Patents

Literature

980results about How to "Reduce extrusion pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

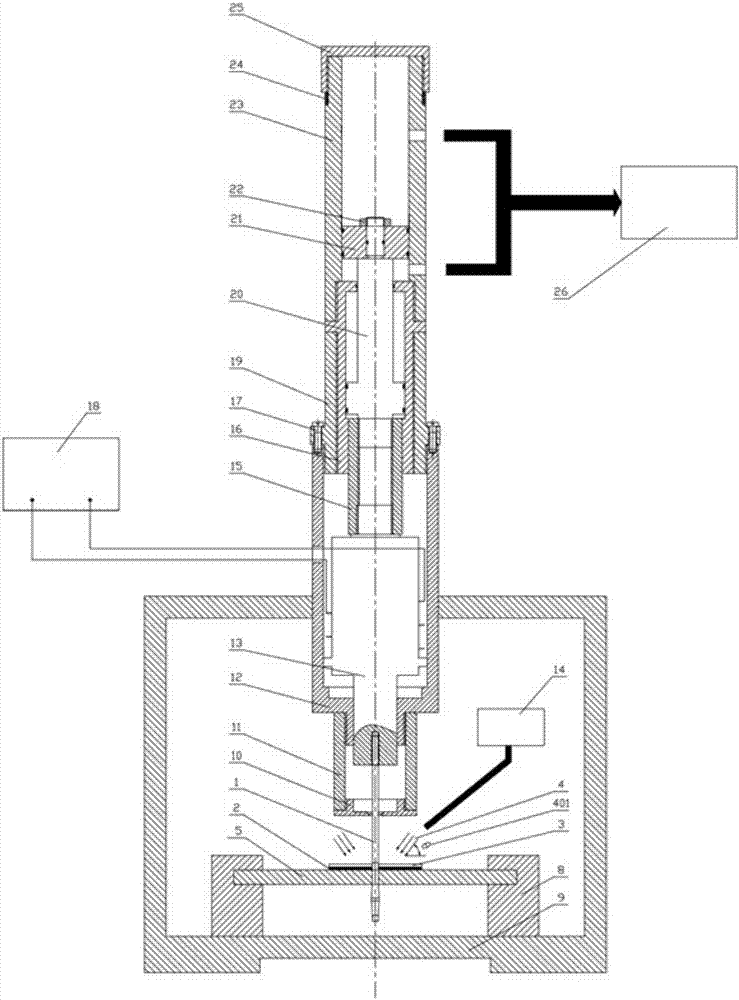

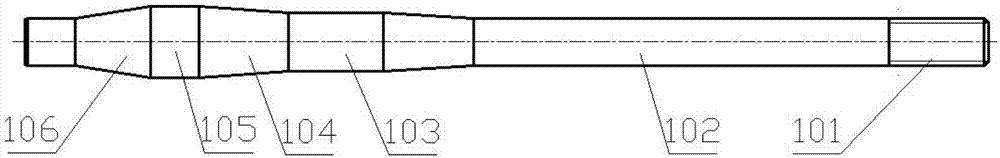

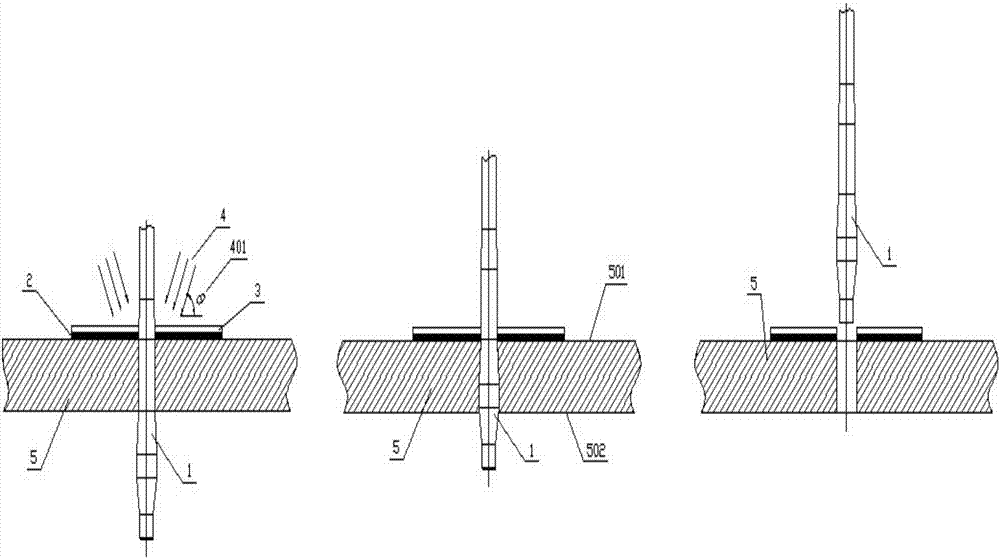

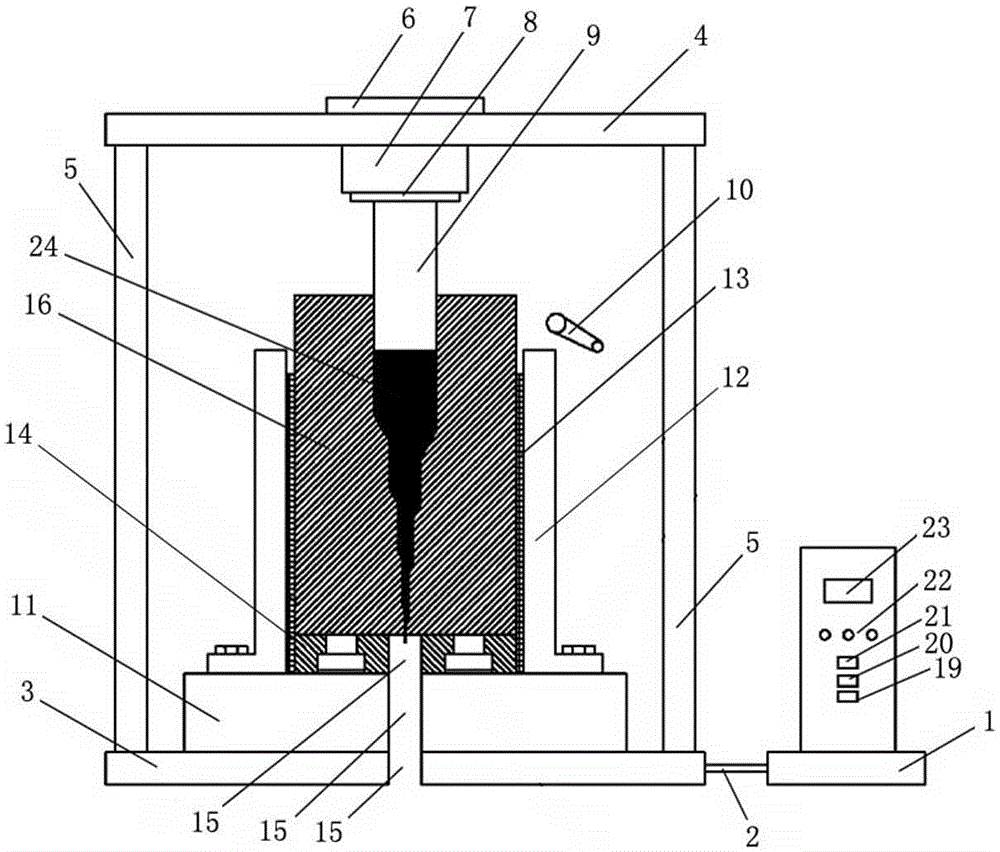

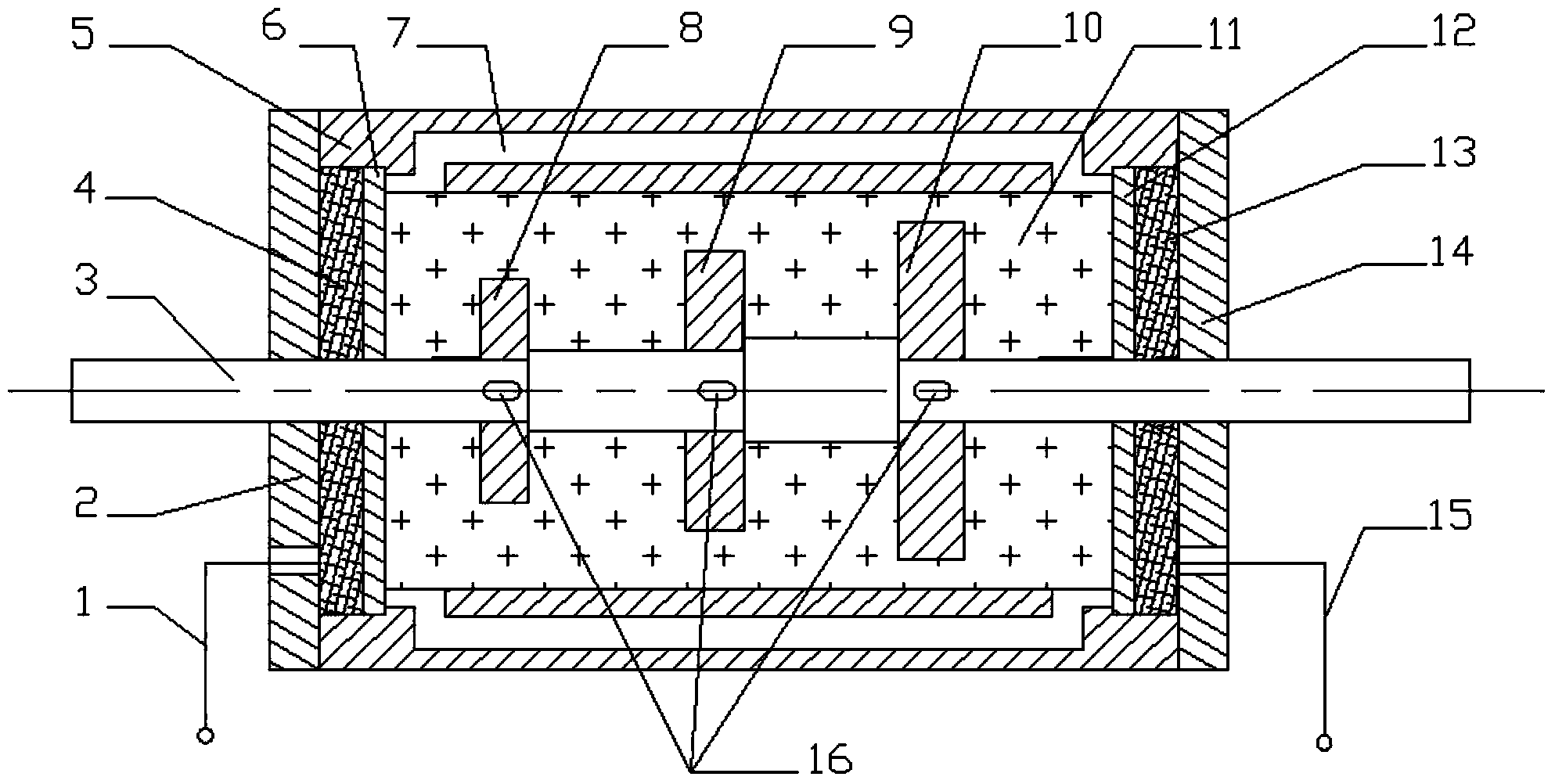

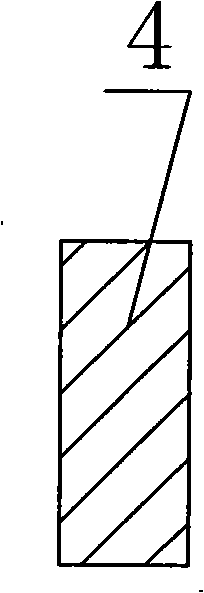

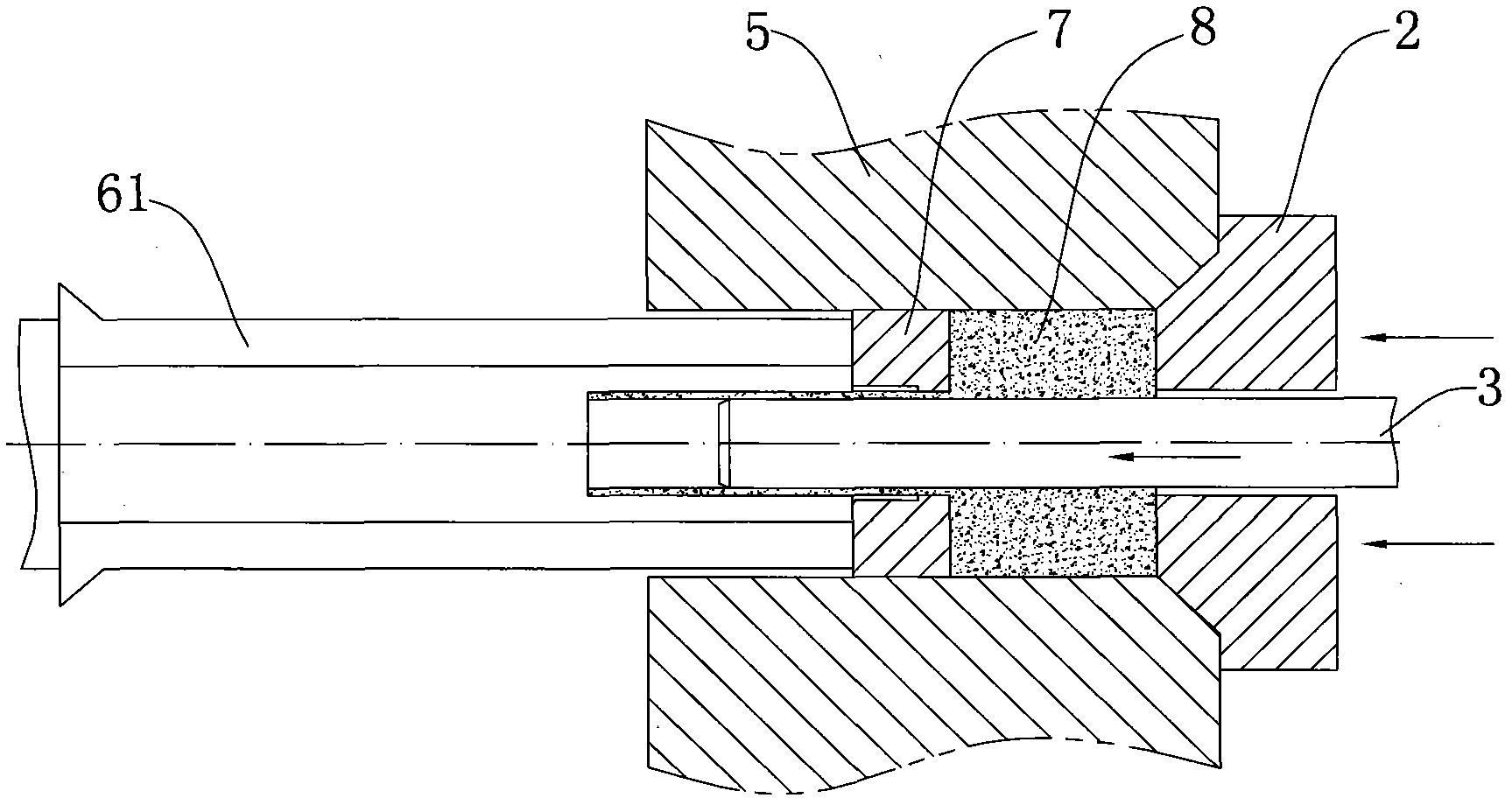

Laser shock and supersonic vibration extrusion co-strengthening device and method

ActiveCN107254581AImprove fatigue resistanceSmooth inner surfaceLaser beam welding apparatusShock waveUltrasonic vibration

The invention provides a laser shock and supersonic vibration extrusion co-strengthening device and method. The device comprises a laser assembly, a vibration assembly, a hydraulic assembly and a connecting assembly. The method comprises steps as follows: a hole formed on sheet metal is strengthened while laser shock strengthening and supersonic vibration extrusion strengthening are adopted, a mandrel forms clearance fit with the hole to constrain the hole, so that distortion of hole and a hole angle when the laser shock is performed on the outer surface of a workpiece is prevented, and the strengthening effect of the hole wall is improved; when the laser shock is performed on the outer surface of the sheet metal, supersonic vibration is applied to the mandrel in the hole, three-dimensional pressure stress distribution is formed nearby the hole wall at certain depth under the interaction produced by laser shock waves and power ultrasound at certain frequency, amplitude and modal, and higher anti-fatigue performance and smoother inner surface of the hole are obtained. With the adoption of the device and the method, defects of a traditional strengthening technology are overcome, and the problem that the hole is strengthened through either single laser shock or single supersonic vibration extrusion is solved.

Owner:JIANGSU UNIV

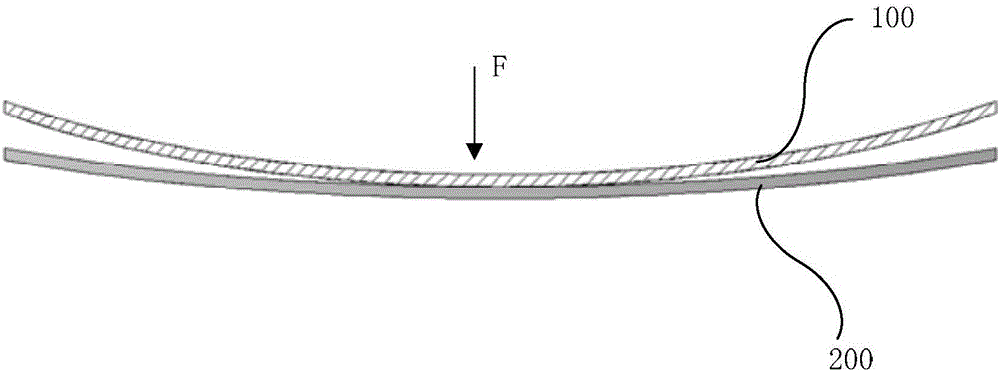

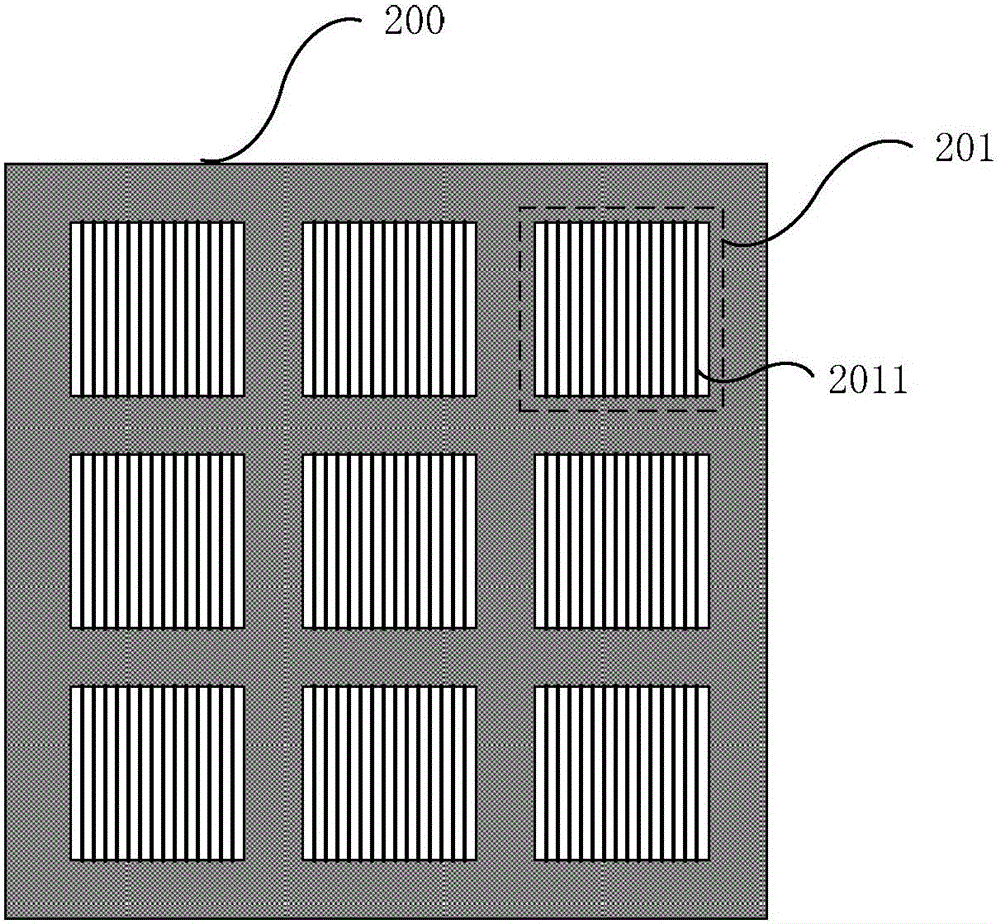

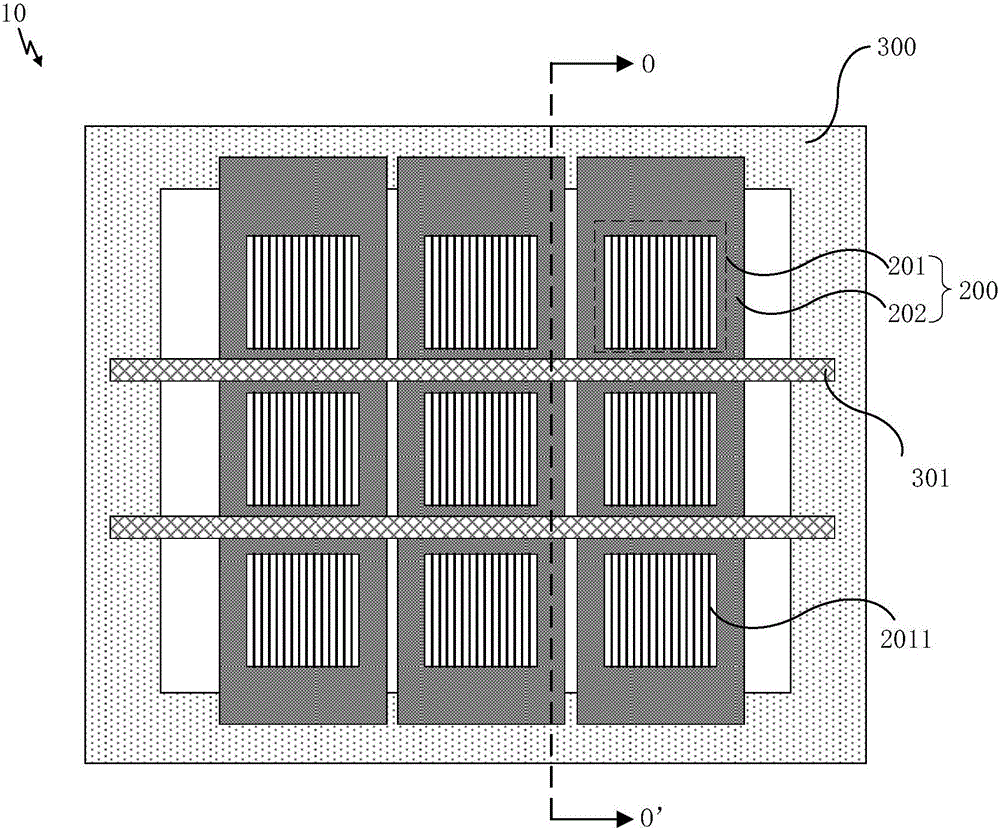

Mask plate assembly, installation method thereof and evaporation device

ActiveCN106086782AReduce saggingReduce extrusion pressureLiquid surface applicatorsVacuum evaporation coatingEvaporationEngineering

The embodiment of the invention provides a mask plate assembly, an installation method thereof and an evaporation device, and relates to the technical field of display. The offset of the mask plate when a mask plate is attached to a backboard can be reduced, and then the product yield is improved. The mask plate assembly comprises a supporting frame and the mask plate fixed to the supporting frame. The mask plate comprises an effective mask area and an ineffective mask area surrounding the effective mask area. The mask plate assembly further comprises a first supporting strip fixed to the supporting frame. The first supporting strip is arranged on the side, away from the supporting frame, of the mask plate, the projection of the first supporting strip in the plane where the supporting frame is located and the projection of the mask plate in the plane where the supporting frame is located have a first overlapped part, and the first overlapped part is located in the projection area of the ineffective mask area in the plane where the supporting frame is located.

Owner:BOE TECH GRP CO LTD +1

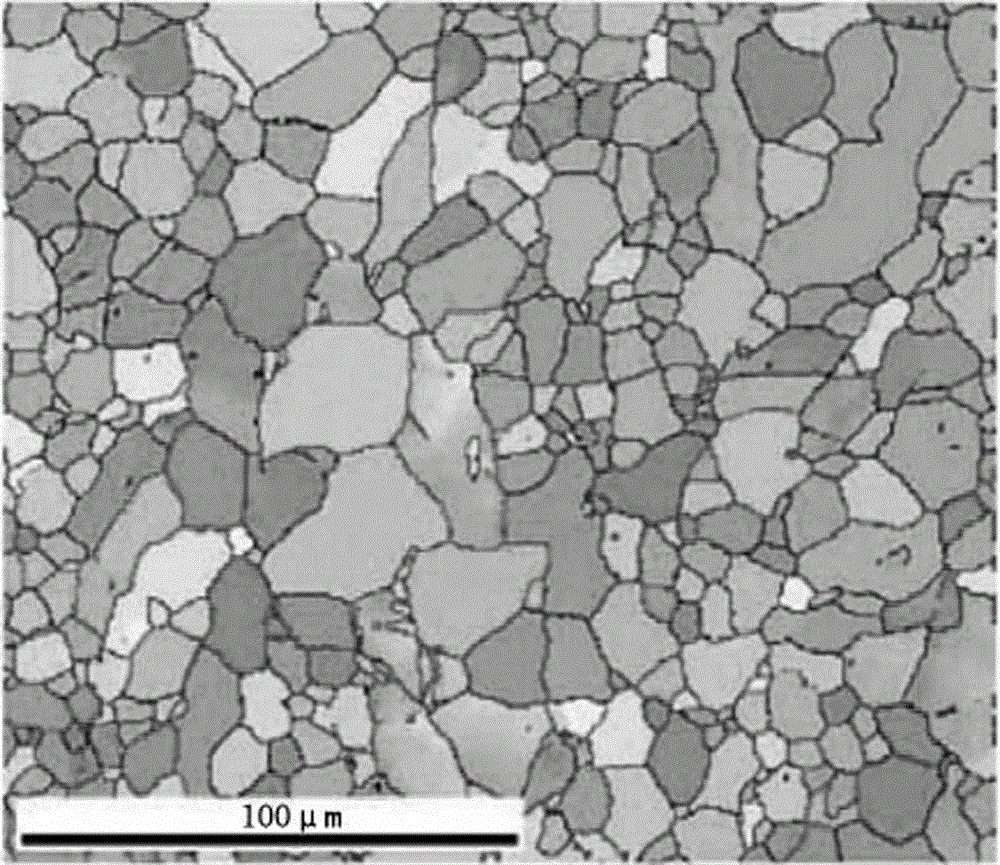

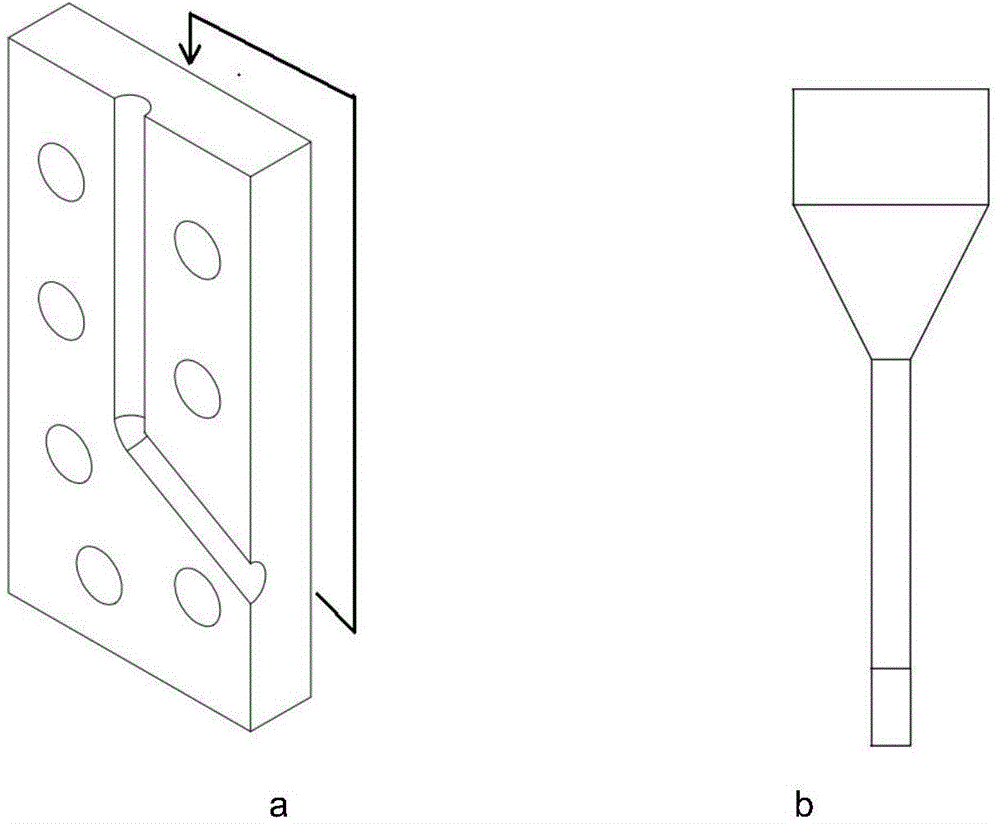

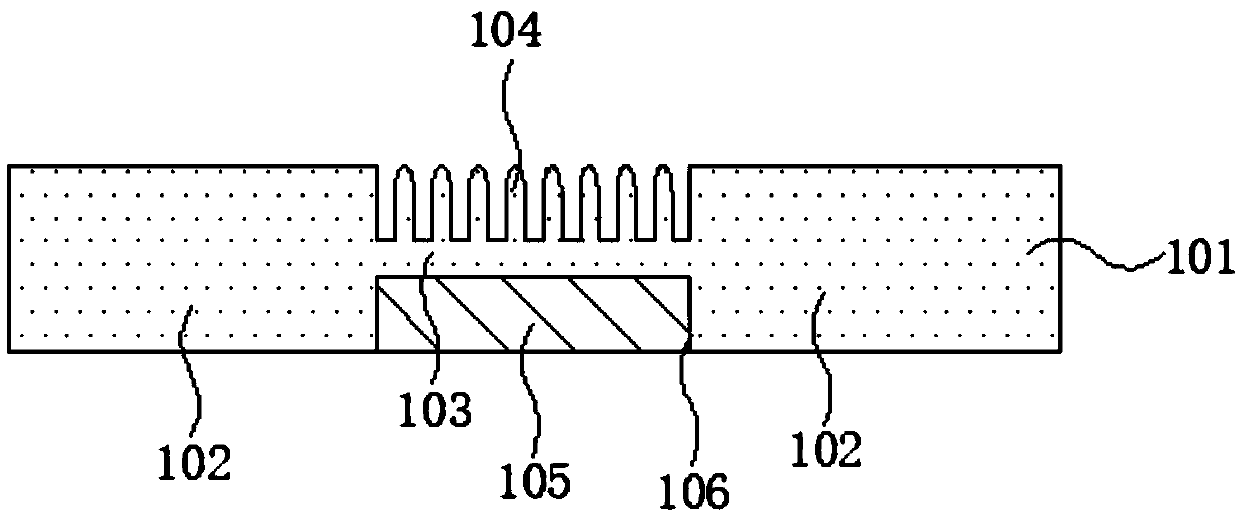

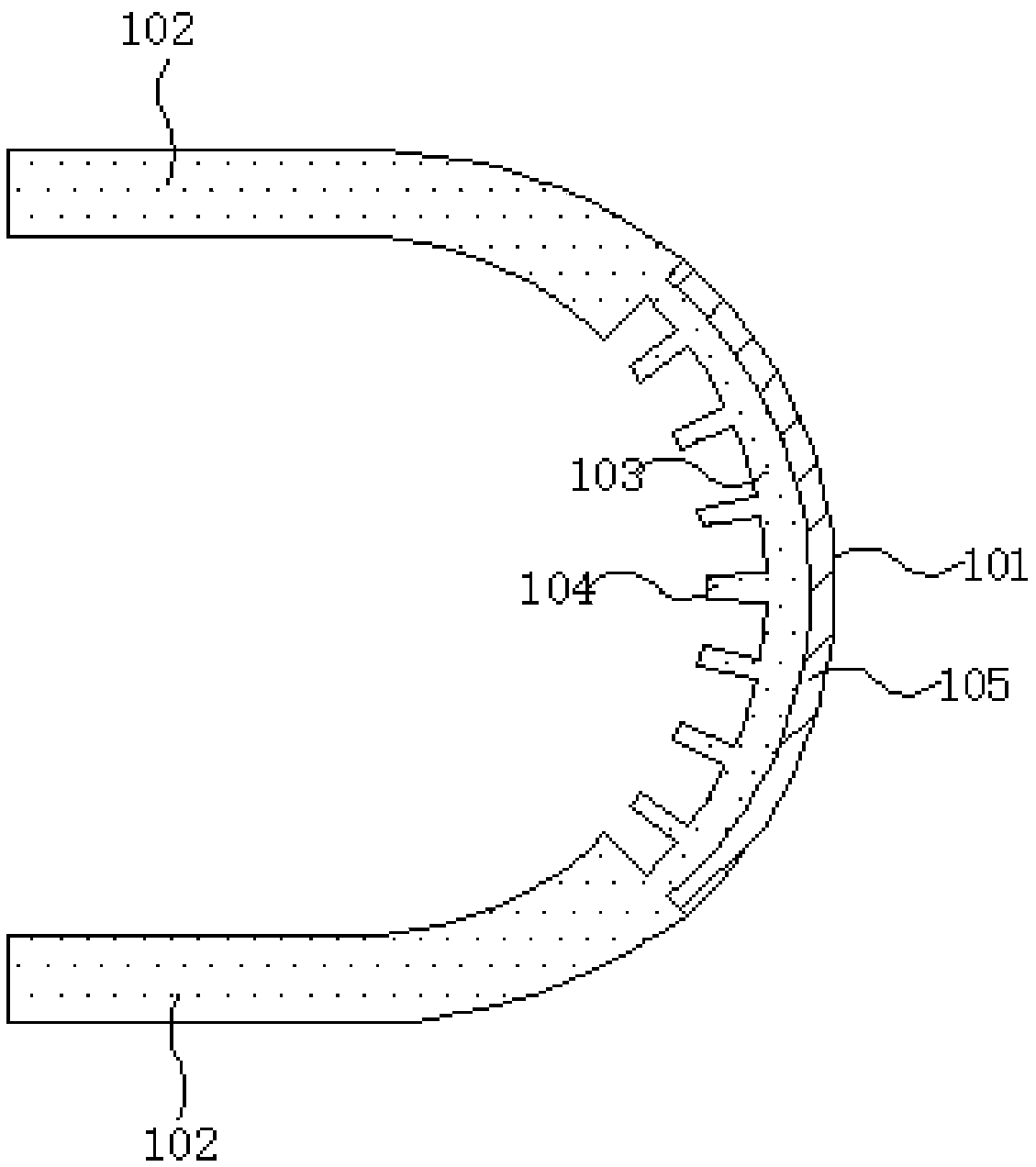

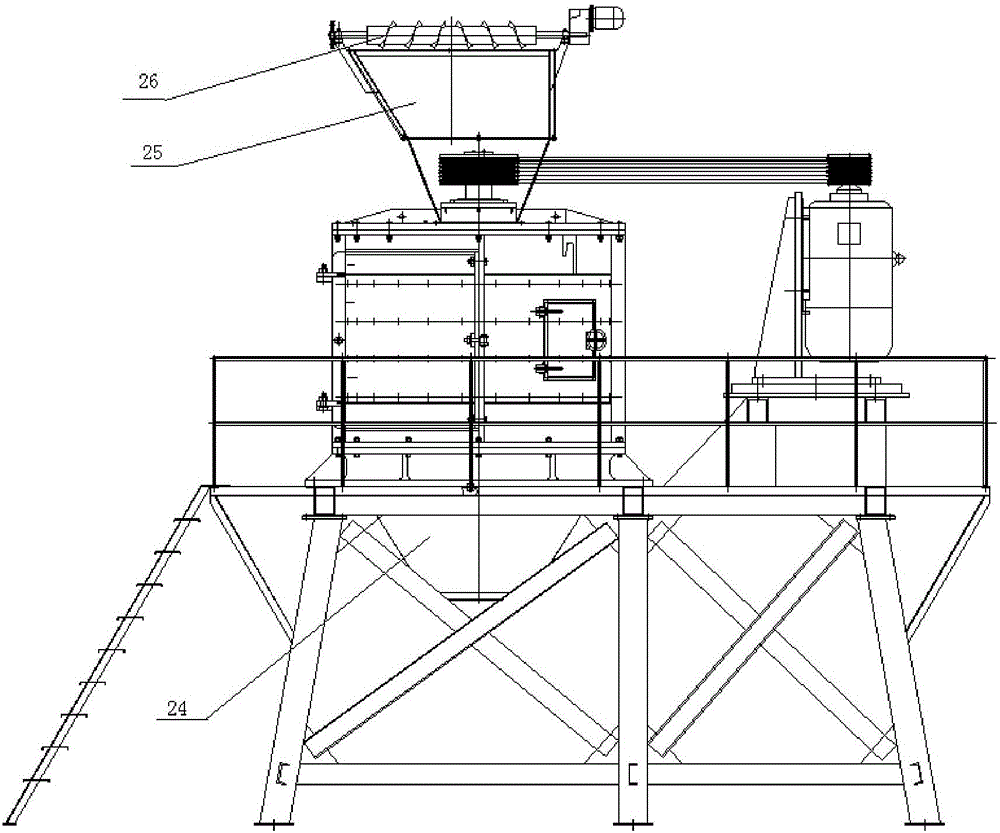

Continuous extrusion machining device used for magnesium alloy sheet strip with weak basal texture and extrusion machining method

ActiveCN105032964AAverage grain size reductionHigh strengthExtrusion diesAsymmetric distributionMachining process

The invention relates to a continuous extrusion machining device used for a magnesium alloy sheet strip with a weak basal texture and an extrusion machining method. The device comprises an extrusion system mainly composed of a pressure motor, an extrusion telescopic head, a male die and a female die, and multiple inclined steps gradually getting close to the axis of a die cavity are arranged at the two sides below the upper middle portion in the die cavity of the female die and are distributed asymmetrically. In the extrusion machining process, a magnesium alloy blank is placed in the die cavity of the female die and extruded by the descending male die, and as the male die descends continuously, the magnesium alloy blank is gradually thinned to form a magnesium alloy sheet with the weak basal texture. Due to step-by-step grain refinement and basal texture weakening, extrusion force in the extrusion process is greatly reduced, the average grain size of the magnesium alloy is greatly reduced compared with that of a magnesium alloy extruded normally, and the (0002) basal texture is reduced to 8.2 from 27.6 compared with that of a sheet obtained through normal extrusion.

Owner:TAIYUAN UNIV OF TECH

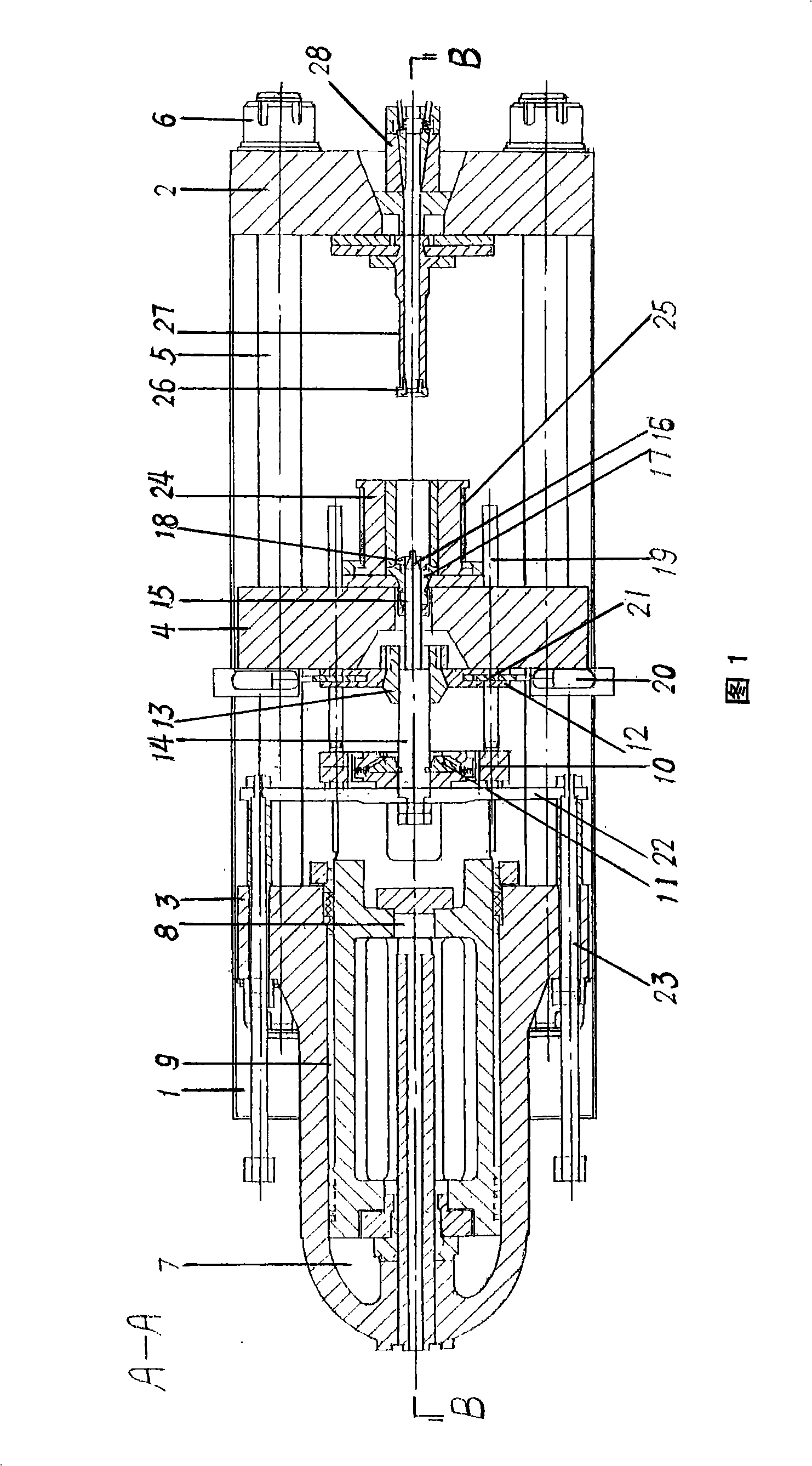

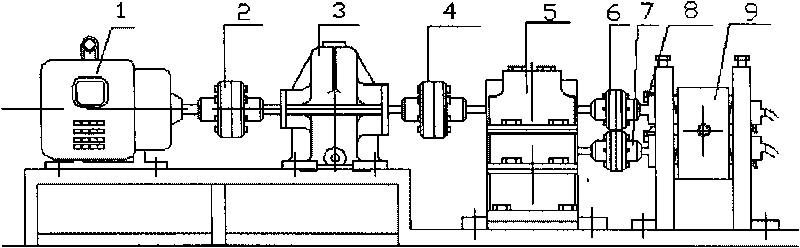

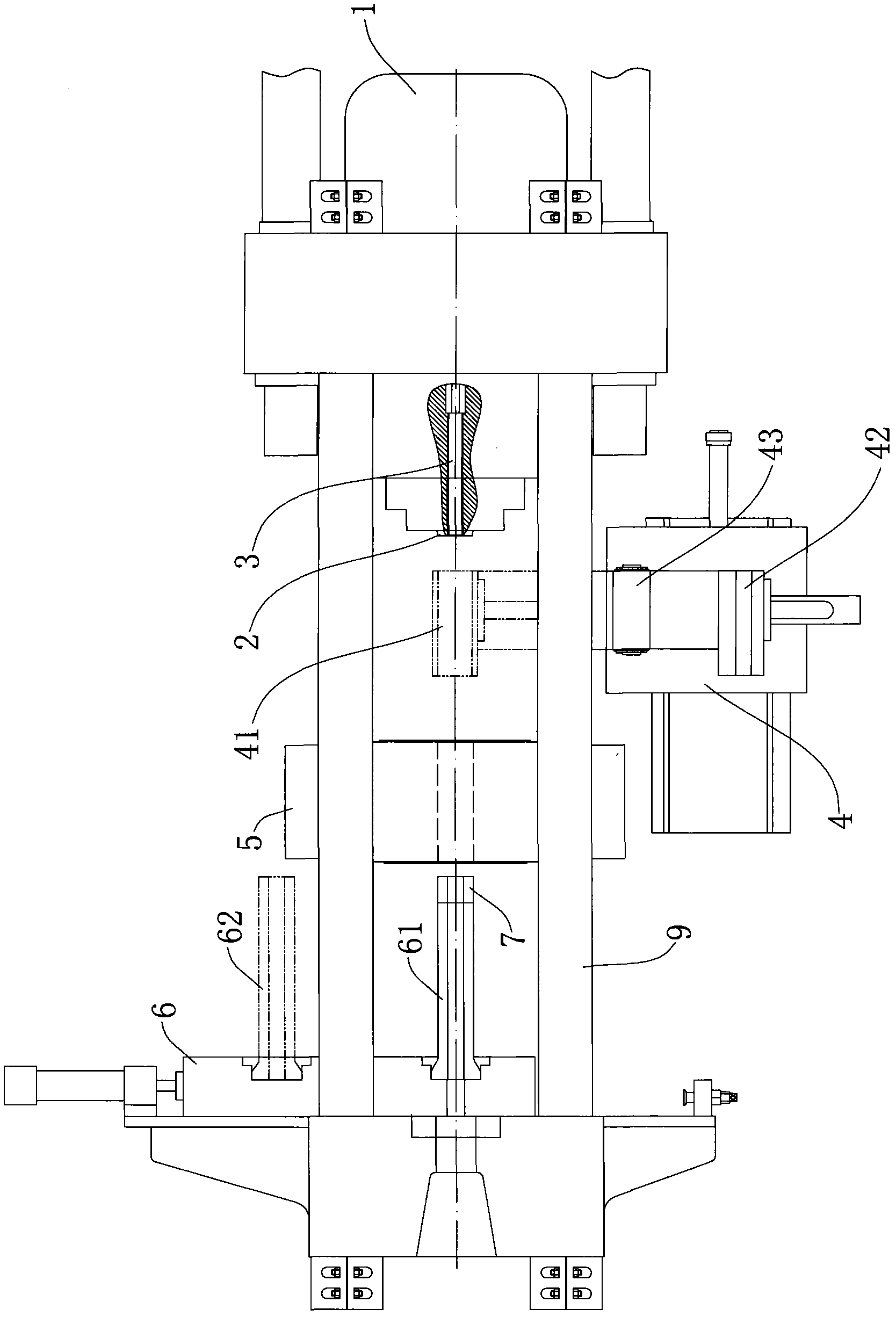

Alloyed steel horizontal type indirect extrusion machine

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation and extrusion and automatic switching system, a hot extrusion / molding system and a die removal and disengaging and residual extrusion and cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

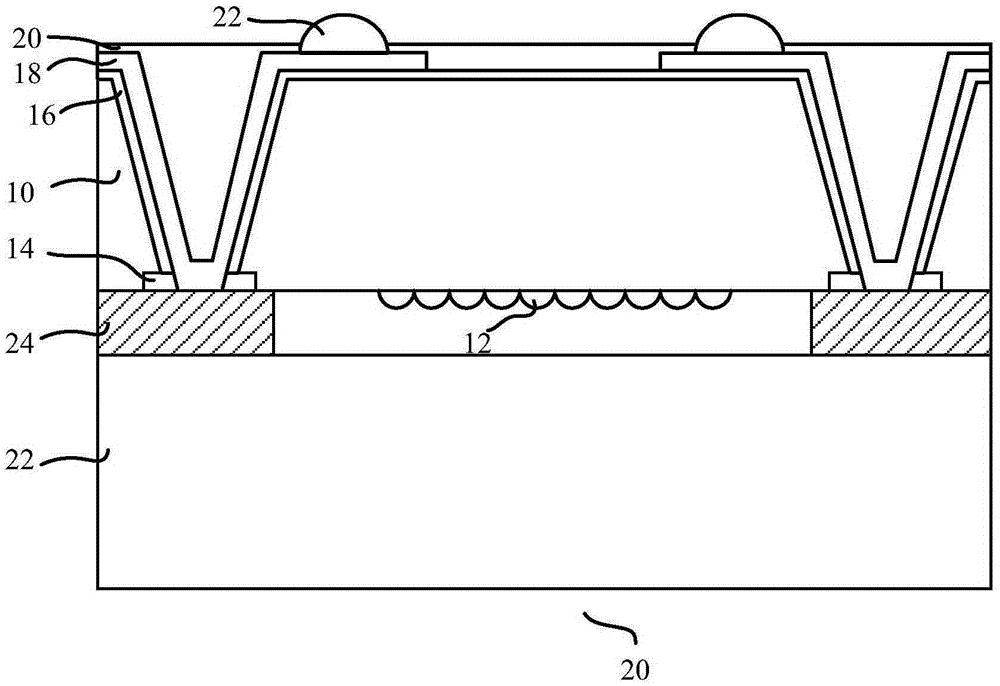

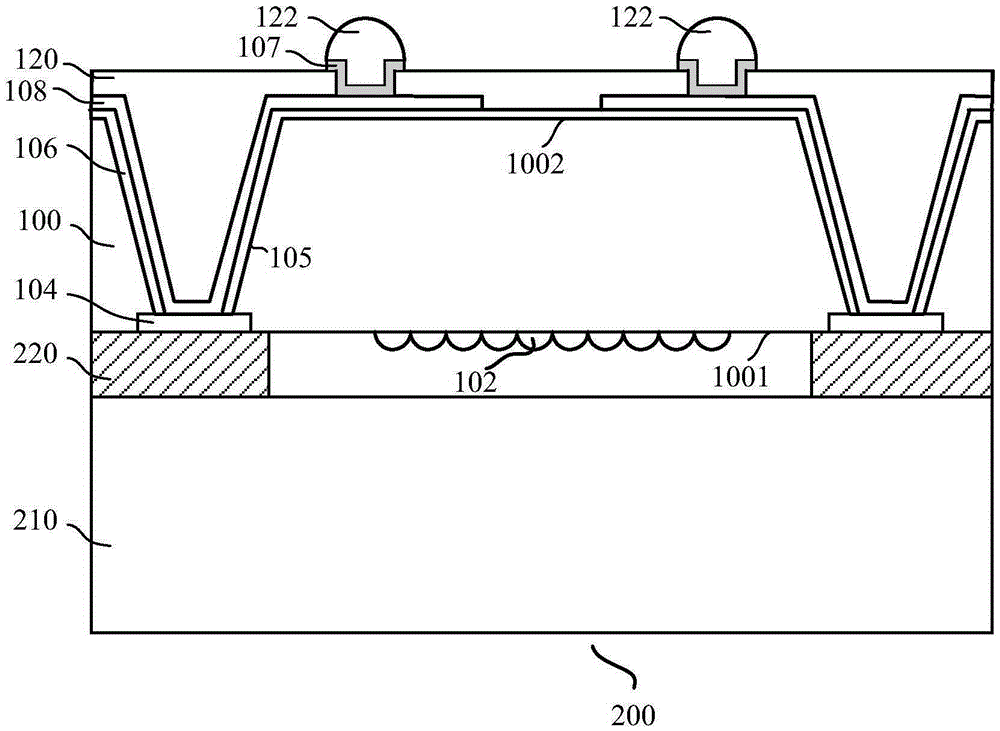

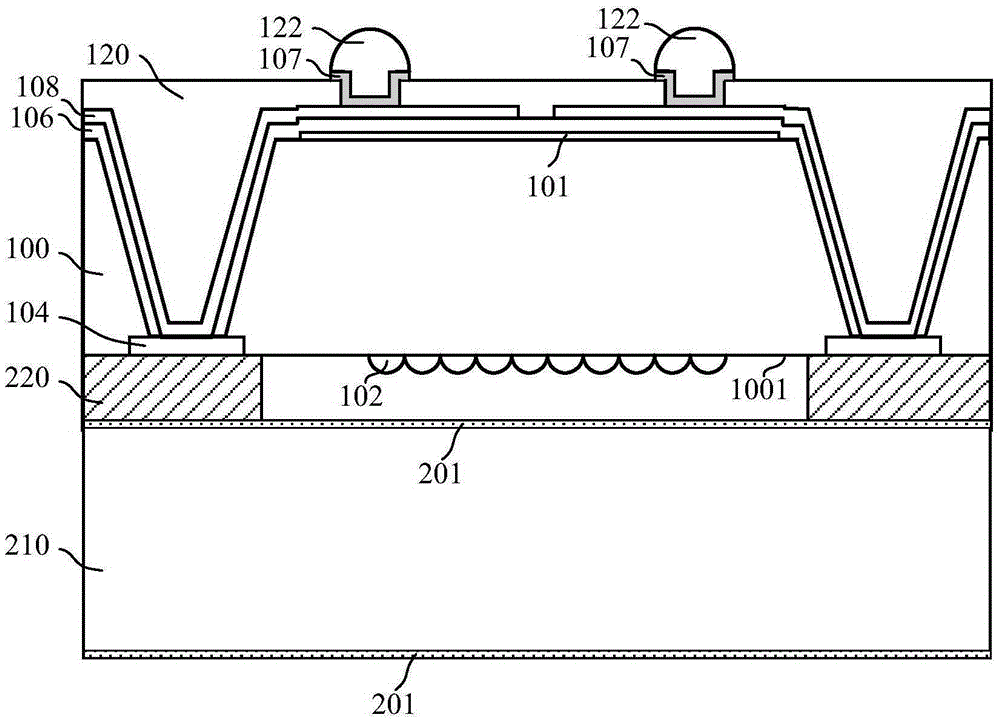

Image sensing chip packaging structure and packaging method

The invention provides an image sensing chip packaging structure. The packaging structure comprises an image sensing chip which has a first surface and a second surface, which are opposite, wherein the first surface is provided with an image sensing area and a welding pad arranged around the image sensing area; a through hole running from the second surface to the welding pad; an electrical wiring layer arranged along the inner wall of the through hole and extending to the second surface, wherein the electrical wiring layer is electrically connected with the welding pad; a solder resist layer filling the through hole and covering the electrical wiring layer, wherein an opening is formed in the solder resist layer, and the bottom portion of the opening exposing the electrical wiring layer; a guide welding pad covering the inner wall of the opening and the bottom portion of the opening and extending to the solder resist layer, wherein the guide welding pad is electrically connected with the electrical wiring layer; and welding bumps arranged on the guide welding pad, wherein the welding bumps are electrically connected with the guide welding pad. The structure reduces the defects of the image sensing chip electrical wiring layer.

Owner:CHINA WAFER LEVEL CSP

High-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and preparation method thereof

The invention discloses high-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and a preparation method thereof. The alloy comprises the following specific components in percentage by weight: 9.50-10.80% of Li, 3.00-5.00% of Al, 0.50-0.70% of Y, 0.10-0.30% of Zr and the balance of Mg; the alloy has the structural characteristics that an alpha phase, a beta phase and a precipitated phase exist at the same time, wherein the alpha phase is a Mg-based solid solution and is in a close-packed hexagonal structure, the beta phase is a Li-based solid solution and is in a body-centered cubic structure, and the precipitated phase is a rare earth compound Al2Y; and the alloy has the characteristics of low density, high plasticity and higher strength. The preparation method disclosed by the invention is a normal-temperature plastic deformation method which combines casting with equal channel angular extrusion or traditional extrusion deformation process; and compared with the traditional high-temperature deformation process, the preparation method has good practicality and is simpler and more convenient to operate, and can be used for effectively lowering the production cost, thus the preparation method has good industrial production prospects.

Owner:SOUTH CHINA UNIV OF TECH

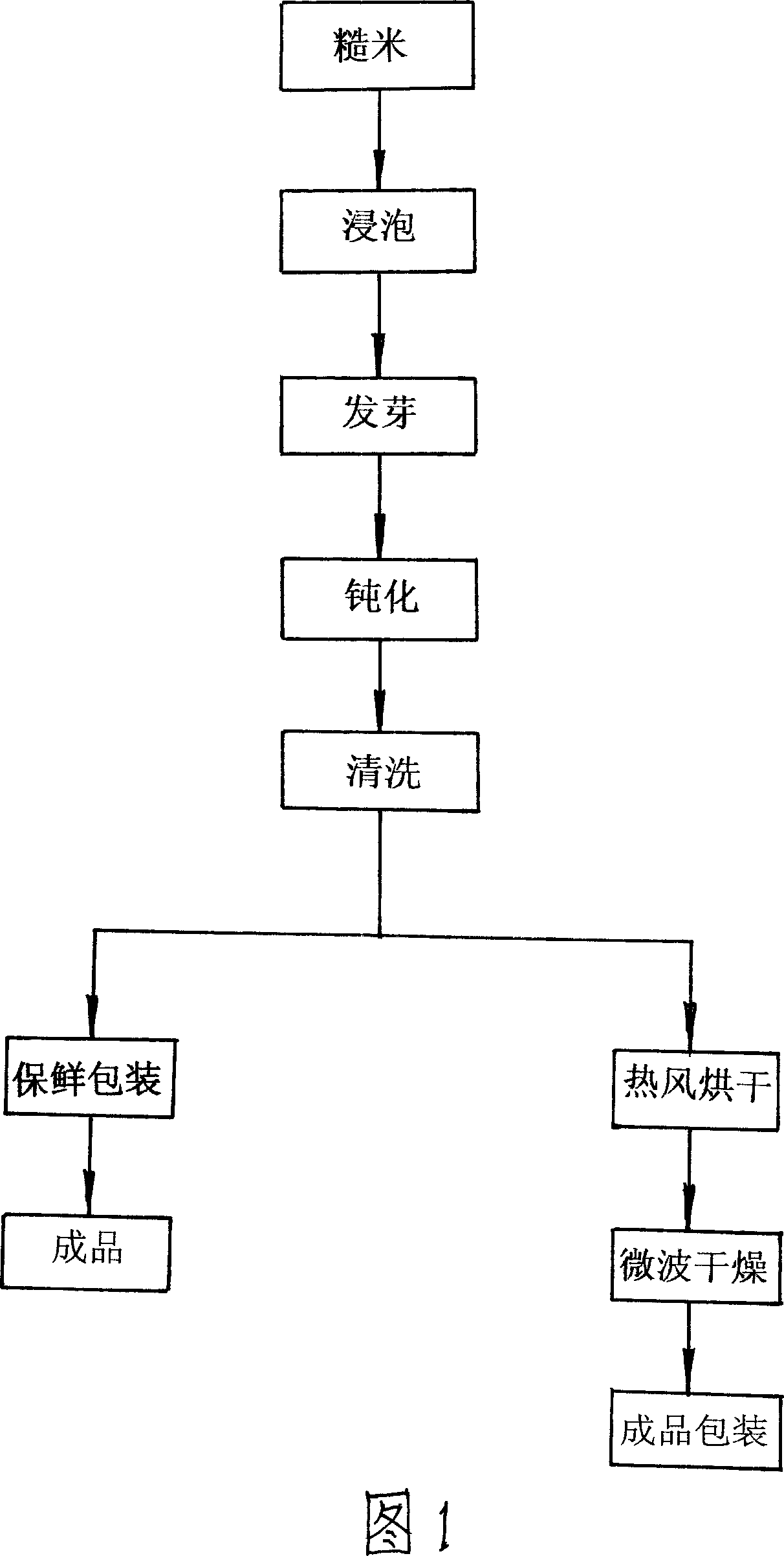

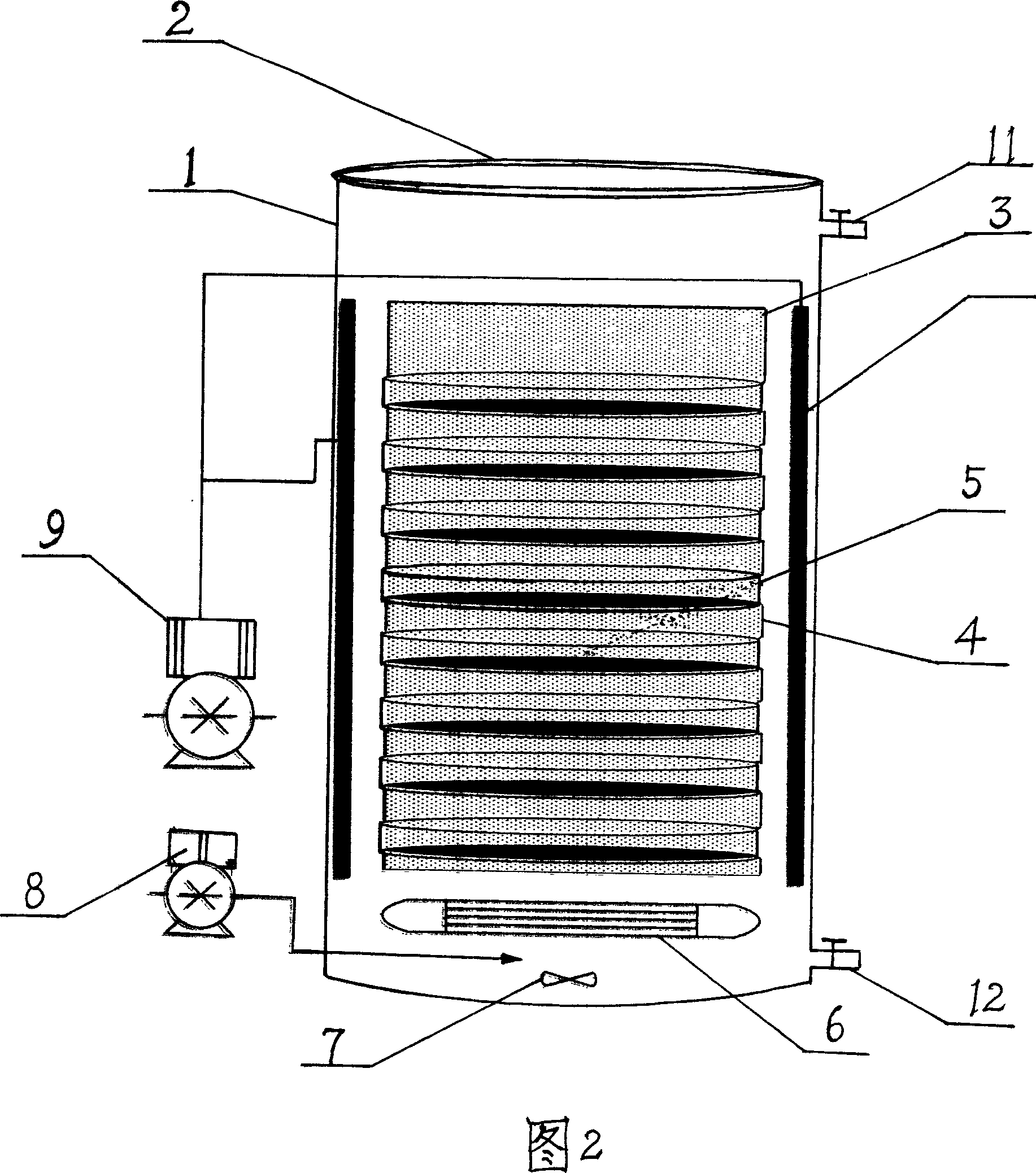

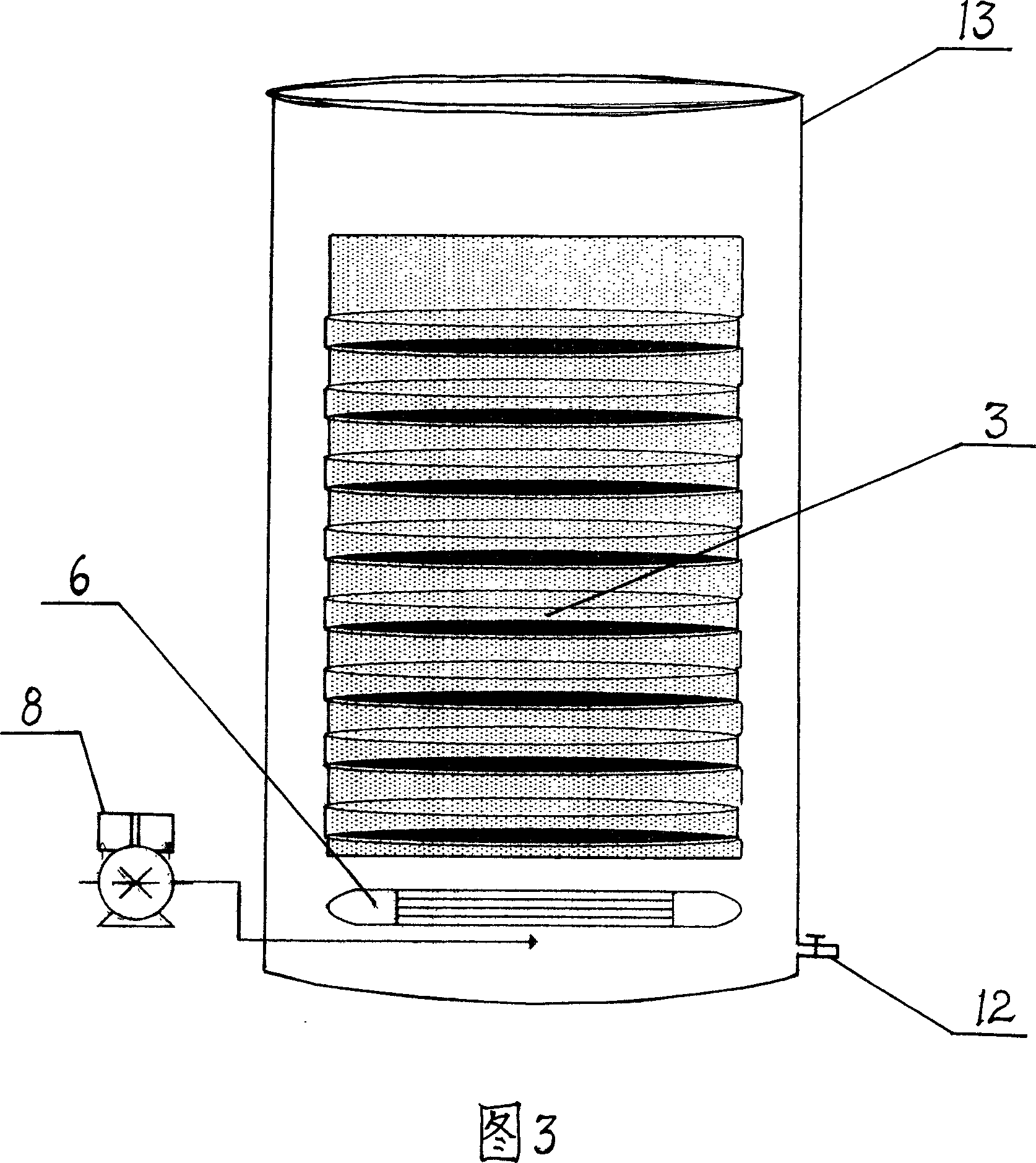

Method and equipment for producing sprouting half-polished rice

ActiveCN100998389AImprove whole bud rateHigh whole germination rateSeed preservation by heatingSeed preservation by dryingMicrowaveThin layer

A method for preparing the germinated embryo rice from non-glutinous rice includes such steps as spreading said rice to become thin layer, immersing in water, germinating, passivating in the water at 70-100 deg.C, washing, and antistaling packing or drying including hot air baking and microwave drying. Its apparatus is composed of container with openable cover or door, and rice spreading unit.

Owner:杨春华

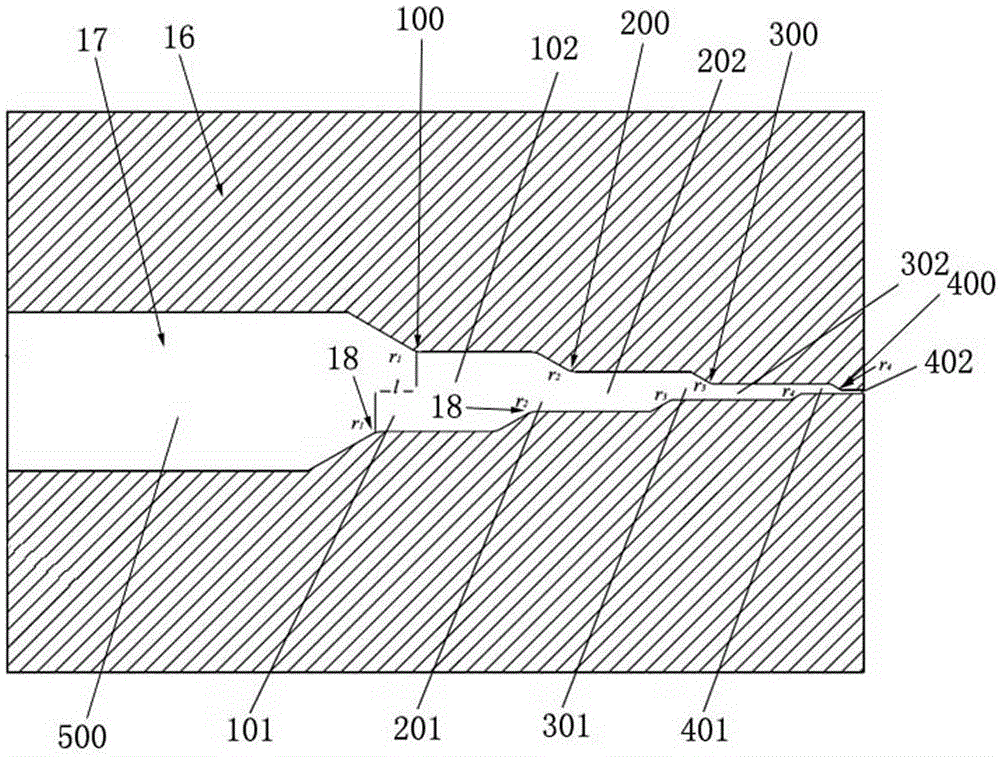

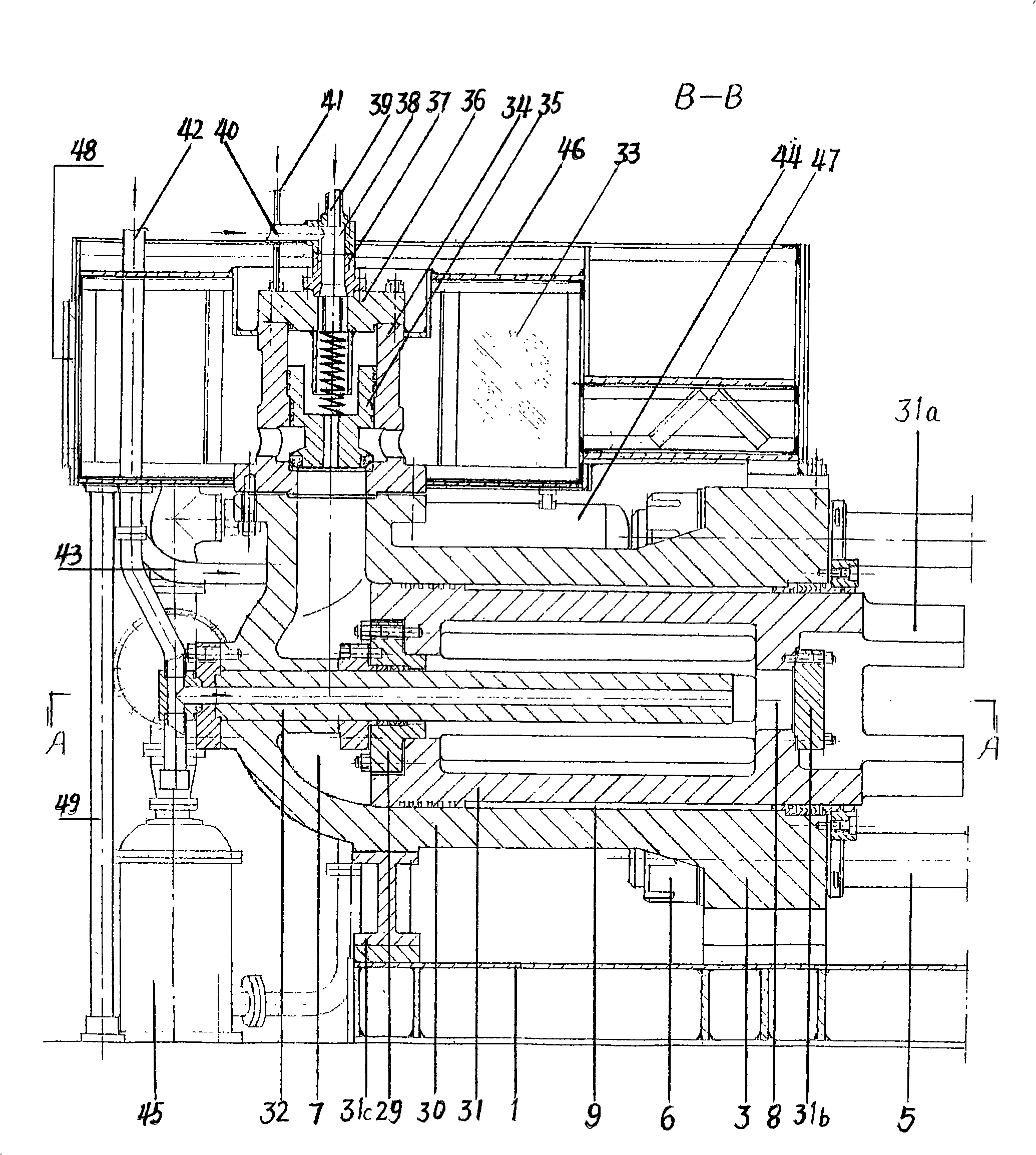

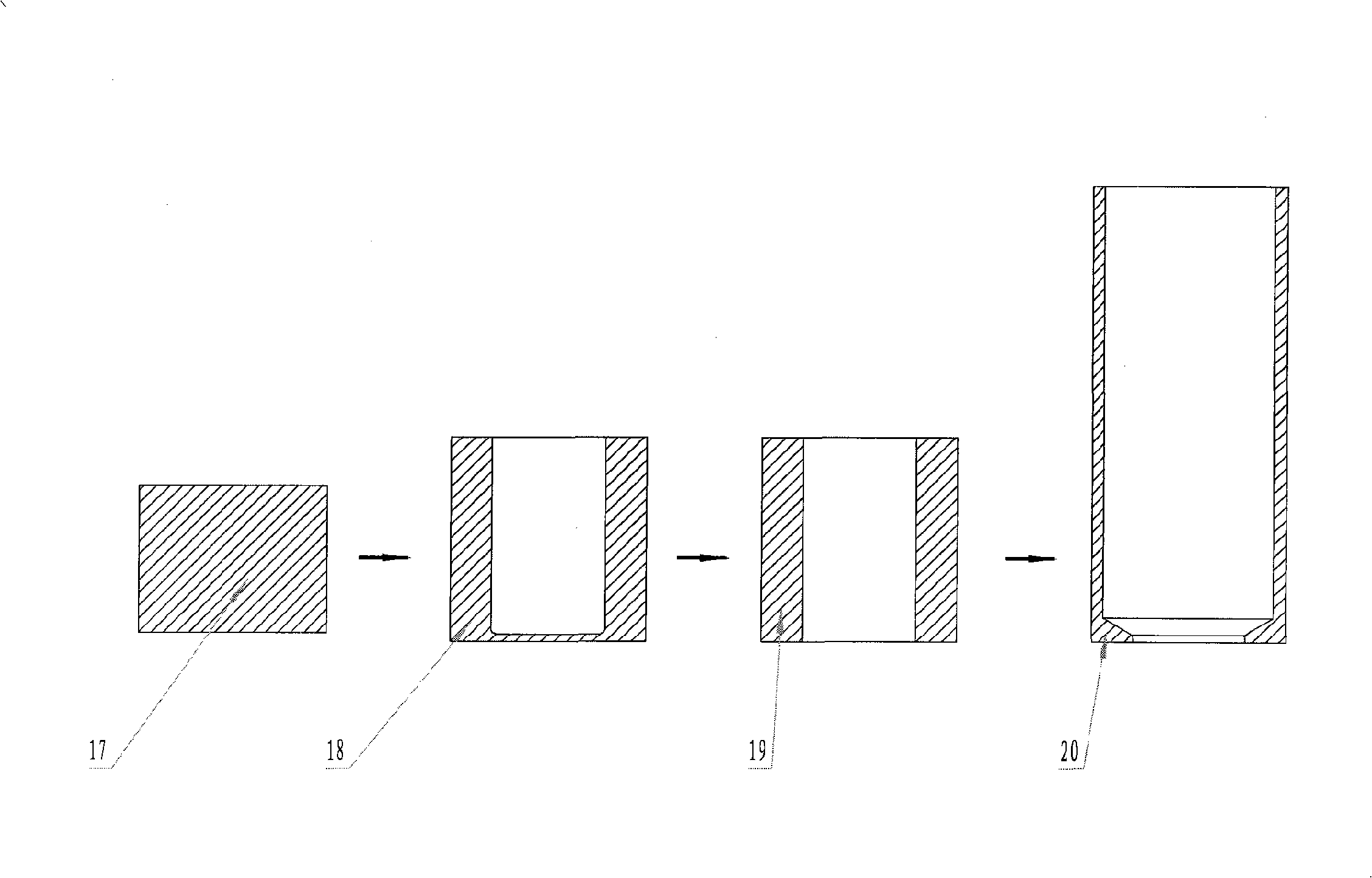

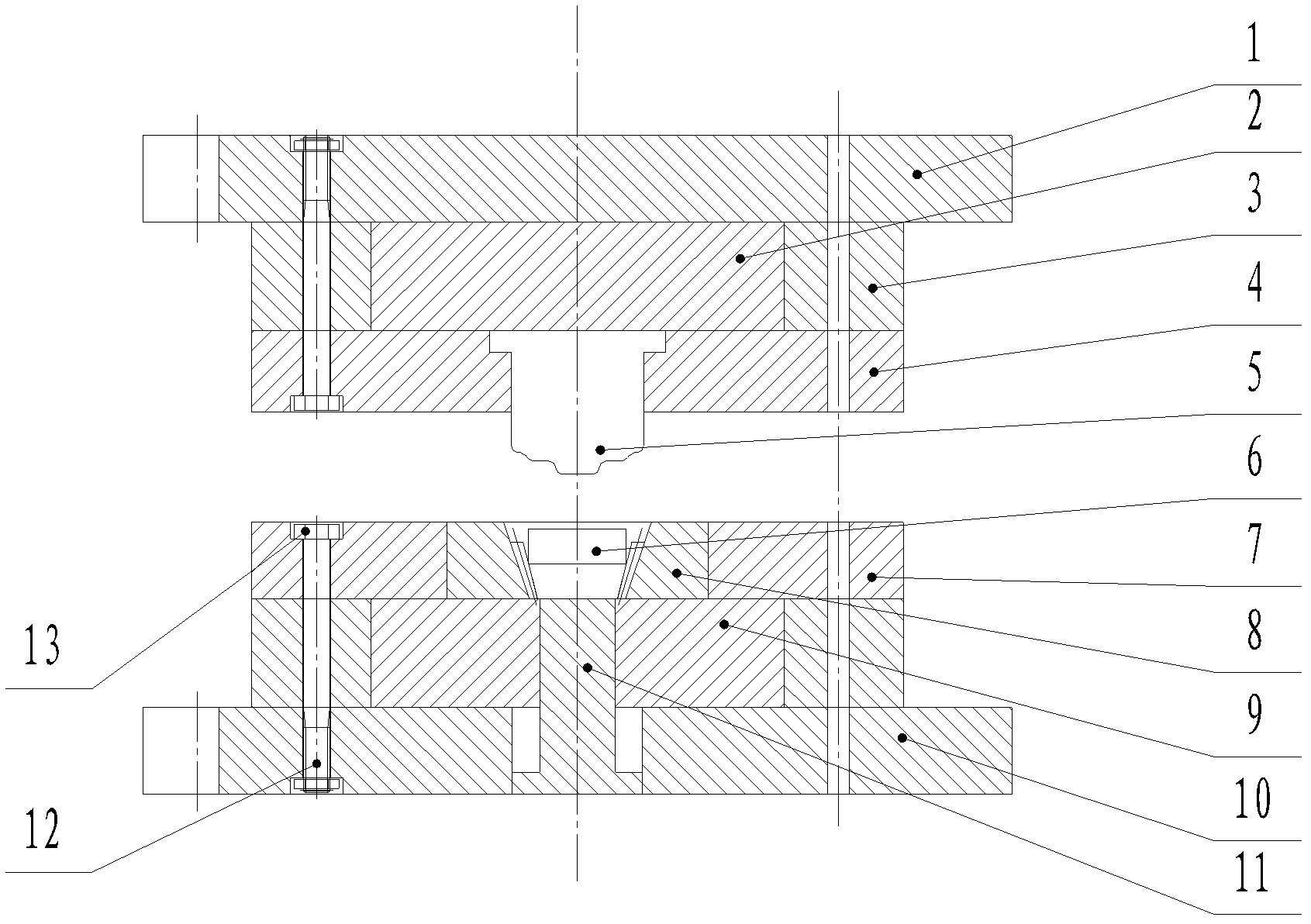

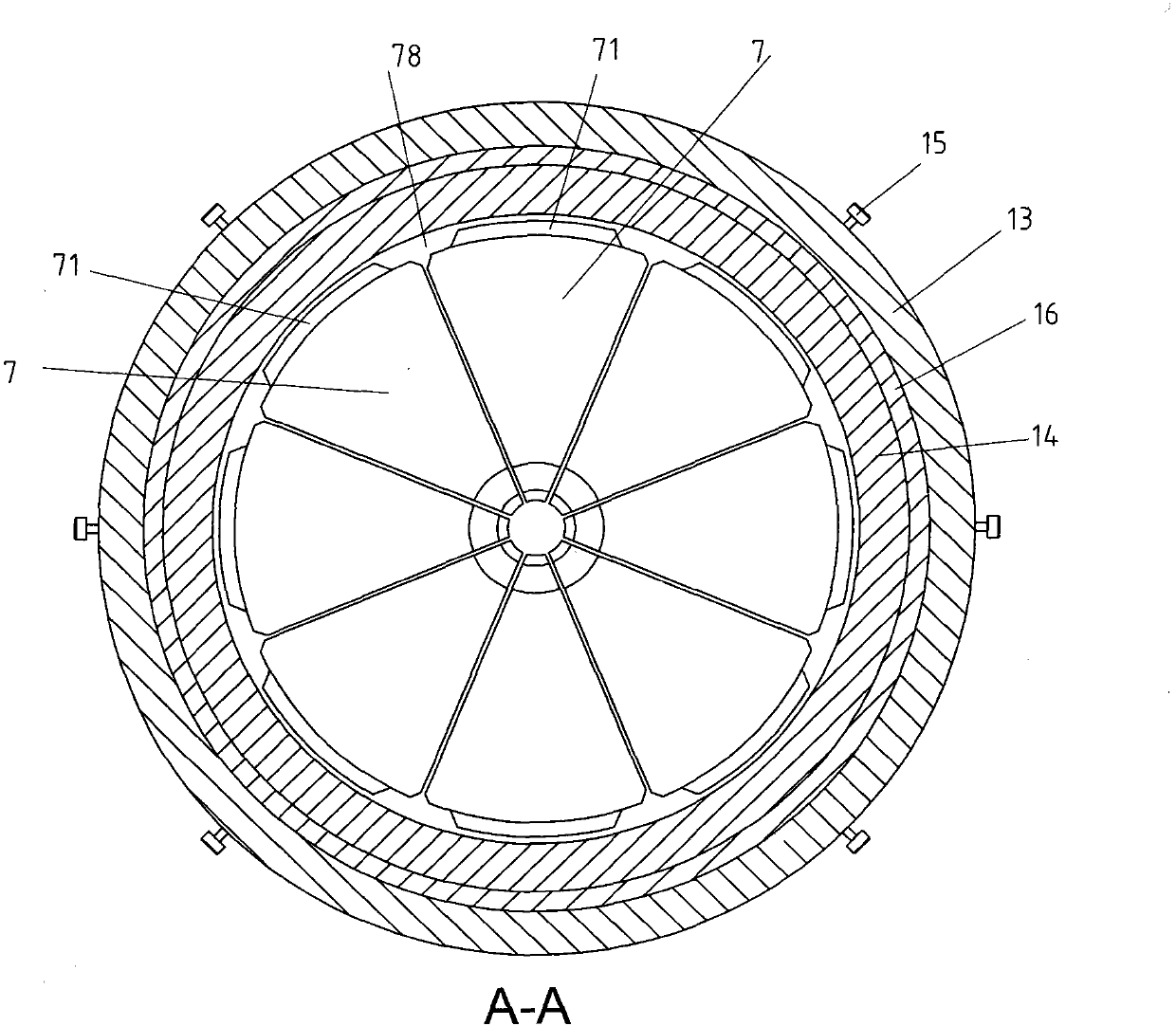

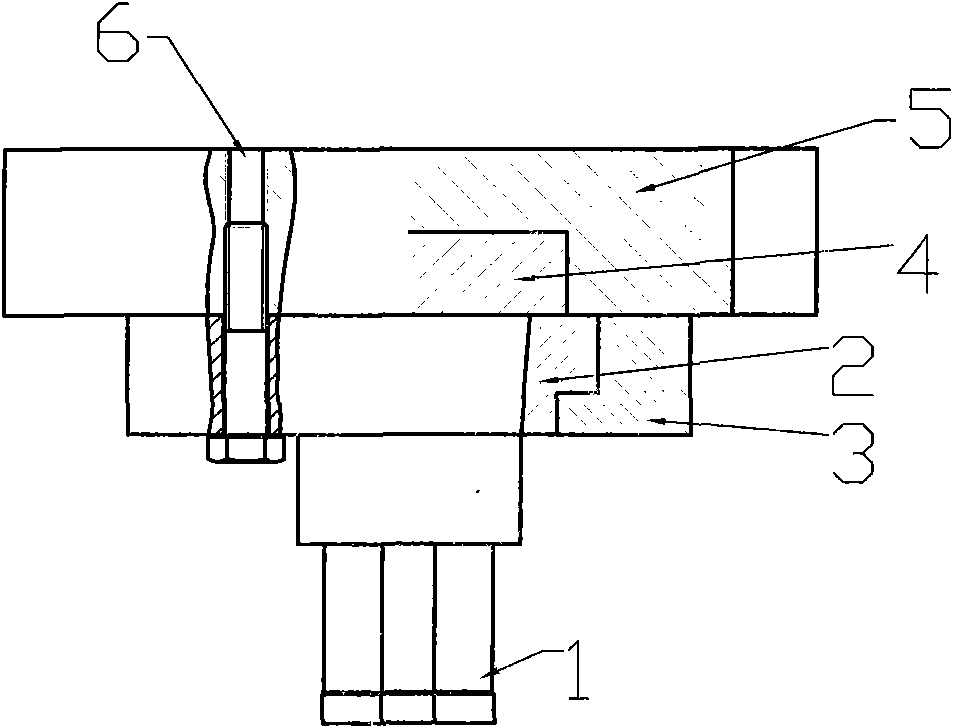

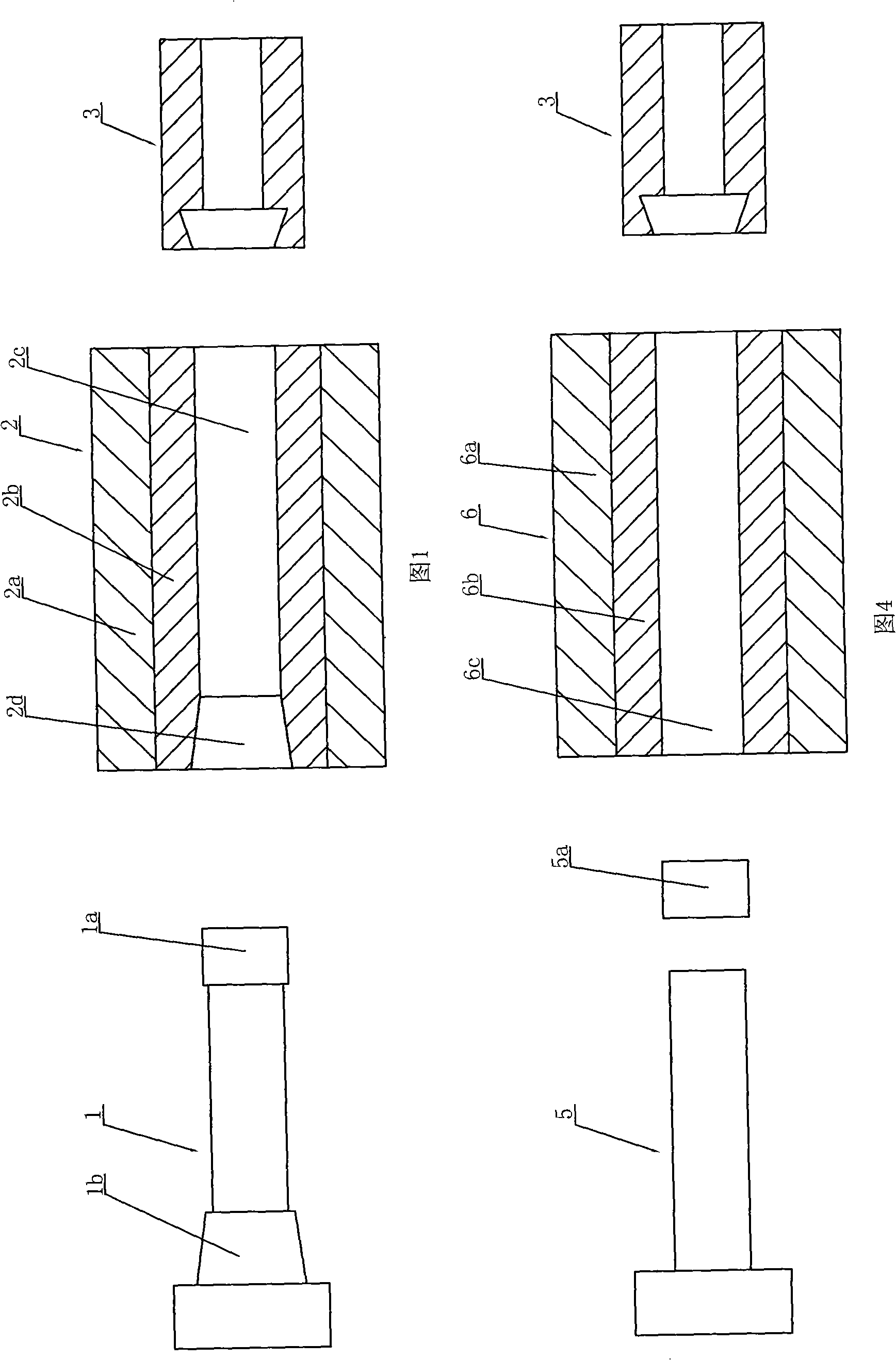

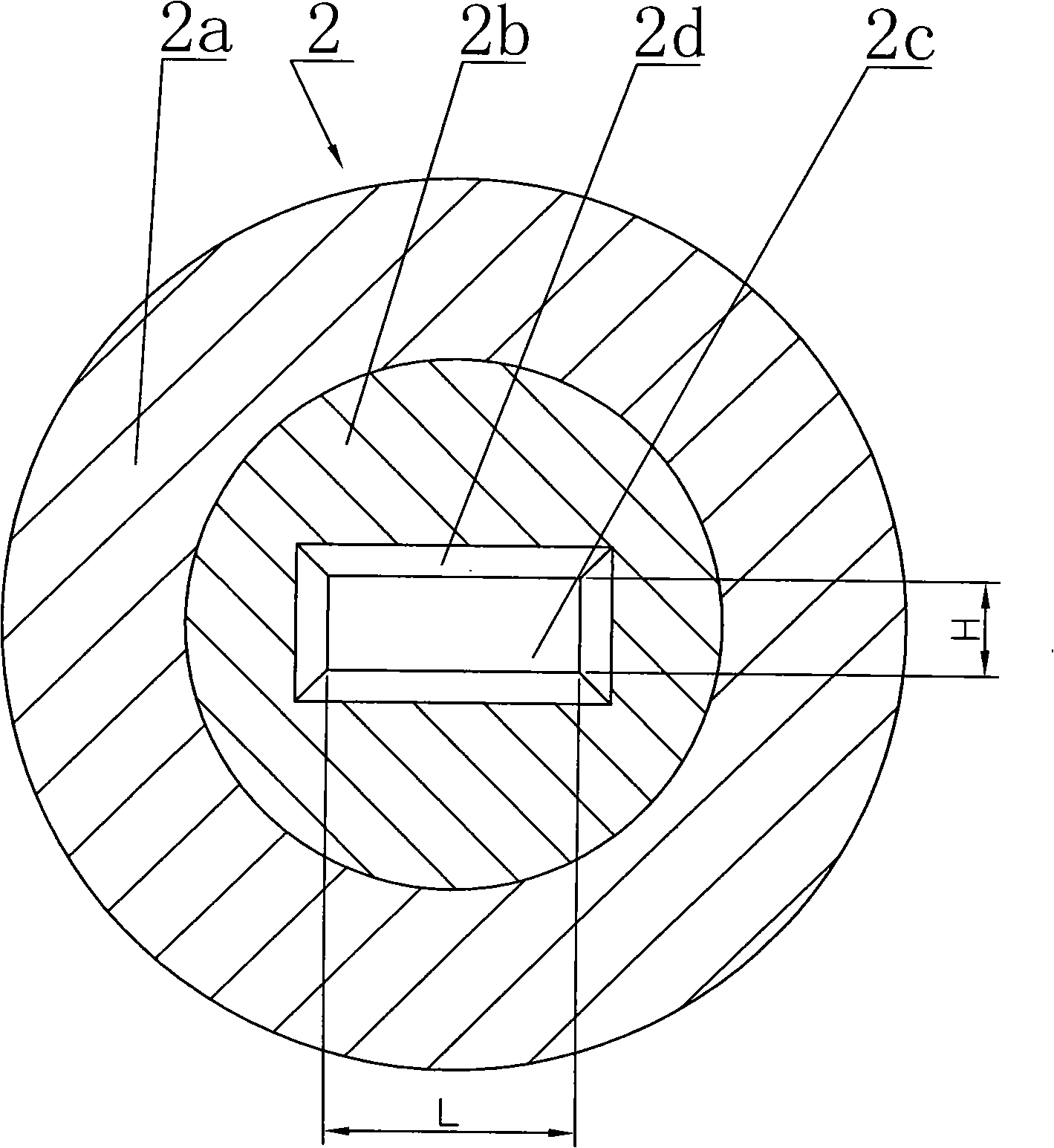

Precise extrusion molding method of thin wall long-pipe shaped parts bland and special mould

InactiveCN101332476AIncreased dimensional accuracy and material utilizationIncrease productivityExtrusion diesThin walledNonferrous metal

The invention belongs to an extrusion forming technique of non-ferrous materials. The precise extrusion forming technique of a thin-wall long-tube part blank comprises two procedures, namely, a primary reverse extrusion and a secondary reverse extrusion; the primary reverse extrusion obtains a primarily extruded tube blank (18) by adopting a primary male die (7) and a primary concave die (8) by virtue of a primary backing-out punch (4), the secondary reverse extrusion is carried out by adopting a secondary fixed male die (16), a secondary movable male die (12), a secondary concave die (6) by virtue of a secondary backing-out punch (14); the secondary movable male die (12) is placed into the primarily extruded tube blank (18), the secondary fixed male die (16) moves downward along the secondary movable male die (12) to extrude the primarily extruded tube blank (18), therefore, the secondary reverse extrusion is completed. The thin-wall long-tube part blank produced by adopting the technique of the invention has the advantages that the internal quality, dimensional accuracy and the utilization ratio of materials are greatly improved, and the production efficiency is improved and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

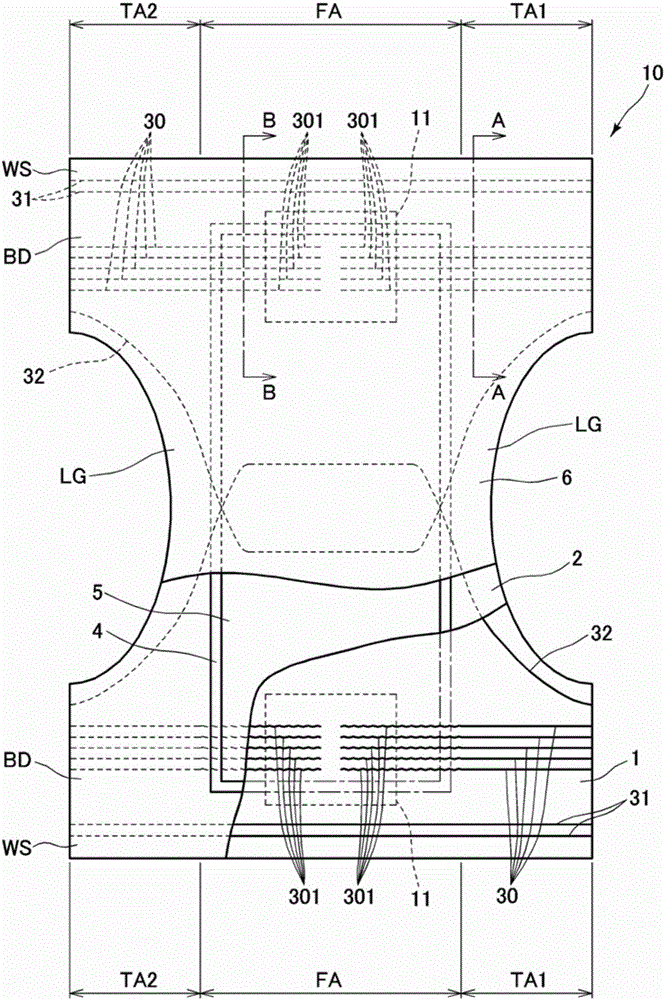

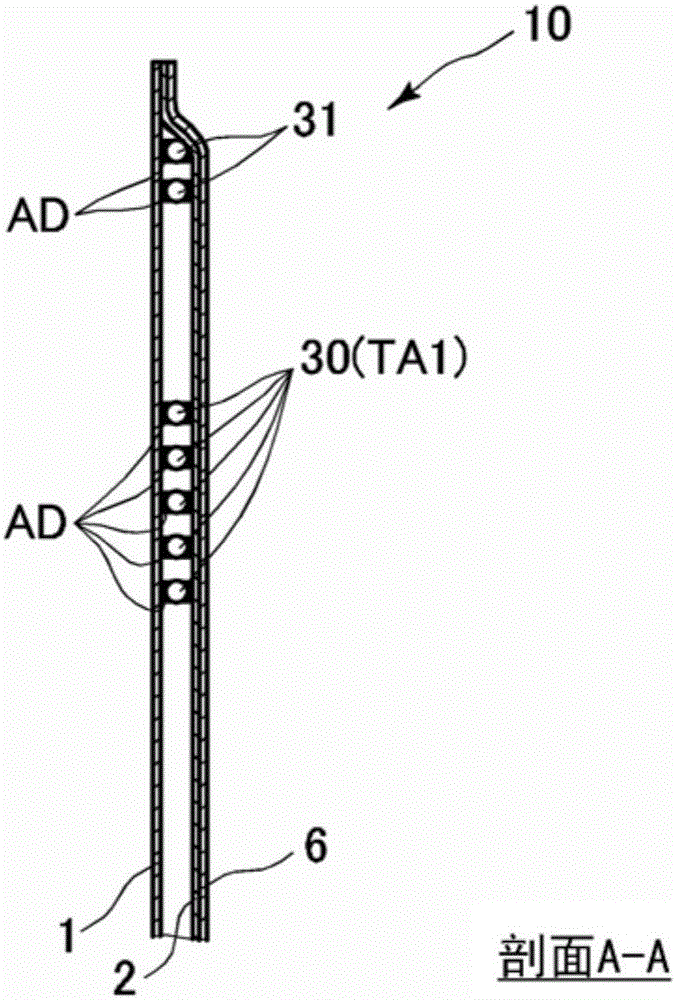

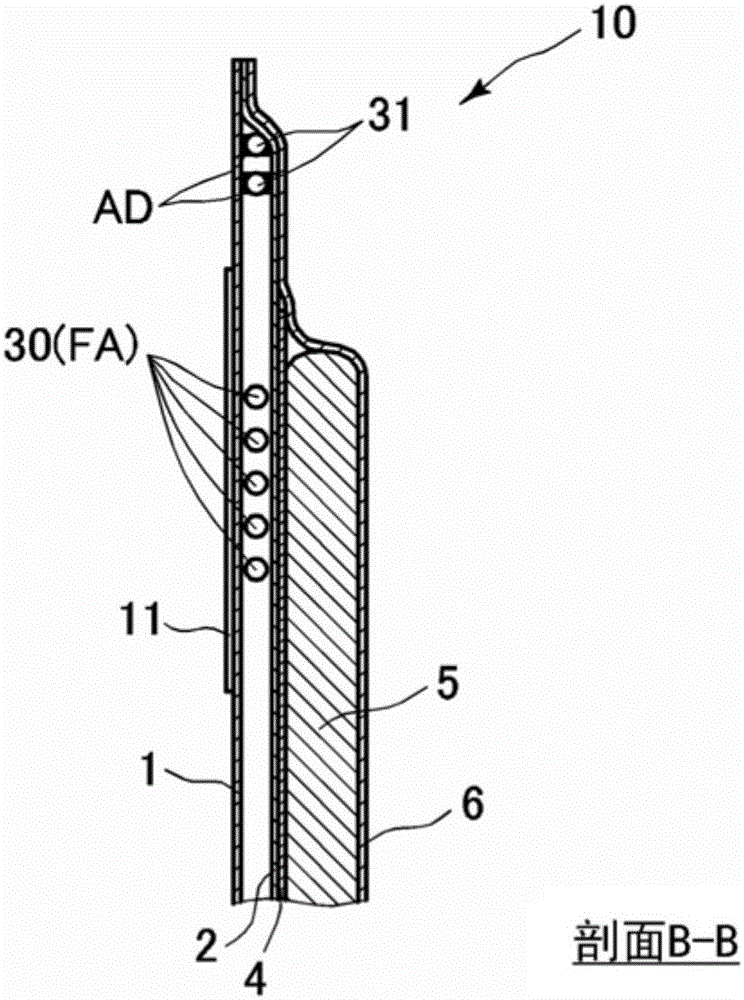

A disposable wearing article, a manufacturing apparatus and a manufacturing method

The invention provides a disposable wearing article having a structure capable of reducing the coating amount (amount of use) of an adhesive and suppressing occurrence of defective products. In addition, the invention provides a manufacturing apparatus and a manufacturing method for easily and inexpensively producing such a disposable wearing article. In the case of a waist gather rubber (30), the adhesive is applied to the outer back sheet and the inner back sheet (1, 2) only in tension areas (TA1, TA2), and a free area (FA) in a relaxed state is formed in a non-adhered state with the back sheet (1, 2). When the wearing article is worn, wrinkles are formed substantially only by the contraction of the tension areas (TA1, TA2) of the wrinkles (30). The free area (FA) in the slack state and the non-adhered state is cut in two at the intermediate position. Each of the cut pieces (301, 301) is integrally connected to an adjoining tension area (TA1, TA2) in a tensioned state and in an adhered state.

Owner:SHINKO KIKAI

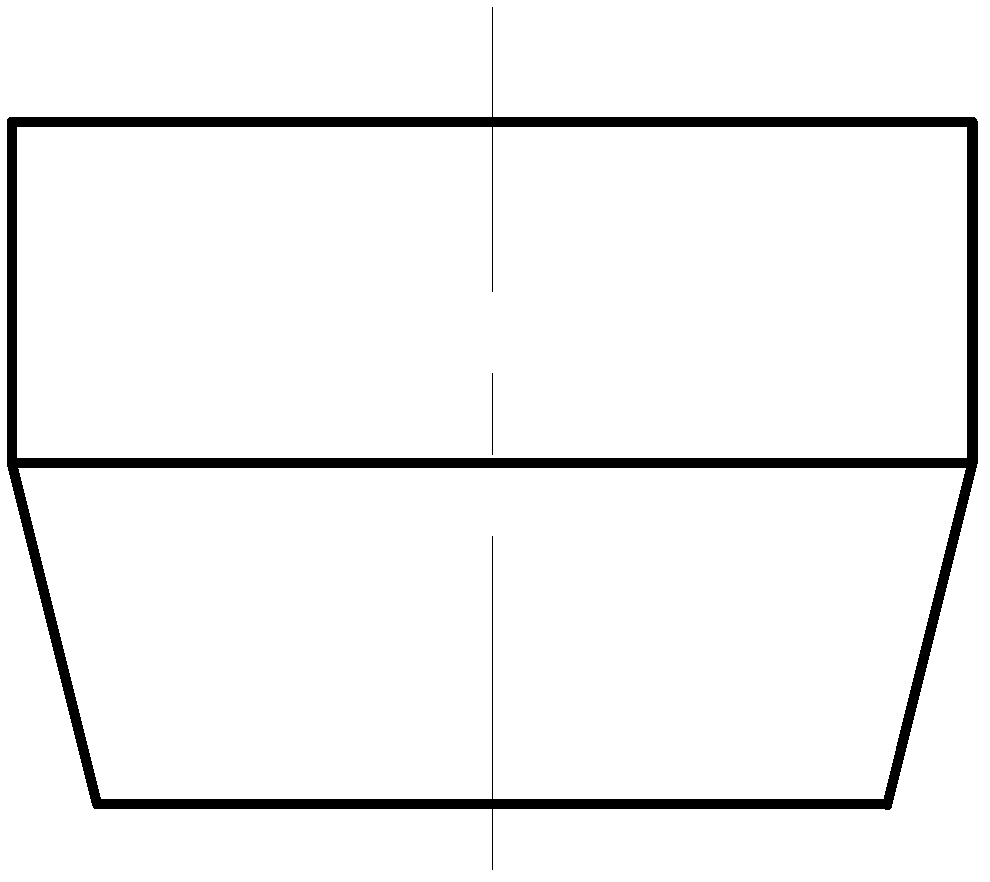

Cold precision forging process for bevel gear and mould thereof

InactiveCN102430692AImprove mechanical propertiesWon't cut offForging/hammering/pressing machinesWheelsHardnessBar stock

A cold precision forging process for a bevel gear is disclosed, and comprises the steps of: cutting the blanking by cylindrical bars; cutting a conical degree on a segmental length of the blank as segmental pre-form for positioning the blank in a die; performing spheroidization for the machined blank to reduce the hardness, then scouring and descaling, phosphorizing, saponifying and lubricating; the first cold precision forging step comprises: upsetting-extruding segmental tooth form in an extrusion mould to obtain a first extrusion which is used as the blank of the second first cold precision forging step; performing spheroidization again for the first extrusion, then scouring and descaling, phosphorizing, saponifying and lubricating; the second cold precision forging step comprises: upsetting-extruding all tooth forms in the extrusion mould to obtain the coarse material of the bevel gear; machining and shaping the coarse material of the bevel gear and cutting unnecessary materials on the end surface to obtain finished products of the bevel gear. The invention further provides an extrusion mould. The invention has higher production efficiency, reduces the material waste, lowers the cost and improves the mechanical property.

Owner:ZHEJIANG UNIV OF TECH

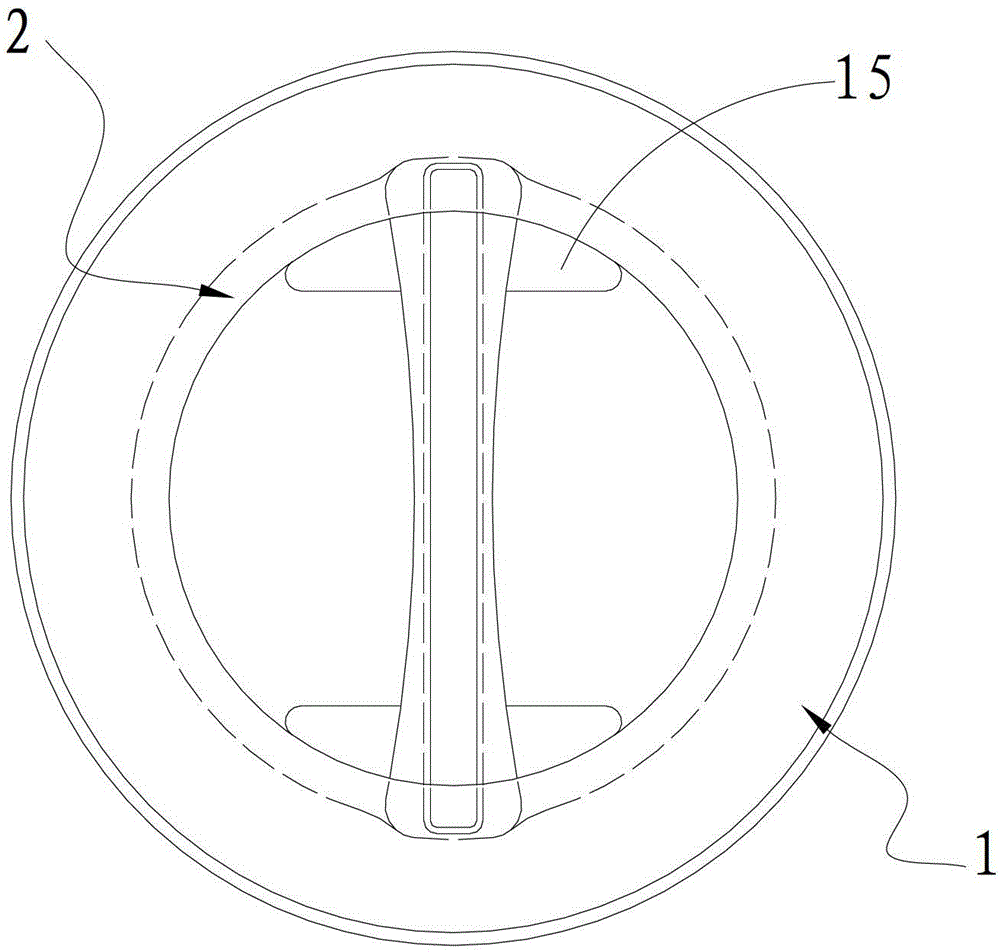

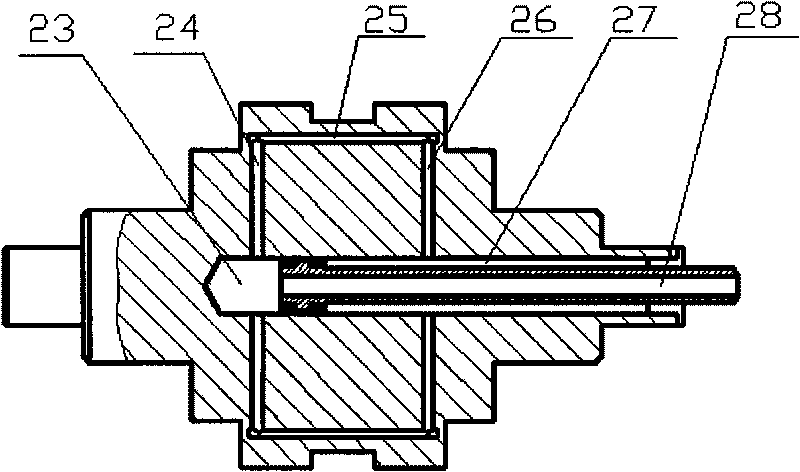

Extrusion forming method for magnesium alloy housing type component ring ribs

The invention discloses an extrusion forming method for magnesium alloy housing type component ring ribs. The extrusion forming method comprises the following steps of: (1), placing a processed hollow blank in a barrel-shaped hollowing block; (2), symmetrically arranging at least two split terrace dies in an inner tube of the hollow blank, moving the split terrace dies in the radial direction, respectively extruding the inner tube wall surface of the hollow blank by extrusion bulges of the split terrace dies, forming a certain vacancy between the extrusion bulges of the two split terrace dies, enabling un-extruded part of the inner wall of the hollow blank to plastically flow towards the vacancy between the extrusion bugles to form radial bulges, and automatically returning the split terrace dies; and (3), rotating the split terrace dies by a certain angle to reach positions at which the extrusion bulges of the split terrace dies correspond to the radial bulges, circulating the extrusion operation in the step (2), retracting the extruded split terrace dies, extruding the ring ribs at the periphery, repeating the operations when the split terrace dies reach the position of the next ring rib, and finally forming the qualified housing component with the ring ribs.

Owner:ZHONGBEI UNIV

Mould for continuous extrusion production of high-width-thickness-ratio profiles

InactiveCN102407244AExtended service lifeReduce extrusion pressureExtrusion diesThermodynamicsEngineering

The invention relates to a mould for the continuous extrusion production of profiles, which can be used for producing large-sized (high-width-thickness-ratio) profiles by using a small-capacity continuous extruder, and belongs to the technical field of metal continuous extrusion. In the invention, an inlet of an opening of the mould is provided with a diversion trench which is completely same as an outlet of an expansion module cavity in shape and size; a 'dumbbell-shaped' diversion trench is arranged behind the diversion trench; a choking surface with a choked angle of 8-15 DEG and a promoted angle of 50-90 DEG is arranged behind the 'dumbbell-shaped' diversion trench through design, and the height of the choking surface is 5-15 mm. A mould design method in the invention is used for the continuous extrusion production of profile products in general specifications, can reduce extrusion forces, increase the productivity, lower the mould loss, and improve the service life of the mould.

Owner:KUNMING UNIV OF SCI & TECH +1

Novel brazing flux-containing aluminum alloy soldering wire and preparation method thereof

InactiveCN101947702AIncrease profitReduce processingWelding/cutting media/materialsSoldering mediaAluminum fluoridePotassium

Owner:BEIJING UNIV OF TECH

Cellulose reinforced resin compositions

InactiveUS20060094802A1Improve extrusion rateHigh tensile strengthNon-fibrous pulp additionPaper/cardboardWaxPolymer chemistry

The present invention provides an extrudable reinforced resin-containing composition comprising resin capable of plastic flow, reinforcing material, and a lubricant composition comprising oxidized polyethylene wax, ester wax, and amide wax. Also provided are the lubricant composition, and extrusion methods and extruded products based on the present compositions.

Owner:HONEYWELL INT INC

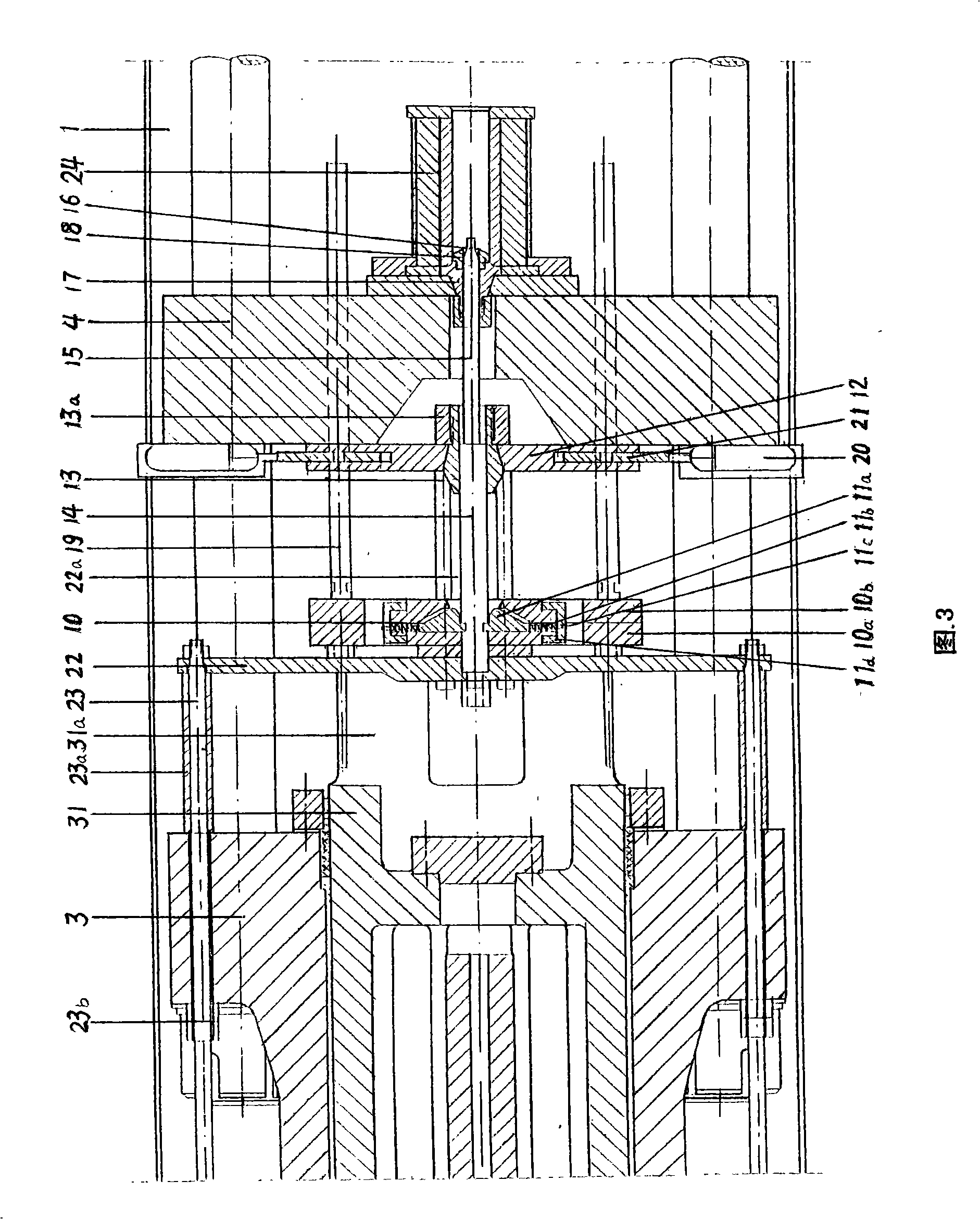

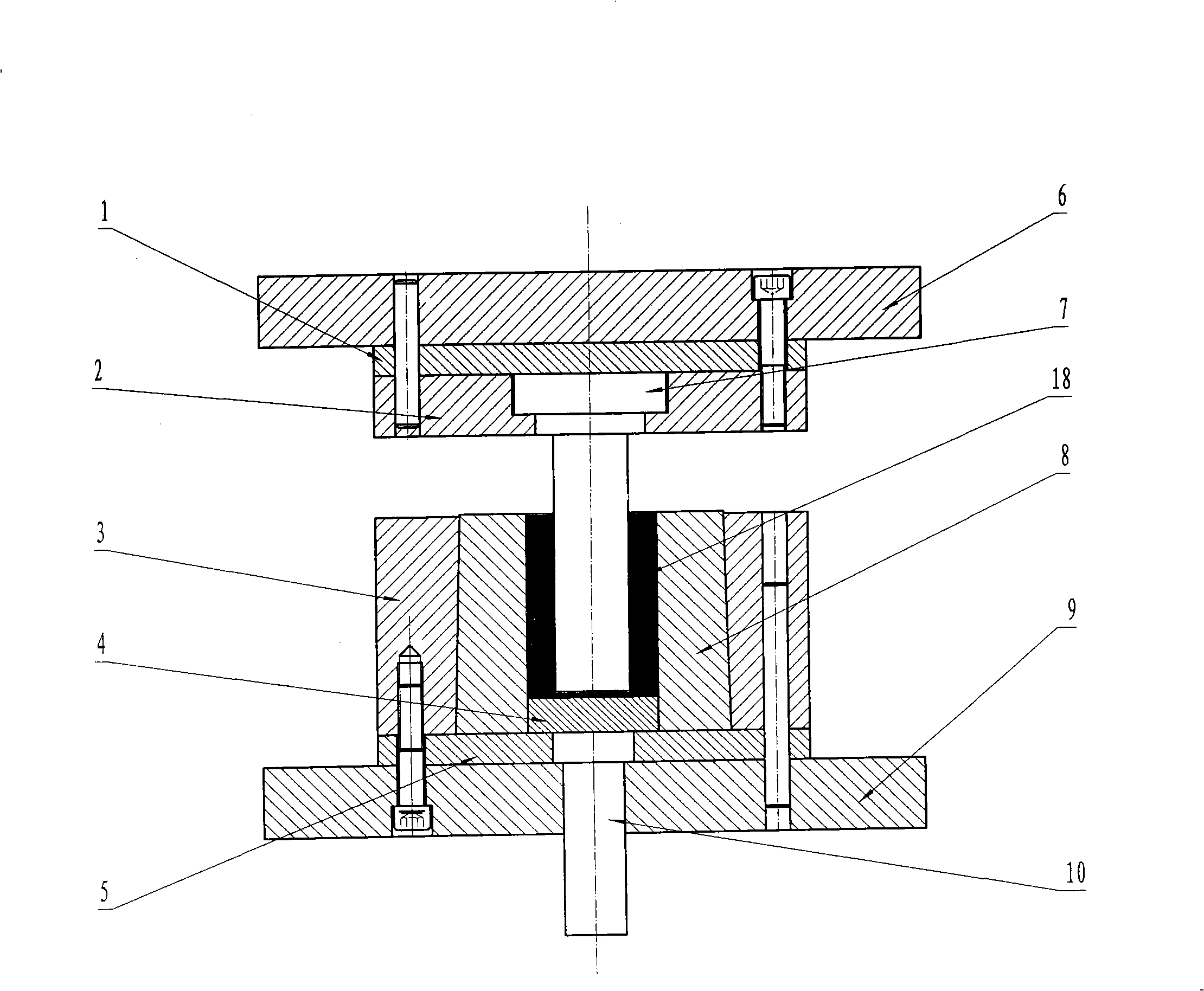

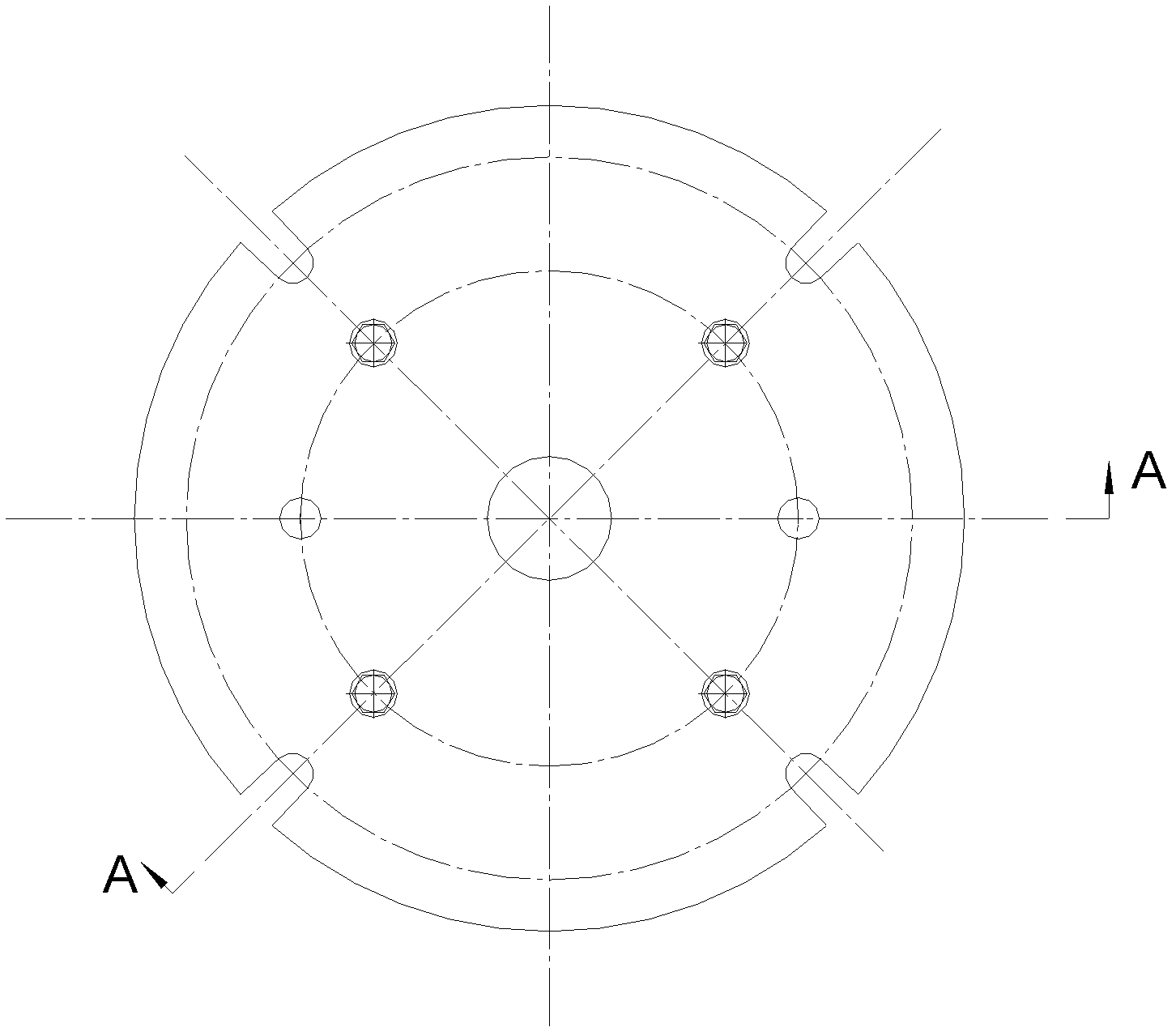

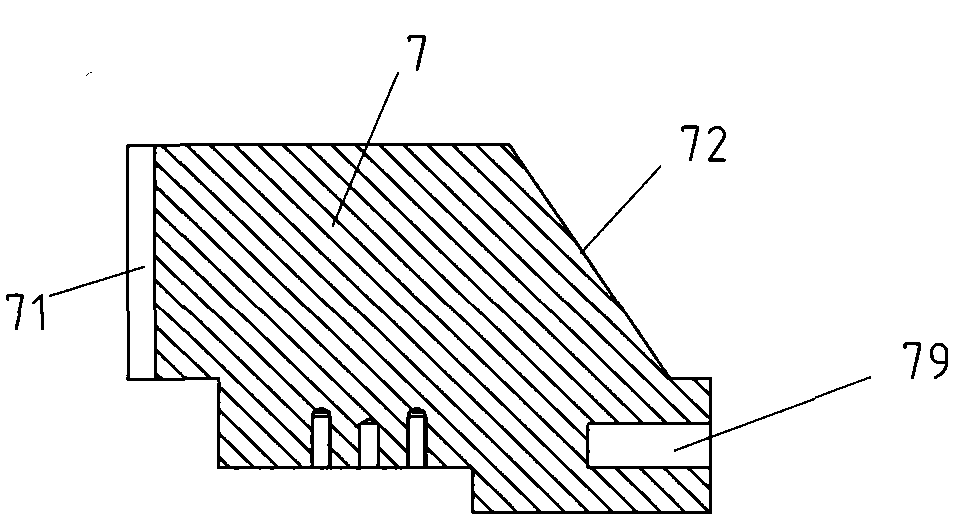

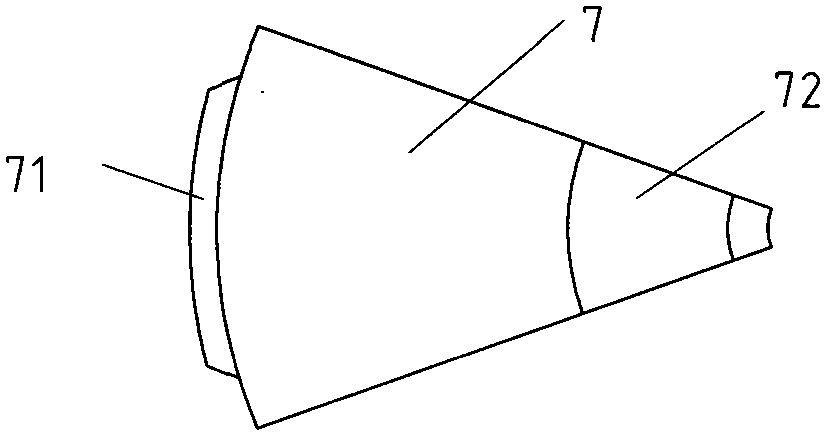

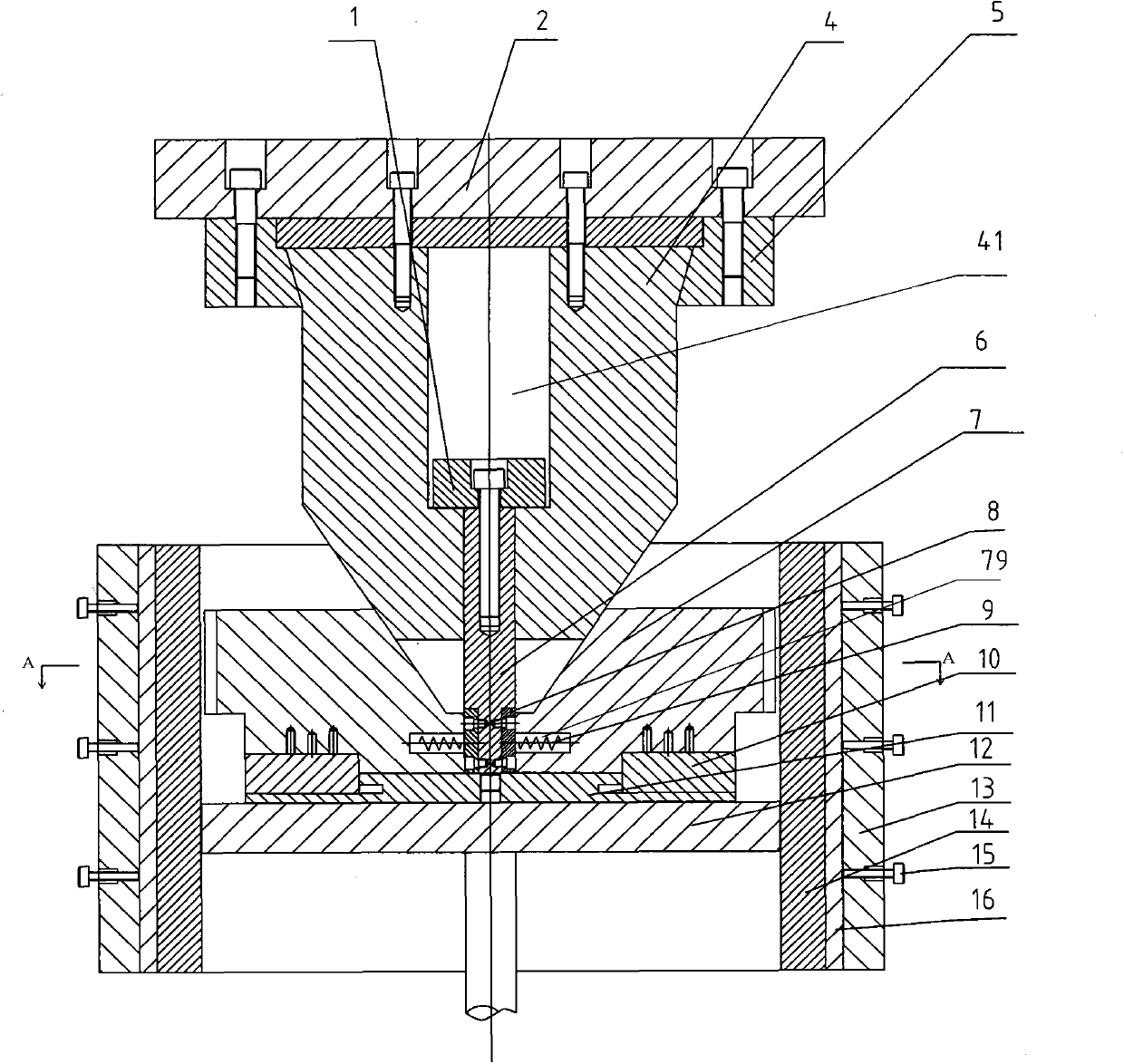

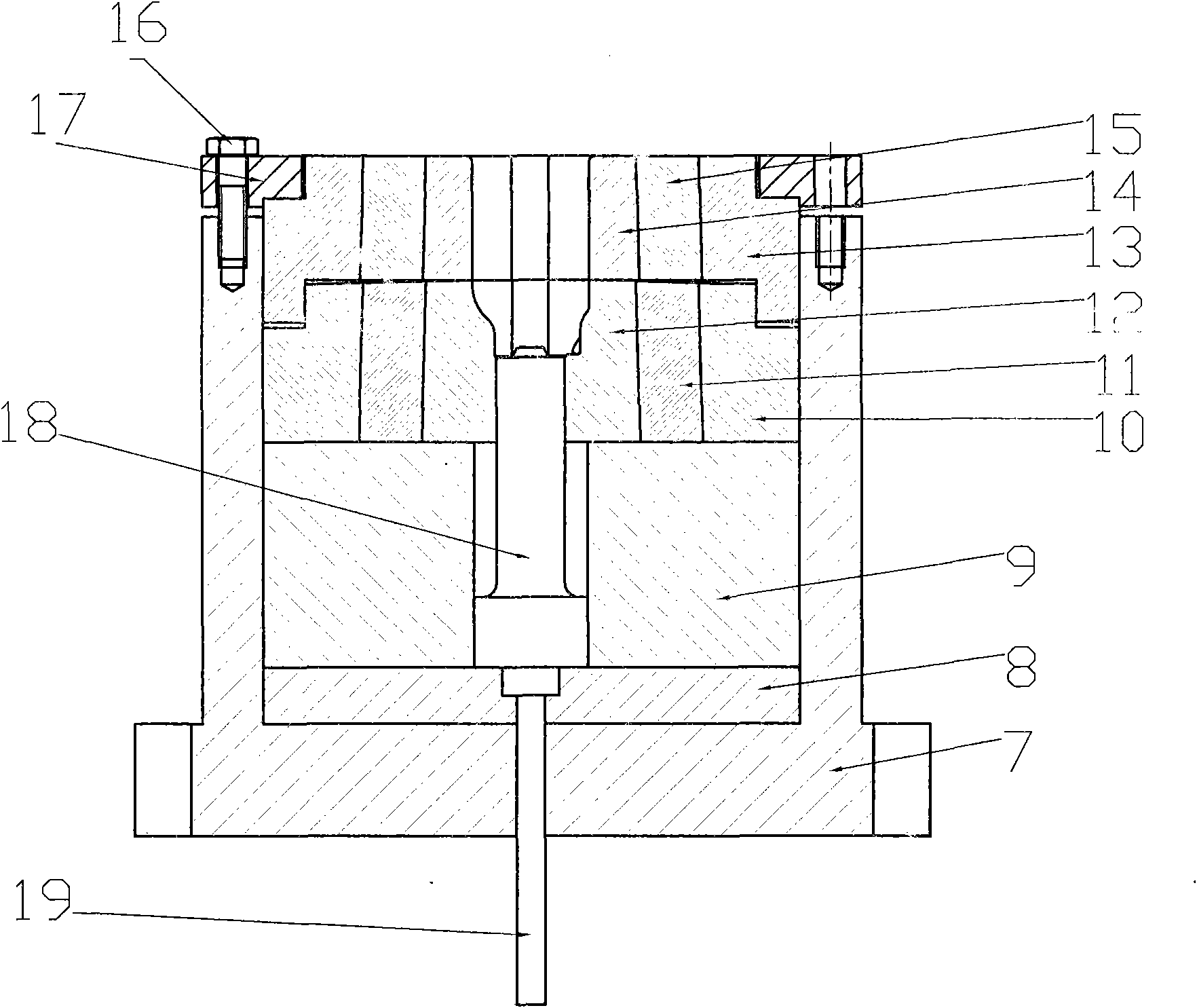

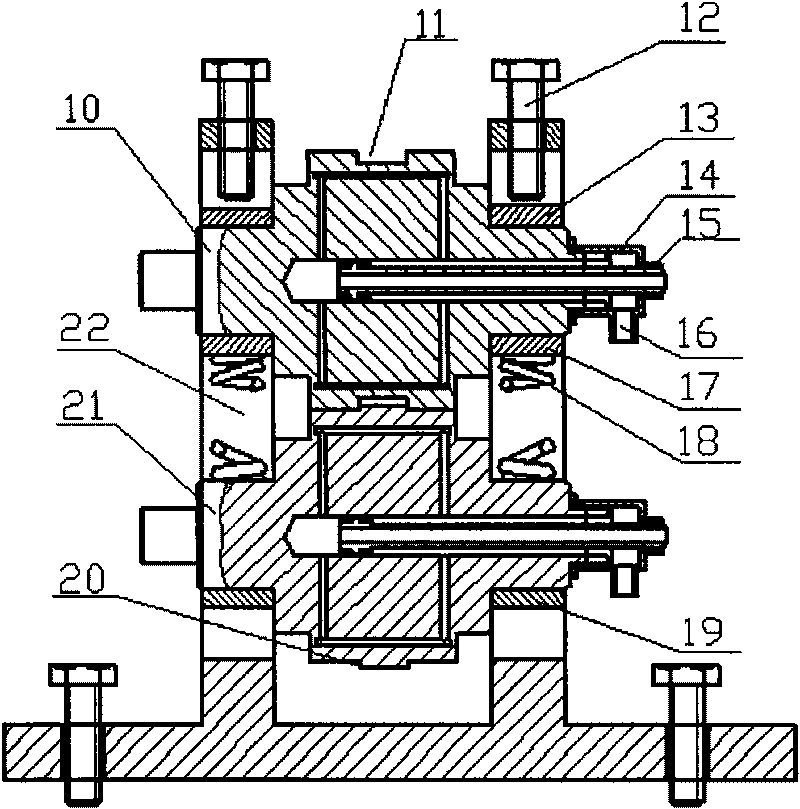

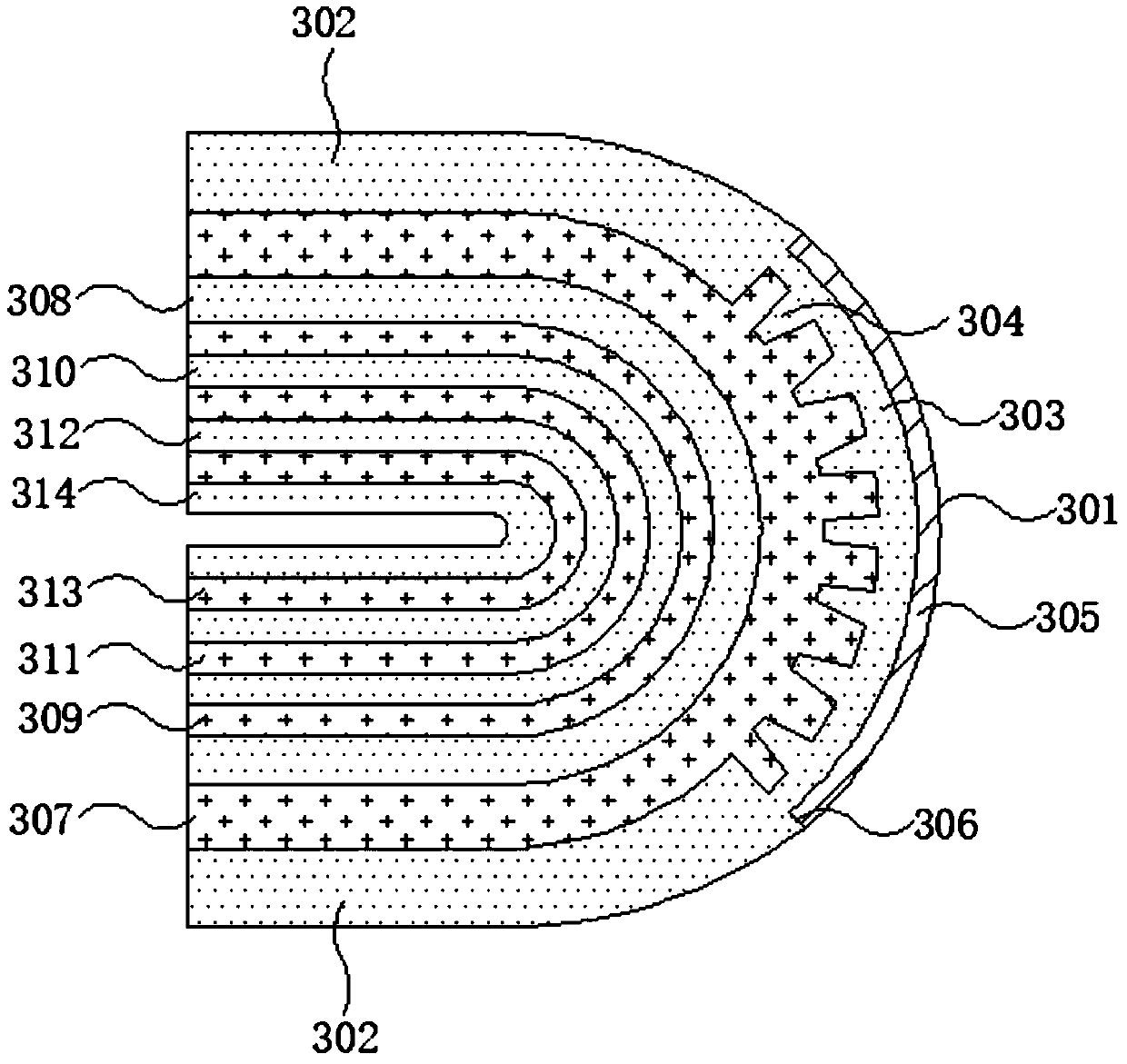

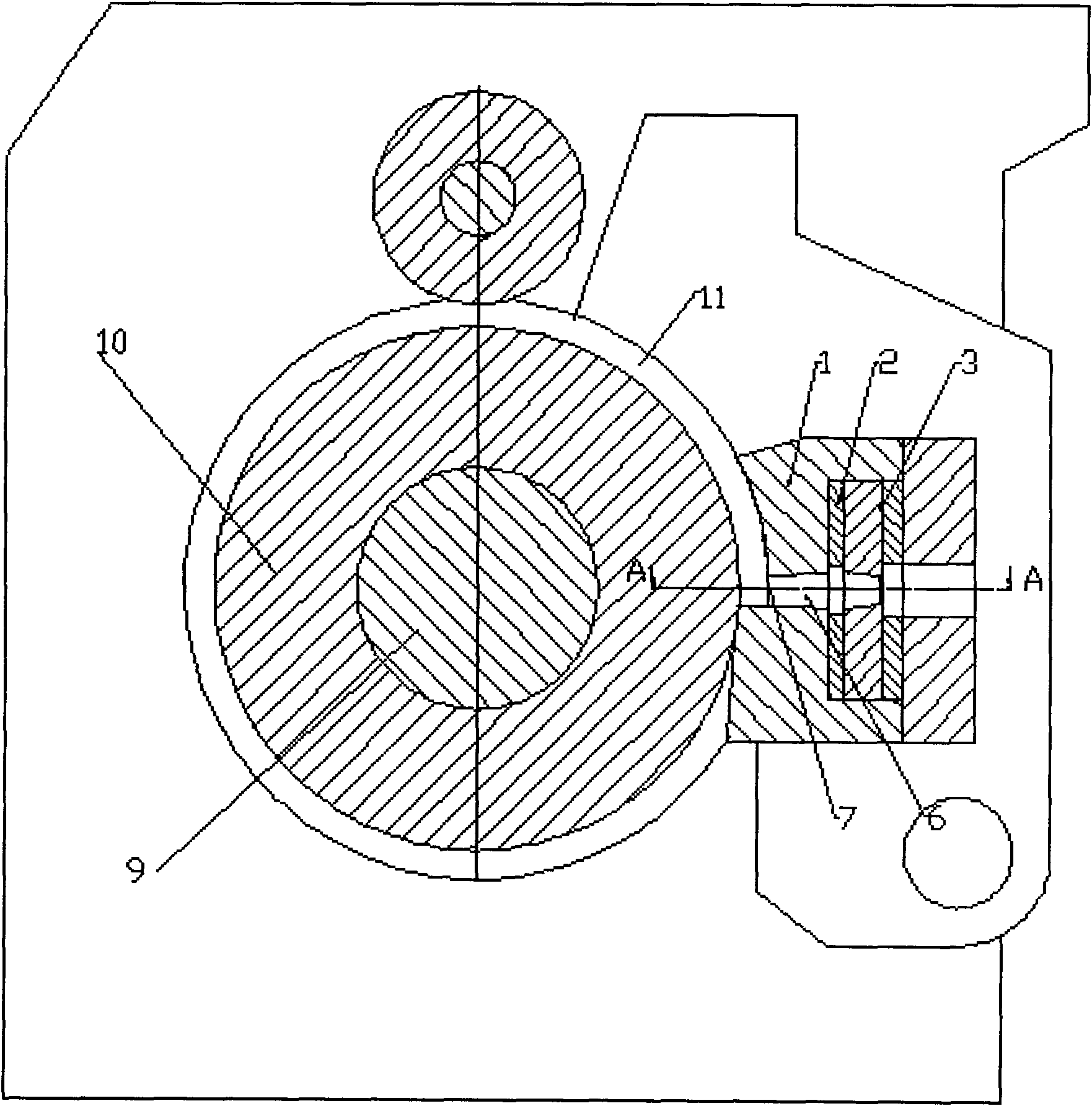

Extrusion forming mould for annular ribs of magnesium alloy shell parts

The invention discloses an extrusion forming mould for annular ribs of magnesium alloy shell parts. The extrusion forming mould mainly comprises an upper mould plate, a mandrel, a split male mould pull rod, split male moulds, tension springs, a male mould sliding guide rail, a split male mould sliding bottom plate, a supporting plate and a cylindrical female mould, wherein the head part of the mandrel is conical, a center hole is formed in the axial direction of the mandrel, one end of the split male mould pull rod is inserted in the center hole, the other end of the split male mould pull rod is fixed on the split male mould sliding bottom plate, the at least two split male moulds are symmetrically arranged around the split male mould pull rod, are fixedly connected with the split male mould pull rod through the tension springs and are arranged in a radial sliding groove of the split male mould sliding bottom plate through the male mould sliding guide rail, a wedge-shaped inclined plane adapting to the conical head part of the mandrel is arranged at the inner side of each split male mould, an arc-shaped extruding bulge is arranged at the arc-shaped wall surface of the outer side of each split male mould, and the arc length of each extruding bulge is more than the distance between each two adjacent extruding bulges. According to the extrusion forming mould, all the split male moulds do radial movement by virtue of the axial movement of the mandrel, metal flows in the radial direction, and thus the annular ribs are generated.

Owner:ZHONGBEI UNIV

Preparation method of high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material

InactiveCN108396168AThe content is easy to controlIntegrity guaranteedTransportation and packagingMetal-working apparatusSemi solidAluminium powder

The invention discloses a preparation method of a high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material. Aluminium powder is modified to improve the affinity of the aluminium powder to graphene, and after that, semi-solid extrusion is performed to obtain the graphene enhanced aluminium alloy material. The preparation method is simple to operate, adjustable in process and controllable in graphene content; graphene is uniformly dispersed in the aluminium alloy material; the demand on an aluminium matrix is less; the high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material can be compounded with various aluminium alloys to obtain corresponding graphene enhanced aluminium alloy materials; meanwhile, the integrity of graphene can be maintained to the utmost extent, and the binding force between the high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material and the matrix is improved. A prepared graphene / aluminium alloy-based composite has the compactness of 98.5% or above, has the conductivity equivalent to that of a matrix aluminium alloy rod piece (more than 61% IACS), and is improved by more than 20% in tensile strength and more than 50% in creep resistance. The preparation method is suitable for preparing the long graphene enhanced aluminium alloy material, and is low in production cost, suitable for industrial production and favorable in market prospect.

Owner:CENT SOUTH UNIV

Short-injection water injection well acidation injectivity process

The invention discloses a short-injection water injection well acidation injectivity process for petroleum industry, which is applied to a short-injection water injection well, improves the acidation effect and improves the water injection success rate. The process comprises the following steps: a prepose acid liquor soaking oil layer is inputted; the well is backwashed at high flow rate so as to discharge the prepose acid liquor; main acid is squeezed in; the well is backwashed by water mixed with gas, the back pressure on the bottom of the well is reduced, the ground layer is induced to flow, and the deep stoppage reactant can be discharged under the effect of the strata pressure. The prepose acid liquor is discharged through the repeated washing of the well, so the effect of the main acid is adequately played, the secondary pollution of the oil layer can be prevented, the deep acidation can be realized, the injectivity valid period is prolonged, the measure success rate is improved, and the recovery rate of the low-permeability reservoir can be improved. The effect of the used acid can be effectively played, the underground tube pile can be free from damaged, the consumption of the main acid can be reduced on the premise of ensuring the construction effect, and the production cost can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Turning method and turning tool

The invention provides a turning method. The method comprises the following step: turning the outer surface of a niobium alloy target material or a niobium alloy target material by adopting a turning tool, wherein the front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees. By selecting the front angle, rear angle, main deflection angle, auxiliary deflection angle and blade inclination angle of the turning tool, cuttings can be discharged from processed surfaces, so that the cuttings are prevented from sticking to the tool, and the cutting difficulty is lowered. The invention further provides a turning tool. The front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees.

Owner:NINGXIA ORIENT TANTALUM IND

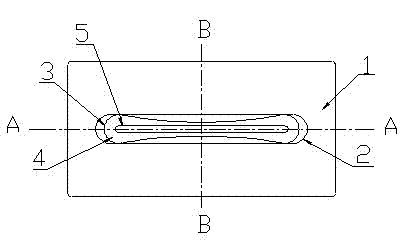

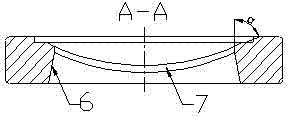

Mould for extruding aluminum alloy

ActiveCN103331322ASmall coarse crystal layerReduce extrusion pressureExtrusion diesPre deformationIngot

The invention discloses a mould for extruding aluminum alloy. The mould comprises a flow guide mould and a section mould, which are arranged at the front and the back along a fluid direction, wherein the corresponding cavity sizes of the flow guide mould and the section mould are designed according to parts, the flow guide mould consists of a sinking table and a transition cavity, the sinking table is in an inner cone structure, the front end of the transition cavity is in a counter bore structure, the diameter size of the counter bore structure is less than the diameter of an external circle, the rear end of the counter bore structure further adopts a broadsiding structure, and a connection place between the cavity and the flow guide mould is in an inverted cone structure. The mould disclosed by the invention has the beneficial effects that the flow guide mould of the side broadsiding of the first counter bore is designed, an ingot is peeled by the side broadsiding of the first counter bore, the extrusion force and broadsiding pre-deformation can be reduced, the high-precision forming can be carried out by the inverted cone section mould, and the extrusion force can be further reduced as well as the tissue can be further improved.

Owner:FUJIAN NANPING ALUMINUM

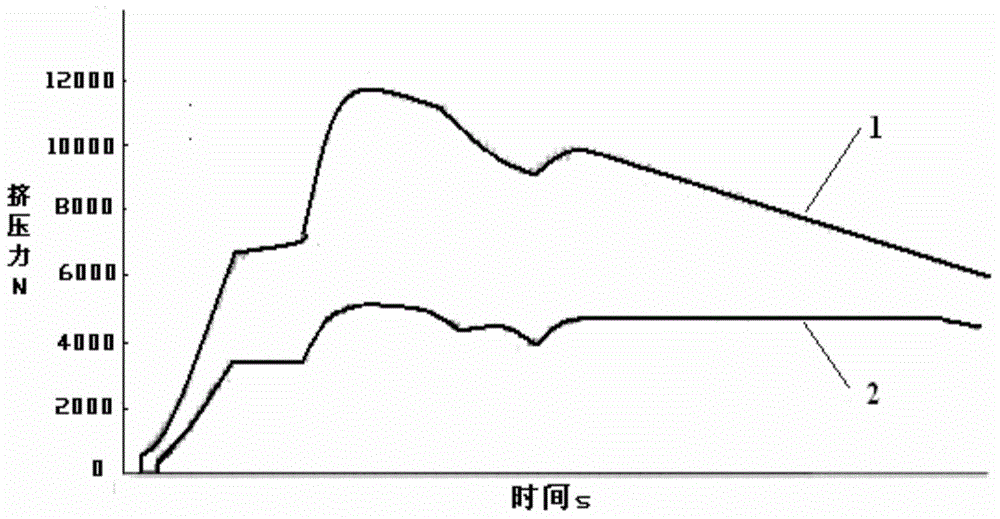

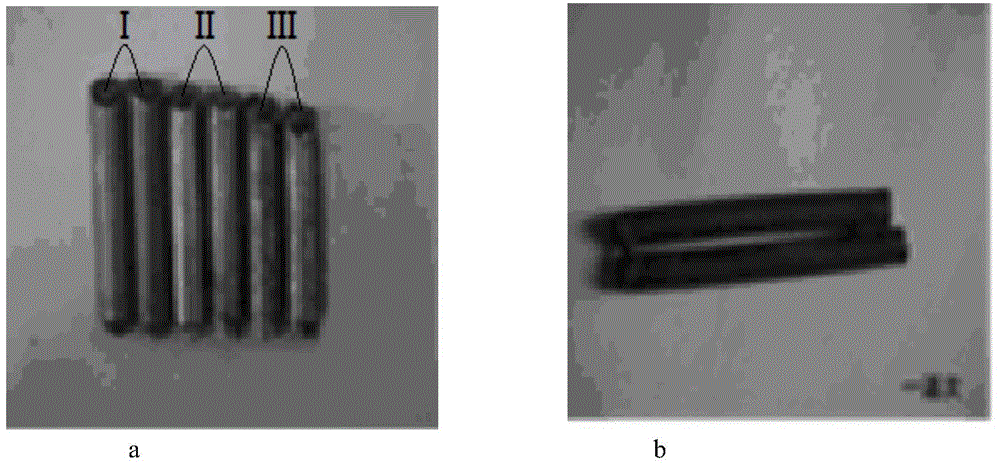

Preparation method for ultra-fine grain pure titanium through equal channel angular pressing

The invention provides a preparation method for ultra-fine grain pure titanium through equal channel angular pressing. According to the invention, test conditions are improved on the basis of the prior art, a to-be-extruded sample is designed to be a copper-wrapped titanium rod, so frictional force generated during contact between the sample and a channel is reduced during extruding; extruding force is decreased to no more than 150 KN, so experimental operability is improved, and refining of industrial pure titanium can be finished at room temperature under small extruding force through equal channel angular pressing. At room temperature, the phenomena of restoring and recrystallization softening of crystal grains during refining hardly occur, so a substantial crystal grain refining effect is obtained and a high-strength industrial pure titanium block can be obtained through few times of extruding. According to results of testing of mechanical properties of the prepared ultra-fine grain pure titanium, the ultra-fine grain pure titanium has substantially improved comprehensive mechanical properties, block ultra-fine grain pure titanium can be used in practice, and the application scope of the ultra-fine grain pure titanium is broadened.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

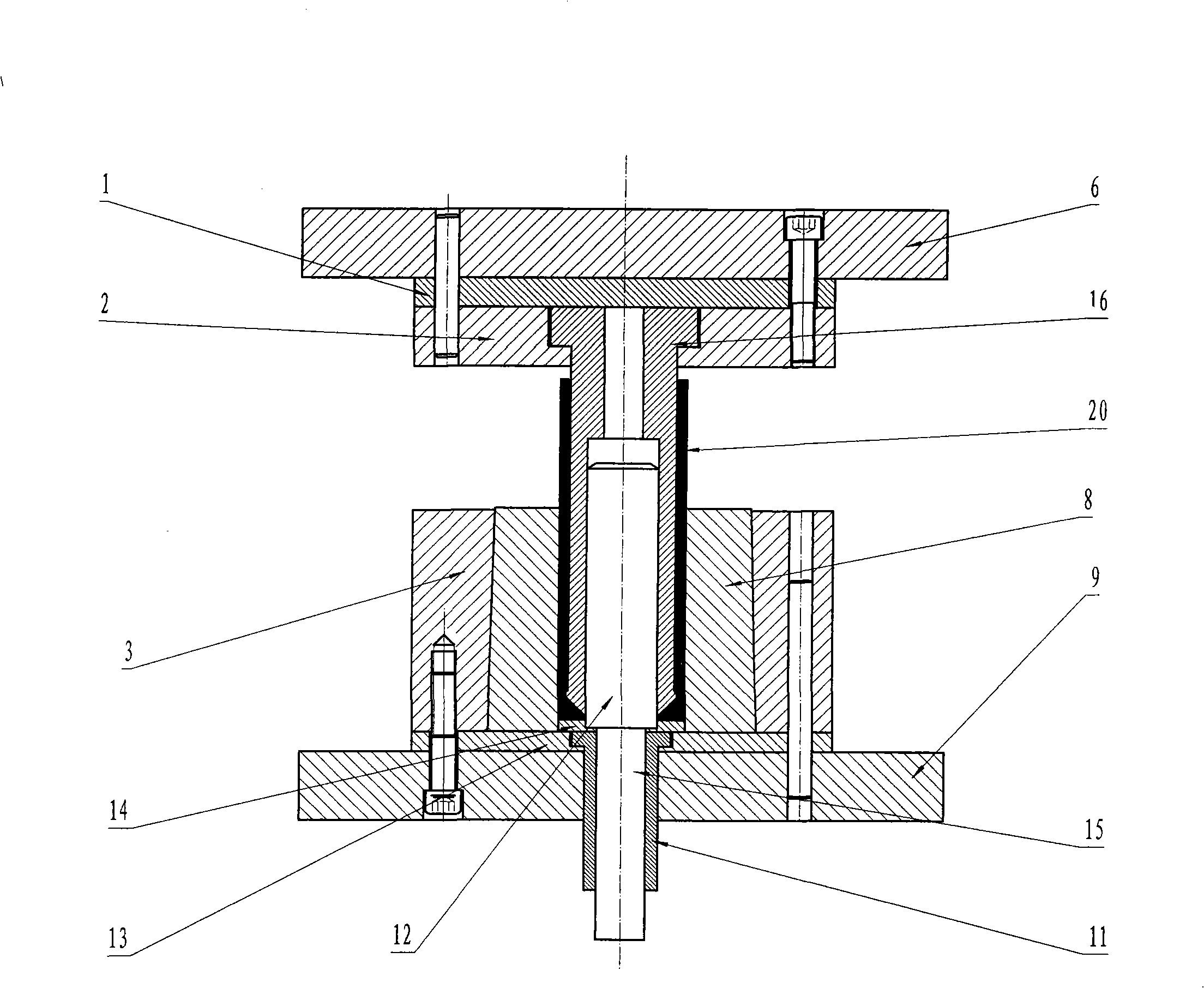

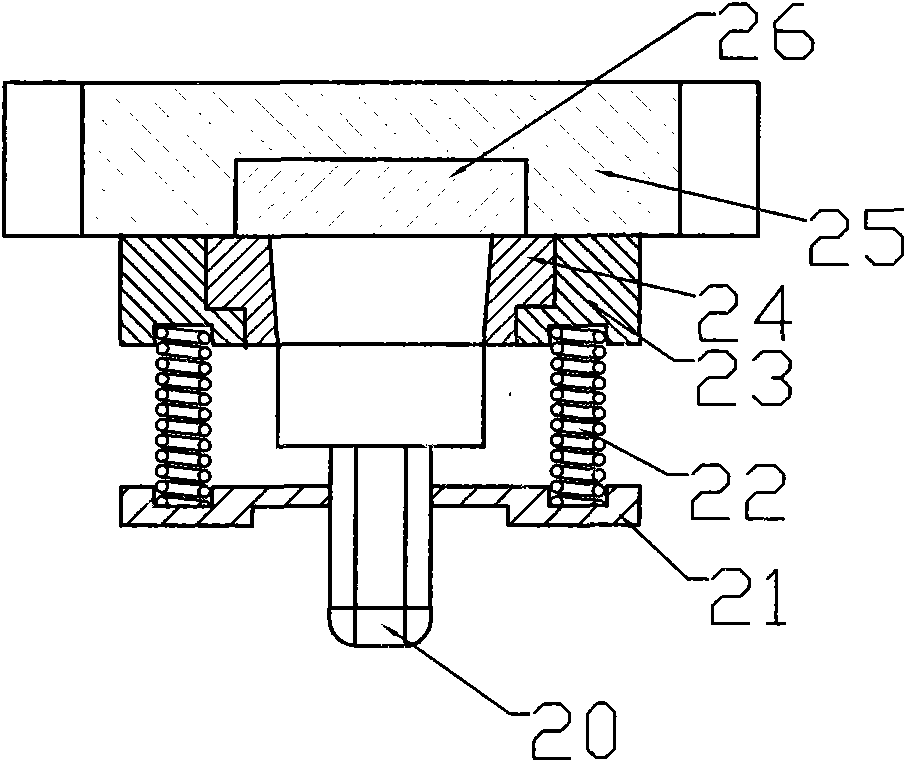

Manufacturing technology of automobile asymmetrical universal joint fork based on cold extruding technology and special mould thereof

InactiveCN101607274ADense tissueGrain refinementExtrusion diesManufacturing technologyUniversal joint

The invention discloses a manufacturing technology of automobile asymmetrical universal joint fork based on cold extruding technology, comprising the following steps: (1) a cylindrical bar stock is adopted for shearing and blanking; (2) spheroidizing annealing is carried out on a blank so as to reduce blank rigidity, then oxide scale is removed by acid washing, and phosphating, saponification and lubrication treatment is carried out to obtain cylindrical blank; (3) direct-extrusion sealing shaping calibration is carried out to extrude and shape the cylindrical blank so as to obtain the needed asymmetrical shape of the bottom half of the universal joint fork; (4) extruded pieces obtained after direction extrusion are performed with spheroidizing annealing, then oxide scale is removed by acid washing and phosphating, saponification and lubrication treatment is carried out; and (5) backward-extrusion shaping is carried out: furcation is formed by backward extrusion, and the furcation of the universal joint fork freely extends upwards; the redundant parts of the furcation end surface are processed and cut off by a successor. The invention also provides a special mould for realizing the manufacturing technology. The invention improves material utilization factor, has high production efficiency, improves production environment, and has high precision of workpiece size and favourable surface quality.

Owner:ZHEJIANG UNIV OF TECH

Seven-level adjustable reciprocating type electrorheological fluid damper

InactiveCN103591209AIncrease structural flexibilityLarge damping forceNon-rotating vibration suppressionLiquid based dampersThrottle controlApparent viscosity

A seven-level adjustable reciprocating type electrorheological fluid damper mainly comprises a positive-pole conducting wire, a negative-pole conducting wire, a positive-pole piston cylinder cover, a negative-pole piston cylinder cover, positive-pole conducting rubber, negative-pole conducting rubber, a piston rod, an insulating piston cylinder, a positive pole, a negative pole, a backflow control path, a small piston, a middle piston, a large piston and electrorheological fluid. The positive-pole conducting rubber and the negative-pole conducting rubber replace sealing materials and play a role in sealing and conducting. Installation forms of the small piston, the middle piston and the large piston are determined by borne damping force, wherein when the damping force is large, stress is not clear, and movement speed is high, the dual-piston or three-piston form is adopted; when the damping force is small, the single-piston form is adopted. The backflow control path replaces a throttling control valve, no external electric field exists, the electrorheological fluid bears the force and flows between the positive pole and the negative pole through the backflow control path, and the seven-level adjustable reciprocating type electrorheological fluid damper is a hydraulic damper; when an external electric field is applied and shearing efficiency is high, apparent viscosity of the electrorheological fluid of the backflow control path changes, the section area of the backflow control path becomes smaller, the backflow control path is even blocked completely, and the electrorheological fluid effectively controls an engineering system by proving shearing force and extruding force.

Owner:QINGDAO AGRI UNIV

Method for preparing magnesium alloy strip blank cogged by flat extruding cylinder

The invention relates to a preparation method for a magnesium alloy sheet strip plate for the cogging of a flat extruding cylinder; the preparation method includes the following steps: the position of the flat extruding cylinder and an extruding rod is adjusted to lead the central line of the extruding rod, the central line of the flat extruding cylinder and the central line of a die for a slab band to be arranged on the same line; an original flat section ingot is uniformly processed for 12 to 24 hours under the temperature of 400 to 420 DEG C after being processed by machine and milled; after being uniformly processed, the flat section ingot of the magnesium alloy is heated to the temperature of 400 to 430 DEG C and heat is preserved; simultaneously, the flat extruding cylinder and the die for the slab band is heated to the temperature of 400 to 430 DEG C and the heat is preserved for 6 hours; the flat section ingot of the magnesium alloy of the steps is fed into a channel of the flat extruding cylinder and enters the die for the slab band to extrude by the channel with a flat hole with the extruding speed of 1.5m / min to 5m / min, thus obtaining the strip plate of the magnesium alloy sheet with a rectangle section. The invention adopts an extruding device with a flat extruding cylinder; the processing method can be used for leading the deformation of magnesium alloy material to be uniform during the extruding process to obtain the magnesium alloy sheet strip plate with excellent anisotropy properties of a tissue.

Owner:CHONGQING UNIV

Multi-layer nuclear shell structural fluorin-containing polymer particle and thermoplastic polyolefin product having the same

ActiveCN101117393AReduce the number of crystal pointsHigh transparencySynthetic resin layered productsPolymer sciencePolyolefin

The present invention relates to a fluorin-containing polymer granule with multilayer core shell structure and thermoplastic polyolefin products. The gross weight of the fluorin-containing polymer granule include: a) 20 to 80 percent by weight of fluorin-carbon polymer core materials; b) 5-30 percent by weight of intermediate-layer of acrylate copolymer, methacrylate copolymer, or their compounds; c) 15-50 percent by weight of polymer outer layer with melting point at 50-100 DEG C; The average granular diameter of fluorin-containing polymer granules is 0.1-10 mm. Fluorin-contain polymer granules of the present invention, being added with thermoplastic polyolefin melt, can be not only dispersed evenly but significantly improve critical shear rate and obviously speed up the time for the removal of melt rupture; thereby reducing surface defects of extruded products and improving transparency of thin film.

Owner:GUANGZHOU SHINE POLYMER TECH

Multi-purpose double-roll continuous rheological forming device for liquid metal

InactiveCN101690941AIncrease productivitySolve low production efficiencyMetal rolling arrangementsLiquid stateCoupling

The invention discloses a multi-purpose double-roller continuous rheological forming device for liquid metal, which is mainly used for double-roller continuous rheological forming of plates, strips, pipes, profiles, wires, composite materials and wrapping materials. The device consists of a motor, a half coupling, a decelerator, a gear box, a main machine, a cooling water tank and a coiling machine, wherein the main machine consists of a stander, an upper working roller, a lower working roller, a feeding shoe, an extrusion shoe, a die in a cavity of the extrusion shoe, and rotating speed sensors at shaft heads of the upper working roller and the lower working roller of the main machine. An annular groove of the upper working roller is mutually matched with an annular lug boss of the lower working roller. The feeding shoe is arranged at the feeding end of the main machine, and the feeding shoe and the annular groove of the upper working roller form a feeding cavity. A metal material enters into a roller gap between the two working rollers through the feeding cavity. When producing pipes, profiles, wires and wrapping materials, the extrusion shoe is arranged at the discharging end of the main machine, and an extrusion forming die can be arranged in the cavity of the extrusion shoe. The device can realize quick continuous rheological forming of the liquid metal, and can also be used for direct forming of a semi-solid metal material.

Owner:NORTHEASTERN UNIV

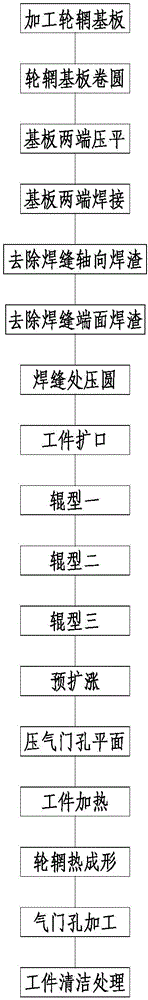

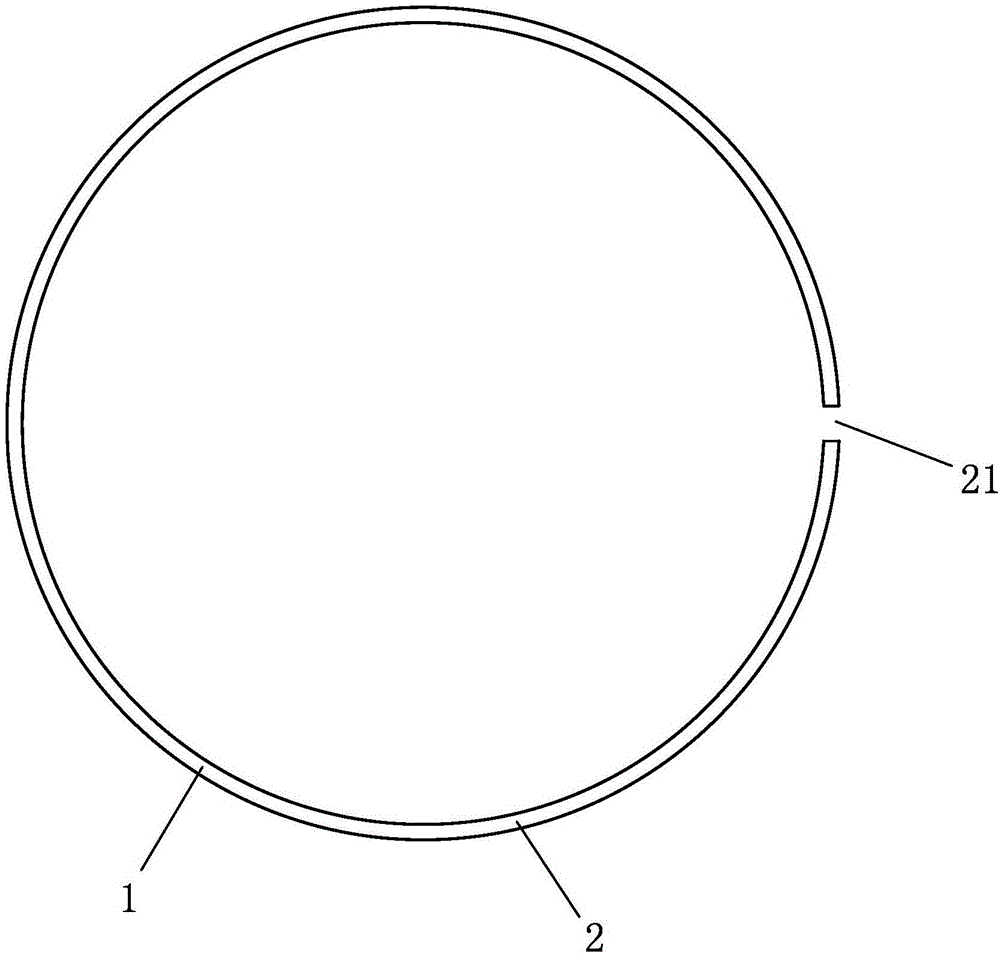

Manufacturing method of hot forming rim

ActiveCN106363353ANot prone to crackingAvoid deformationVehicle componentsEngineeringMechanical engineering

The invention relates to a manufacturing method of a hot forming rim. The manufacturing method comprises following manufacturing steps of A1, rim round pipe forming, wherein a metal plate is used for manufacturing a closed round pipe with the closed circumferential direction; A2, rim workblank forming, wherein the closed round pipe is manufactured into a rim workblank with the diameter smaller than the rim designed diameter; A3, rim workblank pre-expanding, wherein the rim workblank is subject to pre-expanding, and the diameter of the expanded rim reaches 99.5% to 99.9% of the designed diameter; A4, rim workblank heating, wherein the rim workblank is heated to the designed temperature; A5, expansion finishing, wherein through the expansion manner, the diameter of the workblank reaches the designed size; A6, stamping and hardening, wherein the strength of the rim workblank is improved to above 1300MPa. Before heating, pre-expanding is carried out, the expansion amount during hot forming is reduced, the size precision of the rim is improved, and the expanding traces are reduced; the precision of out-of-roundness of the rim is improved; after heating, the manner of expansion finishing and stamping and hardening is adopted, and the forming precision and the forming strength are more effectively improved.

Owner:ZHEJIANG JINGU CO LTD

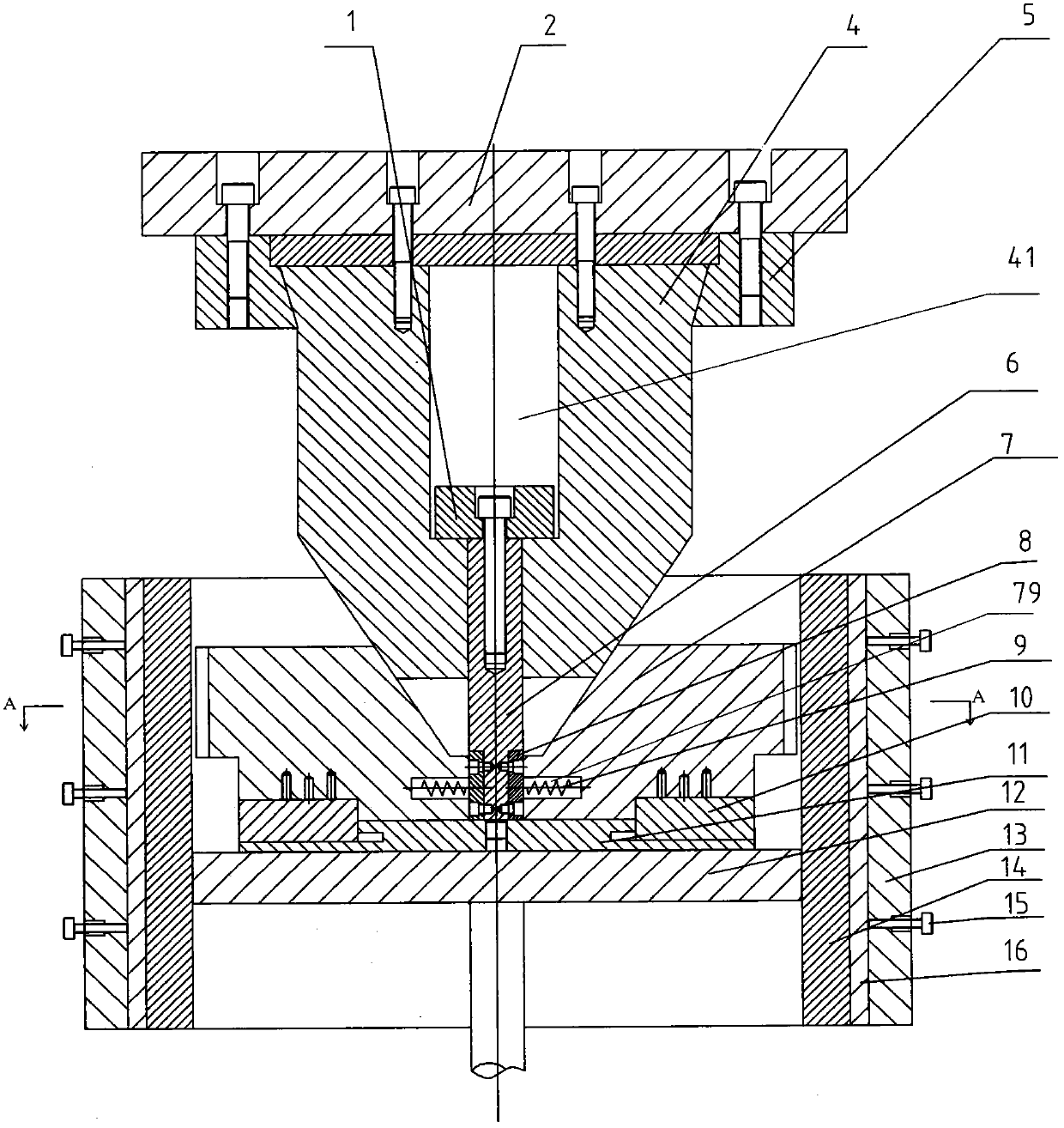

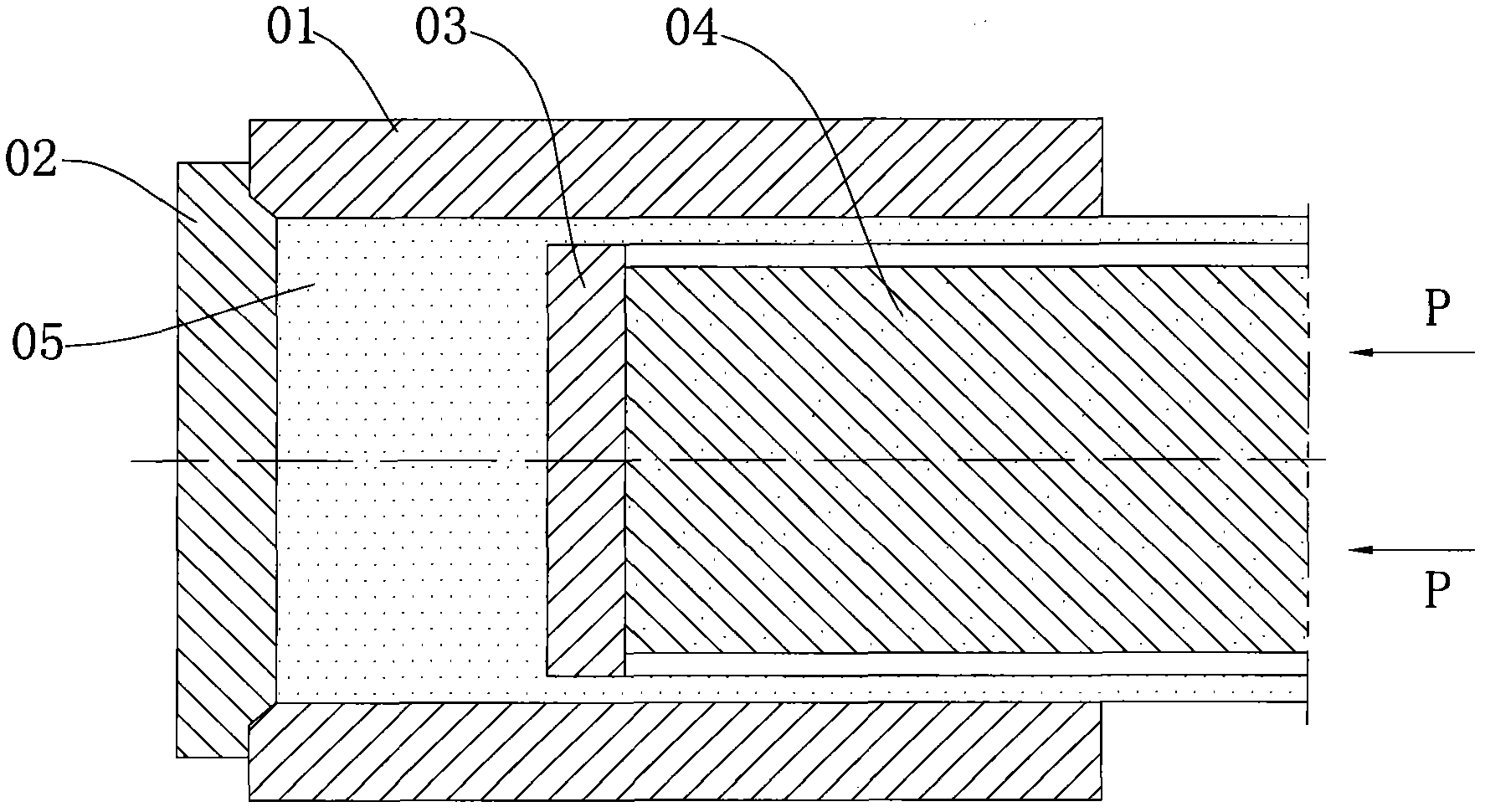

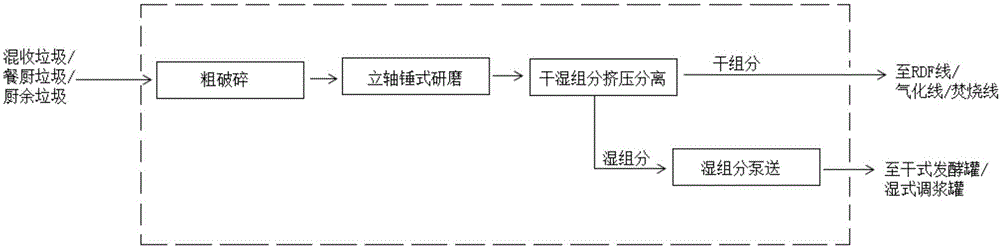

Reverse dual-powered pipe extrusion device and reverse dual-powered pipe extrusion method thereof

The invention discloses a reverse dual-powered pipe extrusion device and a reverse dual-powered pipe extrusion method thereof, the extrusion device comprises a frame sliding rail, a main extrusion cylinder having an extrusion choke plug, an extruding container and a moving die holder having an extrusion die shaft, the main extrusion cylinder, the extruding container and the moving die holder are orderly installed on the frame sliding rail and can axially move along the same; the main extrusion cylinder is internally provided with a punching tank on which punching needles are installed, one end of the extrusion die shaft corresponding to the extruding container is provided with an extrusion die, the punching tank drives the punching needles to penetrate out from the centre of the extrusionchoke plug so as to push an ingot blank out of the extruding container and finish ingot blank punching; in an extrusion process, under the driving of the main extrusion cylinder, the extrusion choke plug pushes the extruding container and the ingot blank to move towards the extrusion die, the punching needles and the extruding container moves synchronously, and the extrusion choke plug is matchedwith the extrusion die to implement reverse extrusion of the ingot blank in the extrusion container; compared with a traditional single-powered extrusion device, the reverse dual-powered pipe extrusion device of the invention has the advantages of high flexibility and convenient and quick die exchange process.

Owner:ZHEJIANG HAILIANG

Foldable backboard structure and display device

InactiveCN109545087AReduce extrusion pressureEnhanced fold recoveryIdentification meansBackplaneEngineering

The invention discloses a foldable backboard structure and display device. The foldable backboard structure comprises a backboard, the backboard comprises a folding area and non-folding areas which are located on the two sides of the folding area, and a micro structure is arranged on the part, close to one side of a displaying layer, of the folding area; an elastic component is included, and the elastic component is arranged on the side, away from the displaying layer, of the folding area. According to the display device, by arranging the micro structure on the side, close to the displaying layer, of the backboard folding area, the squeezing force on other membrane layers by the inner surface of the backboard is reduced in the state where a screen is folded inwards, waves are reduced, theelastic component is arranged on the side, away from the displaying layer, of the folding layer, a display screen of the foldable display device can be pulled to reach a flat state by using better deformation restoring capability of the elastic component, and the folding restoring capability of the foldable display device is enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Continuous extrusion method of stacked assembling die with reversed cone angle and equipment

InactiveCN101607271AReduce manufacturing costReduce the temperatureExtrusion diesEngineeringEnergy expenditure

The invention relates to a metal continuous extrusion method, in particular to a continuous extrusion method of a stacked assembling die with a reversed cone angle. The height of the die assembly of the related die with a reversed cone angel is not changed, after blank material enters the die assembly, the sectional area of an extrusion product is maximally nine times larger than that of the blank material, and the height of the die with a reversed cone angle is shortened as much as possible. In the invention, the extrusion force and energy consumption in extrusion are reduced to the greatest extent in the condition of guaranteeing a required size of expanding extrusion, product quality and product forming. The die has a reversed cone angle, and the reversed cone angle can increase the lateral spreading flowing capacity of the blank material in the die. The range of the size of a product produced in a cavity with the same specification is enlarged greatly, and a product with a larger size can be produced by a small machine, so that the service life and the production efficiency of the cavity are improved greatly, and the product with the same size produced by the method consumes less electric energy.

Owner:大连康丰科技有限公司

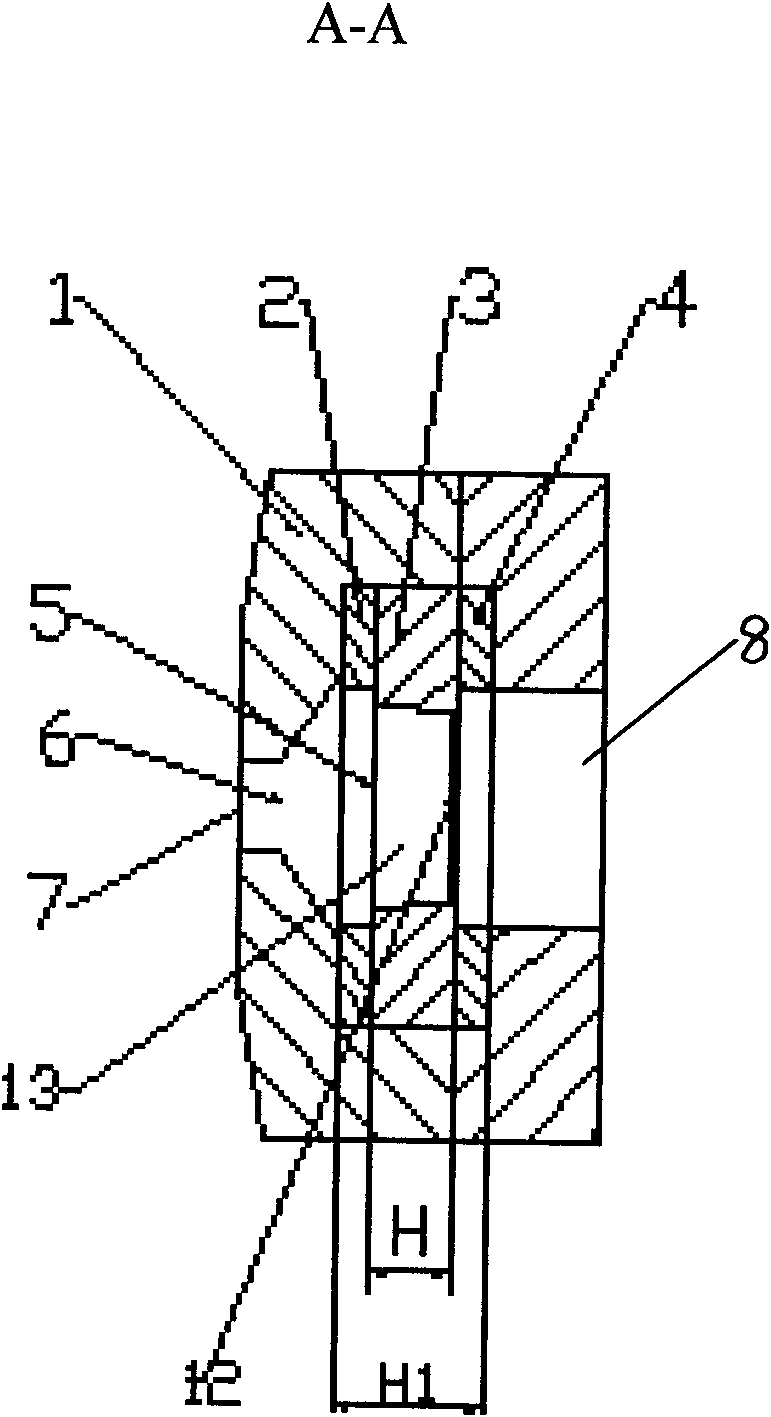

Mechanical pretreatment system and process for municipal domestic waste comprehensive treatment

ActiveCN106734083AEnable co-processingAdvanced principleSolid waste disposalGrain treatmentsAdditive ingredientOrganic matter

The invention discloses a mechanical pretreatment system for municipal domestic waste comprehensive treatment (marsh production). The system comprises a coarse crushing unit, a vertical shaft hammer type grinding unit and a dry-wet component extrusion and separation unit which are arranged in sequence. The units are sequentially connected through a conveying machine. The invention further discloses a mechanical pretreatment process for municipal domestic waste comprehensive treatment adopting the mechanical pretreatment system. The process comprises the process steps of coarse crushing, vertical shaft hammer type grinding and dry-wet component extrusion and separation. The technical defects that organic matter separation efficiency is low and the impurity content is high according to existing domestic waste comprehensive treatment mechanical pretreatment are overcome, the waste receiving adaptability is high, the equipment integration degree is high, continuous stable operation is achieved, various kinds of domestic waste with complex ingredients are used as raw materials, dry and wet components are produced to meet different follow-up technological requirements, coordinated treatment of various kinds of municipal domestic waste is achieved, and the system and the process are suitable for being applied and popularized.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com