Patents

Literature

129 results about "Asymmetric distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

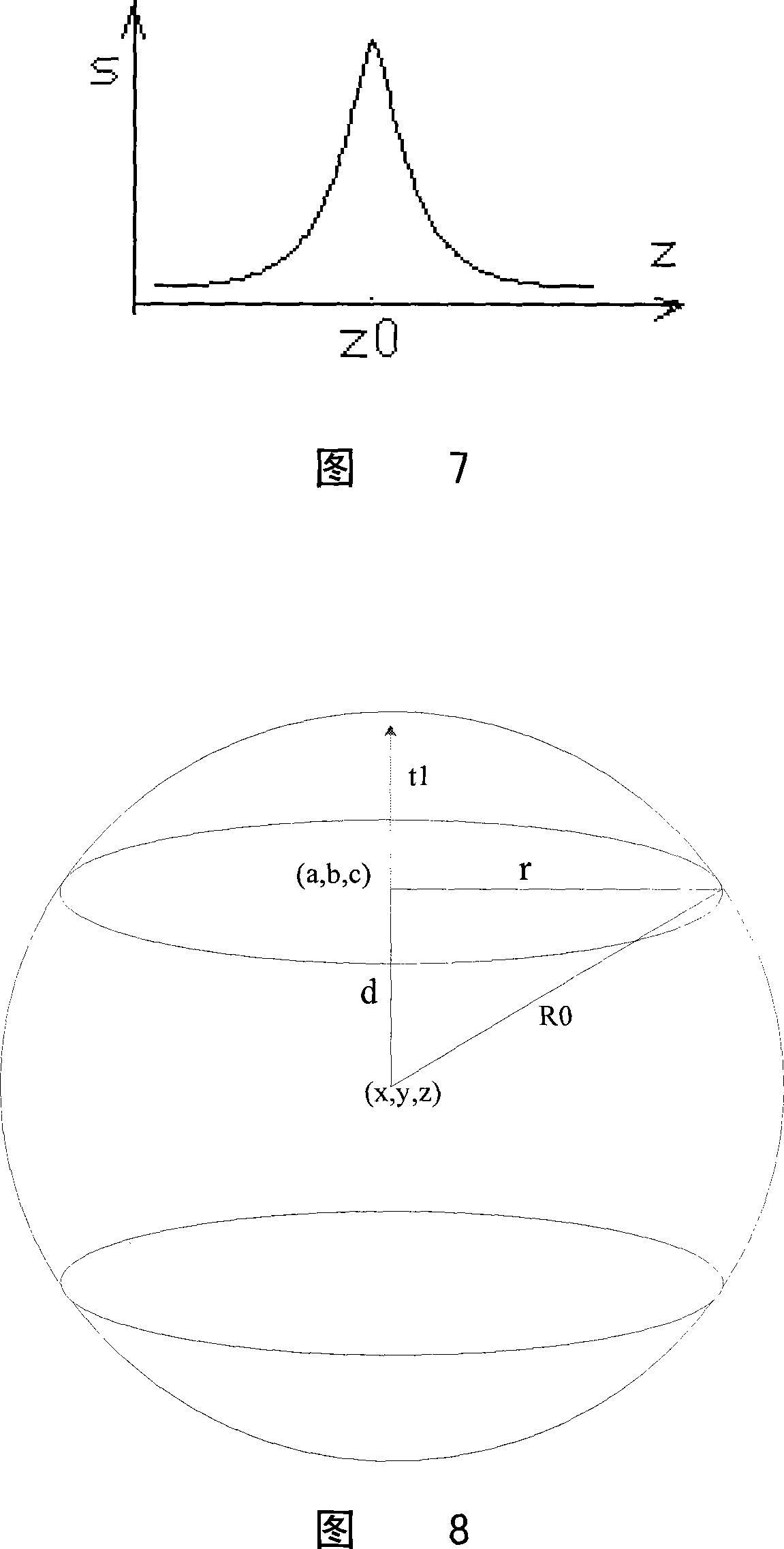

Asymmetrical distribution is a situation in which the values of variables occur at irregular frequencies and the mean, median and mode occur at different points. An asymmetric distribution exhibits skewness.

Electrochemical Analyte Detection Apparatus and Method

InactiveUS20090026075A1Easy to useLow costImmobilised enzymesBioreactor/fermenter combinationsRedox enzymesAnalyte

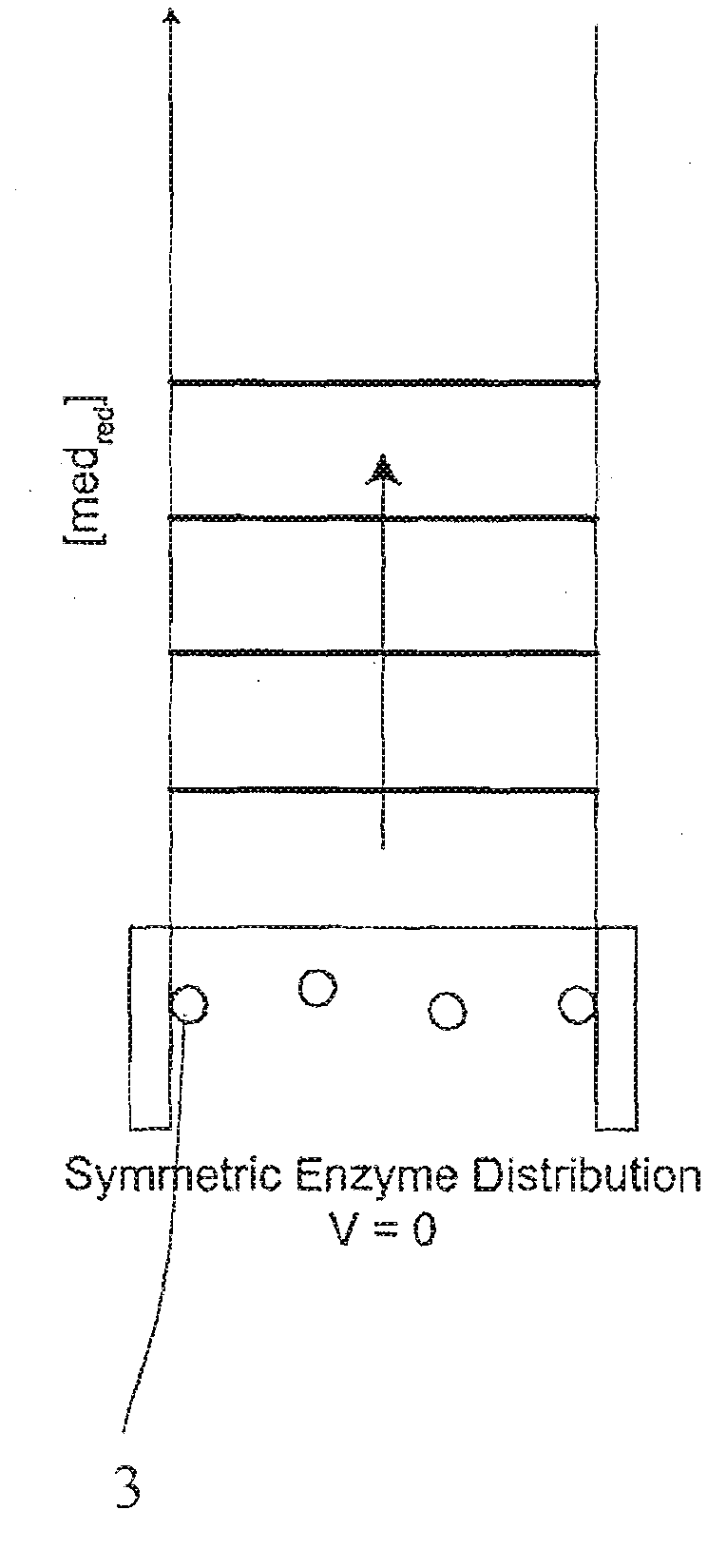

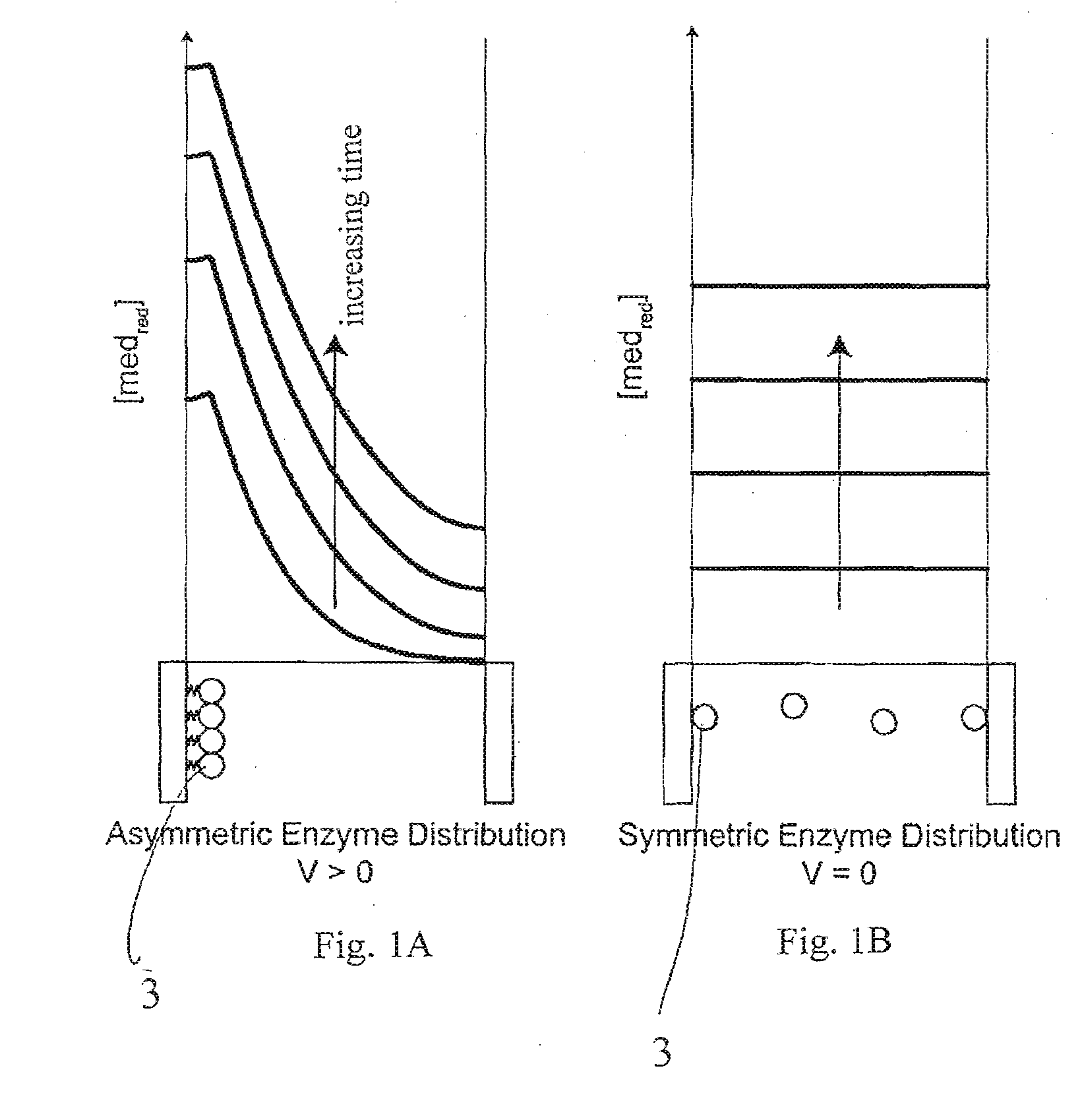

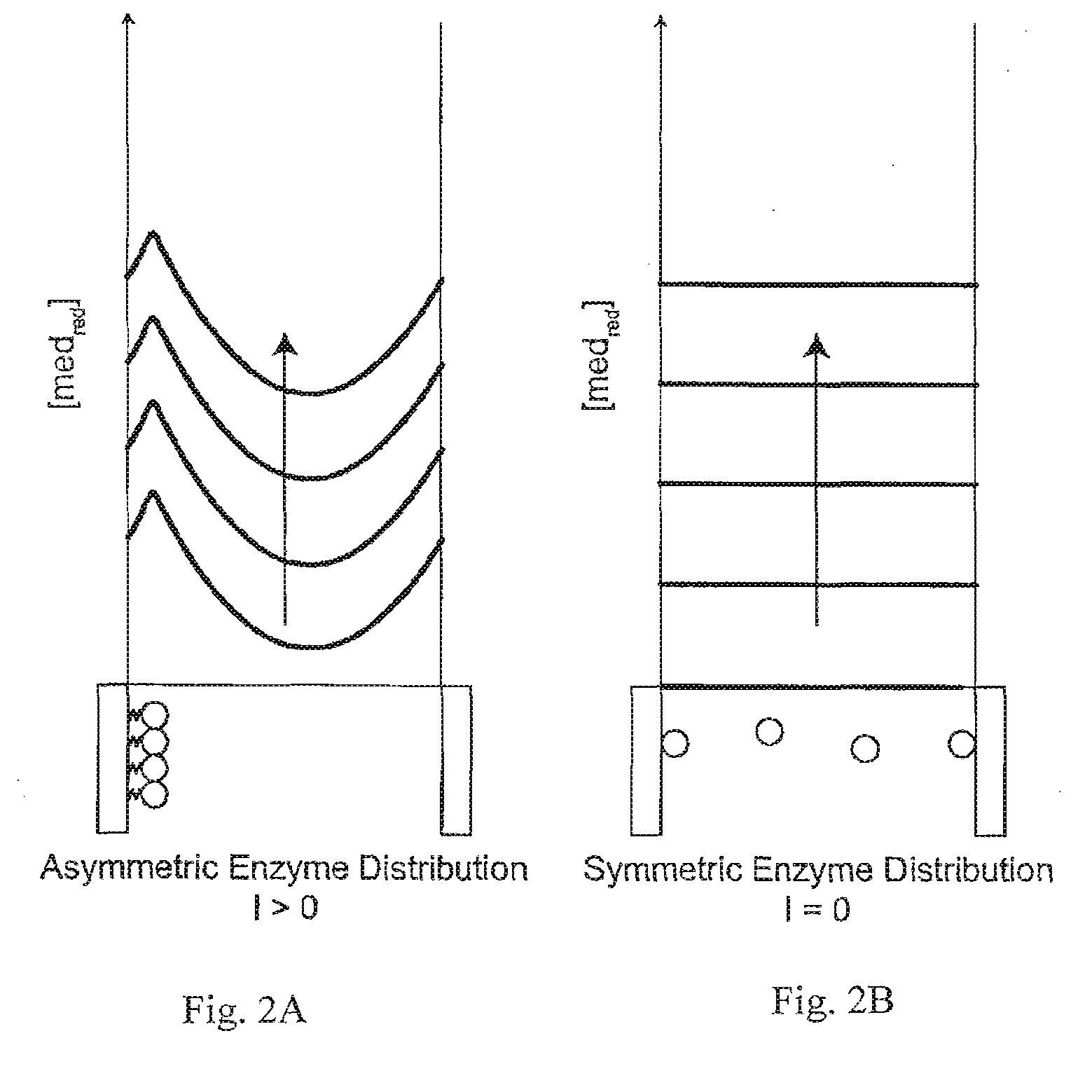

A method and apparatus for electrochemical detection of analyte in a sample makes use of a binding interaction and relies on the discovery that asymmetric distribution of a redox enzyme between two electrodes that occurs when a redox enzyme-containing reagent is immobilized at the surface of one electrode can be detected as a chemical potential gradient arising from an asymmetry, in the distribution of oxidized or reduced redox substrate. This chemical potential gradient can be detected potentiometrically by observing the potential difference between the electrodes in an open circuit, or amperometrically by observing the current flow between the electrodes when the circuit is closed. In both cases, the observation of asymmetry can be done without the application of an external potential or current to the electrodes.

Owner:AGAMATRIX INC

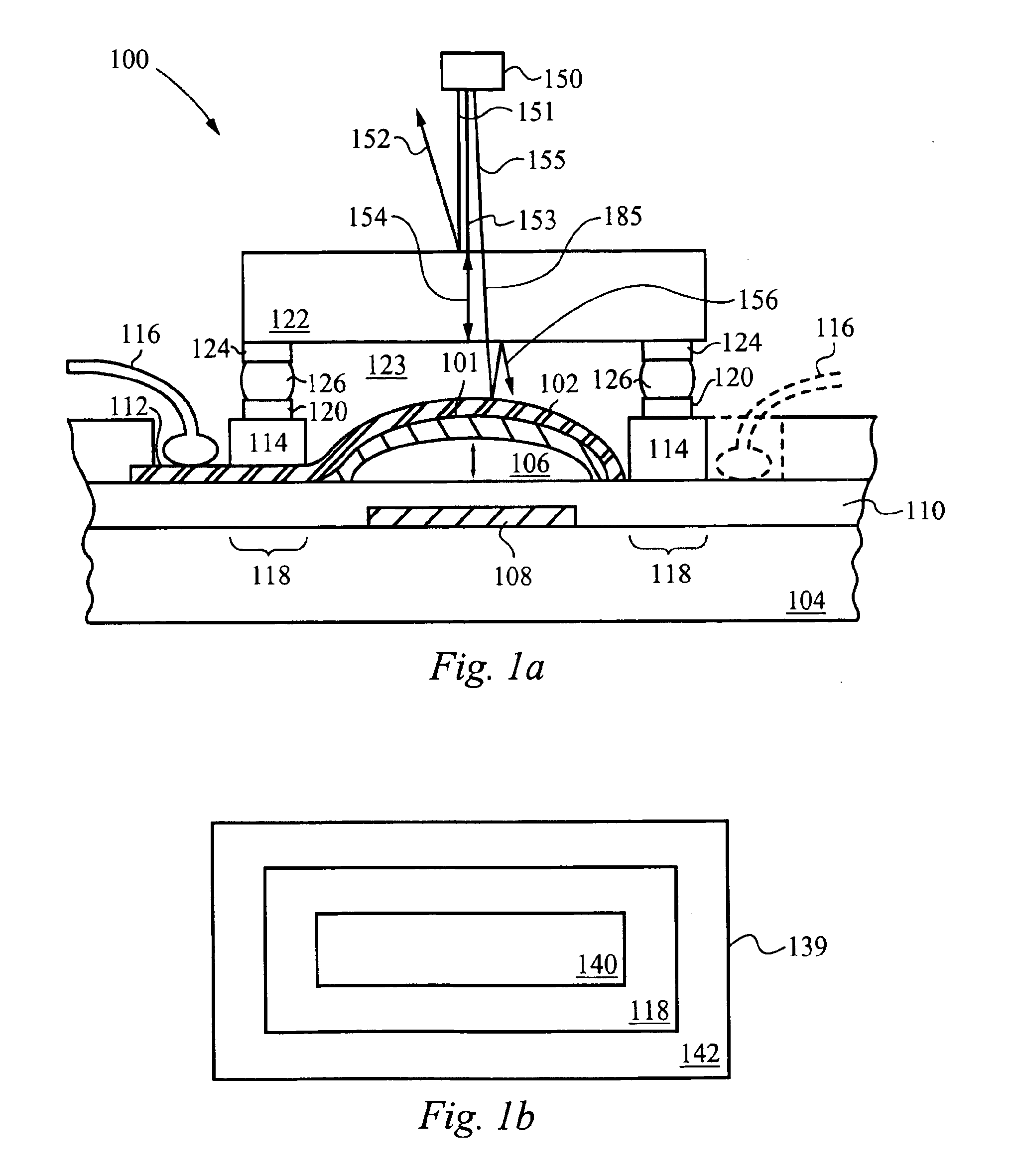

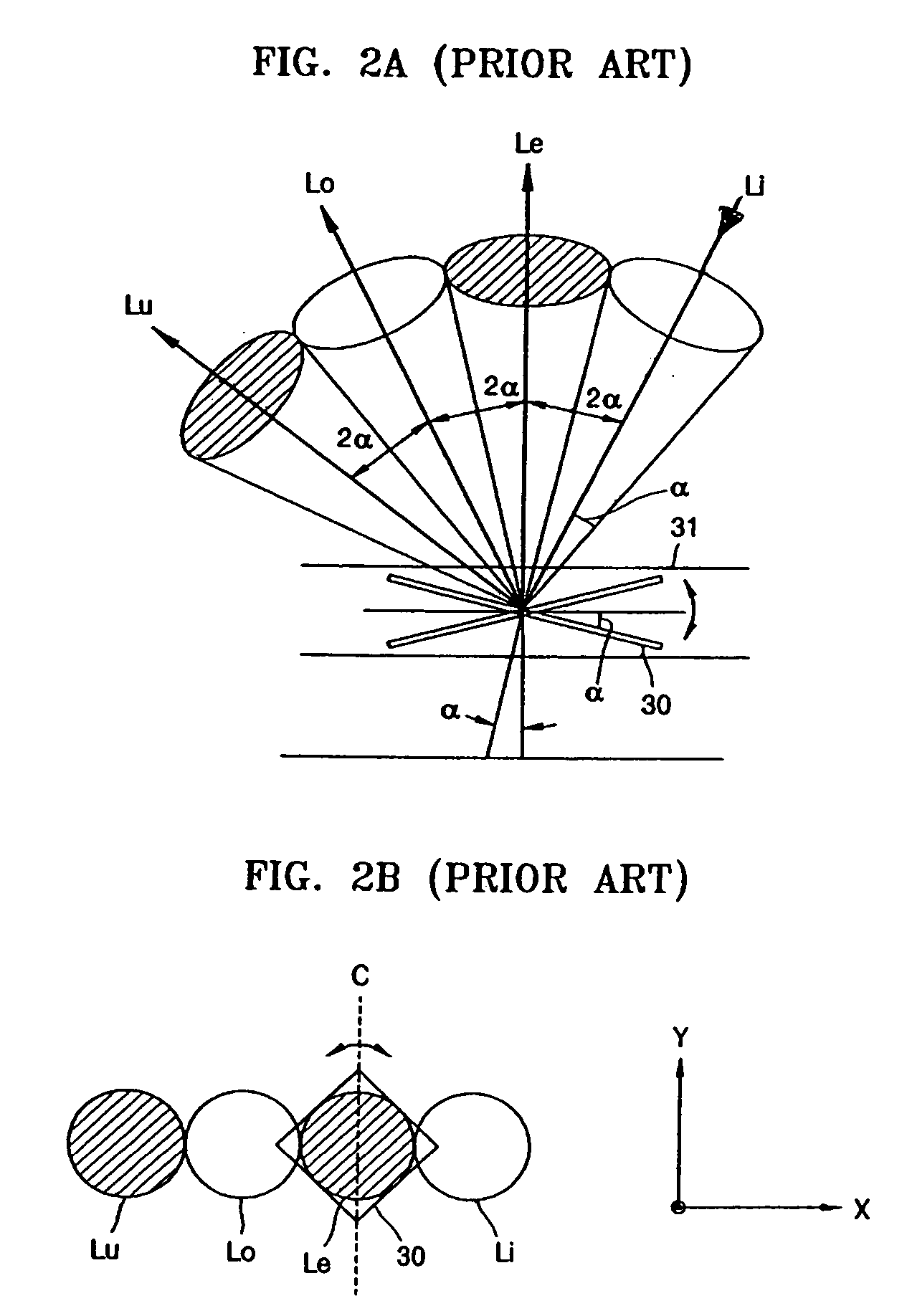

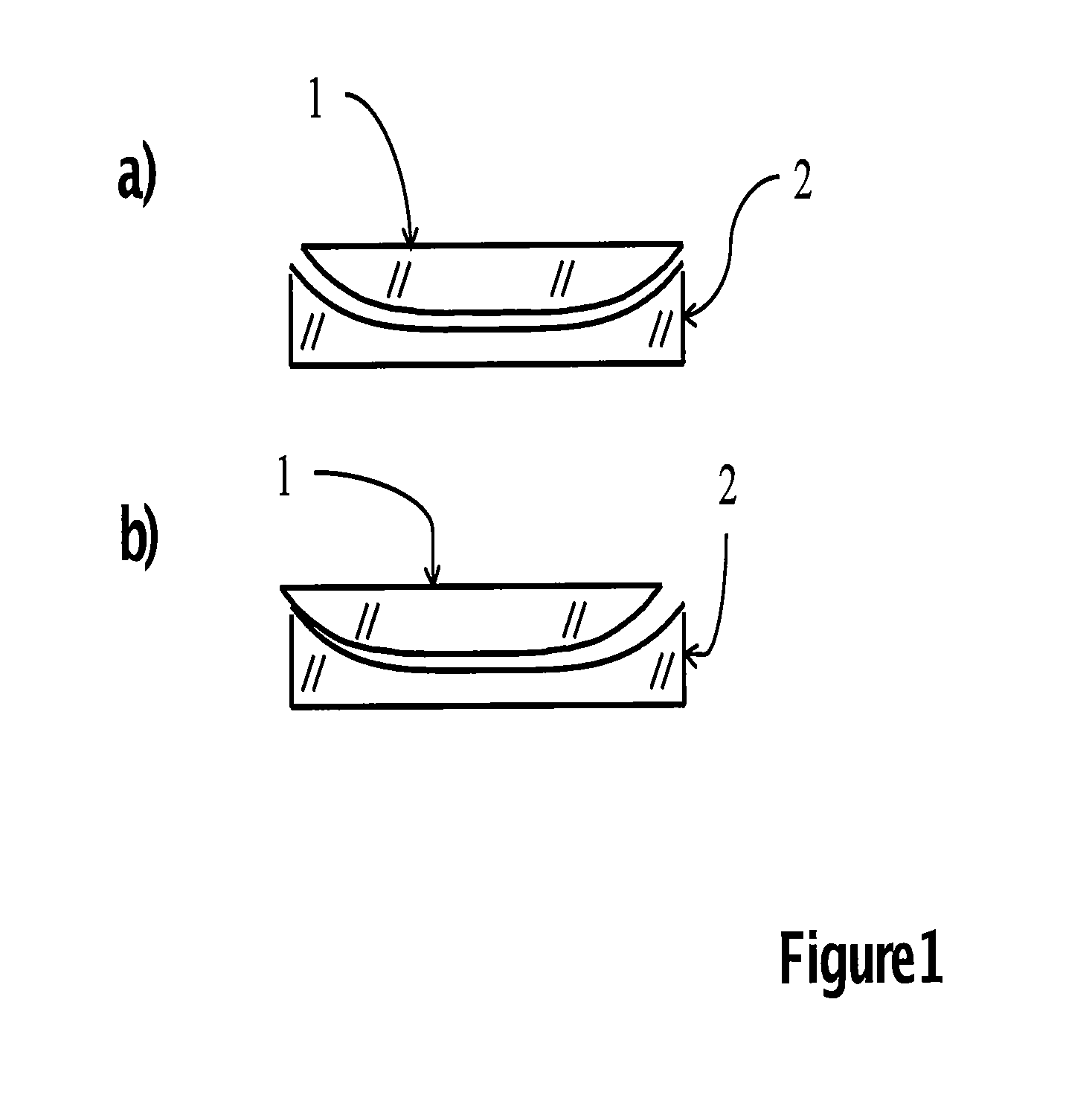

Method of sealing a hermetic lid to a semiconductor die at an angle

InactiveUS6872984B1Reduce Optical InterferenceSemiconductor/solid-state device detailsSolid-state devicesHermetic sealAsymmetric distribution

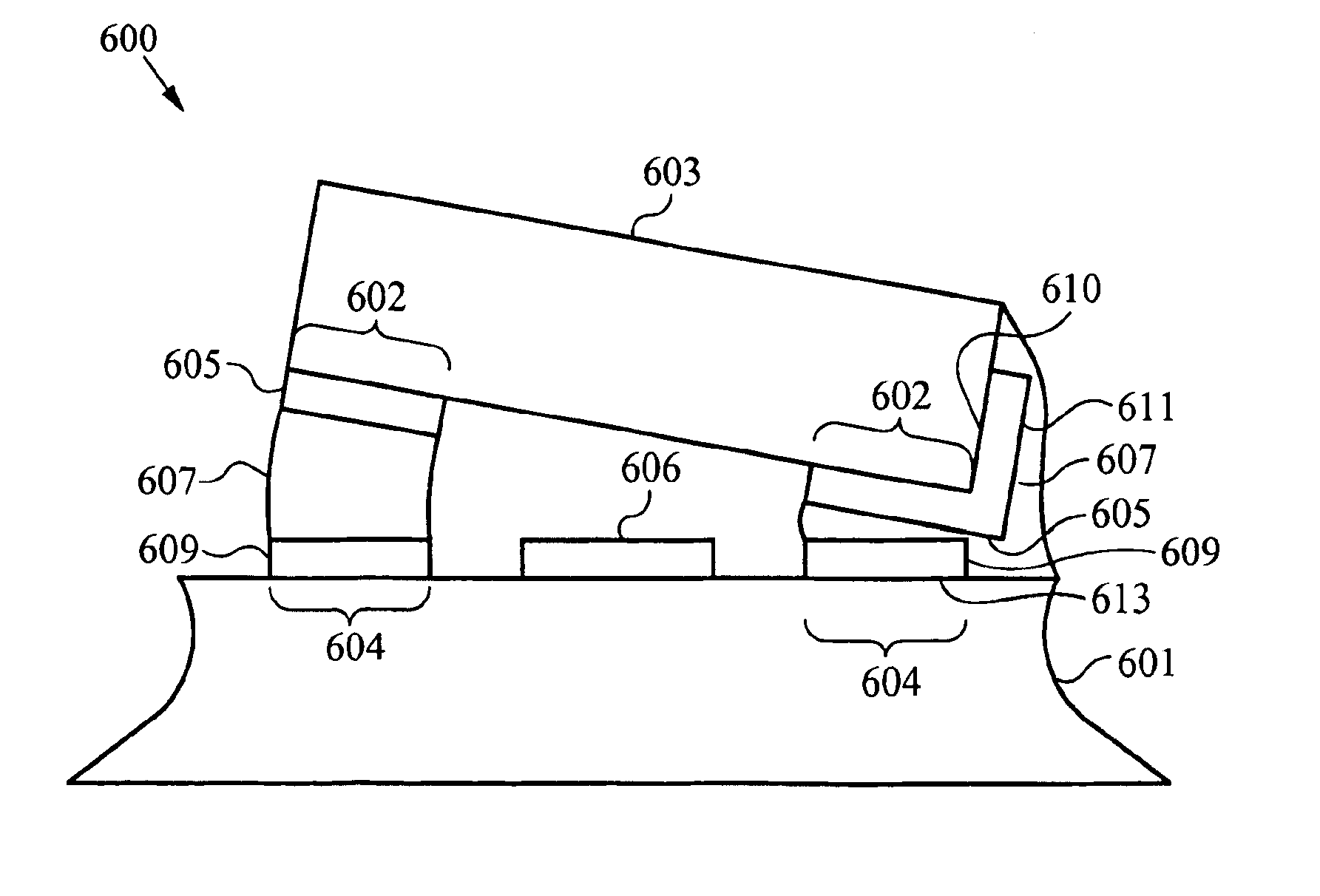

The current invention provides a optical MEM device and system with an angled lid for hermetically sealing an active MEMS structure. The lid is sealed through an asymmetric seal formed with sealing rings having an asymmetric distribution of solder wetting surfaces which tilts the lid, when the lid and a substrate are soldered together. The asymmetric distribution wetting surfaces can be provided by forming one or more edge features, by patterning portions of the sealing rings or both. Preferably, the lid is transparent to one or more wavelengths of light in a range of 300 to 3000 Angstroms and hermetically seals a grating light valve structure having a plurality of movable ribbon for modulating light through the lid.

Owner:SILICON LIGHT MACHINES CORP

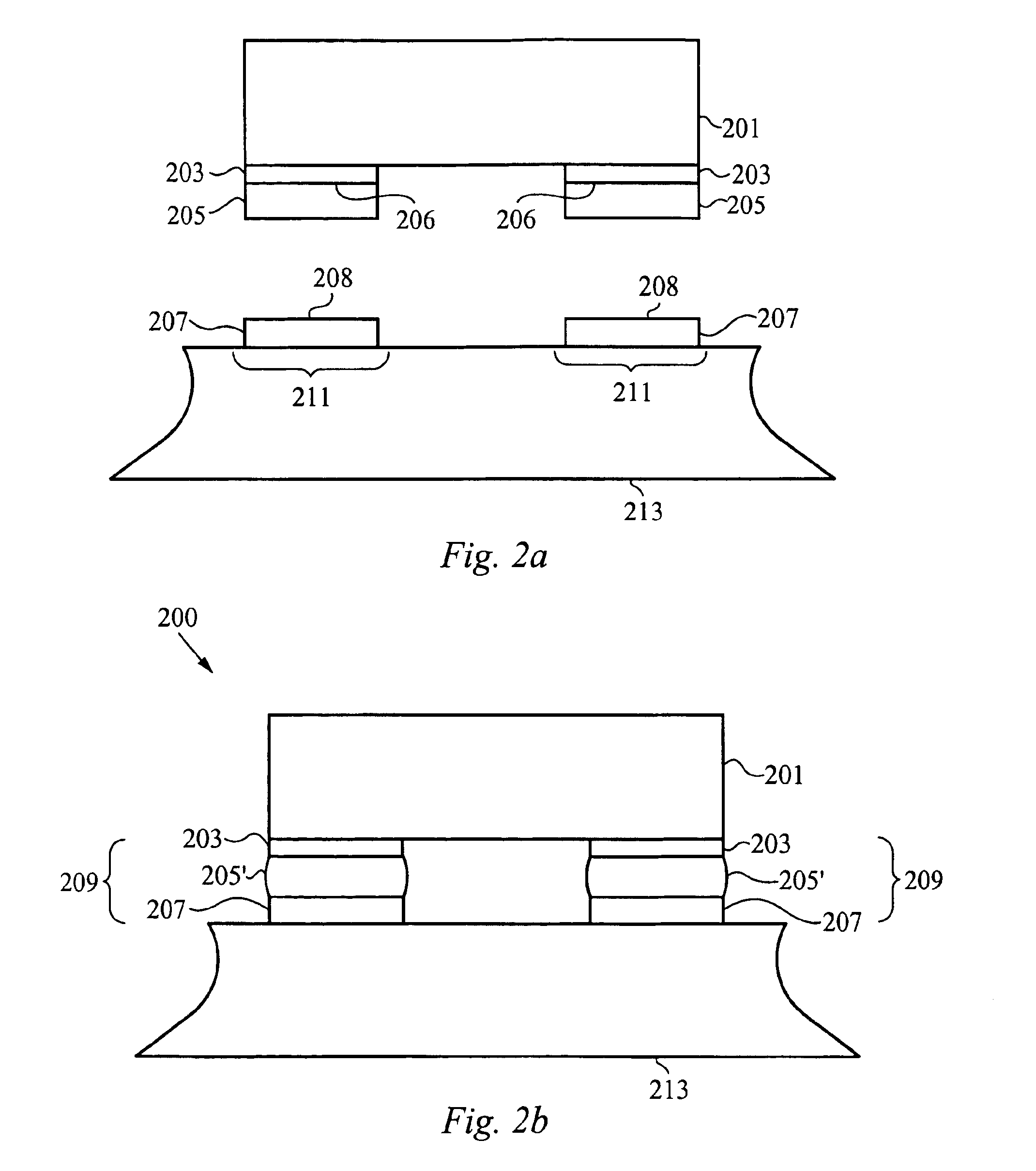

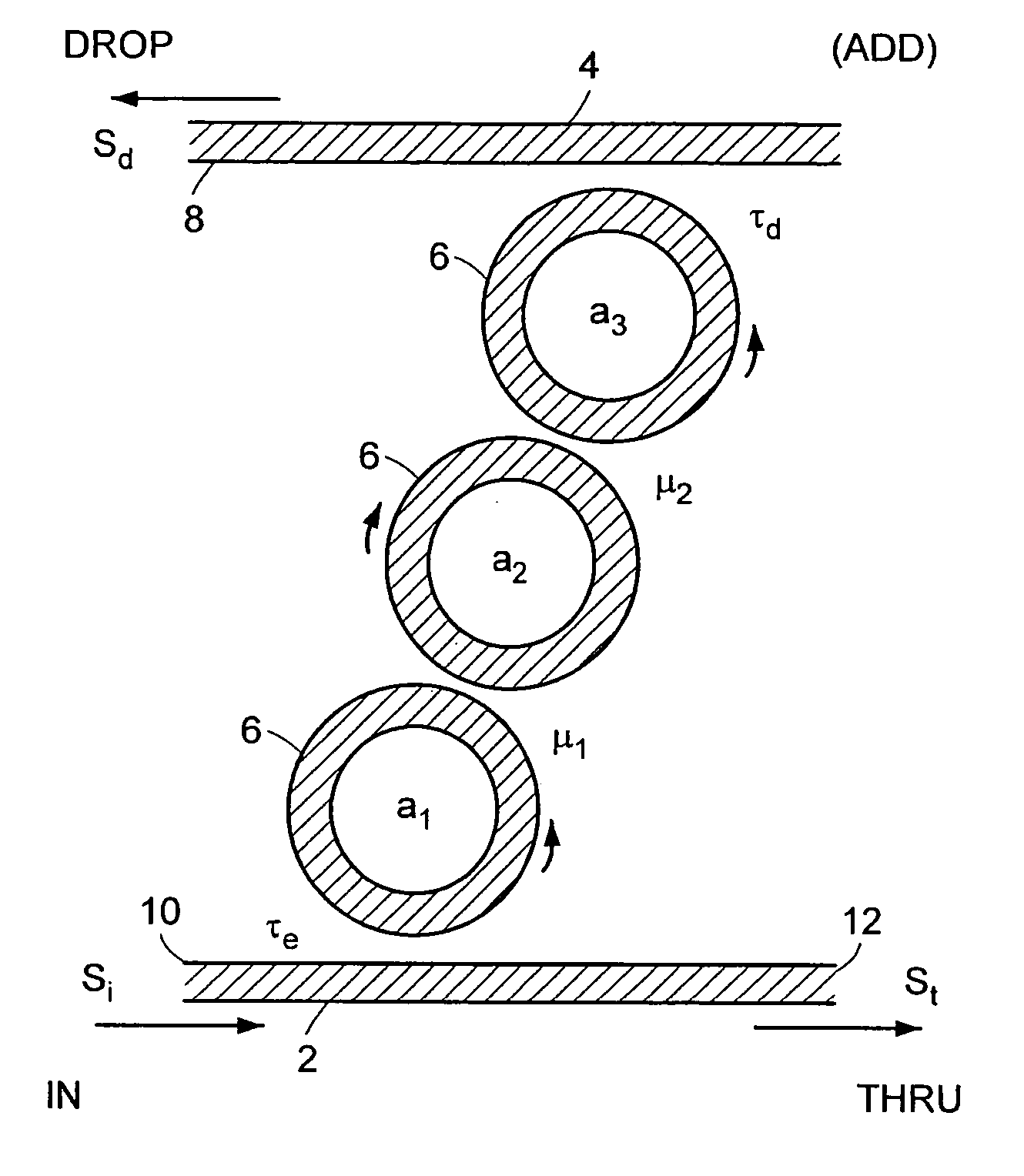

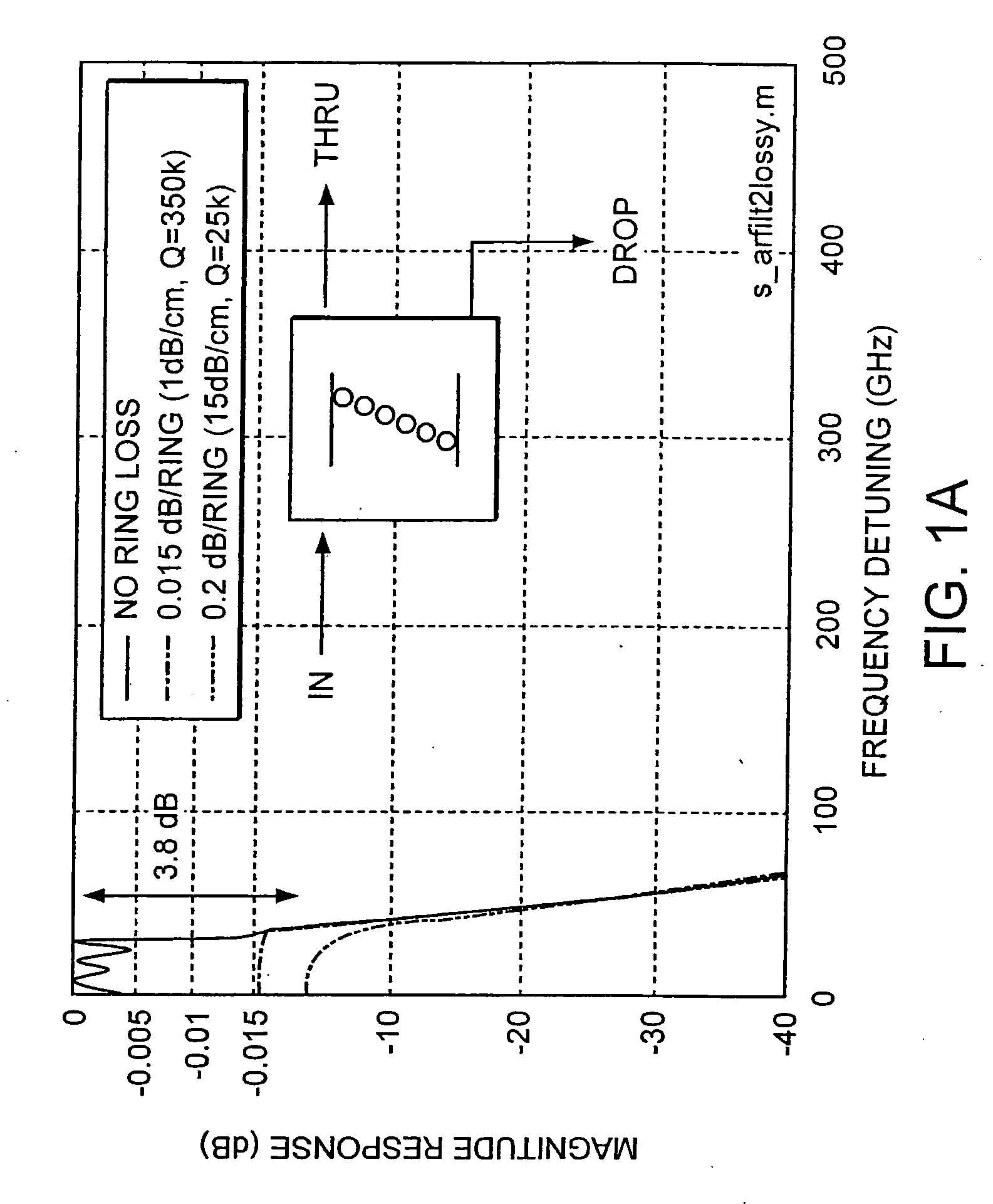

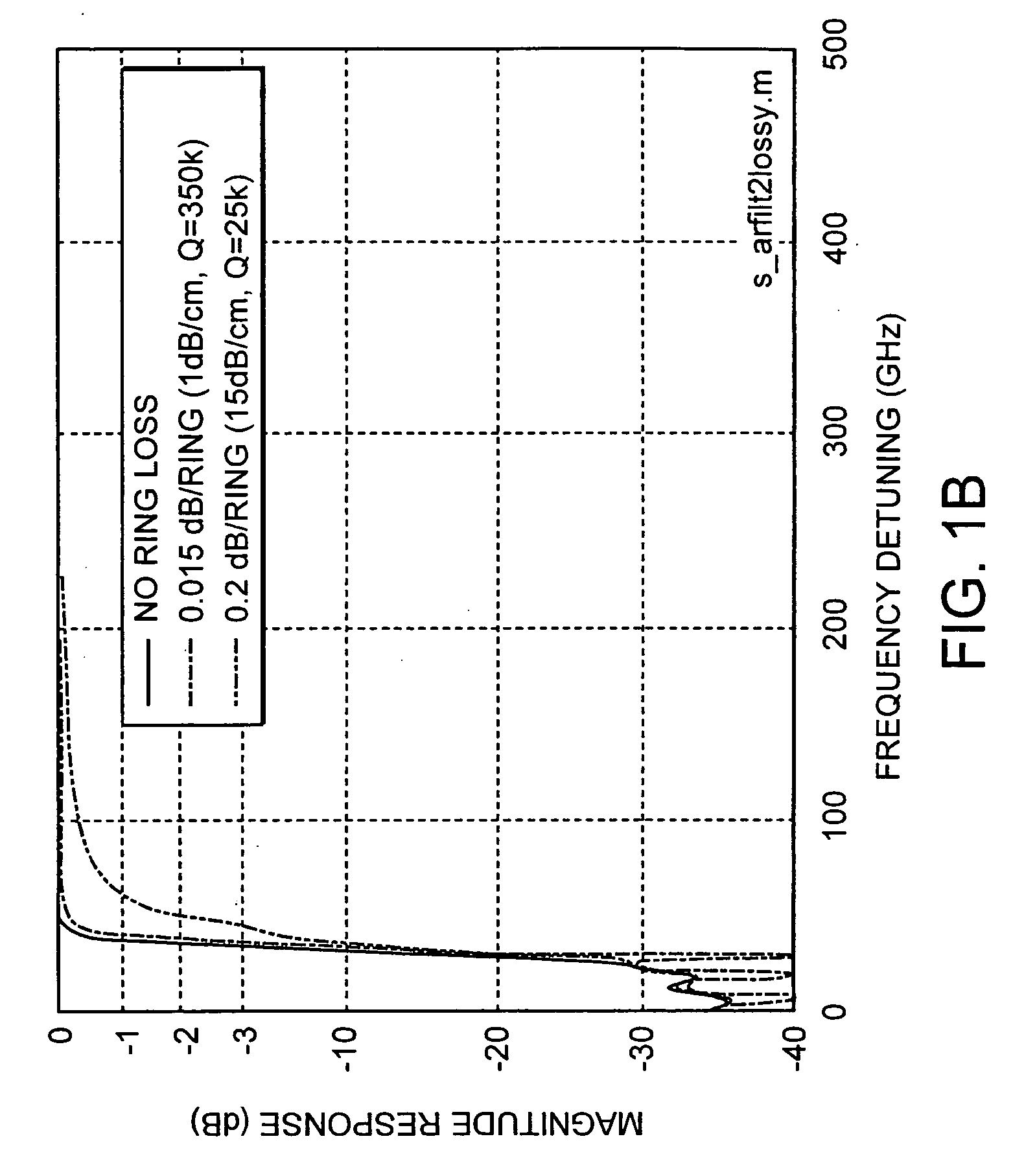

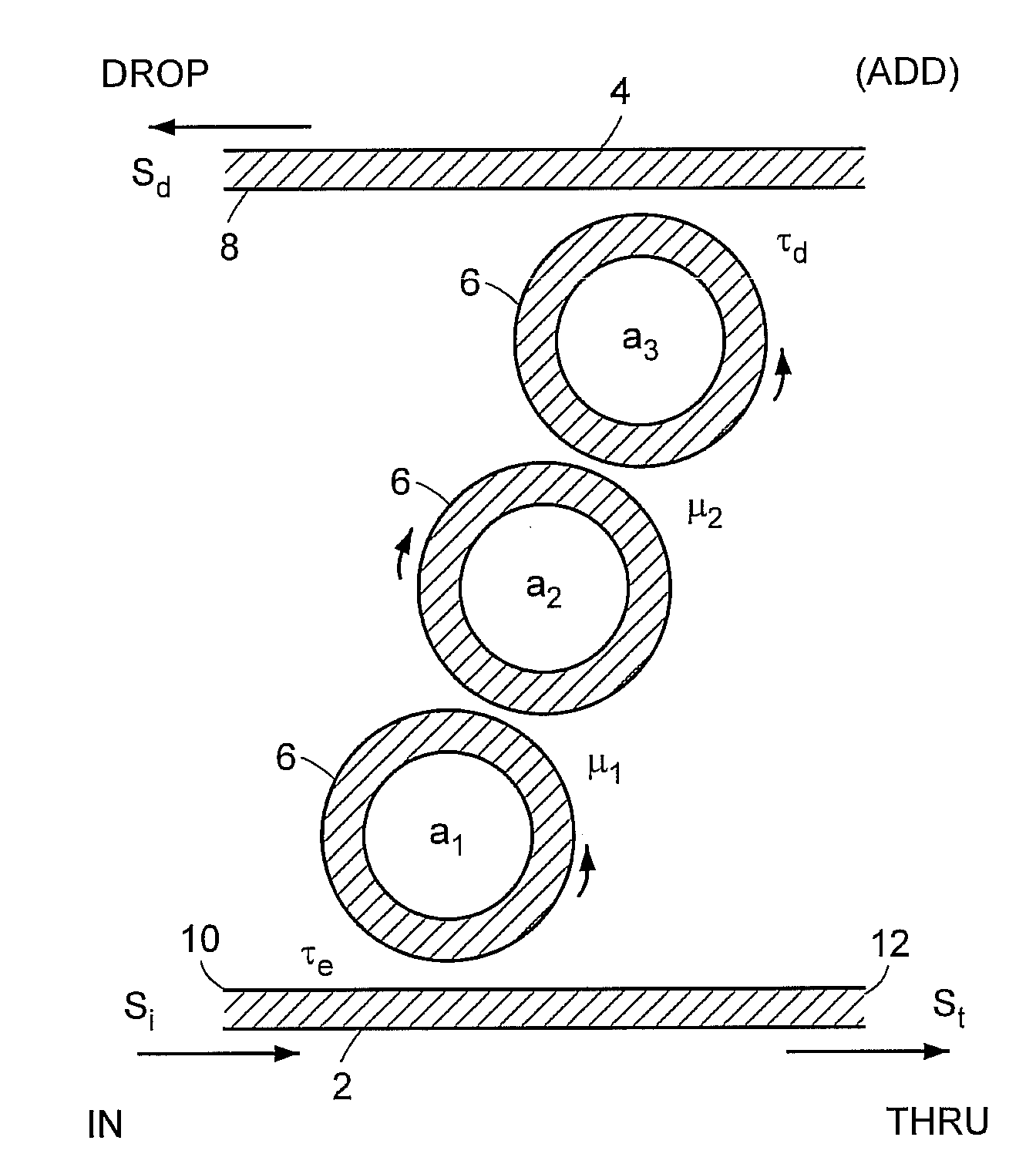

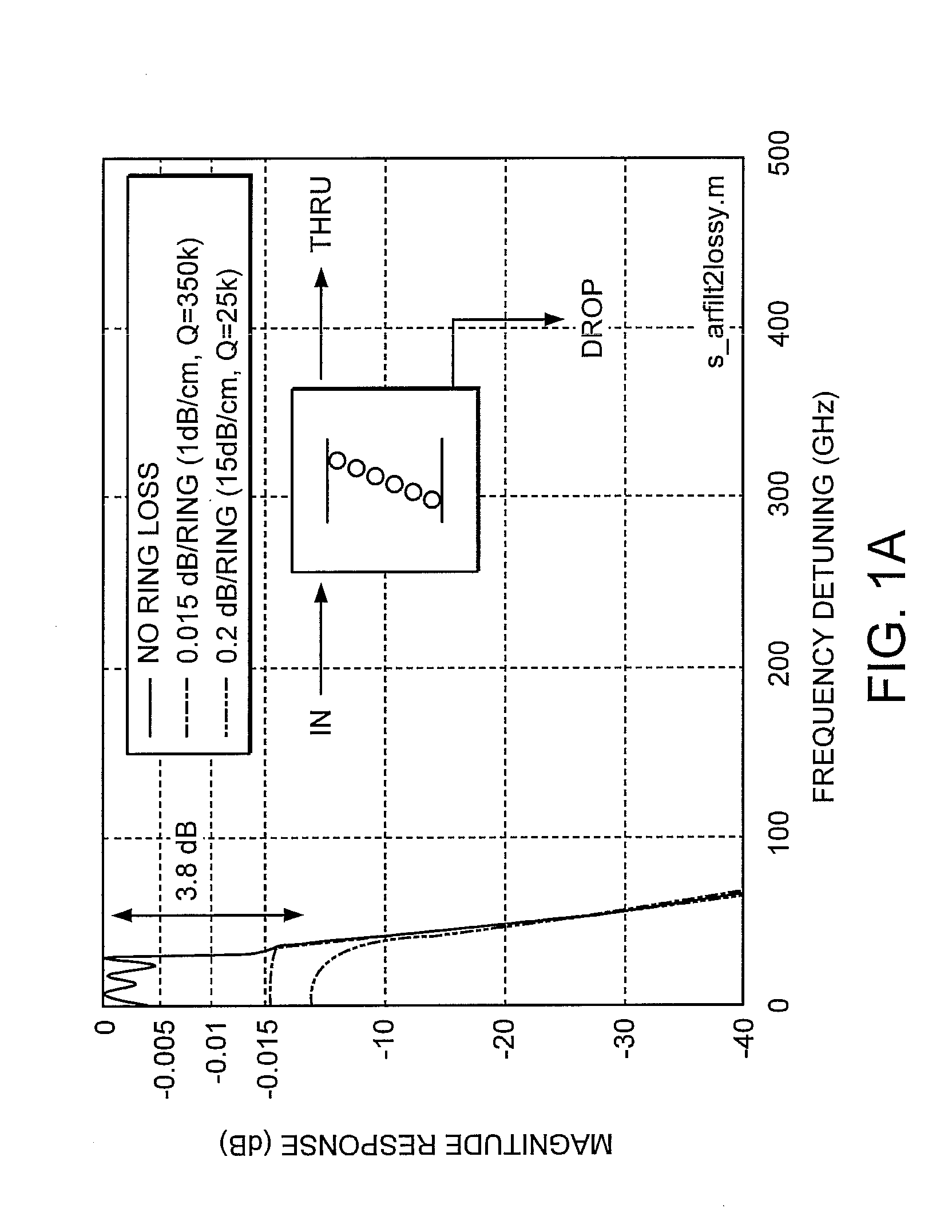

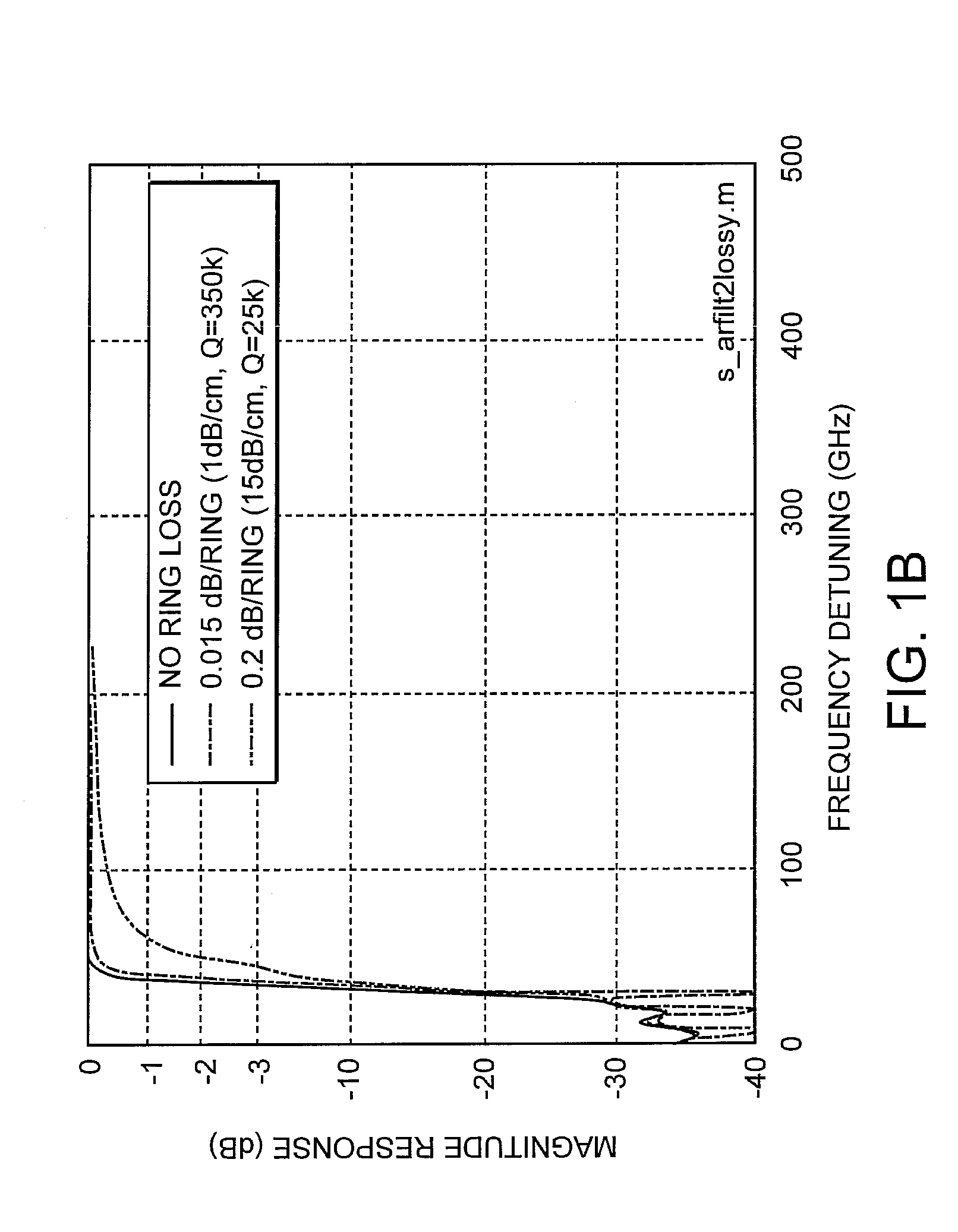

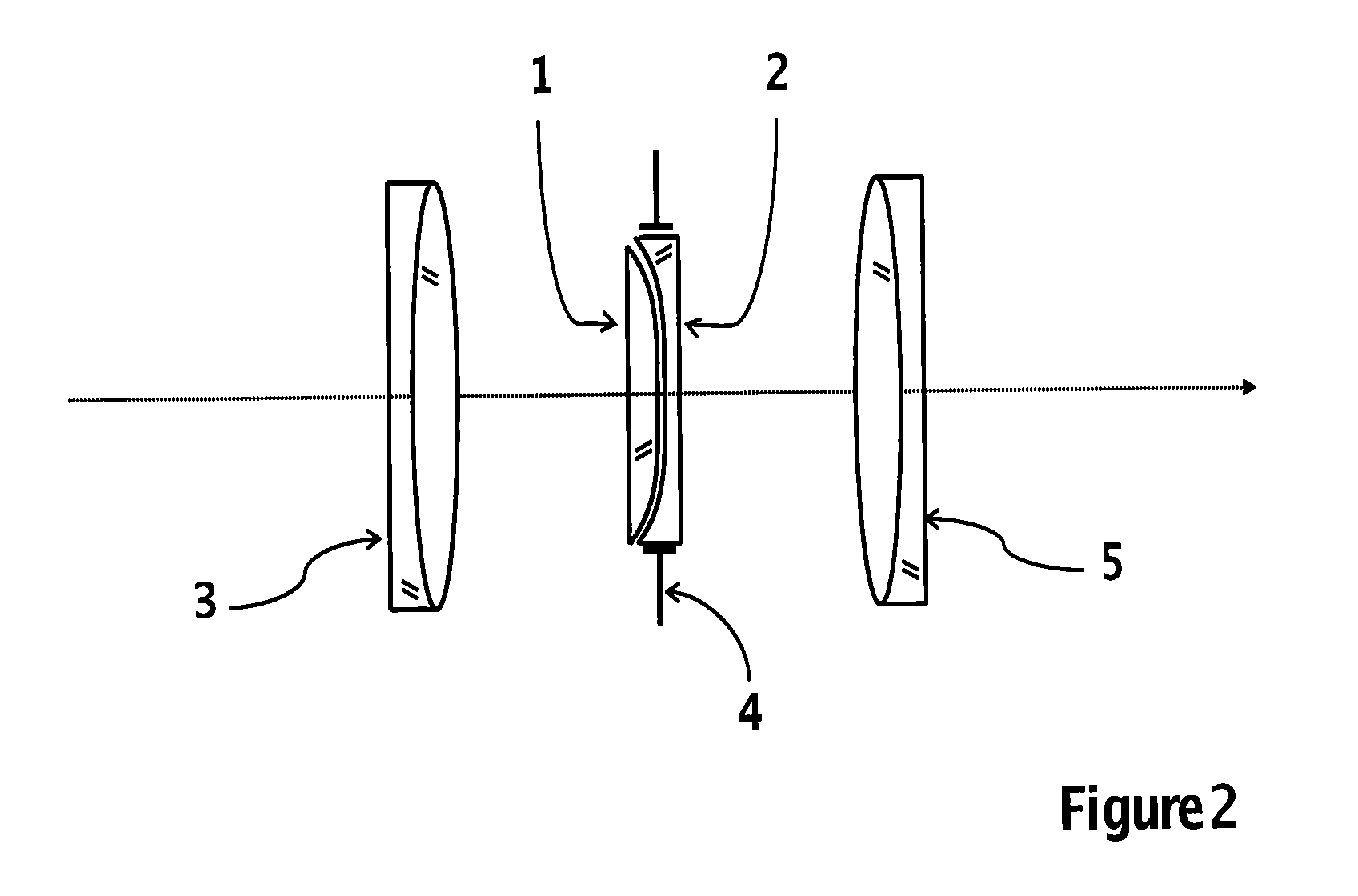

Optical coupled-resonator filters with asymmetric coupling

InactiveUS20060159392A1Coupling light guidesOptical waveguide light guideResonator filterAsymmetric distribution

An optical filter includes at least one waveguide structure. The optical filter also includes a plurality of optical resonators that are aligned in an coupled arrangement with the at least one waveguide structure so as to produce an asymmetric distribution of coupling coefficients.

Owner:MASSACHUSETTS INST OF TECH

Optical coupled-resonator filters with asymmetric coupling

InactiveUS7292751B2Coupling light guidesOptical waveguide light guideResonator filterAsymmetric distribution

An optical filter includes at least one waveguide structure. The optical filter also includes a plurality of optical resonators that are aligned in an coupled arrangement with the at least one waveguide structure so as to produce an asymmetric distribution of coupling coefficients.

Owner:MASSACHUSETTS INST OF TECH

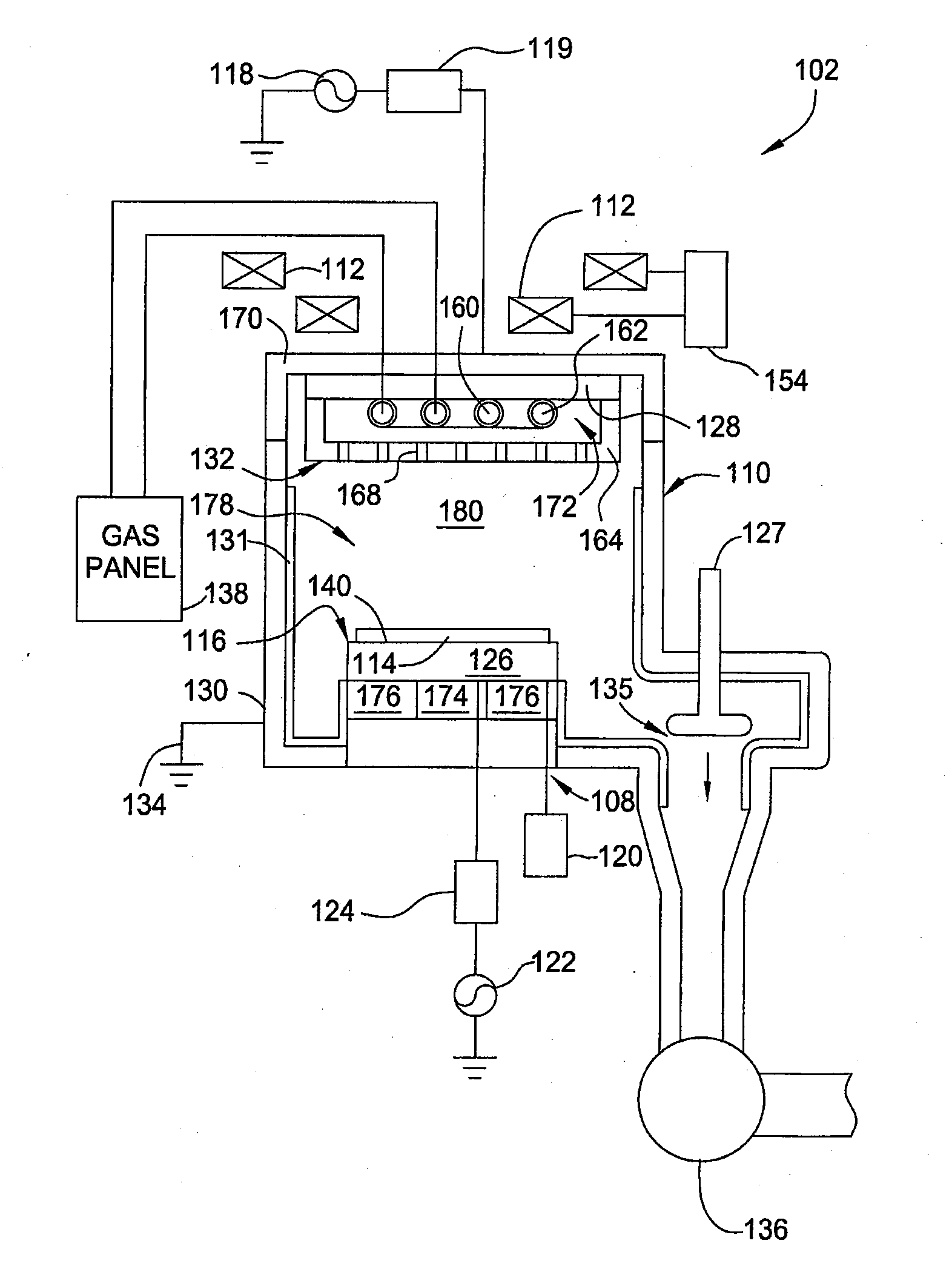

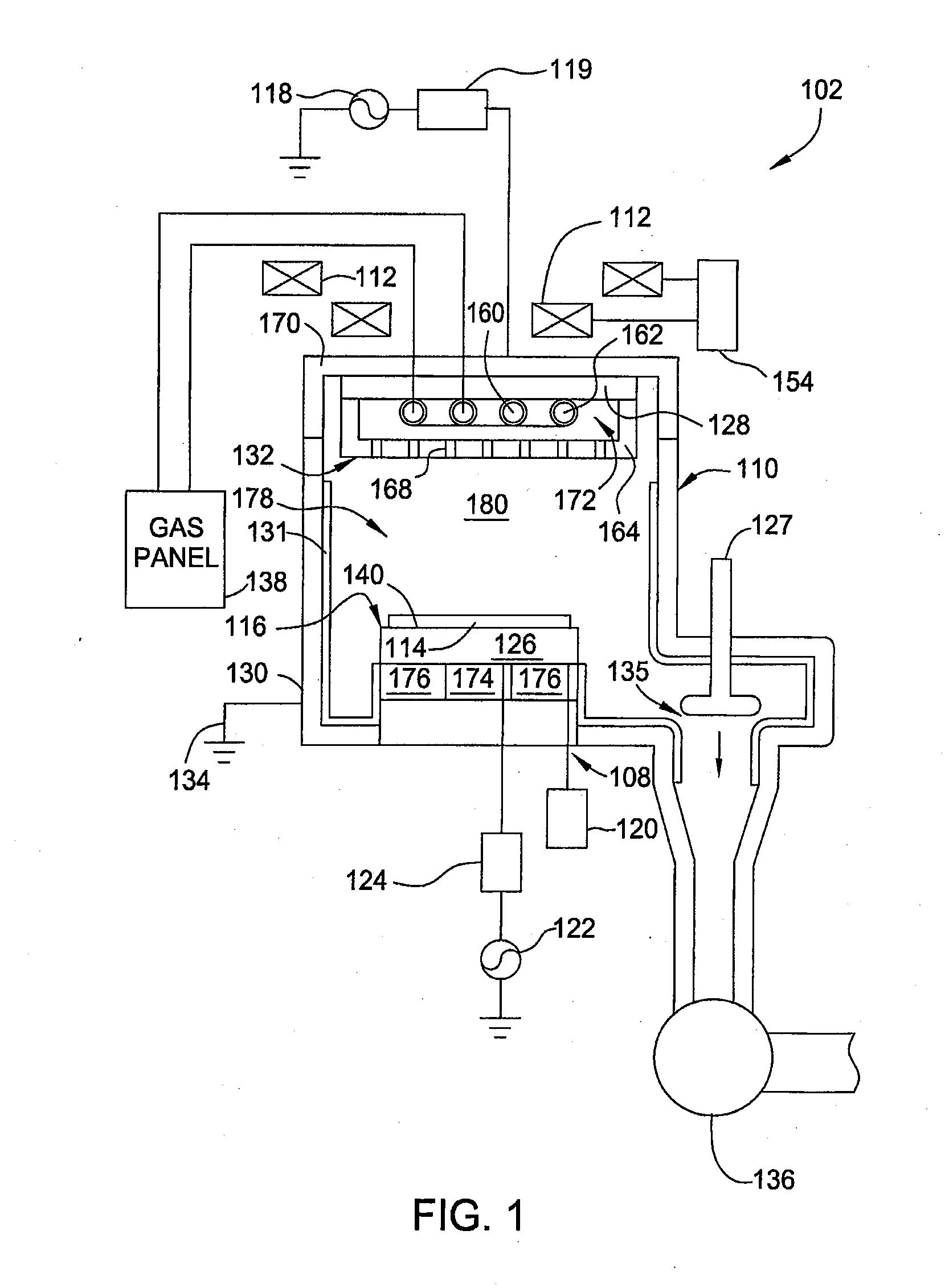

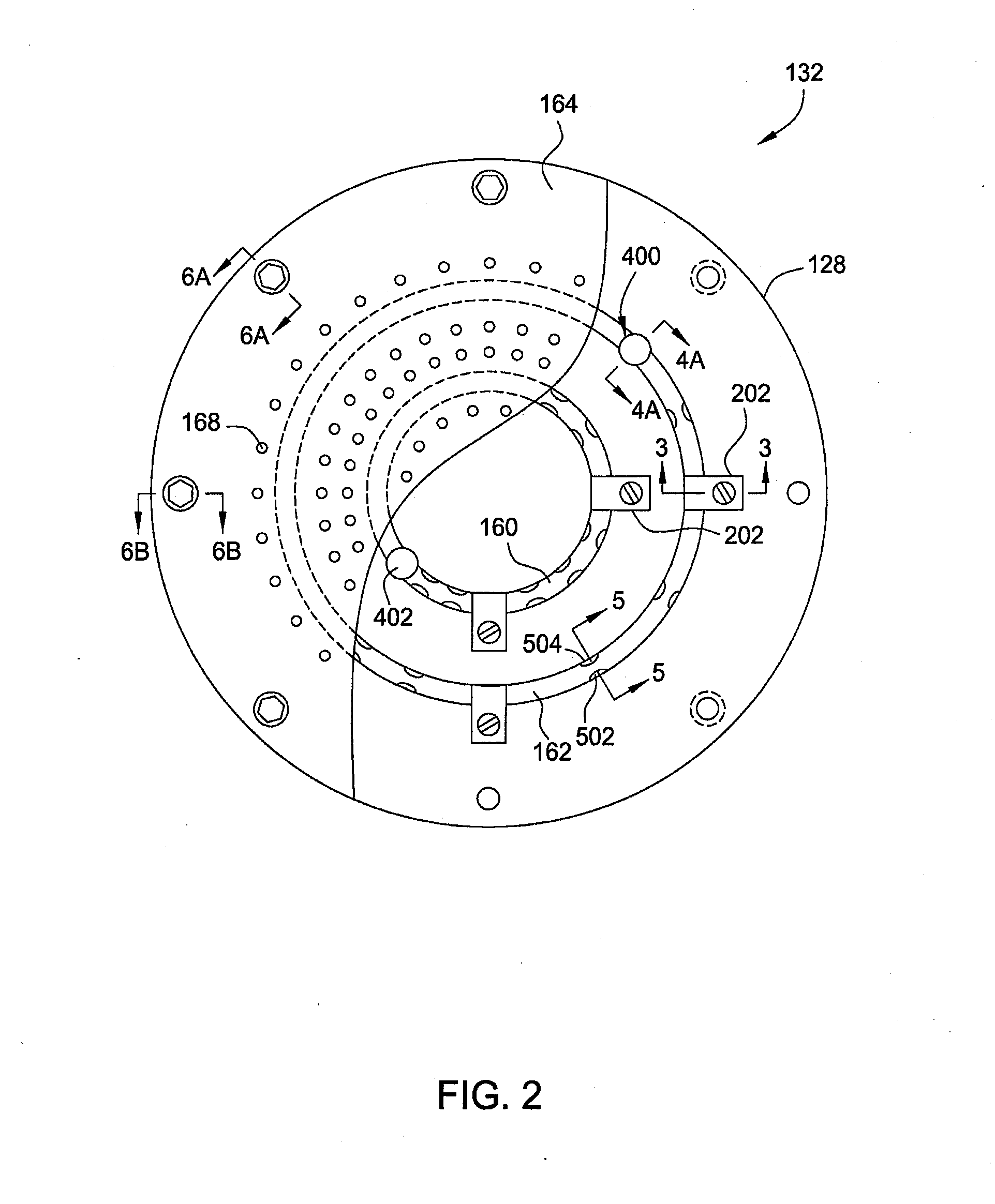

Gas flow diffuser

InactiveUS20080230518A1Electric discharge tubesDecorative surface effectsInjection portAsymmetric distribution

A method and apparatus for providing flow into a processing chamber are provided. In one embodiment, a vacuum processing chamber is provided that includes a chamber body having an interior volume, a substrate support disposed in the interior volume and a gas distribution assembly having an asymmetrical distribution of gas injection ports. In another embodiment, a method for vacuum processing a substrate is provided that includes disposing a substrate on a substrate support within in a processing chamber, flowing process gas into laterally into a space defined above a gas distribution plate positioned in the processing chamber over the substrate, and processing the substrate in the presence of the processing gas.

Owner:APPLIED MATERIALS INC

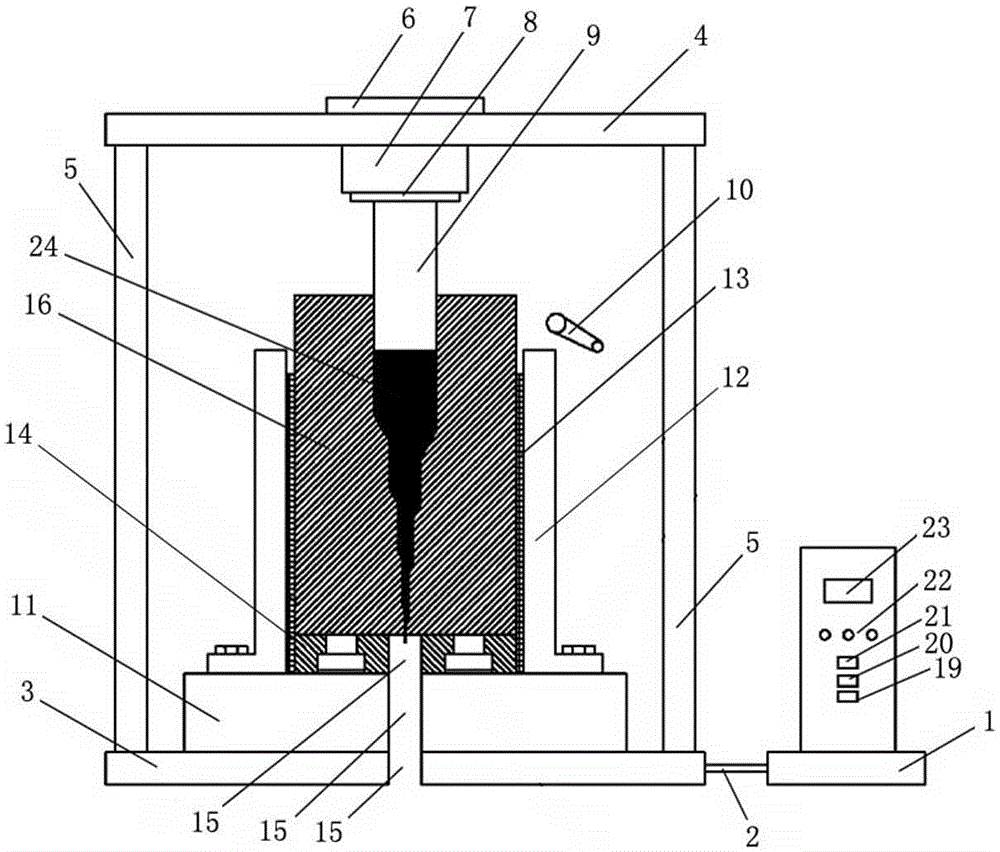

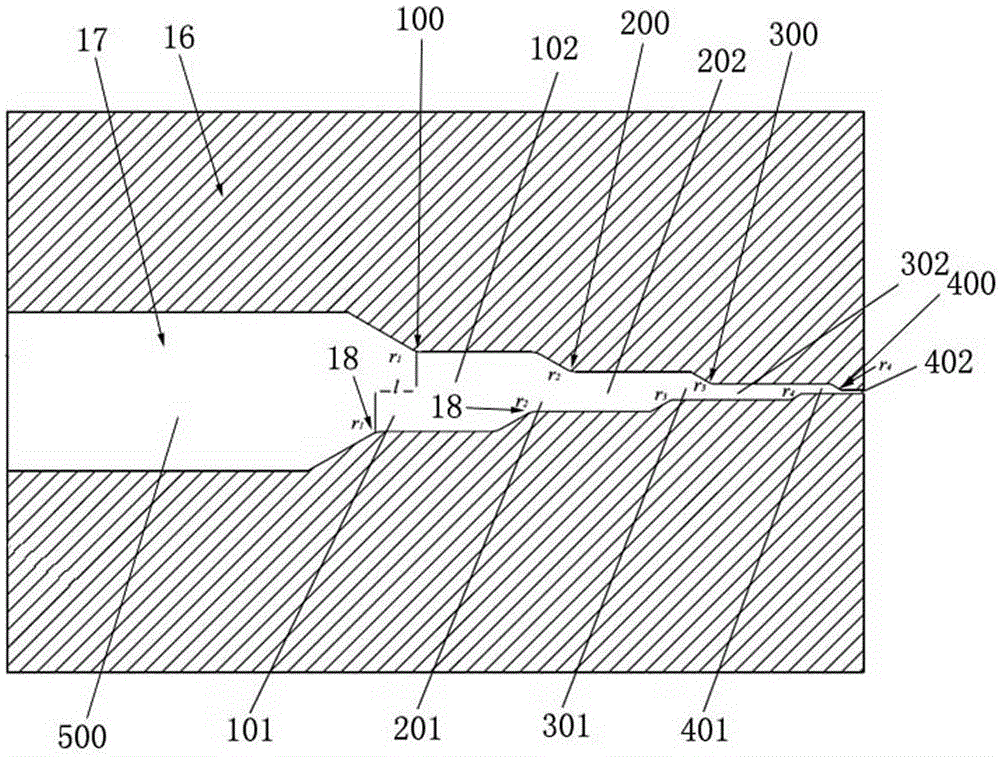

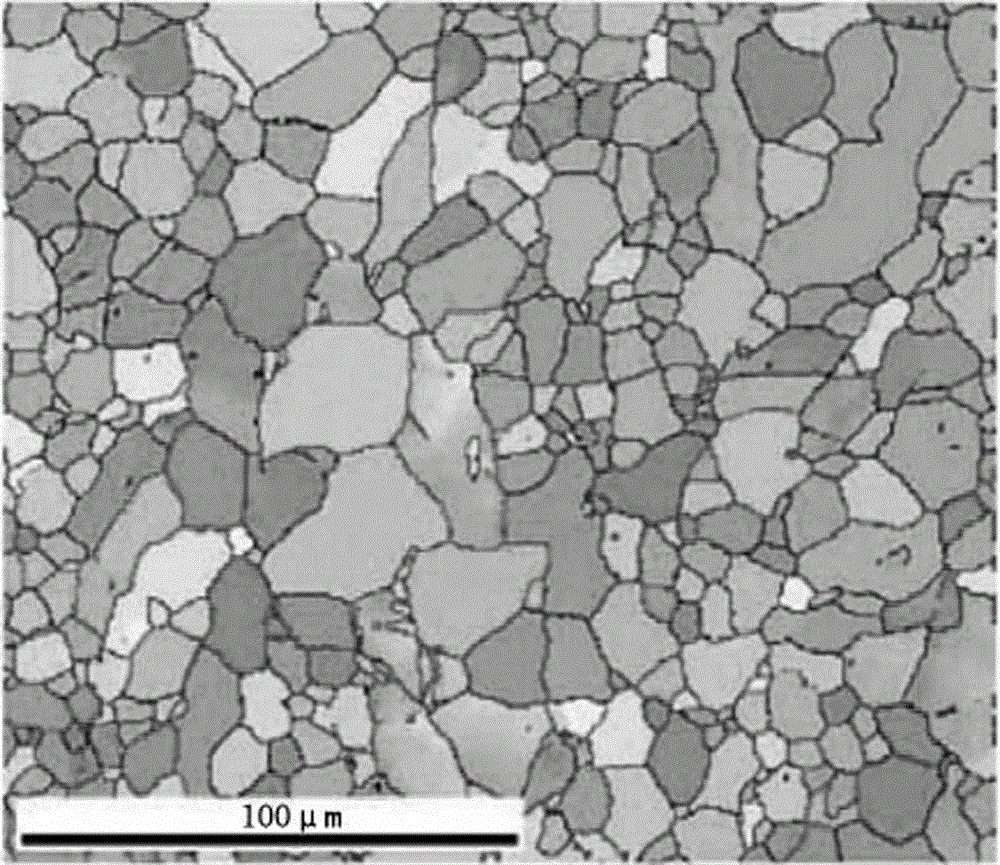

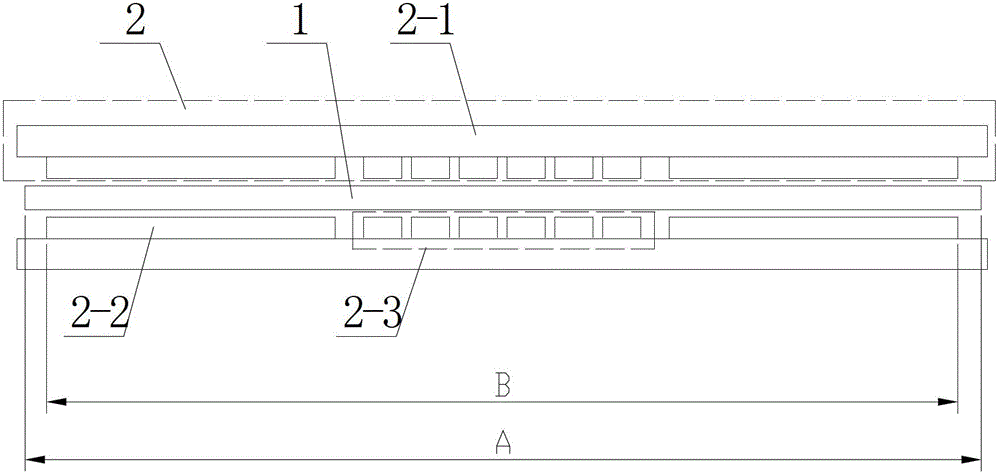

Continuous extrusion machining device used for magnesium alloy sheet strip with weak basal texture and extrusion machining method

ActiveCN105032964AAverage grain size reductionHigh strengthExtrusion diesAsymmetric distributionMachining process

The invention relates to a continuous extrusion machining device used for a magnesium alloy sheet strip with a weak basal texture and an extrusion machining method. The device comprises an extrusion system mainly composed of a pressure motor, an extrusion telescopic head, a male die and a female die, and multiple inclined steps gradually getting close to the axis of a die cavity are arranged at the two sides below the upper middle portion in the die cavity of the female die and are distributed asymmetrically. In the extrusion machining process, a magnesium alloy blank is placed in the die cavity of the female die and extruded by the descending male die, and as the male die descends continuously, the magnesium alloy blank is gradually thinned to form a magnesium alloy sheet with the weak basal texture. Due to step-by-step grain refinement and basal texture weakening, extrusion force in the extrusion process is greatly reduced, the average grain size of the magnesium alloy is greatly reduced compared with that of a magnesium alloy extruded normally, and the (0002) basal texture is reduced to 8.2 from 27.6 compared with that of a sheet obtained through normal extrusion.

Owner:TAIYUAN UNIV OF TECH

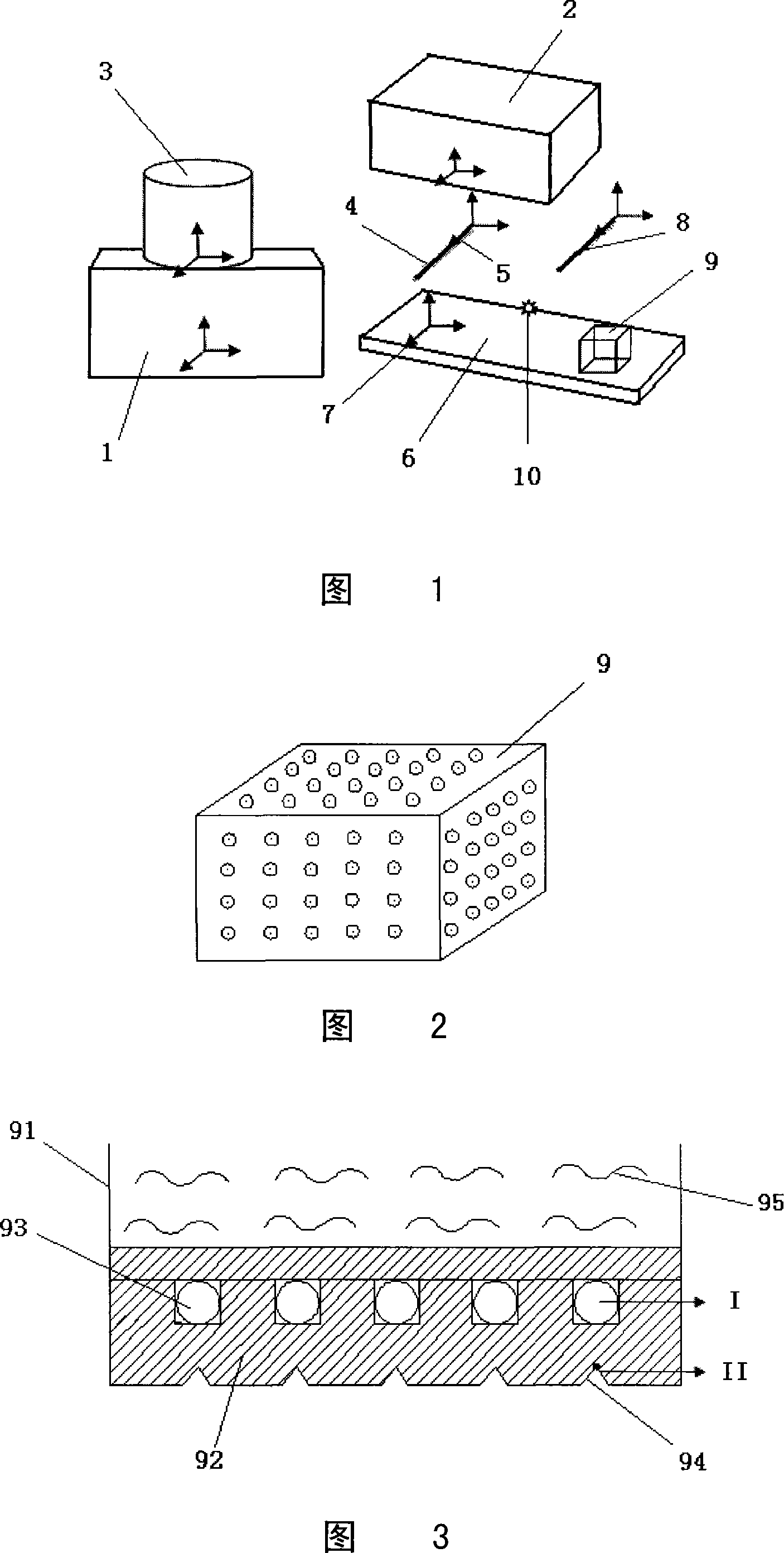

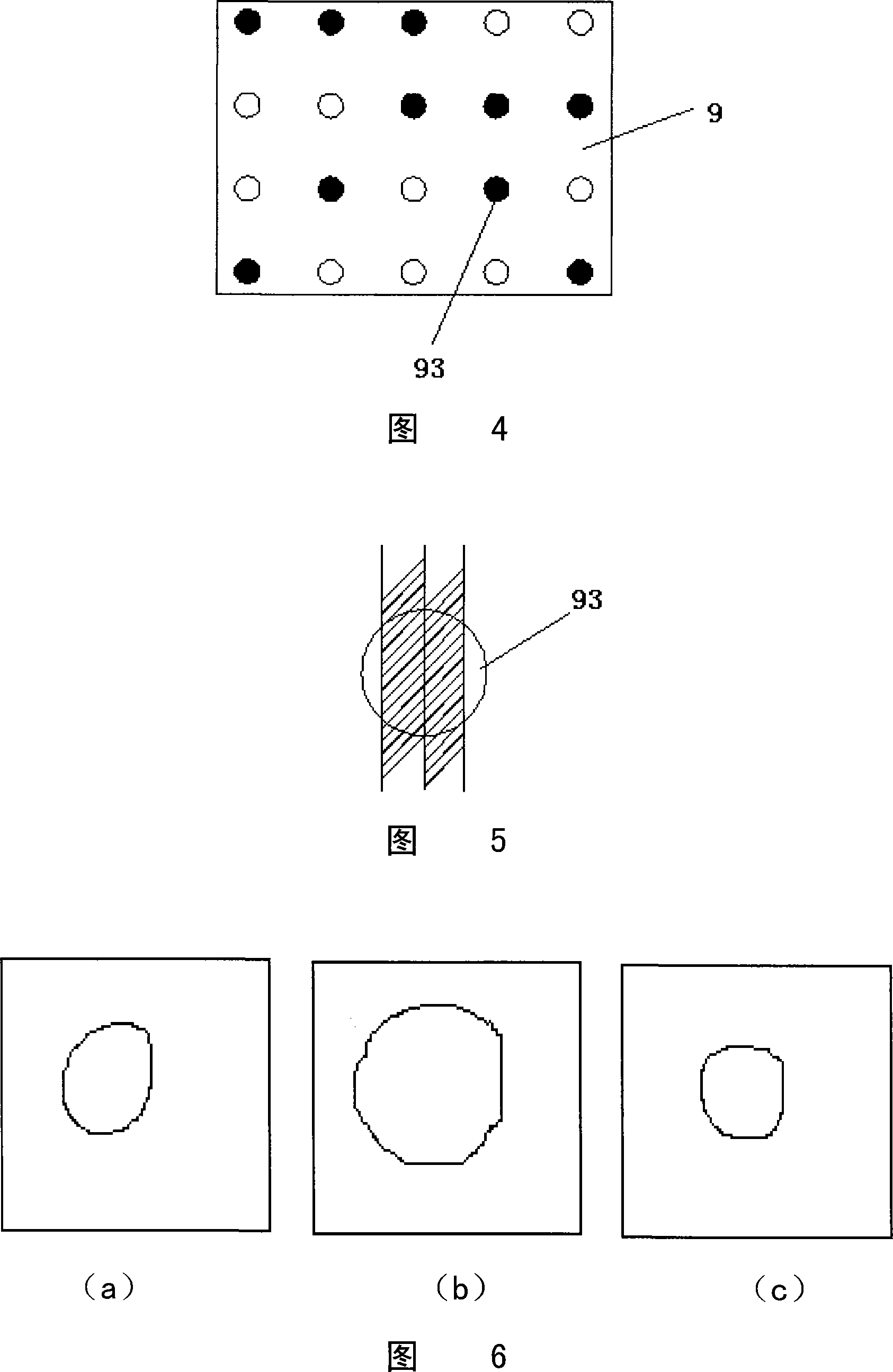

Navigation system and method backing up several modes

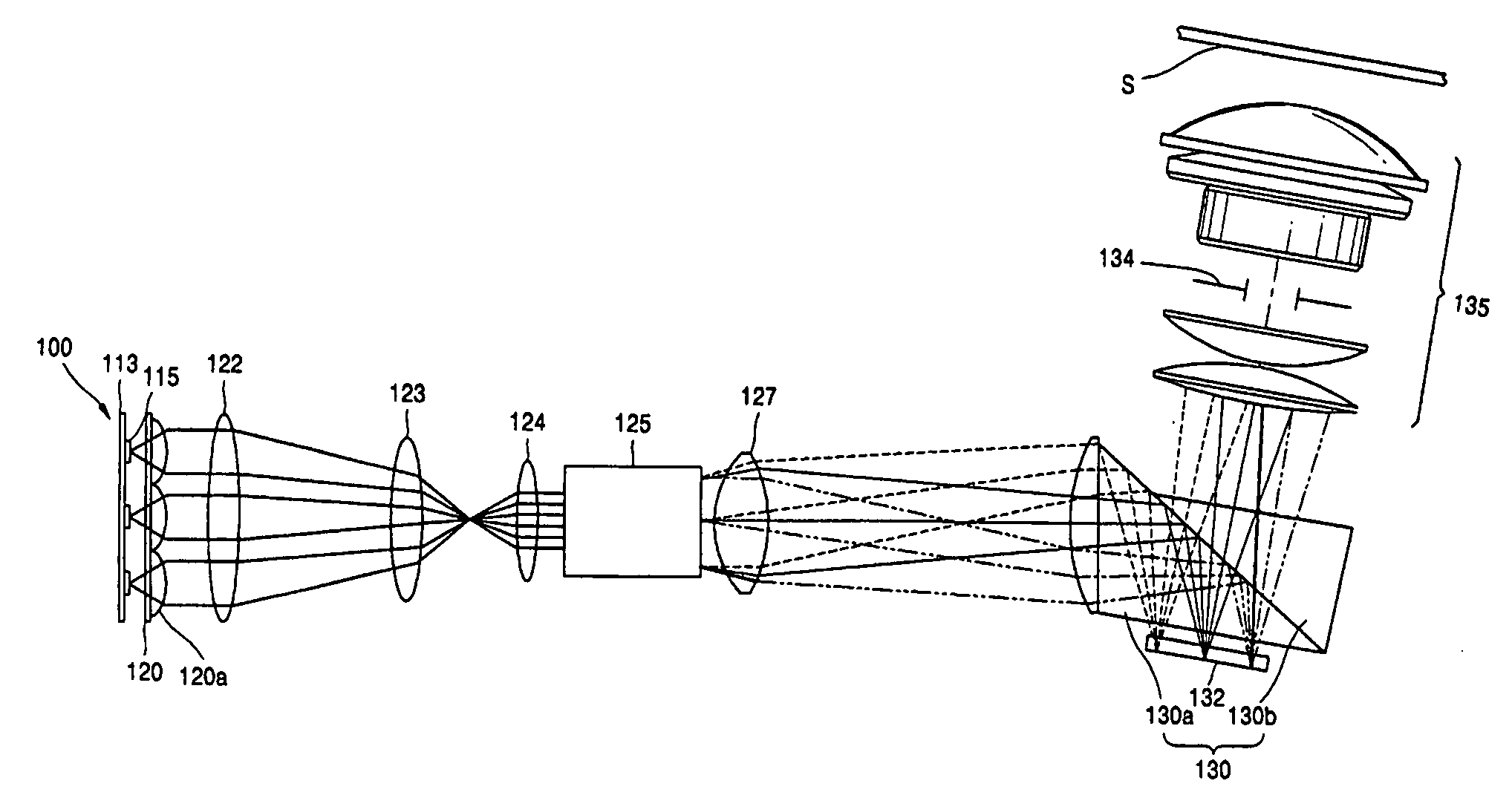

ActiveCN101019771APrecise Navigation EffectGuaranteed navigation accuracyDiagnosticsSurgical navigation systemsSurgical operationDisease

The present invention is navigation system and method backing up several modes. The navigation system includes fixed imaging equipment, tracking system, surgical operation equipment, sick bed, calibrating pin, calibrating mold and navigation software. It has at least one tracer constituting the world coordinate system, one surgical operation equipment tracer as the surgical operation equipment coordinate system, one sick bed tracer constituting the sick bed coordinate system, one characteristic point set I and one characteristic point set II set inside and outside the calibrating mold separately. After calibration, the disease focus image and the surgical operation equipment are shown in the same coordinate system. The present invention may be used widely in the navigation course of different surgical operations.

Owner:SYMBOW MEDICAL TECH

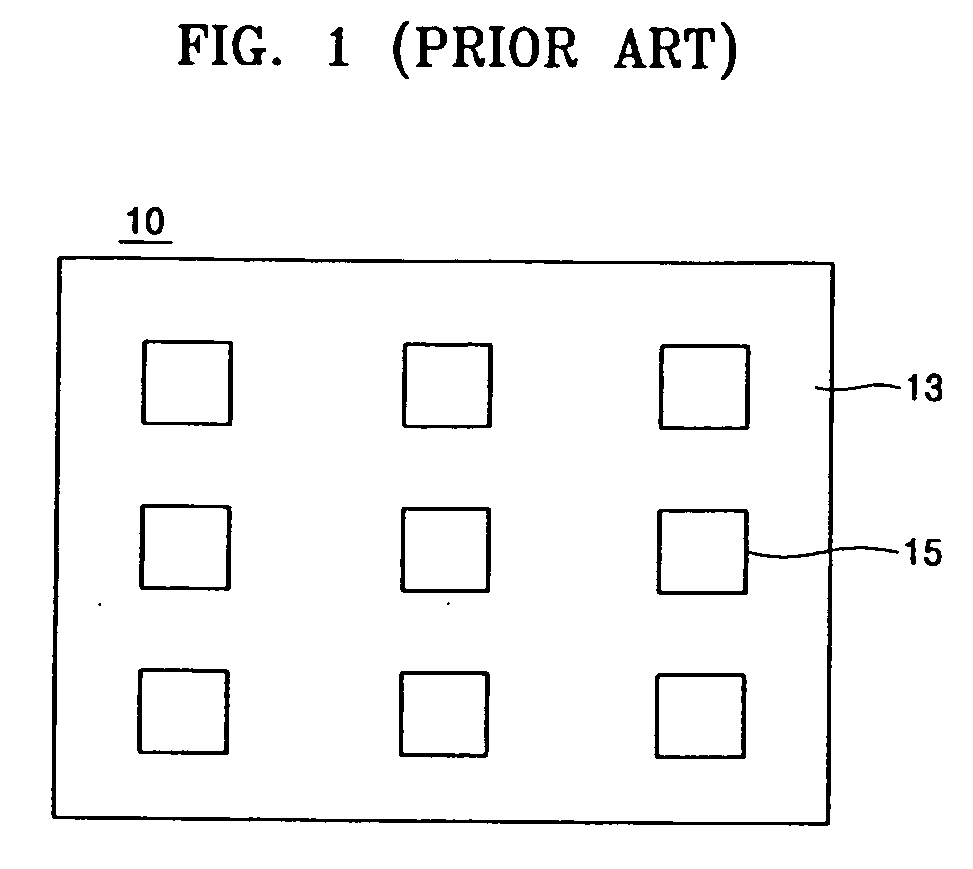

LED package, display panel, illumination system and projection system employing the same

InactiveUS20060146297A1Improve lighting efficiencyArrangement structure optimizationTelevision system detailsData processing applicationsAsymmetric distributionEngineering

An LED package having improved light efficiency, and an illumination system and a projection system employing the LED package. An LED package to provide light to a display panel having a plurality of rotatable micromirrors to form images, the LED package includes a substrate and a plurality of LED chips. The plurality of LED chips are slanted with respect to the substrate at a predetermined angle. The LED package improves the light efficiency by arranging the plurality of LED chips so as to correspond to a shape of effective light having an asymmetric distribution with respect to a stop of a projection lens unit.

Owner:SAMSUNG ELECTRONICS CO LTD

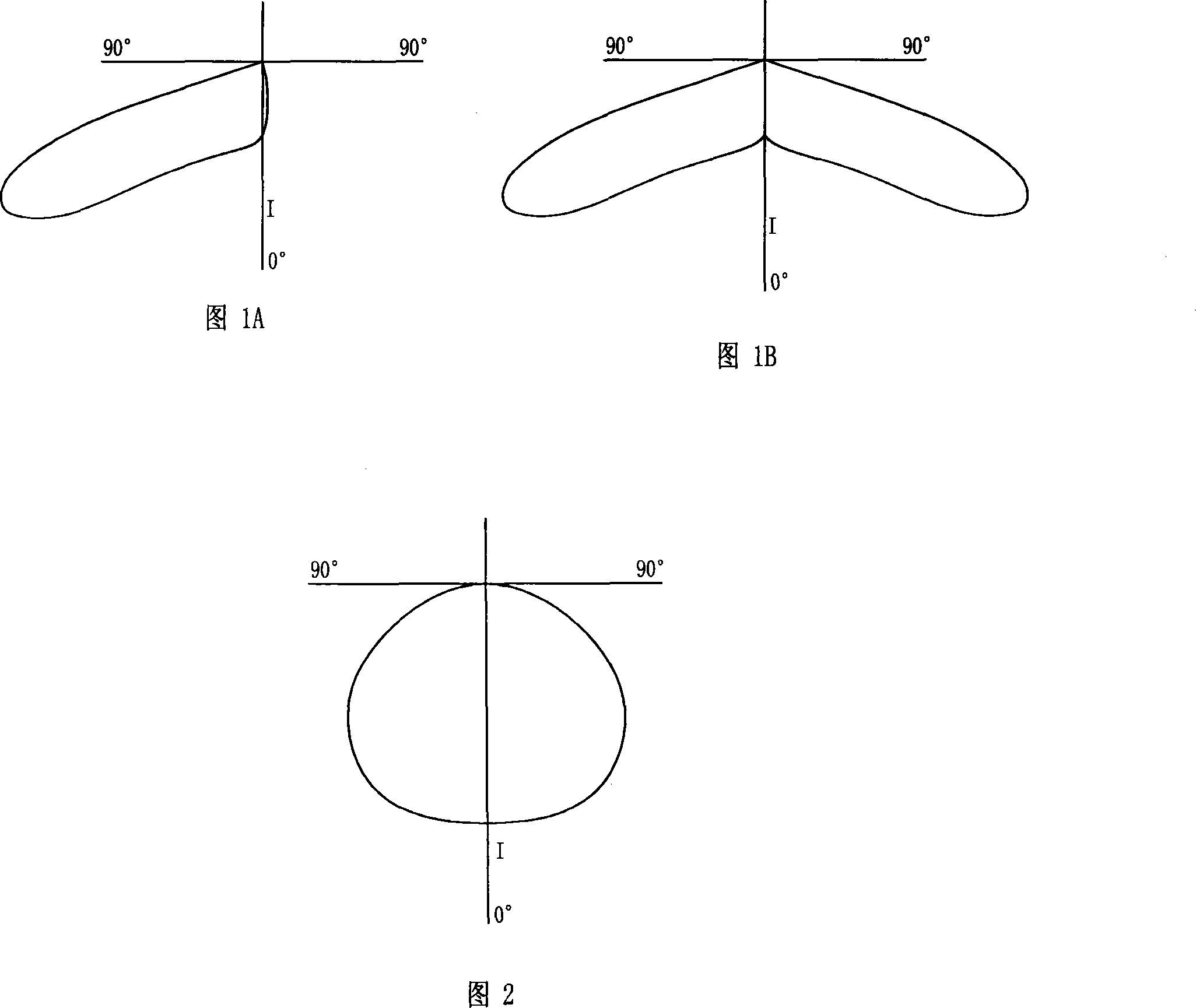

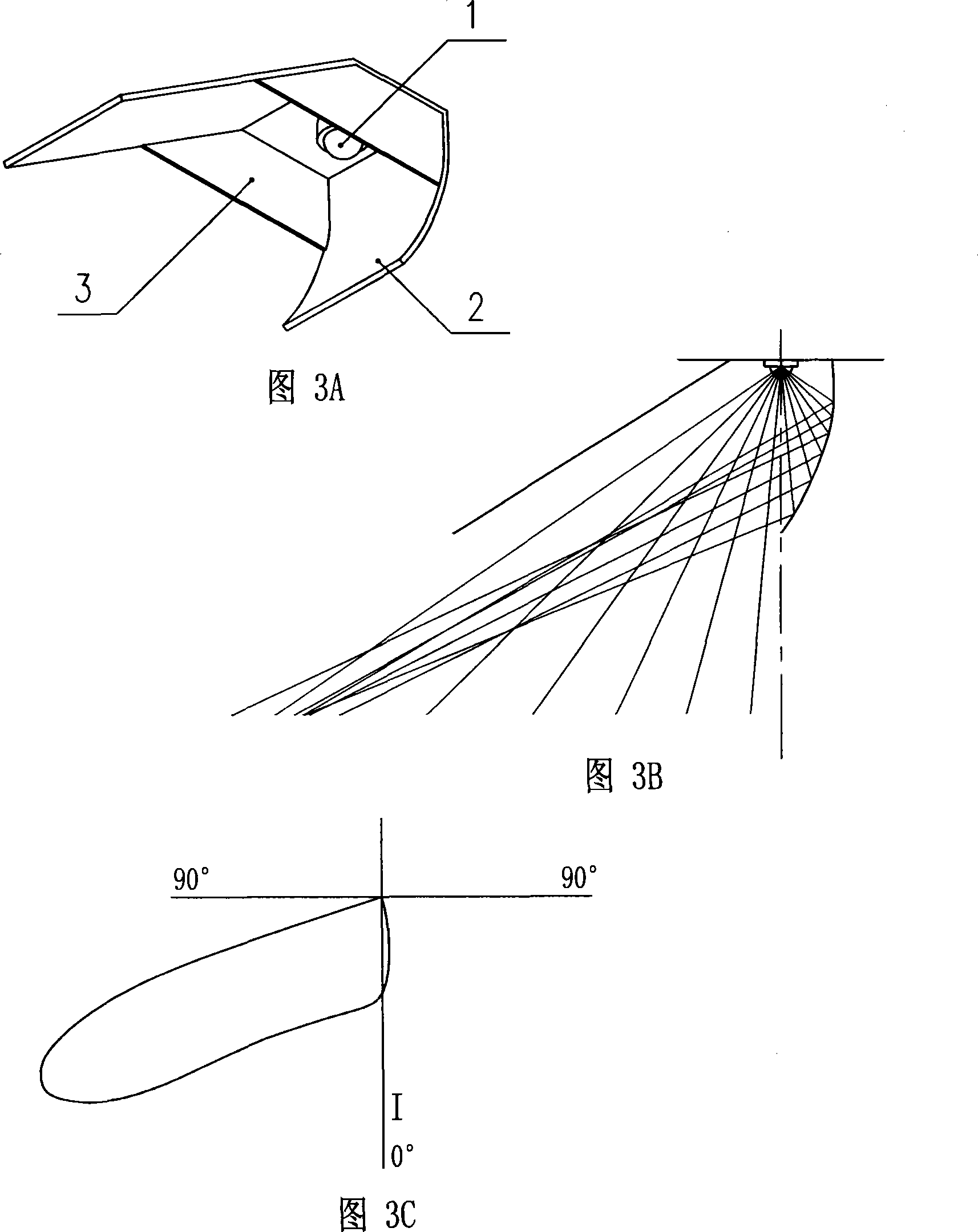

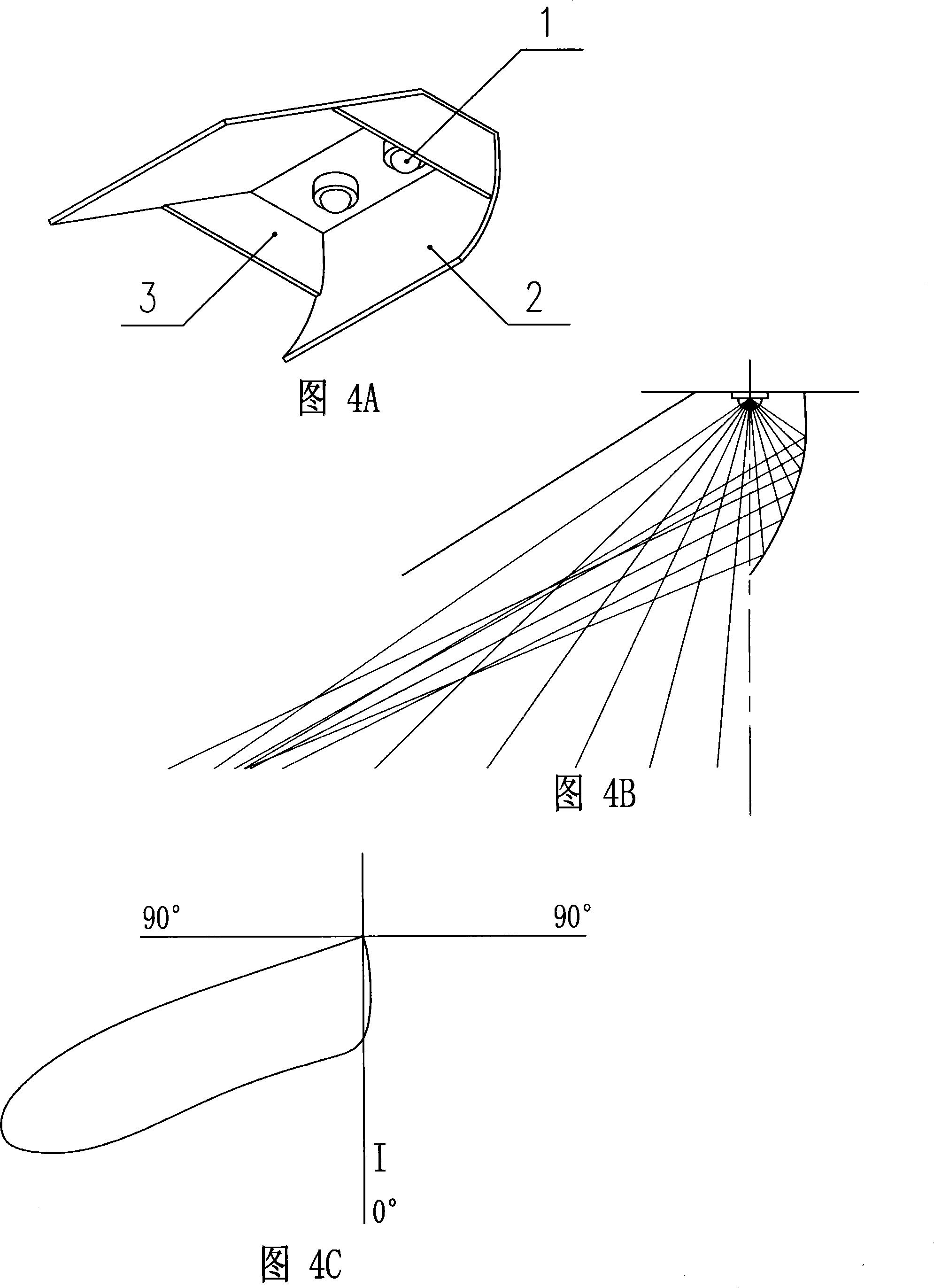

Anti-dazzle LED illumination device

InactiveCN101220928AImprove applicabilityDesign sciencePoint-like light sourceElectric lightingAsymmetric distributionEngineering

An anti-glare LED illuminating apparatus belongs to the semiconductor illuminating technology field and is characterized by being provided with an anti-glare LED illuminating unit U, which comprises an LED light source 1, a combined type reflector 2 and a shielding lace bar 3, or an LED anti-glare illuminating module or an LED anti-glare illuminating die set consisting of the anti-glare LED illuminating unit, the LED light source is arranged between two adjacent shielding lace bars 3, the inner wall of the combined type reflector 2 is an asymmetry reflection plane, optical intensity is distributed asymmetrically along the direction vertical to the combined type reflector 2 axes, a light distribution curve is of lateral wing type, the shielding lace bar 3 limits the glare generated by the LED light source 1 along the axial direction of the combined type reflector 2. The invention has scientific design, reasonable structure, easy production, convenient assembly and good anti-glare effect, reduces the difficulties of manufacturing, processing and assembly and production cost, thus being beneficial to large-scale application.

Owner:史杰

Faceted LED street lamp lens

ActiveUS20150078011A1Uniform light distributionMechanical apparatusPoint-like light sourceWide areaAsymmetric distribution

A lens for an LED street lamp has an external curved surface that has a concave surface portion on one side thereof. A back surface of the lens has a micro-prism array and retainer feet. A recess in the back surface receives an LED light source. The outer surface of the lens has facets or windows that provide overlapping projections of light from adjacent facets. The lens is generally cushion shaped with an indentation at one side. The lens directs light in an asymmetrical distribution transverse to the lens and to direct light symmetrically over a wide area in a longitudinal direction of the lens.

Owner:LIGHT ENGINE

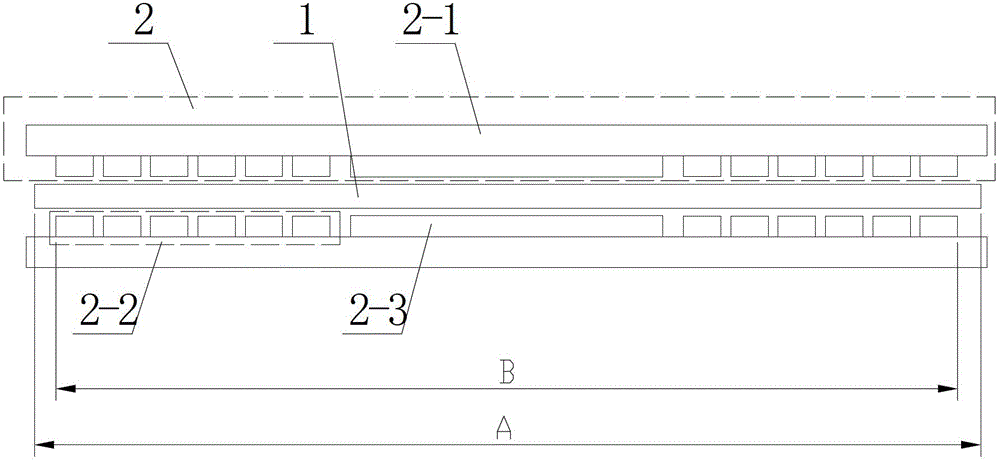

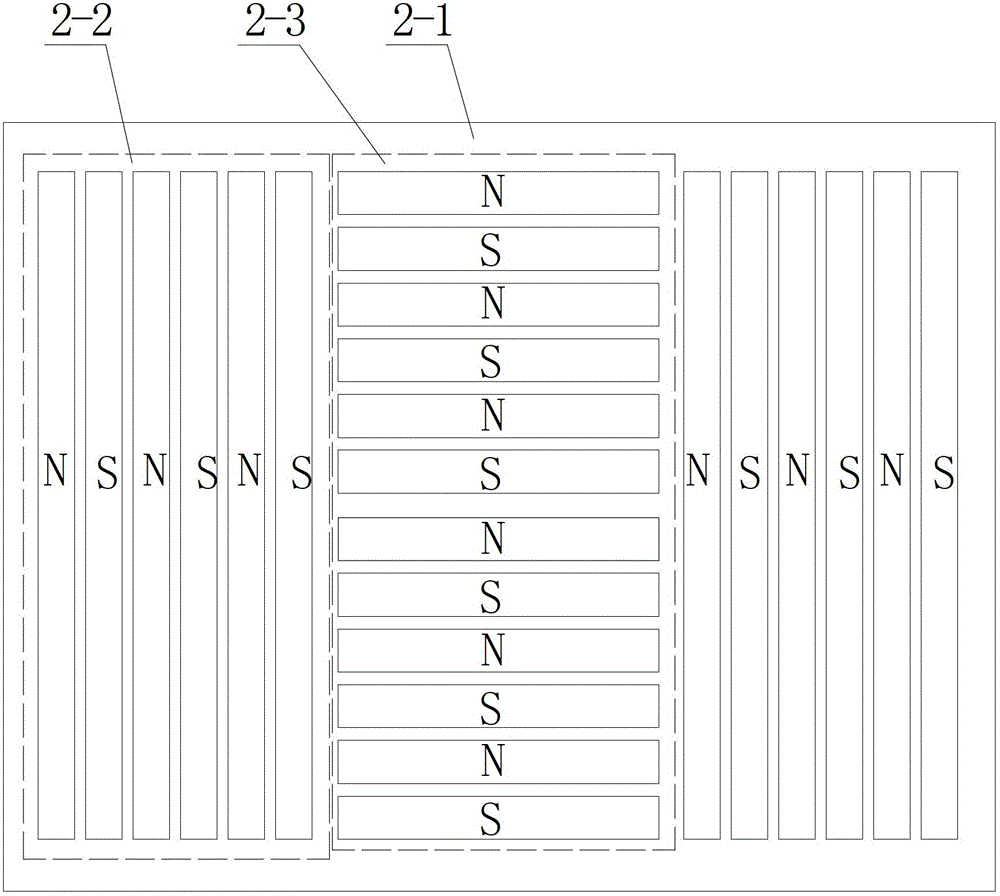

Multi-degree of freedom electromagnetic damper

ActiveCN102720786AEvenly heatedReduce distortionMagnetic springsElectric machineAsymmetric distribution

The invention discloses a multi-degree of freedom electromagnetic damper which belongs to the technical field of motors, solving the problems of the traditional electromagnetic damper of large damping force fluctuation and asymmetric distribution of generated damping force. The multi-degree of freedom electromagnetic damper mainly comprises a primary coil and secondary coils, wherein the primary coil mainly comprises a low-resistivity non-magnetic metal plate, the two-side secondary coils are distributed on the upper side and the lower side of the primary coil symmetrically, two air gaps are arranged between the primary coil and the two-side secondary coils, each-side secondary coil mainly comprises a yoke plate, (n+1) groups of X-direction excitation units and n groups of Y-direction excitation units, n is a positive integer, each X-direction excitation unit or Y-direction excitation unit comprises a plurality of strip-shaped permanent magnets which are sequentially and uniformly arranged on the flat yoke plates along the same direction, the magnetizing direction is vertical to a plane where the air gaps exist, magnetizing directions of every two adjacent permanent magnets are opposite, and magnetizing directions of permanent magnets on the two-side secondary coils corresponding to two sides of the primary coil are the same. The multi-degree of freedom electromagnetic damper is suitable for an electromagnetic damper.

Owner:HARBIN INST OF TECH

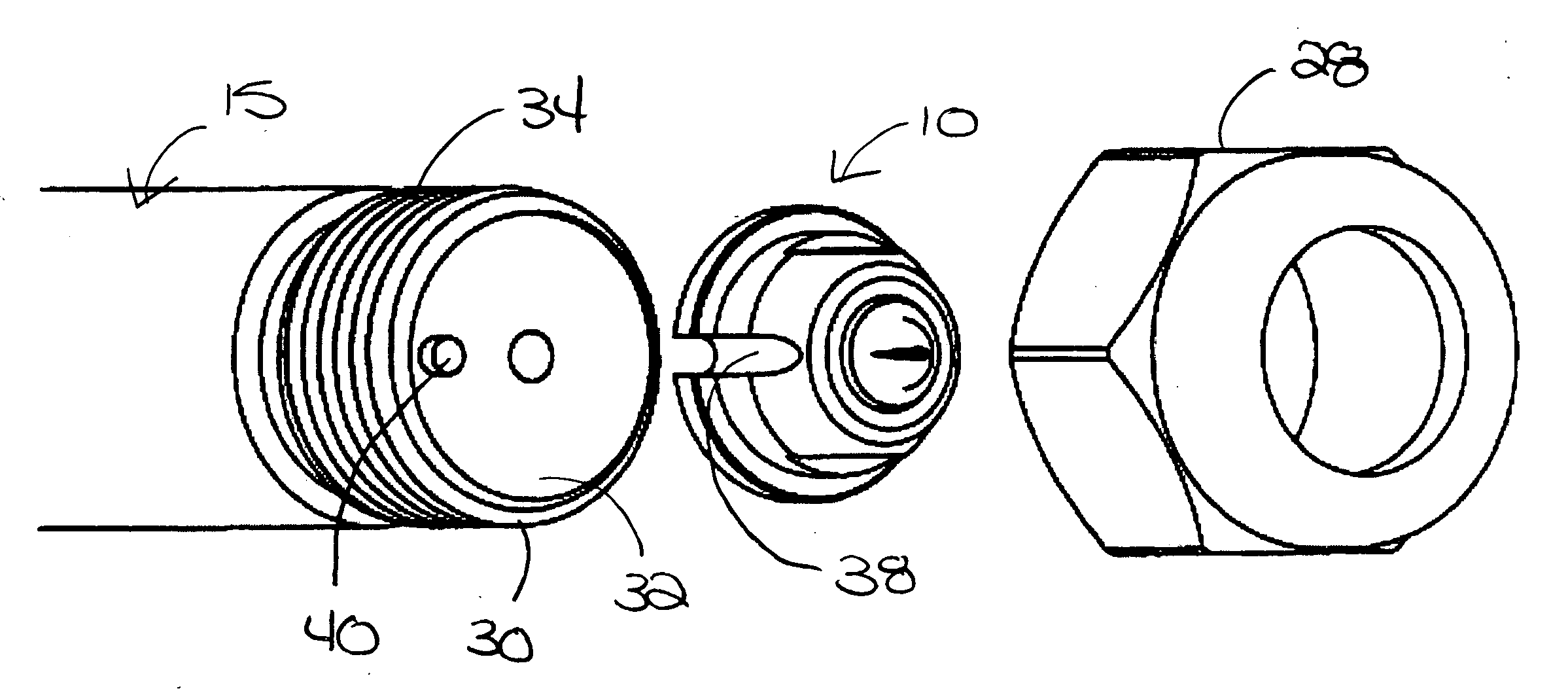

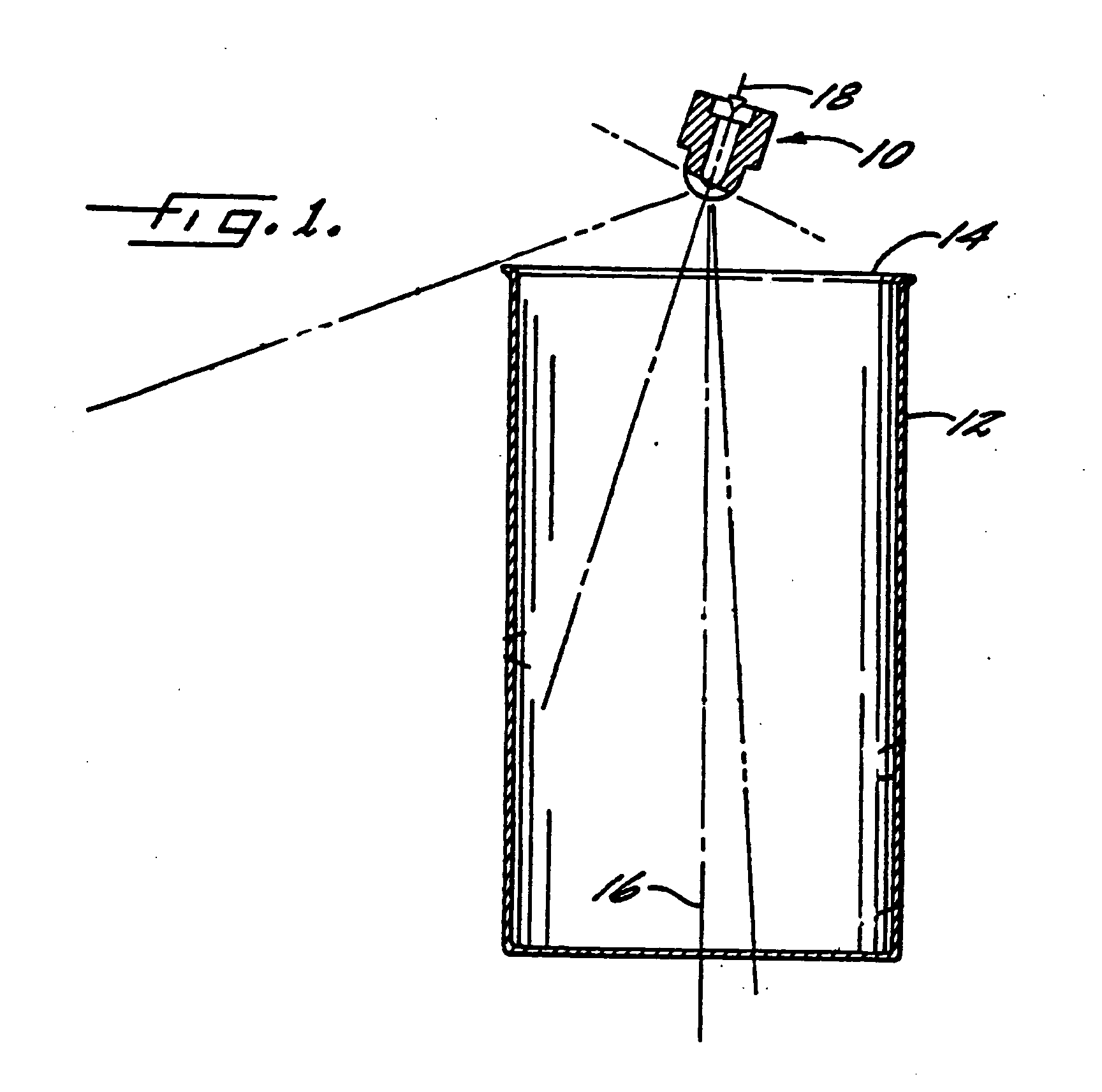

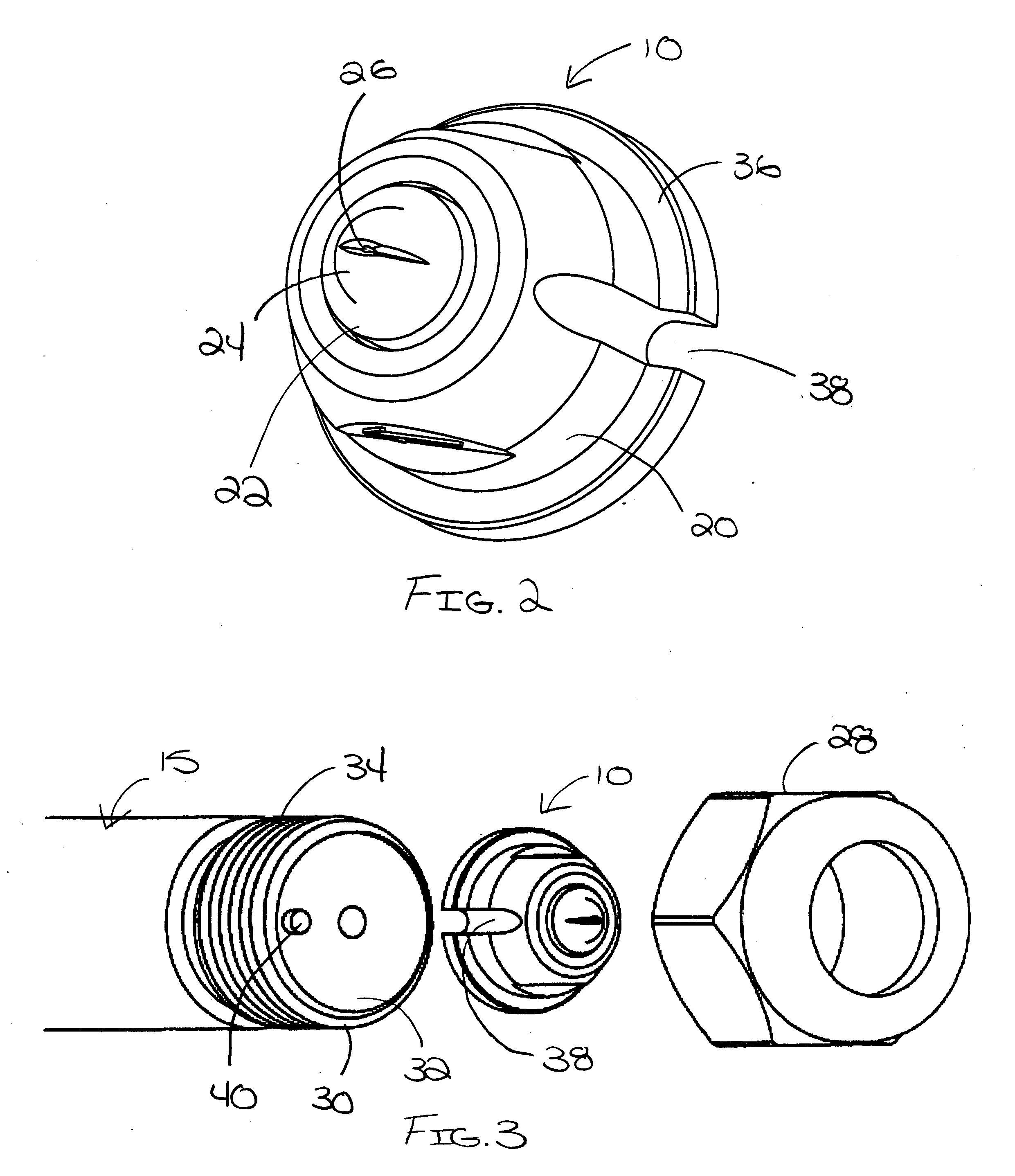

Asymmetrical spray nozzle with alignment notch

A spraying system is provided including a spray gun and a spray nozzle. The spray gun has a discharge end. A locating pin is arranged on the discharge end of the spray gun. The spray nozzle is selectively mountable on the discharge end of the spray gun. The spray nozzle has a discharge orifice configured to produce a asymmetrically distributed fluid discharge pattern wherein the location of maximum fluid discharge is offset from the center of the fluid discharge pattern. The spray nozzle has an alignment notch extending along an outer surface of the spray nozzle. The locating pin is arranged on the spray gun and the alignment notch is arranged on the spray nozzle such that when the spray nozzle is mounted on the discharge end of the spray gun in a predetermined orientation the locating pin extends into the alignment slot.

Owner:SPRAYING SYST

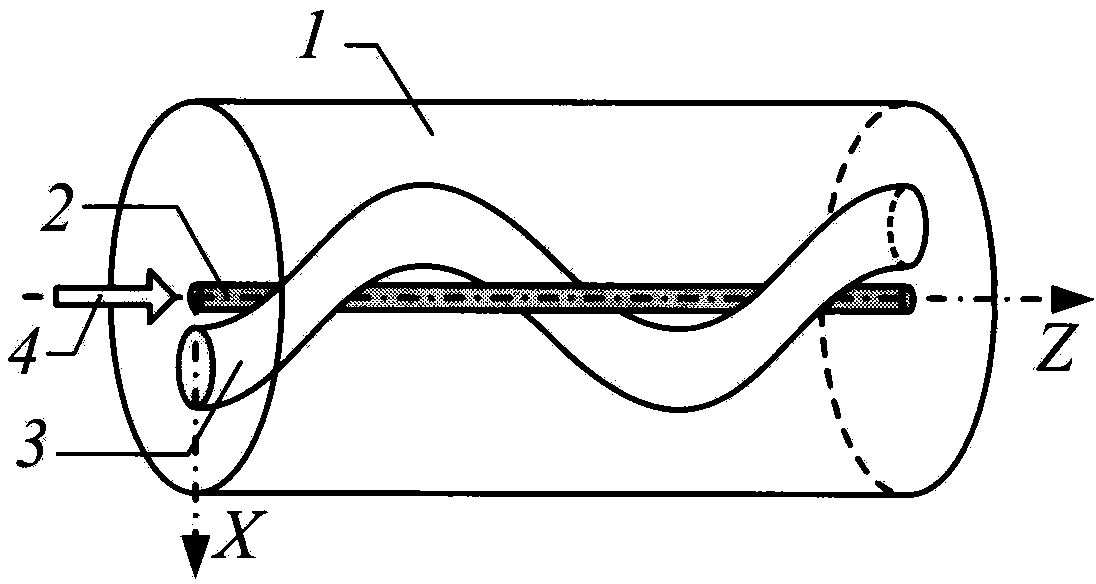

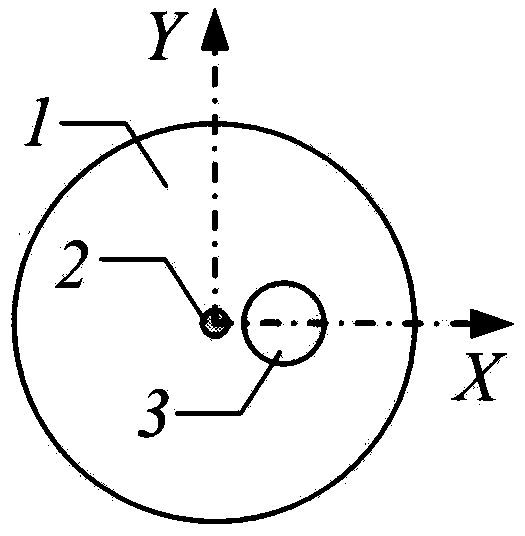

Asymmetric birefringence vortex fiber and manufacturing method of asymmetric birefringence vortex fiber

ActiveCN103969737AEasy to makeEasy to controlGlass making apparatusCladded optical fibreFiberNon symmetric

The invention discloses an asymmetric birefringence vortex fiber and a manufacturing method of the asymmetric birefringence vortex fiber. The asymmetric birefringence vortex fiber is formed by drawing an optical fiber perform with a single stress area or dual stress areas in a rotary mode, and therefore the asymmetric birefringence vortex fiber has a single spiral stress area or dual spiral stress areas; in addition, due to asymmetric distribution of the stress areas or different materials of the stress areas, spirally-distributed asymmetric stress birefringence is generated in a fiber core of the asymmetric birefringence vortex fiber, a radial phase difference of transmission light waves is accordingly formed, the light waves transmitted in the asymmetric birefringence vortex fiber can accordingly obtain the orbital annular momentum, vortex phase transmission is generated, and a similar vortex light transmission mode is achieved. The asymmetric birefringence vortex fiber overall has the advantages of being tiny in structure, flexible in operation, stable in system, high in interference resistant capacity and the like, and can be used for vortex beam generation, particle control, sensing application and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

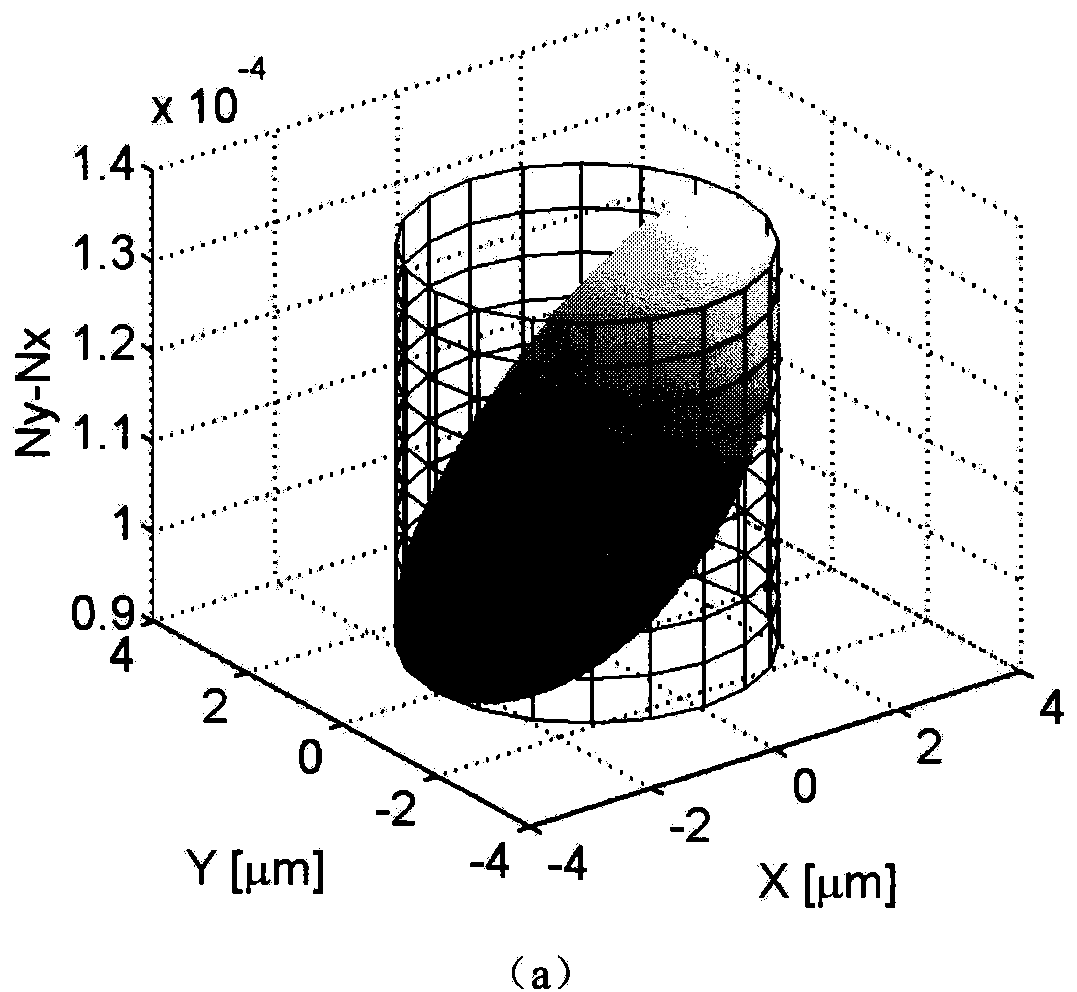

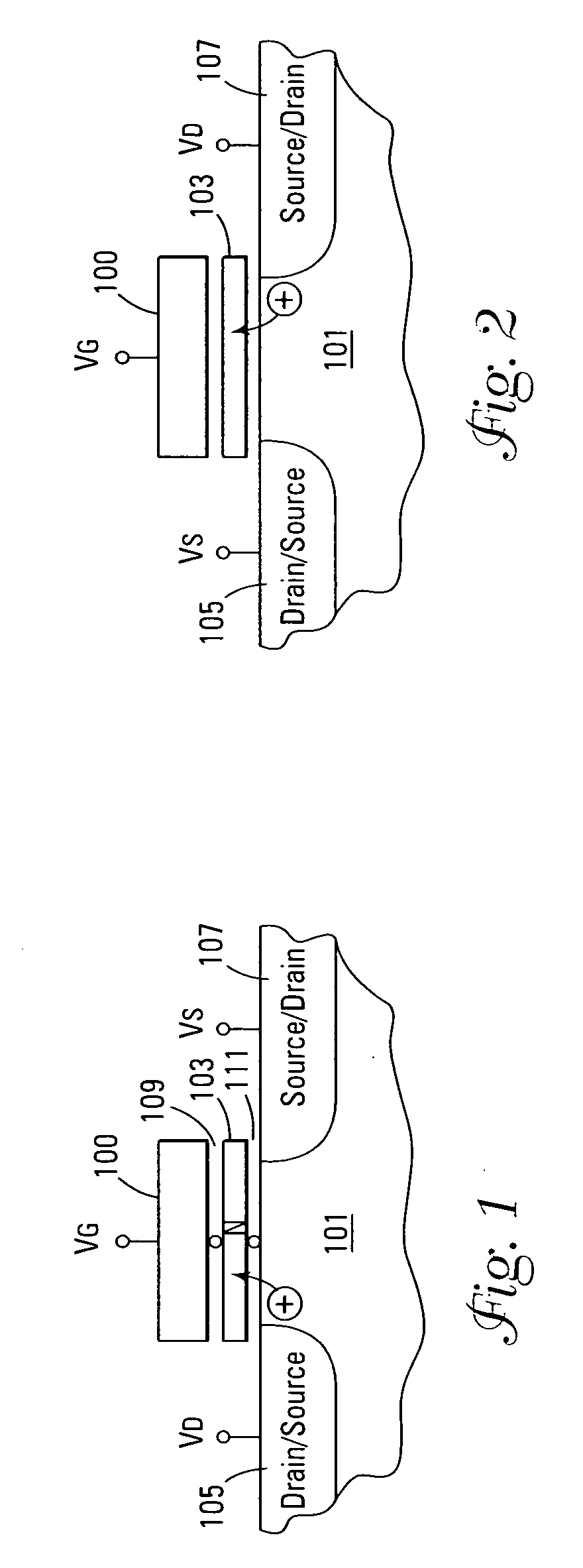

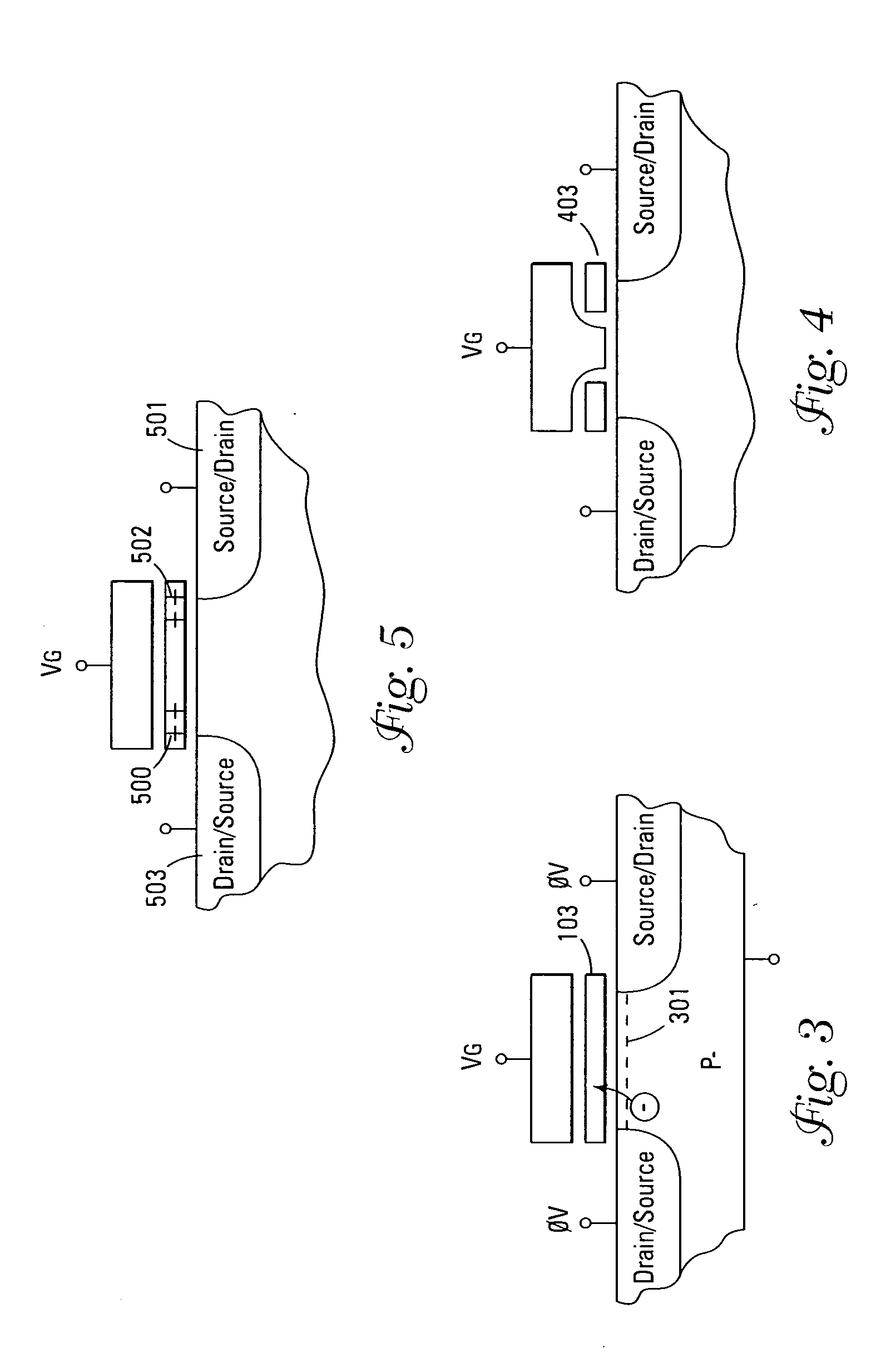

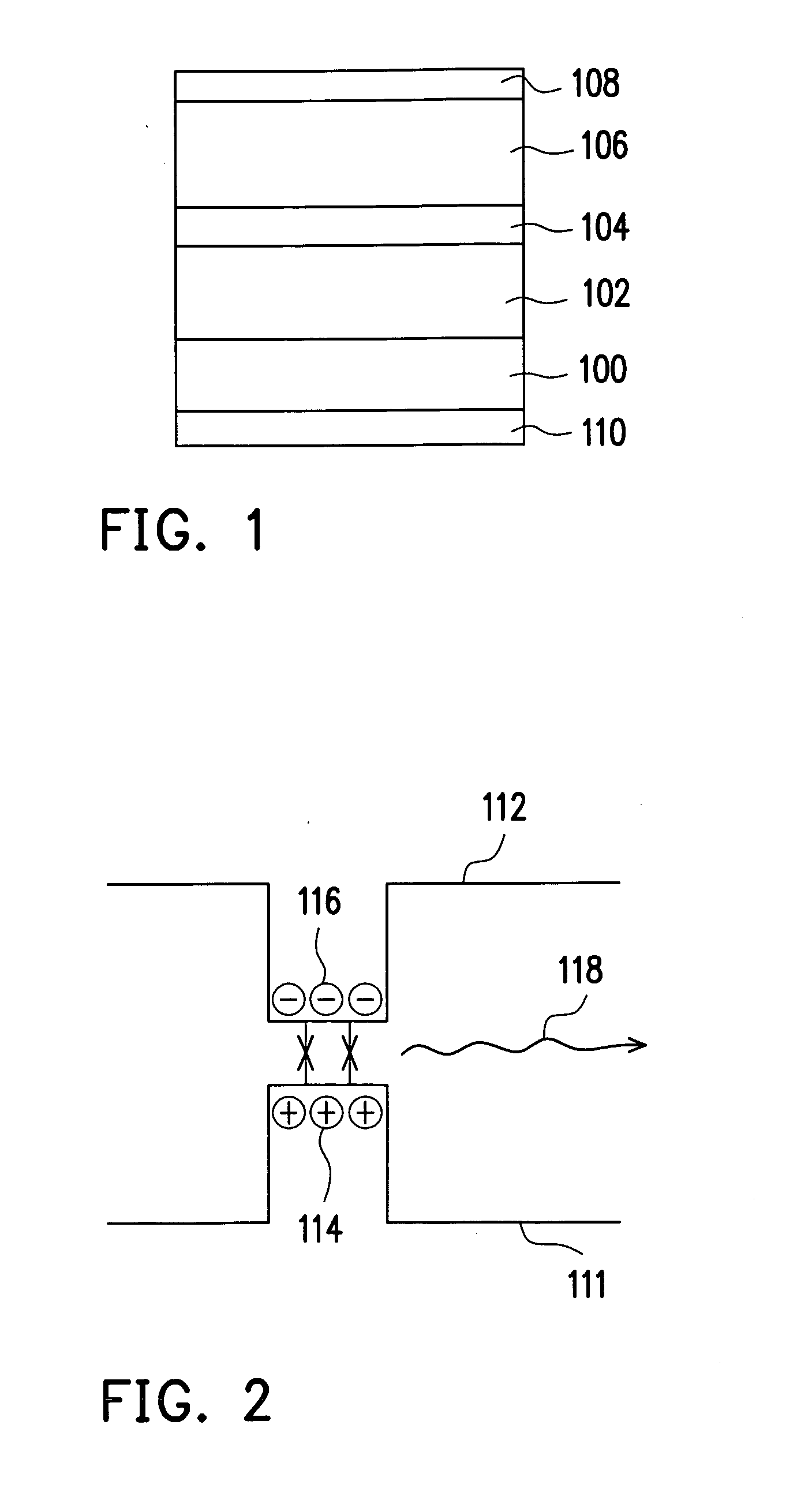

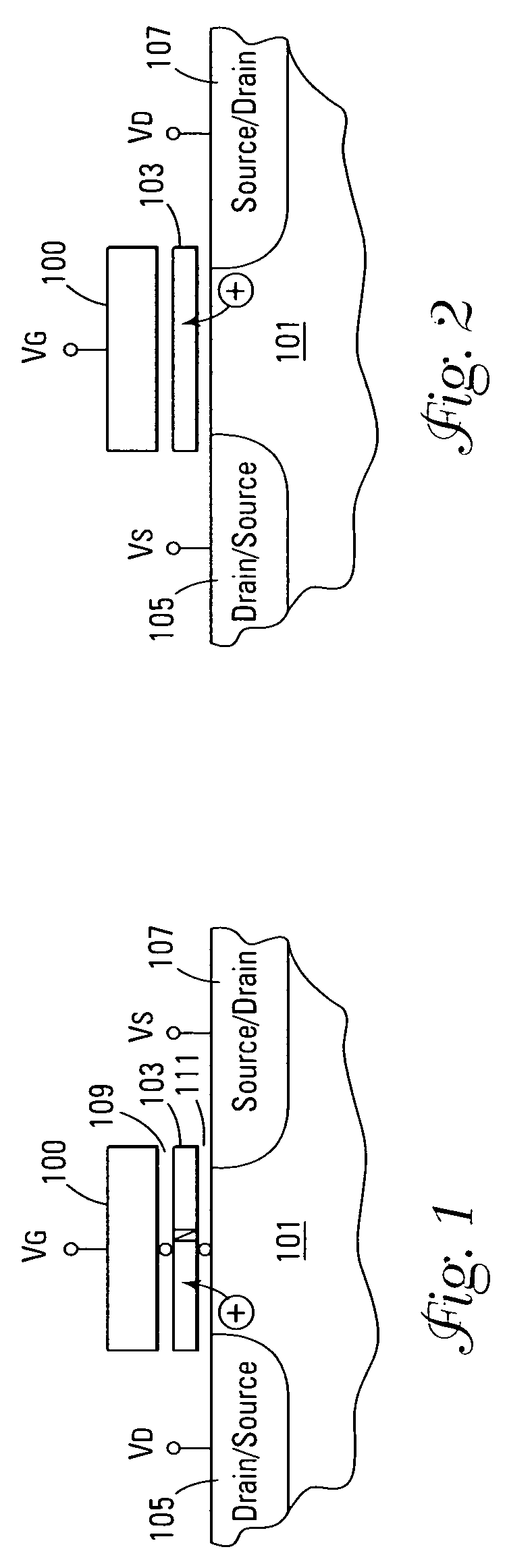

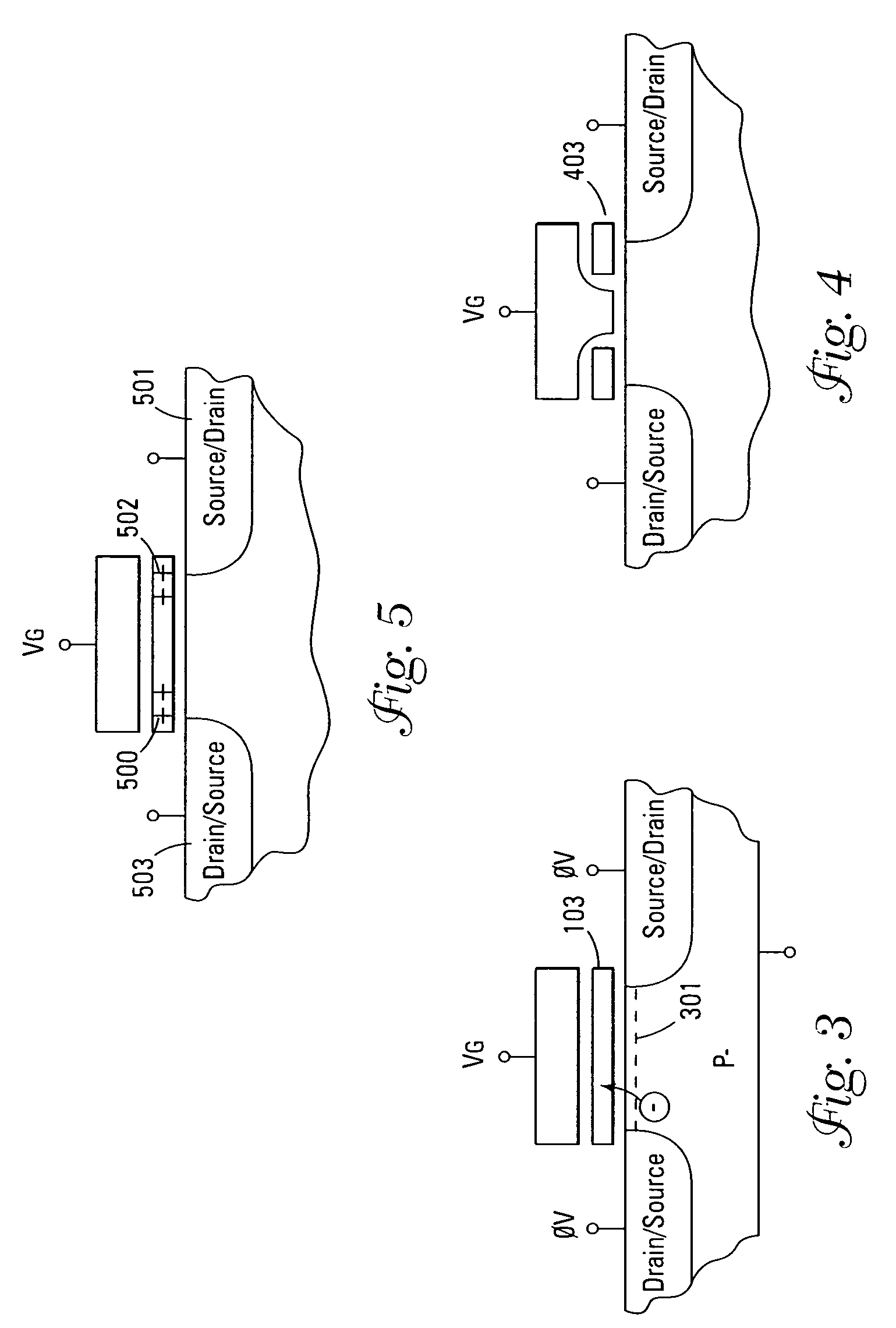

Multi-state memory cell with asymmetric charge trapping

A multi-state NAND memory cell is comprised of two drain / source areas in a substrate. An oxide-nitride-oxide structure is formed above the substrate between the drain / source areas. The nitride layer acting as an asymmetric charge trapping layer. A control gate is located above the oxide-nitride-oxide structure. An asymmetrical bias on the drain / source areas causes the drain / source area with the higher voltage to inject an asymmetric distribution hole by gate induced drain leakage injection into the trapping layer substantially adjacent that drain / source area.

Owner:MICRON TECH INC

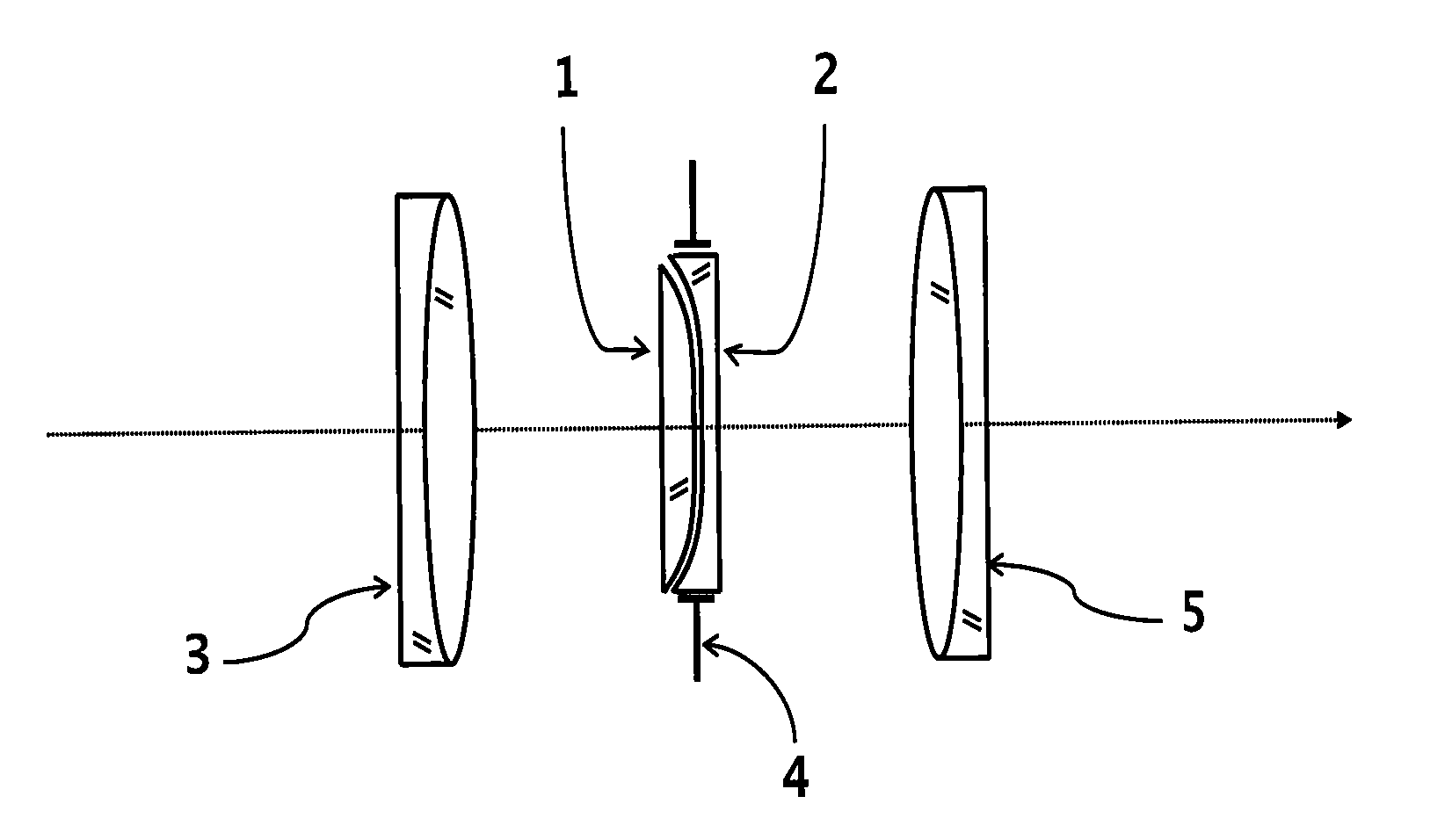

Optical system with variable field depth

An optical lens which, in a controlled manner, and without altering either the resolution or luminous capture, helps to extend the depth of field of any other optical system. The optical lens of the present invention is composed of two optical lenses that form a pair. Each of the lenses of the pair produces a change of optical path with a symmetrical distribution. If there is no relative displacement, the lenses of the pair generate an optical path difference equal to zero. When there is relative displacement, the lenses of the pair generate a change of optical path with asymmetric distribution, which helps to extend the depth of field without reducing either the resolution or luminous capture. The optical lens of this invention, in the form of an optical pair, serves any other optical system to capture images without loss of modulation, but with attenuated modulation which can be retrieved with digital processing algorithms known in the art.

Owner:UNIV DE GUANAJUATO

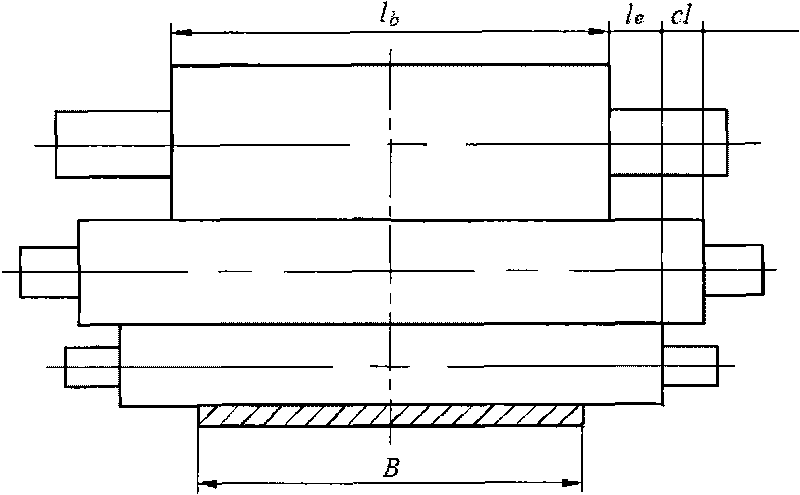

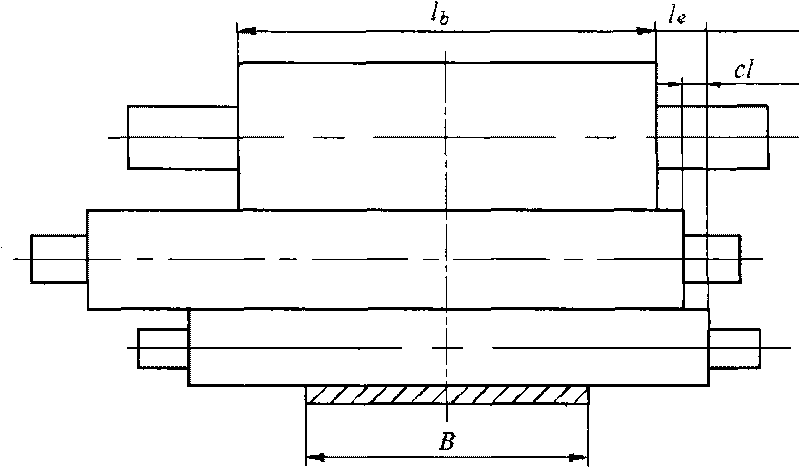

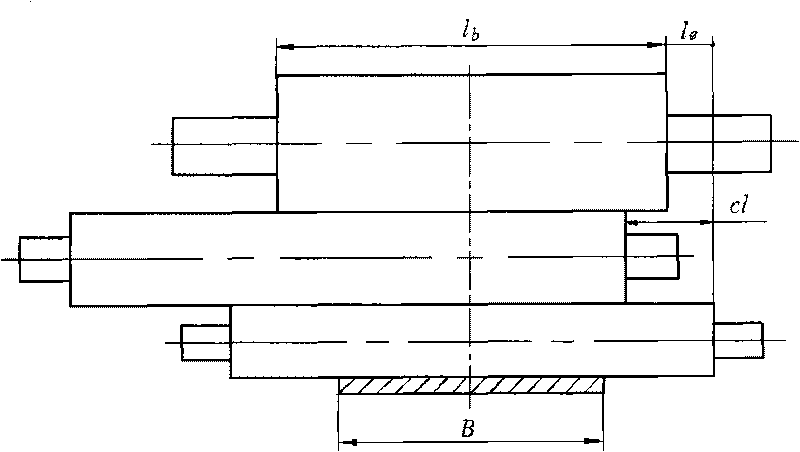

Method for controlling asymmetric transverses shifting plate shape of asymmetric bending roller of HC rolling mill

InactiveCN101716607AImproved shape controlReduce mistakesProfile control deviceAsymmetric distributionPiece Unit

The invention discloses a method for controlling an asymmetric transverses shifting plate shape of an asymmetric bending roller of a HC rolling mill. The method comprise the following steps of: (a) collecting equipment and process parameters of an HC rolling mill and band steel; (b) discretizing a roller system and a rolling piece unit; (c) computing a preceding tensile stress lateral distribution value and a unit width rolling pressure, which comprise the following steps implemented by a computer system; (d) setting bending roller influence coefficients of a supporting roller, a middle roller and a working roller during an asymmetric rolling according to an asymmetric rolling stressed model of the HC rolling mill; and (e) establishing an asymmetric rolling roller system model on the basis of a model partitioning influence coefficient method. The invention provides a roller system elastic distorted model and a metal three-dimensional plastic distortion model which are suitable for the HC rolling mill; and the preceding tensile stress and a plate convexity of the roller system elastic distorted model and the metal three-dimensional plastic distortion model are in an asymmetric distribution, the error compared with a measured value is small and precision is high. After changing adjusting parameters of the plate shape, the asymmetric rolling controlling model is also suitable for symmetric rolling; and the invention improves plate shape controlling ability of the HC rolling mill and achieves precision requirements of industrial application.

Owner:YANSHAN UNIV

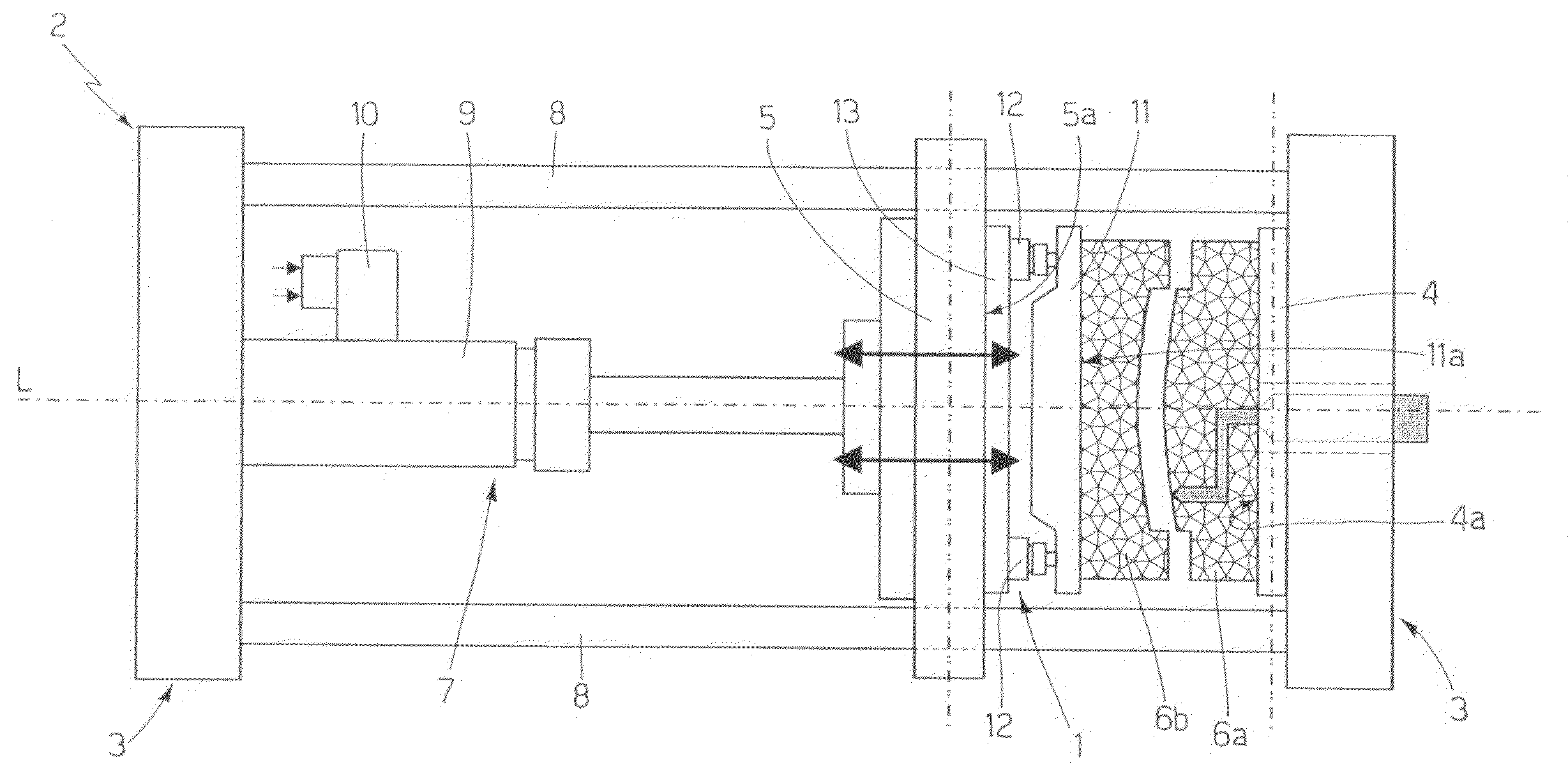

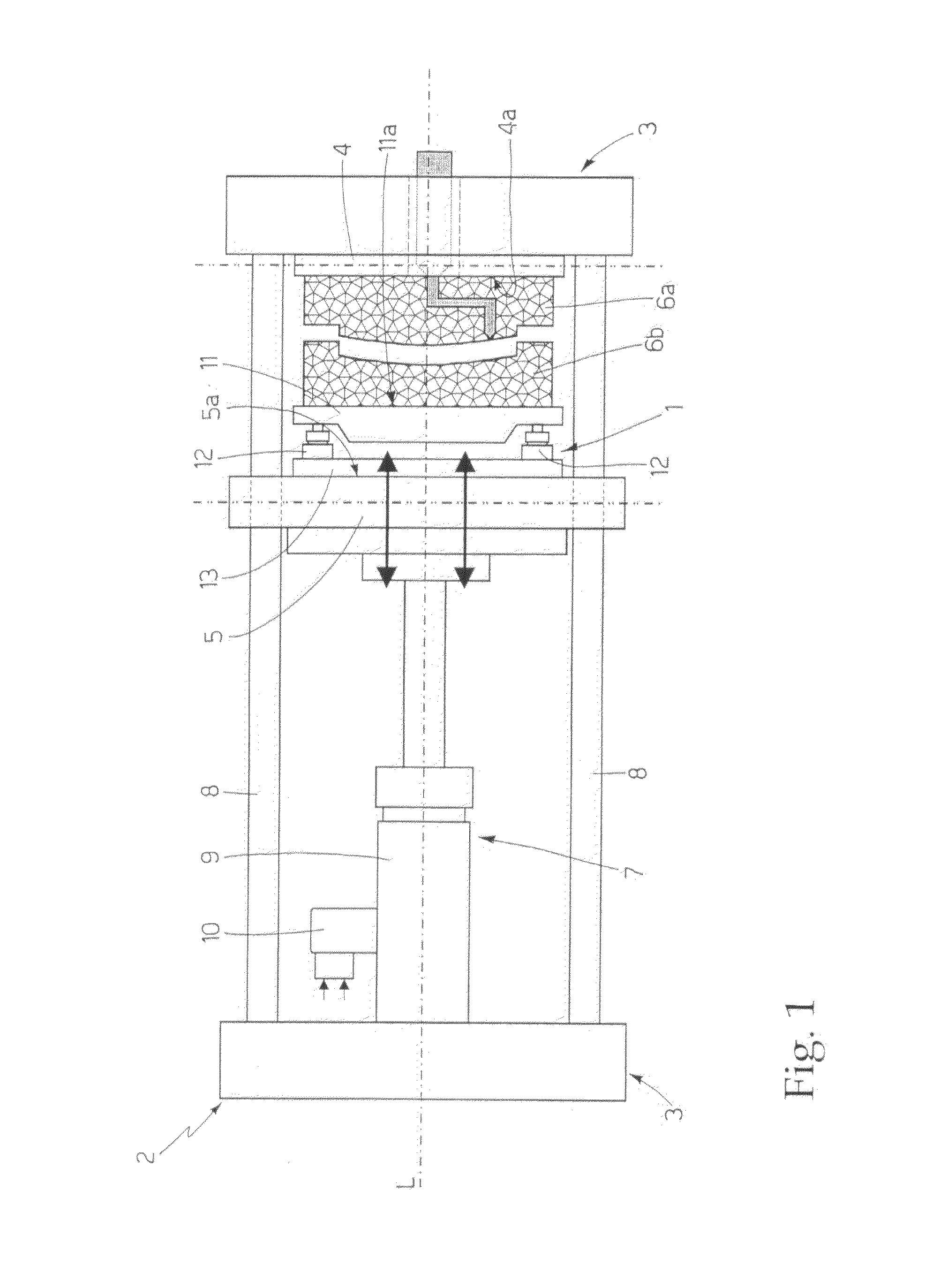

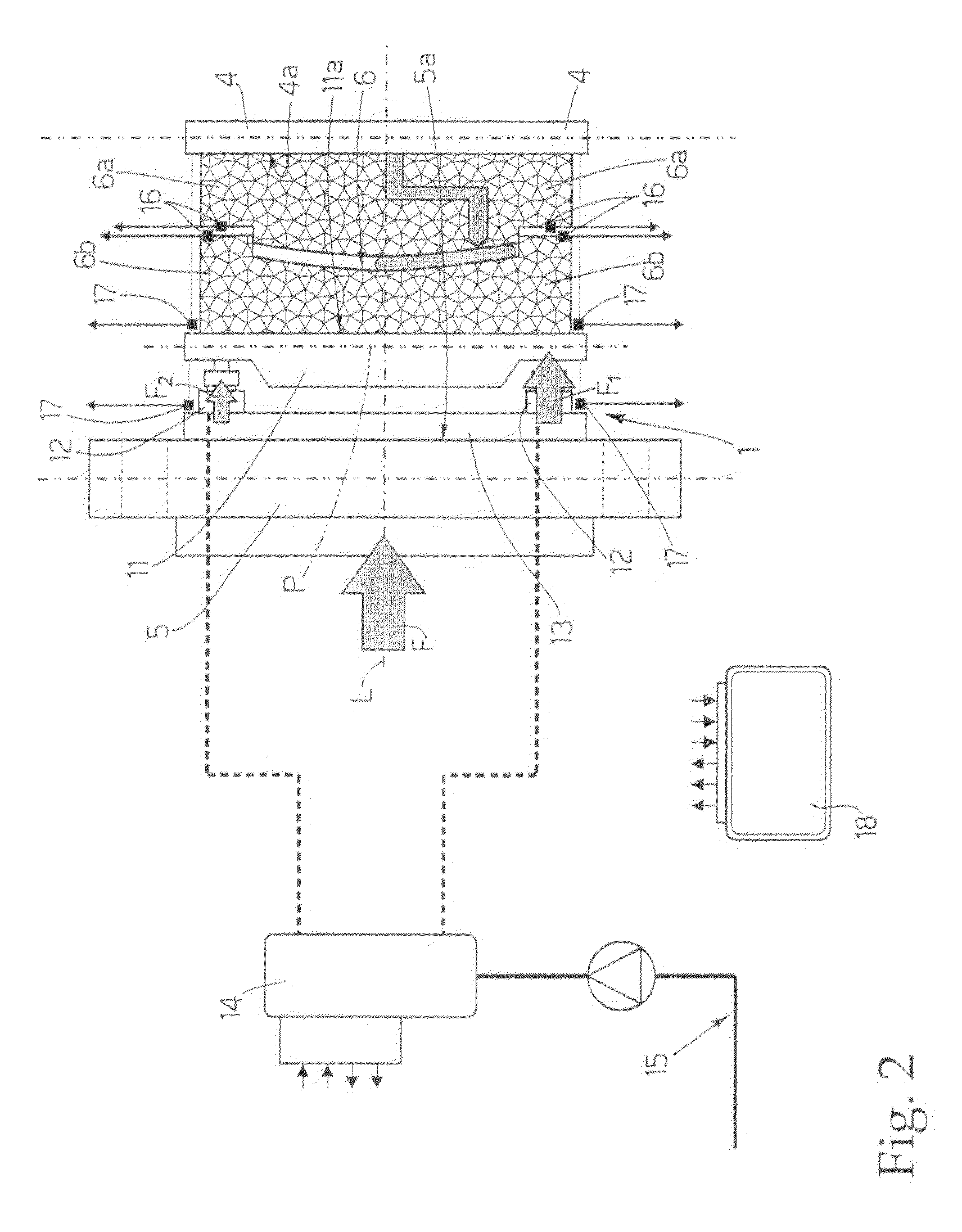

Auxiliary supporting structure for presses, and plastics molding press equipped with such a structure

InactiveUS20090117220A1Easy and cheap to produceAuxillary shaping apparatusPressesHydraulic cylinderPlastic materials

An auxiliary supporting structure for presses, having an auxiliary mold platen having a front surface designed to firmly, but removably, support a half-mold; a number of hydraulic supporting cylinders, which project from the rear of the auxiliary mold platen, in a direction parallel to a reference axis perpendicular to the plane of the auxiliary mold platen; mounting means for firmly, but removably, fixing the hydraulic cylinders to the front surface of a movable mold platen of the press; a hydraulic distributor for regulating pressurized-oil flow to and from each hydraulic cylinder independently of the others; and an electronic central control unit for controlling the hydraulic distributor as a function of signals from a number of external sensors, to enable the hydraulic cylinders to instantaneously compensate any asymmetric distribution of the mechanical forces exerted on the half-mold as the plastic material is injected.

Owner:INGLASS SPA

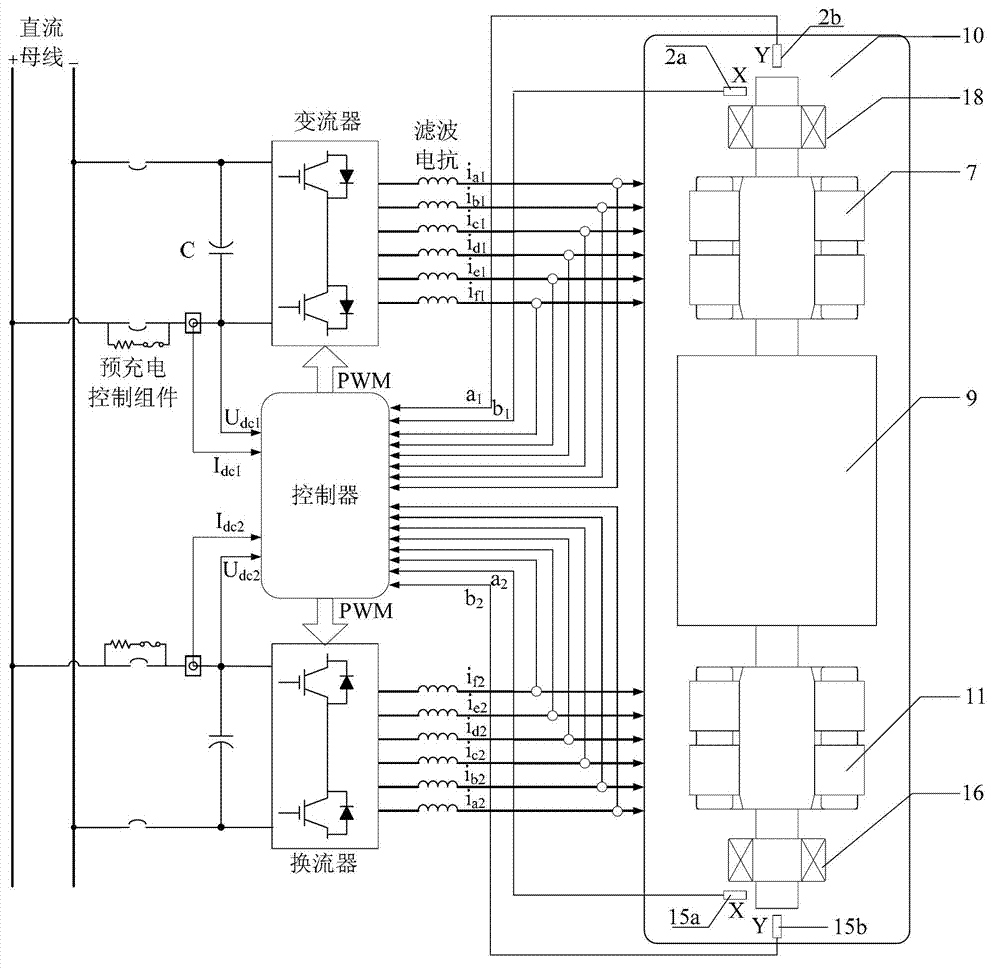

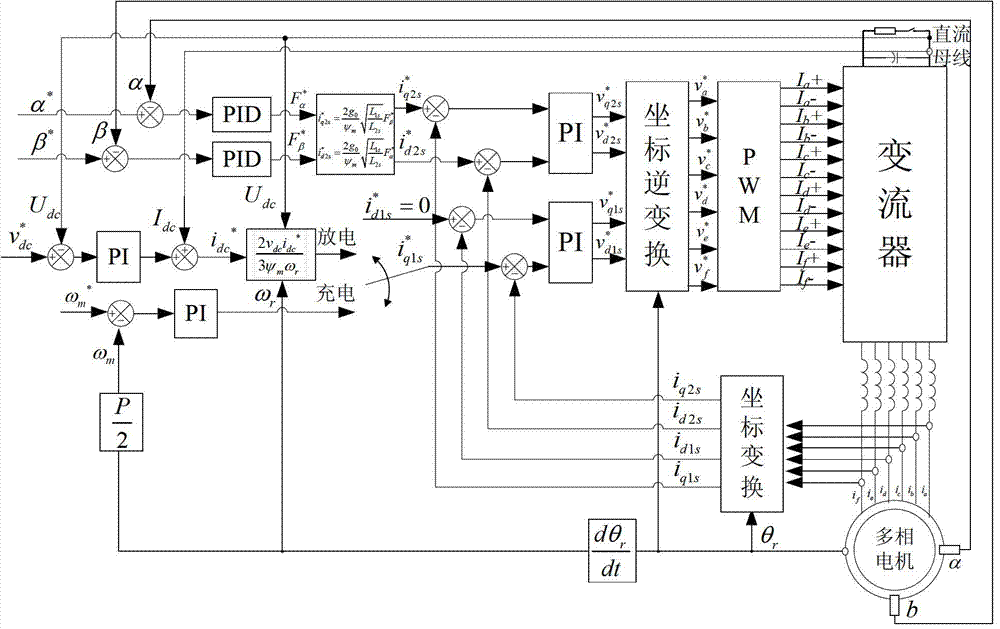

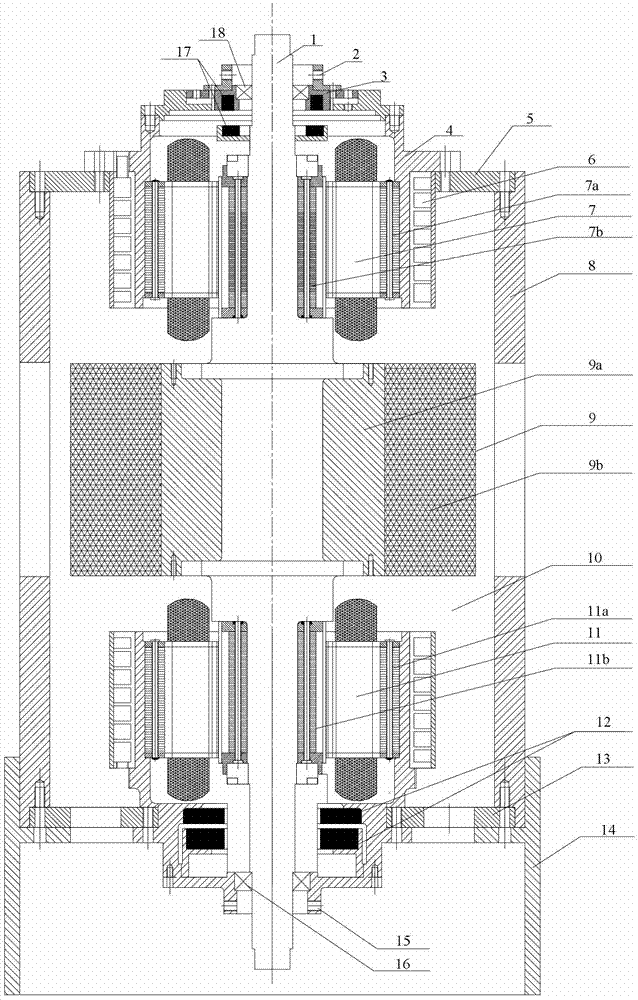

Driving and suspension integrated multi-phase fly wheel energy storage device

ActiveCN103051104AIncrease stiffnessImprove space utilizationMechanical energy handlingPhase currentsMagnetic bearing

The invention discloses a driving and suspension integrated multi-phase fly wheel energy storage device, which comprises a shell, a main shaft, a current transformer and a controller, wherein the upper, middle and lower parts of the main shaft are provided with a first multi-phase motor, a fly wheel and a second multi-phase motor respectively; each multi-phase motor comprises a rotor and a stator; each stator is provided with n phases of windings; each phase of winding is a distributed winding and is asymmetrically distributed along the circumference of an air gap; and the current transformer is an n-phase current transformer. According to the driving and suspension integrated multi-phase fly wheel energy storage device, fly wheel energy storage, and driving and magnetic suspension functions of the multi-phase motors are integrated into a whole; radial magnetic bearing components at two ends of the main shaft are reduced, so that extra axial space is not occupied; the system has a simpler and more compact structure; the bearing rigidity and the space utilization rate are greatly improved; and the driving and suspension integrated multi-phase fly wheel energy storage device has broad application and development prospect in the high-speed fly wheel energy storage system of high energy storage density, high transformation efficiency, low idle speed loss and long service life.

Owner:ZHEJIANG UNIV

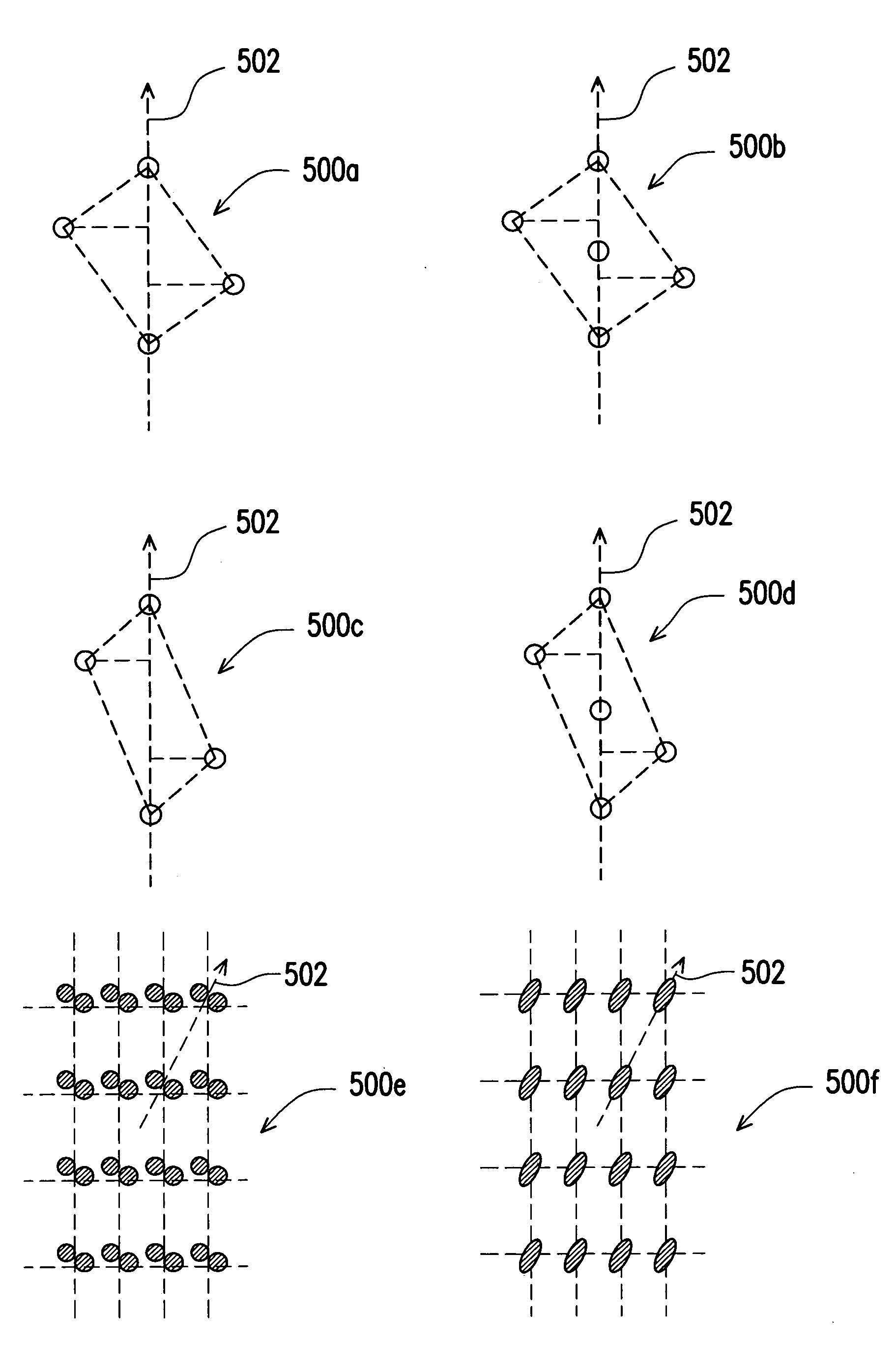

Electromagnetic polarizing structure and polarized electromagnetic device

InactiveUS20070109639A1Reduce disadvantagesSimple structureLaser detailsPolarising elementsAsymmetric distributionOptical polarization

An electromagnetic polarizing structure can polarize a non-polarized (or a partially polarized) electromagnetic (EM) wave completely. The EM polarizing structure includes a layered structure. Several medium nodes are located in such a polarizing layer and distributed as a two-dimensional unit cell array on a plane. The array unit cell has an operation axis, which passes the diagonal. These medium nodes are distributed asymmetrically with respect to the operation axis. A polarizing EM device with the foregoing EM polarizing structure and a radiation-active structure can thus emit a polarized EM wave.

Owner:IND TECH RES INST

Glass ceramic plate providing a cooking surface for a cooking apparatus and having a coating on an underside thereof and coating process for making same

InactiveUS20080035896A1Good chemical resistanceEasily oxidizableConductive materialHot plates heating arrangementsSpectral transmissionAsymmetric distribution

The glass ceramic plate for a cooking apparatus is transparent to visible light and IR radiation and has a noble metal film on its underside. The noble metal film is composed of an alloy of gold, platinum and / or palladium, which imparts a reflective property to it. It contains from 0 to 5 percent by weight, in relation to a total metal content, of silver, copper, silicon, bismuth and other metals that are not noble metals. The glass ceramic plate coated with the noble metal film has a spectral transmission of 0 to 12% in the infrared region of the spectrum. When a decoration consisting of a grid of unsymmetrically distributed elements is provided on the topside of the glass ceramic plate, defects in the glass ceramic material can be concealed. The invention also includes a method of coating.

Owner:SCHOTT AG

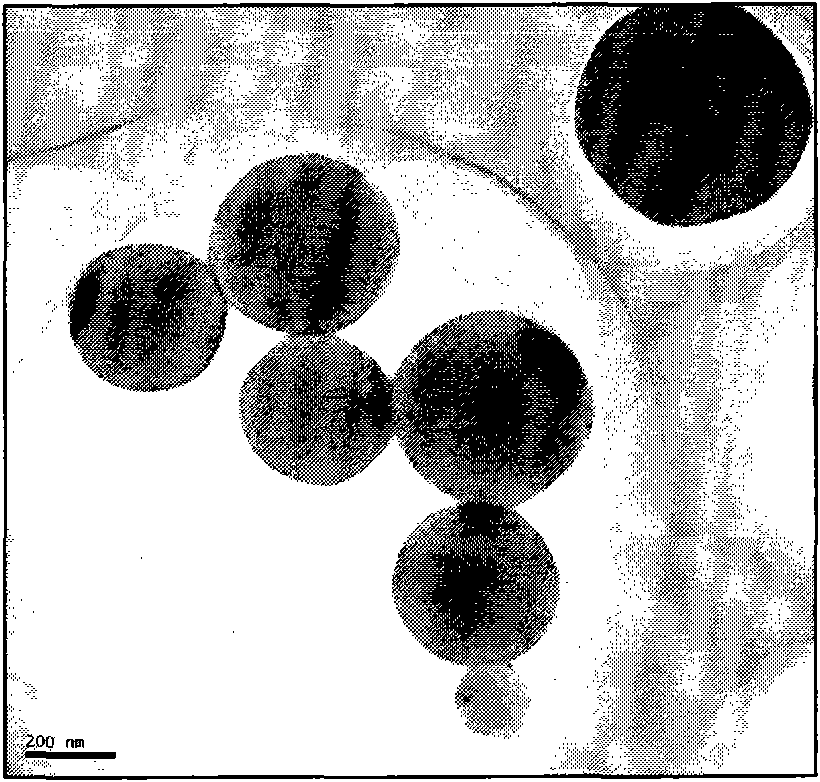

Method for preparing organic-inorganic composite microspheres with eccentric structure

ActiveCN101857699AMicroballoon preparationMicrocapsule preparationMicrosphereAsymmetric distribution

The invention relates to a method for preparing organic-inorganic composite microspheres with eccentric structures, which is characterized by comprising the following steps of: performing surface modification on inorganic particles; adding a hyperdispersant, an assistant emulsifier, and a styrene monomer into the modified inorganic particles to prepare an oleic phase; and then mixing the oleic phase and an aqueous phase prepared from a surfactant and distilled water to pre-emulsify, stirring the mixture, raising the temperature and performing centrifugal separation on the mixture to obtain the organic-inorganic composite microspheres with the eccentric structures. In the method for preparing the organic-inorganic composite microspheres with the eccentric structures, the inorganic particles are subjected to surface modification, and then the composite microspheres in which the inorganic particles are distributed asymmetrically in the organic microspheres are prepared by a miniemulsion polymerization method. The organic-inorganic composite microspheres with complex eccentric structures are prepared by the simple and convenient miniemulsion polymerization method; and the grain size of the microspheres is 300 to 900 nm, and the solid content is 8 to 40 percent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

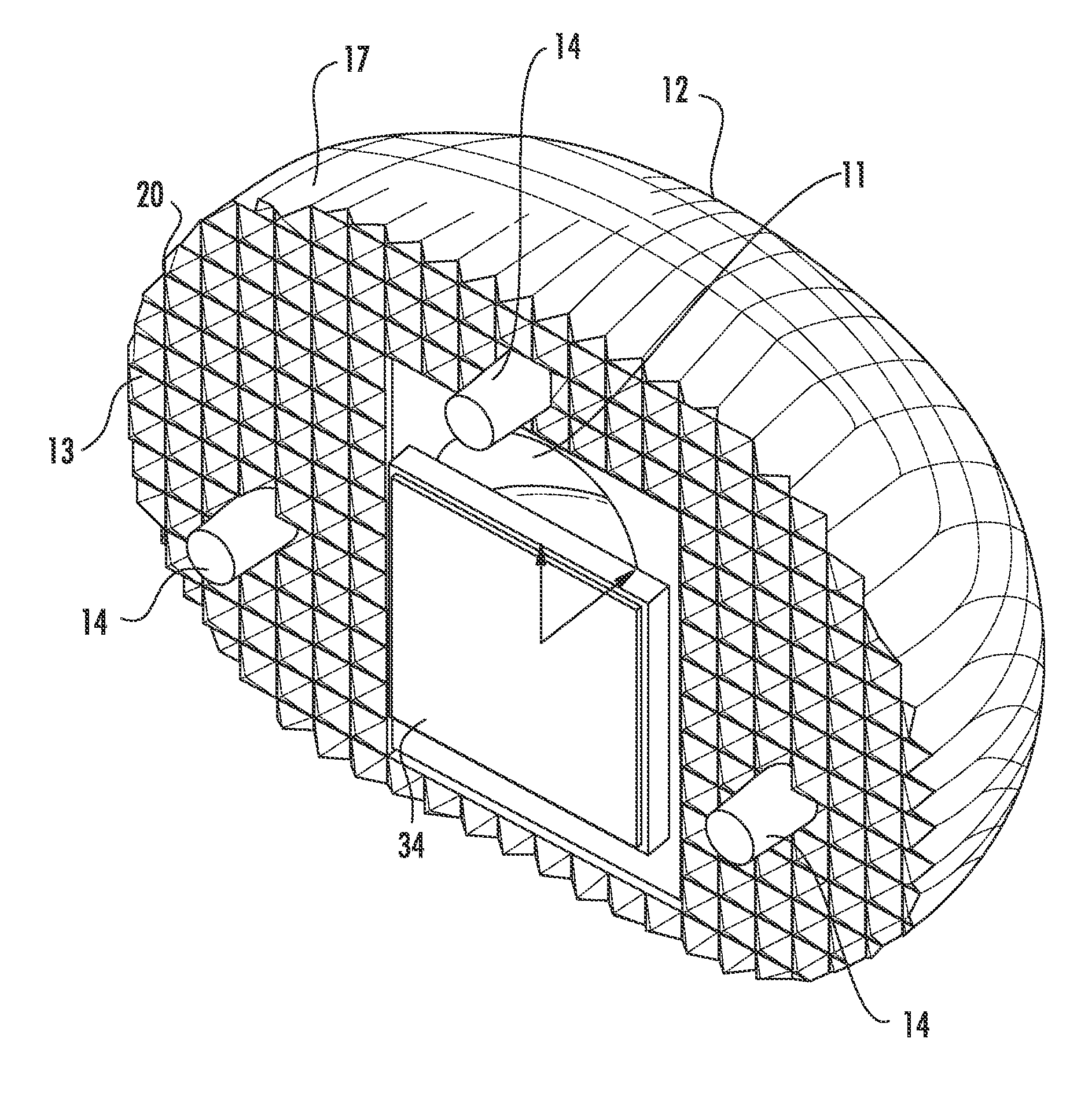

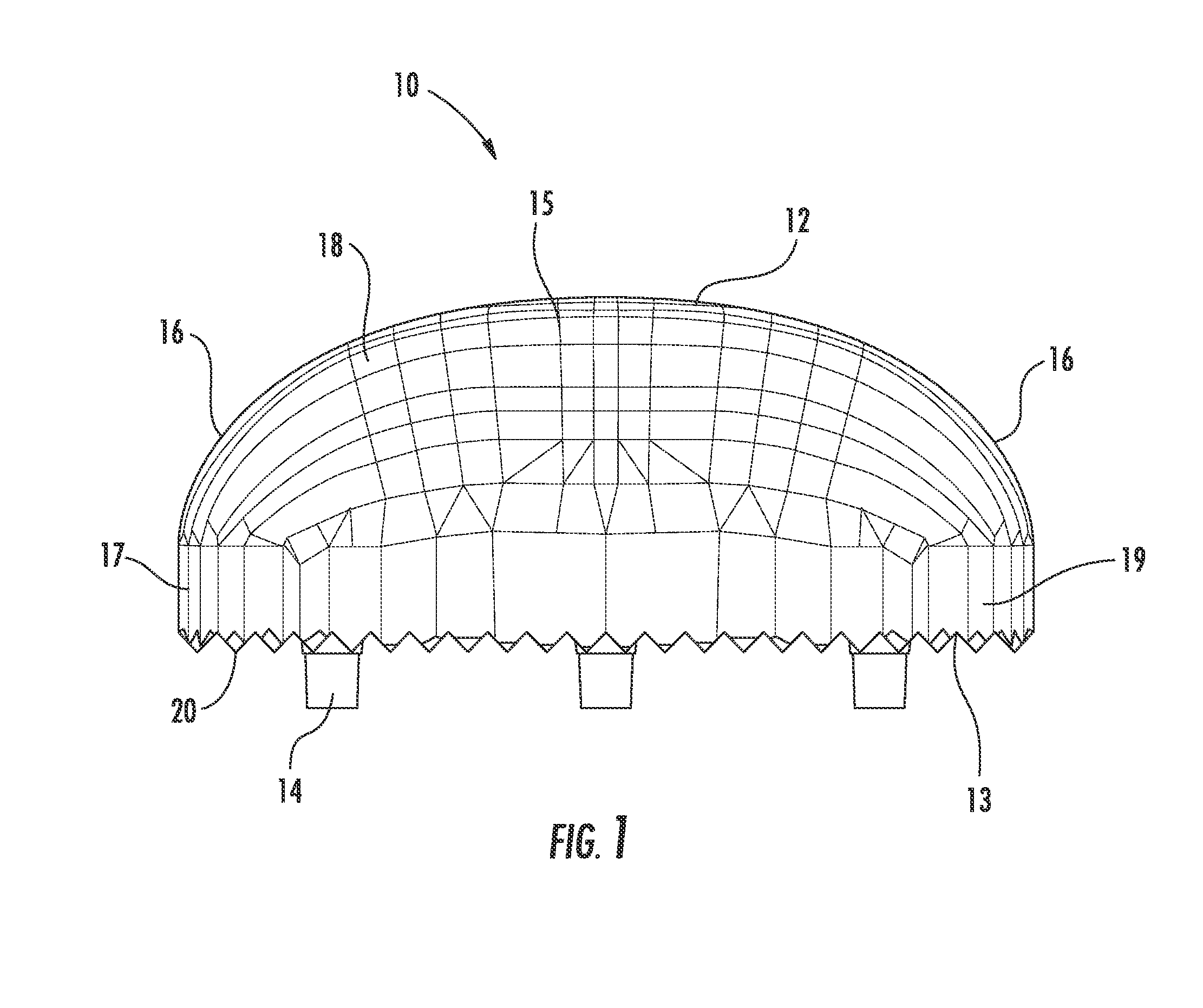

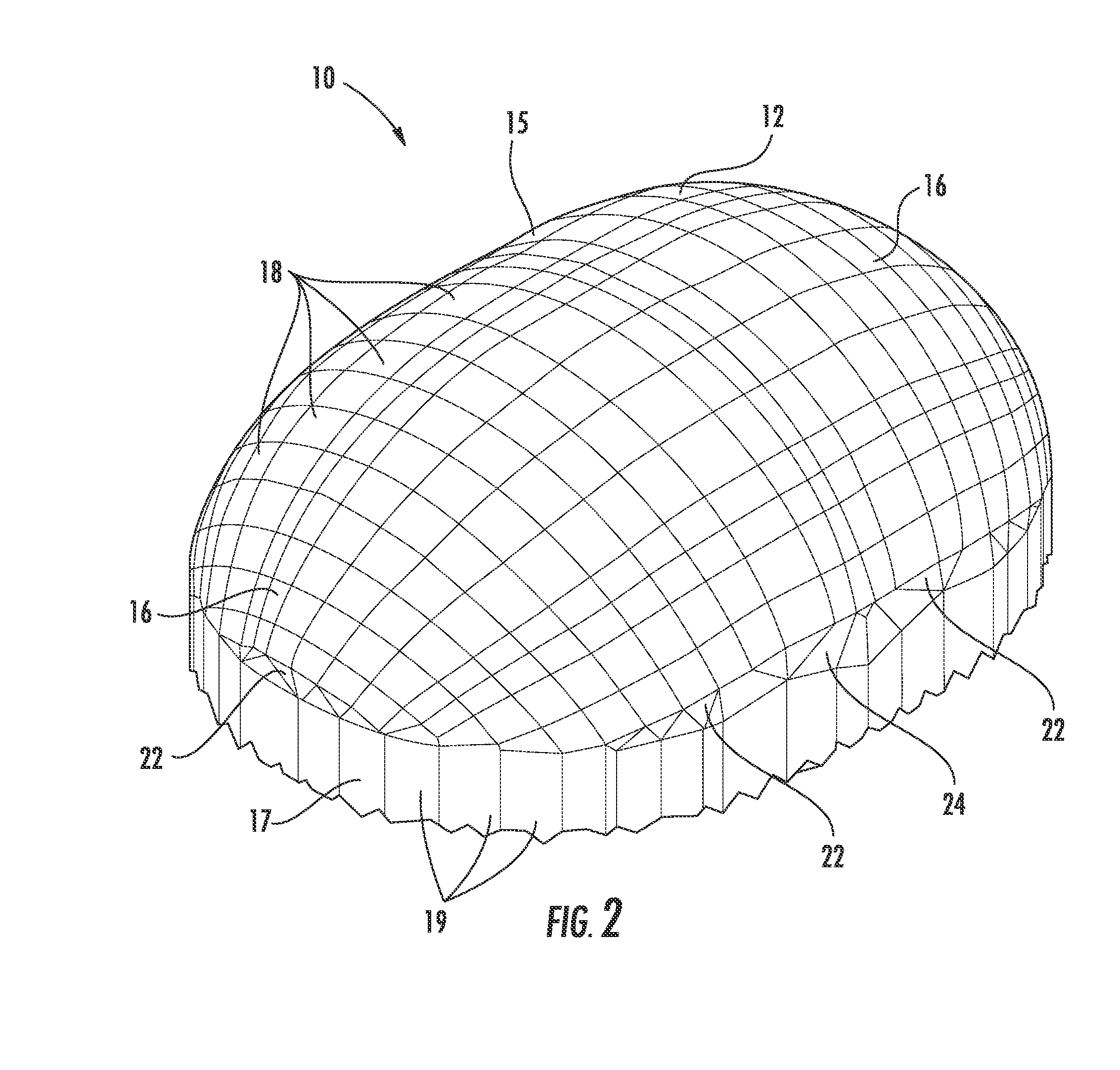

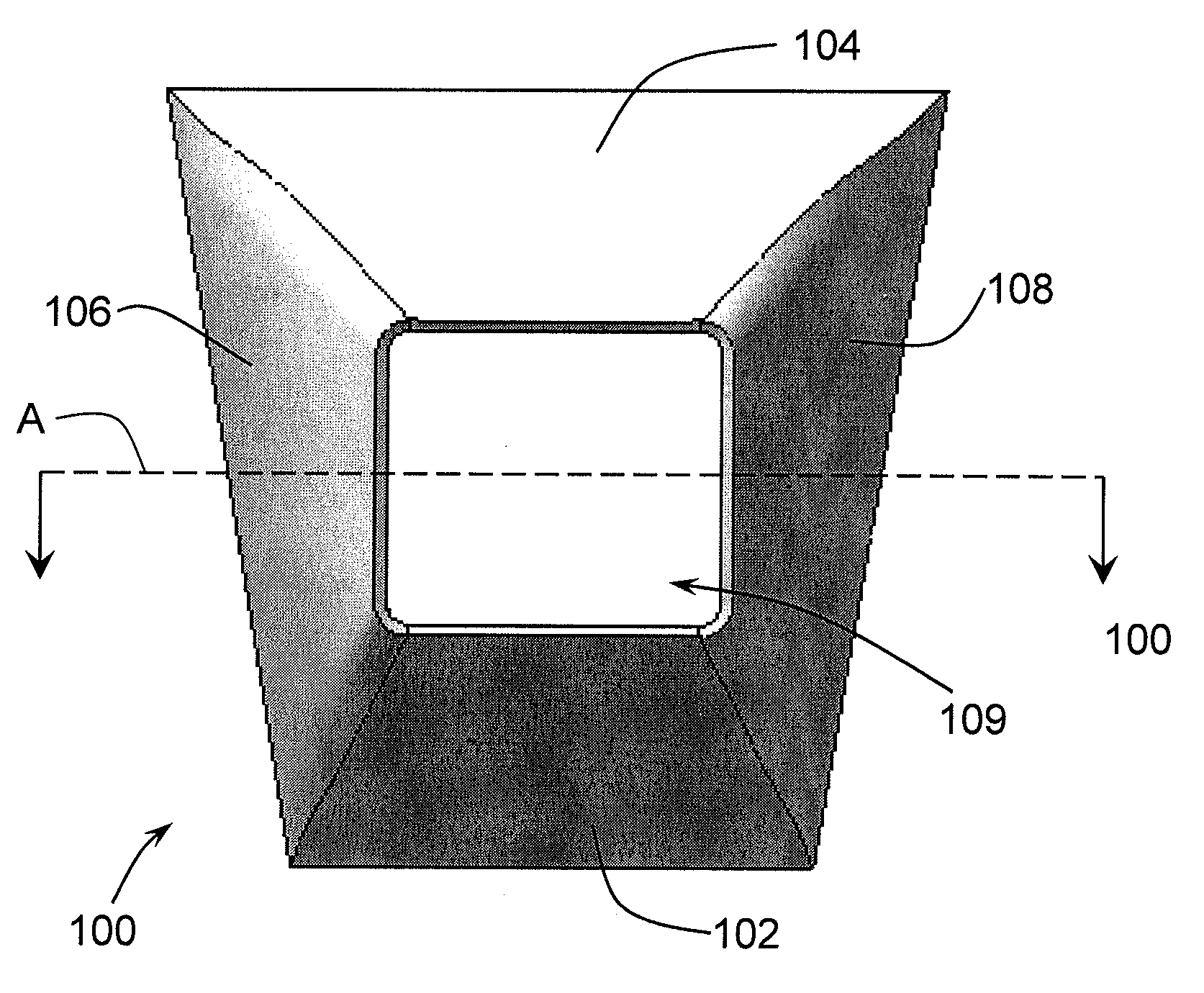

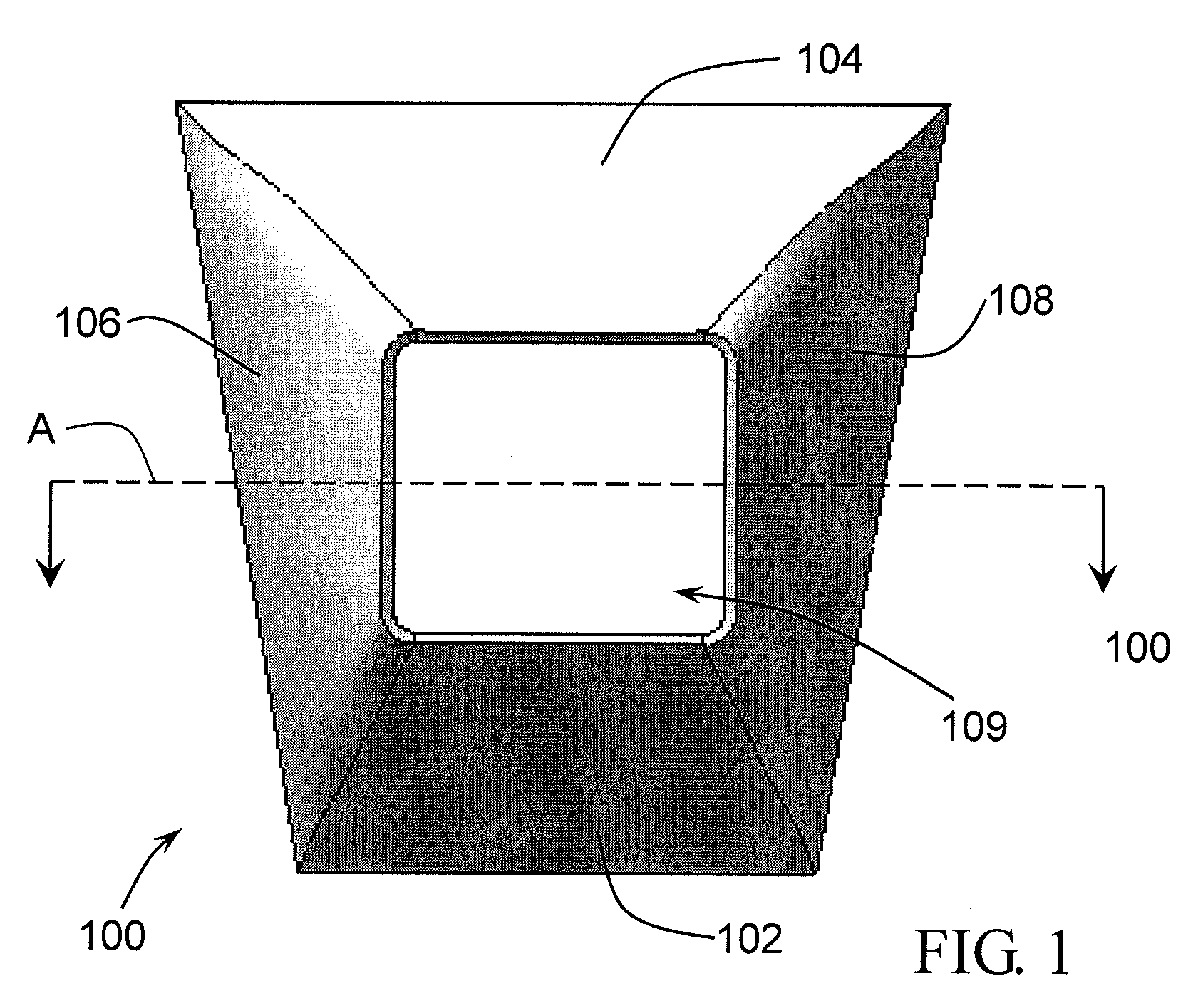

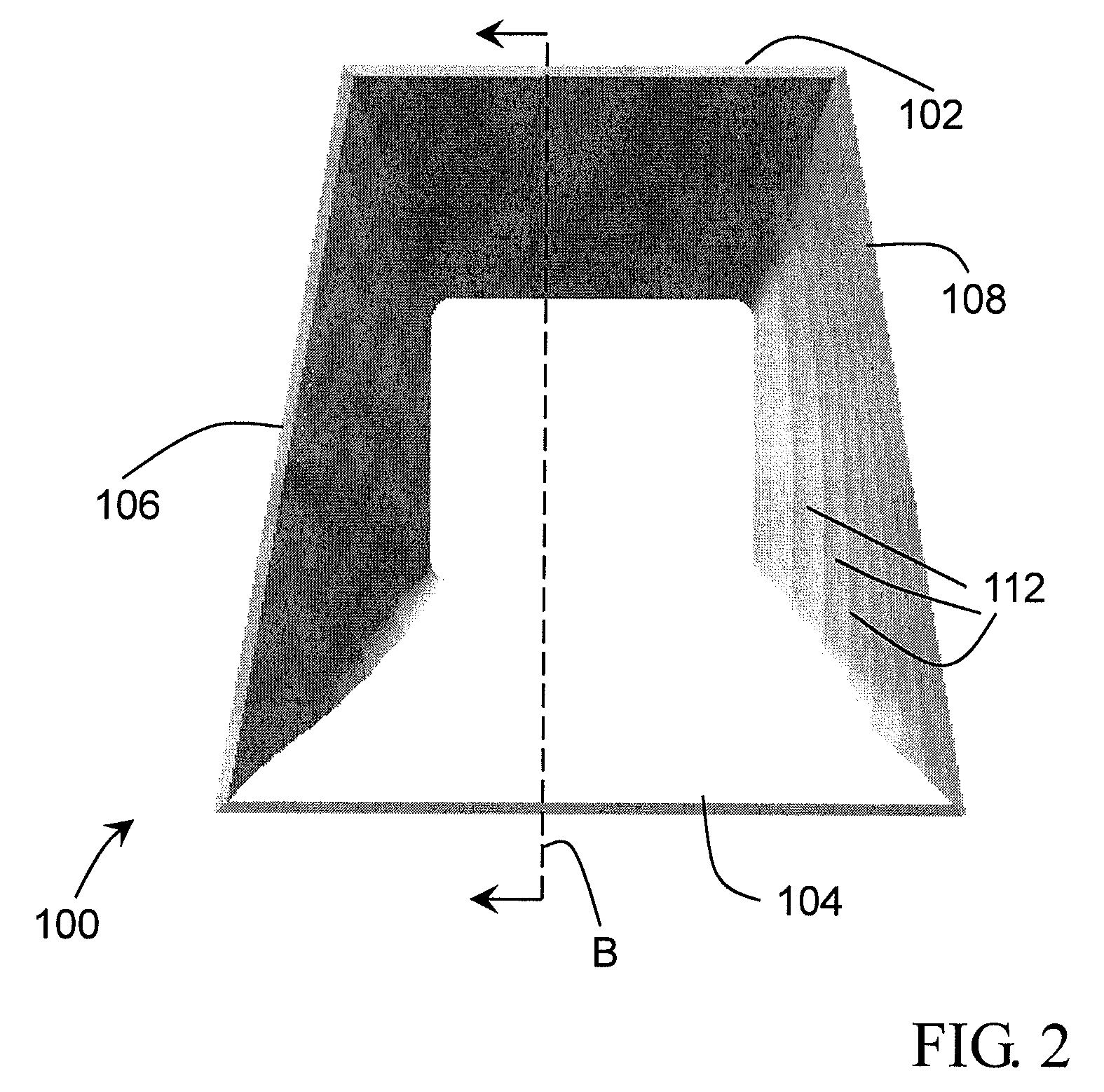

Optical reflector

An optical reflector for emitting light generated from a light source, such as a light emitting diode. According to one embodiment, the optical reflector includes a plurality of panels forming a cavity, the cavity having a light receiving end and a light output end, the inner side of the cavity having a reflective surface, and wherein the cavity has a plurality of stepped layers along the inner surface of the cavity extending from the light receiving to the light output end; and wherein the light receiving end is configured to receive the light generated from the light source, and the stepped layers of the cavity are configured to reflect the light generated from the light source and emit the reflected light from the light output end in an asymmetrical distribution. Embodiments of present invention use a trapezoidal shape to create the asymmetrical output distribution.

Owner:HONG KONG APPLIED SCI & TECH RES INST

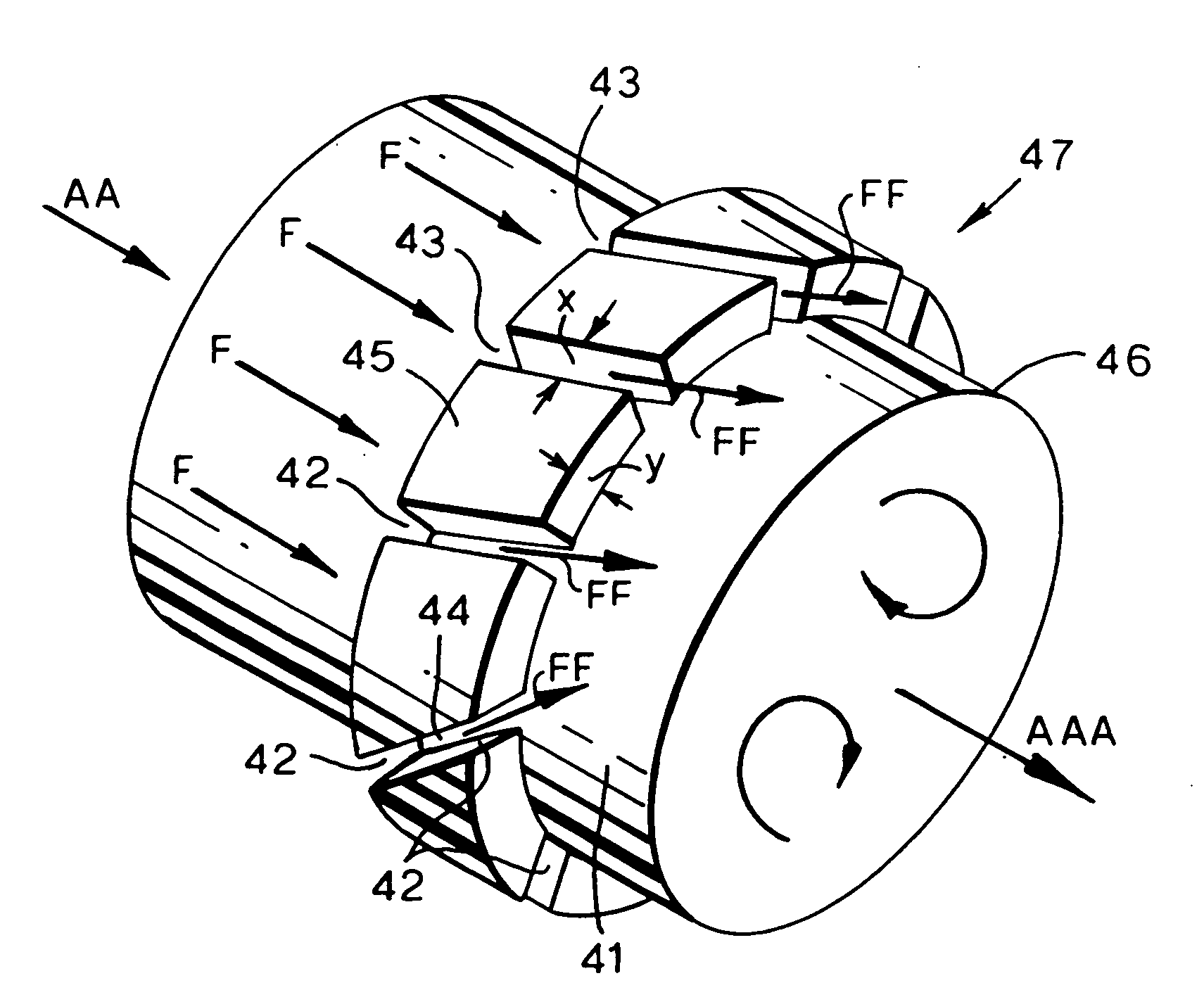

Fuel nozzles

InactiveUS20090217669A1Turbine/propulsion fuel supply systemsContinuous combustion chamberInjector nozzleFuel distribution

In order to achieve better fuel distribution despite an oversized fuel injector nozzle relative to the impingement cross-section of an air flow directed towards that nozzle, an asymmetric distribution of fuel is provided. This asymmetric distribution is achieved by providing fuel distribution structures about the injector nozzle which present varying amounts of fuel to the air flow dependent upon the localised flow pressure in the air flow presented to the nozzle. Such asymmetric distribution of fuel is achieved by providing passages or jets of varying cross-section or distribution / spacing at different parts of the fuel injection nozzle dependent upon incident flow pressure. Thus, both parts of the injector nozzle directly impinged by the air flow generally present more fuel to that flow compared to depleted flow pressure zones of the air flow.

Owner:ROLLS ROYCE PLC

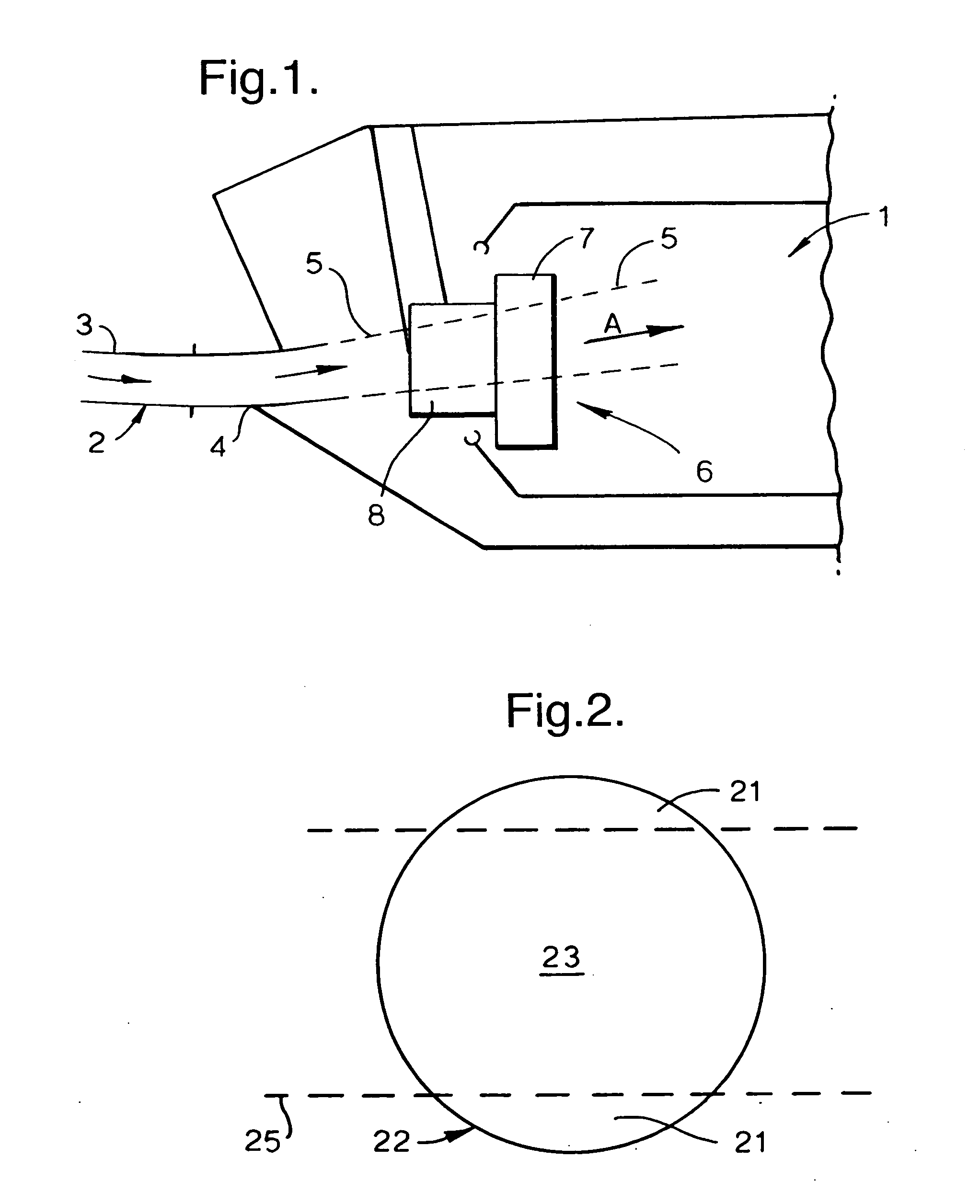

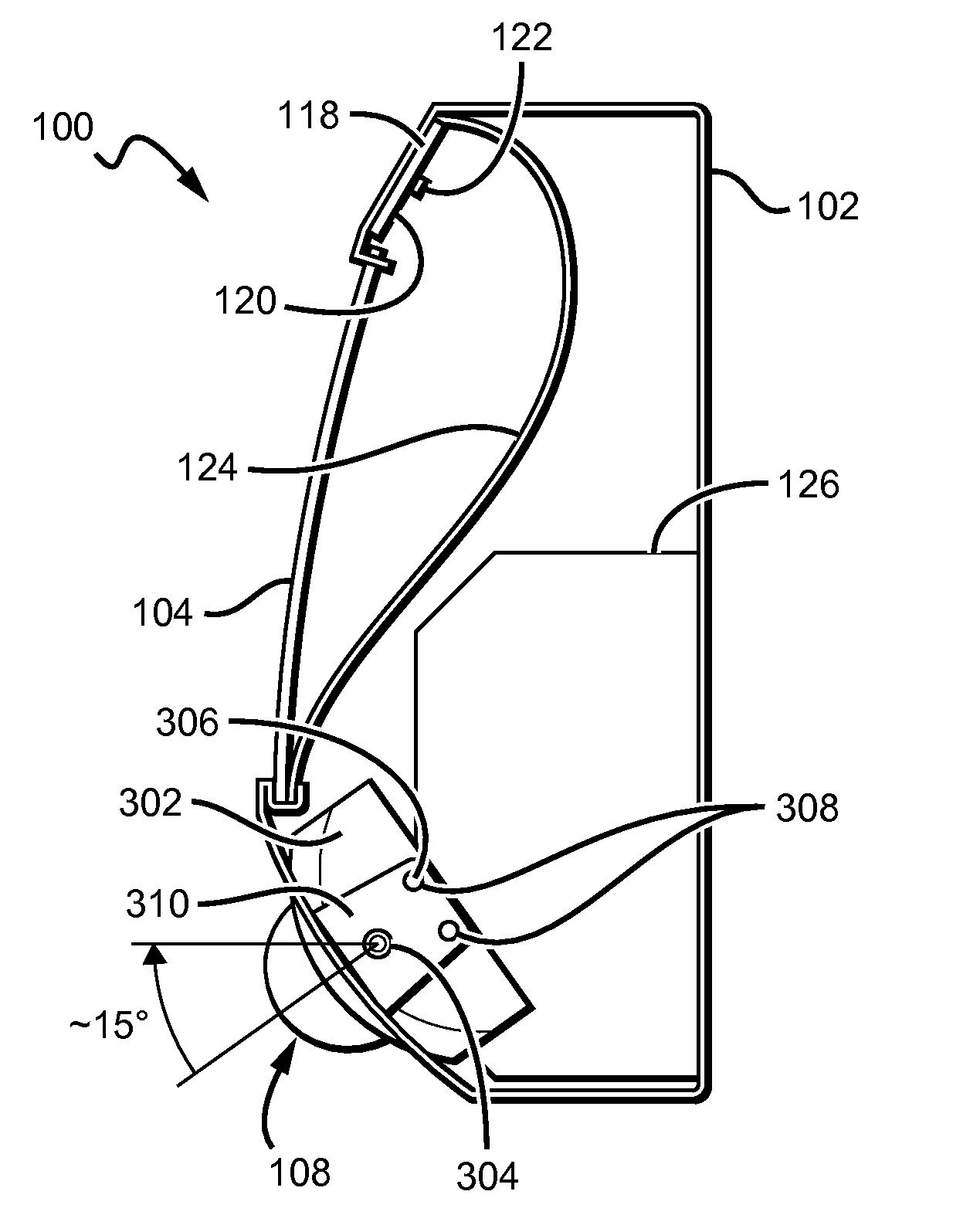

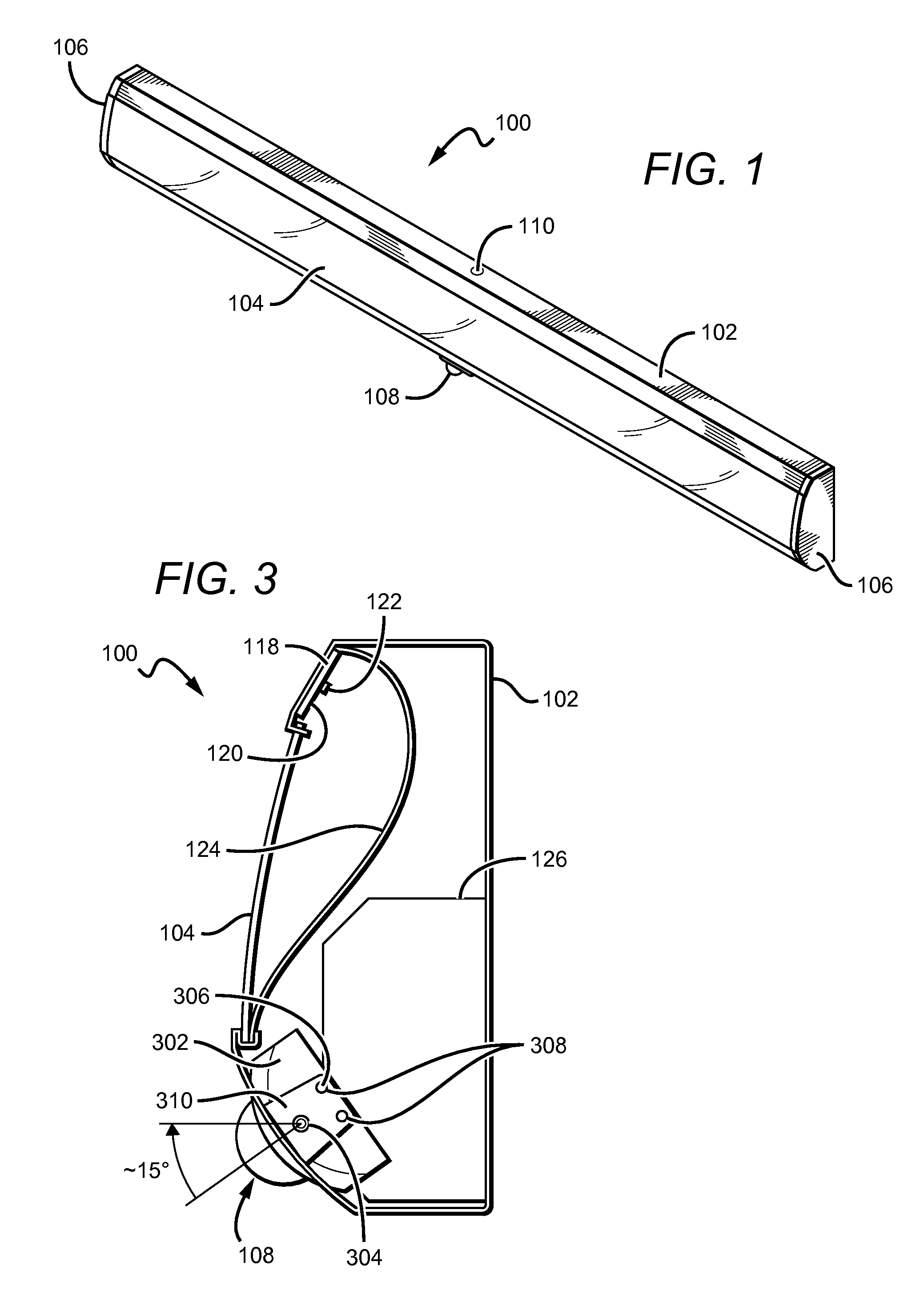

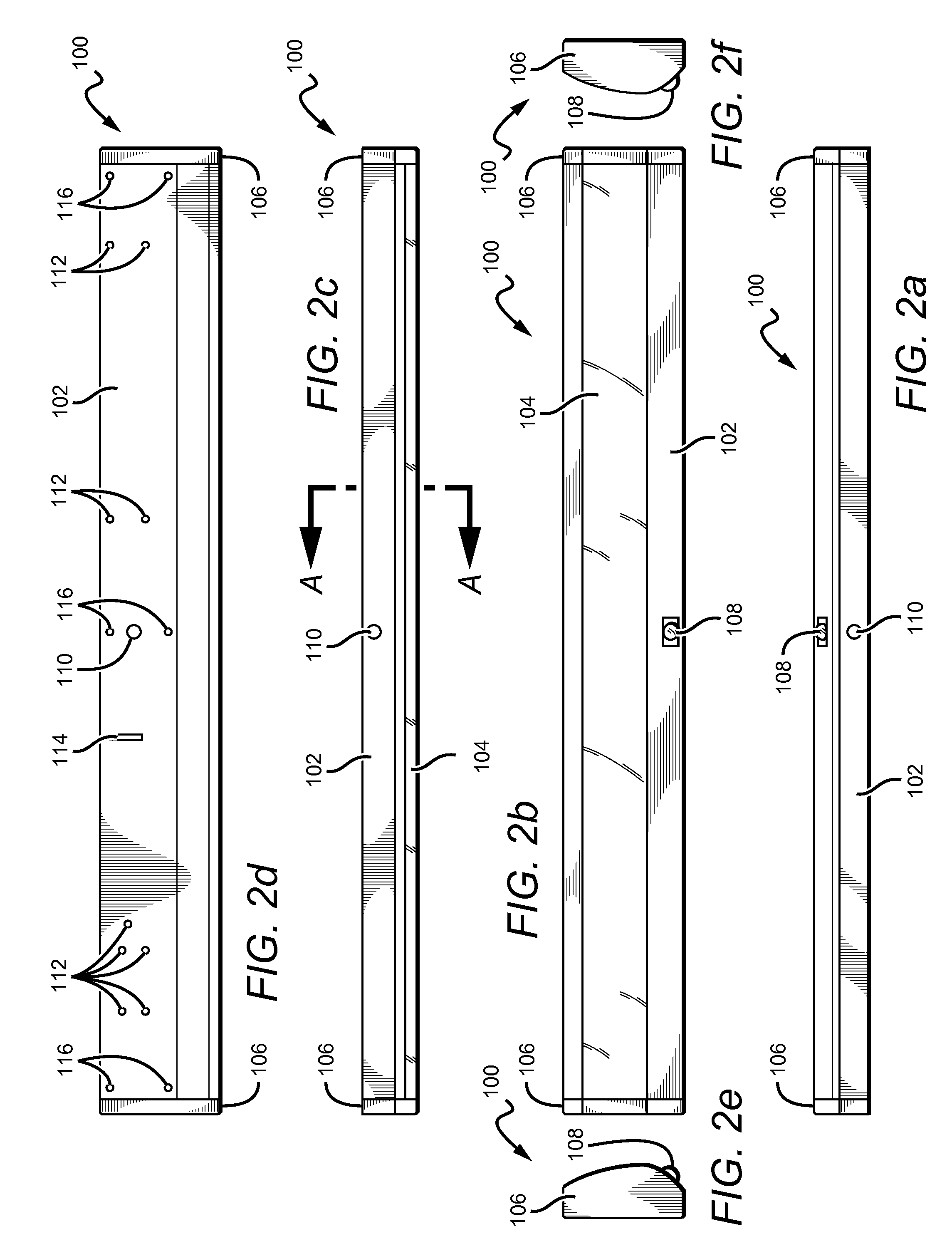

Linear solid state lighting fixture with asymmetric distribution

ActiveUS20140268721A1Non-electric lightingLight source combinationsBack reflectorAsymmetric distribution

A linear solid state lighting fixture with asymmetric distribution. The fixture comprises an elongated back reflector along the longitudinal direction of the fixture. At least one light source is arranged to emit toward the back reflector. The source(s) are mounted to a heat sink structure such that at least a portion of light emitted from the source(s) first impinges on the back reflector which redirects at least a portion of the light toward an exit lens. The exit lens interacts with the light as it is emitted from the fixture. Both the shape of the individual fixture elements (e.g., the back reflector and the exit lens) and the arrangement of these elements provide an asymmetrical light output distribution. Various mount mechanisms may be used to attach the fixture to a surface such as a ceiling or a wall, or the fixture may be suspended from a in a pendant configuration.

Owner:IDEAL IND LIGHTING LLC

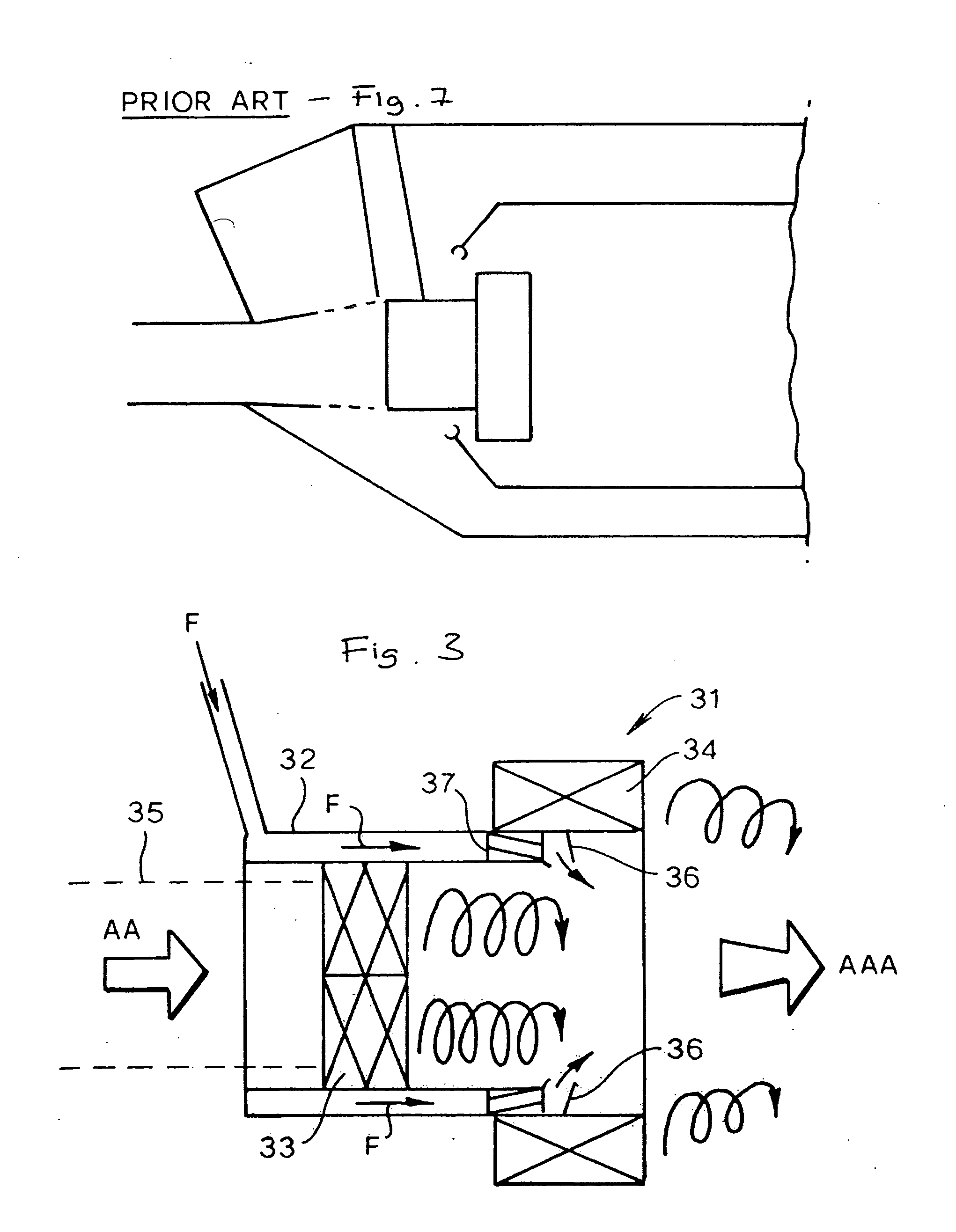

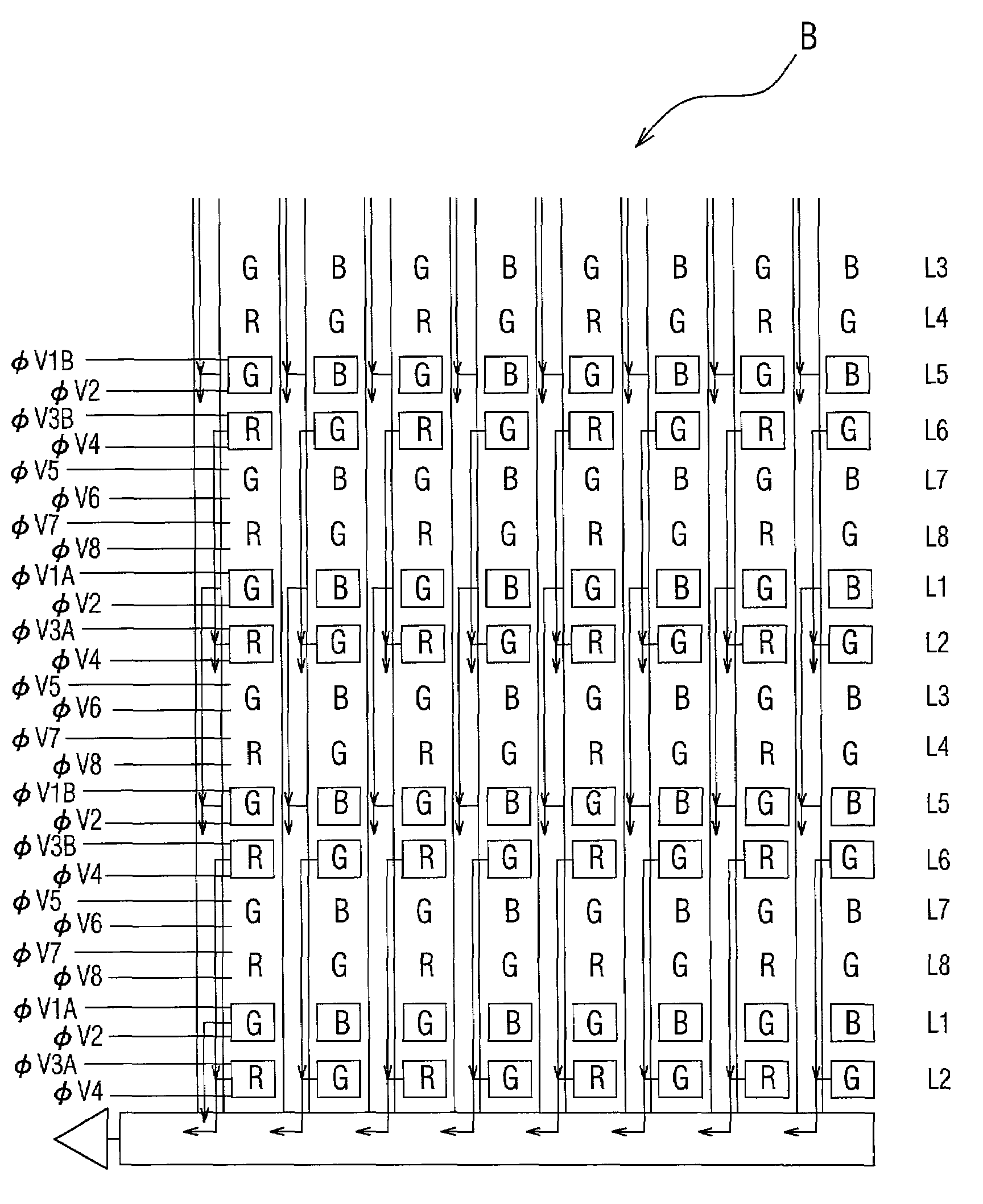

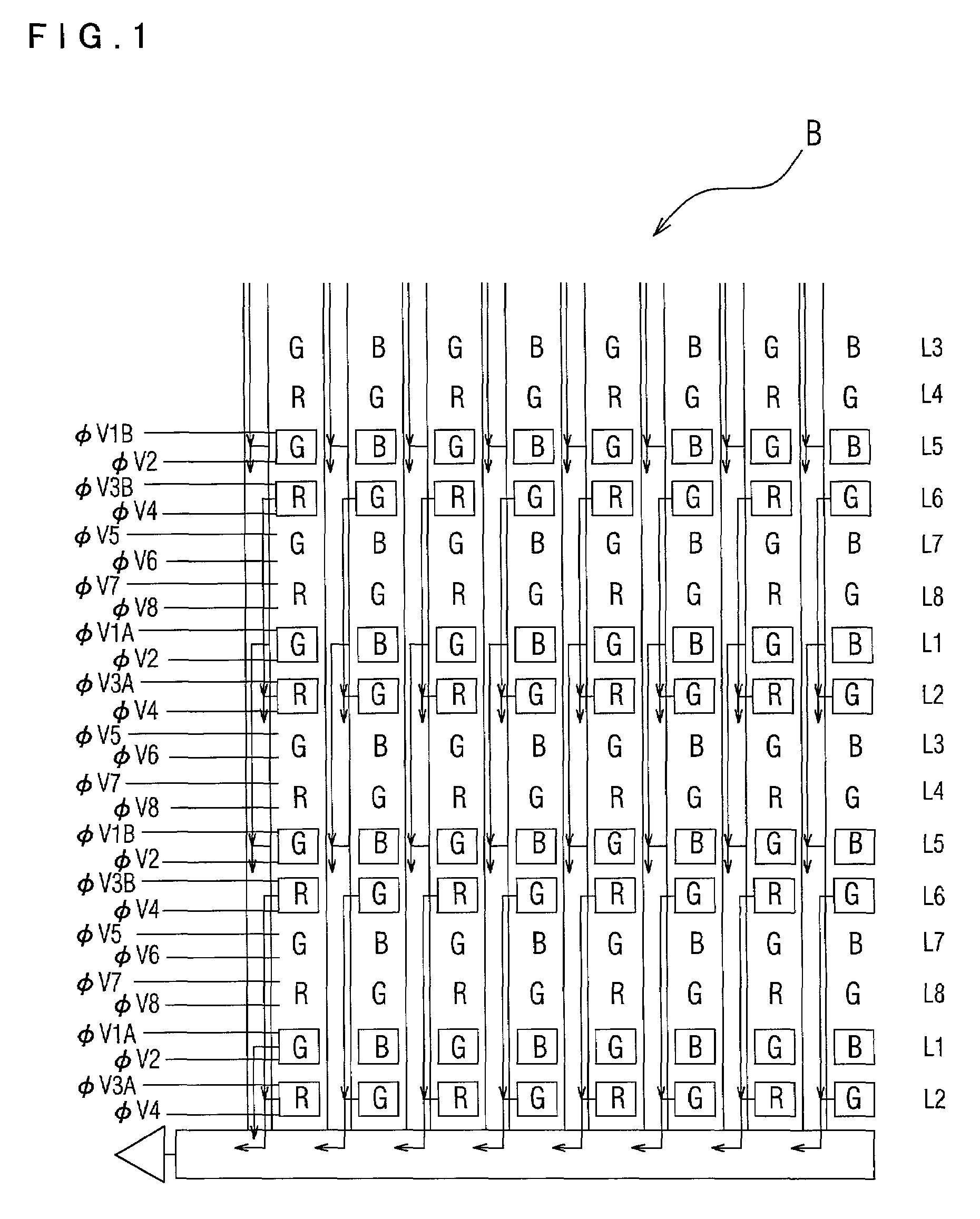

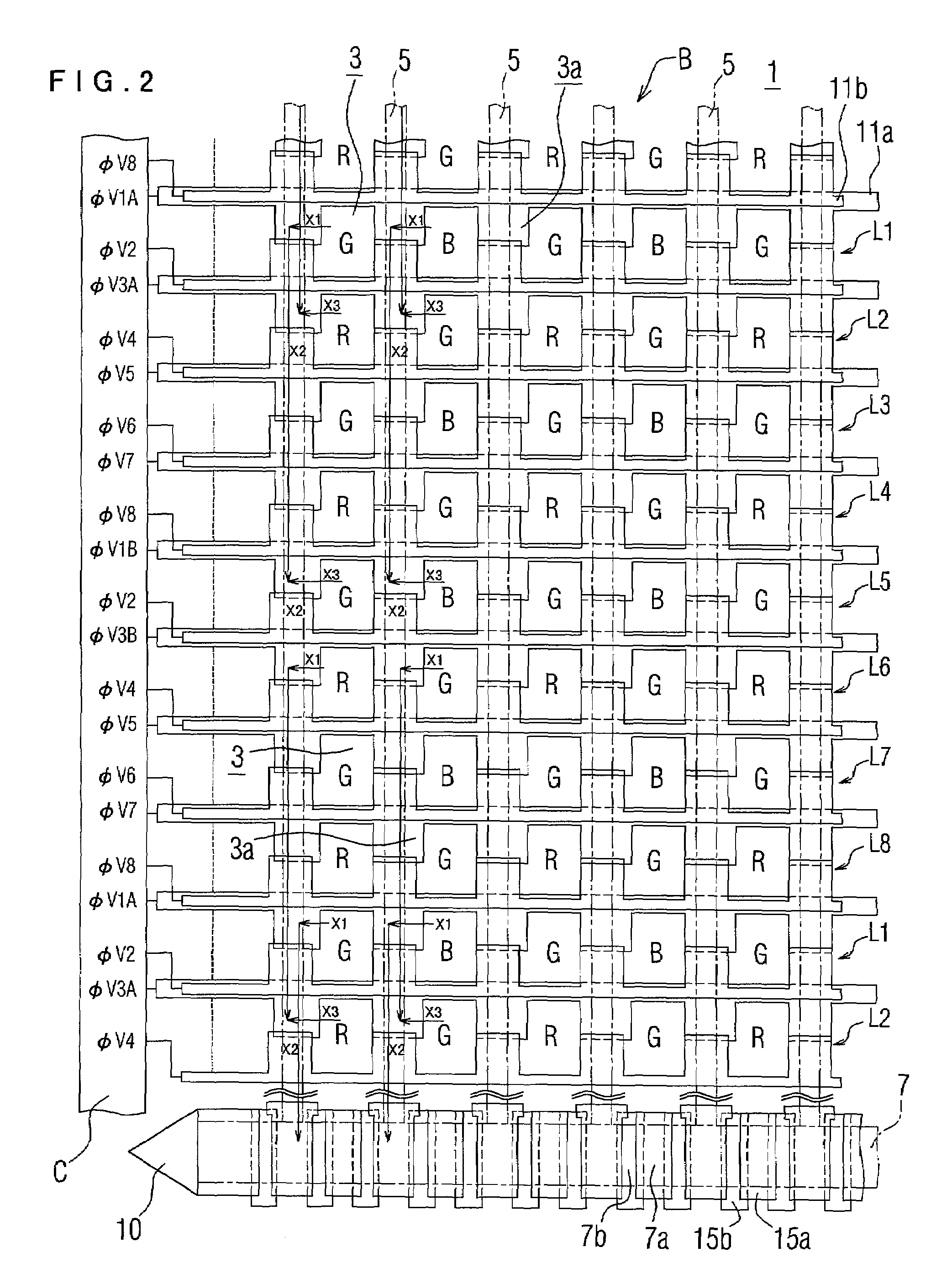

Thin-out drive method for CCD image sensor

InactiveUS7199826B2High sensitivityReduce impactTelevision system detailsTelevision system scanning detailsAsymmetric distributionTransfer operation

A solid-state image pickup device includes photoelectric converters in row-column matrix configuration, VCCDs, one for each column, a color filter disposed above each converter to form a color filter array including layouts each including n rows, and a drive circuit for conducting readout treating (m*n) rows as one set, and selecting from the sets a plurality of units symmetrically distributed. Electric charge is read from the plural units. A first readout operation reads electric charge from a first group of rows having asymmetric distribution. A j-row transfer operation transfers the electric charge for j rows. A second readout operation reads electric charge from a second group of rows having asymmetric distribution at positions to which the electric charges are transferred by the j-row transfer operation. The electric charges are added in the VCCDs.

Owner:FUJIFILM CORP

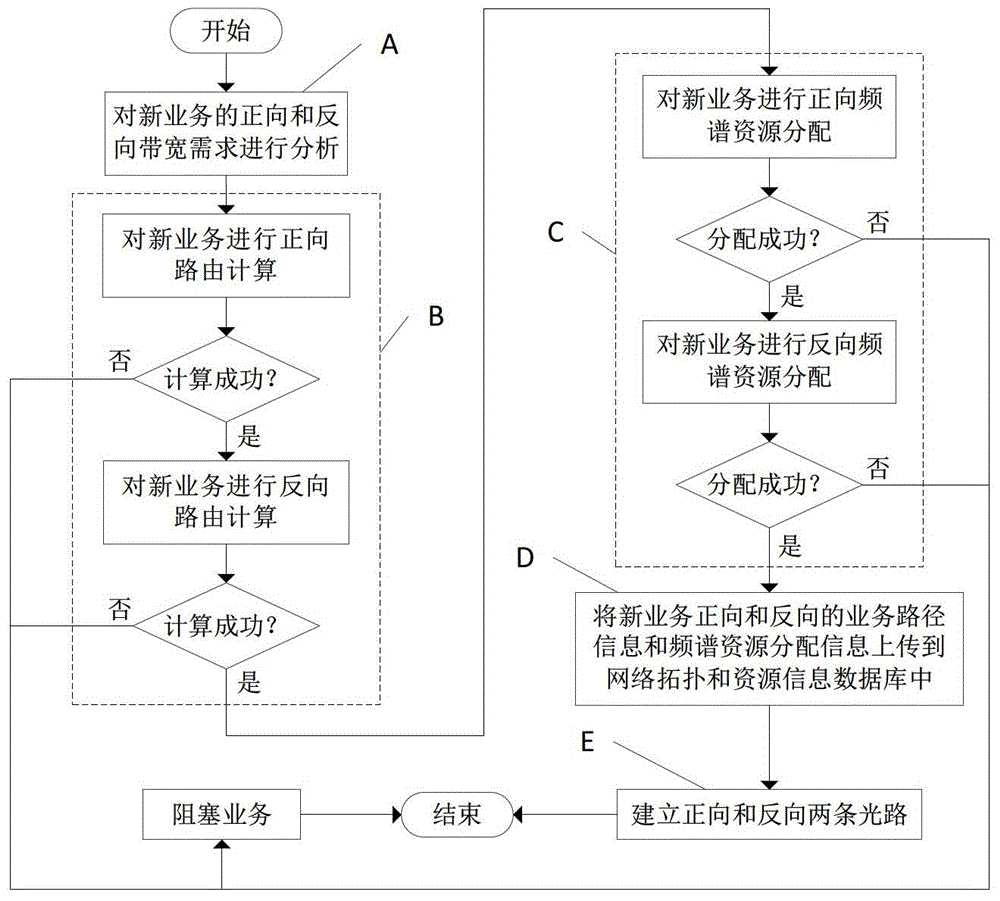

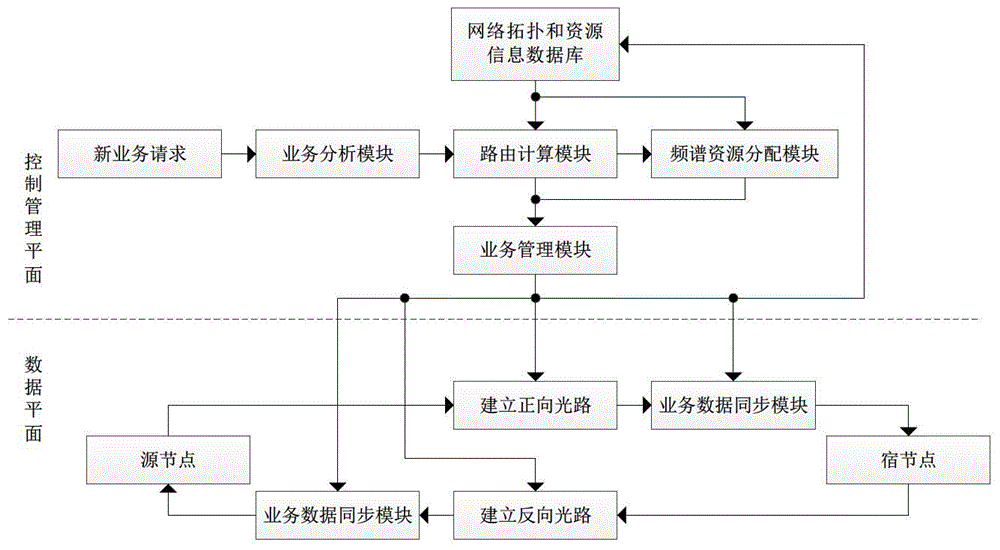

Bidirectional asymmetric distribution method and device of frequency spectrum resources of optical network

InactiveCN103338162AReduce blocking rateImprove spectrum utilizationData switching networksFrequency spectrumResource information

The invention discloses a bidirectional asymmetric distribution method and a device of frequency spectrum resources of an optical network. The method comprises the steps of: A, analyzing forward and inverse bandwidth requirements of a new service, B, calculating forward and inverse routing of the new service, C, distributing the forward and inverse frequency spectrum resources for the new service, D, uploading forward and inverse service path information and frequency spectrum resource distribution information of the new service to a network topology and resource information database, and E, establishing a forward light path and an inverse light path. The method and the device can make full use of the frequency spectrum resources in the optical network and reduce the service blocking rate by using the difference between the forward and inverse bandwidth requirements of the new service on the premise of keeping the currently available total frequency spectrum resources unchanged.

Owner:BEIJING UNIV OF POSTS & TELECOMM

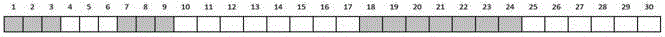

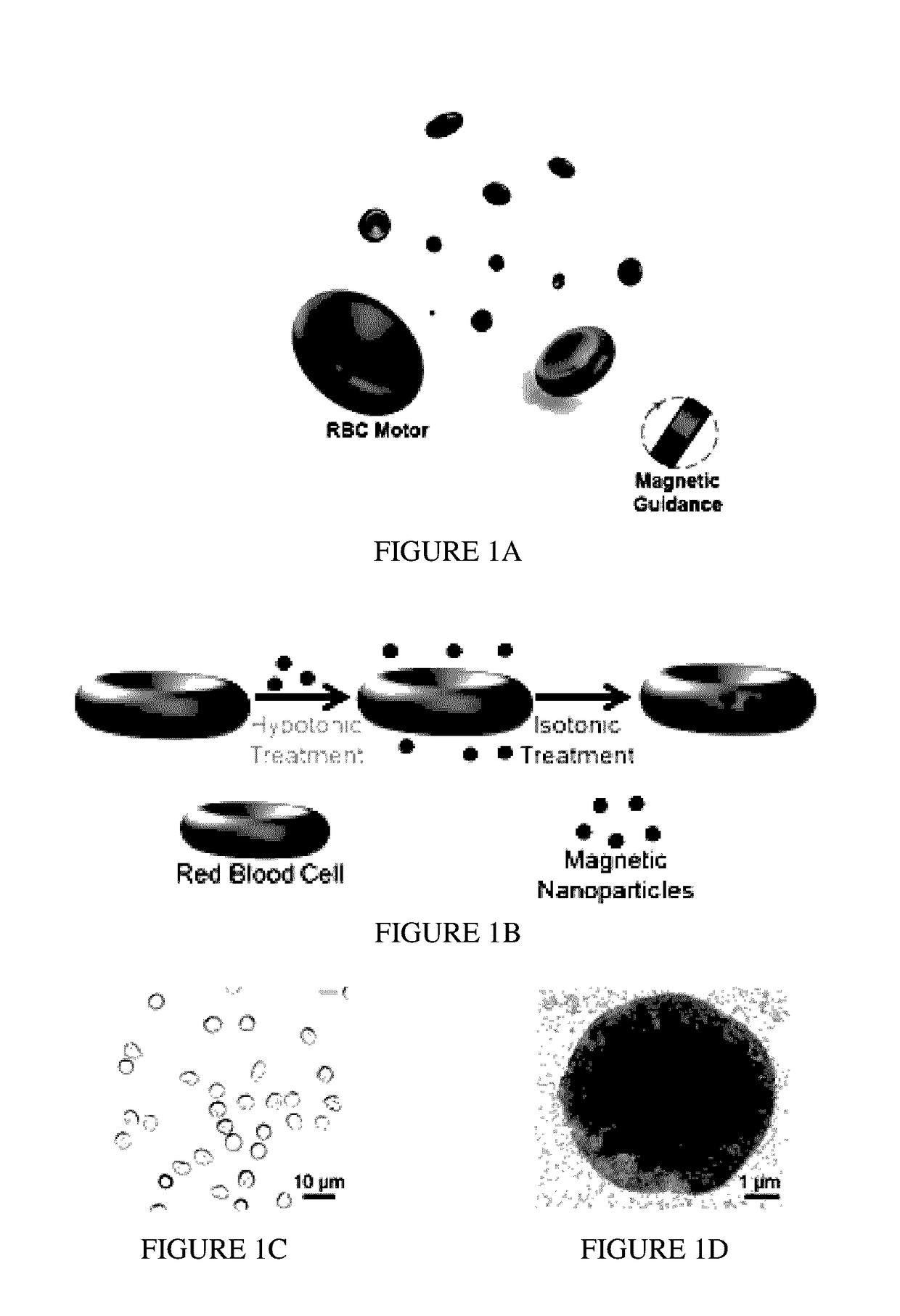

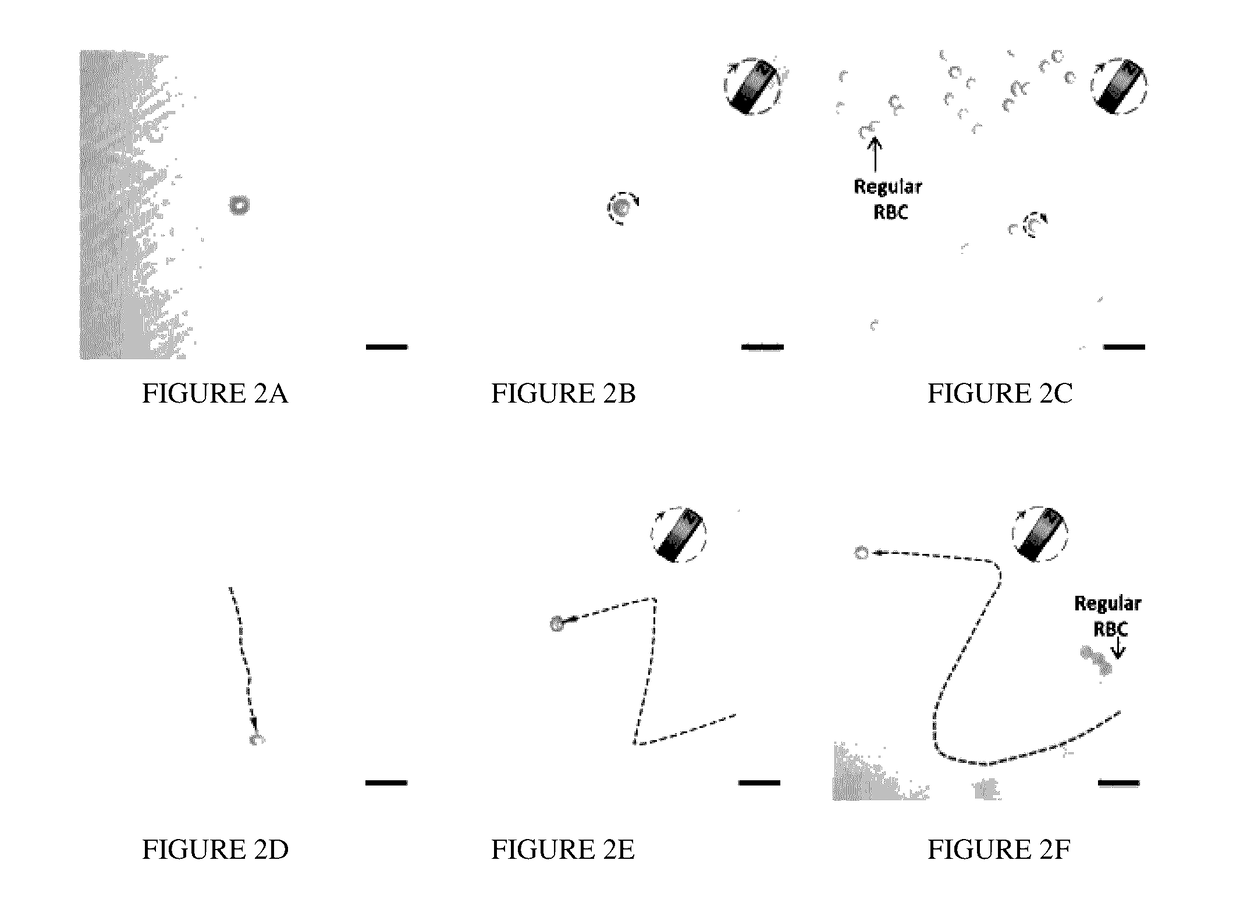

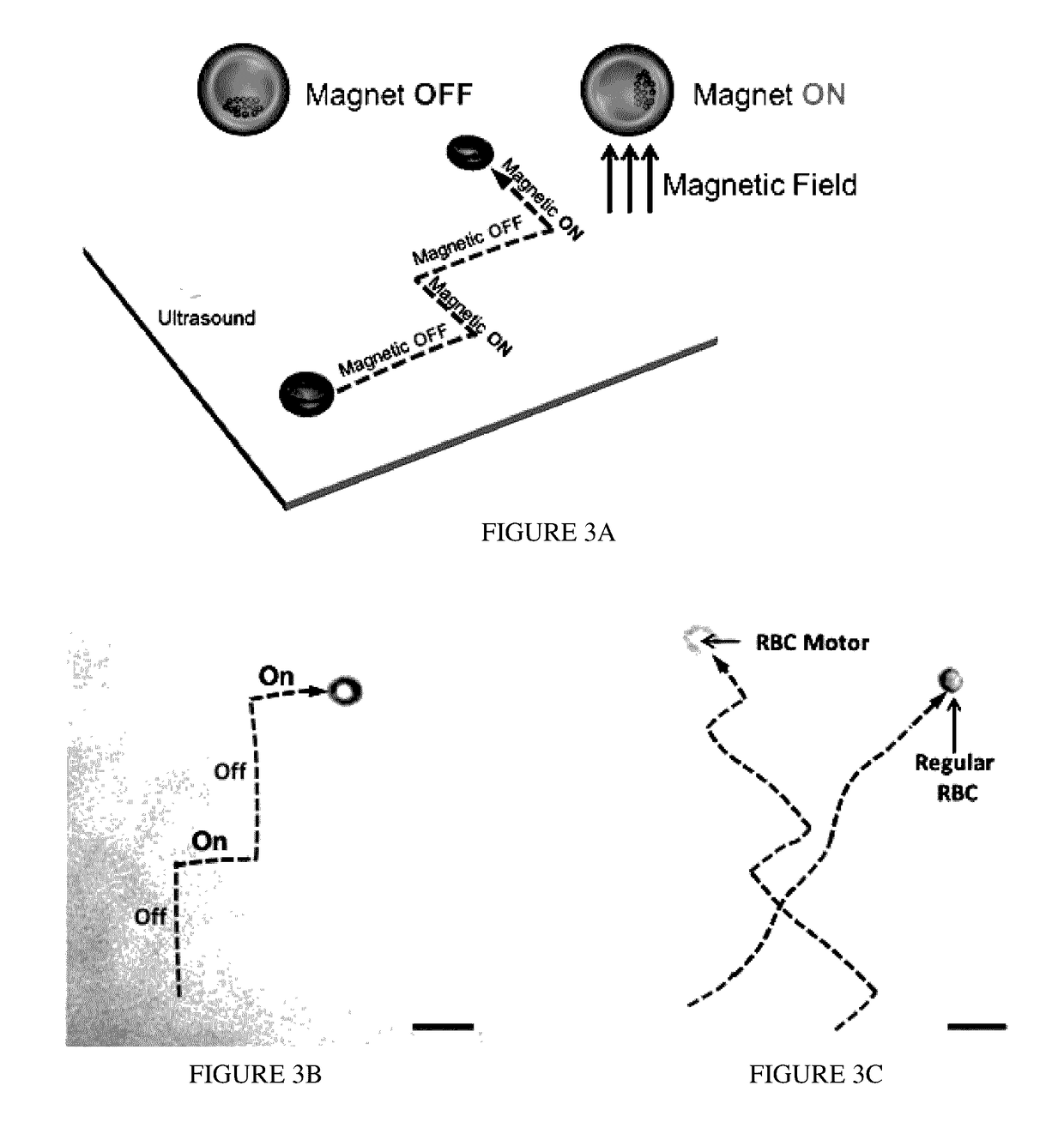

Cellular Micromotors and Uses Thereof

ActiveUS20170143830A1Efficient advancementPrevent detection and uptakeSonopheresisMammal material medical ingredientsRed blood cellAsymmetric distribution

Living cells, such as red blood cells (RBCs) modified with functional micromotors with the aid of ultrasound propulsion and magnetic guidance. Iron oxide nanoparticles are loaded into the RBCs, where their asymmetric distribution within the cells results in a net magnetization, thus enabling magnetic alignment and guidance under acoustic propulsion. The RBC motors display efficient guided and prolonged propulsion in various biological fluids, including undiluted whole blood.

Owner:RGT UNIV OF CALIFORNIA

Vias in porous substrates

ActiveUS20120267789A1Semiconductor/solid-state device detailsSolid-state devicesPorous substrateAsymmetric distribution

A microelectronic unit can include a substrate having front and rear surfaces and active semiconductor devices therein, the substrate having a plurality of openings arranged in a symmetric or asymmetric distribution across an area of the rear surface, first and second conductive vias connected to first and second pads exposed at the front surface, pluralities of first and second conductive interconnects extending within respective ones of the openings, and first and second conductive contacts exposed for interconnection with an external element. The plurality of first conductive interconnects can be separated from the plurality of second conductive interconnects by at least one of the plurality of openings, the at least one opening at least partially filled with an insulating material. The distribution of the openings can include at least m openings spaced apart in a first direction and n openings spaced apart in a second direction transverse to the first direction.

Owner:TESSERA LLC

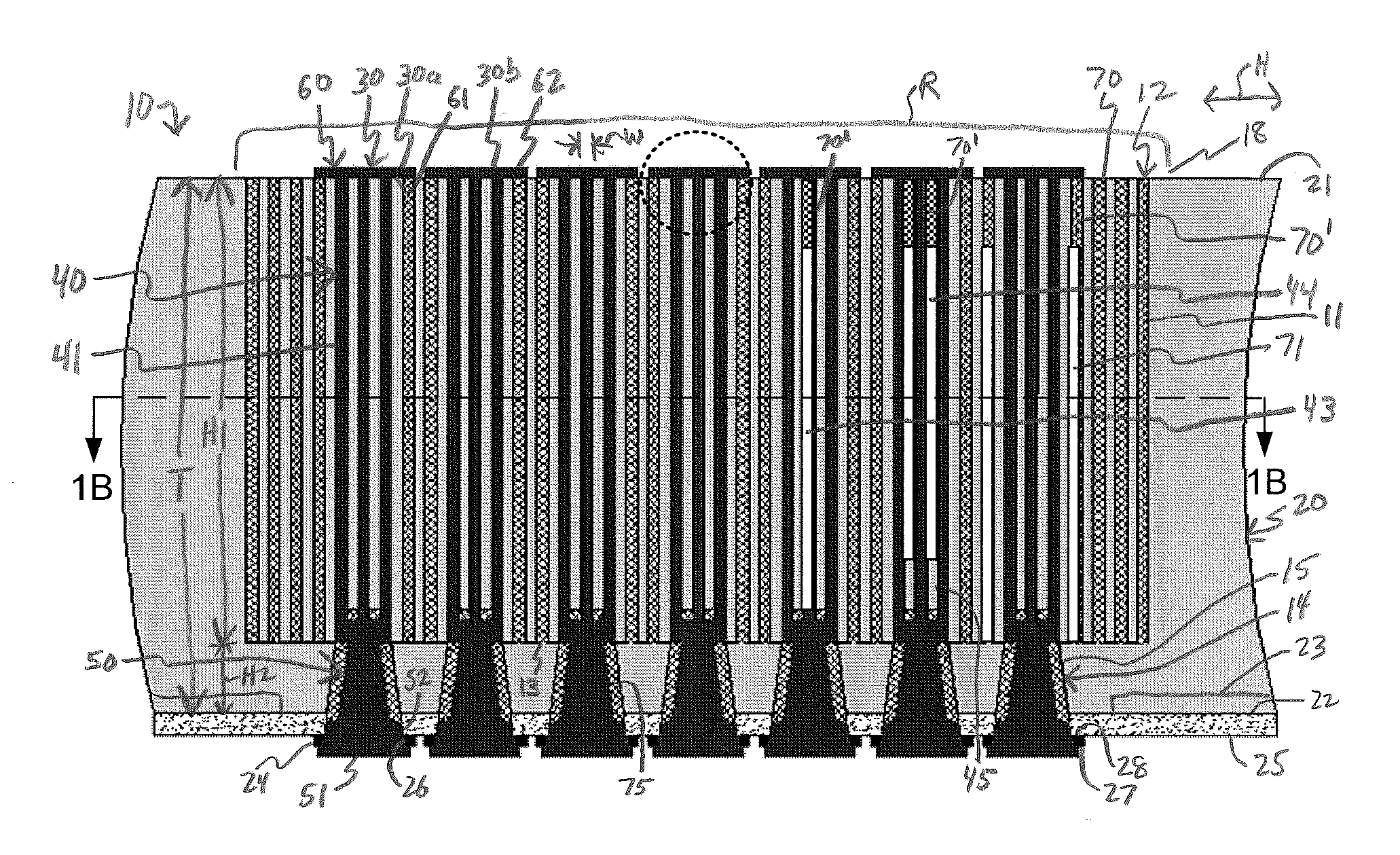

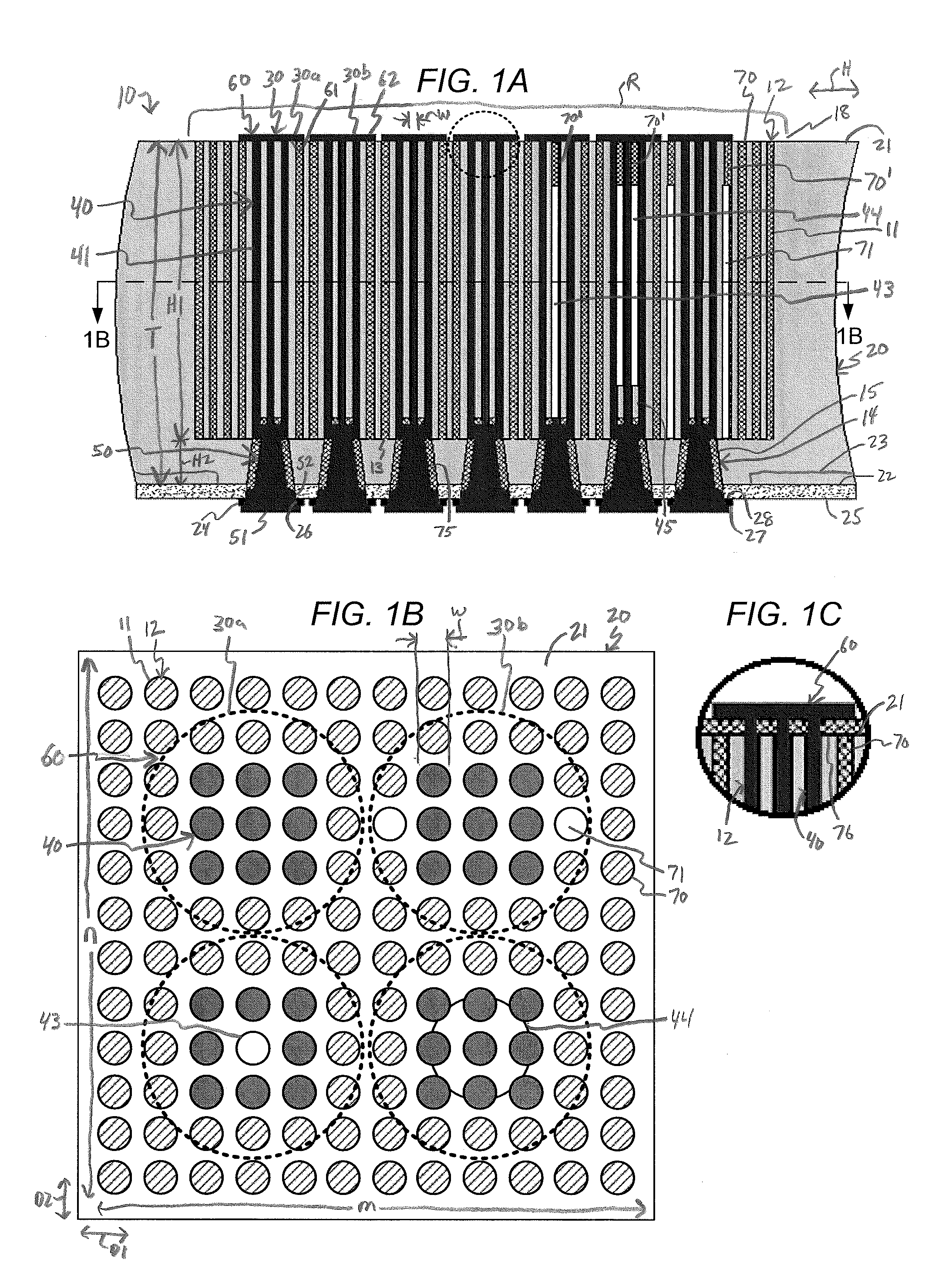

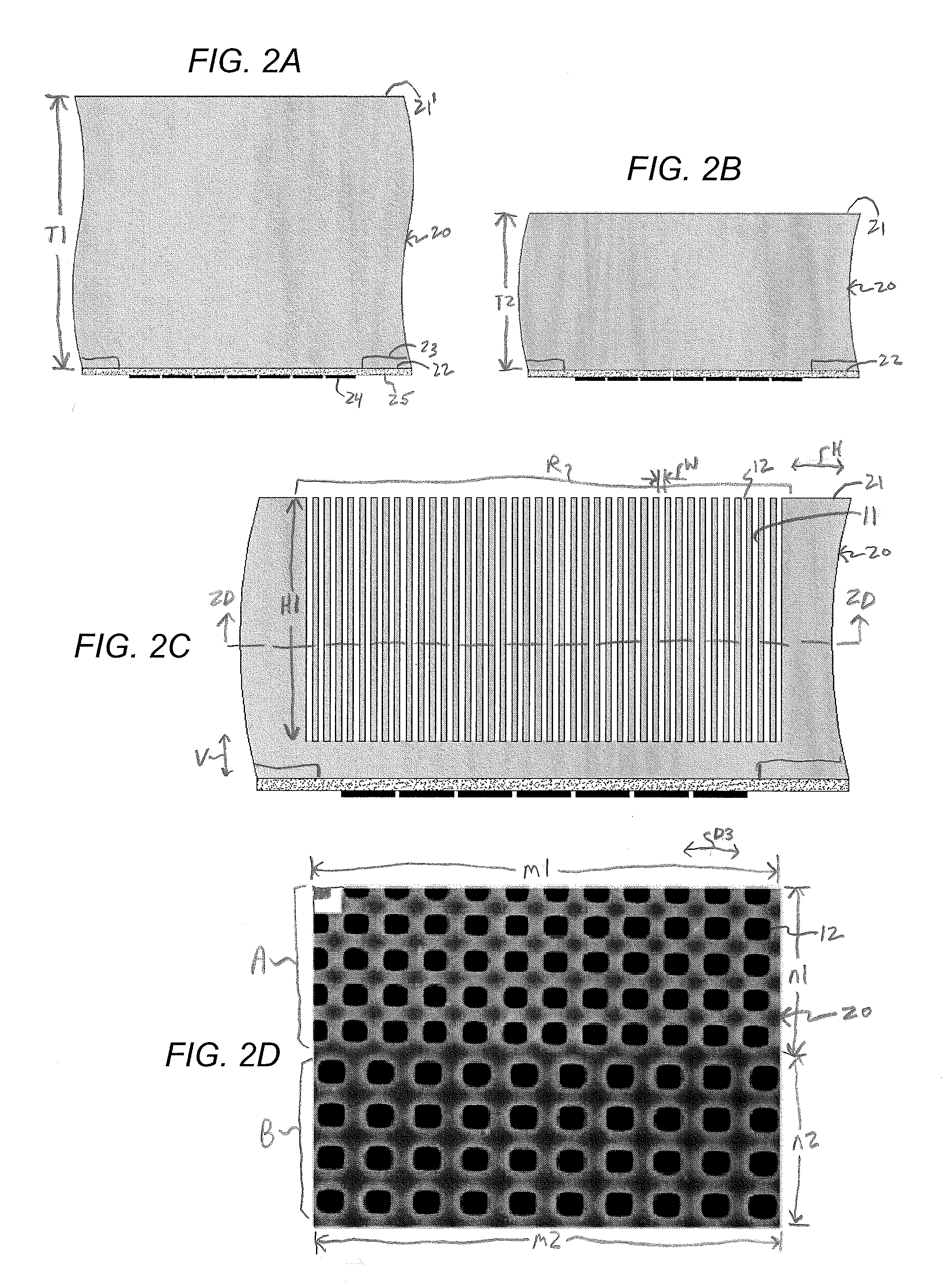

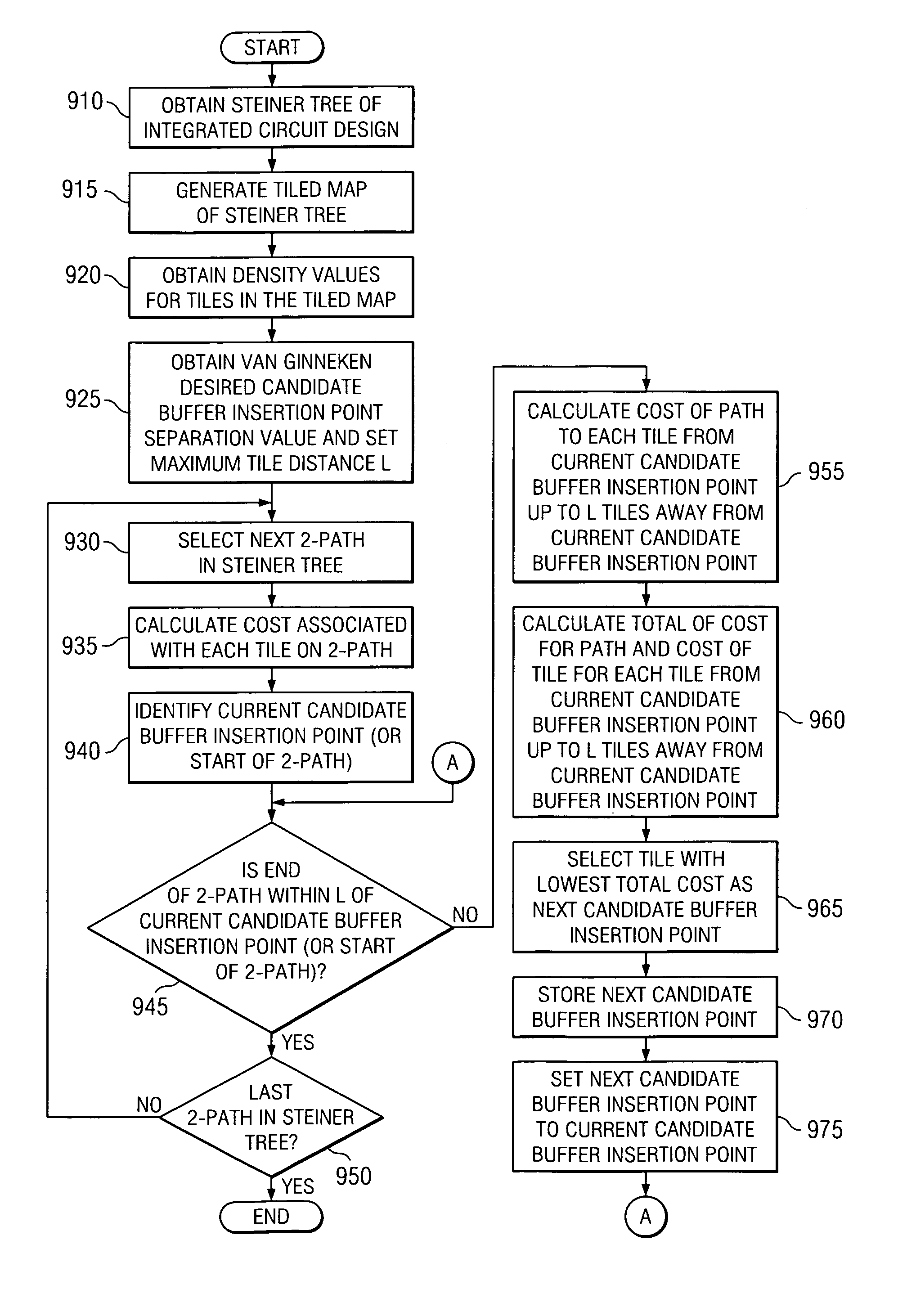

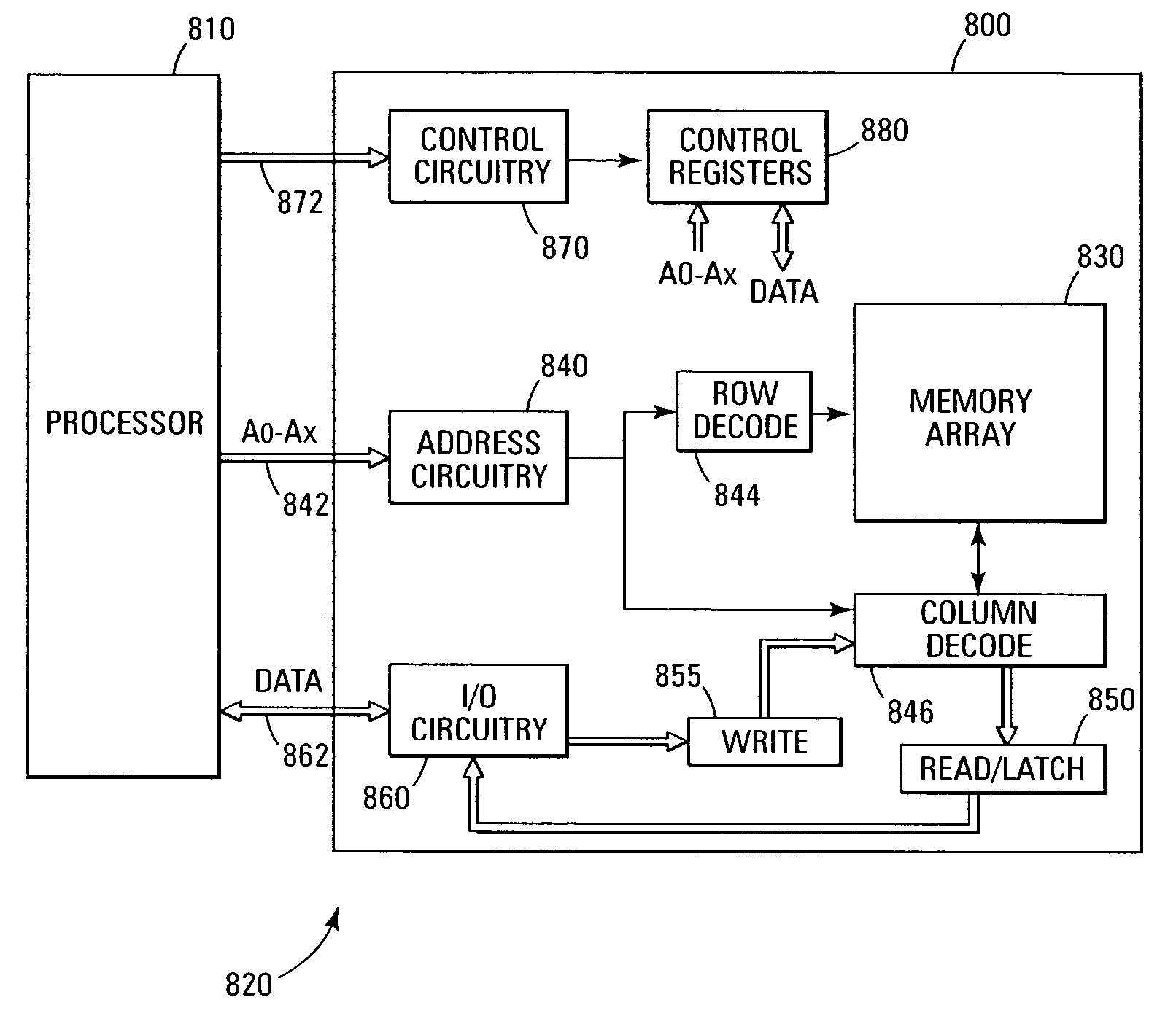

Method and apparatus for performing density-biased buffer insertion in an integrated circuit design

InactiveUS7137081B2Computer aided designSoftware simulation/interpretation/emulationAsymmetric distributionTheoretical computer science

Owner:GLOBALFOUNDRIES INC

Multi-state memory cell with asymmetric charge trapping

A multi-state NAND memory cell is comprised of two drain / source areas in a substrate. An oxide-nitride-oxide structure is formed above the substrate between the drain / source areas. The nitride layer acting as an asymmetric charge trapping layer. A control gate is located above the oxide-nitride-oxide structure. An asymmetrical bias on the drain / source areas causes the drain / source area with the higher voltage to inject an asymmetric distribution hole by gate induced drain leakage injection into the trapping layer substantially adjacent that drain / source area.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com