Lifting appliance for crucible for growing sapphire single crystal

A sapphire and crucible technology, which is applied in the field of sapphire single crystal manufacturing, can solve the problems of inconvenient operation, difficult movement, and high production cost, and achieve the effects of safe and reliable lifting and moving, convenient assembly and disassembly, and shortened non-production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

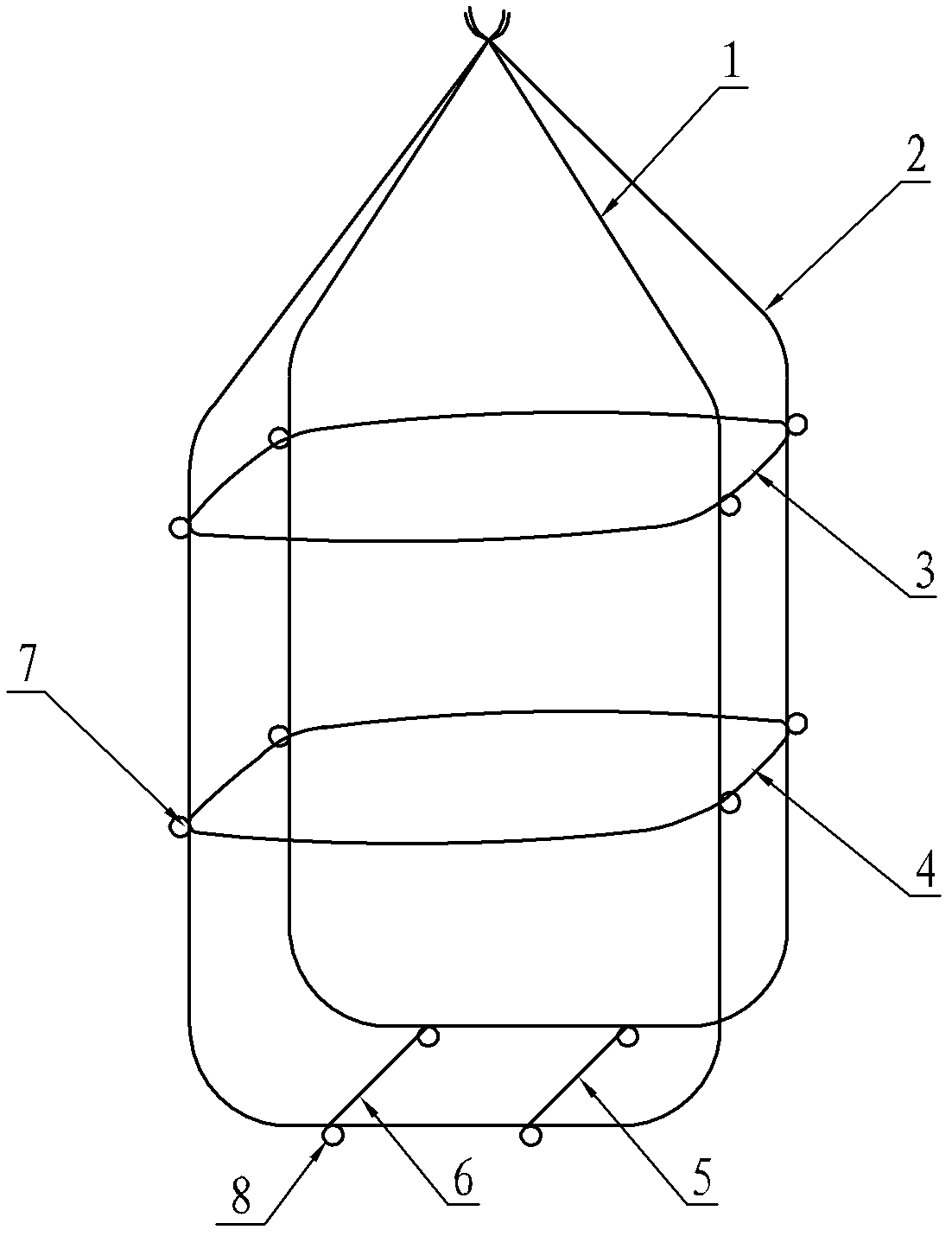

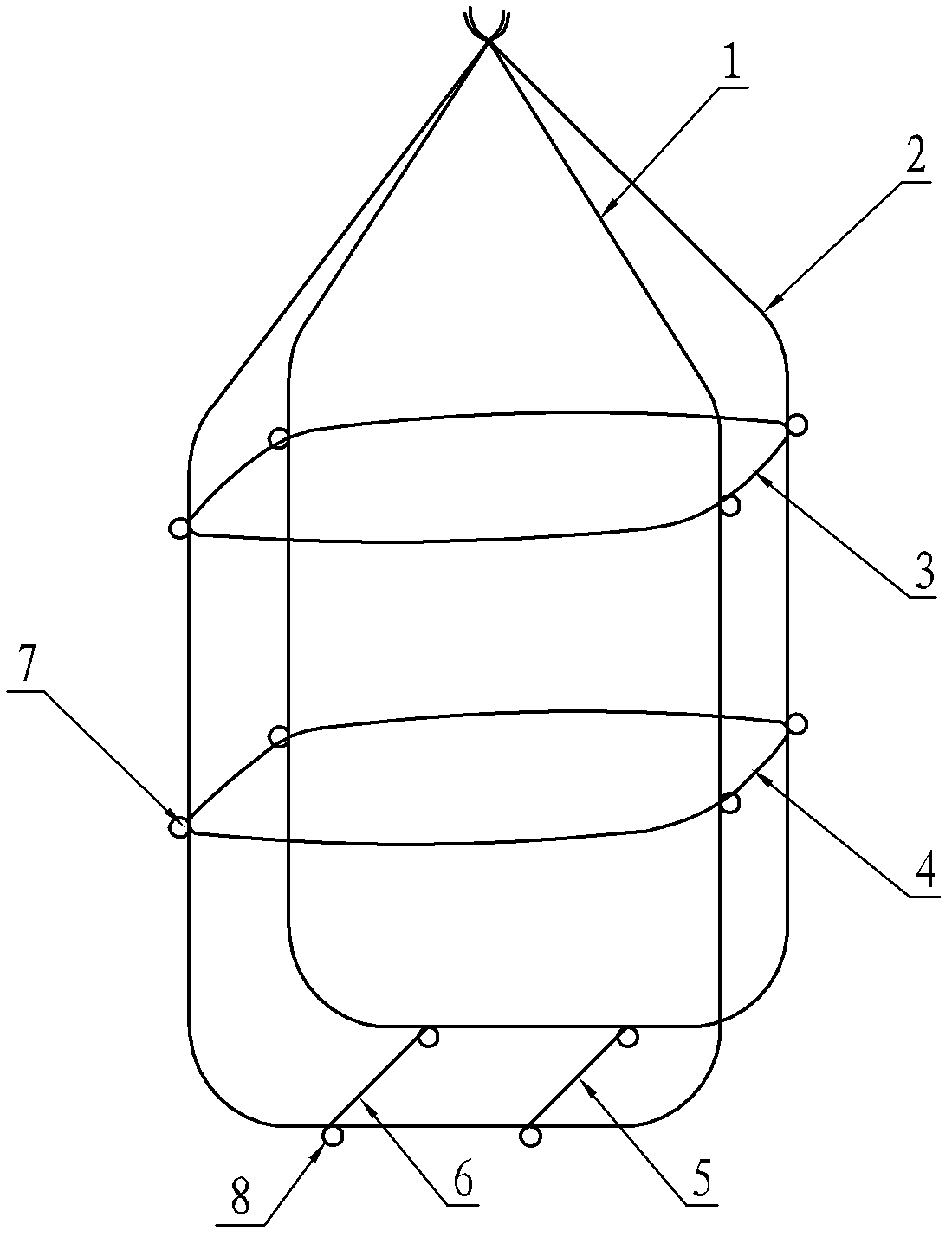

[0013] The crucible hanger for the sapphire single crystal growth, such as figure 1 Shown, comprise hoisting steel wire rope one 1, hoisting steel wire rope two 2, upper steel wire rope ring 3, lower steel wire rope ring 4, bottom support steel wire rope one 5, bottom support steel wire rope two 6 and rope-piercing ring 7, on steel wire rope ring 3 and lower steel wire rope ring 4 are all provided with four threading rings 7, steel rings 8 are all fixed at the two ends of bottom supporting wire rope one 5, bottom supporting steel wire rope two 6, lifting steel wire rope one 1 passes through upper steel wire rope ring 3 and lower steel wire rope ring 4 successively The upper two adjacent rope loops 7, the lifting wire rope two 2 pass through the upper steel rope loop 3 and the lower steel rope loop 4 in turn through the other two adjacent rope loops 7, the bottom support wire rope one 5 and the bottom support steel wire rope two 6 The steel rings 8 at both ends are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com