Method for controlling asymmetric transverses shifting plate shape of asymmetric bending roller of HC rolling mill

A technology of strip shape control and asymmetric rolling, which is applied in the direction of contour control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Below further describe the present invention by means of embodiment and accompanying drawing:

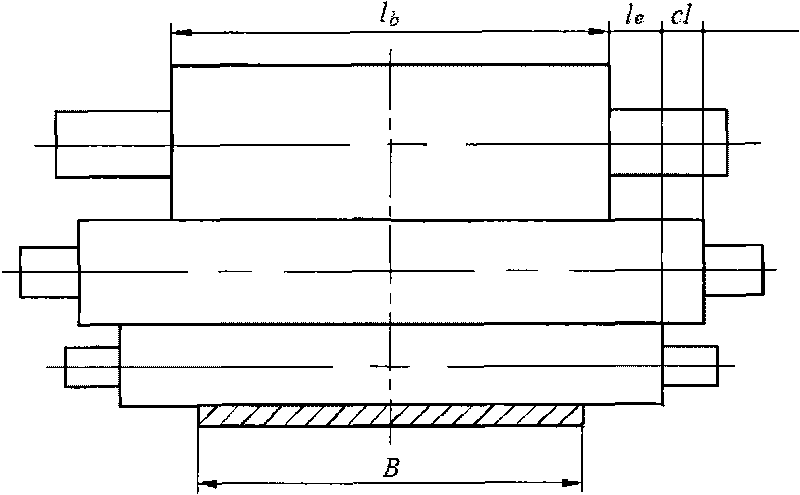

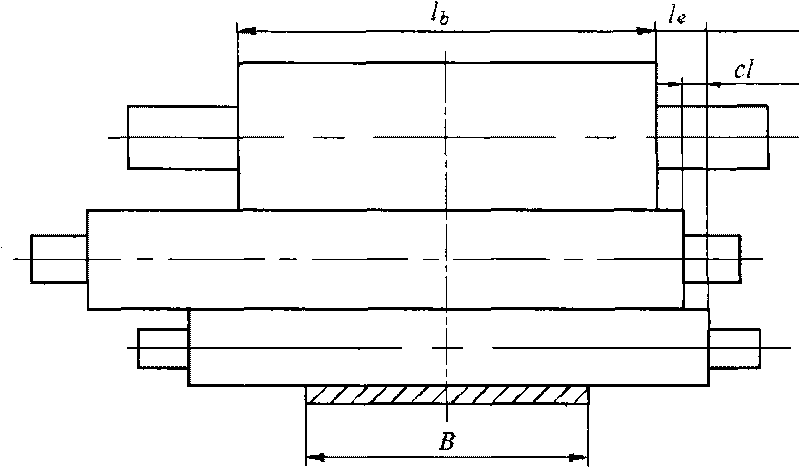

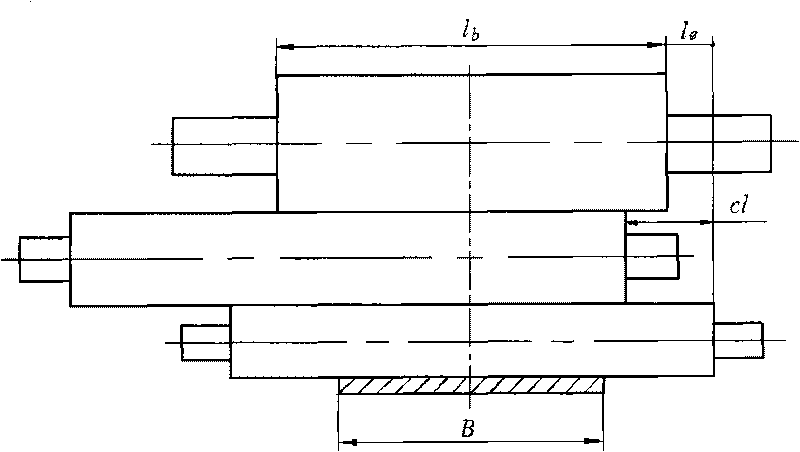

[0109] The solution process of adopting the method of the present invention to optimize the design of certain six-high HC rolling mill asymmetrical bending roll asymmetrical traversing strip shape control method is provided below, as figure 2 shown.

[0110] e1) Collection of equipment and process parameters of HC rolling mill and strip steel include: roll body length l of backup rolls, intermediate rolls and work rolls b =850mm, l m =920mm and l w =900mm and roll diameter D b =850mm, D m = 340mm and D w =270mm, distance A between the drive side of the back-up roller and the pressure cylinder on the operation side 3 =1150mm, center distance L between back-up rolls, intermediate rolls and work rolls, positive and negative bending rolls, driving side and operating side bending roll hydraulic cylinders 3 =1410mm, L 2 =1180mm and L 1 =1020mm, Bending force F of work rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com