Continuous extrusion machining device used for magnesium alloy sheet strip with weak basal texture and extrusion machining method

A technology of extrusion processing and magnesium alloys, applied in the direction of metal extrusion dies, etc., can solve the problems of restricting the use range of reinforced magnesium alloys, strict equipment tonnage requirements, and difficulty in industrial production, etc., to achieve good large-scale application prospects and reduce Equipment tonnage requirements, the effect of easy extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

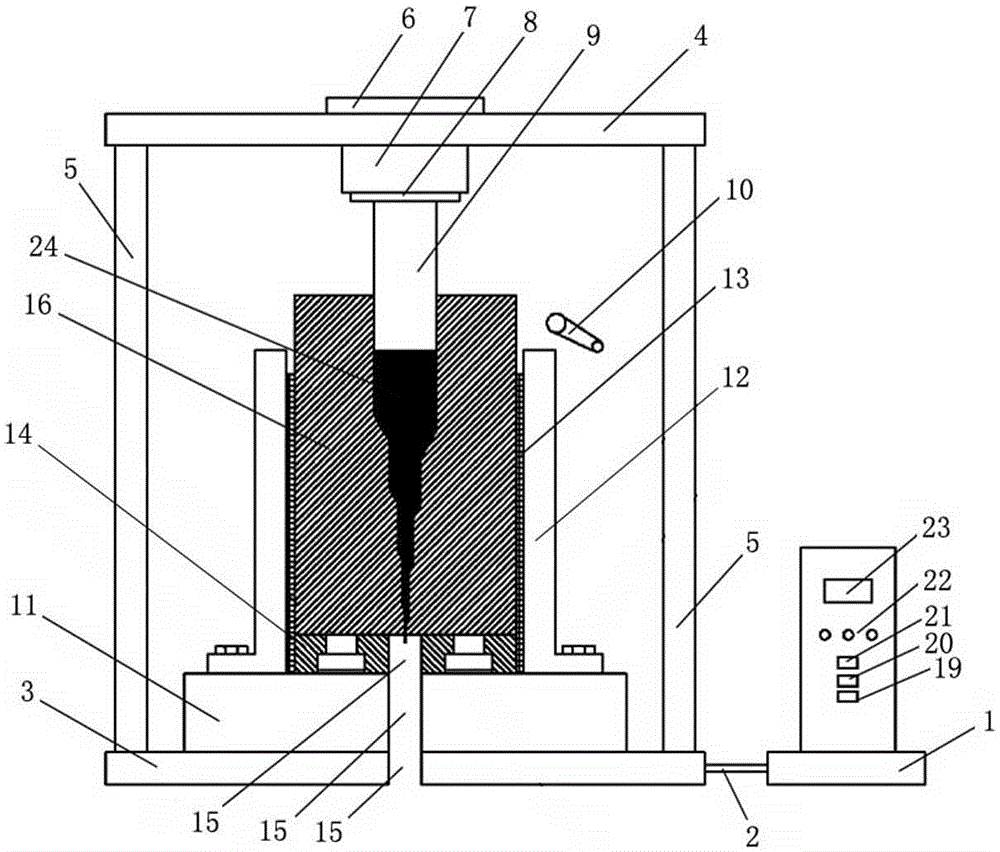

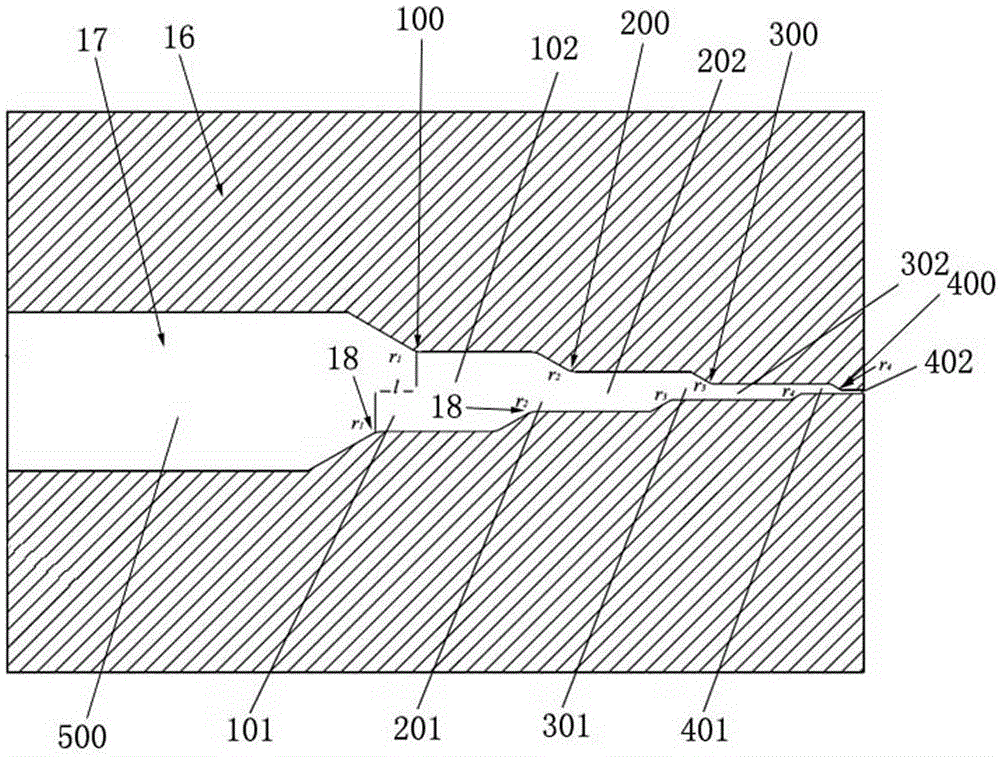

[0033] Such as figure 1 As shown, a continuous extrusion processing device for magnesium alloy sheet strip with weak base surface texture includes an extrusion system and an electric control box 1. The electric control box 1 is connected to the extrusion system through a wire 2 and is used to control extrusion. Various actions of the pressing system; the pressing system includes a base 3, a top seat 4 and a column 5 fixed between the base 3 and the top seat 4; a pressure motor 6 is installed at the center of the top seat 4, and the pressure motor 6 The bottom is connected with an extruding telescopic ram 7, and the bottom end of the extruding telescopic ram 7 is connected with a briquetting block 8, and the bottom of the briquetting block 8 is connected with a cylindrical punch die 9, and a control extruder is installed on the column 5. The lifting handle 10 that compresse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com