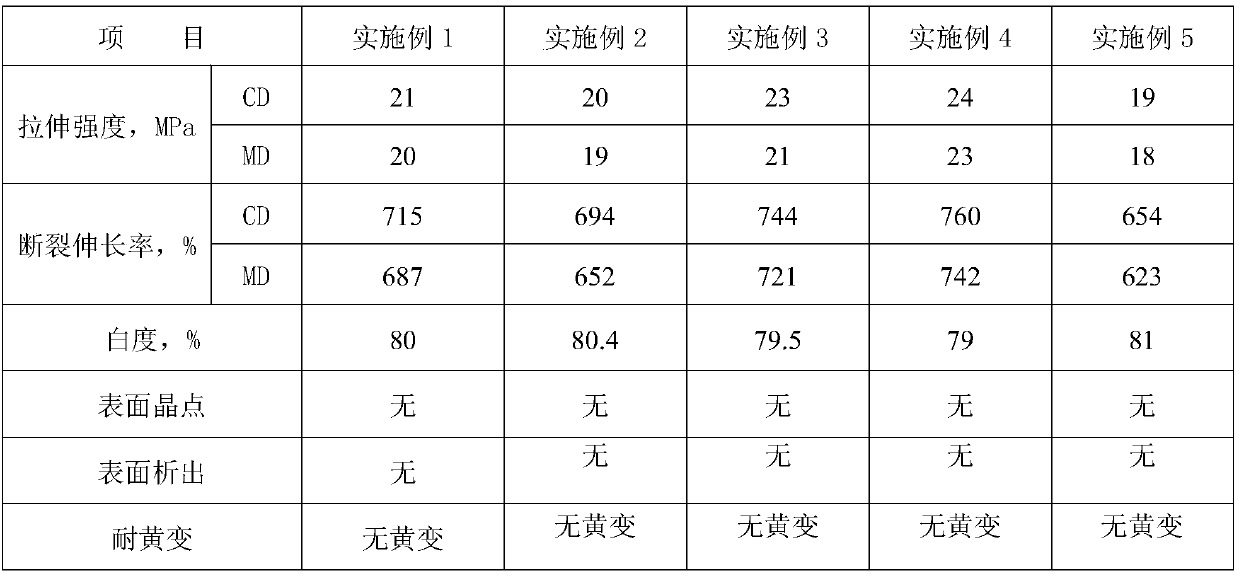

Transparent PE label film and production method thereof

The invention relates to a transparent PE label film. The transparent PE label film comprises an outer film layer, a middle film layer and an inner film layer; the outer film layer and the inner filmlayer are prepared from 68.5-70.5 wt% of LDPE, 29-31 wt% of casting-level HDPE and 0.2-0.8 wt% of PPA, and the middle film layer is prepared from 44-46 wt% of film-blowing-level HDPE, 53.5-55.5 wt% ofLDPE and 0.2-0.8 wt% of PPA. The invention further provides a production method of the transparent PE label film. The transparent PE label film has the advantages of being low in crystal point, freeof surface precipitation, high in stiffness and resistant to yellowing, and the printing and use requirements are met.

Owner:永新股份(黄山)包装有限公司

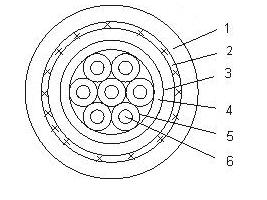

Armored tactical optical cable

InactiveCN102565972AGood mechanical propertiesExcellent flame retardant and chemical propertiesFibre mechanical structuresTension stressExplosion protection

For meeting the requirement that when the force operates in the field and complex environments, the rapid wiring and repeated take-up and pay-off of an optical cable can be temporarily implemented, an armored tactical optical cable with the characteristics of strong tension stress, strong compressive resistance, high flexibility, bending resistance, oil resistance, wear resistance, flame retardance, wide temperature application range and the like needs to be developed. The optical cable is formed in a mode that a plurality of optical fibers coated with tightly sleeving layers are twisted into the cable in a double helix mode and Aramid yarns, a metal hose and a metal woven mesh are sequentially coated outside a cable conductor. The armored optical cable can overcome the defect that the optical fibers are easy to break and are easy to damage and has the characteristics of tensile strength, compressive resistance, explosion protection, rat mammal insect damage prevention and the like. The Aramid yarns which are armored on the optical cable provide a larger short-time bearing tensile force for the optical cable. TPU (thermoplastic polyurethanes) sheaths have excellent flame retardant property, chemical property and high-strength wear resistance. The armored tactical optical cable can be suitable for various outdoor harsh environments. The tension resistance of the optical cable is implemented by the Aramid yarns, the metal hose and the metal woven mesh together.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

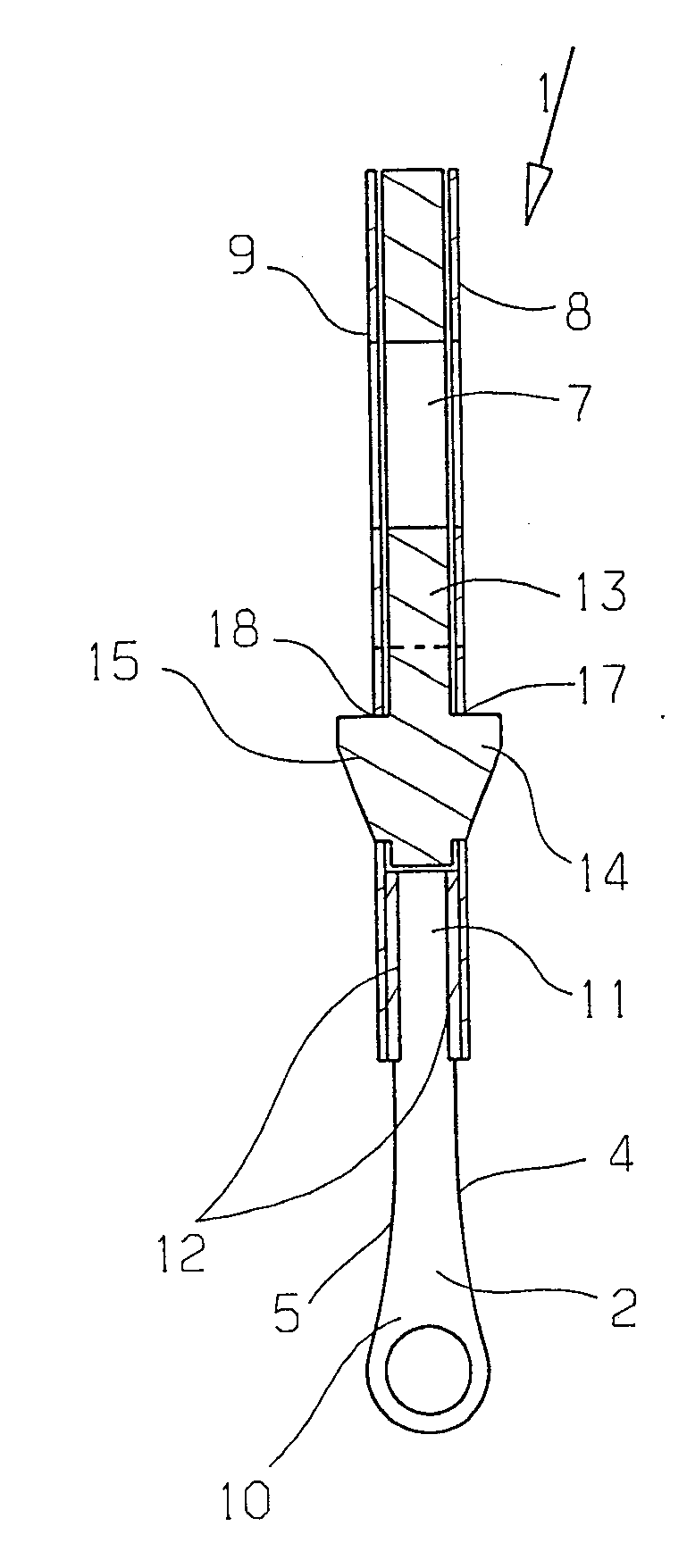

Probe head adapter for checking probe

InactiveCN1340714ASufficient tensile strengthSufficient compression setElectrical testingMeasurement leads/probesElastomerDifferential measurement

A probe tip adapter for a measurement probe has at least a first electrically conductive element with a bore at one end and a probing contact formed on the other end. The bore of the electrically conductive element has an electrically conductive elastomer disposed therein having sufficient tensile strength, compression set, hardness, deflection force, elongation and percent recovery for repeatably securing the electrically conductive element to the probing tip of the measurement probe. The probing contact may be configured as a probing tip having a shaft that tapers at one end to a point and as a square pin adapter with a bore formed in the electrically conductive element that receives a spring contact. The probe tip adapter is useable with both single ended and differential measurement probes.

Owner:TEKTRONIX INC

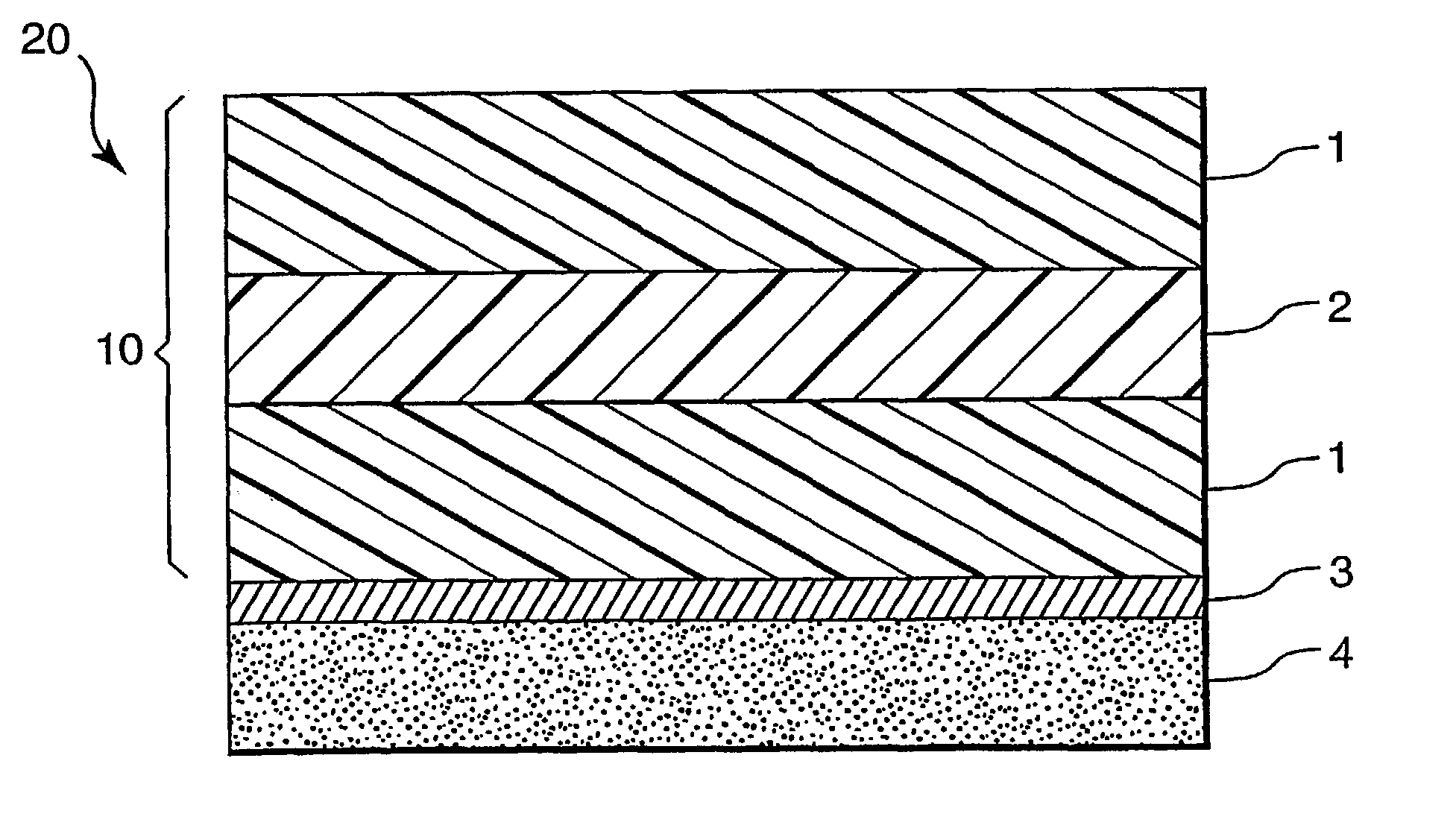

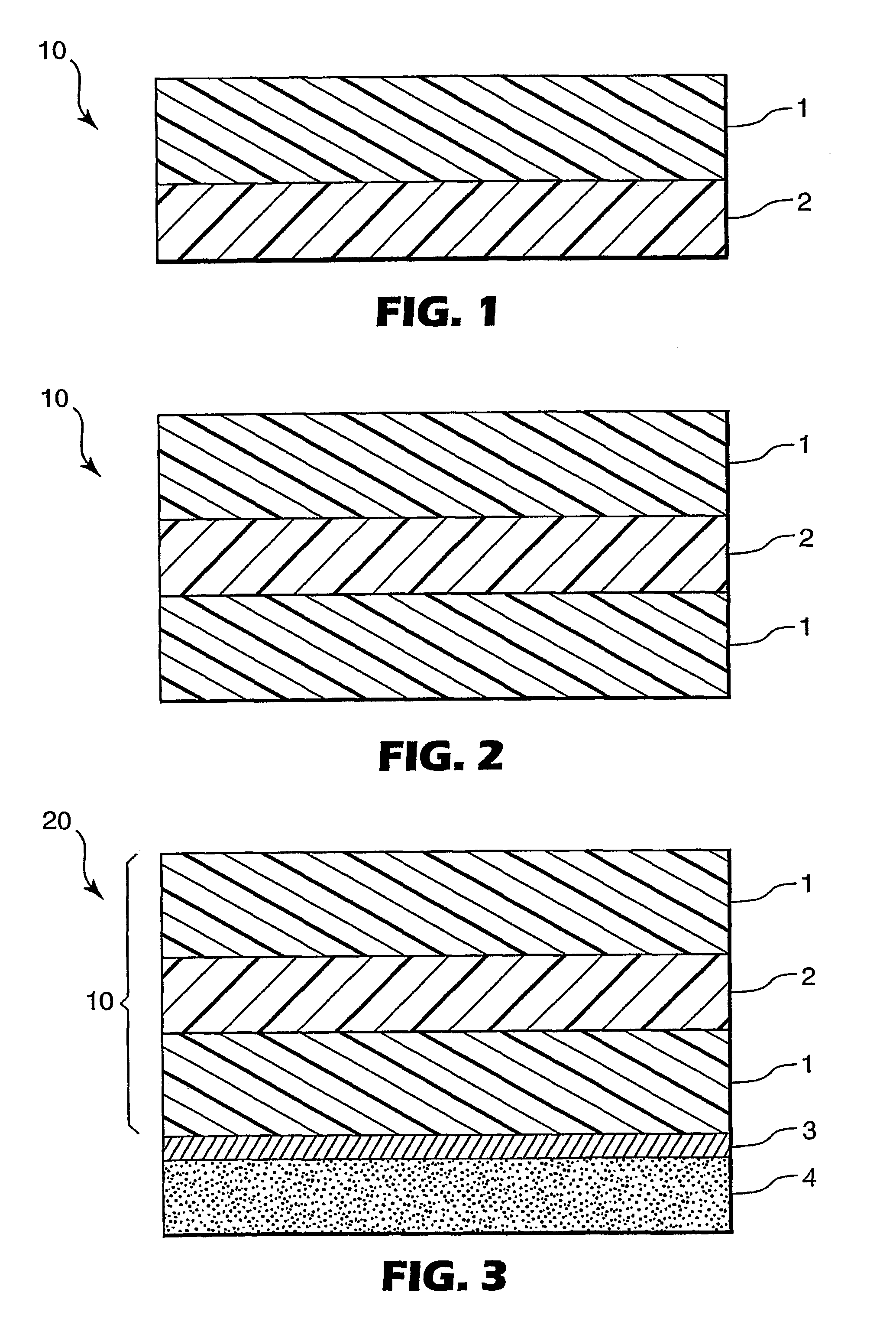

Composite base material and adhesive film

InactiveUS7179529B2Sufficient tensile strengthHigh tensile strengthPicture framesFilm/foil adhesivesChemistryFlexural modulus

To provide an adhesive film that can be easily released leaving substantially no adhesive residue and without damaging the adherend surface when released from an adherend. A base material comprising at least a first resin film with a breaking elongation in the lengthwise direction of 300 to 1500% and a breaking strength of at least 2 kg / 12 mm, and a second resin film with a lower breaking elongation and a higher flexural modulus than the first resin film is used. The second resin film can break before the first resin film when the base material is stretched.

Owner:3M INNOVATIVE PROPERTIES CO

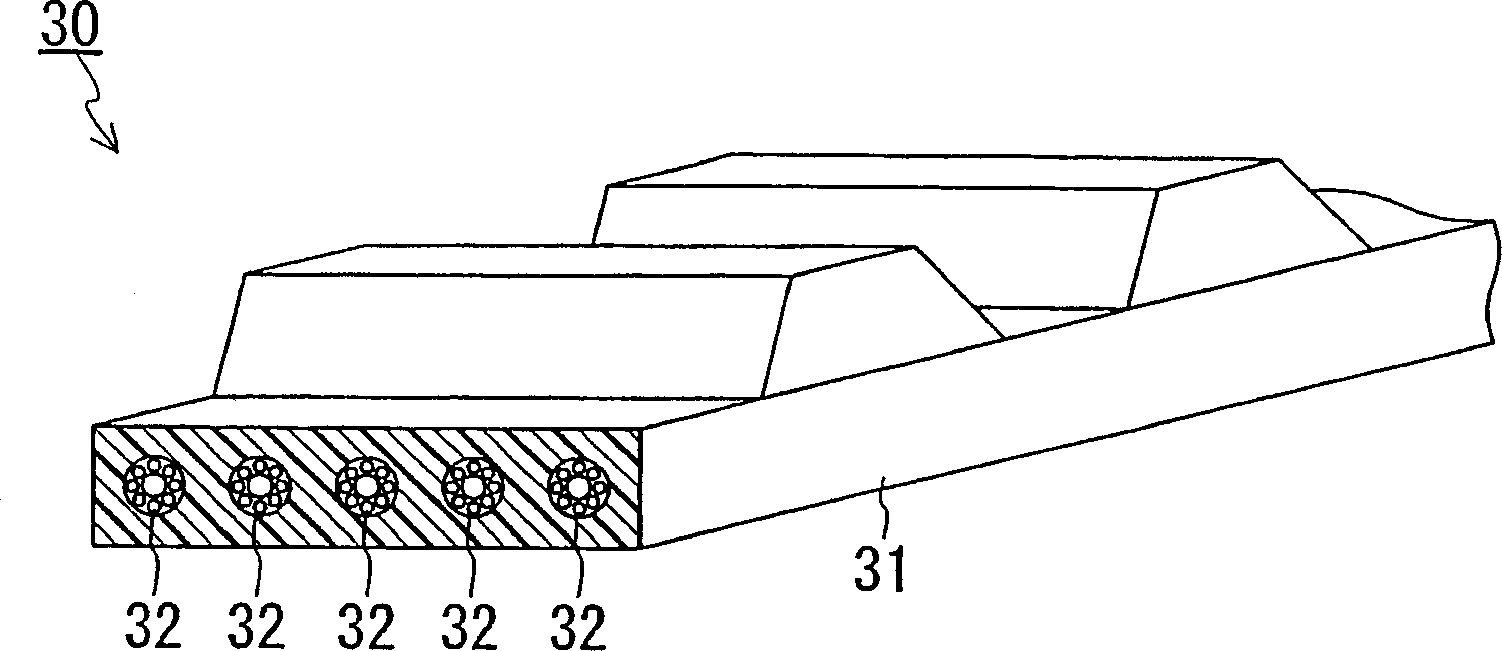

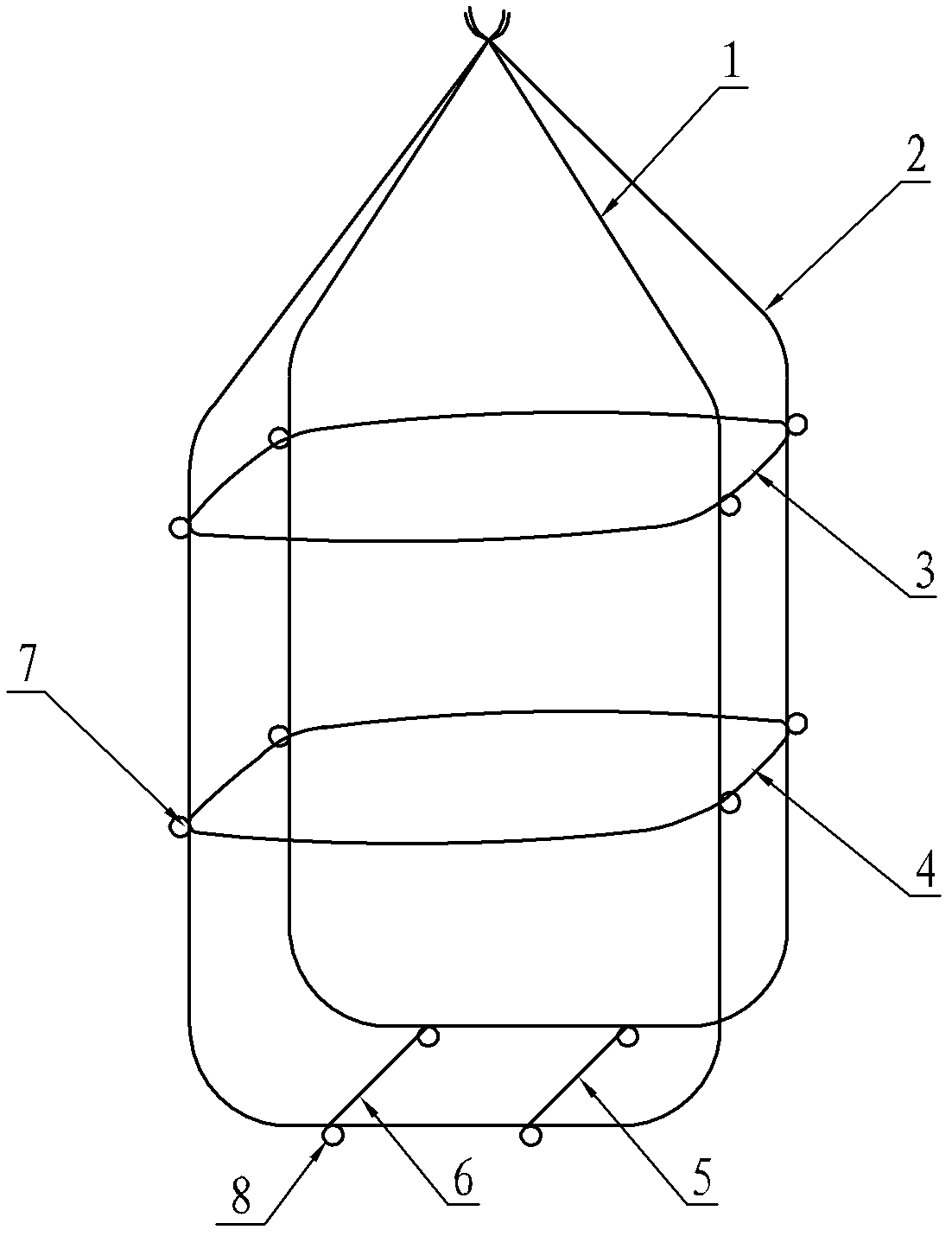

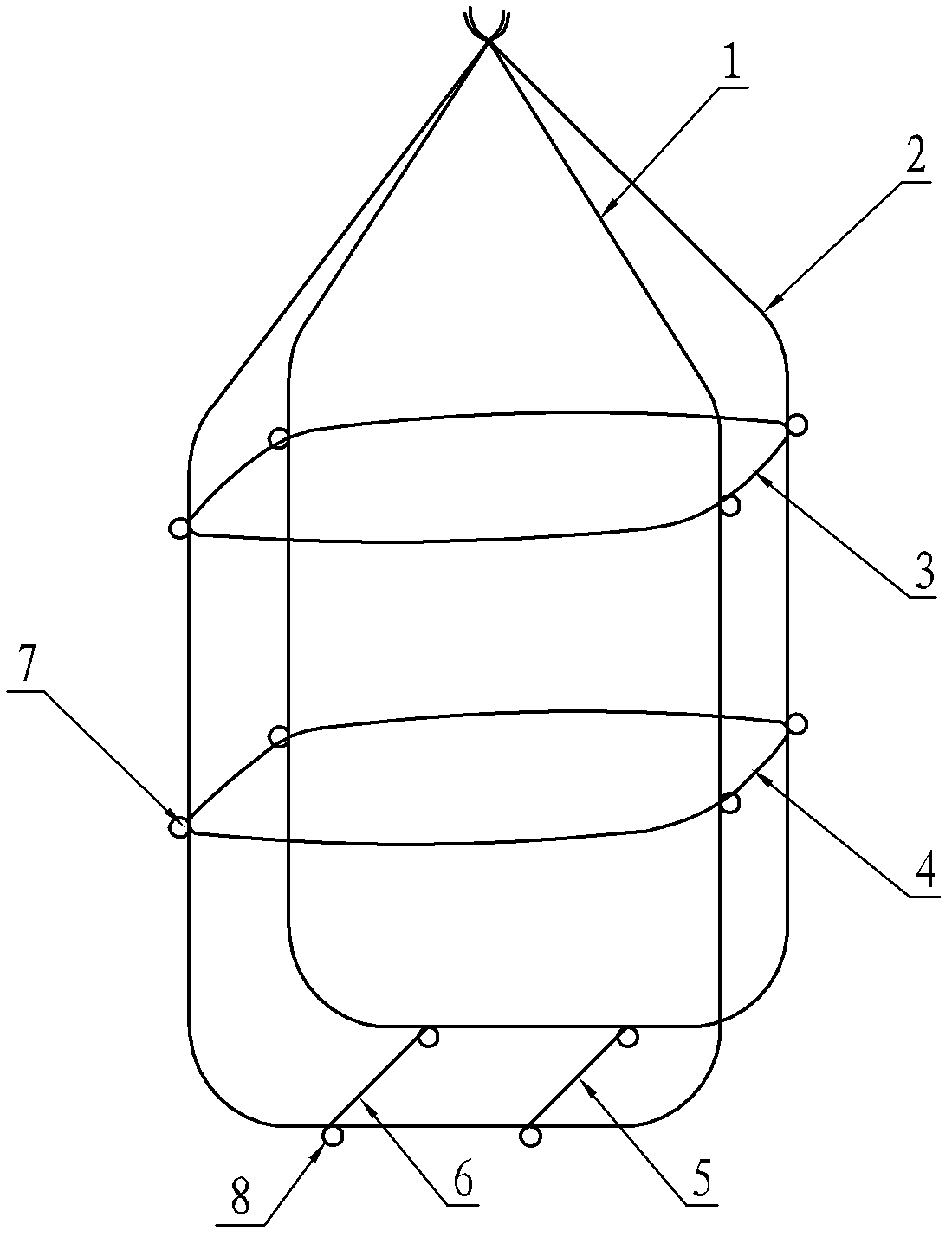

Lifting appliance for crucible for growing sapphire single crystal

ActiveCN102560653AGood flexibilityEasy to assemble and disassemblePolycrystalline material growthBy pulling from meltSapphireWire rope

The invention discloses a lifting appliance for a crucible for growing a sapphire single crystal. The lifting appliance comprises a lifting steel wire rope 1, a lifting steel wire rope 2, an upper steel wire rope ring, a lower steel wire rope ring, a bottom support steel wire rope 1, a bottom support steel wire rope 2 and rope threading rings, wherein four rope threading rings are arranged on each of the upper steel wire rope ring and the lower steel wire rope ring; each of the lifting steel wire rope 1 and the lifting steel wire rope 2 passes through two adjacent rope threading rings on the upper steel wire rope ring and two adjacent rope threading rings on the lower steel wire rope ring in turn; and the bottom support steel wire rope 1 and the bottom support steel wire rope 2 are respectively sleeved on the lifting steel wire rope 1 and the lifting steel wire rope 2 through steel rings at the two ends and are positioned below the lower steel wire rope ring. The lifting appliance formed by combining flexible steel wire ropes is convenient to sleeve and detach and lifts and moves the crucible safely and reliably; extruding force applied to the crucible is small when the crucible is lifted, so that the crucible cannot be damaged due to pressing, and the service life of the crucible can be prolonged; and more importantly, the crucible can be lifted before a furnace is cooled, unproductive time can be greatly shortened, work efficiency is improved, and production cost is reduced.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Heat-treated steel sheet member and method for producing the same

ActiveUS20180135145A1Sufficient tensile strengthHigh yield ratioFurnace typesHeat treatment furnacesNumber densityAluminium

A heat-treated steel sheet member having a composition including, by mass %: C: 0.05 to 0.50%; Si: 0.50 to 5.0%; Mn: 1.5 to 4.0%; P: 0.05% or less; S: 0.05% or less; N: 0.01% or less; Ti: 0.01 to 0.10%; B: 0.0005 to 0.010%; Cr: 0 to 1.0%; Ni: 0 to 2.0%; Cu; 0 to 1.0%; Mo: 0 to 1.0%; V: 0 to 1.0%; Ca: 0 to 0.01%; Al: 0 to 1.0%; Nb: 0 to 1.0%; REM: 0 to 0.1%; and the balance: Fe and impurities. The steel sheet member has a microstructure comprising mainly martensite and retained austenite of which a volume ratio is 0.2 to 1.0%, a number density of retained carbide in the steel sheet member having circle-equivalent diameters of 0.1 mm or larger is 4.0×103 / mm2 or lower, a tensile strength is 1.4 GPa or higher, and a yield ratio is 0.65 or higher.

Owner:NIPPON STEEL CORP

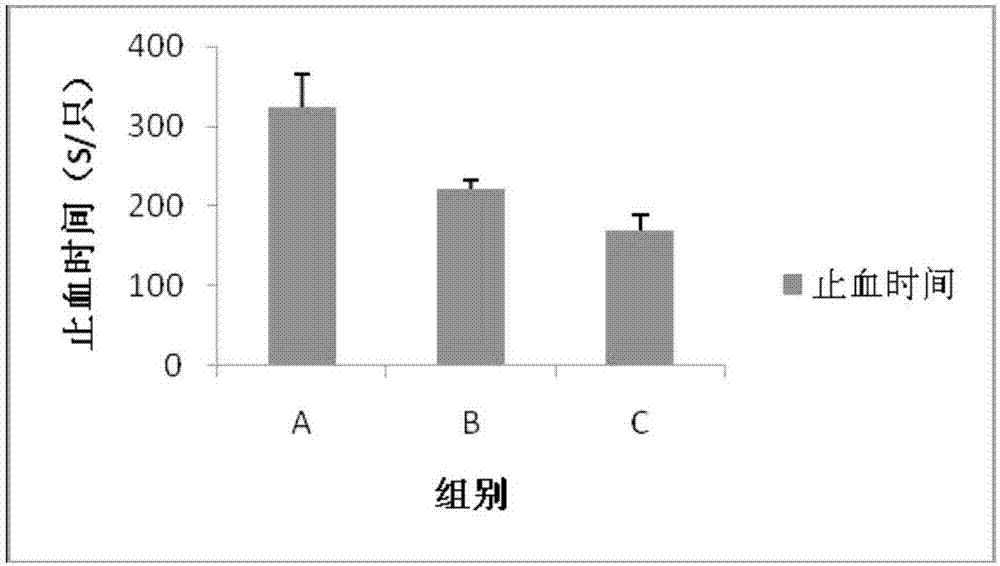

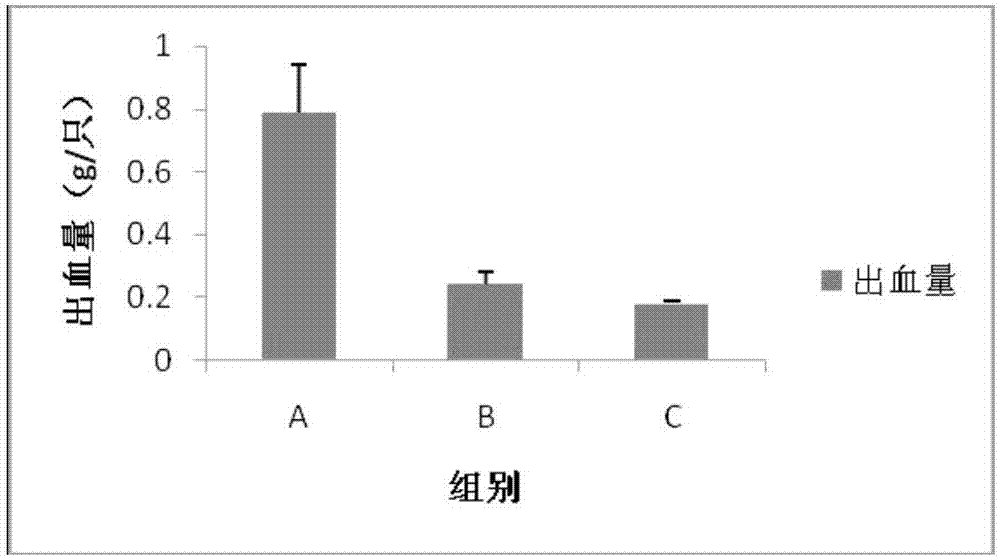

Microfiber collagen hemostatic material and preparation method thereof

ActiveCN107137758ASufficient tensile strengthGood hemostatic effectSurgical adhesivesHeatFibrosisRadiation Sterilization

The invention relates to a microfiber collagen hemostatic material and a preparation method thereof. The preparation method of the material includes the first step of sodium sulfide unhairing, the second step of shredding and fibrosis, the third step of swelling control, the fourth step of drying, the fifth step of depolymerisation and fluffing, and the sixth step of Co60 radiation sterilization, wherein in the fifth step, the obtained fasciculus is treated using a hammer mill to obtain a microfiber collagen product. According to the method, the use concentration of sodium sulphide is reduced, the efficiency of unhairing is improved, and degreasing and impure protein removal are effectively conducted; collagen materials are not oxidized and degenerated, the activity of microfiber collagen is easy to maintain, and the hemostatic effect is improved. Acid is introduced in the treating process, the degreasing and protein removal are more effective, and the adhesion property of the hemostatic material is guaranteed.

Owner:林贵梅

Extruding and drawing forming process for glass fiber reinforced plastic bar surface

The present invention relates to extruding and drawing formation process for GRP bar surface, and features that the extruding and drawing former is provided with glue dipping tank with compounded adhesive filled and bar surface mold. Certain amount of no-alkali and no-twist roving is soaked into the adhesive inside the glue dipping tank, then threaded into mold preheated to certain temperature and finally extruded in extruding and drawing former to form. The formed product is stoved in electric stove and cooled naturally. High strength adhesive is compounded to ensure enough tensile strength and round strength of the bar surface, and the bar surface has no residual deformation under tensile force up to 700 kg. The bar surfaces of parallel bars and uneven bars may be used in the temperature range of -70 deg.c to +50 deg.c and maintain excellent mechanical performance.

Owner:天津市春合体育用品有限公司

Solvent-free type base adhesive for nail painting and preparation method thereof

ActiveCN108635248AFast curingHigh hardnessCosmetic preparationsNon-macromolecular adhesive additivesAdhesiveAcrylic resin

The invention relates to a solvent-free type base adhesive for nail painting and a preparation method thereof. The solvent-free type base adhesive for nail painting is prepared from the following ingredients of 0.5 to 1.5 parts of a titanate coupling agent, 25 to 30 parts of epoxy acrylic resin, 25 to 30 parts of aliphatic polyurethane acrylic resin, 3 to 10 parts of pure acrylic resin, 25 to 35 parts of acrylate monomers, 0.5 to 1.5 parts of a photoinitiator 184, 2 to 5 parts of TPO, 0.05 to 0.2 part of a flatting agent and 0.1 to 0.3 part of an antifoaming agent. The solvent-free type base adhesive for nail painting has the advantages that the durability can reach three weeks or more than three weeks; the breaking elongation is greater than 7 percent; the tensile strength is greater than500psi; the adhesion test ISO grade is 0; and the viscosity at 25 DEG C is 1000 cps to 40000cps.

Owner:SHANGHAI ONINE TECH LTD

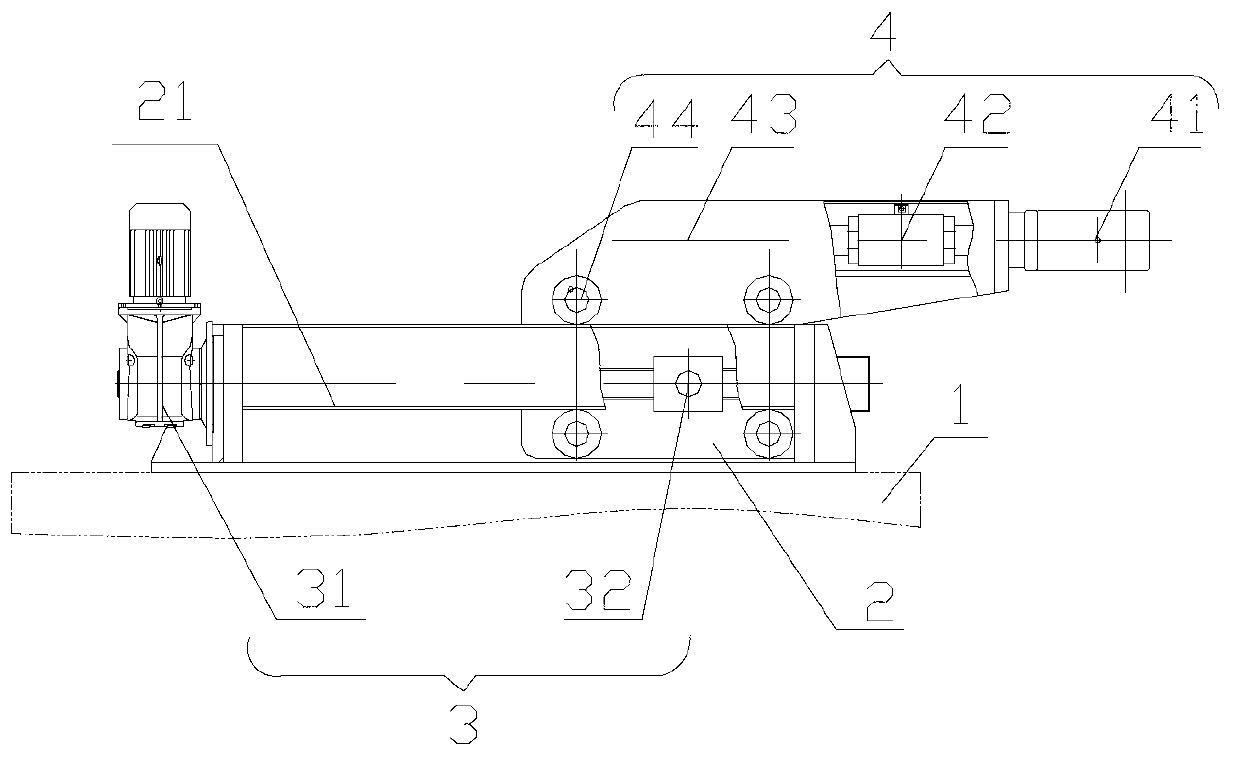

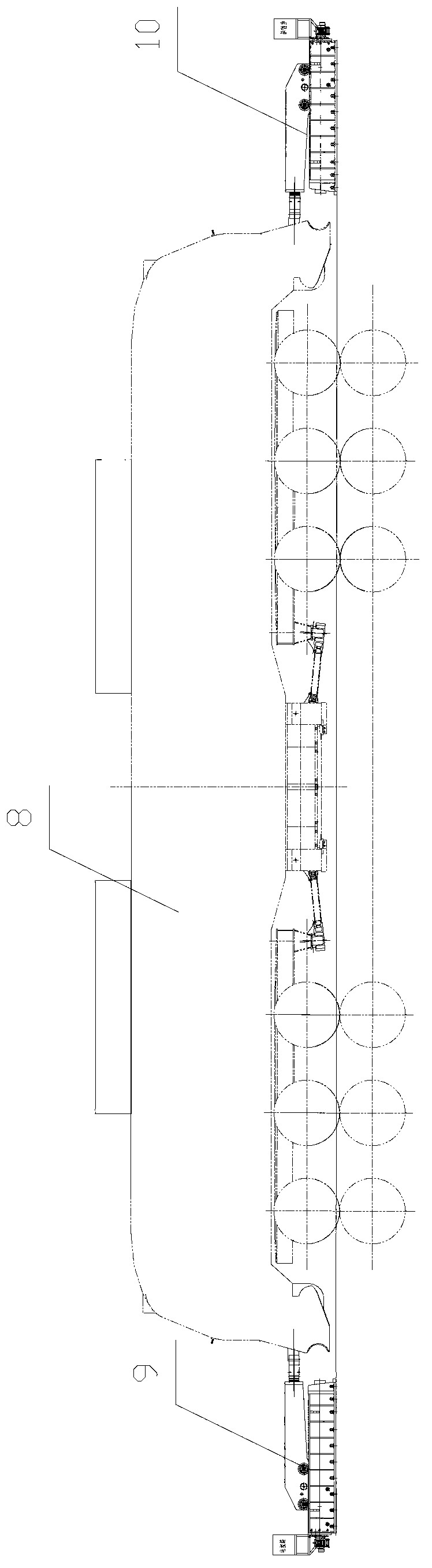

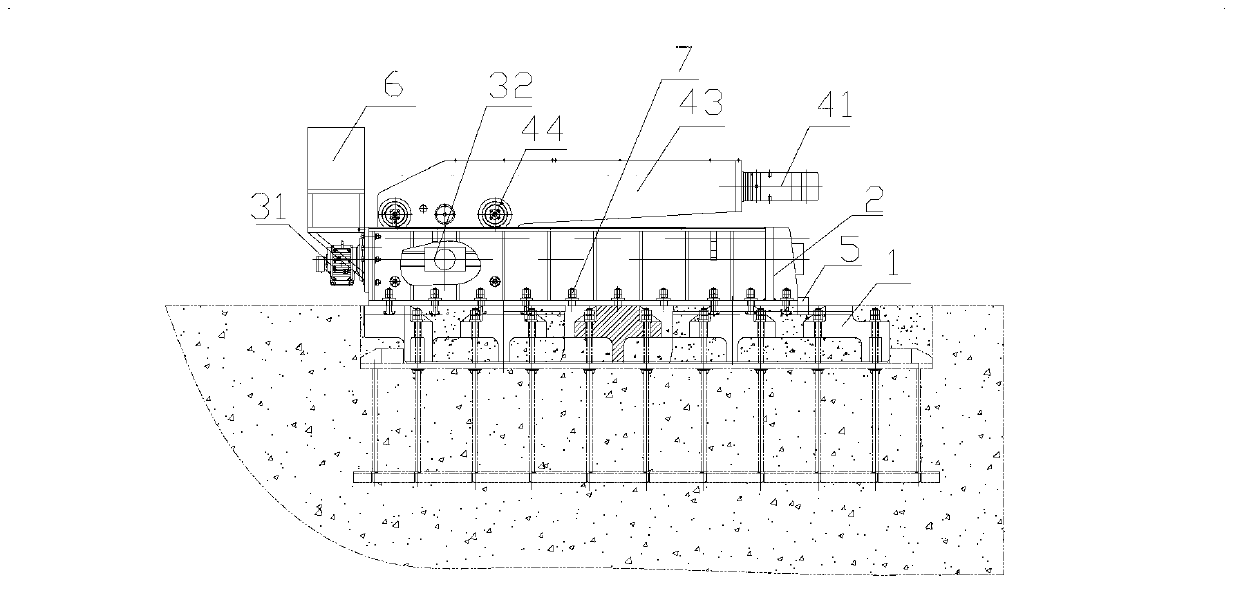

Device and system for positioning locomotive testing bed ground draw gear

ActiveCN103278342ASufficient flexibilityMeet the needs of accurate positioningRailway vehicle testingEngineeringMechanical engineering

The invention discloses a device and system for positioning a locomotive testing bed ground draw gear. The device comprises a foundation base platform, a device base, a transmission system and a movable draw gear assembly. The device base is installed on the foundation base platform and comprises an device base track, the movable draw gear assembly comprises the draw gear, a tension sensor, a draw gear bracket and draw gear bracket rolling wheels, the rear end of the draw gear is connected with the tension sensor which is installed in the draw gear bracket, the draw gear bracket rolling wheels are installed on the draw gear bracket and installed on the device base track in a rolling mode, and the transmission system drives the movable draw gear assembly to move. According to the device for positioning the locomotive testing bed ground draw gear, the transmission system is adopted for driving the movable draw gear assembly to move on the device base track of the device base, the travel distance of the device is large, and requirements for accurate positioning for different vehicle types are met.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

Milky white PE (polyethylene) label film and production method thereof

ActiveCN109616005AGood glossImprove opticsStampsSynthetic resin layered productsHigh-density polyethyleneLow-density polyethylene

The invention relates to a milky white PE (polyethylene) label film. The milky white PE label film comprises an outer film layer, an intermediate film layer and an inner film layer, wherein the outerfilm layer and the inner film layer respectively comprise 68.5-70.5 wt% of LDPE (low-density polyethylene), 29-31 wt% of casting grade HDPE (high-density polyethylene) and 0.2-0.8 wt% of PPA (phenyl-propanolamine), and the intermediate film layer comprises 44-46 wt% of blown film grade HDPE, 35.5-37.5 wt% of LDPE, 17-19 wt% of white masterbatch and 0.2-0.8 wt% of PPA. In addition, the invention also provides a production method of the milky white PE label film. The milky white PE label film has the characteristics of low crystal point, no surface precipitation, high stiffness and yellowing resistance, and meets requirements for printing and use.

Owner:永新股份(黄山)包装有限公司

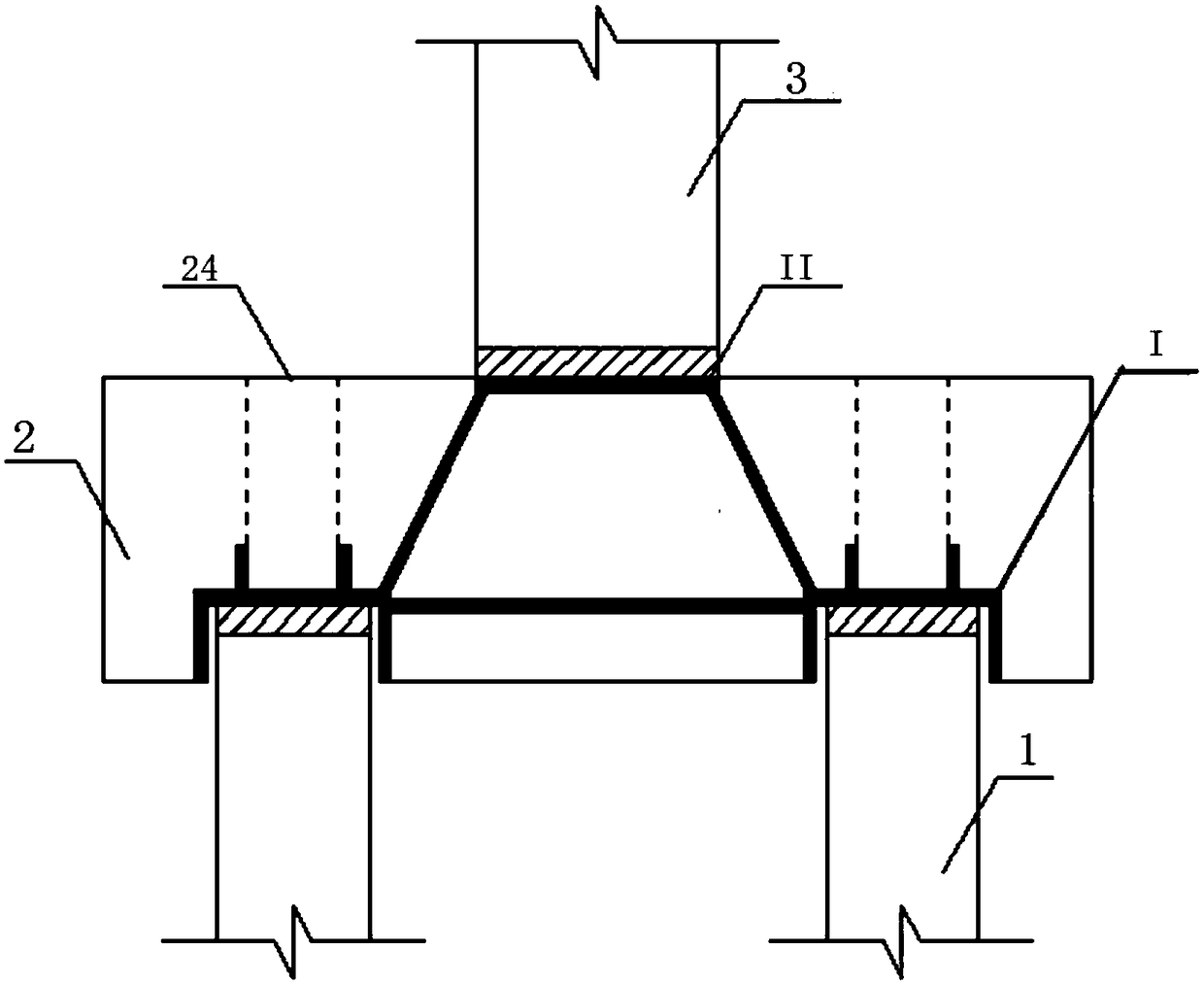

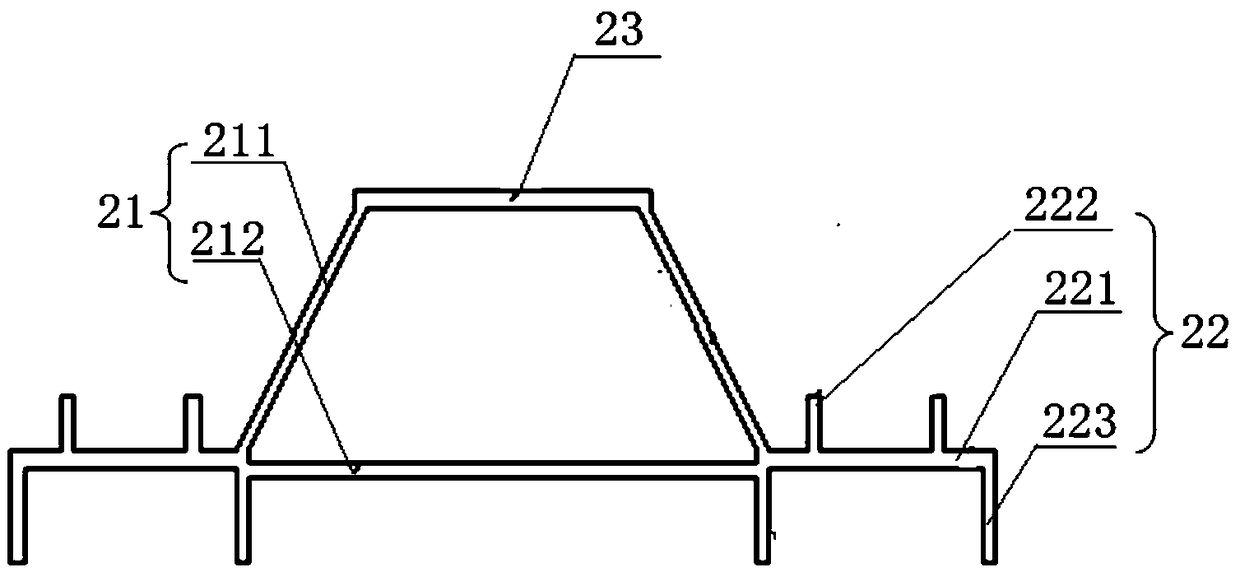

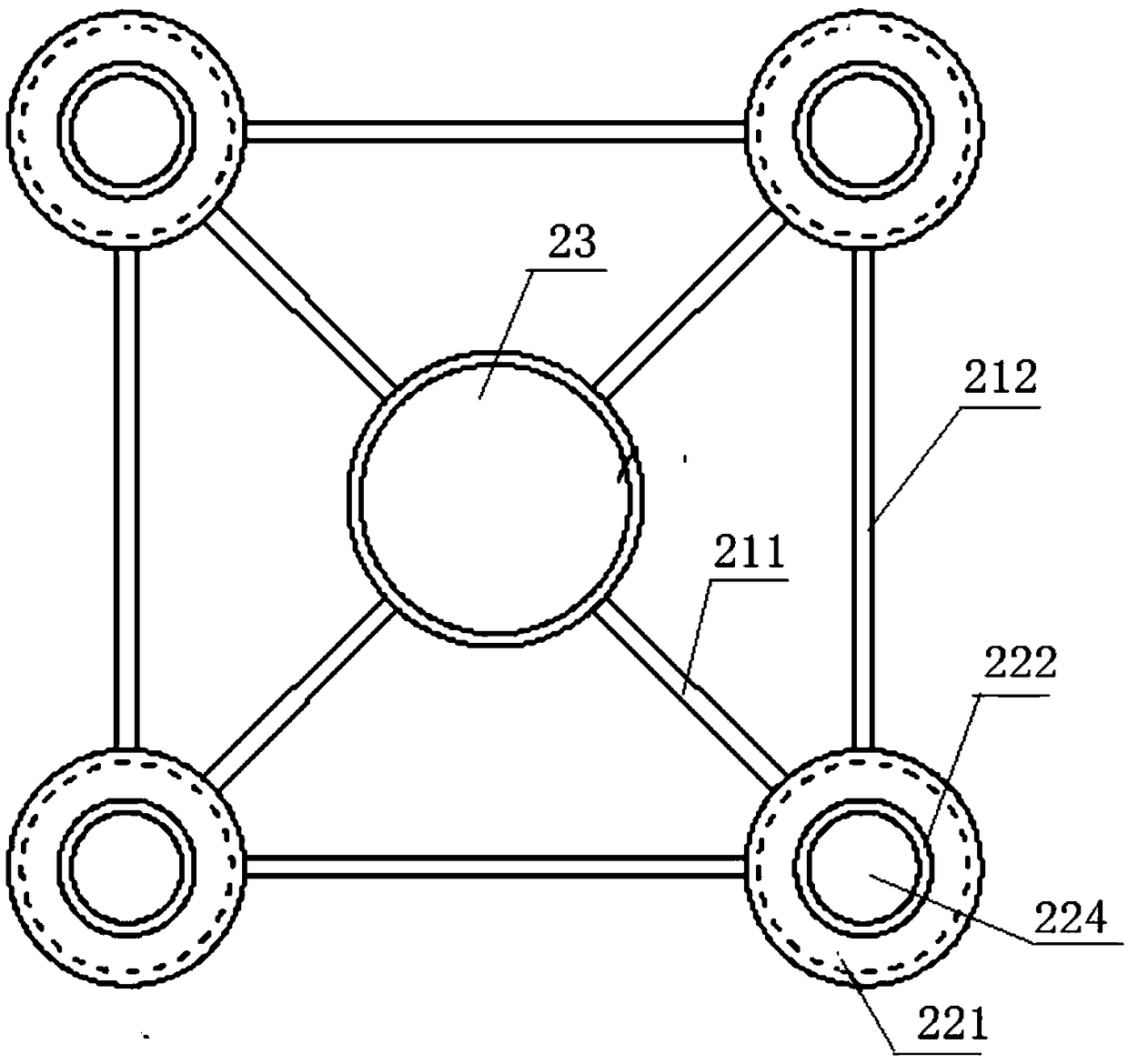

Precast assembled pile foundation pier and construction method thereof

PendingCN109267472AConducive to the realization of prefabricated assembly construction of the whole bridgeRealize the prefabricated assembly construction of the whole bridgeBridge structural detailsFoundation engineeringShear capacityDuctility

The invention relates to a prefabricated pile foundation pier and a construction method thereof, comprising a prefabricated pile, a prefabricated bearing cap and a prefabricated pier column, wherein the pile foundation pier is integrally connected by a first connection structure for connecting the prefabricated pile and the prefabricated bearing cap and a second connection structure for connectingthe prefabricated pier column and the prefabricated bearing cap; the first connection structure connects the precast pile and the bearing cap into a whole, which ensures the reliability of the connection between the pile and the bearing cap, and at the same time satisfies the sufficient compression, bending and shearing capacity and certain tensile capacity at the pile top. The second connectionstructure connects the precast pier column with the cap, and ensures that the bottom of the pier has sufficient compression, bending, shear and ductility seismic capacity. Compared with the prior art,the invention is conducive to realizing the whole bridge segment assembly construction of the concrete bridge, improving the construction quality, greatly accelerating the construction process, shortening the construction period, reducing the adverse impact on the environment, reducing the construction noise and the like.

Owner:TONGJI UNIV +1

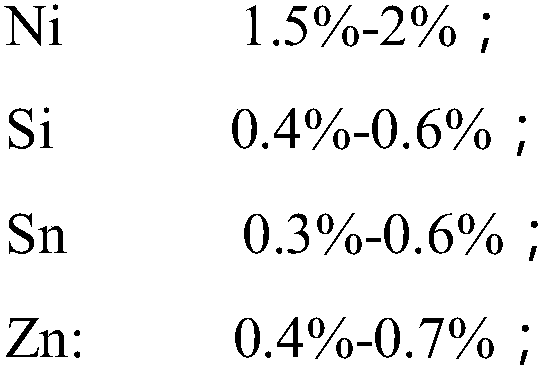

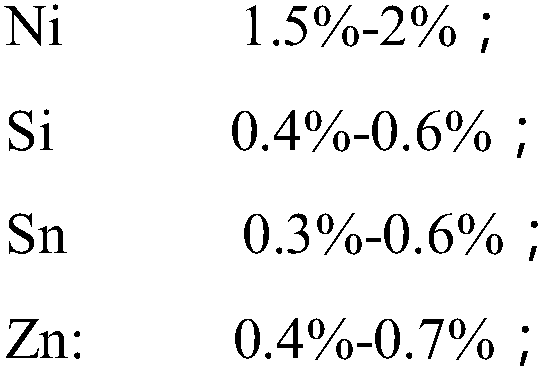

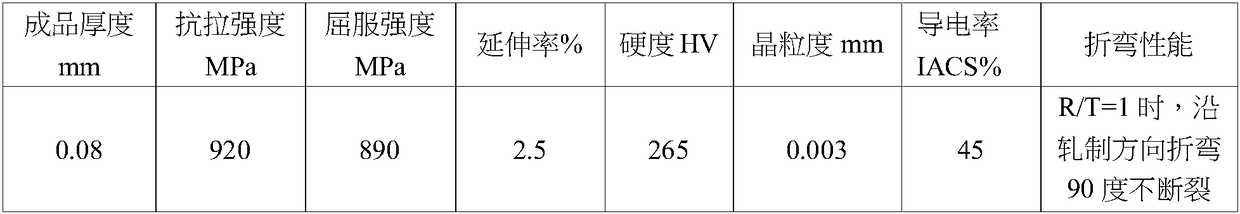

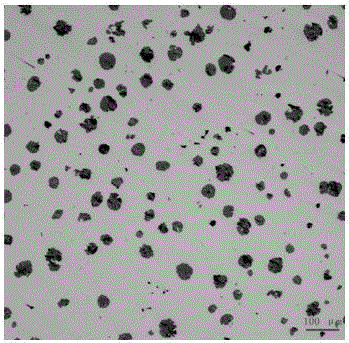

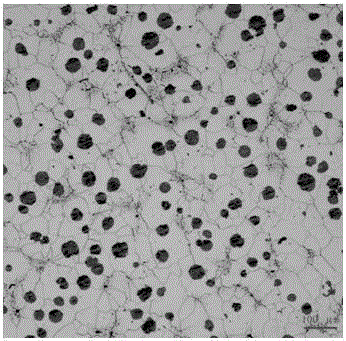

Copper alloy strip with high intensity, high conductivity and high bending performance and preparation method thereof

InactiveCN108998695ASufficient tensile strengthLow conductivityMetal rolling arrangementsGrain structureImpurity

The invention provides a copper alloy strip with high intensity, high conductivity and high bending performance and a preparation method thereof. The copper alloy strip is prepared from the followingraw material components in percentage by weight: 1.5 to 2 percent of Ni, 0.4 to 0.6 percent of Si, 0.3 to 0.6 percent of Sn, 0.4 to 0.7 percent of Zn, less than or equal to 0.02 percent of Fe, less than or equal to 0.01 percent of Mg and the balance of Cu and unavoidable impurities. The preparation method comprises the following steps: adding the raw materials during semi-continuous casting for casting to form a cast blank, performing high-temperature annealing, hot-rolling cogging, all-side milling, rough rolling, intermediate rolling, softening annealing in an elevator furnace, cleaning, secondary intermediate rolling, solution treatment in an air-cushion furnace, aging in the elevator furnace, rolling of a twenty-roller finished product, cleaning, low-temperature annealing in the elevator furnace, secondary cleaning, bending and straightening and shearing of the finished product, and packaging the product in a warehouse. The copper alloy strip can solve the problem that an existingelectronic copper strip cracks during bending and is low in anti-softening temperature due to low strength, poor conductivity and thick grain structures.

Owner:FUJIAN ZIJIN COPPER

Preparation method of high silicon molybdenum nodular cast iron material and high silicon molybdenum nodular cast iron material

A high silicon molybdenum nodular cast iron material is characterized in that the high silicon molybdenum nodular cast iron material is prepared from 3.3%-3.5% of carbon, 3.4%-3.6% of silicon, 0.5% or less of manganese, 0.05% or less of phosphorus, 0.006%-0.012% of sulphur, 0.04%-0.06% of magnesium, 0.4%-0.6% of molybdenum and the balance iron; for the high silicon molybdenum nodular cast iron material, the tensile strength is larger than or equal to 460 Mpa, the yield strength is larger than or equal to 350 Mpa, and the ductility is larger than or equal to 10%. The invention further provides a preparation method of the high silicon molybdenum nodular cast iron material.

Owner:KOCEL EQUIP

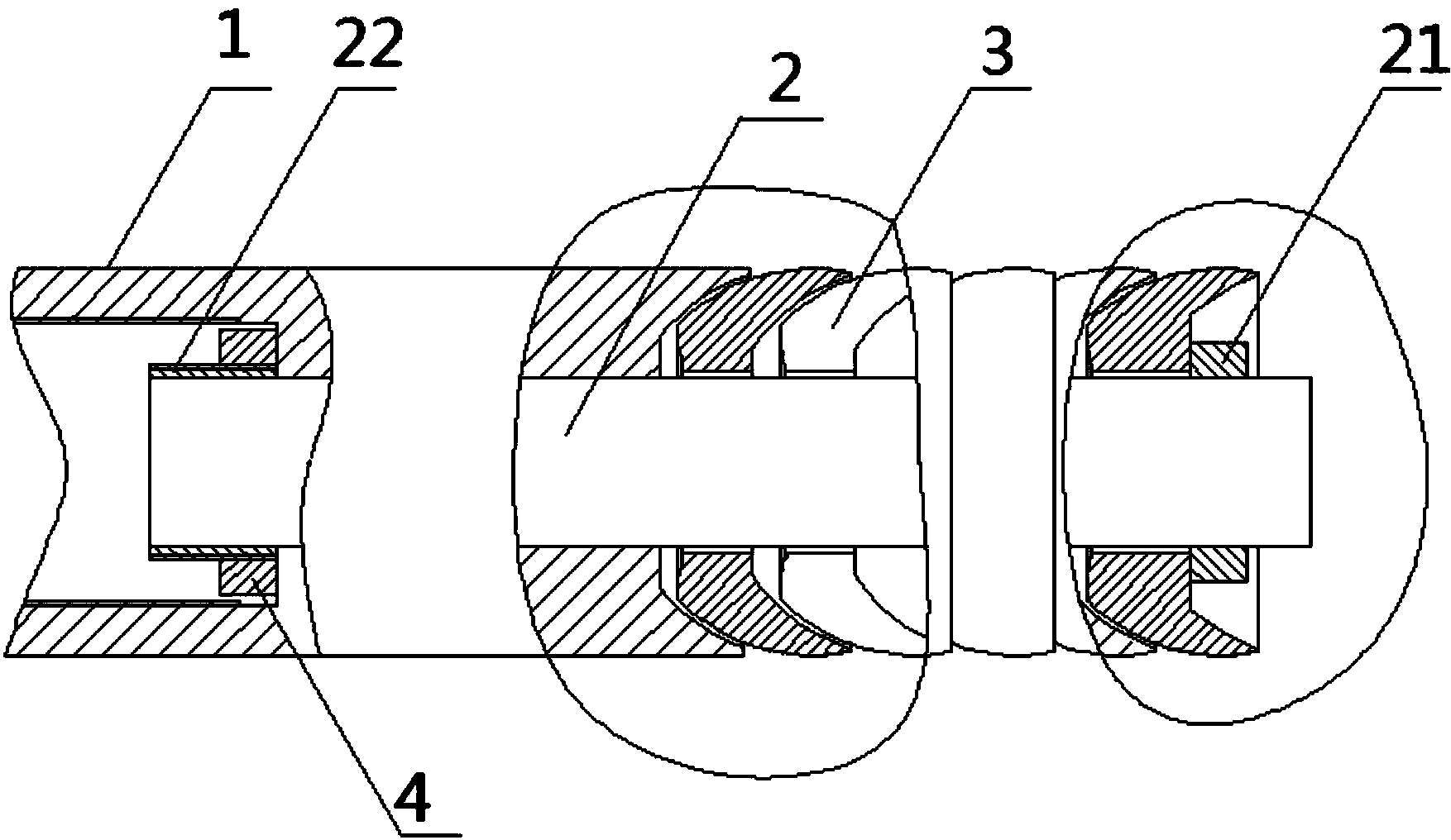

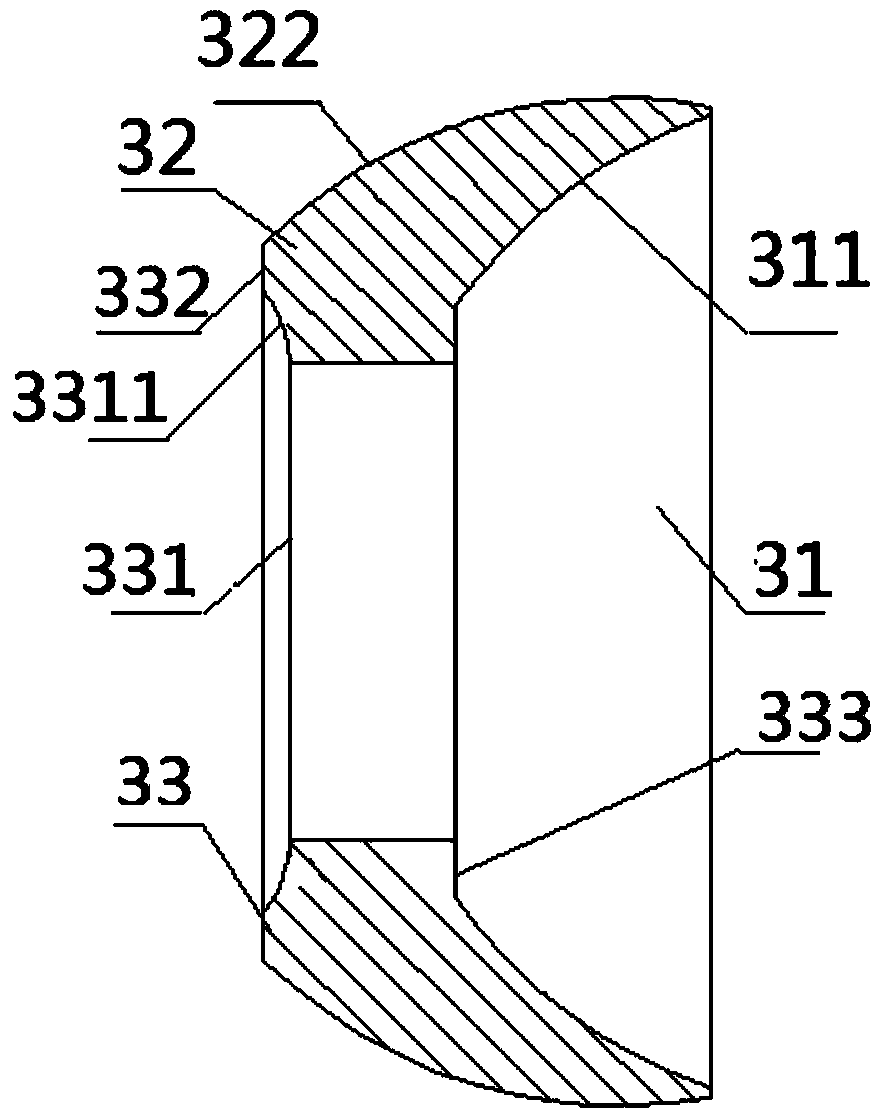

Hose coupler for seabed flexible hose

A hose coupler for a seabed flexible hose comprises a coupler flange, a coupler front end, a coupler sleeve, polyurethane rubber, a high-strength screw, a rubber sealing member, a metal compression ring, a Y-shaped sealing ring, a coupler core, a sealing flange and a coupler tail end. Tensile layer flat steel is respectively and fixedly connected with the hose coupler and the sealing flange at the front end of the coupler through the high-strength screw, then the coupler is integrated with the flexible hose in curing mode through the hose, and the connection of the hose coupler and the flexible hose has enough tensile strength. Annular grooves are designed at the front end and the tail end of the coupler, the Y-shaped sealing ring, the metal pressure ring and the rubber sealing member are placed in the annular grooves, and the sealing flange extrudes the rubber sealing member, the metal pressure ring and the Y-shaped sealing ring by screwing the high-strength screw to generate sealing effect.

Owner:NEPTUNE OFFSHORE ENG DEV

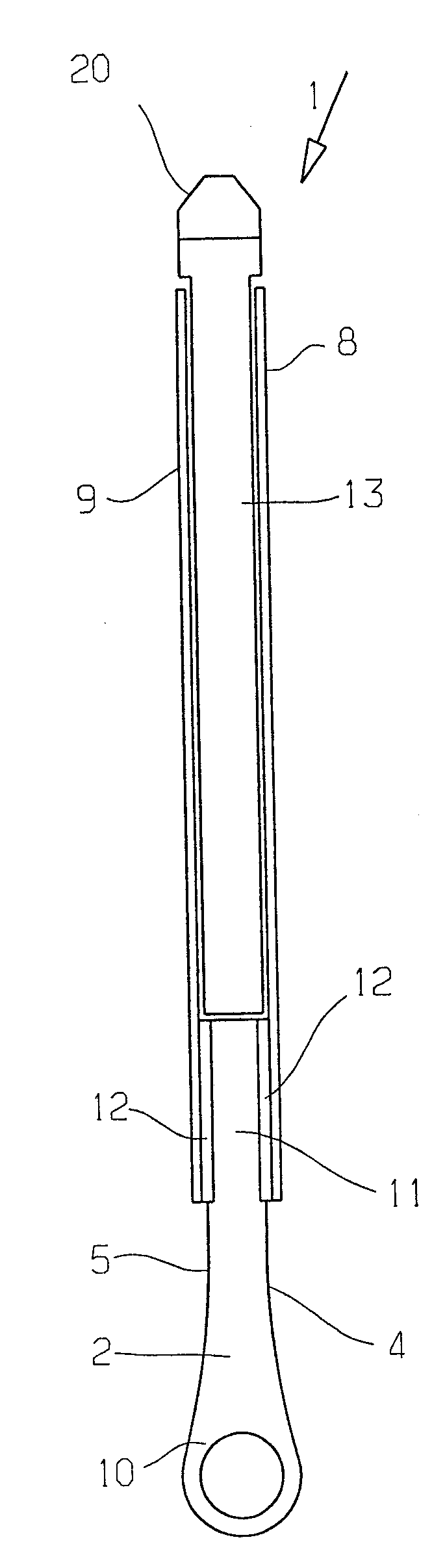

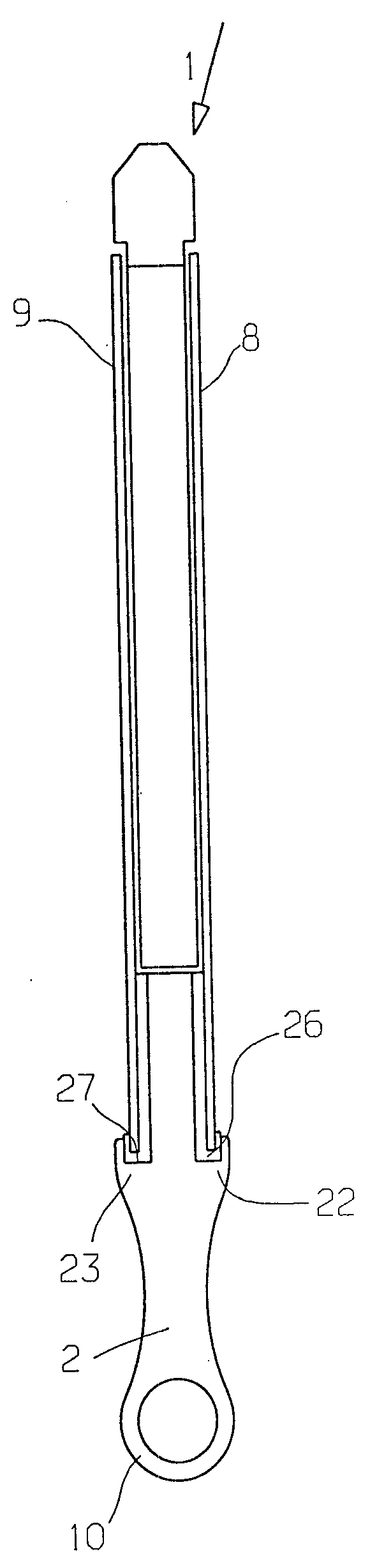

Knitting tool holder

The tool holder (1) has a spacer (13) made from light metal or plastic, which is arranged between steel or plastic made cover plates (8,9) each with a thickness of about 0.1-0.8 mm. The knitting tools (2) are arranged parallel to each other with a predetermined distance. The front and rear narrow sides (4,5) of the knitting tools are bonded to the respective cover plates (8,9) through adhesive (12).

Owner:KARL MAYER TEXTILMASCHFAB GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com