Patents

Literature

853results about How to "Improve surface wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength wear-resistant plastic wood composite material and preparation method thereof

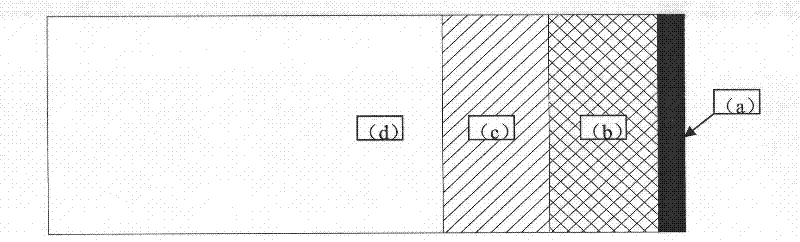

The invention relates to a plastic wood composite material, and provides a high-strength wear-resistant plastic wood composite material and a preparation method thereof. The high-strength wear-resistant plastic wood composite material of the invention is prepared by the following components by weight: 20-35 parts of plastics, 20-70 parts of natural wood fibers, 5-45 parts of a fire retardant, 1-10 parts of a compatibilizer, 0.1-3 parts of a lubricant, 0.5-3 parts of plasticizer, 5-20 parts of reinforcing wear resistant filling materials, and 0.05-4 parts of a processing auxiliary agent. The invention adopts a co-extrusion process; the plastic wood profile is divided into several layers (two or more than two layers); the reinforcing wear resistant filling materials are added only in the surface layer, which significantly reduces the using amount of the filling materials, and reduces the production cost. The produced high-strength wear-resistant plastic wood composite material not only has the characteristics of other plastic wood profiles, but also greatly reduces the production cost.

Owner:GEM CO LTD

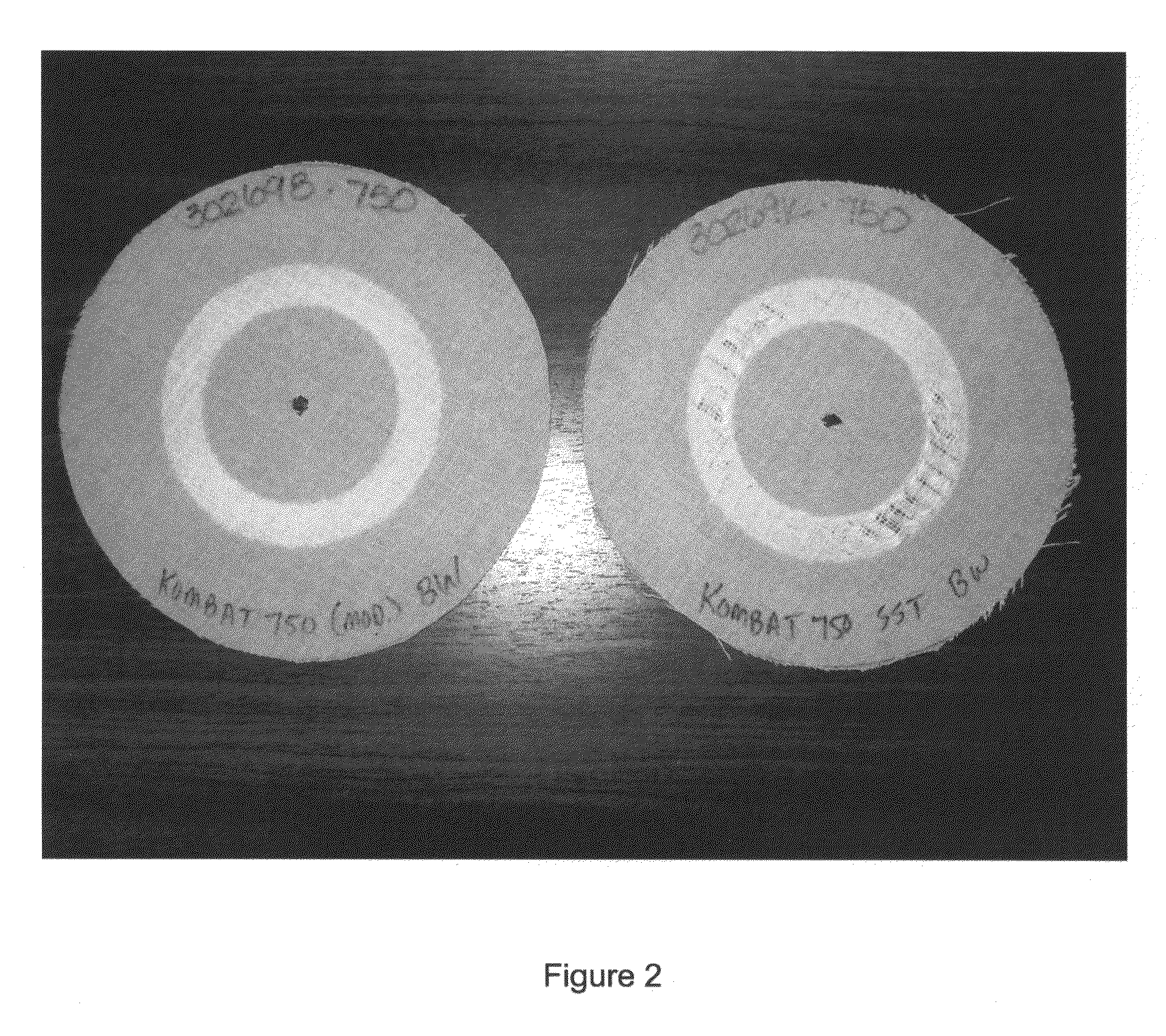

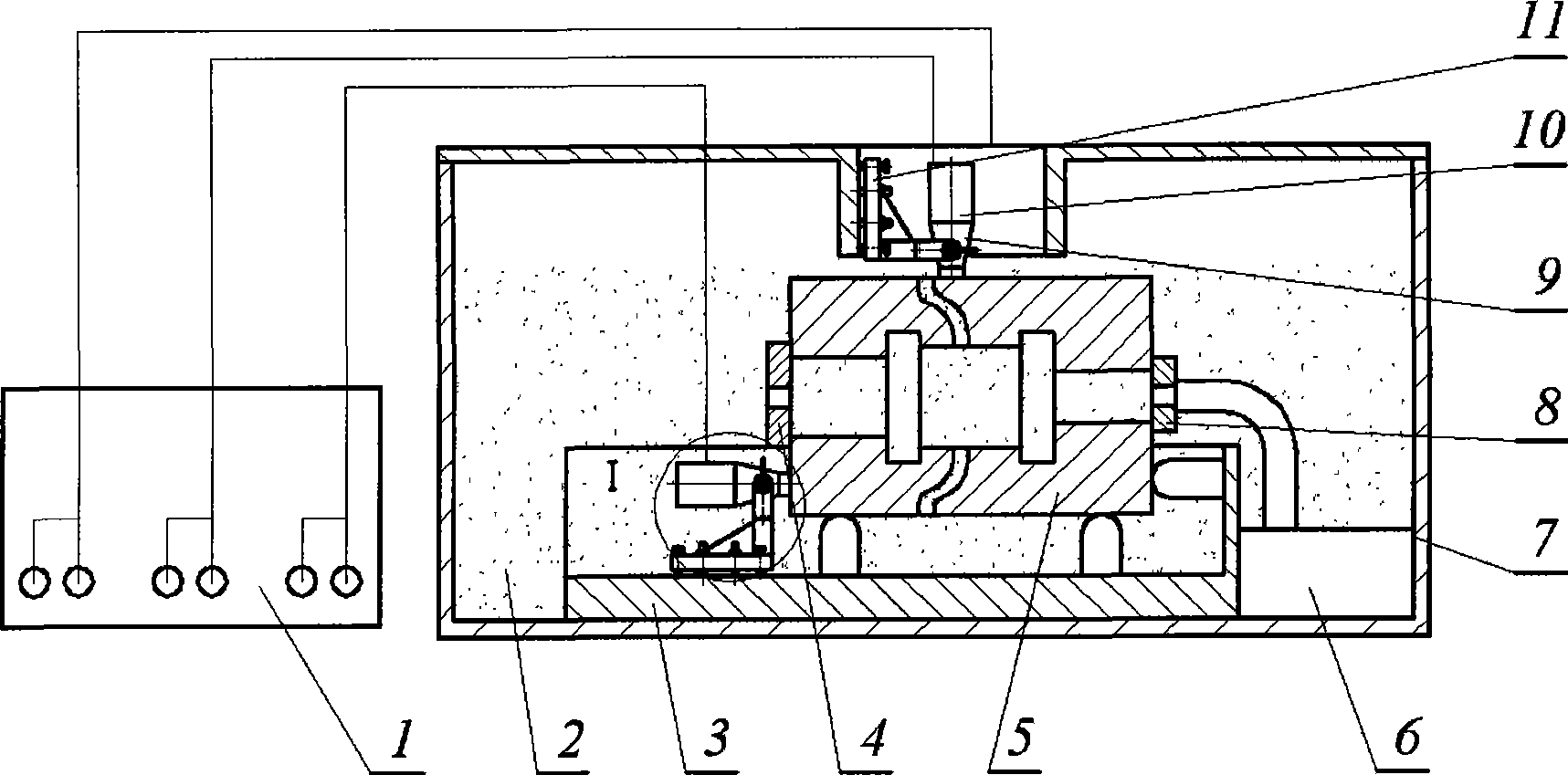

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

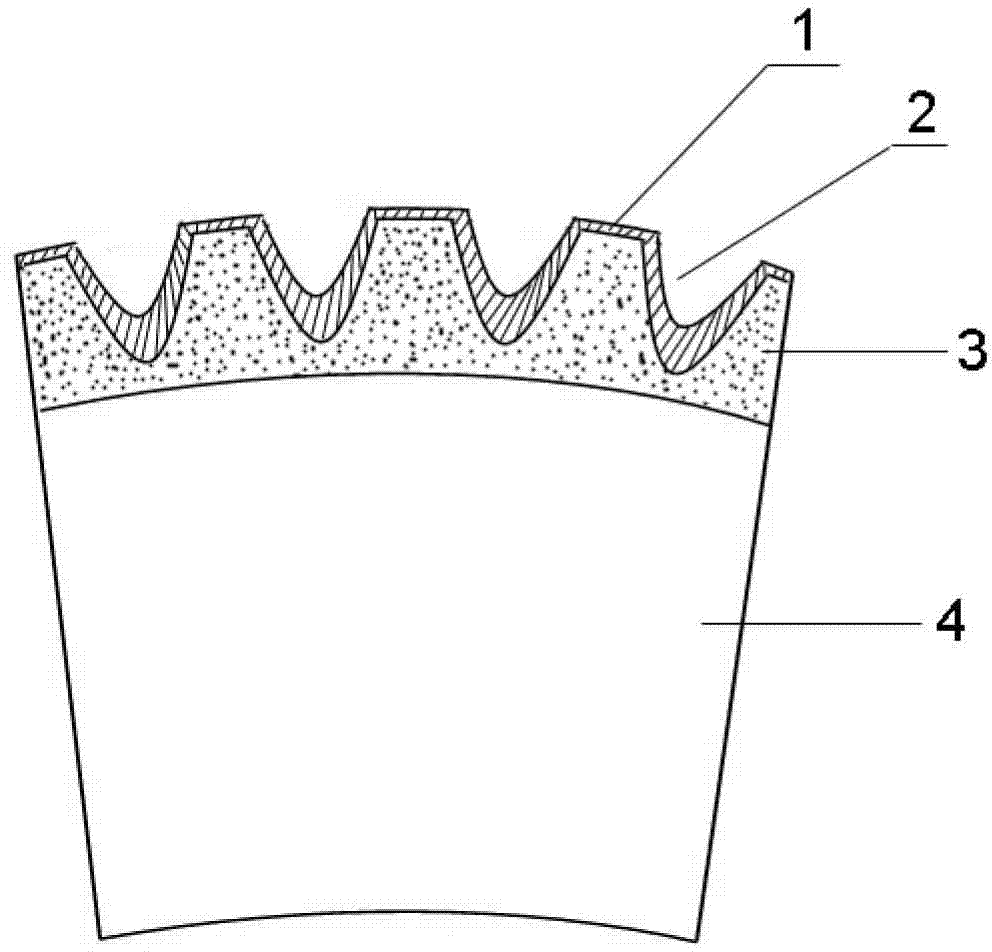

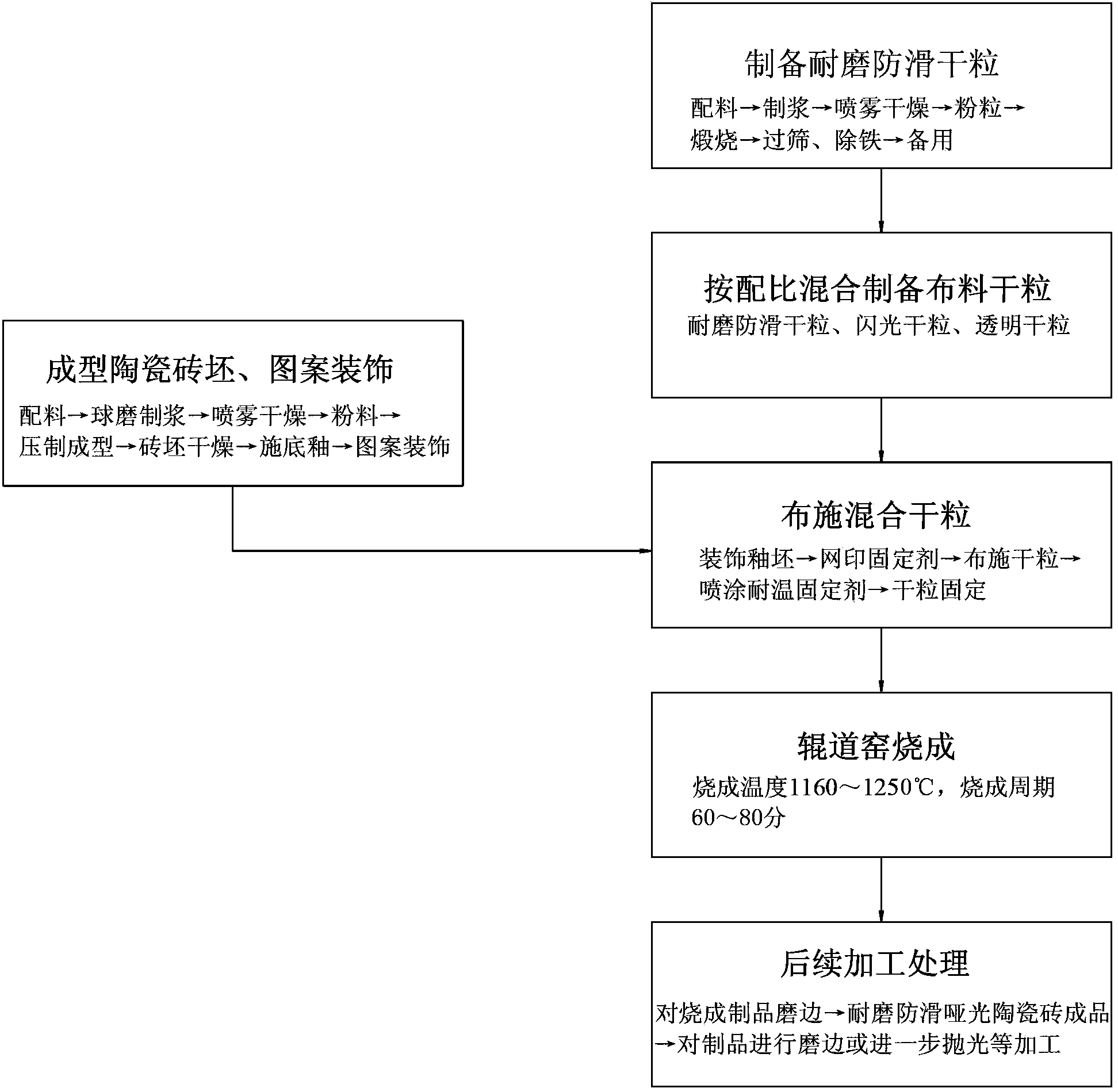

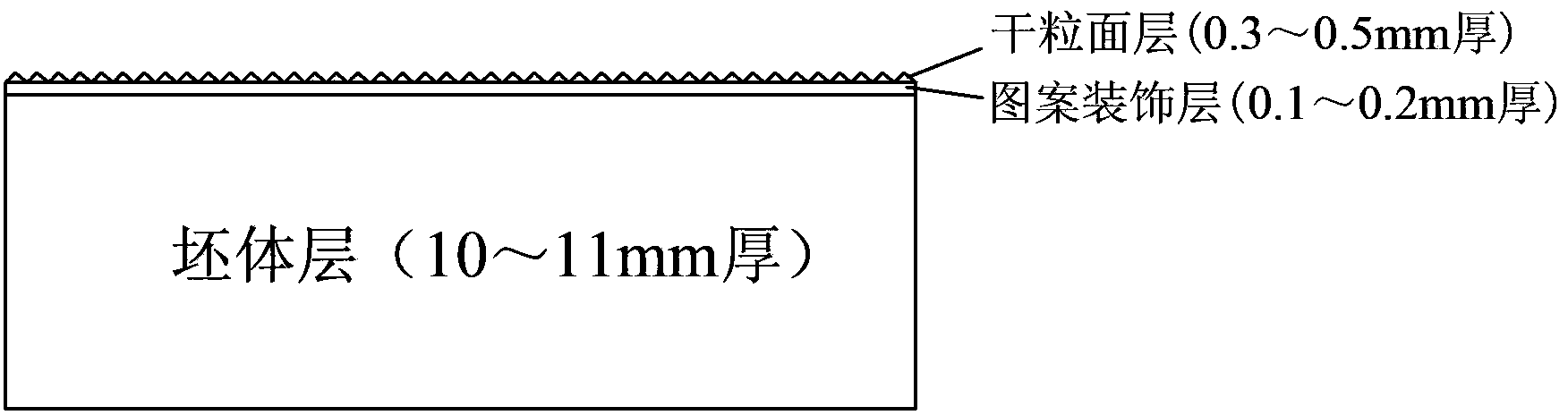

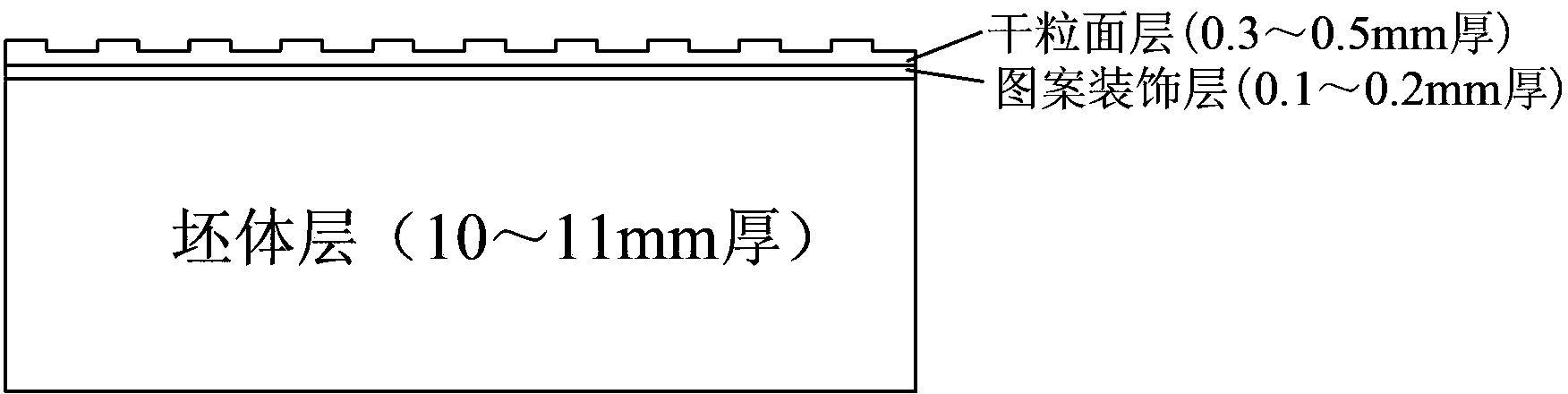

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

Foamed ceramics energy saving and heat preservation decorative wall brick and manufacture method thereof

InactiveCN101560111ALow thermal conductivityLow densityCeramic materials productionCeramicwareBrickSlurry

The invention discloses a foamed ceramics energy saving and heat preservation decorative wall brick and a manufacture method thereof, including the steps of conducting ball milling on 15-65 percent wt of industrial residues, 10-45 percent wt of plastic clay, 15-60 percent wt of solvent, 10-45 percent wt of pore-forming agent with the fineness being 1-100mum and proper amount of water to form slurry; spray drying or dehydration and clay preparation, and forming powder material or clay segment through staleness; and implementing pressure forming to make billet which is burned under heat preservation at temperature of 1140-1240 DEG C to finally form the foamed ceramics wall brick. The wall brick can be used not only for the heat preservation and decoration of external walls, but also for indoor heat preservation and decoration, and the external wall and the indoor space can realize the organic combination of uniform heat preservation and decoration, which agrees with the development direction of heat preservation material industry of external walls. The wall brick has the advantages of: I. high temperature resistance, acid and alkali-resistance, good chemical stability, no ageing, strong durability, long service life, no generation of heat channel and good adhesive fixity; and II. difficult water seepage and crack, strong anti-corrosion capacity, uneasy deformation and damage, simplification of mounting, laying and sticking procedures, convenience for construction, relief of labor intensity and decrease of material consumption quantity.

Owner:吴汉阳

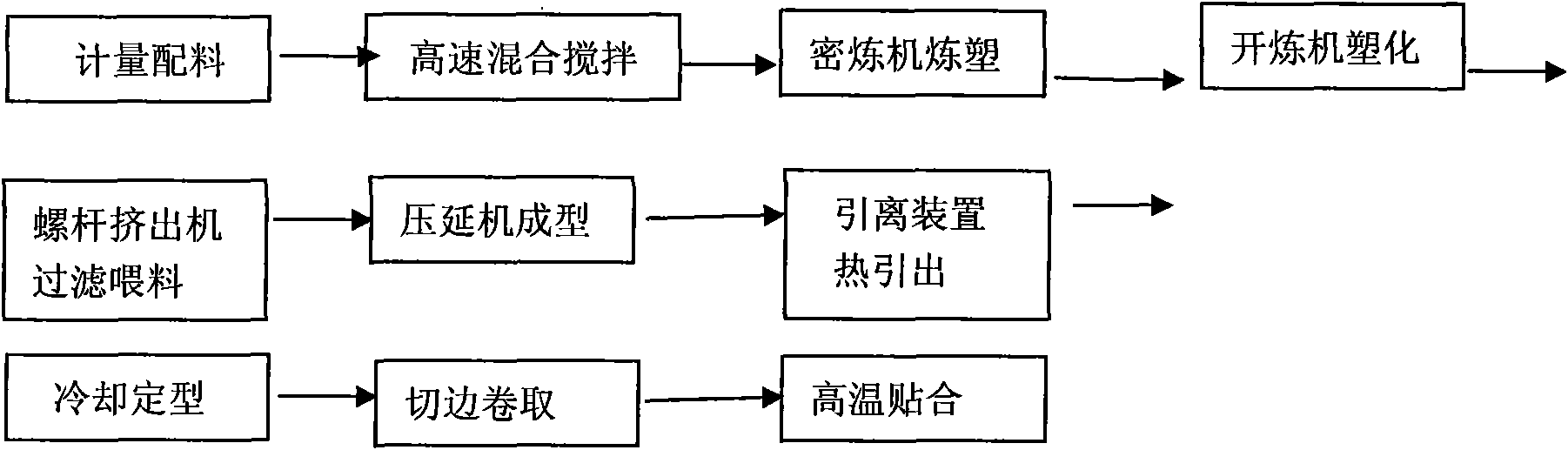

High-elastic wearproof athletic floor material and preparation method thereof

ActiveCN101538393AIncrease elasticityGood surface wear resistanceResiliently-mounted floorsPlasticizerPolyresin

The invention discloses a high-elastic wearproof athletic floor material, which is prepared by raw materials with the following proportioning by weight: 100 portions of PVC high-polymerization degree resin, 40-60 portions of plasticizer, 5-10 portions of TPU polyurethane elastomer, 2.5-4.0 portions of composite heat stabilizer, 0.05-0.1 portion of mildew inhibitor, and 30-50 portions of filler modifier. The method adopts the technology of laminating high-strength ultralow-shrinkage fibre glass mesh cloth in the high-performance rolling embryonic membrane, and the athletic floor produced by the method completely meets the service performance requirements, and simultaneously has high elasticity, good surface abrasion resistance and small shrinkage factor of product size.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Method for acquiring highly-adaptive abrasion-proof titanium-based composite material on titanium alloy surface

InactiveCN101139709AReduce stressReduced tendency to crackMetallic material coating processesLaser beam welding apparatusIn situ reactionHigh power lasers

The invention discloses a method for preparing a Ti-based composite with high adaptability on a Ti-alloy surface, which pertains to the field of surface modification of metallic materials. The method comprises such procedures as: weighing by certain proportion spherical Ti alloy powder particles in proper particle sizes (45-150 micro meter) and TiB2, Cr3C2, TiC or B4C powder particles (3.4-30vol%, particle size 38-106 micrometer); mixing the powder evenly by a mechanical way; sending at the set powder-feeding rate the mixed powder by a powder feeder and coaxial powder-feeding nozzles into a molten bath formed by a high-power laser at the surface of a Ti-alloy substrate; the mixed powder carrying out in-situ reaction by the high temperature from the molten bath, and forming such steady and dispersion reinforced phases as in-situ self-grown TiC or TiB. The reinforced phases are featured by small particle size, steady thermal and mechanical properties, free pollution in interfaces, and high bond strength with the substrate. The method can substantially improve the hardness and wear resistance of Ti alloy surfaces, guarantees the high adaptability between the surface modified layer and the substrate, can be used for repairing and surface reinforcing treatment of Ti alloy parts bearing impact vibration load and thermal fatigue, etc.

Owner:有研科技集团有限公司

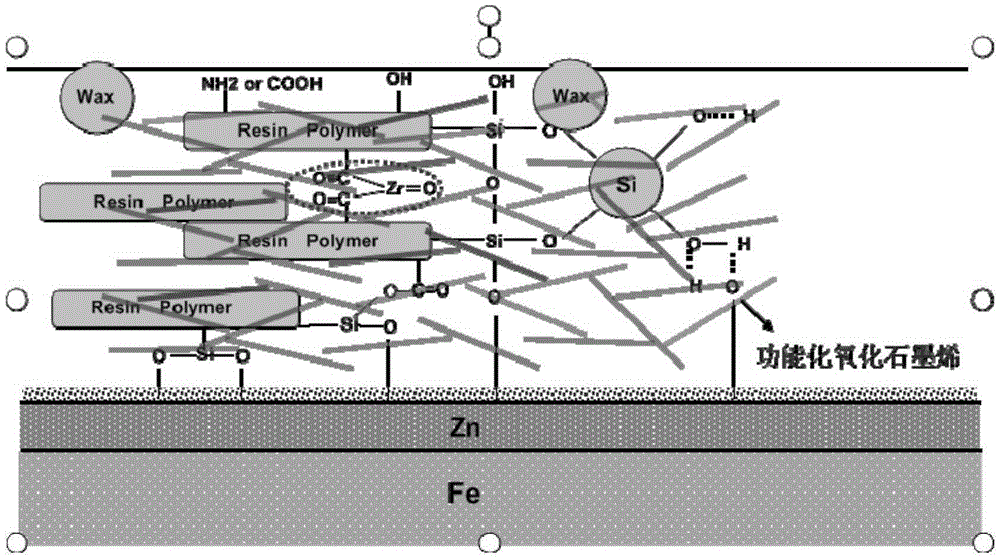

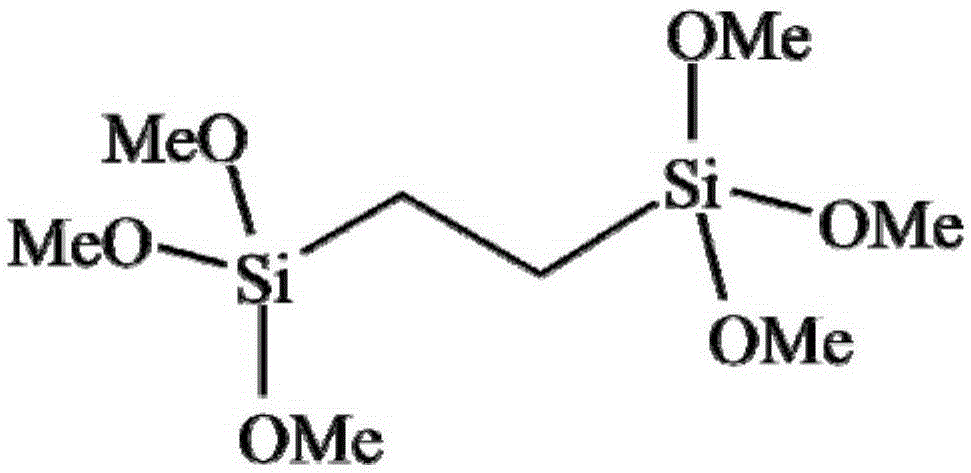

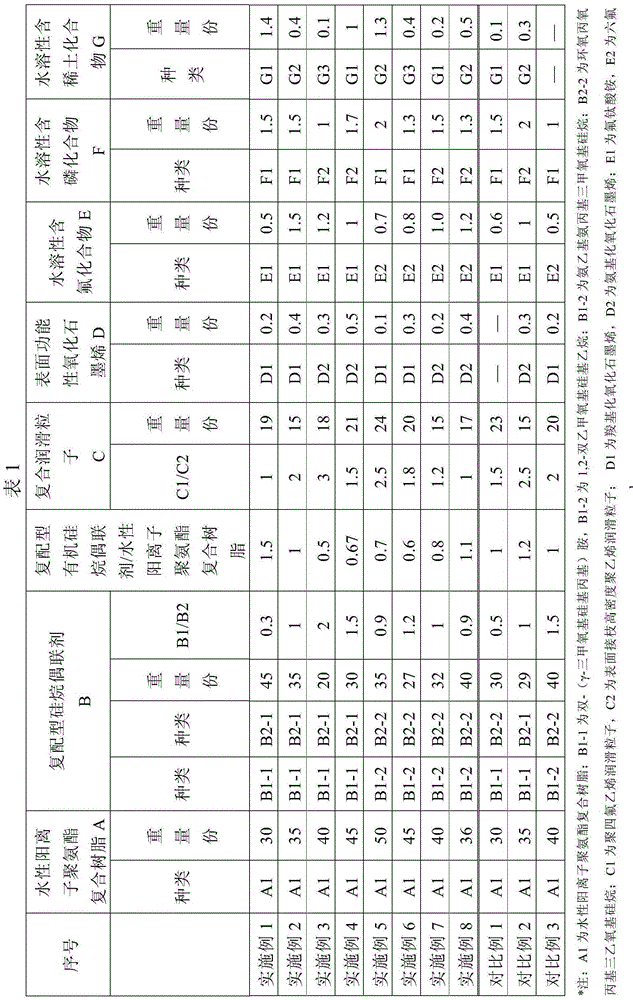

Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

ActiveCN105255338AGood acid and alkali resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCompound organic

The invention relates to a galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and a water-based surface treating agent. The surface of a galvanized steel sheet is coated with the surface treating agent in a solidified mode, wherein the surface treating agent includes water-based positive ion polyurethane composite resin, compound organic silane coupling agents containing bis-organic silane coupling agents and mono-organic silane coupling agents, compound lubrication particles containing teflon-surface modification high-density polyethylene particles, oxidized graphene, water-soluble fluorine-containing compounds, water-soluble phosphorous compounds, water-soluble rare earth salt compounds and other components, and therefore the surface treatment galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance is obtained. Meanwhile, the surface treatment galvanized steel sheet has good resistance, such as solvent resistance, to all kinds of chemical media.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing sofa leather with strong wear resistant property and flame retardant property

A high-wearing and fire-retardancy sofa leather is made by 1) wet condensing coating, molding in condensing groove, washing in water groove, drying and shaping and finally cooling and winding to become semi product wet process Bayes; 2) back spread coating with the semi product going through drawoff roller extraction shaping, dressing and spread coating, drying and baking and becoming fire-retardancy Bayes after cooling and winding; 3)nonaqueous shifting surface making, namely, separate paper shifting overlay; 4) kneading after treatment with pre-soaking of semi product sofa, squeezing out partial liquid, kneading and drying and finally batching on checking and final product packing. Apart from the major features of anti-friction and anti-retardancy, it can keep fine physical and mechanical performance and cosmetic styles with good quality and durable service.

Owner:HAININ JINDA COATING

Particle reinforced iron-based metal powder for ultra-high speed laser cladding

ActiveCN108103499AImprove surface wear resistanceExtended service lifeTransportation and packagingMetal-working apparatusUltra high speedChemical composition

The invention provides particle reinforced iron-based alloy powder for ultra-high speed laser cladding. The iron-based alloy powder is composed of iron matrix metal powder and oxide particles or carbide particles and comprises 50-98% of iron matrix metal powder and 2-50% of oxide particles or carbide particles, wherein an iron matrix is composed of, by mass, 0.03-2% of C, 0.50-2.80% of Si, 0.30-1.60% of Mn, 2-12% of Cr, 0.5-3% of V, 0.5-4% of Mo, 0.3-1% of Nb, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.05-3.0% of B and the balance Fe and inevitable impurities. Theparticle size of the metal power is 10-100 microns, and the flowability of the metal power is 32-45 s / 100 g. By adopting the particle reinforced iron-based metal powder, the laser cladding technologyis adopted and matched with different processes for reinforcing and repairing matrix surfaces.

Owner:中机新材料研究院(郑州)有限公司

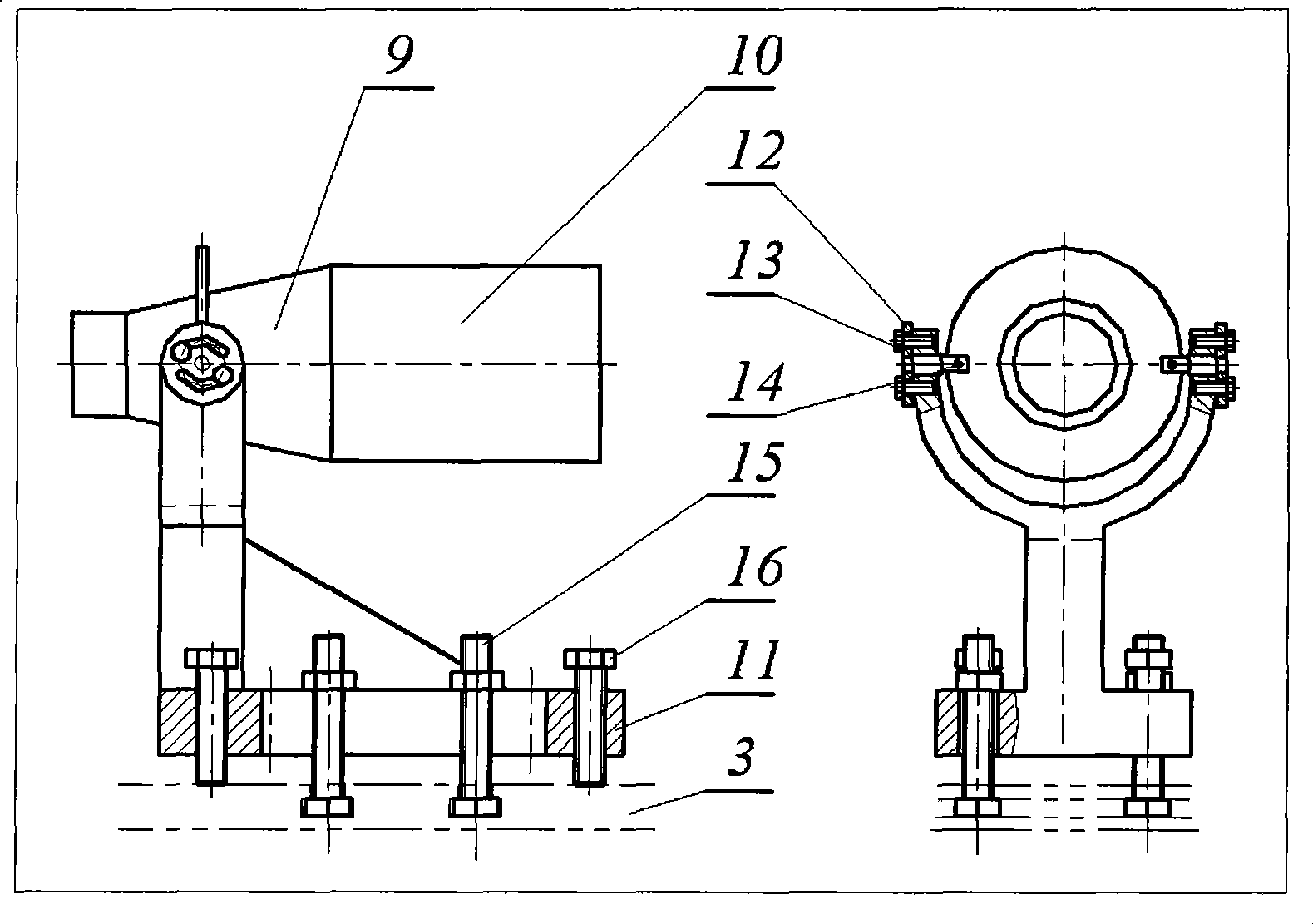

Technique for restoring precision of stepped cushion of rolling mill by adopting laser cladding technology

ActiveCN109468634ASimple and fast operationReduce labor intensityMetallic material coating processesSurface fatigueOptoelectronics

The invention belongs to the field of laser repairing and particularly relates to a technique for restoring the precision of a stepped cushion of a rolling mill by adopting a laser cladding technology. The technique is specifically implemented by the following steps of: surface derusting, detection before repair, processing for removing surface fatigue layers, detection after processing, determination of a laser cladding process (including technological parameters and alloy powder constituents), detection after laser cladding, rough and fine machining, and detection after repair; the techniqueis simple and convenient to operate, greatly alleviates the labor intensity, has the characteristics of restoring the dimensional precision of the original design and improving the corrosion resistance and the wear resistance of the surface, improves the overall use efficiency, has quite small influences on the surface and prevents relatively large deformation; after being machined by a grindingmachine, the surface is smooth, uniform and high in glossiness; after repairing, a product is tracked and detected; the dimensional precision of the stepped cushion can be restored after laser cladding; the running cost is low; the surface is free of detection flaws and cracks after being machined; the product can meet the requirements of normal use; and the service life of the product is prolonged by at least three times.

Owner:SHENYANG DALU LASER TECH

42CrMoE thermal treatment technique

ActiveCN101368275AHigh surface hardnessImprove surface wear resistanceSolid state diffusion coatingFurnace typesMiddle frequencyCase hardening

The invention belongs to a heat processing technique of 42CrMoE material used for a reciprocating compressor. The technique is suitable for the heat processing technique for the 42CrMoE piston rods used for all the reciprocating compressors and can also be applied to the mechanical devices which require high rigidity, wear resistance and corrosion resistance. The invention can solve the problems of cracks, low surface hardening rigidity as well as poor wear resistance, poor acid resistance and poor corrosion resistance generated when the traditional surface heating processing technique is applied to the 42CrMoE piston rod, and the like. The invention includes the forging and shaping, hardening and tempering, stabilizing, nitriding, middle frequency or high frequency quenching as well as low temperature annealing of the 42CrMoE material; a surface compounded heat processing technology combined with nitriding and middle frequency or high frequency quenching is adopted: the 42CrMoE material is arranged in a nitriding furnace; ammonia gas is pumped in after the treatments of temperature rising and pro-oxidation to carry out nitriding treatment; then the middle frequency or high frequency quenching on the surface is carried out. The heat processing technique can be adopted to completely prevent the quenching cracks generated during the traditional high frequency quenching, improve the surface rigidity to be more than HRC60, improve the wear resistance by 34 percent and improve the acid and corrosion resistance by 40 percent.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Film for suction plastic packaging of medical equipment and method for preparing same

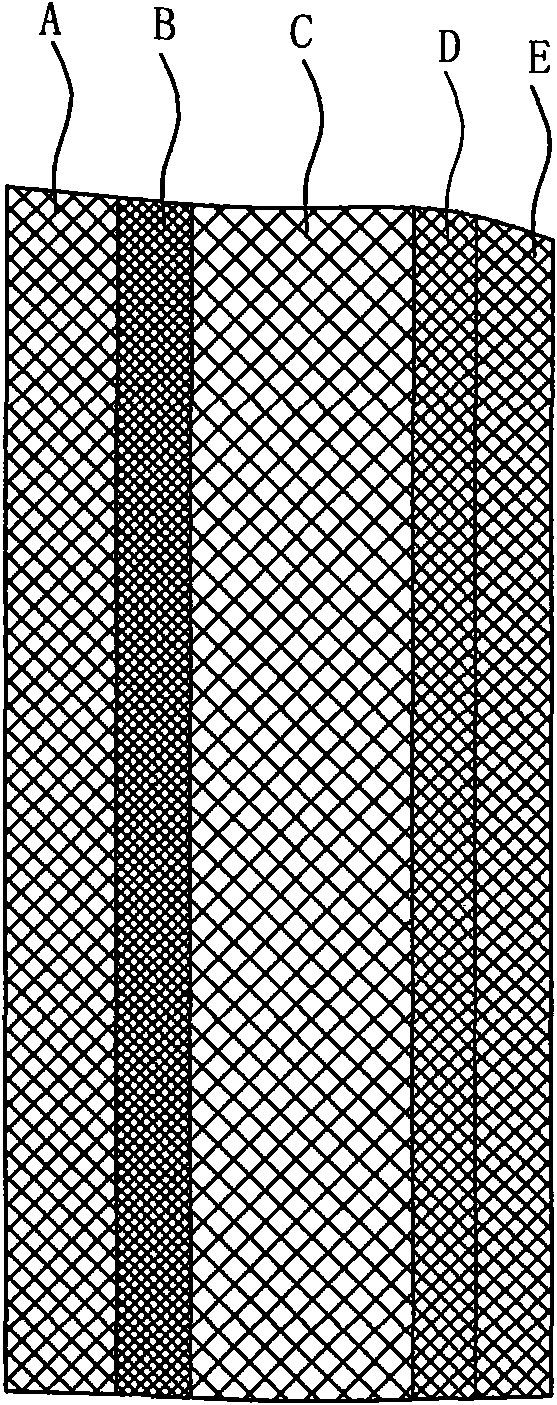

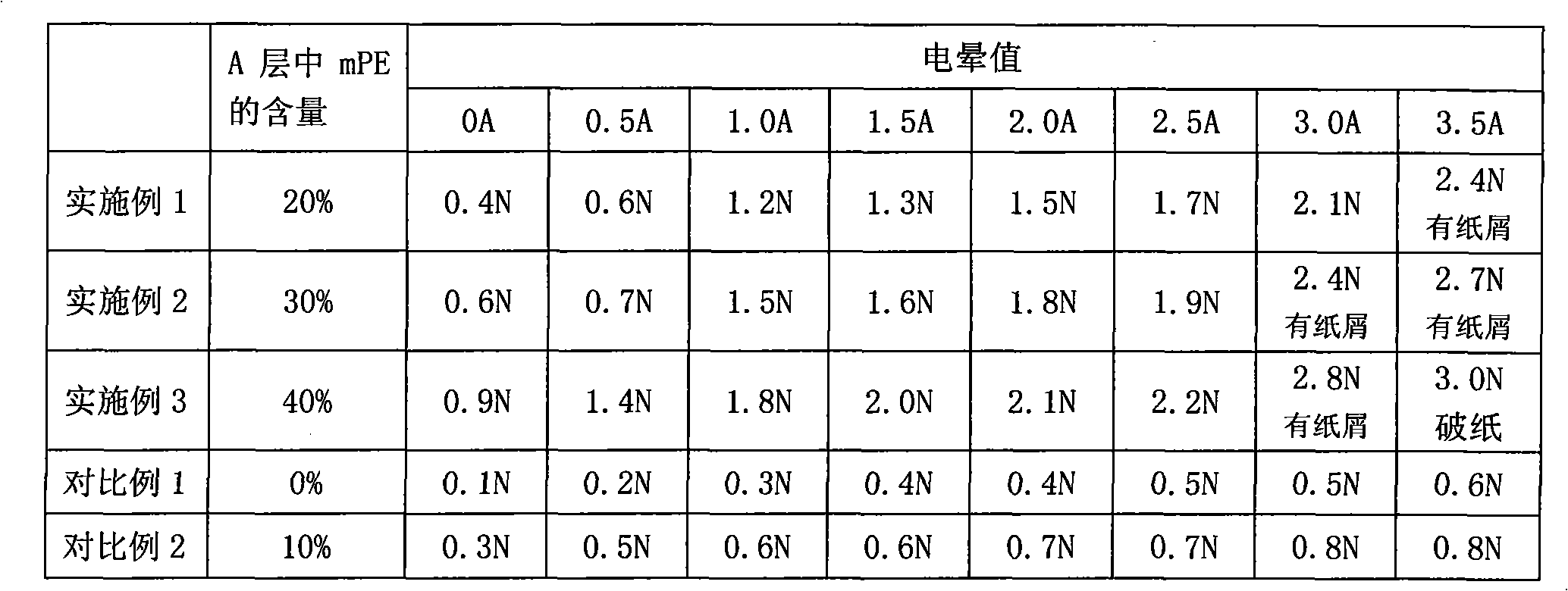

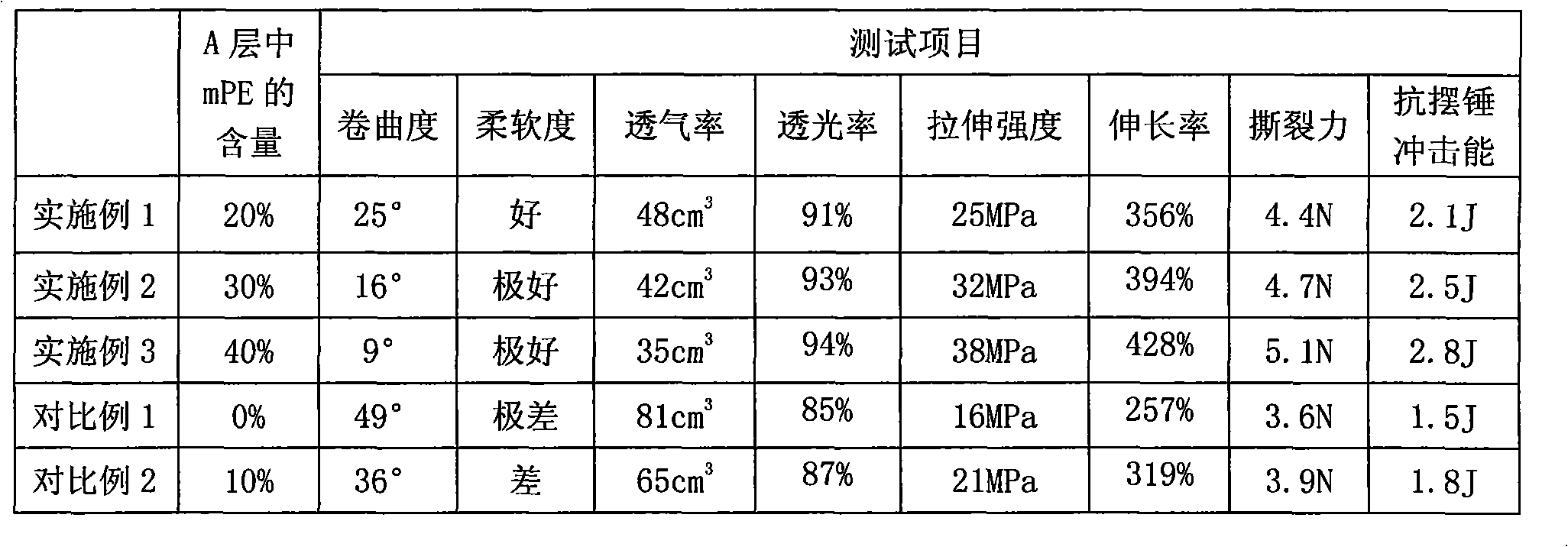

InactiveCN101559854AGood heat sealing effectReduce production linksFlexible coversWrappersMaleic anhydrideMetal

The invention relates to a film for suction plastic packaging of medical equipment and a method for preparing the same. The film adopts a five-layer structure; the first layer is a heat seal layer A, of which the component is co-mixing resin of linear low-density polyethylene and metallocene catalytic polyethylene taking octene as a comonomer, wherein the content of the metallocene catalytic polyethylene in the co-mixing resin is 20 to 40 weight percent; the second layer is an inner layer B, of which the component is linear low-density polyethylene containing a hexene comonomer; the third layer is a core layer, of which the component is linear low-density polyethylene containing a butene comonomer; the fourth layer is a bonding layer D, of which the component is maleic anhydride grafted polyethylene; and the fifth layer is a weathering resistant layer E, of which the component is nylon 6 or 66. The preparation method comprises the following steps that: the bottom blowing water cooling type co-extrusion process or flow casting method is adopted, and the plastics is subjected to fusion and die inflation or flow casting, and quick cooling at water temperature of between 15 and 18 DEG C. The film and the preparation method have the advantages that: the method is simple; the products have merits of various resins; the film can be thermally sealed with the dialyzing paper without glum spreading; and moreover, the method and the film also have the advantages of low film thickness, good comprehensive property and reutilization.

Owner:NINGBO HUAFENG PACKAGE

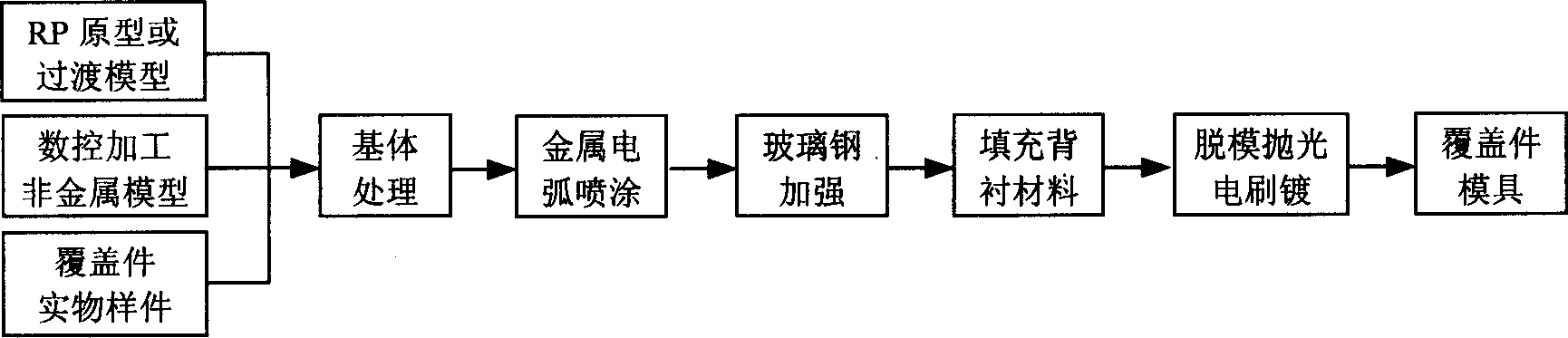

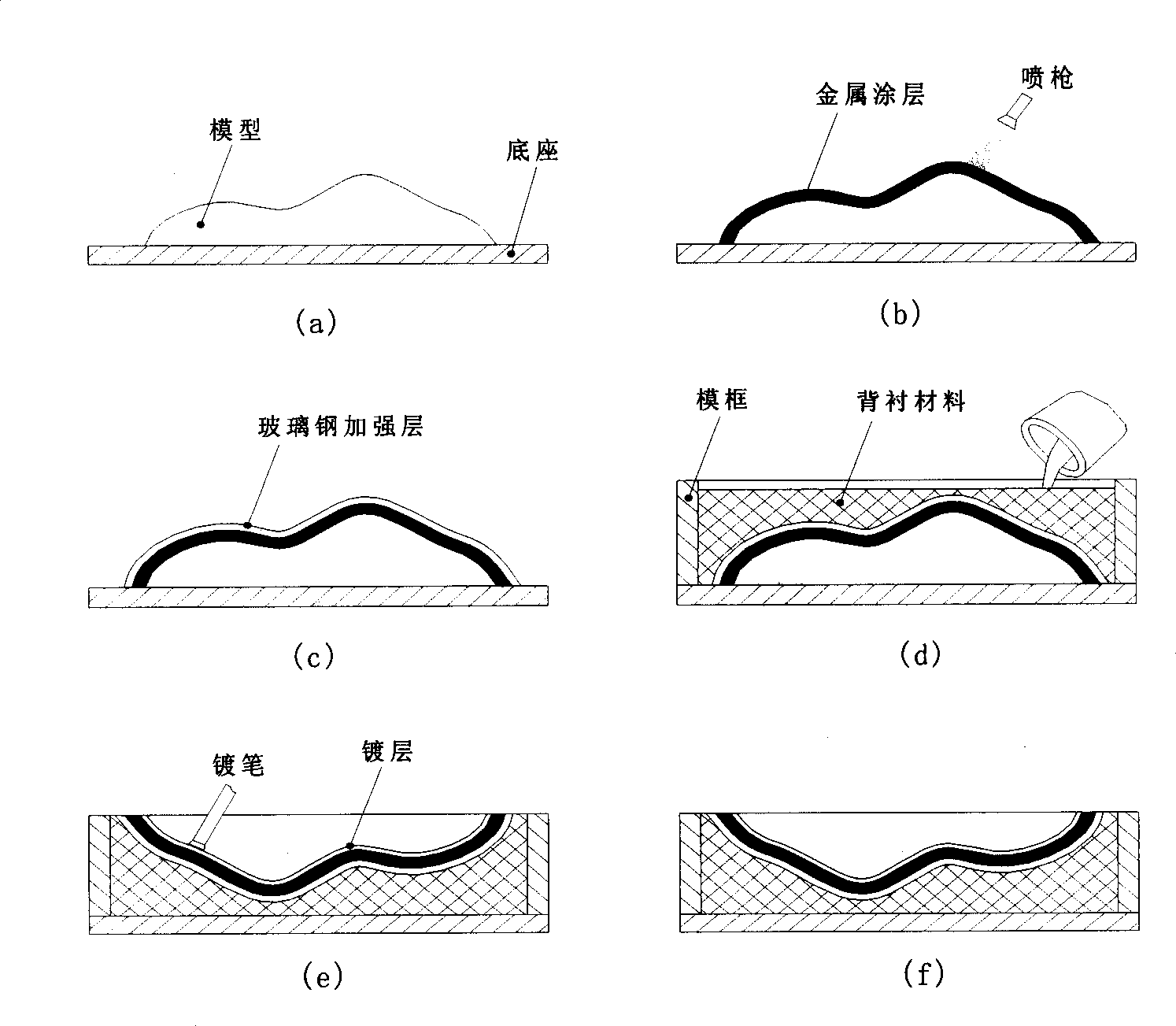

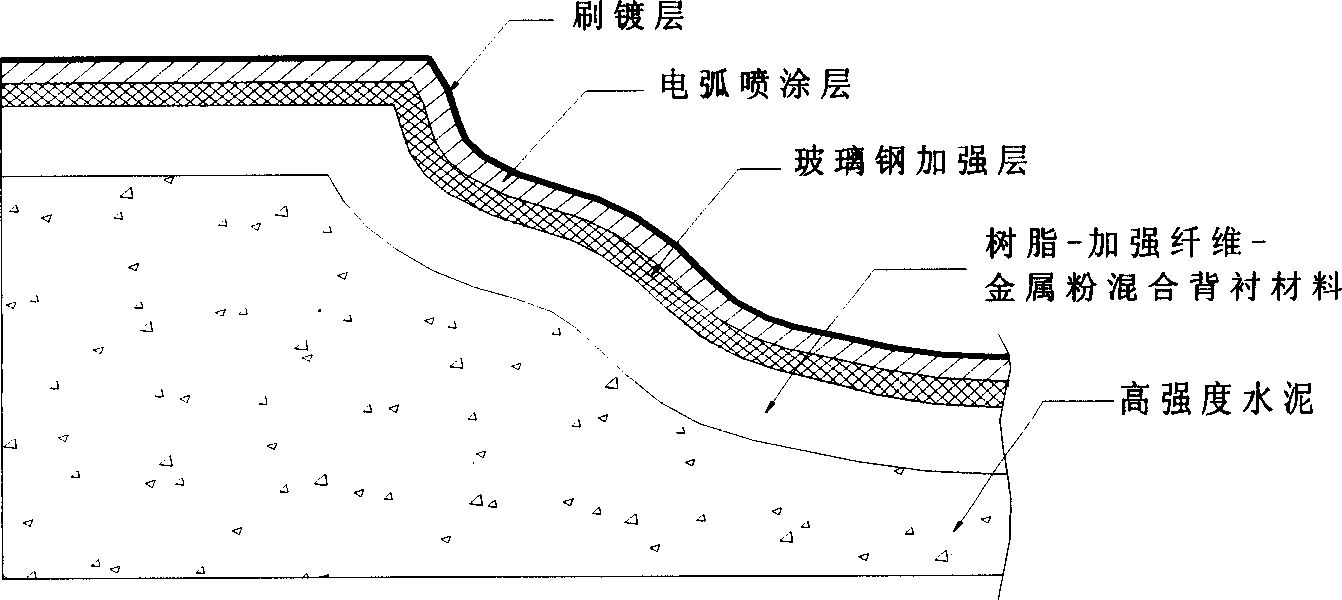

Method of rapid manufacture of stamping die for arc spraying covering-piece for automobile

The invention discloses a fast manufacturing method for punching die of metal arc painting car covers. The invention mainly uses metal arc paint technology, combines with glass steel forming, epoxy forming, electrical brush plating. The method includes: paint mother die preparation, basic process, metal arc paint, back materials filling, electrical brush plaiting. The final die is grad layer structure, each layer has different mechanism performance, easy to display material speciality. The invention simplifies the craft and reduces the cost.

Owner:XI AN JIAOTONG UNIV

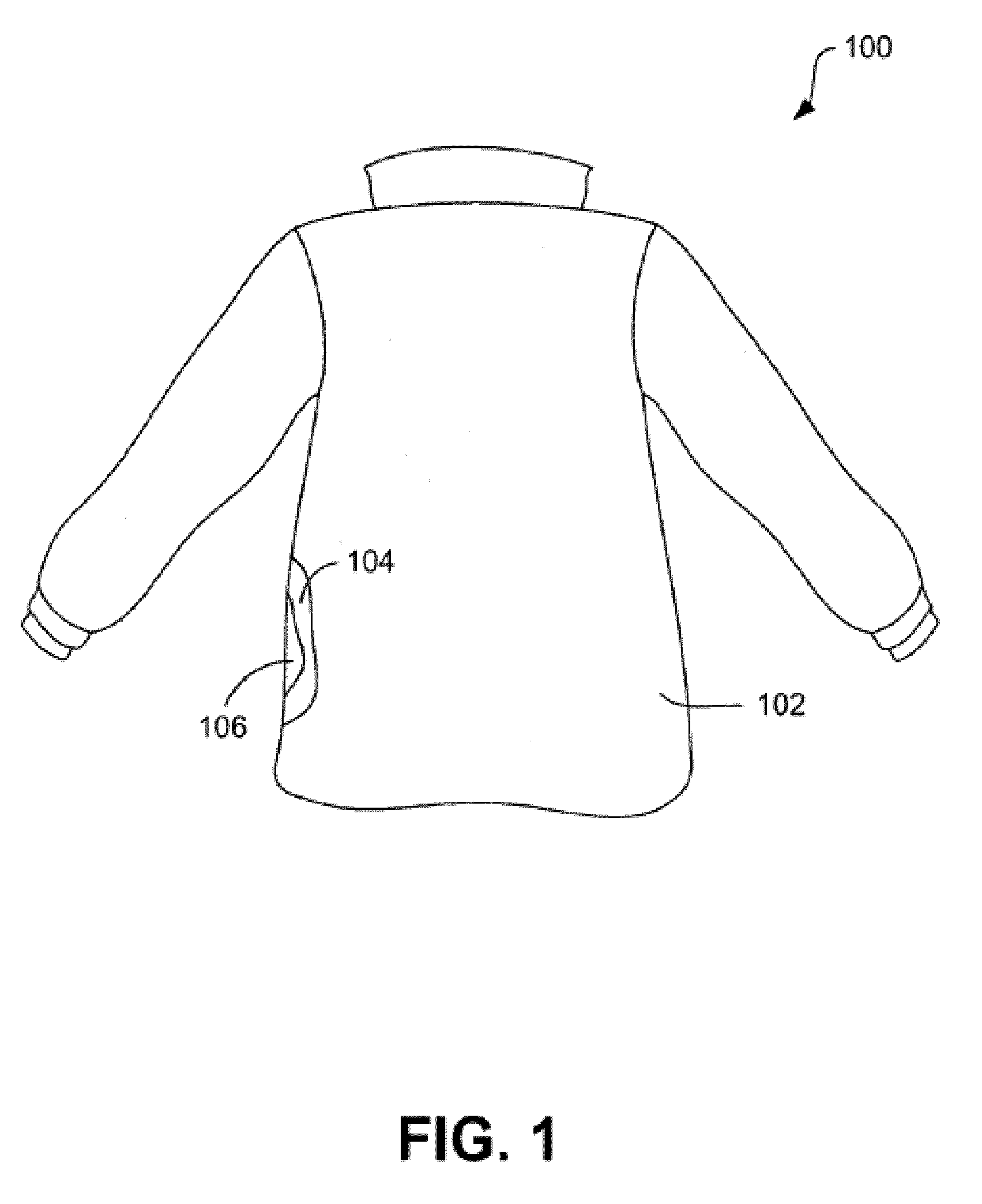

Flame Resistant Fabrics Having Improved Resistance to Surface Abrasion or Pilling and Methods for Making Them

ActiveUS20090178186A1Improve the immunityImprove surface wear resistanceChemical protectionHeat protectionFiberYarn

Flame resistant fabrics and garments that have improved resistance to pilling and / or abrasion are disclosed. The fabrics, the fibers or yarns that make up the fabrics, or garments made from the fabrics are treated with a finish composition that is applied to the fibers, yarns, fabrics, or garments and then cured. The finish composition increases the resistance to pilling and / or abrasion of the fibers, yarns, fabrics, or garments. The finish composition includes a polymeric abrasion resistance aid, an alkylfluoropolymer, a polyethylene, and a wetting agent.

Owner:SOUTHERN MILLS

Method for preparing WC hard alloy wear resistance area on petroleum drill rod surface

ActiveCN102453901AExtended service lifeImprove toughnessMetallic material coating processesLaser beam welding apparatusHigh power lasersAlloy coating

The invention relates to a method for preparing a WC hard alloy wear resistance area on a petroleum drill rod surface. The method is characterized in that: the method comprises the following steps: (1) carrying out a pretreatment for the petroleum drill rod surface; (2) selecting alloy powder and adjusting an automatic powder feeding device; (3) cladding a bottoming alloy coating by a high power laser; (4) cladding spherical WC and Ni-Cr-B-Si mixed alloy powder by the high-power laser; (5) carrying out defectoscopy inspection after cladding. According to the present invention, the gradient coating method is adopted to prepare the WC hard alloy wear resistance area on the petroleum drill rod surface, the nickel-base alloy powder is adopted as the bottoming layer, the high wear resistance WC hard alloy powder is adopted as the working layer, such that the good binding strength of the working layer and the substrate is ensured in the case of meeting of the working layer characteristics, and the cracks can be prevented from expanding to the substrate during the using process, wherein the nickel-base alloy powder has good toughness and high strength, and has good metallurgy compatibility with the substrate.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

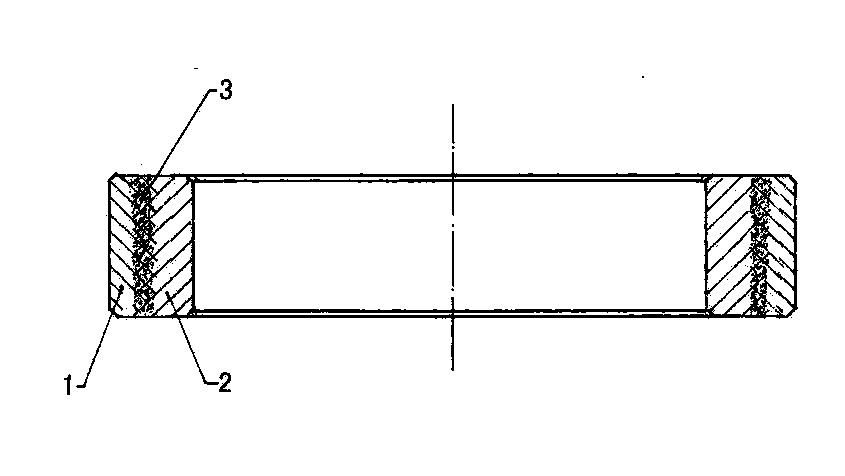

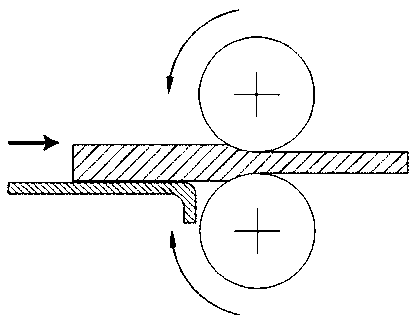

Gradient-structure hard alloy roll collar and manufacturing process thereof

ActiveCN103817150AImprove surface wear resistanceExtended service lifeRollsMetal rolling arrangementsMixed materialsAlloy

The invention discloses a gradient-structure hard alloy roll collar and a manufacturing process of the gradient-structure hard alloy roll collar. A compositional gradient is formed between a roll collar outer layer and a roll collar core. The roll collar outer layer and the roll collar core respectively contain a hard material, a binding material and / or an additive, wherein the hard materials, the binding materials and / or the additives are different in mass content. The hard materials, the binding materials and / or the additives are mixed in a ball-milling mode into roll collar ball-milling mixed materials. The roll collar ball-milling mixed materials are dried, mixed with wax and then dried again. The roll collar outer layer ball-milling mixed material mixed with the wax and the roll collar core ball-milling mixed material mixed with the wax are laid in a layered mode to be loaded, and are subjected to cold press molding to form a roll collar blank. The roll collar blank is subjected to sintering and dewaxing to become hard alloy, and the hard alloy is subjected to thermal treatment to become the hard alloy roll collar. The surface abrasion resistance of the hard alloy roll collar with the compositional gradient is improved remarkably, the service life of the hard alloy roll collar is prolonged by about 15 percent under the same abrasion condition, production cost is reduced, and practical value and promotional value are obvious.

Owner:湖南天益高技术材料制造有限公司 +1

Method for preparing reaction nitrogen arc surfacing titanium carbonitride reinforced titanium based complex coating

InactiveCN101590558AImprove production efficiencyEasy to prepareArc welding apparatusWelding/cutting media/materialsTitanium nitrideTitanium carbonitride

The invention provides a method for preparing a reaction nitrogen arc surfacing titanium carbonitride reinforced titanium based complex coating. The method comprises the following steps: adopting the prior direct current tungsten nitrogen arc welding equipment; taking tungsten electrode as cathode and substrate of titanium and titanium alloy as anode; using nitrogen arc surfacing under the protection of nitrogen gas; and performing the reaction on the surfaces of the substrates of titanium and titanium alloy to synthesize the titanium carbonitride reinforced titanium based complex coating. The titanium carbonitride reinforced titanium based complex coating prepared by the method has the advantages of large thickness, metallurgical bonding with the substrates, high bonding strength, high hardness of the coating, and good wear resistance.

Owner:HEBEI AGRICULTURAL UNIV.

Polyphenylene sulfide compound material, and preparation method and application thereof

InactiveCN102391648AStrong surface hardnessHigh strengthPositive displacement pump componentsLiquid fuel engine componentsFiberPolymer science

The invention relates to a polyphenylene sulfide compound material and a preparation method thereof, and a process for preparing an anticorrosion pump overflowing assembly by using the compound material, and belongs to the technical fields of anticorrosion materials and application of the anticorrosion materials. The compound material mainly comprises the following components in part by mass: 100 parts of polyphenylene sulfide, 40 to 100 parts of reinforcement fibers, 18 to 35 parts of hollow glass microspheres, and 25 to 60 parts of polyamide. The compound material is prepared by a melt cladding method. The anticorrosion pump overflowing assembly is prepared by using the compound material and a compression molding process or an injection molding process. The prepared polyphenylene sulfide compound material has high intensity, toughness, surface hardness, corrosion resistance, and small friction coefficients; and the manufactured overflowing assembly has high intensity, wear resistance and corrosion resistance, and long service life and can be used for high-corrosion using conditions where pumps of other materials cannot be used.

Owner:BOSHAN WATER PUMP MFG FACTORY

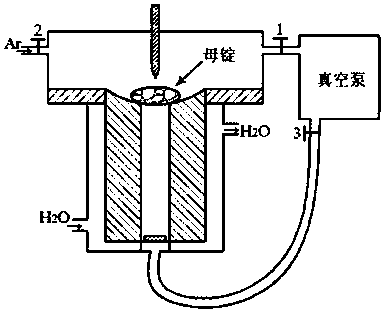

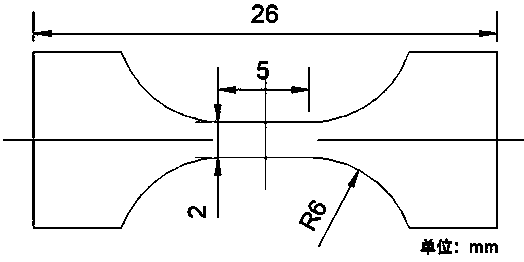

Method for improving Al0.3CoCrFeNi high-entropy alloy intensity

ActiveCN109797303AFine grain boundaryUniform tissueVacuum evaporation coatingSputtering coatingHigh entropy alloysWire cutting

The invention discloses a method for improving Al0.3CoCrFeNi high-entropy alloy intensity. Five kinds of analytical pure metals of Al, Co, Cr, Fe and Ni are blended according to the atomic ratio of 0.3 to 1 to 1 to 1 to 1, smelting is carried out in a vacuum arc melting furnace, the molten alloy is subjected to suction casting to form plate-shaped high-entropy alloy materials with 2mm thickness, 10mm width and 85mm length, and then a high-entropy alloy is subjected to cold rolling and annealing heat treatment to eliminate the residual internal stress, generated in the casting process, of the high-entropy alloy; and then a wire cutting machine is used for cutting bone-shaped standard tensile samples with a standard distance of 5mm, the front faces and back faces and the two side faces of the tensile samples are polished, and the polished samples are subjected to a double-glow chromizing test by using a double-glow metal furnace, and finally, the obtained samples are strengthened high-entropy alloy samples. According to the method for improving the Al0.3CoCrFeNi high-entropy alloy intensity, through a double-glow chromizing technology, the friction coefficient of the high-entropy alloy is reduced, and the amplitude is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

Polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and preparation method thereof

InactiveCN102086348AStrong anti-fogHigh transparencyPolyurea/polyurethane coatingsAcrylic resinPolypropylene glycol

The invention discloses polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and a preparation method thereof. The paint is prepared from the following components in parts by weight: 130-190 parts of hydrophilic acrylic resin, 210-525 parts of blocked polyether-isocyanate used as curing agent and 2.00-5.00 parts of butyltin dilaurate used as catalyst, wherein the blocked polyether-isocyanate curing agent uses polypropylene glycol and isophorone diisocyanate as raw materials. The preparation method of the paint comprises the following steps: reacting to obtain polyether-isocyanate prepolymer and then reacting with methyl ethyl ketoxime used as sealing agent. The test result shows that the paint prepared by the method has high anti-fogging property, good transparency and abrasion resistance and low production cost; and under the premise of ensuring the good anti-fogging property of the paint, the surface wear resistance can be increased and the application prospectis wide.

Owner:上海旺俊化工有限公司

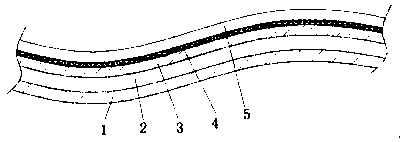

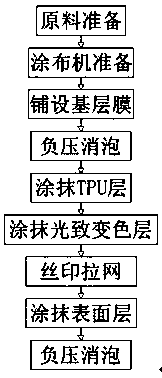

Anti-broken hot melt adhesive membrane used for automobile decoration and preparation method of anti-broken hot melt adhesive membrane

InactiveCN109135605AImprove the adhesion effectImprove surface wear resistanceFilm/foil adhesive primer layersHeat-activated film/foil adhesivesSurface layerWear resistant

The invention discloses an anti-broken hot melt adhesive membrane used for automobile decoration and a preparation method of the anti-broken hot melt adhesive membrane. The anti-broken hot melt adhesive membrane comprises a PVB base adhesive, a TPU adhesive layer is stuck to the outer wall on one side of the PVB base adhesive, a photochromic layer is stuck to the outer wall on the side, away fromthe PVB base adhesive, of the TPU adhesive layer, a nylon mesh cloth layer is stuck to the outer wall on the side, away from the TPU adhesive layer, of the photochromic layer, and a membrane surface layer is stuck to the outer wall on the side, away from the photochromic layer, of the nylon mesh cloth layer. The preparation method comprises the following steps of preparation of raw materials, wherein a PVB adhesive solution, an EVA adhesive solution and a TPU adhesive solution which are needed during production are mixed and stirred respectively, and then sampled and inspected respectively; preparation of coating machines, wherein the three coating machines are prepared, and adhesive storage cylinders and coating heads of the three coating machines are cleaned. By means of the anti-brokenhot melt adhesive membrane, improvement of the wear-resistant performance of the surface of the hot melt adhesive membrane is facilitated, by cooperatively arranging the nylon mesh cloth layer, improved of the adhesion effect of the surface layer of the membrane can be facilitated, the box stretching performance of the hot melt adhesive membrane is improved, and improvement of the elasticity of the hot melt adhesive membrane is facilitated.

Owner:安徽天念材料股份有限公司

High-strength cast steel for coal cutter rocking arm and heat treatment process thereof

InactiveCN102345072AImprove mechanical propertiesExtended service lifeChemical compositionHigh intensity

The invention discloses a high-strength cast steel for a coal cutter rocking arm and a heat treatment process thereof. The high-strength cast steel comprises the following chemical components in part by weight: 0.30-0.37 part of C, 0.45-0.60 part of Si, 0.90-1.10 part of Mn, 1.40-1.60 part of Cr, 1.40-1.60 parts of Ni, 0.20-0.30 part of Mo, not more than 0.020 part of P and not more than 0.020 part of S. The heat treatment process of the high-strength cast steel for the coal cutter rocking arm comprises the steps of: carrying out diffusion annealing at 1,040-1,060 DEG C; and then sequentially carrying out normalizing at 890-910 DEG C and tempering at 590-610 DEG C. In the invention, because the technical scheme is adopted, the mechanical property of the product is improved, meanwhile the wearing resistance is favorable, the surface rigidity reaches HB260-285, the surface wearing capability is improved, the service life of the product is prolonged, the deformation in the use process is reduced, and the operation reliability of a device is enhanced.

Owner:HUZHOU ZHONGLIAN MACHINERY EQUIP

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804655AReduce energy consumptionTake advantage ofLiquid surface applicatorsWood compressionSolid woodWear resistant

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: forming a solid wood flooring block, sanding the block, removing dust, coloring, coating UV putty coat I, solidifying I, sanding I, coating UV putty coat II, solidifying II, sanding II, coating wear resistant base coat, semi-solidifying I, coating transparent UV base coat, solidifying III, sanding III, coating UV finishing coat, semi-solidifying II, coating formaldehyde-removing UV wear resistant finishing coat, solidifying IV, and forming the finished product. The solid wood flooring produced by the process has the advantages of good colour and lustre, clear texture, high anti-bending static bending strength, good surface abrasion resistance, stable size, small deformation and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

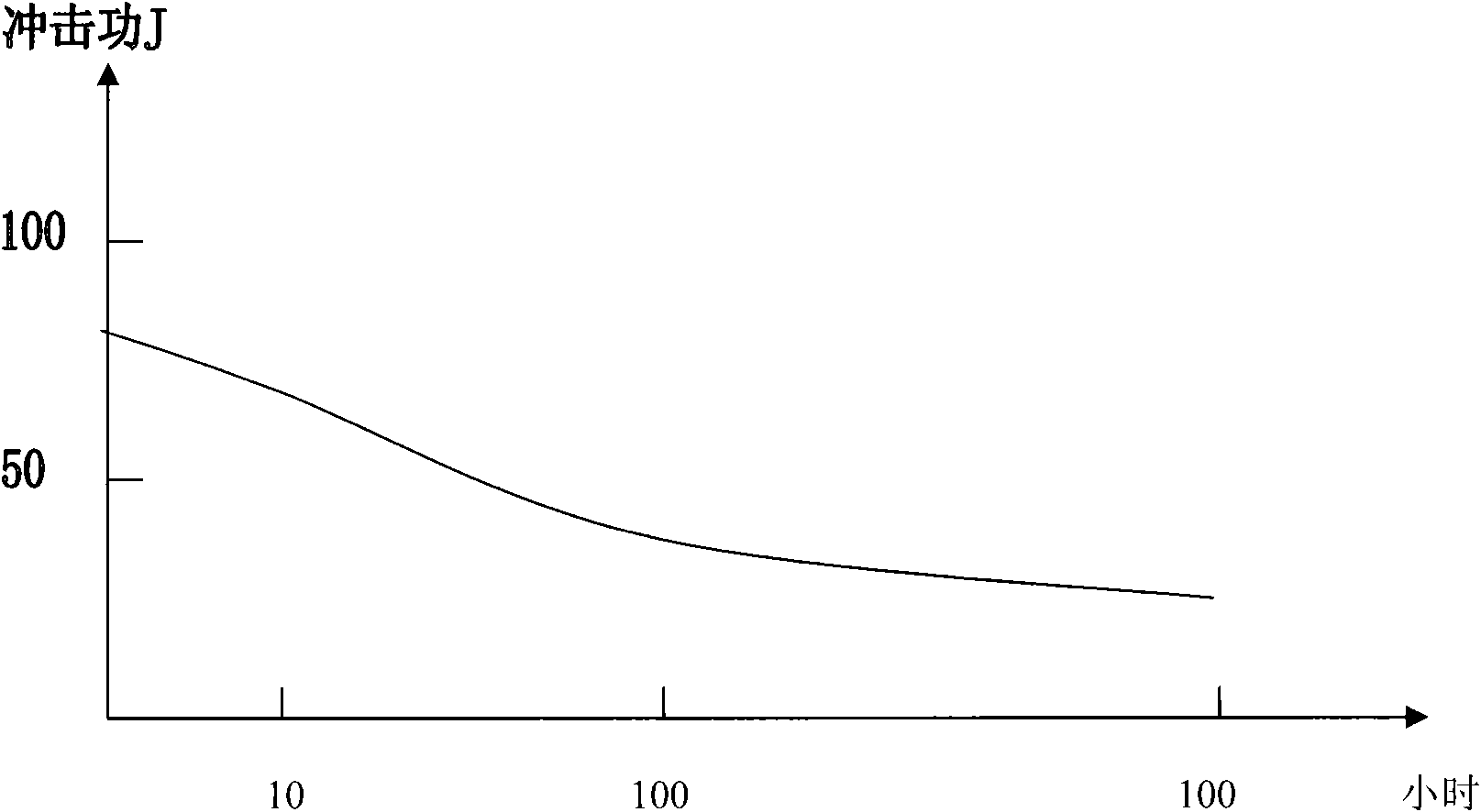

2Cr13 heat treatment process

InactiveCN101608252AHigh surface hardnessImprove surface wear resistanceFurnace typesQuenching agentsLong axisMechanical equipment

The invention belongs to the field of a heat treatment process for reciprocating-compressor 2Cr13 piston-rods, and is applicable to all reciprocating compressors adopting a 2Cr13 piston-rod heat treatment process and mechanical equipment which requires high toughness and needs post-order surface heat treatment. The process can solve the problem that the prior heat treatment adopted for 2Cr13 piston rods is low in impact toughness, large in high-frequency quenching deformation of long-axis parts, large in hardening cracks and workpiece residual stress, and the like. The process comprises the forging molding of 2Cr13 piston rods, annealing, quenching-tempering, stabilizing, medium-frequency or high-frequency quenching and low-temperature tempering. The 2Cr13 heat treatment process can completely overcome the disadvantages of the prior heat treatment process such as incapability of eliminating residual stress and serious high-frequency quenching workpiece distortion, and is an ideal heat treatment process for long-axis workpieces.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

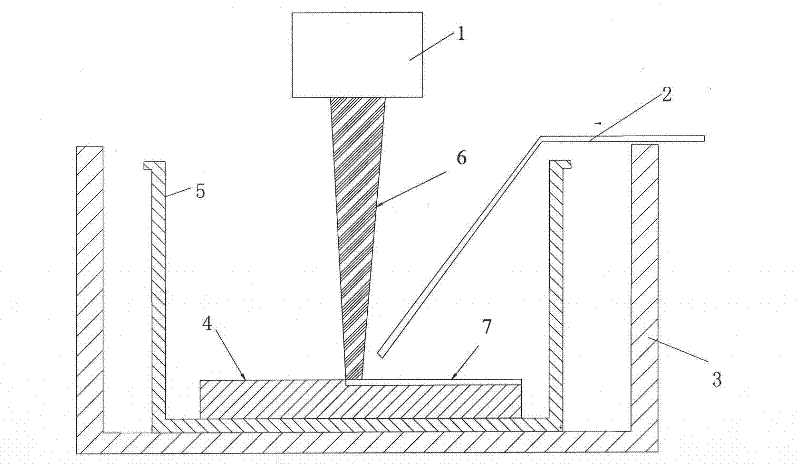

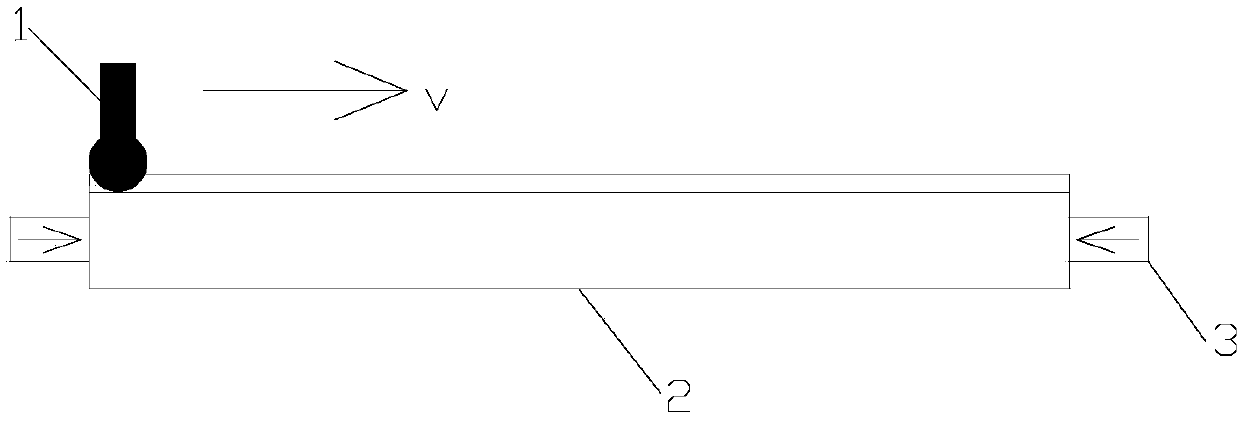

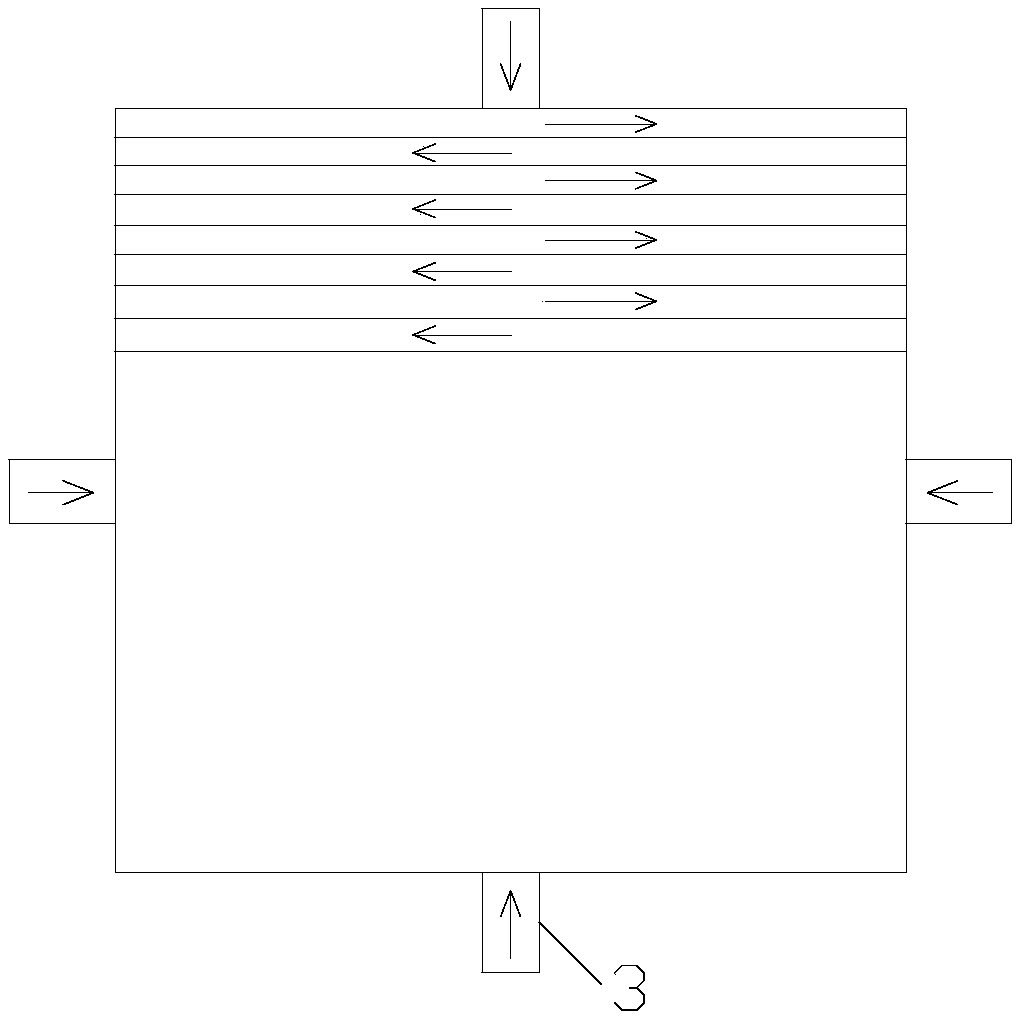

Complicated surface optical finishing processing device and technique

InactiveCN101417401ASolve the problems that cannot be finishedSolve the problem that cannot be finishedCavitationWear particle

The invention discloses a finishing machining device of complex surfaces and a technique thereof, belongs to the field of special processing technology and is characterized in that high-intensity supersonic vibration produced by direct shock excitation to workpieces by an ultrasonic horn acts with the liquid and solid two-phase flow forced on surfaces of complex workpieces, thus producing the impact of workpiece surfaces and grinding particles and liquid cavitation to cause the impact to workpiece surfaces by the grinding particles, and the finishing machining of complex workpiece surfaces is realized; and particularly, inner concave surfaces with complex channels also have the high-intensity supersonic vibration and the all-pervasive characteristic of the liquid and solid two-phase flow. The device and the technique have the advantages of realizing the finishing machining of complex inner and outer surfaces and also solving the problem that inner concave surfaces and dead corners can not be finished and machined. The technology can fully and effectively finish and process inner surfaces, and effectively reduce the surface roughness value of parts, thus greatly improving the surface matching quality, surface wear resistance, surface air tightness, cleanliness and service life of parts.

Owner:TAIYUAN UNIV OF TECH

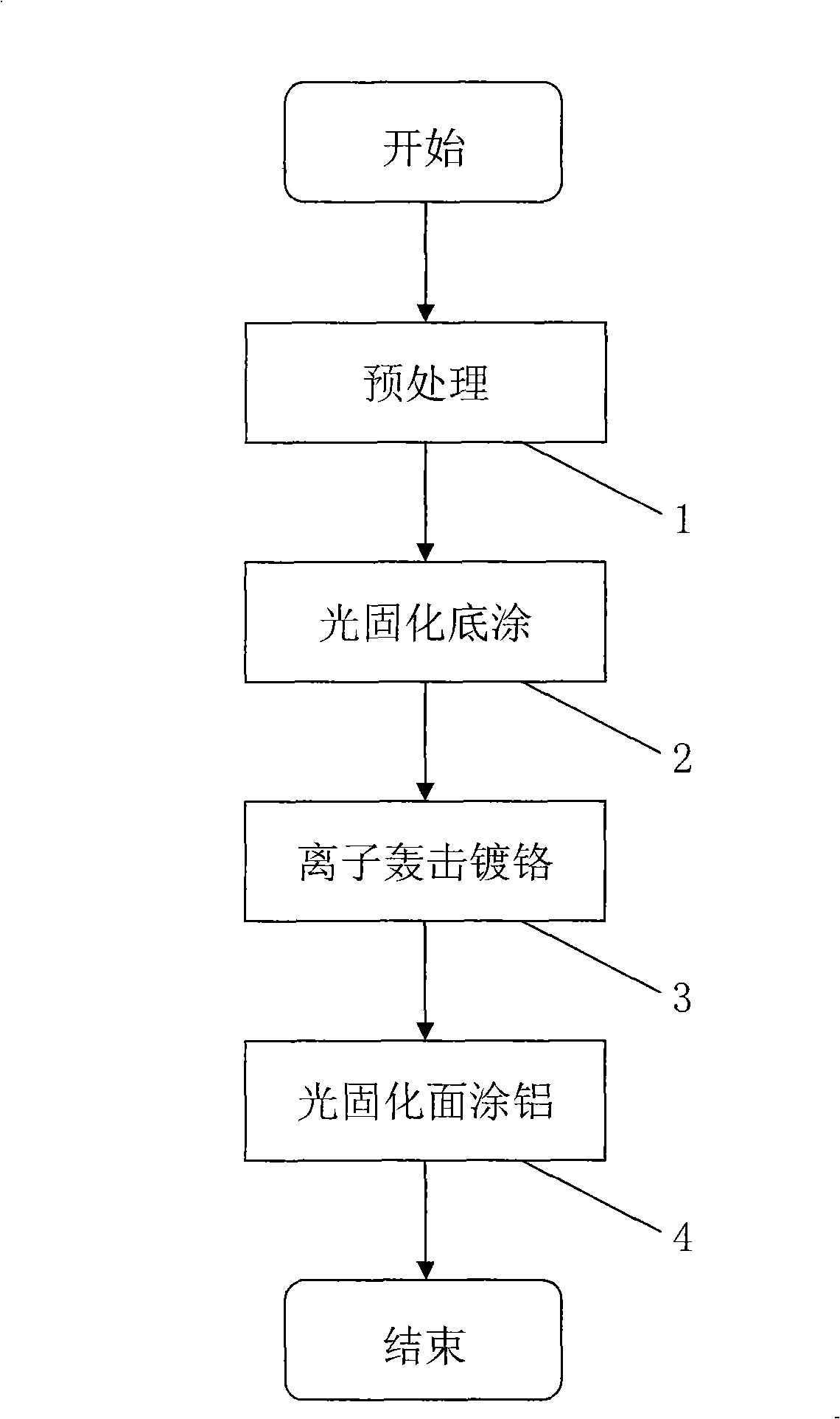

Coating method of automobile hub cover

InactiveCN101338409AConsistent bindingConsistent usabilityVacuum evaporation coatingSputtering coatingPhysical well beingEngineering

The invention discloses a membrane-plating method for a hub cover of a vehicle which includes the steps of pre-processing, bottom coating through light curing, chromeplating through ion bombardment, surface coating through light curing, etc. The invention adopts a dry plating to replace the traditional wet electric plating and adopts an aluminum layer to replace the traditional metal coat of Ni-Cu-Cr. The dry plating method does not contain poison matters, does not have the problem of three wastes, does not need three-waste processing, has a simple technique process and has no pollution to the environment. The working condition of a worker is good; the effect to the body health is small. The noble metals like Cu, Ni and Cr are not needed to be used; only less aluminum is used, thus greatly reducing the cost. The technique is simple; the working procedures are less; the production cost is low. The power consumption is about one fifths to one sevenths of the electric plating; the water consumption is about one tens to one twentieths of the electric plating. The integral production cost is about one seconds of the electric plating. The method of the invention has a high economic benefit; besides, nano-ceramics particles are added in the surface coating material of light curing which improves the techniques of dispersing and mixing as well as remarkably improves the surface wear-resistance.

Owner:HUZHOU JINTAI PLATING IND

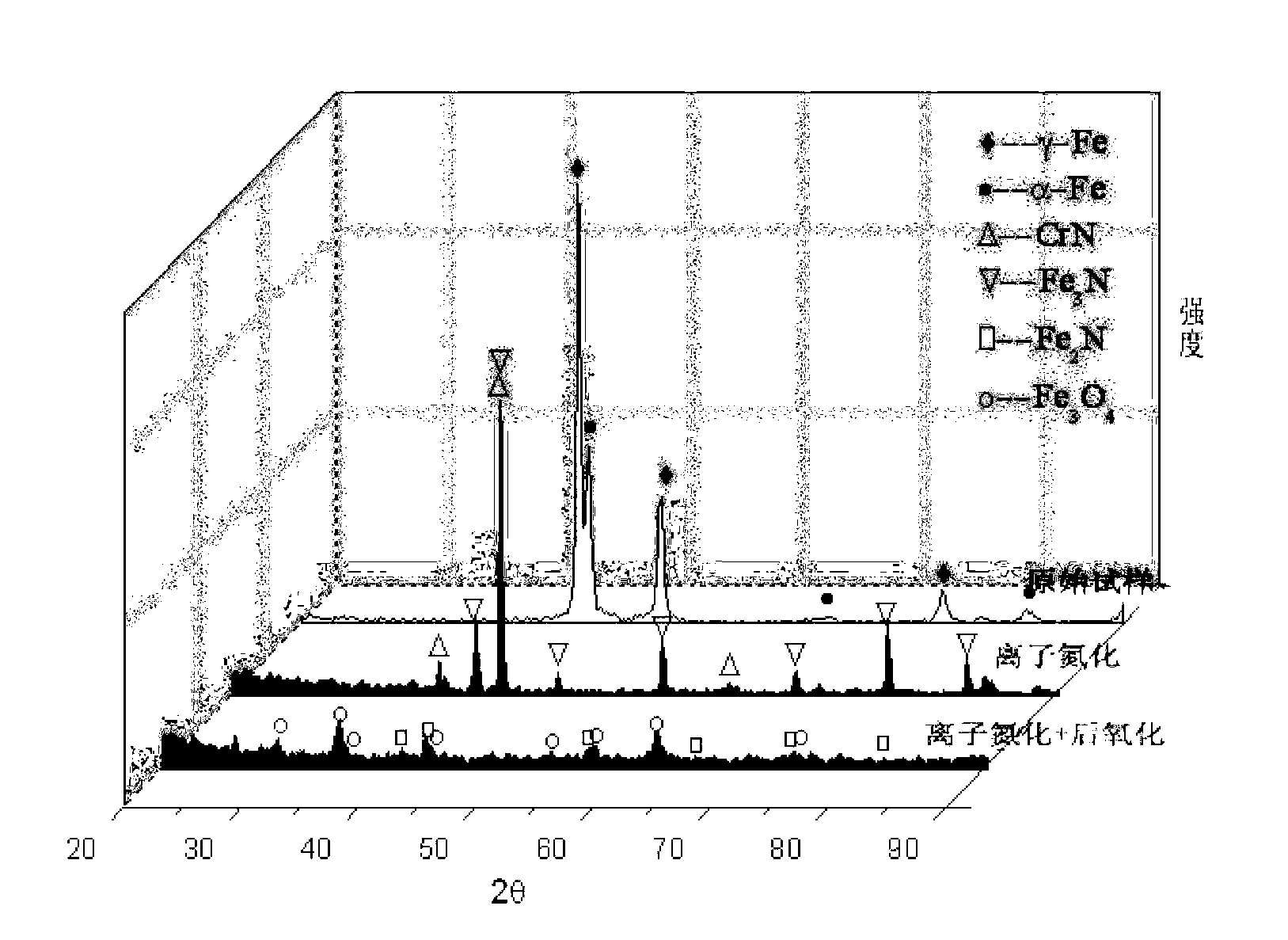

Treatment process of composite surface of austenitic stainless steel

ActiveCN103014599AHigh hardnessImprove surface wear resistanceSolid state diffusion coatingNitrogen gasAustenite

The invention belongs to the technical field of metal surface modification, and in particular relates to a treatment process of a composite surface of an austenitic stainless steel. The process mainly comprises the following steps: 1) washing the surface of a workpiece, and removing the oil stain and impurities on the surface of the workpiece; 2) putting the stainless steel workpiece into an ion nitriding furnace after being cooled down, introducing dried hydrogen, building up of luminance and heating up, after reaching a certain temperature, introducing nitrogen, adjusting the ratio of the nitrogen to the hydrogen and the pressure in the furnace, and subsequently starting to time; and 3) after nitriding for a certain time, stopping introducing the nitrogen, introducing dried air and keeping the temperature for a certain time. Not only is the surface abrasion resistance of the stainless steel treated by using the treatment process improved, but also the excellent corrosion resistance of the stainless steel self is maintained.

Owner:CHANGZHOU UNIV

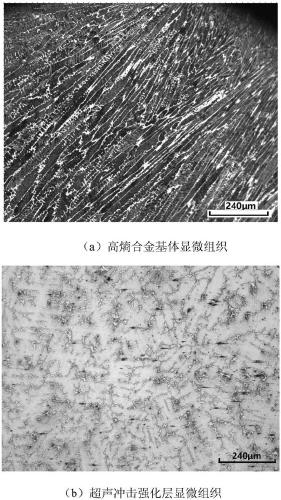

Method for improving surface performance of single-phase high-entropy alloy

The invention discloses a method for improving surface performance of a single-phase high-entropy alloy, and belongs to the technical field of high-entropy alloy surface strengthening. The single-phase high-entropy alloy is an Al<x>CrCoFeMnNi alloy, wherein x represents the mole number, and is equal to 0-0.5; after the single-phase high-entropy alloy is subjected to solution treatment and surfacepretreatment, the surface of the high-entropy alloy is strengthened through ultrasonic impact equipment; and the high-entropy alloy is of a single-phase face-centered cubic structure, a certain depthof plastic deformation layer is formed on the surface of the high-entropy alloy after ultrasonic impact, grains are obviously refined, a gradient structure is formed from the surface to the core, andhardness and abrasion resistance are significantly improved. According to the method, a fine structure and a large number of microscopic defects can be obtained on the surface of the high-entropy alloy while the chemical composition of the surface of the high-entropy alloy is ensured to be unchanged and the toughness of the core is ensured, thus the hardness of the surface of the high-entropy alloy is increased by 1.8-2.5 times, the abrasion resistance is increased by 1.3-2.5 times, the method is simple, easy to operate, safe, reliable, small in energy consumption, economical and practical.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

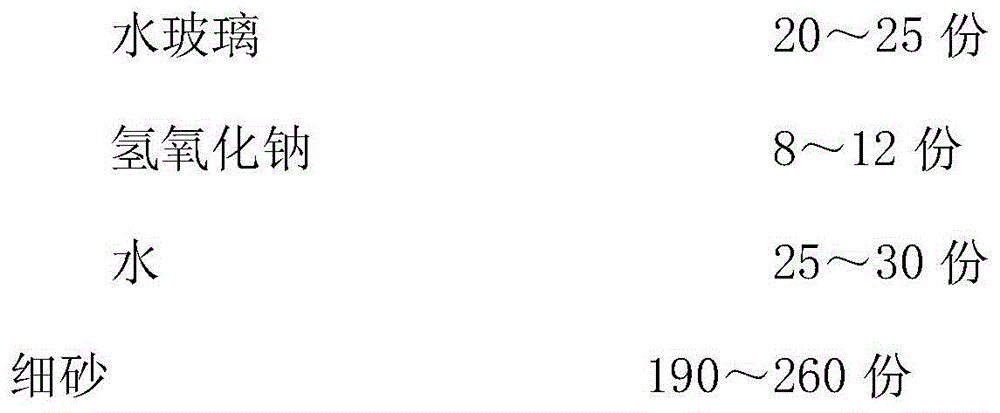

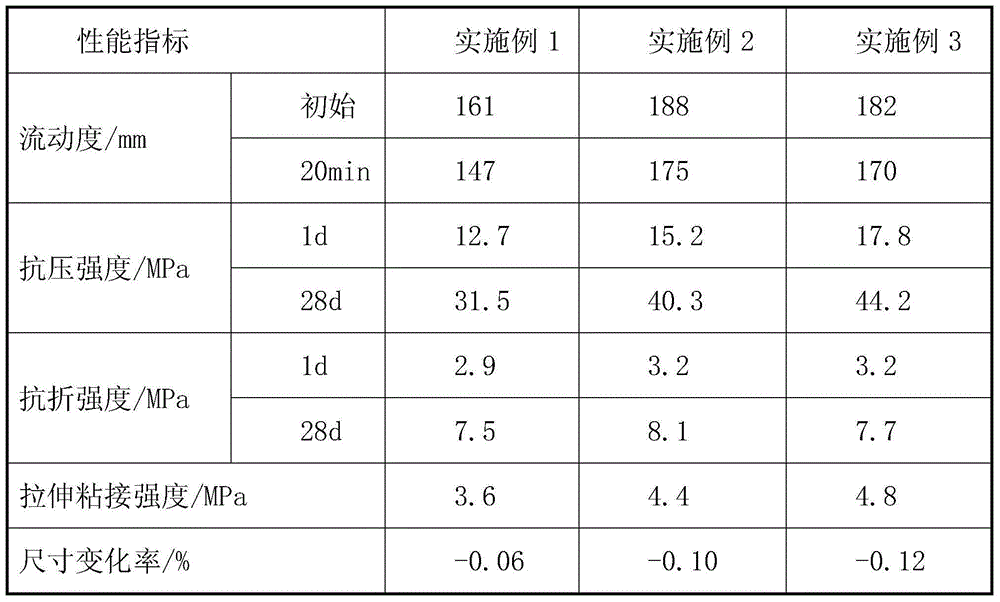

Inorganic mineral polymer self-leveling mortar and preparation method thereof

The invention relates to inorganic mineral polymer self-leveling mortar and a preparation method thereof. The mortar mainly comprises the raw materials in parts by weight: 64-72 parts of mine residues, 18-22 parts of kaolin, 10-14 parts of fly ash, 20-25 parts of water glass, 8-12 parts of sodium hydroxide, 25-30 parts of water, and 190-260 parts of fine sand, wherein additives are a water reducing agent, a stabilizing agent and an antifoaming agent; gelating materials adopt inorganic mineral polymers which are made from the mine residues, the kaolin and the fly ash and stimulated by the water glass with a specific modulus of 1.4-1.5; because of a dimensional net structure in the inorganic mineral polymers, the self-leveling mortar disclosed by the invention has higher compressive strength, higher rupture strength and durable and abrasion-proof performance. The 28d compressive strength is 45MPa, the 28d rupture strength is 9MPa, and the cohering strength is 4.5MPa. The mortar disclosed by the invention also solves the problems that the surface is not smooth after the mortar is hardened, the surface is cracked after being retracted, the surface is hollow and peeled; moreover, the utilization rates of industrial by-products are also improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com